Patents

Literature

62results about How to "Low volatility" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

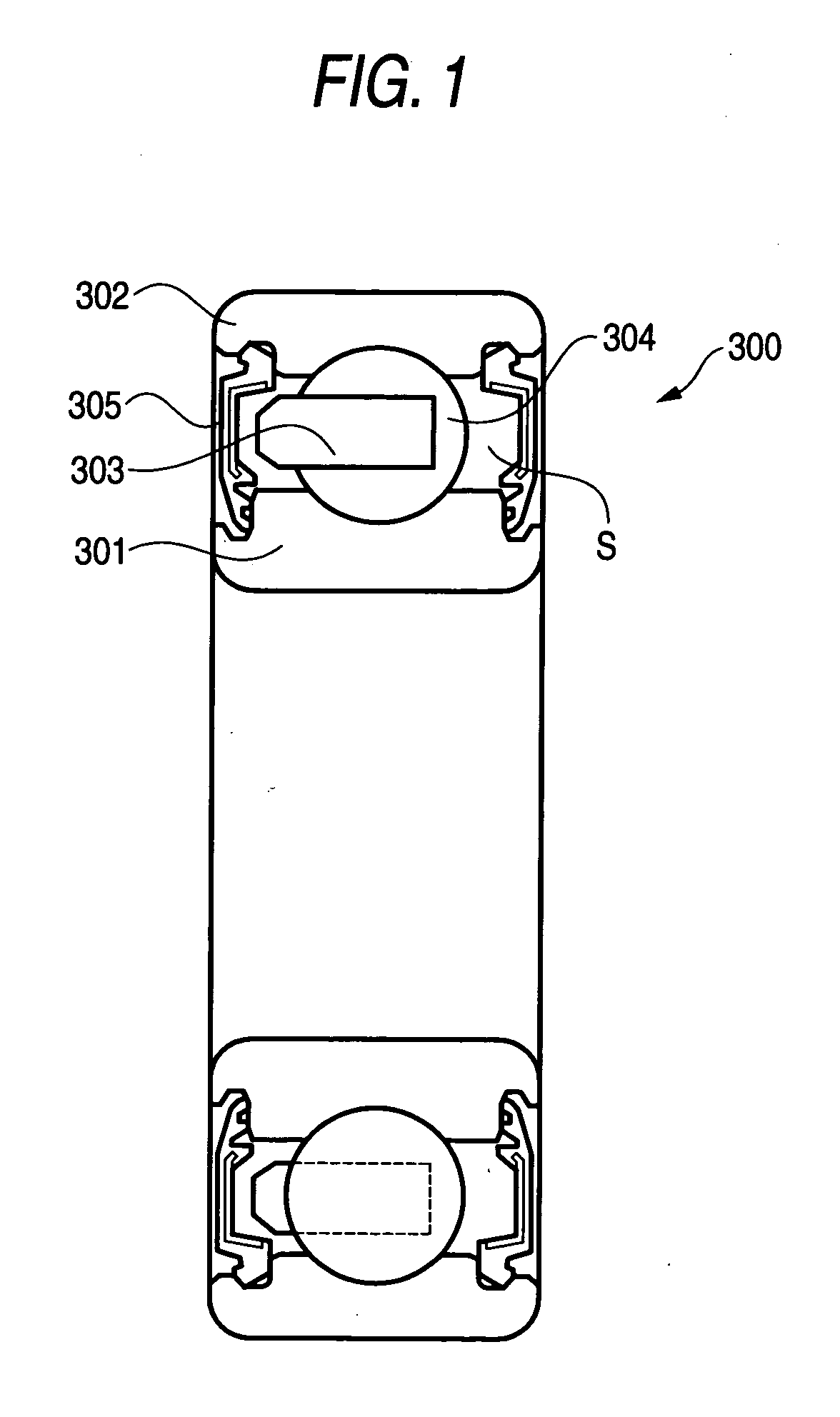

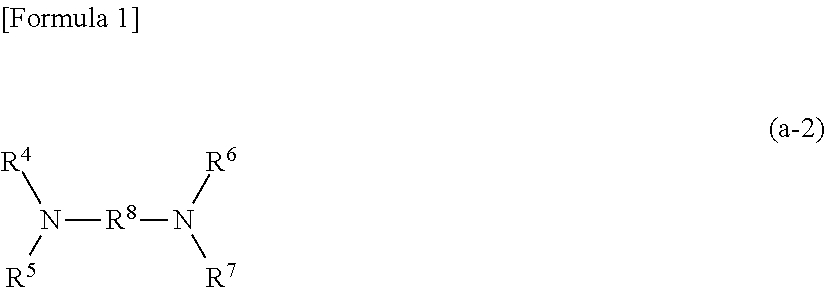

Rolling bearing, rolling bearing for fuel cell, compressor for fuel cell system and fuel cell system

InactiveUS20050261141A1Low volatilityExcellent heat resistance and load resistanceMaterial nanotechnologyOrganic chemistryAutomotive engineeringUrea

The rolling bearing of the invention to be incorporated in the compressor for fuel cell system comprises a fluorine-based grease containing a fluororesin and a fluorine-based oil, a urea grease containing a urea compound and a synthetic oil or a lithium complex grease containing a lithium complex and a synthetic oil encapsulated therein. In this arrangement, the grease deterioration of the rolling bearing incorporated in the compressor for force-feeding various fluids between machines can be prevented, making it possible to provide a fuel cell system which can maintain stable operation over an extended period of time.

Owner:NSK LTD

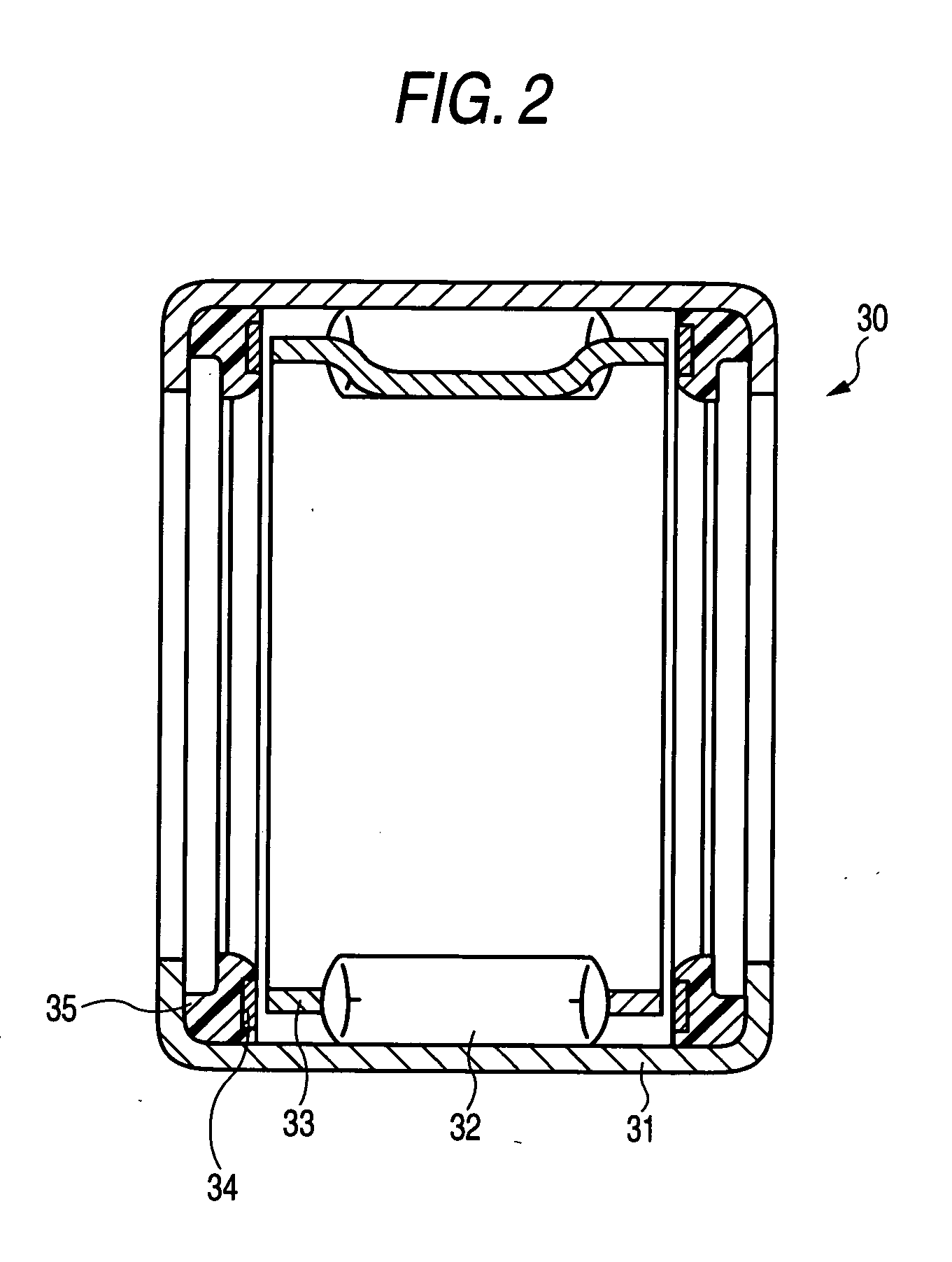

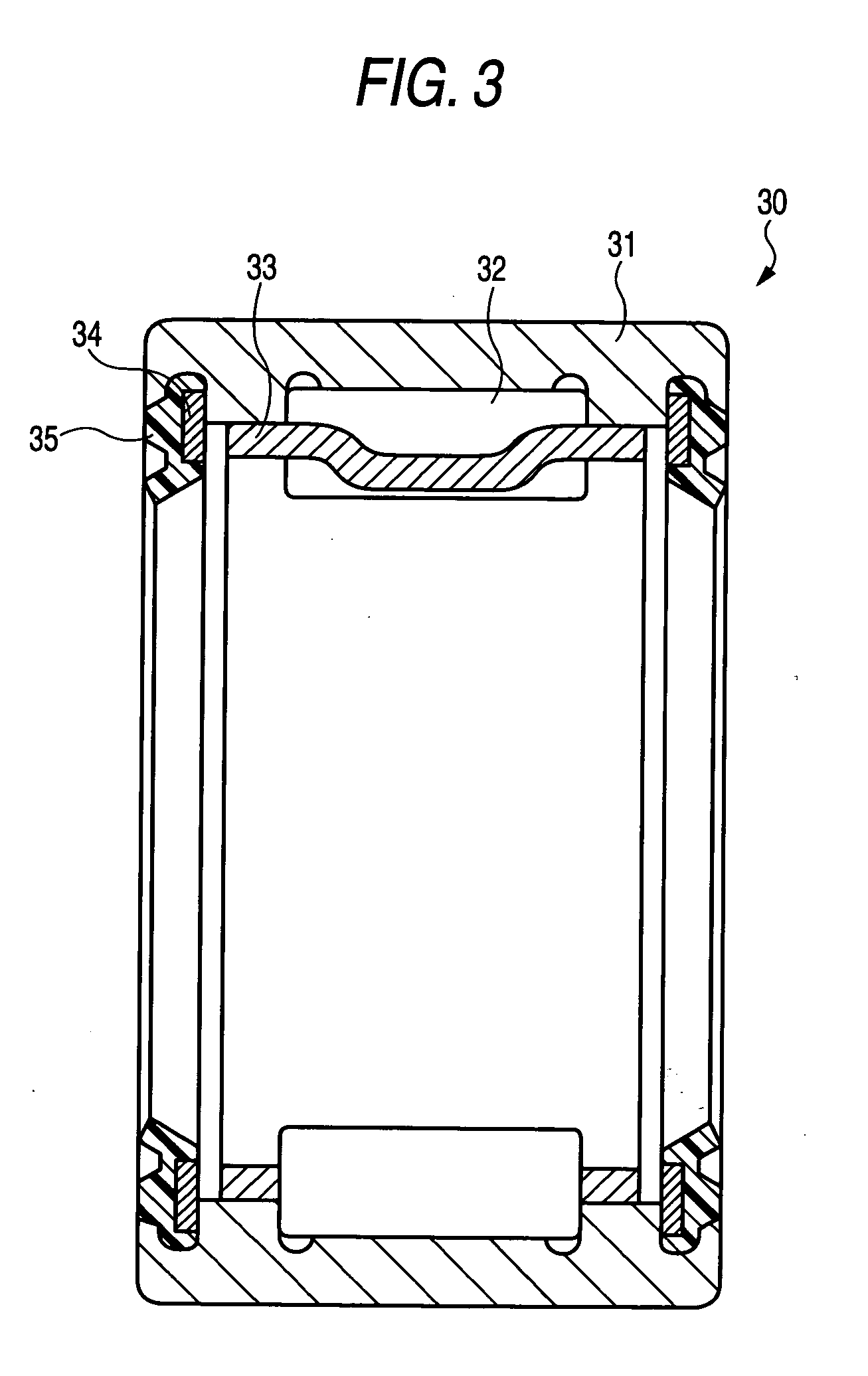

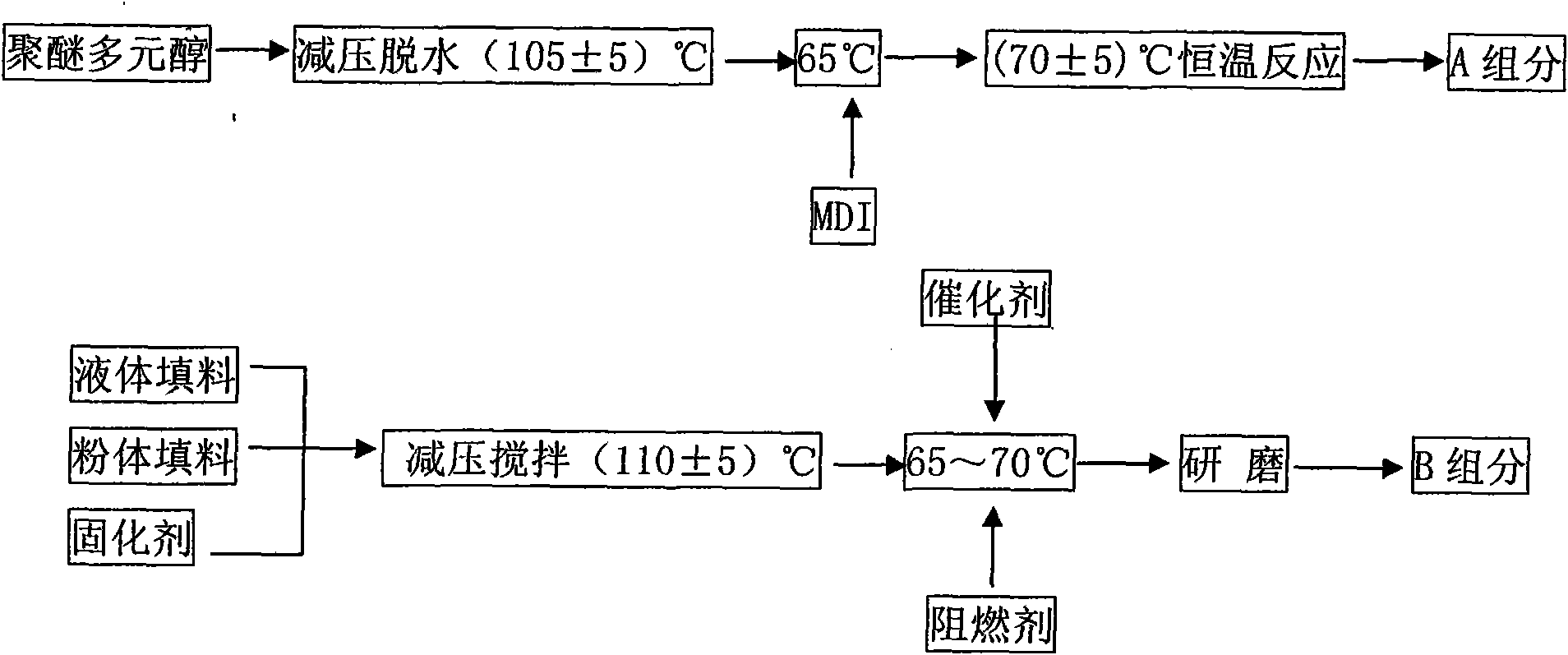

High-iron special flame-resistant polyurethane waterproof coating and preparation method thereof

InactiveCN101619193ALow volatilityLow vapor pressureFireproof paintsPolyurea/polyurethane coatingsPrepolymerHigh intensity

The invention discloses a high-iron special flame-resistant polyurethane waterproof coating and a preparation method thereof. The high-iron special flame-resistant polyurethane waterproof coating comprises an A component of an isocyanate group terminated polyurethane prepolymer and a B component of a dense cure-crosslinking agent. The prepared double-component high-strength flame-resistant polyurethane waterproof coating has tensile strength of 3.5-10MPa, at-break elongation of 450-600 percent and concrete interface boning strength greater than 2.5MPa and is used by uniformly mixing the A component and the B component according to a certain proportion and coating the mixture on a concrete waterproof plane to solidify into an integral waterproof coating with elasticity, firmness and durability. The coating is suitable for concrete ballast bridge floors and non-ballast bridge floors of high-iron passenger special line bridges and railway bridge culvert waterproof engineering and is suitable for the waterproofness of other buildings and constructions with higher requirements on waterproof performance.

Owner:天津市耀新科技发展有限公司

Flexible vinyl dedicated to wire and cable

ActiveCN1760258AGood heat resistanceLow volatilityPlastic/resin/waxes insulatorsTransmission linePlasticizer

A soft polyviny chloride plastic for electric transmission line or cable is proportionally prepared from PVC resin, refractory plasticizer, stabilizer, antioxidizing agent, filler and lubricant. Its advantages are high refractory class (120deg.C), long high-temp stabilizing duration (300 min), and low high-temp volatilization.

Owner:CHANGSHU ZHONGLIAN PHOTOELECTRICITY NEW STUFF +1

Cleaning agent for automobile windshield

ActiveCN101831360ALow volatilityImprove washing effectInorganic/elemental detergent compounding agentsOrganic detergent compounding agentsChemistryNonionic surfactant

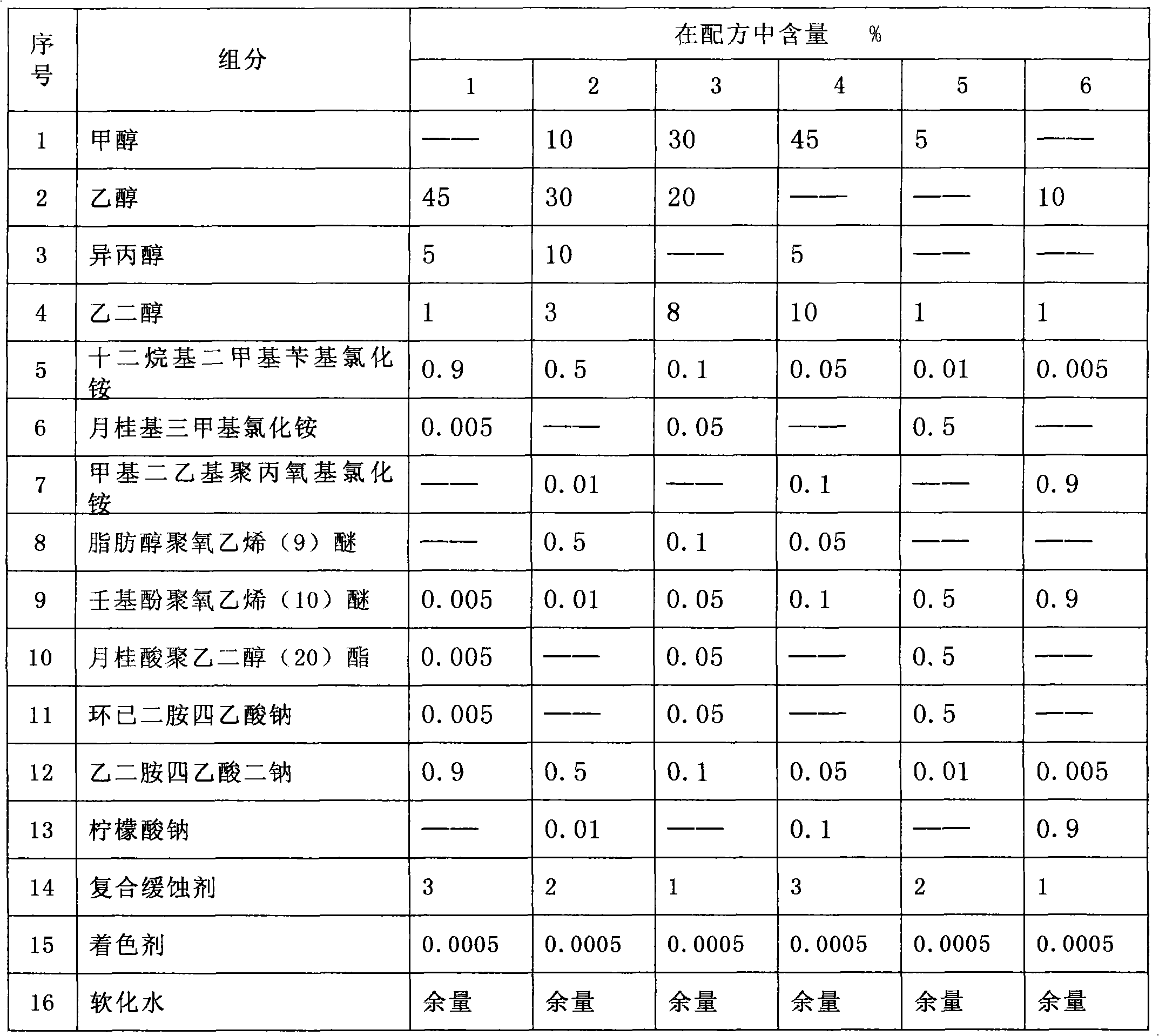

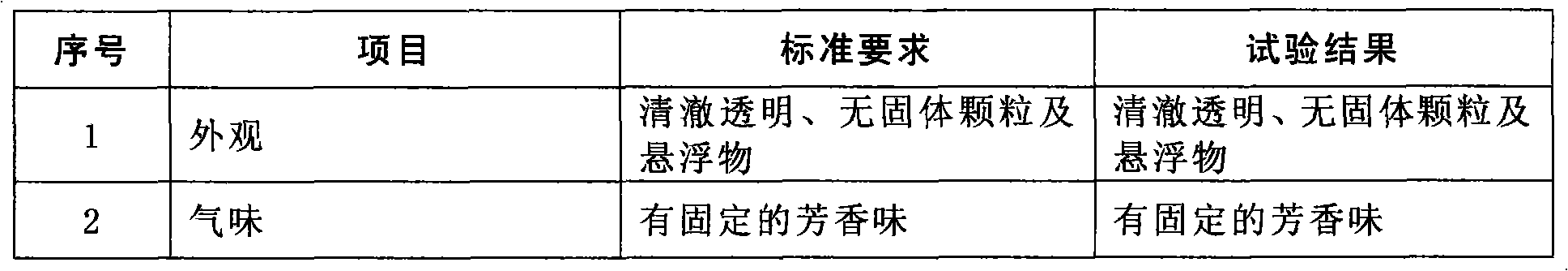

The invention relates to a cleaning agent for an automobile windshield, which consists of the following components in percentage by weight: 1 to 50 percent of monobasic alcohol, 1 to 10 percent of ethylene glycol, 0.005 to 0.1 percent of complexing agent, 0.005 to 0.1 percent of cationic surfactant, 0.005 to 0.1 percent of nonionic surfactant, 0.1 to 3 percent of composite corrosion inhibitor, 0.005 to 0.1 percent of colorant and the balance of water. The cleaning agent has cleaning, anti-freezing, anti-fog, anti-corrosion, anti-static, lubricating properties, can effectively remove dust, dirt, spray mark, gum, lac and the like on the windshield, and has high stability of high and low temperature and no damage to the automobile windshield.

Owner:北京蓝星清洗有限公司

Flat glass substrate attenuation etching liquid

The invention relates to a reduction etching liquid for base plates of sheet glass, components percentage by weight of which comprise: hydrofluoric acid holding 5-25%, strong acid holding 5-30% and pure water holding 45-90%. The reduction etching liquid for base plates of sheet glass of the invention is less in volatilization and toxicity. The using rate of the etching liquid is high and etching speed is rapid and stable. Costs of waste liquor treatment and subsequent treatment are low. The etching effect is excellent. Therefore, the invention has wide prospects for application.

Owner:BOE TECH GRP CO LTD +2

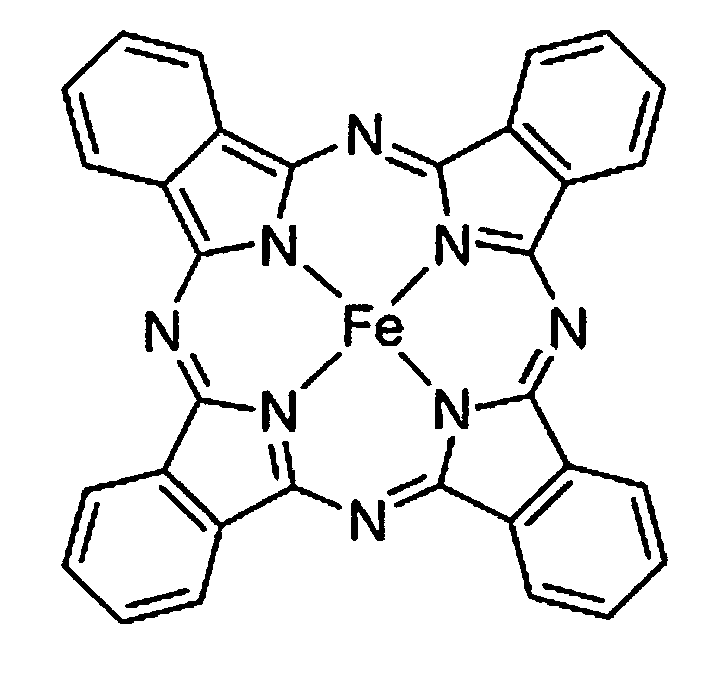

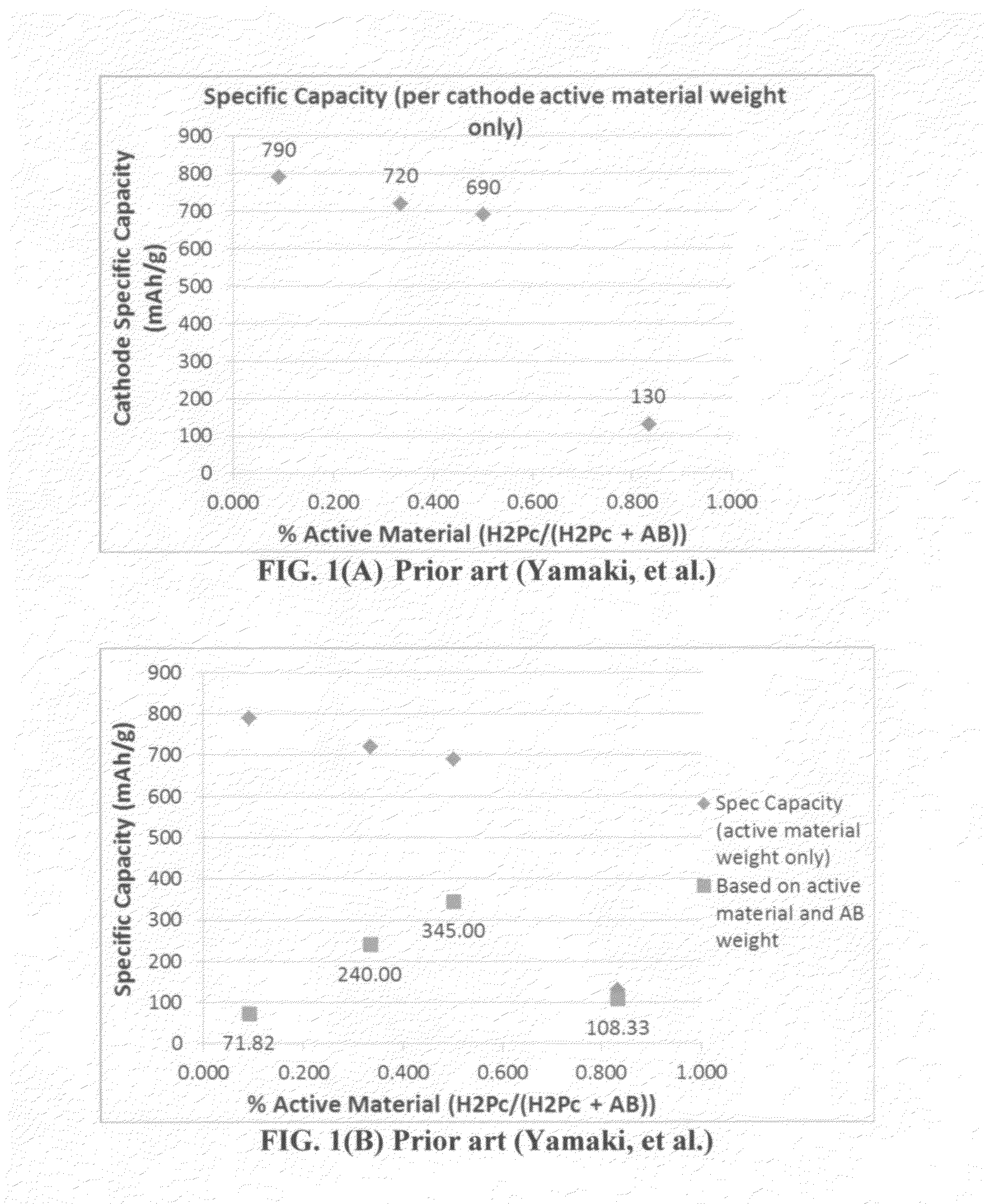

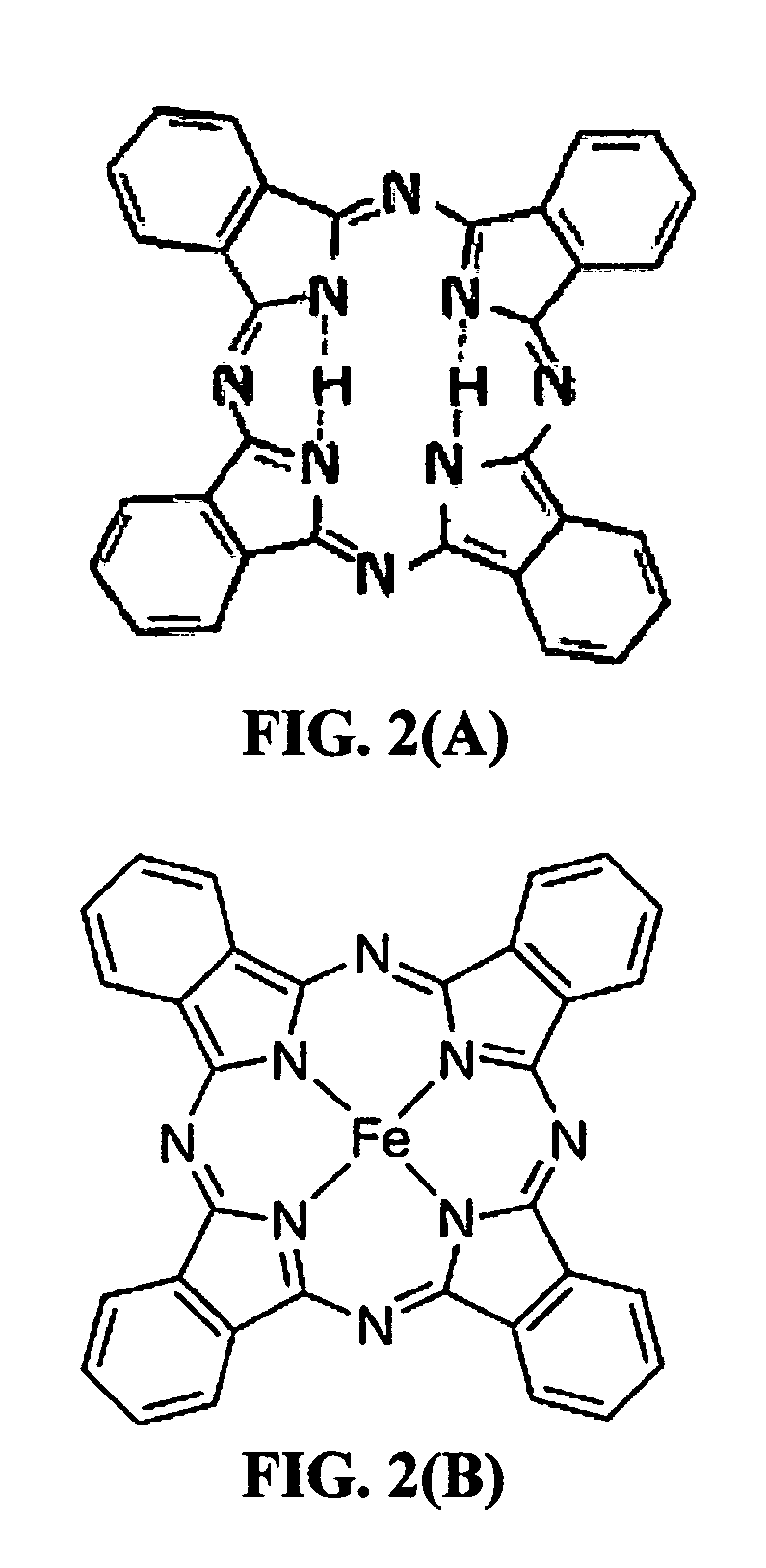

Rechargeable lithium cell having a phthalocyanine-based high-capacity cathode

ActiveUS20130309561A1High coefficientLow volatilityMaterial nanotechnologyElectrode carriers/collectorsSpecific energyLarge capacity

A rechargeable lithium cell comprising: (a) an anode; (b) a cathode comprising a hybrid cathode active material composed of a graphene material and a phthalocyanine compound, wherein the graphene material is in an amount of from 0.1% to 99% by weight based on the total weight of the graphene material and the phthalocyanine compound combined; and (c) a porous separator disposed between the anode and the cathode and electrolyte in ionic contact with the anode and the cathode. This secondary cell exhibits a long cycle life and the best cathode specific capacity and best cell-level specific energy of all rechargeable lithium-ion cells ever reported.

Owner:GLOBAL GRAPHENE GRP INC

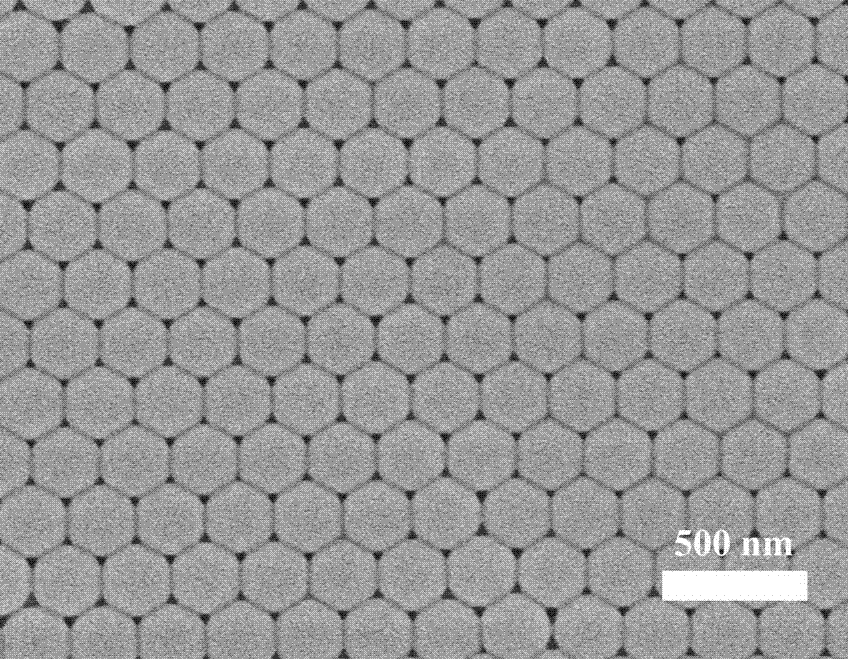

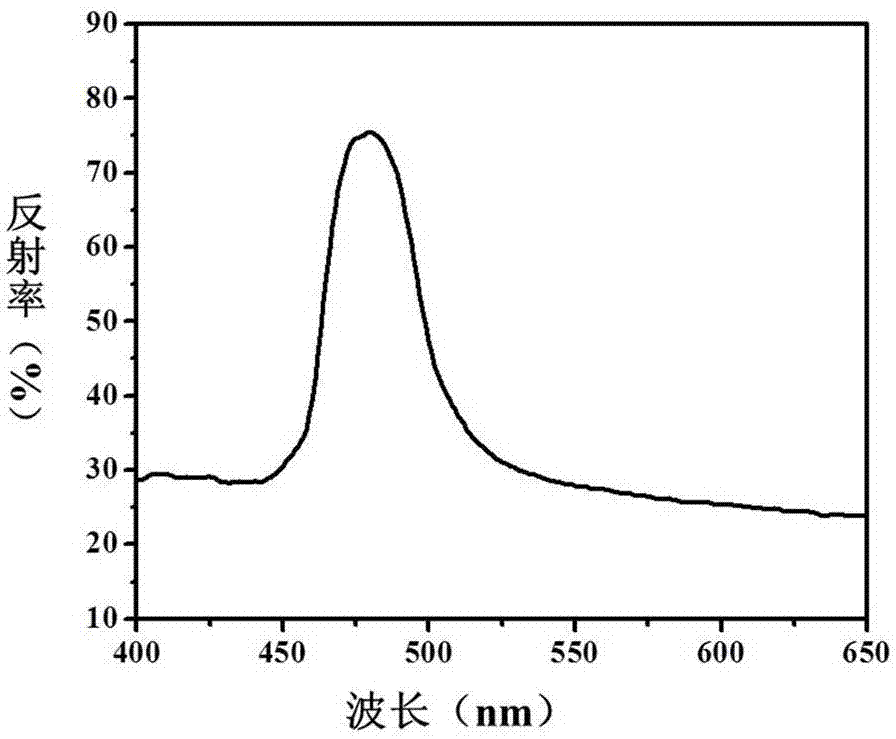

Structural color material for photosensitive three-dimensional printing and preparation method thereof

The invention belongs to the technical field of printing and in particular relates to a structural color material for photosensitive three-dimensional printing and a preparation method thereof. The structural color material is prepared from the following components: 5 to 15 parts of monodisperse nanoparticle, 15 to 35 parts of hyperbranched polyurethane acrylic resin, 40 to 50 parts of an active diluting agent, 0 to 10 parts of an alcohol solvent, 2 to 5 parts of a photoinitiator, 2 to 10 parts of an auxiliary agent. According to the structural color material provided by the invention, the monodisperse nanoparticles are used as a basic unit for assembling structural color to form a color generation part of a photosensitive three-dimensional printing material; the structural color materialis environmentally friendly and has a bright color, and a condition that a spraying nozzle is blocked can be avoided; meanwhile, the hyperbranched polyurethane acrylic resin with good compatibility and photoreaction properties is utilized so that the problems that a current 3D printing photo-curing speed is not rapid enough, the compatibility between the materials is poor and the shrinkage rate isrelatively large in a curing process are improved. By adopting the structural color material for the photosensitive three-dimensional printing, provided by the invention, produced colored componentswith high precision, environment protection and low cost can be widely applied to fields including decorations, anti-counterfeiting labels and the like and have a wide market prospect.

Owner:JIANGMEN HENGZHIGUANG ENVIRONMENTAL PROTECTION NEW MATERIAL CO LTD

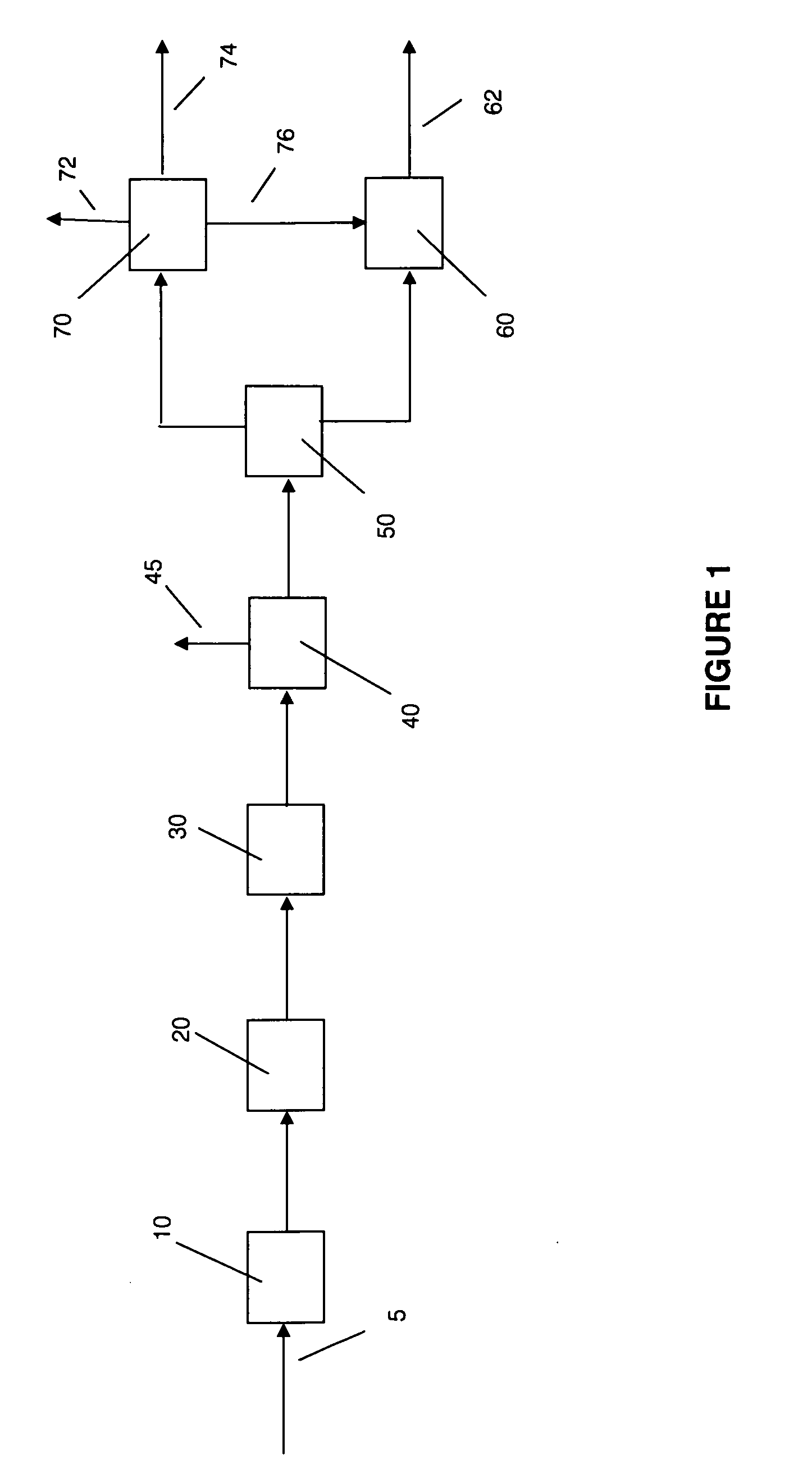

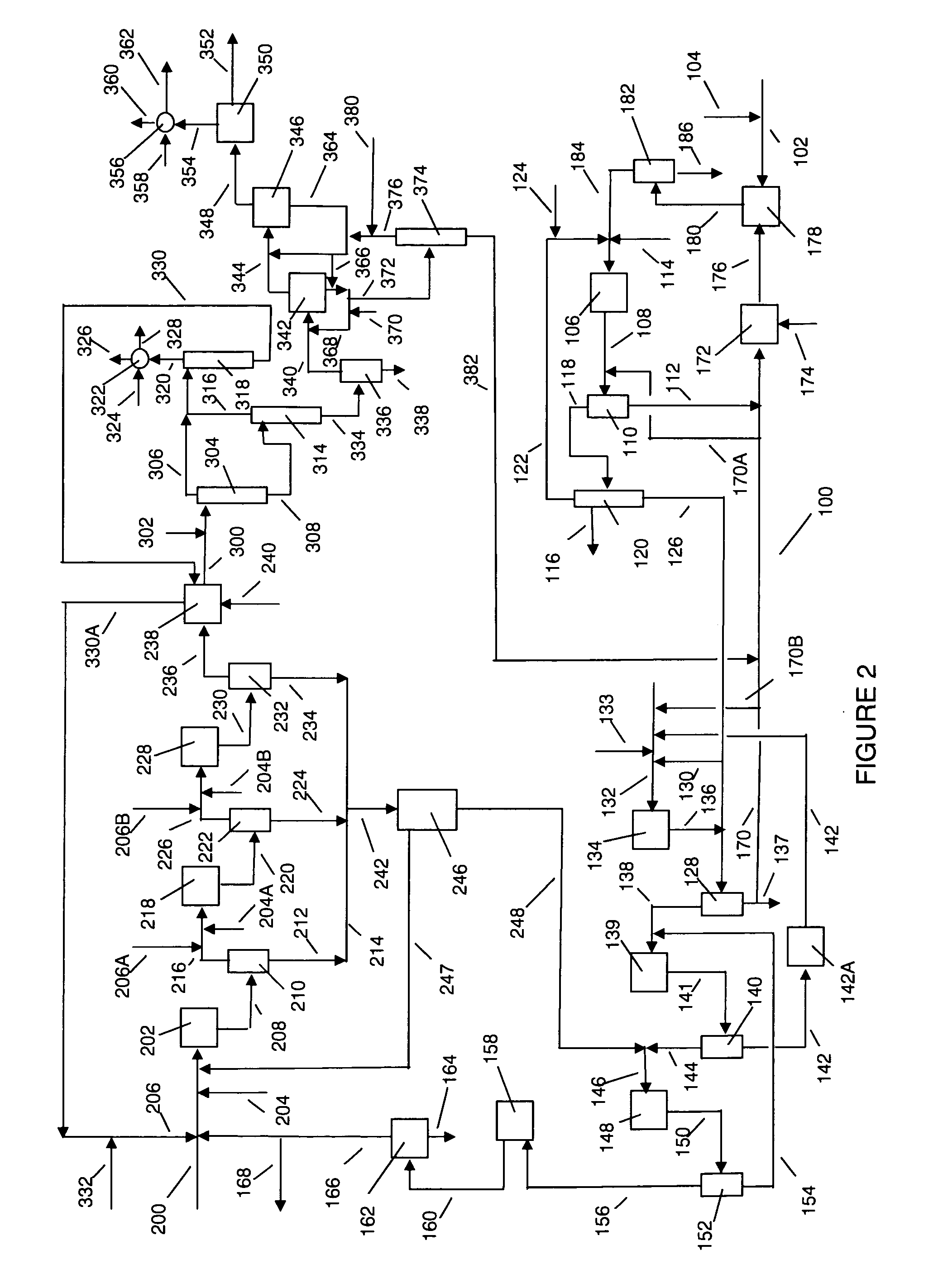

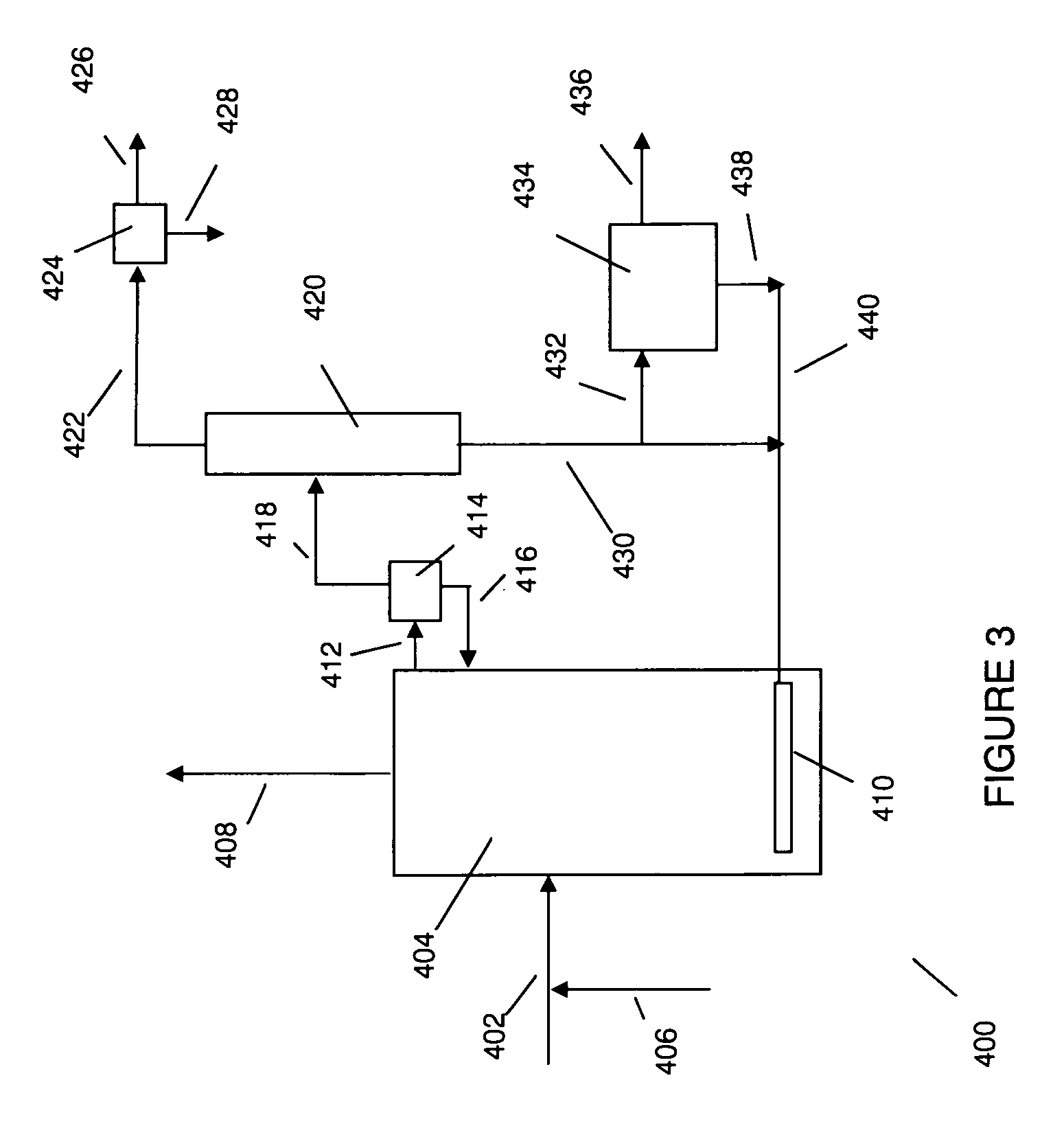

Integrated glyceride extraction and biodiesel production processes

InactiveUS20090148920A1Point become highLow volatilityFatty acid esterificationOrganic compound preparationBiomassGlycerol ester of wood rosin

Owner:RIDTONE BANK +1

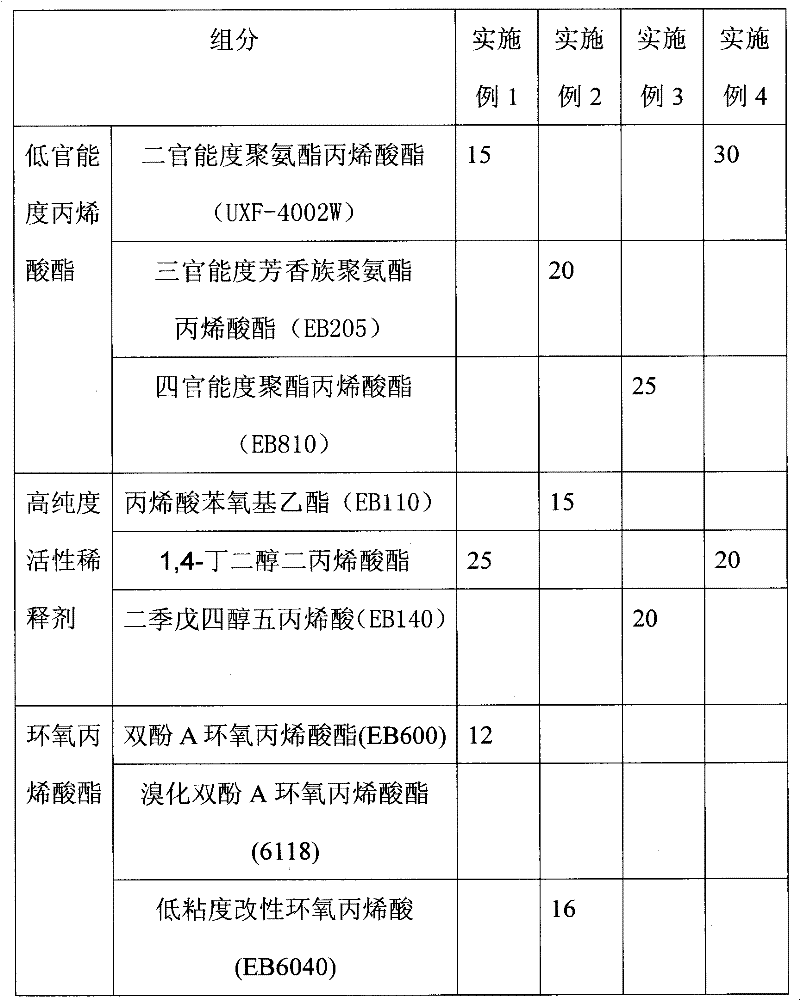

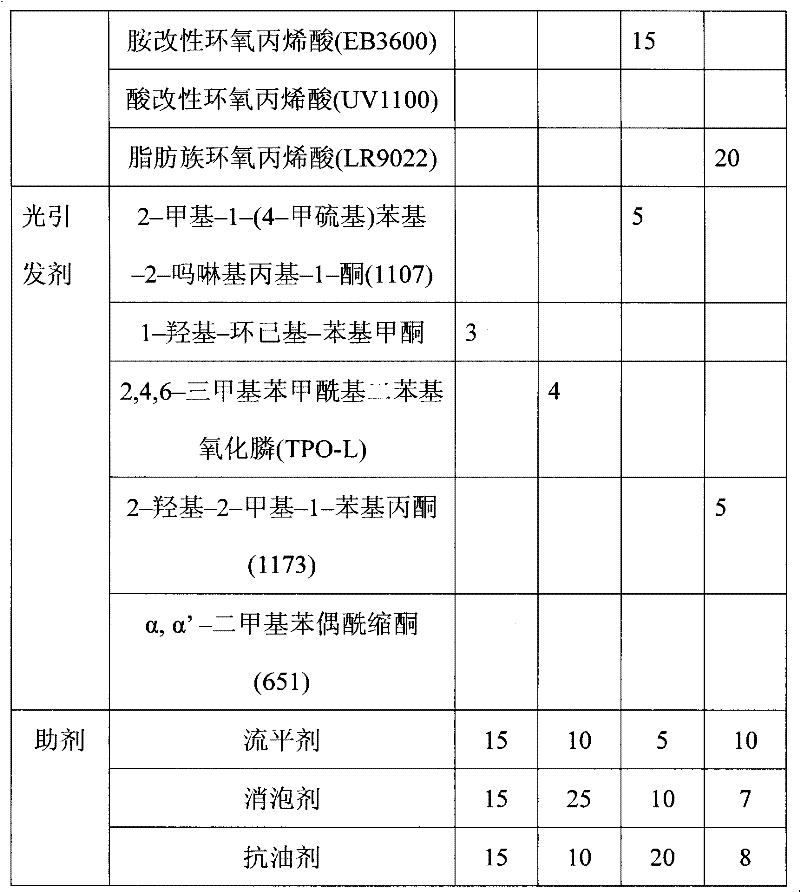

Vacuum plating UV cured primer

ActiveCN102206463AHigh glossLow volatilityPolyurea/polyurethane coatingsEpoxy resin coatingsPhotoinitiatorElectroplating

The invention belongs to the technical field of coating, and especially relates to a vacuum plating UV cured primer. The primer includes the following materials of, by weight, 15-30% of low-functionality acrylic ester, 10-25% of high-purity reactive diluent, 10-20% of epoxy acrylate, 25-45% of accessory ingredient, and 3-5% of photoinitiator. The primer of the invention can be cured fast and has good abrasive resistance, pollution tolerance, scratch resistance to hard objects, high glossiness, low volatility and no pollution. Therefore, the primer can be widely applied to flame plating of electron products or electrical equipment and cosmetic containers.

Owner:苏州佩琦材料科技有限公司

Thermal stability metaformaldehyde and its preparation method

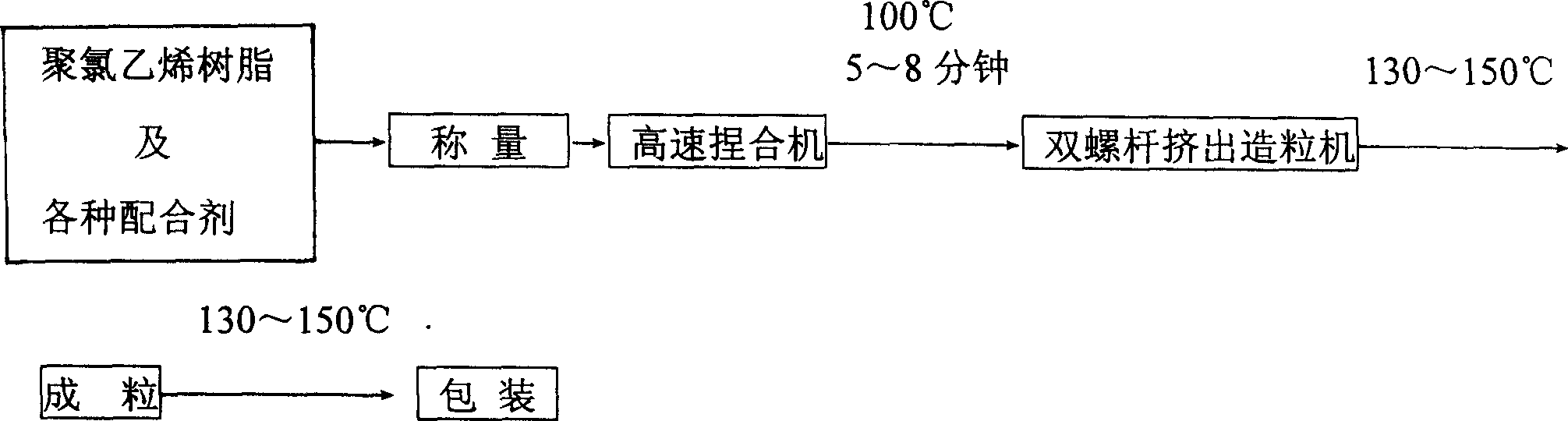

The invention discloses a thermal stability metaformaldehyde and its preparation method which comprises, charging polyoxymethylene resin, anti-oxidizing agent, methylene oxide absorbing agent, methanoic acid absorbing agent and auxiliary methylene oxide absorbing agent into high speed mixing machine, melting and co-blending by employing exhaust type double screw stem extrusion machine, finally squeezing and granulating.

Owner:YUNNAN YUNTIANHUA +1

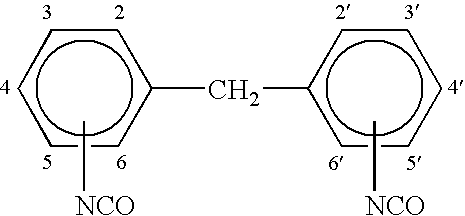

Water curable polyurethane compositions and uses thereof

InactiveUS20070083003A1Low vapor pressureLow volatilityConductive materialOrganic conductorsSolventIsocyanate

Increased health, safety, and environmental awareness motivated the development of new and improved water curing technology for formulating, manufacturing, and using water curable compositions (also referred to in the art as water induced urethanes). The present invention is based, at least in part, upon the concept of formulating NCO functional resins used in water curable compositions from one or more polyisocyanate constituents that comprise at least one sterically hindered isomer of diphenyl methane diisocyanate (MDI). These isomers have a combination of exceptionally low vapor pressure and suitable moisture reactivity that lead to numerous advantages. Due to their low volatility, these isomers may be substituted for all or a portion of the TDI content of a conventional water induced urethane formulation. In a preferred embodiment, fly ash is incorporated into the water-curable compositions described herein. Particularly preferred embodiments eliminate any TDI, have 100% solids, are solvent free, and are characterized by essentially zero VOC emissions with respect to isocyanate. The compositions are substantially more environmentally friendly than conventional formulations.

Owner:GUPTA LAXMI C

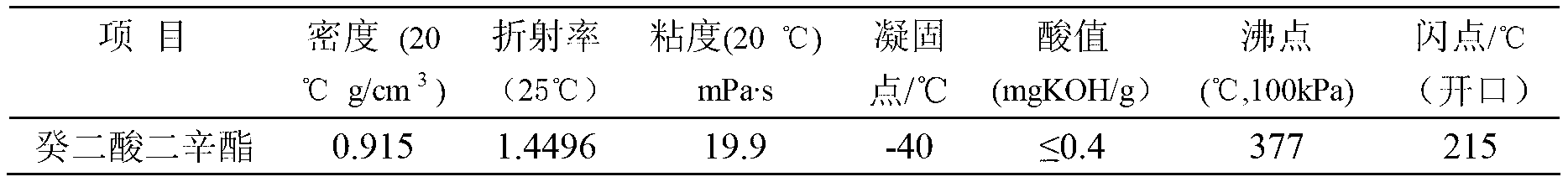

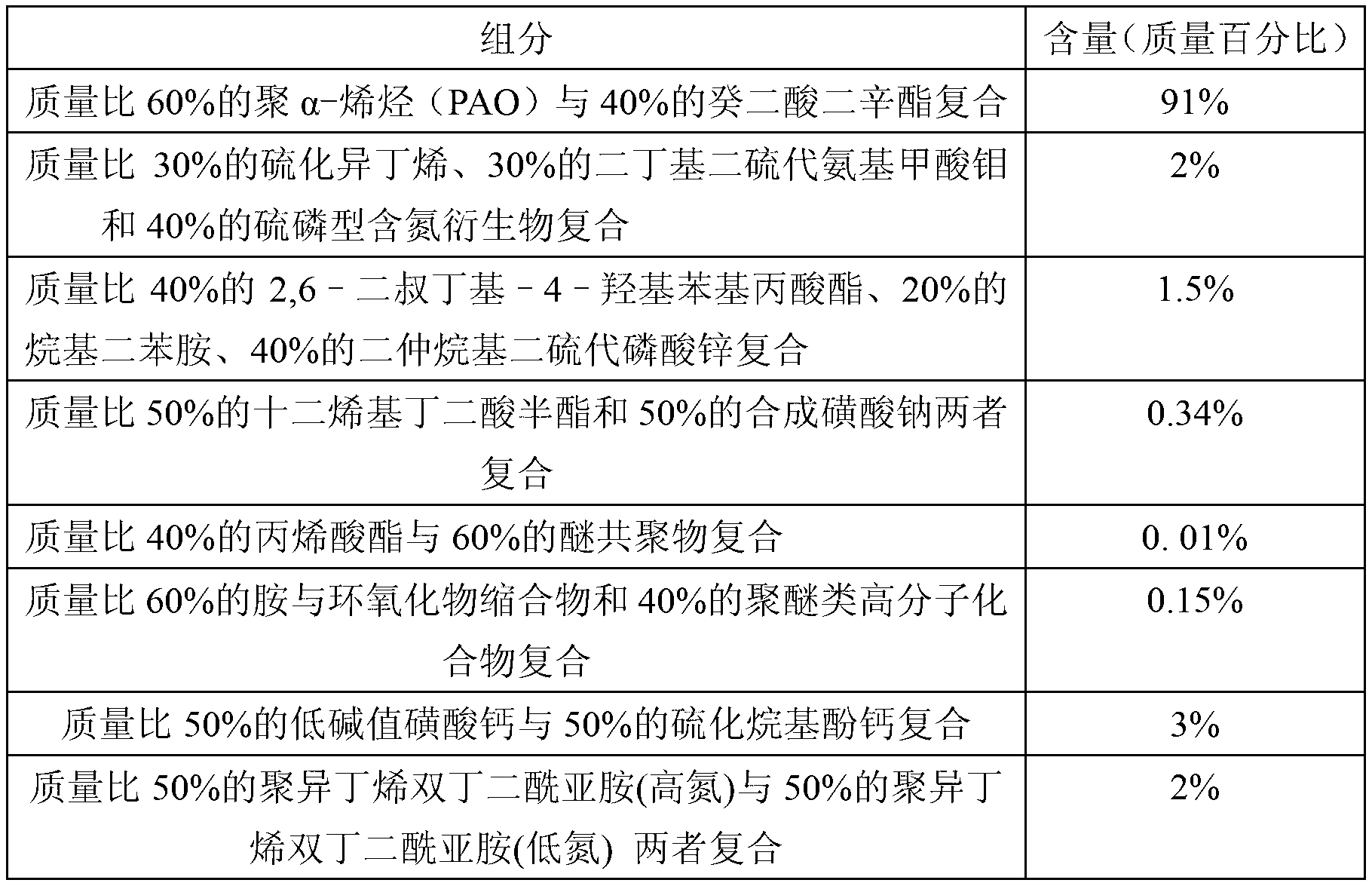

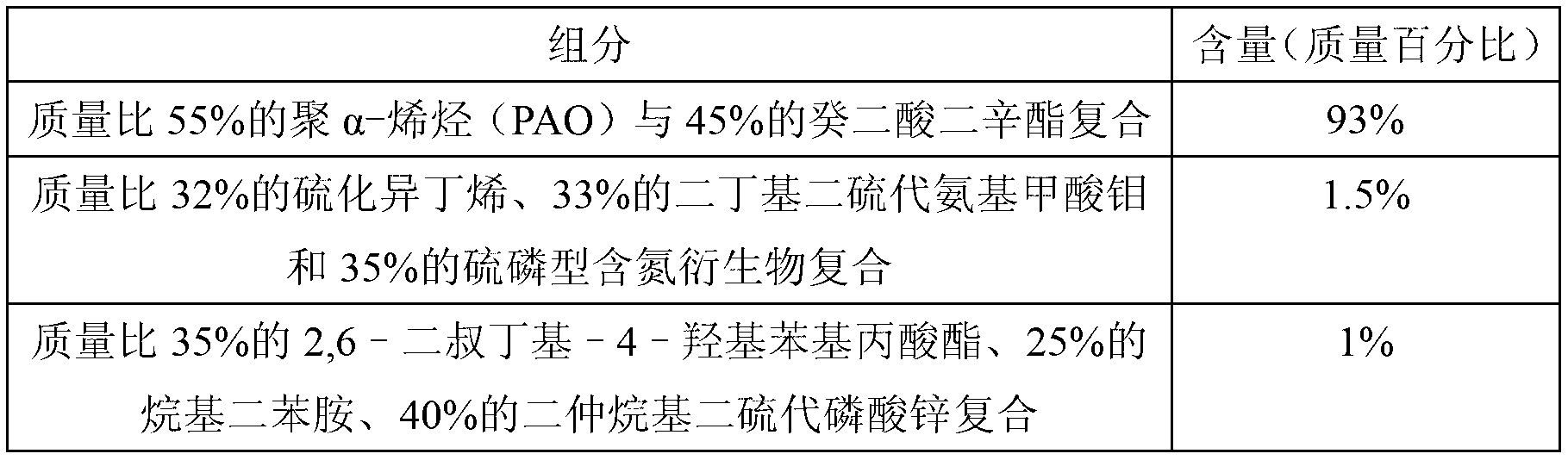

Environmentally-friendly energy-saving-type heavy loading screw compressor oil

ActiveCN103194301AGood low viscosityLow volatilityLubricant compositionLubricationEnvironmentally friendly

The invention provides environmentally-friendly energy-saving-type heavy loading screw compressor oil. The environmentally-friendly energy-saving-type heavy loading screw compressor oil comprises 90-95% of composite base oil and 10%-5% of other additives in percentage by weight. Poly Alpha-Olefins (PAO) and dioctyl sebacate are compounded to serve as the base oil of the environmentally-friendly energy-saving-type heavy loading screw compressor oil. The environmentally-friendly energy-saving-type heavy loading screw compressor oil provided by the invention has the advantages of good operating characteristics, long service life and good biodegradability and also has effects of improving the efficiency of a screw compressor, reducing the abrasion and corrosion of a screw, effectively prolong the service life and the oil draining period of the screw compressor and meeting the requirements under special service conditions. The environmentally-friendly energy-saving-type heavy loading screw compressor oil provided by the invention is not only suitable for the requirements of various middle-heavy loading screw compressors under service conditions, and but also can meet the lubrication, cooling and sealing requirements of the middle-heavy loading sliding vane compressors.

Owner:GUANGXI UNIV

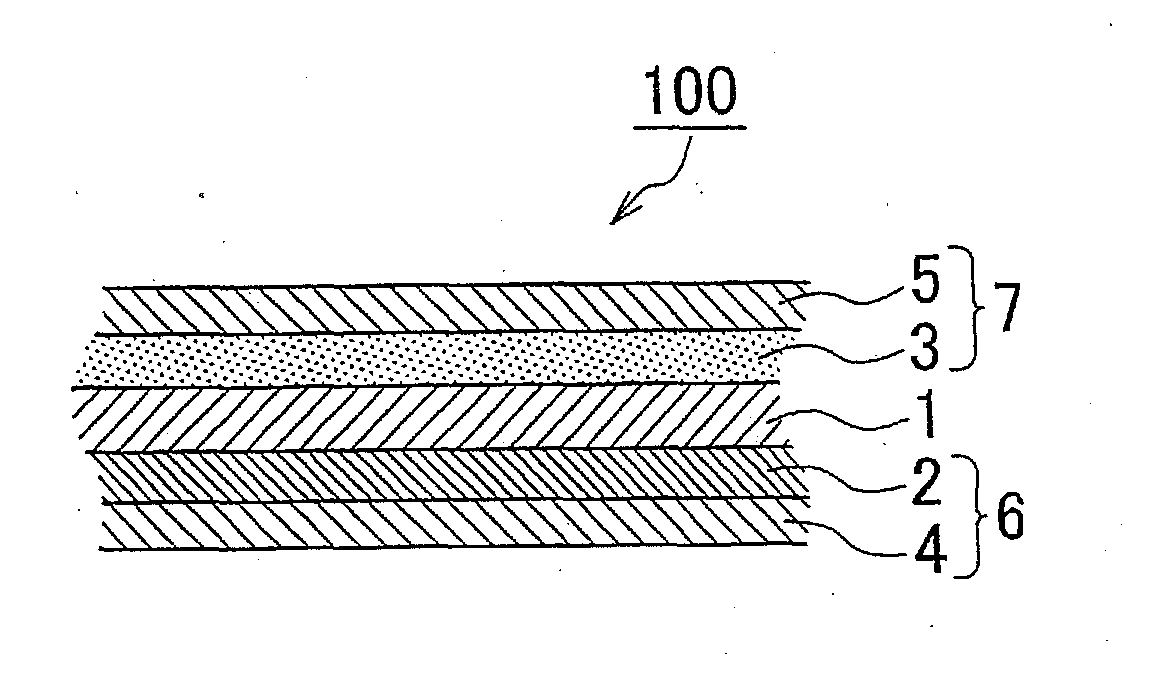

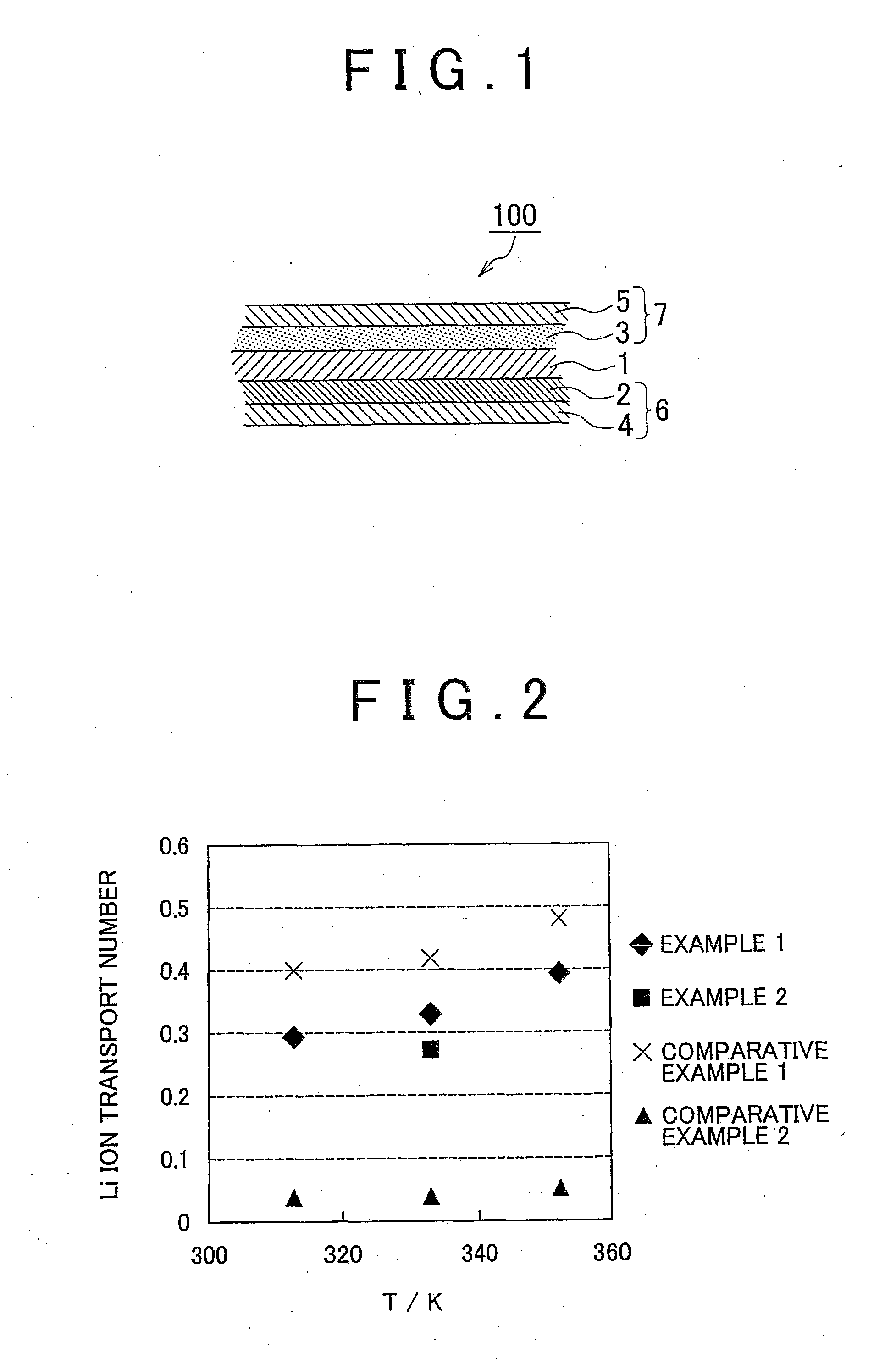

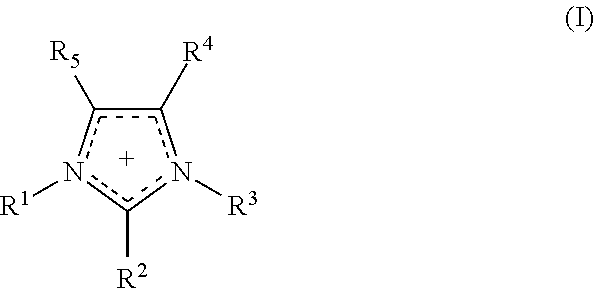

Electrolyte solution for lithium battery, lithium battery including electrolyte solution, electrolyte solution for lithium air battery, and lithium air battery including electrolyte solution

InactiveUS20130209915A1Low volatilityExcellent conductivityFuel and secondary cellsAqueous electrolyte fuel cellsLithium–air batteryLithium-ion battery

An electrolyte solution for a lithium battery contains 1-butyl-3-methyltetrazolium-5-olate represented by formula (1).

Owner:TOYOTA JIDOSHA KK +1

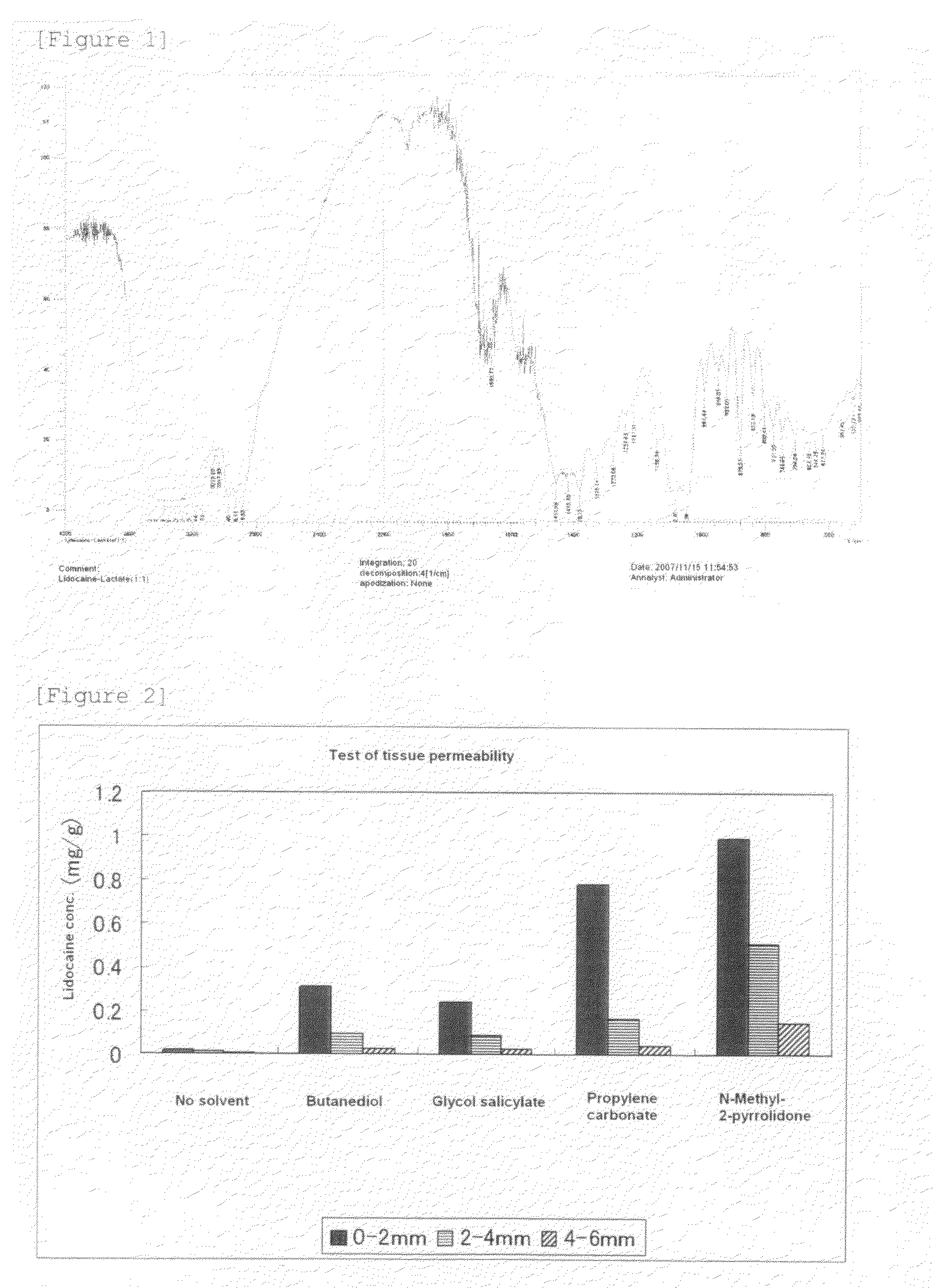

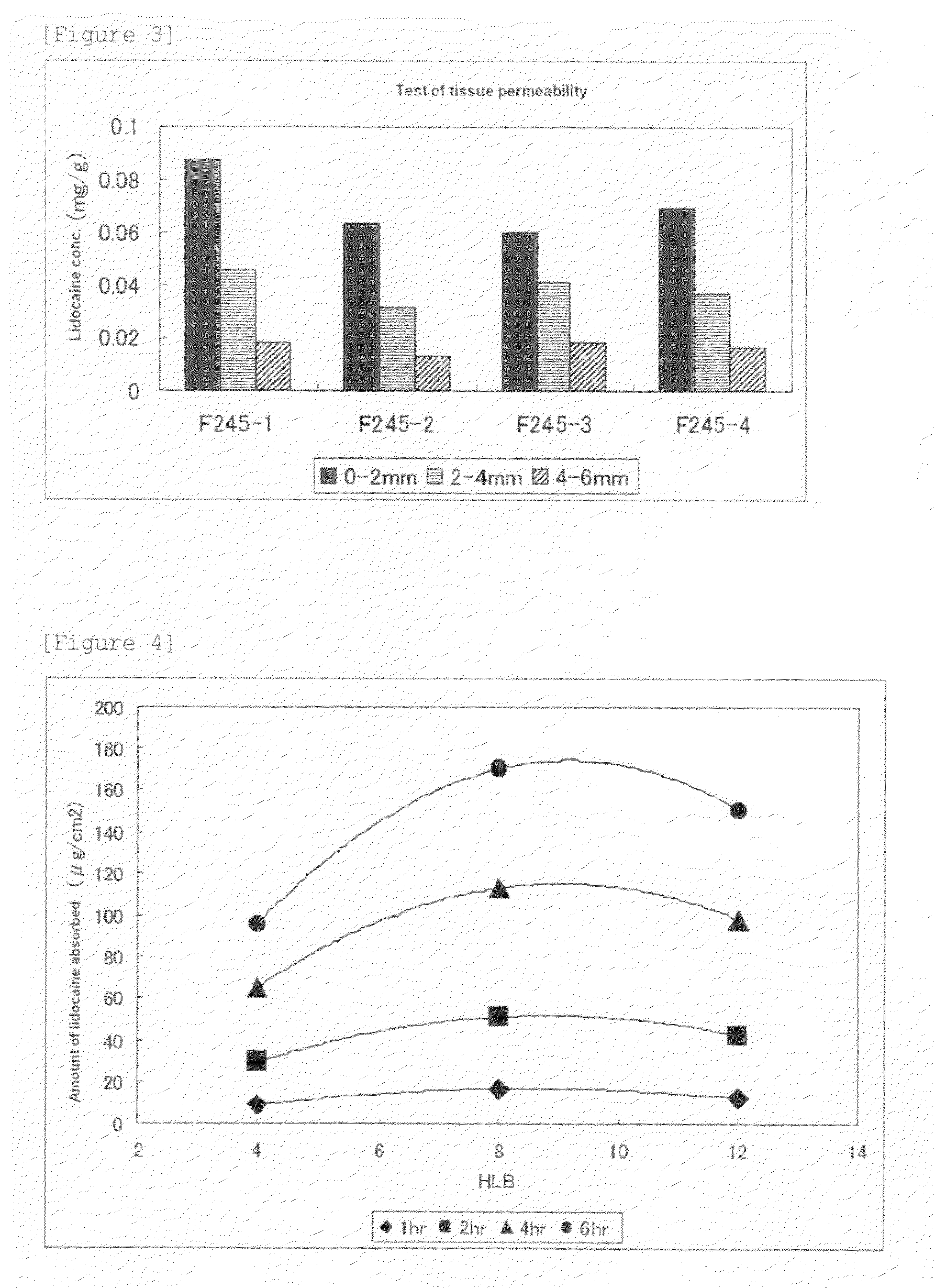

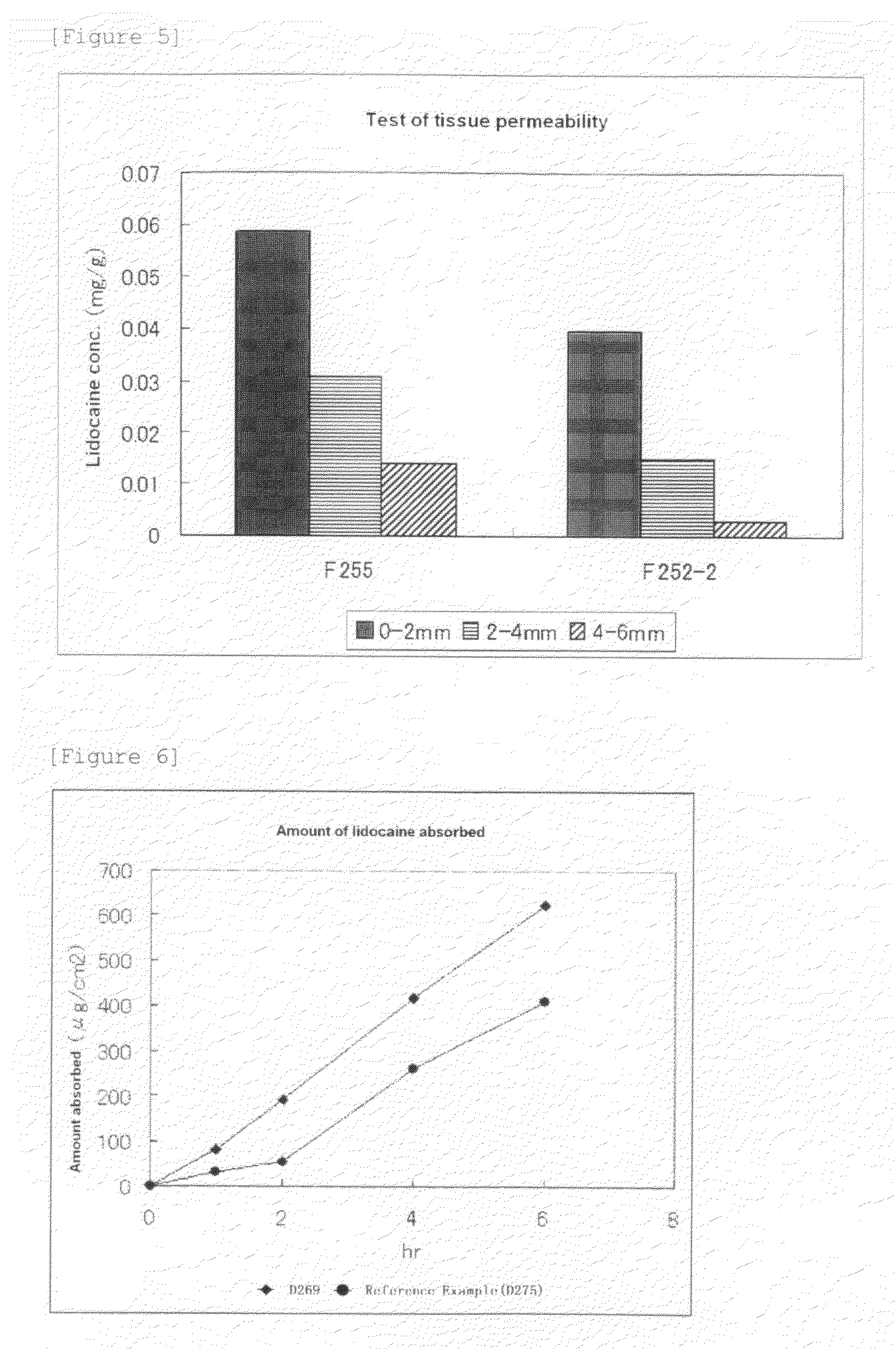

Lidocaine tape preparation

ActiveUS20100234471A1Low volatilitySuppresses deterioration of adhesive powerBiocideOrganic chemistryHigh concentrationHomosalate

The present invention discloses a novel tape preparation containing lidocaine at a high concentration. A tape preparation containing lidocaine at a high content, which has a lidocaine contant of 10 w / w % or more, can be produced by using a lactic acid salt of lidocaine, while preventing the precipitation of a crystal of lidocaine.

Owner:MEDRX CO LTD

Vacuum-plating ultraviolet curing intermediate paint

The invention belongs to the technical field of paints, and particularly relates to a vacuum-plating ultraviolet curing intermediate paint, which includes the following raw materials by weight: 10%-20% of hydroxy acrylic resin, 25%-35% of polyurethane acrylates, 15%-20% of thermoplastic acrylic acid resin, 15%-25% of ethyl acetate, 10%-15% of butyl acetate, 8%-15% of isobutanol, 3%-10% of nano-pigments, 3%-5% of ultraviolet-curing initiators, and 1%-3% of additives. The invention has a fast-curing property, good wearability, pollution resistance, hard-object scratch resistance, high glossiness, low volatility, is environment-friendly and free of pollution, can be widely used to spray electronic or electric appliance products and cosmetic containers.

Owner:苏州佩琦材料科技有限公司

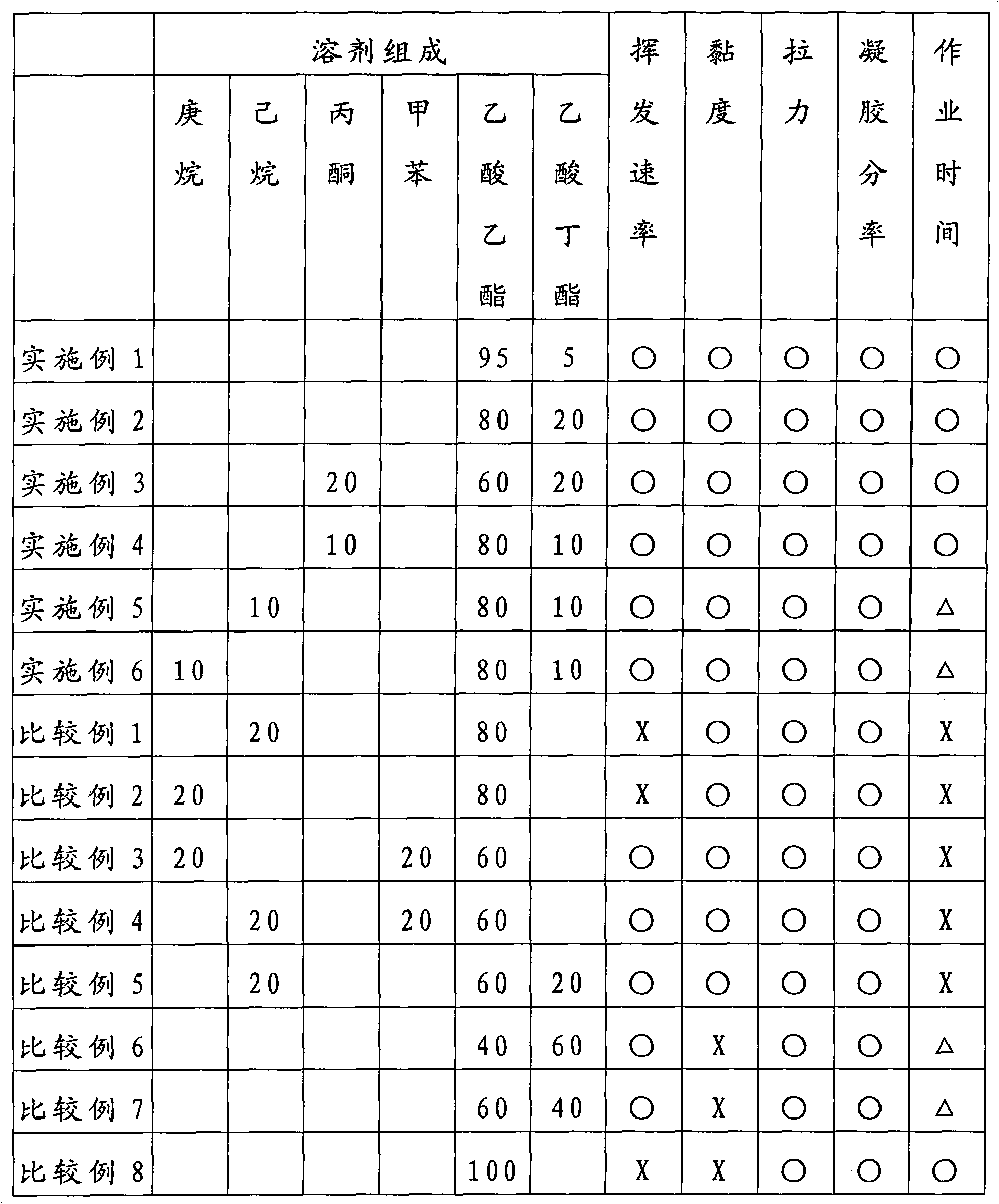

Adhesive composition and adhesion layer

ActiveCN102031077ALow volatilityExcellent spreadabilityFilm/foil adhesivesEster polymer adhesivesSolventChemistry

The invention discloses an adhesive composition and an adhesion layer. The adhesive composition comprises acrylic copolymer, total solvent and cross linking agent, wherein the total solvent comprises a first solvent and a second solvent, and the boiling point of the second solvent is higher than 111 DEG C. After being polymerized, the adhesive composition forms a viscose, and the first solvent has favorable solubility to the viscose. The weight ratio of the first solvent to the second solvent is 80-90:1-20. The adhesive composition is prepared by regulating the types and the proportion of the solvents, and the adhesive composition has the characteristics of low volatility, good coating property, good processability, etc. In addition, the adhesion layer formed by the adhesive composition has favorable durability and appropriate flexibility relative to base materials.

Owner:BENQ MATERIALS +1

Process for fibrillating lignocellulosic material, fibres and their use

InactiveUS20130056165A1Low volatilityExcellent propertyPulp properties modificationPulping with organic solventsIonBioplastic

The invention relates to a process for fibrillating lignocellulosic material wherein the process comprises treating lignocellulosic material with ionic liquid and recovering basically intact fibres of said lignocellulosic material. Another object of the invention is to provide an activated and / or basically intact fibre wherein the lignocellulosic material is treated with ionic liquid and a basically intact fibre of said lignocellulosic material is recovered. The invention further relates to the use of the basically intact fibre of the invention in the production of bio-based materials, preferably bio-plastics, more preferably conductive polymers, stimuli-responsive polymers, bio-based polymer composites, ceramics, fabrics, or elastomers. A process for producing paper, board, pulp or the like from fibers of lignocellulosic material which have been treated with ionic liquid and recovered as basically intact fibres is also enclosed.

Owner:UNIVERSITY OF HELSINKI

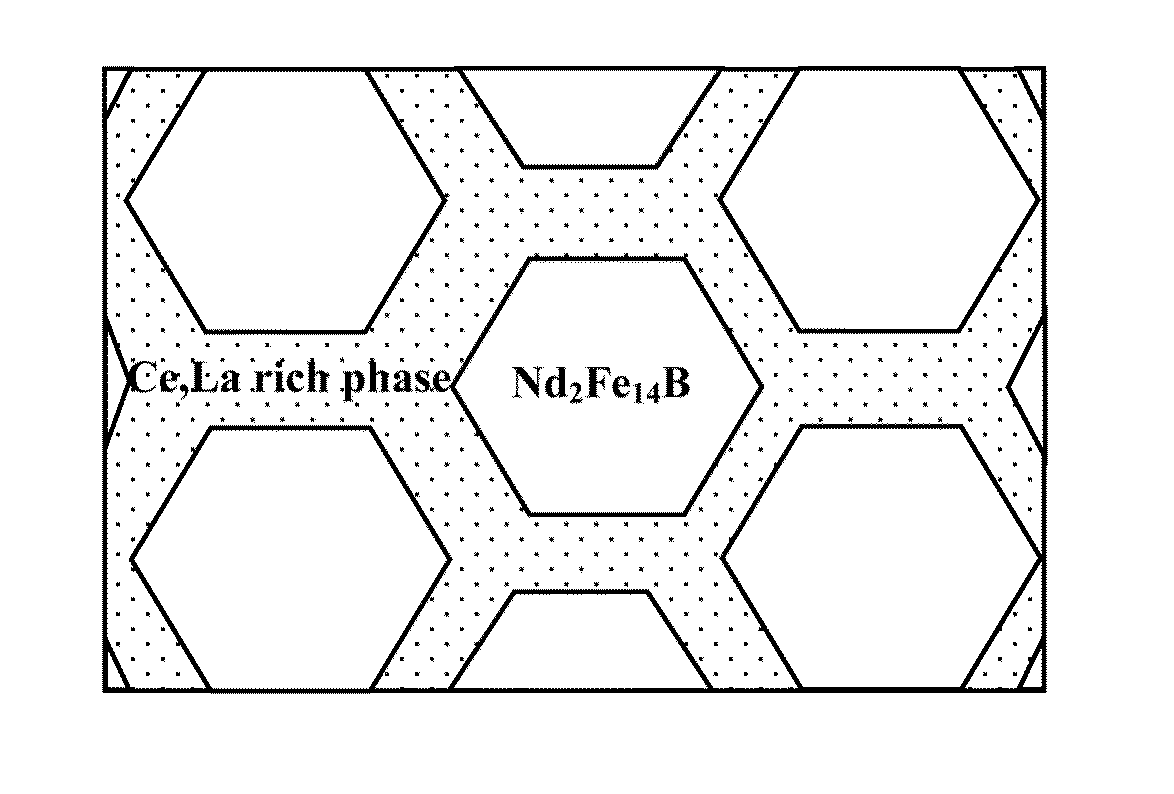

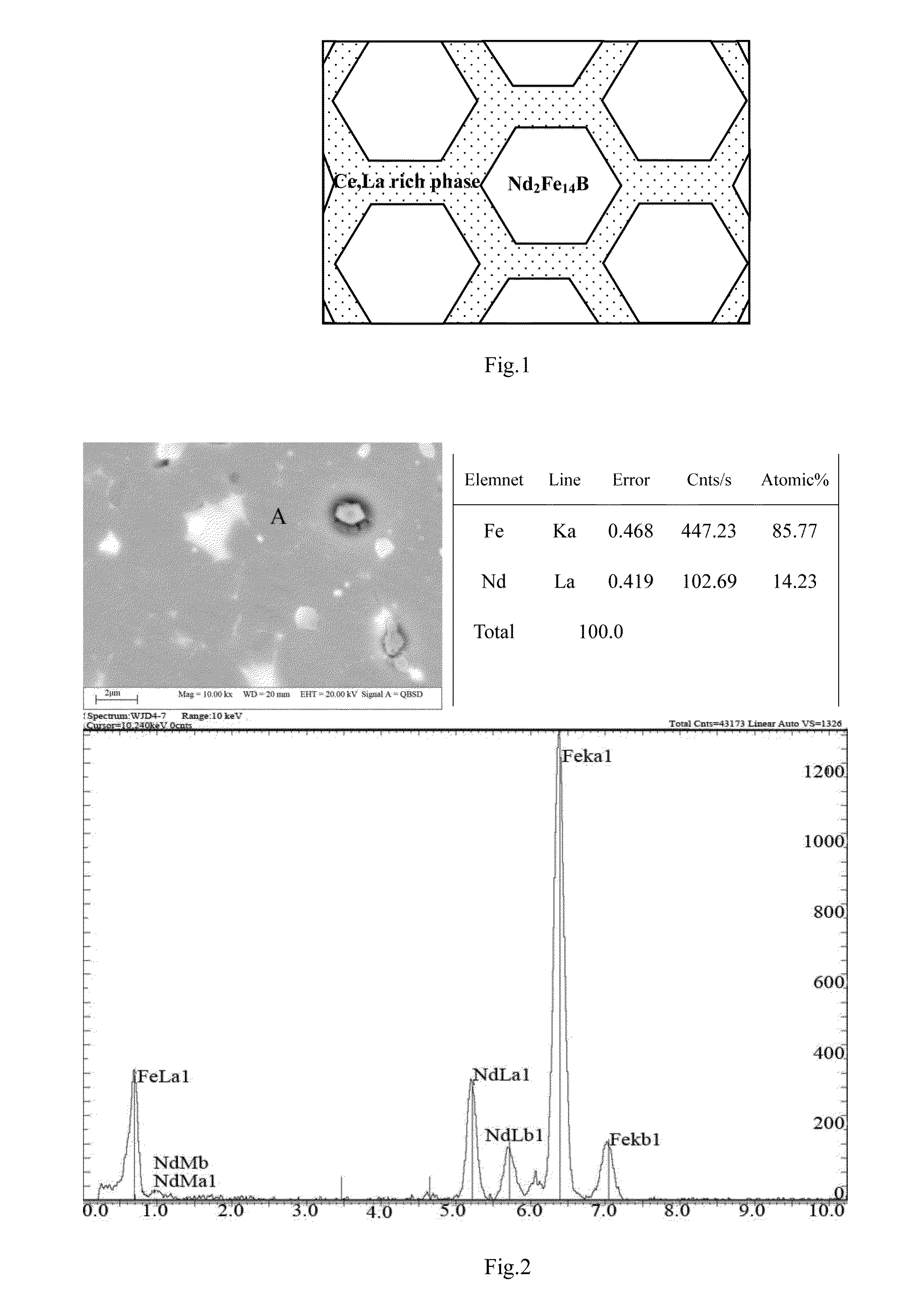

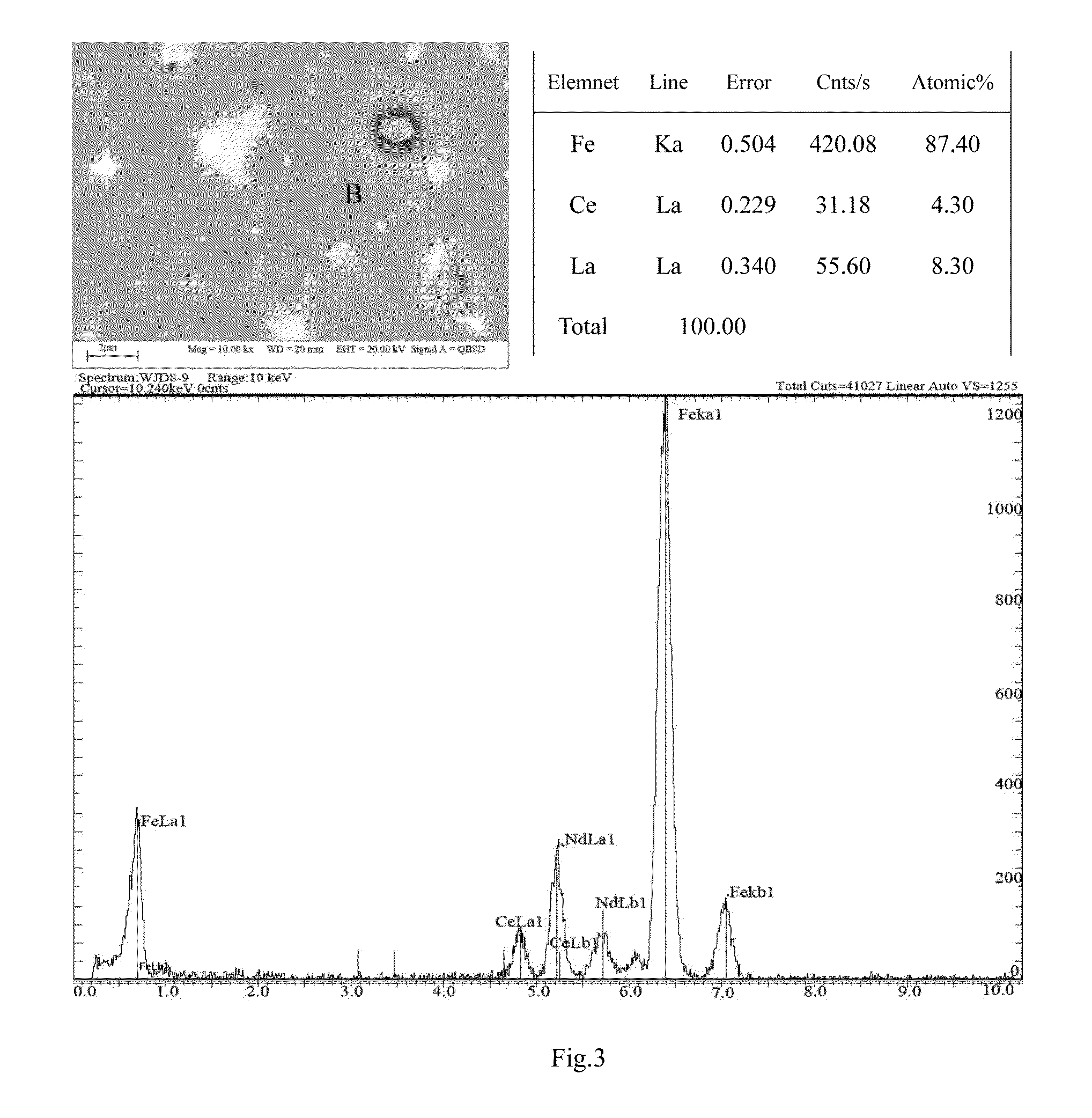

Low-neodymium, non-heavy-rare-earth and high performance magnet and preparation method

ActiveUS20130154778A1Excellent thermal oxidation stabilityLow volatilityPermanent magnetsInorganic material magnetismMagnetic energyMagnetic powder

The invention discloses a low-neodymium, non-heavy-rare-earth and high-performance magnet and its preparing method, and belongs to technical field of rare earth permanent magnetic material. The magnet has a chemical formula of [(Nd, Pr)100-x(Ce100-yLay)x]aFe100-a-b-cBbTMc, wherein x, y, a, b and c represent mass percents of corresponding elements respectively, 0≦x≦40%, 0≦y≦15%, 29≦a≦30%, 0.5≦b≦5%, 0.5≦c≦5%; and TM is one or more selected from Ga, Co, Cu, Nb and Al elements. A series of grades of magnets can be prepared with rapidly solidified strips of only three components. Component proportioning of magnet can also be directly performed by using mixed rare earth, so that the cost increased by further separation and purification of the rare earth is reduced. During the preparation of magnetic powder with a jet mill, an antioxidant lubricant which is composed of alcohol, gasoline and basic synthetic oil is added. A low-temperature sintering technology is adopted; and the sintering temperature is 1, 010-1, 050° C. and the annealing temperature is 450-550° C. The magnetic energy product (BH)m is more than 40 MGOe; and the coercive force Hcj is more than 10 kOe. The production time and the energy loss can be significantly reduced.

Owner:CENT IRON & STEEL RES INST

Oxidation resistant coating for hot stamping parts of ultrahigh strength sheet steel at high-temperature

InactiveCN101624500ALow volatilityImprove thermal stabilityAnti-corrosive paintsBulk chemical productionIonOxidation resistant

The invention relates to an oxidation resistant coating for hot stamping parts of ultrahigh strength sheet steel at high-temperature, comprising the following main components: boron modified organic silicon resin, polymethylsiloxane resin, tetraborate nitride powder, ionic liquid, aluminum powder, and polydimethylsiloxane. The coating has the advantages that the ionic liquid is used as organic solvent, therefore, the volatility is low and the thermal stability is high, in addition, solid lubricant is added, which can effectively prevent sheet materials from being oxidized, improves the frictional behaviour and the shaping property of the sheet materials; the thermal conduction of the coating is improved by adding metal particles, thus being beneficial to quenching. The coating can be directly applied to direct hot stamping forming process and indirect hot stamping forming process.

Owner:JILIN UNIV

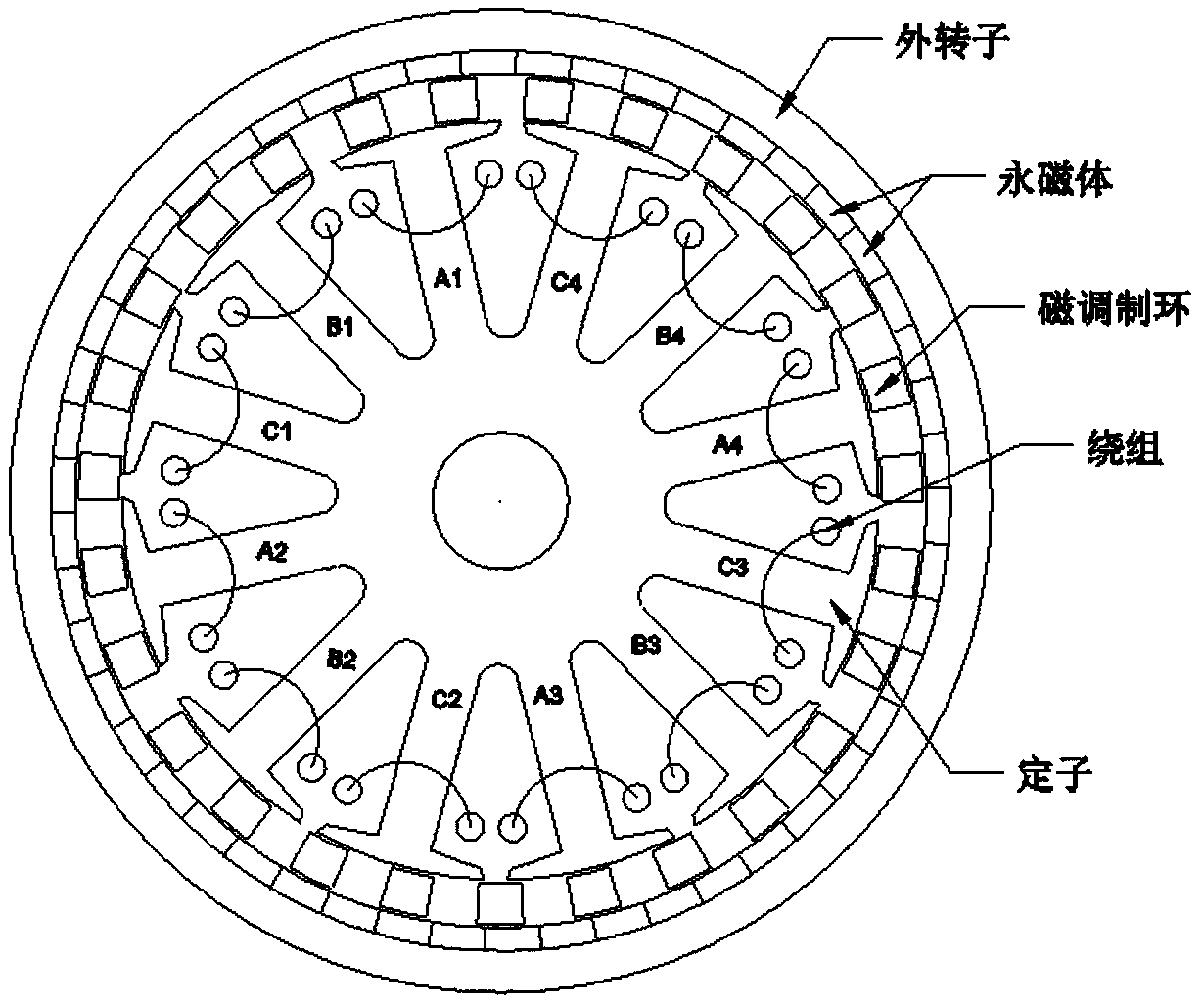

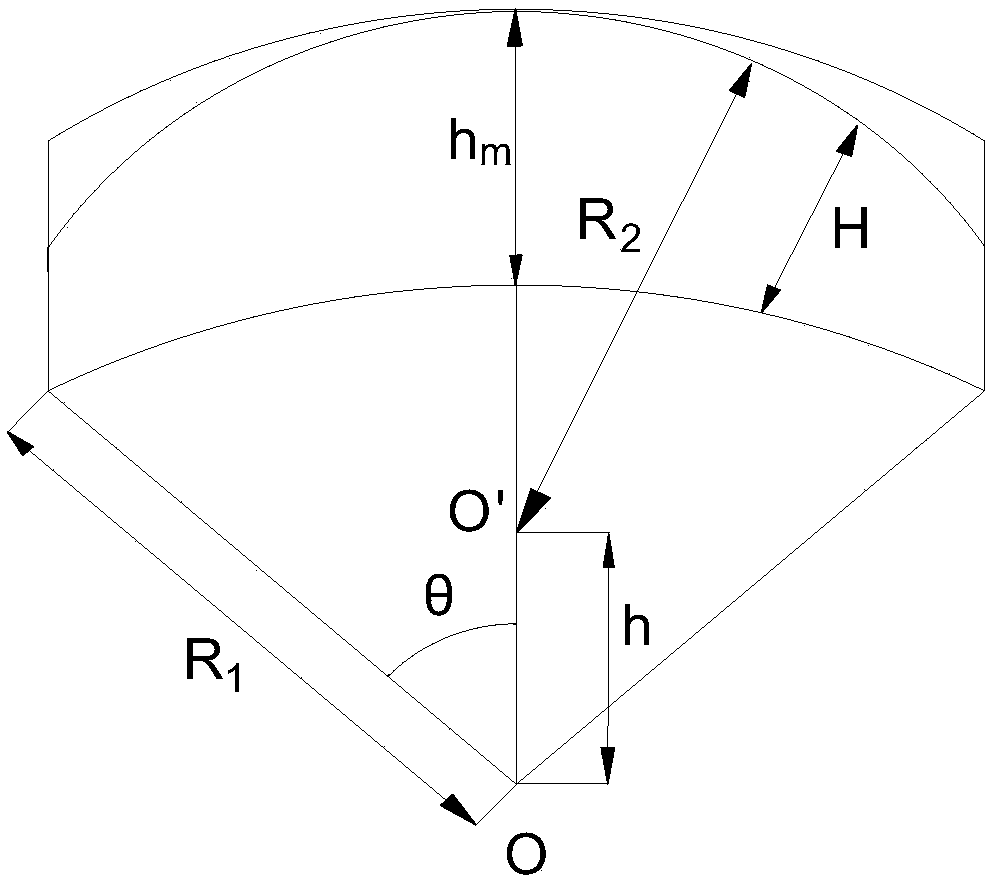

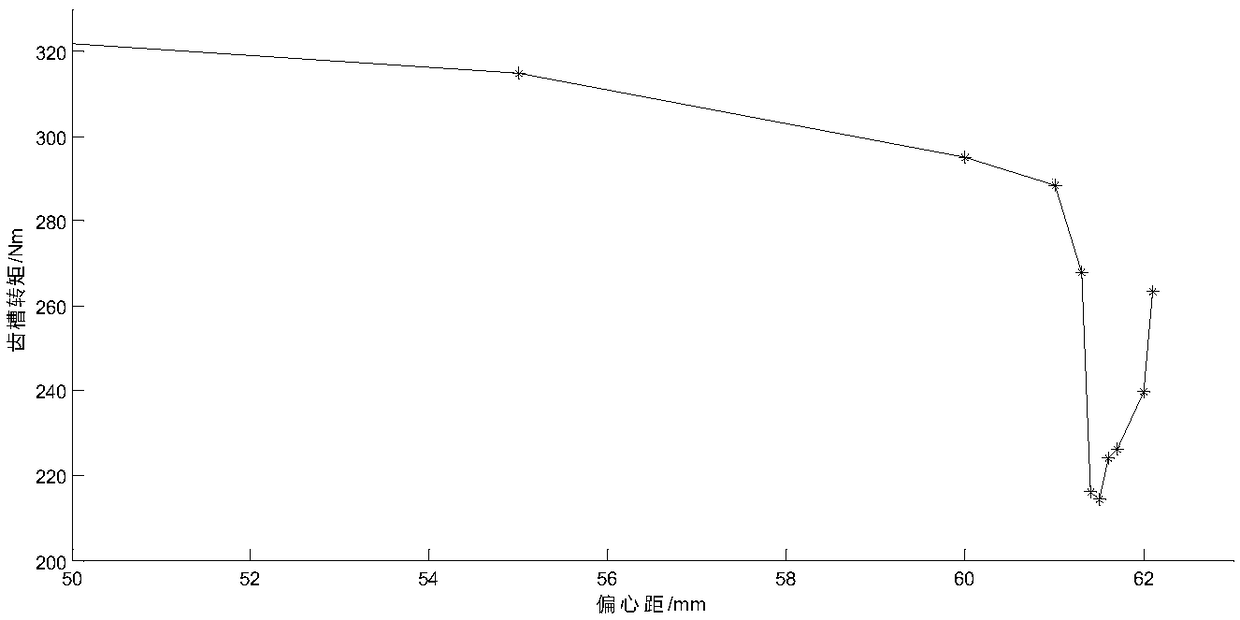

Magnetic-field modulation wave power generator with permanent-magnet concentric structure

InactiveCN108736607AThe number of stator teeth is smallSimple topologyMagnetic circuit rotating partsSurface mountingMagnetic poles

The invention relates to a magnetic-field modulation wave power generator with a permanent-magnet container structure. The magnetic-field modulation wave power generator comprises a stator and an outer rotor, wherein the outer rotor comprises a rotor core and a surface-mounting permanent body, a magnetic regulation block is additionally arranged in a gap between the outer rotor and the stator andis used for modulating a magnetic field, a circle center of an outer edge of a magnetic pole of each permanent magnet is not coincided with a circle center of an inner diameter, the thicknesses of thepermanent magnets are not uniform, the circle center of an arc of the outer edge of the magnetic pole moves at concentric distance h so that the arc radius of the outer edge is reduced, and the thickness of the permanent magnet of the outer rotor is gradually reduced from a middle part from two ends.

Owner:TIANJIN UNIV

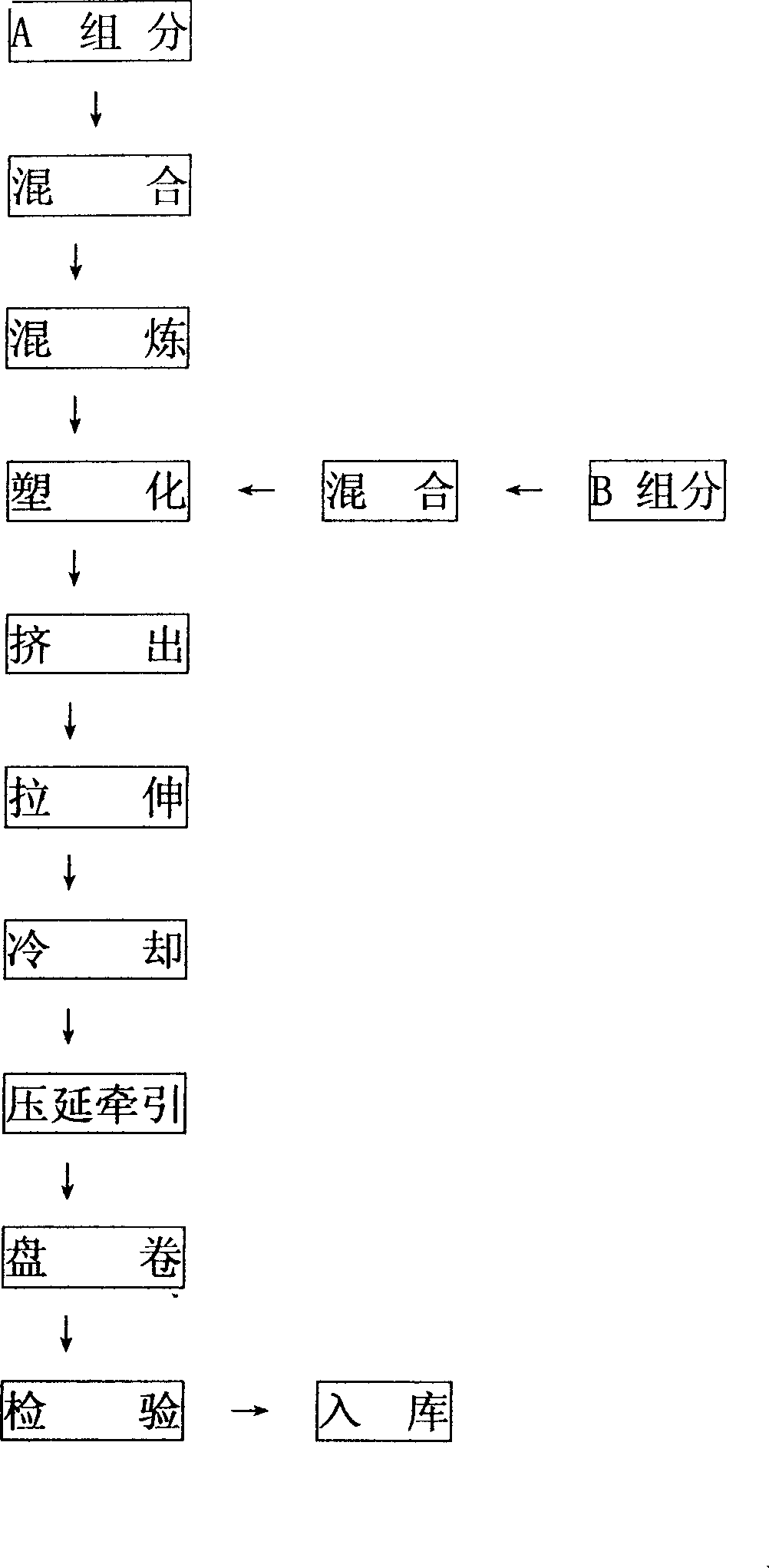

Composite nano plastic hose and its making process

The invention relates to a kind of fluid-conveying pipe, especially refers to one kind of composite nano-plastic hose and its manufacturing technology. The described hoses are made from VLDPE, ULDPE, EVA ,nano-CaCO3, nano-SiO2, nano-TiO2, antioxidant 1010, antioxidants DSTP, light stabilizer UV-326, titanate TTS, zinc stearate through the way of mixing, plastifying, extruding, stretching, cooling, calendering, traction shaping, then coiling and packaging.

Owner:吕佳来

Ink for screen printing

ActiveUS20190119519A1Excellent conductivityLow volatilityMaterial nanotechnologyTransportation and packagingSolventBoiling point

Provided is an ink for use in electronic component production making use of screen printing, which is suitable for actually allowing fine lines with high precision to be drawn in screen printing, and for actually allowing successive screen printing operations to be performed. The ink for screen printing of the present invention includes surface-modified silver nanoparticles (A) and a solvent (B), and has a viscosity at a shear rate of 10 (1 / s) and 25° C. of 60 Pa·s or more. The surface-modified silver nanoparticles (A) each include a silver nanoparticle and an amine-containing protective agent coating the silver nanoparticle. The solvent (B) includes at least a terpene solvent. In solvent (B), a content of solvents having a boiling point of less than 130° C. is 20 wt % or less based on the total amount of solvents.

Owner:DAICEL CHEM IND LTD

Catalyst slurry and preparation method for air cathode

ActiveCN105161734ALow volatilityDetermine the solid contentFuel and primary cellsCell electrodesChemistryCarbon black

Catalyst slurry used for a metal air battery is disclosed. The catalyst slurry comprises the following components: 1-10% by mass of surfactant, 5-30% by mass of catalyst, 5-20% by mass of carbon black, 3-5% by mass of binder and the balance of terpilenol. The catalyst slurry provided by the invention can effectively solve the problems of bad dispersity of the catalyst slurry and high possibility of dropping off of the catalyst in the discharging process of batteries in the prior art. The invention also provides a method for preparing an air cathode from the catalyst slurry.

Owner:NINGBO GRAPHENE INNOVATION CENT CO LTD

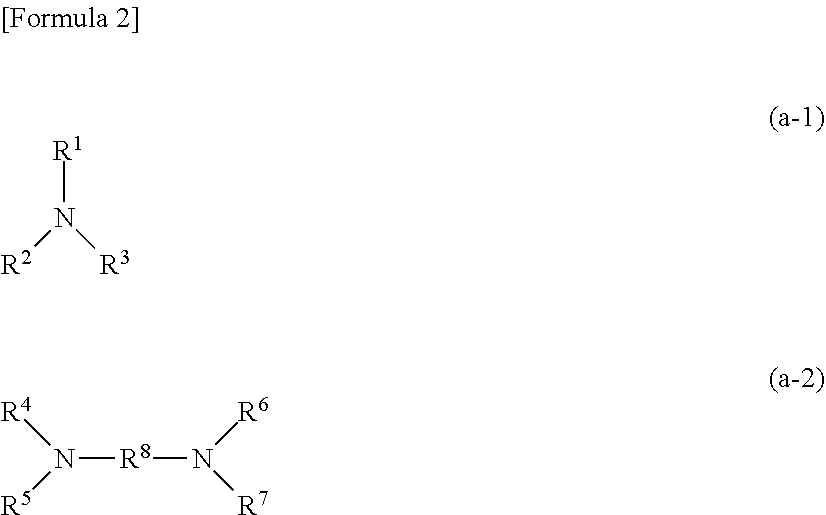

Conductive silver adhesive for micropore filling and preparation method thereof

InactiveCN103184023AGood dimensional stabilityLow volatilityEpoxy resin adhesivesElectrically-conducting adhesivesElectrically conductivePolymer chemistry

The invention discloses a conductive silver adhesive for micropore filling and a preparation method of the conductive silver adhesive. The conductive silver adhesive comprises epoxy resin, a liquid crystal epoxy polymer, a curing agent, a curing accelerator and a conductive material, wherein the conductive material is silver powder. The preparation method comprises the following steps of: 1) taking the epoxy resin and liquid crystal epoxy polymer, stirring at the temperature of 90-150 DEG C so as to uniformly mix; 2) naturally cooling down, adding the curing agent and the curing accelerator when the temperature is decreased to the room temperature, and sufficiently stirring; 3) adding the silver powder into the obtained system, sufficiently stirring, and putting a three-roller machine to uniformly mix; and 4) curing for 2 hours at 80 DEG C, and curing for 4 hours at 150 DEG C. Compared with the prior art, the conductive silver adhesive has the benefits of low viscosity, low volatility, high connection strength, thermal compact resistance and applicability to micropore filling.

Owner:GUANGDONG DANBOND TECH

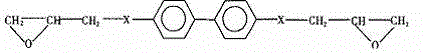

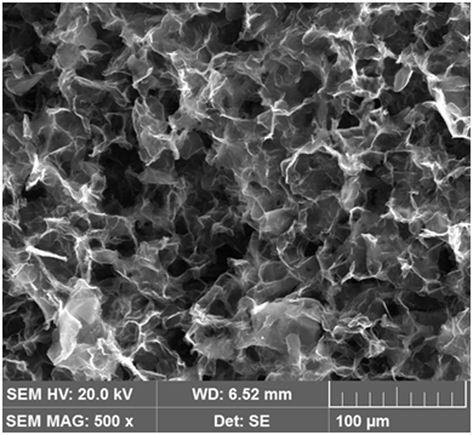

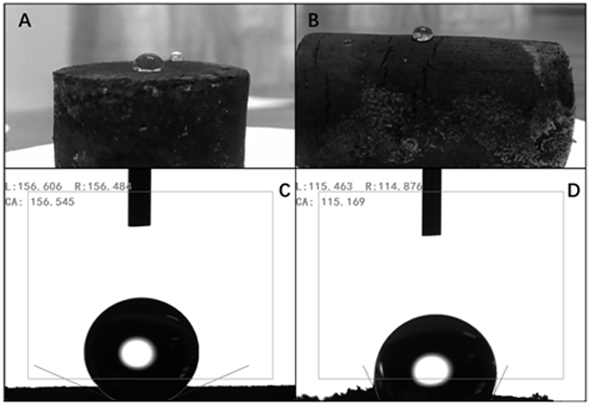

Preparation method and application of hydrophobic graphene aerogel

ActiveCN111994901AImprove structural strengthThe synthesis process is clearGas treatmentOther chemical processesTrimethylsilyl chlorideCross linker

The invention discloses a preparation method and application of hydrophobic graphene aerogel. The invention belongs to the field of graphene aerogel. The problems that an existing hydrophobic grapheneaerogel material is high in preparation cost, poor in structural strength and the like can be solved. A hydrothermal reaction method is adopted, a saccharide cross-linking agent which is low in priceand easy to obtain is adopted, an organic auxiliary agent and efficient and cheap modifiers such as trimethylchlorosilane are added, and the hydrophobic and oleophylic graphene aerogel material is obtained through a normal-pressure drying method and a microwave annealing method. It can be seen through scanning electron microscope imaging that the material is structurally a thin-wall porous material formed by three-dimensional crosslinking of thin-layer graphene. The material is definite in synthesis process, short in synthesis time, low in cost, free of heavy metal and organic pollutants, high in structural strength and capable of bearing the heavy pressure which is more than one hundred times of the mass of the material. The material has super-hydrophobicity, and the contact angle measured by experiments is as high as 150 degrees or above. The hydrophobic graphene aerogel can be used in the fields of protection and removal of volatile organic compounds in air and water, and other oil-water separation applications.

Owner:SHANXI DATONG UNIV +1

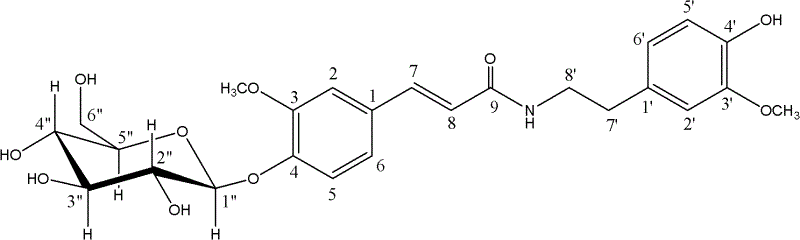

Preparation method and application of compound cimicifugamide

The invention provides a preparation method for a compound I and the application of the compound I as a tobacco flavor modifier. The method comprises the following steps of: extracting cured tobacco leaves which serve as a raw material by using water, an organic solvent or a mixed solvent consisting of the water and the organic solvent, concentrating extract under reduced pressure, dissolving concentrate in the water, performing extraction sequentially by using petroleum ether, ethyl acetate and N-butanol, concentrating extract under reduced pressure, and chromatographically separating N-butanol extract by using a macroporous adsorption resin, silica gel and a C-18 silica gel column to obtain the compound. When the compound is added into tobacco shreds, tobacco leaves, expanded tobacco shreds and flaky tobacco shreds, the tobacco flavor can be remarkably improved, smoke can be rounded, remaining taste can be improved, and the inner quality of the tobacco can be improved. The compound I is extracted from the tobacco for the first time, is low in volatility, is flavorless at normal temperature, releases flavor components only after glucosidic bonds of the compound are split when a cigarette is lighted, and has the characteristic of flavor releasing persistence.

Owner:CHINA TOBACCO SICHUAN IND CO LTD +1

Laminated windows that are resistant to extreme heat or fire conditions

InactiveUS20050260418A1Low volatilityFireproof doorsGlass/slag layered productsExtreme heatGlass window

The present invention is a laminated glass window that is resistant to extreme heat, or fire as the heat source, comprising a coating on the surface of the glass nearest the heat source.

Owner:DAVIES PHILLIP SYDNEY +1

Axilla drying powder

InactiveCN104173262AGood stabilityLow volatilityCosmetic preparationsToilet preparationsGypsumBorneol

The invention discloses axilla drying powder which is characterized by comprising the following raw materials in parts by weight: 18-21 parts of alums, 3-5 parts of gypsum, 3-5 parts of talc, 4-6 parts of borneol, 1-3 parts of pearl and 0.003-0.005 part of menthol. A preparation method of the axilla drying powder comprises the following steps: grinding the raw materials into powder, and fully mixing, thereby obtaining the medicinal powder. The axilla drying powder is high in stability, low in volatility, long in validity period, relatively low in cost, non-toxic and harmless, can be used for a long time, does not influence normal perspiring function of a human body and has good and obvious effects of cleaning and deodorizing the human axilla.

Owner:谭茂维

Method for refining fosfomycin phenylethylamine salt through cooling-solvating-out coupling crystallization

ActiveCN107098935AImprove equipment utilizationLow volatilityOrganic compound preparationGroup 5/15 element organic compoundsIonSolvent

The invention relates to the technical field of compound separation and purification and in particular relates to a method for refining fosfomycin phenylethylamine salt through cooling-solvating-out coupling crystallization. The method comprises the following steps: with deionized water as a solvent, dissolving crude salt, then adding ethylene glycol, heating the solution to 40-45 DEG C, then oxidizing with hydrogen peroxide and decolorizing with activated carbon, stirring, heating the mixed solution to 70-75 DEG C, filtering the heated solution, cooling filtrate to 20-30 DEG C for crystallization, filtering, adding acetone into filtrate, carrying out solvating-out crystallization, filtering again, distilling filtrate, and then separating acetone and water to be recycled, wherein the yield of fosfomycin phenylethylamine salt refined product obtained after crystallization for twice reaches up to more than 80%. The method provided by the invention is simple in technology and can be carried out at normal temperature, cryogenic crystallization is not needed, energy consumption is low, the solvent, acetone, and water can be basically completely recycled, and fewer pollutants are discharged.

Owner:HUBEI XUNDA PHARMA

Water-based adhesive removal agent for plastic film for package printing

InactiveCN105886130ALow volatilityShort degumming timeCationic surface-active compoundsOrganic detergent compounding agentsSolventChemistry

A water-based adhesive removal agent for a plastic film for package printing is prepared from components in percentage by weight as follows: 17%-40% of a main solvent, 17%-40% of a cosolvent, 0.05%-5% of a surfactant, 0.5%-5% of an antifoaming agent and 20%-60% of water. With use of a swelling action of effective ingredients in the adhesive removal agent on a composite adhesive, a composite adhesive layer on the surface of the film is swelled rapidly to fall off. Under the action of the antifoaming agent, the adhesive removal agent cannot produce a large amount of foam when reused in a cleaning machine. The adhesive removal agent has the characteristics that a preparation method is simple, the adhesive removal agent is stable and not prone to delamination or volatilization, the adhesive is removed rapidly, damage to a film substrate is not produced, heating is not needed when the adhesive removal agent is used at the room temperature, the adhesive removal agent can be reused in the cleaning machine, a large amount of foam cannot be produced and the like.

Owner:GUANGDONG ZHUANGLI COLOR PRINTING

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com