Conductive silver adhesive for micropore filling and preparation method thereof

A conductive silver glue and microporous technology, applied in the field of conductive glue, can solve the problems of low viscosity, complex conductive composition system, limited applicability, etc., and achieve the effects of low volatility, excellent dimensional stability, and high connection strength.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

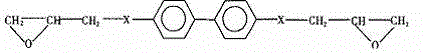

Method used

Image

Examples

Embodiment 1

[0051] 100 parts by weight of glycidyl phthalate epoxy resin with an epoxy equivalent of 150, 15 parts of liquid crystal epoxy polymer, 8 parts of dispersant and antioxidant, stirring and mixing at a temperature of 90-150 ° C Uniform; cool down naturally, after cooling down to room temperature, add 35 parts of curing agent 4,4'diaminodiphenylmethane (DDM), curing accelerator 2, 4, 6-tri-(dimethylaminomethyl)-phenol 6 parts, stir and mix evenly; then add 500 parts of silver powder, stir thoroughly, and then put it into a three-roller machine and mix evenly to obtain conductive silver glue A1. The conductive silver paste was cured at 80°C for 2 hours, and then completely cured at 150°C for 4 hours.

Embodiment 2

[0053] Glycidyl phthalate epoxy resin with an epoxy equivalent of 150 in a weight ratio of 100 points, 30 parts of a liquid crystal epoxy polymer, and 10 parts of a dispersant and an antioxidant are stirred and mixed at a temperature of 90-150°C Uniform; natural cooling, after cooling down to room temperature, add 40 parts of curing agent 4,4'diaminodiphenylmethane (DDM), curing accelerator 2, 4, 6-tri-(dimethylaminomethyl)-phenol 8 parts, stir and mix evenly; then add 600 parts of silver powder, stir thoroughly, and then put it into a three-roller machine and mix evenly to obtain conductive silver glue A2. The conductive silver paste was cured at 80°C for 2 hours, and then completely cured at 150°C for 4 hours.

Embodiment 3

[0055] Glycidyl phthalate epoxy resin with an epoxy equivalent of 150 in a weight ratio of 100 points, 5 parts of a liquid crystal epoxy polymer, and 5 parts of a dispersant and an antioxidant are stirred and mixed at a temperature of 90-150°C Uniform; natural cooling, after cooling down to room temperature, add 25 parts of curing agent 4,4'diaminodiphenylmethane (DDM), curing accelerator 2, 4, 6-tri-(dimethylaminomethyl)-phenol 5 parts, stir and mix evenly; then add 450 parts of silver powder, stir thoroughly, and then put it into a three-roll machine and mix evenly to obtain conductive silver glue A3. The conductive silver paste was cured at 80°C for 2 hours, and then completely cured at 150°C for 4 hours.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com