Patents

Literature

10443results about How to "Improve connection strength" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

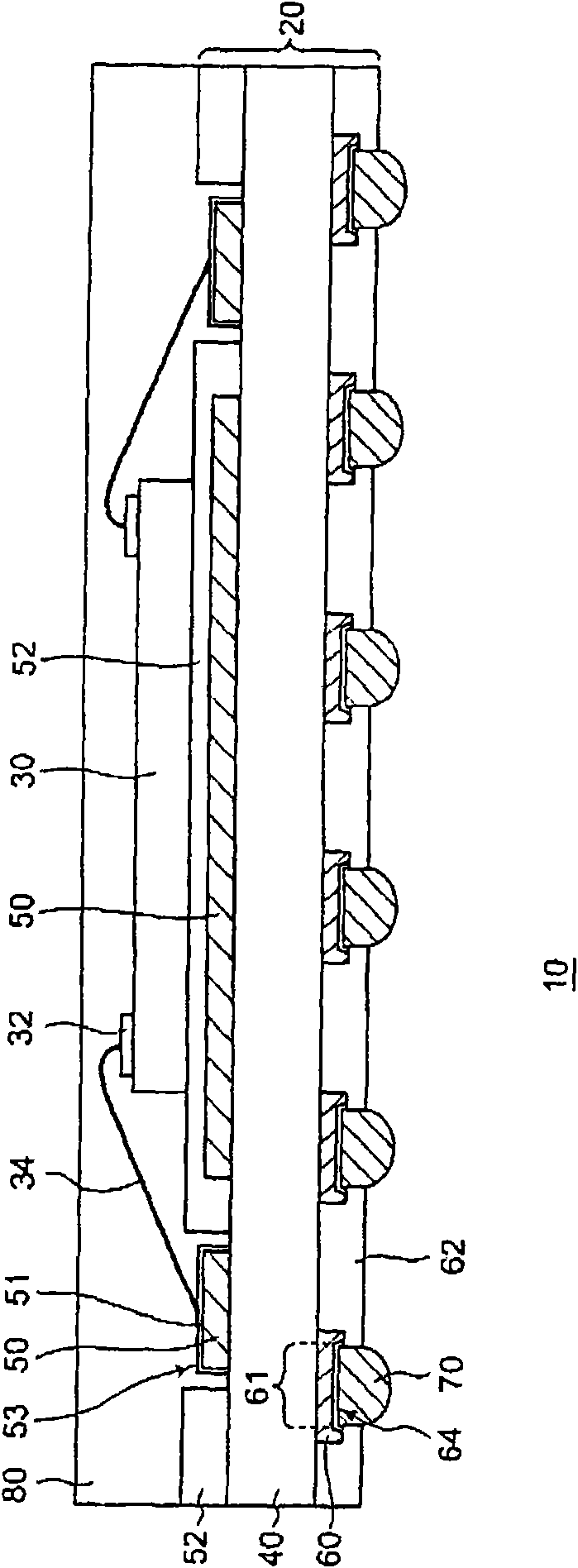

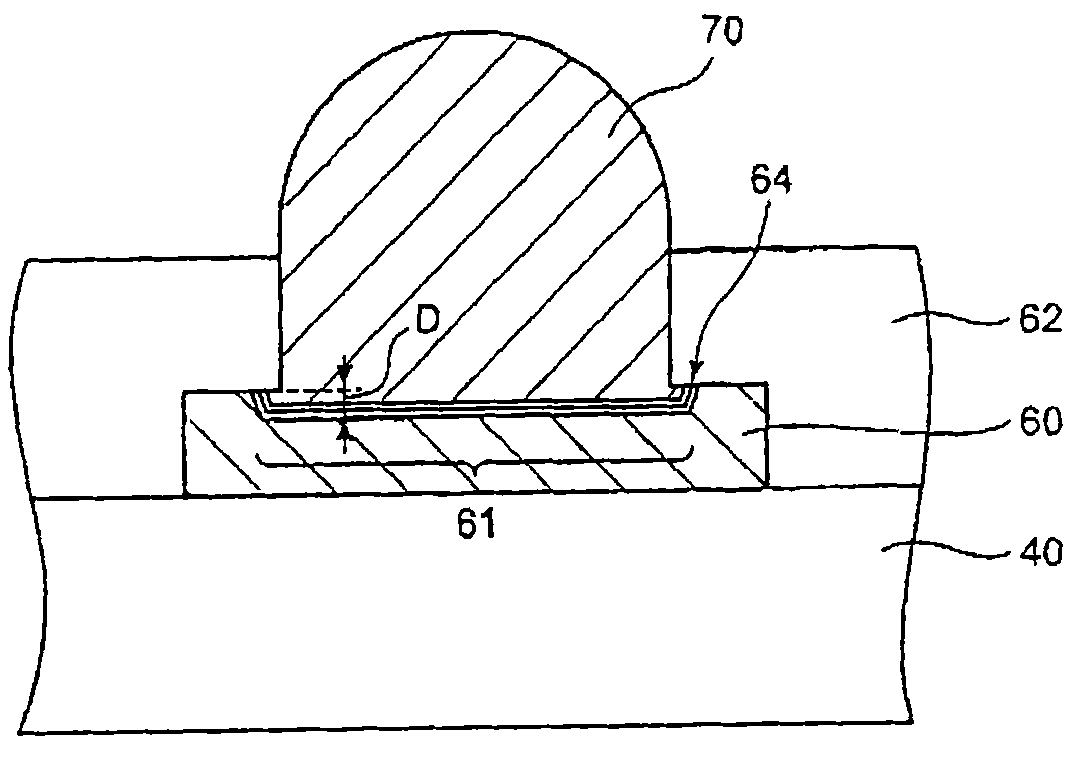

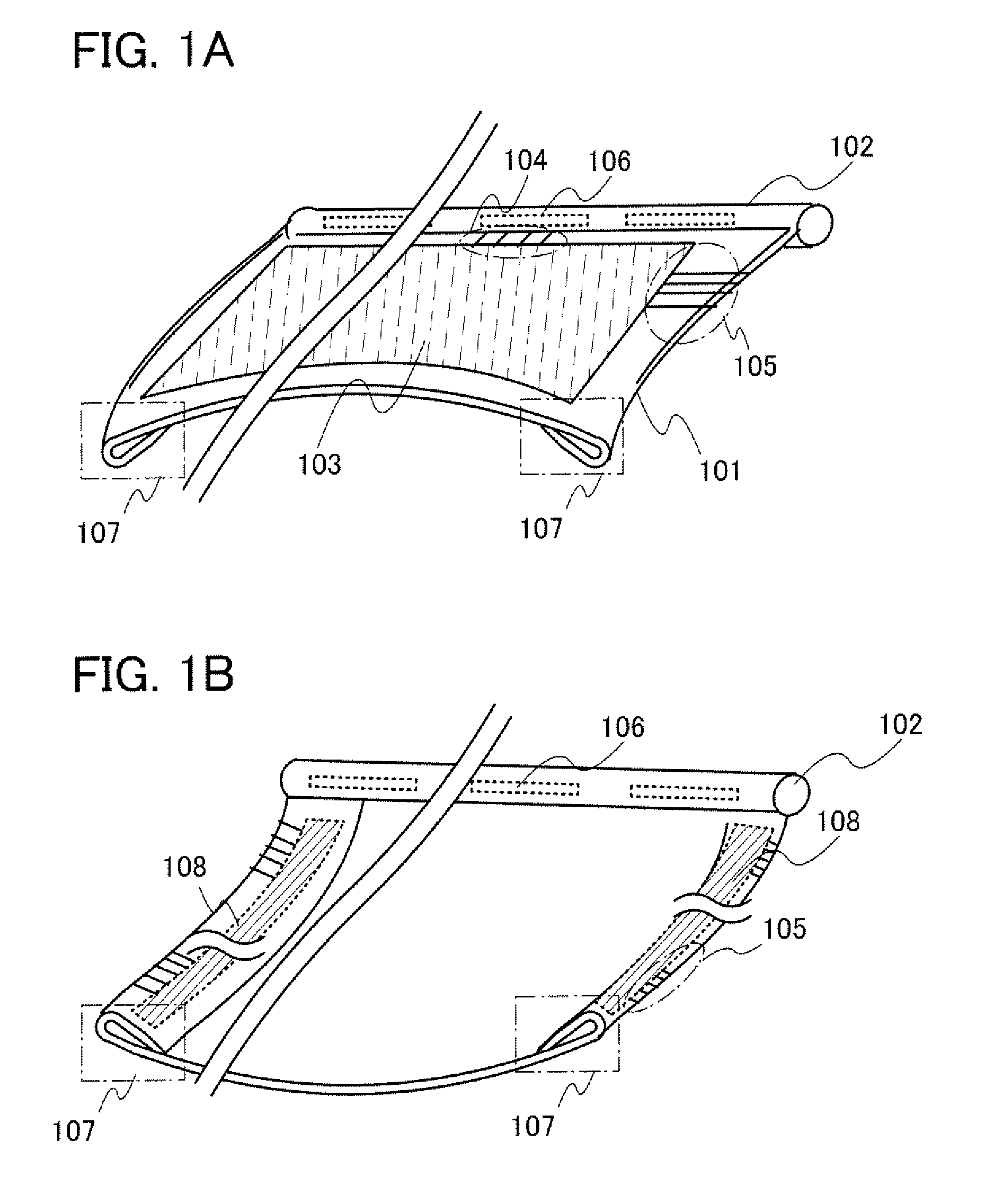

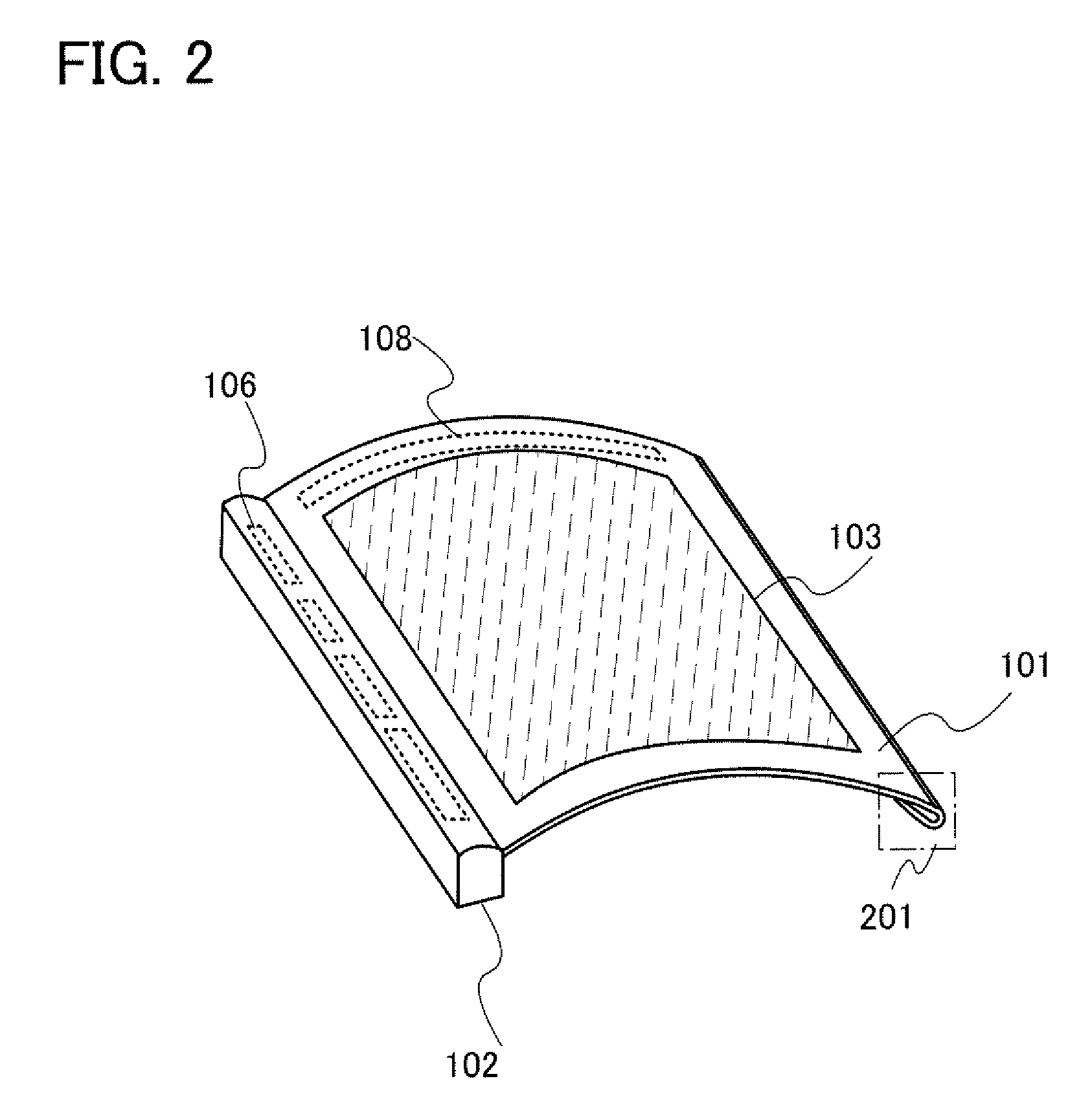

Display device

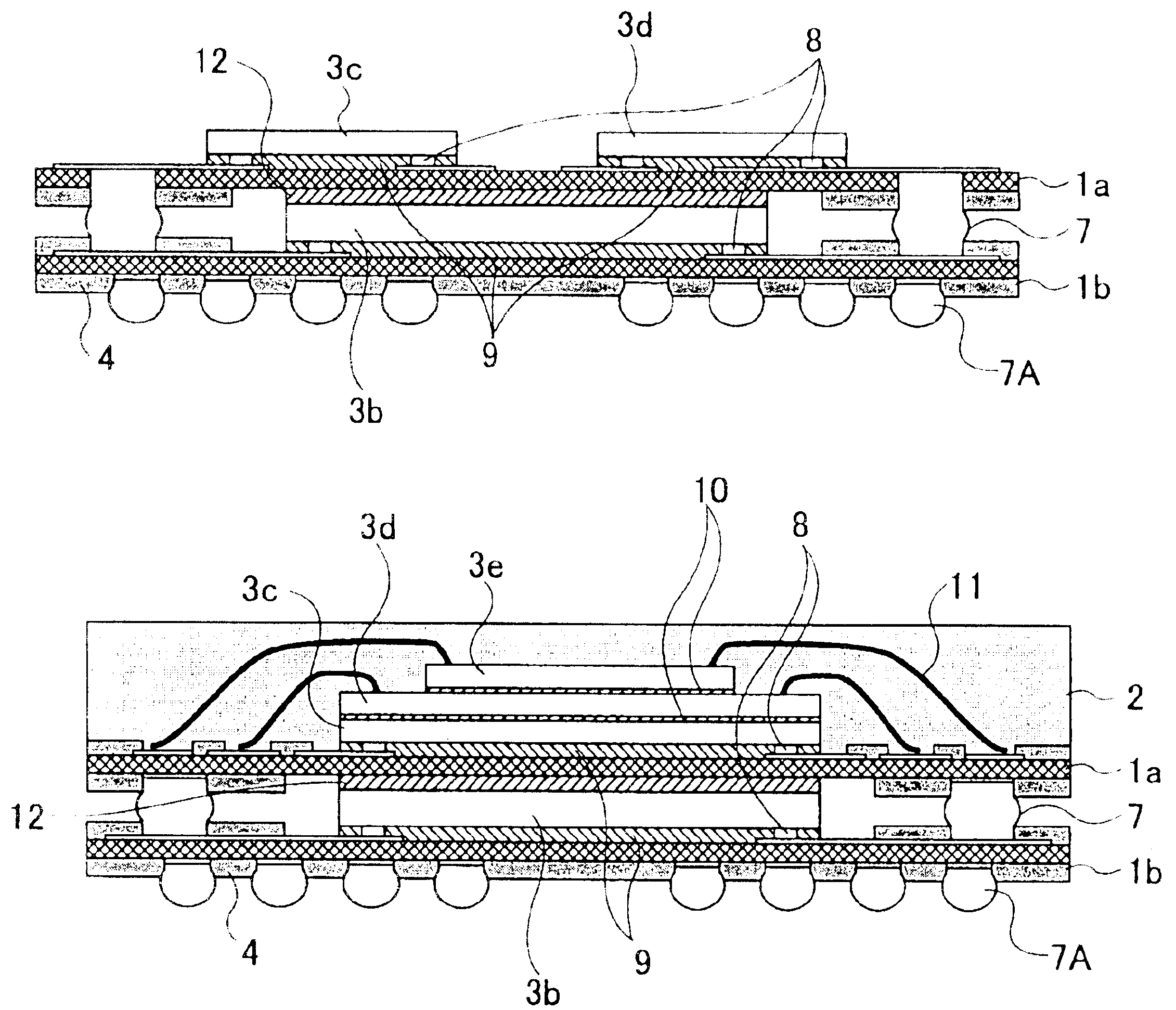

ActiveUS20110007042A1Reduce failureImprove connection strengthDigital data processing detailsCasings with display/control unitsDriver circuitDisplay device

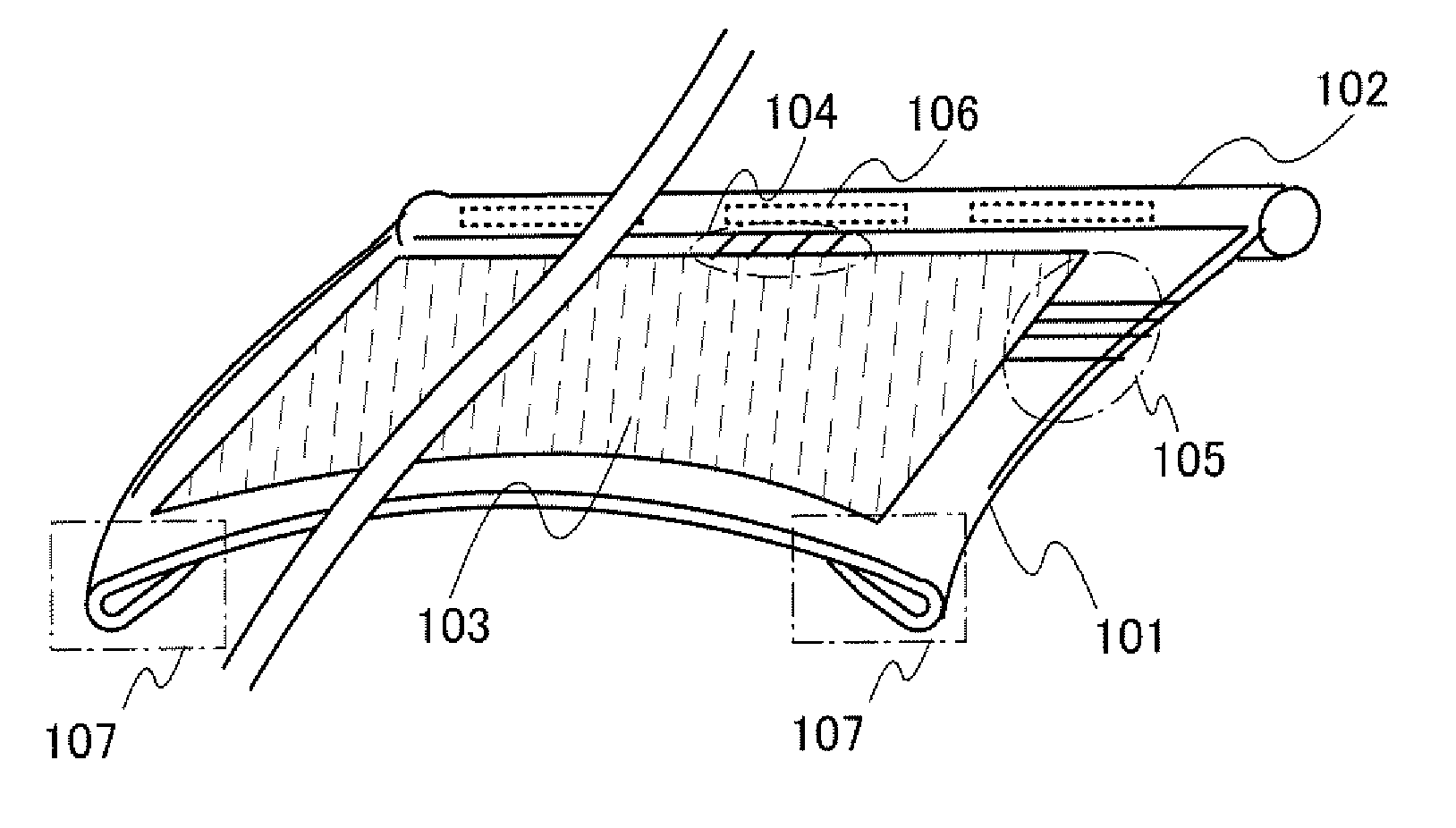

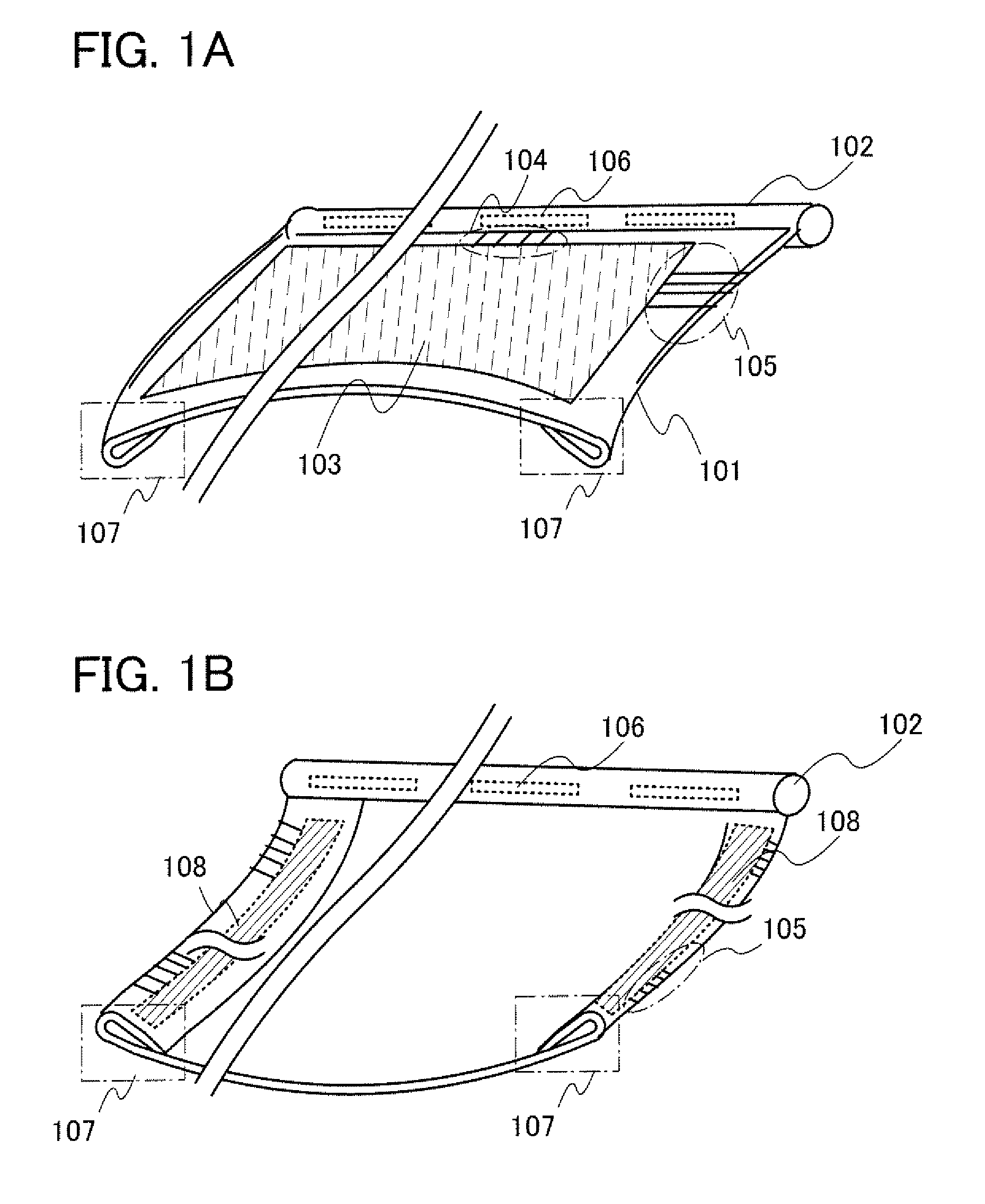

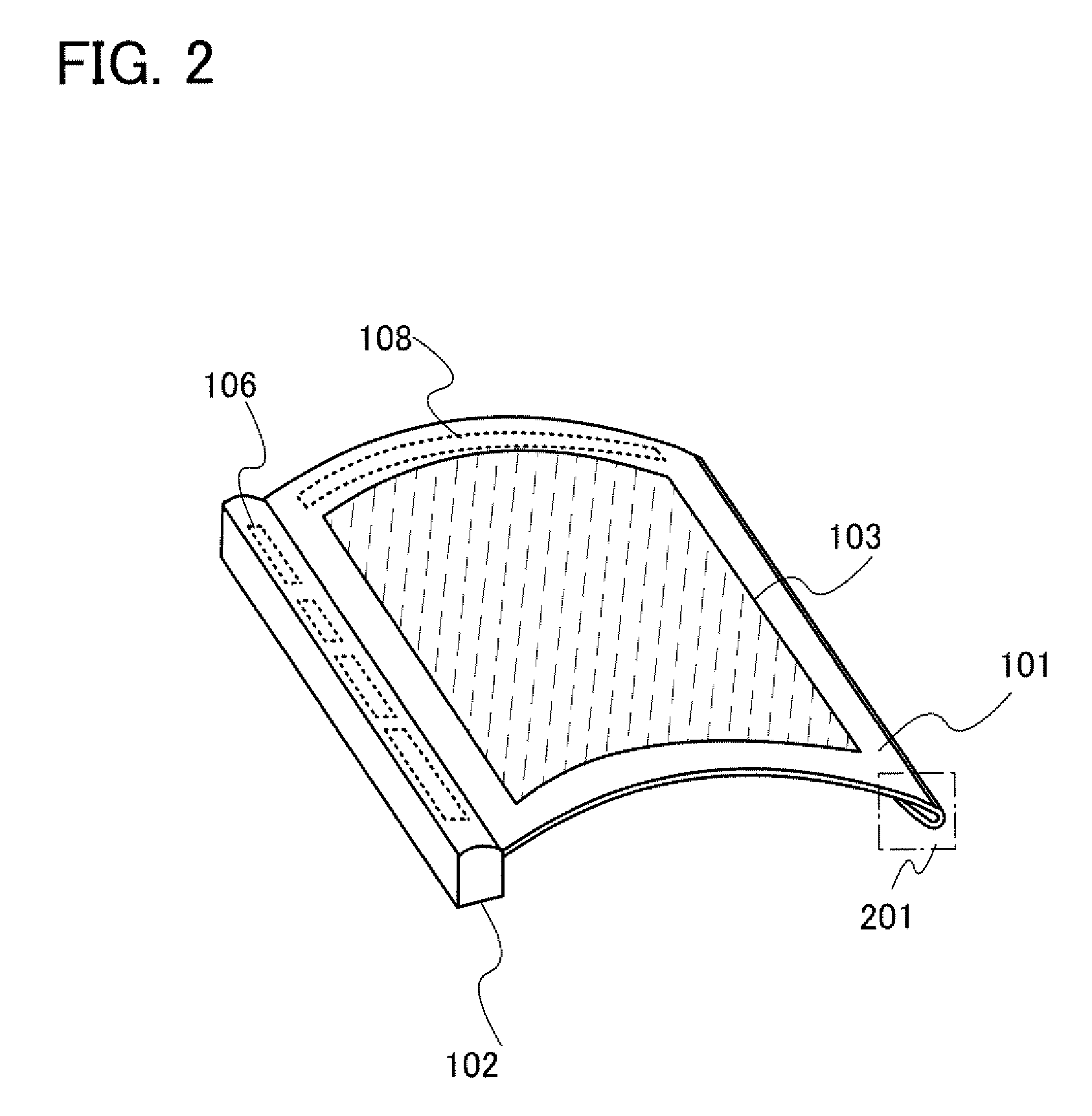

To provide a display device including a flexible panel that can be handled without seriously damaging a driver circuit or a connecting portion between circuits. The display device includes a bent portion obtained by bending an element substrate. A circuit for driving the display device is provided in the bent portion and a wiring extends from the circuit, whereby the strength of a portion including the circuit for driving the display device is increased and failure of the circuit is reduced. Furthermore, the element substrate is bent in a connecting portion between an external terminal electrode and an external connecting wiring (FPC) so that the element substrate provided with the external terminal electrode fits the external connecting wiring, whereby the strength of the connecting portion is increased.

Owner:SEMICON ENERGY LAB CO LTD

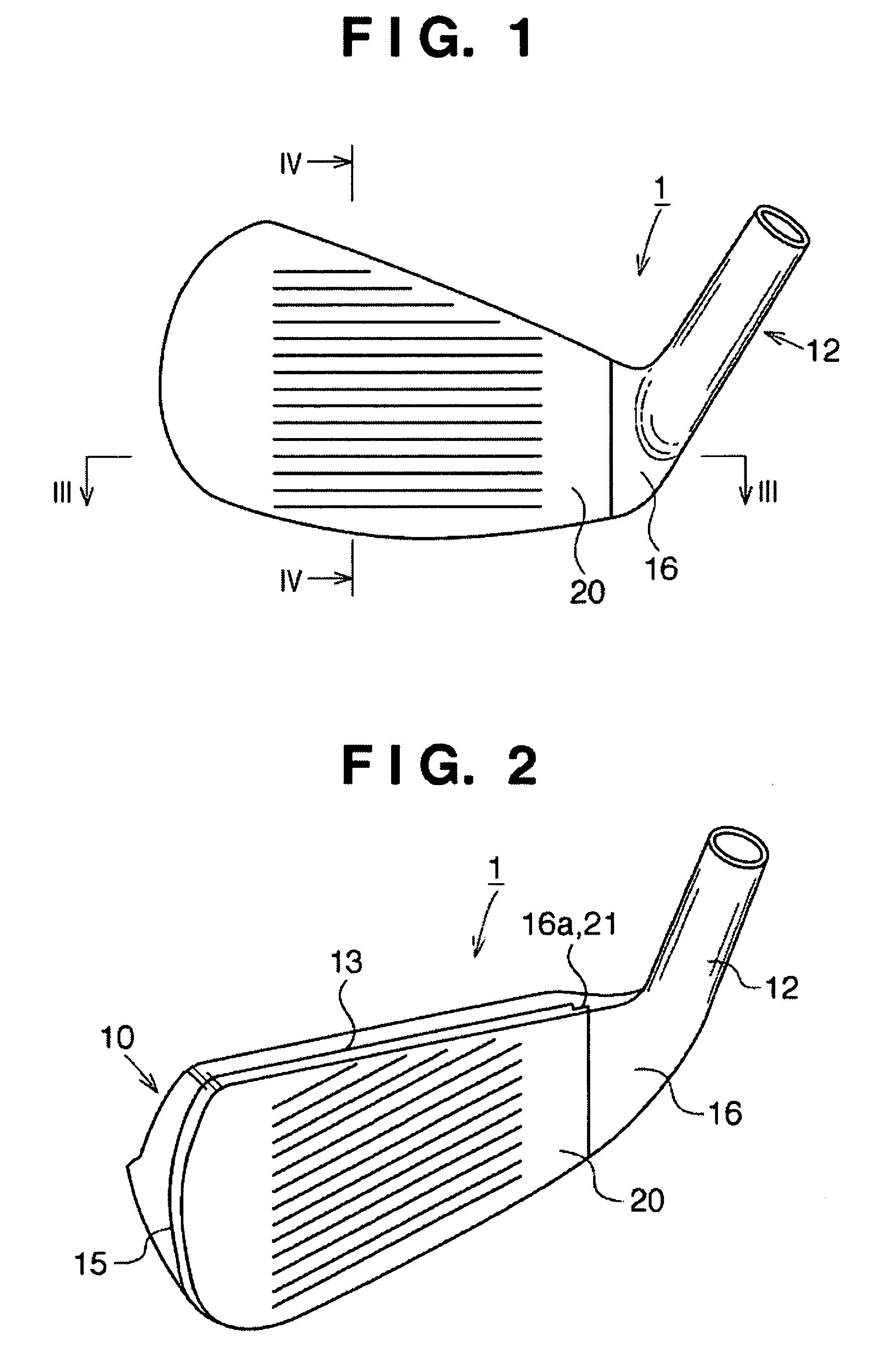

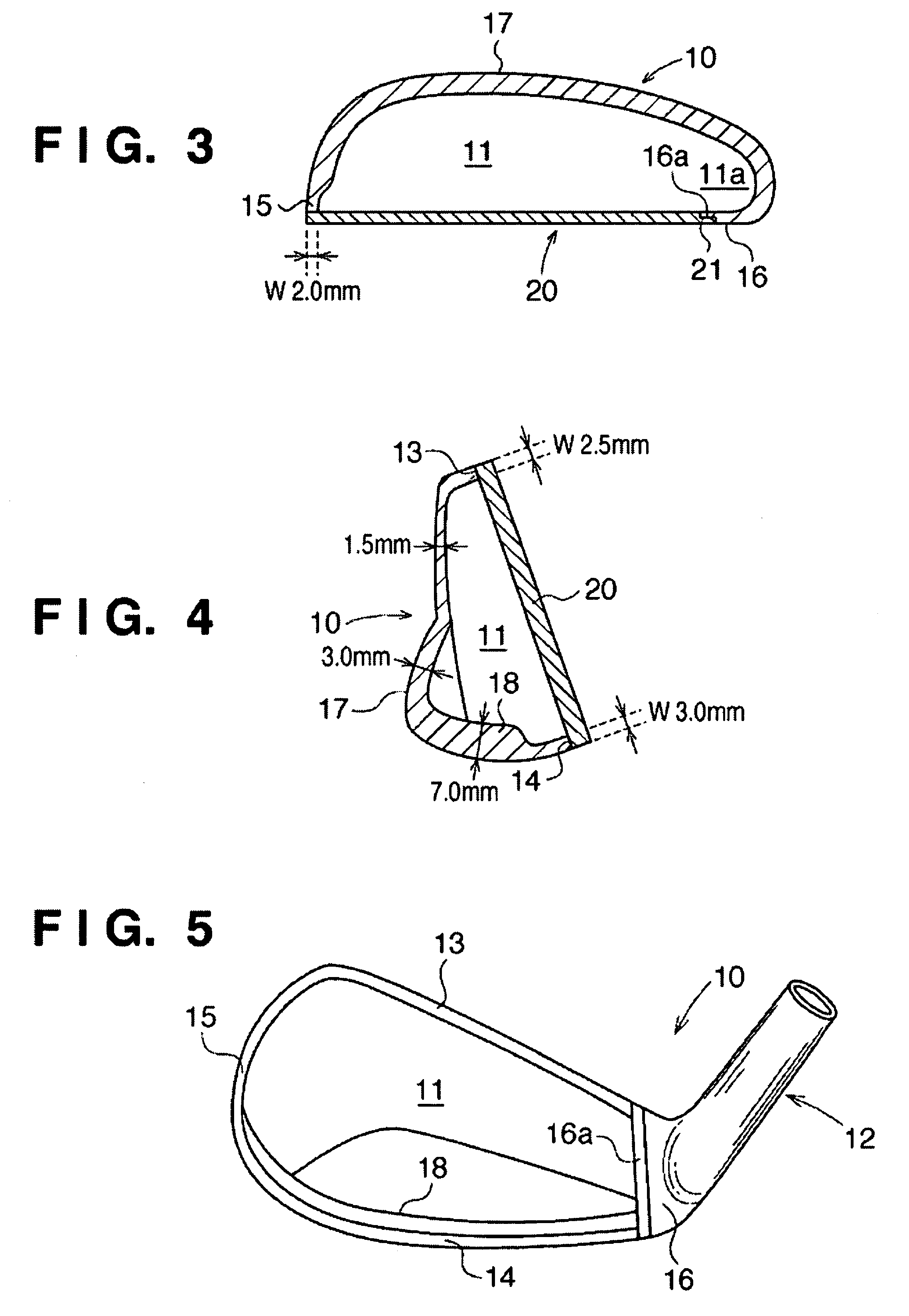

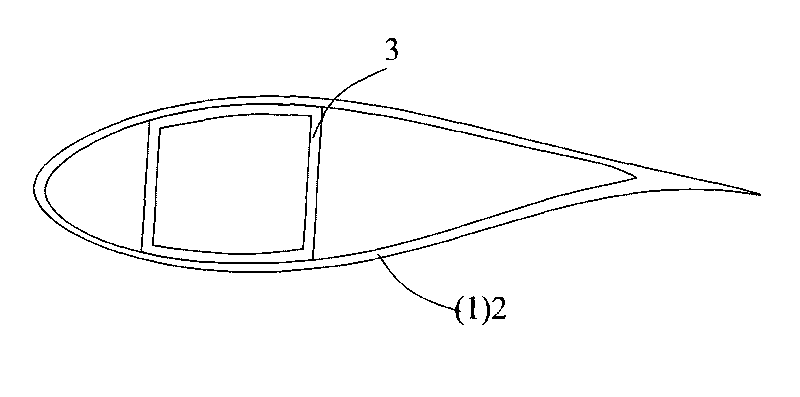

Iron golf club head

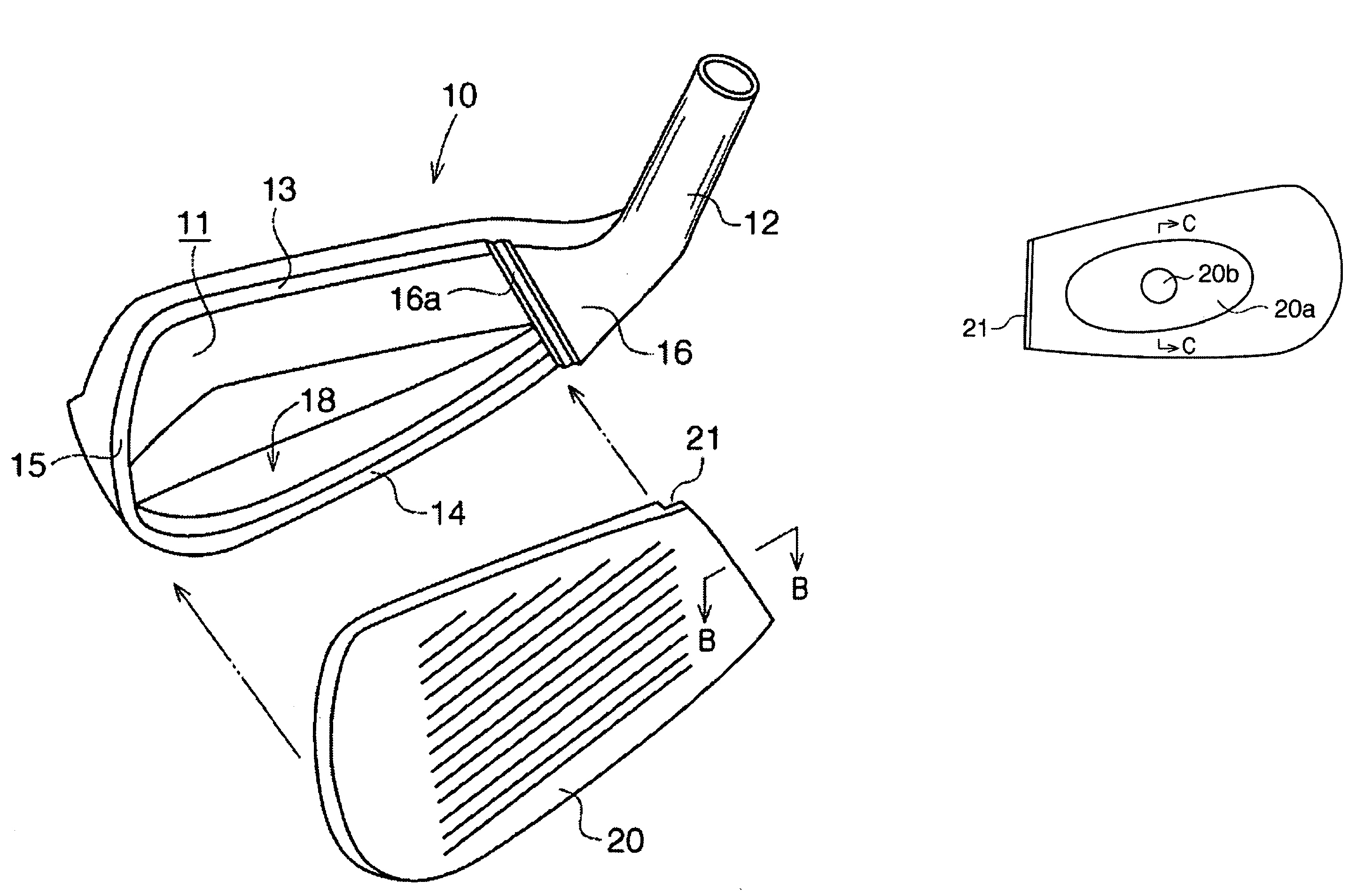

A golf club head (1) comprises a head main body (10) having a concave portion (11) formed in the face side and a face plate (20) fixed to the head main body (10). The face plate (20) is mounted on the head main body (10) such that a concave step portion (21) engages with a convex step portion (16a) of the head main body (10), and the upper edge portion, lower edge portion, and toe-side edge portion of the face plate (20) abut against edge portions (13), (14), and (15) of the head main body, respectively. The face plate (20) is laser-welded along its perimeter and fixed to the head main body (10).

Owner:BRIDGESTONE SPORTS

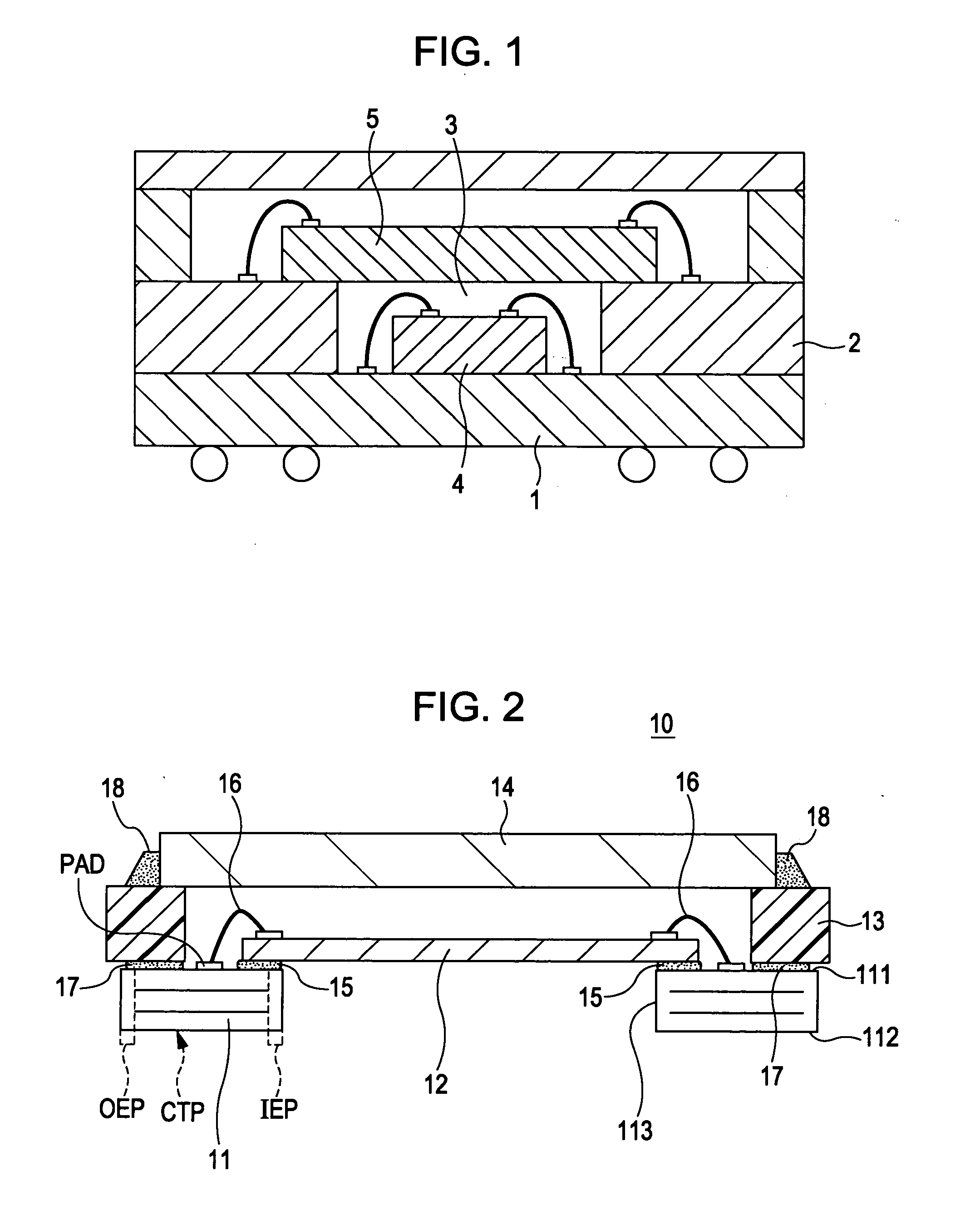

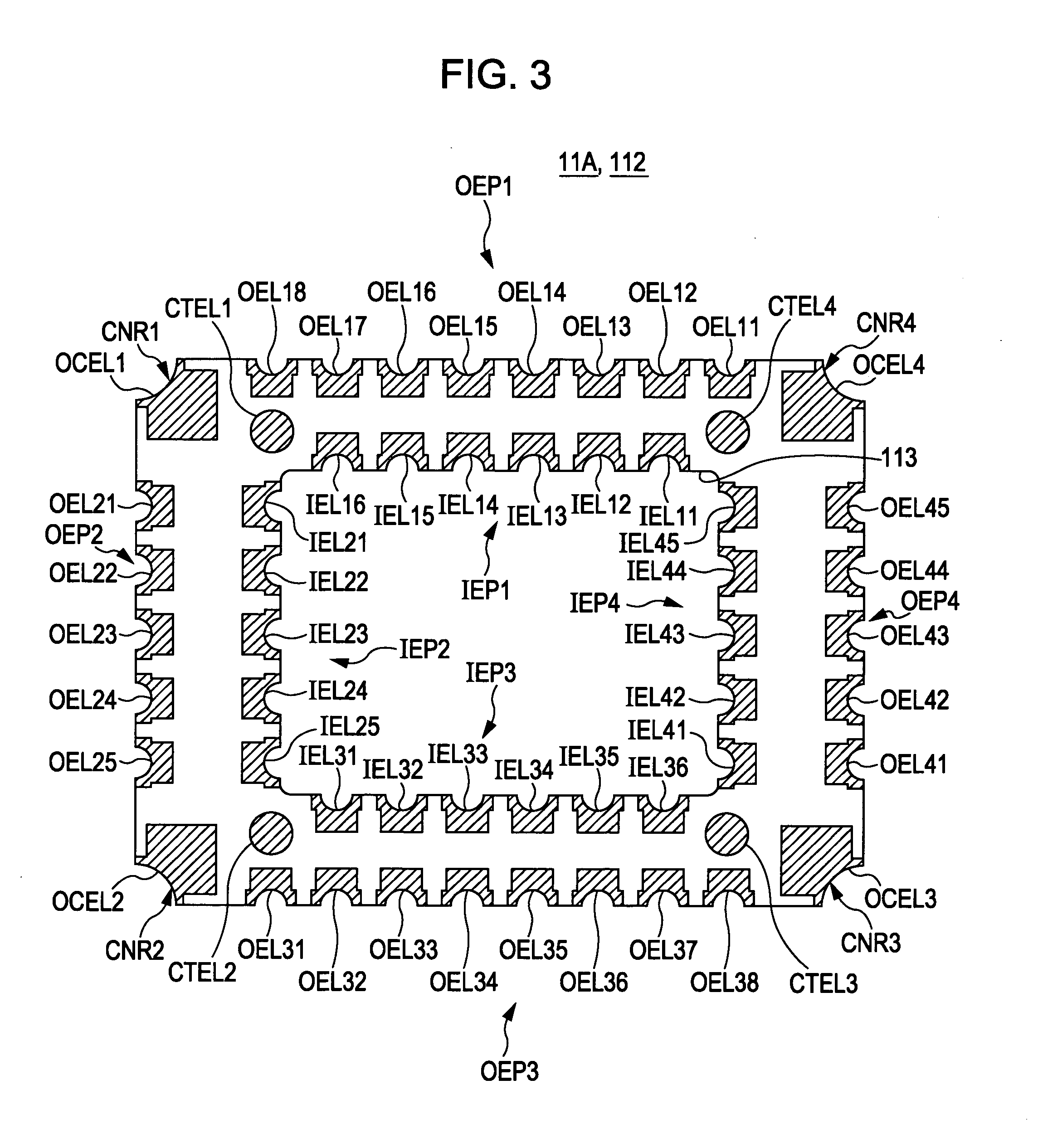

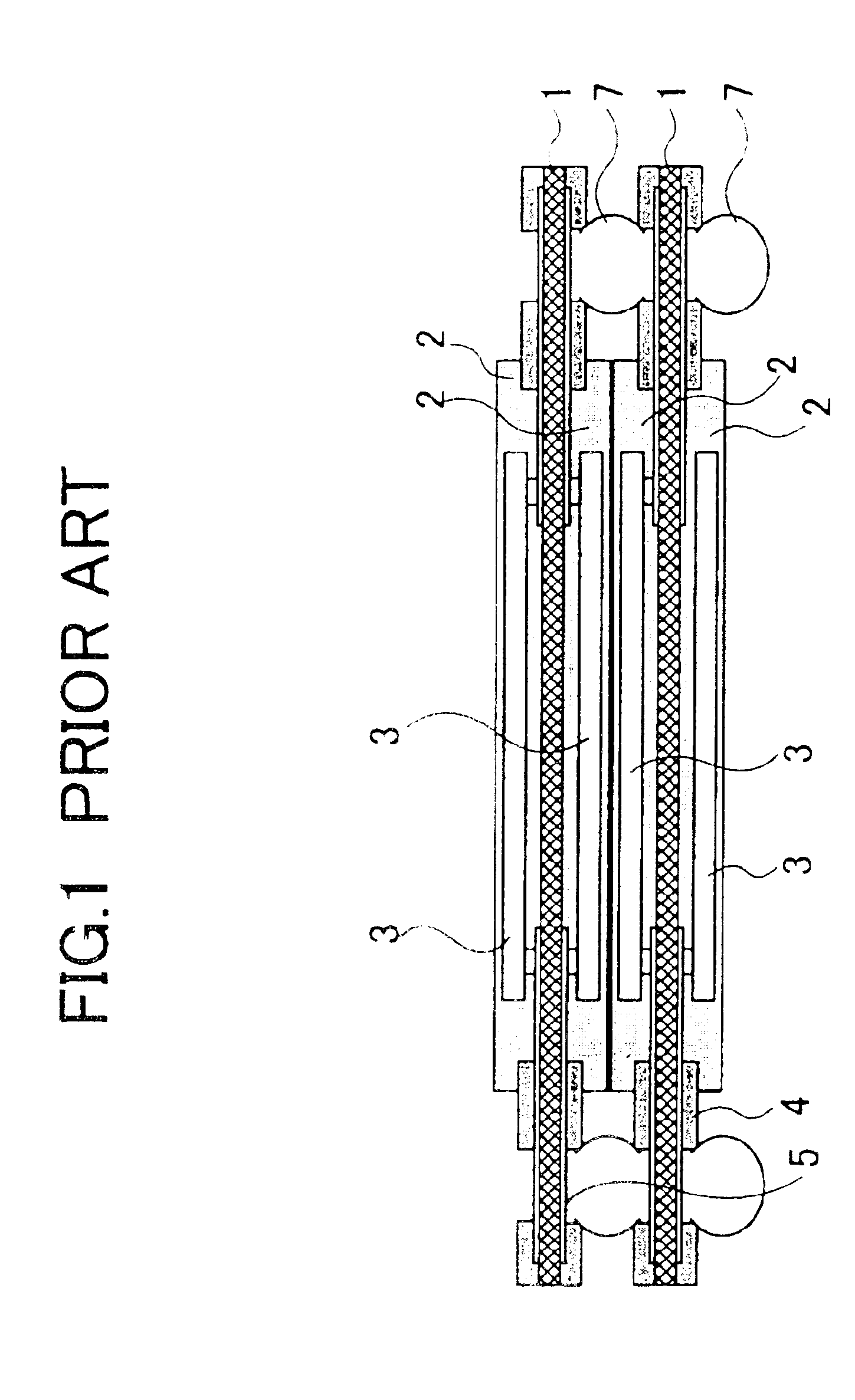

Multilayer wiring substrate, stack structure sensor package, and method of manufacturing stack structure sensor package

ActiveUS20100244166A1Improve connection strengthThin and small structureTelevision system detailsSemiconductor/solid-state device detailsElectrical connectionEngineering

A multilayer wiring substrate has a through hole that passes from a first surface through to a second surface. The multilayer wiring substrate includes an electrical connection terminal formed in at least one of an inner edge portion which is a periphery of the through hole, an outer edge portion which is an outer periphery of the substrate, and a non-edge portion, on at least one of the first surface and the second surface. The electrical connection terminal has a castellation structure that does not pass through to a surface opposite to a formation surface.

Owner:SONY CORP

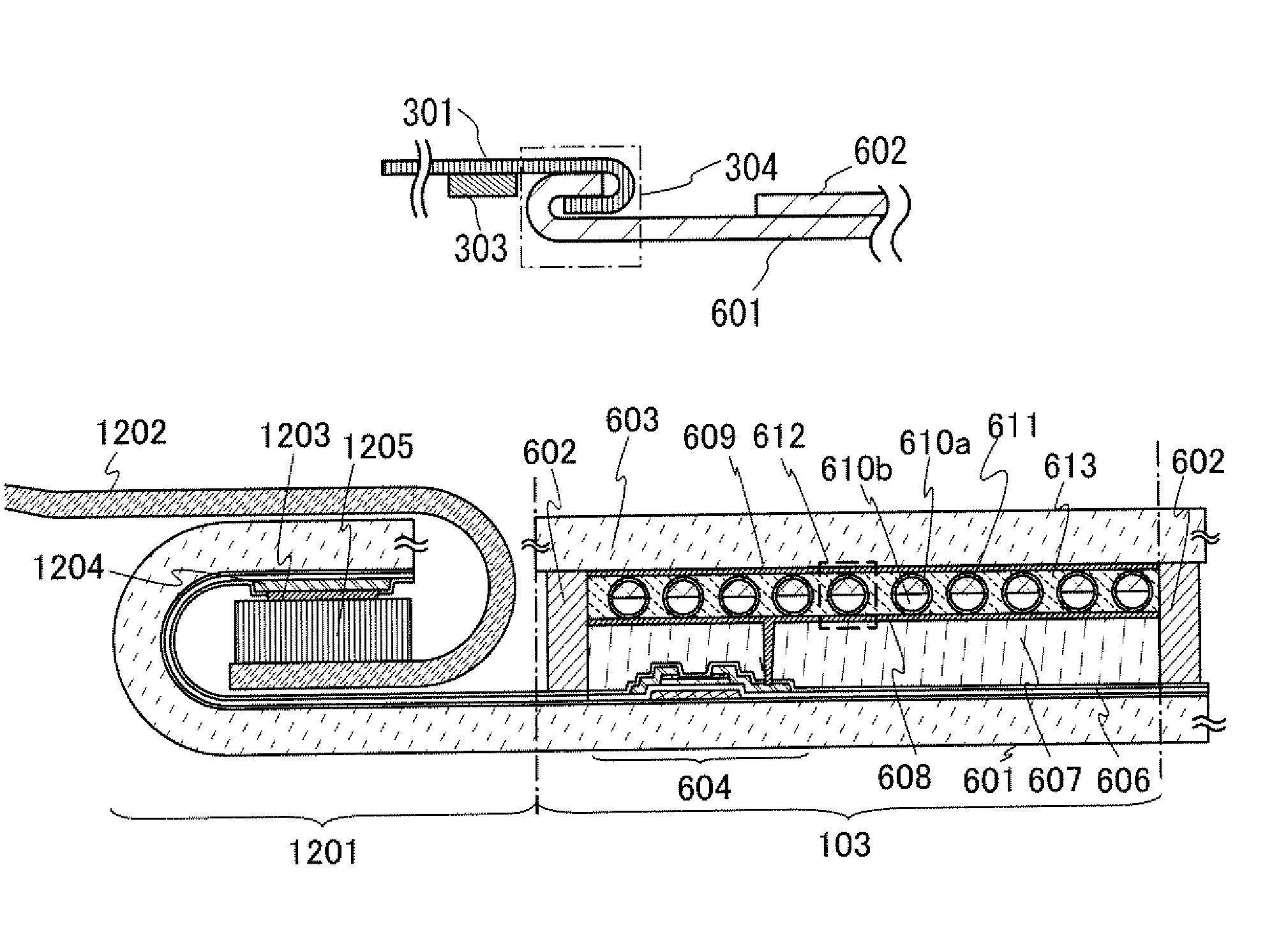

Semiconductor module and portable device

InactiveCN101819959AImprove connection reliabilityIncrease contact areaSemiconductor/solid-state device detailsSolid-state devicesSolder ballEngineering

The invention provides a semiconductor module and a portable device. A wiring layer including external connection regions is provided on a main surface of an insulating resin layer on a side opposite to that of a semiconductor device mounting face. The wiring layer is coated with a protection layer. An opening is provided to the protection layer such that each external connection region is exposed. Each external connection region has a curved surface recessed toward the insulating resin layer side. The entire area of each opening is filled with a solder ball for mounting a substrate, and the recess of each external connection region is filled with the solder ball, thereby connecting each solder ball to the intermediate layer.

Owner:SANYO ELECTRIC CO LTD

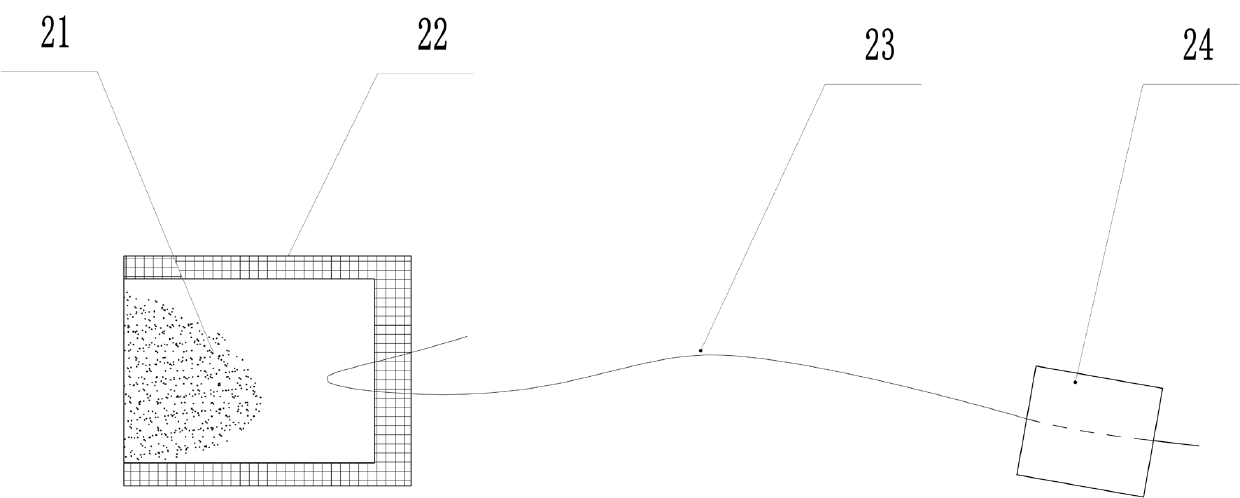

Tea bag packer

ActiveCN101992868AInhibit sheddingExtended sealing lengthWrapper twisting/gatheringPackaging foodstuffsReciprocating motionEngineering

The invention discloses a tea bag packer. A hanging wire coil component thereof comprises a central shaft, wherein one end of the central shaft is fixedly connected to a frame; a shaft sleeve is assembled on the periphery of the central shaft by rotating the shaft; a hanging wire coil is coaxially fixed with an external end face of the shaft sleeve away from the frame along the radial direction; hanging wire claws extending along radial direction are uniformly distributed on the periphery of the hanging wire coil; a support rod for supporting cotton wires is slidingly penetrated through each hanging wire claw along the radial direction of the hanging wire coil; a cam connecting rod transmission mechanism which is in transmission connection with each support rod and drives the support rod to have linear reciprocating motion along the axis thereof is sleeved on the periphery of the shaft sleeve close to the hanging wire coil; and the cam is fixedly connected to the frame. Through the structure of the invention, the cotton wire can avoid the non-heat-seal area on the tea bag when the cotton wire is heat-sealed with the tea bag, so as to prolong the sealing length between the cotton wire and the tea bag, enhance the connecting strength between the cotton wire and the tea bag and avoid the phenomenon in the prior art that the cotton wire drops off.

Owner:CAMALUOYANGELECTROMECHANIC

Photo-curable conductive adhesive and method for making same

InactiveCN1699492ALow curing temperatureLow resistivityPolyureas/polyurethane adhesivesEster polymer adhesivesPolymer scienceSilver plate

Disclosed is a photo-curable conductive adhesive and method for preparation, which is prepared from light-sensitive high molecular polymer, reactive dilution monomer, conducting particles, light-summing heat initiating agent and anti-oxidant through mixing and grinding, wherein the light-sensitive high molecular polymer is epoxy acrylic resin or / and polyurethane-acrylate, the reactive dilution monomer is the single, double and multiple functional monomers of acrylic acid, the conducting particle is silver powder, copper powder or silver-plated copper powder, the light initiating agent is alpha-amine alkyl methyl ketone, benzoin (or substituted benzoin) ether or acyl phosphines, the heat initiating agent is azocompound or peralcohol, the antioxidant is hydroquinone, p-hydroxybenzene methyl ether, 2,6-ditertiary-butyl-4-methylphenol.

Owner:DALIAN POLYTECHNIC UNIVERSITY

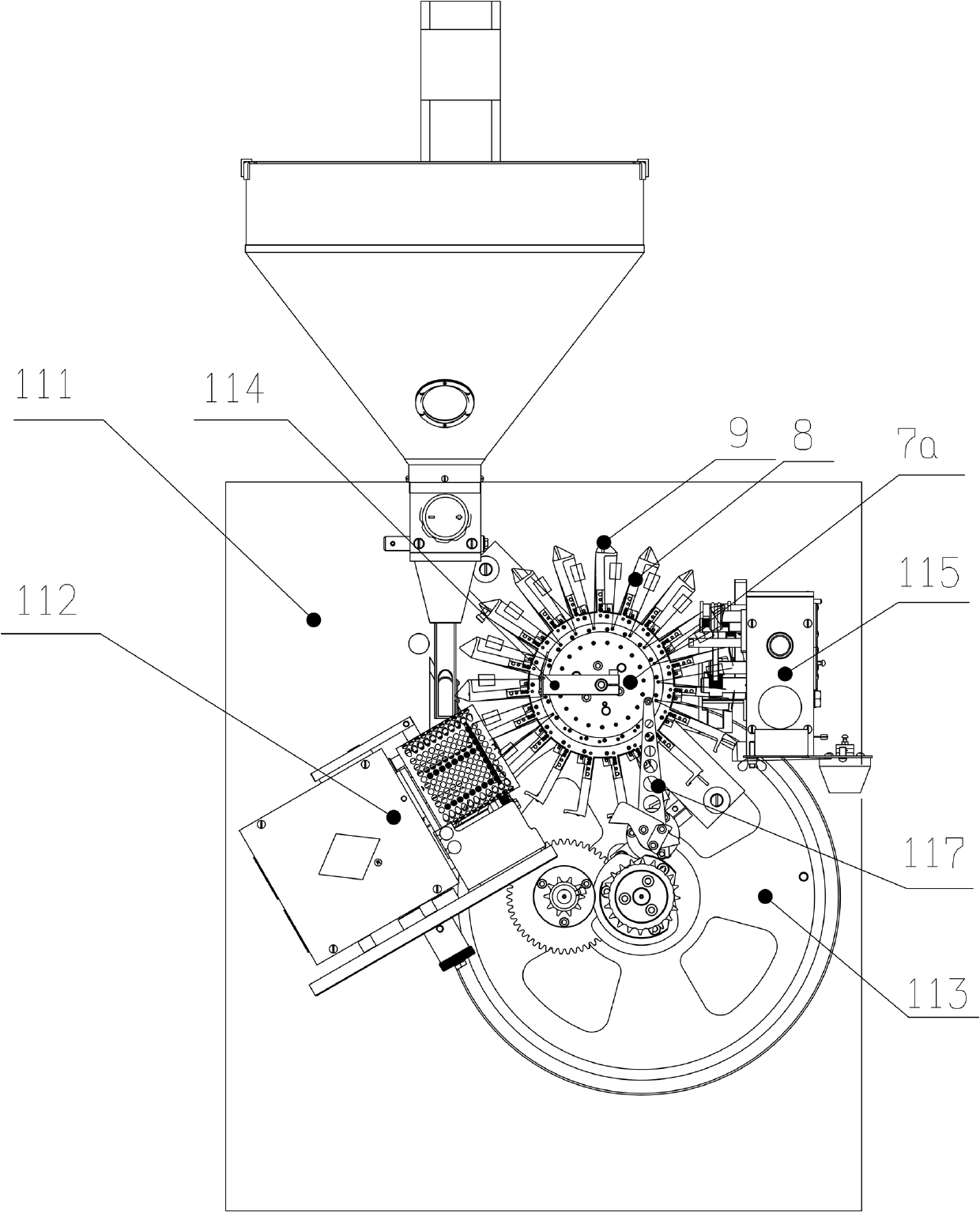

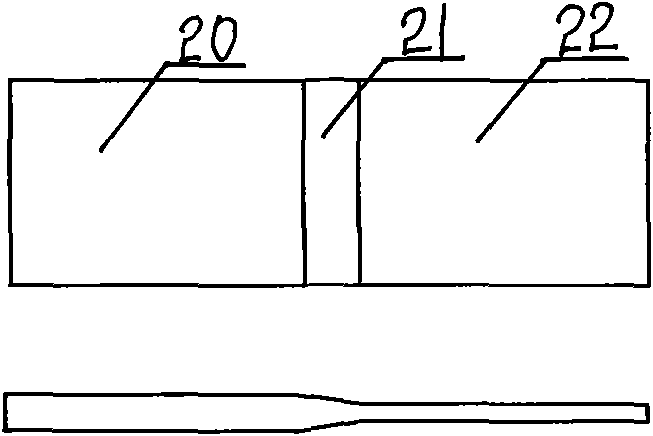

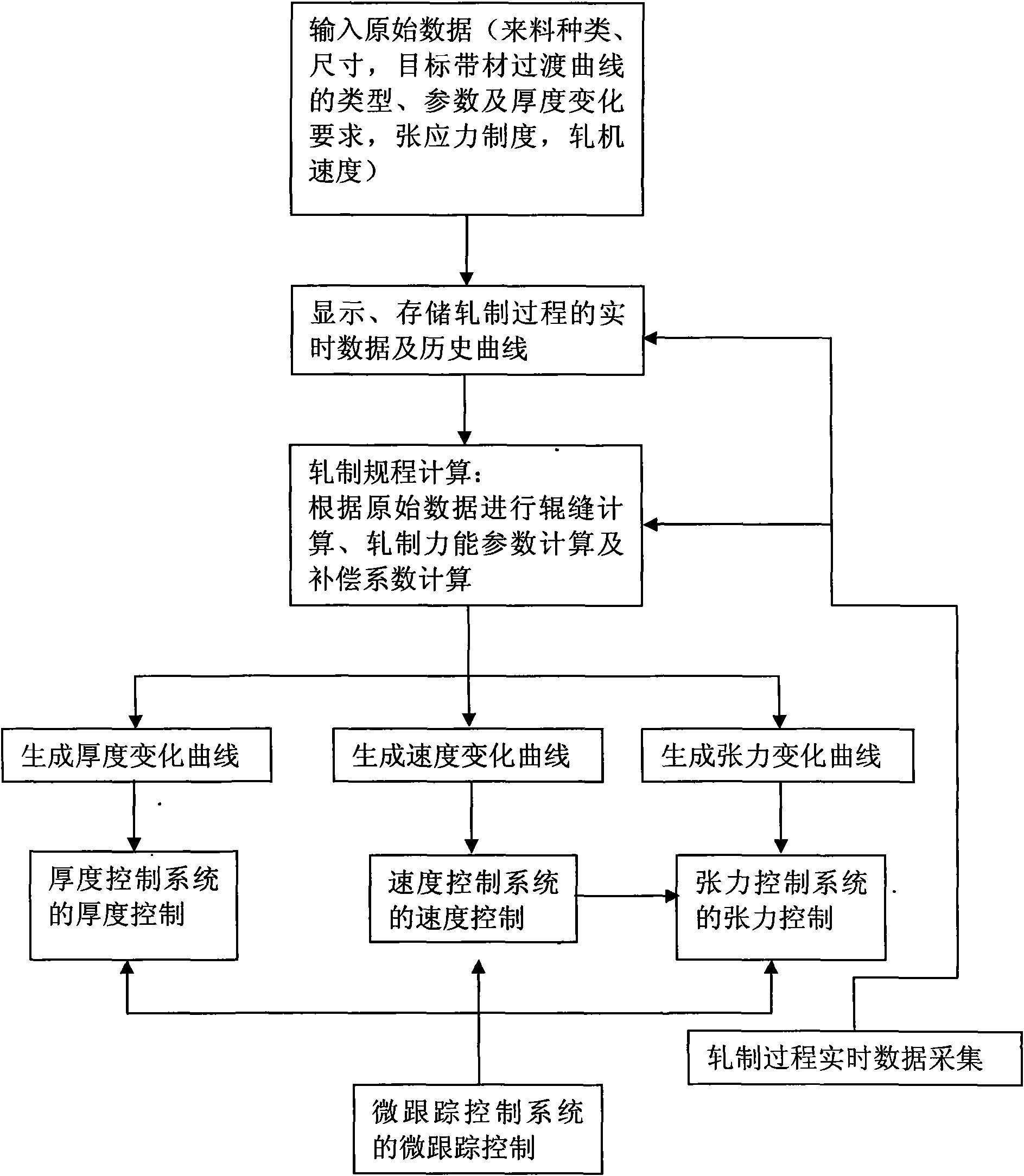

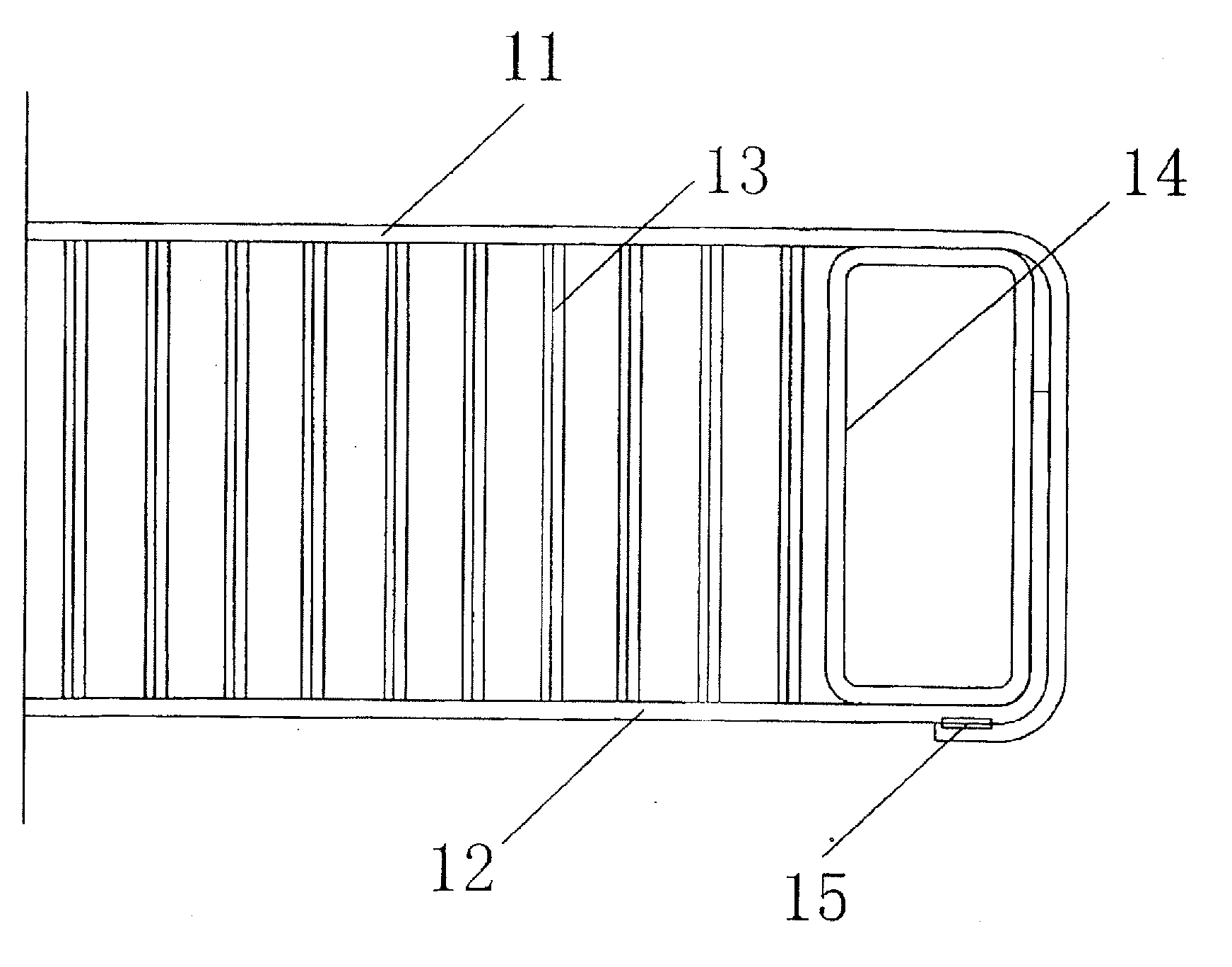

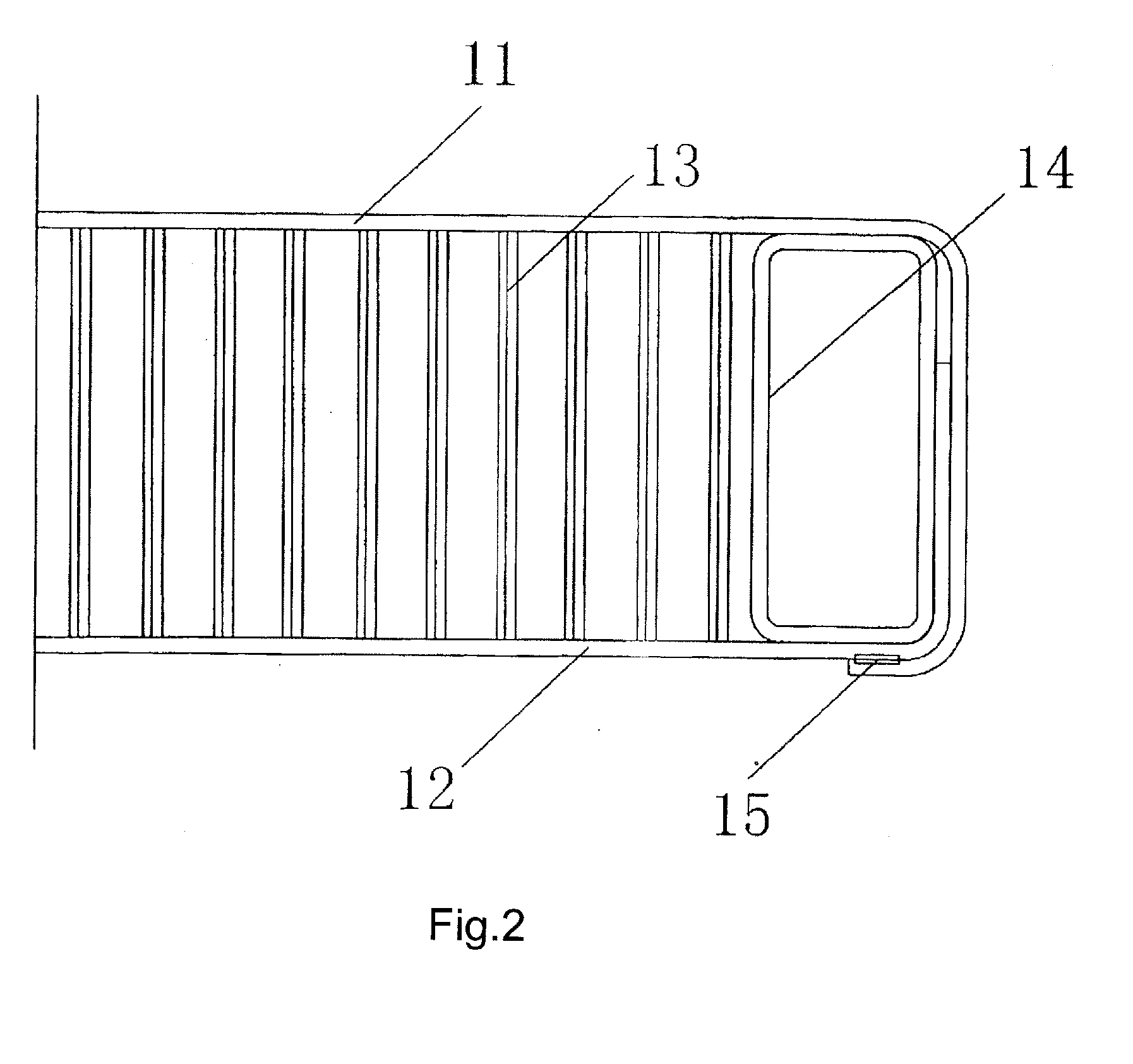

Periodic longitudinal variable-thickness strip and longitudinal variable-thickness plate and preparation method thereof

ActiveCN101607264AReduce welding processReduce manufacturing costProgramme control in sequence/logic controllersMetal rolling arrangementsComputer control systemVariable thickness

The invention belongs to the rolling technical field. The thickness of a periodic longitudinal variable-thickness strip changes periodically, the periodic longitudinal variable-thickness strip has more than two kinds of thicknesses regions and transition regions within a change period, and is formed by rolling. The control procedure of the periodic longitudinal variable-thickness strip comprises the following steps: inputting original data; displaying and storing real-time data and a history curve; computing the rolling procedure; generating a change curve; tracking the position of a rolling piece; and controlling the thickness, the speed and the tension. A device comprises a rolling mill, a reeling machine and a thickness measurer which are arranged at two sides of the rolling mill, and a length measuring roll arranged between the reeling machine and the rolling mill, wherein a reel diameter measurer is arranged on the reeling machine; a rolling force sensor and a hydraulic cylinder are arranged on the rolling machine; a pulse coder and a tension meter are respectively arranged on and below the length measuring roll; and the thickness measurer and the like are connected with a computer control system. A longitudinal variable-thickness plate has two or more kinds of different thickness regions, transition regions are arranged among the thickness regions, and the plate is formed by the strip through the steps of annealing, unreeling by an unreeler, leveling by a leveler, and cutting by a cutting machine.

Owner:SHENYANG DONGBAO HAIXING METAL MATERIAL TECH

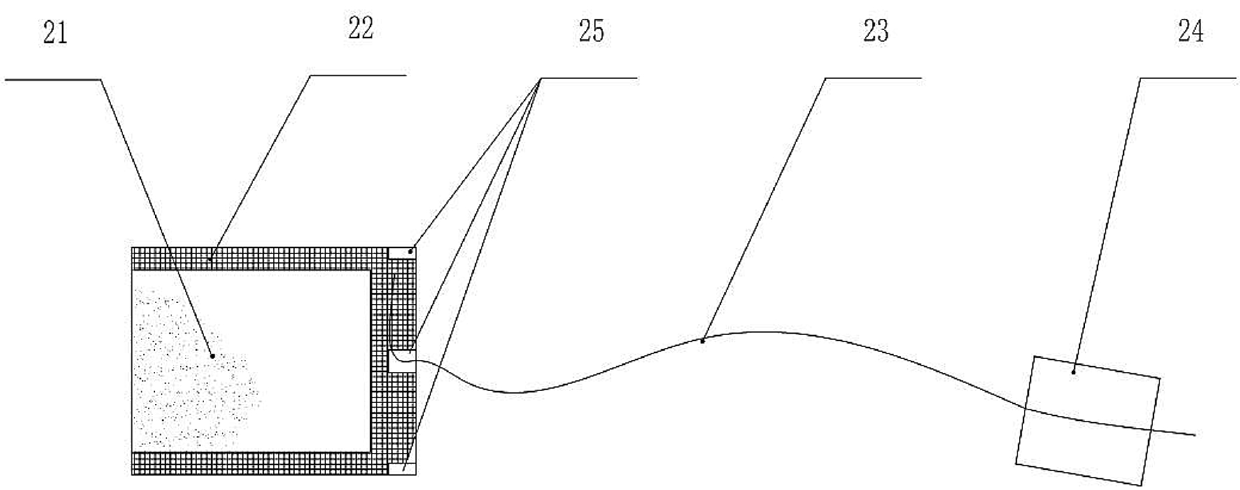

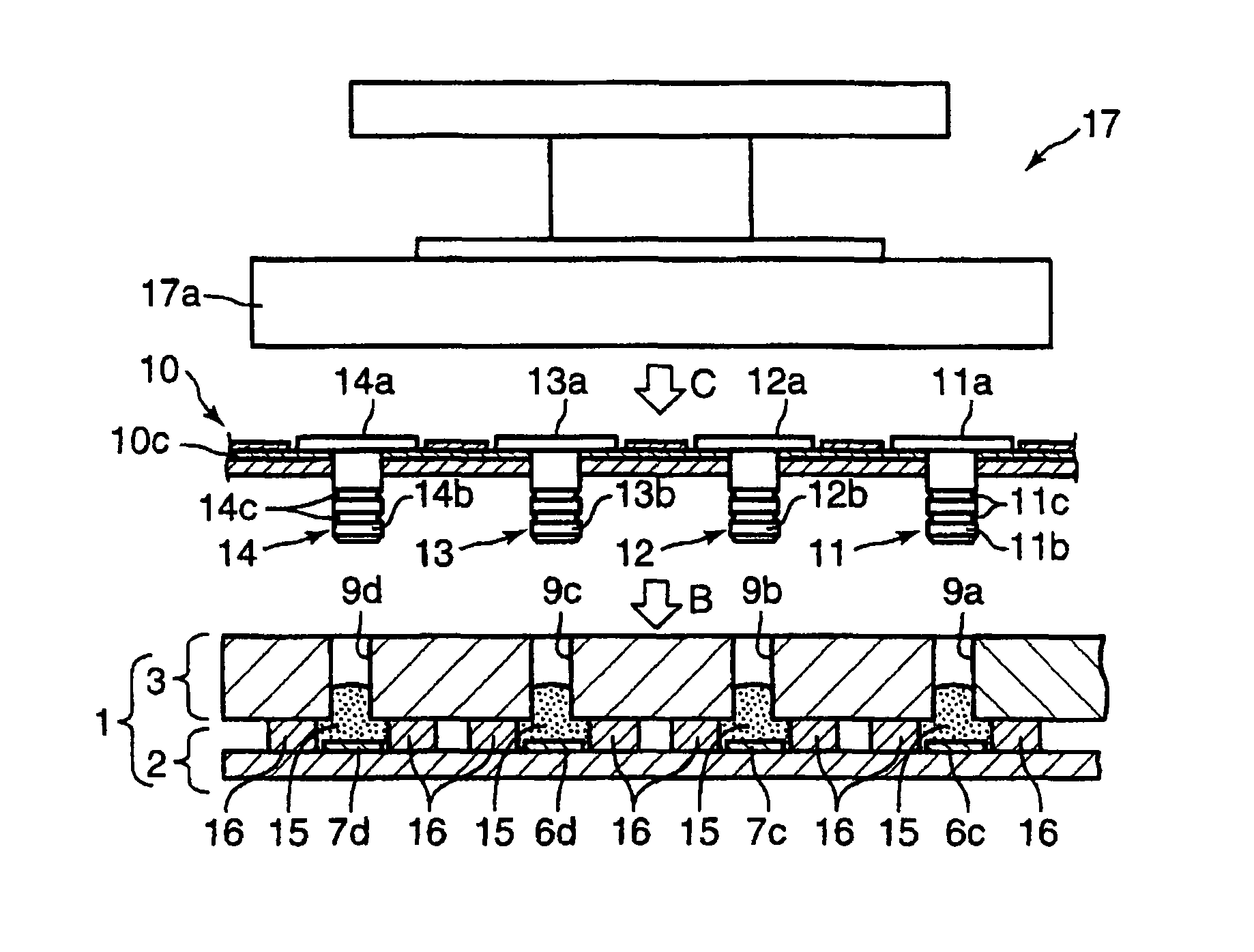

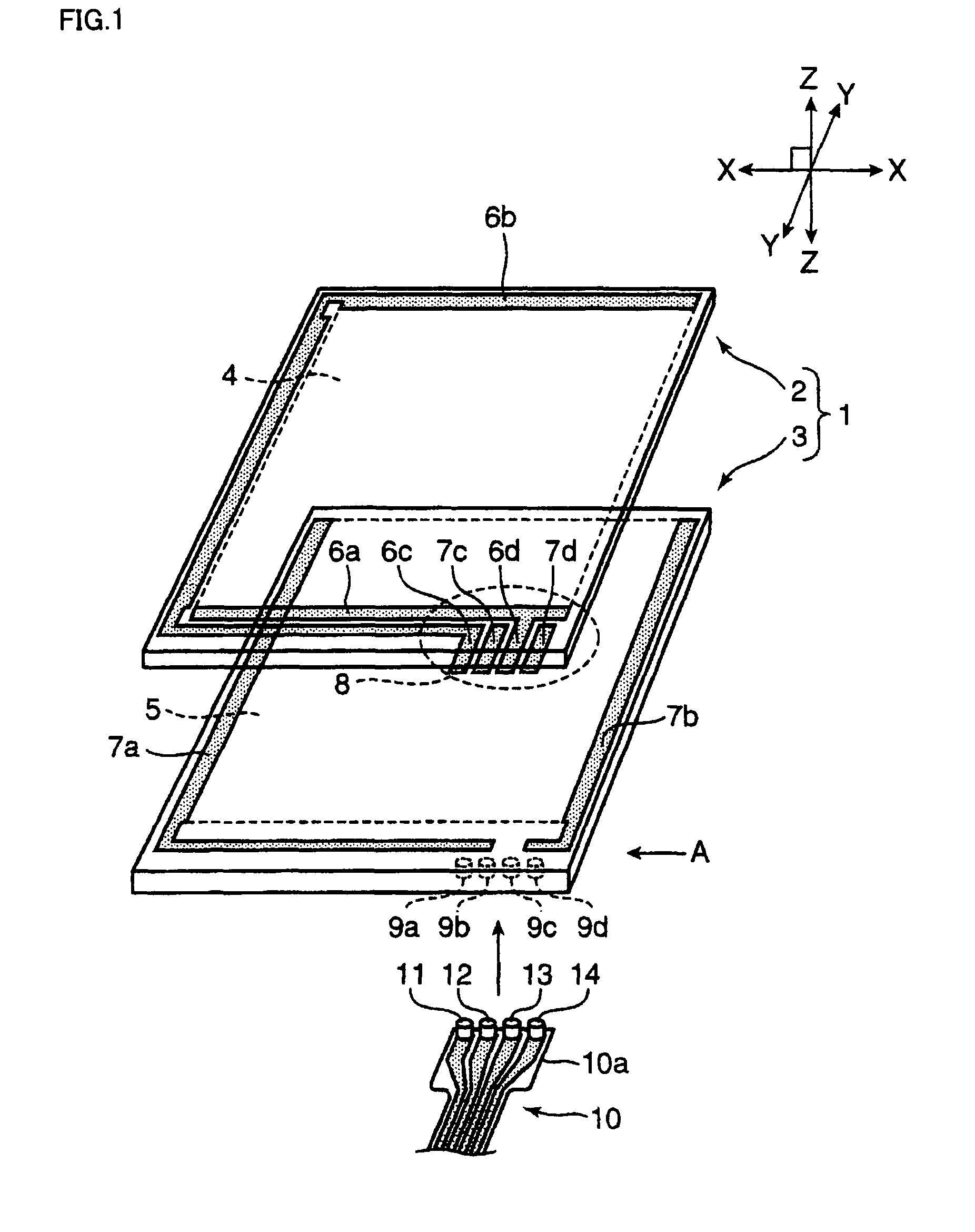

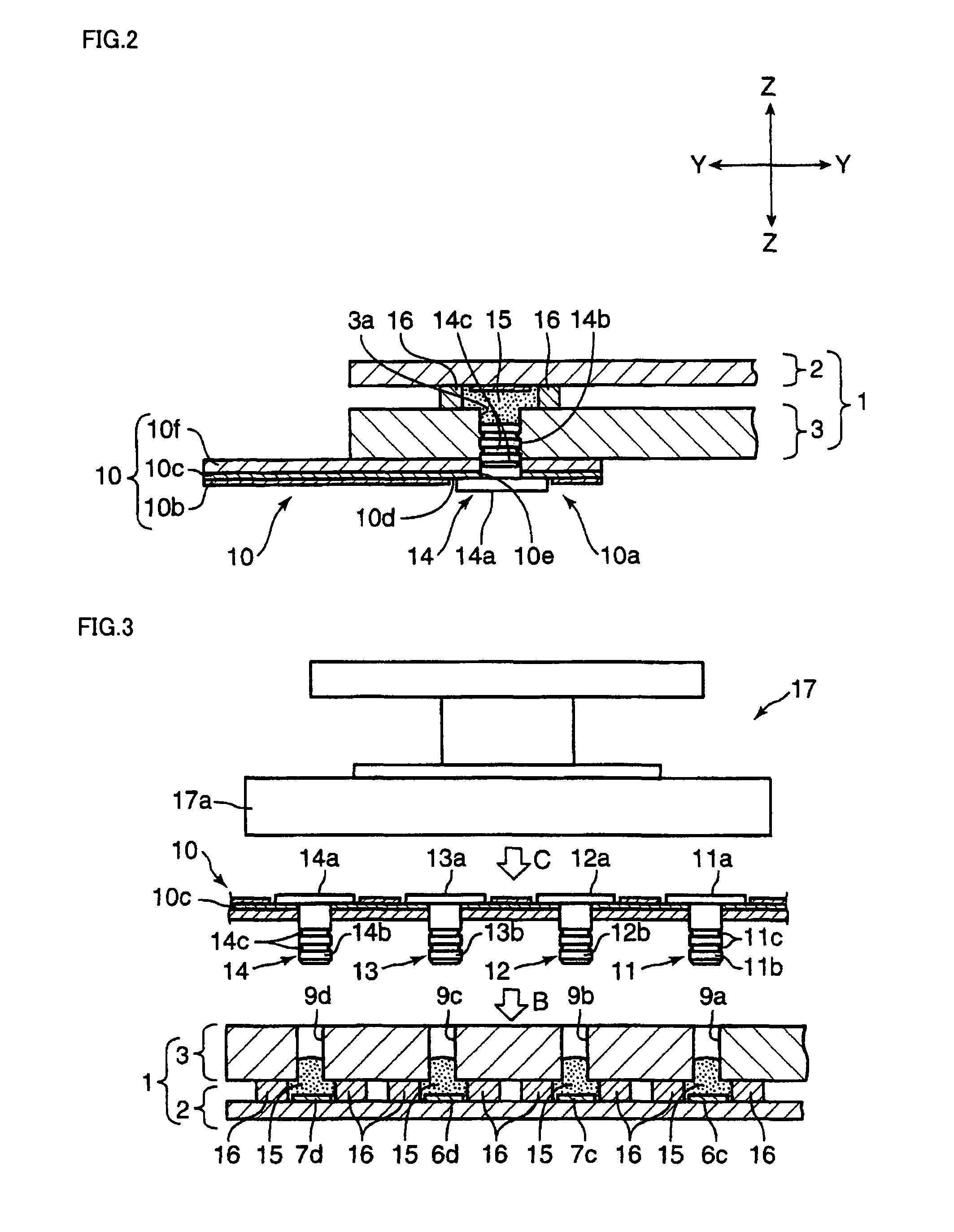

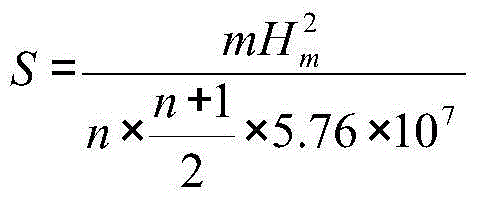

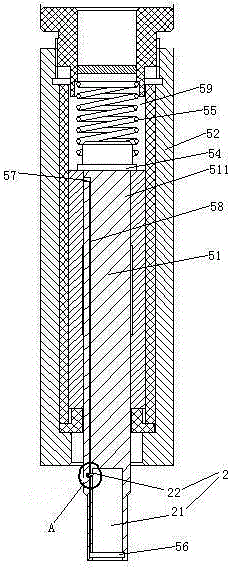

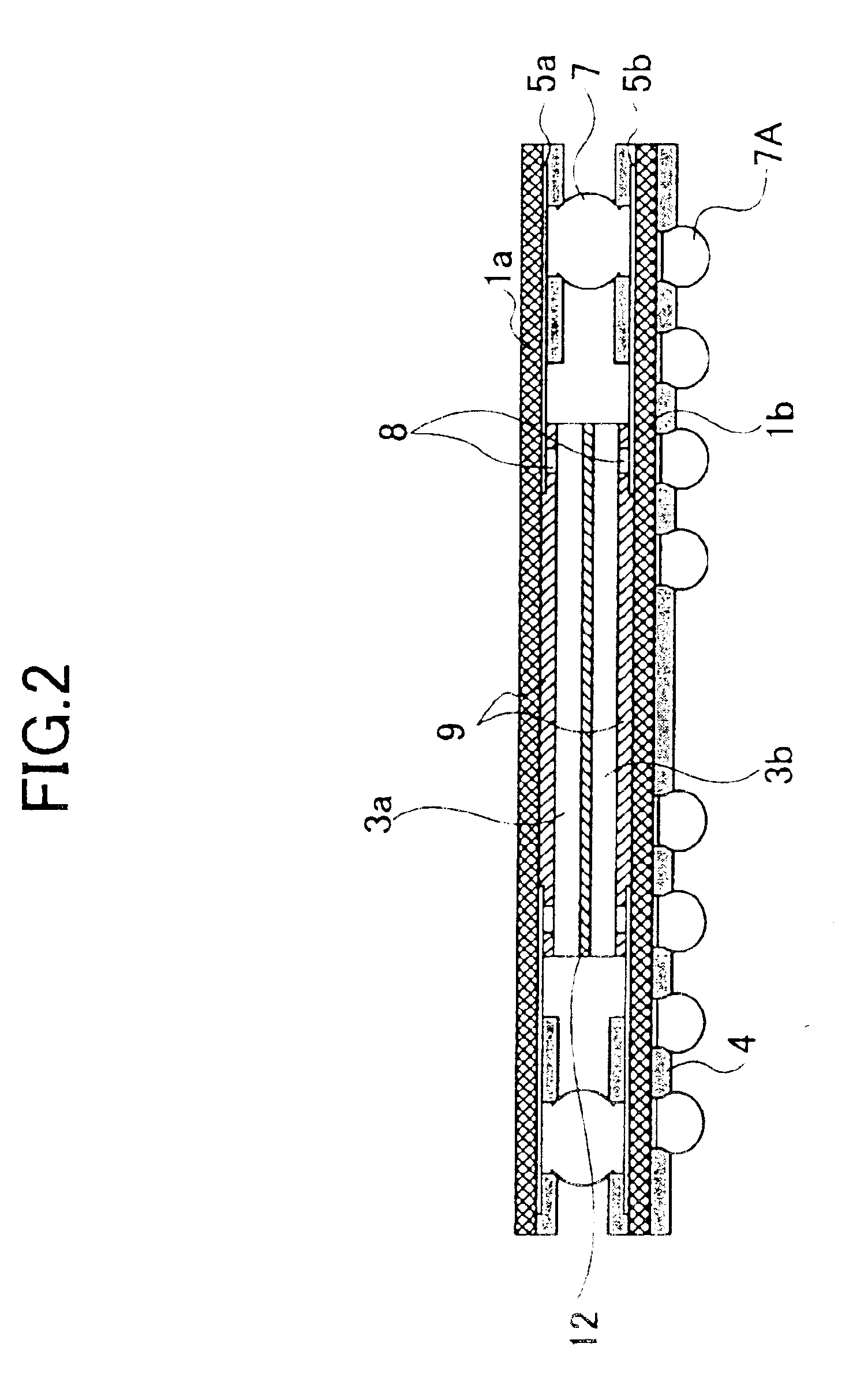

Lead wire connection method for touch panel

InactiveUS8614689B2Control depthImprove connection strengthCoupling device connectionsTransmission systemsAdhesiveEngineering

In a method for connecting lead wires to a touch panel, the method includes the steps of: providing through holes 9a to 9d the number of which corresponds to the number of electrode ends by perforation in a lower electrode plate 3; using a metal-pin 11 having a pin-shaft 11b and a disk shaped pin-head 11a with a diameter larger than an outer diameter of the pin-shaft; inserting the pin-shaft 11b into a metal-pin fixing hole formed corresponding to the through hole 9a at a circuit 10c in a connector tail of a lead wire 10, whereby the pin-shaft 11b is erectly provided on the connector tail of the lead wire 10; and inserting the pin-shafts 11b to 14b into the through holes 9a to 9d, and in addition, electrically connecting the pin-shaft inserted into a lower electrode plate 3 through a conductive adhesive 15 to electrode ends 6c, 7c, 6d, 7d.

Owner:NISSHA PRINTING COMPANY

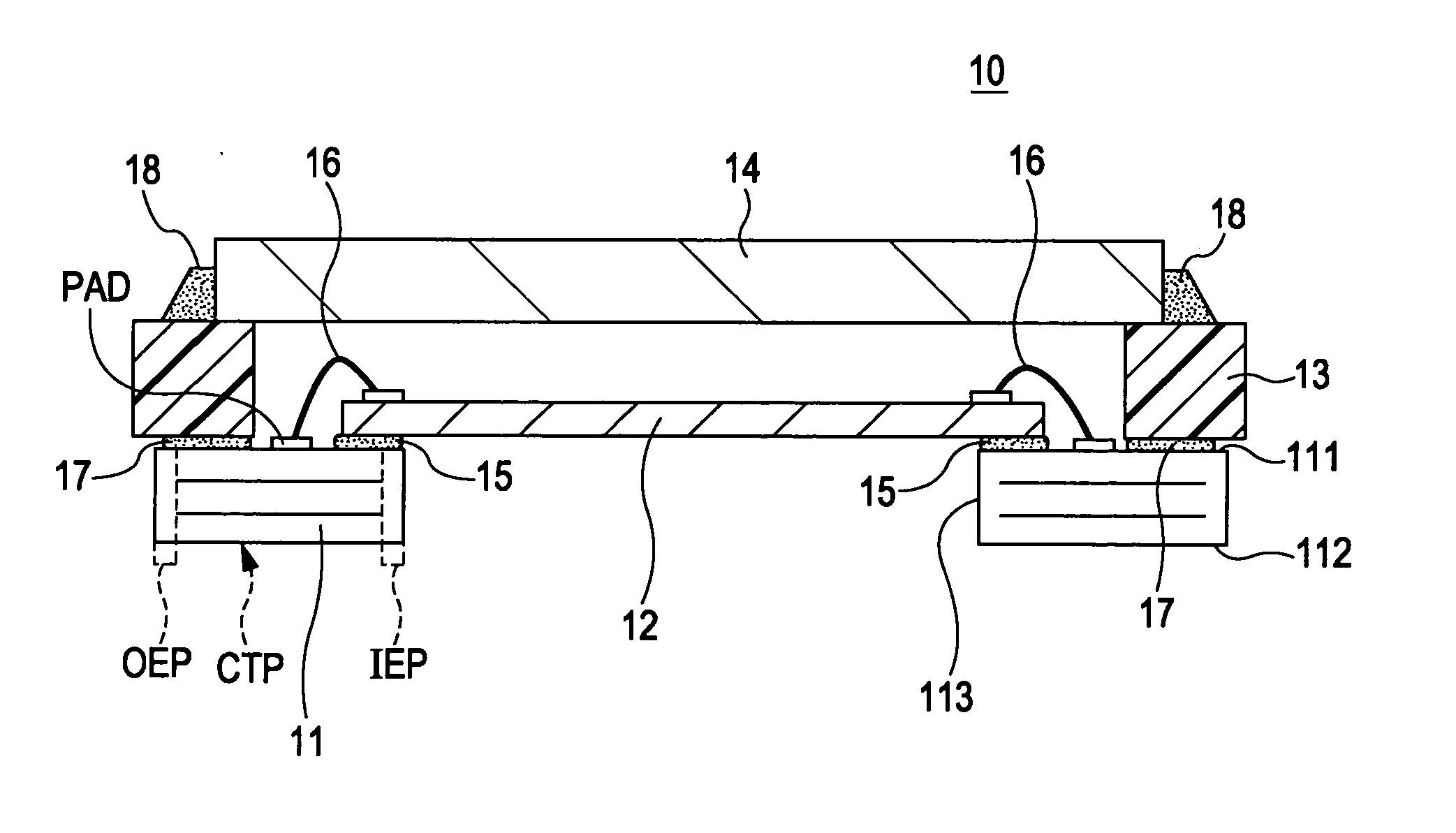

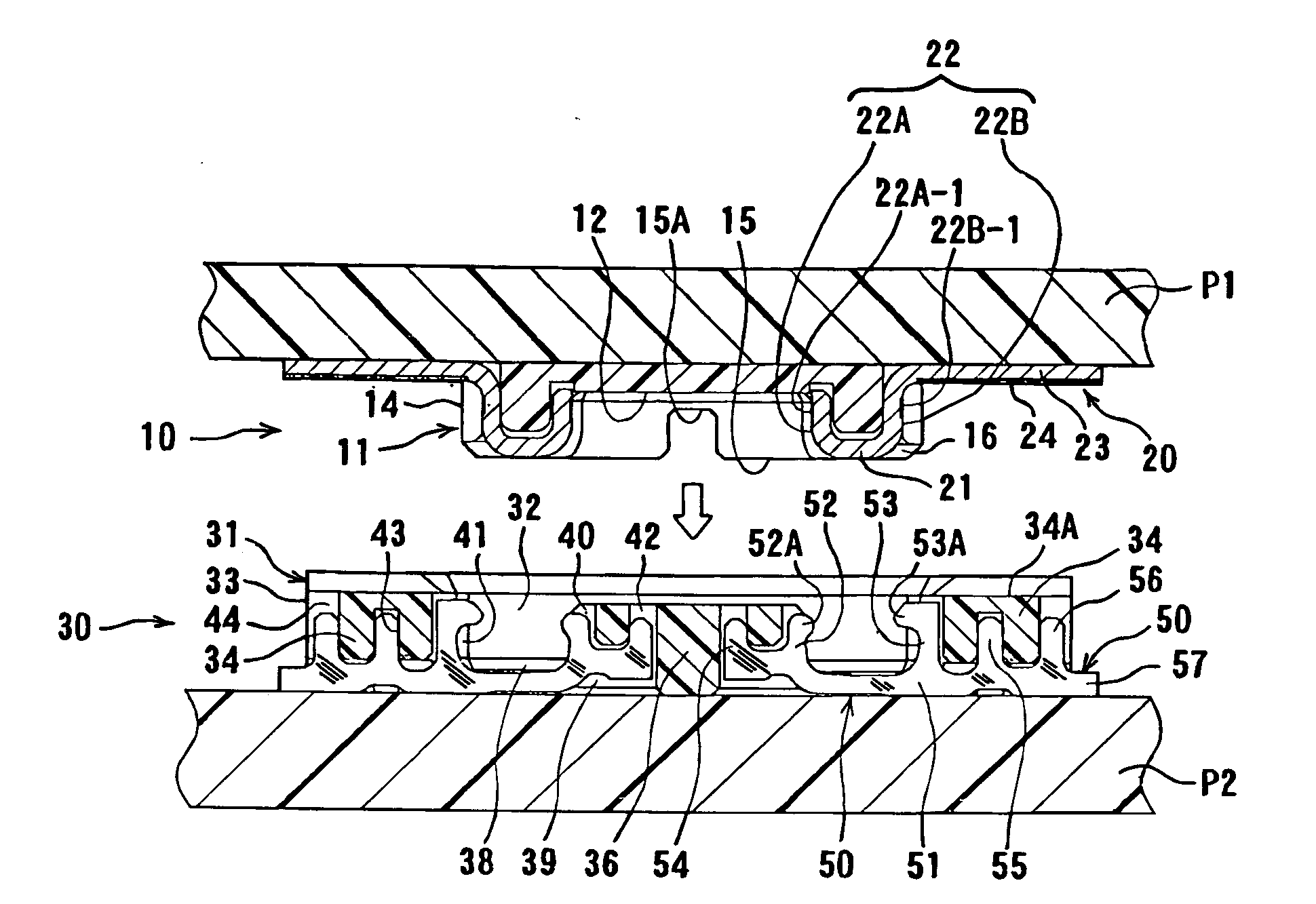

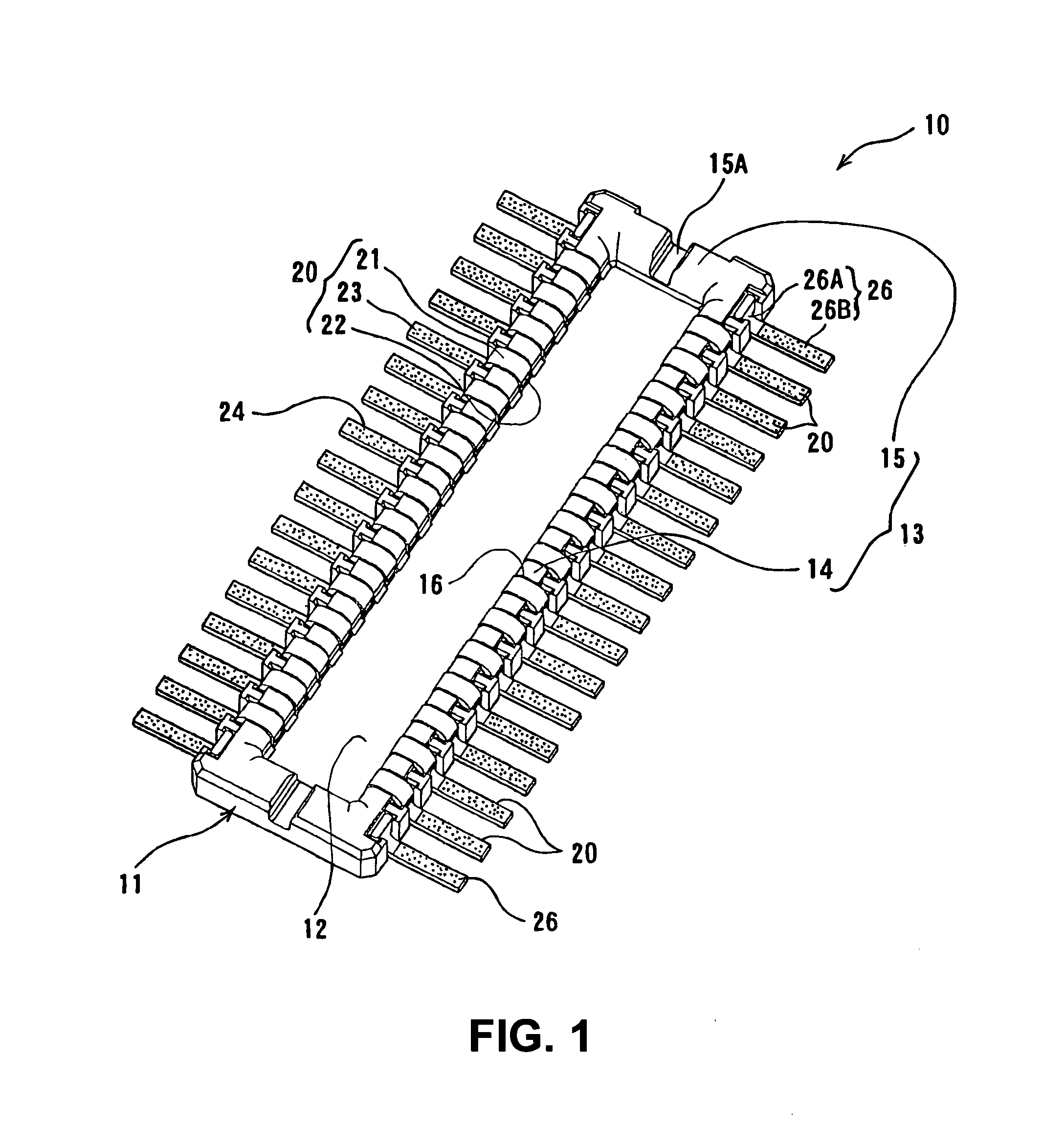

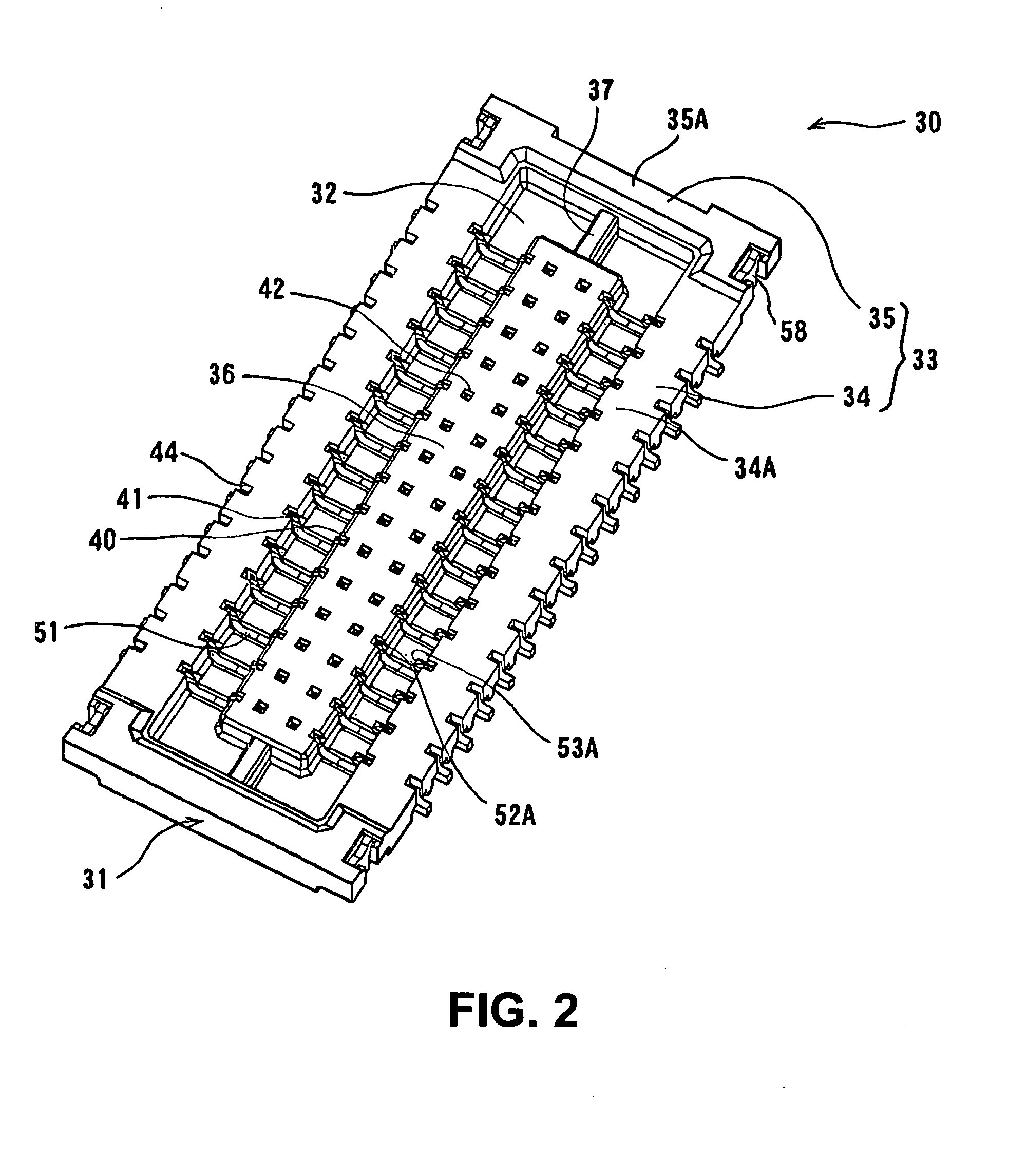

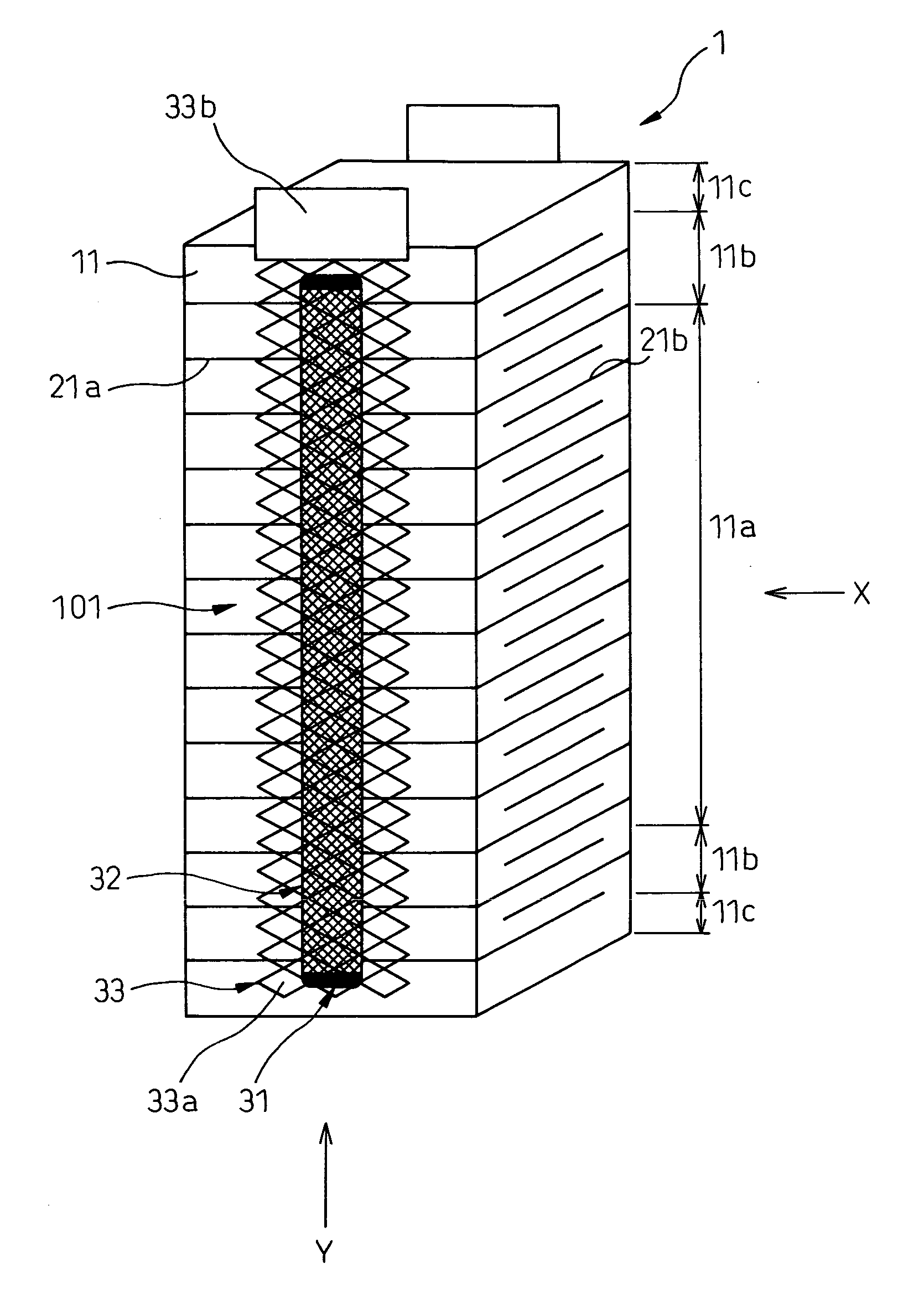

Display device

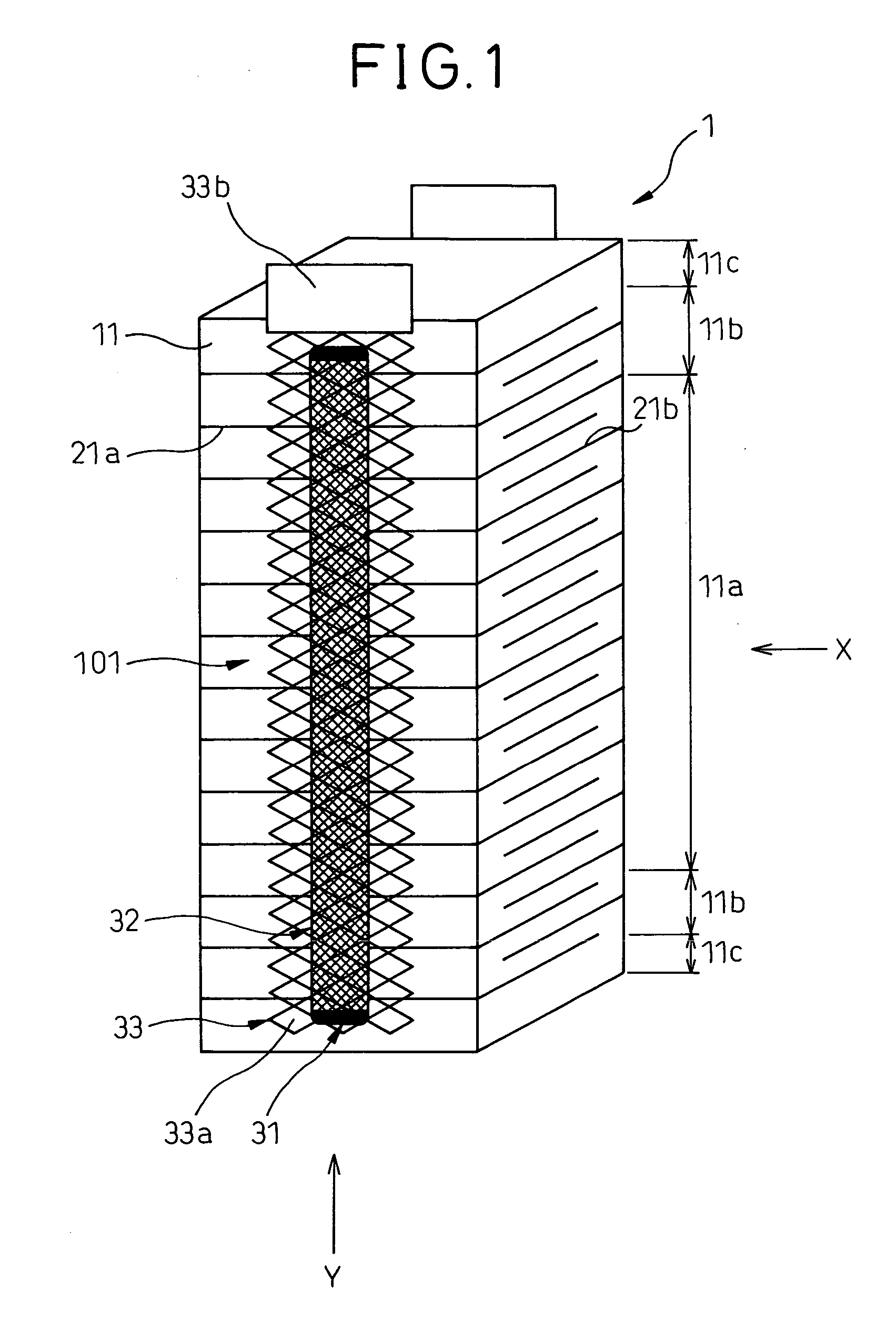

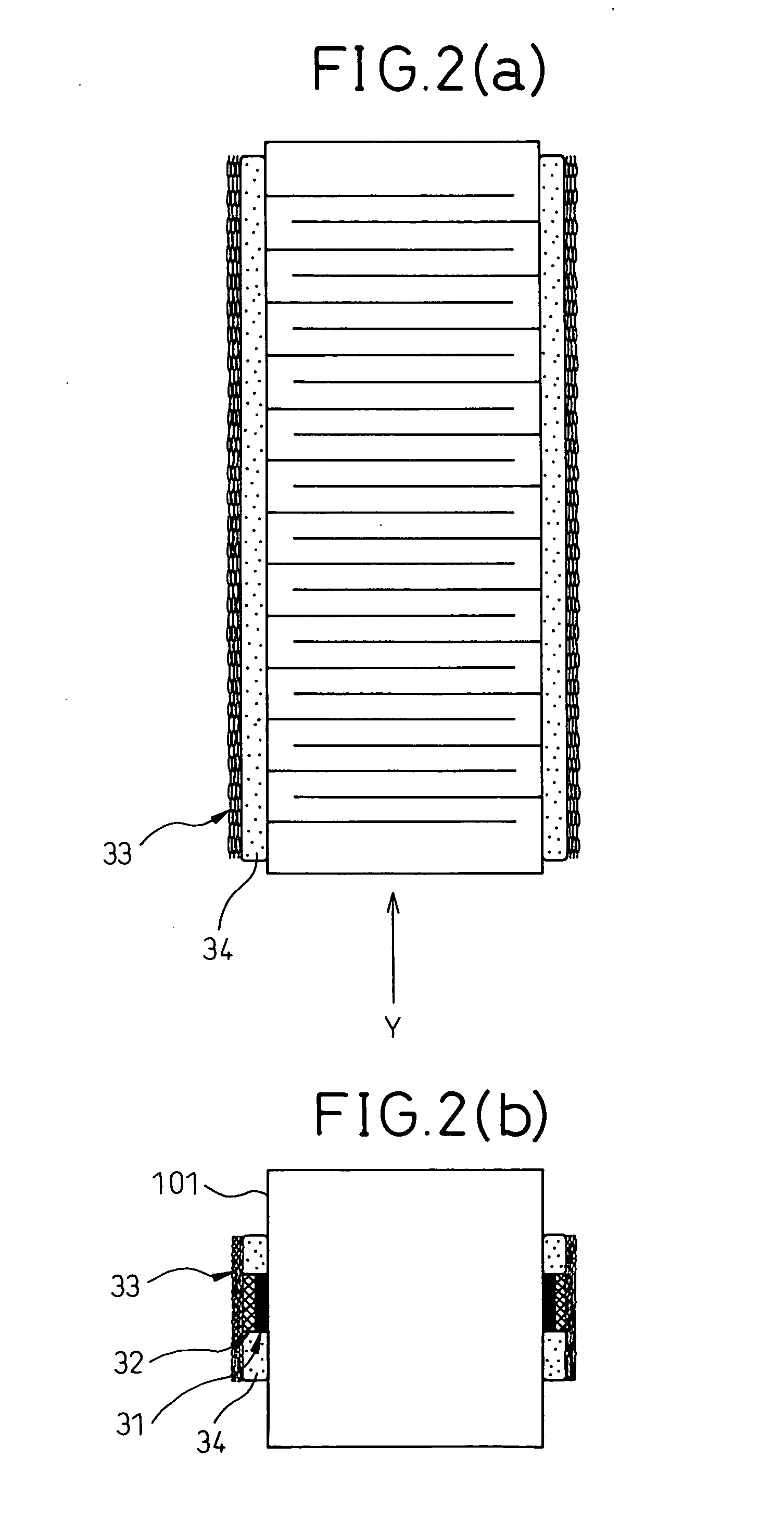

ActiveUS8576209B2Reduce failureImprove connection strengthDigital data processing detailsSemiconductor/solid-state device detailsDriver circuitDisplay device

To provide a display device including a flexible panel that can be handled without seriously damaging a driver circuit or a connecting portion between circuits. The display device includes a bent portion obtained by bending an element substrate. A circuit for driving the display device is provided in the bent portion and a wiring extends from the circuit, whereby the strength of a portion including the circuit for driving the display device is increased and failure of the circuit is reduced. Furthermore, the element substrate is bent in a connecting portion between an external terminal electrode and an external connecting wiring (FPC) so that the element substrate provided with the external terminal electrode fits the external connecting wiring, whereby the strength of the connecting portion is increased.

Owner:SEMICON ENERGY LAB CO LTD

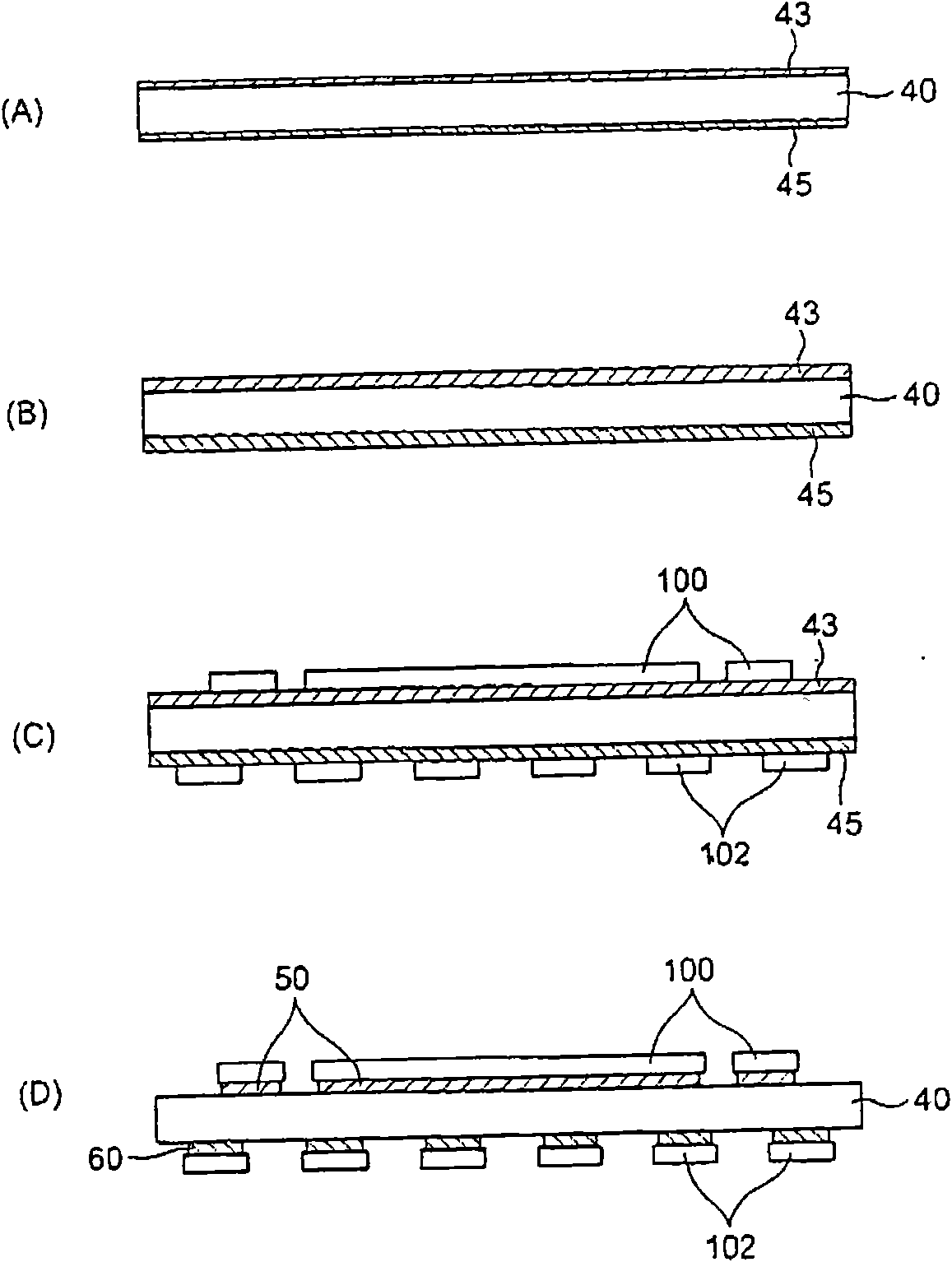

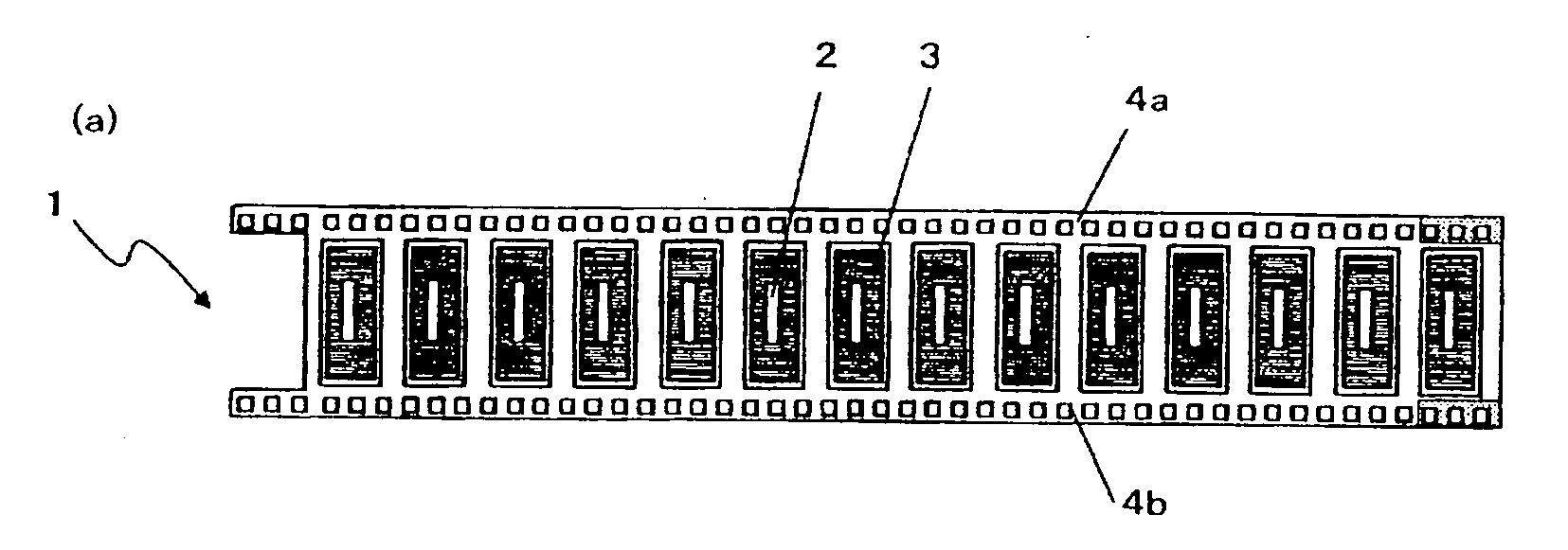

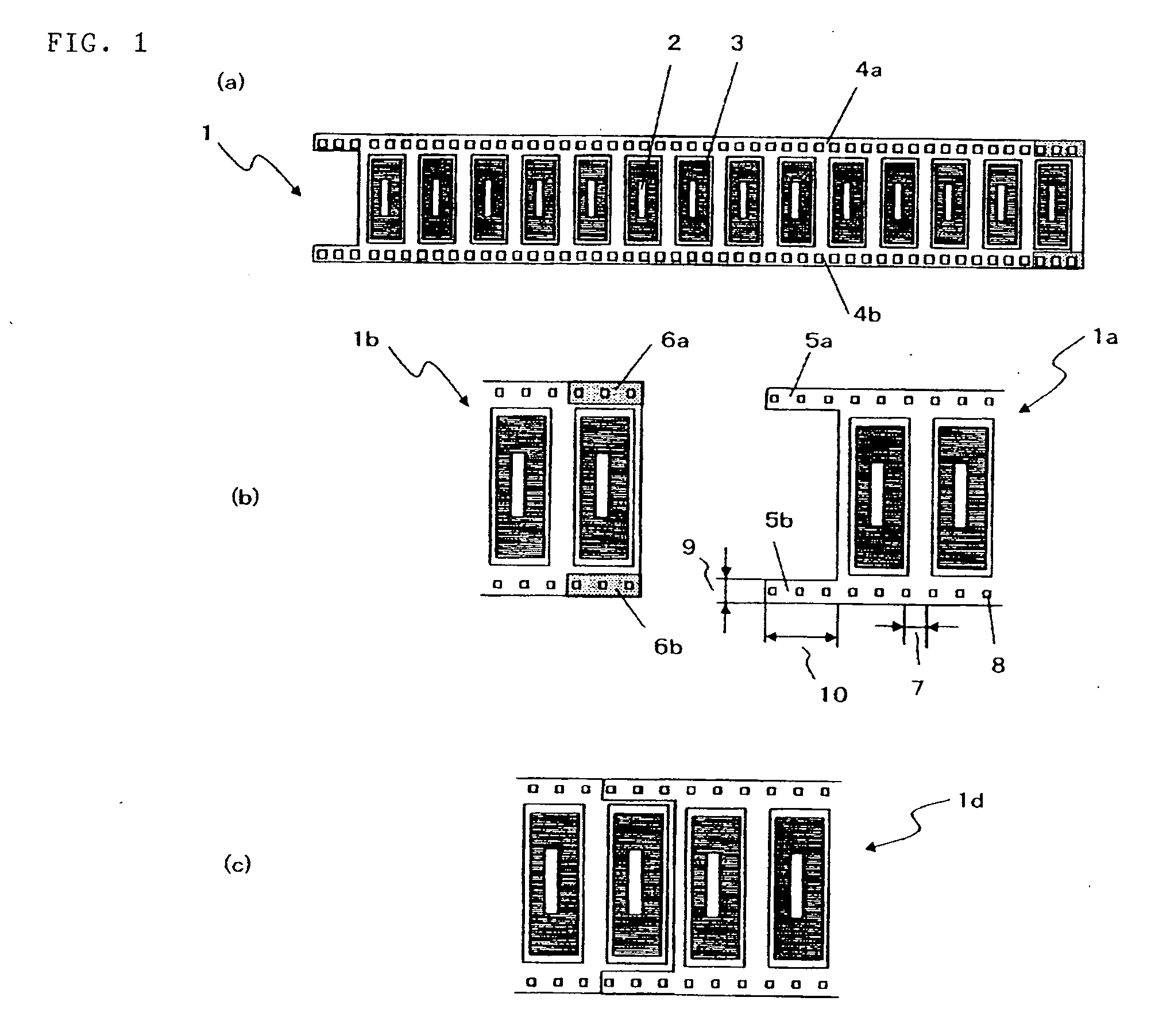

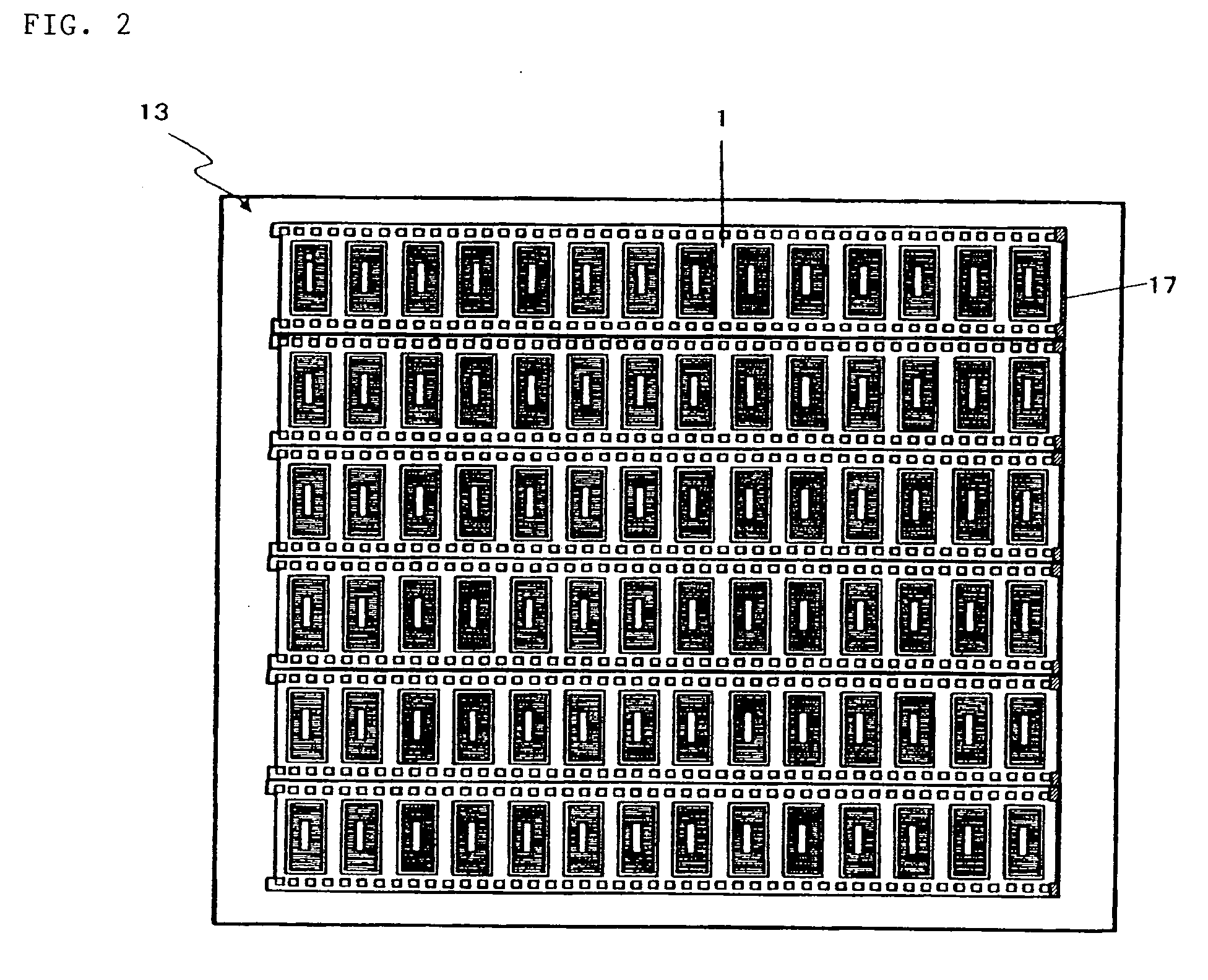

Tape-Style Flexible Circuit Board, and Manufacturing Method and Manufacturing Apparatus for the Same

InactiveUS20080259575A1Reduce lossesEasy to handleLamination ancillary operationsPrinted circuit aspectsFlexible circuitsEngineering

Owner:TORAY IND INC

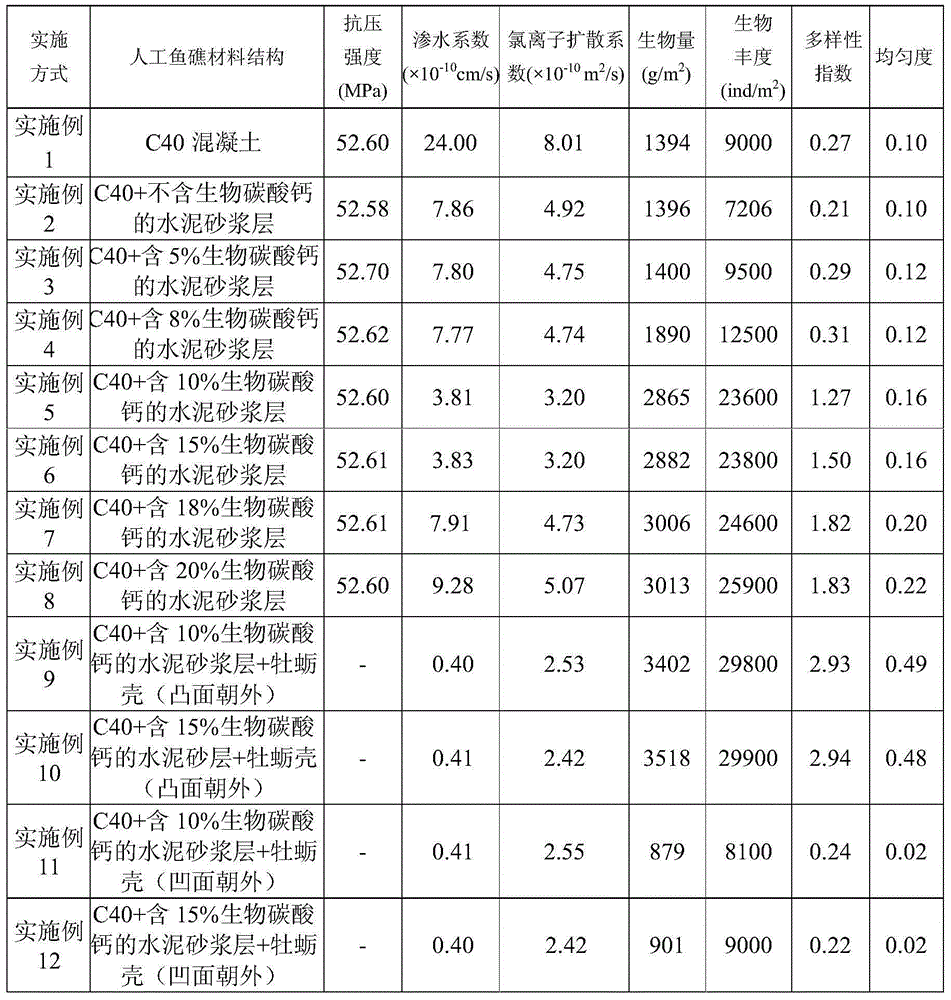

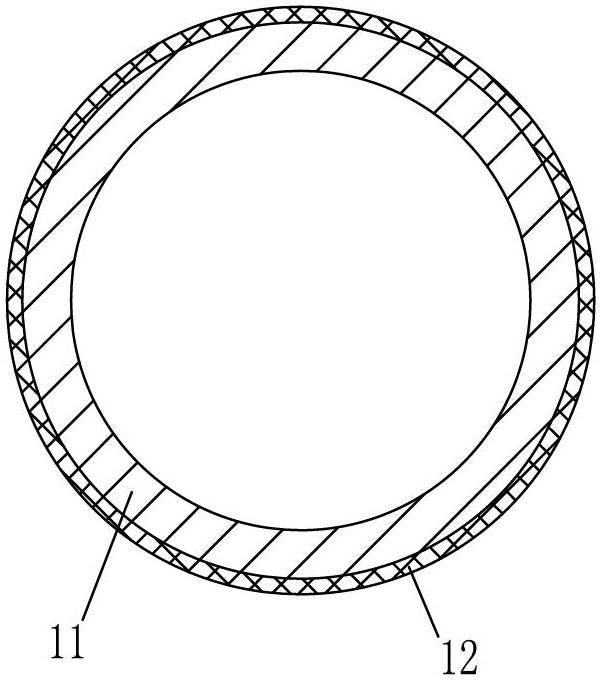

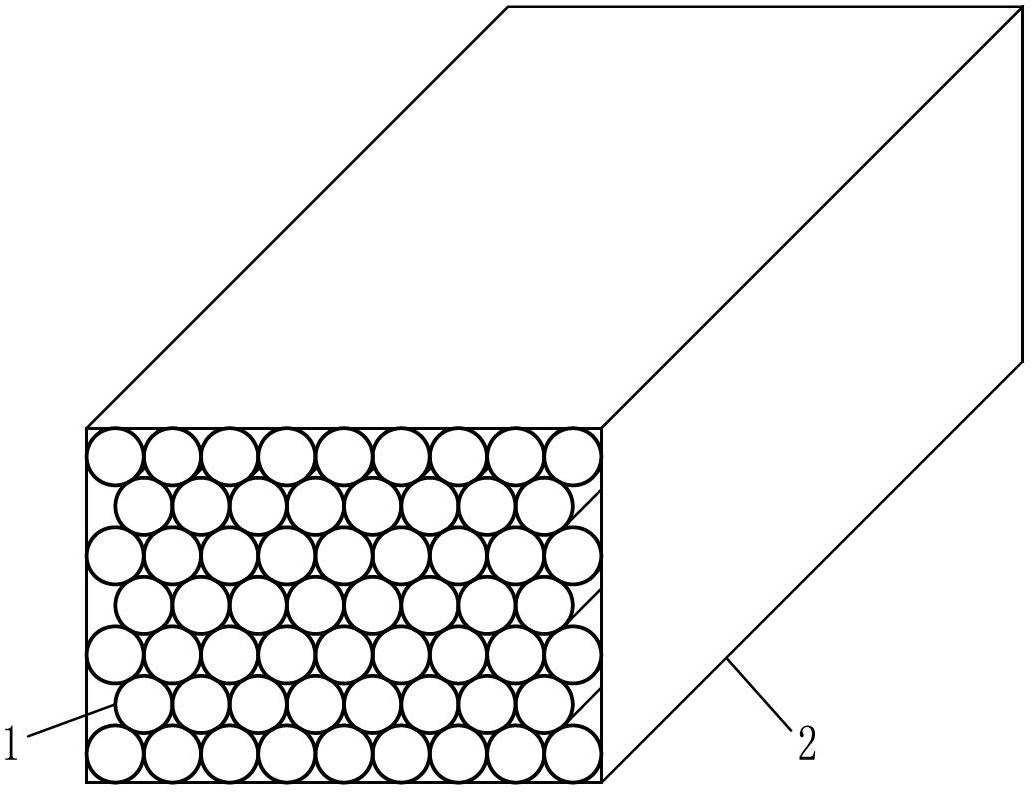

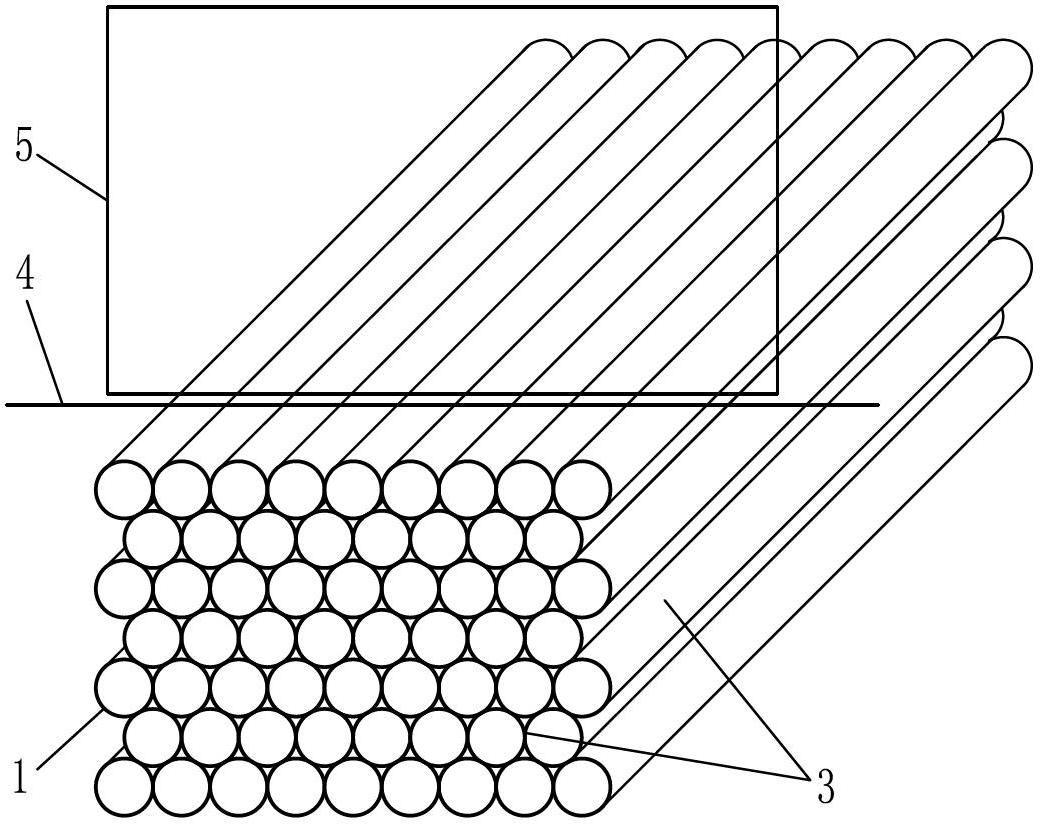

Bionic concrete artificial fish reef and preparation method thereof

InactiveCN104938384AReduce porosityIncreased Durability LifeClimate change adaptationPisciculture and aquariaEggshellOyster shells

The invention discloses a bionic concrete artificial fish reef arranged on the seafloor. According to the fish reef, C40 concrete is used for pouring to form an artificial fish reef base body, the surface of the base body is covered with a protective layer which is composed of cement mortar, biological calcium carbonate and oyster shells, the biological calcium carbonate is made of eggshells, corals, seashells and fishbone and is used as an additive to be added into the cement mortar, the cement mortar mixture is smeared on the surface of the fish reef base body to form cement paste after the biological calcium carbonate and the cement mortar are evenly stirred together, and the oyster shells are inlaid in the cement paste in a convex face outward mode. According to the artificial fish reef, the environment-friendly function, the durable function and the trapping function are integrated, the cement mortar covering layer doped with the biological calcium carbonate and the coating of the oyster shells can attract marine organisms to inhabit, and thus the trapping effect of the artificial fish reef can be better achieved; compared with a traditional concrete fish reef, the artificial fish reef has good waterproof property and chloride ion resistance, surface roughness and alkalinity of the surface of the fish reef are appropriate, bionic performance is achieved, and the fish collecting effect is excellent.

Owner:GUANGDONG UNIV OF TECH +1

Cellular board and manufacturing method thereof

ActiveCN102689458AIncrease in sizeHigh plate strengthSynthetic resin layered productsHoneycombHigh intensity

The invention discloses a manufacturing method of a cellular board which comprises the following steps of: producing a double-layer composite pipe, wherein the inner layer of the double-layer composite pipe is a high-melting-point material layer, the outer layer of the double-layer composite pipe is a low-melting-point material layer, and the melting point of the low-melting-point material layer is lower than that of the high-melting-point material layer; bundling the multiple double-layer composite pipes in order, heating so that the outer layer of the double-layer composite pipe is melted and the inner layer is not melted and cooling to enable the adjacent attached outer layers of the double-layer composite pipe are bonded together to form a honeycomb; cutting the honeycomb along the cross section of the double-layer composite pipe so as to obtain a platy honeycomb base material; and hot pressing the top surface and the bottom surface of the multiple honeycomb base materials in the same plane so that the end surface of the adjacent attached inner layers of the double-layer composite pipe is fused to form a fillet to obtain the cellular board. The invention also discloses a cellular board manufactured by using the method. According to the technical scheme, the cellular board with stability, evenness, reliable quality, high intensity and large area can be obtained.

Owner:HANGZHOU HOLYCORE COMPOSITE MATERIAL +1

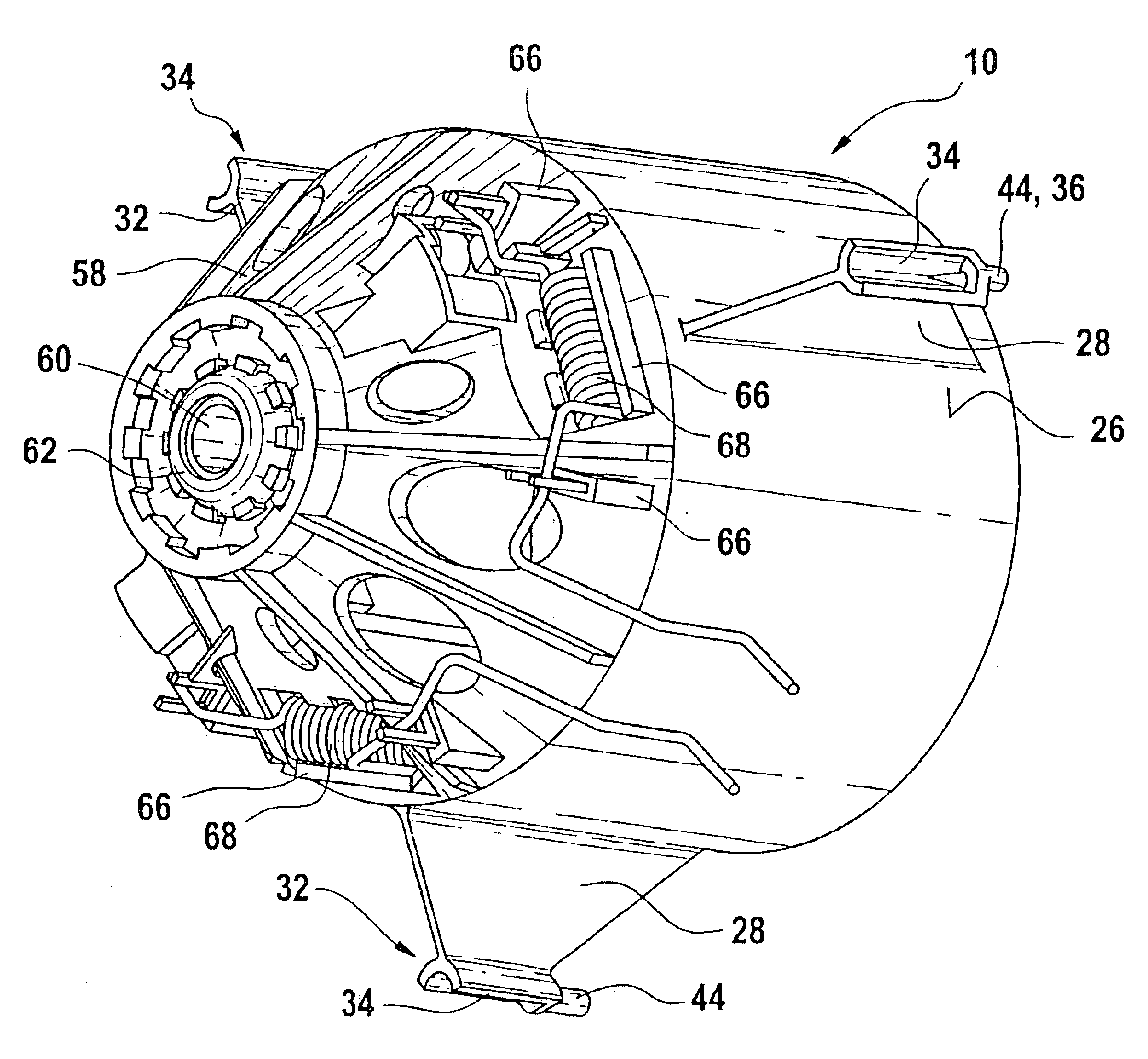

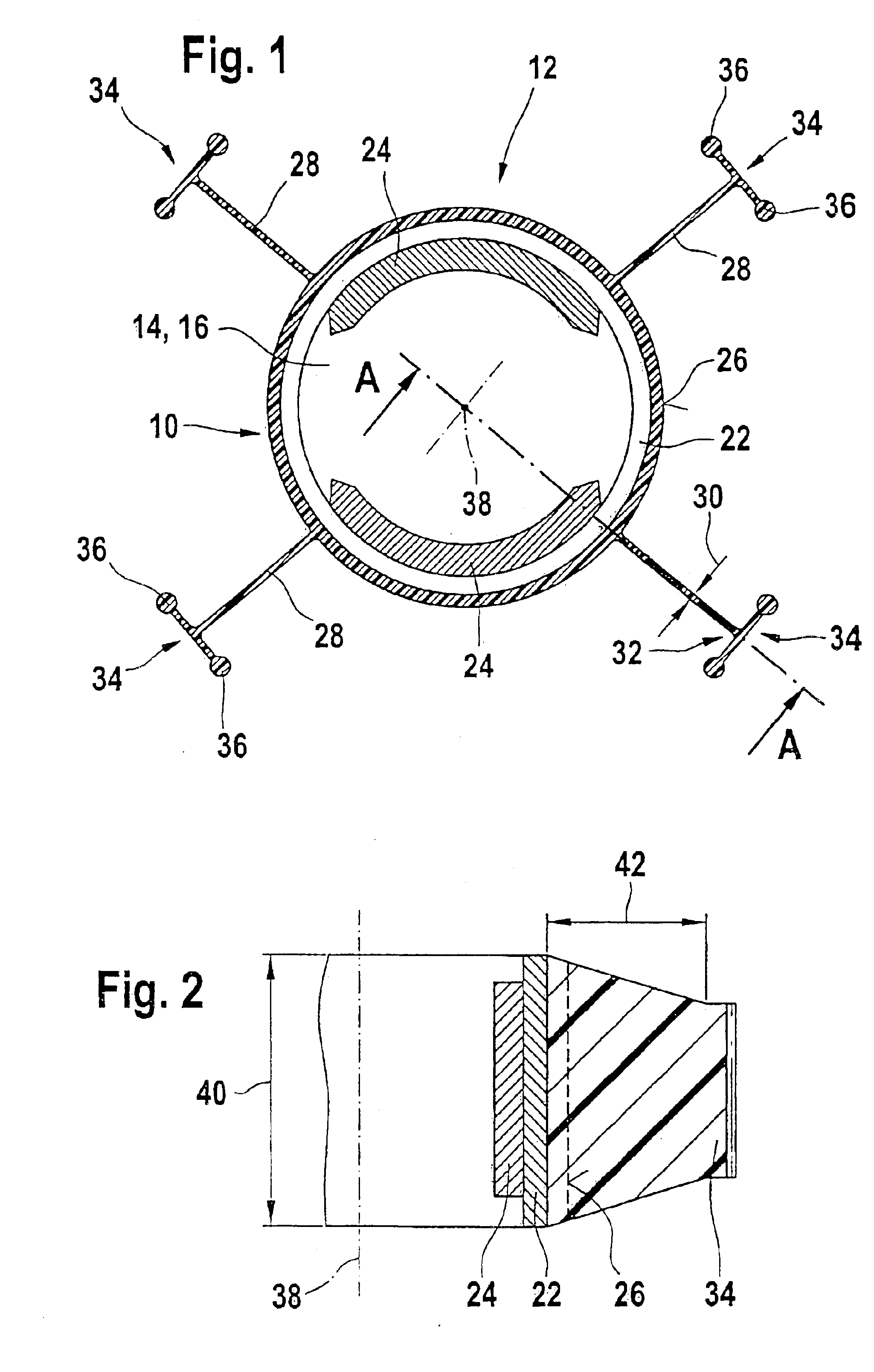

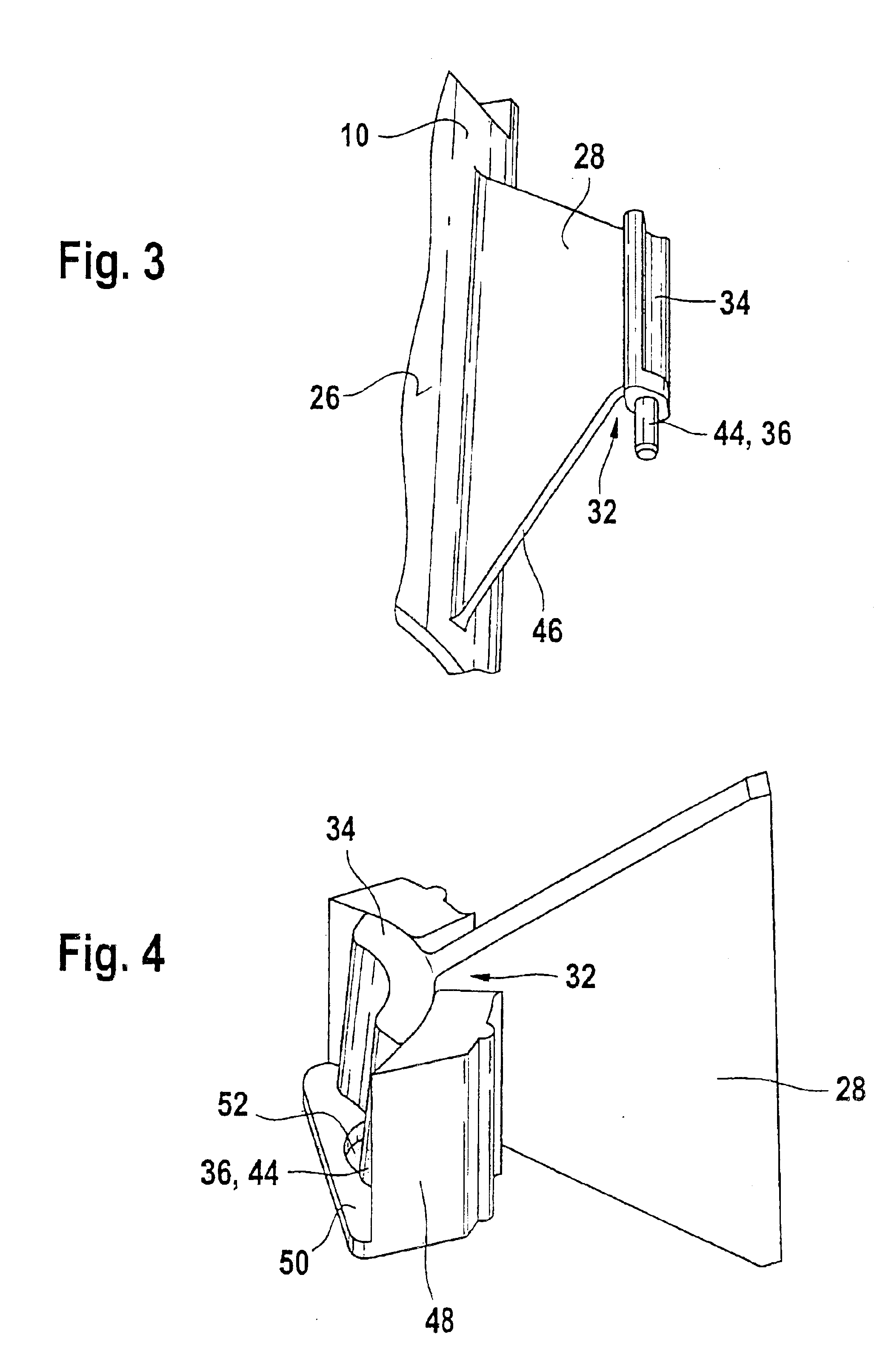

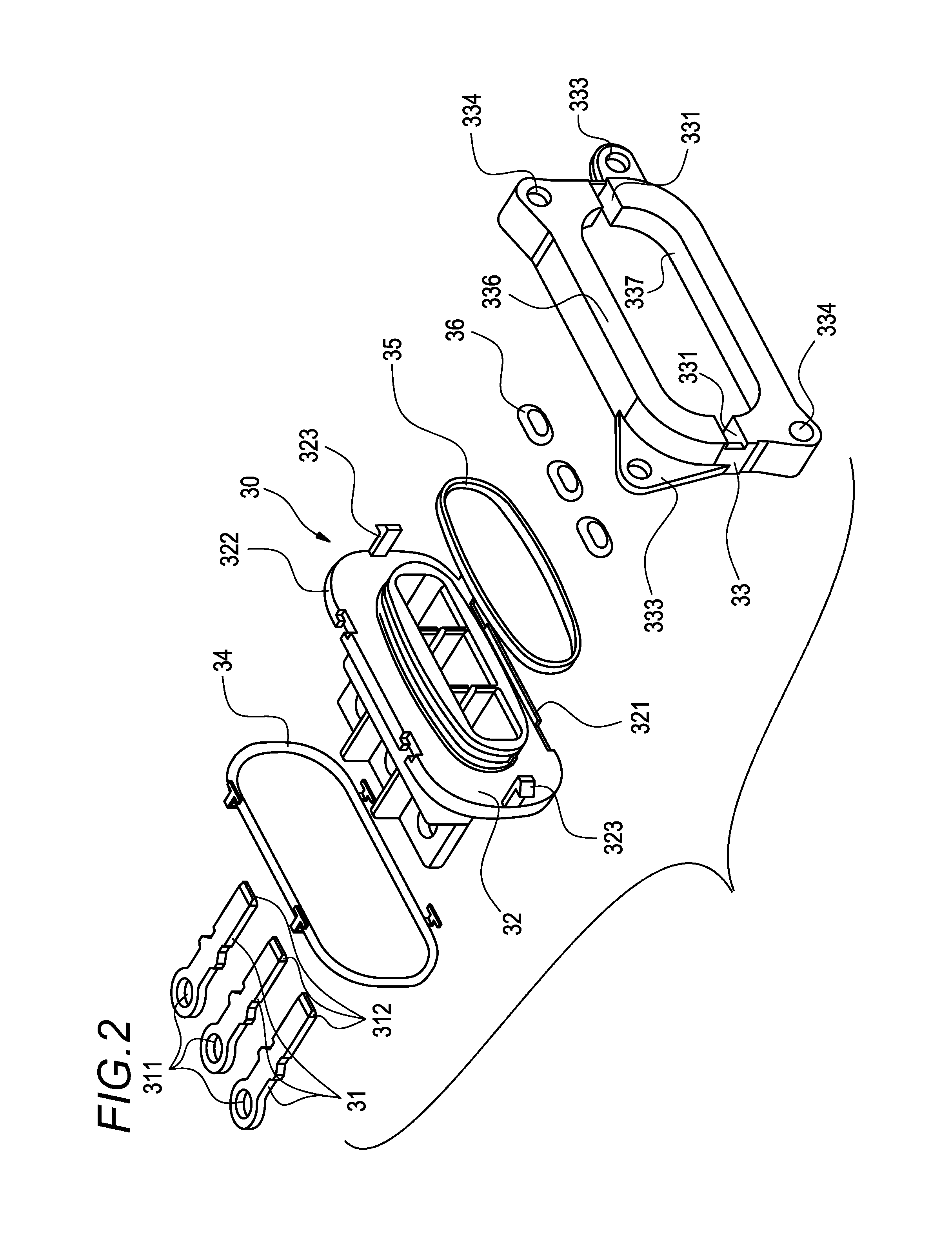

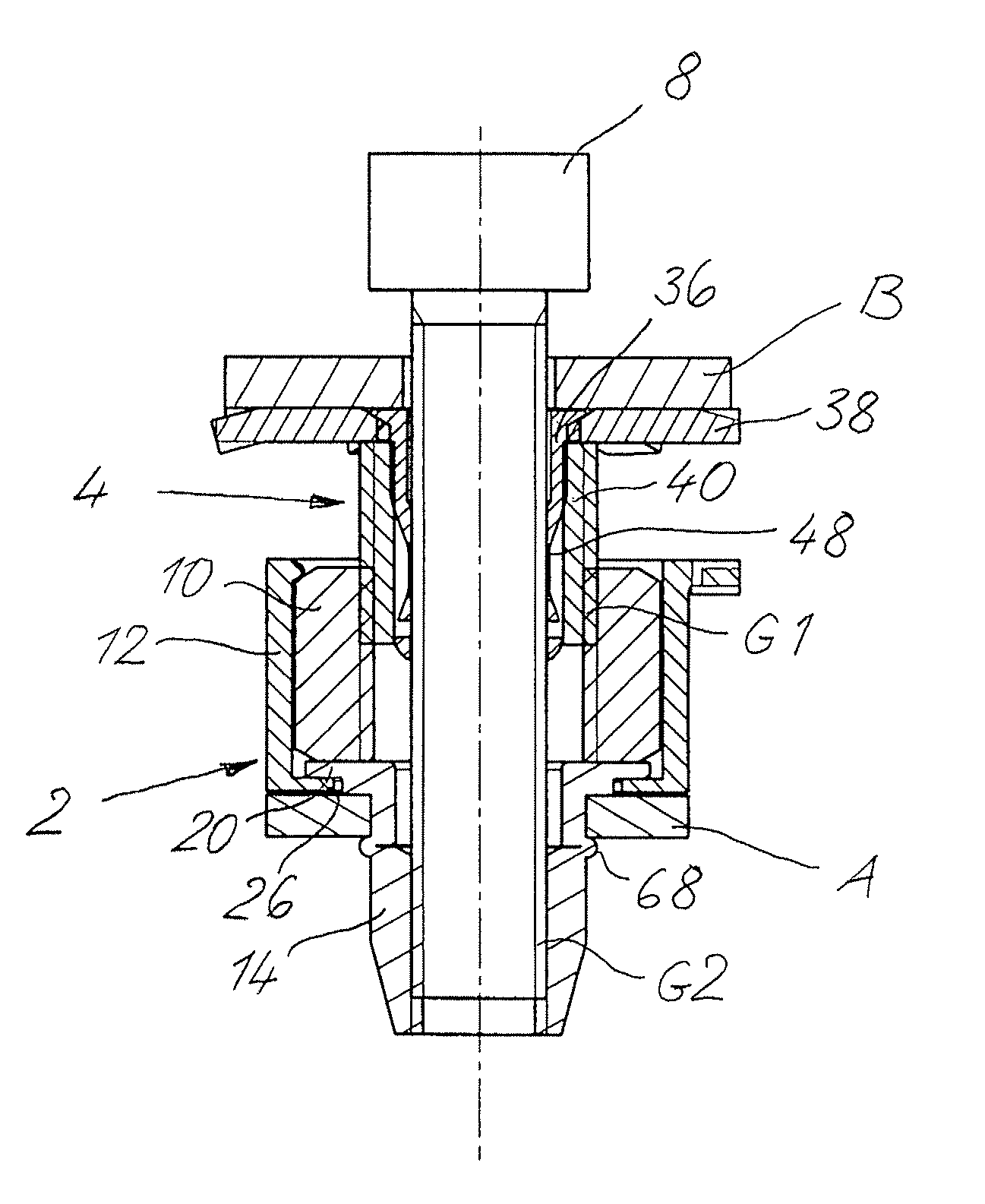

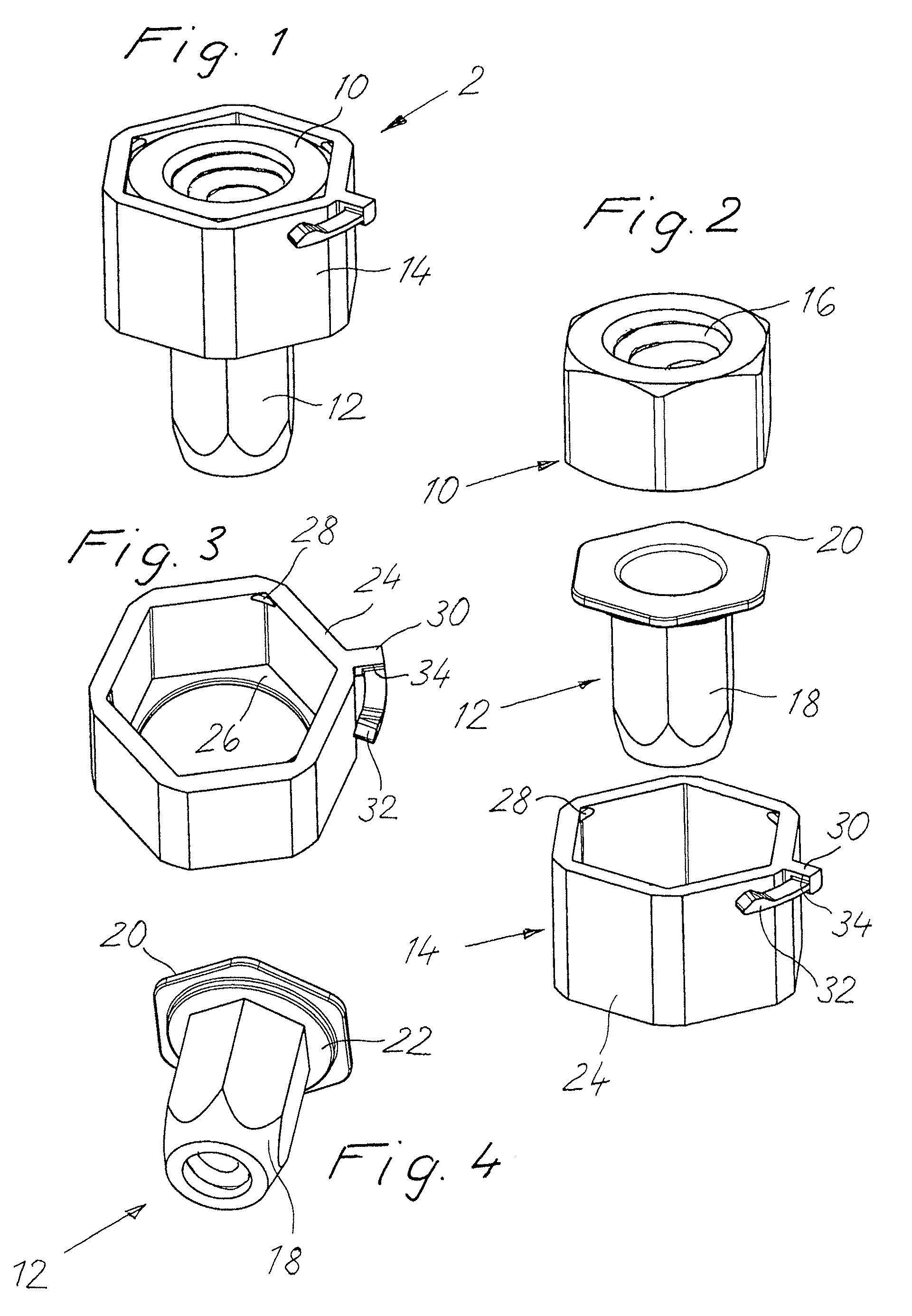

Anti-vibrational holding device for an electric motor

InactiveUS6897580B2Solve excessive vibrationReduce noise levelPump componentsNon-rotating vibration suppressionMotor shaftMagnet

The invention relates to an apparatus for vibration-insulated mounting of an electric motor (20), in particular a blower motor, having a first housing part (10), which encloses at least one pole ring (22) and magnets (24) of the electric motor (20) and has at least one opening (14, 16), through which the shaft (18) of the motor (20) reaches, and having a second housing part (54), which is embodied as a motor flange for securing the electric motor (20) to a carrier element, for instance a motor vehicle heating and / or air conditioning system, and at least partly embraces the first housing part (10) in the axial direction of the motor shaft (18).It is proposed that on the outer circumference (26) of the first housing part (10), a plurality of radially extending, relatively flat plastic spokes (28) are provided, which engage associated, radially and axially extending recesses (57) of the second housing part (54), and which in the region of their radially outer end (32) have connecting means (36) for securing them to the second housing part (54).

Owner:ROBERT BOSCH GMBH

Integral engineering rack of interface osteochondro tissue with bionic function

InactiveCN101020083AIncrease connection areaImprove connection strengthJoint implantsSubchondral boneBiocompatibility Testing

Owner:THE FIRST AFFILIATED HOSPITAL OF THIRD MILITARY MEDICAL UNIVERSITY OF PLA

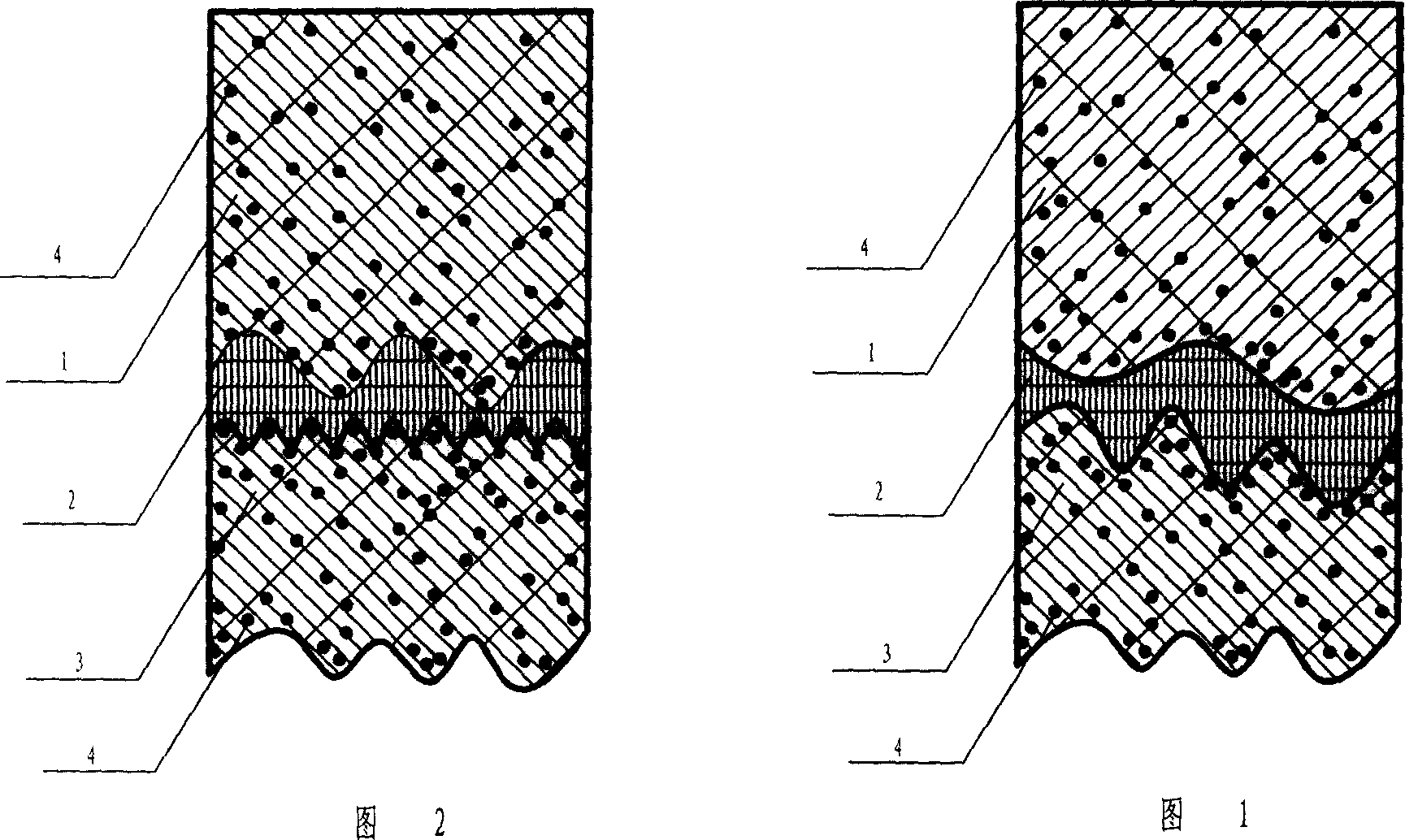

Drainage plate for silt consolidation, filter cloth and drainage plate core

The invention is the improvement on a longitudinal drainage plate for silt consolidation, filter cloth and a drainage plate core, which is characterized in that fibrous hot-pressed microporous filter cloth is planar filter cloth hot-rolled by a flat roller, the filter cloth is adhered to the surfaces of convex ribs of the drainage plate core through thermal thawing or a chemical way, the filter cloth adopts silk reeling and hot-press forming separation technology, and the drainage plate core is made of co-polypropylene, thereby overcoming the disadvantages of the prior art; and the aperture of the filter cloth can be adjusted according to treated silt, the drainage plate is difficult to block, the engineering on a soft foundation after the treatment cannot have the settlement after the construction and has smooth drainage and high drainage efficiency, and the plate core has long effective service life.

Owner:JIANGSU XINTAI GEOTECHNICAL TECH CO LTD

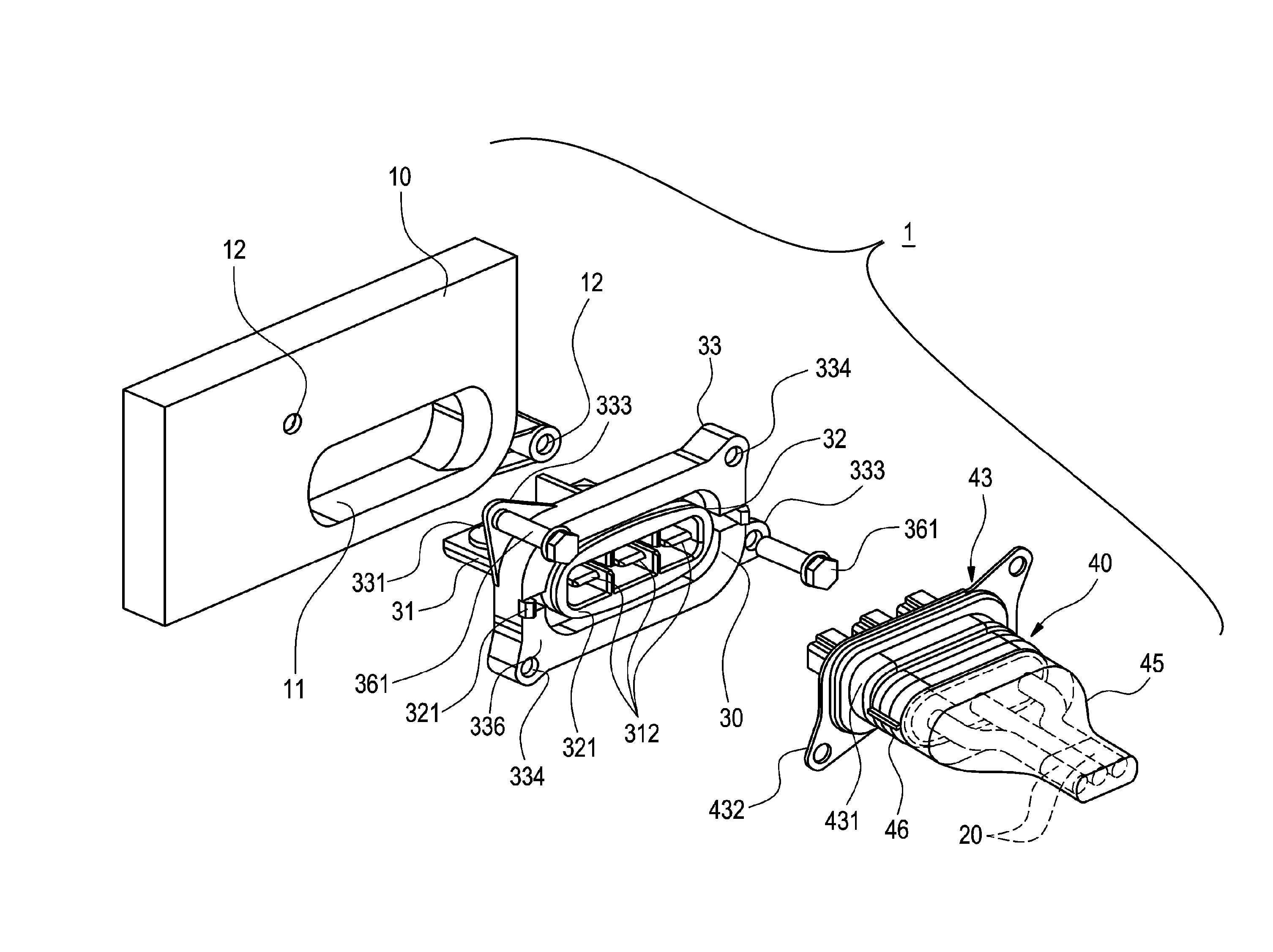

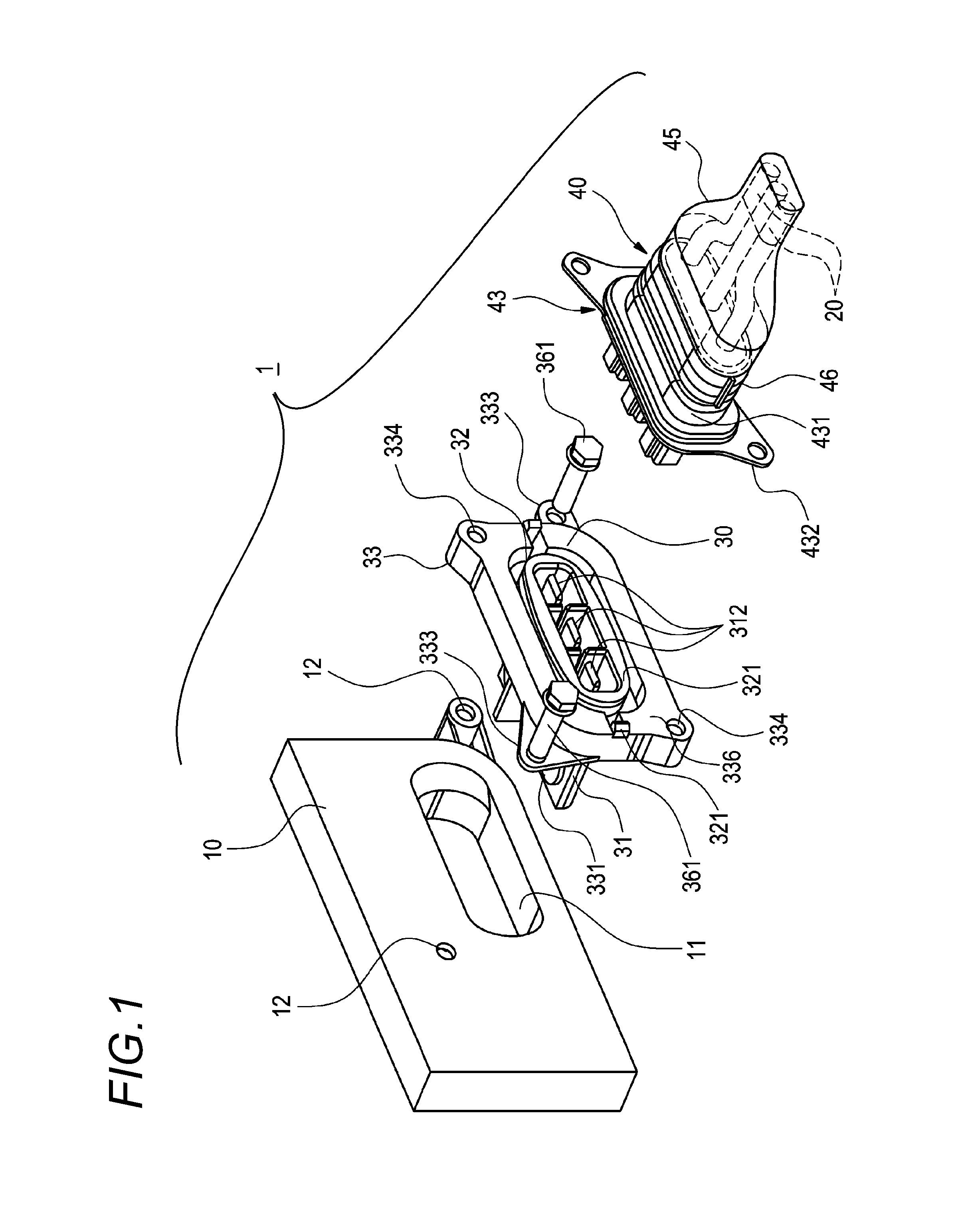

Shielded connector

ActiveUS8992249B2Easy to implementImprove performanceVehicle connectorsSubstation/switching arrangement detailsEngineeringElectrical and Electronics engineering

A shielded connector includes device-side connector which is fixed to a shield case and a cable-side connector which is attached to an end of an external cable and is fitted to the device-side connector. The device-side connector includes a device-side connection terminal, a device-side resin housing, and a device-side shield shell. The device-side shield shell includes a mating shell fixing part which electrically connects the device-side shield shell and a cable-side shield shell.

Owner:YAZAKI CORP

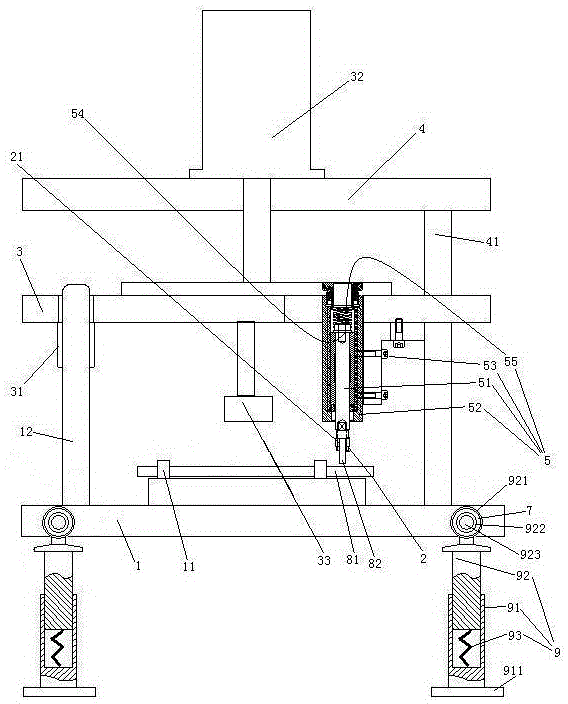

Welding device for side sealing plate barb of switch cabinet

InactiveCN105057865AImprove connection strengthImprove quality consistencyResistance electrode holdersWelding/cutting auxillary devicesRubber ringElectricity

The invention relates to the technical field of manufacturing of low-voltage drawer-type switch cabinets and discloses a welding device for a side sealing plate barb of a switch cabinet. The welding device comprises an electric welding machine, a spot welding gun, supporting pillars, a lower base, an electric conduction block, a suspending plate and an upper seat. The electric welding machine is provided with two electrodes, and the spot welding gun is connected with one of the electrodes. Clamps are arranged on the lower seat, and the suspending plate is connected with the upper seat through an air cylinder. The electric conduction block is connected to the suspending plate. The electric conduction block is electrically connected with the other electrode. The spot welding gun is connected to the suspending plate and is provided with a barb fixing structure. The supporting pillars comprise damper springs, upper sections and lower sections, wherein the upper sections and the lower sections are sleeved together. The upper ends of the upper sections are provided with connecting rings, inner rings are arranged in the connecting rings in a penetrating mode, the inner rings and the connecting rings are connected together through rubber rings, and connecting pins connected to the lower seat are arranged in the inner rings in a penetrating mode. The welding device has the advantages that a welded part does not need to be fixed manually, and the vibration isolation effect is good; the problems that much effort is cost in welding and the welding quality is poor due to welding by manually fixing the welded part are solved.

Owner:张进

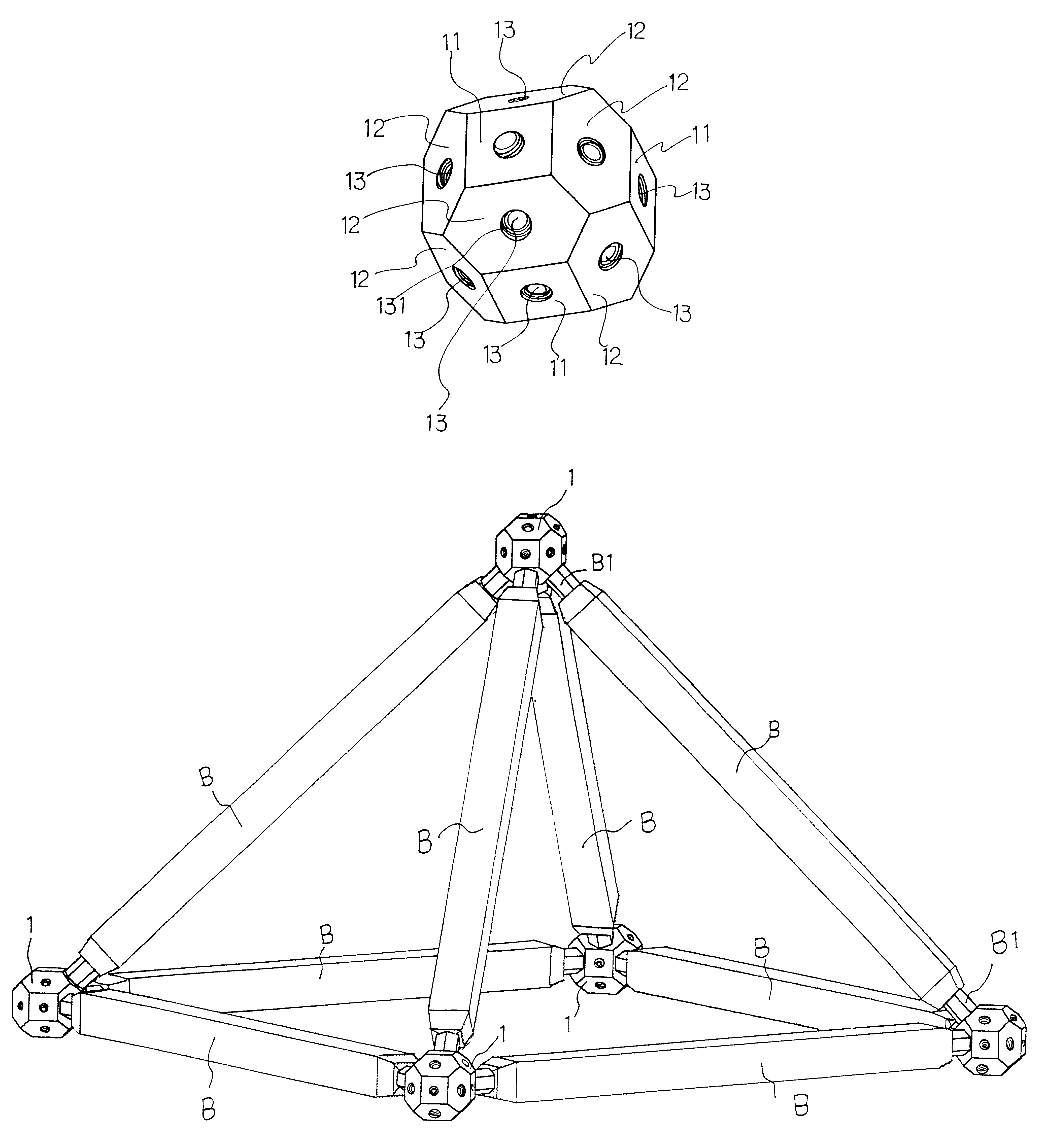

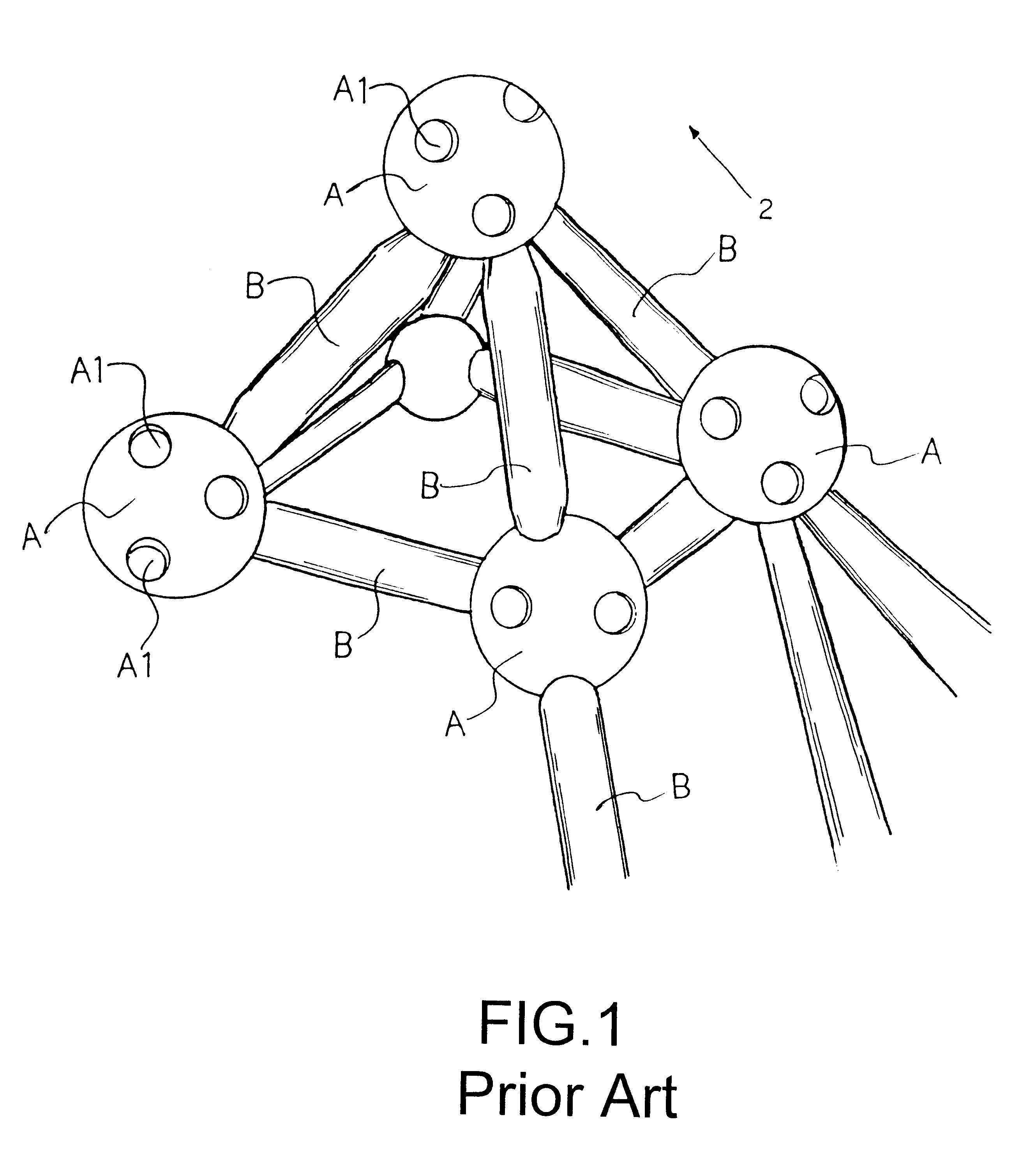

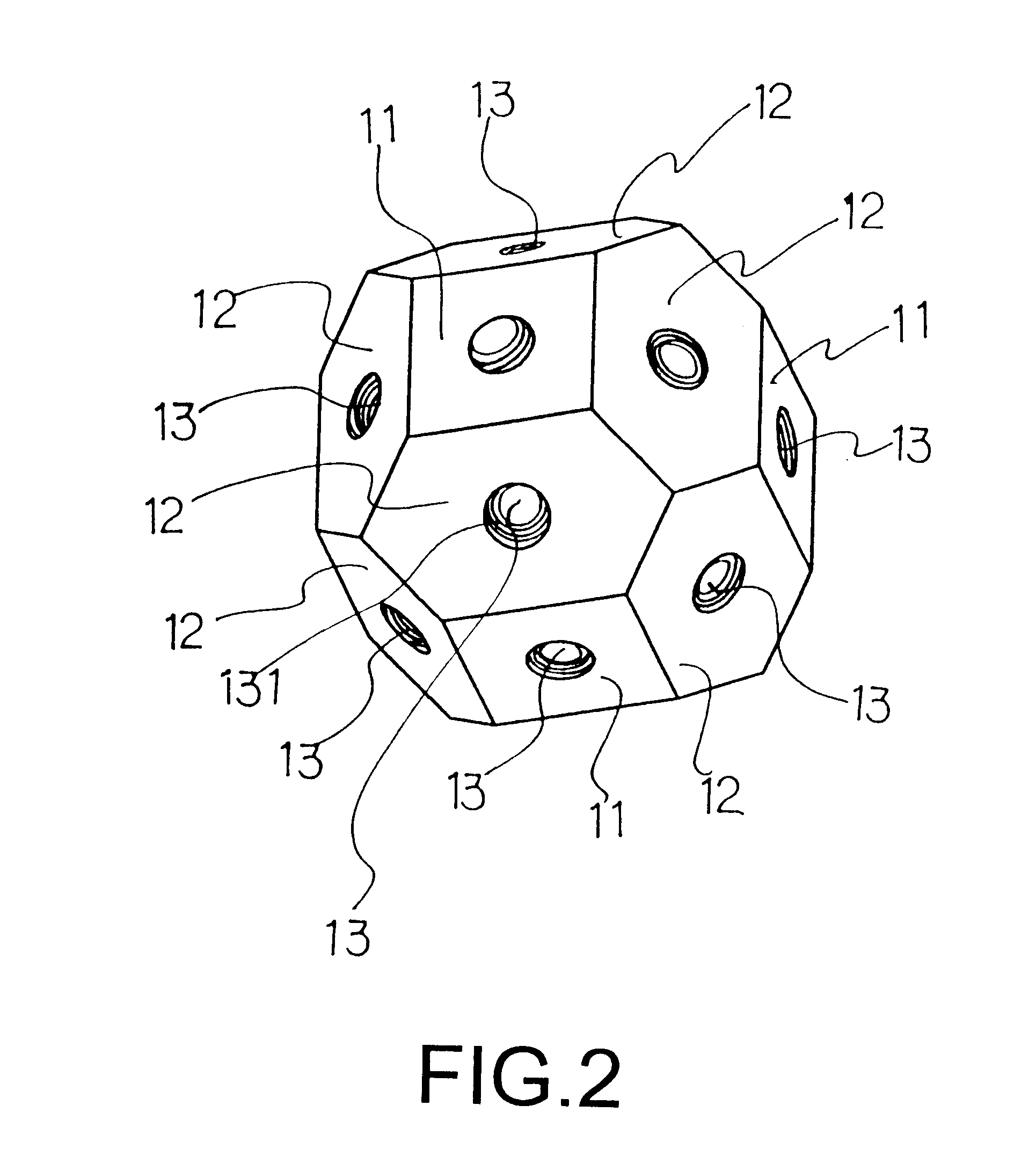

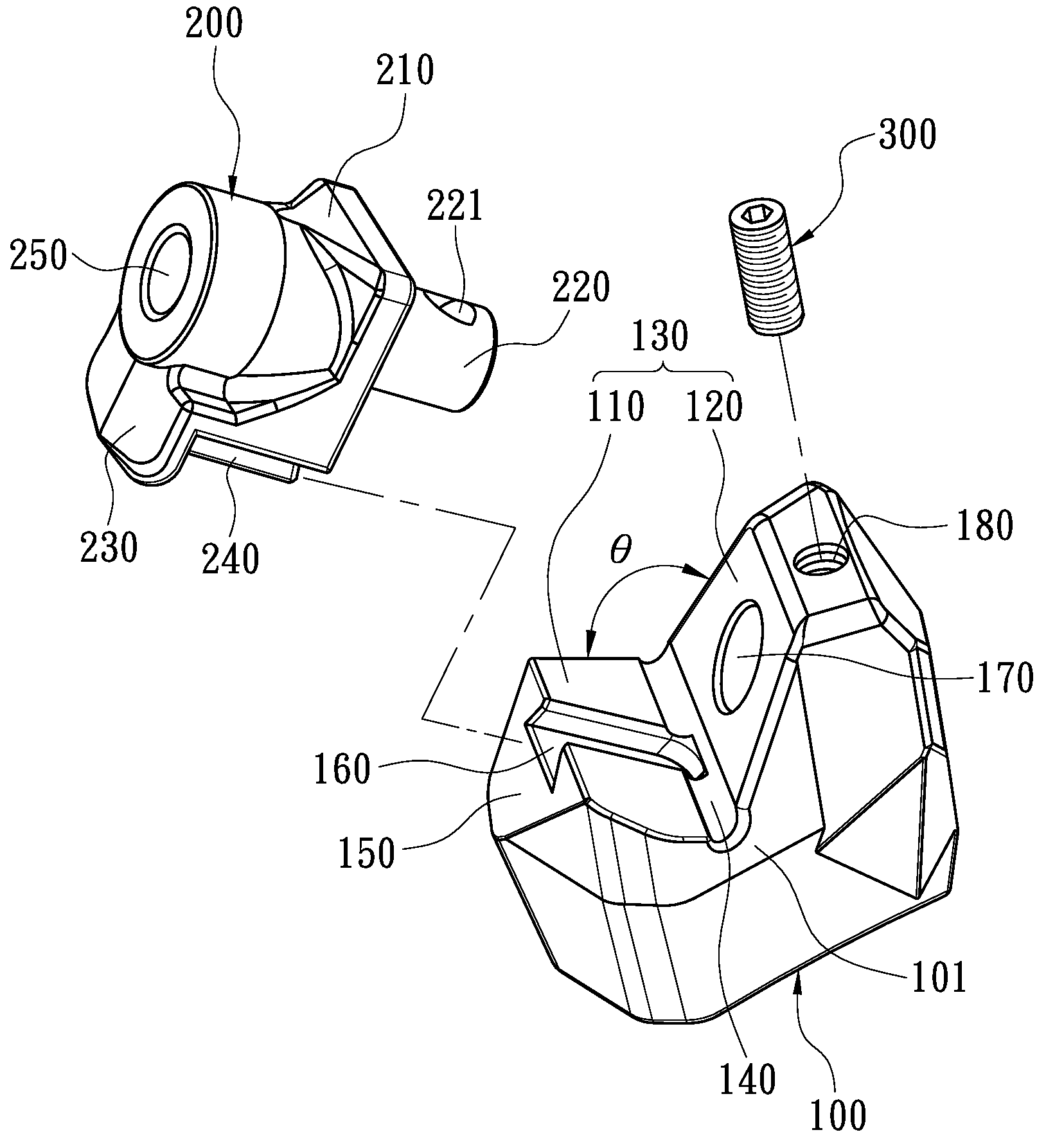

Spherical connector and supporting rod assembly

InactiveUS6672789B2Broaden applicationMeet the requirementsYielding couplingRopes and cables for vehicles/pulleyEngineeringMechanical engineering

The invention herein of a spherical connector and supporting rod assembly is mainly designed as a structure of a multi-angular spheroid with multiple tangent planes of six cubical quadrilaterals and twelve beveled hexagons, and with mounting holes disposed respectively at the centers of the quadrilateral and the beveled hexagonal tangent planes to make each spherical connector having eighteen mounting holes with included angles pointing at different directions so as to increase the application of a single spherical connector and to make all the spherical connectors have the identical structure for exchangeable connection to not only fully comply with the needs of specific application, but also to be able to make various applications by using the supporting rods pointing at different mounting angles to directly fulfill the specific need of the assembly.

Owner:CHEN CHUNG TENG

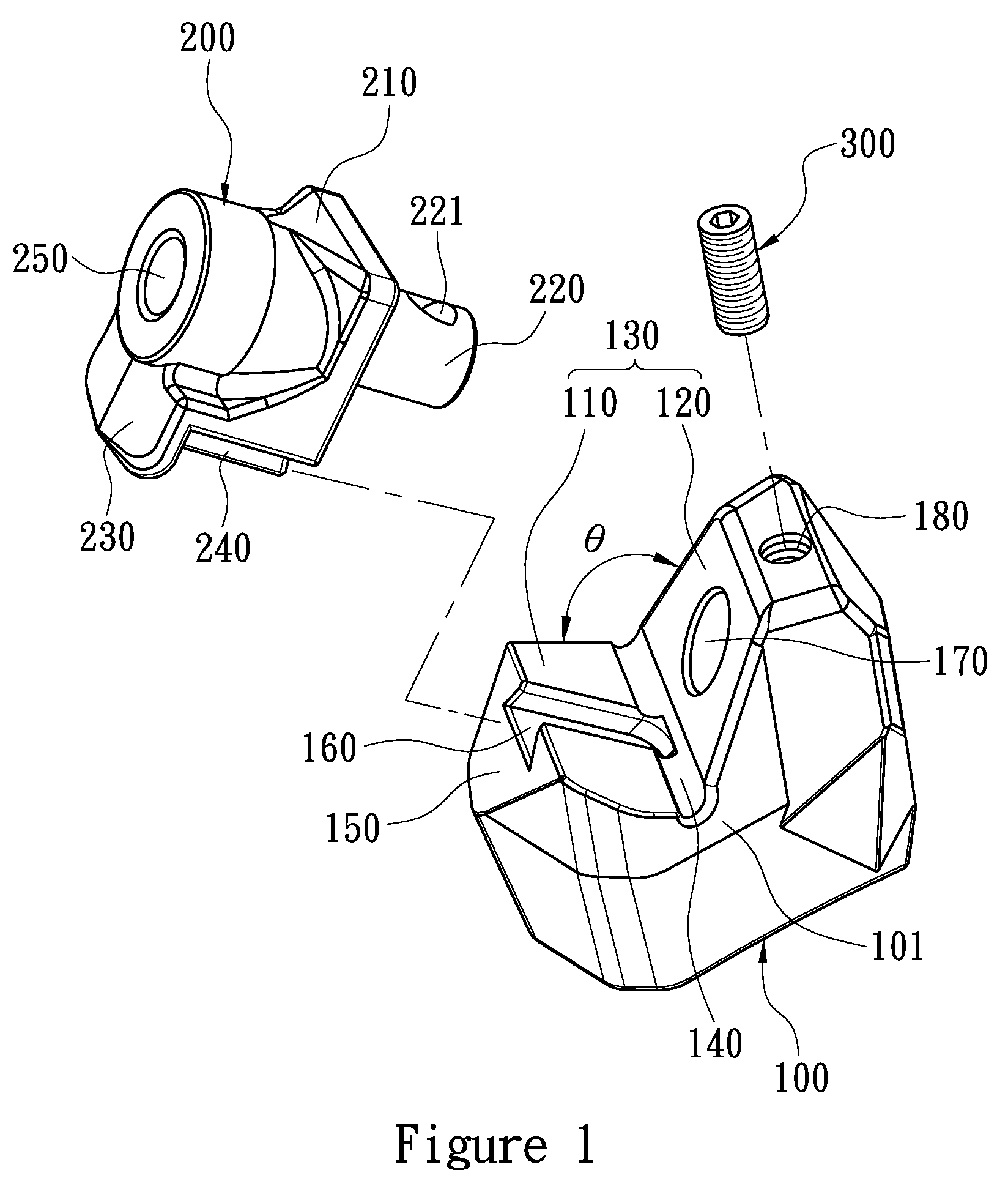

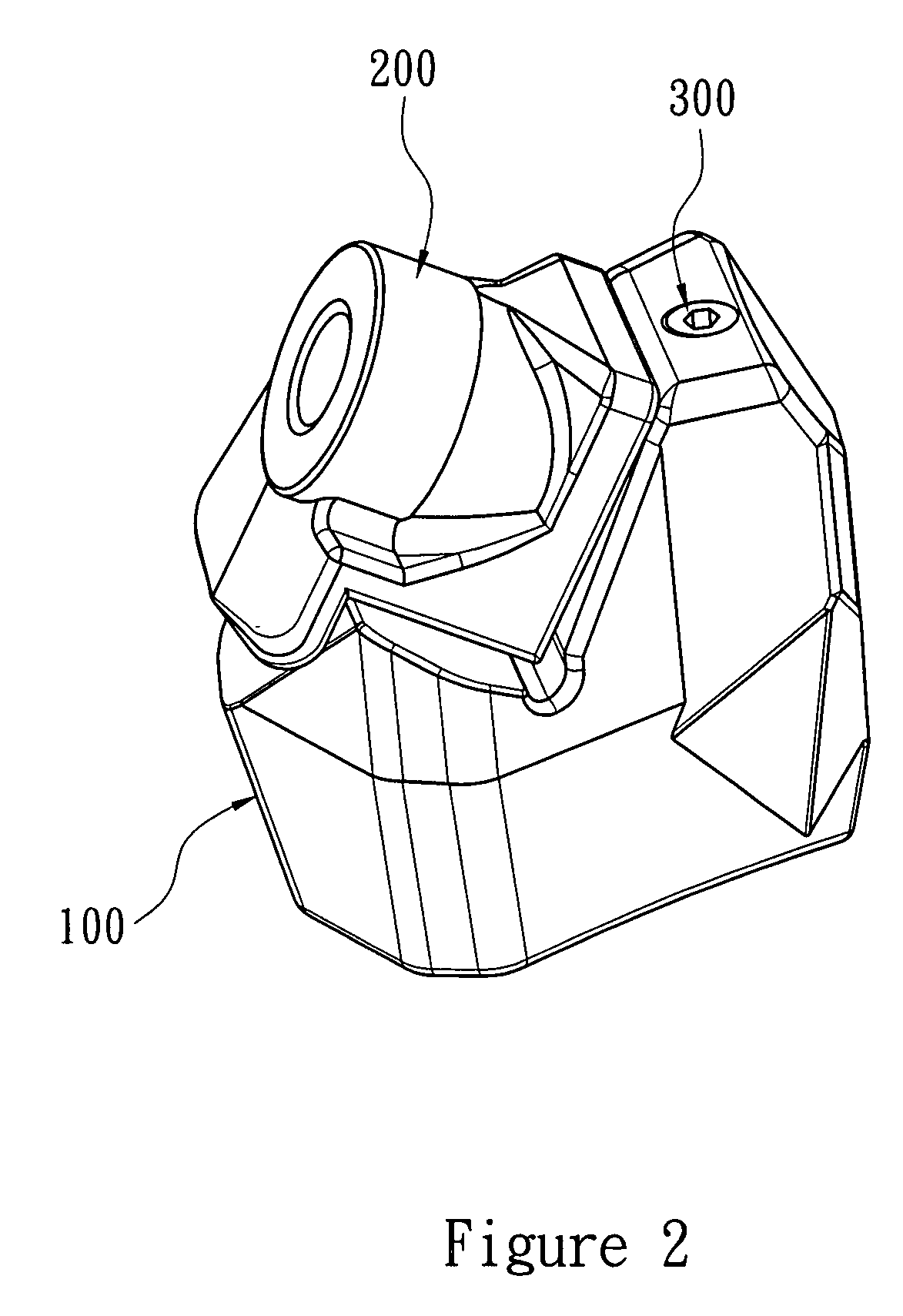

Tool holding device

ActiveUS7537288B2Enhance counterforce bearingImprove connection strengthSlitting machinesStone-like material working toolsEngineeringUltimate tensile strength

A tool holding device is disclosed, and the tool holding device includes a base, a block, and a fastening member for securing the block. The base includes a receiving portion defined between a countering wall and a shoulder wall, a surface defined adjacent to the shoulder wall perpendicularly and away from the countering wall, a penetrated hole defined on the countering wall, and a positioning hole communicating with the penetrated hole. The block includes a holding portion held in the receiving portion, a handle received in the penetrated hole, and a holding hole for holding a chisel. The countering wall and the shoulder wall define an angle less than or equal to 90 degrees. Therefore, the counterforce bearing of the base and block are both enhanced to raise the strength of the tool holding device.

Owner:EVERPADS

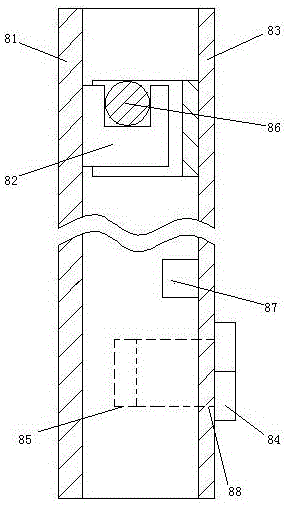

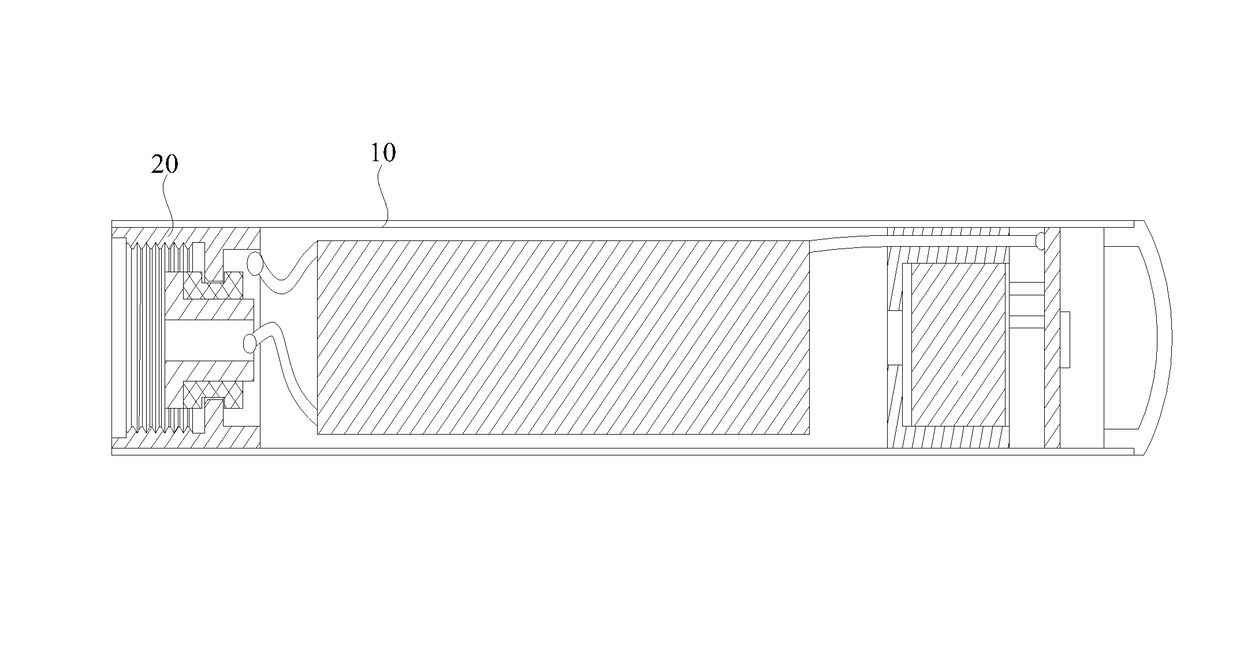

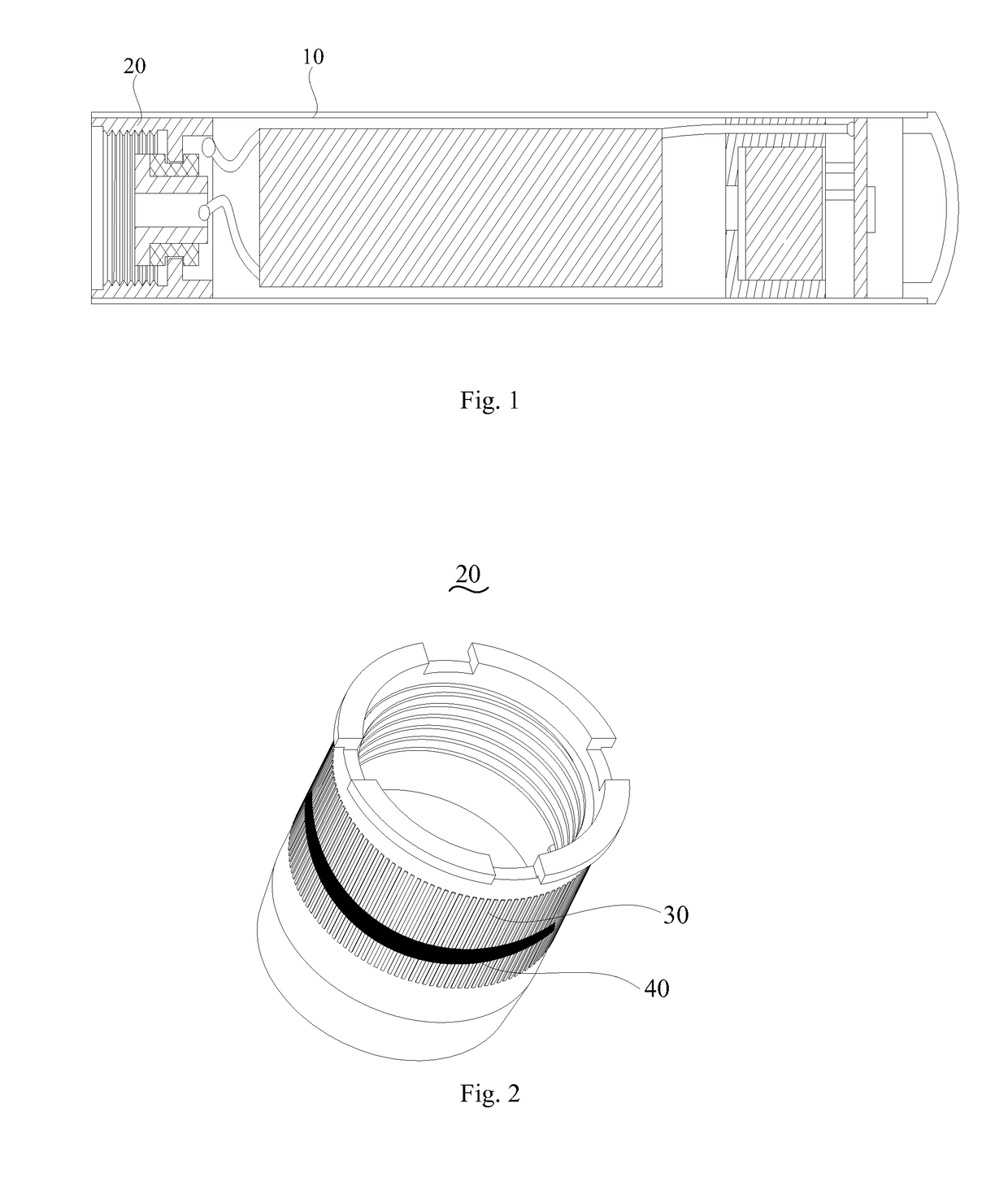

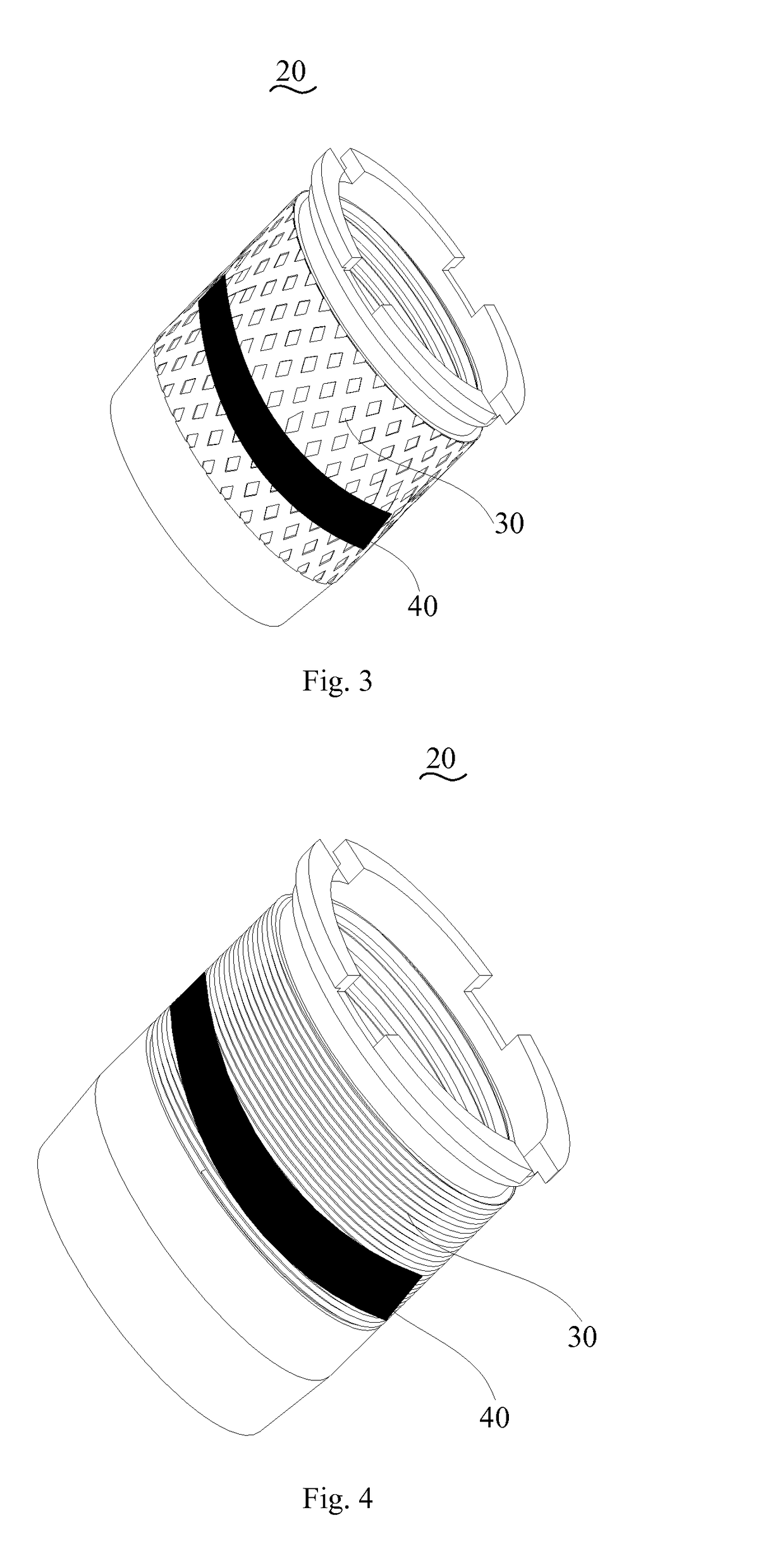

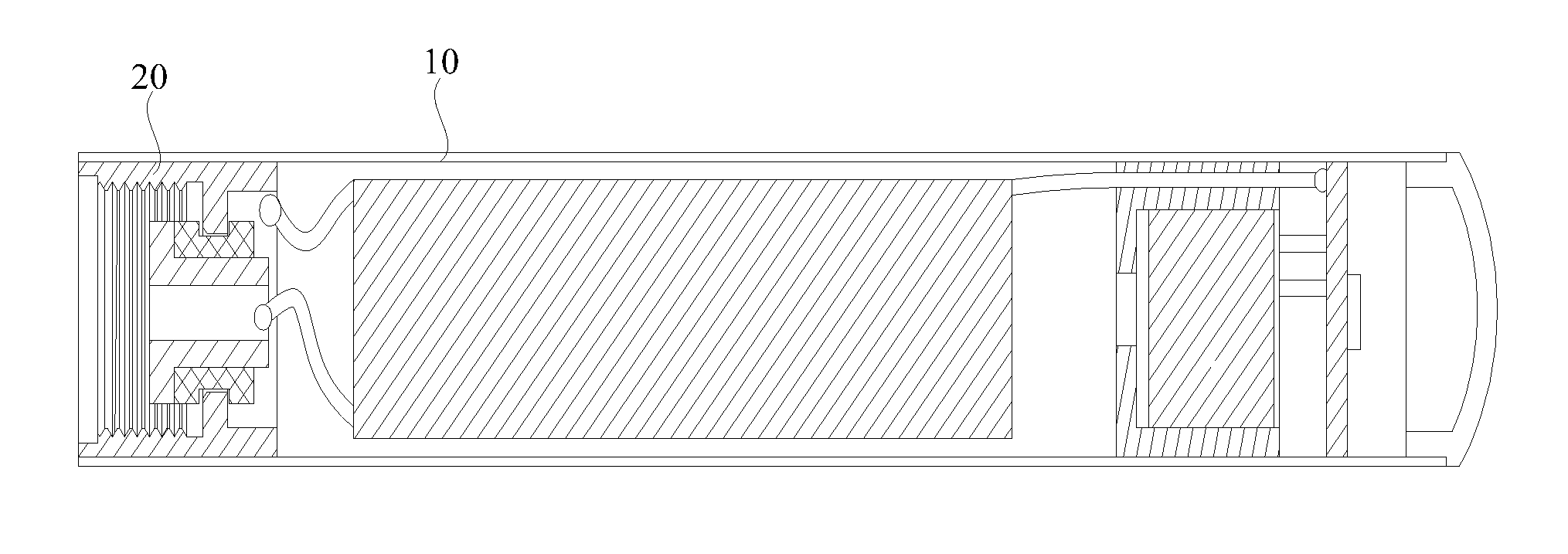

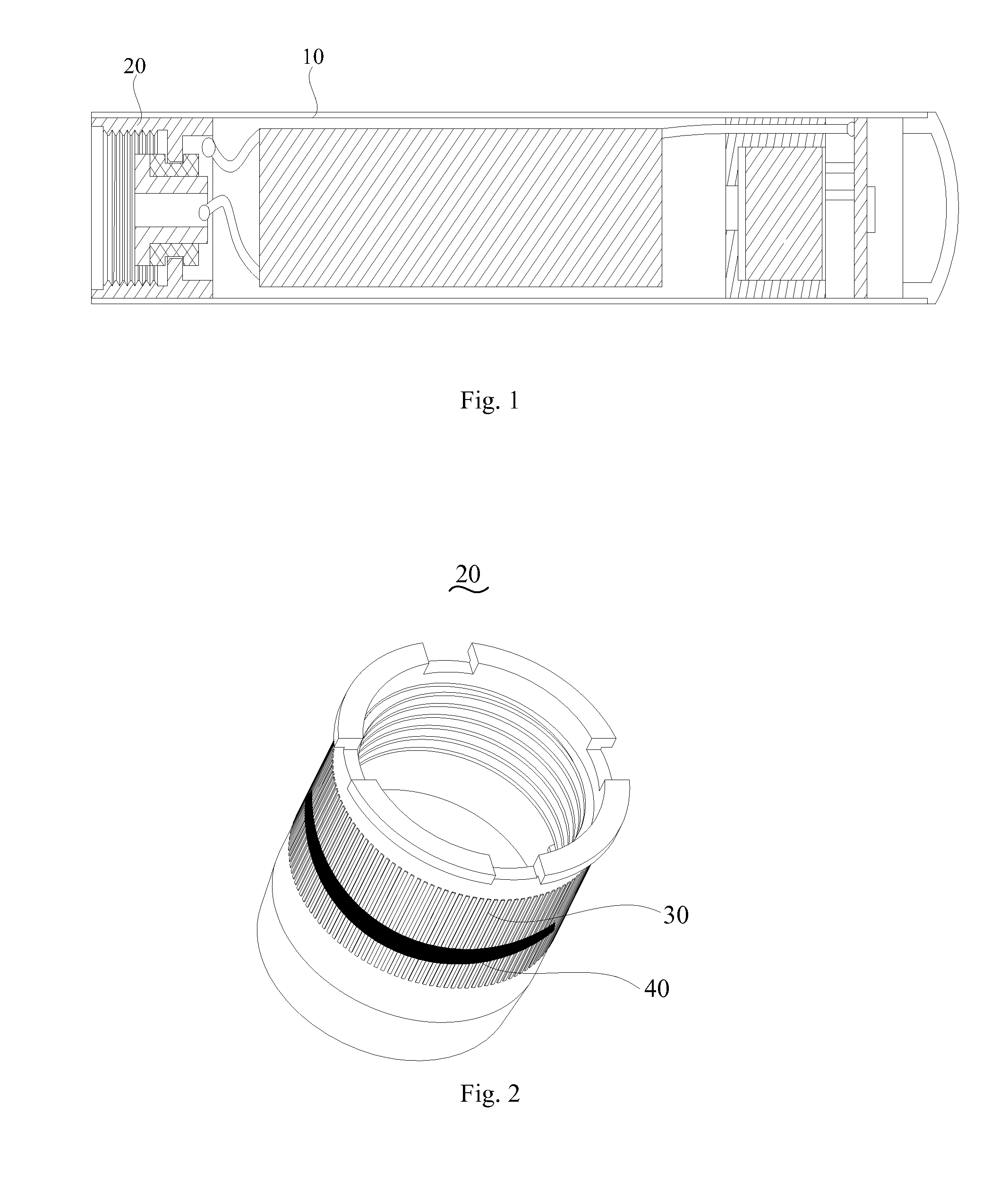

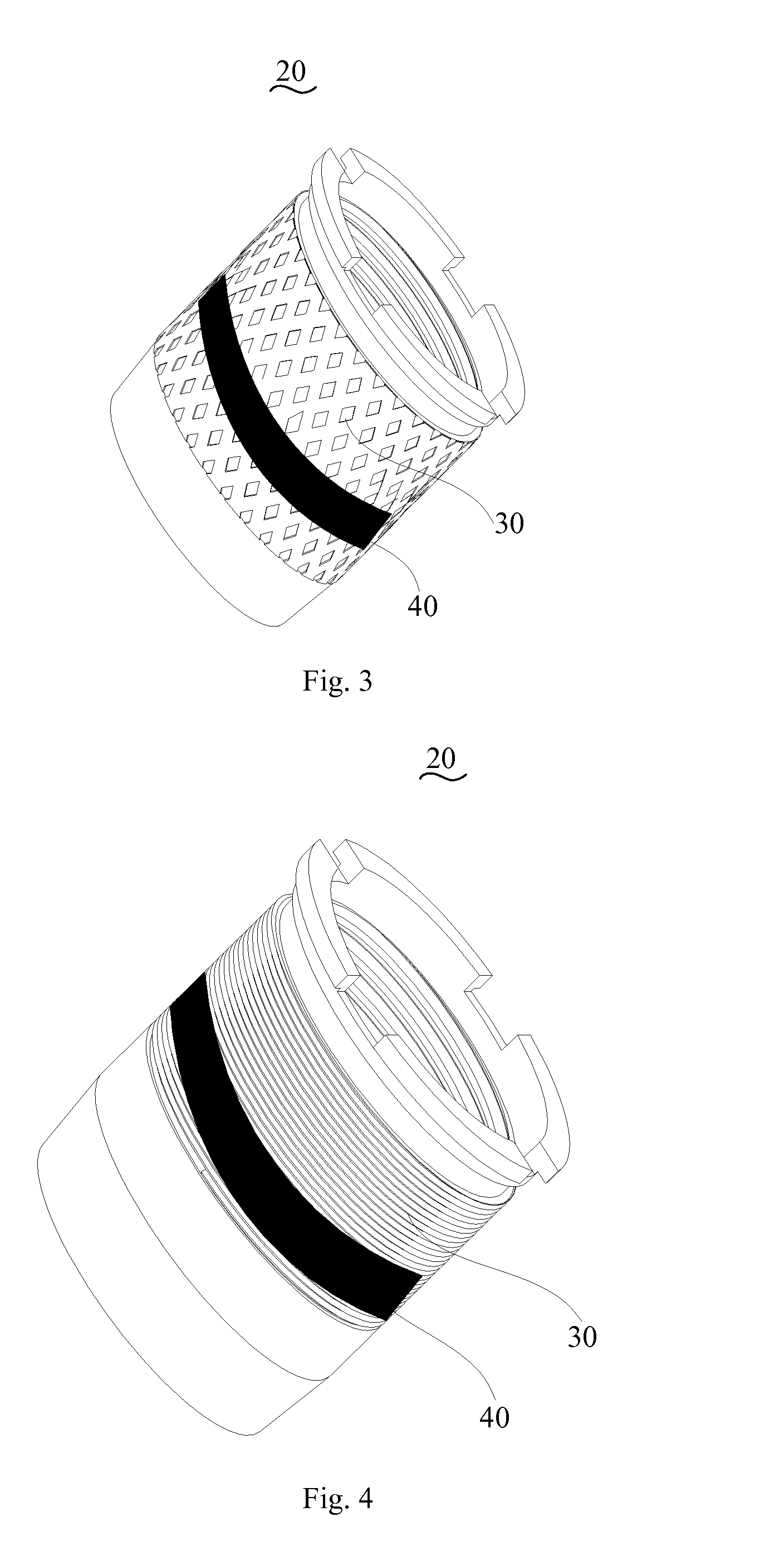

Battery assembly, atomizer assembly, and electronic cigarette

InactiveUS9675108B2Improve connection strengthSmooth connectionTobacco devicesCell component detailsElectronic cigaretteElectrical and Electronics engineering

The present invention discloses a battery assembly, an atomizer assembly, and an electronic cigarette. The battery assembly is connected to the atomizer assembly to form the electronic cigarette. The battery assembly includes a battery sleeve and a first connection member, and the atomizer assembly includes an atomizer sleeve and a second connection member. The first connection member and the second connection member are connected with each other. A portion of the first connection member contacting the battery sleeve and / or a portion of the second connection member contacting the atomizer sleeve protrude(s) to form an anti-slip structure, and Teflon paste configured to enhance a connection strength between the first connection member and the battery sleeve and / or enhance a connection strength between the second connection member and the atomizer sleeve is spread on a circumferential outer wall of the anti-slip structure.

Owner:HUIZHOU KIMREE TECH

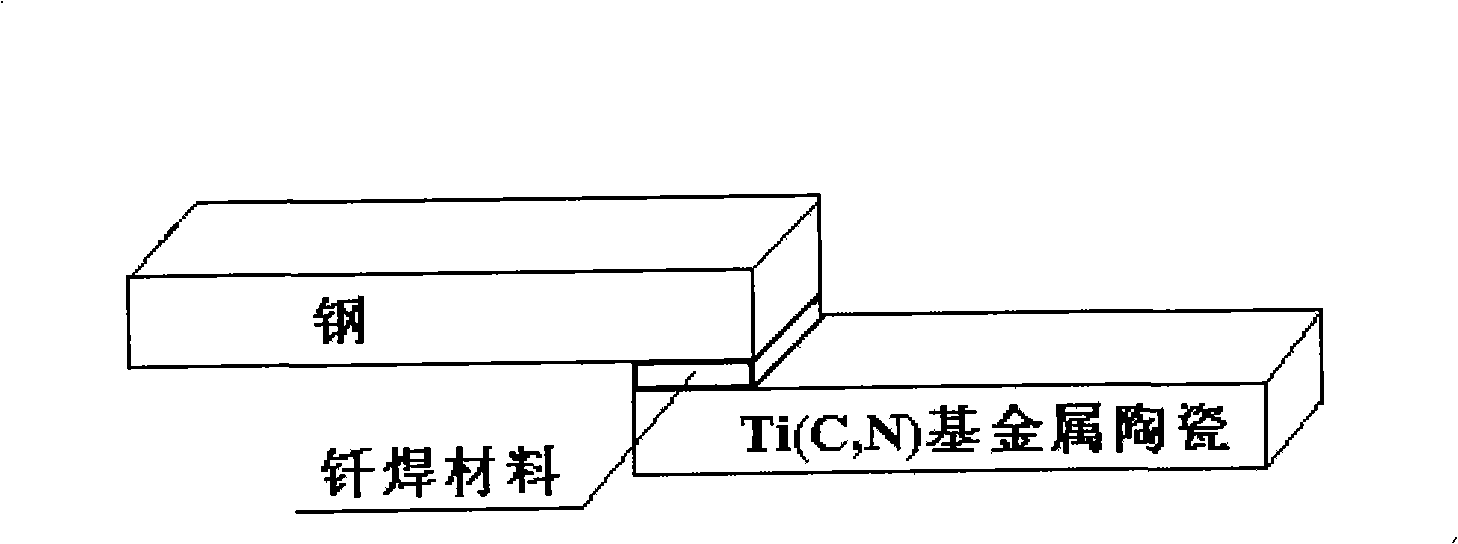

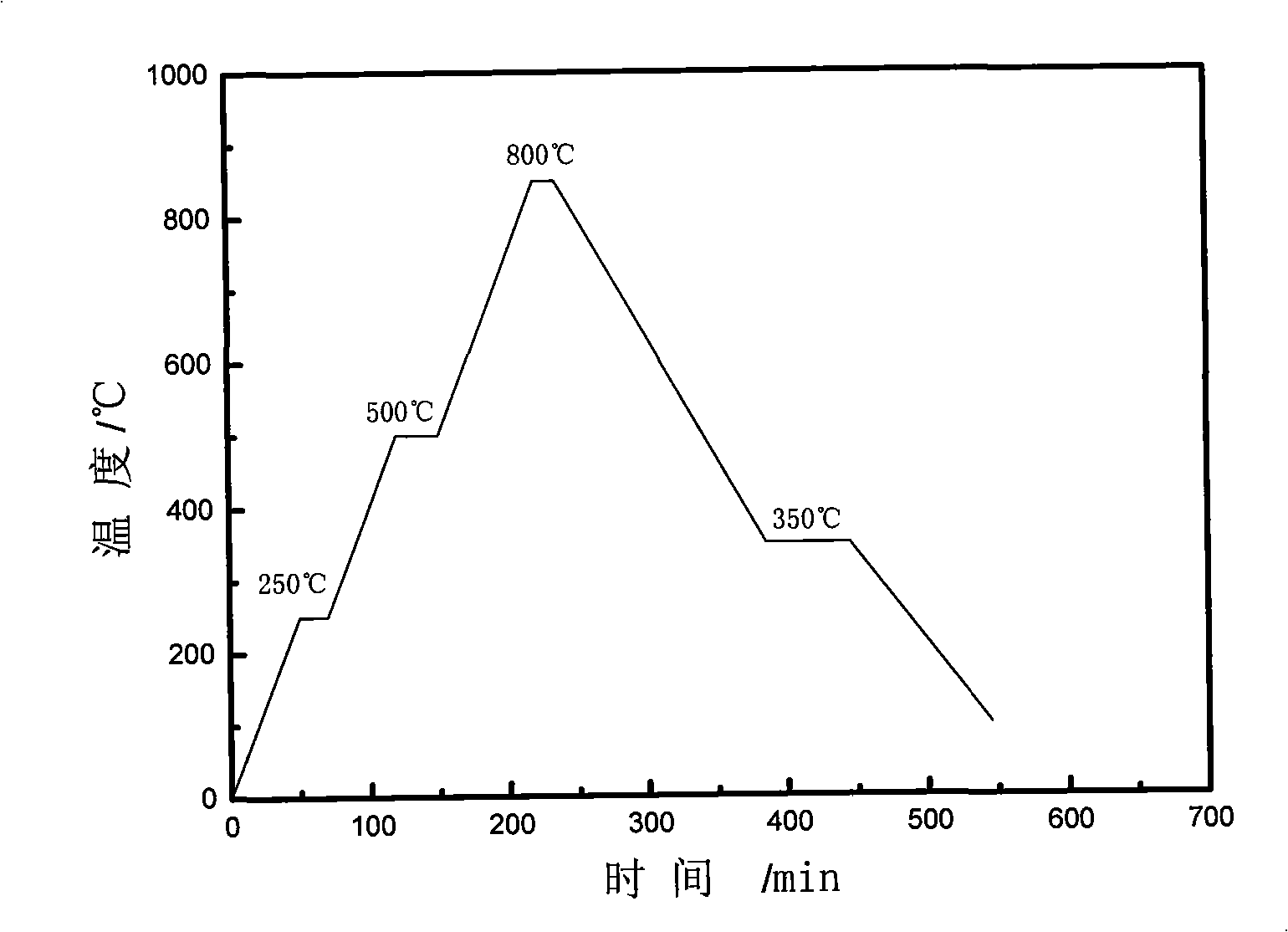

Brazing material and preparation method thereof as well as brazing method using the material

InactiveCN101327551AFirmly connectedIncreased shear strengthWelding/cutting media/materialsSoldering mediaRoom temperatureWorking temperature

The present invention relates to a soldering material, a preparation method thereof and a soldering method with the soldering material, which belong to the preparation methods and applications of soldering materials. The present invention resolves the problem that the connection strength and the working temperature are low after the prior Ti(C, N)-based cermet is connected with a metal, thus realizing the firm connection between the Ti(C, N)-based cermet and steel, and ensures that the joint has good connection strength and a high working temperature. The mass percentage of the ingredients of the soldering material of the present invention is as follows: 40 percent to 45 percent of Cu, 20 percent to 25 percent of Ag, 21 percent to 23 percent of Zn, 5 percent to 10 percent of Ni, 1 percent to 3 percent of Ti and 1 percent to 5 percent of Si. The preparation method includes the following steps: mixing, pressing, sintering and rolling, rolling the soldering material into a soldering material sheet. The soldering method with the soldering material includes the following steps: presoldering preparation, assembly, temperature increasing and temperature decreasing. The soldering material and the soldering method which are adopted by the present invention successfully realize the firm connection between the Ti(C, N)-based cermet and 45 steel, the maximum room-temperature shearing strength of the joint reaches 268.5MPa, and the average shearing strength reaches 240.9MPa.

Owner:HUAZHONG UNIV OF SCI & TECH

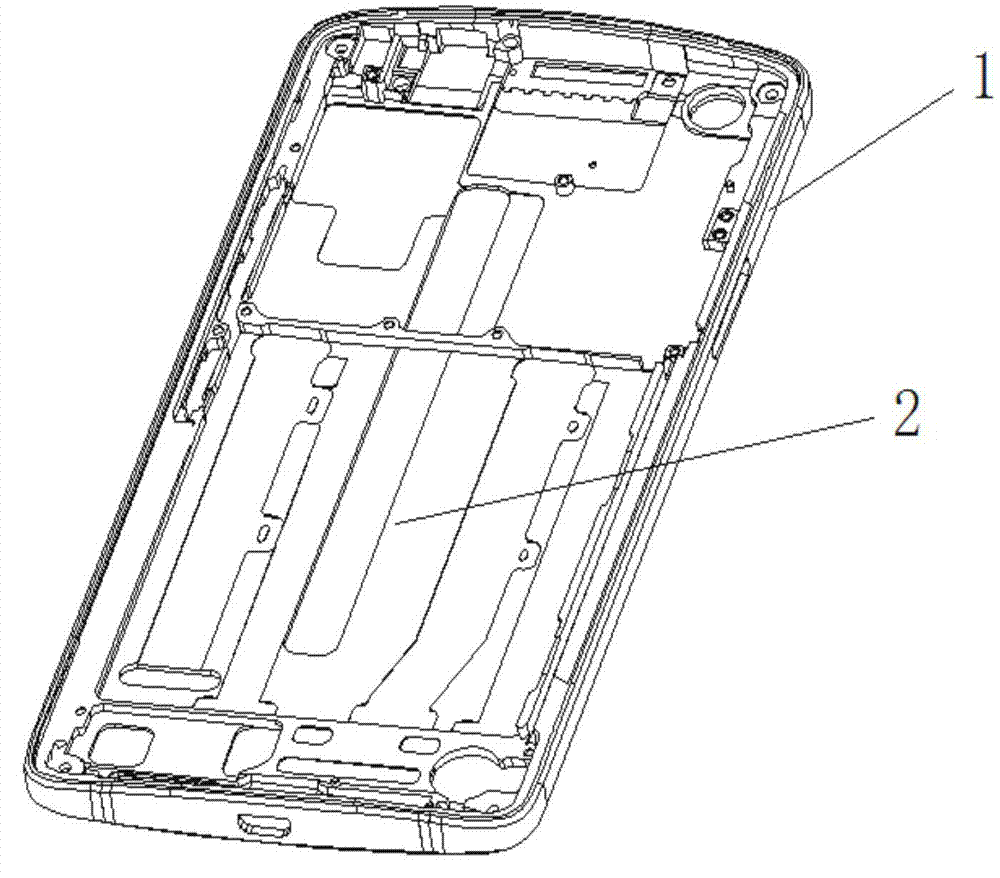

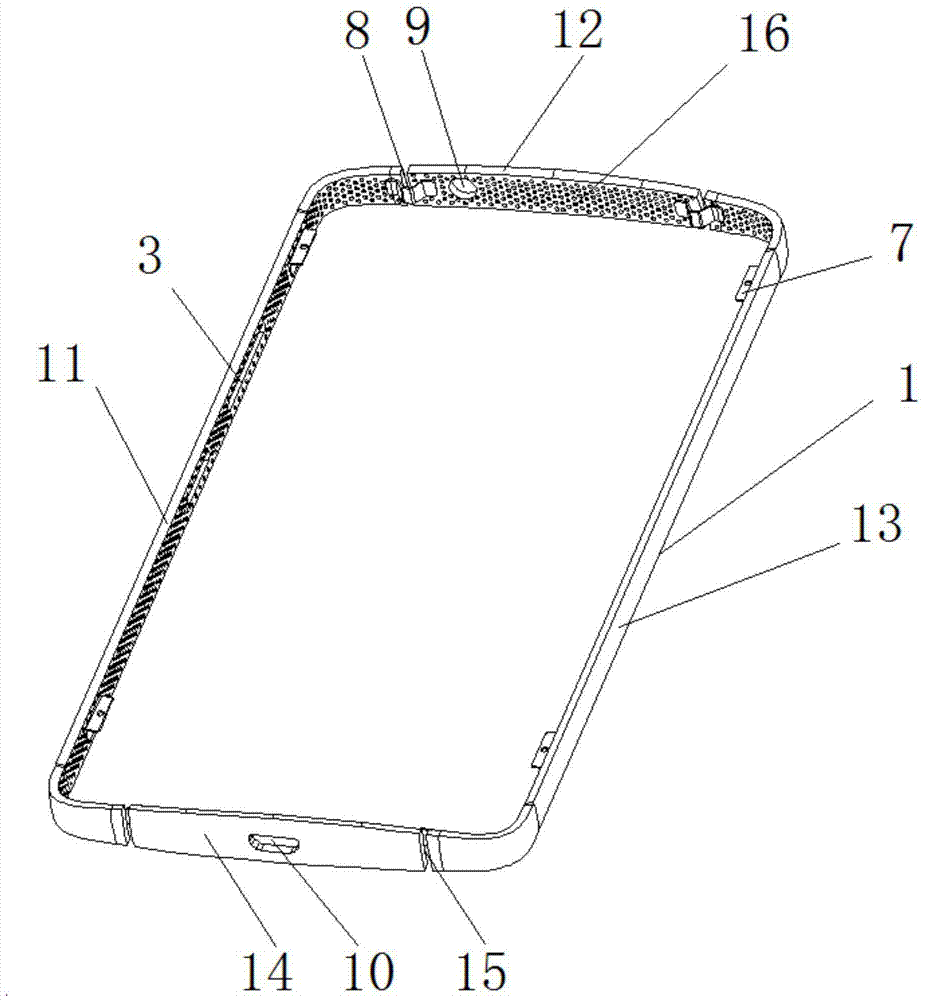

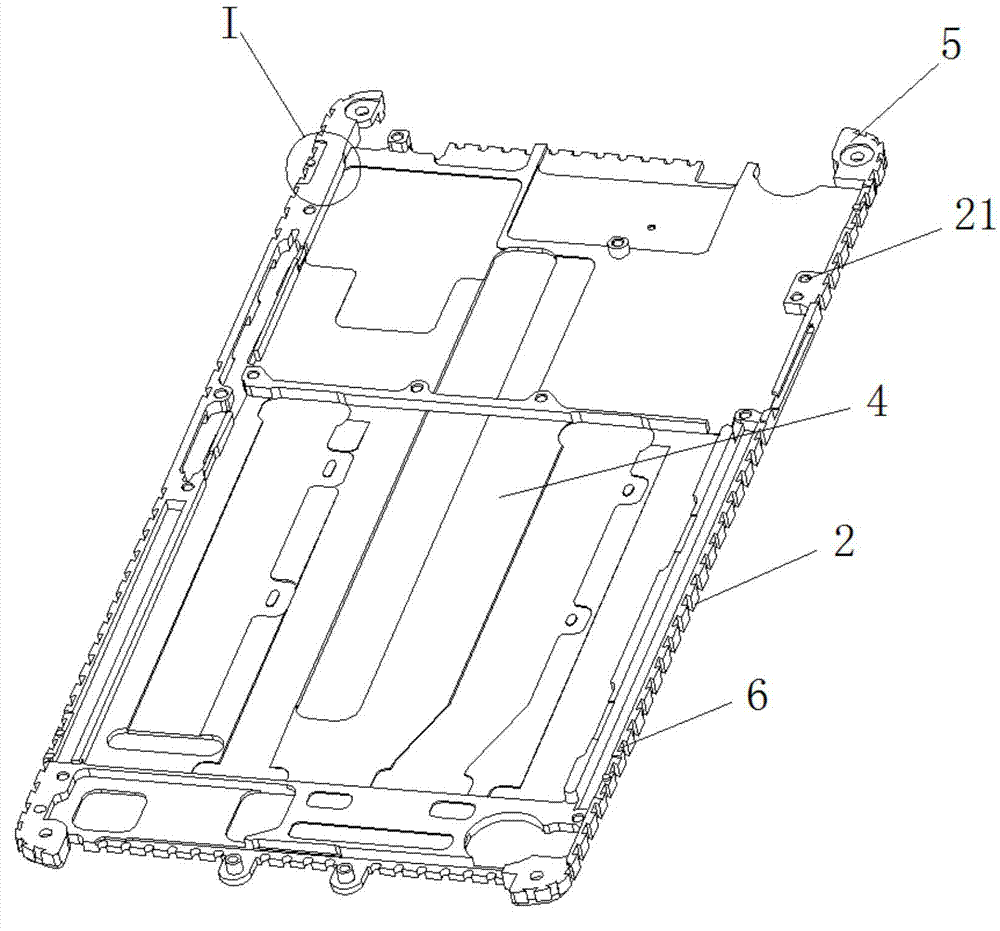

Mobile electronic product metal middle frame and processing technique thereof

InactiveCN104853549AHigh hardnessAvoid breakingCasings/cabinets/drawers detailsMetal casingsManufacturing technologyEngineering

The present invention relates to the technical field of mobile electronic product housing manufacturing, and especially relates to a mobile electronic product metal middle frame. The mobile electronic product metal middle frame comprises a side frame and a middle board, wherein the middle board is internally installed inside the side frame; the side frame comprises a first side wall, a second side wall, a third side wall and a fourth side wall which are arranged in turn; a plurality of key holes are disposed on the first side wall; the middle board comprises a middle board body and arc-shaped plates arranged at two ends of the middle board body; and a plurality of dovetail grooves are formed in the outer wall of the middle board. Through the above structure, the hardness is raised, and the structure is not easy to damage and is attractive and elegant in appearance. The present invention also relates to a processing technique for manufacturing the above mobile electronic product metal middle frame. The technique is little in processing time, and the processing time is saved.

Owner:AOJIE HARDWARE JIANGSU

Battery assembly, atomizer assembly, and electronic cigarette

InactiveUS20150068543A1Frictional forceImprove product qualityEngagement/disengagement of coupling partsCurrent conducting connectionsElectronic cigaretteElectrical and Electronics engineering

The present invention discloses a battery assembly, an atomizer assembly, and an electronic cigarette. The battery assembly is connected to the atomizer assembly to form the electronic cigarette. The battery assembly includes a battery sleeve and a first connection member, and the atomizer assembly includes an atomizer sleeve and a second connection member. The first connection member and the second connection member are connected with each other. A portion of the first connection member contacting the battery sleeve and / or a portion of the second connection member contacting the atomizer sleeve protrude(s) to form an anti-slip structure, and Teflon paste configured to enhance a connection strength between the first connection member and the battery sleeve and / or enhance a connection strength between the second connection member and the atomizer sleeve is spread on a circumferential outer wall of the anti-slip structure.

Owner:HUIZHOU KIMREE TECH

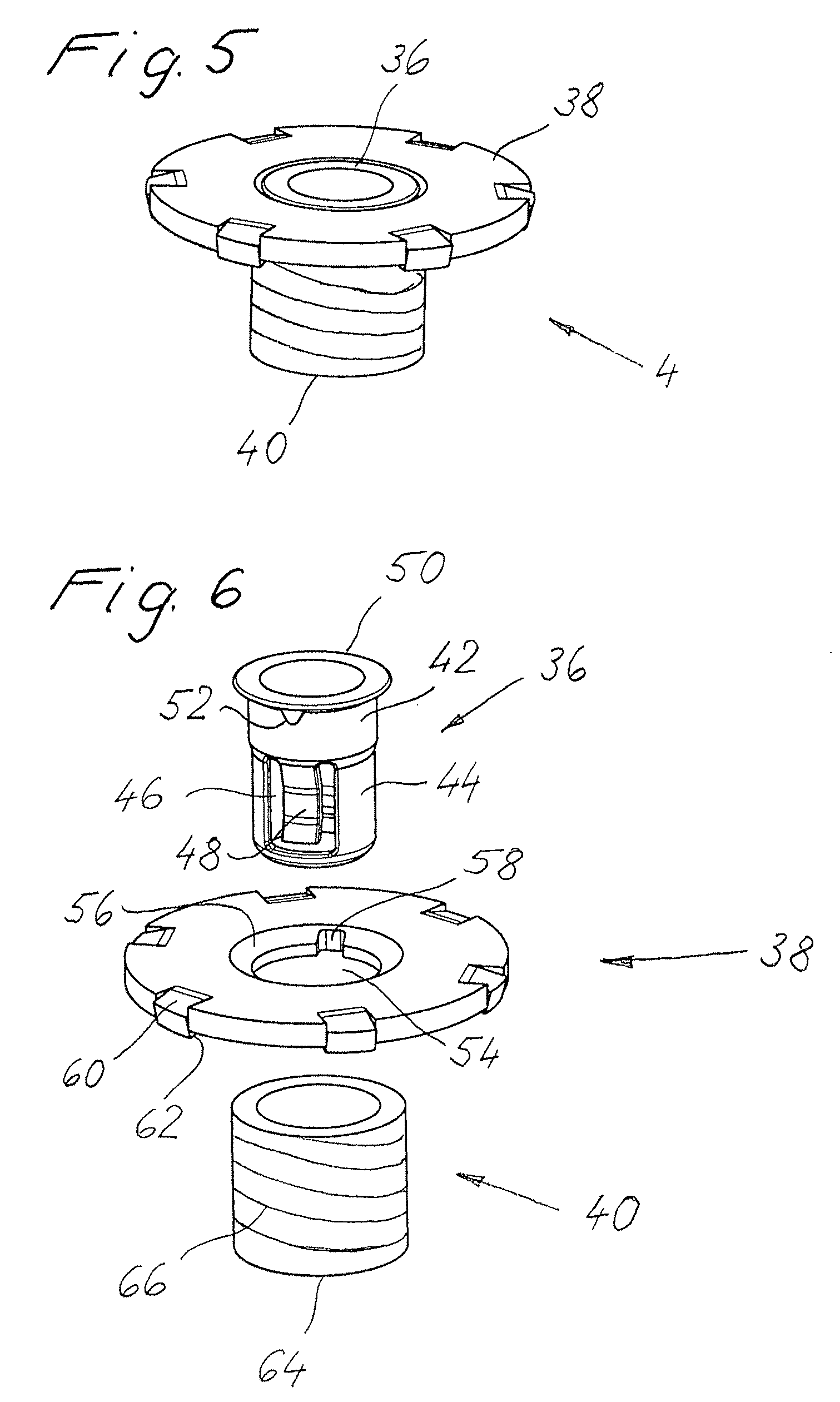

Fastening device with tolerance compensation

ActiveUS8066465B2Easy to produceProduced cost-effectivelyWashersSheet joiningEngineeringScrew thread

Owner:BOLLHOFF VERBINDUNGSTECHNIK GMBH

Semiconductor device and manufacturing method thereof

InactiveUS6960827B2Reduce thicknessAvoid warpingSemiconductor/solid-state device detailsSolid-state devicesElectrical conductorAdhesive

A stacked-type semiconductor device has a reduced overall height and an improved reliability in the mechanical strength of the stacked structure. The semiconductor device also has an improved heat release characteristic. A first interposer has a surface on which first electrode pads are formed and a first semiconductor element is mounted with a circuit forming surface facing the first interposer. A second interposer has a surface on which second electrode pads are formed and a second semiconductor element is mounted with a circuit forming surface facing the second interposer. External connection terminals are provided on a surface of the second interposer opposite to the surface on which the second semiconductor element is mounted. The first and second interposers are electrically connected to each other by conductive members provided therebetween. A back surface of the first semiconductor element and a back surface of the second semiconductor element are fixed to each other by an adhesive.

Owner:FUJITSU LTD

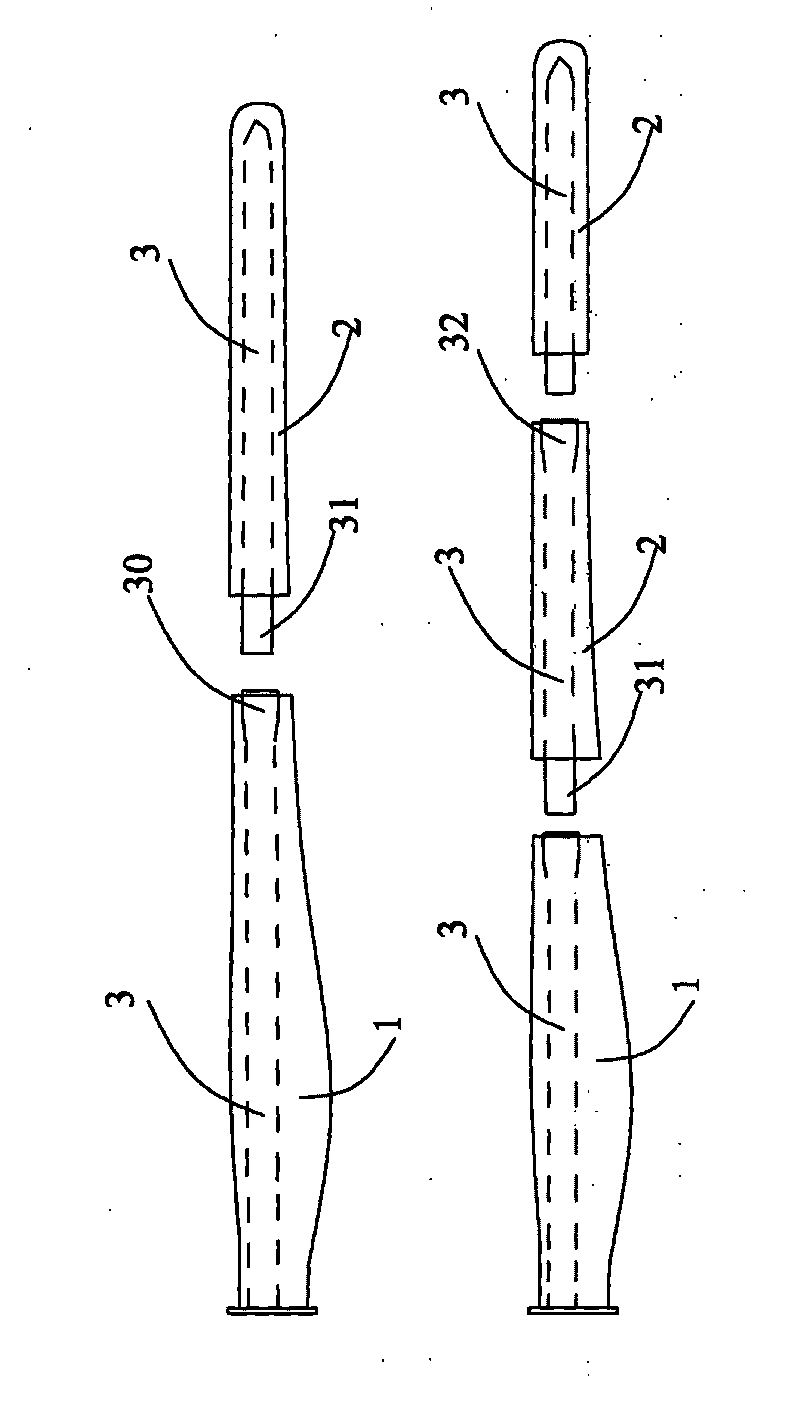

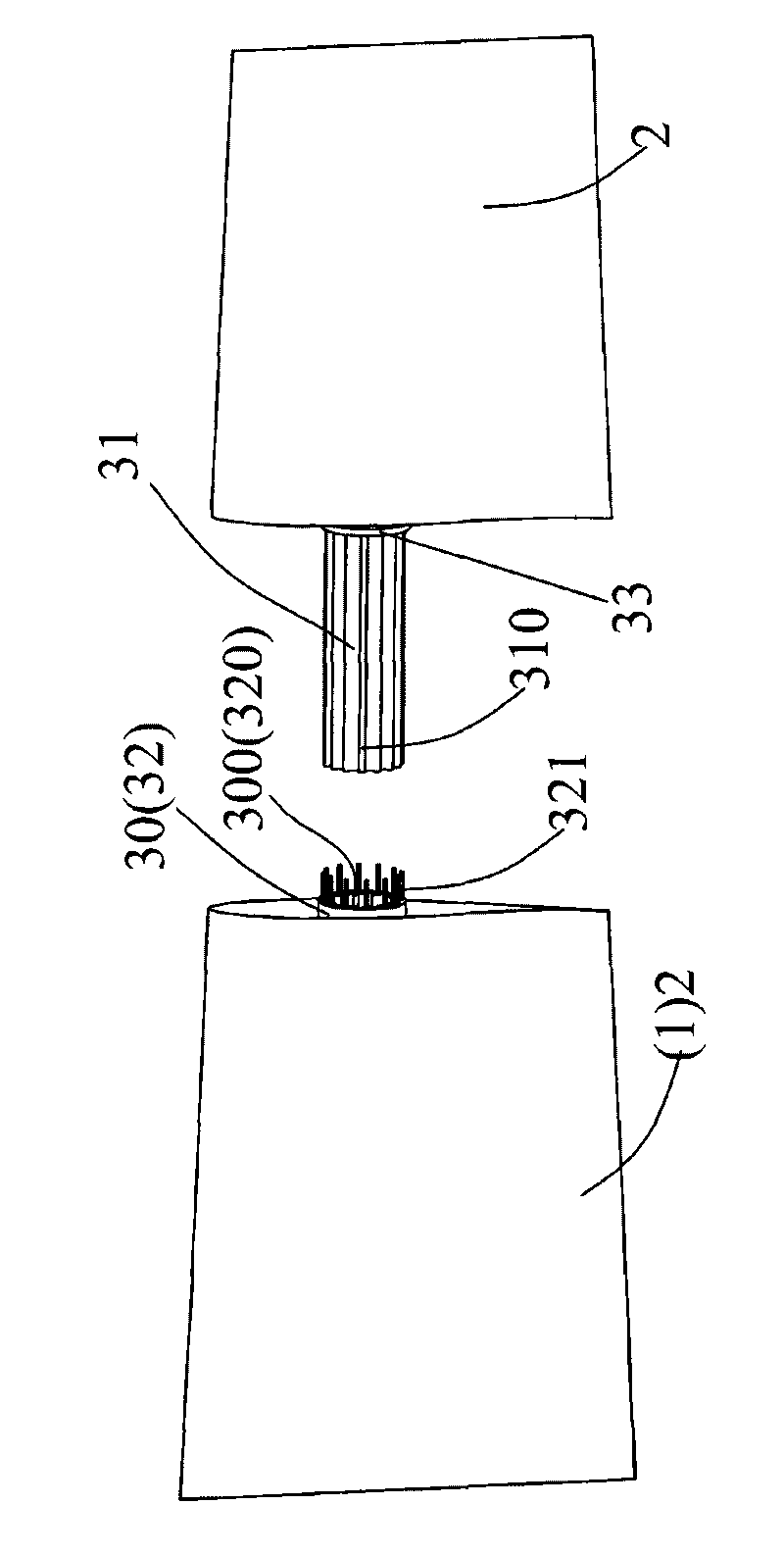

Sectional type wind wheel vanes of wind power generator set and assembly method thereof

ActiveCN101718250ASimple structureEasy to assembleMachines/enginesEngine componentsWind forceWind power generator

The invention discloses sectional type wind wheel vanes of a wind power generator set and an assembly method thereof. The sectional type wind wheel vanes comprise a vane root segment and at least one radial vane, wherein the vane root segment is close to one side of a wheel hub, main beams are embedded in the vane root segment and all radial vanes, and the vane root segment and each radial vane are connected end to end by sequentially joining the main beams. By the sectional type wind wheel vanes, the effects of large connection strength and small pneumatic loss can be realized.

Owner:SINOVEL WIND GRP

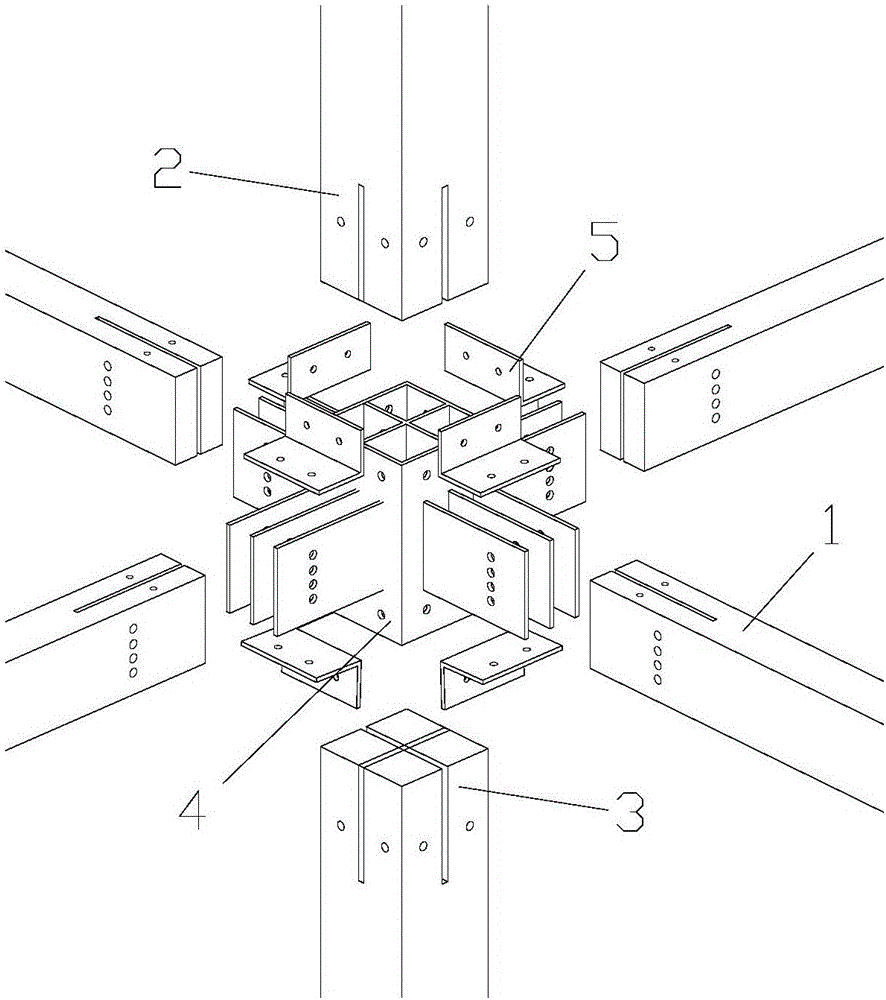

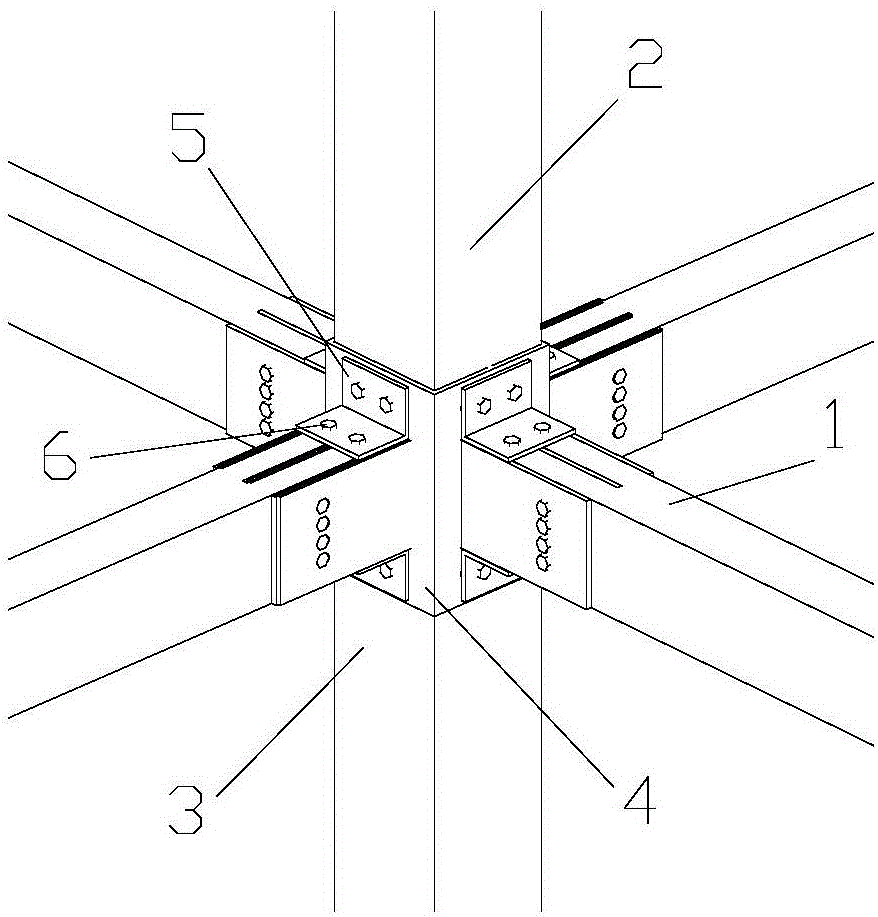

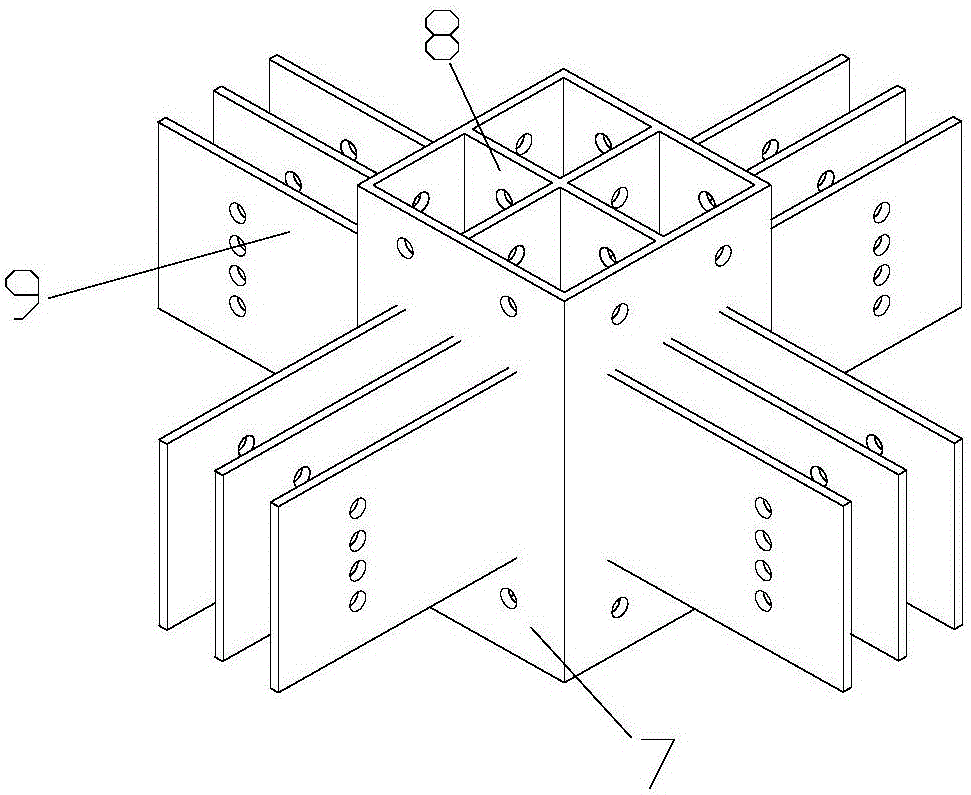

Assembly type wood frame structure beam-column joint with sleeve

InactiveCN106368315AAvoid weakeningIncrease profitBuilding constructionsAgricultural engineeringUltimate tensile strength

The invention discloses an assembly type wood frame structure beam-column joint with a sleeve. The assembly type wood frame structure beam-column joint comprises an upper wood column, a lower wood column, wood beams, a sleeve joint and reinforcing corner pieces. A middle vertical inserting groove is formed in the end of each wood beam. A cross-shaped inserting groove is formed in the upper end of the lower wood column, and a cross-shaped inserting groove is formed in the lower end of the upper wood column. The sleeve joint is provided with a column sleeve; a cross-shaped sleeve longitudinal rib plate and a sleeve middle transverse partition plate are arranged in the column sleeve; and wing type sleeve connecting plates are arranged outside the column sleeve. The column sleeve is arranged at the upper end of the lower wood column in a sleeving mode; the lower end of the upper wood column is inserted into the column sleeve; the ends of the wood beams are inserted into the wing type sleeve connecting plates; and the upper side and the lower side of each wood beam are each provided with a reinforcing corner piece. The reinforcing corner pieces, the sleeve joint, the wood beams and the wood columns are connected through bolts. The assembly type wood frame structure beam-column joint is little in wood consumption, low in manufacturing cost, high in connection strength, easy to manufacture, convenient to construct, definite in stress, and beneficial to the population and the application of assembly type wood frame structures.

Owner:TIANJIN UNIV

Male connector and connector assembly

ActiveUS20080305657A1Easily fitDeterioration of connection strengthLine/current collector detailsElectrically conductive connectionsEngineeringElectrical and Electronics engineering

A male connector is attached to a circuit board and fits with a female connector in a fitting direction perpendicular to a surface of the circuit board. A terminal of the male connector extends outside a housing thereof in parallel to the circuit board. The terminal has a connection portion to be connected with a circuit portion of the circuit board with solder. When the male connector and the female connector are fitted with each other, the connection portion has a facing region facing a top face of a peripheral wall of a housing of the female connector. The terminal includes a solder barrier layer formed at least in a nearest facing region of the facing region. The nearest facing region is situated to be closest to the top face.

Owner:HIROSE ELECTRIC GROUP

Panel with paper honeycomb cores using as a table top

InactiveUS20090324872A1Highly strongCost-effectiveDomestic upholsterySynthetic resin layered productsHoneycombPulp and paper industry

The present invention relates to a panel with paper honeycomb cores, which is usable as a table top. The panel comprises a top panel, a bottom panel, paper honeycomb cores and an internal fixed part, in which the paper honeycomb cores are filled in the closed space which is enclosed by the top panel and the bottom panel, and are fixed with the top panel and the bottom panel. The peripheries of the paper honeycomb cores are completely or partially surrounded by the internal fixed part, or the internal fixed part is installed in the suited position of the panel, and the internal fixed part serves as the stiffening art of the panel. The edge of the bottom panel and the lower edge of the top panel, which is formed by ending the top panel downwards are cohered together, and the flection of the top panel forms the side edge of the panel. The top panel and the bottom panel may be formed by suction moulding process or contour machining process directly. The panel having the structure described above can connect with other parts of the table.

Owner:LENG LUHAO

Laminated-type piezoelectric element

InactiveUS20060232172A1Easily connectDecrease thermal stressPiezoelectric/electrostrictive device manufacture/assemblyPiezoelectric/electrostriction/magnetostriction machinesOptoelectronicsElectrically conductive adhesive

A laminated-type piezoelectric element 1 is provided, which comprises a first external electrode layer 33, which is located at a side area of the laminated-type piezoelectric element 1, is electrically continuous to internal electrode layers 21, and comprises plural expansible and contractible opening portions 33a in a stacking direction of the laminated-type piezoelectric element 1. As the first external electrode layer 33 is connected to the laminated-type piezoelectric element 1 with an electrically conductive adhesive member 32 and the electrically conductive adhesive member 32 is narrower than the first external electrode layer 33, the electrically conductive adhesive member 32 penetrates into the opening portions 33a of the first external electrode layer 33 to form connections in a shape of an anchor. Therefore, the first external electrode layer 33 is firmly connected to the laminated-type piezoelectric element 1.

Owner:DENSO CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com