Periodic longitudinal variable-thickness strip and longitudinal variable-thickness plate and preparation method thereof

A longitudinally variable thickness and periodic technology, applied in the direction of material size control, non-electric variable control, electric speed/acceleration control, etc., can solve the problem of inability to achieve transitional connection between thick plates and thin plates, and achieve thickness control easily , good reliability and good surface quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0368] Such as Figure 17 As shown, the preparation method of the longitudinally variable thickness plate comprises the following steps:

[0369] Step 1: According to the requirements of the user and the characteristics of the steel type, the coiled periodic longitudinally variable thickness strip is divided into two types that require annealing and do not require annealing;

[0370] Step 2: Perform annealing treatment on the coil that needs to be annealed. The purpose of annealing is to eliminate work hardening and improve formability. Annealing can be carried out in an ordinary bell annealing furnace with atmosphere protection, and the annealing temperature can be selected between 550-750°C according to the steel type of the strip;

[0371] Step 3: The annealed and non-annealed coils are transported to the finishing line and uncoiled by the uncoiler;

[0372] Step 4: The variable-thickness strip after uncoiling is straightened by a straightening machine;

[0373] Step 5: ...

Embodiment 1

[0375] Incoming material status: Uniform thickness, steel type is IF steel, width 500mm, thickness 1.3mm.

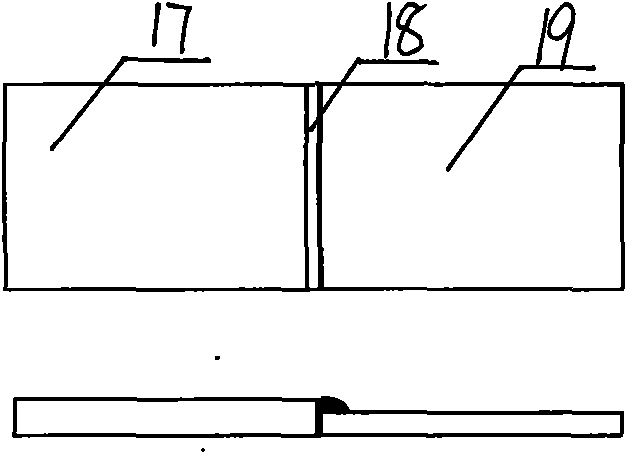

[0376] Product size: three thicknesses, two transition areas; the thickness of the thick area is 1.2mm, and the length is 300mm; the transition area 1 is a double-arc dominant transition curve, and the length of the transition area 1 is 50mm; the thickness of the thin area 1 is 1.0mm, and the length is 300mm; the transition area 2 is a concave-arc-dominated transition curve, the length of the transition zone 2 is 50mm; the thickness of the thin zone 2 is 0.8mm, and the length is 300mm.

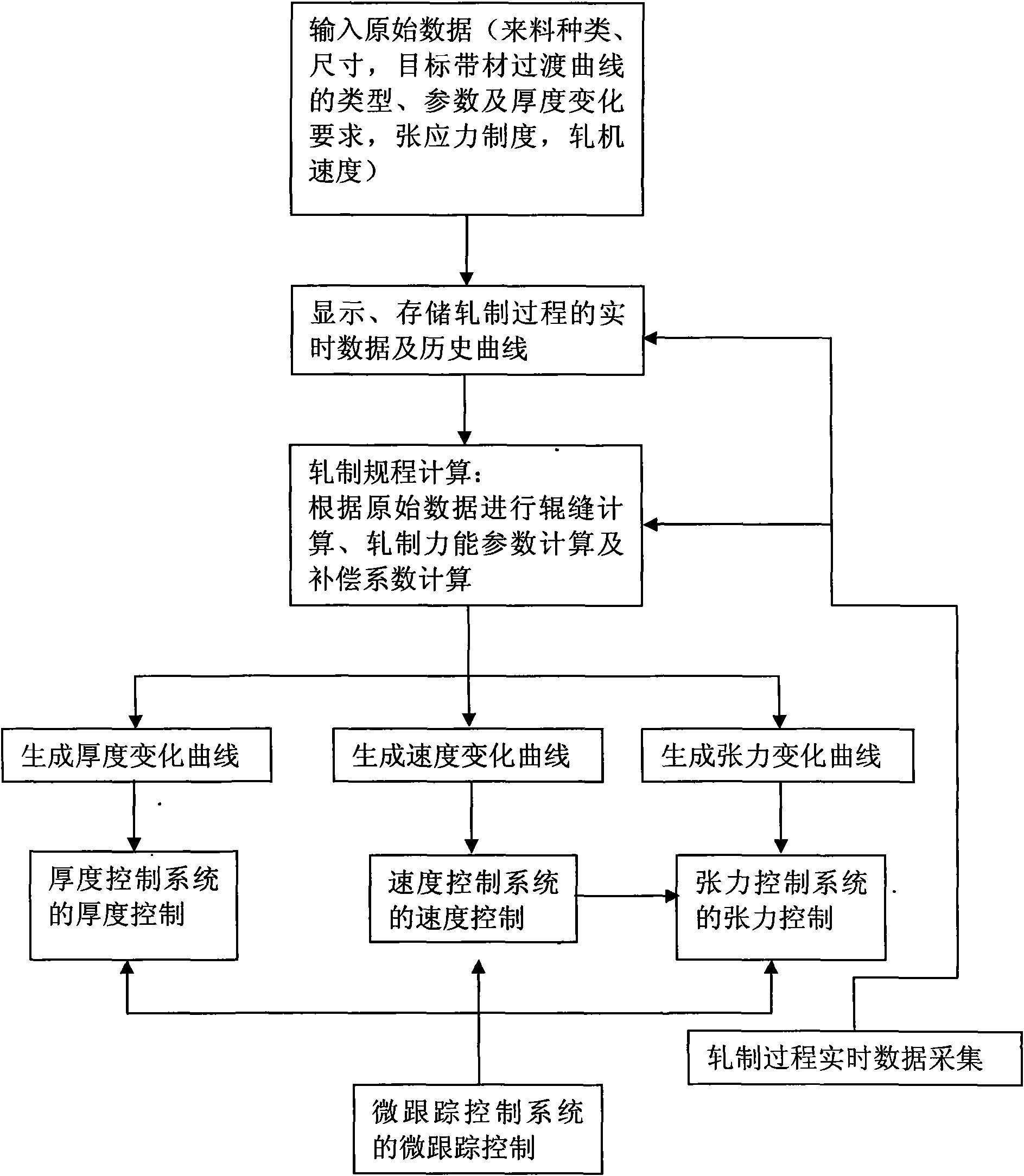

[0377] The specific rolling process is as follows:

[0378] 1) Calculate the mathematical model of the transition curve of the transition zone of the set target strip;

[0379] The mathematical model of the transition curve in transition zone 1 is:

[0380] Y = 250001 40 + ( ...

Embodiment 2

[0404] Incoming material status: uniform thickness, steel type is ST12, width 450mm, thickness 2mm;

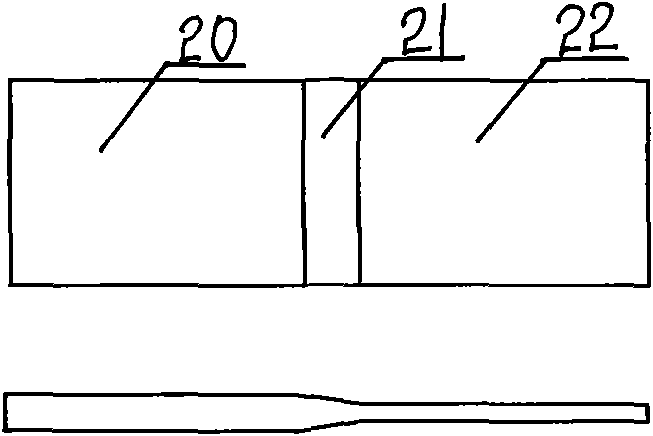

[0405] Product size: two thicknesses, one transition zone; thick zone thickness 1.5mm, length 200mm; transition zone length 100mm; thin zone thickness 0.8mm, length 200mm; transition zone is a curve-dominated transition curve.

[0406] The specific rolling process is as follows:

[0407] 1) Calculate the mathematical model of the transition curve of the transition zone of the set target strip;

[0408] The mathematical model of the transition curve in the transition zone is:

[0409] y = 21 200000 x 2 - 7 10000000 x 3

[0410] 2) Input the original data on the man-machine interface computer according to the above requirements

[0411] 3) The process control computer calculates the rolling schedule ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com