Patents

Literature

101results about How to "No weld" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

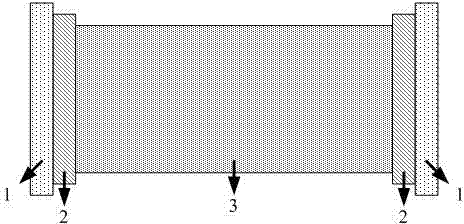

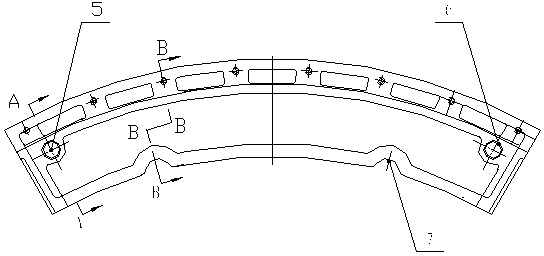

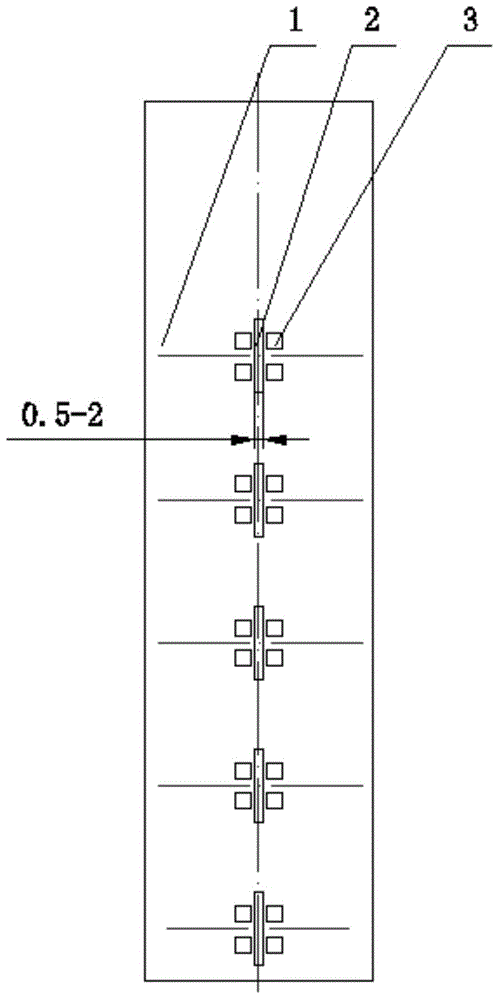

Periodic longitudinal variable-thickness strip and longitudinal variable-thickness plate and preparation method thereof

ActiveCN101607264AReduce welding processReduce manufacturing costProgramme control in sequence/logic controllersMetal rolling arrangementsComputer control systemVariable thickness

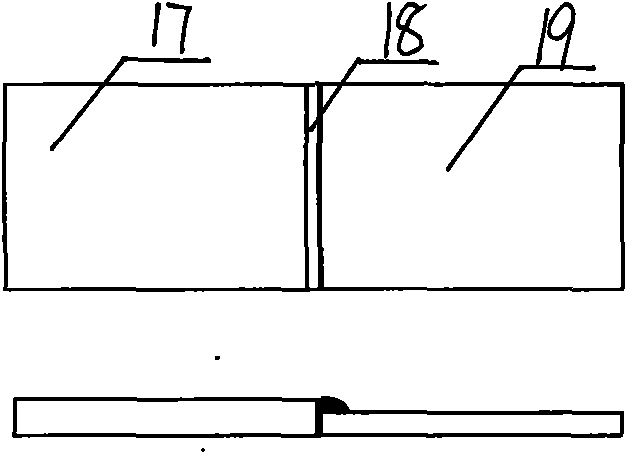

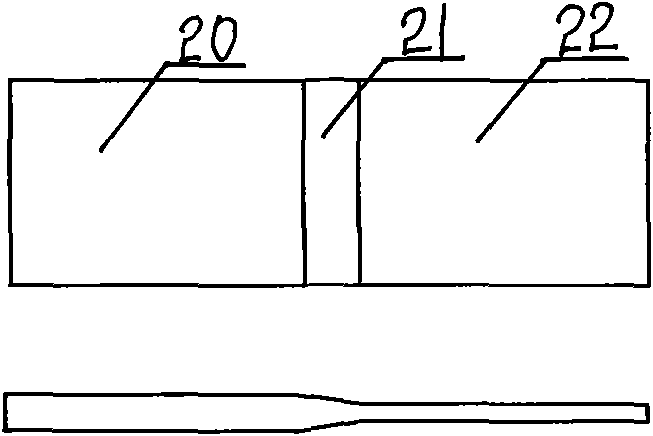

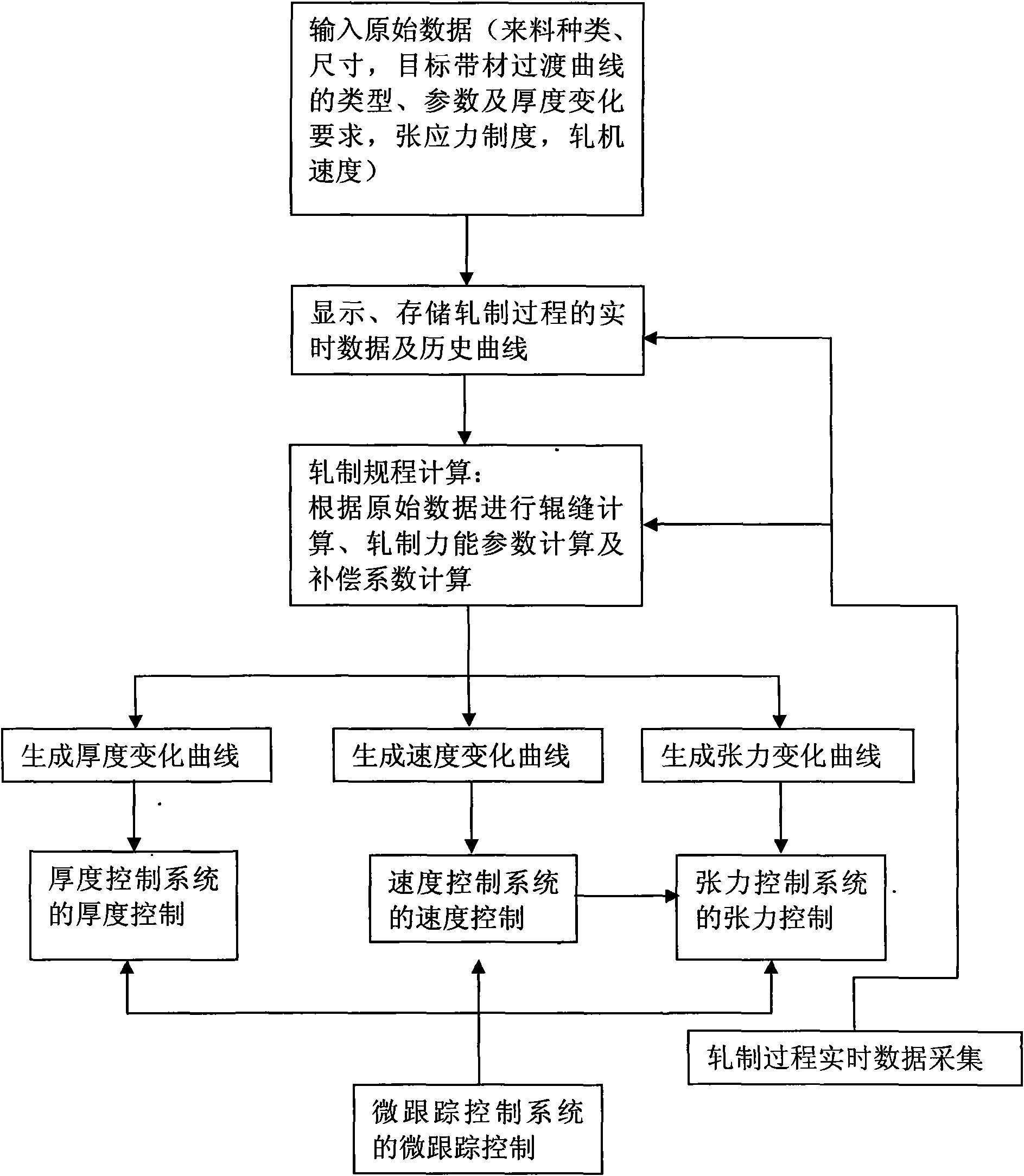

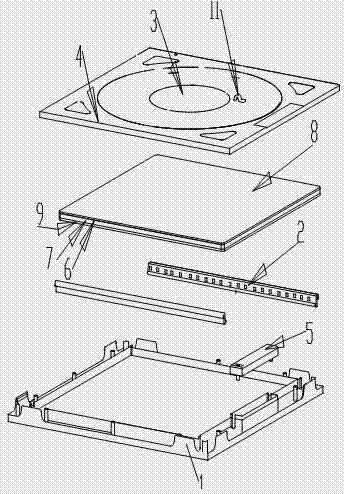

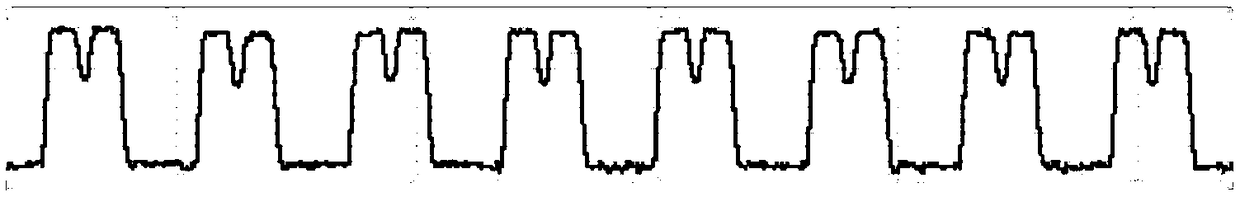

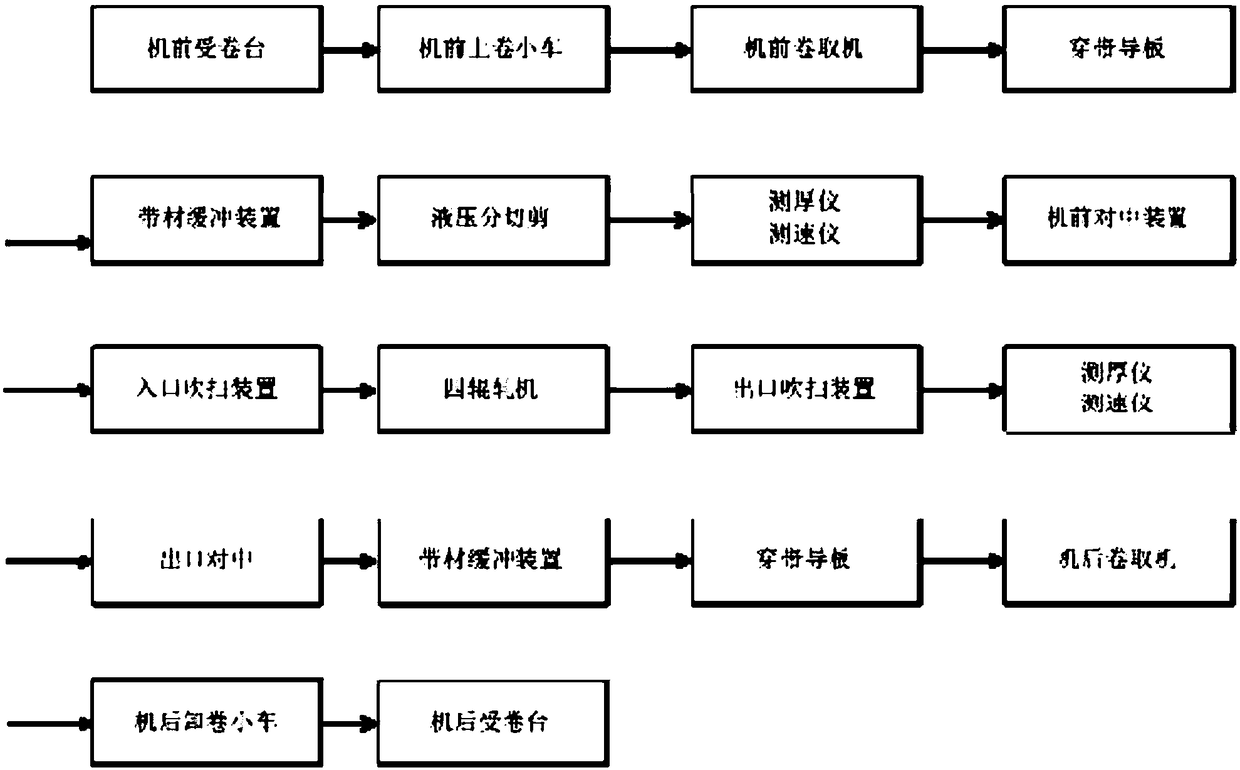

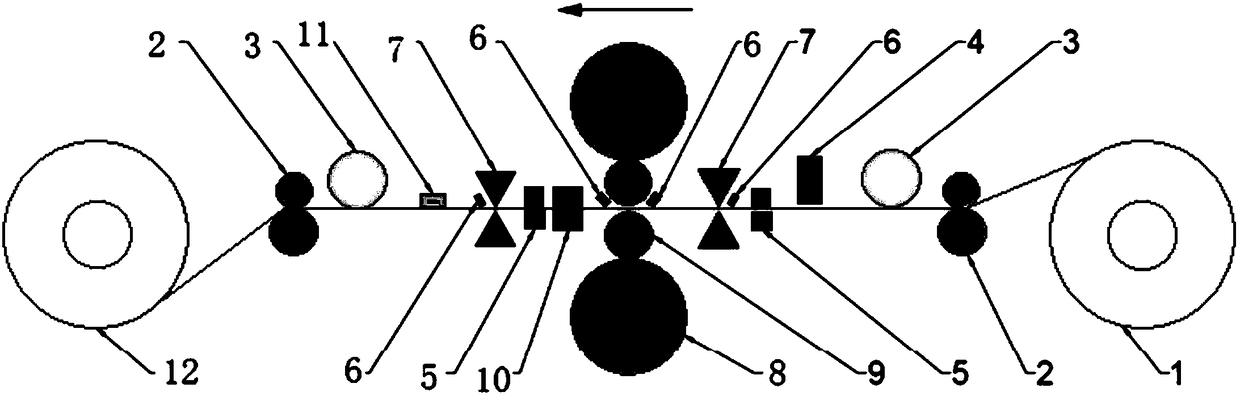

The invention belongs to the rolling technical field. The thickness of a periodic longitudinal variable-thickness strip changes periodically, the periodic longitudinal variable-thickness strip has more than two kinds of thicknesses regions and transition regions within a change period, and is formed by rolling. The control procedure of the periodic longitudinal variable-thickness strip comprises the following steps: inputting original data; displaying and storing real-time data and a history curve; computing the rolling procedure; generating a change curve; tracking the position of a rolling piece; and controlling the thickness, the speed and the tension. A device comprises a rolling mill, a reeling machine and a thickness measurer which are arranged at two sides of the rolling mill, and a length measuring roll arranged between the reeling machine and the rolling mill, wherein a reel diameter measurer is arranged on the reeling machine; a rolling force sensor and a hydraulic cylinder are arranged on the rolling machine; a pulse coder and a tension meter are respectively arranged on and below the length measuring roll; and the thickness measurer and the like are connected with a computer control system. A longitudinal variable-thickness plate has two or more kinds of different thickness regions, transition regions are arranged among the thickness regions, and the plate is formed by the strip through the steps of annealing, unreeling by an unreeler, leveling by a leveler, and cutting by a cutting machine.

Owner:SHENYANG DONGBAO HAIXING METAL MATERIAL TECH

Lead-free halogen-free tinol and preparation process

ActiveCN1876311AImprove compatibilityImprove antioxidant capacityWelding/cutting media/materialsSoldering mediaOrganic acidHalogen

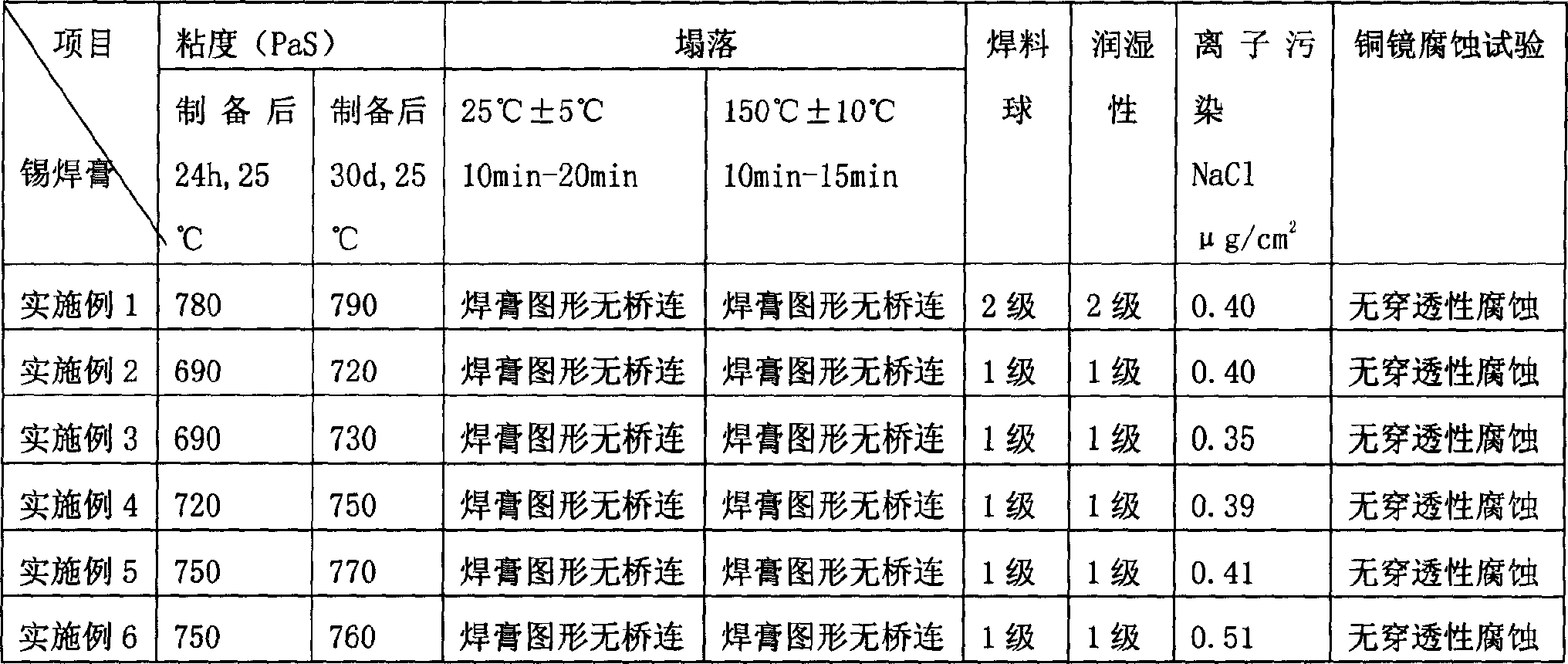

The invention discloses a leadless and no-halogen tonal, comprising following components with percent by weight: alloy powder 80-98 and welding flux 2-20; said alloy powder is one of SnAgCu, SnAgNi, SnAgBiCu, SnAgBiSb, SnCu and SnAg; said welding flux concludes following components with percent by weight: modified resin antioxidant 30-60, organic acid activating agent 5-15, thixotropic agent 4-14, plasticizing agent 2-6, plasticizing agent 0.4-2, inhibitor 0.1-0.5 and organic solvent 20-40; said modified resin antioxidant comprises following components with percent by weight: modified rosin resin 80-90, anti-oxidant 2-8, and reducer 2-8. The tonal is characterized by good thixotropic behavior, no oxidation, no dry welding and no short circuit.

Owner:BEIJING XINLI MACHINERY

Vacuum pump impeller integral casting process

The present invention provides an integral casting process of vacuum pump blade wheel. It uses copper alloy to make the integral pattern prepared by using intermediate partition board, blade and wheel hub undergo the processes of numerically-controlled processing and moulding treatment. Its sand core is placed in lower mold, on the sand core of internal cavity place a ceramic core is set, upper blade wheel and upper wheel hub top portion are equipped with riser, undersurface of lower wheel hub and shaft hole place are equipped with external chill, the internal running channel set in lower blade bottom end is communicated with straight running channel in the mold. The molten metal can be fed into internal running channel via straight running channel, then passed through the lower blade bottom end and introduced into mold cavity to make bottom casting operation, when the molten metal is reached to riser top from bottom to top, an exothermic mixture is added into riser interior, after the casting is cooled, the molding box is opened, sand is removed and the casting is undergone the process of heat treatment.

Owner:遵义拓特铸锻有限公司

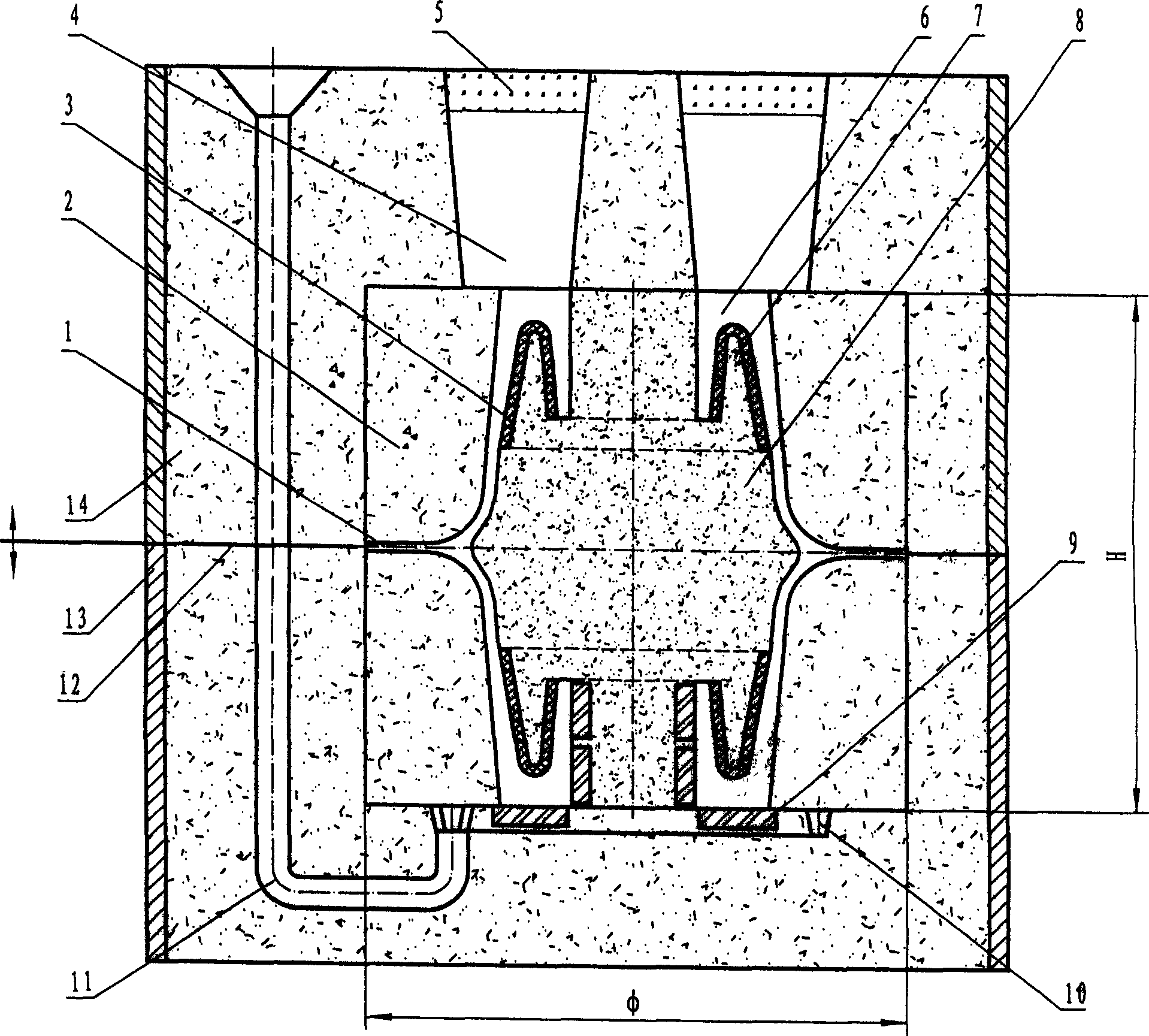

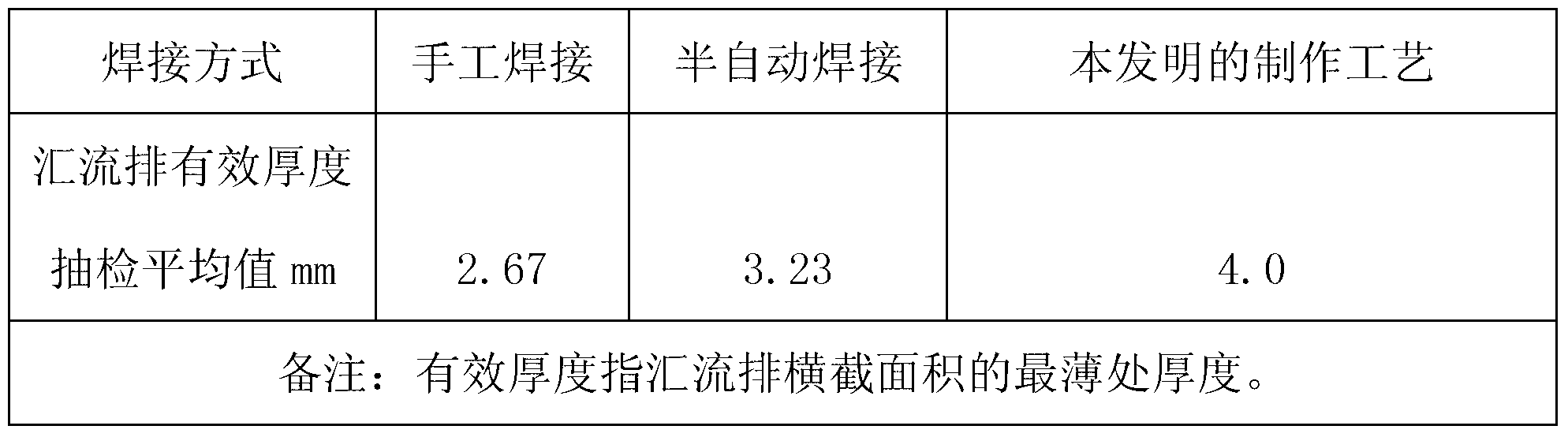

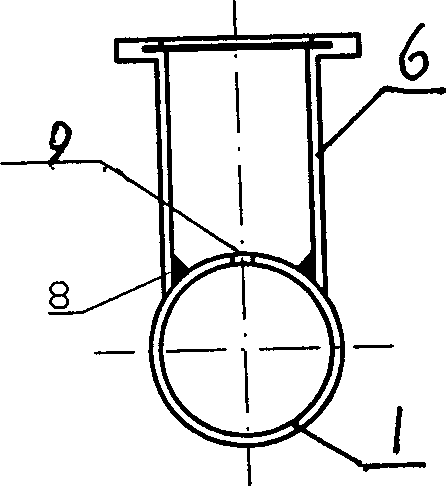

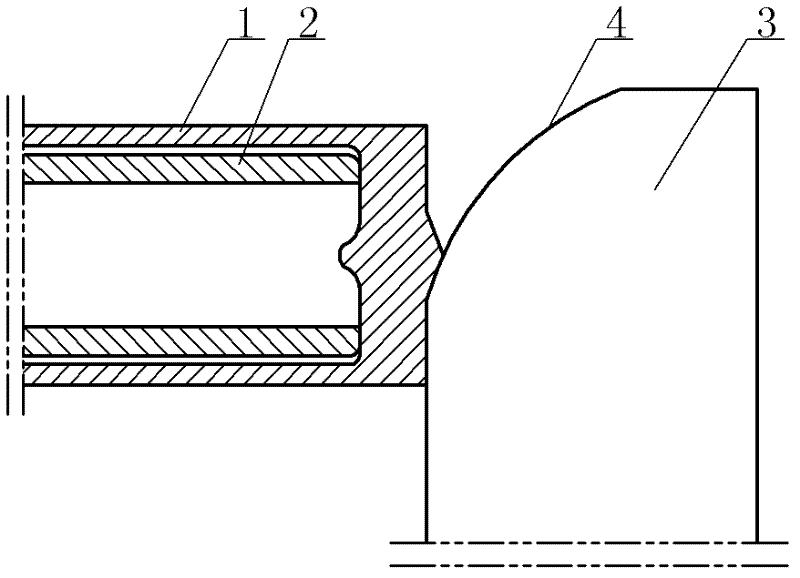

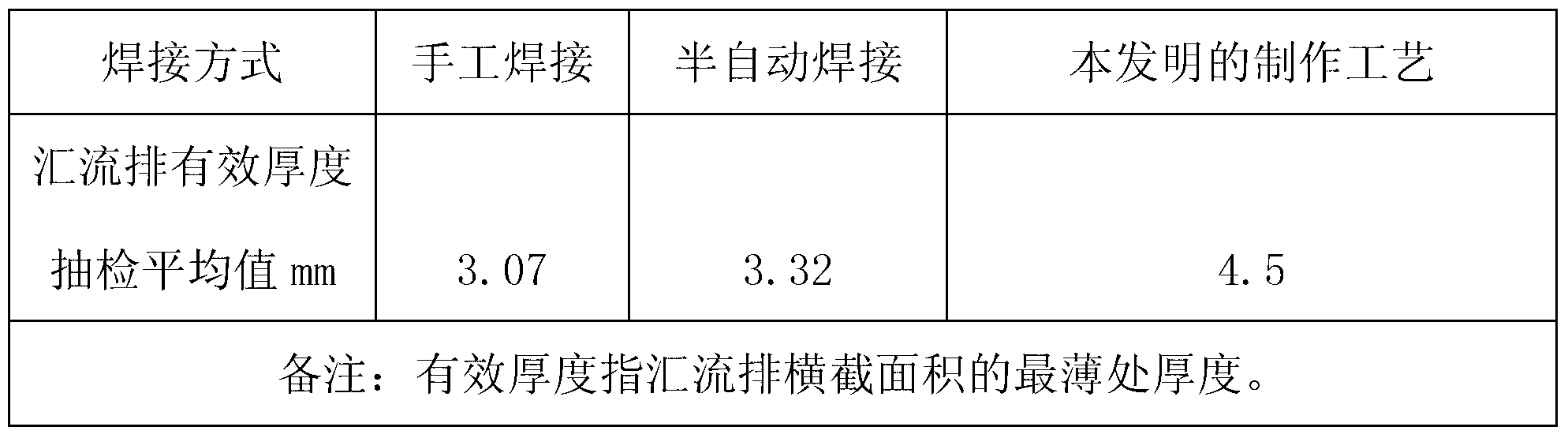

Production process of inner formation storage battery

ActiveCN103268963AGood corrosion resistanceNo burning lossFinal product manufactureCell component detailsGrid alloyL&D process

The invention discloses a production process of an inner formation storage battery, and belongs to the field of a lead-acid storage battery, and solves the easily occurring welding quality problem of a bus-bar and a lug. The process comprises the following steps of loading a plate group into an assembling box, arranging a lug, cutting and brushing the lug, dipping soldering flux, cast welding, inspecting and qualification and down-conversion, wherein the cast welding flow is carried out by adopting a cast welding machine. The cast welding flow comprises the following steps of (1) heating a lead pot; (2) loading a mold and preheating the mold; (3) scraping the lead liquid; (4) cast welding the plate group; (5) cooling the plate group through water; (6) cooling the plate group collectively through water and air; (7) cooling the plate group through the air; (8) loading the mold and preheating the mold again; and (9) loading the plate group into a tank. The production process is suitable for the cast welding of the inner formation storage battery with positive grid alloy being lead calcium tin aluminum or lead calcium alloy series grid.

Owner:CHAOWEI POWER CO LTD

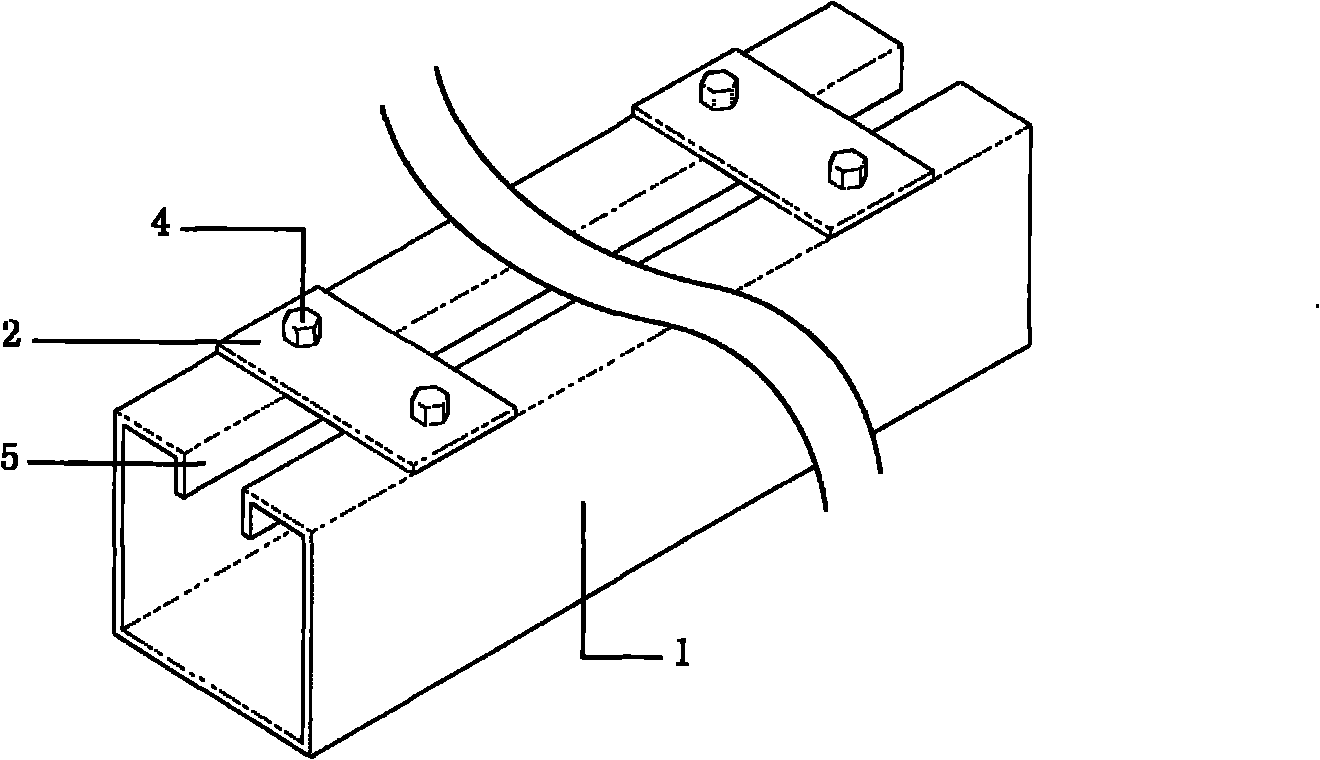

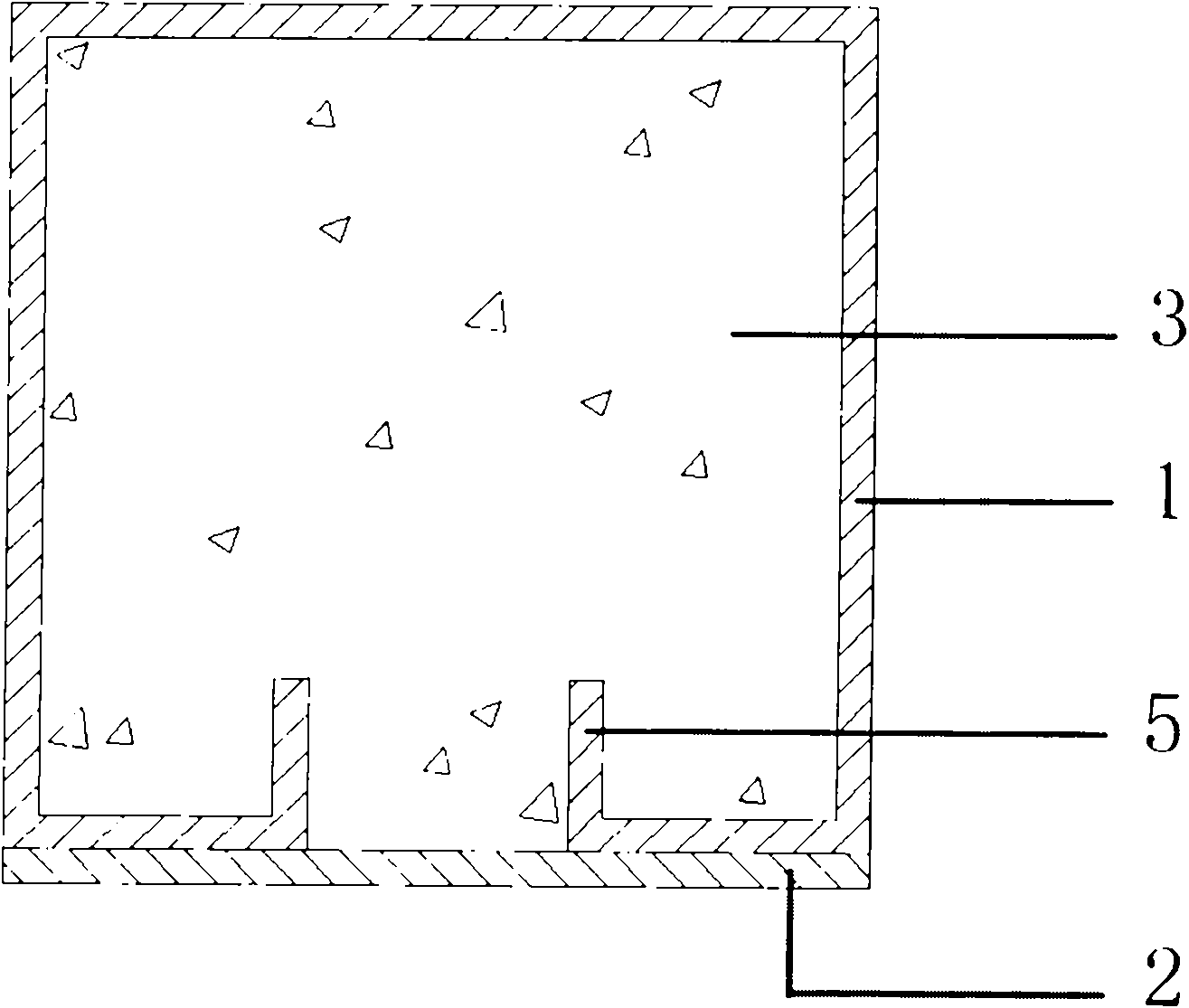

Square light steel member with reinforcement parts

The invention relates to a square light steel member with reinforcement parts, which comprises a main structure and the reinforcement parts, wherein the main structure is a square steel tube which is integrally formed by a steel plate with a certain thickness, an opening is arranged at one side of the square steel tube, the two side edges of the opening are respectively provided with bending edges, and the reinforcement parts are fixedly connected with the side of the main structure provided with the opening, and are arranged at certain intervals. The square light steel member with the reinforcement parts provided by the invention has the advantages of strong compressive resistance and deformation resistance, relative low manufacturing cost, good corrosion resistance, easiness in processing, convenience in being connected and constructed with other components and the like.

Owner:谢英俊

Air pressure spot coating soldering paste for connector

ActiveCN101992361AWon't clogEasy to useWelding/cutting media/materialsSoldering mediaActive agentAlloy

The invention relates to a soldering paste for a connector and an air pressure spot coating mode. In order that the liquidity of the soldering paste is good, the liquidity can be kept for long time during use and a needle tube is not plugged, a lubricating agent is added based on a common soldering paste formula; and in order that the collapse resistance of the soldering paste is not affected at the same time of improving the liquidity of the soldering paste, a nucleation transparent agent is added based on the original soldering paste formula. The soldering paste consists of lead-free alloy powder and flux paste, wherein the flux paste comprises the following components in percentage by mass: lubricating agent, nucleation transparent agent, rosin, active agent, solvent, thixotropic agentand antioxidant.

Owner:厦门市及时雨焊料有限公司

Welding method for yttrium series high-temperature superconducting tape

ActiveCN102837093ADoes not affect superconducting propertiesShort heating timeSoldering apparatusHigh temperature superconductingSoldering

The invention relates to a welding method for an yttrium series high-temperature superconducting tape. The welding method comprises the following steps of: fixing two sections of yttrium series high-temperature superconducting short tapes on two sides of one section of yttrium series high-temperature superconducting long tape to be welded to form a spreading plane area; flatly paving solder in the spreading plane area by adopting a solder heating mode to form a lapping area; lapping another section of yttrium series high-temperature superconducting long tape to the lapping area of the superconducting long tape to enable two sections of superconducting long tapes to have overlapped parts; respectively heating solder in the lapping areas of two sections of superconducting short tapes; melting the solder between the overlapped parts of two sections of superconducting long tapes by self heat transfer of the solder; after melting, wetting and spreading to enable the two sections of superconducting long tapes to be welded together through the solder between the overlapped parts; and finally, stripping two sections of superconducting short tapes by heating and finishing the welding. According to the welding method, the mode of directly heating the high-temperature superconducting tapes to be welded can be avoided, and thus the heating time is short, the superconducting performance of the high-temperature superconducting tapes are prevented from being influenced by high temperature during soldering; and the welding method has the advantages of strong operability, low possibility of generating pseudo soldering and high rate of finished products.

Owner:DONGFANG ELECTRIC CORP LTD

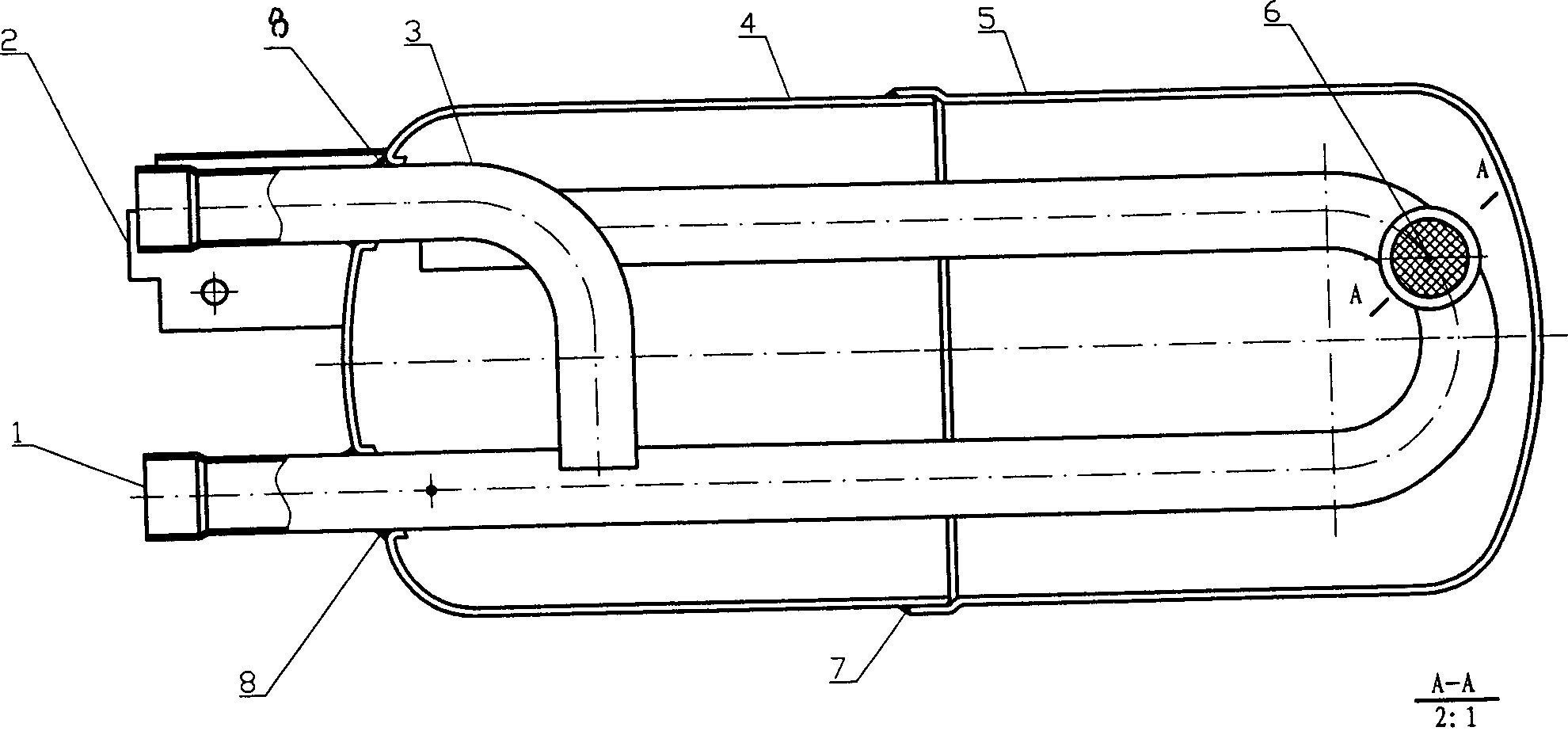

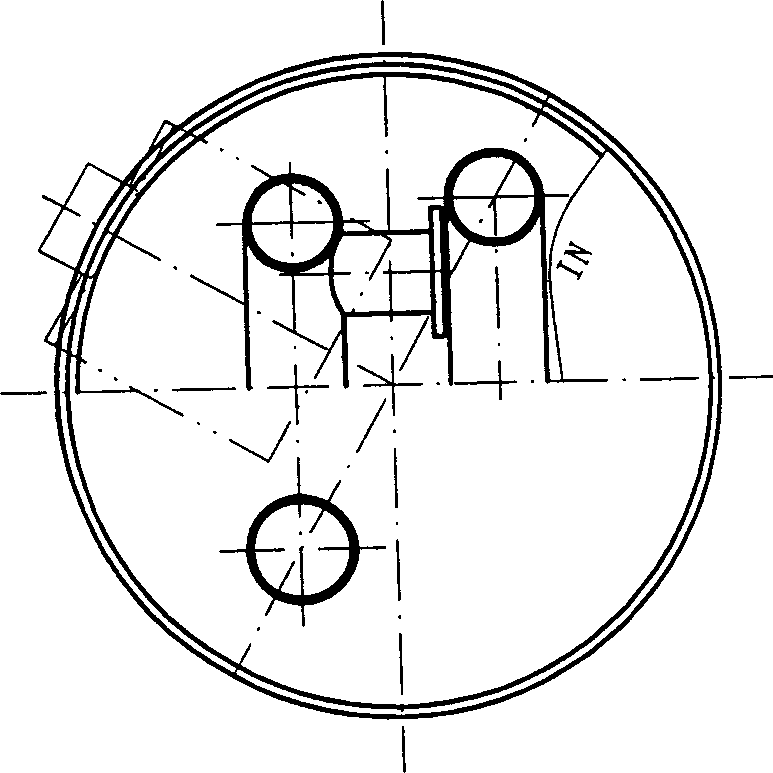

Steam and liquid separator for air conditioner and its producing method

Separator for steam and liquid includes exhaust pipe, mounting plate, air inlet pipe, filter, and barrel characters are that both exhaust pipe and air inlet pipe are prepared from iron pipe. Advantages are: reasonable structure, lowering production cost, no lap joint in one whole iron pipe, no welding line. Procedure for welding exhaust pipe, air inlet pipe and up barrel is changed to about 1130 deg.C furnace brazing under protective atmosphere from flame weld. Advantages of the procedure are: simplified operation technique, fine welding line, high weld strength, good air-tightness, and no pile of solder. Protection weld of CO2 gas is adopted for welding between up barrel and low barrel. Then, tube end expansion is carried out for exhaust pipe, and air inlet pipe so as to guarantee reasonable assembly technique.

Owner:广州大津电器制造有限公司

Technology for producing lead-acid storage batteries through temperature control method

The invention discloses a technology for producing lead-acid storage batteries through temperature control method, belongs to the field of lead-acid storage battery production and solves the problem of the poor battery welding quality of a cast-welding technology through a time control method. The method comprises the processes of feeding of plate packs in an assembly box, electrode tab arranging, cutting and brushing of electrode tabs, dipping of flux, cast-welding, inspection and discharging after qualification. The cast-welding process is completed through a cast-welding machine and comprises the following steps: 1) heating of a lead pan; 2) preheating of a lower die; 3) scrapping of molten lead; 4) electrode tab cast-welding; 5) die removal; and 6) secondary preheating of the lower die. The technology is used for manufacturing lead-acid storage batteries.

Owner:CHAOWEI POWER CO LTD

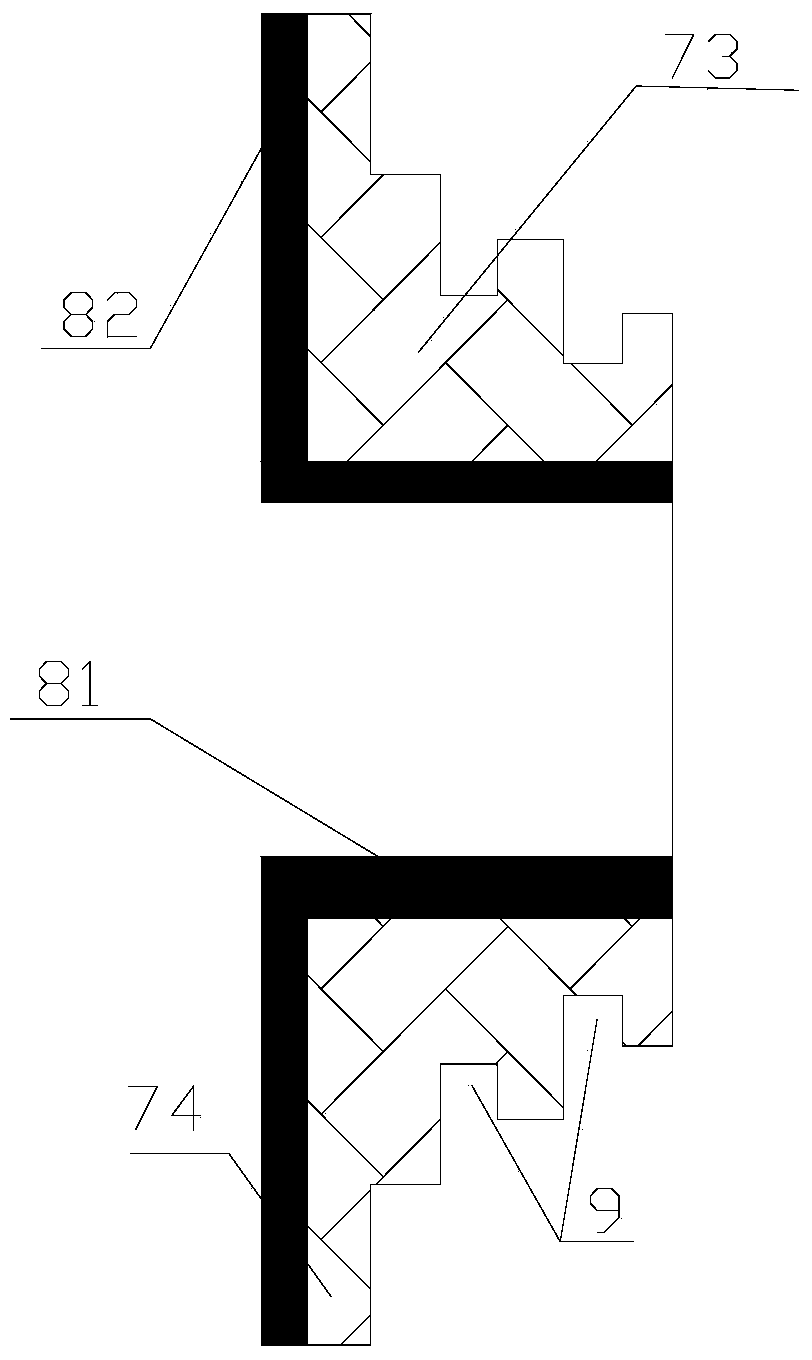

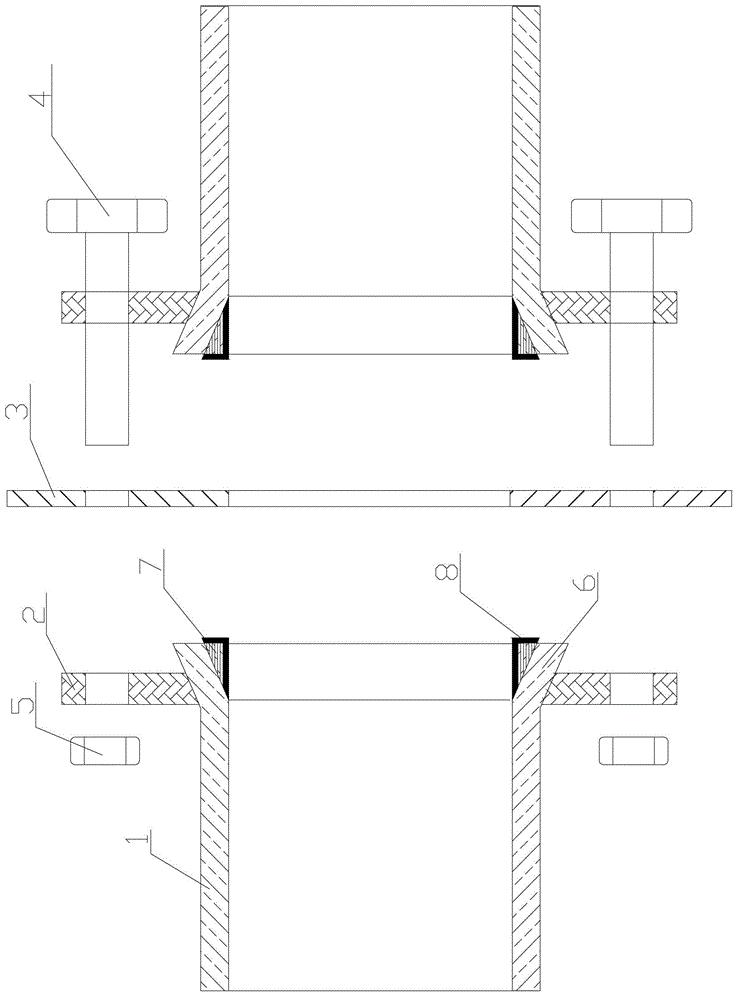

Enhanced blind joint and metal lining ring of flaring

InactiveCN103527886ASimple structureEasy connectionEngine sealsPipe connection arrangementsBell mouthEngineering

The invention provides a metal lining of a flaring. The metal lining of the flaring comprises an inner pipeline part and a horn mouth part, wherein the inner pipeline part is arranged on the inner side of a horn mouth of a pipeline in a sleeved mode, the outer wall of the inner pipeline part is matched with the inner wall of the horn mouth, and the horn mouth part covers the front end face of the horn mouth and matched with the front end face of the horn mouth. The horn mouth part and the horn mouth part are of an integrally formed structure which can protect the front end face of the horn mouth against damage caused by foreign bodies. The invention further provides an enhanced blind joint of the flaring. According to a main structure of the enhanced blind joint of the flaring, the bind joint comprises two pipeline bodies respectively provided with the horn mouth, wherein a movable flange is arranged on the outer wall of each pipeline body in a sleeved mode, the inner diameter of each movable flange is smaller than the largest diameter of the corresponding horn mouth, the corresponding movable flanges of the two pipeline bodies are connected through fixing parts, and each horn mouth is provided with the metal lining ring of the flaring. The contact area between the two metal lining rings when two pipelines are connected in an abutted mode or the contact area between rubber lining layers on the metal lining rings can be increased, and therefore better sealing is achieved.

Owner:荣京柯

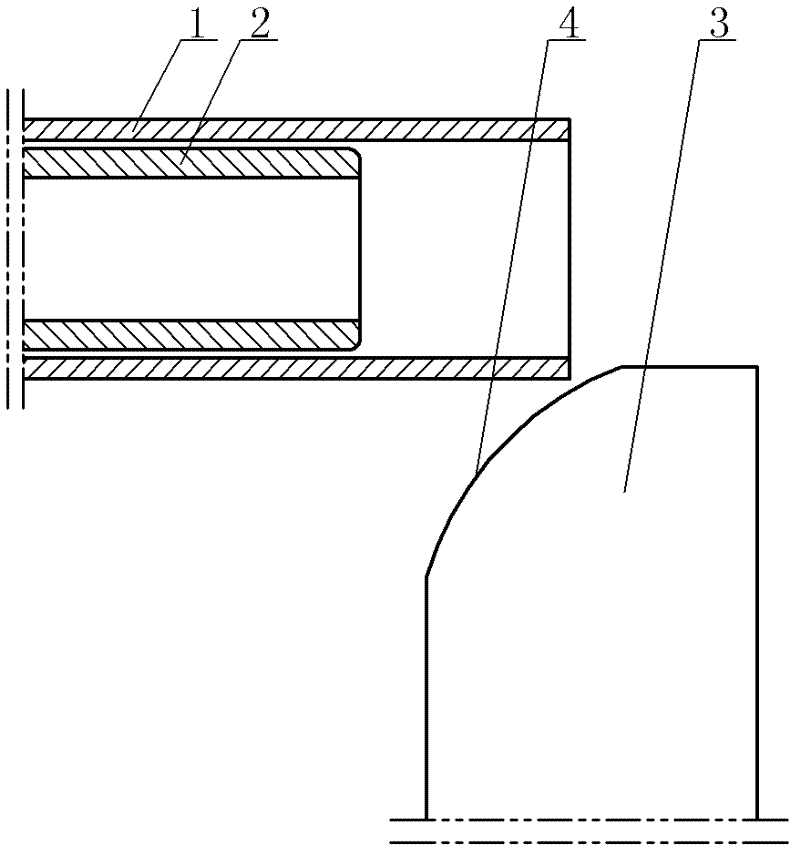

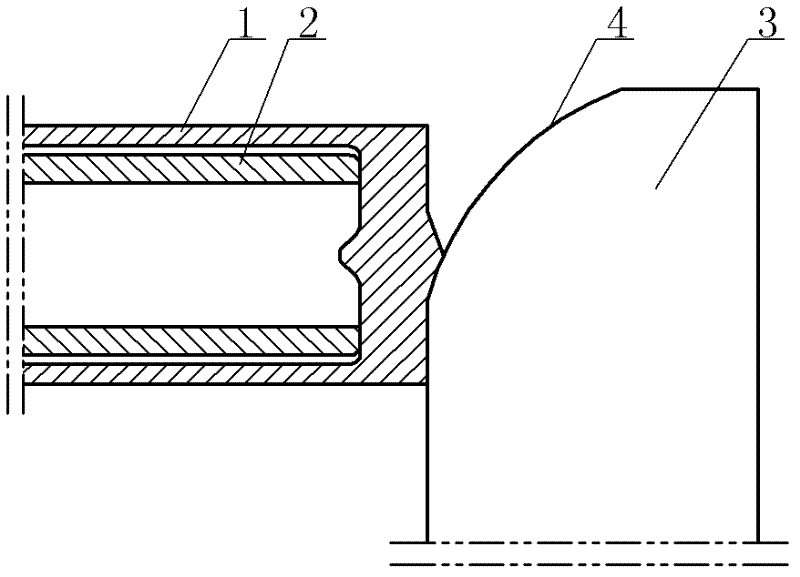

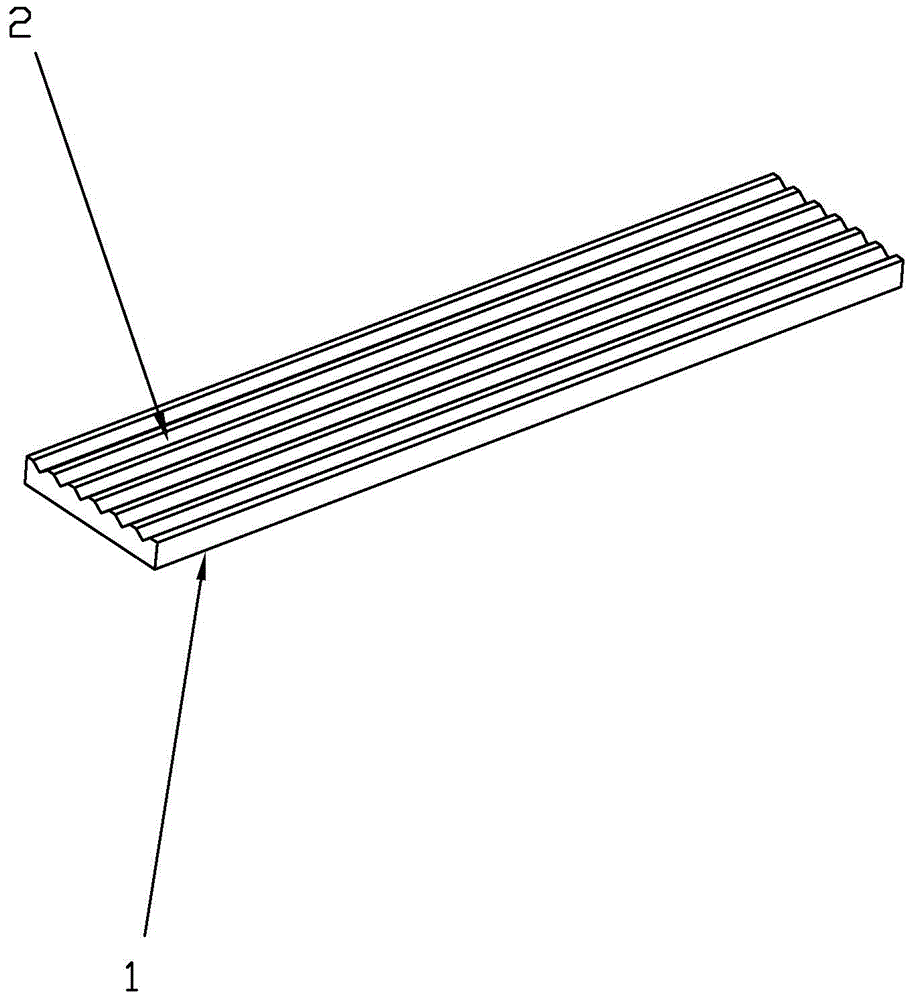

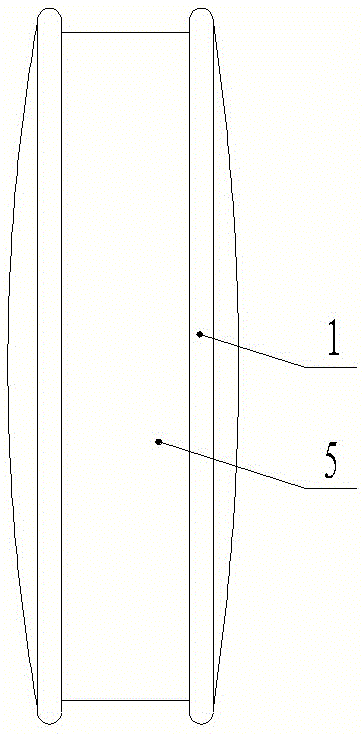

Process for sealing port of metal pipe

The invention relates to a process for sealing the port of a metal pipe. The problems of low processing efficiency and low yield in the current method for sealing the port of the metal pipe fitting can be mainly solved. The process is characterized by comprising the following steps of: a, clamping the metal pipe (1) in an elastic jacket capable of rotating on a machine tool, wherein a locating piece (2) extends in the elastic jacket; and the metal pipe (1) is sleeved outside the locating piece (2); b, extruding the port of the metal pipe (1) which rotates at high speed by using a cutter (3) without a blade till the port of the metal pipe (1) is completely closed and molten integrally at high temperature; and c, flat turning the metal pipe (1) by using a turning tool, closing the outer end face of the port, chamfering and then polishing. According to the process for sealing the port of the metal pipe disclosed by the invention, the port of the metal pipe is sealed through one-time tooling by using the machine tool; the process is simple, low in cost, high in processing efficiency and high in yield; no welding line exist; and the appearance is flat and smooth.

Owner:WENZHOU XUNKEDA SANITARY WARE

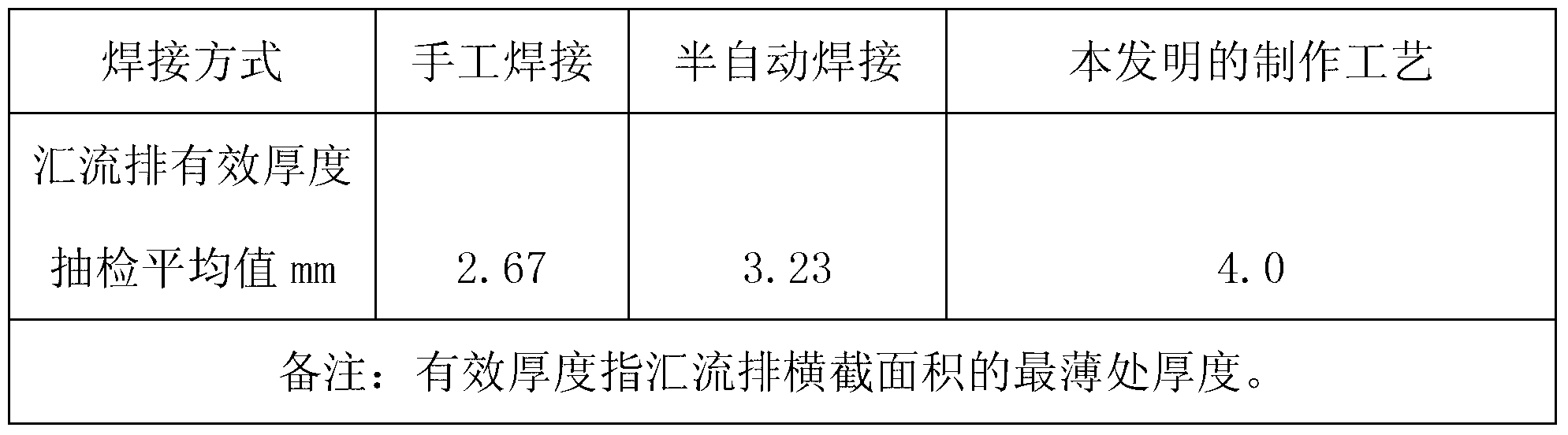

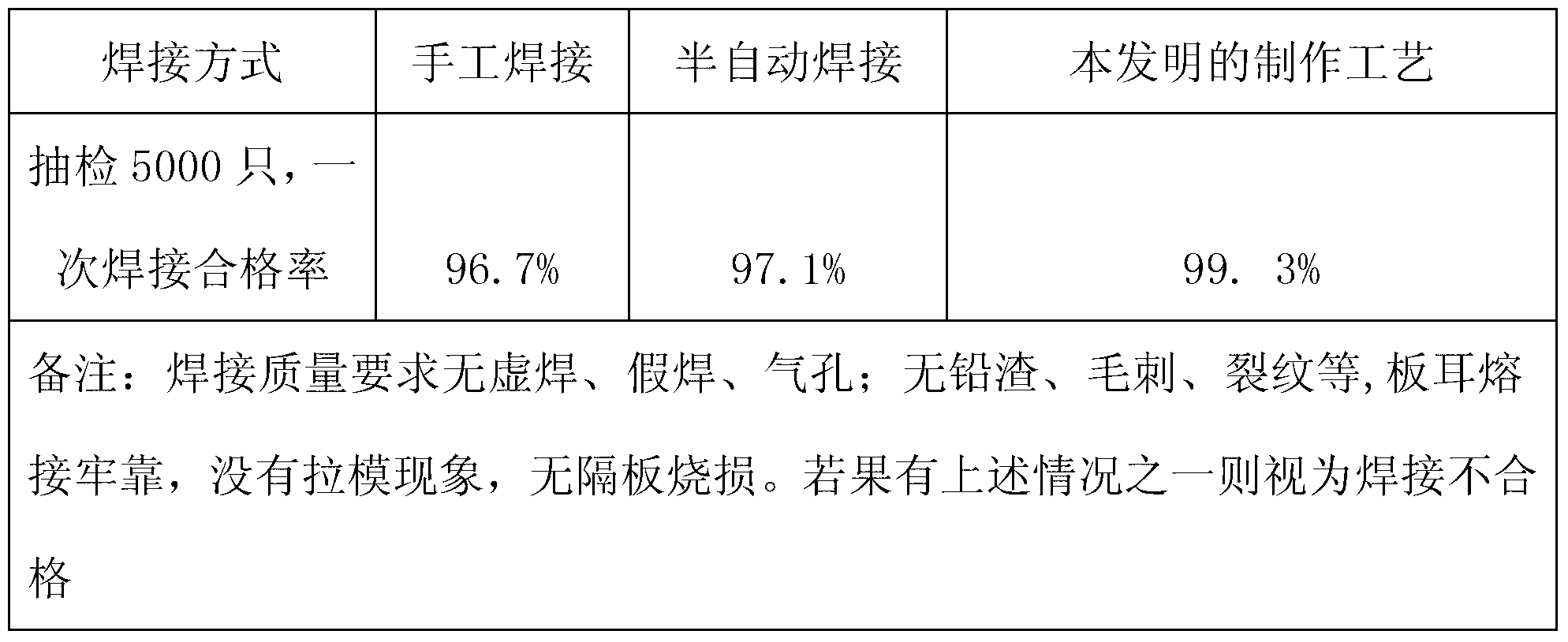

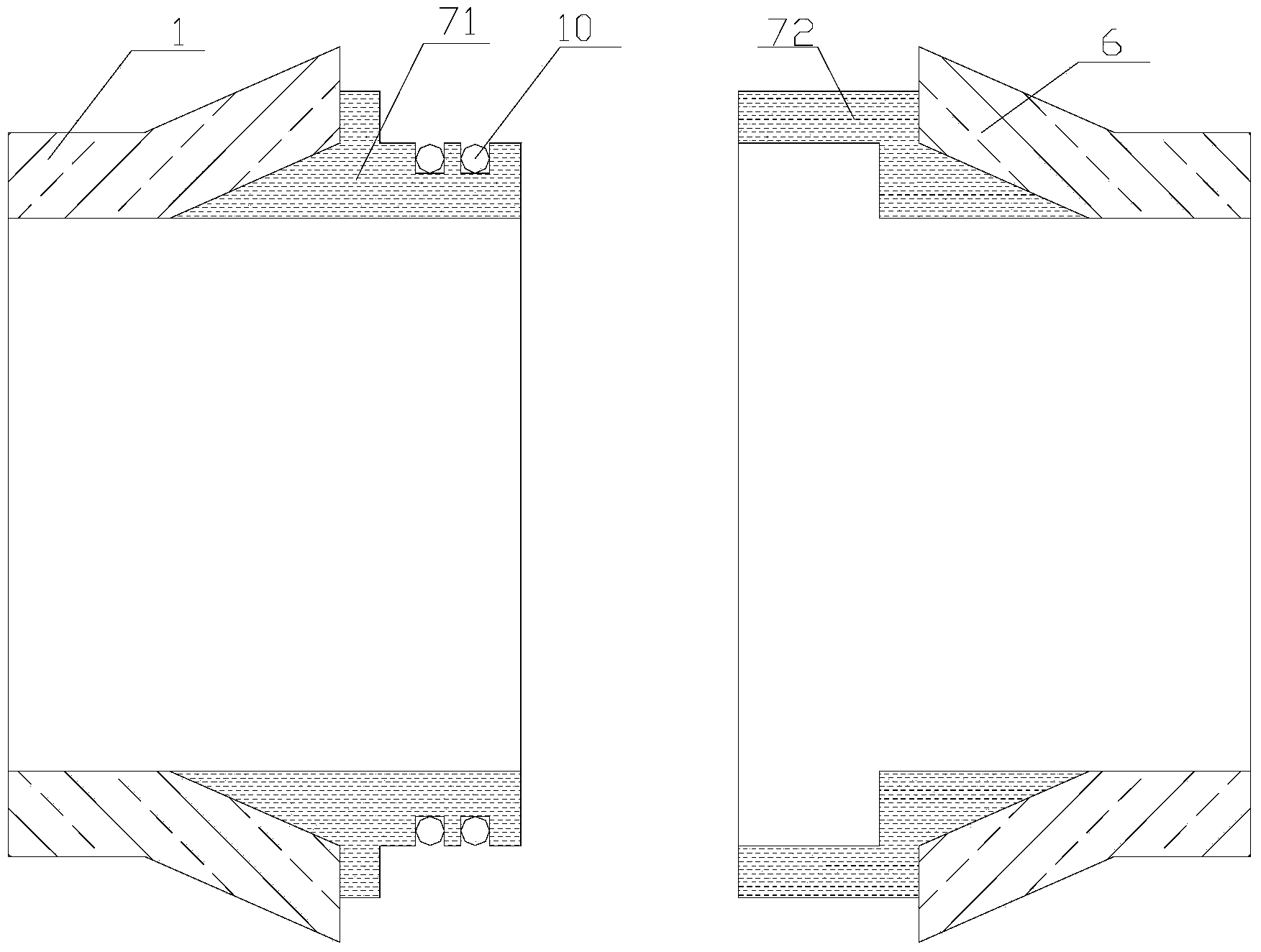

Tank formation manufacturing technology for storage batteries

ActiveCN103264154AIncrease the effective thicknessImprove welding qualityManufacturing technologyWater vapor

The invention discloses a tank formation manufacturing technology for storage batteries,relates to the field of lead-acid storage battery production and solves the problem of the poor welding quality between bus-bars and electrode tabs. The manufacturing technology comprises the technological processes of feeding of plate packs in an assembly box, electrode tab arrangement, cutting and brushing of electrode tabs, dipping of flux, cast-welding, inspection and discharging after qualification. The cast-welding process is performed through a cast-welding machine and comprises the following steps: 1) heating of a lead pan; 2) preheating of a lower die; 3) scrapping of molten lead; 4) electrode tab cast-welding; 5) water cooling; 6) water vapor mixing cooling; 7) gas cooling; 8) secondary preheating of the lower die; and 9) feeding of the electrode tabs in battery containers. The manufacturing technology is used for cast-welding of lead-acid storage battery grids.

Owner:CHAOWEI POWER CO LTD

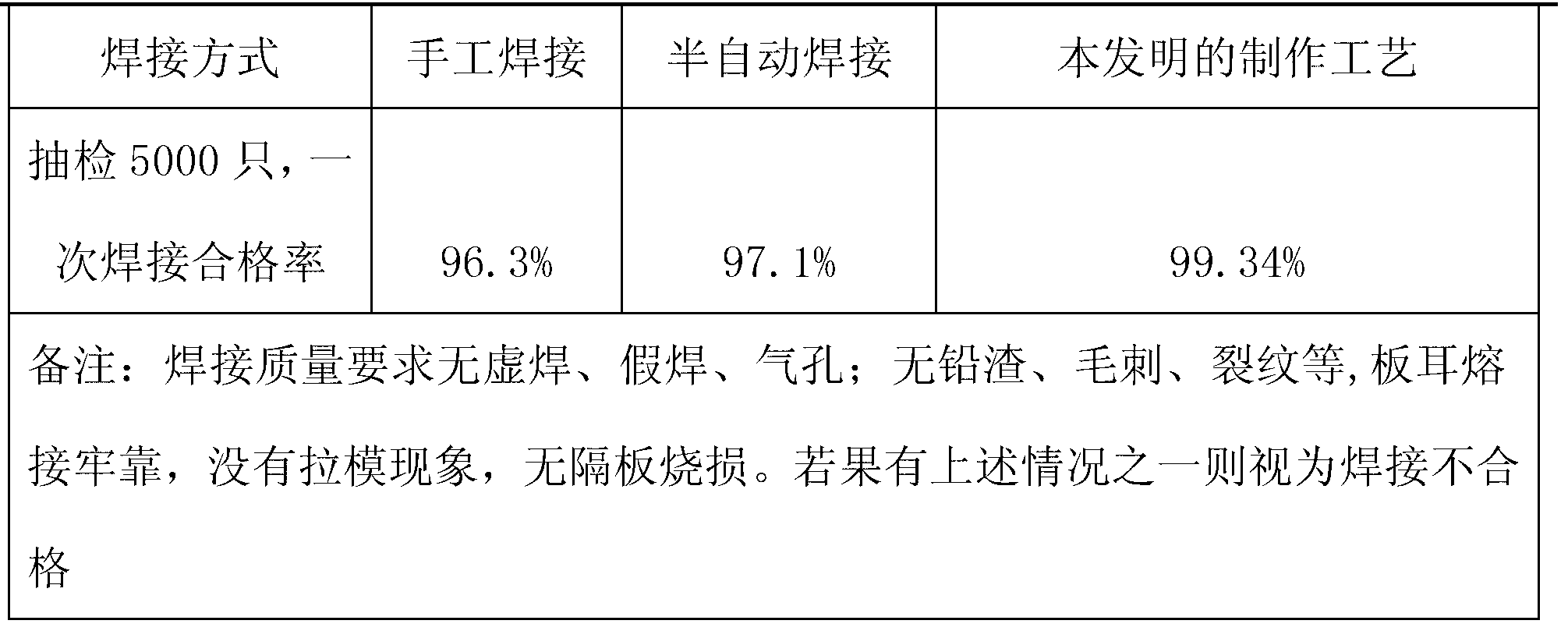

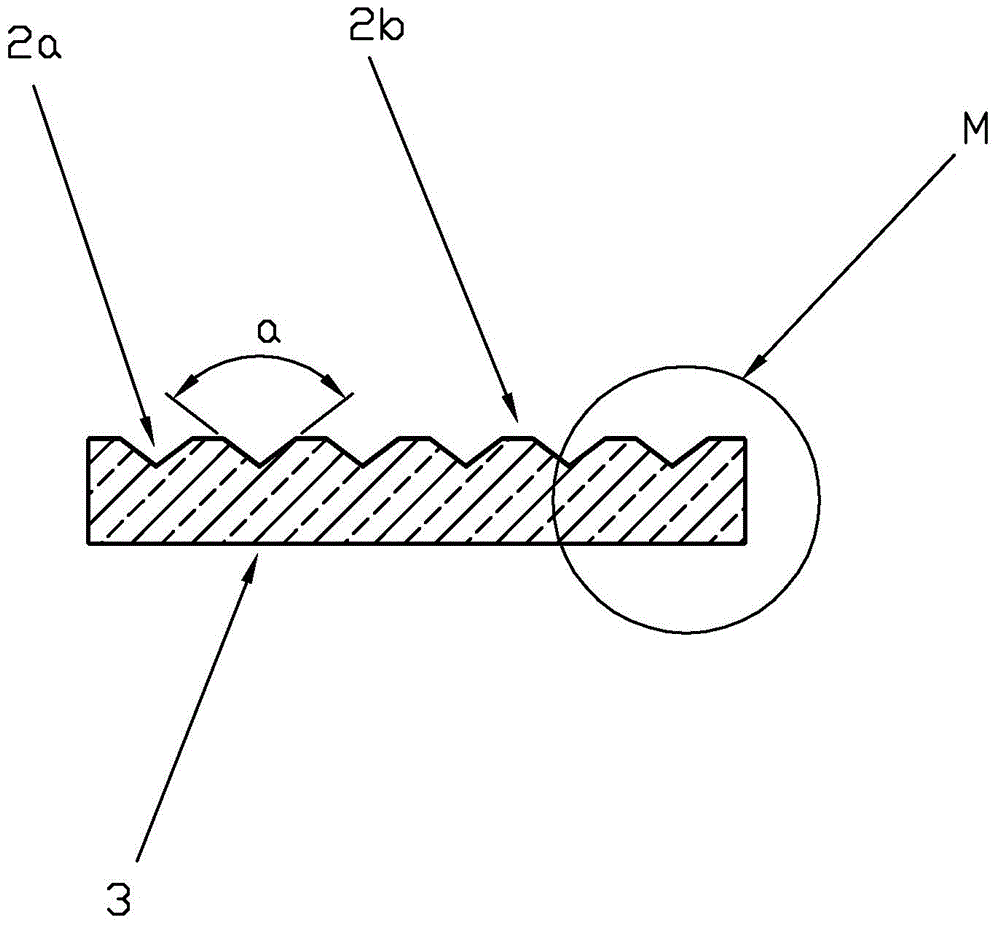

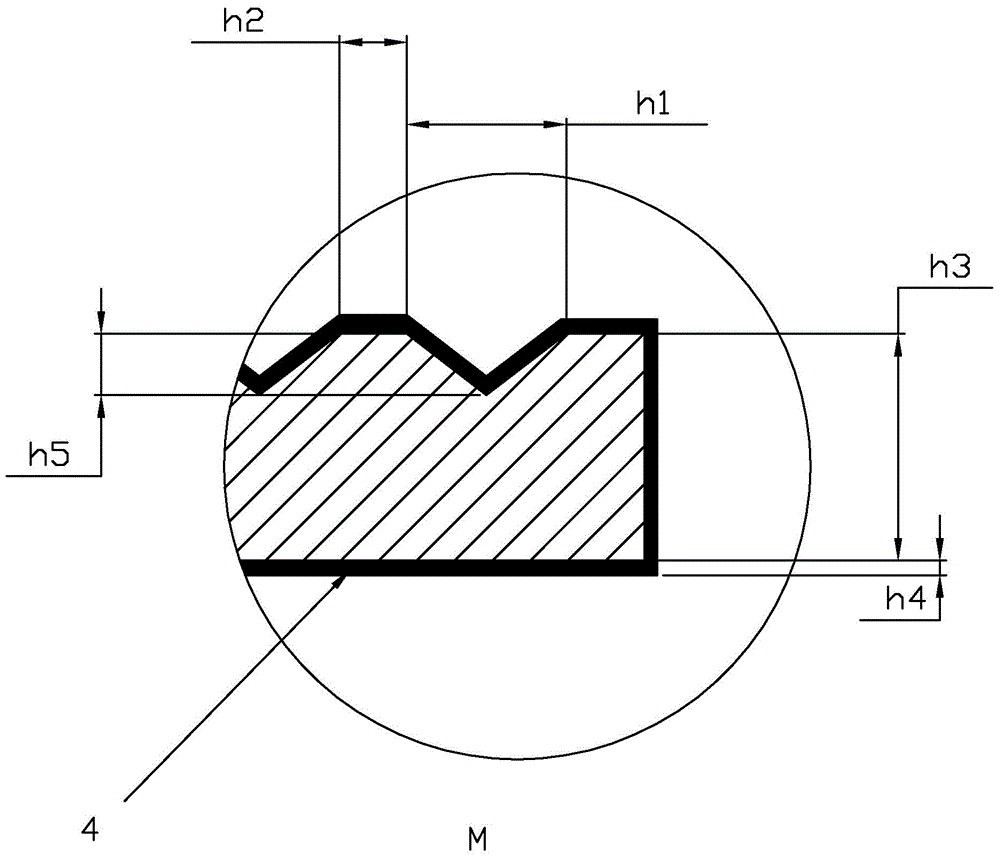

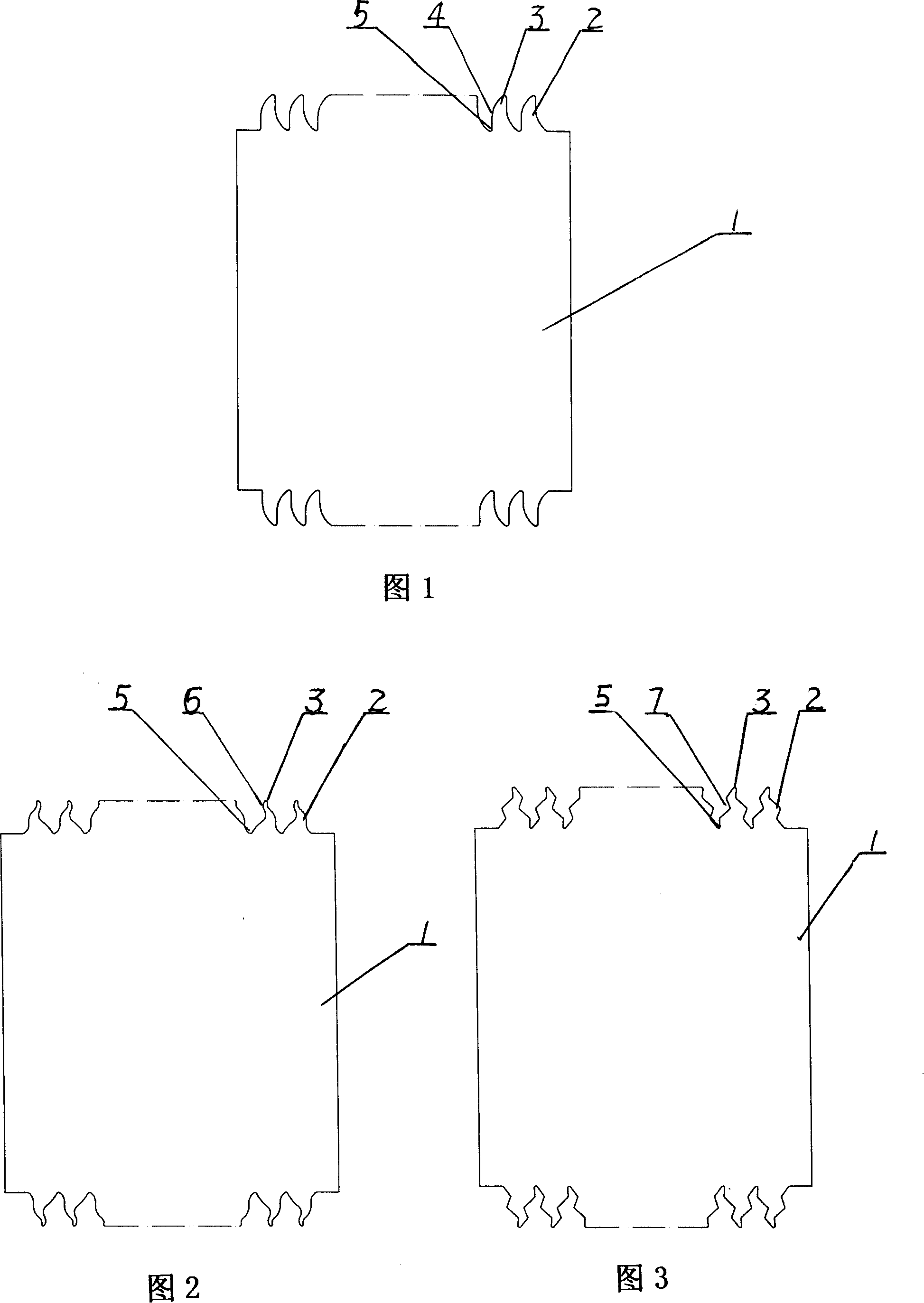

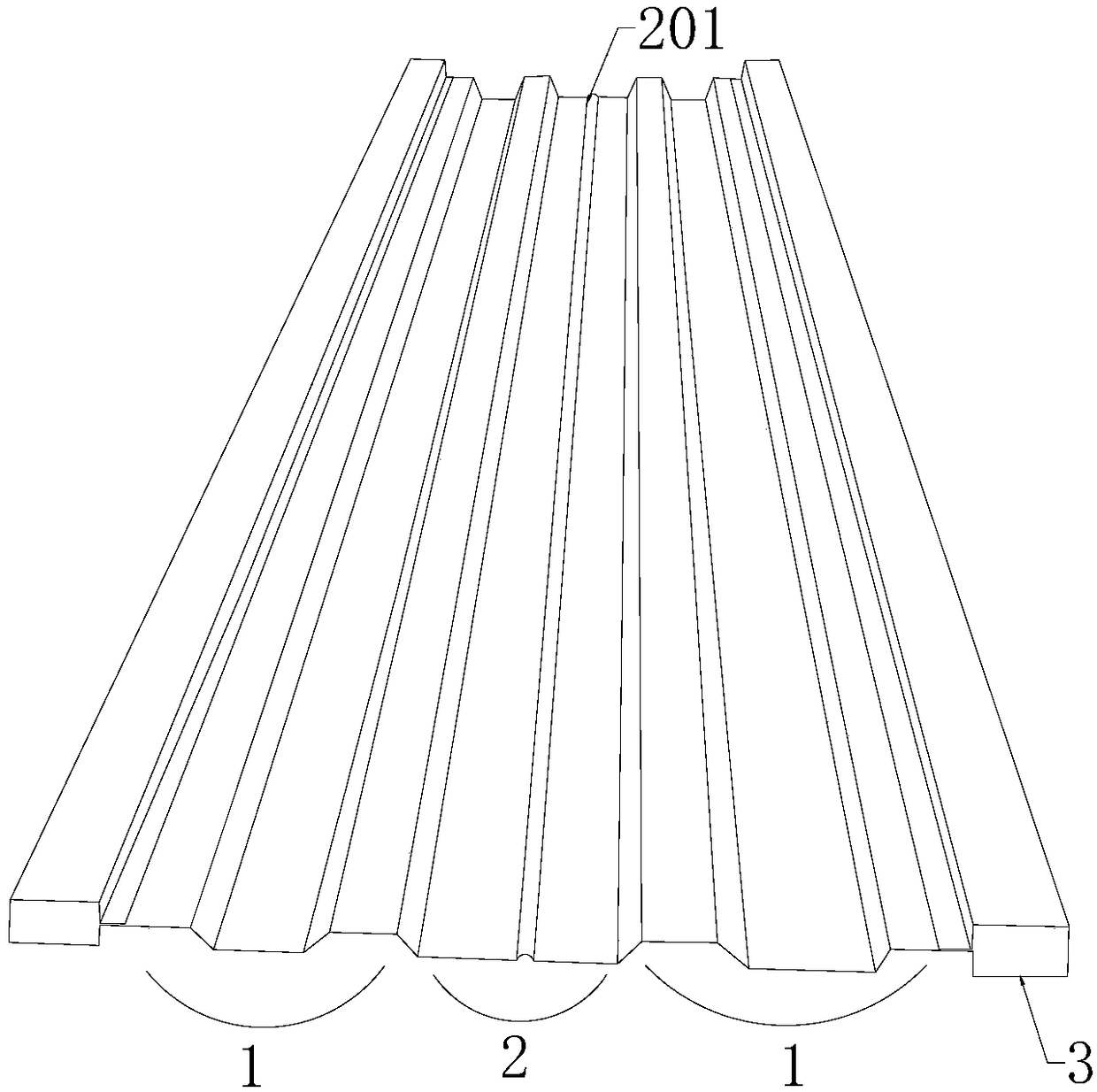

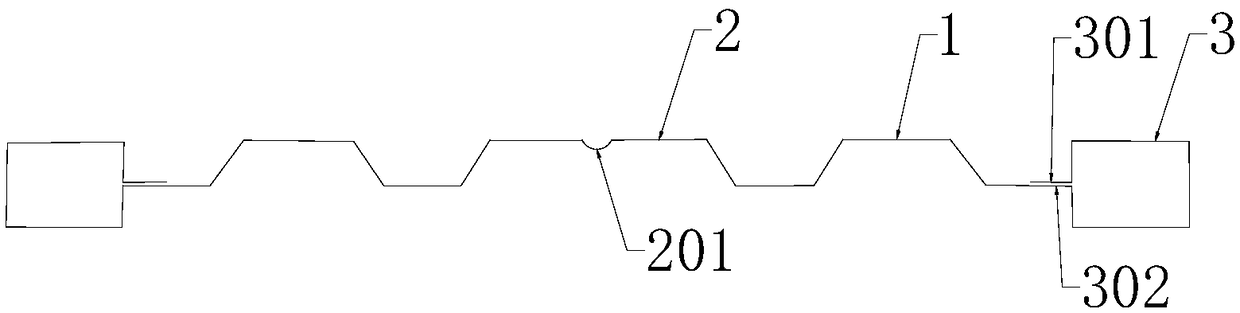

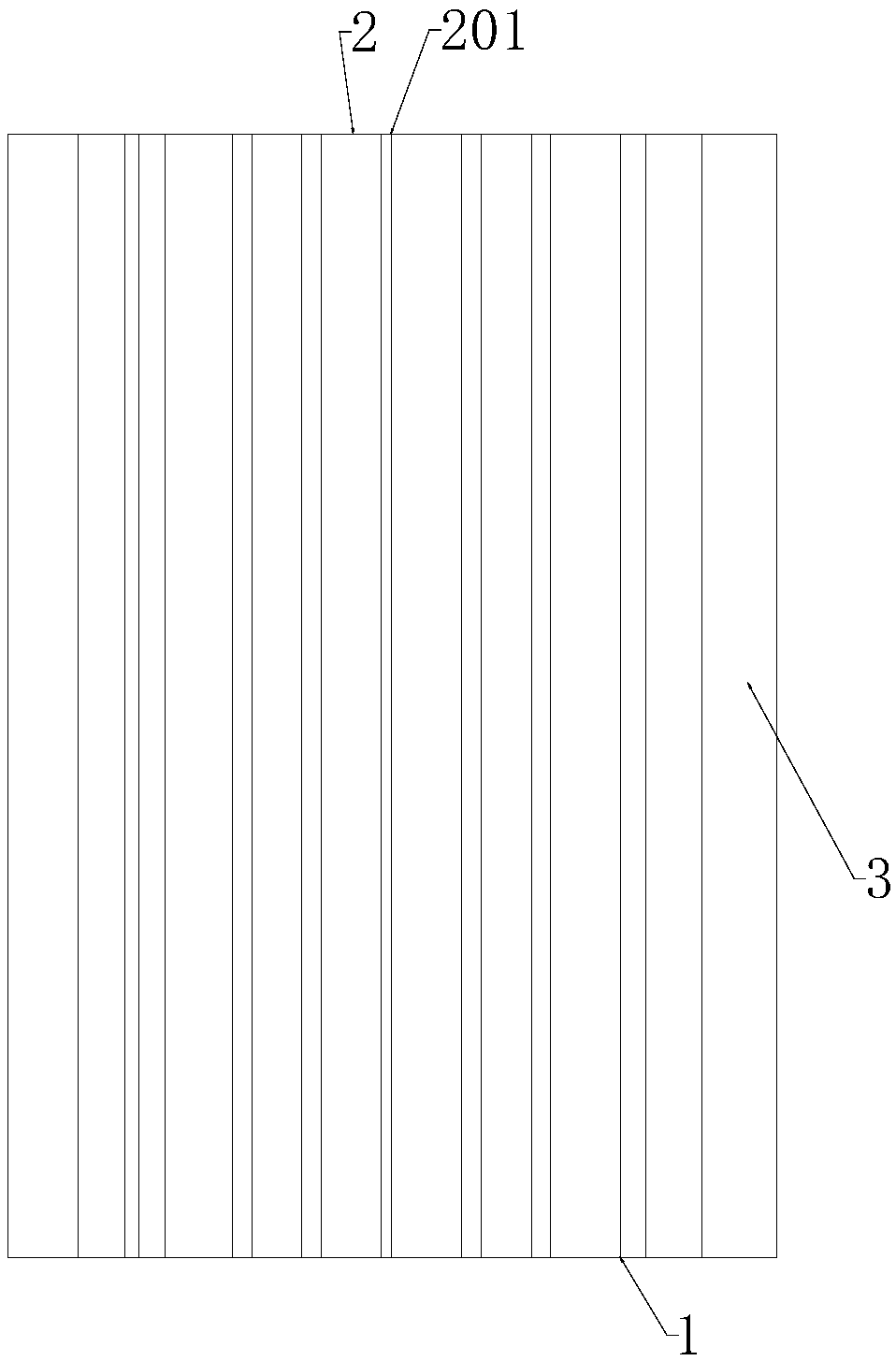

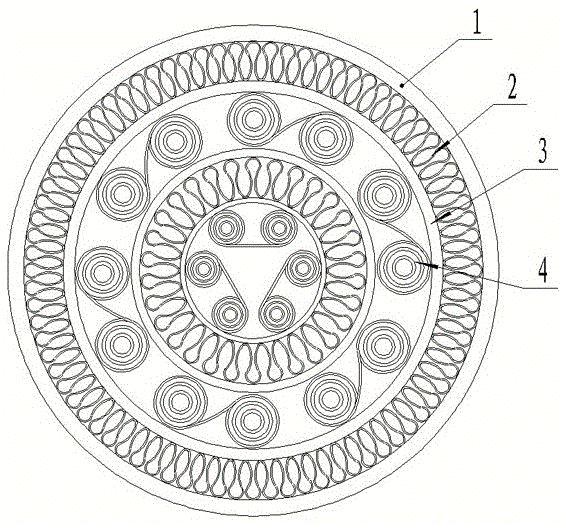

Embossed photovoltaic welding band and processing method thereof

ActiveCN104992999AGood flexibilityImprove tensile propertiesPhotovoltaic energy generationSemiconductor devicesCouplingEngineering

The invention discloses an embossed photovoltaic welding band and a processing method thereof. The embossed photovoltaic welding band includes a conducting base band having a lower adhering face and an upper reflecting face. The lower reflecting face is a flat face. Reflecting grooves are distributed in the upper reflecting face. Coupling bands are formed between the adjacent reflecting grooves. The embossed photovoltaic welding band is characterized in that the reflecting grooves extend in the length direction, being parallel to each other. The width of each coupling band is 0.2 to 0.4 times of the width of the top part of each reflecting groove. The thickness of the conducting base band is 0.5 to 1.0 mm. The depth of each reflecting groove is 0.1 to 0.2 mm. The invention also discloses a method for processing the above embossed photovoltaic welding band. By adopting the scheme, good incident light utilization rate can be achieved. Besides, good welding strength of the photovoltaic welding band and a back electrode of a crystalline silicon solar cell can be ensured.

Owner:WENLING XUSHENG OPTOELECTRONICS TECH

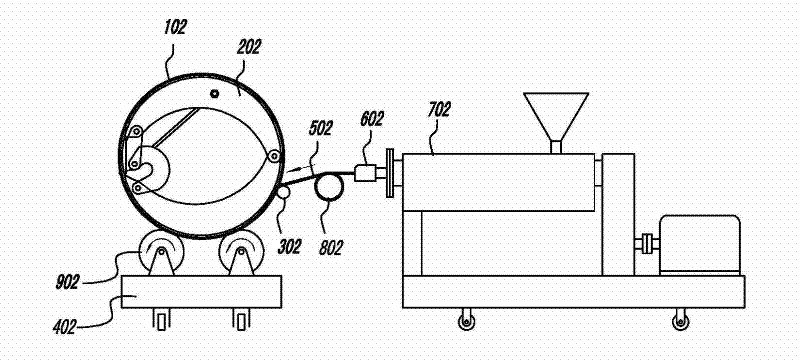

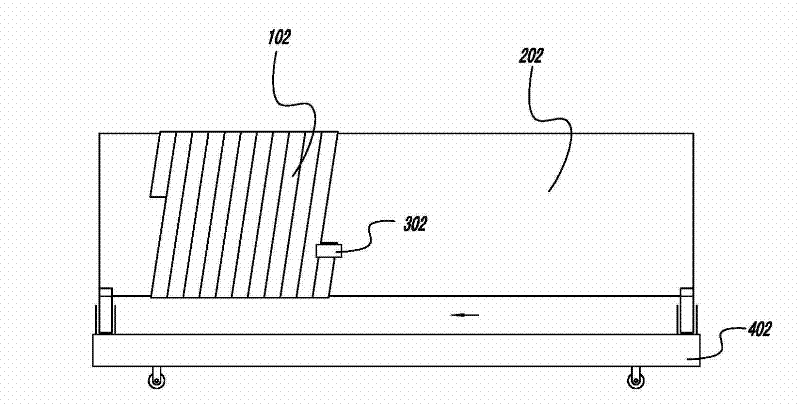

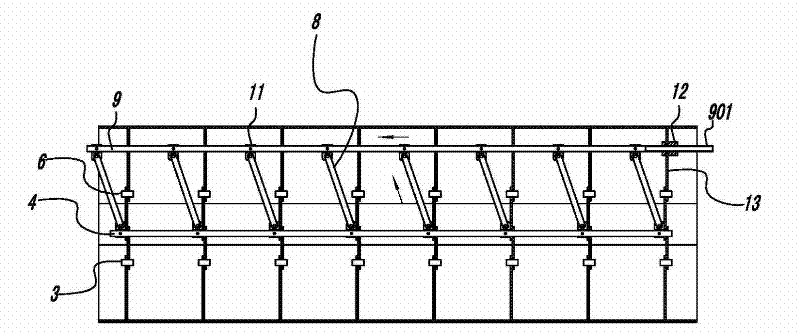

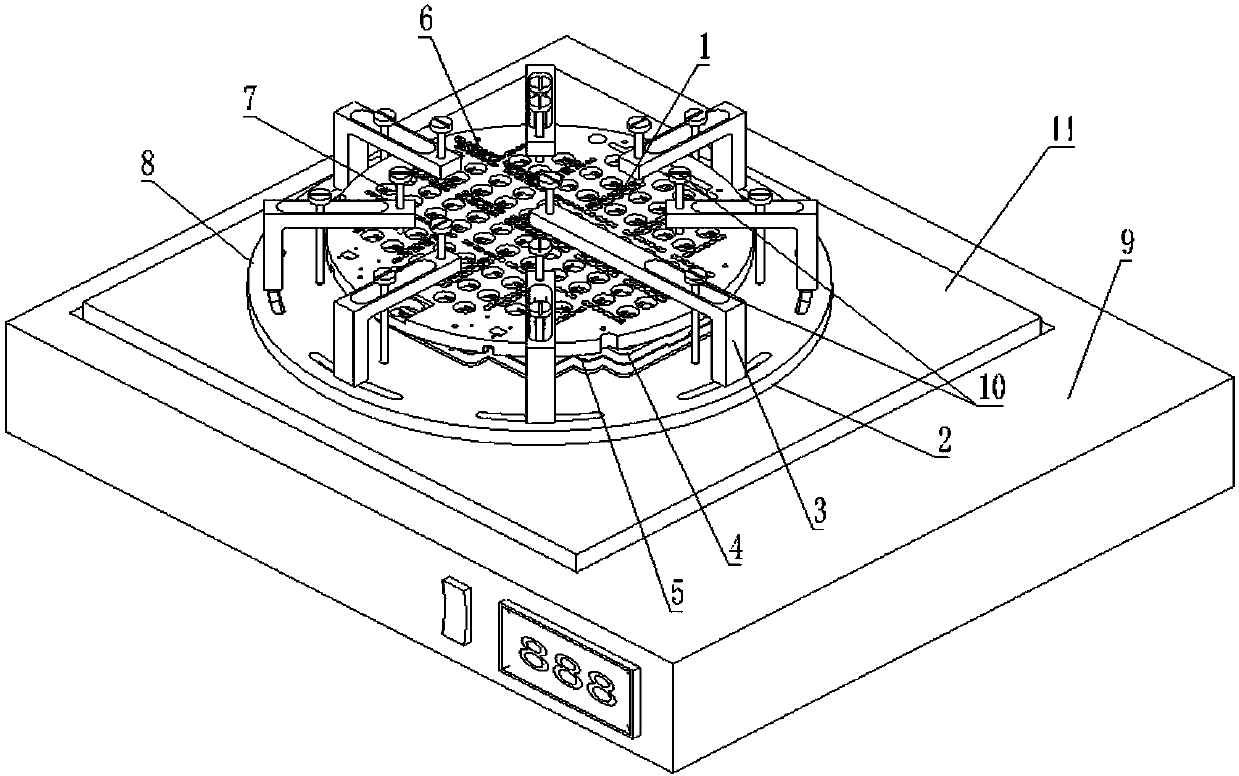

Seamless spiral winding and laminating molding process and equipment for plastic storage tank

The invention belongs to the technical field of drum body manufacturing of plastic equipment, and particularly relates to a seamless spiral winding and laminating molding process and equipment for a plastic storage tank. The molding process is implemented by the following steps of: (1) heating and extruding plastic resin by an extruder and a material belt forming mold to obtain plastic material belts; (2) extruding the plastic material belts to a mold; (3) simultaneously rotating and moving the mold to spirally wind the material belts on the mold; and (4) integrally melting the adjacent material belts under the action of a pressing roller. The molding equipment comprises a mold towing trolley (402), a drum body winding forming mold (202), the extruder (702), the material belt forming mold (602) and the pressing roller (302), wherein the pressing roller (302) is matched with the outer wall of the drum body winding forming mold (202); a support roller (902) is arranged on the mold towing trolley (402); and the drum body winding forming mold (202) is placed on the support roller (902). The molding process and equipment provided by the invention have the advantages of no seam, low raw material consumption, high finished product strength and ideal processing precision.

Owner:营口孚拉瑞斯塑料防腐设备有限公司

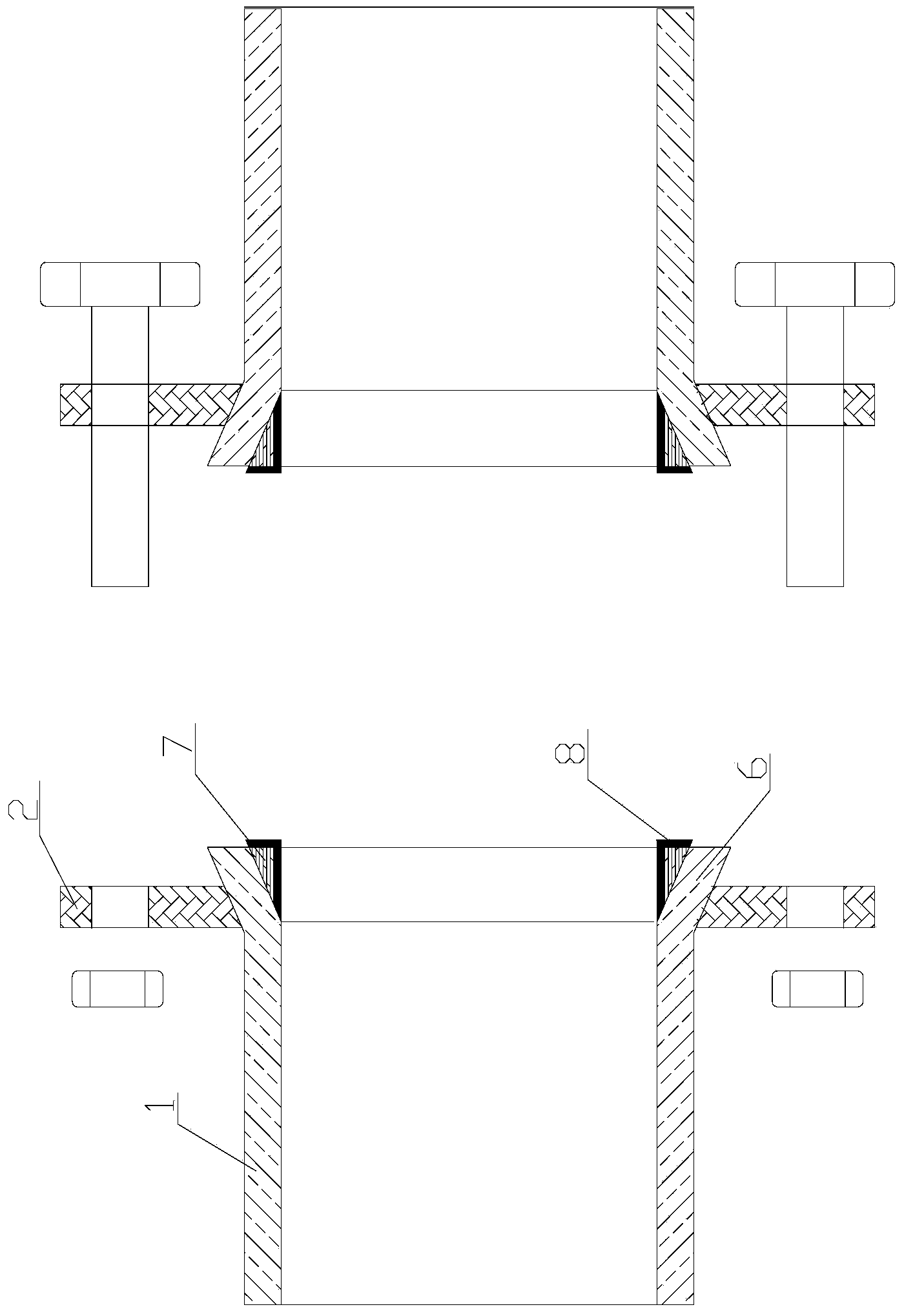

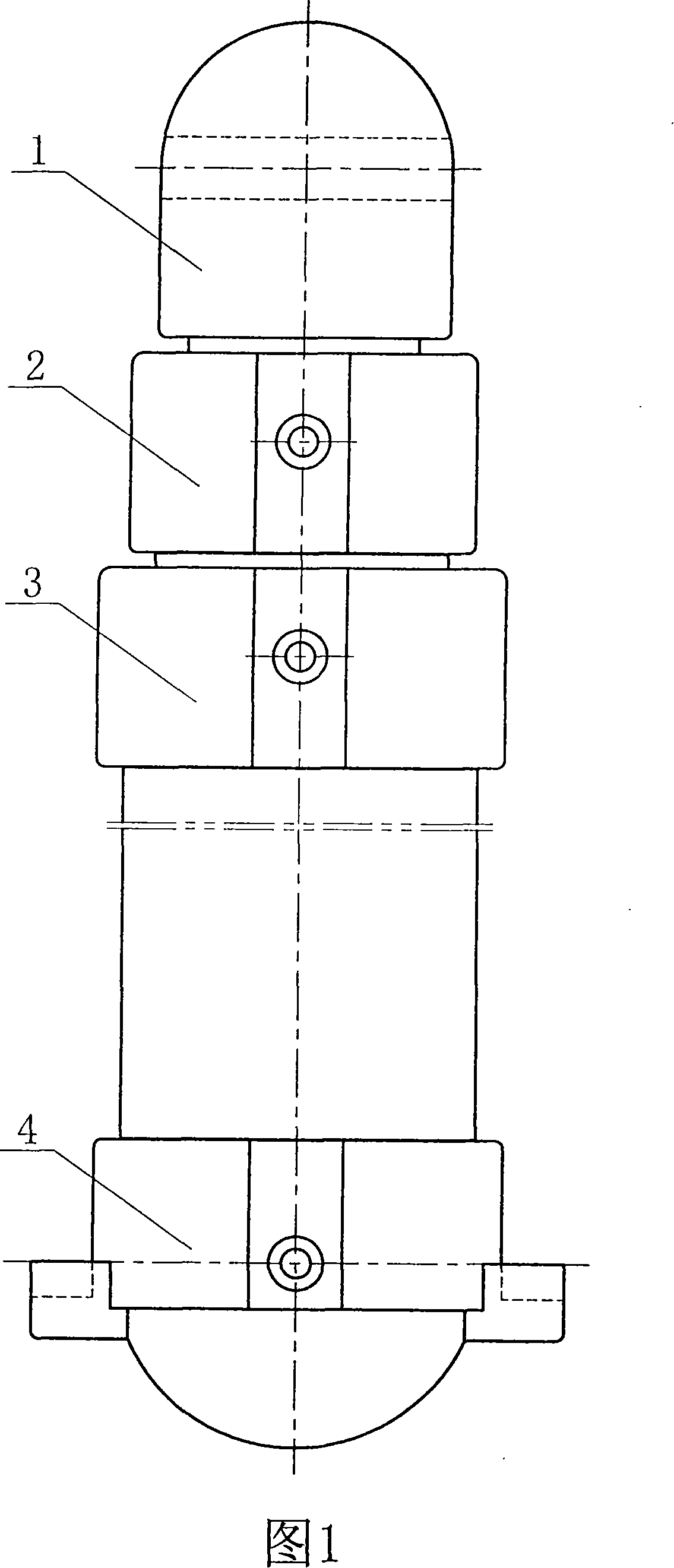

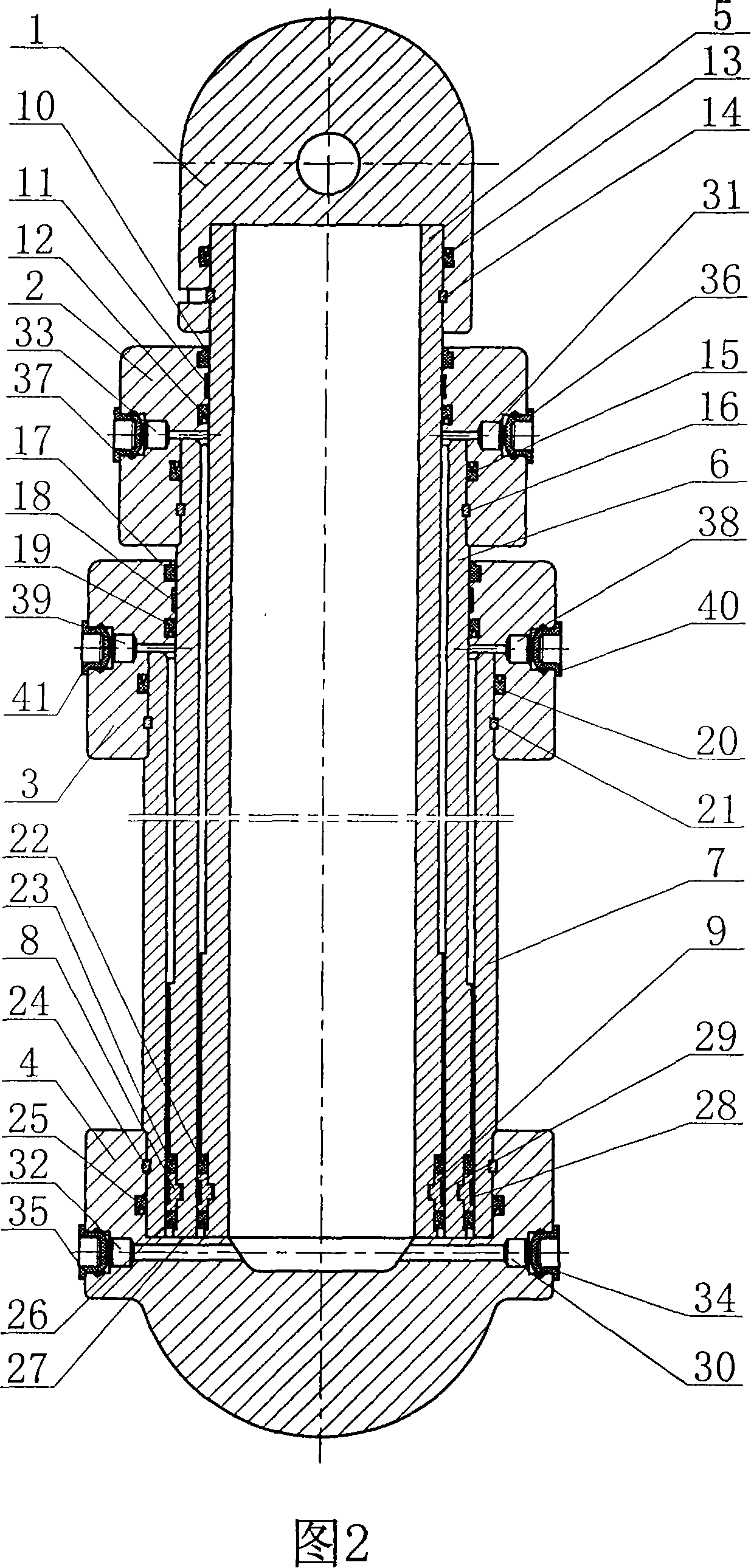

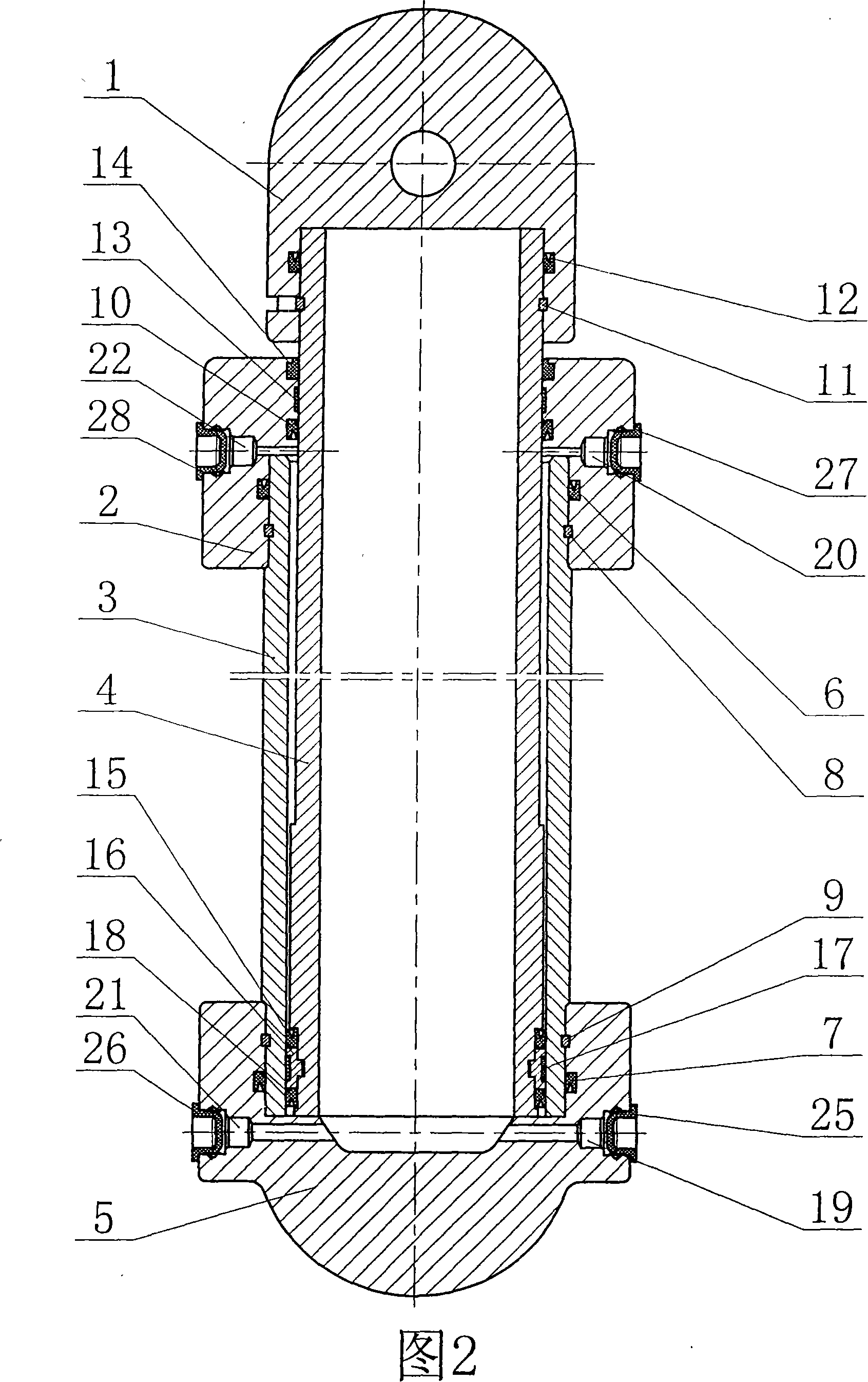

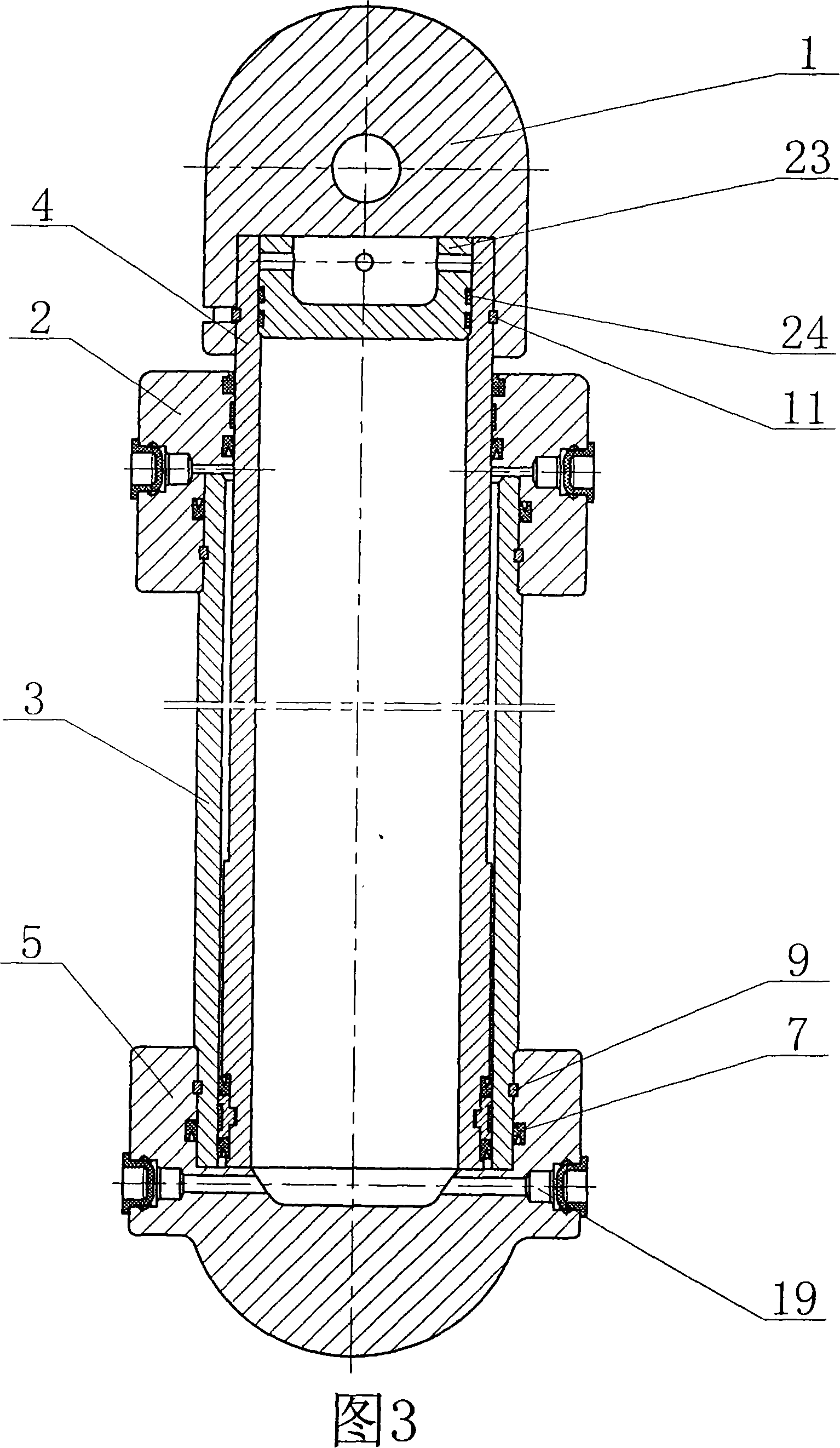

Double extension suspended type hydraulic vertical prop

A double-extension suspended type hydraulic upright column comprises an oil cylinder, a middle cylinder, a plunger, a top cover with an ear plate or hemispherical body at upper end thereof, a pedestal with an ear plate or hemispherical body at lower end thereof, a cylinder sleeve, a column sleeve, a clamping band, a guide ring and a sealing element, wherein the lower part of the plunger is provided inside the middle cylinder, the column sleeve is provided outside the plunger and at the outflow point at the upper end of the middle cylinder; the lower part of the middle cylinder is provided inside the oil cylinder, the cylinder sleeve is provided outside the middle cylinder and at the outflow point at the upper end of the oil cylinder; the clamping band and guide ring are provided outside the lower end of the plunger and middle cylinder, the top cover is provided on the plunger, the oil cylinder is provided in the pedestal, and a liquid inlet / outlet through-hole is provided on the pedestal and communicated with larger variable sealing cavity; a liquid inlet / outlet through-hole is provided on column sleeve and communicated with the middle cylinder; and a liquid inlet / outlet through-hole is provided on the cylinder sleeve and communicated with the oil cylinder. The invention has the advantages of compact and reasonable structure, no welding seam structure, good stability, high strength, large carrying capacity, large working stroke, light weight, good sealing performance, long service life, low cost, wide application range, and good practicability.

Owner:CHINA UNIV OF MINING & TECH

Novel LED panel lamp

ActiveCN103791357AWith replaceableImprove cooling effectPlanar light sourcesPoint-like light sourceEngineering

The invention discloses a novel LED panel lamp. The novel LED panel lamp comprises an outer plastic frame, an optical assembly, an LED luminous module, a rear cover and a power source; the outer plastic frame and the rear cover are matched to constitute a large cavity, and the optical assembly, the LED luminous module and the power source are all arranged inside the large cavity; the LED luminous module is composed of at least one LED luminous lamp strip, and each LED luminous lamp strip is arranged on the periphery of the optical assembly; the power source is electrically connected with the LED luminous module. The novel LED panel lamp has the advantages that the LED luminous lamp strips can be replaced, the heat dissipation effect is good, assembly and disassembly are easy, the flame retardant rating is improved, no weld joint is produced, production cost is lowered, the power source is arranged inside, and the novel LED panel lamp is beautiful.

Owner:林健洪

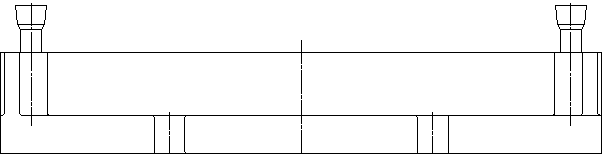

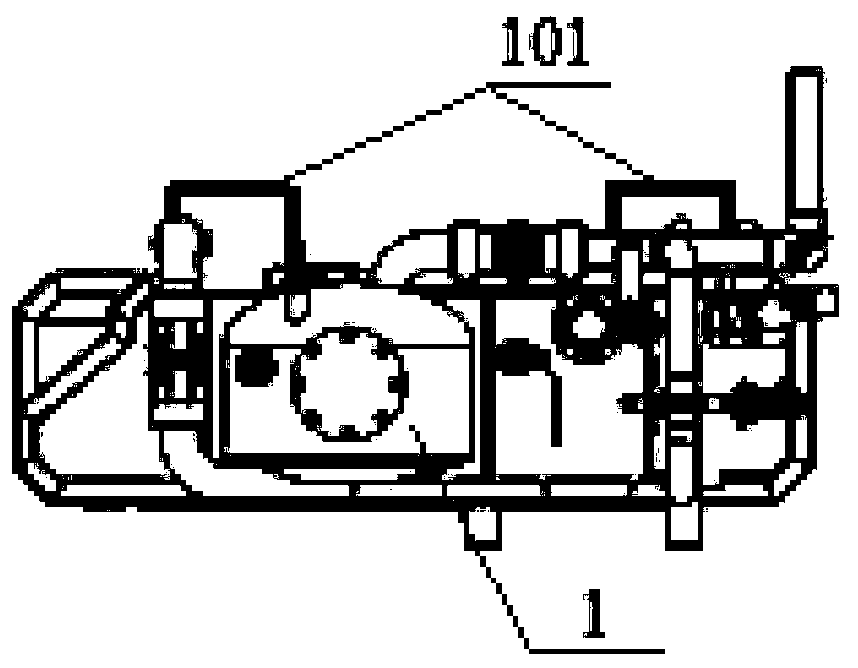

Rolling method of front crossbeam eleventh section of automobile variable thickness rear floor

ActiveCN109482643ANo weldImprove surface qualityMetal rolling stand detailsMeasuring devicesVariable thicknessEnergy absorption

The invention relates to a rolling method of a front crossbeam eleventh section of an automobile variable thickness rear floor. The rolling method comprises the following steps that an aluminum-coatedsilicon material is selected as the raw material for a front crossbeam of the automobile rear floor, rolling is carried out by a steel plate rolling method, the rolling speed in the controlled rolling process is 4-10m / min, the rolling force is 1000-4500kN, a roll gap is 0.7-2.2 mm, the roller spacing is controlled and adjusted in real time, and a plate changing continuously in the rolling direction according to the customized thickness is obtained. Compared with the prior art, the rolling method of the front crossbeam eleventh section of the automobile variable thickness rear floor has the following beneficial effects that 1, the variable thickness plate has no weld joint, and the surface quality is good; 2, a transition area is used instead of a welding joint, and the connection strengthis greatly improved; 3, continuous production is achieved, the production efficiency is high, and the thickness combination is flexible; 4, connection of the transition area is smooth, and the designof a stamping die is simple; and 5, the transition area has a good energy absorption effect and better impact resistance performance.

Owner:上海宝钢新材料技术有限公司

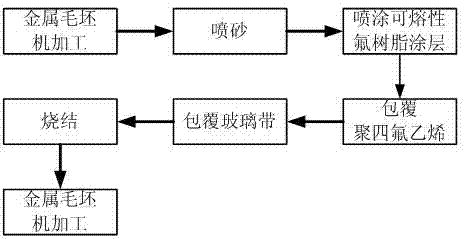

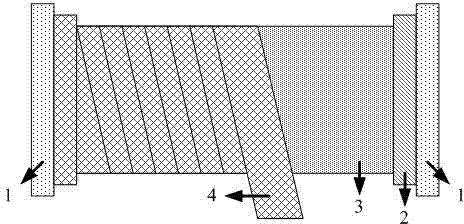

Preparation method for metal-based polytetrafluoroethylene bearing

The invention relates to a preparation method for a metal-based polytetrafluoroethylene bearing. The method comprises the following steps of: (1) machining a metal blank; (2) performing sand blasting; (3) spray-coating a meltable fluororesin coating; (4) covering a polytetrafluoroethylene film; (5) covering a glass tape; (6) sintering; and (7) machining a finished product. By adopting the method,since the meltable fluororesin coating is additionally arranged between the polytetrafluoroethylene layer and metal, stripping strength between the polytetrafluoroethylene layer and metal is increased; the polytetrafluoroethylene layer and metal layer are compounded together through high temperature; a formula of polytetrafluoroethylene is not limited and can be adjusted with high flexibility according to actual requirements; the type of the metal adopted by the bearing can be expanded, namely the metal can be a tough metal material, and can also be a friable metal material; and finally, the prepared metal-based polytetrafluoroethylene bearing does not have a weld joint or a connection point, the dimensional accuracy can be accurately controlled, and the high-accuracy requirements of aerospace and military machinery on dimension are met.

Owner:SHANGHAI PLASTICS RES INST CO LTD

Bottom ring for submerged arc furnace and manufacturing method thereof

InactiveCN102997687APouring evenlySmooth solidification processFoundry mouldsFoundry coresVacuum pumpingWater leakage

The invention relates to a bottom ring for a submerged arc furnace and a manufacturing method thereof. The bottom ring comprises a bottom ring body with a cavity structure, wherein the bottom ring body is provided with a water inlet and a water outlet. The bottom ring is characterized in that the bottom ring body is cast by adopting an integral casting method; the upper ends of the water inlet and the water outlet are additionally provided with extending segments; the extending segments and the bottom ring body are made of same materials, and joint parts are in threaded connection. The bottom ring for the submerged arc furnace, which is disclosed by the invention, is cast into an integral structure by adopting an integral casting process without welding seams or water leakage and does not need to be maintained, thereby prolonging the service life, reducing the production cost and achieving the safety guarantee; and when the bottom ring is manufactured, the water inlet and the water outlet are utilized as a clearance hole and an air hole, no process hole is additionally arranged, a cavity is formed by adopting a sand core which is easy to disperse, and a gas generated in the sand core during pouring is discharged through the water inlet and the water outlet by utilizing a vacuum pumping method so that liquid metal can be stably operated in the pouring and solidifying process, therefore the quality of a product is ensured.

Owner:姚会元

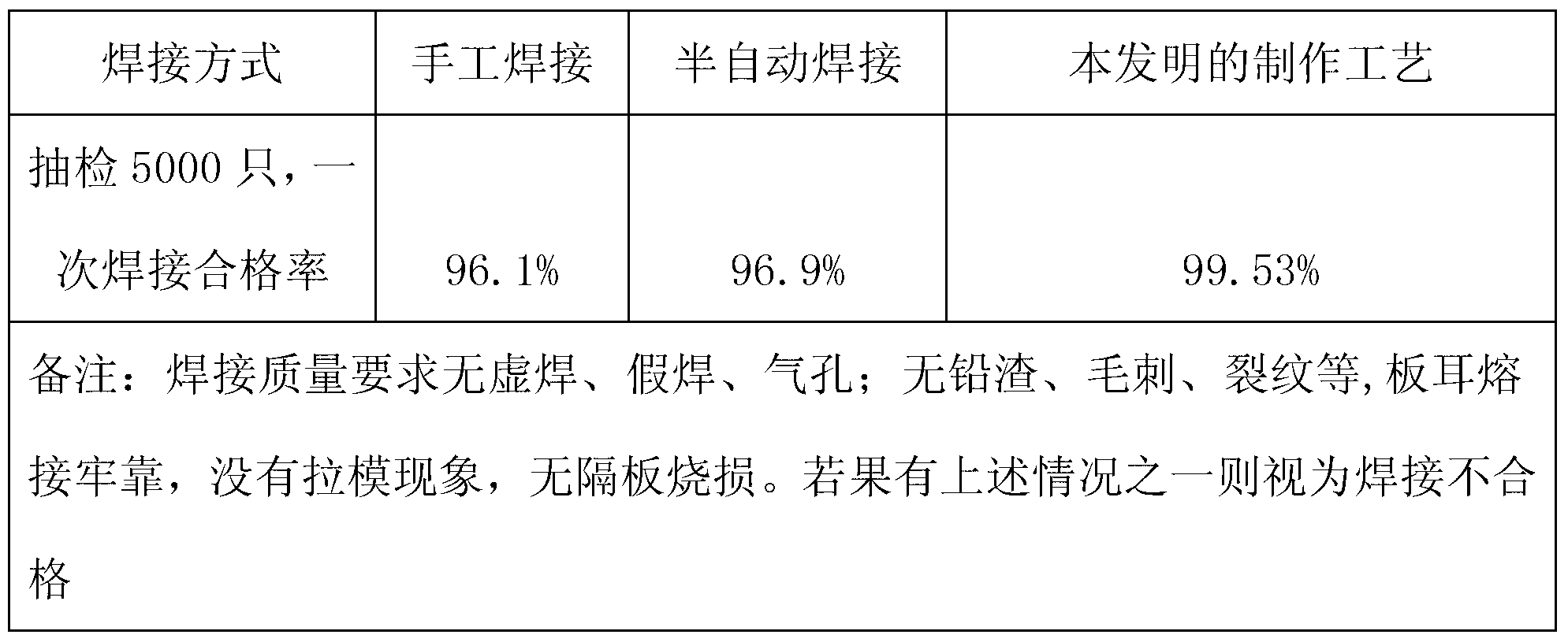

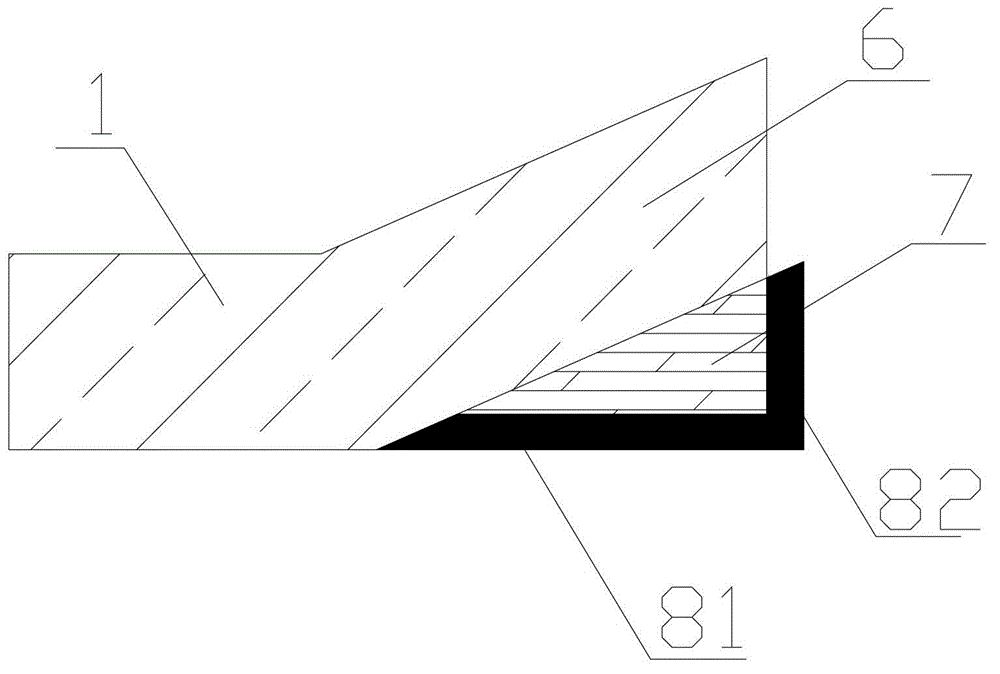

Large displacement corrugated pipe

InactiveCN101113797ALarge displacementSimple preparation processFlexible pipesEngineeringCircular surface

A large displacement corrugated pipe relates to a modified corrugated pipe structure. The invention provides a large displacement corrugated pipe with the advantages of a shaping corrugated pipe and a welding corrugated pipe. The invention comprises a corrugated pipe, the structure key points of which is that: the outside of the corrugated pipe is provided with a circular surface with the same shape and arranged in the same direction, and the top end and the bottom end of the circular are all connected by a round angle.

Owner:沈阳东韩波纹管有限公司

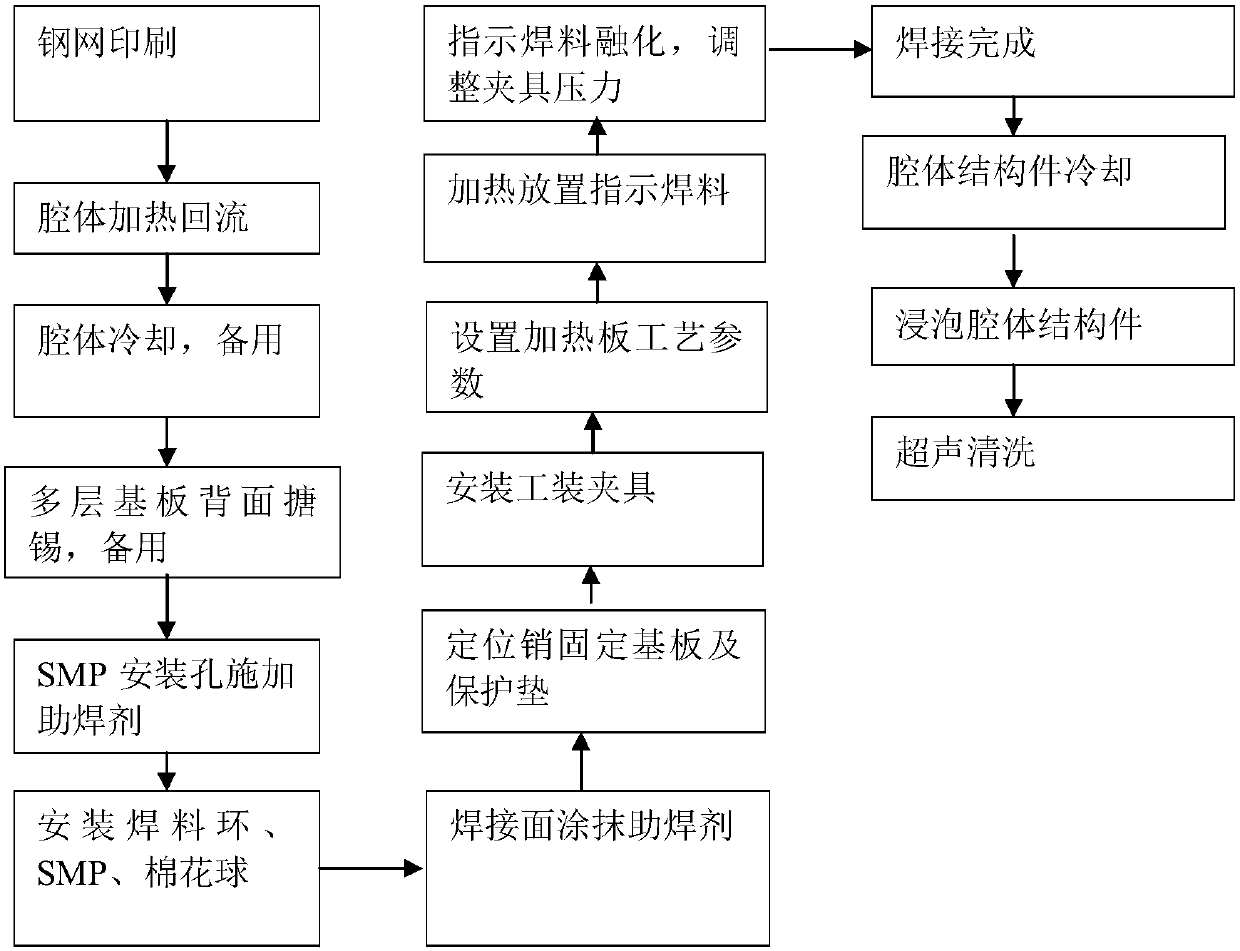

Welding method of multilayer copper-clad substrate of phased array active antenna array

ActiveCN107745166AGood welding performancePromote infiltrationWelding/cutting auxillary devicesAuxillary welding devicesRefluxEngineering

The present invention provides a welding method of a multilayer copper-clad substrate of a phased array active antenna array, and aims at providing a welding method capable of effectively preventing unstable welding quality of the multilayer copper-clad substrate. The welding method is implemented by the following technical scheme that a tool having the same shape with the multilayer copper-clad substrate and L-shaped clamps, an circular array of which is distributed on a tool pedestal, are prepared; steel mesh printing solder is applied to a front surface welding area of a cavity structural member and disposed on a reflux heating plate of a heater; the tool having the same shape with the multilayer copper-clad substrate and L-shaped clamps, the circular array of which is distributed on the tool pedestal, are prepared; the surface of the multilayer copper-clad substrate equipped with an SMP solder side is upward, the multilayer copper-clad substrate is fixed on a projection surface ofthe tool pedestal, solder rings and SMP radio frequency connectors are disposed in SMP installing holes in the reverse side of the cavity structural member, and soldering flux is applied; the back side of the multilayer copper-clad substrate is tinned, and the multilayer copper-clad substrate is fixed on the solder side of the cavity structural member coated with the soldering flux through pins and disposed on the reflux heating plate of the heater; and front surface welding of the multilayer copper-clad substrate and the cavity structural member is performed by hot reflux, and cavity back surface welding of the SMP radio frequency connectors to the cavity structural member is performed.

Owner:10TH RES INST OF CETC

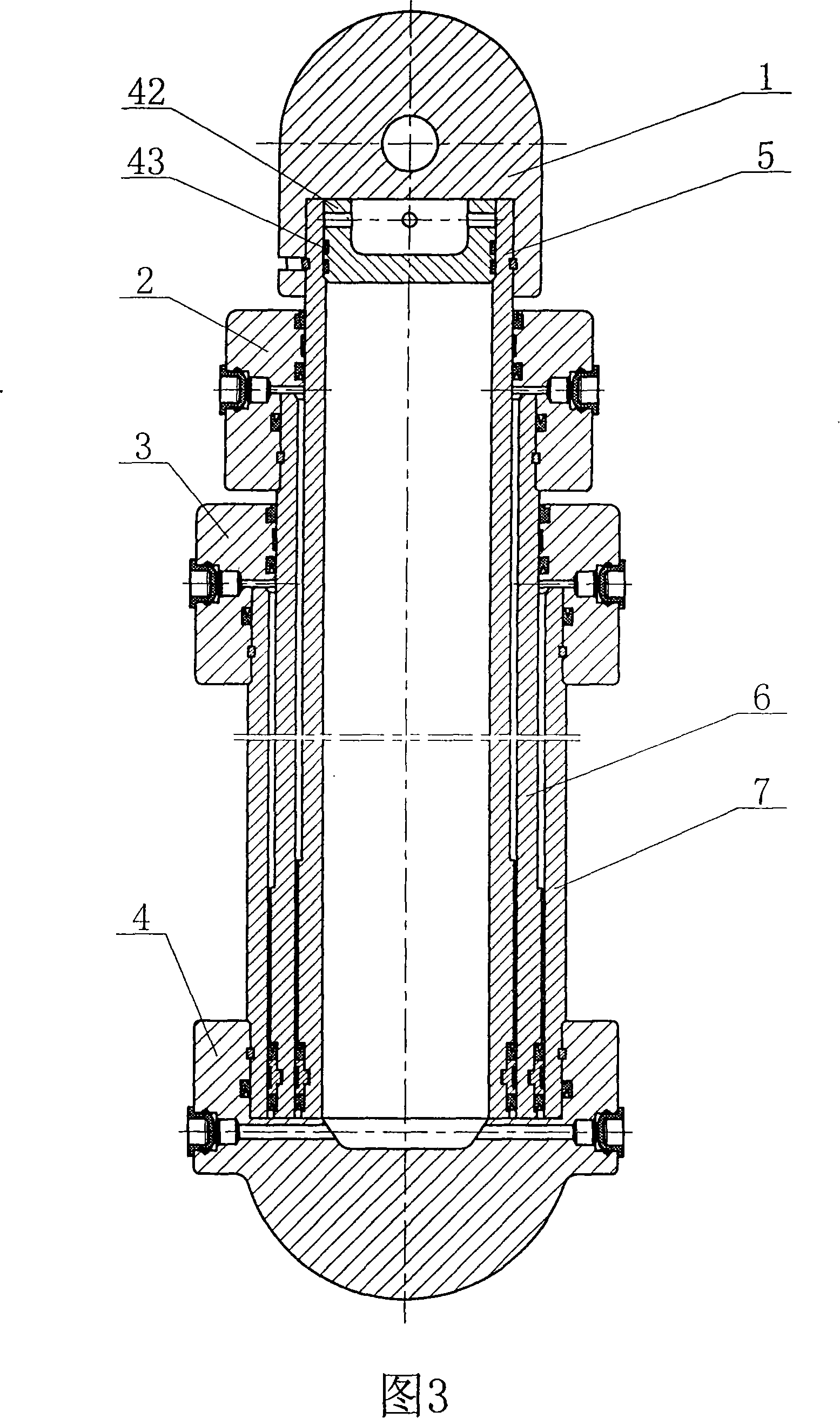

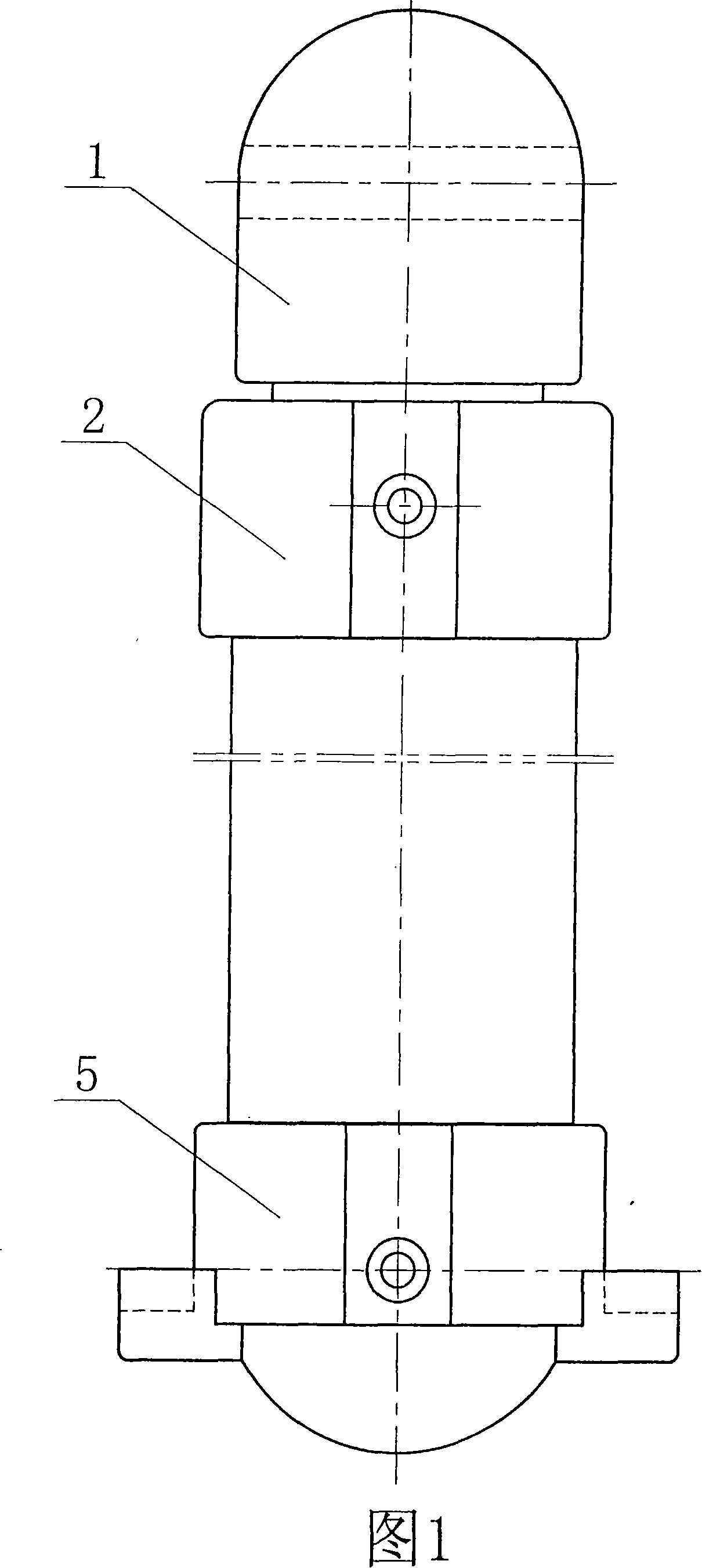

Single extension suspended type hydraulic vertical prop

A single-extension suspended type hydraulic upright column comprises a top cover with an ear plate or hemispherical body at upper end thereof, a cylinder sleeve, an oil cylinder, a plunger, a pedestal with an ear plate or hemispherical body at lower end thereof, a guide ring and a sealing element, wherein the top cover with an ear plate or hemispherical body at upper end thereof is provided on the plunger, the oil cylinder is provided inside the pedestal with an ear plate or hemispherical body at upper end thereof, and the lower part of the plunger is sheathed inside the oil cylinder; the cylinder sleeve is provided between the outer side of the plunger and the end of the oil cylinder; a liquid inlet / outlet through-hole is provided on the pedestal with an ear plate or hemispherical body at upper end thereof and communicated with larger variable sealing cavity, and an oil seal is provided on the liquid inlet / outlet through-hole; a liquid inlet / outlet through-hole is provided on cylinder sleeve and communicated with smaller variable sealing cavity, and an oil seal is provided on the liquid inlet / outlet through-hole. The invention is suitable for the hydraulic support of downhole integrated coal mining mechanical working face in coal mine; and has the advantages of compact and reasonable structure, no welding seam structure, good stability, high strength, large carrying capacity, large working stroke, light weight, good sealing performance, long service life, and low cost.

Owner:CHINA UNIV OF MINING & TECH

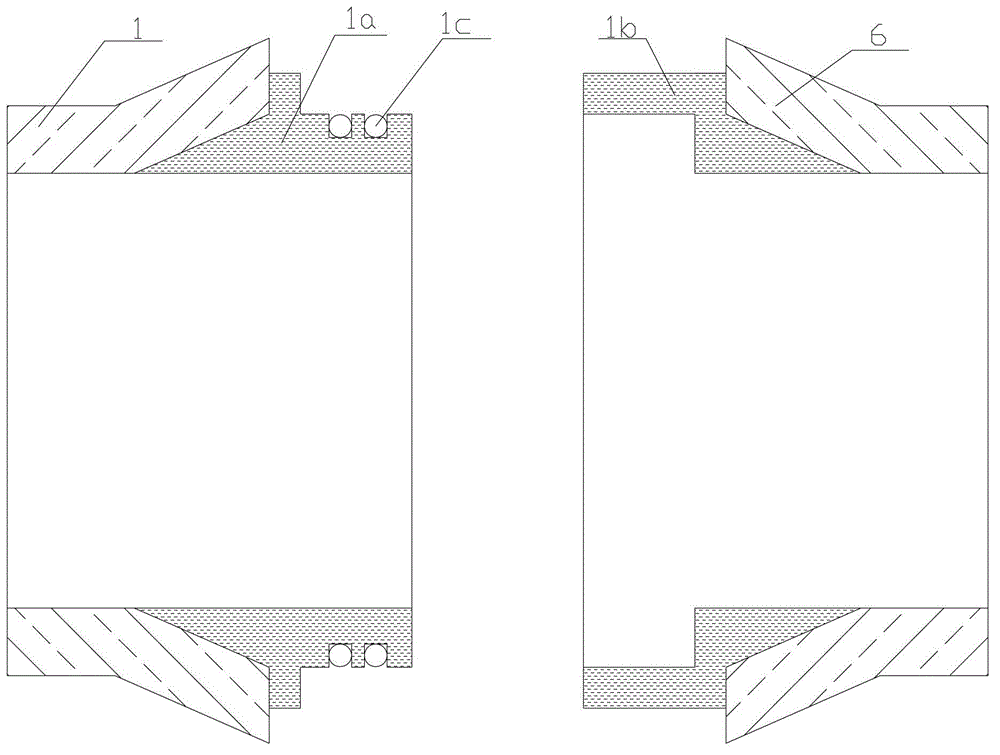

New integrated compartment board and production process

PendingCN108974145AHigh strengthNot easy to enter waterLoading-carrying vehicle superstructuresWeld seamAgricultural engineering

The invention provides a novel integrated compartment board and a production process thereof, which relates to the technical field of car panels, and solves the technical problems of easy water inflowcracking and low strength at the welding seam of the compartment board produced by the split production method. The device comprises a flat plate part and a corrugated part, wherein the corrugated part is arranged on either side or both sides of the flat plate part, and the corrugated part and the flat plate part are integrally formed; The invention also discloses a manufacturing process for producing the integrated box plate, wherein the special-shaped wheels of more than 30 groups are used to perform rolling in a small amount for many times; The rectangular folded edge and the integrally formed structure of the invention can ensure that the strength of the whole compartment plate is greatly increased; And the whole box plate has no welding seam, and the whole box plate is not easy to befilled with water, so that the service life of the box plate is enhanced; 30 or more group of rollers are arranged in that production process, and the angle of the rollers is adjusted for many time to press and deform, so that the cold-rolled sheet is not easy to break in production, and the box plate is seamless and integrally formed.

Owner:陈克山

Seamless joint provided with rubber lined layers

InactiveCN104100793ASimple structureFirmly connectedCorrosion preventionPipe protection against corrosion/incrustationEngineeringMetal

The invention provides a seamless joint provided with rubber lined layers used for solving the problems of no corrosion resistance and low sealing property of the seamless joint provided with metal lining rings with son ports and mother ports in the prior art, and simplifying the structure and a production process. The seamless joint comprises a pipeline body, movable flanges, fixed bolts, screw caps and metal lining rings, wherein horn mouths are arranged on two ends of the pipeline body; the movable flanges are arranged on the outer wall of the pipeline body; the inner diameter of the movable flanges is smaller than the diameter of the horn mouths; each metal lining ring is arranged on the inner side of the corresponding horn mouth, and the outer wall of each metal lining ring is matched with the inner wall of the corresponding horn mouth; the rubber lined layers are arranged on the inner wall and the front end face of each metal lining ring; the front end faces of the metal lining rings and the front end faces of the horn mouths are positioned on one plane, the rubber lined layers on the front end faces of the metal lining rings protrude the metal lining rings; the inner diameter of the metal lining rings is greater than the inner diameter of the pipeline body; the inner diameter of the rubber lined layers on the inner walls of the metal lining rings is equal to the inner diameter of the pipeline body.

Owner:荣京柯

Tin-lead solder for brazing copper radiator

InactiveCN103722301ALower melting temperatureGood wetting and spreading propertiesWelding/cutting media/materialsSoldering mediaWeld seamMelt temperature

The invention relates to a brazing solder, in particular to a tin-lead solder for brazing a copper radiator. The tin-lead solder comprises Sn, Pb and microelements. The tin-lead solder is low in melting temperature, good in mechanical property and not high in price, and has good wettability and spreading performance; the brazed copper radiator is good in stability, high in welding efficiency, reliable in quality, thin and firm in weld seam, free of pseudo soldering and solder accumulation, good in performance and good in cost performance, and residues produced after welding can be easily cleaned away.

Owner:QINGDAO SHENGJIA INFORMATION TECH

Production method of sun drum silver ornament

InactiveCN105620155APrevent oxidationEvenly distributedDecorative surface effectsOrnamental structuresEngineeringSoldering

The invention discloses a production method of a sun drum silver ornament, belongs to a production method of a silver ornament, and aims to provide a silver ornament production method with convenient and simple production, high efficiency and delicate and beautiful ornament patterns. The production method comprises the steps of weaving of patterns by using silver wires, combination and welding of the patterns to form hollowed drum surfaces, and welding of the drum surfaces with a drum body to form a drum shape; the silver wires include fine round wires, square wires, twisted wires and flat wires; one of the silver wires is selected to wind a drum ring; one or several silver wires are selected to wind decoration rings with different diameters, lace rings with different diameters and decoration patterns; all parts are dip in borax water; the drum ring and all the decoration rings are taken out and arranged in a concentric circle manner; all the lace rings and all the decoration patterns are arranged between the drum ring and the decoration rings or between the adjacent decoration rings; silver welding powder is spread in the connecting places of all the parts for gas welding to obtain the drum surfaces; and the two drum surfaces are welded at two ends of the drum body. The silver ornament, produced by the method, is delicate and beautiful in patterns, fine and uniform in crators and free of pseudo soldering.

Owner:GUIZHOU TOURISM CO LTD

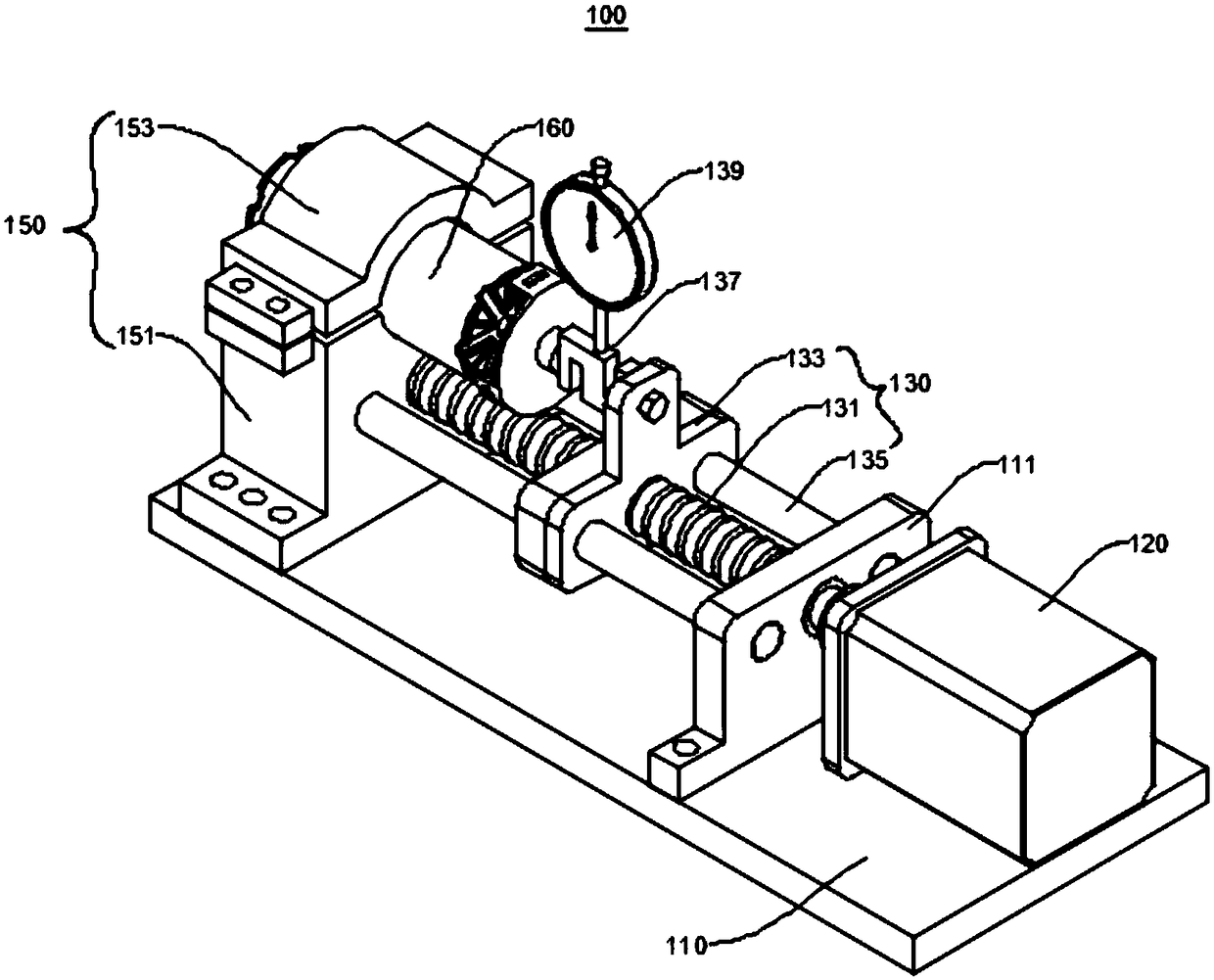

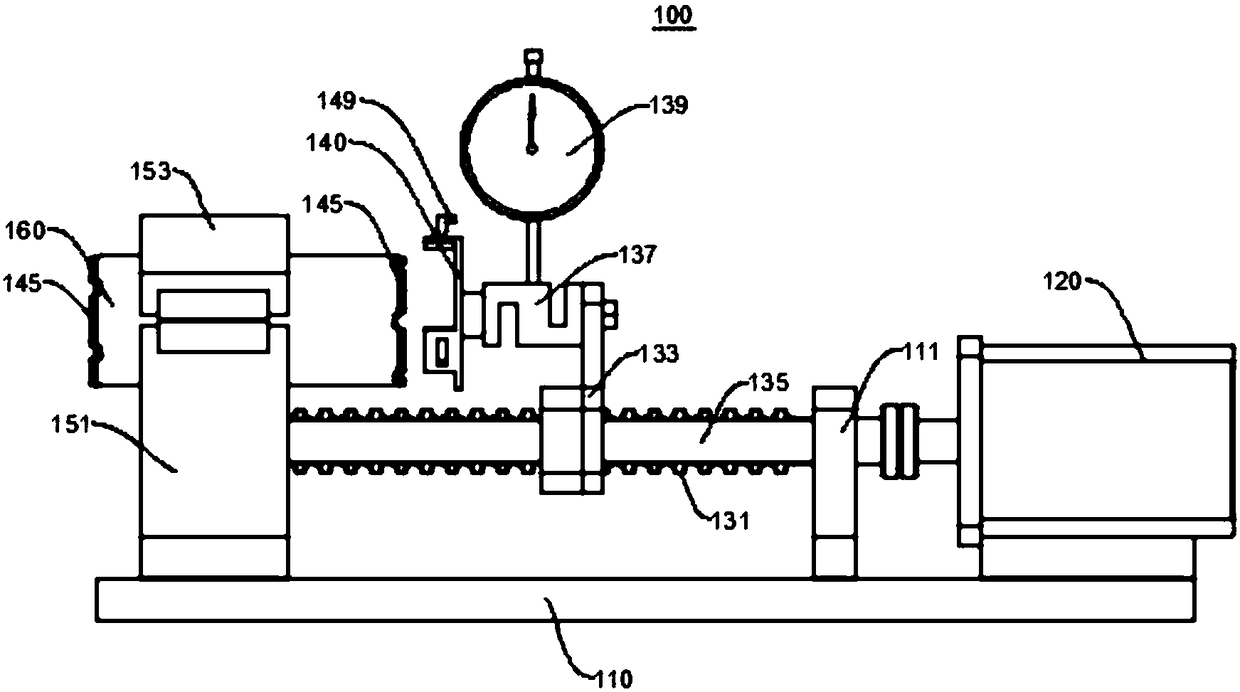

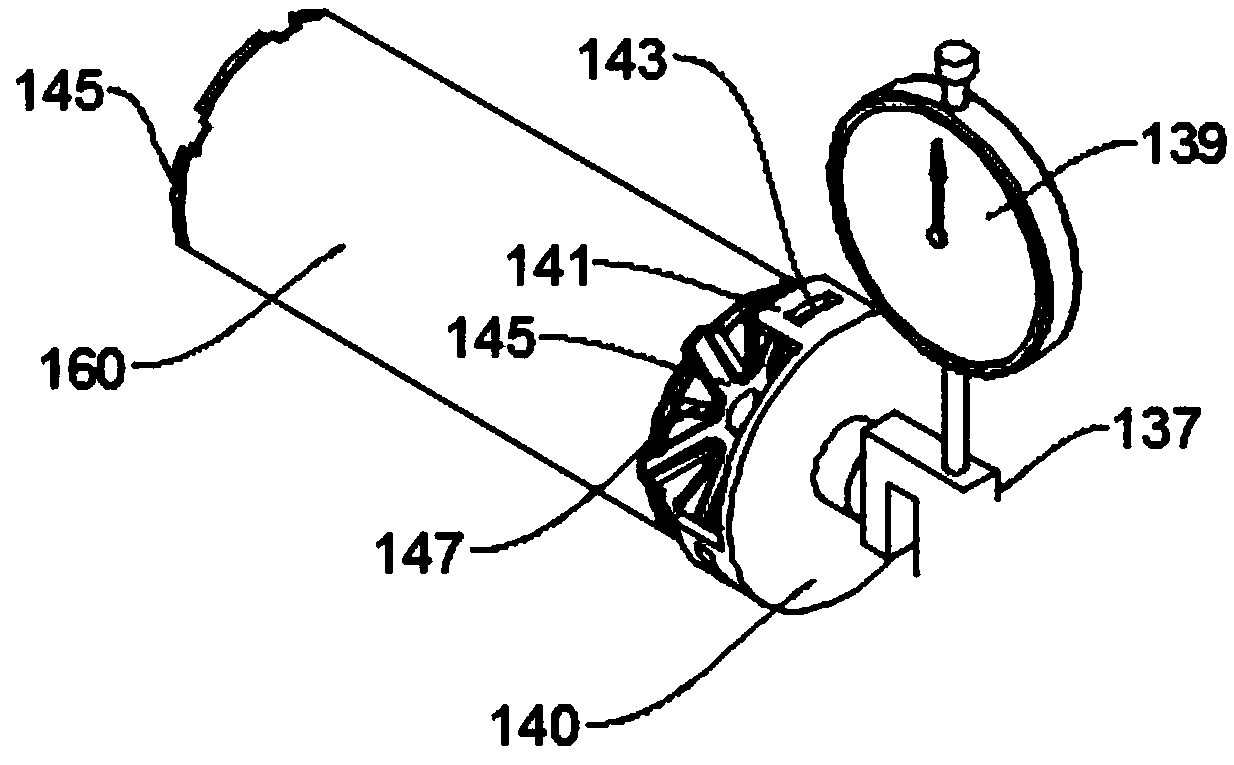

Tension test structure

PendingCN108267368AFirmly connectedNo WeldMaterial strength using tensile/compressive forcesEngineeringDriven element

The invention provides a tension test structure, and relates to the technical field of battery detection. The tension test structure comprises a driving element, a moving assembly, a tension detectorand a fixing clamp, wherein the driving element is connected with the moving assembly; an element to be detected is arranged on the fixed clamp and is connected with the moving assembly; the moving assembly moves under the effect of the driving element and exerts tension on the element to be detected; the tension detector is arranged on the moving assembly and is used for detecting the tension born by the element to be detected so as to judge whether the connection of the element to be detected is reliable or not. The tension test structure has the advantages that the operation is convenient;the test precision is high; the product qualification rate is favorably improved; the product quality and competitive power are improved.

Owner:HEBEI YINLONG NEW ENERGY +1

Copper sheet flow guiding welding design and welding method for battery copper top cover

ActiveCN104625384AReduce procurement costsIncrease productivityWelding/soldering/cutting articlesMetal working apparatusPower flowIntermediate frequency

The invention discloses copper sheet flow guiding welding design and a welding method for a battery copper top cover. A flow guiding groove is added in the welding position of a copper sheet, a loop can be formed by current between the copper top cover below and an electrode, intermediate-frequency inversion direct-current resistance welding is adopted, it is ensured that a molten core can be formed by the copper sheet and the copper top cover, and the welding process is stable. According to the copper sheet flow guiding welding design and the welding method for the battery copper top cover, it can be ensured that the copper sheet can be directly welded to the battery copper top cover, soldering flux such as soldering paste does not need to be brushed for auxiliary welding, pseudo soldering does not happen, soldering paste brushing personnel are reduced, the production efficiency is improved, pseudo soldering is avoided, the product quality is improved, and the soldering paste purchasing cost is saved.

Owner:HEFEI GUOXUAN HIGH TECH POWER ENERGY

Low-solid-content soldering flux for pressure hot melting welding solder paste spot coating and preparation method

ActiveCN111745323AImprove performanceNot easy to produceWelding/cutting media/materialsSoldering mediaOrganic acidFilm-forming agent

The invention discloses a low-solid-content soldering flux for pressure hot melting welding solder paste spot coating and a preparation method. The soldering flux comprises, by mass, 8%-22% of organicacid, 4%-8% of organic amine, 1%-5% of a film forming agent, 1%-3% of a thixotropic agent, 1%-2% of a corrosion inhibitor and 60%-80% of a solvent. The soldering flux and SnAgCu spherical alloy powder can be prepared into needle tube solder paste, under the pressure hot melting welding condition, the welding effect is good under the condition that the welding time is very short, insufficient solder, tin beads and tin explosion are avoided, the content of condensate is small, and the viscosity of residues is low.

Owner:云南锡业新材料有限公司

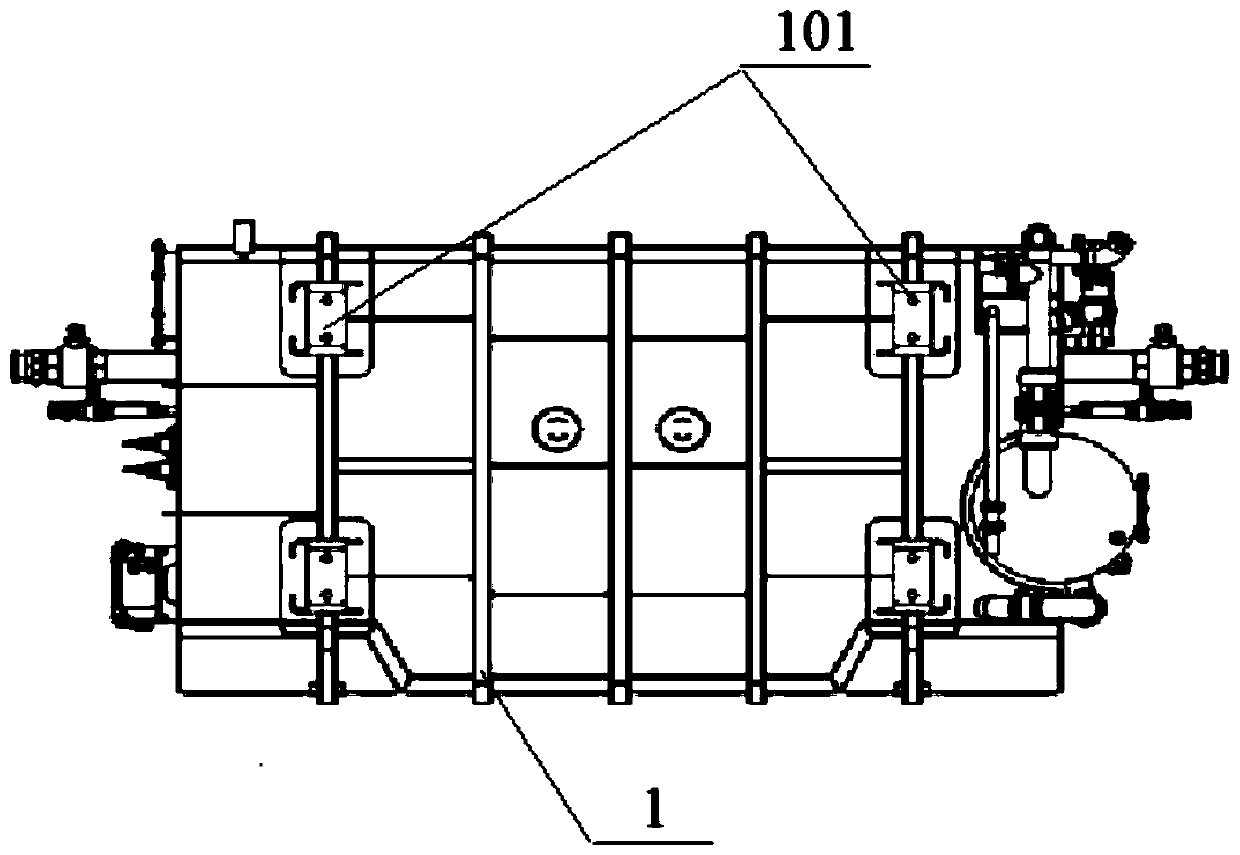

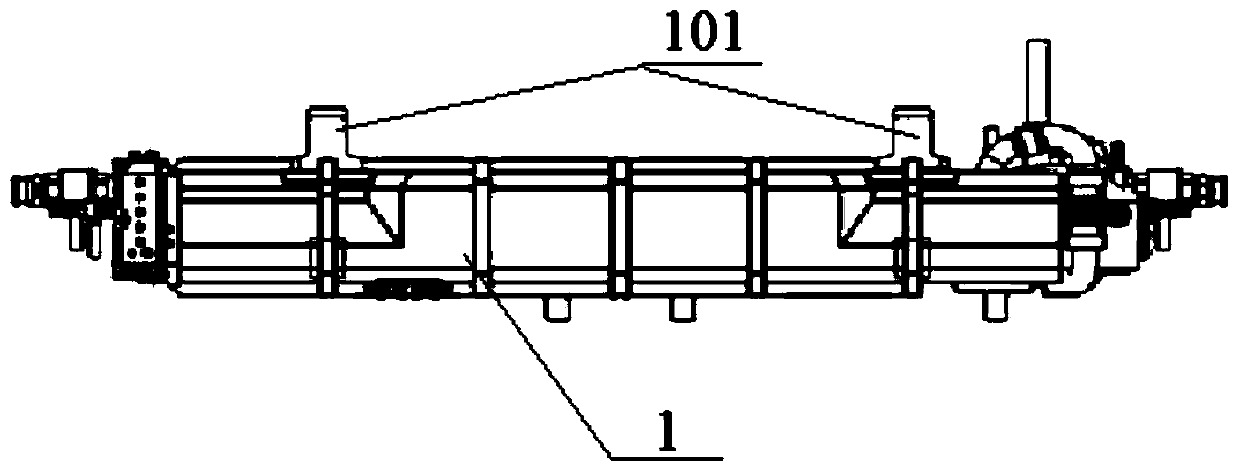

Motor train unit and chassis end integration device thereof

PendingCN109720369AIncrease storage spaceAvoids deterioration of directional strength for transmitting longitudinal forcesSanitationEngineeringUltimate tensile strength

The invention discloses a motor train unit and a chassis end integration device thereof. The chassis end integration device comprises a dirt box and dirt box lifting points, wherein the dirt box is aspecially-shaped dirt box and used for containing dirt, and when installed at the end of a vehicle chassis, the dirt box can be attached to the end of the vehicle chassis; and the dirt box lifting points and a traction beam at the end of the vehicle chassis are integrally formed, and the dirt box is installed at the end of the vehicle chassis through the dirt box lifting points. Due to the fact that the dirt box containing the dirt is of a specially-shaped structure and the dirt box can be attached to the end of the vehicle chassis when installed at the end of the vehicle chassis, the containing space of the dirt box is enlarged; and in addition, the dirt box lifting points and the traction beam of the vehicle chassis are integrally formed, and the situation that the direction strength oflongitudinal force transmission of the vehicle chassis becomes poor due to the fact that holes are formed in the traction beam is avoided. In conclusion, the containing space of the dirt box is enlarged, and the situation that the direction strength of longitudinal force transmission of the vehicle chassis becomes poor is avoided.

Owner:CRRC CHANGCHUN RAILWAY VEHICLES CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com