Preparation method for metal-based polytetrafluoroethylene bearing

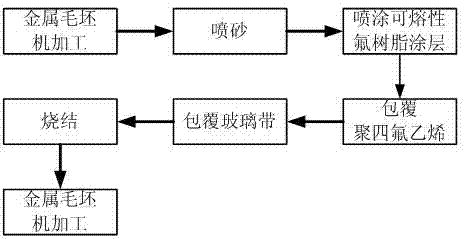

A technology based on polytetrafluoroethylene and polytetrafluoroethylene film, which is applied in the field of preparation of metal-based polytetrafluoroethylene bearings, can solve the problem that the long-term use temperature cannot be higher than 120°C, and achieve low one-time investment costs and stripping The effect of increased strength and simple equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Example 1: Prepare a high-speed water-lubricated bronze-based polytetrafluoroethylene bearing. The operating temperature is 120° C., the bearing speed is 8000 r / min, the working medium is boiler water, and the working water pressure is 1.2-1.5 MPa.

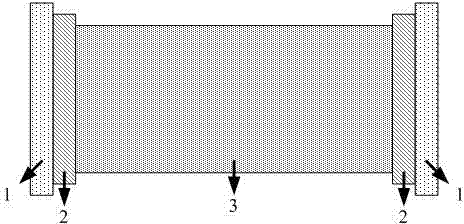

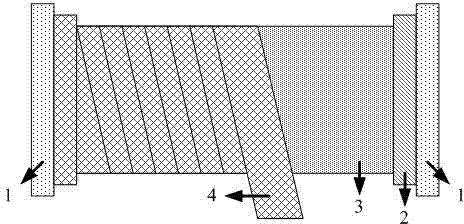

[0027] 1) Process the bronze blank to figure 2 Among them, 1 is the baffle plate, which prevents polytetrafluoroethylene from overflowing due to expansion during sintering, and is the processing benchmark, 2 is the metal blank processing baseline, which belongs to the non-processing area, and 3 is the area covered with polytetrafluoroethylene film, which belongs to In the processing area, sandblasting, spraying of fusible fluororesin coating and coating of polytetrafluoroethylene film are required in this section, and the specific process parameters are different according to the final product;

[0028] 2) Use a high-pressure sandblasting air gun to spray sand particles with a particle size of about 0.5mm on the area that ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com