Patents

Literature

4063results about How to "High peel strength" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

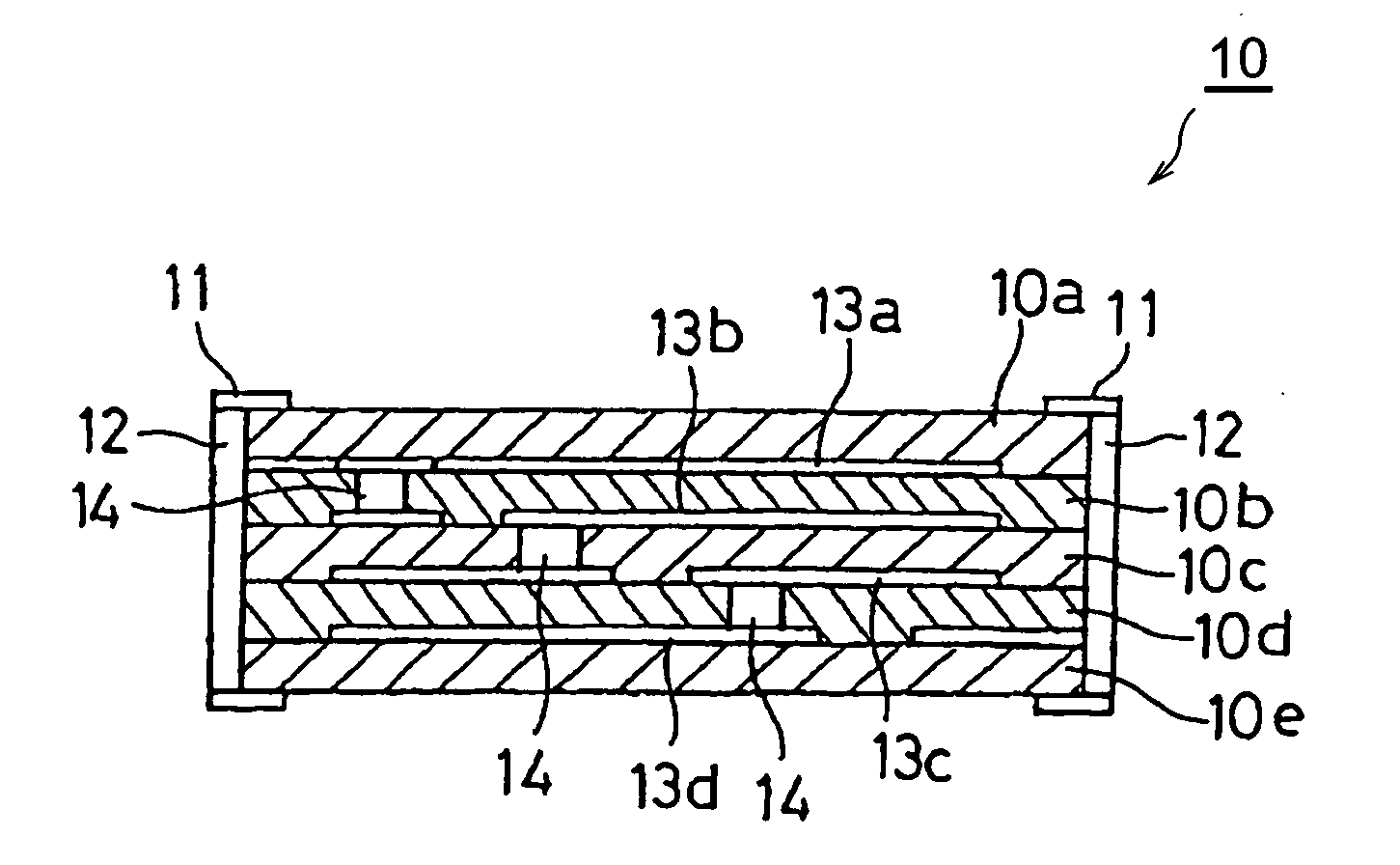

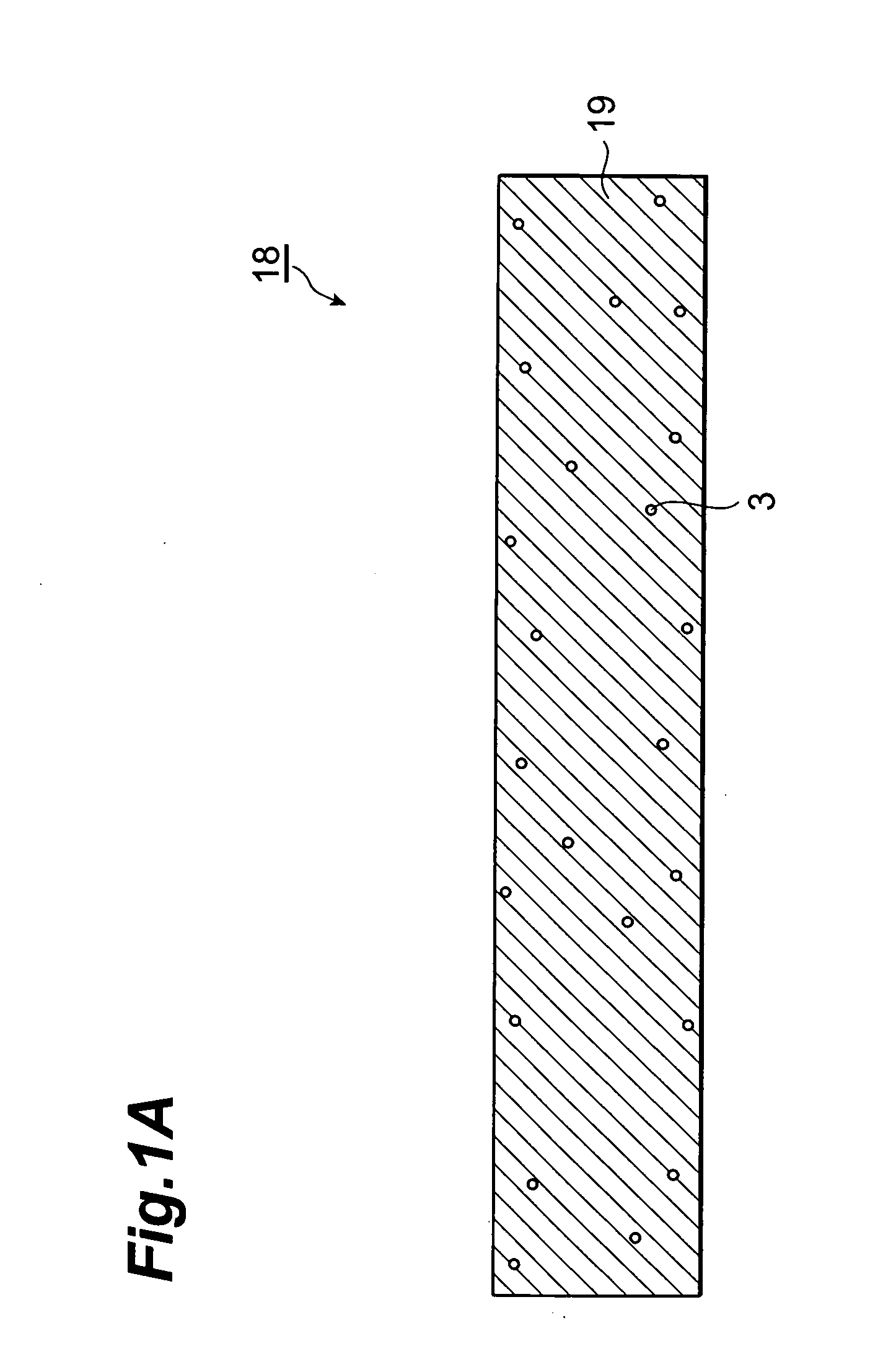

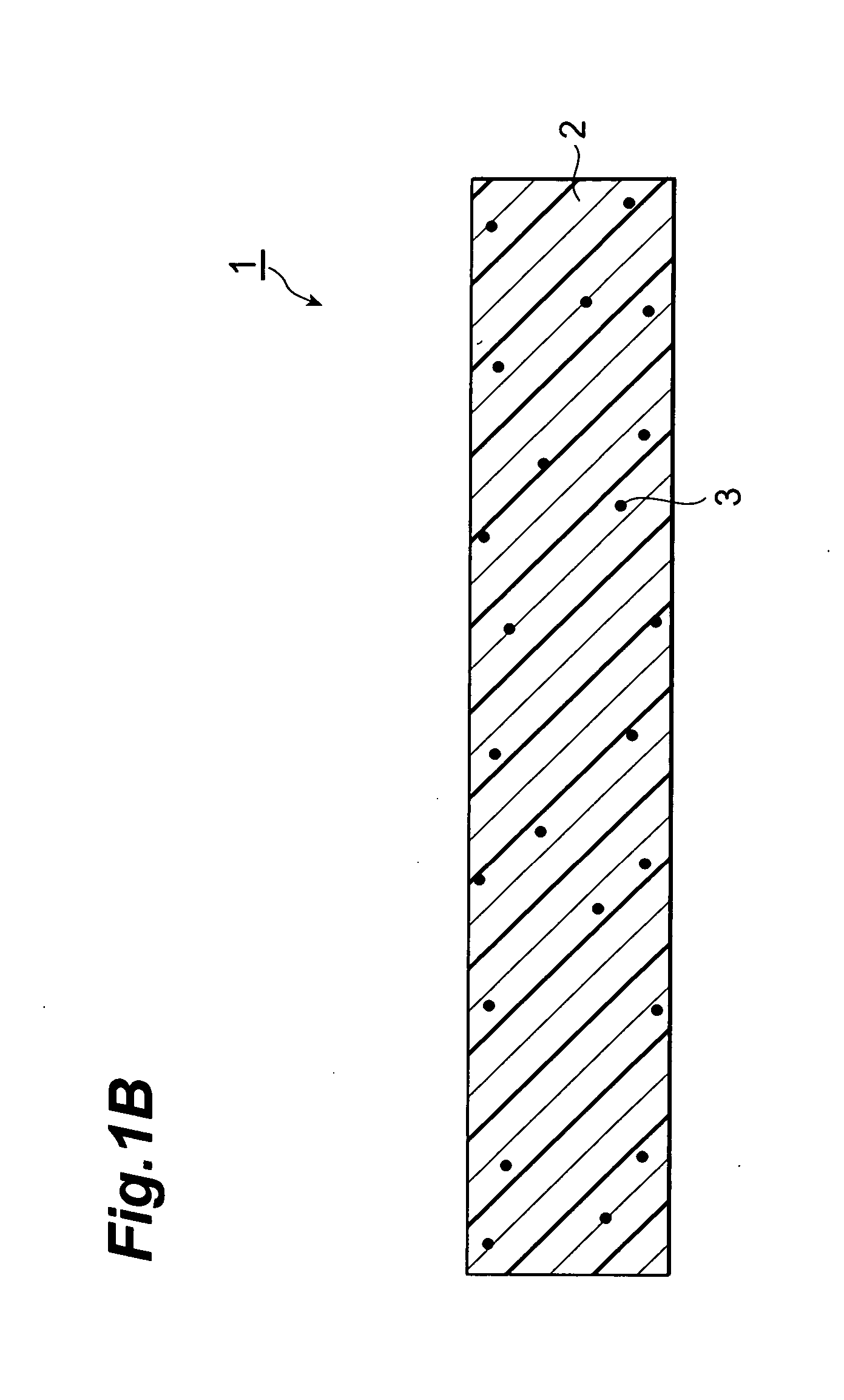

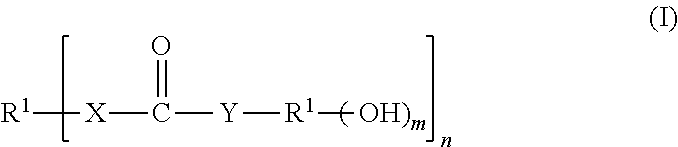

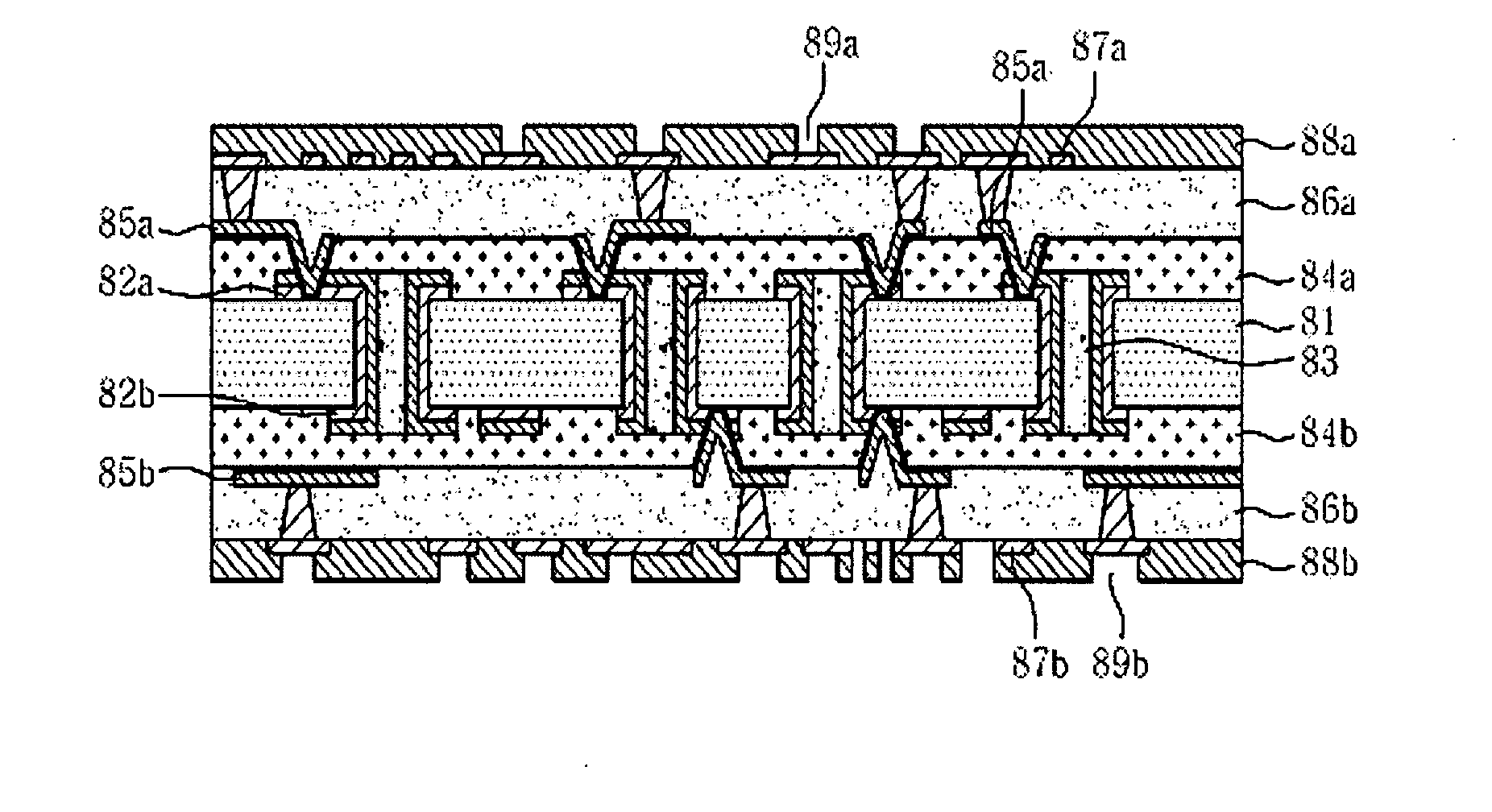

Resin composition, cured resin, sheet-like cured resin, laminated body, prepreg, electronic parts and multilayer boards

InactiveUS20050003199A1Maintain electrical propertiesHigh dielectric constantSemiconductor/solid-state device detailsTransformers/inductances coils/windings/connectionsEpoxyDielectric loss

The invention provides electronic parts which comprise a composite dielectric layer composed of an organic insulating material and a dielectric ceramic powder having a larger relative dielectric constant than the organic insulating material, and which also comprise conductive element sections forming inductor elements, etc., wherein the organic insulating material comprises a cured resin obtained by curing reaction of an epoxy resin with an active ester compound obtained by reaction between a compound with two or more carboxyl groups and a compound with a phenolic hydroxyl group. The dielectric ceramic powders of the described electronic parts have larger relative dielectric constants than the organic insulating materials, and the organic insulating materials have low dielectric loss tangents. It is possible to adequately reduce time-dependent dielectric constant changes in the high-frequency range of 100 MHz and above even with prolonged use at high temperatures of 100° C. and higher, while it is also possible to satisfactorily prevent deformation and other damage to the electronic parts during their handling.

Owner:TDK CORPARATION

Accelerated and toughened two part epoxy adhesives

InactiveUS20150184039A1High dynamic impact peel strengthFast curing timeMacromolecular adhesive additivesEpoxy resin adhesivesFiberGlass fiber

A 2K epoxy adhesive is provided that has rapid cure time and good strength characteristics. Both the epoxy resin composition and the hardener composition of the 2K epoxy comprise a reactive toughener. Such adhesives are useful in the manufacture and / or repair of large machinery (e.g., automobiles), and are useful for bonding like or unlike materials, such as metal and composites (e.g., carbon fiber or glass fiber composites).

Owner:DOW GLOBAL TECH LLC

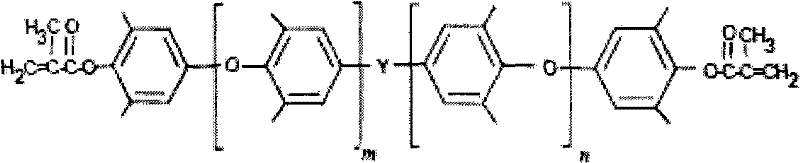

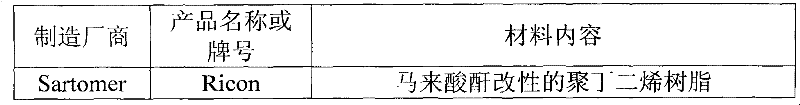

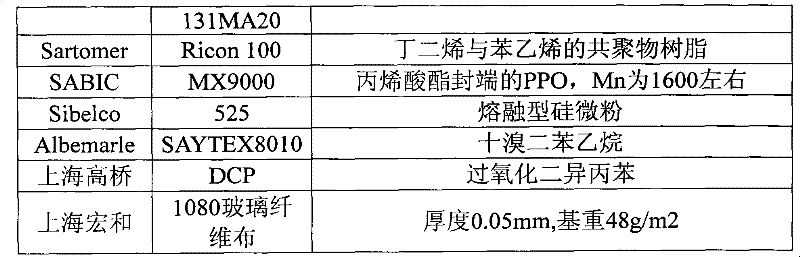

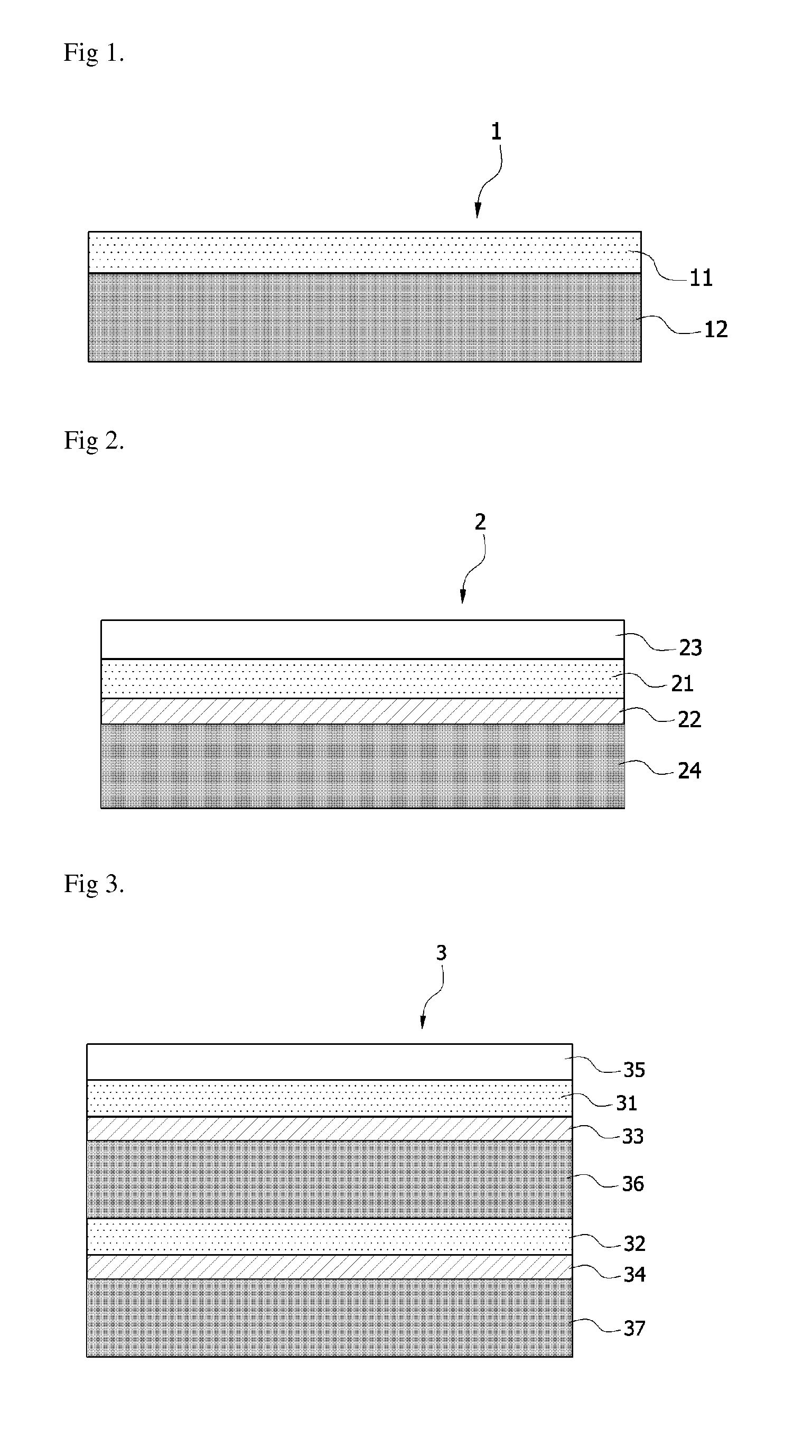

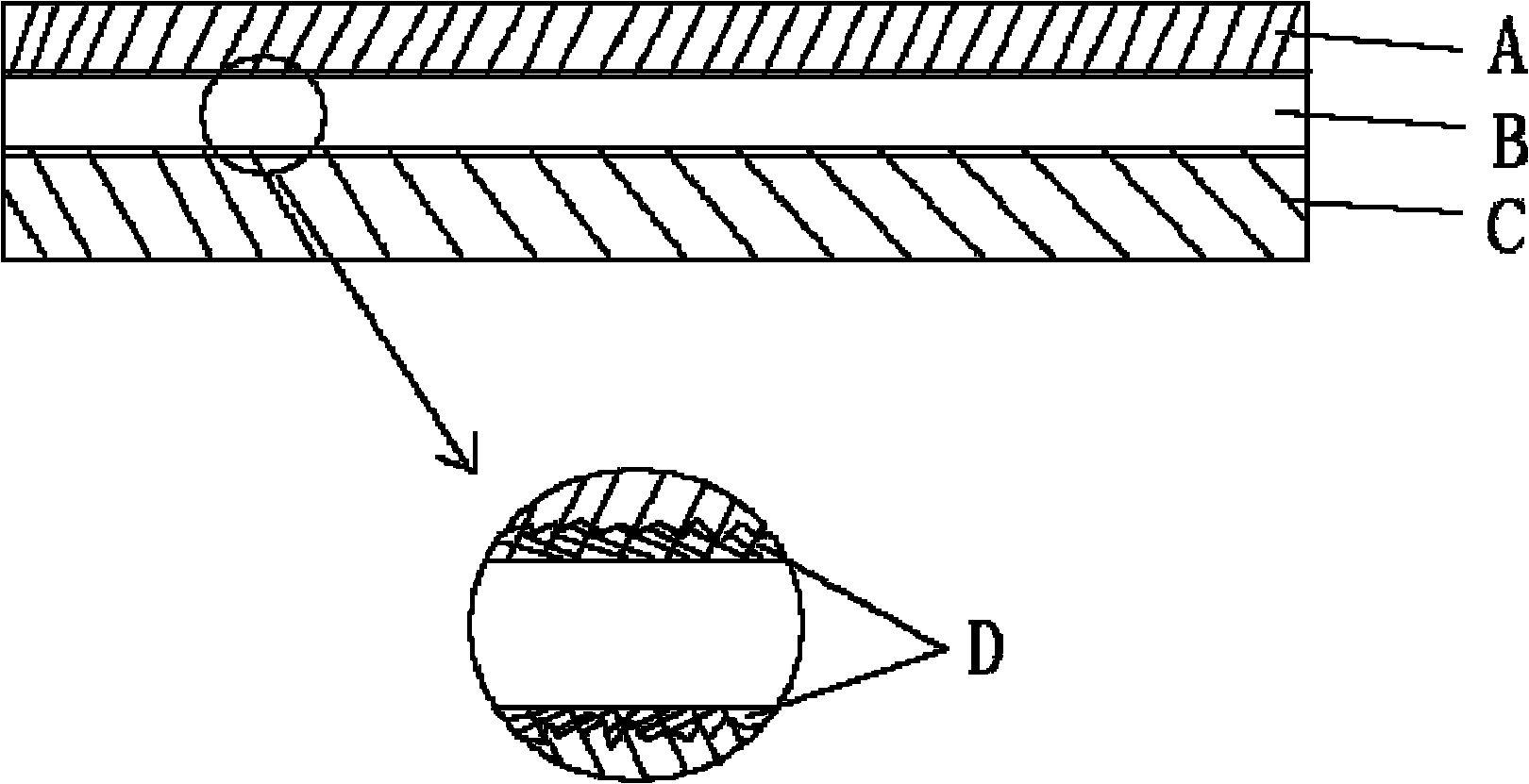

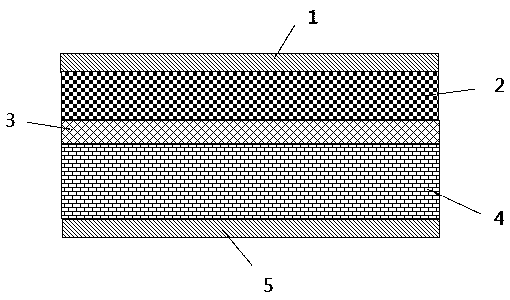

Composite material, high-frequency circuit substrate therefrom and manufacture method thereof

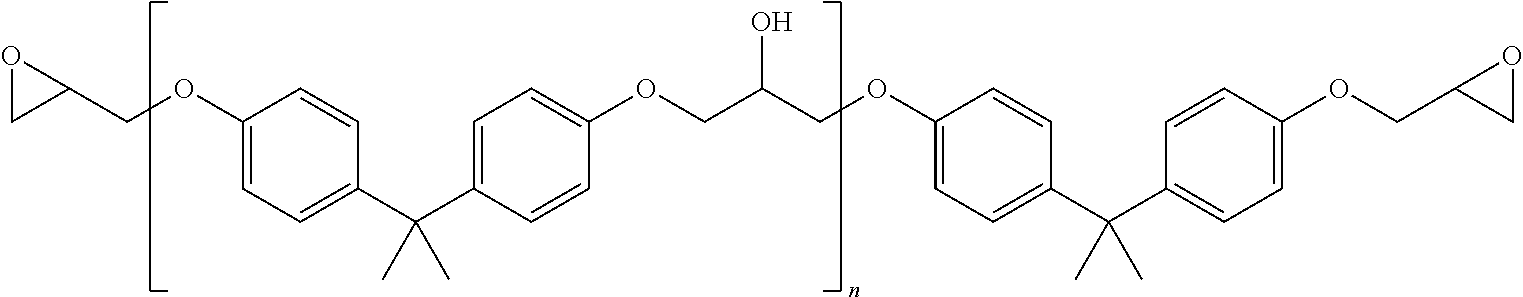

ActiveCN102161823AHigh peel strengthImprove the sticky problemPrinted circuit manufactureCircuit susbtrate materialsDouble bondCopper foil

The invention relates to a composite material, a high-frequency circuit substrate therefrom and a manufacture method thereof. The composite material comprises thermoset mixture, glass fiber cloth, power filler, a fire retardant and a curing initiator, wherein the thermoset mixture comprises more than one kind of vinyl liquid resin and polyphenyl ether resin; the molecular weight of the vinyl liquid resin is below 10000, and the vinyl liquid resin is provided with a polar functional group; the molecular weight of the polyphenyl ether resin is less than 5000, and the molecular tail end of the polyphenyl ether resin is provided with unsaturated double bonds. The high-frequency circuit substrate manufactured with the composite material comprises multiple layers of semi-solidified sheets and copper foils, wherein the semi-solidified sheets are mutually overlaid, and the copper foils are respectively pressed on two sides. The composite material disclosed by the invention causes the semi-solidified sheets to be easily manufactured and have high adhesive bonding force with the copper foils. The high-frequency circuit substrate manufactured by the material has the advantages of low dielectric constant, low dielectric loss angle tangent, good heat resistance and simple technical operation. Thus, the composite material disclosed by the invention is suitable for manufacturing the circuit substrate of the high-frequency electronic equipment.

Owner:GUANGDONG SHENGYI SCI TECH

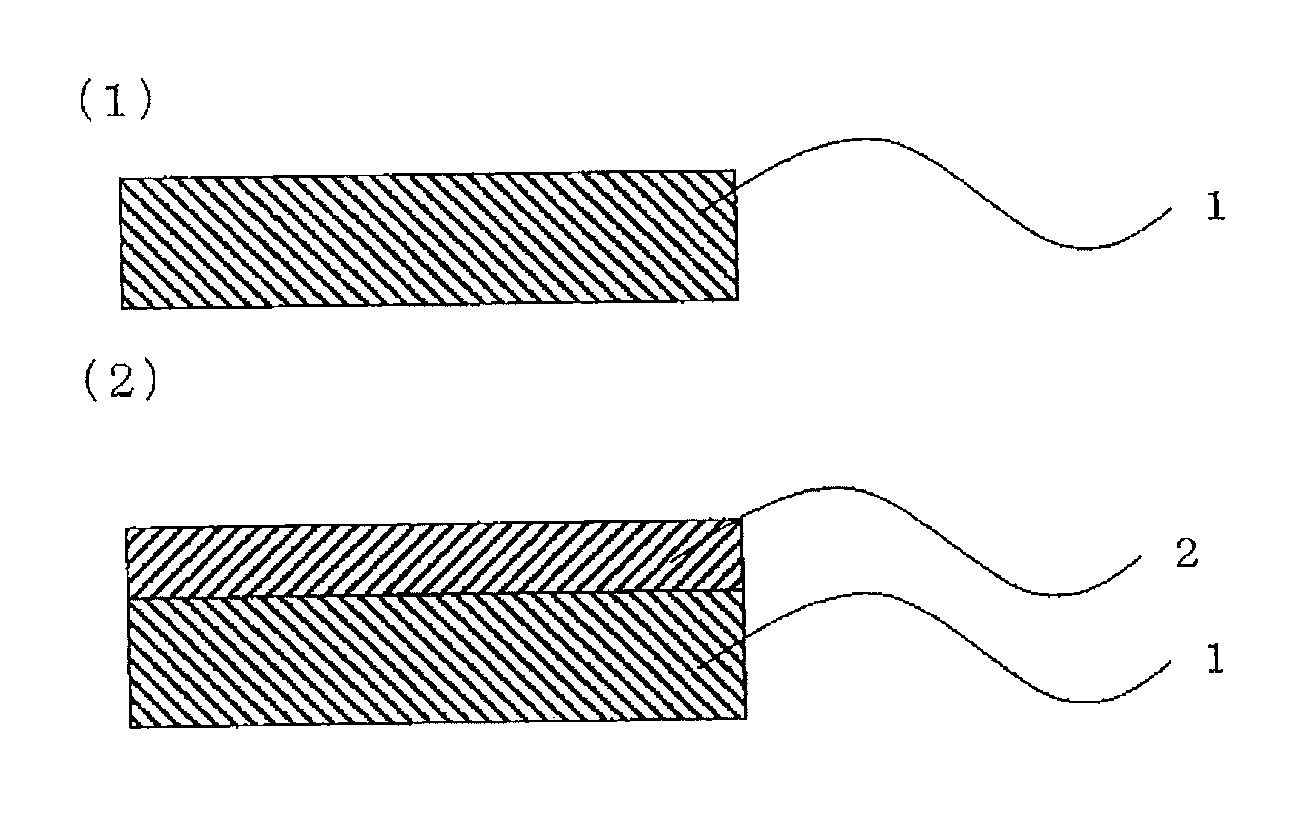

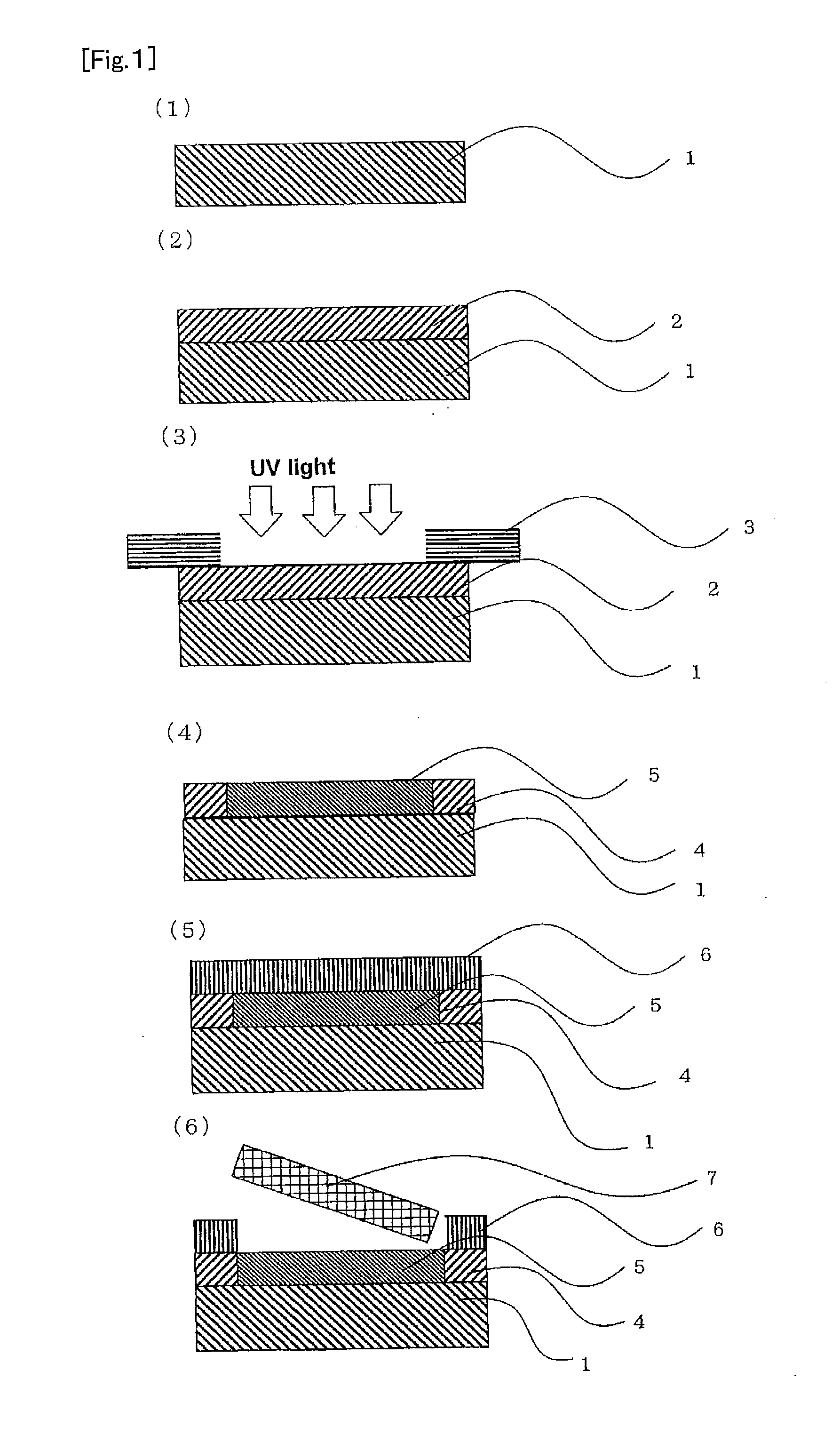

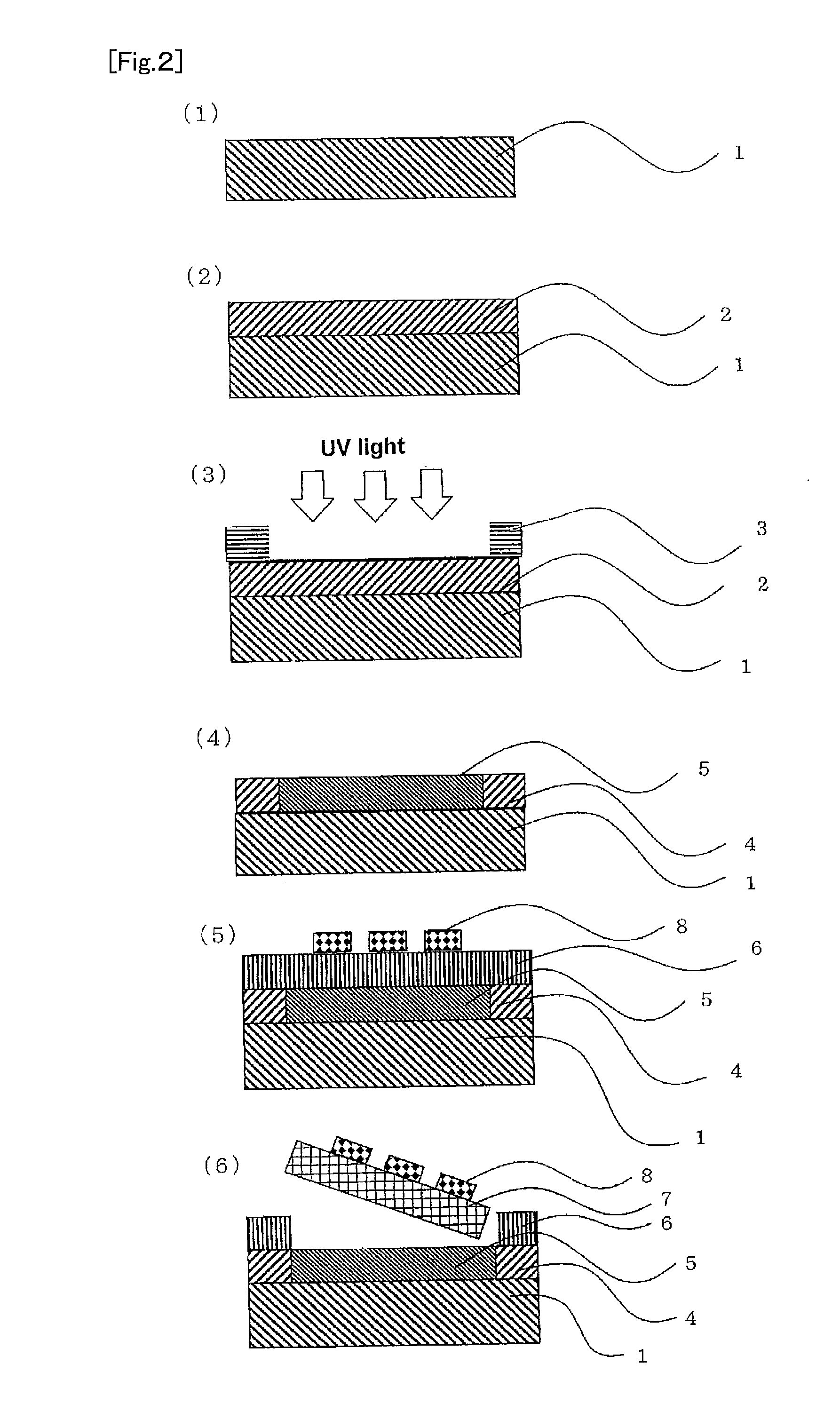

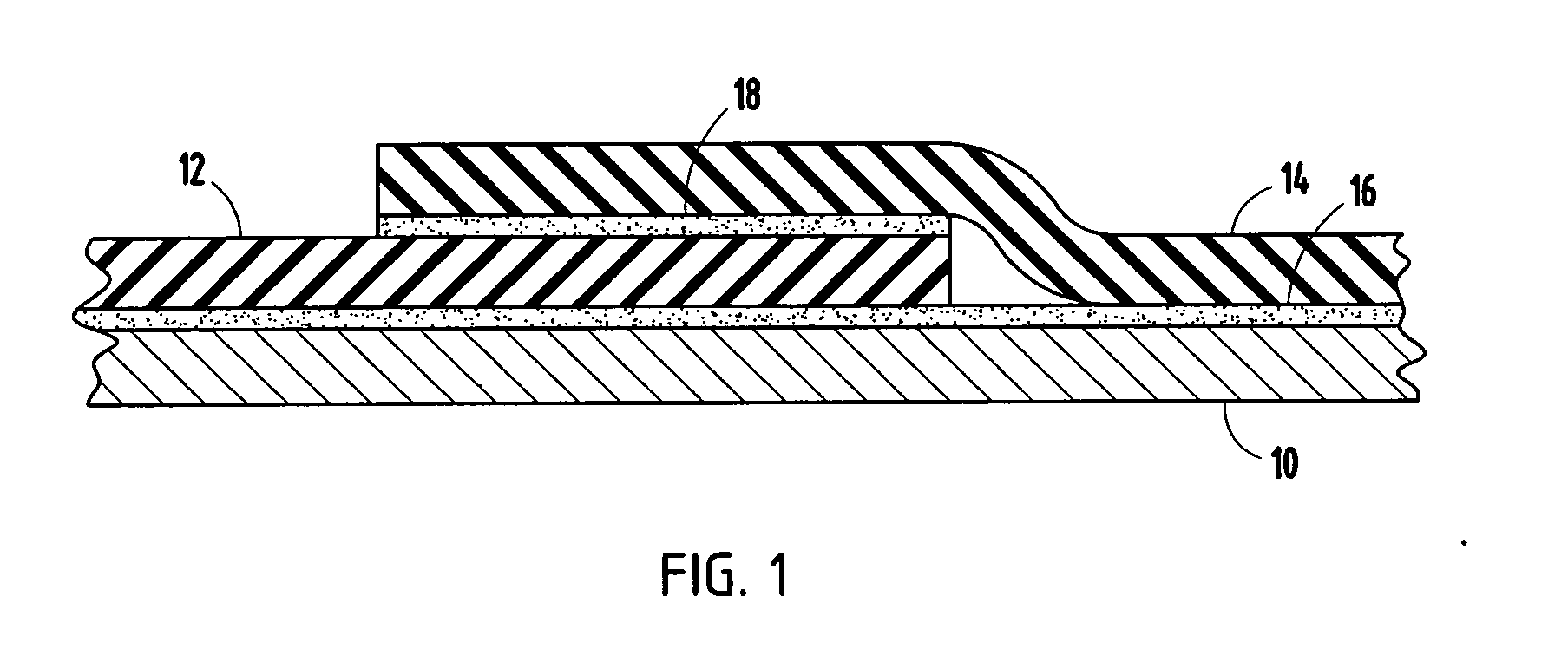

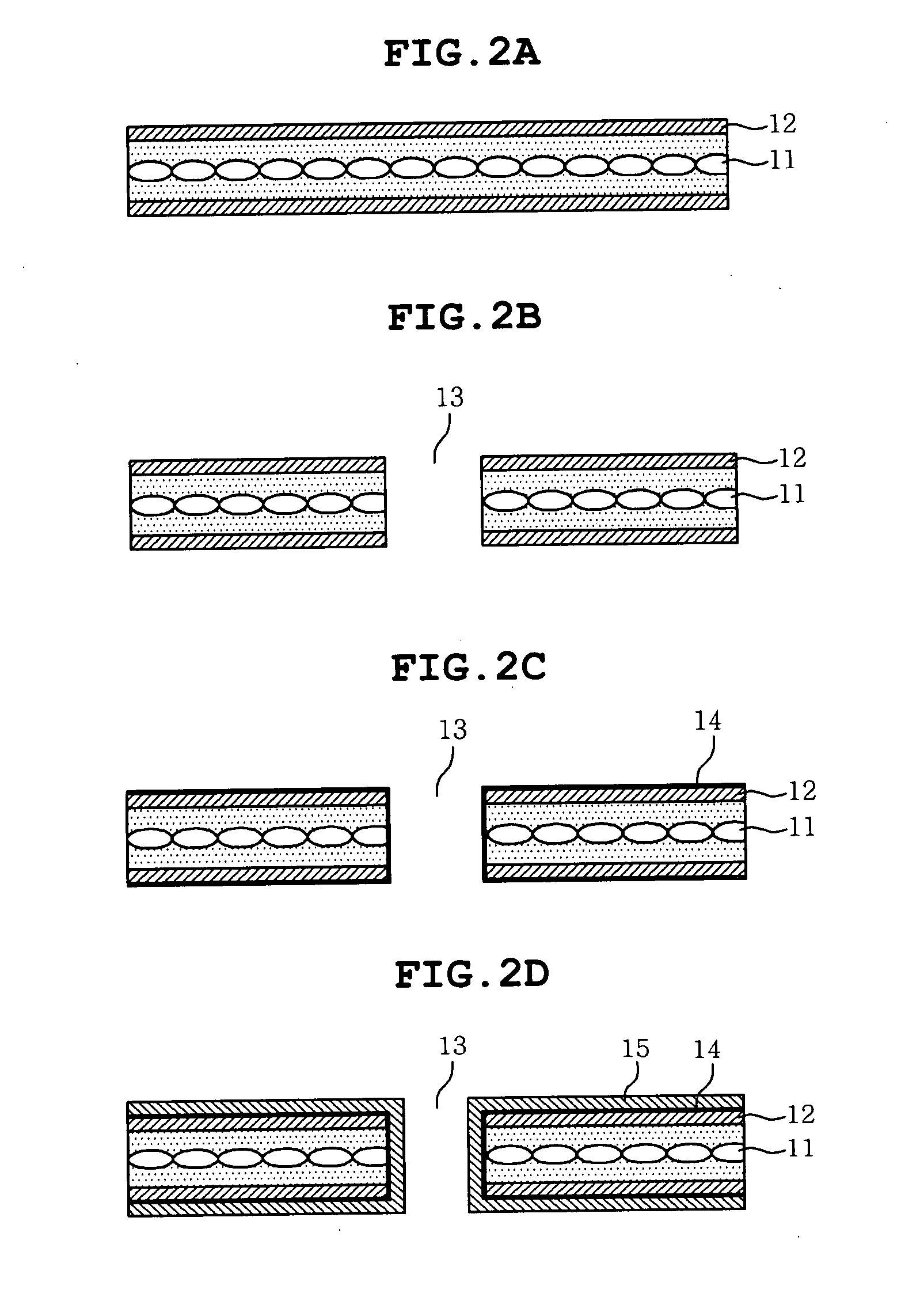

Laminate, method for producing same, and method for producing device structure using same

ActiveUS20140041800A1Easy to getGood partitionLamination ancillary operationsDecorative surface effectsCouplingEngineering

The invention provides a laminate of a substrate, a polyimide film, and a coupling treatment layer interposed therebetween, which provides different delamination strengths between the substrate and the polyimide film to form a prescribed pattern. The invention also provides a method for producing such a laminate formed from at least a substrate and a polyimide film, whereby, using a film obtained by plasma treatment of at least the surface facing the substrate as the polyimide film, coupling agent treatment is performed on at least one of the surfaces facing the substrate and the polyimide film to form a coupling treatment layer, deactivation treatment is performed on a portion of the coupling treatment layer to form a pre-determined pattern, and then pressing and heating are performed with the substrate and polyimide film overlapping.

Owner:TOYO TOYOBO CO LTD

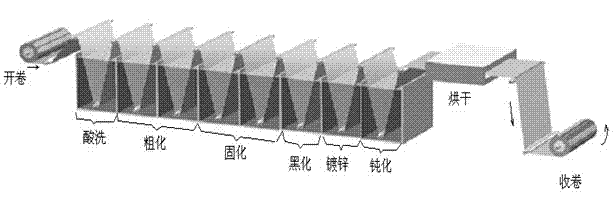

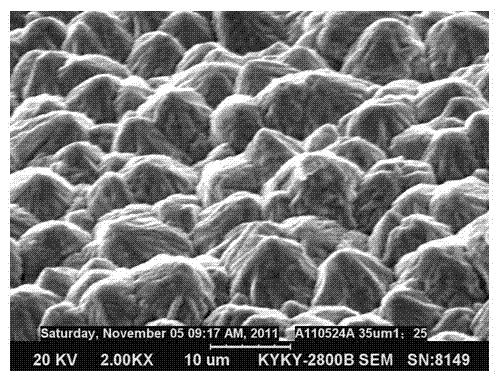

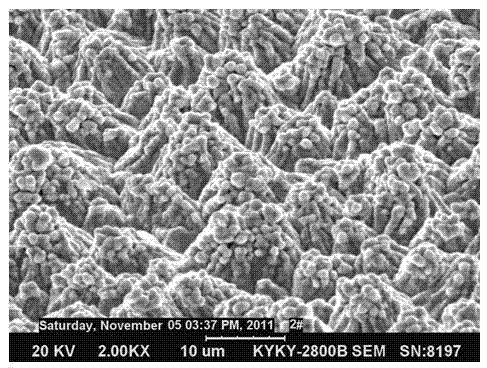

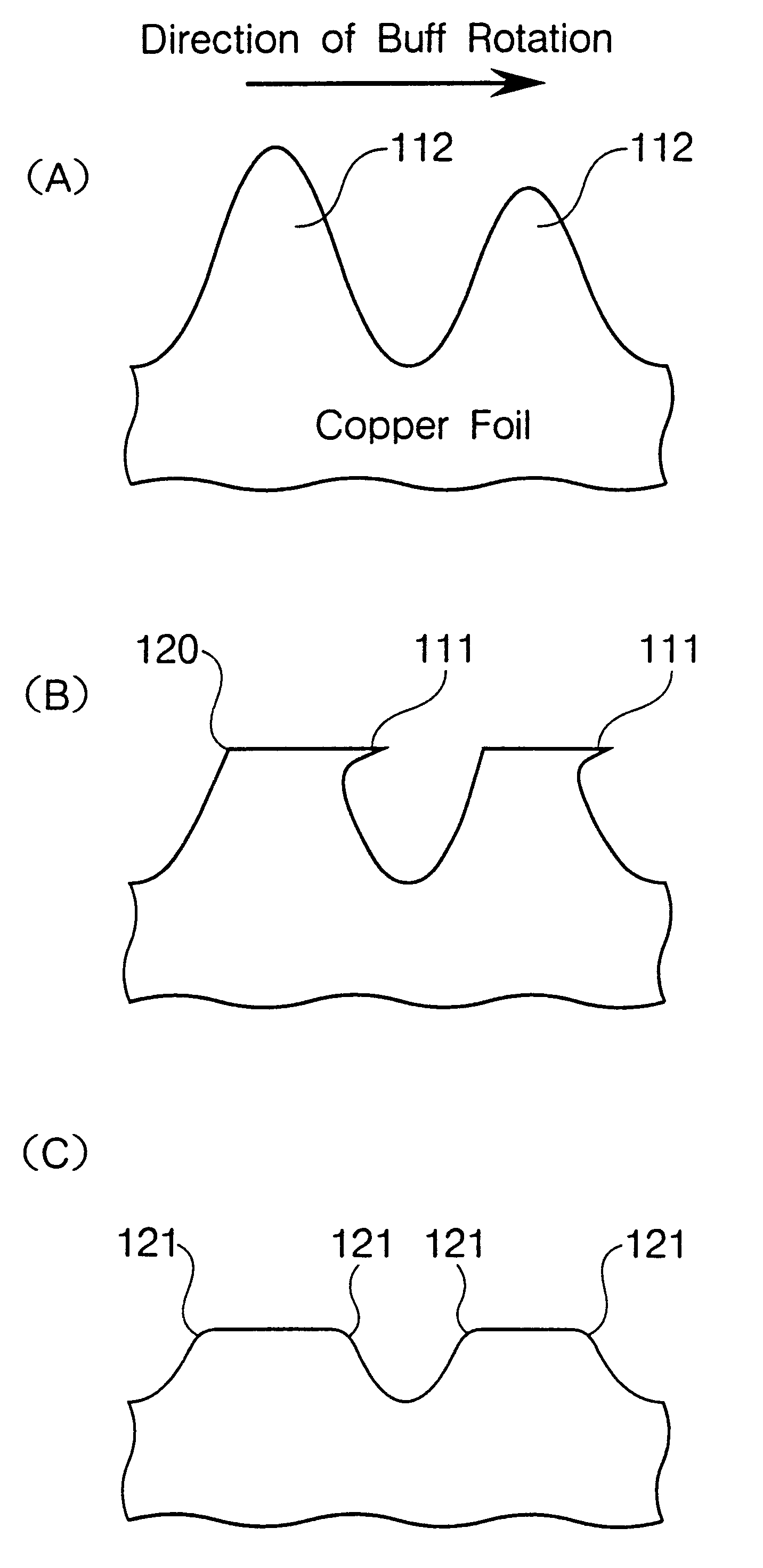

Surface treatment process of copper foil for high-Tg halogen-free plate

InactiveCN102418129AHigh peel strength and corrosion resistanceStrong antioxidantAnodisationCopper foilHexavalent chromium

The invention relates to a surface treatment process of a copper foil for a high-Tg halogen-free plate, belonging to the technical field of a production process of a high-precision electrolytic copper foil. In the surface treatment process provided by the invention, a structure shape of a coarsening layer is changed by using a special mixed additive in a coarsening step so as to improve anti-stripping strength; an ultra-fine nanoscale electroplated nickel-zinc alloy is used as a barrier layer to assure the corrosion resistance of the copper foil. Internal properties and pressure plate back color of the copper foil which is treated by the process provided by the invention are similar with those of the copper foil which is imported abroad; the anti-stripping strength on the high-Tg (Tg170) and the halogen-free plate is more than 1.5 N / mm; and the copper foil has characteristic of environmental friendliness and does not contain harmful matters, such as arsenic, antimony, mercury, cadmium, hexavalent chromium and the like.

Owner:SHANDONG JINBAO ELECTRONICS

Moisture-curable adhesive composition

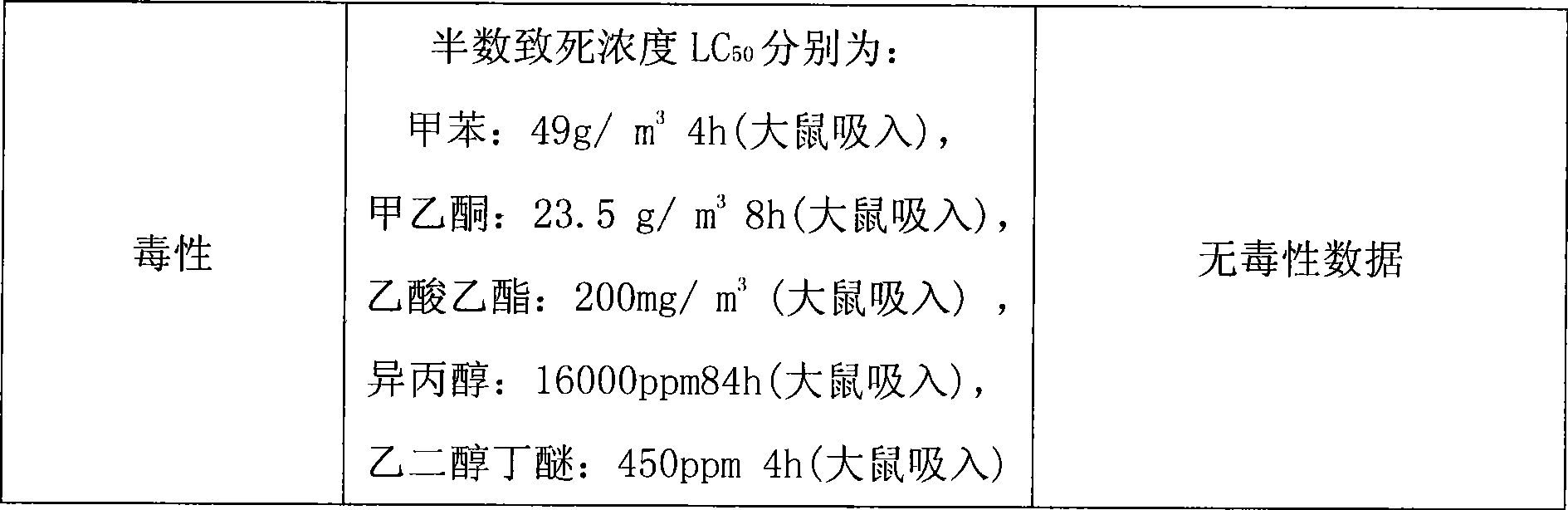

InactiveUS20070088137A1Safe for chronic exposureHigh peel strengthPolyureas/polyurethane adhesivesSynthetic resin layered productsRubber membraneCombustion

A moisture-curable adhesive composition that may be formulated to be free of volatile organic compounds, or substantially free of volatile organic compounds which is safe for chronic exposure, resistant to combustion, and provides a high peel strength useful for securing a rubber membrane material to a rigid roof deck includes a polymer having silicon-containing hydrolyzable terminal groups, a phenolic resin, and a non-polymeric silicon-containing hydrolyzable compound, wherein the ratio of the amount of polymer having silicon-containing hydrolyzable terminal groups by weight to the amount of phenolic resin by weight is greater than 2:1.

Owner:CHEMLINK

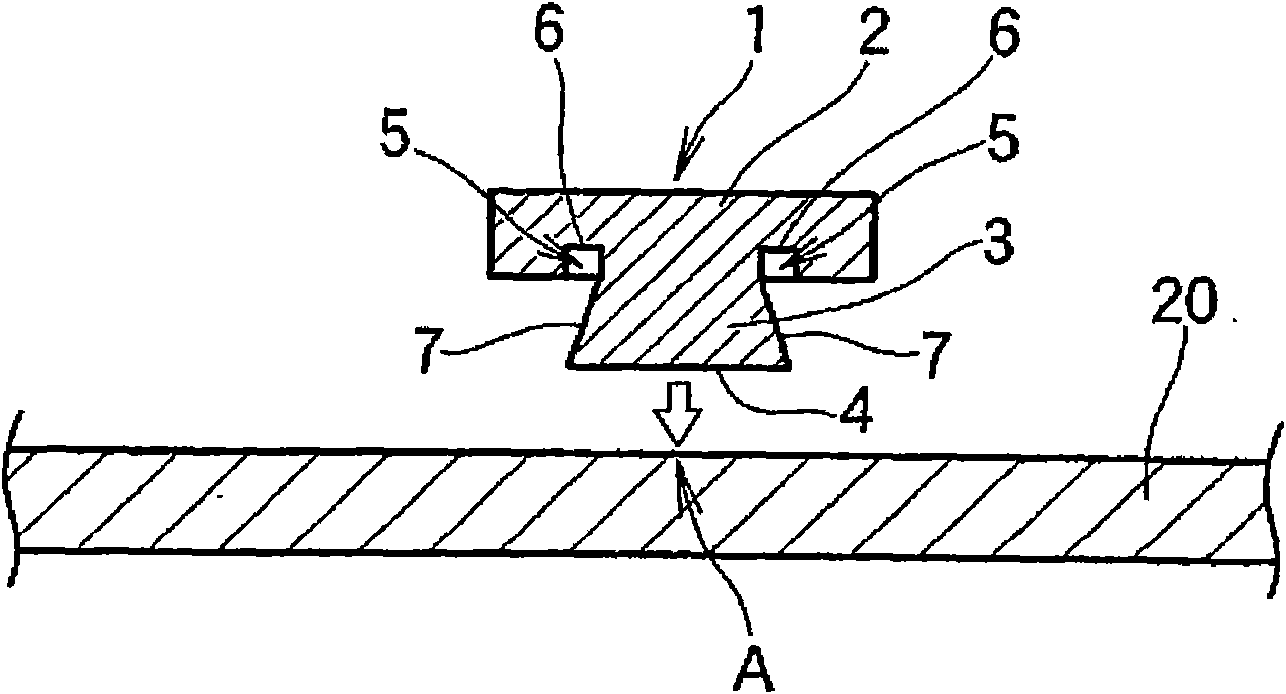

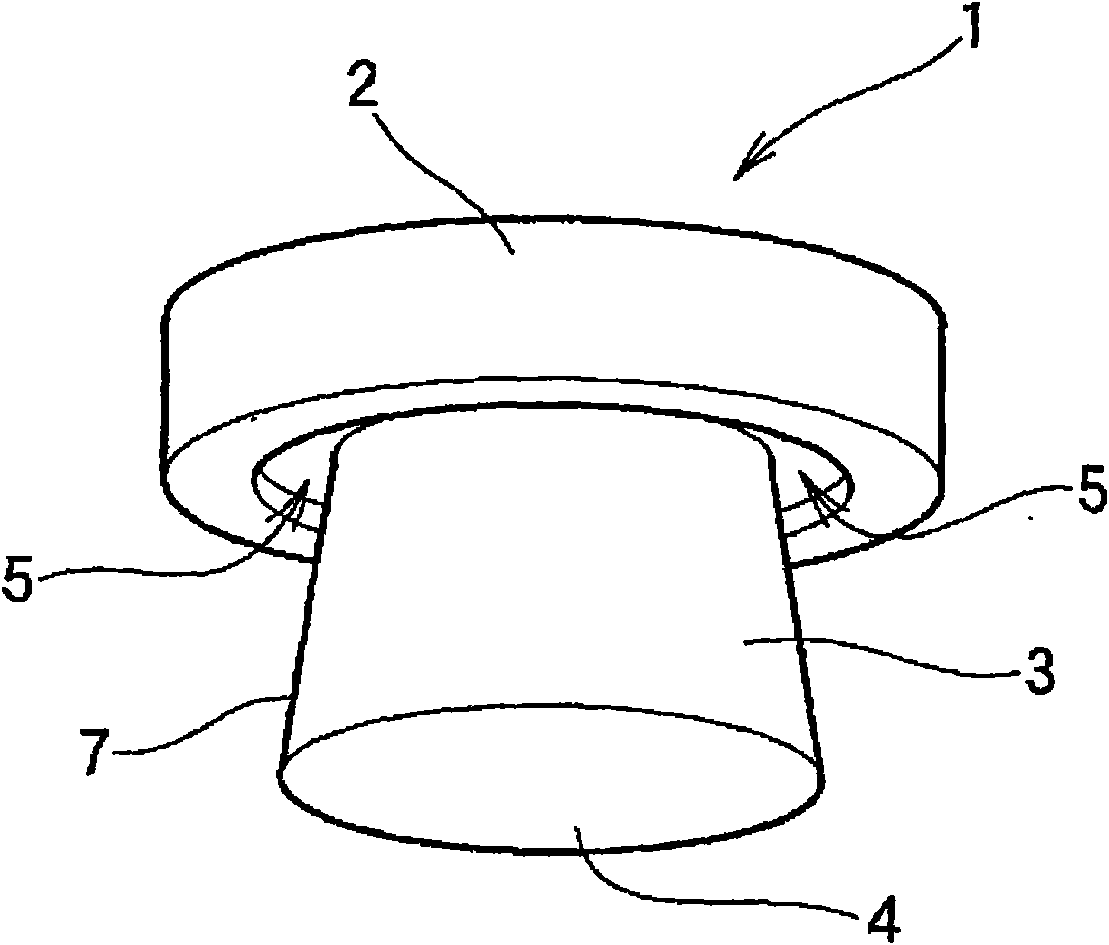

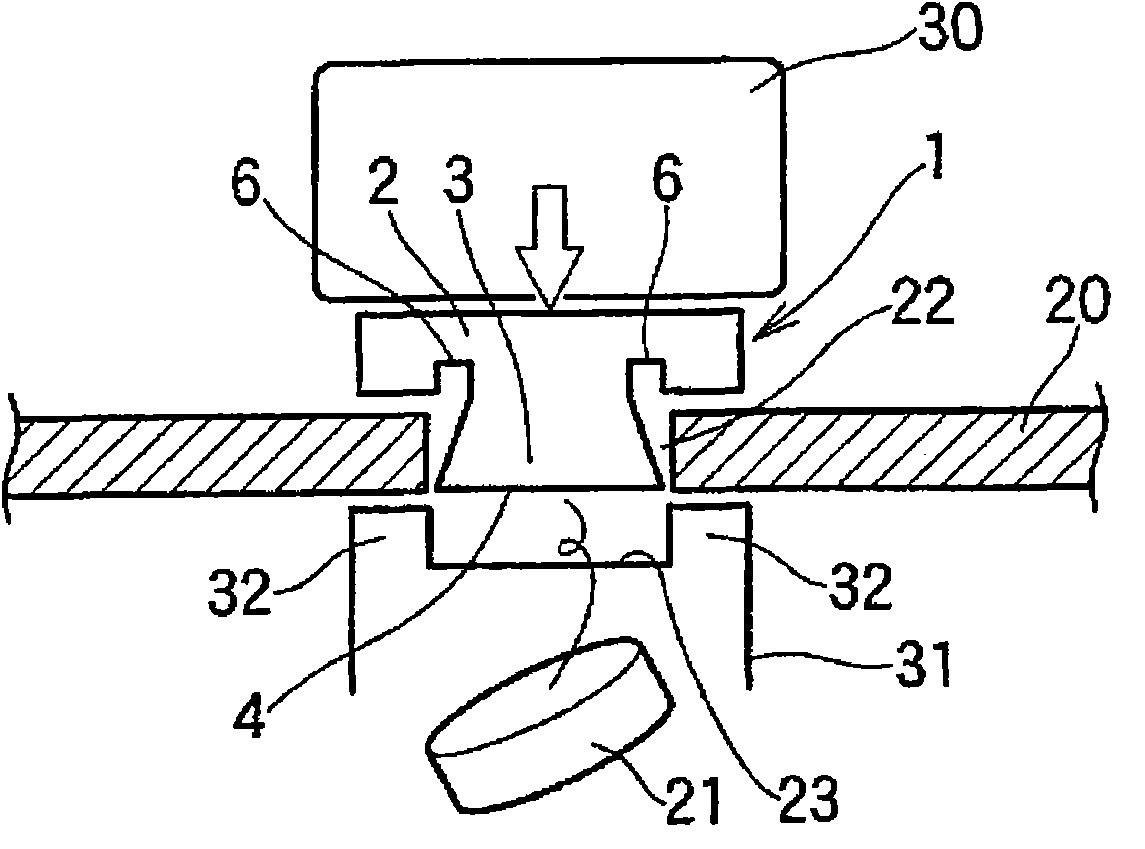

Method for joining dissimilar metals of steel product and light metal product

InactiveCN101590598AOvercome limitationsRemove constraintsShrinkage connectionsSheet joiningMetallic materialsSpot welding

There is provided method for joining dissimilar metals of a steel product and a light metal product with each other, wherein the light metal product and a rivet made of an iron-base metal are connected with each other beforehand in a previous process preceding spot welding, and subsequently, the rivet and the steel product are spot welded with each other. Then, a cavity for use in clinching the light metal product is formed, and upon the stem of the rivet is embedded into the light metal product to penetrate therethrough, light metal is caused to undergo plastic flow into the cavity of the rivet, for clinching the light metal product to be thereby clinched with the rivet whereupon spot welding for forming a weld nugget only within the scope of an interface between the stem of the rivet, and the steel product is carried out. Thus, the present invention can implement the spot welding between iron-iron similar metals, without a constraint on, and a problem with conditions applicable to the spot welding and a high joint strength can be obtained owing to the synergistic effect of the spot welding and connection by clinching of the aluminum alloy product with the iron-base rivet, added thereto.

Owner:KOBE STEEL LTD

Touch panel

ActiveUS20140134434A1Improve cohesionIncrease elasticityFilm/foil adhesivesLayered productsElectrical conductorSide chain

Provided is a touch panel. The touch panel includes a base and a pressure-sensitive adhesive layer attached to the base and having a peel strength with respect to a polycarbonate sheet of 1,900 g / 25 mm or more. The pressure-sensitive adhesive layer includes an acryl polymer compound containing an acryl polymer and a thiol polymer derived by binding a thiol compound into a chain, or a side chain or terminal end of a chain of the acryl polymer. Accordingly, penetration of oxygen, moisture or other impurities at an interface between the base film and the pressure-sensitive adhesive layer, or at an interface between a conductor thin film and a pressure-sensitive adhesive layer may be effectively inhibited, and degradation in optical properties such as visibility due to bubbles generated at a pressure-sensitive adhesive interface may be prevented. In addition, when the pressure-sensitive adhesive layer is directly attached to the conductor thin film and even exposed to severe conditions such as high temperature or high temperature and high humidity, the change in the resistance of the conductor thin film may be effectively inhibited, and thus the touch panel may be stably driven for a long time.

Owner:LG CHEM LTD

Ultraviolet curing pressure sensitive adhersive for polyethylene protective film and preparation method thereof

ActiveCN101649165AStrong adhesionStrong initial adhesionOrganic non-macromolecular adhesiveTectorial membraneSolvent

The invention discloses an ultraviolet curing pressure sensitive adhersive for the polyethylene protective film and a preparation method thereof. The ultraviolet curing pressure sensitive adhersive comprises the following components by weight percent: 30-80% of acrylate prepolymer, 0.03-4.5% of photoinitiator, 0.2-2.5% of photocuring crosslinking agent, 3-25% of tackifier and 5-40% of solvent. Theultraviolet curing pressure sensitive adhersive disclosed in the invention has good adhesive force to the polyethylene film and can realize good balance among initital adhesive force, peeling strength and cohesive force.

Owner:无锡达美新材料有限公司

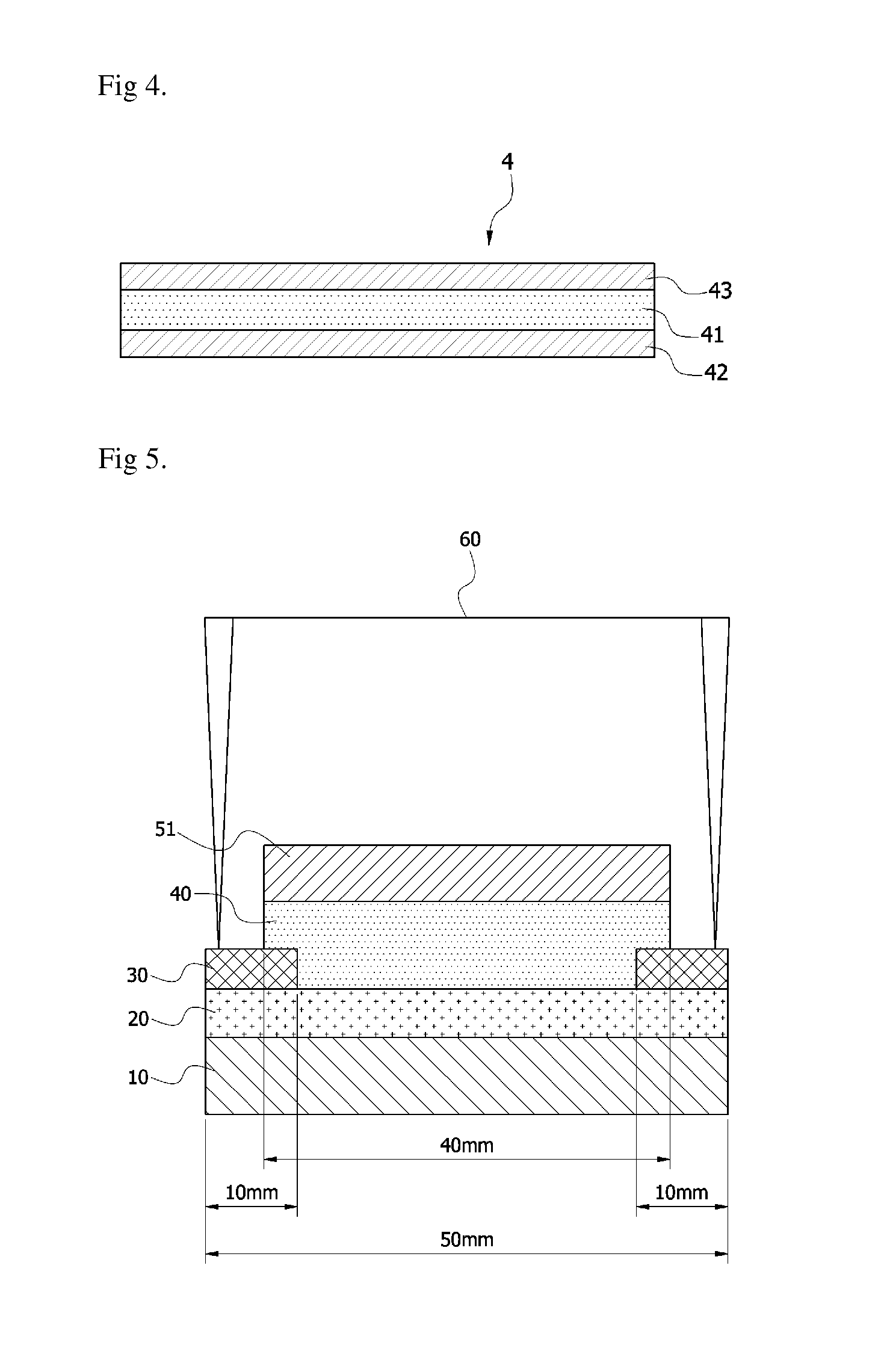

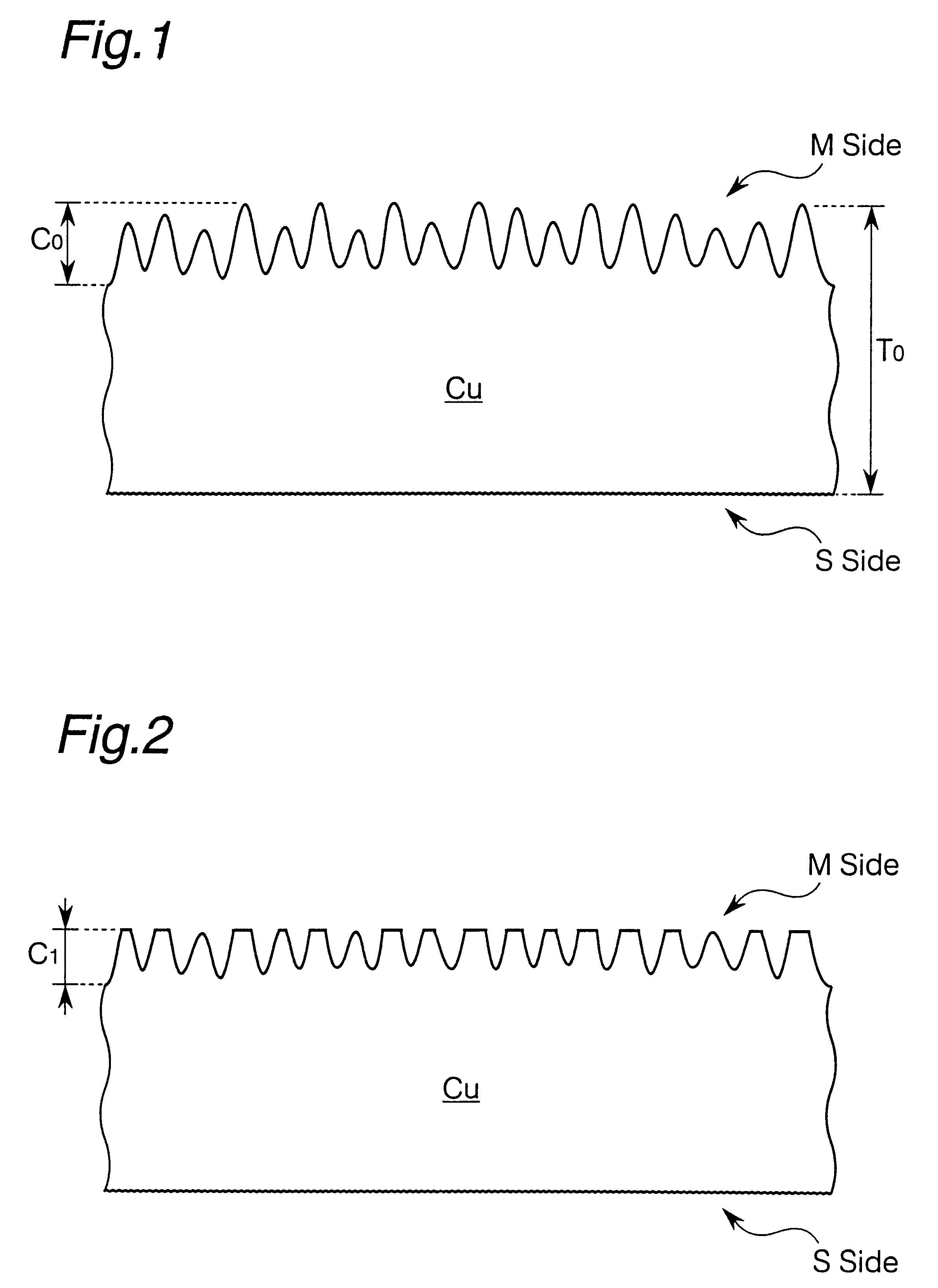

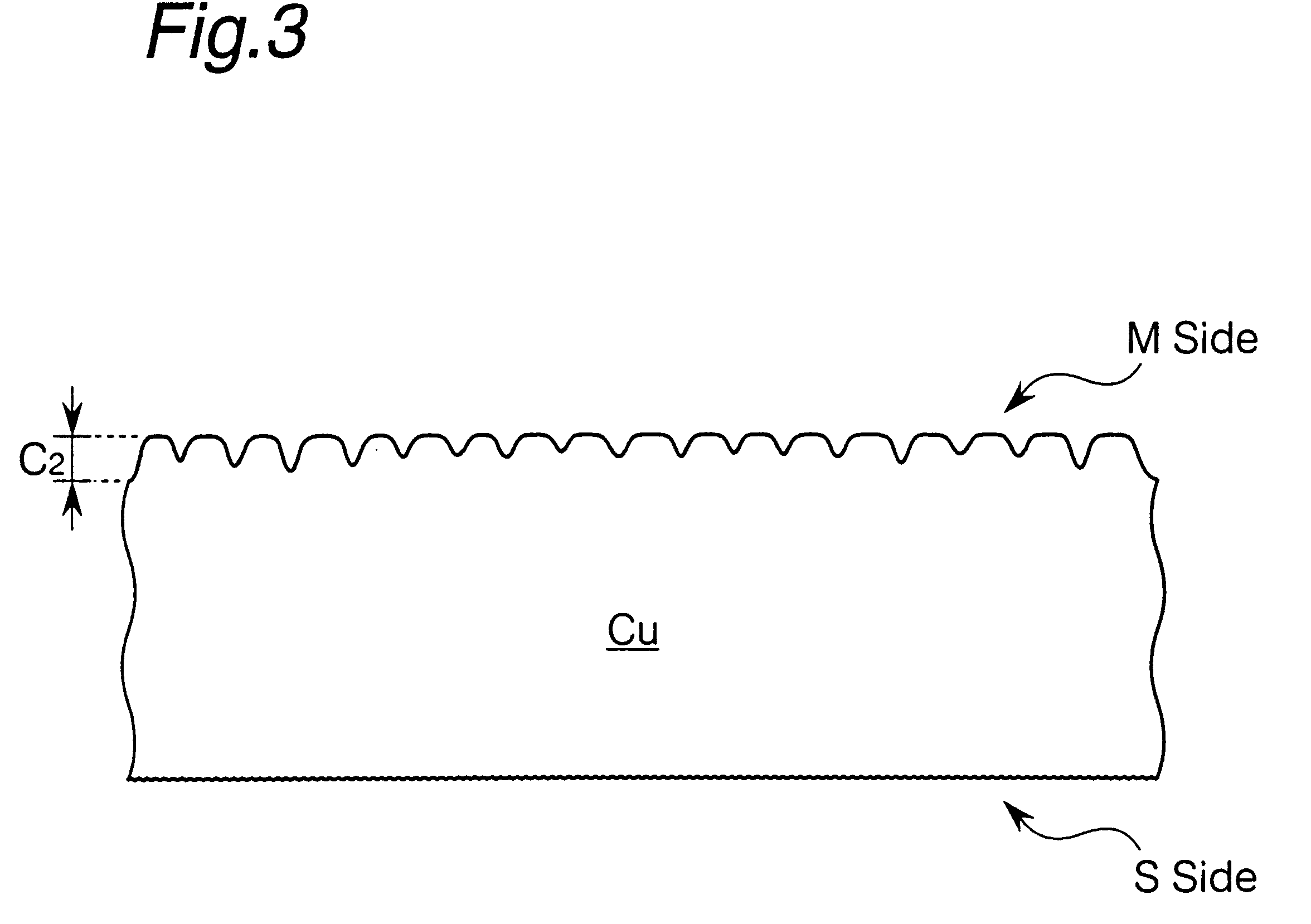

Electrodeposited copper foil with its surface prepared, process for producing the same and use thereof

InactiveUS6475638B1Eliminate deformationHigh peel strengthInsulating substrate metal adhesion improvementLapping machinesSurface roughnessCopper foil

A process for producing an electrodeposited copper foil with its surface prepared, comprising the steps of: subjecting an electrodeposited copper foil having a shiny side and a matte side whose average surface roughness (Rz) is in the range of 2.5 to 10 mum to at least one mechanical polishing so that the average surface roughness (Rz) of the matte side becomes in the range of 1.5 to 3.0 mum; and subjecting the matte side having undergone the mechanical polishing to a selective chemical polishing so that the average surface roughness (Rz) of the matte side becomes in the range of 0.8 to 2.5 mum. The invention further provides an electrodeposited copper foil with its surface prepared, produced by the above process, and still further provides PWBs and a multilayer laminate of PWBs, produced with the use of the above electrodeposited copper foil with its surface prepared. The mechanical polishing followed by chemical polishing of the matte side enables obtaining an electrodeposited copper foil with its surface prepared, the matte side of which exhibits excellent properties, and hence enables obtaining PWBs and a multilayer PWBs which have excellent properties.

Owner:MITSUI MINING & SMELTING CO LTD

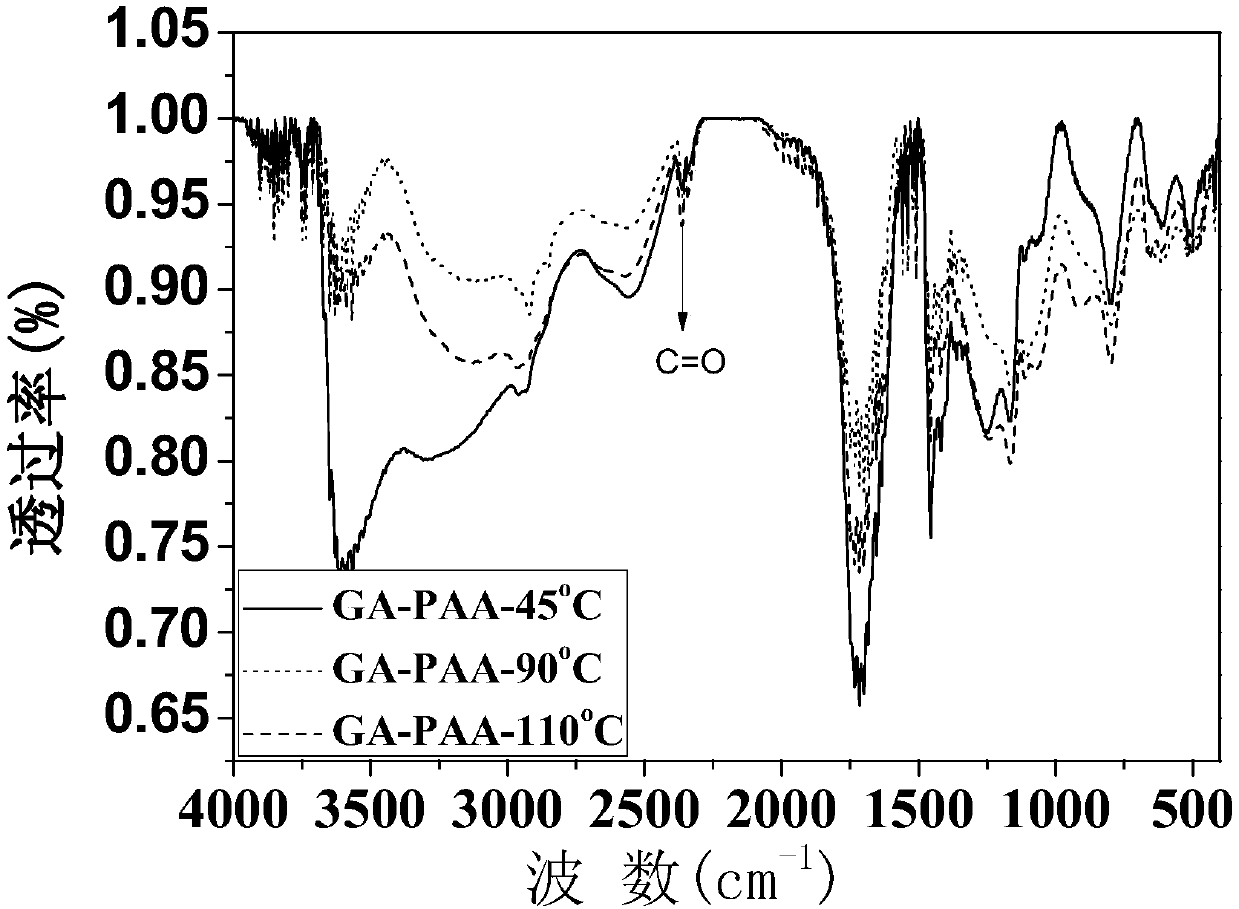

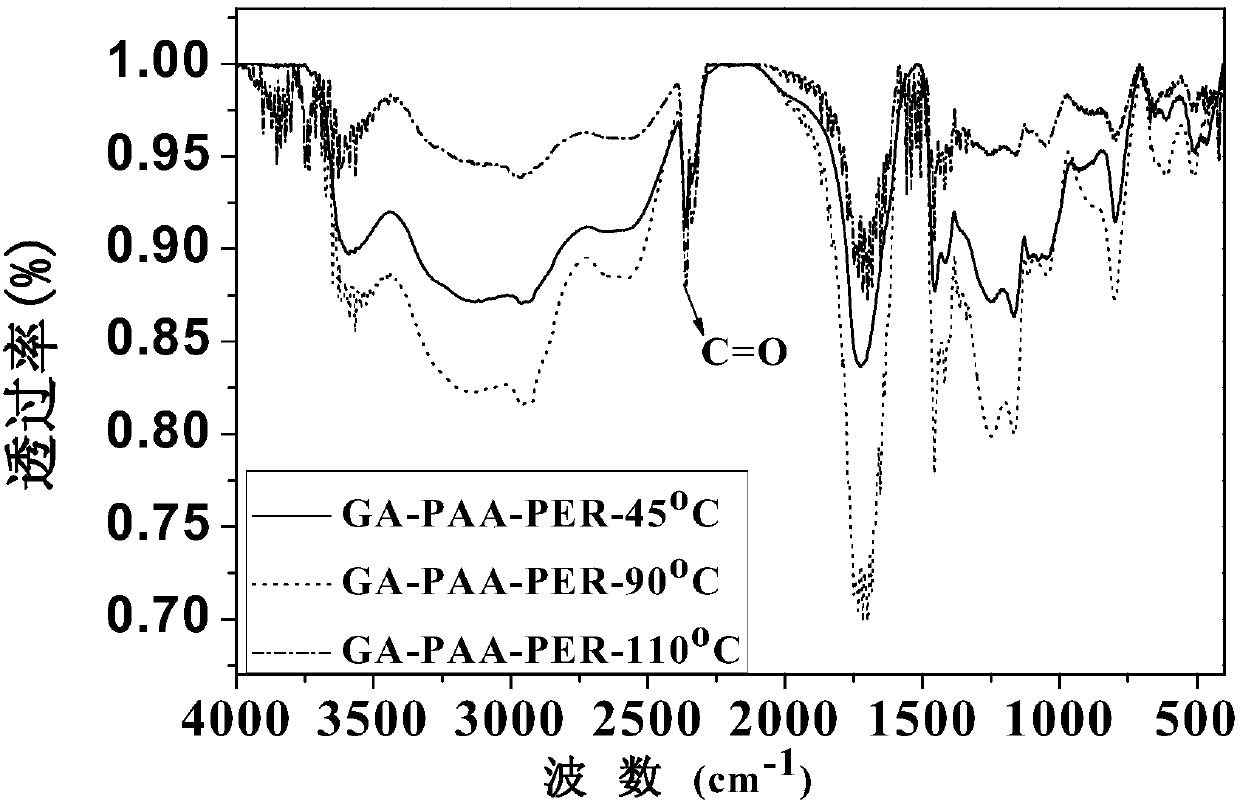

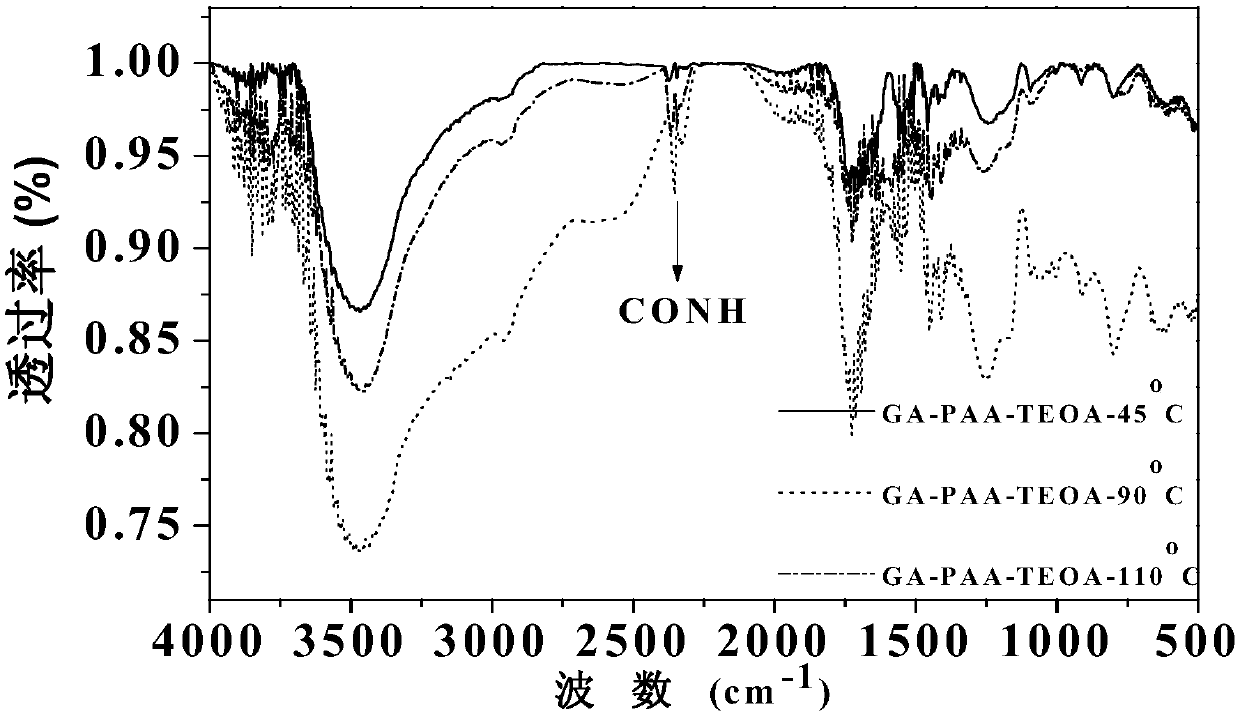

Method for preparing cross-linking waterborne adhesive for lithium ion batteries

ActiveCN107793967AIncrease transfer rateConducive to conductionSecondary cellsNegative electrodesWater solubleCurrent collector

The invention discloses a method for preparing cross-linking waterborne adhesive for lithium ion batteries. Waterborne polymers containing organic carboxylic acid, amino or hydroxyl and a water-soluble micromolecular cross-linking agent containing hydroxyl, amino or carboxyl are jointly used as raw materials of the waterborne adhesive and subjected to cross linking through esterification and amidation under the condition of coating and drying of electrode plate paste of the lithium ion batteries. A preparation process is simple, existing lithium ion battery production process conditions are unchanged, electrodes high in bonding performance, flexibility and elasticity are obtained, and problems of low bonding strength among electrode active substances, conductive agents and current collectors and looseness and shedding due to insufficiency in elasticity for relieving expansion and contraction in charging and discharging processes of the lithium ion batteries in the prior art are solved.

Owner:GUANGZHOU INST OF ENERGY CONVERSION - CHINESE ACAD OF SCI

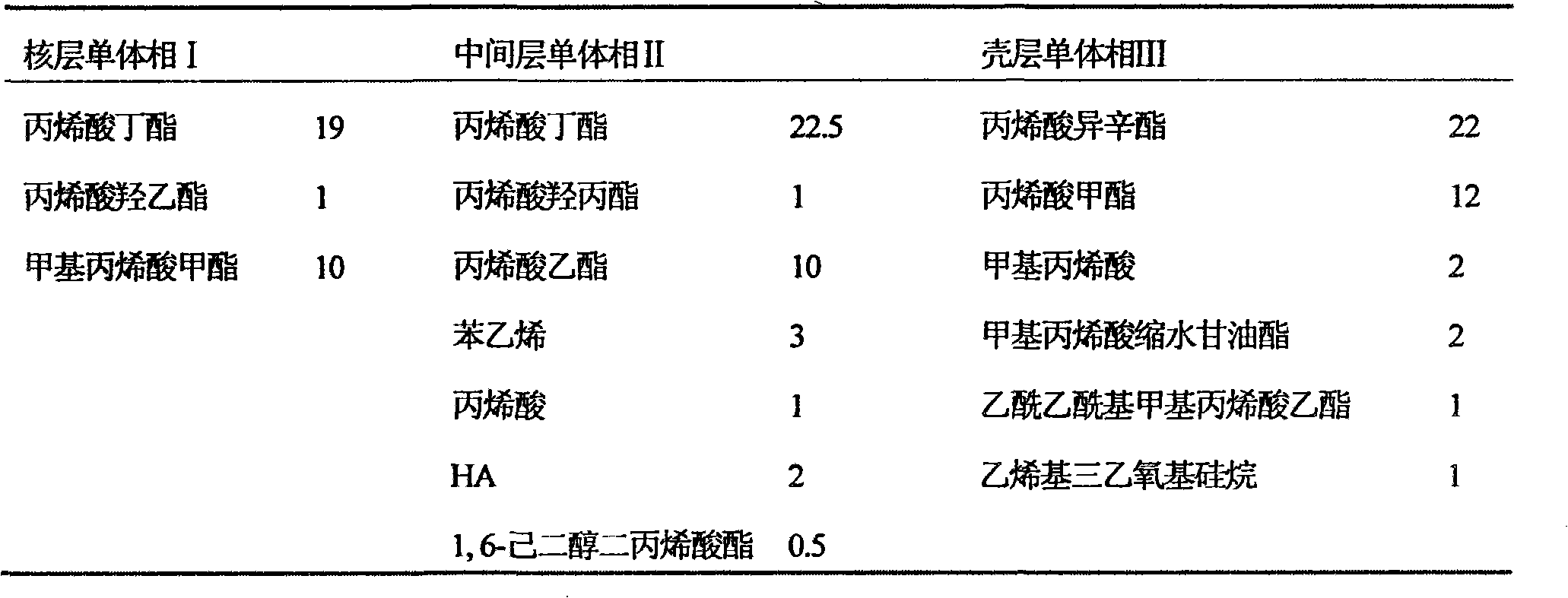

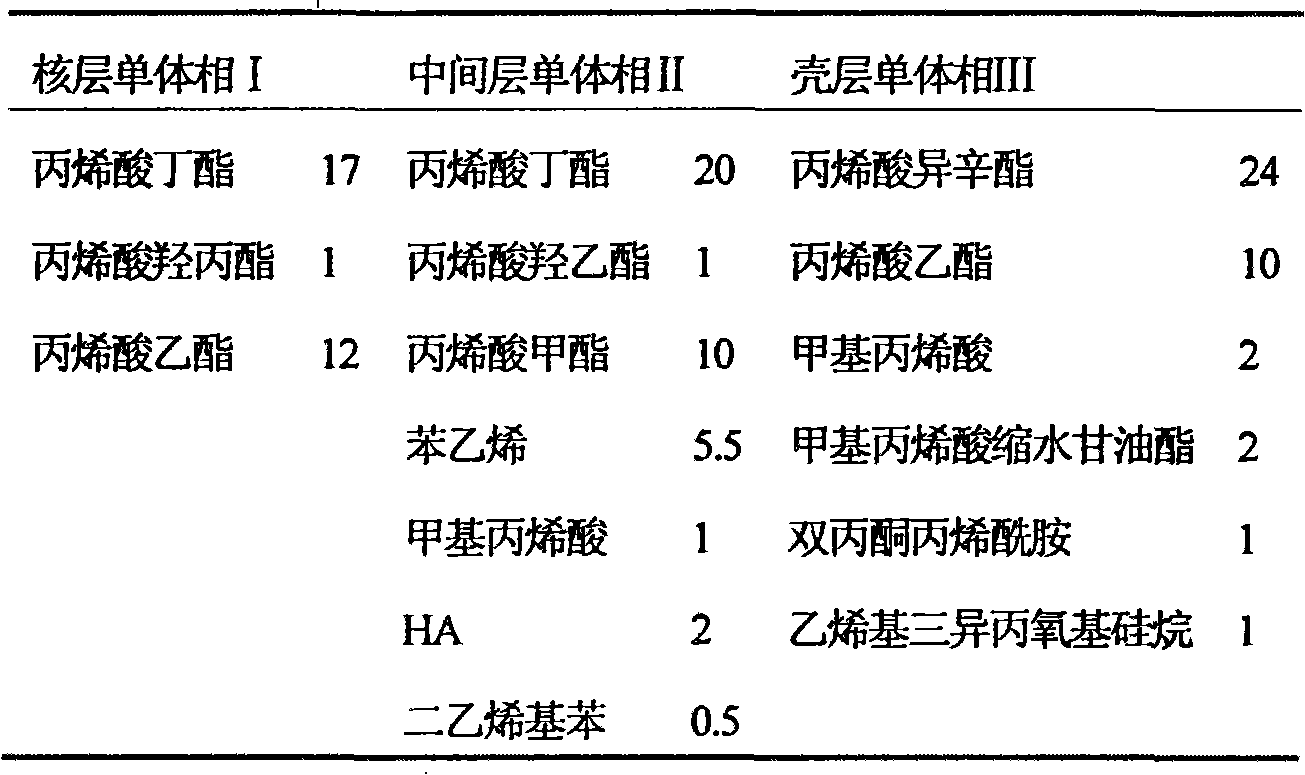

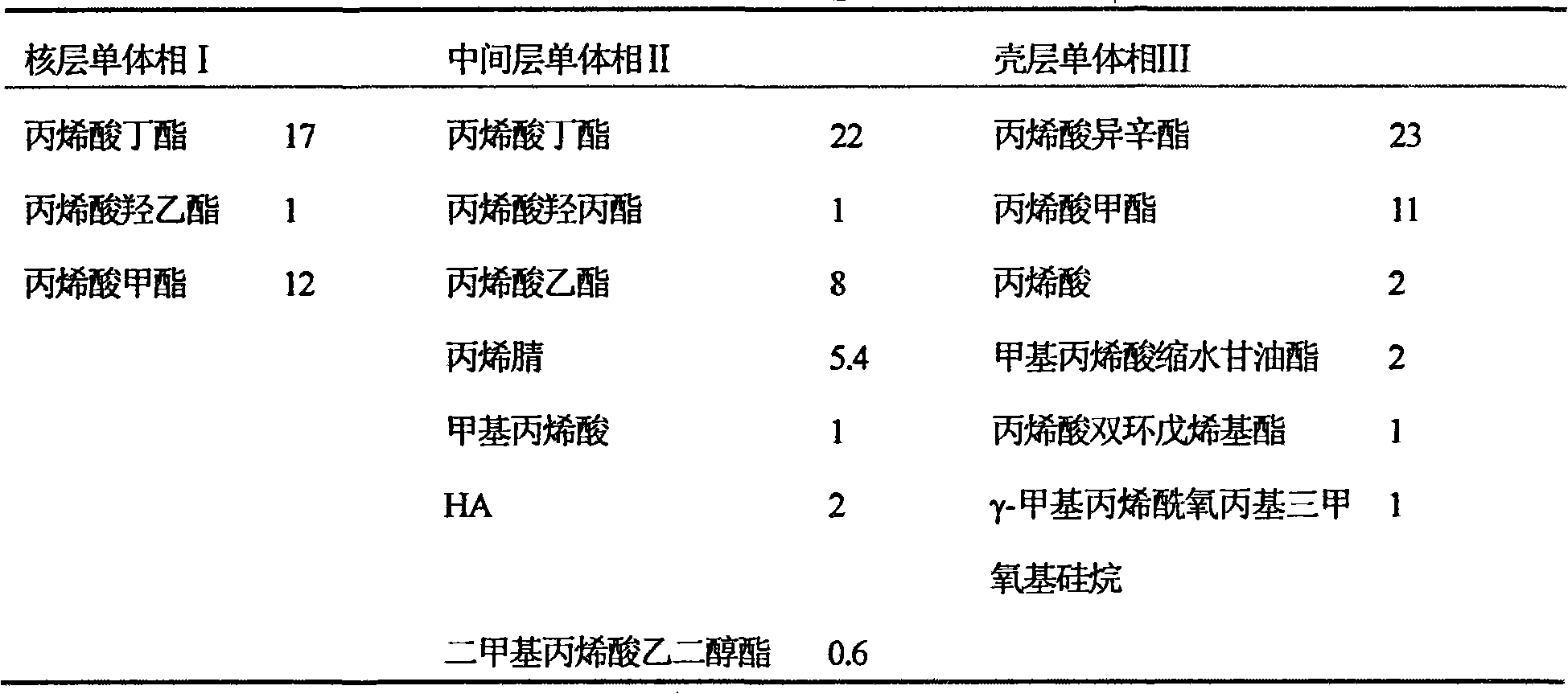

Single-component low temperature self-crossing emulsion adhesive for paper and plastic compounds and preparing method thereof

InactiveCN101928534ALess slagHigh affinityNon-macromolecular adhesive additivesEster polymer adhesivesPolymer scienceAdhesive

The invention discloses a single-component low temperature self-crossing emulsion adhesive for paper and plastic compounds and a preparing method thereof. The raw materials of the self-crossing emulsion adhesive comprise the following components in part by weight: 100-150 parts of de-ionized water, 0.8-3.0 parts of emulsifier, 20-40 parts of nuclear layer monomer, 30-50 parts of interlayer monomer, 20-40 parts of shell layer monomer, and 0.2-0.6 part of initiator. The invention uses a small amount of anionic emulsifier to prepare nuclear emulsion, uses polymerisable emulsifier to prepare interlayer and shell layer pre-emulsion, and adopts semi-continuous seeded low emulsion polymerization process to prepare emulsion particles that have a three-layer core-shell microstructure to obtain the exquisite and stable emulsion. The product has no organic solvent, and does not release methanal, contains no APEO and no phthalate; the film coating has high transparency, high water resistance and high heat and humidity resistance; and the emulsion adhesive is applied to plastic and paper compounds, has high adhesive strength, peel strength and permanent adhesion, is also compatible to oil and ink and has high oil / ink transferring rate.

Owner:SOUTH CHINA UNIV OF TECH

Solvent-free organic silicon pressure-sensitive adhesive and preparation method thereof

ActiveCN102174309AReduce or eliminate the generation ofGood compatibilityAdhesivesEnd-groupSolvent free

The invention relates to a solvent-free organic silicon pressure-sensitive adhesive. The organic silicon pressure-sensitive adhesive comprises the following components in part by mass: 100 parts of polydimethylsiloxane of which the end group is alkenyl; 1 to 300 parts of polydimethylsiloxane of which the end group is hydroxyl; 1 to 50 parts of MQ resin, 1 to 30 parts of polyisobutylene, 20 to 200 parts of diluting agent, 0.1 to 5 parts of crosslinking agent and a platinum catalyst capable of curing the organic silicon pressure-sensitive adhesive. The invention also relates to a preparation method of the organic silicon pressure-sensitive adhesive. The organic silicon pressure-sensitive adhesive has the characteristics of high initial tack, long residual action, proper peeling strength, drug penetration and the like, is nontoxic, environmentally-friendly and reusable, and can be prepared into pressure-sensitive adhesive tapes, medical pressure-sensitive adhesive strips and other functional materials requiring the pressure-sensitive performance.

Owner:SHENZHEN CITY SQUARE SILICONE MATERIALS

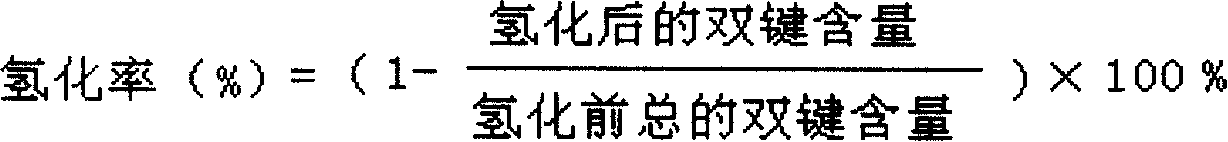

Adhesion agent and method of manufacturing the same

The invention discloses an adhesive, which comprises the following parts: epoxy resin, flexibilizer, catalyst, hardener, accelerant, mineral filler and solvent, wherein the flexibilizer consists of 10-100wt% hydrogenated acrylonitrile butadiene and 0-90wt% acrylonitrile butadiene with hydrogenated rate of hydrogenated acrylonitrile butadiene at 50-100%. The invention has good expression in peel strength of flexible printing circuit, flexibility, size stability, chemical-resisting and electric insulativity, which also possesses superior thermostable decomposability and anti-metal mobility.

Owner:BYD CO LTD

Method for preparing aqueous polyurethane adhesive and superfine fiber synthetic leather

ActiveCN101665675AHigh peel strengthIncrease elasticityPolyureas/polyurethane adhesivesSynthetic resin layered productsPolyesterFolding endurance

The invention relates to a method for preparing an aqueous polyurethane adhesive and superfine fiber synthetic leather, which belongs to the technical field of chemical products and preparation methods thereof. The method is characterized by comprising the following steps: mixing polyester polyol, isocyanate, a hydrophilic chain extending agent, a micromolecule chain extending agent and an amine environment friendly catalyst to obtain a hydrophilic aqueous polyurethane prepolymer; adding a neutralizing agent to the aqueous polyurethane prepolymer to obtain an aqueous polyurethane latex; then adding an amine chain expanding agent, a thickening agent, a defoaming agent and a flatting agent to the aqueous polyurethane latex to obtain the aqueous polyurethane adhesive; coating the aqueous polyurethane latex on release paper; drying the release paper; then coating the aqueous polyurethane adhesive on the dried release paper; and pressing the release paper and base cloth together to obtain the superfine fiber synthetic leather. The high solid content aqueous polyurethane adhesive prepared by the method has better initial tack and rebound resilience and higher final strength, and the prepared superfine fiber synthetic leather has higher peel strength and low-temperature folding endurance. The preparing process of the method greatly reduces the use and the discharge of organic solvents, reduces the energy consumption and furthest reduce the environmental pollution.

Owner:HUADA CHEM GRP CO LTD

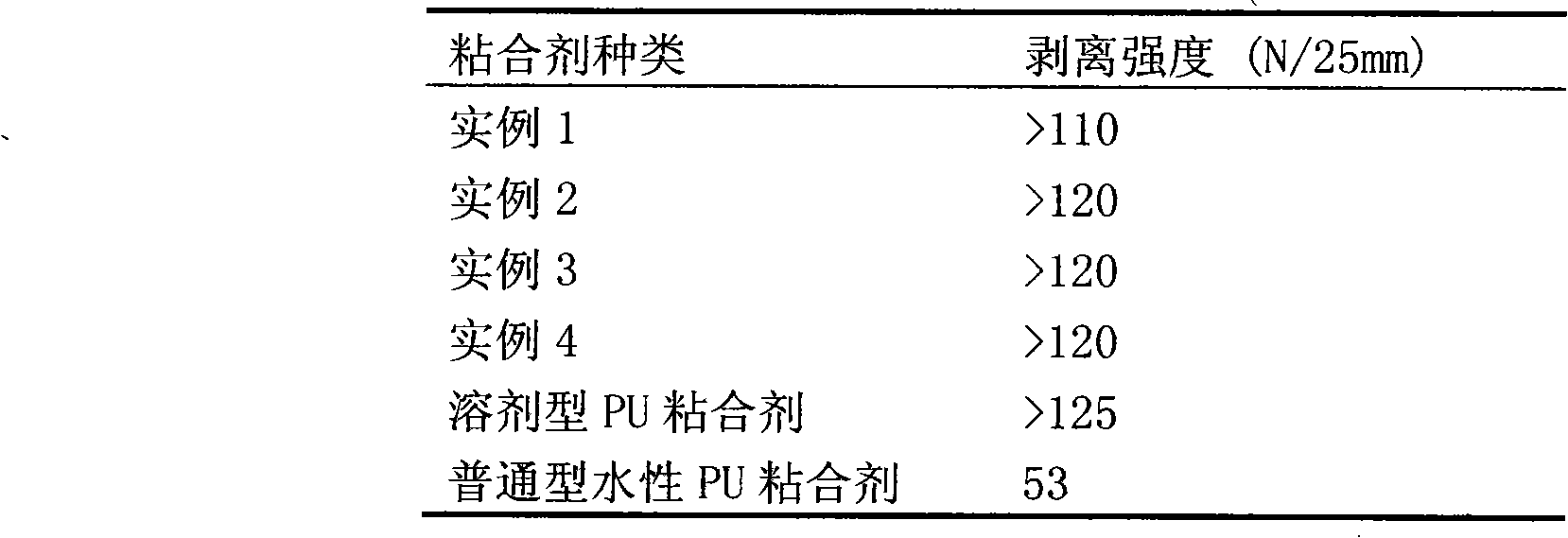

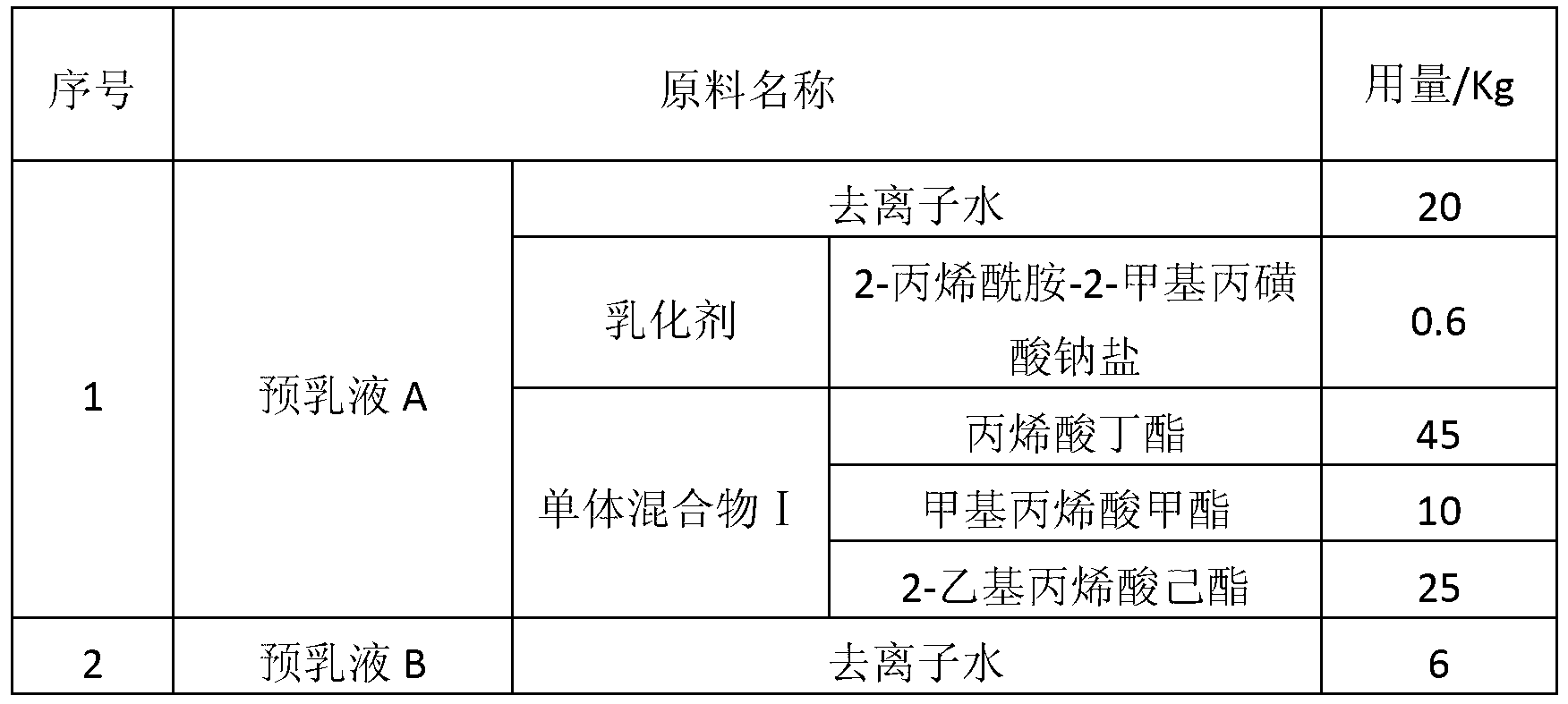

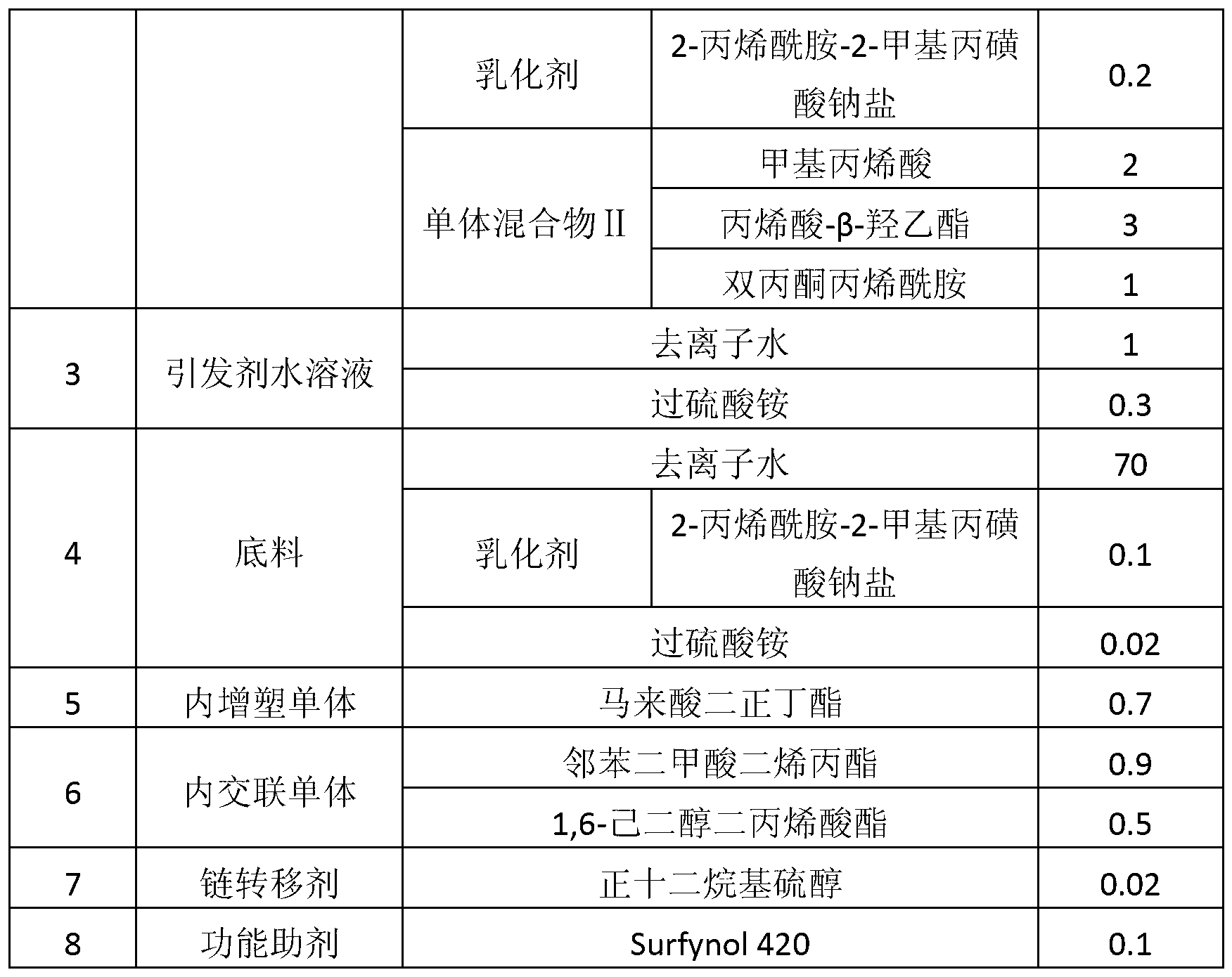

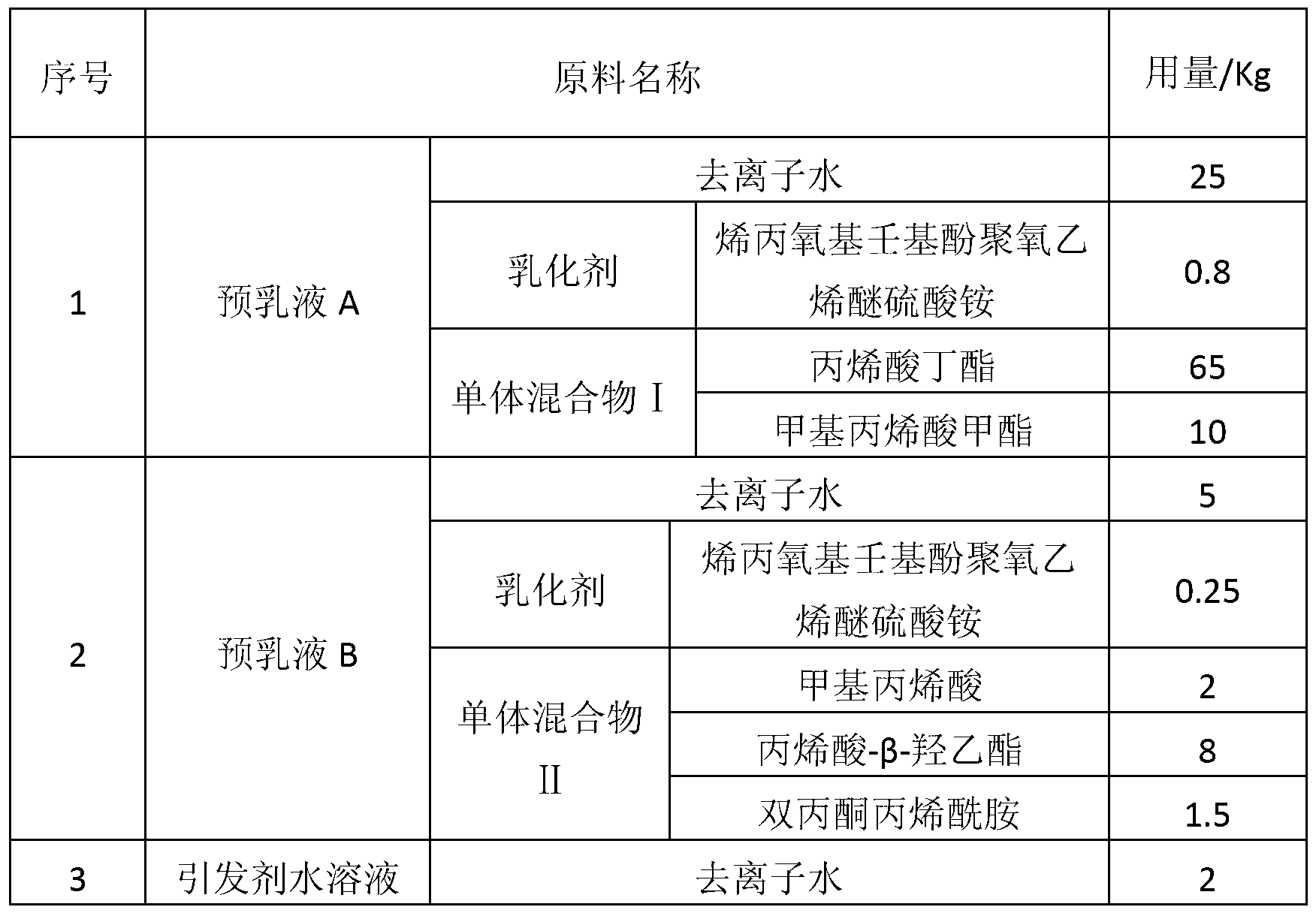

Water-based plastic-plastic compound adhesive for food and drug flexible package and preparation method thereof

ActiveCN103059784AHigh bonding strengthImprove stabilityEster polymer adhesivesWater basedPolyurethane adhesive

The invention discloses a water-based plastic-plastic compound adhesive for food and drug flexible packages and a preparation method thereof. The preparation method comprises the following steps of: carrying out pre-emulsification by using 20-30 parts by weight of deionized water, 0.4-1.0 part by weight of emulsifying agents and 75-90 parts by weight of monomer mixtures to obtain a pre-emulsion A; then carrying out the pre-emulsification by using 5-8 parts by weight of the deionized water, 0.2-0.3 part of the emulsifying agents and 3-20 parts by weight of the monomer mixtures to obtain a pre-emulsion B; preparing an initiator water solution C by using 1-3 parts by weight of the deionized water and 0.2-0.8 part by weight of initiators; and dropping the monomer mixture I with lower polarity and the monomer mixture II with higher polarity step by step by adopting a pre-emulsification seed emulsion polymerization process to obtain the water-based plastic-plastic compound adhesive for the food and drug flexible packages. The water-based plastic-plastic compound adhesive disclosed by the invention has the advantages of no organic solvent, no formaldehyde release, good adhesivity and high stripping strength and permanent adhesion and can be applied to a flexible package industry and substitute for a solvent type two-component polyurethane adhesive maturely applied to the present market.

Owner:DONGGUAN STAR COSM POLYMER

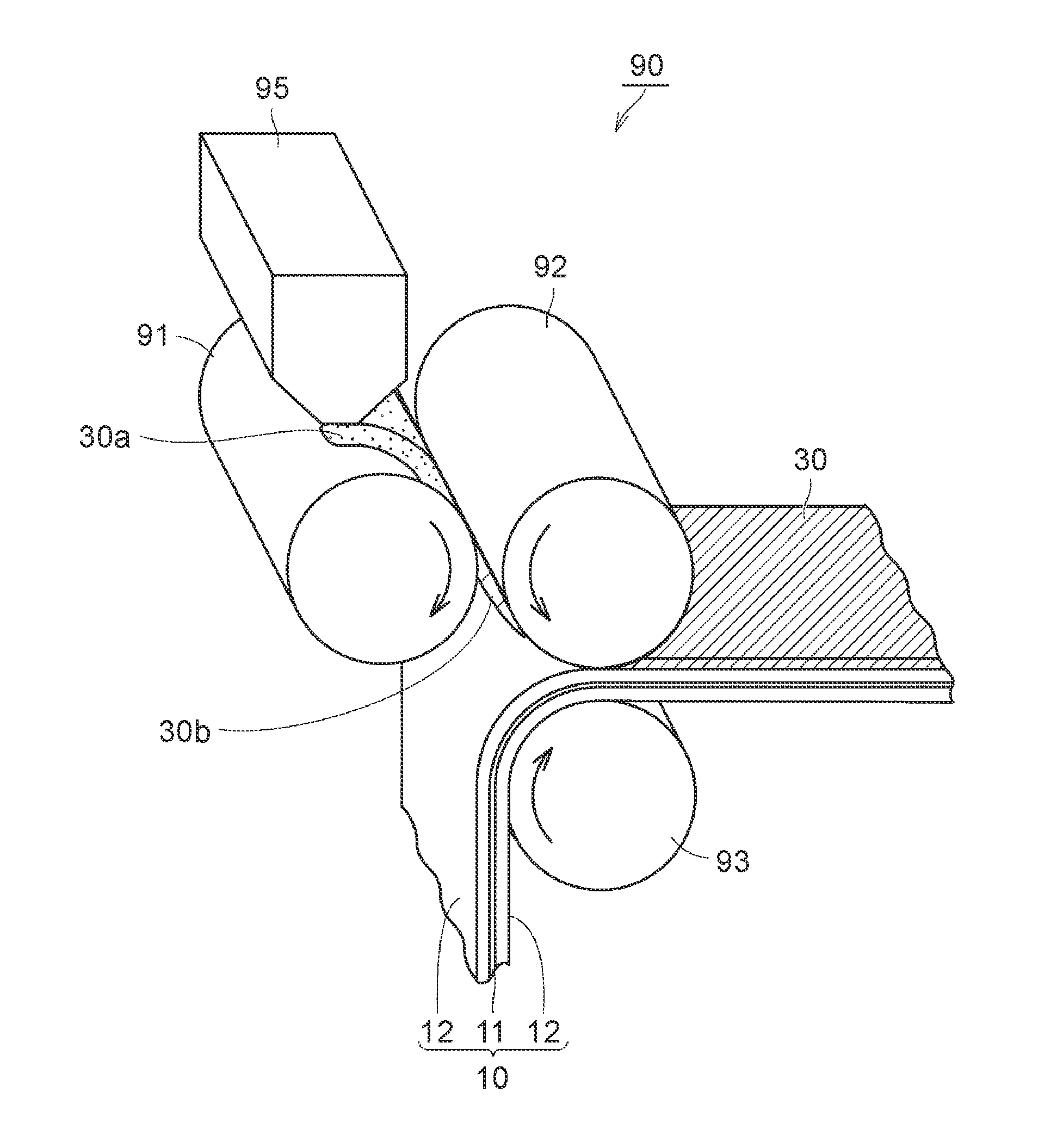

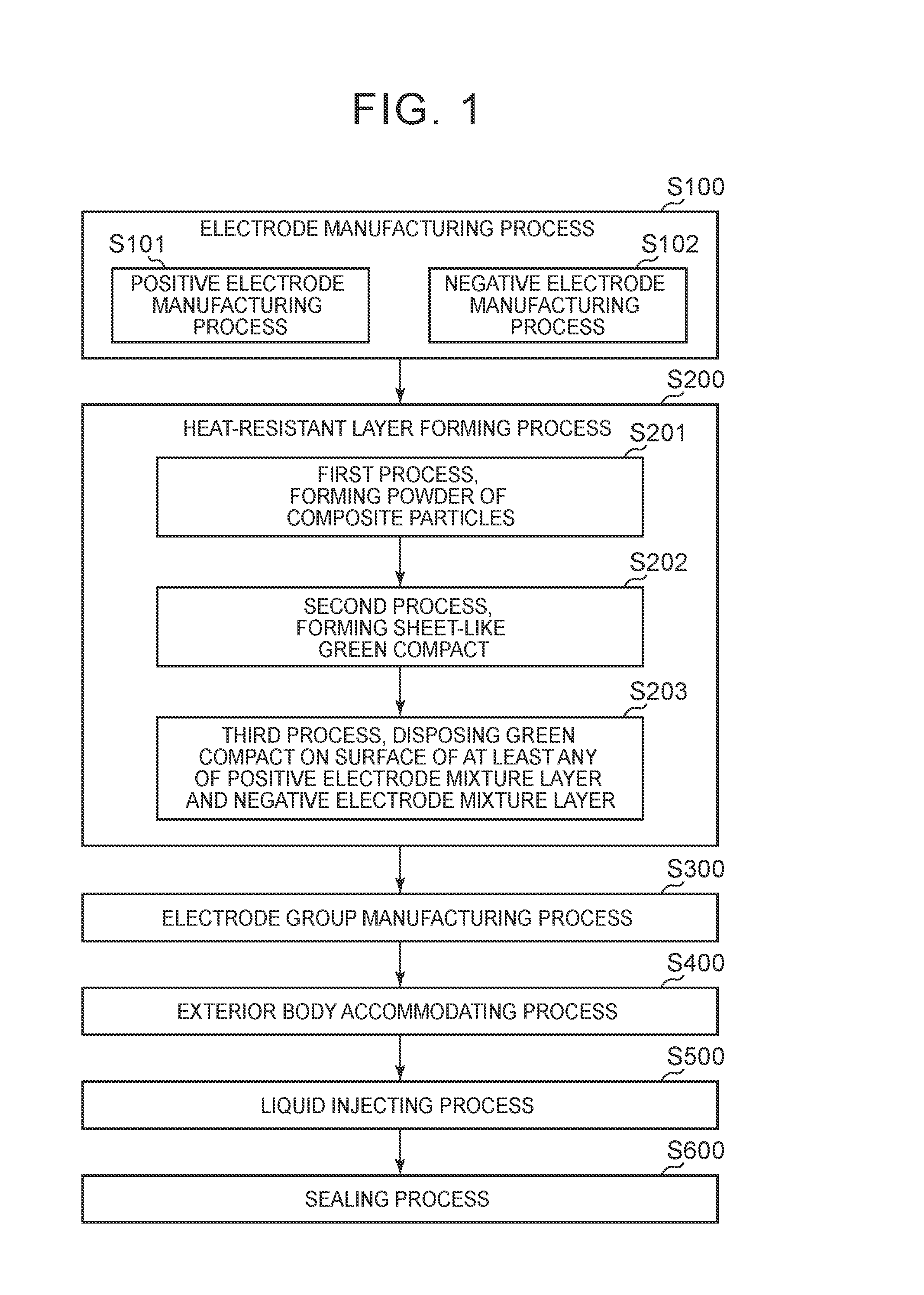

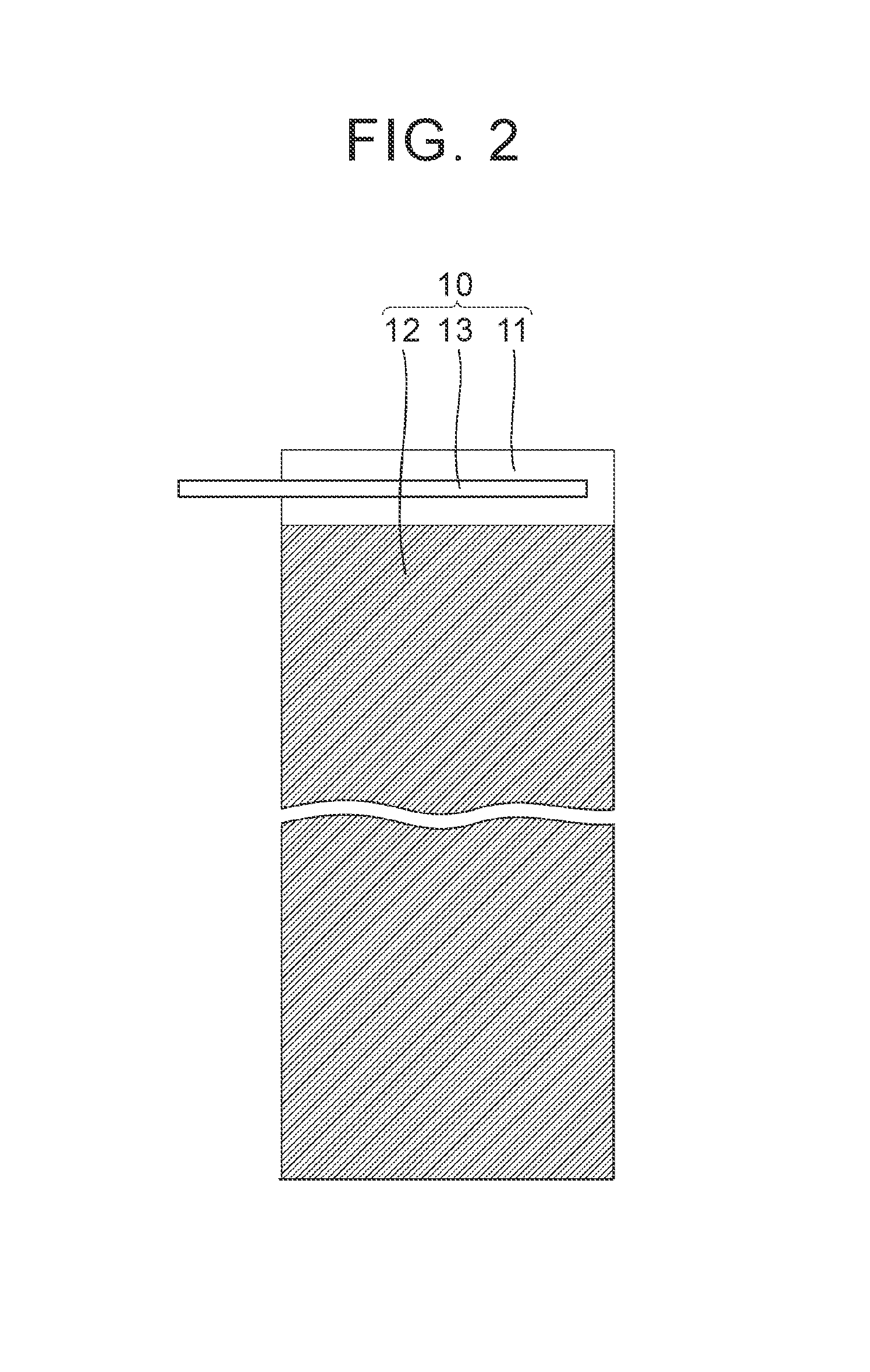

Manufacturing method for non-aqueous electrolyte secondary battery

ActiveUS20160240839A1Reduce the amount requiredHigh strengthElectrode rolling/calenderingNon-aqueous electrolyte accumulatorsSolventInorganic filler

A manufacturing method for a non-aqueous electrolyte secondary battery includes: forming a powder; forming a sheet-like green compact; and forming a heat-resistant layer. The powder contains composite particles and a solvent. The composite particles contain inorganic filler particles and a binder. The green compact is formed by pressing the powder in a state in which the solvent remains. The heat-resistant layer is formed by disposing the green compact on a surface of at least any of a positive electrode mixture layer and a negative electrode mixture layer after the green compact is formed.

Owner:TOYOTA JIDOSHA KK

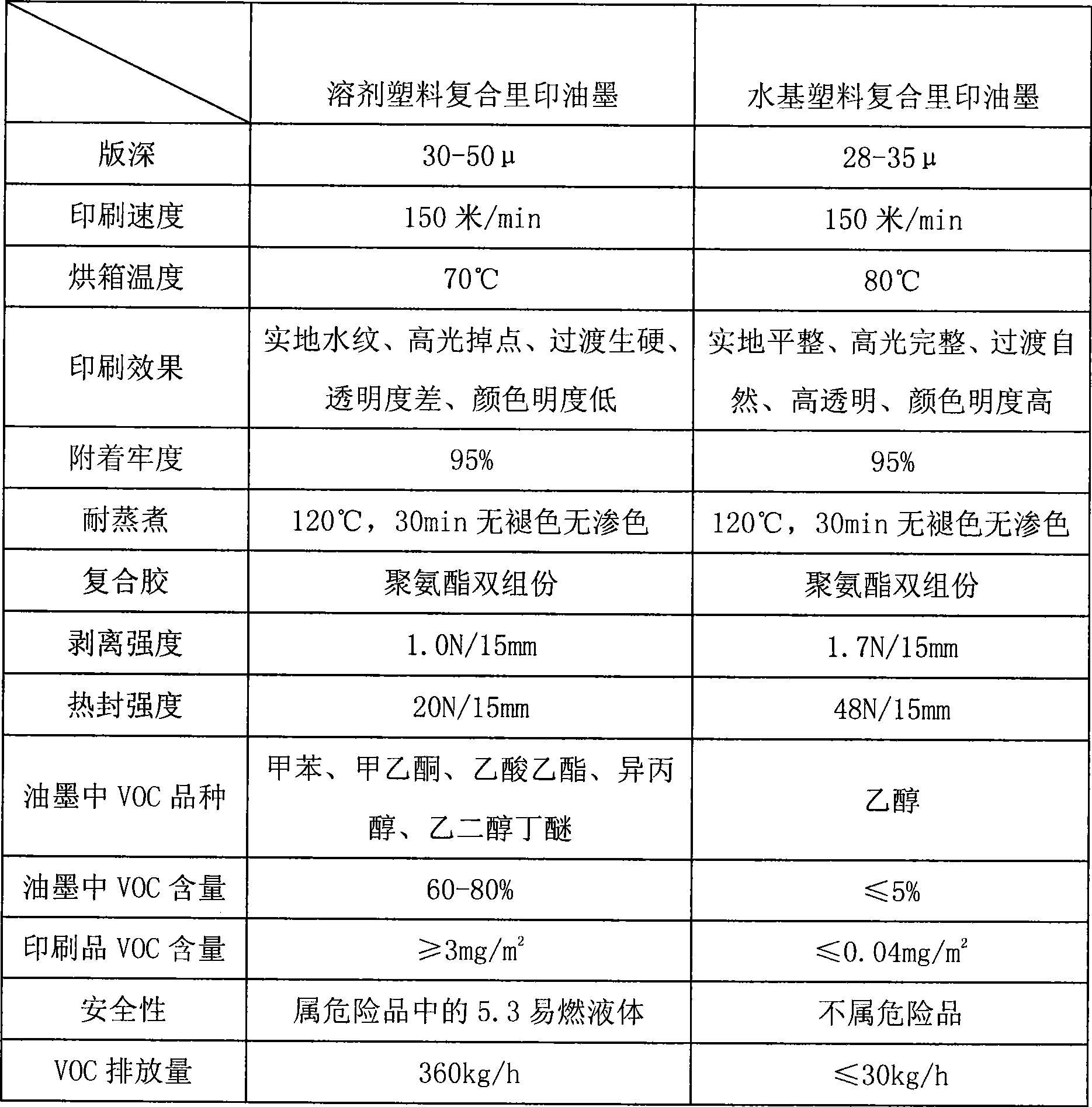

Water-based plastic composite inner-printing ink

The invention discloses a water-based plastic composite printing ink, in particular to a water-based ink needed in the plastic film intaglio printing composite process. To solve problems, the invention provides the water-based ink which remarkably improves composite strength, sealing strength and printing mass relative to the prior solvent ink on the premise of not reconstructing the prior printing equipment or adjusting the printing process; the water-based ink adopts the following technical proposal: the water-based plastic composite printing ink is prepared from the following raw materials in weight portion: 10 to 35 portions of aqueous polyurethane emulsion, 0 to 8 portions of aqueous acrylic resin, 0 to 7 portions of aqueous wetting dispersant, 0.2 to 2 portions of aqueous dampness levelling agent, 0.1 to 2 portions of aqueous defoaming agent, 0.1 to 5 portions of PH regulator, 6 to 30 portions of pigment, 0 to 5 portions of ethanol and 6 to 73.6 portions of water. The water-based ink can be widely applied in the field of ink manufacturing.

Owner:山西鹰鲲科技有限公司 +1

Method for joining laser transmitting resin member and porous member, method for joining thermoplastic resin, and fuel cell

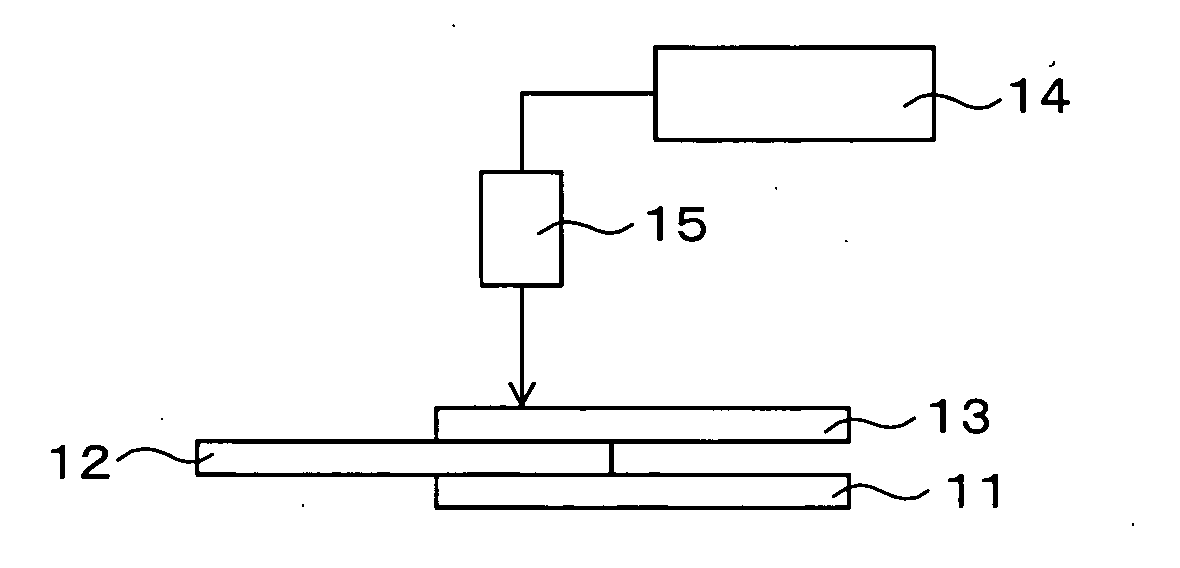

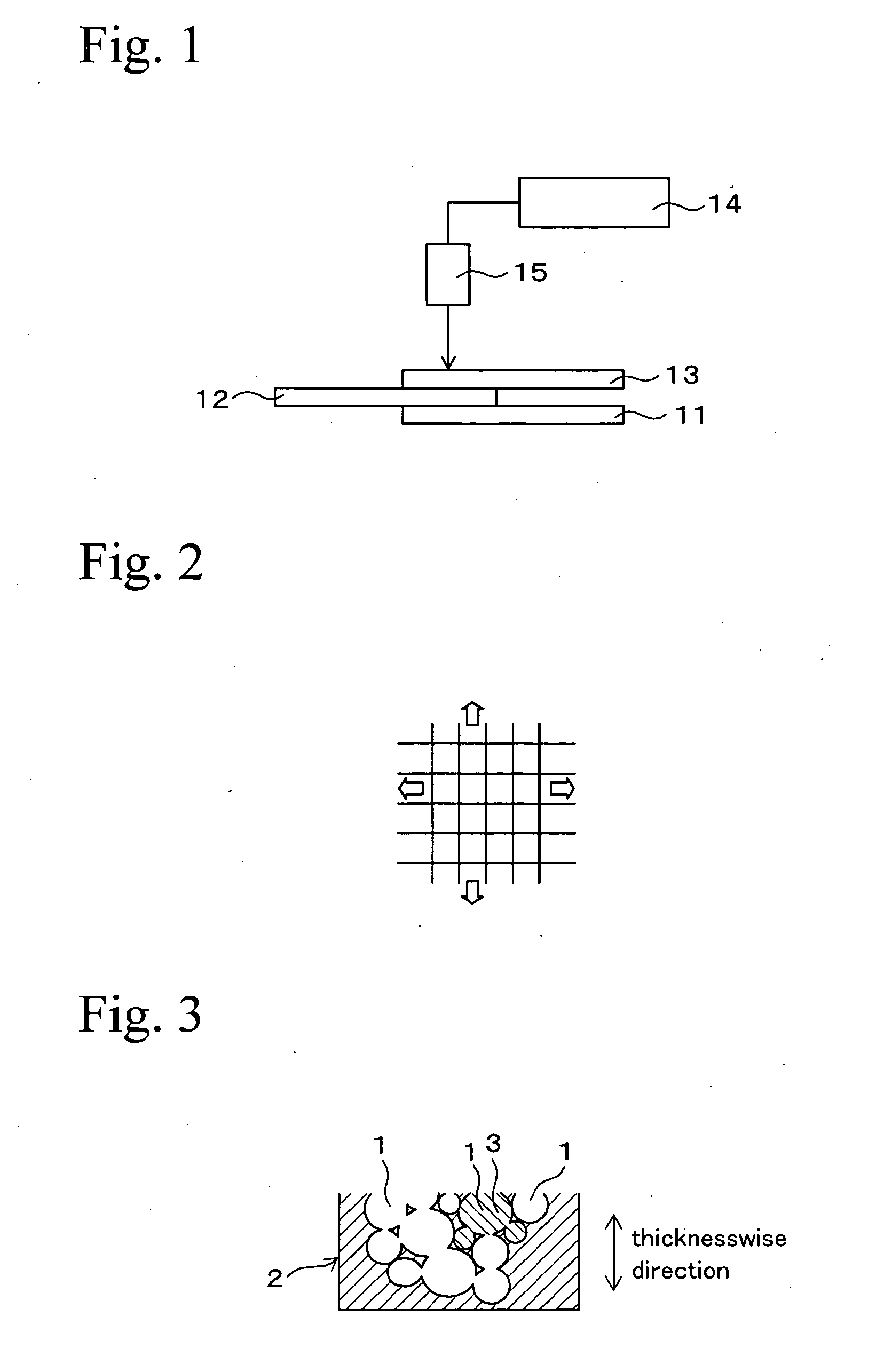

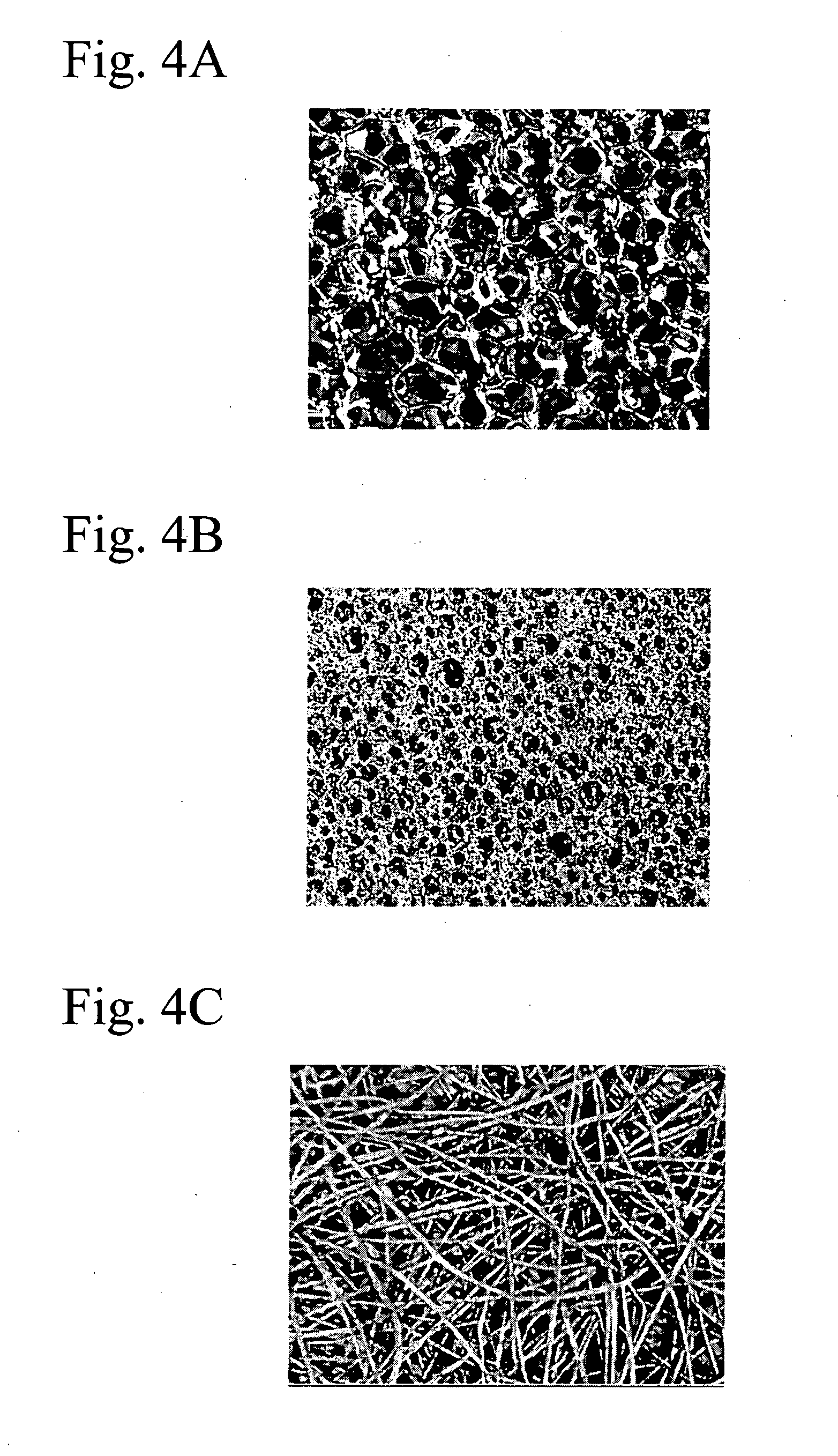

InactiveUS20050208361A1Decrease productivityImprove productivityLamination ancillary operationsFuel cells groupingFuel cellsLaser beams

A method for joining a resin member and a porous member can prevent peeling in a specified direction. When a thermoplastic laser transmitting resin member and a porous member are joined, the laser transmitting resin layer and the porous member are laminated, and a laser beam is emitted at a side of the laser transmitting resin member. The porous member is heated so that the laser transmitting resin member is melted, and the melted resin is impregnated with holes of the porous member. The resin is cooled so as to solidify.

Owner:HONDA MOTOR CO LTD

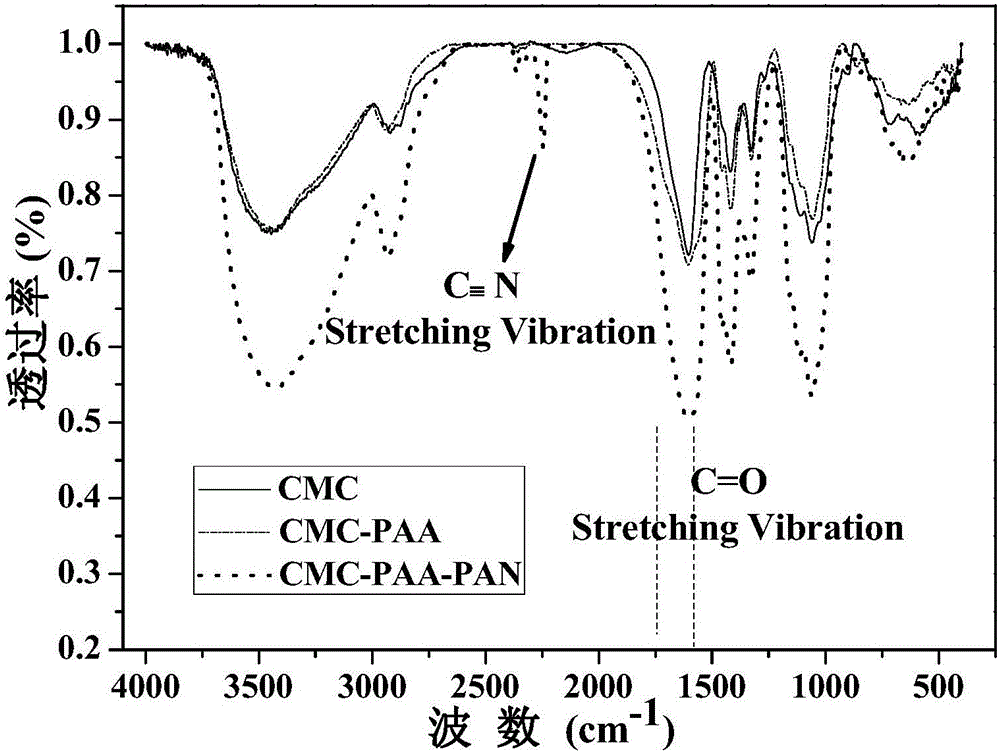

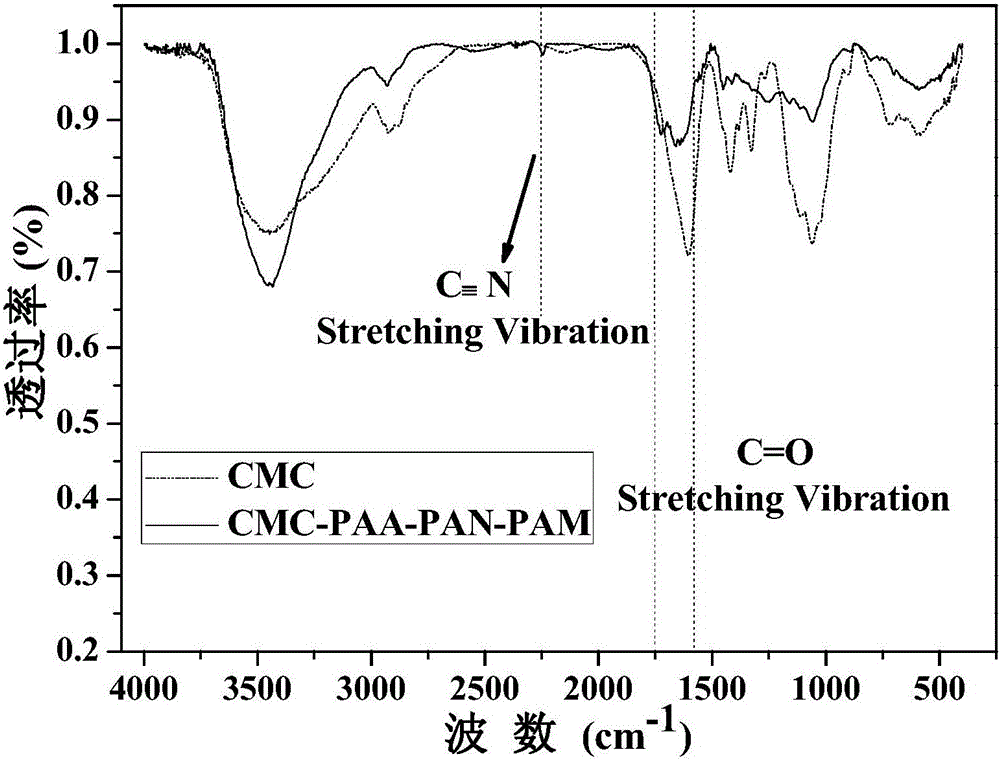

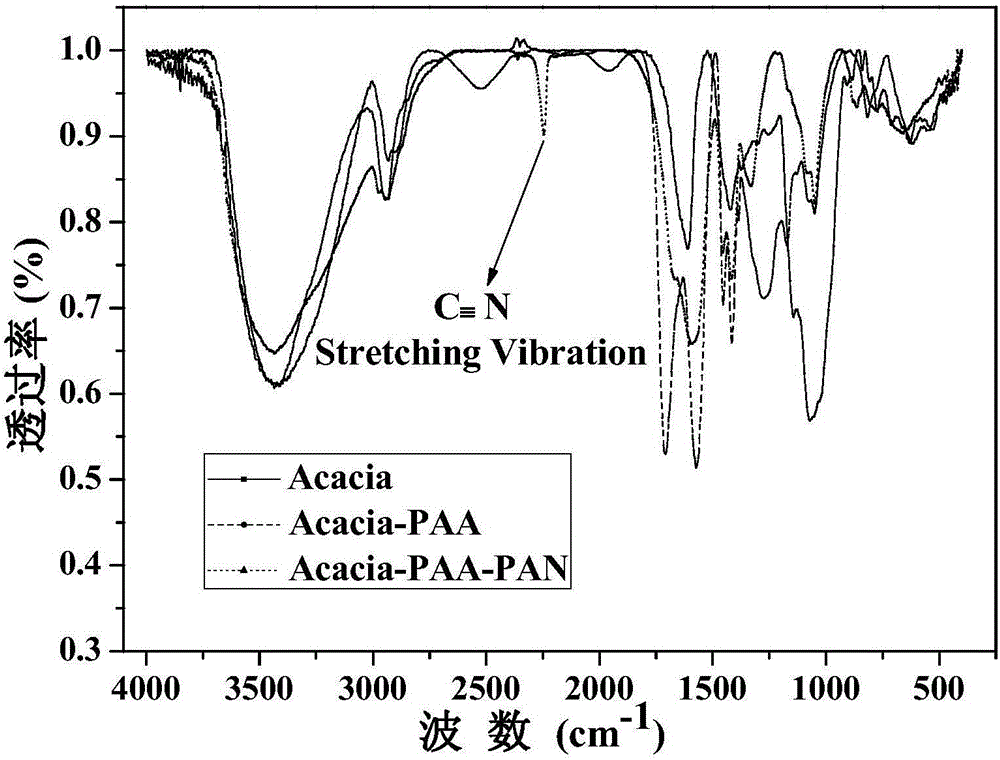

Multielement functional modified polymer binder for lithium ion battery and application of binder in electrochemical energy storage device

ActiveCN105914377AStable and uniform qualityGood overall performanceCyclodextrin adhesivesCellulose derivative adhesivesBiomassAddition reaction

The invention discloses a multielement functional modified binder for a polymer lithium ion battery. The binder takes a biomass polymer or a synthetic polymer as the substrate, takes a hydrophilic monomer and an oleophilic monomer as the functional modified monomer; and then the binder is prepared through a free radical graft copolymerization reaction or a Michael addition reaction in a modification manner. The binder has a multi-branch structured three-dimensional space network body, so that more active sites in contact with the electrode active material can be provided, and the uniformity and the smoothness of the electrode slurry in film-forming can be improved; the peeling strength of the active materials and the conductive agent on the metal substrate is reinforced; and meanwhile, the binder is excellent in elasticity and binding force, can be applied to water / organic solvent and can be applied to the positive electrode and negative electrode of the lithium ion battery; the conduction of electrons / ions in the charging-discharging process can be promoted; the electrochemical interface impedance of the pole piece is lowered; the high rate capacity and the cycling stability of the positive electrode material and the negative electrode material of the lithium battery are relatively improved; in addition, the synthetic raw material is wide in source, so that the cost can be obviously lowered; and therefore, the binder has a wide market prospect.

Owner:GUANGZHOU INST OF ENERGY CONVERSION - CHINESE ACAD OF SCI

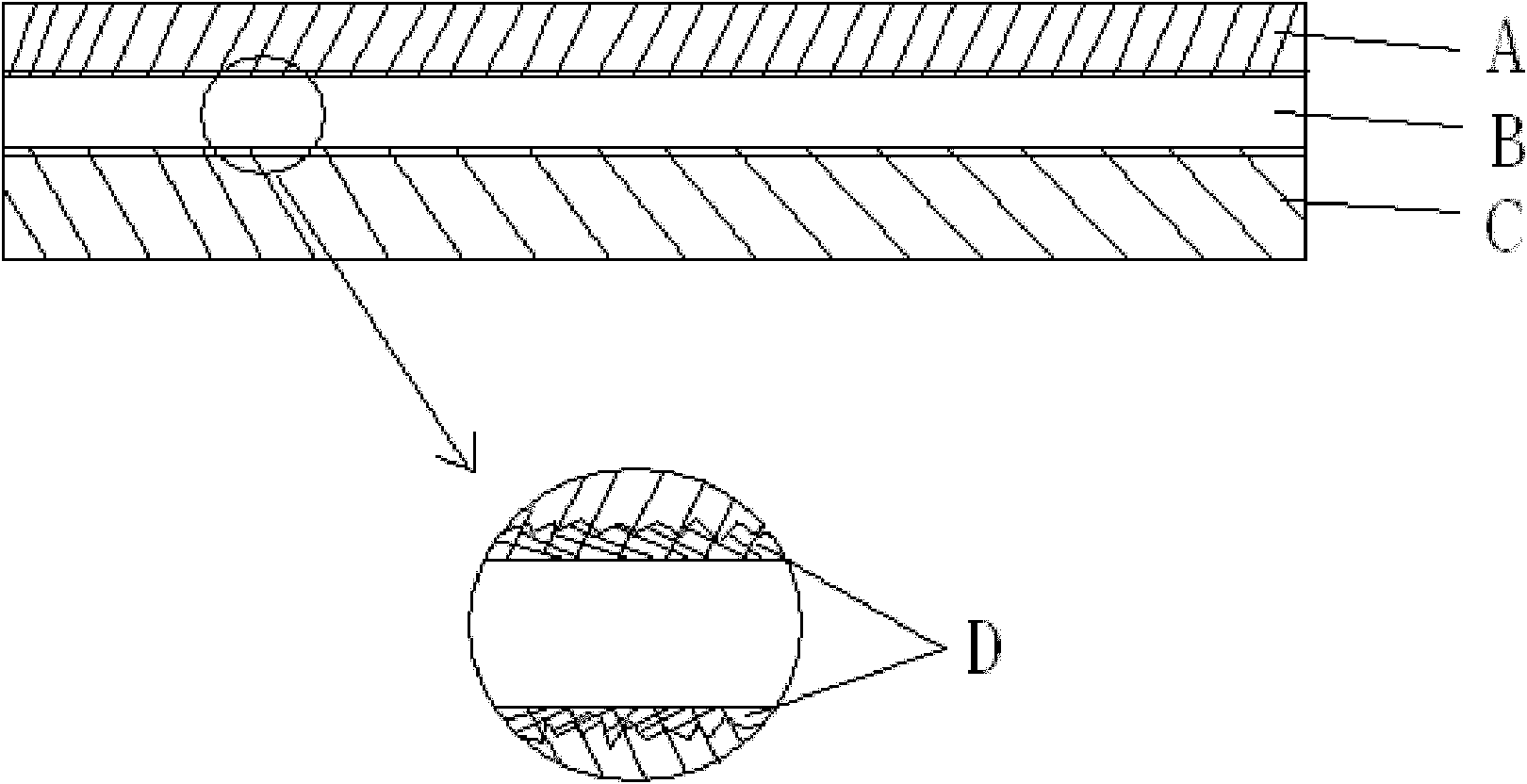

Polytetrafluoroethylene composite membrane and preparation method thereof

The invention provides a polytetrafluoroethylene composite membrane. The polytetrafluoroethylene composite membrane comprises a supporting layer, a polytetrafluoroethylene layer, and a bonding layer for bonding the supporting layer and the polytetrafluoroethylene layer, wherein the supporting layer is one or more of a polypropylene non-woven fabric, a polyester non-woven fabric, and a nylon membrane; and the bonding layer comprises a porous polymer, a solvent and an additive, and the weight ratio of the porous polymer to the solvent to the additive is (15-20):(10-15):(50-70). In polytetrafluoroethylene composite membrane, the porous polymer has uniform pores and high viscosity, and can permeate into the supporting layer and the polytetrafluoroethylene layer, and a hinge structure between the supporting layer and the polytetrafluoroethylene layer is formed after the solidification to fix the supporting layer and the polytetrafluoroethylene layer so as to increase the peeling strength of the composite membrane and improve the service life of the composite membrane. The invention also provides a preparation method of the polytetrafluoroethylene composite membrane; the process conditions are mild; and the method is suitable for mass production.

Owner:CHANGCHUN INST OF APPLIED CHEMISTRY - CHINESE ACAD OF SCI

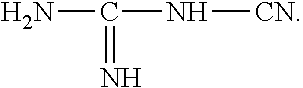

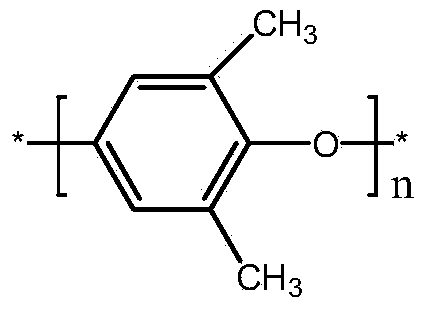

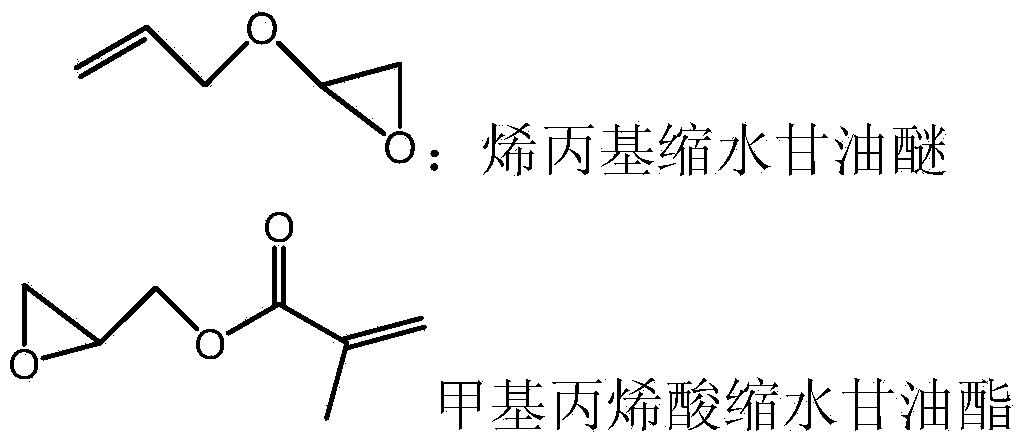

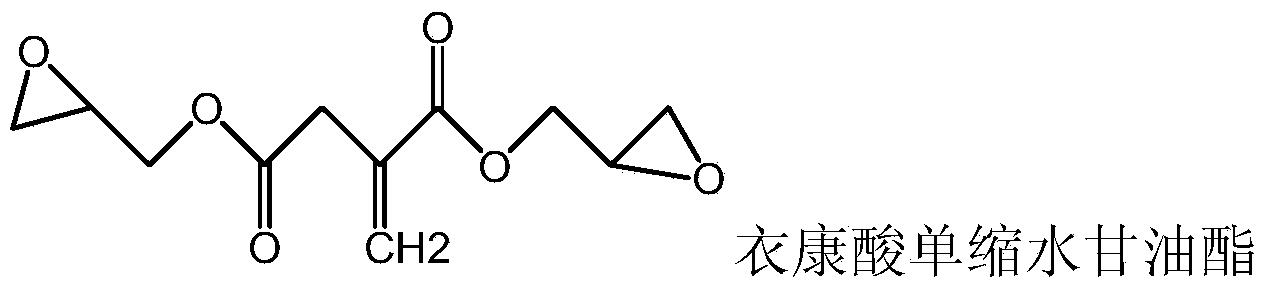

Thermosetting resin composition and use thereof

InactiveCN103467967ALow dielectric constantImprove adhesionSynthetic resin layered productsCircuit susbtrate materialsDielectric lossDouble bond

The invention relates to a thermosetting resin composition. The thermosetting resin composition comprises (A) polyphenylene ether resin; (B) epoxy resin; (C) a curing agent and (D) an initiating agent. The thermosetting resin composition can also comprise a compound which simultaneously contains an epoxy group and an olefinic bond type unsaturated group, the curing agent, a flame retardant, an accelerant and the like. The thermosetting resin composition has the characteristics of low dielectric constant and dielectric loss, high heat resistance, flame retardance and the like, and is suitable for laminated boards and the like for prepregs and printed circuits.

Owner:GUANGDONG SHENGYI SCI TECH

A preparation method of a ceramic coated separator for lithium ion batteries

The invention discloses a preparation method of a ceramic coating separator for lithium ion batteries and belongs to the technical field of lithium ion battery separator production. The method involves a polymer porous base film, a polymer glue applied on one or both sides of the base film surface, a ceramic coating applied on the surface of the polymer glue, and a PVDF and its copolymer glue applied on the other side of the ceramic coating surface and the base film surface, wherein the PVDF and its copolymer glue are coated on the other side of the ceramic coating surface and the base film surface. The inorganic ceramic particles adopted by the invention are non-spherical and multi-particle, which can greatly improve the porosity of the ceramic coating, increase the lithium ion transit property, improve the liquid absorption rate of the diaphragm, and improve the rate performance and cycle life of the lithium ion battery. As the structure design of the ceramic coat diaphragm of the invention can increase the adhesive force of the ceramic coating and the polymer porous base membrane, the adhesive strength of the diaphragm and the positive and negative electrode sheets is improved,the problems of powder dropping and coating peeling off are effectively improved, the high-efficient automatic assembly of the lithium battery is realized, and the heat resistance and electrochemicalstability of the diaphragm are greatly improved.

Owner:HENAN FUSEN NEW ENERGY TECH

Aqueous acrylic emulsion, aqueous adhesive for pearlized film composite materials and preparation method thereof

InactiveCN101717467AGood adhesionImprove the level ofEster polymer adhesivesFunctional monomerMetal foil

The invention discloses an aqueous acrylic emulsion, an aqueous adhesive for pearlized film composite materials and a preparation method thereof, and belongs to the field of preparation of adhesive. The acrylic emulsion is polymerized from 20-40 wt% of acrylic acid hard monomer and 55-70 wt% of acrylic acid soft monomer and 1-5 wt% of acrylic acid functional monomer under the action of water, an emulsifying agent, an initiator, a buffering agent and a pH regulator. The invention also provides an aqueous adhesive and a preparation method thereof. The molecule segment of the film forming matter (acrylate copolymer) in the aqueous acrylic emulsion has various chemical groups, such as -OH, -COOH, -NH and the like; and the chemical groups can form various chemical bonds and hydrogen bonding acting force, and thereby having favorable adhering force for various composite substrates (plastic films, aluminum plating films, metal foils and the like). The polymer obtained by polymerization has higher molecular weight, lower coating viscosity and favorable levelling property; and thus, the polymer has high shear strength and initial strength and can achieve the best bonding strength without curing for a long time.

Owner:BEIJING COMENS NEW MATERIALS

Solvent-free ultraviolet curing pressure sensitive adhersive for polyethylene protective film and preparation method thereof

ActiveCN101649171AStrong adhesionStrong initial adhesionFilm/foil adhesivesMacromolecular adhesive additivesTectorial membraneSolvent free

The invention discloses a solvent-free ultraviolet curing pressure sensitive adhersive for polyethylene protective film and a preparation method thereof. The solvent-free ultraviolet curing pressure sensitive adhersive comprises the following components by weight percent: 60-90% of acrylate prepolymer, 0.1-5% of photoinitiator and 5-35% of tackifier. The solvent-free ultraviolet curing pressure sensitive disclosed by the invention has good adhesive force to the polyethylene film and can realize good balance among initital adhesive force, peeling strength and cohesive force.

Owner:无锡达美新材料有限公司

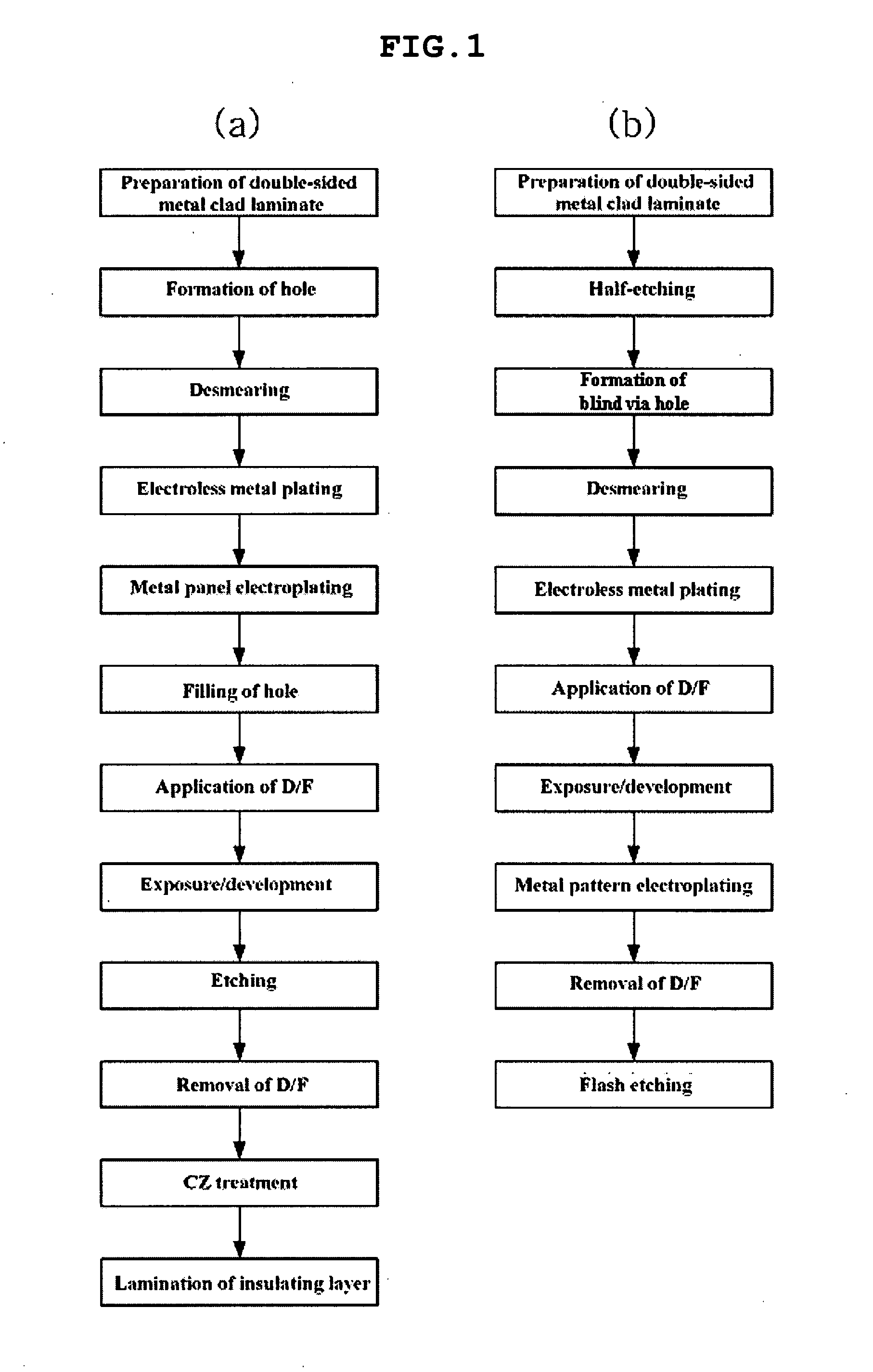

Method of manufacturing build-up printed circuit board

InactiveUS20070261234A1Fine circuitHigh peel strengthPrinted circuit assemblingPrinted circuit detailsIon beamEngineering

Disclosed is a method of manufacturing a build-up printed circuit board, in which the circuit of a build-up printed circuit board including a core layer and an outer layer is realized by forming the metal seed layer of the core layer using a dry process, consisting of ion beam surface treatment and vacuum deposition, instead of a conventional wet process, including a wet surface roughening process and electroless plating. When the wet process is replaced with the dry process in the method of the invention, the circuit layer can be formed in an environmentally friendly manner, and as well, all circuit layers of the substrate including the core layer and the outer layer can be manufactured through a semi-additive process. Further, the peel strength between the resin substrate and the metal layer can be increased, thus realizing a highly reliable fine circuit.

Owner:SAMSUNG ELECTRO MECHANICS CO LTD

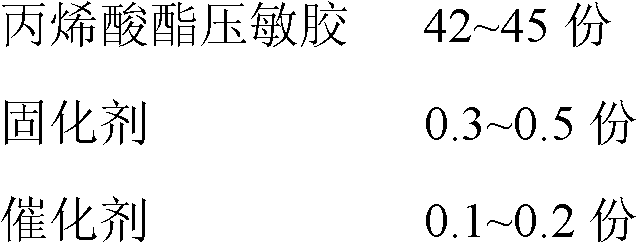

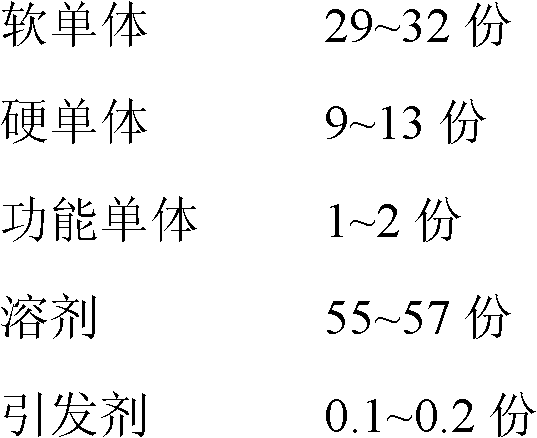

Solvent-based reticulated pressure-sensitive adhesive for polyethylene protective film and preparation method thereof

ActiveCN102504732AStrong adhesionStrong initial adhesionFilm/foil adhesivesEster polymer adhesivesSolvent basedUltimate tensile strength

The invention discloses a solvent-based reticulated pressure-sensitive adhesive for a polyethylene protective film and a preparation method thereof. The solvent-based reticulated pressure-sensitive adhesive comprises the following components in parts by weight: 42-45 parts of acrylate pressure-sensitive adhesive, 0.3-0.5 part of curing agent, 0.1-0.2 part of catalyst and 54-57% of solvent. The solvent-based reticulated pressure-sensitive adhesive disclosed by the invention has good adhesion to a polyethylene protective film and can realize good balance among Initial adhesion, peel strength and cohesion.

Owner:无锡达美新材料有限公司

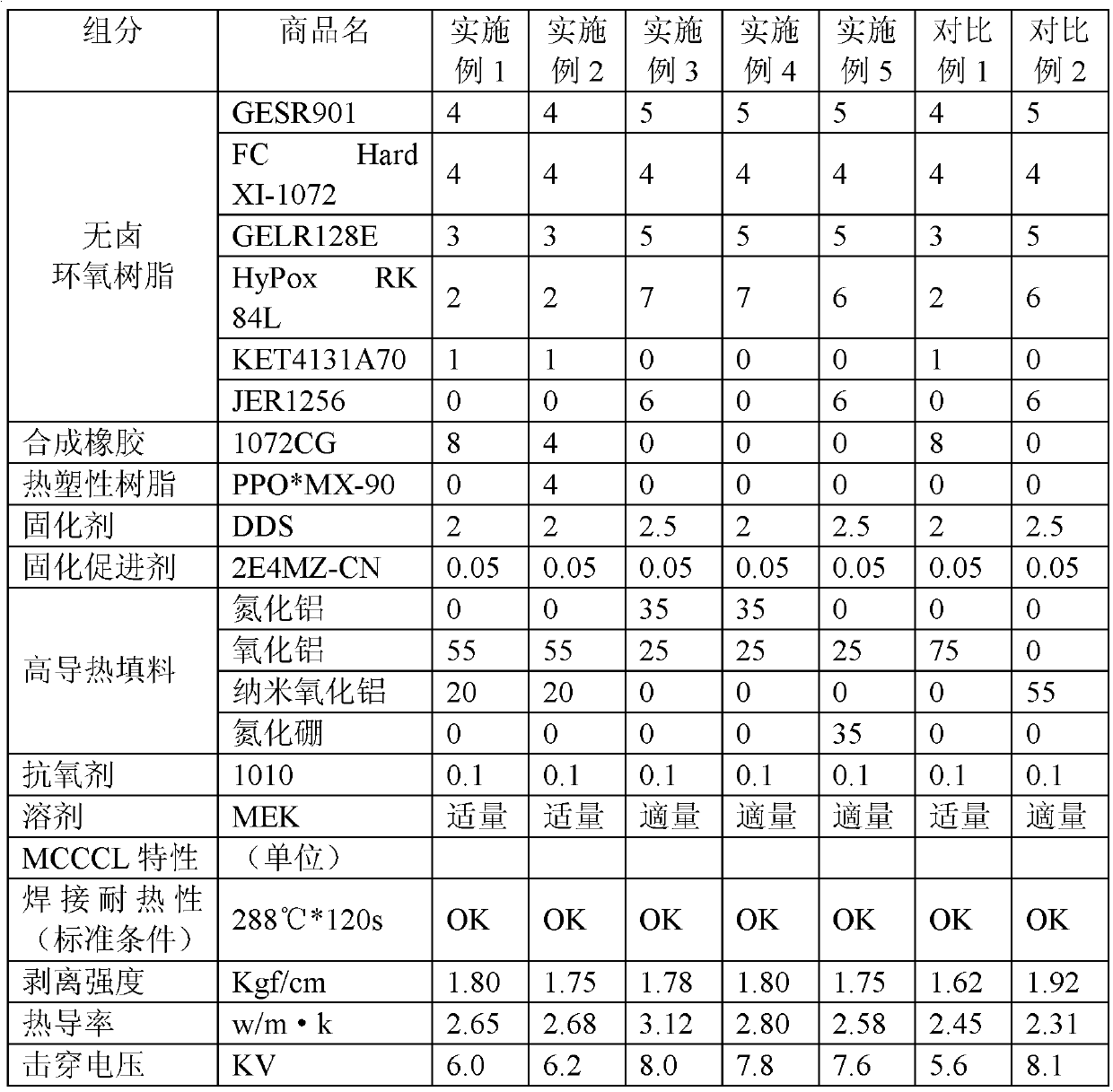

Halogen-free fire-retardant high heat conducting insulating resin composition and heat dissipation metal-base copper clad plate

ActiveCN102558765AImprove heat resistanceHigh peel strengthSynthetic resin layered productsEpoxy resin adhesivesEpoxyHeat conducting

The invention discloses a halogen-free fire-retardant high heat conducting insulating resin composition and a heat dissipation metal-base copper clad plate (CCL). The composition comprises the following components in parts by weight: 10-45 parts of halogen-free epoxy resin, 0-15 parts of thermoplastic resin and / or synthetic rubber, 0.1-5 parts of curing agent, 0.02-1 parts of accelerator, 0.5-1 parts of antioxidant and 25-80 parts of heat conducting filler. The halogen-free fire-retardant high heat conducting insulating resin composition of the invention adopts high heat conducting filler, and the cured composition shows good thermal conductivity, electric insulativity and welding heat resistance as well as high adhesive force. The invention also discloses a heat dissipation metal-base CCL prepared by using the above halogen-free fire-retardant high heat conducting insulating resin composition, which has high thermal conductivity and high peel strength, does not have the problems of peel-off and deterioration even being subjected to thermal cycle of quick heating and quick cooling, and also has high electrical breakdown resistance, good heat resistance and soldering resistance and the like, and the flame retardant rating of the heat dissipation metal-base CCL reaches UL-94V0.

Owner:ALLSTAE TECH ZHONGSHAN

Conductive paste for crystalline silicon solar cell and preparation method of conductive paste

ActiveCN104078090AHigh tear strengthImprove adhesion strengthNon-conductive material with dispersed conductive materialCable/conductor manufactureSilver pasteConductive paste

The invention provides conductive paste for a crystalline silicon solar cell. The conductive paste comprises the following components in parts by weight: 100 parts of conductive metal powder, 1.0-10 parts of inorganic binder, 10-65 parts of organic carrier and 0.05-5.0 parts of conductive carbon. The conductive paste is excellent in conductivity; the photoelectric conversion efficiency of the cell is not influenced; and widely applied conductive paste for the crystalline silicon solar cell such as front-side silver paste, front-side seed layer silver paste, back-side silver paste and back electric field aluminum paste can be prepared.

Owner:BYD CO LTD

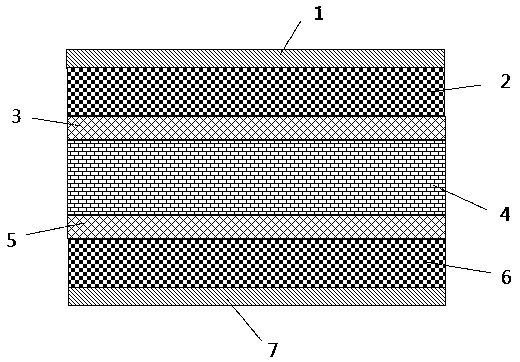

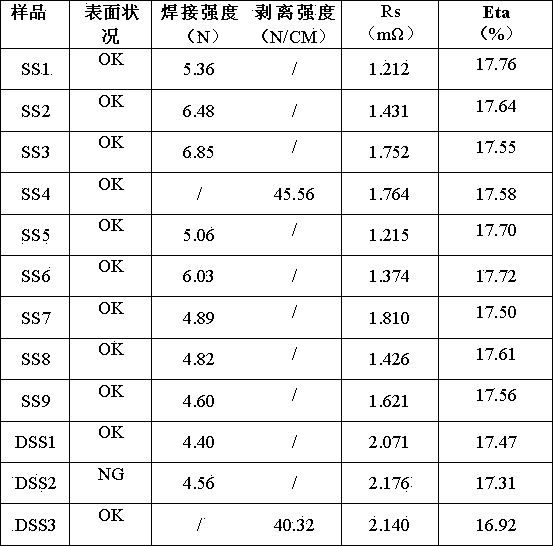

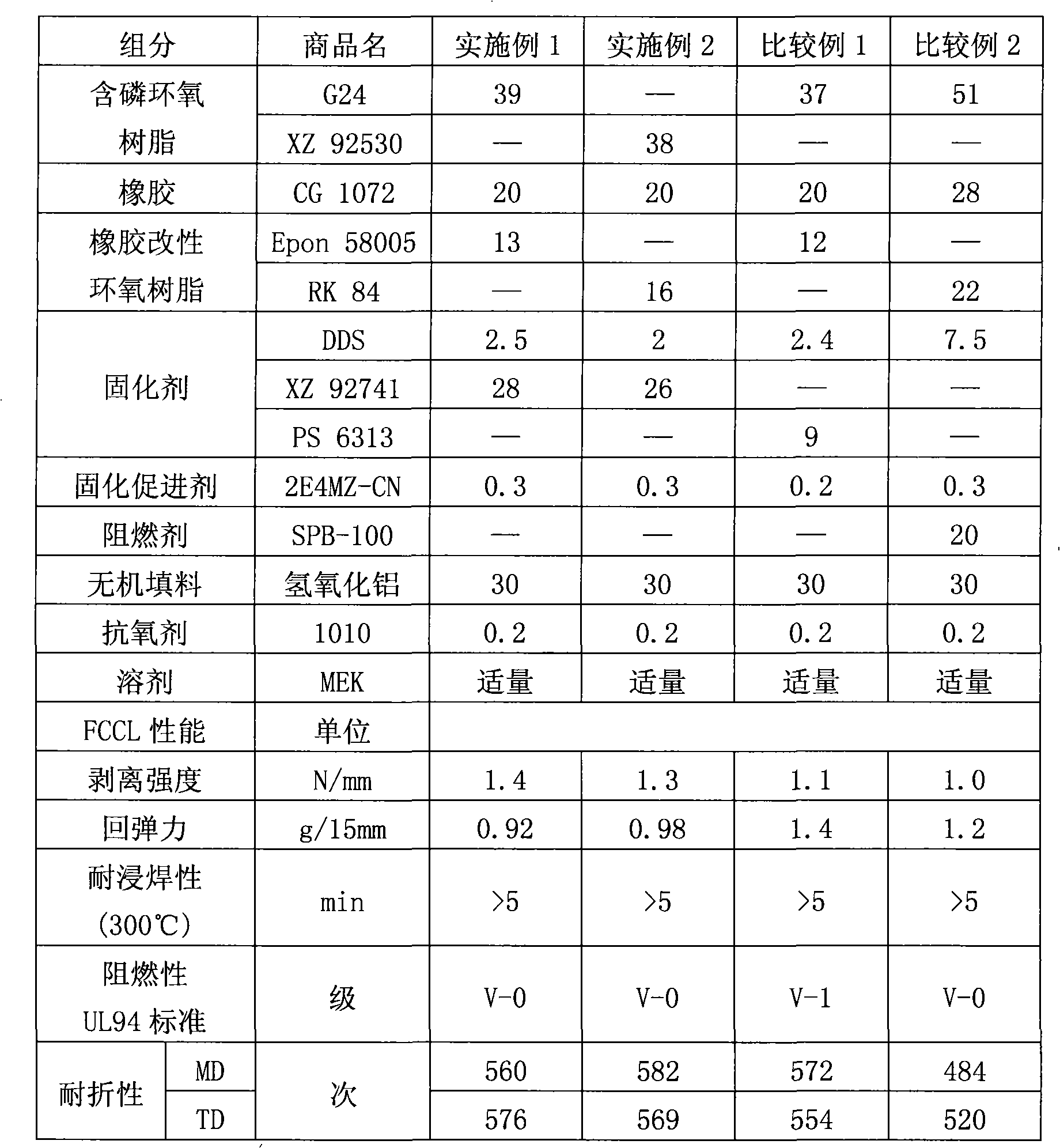

Halogen-free flame-retardant epoxy resin composition, flexible copper clad laminate made therefrom and preparation of the flexible copper clad laminate

InactiveCN101280093AGood compatibilityImprove mechanical propertiesCircuit susbtrate materialsSolid componentEpoxy

The invention relates to a halogen-free flame-retardant epoxy resin composite, the flexible copper clad laminate made from the epoxy resin composite and the production method. The halogen-free flame-retardant epoxy resin composite is composed of solid components and organic solvents, wherein, the solid components include: phosphorus epoxy resin, synthetic rubber, rubber-modified epoxy resin and composite curing agent. The flexible copper clad laminate made from the halogen-free flame-retardant epoxy resin composite is a three-layer flexible copper clad laminate, including a polyimide insulation film, a coating of halogen-free flame-retardant epoxy resin composite coated on the polyimide insulation film, and a copper foil pressed on the coating of halogen-free flame-retardant epoxy resin composite. The resin composite of the invention is halogen-free and dispenses with other organic phosphorus flame retardants; the flexible copper clad laminate made from the composite has the flame retardancy up to UL94 V-0-level and has the advantages of high peeling strength, excellent dimensional stability, softness, good ion migration resistance and processing performance.

Owner:GUANGDONG SHENGYI SCI TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com