Patents

Literature

125results about How to "Improve anchor strength" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

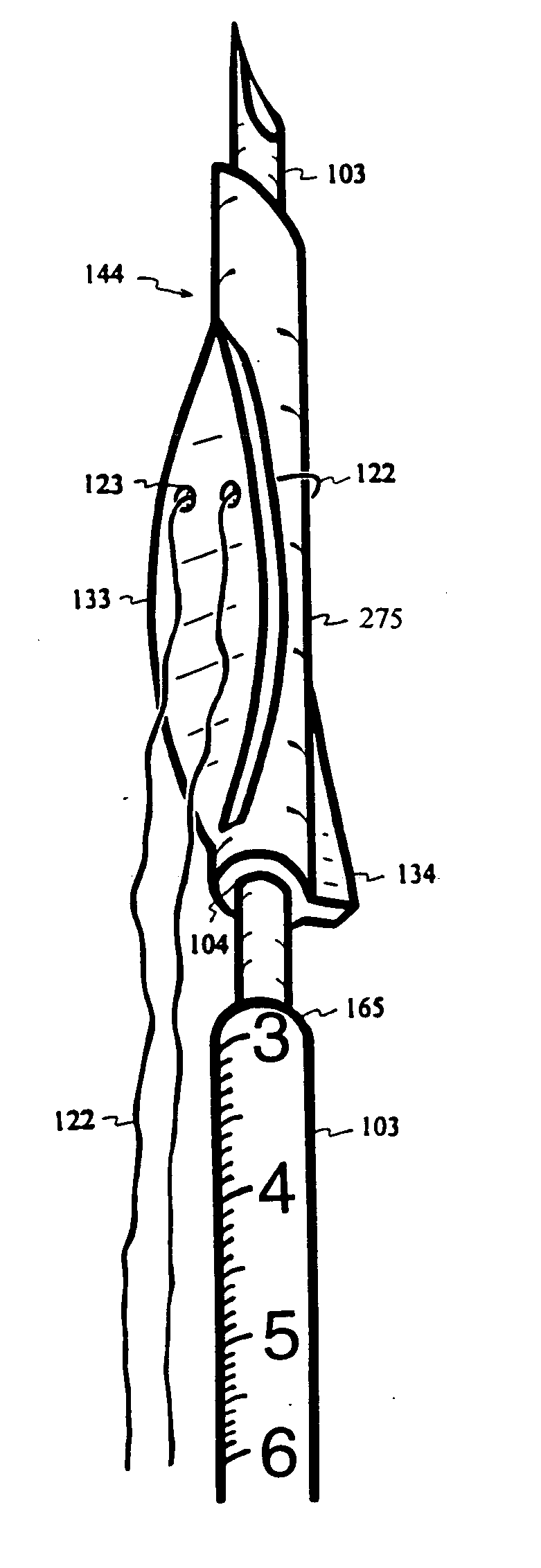

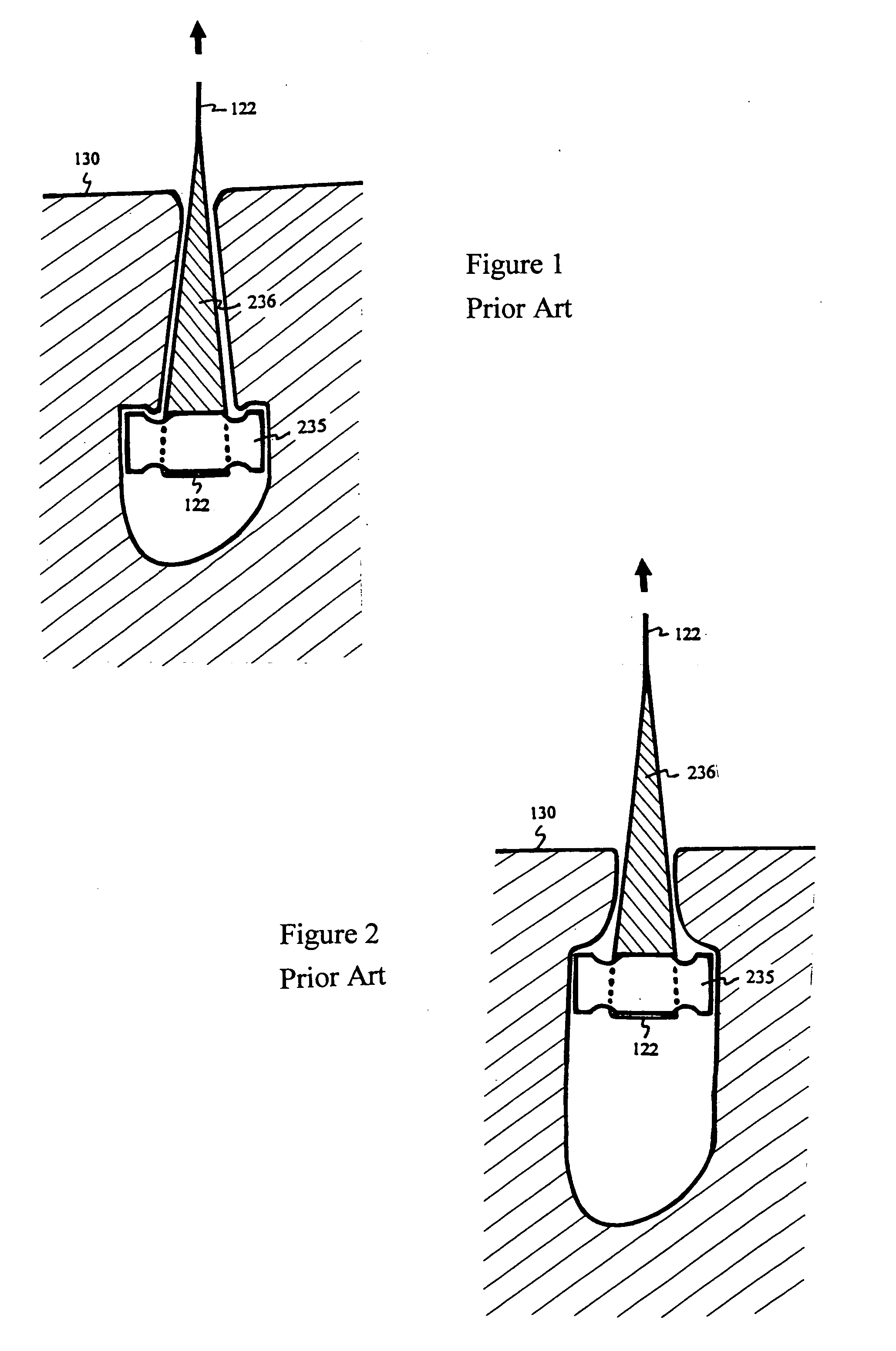

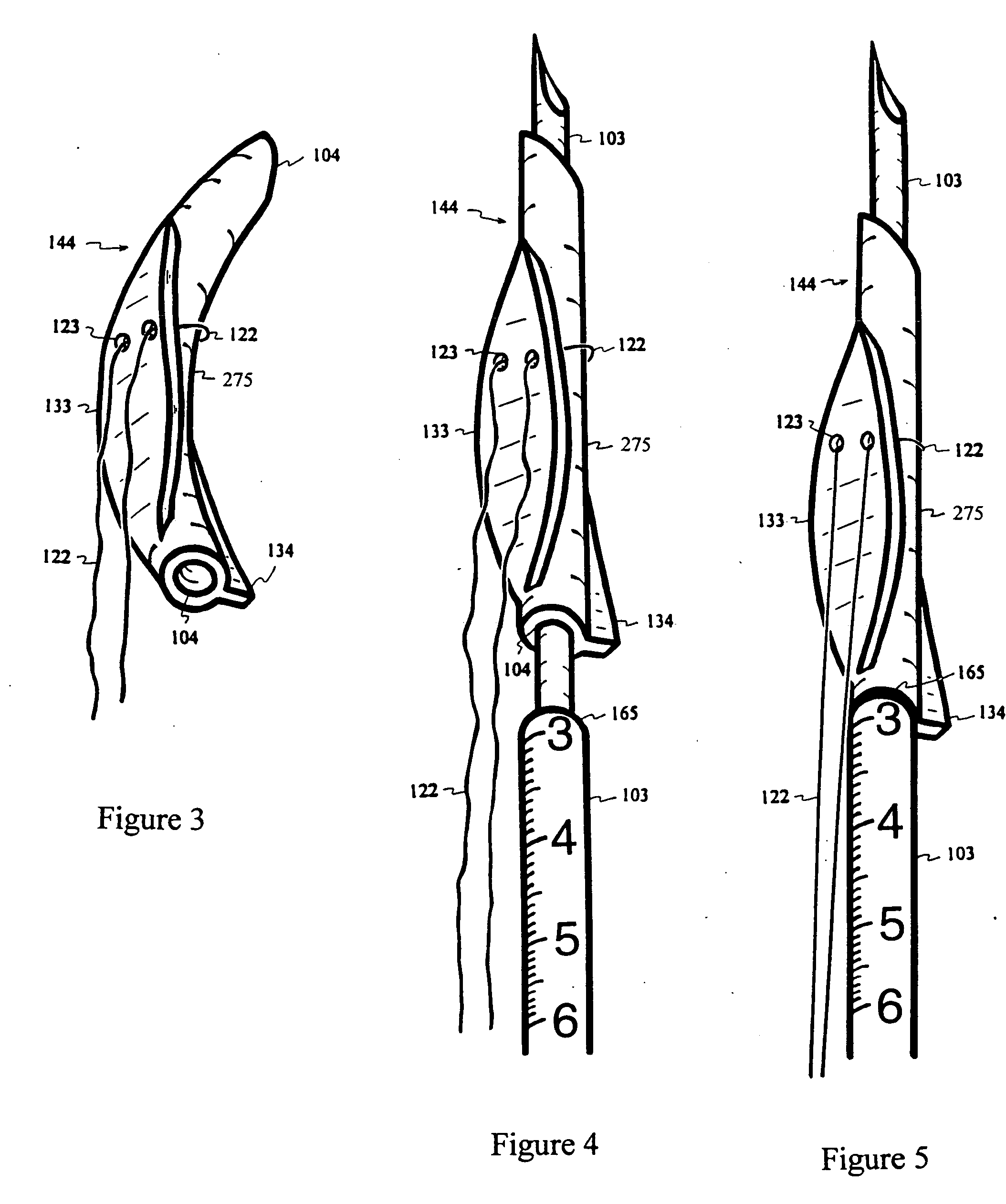

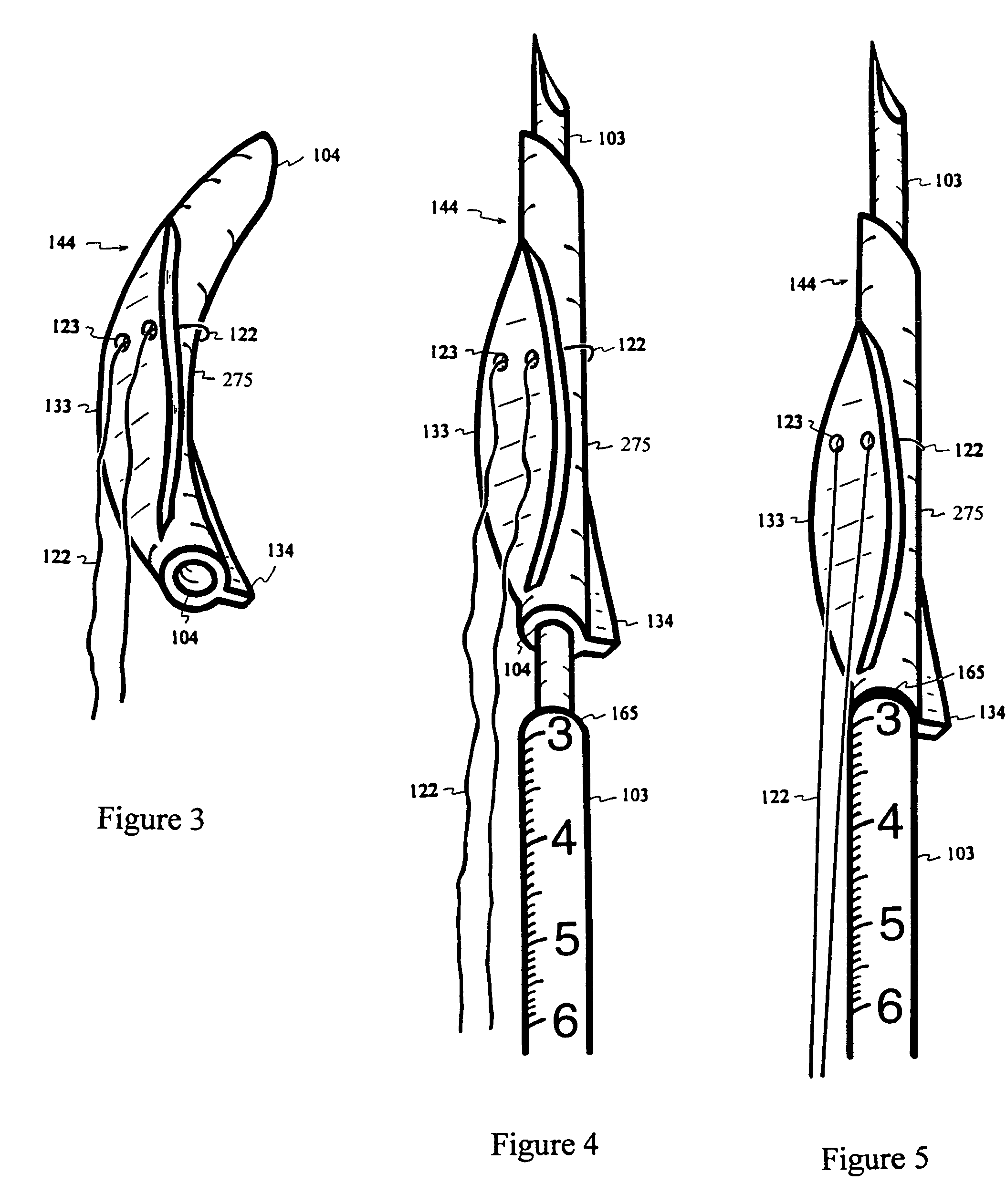

Suture anchor and approximating device

InactiveUS20060030884A1Improve anchor strengthIncrease distanceSuture equipmentsDiagnosticsSuture anchorsSurgery

Owner:TELEFLEX LIFE SCI LTD

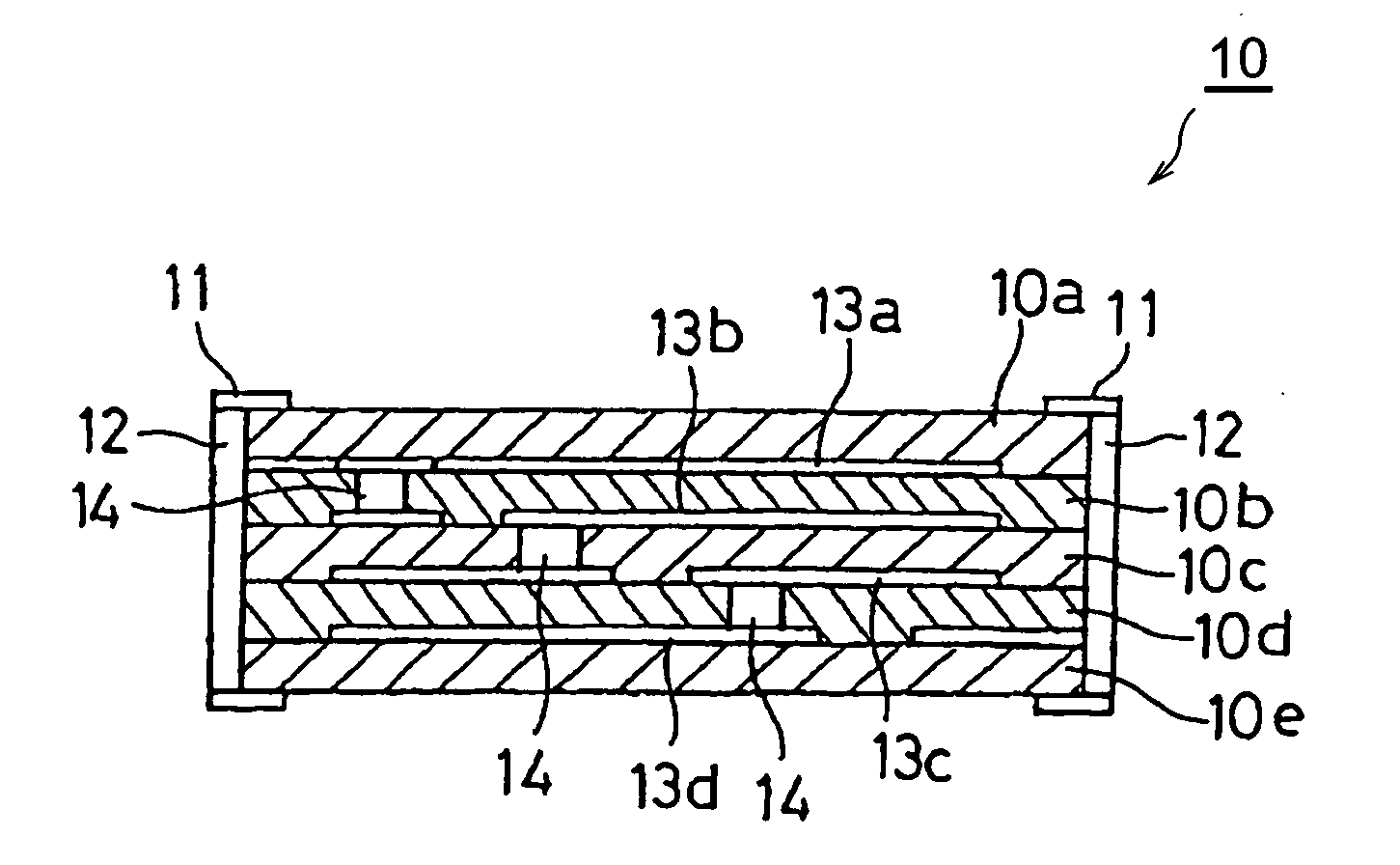

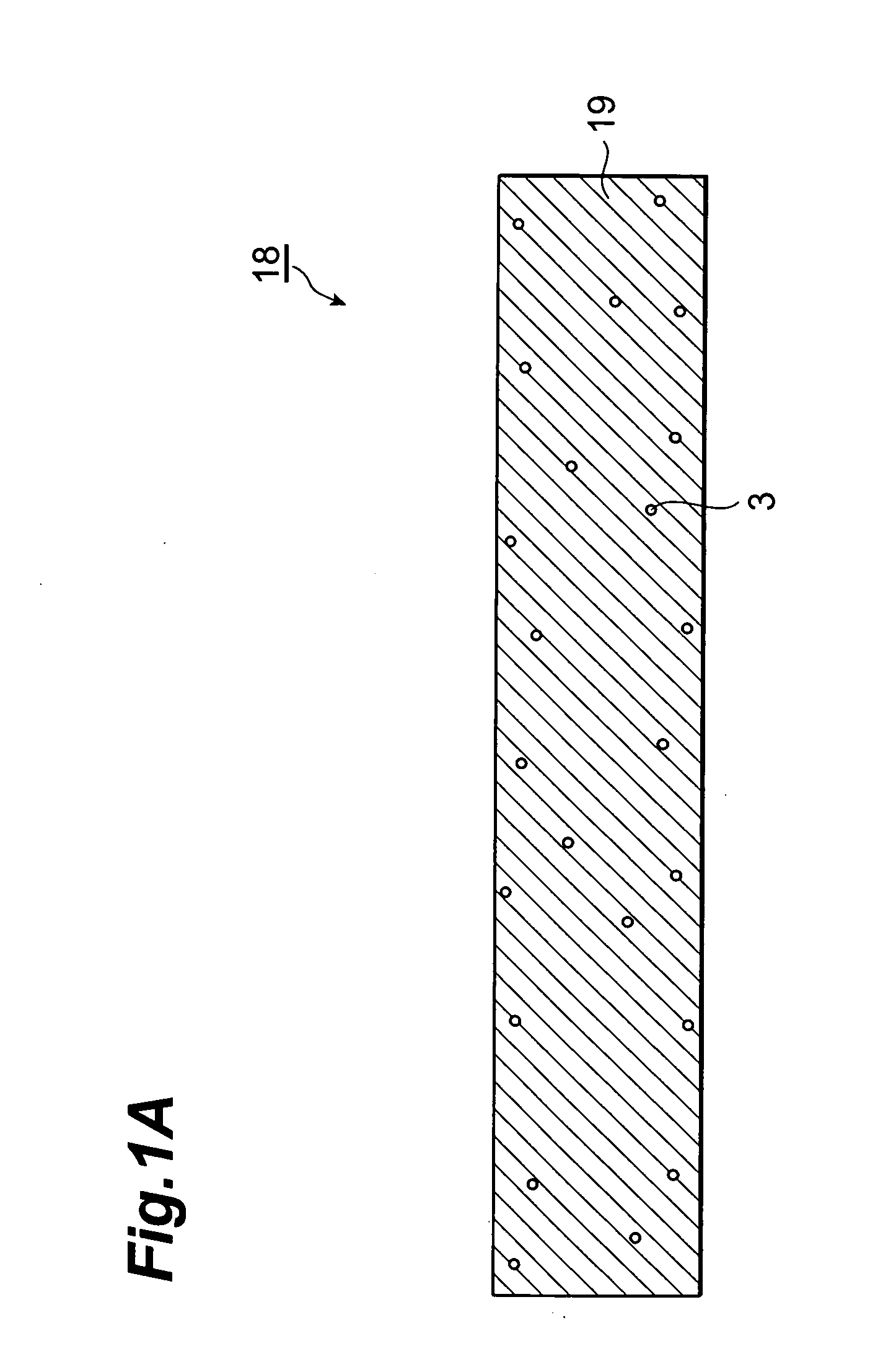

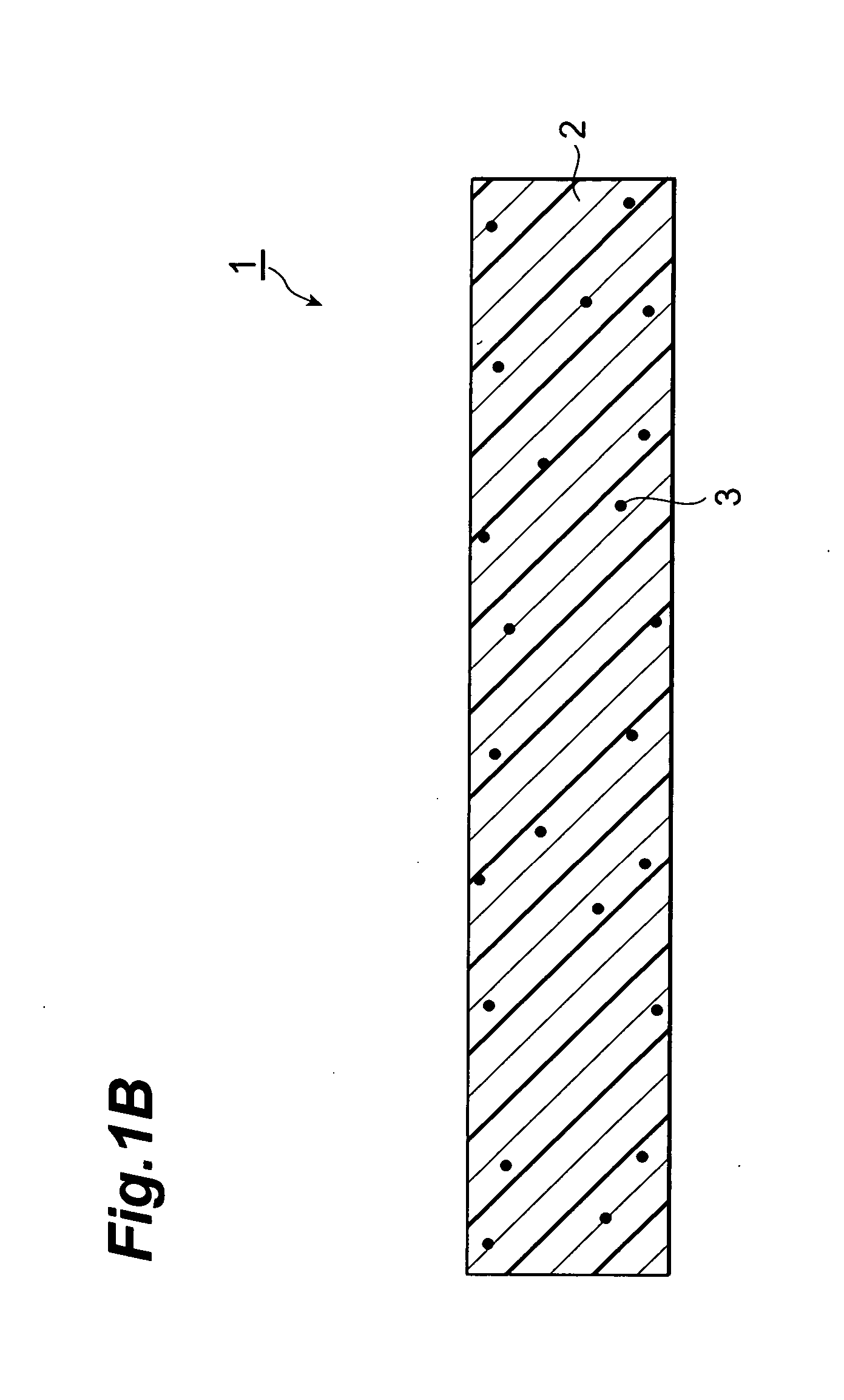

Resin composition, cured resin, sheet-like cured resin, laminated body, prepreg, electronic parts and multilayer boards

InactiveUS20050003199A1Maintain electrical propertiesHigh dielectric constantSemiconductor/solid-state device detailsTransformers/inductances coils/windings/connectionsEpoxyDielectric loss

The invention provides electronic parts which comprise a composite dielectric layer composed of an organic insulating material and a dielectric ceramic powder having a larger relative dielectric constant than the organic insulating material, and which also comprise conductive element sections forming inductor elements, etc., wherein the organic insulating material comprises a cured resin obtained by curing reaction of an epoxy resin with an active ester compound obtained by reaction between a compound with two or more carboxyl groups and a compound with a phenolic hydroxyl group. The dielectric ceramic powders of the described electronic parts have larger relative dielectric constants than the organic insulating materials, and the organic insulating materials have low dielectric loss tangents. It is possible to adequately reduce time-dependent dielectric constant changes in the high-frequency range of 100 MHz and above even with prolonged use at high temperatures of 100° C. and higher, while it is also possible to satisfactorily prevent deformation and other damage to the electronic parts during their handling.

Owner:TDK CORPARATION

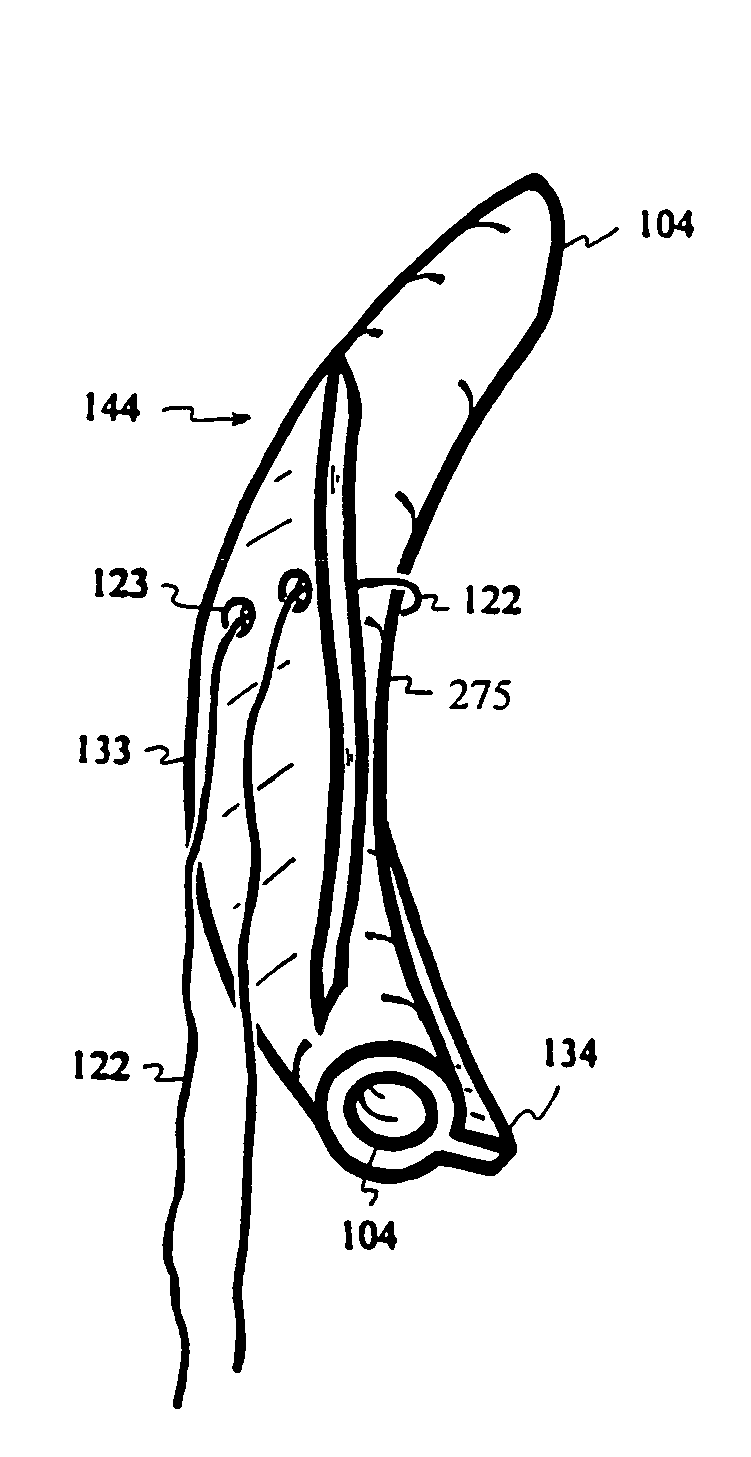

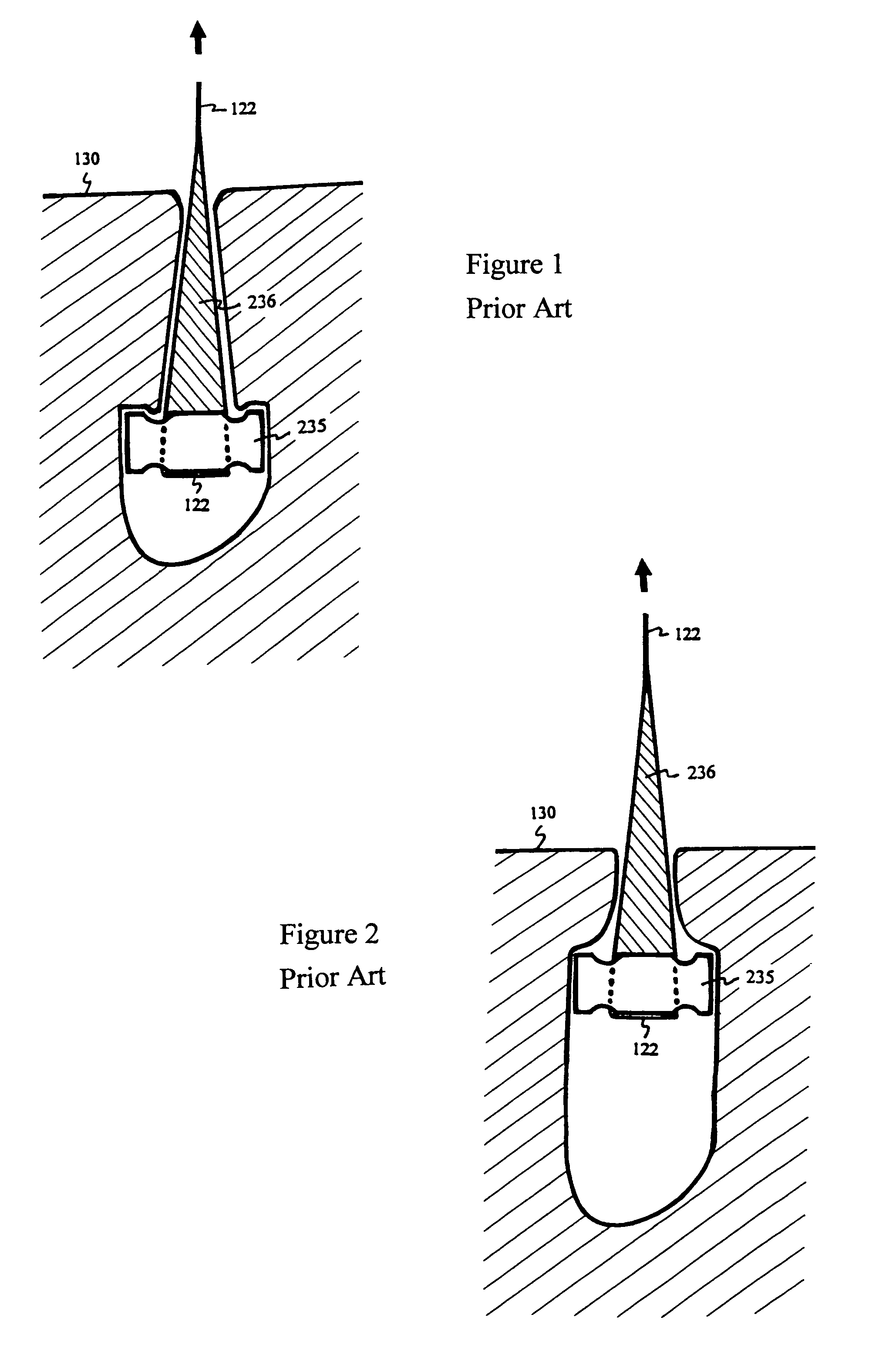

Suture anchor and approximating device

InactiveUS7766939B2Improve anchor strengthIncrease distanceSuture equipmentsDiagnosticsSuture anchorsMedicine

Owner:TELEFLEX LIFE SCI LTD

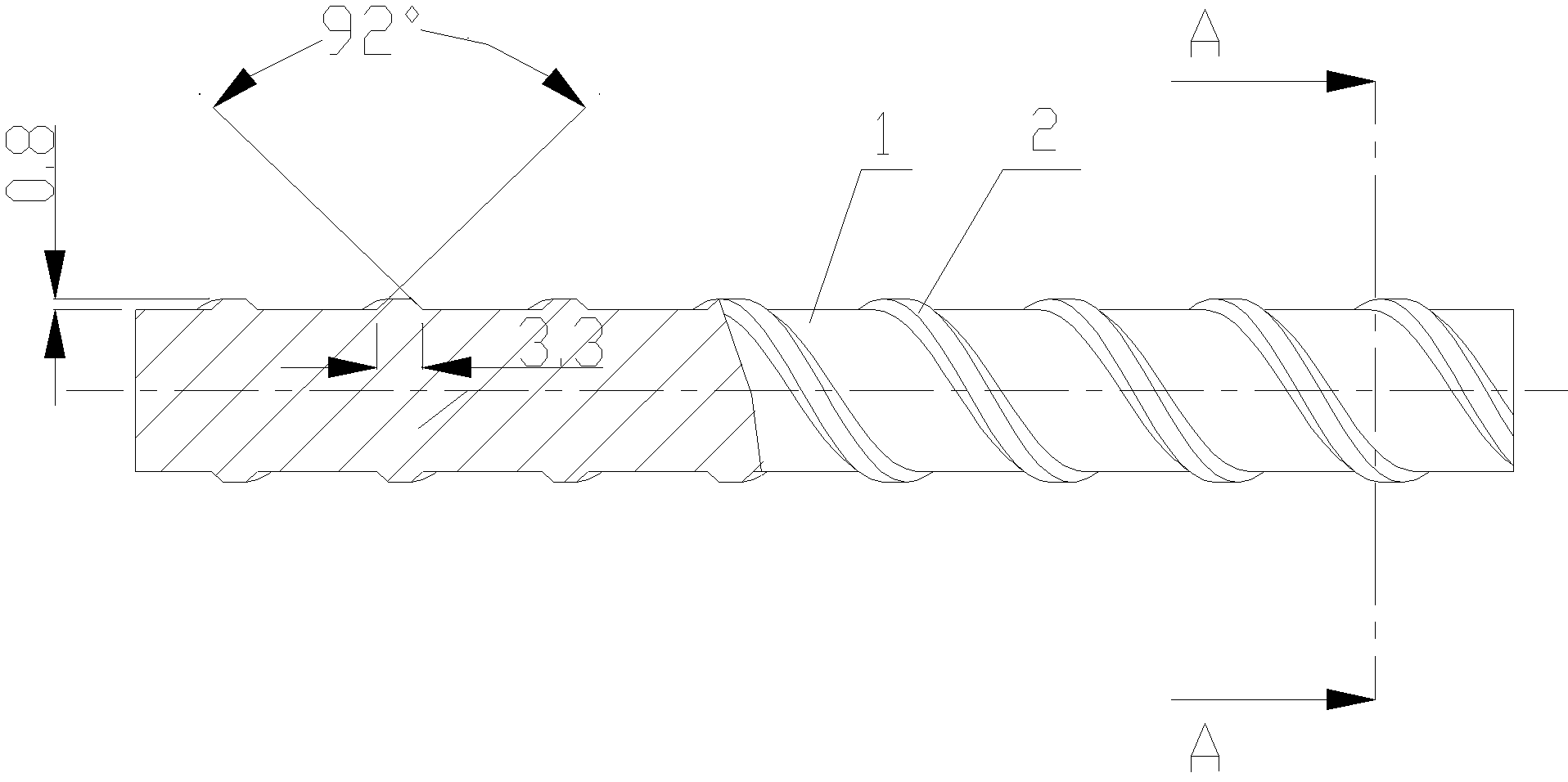

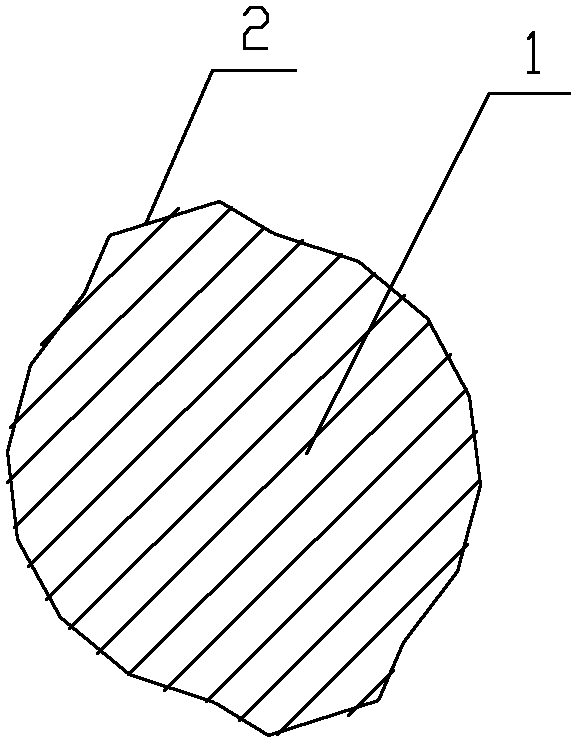

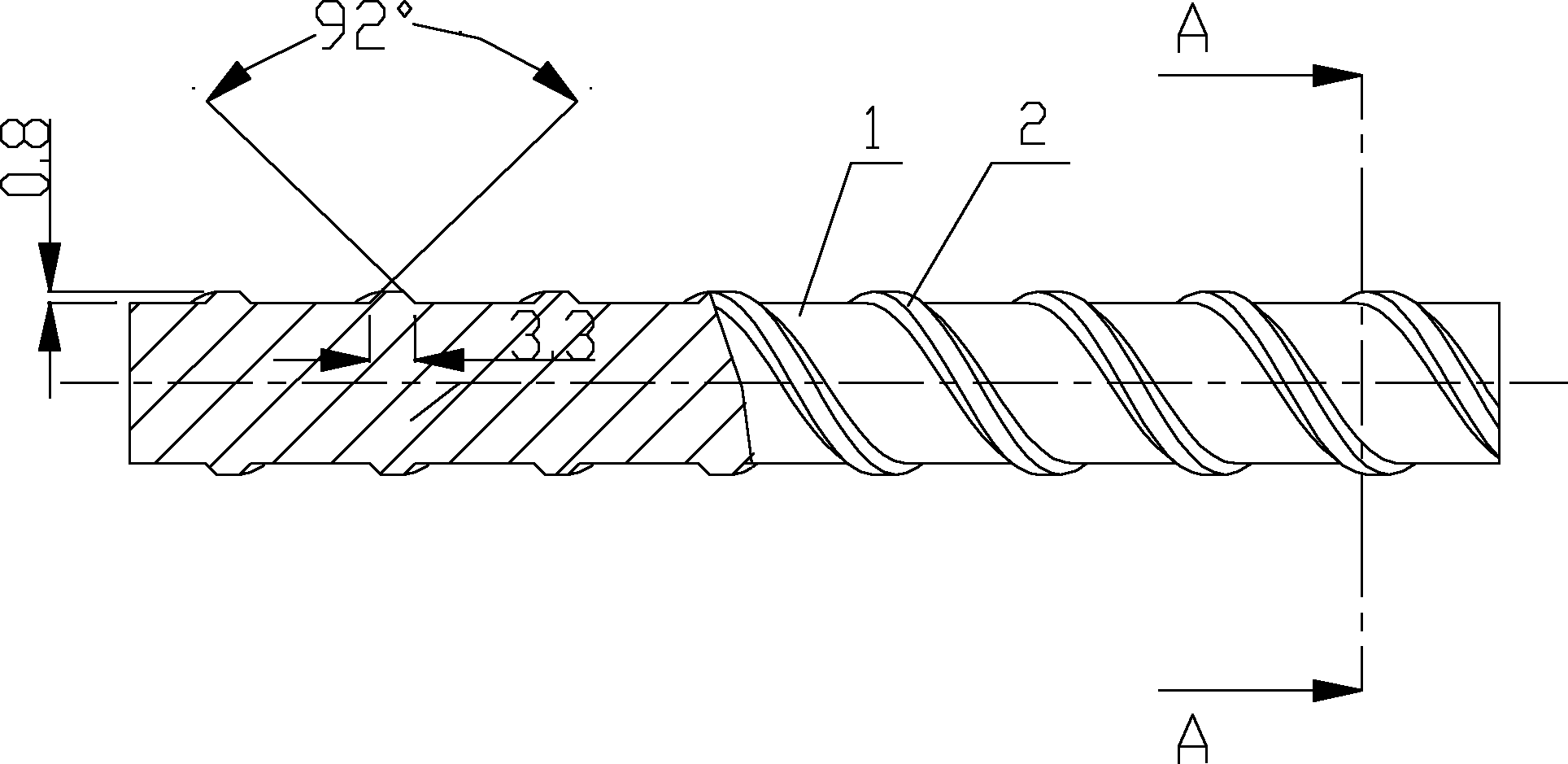

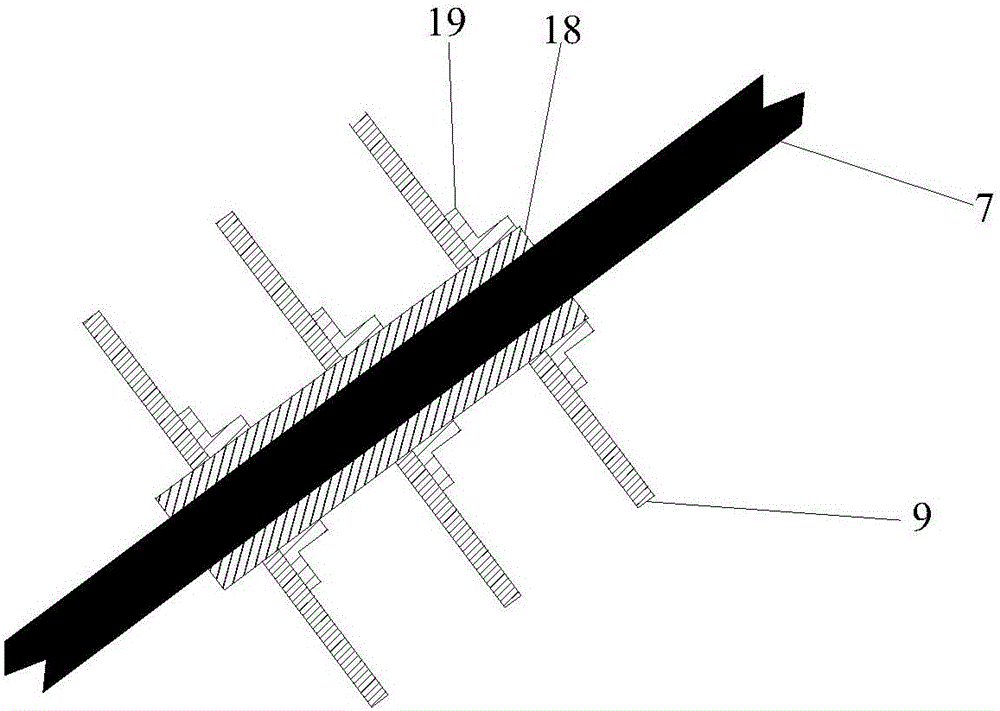

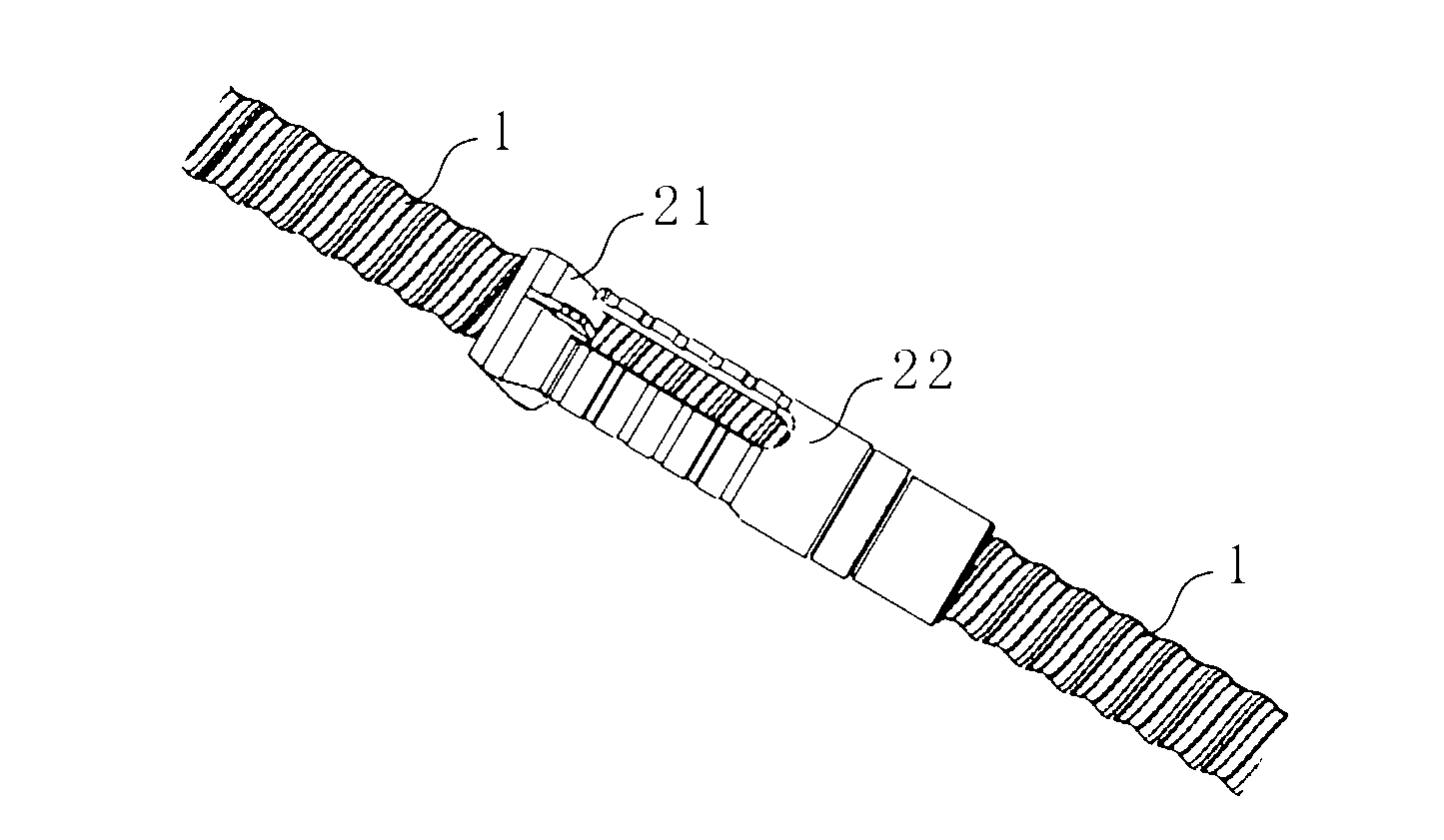

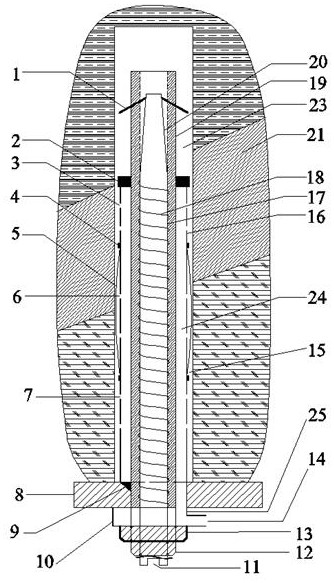

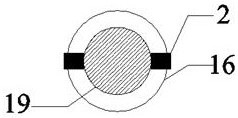

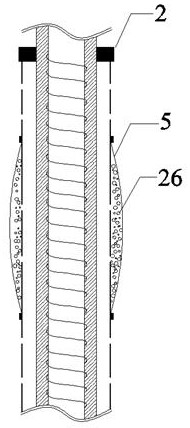

High-strength reinforcing steel bar with spiral fins and processing method of high-strength reinforcing steel bar

The invention relates to a reinforcing steel bar and a processing method thereof, in particular to a high-strength reinforcing steel bar with spiral fins and a processing method of the high-strength reinforcing steel bar. The high-strength reinforcing steel bar consists of following components including, in weight percentage, from 0.25 to 0.4% of C, from 0.1 to 0.2% of Si, from 0.3 to 0.45% of Mn, from 0.04 to 0.05% of Nb, from 0.08 to 0.09% of Cr, from 0.01 to 0.04% of V, from 0.002 to 0.003% of B, from 0.001 to 0.003% of Mo, from 0.015 to 0.03 of Al, from 0.002 to 0.003% of S, from 0.008 to0.009% of Ti, from 0.004 to 0.005% of Ni, from 3 to 5% of composite rear earth and the balance Fe. The processing method includes using a roll to roll a reinforcing steel bar into a reinforcing steelbar with the continuous spiral fins on the surface in a hot state; feeding the reinforcing steel bar with the continuous spiral fins on the surface after hot rolling into a heating furnace and heating the reinforcing steel bar to the temperature of 880-990 DEG C; then fast cooling the reinforcing steel bar to the temperature of 650-680 DEG C by an online cooling device via compressed air or vaporous quenching liquid; quenching in a quenching device by water or quenching liquid for 15-25 seconds; and tempering after heating the reinforcing steel bar to the temperature of 500-550 DEG C via a tempering heating furnace. The high-strength reinforcing steel bar with the spiral fins has a good anchoring property, fine ductility and a high yielding-to-tensile ratio.

Owner:TIANSHUN GROUP +2

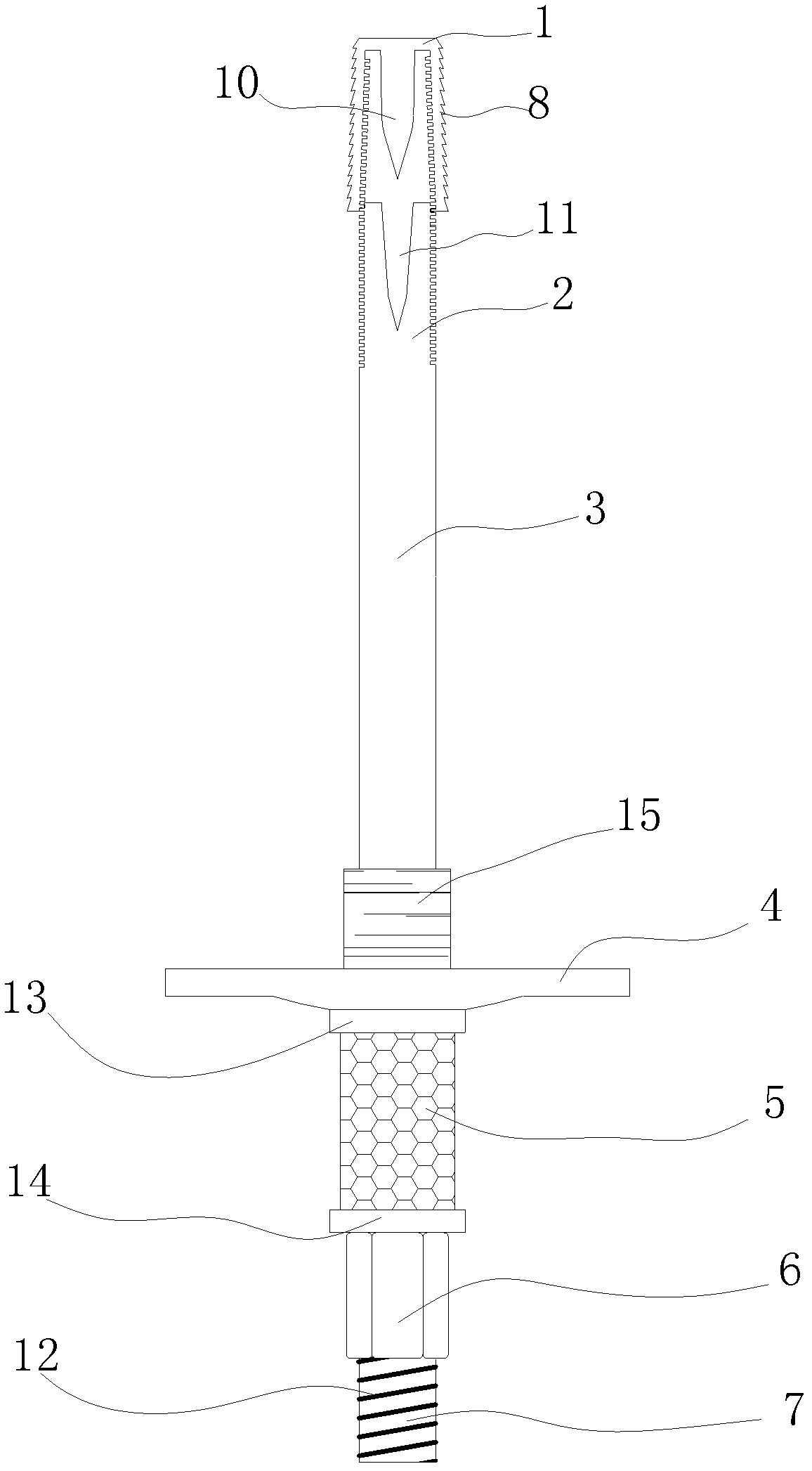

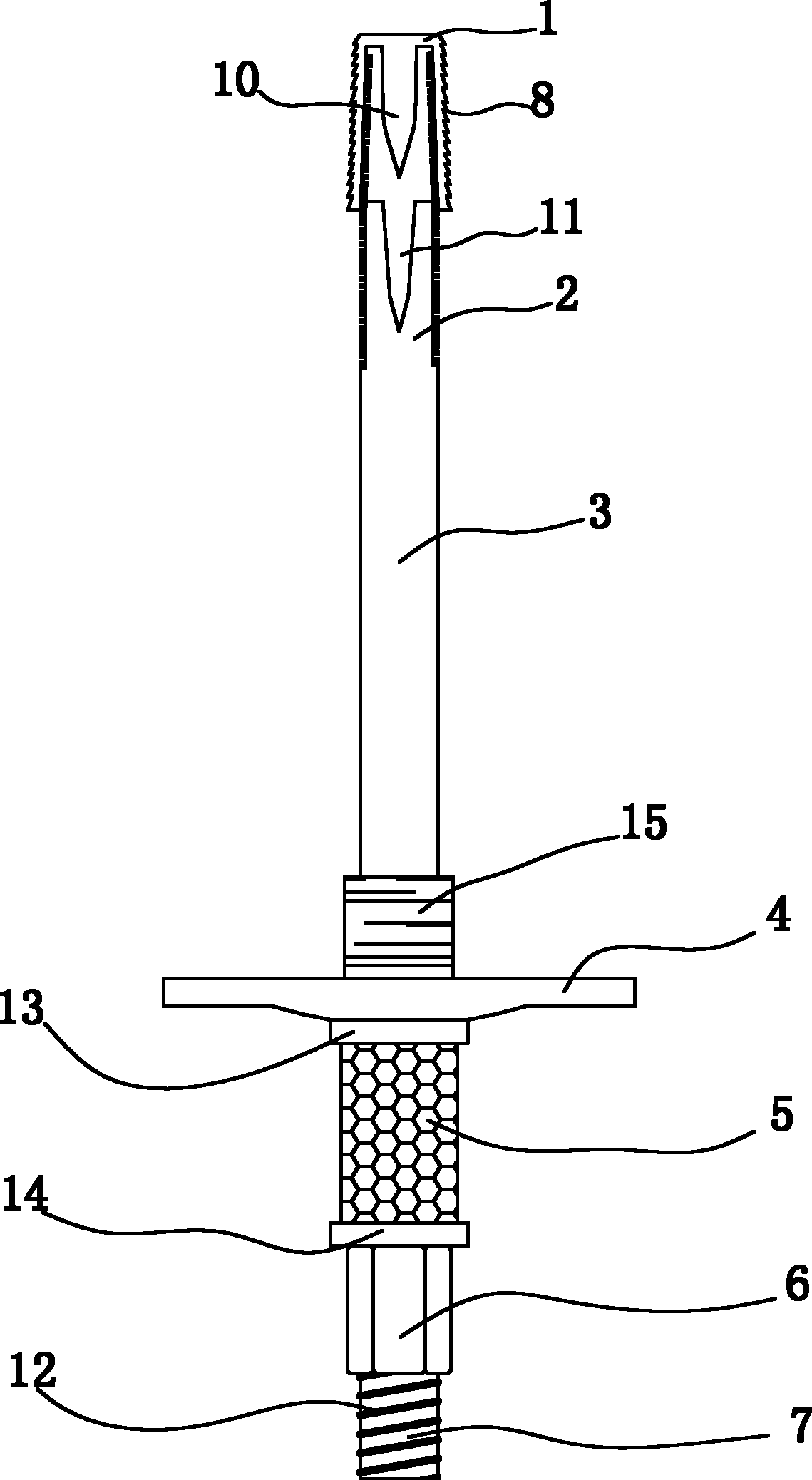

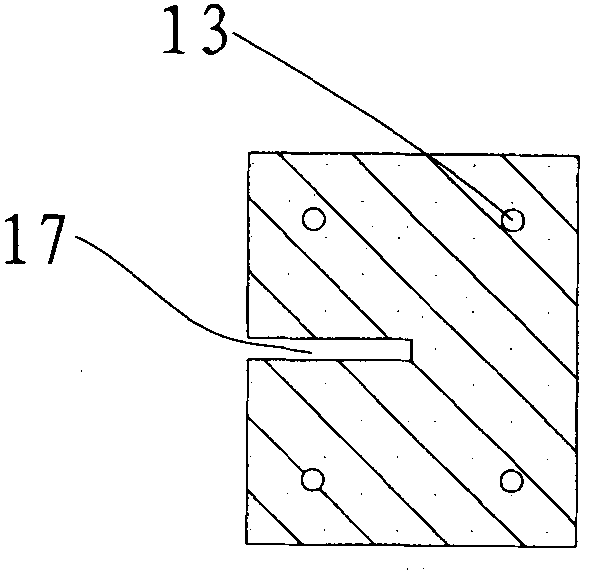

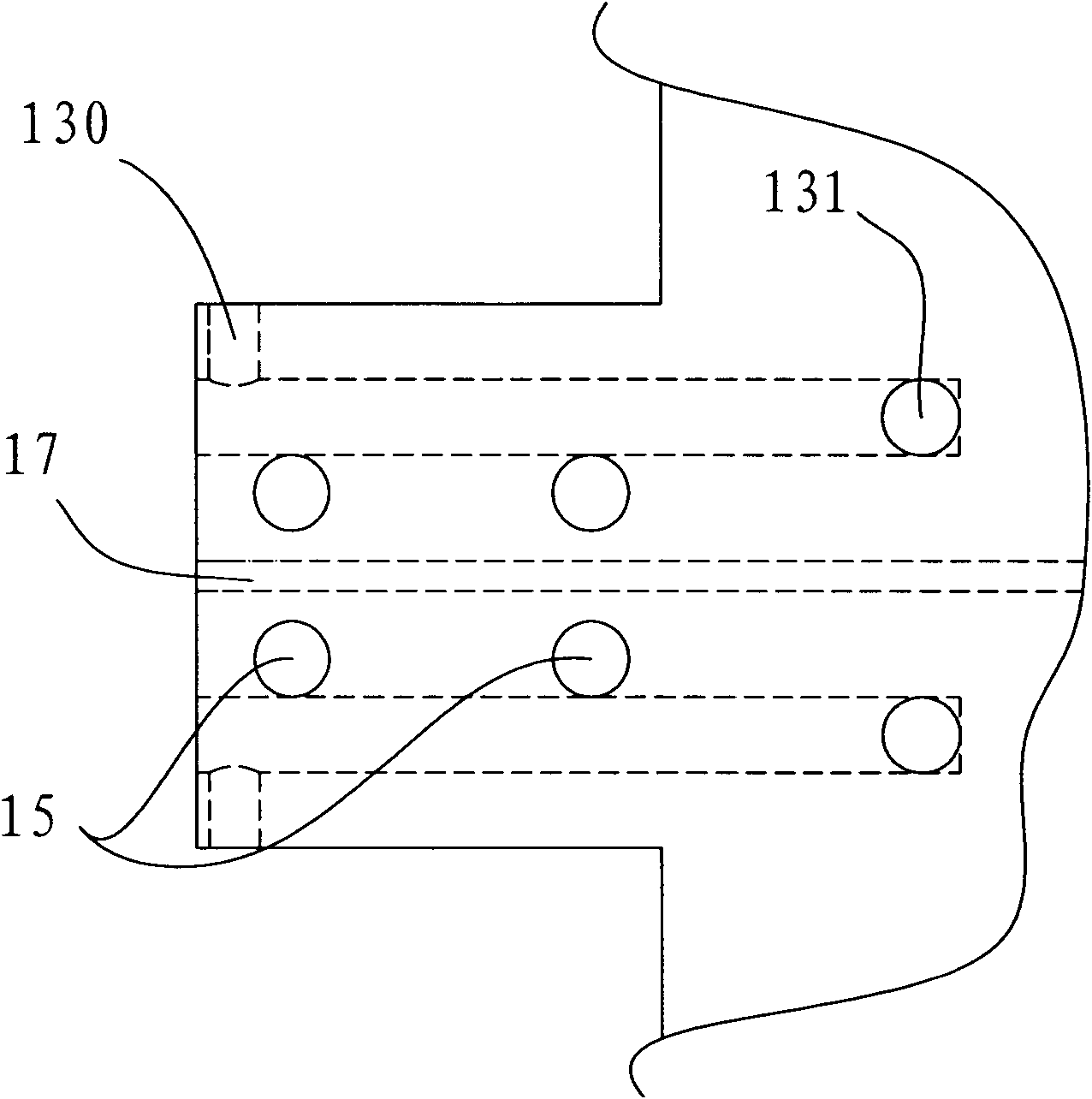

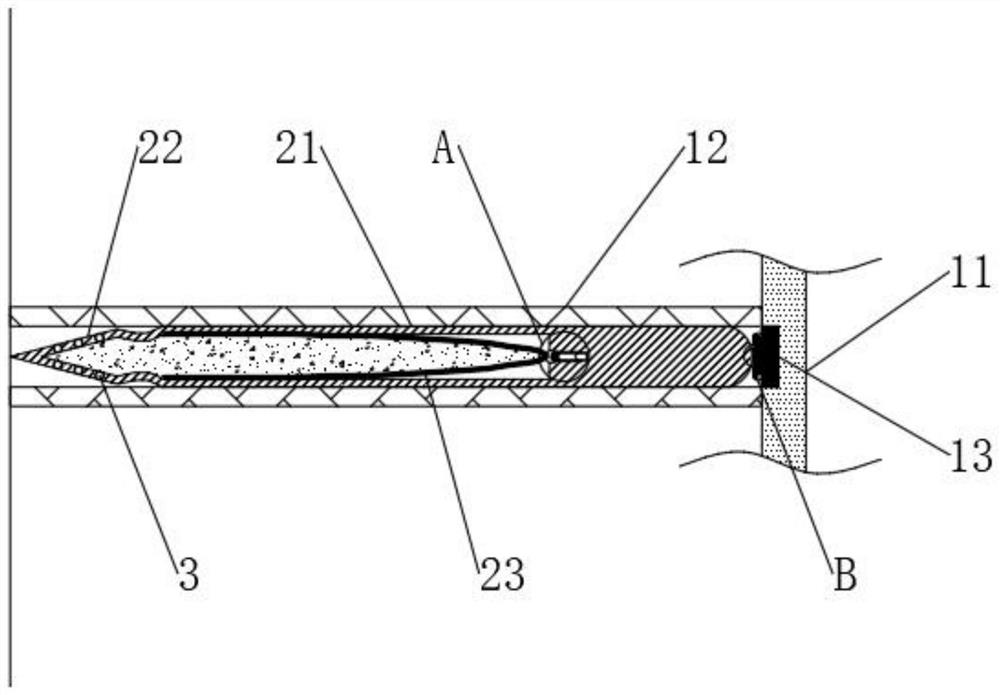

Quickly mounted efficient energy-absorbing mining anchor rod

The invention discloses a quickly mounted efficient energy-absorbing mining anchor rod which comprises an expansion shell, a rod head, a rod body, a tray, an anti-seismic buffering material, a nut and a rod tail, wherein a tooth-shaped bulge is arranged on the outer surface of the expansion shell; matched threads are respectively arranged on the inner surface of the expansion shell and the outer surface of the rod head; a tapered bulge is arranged in the expansion shell; a tapered groove is arranged at the top of the rod head; a vertex angle of the tapered bulge is more than the vertex angle of the tapered groove; the thread is arranged on the rod tail; and the tray and the anti-seismic buffering material are respectively sleeved on the rod tail and are positioned and pre-tensioned by the nut. According to the invention, quick loading is realized by the anchor rod; mounting process is simplified; mounting time is shortened; driving speed is increased; the anti-seismic buffering material has a compressing buffering function when rock is burst, so as to effectively resist the dynamic loading effect at rock bursting moment; a certain anchoring force is kept by the anchor rod; and the anchor rod is prevented from being broken and invalid. Besides, the quickly mounted efficient energy-absorbing mining anchor rod has the beneficial effects of simple structure, convenience in mounting, high operability, and the like, and is widely applied to underground supporting for deep well.

Owner:CENT SOUTH UNIV

Apparatus of anchoring capable of repeating use and its construction method

InactiveCN1786352AReduce pollutionReduce anchoring costsBulkheads/pilesUpper jointMetallic materials

The invention relates to repeated use anchor fitting and its construction method. It is applied in foundation ditch anchoring, slope protection anchoring, electric force transporting tower wind proofing, large-scale billboard and temporary anchoring, road, bridge, and railway signs anchoring in industrial and civil architecture. Anchor fitting is made up of squeezing enlarging machine, connection link and spanner. The upper joint of the squeezing enlarging machine is connected to inner pipe, and connected to the under joint by axle pin. The under joint is connected to the outer pipe. The connection link outer pipe is connected by bearing and roll bearing. The spanner is connected to roll bearing. The invention presses metal anchor bar into soil and opens the squeezing enlarging machine to greatly increase anchoring force while anchoring. The anchor bar is metal, not need concrete pouring, so it is environmental protection. When the anchoring is finished, the squeezing enlarging machine can reclaim to use repeatedly. Thus it can save cost, and has no needless barrier left above or under ground.

Owner:北京中阔地基基础技术有限公司

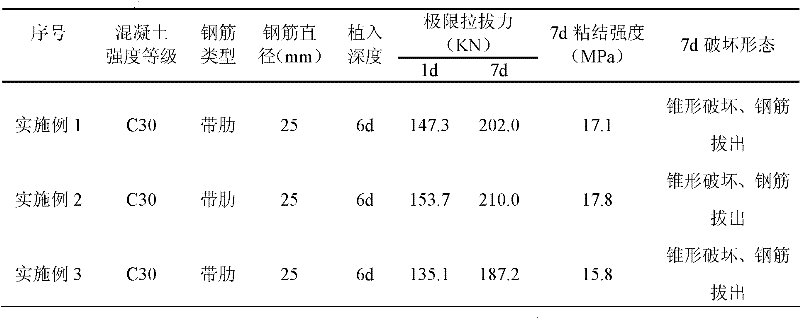

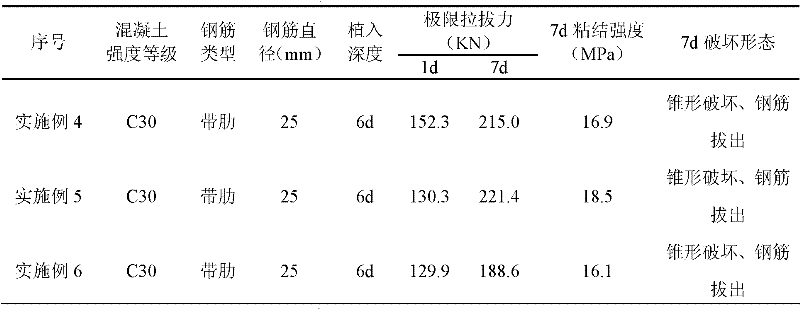

Non-cement-based inorganic anchoring bonded bar adhesive and preparation method thereof

The invention discloses a non-cement-based inorganic anchoring bonded bar adhesive and a preparation method thereof. The preparation method of the non-cement-based inorganic anchoring bonded bar adhesive disclosed by the invention comprises the following steps of: uniformly mixing one or several kinds of powder of slag powder, metakaolin powder, coal ash, coarse calcium powder, quartz sand, a swelling agent and the like; mixing a sodium silicate solution, a sodium phosphate solution, a sodium hydroxide solution, water and the like into emulsion; and weighing threes parts of bonded bar adhesive powder and one part of the emulsion in terms of weight part, and uniformly mixing to prepare the non-cement-based inorganic anchoring bonded bar adhesive. The non-cement-based inorganic anchoring bonded bar adhesive disclosed by the invention has the advantages of early strength, high strength, stable volume, good durability, high-temperature resistance, large bond stress to reinforcing steel bars, high anchoring strength, seismic resistance, impact resistance and favorable fatigue resistance, and can be widely applied to surrounding rock anchoring for engineering, equipment foundation bar bonding, building structure bar bonding, reinforcing steel bar anchoring for water conservancy, hydropower, roads, bridges, tunnels and other projects, and the like.

Owner:GUANGZHOU INSTITUTE OF BUILDING SCIENCE CO LTD

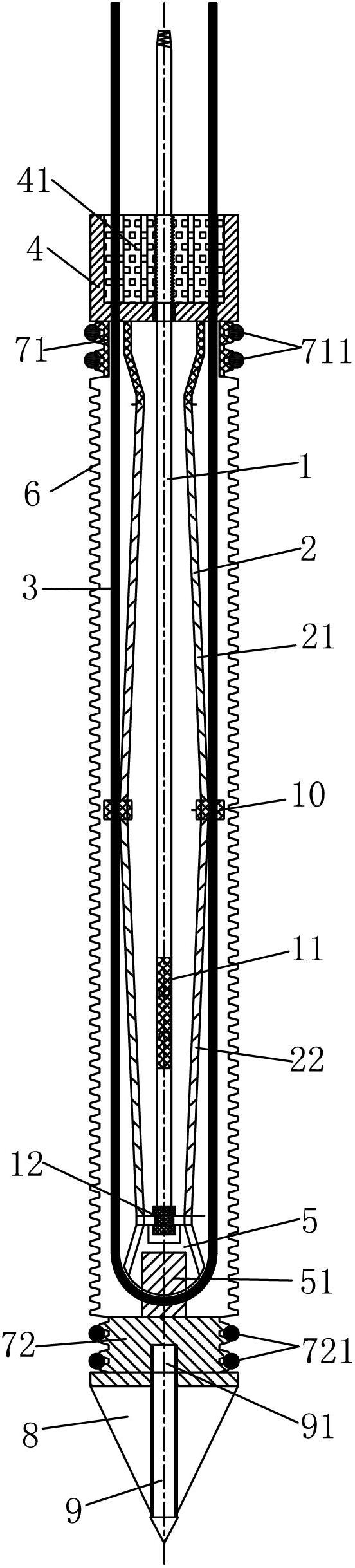

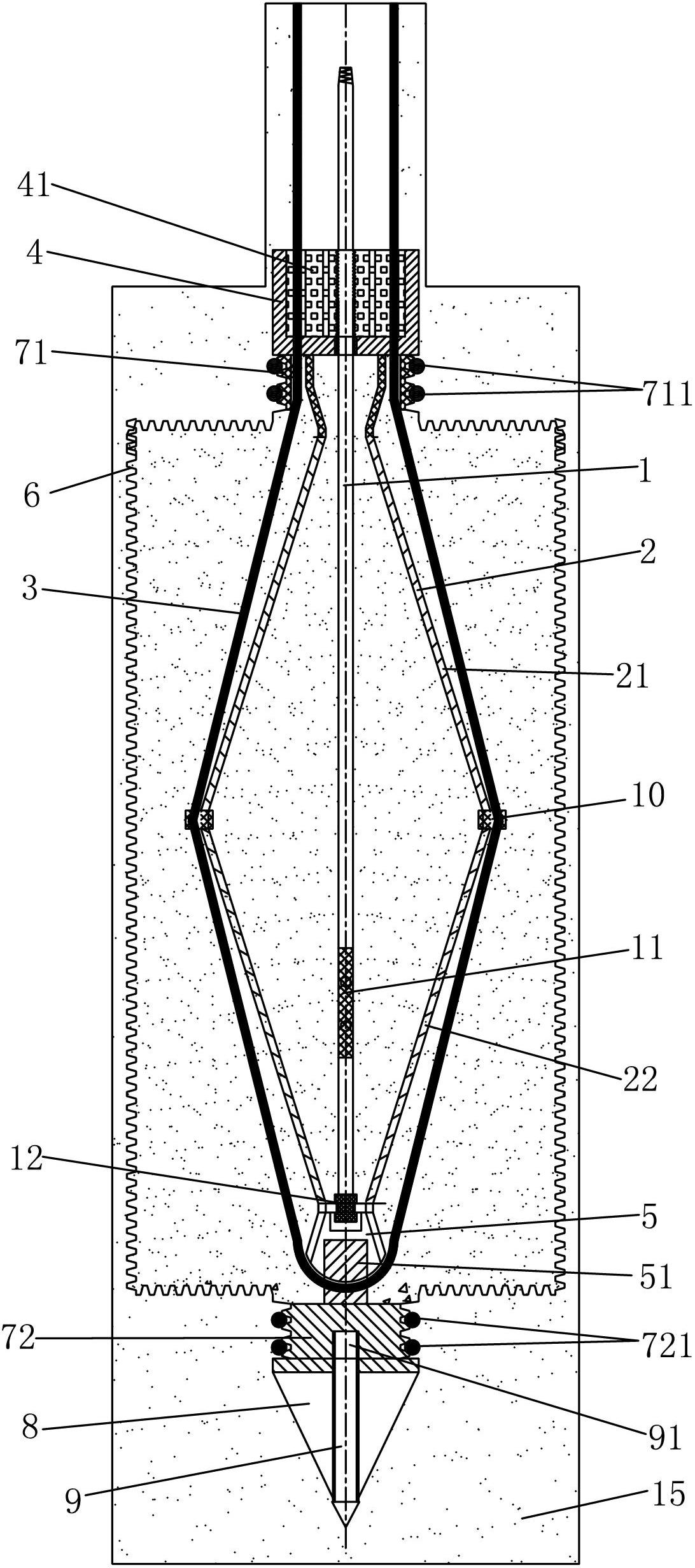

Embedded recoverable expansion anchor cable and construction method thereof

ActiveCN102650132AImprove bearing capacityDowngradeBulkheads/pilesArchitectural engineeringBearing capacity

The invention discloses an embedded recoverable expansion anchor cable and a construction method thereof. The embedded recoverable expansion anchor cable comprises a grouting pipe, expansion unfolding arms, steel strand wires, a steel strand wire free sliding cabin, a fixing and bearing device, and a flexible telescopic sleeve, wherein the steel strand wire free sliding cabin is sleeved onto the upper part of the grouting pipe; the fixing and bearing device is arranged at the lower end of the grouting pipe; the expansion unfolding arms are uniformly distributed on the periphery of the grouting pipe; the upper ends of the expansion unfolding arms are fixed to the bottom of the steel strand wire free sliding cabin; the lower ends of the expansion unfolding arms are fixed to the top of the fixing and bearing device; the steel strand wire free sliding cabin can move in the axial direction with respect to the grouting pipe; the middle of each of the steel strand wires moves around the bottom of the fixing and bearing device; the two ends of each of the steel strand wires are respectively fixed onto the steel strand wire free sliding cabin and the two end parts of each of the steel strand wires respectively extend from the steel strand wire free sliding cabin; and the flexible telescopic sleeve is sleeved on the expansion unfolding arms and the steel strand wires. According to the embedded recoverable expansion anchor cable, the steel strand wires can be recovered and have higher bearing capacity.

Owner:CHINA JINGYE ENG +1

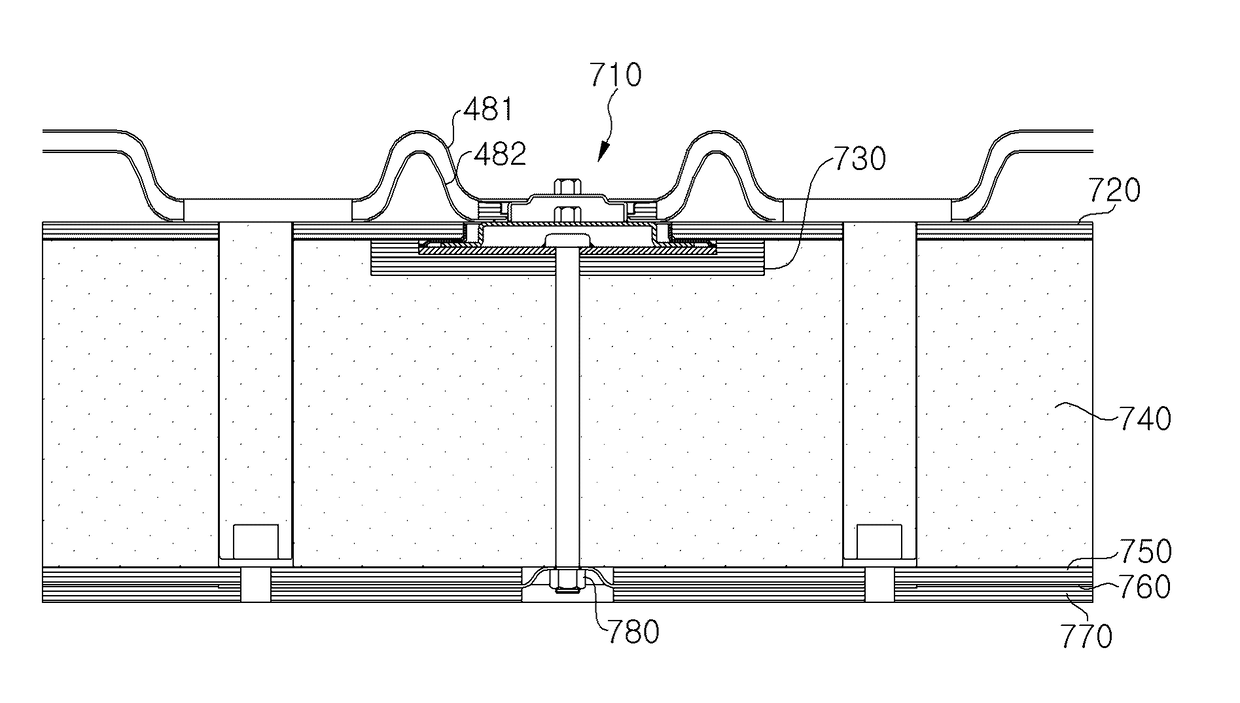

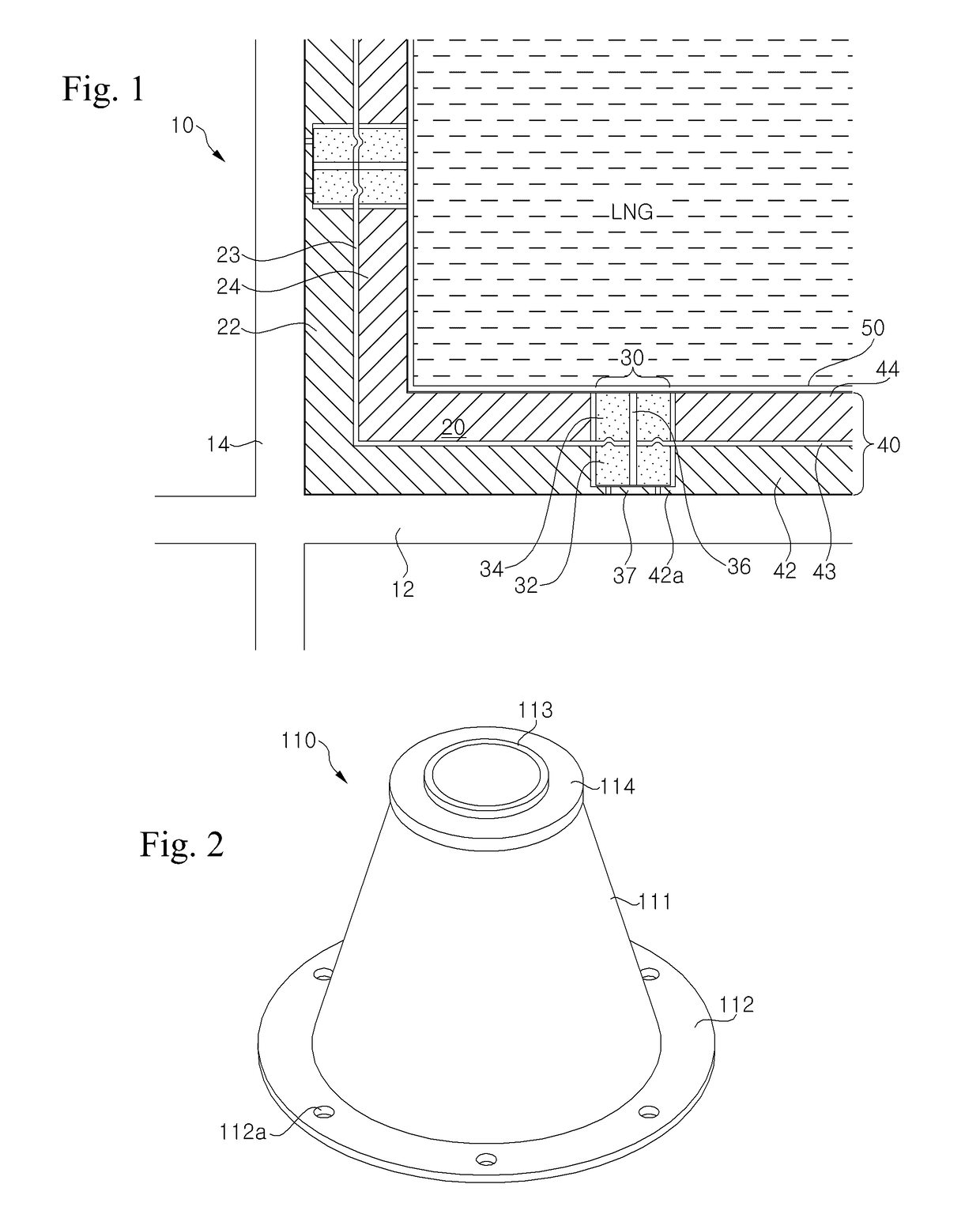

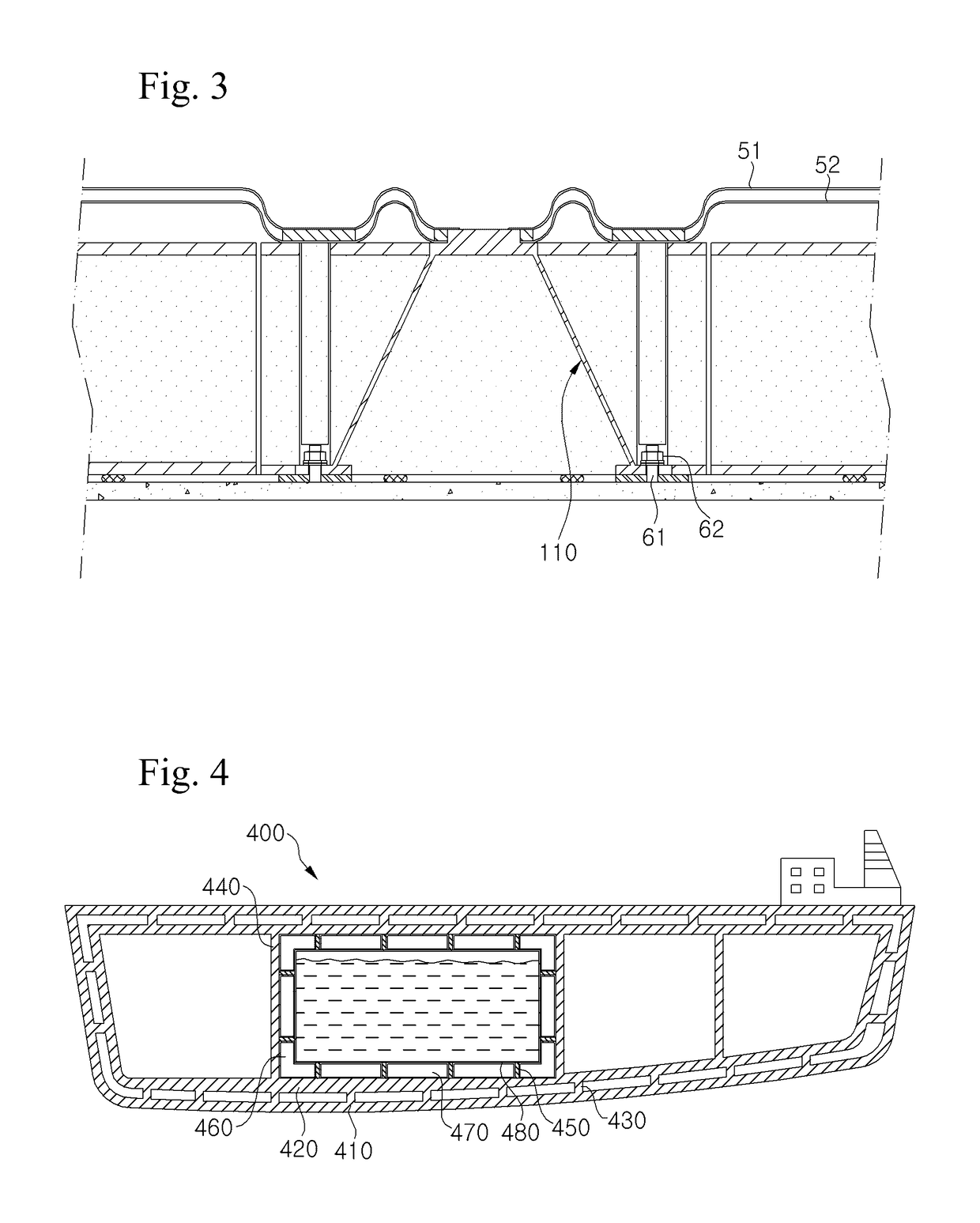

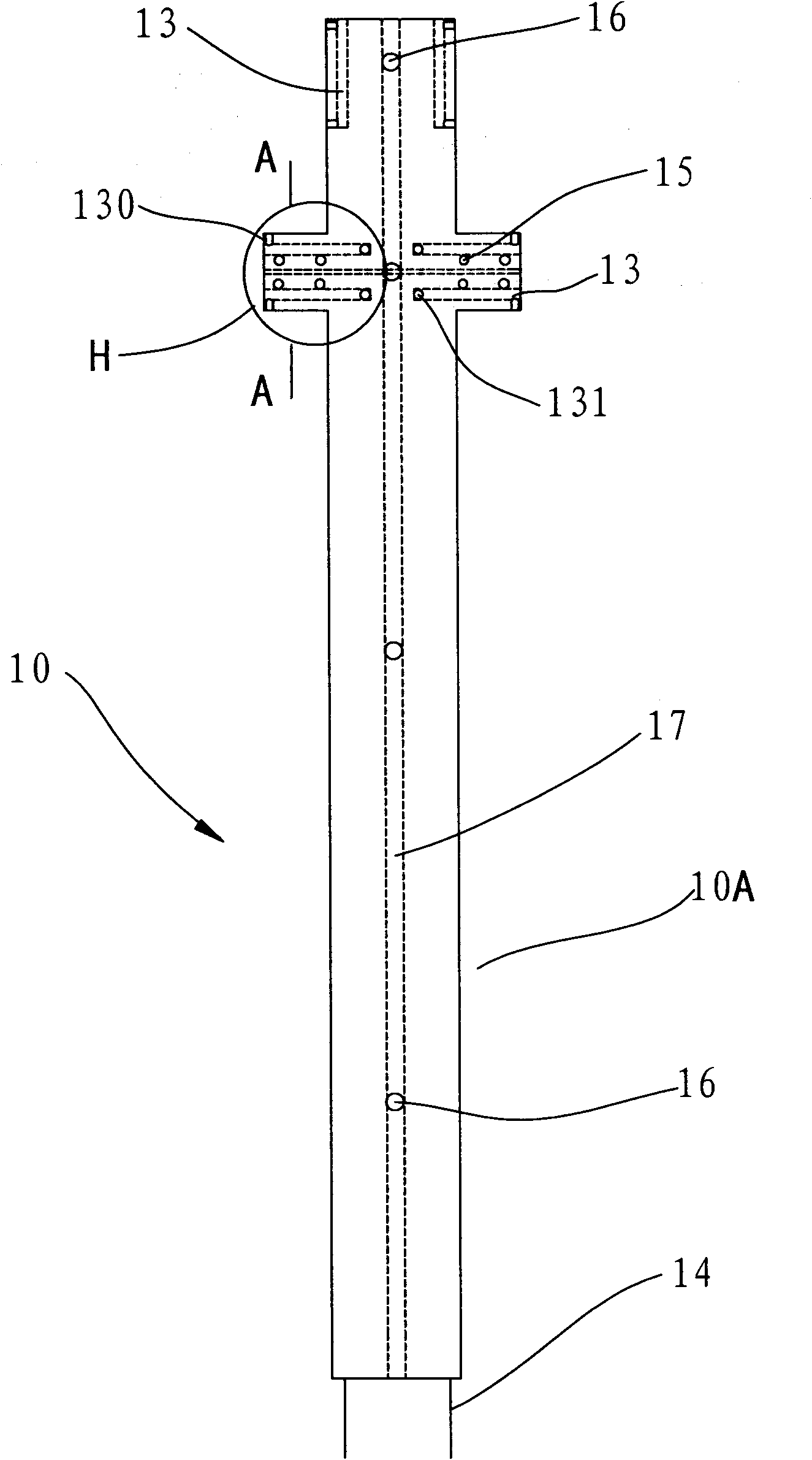

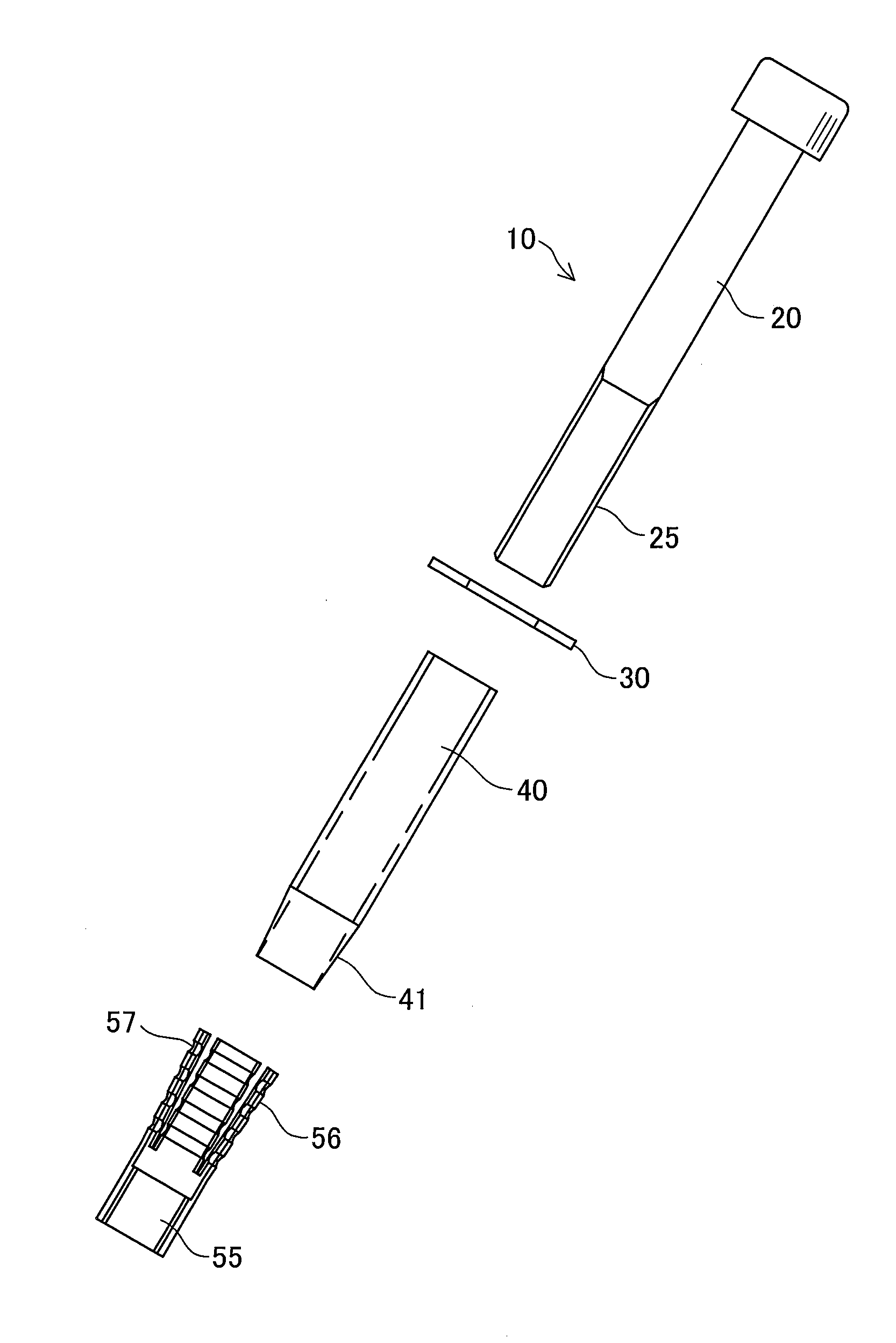

Anchor structure, and liquefied natural gas storage tank comprising said anchor structure

ActiveUS20170159888A1Stress concentration is thereby relievedImprove anchor strengthContainer filling methodsLarge containersNatural gas storageEngineering

The present invention relates to an anchor structure able to actively cope with hull deformation, and to a liquid natural gas storage tank and a production method for a liquid natural gas storage tank comprising the anchor structure. According to one embodiment of the present invention, an anchor structure is provided wherein an anchor structure, for linking a sealing wall and an inner wall of a liquid natural gas storage tank, comprises: an anchor member adapted such that a joining part, which is joined to the sealing wall, can slide horizontally; and a thermally insulating material formed around the anchor member.

Owner:KC LNG TECH CO LTD

Fast building earthquake-resisting reinforcing method and device

InactiveCN101936074AGuarantee product qualityShorten the on-site construction periodBuilding repairsShock proofingHalf fieldEngineering

The invention provides fast building earthquake-resisting reinforcing method and device. The fast building earthquake-resisting reinforcing device is a prefabricated part, the inner side of the prefabricated part is provided with a grout groove, and the grout groove is communicated with the outer side of the prefabricated part through more than one grout hole. The reinforcing method comprises the following steps of: removing the skin of the junction surface at the junction part between a wall of the reinforced building and the prefabricated part, and drilling anchoring holes in the wall, wherein the position of each anchoring hole is corresponding to the junction hole in the prefabricated part; installing the prefabricated part on the wall of the reinforced building through anchoring bolts, anchoring adjacent prefabricated parts, and fixedly bonding the prefabricated parts to the surface of the wall together. The technical scheme of field assembly of the prefabricated parts is adopted to reinforce the building, more than half field construction period can be shortened, the prefabricated parts can be produced in factories during school time, and enough time for ensuring production quality is guaranteed.

Owner:BEIJING TEXIDA TECH CO LTD

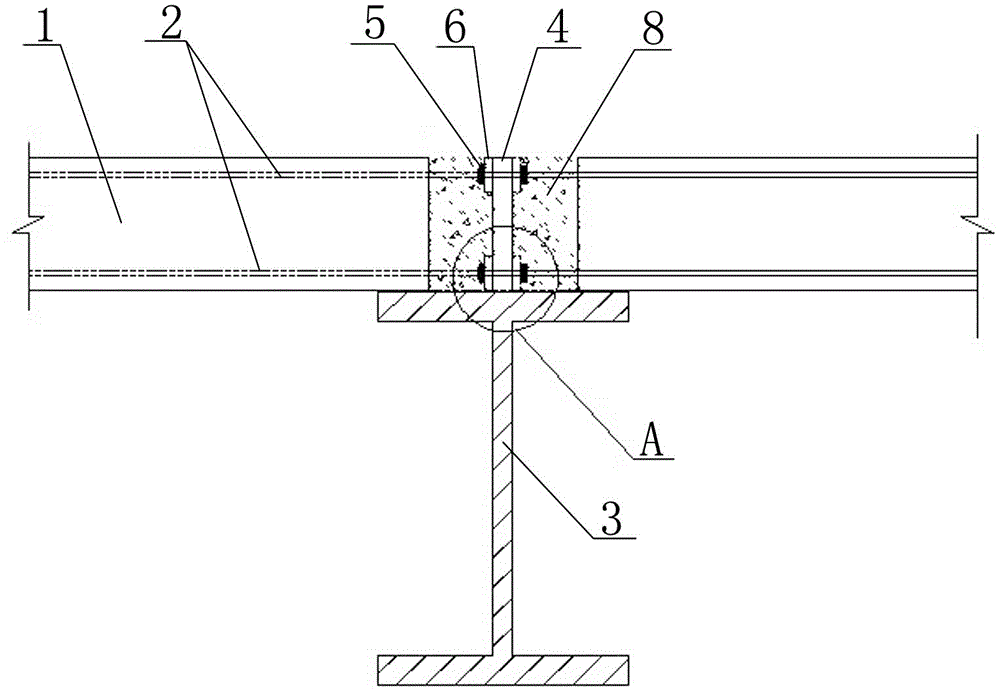

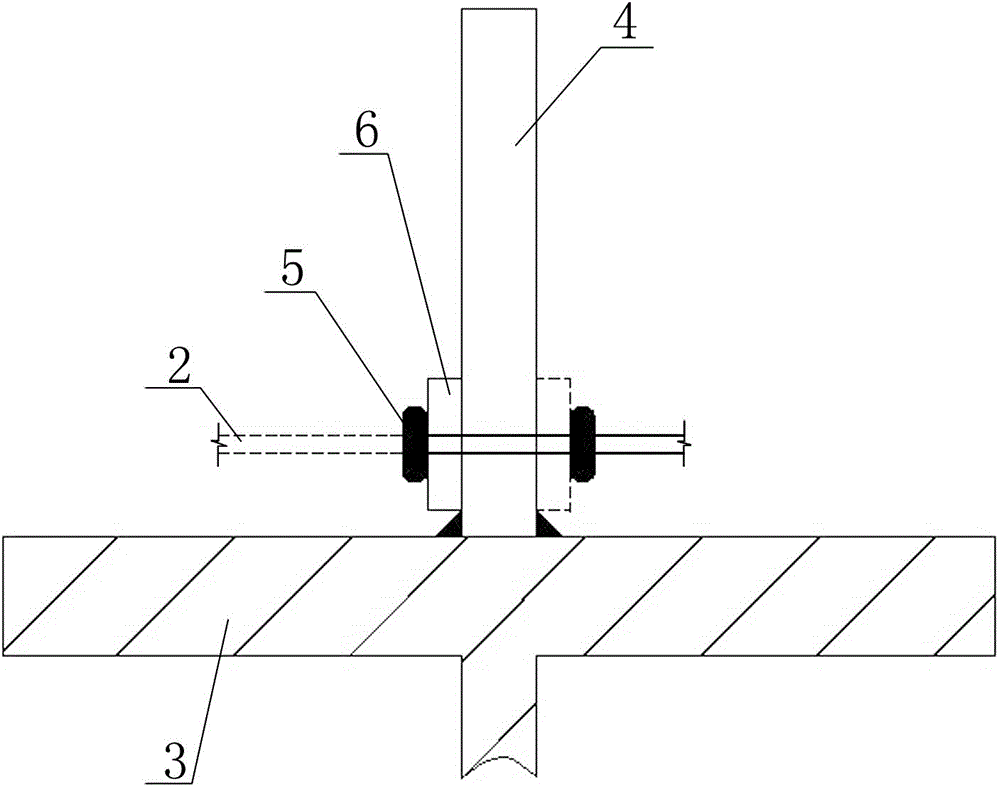

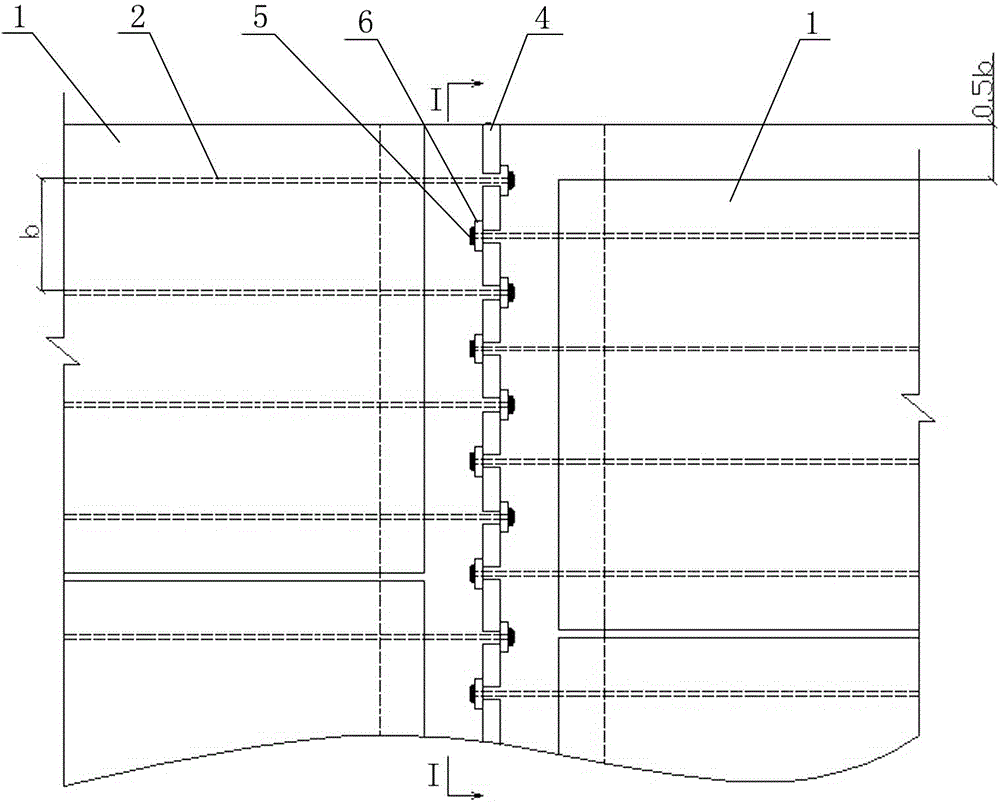

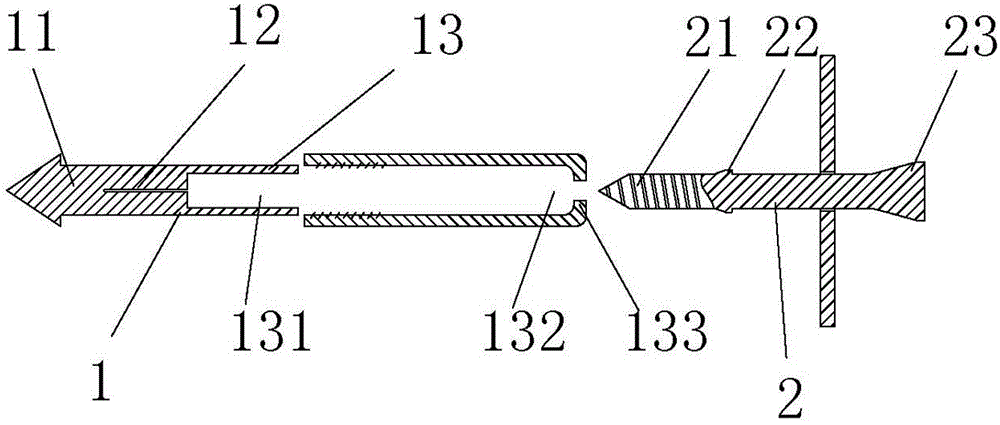

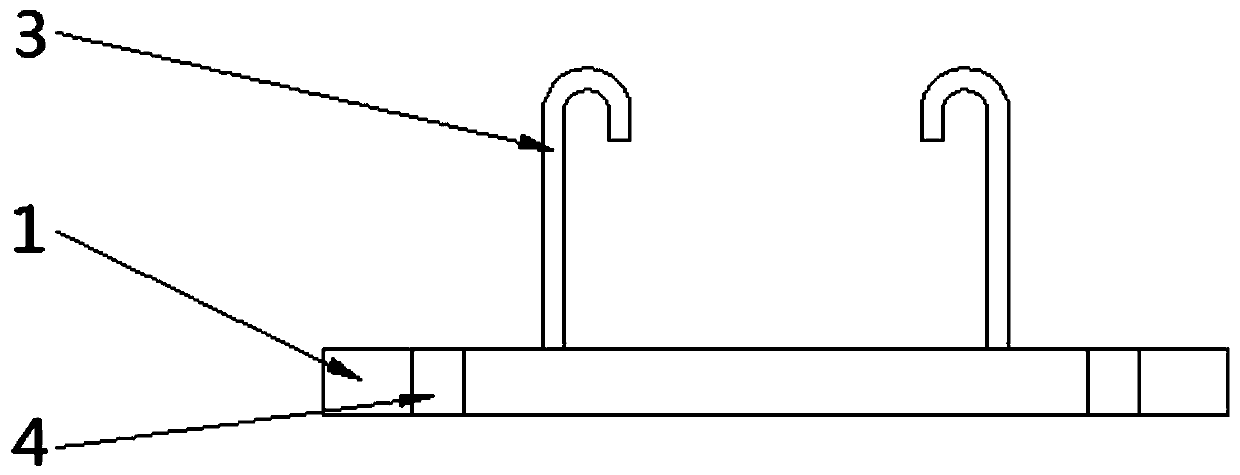

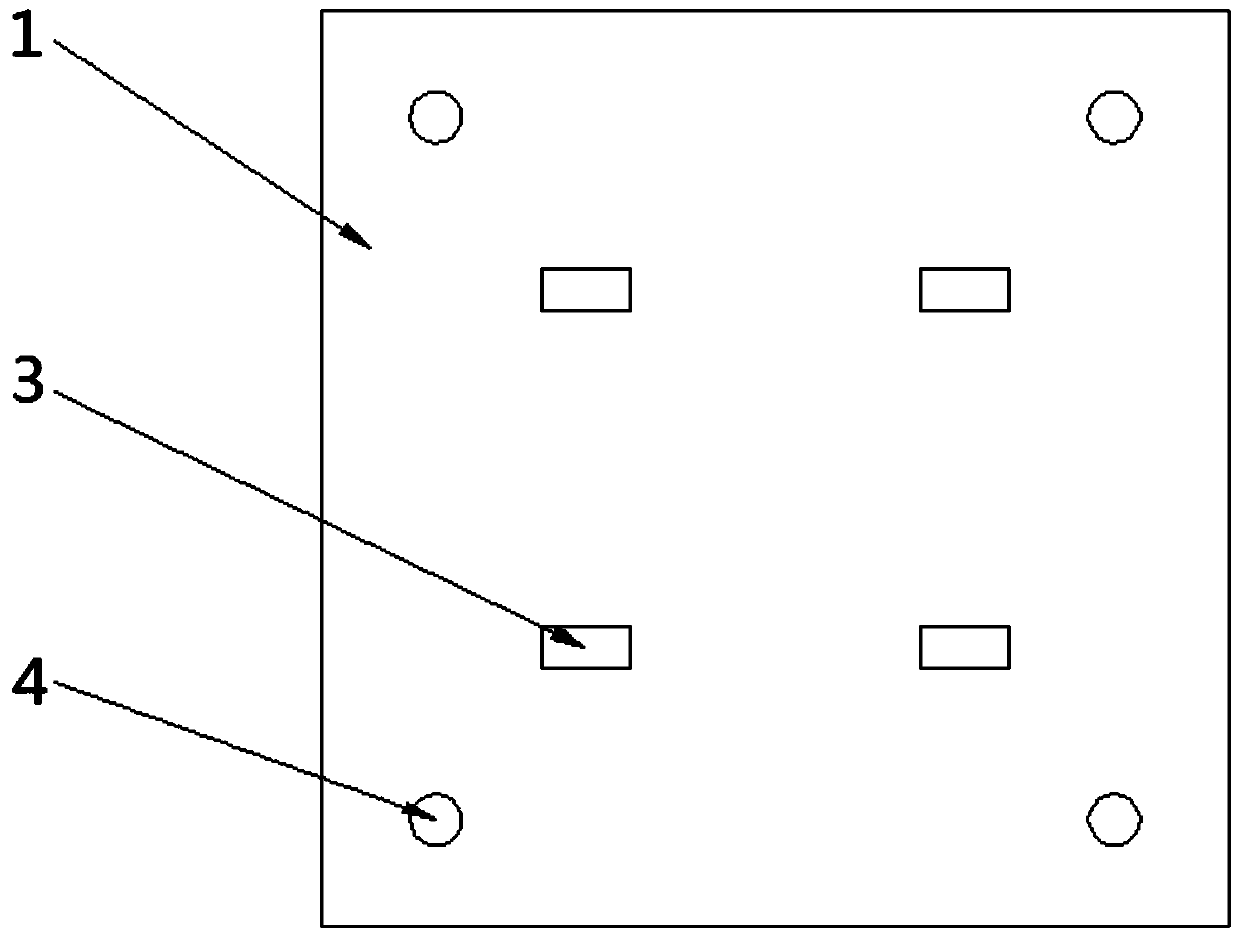

Assembly type prefabricated floor slab connecting piece for steel structure building and mounting method thereof

ActiveCN104405041AEasy positioning into slotImprove anchor strengthBuilding constructionsFloor slabRebar

The invention discloses an assembly type prefabricated floor slab connecting piece for a steel structure building and a mounting method thereof. Exposed reinforcement end parts at the two ends of a prefabricated floor slab are both reinforcement pier heads of which the end parts are additionally provided with base plates, or the exposed reinforcement end part at one end of the prefabricated floor slab is a reinforcement pier head of which the end part is additionally provided with a base plate, and the exposed reinforcement end part at the other end is provided with an extrusion sleeve; an I steel beam is vertically welded with a strip-shaped steel plate in the full length along a top surface; reinforcement positioning grooves are spaced in the strip-shaped steel plate in the length direction; the prefabricated floor slabs on the two sides of the strip-shaped steel plate on each I steel beam are arranged in a staggering manner; the exposed reinforcements of the prefabricated floor slabs on the two sides of the strip-shaped steel plate are placed in the reinforcement positioning grooves in a mutual staggering manner and are fixed to the strip-shaped steel plate through the reinforcement pier head or the extrusion sleeve of which the end part is additionally provided with the base plate. The connecting piece is extremely convenient to mount, the construction processes can be greatly reduced, the anchoring time of the prefabricated floor slab and the steel beam is saved, and the anchoring strength of the floor slab can be obviously improved. The connecting piece can be widely applied to connection between the prefabricated floor slab and the steel beam in an assembly type steel structure building.

Owner:DAYUAN CONSTR GRP

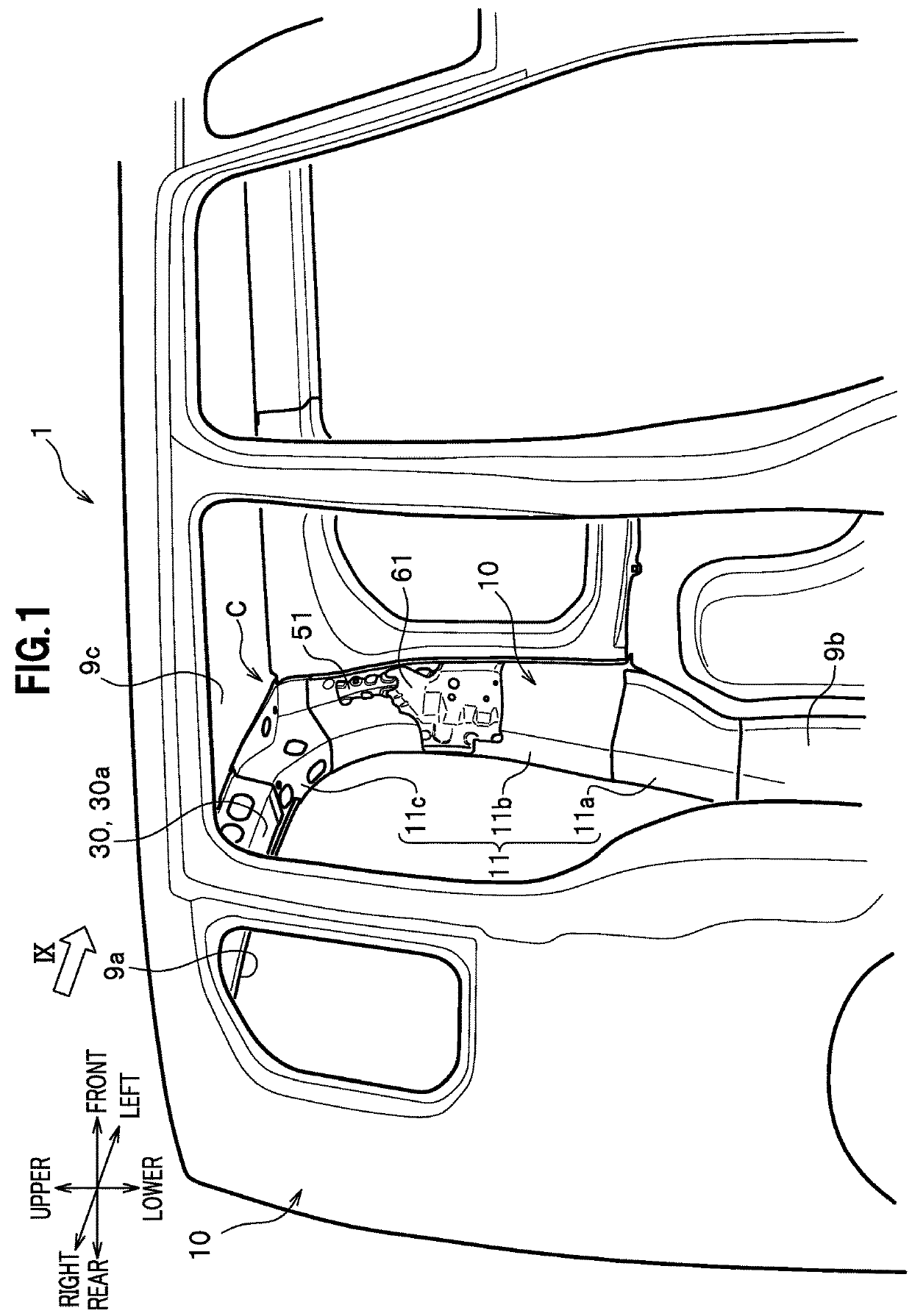

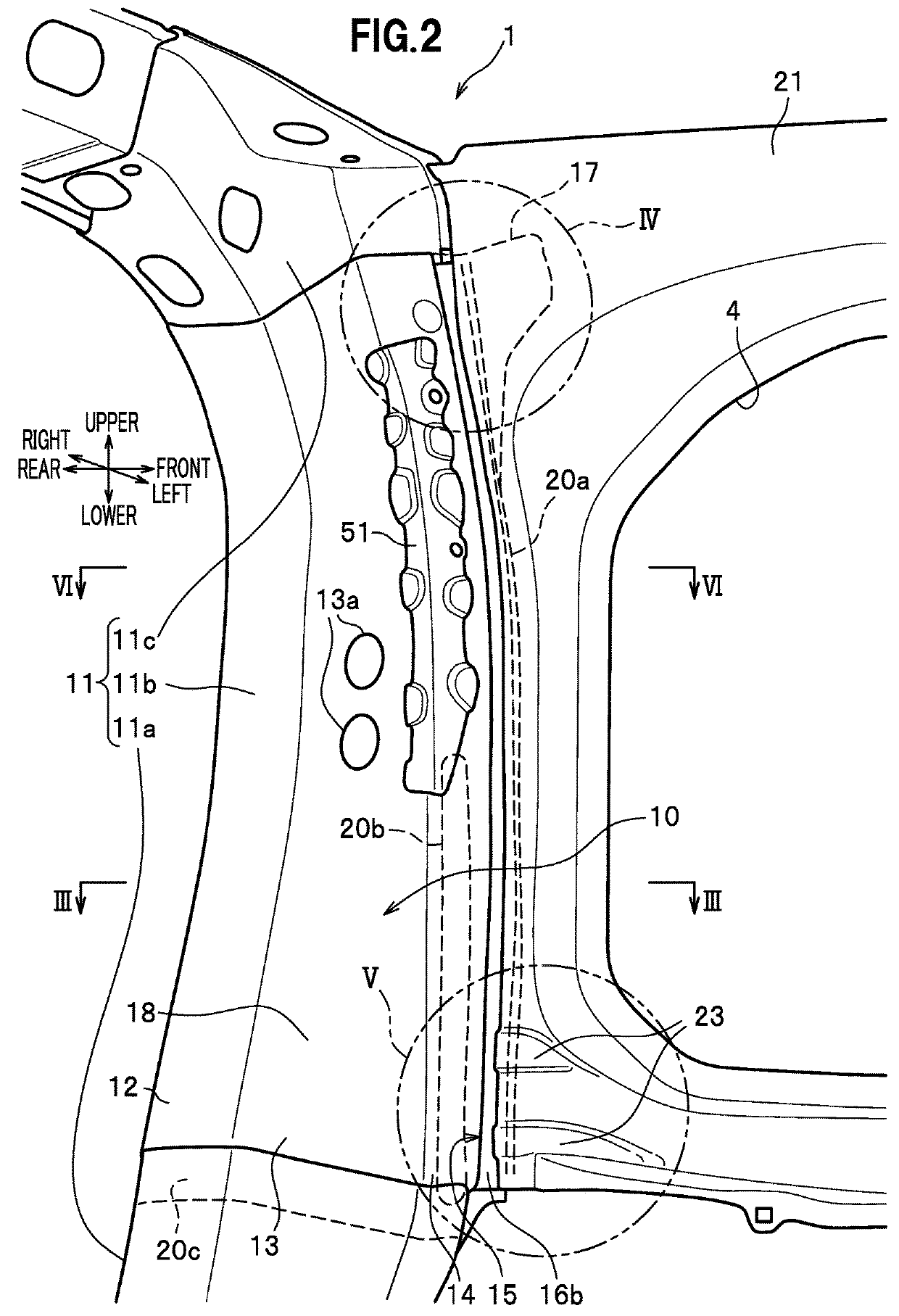

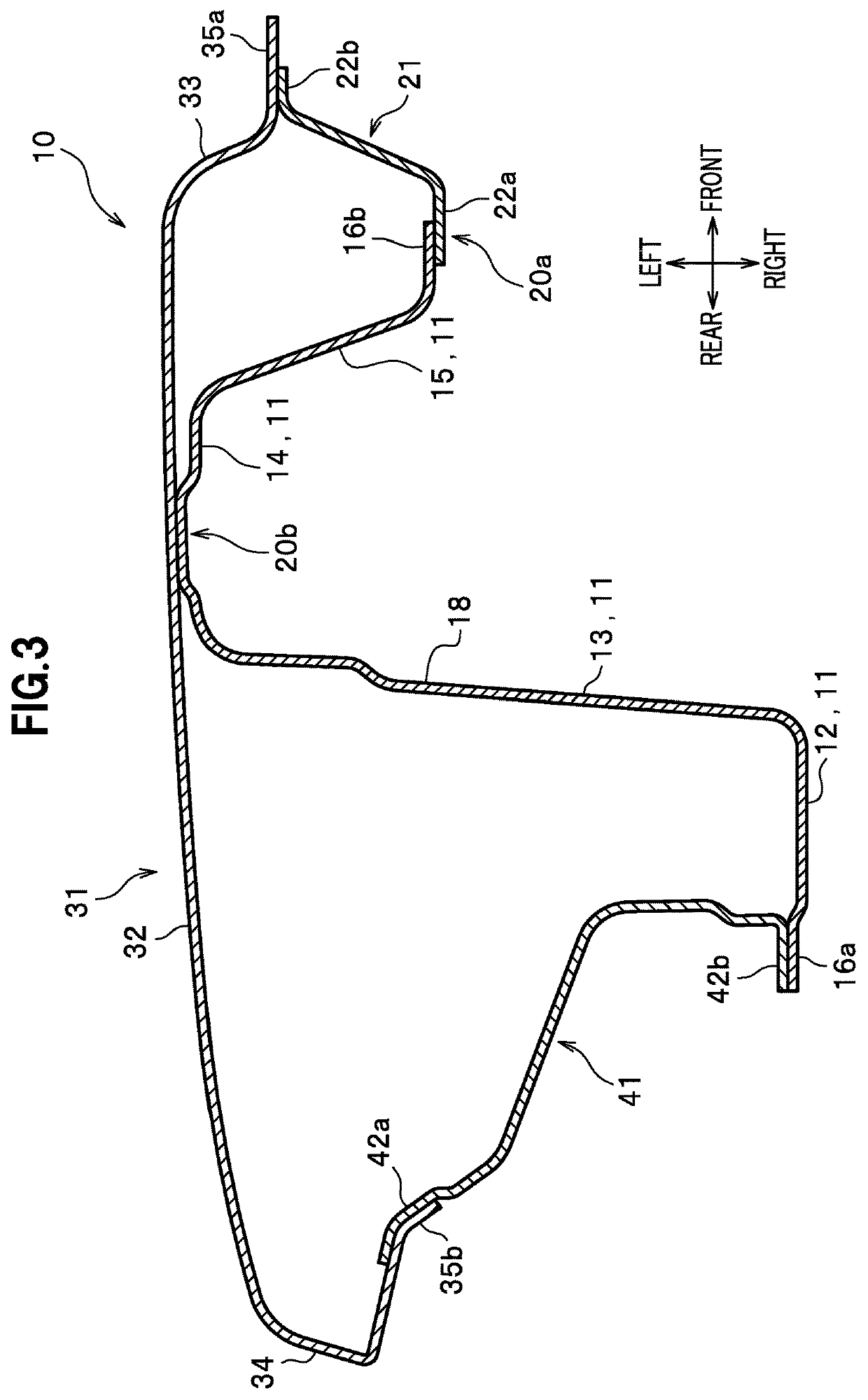

Rear body structure

ActiveUS20180265138A1Rigid enoughImprove rigiditySuperstructure subunitsSuperstructure connectionsEngineeringMechanical engineering

Owner:HONDA MOTOR CO LTD

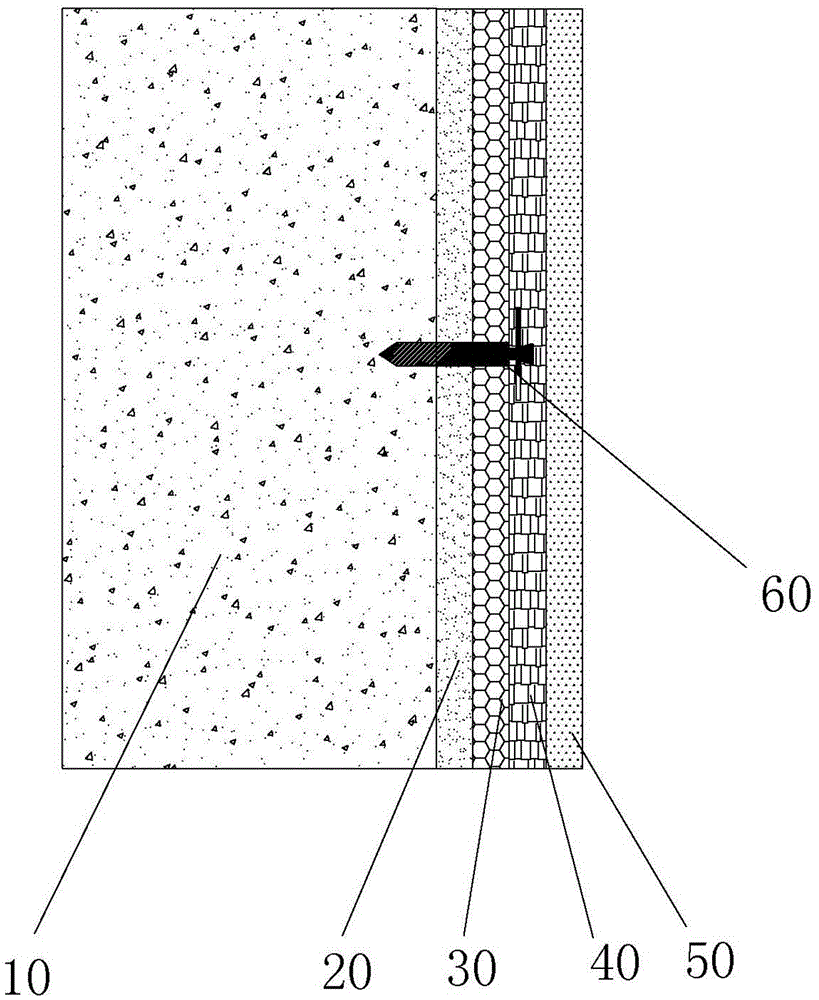

Inorganic thermal mortar external wall insulation system

ActiveCN104481038AMeet insulationMeet fire protectionCovering/liningsWallsUltimate tensile strengthFire prevention

The invention relates to an inorganic thermal mortar external wall insulation system and belongs to the technical field of new materials for construction. The inorganic thermal mortar external wall insulation system comprises a concrete wall or a masonry wall, wherein the concrete wall or the masonry wall is covered with multiple coatings; the multiple coatings sequentially comprise an interface mortar layer, an inorganic light-weight aggregate thermal mortar layer, a plastering anti-crack mortar layer and a finishing layer from inside to outside. The inorganic thermal mortar external wall insulation system can simultaneously meet the requirements on much performance such as thermal insulation, fire prevention, sound insulation, strength and anchorage of the wall; an anchorage piece has the advantages of convenience in use and high anchoring strength.

Owner:ANJI QILONG NEW BUILDING MATERIAL

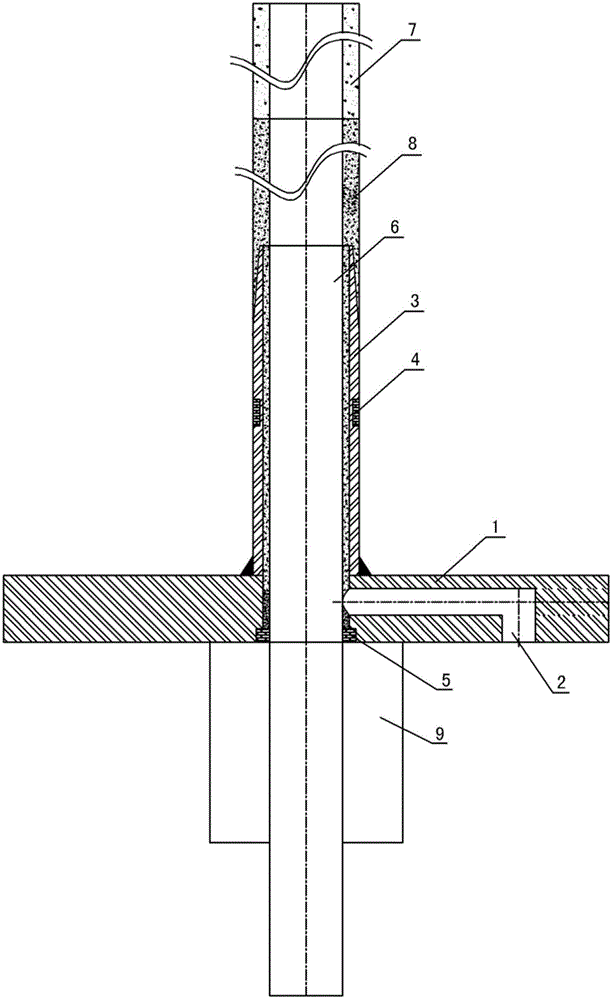

Hole wall grouting anchor cable

InactiveCN102748048AImprove support strength or breaking forceImprove anchor strengthAnchoring boltsDrill holeGrout

The invention discloses a hole wall grouting anchor cable which is characterized in that an L-shaped grouting hole is formed in an anchor cable supporting plate and on the periphery of a steel strand mounting hole, wherein one end of the grouting hole is communicated with an anchor cable hole in the anchor cable supporting plate and is communicated with an annular grouting cavity between a steel strand and a hole drilling wall through the anchor cable hole, and the other end of the grouting hole is located on the surface of the anchor cable supporting plate and is connected with an external grouting pipe; a hole pipe located in a drilled hole is connected with the anchor cable supporting plate; and a groove is turned on the periphery of the hole pipe and is internally provided with a hole wall sealing ring. The hole wall grouting anchor cable disclosed by the invention can effectively improve the grout anchoring strength of an anchor cable and reduces the manufacturing cost of the anchor cable.

Owner:ANHUI PROVINCE COAL SCI RES INST

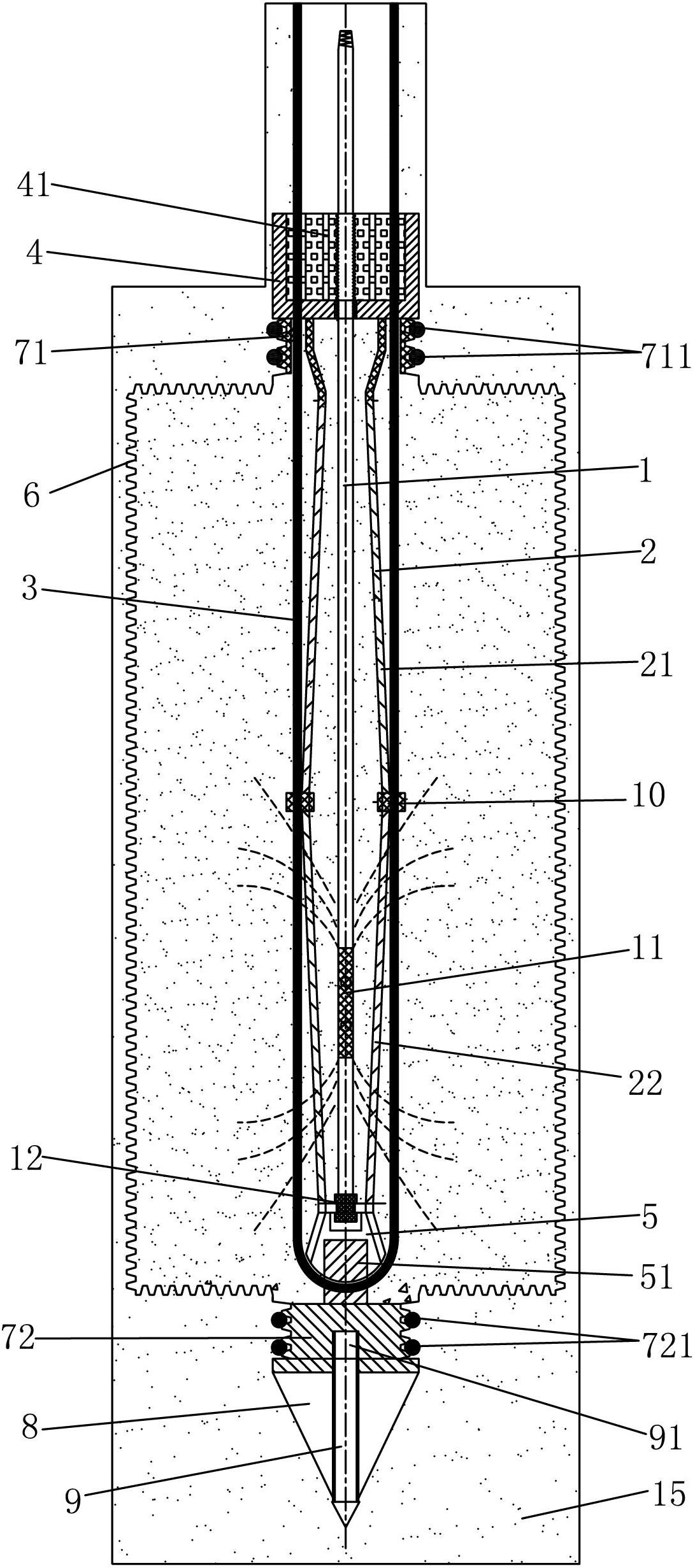

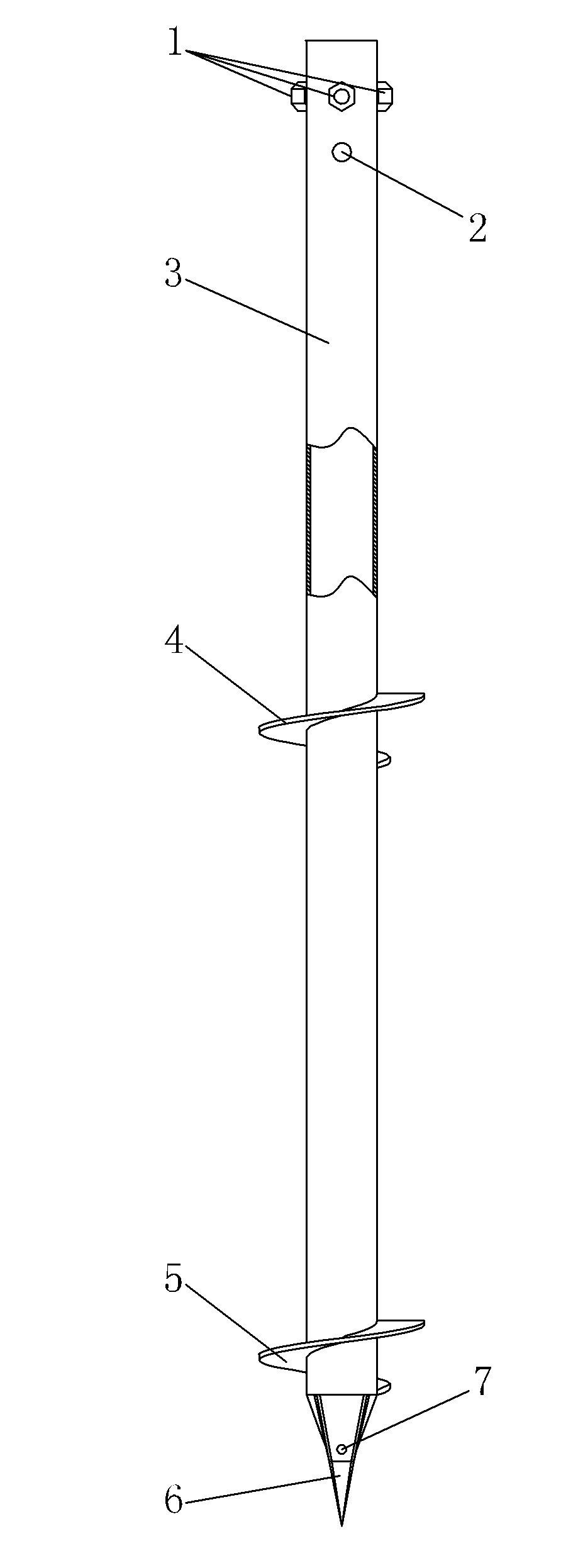

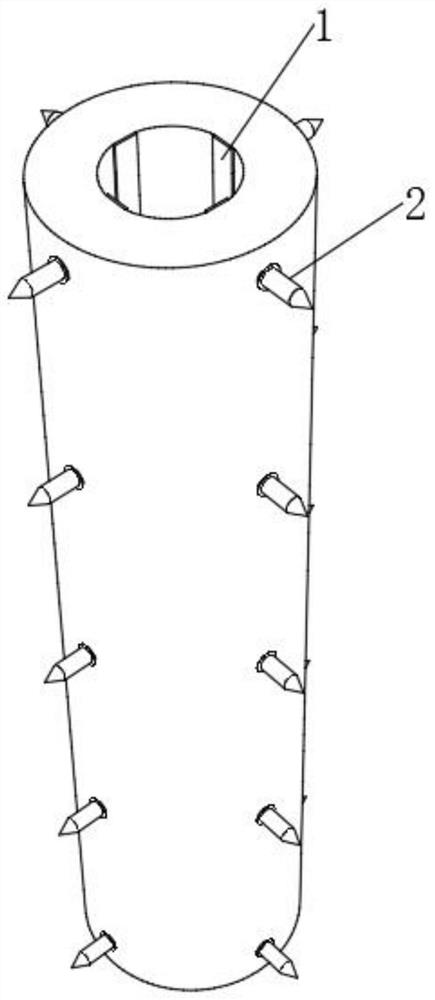

Spiral ground pile

InactiveCN102493442AEasy constructionImprove anchor strengthBulkheads/pilesSpiral bladeArchitectural engineering

The invention discloses a spiral ground pile which comprises a tubular-shaped pile body, wherein the bottom of the tubular-shaped pile body is provided with a sharp cone part, the sharp cone part is provided with two to eight cutting ridges from top to bottom, the upper part of the tubular-shaped pile body is provided with multiple through holes, the outside of at least one through hole is welded with a nut, and a spiral blade is arranged on the tubular-shaped pile body. The technical scheme disclosed by the invention can not only facilitate the construction and meet the strength requirement of anchoring, but also effectively reduce the cost and save the labor capacity.

Owner:浙江博雷重型机床制造有限公司

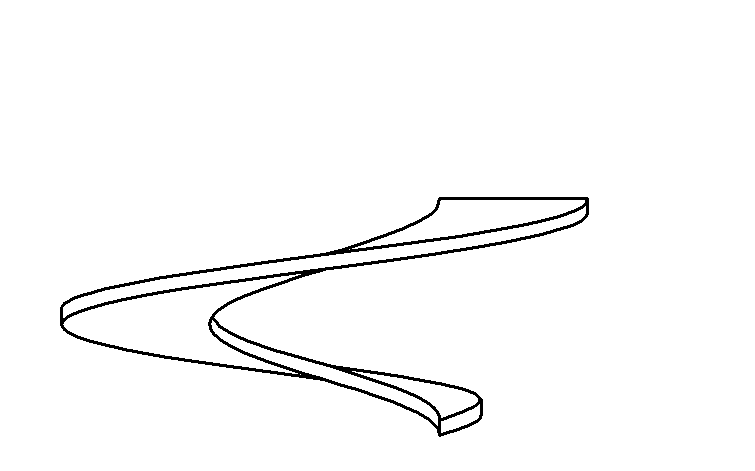

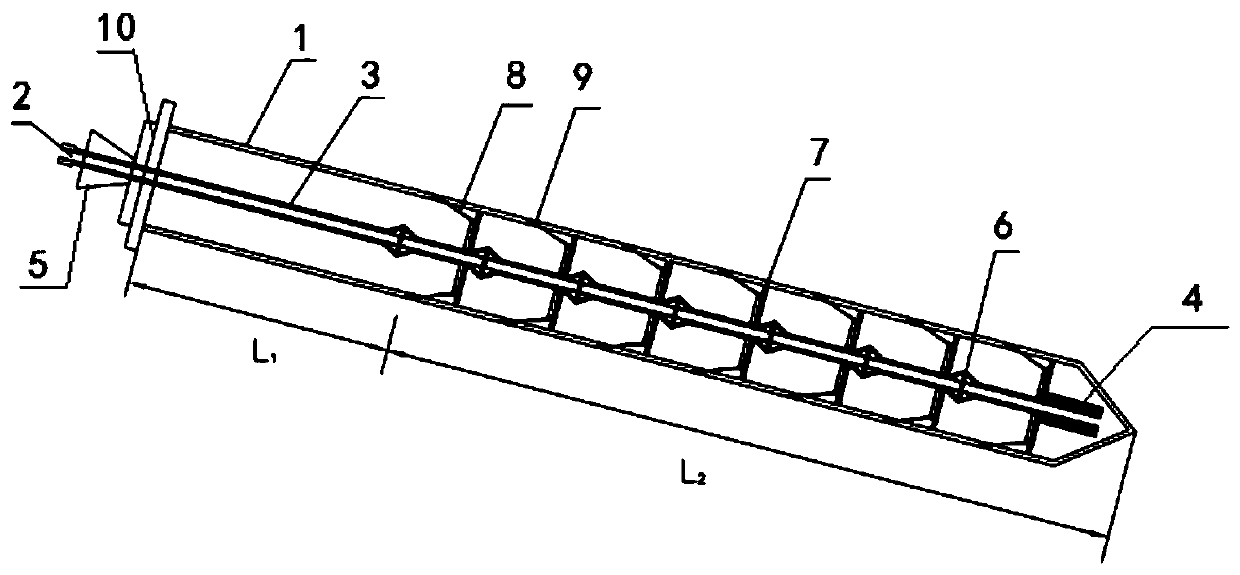

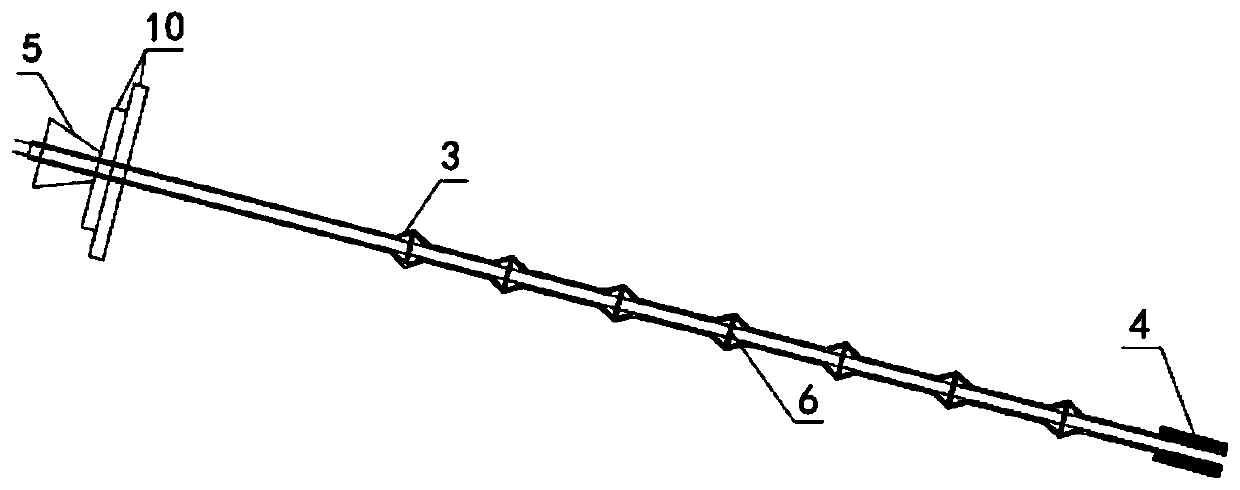

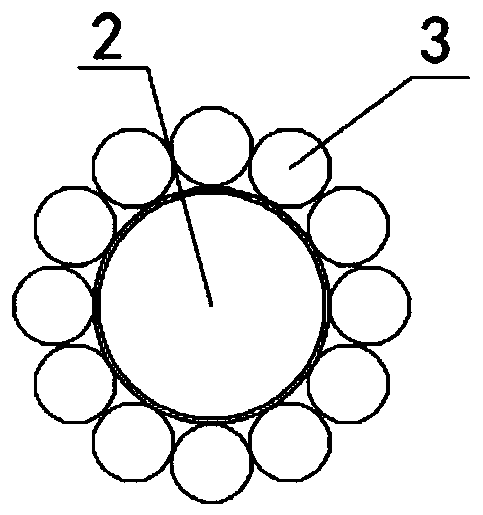

Spiral fin grouting anchor cable assembly with adjustable angle

InactiveCN103306695AImprove adsorption capacityImprove the support effectAnchoring boltsBite force quotientEngineering

The invention designs a spiral fin grouting anchor cable assembly with an adjustable angle. The spiral fin grouting anchor cable assembly comprises an anchor cable body and an anchorage device, wherein the anchor cable body is formed by stranding steel strands by taking a grouting pipe as a cable core; the grouting pipe is in a pipe shape, and is composed of a cement outlet, a cement spraying hole and a grouting opening; the anchorage device comprises a tray, an anchor ring and an anchor cable clamping piece, wherein a hemispherical concave table of the tray is matched with a hemispherical protruding end of the anchor ring; the anchor cable body penetrates a through hole of the tray, and penetrates out from an anchoring hole of an anchor ring cylinderical end through the matched tray and anchor ring; the anchor cable body is clamped by the anchor cable clamping piece in the anchoring hole; the anchorage device and an anchor cable are enabled to always keep vertical after being stressed by the anchorage device through a self-adjusting function, so that a bite force can be guaranteed to be uniform; under an equivalent acting force, the probability that the anchorage device drops off and glides can be greatly reduced. With the adoption of the spiral fin grouting anchor cable assembly with the adjustable angle, the combination of anchor cable support effect and grouting reinforcement effect is realized, so that the anchoring range and the anchoring force are greatly increased, and the consumption of a drill hole drilling machine and anchor cable materials is saved, thereby the cost is lowered.

Owner:CHANGZHOU SHUANGJIANG MACHINERY TECH

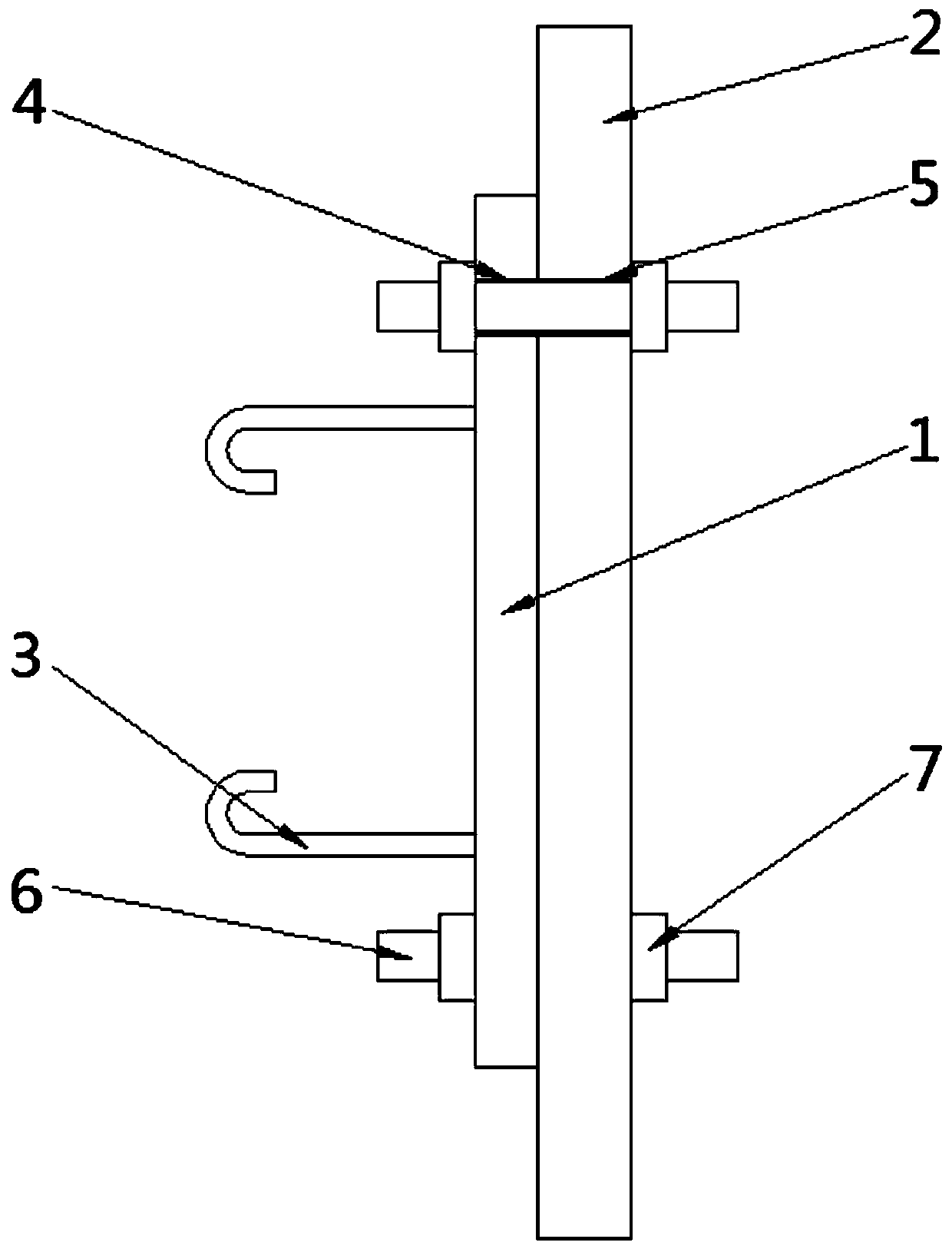

Self-adjusting building embedded part and embedded method thereof

InactiveCN110984397AImprove anchor strengthReduce workloadBuilding constructionsConstruction engineeringWelding process

The invention discloses a self-adjusting building embedded part and an embedded method thereof, and belongs to the technical field of building construction. The self-adjusting building embedded part comprises an embedded part body and an anchor bar welding device, wherein the embedded part body comprises an embedded plate and a template, the embedded plate is provided with four anchor bars, mounting holes are formed in the four corners of the embedded plate, and positioning holes corresponding to the mounting holes are formed in the template. Deformation of the embedded plate can be effectively prevented in the welding process of the anchor bars, it is ensured that when pouring space is filled with pouring media, the position of the embedded part cannot be easily moved due to easy touch ofa vibrator, after the template is removed, the embedded part cannot be wrapped by the pouring media, thus the amount of work required for chiseling away and cleaning is reduced, the fixing stabilityand positioning accuracy of the embedded part are guaranteed, the amount of rework of the embedded part is reduced, the flatness of the embedded part and a concrete surface course is effectively improved, and the mounting quality of the embedded part is improved effectively.

Owner:朱崇峰

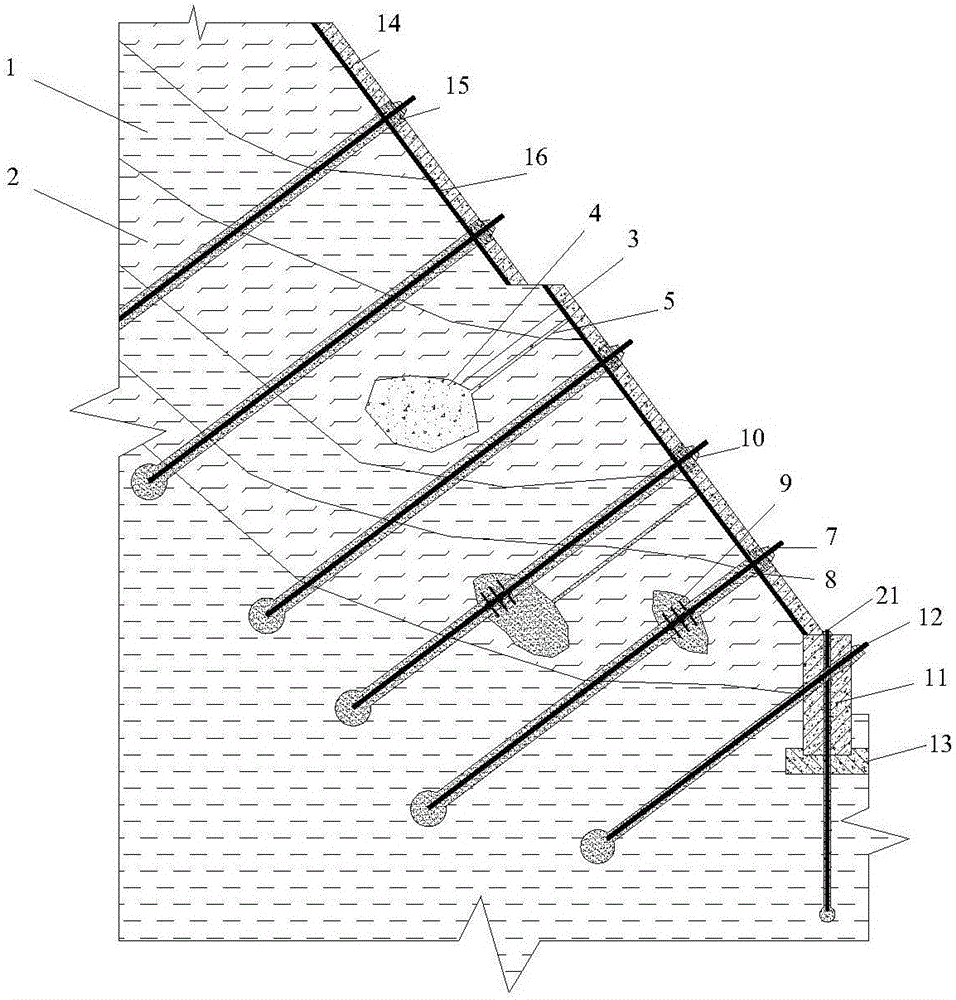

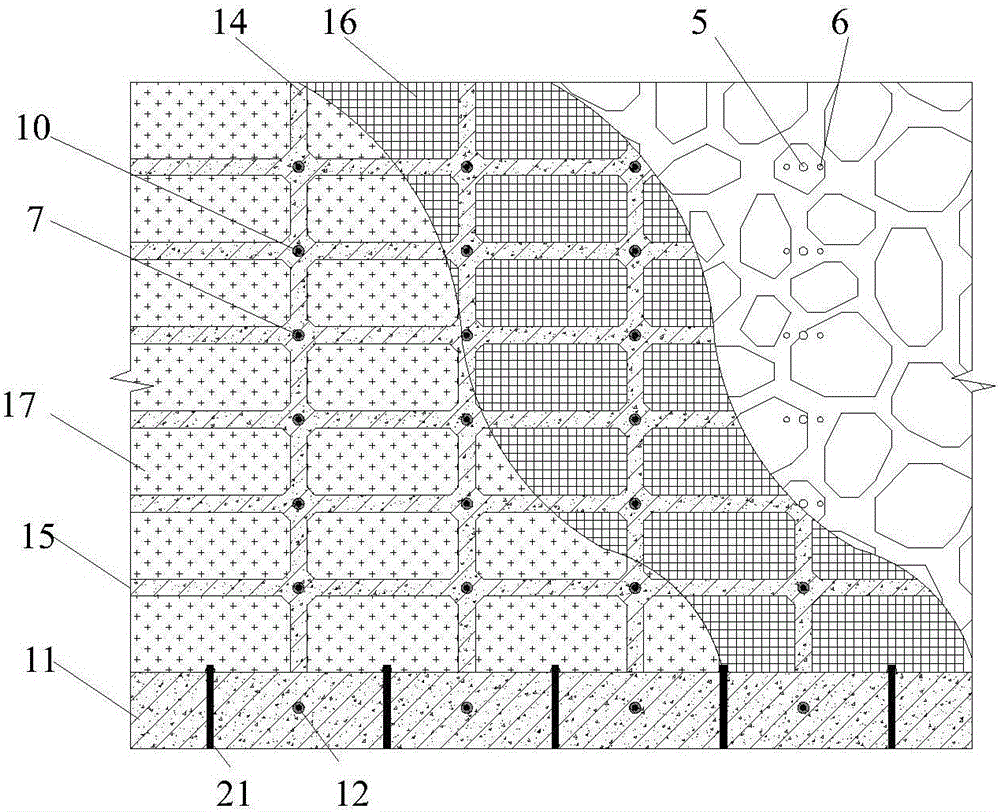

High-pressure washing anchor planting and recharging comprehensive biological protection structure of soft and hard smashing interbedding type composite rock slope and construction method of structure

ActiveCN105040712AHigh strengthAvoid shear damageExcavationsHorticultureSoil scienceEconomic benefits

The invention relates to a high-pressure washing anchor planting and recharging comprehensive biological protection structure of a soft and hard smashing interbedding type composite rock slope and a construction method of the structure. A retaining wall is arranged at the bottom of the slope, and self-compacting concrete is arranged in a crushed zone; slope anchor cables penetrate through an incompetent bed, and the bottom ends of the slope anchor cables extend into a hard rock layer; transverse frame beams and longitudinal frame beams are arranged on the surface of the slope, galvanized meshes are arranged in the longitudinal frame beams and the transverse frame beams and are filled with planting soil, and vegetation is planted on the planting soil. The construction method includes the steps that firstly, the retaining wall is arranged and reinforced on a retaining wall cushion layer; then, the crushed zone is drilled and cleaned, and holes are recharged with filling materials; the transverse frame beams and the longitudinal frame beams are poured in the slope, and the galvanized meshes are laid between the longitudinal frame beams and the transverse frame beams; the slope anchor cables penetrate and are inserted in the slope, and the ends of the slope anchor cables are fixed through anchors; finally, the planting soil is laid and the vegetation is planted. The slope protection structure has the advantages that the reinforcing effect is remarkable, self strength of rock is high, and the use amount of concrete and the use quantity of the anchor cables are small, and has good technological and economic benefits.

Owner:QINGDAO HAIDE ROAD & BRIDGE ENG

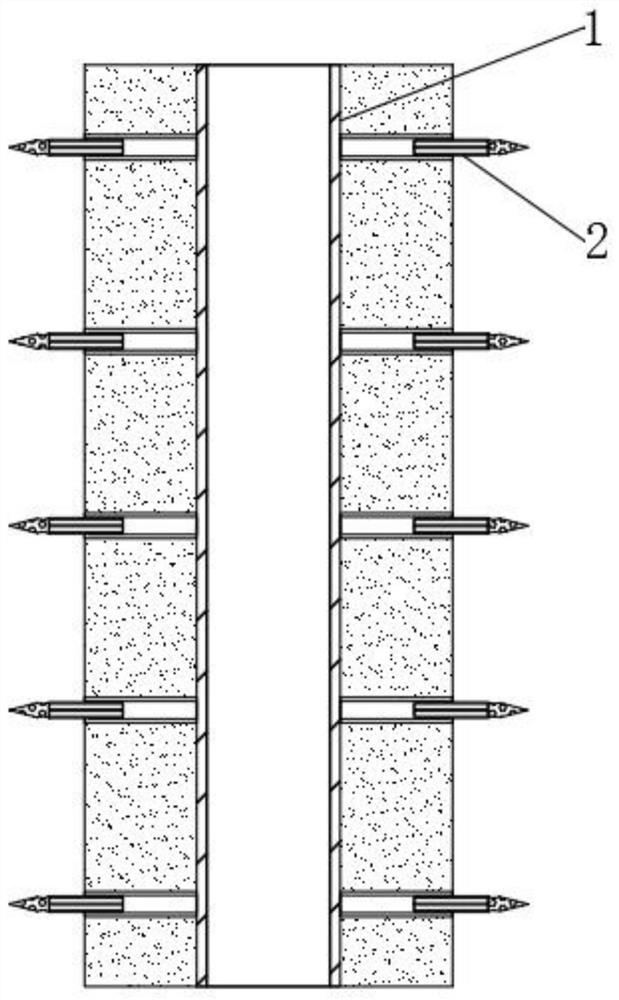

Preparation process of anti-settling prestressed concrete pipe pile

InactiveCN112092179AImprove subsidenceImprove anchor strengthShaping reinforcementsBulkheads/pilesPre stressRock bolt

The invention discloses a preparation process of an anti-settling prestressed concrete pipe pile, and belongs to the technical field of concrete pipe piles. A steel reinforcement cage can be pre-embedded into the concrete pipe pile in a manner of installing a magnetic pushing net rack, then a magnetic migration anchor rod is embedded after maintenance and molding, then pile sinking is carried outby adopting a conventional pile sinking process, after pile sinking is finished, the magnetic field leakage work is triggered in a mode of heating the magnetic pushing net frame, then a disconnectionaction is triggered in the magnetic migration anchor rod through the magnetic repulsion effect, within the time difference from disconnection action to thorough disconnection and by continuing to relyon the magnetic repulsion function, the magnetic migration anchor rod is pushed to migrate from the magnetic pushing net rack and inserted into the foundation environment to form an anchoring hole, mortar is automatically released after thorough disconnection and escapes along the anchoring hole to reversely enter the magnetic migration anchor rod, and the anchoring strength can be remarkably improved after the mortar is solidified; and therefore, the settlement phenomenon of the concrete pipe pile in the foundation environment is effectively improved.

Owner:黄娟玲

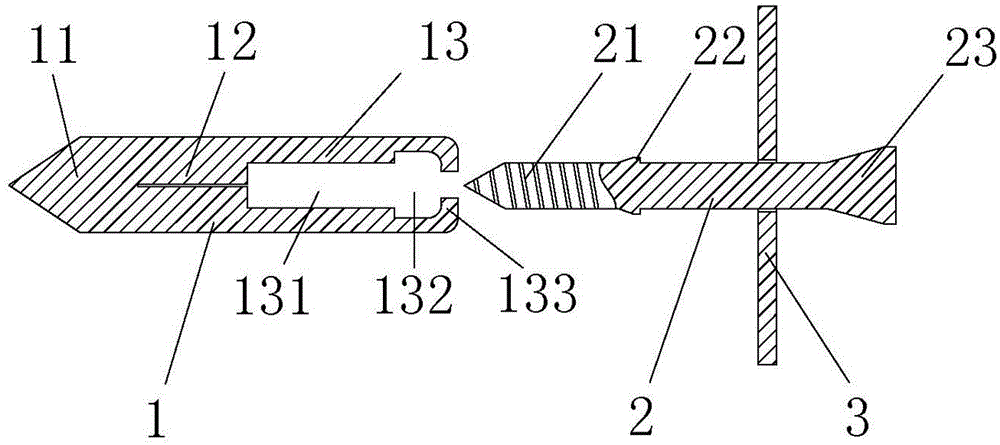

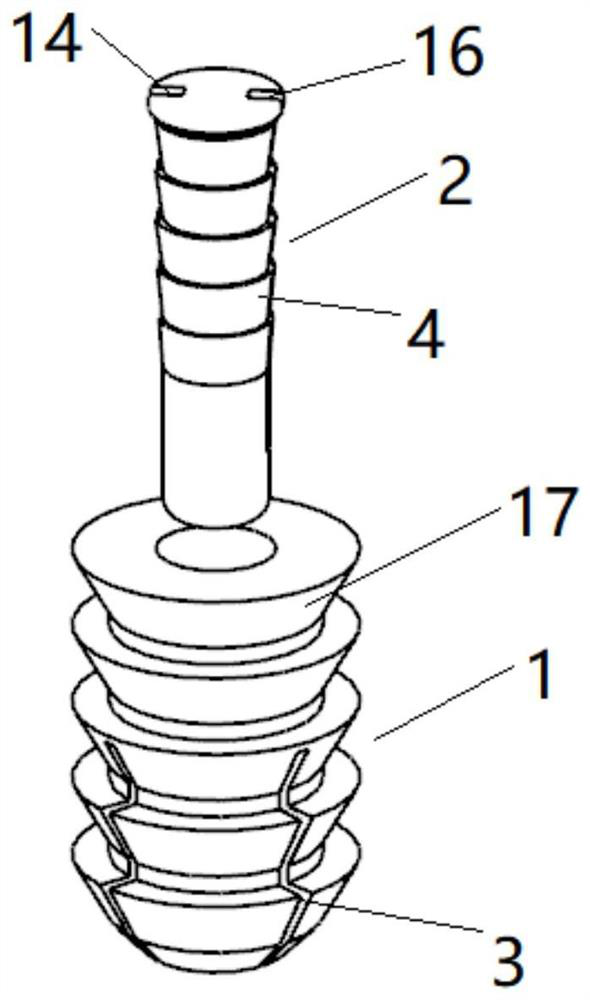

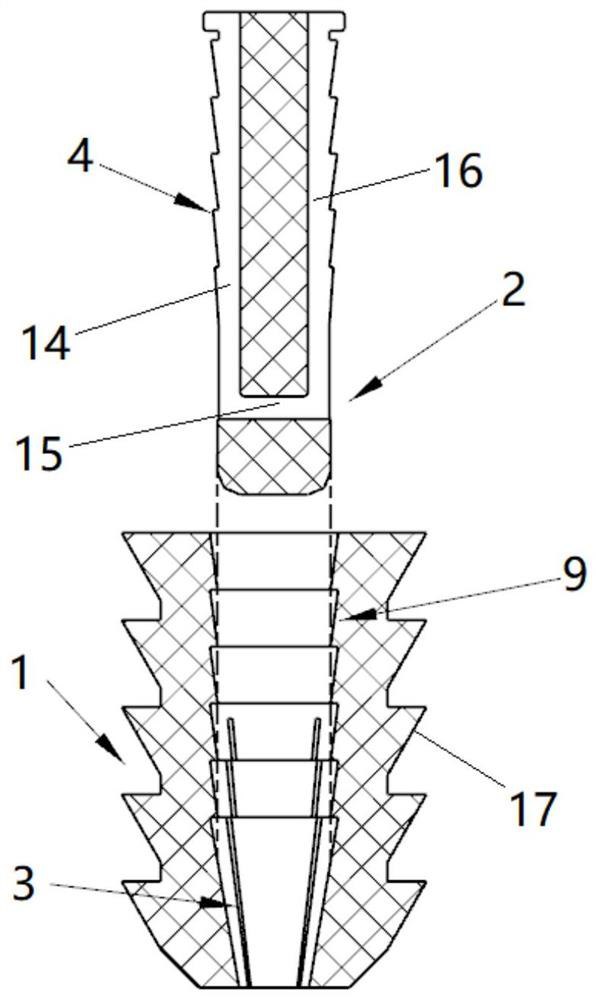

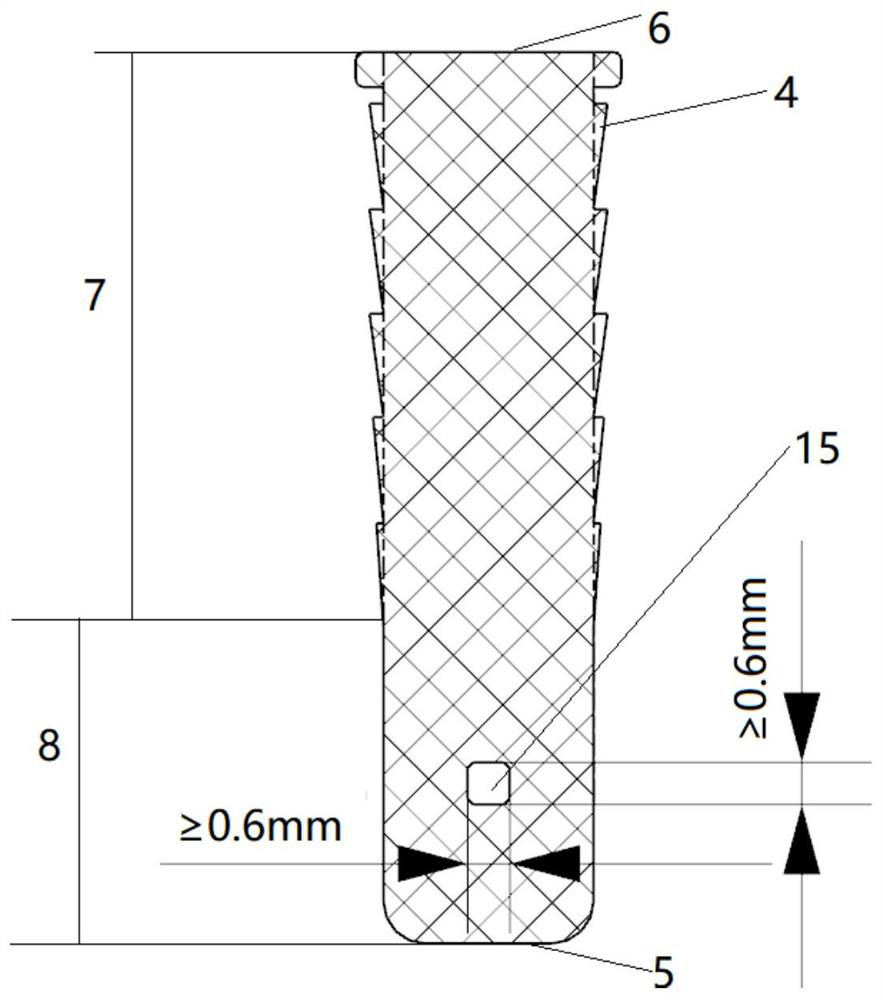

Extrusion type expansion anchor

PendingCN112244914APrevents detachment from the anchor bodyImprove pullout resistanceSuture equipmentsStructural engineeringMechanical engineering

The invention relates to an extrusion type expansion anchor. The extrusion type expansion anchor comprises an anchor body and an expansion element, wherein a notch is formed in a position near the front end of the anchor body, the expansion element is used for being inserted into an inner cavity of the anchor body from the rear end of the anchor body to enable the front end of the anchor body to expand in the radial direction, and an annular groove A is formed in the inner side wall of the anchor body; the expansion element is of a columnar structure, and an annular protrusion B is arranged onthe side wall of the expansion element; and the annular groove A and the annular protrusion B are matched with each other to achieve retaining clamping fit. According to the extrusion type expansionanchor, the anti-pulling force of the anchor body is increased by adopting a self-locking expansion structure, so that the anchor body is not prone to falling off after being implanted into a bone, the number of elements used for anchoring outside the anchor body does not need to be increased, and the circumstance that the overall operation time is influenced due to the fact that the anchor is difficult to knock in or the screwing-in time is long is avoided; and meanwhile, a one-way self-locking structure of the anchor body and the expansion element is formed by utilizing the retaining clamping fit of the annular groove A and the annular protrusion B, so that the expansion element is not prone to loosening after being extruded into the anchor body, the expansion element does not need to have high shear strength, and the expansion element can be suitable for an absorbable material and a PEEK material.

Owner:HANGZHOU REJOIN MASTIN MEDICAL INSTR CO LTD

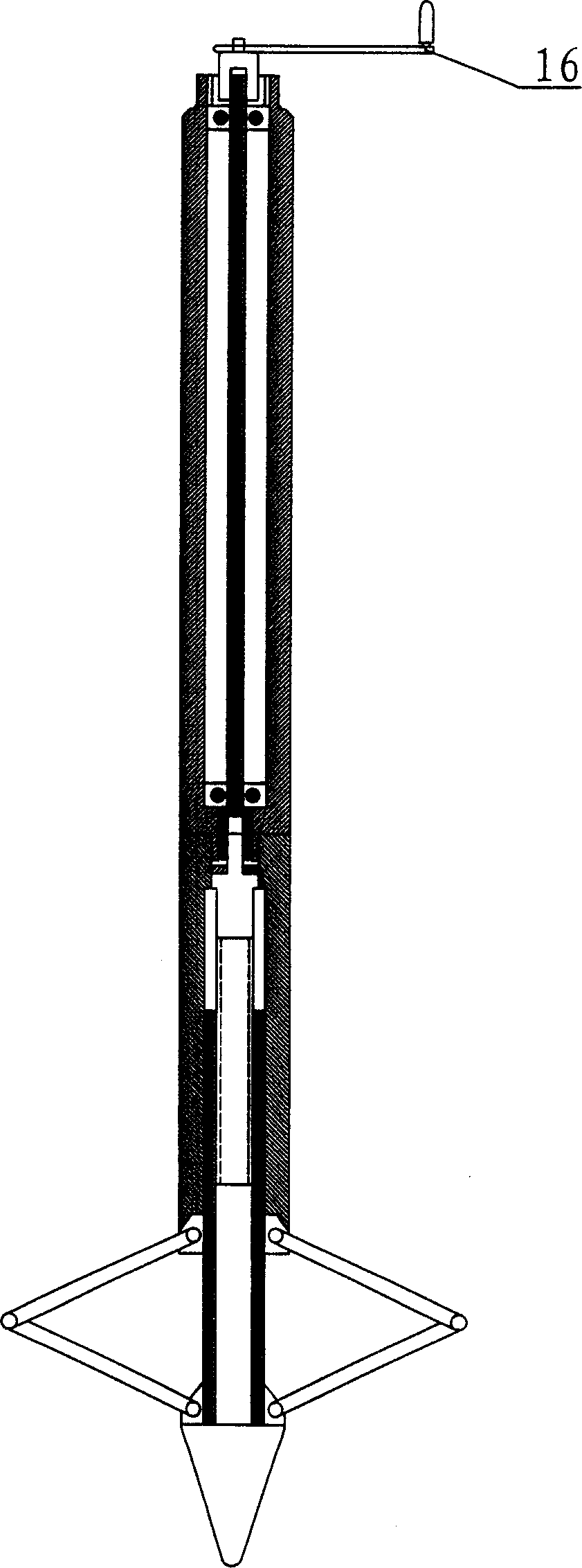

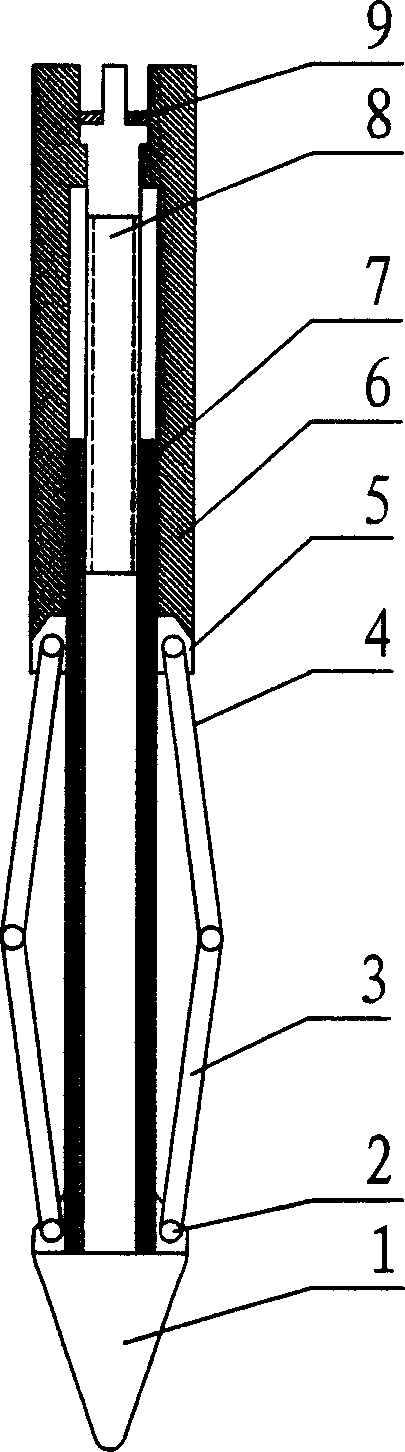

Retractable teasel thorn type anchor cable suitable for weak soil and construction method

ActiveCN111074885ASolve the problem of poor anchoring effectIncrease contact areaBulkheads/pilesSteel tubeOpen hole

The invention relates to a retractable teasel-thorn-type anchor cable suitable for weak soil and a construction method. The anchor cable comprises a grouting pipe located in a hollow steel pipe. Multiple steel strands wrap the periphery of the grouting pipe, the grouting pipe can move in a space wrapped by the steel strands in the axial direction of the grouting pipe, one end of each steel strandis fixedly connected with an anchoring part, the other end of each steel strand is connected with an anchor, anchoring segments of the steel strands are provided with multiple supporting rings, and the portions, where the supporting rings are located, of the steel strands are stretched out. The supporting rings are fixedly connected with the steel strands, so that the adjacent steel strands form gaps for slurry to flow out, multiple ring push discs sleeve the peripheries of the steel strands, multiple steel thorns are rotatably connected to the ring push discs, open holes matched with the steel thorns are formed in the pipe wall of the hollow steel pipe, and the push discs move in the axial direction of the hollow steel pipe to drive the steel thorns to extend out of the hollow steel pipethrough the open holes. The retractable teasel-thorn-type anchor cable increases the anchoring force and has a good anchoring effect.

Owner:JINAN MUNICIPAL ENG DESIGN & RES INSITITUTE GRP

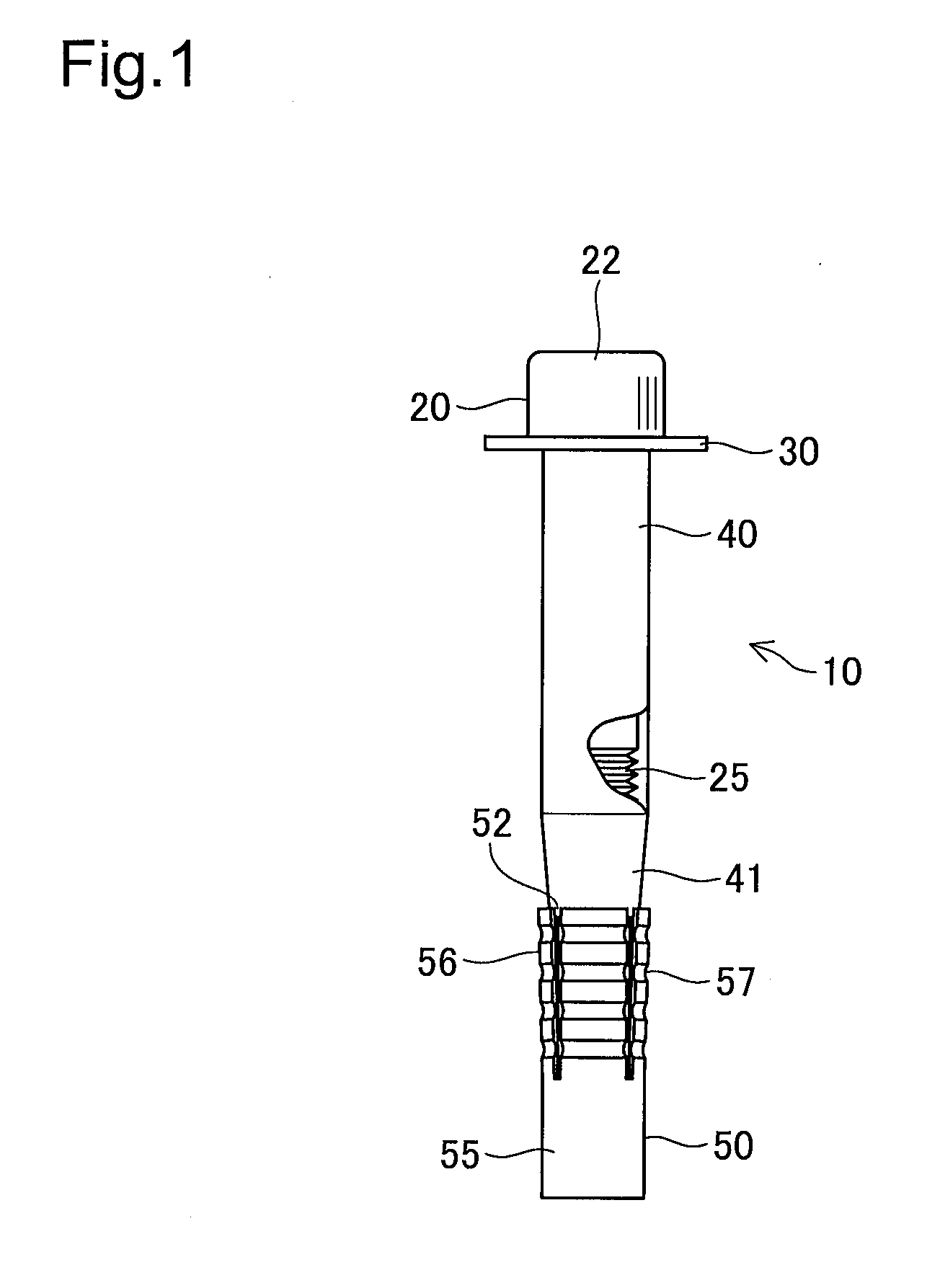

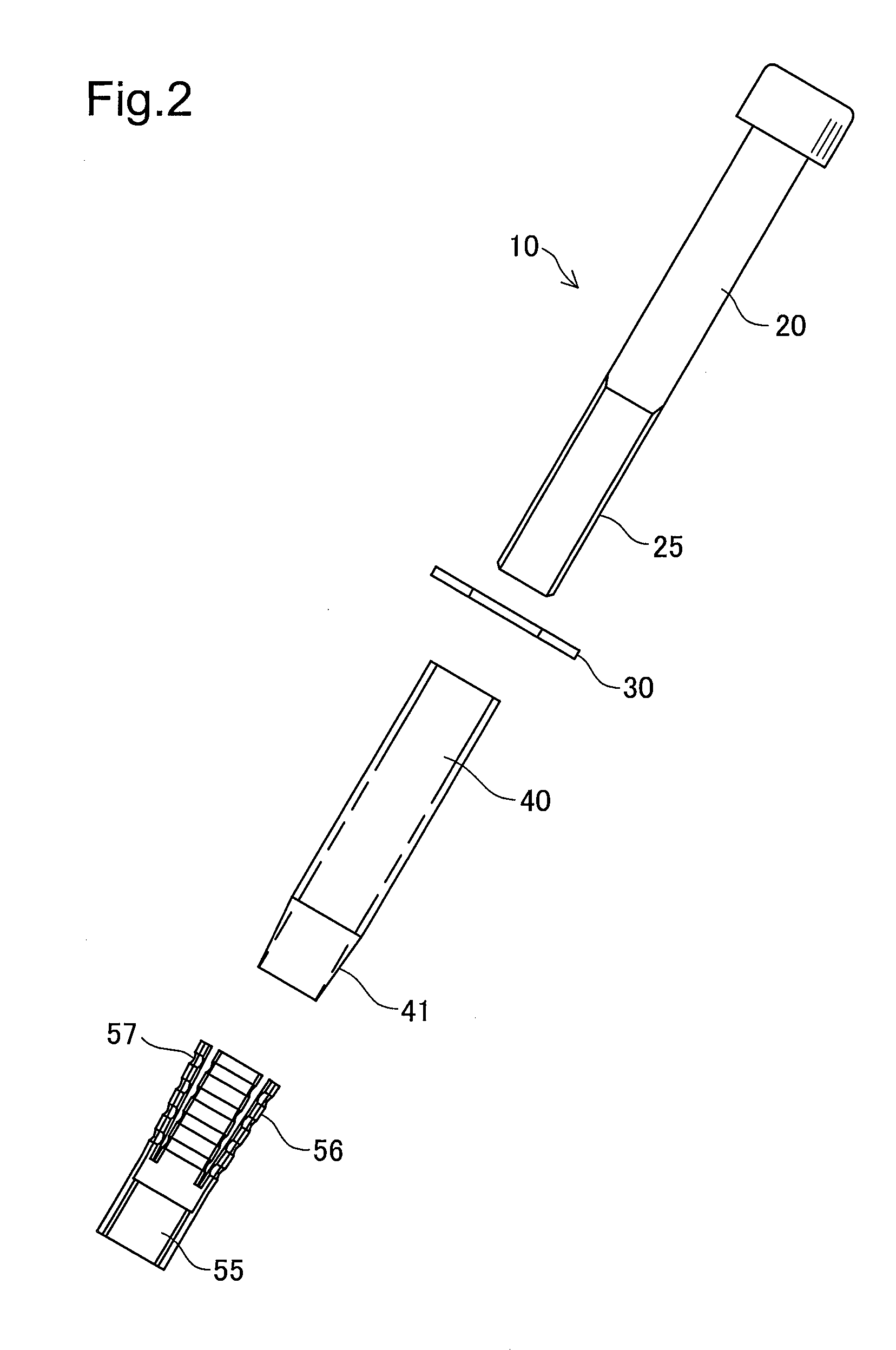

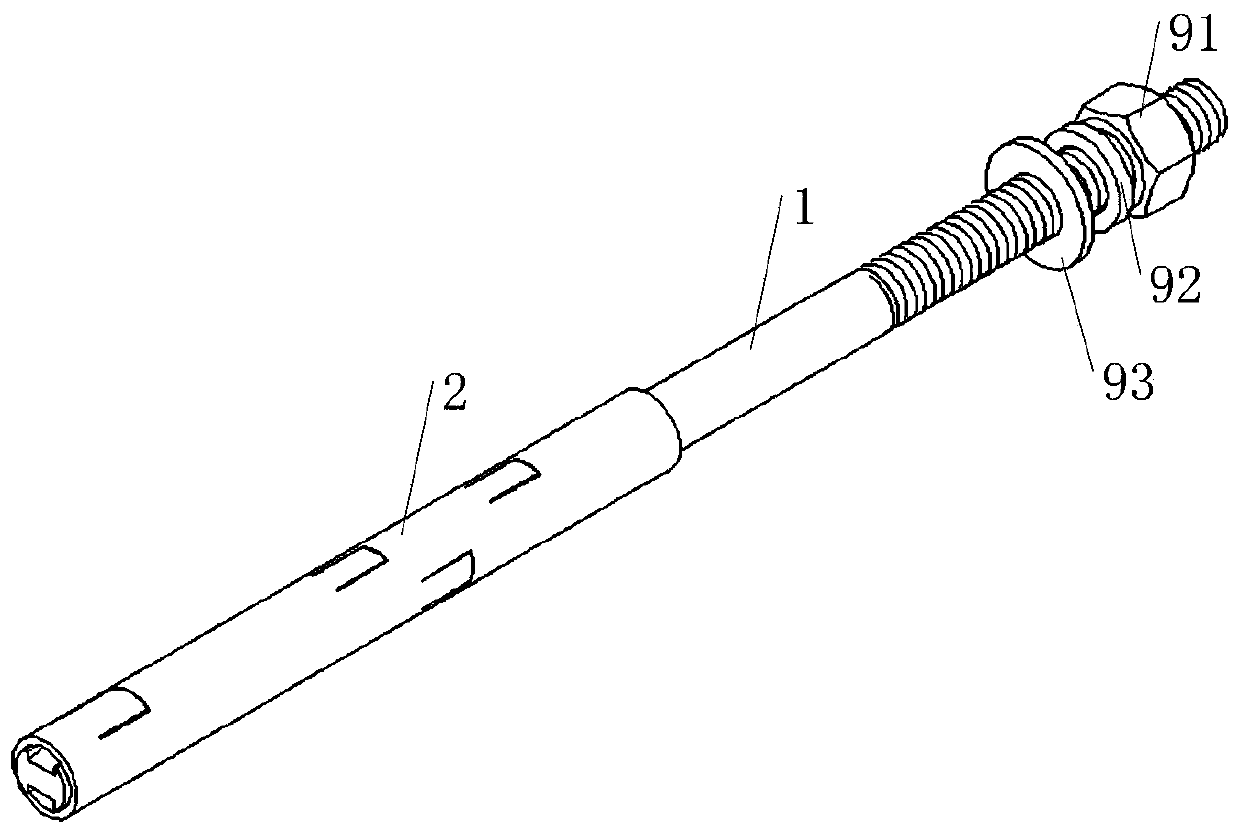

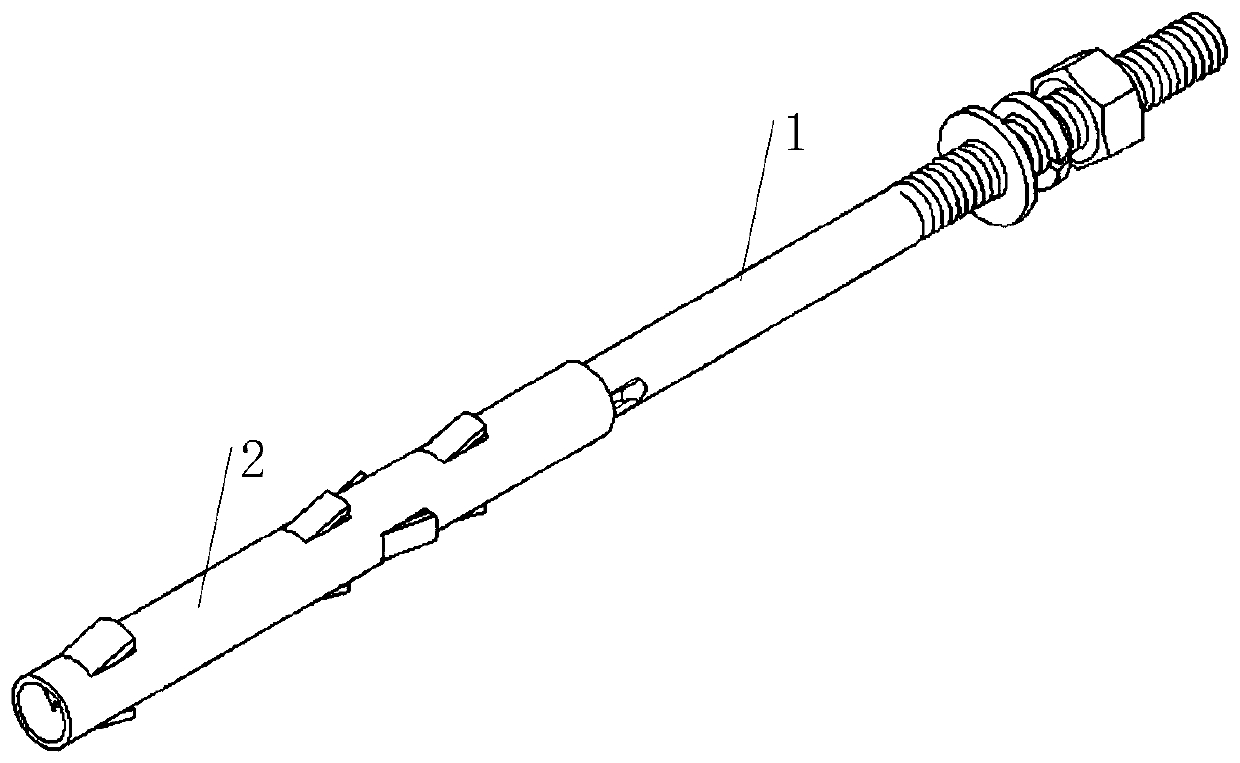

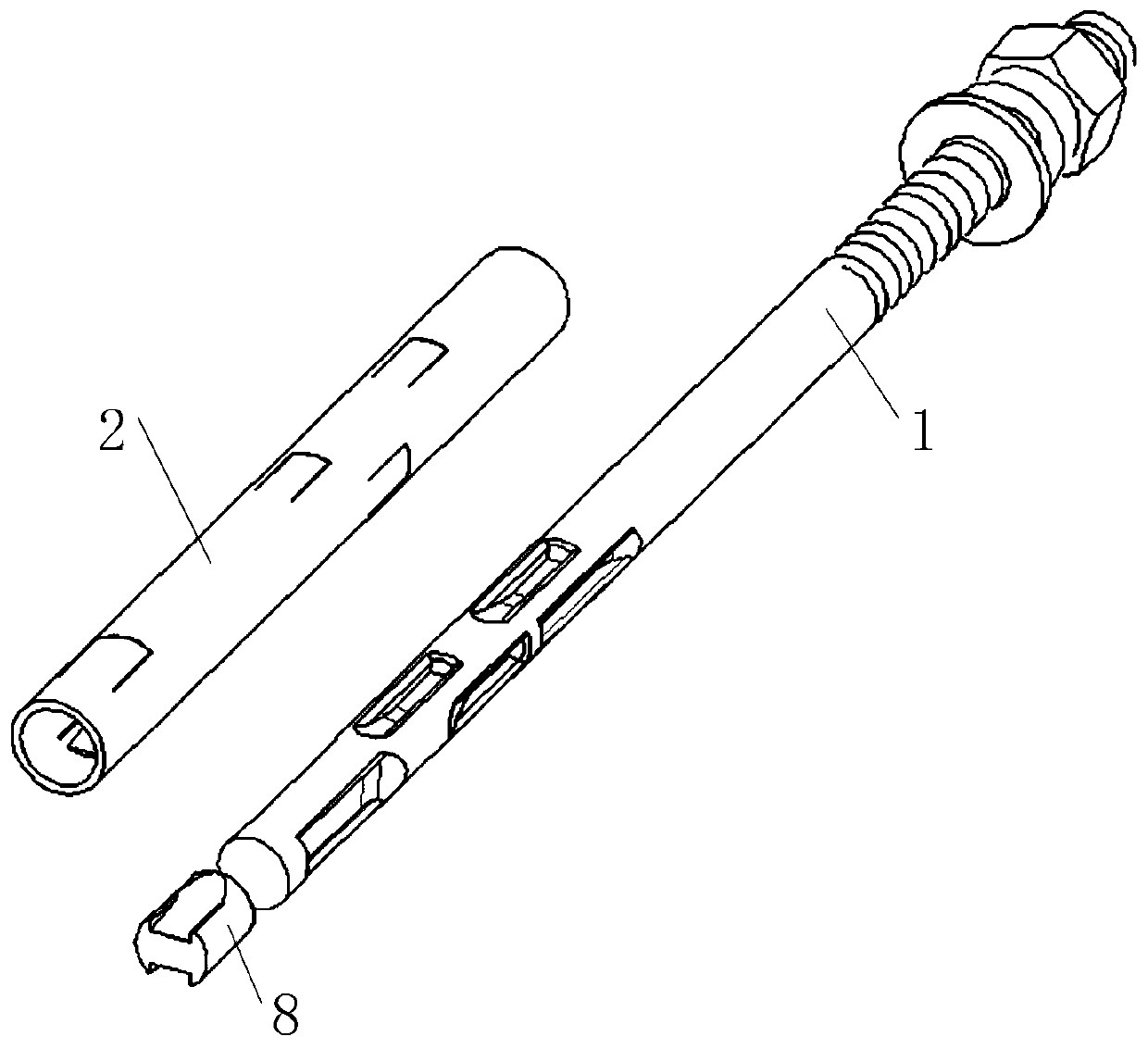

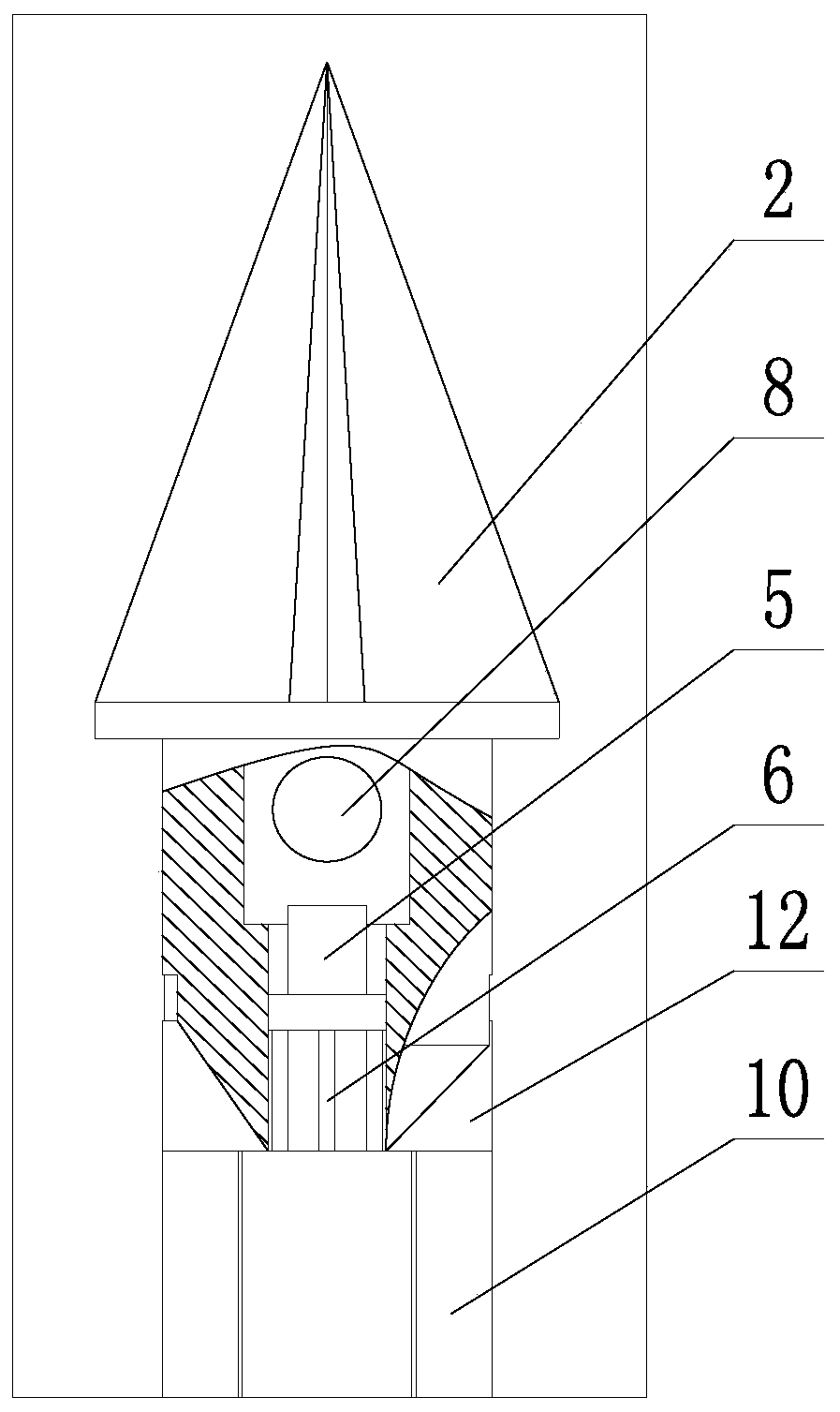

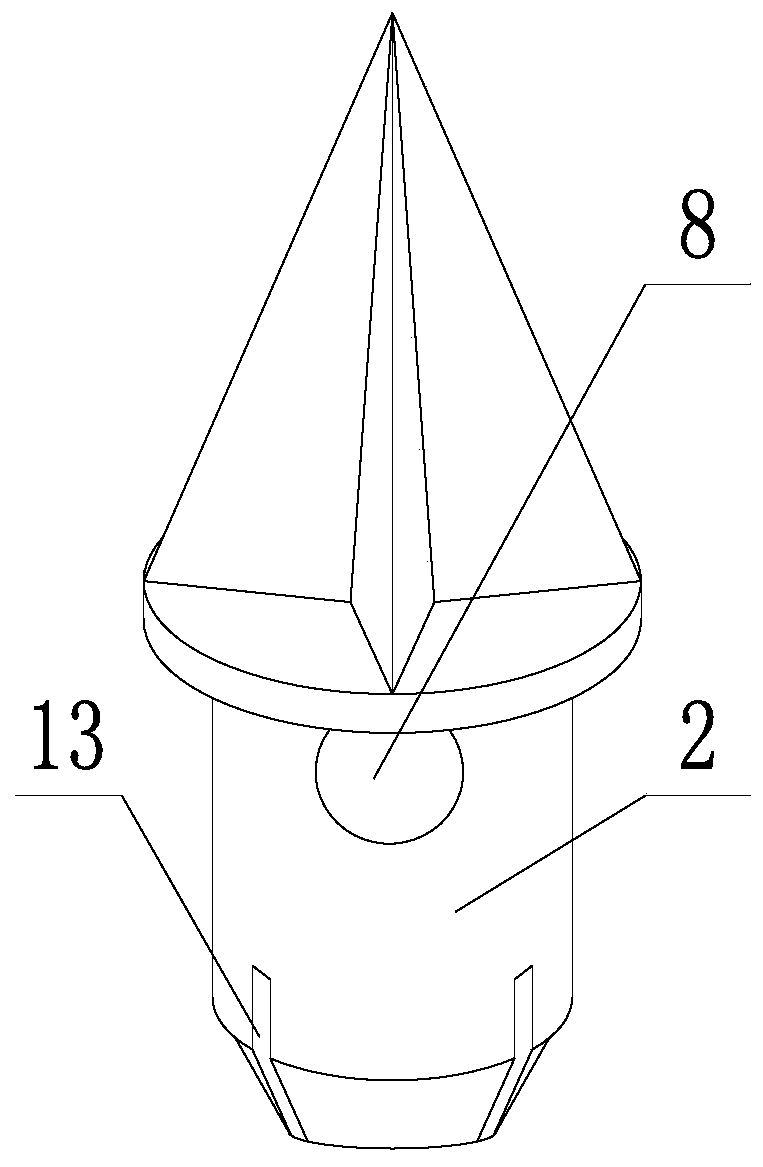

After application anchor bolt

The present invention relates to an anchor bolt and more specifically pertains to a post-installed anchor that is securely anchored to, for example, an existing concrete floor. The post-installed anchor has a sleeve fit on a bolt body and a fixation member arranged on an edge of the bolt body and screwed to a threaded end of the bolt body. The fixation member has an internal threaded end and an expansion end. The expansion end is divided into four expansion pieces by slits. The expansion pieces are arranged to face a head of the bolt body and are slightly widened toward the head of the bolt body. One end of the sleeve forms a tapered face. After insertion of the post-installed anchor into a pilot hole (installation hole) bored in the concrete floor, as the bolt body rotates, the fixation member screwed to the bolt body moves toward the sleeve. This movement causes the expansion end of the fixation member to ride on the tapered face of the sleeve and to be pressed open and extended outward. The expansion pieces of the expansion end are then buckled and bite into an inner circumferential face of the installation hole, so that the post-installed anchor is securely fixed to the installation hole.

Owner:TAISEI KOUGYOU

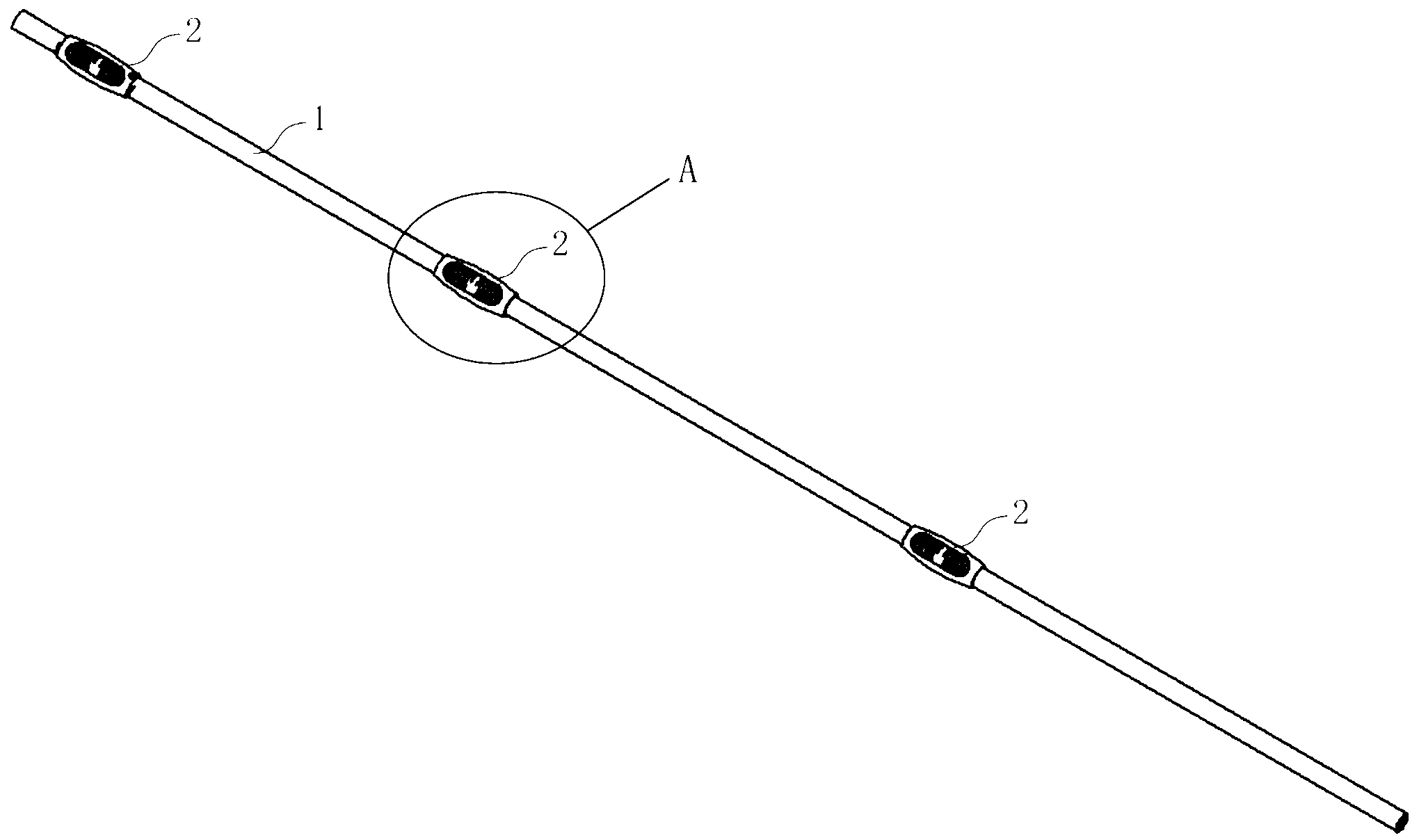

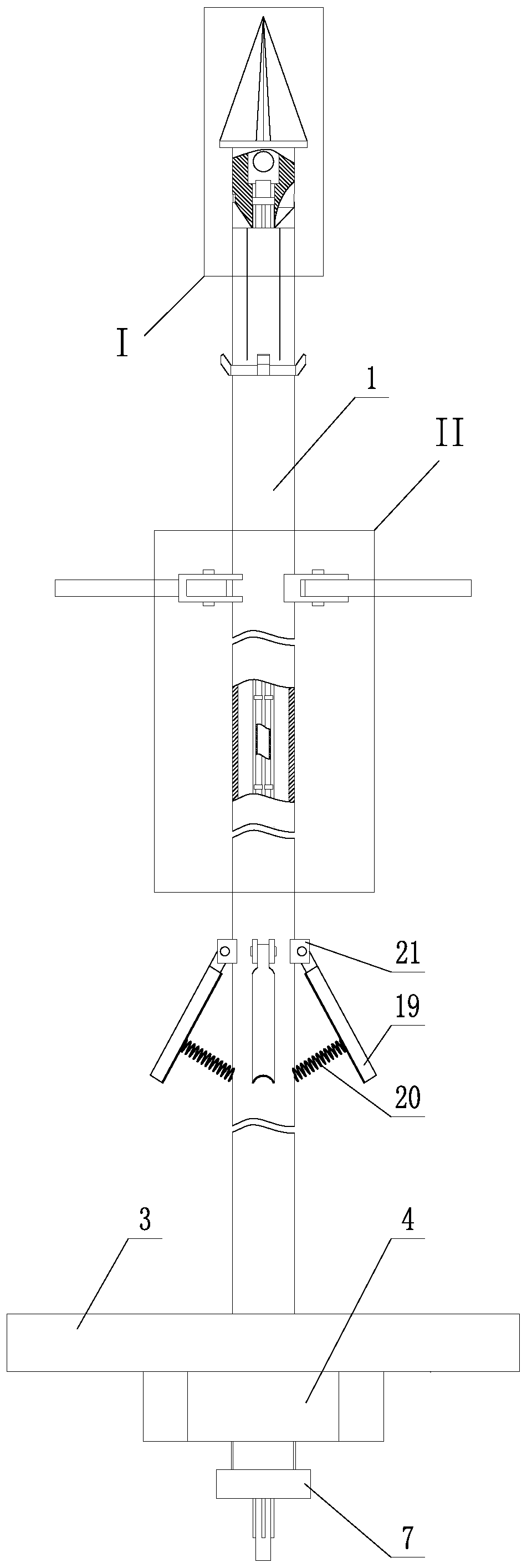

Anchor rod with external expanding devices

ActiveCN103291337AIncrease anchoring forceImprove tensile propertiesAnchoring boltsEngineeringRock bolt

The invention discloses an anchor rod with external expansion devices and belongs to an expansion anchor rod. The anchor rod comprises an elongated anchor rod body, at least one expansion devices are mounted outside the anchor rod body, each expansion device at least comprises an extrusion structure and an expansion structure and is used for the circumstance that when the anchor rod body rotates, the extrusion structure moves along the axial direction of the anchor rod body to realize mutual extrusion with the expansion structure so as to finally enable any or two of the extrusion structure and the expansion structure to simultaneously form radial expansion. By arranging one or multiple expansion devices outside the anchor body, multiple supporting points can be formed on the anchor rod body; when the anchor rod body rotates, the expansion devices are under the action of threads to be extruded to expand, and expanded structures can form mechanical supporting on the hole wall of a rock stratum anchor hole, so that anchoring force and tensile effect of the anchor rod are substantially increased; anchoring strength and permanent supporting effect of the anchor rod can be further improved by means of hollow anchor rod grouting.

Owner:CHENGDU MODERN WANTONG ANCHOR TECH

Full-anchor grouting anchor rod and anchoring method thereof

PendingCN112360534AStrong shear resistanceImprove grouting efficiencyAnchoring boltsRock boltThreaded rod

The invention relates to a full-anchor grouting anchor rod and an anchoring method thereof, and belongs to the technical field of anchor rod supporting. The full-anchor grouting anchor rod specifically comprises an anchoring section, a grouting section and a rod body. Two limiting blocks are arranged on the rod body, and the anchoring section and the grouting section are bounded by the limiting blocks. The anchoring section is used for solidifying the rod body in a drill hole, and the grouting section is used for grouting the drill hole. An inverted nail is arranged on the rod body, an inner threaded rod is arranged in the rod body, and a steel pipe is arranged outside the rod body. When the full-anchor grouting anchor rod is used, the anchoring of an anchoring agent is completed firstly,then anchorage device pre-tightening is completed, and finally grouting is conducted. According to the full-anchor grouting anchor rod and the anchoring method thereof, a common solid anchor rod and the grouting function are combined together, and full-anchor grouting is achieved through the connection of the anchoring section and the grouting section; and roadway surrounding rock can be activelysupported in time, the stress state of the roadway surrounding rock is improved, the bearing capacity of the surrounding rock is fully exerted, and the stability of the roadway surrounding rock in a high-stress environment is ensured.

Owner:KUNMING UNIV OF SCI & TECH

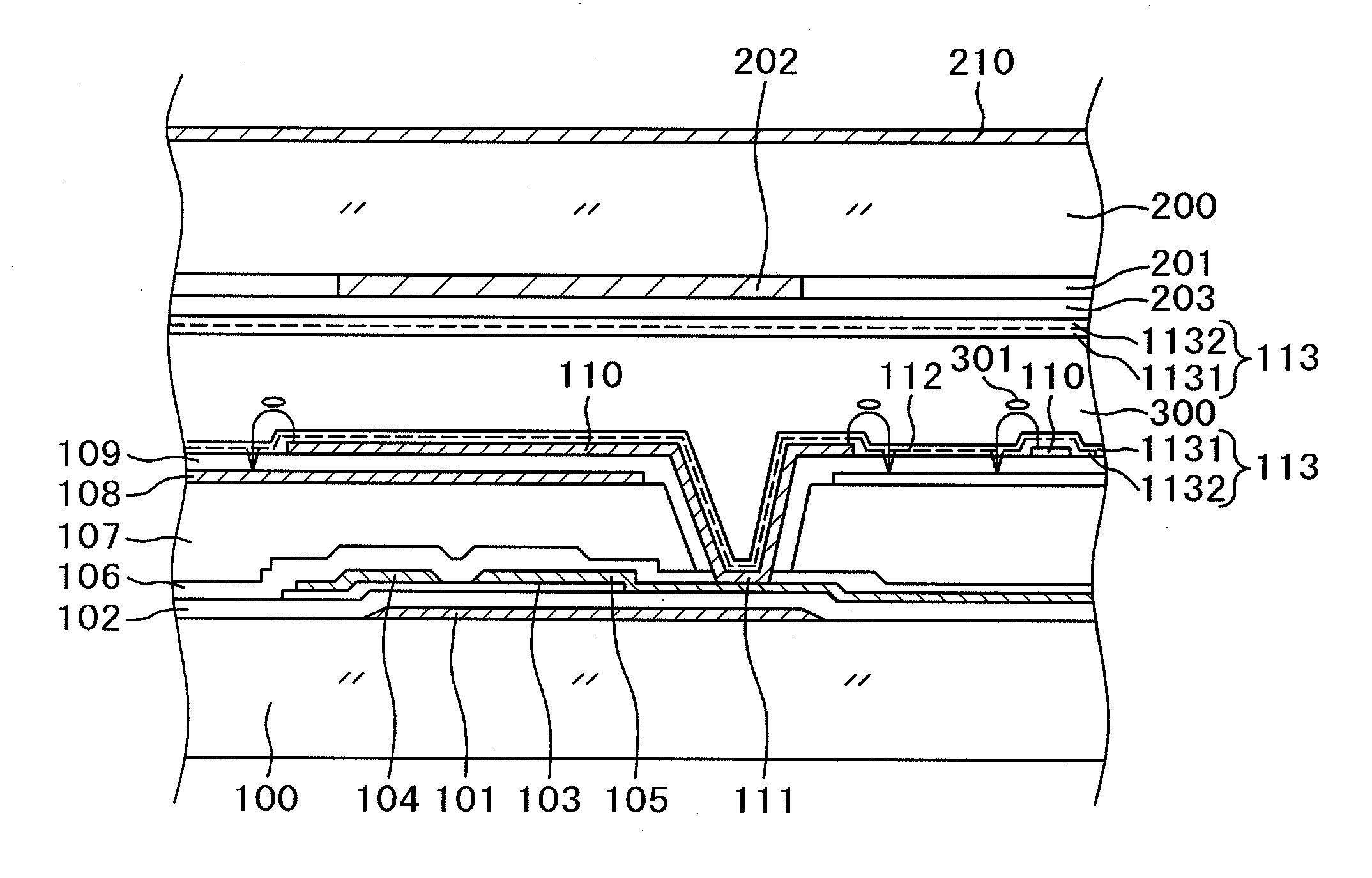

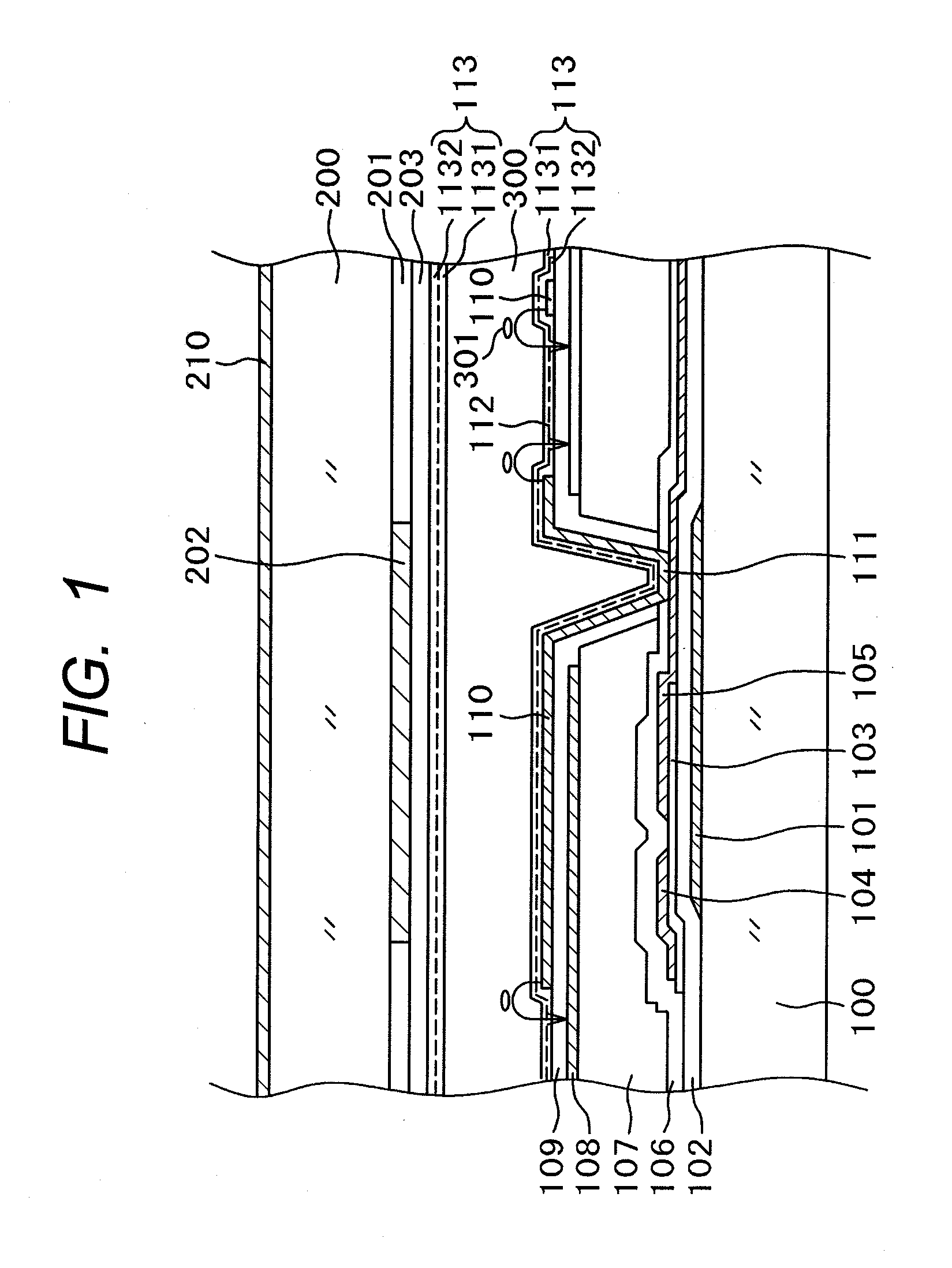

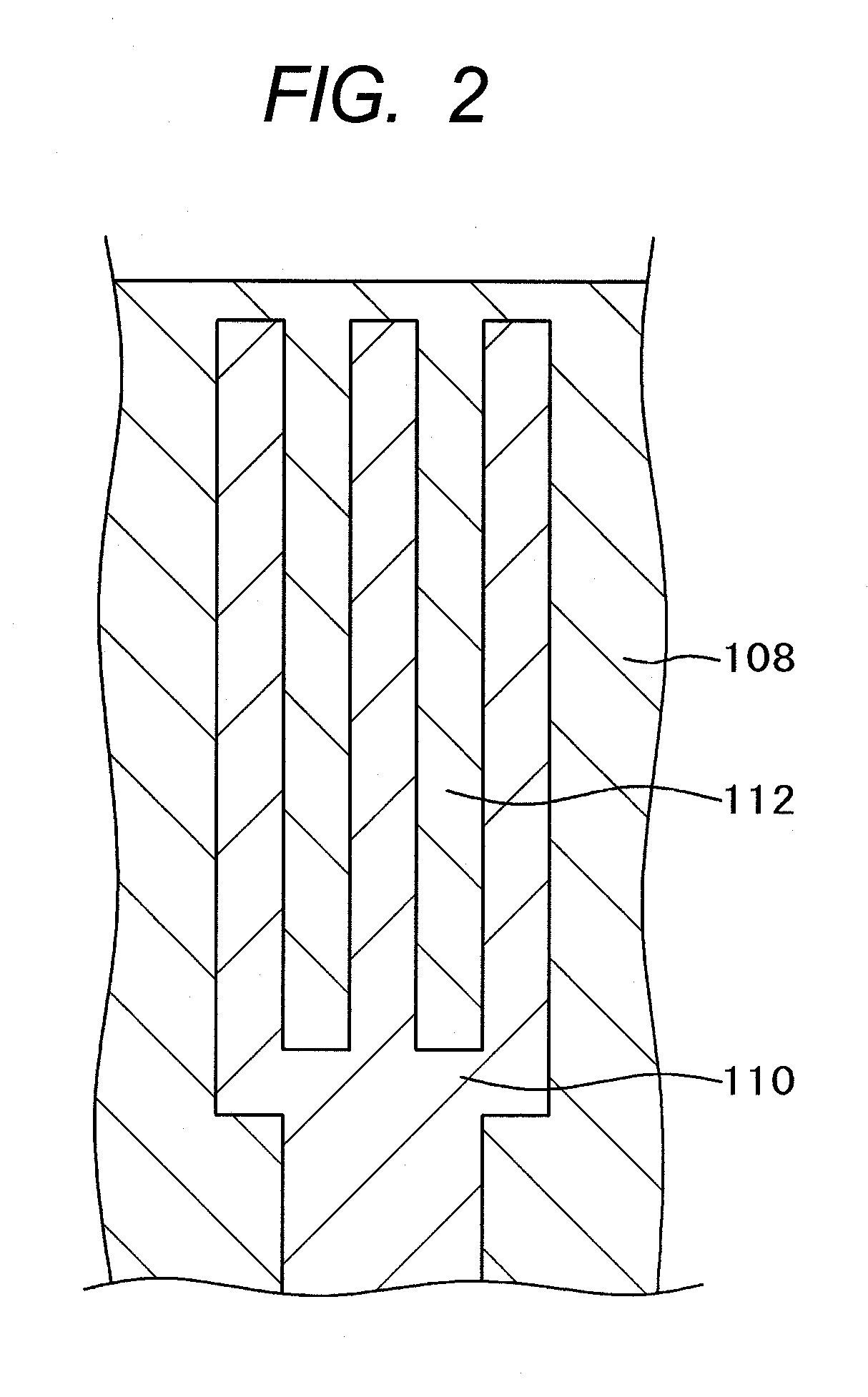

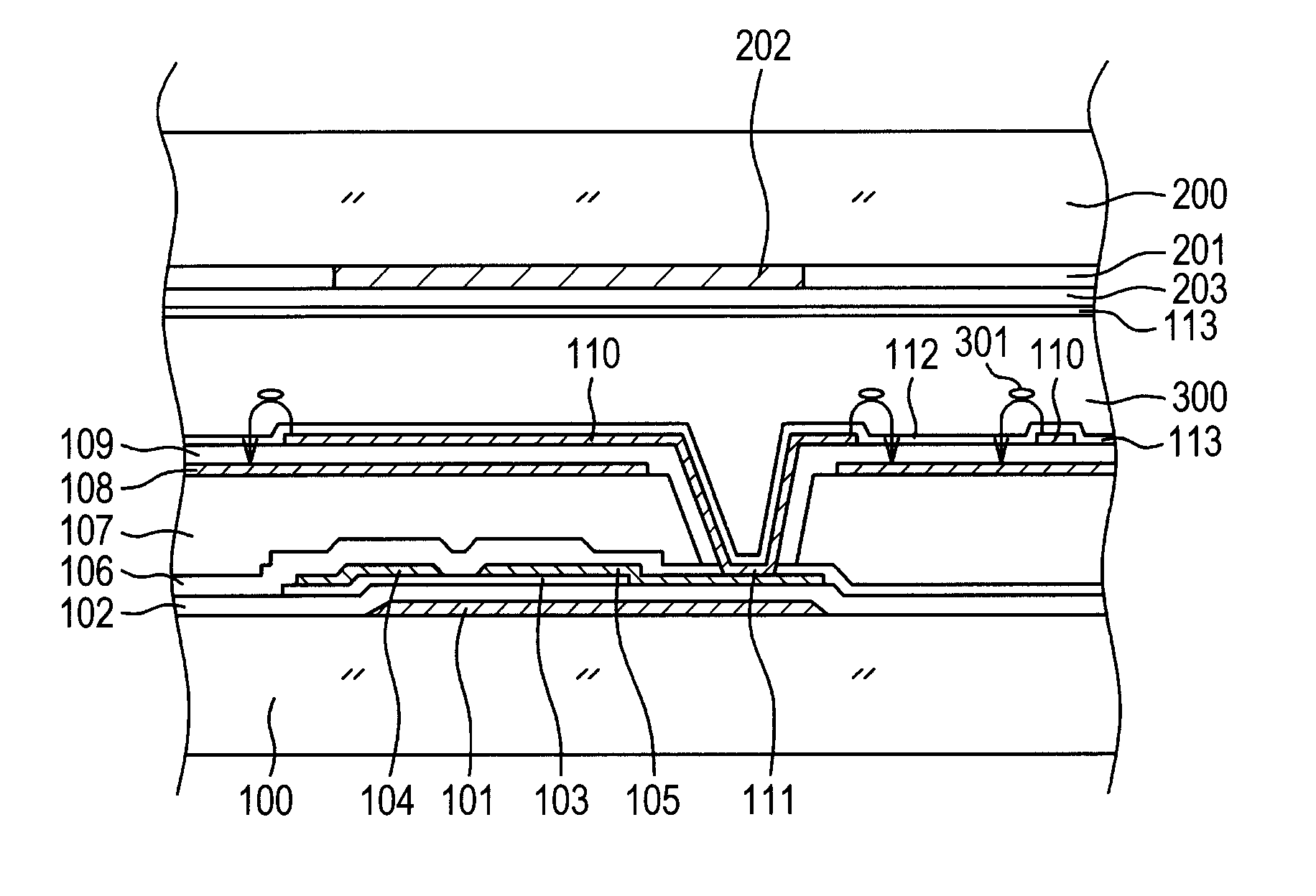

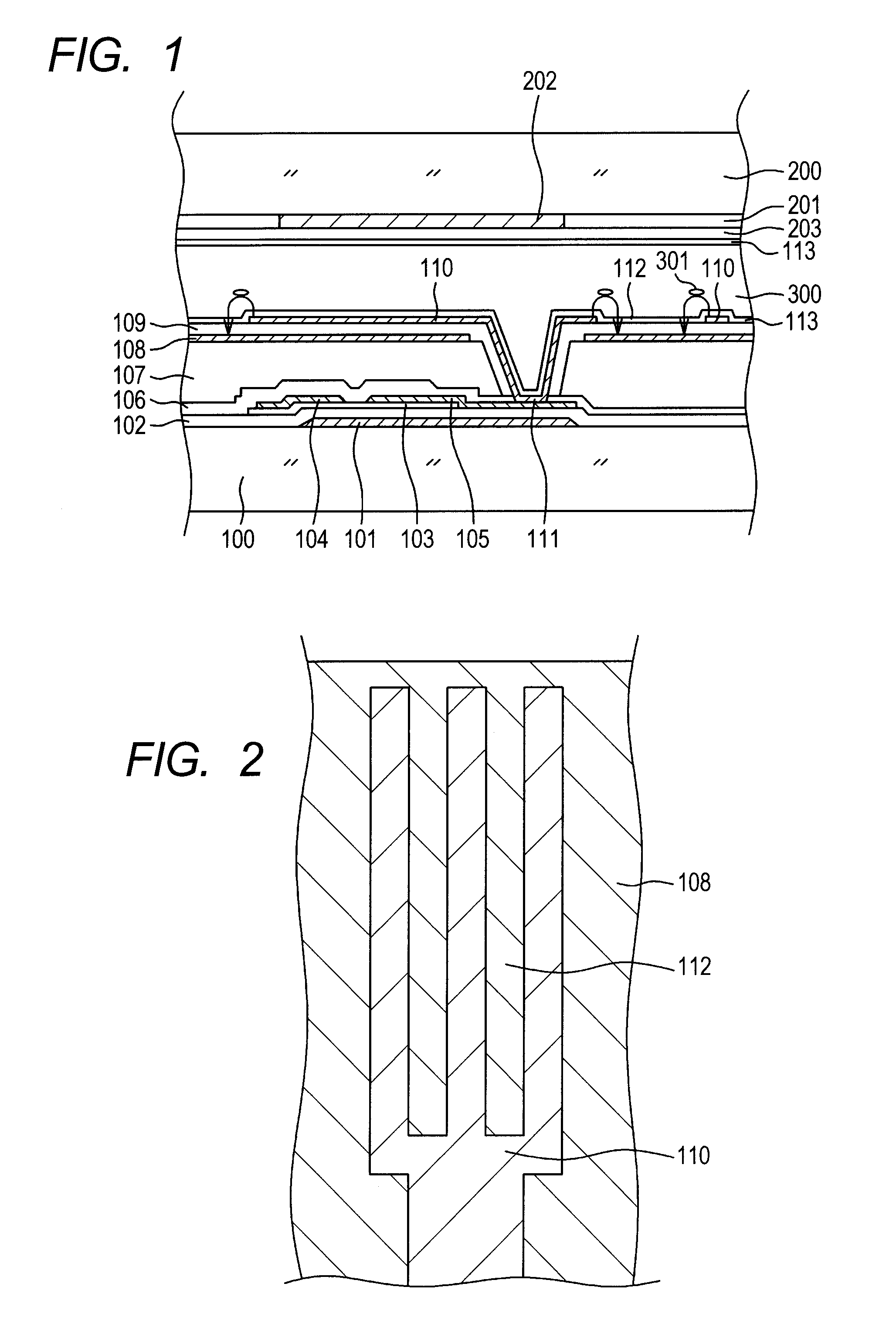

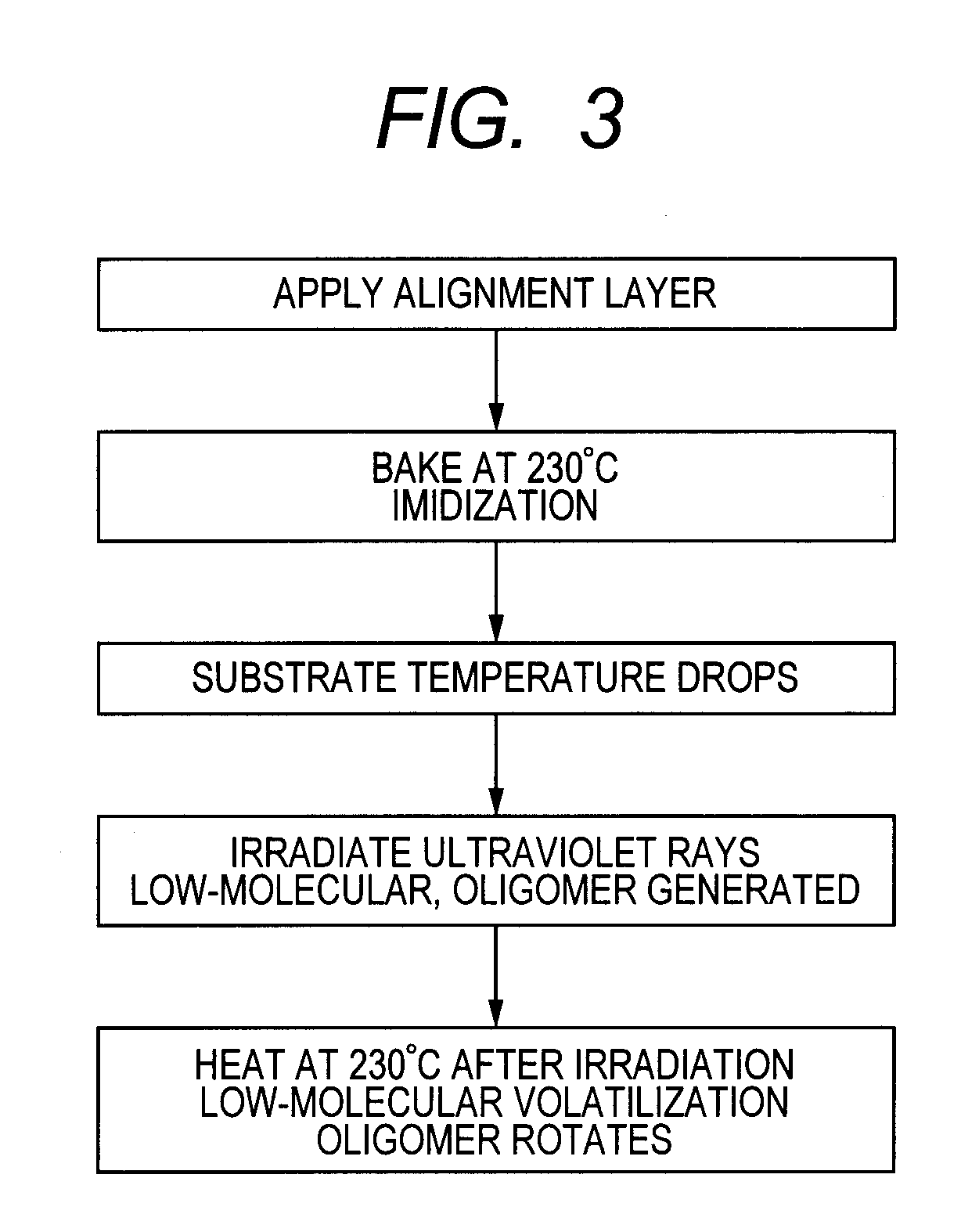

Liquid crystal display device comprising an alignment film that includes a first alignment film formed of a precursor of polyamide acid or polyamide acid ester and a second alignment film underlying the first alignment film wherein the first alignment film accounts for between 30% and 60% of the alignment film

ActiveUS8648988B2Improve stabilityHigh molecular weightLiquid crystal compositionsSolid-state devicesLiquid-crystal displayUltraviolet lights

This invention enables forming a photo-alignment film having a large LC anchoring strength in an IPS type liquid crystal display device. An alignment film is adapted to have a two-layer structure including a photo-alignment film and an alignment film with enhanced film strength. The photo-alignment film is formed of a precursor of polyamide acid ester, 80 percent or more of which is polyamide acid ester including cyclobutane. The alignment film with enhanced film strength is formed of a precursor of polyamide acid. After irradiating the substrate with ultraviolet light for photo-alignment, the substrate is heated. Thus, it is possible to achieve a high LC anchoring strength of the alignment film as the whole for photo-alignment, without degrading the mechanical strength of the alignment film with enhanced film strength.

Owner:JAPAN DISPLAY INC +1

Liquid crystal display device and alignment film material thereof

ActiveUS20120300162A1Improve anchor strengthEasy to burnLiquid crystal compositionsWater-repelling agents additionOligomerLiquid-crystal display

To form an optical alignment film having large anchoring strength and suppress an AC afterimage of a liquid crystal display device, in a liquid crystal display device of an IPS mode. In an alignment film material subjected to optical alignment processing, polyimide which becomes a rigid high molecule and polyimide which becomes a flexible high molecule are mixed and used. The material of the present invention can easily rotate oligomer after irradiating polarized ultraviolet rays and improve a UV-absorbed two-color ratio of an alignment film. Accordingly, an anchoring strength for liquid crystals by the alignment film is large to suppress an AC afterimage.

Owner:JAPAN DISPLAY INC

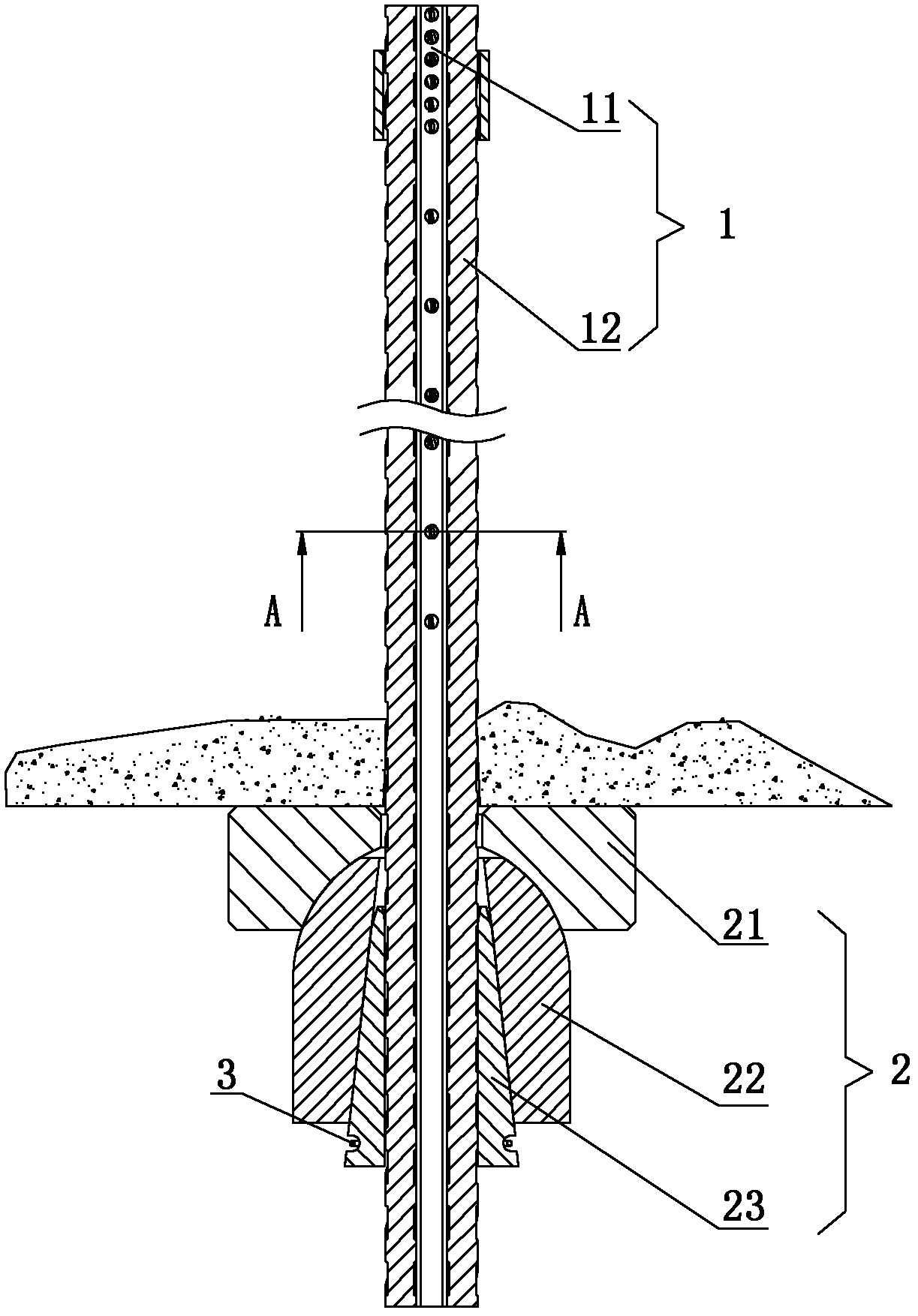

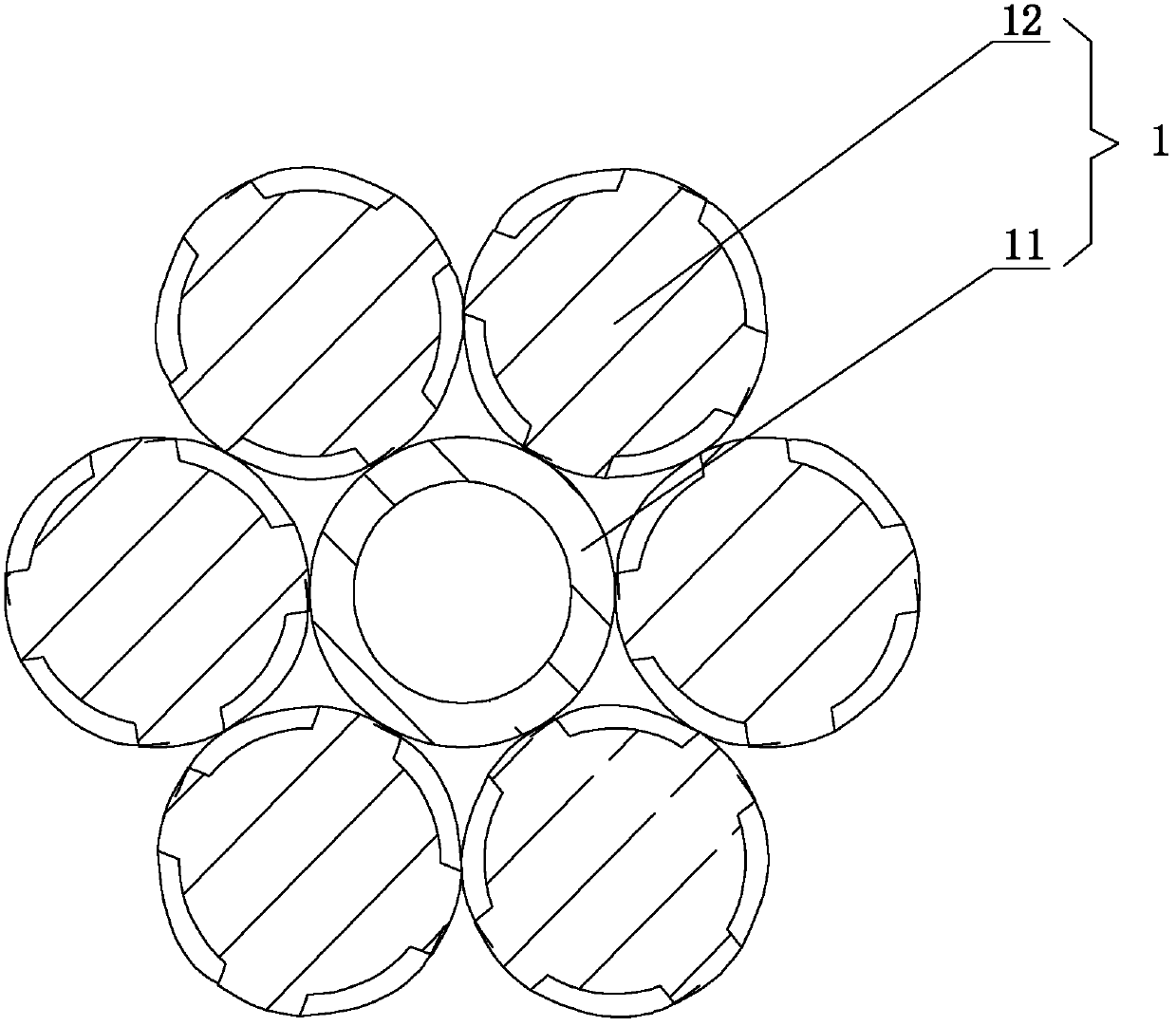

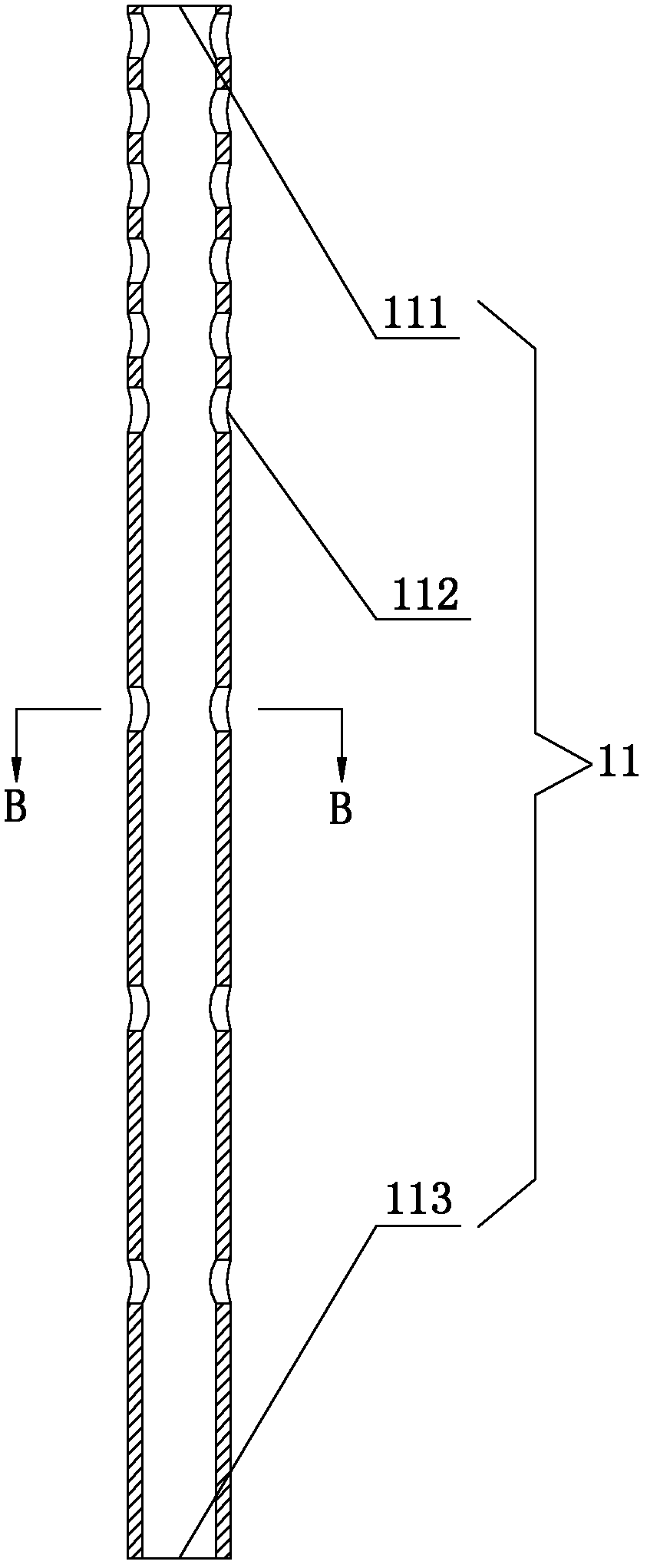

Anchor rod

PendingCN109853554AAchieve fixationImprove anchor strengthBulkheads/pilesEngineeringUltimate tensile strength

Owner:罗定市麟千机电有限公司

Grouting type anchor rod suitable for soft soil dam and soft soil dam anchoring construction method

The invention provides a grouting type anchor rod suitable for a soft soil dam and a soft soil dam anchoring construction method. A grouting pipe is mounted in a rod body in a penetrating manner, a steel strand is arranged outside the pipe, one end of the steel strand is fixedly connected with an anchor head, and the other end is fixed at the rear end of the rod body through an anchorage device; an expansion piece structure is adopted at the front end of the rod body, and the anchor head and the expansion piece structure are matched through guiding limit slots and rib plates to transmit torque; an anchoring hole diameter expanding mechanism and a rod body automatic centering mechanism are arranged on the rod body. The method comprises steps as follows: a steel-plastic grating is laid, a drilling machine is erected, the anchor rod is mounted, the drilling machine is started clockwise, the anchor head drills in the dam in advance, the anchoring hole diameter expanding mechanism drills inthe dam successively and performs first-stage hole expanding, when the ratio of the drilling depth to the length of the anchor rod reaches a set value, the drilling machine is adjusted to rotate anticlockwise, the anchoring hole diameter expanding mechanism performs second-stage hole expanding until the anchor rod reaches the set drilling depth, the drilling machine is shut down, an anchoring hole is in a variable-diameter stepped hole state, an expansion piece is enabled to be expanded by drawing the steel strand, and grouting work is implemented until slurry reaches designed strength.

Owner:NORTHEASTERN UNIV

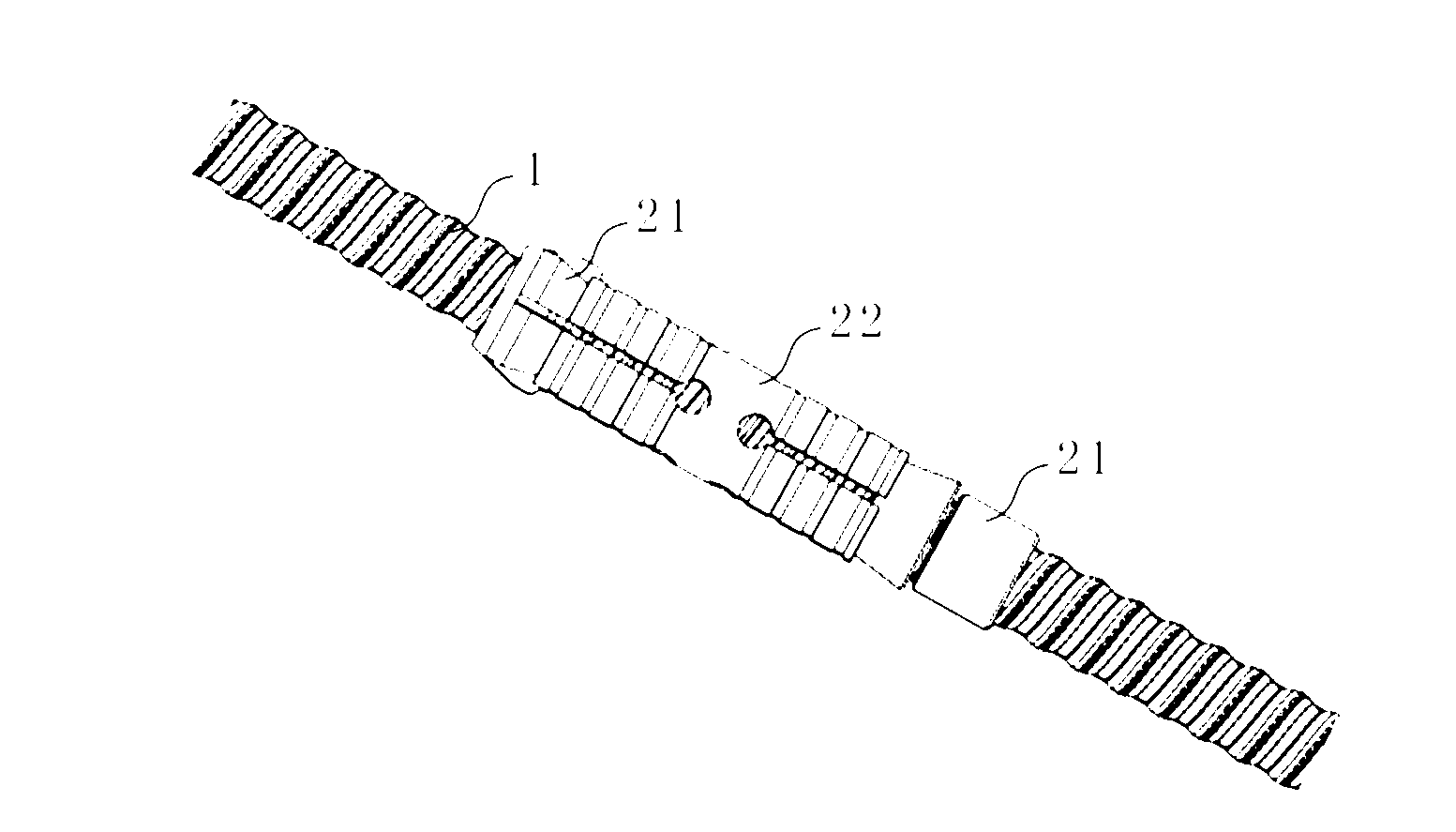

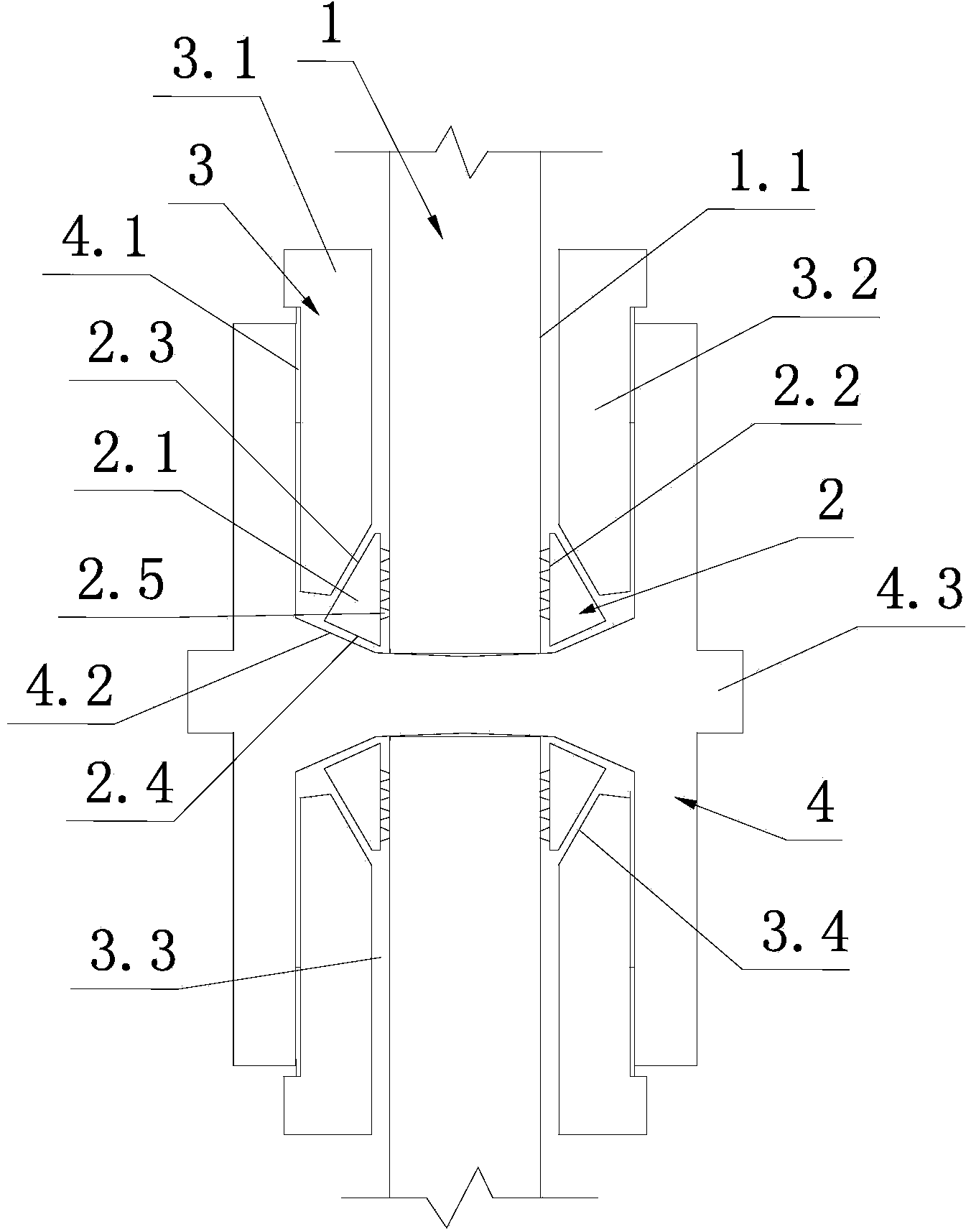

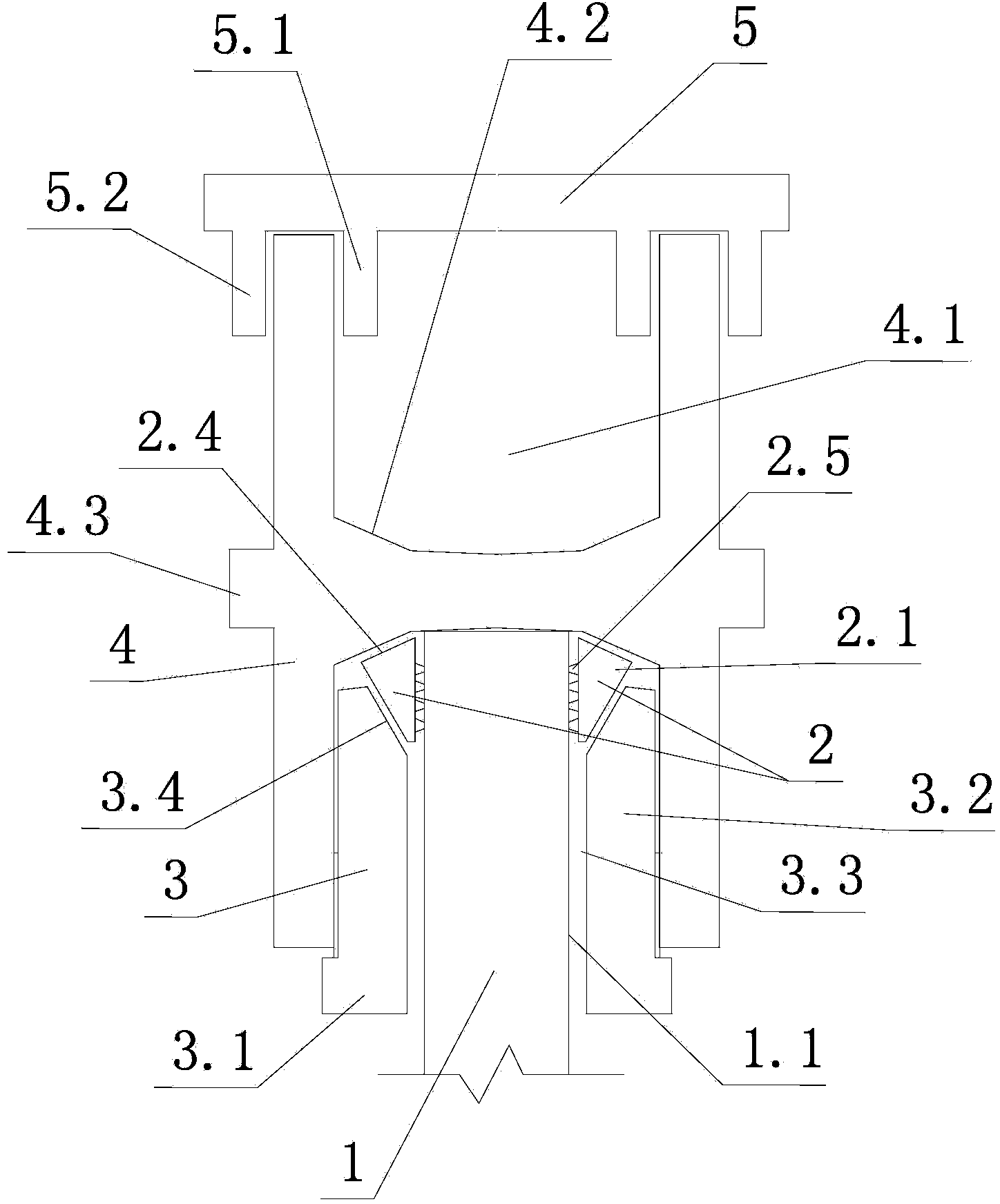

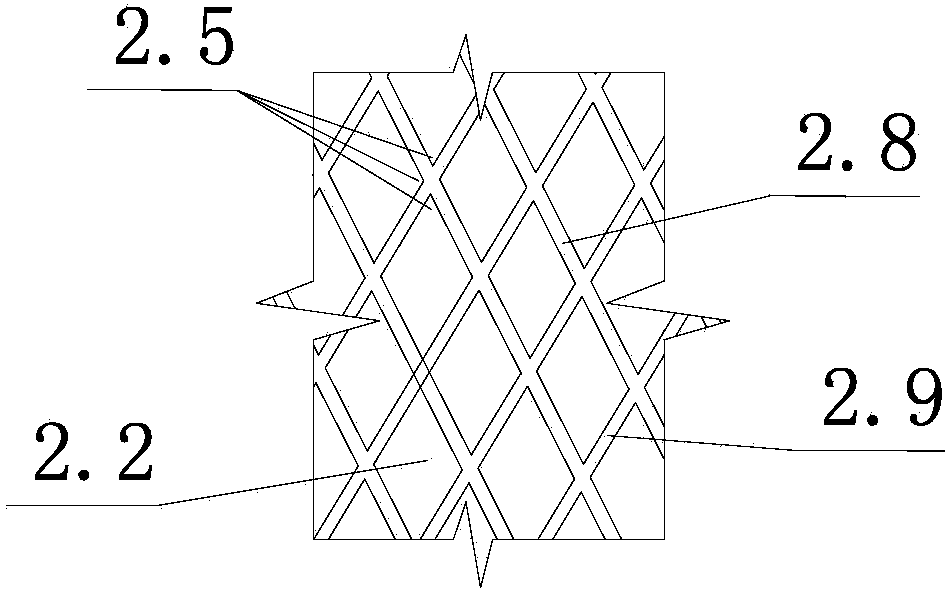

Anchoring type connecting device for steel bar wedge cone and connecting method thereof

ActiveCN104328869ANo pollution in the processHigh strengthBuilding reinforcementsDesign standardResidual deformation

The invention discloses an anchoring type connecting device for a steel bar wedge cone and a connecting method thereof. The anchoring type connecting device comprises a connected steel bar (1), a wedge cone sleeve (2), an inner sleeve specially-shaped nut (3) and an outer sleeve support frame (4), wherein the connected steel bar (1) is supported by the sawteeth (2.5) of the wedge cone sleeve (2); the second conical surface (2.4) of the wedge cone sleeve (2) supports against a blind hole (4.1) of the outer sleeve support frame (4); the wedge cone sleeve (2) is supported by the inner sleeve specially-shaped nut (3); and the inner sleeve specially-shaped nut (3) is screwed with the outer sleeve support frame (4). The connecting method is characterized in that the external thread of the inner sleeve specially-shaped nut (3) is screwed into the internal thread of the blind hole (4.1) of the outer sleeve support frame (4). The connecting device and the connecting method which are disclosed by the invention have the advantages of easiness and convenience in operation, no need of adopting special machining equipment, firmness in connecting effect and ideal tensile strength of connected steel bars, and residual deformation amount accords with a design standard after connection.

Owner:NINGBO CONSTR ENG GROUP

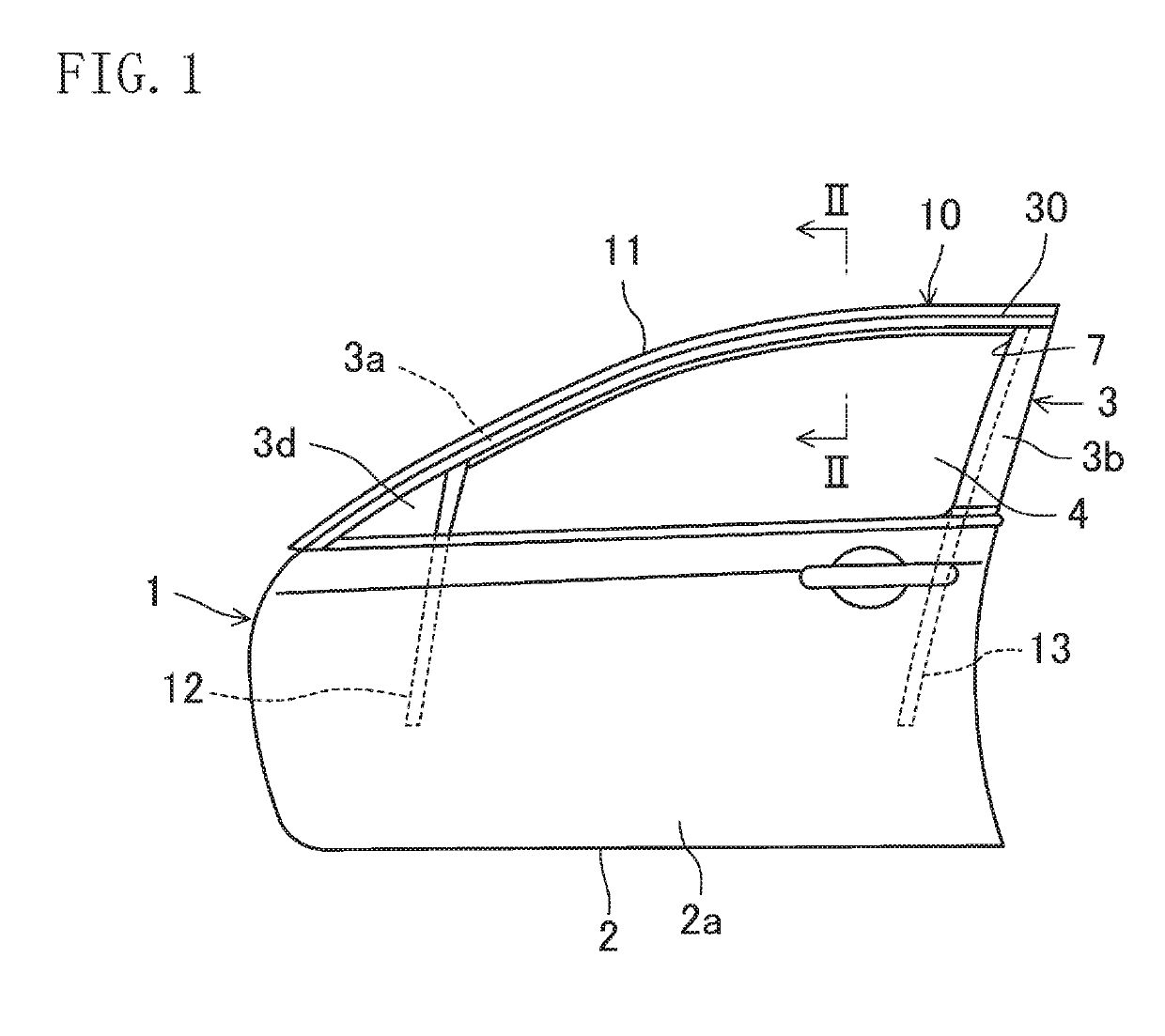

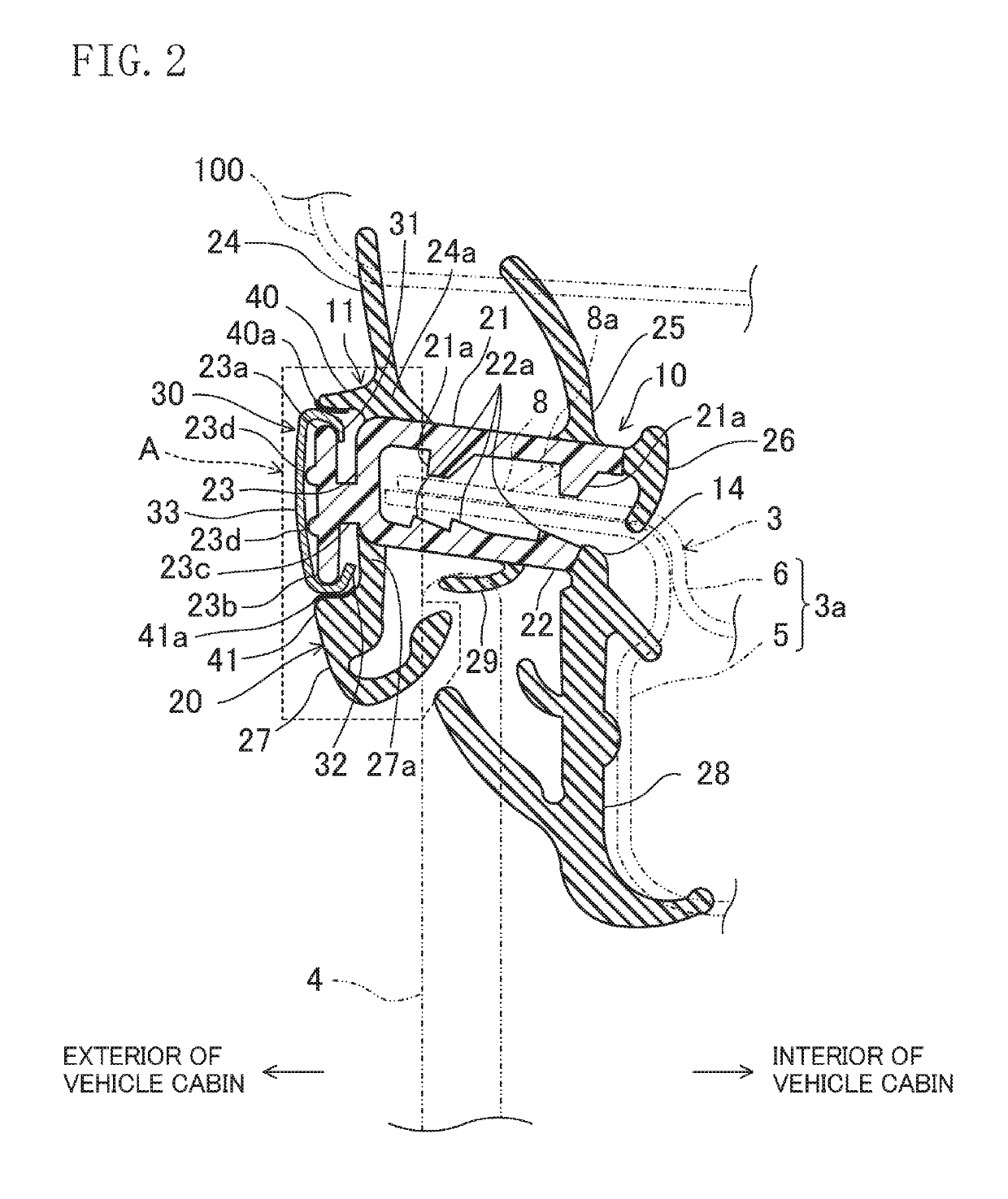

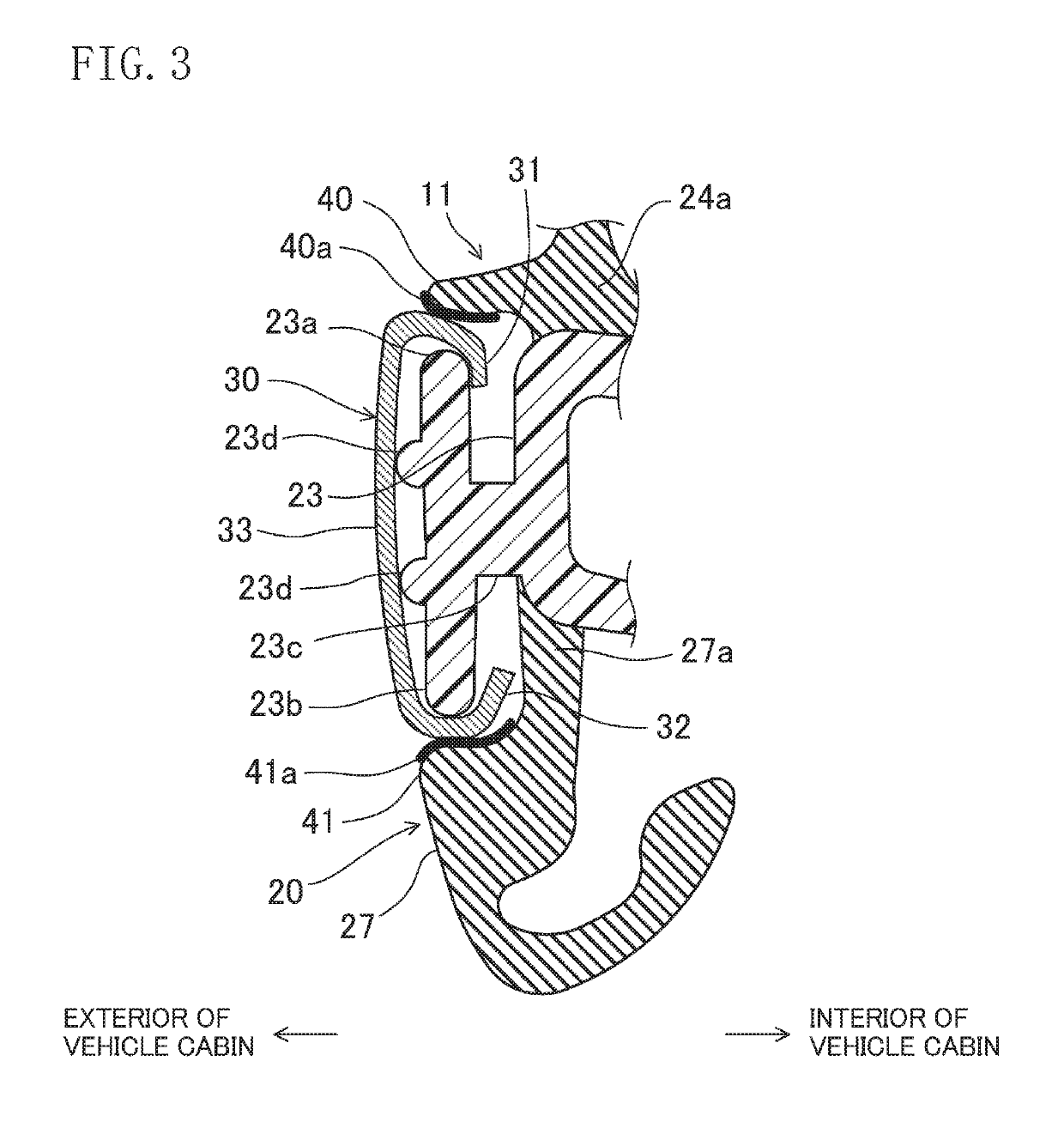

Vehicle door glass run and method for assembling the same

ActiveUS20190118732A1Improve anchor strengthReduced sliding resistanceEngine sealsVehicle sealing arrangementsEngineeringCoating

A trim strip has upper and lower trim-strip-side mating portions. A glass run body has, at its exterior part, body-side mating portions and an upper contacting portion contacting an upper part of an exterior surface of the trim strip. The upper contacting portion has a portion contacting the trim strip, and the portion is provided with a coating. The coating is formed of an elastic material reducing the sliding resistance to the trim strip.

Owner:NISHIKAWA RUBBER

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com