Spiral fin grouting anchor cable assembly with adjustable angle

A technology of grouting anchor cables and spiral ribs, which is applied in the installation of anchor rods, mining equipment, earthwork drilling and mining, etc., which can solve the problem that the bite force of anchors cannot be maximized and the force of tensioning anchor cables of anchors is not vertical, and cannot Ensure the verticality of the orifice plane, etc., to achieve the effects of not being easy to scatter, increasing the anchorage range, and obvious grouting effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

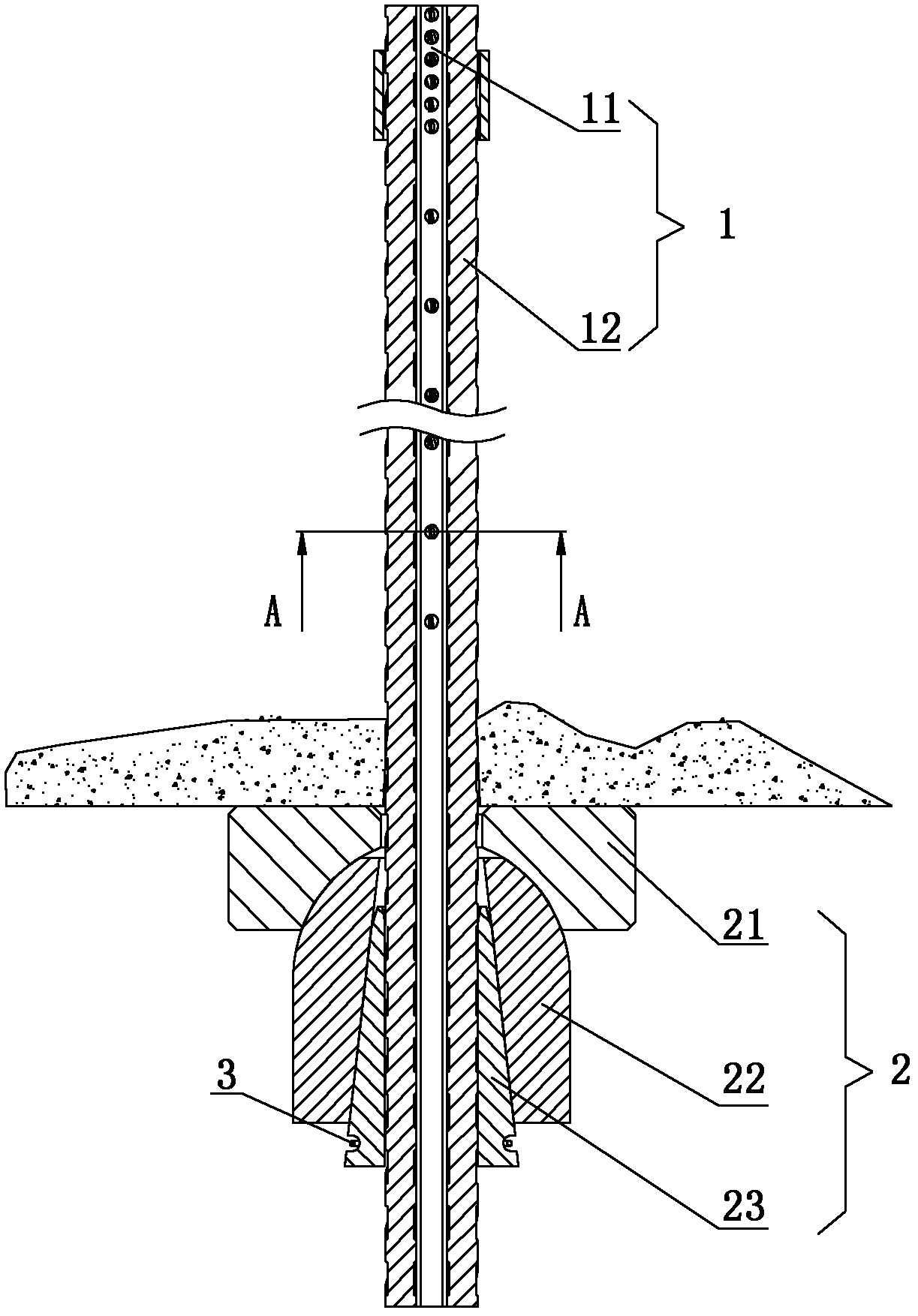

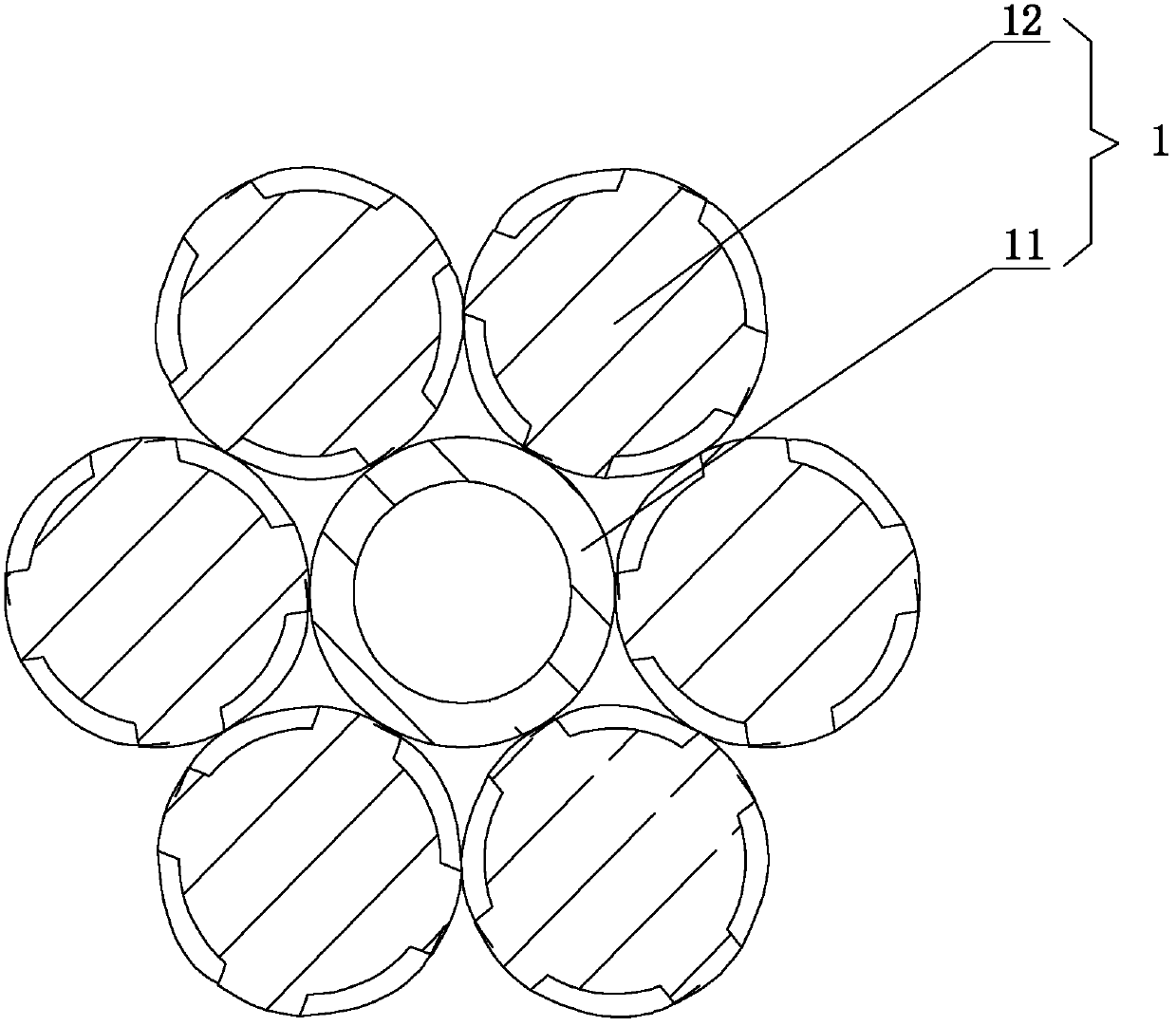

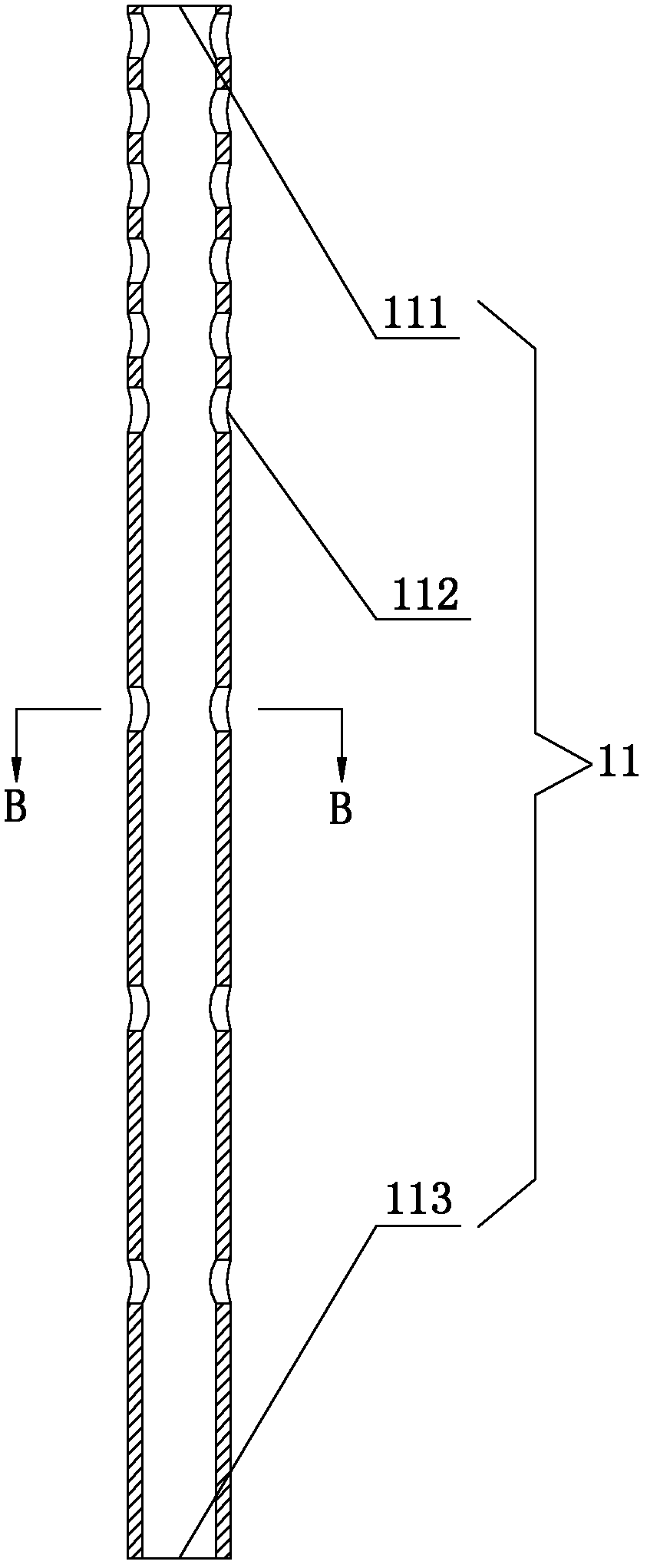

[0031] See Figure 1 to Figure 7 , the present invention has an anchor cable body 1 and an anchorage 2; the anchor cable body 1 is formed by twisting six steel strands 12 with the grouting pipe 11 as the cable core. The grouting pipe 11 is tubular and consists of a grouting port 111, a grouting hole 112 and a grouting port 113, thereby realizing the combination of anchor cable support and grouting reinforcement, greatly increasing its anchoring range and anchoring force . The grouting pipe 11 is provided with two opposite grouting holes 112 at intervals of 50 mm from zero to one meter from the grouting port 111, and every 300 mm from one meter away from the grouting port 111 to one meter away from the grouting hole 113 There are two opposite grouting holes 112, so as to realize the anchor injection in the whole section, which greatly increases the supporting capacity of the anchor cable. The surface of the steel strand 12 is evenly distributed with four ribs 121 in the axial...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com