Patents

Literature

562results about How to "Increase anchoring force" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

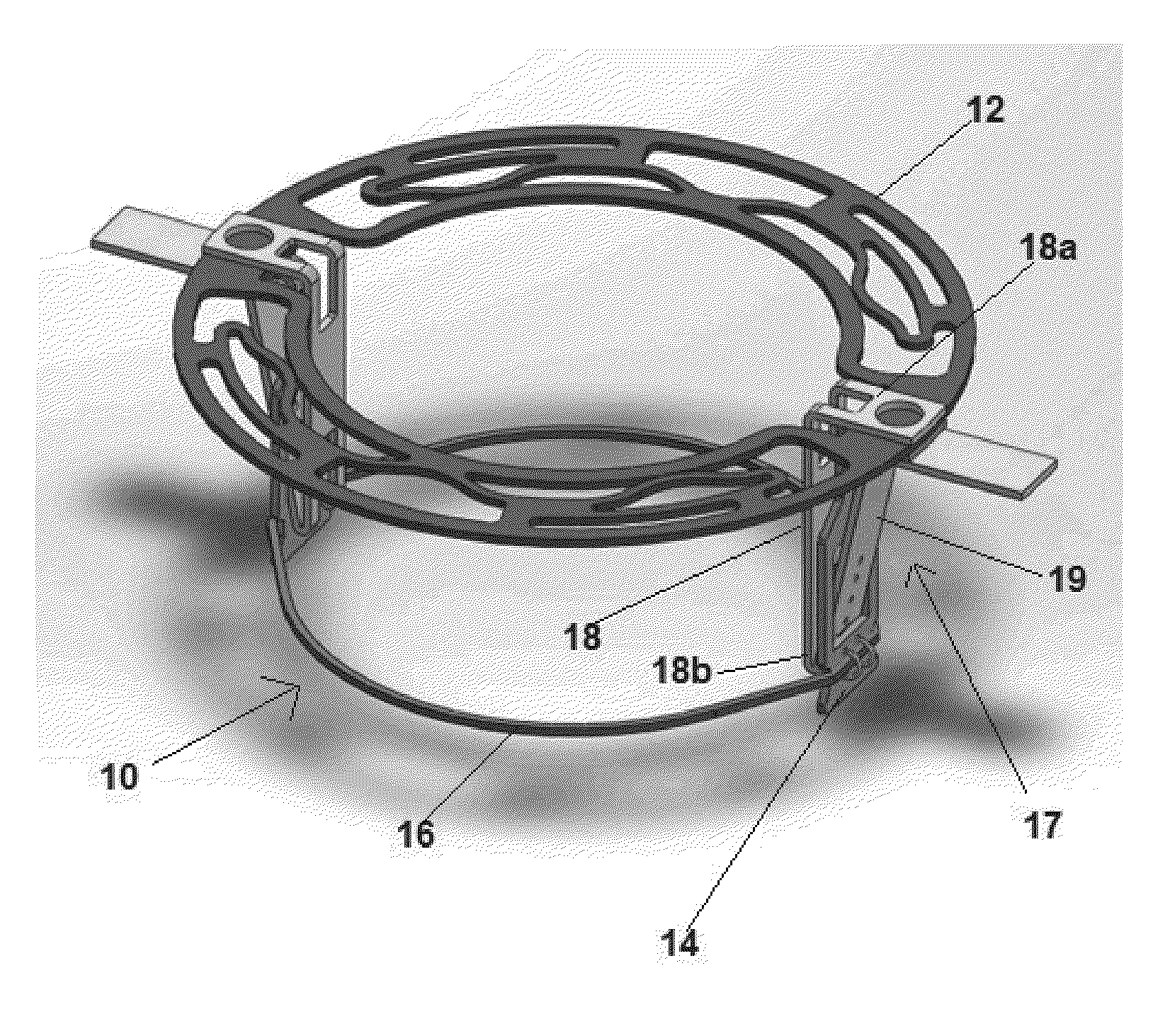

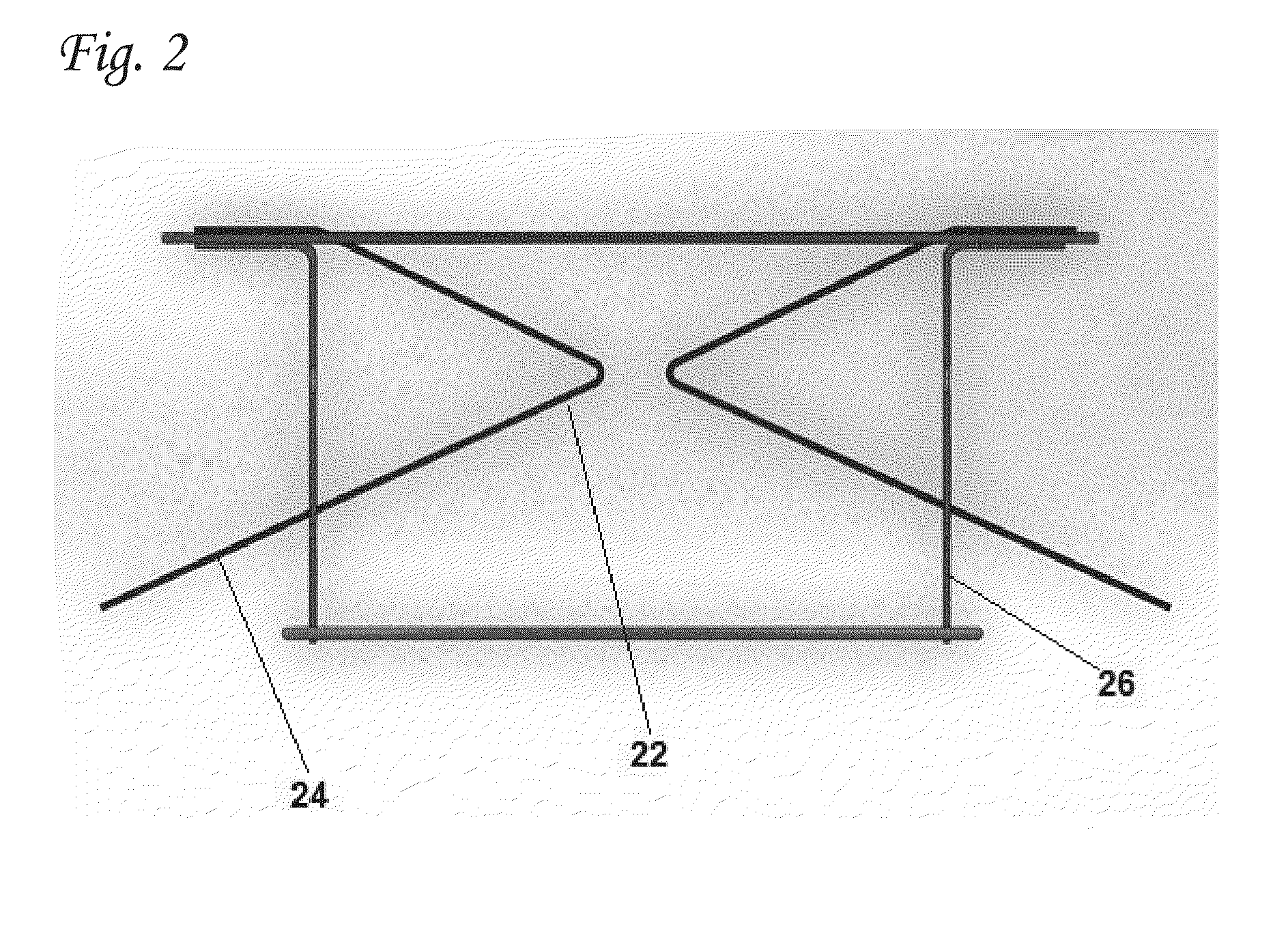

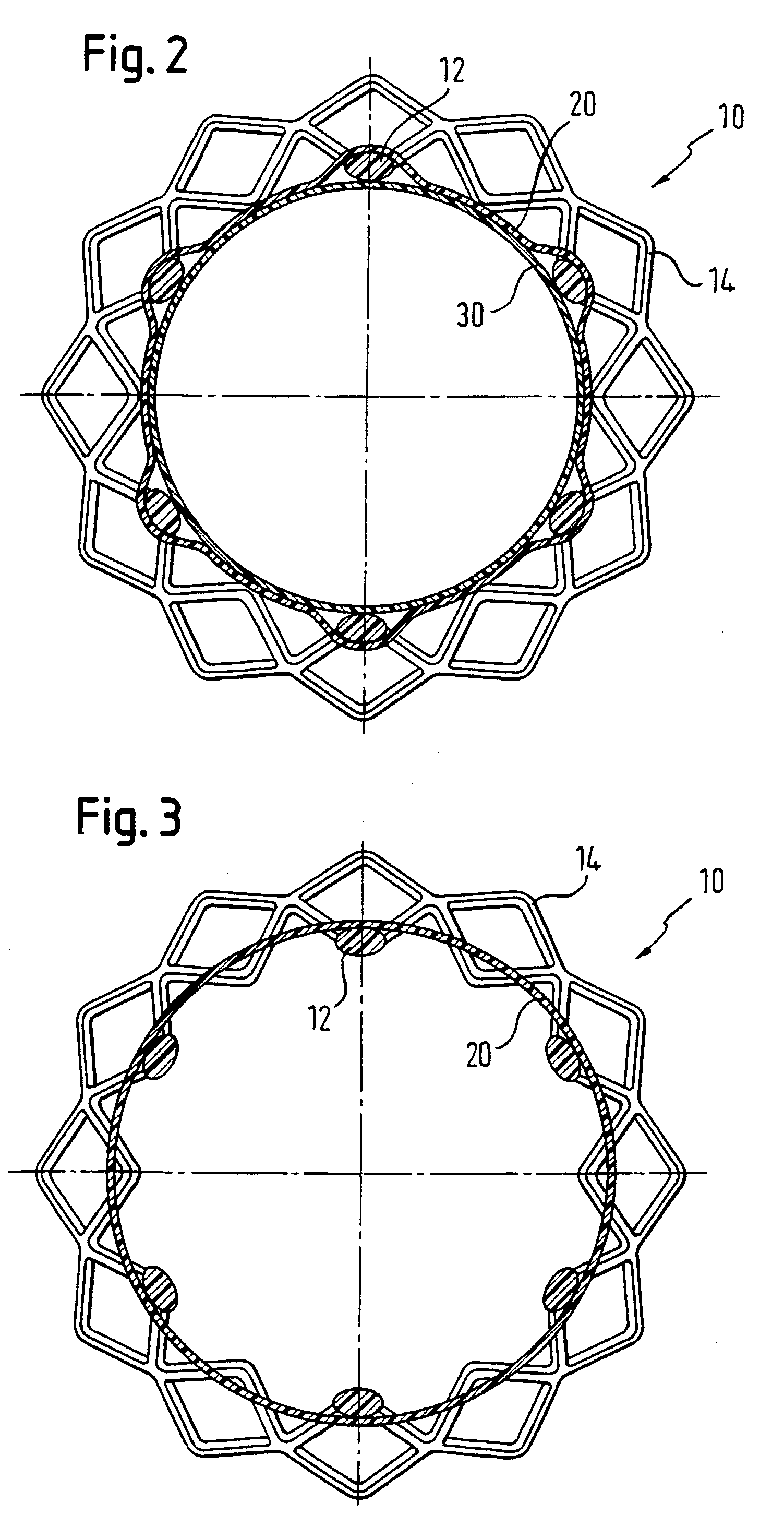

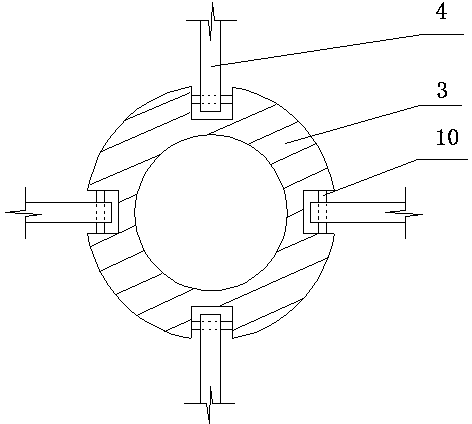

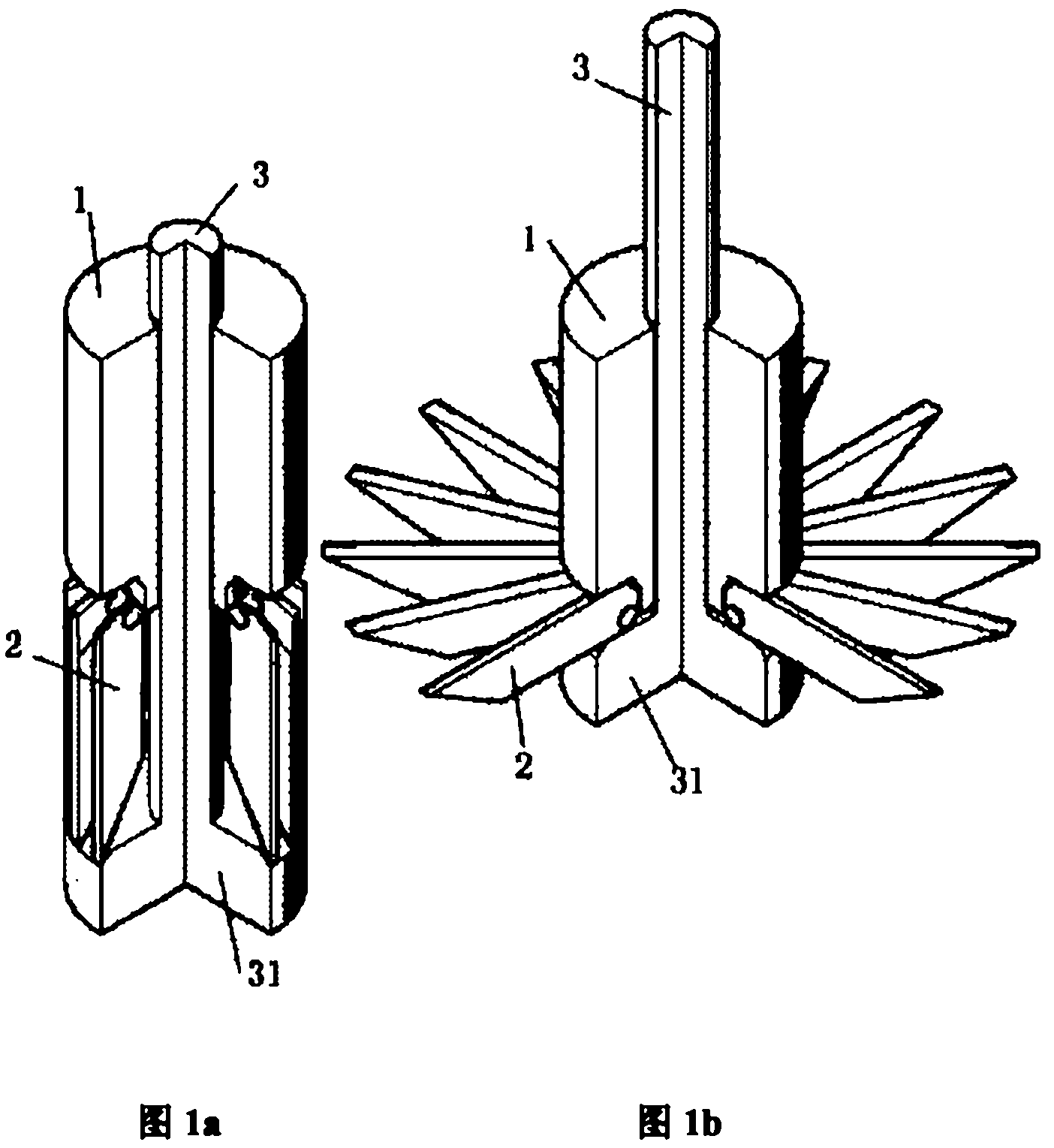

Anchoring elements for intracardiac devices

InactiveUS20140200662A1Prevent leakageGood equipment stabilityAnnuloplasty ringsLateral extensionBiomedical engineering

An intracardiac device comprising a ring-shaped body and one or more anchoring or stabilizing elements attached to said body, said elements being selected from the group consisting of levered anchoring arms, elongate anchoring arms, and lateral extension elements, wherein said device is able to move between two conformations, a collapsed conformation suitable for insertion into a delivery catheter, and an open conformation, suitable for implantation at a cardiac valve annulus.

Owner:MVALVE TECH

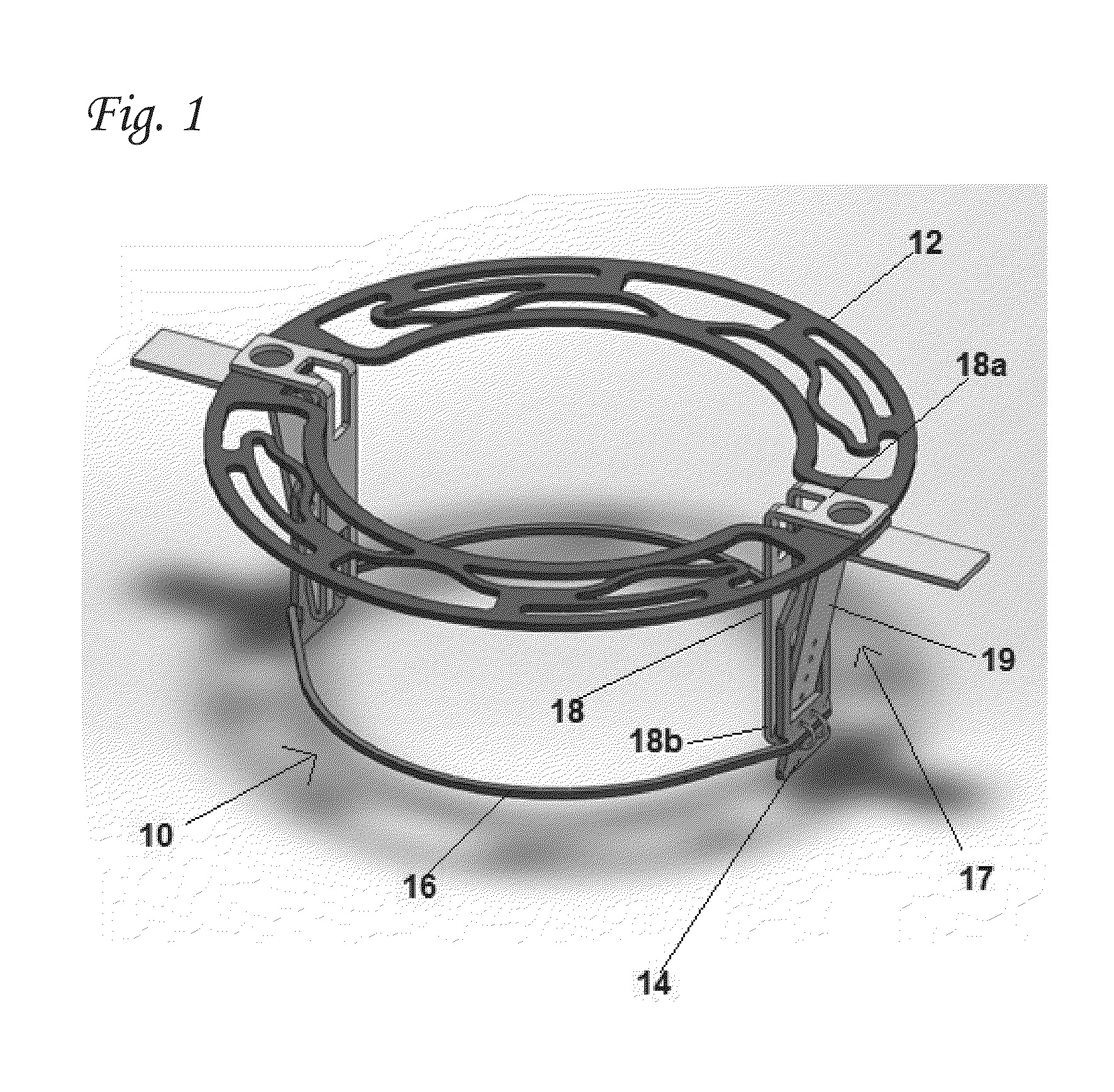

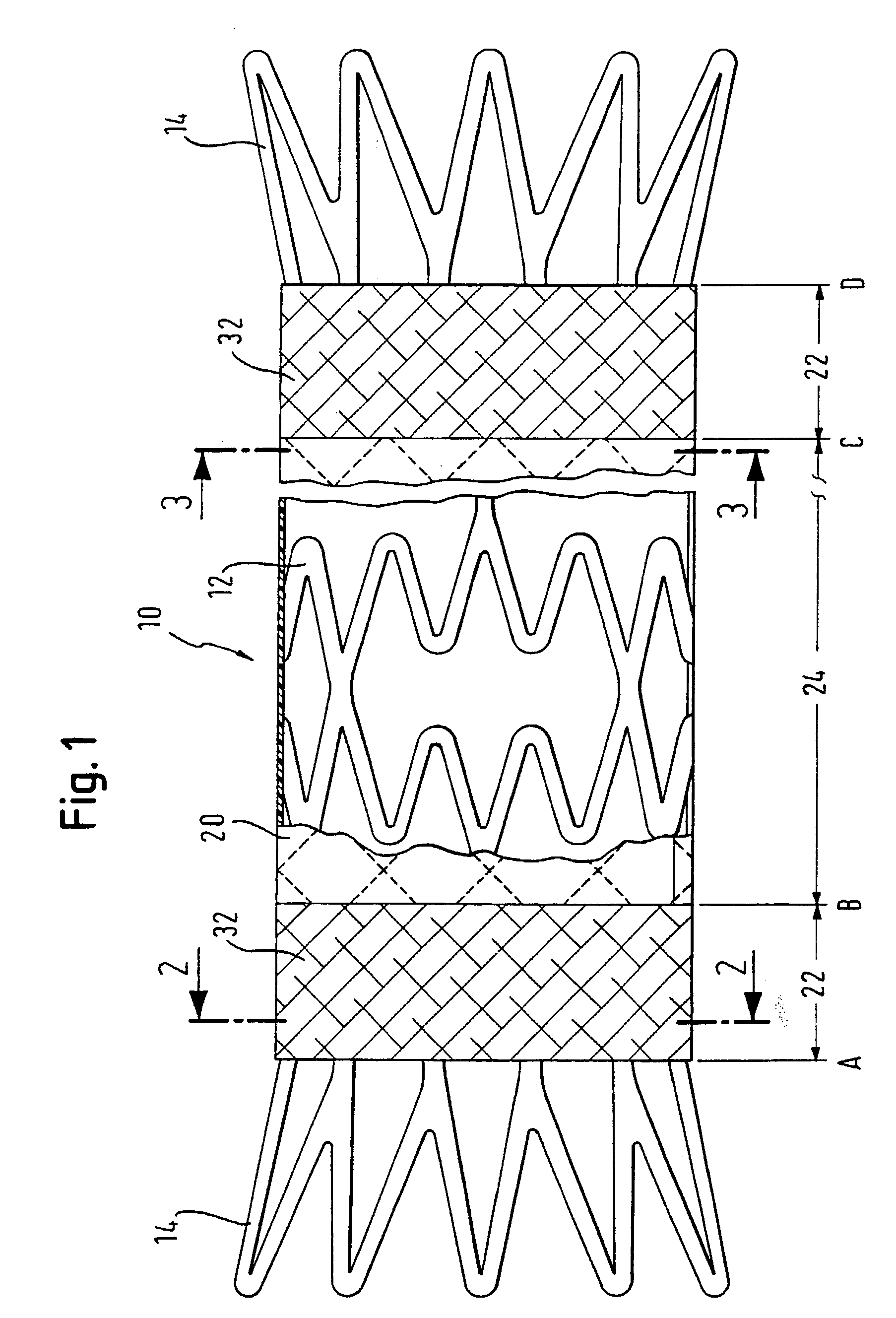

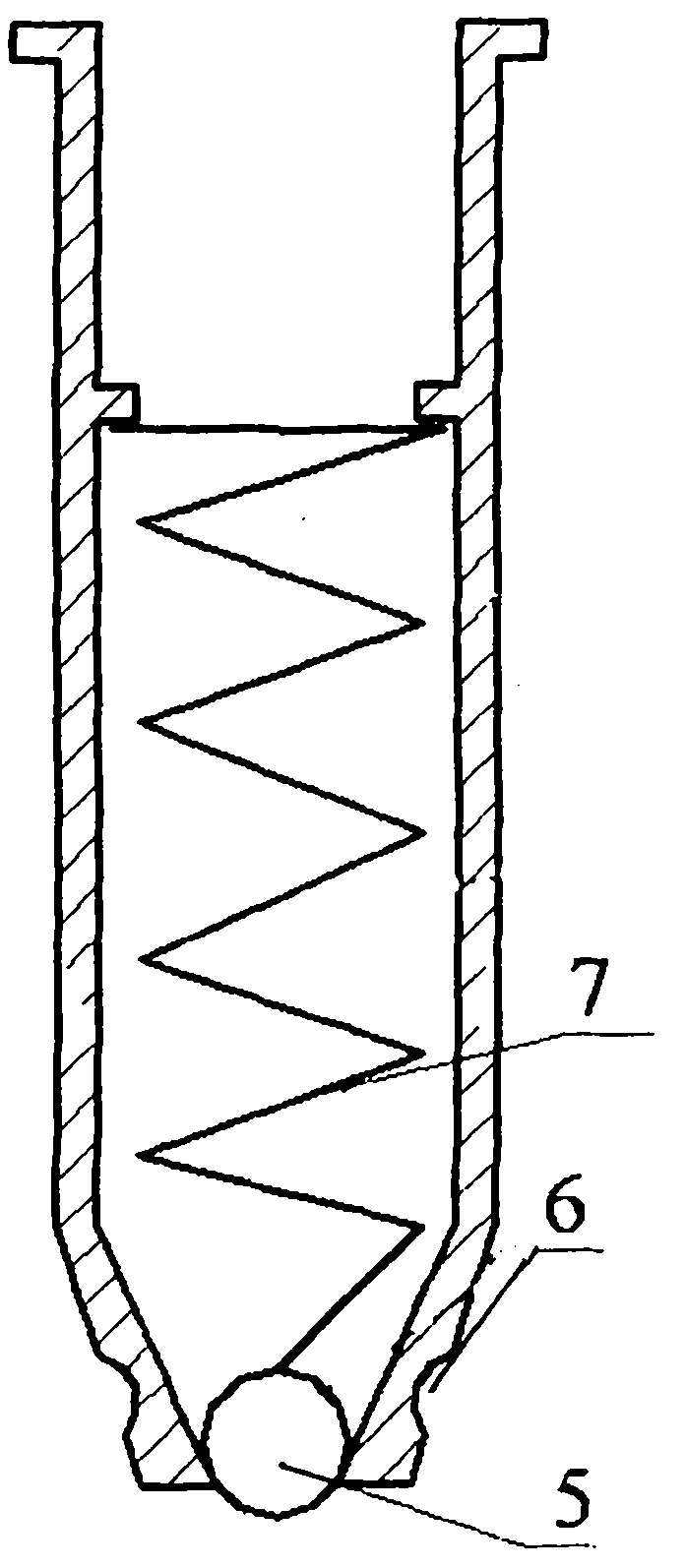

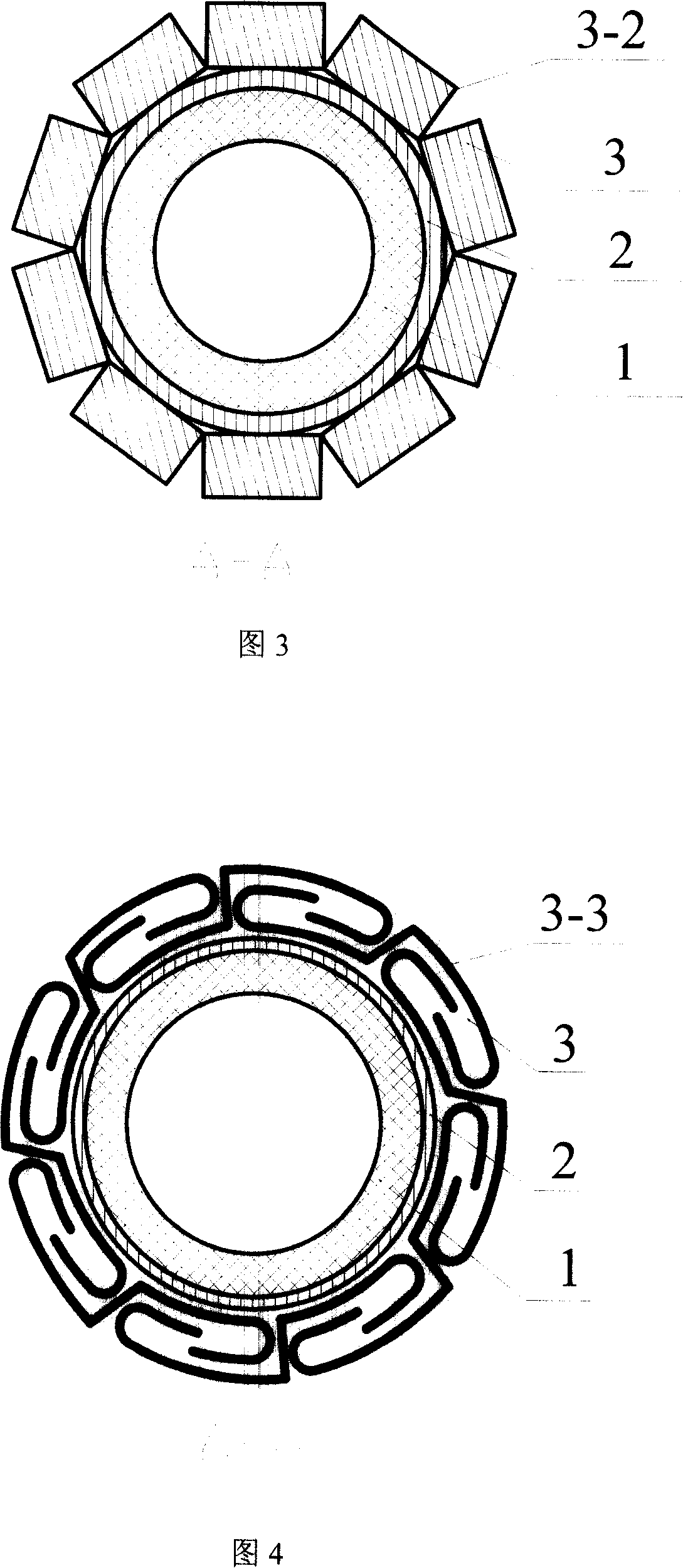

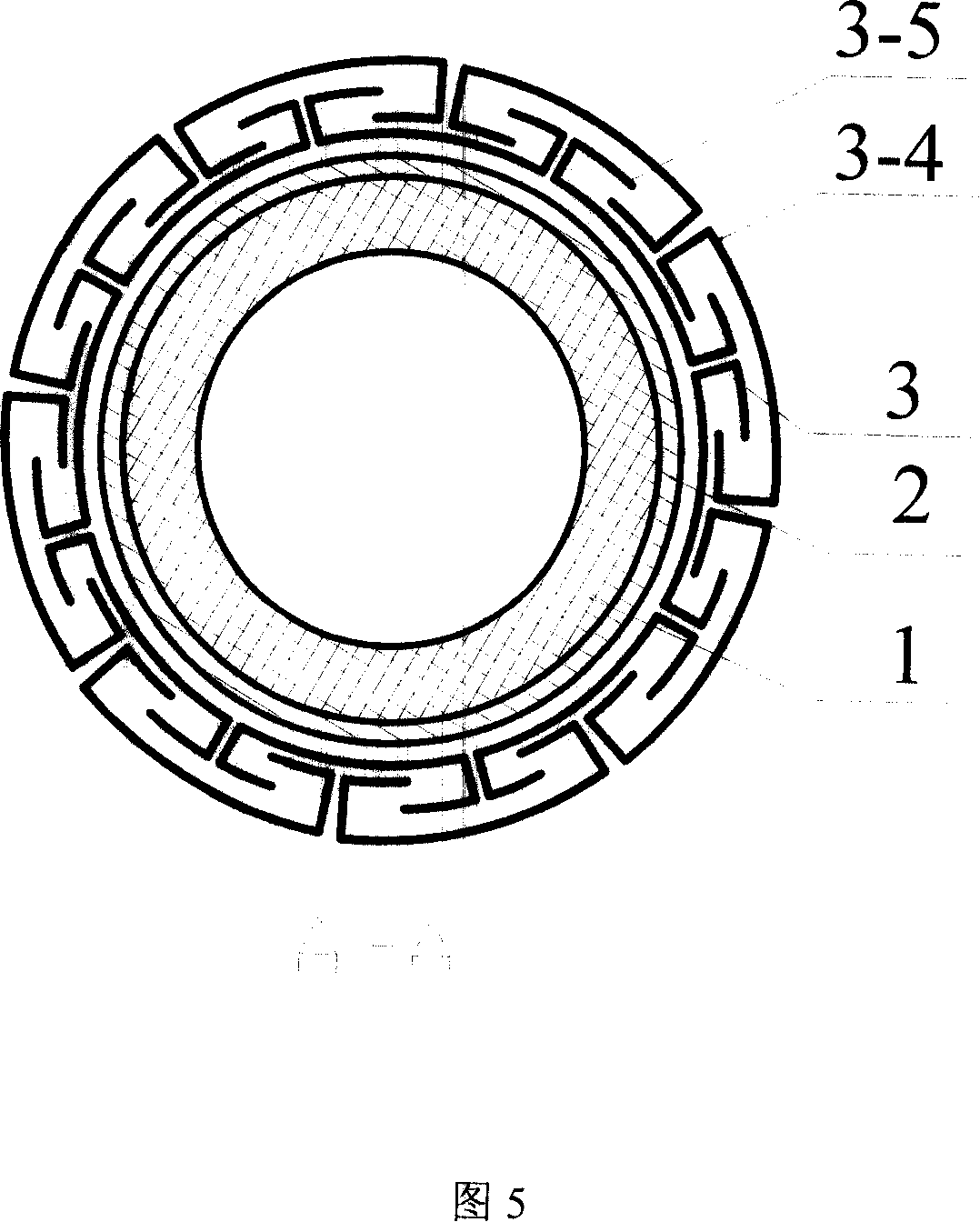

Stent matrix

InactiveUS20030144725A1Increase anchoring forceAmeliorate degree of traumaStentsSurgeryMedicineUnit structure

An object of this invention is to provide a radially expandable stent (1) that holds a passageway enlarged by placing the stent (1) into a lumen. The stent (1) comprises a cylindrical frame formed by a plurality of unit structures (11, 12, . . . 16, . . . ); said unit structures (11, 12, . . . 16, . . . ) formed into a closed zig-zag configuration including an endless series of straight sections (111) and joined by bends (112), and arranged face to face into a shape of multistage; connecting members (31, 33, 35, 37 . . . ), which connect said unit structures (11, 12, . . . 16, . . . ); and a mesh (91), which is wrapped around an outside of said frame.

Owner:ANGIOMED GMBH & CO MEDIZINTECHNIK KG

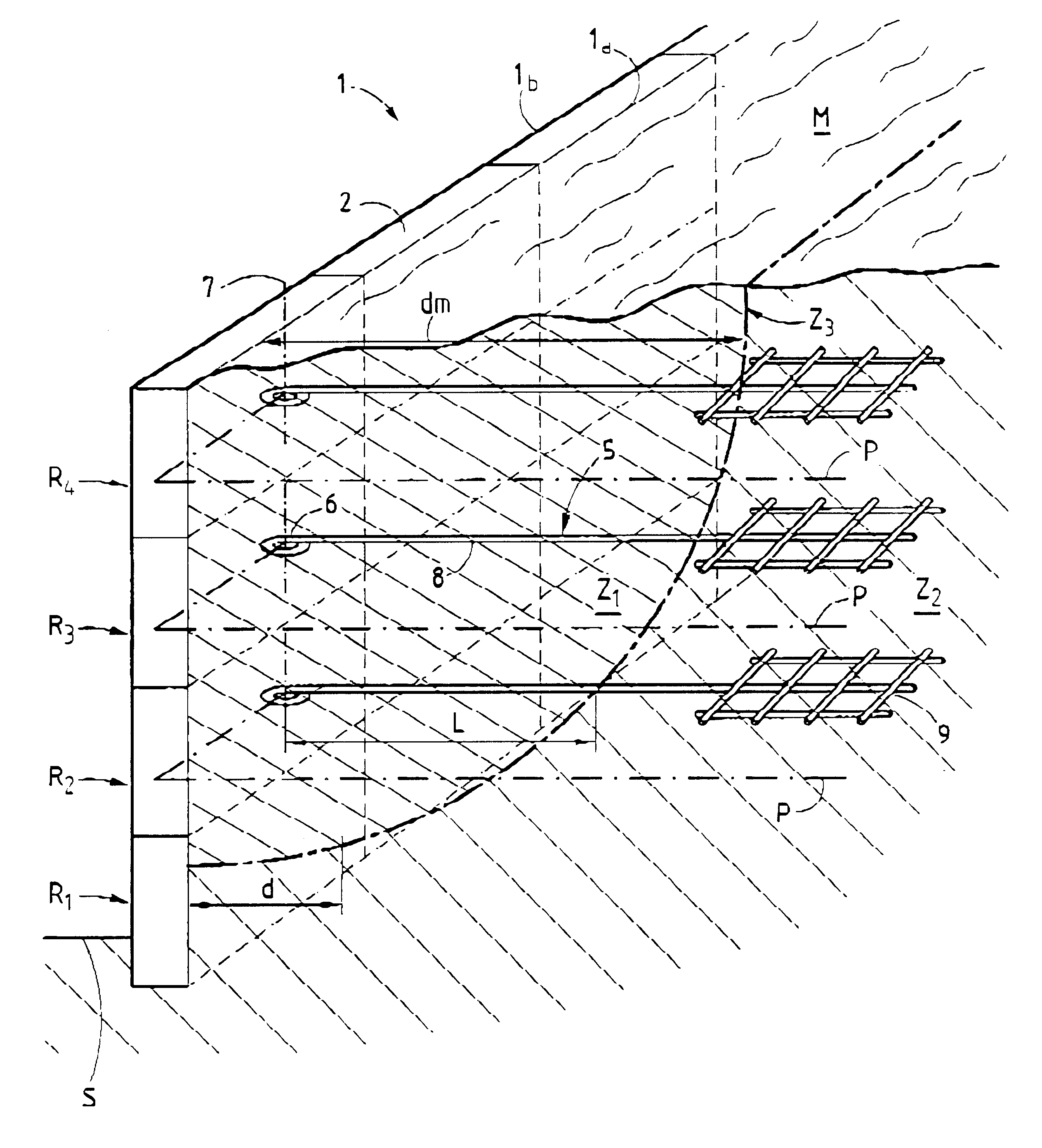

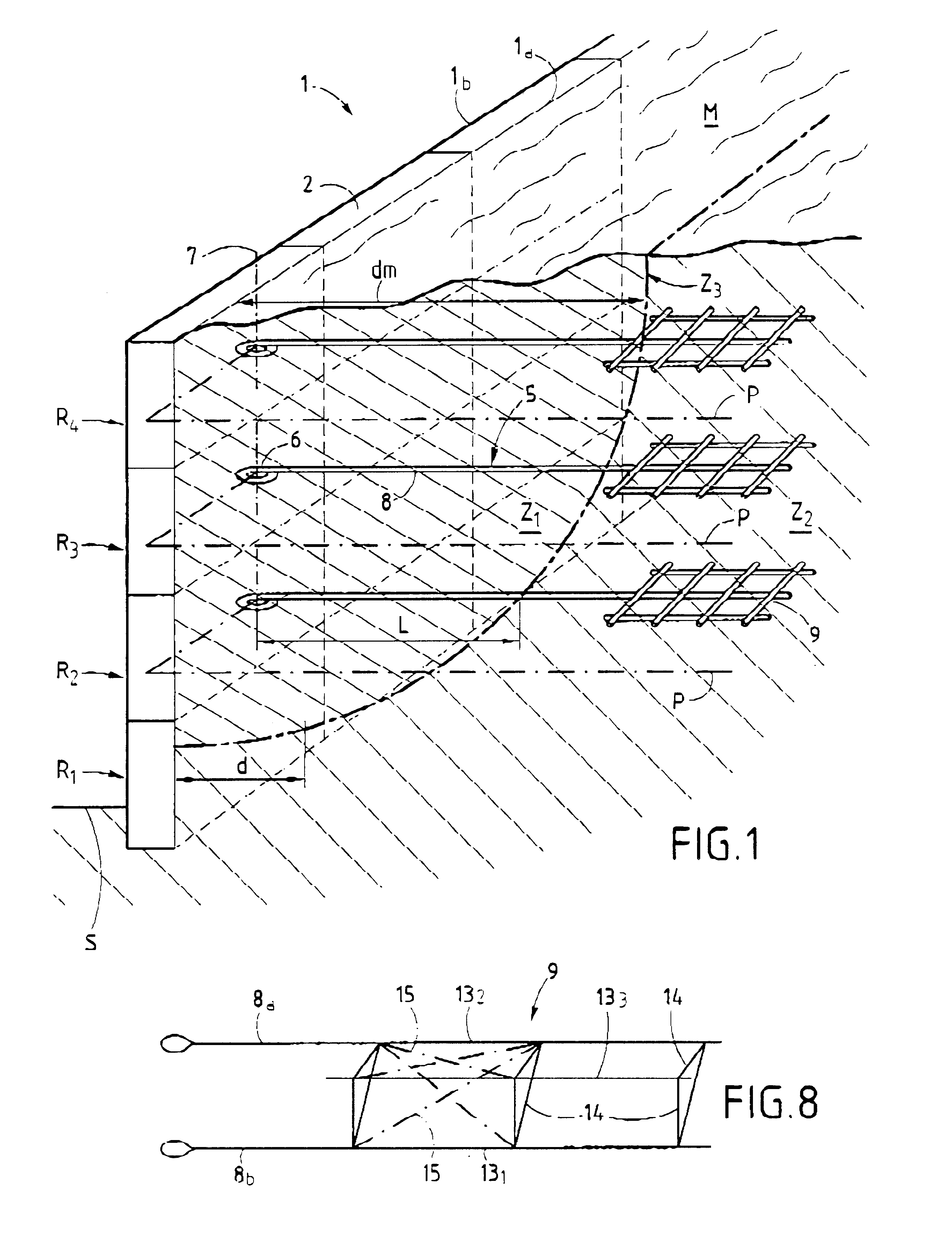

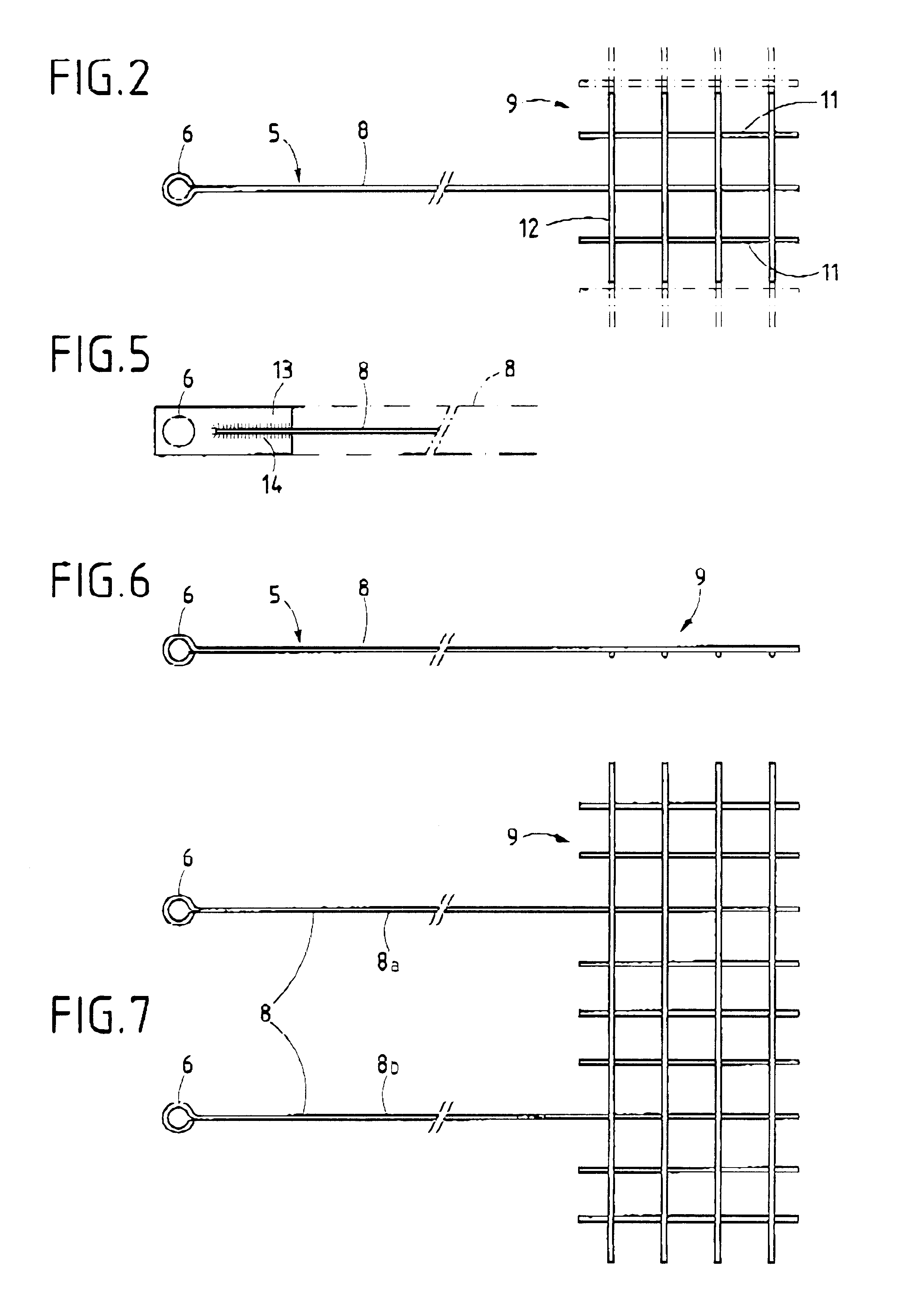

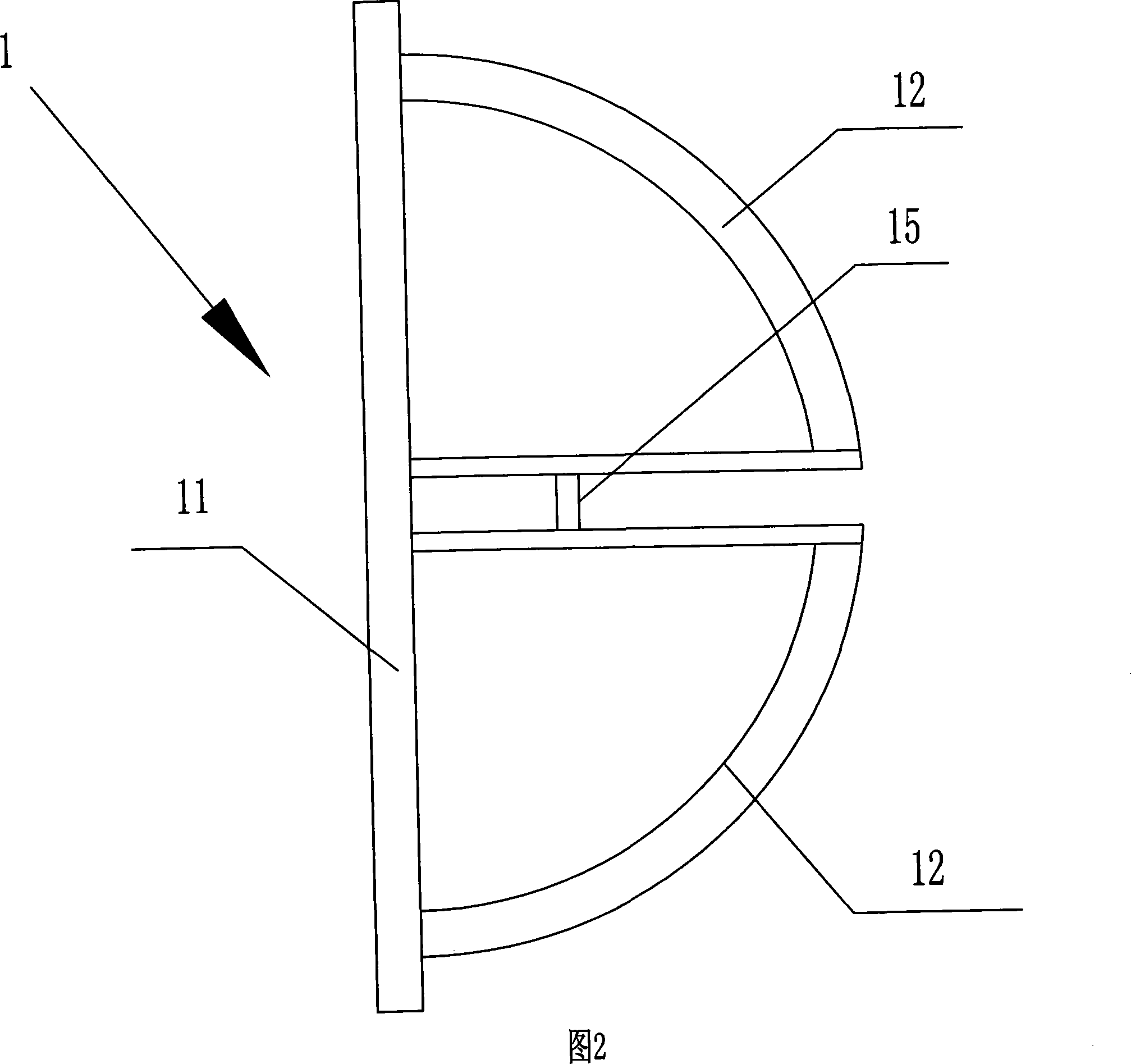

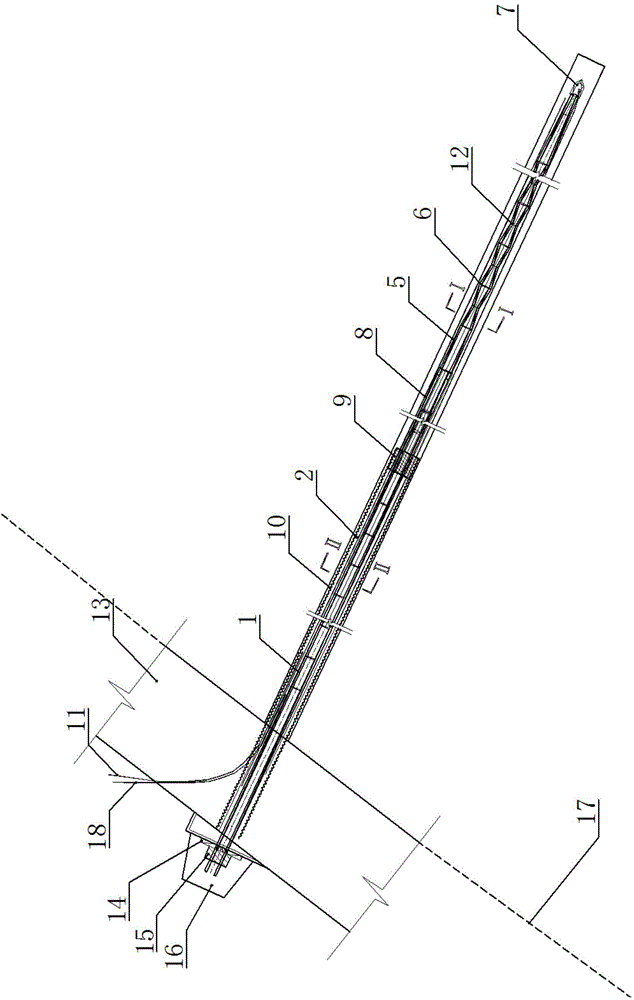

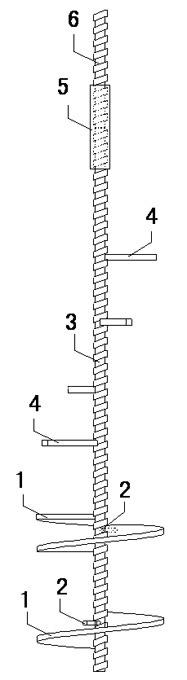

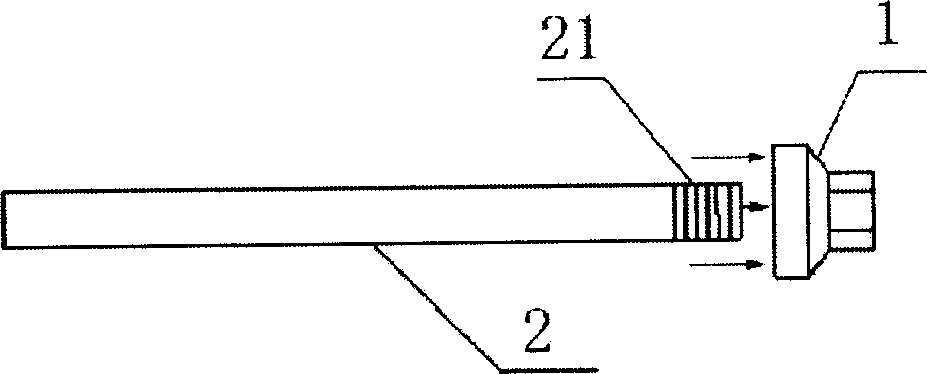

Flexible umbrella supporting anchor bolt and method for supporting soil slope thereby

ActiveCN104179178AIncrease anchoring forceConstruction quality is easy to ensureExcavationsBulkheads/pilesGeogridRock bolt

The invention relates to a flexible umbrella supporting anchor bolt and a method for supporting a soil slope thereby. An end ring and an end circular connector are fixedly disposed at one end of a round anchor bolt. A spring circular connector and a middle ring are fixedly disposed in the middle of the round anchor bolt. A lower circular connector adjacent to the right side of the middle ring movably sleeves the round anchor bolt. A drag umbrella surrounding the round anchor bolt comprises reacting plates evenly arranged, pull rods and compression springs. One end of a flexible pull rope is fixed to a round hole arranged in the other end of the round anchor bolt. More than one flexible umbrella supporting anchor bolt is connected with a soil high slope protective structure, composed of a geogrid mesh, a vegetation protective layer and a retaining wall, through the flexible pull ropes, and a whole for firmly and reliably anchoring and protecting the soil high slope is formed. The umbrella reacting plates are connected with the protective structural mesh through the flexible pull rope, anchoring force is greatly higher than that of a traditional anchor bolt, anchoring effect is more reliable, and engineering cost can be decreased by 50-60%.

Owner:NANCHANG INST OF TECH

Method for forming a head wall from an anchor pile and reinforcing member for said anchor pile structure

InactiveUS6675547B1Function increaseIncrease anchoring forceArtificial islandsConstruction materialMechanical engineeringRetaining wall

Owner:GOLCHEH JOSEPH

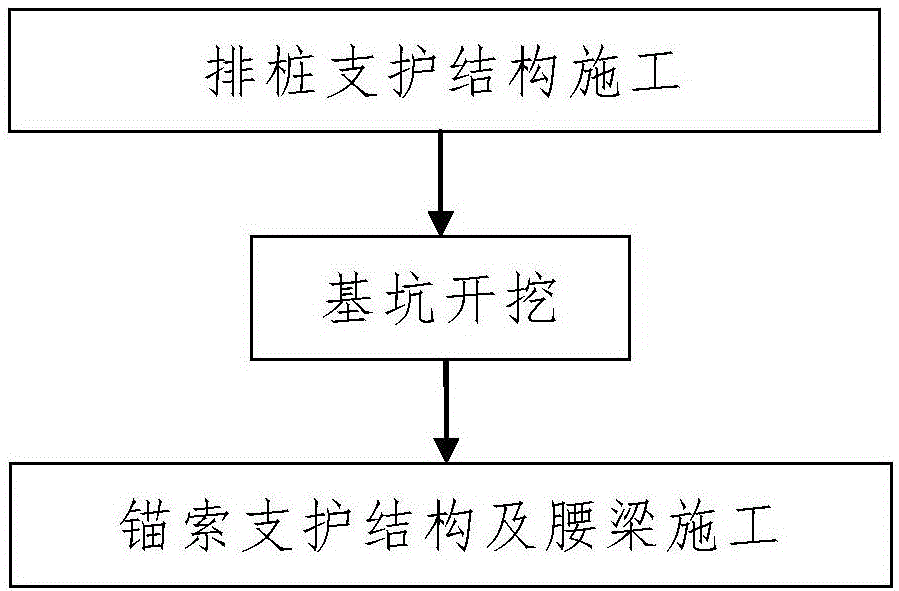

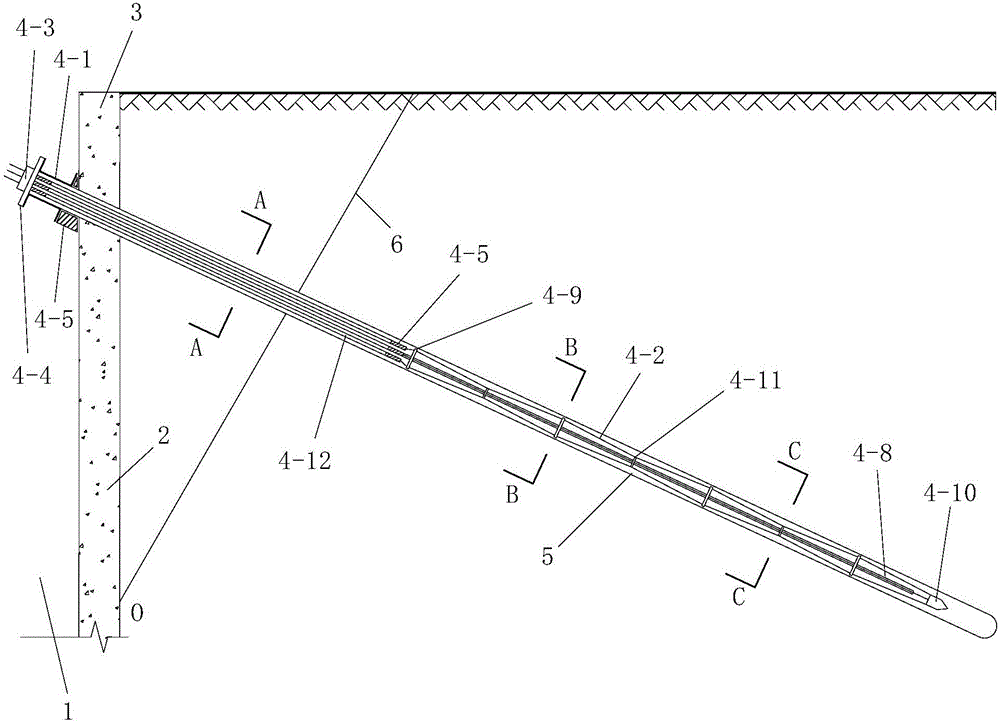

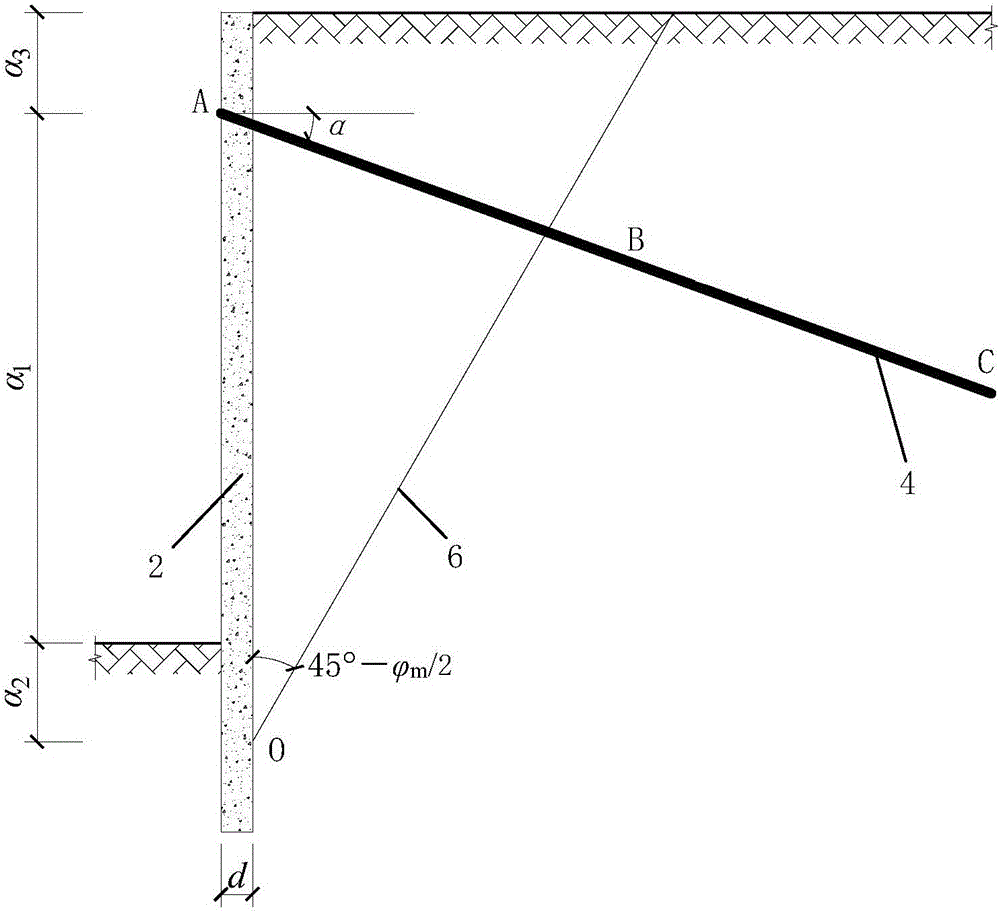

Construction method for supporting deep foundation pit through grouting after pile arrangement and anchor cable mounting

ActiveCN106320346AThe method steps are simpleReasonable designExcavationsBulkheads/pilesPre stressEngineering

The invention discloses a construction method for supporting a deep foundation pit through grouting after pile arrangement and anchor cable mounting. The construction method comprises the steps that firstly, pile arrangement supporting structure construction is performed, wherein a pile arrangement supporting structure comprises multiple slope protection piles which are arranged along the peripheral edge line of the constructed foundation pit from front to rear and a crown beam connected to the upper portions of the slope protection piles; secondly, foundation pit excavation is performed, wherein the constructed foundation pit is excavated from top to bottom; and thirdly, anchor cable supporting structure and waist beam construction is performed, wherein during excavation of the constructed foundation pit, the constructed foundation pit is excavated to the anchoring position of an anchor cable supporting structure, and the anchor cable supporting structure is constructed; and the anchor cable supporting structure comprises multiple prestress anchor cables, each prestress anchor cable comprises an anchor cable body, a primary grouting pipe and a secondary grouting pipe, and each anchor cable body comprises multiple steel strands. The method has the beneficial effects that the steps are simple, the design is reasonable, construction is easy and convenient, the use effect is good, the deep foundation pit supporting construction process can be completely easily, conveniently and quickly, the cost of the adopted prestress anchor cables is low, the anchoring force is high, and the deep foundation pit can be supported effectively.

Owner:SCEGC NO 6 CONSTR ENG GRP CO LTD

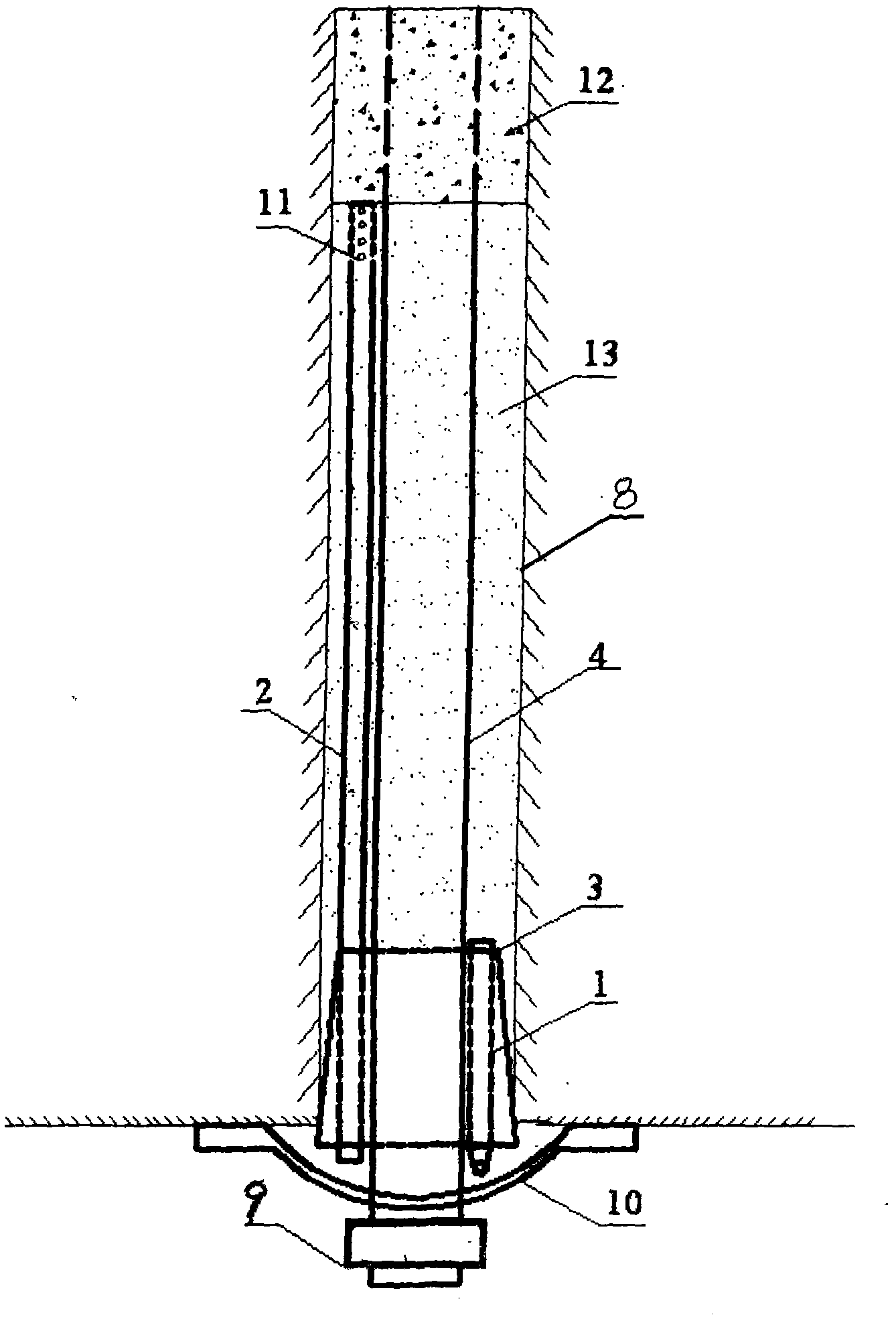

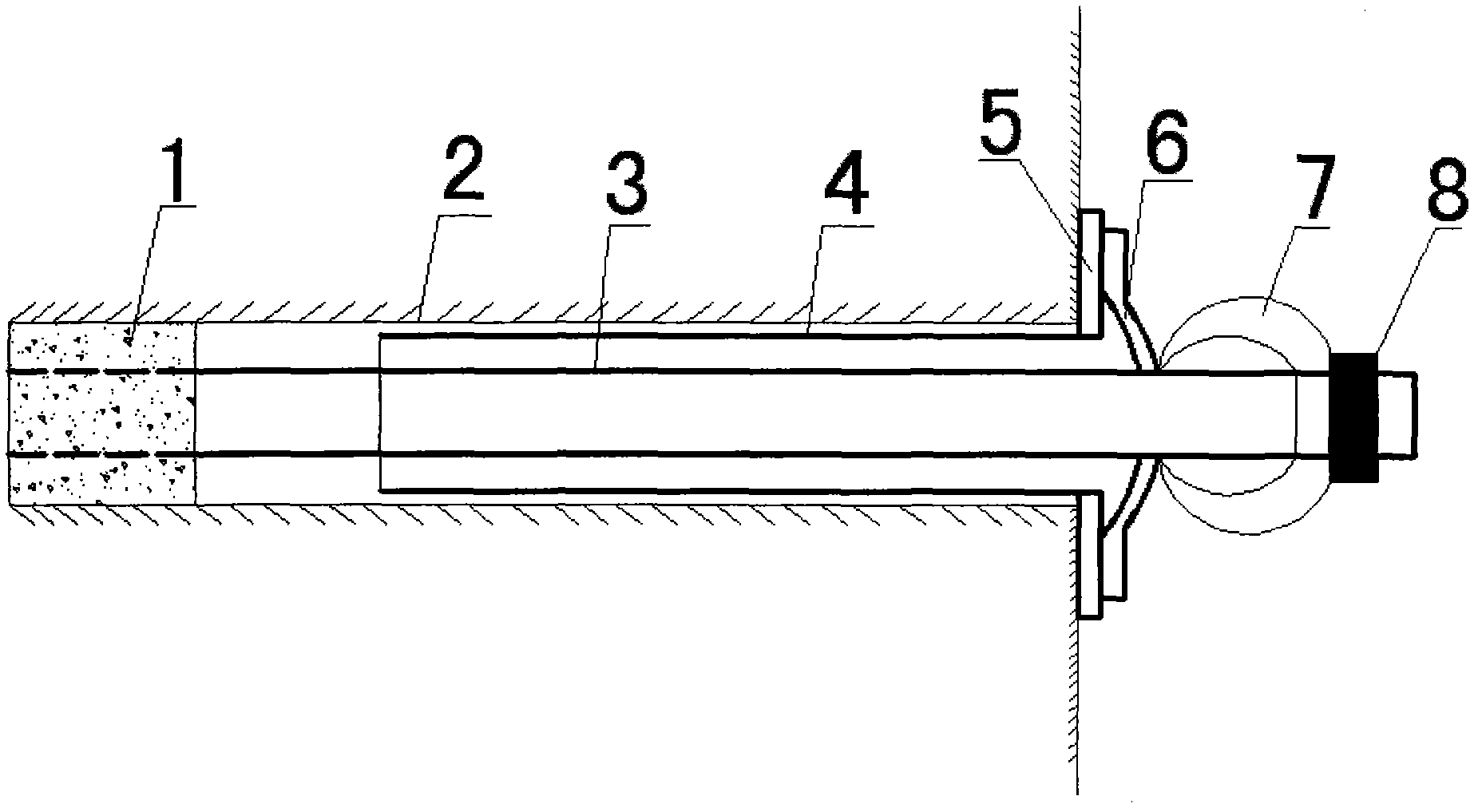

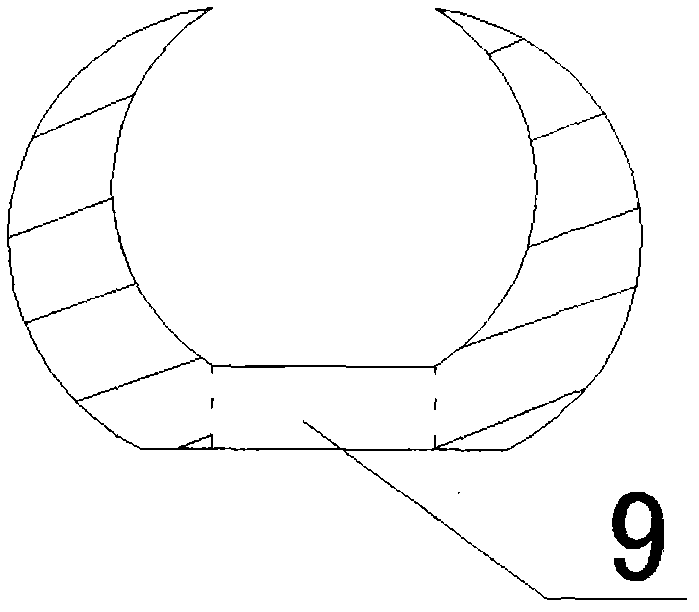

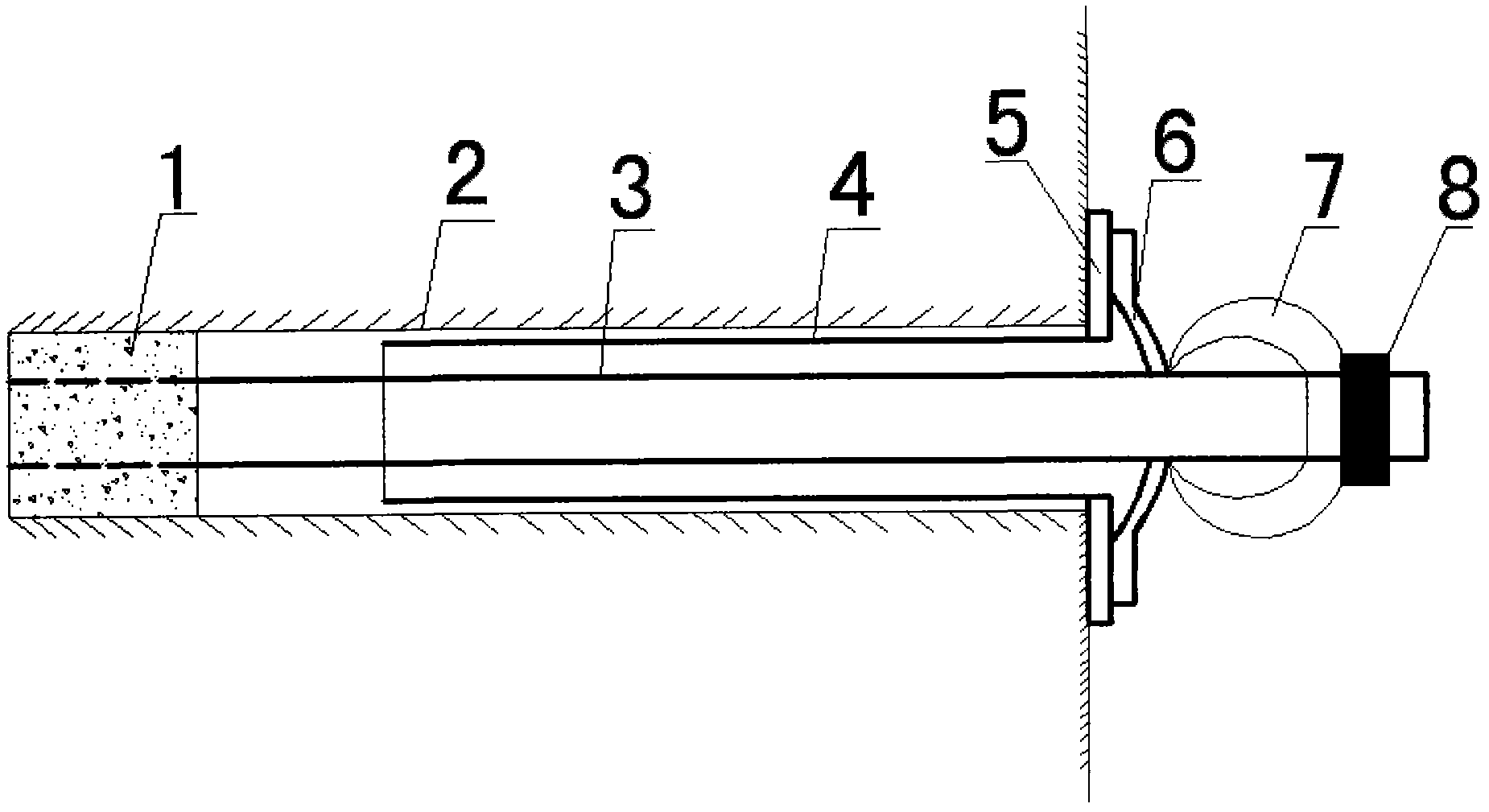

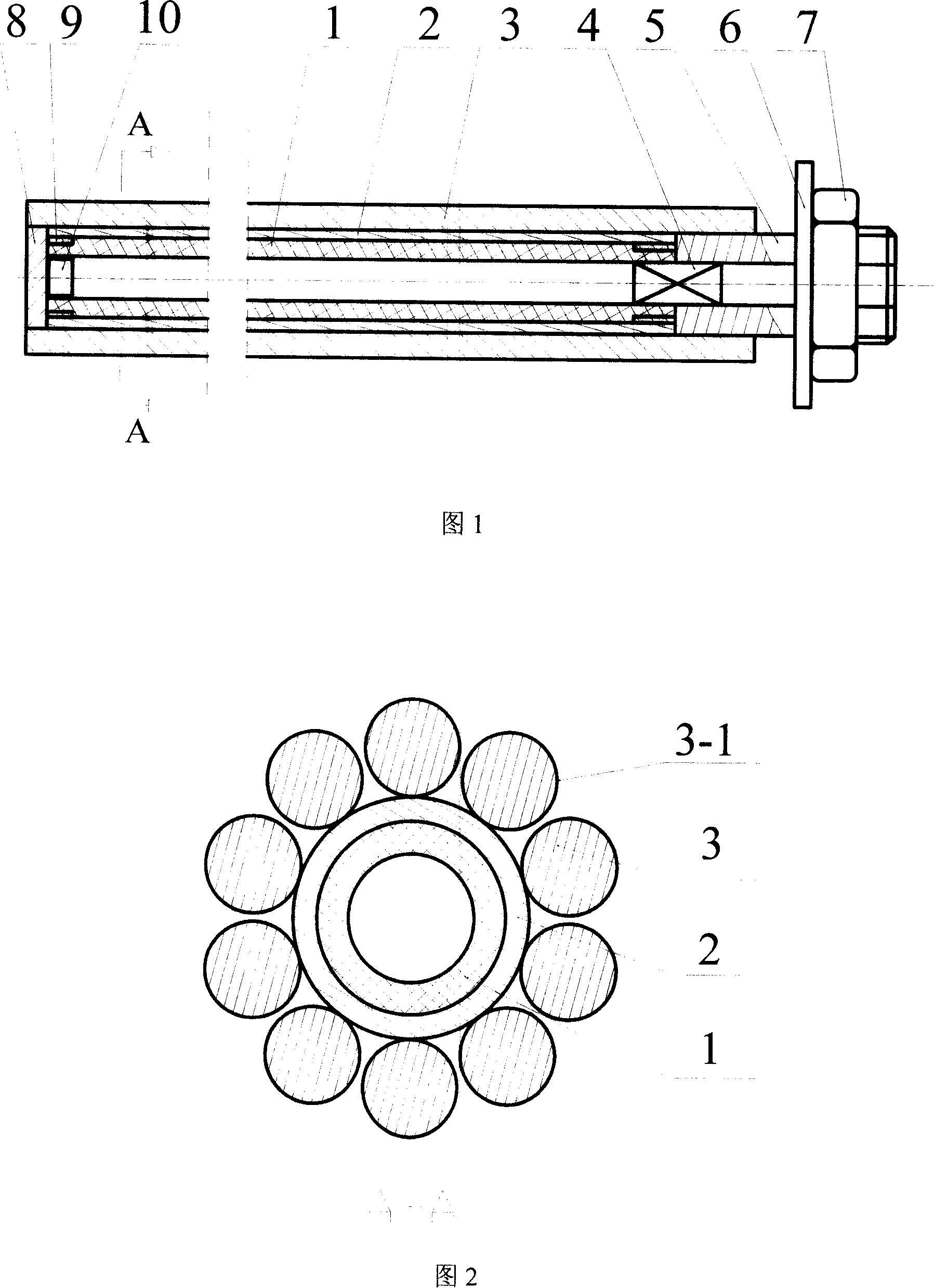

Anchoring structure for liquid-injection corrosion-resistant anchor rod or anchor cable and construction method thereof

InactiveCN102146673ASolve the sealing waterSolve corrosionAnchoring boltsBulkheads/pilesEngineeringSlurry

The invention discloses an anchoring structure for a liquid-injection corrosion-resistant anchor rod or anchor cable and a construction method thereof. The anchoring structure comprises a resin end-anchored anchor rod or anchor cable body arranged in an anchor hole, wherein a grouting-stop plug is also arranged at the opening of the anchor hole; an anchor rod head or an anchor cable head is exposed out of the anchor hole from the plug hole of the grouting-stop plug; the grouting-stop plug is also provided with two plug holes; a liquid injection nozzle is inserted into one plug hole and chemical grout is filled into the anchor hole through the liquid injection nozzle; an exhaust pipe with two open ends is inserted into the other plug hole; a check-valve ball and a return spring are arranged in the liquid injection nozzle; a locking slot connected with grouting equipment is reserved on the peripheral surface of the liquid injection nozzle; the length of the exhaust pipe is equivalent to that of the end-anchored anchor rod or anchor cable; and exhaust holes are reserved on the peripheral surface of the exhaust pipe close to the bottom of a drilled hole. The anchoring structure solves the problem of sealing water and preventing corrosion of anchor rod holes at the positions such as an arch part and the like, not only can serve as permanent support, but also can serve as temporary support.

Owner:SHANDONG UNIV OF SCI & TECH

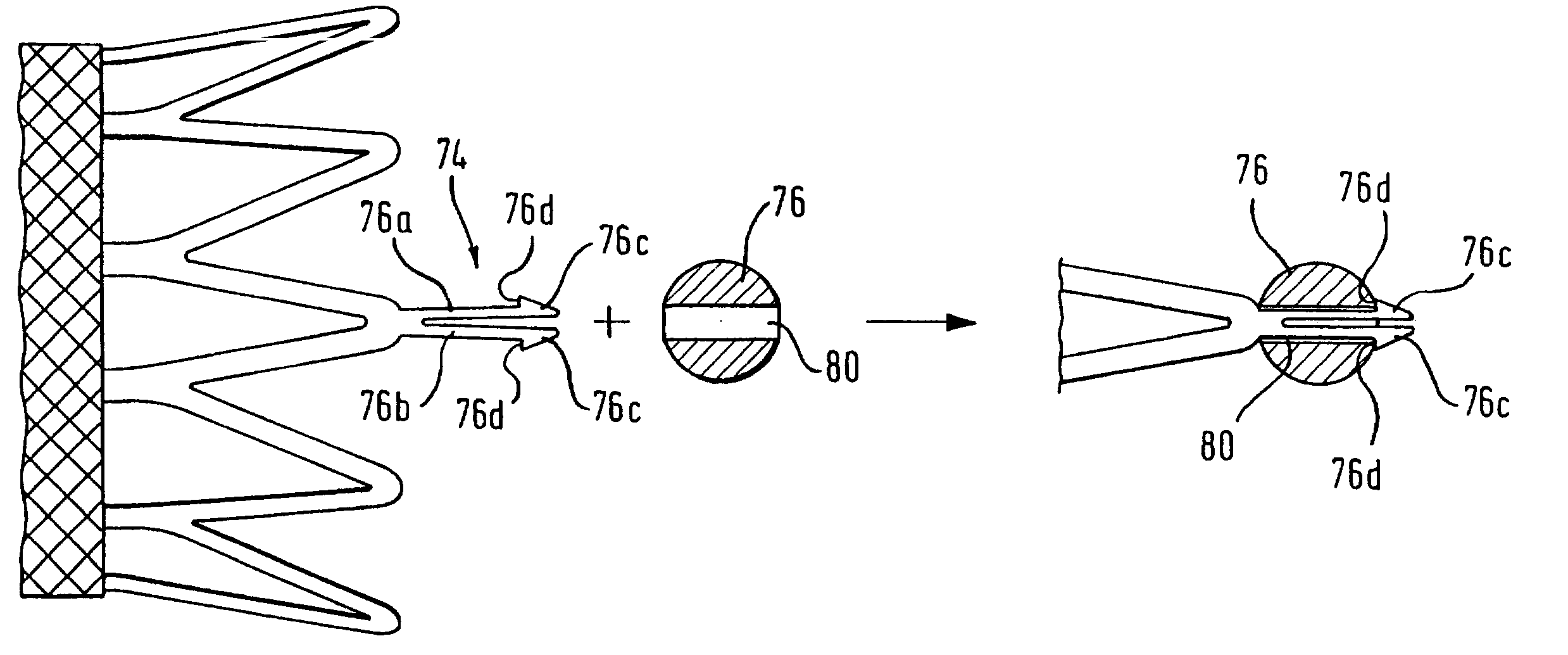

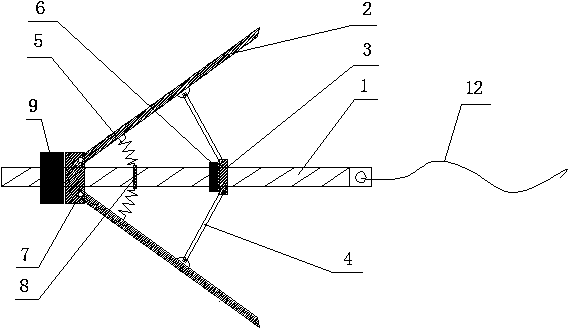

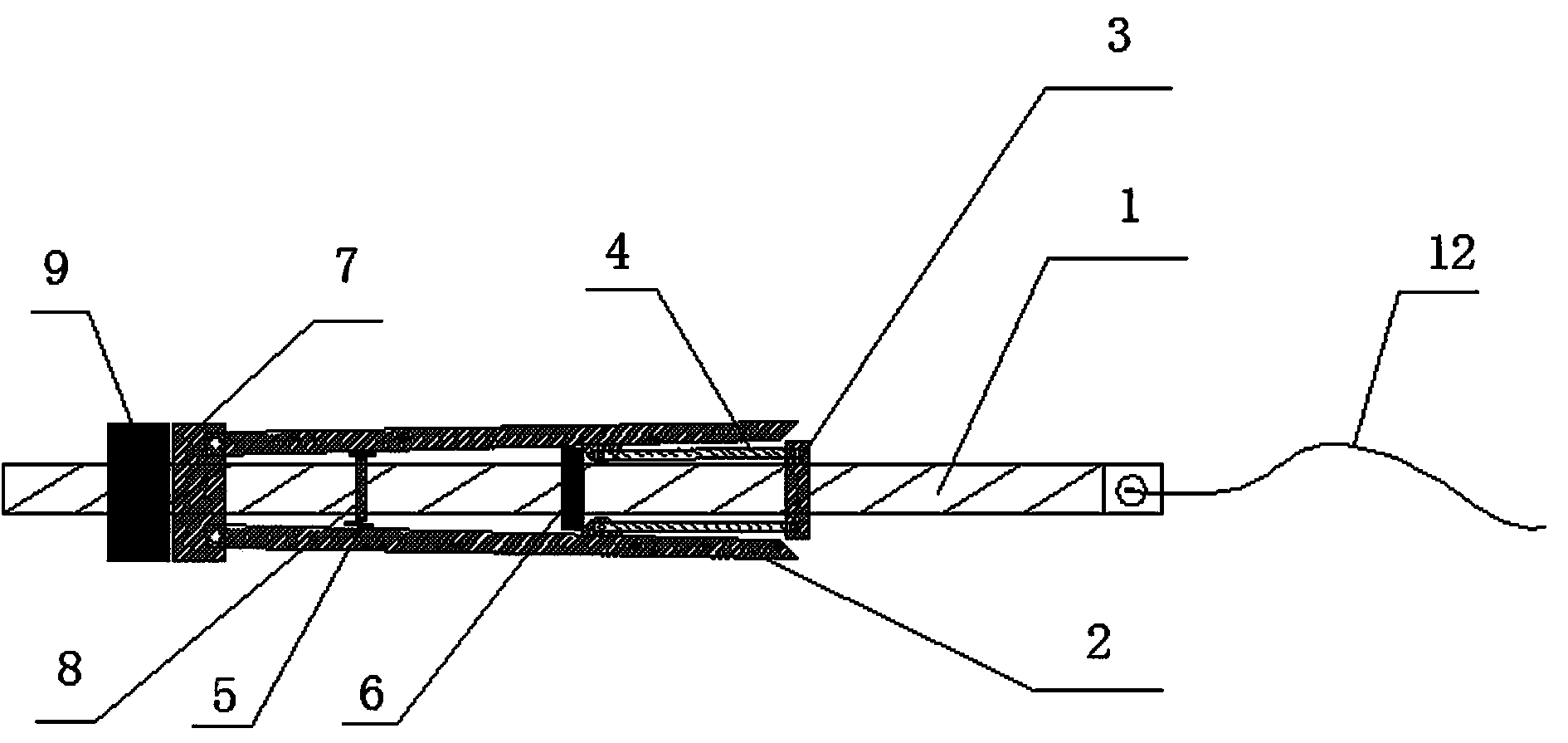

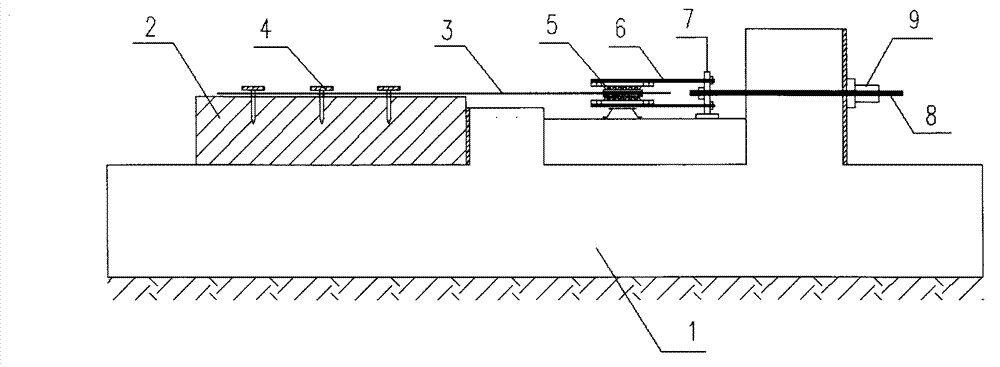

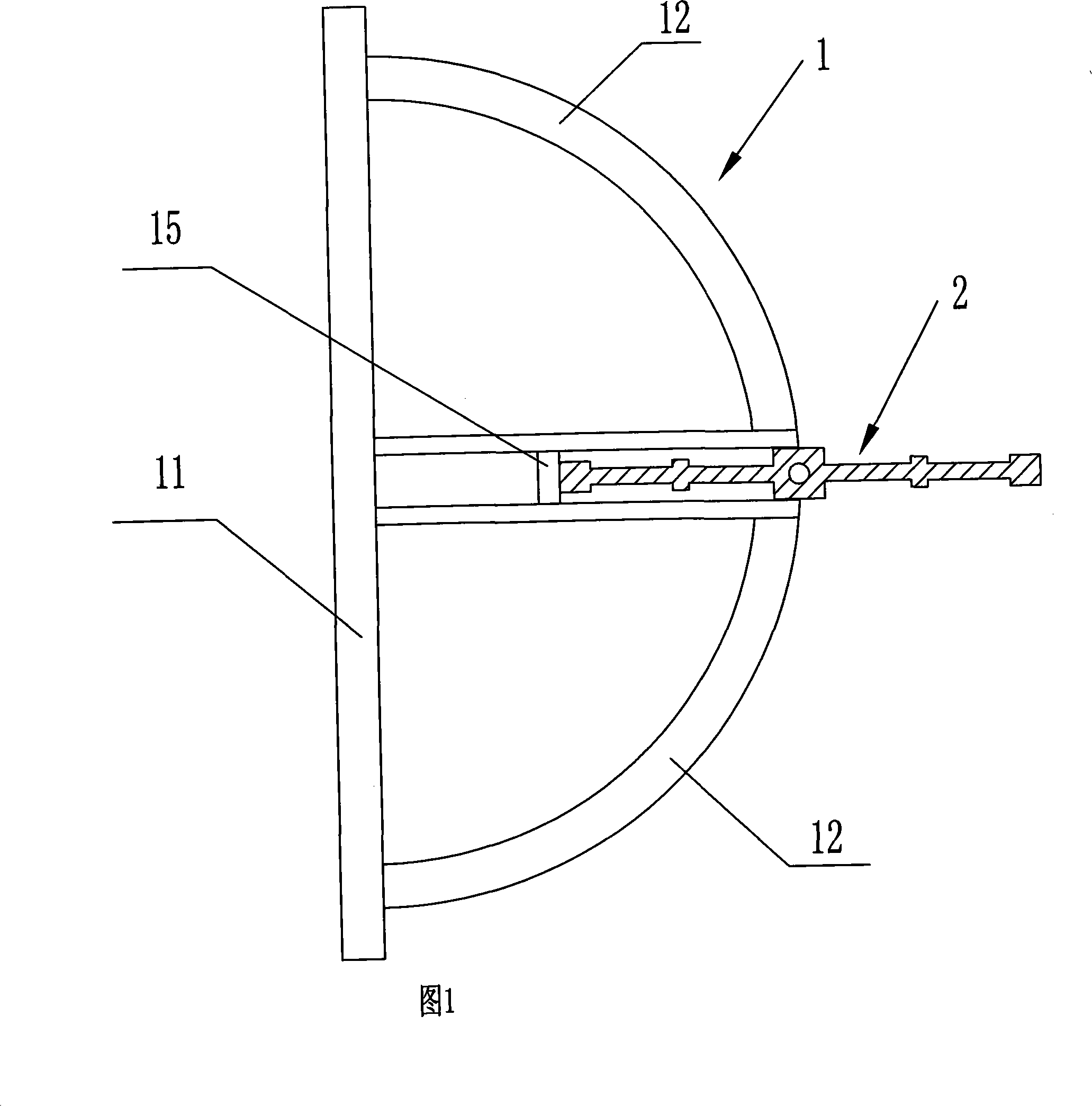

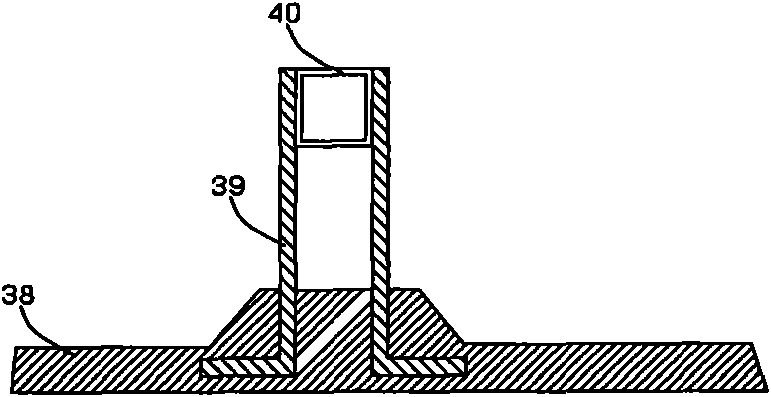

Anchorage performance detection testing apparatus and method for carbon fiber adhesion reinforcement

InactiveCN103048264AJudging the mechanical performance of anchorageCheck construction qualityUsing mechanical meansMaterial analysisFiberCarbon fibers

The invention discloses an anchorage performance detection testing apparatus for carbon fiber adhesion reinforcement. The testing apparatus comprises a testing bench, a concrete test piece, a test fixture and a loading system. The reinforced concrete test bench is composed of a base, a blocking bed, a connecting bed and a stretching bed, carbon fiber sheets are adhered to the test piece, and a steel pressing plate and an anchor bolt are taken as auxiliary anchoring pieces; the test fixture is composed of an external covering steel plate, two inner clamping steel plates and a high-strength split bolt, strip-shaped steel teeth are formed on the surface of the external covering steel plate, pole steel teeth are formed on the surfaces of the inner clamping steel plates, the carbon fiber sheets are placed between the two inner clamping steel plates, the carbon fiber sheets and the two inner clamping steel plates are firmly adhered together by dipping glue, and the high-strength split bolt clamps the external covering steel plate, the inner clamping steel plates and the carbon fiber sheets; and the loading system is composed of a connecting screw rod, a tensile connecting steel plate, a tensile screw rod, a lifting jack and a sensor. The testing apparatus provided by the invention can quickly carry out an anchorage zone stress performance test on a concrete beam reinforced with adhesion of the carbon fiber sheets, and has the advantages of being convenient to make and simple to operate, and the like.

Owner:江苏华通工程技术有限公司

Compound-type prestressed anchor cable structure and construction method thereof

ActiveCN104775428AThe reverse self-locking function generatesImprove anti-corrosion performanceExcavationsBulkheads/pilesPre stressFree state

The invention relates to a compound-type prestressed anchor cable structure. The compound-type prestressed anchor cable structure comprises a prefabricated inner anchor head, a free section, an outer anchoring section and an anchor head part, wherein the prefabricated inner anchor head is provided with steel strands in a penetrating manner; the prefabricated inner anchor head is manufactured in a factory; the prefabricated inner anchor head and the steel strands are adhered to the bottom of a drill hole by using a grouting body; the upper part of the drill hole is the free end, which is at a free state, of each steel strand; the outer anchoring section is arranged at an opening of the drill hole; the anchor head part is arranged outside the opening of the drill hole and is fixed with the top end of each steel strand. The compound-type prestressed anchor cable structure is characterized in that the prefabricated inner anchor head is arranged on the bottom of the drill hole; the outer anchoring section is arranged between the upper end of the free section and the opening of the drill hole; grouting by the grouting body is carried out by three times, wherein the first grouting is stopped in the middle of the free section, fracturing grouting is adopted in the second grouting process to form the anchoring section, and the third grouting is carried out after a grout body of the anchoring section reaches an age and has the capability of stretching the steel strands, namely, the outer anchoring section is subjected to grouting, and except that the steel strand of the free section is at a free state, the steel strands of the inner anchor head and the outer anchoring section are adhered with the grouting body to form the compound-type prestressed anchor cable with the prefabricated inner anchor head and the outer anchoring section.

Owner:铁科检测有限公司 +1

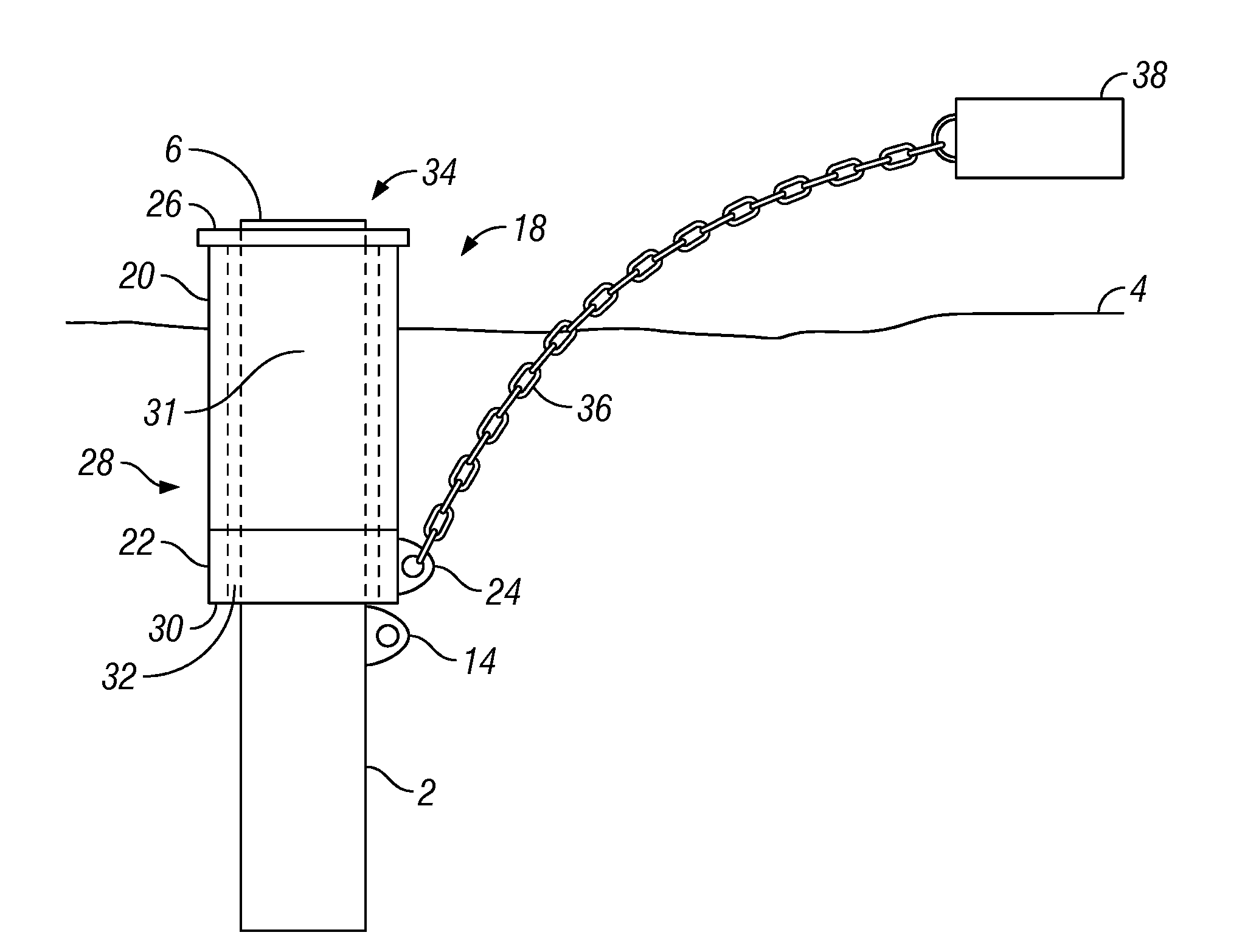

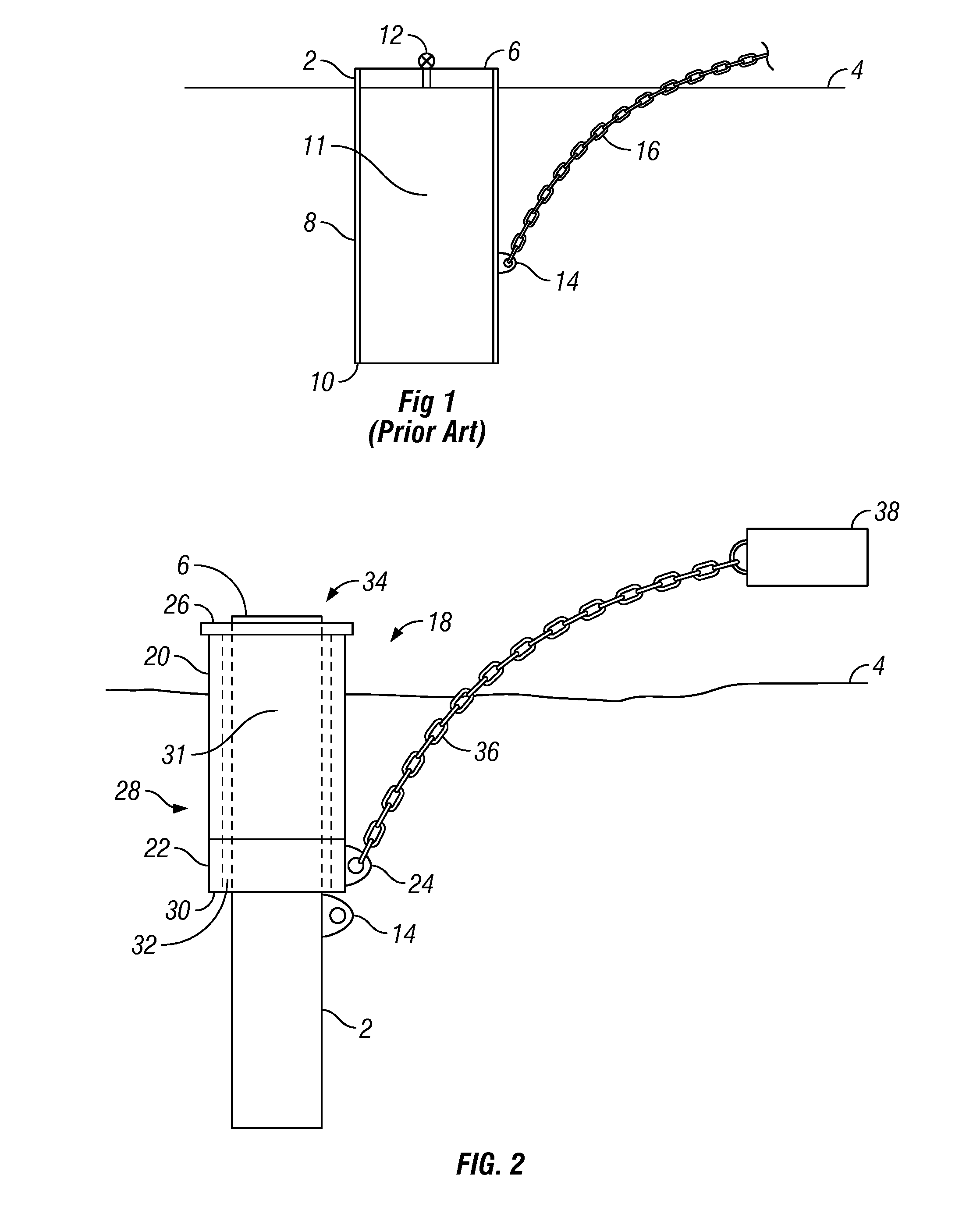

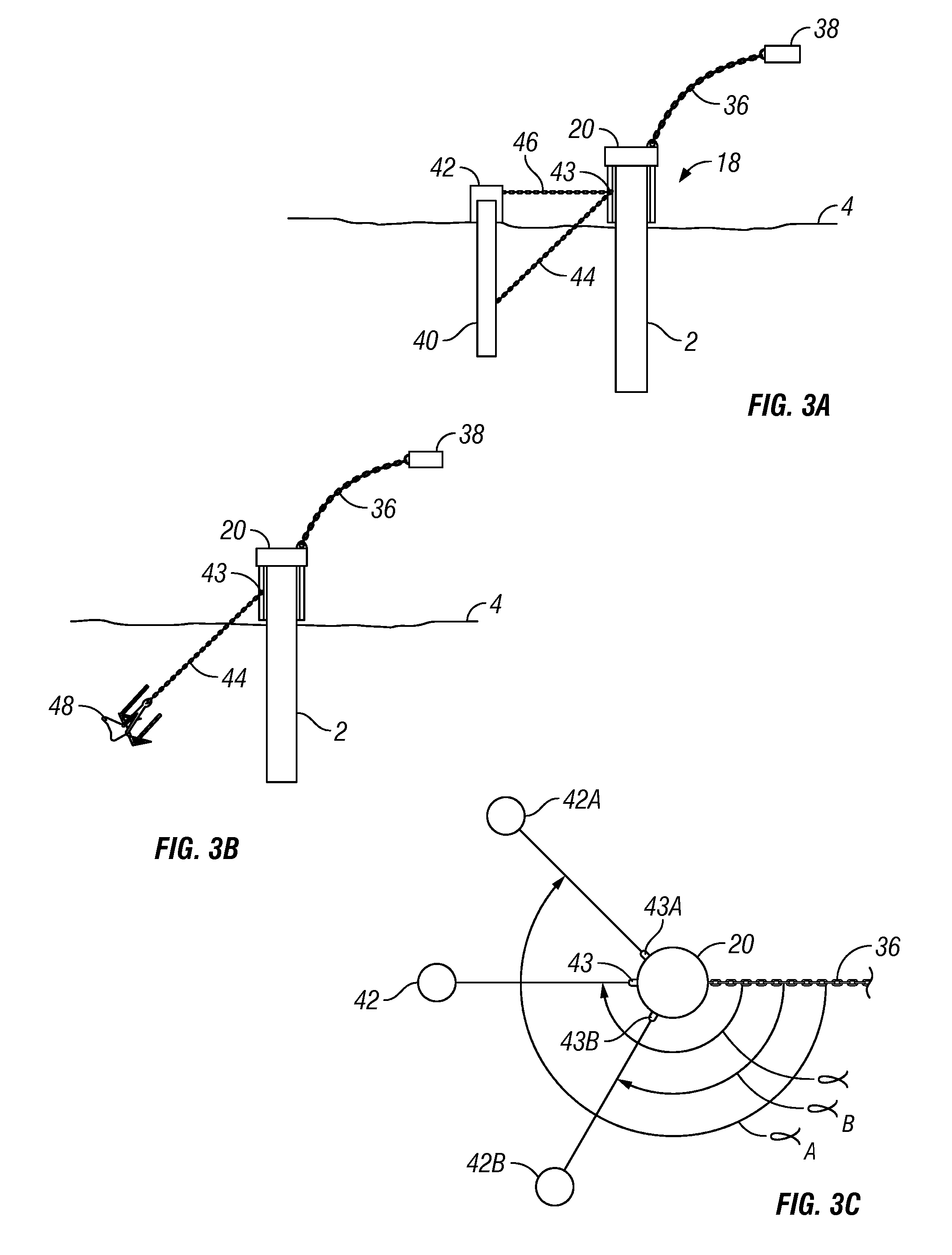

Outer pipe sleeve for a sea floor mooring pile

InactiveUS20090123235A1Increase anchoring forceReduce frictionAnchorsBulkheads/pilesOcean bottomEngineering

The present disclosure provides an improved system and method for increasing an anchoring force on a pile. The concepts regarding the pile can apply whether the pile is degraded and no longer able to support its intended load, or a load on the pile has increased to a level that may overstress the pile. A sleeve can be installed even in subsea conditions over the pile and can be used to provide an additional securing force to the existing pile. The sleeve may include its own padeye for coupling an anchor line or other coupling member to a structure to be secured. The sleeve may also include an assembly of rings coupled together with at least one longitudinal member. The assembly with the rings spaced a distance away from each other may help reduce an installation friction on the sleeve, as it is installed into the sea floor.

Owner:TECH FRANCE SA

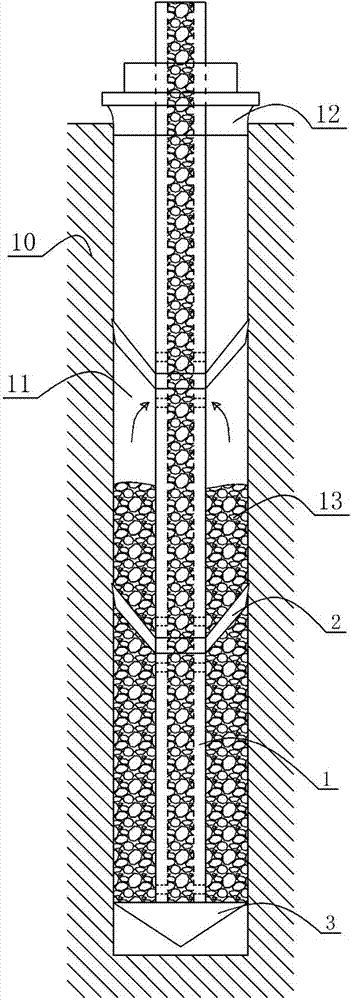

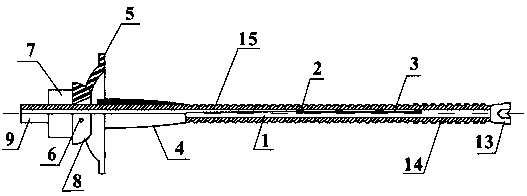

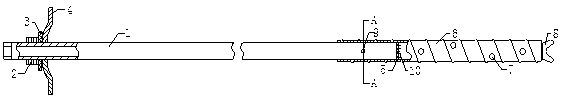

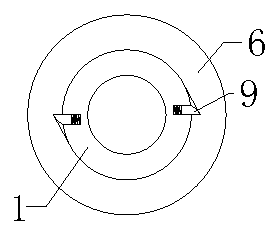

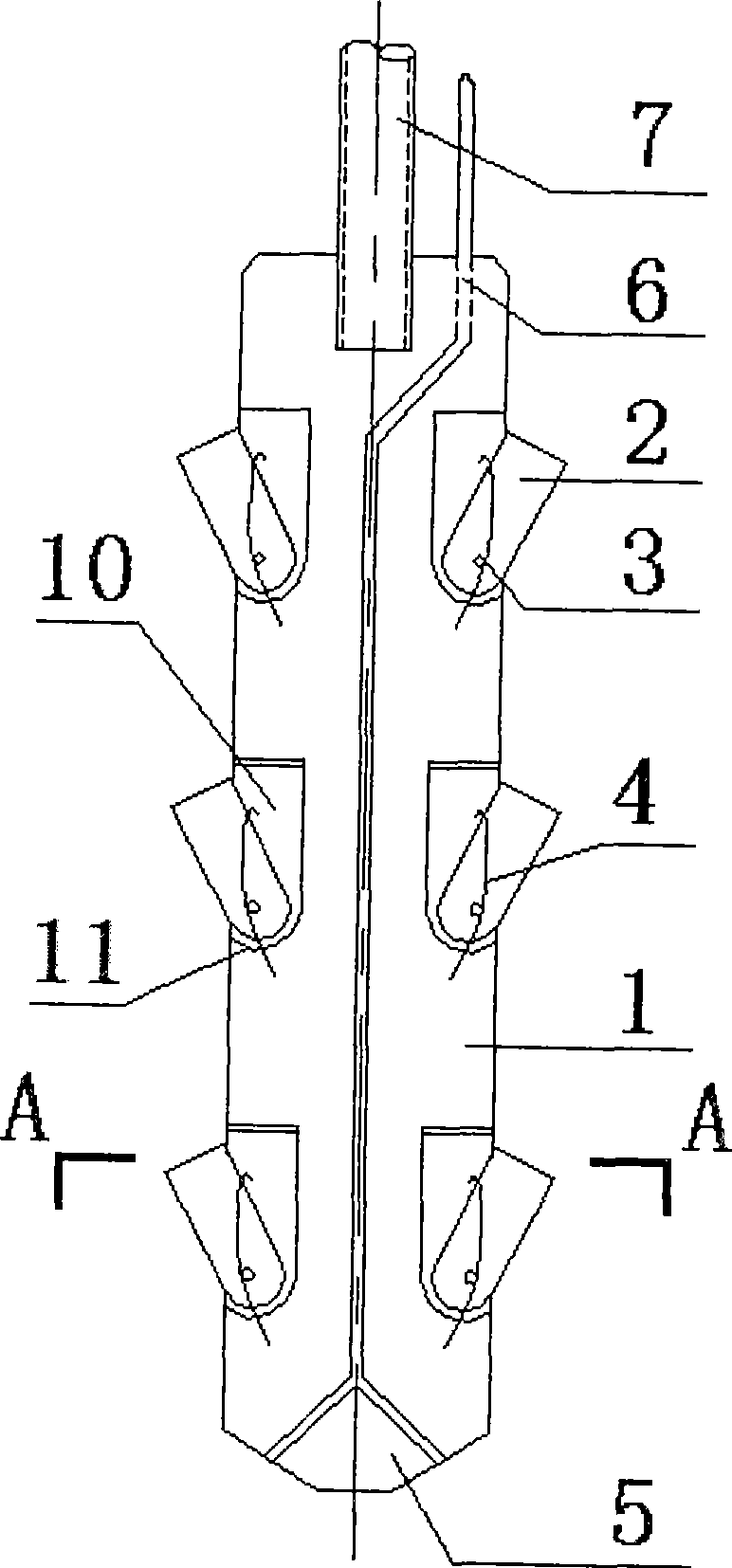

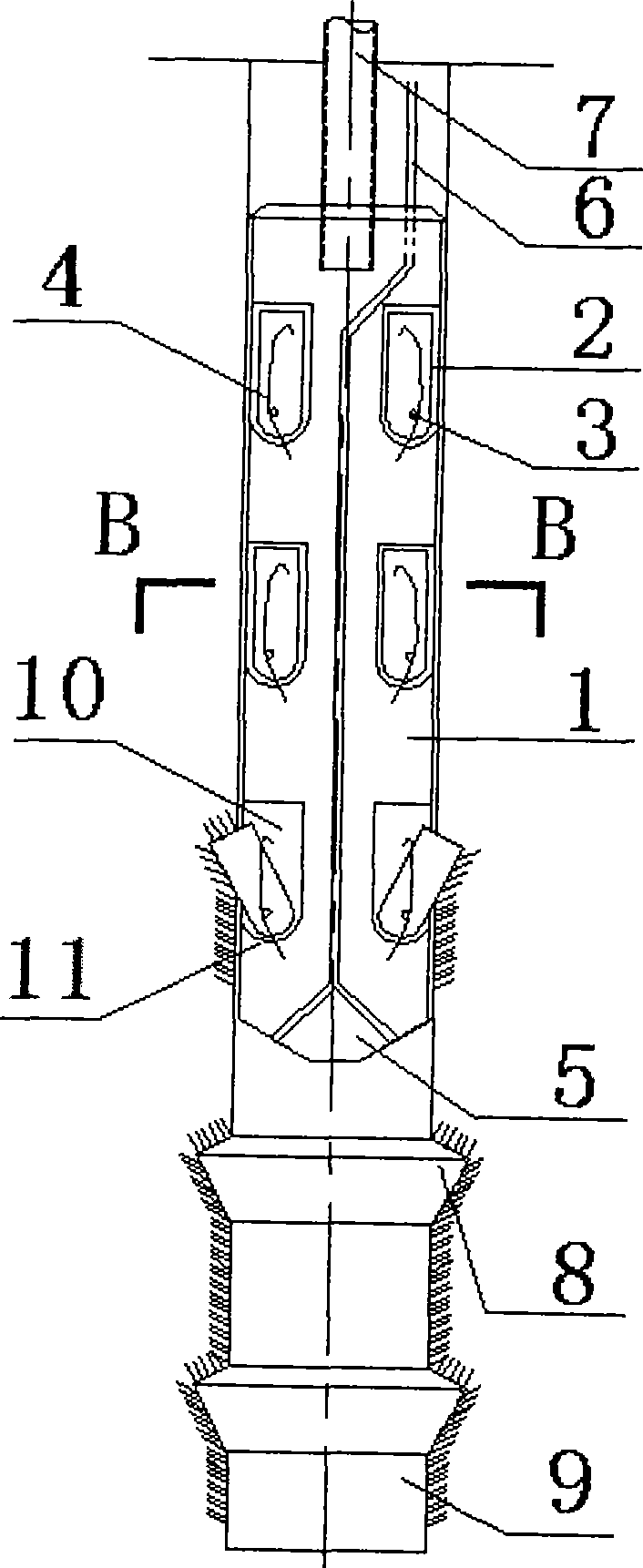

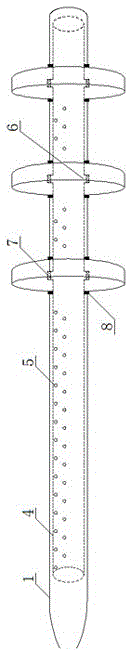

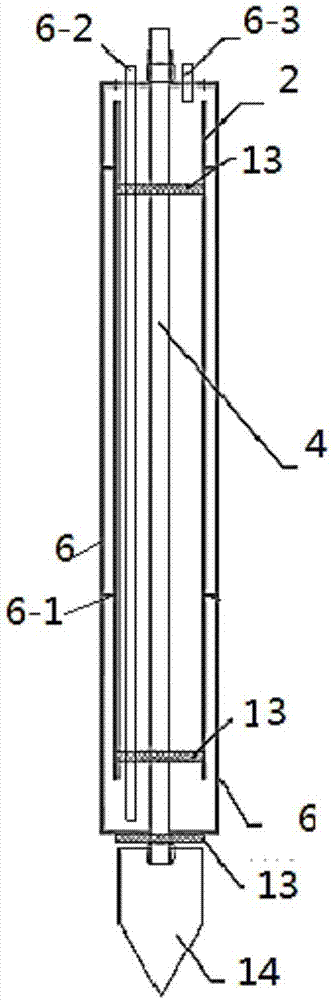

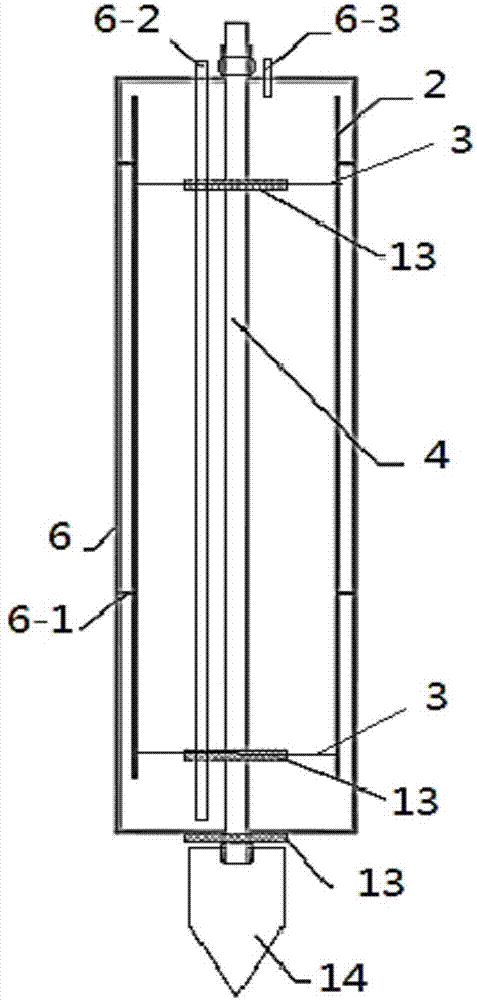

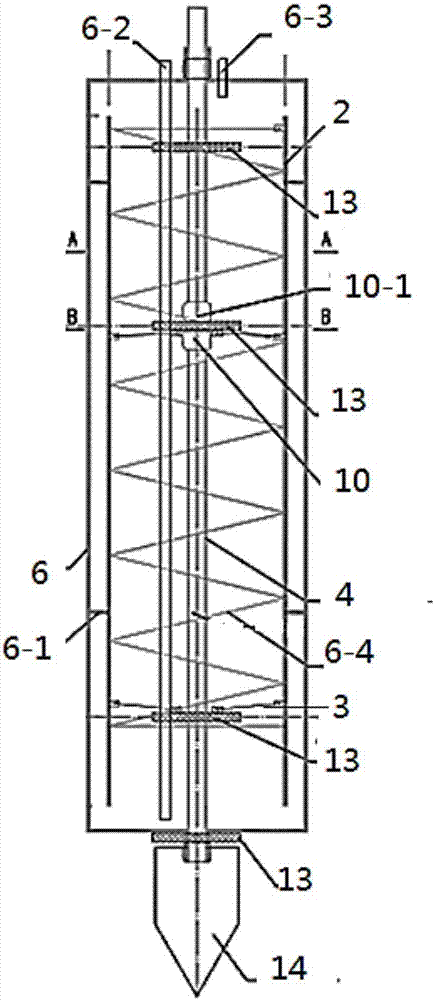

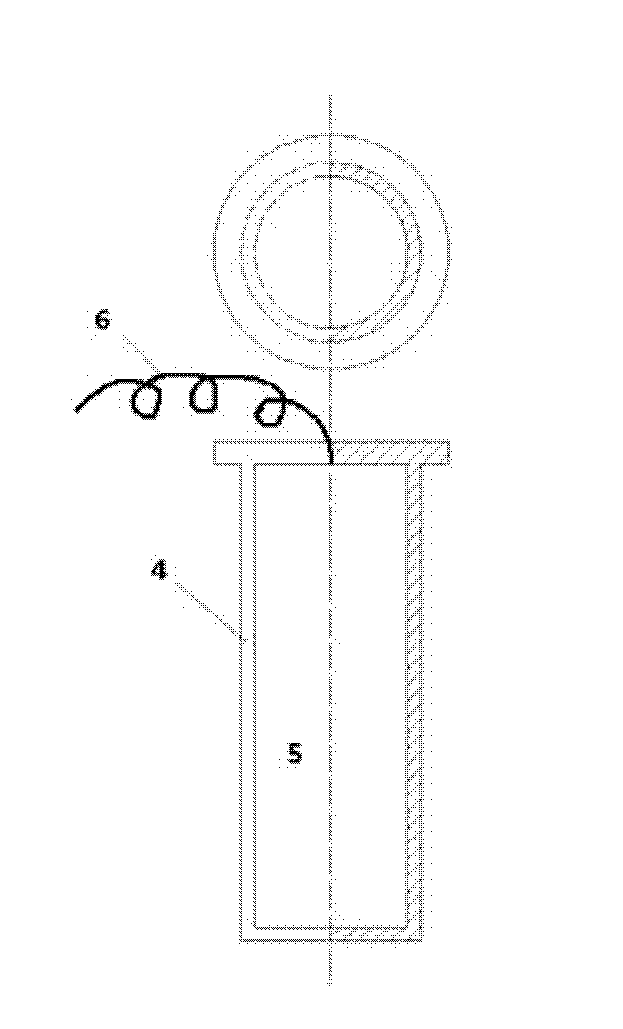

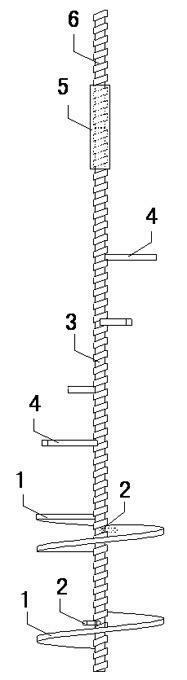

Multi-level back-grasp-type hollow anchor rod and construction method thereof

InactiveCN103572757AIncrease contact areaOutflow smoothlyBulkheads/pilesAnchoring boltsRock boltCement mortar

The invention discloses a multi-level back-grasp-type hollow anchor rod. The multi-level back-grasp-type hollow anchor rod comprises an anchoring rod with a grouting passage inside, an anchor head is fixed at the lower end of the anchoring rod, a plurality of back-grasp buckles are fixed on the anchoring rod, a grout outlet is formed in the anchor head, and the parts, at the upper side of the back-grasp buckles, of the anchoring rod and the parts, at the lower side of the back-grasp buckles, of the anchoring rod are provided with grout outlets and air return holes respectively, and the grout outlets and the air return holes are communicated with the grouting passage. Compared with the construction method of a hard rock body and a soil body, the construction method of the multi-level back-grasp-type hollow anchor rod comprises the steps of (a) preparation of equipment, (b) measurement and distribution of holes, (c) drilling, (d) hole cleaning and detection, (e) inserting of the anchor rod, (f) installation of a grout stop plug, (g) screwing of nuts and (h) grouting, and the anchor rod is directly inserted through the anchor head according to the construction method of a soft soil body, sand and water. The multi-level back-grasp-type hollow anchor rod and the construction method of the multi-level back-grasp-type hollow anchor rod increase the contact area and anchoring force between the anchor rod and the hole wall and prevent the anchor rod from falling out and injuring people. A uniform cement mortar layer can be formed around the anchor rod through the grout outlets and the air return holes, the damage of corrosion is avoided, and the purpose of long-time supporting is achieved.

Owner:SHANDONG JIAOTONG UNIV

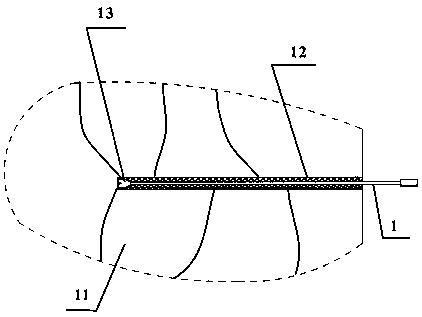

Vacuum drainage anchor rod and construction method thereof

ActiveCN109629566AIncrease anchoring forceGood governanceExcavationsBulkheads/pilesSleeve valveSlurry

The invention provides a vacuum drainage anchor rod and a construction method thereof. The anchor rod is composed of an anchoring system and a vacuum drainage system; a thread is arranged at the frontend of each hollow anchor pipe, the middle rear part of each hollow anchor pipe is connected with a slurry outlet pipe, water permeable holes are formed in each hollow anchor pipe which is wrapped bya filter screen, a rubber sleeve valve and a geotextile bag sleeve an opening of each slurry outlet pipe, and each geotextile bag is clamped in the corresponding hollow anchor pipe through a hoop; the hollow anchor pipes are obliquely arranged in a slope, pressure grouting is conducted on the interior and the periphery of the front end of each hollow anchor pipe, and the hollow anchor pipes are anchored on backing plates through anchorage devices; a controller and a vacuum pump are installed outside the slope; moisture meters are embedded in the slope and connected with the controller; waterabsorbing pipes penetrate through sealing covers and are inserted into the hollow anchor pipes, connected with a drain pipe through sealing joints and connected with the vacuum pump; the controller and the vacuum pump are switched on, pumping starts to be conducted, a negative pressure zone is formed in each hollow anchor pipe, and the water in the slope enters a water suction pipe and then is discharged out of the slope. Accordingly, the structure is simple, anchorage and drainage can be achieved simultaneously, a good effect is achieved, construction is easy, and the manufacturing cost is low.

Owner:NINGXIA UNIVERSITY

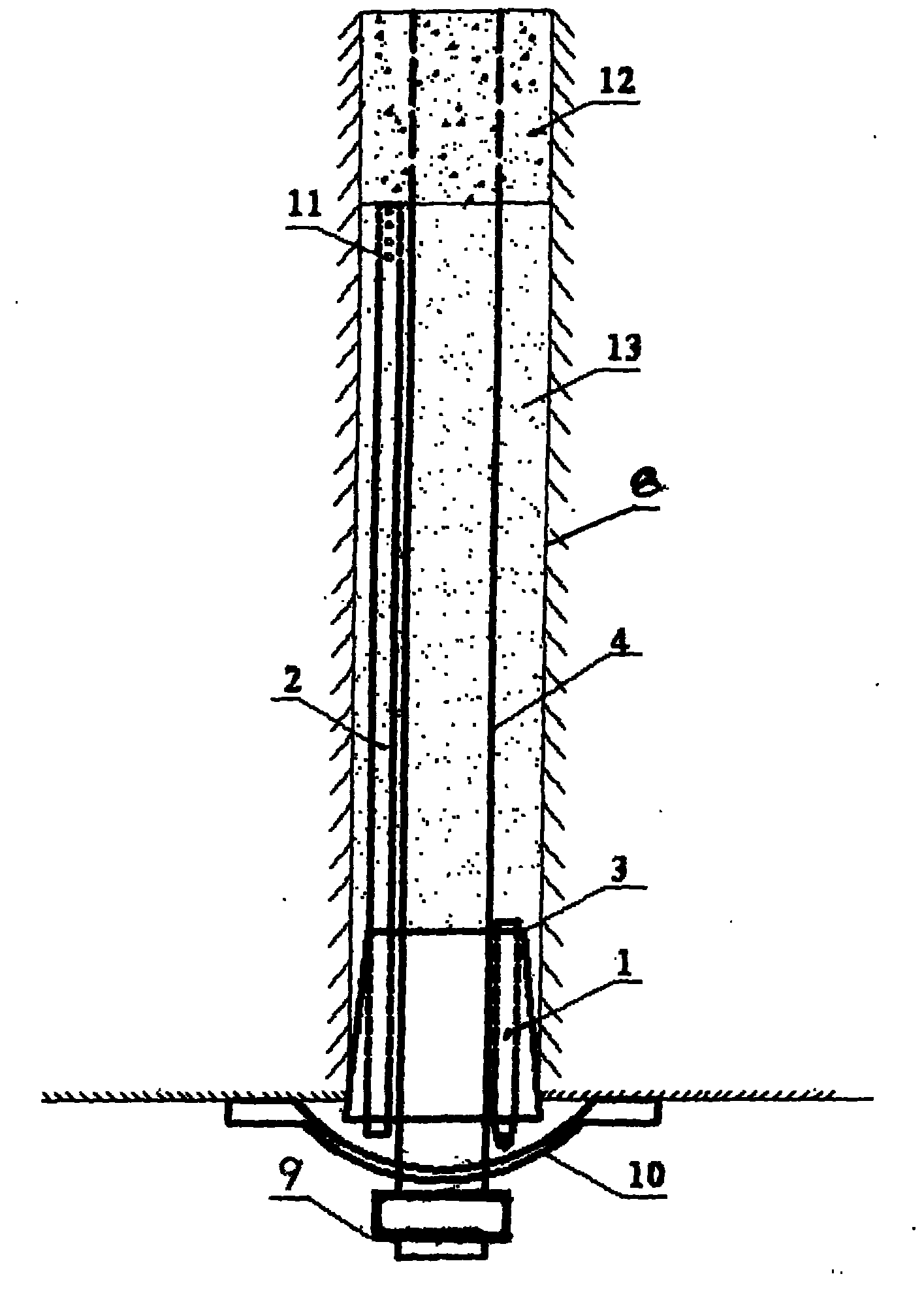

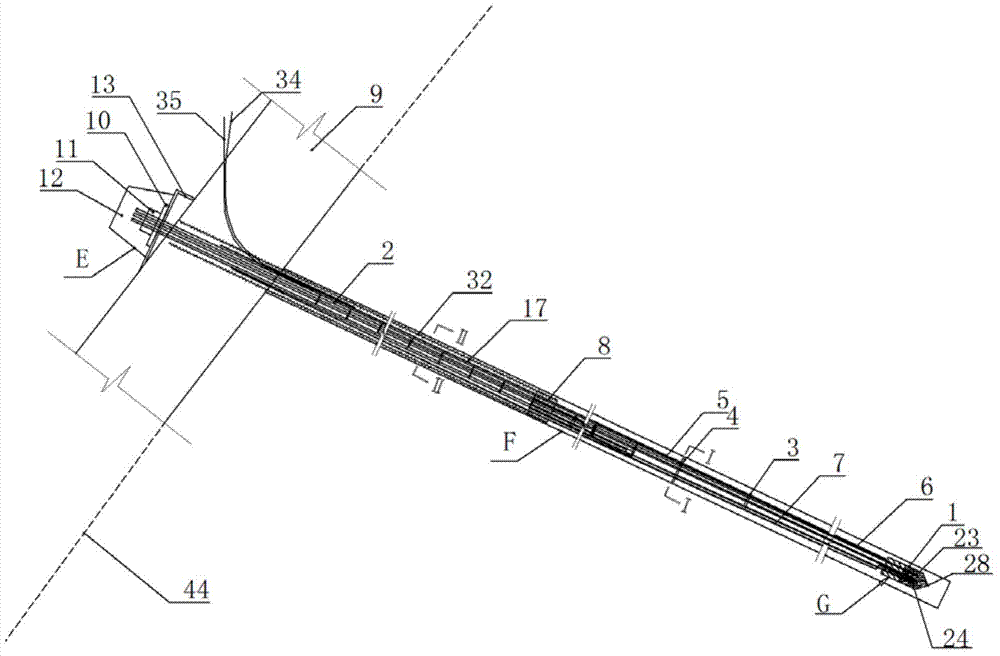

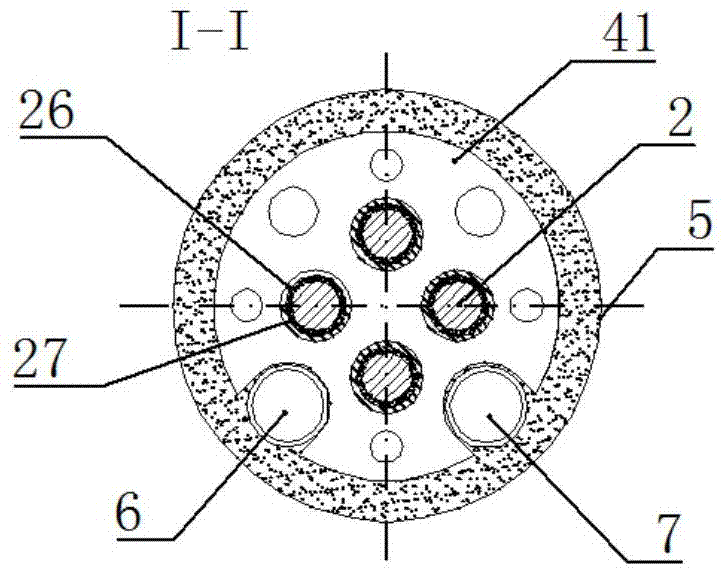

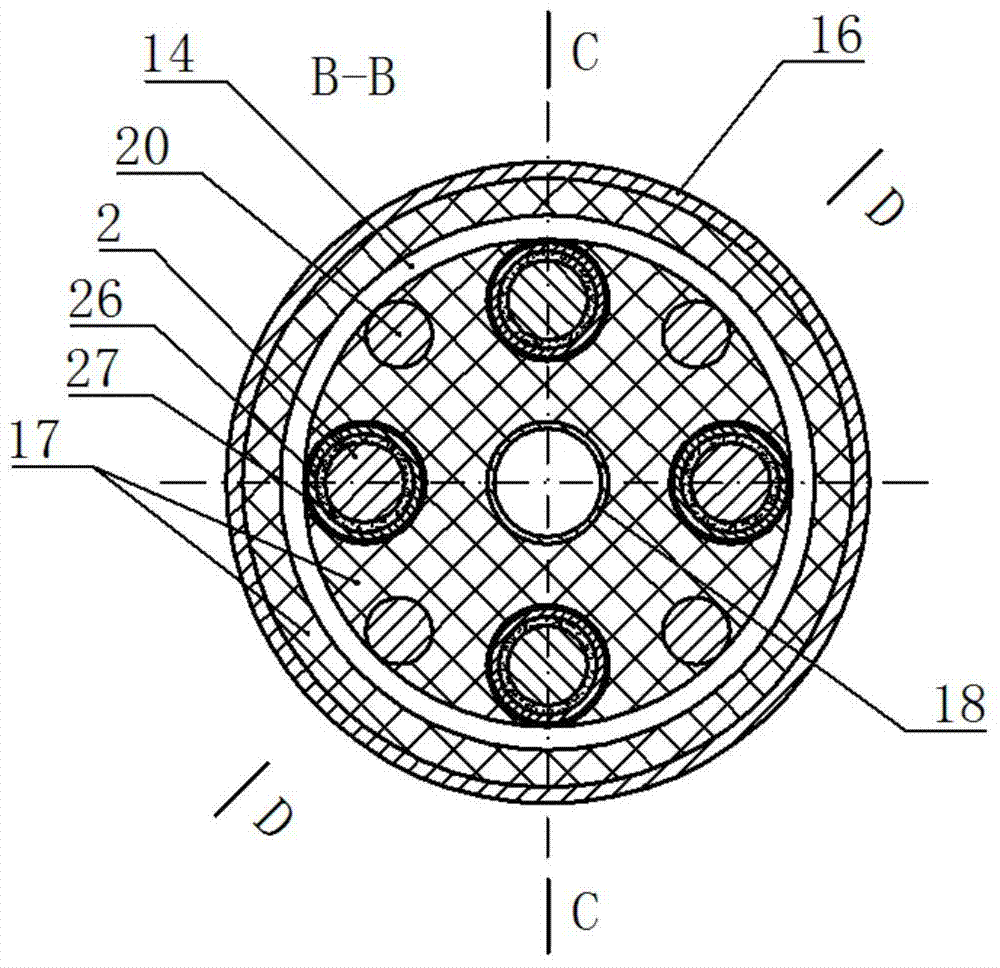

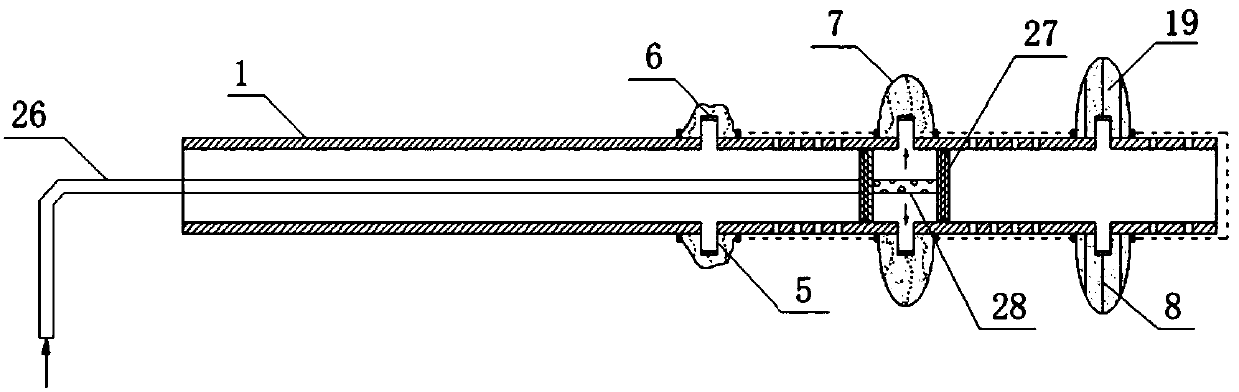

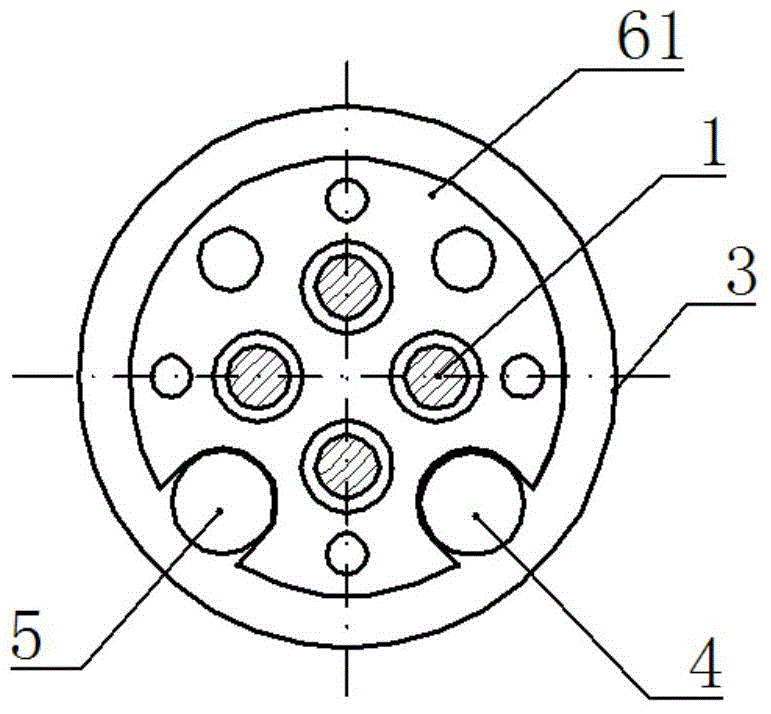

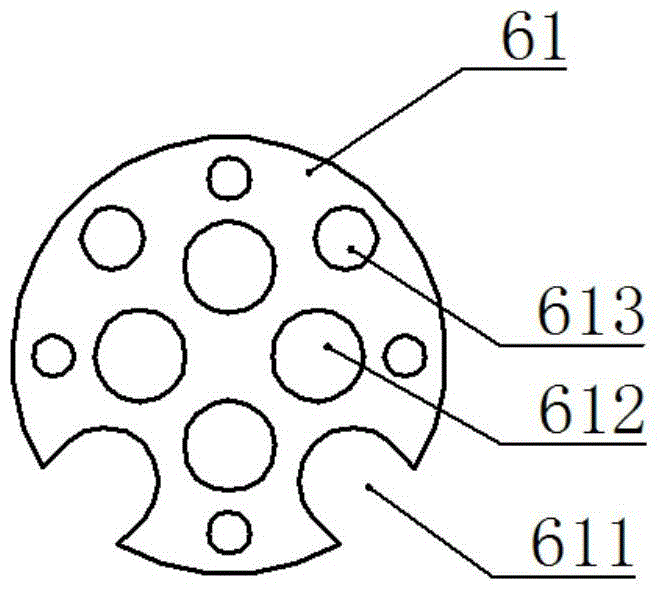

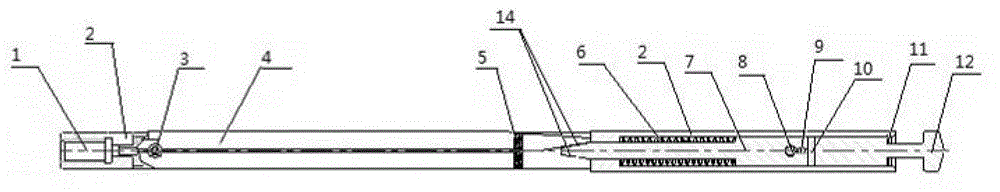

Self-propelled hollow slip casting anchor rod with stress-measuring function and operating method

InactiveCN107905827ASimplify the construction processImprove construction efficiencyAnchoring boltsStress measuresStress conditions

The invention relates to the technical field of tunnel and underground construction anchoring equipment, in particular to a self-propelled hollow slip casting anchor rod with a stress-measuring function and an operating method. The self-propelled hollow slip casting anchor rod with the stress-measuring function includes a rod body with a hollow structure, a self-propelled drill is connected at thefront end of the rod body, and the back end of the rod body is provided with a slip casting opening which communicates with an inner cavity of the rod body; and the rod body is further provided witha stress-measuring device and an anchoring structure which is close to the self-propelled drill. According to the self-propelled hollow slip casting anchor rod with the stress-measuring function, thestress-measuring device is arranged to combine the processes of drilling, anchoring and slip casting into the same construction process, and the anchoring can be achieved in short time; and stress conditions of all sections of the anchoring rod in the supporting process can be monitored, so that the supporting mechanism of action and the stress conditions of the anchoring rod under the various kinds of surrounding rock conditions can be known, and critical evidences and references are supplied to the research of design parameters for the anchoring rod, improvement of the construction techniqueand the surrounding rock failure mechanism.

Owner:SOUTHWEST PETROLEUM UNIV

Recoverable anchor rod for drilling, anchoring and grouting and supporting method thereof

The invention relates to a recoverable anchor rod for drilling, anchoring and grouting and a supporting method thereof. The anchor rod comprises a hollow grouting rod body, a nut, a gasket, a tray and a hollow threaded rod body. A drill bit is arranged at the front end of the hollow threaded rod body, and the hollow threaded rod body is provided with multi-purpose holes; the hollow grouting rod body advances inwards through threads, metal nails welded to the internal surface of the front end of the hollow grouting rod body pierce an anchoring agent package inside the hollow threaded rod body, and then, an anchoring agent is mixed and is then discharged through the holes, so as to play an anchoring role; the hollow grouting rod body is used for grouting, and slurry is exported through the multi-purpose holes, so as to cement and solidify loose coal rock bodies; and the hollow threaded rod body is snapped with the wall of a drilled hole through threads on the external surface of the hollow threaded rod body, so as to strengthen an anchoring role in end parts. The one-time drilling, anchoring and grouting supporting of loose coal rocks is realized through tightening and tensioning the tail of the hollow anchor rod, so that the difficult problem that the anchor rod dose not easily enter the loose coal and rocks caused by the fact that the loose coal rocks are subjected to hole collapsing after the loose coal and rocks are subjected to drilling is solved, the load capacity of a coal body is increased, and the supporting strength for surrounding rock of a roadway is enhanced. The recoverable anchor rod for drilling, anchoring and grouting and the supporting method thereof have the advantages of simple structure, low cost, little waste, easiness in construction, and good supporting effect.

Owner:CHINA UNIV OF MINING & TECH

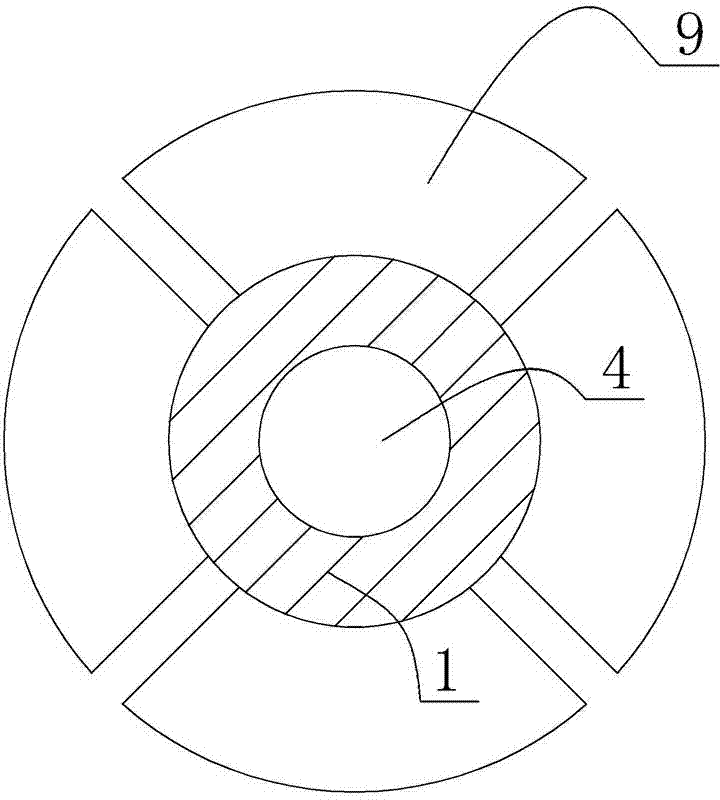

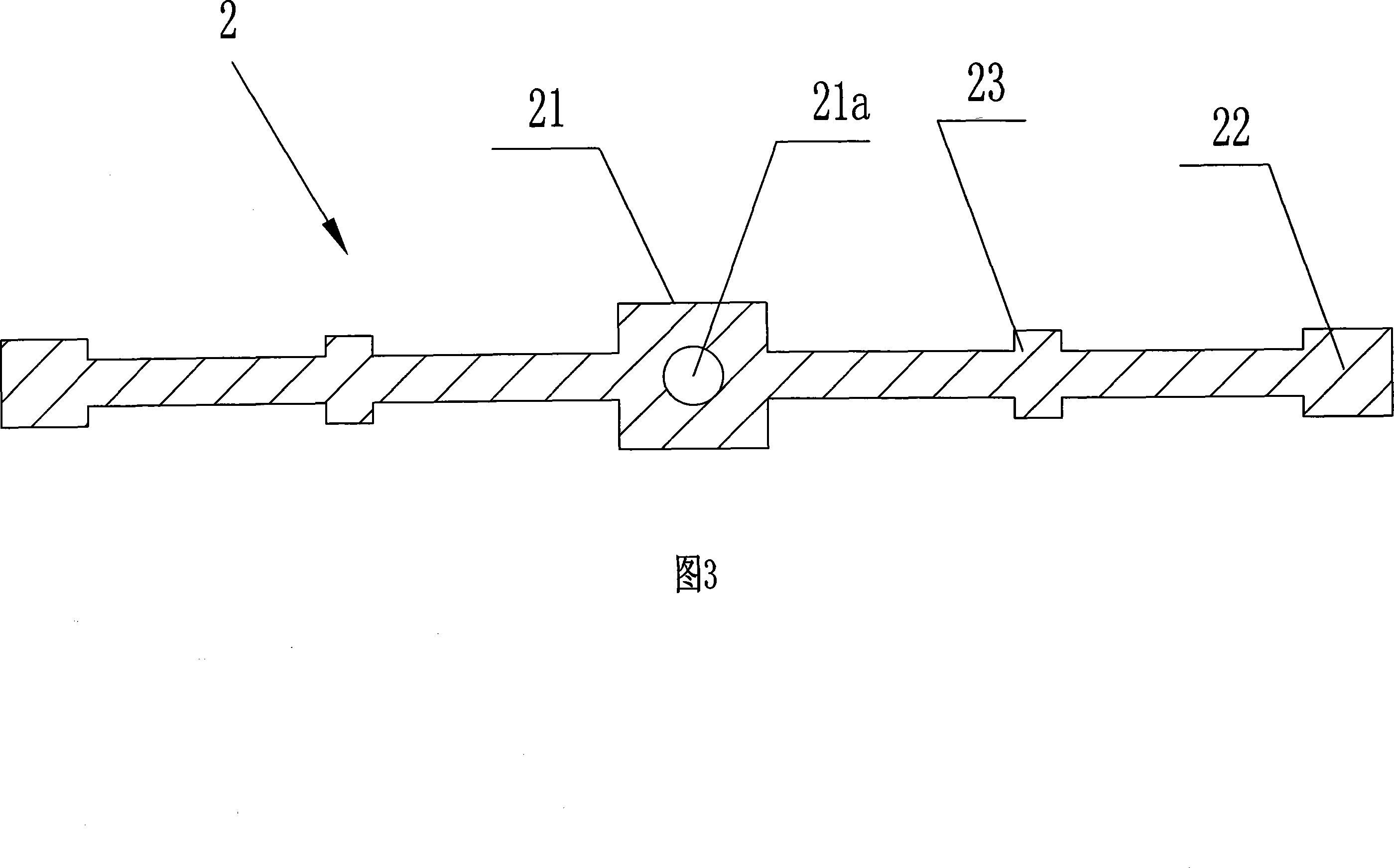

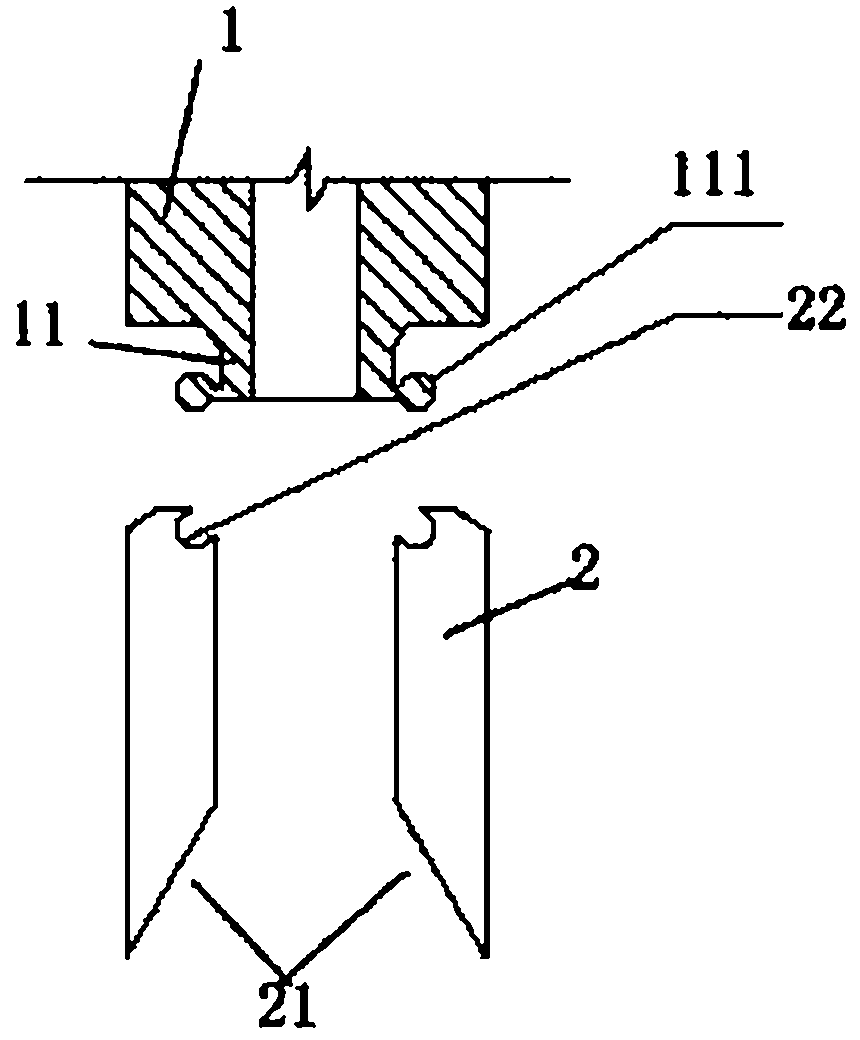

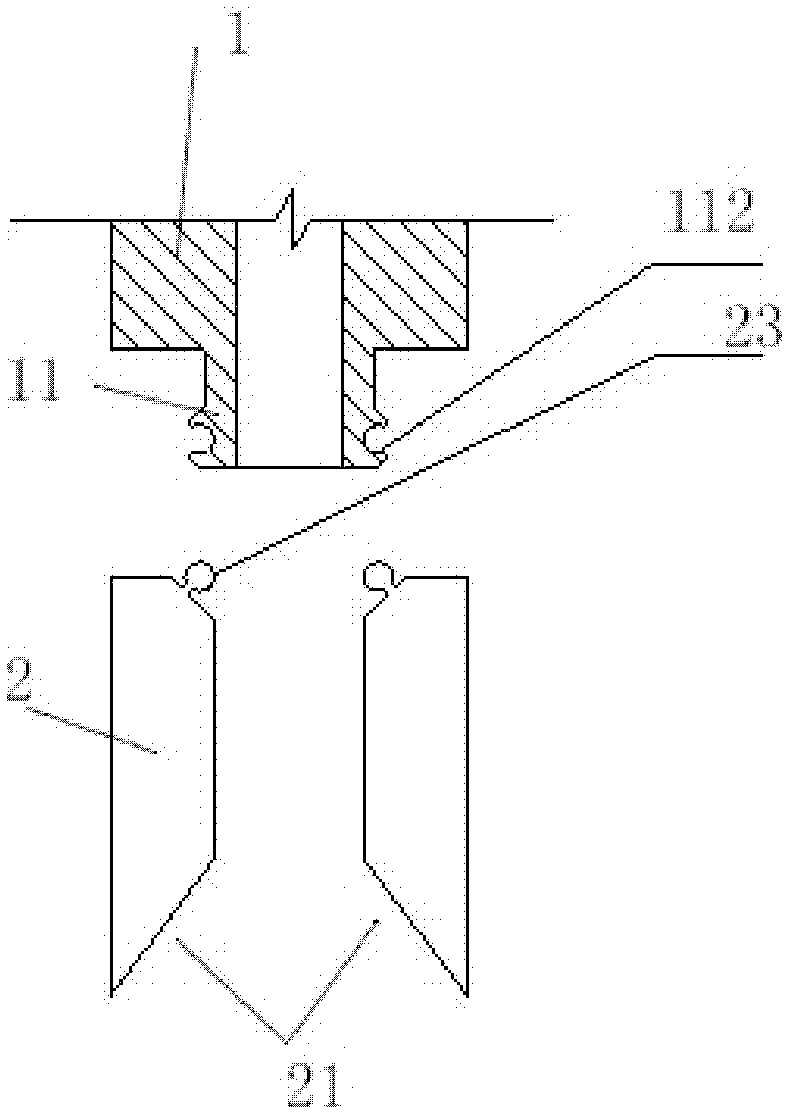

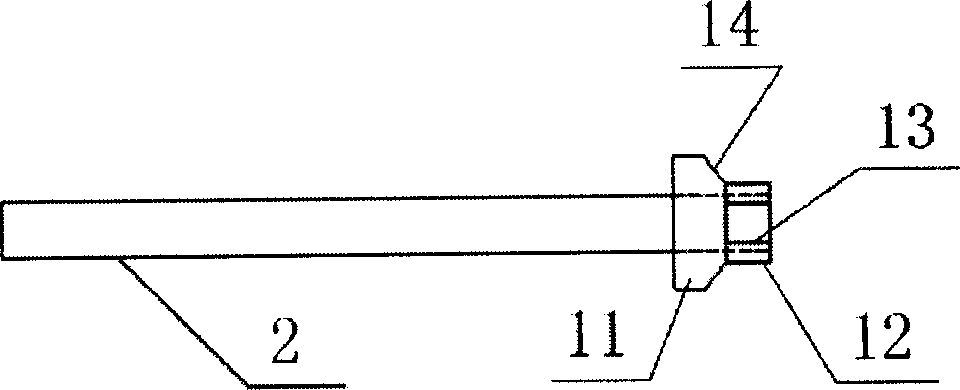

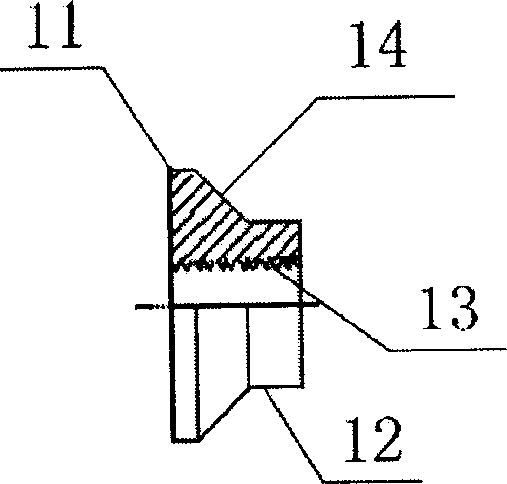

Block-wedge-type self-locking inner anchor head

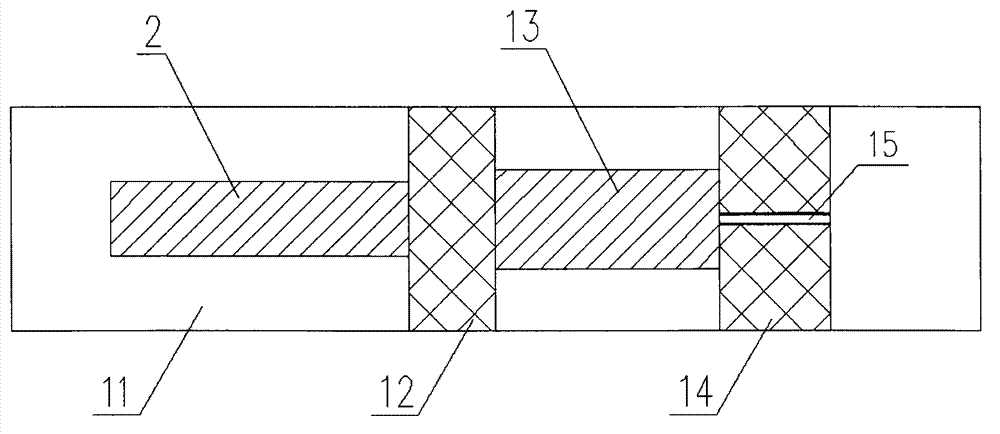

InactiveCN101509253AImprove antioxidant capacityImprove corrosion resistanceBulkheads/pilesPre stressEngineering

A jam-wedge type self-locking inner anchor head belongs to the technical field of rock or concrete anchoring, which is characterized in that: a body (1) is provided with a wedge groove (10) corresponding to an endocone segment (8) in an anchor eye (9); in the wedge groove (10), a pin roll (3) is hinged with one end of a wedge block (2) and the other end of the wedge block (2) faces the orifice of the anchor eye (9) radially extends through an extending mechanism (4). The jam-wedge type self-locking inner anchor head with wide application has the advantages of satisfying the design requirements that anchorage force is allotted to multilayer anchor heads as design requires; the anchor head can be applied to both frontal and inverted conical-surface hole slashes of the anchor eye endocone segment, the anchor head can be linked with various anchor material, such as an anchor rod or an anchor rope, the reliability and durability of anchoring are greatly enhanced, big technical difficult problems in inherent stress anchoring project are solved and the anchor head is particularly applicable to inherent stress anchoring of important projects.

Owner:WUDA JUCHENG STRUCTURE CO LTD

Non-sprayed-concrete anchor net supporting method of underground construction broken surrounding rocks

InactiveCN103277114AResist usage requirementsMeet the use requirementsUnderground chambersTunnel liningHigh intensityUltimate tensile strength

The invention discloses a non-sprayed-concrete anchor net supporting method of underground construction broken surrounding rocks. According to the method, eight anchor rod drill holes are formed in a roadway or a tunnel, and each row of holes are basically required to be located on the same cross section; a galvanized high-strength steel wire net prepared in advance is attached to the rock surface to be paved, so that a whole roadway or tunnel non-sprayed-concrete anchor net is supported to form a whole; tube seam type anchor rods are pressed into the anchor rod drill holes by an anchor rod mounting machine sequentially from one side of the roadway or the tunnel to the vault and the other side of the roadway or the tunnel. The method is low in cost, good in supporting effect, timely in supporting and low in labor intensity.

Owner:SOUTHWEAT UNIV OF SCI & TECH

Large depth underground continuous wall water-stop joint device

ActiveCN101168963AAvoid generatingSave the process of brushing the wallArtificial islandsUnderwater structuresSlurry wallArchitectural engineering

The invention relates to a water sealing joint device of a large-depth underground continuous wall. The water sealing joint device consists of a water sealing connector plate and a rubber water stop; the water sealing connector plate comprises connector side plates connected in sequence, two arc shape plates, an H-shaped groove plate, an upper end plate and a lower end plate; the two arc shape plates are oppositely arranged in the middle at intervals along the width of a connector side plate, and the H-shaped groove plate is arranged in the middle between the two arc shape plates; the H-shaped groove plate has two opening ends, one end is fixed and connected with the two arc shape plates, and the other end is fixed and connected with the connector side plate; and the upper end plate and the lower end plate are arranged at the end parts of the two arc shape plates and the H-shaped groove plate. An opening slot is arranged at the middle part of the upper end plate and the lower end plate, and the rubber water stop is embedded in a gap between the opening slot and the opening end of the H-shaped groove plate. The connector side plate adopts a long strip shape thick steel plate, the upper end plate and the lower end plate adopt semi-circular steel plates, and the composite cross section of the two arc shape plates is matched with the shape of the upper end plate and the lower end plate. The depth of the opening slot of the upper end plate and the lower end plate is approximately identical to half of the width of the rubber water stop. The invention can improve the prior construction process, reduce the construction cost, and effectively improve the water sealing performance of the structure of the underground continuous wall.

Owner:SHANGHAI URBAN CONSTRUCTION MUNICIPAL ENGINEERING (GROUP) CO LTD

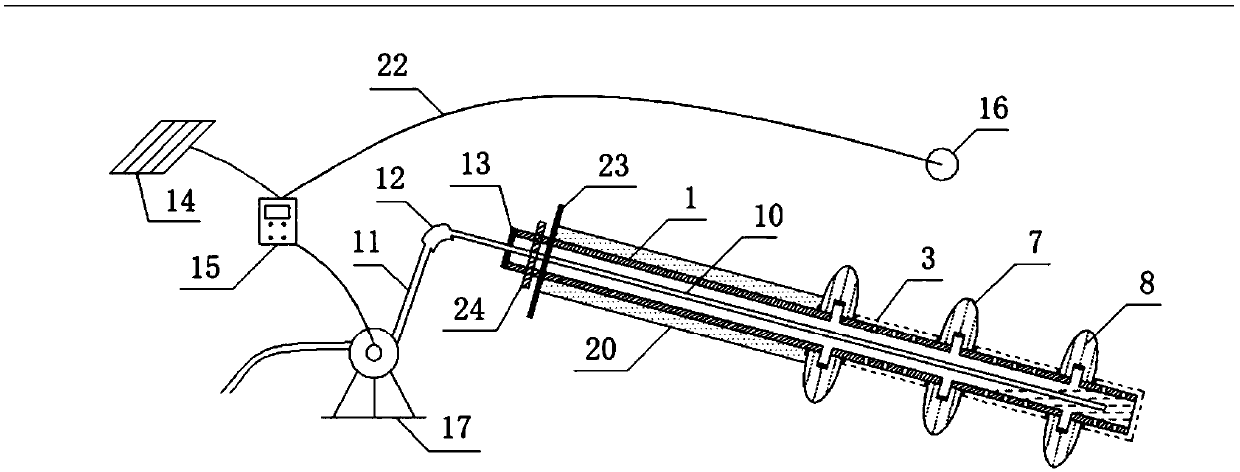

Side slope self-drainage electroosmosis anchor rod and construction method thereof

ActiveCN104878760AAvoid instabilityImprove bearing capacityBulkheads/pilesSoil preservationSiphonWater discharge

The invention discloses a side slope self-drainage electroosmosis anchor rod and a construction method thereof, and belongs to the technical field of rock-soil anchoring. The self-drainage electroosmosis anchor rod comprises two electric geotechnical bags, anchors, base plates and a siphon. Hollow tubes are sleeved with the electric geotechnical bags to extend to the bottoms, sleeve valves are fastened to reserved holes in the electric geotechnical bags, and the electric geotechnical bags are strapped to the hollow tubes externally through plastic clamps on the left sides and the right sides of bags. Slurry is solidified and anchored in a stable side slope, and the front sections of the electric geotechnical bags are anchored on the base plates by the anchors. A moisture inductive control switch is buried in soil of the slope surface, a solar battery is disposed outside the slope, and a positive pole, the moisture inductive control switch, the solar battery and a negative pole are sequentially connected in series through wires. A water suction tube is inserted into the hollow tube of the negative pole and is connected with a balance water discharge device on the slope surface through a connection elbow and a water discharge tube. A water inlet of the water suction tube is the same as a water outlet of the balance water discharge device in elevation. The side slope self-drainage electroosmosis anchor is ingenious in structure, has functions of anchoring, water discharging and solidification acceleration and is high in automation degree, and the construction method is simple and convenient.

Owner:LANZHOU UNIVERSITY OF TECHNOLOGY

Bag expansion diameter-variable steel reinforcement cage and anchor rod or pile foundation

The invention discloses a bag expansion diameter-variable steel reinforcement cage. The bag expansion diameter-variable steel reinforcement cage comprises an axial rod, a circular ring or an annular plate, several longitudinal ribs, several rib strips and a ring-shaped fixator, the circular ring or the annular plate is perpendicular to the axial rod, one end of each longitudinal rib is uniformly fixed to the circular ring or the annular plate, the other end or the middle of each longitudinal rib is connected to one end of a corresponding rib strip, several longitudinal ribs surround the axialrod, the other end of each rib strip is connected to the ring-shaped fixator, and the ring-shaped fixator is fixed to or slides on the axial rod or a pile foundation rod; an outer bag covers the bottoms of the several longitudinal ribs, at least the bottom of the bag is sealed, and the bag with an expanded pile bottom end covers several longitudinal ribs; at least one slurry injecting opening anda slurry outlet with a one-way valve are formed in the bag.

Owner:JIANGSU GREEN RIVER ENVIRONMENTAL TECH CO LTD

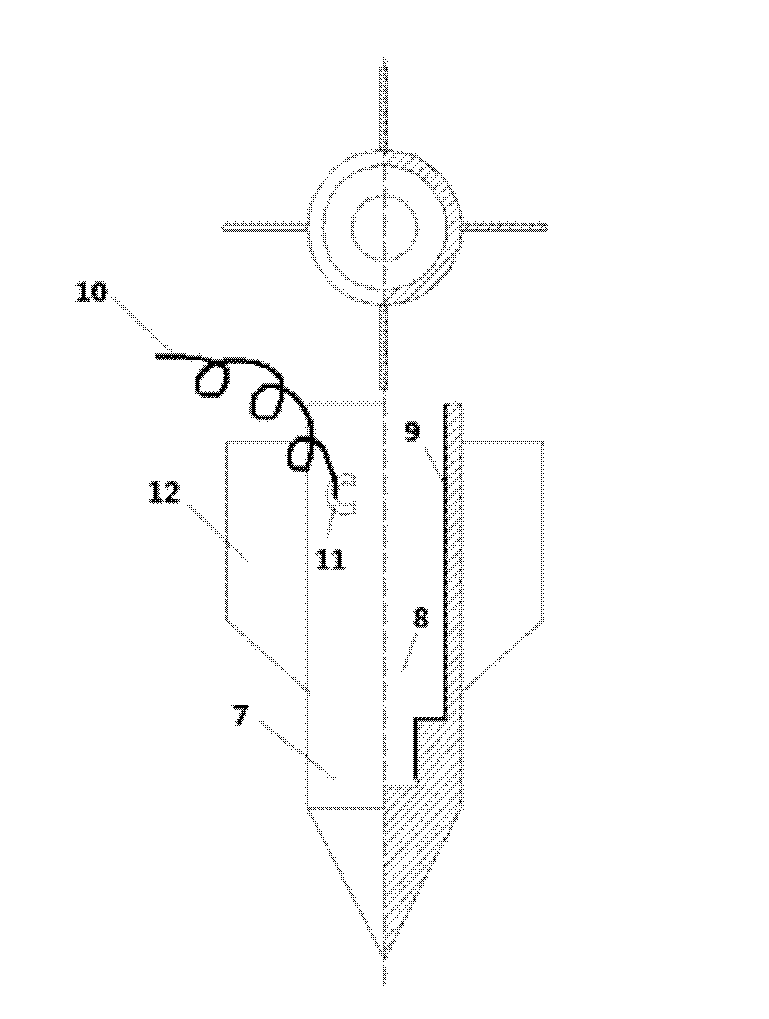

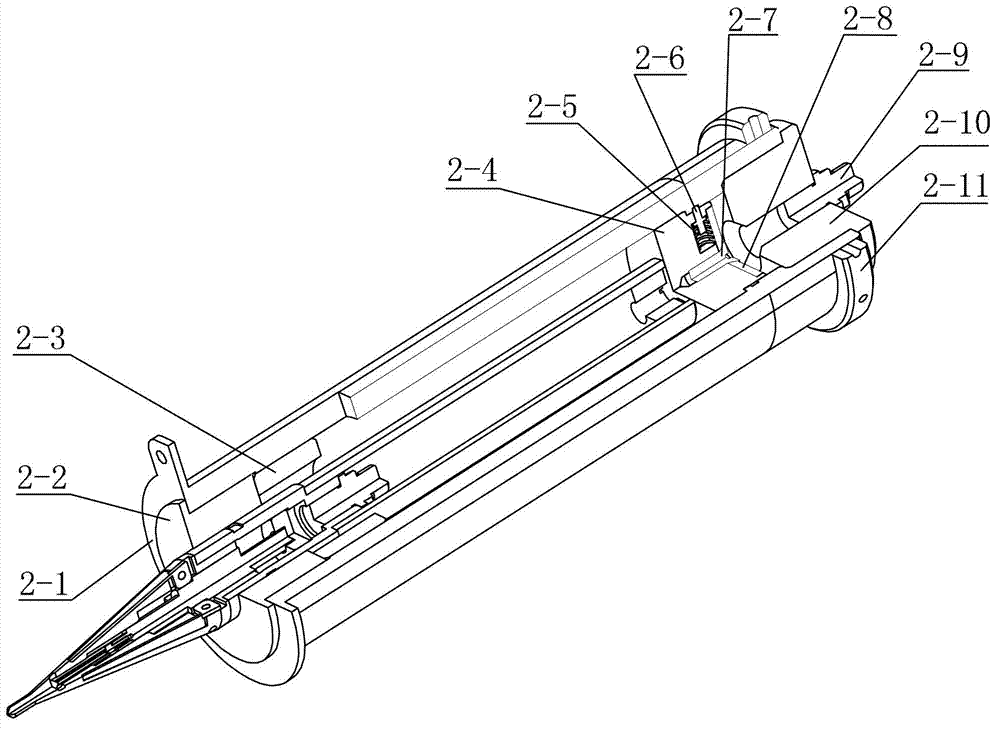

Completely recyclable end support ground anchor

ActiveCN102587368ASmall distance between anchor flukesIncrease anchoring forceBulkheads/pilesFlangeEarth anchor

The invention discloses a completely recyclable end support ground anchor, which comprises an anchor rod, an anchor rod sleeve and anchor flukes. The anchor rod is a straight rod with the lower end provided with disc-shaped flanges; the tubular anchor rod sleeve is sheathed on the lower part of the anchor rod; circular flanges are arranged on the bottom surface of the anchor rod sleeve; and upper ends of a plurality of anchor flukes are hinged on the outer edges at the lower ends of the circular flanges arranged on the bottom surface of the anchor rod sleeve. According to the invention, the end support ground anchor can be put into use immediately after being assembled and has a plurality of anchor flukes and large anchoring force, the assembly and the disassembly is fast and convenient, and the complete recycling of the ground anchor is not influenced even if collapse happens to the bottom of an anchor hole.

Owner:覃永忠

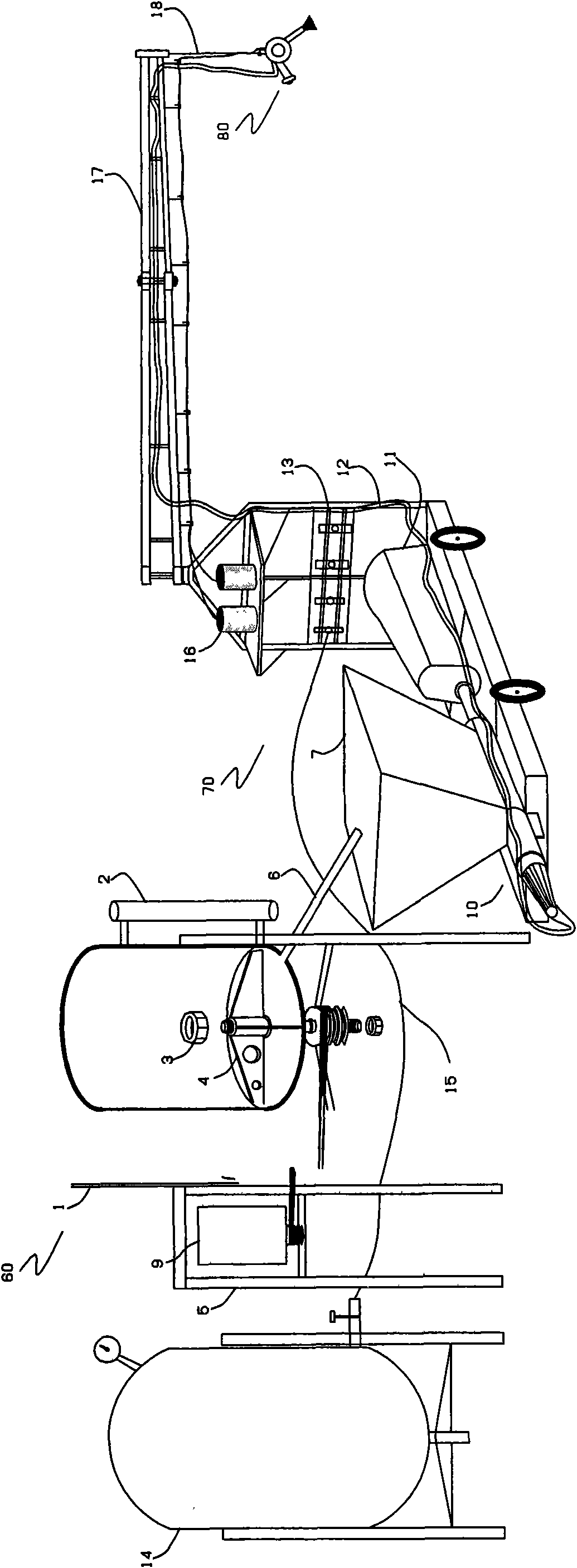

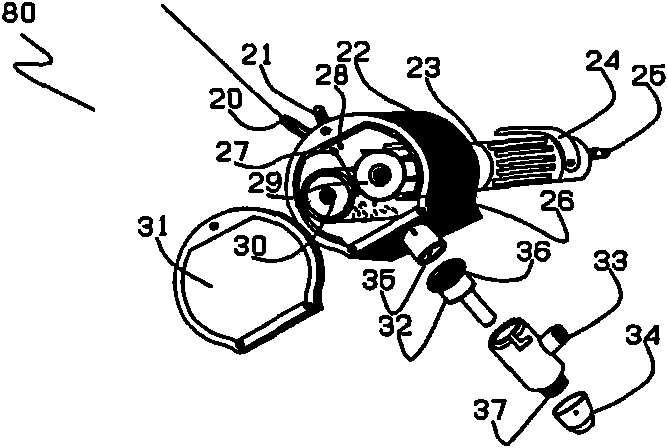

Separable self-drilling embedment anchor

A separable self-drilling embedment anchor belongs to the technical field of water conservancy and ship ocean engineering, and comprises an anchor body with an internal hollow cavity, a propeller and a separating component, wherein the propeller is used for providing power to lead the anchor body to be automatically drilled into and embedded into the soil, and the separating component arranged on the propeller is used for connection and disconnection of the propeller with the anchor body. Connection and disconnection of the anchor body with the propeller are completed by the separating component. The anchor body can be embedded into the soil under the action of exciting force of the propeller and gravity, and when the anchor body is embedded with a certain depth, a catapult is started to generate jet impact to push the propeller out of the anchor body, the anchor body is embedded into a deeper position of a bed material, peripheral liquefied bed materials backfill the hollow cavity of the anchor body to enhance the anchoring force, and embedment of the anchor body and recovery of the propeller are finally completed. Therefore, the embedment depth and the anchoring force of the dynamic anchor are increased, operating efficiency is improved, and technological implementation is simple. The separable self-drilling embedment anchor is low in construction cost as the propeller can be recovered and reused, and is low in manufacture cost as the hollow cavity designed in the anchor body can be used for backfilling the bed materials.

Owner:SHANGHAI JIAO TONG UNIV

Glass fiber reinforced gypsum product, and preparation method and equipment thereof

The invention relates to a glass fiber reinforced gypsum product, which comprises the ingredients including gypsum powder, glass fiber, water reducing agents, retarding agents and water, wherein the glass fiber is short glass fiber with the length ranged form 1 to 3cm, and is uniformly distributed in the gypsum product. Because the glass fiber reinforced gypsum product of the invention adopts 1 to 3 cm of glass fiber uniformly and disorderly distributed in the gypsum product, the intensity and the toughness of each part of the gypsum product are enhanced, and the delamination structure is avoided. The invention also provides a method for preparing the glass fiber reinforced gypsum product, and special equipment for implementing the method.

Owner:秦永超

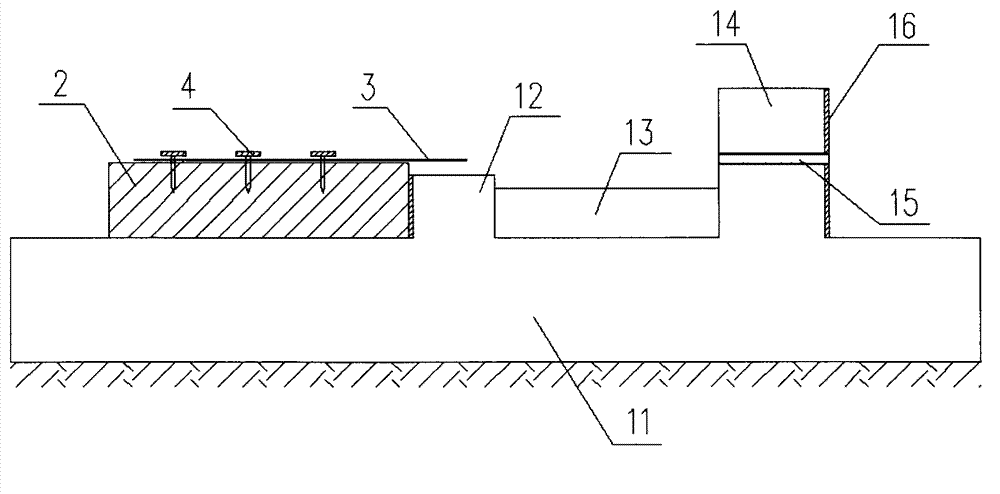

Double-anchoring-section prestress anchor cable structure and constructing method thereof

ActiveCN104790393AThe reverse self-locking function generatesReasonable structureBulkheads/pilesEngineeringGrout

The invention discloses a double-anchoring-section prestress anchor cable structure and a constructing method thereof. The double-anchoring-section prestress anchor cable structure comprises an inner anchoring section, a free section, an outer anchoring section and an anchor head part, wherein a steel strand penetrates through the inner anchoring section, the free section, the outer anchoring section and the anchor head part. The portion, located on the inner anchoring section, of the steel strand is attached to one section of the bottom of a drilled hole through a grouting body. The free section is arranged at the upper portion of the inner anchoring section. The anchor head part is arranged outside a drilled hole opening and fixed to the top end of the steel strand. The outer anchoring section is arranged between the upper end of the free section and the drilled hole opening. Grouting is conducted through three steps, the first step of grouting is ended in the middle of the free section B, the inner anchoring section is formed through fracturing grouting in the second step of grouting, and the third step of grouting is conducted on the outer anchoring section C after a grout body of the inner anchoring section reaches the age and the steel strand is stretched. Except that the portion, located on the free section, of the steel stand is free, the portions, located on the inner anchoring section and the outer anchoring section, of the steel strand are both attached to the grout body to form a double-anchoring-section anchor cable with the inner anchoring section and the outer anchoring section. The double-anchoring-section prestress anchor cable structure has the advantages of being advanced in technology, economical, reasonable, rapid in construction and the like, and is a novel slope strengthening technology with prospects.

Owner:铁科检测有限公司

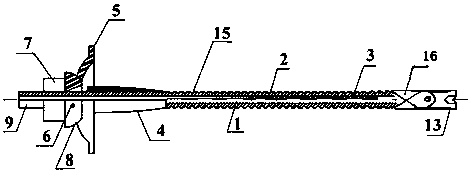

Progressive yielding combined-type extensible anchor rod and construction method thereof

ActiveCN102536278AGive full play to self-supporting abilityProtection from destructionAnchoring boltsSteel barPallet

The invention discloses a progressive yielding combined-type extensible anchor rod and a construction method thereof. The extensible anchor rod comprises a pipe seam-type anchor rod and a resin anchor rod made of a deformed steel bar, which are mounted in anchoring holes; the resin anchor rod is longer than the pipe seam-type anchor rod, and penetrates the rod body of the pipe seam-type anchor rod; a progressive yielding piece, which is a steel spherical housing, is arranged between a pallet and a nut of the resin anchor rod; the section of the steel spherical housing takes the shape of a cavel; and a through hole, through which the rod body of the resin anchor rod penetrates, is formed on the bottom surface of the steel spherical housing. The progressive yielding combined-type extensible anchor rod can serve as not only a temporary support, but also a permanent support, so as to solve problems in supporting deep, soft and crushed surrounding rock laneway.

Owner:滕州市产品质量监督检验所

Method and device for supporting weak adhesion bond soft rock roadway

InactiveCN102943681ASimple structureExcellent hole expandabilityDrill bitsAnchoring boltsSolid structureEngineering

The invention discloses a method and device for supporting a weak adhesion bond soft rock roadway. The method includes that step 1, a drilling machine is adopted for drilling holes; step 2, a reamer bit and a drilling stem are connected, and the bottom of a drilled hole is chambered; step 3, an anchoring agent and an anchor rod are placed in the drilled hole, the anchor rod and the drilling machine are connected, the drilling machine drives the anchor rod to rotate and stir the anchoring agent, after the anchoring agent is solidified, a chambering portion is full with the anchoring agent to form a solid structure in a reverse wedge shape, and the solid structure is used for fixing an anchoring section of the anchor rod; and step 4, a tray is arranged on top of the drilled hole, a nut is used for screwing a free end of the anchor rod tightly, and pre-tightening torsion meets design value. The device is a chambering reamer bit comprising a casing, a cutter and a cutter control device, wherein one end of the casing is a connector, the cutter is connected with the bottom of the connector in pivoted mode, and the cutter control device is connected with the cutter and controls the cutter to be screwed out from the casing or withdrawn. By means of the device and method, an effect of the anchor rod is good.

Owner:TIANDI SCI & TECH CO LTD

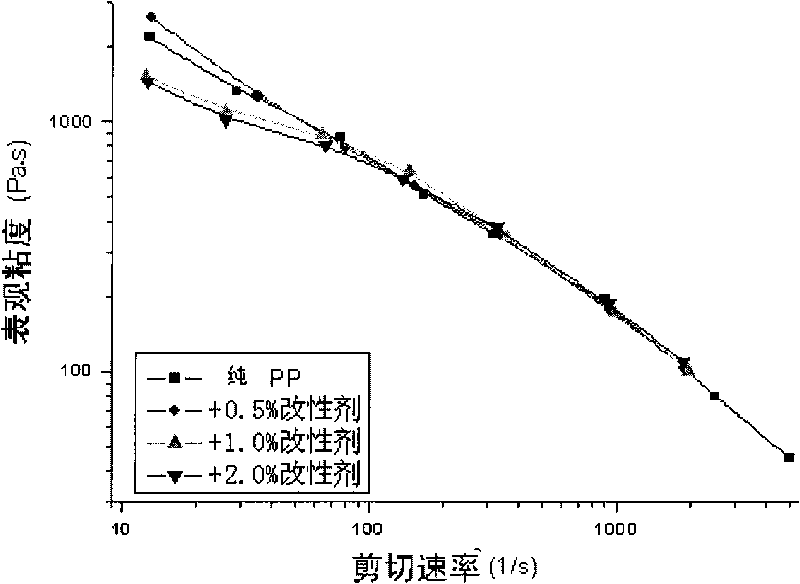

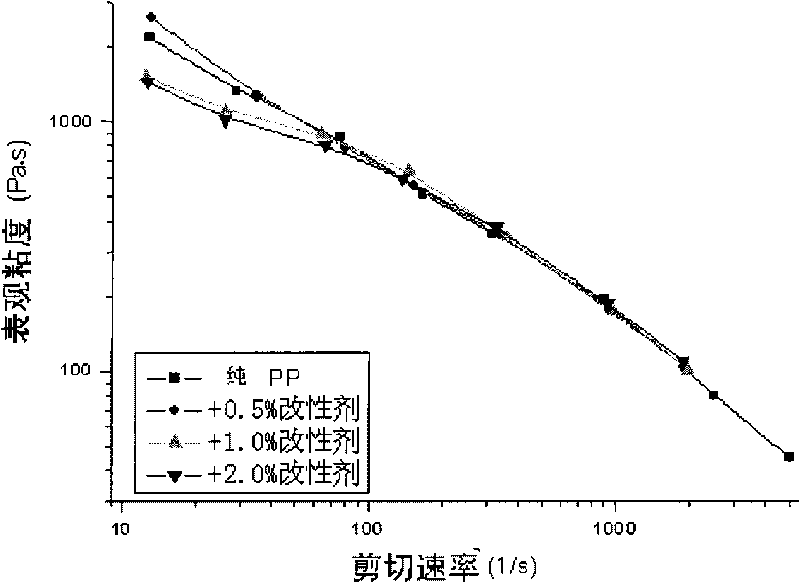

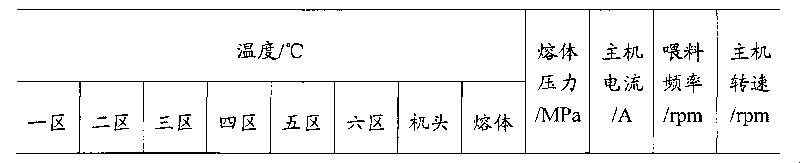

Processing aid of polyolefine for food flexible packing, preparation method and application thereof, and modified polyolefine adopting processing aid

The invention relates to a processing aid of polyolefine resin for food flexible packing, a preparation method and application thereof, and a modified polyolefine material used in the food flexible packing and adopting the processing aid. The processing aid consists of nano silicon dioxide and ethylene-vinyl acetate copolymer and is prepared through adopting a coprecipitation method. The processing aid can reduce the melt viscosity of polyolefine and obviously improve the processing performance of the polyolefine; and meanwhile, the processing aid increases the polarity of the polyolefine while improving the composite performance and printing performance of the polyolefine.

Owner:BEIJING INSTITUTE OF GRAPHIC COMMUNICATION

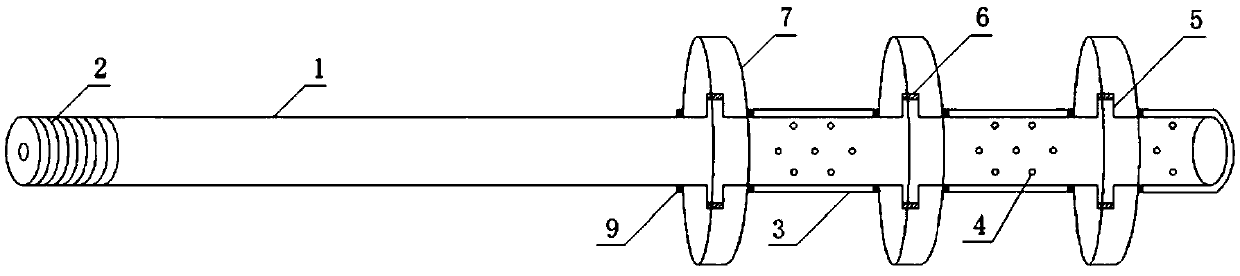

Self-drilling type spiral anchor rod and construction process using self-drilling type spiral anchor rod for grouting along with drilling, stirring and curing

InactiveCN102587366AGood effectImprove construction safetyExcavationsBulkheads/pilesHelical bladeEngineering

The invention discloses a self-drilling type spiral anchor rod and a construction process using the self-drilling type spiral anchor rod for grouting along with drilling, stirring and curing, which are suitable for support engineering of anchor-pulling slopes in weak soil regions. A paste outlet is arranged on a rod body of the spiral anchor rod, the front end of the rod body of the anchor rod is enclosed, a spiral vane is welded at the front end of the rod body of the anchor rod, and a stirring slice is welded behind the spiral vane on the rod body of the anchor rod. The construction process using the self-drilling type spiral anchor rod for grouting along with drilling, stirring and curing comprises the following steps of: injecting cement paste while drilling by rod body of the anchor rod, so that a paste body of the cement paste is ejected out of the paste outlet of the rod body of the anchor rod, mixing the paste body and a soil body cut by using the spiral vane on the front end, uniformly stirring the soil body and the cement paste by using the stirring slice arranged behind the spiral vane, forming an irregular anchor body after curing so that the anchoring force of the anchor rod is increased. Because the drilling and the grouting are integrated, the pressure influence of subsequent grouting on the side wall of a foundation pit is avoided; and meanwhile, the grouting pressure can be effectively controlled so that the grouting quality can be ensured.

Owner:中石化胜利建设工程有限公司

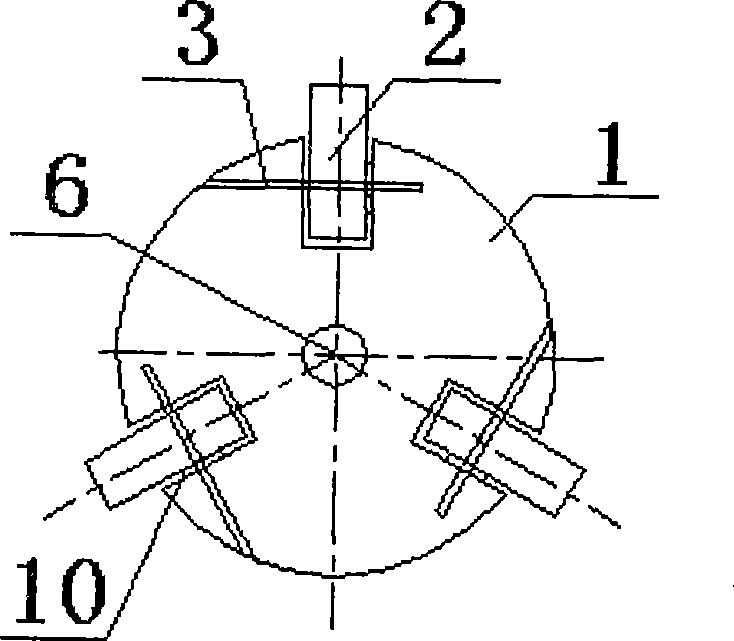

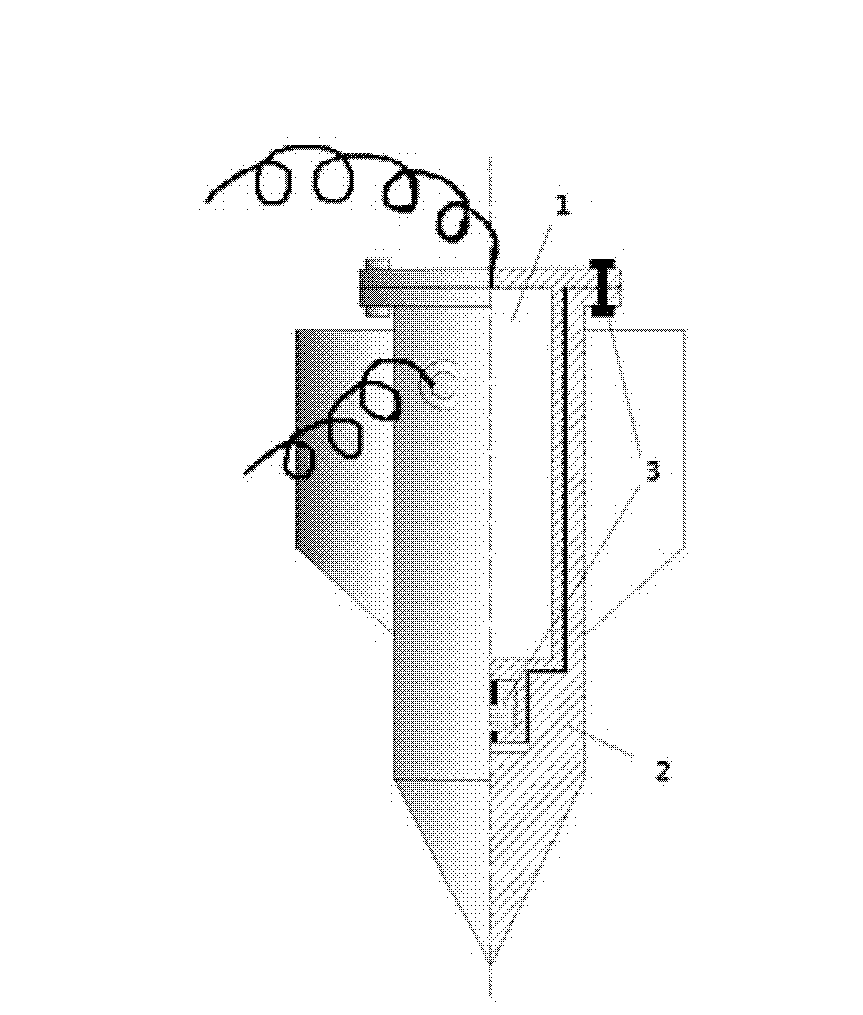

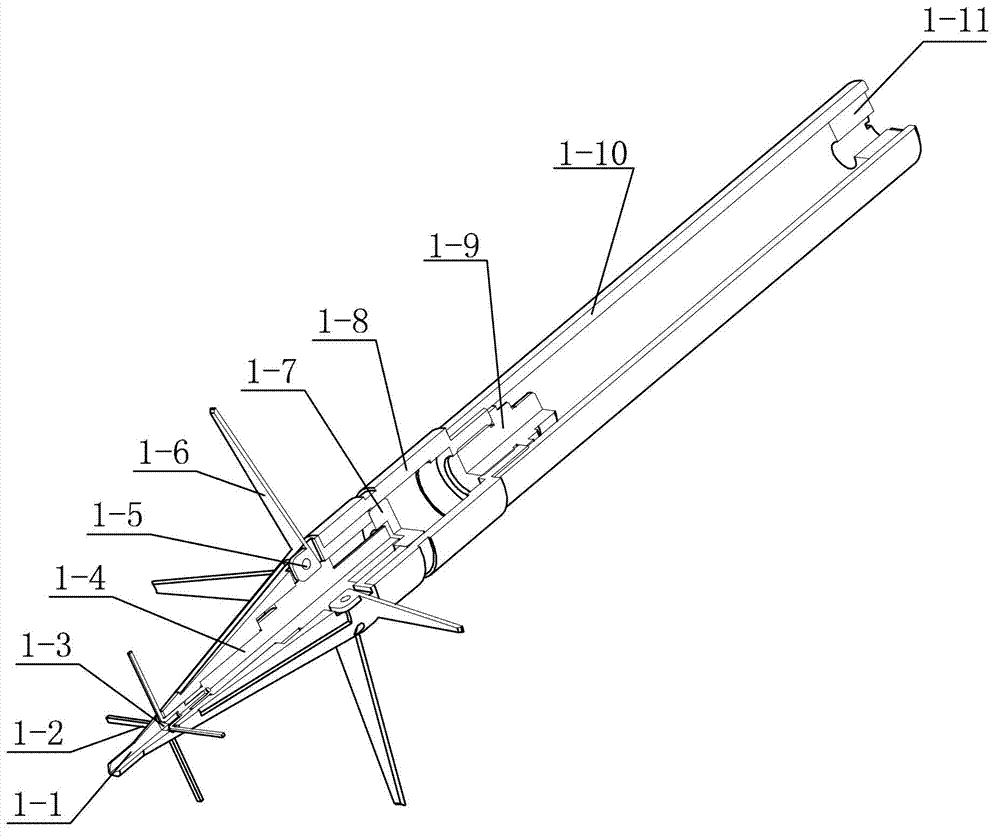

Active anchoring mechanism with two-time drive function

The invention provides an active anchoring mechanism with the two-time drive function and relates to the active anchoring mechanism. The active anchoring mechanism aims at solving the problem that anchoring force is small after media are thrown into an existing anchoring mechanism due to the fact that an anchor tip in the existing anchoring mechanism can not be deformed. The large end of a step pushing rod is fixedly connected with a piston. A back taper is arranged inside the anchor tip and is arranged adjacent to the small end of the step pushing rod. An anchoring claw is fixed at the small end of the step pushing rod. Each stretching wing is installed on the large end of the anchor tip through each stretching wing pin, and a plurality of the stretching wings are arranged in a star-shaped mode. A thrust end cover is connected with the lower end of an expansion cylinder in a threaded mode. An anti-vibration pad is arranged on the upper end face of the thrust end cover. A piston body is arranged inside the expansion cylinder and connected with the expansion cylinder in a sliding mode. A plurality of blind holes are evenly distributed in the piston body along the radial direction of the piston body. A fire device is arranged on a fire connector. The outer wall of the upper end of the expansion cylinder is connected with a limiting ring in a threaded mode. The outer wall of a combustion room of an anchoring unit is in sliding connection with the inner wall of an end cover of the expansion cylinder. The active anchoring mechanism is applied to anchoring of landing devices and instruments and equipment under a micro gravity environment.

Owner:HARBIN INST OF TECH

Steel bar anchoring device and construction method thereof

ActiveCN1827976AEasy to installIncrease anchoring forceBuilding reinforcementsBuilding material handlingRebarEngineering

The invention relates to a steel bar anchor device and relative method, which is formed by connecting anchor plate and the end part with rib steel bar. Wherein, the anchor plate is in head-shoulder integrated shape, while the insert end of shoulder is a plane and the head is in screw cap shape or nut shape. The center of anchor plate has an inner screw matching the external screw of said end part. The anchor plate can be classified into two kinds as full-anchor plate and part-anchor plate, according to the ratio between the area of bearing plate and the section area of steel bar, which can be used in different areas to reduce adhesive anchor length or fully eliminate the length. The invention can reduce 40-50% of anchor steel material, to improve the concrete irrigate quality, the constructing speed, reduce the cost and simplify the process.

Owner:CABR TECH CO LTD

Expansion anchor rod

InactiveCN101126321ARigid AnchorIncrease anchoring forceExcavationsAnchoring boltsFiberWear resistant

The invention relates to the technical field of a support facility for the rock, earth and mining engineering, in particular to an expansion anchor rod. The expansion material of the anchor rod adopts a high-elasticity high molecular material, or a compound intensified material made of the steel wire or fibrous material and the high-elasticity and high molecular material or the thin corrugated metal sheet. The expansion body of the anchor rod has a hollow structure; the hollow part is a pressure cavity for injection, one end of the cavity is sealed and an introduction valve and a tube orifice anchor head are closely arranged at the other end ; an expansive force transfer layer is sleeved around the outer edge of the expansion body of the anchor rod and an anchor layer is sleeved around the outer edge of the expansive force transfer layer to form the expansion anchor rod. The expansion anchor rod additionally has the advantages of the rigid anchor rod on the base of keeping the application effect of the flexible injection bolt. The anchoring force is reliable and is easy to be adjusted, supplement and reclaimed; the creep resistance is strong and the anchoring effect is not affected if the geotechnical or the hole wall has honeycombed crack or collapse of artifices; also, the anchor rod is high in strength, low in cost, wear-resistant and is easy to be processed and manufactured.

Owner:SHANDONG UNIV

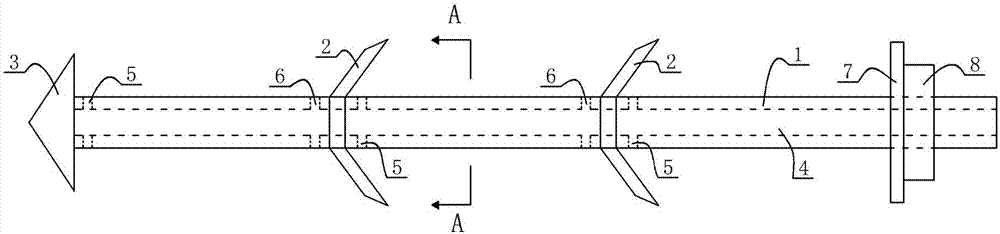

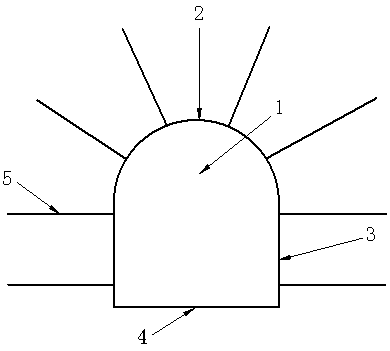

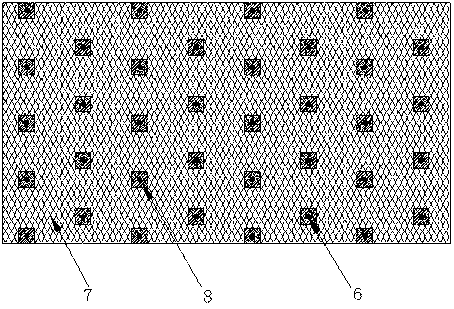

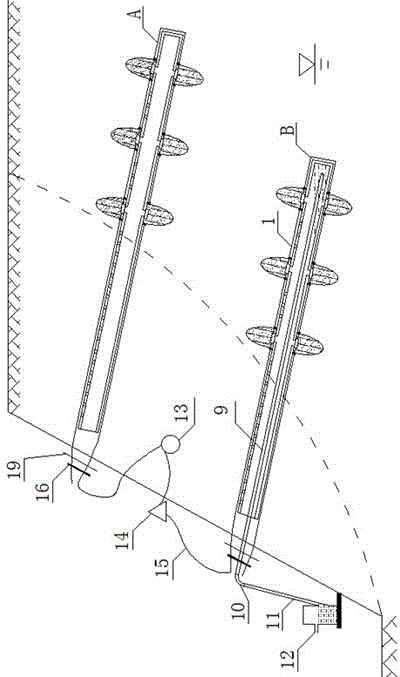

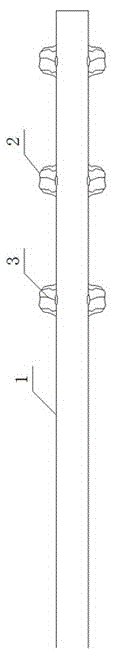

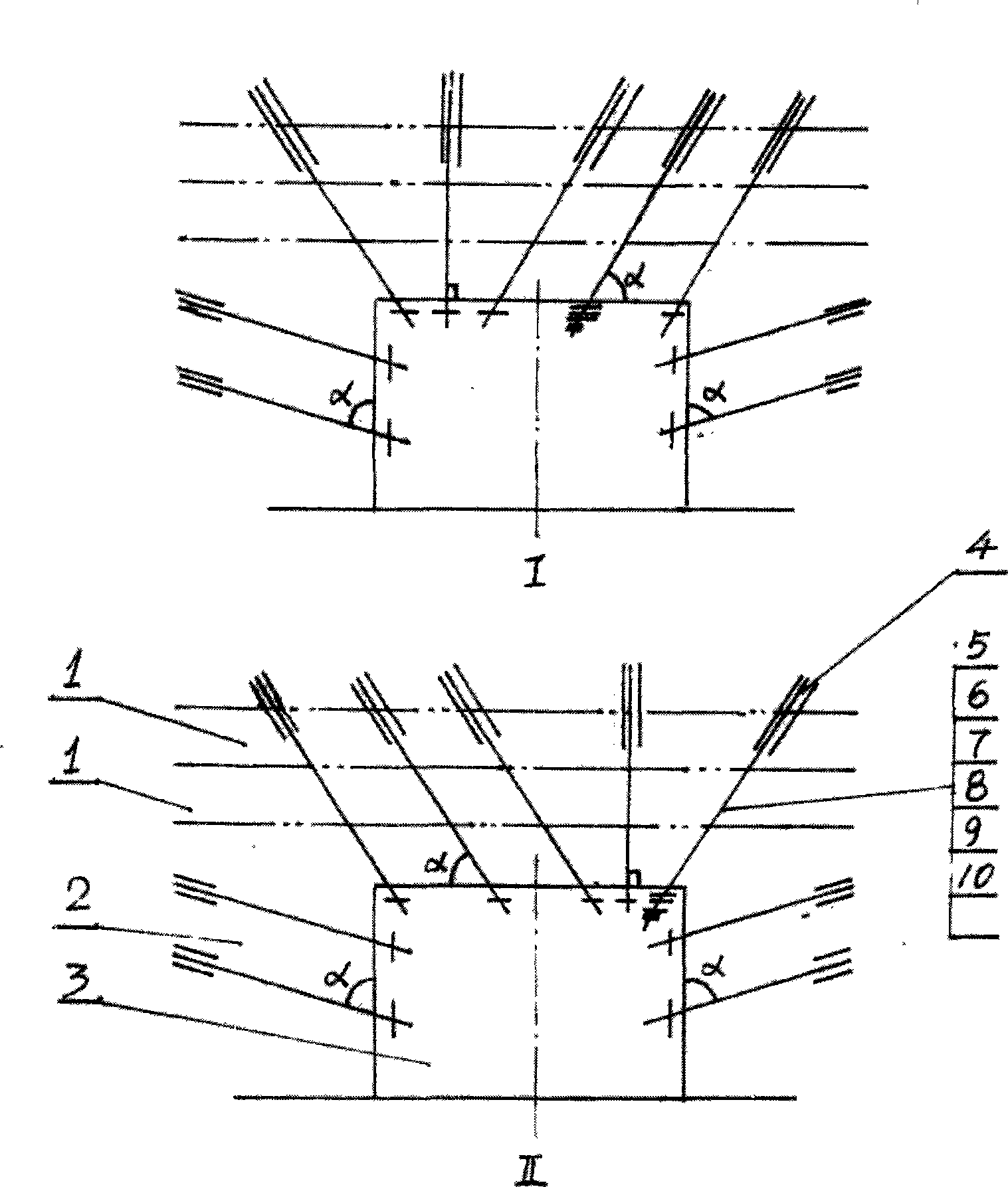

Novel tunnel anchor cable/rod support method

InactiveCN101482023AIncrease anchoring forceThe contact area is solidAnchoring boltsGeomorphologyHole drilling method

The invention relates to the technical field of a coal mine downhole extracting working face roadway support. In the existing roadway support anchor, the phenomenon of insufficient locking force is general; the rock surface of the roadway is uneven; and the bearing contact surface of a pallet surface is point-typed stress. The invention is characterized in that an original matrix-shaped hole-distributing drilling method in which the drilling direction is perpendicular to or homodromous with the cross-section of a roadway 3 is changed into a quincunx-shaped hole-distributing drilling method in which the drilling direction is tilted to the cross-section slope wall of the roadway, moreover, the drilling inclination angle of a rock mass top plate 1 is staggered row by row, namely, the drilling inclination angle the row is opposition to the direction of neighboring two rows; and the drilling directions of two slope walls 2 of the roadway cross-section are tilted upwards. The top end of an anchor cable (rod) 5 is used for pushing a resin explosive roll 4 to the drilling bottom of the rock mass top plate 1 and the slope walls 2 and then being fixed into a whole by stirring, later sleeved in a rubber wedge plate 6, a steel strip fictitious graticule 7 and a hemispheric concave hole pallet 8, and next locked by a hemispheric convex nut 9, so as to cause the anchoring contact surface among the anchor cable (rod) 5 and the rock mass top plate 1 and the slop walls 2 to be larger and firmer with stronger reliability and stability. Finally, reflective paint 10 is coated and brushed at the external end part of the anchor cable (rod).

Owner:卢泉生

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com