Multi-level back-grasp-type hollow anchor rod and construction method thereof

A construction method and bolt technology, which are applied in the installation of bolts, earthwork drilling, infrastructure engineering, etc., can solve the problems of difficult installation of bolts, difficulty in forming holes, and waste of materials, so as to achieve good anchoring effects and increase anchorage Force, increase the effect of the contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

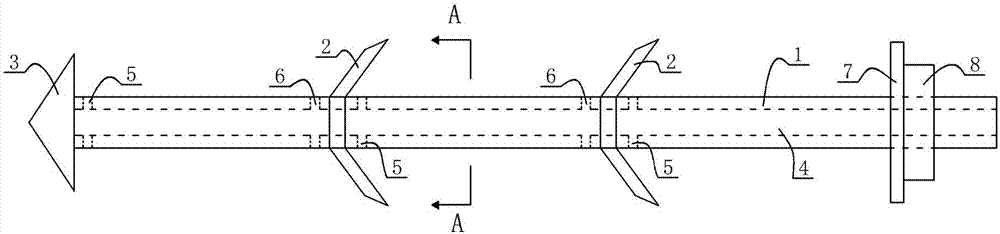

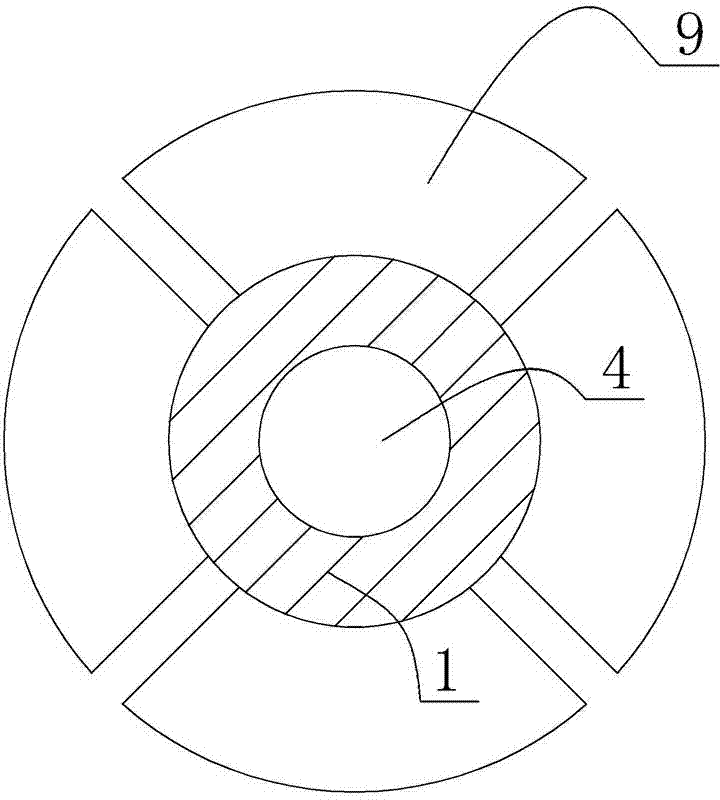

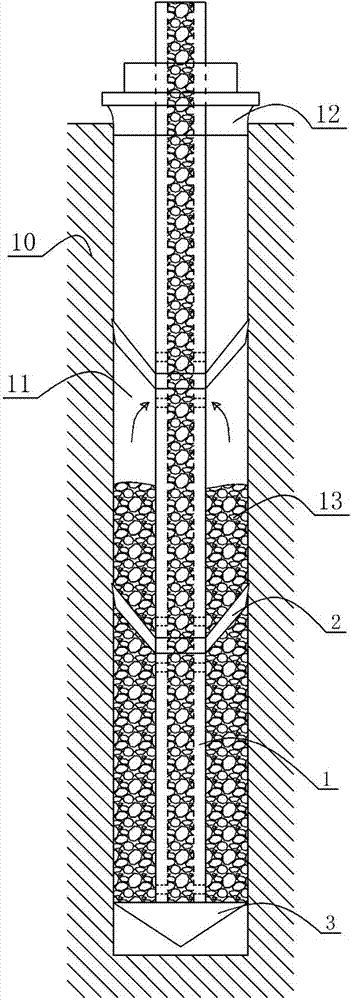

[0020] Such as figure 1 As shown, the structural diagram of the invented inverted hollow anchor is given, which includes an anchor rod 1, an inverted buckle 2, an anchor head 3, a grouting channel 4, a grouting hole 5, a return hole 6, and a backing plate 7 and a nut 8; the anchor rod 1 shown is rod-shaped, and the center of the anchor rod 1 is provided with a grouting channel 4 for injecting cement mortar 13 . The left end of the anchor rod 1 is fixed with an anchor head 3, so that the whole anchor rod is driven into the drilled anchor rod fixing hole 11, or the anchor rod is directly driven into soft soil, sandy soil and water. The anchor rod 1 is evenly fixed with a plurality of upside-down buckles 2, which are bowl-shaped towards the right; It can shrink in the forward direction; when the fastening force is applied through the nut 8, the buckle 2 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com