Patents

Literature

1014results about How to "Outflow smoothly" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

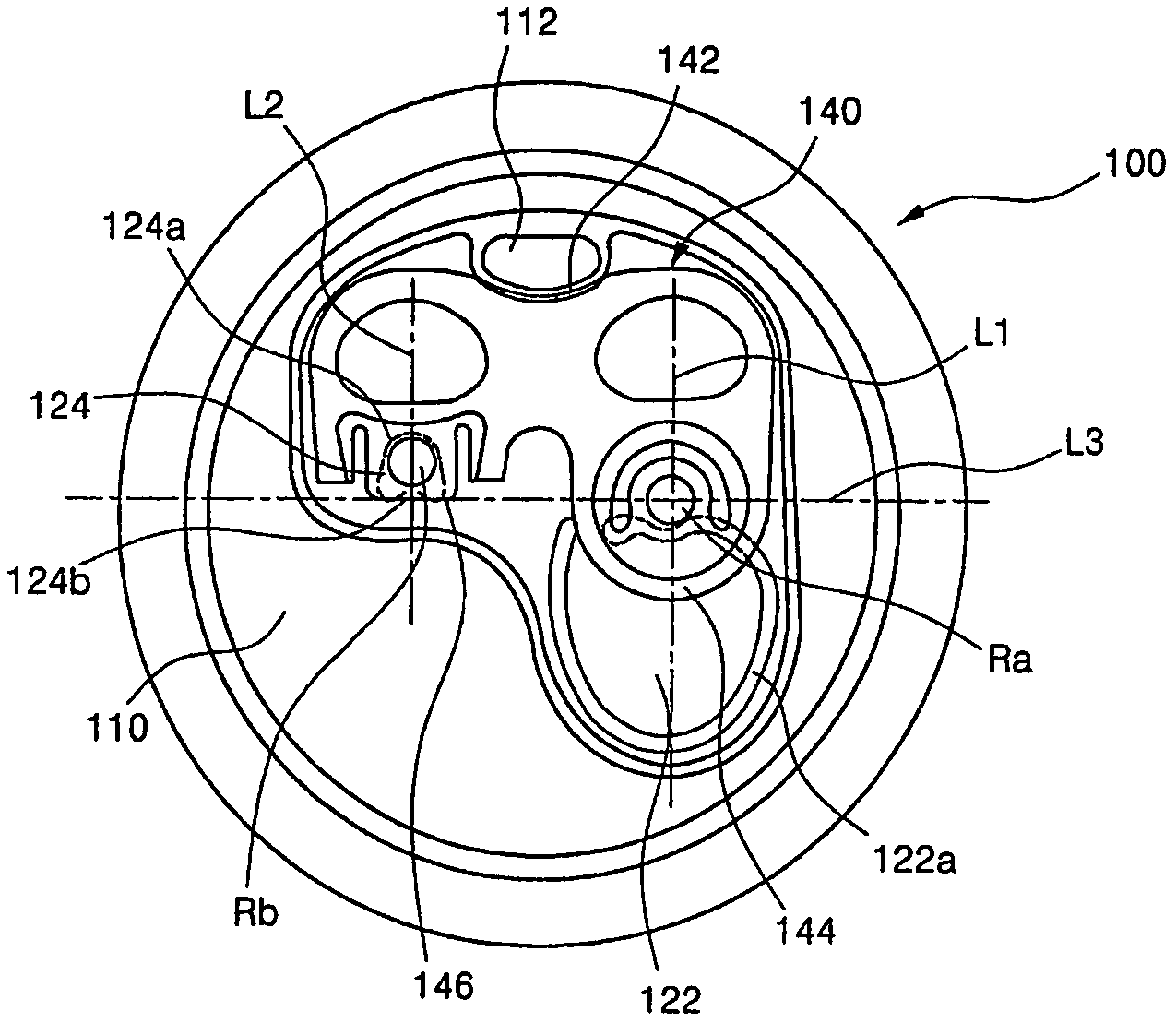

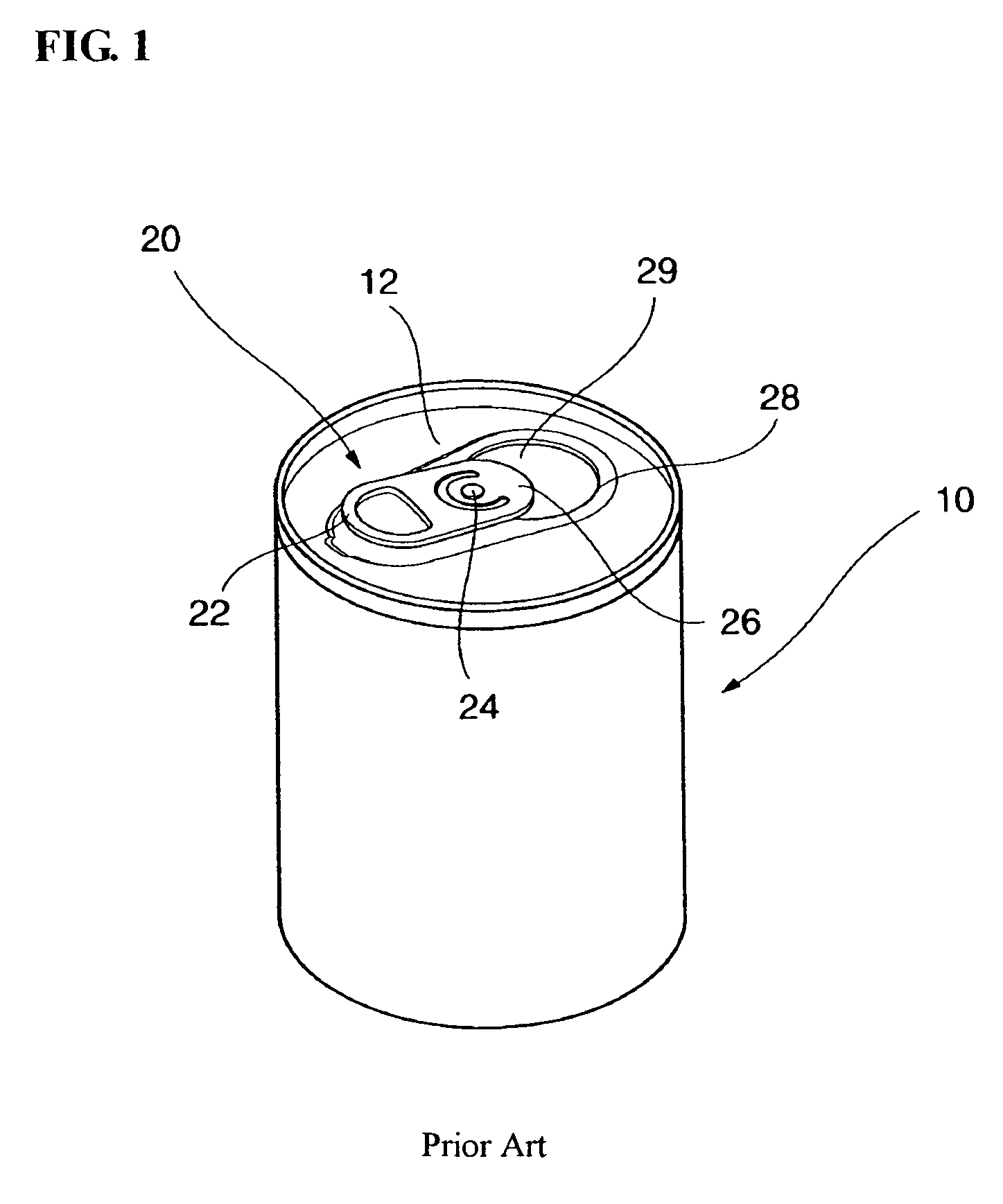

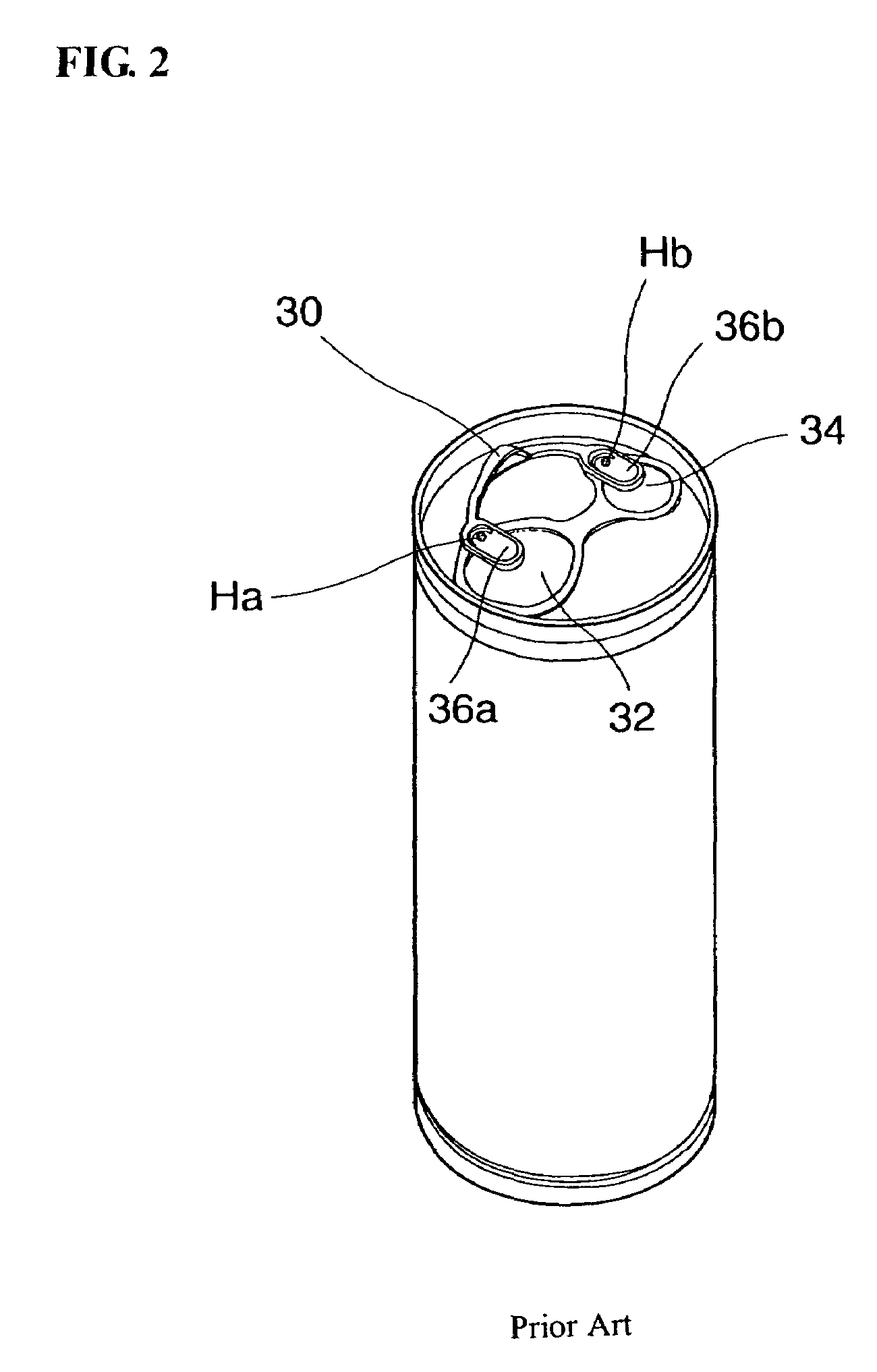

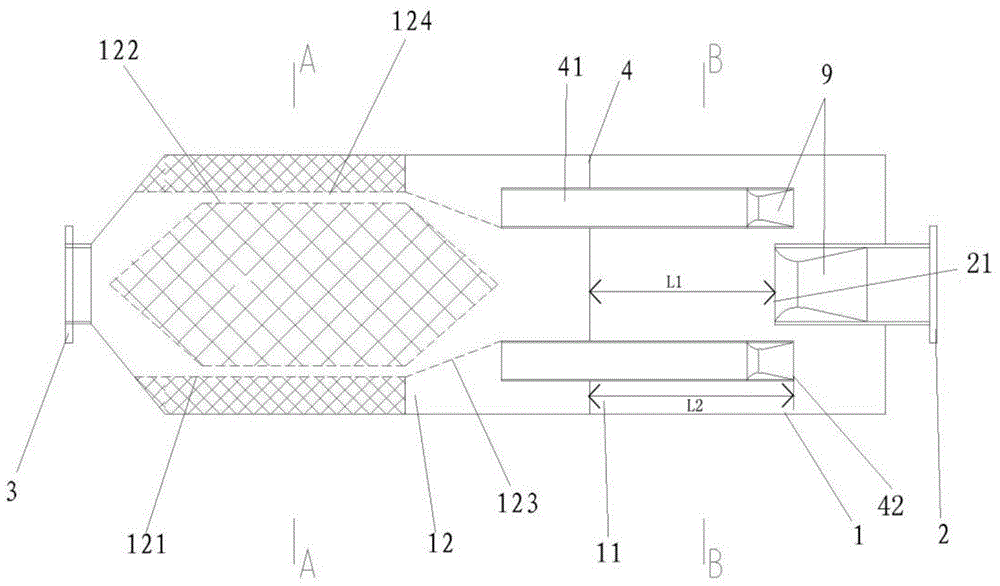

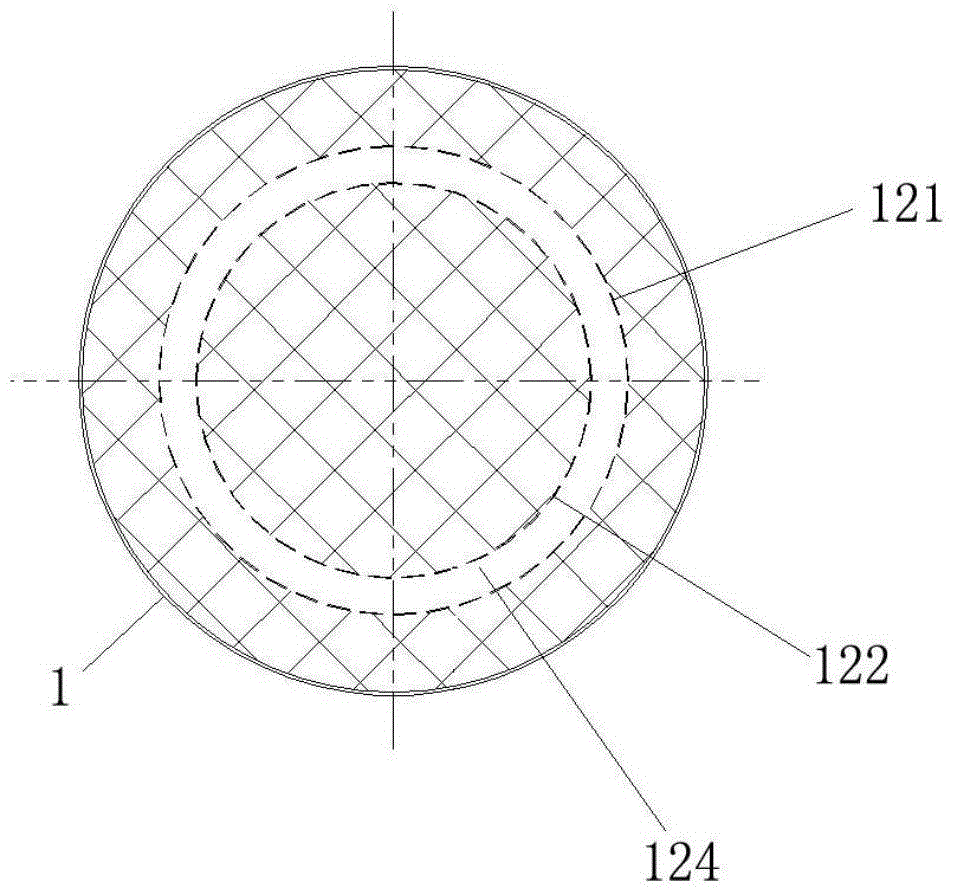

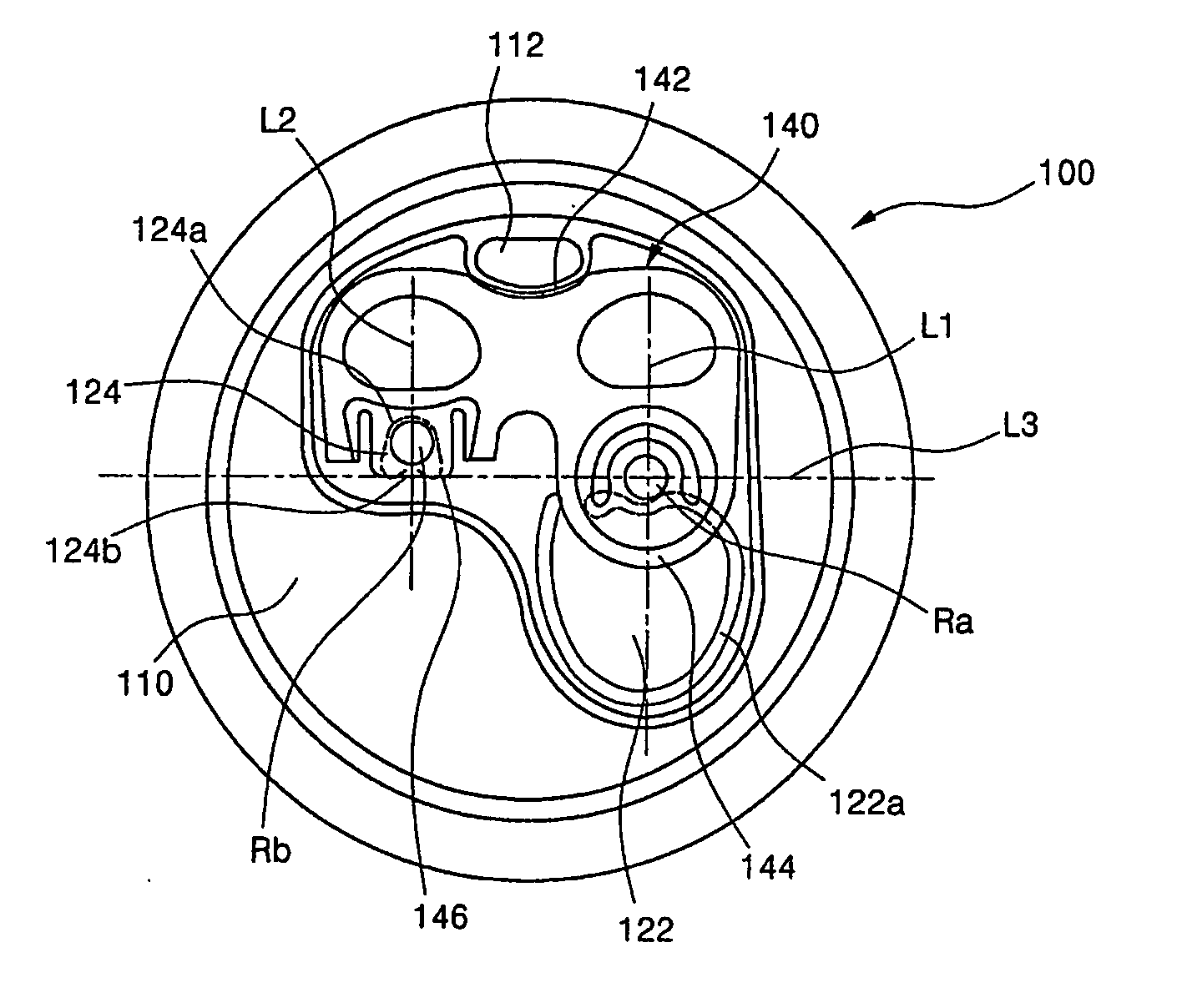

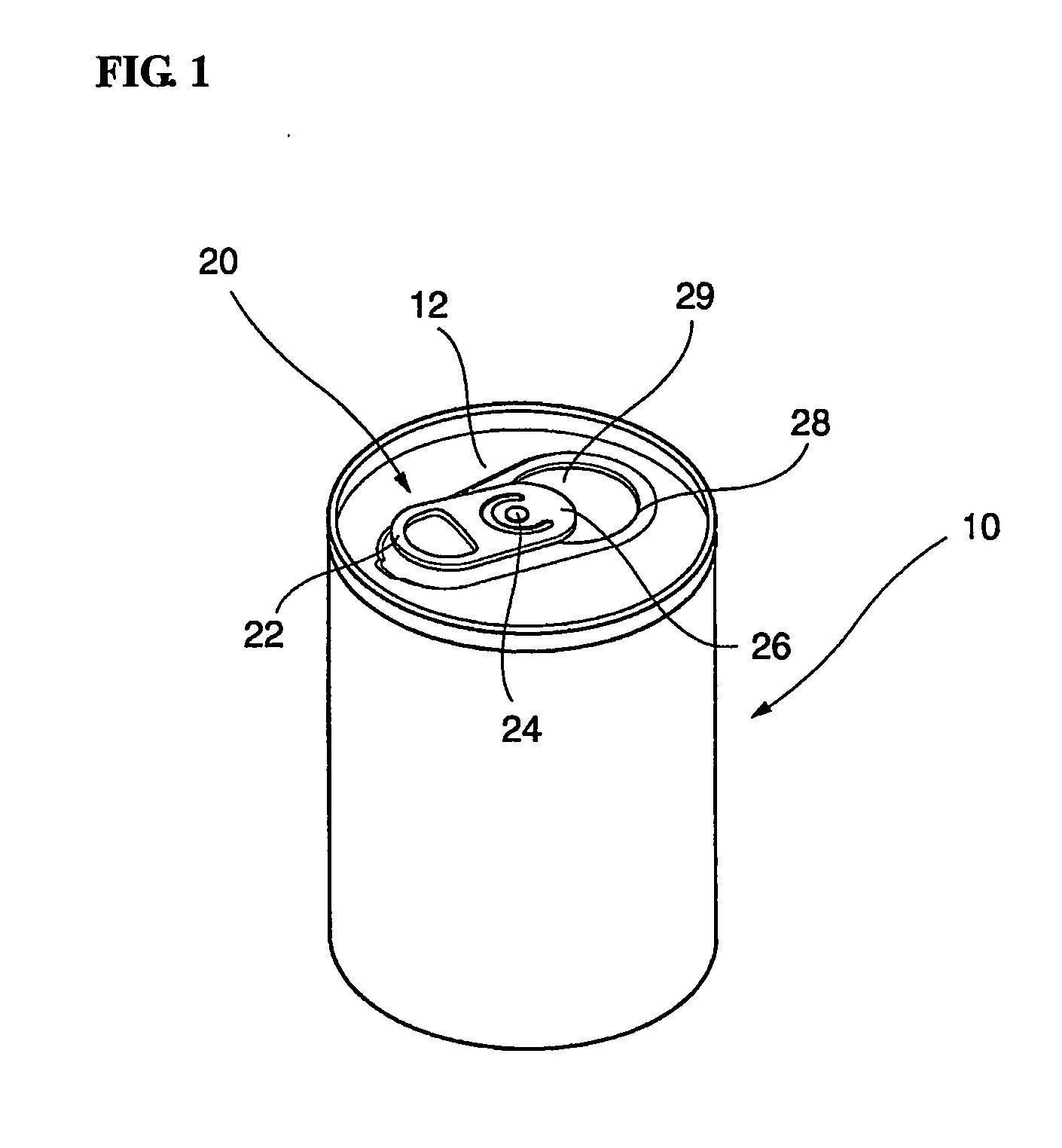

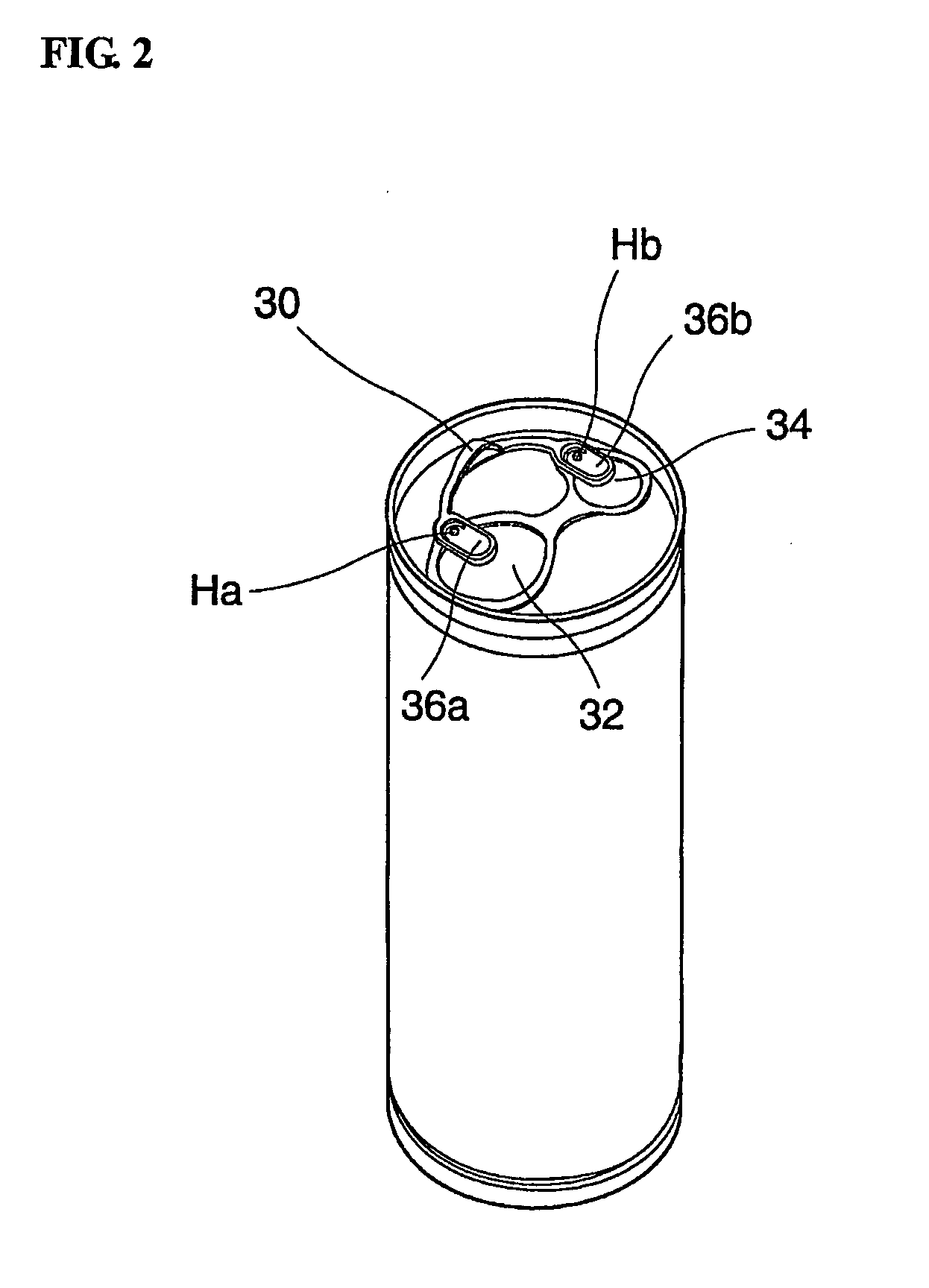

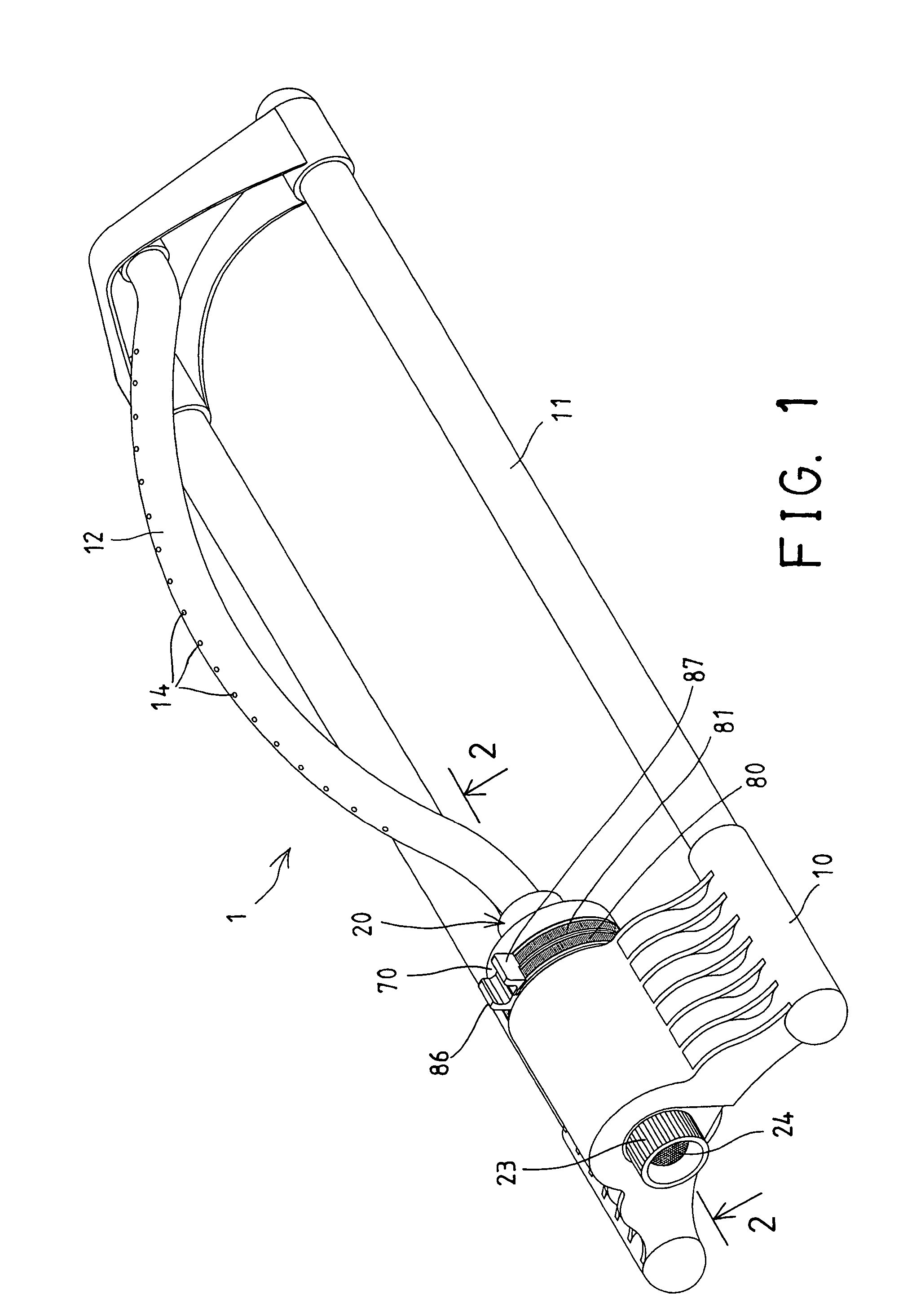

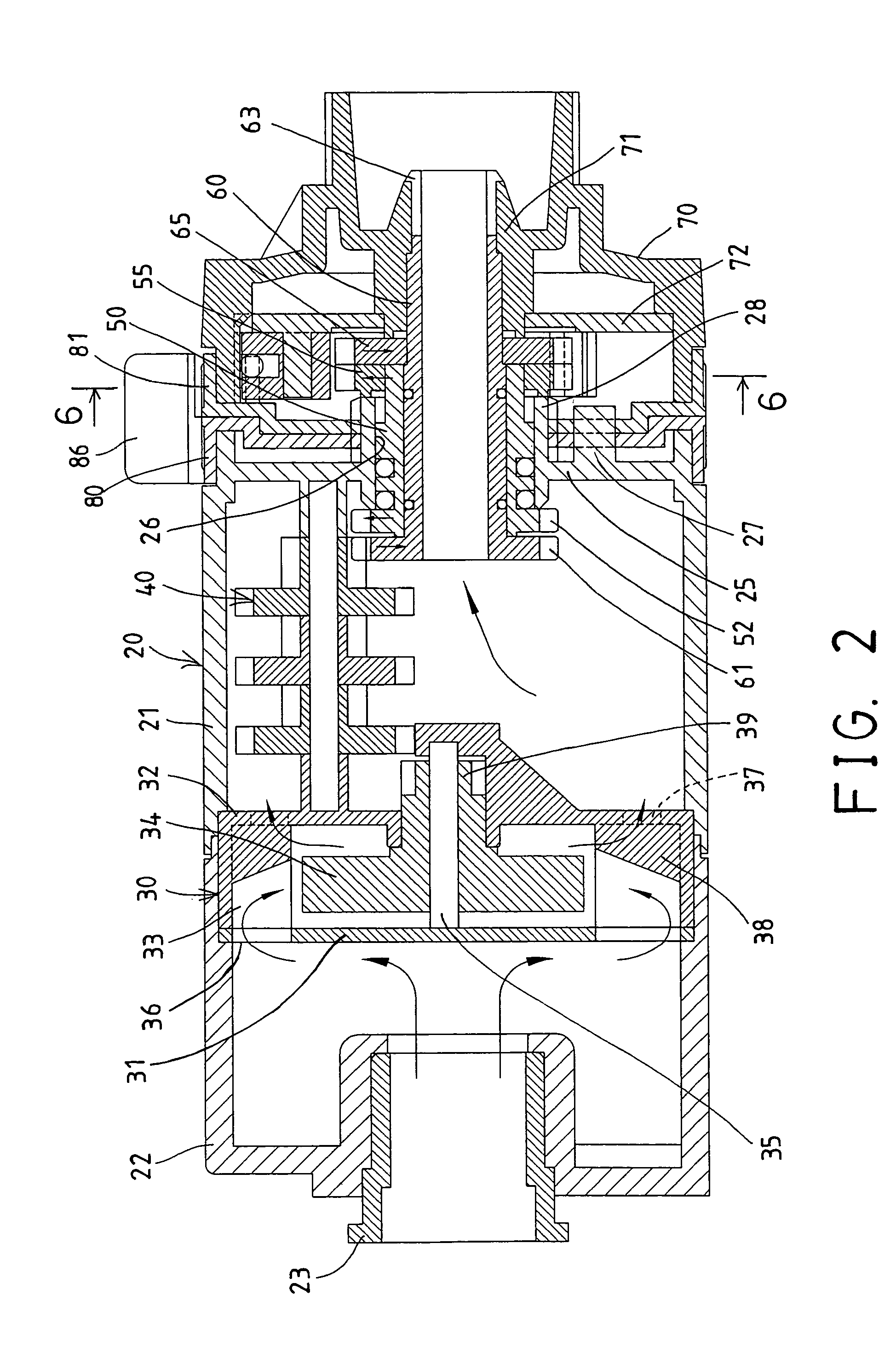

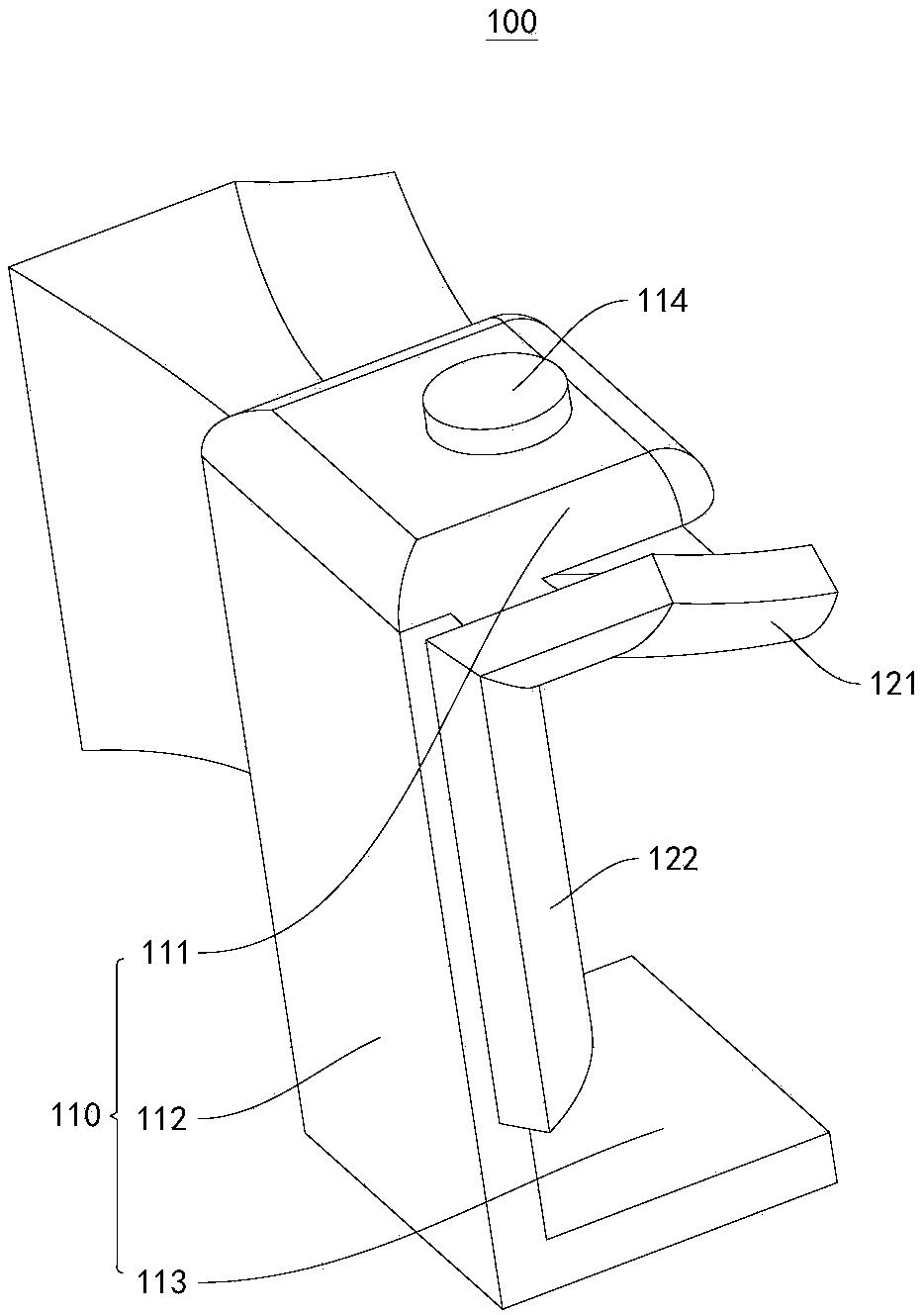

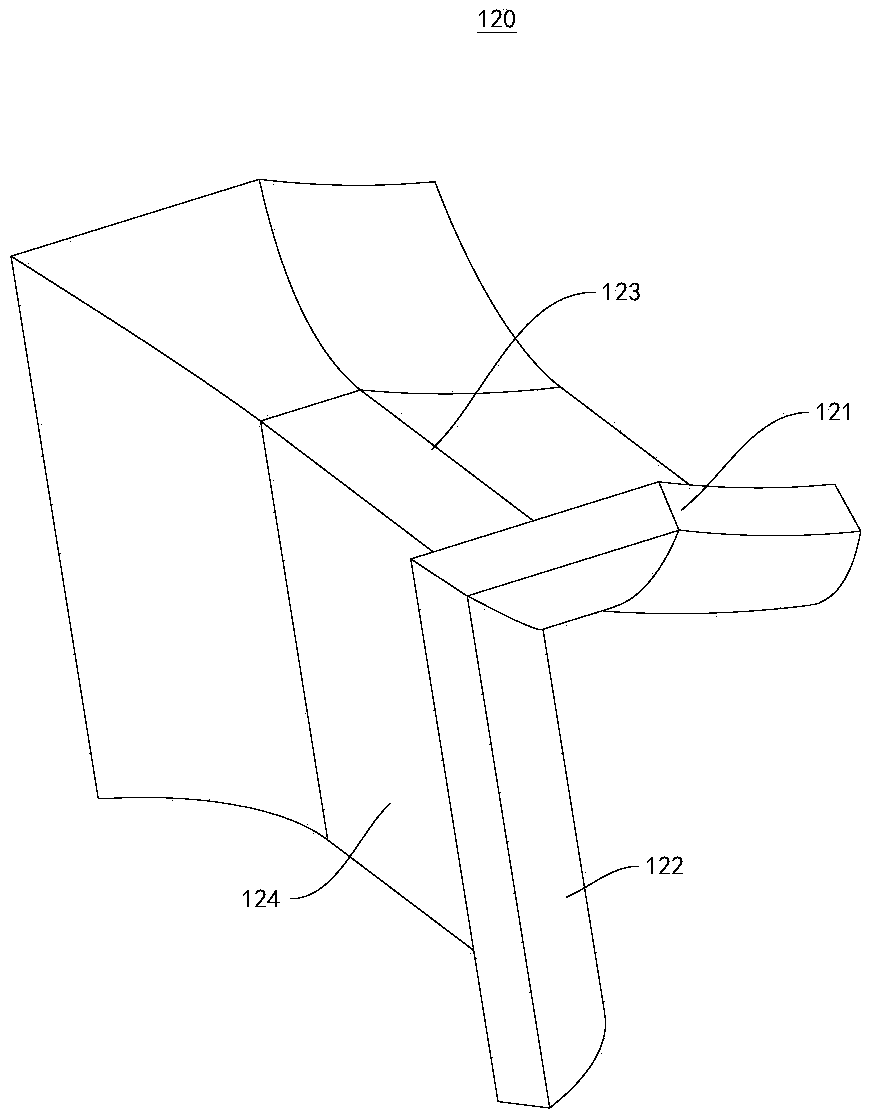

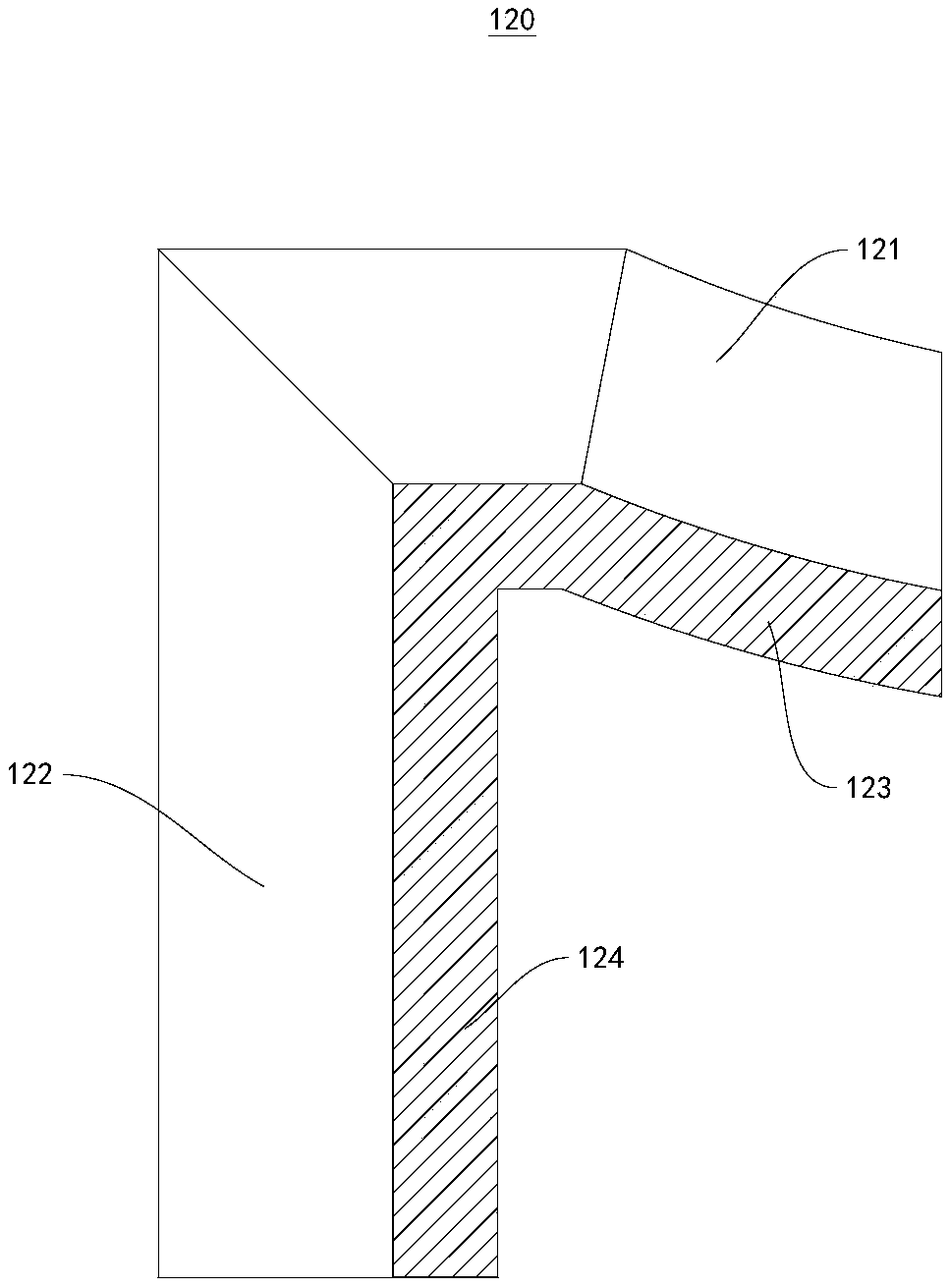

Opening device for can

The present invention relates to an opening device for a can, which is constructed such that the contents of the can flow out and exterior air is simultaneously introduced into the can. The opening device of the present invention comprises first and second opening portions 122 and 124 through which the contents flow out and the exterior air is introduced into the can upon opening thereof, respectively, and which are disposed to be opposite to each other at both sides of the top surface 110 of the can and defined by incision lines 122a and 124a so that a part of each of the opening portions is attached to the top surface; and a tab 140 mounted on the top surface of the can by means of a first rivet stub Ra installed outside of the first opening portion and a second rivet stub Rb installed within the second opening portion. The second opening portion is opened while being lifted together with the second rivet stub Rb, the first opening portion is opened while being pressed by a pressing portion 144 around the first rivet stub, and the second rivet stub is formed to be closer to a grip 172 of the tab 170 than the first rivet stub.

Owner:HWANG BO YEOUN

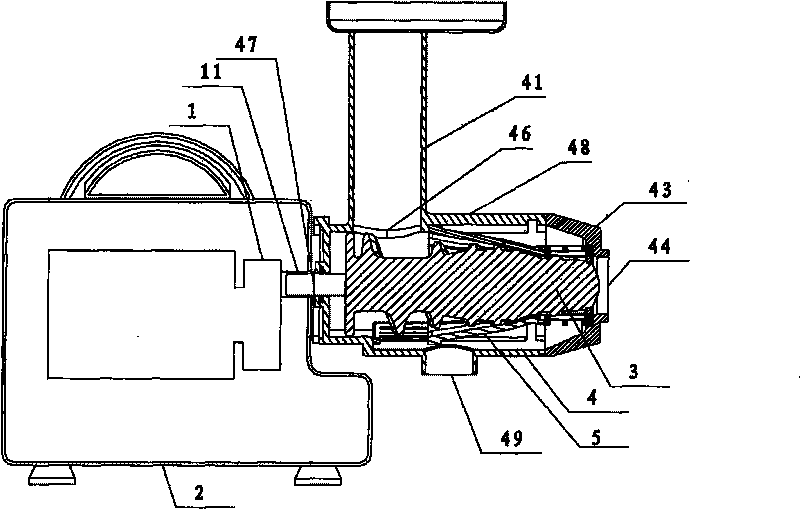

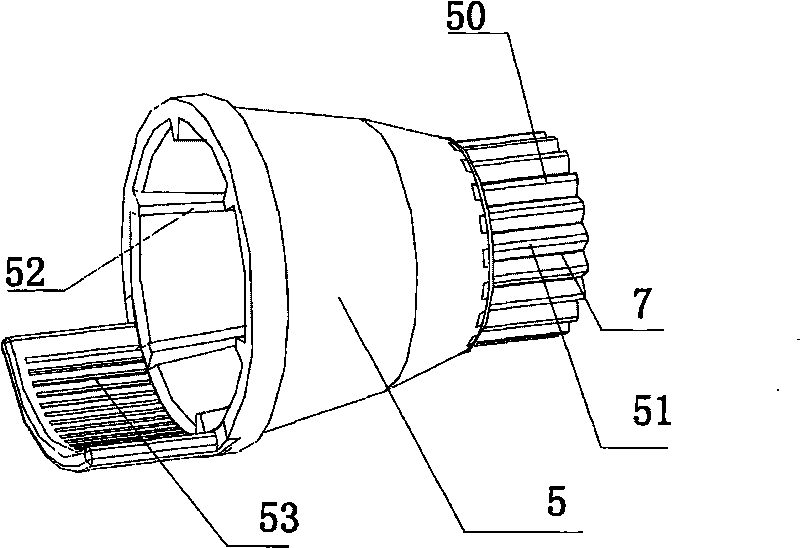

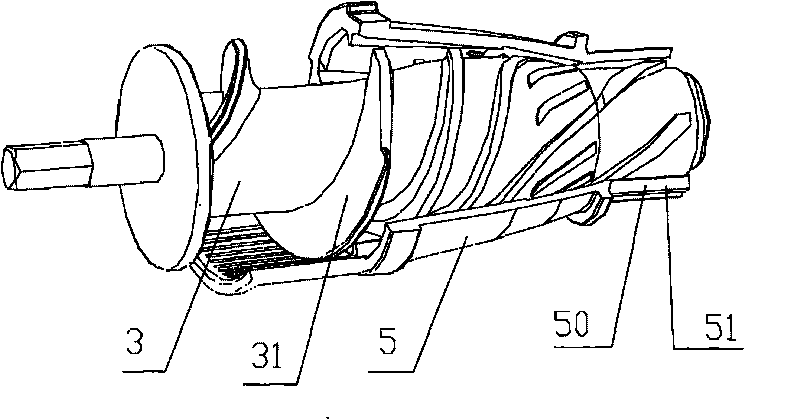

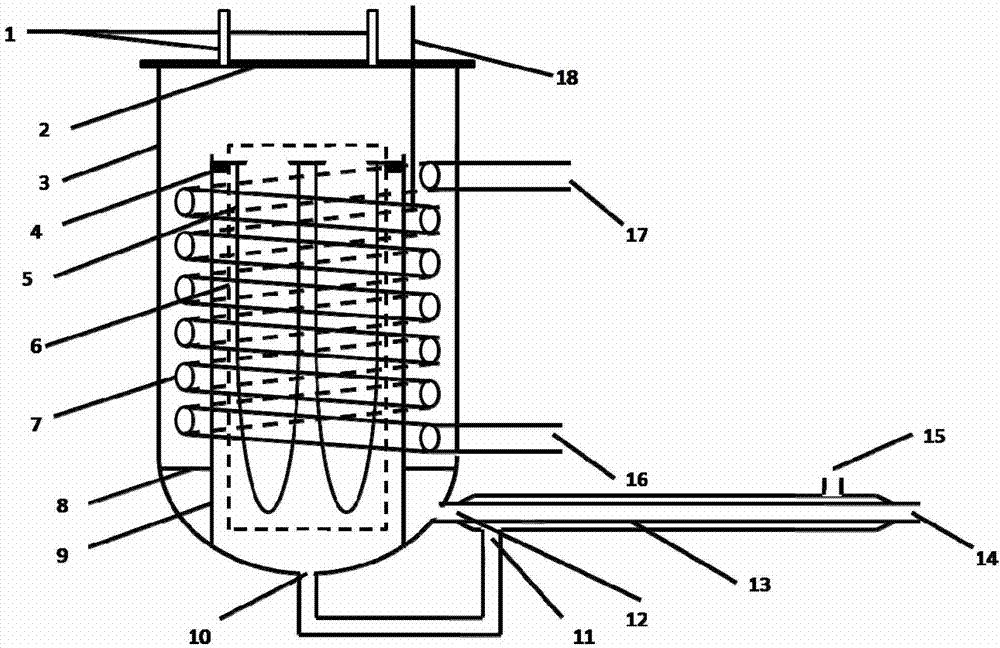

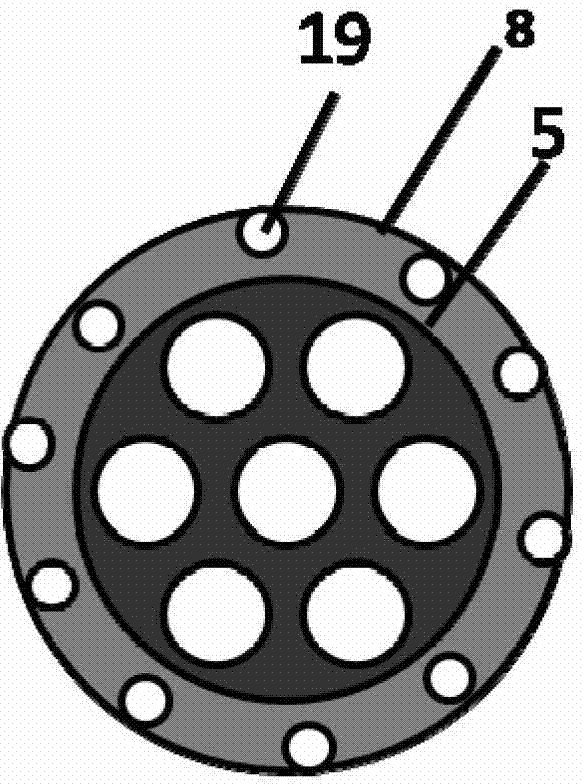

Easy cleaning extrusion type juicer

ActiveCN101697857AOutflow smoothlyImprove Juicing EfficiencyStrainersAgricultural engineeringFruits and vegetables

The invention discloses an easy cleaning extrusion type juicer which comprises an engine base, a motor, a juice collecting chamber, an extruding and crushing part and a filtering part, wherein the extruding and crushing part comprises a push-in screw and an extrusion cylinder matched with the push-in screw. The extrusion cylinder is arranged in the juice collecting chamber, and the filtering part is arranged on the lower part of the extrusion cylinder. The filtering part is characterized in comprising grids, and scum juice filtering gaps are arranged between the grids. The easy cleaning extrusion type juicer of the invention has the advantages that the size of the scum juice filtering gaps can change according to the size of the material under the action of the push-in screw to the material, the juice extrusion rate is high, so that the juicer is especially suitable for lone-term material feed; the juicer is easy to clean after being used, the extruded fruit and vegetable juice has less foam, and the inherent colour and taste of the fruit and vegetable juice can be kept to the maximum extend.

Owner:JOYOUNG CO LTD

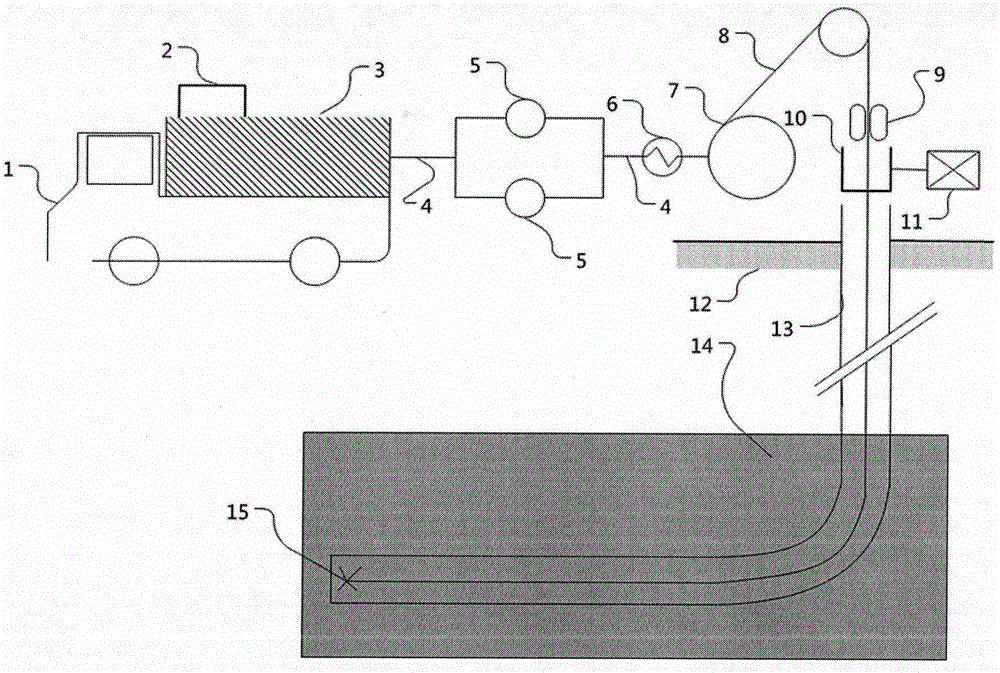

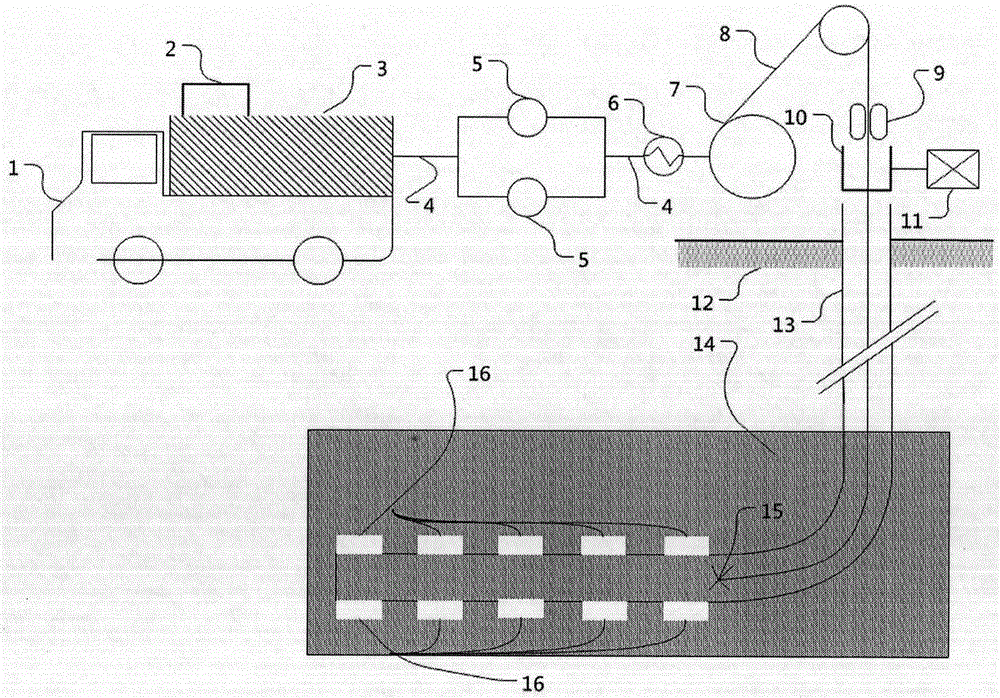

Coalbed methane horizontal well supercritical CO2 jet flow cavity construction and multi-segment synchronous deflagration fracturing method

InactiveCN105625946AAids in stress unloadingImprove permeabilityLiquid/gas jet drillingFluid removalHigh energyHigh pressure

The invention relates to a coalbed methane horizontal well supercritical CO2 jet flow cavity construction and multi-segment synchronous deflagration fracturing method. The method comprises the following steps: completing coalbed methane horizontal well drilling, introducing a coiled tubing into an supercritical CO2 rotary jet flow rock-breaking device to the bottommost end of a shaft, and performing pore broadening on the shaft by using an underground supercritical CO2 rotary jet flow rock-breaking device in order to form a cylindrical pore which is 1.0-1.5 meters in diameter and is 2-4 meters in length underground; after first-segment pore broadening is finished, lifting a rotary jet-flow tool to perform second-segment pore broadening work and so forth to finish pore broadening work of all well segments, wherein the segment distances are 80-100 meters; putting a solid explosive into a pore broadening cavity by using the coiled tubing after finishing pore broadening, and introducing a screen pipe; lastly, pressurizing by using a ground high-pressure CO2 pump to ignite the explosive, and mixing generated high-energy gas with a supercritical CO2 fracturing coalbed. By adopting the method, a plurality of complex volume cracks can be generated in the coalbed, explosive fracturing contributes to coalbed stress unloading after pore broadening, and the coal rock permeability can be improved effectively, so that the yield of a coalbed methane horizontal well is improved.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

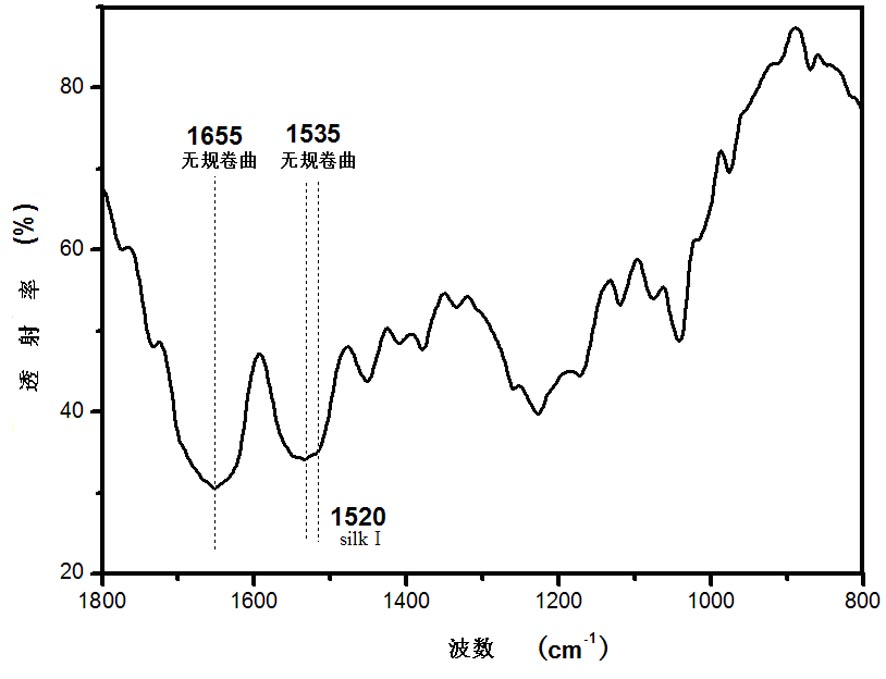

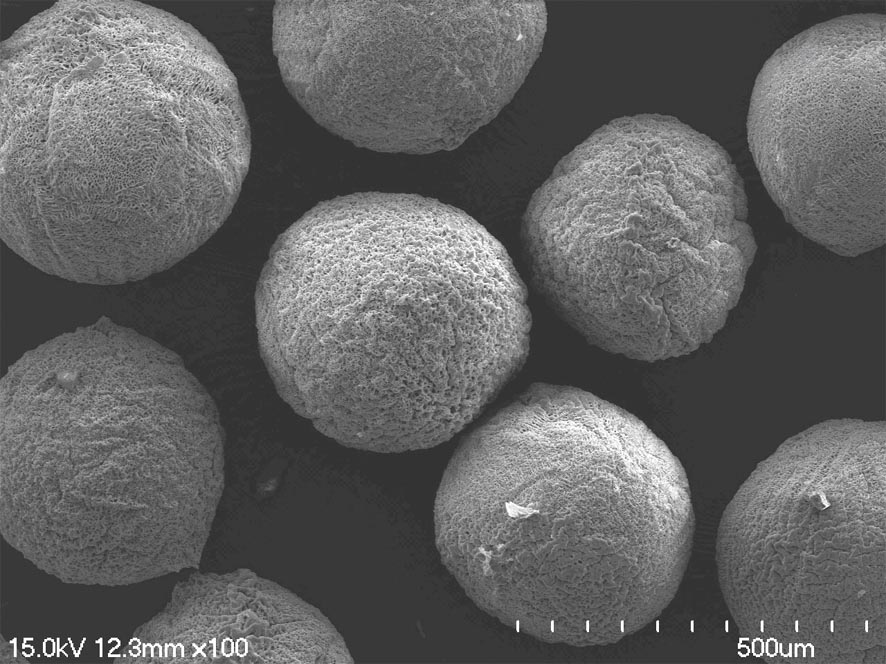

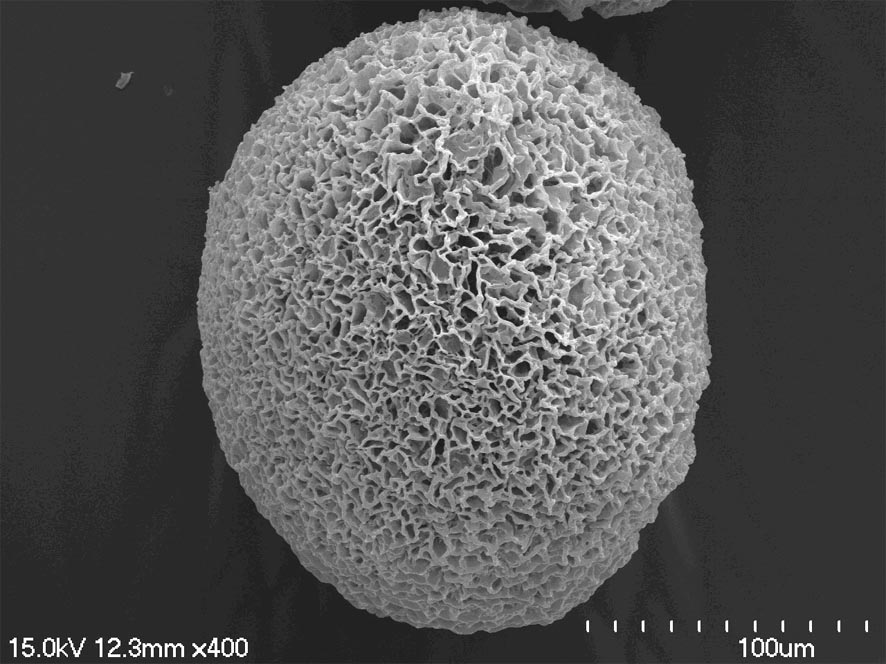

Macromolecular microcarrier and preparation method thereof

InactiveCN101972481AOutflow smoothlyHigh drug entrapment ratePeptide/protein ingredientsDrug compositionsDrugs solutionFreeze-drying

The invention discloses a macromolecular microcarrier and a preparation method thereof, belonging to the technical field of biomedicine. The preparation method comprises the following steps of: splitting a silk solution and a drug solution into micrometer grade liquid drops with core-shell structures under the action of a high-voltage electric field by adopting a coaxial high-voltage electrostatic technology and a freeze drying method; concreting through liquid nitrogen, and then preparing the microcarrier which is difficult to dissolve in water through freeze drying. The microcarrier is in the shape of a microsphere with the core-shell structure, and the diameter of the microsphere is 100-500 micrometers; the shell of the microcarrier comprises the components of silk fibroin; the random-coil conformation of silk fibroin molecules is 80-90 percent; the shell is in a porous structure, and an aperture is 5-20 micrometers; and a core of the microcarrier comprises the components of water-soluble drugs. The silk microcarrier has extensive application prospect in the fields of cell culture, drug release, and the like.

Owner:SUZHOU UNIV

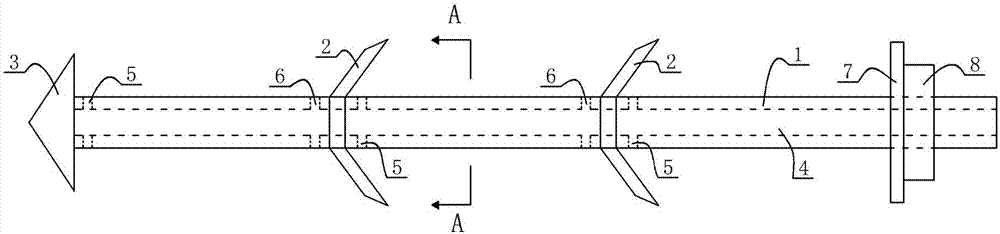

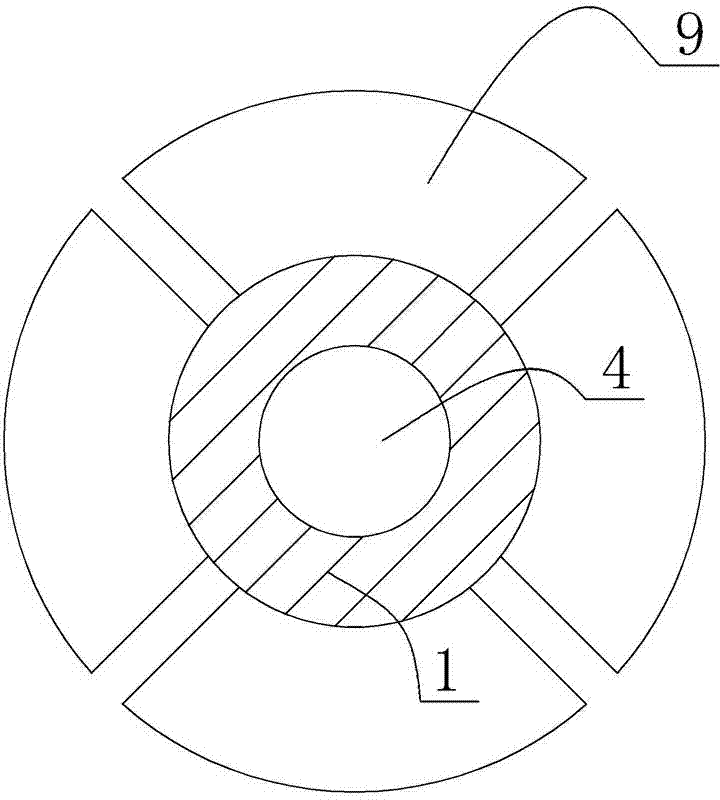

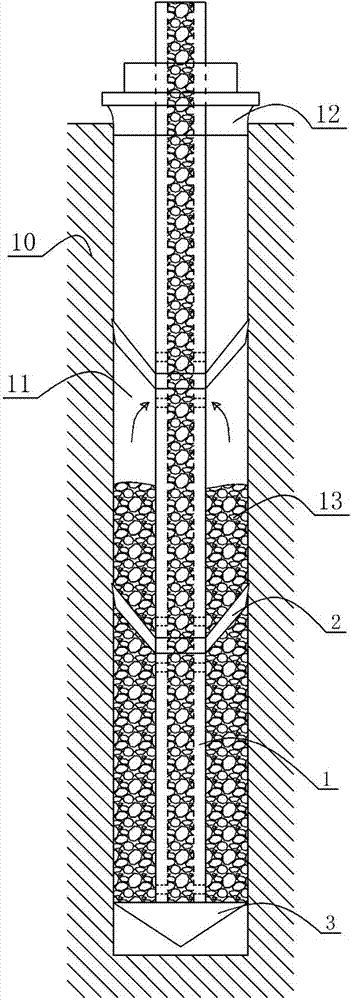

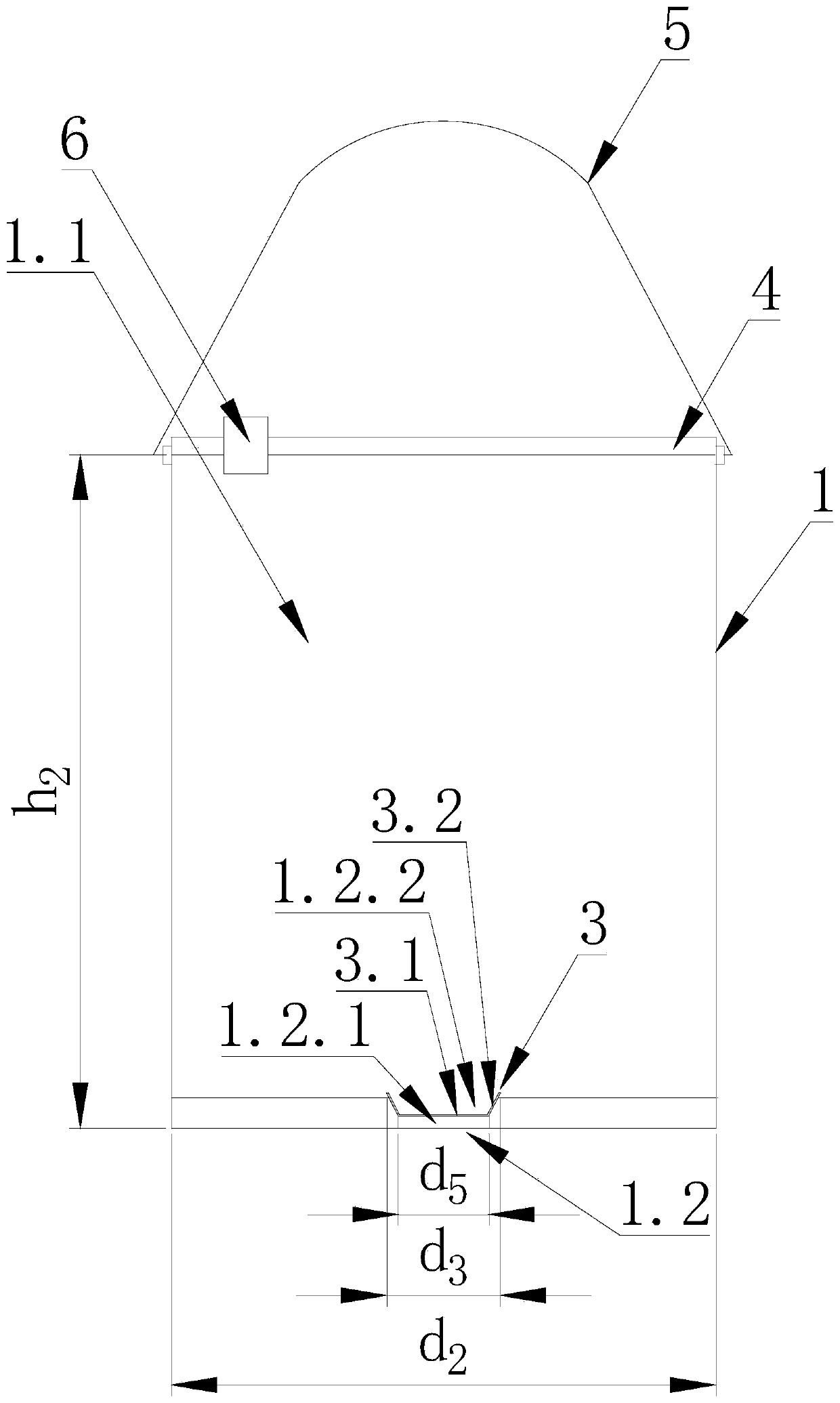

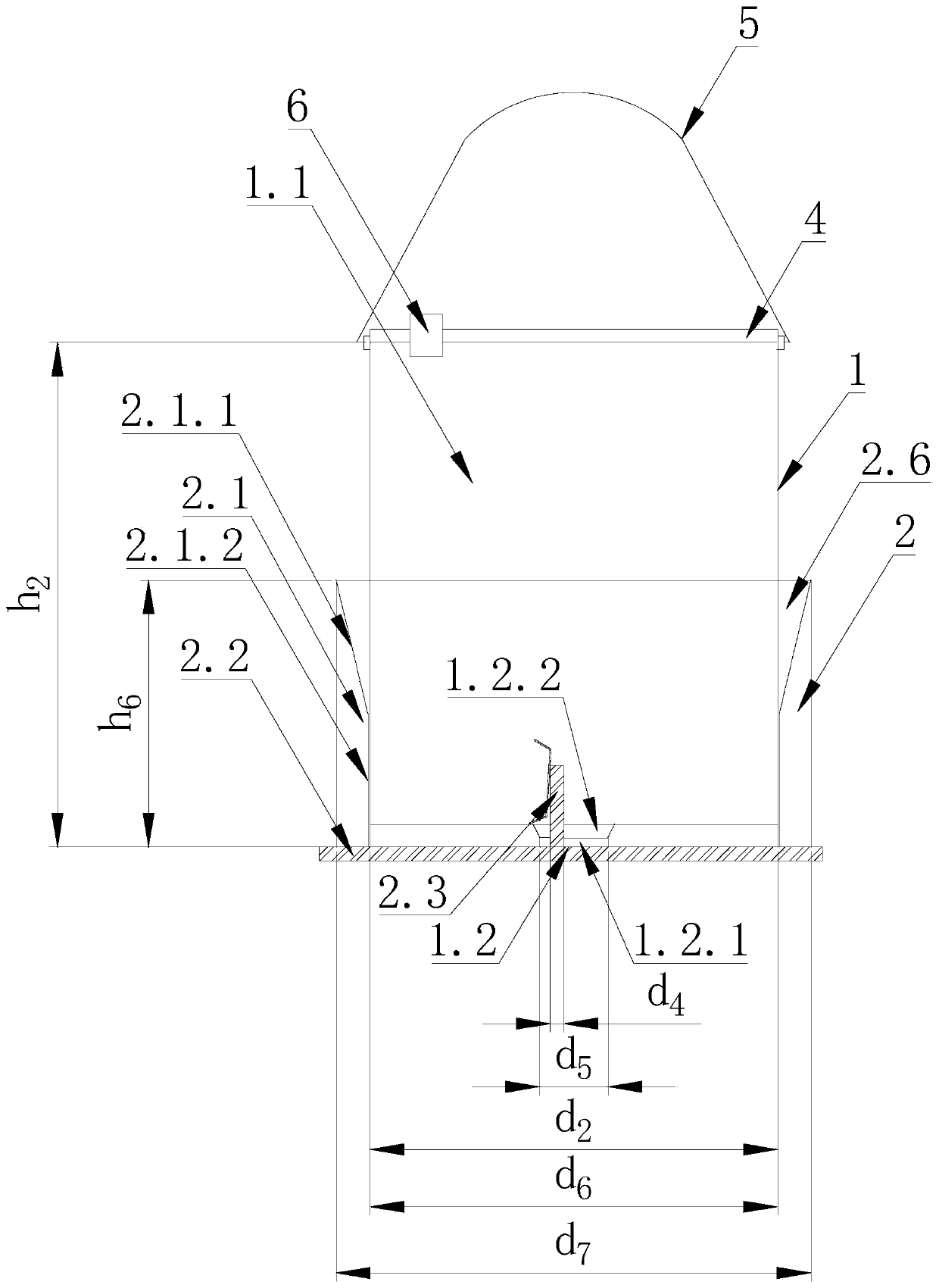

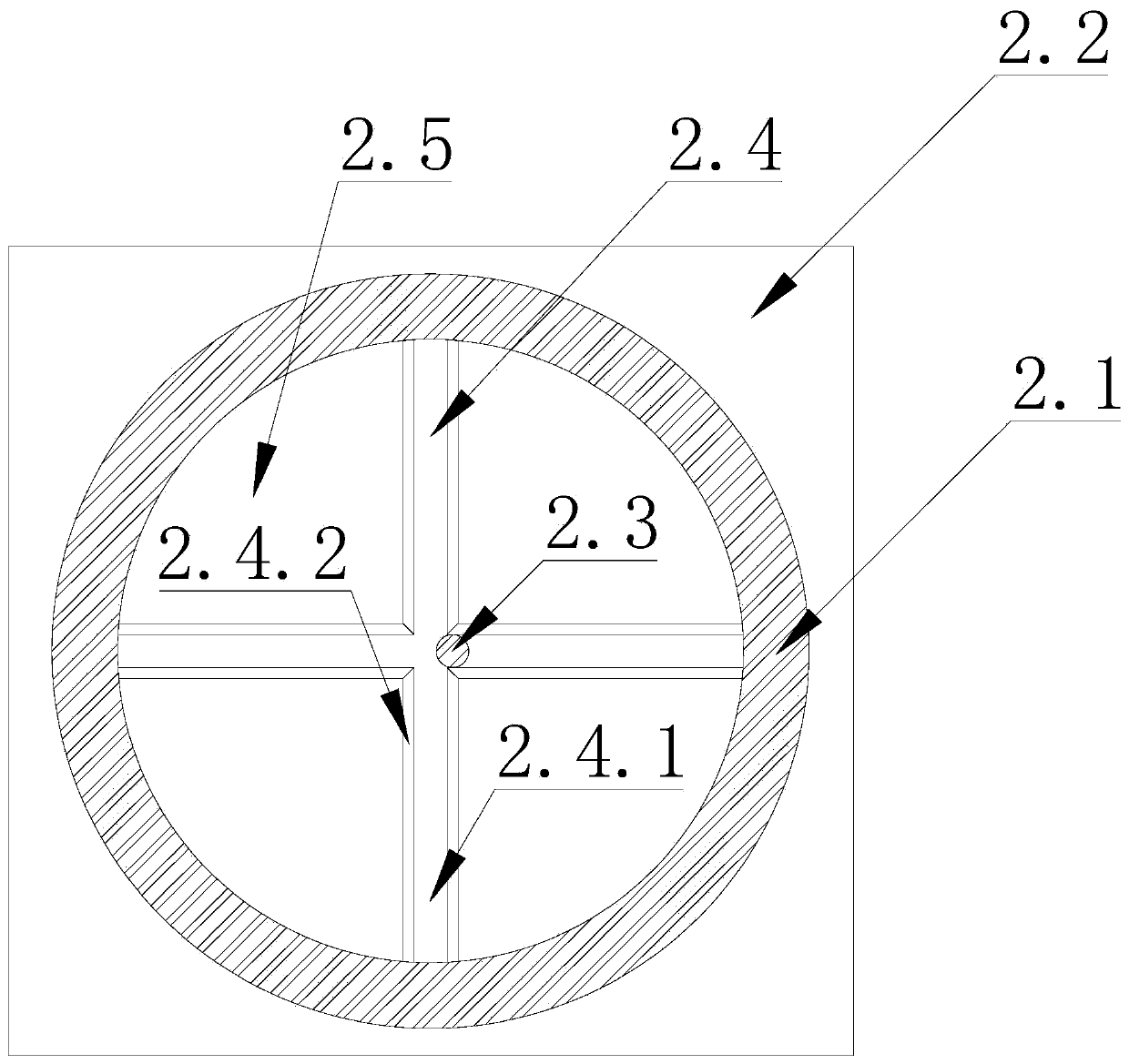

Multi-level back-grasp-type hollow anchor rod and construction method thereof

InactiveCN103572757AIncrease contact areaOutflow smoothlyBulkheads/pilesAnchoring boltsRock boltCement mortar

The invention discloses a multi-level back-grasp-type hollow anchor rod. The multi-level back-grasp-type hollow anchor rod comprises an anchoring rod with a grouting passage inside, an anchor head is fixed at the lower end of the anchoring rod, a plurality of back-grasp buckles are fixed on the anchoring rod, a grout outlet is formed in the anchor head, and the parts, at the upper side of the back-grasp buckles, of the anchoring rod and the parts, at the lower side of the back-grasp buckles, of the anchoring rod are provided with grout outlets and air return holes respectively, and the grout outlets and the air return holes are communicated with the grouting passage. Compared with the construction method of a hard rock body and a soil body, the construction method of the multi-level back-grasp-type hollow anchor rod comprises the steps of (a) preparation of equipment, (b) measurement and distribution of holes, (c) drilling, (d) hole cleaning and detection, (e) inserting of the anchor rod, (f) installation of a grout stop plug, (g) screwing of nuts and (h) grouting, and the anchor rod is directly inserted through the anchor head according to the construction method of a soft soil body, sand and water. The multi-level back-grasp-type hollow anchor rod and the construction method of the multi-level back-grasp-type hollow anchor rod increase the contact area and anchoring force between the anchor rod and the hole wall and prevent the anchor rod from falling out and injuring people. A uniform cement mortar layer can be formed around the anchor rod through the grout outlets and the air return holes, the damage of corrosion is avoided, and the purpose of long-time supporting is achieved.

Owner:SHANDONG JIAOTONG UNIV

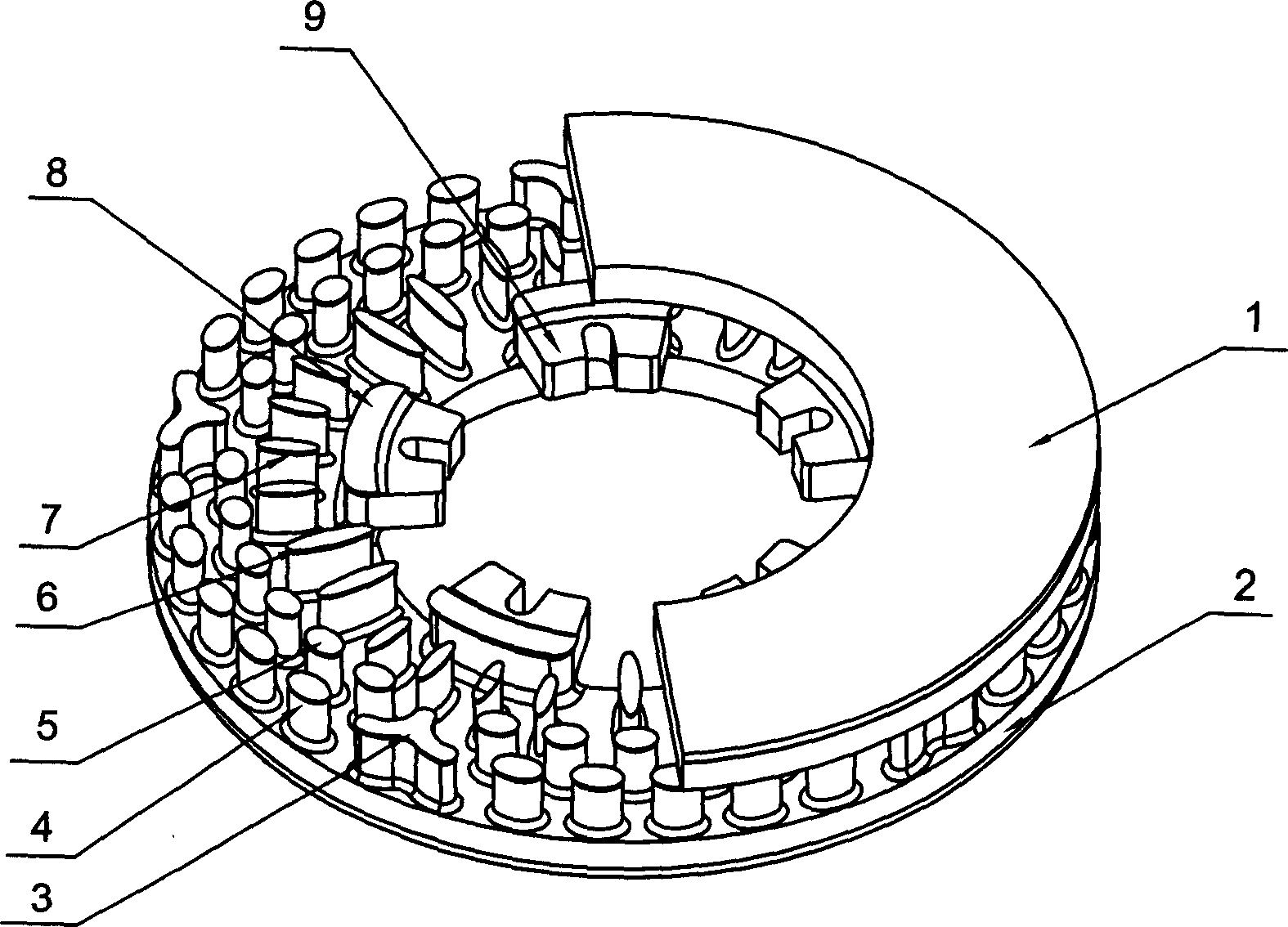

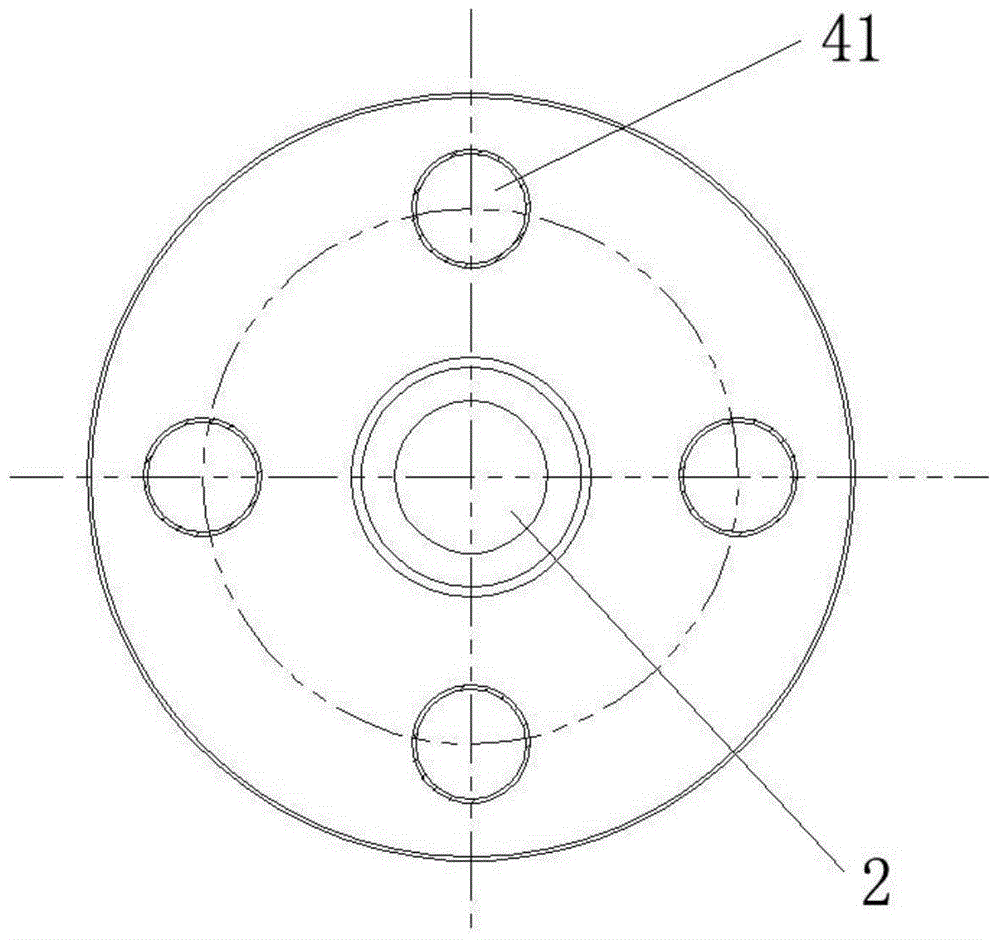

Shaft mounted brake disk of SiC granule enhanced aluminium based composite material

The invention consists of upper and lower friction disks, cooling fins and a flange. The cooling fins have six shapes. Five T-shaped cooling columns are uniformly distributed on the circle phi 600 mm of the friction disk and between two T-shaped cooling columns are uniformly distributed five cylindrical cooling fins. Ten plate cooling fins located on the circle phi 420 mm is divided into five groups with two fins each distributed uniformly along circumference and twenty plate cooling fins located on the circle phi 454 mm is divided into five groups with four fins each distributed uniformly along circumference. Five arc cooling fins are uniformly distributed along the inner ring of the friction disk. The flange of the brake disk is connected with the arc cooling column.

Owner:BEIJING JIAOTONG UNIV

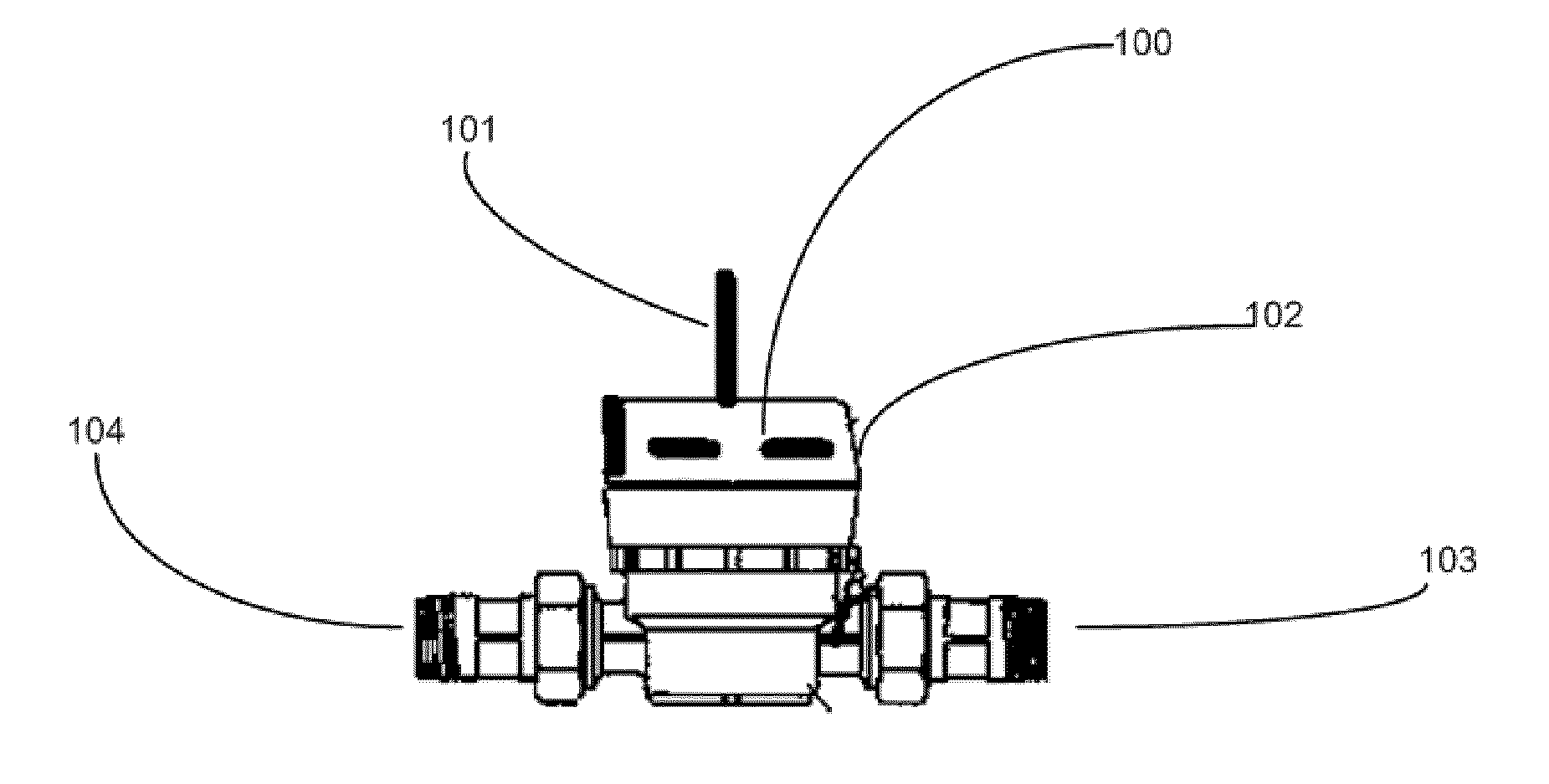

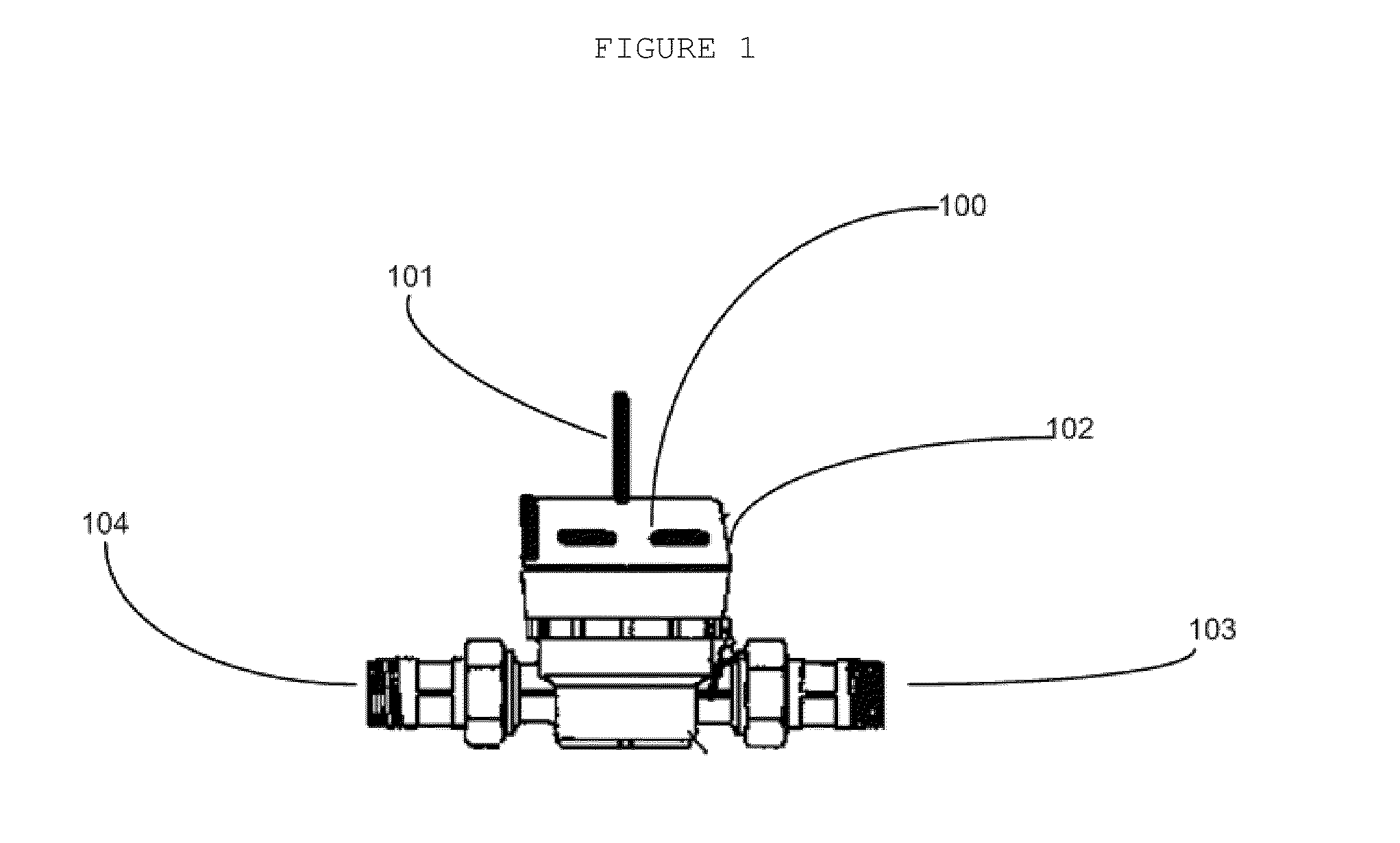

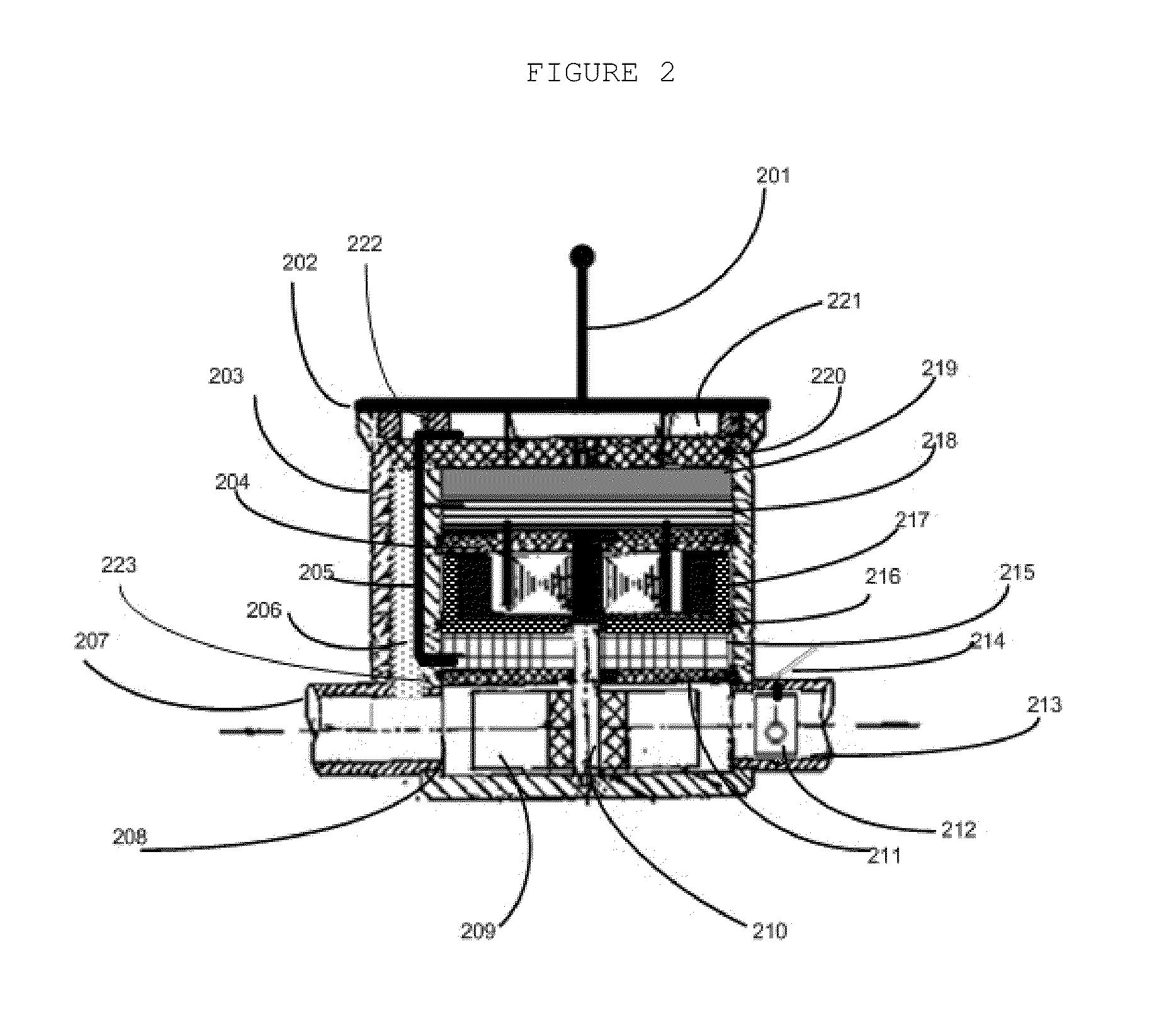

Self dynamo smart flow utility meter and system for flow utility real-time flow usage monitoring and control, self error and leakages monitoring

InactiveUS20110298635A1Reduce chanceImprove efficiencyVolume meteringVolume/mass flow by mechanical effectsTraffic volumeElectric energy

A self dynamo smart flow utility meter providing self electric energy, real-time wireless data transmission ability and remotely flow control ability is disclosed. Also, a method and system for flow utility real-time flow usage monitoring and control, self error diagnostic and self leakage monitoring is disclosed.

Owner:YIP BERNIE

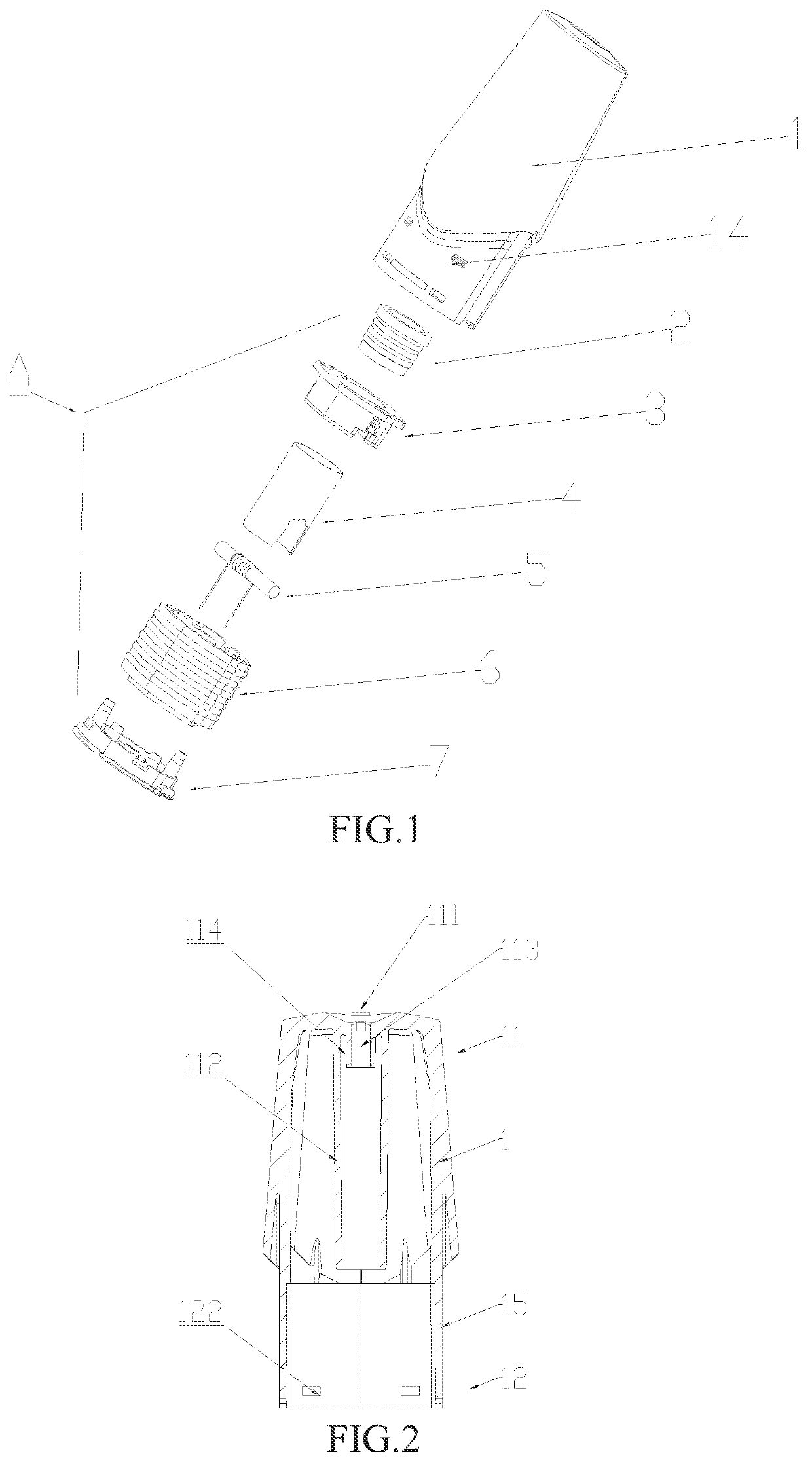

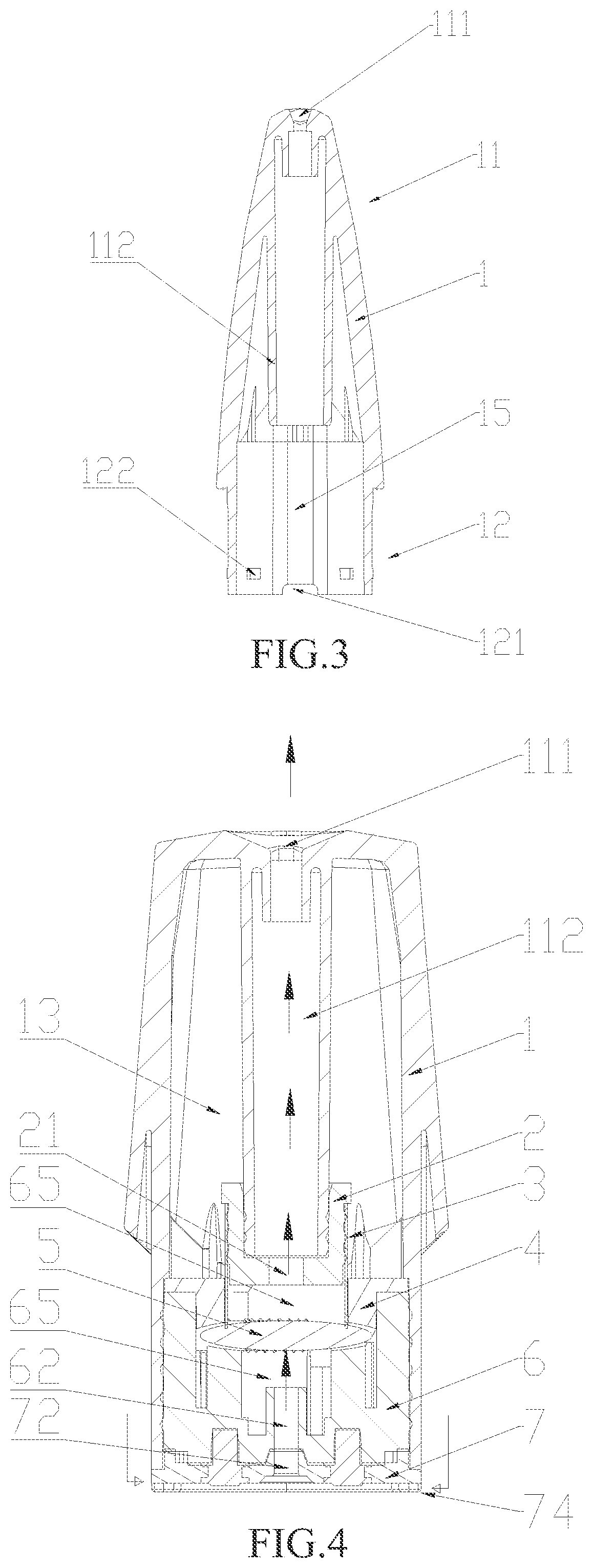

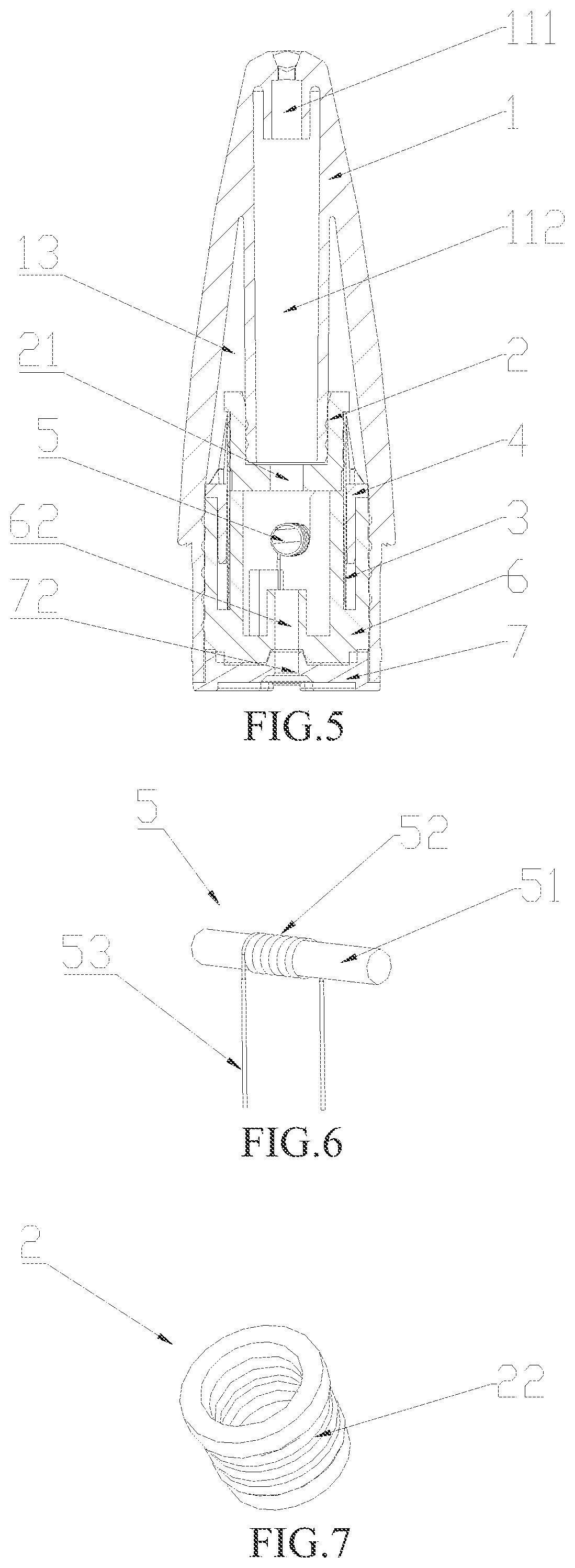

Electronic cigarette vaporizer

ActiveUS20190364972A1Fast supplyIncrease productionEngine sealsHeater elementsEngineeringElectronic cigarette

An electronic cigarette vaporizer comprises a hollow vaporizer housing and a vaporizing device sleeved inside the vaporizer housing; wherein the vaporizer housing has a mouthpiece end and an opening end arranged with a connecting device for connection with the battery component, a mouthpiece is arranged in a center of the mouthpiece end, a vapor outlet tube extending in an inward direction from the mouthpiece to a middle portion of the vaporizer housing is arranged; wherein the vaporizing device is disposed in the vaporizer housing at one side where the opening end is formed, and comprises a vapor tube sleeve, a throttle lid, a heating unit, a vaporizing base and an electrode lid, which are arranged in turn towards the outer side from the inner side, and the throttle lid is provided with throttle orifices for directly communicating the liquid storage chamber and the end portions of the liquid guiding strip.

Owner:HUIZHOU HAPPY VAPING TECH LTD

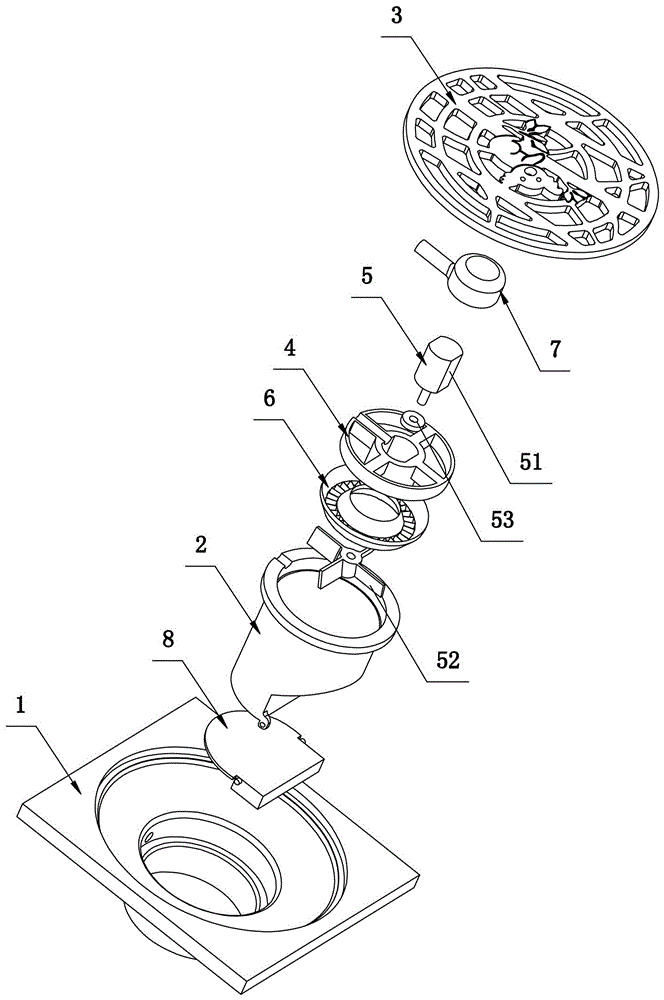

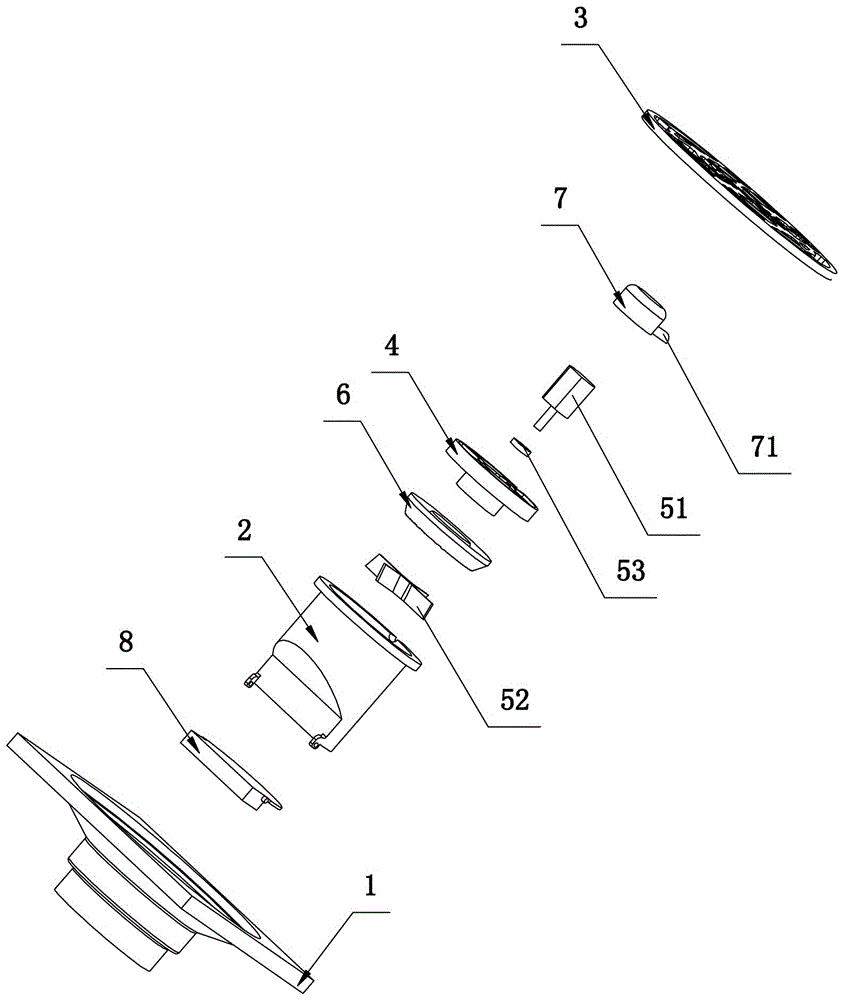

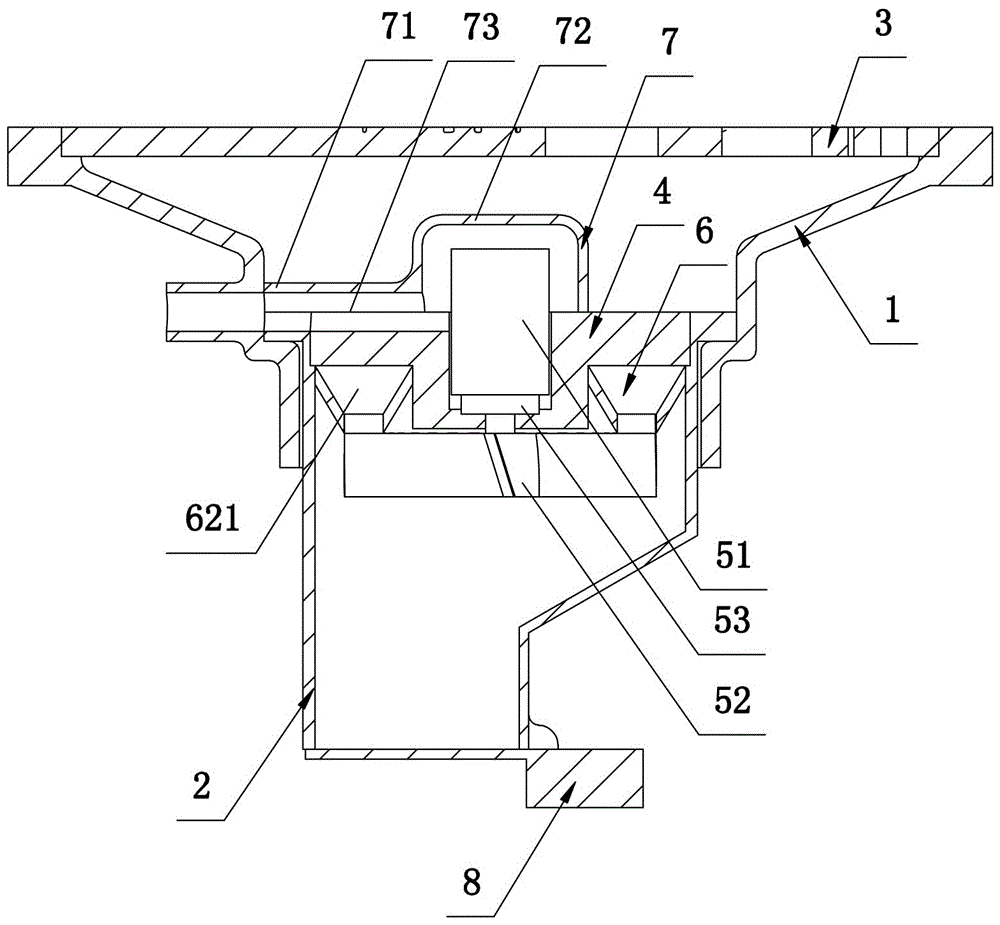

Anti-blocking floor drain for bathroom

ActiveCN106245746ASimple structurePracticalSewerage structuresDomestic plumbingHydroelectricityElectric energy

The invention provides an anti-blocking floor drain for a bathroom. The anti-blocking floor drain comprises a floor drain frame body which is used for connecting a bathroom water discharging pipeline and bathroom ground; a floor drain core body for discharging water is erected at the lower side in the floor drain frame body, and a round cover is erected at the upper side of the floor drain frame body; the anti-blocking floor drain further comprises a hydroelectric generator which is arranged in a water inlet pipeline of the bathroom; a tool rest is embedded into the upper side of the floor drain core body; the tool rest is provided with a cutting mechanism capable of cutting hairs; the cutting mechanism comprises a mini-type direct current motor and a rotary blade; and a current input end of the mini-type direct current motor is electrically connected with the hydroelectric generator, and an output shaft of the mini-type direct current motor is in transmission connection with the rotary blade. As the cutting mechanism and the hydroelectric generator are arranged, when a user utilizes water, the hydroelectric generator can generate electric energy under the action of hydraulic power, and the electric energy is transmitted to the mini-type direct current motor, so that the rotary blade is controlled to rotate and the hairs are cut off, and furthermore, the hairs can smoothly flow out from the water discharging pipeline; and the electric energy can be saved, and the blocking of the water discharging pipeline can also be effectively avoided.

Owner:SANMING CITY YIJUN MACHINERY FOUNDRY

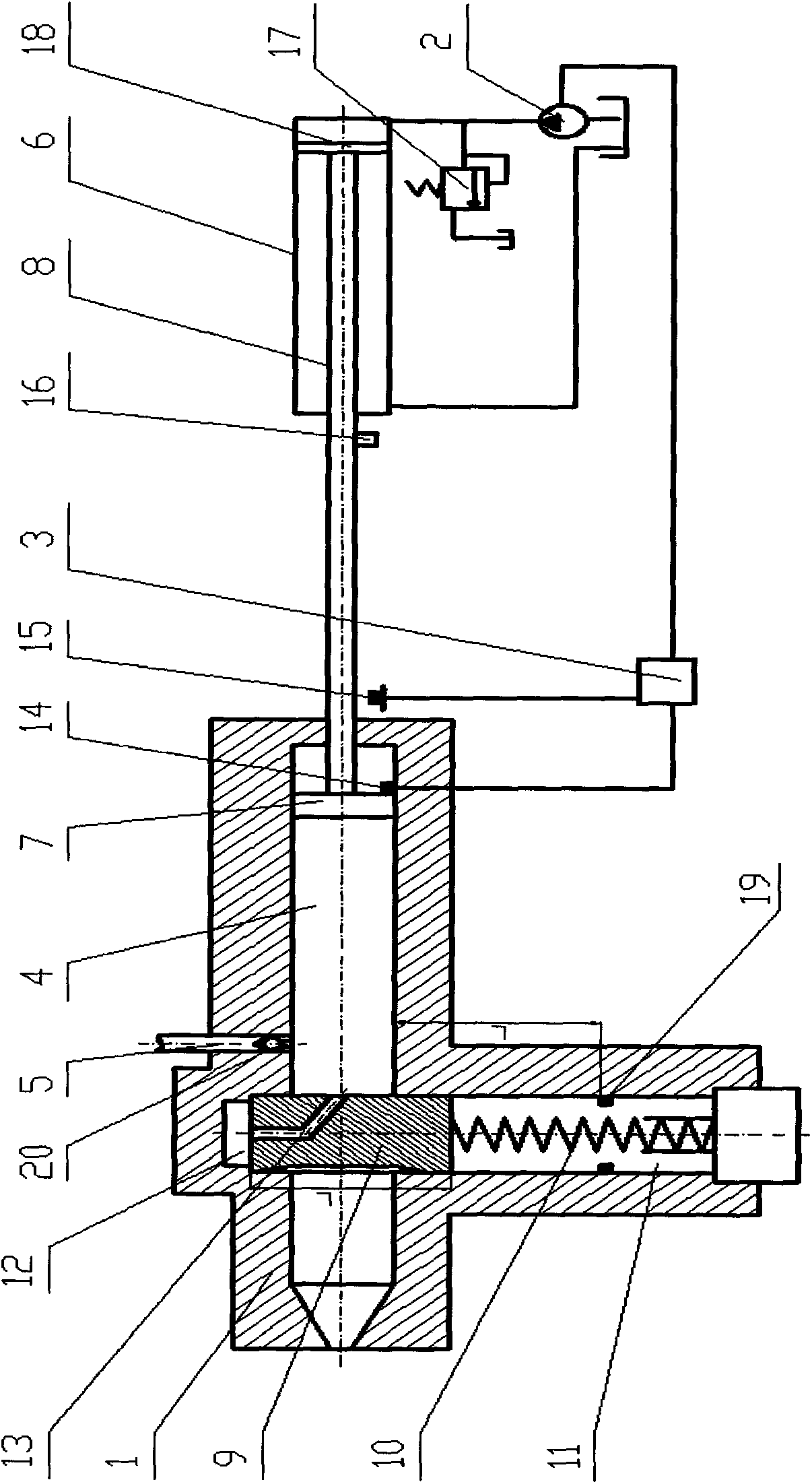

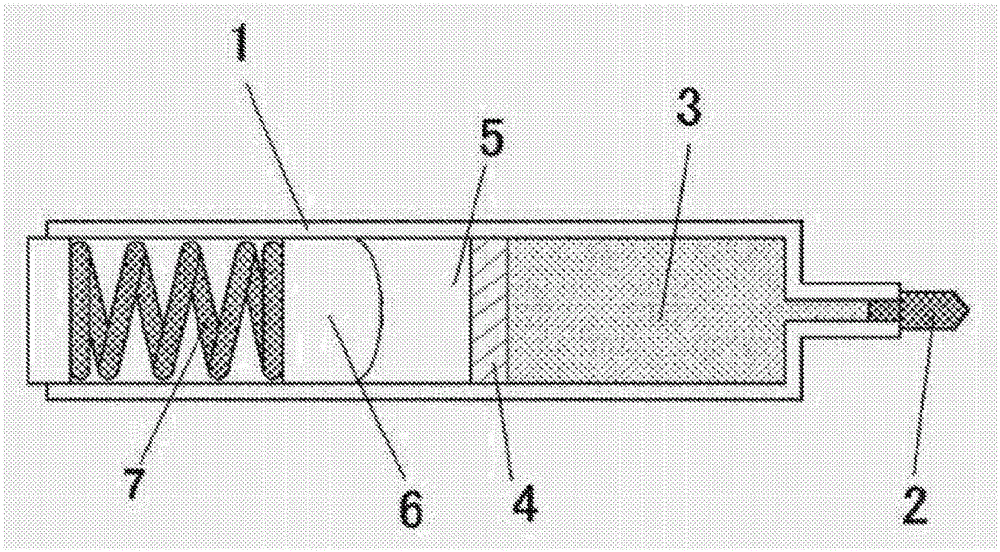

Non-return quantitative constant-pressure injection device

The invention discloses a non-return quantitative constant-pressure injection device which comprises a nozzle body, a valve core mechanism, an injection oil cylinder, a hydraulic system and a controller, wherein a flow channel and a liquid inlet are formed in the nozzle body; the valve core mechanism for opening or closing the nozzle body is mounted in the nozzle body; the injection oil cylinder comprises an oil cylinder body and a hydraulic rod with a first piston at the front end part; the hydraulic rod with the first piston extends into the flow channel of the nozzle body; the hydraulic system is connected with the oil cylinder body and is used for driving the injection oil cylinder. The injection device is characterized by further comprising a hydraulic rod stroke control device; both the hydraulic system and the hydraulic rod stroke control device are electrically connected with the controller. The injection device is simple in structure and high in reliability, and can achieve intermittent, quantitative and constant-pressure injection.

Owner:佛山市韵雄塑料五金制品有限公司

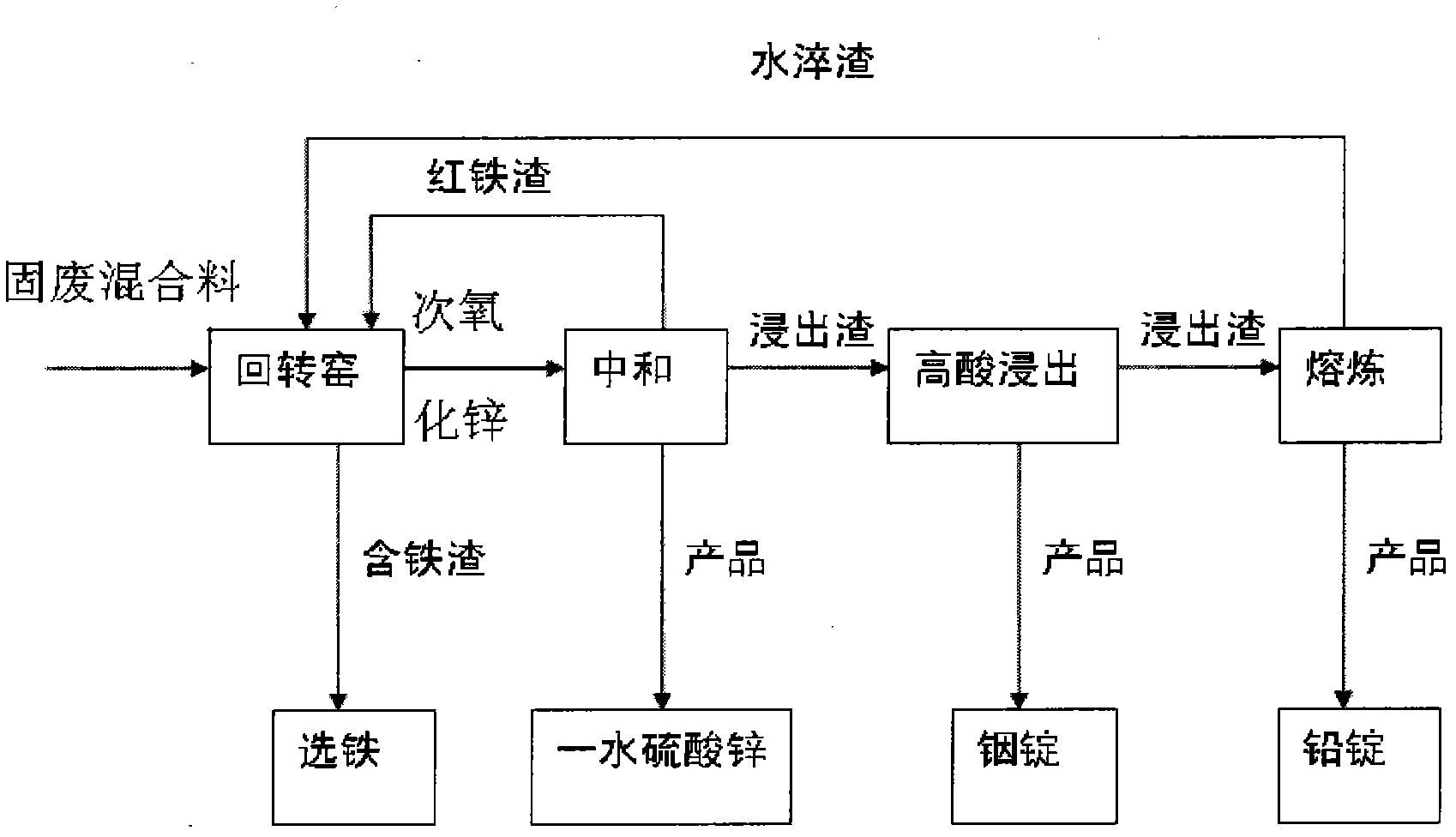

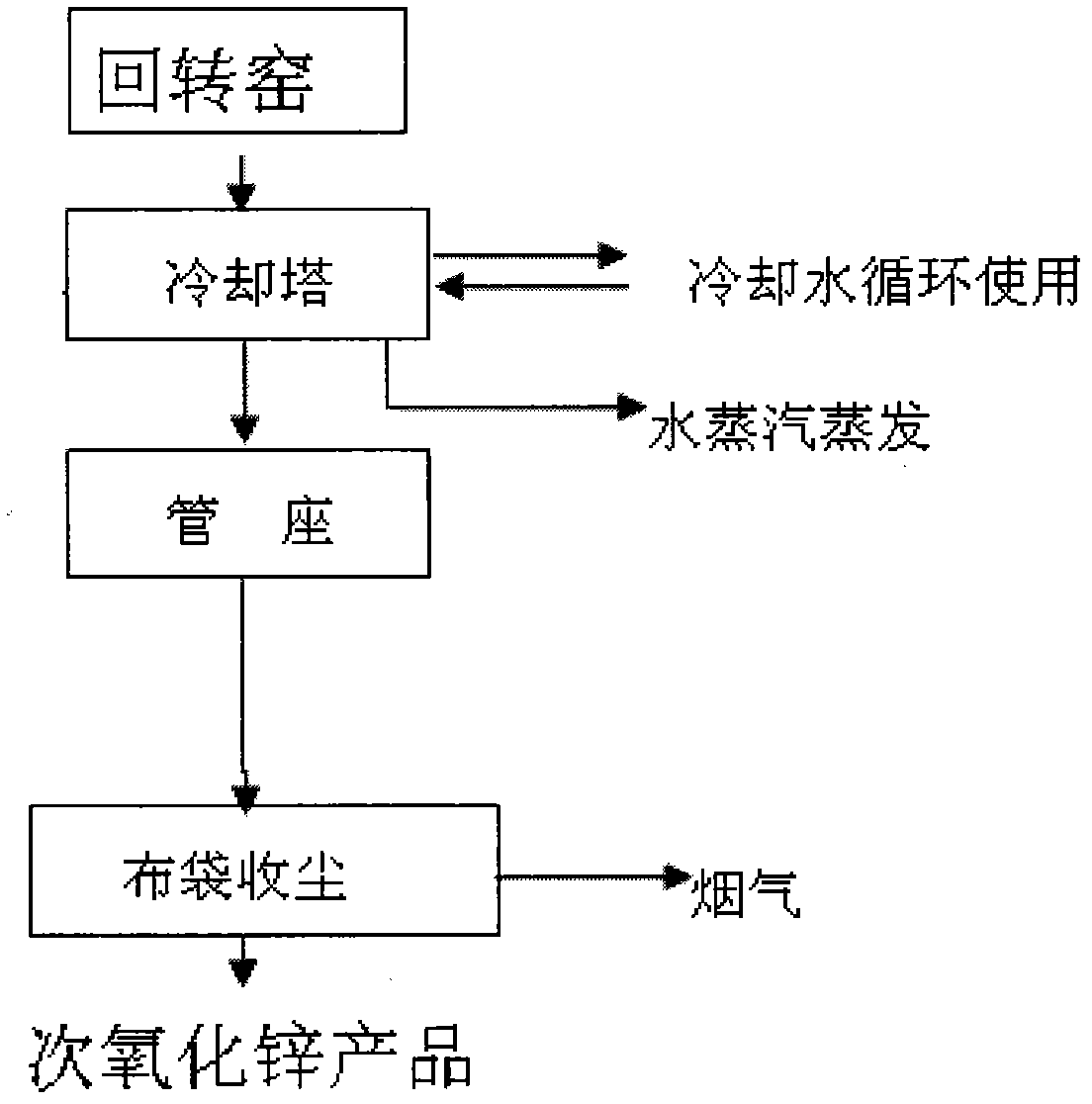

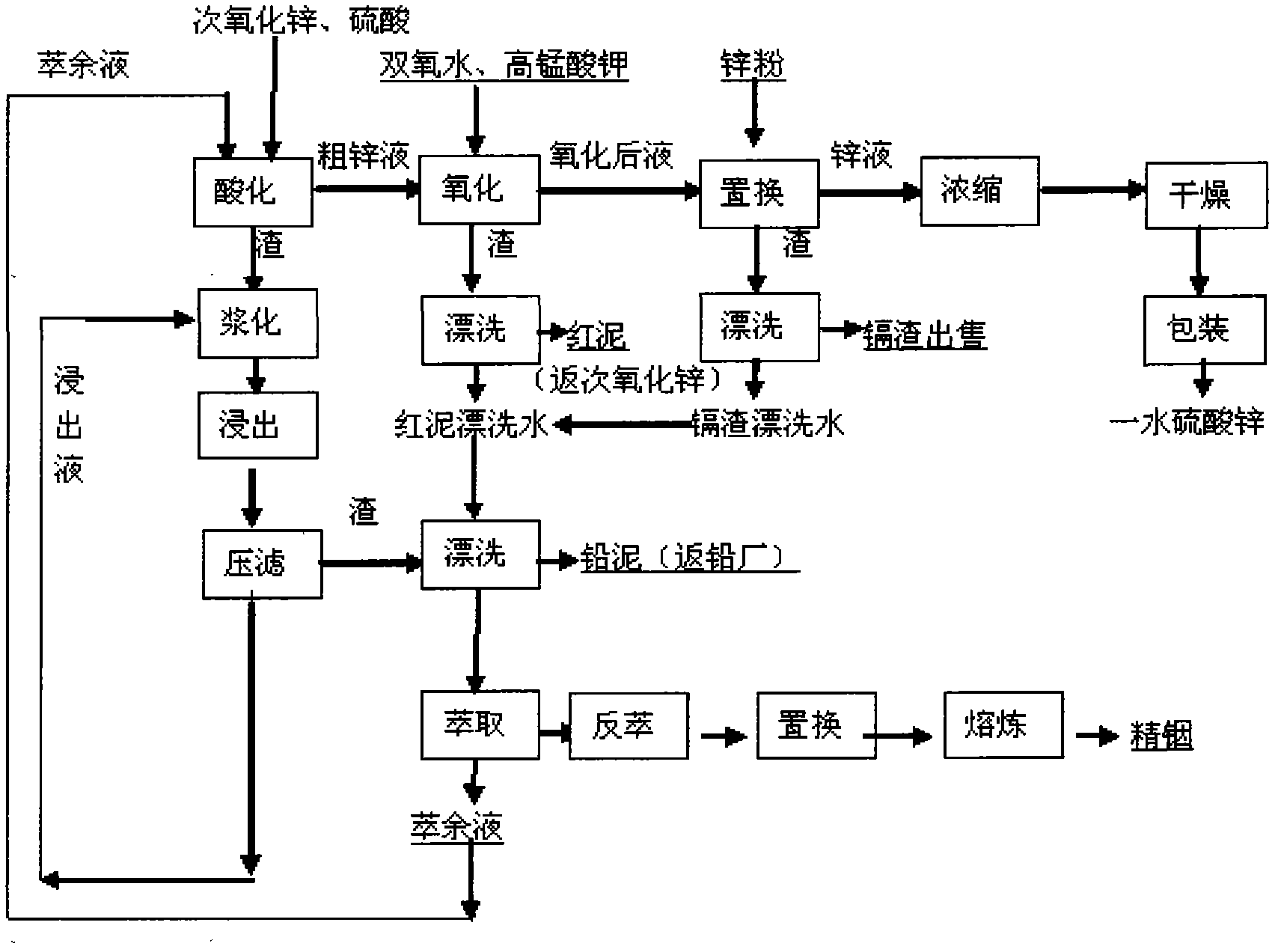

Treatment method for harmless reclamation of solid waste of heavy metal

ActiveCN102560124ABurn fullyReduce maintenance costsProcess efficiency improvementSlagZinc sulfate monohydrate

The invention discloses a treatment method for harmless reclamation of solid waste of heavy metal, comprising the following steps: adding coal-free solid waste mixture with low heat value to a rotary kiln for harmless reclamation of solid waste of heavy metal; combusting the solid waste mixture at a high temperature in the rotary kiln to produce zinc hypoxide and gather other valued metals; producing iron powders from the iron-containing slag that is generated in the rotary kiln as iron screening raw material; using zinc hypoxide as raw material to conduct acid leaching for neutralization to produce zinc sulfate monohydrate, then using the red iron slag that produces zinc sulfate monohydrate as the raw material for zinc hypoxide and leaching the leached slag that produces zinc sulfate monohydrate with high acid to reclaim indium ingot; after reclamation of the indium ingot, smelting the leached slag as raw material of lead to produce lead ingot; and recovering the water-hardening slag that produces lead ingot as the raw material for zinc hypoxide. The treatment method of the invention realizes zero discharge of waste water and slag, which not only saves the energy, but also realizes reclamation and comprehensive utilization of the resources and greatly lowers the production cost of the companies so as to create a core competence of the company.

Owner:唐锡中

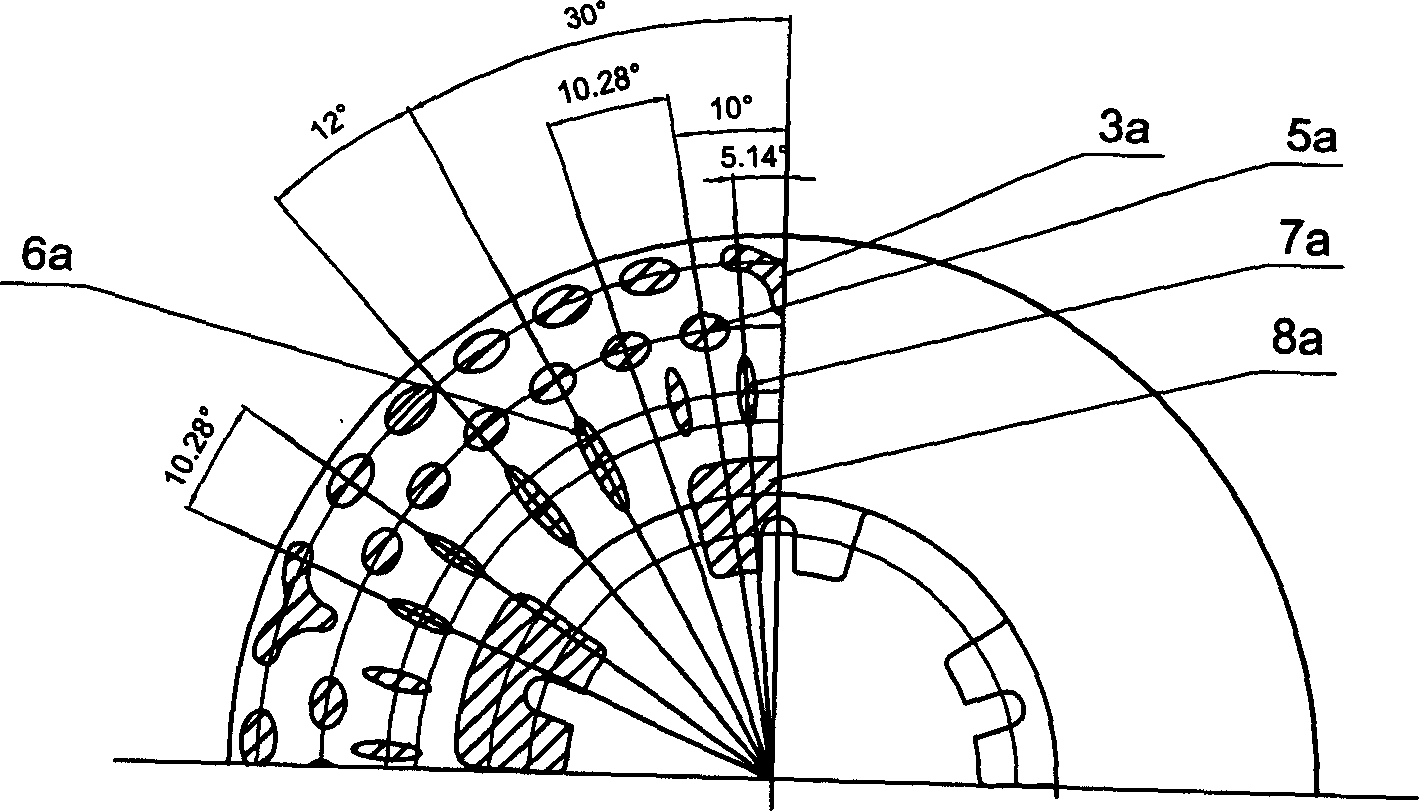

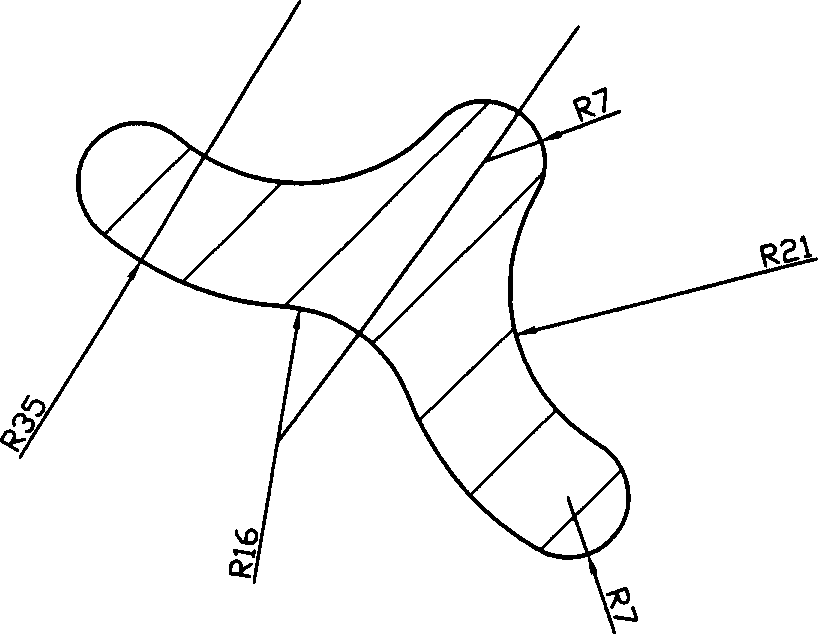

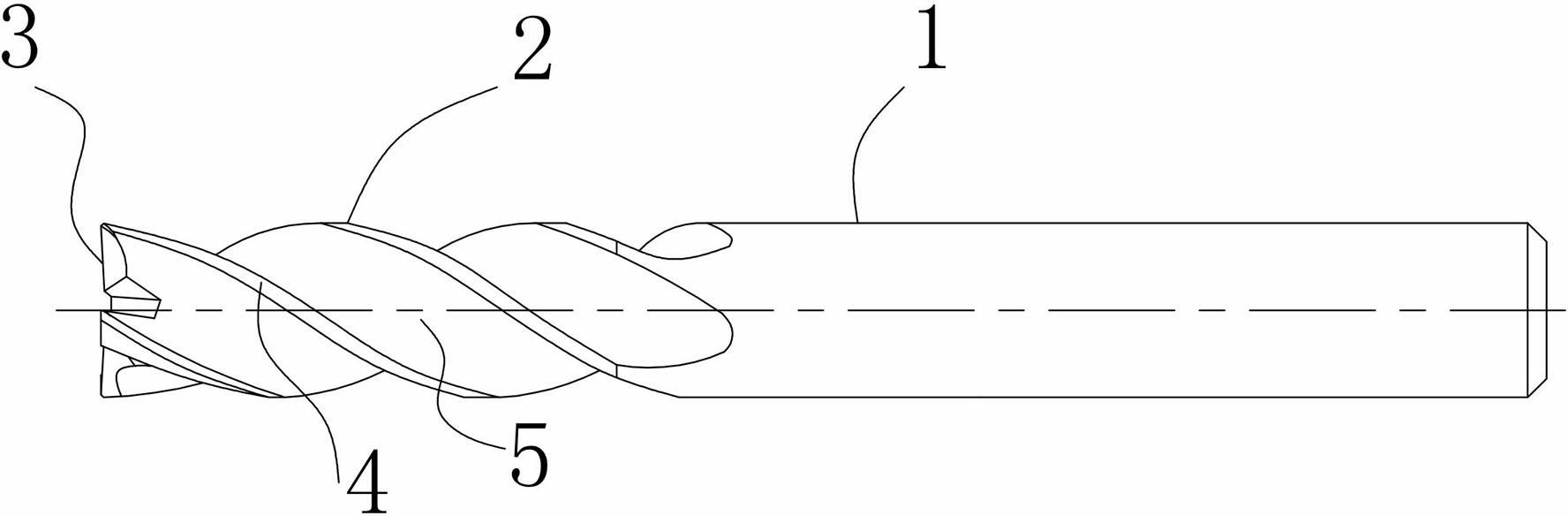

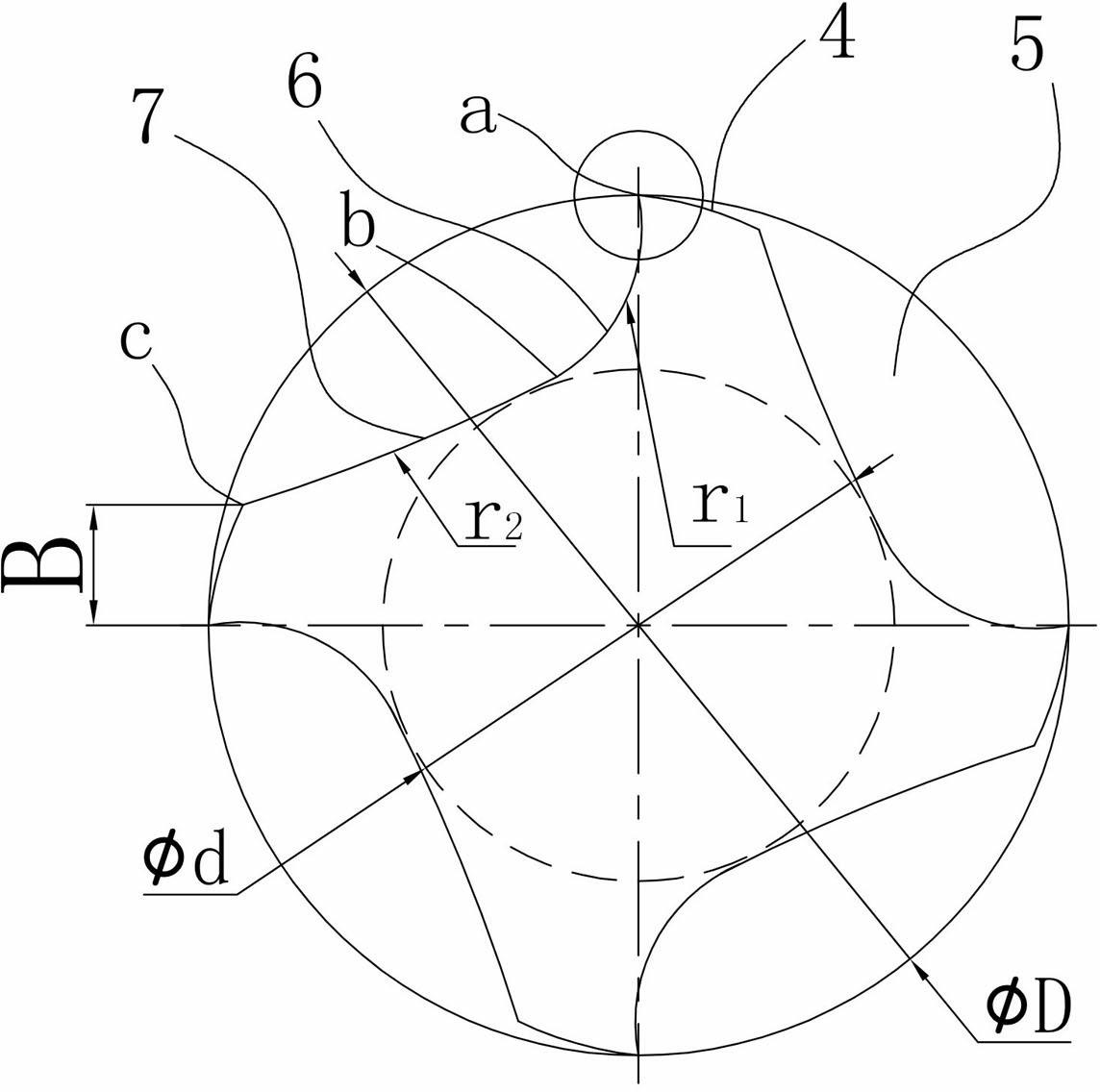

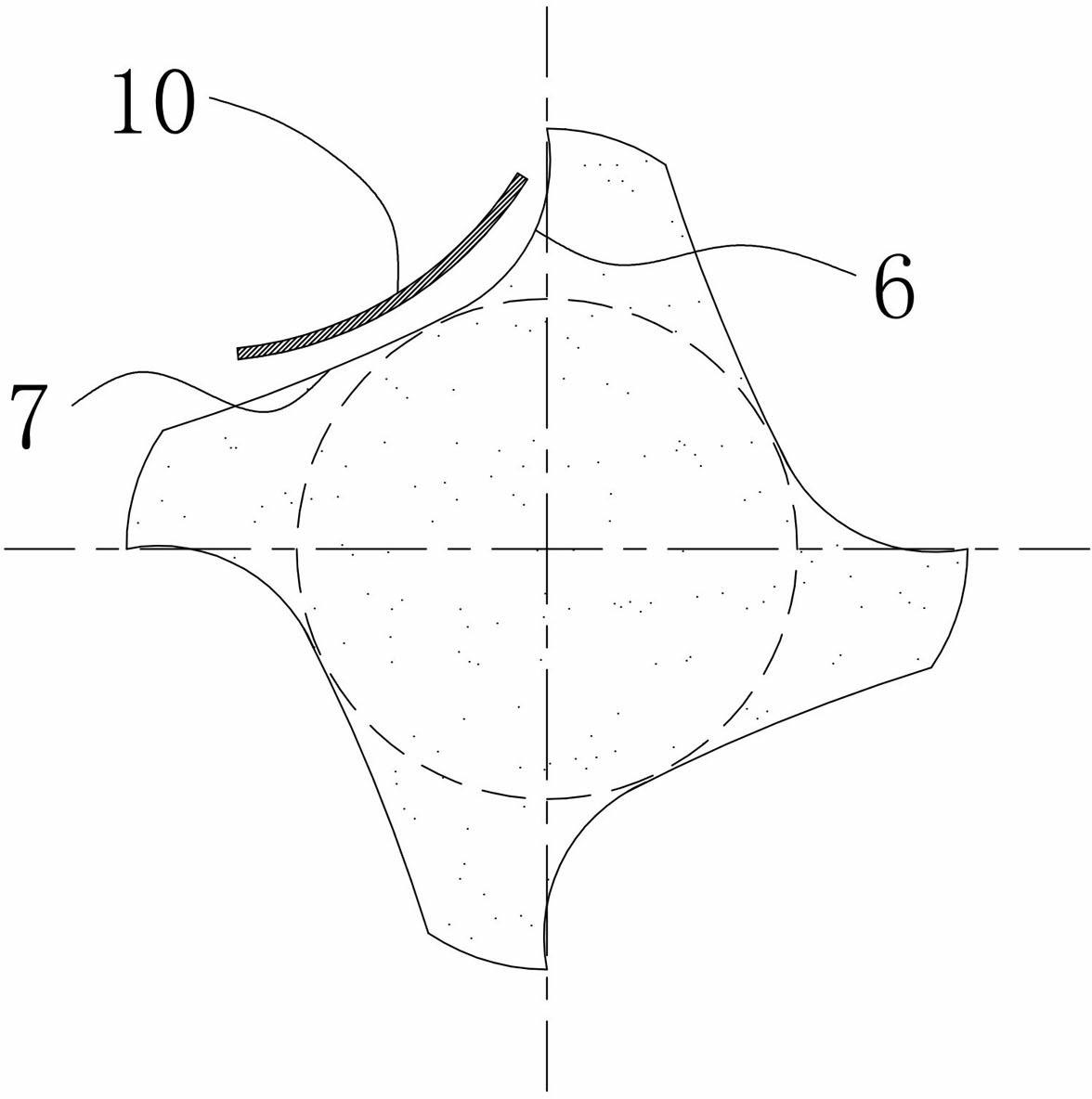

Groove type end mill with double arcs

The invention relates to a groove type end mill with double arcs. The end mill comprises a handle part and a cutting part, wherein the cutting part comprises an end surface cutting teeth, a peripheral cutting teeth and a chip storage groove. The radial profile of the chip storage groove is formed through a groove front tool face arc and a groove back tool face arc. The groove front tool face arc passes the point a and the point b. The groove back tool face arc passes the point b and the point c. The point b is the inner tangent point of the groove back tool face arc and the groove front tool face arc. With adopting the rotating center of the end mill as the origin, the coordinates of all the points on the groove front tool face arc are meet the following formula: (x-a1)*2+(y-b1)*2=r12, wherein the r1 is the radius of the groove front tool face arc, the a1 is not equal to 0, the b1 is not equal to 0; the coordinates of all the points on the groove back tool face arc are meet the following formula: (x-a2)*2+(y-b2)*2=r22, wherein the r2 is the radius of the groove back tool face arc, the a2 is not equal to 0, the b2 is not equal to 0. The end mill provided by the present invention has characteristics of simple structure, rigidity of the cutting tool, chip accommodation capacity of the cutting tool, and chip discharging capacity of the cutting tool; when the cutting tool is adopted for processing titanium alloy, high temperature alloy, stainless steel and other difficult processing materials, the service life of the cutting tool can be significantly improved, and the cost can be reduced.

Owner:ZHUZHOU CEMENTED CARBIDE CUTTING TOOLS CO LTD

Air silencer

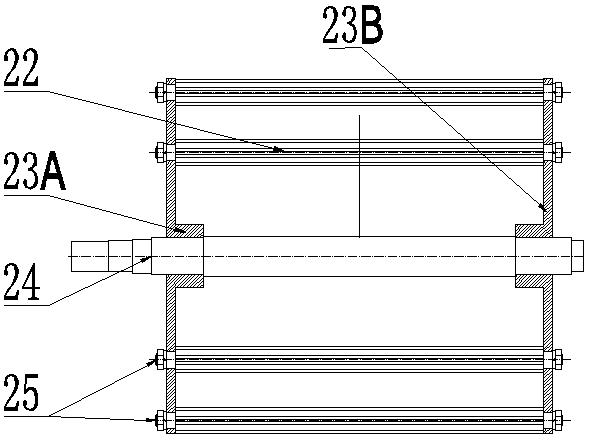

InactiveCN104575482AImprove the noise reduction effectFast solutionSound producing devicesAirflowEngineering

The invention relates to an air silencer which comprises an outer barrel body, an air inlet pipe and an air outlet pipe, wherein the inner part of the outer barrel body is partitioned into a first cavity and a second cavity by a partition plate; a plurality of air pipes communicated with the first cavity and the second cavity are arranged on the partition plate; a distance between the first end face, positioned in the first cavity, of the air inlet pipe and the partition plate is smaller than a distance between the second end face, positioned in the first cavity, of each air pipe; a sound absorption structure for sound absorption is formed in the second cavity; a resisting silencer is arranged in the first cavity, and a resistive silencer is arranged in the second cavity, so that low, medium and high-frequency noise in high-speed air flow can be eliminated; after entering the first cavity, external high-speed air flow flows towards the partition plate and then returns so as to enter the second cavity from the air pipes; therefore, all the air flows go through such a 'backflow' process in the first cavity, and the air silencer disclosed by the invention is extremely good in silencing and noise reduction effects under an environment with high pressure difference and high flowing speed.

Owner:ZHEJIANG TIANCHEN PLASTIC IND

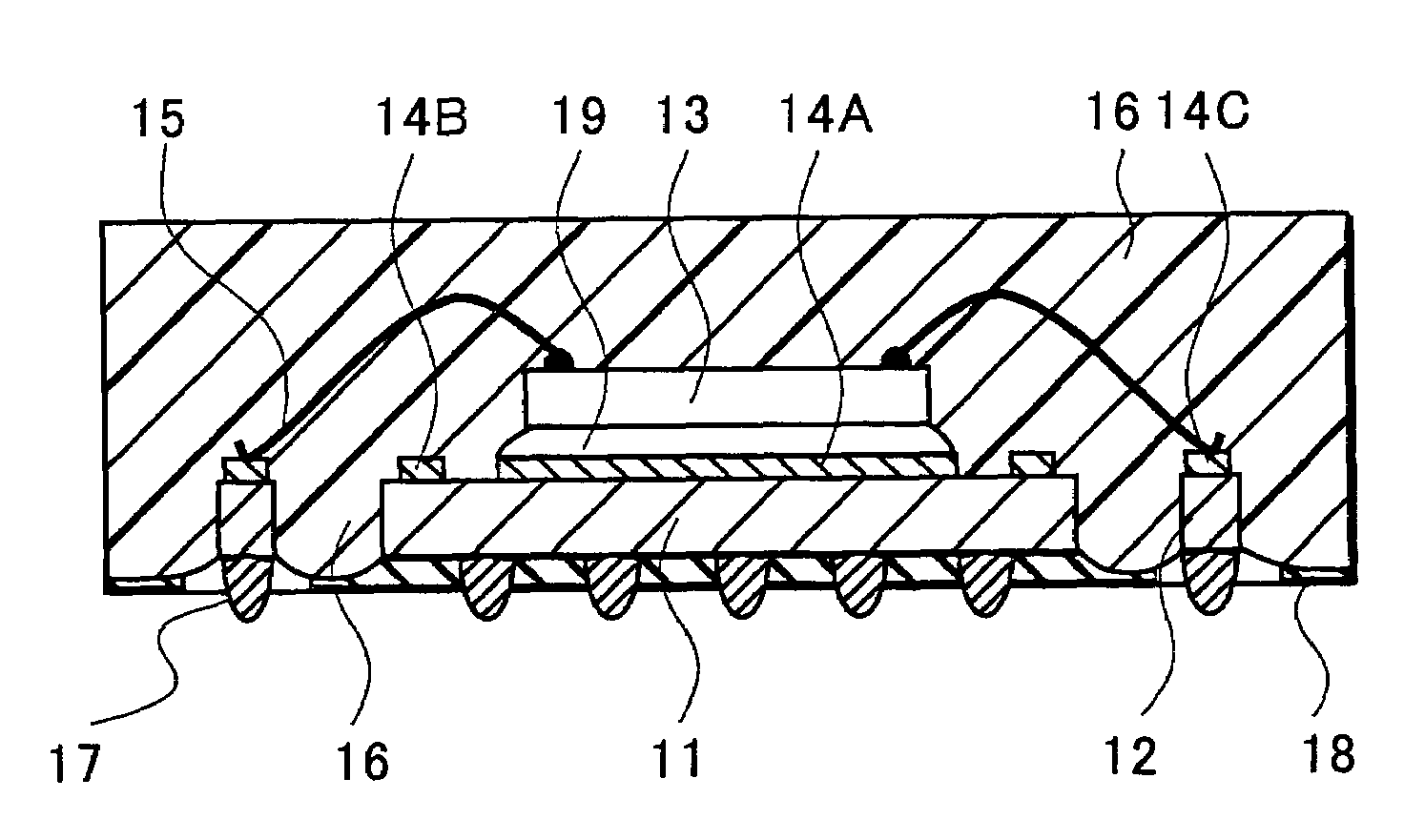

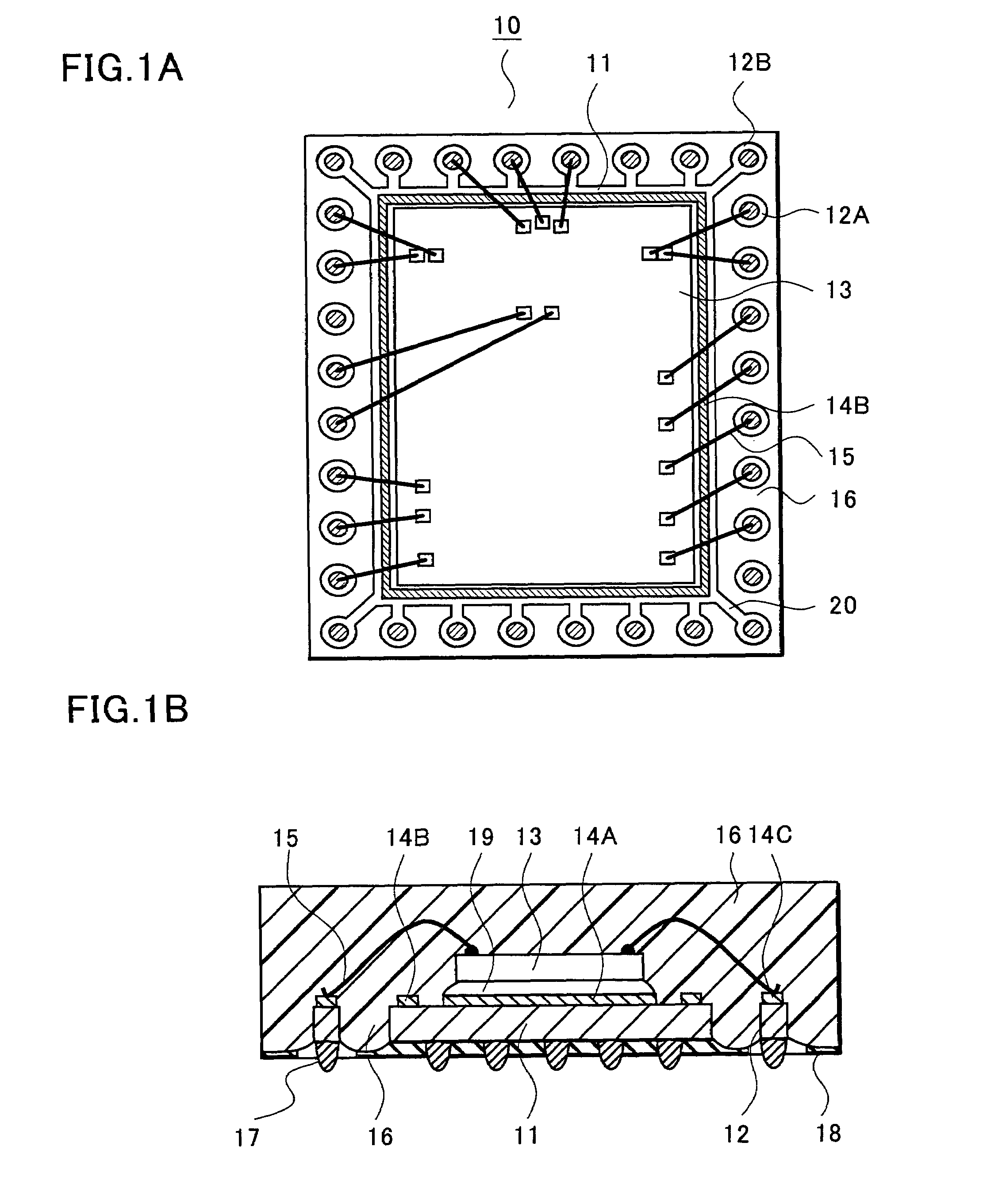

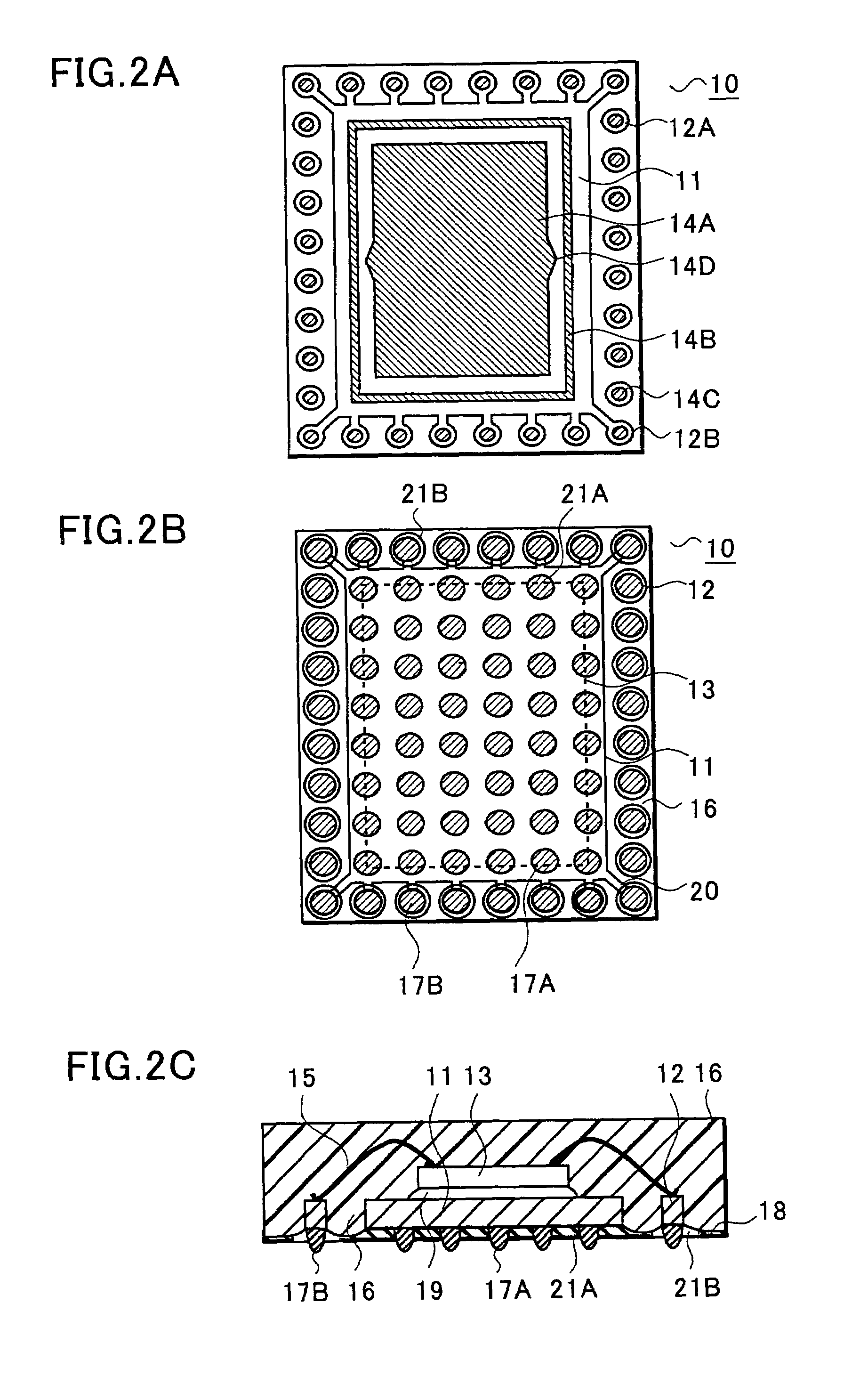

Circuit device and method of manufacturing the same

InactiveUS7053492B2Constant thicknessOutflow smoothlySemiconductor/solid-state device detailsSolid-state devicesBrazingCoating

The overflow of a brazing material (19) from a die pad (11) is prevented by forming a second plating film (14B) on the surface of the die pad (11). The second plating film (14B) is provided around the surface of the die pad 11 so as to enclose an area where a semiconductor element (13) is mounted. In a step of mounting the semiconductor element (13) on the die pad (11) with the brazing material (19), the brazing material (19) overflows from the first plating film (14A) when the semiconductor element (13) is mounted on the upper part of the molten brazing material. However, the second plating film (14B) functions as a blocking area by which the overflow of the brazing material is prevented. Therefore, a short circuit can be prevented from arising between the die pad (11) and the bonding pad (12) because of the brazing material that has spread.

Owner:SANYO ELECTRIC CO LTD +1

Opening device for can

InactiveUS20050173437A1Easy to openOutflow smoothlyRefuse receptaclesRigid containersEngineeringRivet

The present invention relates to an opening device for a can, which is constructed such that the contents of the can flow out and exterior air is simultaneously introduced into the can. The opening device of the present invention comprises first and second opening portions 122 and 124 through which the contents flow out and the exterior air is introduced into the can upon opening thereof, respectively, and which are disposed to be opposite to each other at both sides of the top surface 110 of the can and defined by incision lines 122a and 124a so that a part of each of the opening portions is attached to the top surface; and a tab 140 mounted on the top surface of the can by means of a first rivet stub Ra installed outside of the first opening portion and a second rivet stub Rb installed within the second opening portion. The second opening portion is opened while being lifted together with the second rivet stub Rb, the first opening portion is opened while being pressed by a pressing portion 144 around the first rivet stub, and the second rivet stub is formed to be closer to a grip 172 of the tab 170 than the first rivet stub.

Owner:HWANG BO YEOUN

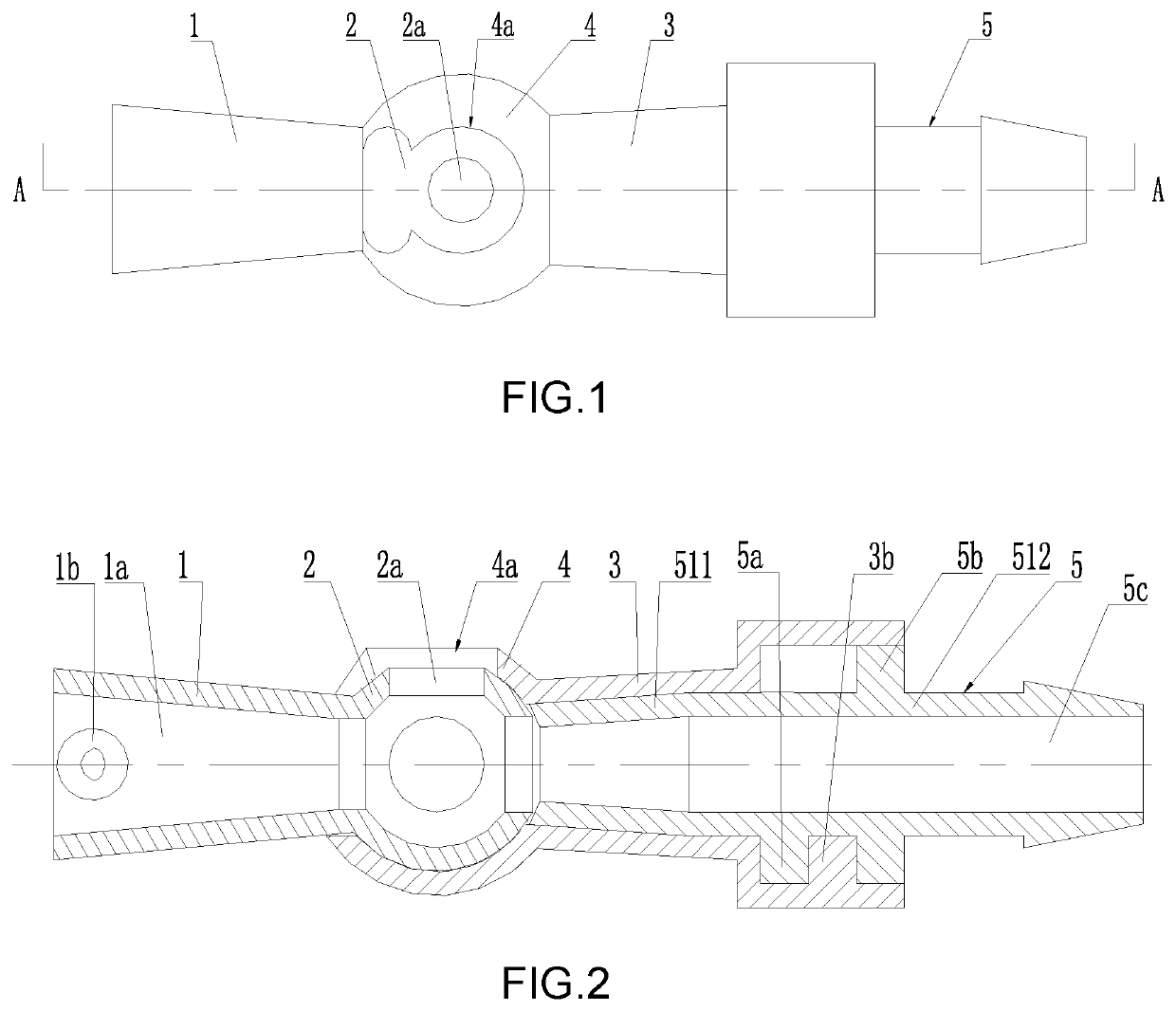

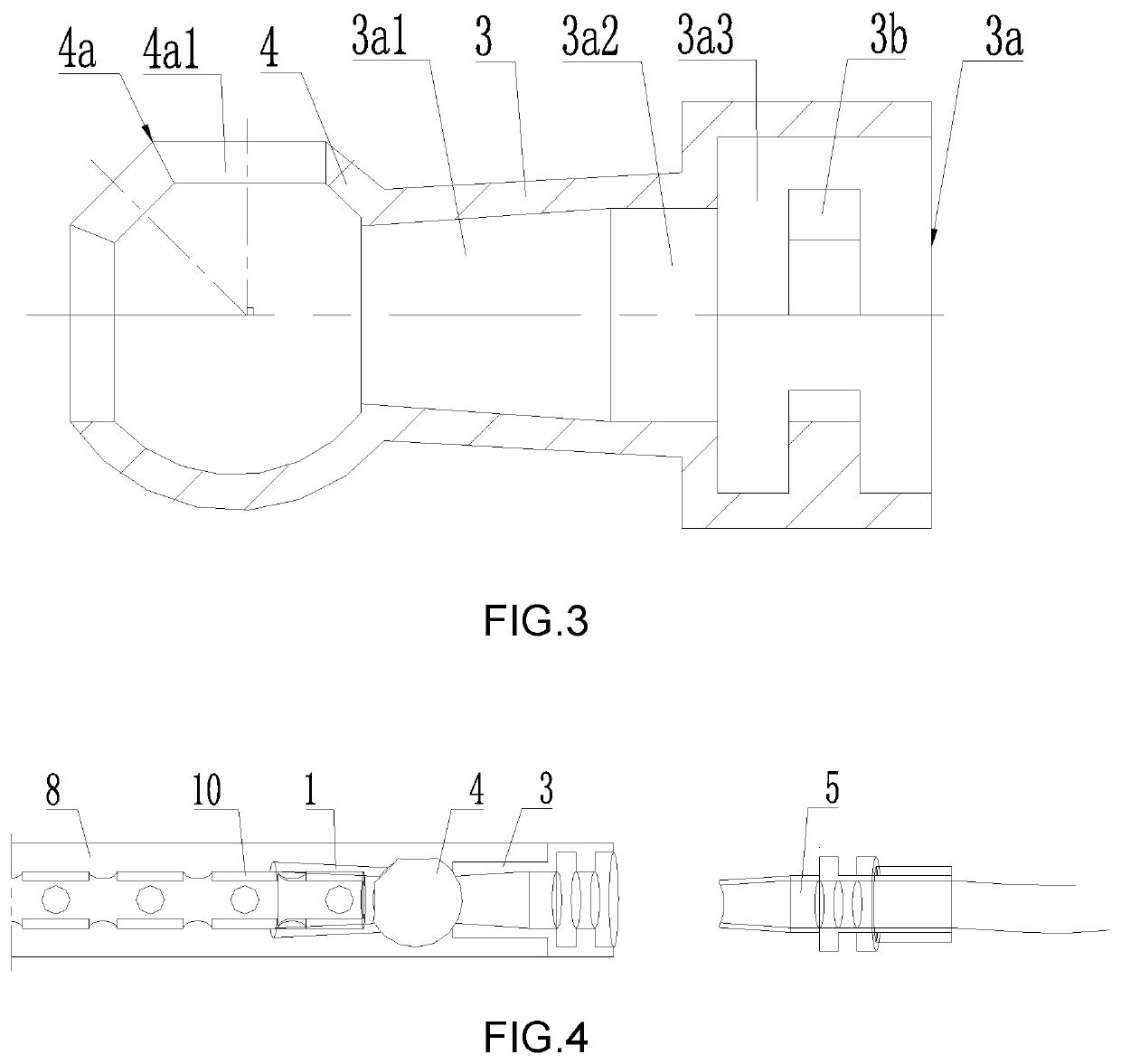

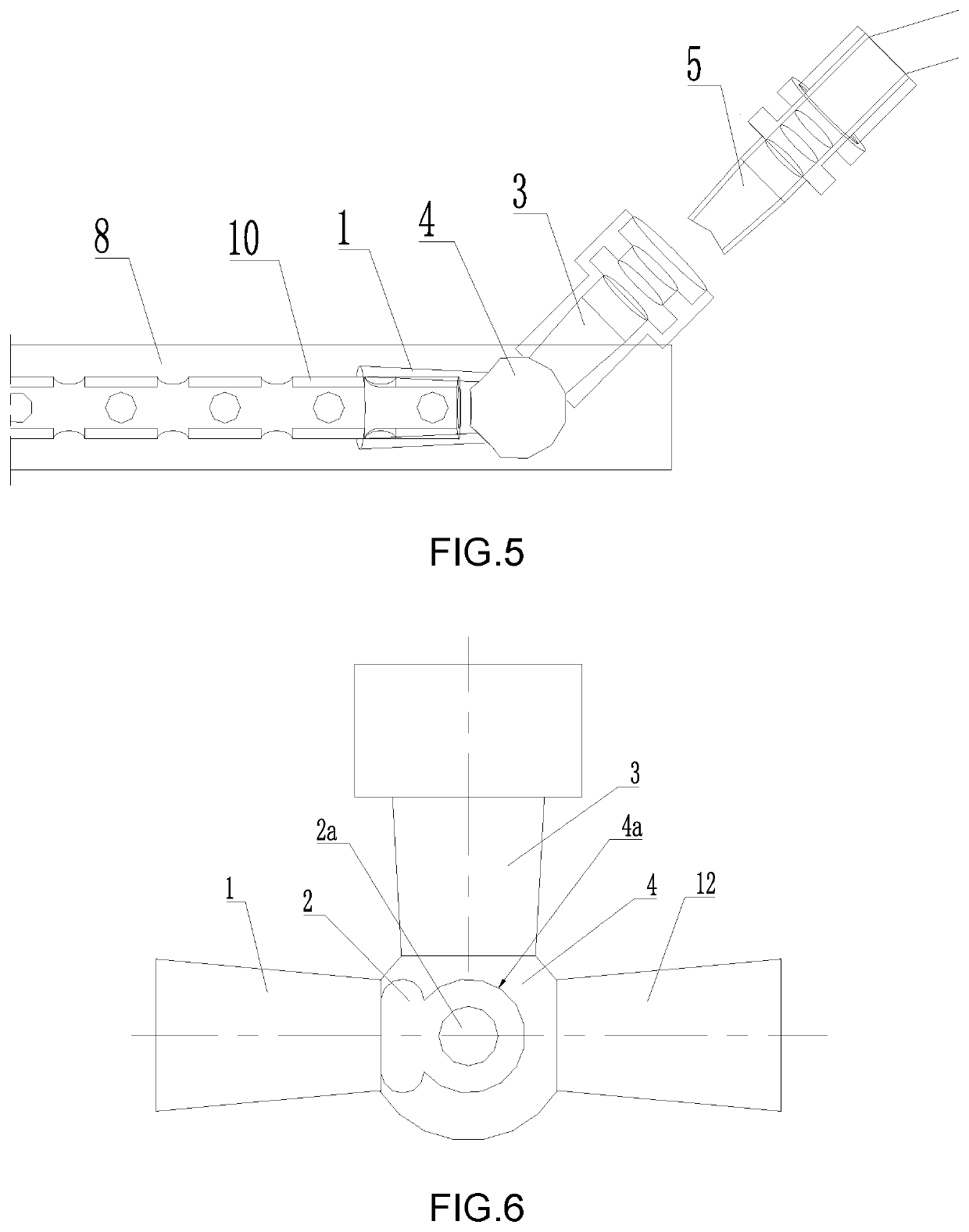

Connecting device for wound protection dressing, and wound protection dressing

InactiveUS20200179673A1Modification cost be lowSmoothly flow outIntravenous devicesSuction irrigation systemsComposite materialEngineering

A connecting device for a wound protection dressing, and a wound protection dressing. The connecting device comprises a first tube connector (1) and a second tube connector (3); the first tube connector (1) and the second tube connector (3) are respectively provided with a first through hole (1a) and a second through hole (3a) that run through the respective ends of the first tube connector (1) and the second tube connector (3); a hollow ball head (2) is integrally formed on one end of the first tube connector (1); the inner cavity of the ball head (2) are in communication with the first through hole (1a); at least one via hole (2a) is provided on the ball head (2); a ball shell (4) adapted to the ball head (2) is integrally formed on one end of the second tube connector (3); the inner cavity of the ball shell (4) is in communication with the second through hole (3a); a snap-fit hole (4a) is provided on the ball shell (4); the snap-fit hole (4a) has at least one circular fastening hole (4a1); the ball head (2) is snap-fit in the ball shell (4); the end of the first tube connector (1) close to the ball head (2) is fastened in one of the fastening hole (4a1) of the snap-fit hole (4a). Thus, the connecting device for a wound protection dressing and the wound protection dressing which avoid pressing the skin and wound surface, allow the liquid to smoothly flow out, and facilitate flexible connection of the tube line are provided.

Owner:WAN MIANSHUI

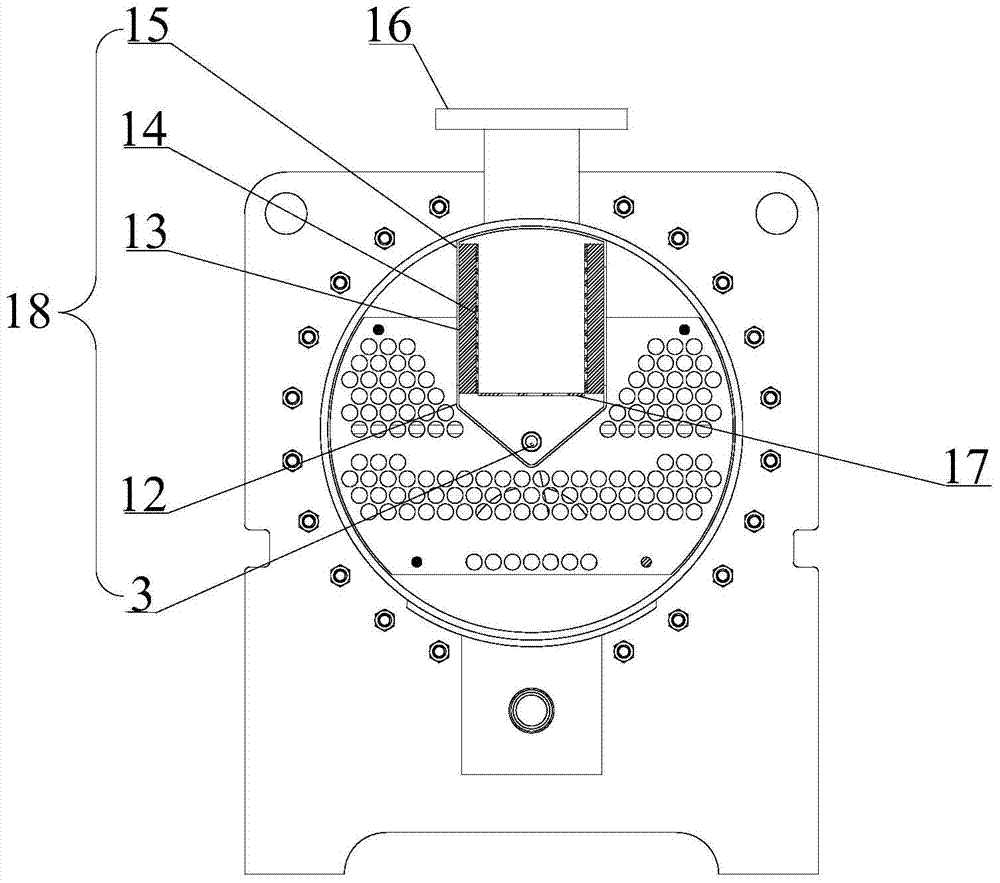

Oil return type condenser and air conditioning system

ActiveCN104729159ASimple structureSimple structural designCompression machines with non-reversible cycleEvaporators/condensersOil separationAir conditioning

The invention provides an oil return type condenser and an air conditioning system. The oil return type condenser comprises a shell assembly, a condensation assembly and an oil separation assembly, wherein both the condensation assembly and the oil separation assembly are installed in the shell assembly; the oil separation assembly comprises a return chute, a baffle and two filter screens, the two filter screens are symmetrically installed on the two sides of the baffle, a plurality of first through holes communicated with the return chute are formed in the edge of the baffle, and the baffle is arranged above the return chute so that the heat exchange efficiency of refrigerants can be guaranteed while oil separation efficiency is guaranteed.

Owner:GREE ELECTRIC APPLIANCES INC

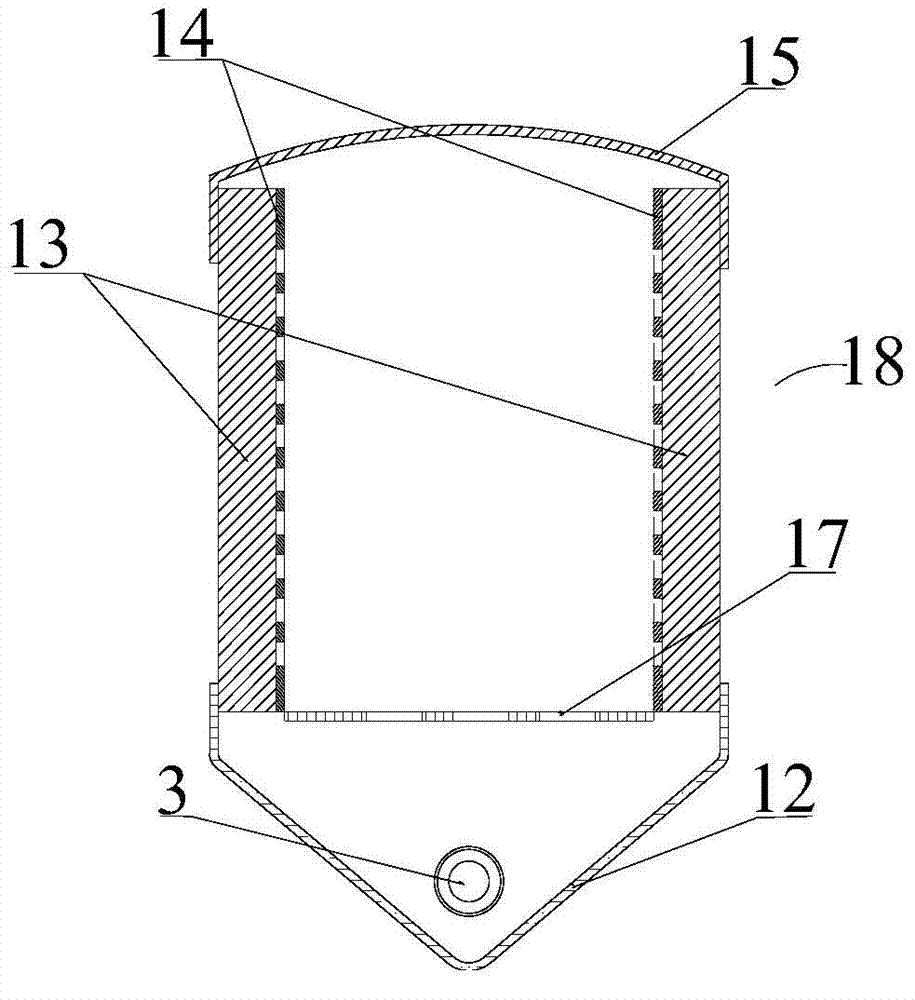

Cold trap for purifying lead and lead-base alloy

InactiveCN103093842AAvoid cloggingImprove heat transfer efficiencySolidificationLiquefactionAlloyImpurity

The invention discloses a cold trap for purifying lead and lead-base alloy. The cold trap comprises a cylinder and a heat economizer, wherein the cylinder is internally provided with a diversion clapboard and a filter core. The cold trap is characterized in that the lower part of the cylinder is provided with a lead and lead-base alloy inlet and a lead and lead-base alloy outlet, a seal flange is adopted at the upper part of the cylinder, a diversion pore plate is arranged at the bottom of the cylinder and is connected with the cylinder and the diversion clapboard, and the filter core is connected with the diversion clapboard through a fixing bolt. According to the technical scheme, the characteristic that impurities in the lead and lead-base alloy float upwards is fully utilized, a manner of upper feeding and lower discharging is adopted, and the heat economizer is arranged outside the cold trap, so that the heat exchange efficiency is improved; and in addition, no limitation is from the main space of the cold trap so that the size can be enlarged, and the impurities are effectively prevented from blocking a pipeline of the economizer. The upper part of the cylinder is sealed by using the flange, the filter core is fixed on the diversion baffle by using the bolt, and the cold trap is suitable for online purification of the lead and lead-base alloy and can be used to carry out purification experiments at the same time.

Owner:HEFEI INSTITUTES OF PHYSICAL SCIENCE - CHINESE ACAD OF SCI

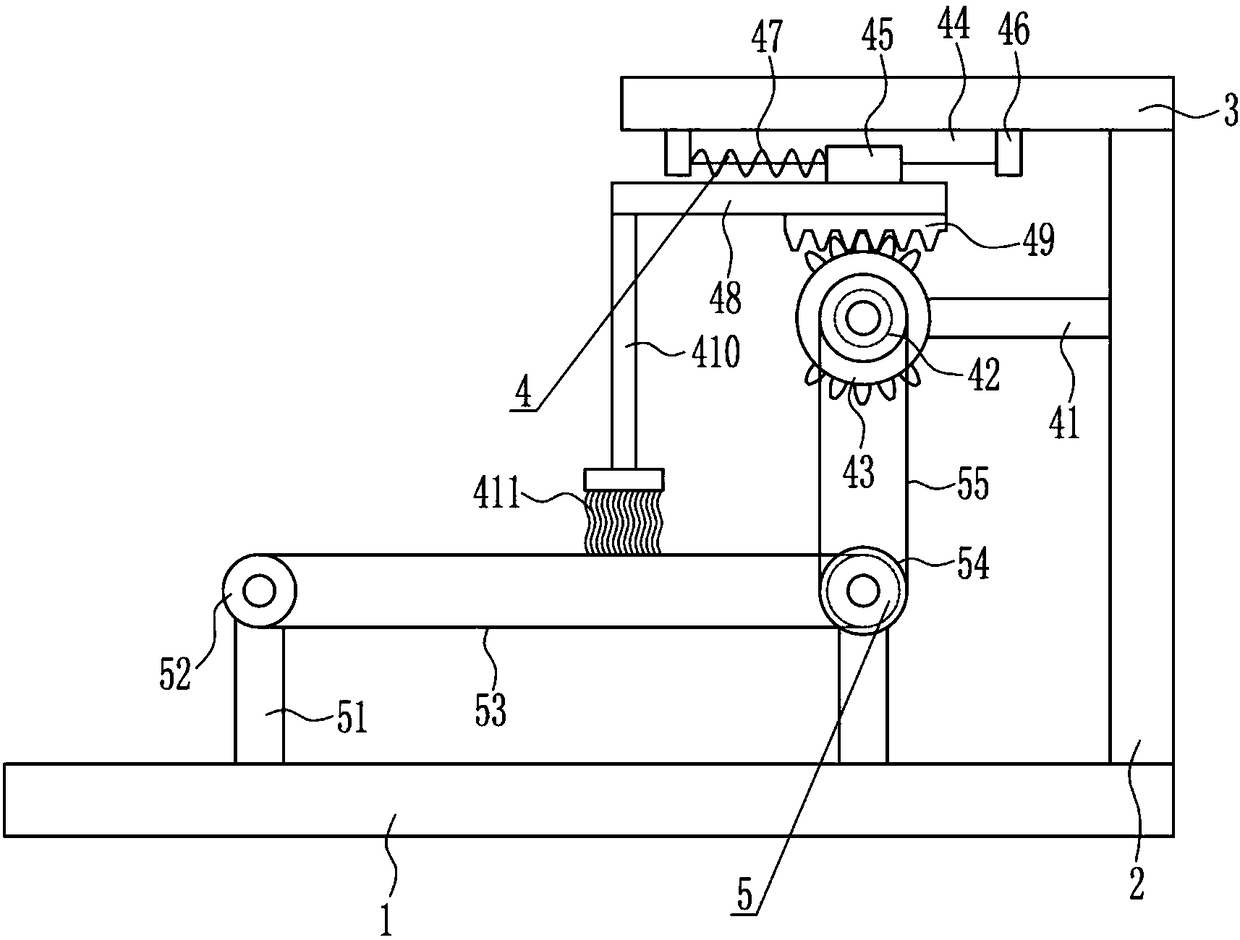

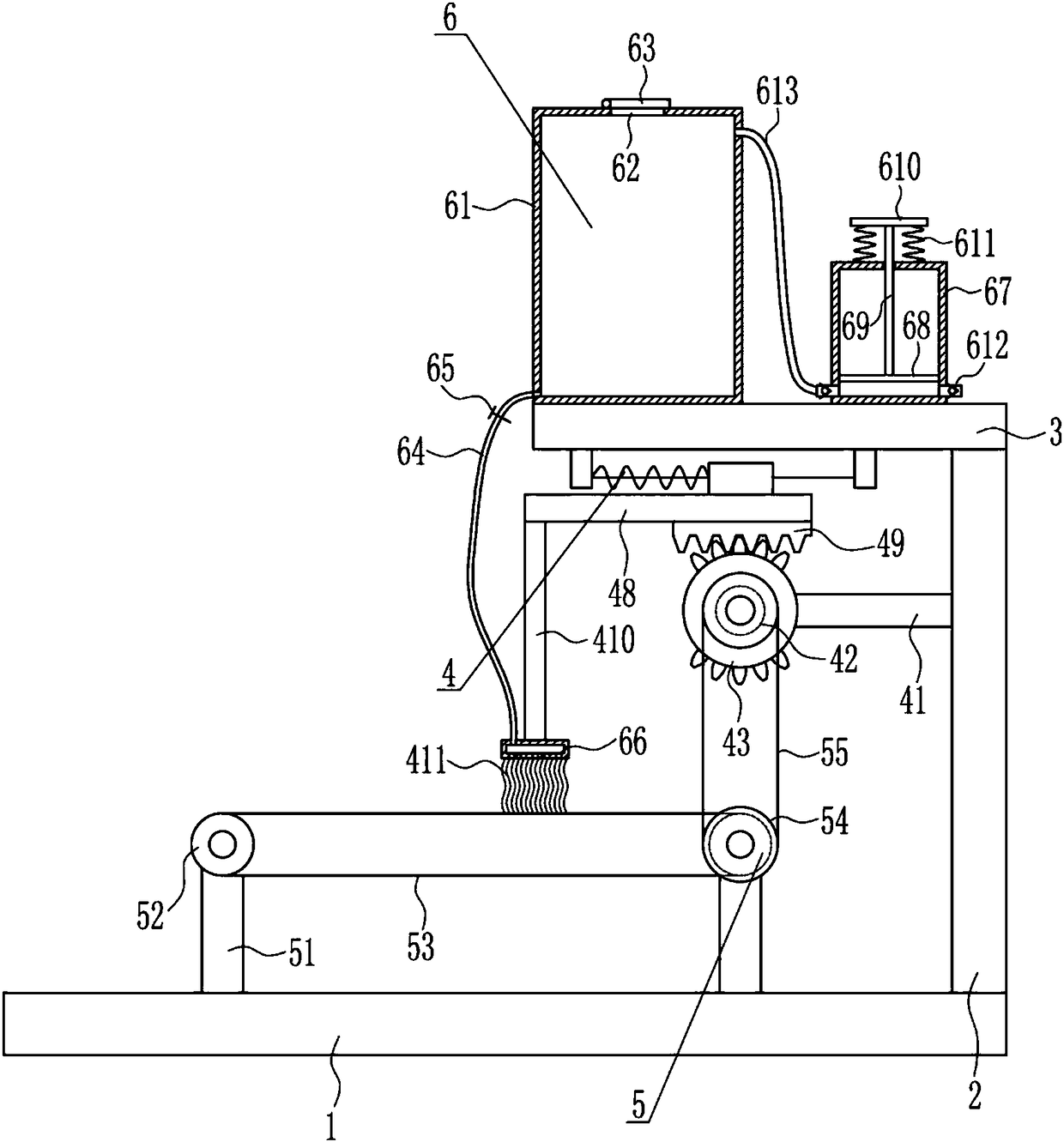

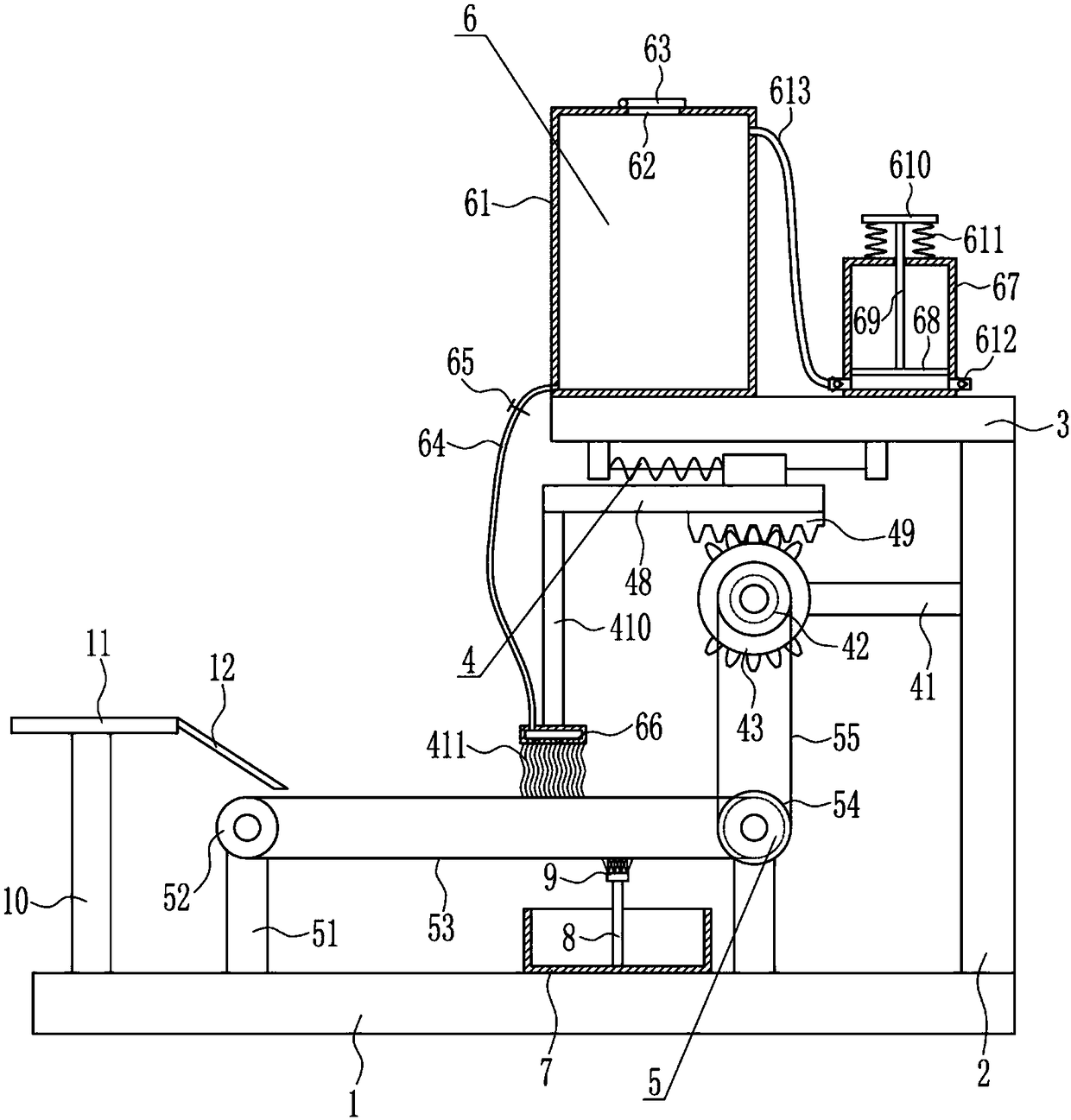

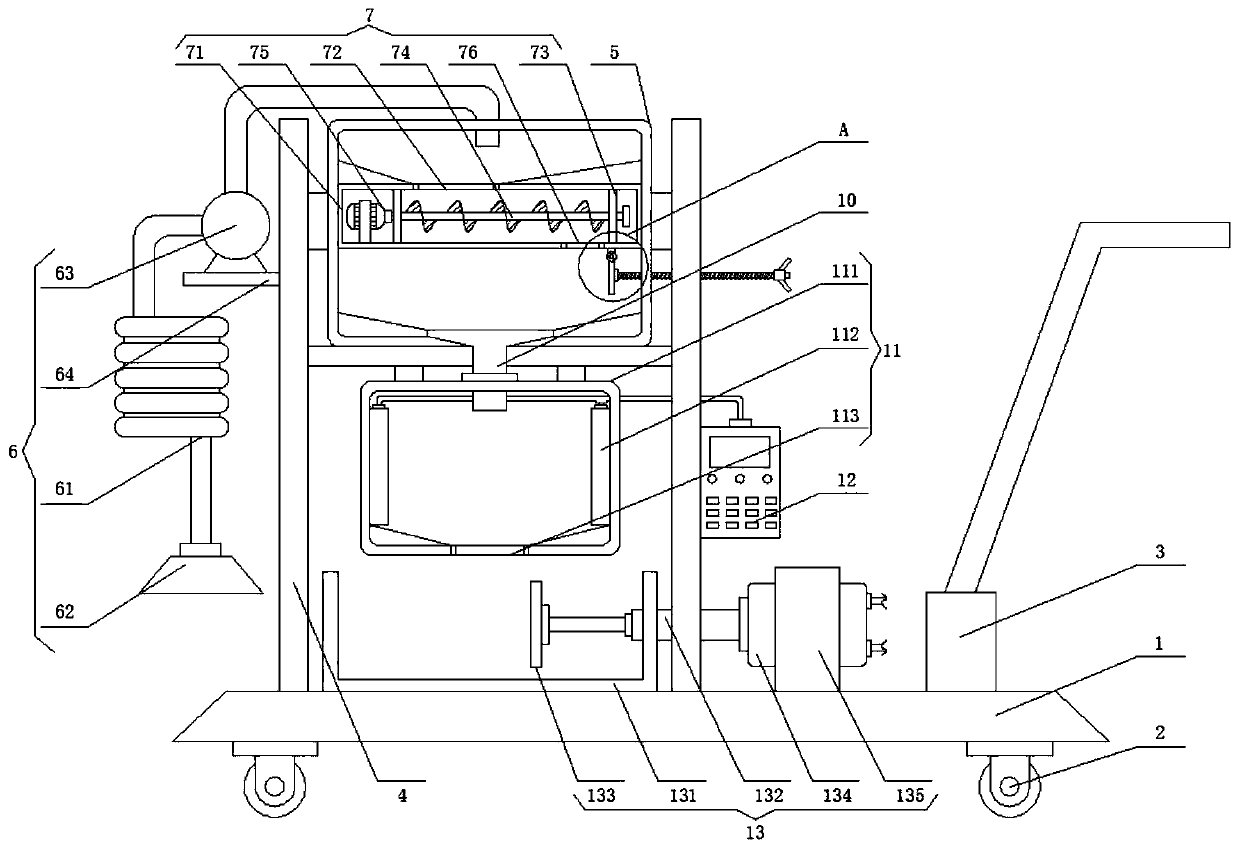

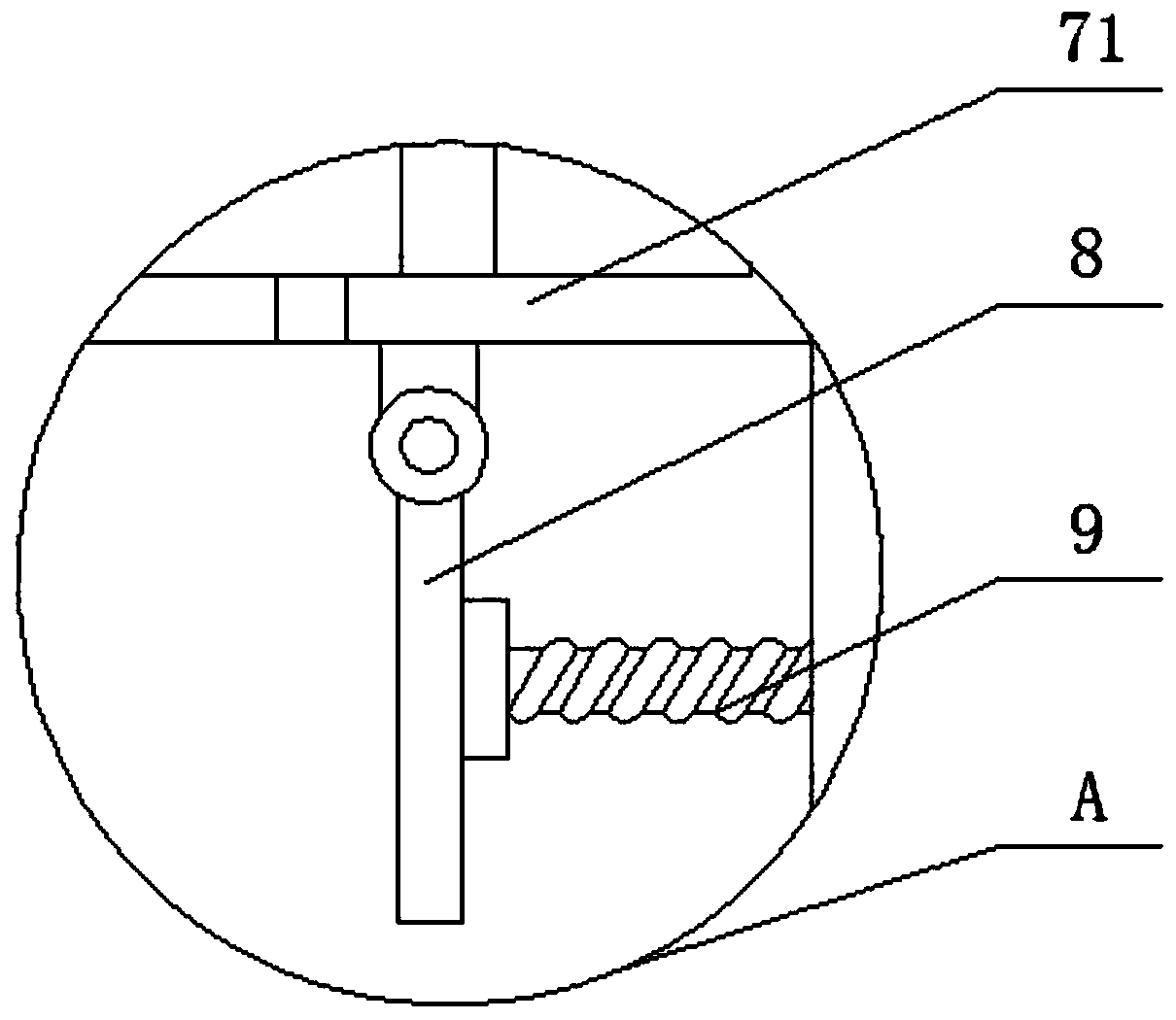

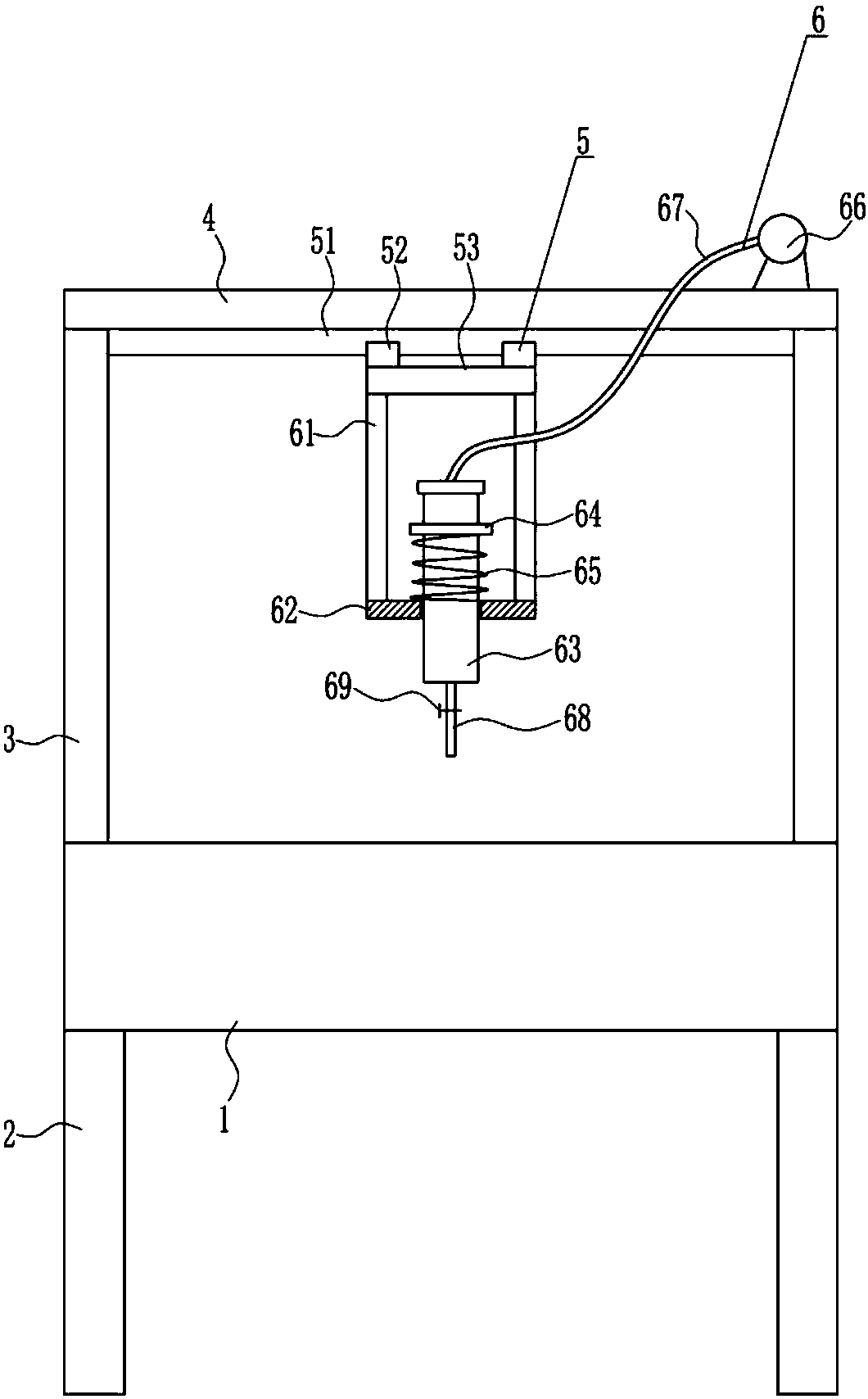

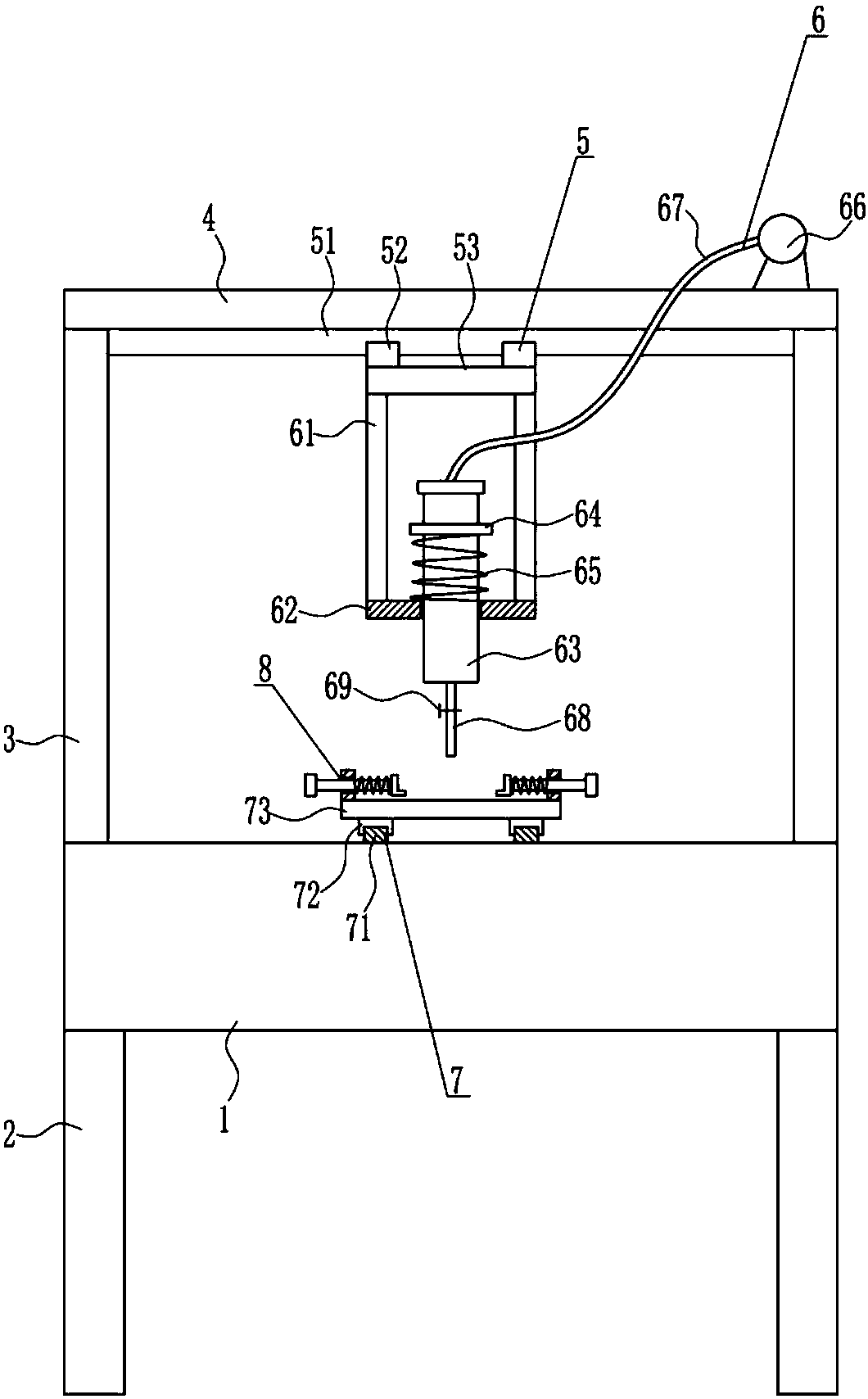

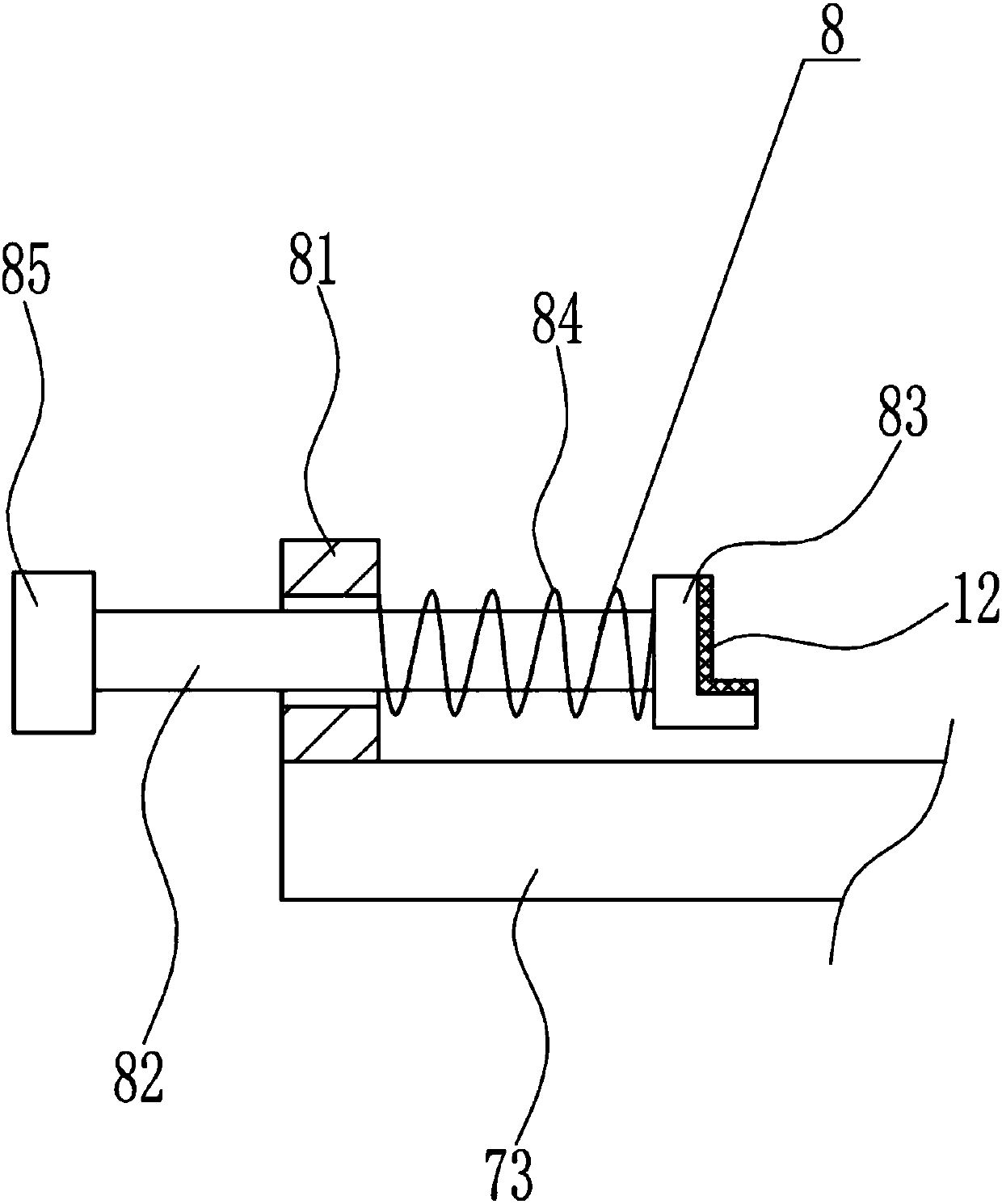

Lubricating oil painting equipment for mechanical part

InactiveCN108355900AOutflow smoothlyImprove application efficiencyLiquid surface applicatorsCoatingsMachine partsMechanical components

The invention relates to painting equipment, in particular to lubricating oil painting equipment for a mechanical part. The lubricating oil painting equipment for the mechanical part has high paintingefficiency and uniform smearing. The lubricating oil painting equipment comprises a bottom plate and the like. A supporting plate is connected with the right side of the top of the bottom plate, a top plate is connected with the top of the supporting plate, a painting device is arranged at the bottom of the top plate, a conveying device is arranged in the middle of the top of the bottom plate, and the painting device is matched with the conveying device. The mechanical part is driven to move to the right through the conveying device, the painting device smears lubricating oil on the mechanical part, and an oil conveying device drives the lubricating oil to uniformly flow onto a first brush, and thus painting is more uniform and the effects of high painting efficiency and uniform paintingare achieved.

Owner:史志成

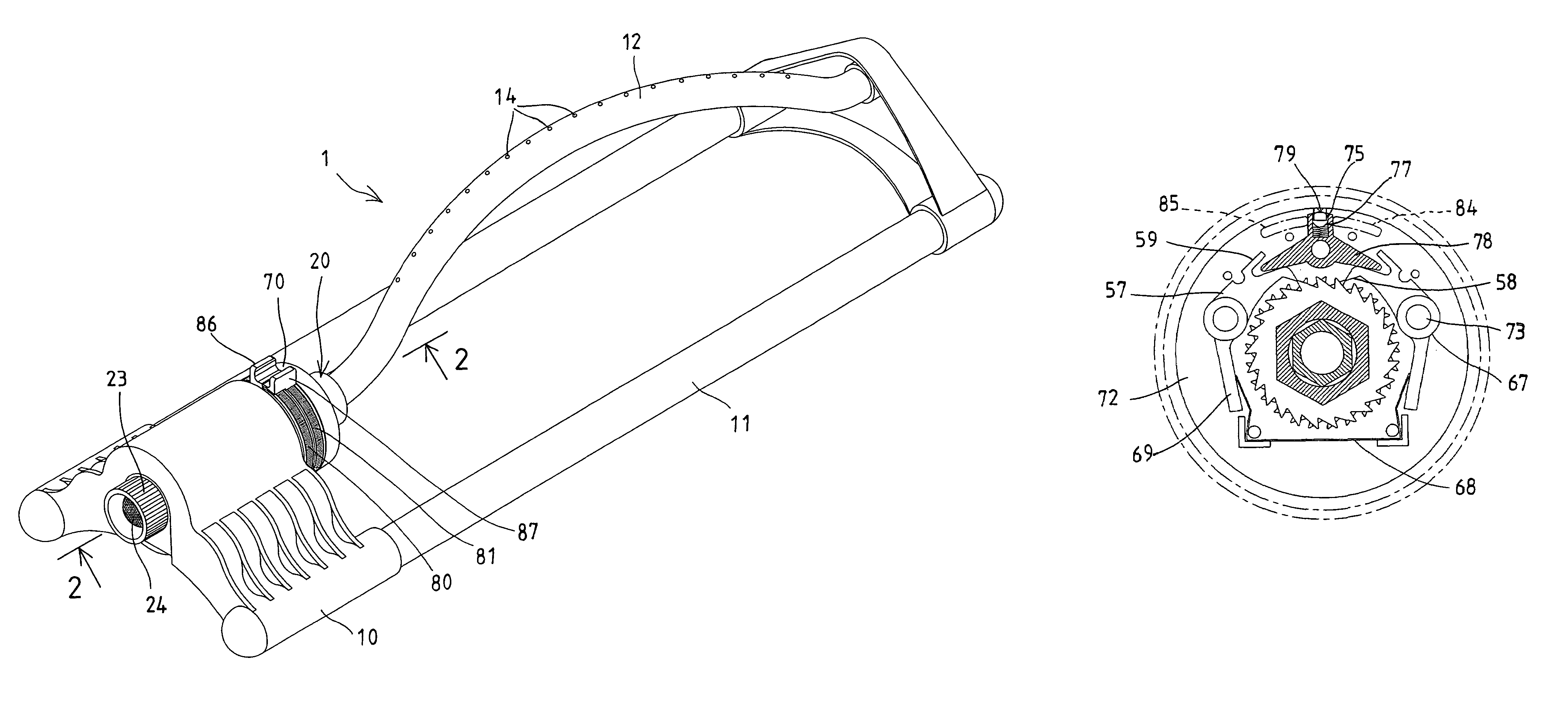

Applicator

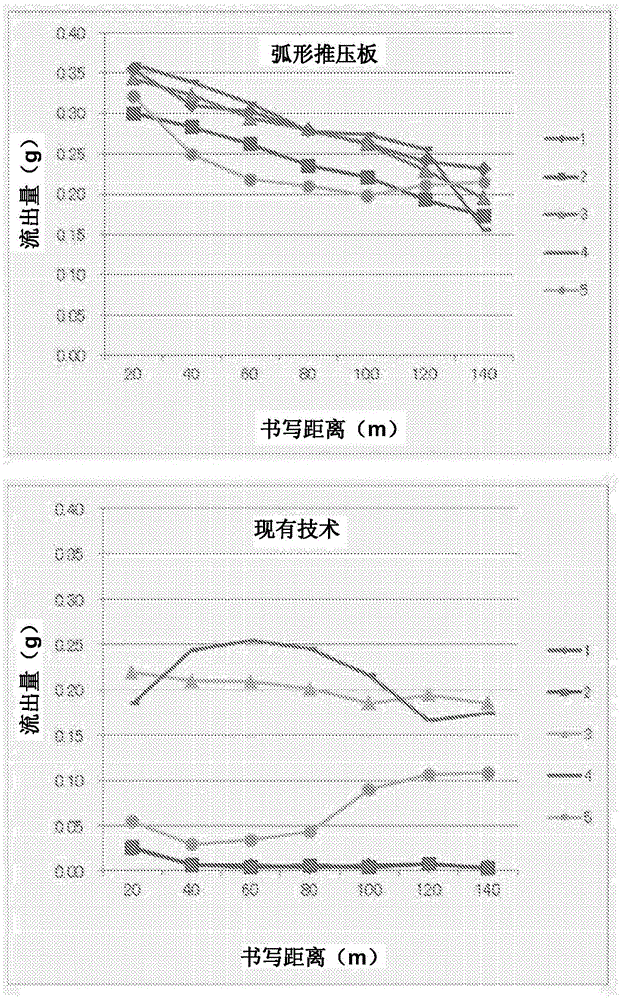

InactiveCN105072950APrevent variation in coating amountSmooth dischargeErasing devicesPen repairingBiomedical engineeringCoating

[Problem] Fluctuations or irregular increases / decreases in the discharged amount of a coating liquid may occur due to large variations in the discharged amount of coating liquid in the coating liquid container tube, or to failure of the curing oil to be uniformly pushed out in the course of using the applicator. [Solution] Provided are a coating liquid container tube and an applicator, the coating liquid container tube being furnished at the distal end with an applicator part, and filled in the interior thereof with a coating liquid for supply to the applicator part; being furnished also with a curing oil to the back of the coating liquid which fills the coating liquid container tube interior; and being further furnished to the back thereof with a pushing means for pushing the curing oil through the agency of a pushing member. The surface of the pushing means on the side facing the curing oil is formed as a convex surface.

Owner:SAKURA COLOR PRODUCTS CORPORATION

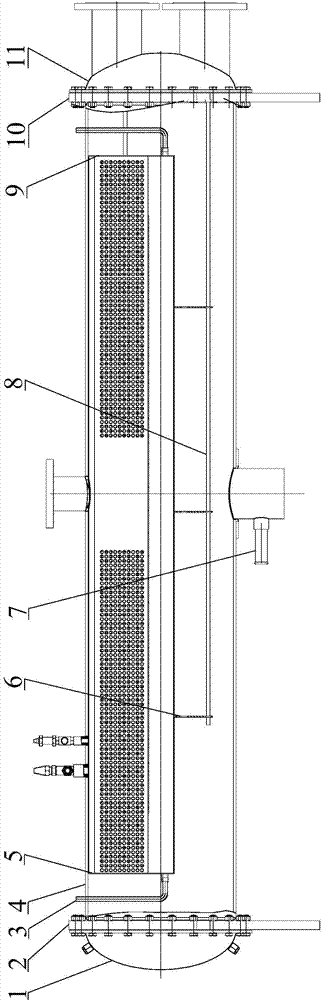

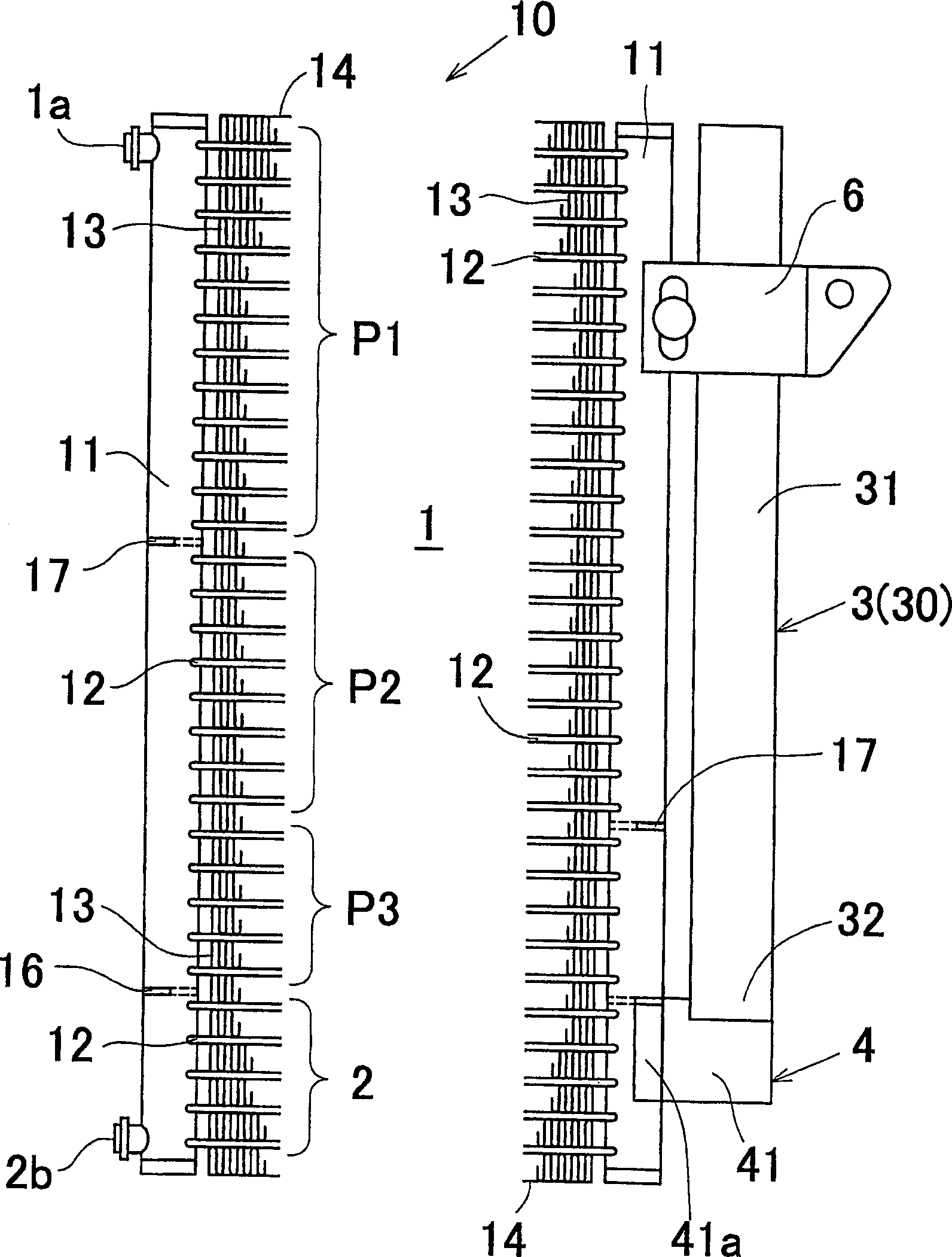

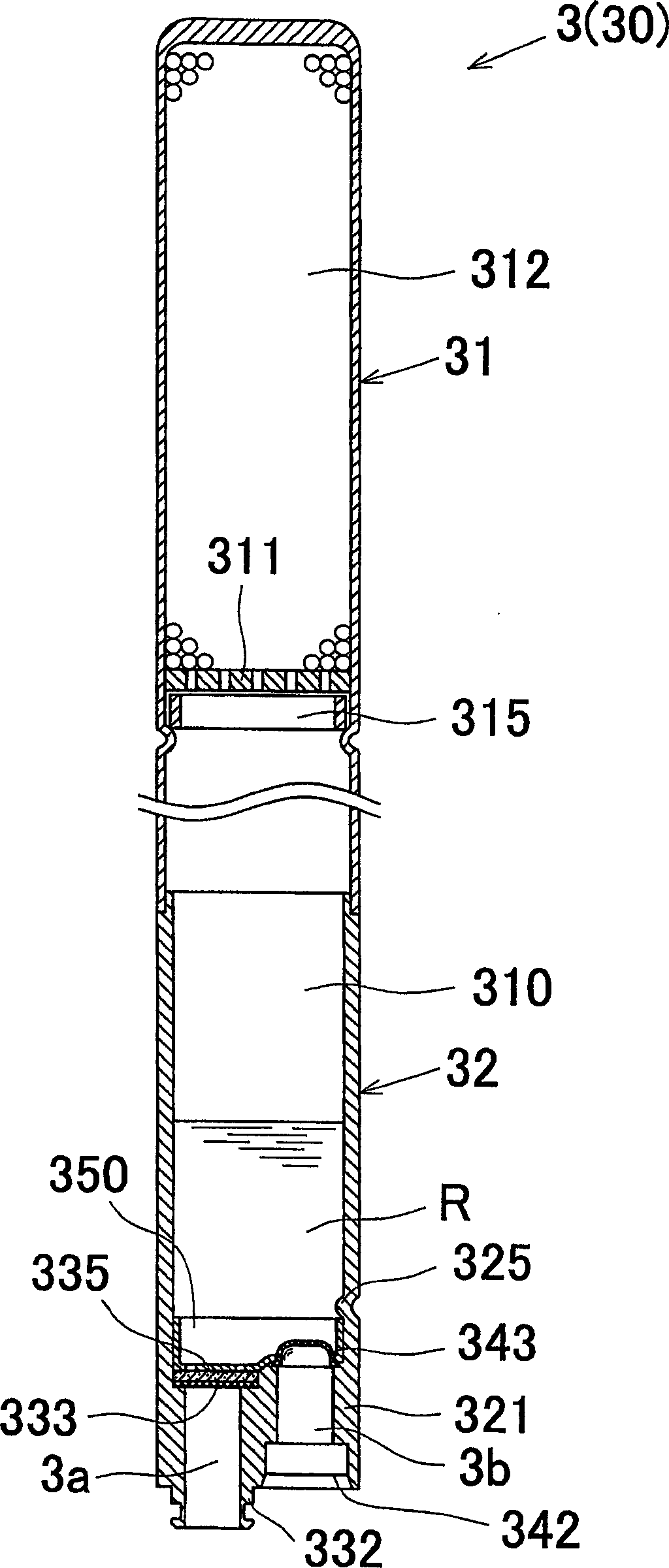

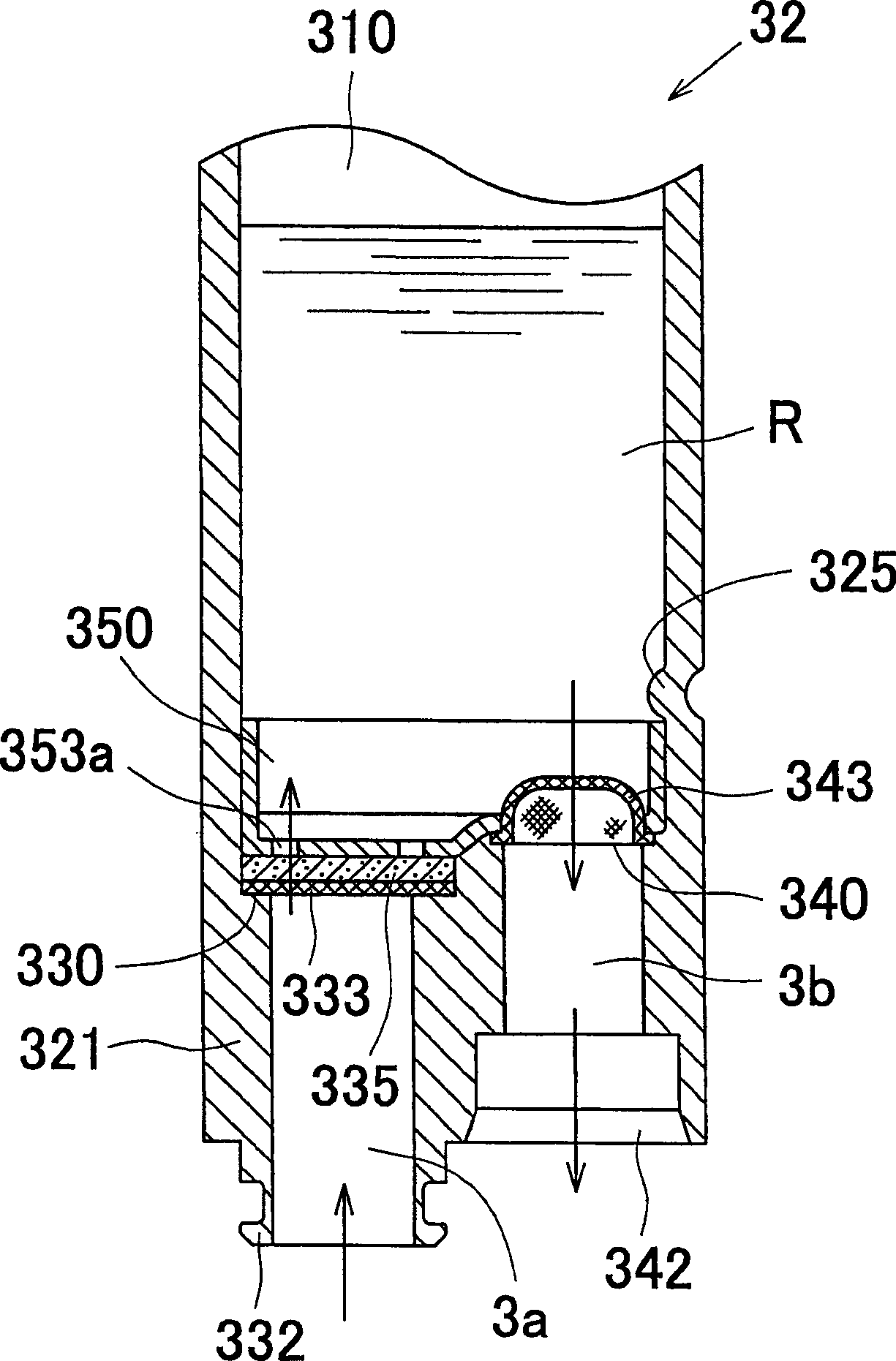

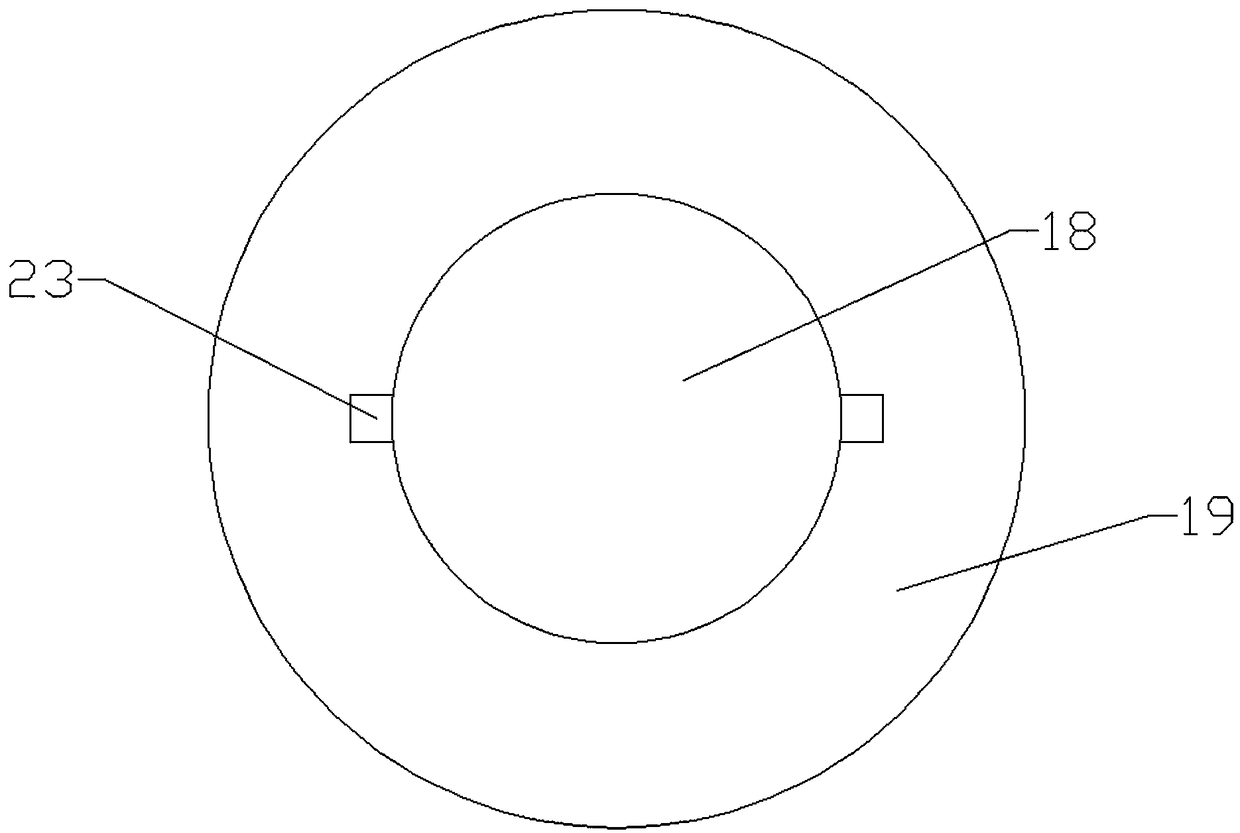

Receiver tank for refrigeration cycle, heat exchanger with the receiver tank, and condensation device for refrigeration cycle

ActiveCN1732364AReduce the numberSimple structureAir-treating devicesEvaporators/condensersEngineeringRefrigeration

A receiver tank has a tubular tank body (30) with a refrigerant inlet hole (3a) and a refrigerant outlet hole (3b) that are formed in its lower wall (321). The upper end of the opening of the refrigerant inlet hole (3a) is positioned lower than the upper end of the opening of the refrigerant outlet hole (3b). At the upper end of the opening of the refrigerant inlet hole (3a) is provided a resistance layer (335) at which the speed of flow of a refrigerant is reduced by permeation of the refrigerant. The refrigerant flowing in from the refrigerant inlet hole (3a) permeates upward the resistance layer (335) to form a collection (R) of liquid in a space in the tank. A liquid refrigerant in the collection (R) is discharged through the refrigerant outlet hole (3b). Because of the structure above, the refrigerant can be saved, the structure can be simplified, and costs can be reduced.

Owner:MAHLE INT GMBH

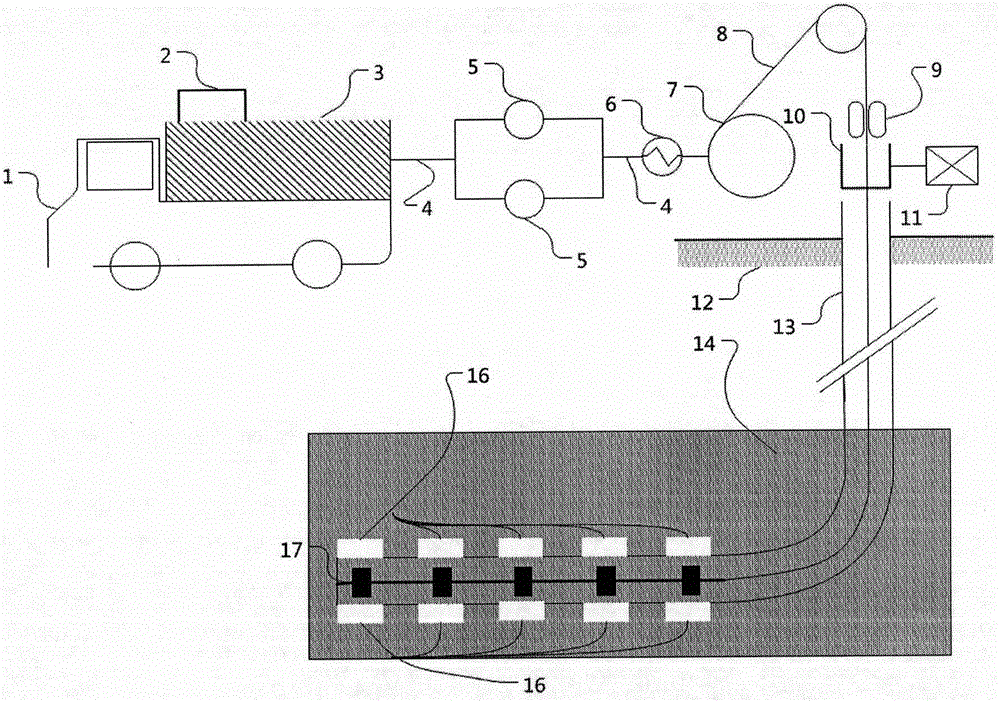

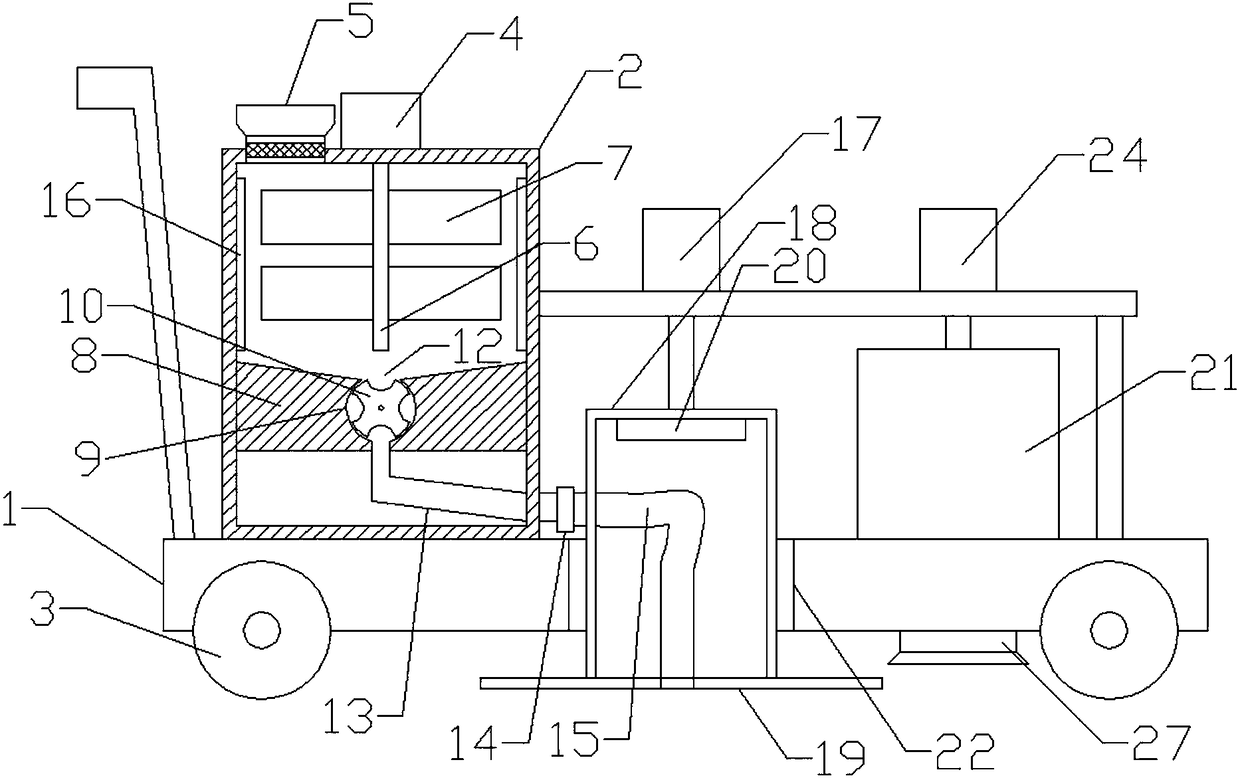

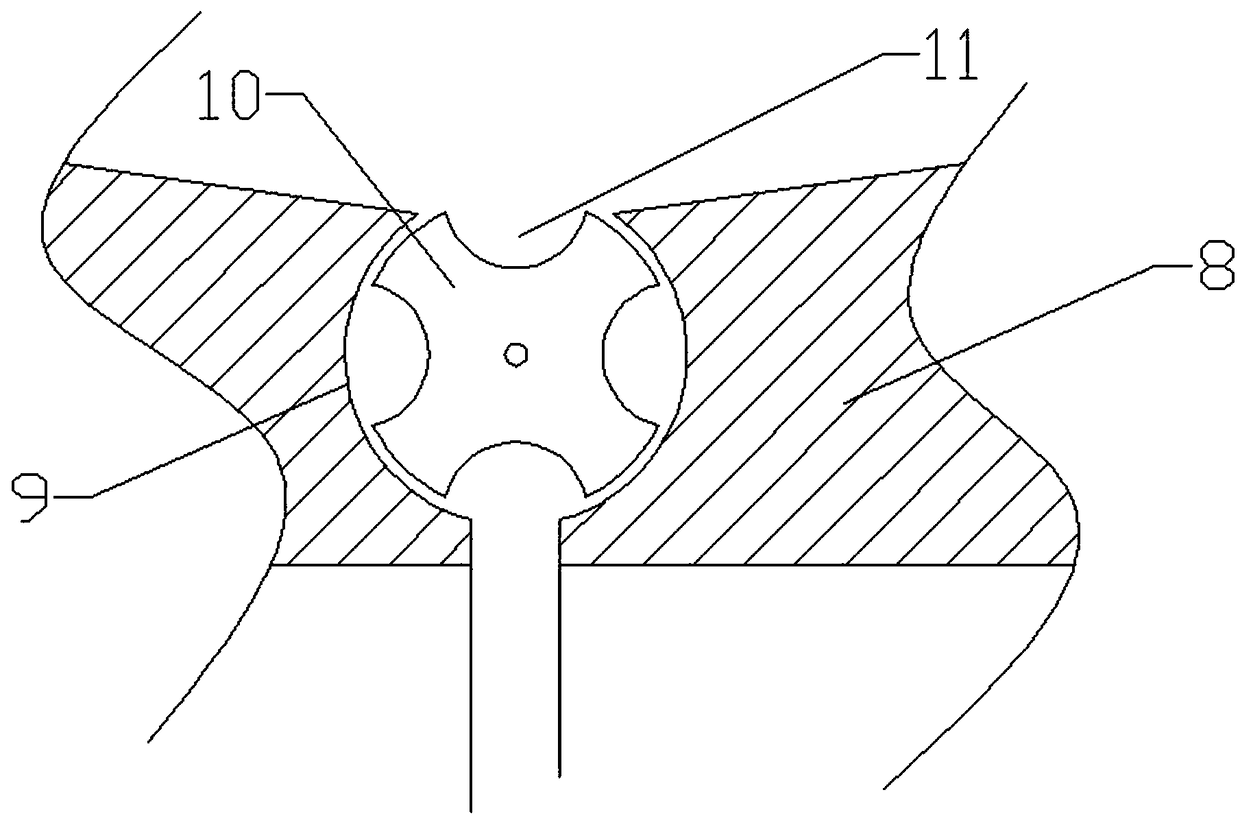

Pretreatment construction device for traffic road maintenance

InactiveCN108221619AAvoid coolingOutflow smoothlyRoad cleaningRoads maintainenceRoad surfacePre treatment

The invention discloses a pretreatment construction device for traffic road maintenance. The pretreatment construction device comprises a base, a heating box, rollers, a stirring motor and a charge hole, wherein an unloading cavity of a horizontal cylindrical structure is arranged in a separating base; a horizontal sealing column is coaxially mounted in the unloading cavity; a plurality of storageslots are uniformly formed in the side wall of the sealing column; the lower end of a lifting box is fixedly equipped with a horizontal pressure plate; a heating device for internally heating is mounted in the lifting box; a fan is further fixedly mounted on a bracket of the base; and the fan is communicated with a clearing box on the base through a pipeline. According to the pretreatment construction device disclosed by the invention, the unloading cavity and the sealing column matched with the unloading cavity are arranged, so that an asphalt raw material uniformly flows out from the heating box, filling amount is easily controlled, and material waste is reduced; impurities such as dust inside are sucked before the material is complemented, so that impurities inside are quickly clearedand reduced, and therefore, the material is extruded to be more compactly, and a repaired road is guaranteed to be not liable to collapse and deform.

Owner:钱幼华

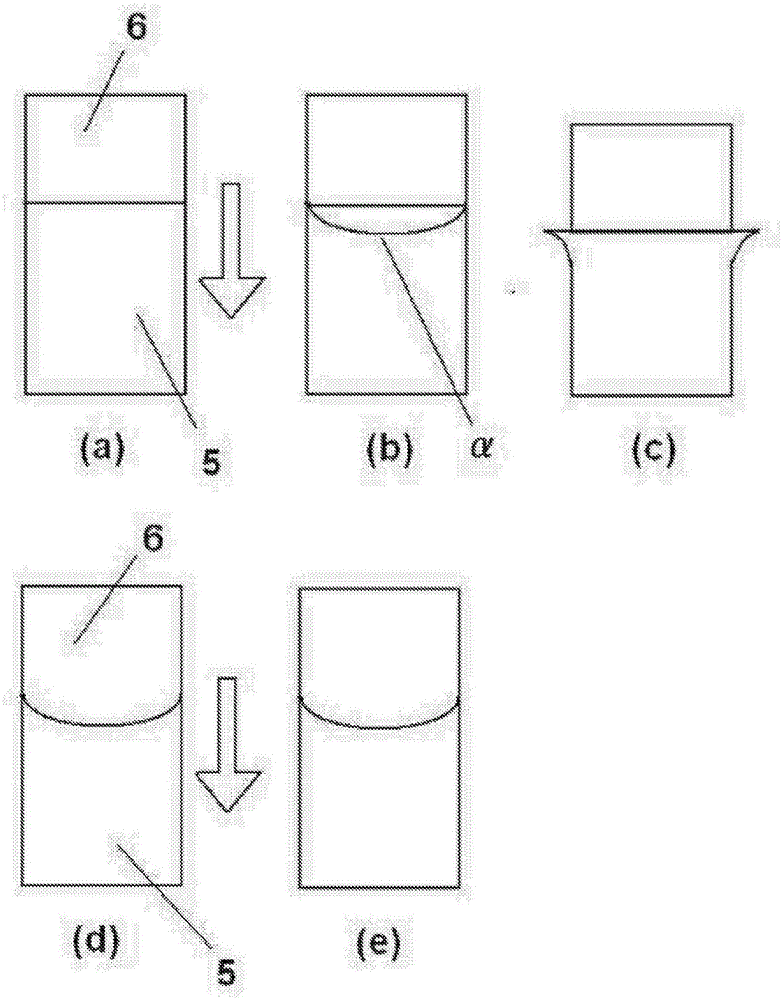

Sprinkler having oscillating mechanism

InactiveUS7226000B2Smoothly rotating or driving the sprinkler tubeOutflow smoothlyControlling membersControlled membersReciprocating motionEngineering

Owner:YUAN PIN IND

Waste recycling device and method for plastic product production

PendingCN110076935APromote softeningStickyPlastic recyclingMechanical material recoveryRecovery methodWaste recycling

The invention belongs to the technical field of plastic products, and particularly relates to a waste recycling device for plastic product production. The waste recycling device comprises a base, wheels are fixedly installed at the bottom of the base, a push rod is fixedly installed on one side of the top of the base, and a supporting frame is fixedly connected to the top of the base. A treatmentbox is fixedly arranged inside the supporting frame, an absorbing mechanism is arranged at the top of the treatment box, and a crushing mechanism is arranged in the treatment box. A movable plate is fixedly arranged at the bottom of the crushing mechanism, and an adjusting rod is fixedly connected to one side of the movable plate. According to the waste recycling device and method for plastic product production, a softening mechanism is arranged so that wastes can be conveniently softened in the waste recycling process, the wastes can have certain viscidity and can be tightly combined when extruded, the problem that gaps are generated between the wastes is avoided, and the compactness of the wastes is improved.

Owner:荆州市今缘塑料股份有限公司

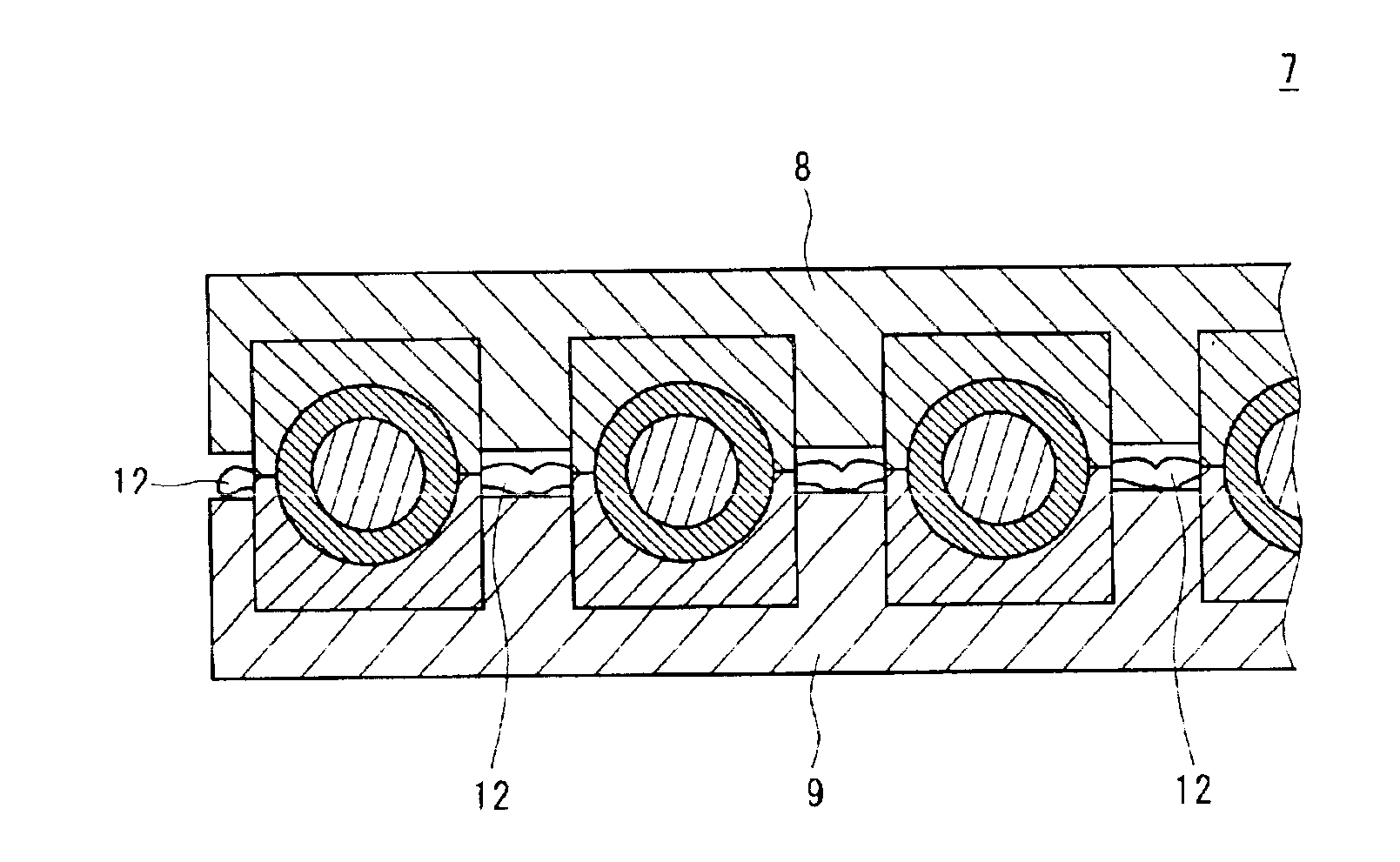

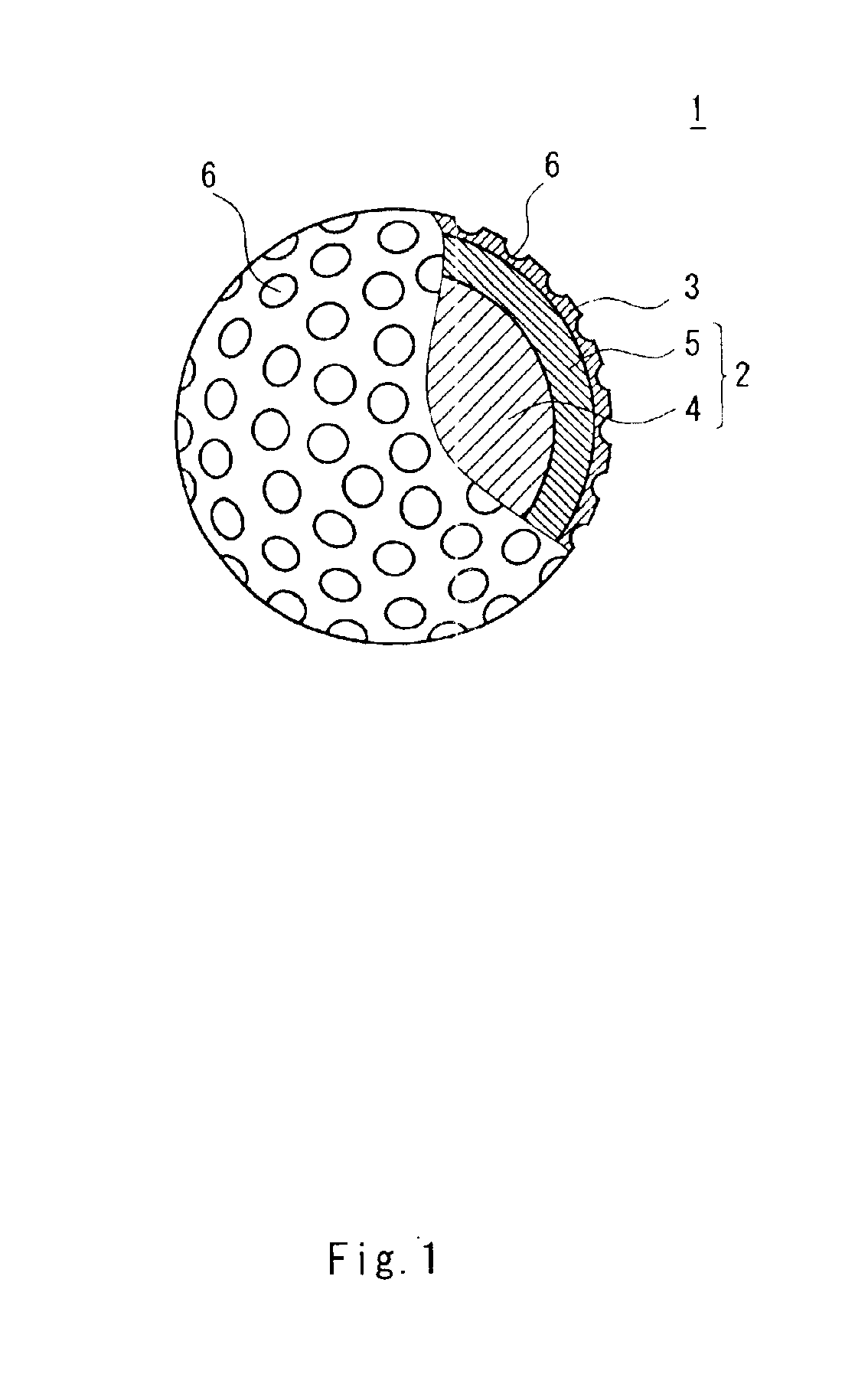

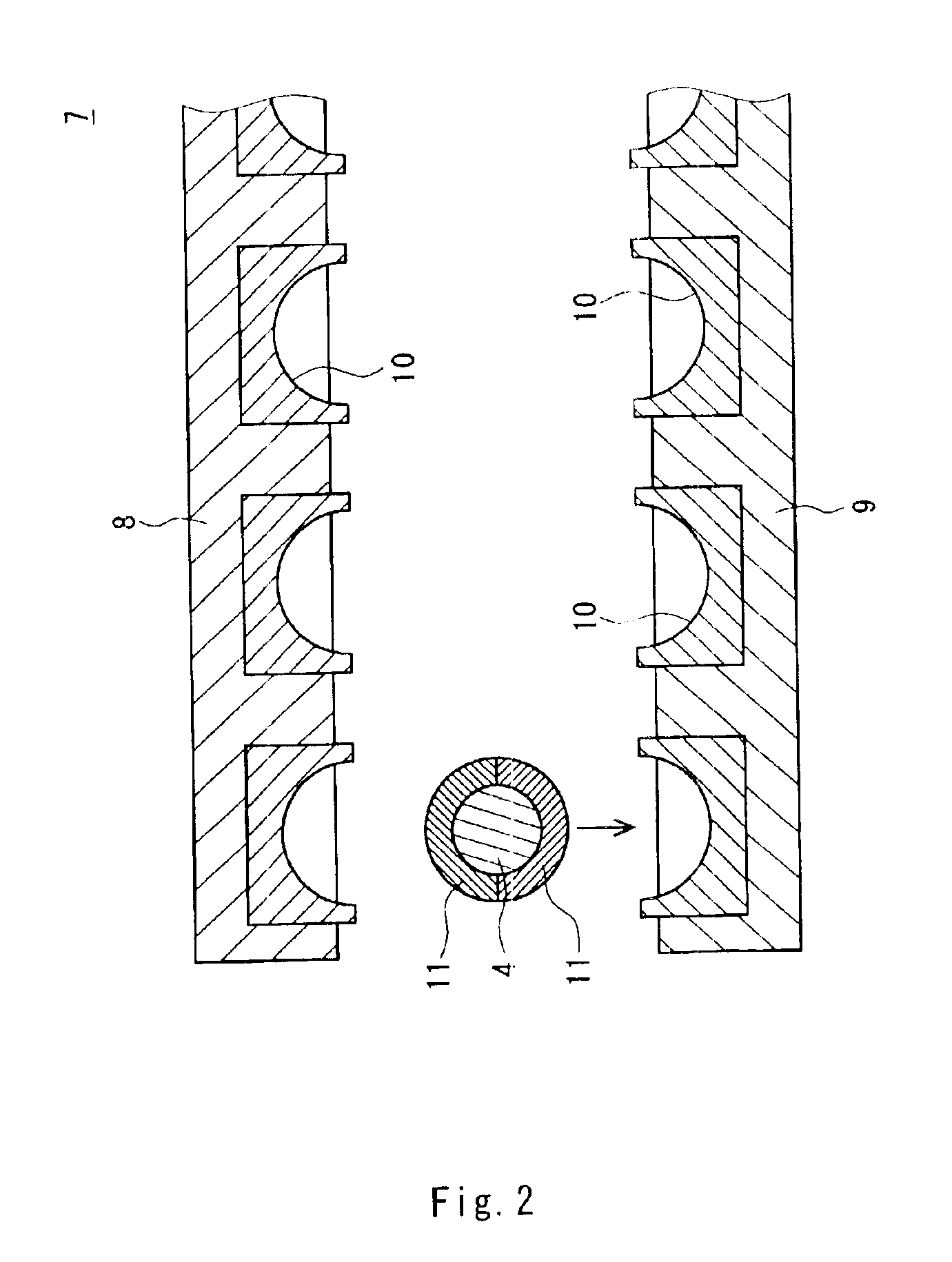

Process for producing golf ball

InactiveUS6846442B2Remarkable effectEasy to operateConfectioneryCeramic shaping apparatusEngineeringGolf Ball

A process for producing a golf ball which includes the steps of placing a rubber composition into the cavity of a mold having an upper portion and a lower portion, clamping the upper portion and the lower portion together at a moving velocity of from 0.03. mm / s to 1.0 mm / s, causing excess rubber composition to flow out from the cavities; and unclamping the mold and removing from the mold cavity spherical bodies and associated rubber flashers formed in the mold cavities.

Owner:SUMITOMO RUBBER IND LTD

Asphalt paint bucket and asphalt paint bucket assembly

PendingCN111392176AAvoid damageAvoid dischargeSealingCans/barrels/drumsAsphaltStructural engineering

The invention discloses an asphalt paint bucket and an asphalt paint bucket assembly. The asphalt paint bucket assembly comprises a bucket body, a bucket cover and a bucket body base; the bucket coveris arranged at the top end of the bucket body, two containing cavities capable of containing paint are formed in the bucket cover, a through material outlet port is formed in the bottom end of the bucket body, the containing cavities communicate with the outside of the bucket body through the material outlet port, a reverse bottom cover is arranged on the material outlet port, the reverse bottomcover can only be opened from the outside of the bucket body to the inside of the bucket body, the bucket body base comprises a cavity capable of containing the bucket body, and the bucket body base is provided with a support pillar and a discharging port. The asphalt paint bucket and the asphalt paint bucket assembly have the beneficial effects that when the heated paint in the bucket body needsto be used, workers only need to place the bucket body in the bucket body base, the reverse bottom cover is jacked to be opened from the outer portion of the bucket body to the inner portion of the bucket body through the support pillar, the paint flows into coating equipment sequentially from the material outlet port and the discharging port, manual cover opening and pouring are not needed, damage to the workers is avoided, the safety of the workers is guaranteed, a large amount of waste gas is prevented from being discharged, and the construction efficiency is high.

Owner:SHENZHEN ZHUOBAO TECH

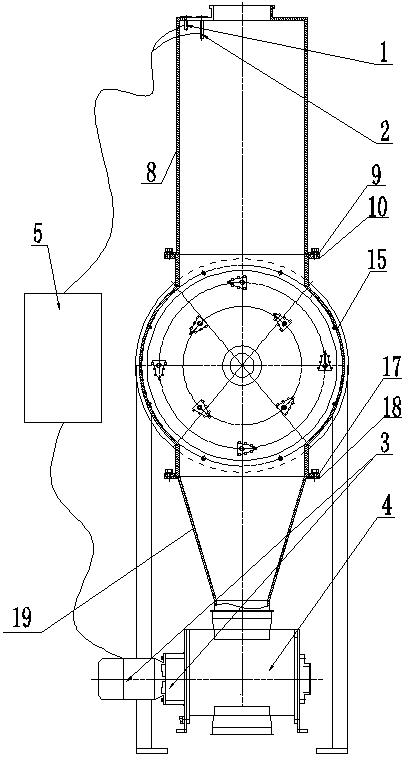

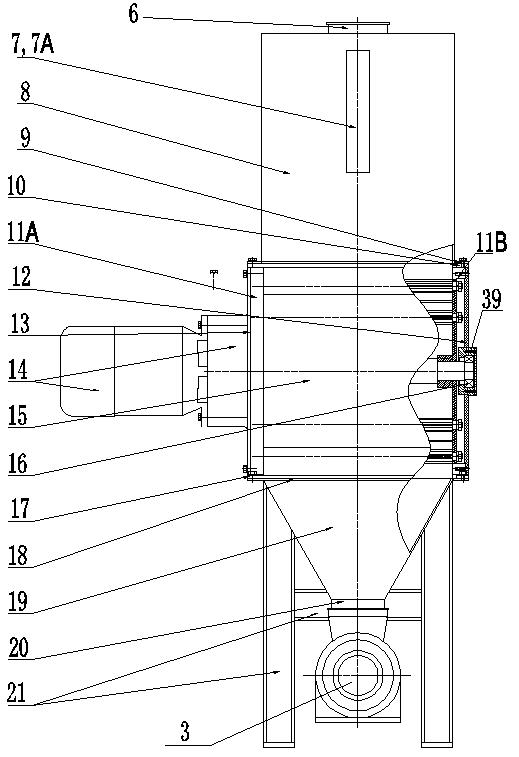

Glue dispensing equipment for integrated circuit packing

InactiveCN107552324AOutflow smoothlyIncrease air pressureLiquid surface applicatorsCoatingsMoving partsIntegrated circuit design

The invention relates to glue dispensing equipment, in particular to glue dispensing equipment for integrated circuit packing. The technical problem to be solved by the invention is to provide the glue dispensing equipment for integrated circuit packing with high glue dispensing efficiency, time and labor saving and low manufacturing cost. In order to solve the technical problem, the invention provides the glue dispensing equipment for integrated circuit packing. The glue dispensing equipment for integrated circuit packing comprises a box and the like; support legs are mounted at four cornersof the bottom of the box through a bolt connecting mode; brackets are connected to the left and right ends of the top of the box; the tops of the brackets are connected with a top plate through a boltconnecting mode; a left-right moving device is arranged at the bottom of the top plate; and a moving part of the left-right moving device is provided with a glue dispensing device. A front-back moving device is driven to operate through a first driving device; a circuit board is fixed by a clamping device; and the left-right moving device is driven to operate by a second driving device, so that the glue dispensing device dispenses glue on the circuit board, and the effects of high glue dispensing efficiency, time and labor saving and low manufacturing cost are achieved.

Owner:怀化华晨电子科技有限公司

Horizontal multifunctional stirring machine

The invention discloses a horizontal multifunctional stirring machine, which comprises a frame, wherein a container component is arranged on the frame; a wheel-type stirrer is arranged in the container component; the upper end of the container component is communicated with a bin component, and the lower end of the container component is communicated with a discharge hopper component; the discharge hopper component is provided with a discharge hole, a discharge device is arranged below the discharge hole, and a material in the discharge hopper enters the discharge device through the discharge hole; the wheel-type stirrer comprises a stirring shaft placed flatly, two ends of the stirring shaft are rotationally supported on and connected to the container component through bearings, left and right disc-shaped end plates are respectively arranged on two sides of the stirring shaft, and more than three stirring bars are arranged between the left end plate and the right end plate; and one end of the stirring shaft extends out of the container component, and a stirring speed reducer is arranged on the extending part of the stirring shaft. The stirring machine overcomes all great defects of the conventional vertical multifunctional stirring machine, and has the obvious advantages of simple structure, low cost, safety and reliability in operation, low fault rate, good process effects of peeling, cleaning and polishing and the like.

Owner:王洪福

Drainage device for photovoltaic power generation panel

PendingCN109617520AWon't clogAvoid bondingPhotovoltaicsPhotovoltaic energy generationEngineeringBiomedical engineering

The invention provides a drainage device for a photovoltaic power generation panel, and belongs to the field of a device for photovoltaic power generation. The drainage device for the photovoltaic power generation panel comprises a guidance piece and a fixed piece, wherein an attachment surface and a guidance surface are arranged on the guidance piece and are connected with each other, the attachment surface comprises a first attachment part and a second attachment part, a surface where the first attachment part is located intersects with a surface where the second attachment part is located,the guidance surface comprises a first guidance part and a second guidance part, the first guidance part is connected with the first attachment part, an included angle between an extension direction of the first guidance part and the surface where the first attachment part is located is an obtuse angle, the second guidance part and the second attachment part are connected, an included angle between an extension direction of the second guidance part and the second attachment part is obtuse angle, the fixed piece is provided with a first connection part and a second connection part, and the guidance piece is made of a material with wettability.

Owner:西安金扫把光伏科技有限公司

Reduction and carbonization method for titanium-containing raw material

The invention relates to a reduction carbonization method of the titanium-bearing material, which belongs to the metallurgy field. The invention solves the technology difficult problem that the bottom of a furnace rises and the generated foamed slag is excessive during the reduction carbonization process of the titanium-bearing material. The reduction carbonization method of the titanium-bearing material in the invention has various power distribution systems in the various implementation stages of material melting, reduction carbonization, and discharging; during the material melting stage, the transformer capacity is fully exerted, to ensure that the material is melted quickly; during the reduction carbonization stage, the electric furnace power is controlled to ensure that the depth of a steady foamed slag layer does not exceed 50 percent of the depth of a material melting tank; during the discharging stage, the electric furnace power is enhanced, to ensure that the melted and carbonized slag flow out of an electric furnace steadily, and the power cannot be shut off during the discharging. The reduction carbonization method of the titanium-bearing material of the invention can realize continuous production, the production operation is secure, the reduction carbonization power consumption and the production cost are reduced, the production efficiency is enhanced, and the invention has broad application prospect.

Owner:PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com