Macromolecular microcarrier and preparation method thereof

A silk fibroin and microcarrier technology, applied in the field of biomedical materials, can solve problems such as unreported, and achieve the effects of simple equipment, increased specific surface area, high drug loading rate and embedding rate of microspheres

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

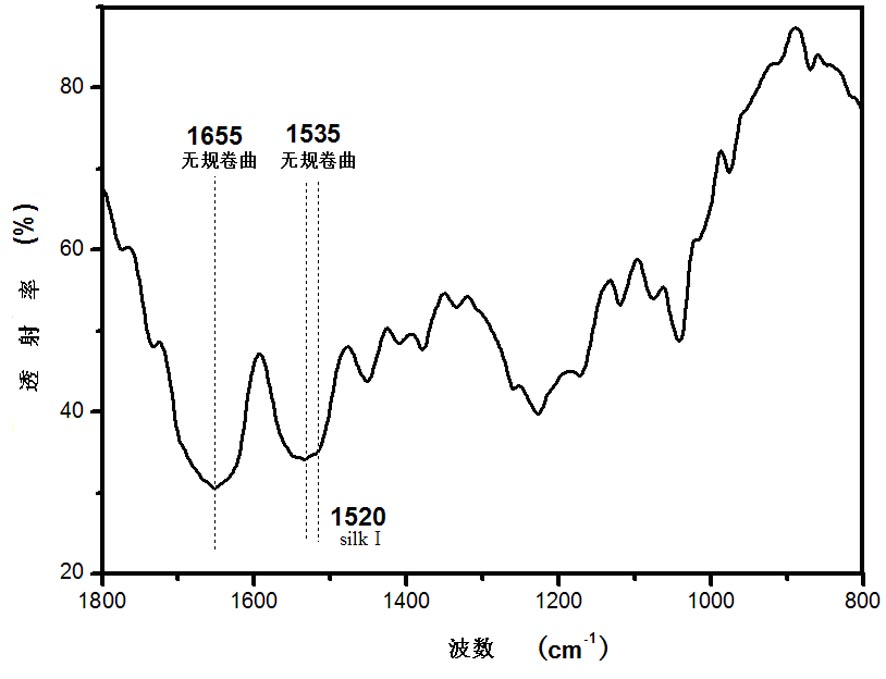

[0031] Put 150 g of silkworm silk into 6 L of 0.05% Na 2 CO 3 In aqueous solution, at 98~100 o C treatment for 30 minutes, repeated 3 times to degumming silk, fully washed and dried to obtain pure silk fiber. Add pure silk fiber to the ternary solution (by CaCl 2 / water / ethanol molar ratio is 1:8:2) solution, at 72 o C stirring and dissolving into a mixed solution of silk fibroin. Put the obtained silk fibroin mixed solution into a dialysis bag, and dialyze with deionized water for 4 days to remove impurities (Li, Br, etc.) to obtain a pure silk fibroin solution.

[0032] Adjust the mass concentration of the silk fibroin solution to 3%, and evenly add 20% EDC, 10% NHS, and 20% MES into the silk fibroin solution to obtain a silk shell solution.

[0033] The vascular endothelial growth factor was configured as a water-soluble drug core layer solution with a concentration of 800ng / ml.

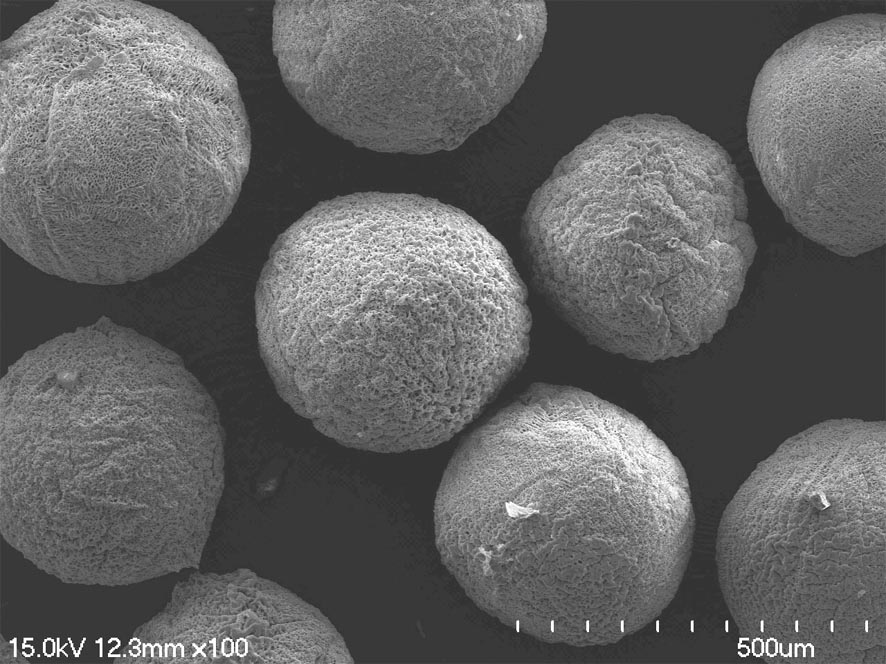

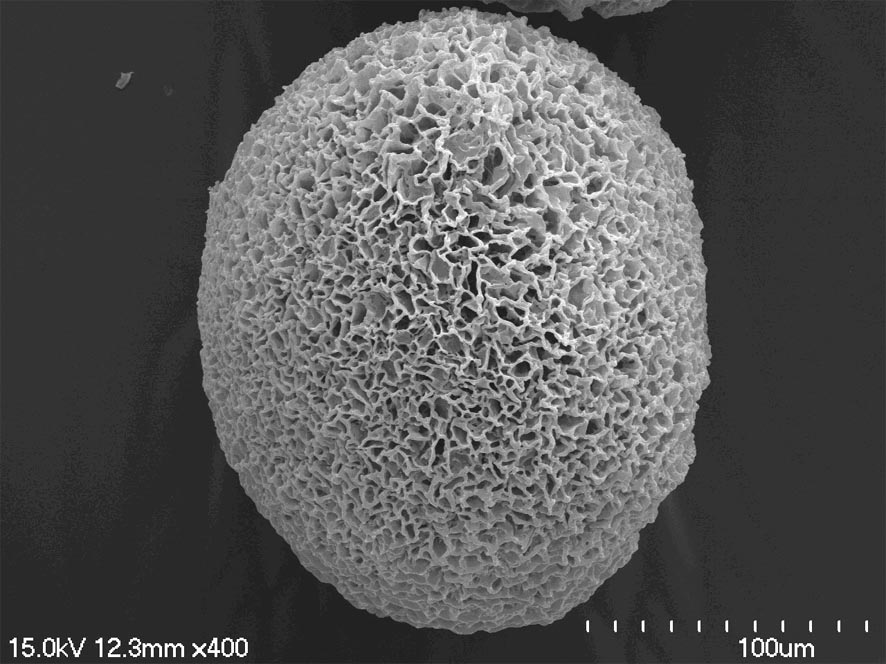

[0034] Add the silk fibroin shell solution and the water-soluble drug core layer solutio...

Embodiment 2

[0040] Put 100 g of tussah raw silk into 5 L of 0.25% Na 2 CO 3 In aqueous solution, at 98~100 o C treatment for 45 min, repeated 3 times to degumming silk, fully washed and dried to obtain tussah silk fiber. Add tussah silk fiber into molten calcium nitrate tetrahydrate, at 105 o C stirring and dissolving into tussah silk protein mixed solution. The obtained mixed solution was put into a dialysis bag, and dialyzed with deionized water for 4 days to remove impurities to obtain a pure tussah silk fibroin protein solution.

[0041] Adjust the mass concentration of tussah silk fibroin solution to 1.5%, and add 20% EDC, 10% NHS, and 20% MES into the silk fibroin solution evenly to obtain a silk shell solution. The insulin-like growth factor was configured as a water-soluble drug core layer solution with a concentration of 500ng / ml.

[0042] The two solutions of the shell layer and the core layer were poured into the syringe respectively, the fixed voltage was 6 kV, the pole d...

Embodiment 3

[0046] Use boiling Na with a concentration of 3.5‰ 2 CO 3 The silkworm cocoons were treated with solution three times, each time for 30 min, to degumming the silk, and after washing and drying thoroughly, the silk fibroin fiber was obtained. Add celestial silk fibroin fiber into molten calcium nitrate tetrahydrate, at 90 o C stirring and dissolving into a mixed solution of silk fibroin protein. The obtained mixed solution was put into a dialysis bag, and dialyzed with deionized water for 4 days to remove impurities to obtain a pure silk fibroin solution.

[0047] Adjust the concentration of the silk fibroin solution to 2%, and evenly add 20% EDC, 10% NHS, and 20% MES of the mass of silk fibroin into the silk fibroin solution to obtain a shell solution.

[0048] The nerve growth factor was configured as a water-soluble drug core layer solution with a concentration of 200ng / ml.

[0049] The two solutions of the shell layer and the core layer were poured into the syringe resp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com