Patents

Literature

1178results about "Cans/barrels/drums" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

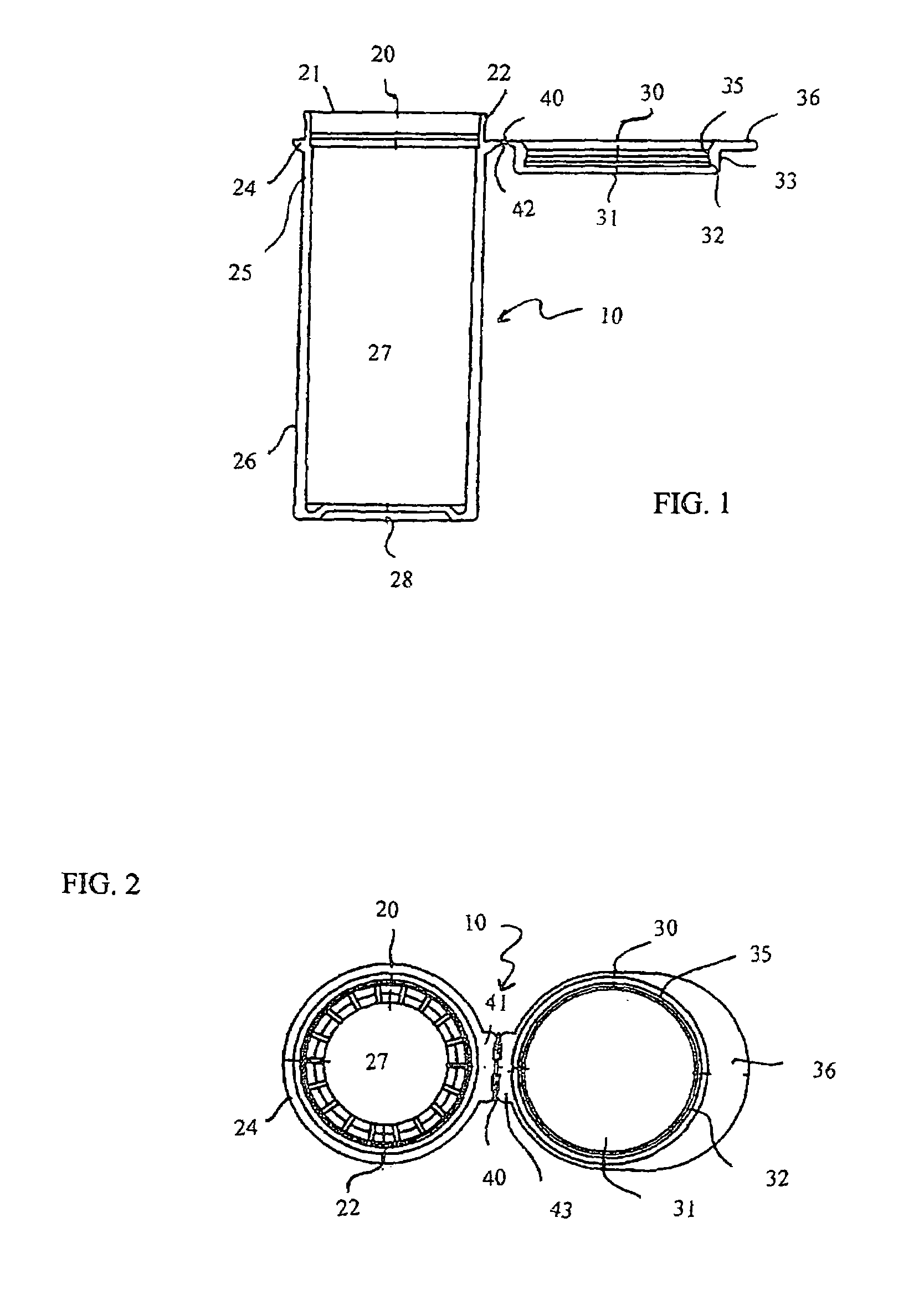

Compositions of ethylene/alpha-olefin multi-block interpolymer for blown films with high hot tack

InactiveUS20060199030A1Superior hot tack propertyWider process windowSynthetic resin layered productsBagsCelsius DegreeVolumetric Mass Density

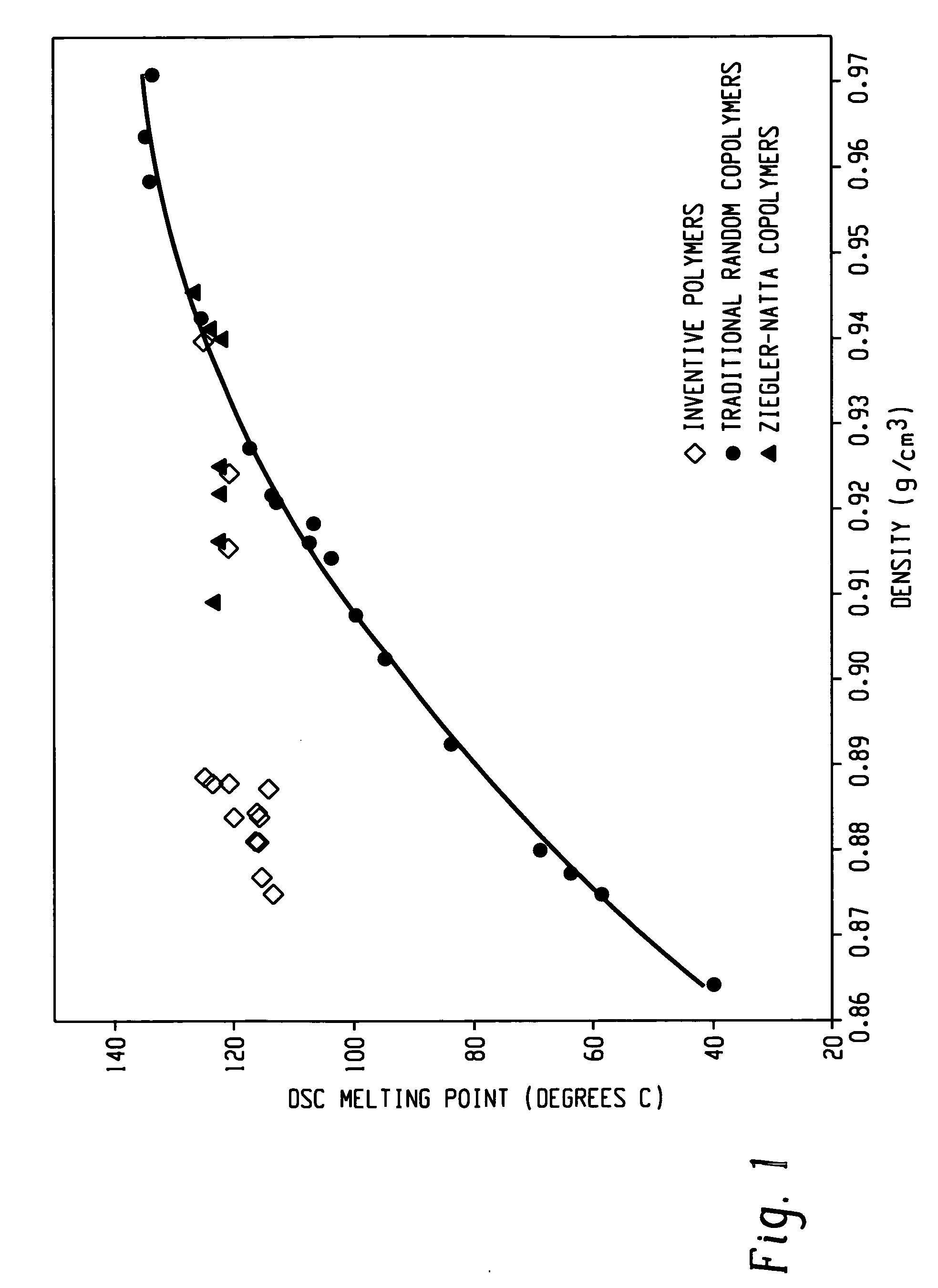

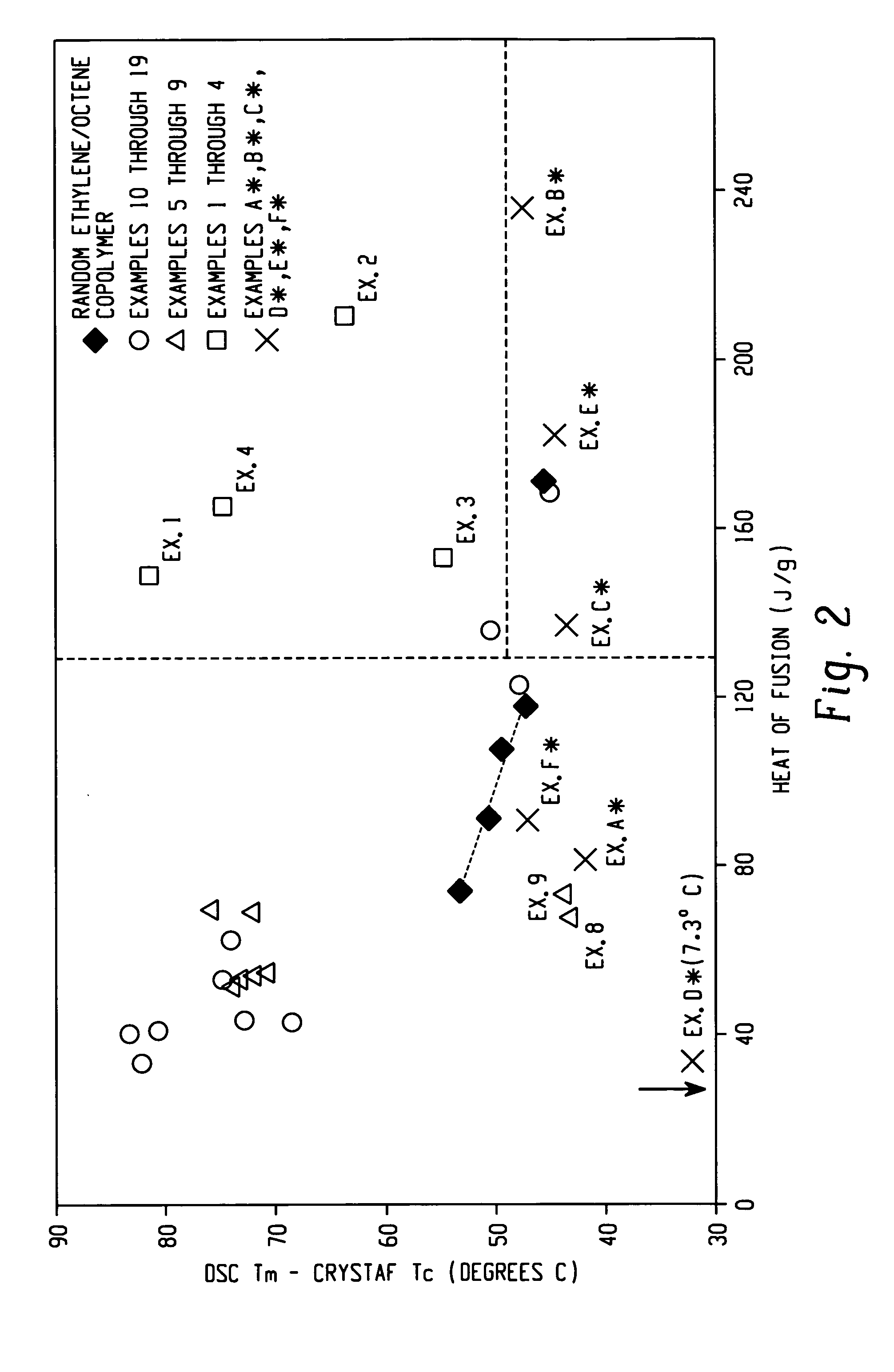

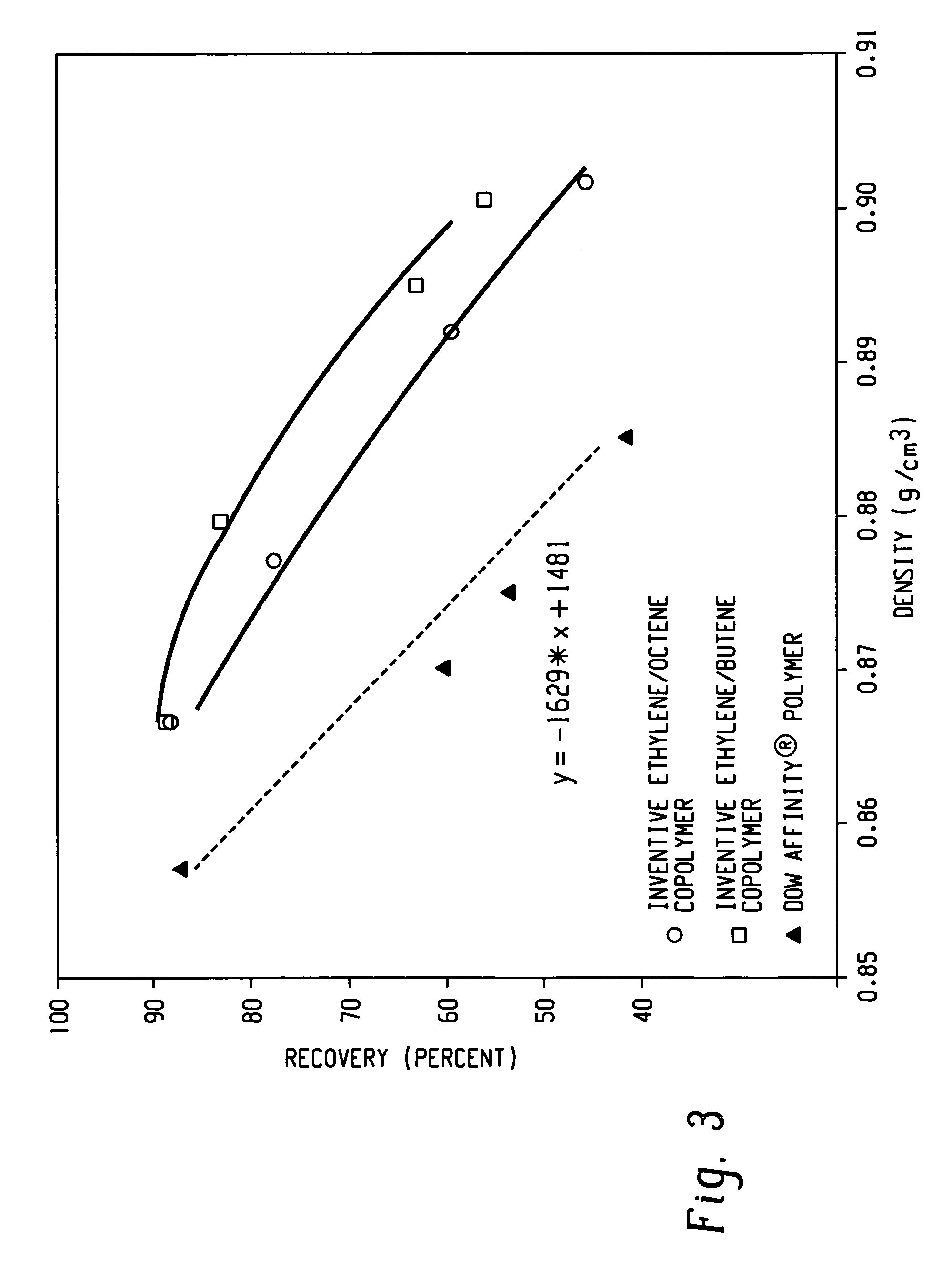

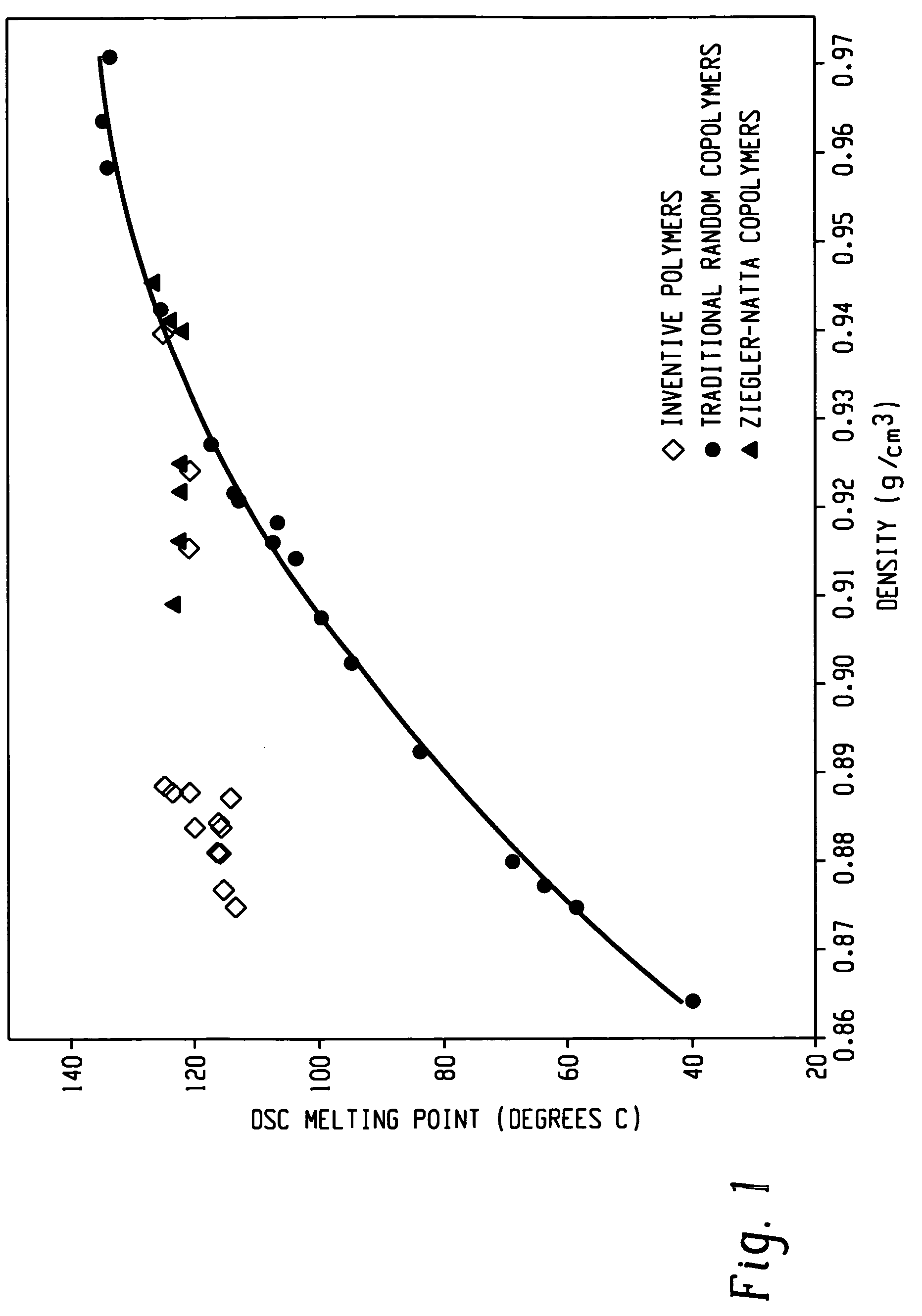

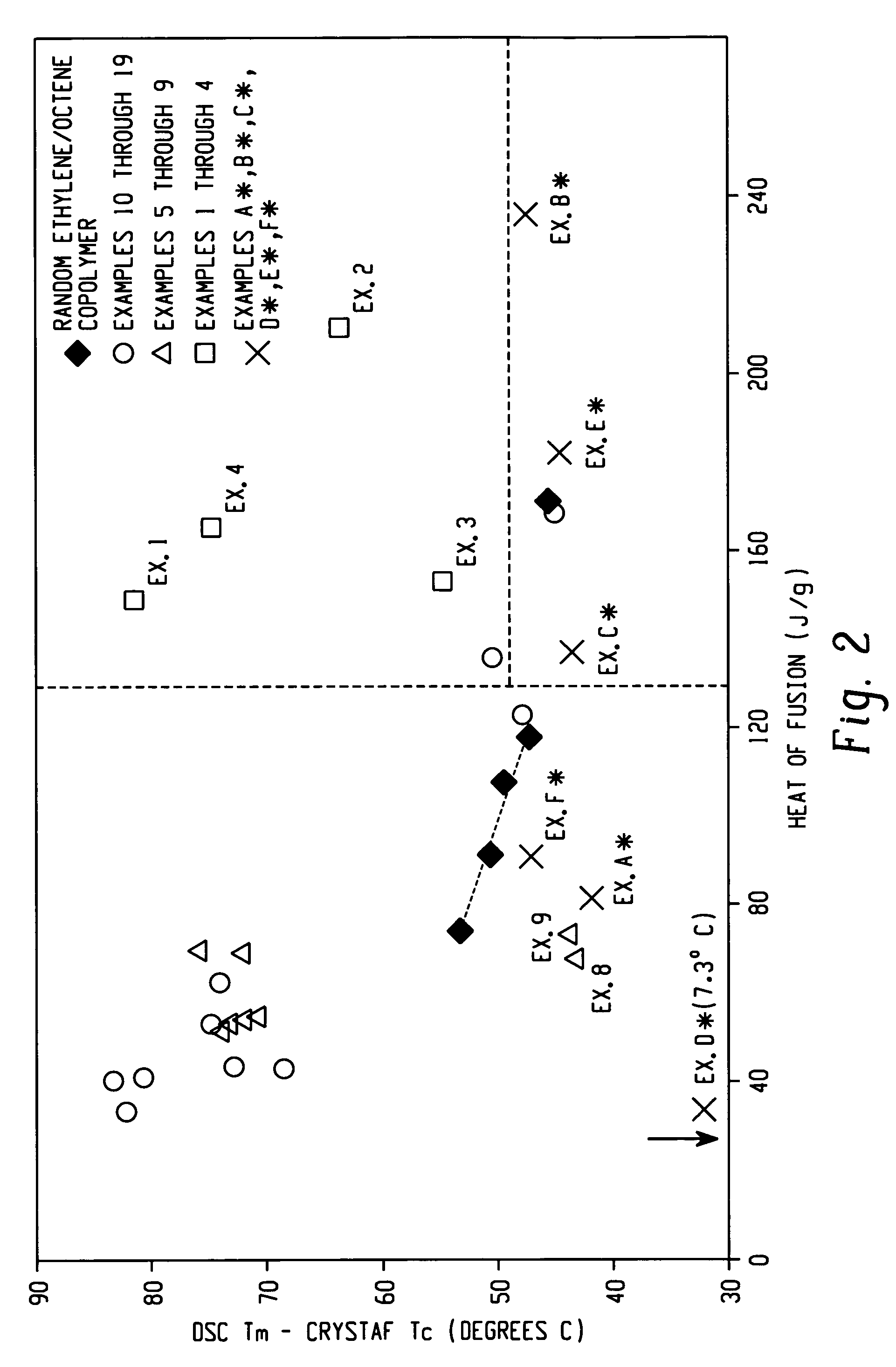

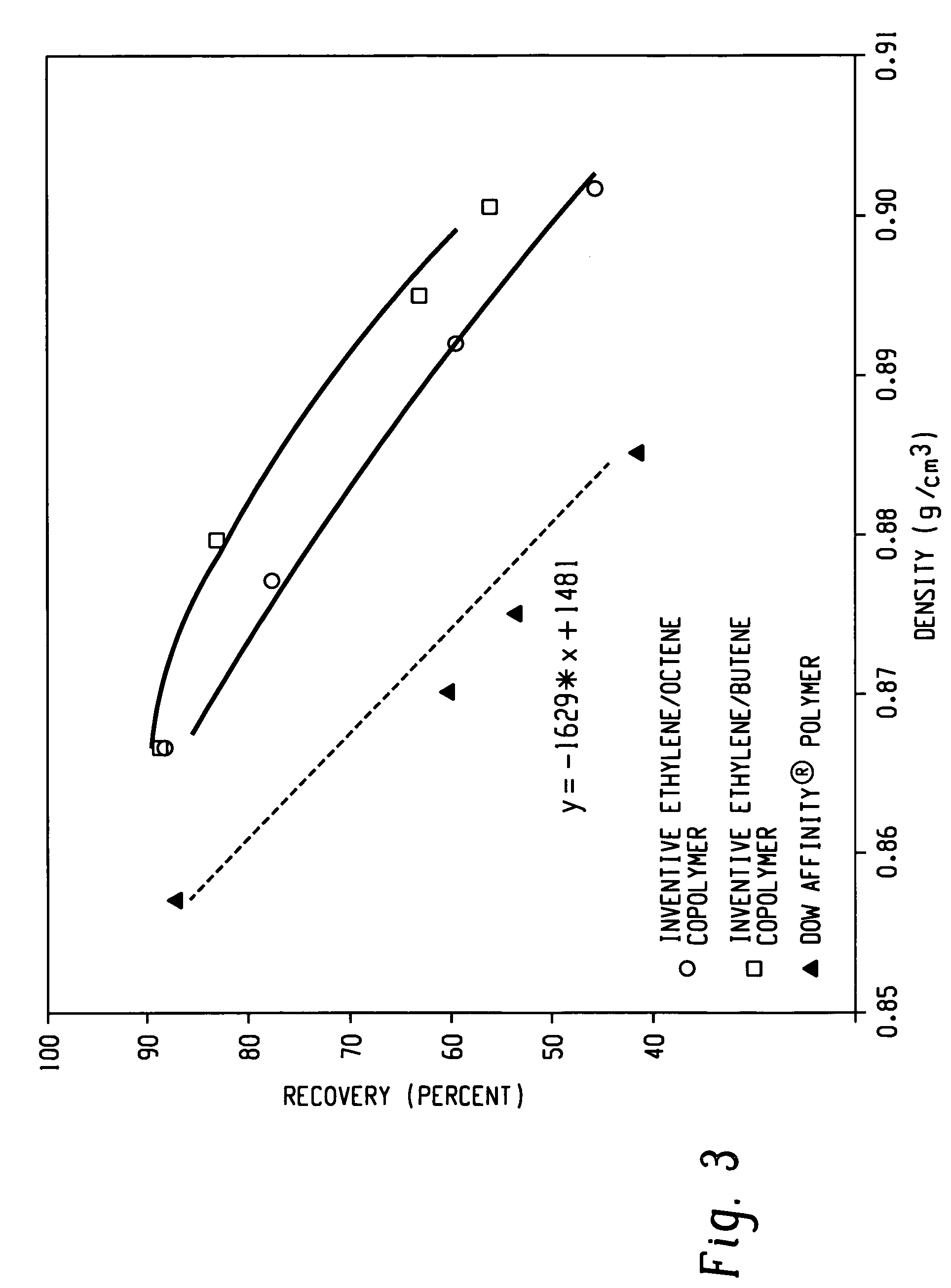

The present invention relates to film layers and compositions having improved hot tack properties. The compositions comprise at least one ethylene / α-olefin interpolymer, wherein the ethylene / α-olefin interpolymer may have, for example, a Mw / Mn from about 1.7 to about 3.5, at least one melting point, Tm, in degrees Celsius, and a density, d, in grams / cubic centimeter, wherein the numerical values of Tm and d correspond to the relationship: Tm>−2002.9+4538.5(d)−2422.2(d)2.

Owner:DOW GLOBAL TECH LLC

Compositions of ethylene/alpha-olefin multi-block interpolymer for blown films with high hot tack

InactiveUS7582716B2Less energyLess timeSynthetic resin layered productsBagsCelsius DegreeAlpha-olefin

The present invention relates to film layers and compositions having improved hot tack properties. The compositions comprise at least one ethylene / α-olefin interpolymer, wherein the ethylene / α-olefin interpolymer may have, for example, a Mw / Mn from about 1.7 to about 3.5, at least one melting point, Tm, in degrees Celsius, and a density, d, in grams / cubic centimeter, wherein the numerical values of Tm and d correspond to the relationship:Tm>−2002.9+4538.5(d)−2422.2(d)2.

Owner:DOW GLOBAL TECH LLC

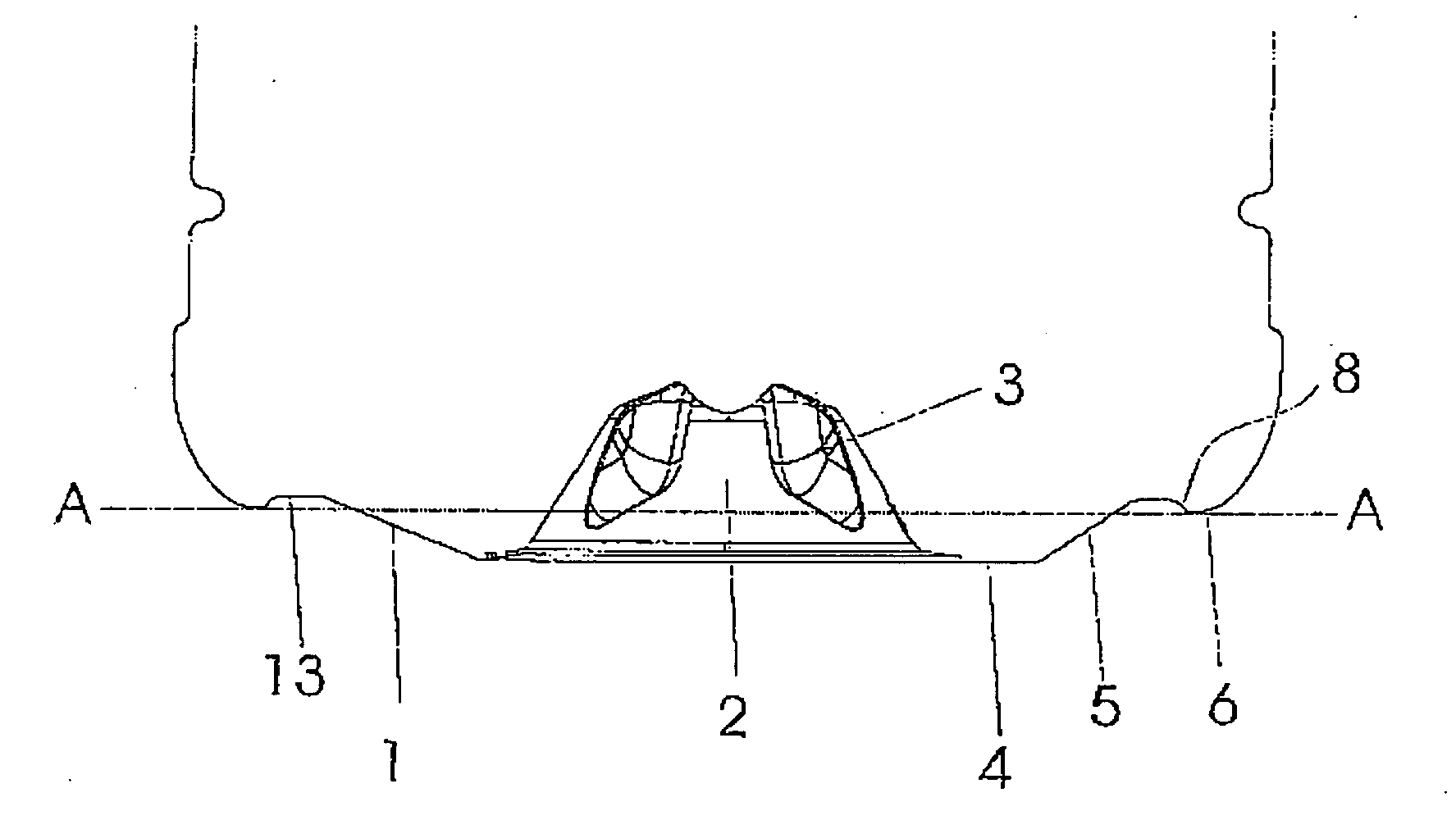

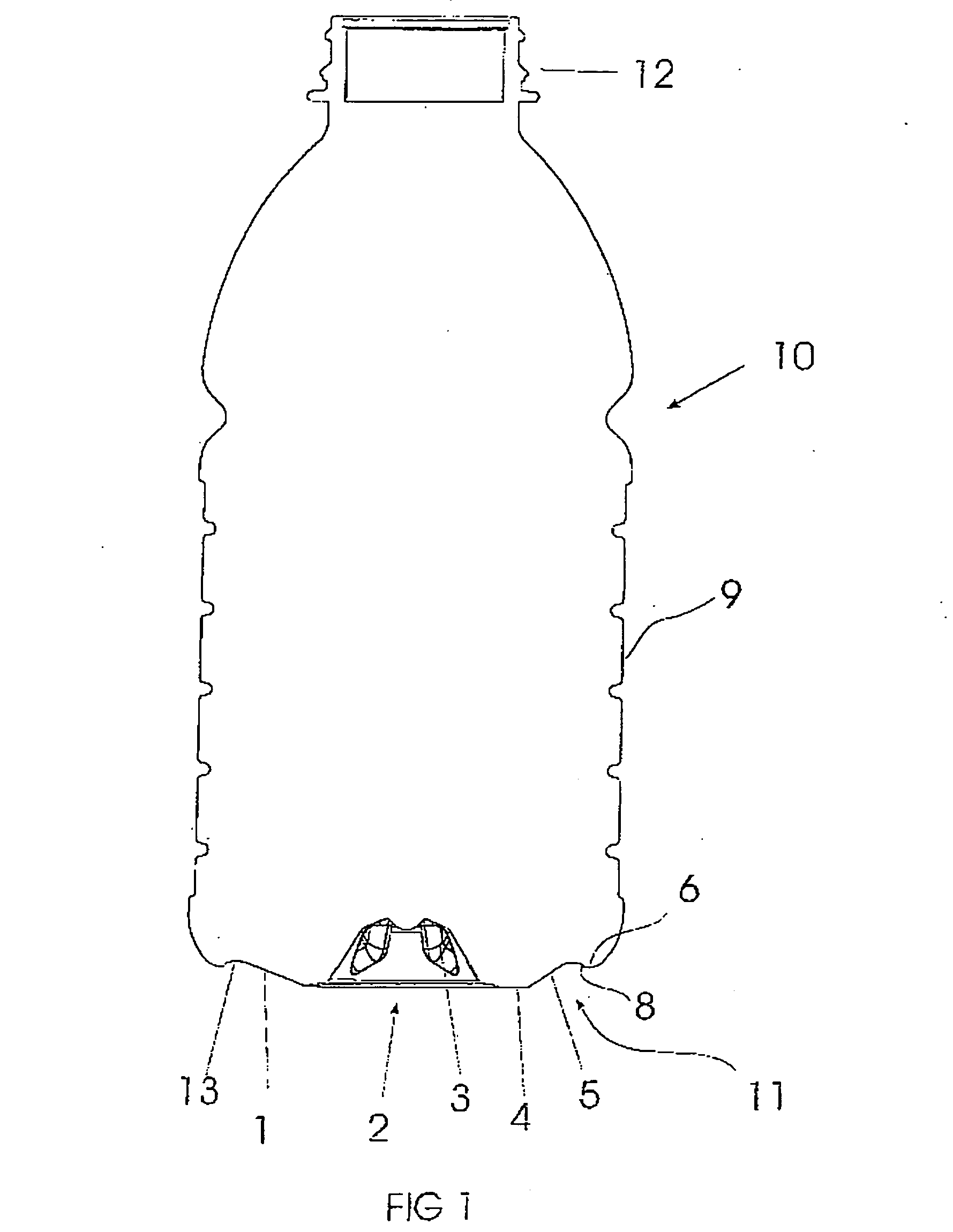

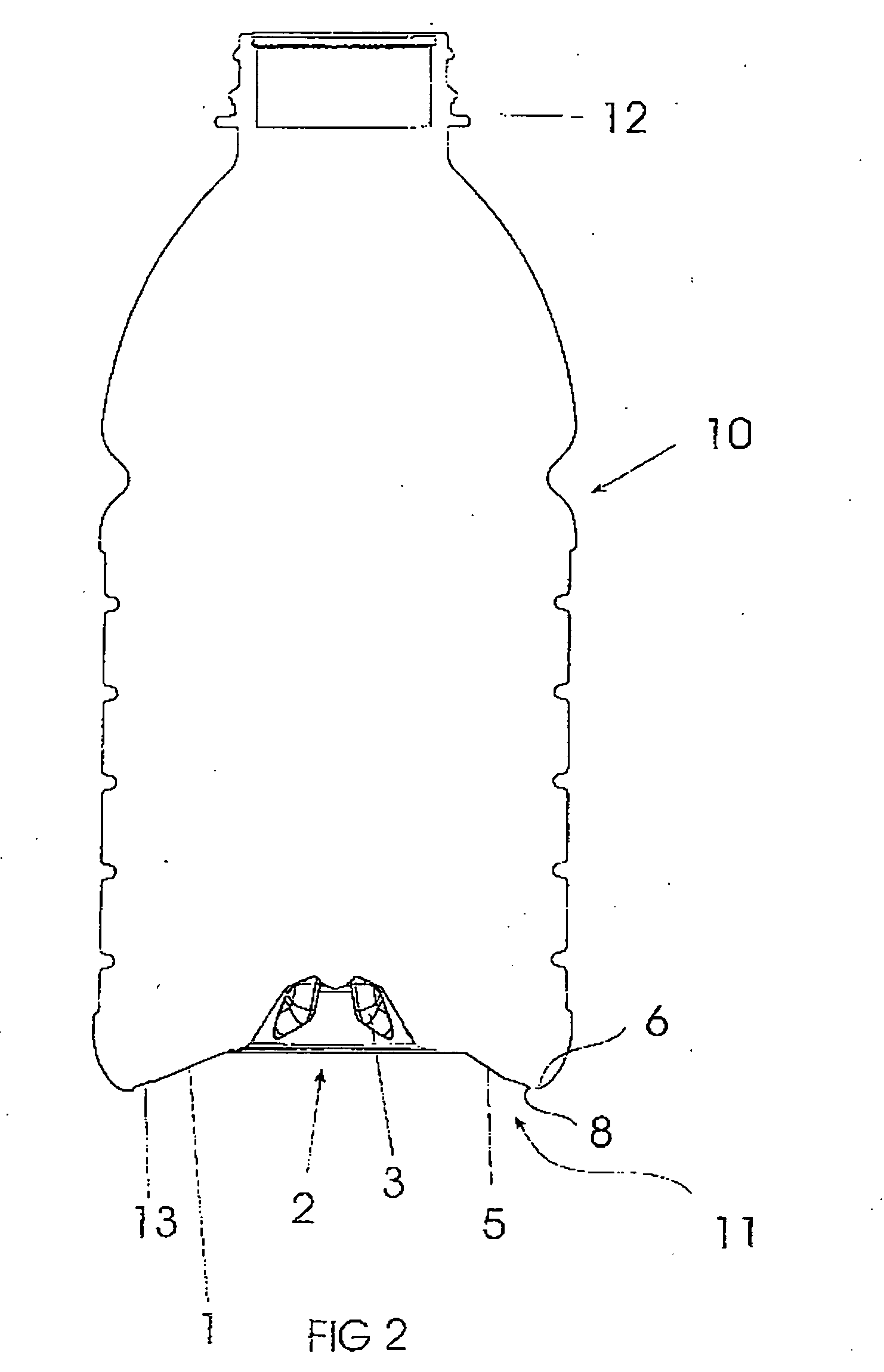

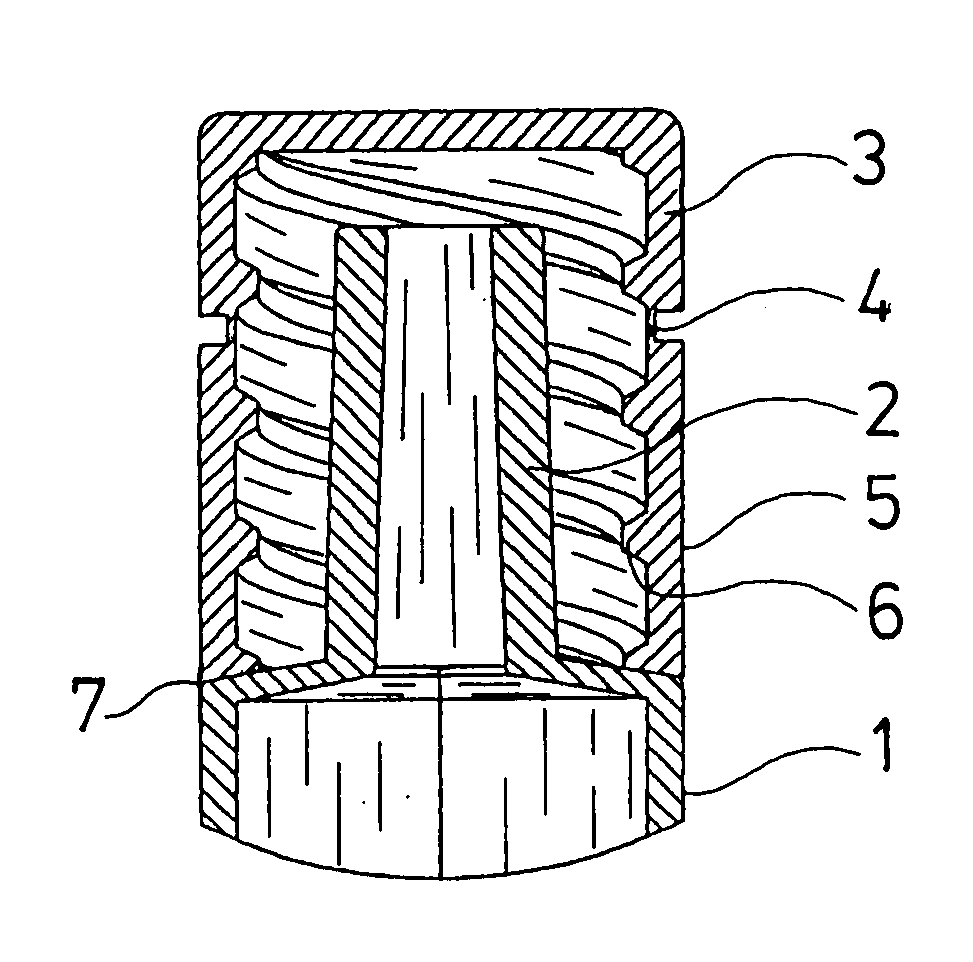

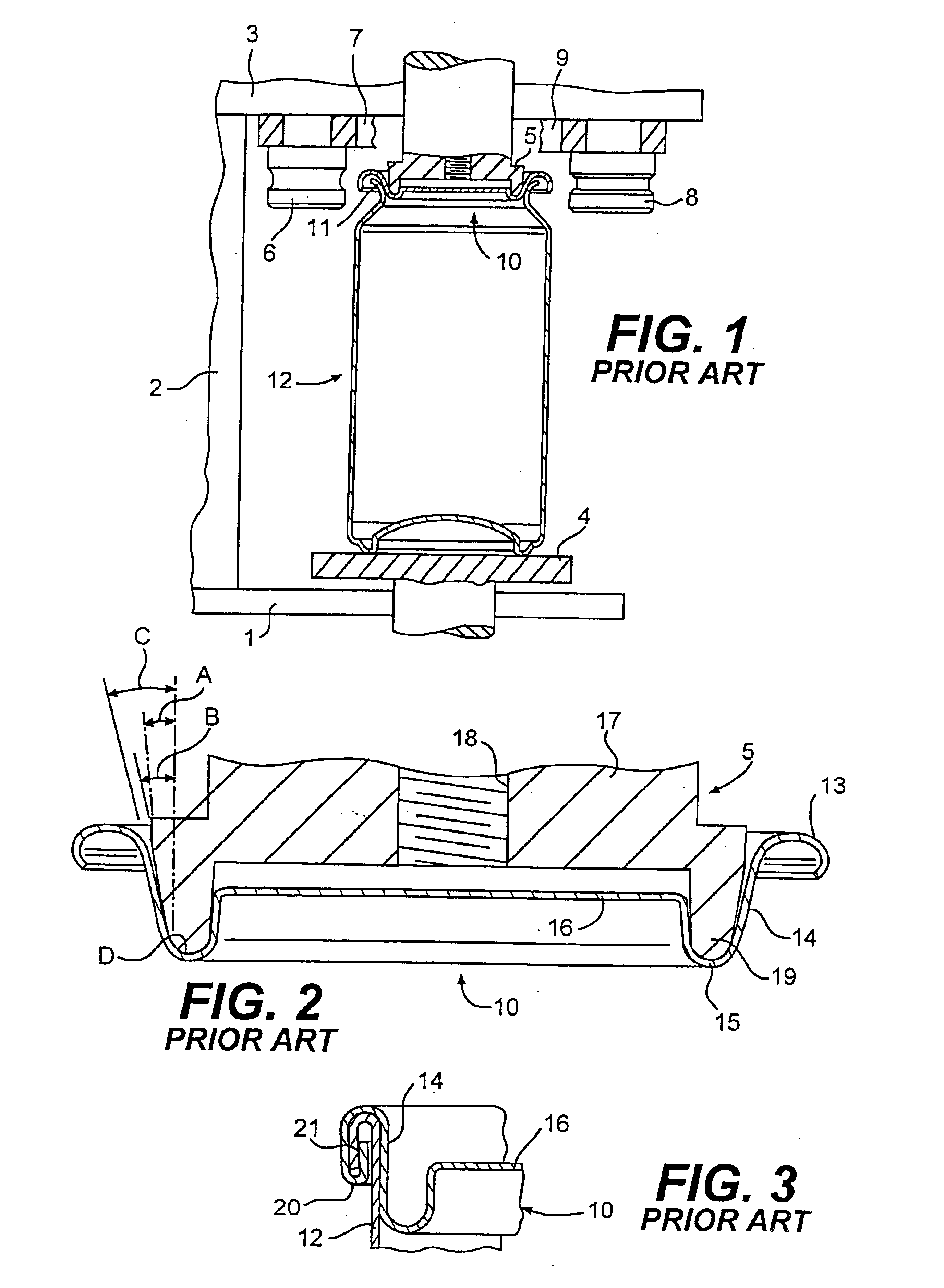

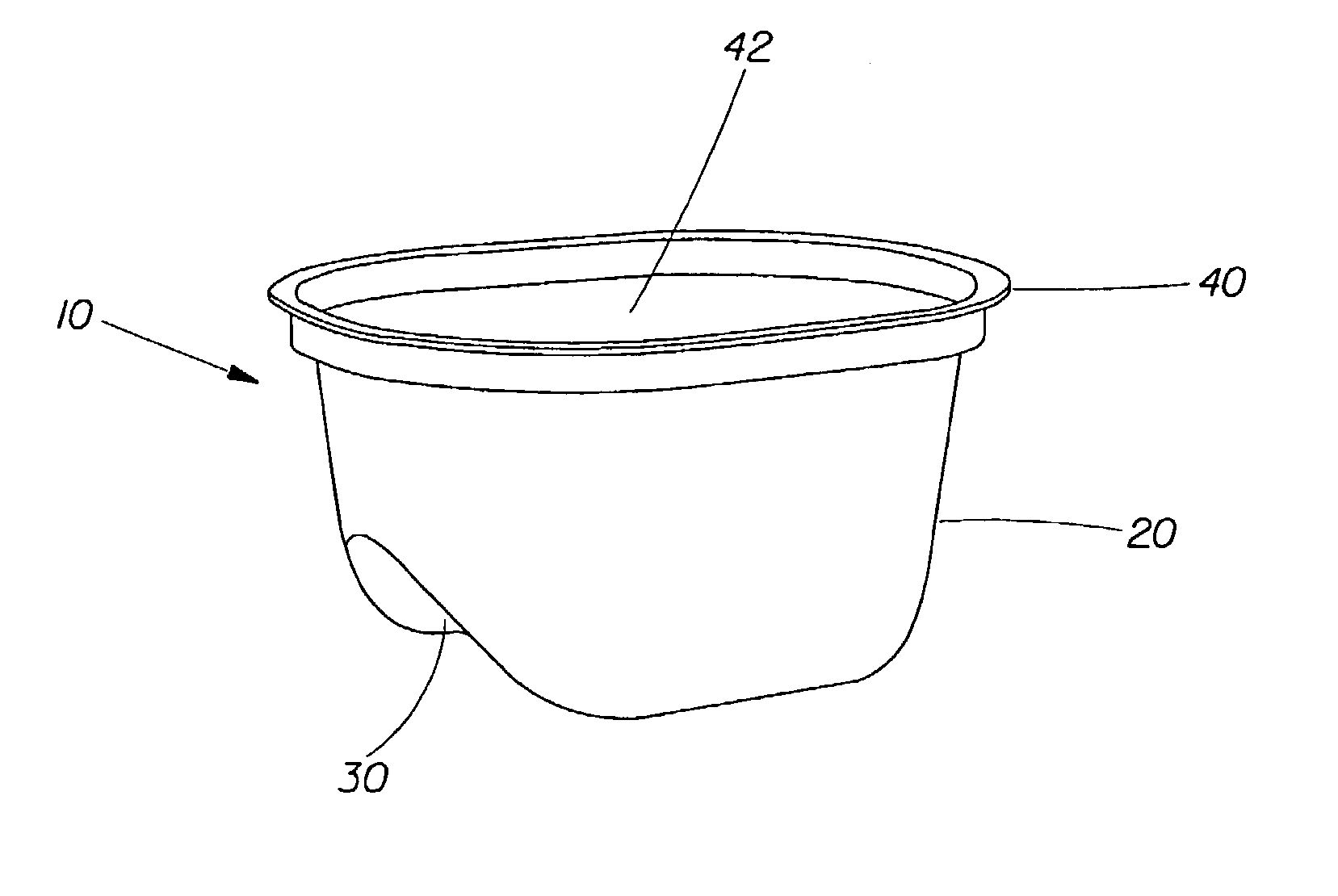

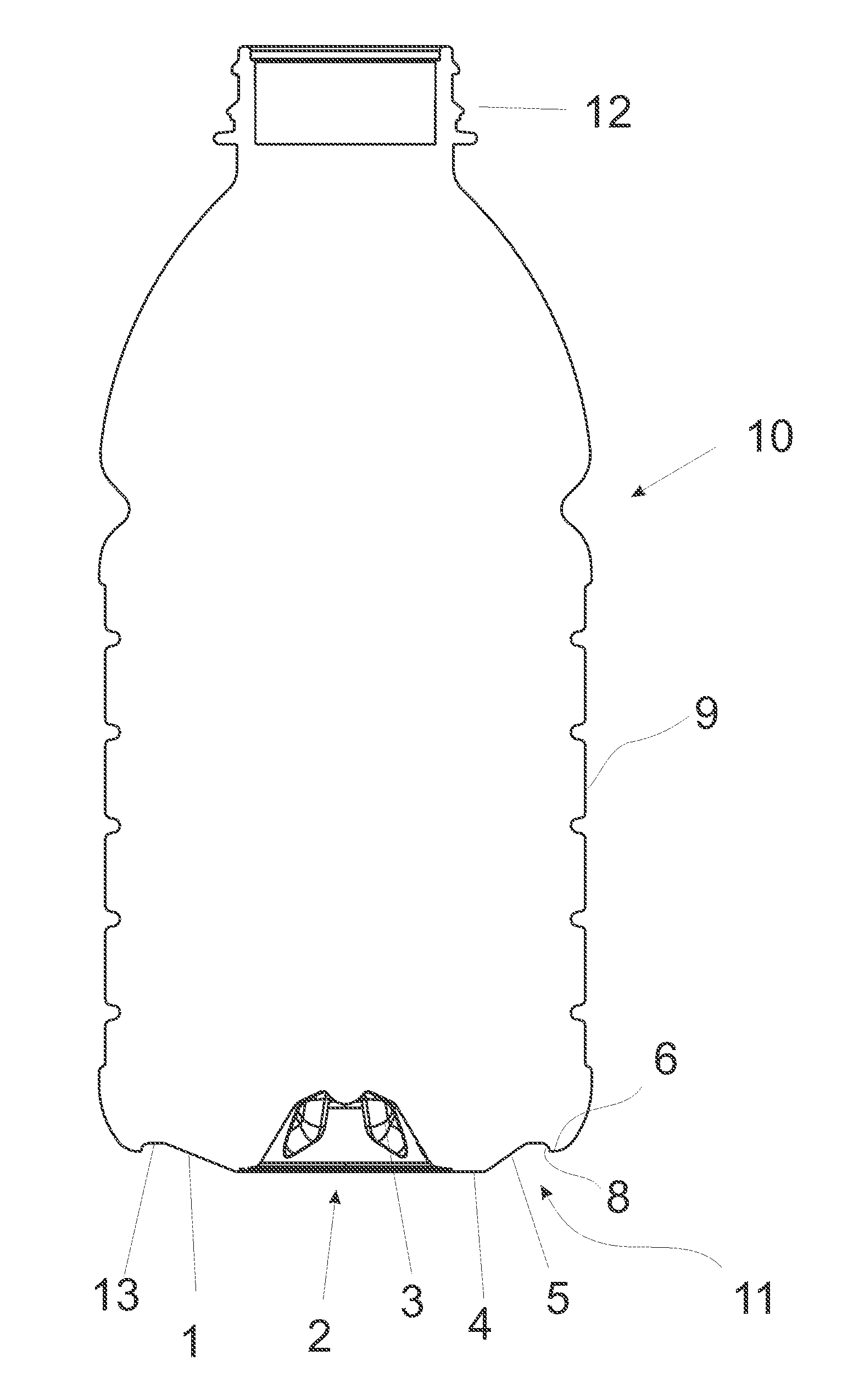

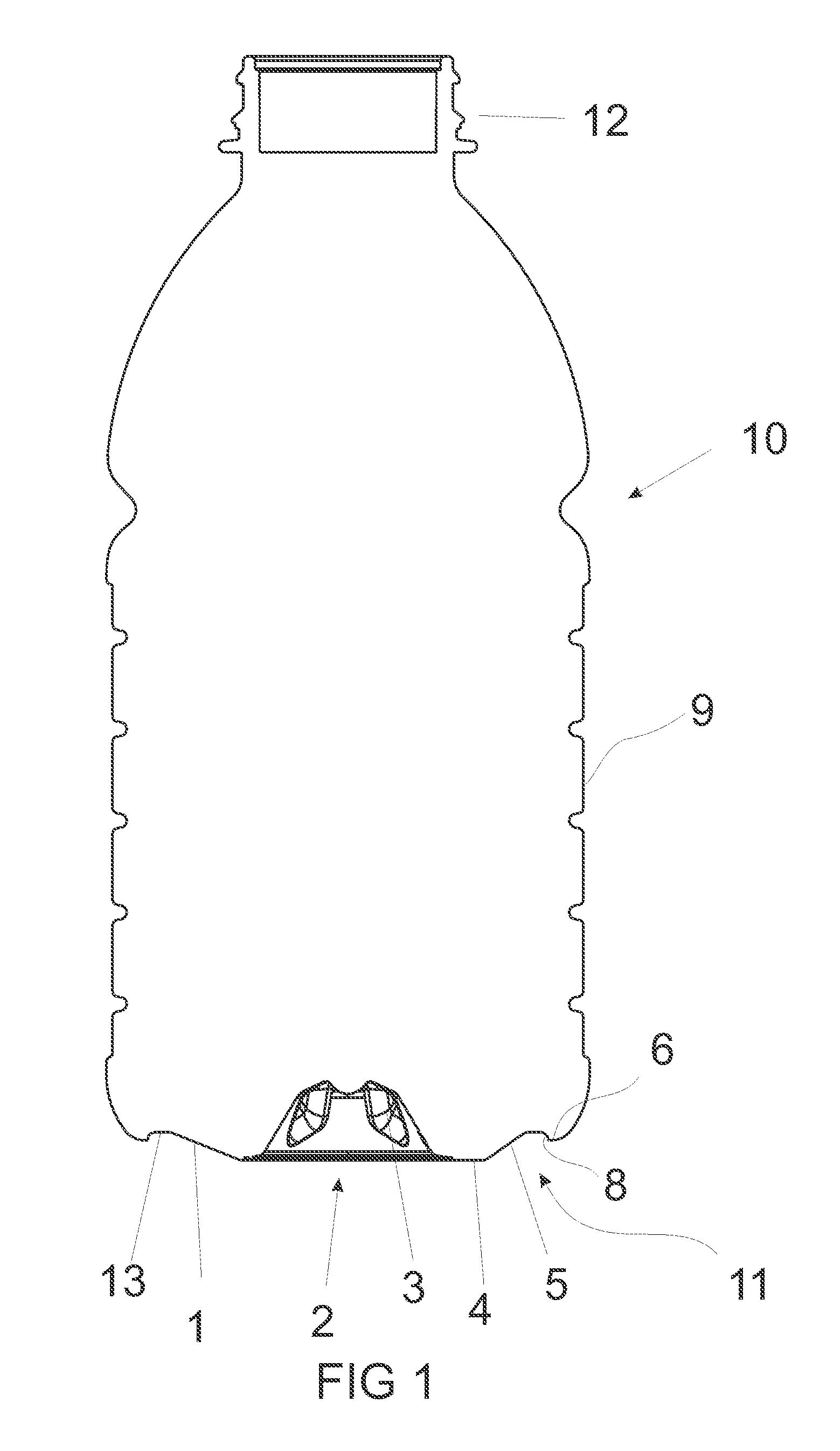

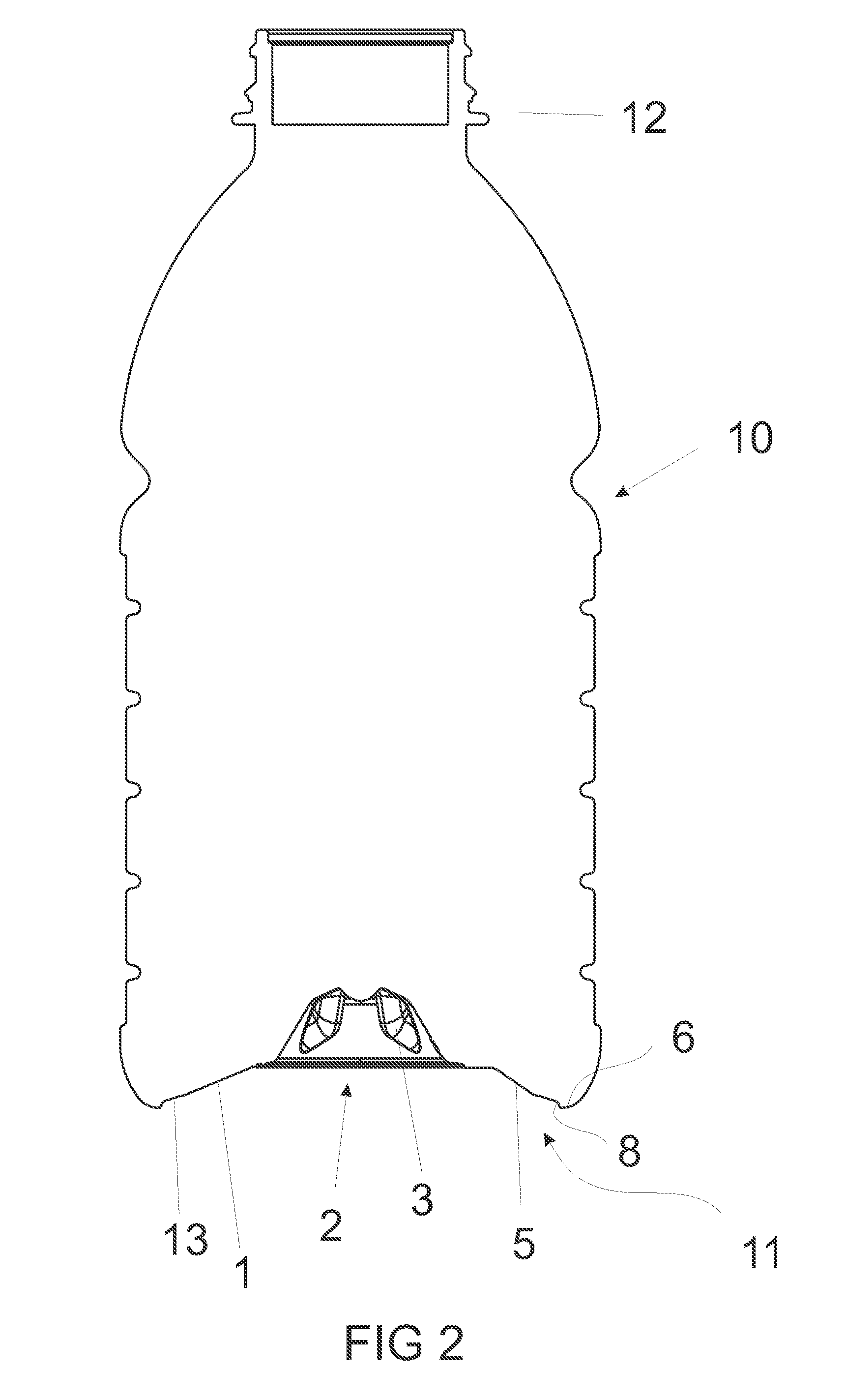

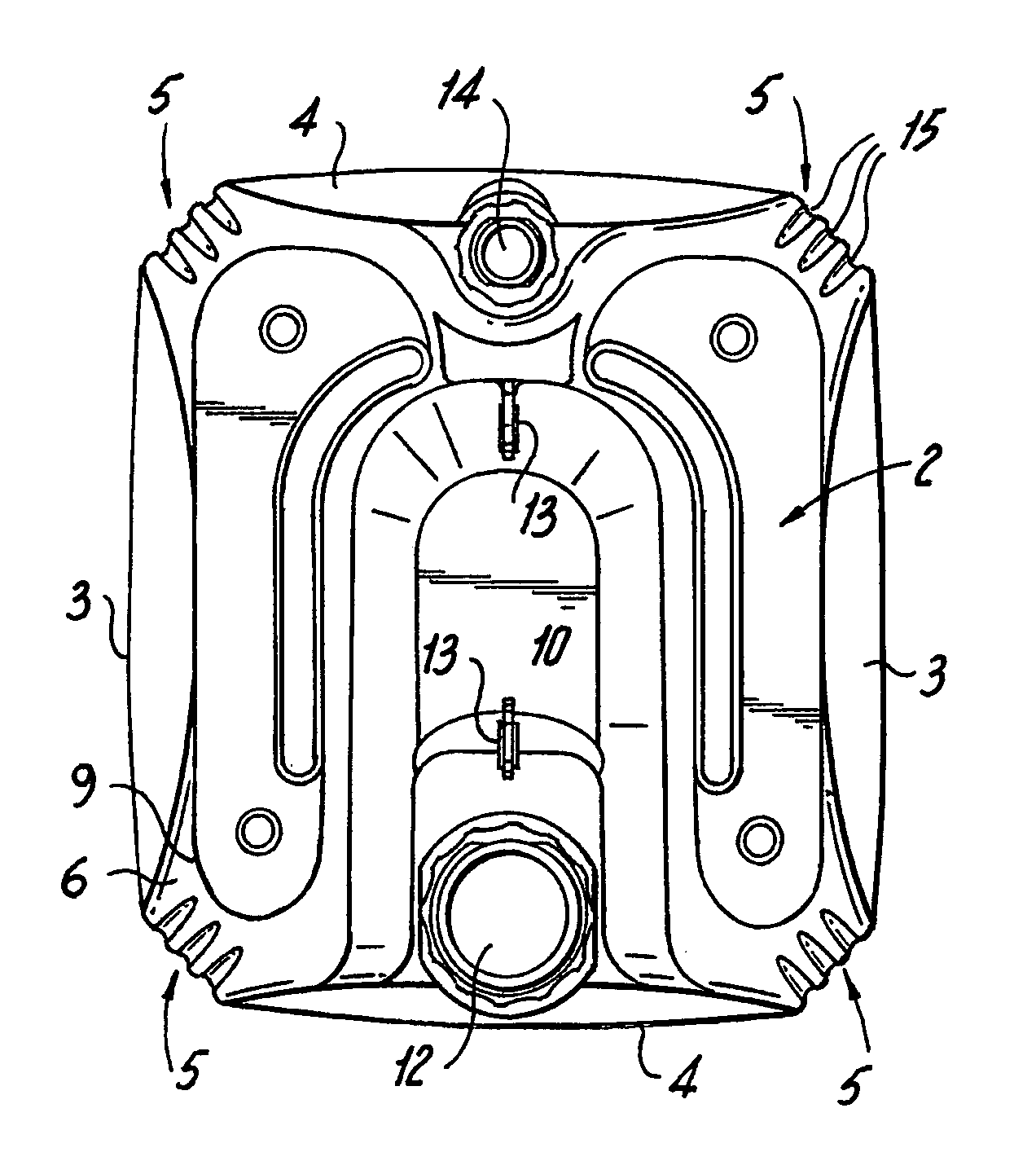

Container structure for removal of vacuum pressure

A hot-fill PET container or bottle (10) filling with a liquid at an elevated temperature has a side wall (9) extending to a lower portion including a pressure panel (11) and a base (21) in its unfolded or pre-fill position. The panel (11) is transversely oriented and has a decoupling or hinge structure (13), an initiator portion (1) and control portion (5) of a steeply angled inverting conical section between 30 and 45 degrees. The control portion enables the inversion of the panel (11) into the container (10) to compensate for vacuum or reduced pressure induced within the container as the liquid cools down. The base (2) can also have a plurality of reinforcing ribs (3).

Owner:CO2 PAC

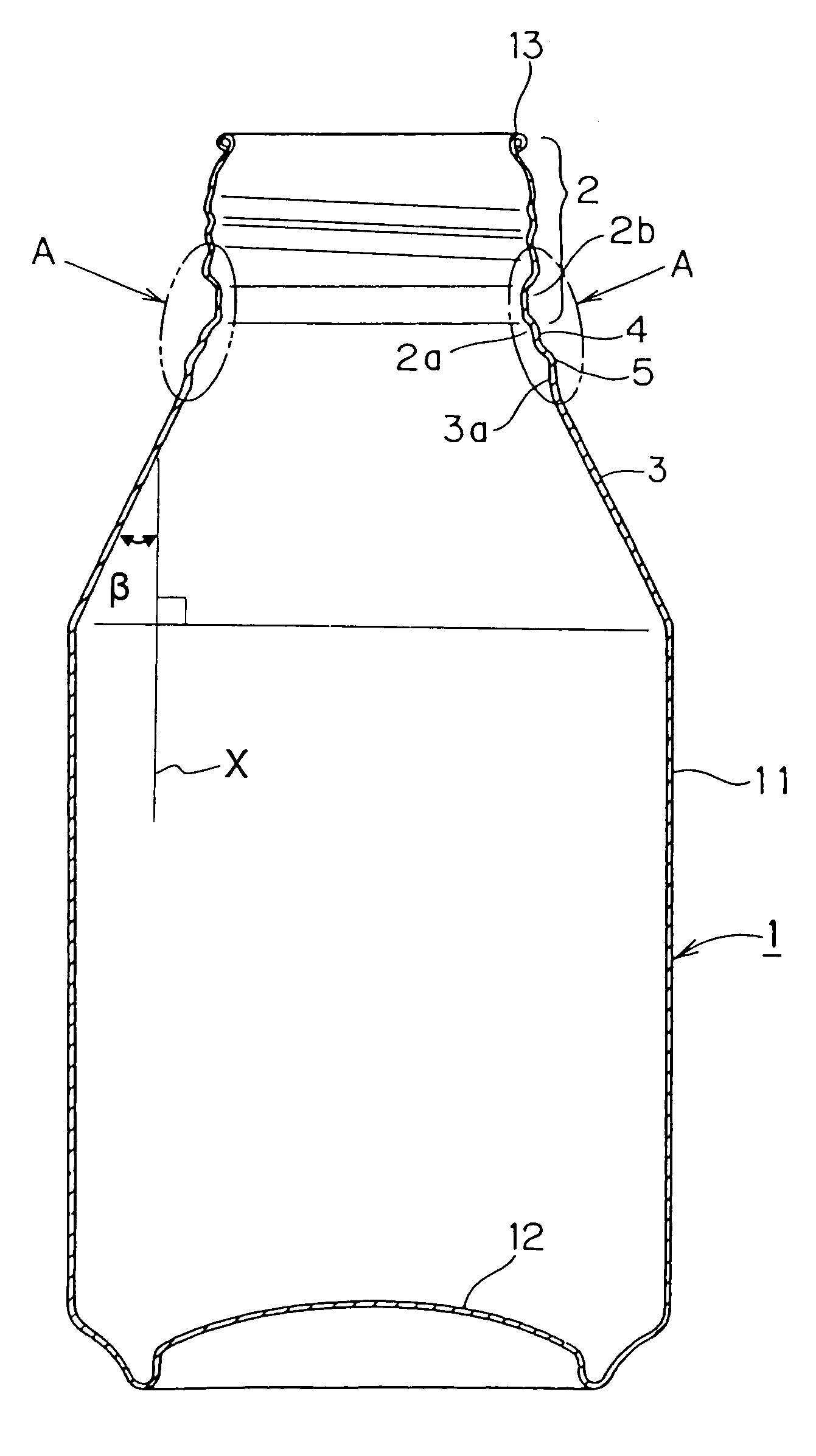

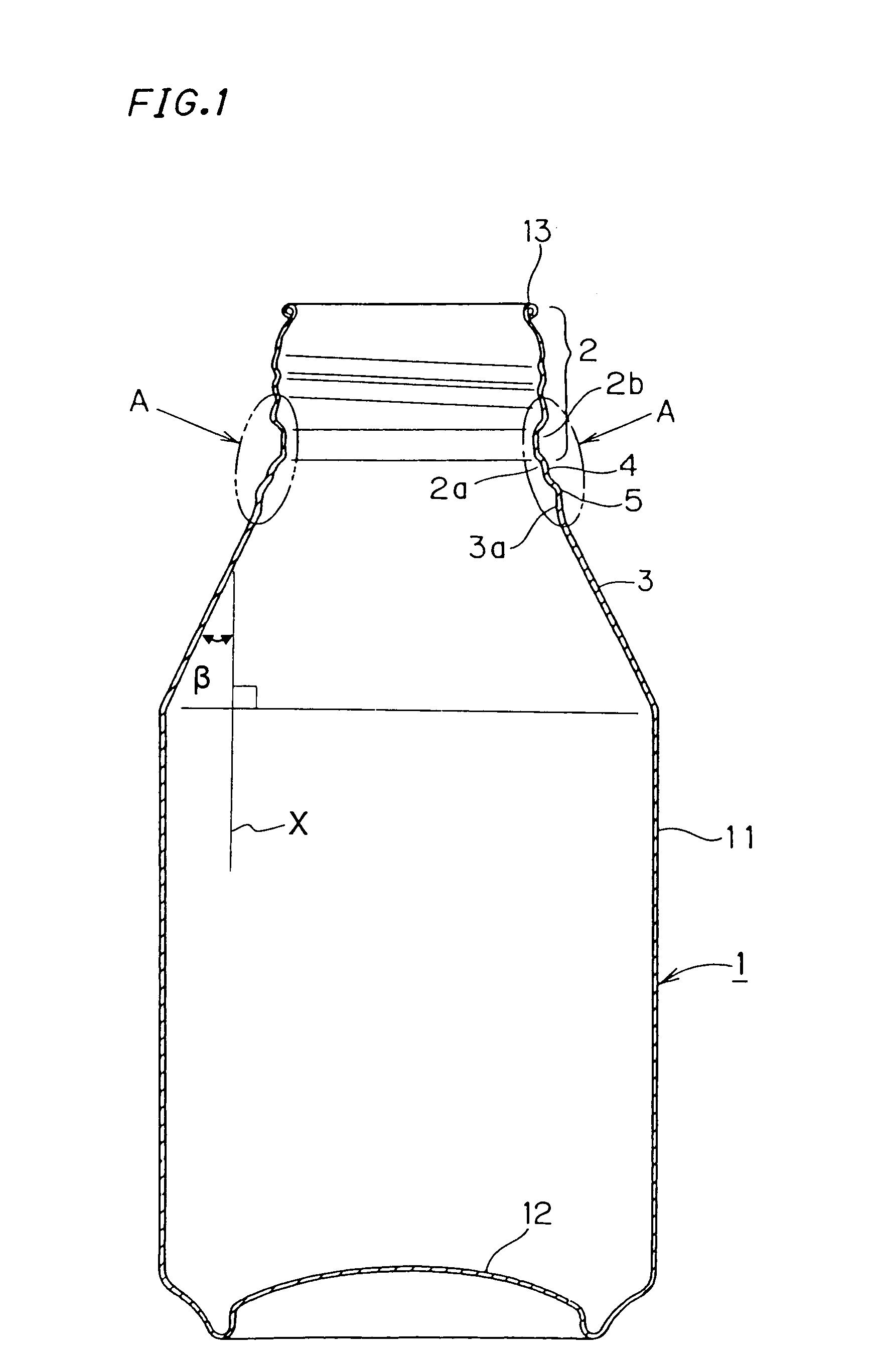

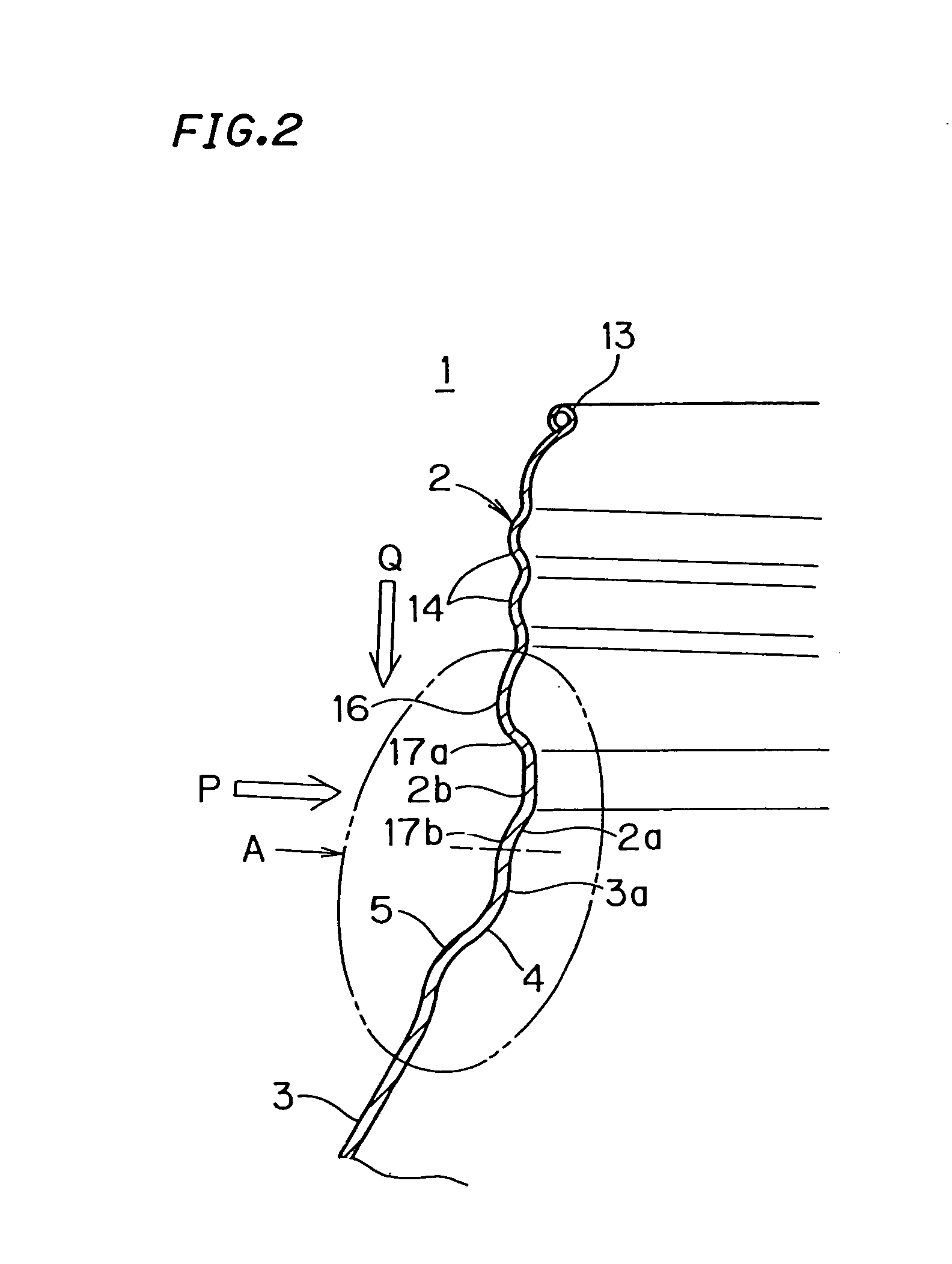

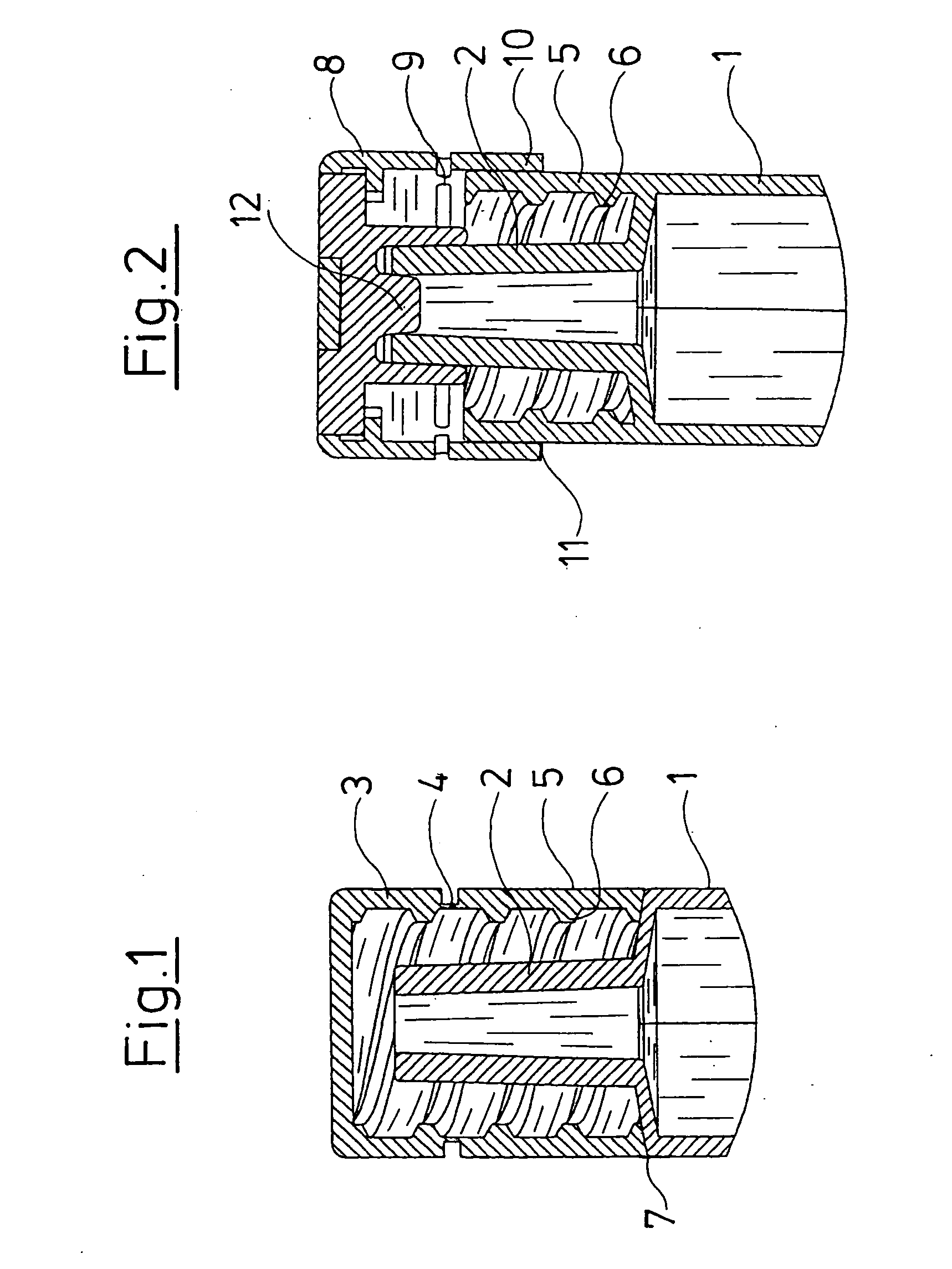

Metal container with thread

A metal container with thread capable of preventing such a defect that the strength of a lower end of a mouth part and an upper end of a shoulder part of a container main body is non-resistant to a pressing force in radial and axial directions, and a part of the container may be collapsed or buckled during a capping operation where content is filled into the container and cap is fitted to the container automatically by a machine, characterized in that at least one or more inwardly curving smooth annular recessed parts(4) and at least one or more outwardly curving smooth annular projected parts(5) are formed in an area ranging from the lower end (2a) of the mouth part(2) of the container main body to around the upper end(3a) of a tapered shoulder part increasing gradually in radial direction.

Owner:TAKEUCHI PRESS IND CO LTD

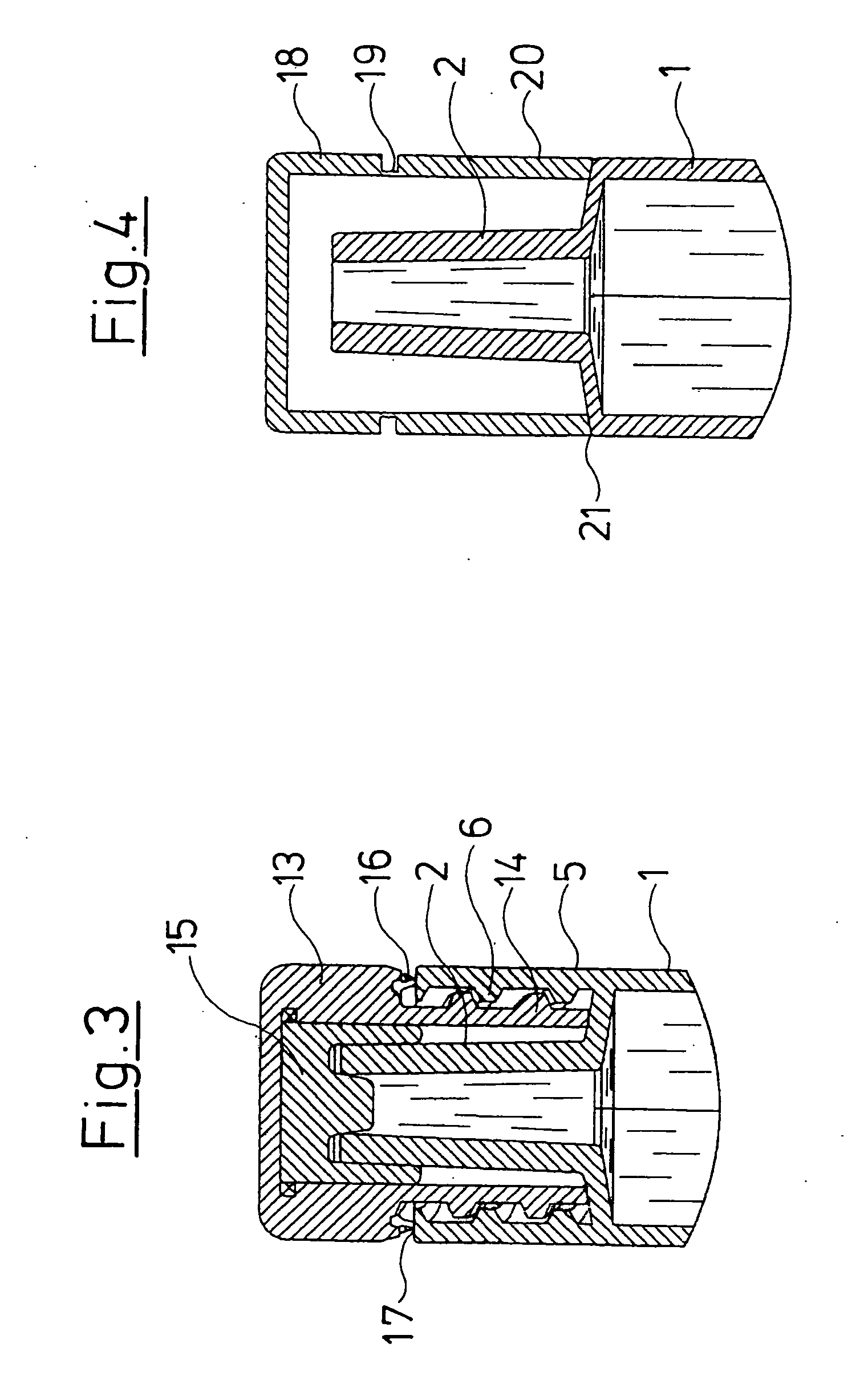

Tamper-evident closure for a syringe

ActiveUS20040116858A1Improve toleranceFirmly connectedClosuresInfusion syringesBiomedical engineeringSyringe

The tamper-evident closure is provided for a syringe with a Luer connection or a Luer lock connection, wherein at least the connection end consists of plastic. A cap which is connected to the syringe via at least one frangible web. The cap and the frangible web together with a fixation component are formed as one piece as a plastic injection molded part and are connected to the connection end of the syringe by way of welding.

Owner:TRANSCOJECT

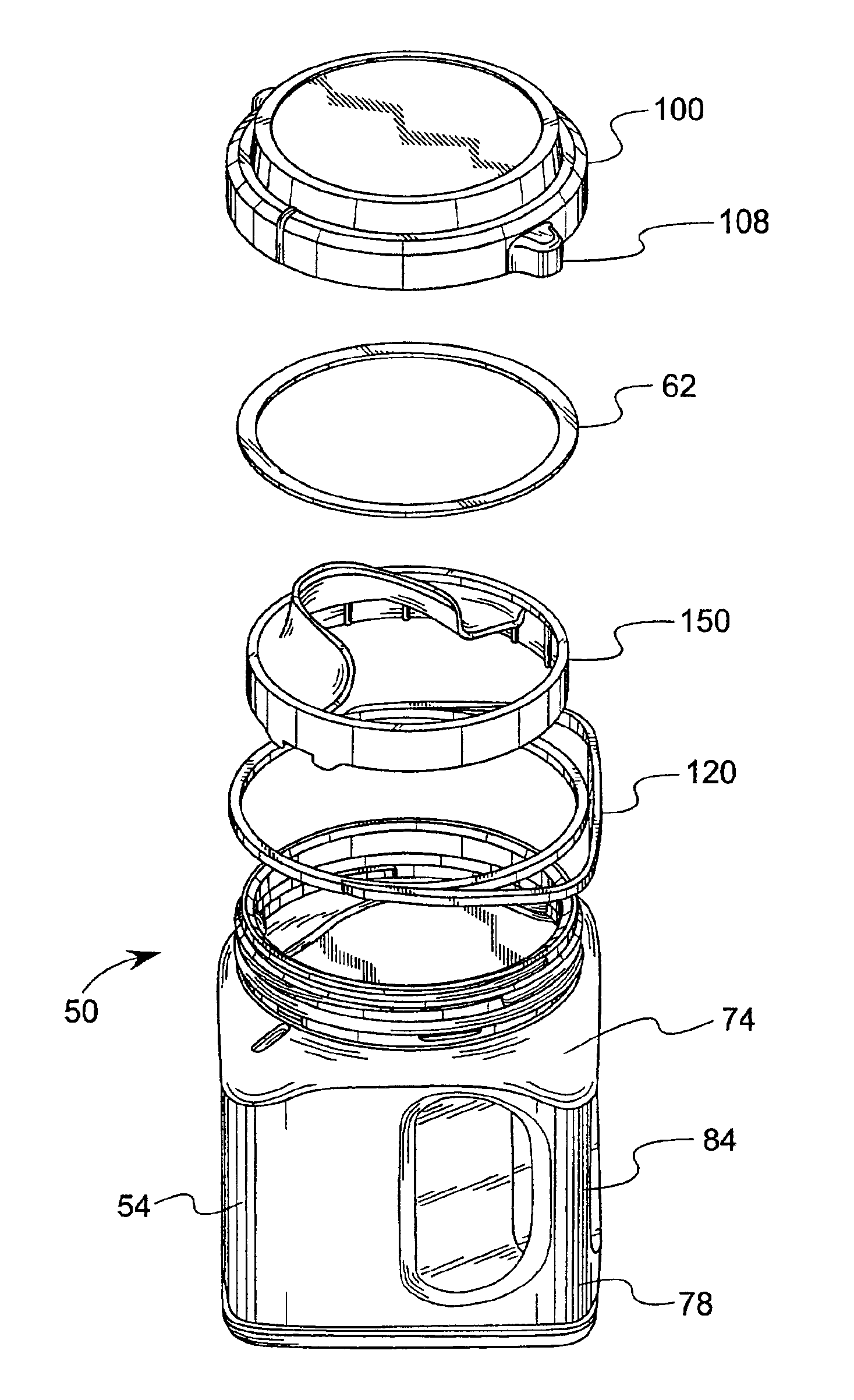

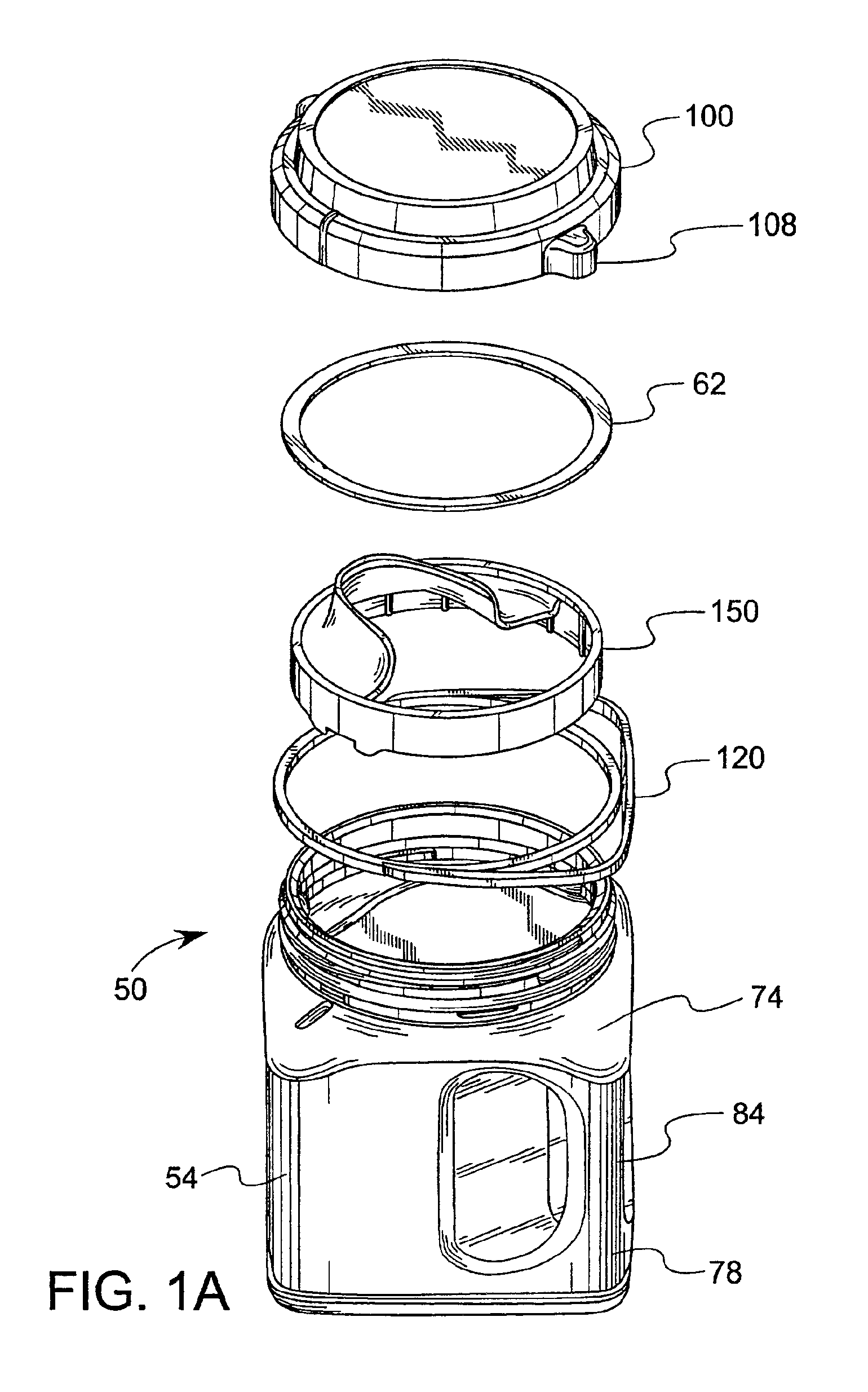

Container and lid assembly

A plastic container and lid assembly for storing liquid coating materials including a container and a lid. The container has a body with a bottom wall, at least four sidewalls and a neck. The neck defines a wide mouth opening and including threads for receiving mating threads on the lid. The lid also has a plurality of lugs, preferably two lugs, extending radially from the lid and terminating at or before the lugs extend beyond the container sidewalls when the lid is in sealed engagement with the container. The body also has an integral handle for lifting the container and the container neck supports a bail-type handle also for lifting said container. The integral handle and bail-type handles do not extend beyond the container sidewall. The container and lid assembly having an effective packing footprint and an effective packing volume which substantially conforms to the effective packing footprint and the effective packing volume of a conventional metal paint can.

Owner:THE SHERWIN-WILLIAMS CO

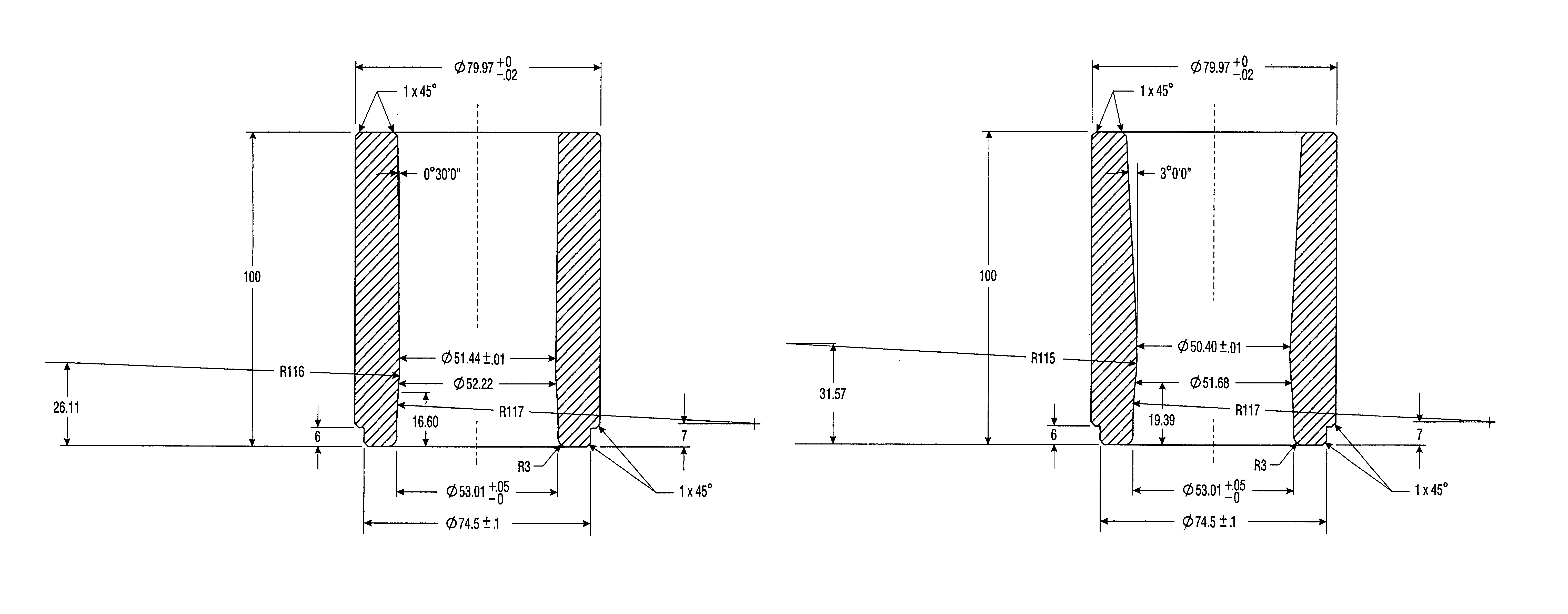

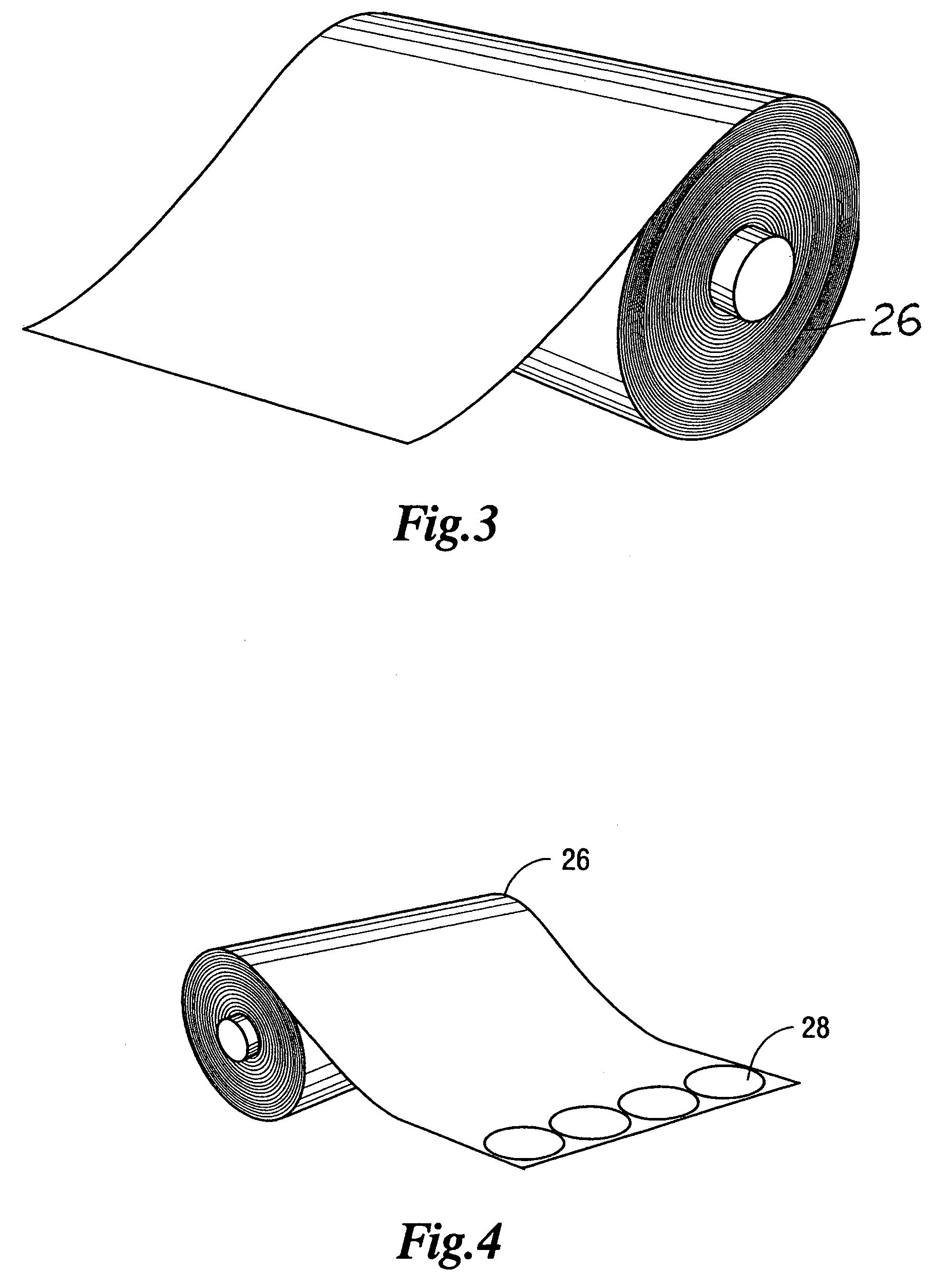

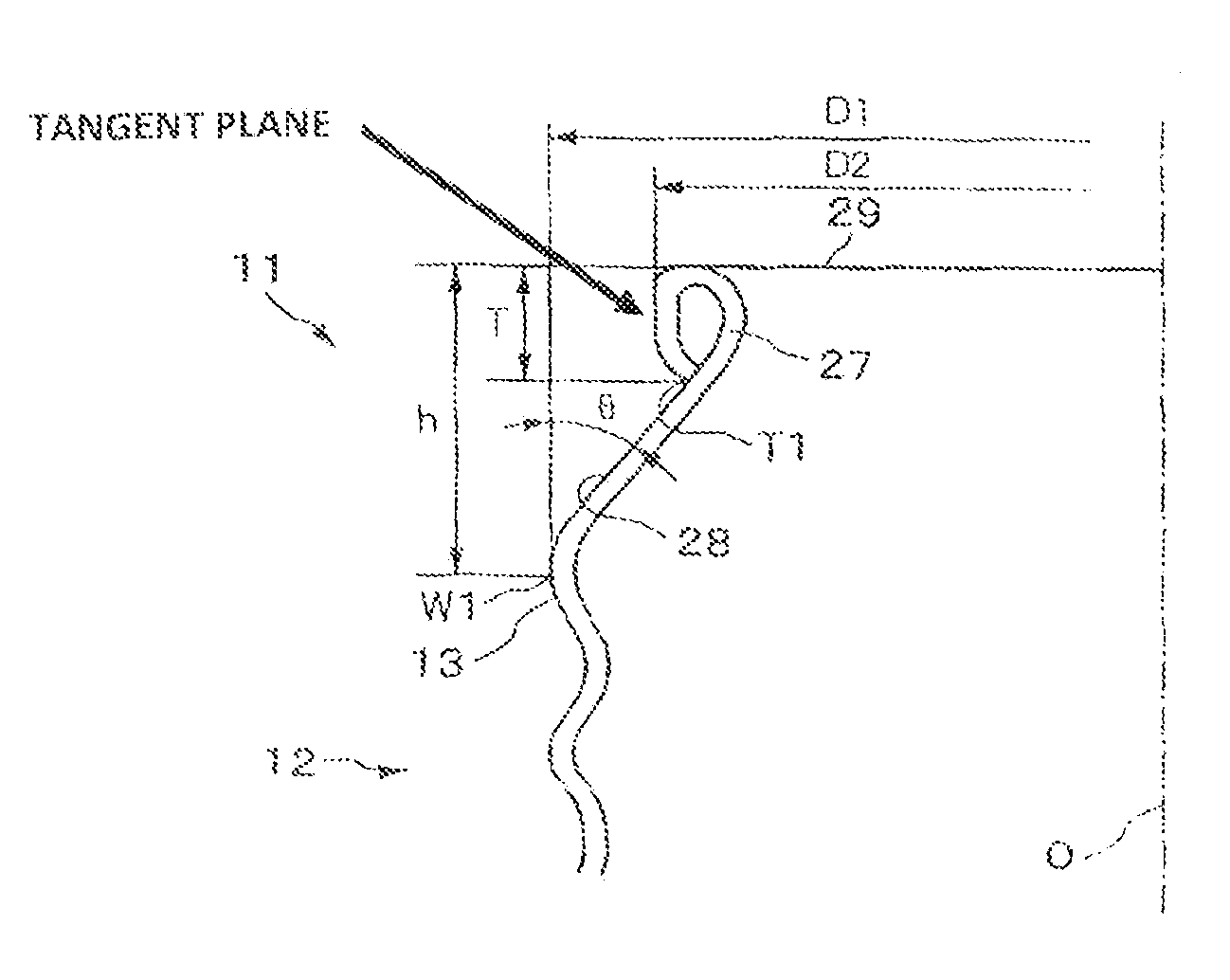

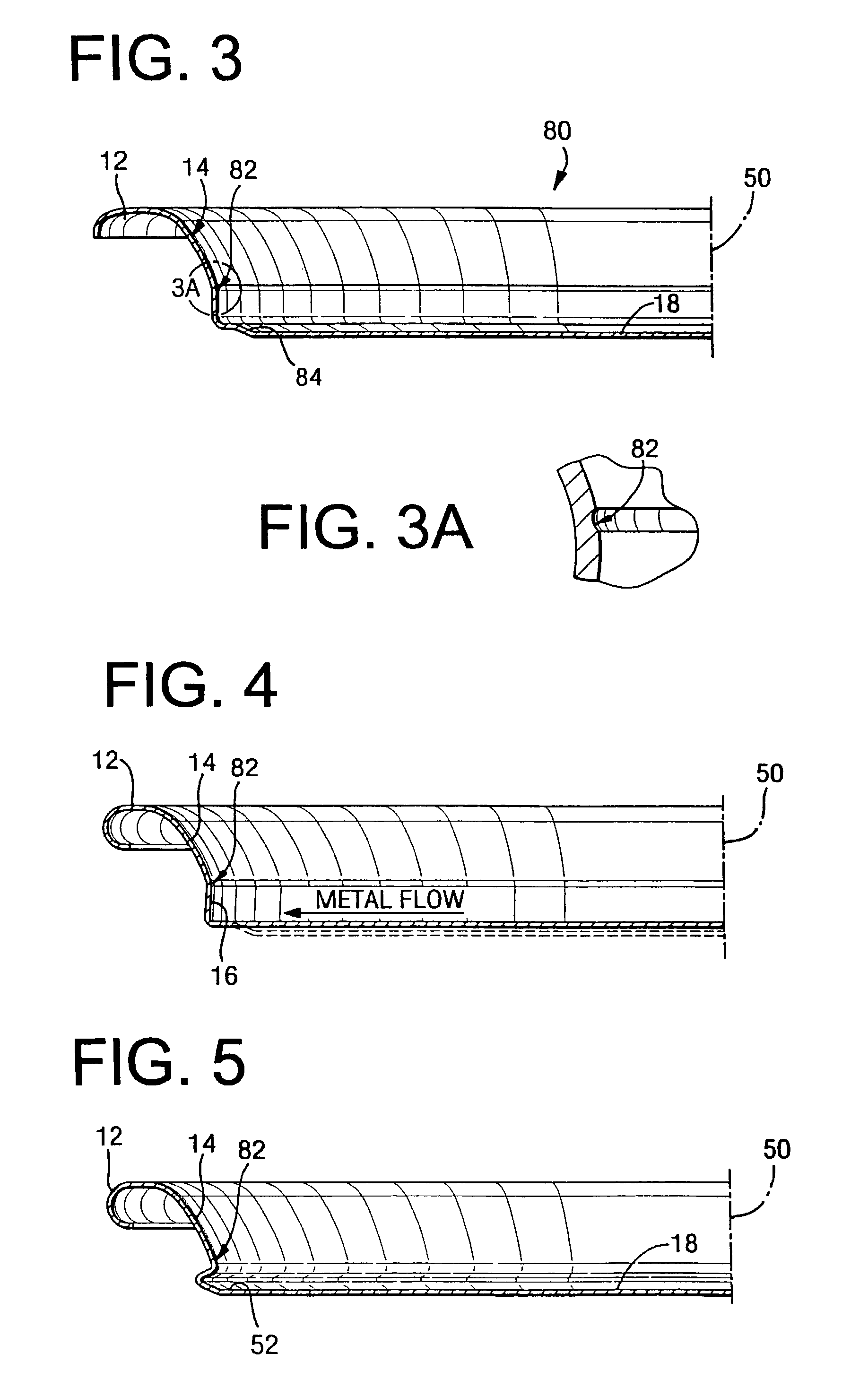

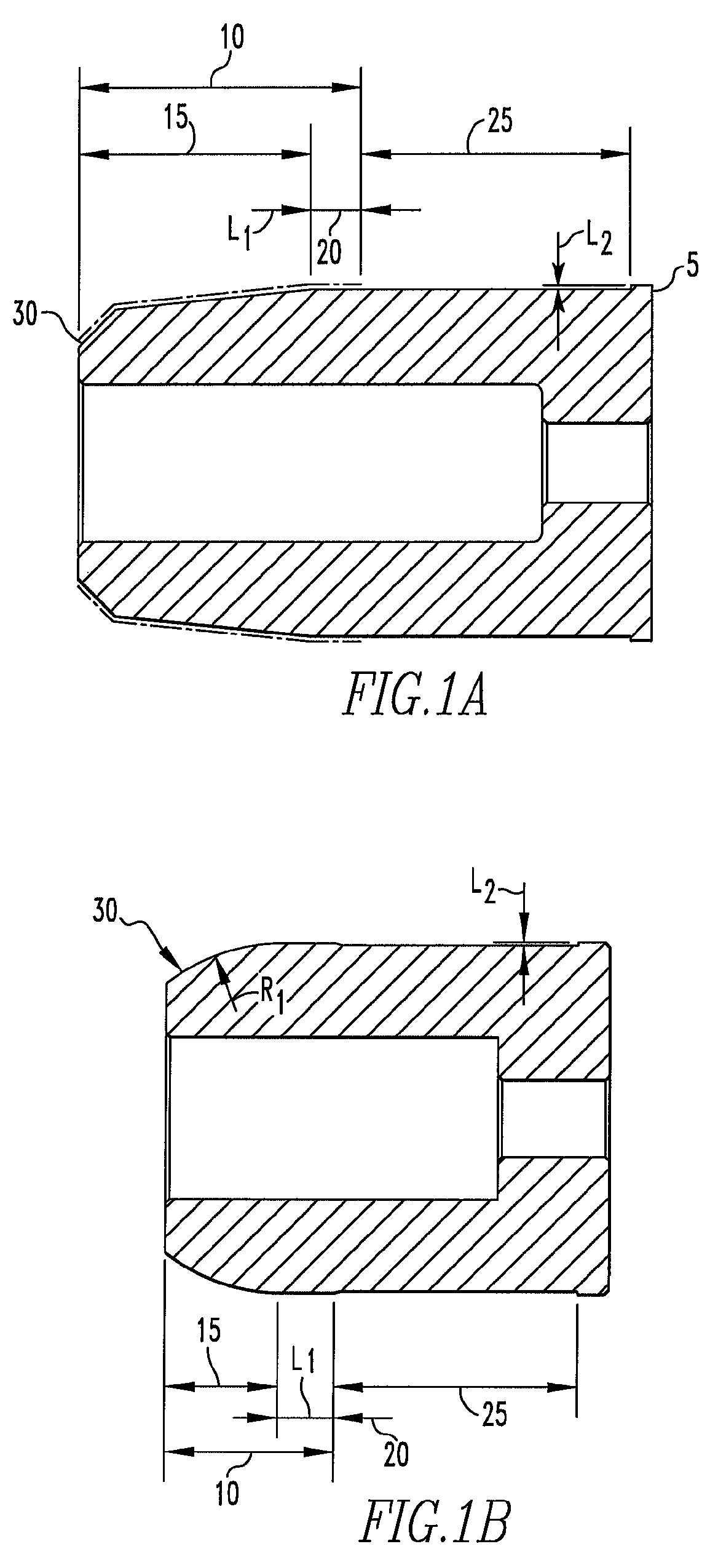

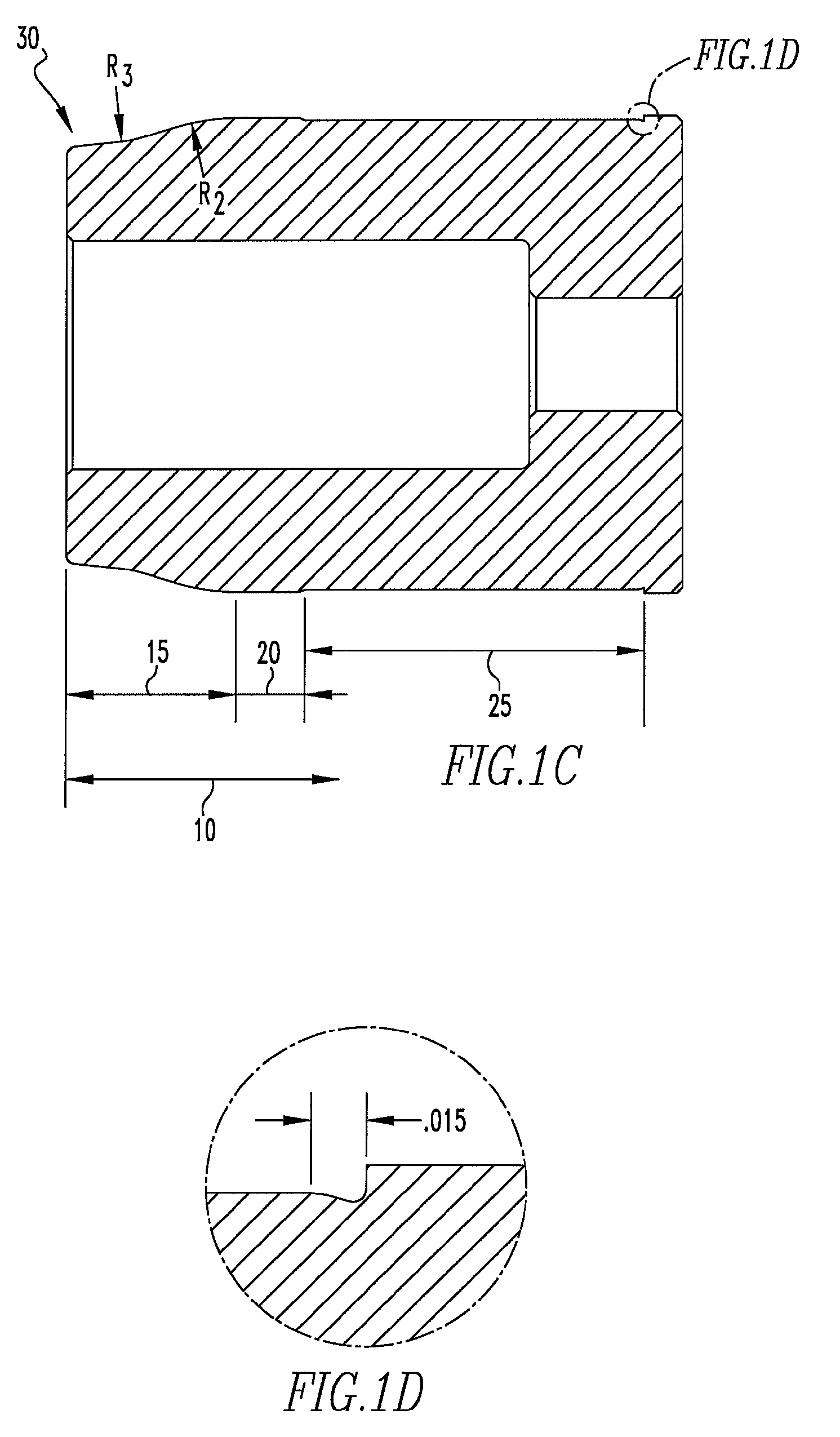

Method of producing aluminum container from coil feedstock

InactiveUS7140223B2Avoid stickingIncrease the number ofCans/barrels/drumsLiquid dispensingUltimate tensile strengthAerosol

Aerosol cans, more particularly, aluminum aerosol cans made from disks of aluminum coil feedstock, are provided. A method for necking aerosol cans of a series 3000 aluminum alloy is also provided. The method prevents the cans from sticking in the necking dies and produces a can with a uniquely shaped profile. The aluminum aerosol cans that are produced have the attributes of strength and quality, while being produced at a cost that is competitive with steel aerosol cans.

Owner:EXAL

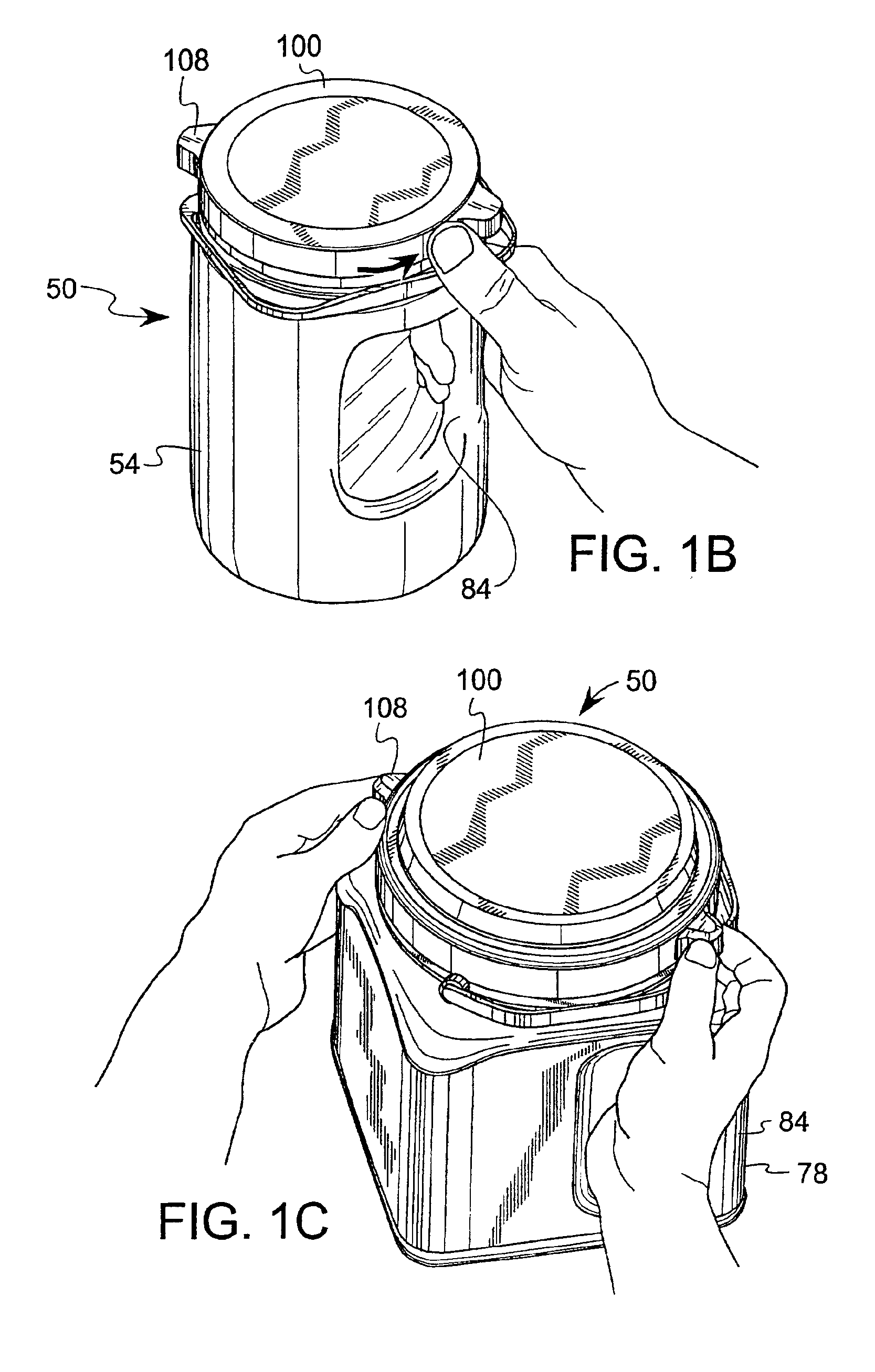

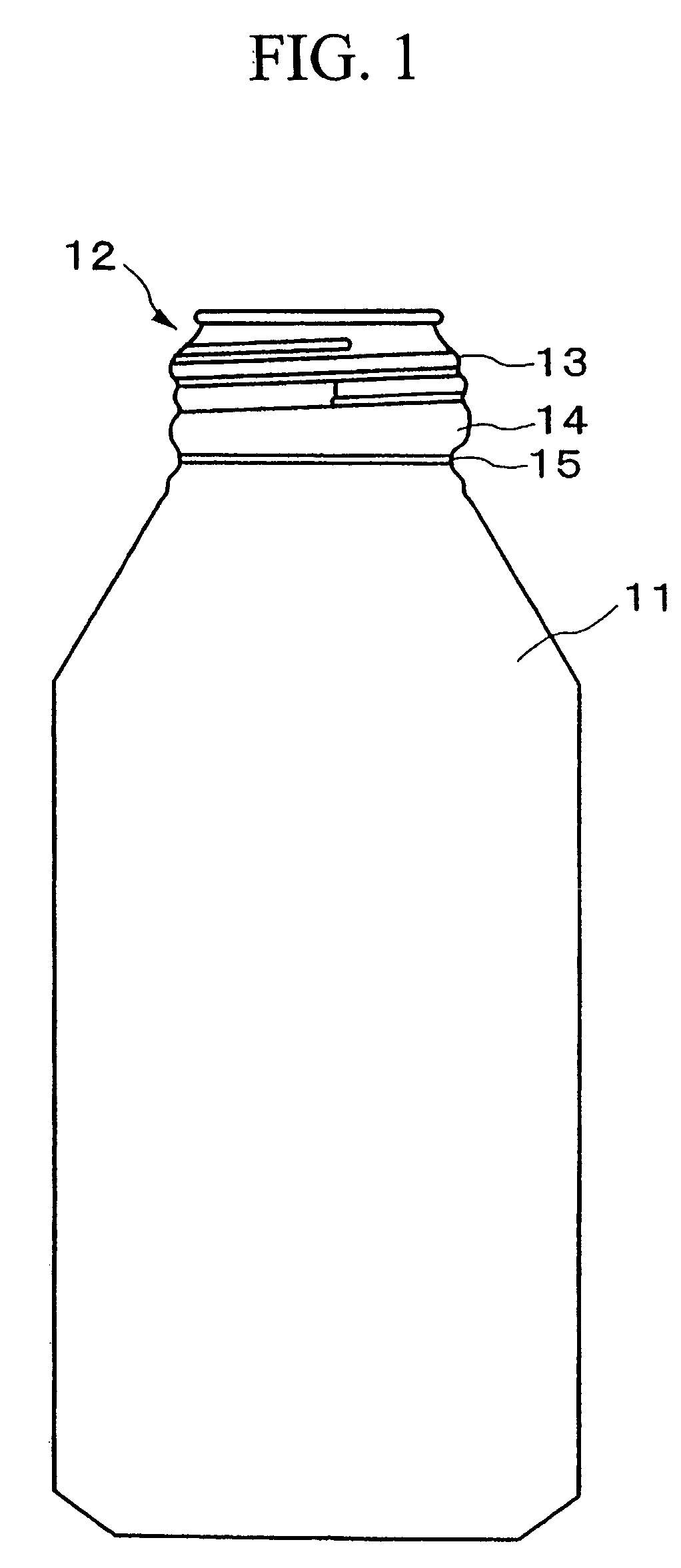

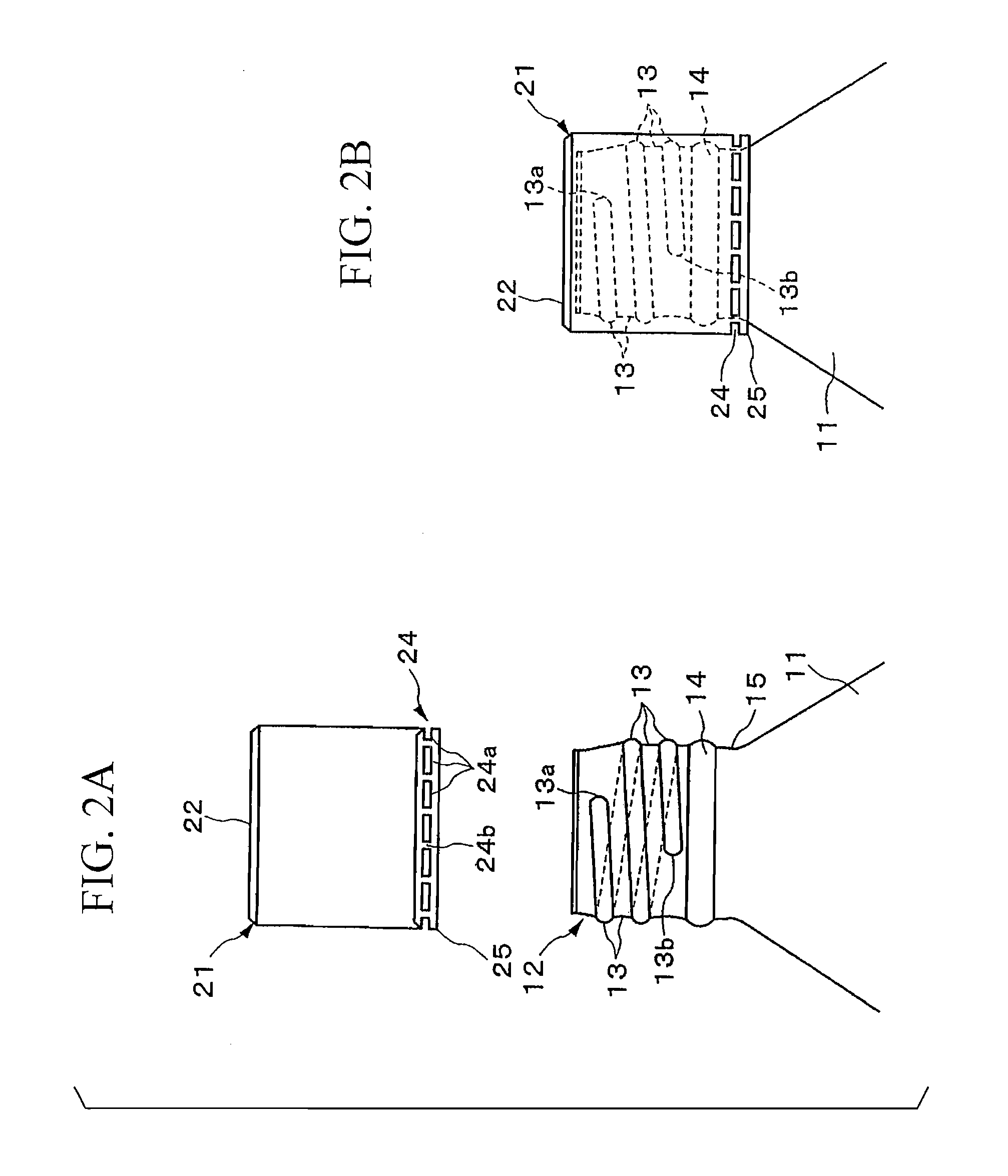

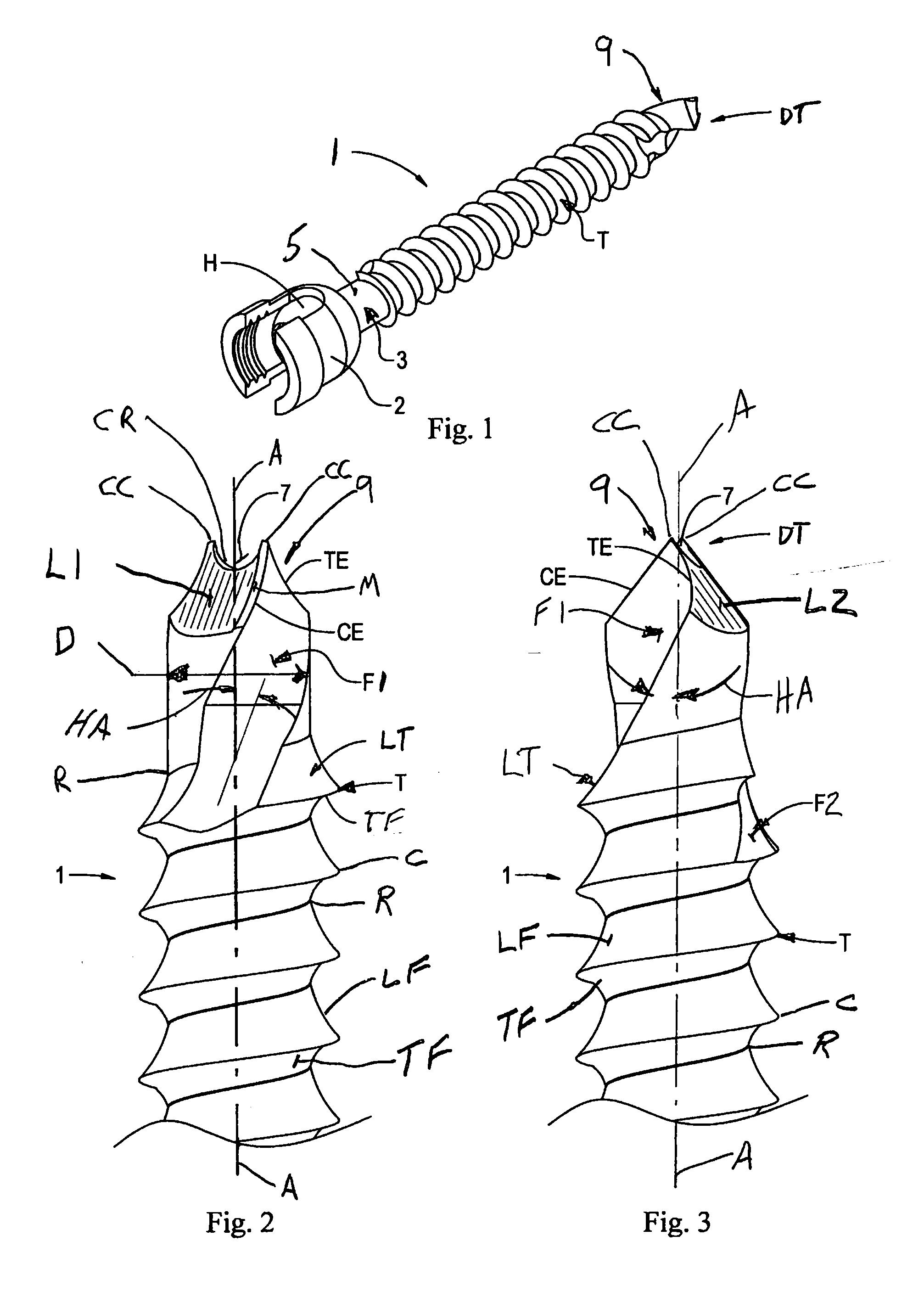

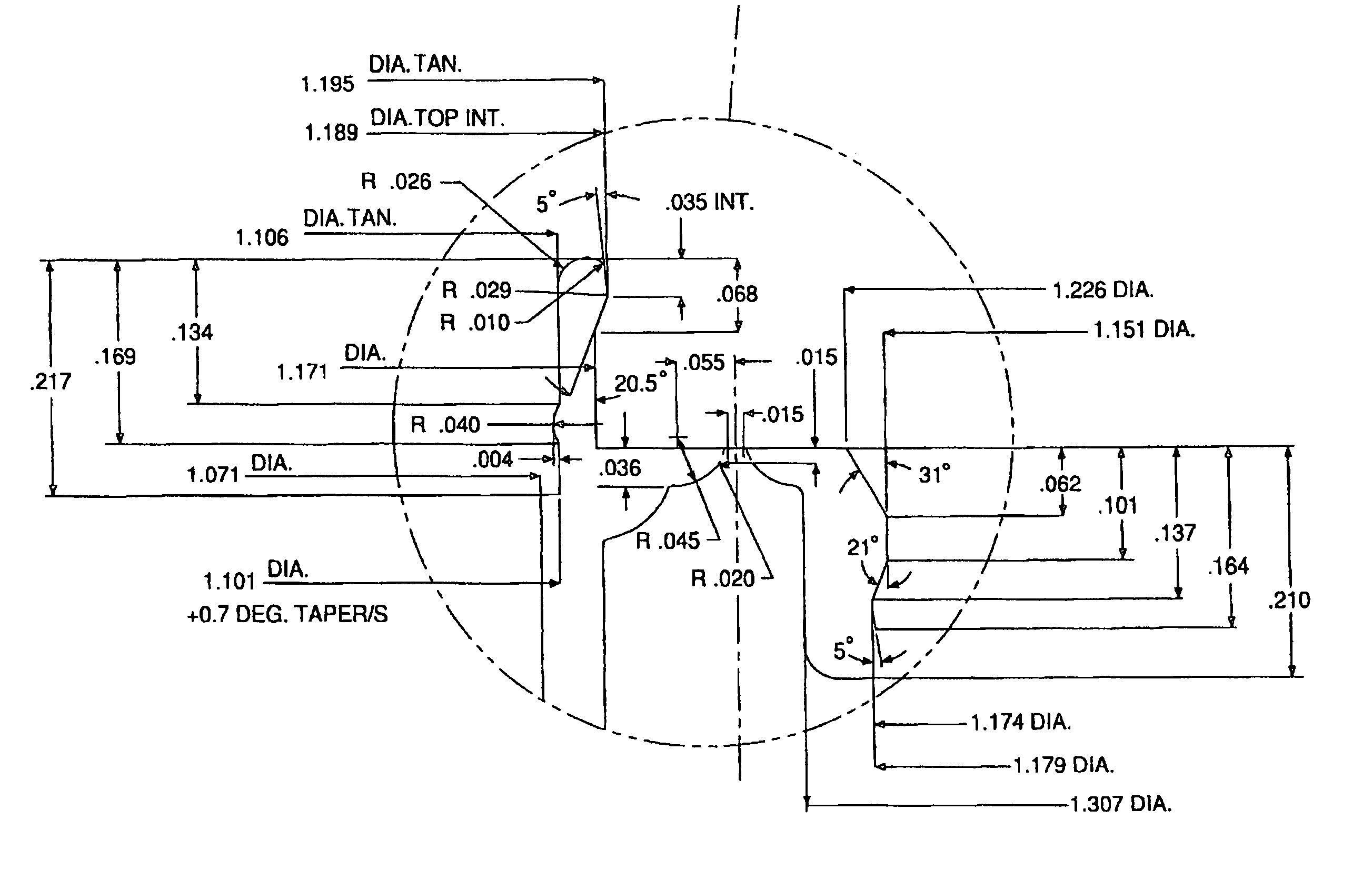

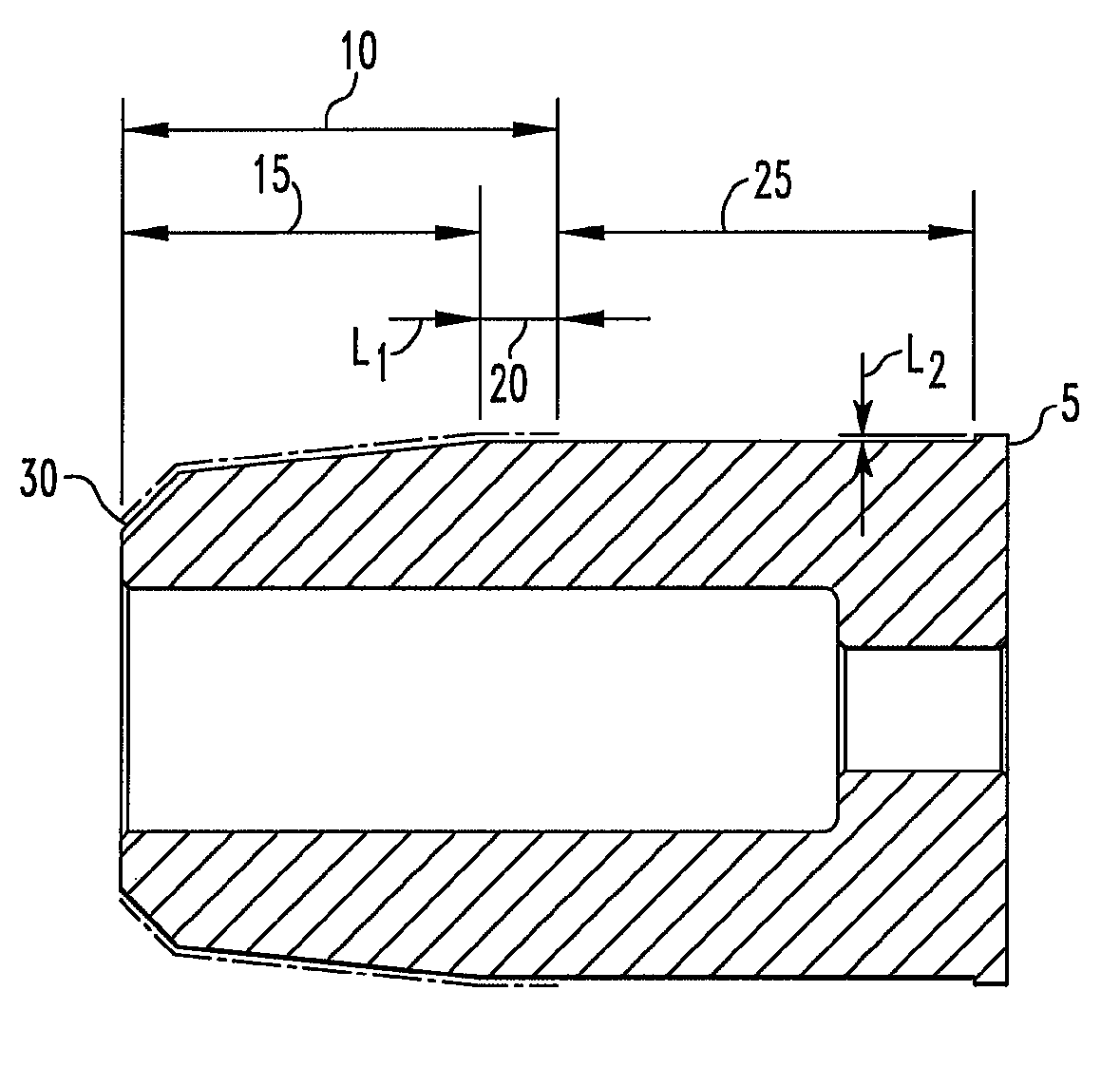

Bottle can member, bottle, and thread forming device

An effective thread number in the thread section which is disposed on the mouth section of the bottle is formed to be 2.2. That is, the thread section is formed such that the thread section 13 should serve effectively in the mouth section such that an interval between a start position and an end position should be 2.0 to 2.5. In the bottle can member 11 which has such a thread section, an outer diameter of the thread section which is formed on the mouth section is 28 to 38 mm. Also, the thickness of the mouth section is 0.25 to 0.4 mm. The thread section which has the effective thread number 2.0 to 2.5 is formed by eight-thread per inch pitch. By doing this, it is possible to put the cap desirably.

Owner:UNIVERSAL CAN CORP

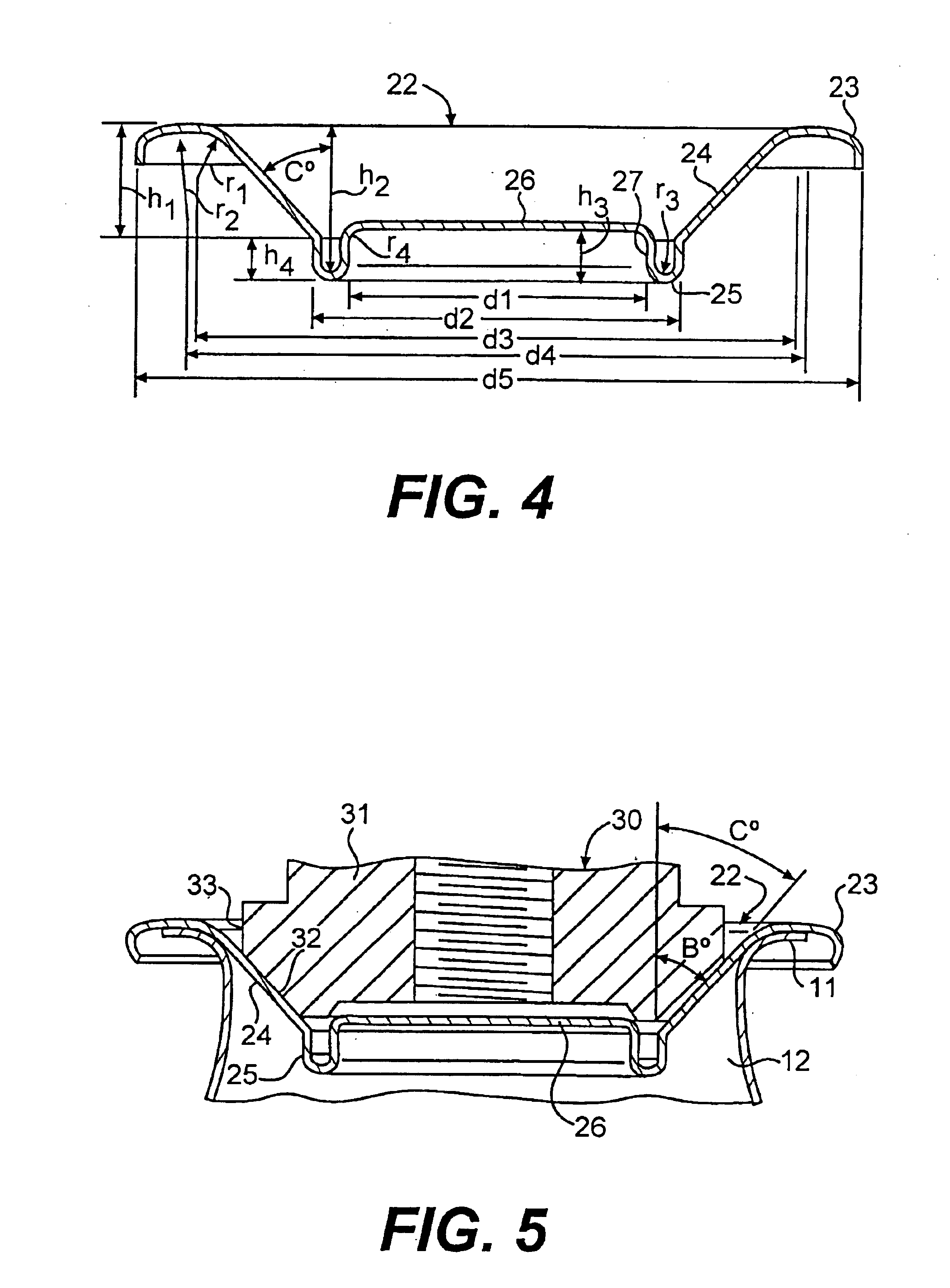

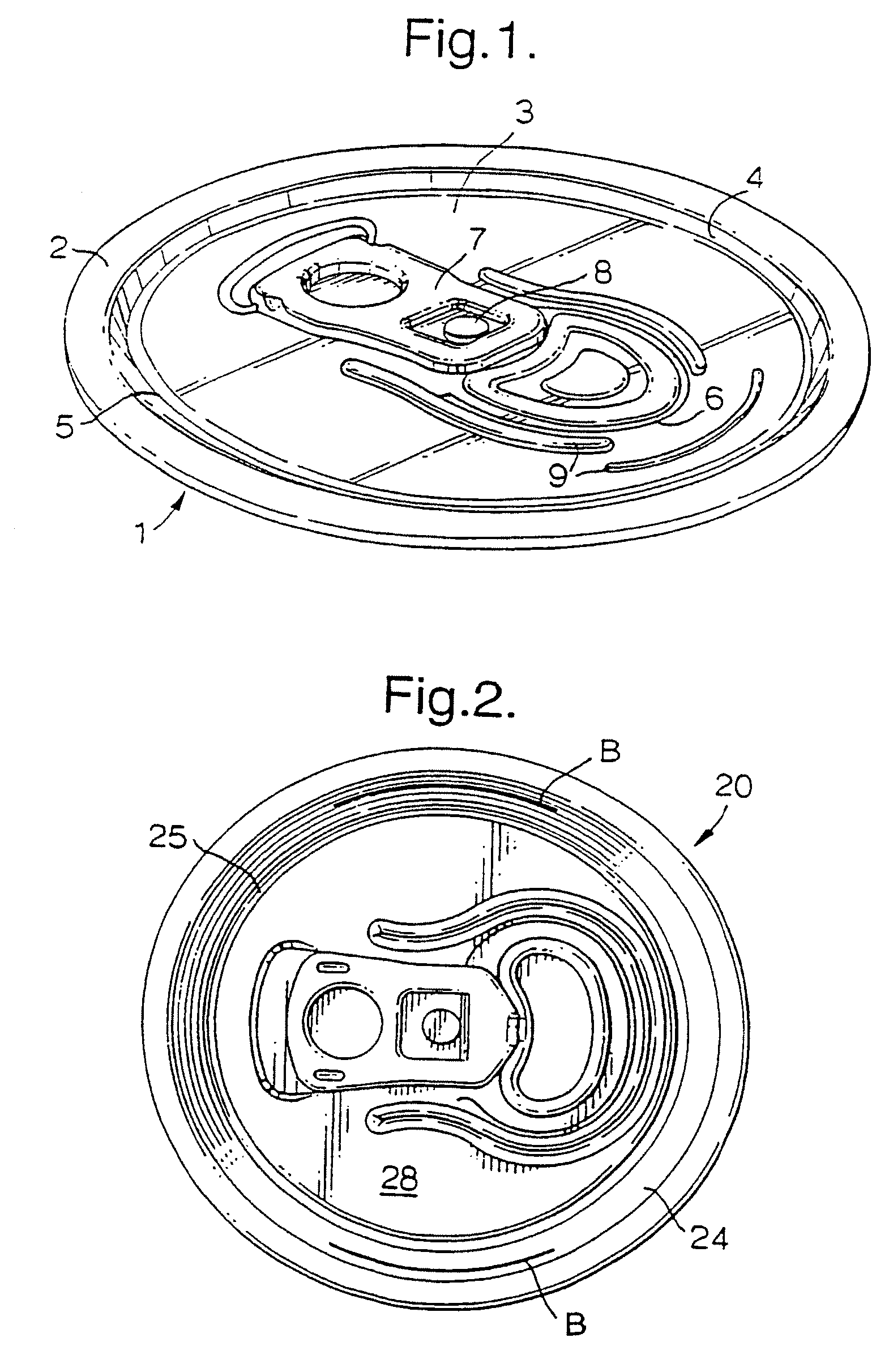

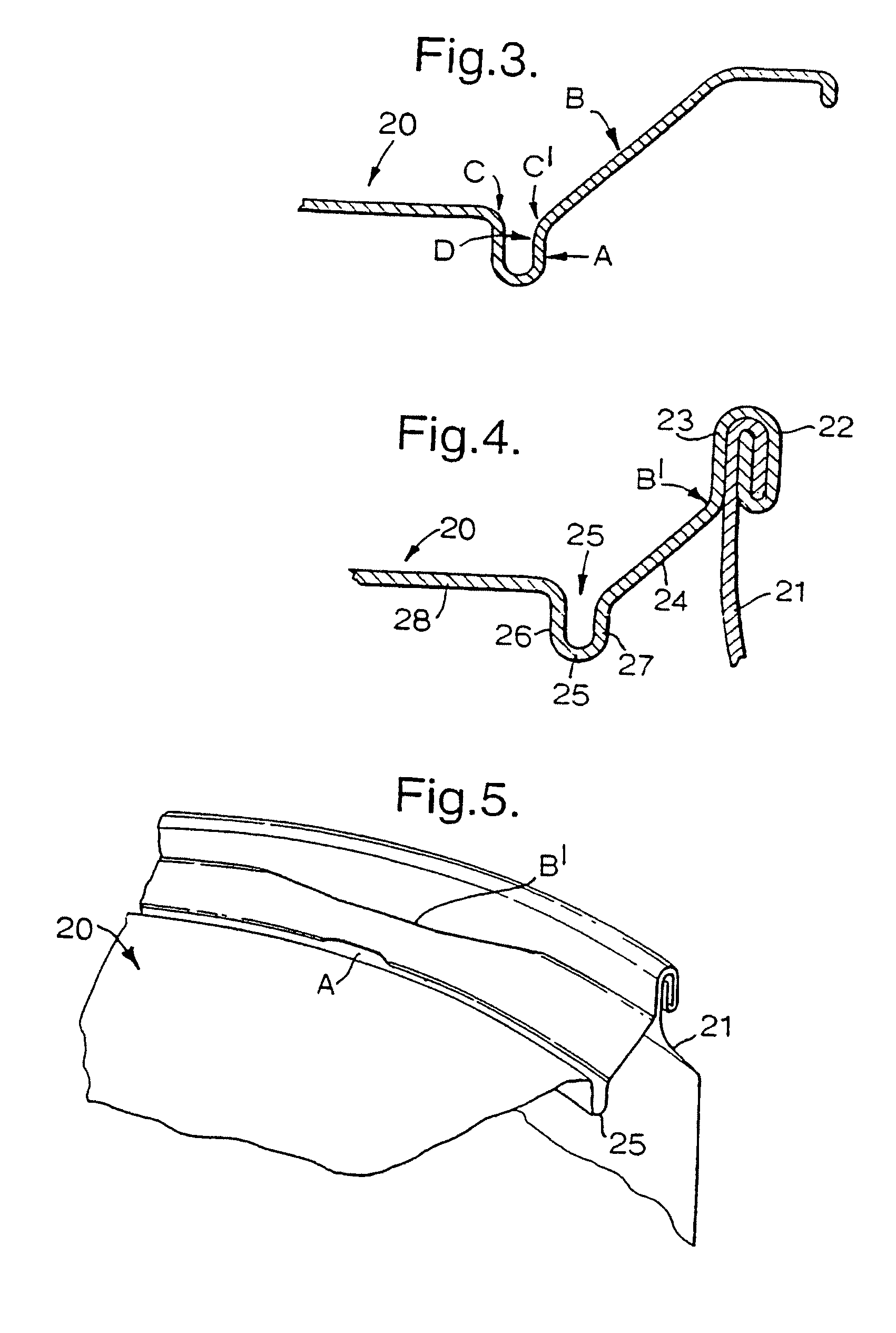

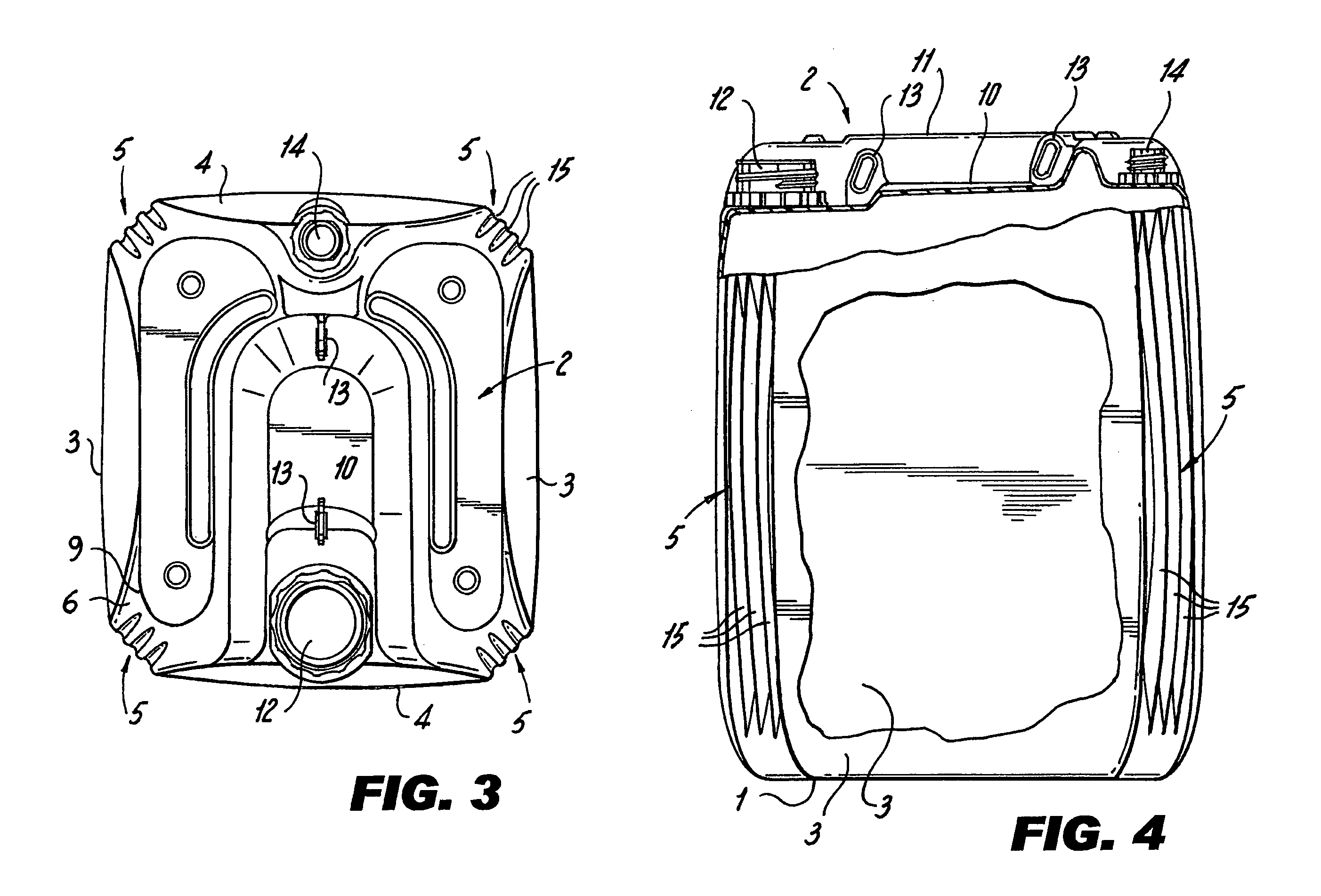

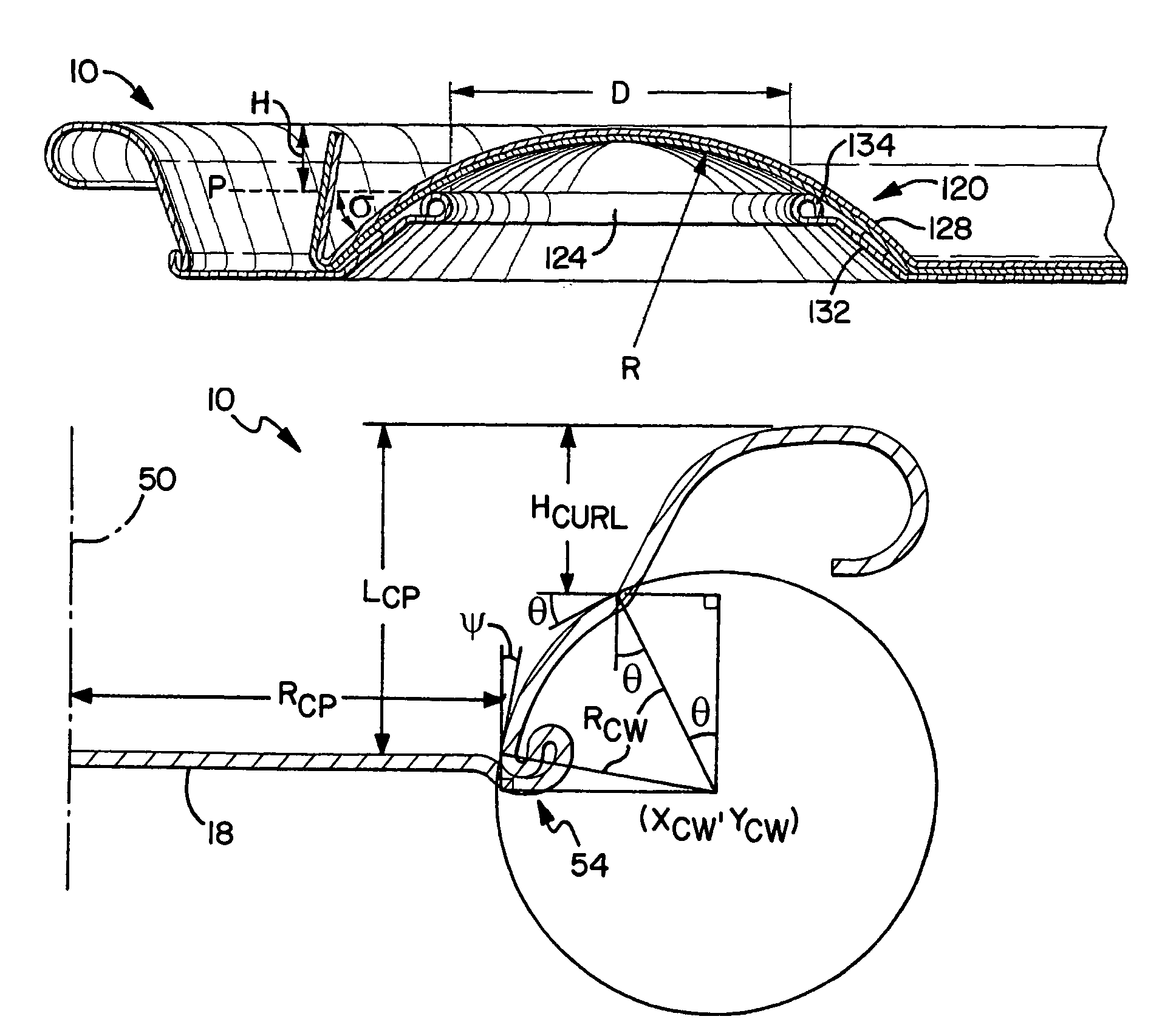

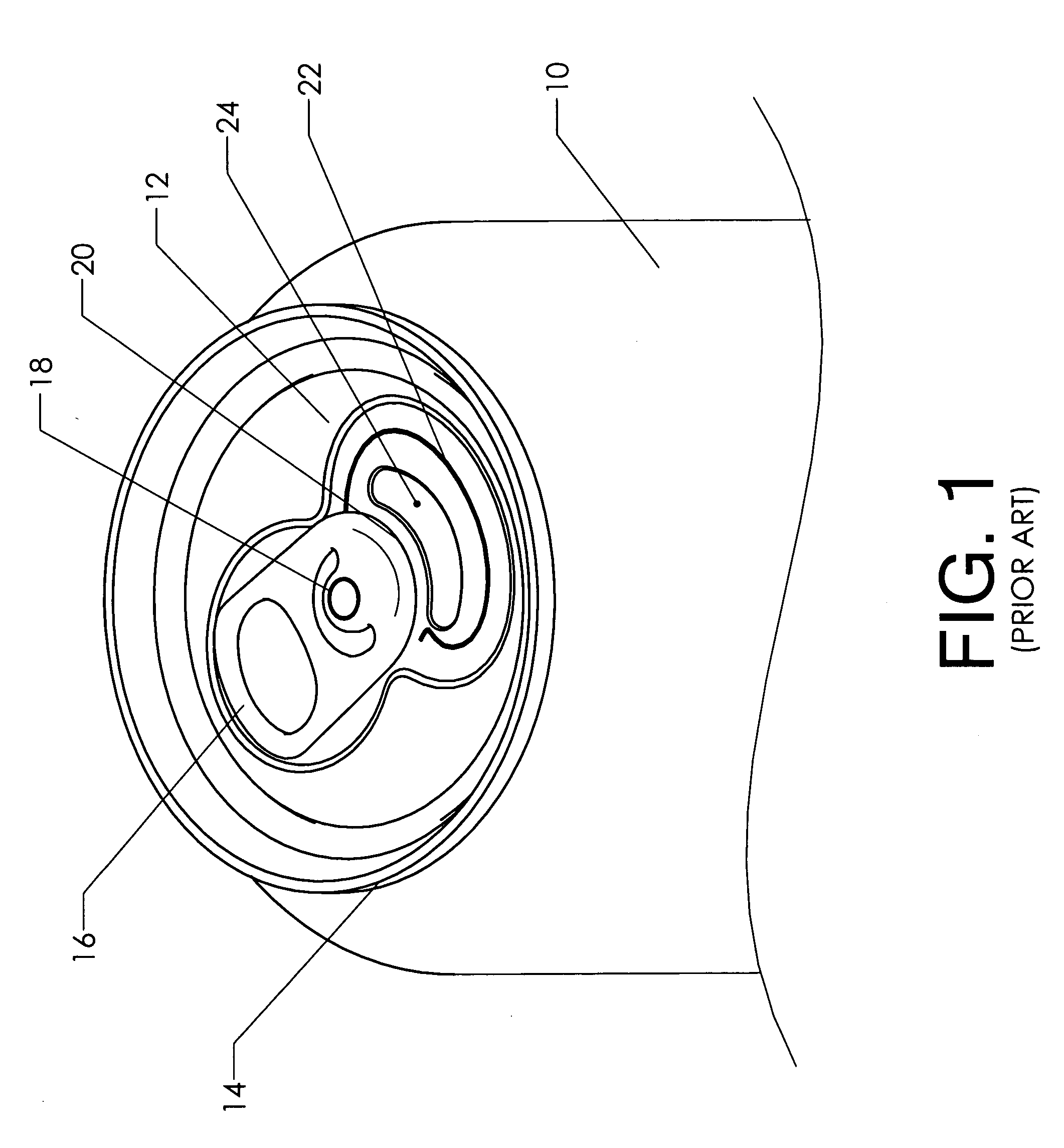

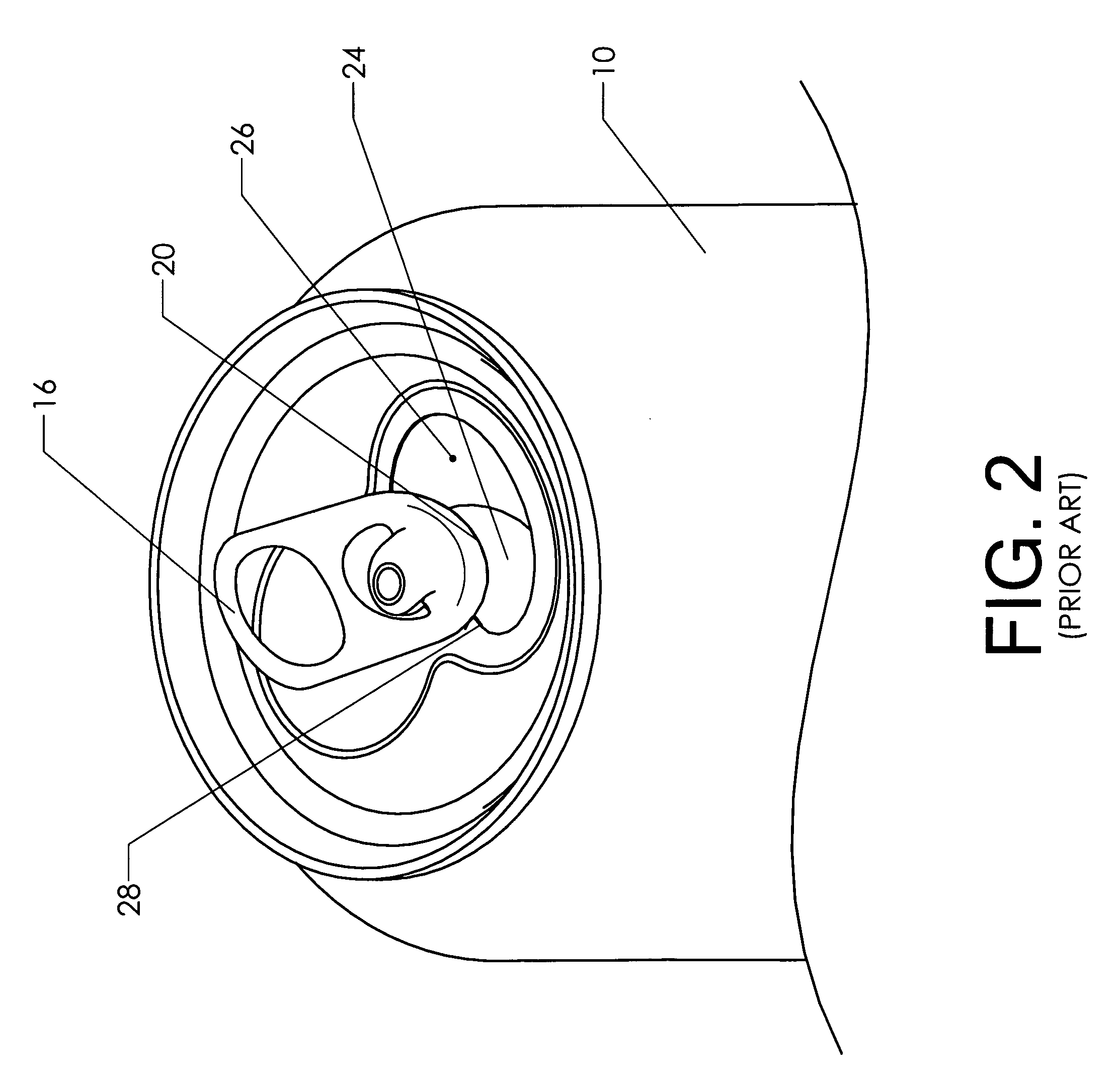

Can end

A can end member has a center panel, a circumferential chuck wall, and a transition wall. The center panel is centered about a longitudinal axis and has a peripheral edge. The center panel also has a step portion located radially outwardly from the longitudinal axis. The step portion has an annular convex portion joined to an annular concave portion and displaces at least a portion of the center panel vertically in a direction parallel to the longitudinal axis. The curl defines an outer perimeter of the end member. The circumferential chuck wall extends downwardly from the curl to the transition wall. The transition wall connects the chuck wall with the peripheral edge of the center panel. The transition wall has a folded portion extending outwardly relative to the longitudinal axis.

Owner:REXAM BEVERAGE CAN

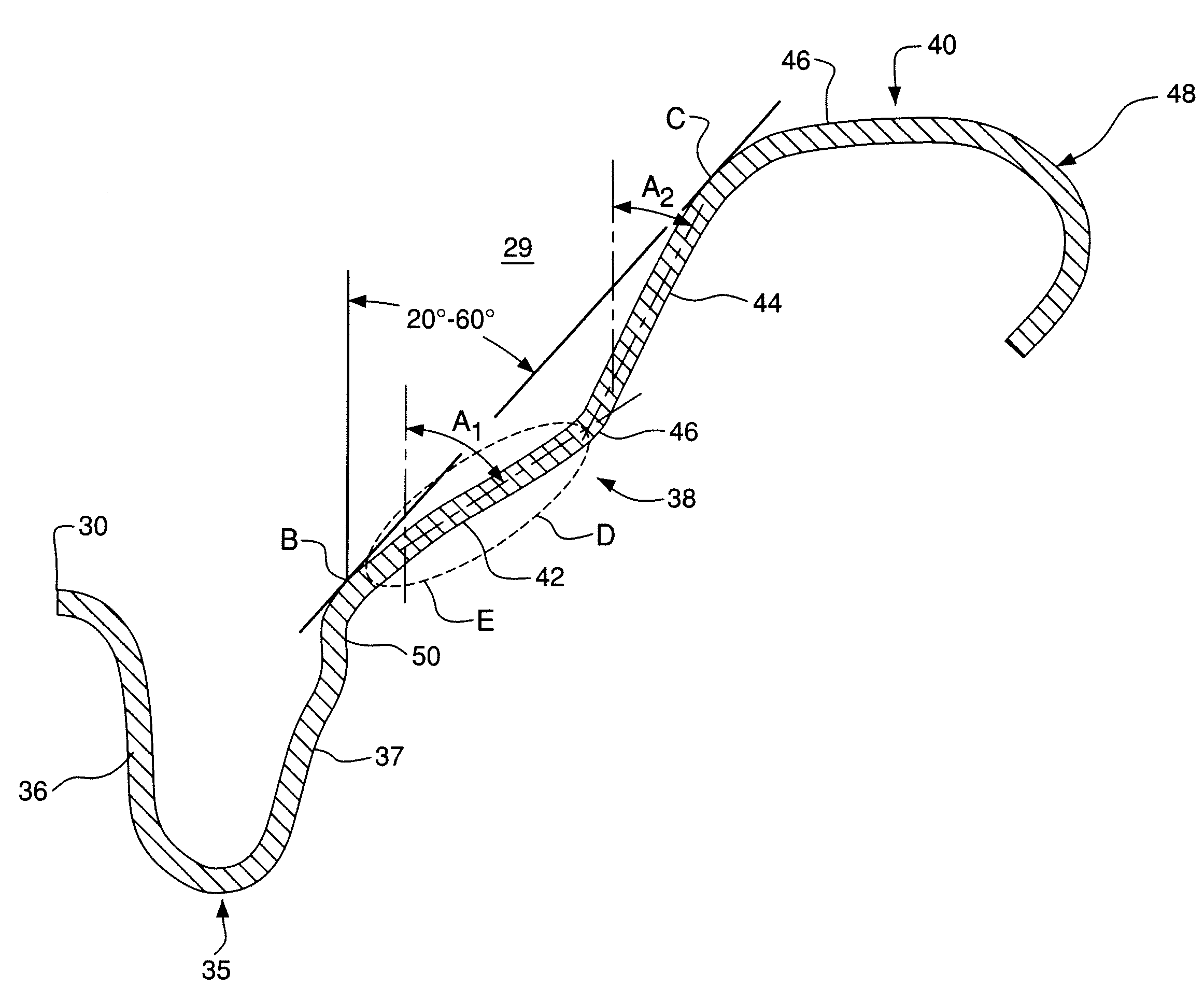

Can end and method for fixing the same to a can body

InactiveUS6877941B2Refuse receptaclesWrapper twisting/gatheringStructural engineeringMechanical engineering

A can end includes a peripheral cover hook a chuck wall dependent from the interior of the cover hook, an outwardly concave annular reinforcing bead extending radially inwards from the chuck wall, and a central panel supported by an inner portion of the reinforcing bead, characterized in that, the chuck wall is inclined to an axis perpendicular to the exterior of the central panel at an angle between 20° and 60°, and the concave cross-sectional radius of the reinforcing bead is less than 0.75 mm.

Owner:CROWN PACKAGING TECH

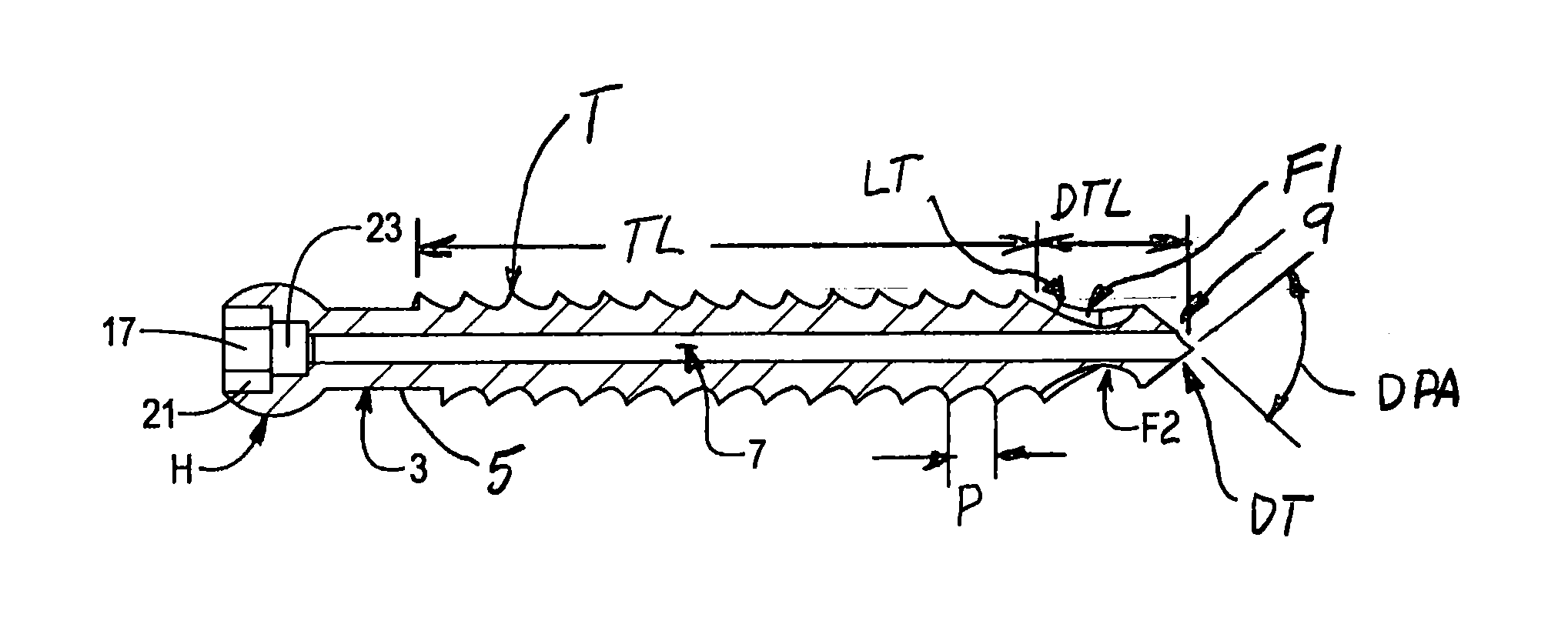

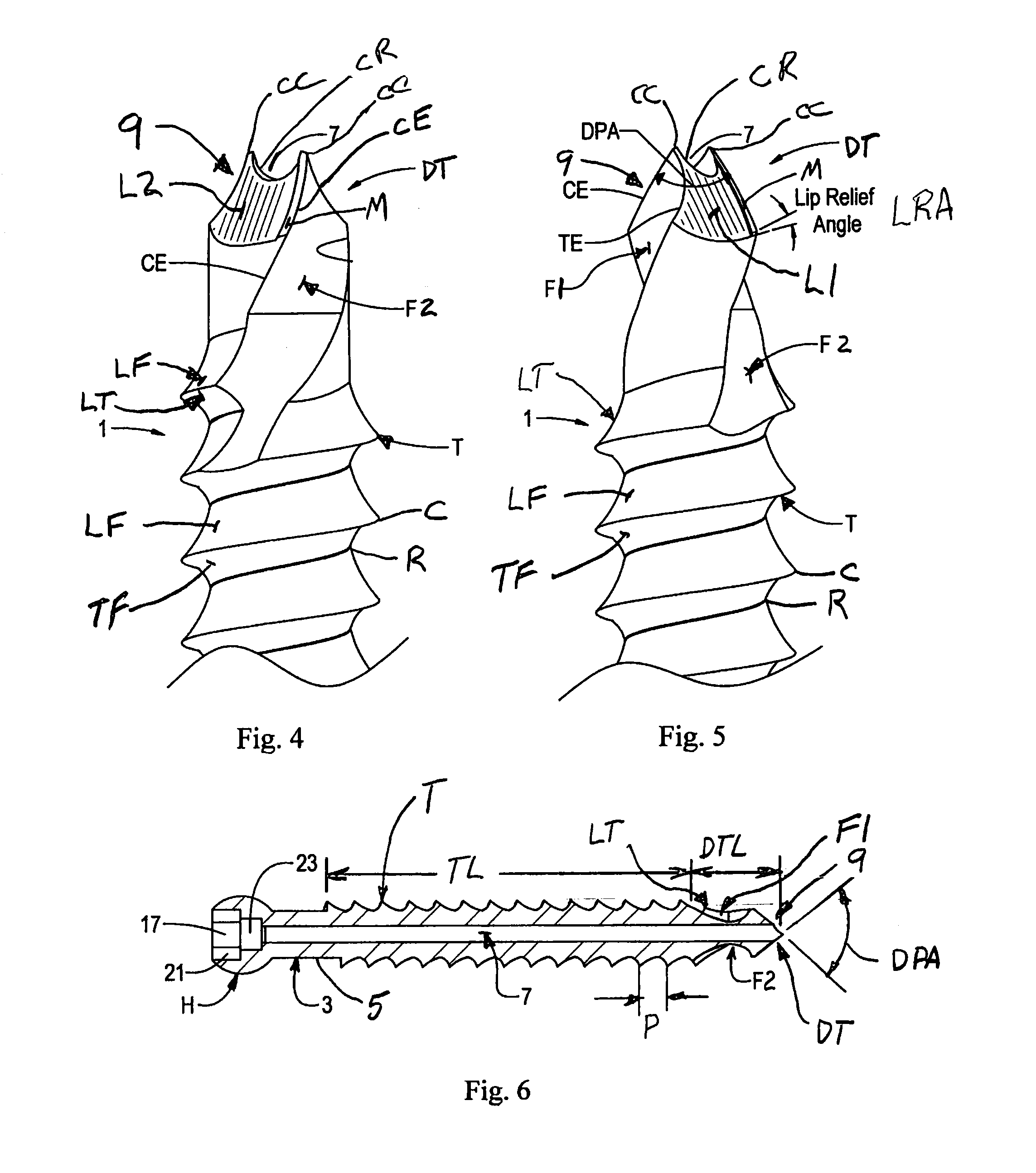

Self drilling, self-tapping bone screw and method of installing for bicortical purchase

ActiveUS20140277188A1Improve productivityShorten the timeSuture equipmentsInternal osteosythesisBone CortexIliac screw

A self-drilling, self-tapping bone screw is described in which the bone screw has a drill tip free of threads and having a length at least as great as about the thickness of a proximal cortical bone layer, with the drill tip having opposed lands and a helical flute between each of the lands with each of the lands having a cutting edge configured to cut bone as the drill tip is rotated into the bone with the flutes conveying the bone debris away from the drill tip, where a lead thread begins to self-tap internal threads in the proximal cortical bone layer after the drill tip has drilled through the proximal cortical bone layer so as to avoid stripping the threads formed in the bone layer. A method of installation is also disclosed.

Owner:POULOS NICHOLAS

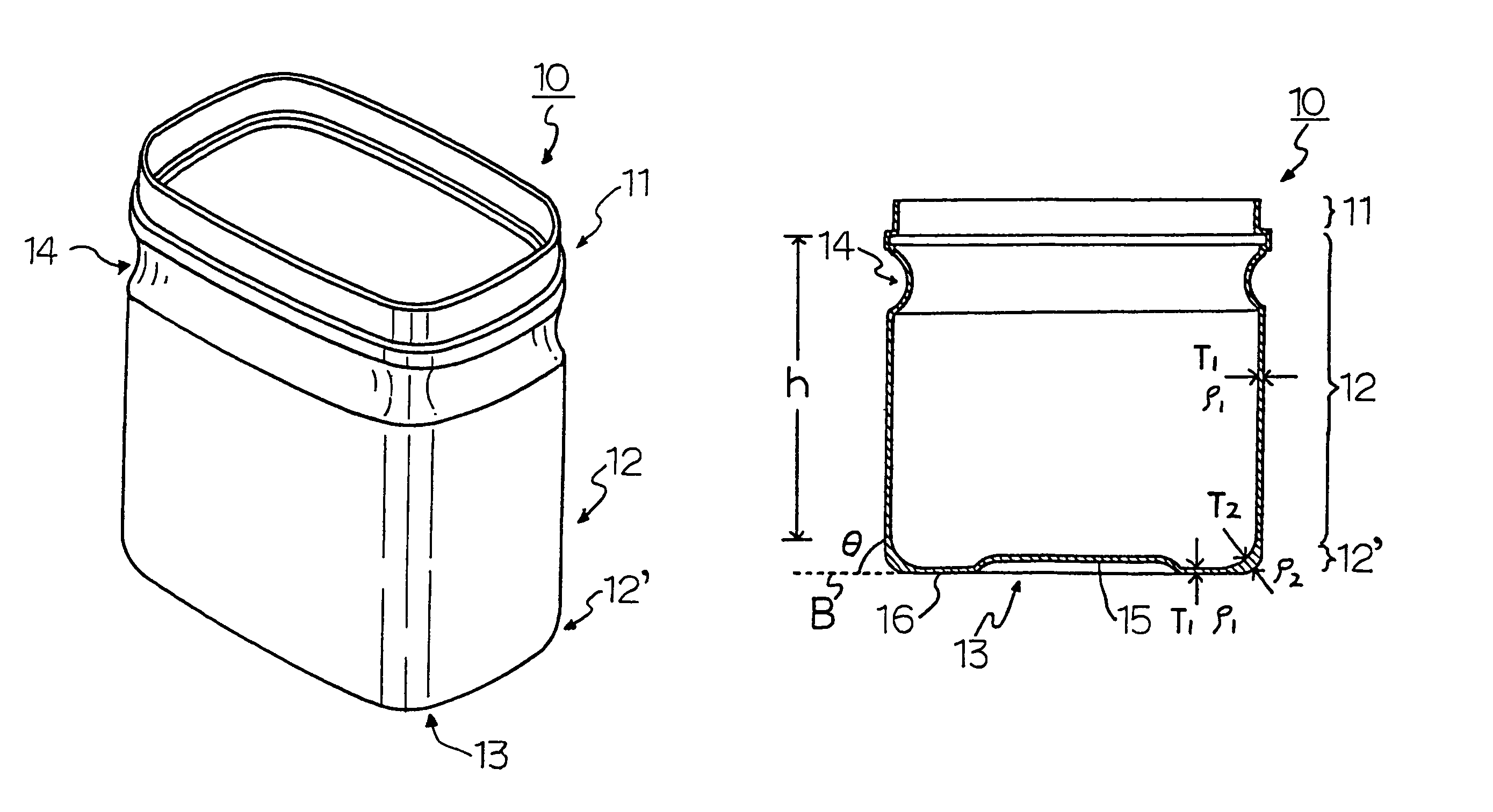

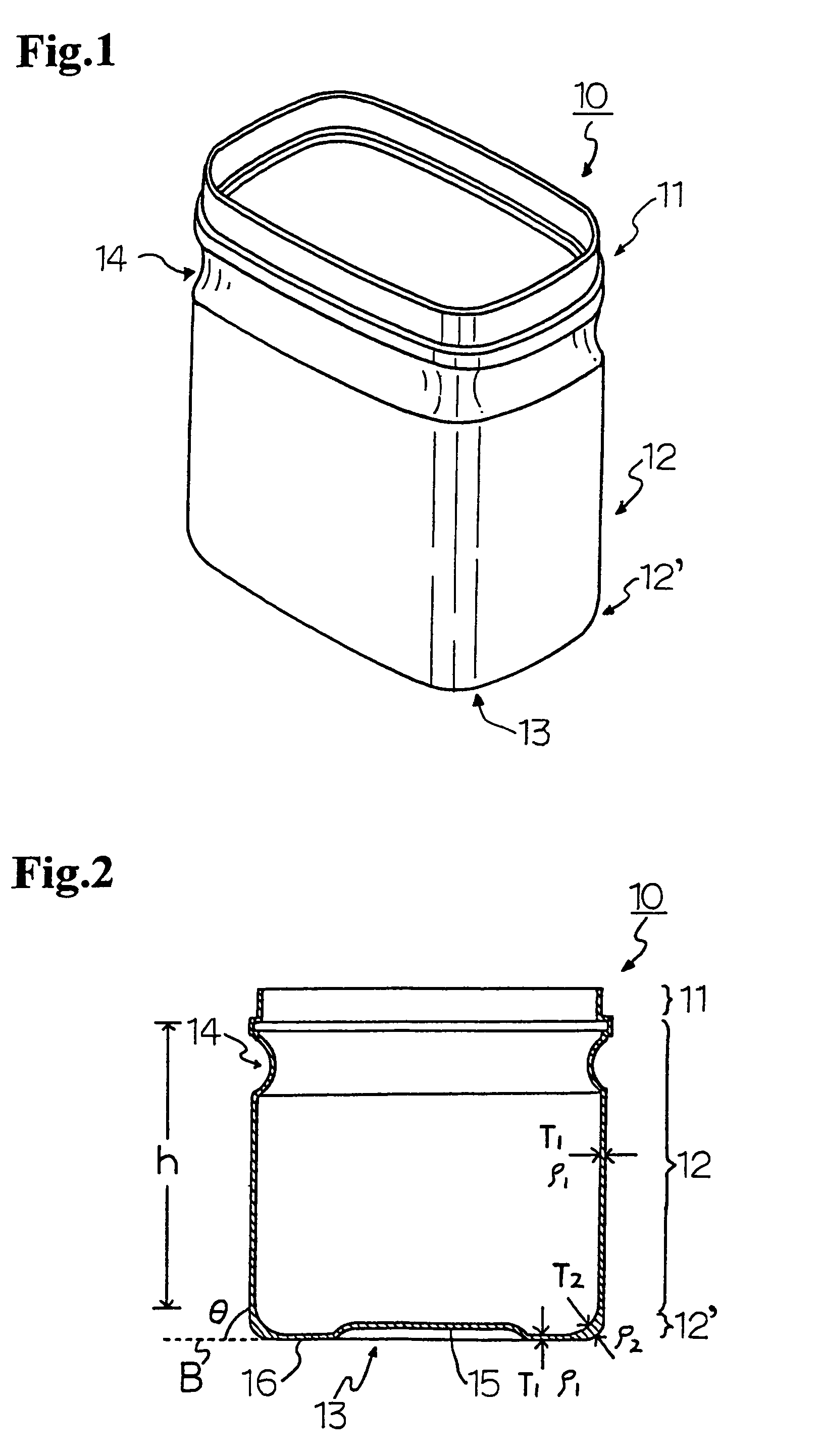

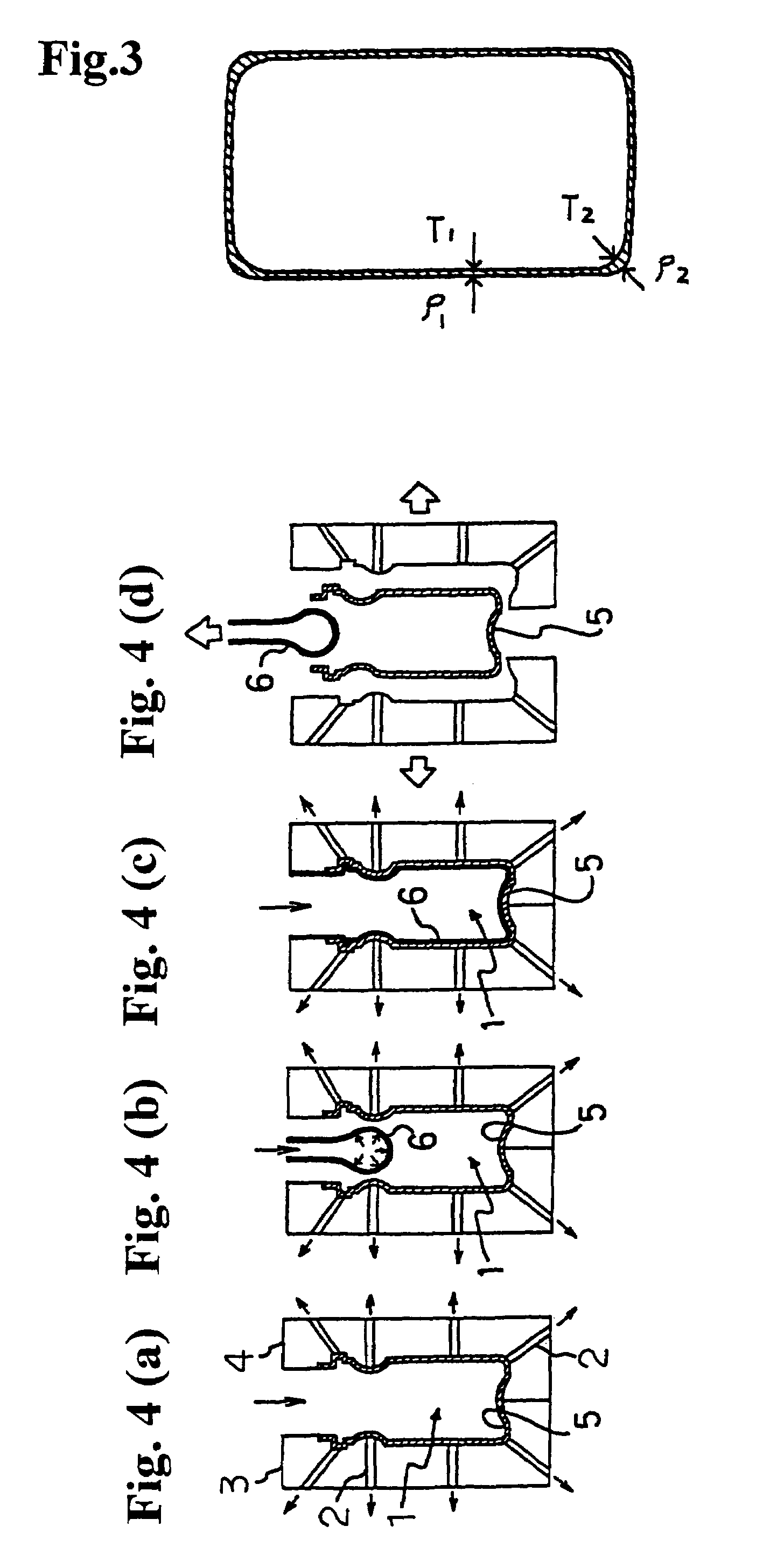

Formed body

A molded article (10) made predominantly of pulp and comprising a bottom portion (13) and a body portion (12), wherein the angle θ between the outer surface of a side wall of the body portion (12) and the ground contact plane (B) of the bottom portion (13) is 85° or greater, and the height of the body portion (12) is 50 mm or more.

Owner:KAO CORP

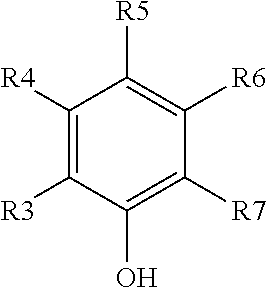

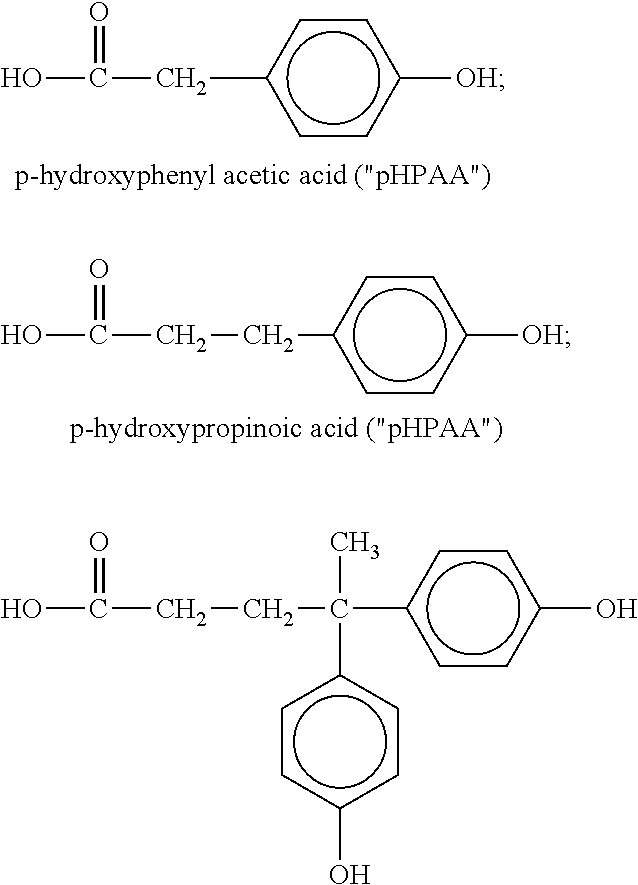

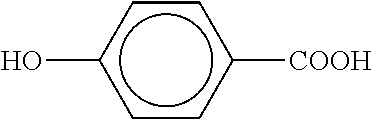

Polyester Polymer Having Phenolic Functionality and Coating Compositions Formed Therefrom

A polyester polymer is provided that includes at least one pendant phenolic-containing group. In one embodiment, the polyester polymer is combined with an optional crosslinker and an optional carrier to form a coating composition suitable for use in coating articles such as packaging articles. The coating composition typically includes a resole phenolic crosslinker. In one embodiment, the polyester polymer has at least one phenolic-containing group that comprises an adduct of cardanol.

Owner:SWIMC LLC

Can end

A can end having a countersink bead, an inclined chuck wall and a strong seam, resists distortion from its circular profile when subjected to thermal processing or when packaging carbonated beverages. This high hoop strength affects the manner in which the can end ultimately fails when placed under extreme abuse conditions, even if buckle pressure performance is within industry specified standards. The can end of the invention has control features introduced which control the failure mode while maintaining specified buckle pressure performance. In one embodiment, the can end has a two part wall and a control feature that comprises expansion of the countersink bead to act as a trigger for local peaking, together with a groove in the chuck wall which prevents the peaking force from being concentrated at a single point which could result in leaking by the production of a pin hole.

Owner:CROWN PACKAGING TECH

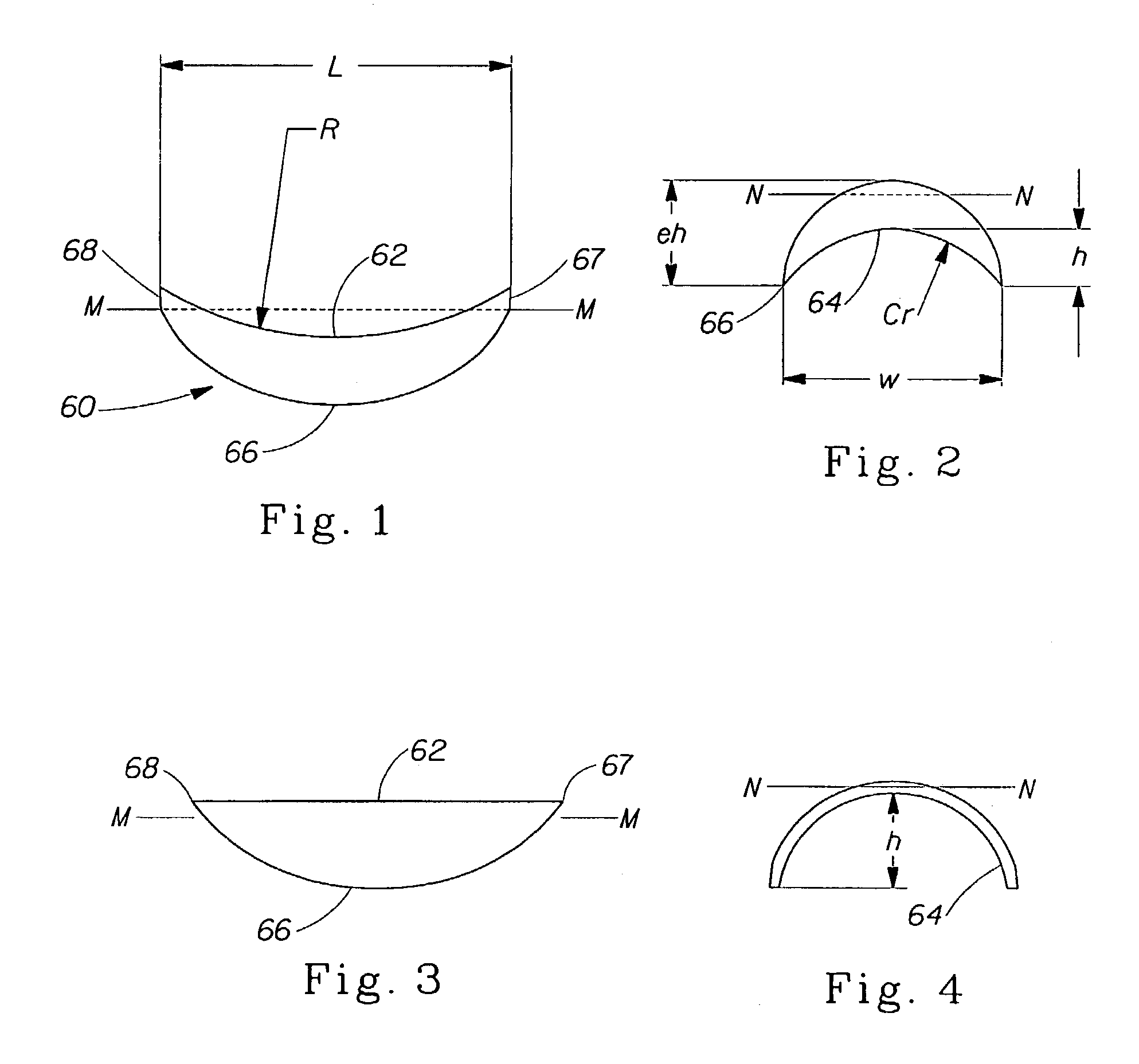

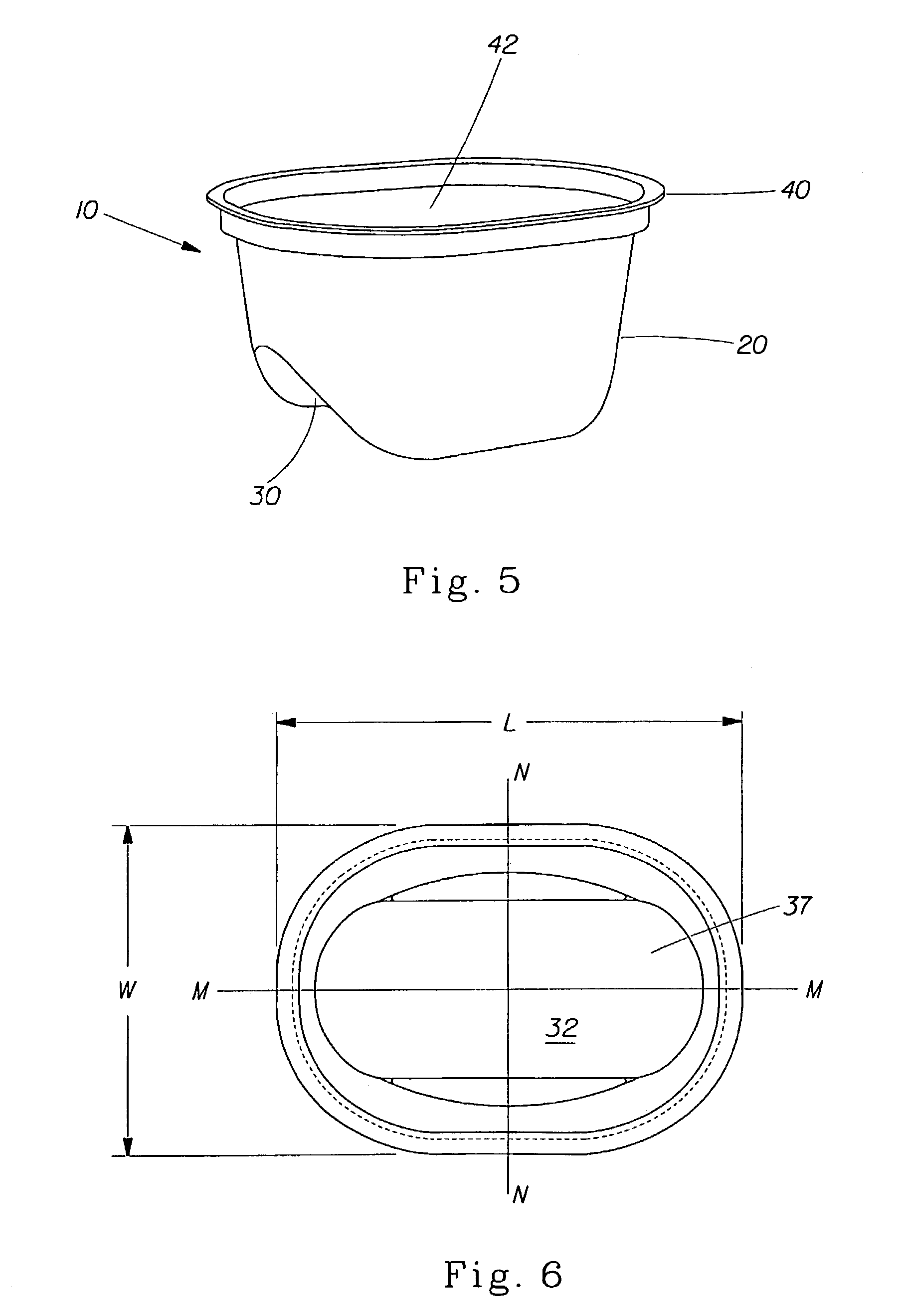

Shaped container bottom

Owner:KELLOGG NORTH AMERICA

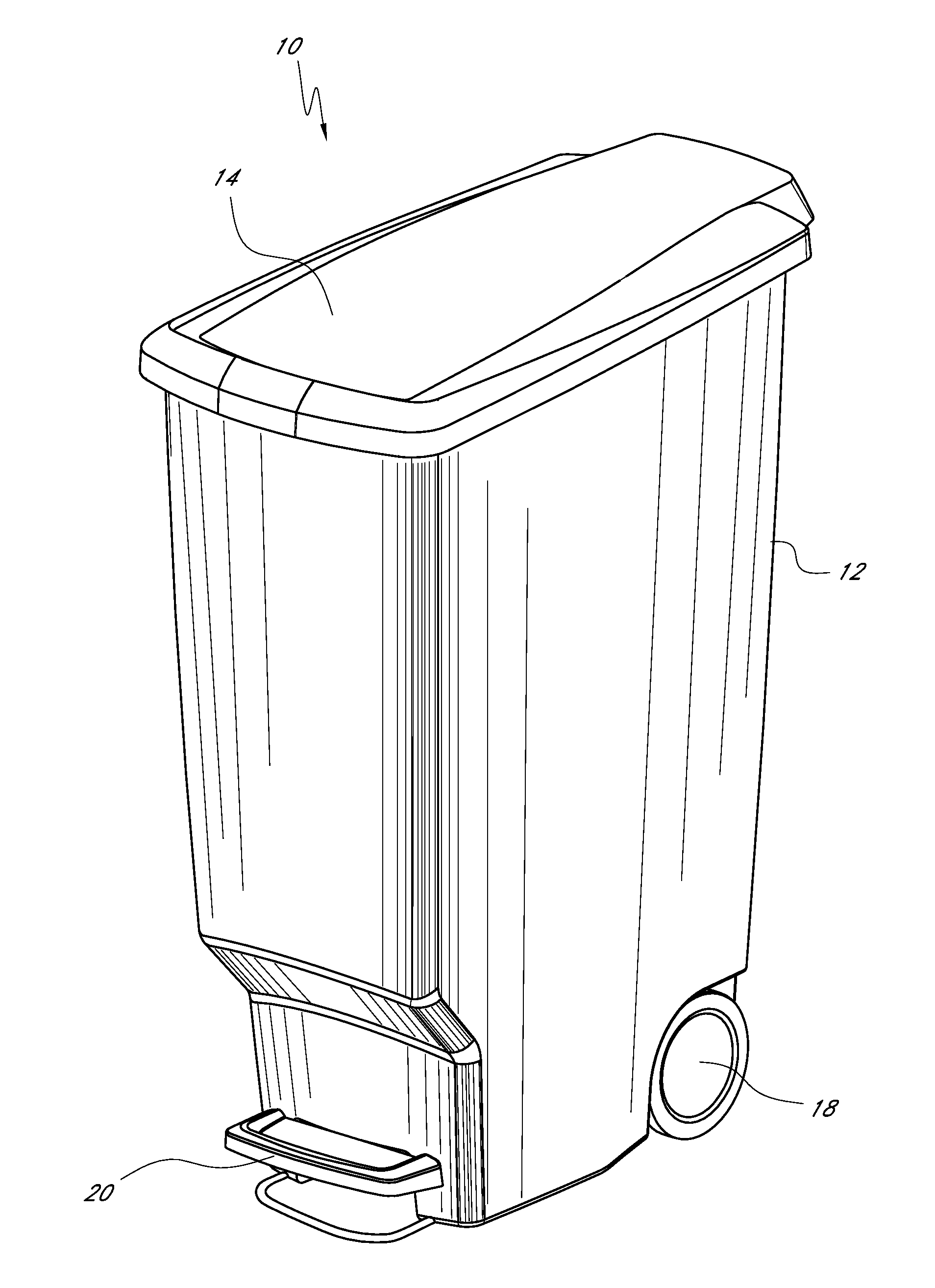

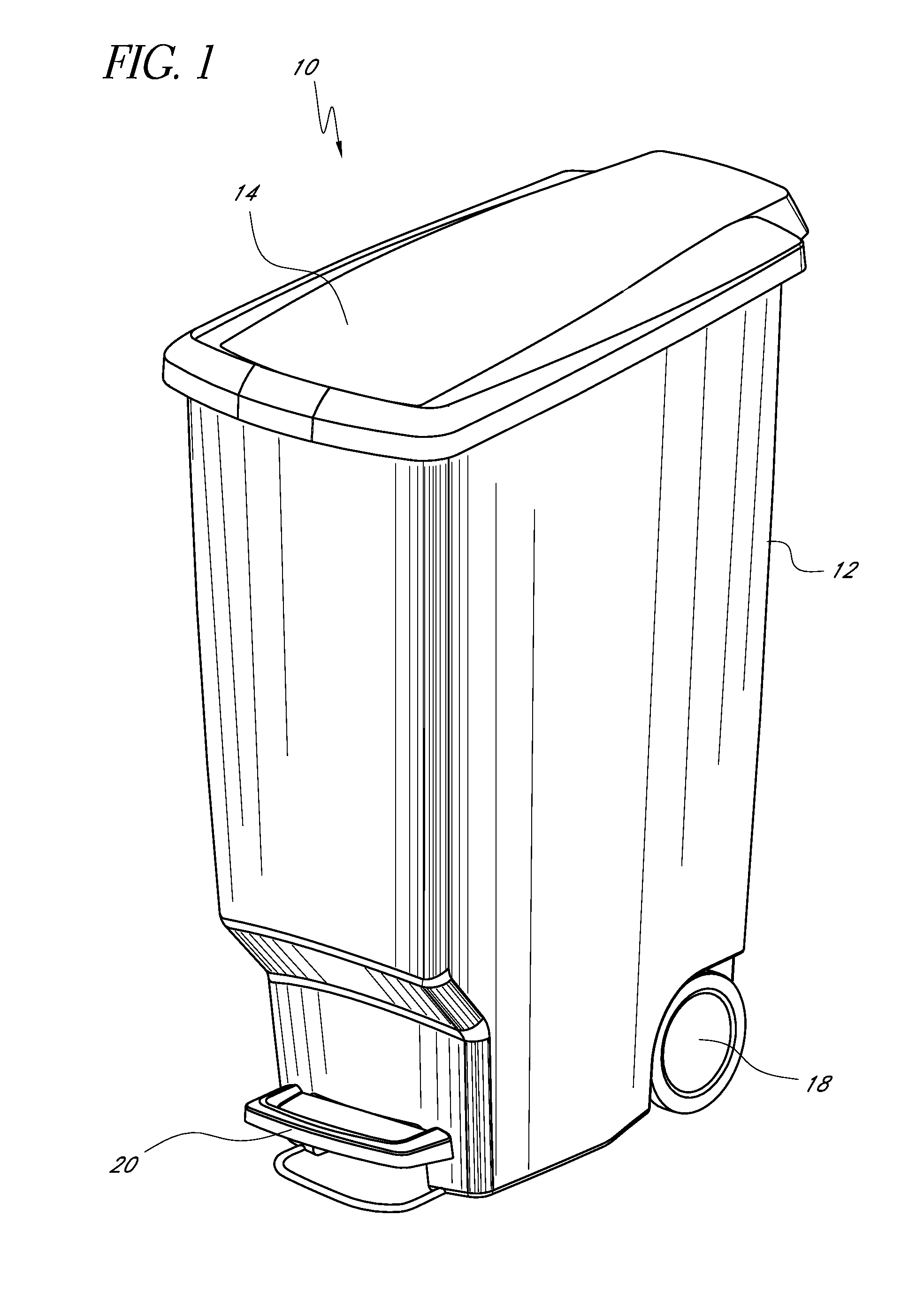

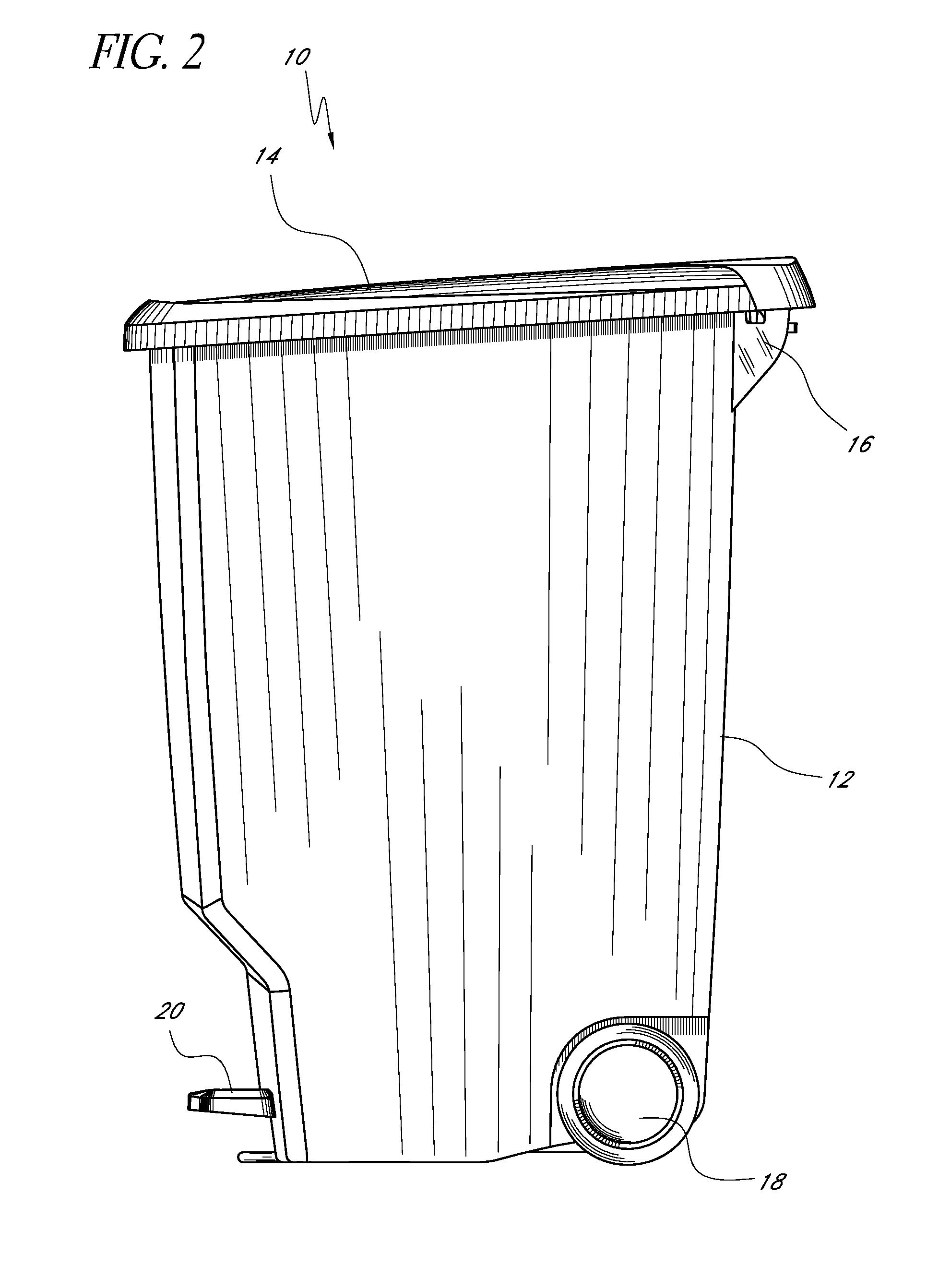

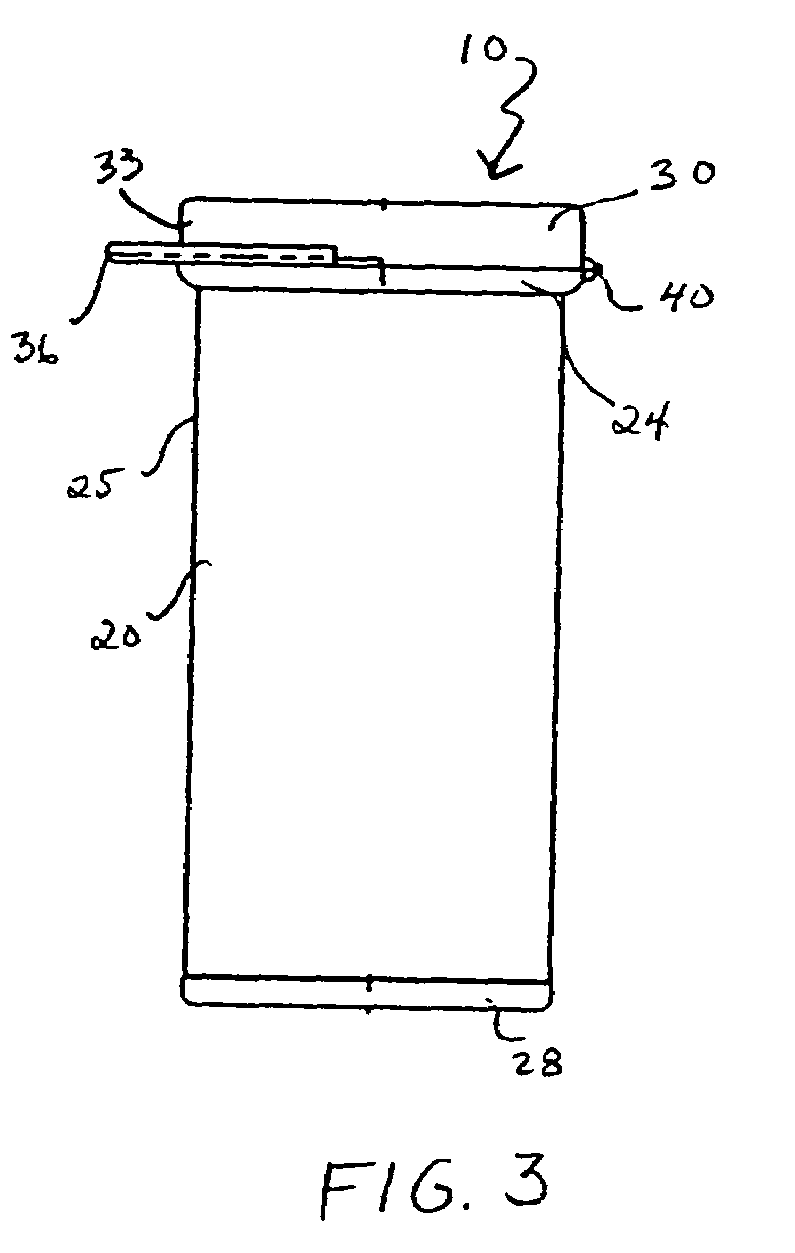

Trash can

A trash can with a lid can include a lock for the lid. The lock can include a latch that cooperates with the trash container body to lock the lid over the opening of the body. The latch can be configured to slide with respect to the edge of the opening of the body from an unlocked position to a locked position. This latch can be integrated into, built into or self contained in the lid. The trash can can also include a pedal actuator for opening the lid. The trash can can also include a damping mechanism mounted to the body of the trash can with a mounting plate. The mounting plate can be made from a material that is harder than the material used for the body of the trash can. Additionally, the trash can can have wheels.

Owner:SIMPLEHUMAN

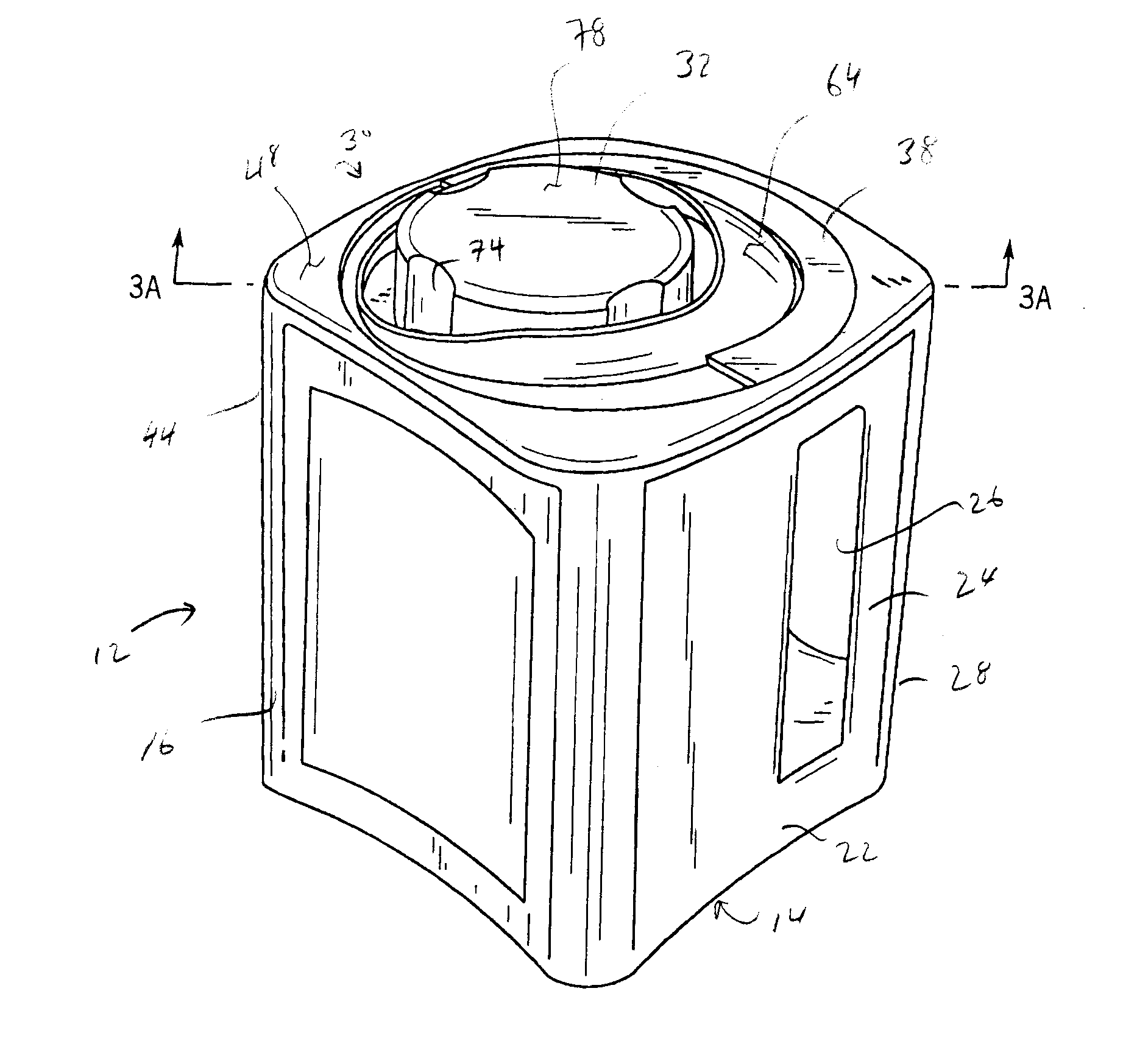

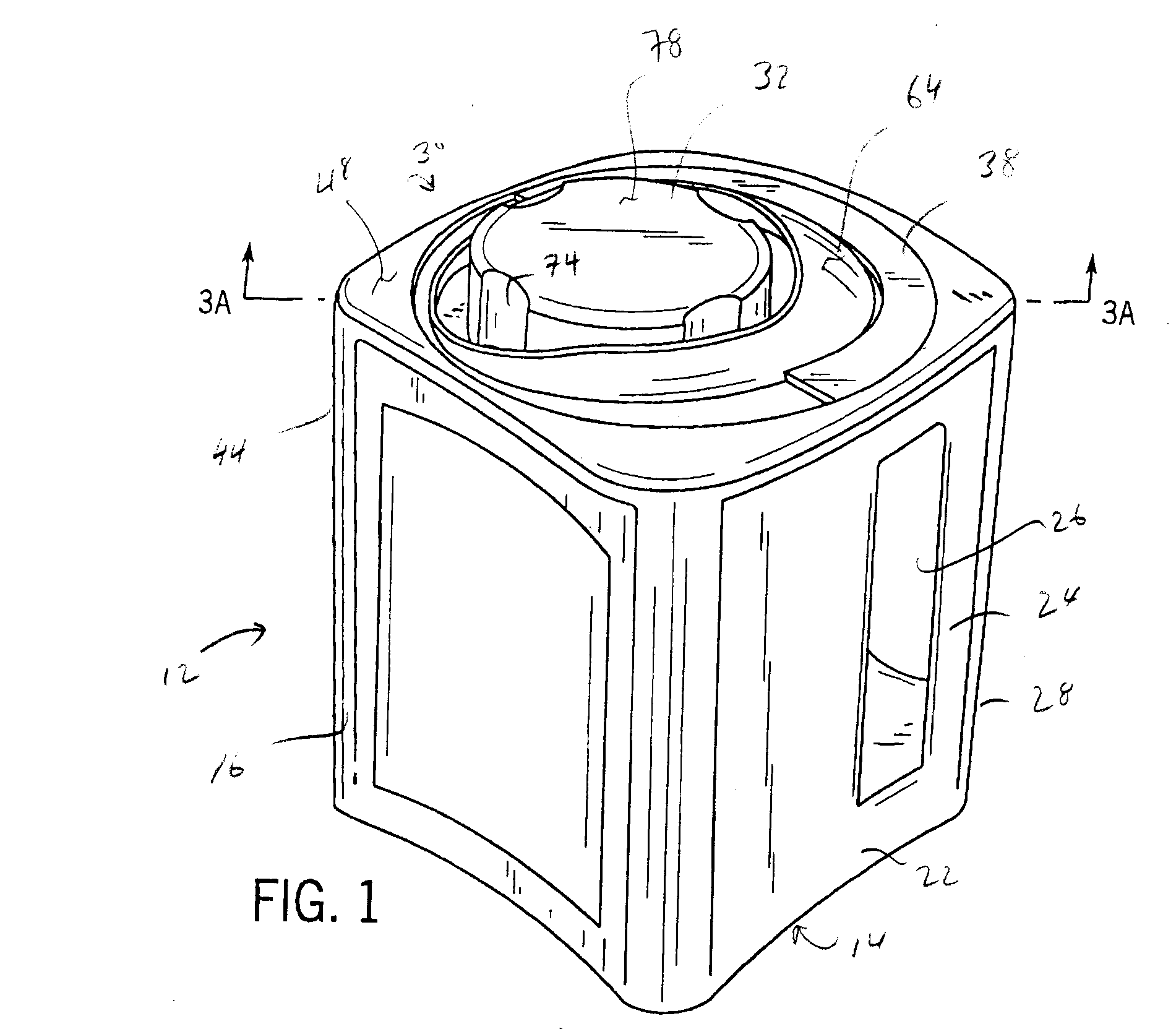

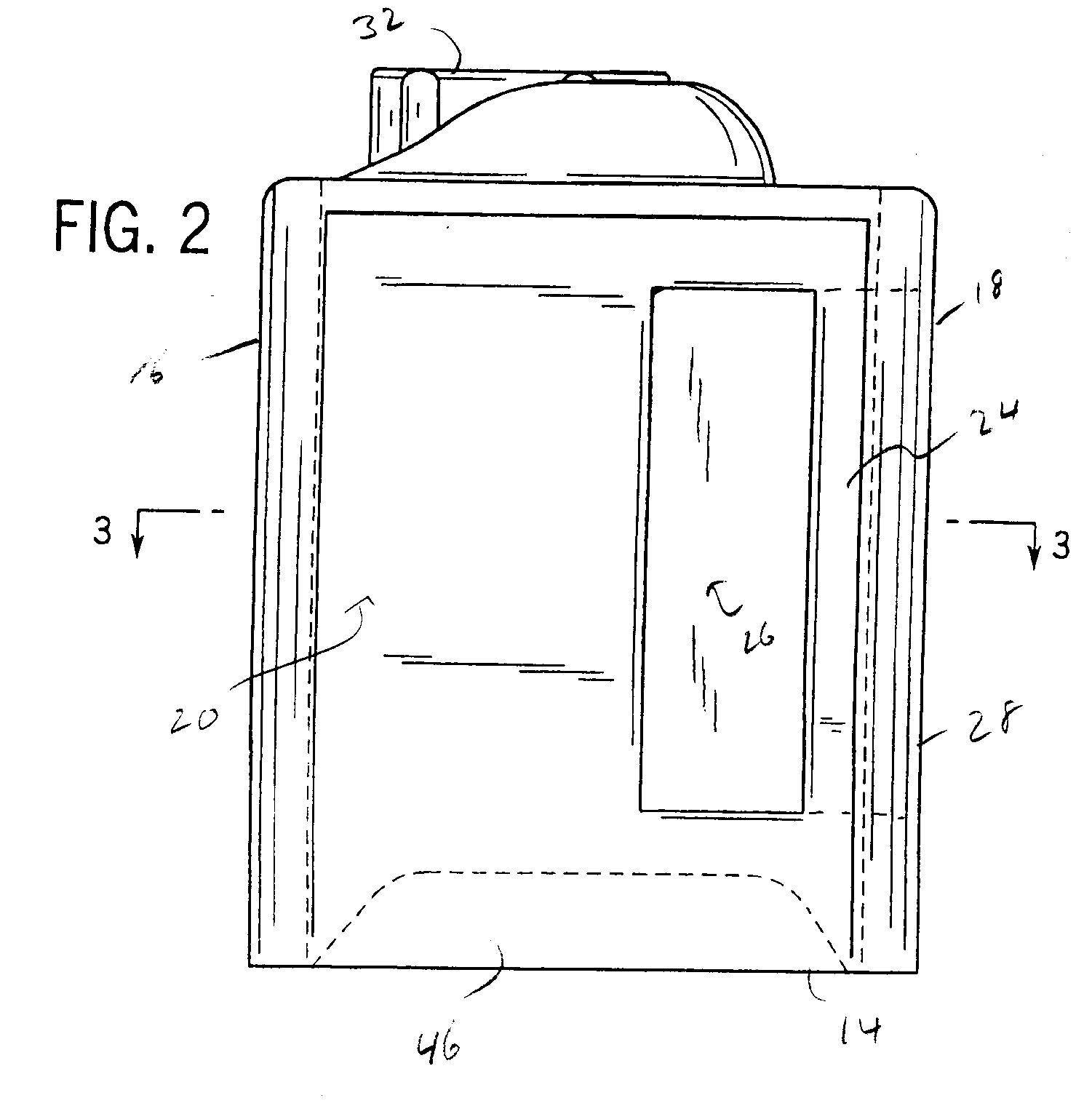

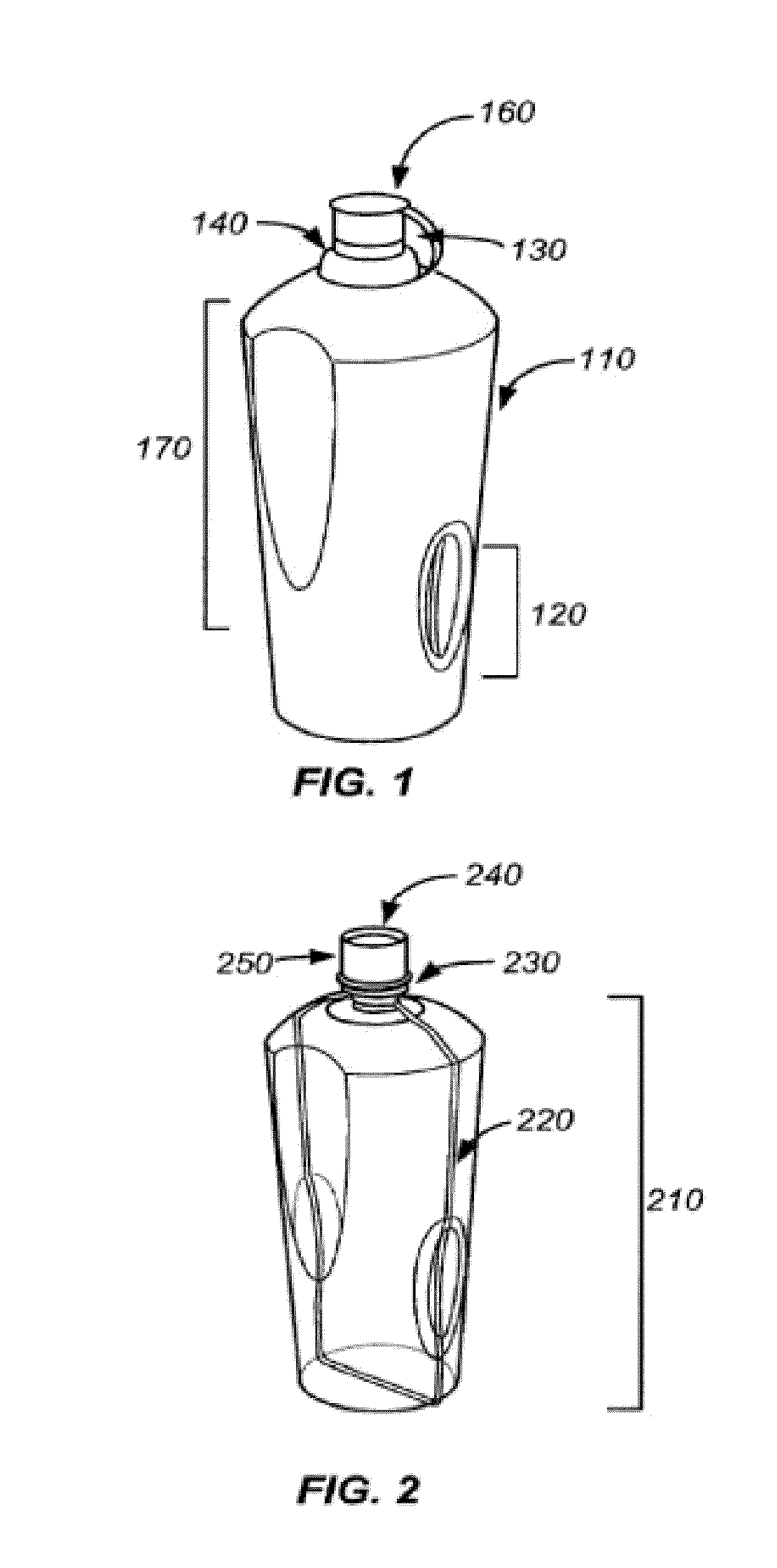

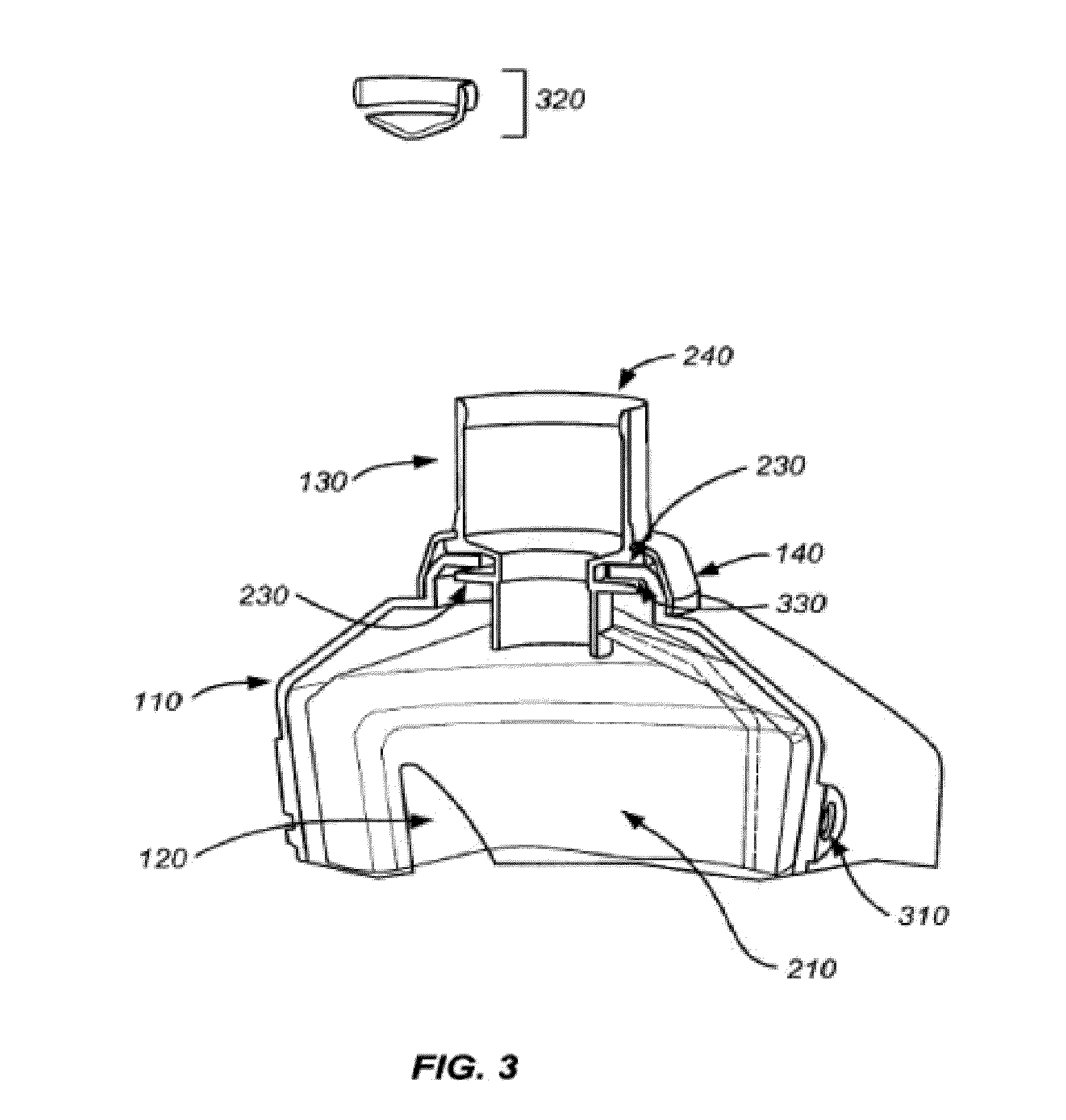

Paint container

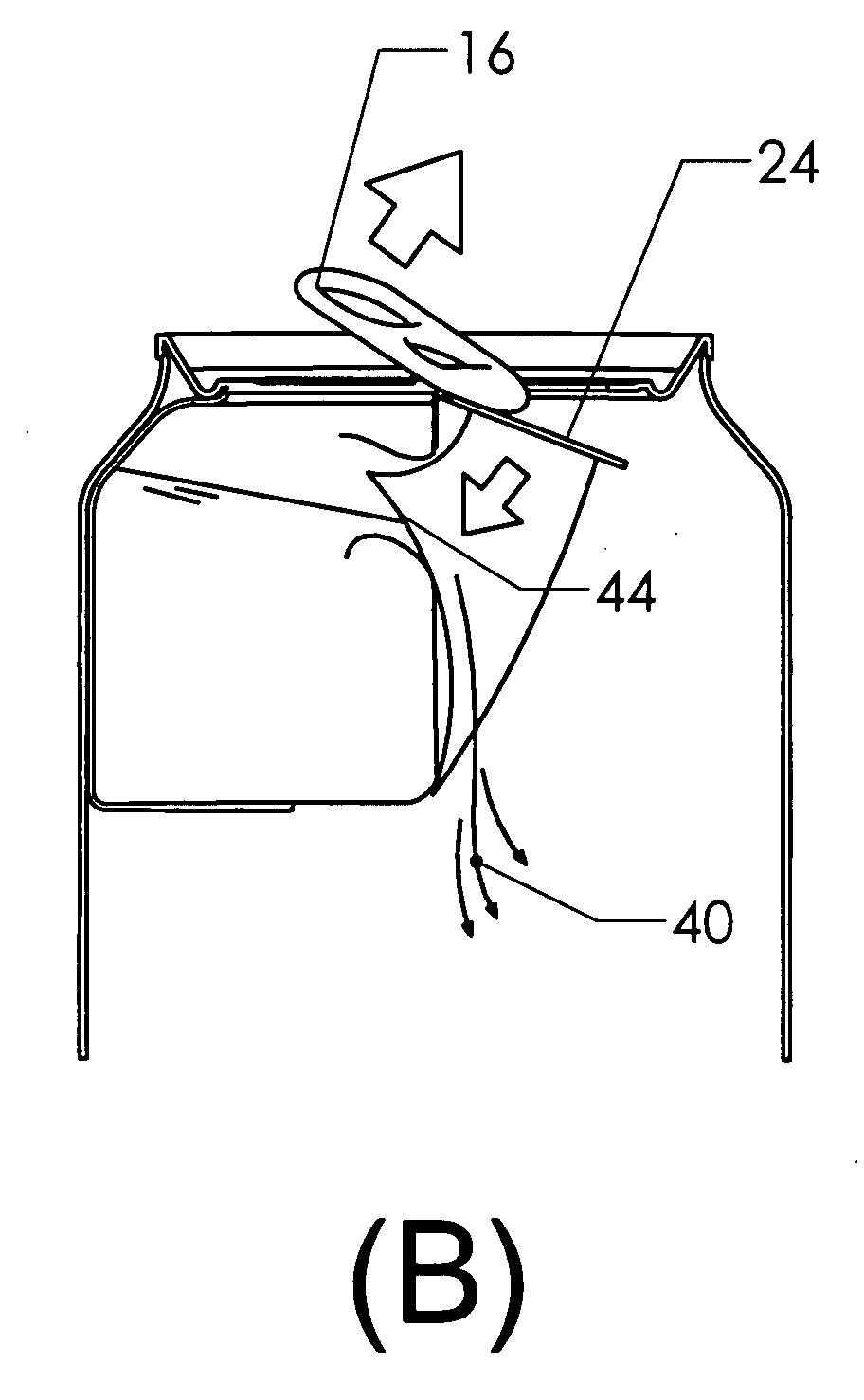

InactiveUS20030102340A1Prevent overflowShaking/oscillating/vibrating mixersCans/barrels/drumsMechanical engineeringEngineering

Abstract of Disclosure A paint container includes a body having a bottom, a plurality of side walls, and a top. An attachment mechanism is located proximate the top. A cap is configured to be secured to the attachment mechanism. A spout extends upward proximate the top and is at least partially surrounded by the attachment mechanism. A channel located between the attachment mechanism and the spout permits paint spilled into the channel to flow back into the paint container.

Owner:MASTERCHEM INDS

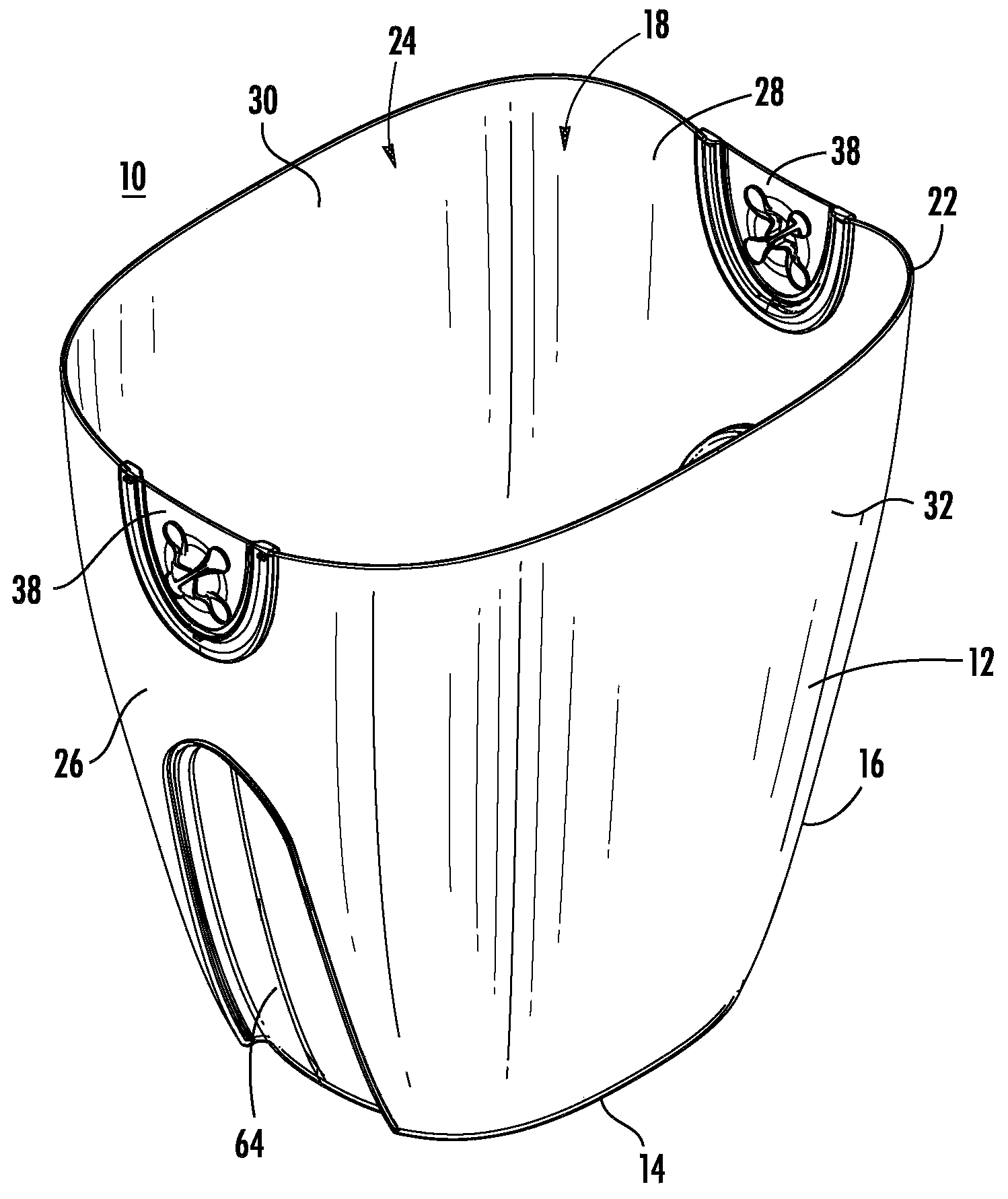

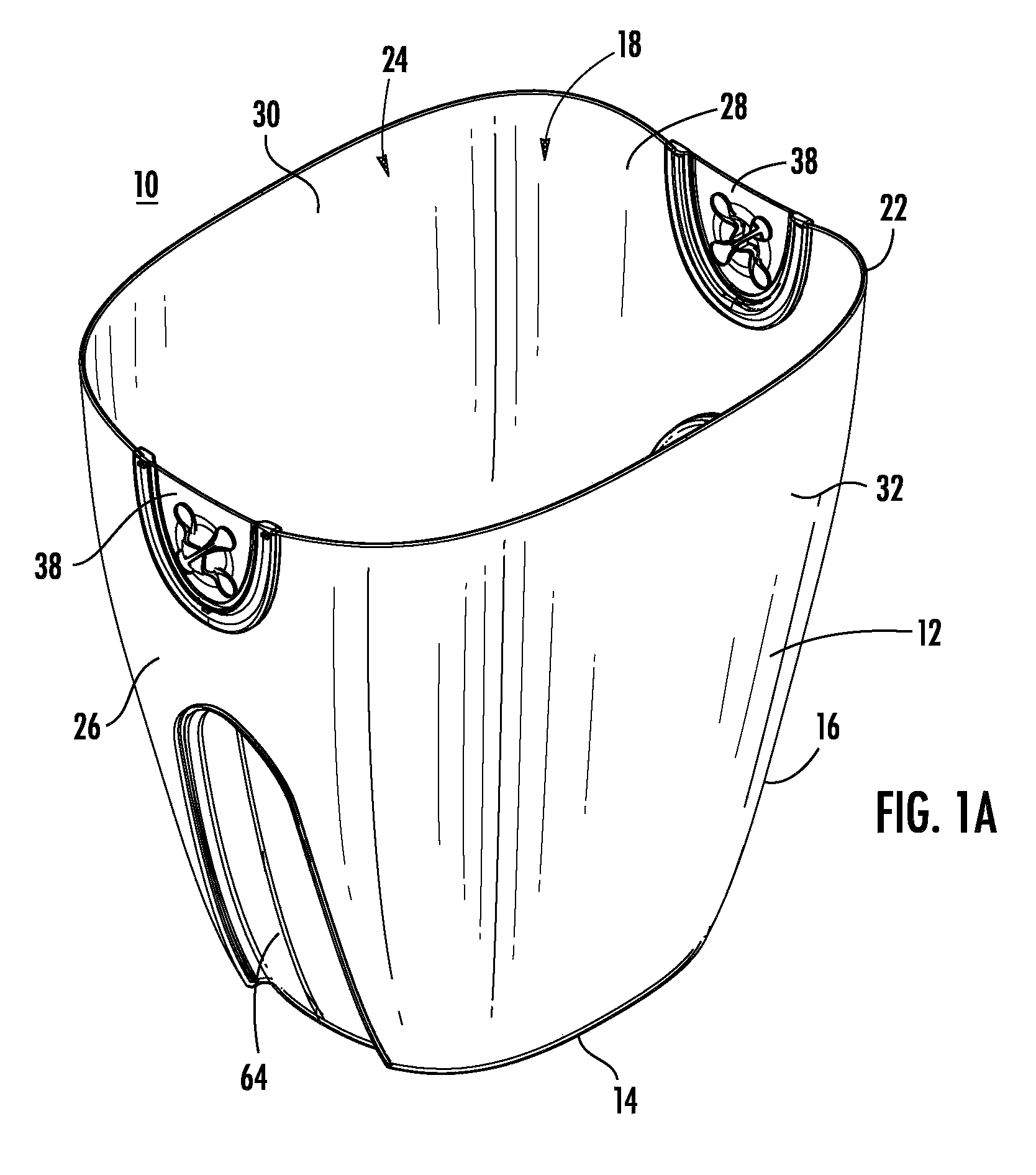

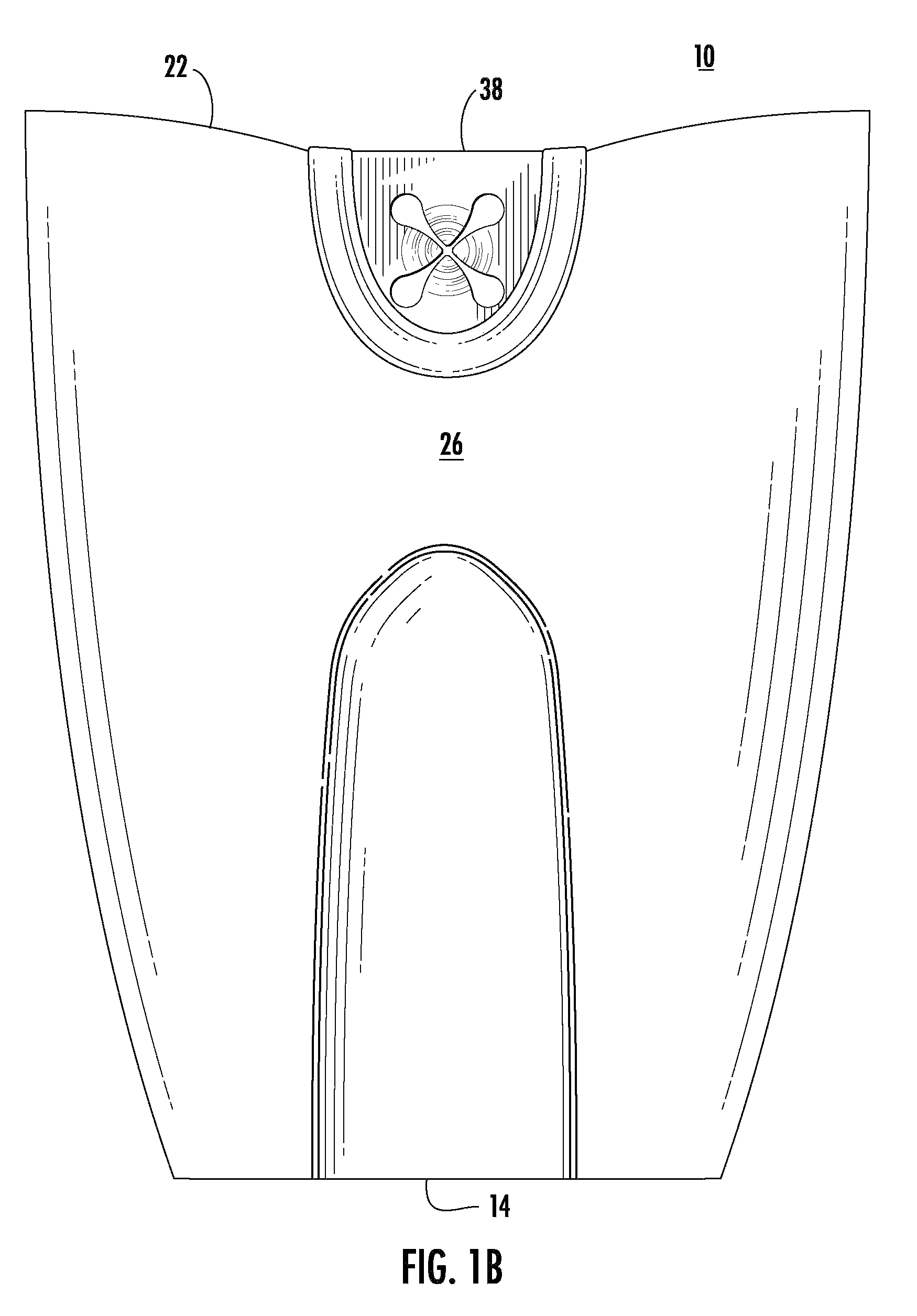

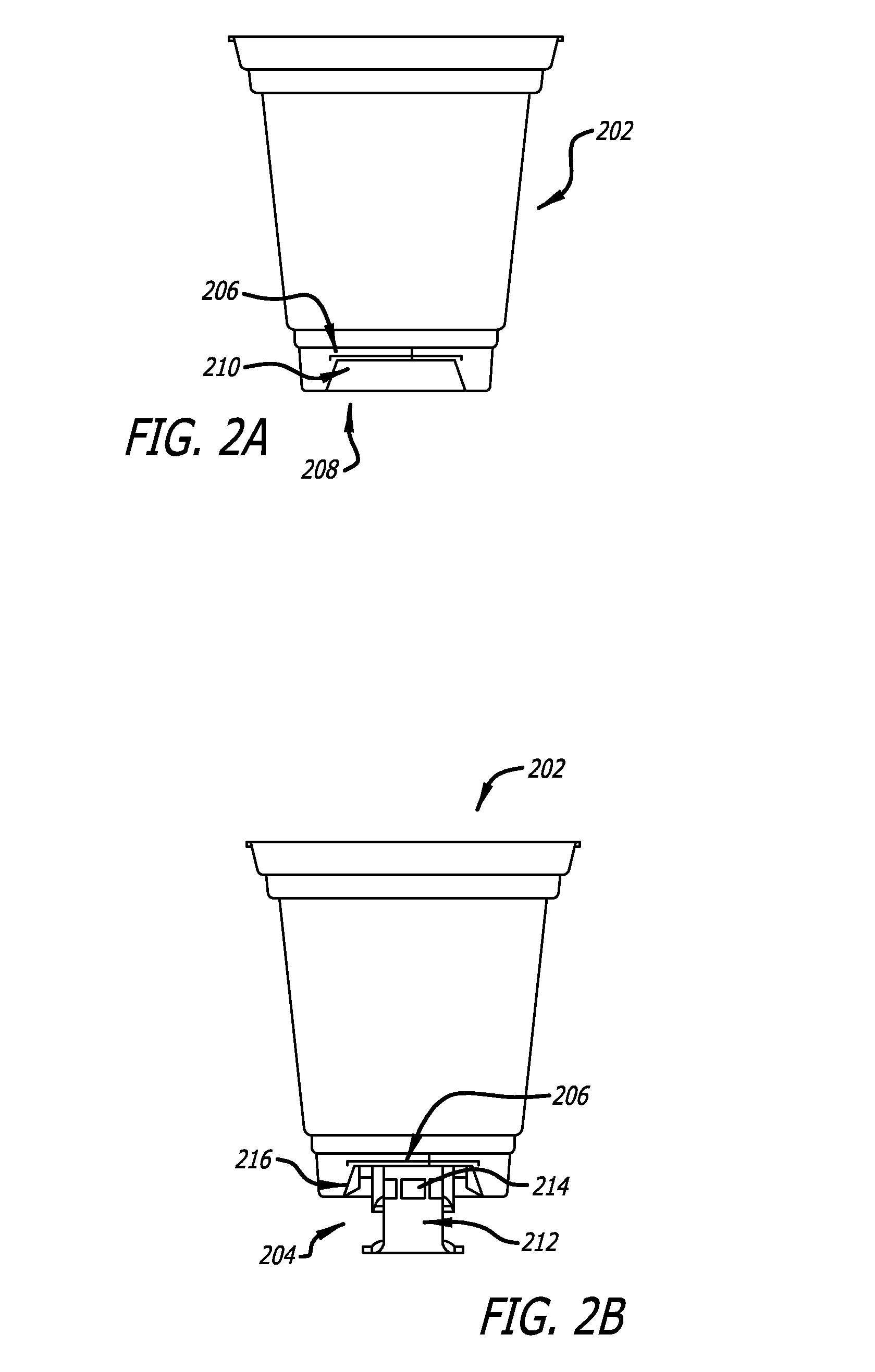

Trashcan having improved bag retention member

A trashcan includes a container having a base and a peripheral wall extending upwardly from the base forming an interior space for receipt of a trash bag therein; and a trash bag retention member disposed on the peripheral wall, the retention member defining a passageway into the interior space of the container and comprising a plurality of resilient, flexible fingers configured to receive and retain therebetween a portion of a trash bag. Each finger includes a portion thereof that extends away from the peripheral wall. Each finger is “bent” and extends away from the peripheral wall. A finger may extend away from the peripheral wall on the exterior of the container, away from the peripheral wall on the interior of the container, or both. A method of making the trashcan includes injection molding the container and the retention member separately or, alternatively, together.

Owner:EDISON NATION

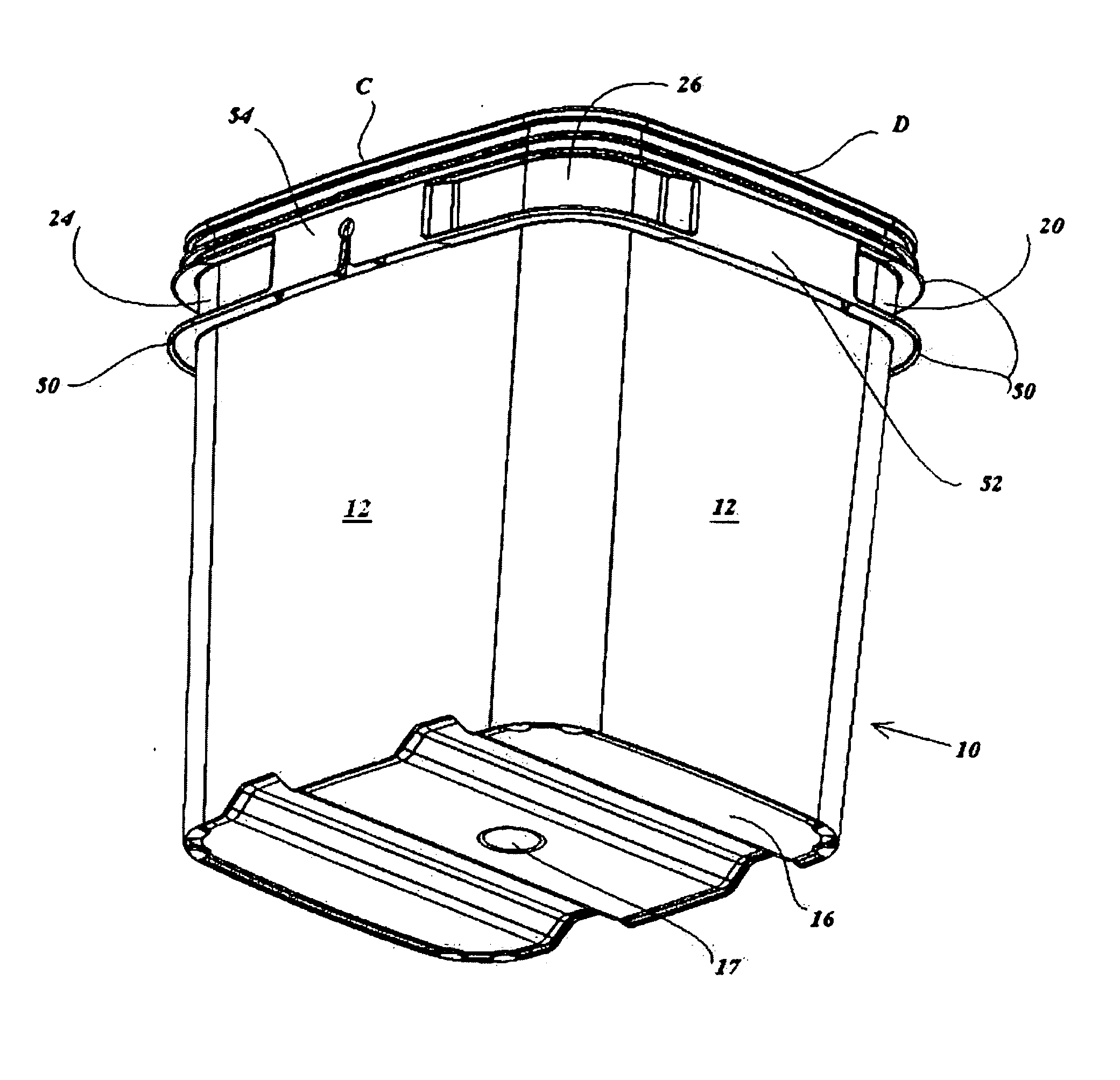

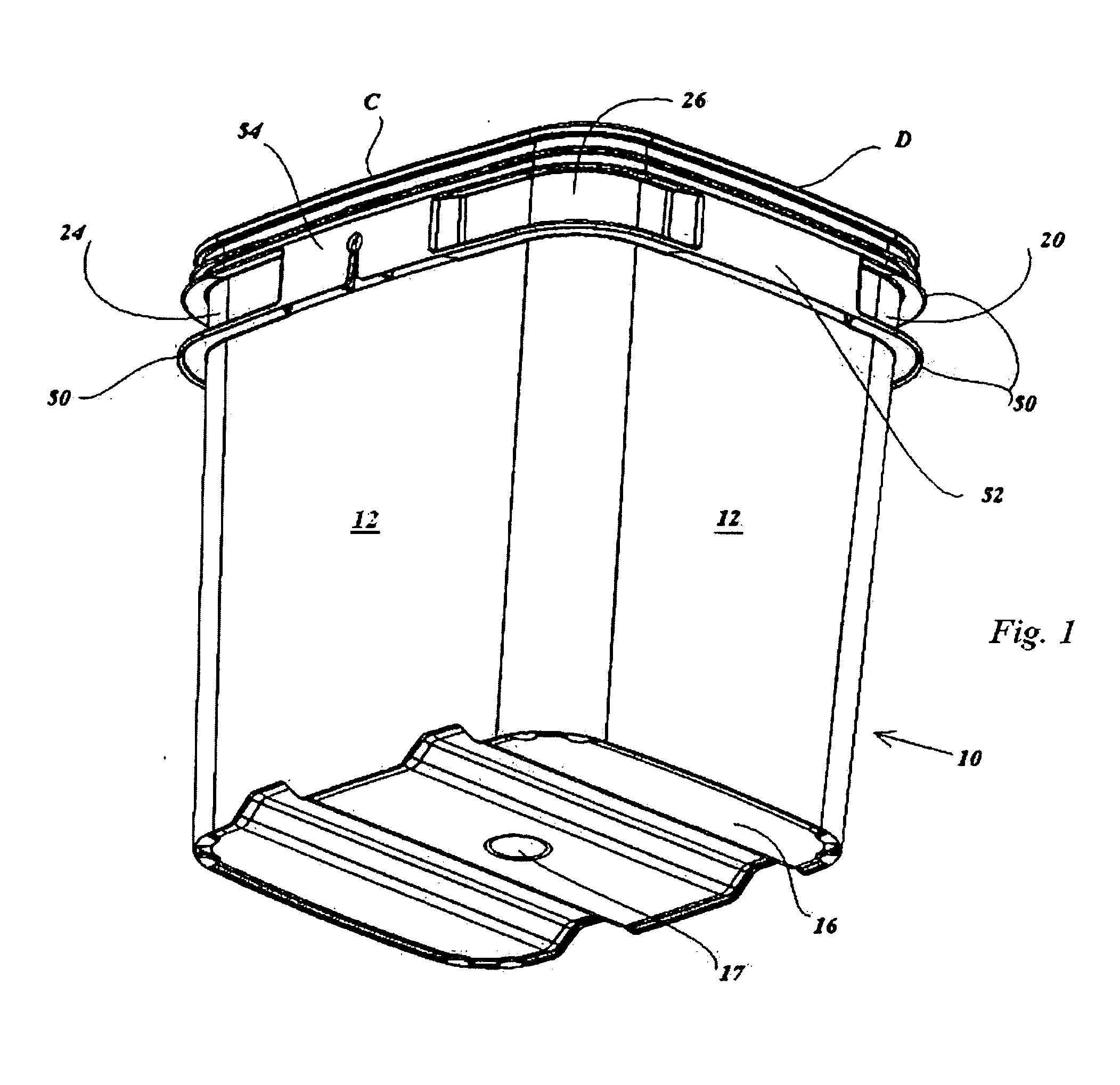

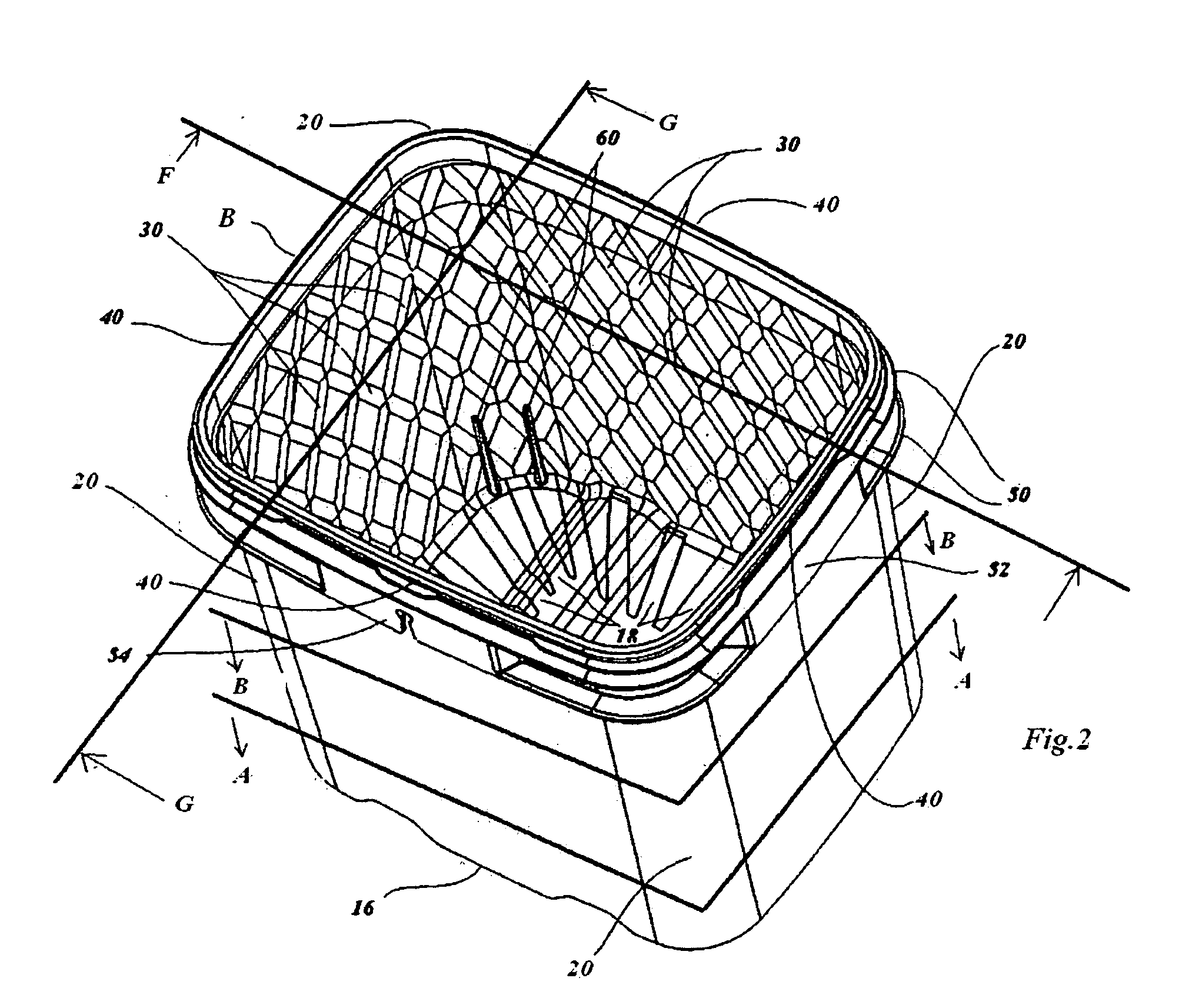

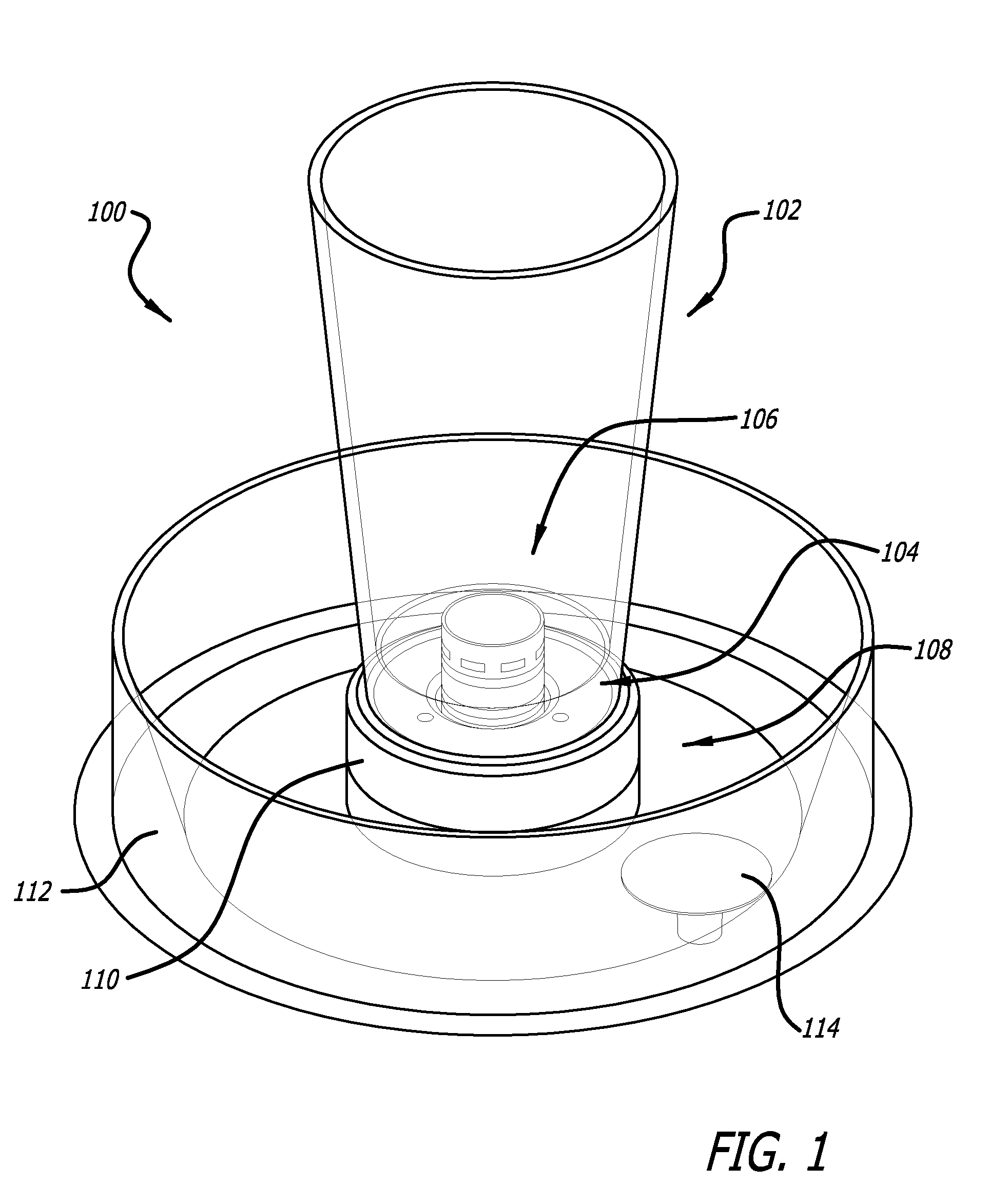

Container apparatus and related methods

ActiveUS20090152280A1Improved strength-to-materialImprove overall strength-to-weight ratioPackage recyclingLarge containersEngineeringInternal cavity

A container includes: a base; one or more sidewalls integrally formed with and extending upwardly from the base, wherein the sidewalls surround an internal cavity and wherein one or more of the sidewalls include a reinforcing web of increased wall thickness; and an upper edge on the sidewalls defining a top opening.

Owner:ROPAK CORP

Container structure for removal of vacuum pressure

A hot-fill PET container or bottle (10) for filling with a liquid at an elevated temperature has a side wall (9) extending to a lower portion including a pressure panel (11) and a base (2) in its unfolded or pre fill position. The panel (11) is transversely oriented and has a decoupling or hinge structure (13), an initiator portion (1) and control portion (5) of a steeply angled inverting conical section between 30 and 45 degrees. The control portion enables the inversion of the panel (11) into the container (10) to compensate for vacuum or reduced pressure induced within the container as the liquid cools down. The base (2) can also have a plurality of reinforcing ribs (3).

Owner:CO2 PAC

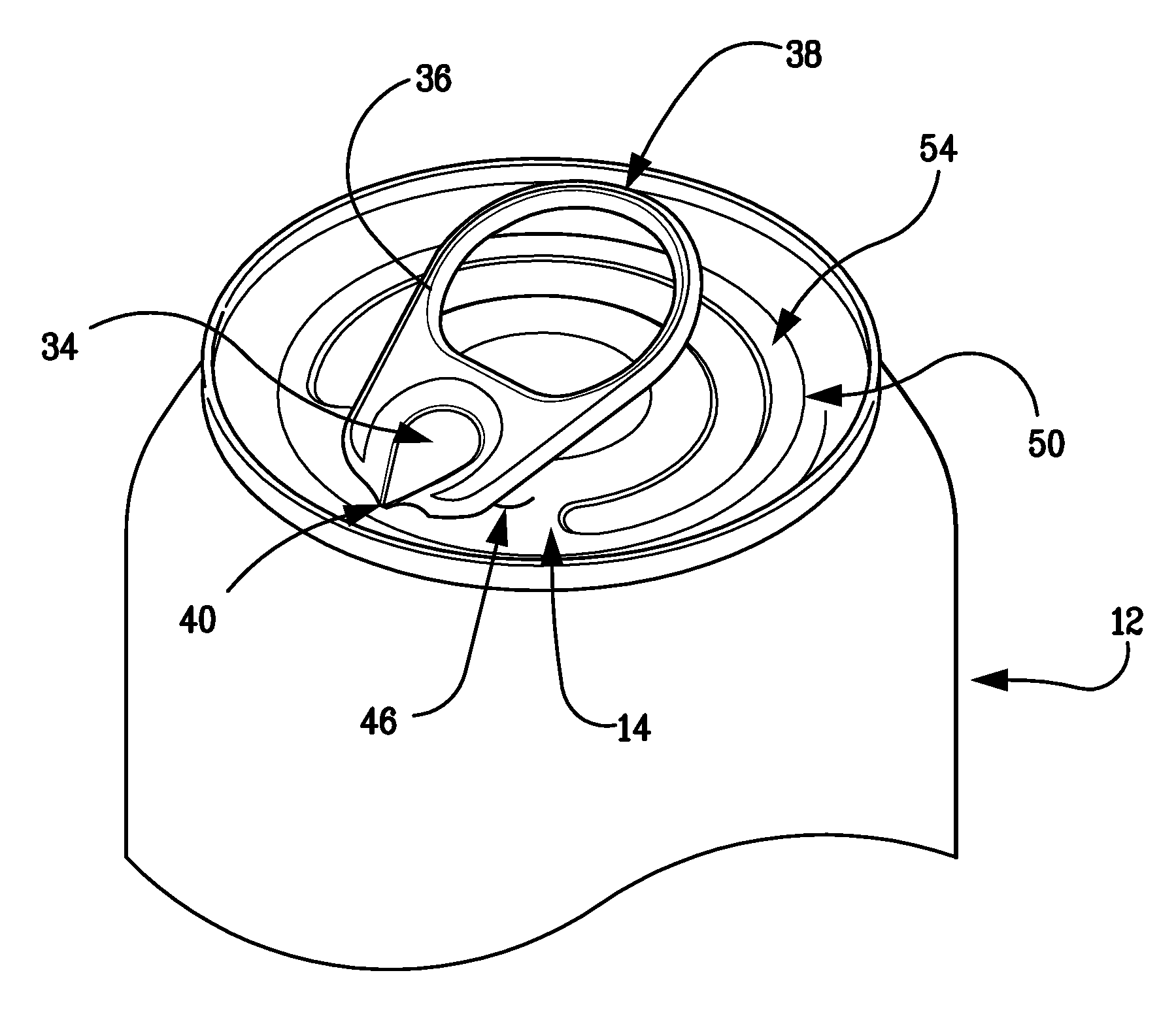

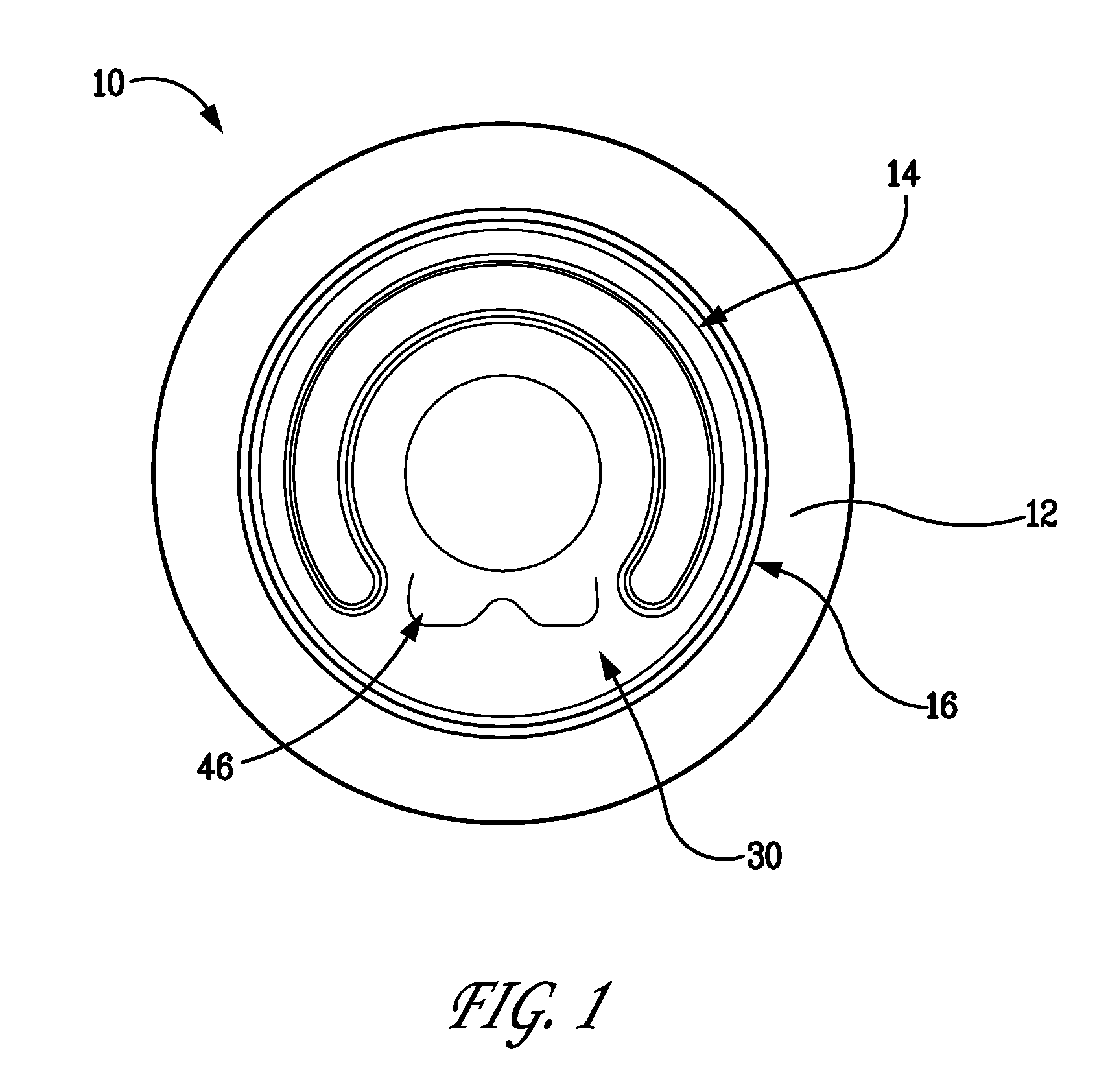

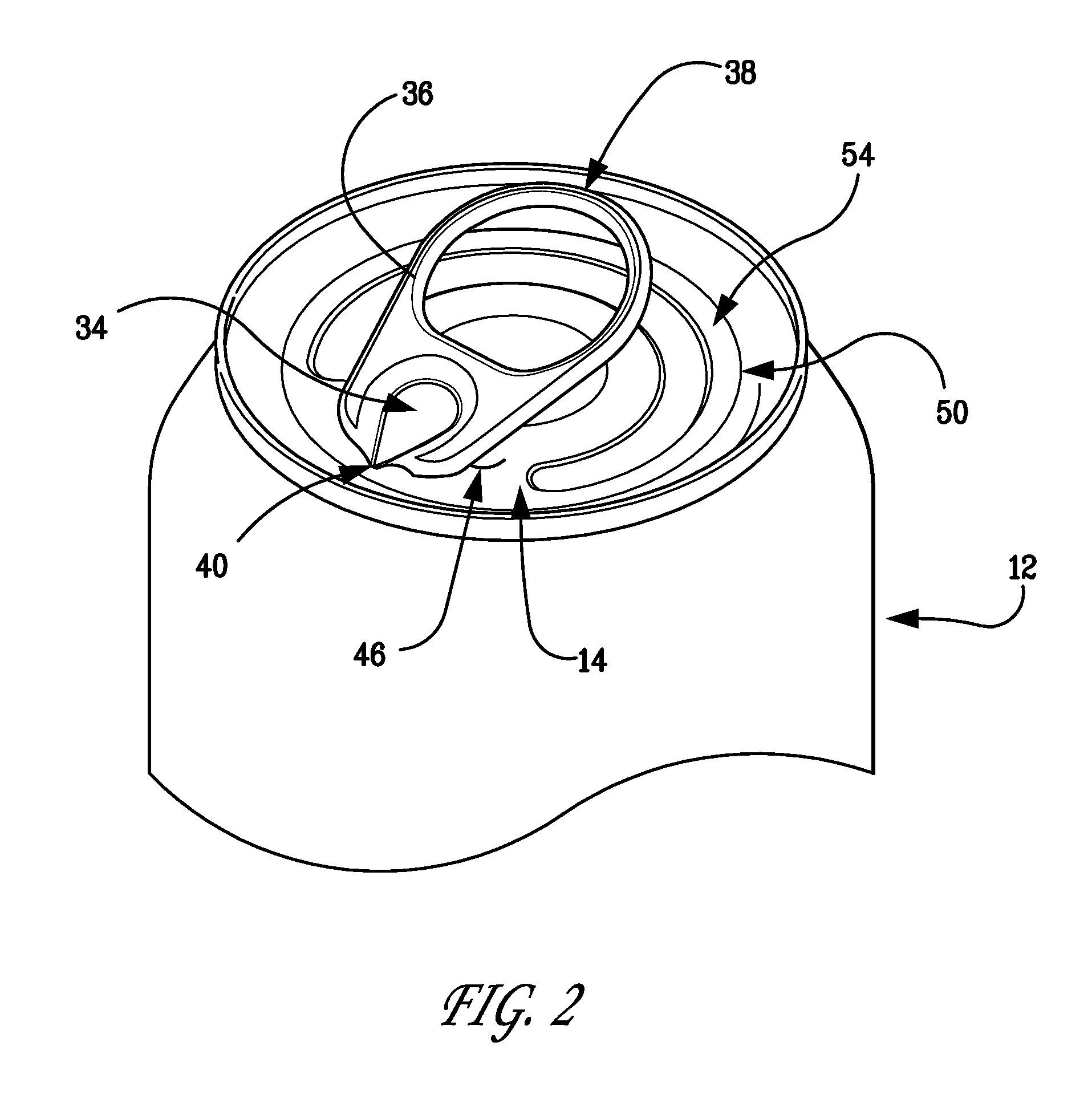

Full aperture beverage end

InactiveUS20110056945A1Content becomes visibleOpening closed containersBottle/container closureDifferential pressureEngineering

A full aperture beverage end has a center panel, a countersink surrounding the centre panel, a main score arranged in proximity to the countersink to define a removable aperture panel and a vent score. The beverage end is adapted for use with products that are pressurized to over 30 psi (200 kPa) when opened, and during opening the vent score is adapted to sever first, controlling the pressure differential between the external surface and internal surface of the centre panel, thereby allowing the main score to tear in a controlled and reliable manner.

Owner:CROWN PACKAGING TECH

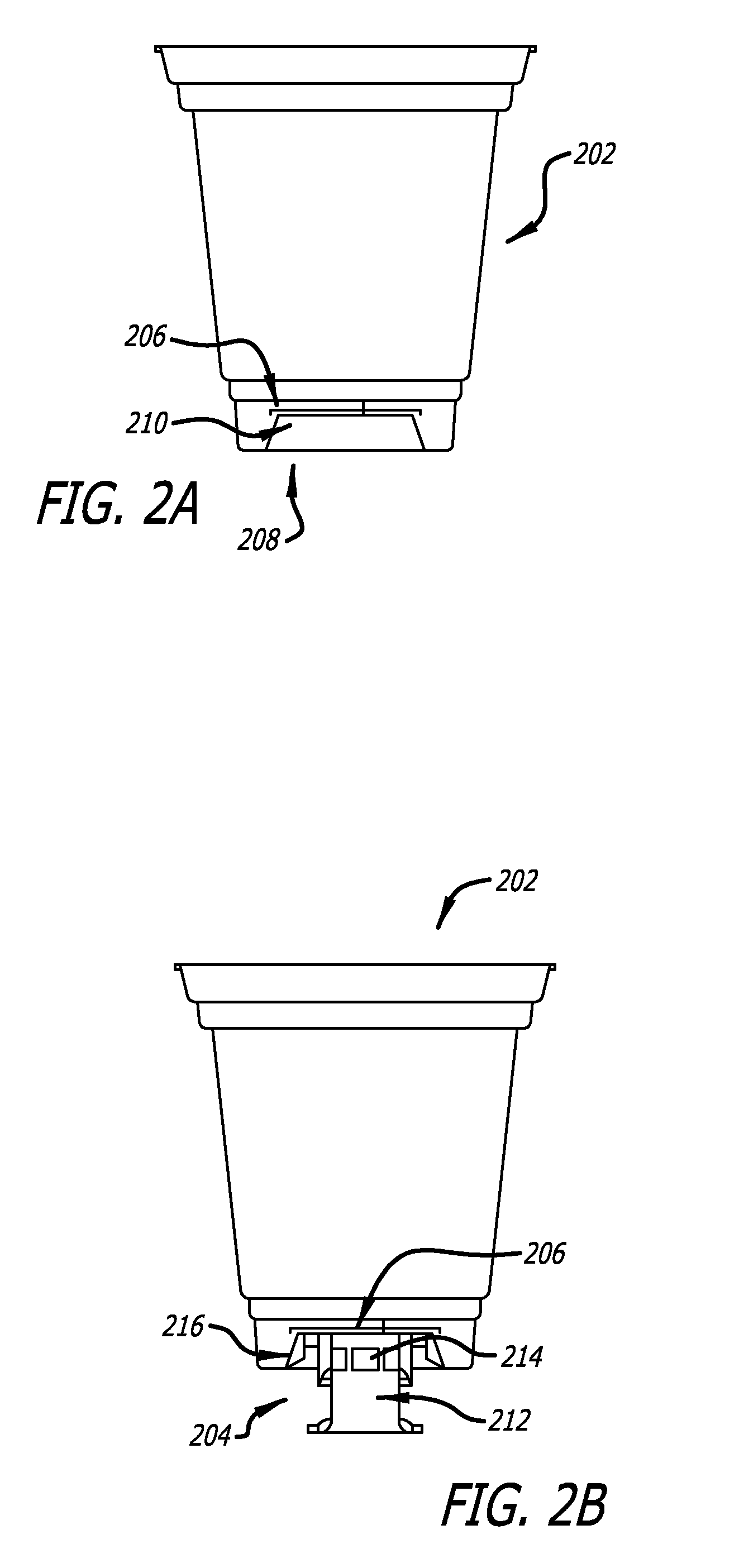

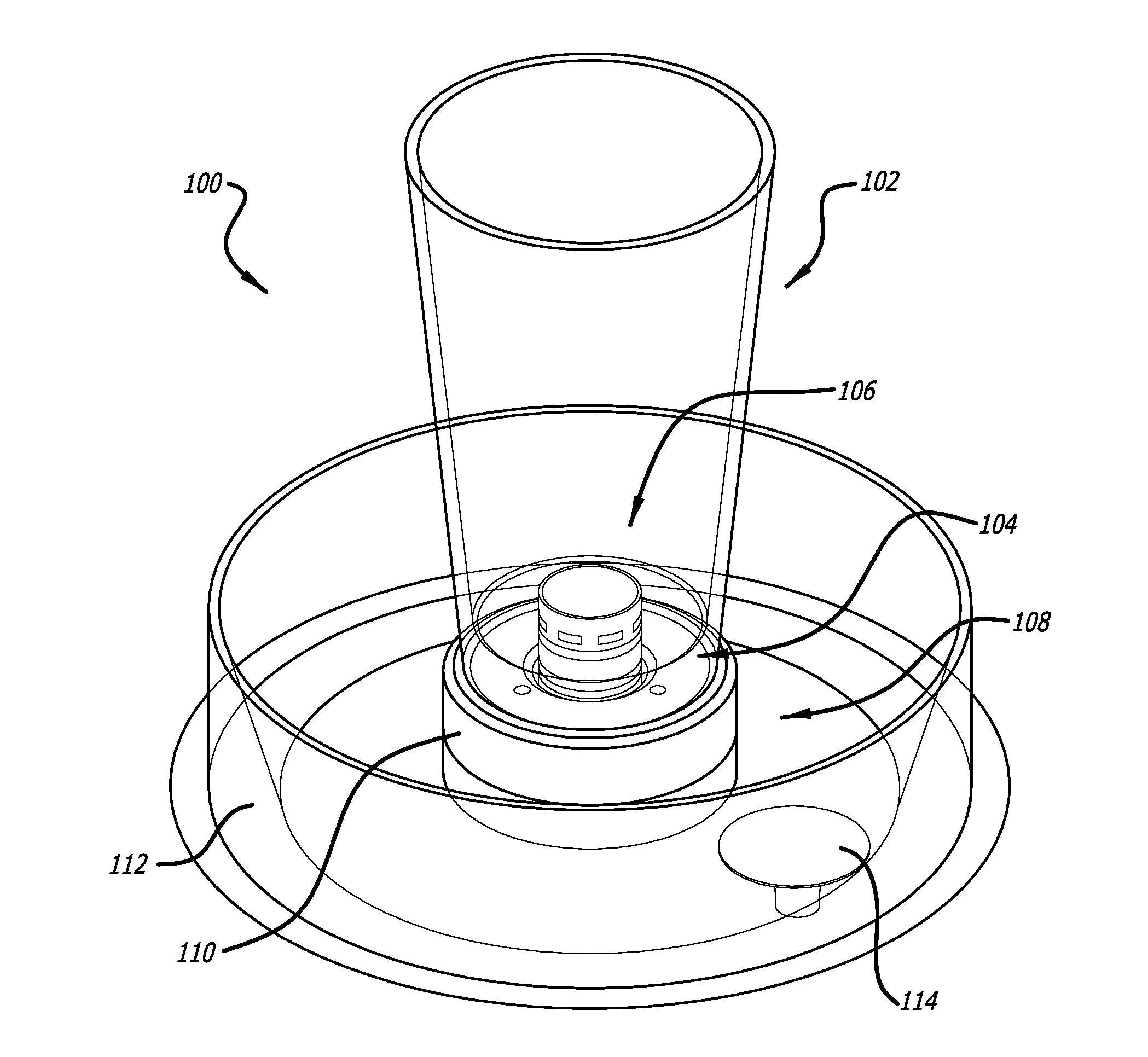

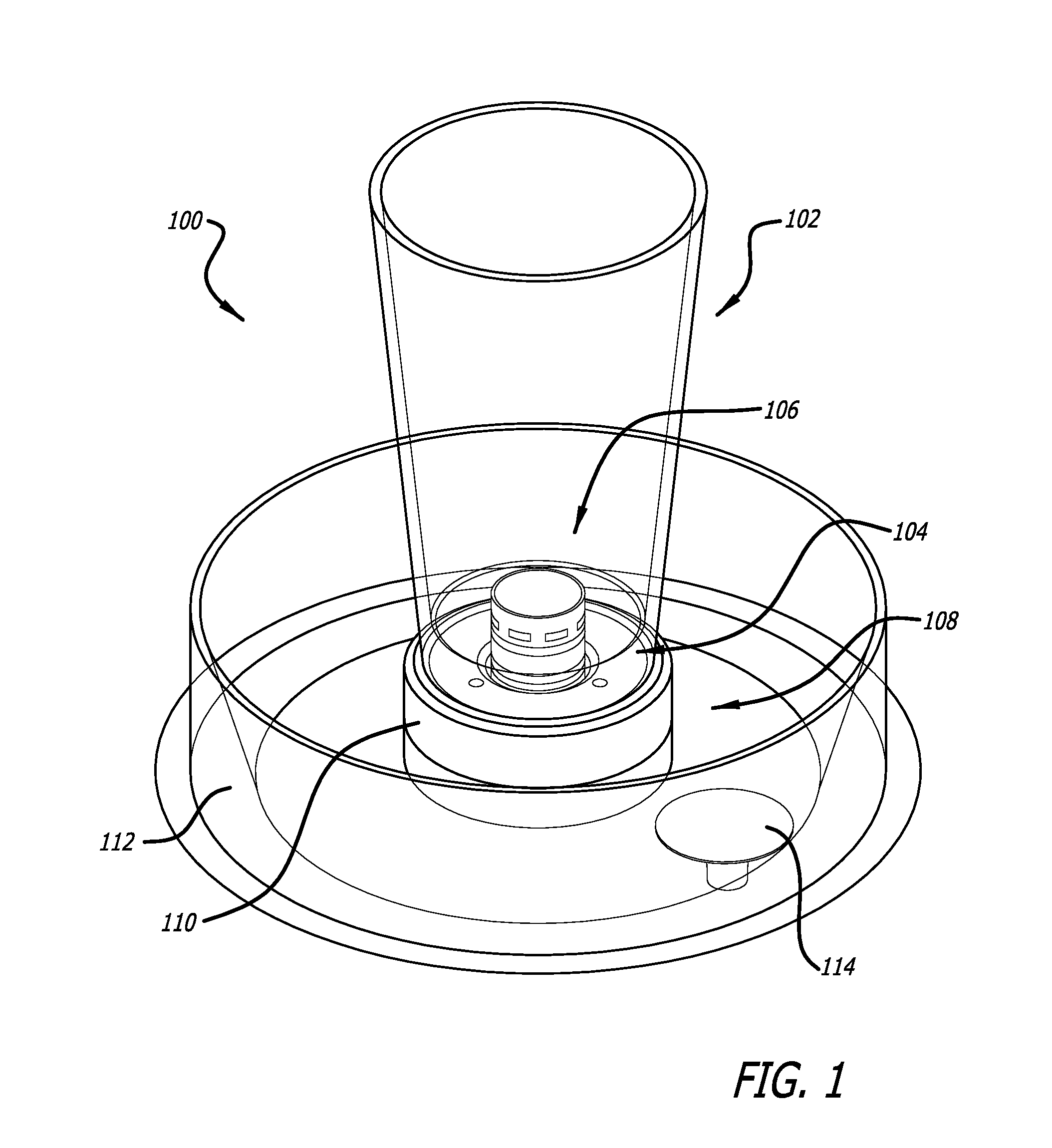

Fluid transfer assembly and methods of fluid transfer

ActiveUS20110061764A1Drain fastEasy to removeOperating means/releasing devices for valvesLiquid fillingEngineeringFill device

A fluid transfer assembly and methods of fluid transfer is described. In one aspect, the fluid transfer assembly includes a fluid container having an opening in a bottom, a coupling device attached to the fluid container at the opening, and a filling device. The coupling device may include a valve biasing the coupling device in a closed fluid-tight position via magnetic attraction of opposing first and second components, each of the opposing first and second components including a magnetic material. The filling device may include a rigid member with a perimeter smaller than a perimeter of the fluid container opening, the rigid member including a passage along a longitudinal axis and one or more apertures through a sidewall in fluid communication with the passage, such that the coupling device is transitioned from the closed fluid-tight position to an open position by pressing the rigid member against one of the opposing first and second components, thereby placing the apertures in fluid communication with an interior of the fluid container.

Owner:GRINON INDS

Leakproof, resealable container and cap assembly

InactiveUS7198161B2Prevent openingUnified positionCapsClosure using stoppersEngineeringMechanical engineering

A leakproof, resealable container and cap assembly, consisting essentially of: a container having a rim at its upper portion and a cap having a circular base with an outer periphery, a cylindrical tubular skirt having an inner wall with at least one recess, a thumb tab for facilitating the opening and closing of the container, and a hinge connecting the cap to the container, and in a closed portion, the skirt of the cap overlies the container and the rim of the container is situated within the recess of the inner wall of the skirt of the cap.

Owner:CSP TECH INC

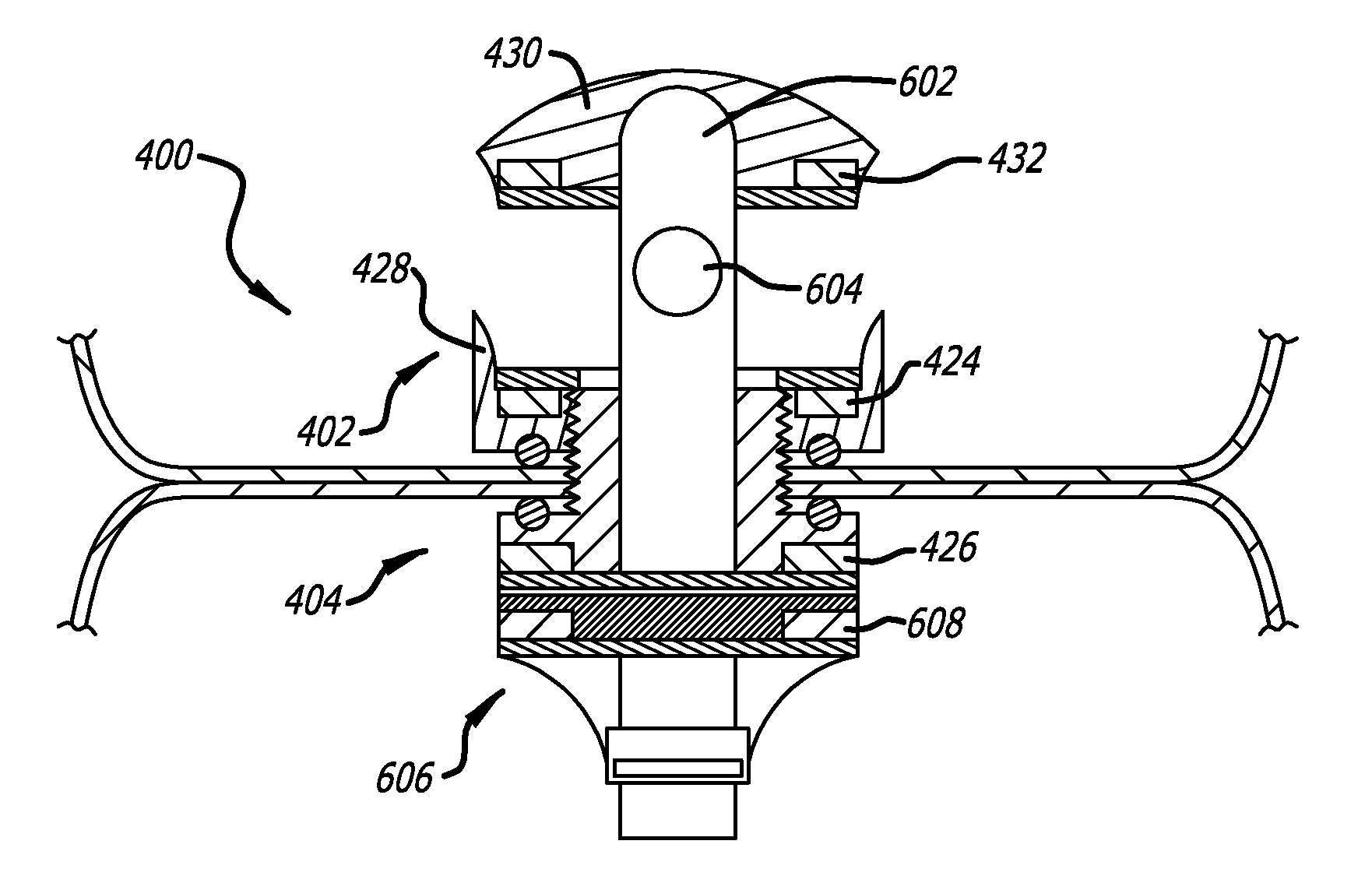

Fluid transfer assembly and methods of fluid transfer

ActiveUS20130118639A1Drain fastEasy to removeClosure using stoppersClosure capsEngineeringMechanical engineering

A fluid dispensing system and assembly, including a connection or coupling device, a valve, a housing, a user interface, a filling device, and a fitting to couple to a fluid source. The connection or coupling device may include a magnetic ring crimped to the bottom of a container, and methods of manufacture are described. The valve may include a first sensor detecting proper placement of the fluid container based on a magnetic material positioned at the bottom of the fluid container, a plunger having a plunger shaft coupled thereto, the plunger selectively placing the valve in fluid communication with the fluid container, and a solenoid coupled to the plunger shaft and moving the plunger shaft to transition the plunger between an open position and a closed position. The user interface may be coupled to the valve to enable selection of at least a fluid container size and a dispensing mode.

Owner:GRINON INDS

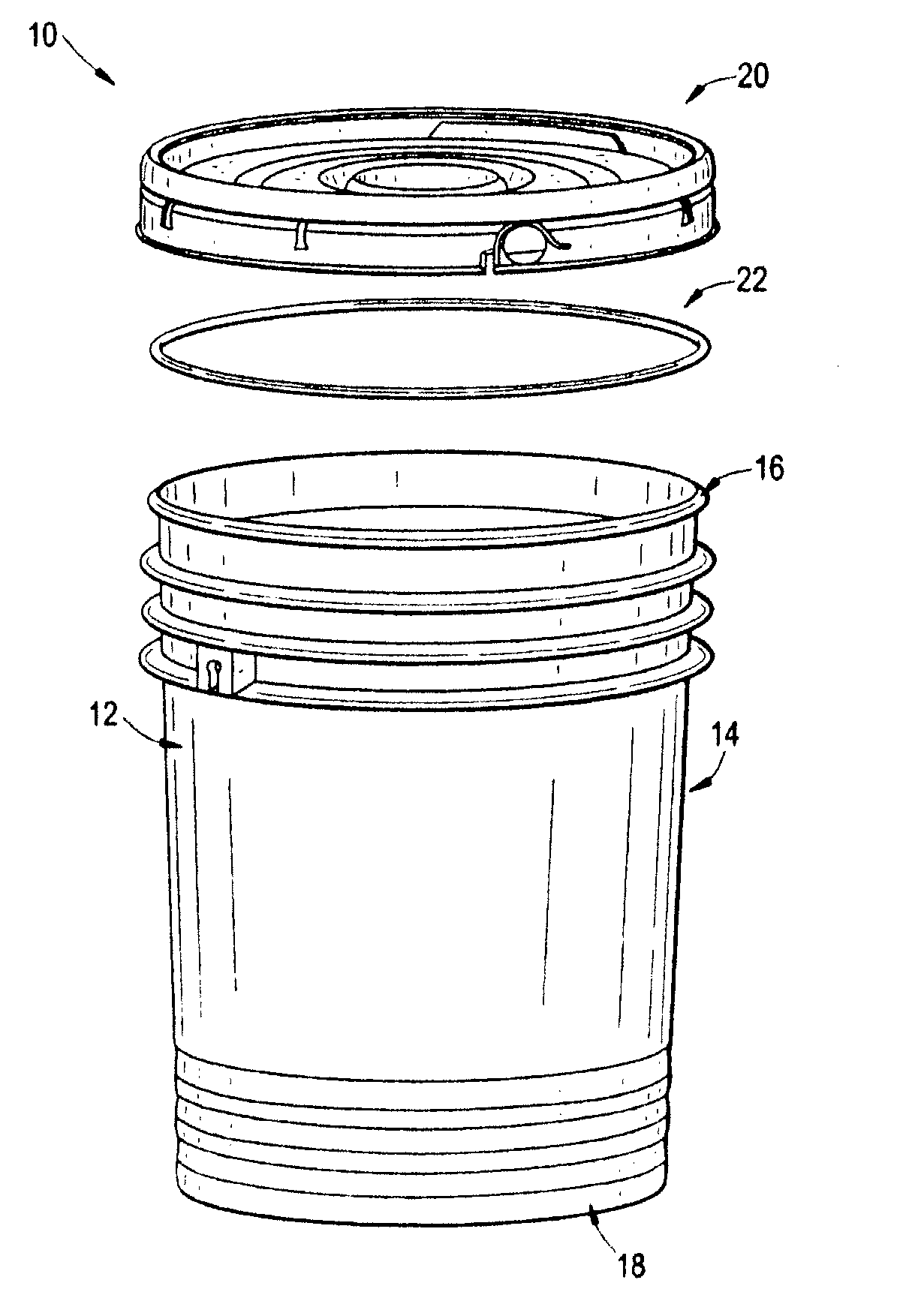

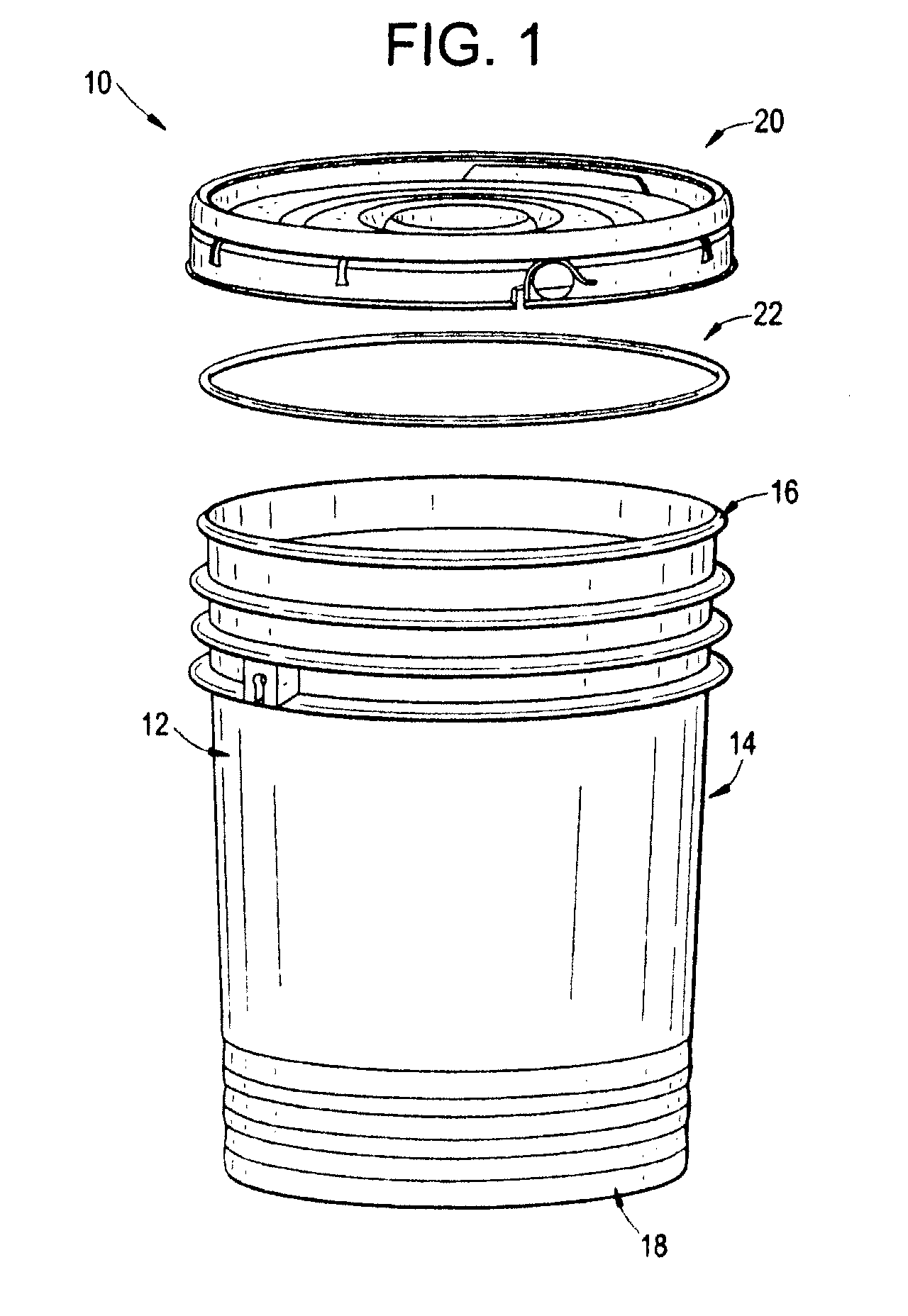

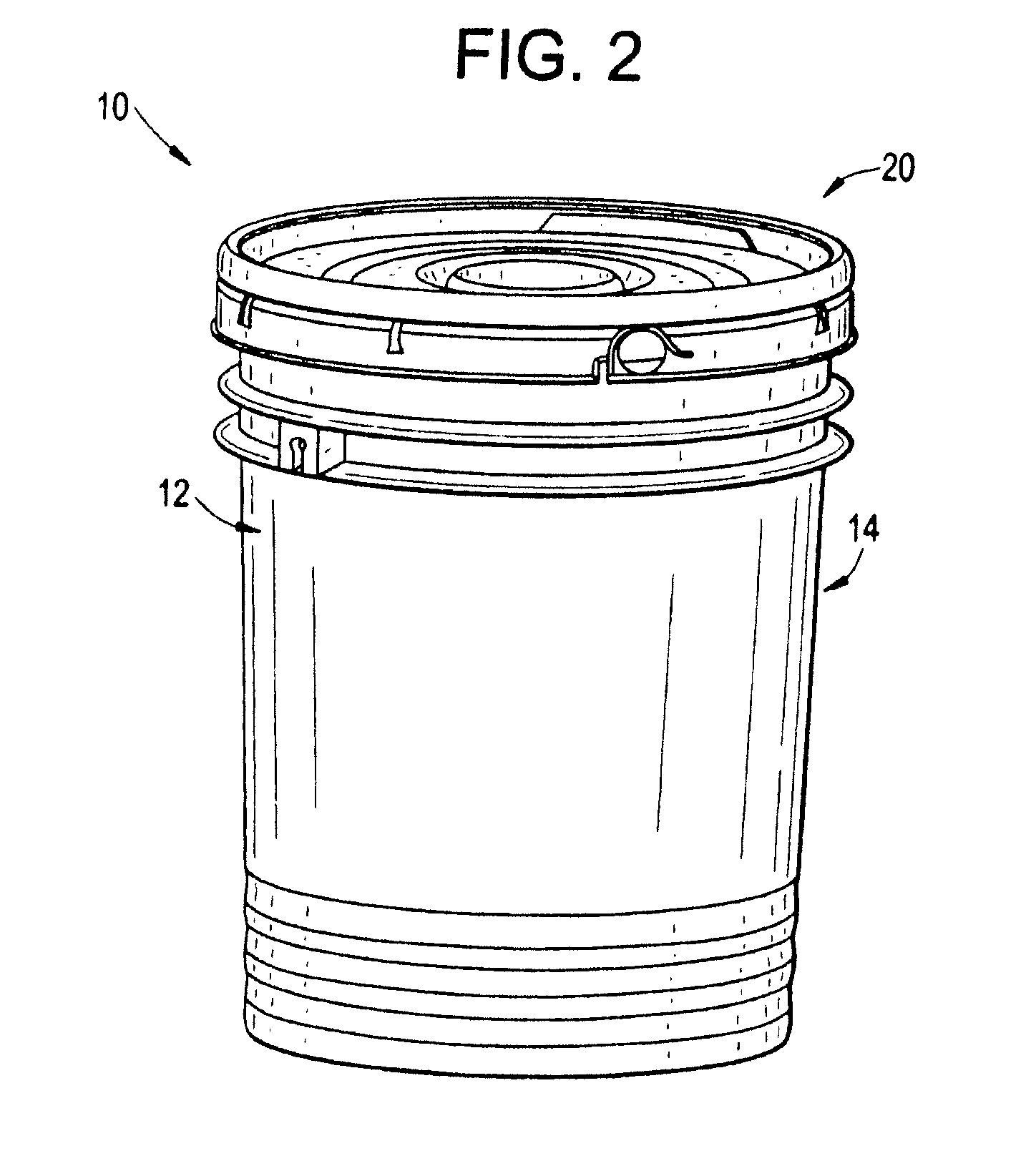

Performance oriented pail

A container comprising a pail, removable cover, and a gasket disposed between the cover and the pail is disclosed. The pail has an angled bead at the proximal end of the pail and a plurality of satellite rings that extend circumferentially around the pail and form a wall junction with the pail. The wall junction has a substantially constant wall thickness. A bail ear is formed to connect at least two of the satellite rings to define an opening between the bail ear and the body. The pail also includes a shock absorbing wall section.

Owner:ROPAK CORP

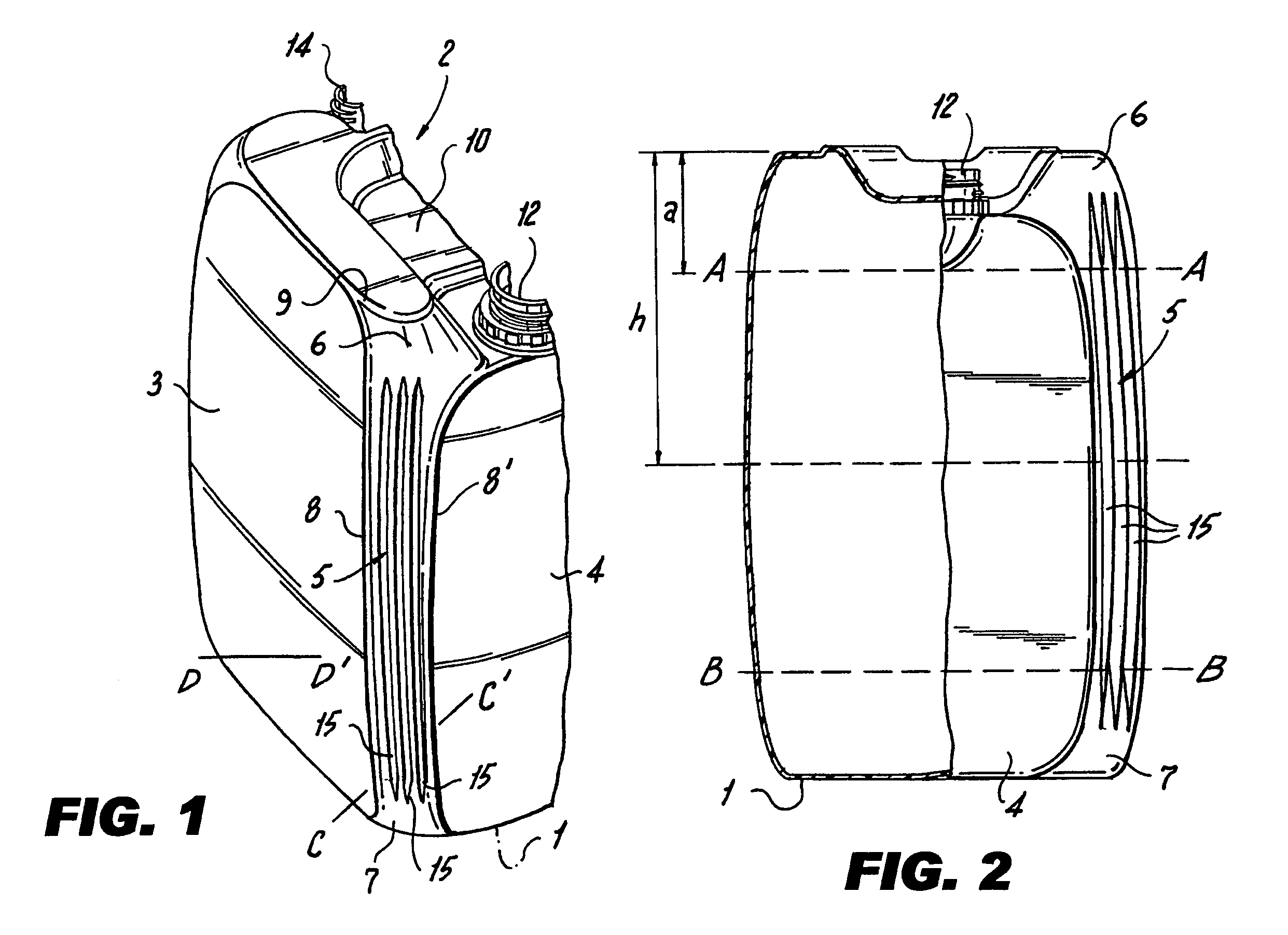

Plastic container with rounded shoulders

A plastic container for the storage and transport of liquids, particularly aggressive liquids, comprising a practically rectangular bottom, a top wall with a filling or pouring hole, and standing walls which each connect to the circumferential seam of both the bottom and the top, and four standing edge strips each connecting two walls, which container is manufactured by the blow-molding process, wherein the standing wall portions have a convex form, wherein either the standing edge strips widen at the top and the bottom and, as seen in a cross-section running parallel to the bottom, the standing edge strips have a radius of curvature equal to or greater than that of the standing wall portions to which they are connected.

Owner:WIVA VERPAKKINGEN +1

Can end

A can end member has a central panel, a circumferential chuckwall, and a transition wall. The central panel is centered about a longitudinal axis and has a peripheral edge. The curl defines an outer perimeter of the end member. The circumferential chuckwall extends downwardly from the curl to the transition wall. The transition wall connects the chuckwall with the peripheral edge of the central panel. The transition wall has a folded portion extending outwardly relative to the longitudinal axis.

Owner:REXAM BEVERAGE CAN

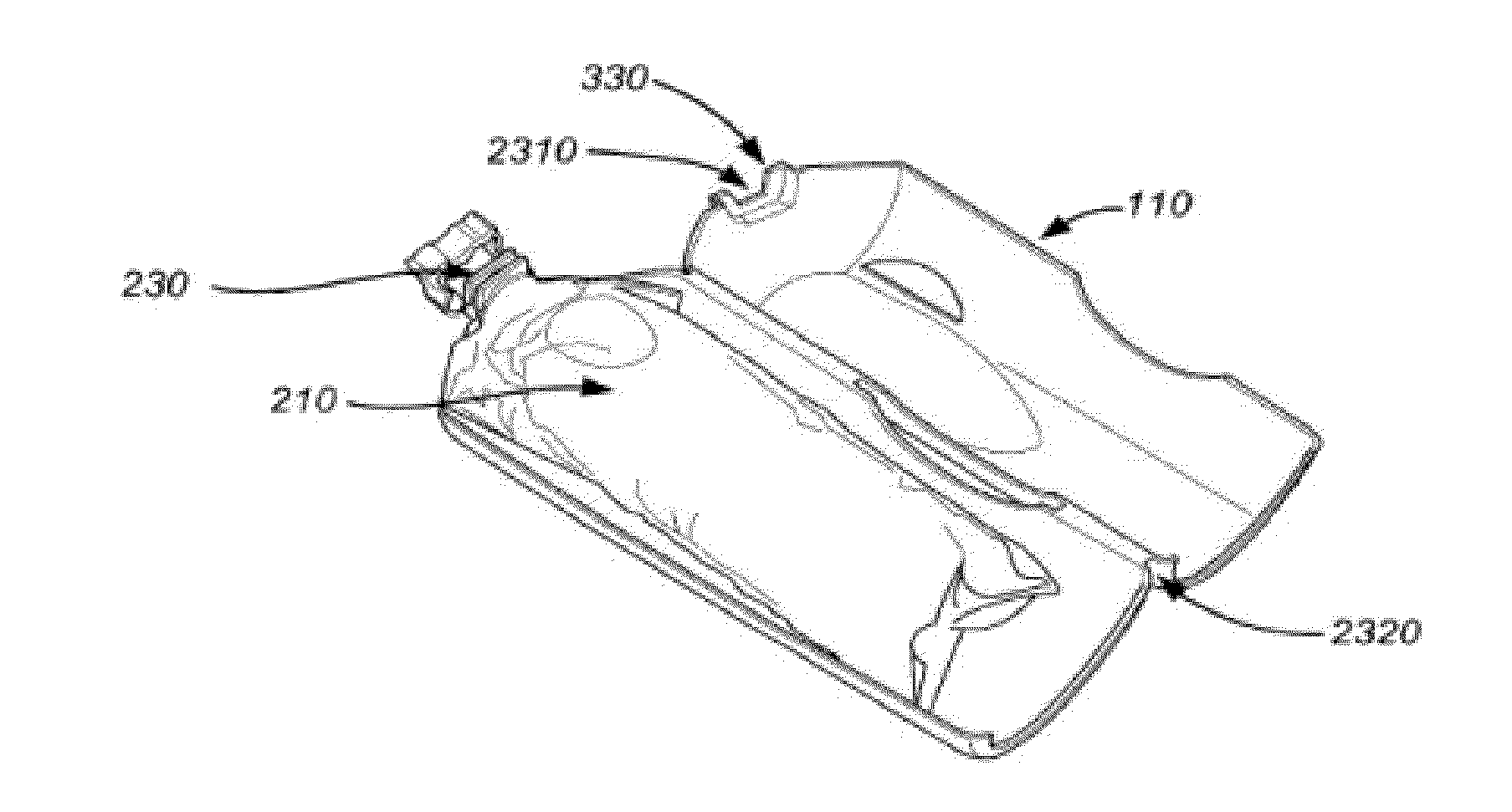

Containers for holding materials

The invention provides for a container that may include a liquid-holding vessel and a skeleton shell supporting the liquid holding vessel. The liquid-holding vessel may comprise a flexible polymer or plastic material for preventing contact between a liquid stored in or dispensed from the container and the skeleton. The liquid-holding vessel and the closure may be formed from a minimal amount of polymer or plastic. The invention also provides for a connection of a liquid-holding vessel with a fitment to the skeleton shell using ultrasonic means. Further, a skeleton shell with mating features allowing the skeleton shell to be formed with smooth edges is provided.

Owner:ECOLOGIC BRANDS INC

Bifurcated beverage can with unified opening and mixing operation

A beverage can having a primary fluid volume and a segregated secondary container. The secondary container could contain a liquid or a granulated solid. The two containers are separated by a barrier which can be opened. The beverage can has a lid with a conventional pull-tab and downward-opening hatch. However, the hatch is equipped with a piercer extending down into the can. When the pull-tab is actuated, the piercer breaches the barrier separating the secondary container from the primary fluid volume. The contents of the secondary container can then be mixed with the primary fluid.

Owner:BOATNER BARRY

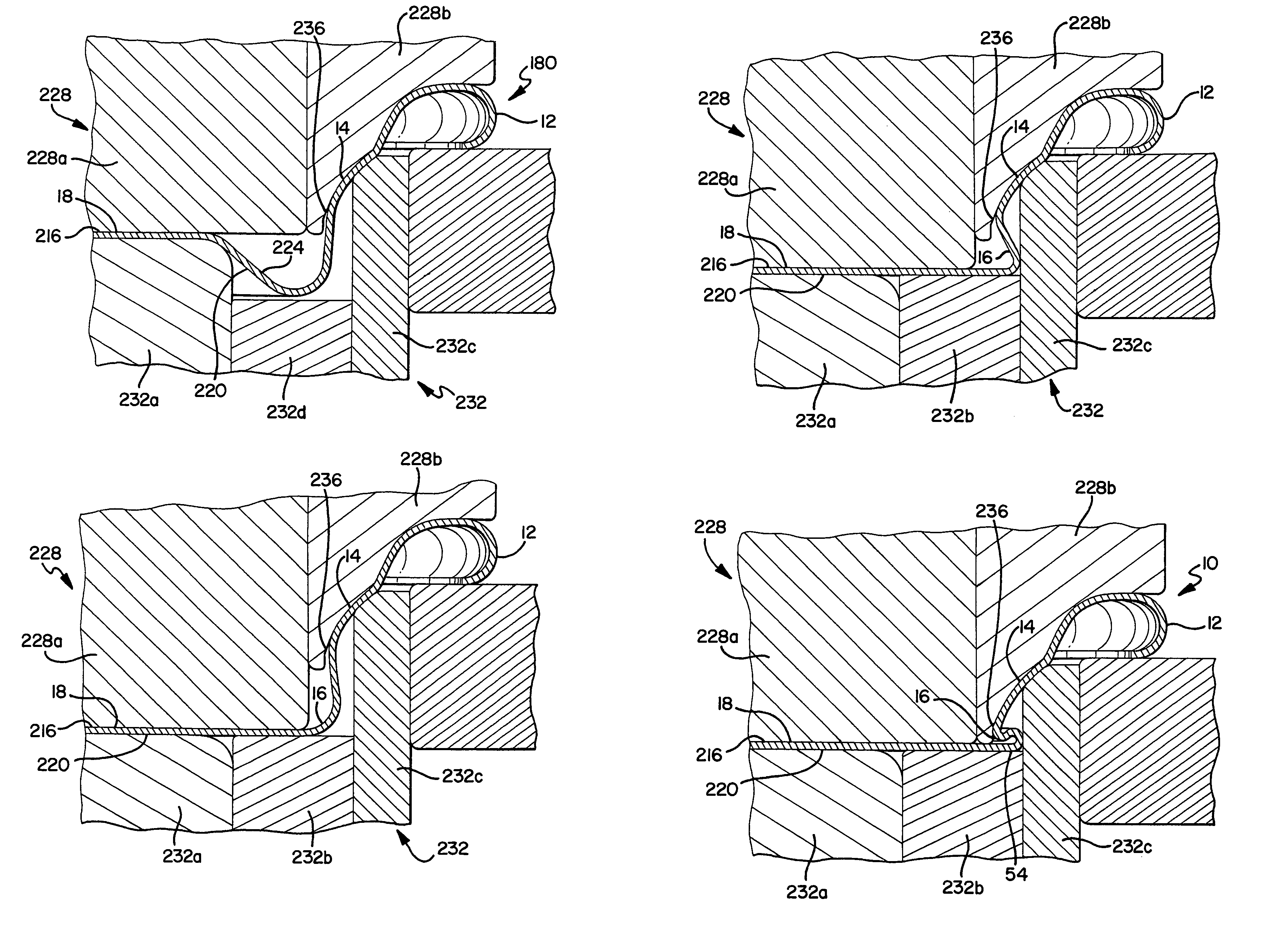

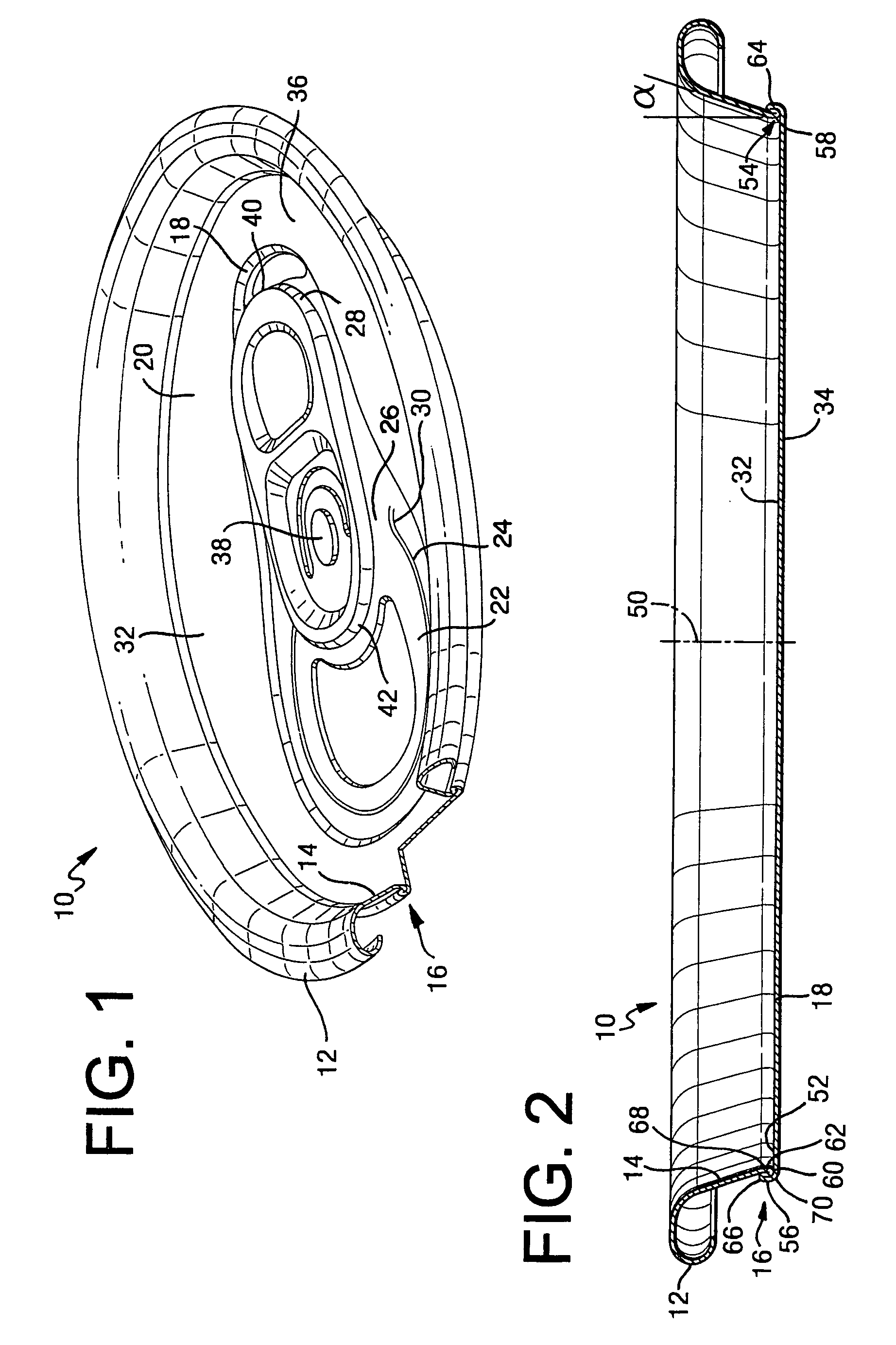

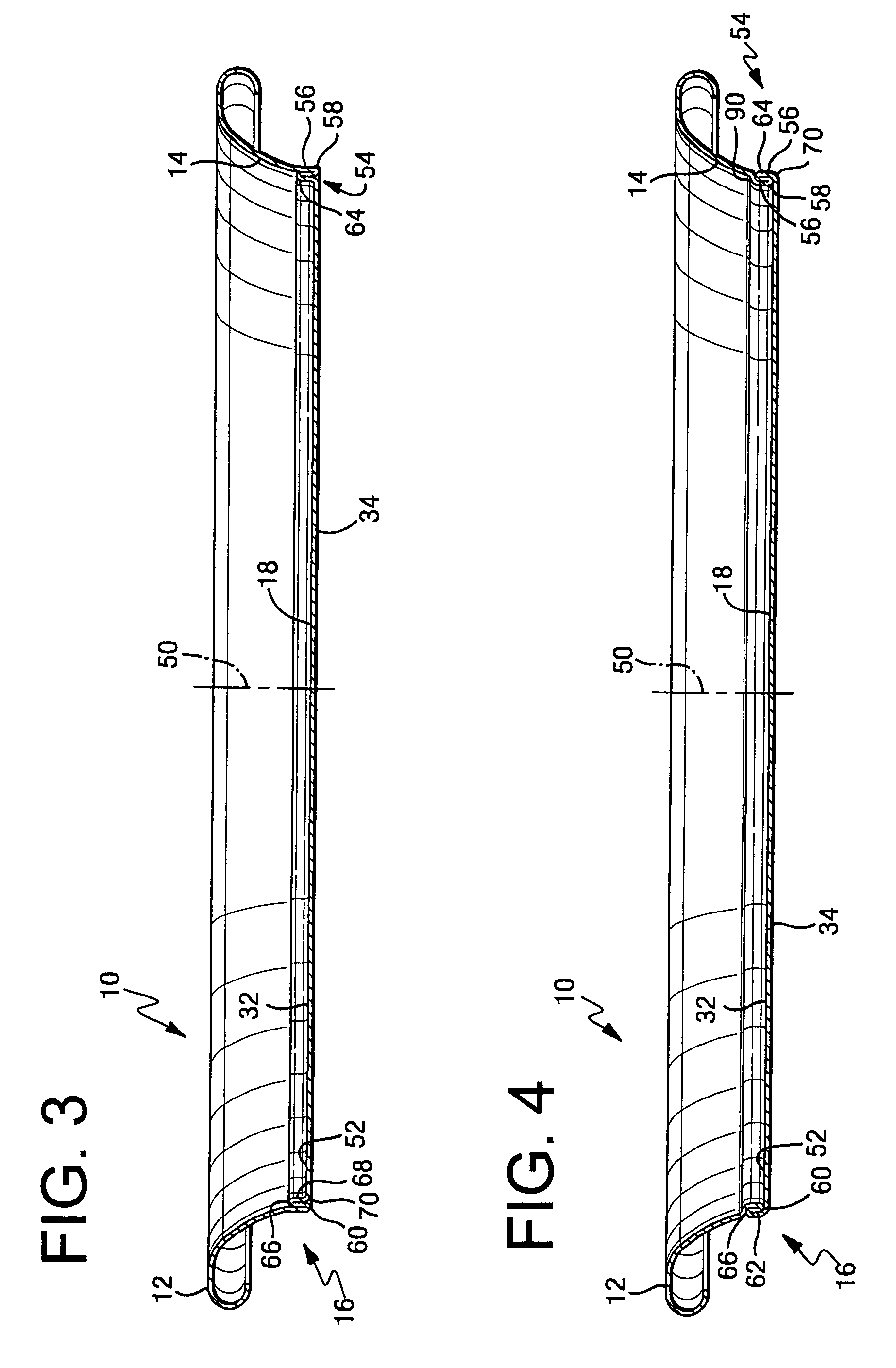

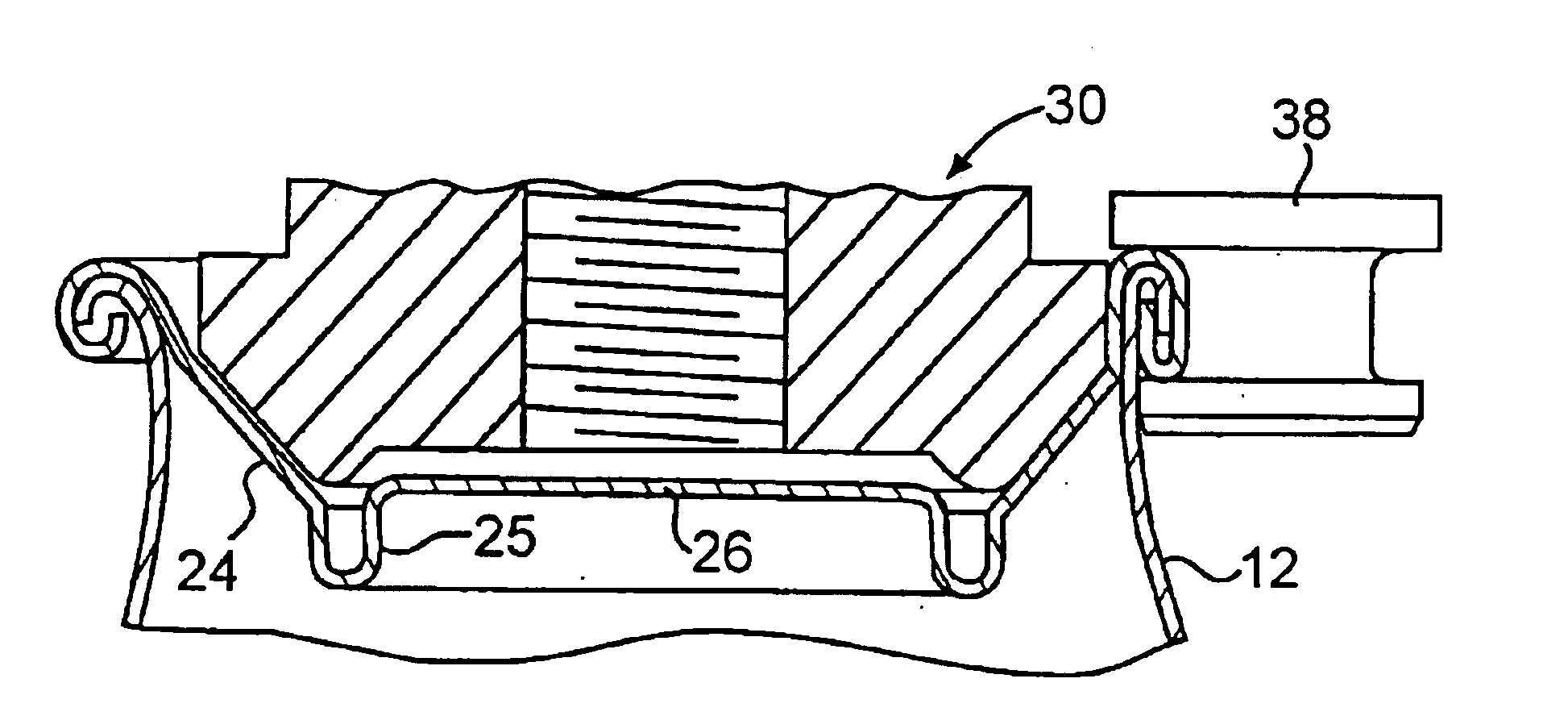

Expanding die and method of shaping containers

The present invention provides an expansion die for manufacturing containers including a work surface including a progressively expanding portion and a land portion; and an undercut portion positioned following the land portion of the work surface. The present invention further provides a process for manufacturing shaped containers including providing a container stock having a first diameter; expanding at least a portion of the container stock to a second diameter with at least one expansion die; and forming an end of the container stock to accept a container lid.

Owner:ALCOA CORP CENT +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com