Expanding die and method of shaping containers

a beverage container and expansion die technology, applied in the direction of shaping tools, manufacturing tools, other domestic articles, etc., can solve the problems of increasing the manufacturing time and hence the cost associated with producing beverage containers, the container body cannot be easily incorporated into the inline process, and the transition is not adequately discriminated or differentiated. , to achieve the effect of uniform diameter and minimal transition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

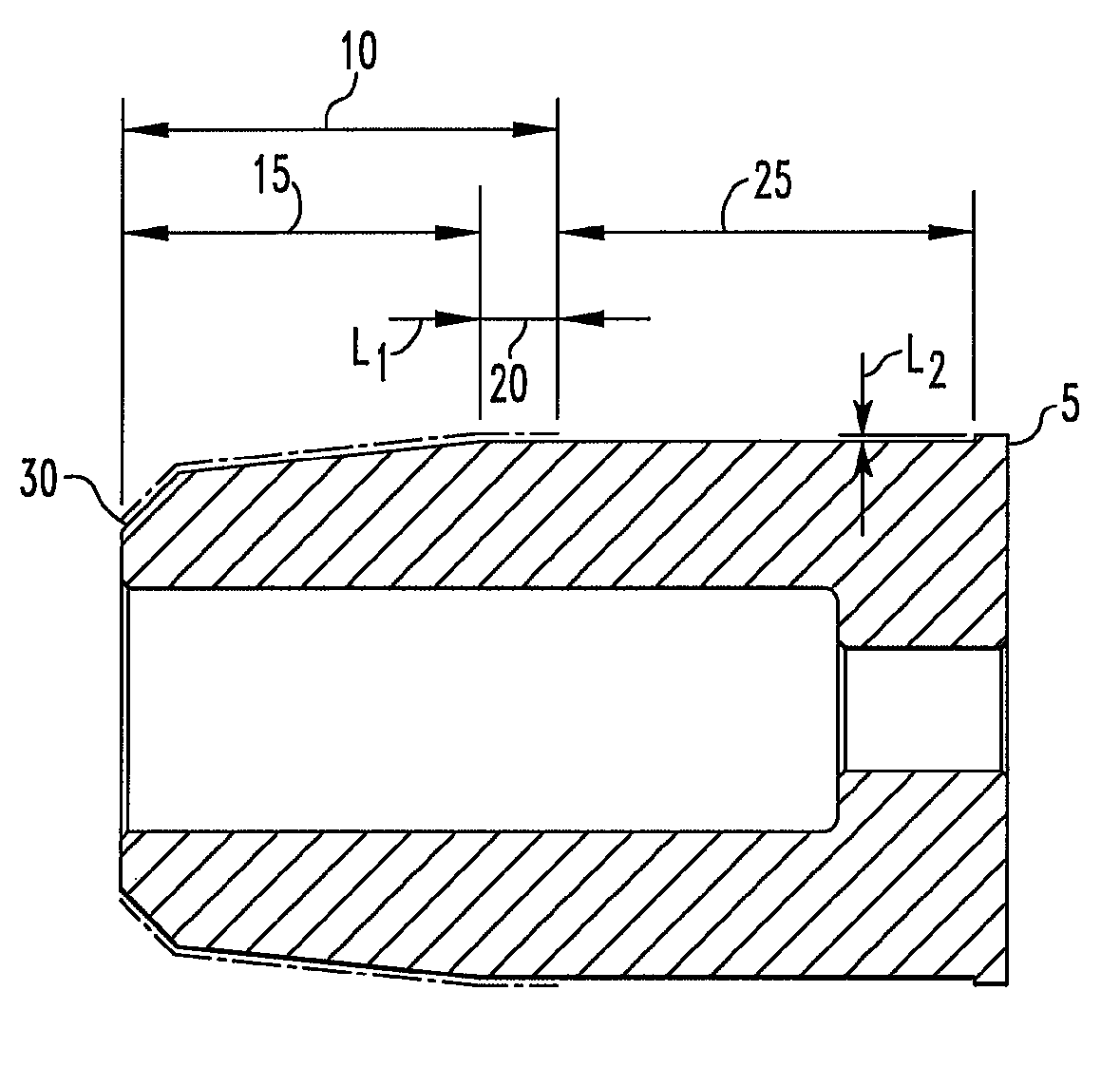

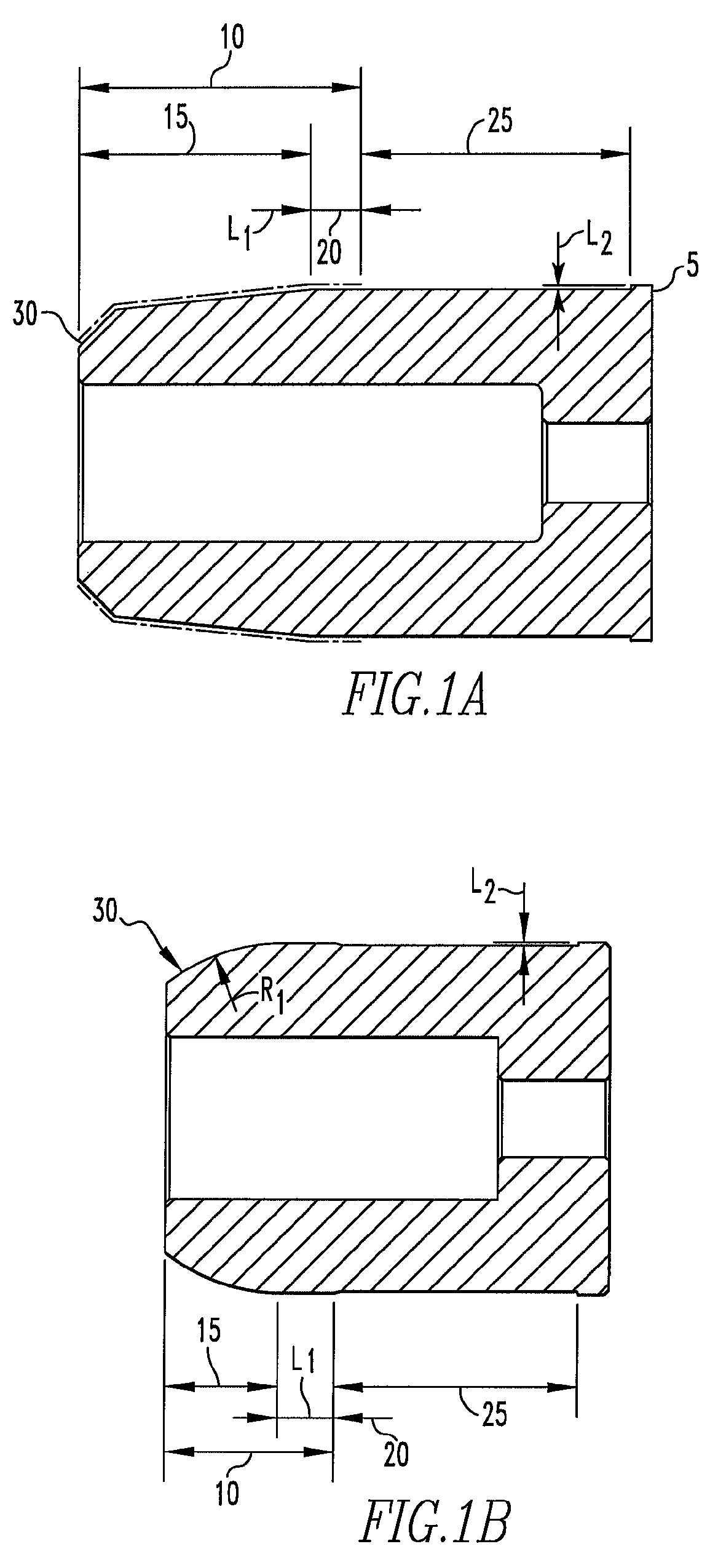

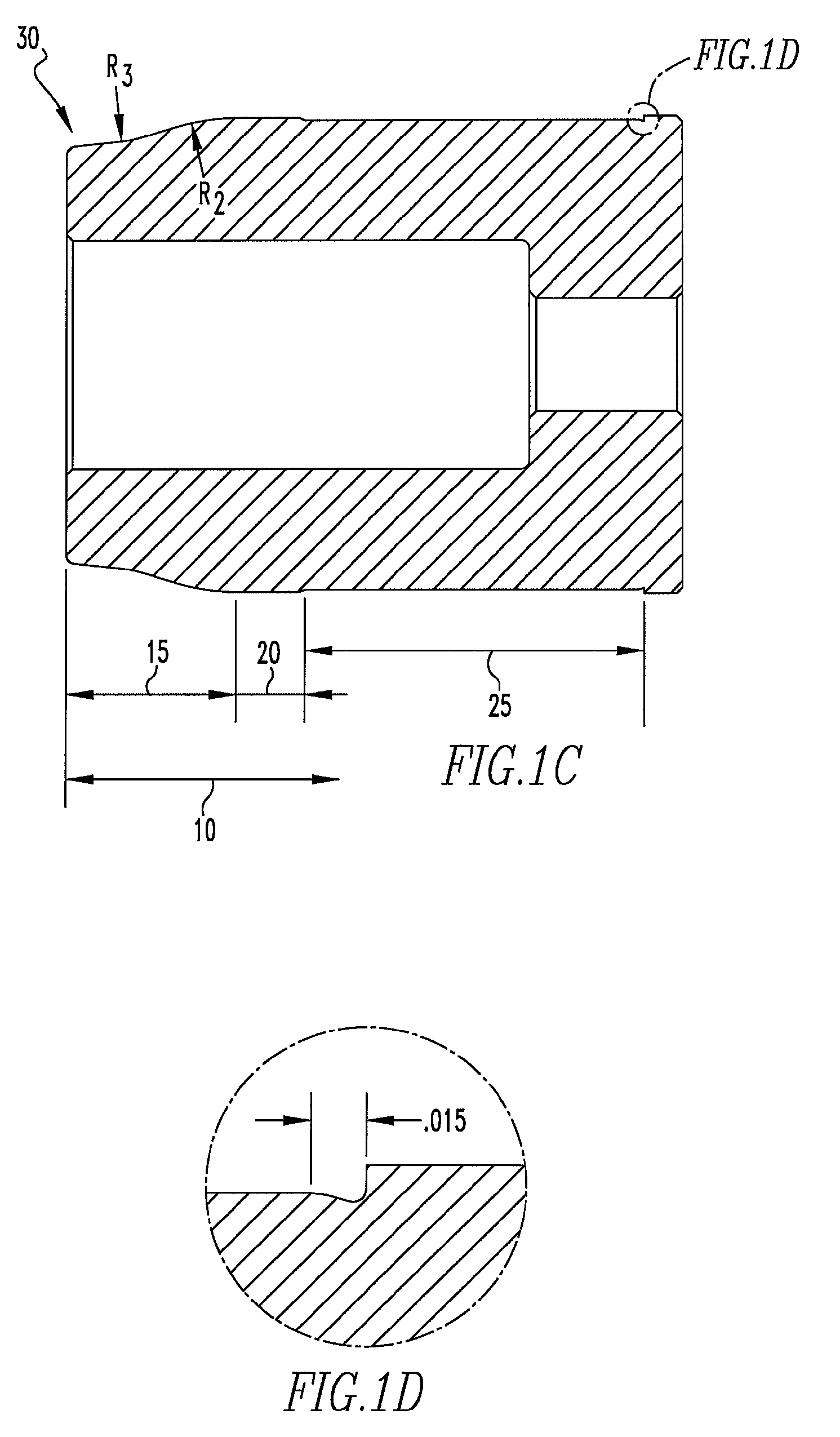

Image

Examples

example 1

Expansion of 2.069″ Internal Diameter

[0047]A five die expansion system was utilized to expand the diameter of a portion of a container stock having a 0.0088 inch thick sidewall of Aluminum Association (AA) 3104 from an original internal diameter of 2.069″ to a final internal diameter on the order of 2.615″. The expansion represents an increase of approximately 24% in the container stock's diameter without the formation of Lueder's lines or metal tears. The first expansion die providing an expansion of approximately 9%; the second and third expansion die each providing an expansion of approximately 4.5%; and a fourth and fifth expansion die each providing an expansion of approximately 3.0%.

example 2

Expansion of 2.603″ Internal Diameter

[0048]A three die expansion system was utilized to expand the diameter of a portion of the container stock of a 211 can having a 0.0056 inch thick sidewall of Aluminum Association (AA) 3104 from an original internal diameter of 2.603″ to a final internal diameter on the order of 2.860″. In each of the three expansion die the degree of expansion increased by 3% per expansion step.

PUM

| Property | Measurement | Unit |

|---|---|---|

| outer diameter | aaaaa | aaaaa |

| internal diameter | aaaaa | aaaaa |

| internal diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com