Patents

Literature

184 results about "Undercut" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

In manufacturing, an undercut is a special type of recessed surface that is inaccessible using a straight tool. In turning, it refers to a recess in a diameter generally on the inside diameter of the part. In milling, it refers to a feature which is not visible when the part is viewed from the spindle. In molding, it refers to a feature that cannot be molded using only a single pull mold. In printed circuit board construction, it refers to the portion of the copper that is etched away under the photoresist. In welding, it refers to undesired melting and removal of metal near the weld bead.

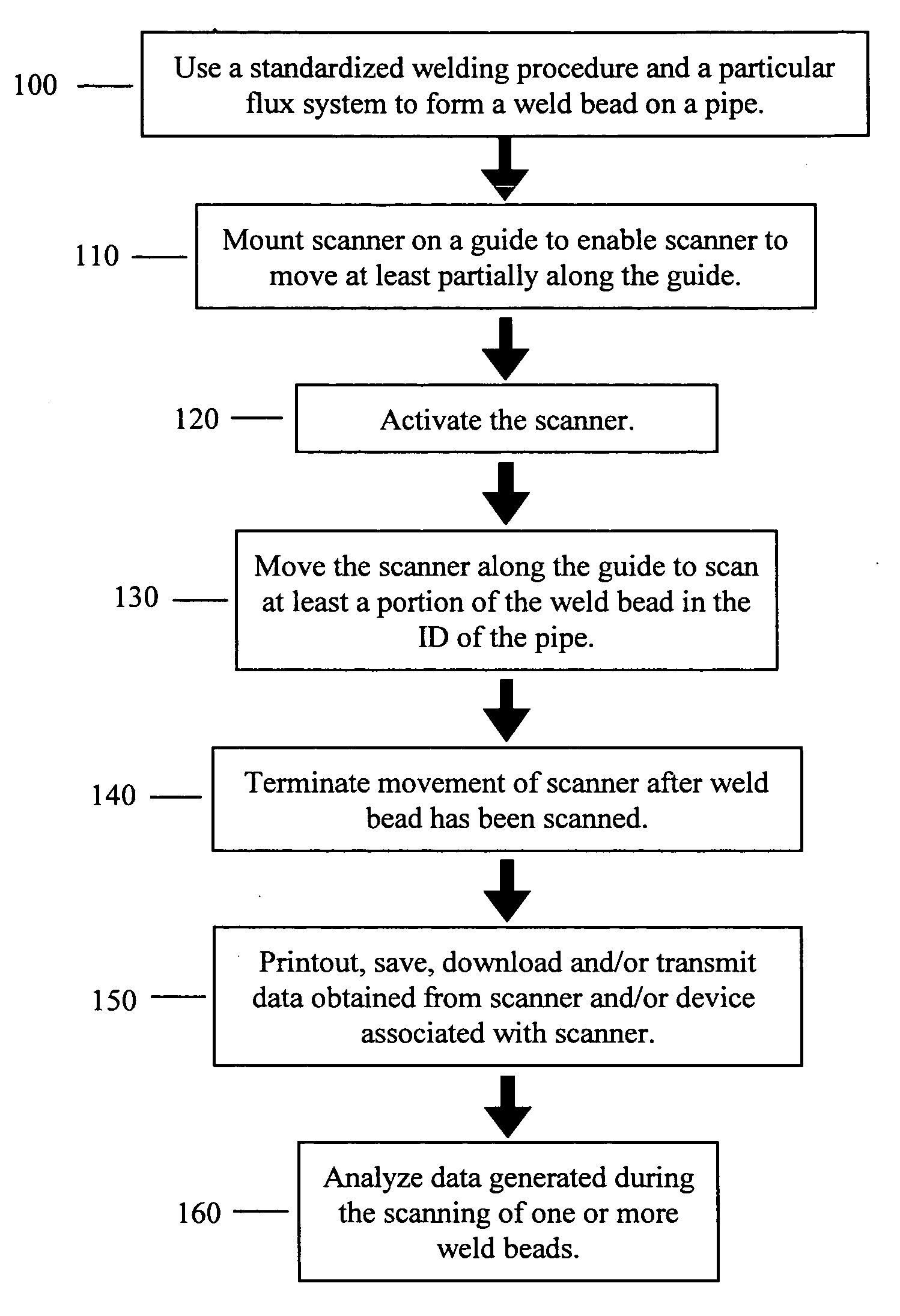

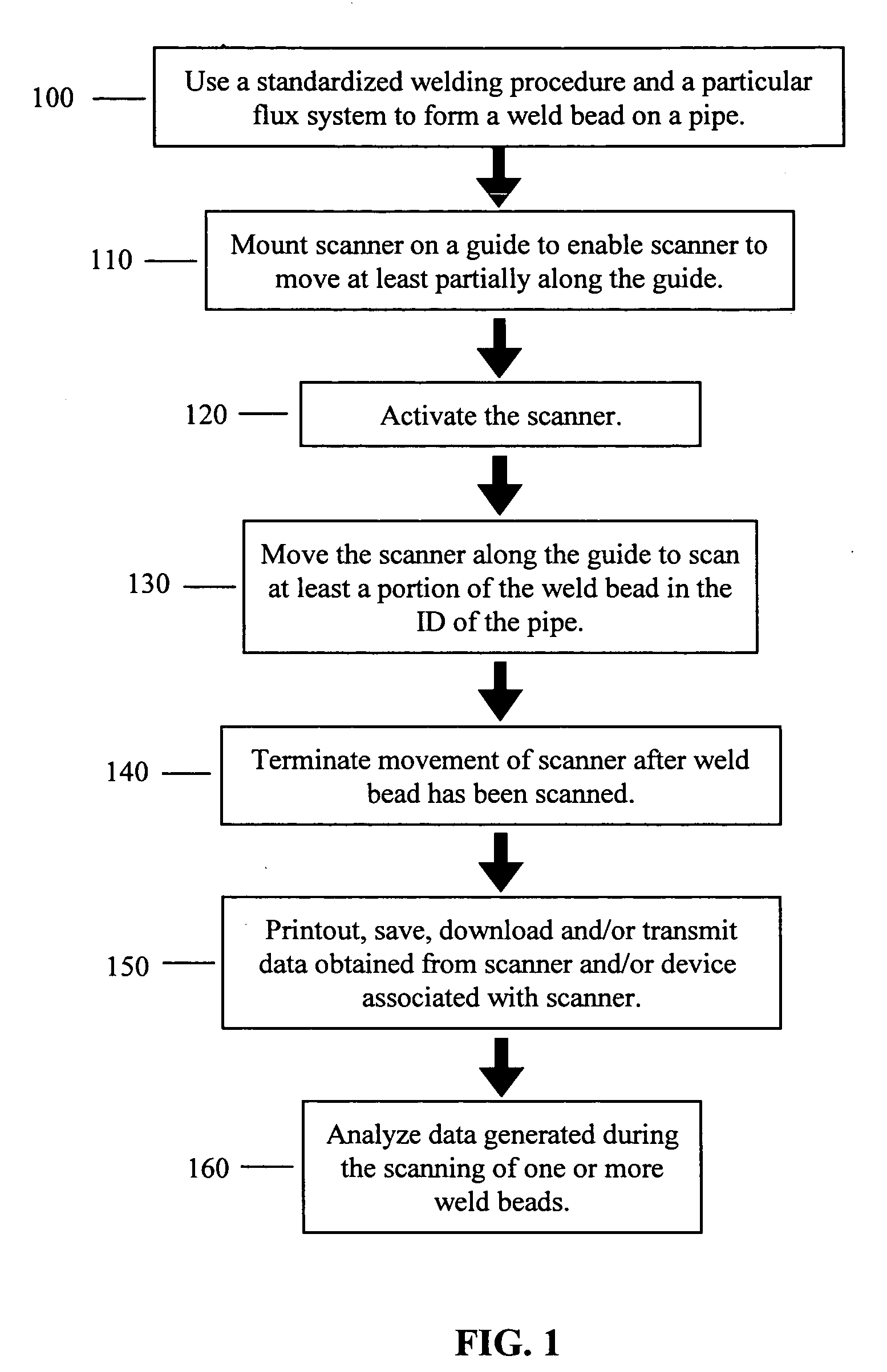

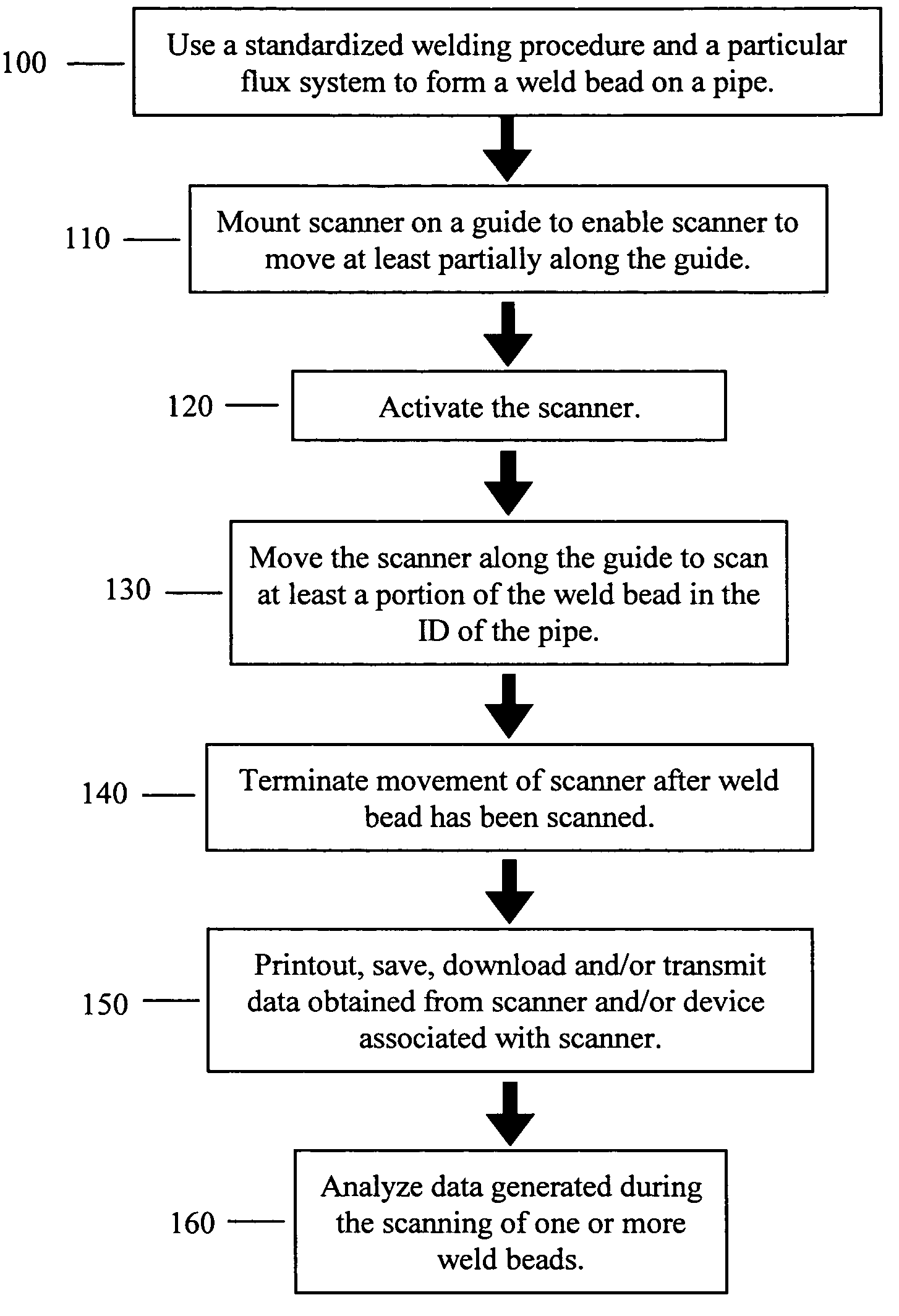

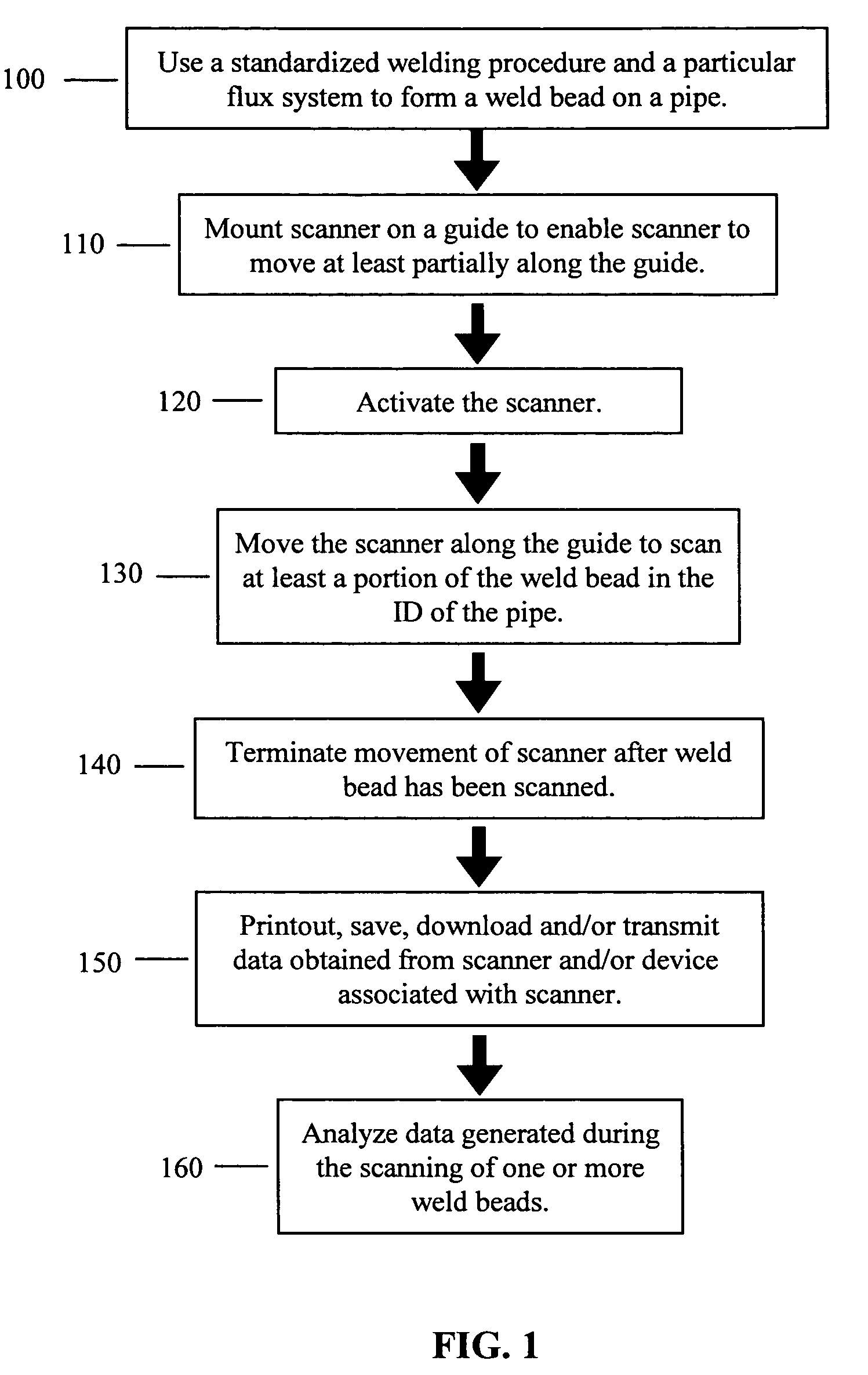

Method for testing undercut on the inner diameter of pipe welds

InactiveUS20070278196A1Reduce and eliminate needArc welding apparatusMetal working apparatusEngineeringElectrical and Electronics engineering

Owner:LINCOLN GLOBAL INC

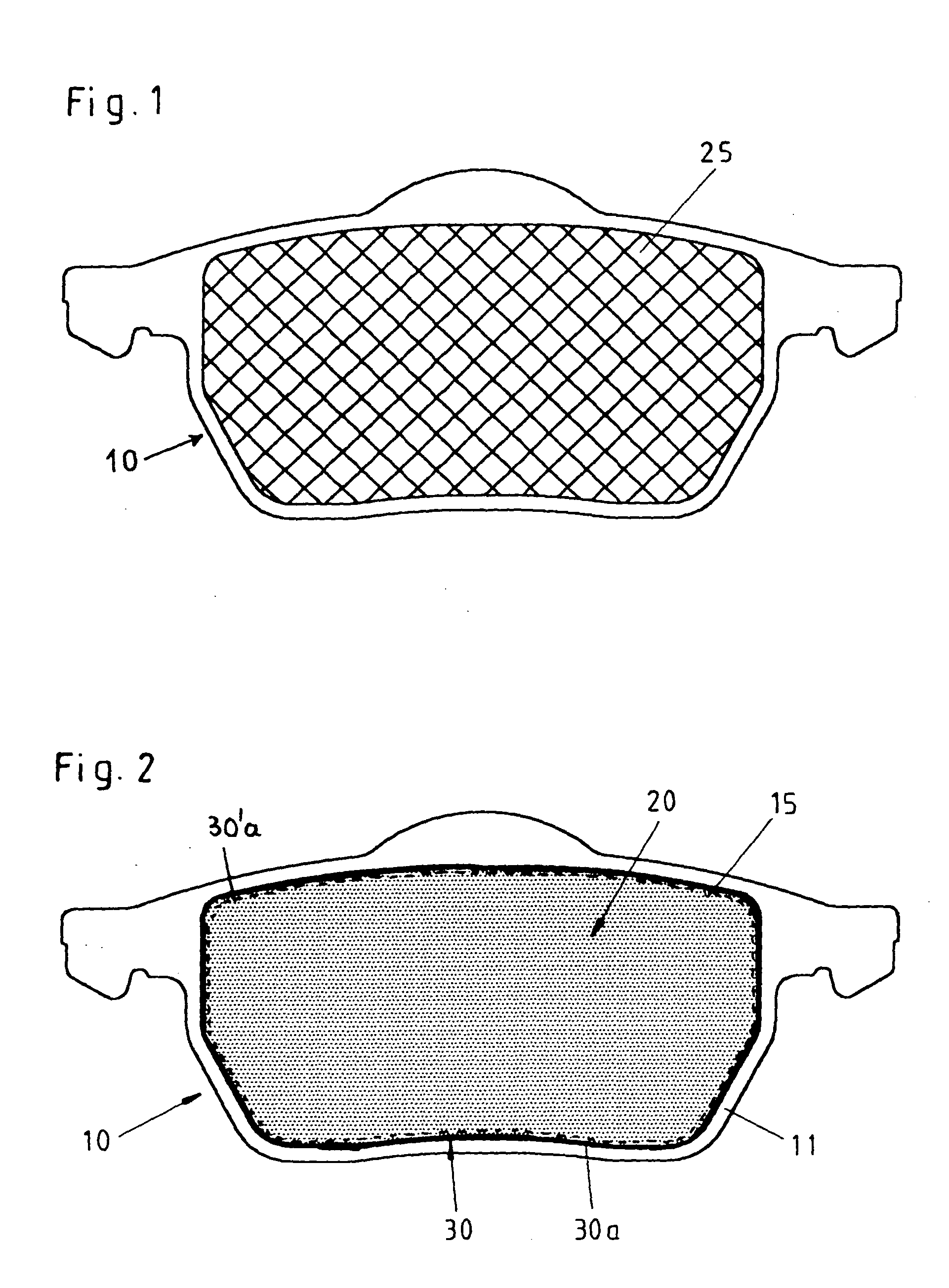

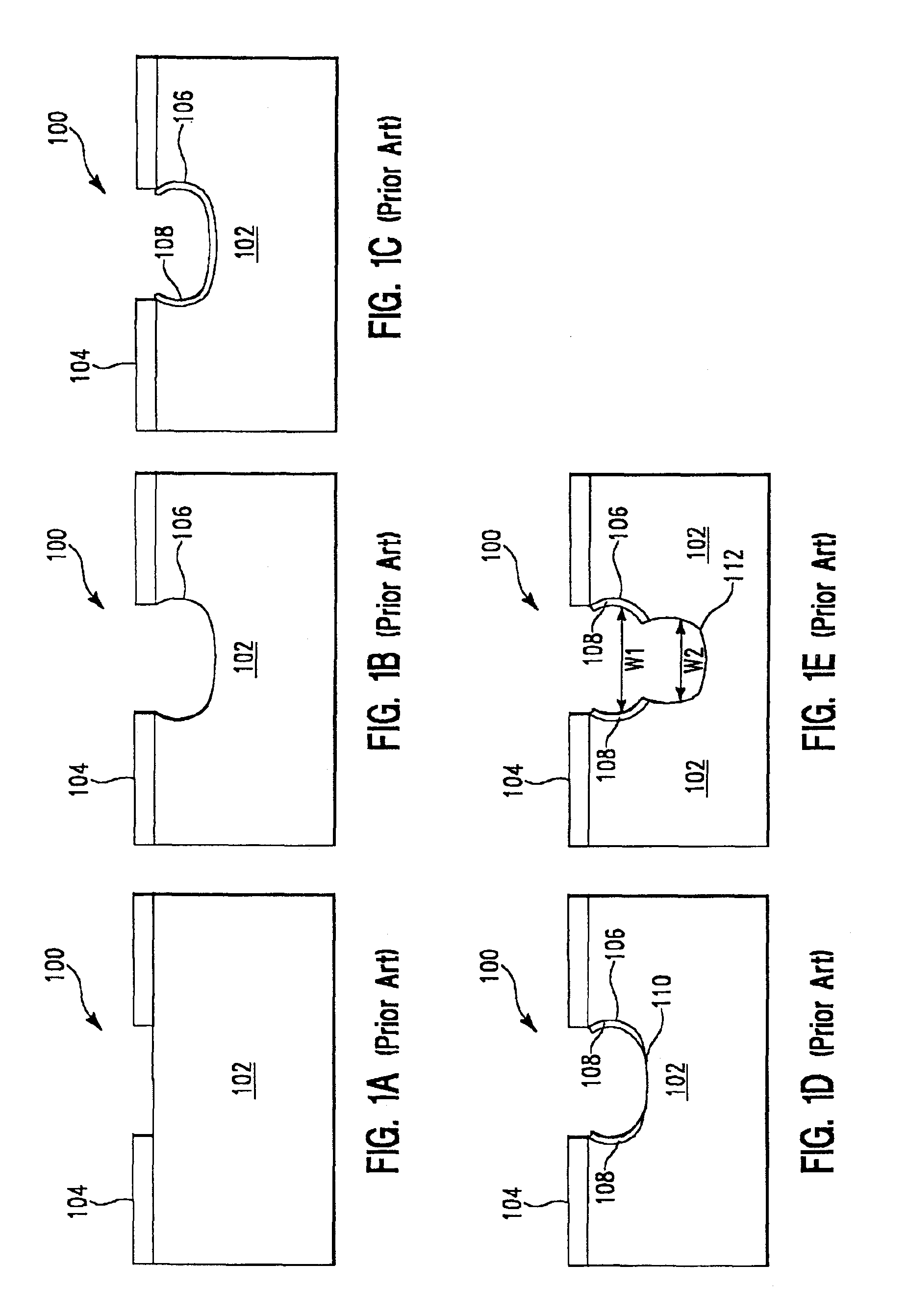

Damascene patterning of barrier layer metal for C4 solder bumps

InactiveUS20060016861A1Reduce the amount presentReduce spacingPrinted circuit assemblingSemiconductor/solid-state device detailsEtchingCopper

A system and method for forming a novel C4 solder bump for BLM (Ball Limiting Metallurgy) includes a novel damascene technique is implemented to eliminate the Cu undercut problem and improve the C4 pitch. In the process, a barrier layer metal stack is deposited above a metal pad layer. A top layer of the barrier layer metals (e.g., Cu) is patterned by CMP. Only bottom layers of the barrier metal stack are patterned by a wet etching. The wet etch time for the Cu-based metals is greatly reduced resulting in a reduced undercut. This allows the pitch of the C4 solder bumps to be reduced. An alternate method includes use of multiple vias at the solder bump terminal.

Owner:GLOBALFOUNDRIES INC

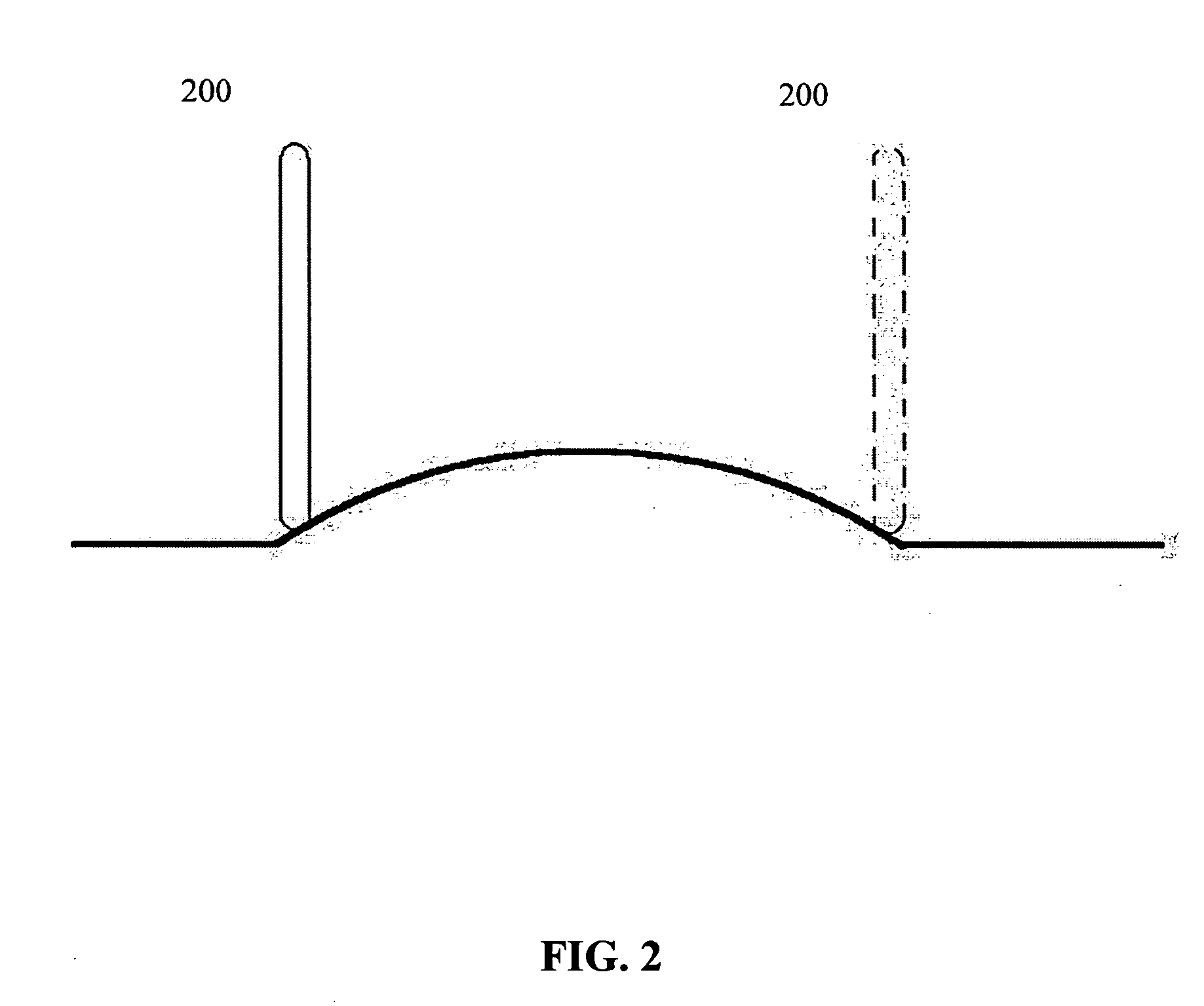

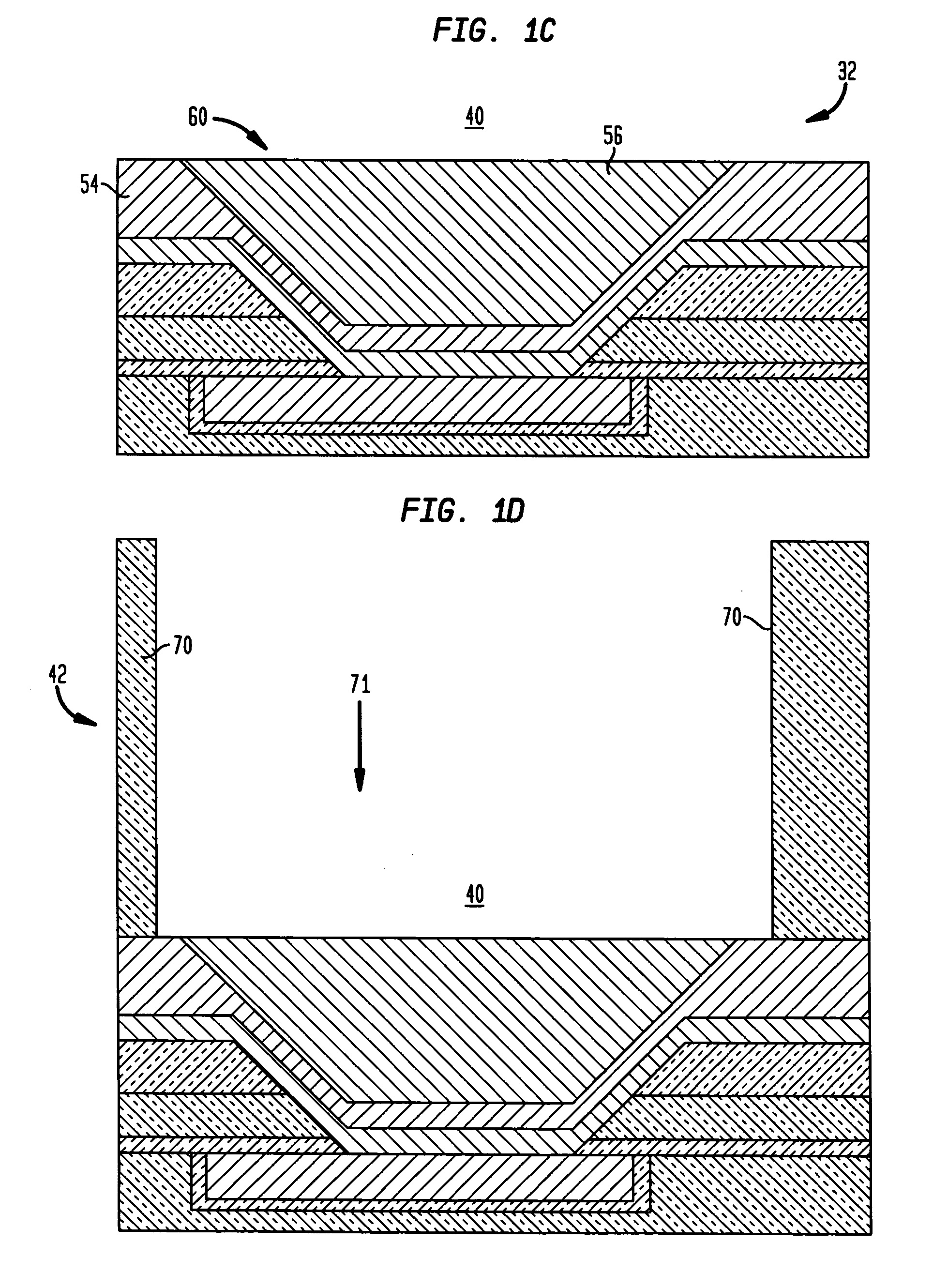

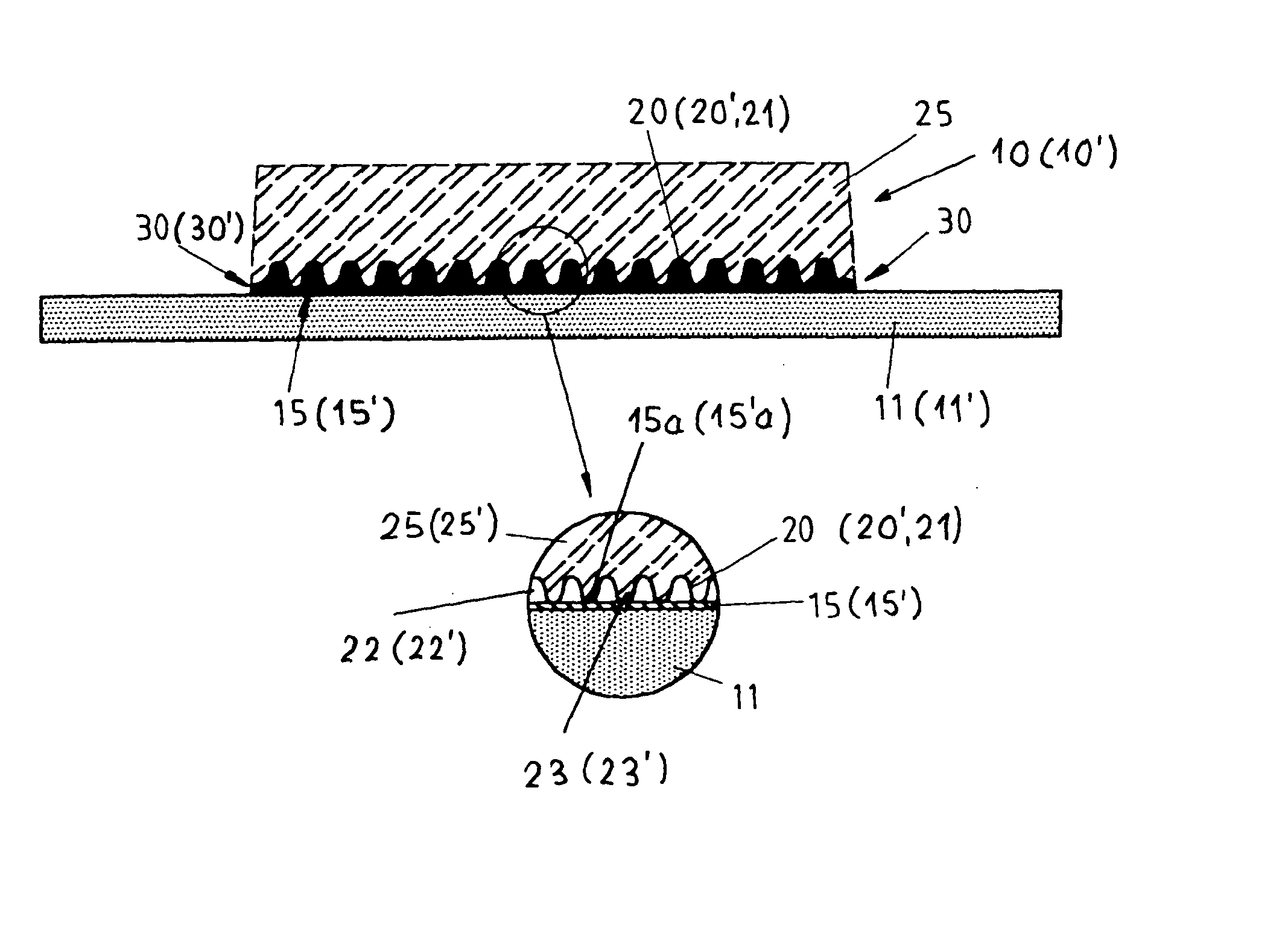

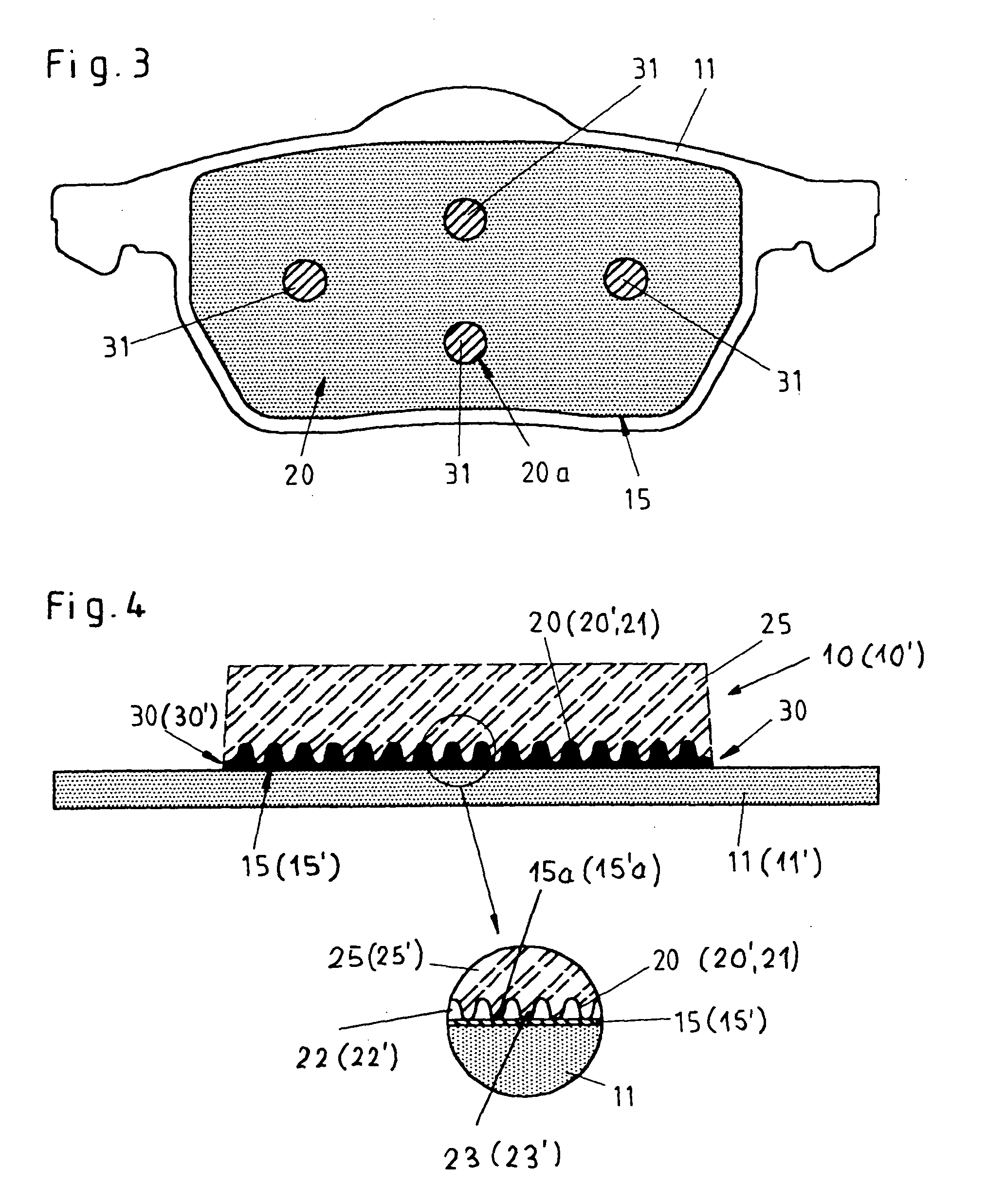

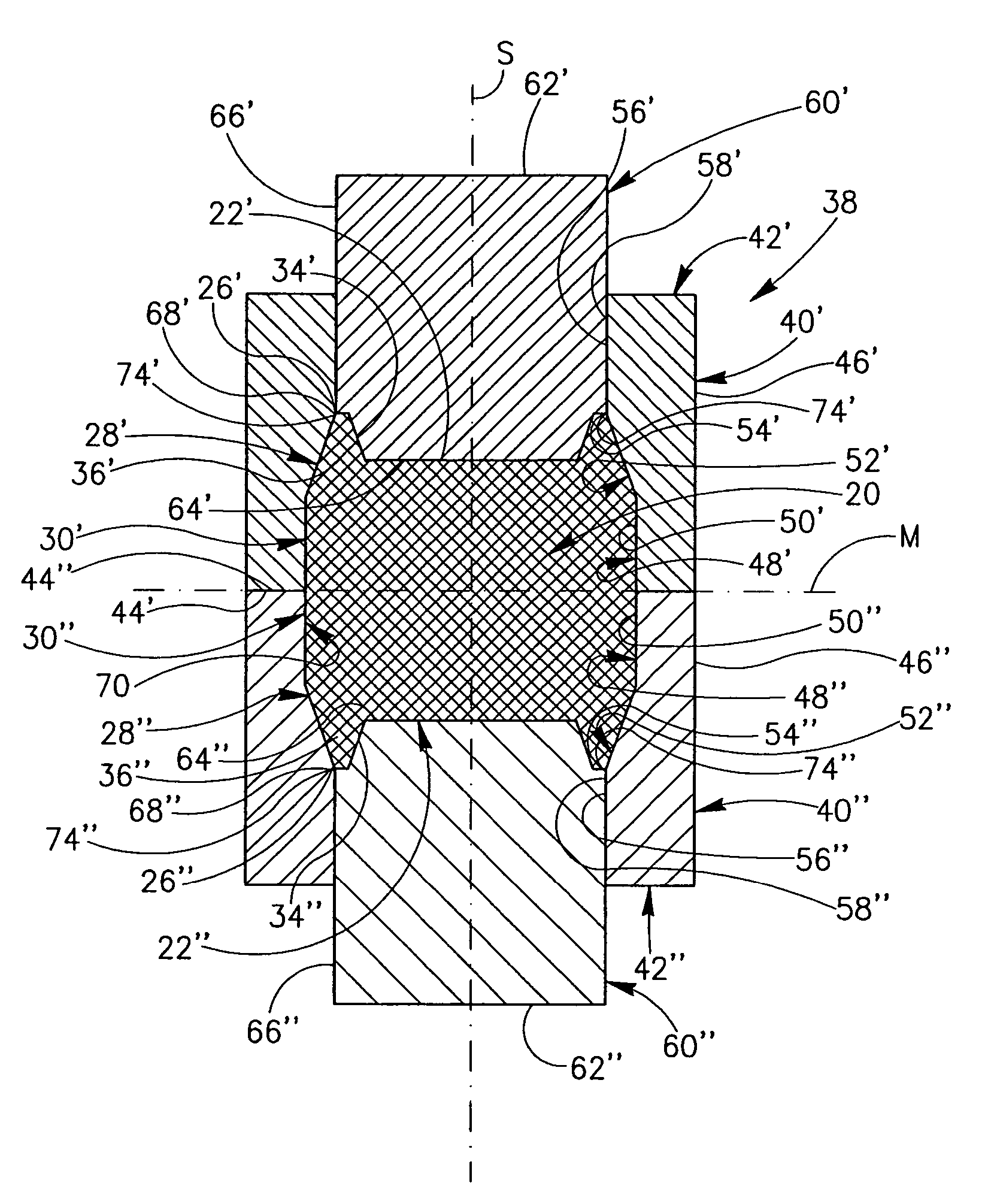

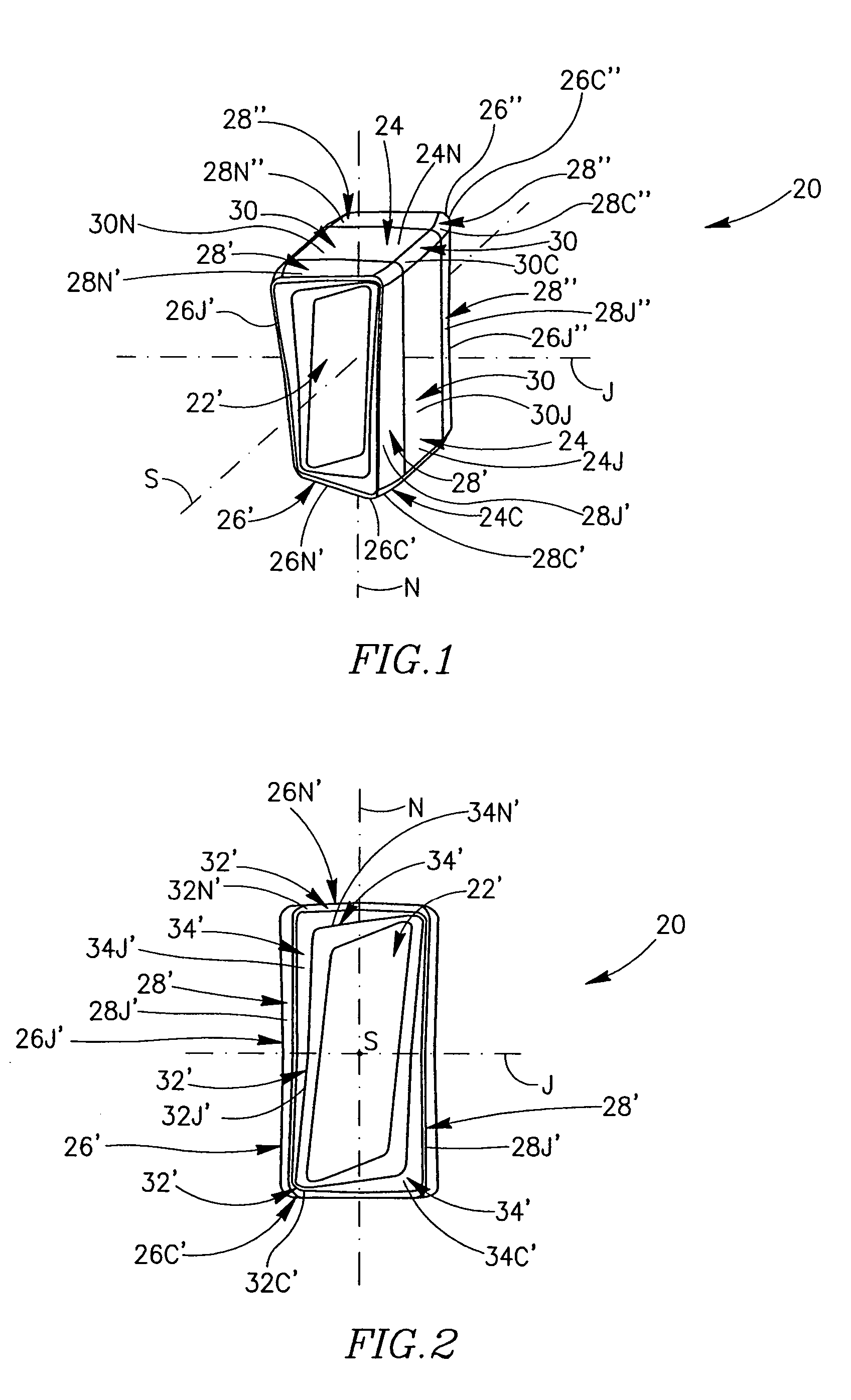

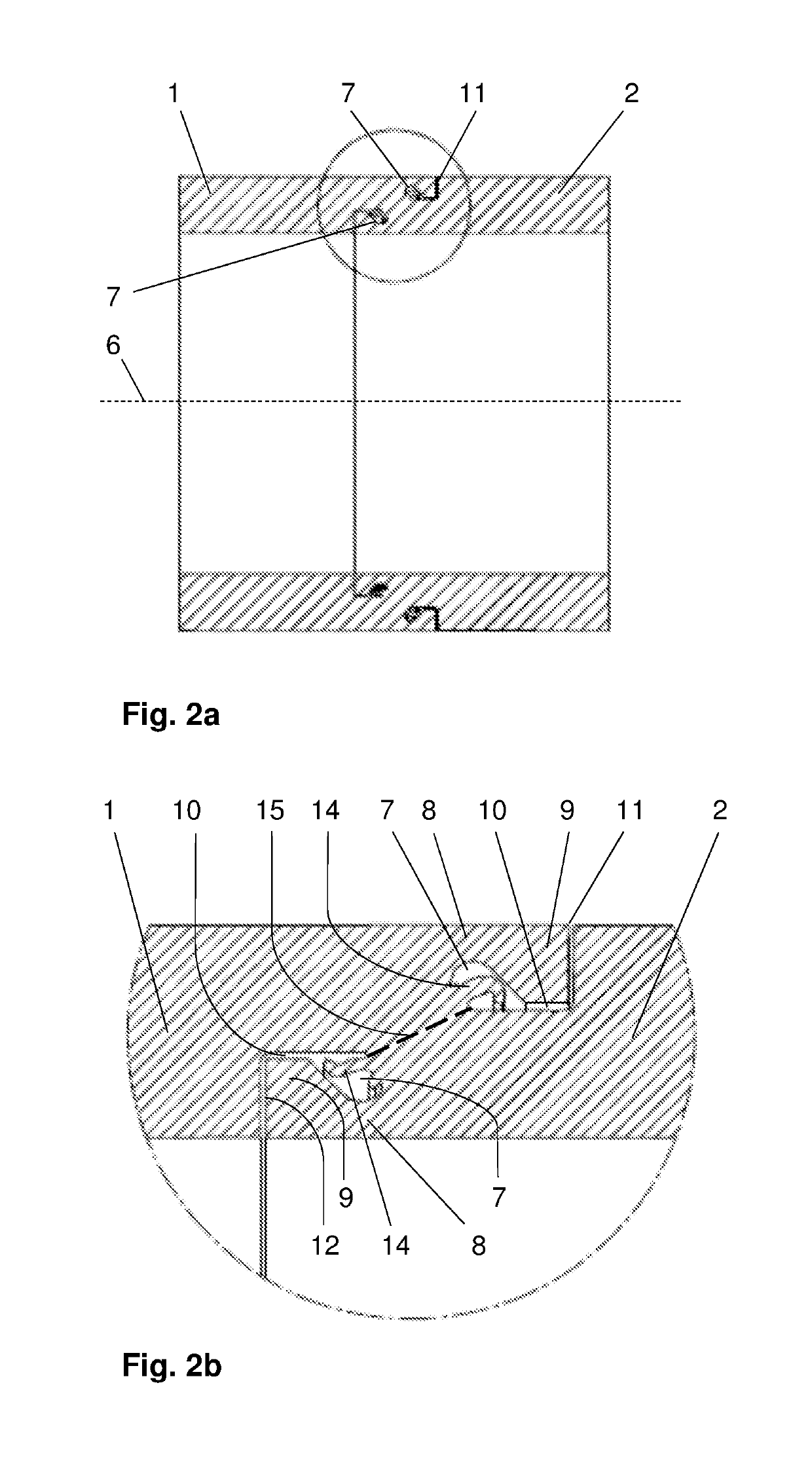

Lining, in particular friction lining for disc brakes

InactiveUS20040099493A1Improve strength propertiesMaintain propertiesNoise/vibration controlFriction liningSynthetic materialsMetal sheet

The lining or functional body (10) consists a carrier (11) in form of a ground plate, for example a carrier plate or a carrier sheet, of a thin-walled rough ground carrier (15; 15') made of a metal sheet or of another appropriate material placed on the carrier (11; 11'), of a rough ground (20') made of a support base (20; 20'; 21) sintered on the surface (15a; 15'a) of the rough ground carrier (15; 15') which is turned away from the lining carrier (11; 11'), this support base being made of single moulded bodies (22') with undercuts, recesses or the like which are positively and frictionally connected with the rough ground carrier (15; 15'), and of a functional block (25; 25') fixed on the rough ground carrier (15; 15') with the rough ground (20'), this functional block being made of a friction material, a synthetic material, in particular of such a synthetic material which is not appropriate to be glued together or to be applied in another manner, for example of a polymer or teflon, whereby the rough ground carrier (15; 15') is fixed on the lining carrier (11; 11') by means of a welded, riveted or glued joint (30; 30') or other connecting procedures, such as engraving.

Owner:HONEYWELL BREMSBELAG GMBH

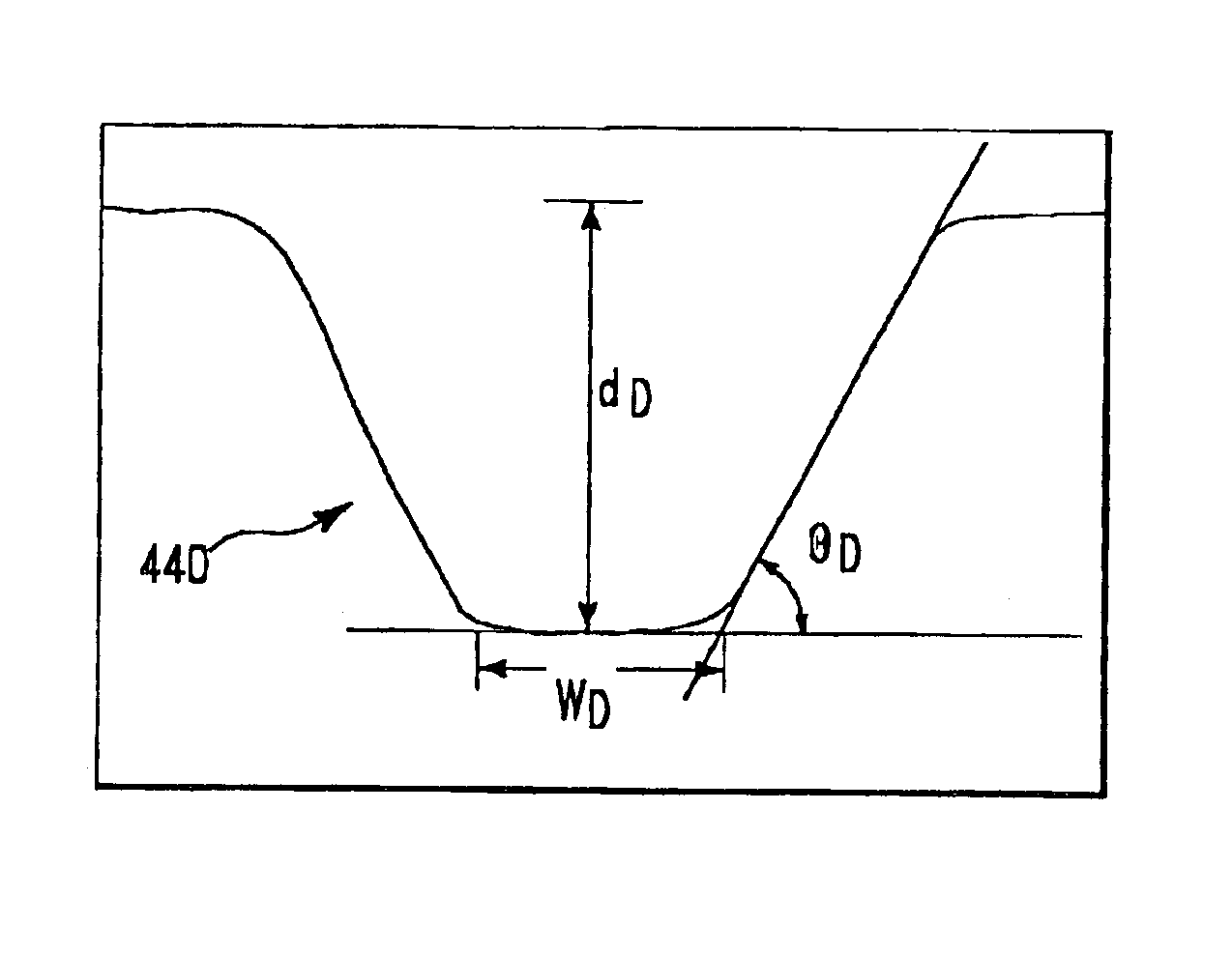

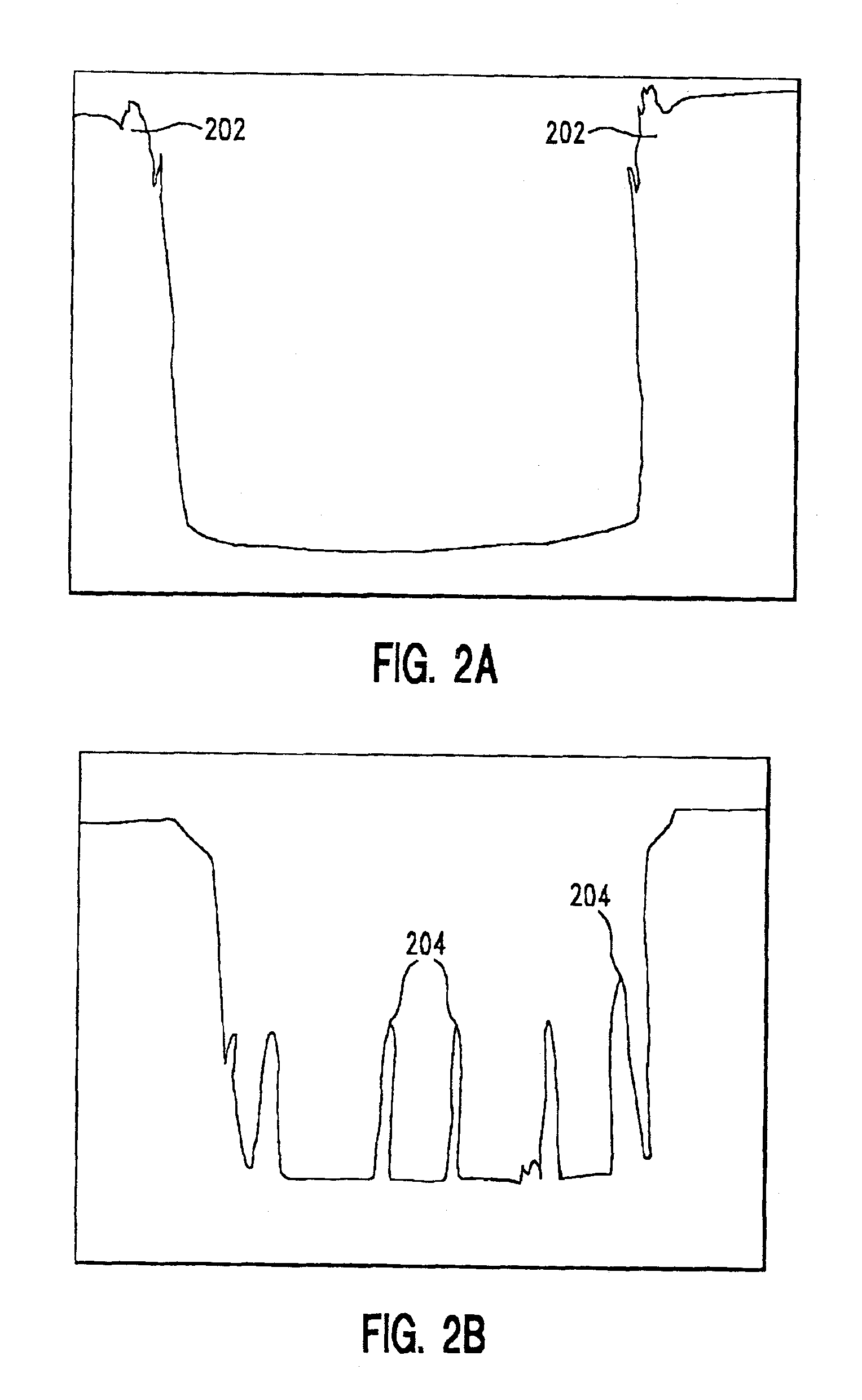

Method of etching a deep trench having a tapered profile in silicon

InactiveUS6849554B2Improve isotropyImprove pressure resistanceDecorative surface effectsSemiconductor/solid-state device manufacturingEtchingEngineering

Disclosed herein is a method of etching deep trenches in a substrate which utilizes the overlying mask structure to achieve a trench having a positive tapered sidewall angle of less than about 88°. The method employs the successive etching of a lateral undercut in the substrate beneath a masking material, while at the same time etching vertically downward beneath the mask. The coordinated widening of the lateral undercut at the top of the trench, while vertically extending the depth of the trench, is designed to provide the desired trench sidewall taper angle.

Owner:APPLIED MATERIALS INC

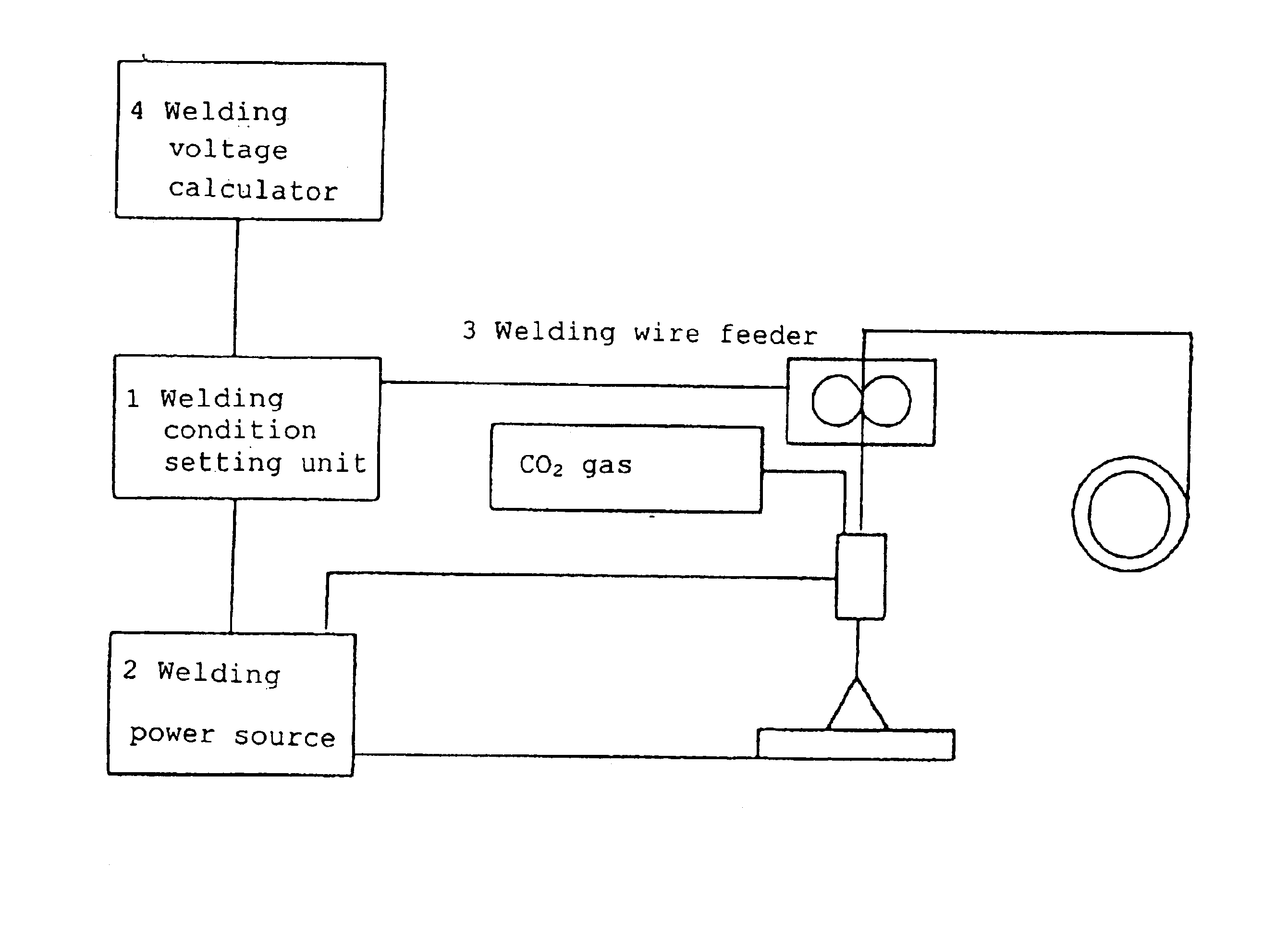

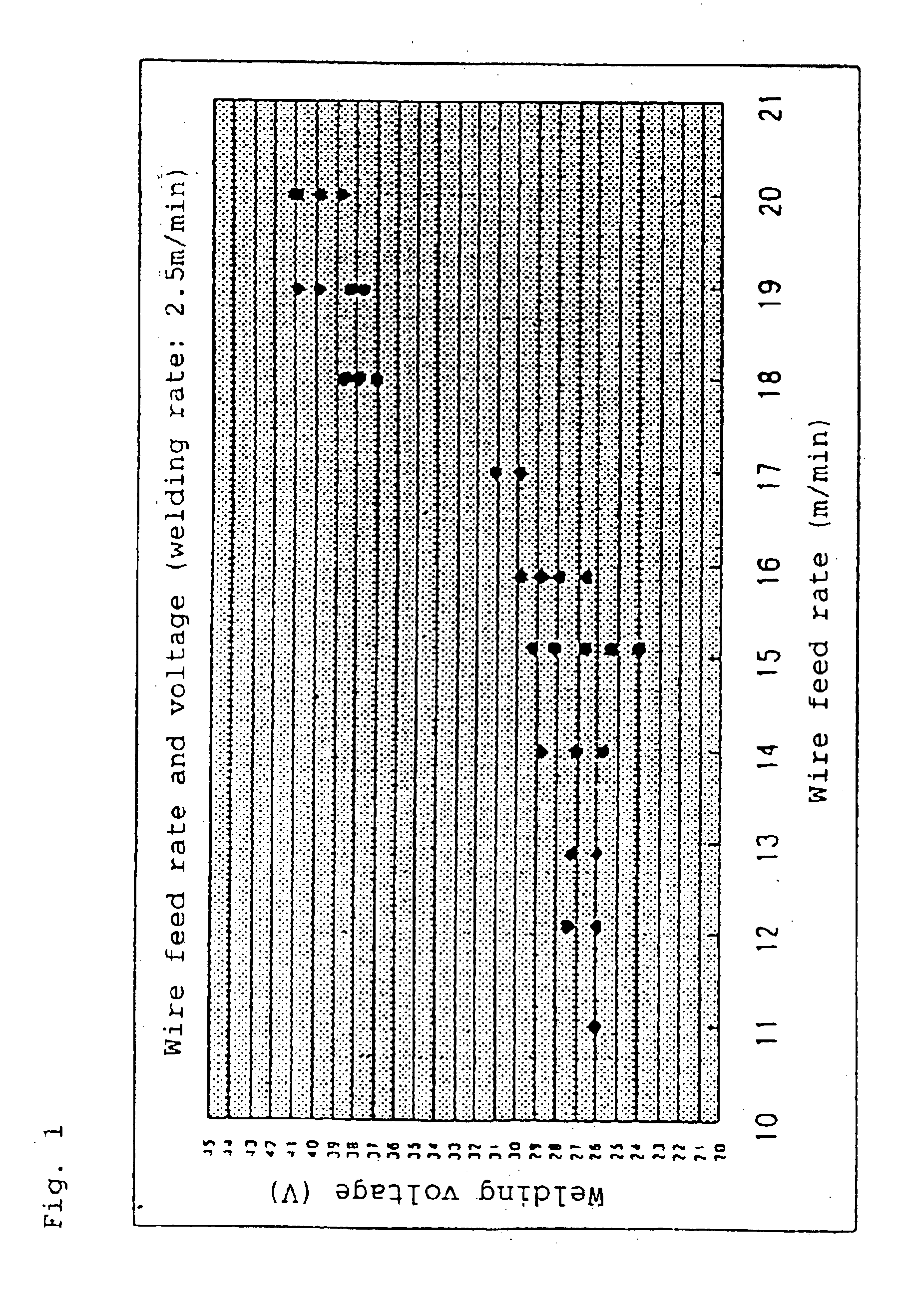

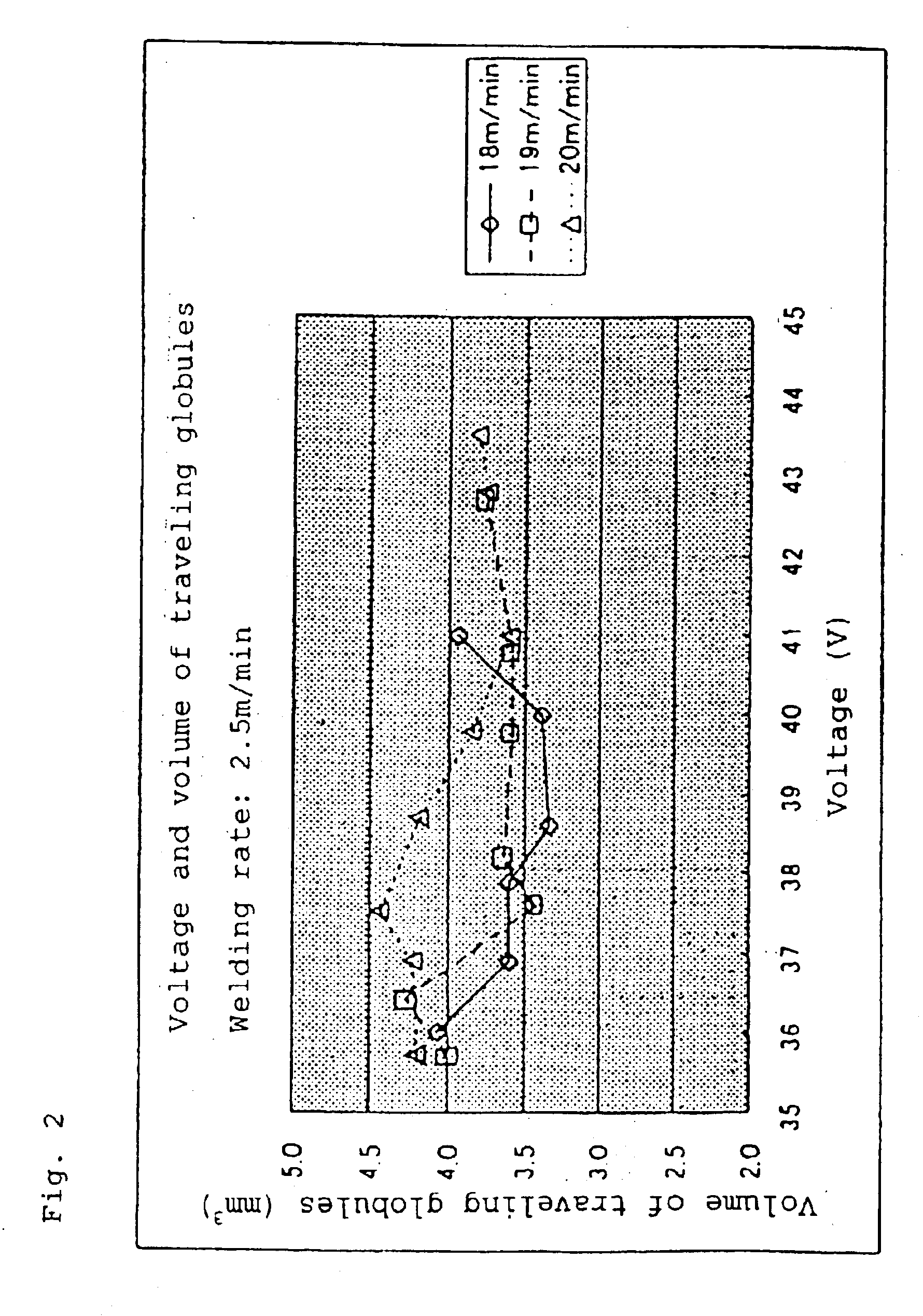

High speed carbon dioxide gas welding method

An arc welding method which suppresses sputtering and which makes it possible to obtain a smooth bead penetration surface shape as in MIG or MAG welding, without producing undercuts or bumping beads. A carbon dioxide gas welding method effecting welding at welding rates of about not less than 1.5 m / minute using a consumable electrode and a welding power source having a control means for opening a short circuit at a rate of at least about 500 A / msec on detection of such short circuit, wherein welding is effected with a proper volume of globules under the welding conditions obtained by computing a welding voltage corresponding to the proper volume of globules by a first formula representing the relationship between the welding wire feed rate, the welding voltage and the volume of globules traveling to a pond of weld as the welding wire is melting and a second formula representing the relationship between the wire feed rate, the welding voltage, and the period of globules traveling to a pond of weld as the welding wire is melting.

Owner:YASKAWA DENKI KK

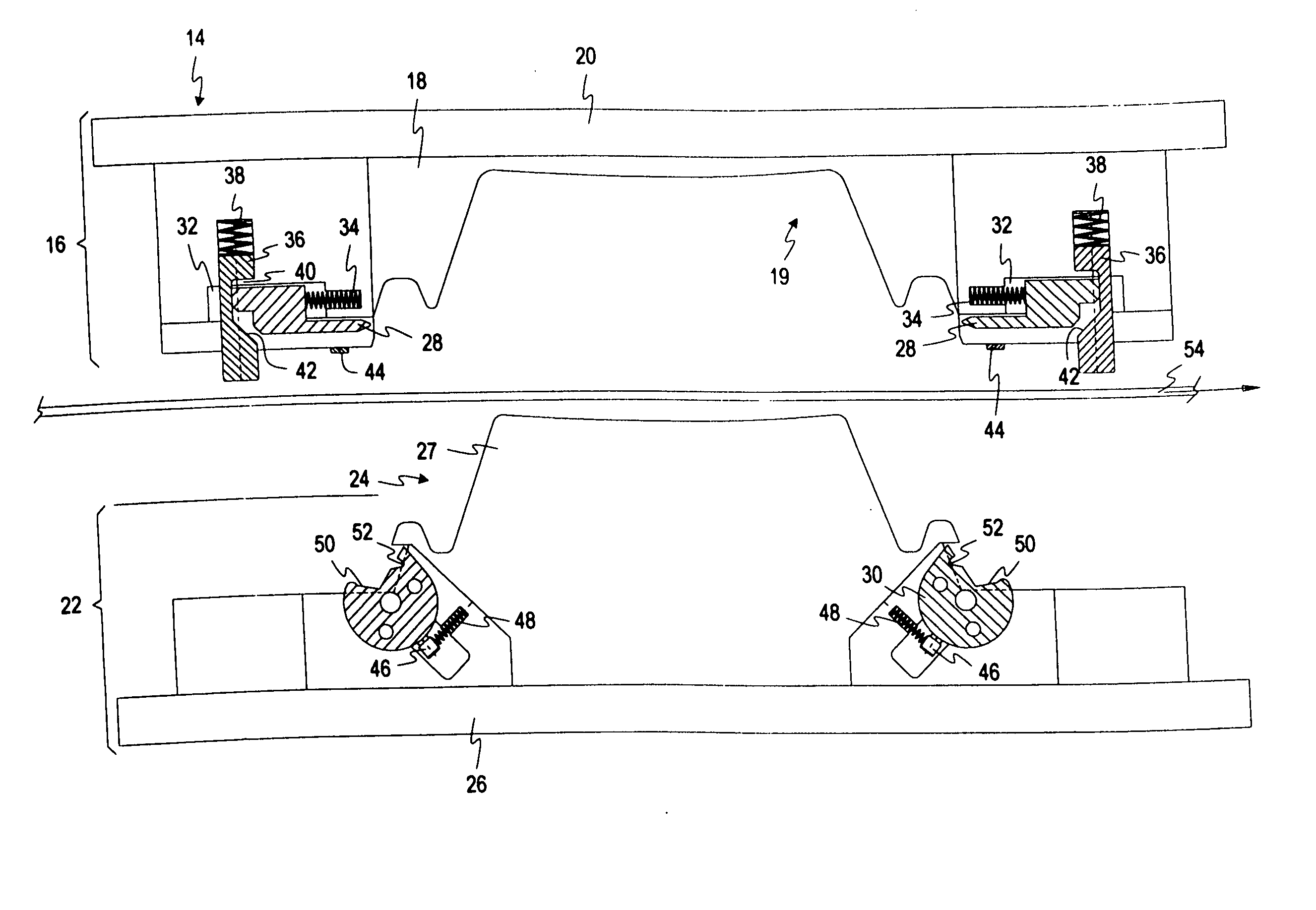

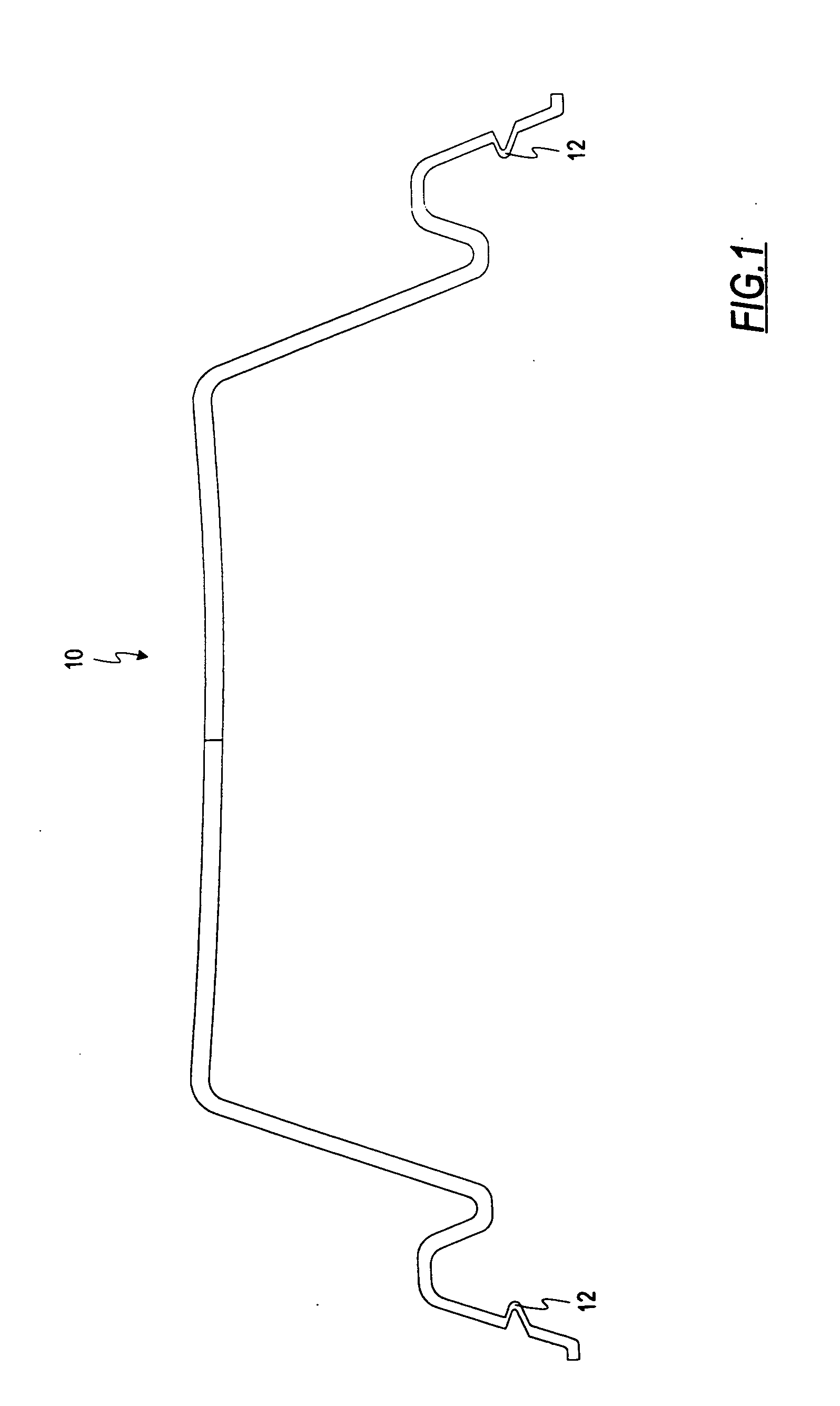

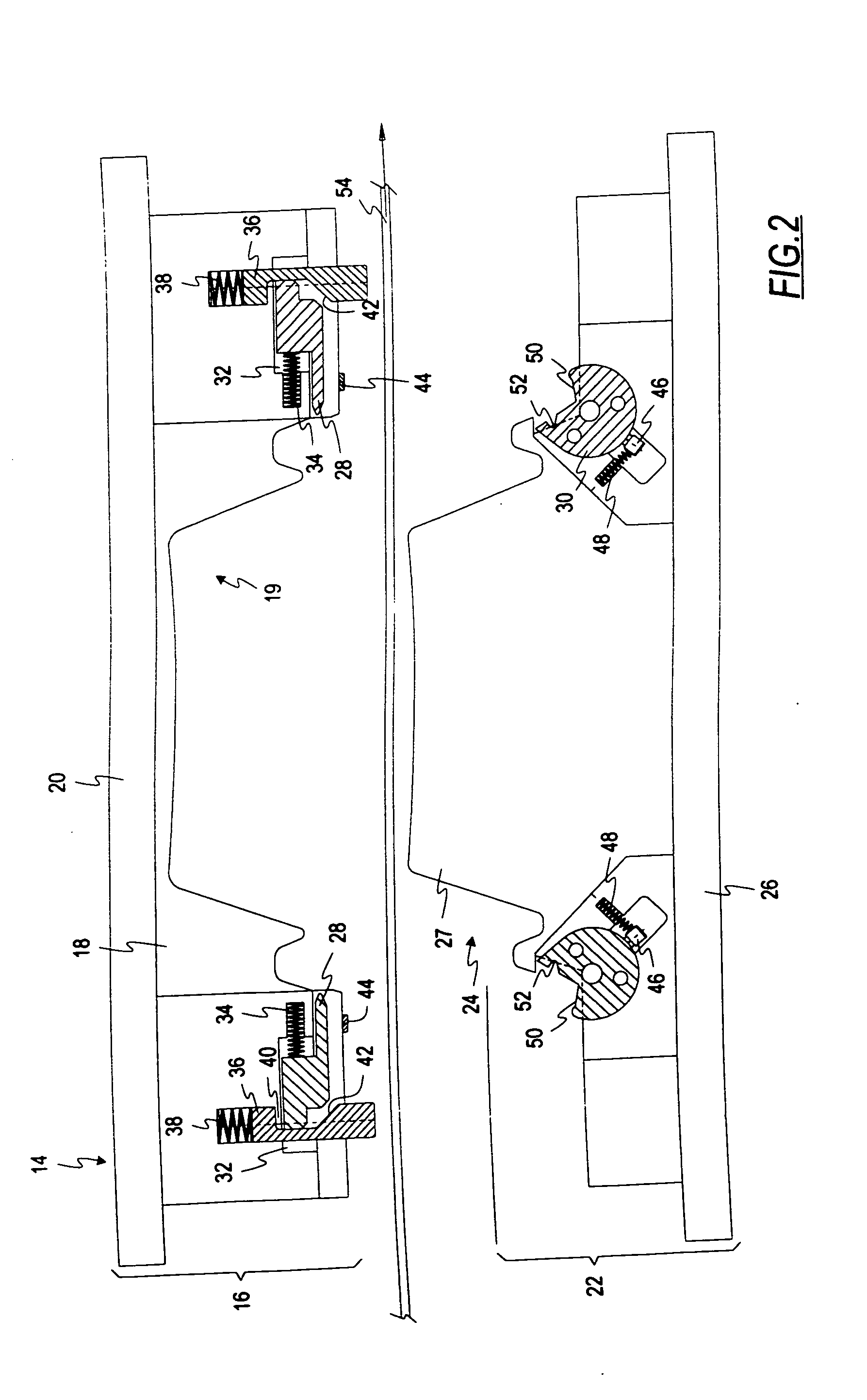

Method of forming a thermoformed foam part

A pair of form keys and a method for forming reverse drafts in foam parts are disclosed. A male form key is reciprocally mounted in a first mold half in a retracted position. A female form key is rotatably mounted in a second mold half in a neutral position. The first mold half includes a first drive pin that when engaged, moves the male form key into engagement with a foam sheet to form an undercut as the first and second mold halves are closed. The first mold half also includes a second drive pin that engages the female form key as the first and second mold halves close rotating the female form key into engagement with the foam sheet and the male form key. After closure of the mold and the product is formed, the mold is opened. As this occurs, the drive pins are disengaged and the male form key retracts and the female form key rotates to their neutral positions. The formed product may then be stripped from the mold while maintaining the reverse draft or undercut. In a further embodiment the male form key and the female-form key are fluid actuated.

Owner:PACTIV LLC

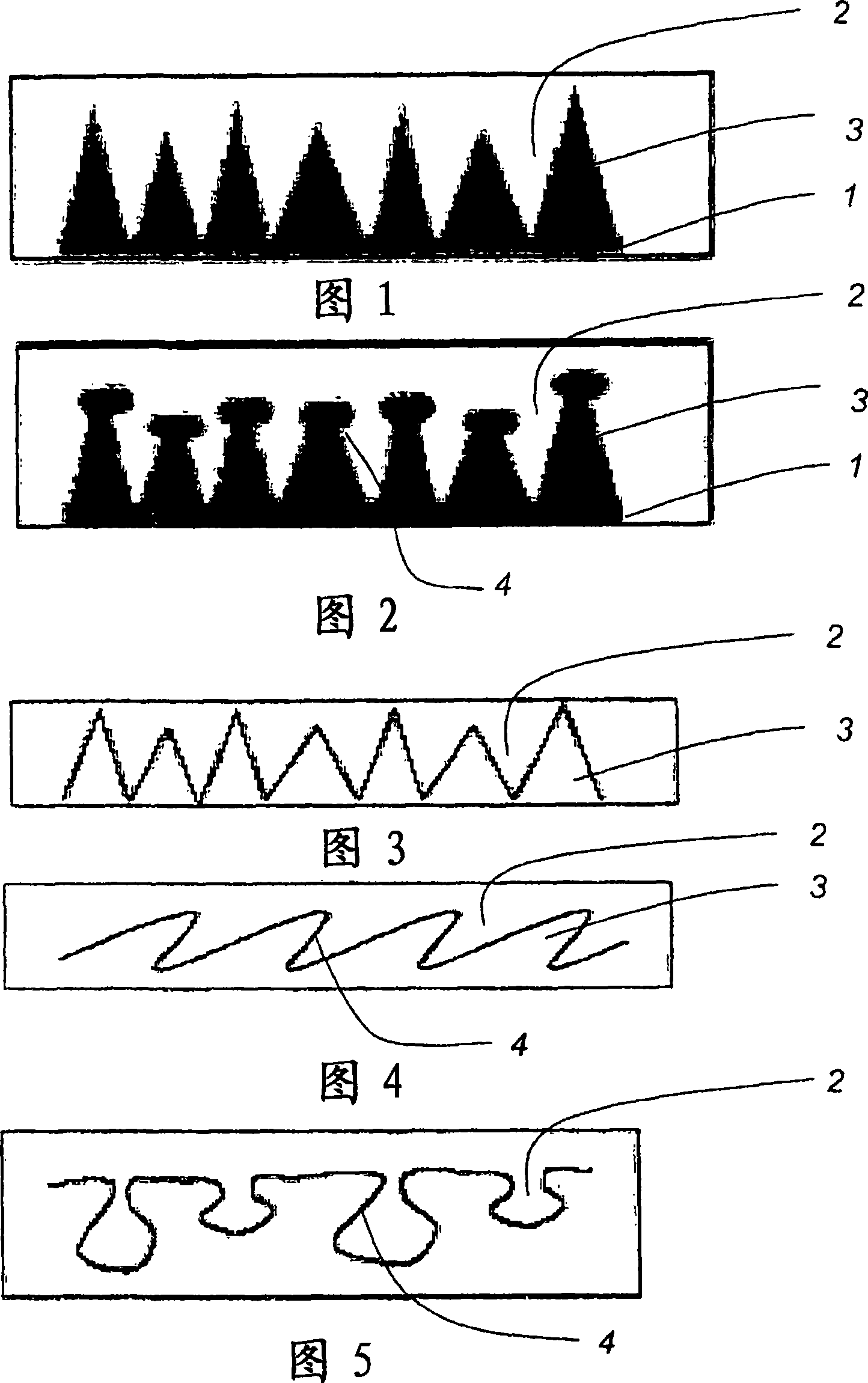

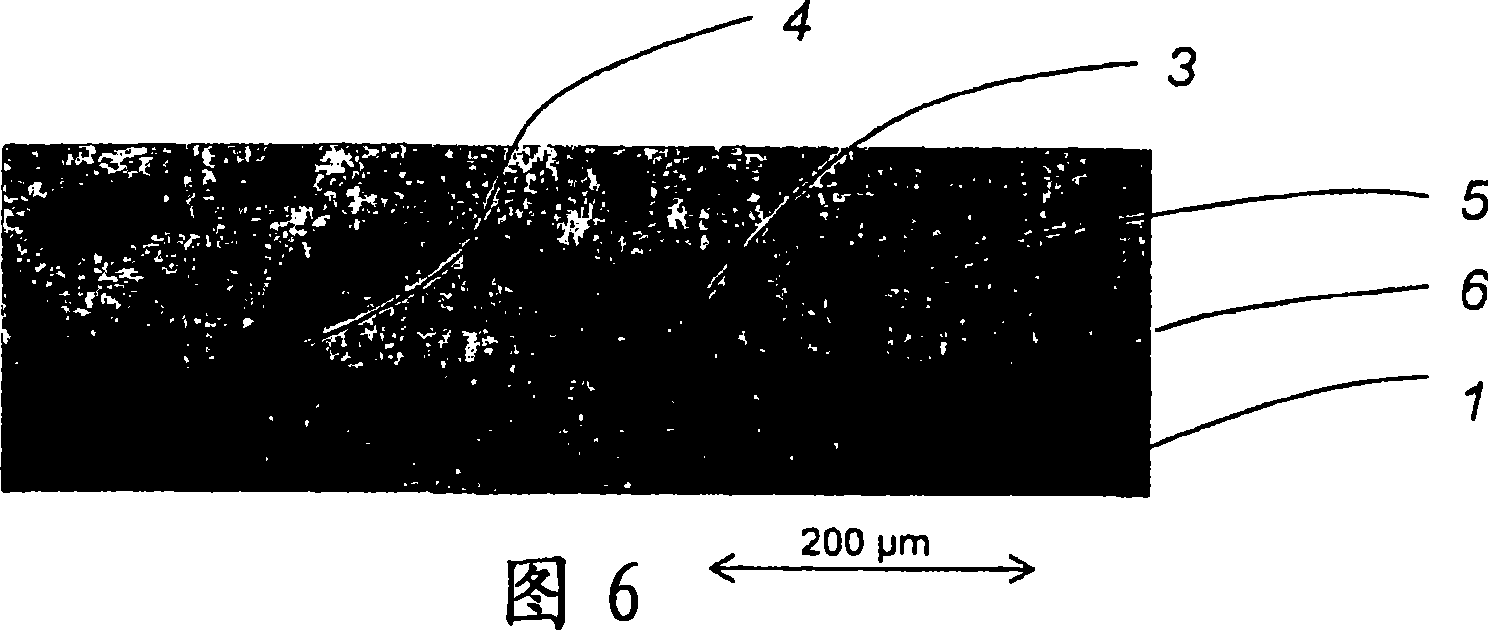

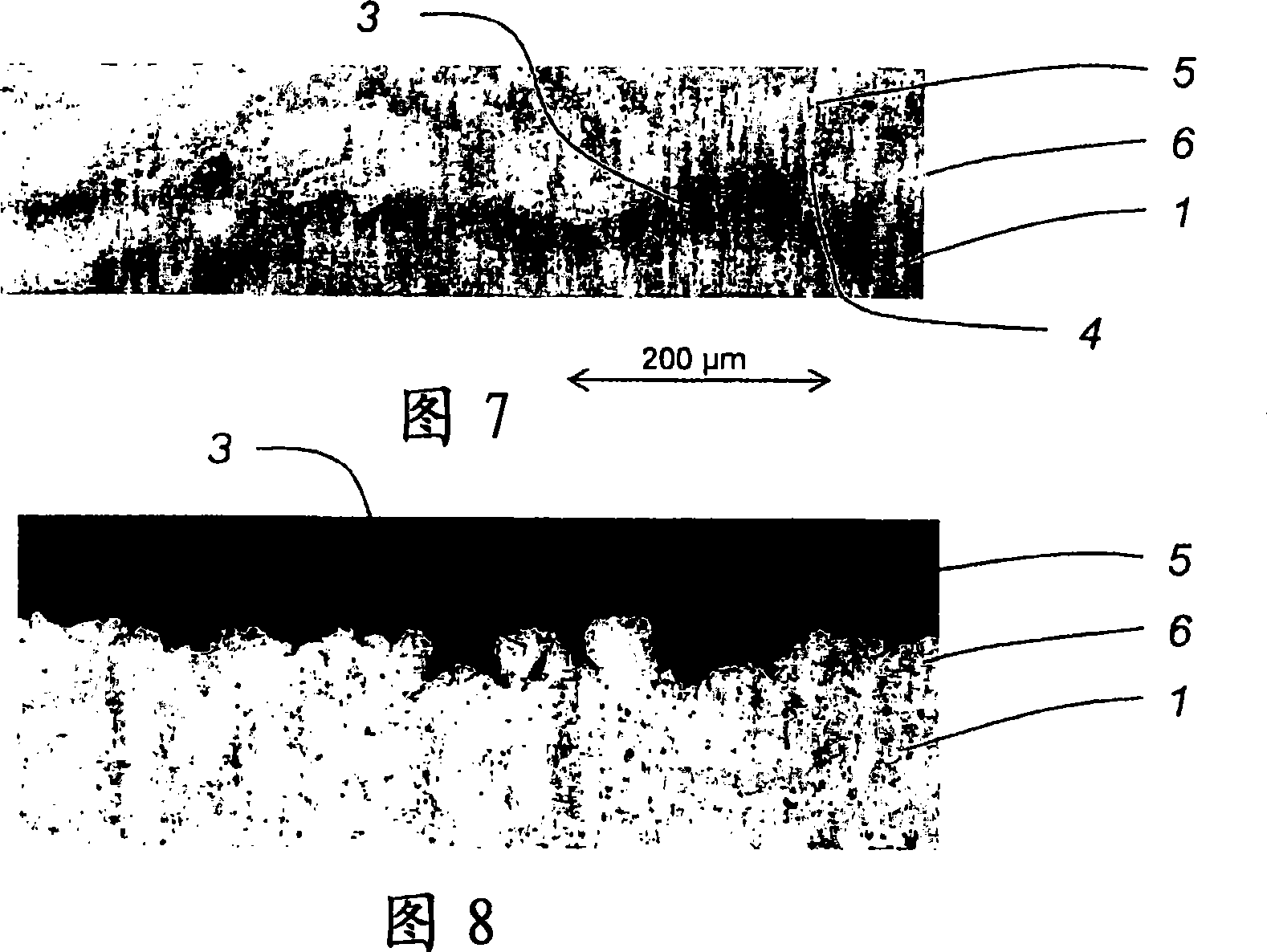

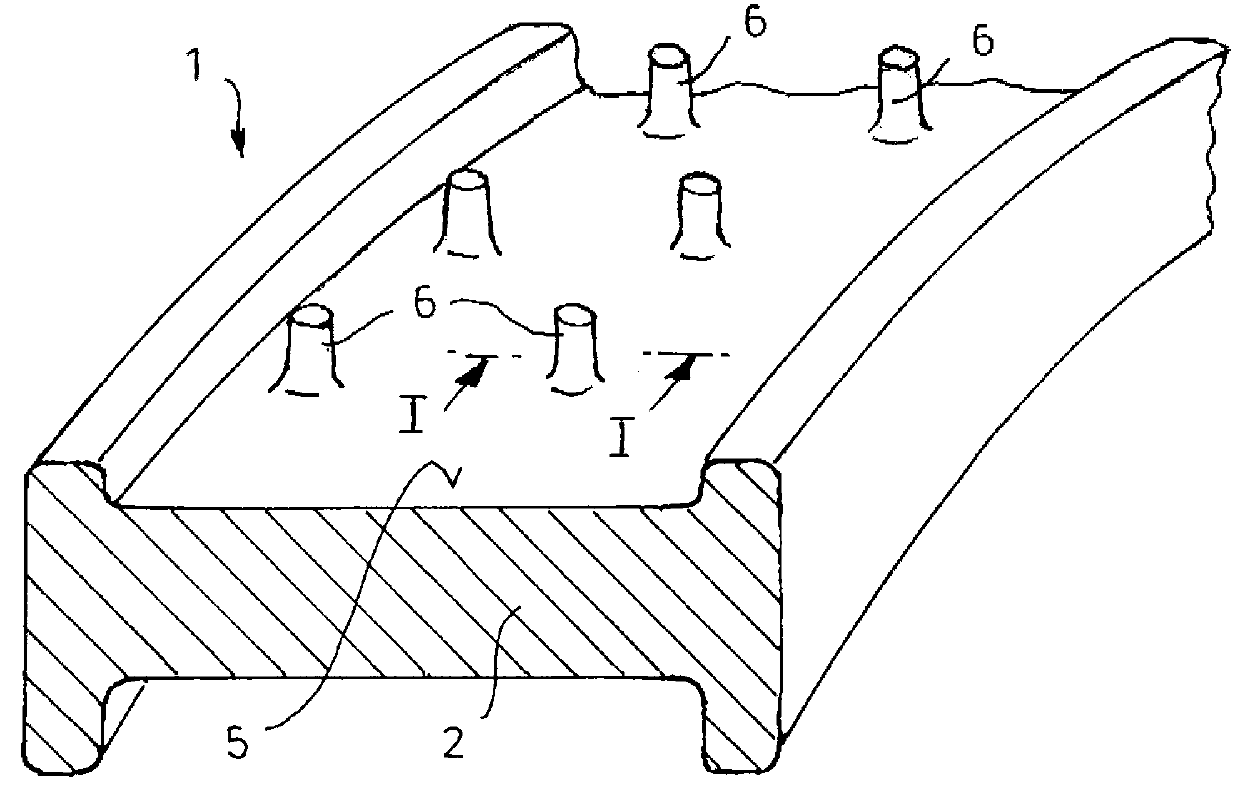

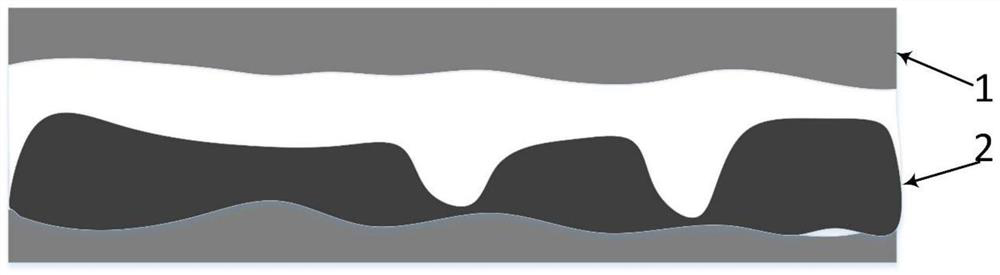

Surface conditioning for thermal spray layers

InactiveCN101379212AImprove adhesionImprove coating adhesionMolten spray coatingThin material handlingMaterial removalSurface conditions

The invention relates to a process for roughening metal surfaces to improve adhesion of layers which are thermally sprayed onto the surface, in which, in a first process step, recesses or depressions (2) are introduced into the surface in a material-detaching or material-removing treatment so that the remaining metal of the surface forms raised microstructures (3), in particular projections, ridges, protuberances or bumps, with these microstructures being further worked in at least one further process step by shaping and / or breaking so that a significant proportion of the structures forms undercuts (4) in relation to the surface.

Owner:DAIMLER AG

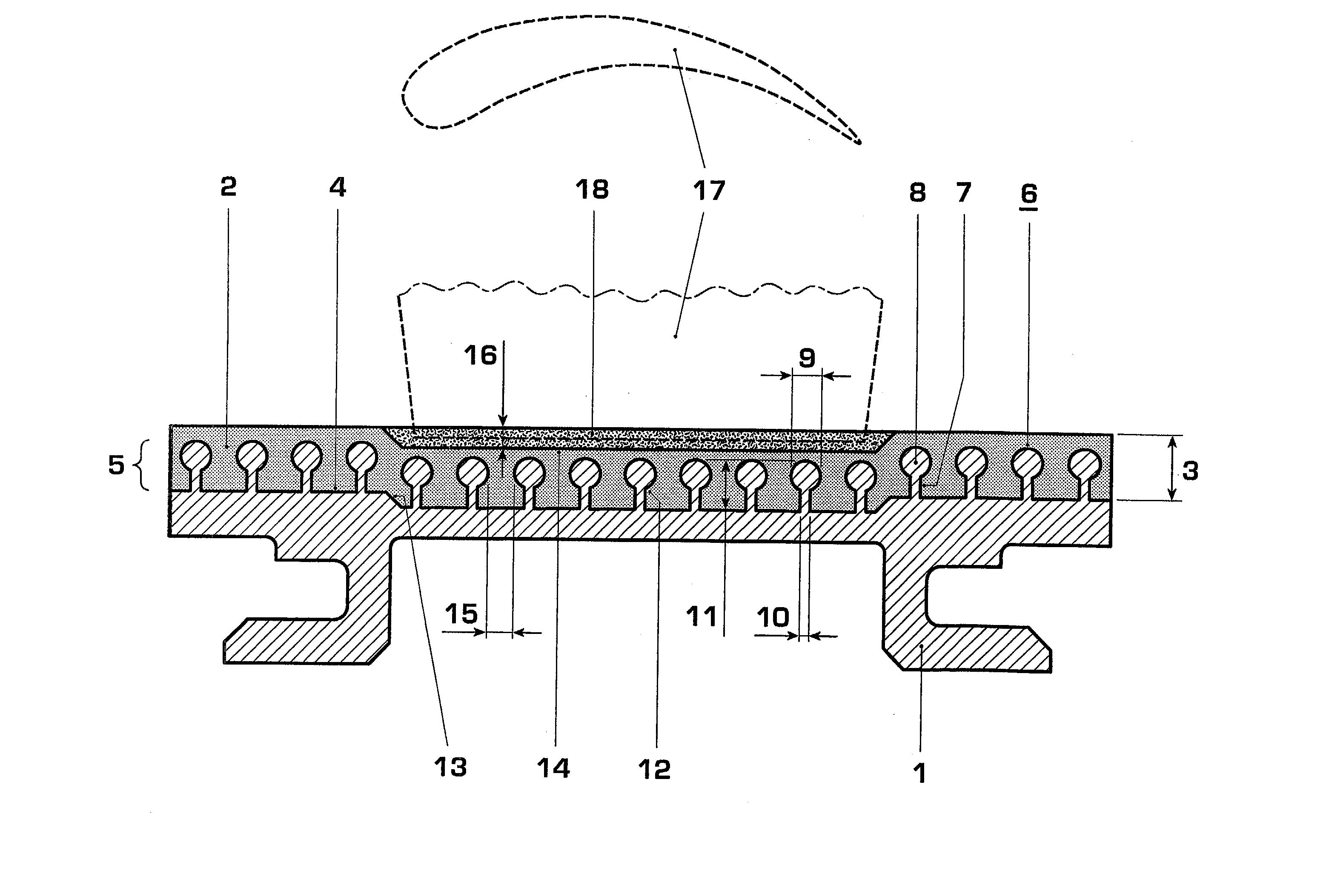

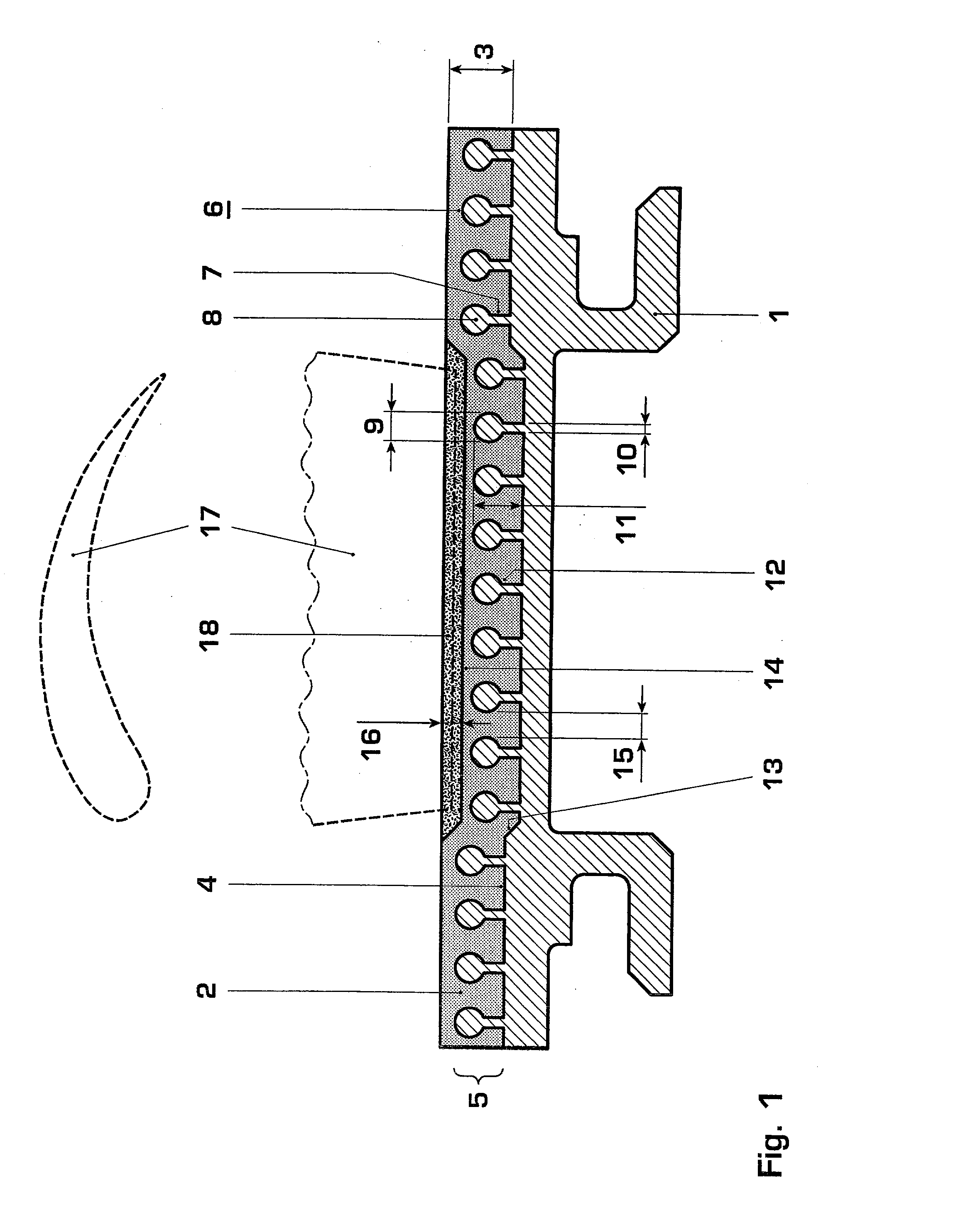

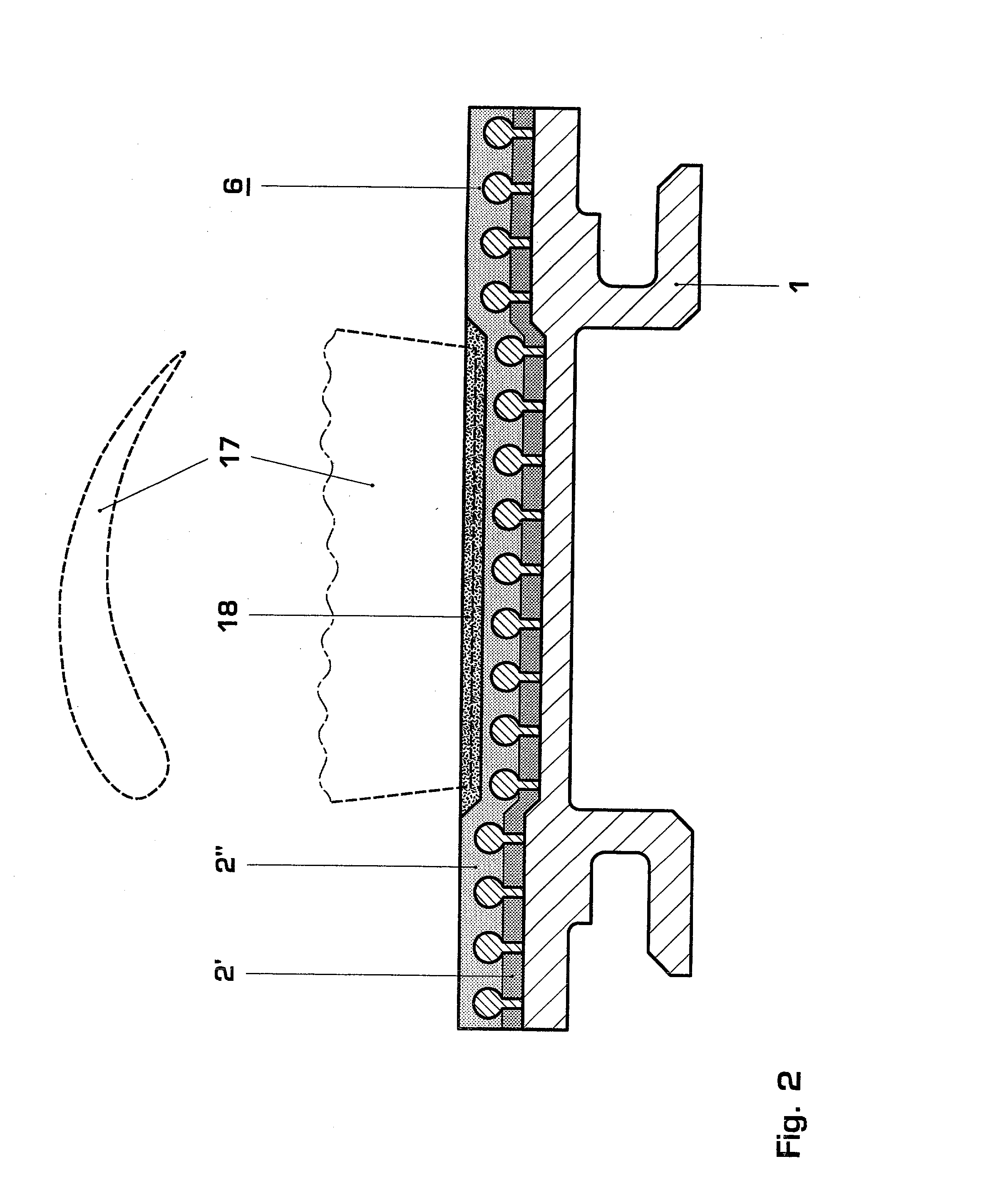

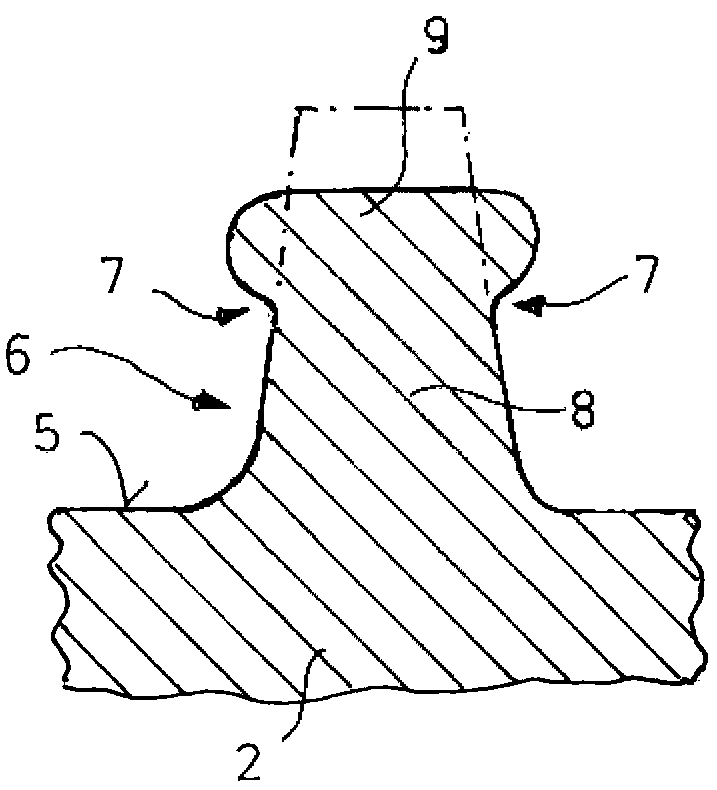

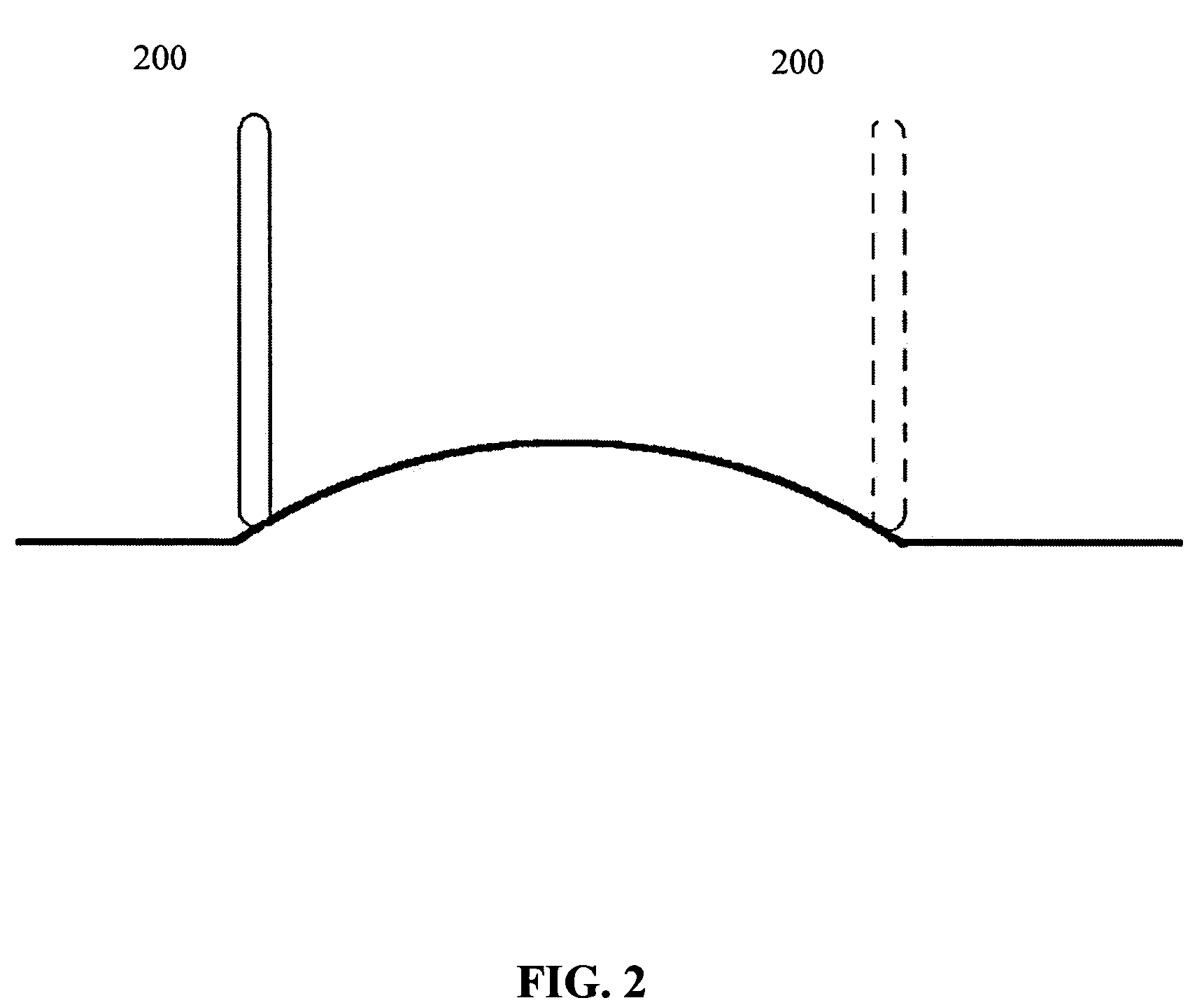

Gas turbine seal

InactiveUS20030170119A1High bonding strengthHigh overheatPump componentsReaction enginesCeramic coatingTangential force

The invention relates to a gas turbine seal, comprising a metallic component (1) with a durable or erosion-resistant ceramic coating (2) and an abradable ceramic layer (18) which is arranged thereon in locally delimited fashion, a bond layer (5) being arranged on the surface (4) of the metallic component (1), to which bond layer the durable or erosion-resistant ceramic coating (2) is applied as a covering layer. The invention is characterized in that the bond layer (5) comprises separate, adjacent spherical rivets (6) or mushroom-shaped rivets (6) which have a web (7) and a head (8). These rivets form individual metal islands with numerous undercuts (12), around which there is a continuous ceramic network. It is possible to produce very thick layers which have a good bond strength, the ceramic not being flaked away even in the event of introduction of radial / tangential forces, sickle-shaped contact or locally high overheating / frictional heat, and a good sealing action being achieved.

Owner:GENERAL ELECTRIC TECH GMBH

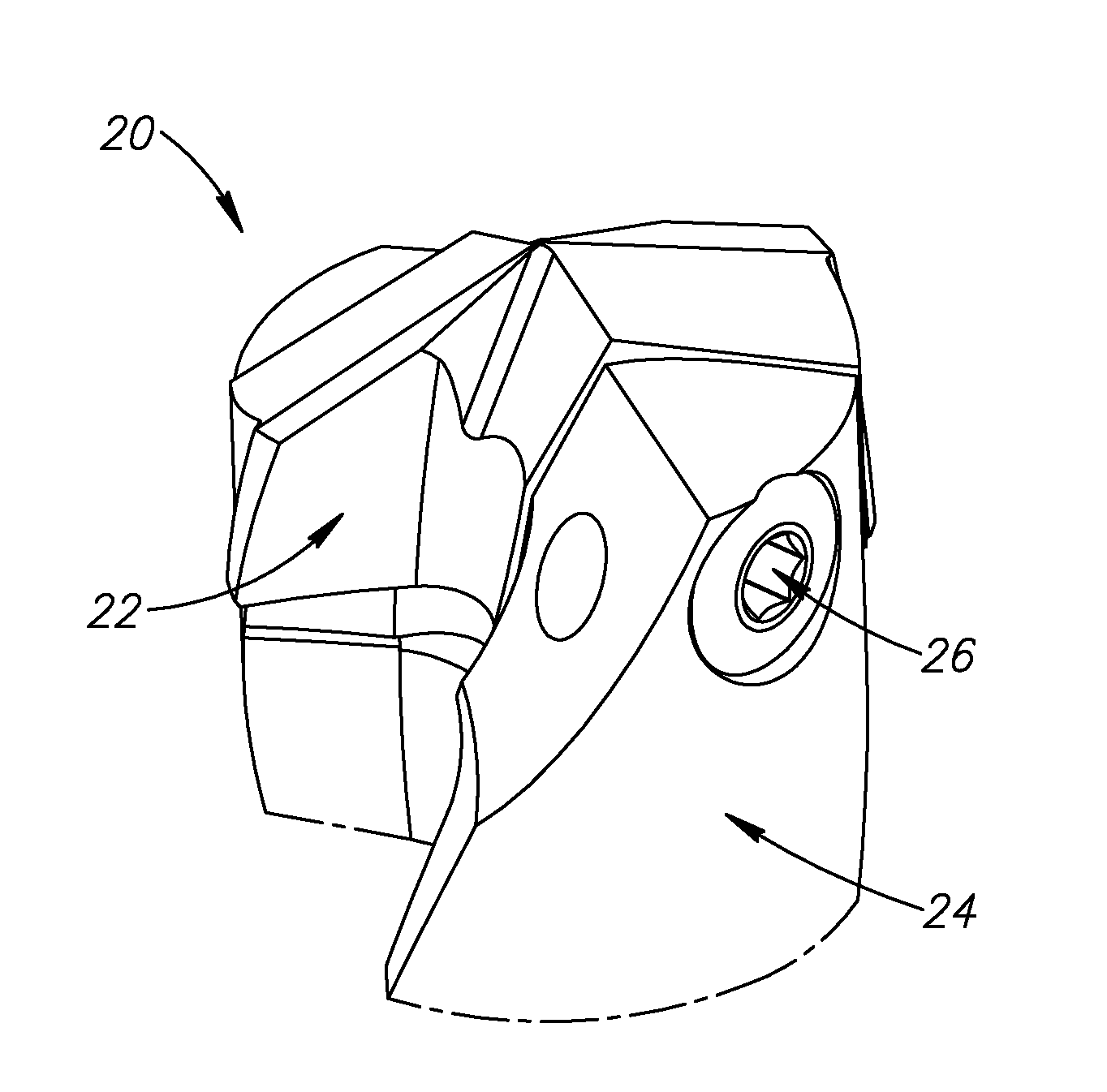

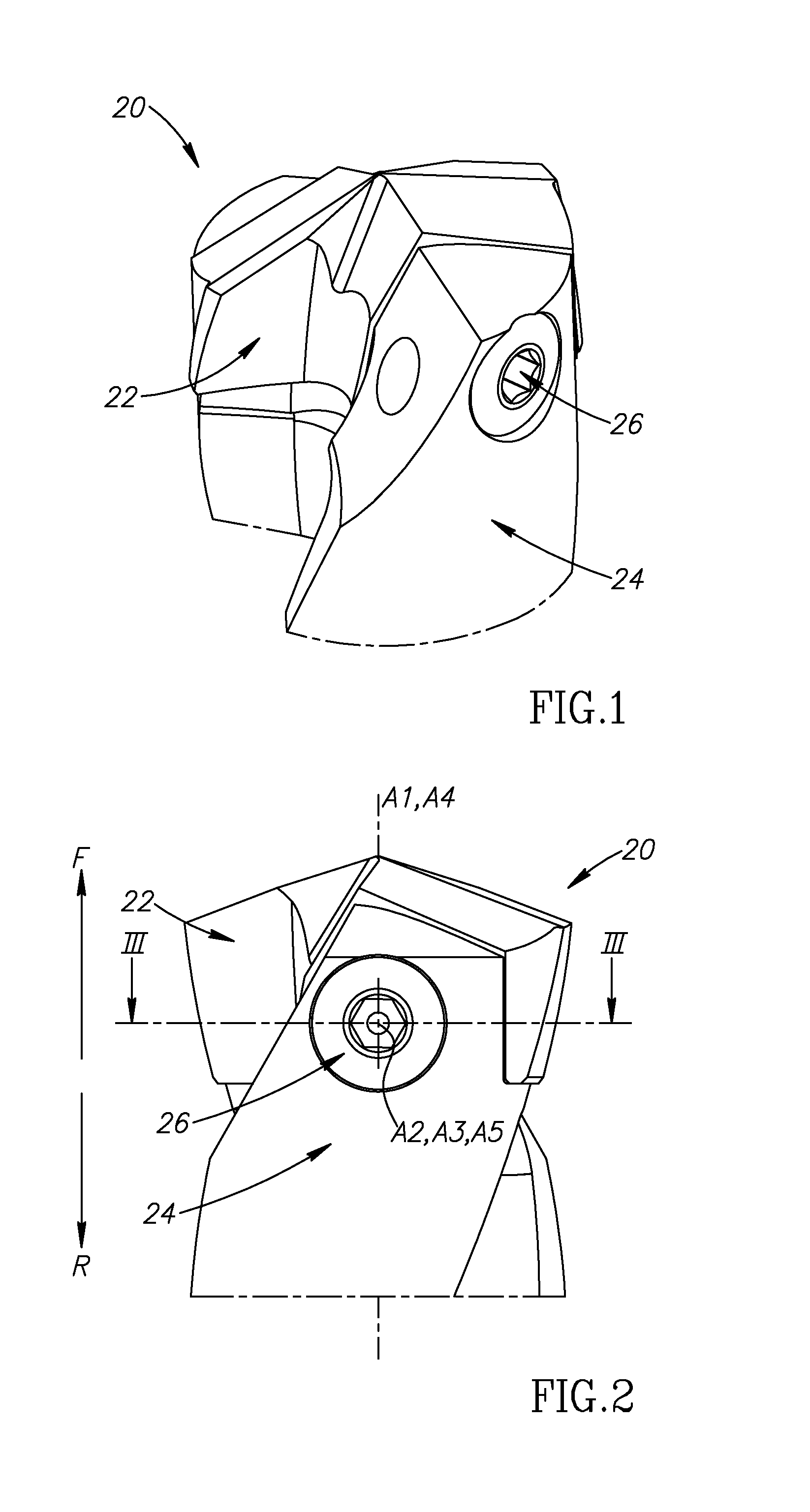

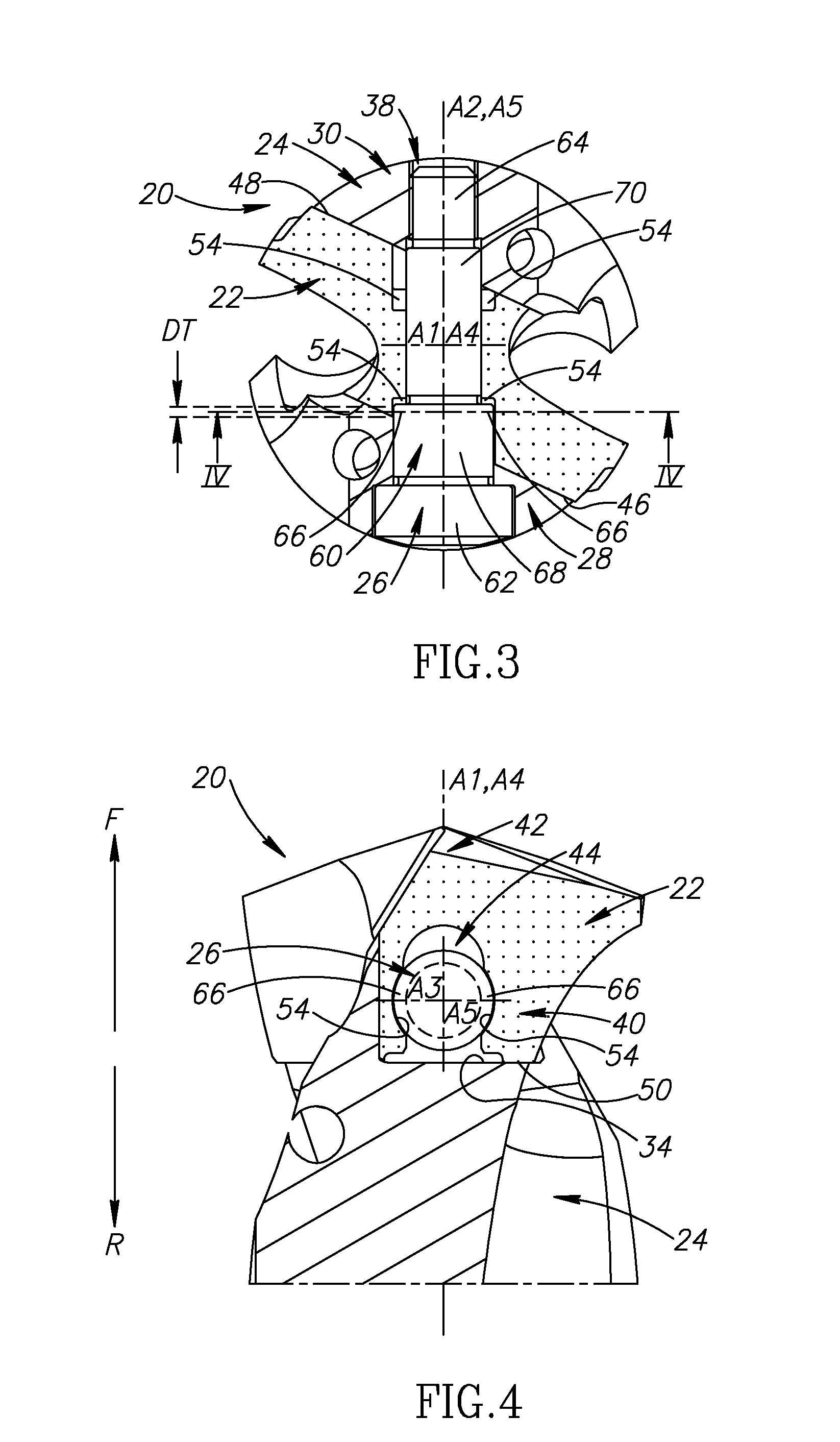

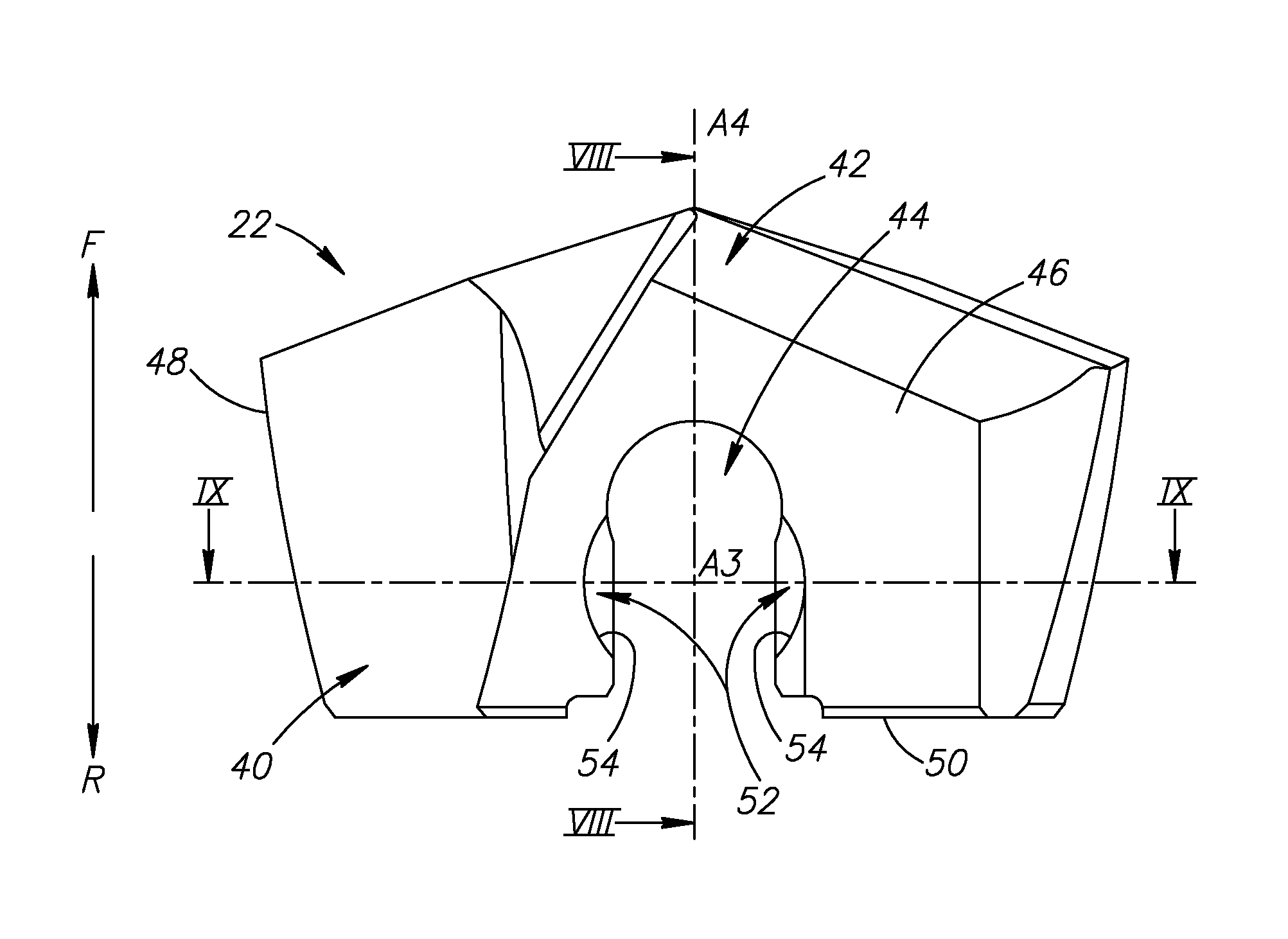

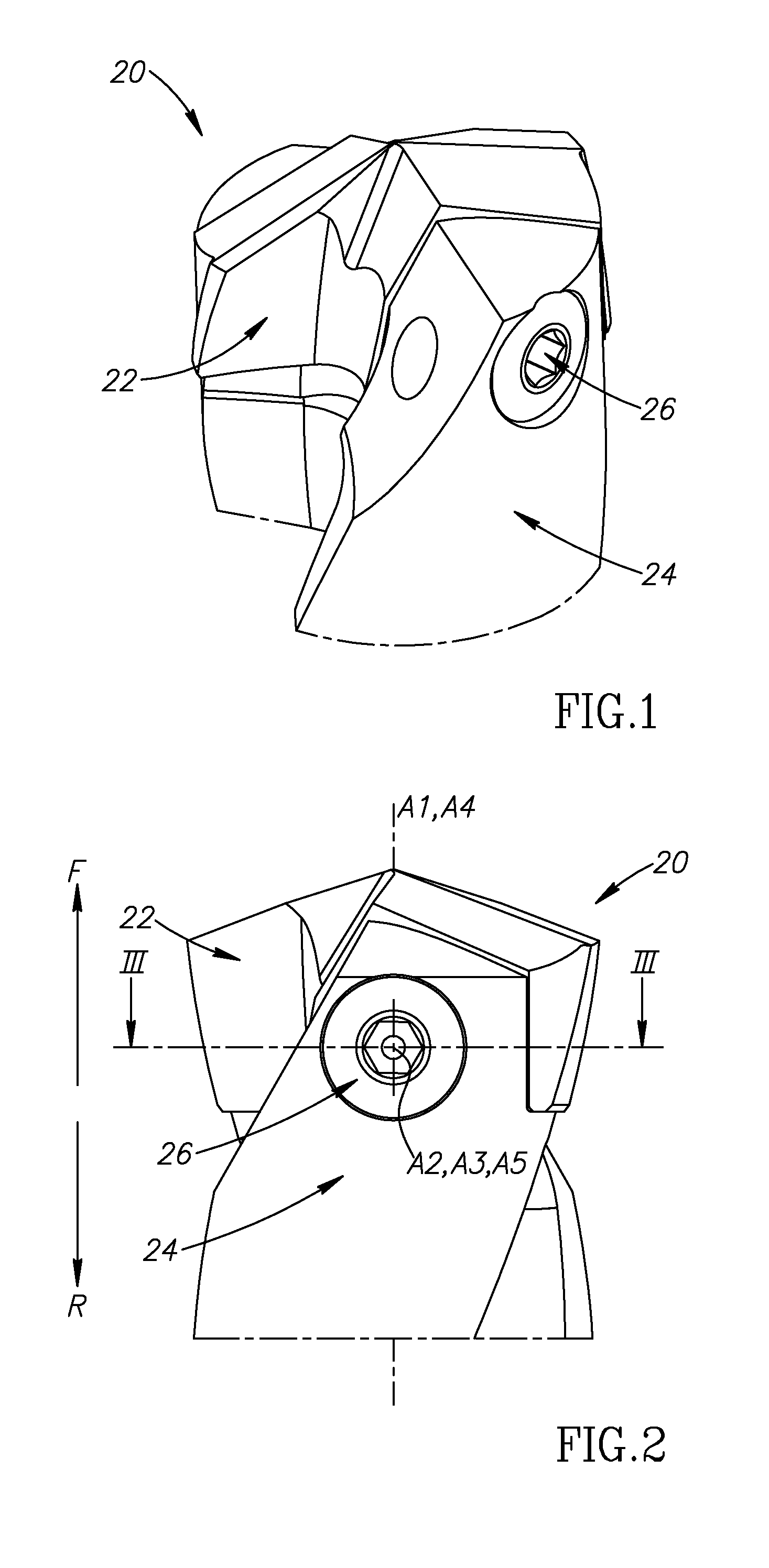

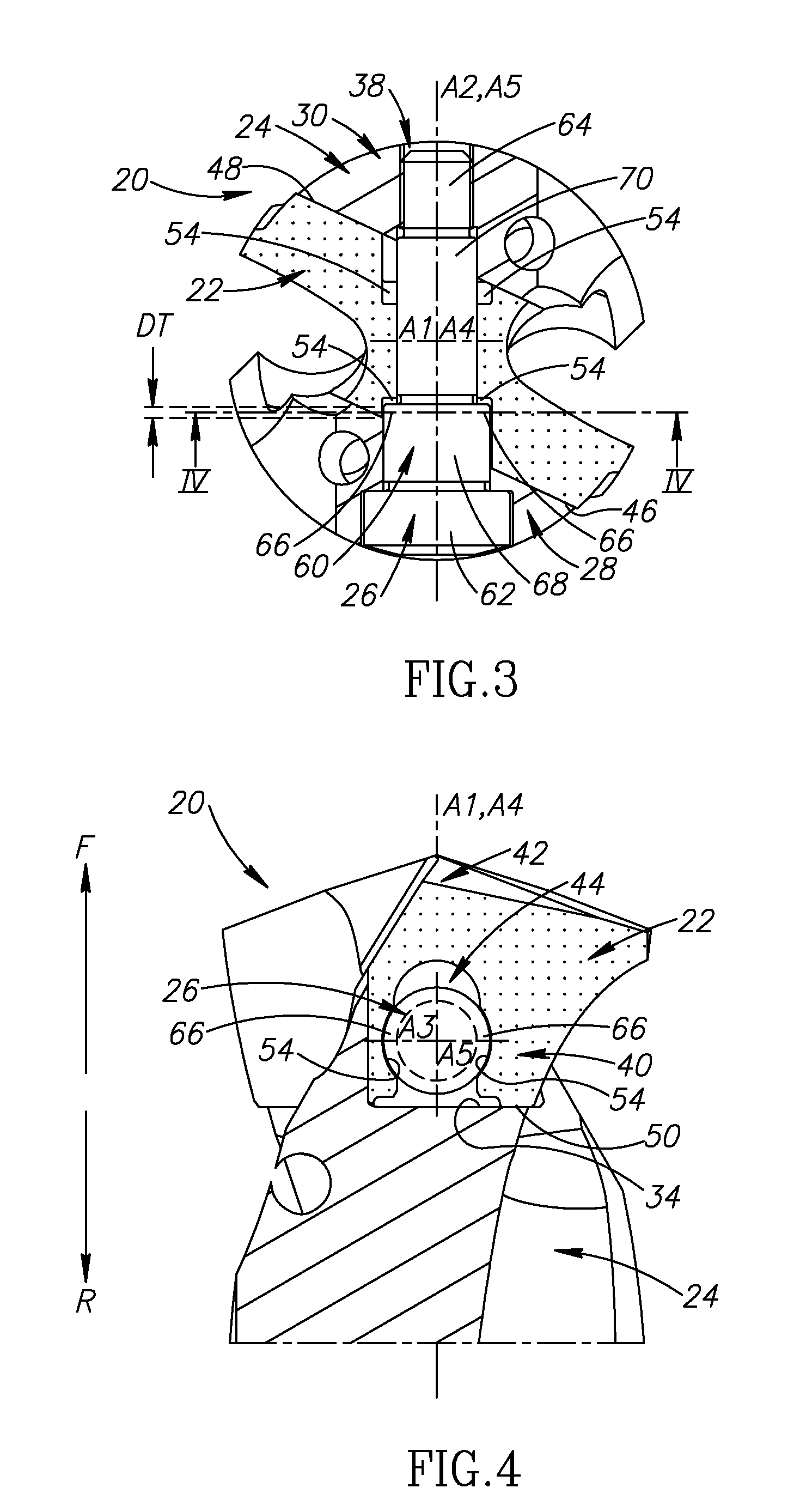

Cutting Tool Having Clamping Bolt Provided with Locking Portion and Cutting Insert Therefor

A cutting tool has a cutting insert secured in a tool shank by means of a clamping bolt, whereby two opposing side surfaces of a body portion of the cutting insert are located between two spaced apart protuberances of the tool shank. The body portion includes a cut-out extending between the two opposing side surfaces and opening out to a bottom surface. The cut-out includes an undercut with at least one undercut sub-surface with respect to a forward direction. The clamping bolt can be rotated from a locked position wherein the bolt shank has a threaded portion engaged in one of the protuberances and a bolt locking portion located directly forward of the at least one undercut sub-surface, to an un-locked position wherein the threaded portion remains engaged in the protuberance and no portion of the bolt shank is located directly forward of the at least one undercut sub-surface.

Owner:ISCAR LTD

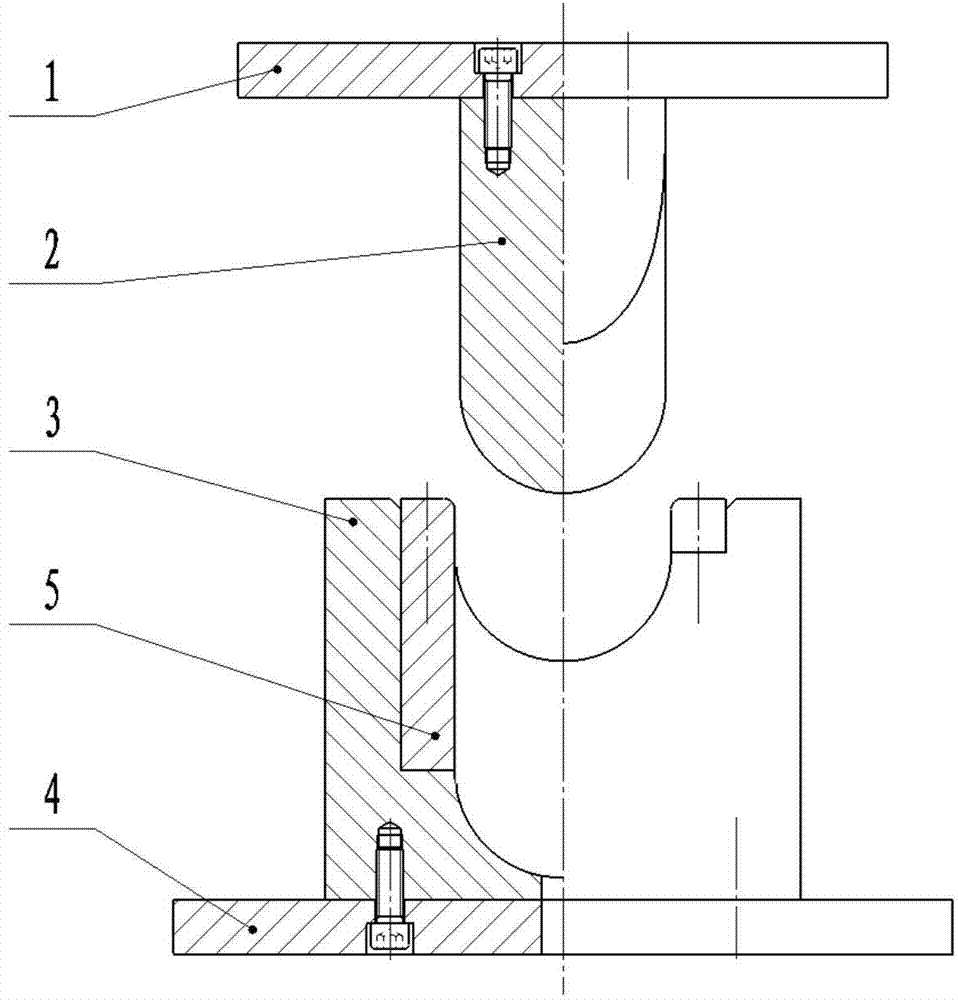

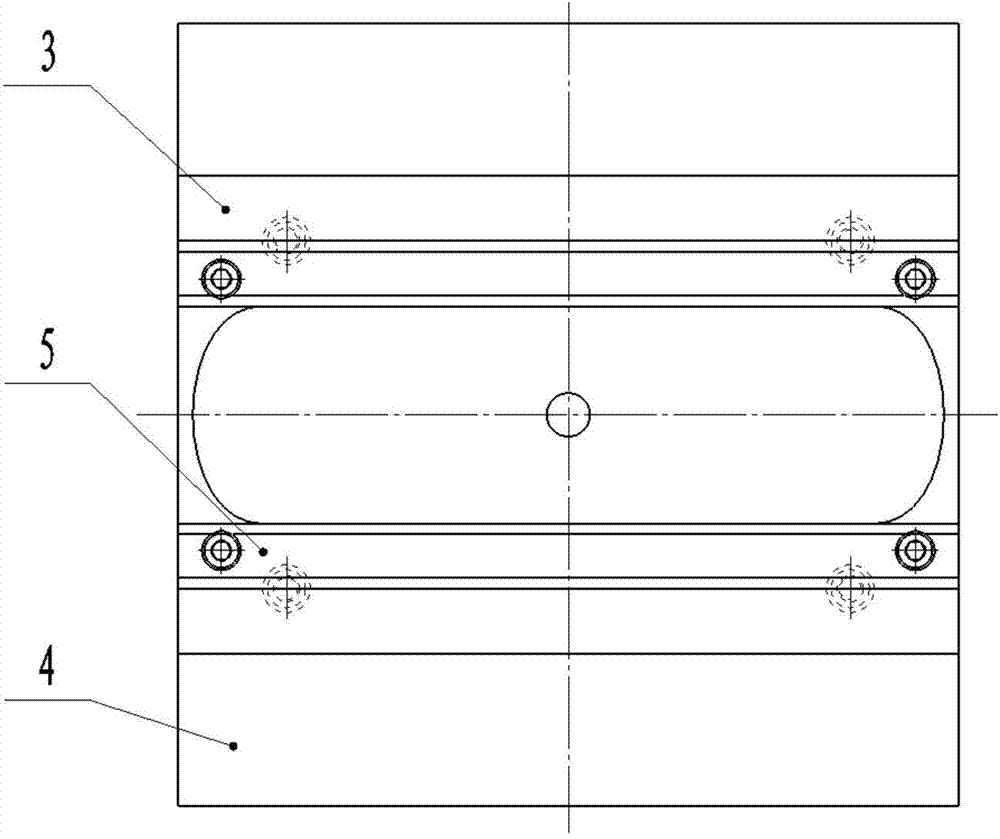

Single-welding bend pressing and molding method

The invention relates to a single-welding bend pressing and molding method. The method comprises the main steps: selecting slabs as thick as the bend wall as raw materials, unfolding the bend by DYNAFORM software to obtain the size of the slab and blanking with a cutter; processing undercuts on both concave sides of the slab; pressing the cross section of the slab to be U-shaped; pressing the slab with the U-shaped cross section to be slab with an O-shaped cross section; welding an inner-arc opening of the slab with O-shaped cross section; and cutting the redundant slab at both ends of the bend and machining both ends according to the requirement to obtain a qualified bend part. Dies for pressing U-shaped cross section and O-shaped cross section comprise a concave die, a convex die I and a convex die II, and the top surface of the convex die I is a plane; the lower part is in a U-shaped structure; the top surface of convex the die II is a plane; both sides perpendicular to the plane are part sector; the arc-shaped surface on the lower part of the convex die II is provided with a groove corresponding to the machined bend surface. The prepared product is few in welding line and high in quality, the dies are simple, core rods are not needed, energy consumption is low as heat is not needed, the process is simple and production efficiency is high.

Owner:YANSHAN UNIV

Method and apparatus for manufacturing a cutting insert

A method for manufacturing a cutting insert green body having undercuts includes providing a die cavity formed in closed top and bottom dies; closing a bottom of the die cavity by a bottom punch accommodated in a punch tunnel formed in the bottom die; filling the die cavity with a pre-determined amount of sinterable powder; moving a top punch towards the die cavity through a punch tunnel formed in the top die; compacting the powder by urging the top and bottom punches towards each other, thereby forming the green body; and moving the top die and punch away from the bottom die and punch, thereby enabling removal of the formed green body. An apparatus for manufacturing a cutting insert green body having undercuts includes top and bottom dies which abut each other and top and bottom punches which slide in their respective dies.

Owner:ISCAR LTD

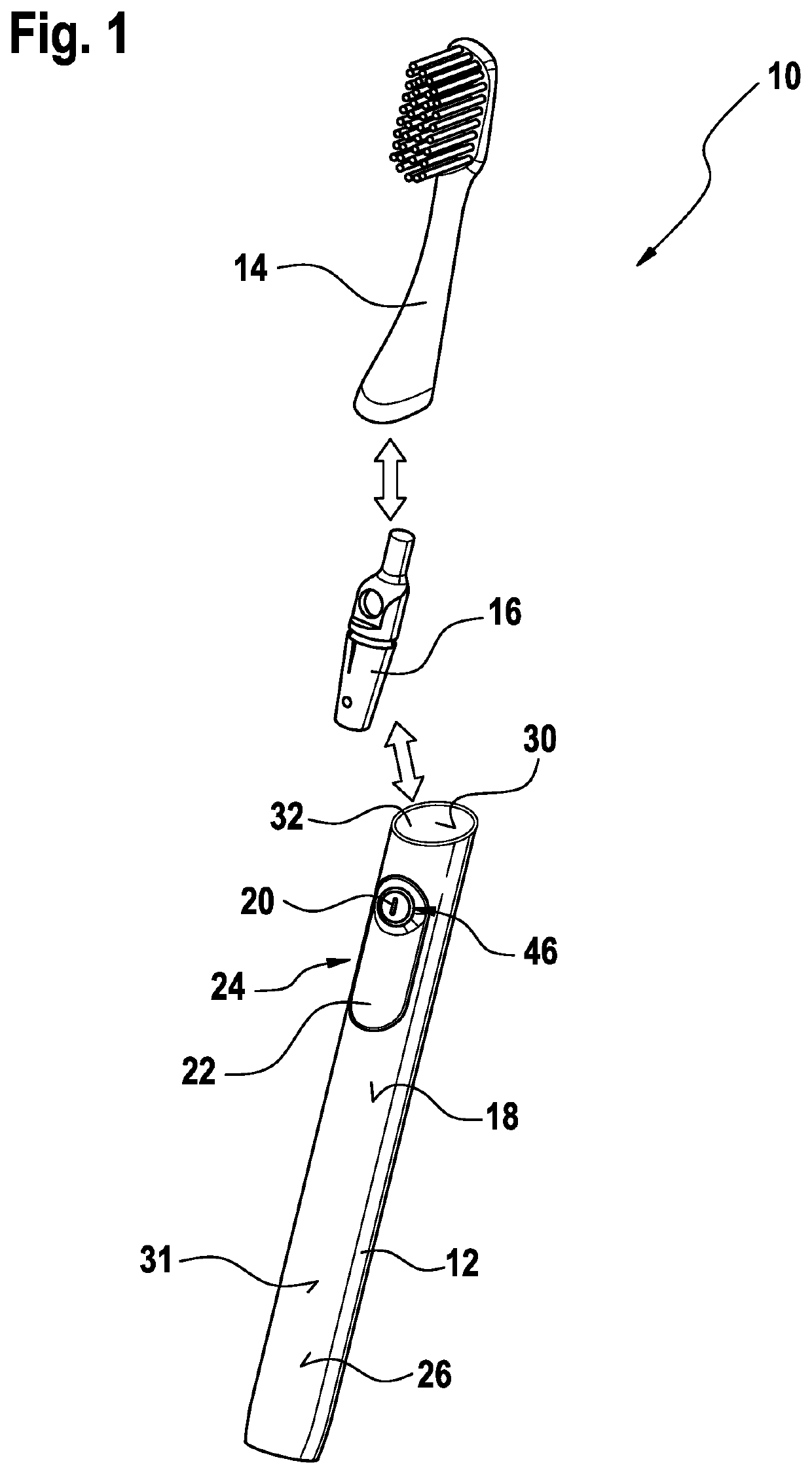

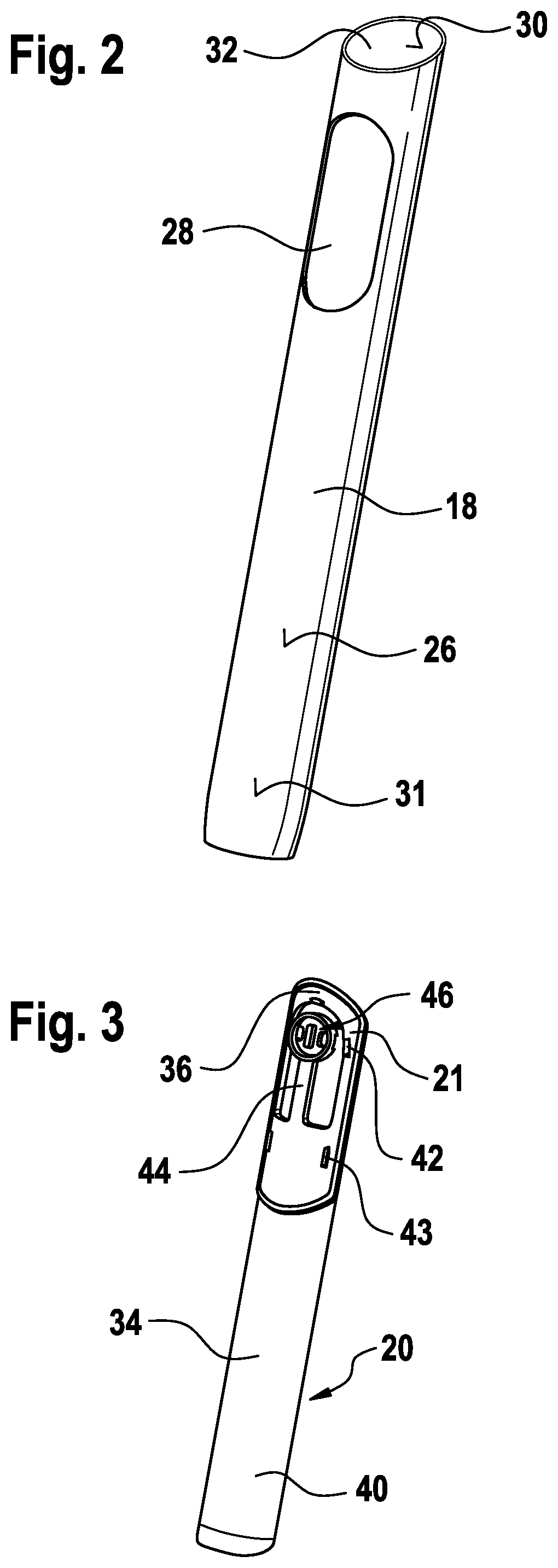

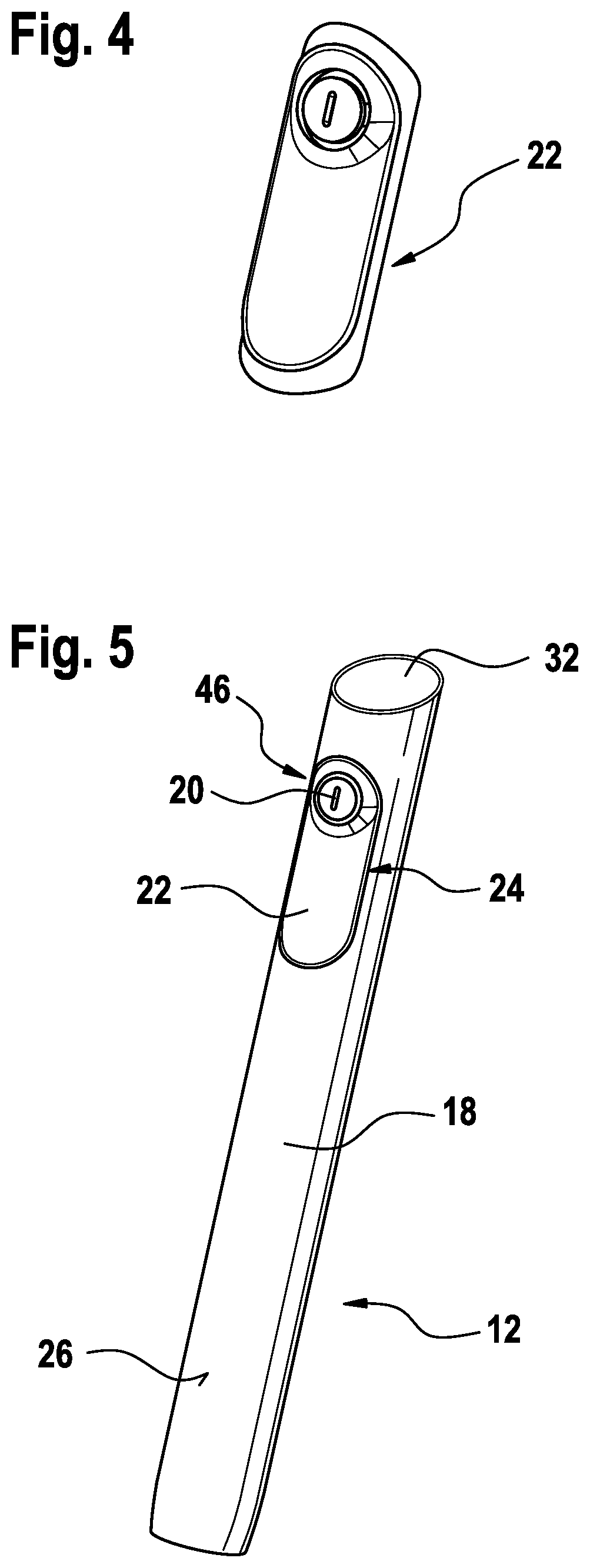

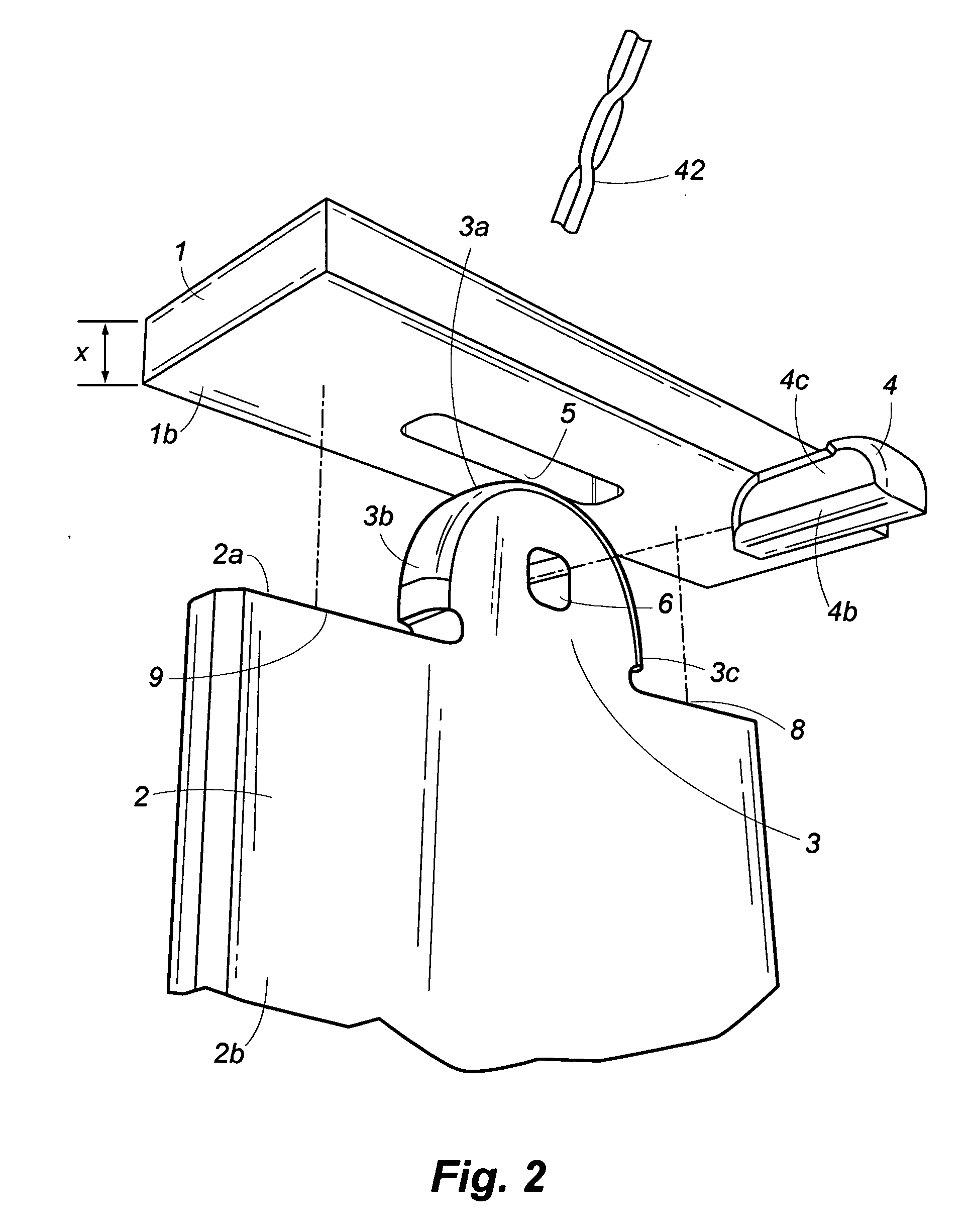

Method for making a handle for an electrically operated personal care implement

A method for manufacturing a handle for an electrically operated personal care implement comprises the following steps: providing a metal tube housing having a metal wall with an opening therein and an inner surface defining an inner cavity for accommodating an energy source; providing a hard switch component comprising a frame with a recess; attaching the frame of the hard switch component to the inner surface of the metal wall, the frame surrounding the opening and providing an undercut between the recess and the inner surface, the undercut being open towards the opening; and at least partially over-molding the opening to form a soft switch component in the undercut, thereby forming with the hard switch component a switch assembly for activating the energy source, the switch assembly sealing the opening from the inner surface of the metal wall.

Owner:THE GILLETTE CO +1

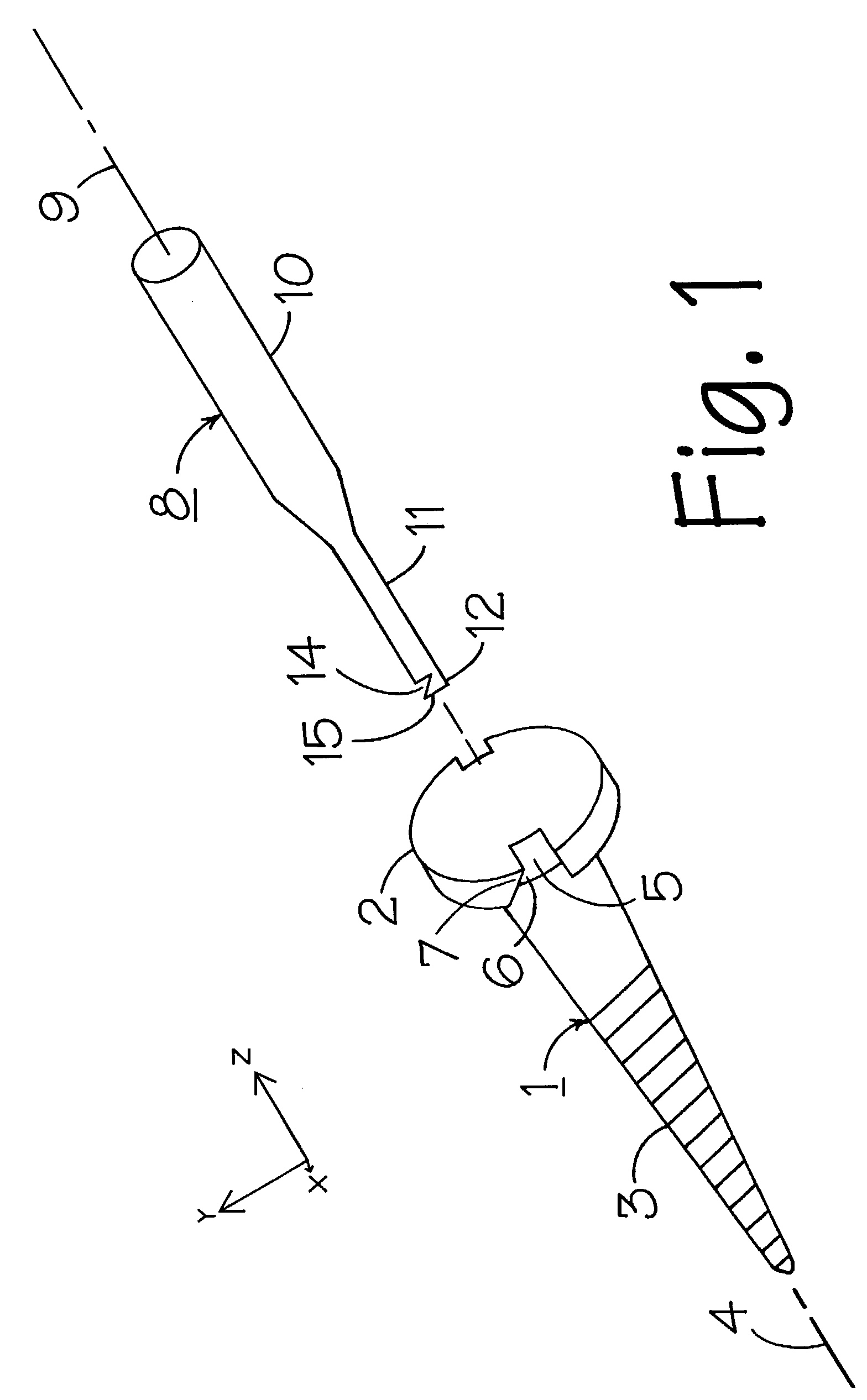

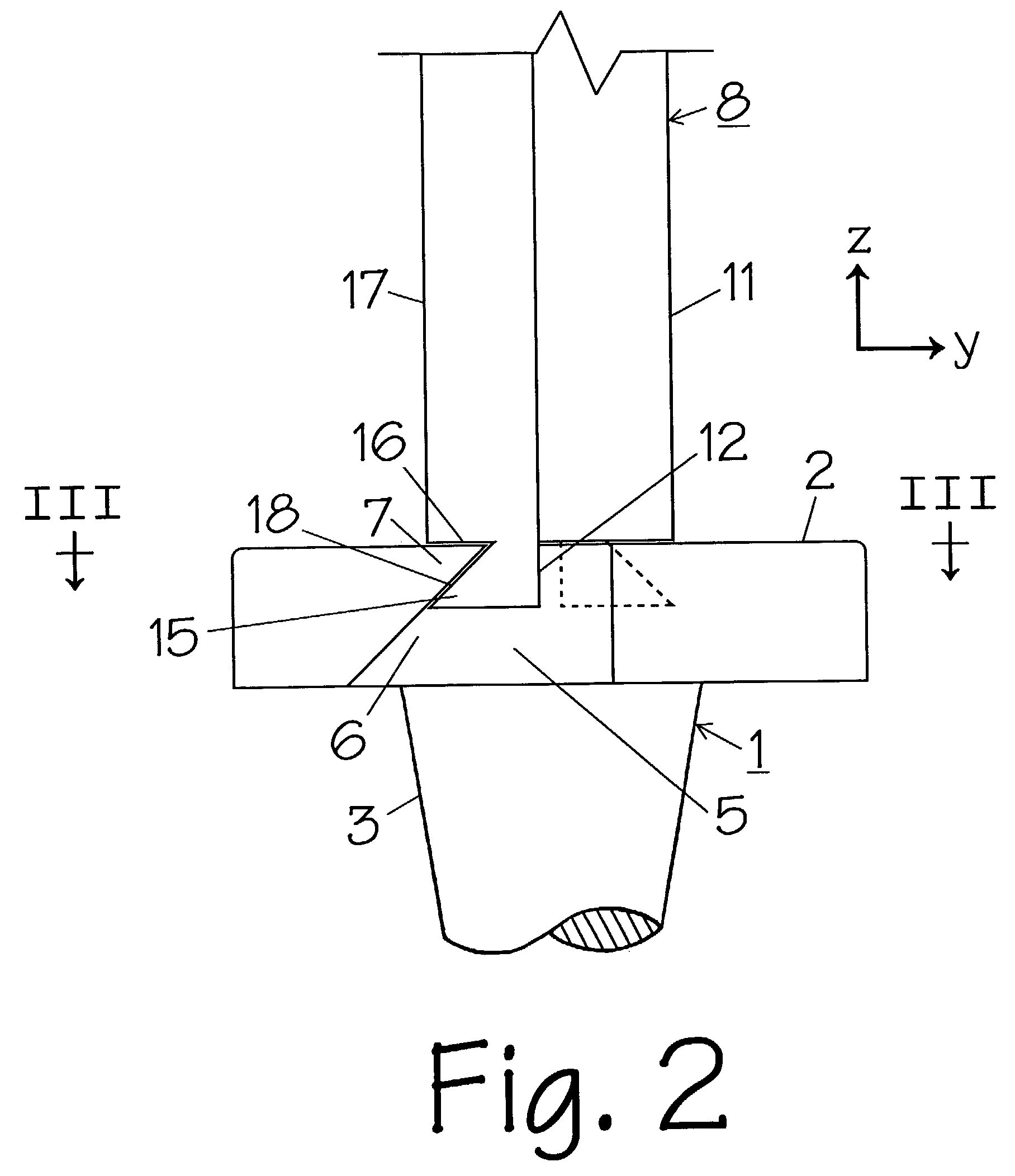

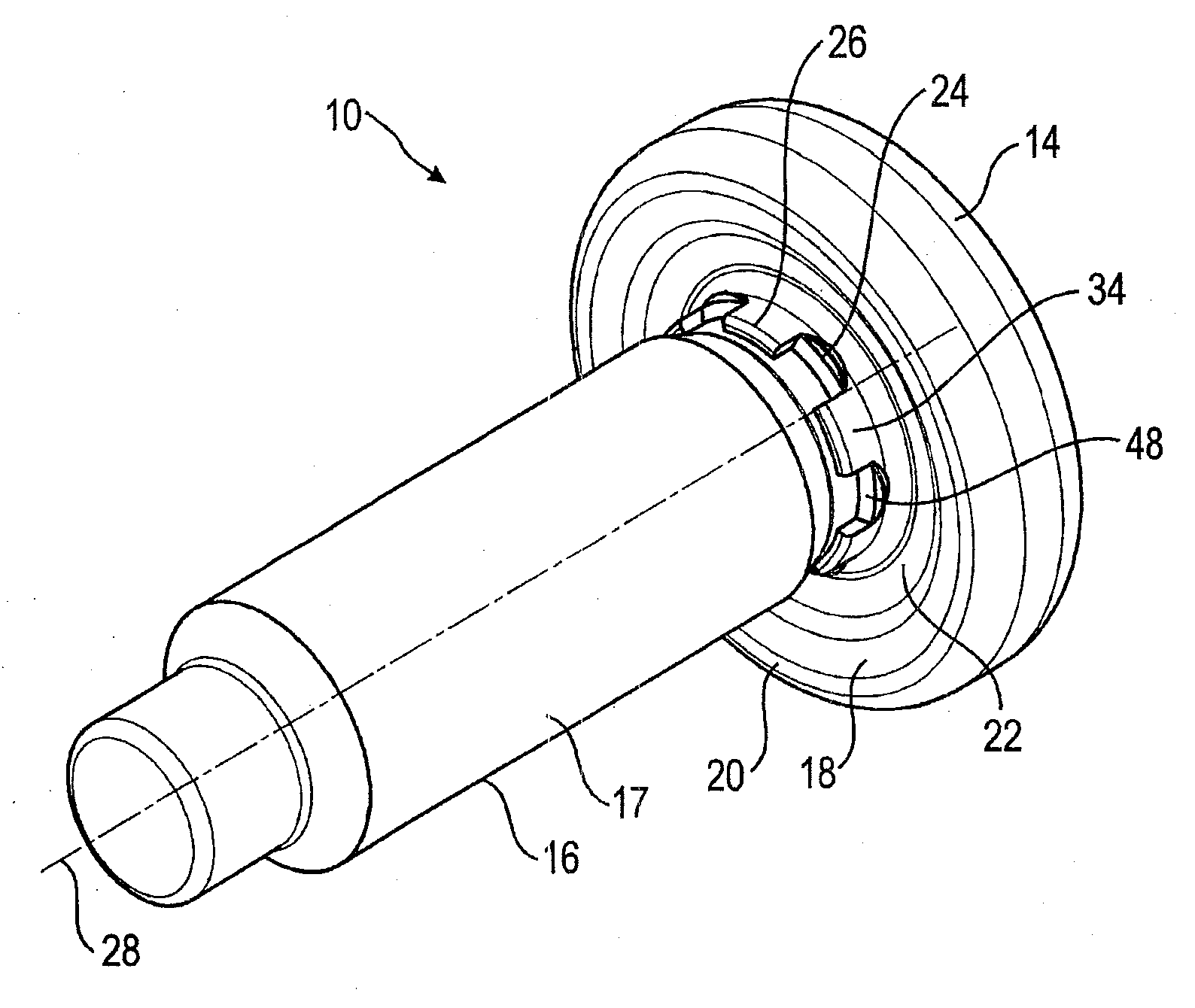

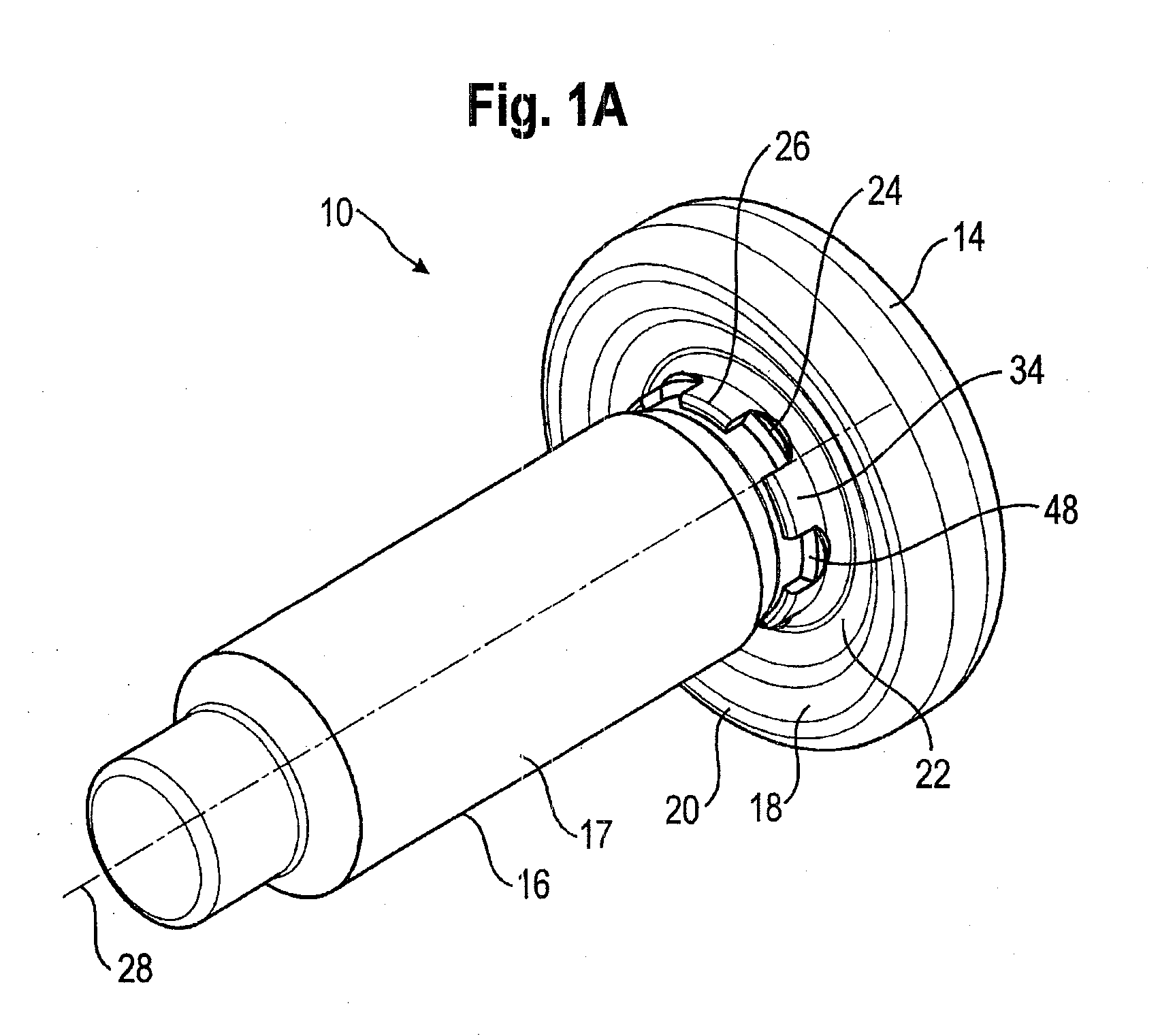

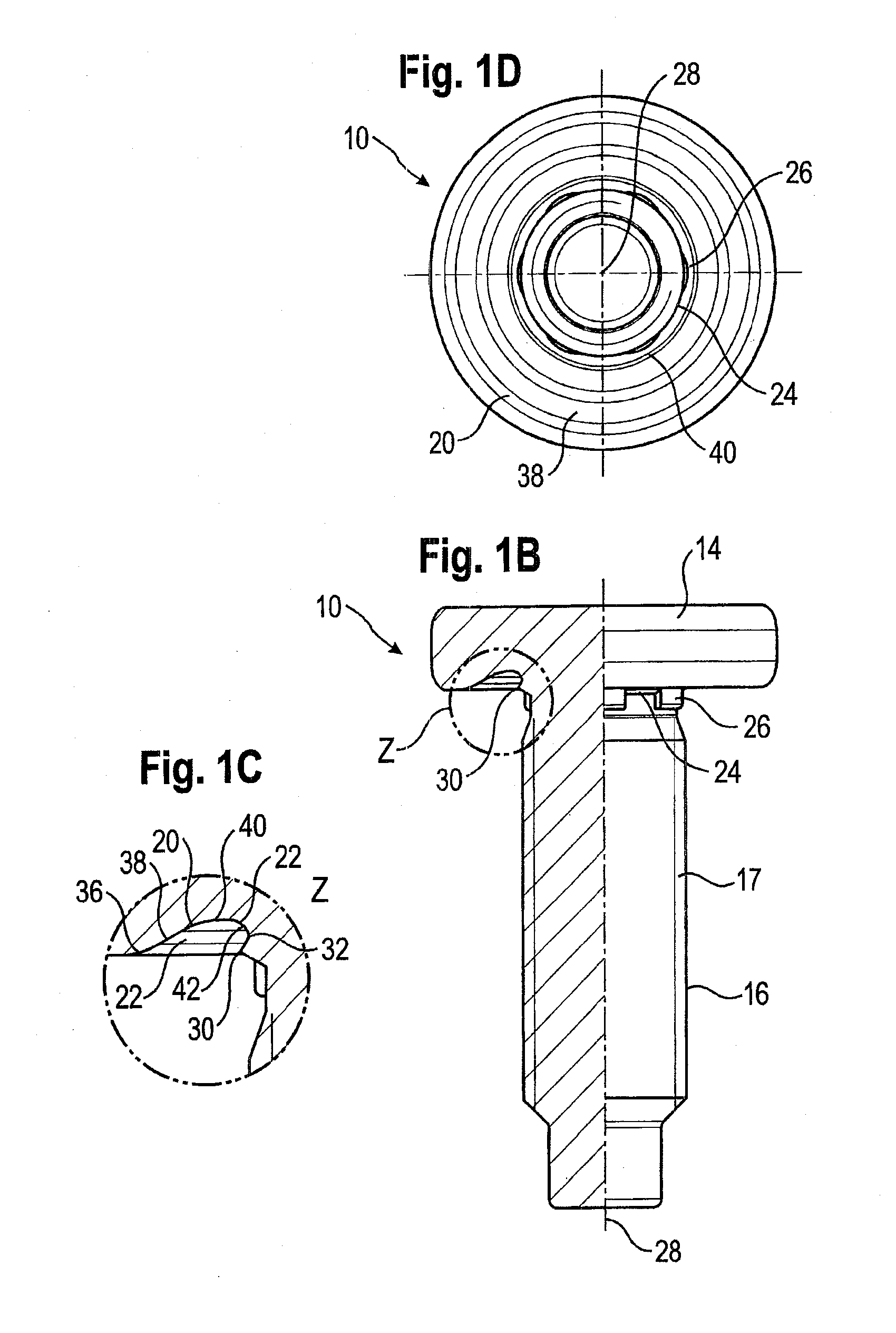

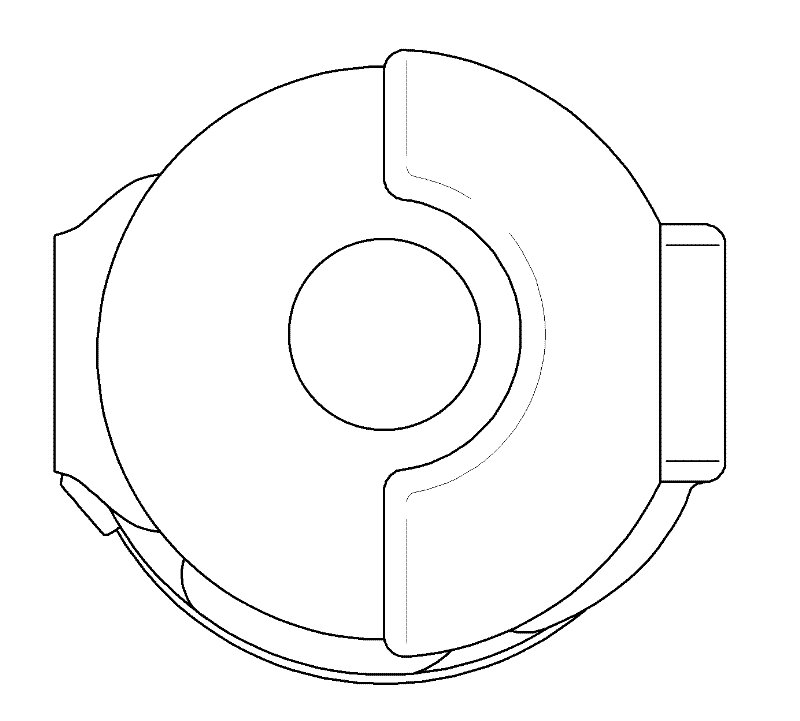

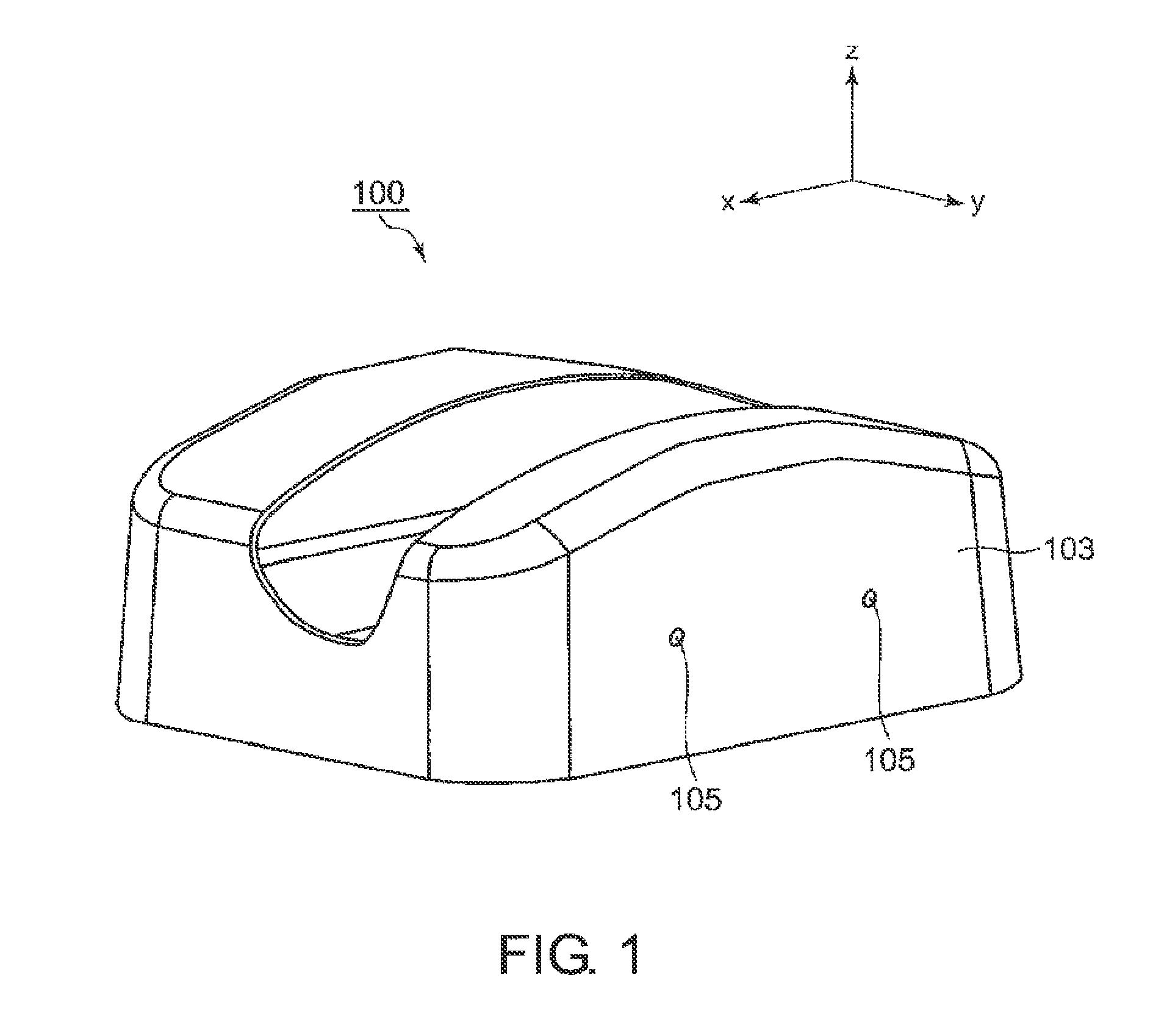

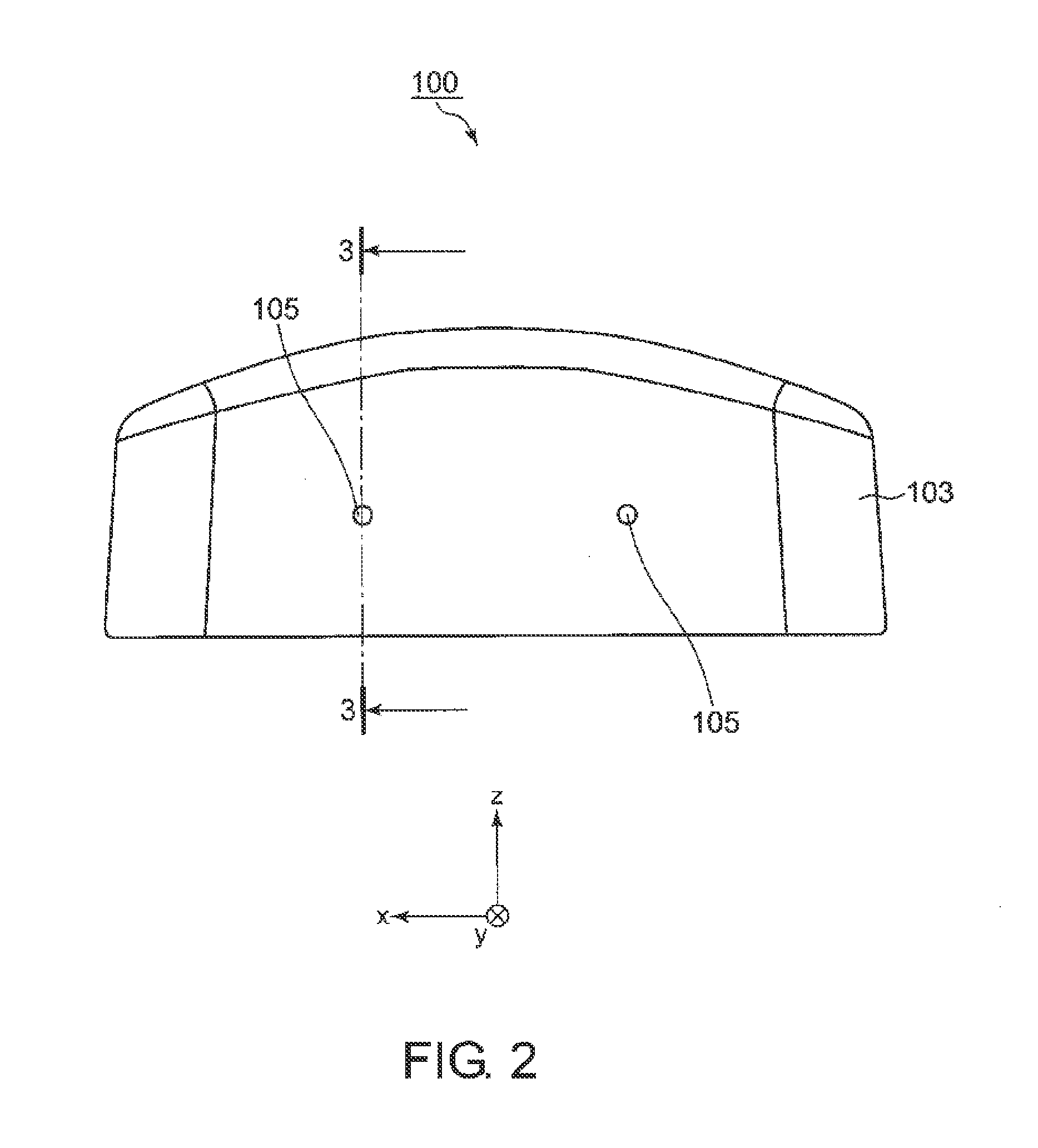

Undercut screw and matching bit

A threaded fastener, such as a screw or a bolt, has a central longitudinal axis in a z-axis direction. The fastener has a head and a threaded shaft. The head has an overhanging periphery in an x-y plane and at least two slots, evenly-spaced apart, that extend completely through the overhanging periphery. Each slot has a sloped surface that undercuts the overhanging periphery in the same tangential direction. The screw is turned by using a bit that has a central longitudinal axis in a z-axis direction. The bit has a shank fixed to an end portion and at least two legs, evenly-spaced apart, extend from the end portion in a z-axis direction. Each leg has a sloped surface that extends in the same tangential direction.

Owner:FUERLE RICHARD D

Cutting tool having clamping bolt provided with locking portion and cutting insert therefor

Owner:ISCAR LTD

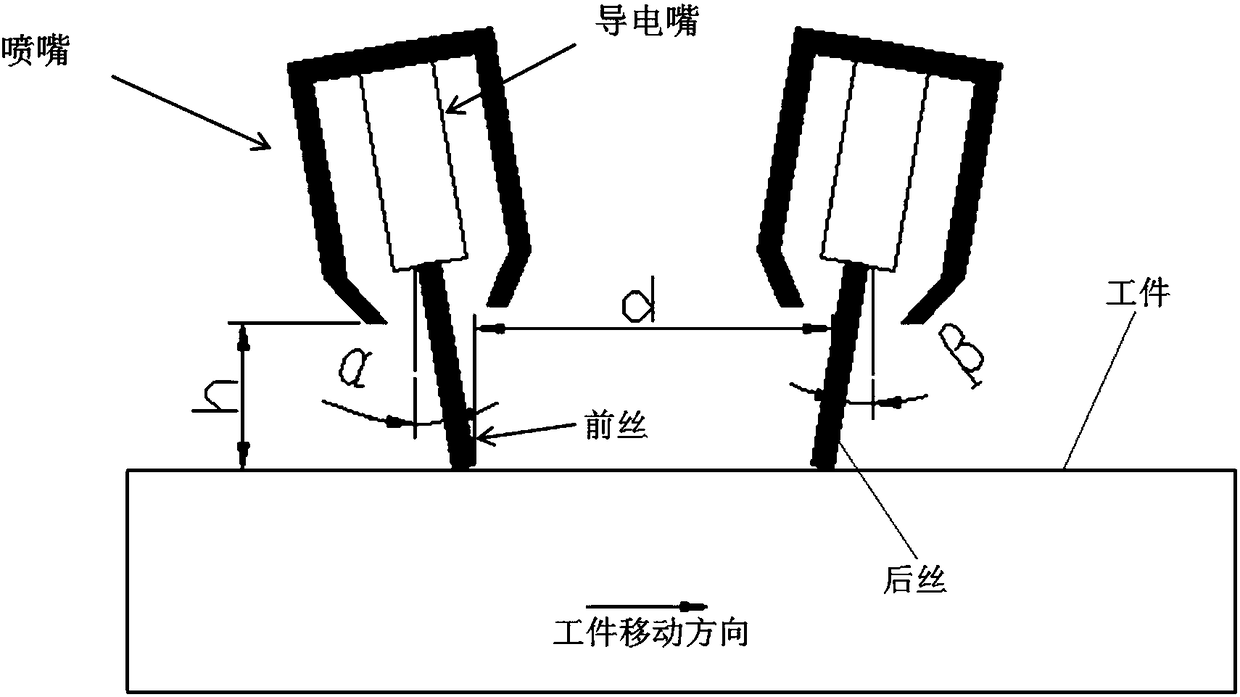

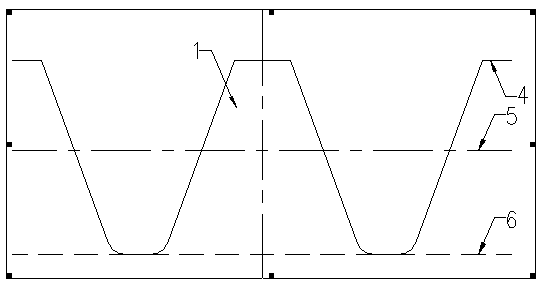

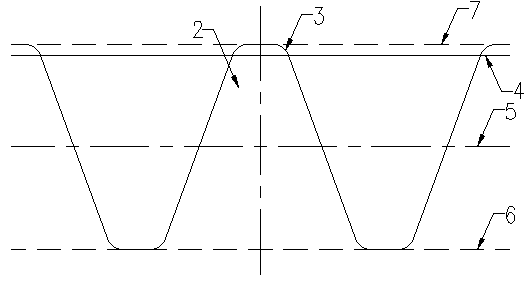

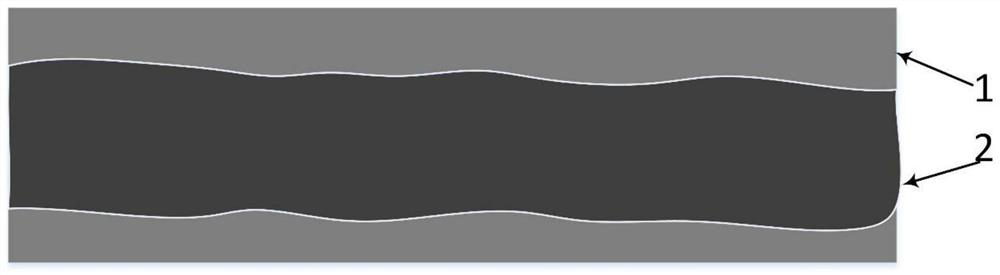

Ultrahigh speed double-wire common molten pool gas metal arc welding process for low carbon steel thin plate welding

ActiveCN108581142AImprove liquidityImprove heat distributionArc welding apparatusMelting tankButt welding

The invention relates to an ultrahigh speed double-wire common molten pool gas metal arc welding process for low carbon steel thin plate welding and belongs to the field of gas metal arc welding. Theprocess comprises the following steps: 1) grinding a to-be-welded region of a workpeice to dedust; 2) clamping two workpieces processed in the step 1) on a worktable capable of moving at a constant speed, wherein no slopes are needed in the workpieces; and 3) fixing a front welding gun and a back welding gun in tandem along the welding direction to the upper part of the to-be-welded region of theworkpeice in the step 2) for ultrahigh speed panel butt welding. The flowing process of molten metal in the molten pool and the heat distribution in the high speed welding process are improved and thefilling process of the molten metal to a weld bead is accelerated by regulating a front wire large current molten pool by means of a relatively small back wire pulse current, so that the defects of undercuts and humps easily generated by single wire welding can be prevented effectively; ultrahigh speed and high quality welding of low carbon steel of the thin plate is achieved at a welding speed reaching 3.4 m / min, the welding speed and the production efficiency are improved effectively, and the welding production cost is lowered obviously.

Owner:SHANDONG UNIV

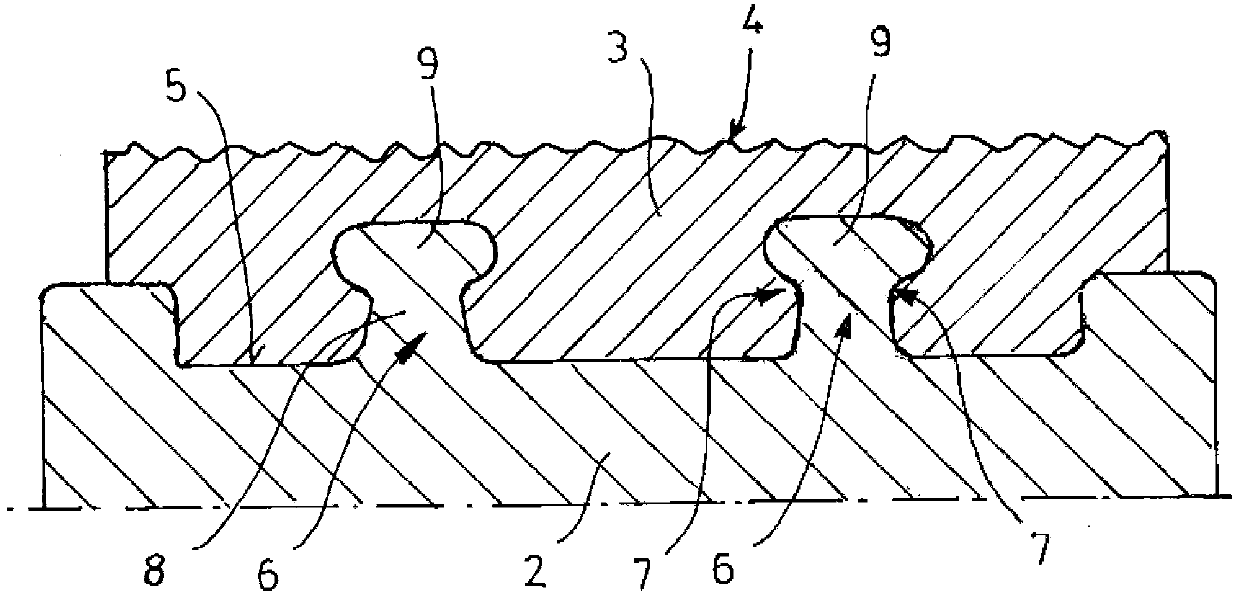

Method of producing composite component coated with friction layer

InactiveCN103132000AEasy DemoldingStrong connectionMolten spray coatingBraking discsThermal sprayingWear resistant

The invention relates to method of producing a composite component coated with a friction layer. A light-metal surface of a molded blank is provided with a friction layer by thermal spraying, and the light-metal surface is provided with projections during molding. The projections have an undercut in which a wear-resistant layer engages for connecting the light-metal surface. The projections are designed as pin-like elevations during the molding and distributed in a uniform spacing from each other on the surface to be coated, where the undercut is inserted into the projections after the molding step and before the thermal spraying step.

Owner:FORD GLOBAL TECH LLC

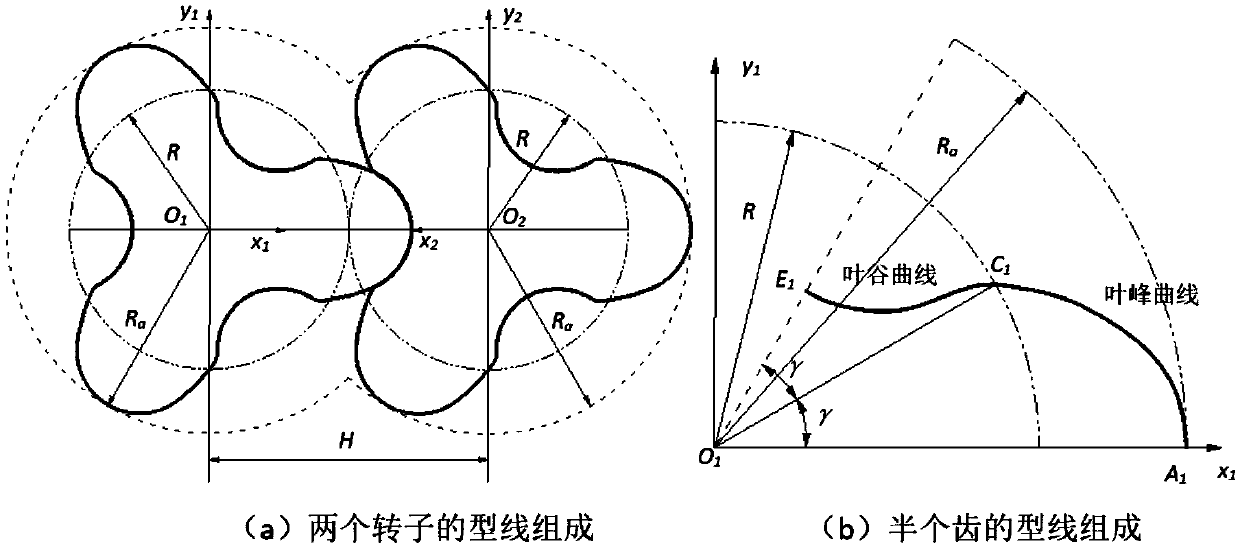

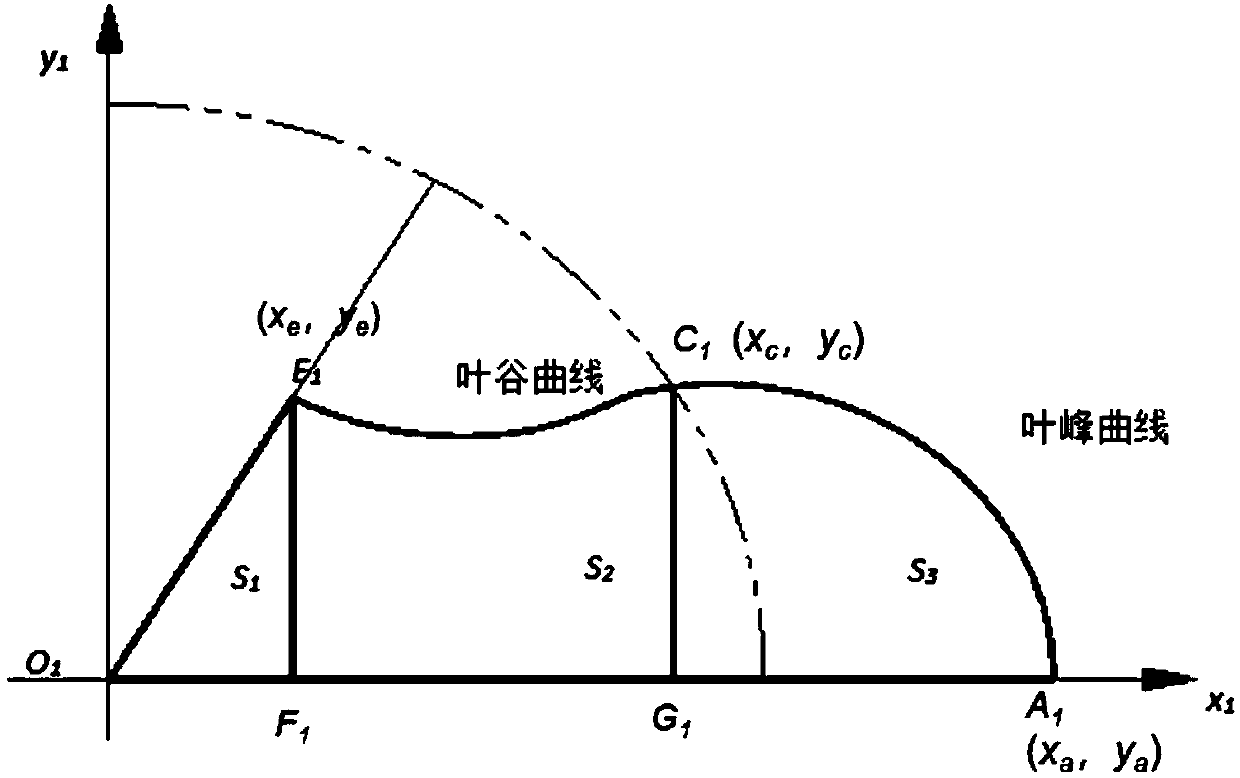

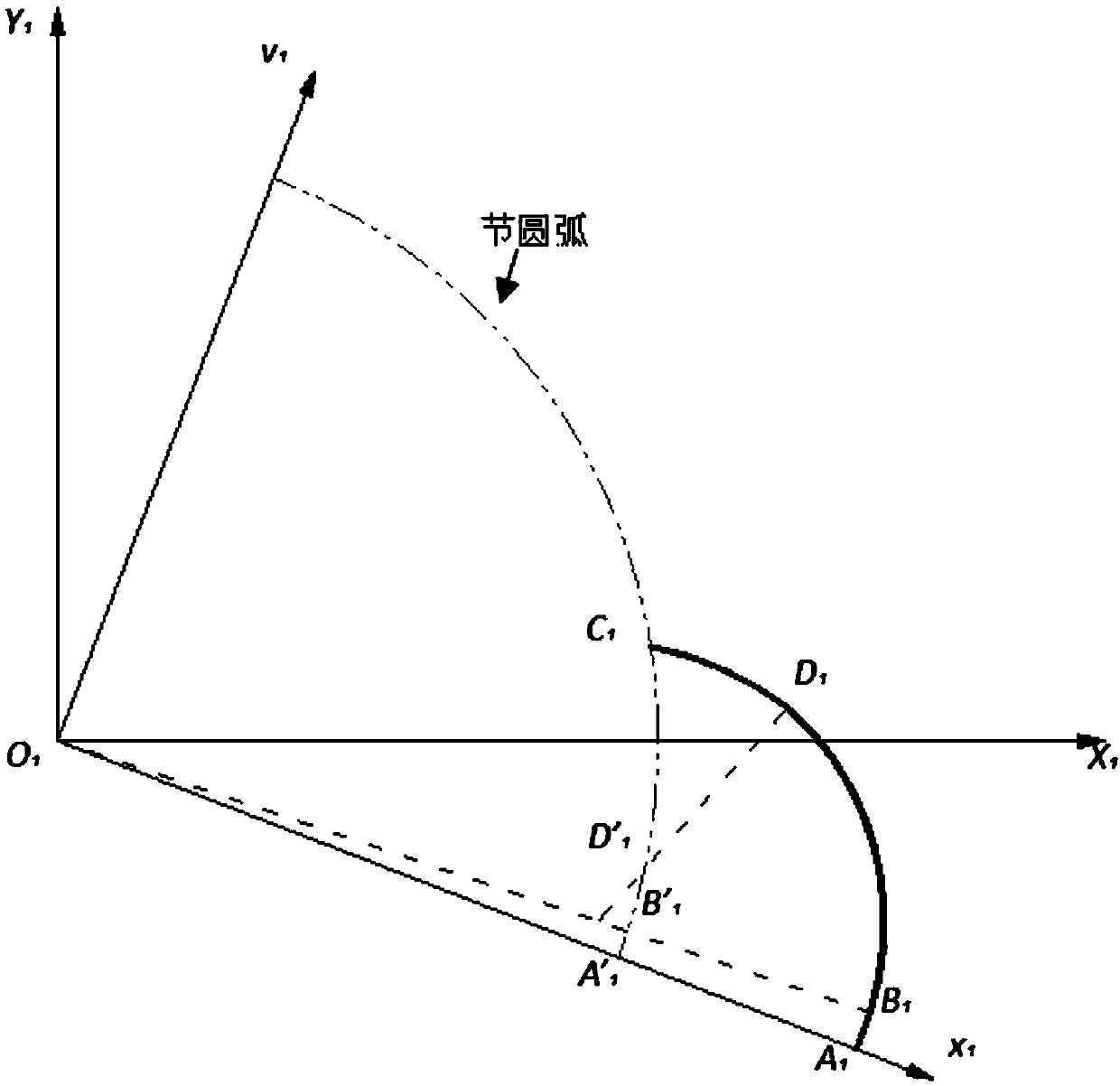

Method for determining reasonable design area of roots pump rotor molding line and application of method

ActiveCN109555681AUnreasonable designImprove design efficiencyRotary piston pumpsRotary piston liquid enginesEngineeringMechanical design

The invention discloses a method for determining a reasonable design area of a roots pump rotor molding line and an application of the method and belongs to the field of mechanical design. According to the method, after a relation between the roots pump rotor molding line and performance parameters is established, constraint conditions for avoiding the closing volume and undercuts are further determined, and thus, the reasonable design area of a roots pump rotor blade peak curve is determined; reference is given when the roots pump rotor molding line is designed, and in other words, a rotor molding line with a blade peak curves being not within the reasonable design area definitely cause the problem of the closing volume and the undercuts in application; so that when the roots pump rotor molding line is designed, the rotor molding line which can cause the closing volume and the undercuts can be avoided; the problem that the rotor molding line is not found being designed unreasonably until design is completed is avoided; and thus, the design efficiency of the rotor molding line is improved.

Owner:JIANGNAN UNIV

Method for eliminating undercut of involute gear

InactiveCN103234020AEliminate hazardsReduced bending strengthPortable liftingSpecial data processing applicationsSpur gearBevel gear

The invention relates to a method for eliminating undercut of an involute gear, and belongs to the technical field of transmission designs and manufacture of involute gears in mechanical equipment. Firstly, the minimum number of teeth which cannot cause undercut of the involute gear is calculated, and a calculation formula of the minimum number of the teeth which cause no undercut during processing is obtained when the involute gear is a straight toothed spur gear, a helical gear or a straight tooth bevel gear respectively; and then the involute gear is processed according to a calculation result, so that the involute gear without the undercut is obtained. The method can eliminate harms of intensity reduction caused by undercut.

Owner:KUNMING UNIV OF SCI & TECH

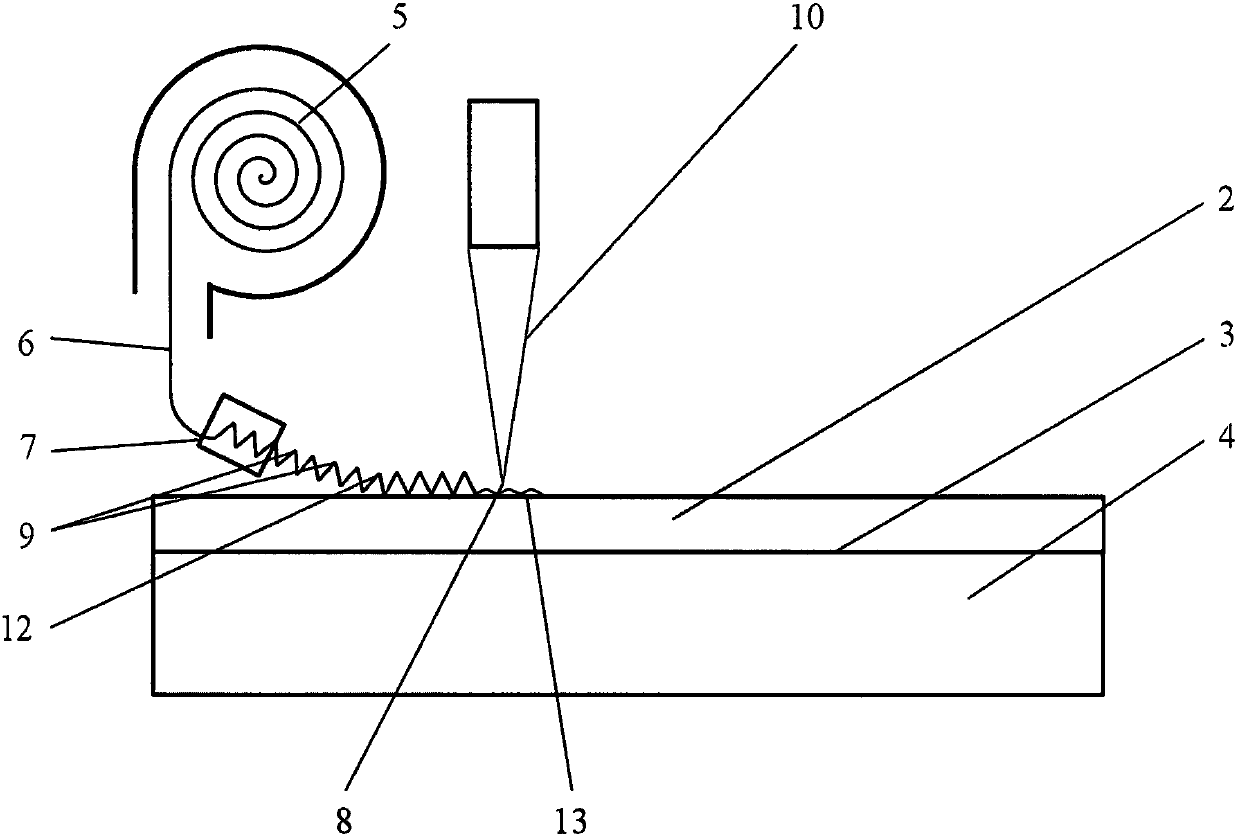

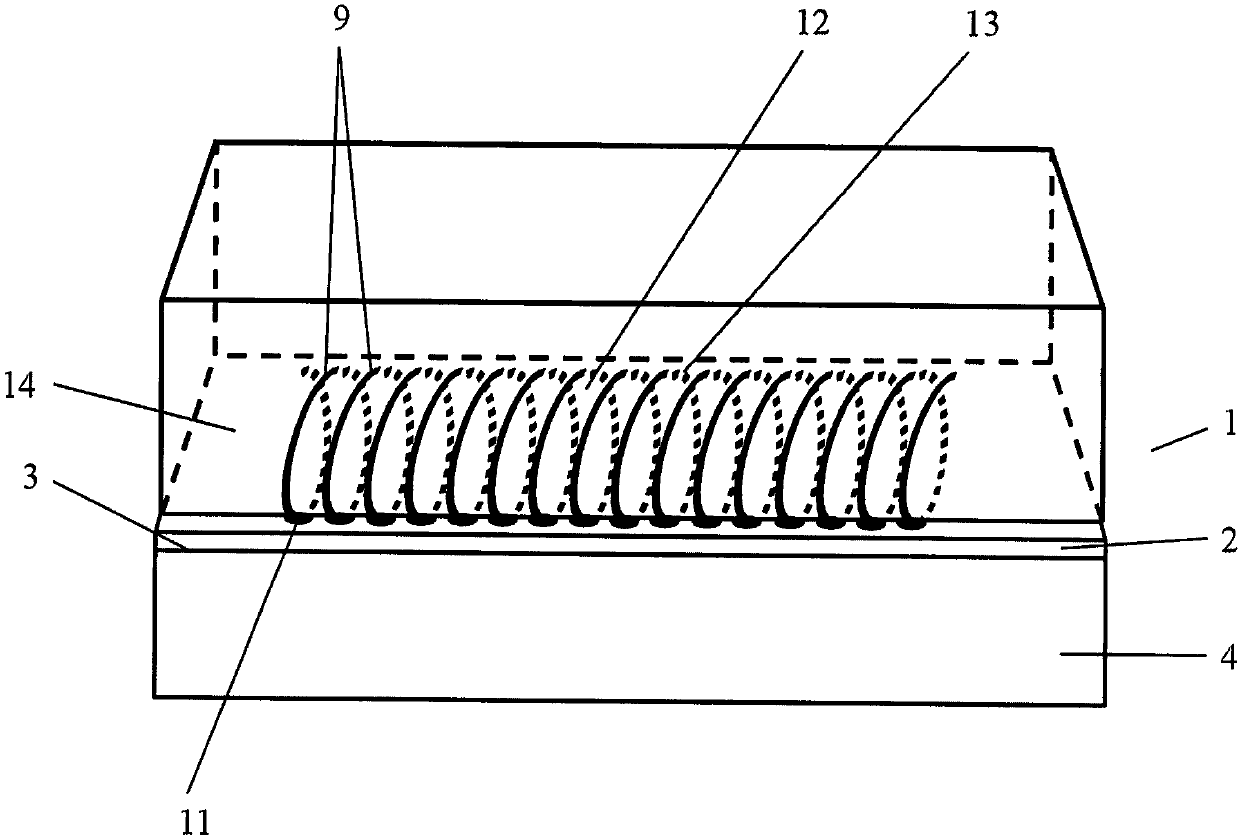

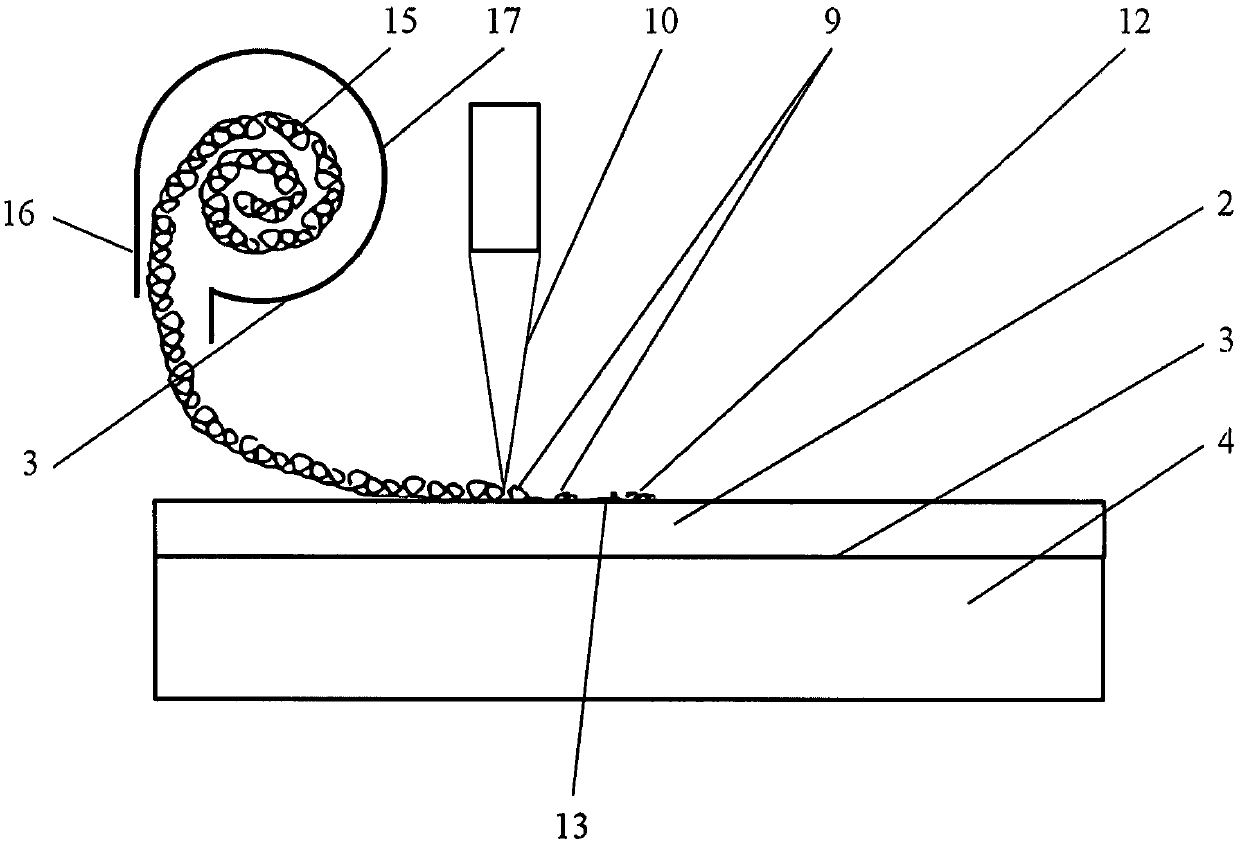

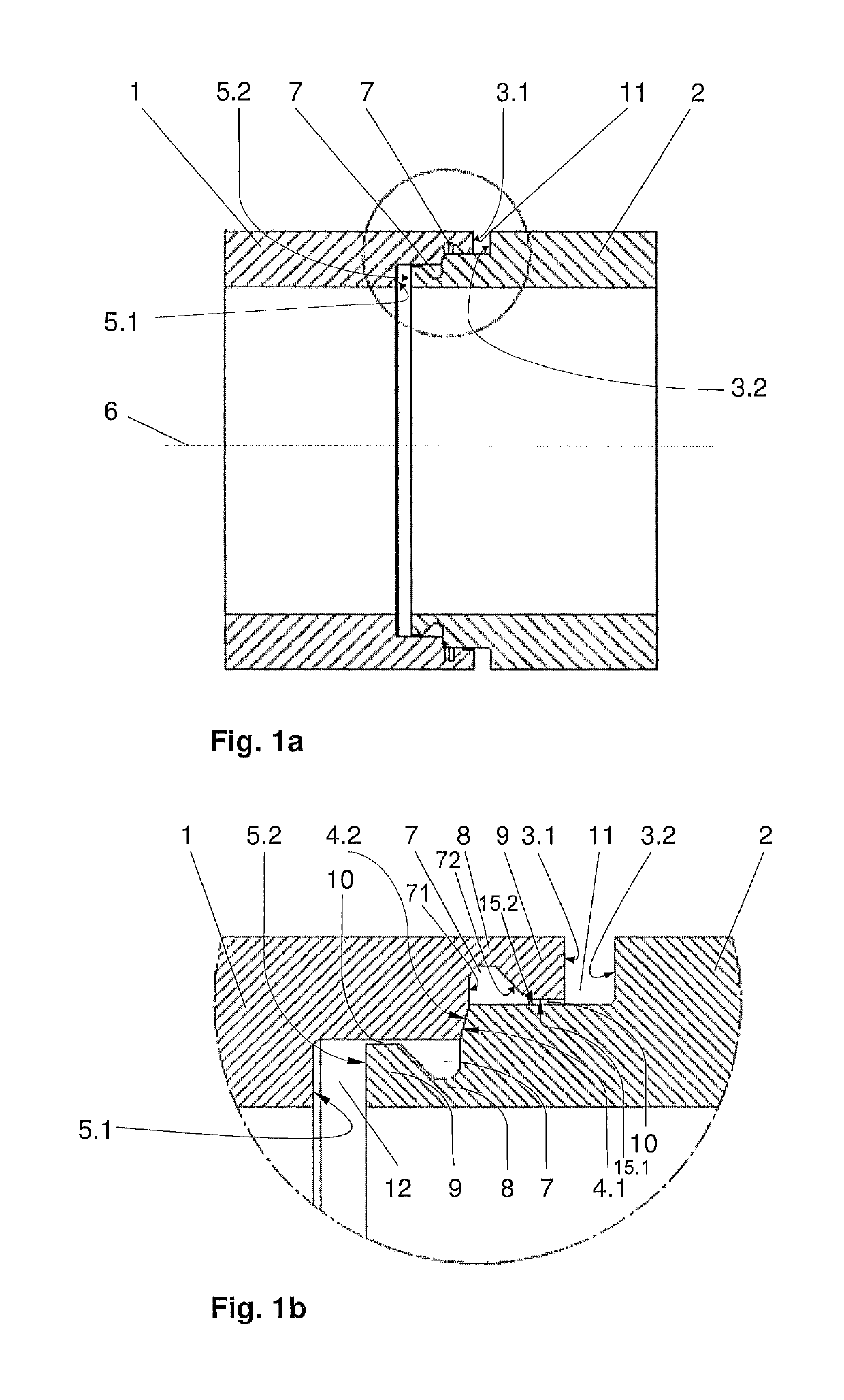

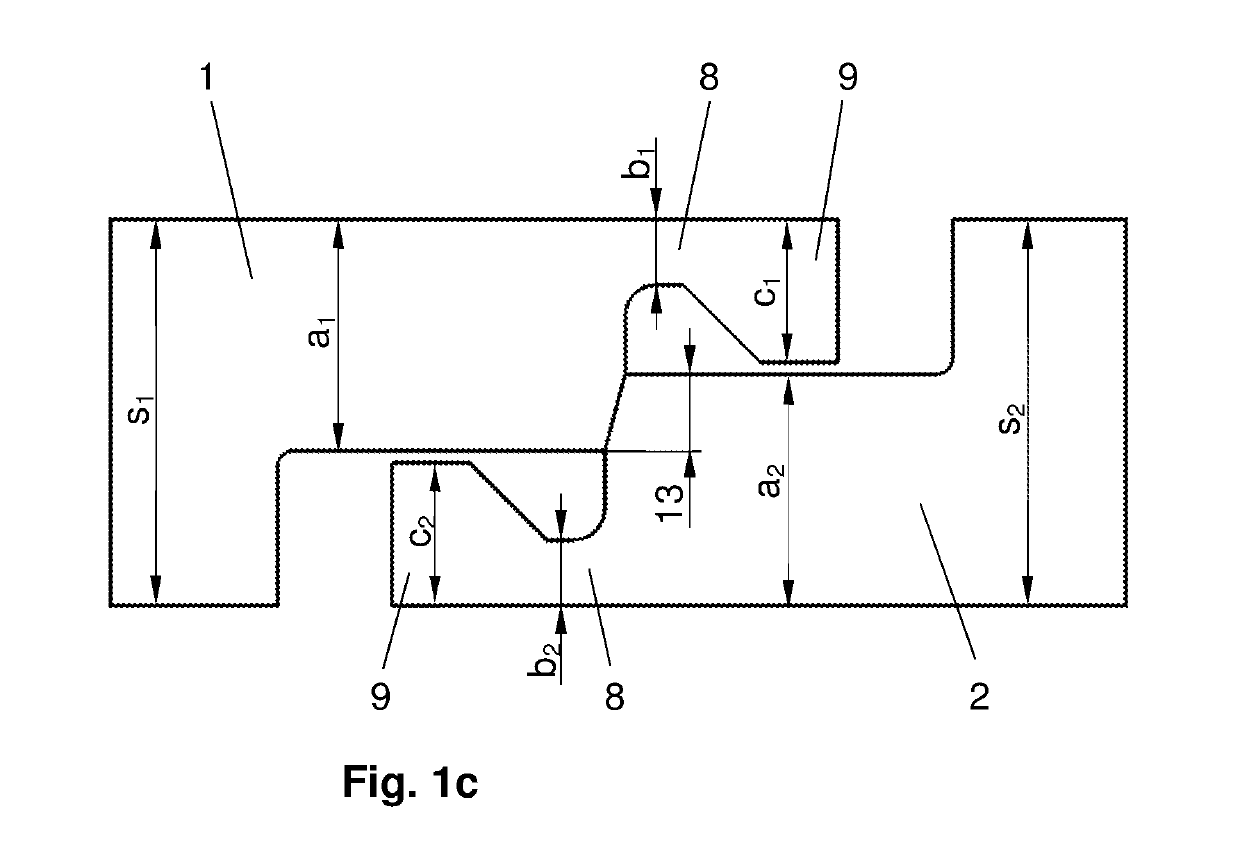

Method for producing a plastic-metal hybrid component

ActiveCN107921586ASmall sizeComposite feature optimizationMolten spray coatingVehicle componentsProtection layerSurface structure

The present invention relates to a method for producing a plastic-metal hybrid component (1), in which, in order to improve the adhesion of a metal surface (3), provided with a corrosion protection layer (2), of a base body (4) made from metal and at least one plastic component (14), the corrosion protection layer (2) of the metal surface (3) of the base body (4) is provided with a surface structure (13) having undercuts (12). In order to avoid damage to the corrosion protection layer (2) a filler material that binds well with the corrosion protection layer (2) is applied on the corrosion protection layer (2) in a specific and limited manner, in the form of successive, preferably metal elements (9) having geometrically determined and / or geometrically indeterminate shape, via relative movement with respect to same. The elements (9) of the filler material applied to the corrosion protection layer (2) are each melted, for example by means of a laser (10), and welded on the corrosion protection layer (2), producing the surface structure (13), having the undercuts (12), of the corrosion protection layer (2) of the metal surface (3) of the base body (4). In a subsequent direct spraying process, the undercuts (12) of the surface structure (13) are at least partially filled with a thermoplastic plastic component (14) in such a way that the latter engages in the undercuts (12), formingthe plastic-metal hybrid component (1).

Owner:INNOVATIONSGES FUR FORTGESCHRITTENE PRODN SSYST & DER FAHRZEUGIND

Method for testing undercut on the inner diameter of pipe welds

InactiveUS7405377B2Reduce and eliminate needArc welding apparatusMetal working apparatusEngineeringElectrical and Electronics engineering

Owner:LINCOLN GLOBAL INC

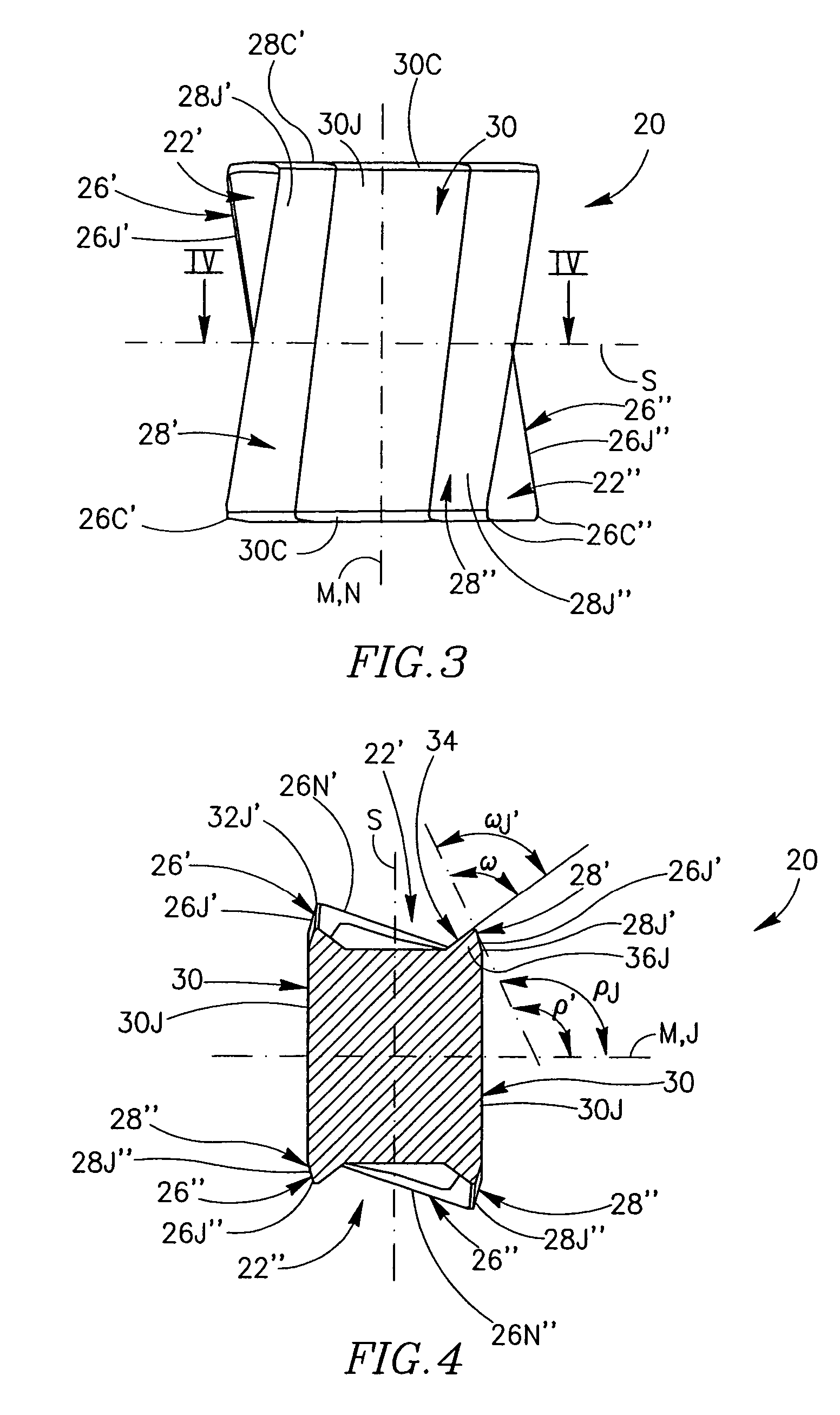

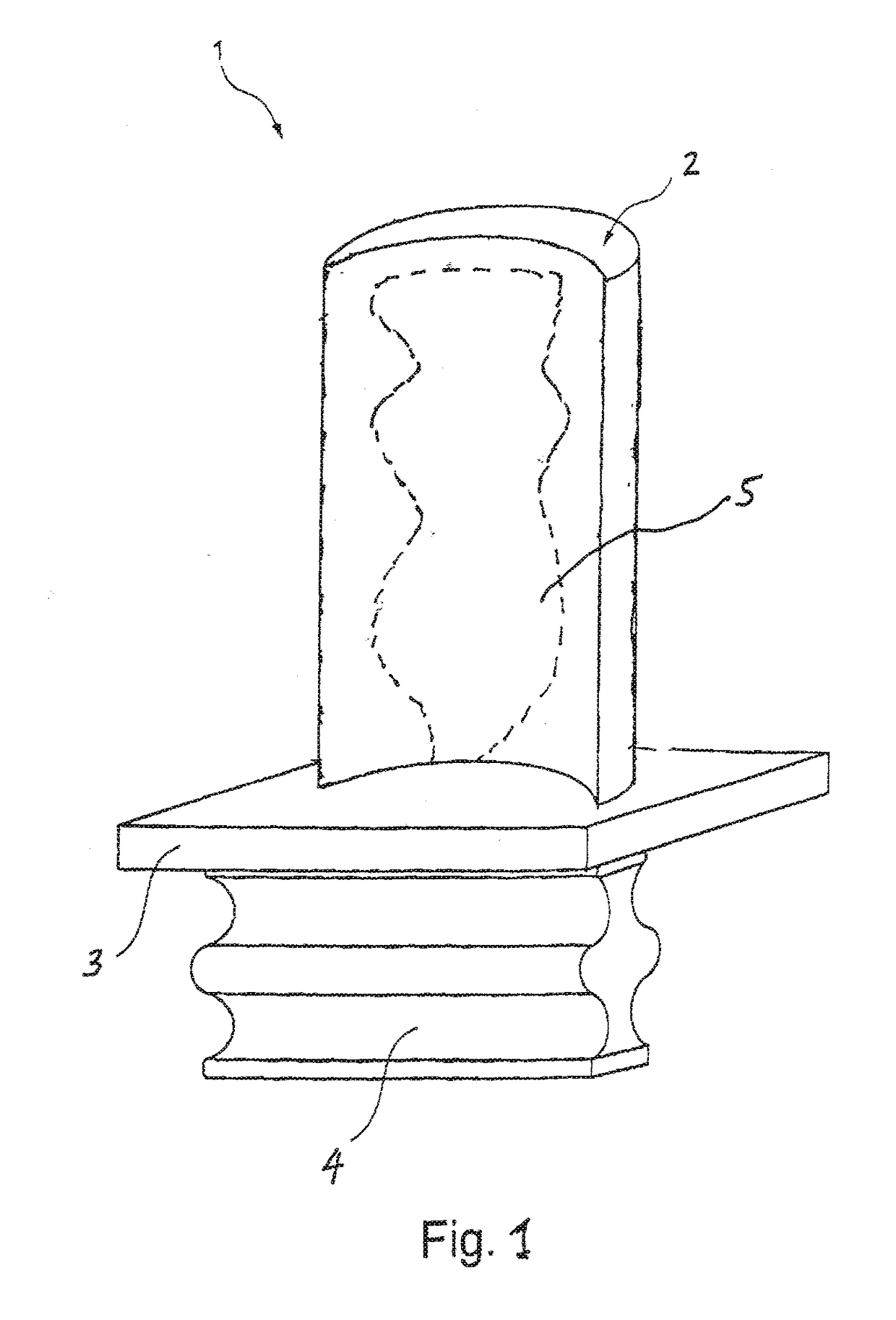

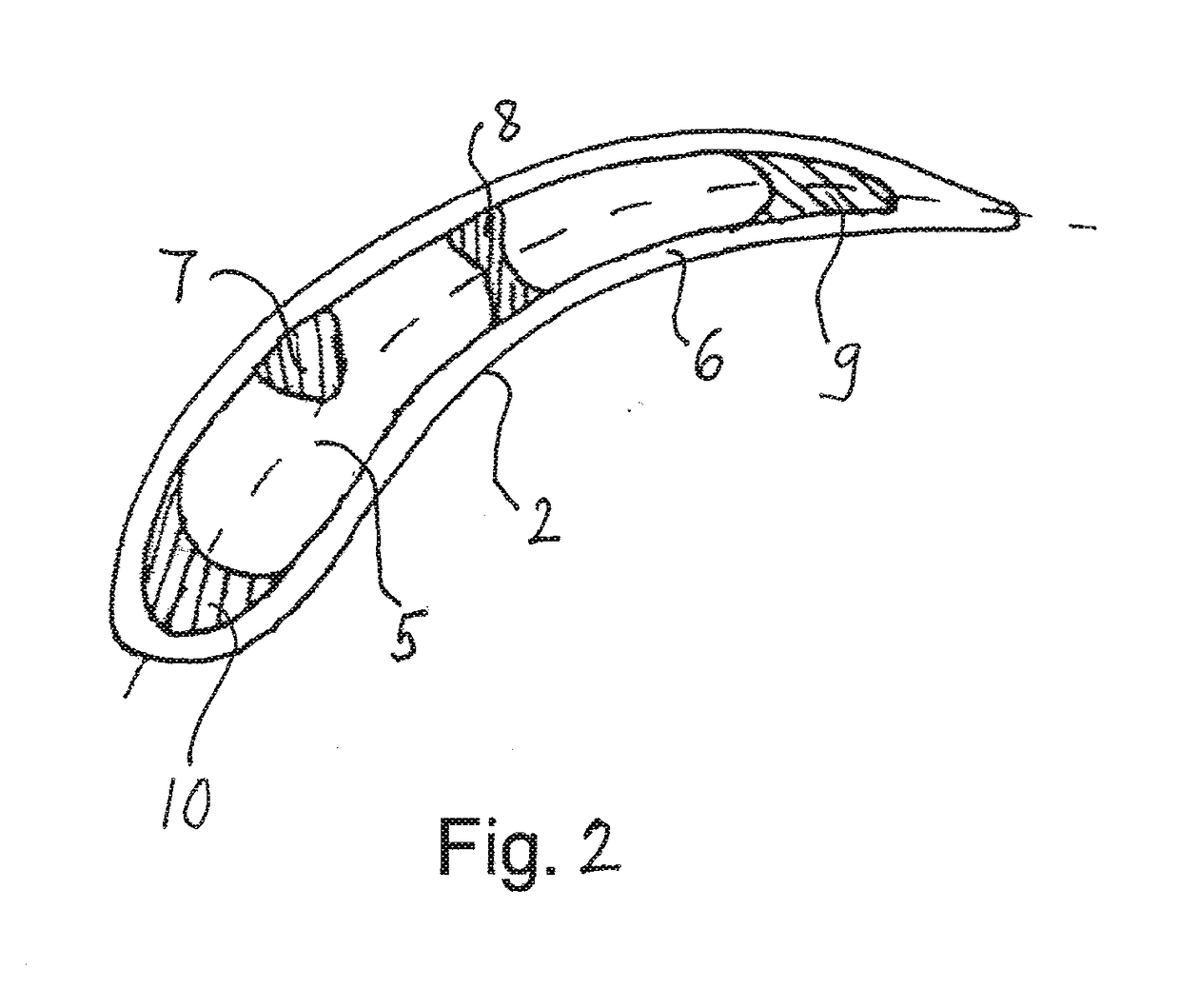

Turbine blade comprising a cavity with wall surface discontinuities and process for the production thereof

ActiveUS20180156037A1Hold steadyAvoid disadvantagesEngine fuctionsBlade accessoriesTurbine bladeEngineering

The invention relates to a turbine blade which comprises at least one cavity that is defined by a wall with one or more surface discontinuities preferably selected from elevations, depressions and undercuts. The blade may suitably be produced by a generative production method.

Owner:MTU AERO ENGINES GMBH

Joint-site structure for components to be connected by means of overlap friction welding, and method for connecting components by means of friction welding

ActiveUS10272520B2Guaranteed supportPipeline systemsMetal working apparatusFriction weldingRadial position

A joint-site structure for components to be connected by overlap friction welding. At least one step of at least one component, on which an axially set-back ring-shaped joining surface is situated, is provided with a radial undercut, in such a manner that on the face side, a region of this step that is unchanged in diameter forms a radial support ridge, which is connected with the at least one component by way of a heat throttle that is reduced in cross-section. The length of each step is designed in such a manner that when the face surface of the one component makes contact with the ring-shaped joining surface of the other component, the other face surfaces of these components, which surfaces lie opposite one another in the same radial position, are still exposed until completion of the friction-welding process.

Owner:IFA TECH

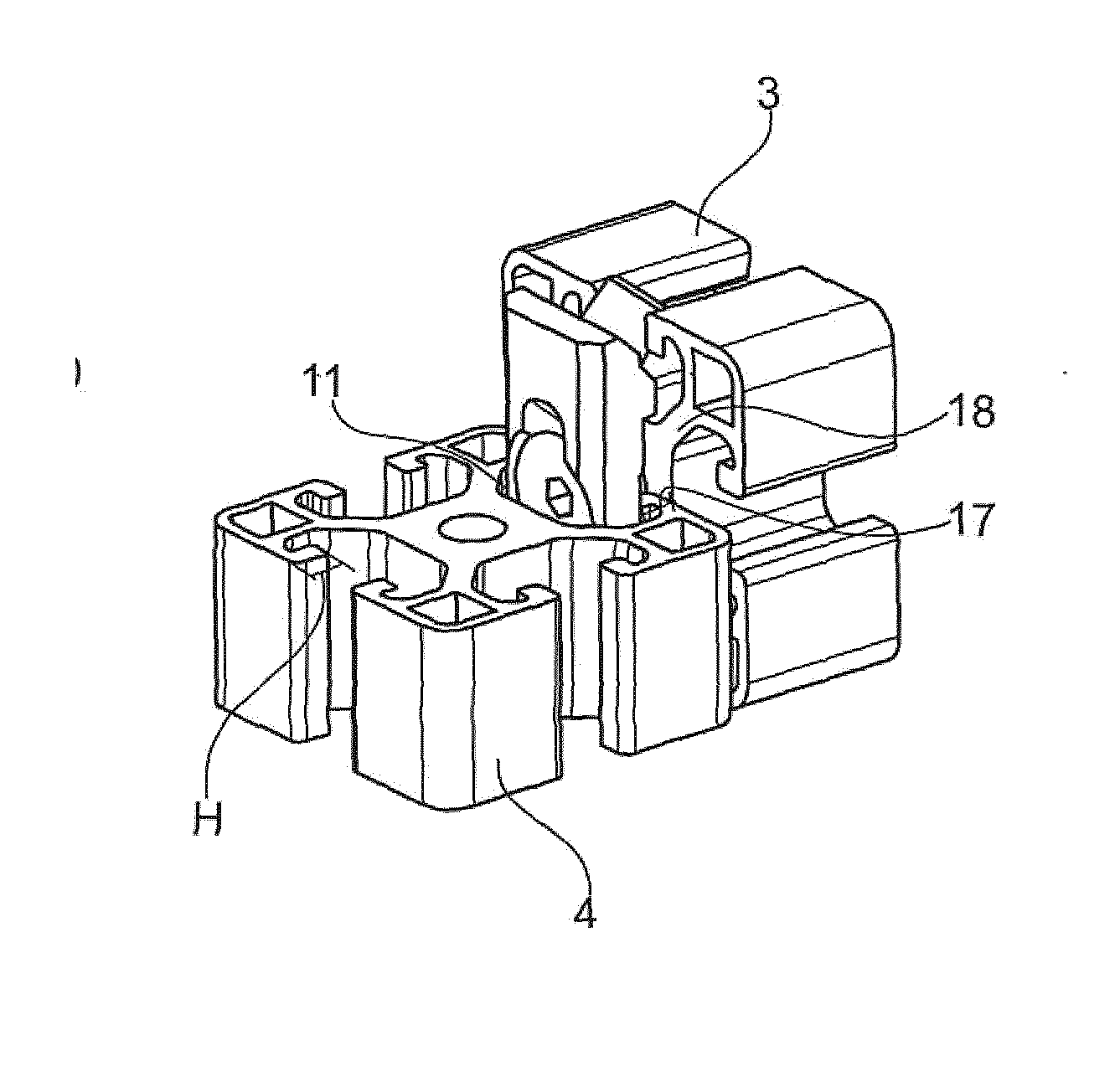

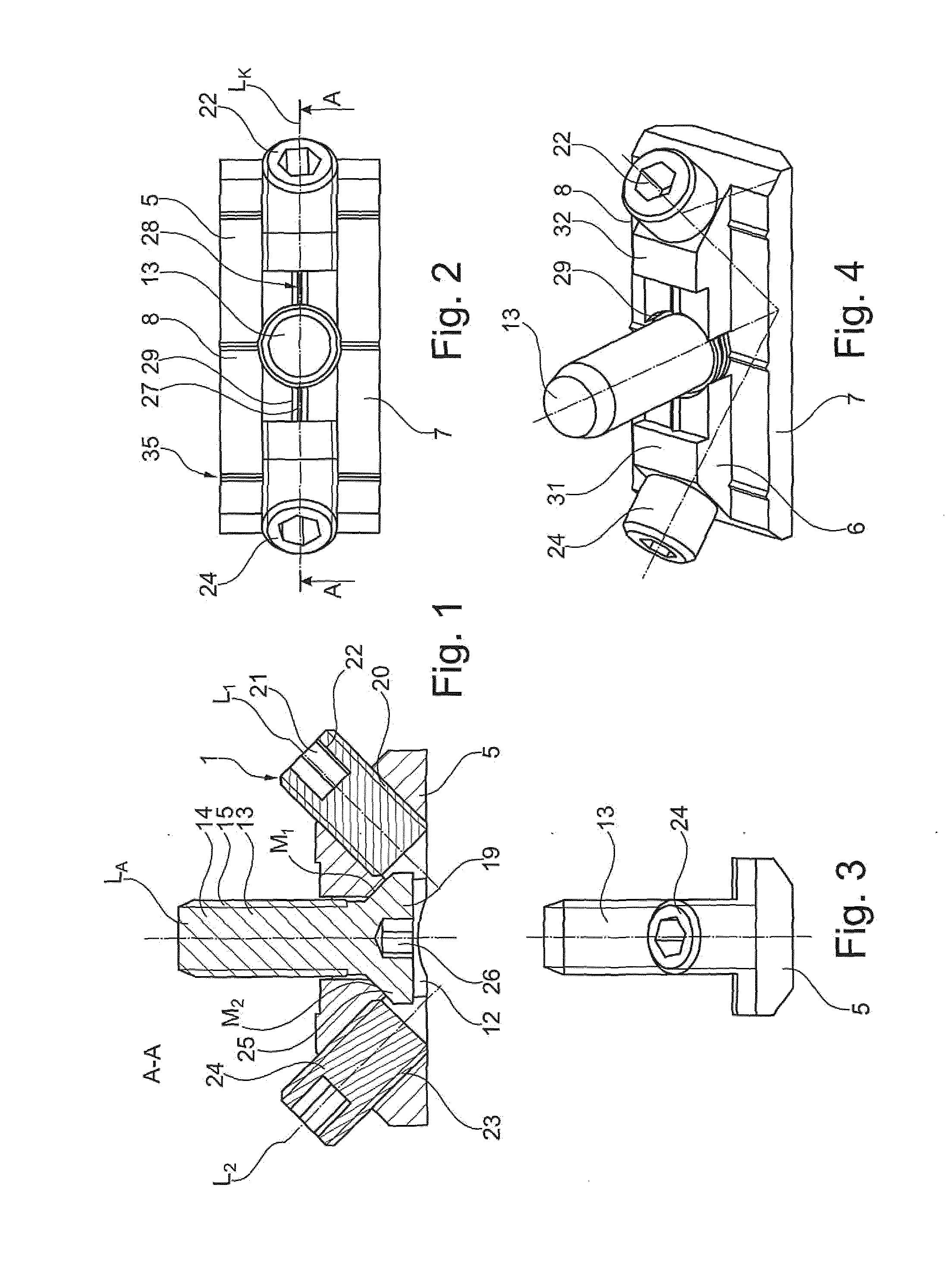

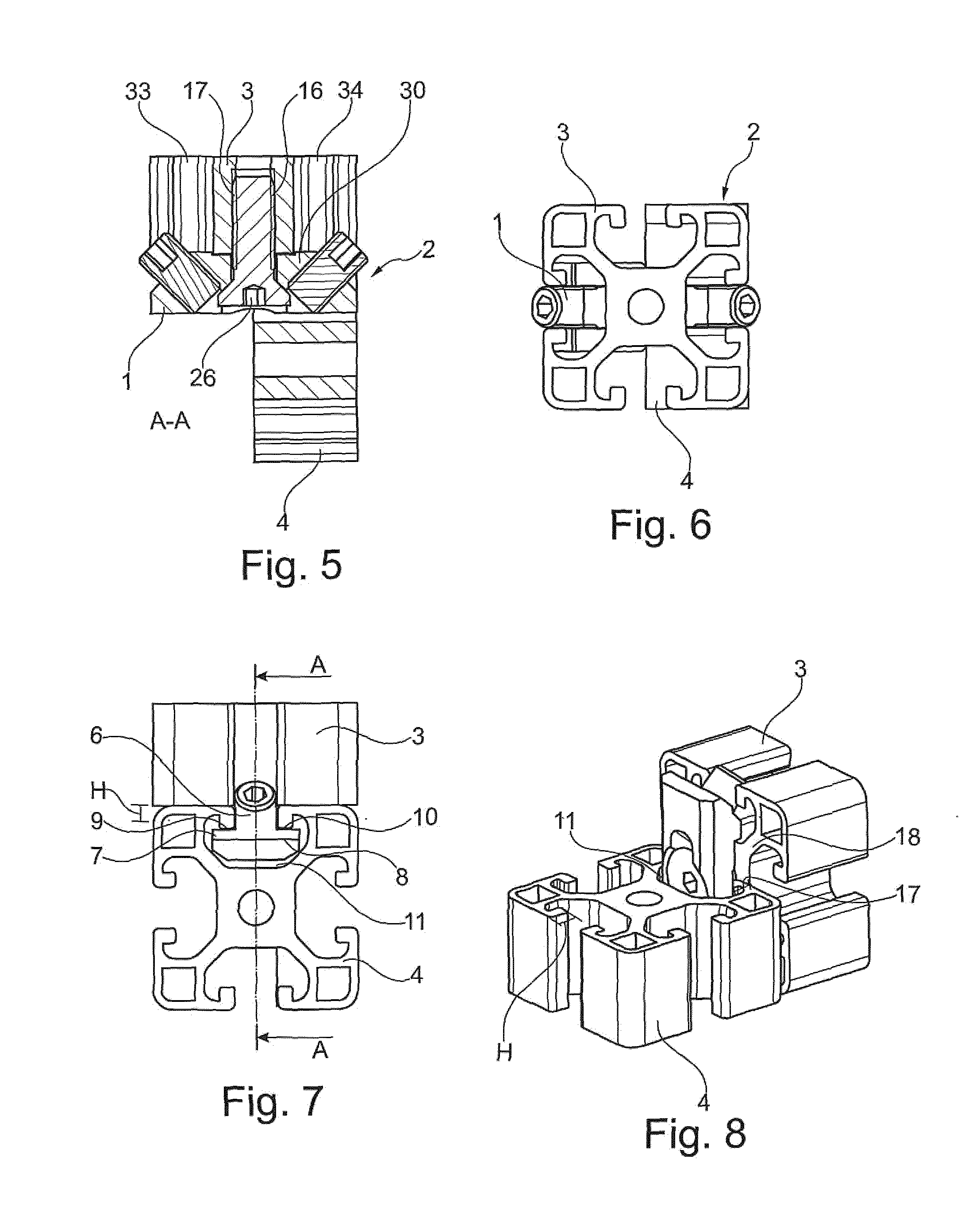

Profile connector and profile assembly

Profile connector for connecting a first and a second profile bar (3, 4), made from a light metal alloy, with a body (5) which can be accommodated in an undercut elongated groove (34) in the second profile bar (4) and has at least one bracing leg (7) for bracing against an undercut (9, 10) of the undercut elongated groove (34) of the second profile bar (4), and an anchor bolt (13) which is accommodated in a through opening (12) that is created in the body (5) and extends at right angles to a longitudinal extension of the body (5), which anchor bolt has an anchor bolt head and fixes the profile connector (1) frontally, on the first profile bar (3), and with a first clamping screw (22) accommodated in an internal threaded opening (20) provided inside the body (5) and extending at an angle to a longitudinal centre line (LA) of the through opening (12), which clamping screw serves to displace the body (5) along the anchor bolt (13) away from the anchor bolt head (19) towards the first profile bar (3) by tightening the first clamping screw (22) in the internal thread of the first internal threaded opening (20), thereby bracing the first clamping screw (22) on the anchor bolt (13), wherein a forming geometry (29) is conformed and arranged on the body (5) for shaping frontally into the first profile bar (3) by tightening the first clamping screw (22) to create a positive locking connection between the body (5) and the first profile bar (3).

Owner:FLAIG HARTMUT

Functional element in the form of a press-in element

The invention relates to a functional element in the form of a press-in element for attachment to a sheet metal part, wherein the functional element has a head part and a shaft part, the head part has a ring-shaped sheet metal contact surface at the side adjacent the shaft part and a ring-shaped axial recess inside this ring-shaped sheet metal contact surface and surrounding the shaft part at the transition from the head part into the shaft part. In accordance with the invention the shaft part has a plurality of circumferentially distributed radial recesses extending in the axial direction and between these noses which likewise extend axially and project radially, wherein raised material portions are present at the positions of the radial recesses at their axial ends adjacent the head part and form undercuts with the head part in the region of the ring-shaped recess.

Owner:PROFIL VERBINDUNGSTECHN

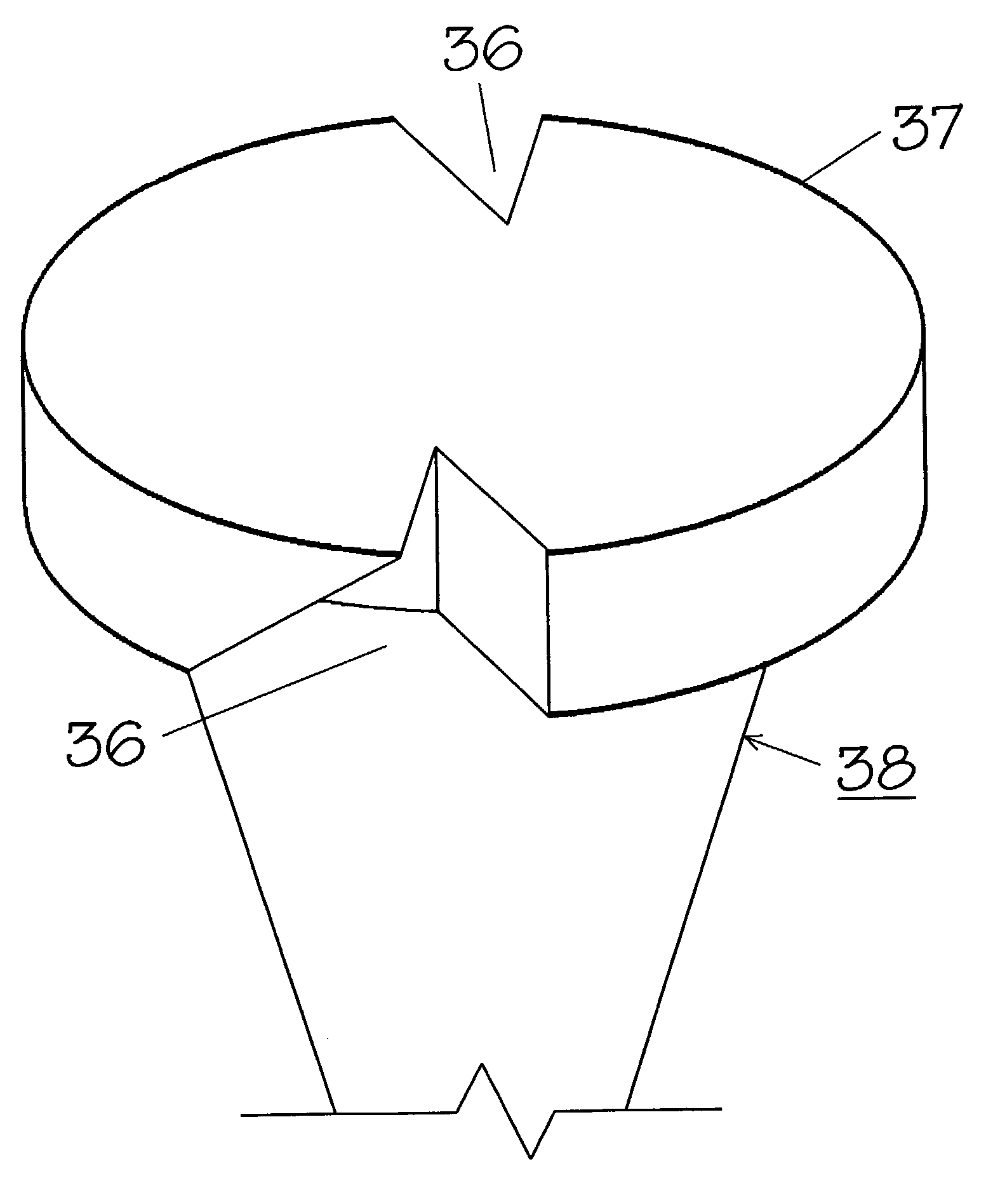

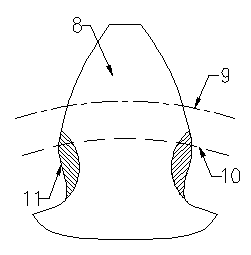

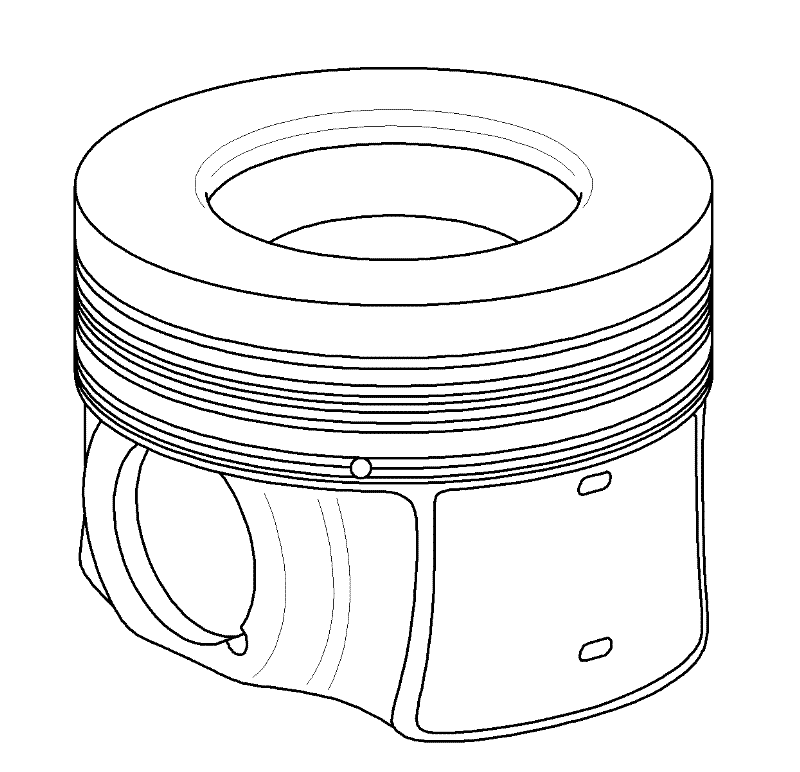

Sand casting a diesel piston with an as-cast, reentrant combustion bowl

A diesel engine piston and a method of making the piston. The method involves casting the piston with complex geometries, including undercut features. The casting uses an aggregate disposable mold that can be removed from the as-cast part. In one form, the complex geometry includes an undercut combustion bowl formed in the piston dome, while in another, it may include an internal cooling passage. The undercut bowl and internal passages may be produced using the aggregate disposable mold.

Owner:GM GLOBAL TECH OPERATIONS LLC

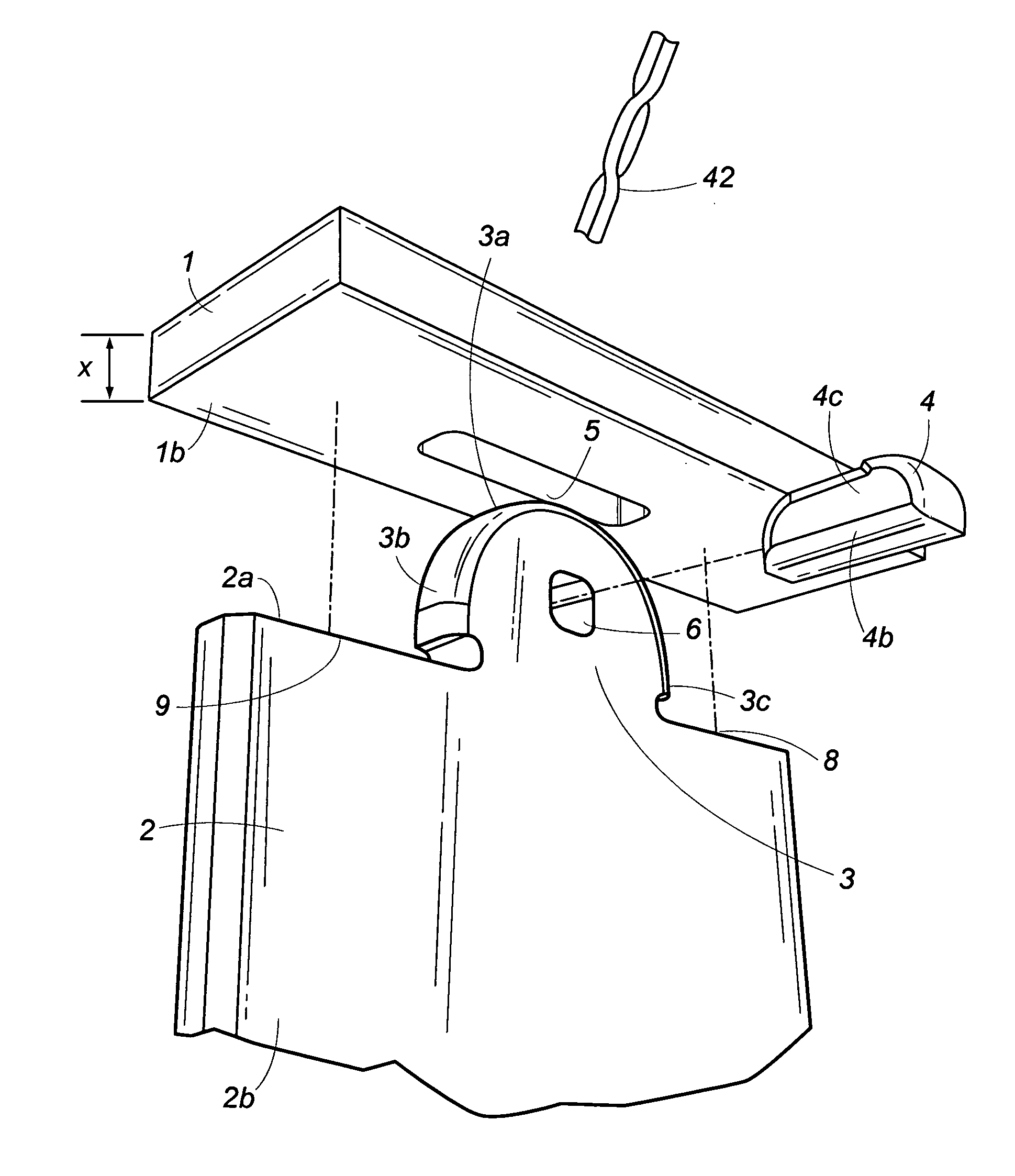

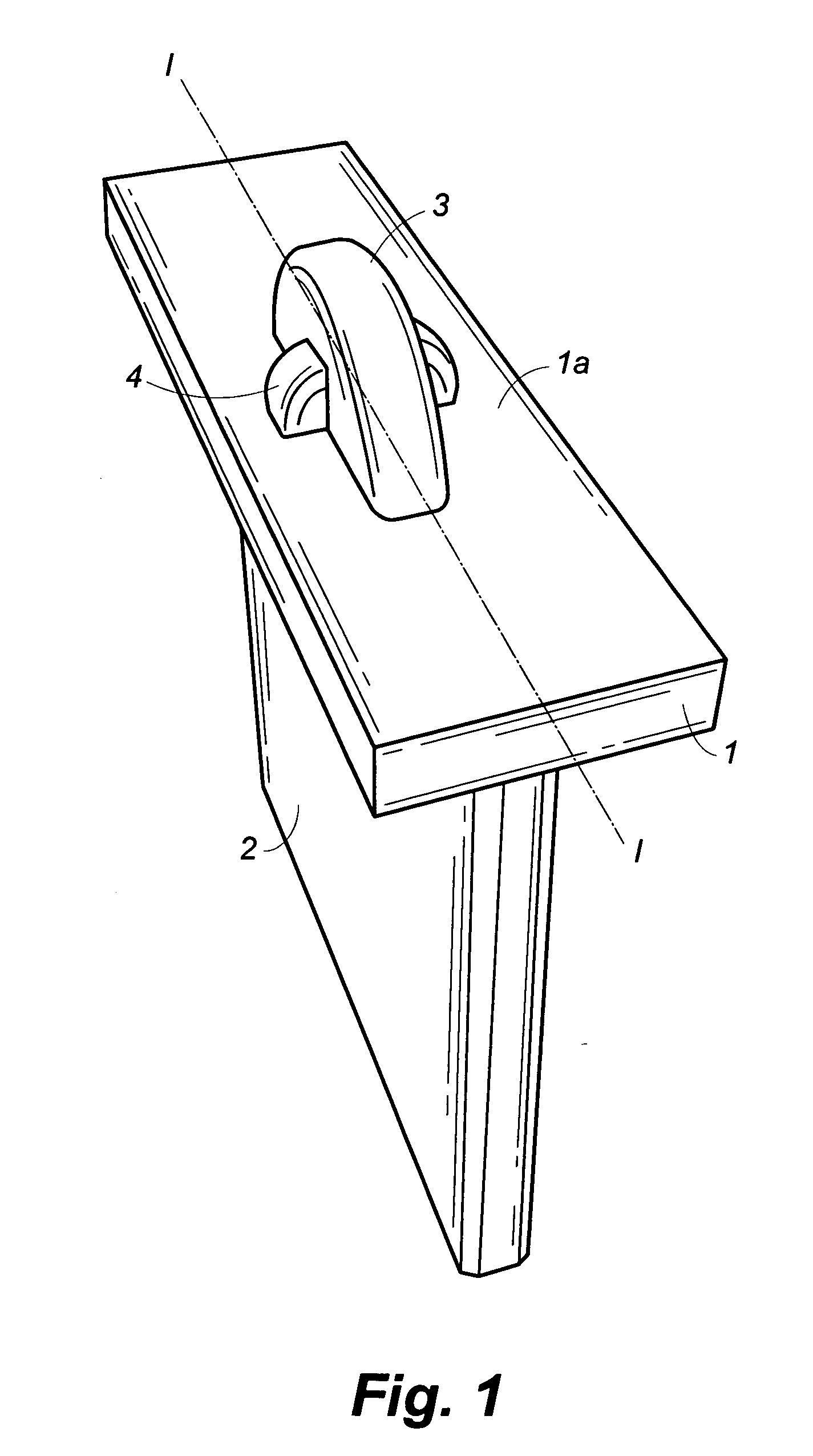

Method for forming a mortise and tenon for tool free joinder, and joint assembled therefrom

InactiveUS20120045278A1Relieve stressReduce gapDovetailed workMulti-purpose machinesRoundingMortise and tenon

A method for making two items and their joinder, one having a mortise and the other a tenon to enable a substantially flush, contiguous, void-free abutment. All cuts are made with a straight router bit having a diameter “Y” from a single sheet of substrate stock having a thickness “X” such that Y≦(½)X. In the mortise, corners are given a rounding defined by Y and a length “L1”. The tenon has a width substantially equal to L1 and a height “Z”, such that Z>2X. On the item having the tenon, at each of the two opposing locations defined by the intersection of the tenon with the shoulder of the item from which the tenon is cut (and also defining a shoulder line from shoulder to shoulder), an additional undercut is given at a minimal, linear displacement sufficient to enable, upon joinder, the mated surfaces of the two items to appear in flush, contiguous, void-free abutment with minimal reduction in the strength of the join. The tenon further has a substantially rectangular peg-receiving aperture set at distance substantially equal to X from the shoulder line, and having a height “H”, such that H=X. A locking peg has a cross-section substantially conforming with the peg-receiving aperture. Rounding of the peg proximate to the undercuts is made with a rounder at a radial rounding substantially equal to (½)Y. The product of the method is also shown.

Owner:SCHOOLEY FRANK W

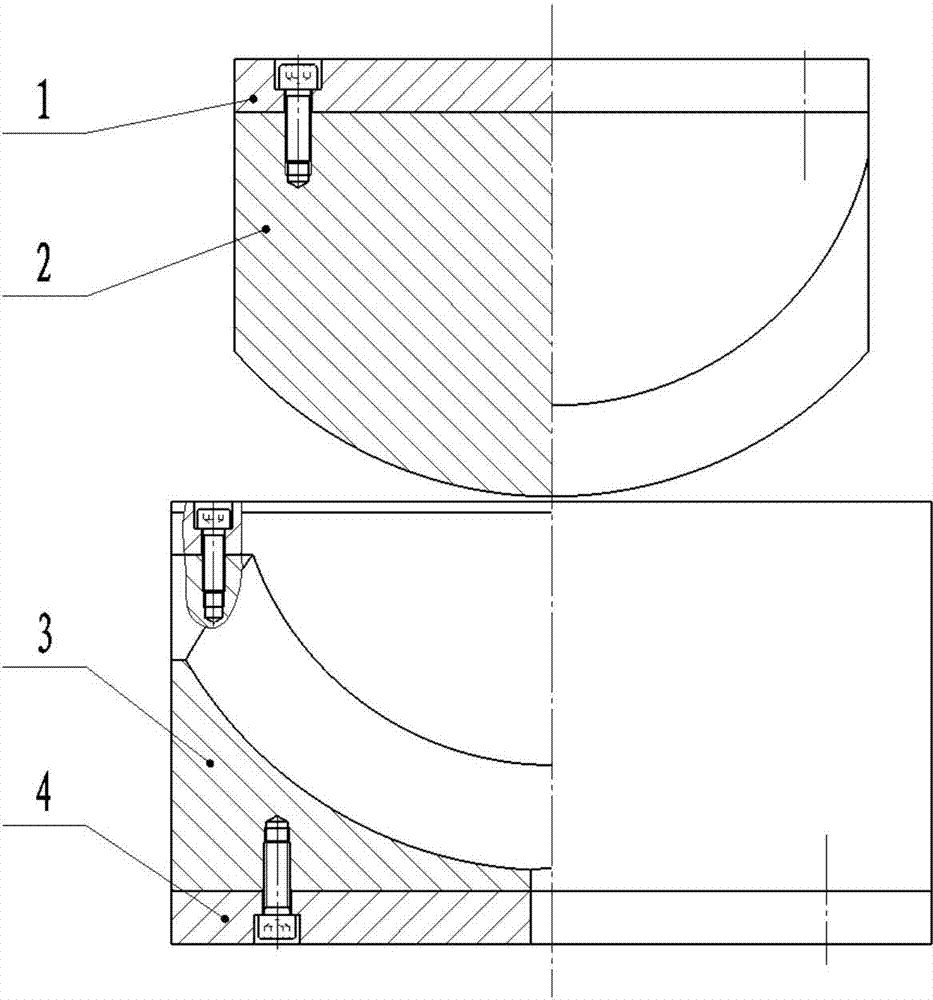

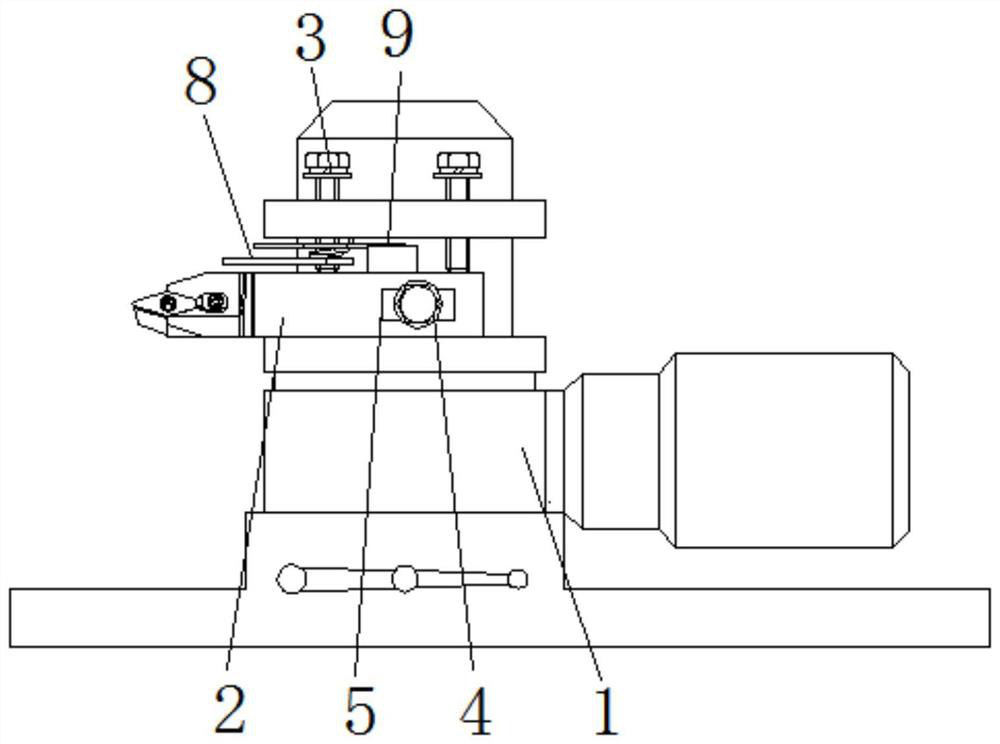

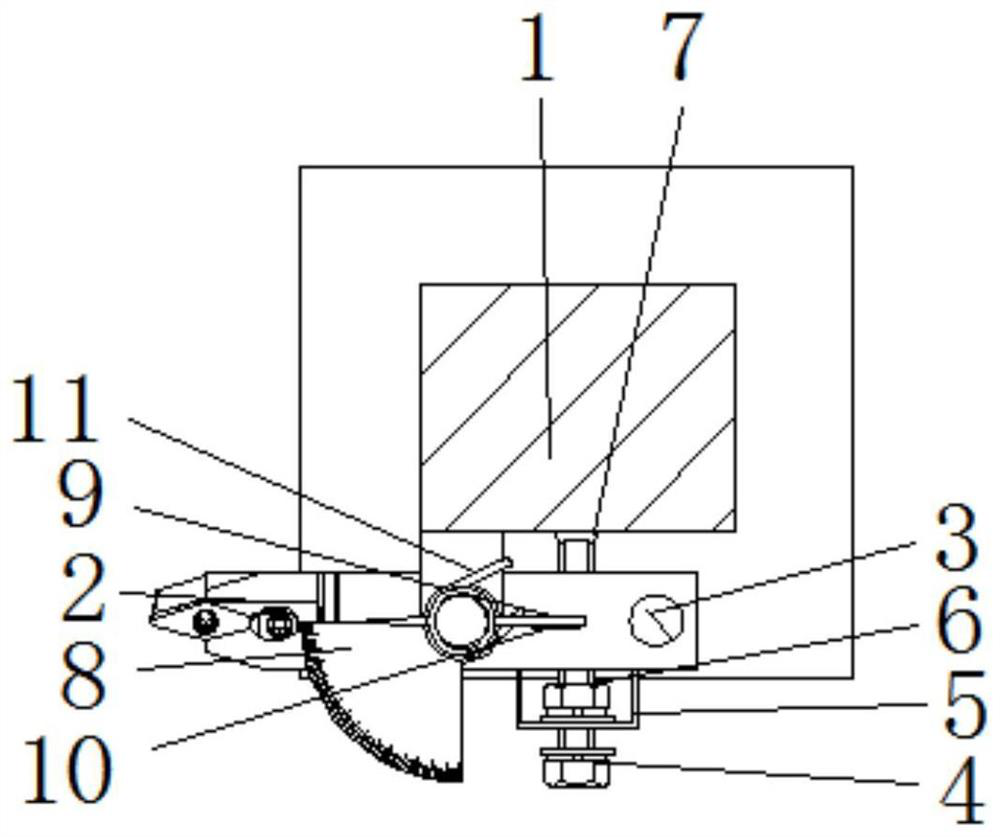

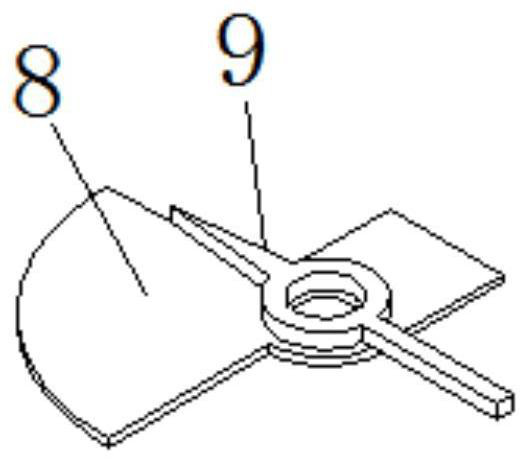

Railway conical rolling bearing inner sleeve raceway grinding undercut machining tool and manufacturing method

PendingCN114589323ALower purchase costShorten adjustment timeMeasurement/indication equipmentsTurning toolsNumerical controlRolling-element bearing

The invention discloses a railway conical rolling bearing inner sleeve raceway grinding undercut machining tool and a manufacturing method, and belongs to the technical field of railway conical rolling bearing inner sleeve raceway grinding undercut machining tool clamping. The device comprises a tool rest and a tool, the tool is arranged in the tool rest, tool pressing bolts are arranged on the left side and the right side of the top of the tool rest, the bottom ends of the tool pressing bolts sequentially penetrate through the tool rest and the tool and extend into the tool, and an adjusting bolt is arranged on the front face of the tool. The rear end of the adjusting bolt penetrates through the tool and makes contact with the surface of the tool rest. The problems that when an existing numerical control machine tool machines a bearing inner sleeve raceway flange grinding undercut, interference is caused by normal clamping of a machining tool of a conventional model, the requirements for the size and angle of the grinding undercut cannot be met, various special tools are needed due to the fact that products are various in variety and not unique in size, the production cost is greatly increased, multiple times of edge grinding clamping and tool setting are needed, and the machining efficiency is high are solved. The working efficiency is greatly influenced, batch product processing cannot be met, and the product quality cannot be fully guaranteed.

Owner:宁夏西北轴承装备制造有限公司

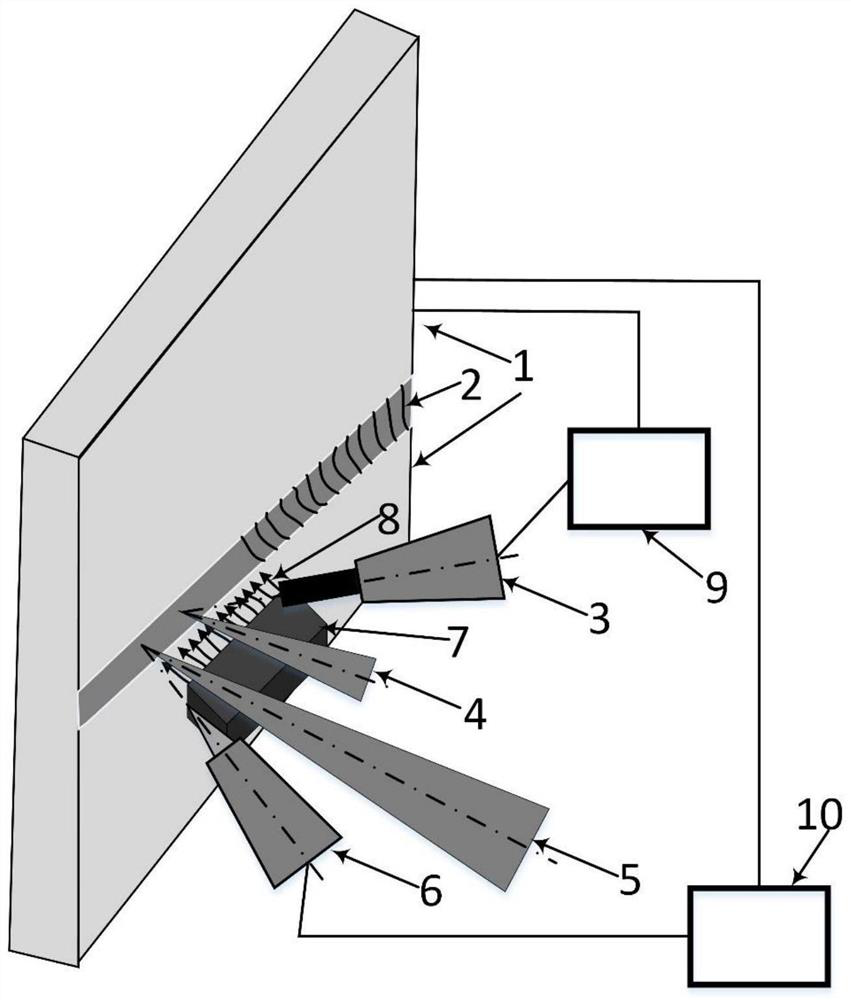

Double-beam laser arc composite single-surface horizontal position welding method and device

The invention provides a double-beam laser arc composite single-surface horizontal position welding method and device. The welding method comprises the following steps: carrying out surface treatment on a welding workpiece, and fixing the welding workpiece; arranging a double-beam laser arc composite device and an air injection device on the to-be-welded side of the welding workpiece; and setting welding process parameters, starting the air injection device and the double-beam laser arc composite device, and carrying out horizontal position welding. A horizontal position welding device used in the welding method comprises a double-beam laser arc composite device and an air injection device. The double-beam laser arc composite device comprises a TIG welding gun, a first laser, a second laser and a GMAW welding gun which are sequentially arranged in the welding direction. The air injection device is placed on the side edge below the first laser device, and the flow and the direction of a sprayed shielding gas can be adjusted. According to the welding method, the problems of incomplete fusion and undercut of the side wall are solved, the porosity of a welding seam is reduced, and the welding efficiency is improved.

Owner:NORTH CHINA UNIV OF WATER RESOURCES & ELECTRIC POWER

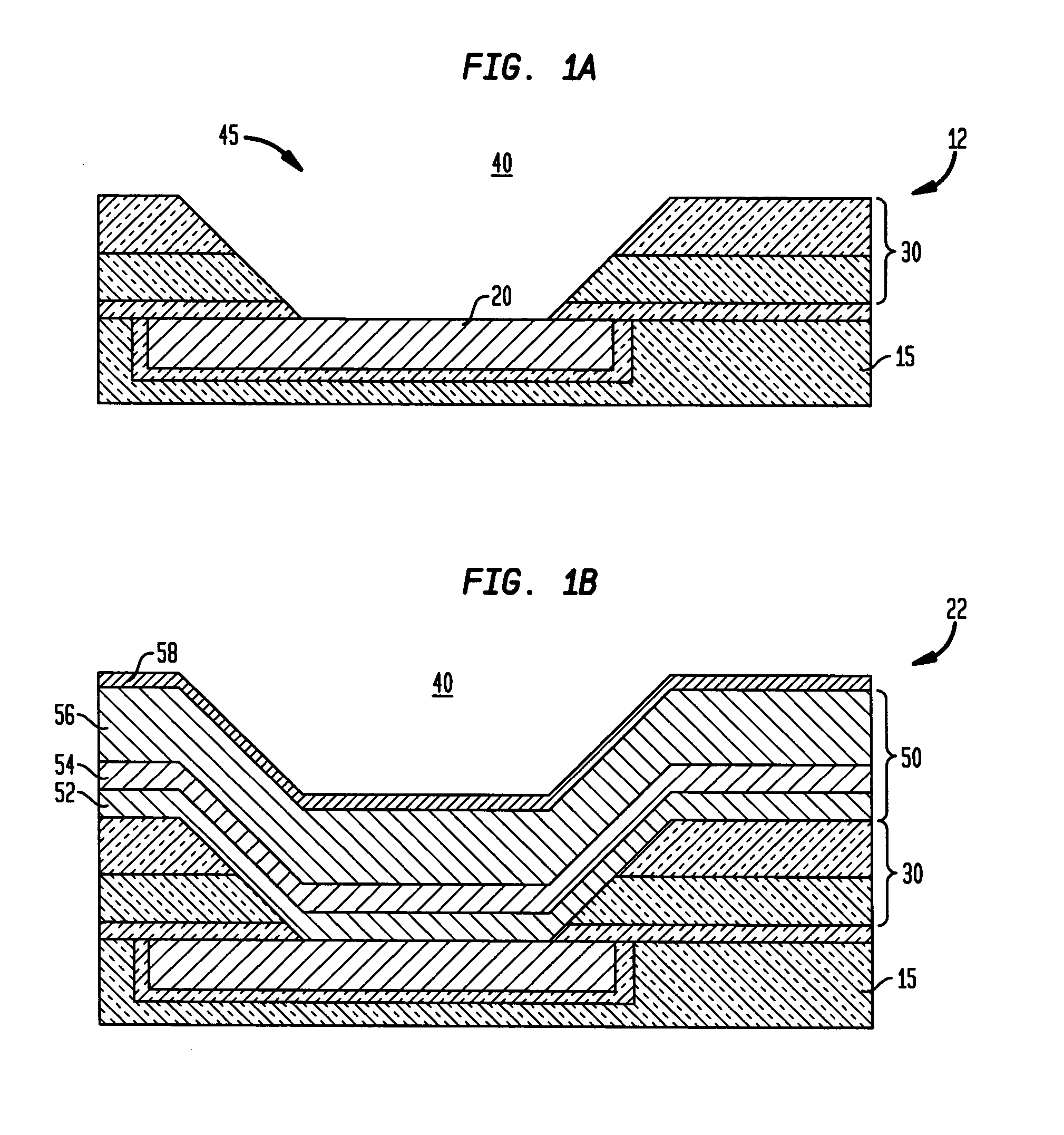

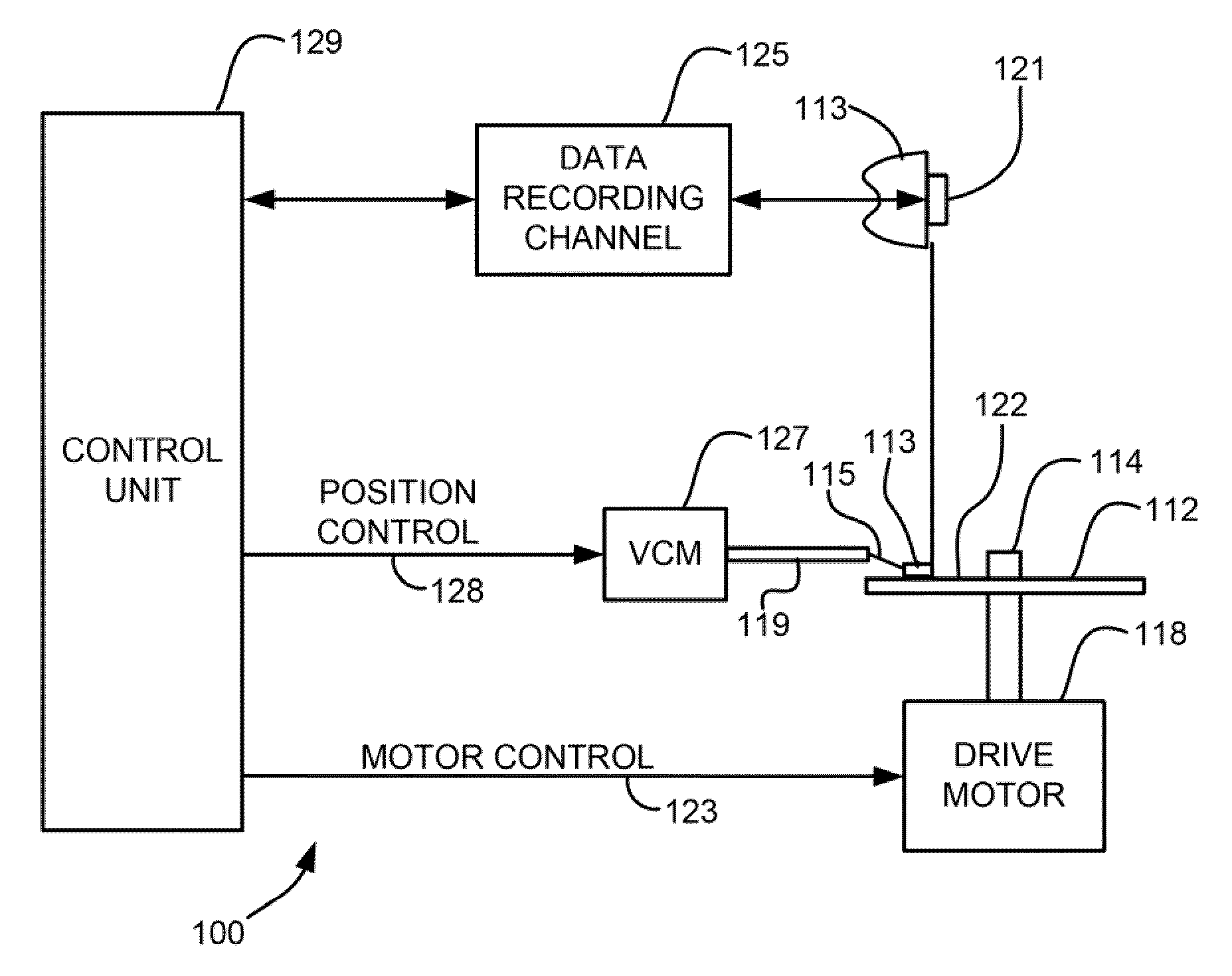

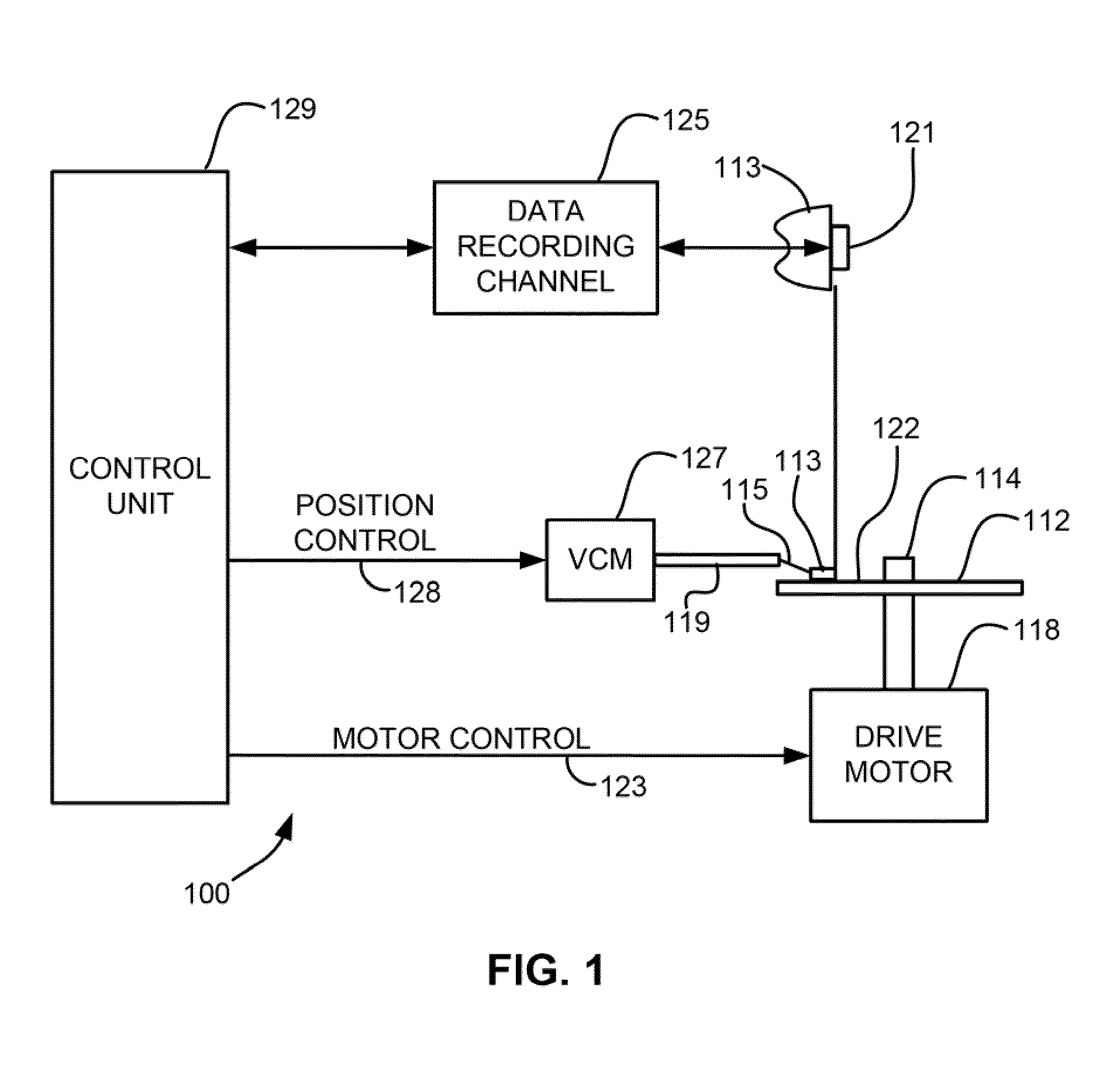

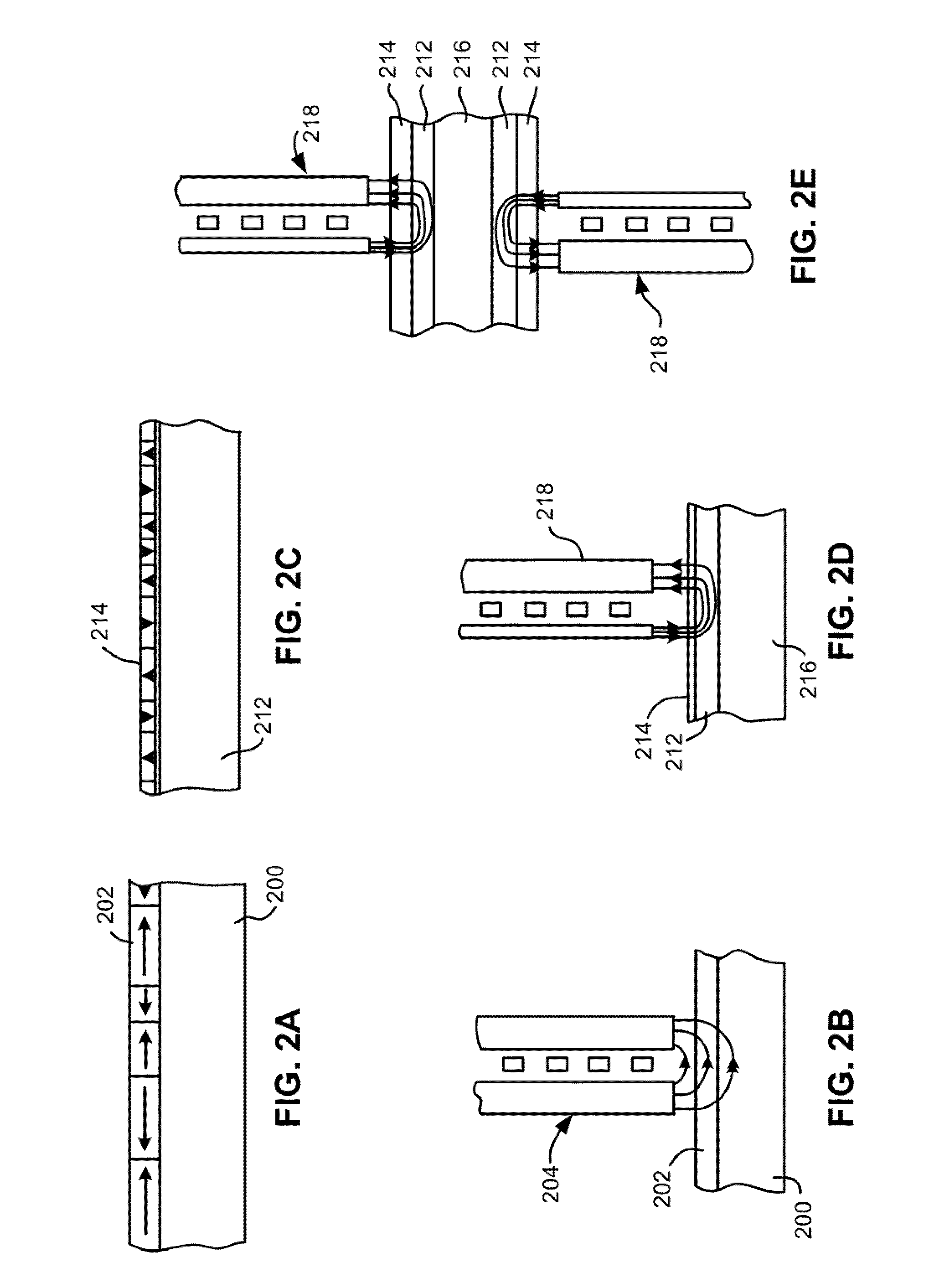

Systems having writer with deeper wrap around shield and methods for making the same

ActiveUS20110096434A1Reduce thicknessConstruction of head windingsDriving/moving recording headsElectrical and Electronics engineeringWrap around

A method according to one embodiment includes etching an underlayer positioned under a main pole for reducing a thickness thereof and creating an undercut under the main pole; adding a gap material along sides of the main pole and in the undercut; and forming a shield along at least a portion of the gap material. A magnetic head according to one embodiment includes a main pole; an underlayer positioned under the main pole and spaced therefrom, thereby defining an undercut therebetween; a first layer of gap material extending along sides of the main pole and in the undercut; a second layer of gap material extending continuously along the underlayer under the main pole; and a shield encircling the main pole, wherein the shield extends between the first and second layers of gap material in the undercut. Additional systems and methods are also presented.

Owner:WESTERN DIGITAL TECH INC

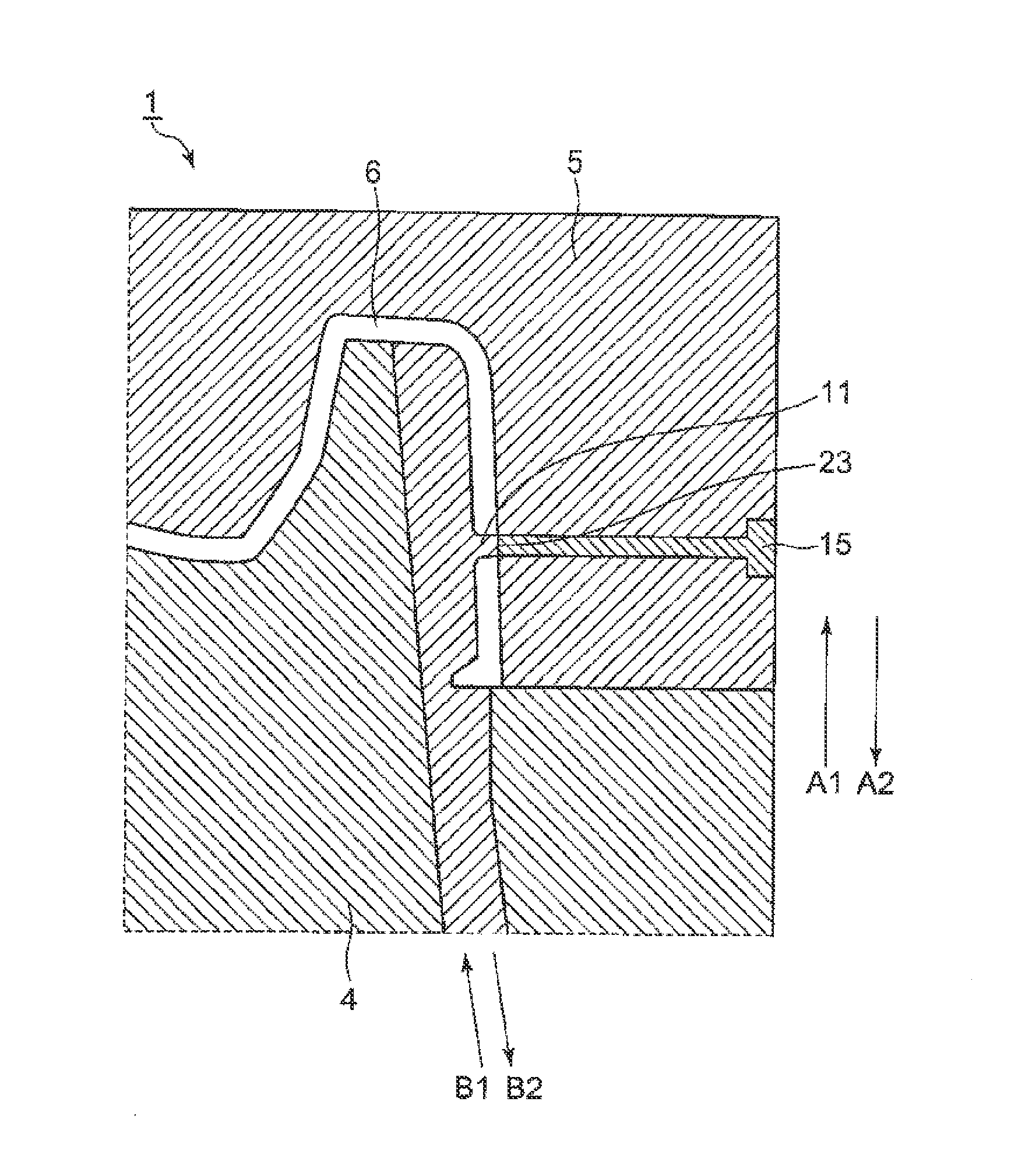

Resin molding die, resin molding method and resin molded product

It is an object of this invention to provide a resin molding die that is capable of suppressing, even when an undercut is provided on a core mold and an embossing process is performed on a cavity mold, generation of burrs attributed to the undercut and the embossing process. A resin molding die (1) of this invention includes: a core mold (4) including a protrusion (11) formed on a surface thereof as an undercut, the protrusion (11) being provided so as to form a through hole (105) in a resin-molded product (100); and a cavity mold (5) provided so as to be engageable with the core mold (4). The cavity mold (5) includes: a cavity main body (13) including an embossed surface that is opposed to the surface of the core mold (4), on which the protrusion (11) in provided, under a state in which the cavity mold (5) and the core mold (4) are engaged with each other; and an insert (15) provided to the cavity main body (13) so as to abut on the protrusion (11), the insert (15) including a mirror-finished surface as an opposing surface (23) thereof that abuts on the protrusion (11).

Owner:NEC PLATFORMS LTD

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com