Patents

Literature

342 results about "Gas metal arc welding" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

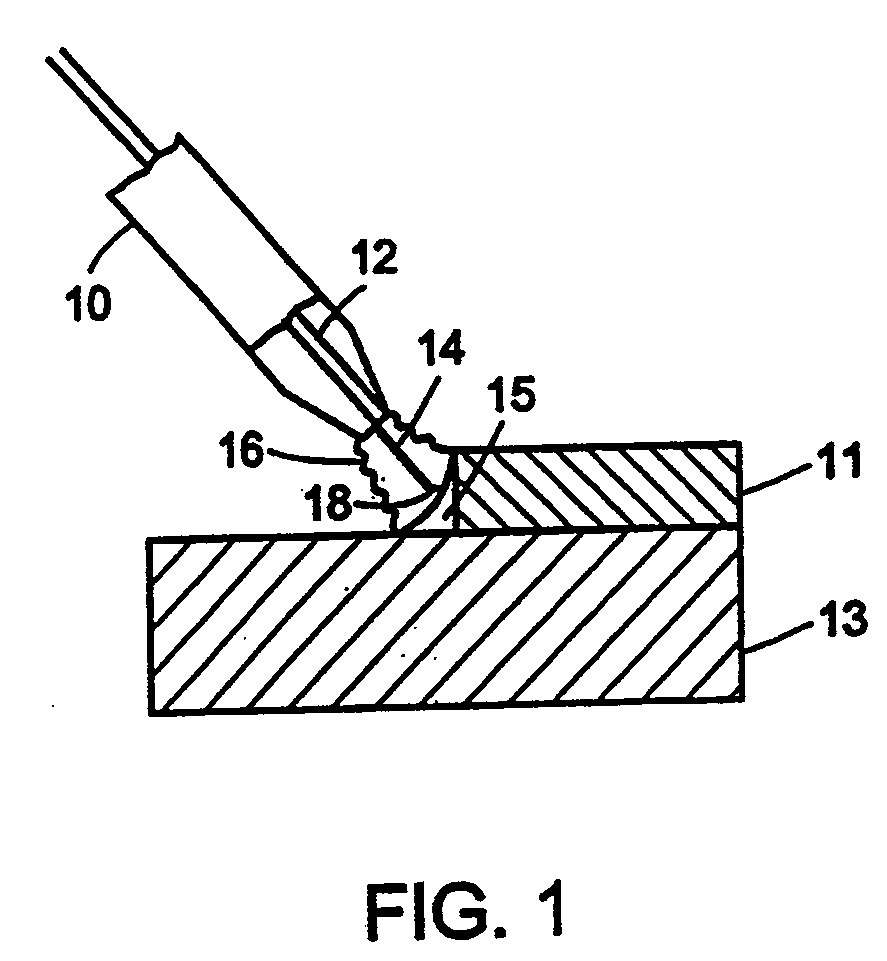

Gas metal arc welding (GMAW), sometimes referred to by its subtypes metal inert gas (MIG) welding or metal active gas (MAG) welding, is a welding process in which an electric arc forms between a consumable MIG wire electrode and the workpiece metal(s), which heats the workpiece metal(s), causing them to melt and join. Along with the wire electrode, a shielding gas feeds through the welding gun, which shields the process from contaminants in the air.

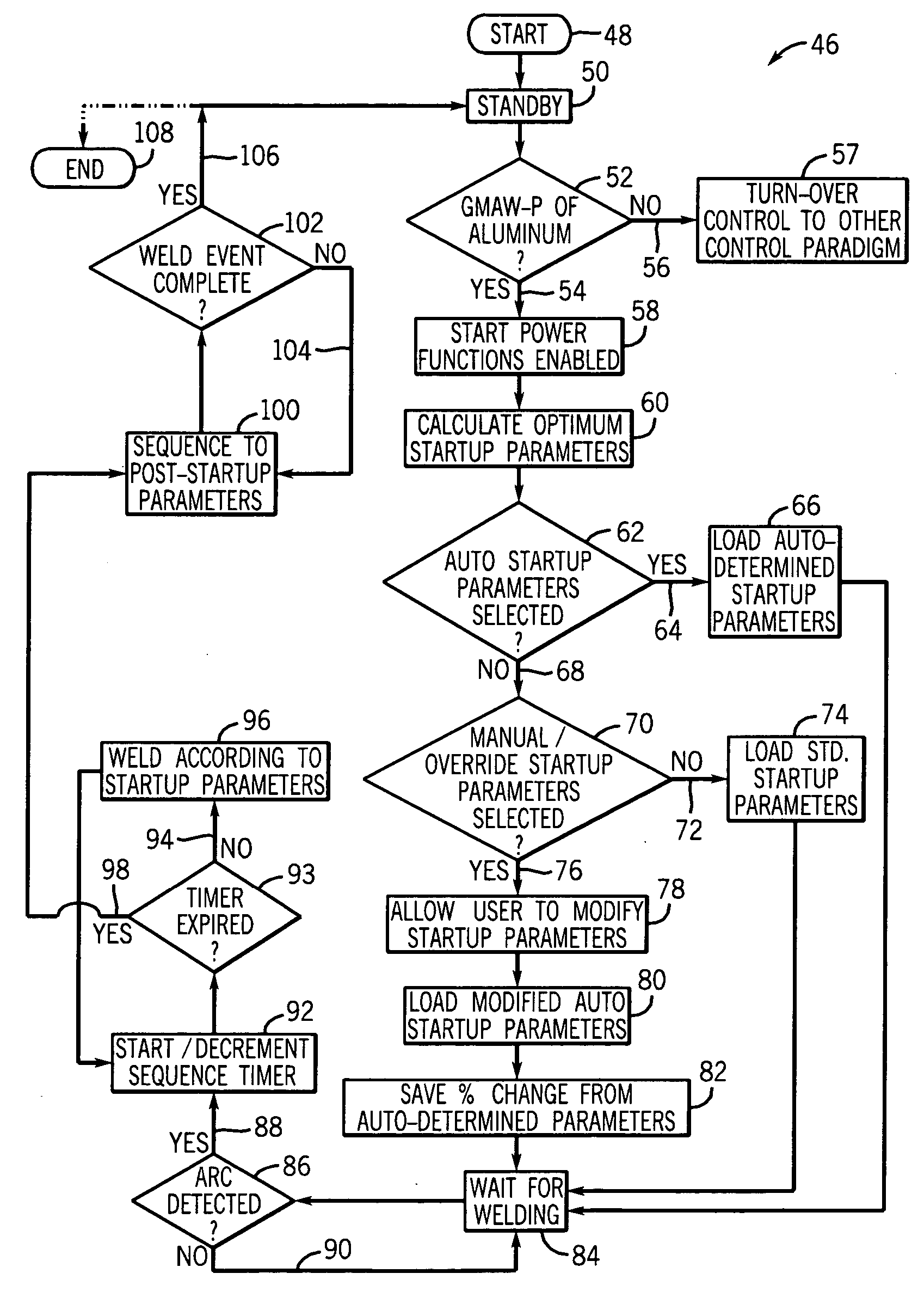

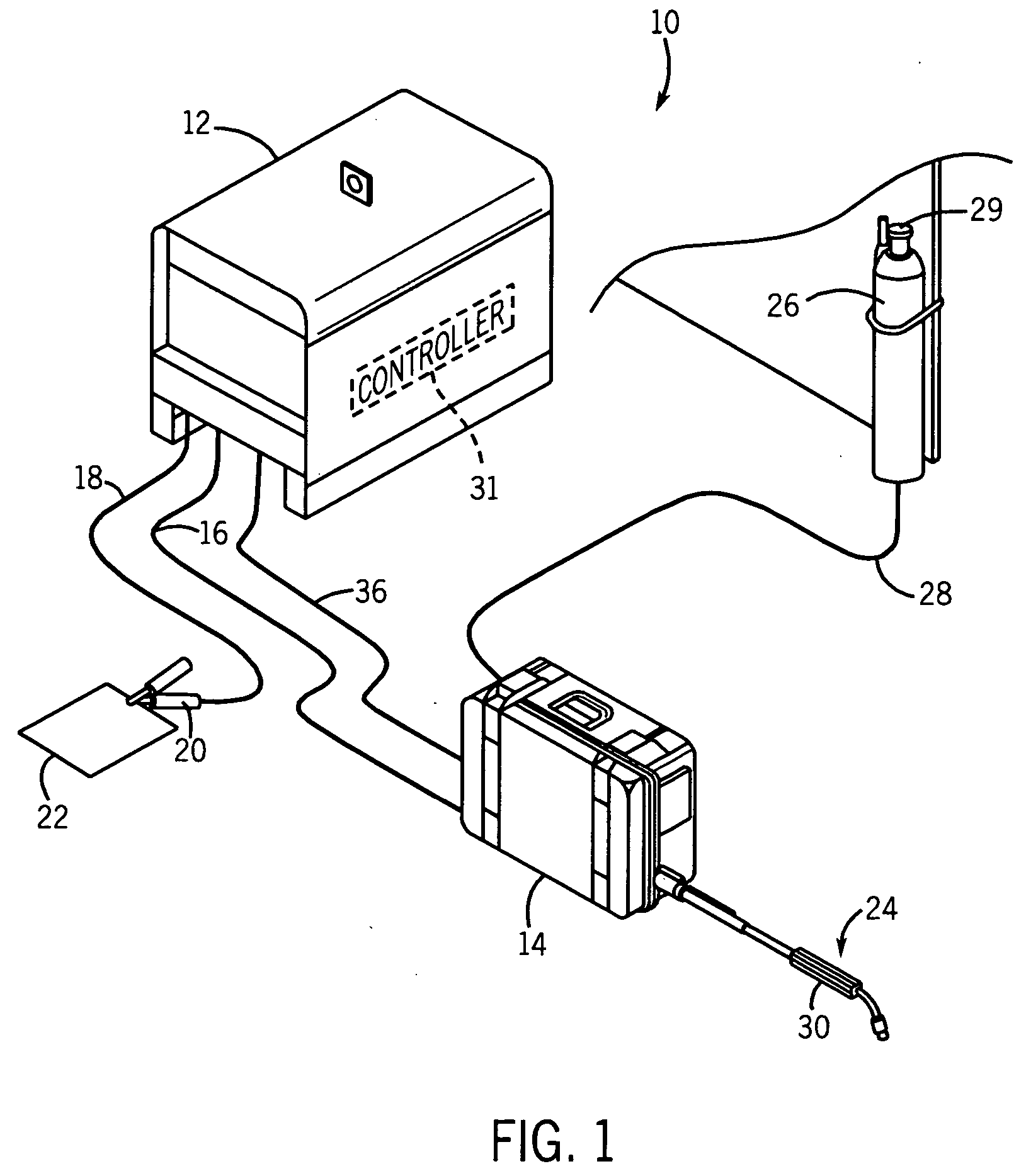

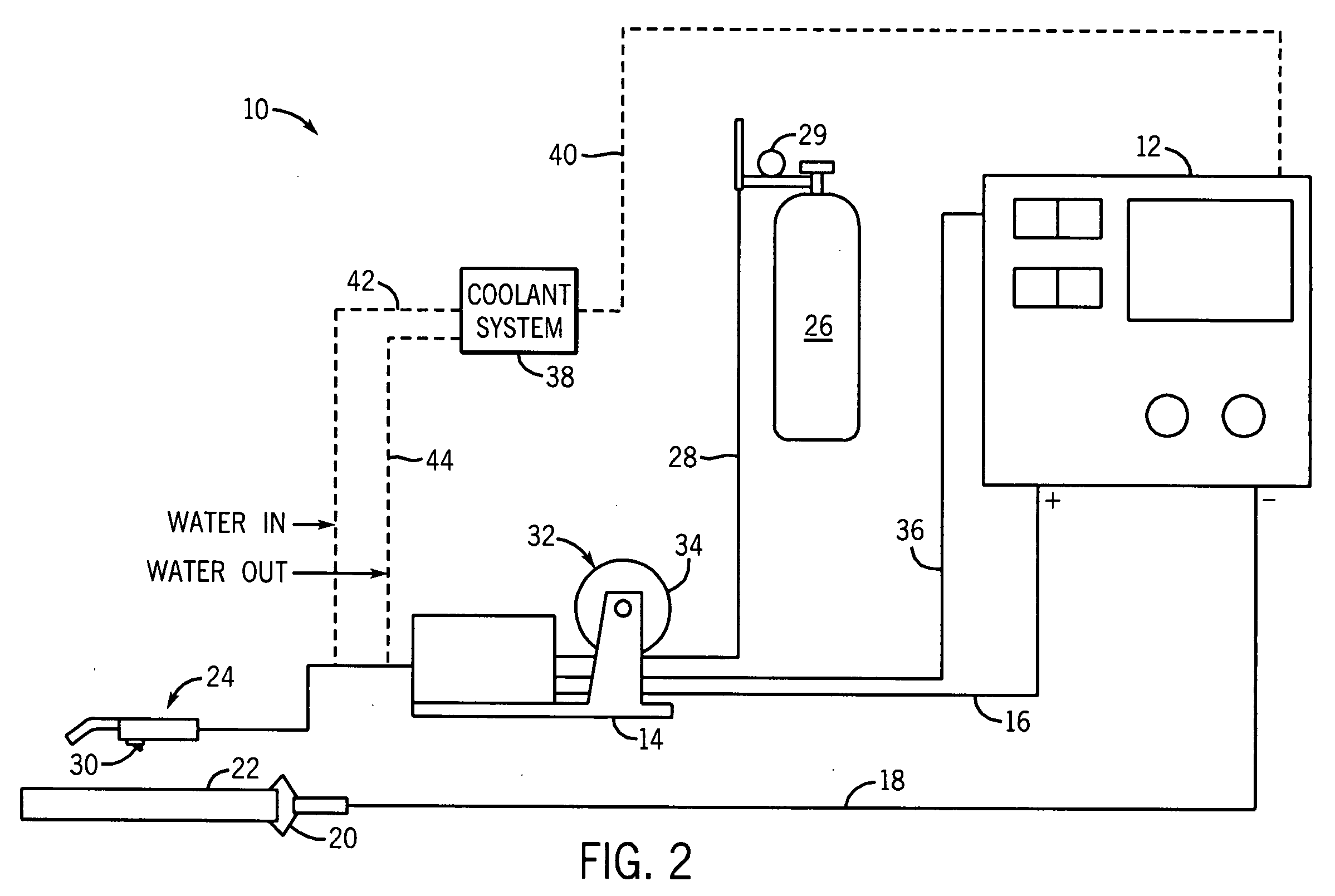

Method and system of welding with auto-determined startup parameters

ActiveUS20060131291A1More powerArc welding apparatusWelding/soldering/cutting articlesControl engineeringGas metal arc welding

A method and system to determine optimum operating parameters for the startup phase of a welding-type process based on user-desired operating parameters of the post-startup or welding phase of the welding-type process are disclosed. While applicable to a number of welding-type processes, the method and system are particularly configured to determine an optimum wire feed speed for Gas Metal Arc Welding of aluminum using pulse spray transfer.

Owner:ILLINOIS TOOL WORKS INC

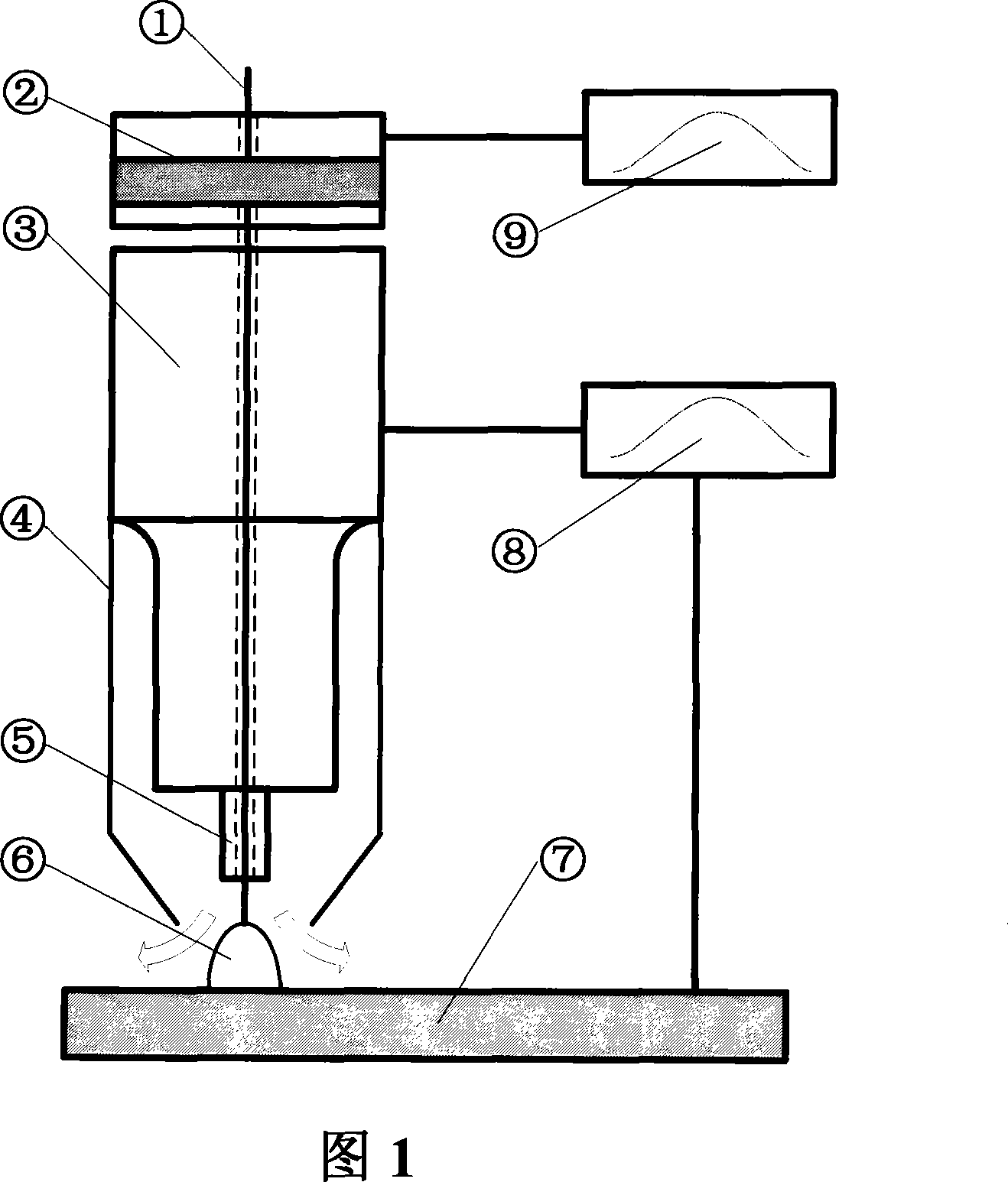

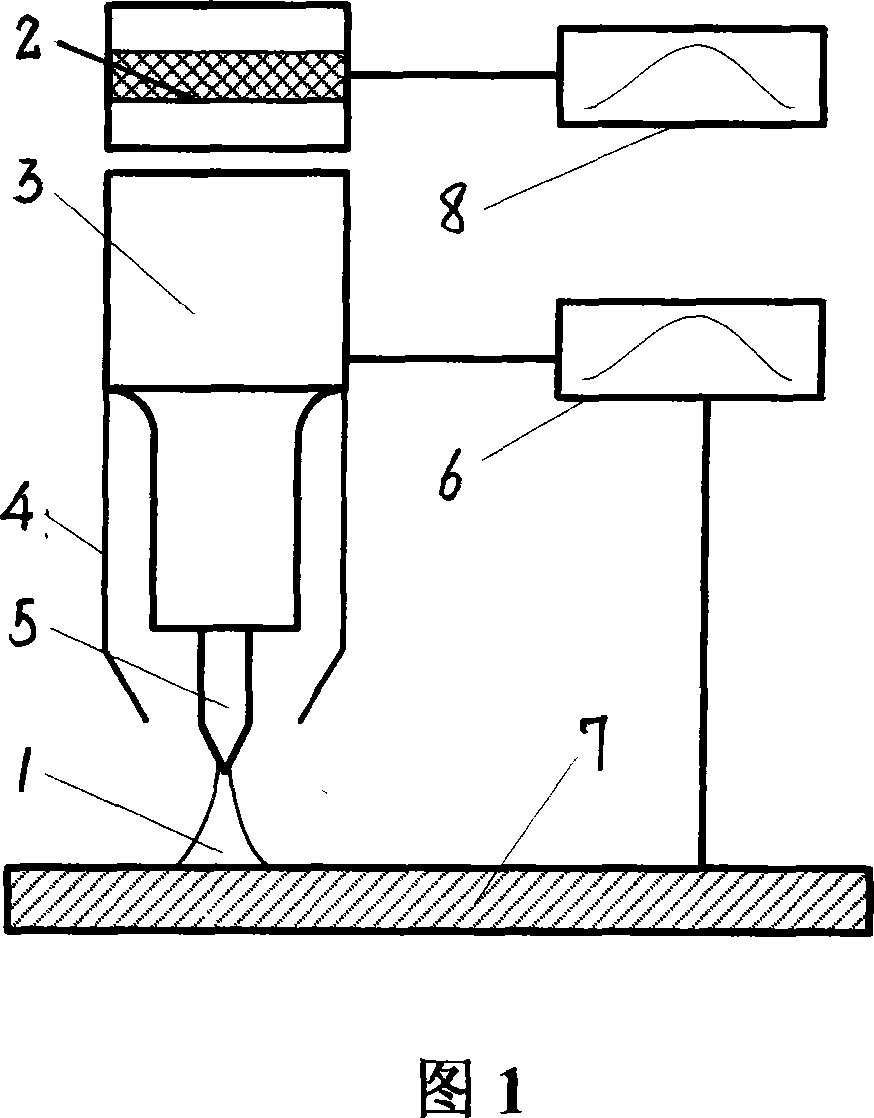

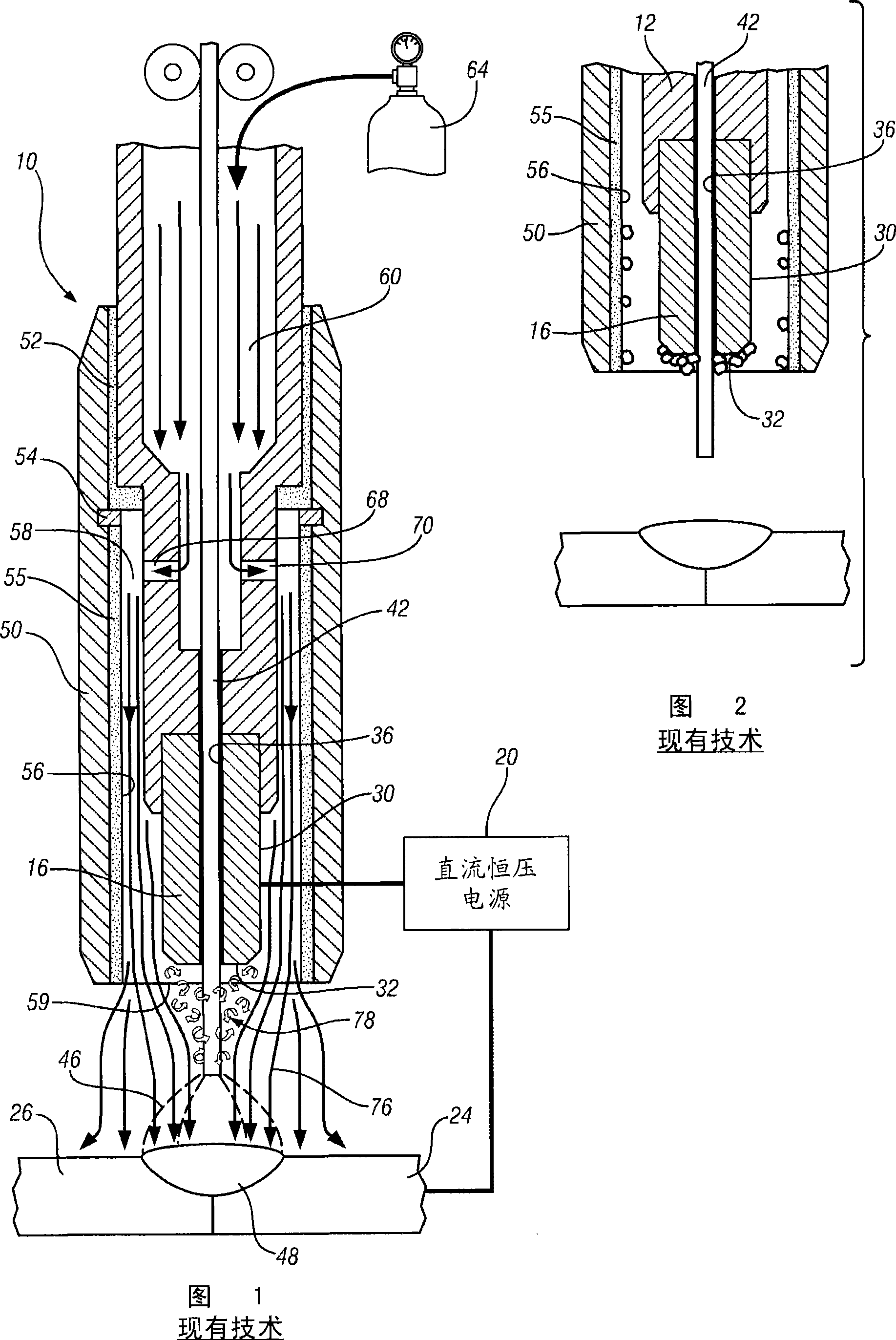

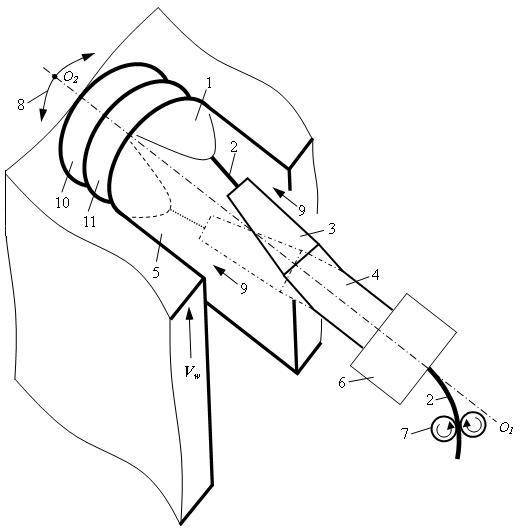

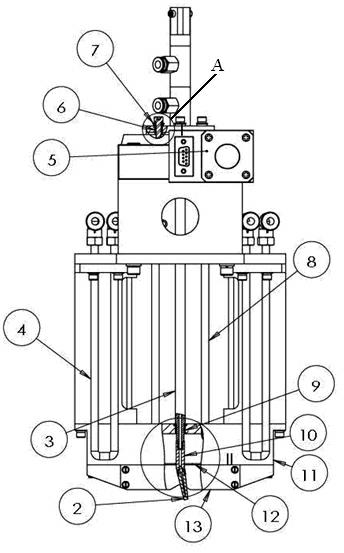

Ultrasound wave and melt pole electrical arc compound welding method

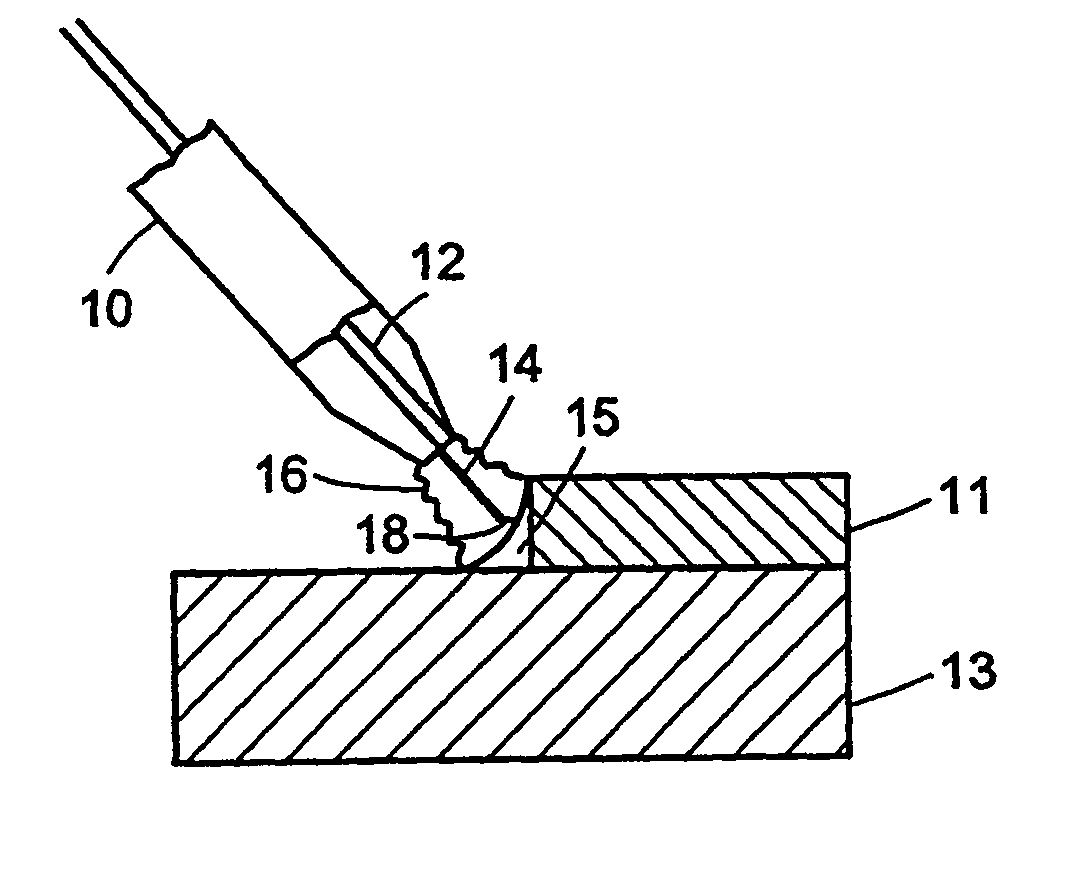

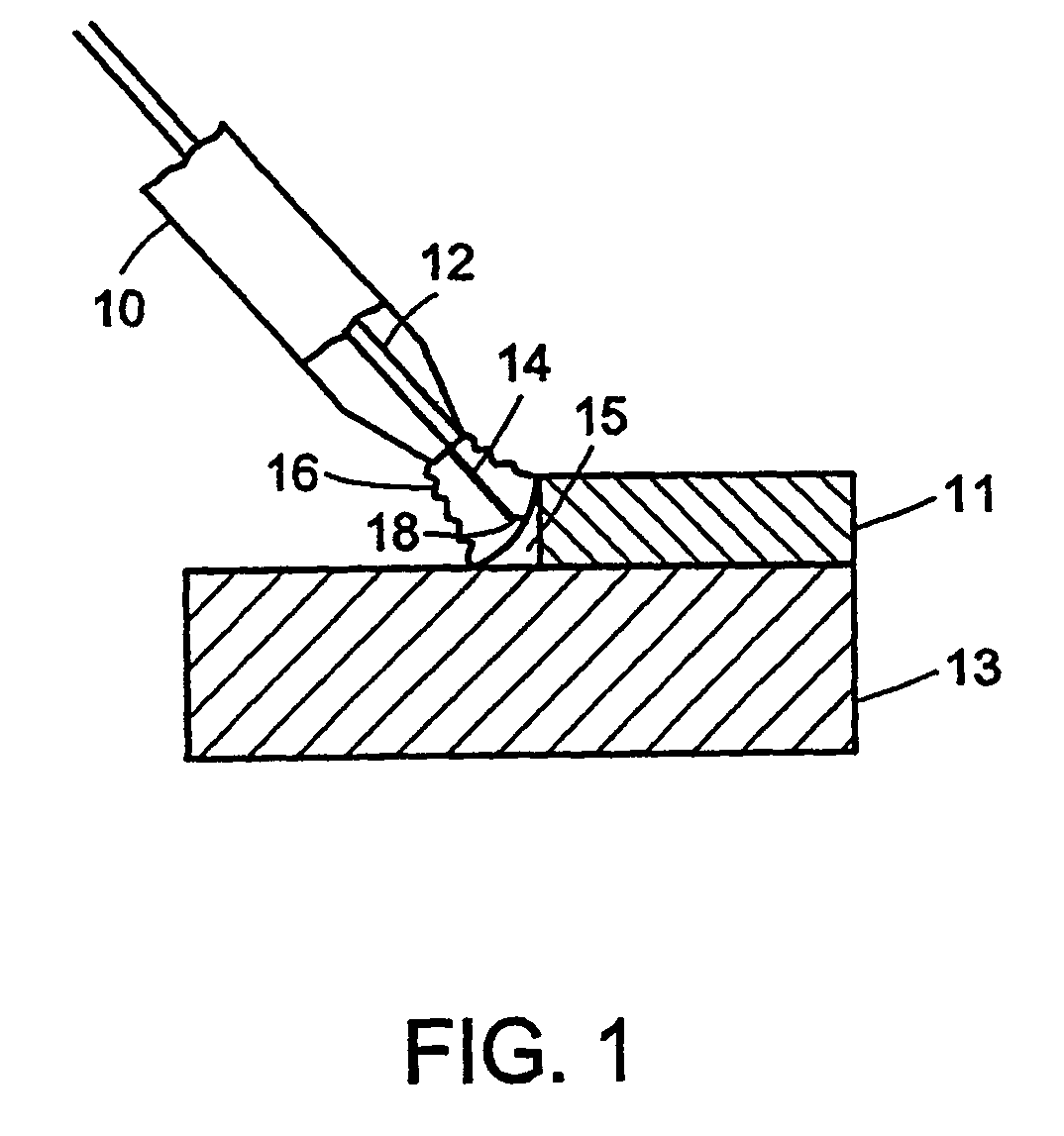

The invention provides a weld method compounding an ultrasonic and a gas metal arc welding so as to make use of the cavitation effect and the vibration effect of the ultrasonic to lead welding drops generated by the gas metal arc welding to be smoothly transmitted to a welding pool when the drops are still small. And when in welding, an electric arc shrinks under the effect of the ultrasonic and then the stiffness of the electric arc can be enhanced, which has a significant application value for welding of special positions such as a full-position welding, an overhead position welding, a flat position welding and a horizontal position welding, etc.. The invention includes the following steps: an ultrasonic generator is connected with an ultrasonic transducer 2 to convert ultrasonic energy into mechanical vibration; an ultrasonic transformer 3 enlarges amplitude; a conductive tip 5 is combined with the ultrasonic transformer; a protective gas nozzle 4 is fixed on the vibration node of the transformer; a welding wire 1 is connected with the conductive tip 5 to start a welding power supply 9 and then start an ultrasonic power supply after the electric arc becomes stable, then the transducer converts electrical energy into vibration and the ultrasonic transformer enlarges the ultrasonic amplitude which is transmitted to a melting electrode.

Owner:HARBIN INST OF TECH

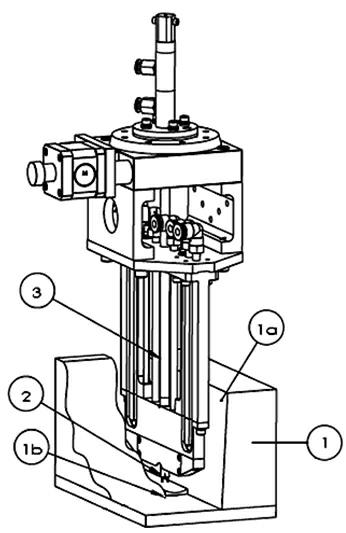

Composite welding method of ultrasound wave and non-melt pole electrical arc

InactiveCN101219499AImprove straightnessImproved arc stabilityElectrode vibration holdersTransformerEngineering

The invention discloses a welding method of compounding ultrasonic and nonconsumable electrode voltaic arc. Under the welding condition of protection of nonconsumable electrode gas, the ultrasonic is conducted into welding arc through the conductive electrode and the voltaic arc obviously contracts after ultrasound is carried on. The invention not only has the advantages of stable welding process and high welding and forming quality which normal TIG welding has, but also can improve weld penetration of single-pass welding and therefore the method can realize high quality welding under normal welding condition. The invention converts the high frequency electrical signals of ultrasound supply into mechanical vibration through an energy conversion device and the mechanical vibration is amplified by an amplitude transformer, and then is transmitted to an electrode studded in the amplitude transformer so as to generate supersonic vibration of corresponding frequency on the electrode. The input power of the ultrasound can be adjusted at will between 1W to 1000W and then welding is carried out by the method of normal gas metal arc welding. When voltaic arc is applied to processing pieces, the energy is concentrated, thereby effectively improving utilization ratio of voltaic arc during welding.

Owner:HARBIN INST OF TECH

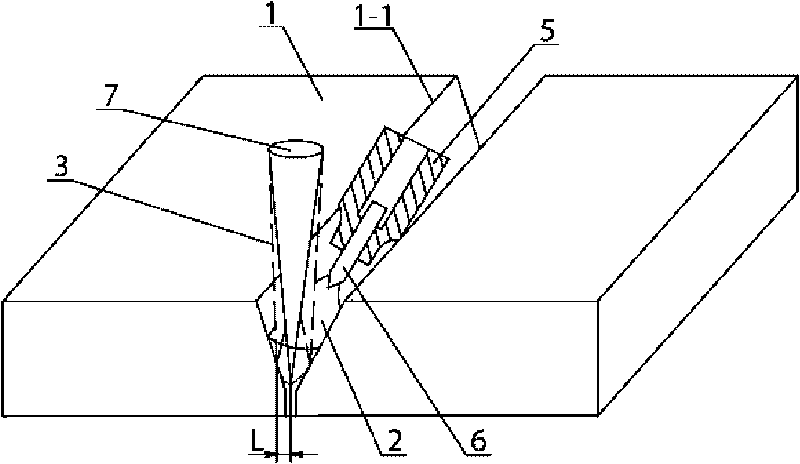

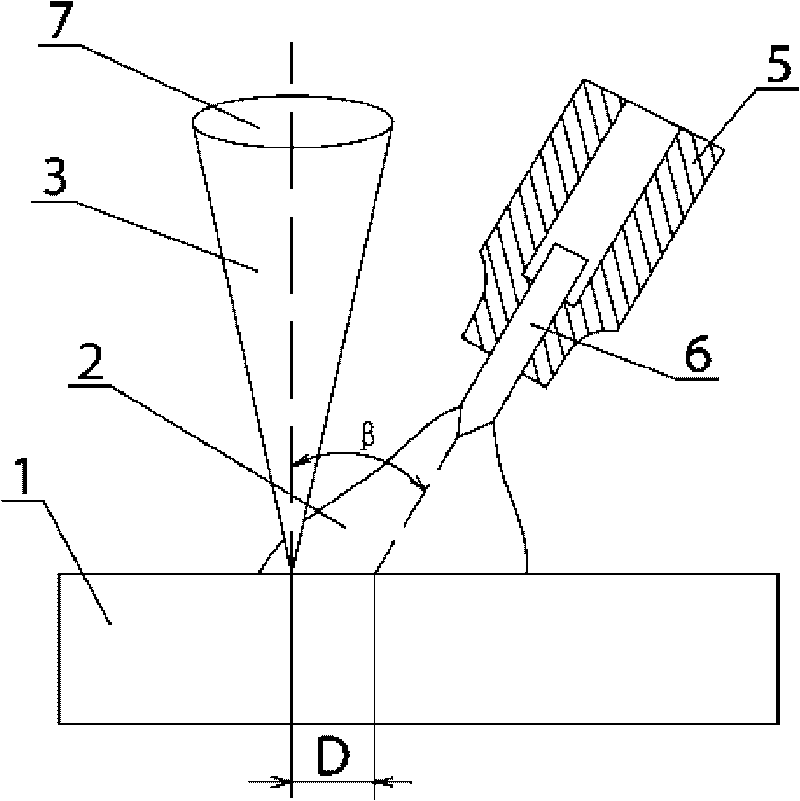

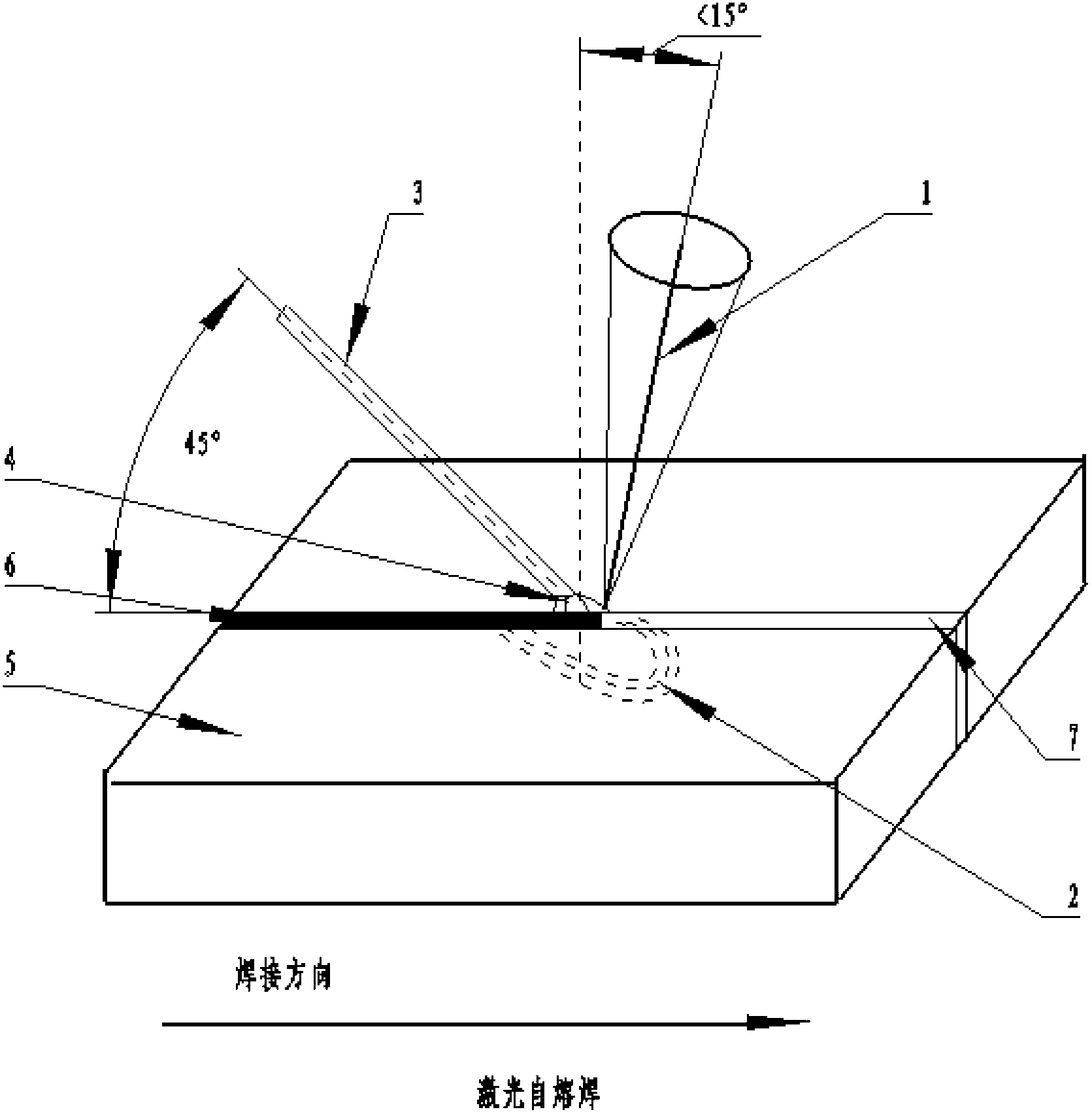

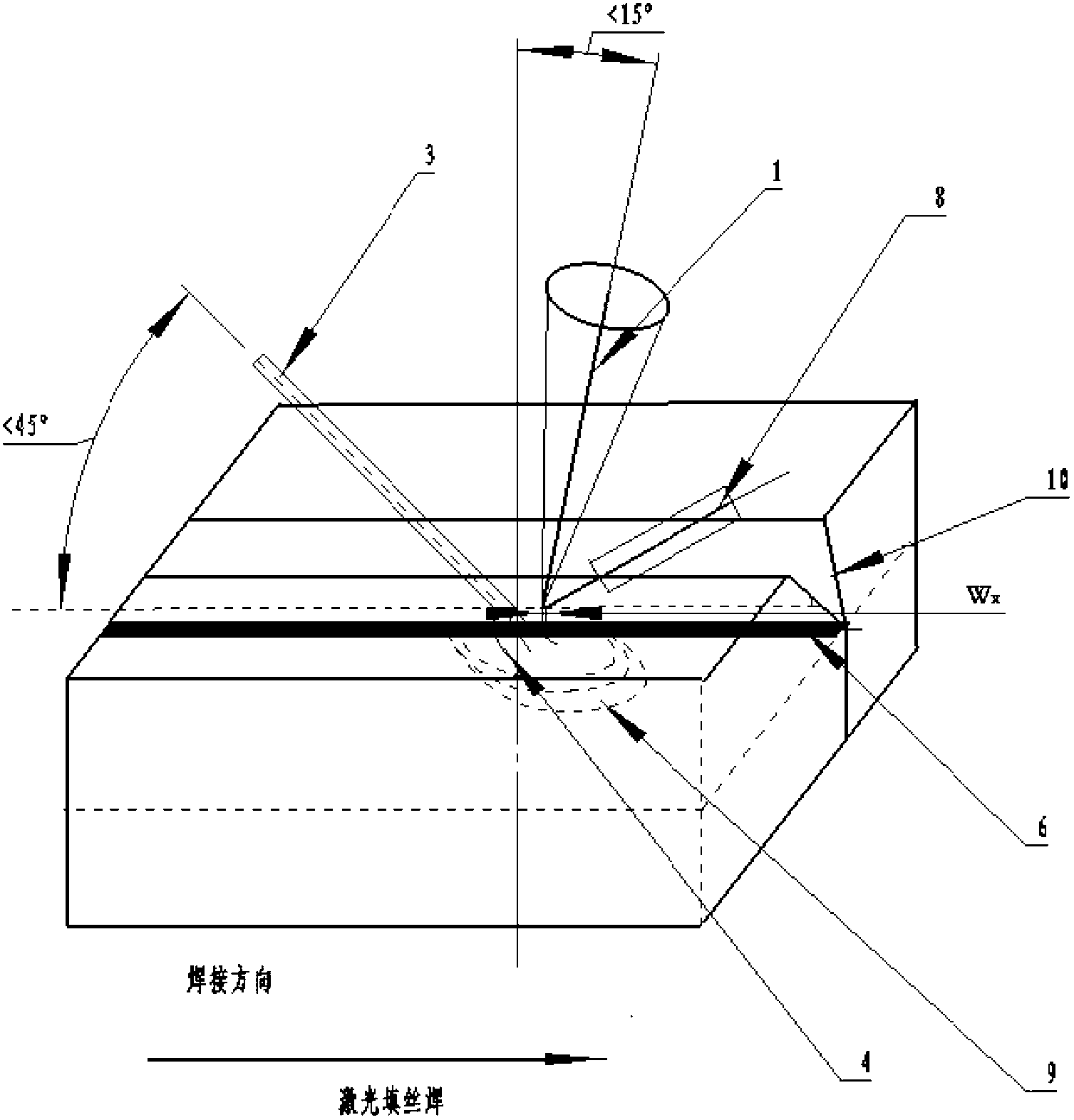

Method for realizing swing welding with laser-GMA electric arc hybrid welding device

The invention discloses a method for realizing swing welding with a laser-GMA electric arc hybrid welding device, relating to a laser-melting electrode gas metal arc welding hybrid welding method. The method solves the problem that the defects such as incomplete fusion, gas hole and included slag, and the like, are easily existed between a side wall and a layer when welding a moderate plate and a thick plate with the laser-GMA electric arc hybrid welding device. The method comprises the following steps of: 1. chamfering; 2. clamping a work piece to be welded; 3. ensuring the positions of an electric arc and a laser beam, wherein the laser beam is perpendicularly irradiated to the surface of the work piece to be welded, an included angle between the electric arc and the laser beam is 15-60 DEG C, and the distance between the laser beam and the sharp end of a GMA electric arc welding wire is 2-6mm; 4. setting a welding technology parameter; and 5. performing the welding, wherein an electric arc welding gun is kept to be immovable when welding, and a laser beam-focused wielding gun swinging welds in the shape of 'S'. The method is used for butt welding of a thick plate more than 10mm in national defense and civil use fields of shipbuilding, petroleum pipe lines, high-pressure vessels, fighting vehicles and nuclear devices, etc.

Owner:HARBIN INST OF TECH

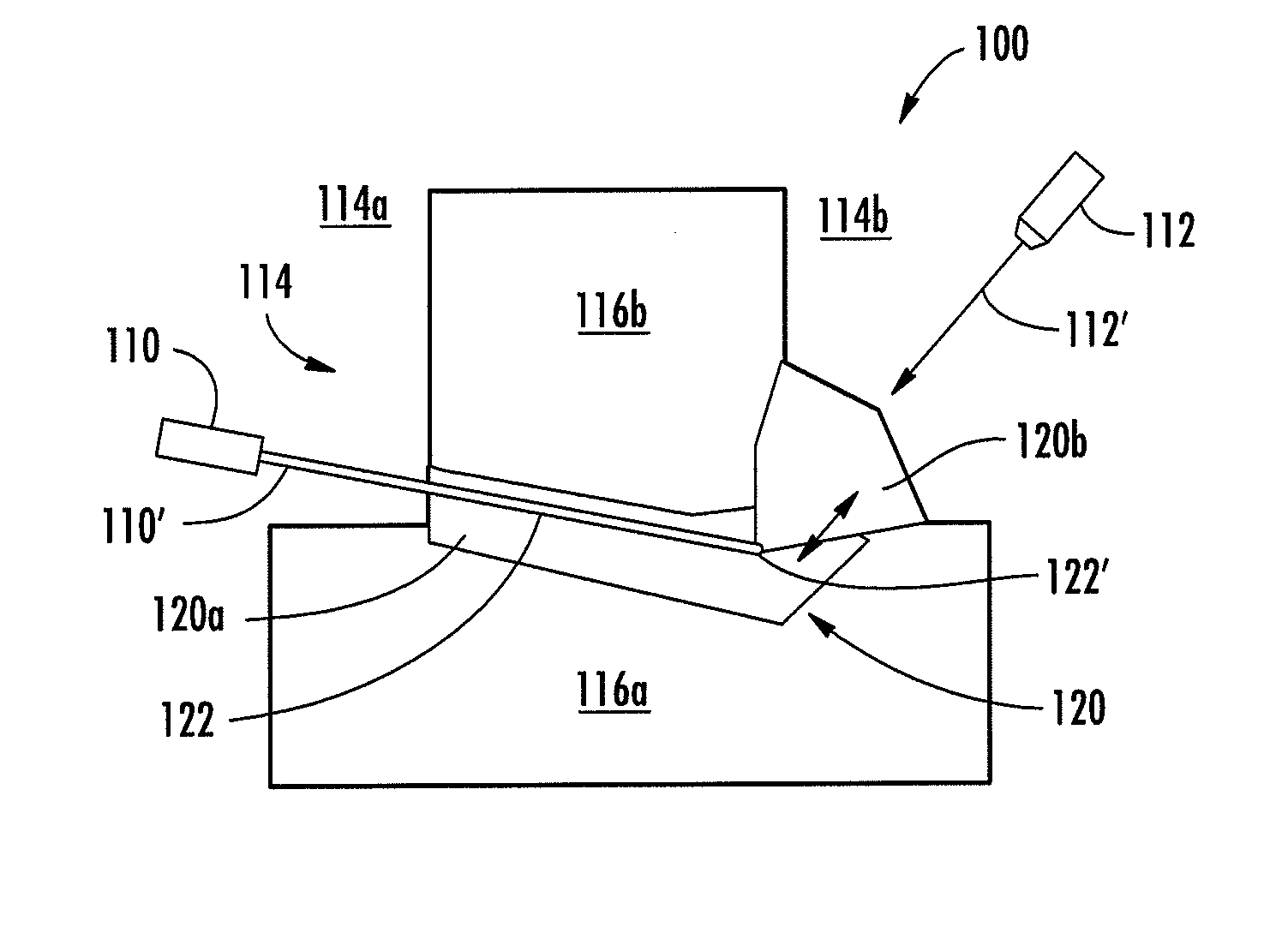

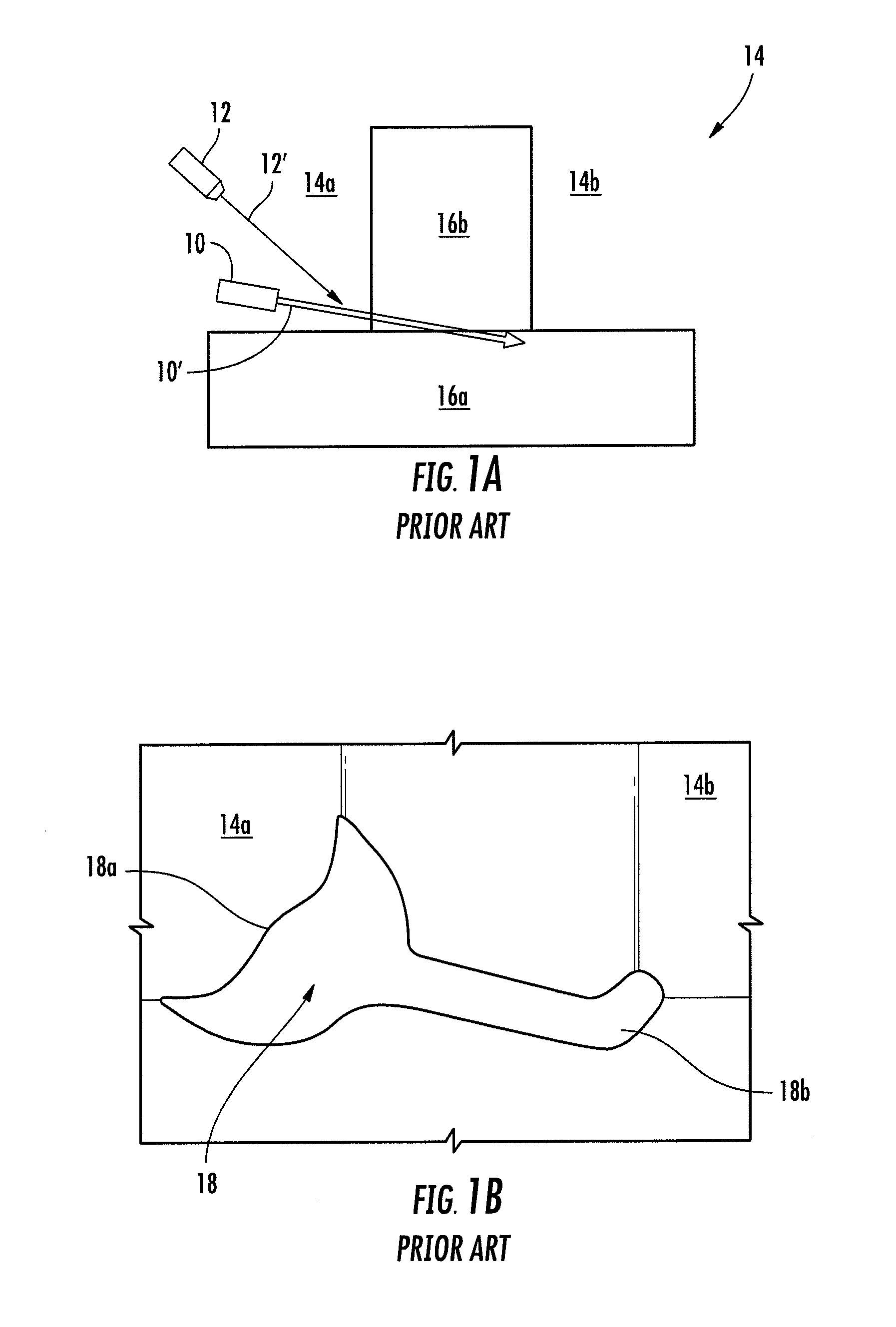

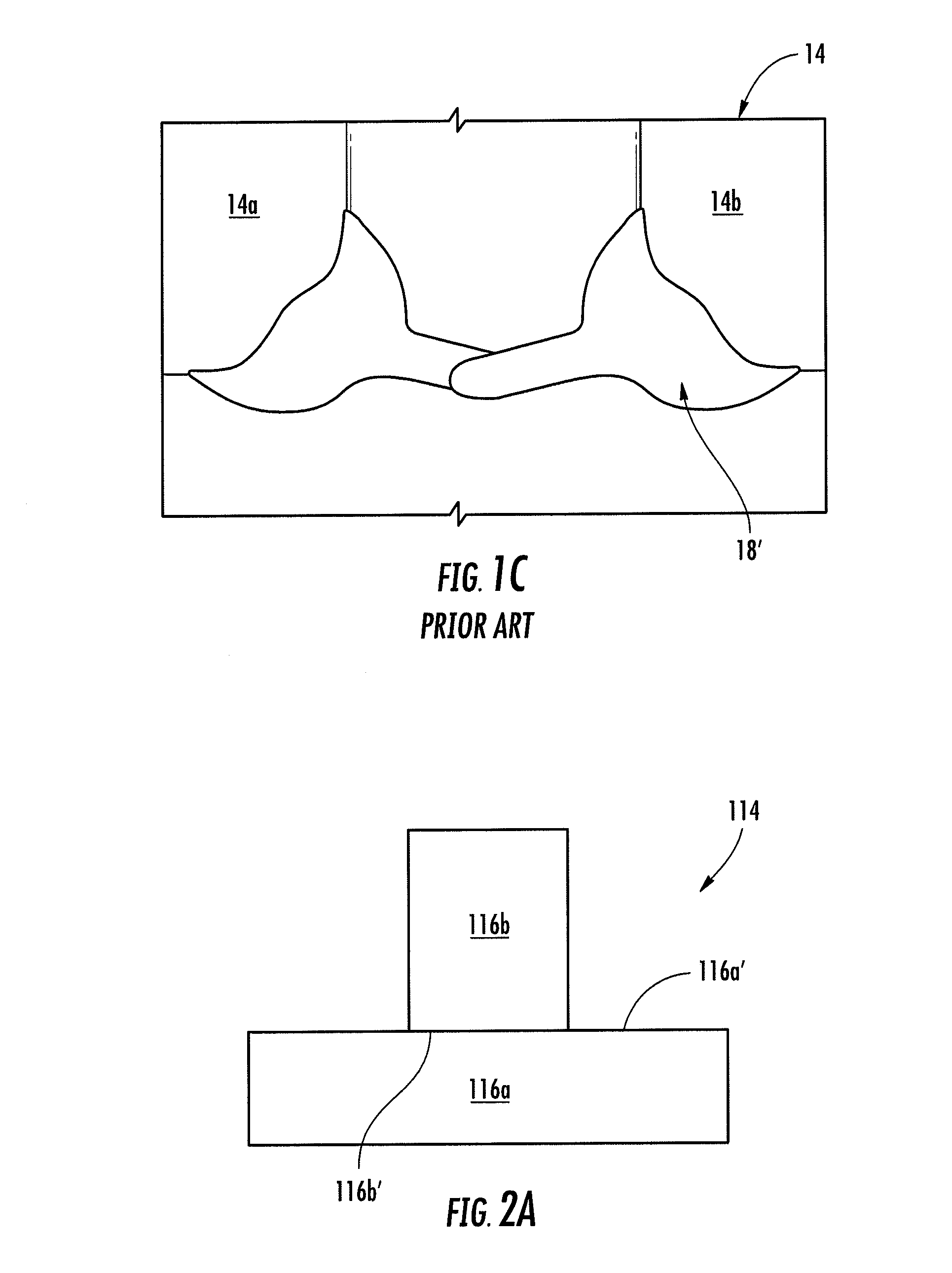

Hybrid welding with multiple heat sources

ActiveUS20110198317A1Improve permeabilityArc welding apparatusElectron beam welding apparatusHigh energyGas metal arc welding

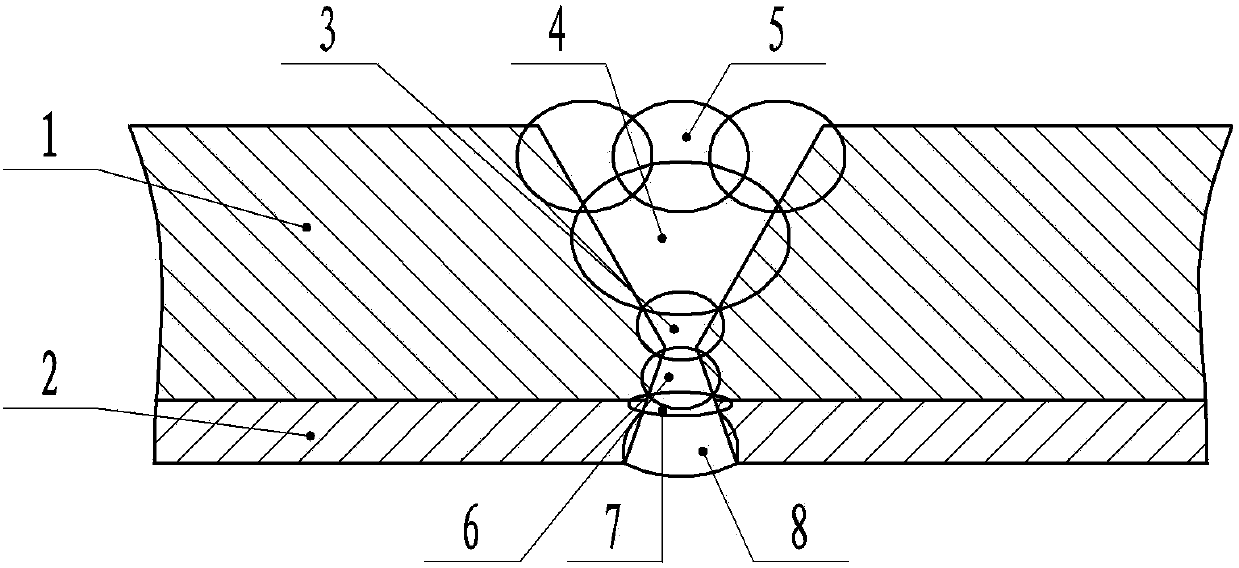

A method of welding a joint includes directing a first output from a high energy density heat source, such as a laser, against a first side of the joint. The method further includes directing a second output from an arc welding heat source, such as a gas metal arc welding torch, against a second side of the joint. The first output produces a keyhole surrounded by a molten metal pool which extends from the first side of the joint toward the second side of the joint. In some embodiments a third output from a second arc welding heat source may also be directed at the first side of the joint. A second molten metal pool produced by the arc welding heat source joins with the first molten metal pool and the third molten metal pool to form a common molten metal pool which solidifies to form the weld.

Owner:THE ESAB GROUP

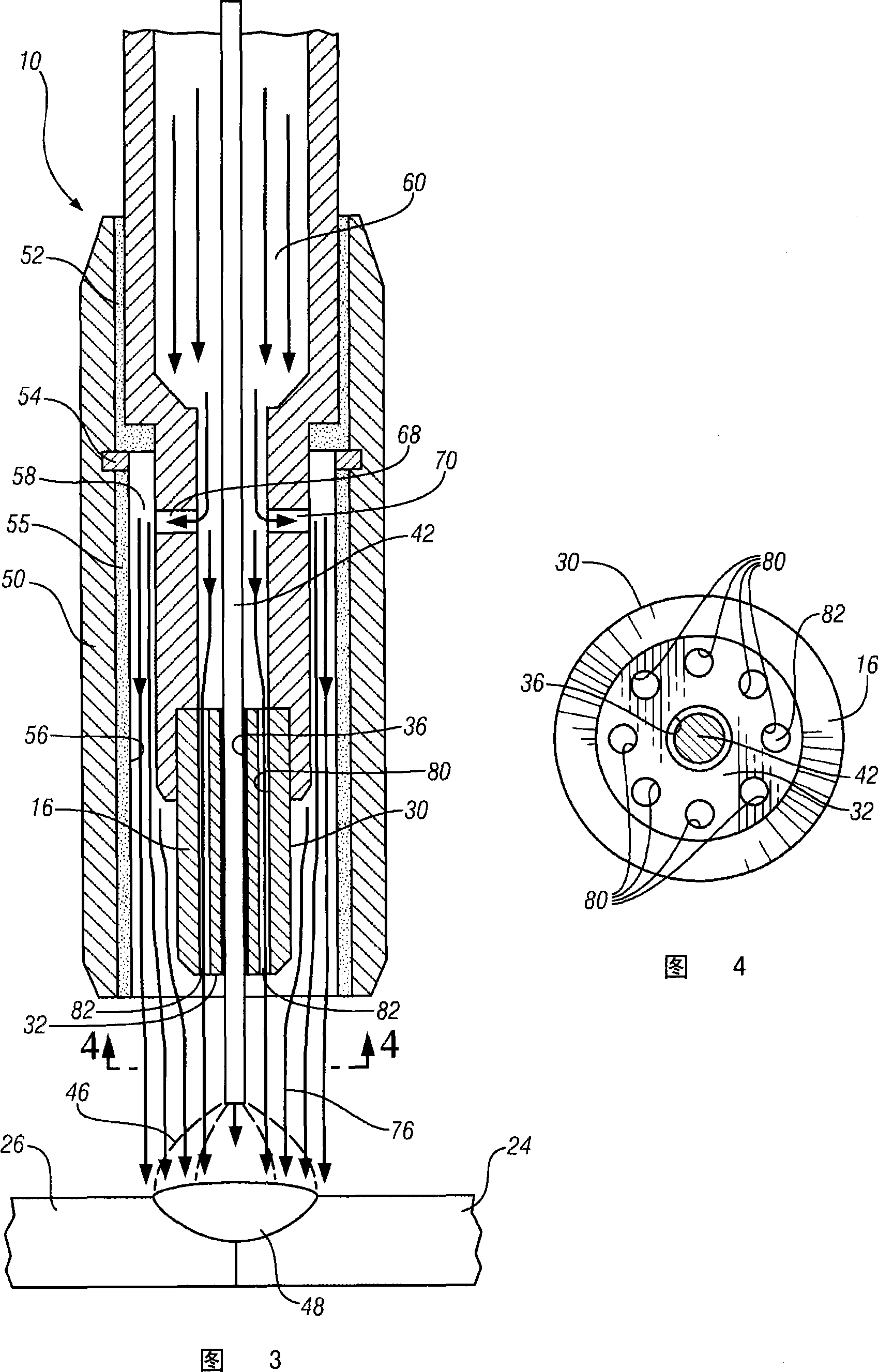

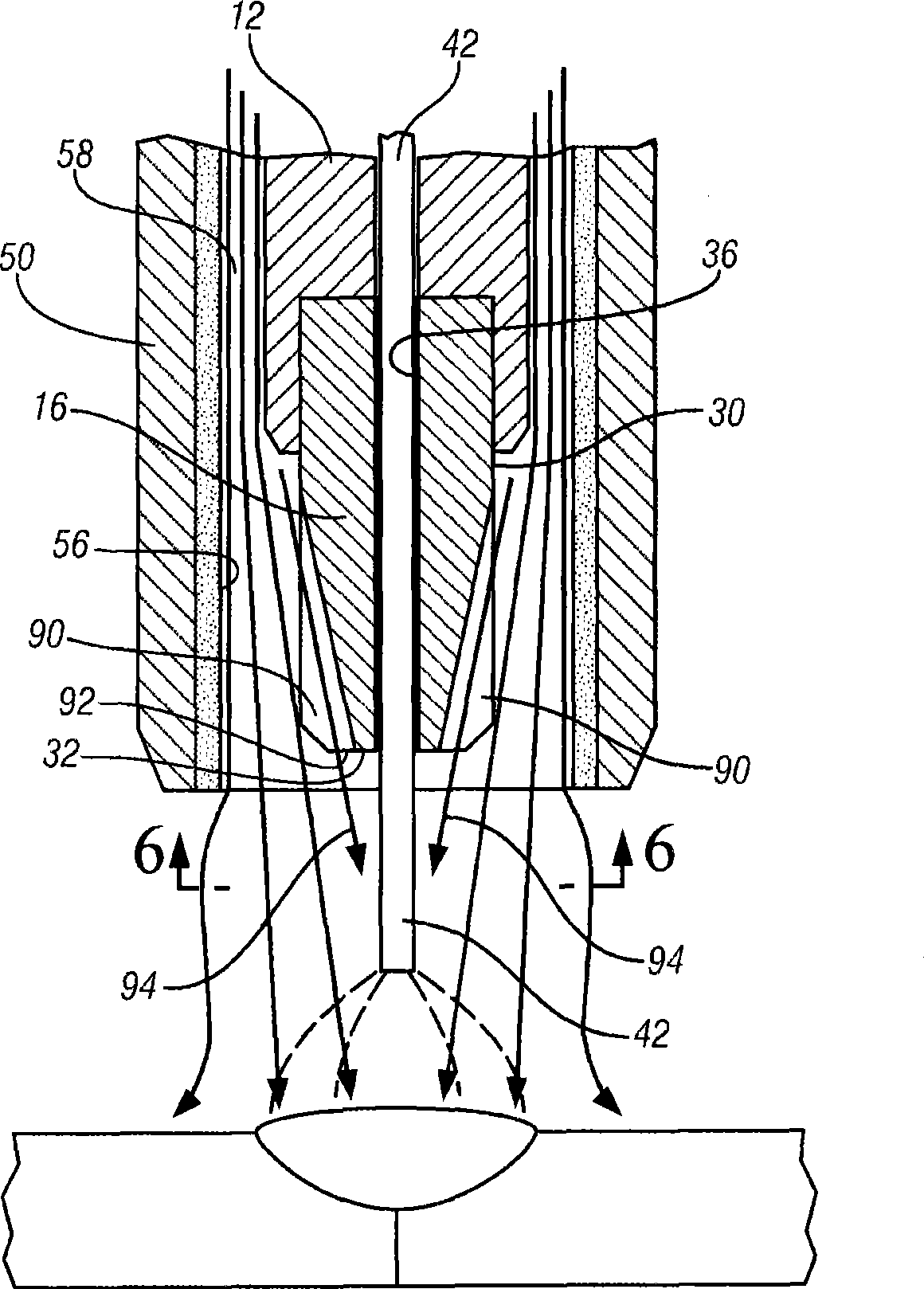

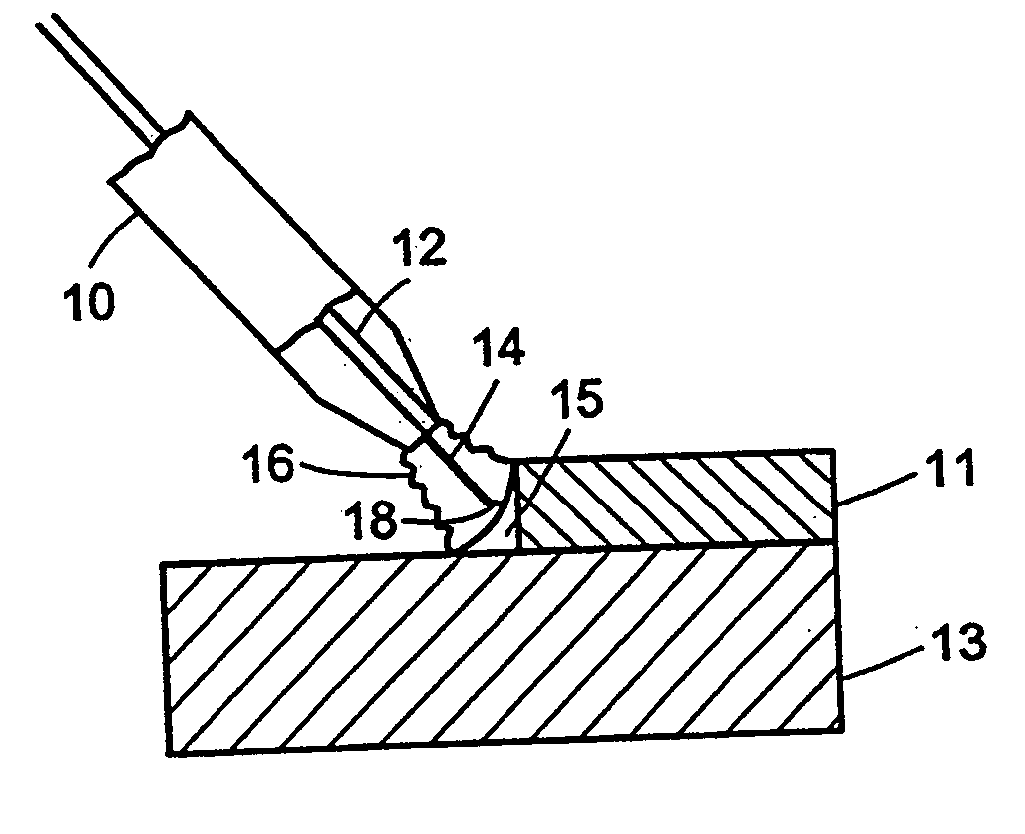

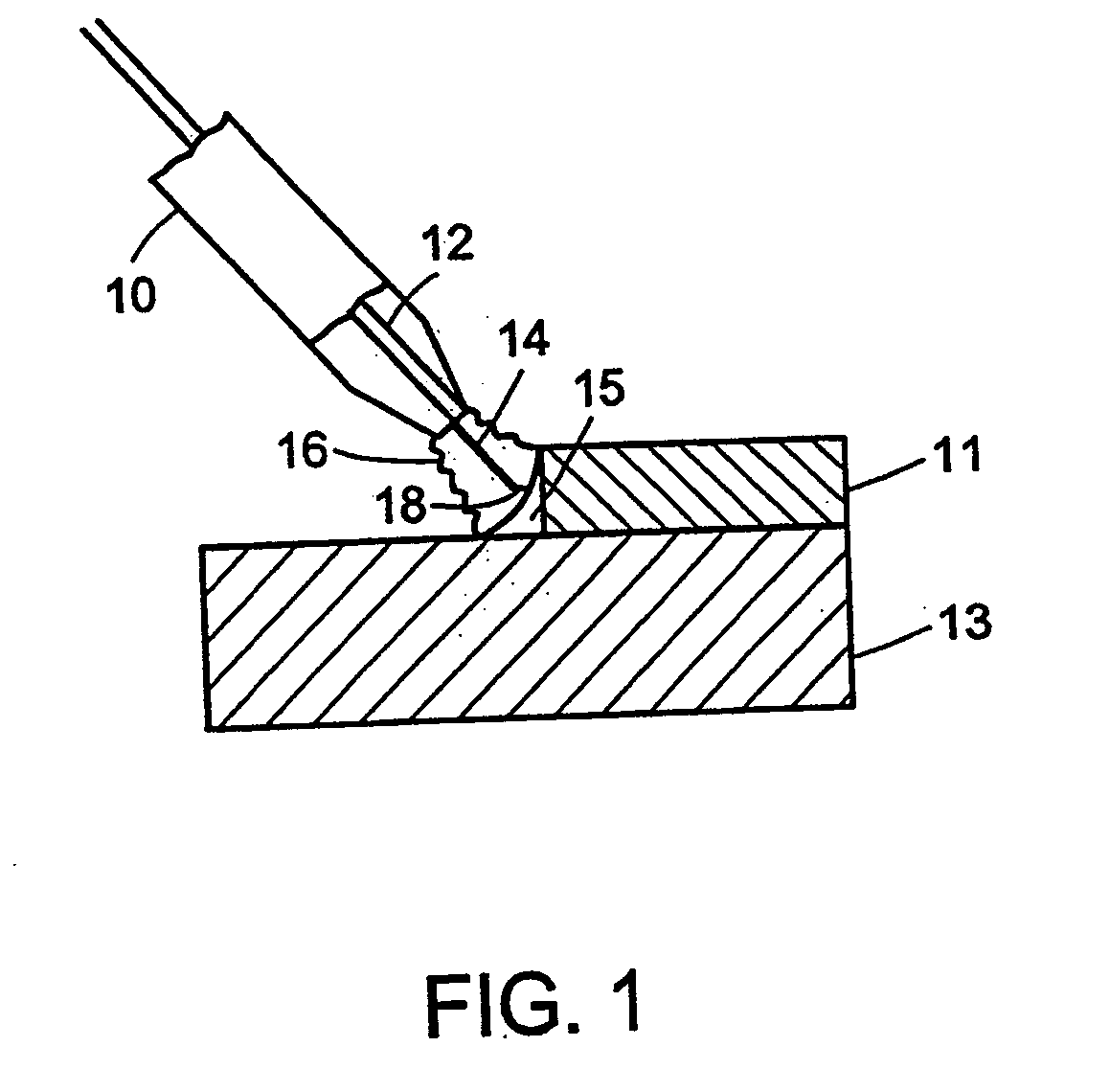

Torch and contact tip for gas metal arc welding

InactiveCN101417365AElectrode supporting devicesElectrode accessoriesCarbon Dioxide / HeliumShielding gas

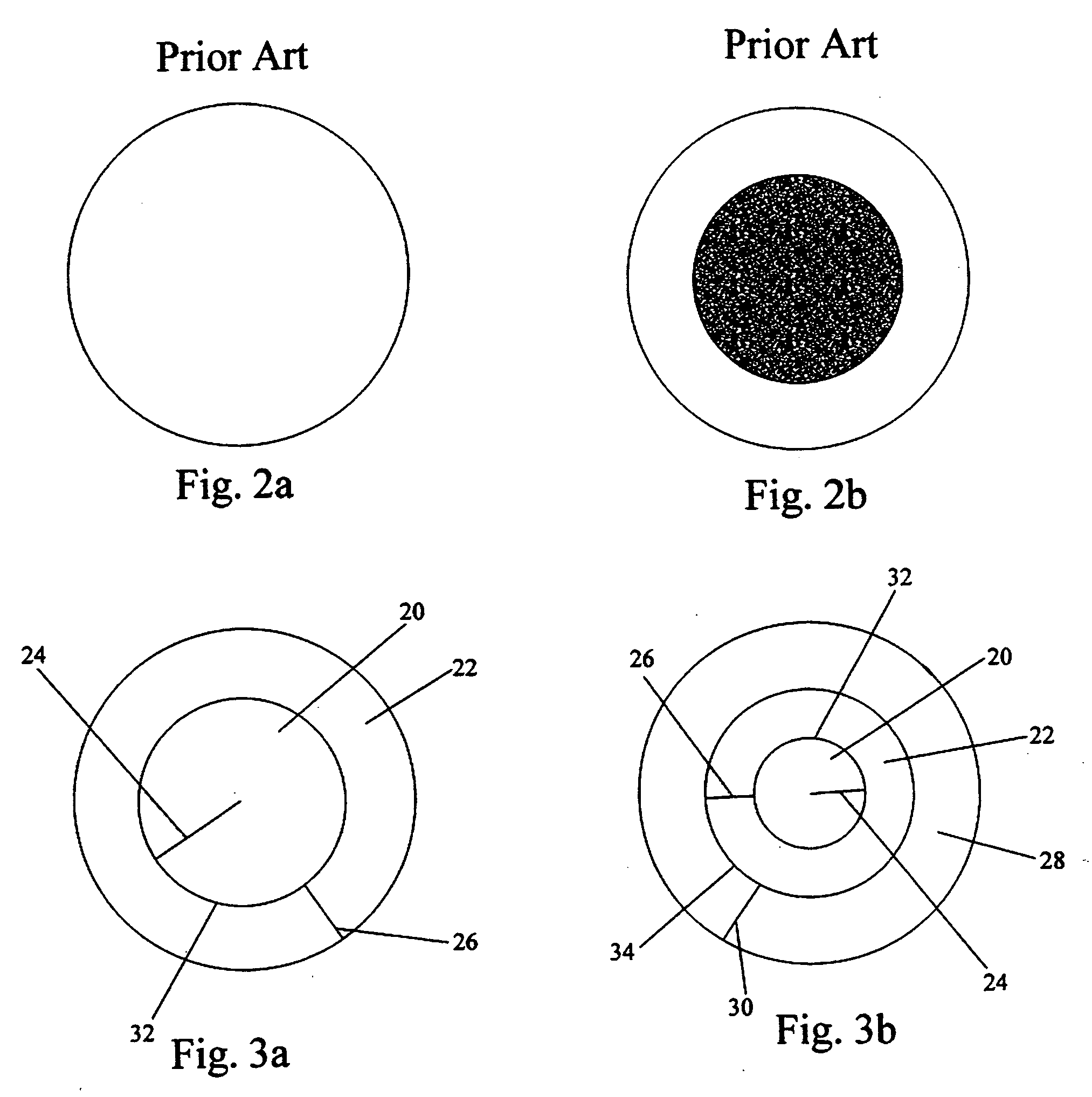

A torch for gas metal arc welding includes a torch housing and a contact tip mounted on the housing and having an electrode bore through which electrode wire is fed. A nozzle mounted on the housing surrounds the contact tip to define an annular gas passage between the contact tip and the inside of the nozzle. A shielding gas inlet communicates a shielding gas into the annular gas passage so that the shielding gas flows out of the nozzle. A plurality of auxiliary flow passages are provided in the contact tip, and have open ends arranged around the electrode bore. The auxiliary flow passages communicate with the gas inlet and surround the electrode wire with an auxiliary flow of shielding gas that is closer to the electrode wire than the shielding gas flow that is provided through the annular gas passage between the contact tip and the nozzle.

Owner:GM GLOBAL TECH OPERATIONS LLC

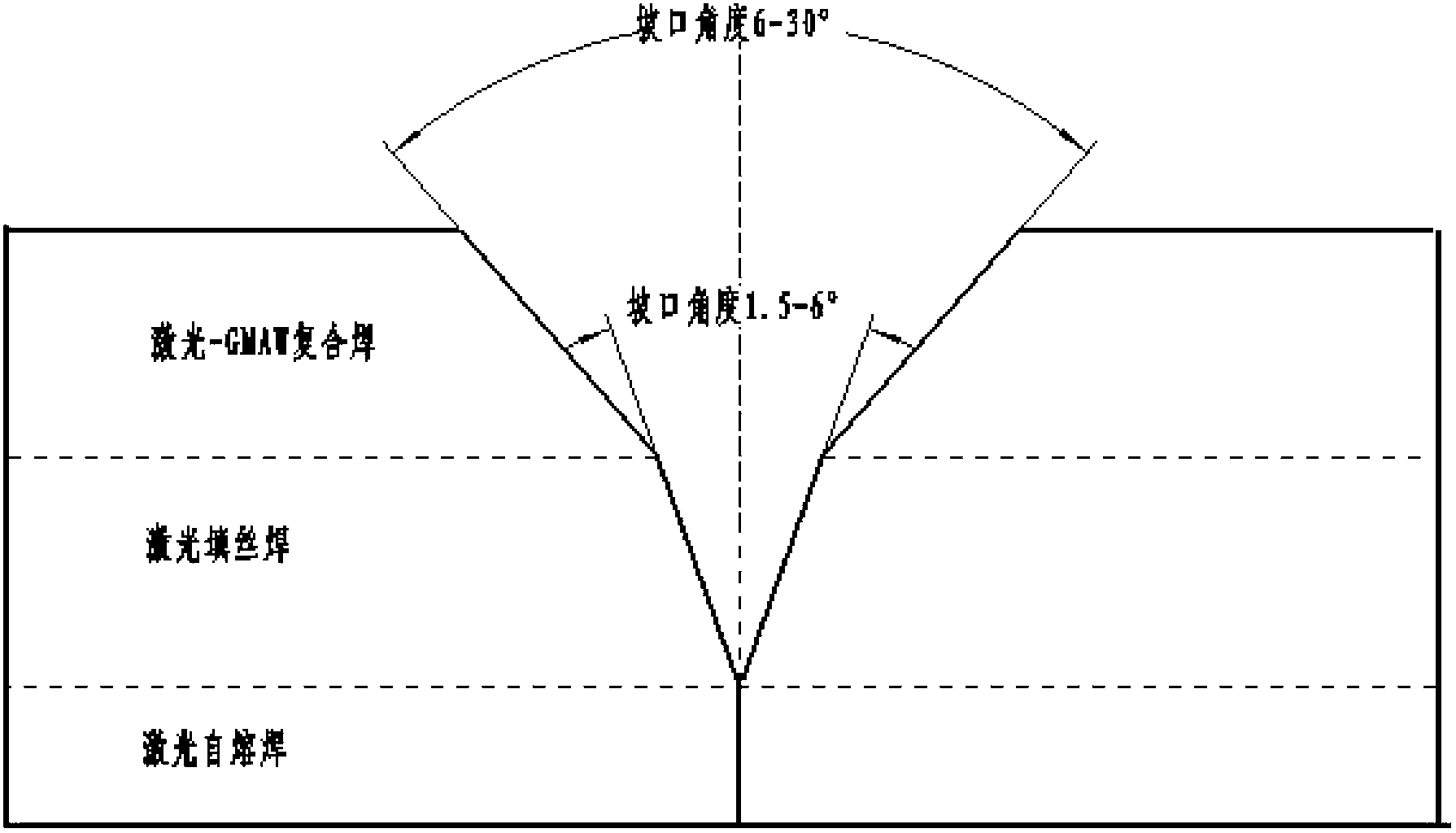

Narrow gap multi-pass laser welding method for thick plate

InactiveCN103008895AReduce consumptionImprove welding productivityLaser beam welding apparatusWorkpiece edge portionsThick plateGas metal arc welding

The invention discloses a laser welding method for a thick plate. A gap is reserved on the thick plate or a divided edge with a blunted edge is performed, a laser autogenous welding is adopted at the welding bead part for welding a pass for bottoming, then, the laser wire filling welding is carried out, a welding wire and a laser beam maintain an included angle being 15 degrees to 75 degrees, the welding wire extends into the divided edge gap from the front of the laser beam, when the filling wire welding cannot fully fill the divided edge gap, the laser-GMAW (gas metal arc welding) composite welding is finally carried out, and the welding of the thick plate is completed. The preserved gap value is respectively smaller than or equal to 0.5mm, the width of the performed welding bead used for the wire filling welding is smaller than or equal to 2.5mm, and the width of the performed welding bead used for the composite welding is smaller than or equal to 10mm. The laser welding method has the advantages that the problem of high-efficiency and high-quality welding of the thick plate is solved, so high-quality and efficient thick plate welding joints with small welding deformation and high gap bridging capability are obtained.

Owner:HUAZHONG UNIV OF SCI & TECH

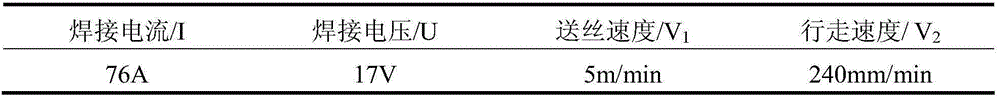

Shaking arc narrow gap melting electrode gas shielded vertical welding method

The invention discloses a rocking-arc narrow-gap vertical gas metal arc welding method comprising the following steps of: assembling metal-piece thick plates into an I-shaped vertical groove to be welded having a gap within a range of 12-15 mm; according to the gap of the groove to be welded and the difference of weld joint passes, firstly selecting a gas protection way, setting an arc rocking frequency, an arc rocking amplitude, arc side wall retention time, an average arc current of pulse welding, an average arc voltage, a welding speed and the dry extension of a welding wire, and selectinga slightly bent conductive rod with an appropriate bending angle; moving a welding torch integrally upwards or downwards in the vertical direction at the welding speed, thereby realizing vertical andautomatic rocking-arc narrow-gap gas metal arc welding in such a manner of single-pass multi-layer welding per layer in a state where a weld joint is freely formed. The method of the invention does not need to form a large welding groove and does not require a forced forming device; besides, the welding device is simple, the welding efficiency is high, the weld joint is formed beautifully, and the performance of the welded joint is good.

Owner:JIANGSU UNIV OF SCI & TECH

In-service weld repairs using metal arc welding under oil (MAWUO) of pipelines, tanks, and vessels

InactiveUS20120111837A1Minimizing debrisReduce porosityArc welding apparatusPipeline systemsCombined useGas metal arc welding

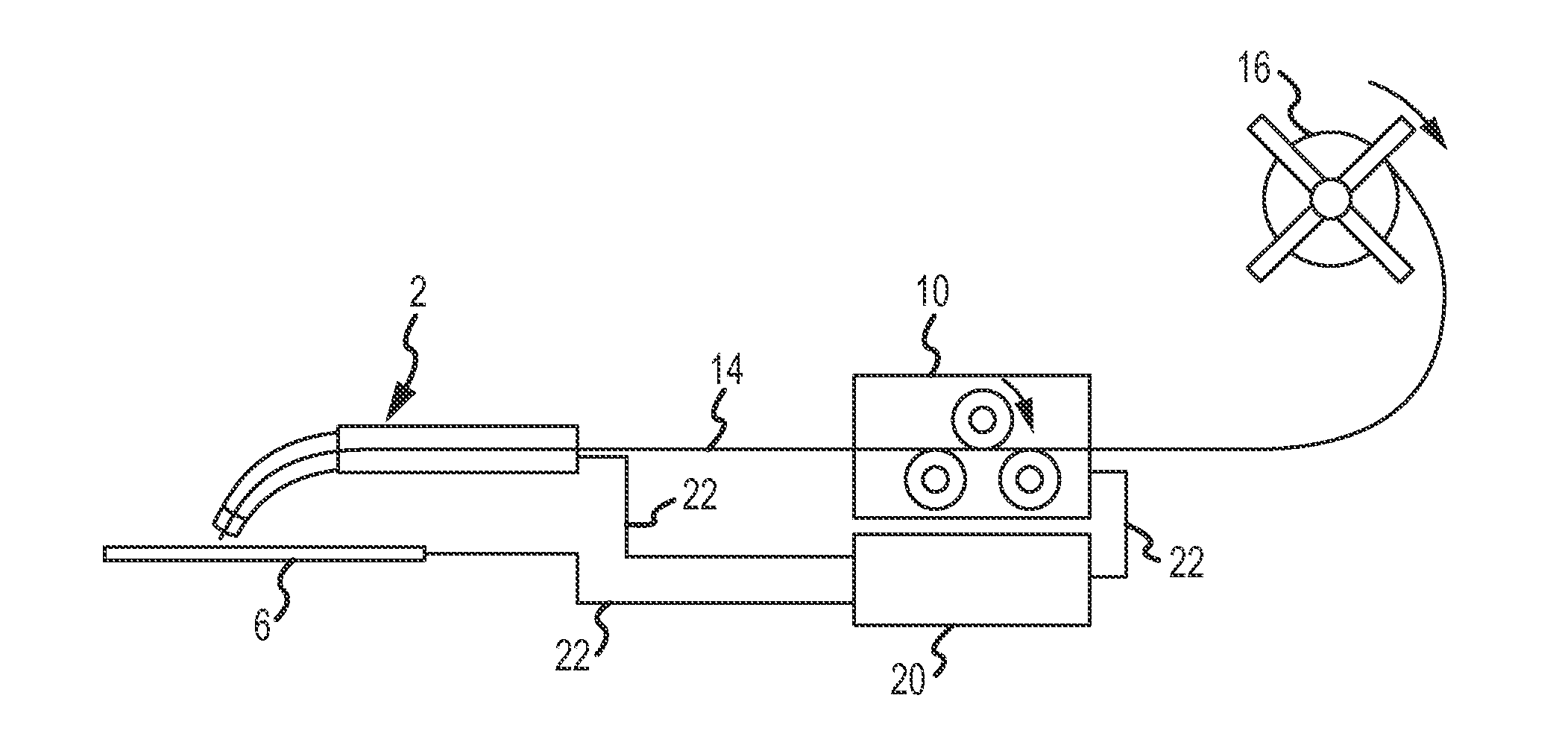

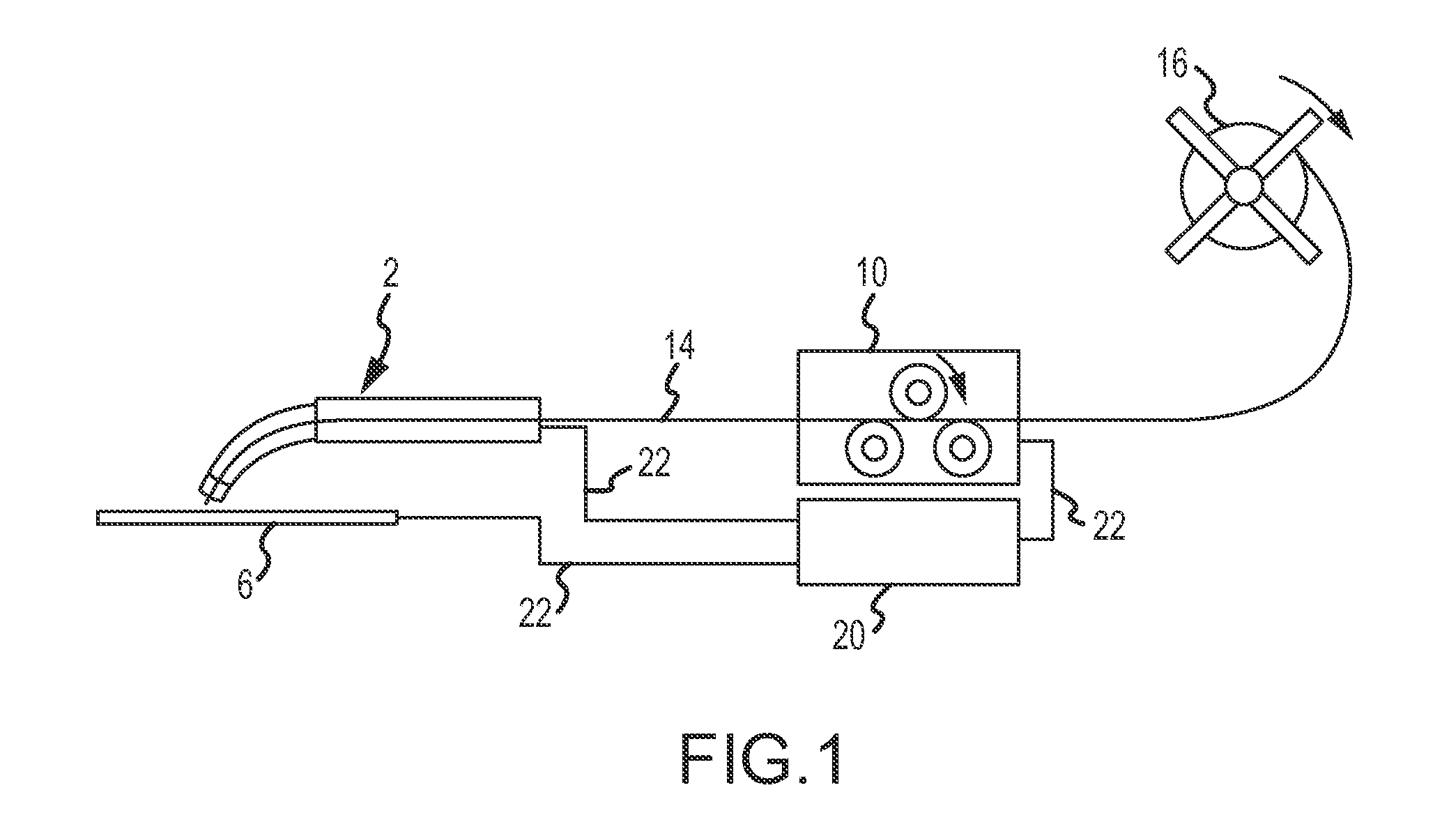

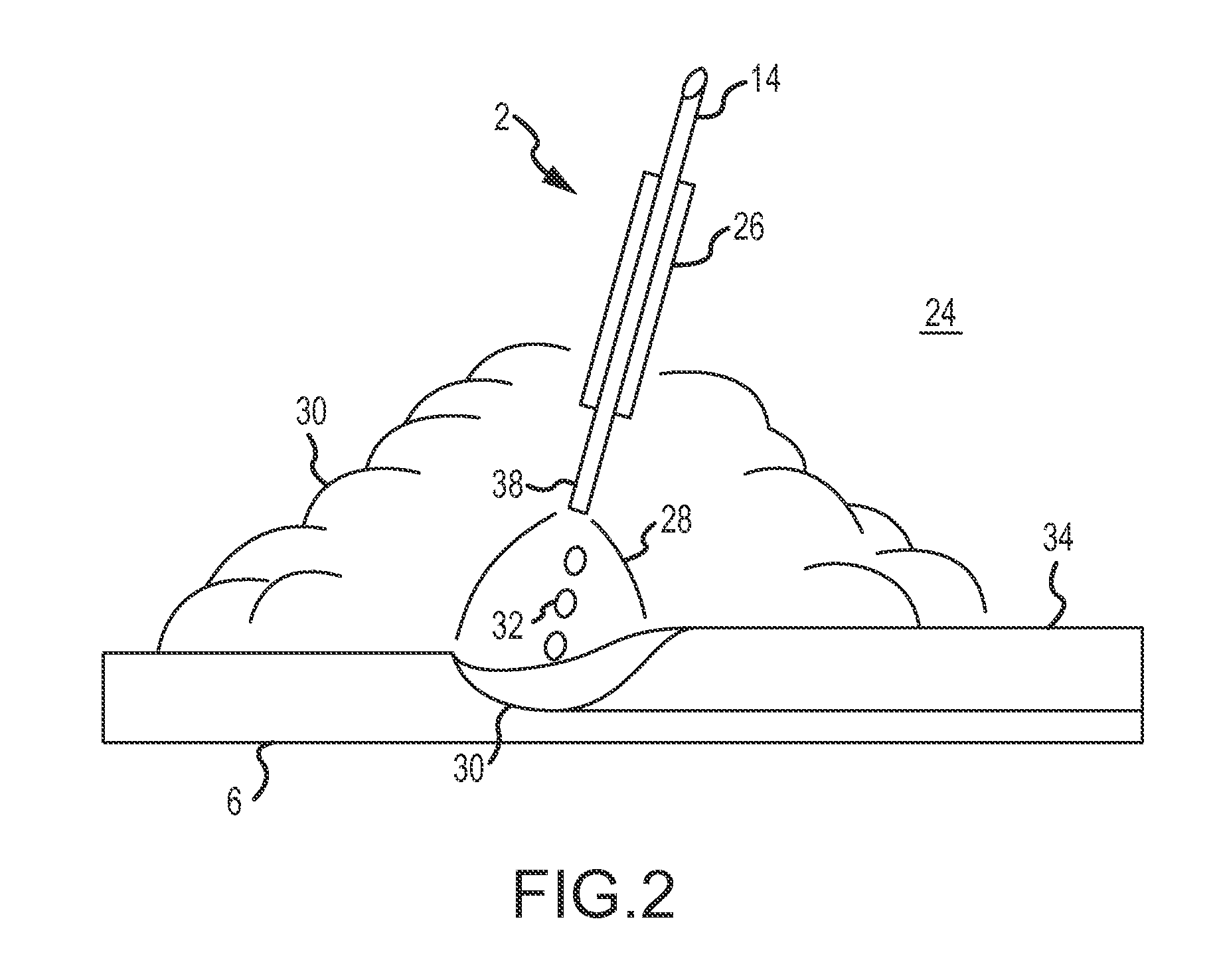

Apparatus and methods of repairing an in-service pipeline, tank, and / or vessel are provided. Generally, a metal arc welding under oil process employing an automated metal arc welding setup with a continuous wire feed is utilized. The process may be used in connection with a smart pig to perform in-situ internal repairs of in-service pipelines, tanks, and / or vessels. For example, a pipeline pig or other device is contemplated that employs an internal power supply, a navigation system, and a metal arc welding under oil system that is able to travel vast distances within a pipeline to reach pipeline segments that are either buried underground, under highways, or underwater making access very difficult. Once at its desired location, the pipeline pig performs in-situ welding or other internal repairs to the in-service pipeline. The disclosed apparatus and methods provide great flexibility to the repair of pipelines, tanks, and / or vessels.

Owner:COLORADO SCHOOL OF MINES

Welding method of stainless steel clad plate

InactiveCN104191072AReduce cooling effectQuality improvementArc welding apparatusWelding/soldering/cutting articlesGas metal arc weldingWeld seam

The invention discloses a welding method of a stainless steel clad plate, and relates to the technical field of welding. The welding method comprises the following steps that surface oxygen complexes of the stainless steel clad plate are removed; a groove is machined, the groove is an X-shaped groove, the angle of the groove is 55-65 degrees, the root gap of the groove is 1-3 millimeters, and the root portion of a joint is placed in a base layer; a base layer is welded, a first welding layer and a third welding layer of a welding seam of the base layer are welded in a submerged automatic arc welding mode, the third welding layer is provided with a plurality of welding beads, and a second welding layer is welded in a gas metal arc welding mode; a transitional layer on the connecting portion of the base layer and a multiple layer is welded, a fourth welding layer and a fifth welding layer of the transitional layer are both welded in the gas metal arc welding layer; the multiple layer is welded, a welding seam of the multiple layer is a sixth welding layer, and the sixth welding layer is welded in a large-current submerged-arc welding mode. Compared with the prior art, the welding method of the stainless steel clad plate improves the quality of a welding joint of the stainless steel clad plate and is high in welding efficiency.

Owner:WUZHOU WANGJIE MACHINERY MFR

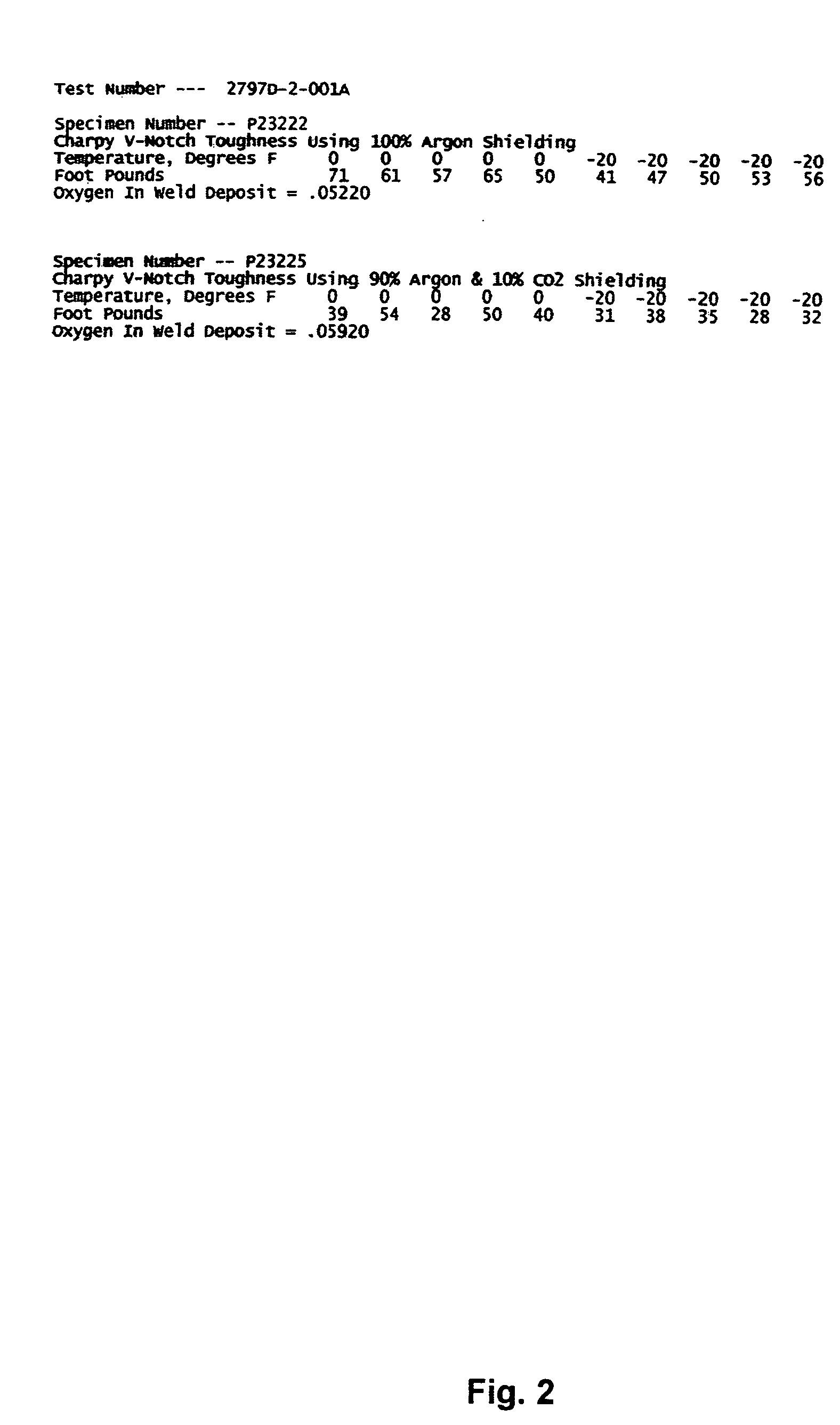

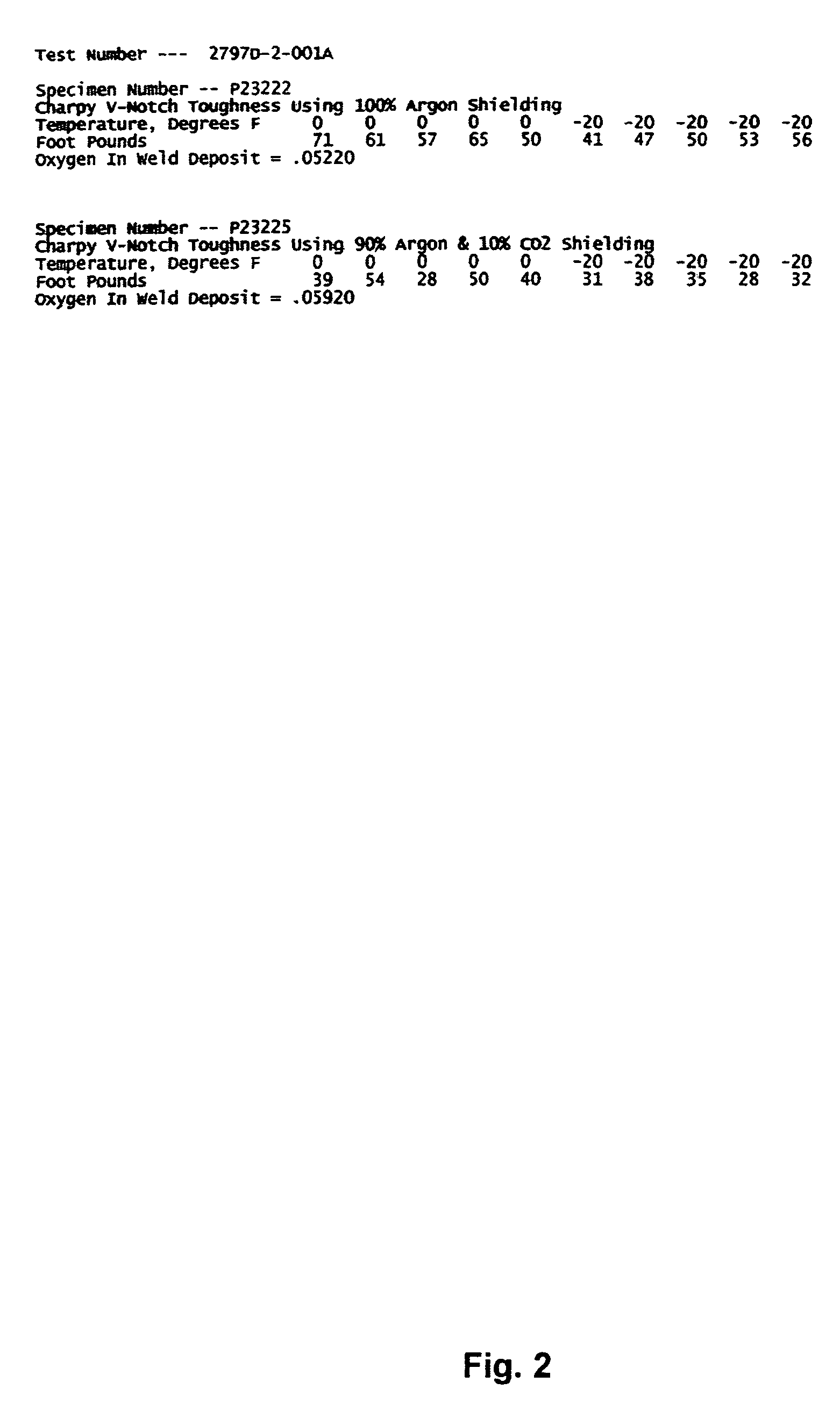

Metal-core gas metal arc welding of ferrous steels with noble gas shielding

ActiveUS20050205525A1Reduce penetrationThin wallArc welding apparatusWelding/cutting media/materialsNoble gasLow voltage

The gas-metal arc welding of metal-core wile electrodes in the pure Ar shielding gas for carbon steel, low alloy steel, and ferritic stainless steel is described. Such shielding gas provides several benefits not realized ??the gas-metal arc welding process with solid wires. When compared to standard argon / oxygen containing gas mixtures normally used for metal cored wires, these benefits include reduced silicate islands on the weld surface for improved weld appearance, reduced welding fume, and lower weld spatter, all of which provide easier clean-up after the welding operation. Benefits also include reduced arc penetration desirable for welding on thinner materials or handling poor joint fit-up. Lower voltage requirement further makes it possible to weld on thinner materials. Lower oxygen content in the weld deposits provide better toughness and easier welding in all-positions.

Owner:HOBART BROS

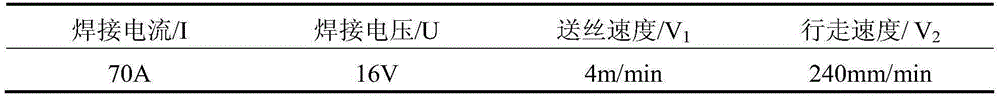

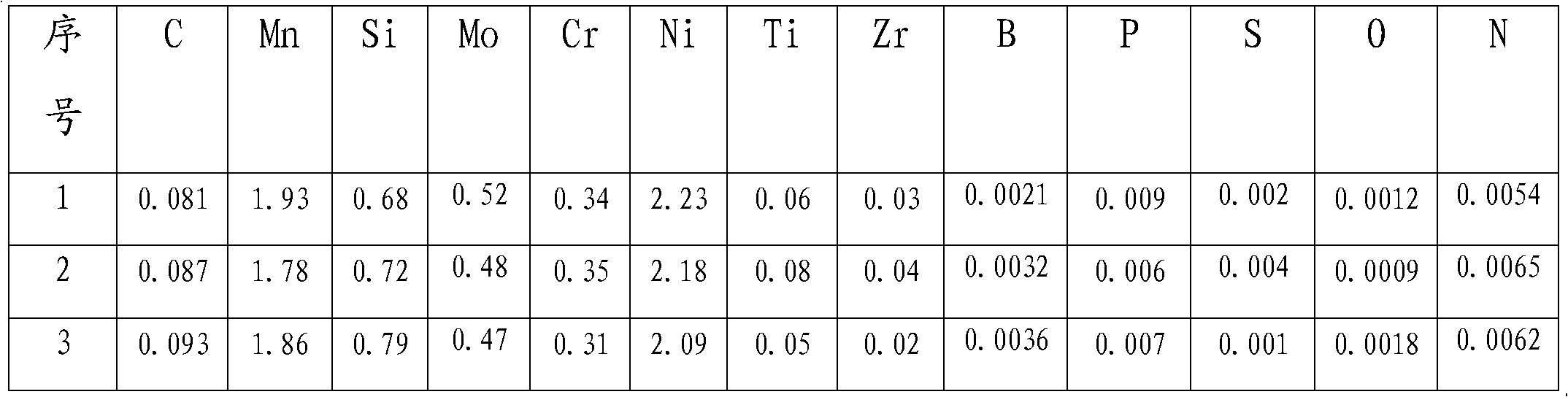

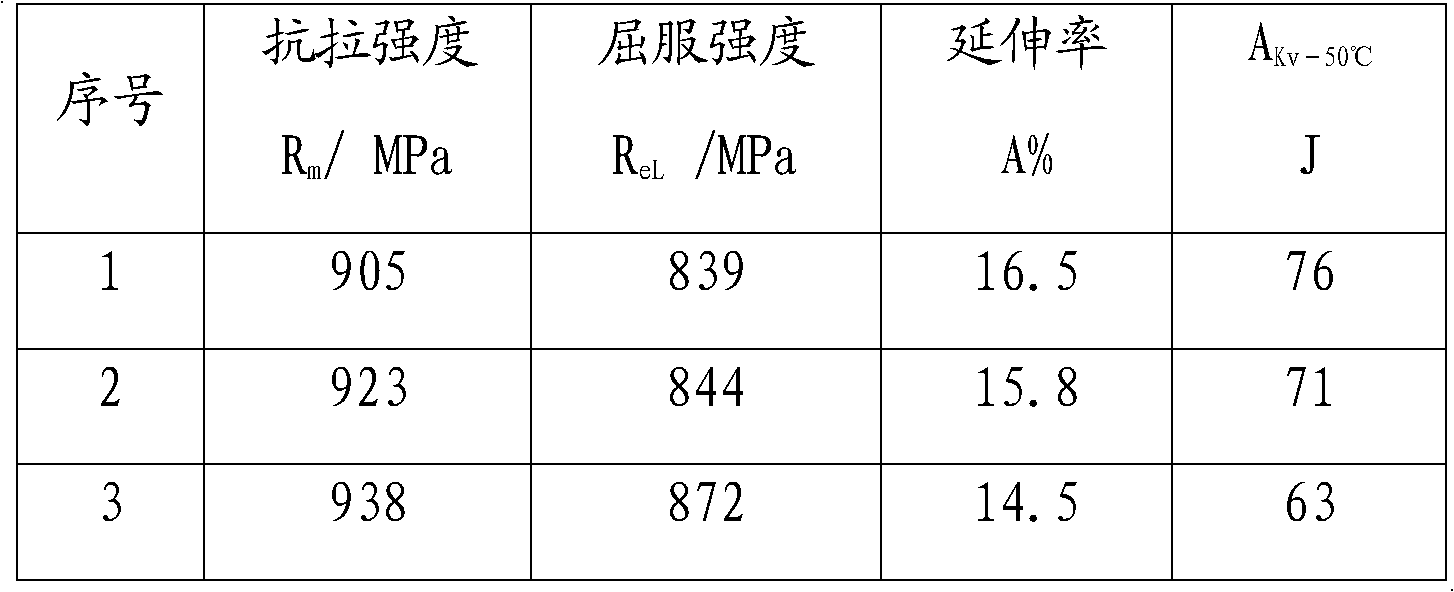

800MPa-grade high-strength high-tenacity gas shielded welding wire

ActiveCN101733580ASuitable for weldingImprove toughnessArc welding apparatusWelding/cutting media/materialsChemical compositionAlloy

The invention provides a 800MPa-grade high-strength high-tenacity gas shielded welding wire which is suitable for welding engineering machinery, coal mine machinery, railroad bridges, hydropower industry, delivery lines and high-pressure containers. The gas metal arc welding wire contains the chemical compositions in weight percent: 0.05-0.10 percent of C, 0.20-0.60 percent of Si, 1.60-2.10 percent of Mn, 1.8-2.4 percent of Ni, 0.2-0.6 percent of Mo, 0.10-0.50 percent of Cr, 0.04-0.10 percent of Ti, 0.02-0.08 percent of Zr, not more than 0.010 percent of S, not more than 0.015 percent of P and the balance of Fe and unavoidable impurities. Since the Ar+20% CO2 argon-rich gas shielded welding is adopted by the welding wire, low-alloy high-strength steel the tensile strength Rm of which is not lower than 800MPa can be welded; under the as welded and postwelding thermal refining condition, weld metal has high strength and good low-temperature impact toughness.

Owner:山东索力得焊材股份有限公司 +1

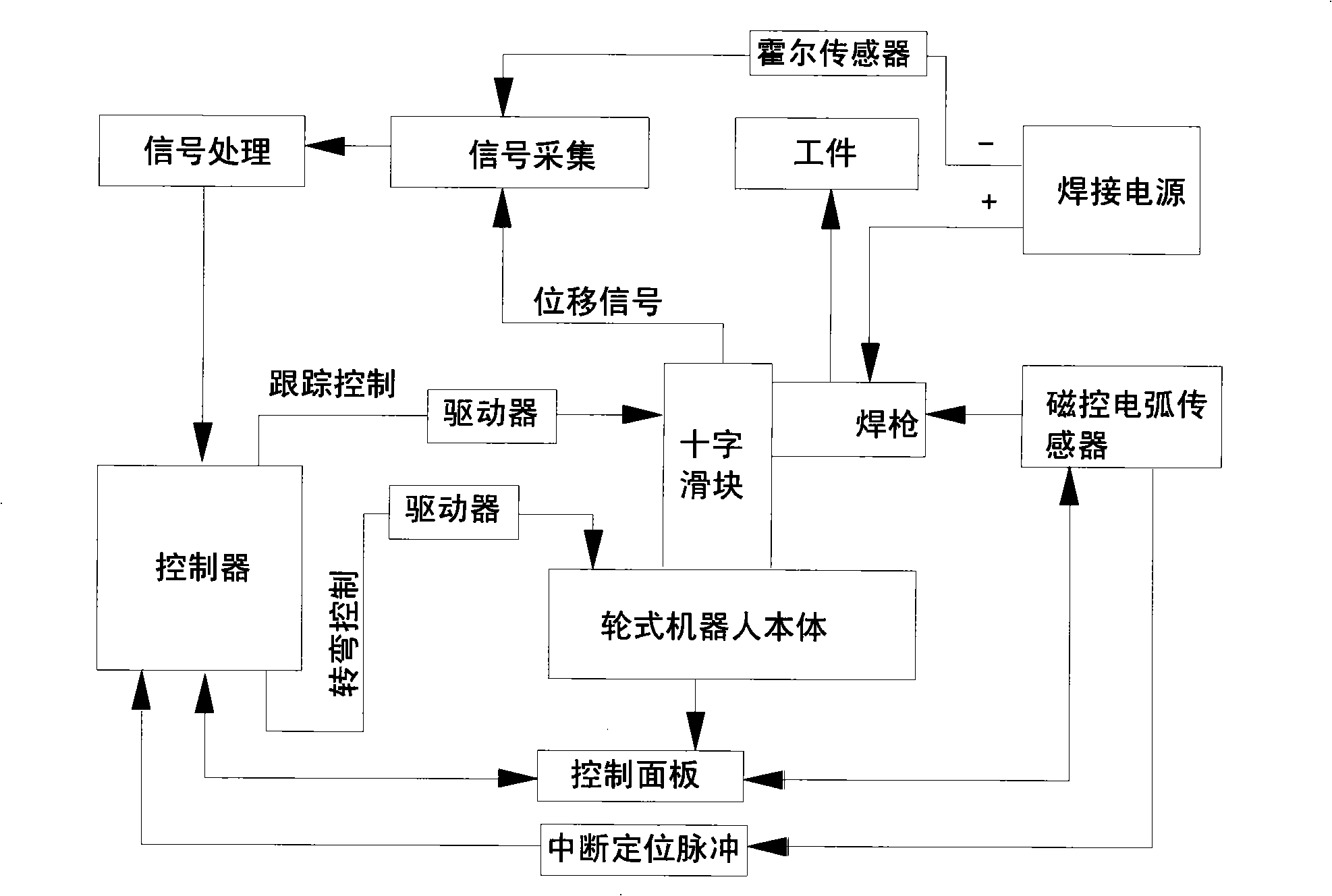

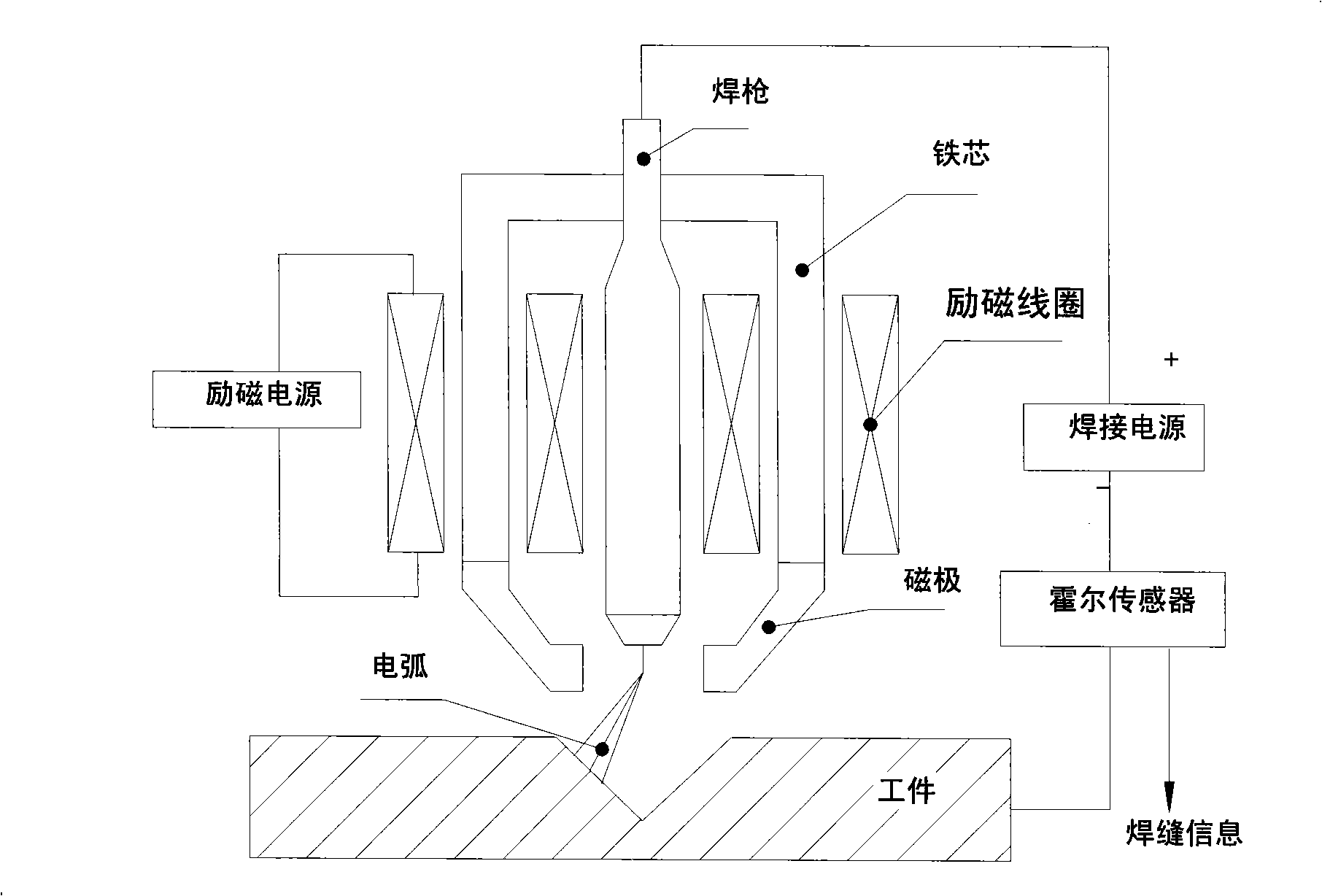

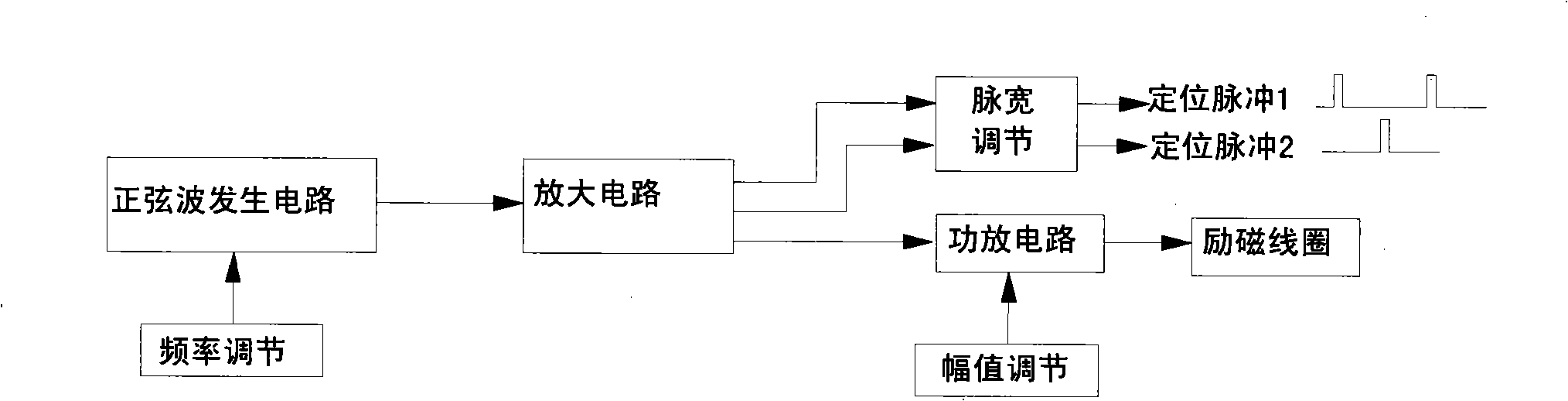

Real time technique for tracking weld joints of gas metal arc welding by magnetic controlled electric arc sensor

InactiveCN101327545AImprove real-time performanceGood tracking effectArc welding apparatusWelding power supplyPre and post

The invention discloses a real-time follow-up technique of a magnetic controlling arc sensing welding line of gas metal arc welding, which belongs to a welding control technique. The invention mainly solves the problems of complex structure, high cost, unstable performance and poor real-time performance, etc, of the prior gas metal arc welding line follow-up system. The invention adopts the technical proposal that the real-time follow-up technique comprises a magnetic controlling voltaic arc sensor, a welding system composed of a welding torch, a welding electric source and so on, a control system, a follow-up actuating mechanism composed of a set of cross sliding guides, a wheel robots and so on; wherein, the magnetic controlling voltaic arc sensor is directly installed on the welding torch, which is used for gas metal-arc welding process, to collect the horizontal and the vertical deviation signals of the welding line; the processed signals are input in a microcomputer for processing by software; the real-time control follow-up actuating mechanism is capable of automatically following up the welding line. The technique achieves automatic following up of the welding line in gas metal arc welding. The magnetic controlling arc sensor is installed on the welding torch used for gas metal-arc welding process, which eliminates the problems of preposing and postposing, and has the characteristics of good real-time performance, low cost, high stable performance and high precision.

Owner:XIANGTAN UNIV

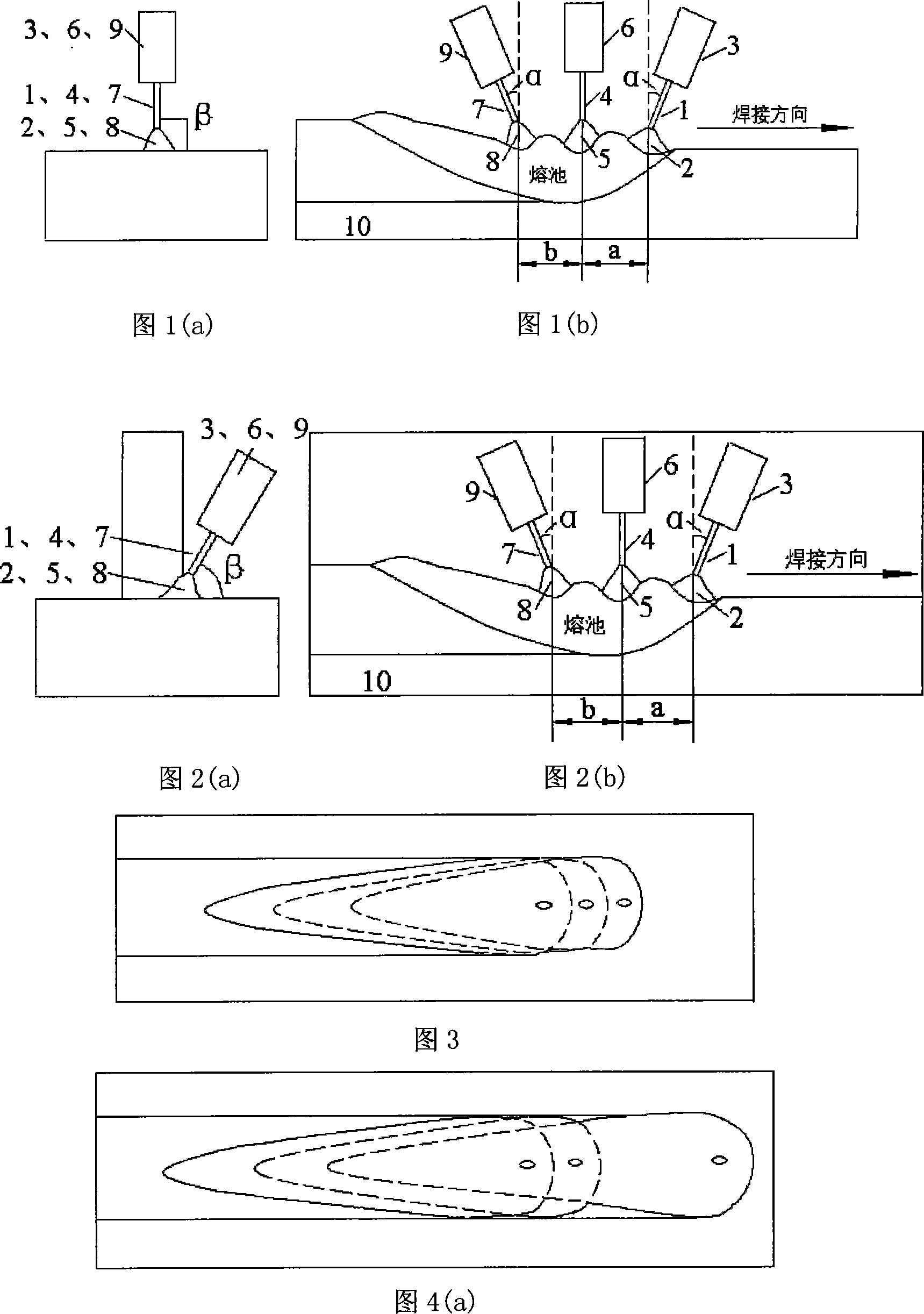

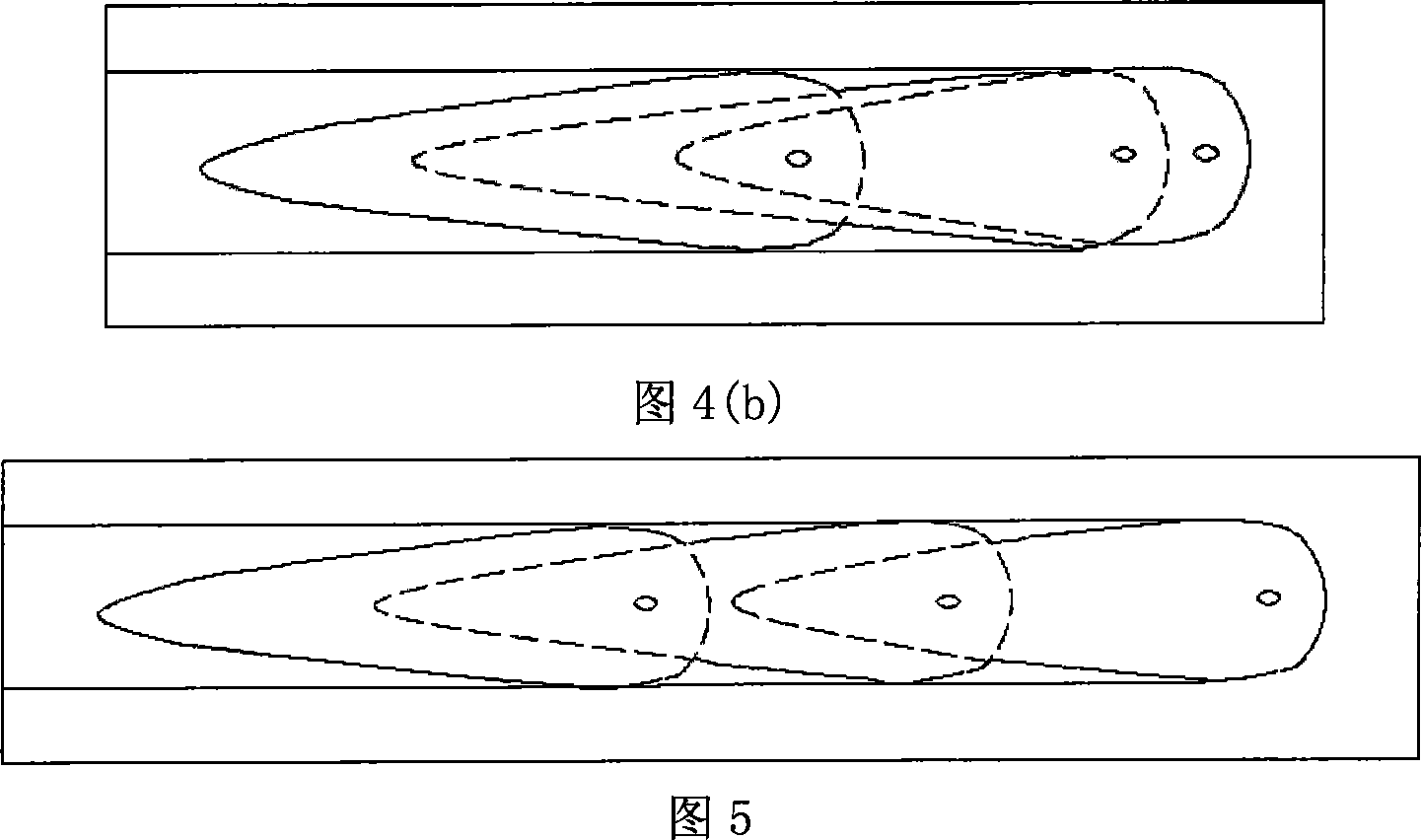

Three-filum open arc welding method

InactiveCN101134260AImprove welding productivityArc welding apparatusWelding power supplyGas metal arc welding

The present invention relates to welding technology, and discloses three wire open arc welding process. Three welding torches with separate welding wires and welding power sources and separate welding parameter adjustments are applied simultaneously in the gas metal-arc welding. These three welding torches are arranged longitudinally in the welding direction for flat welding or corner welding, and their angles and intervals are regulated separately. For high welding speed and welding quality, their electric arc parameters are regulated separately and they may operate in the welding mode of one, two or three molten pools. The present invention has high welding efficiency and is especially suitable for long weld seam welding.

Owner:SHANGHAI JIAO TONG UNIV +1

Metal-core gas metal arc welding of ferrous steels with noble gas shielding

ActiveUS7863538B2Reduce the amount requiredQuality improvementArc welding apparatusWelding/cutting media/materialsNoble gasLow voltage

The gas-metal arc welding of metal-core wile electrodes in the pure Ar shielding gas for carbon steel, low alloy steel, and ferritic stainless steel is described. Such shielding gas provides several benefits not realized ??the gas-metal arc welding process with solid wires. When compared to standard argon / oxygen containing gas mixtures normally used for metal cored wires, these benefits include reduced silicate islands on the weld surface for improved weld appearance, reduced welding fume, and lower weld spatter, all of which provide easier clean-up after the welding operation. Benefits also include reduced arc penetration desirable for welding on thinner materials or handling poor joint fit-up. Lower voltage requirement further makes it possible to weld on thinner materials. Lower oxygen content in the weld deposits provide better toughness and easier welding in all-positions.

Owner:HOBART BROS

Special flux-cored wire for hot-working die repairing surfacing

ActiveCN105057926AGood workmanshipSuitable for automatic weldingArc welding apparatusWelding/cutting media/materialsSlagGas metal arc welding

The invention provides a special flux-cored wire for hot-working die repairing surfacing. The special flux-cored wire comprises the wire tube wall and powder covered by the wire tube wall, wherein the powder comprises a deoxidation alloying agent and a slag former; by adding nanometer chromium nitride powder into iron-base alloy powder, a thin nitride interstitial phase is formed in the deposited metal, so that the deposited metal has good tenacity and anti-cracking capacity; meanwhile, yttria is added into the alloy powder, so that the deposited metal is purified, the occluded foreign substances are nodulized, the nitride strengthening phase is formed, and the anti-fatigue performance of the deposited metal is improved; by adopting the gas metal arc welding technology combining flux-cored wire and argon-rich gas protection to repair the hot-working die, the obtained deposited metal has excellent high-temperature oxidation resistance, excellent abrasive resistance, excellent cleanliness and good anti-fatigue performance.

Owner:SHANDONG UNIV

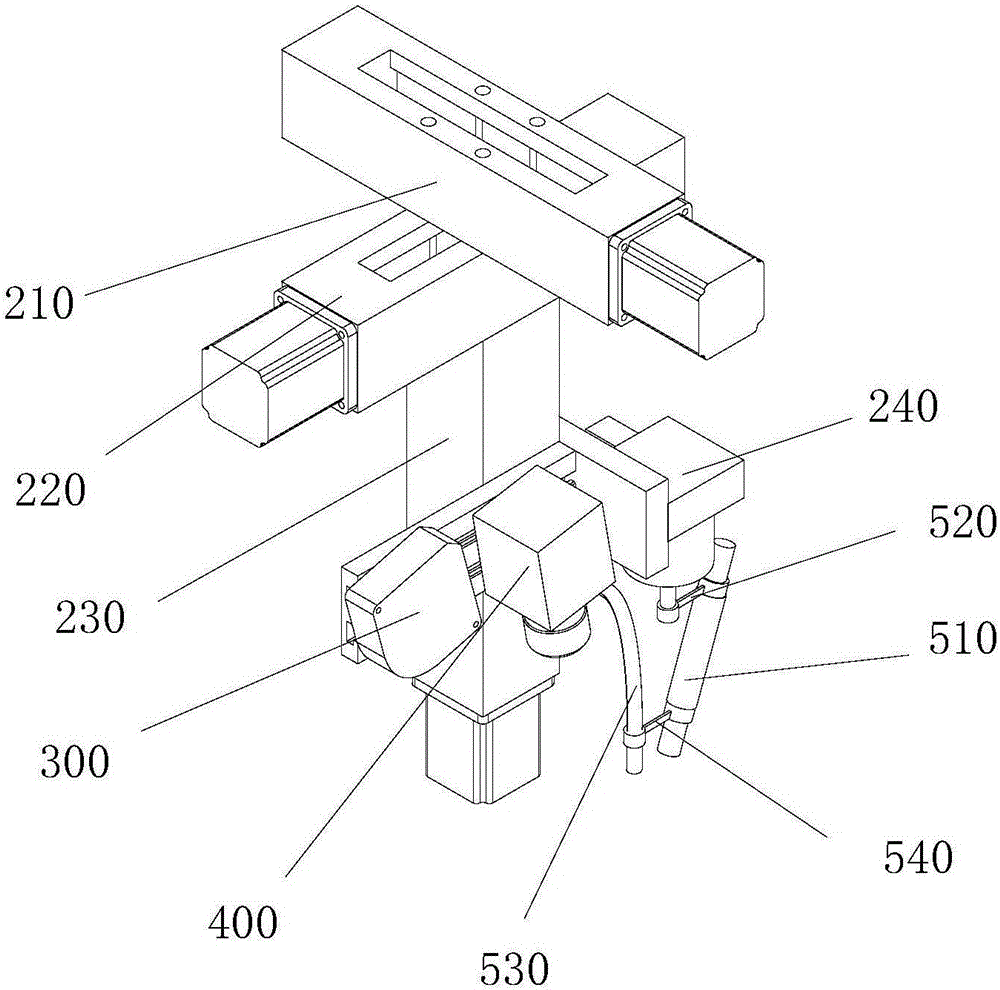

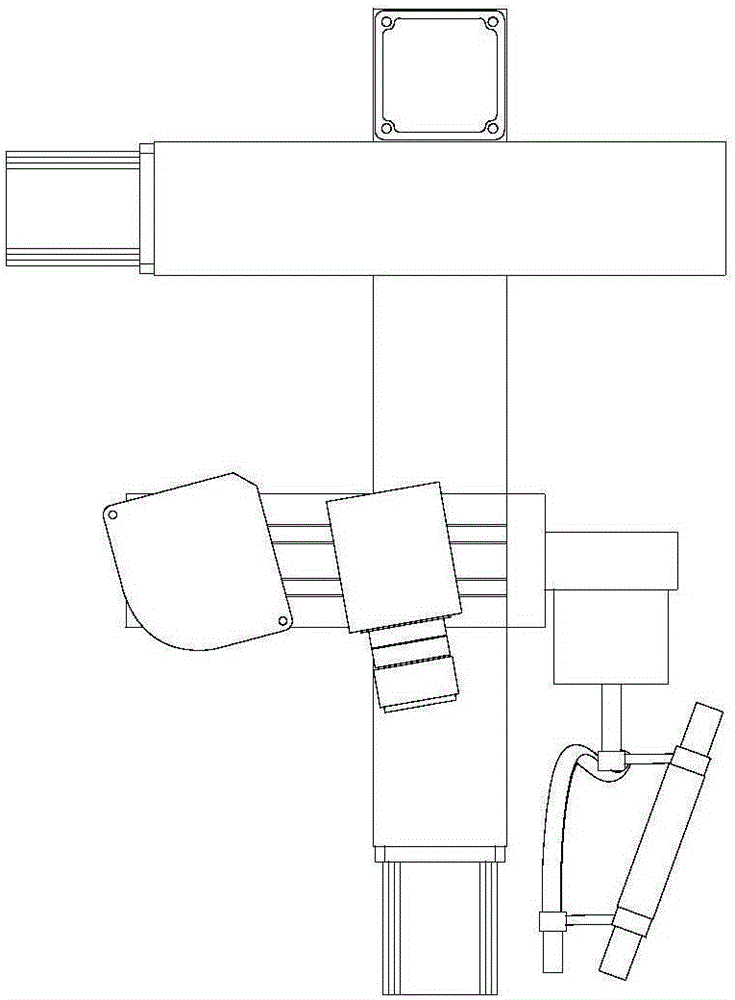

3D metal welding and printing method based on gas metal arc welding and numerical control machining

ActiveCN105252119AHigh densityImprove mechanical propertiesWelding accessoriesNumerical controlTransfer mode

Owner:四川康铭智能装备科技有限公司

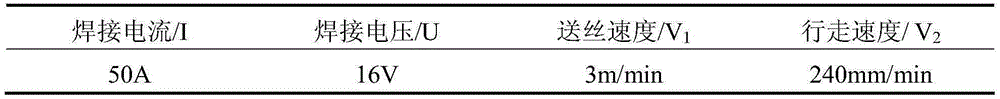

900MPa-level high-performance gas shielded welding wire

InactiveCN101987403AImprove crack resistanceImprove low temperature toughnessWelding/cutting media/materialsSoldering mediaCrack resistanceAlloy

The invention provides a 900MPa-level high-performance gas shielded welding wire, which is suitable for welding large-sized important structural members in the heavy load fields of engineering machinery, coal mine machinery, railroad bridges, automobile cranes, high pressure vessels and the like. The gas metal arc welding welding wire comprises the following chemical components in percentage by mass: 0.05 to 0.10 percent of C, 0.40 to 0.80 percent of Si, 1.60 to 2.00 percent of Mn, 2.0 to 2.6 percent of Ni, 0.3 to 0.7 percent of Mo, 0.20 to 0.60 percent of Cr, 0.02 to 0.08 percent of Ti, 0.002 to 0.006 percent of B, 0.02 to 0.08 percent of Zr, less than or equal to 0.010 percent of S, less than or equal to 0.010 percent of P, less than or equal to 0.003 percent of O, less than or equal to 0.007 percent of N, and the balance of Fe and inevitable impurities. The welding wire adopts Ar+20 percent CO2 gas shielded welding rich in argon, can be used for welding high-strength low ally steel of which the tensile strength Rm is more than or equal to 900MPa, and a weld metal has high obdurability and cracking resistance under a welding condition and a post-welding hardening and tempering condition.

Owner:SHENYANG AEROSPACE UNIVERSITY

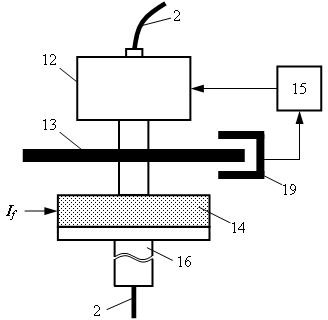

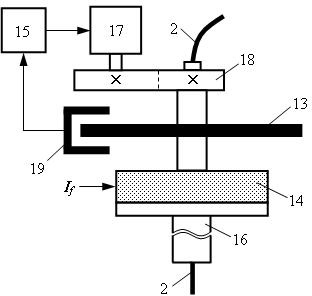

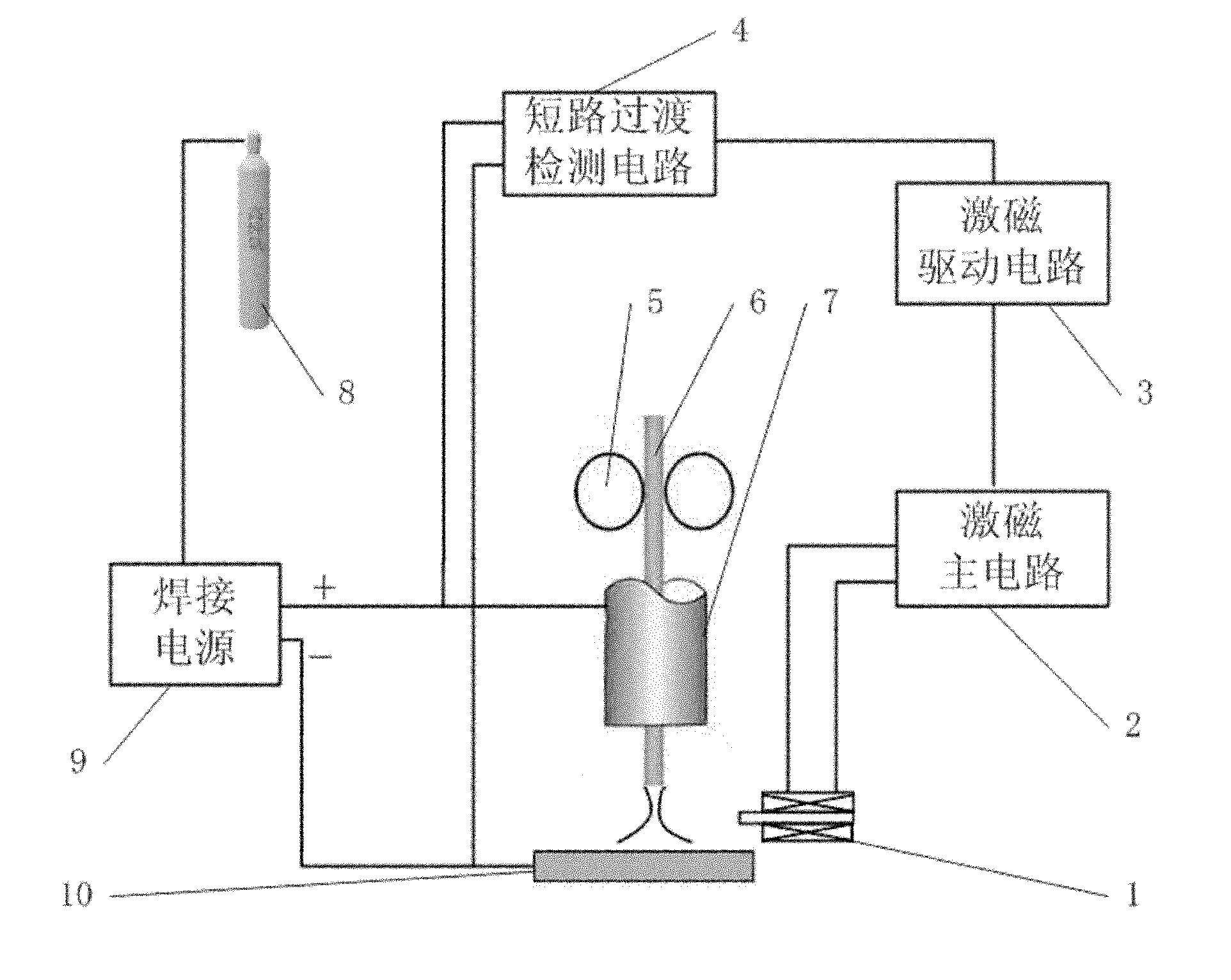

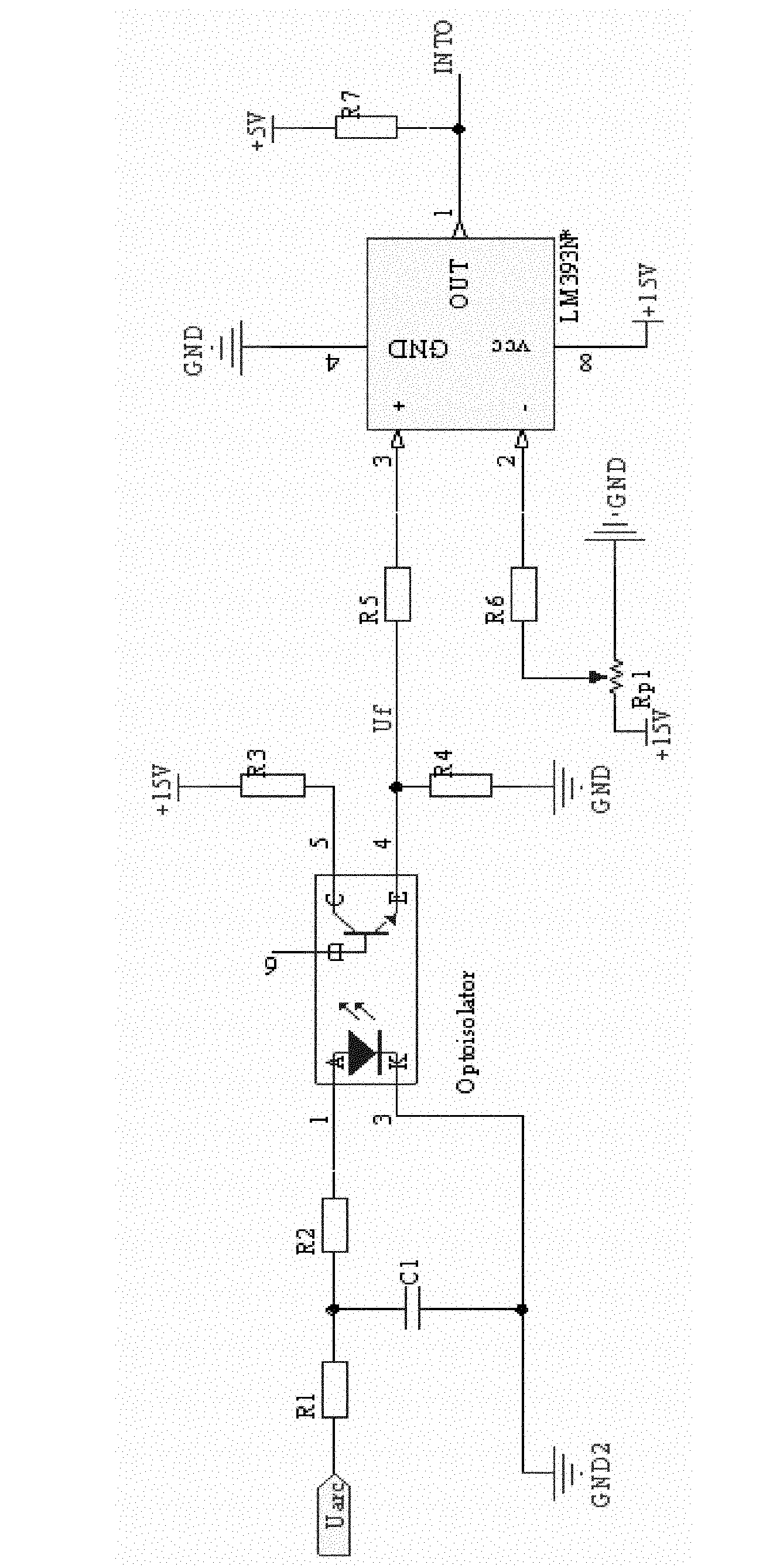

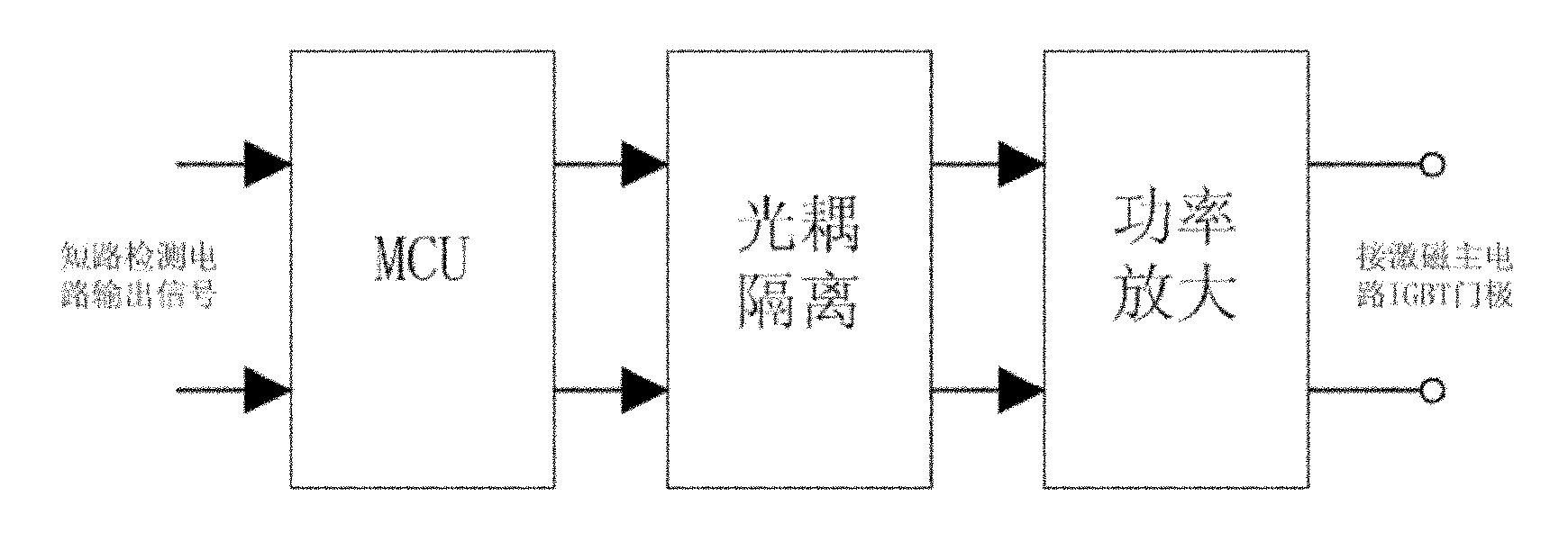

Device and method for assisting gas metal arc welding by using externally applied magnetic fields

InactiveCN102133679AImproving Short Circuit Transition Welding ProcessReduce peak currentArc welding apparatusElectricityPulsed magnet

The invention discloses a device and a method for assisting gas metal arc welding by using externally applied magnetic fields, belonging to the field of welding techniques under the action of magnetic fields. The device comprises necessary conventional equipment for gas metal arc welding, a short circuiting transfer detection circuit, an exciting drive circuit, a main exciting circuit and a magnetic head device. According to the invention, during droplet short circuit period, a transverse pulsed magnet field which is acted on a short circuit liquid bridge and perpendicular to a welding-wire axis can be generated so as to promote the advanced fracture of the short circuit liquid bridge; and compared with the conventional method, the method provided by the invention has the advantages that the peak current during the short circuit period is reduced, the induced explosion and splash are lowered, and the regularity of a short circuit cycle in the process of short circuiting transfer welding can be improved. The device disclosed by the invention is simple in manufacturing, and the welding process of short circuiting transfer is obviously improved.

Owner:BEIJING UNIV OF TECH

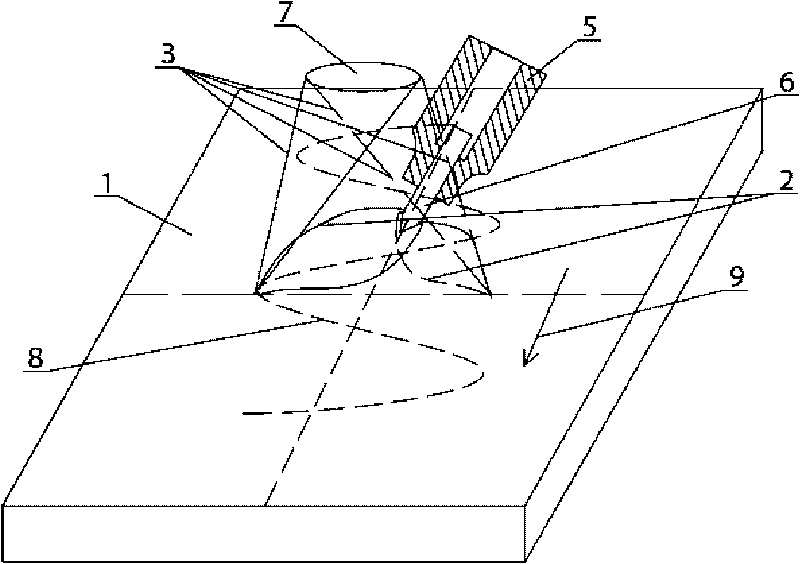

Laser guide GMAW (Gas Metal Arc Welding) electric arc compound transverse welding method

ActiveCN102922153ASuppression of drippingEliminate undercut defectsLaser beam welding apparatusVertical planeArchitectural engineering

The invention provides a laser guide GMAW (Gas Metal Arc Welding) electric arc compound transverse welding method, relates to a transverse welding method and solves the problem of the existing welding method that fused metal flows down when transverse welding is carried out in a vertical plane so as to cause undercut and deviation of a central line of a welding line. The laser guide GMAW electric arc compound transverse welding method is carried out by the following steps of: 1, carrying out oil-removing and oxidization-film-removing treatment on a work piece to be welded; 2, filling a welding wire; and 3, starting a laser device and a GMAW electric arc welding machine. With the adoption of the laser guide GMAW electric arc compound transverse welding method, the flowing of the fused metal can be controlled under the condition with a large welding current, so that the undercut defect of the welding line is eliminated and the central line of the welding line is rightly centered. The laser guide GMAW electric arc compound transverse welding method is applicable to the field of metal transverse welding engineering.

Owner:哈尔滨工大焊接科技有限公司

Gas metal arc welding weld wire suitable for working temperature being -196 DEG C

ActiveCN106938375ALow content priceReduce manufacturing costWelding/cutting media/materialsSoldering mediaWorking temperatureGas metal arc welding

The invention relates to a gas metal arc welding weld wire suitable for the working temperature being -196 DEG C. According to the technical field, the gas metal arc welding weld wire is prepared from, by weight, 0.30%-0.55% of C, 24%-26% of Mn, 6.4%-8.2% of Ni, 2.5%-4.0% of W, not larger than 0.002% of P, not larger than 0.001% of S and the balance Fe and inevitable impurities. The gas metal arc welding weld wire is low in preparation cost and simple in alloy composition system; formed weld metal has the characteristic of ultralow temperature high toughness, and the strength is matched with that of ultralow-temperature high manganese steel; and a welding joint has the mechanical properties of high strength and excellent ultralow temperature toughness, and the technical requirements for the strength and ultralow temperature toughness of equipment welded when the working temperature is -196 DEG C can be met.

Owner:WUHAN UNIV OF SCI & TECH

Method for welding pile leg main board pipe

ActiveCN101987399AEnsure welding quality requirementsReduce welding costsArc welding apparatusGas metal arc weldingEngineering

Owner:TIANJIN HOIDI OFFSHORE ENG +2

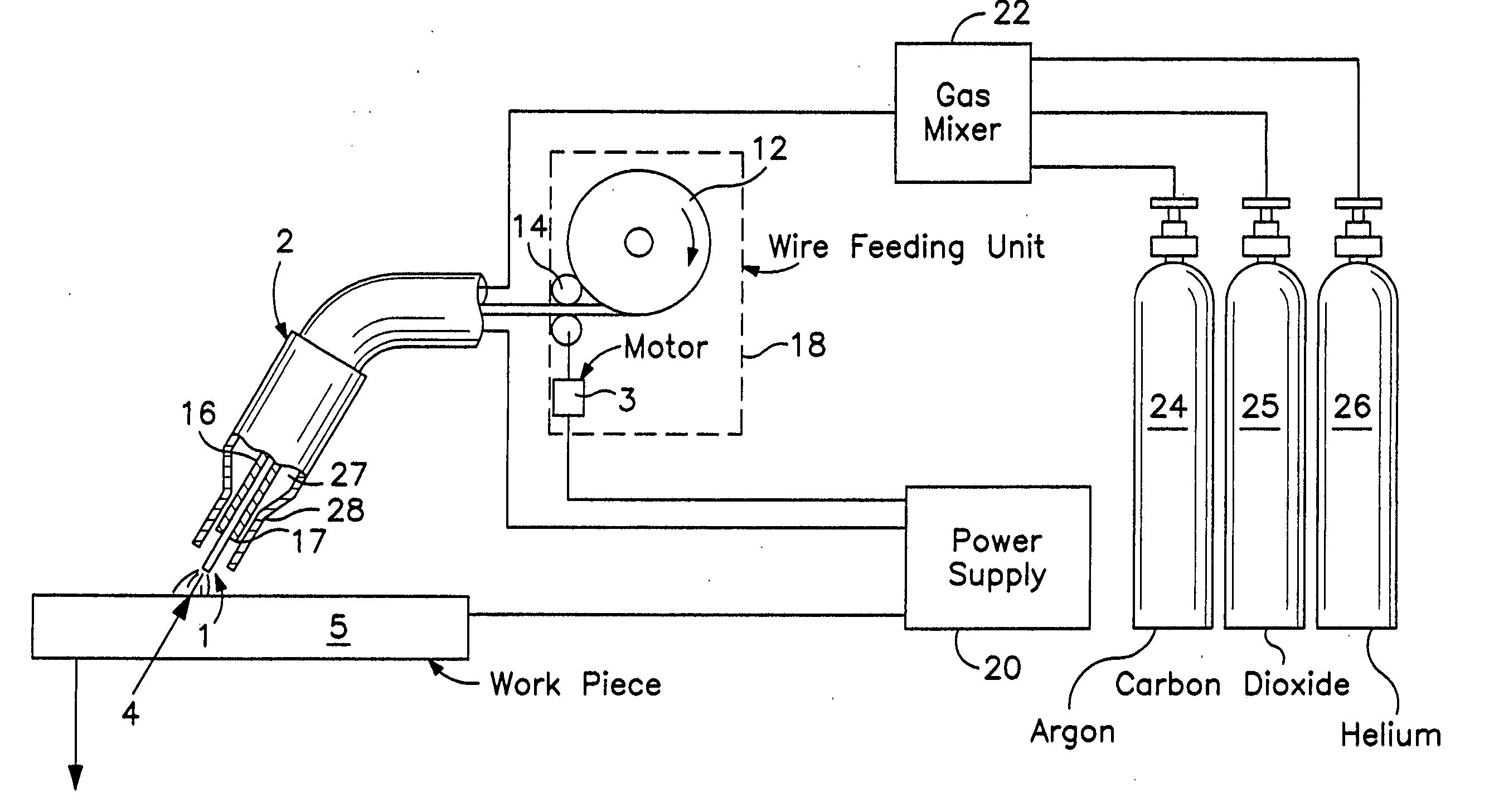

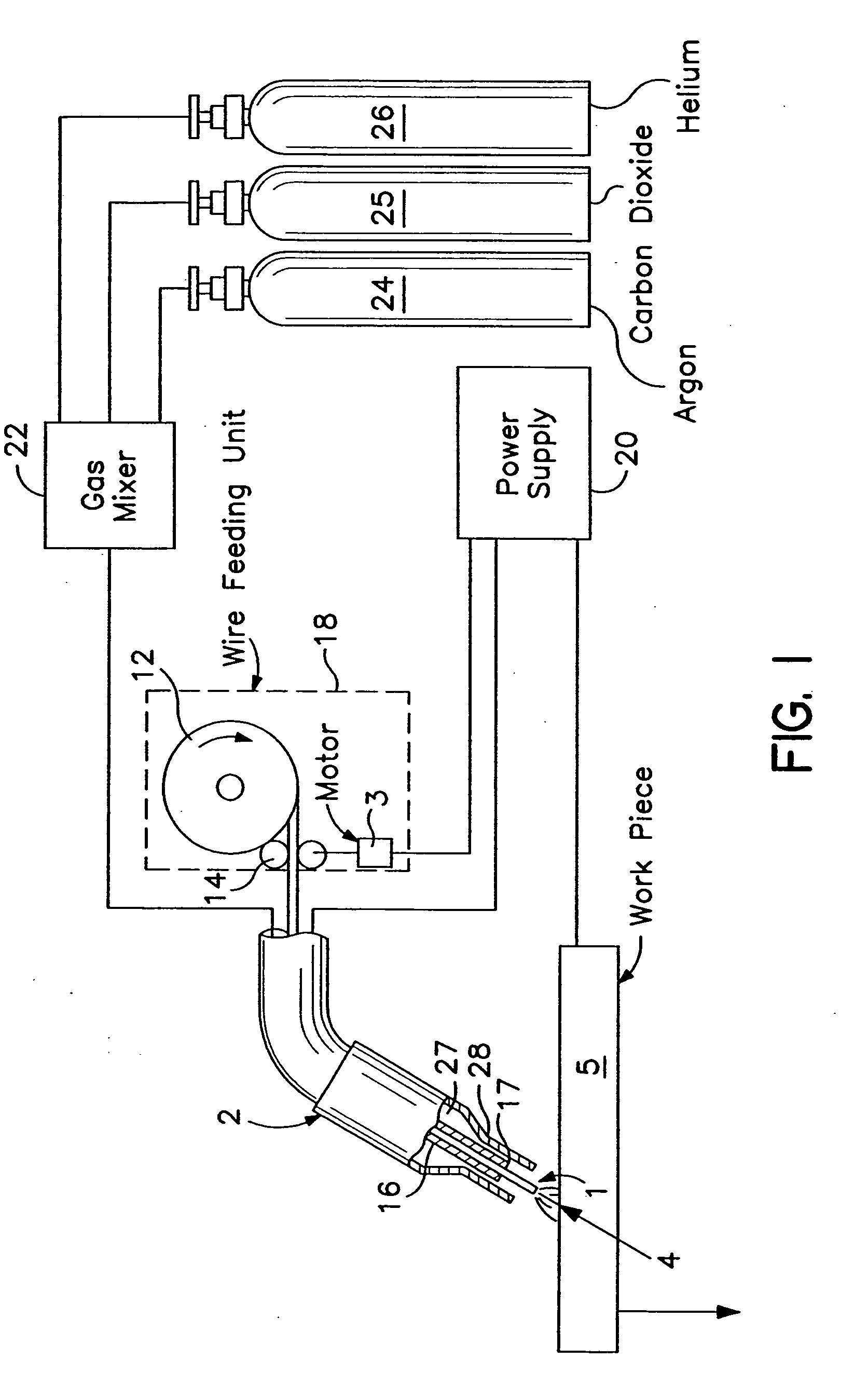

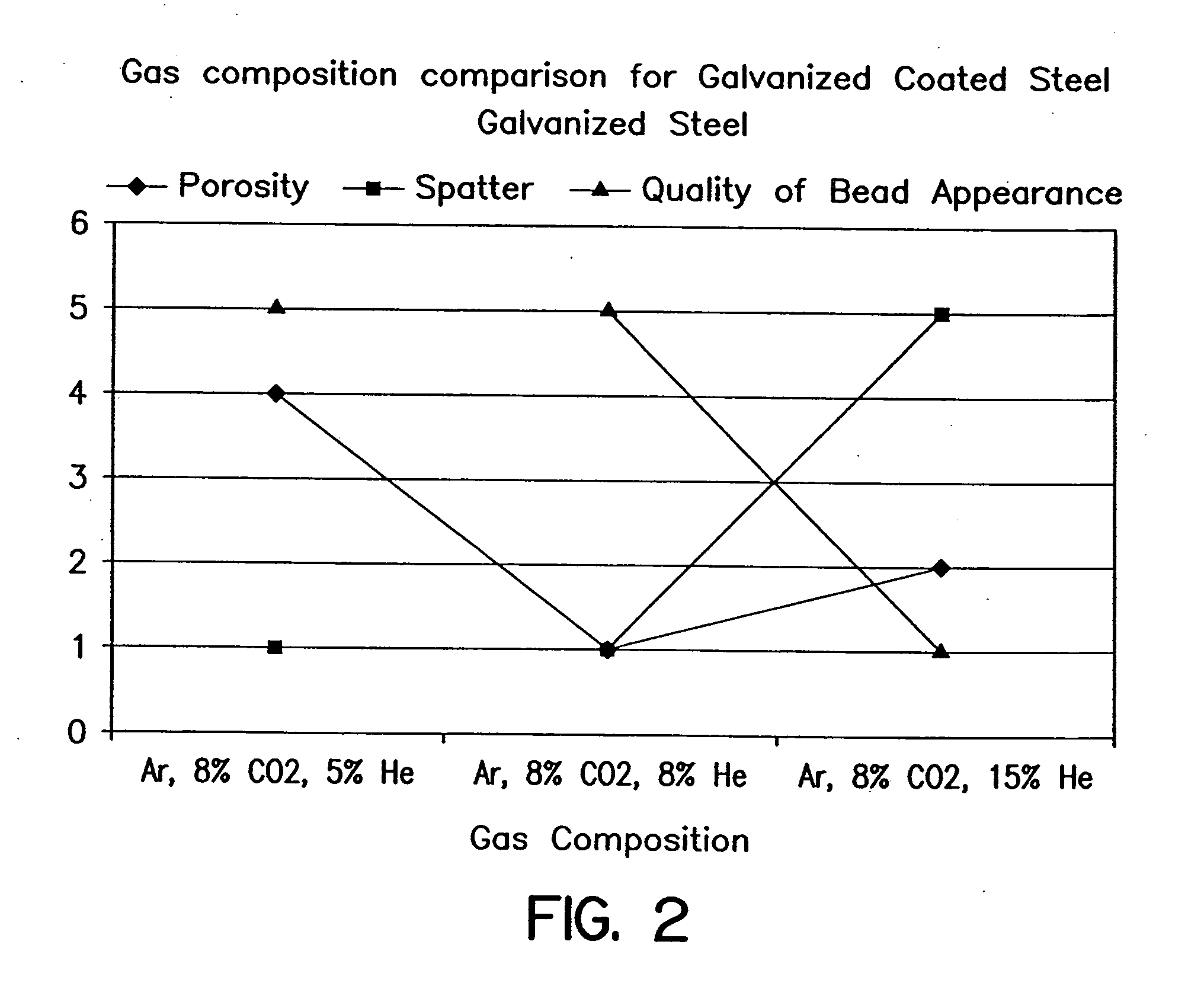

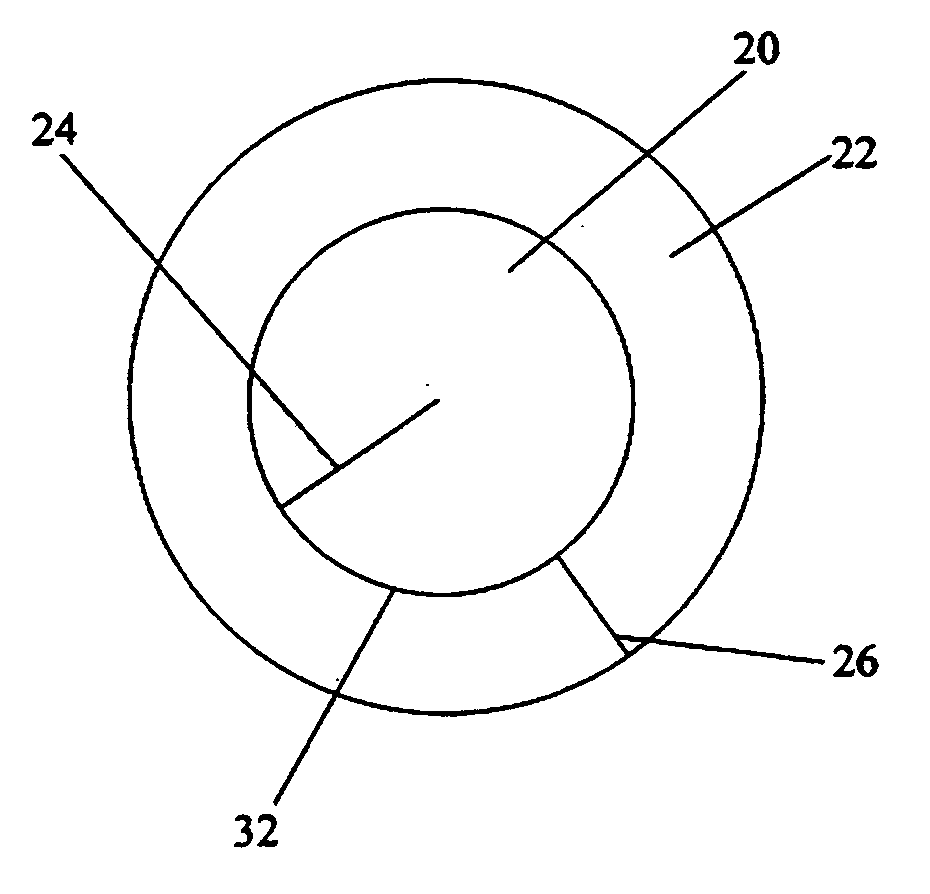

Shielding gas mixture for gas metal arc welding of coated steels

InactiveUS20070051703A1Improve welding qualityMaximum manufacturing flexibilityArc welding apparatusWelding/cutting media/materialsChemical compositionShielding gas

This invention relates to a shielding gas mixture for use with gas metal arc welding with a consumable wire electrode of coated steels, said shielding gas mixture consisting essentially of: (vii) from 6 to 10 volume percent carbon dioxide; (viii) from 6 to 10 volume percent helium; and (ix) the balance argon; wherein the consumable wire electrode is a solid wire, a solid wire having silicon content of from about 0.5 to 1.0 weight percent of the total wire chemistry, a metal-cored wire or a flux-cored wire.

Owner:PRAXAIR TECH INC

Weld wire electrode for gas metal arc welding

InactiveUS20060076336A1Improve electrical resistanceIncrease deposition rateWelding/cutting media/materialsWelding electrode featuresEngineeringGas metal arc welding

A weld wire electrode for use as a consumable in a gas-metal arc welding process comprises two or more strips wrapped around one another and drawn to a desired wire diameter.

Owner:HOBART BROS

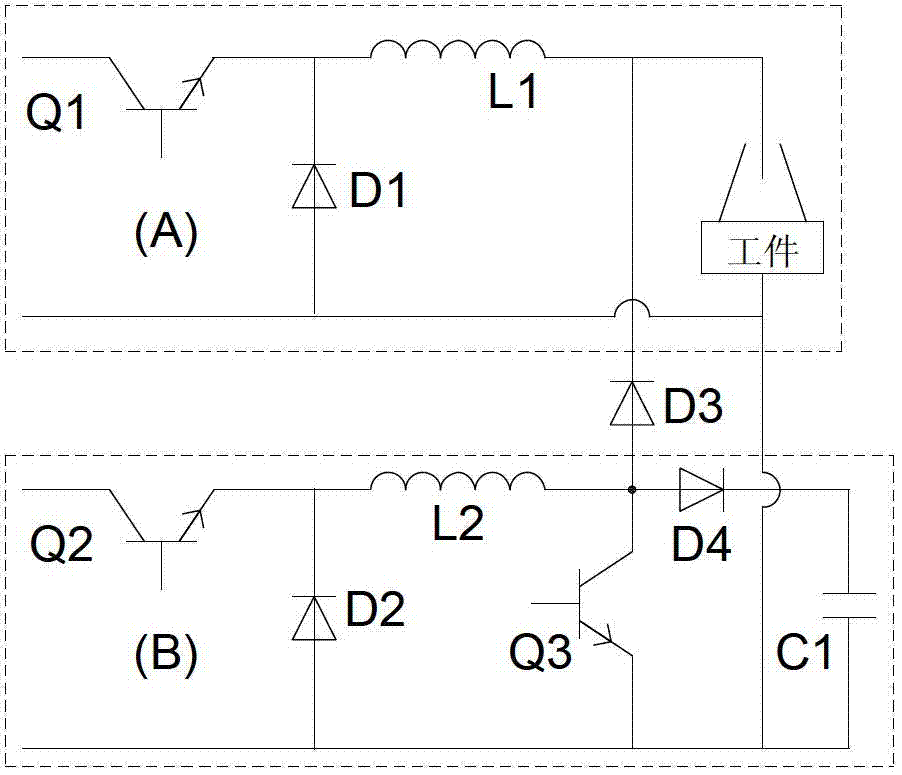

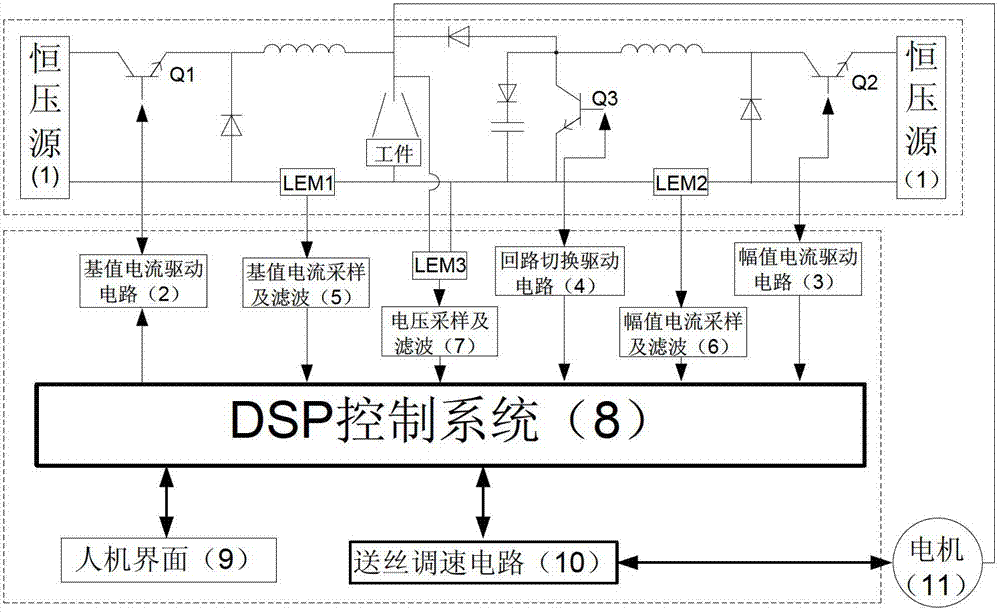

Gas metal arc welding method and system

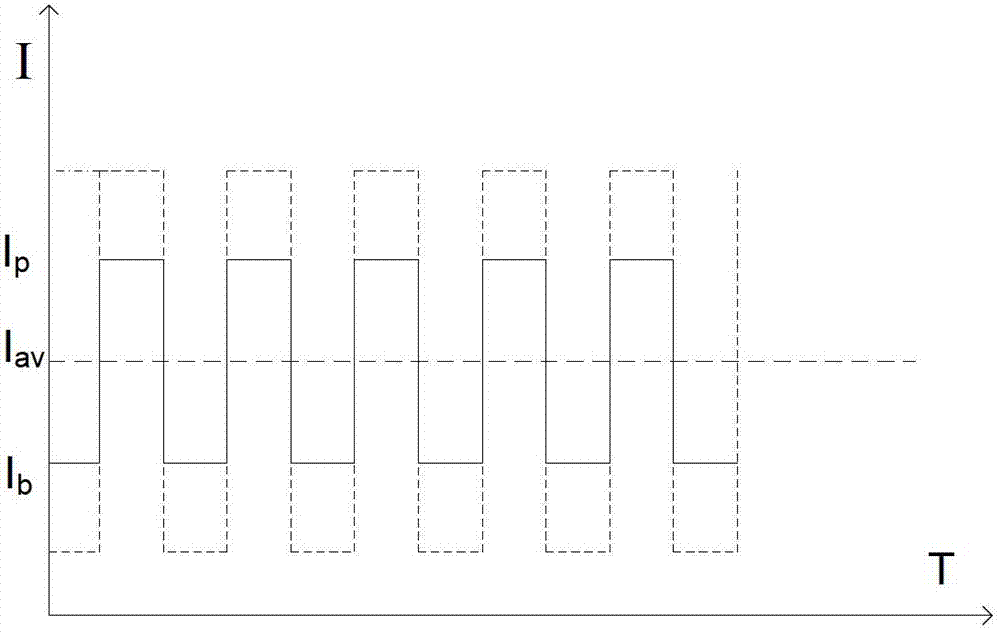

InactiveCN102873435AIncrease the conductive areaLower resistanceArc welding apparatusWelding power supplyPeak value

The invention discloses a gas metal arc welding method and a gas metal arc welding system, and belongs to the field of gas metal arc welding control. Constant wire feed is adopted, the wire feed rate ranges from 1.5 to 18m / min, a welding source outputs pulse current, and the average value of the pulse current is preset according to the wire feed rate before welding and is kept unchanged in the welding process; the arc voltage Ug is given before welding, a feedback value Uf of the arc voltage is sampled in real time in the welding process, and delta I is equal to the absolute value of k(Uf-Ug), wherein delta I is regulation current, and k is a proportionality coefficient and ranges from 10 to 100; when the feedback value Uf of the arc voltage increases, delta I is subtracted from the peak value Ip of the pulse current, and the basic value current Ib is added to delta I to keep the arc voltage stable; and when the feedback value Uf of the arc voltage decreases, the adjusting process is reversed. By the high frequency pulse current, the average value and the effective value of the current are obviously different, so that on the premise that the heat input of a base metal the heating of a solder wire is not changed basically, the heating of a solder wire is changed, the melting rate of the solder wire is adjusted and the arc length is adjusted.

Owner:BEIJING UNIV OF TECH

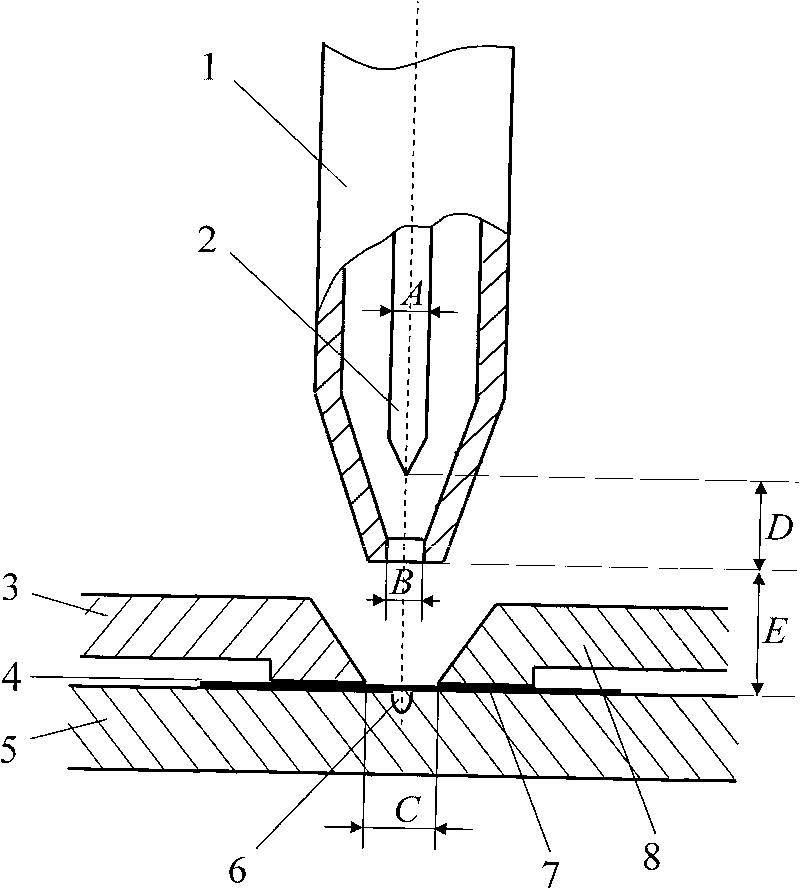

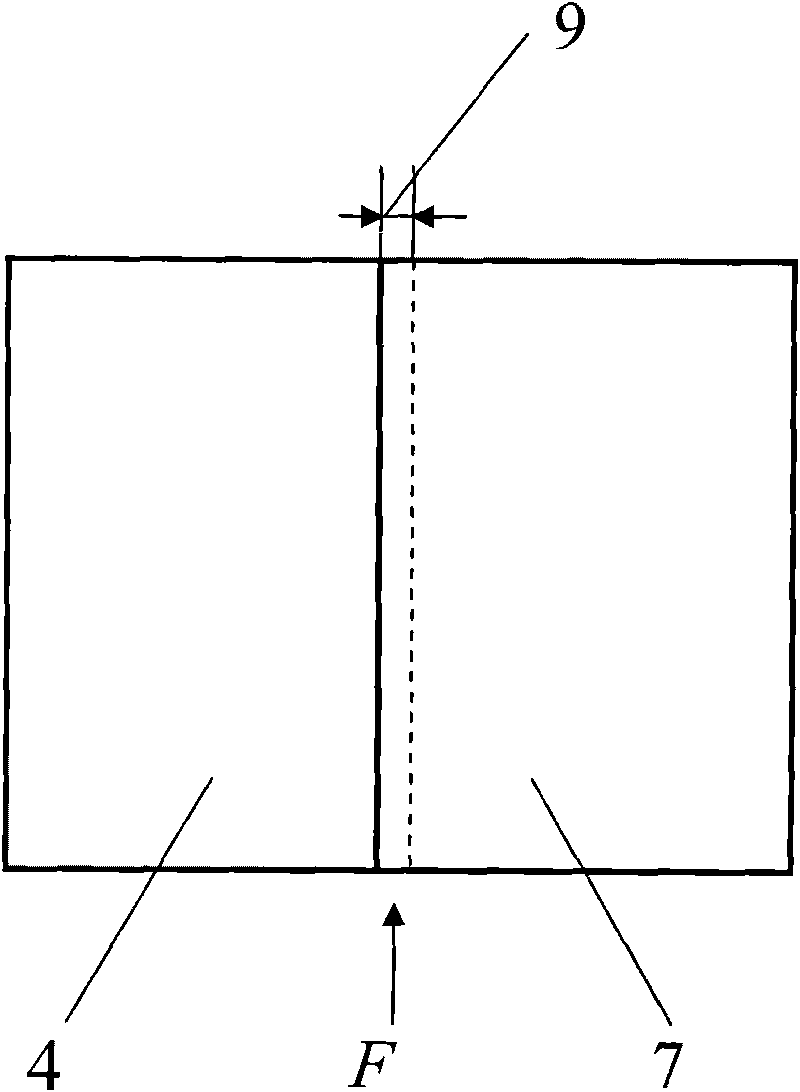

Welding method for micro-plasma arc welding of pure titanium foil

InactiveCN101722353ASolve the deformationSolve the burn-through problemPlasma welding apparatusWelding/soldering/cutting articlesButt weldingWeld seam

The invention discloses a welding method for micro-plasma arc welding of a pure titanium foil, in particular the welding of the pure titanium foil of which the titanium content is over 99 percent and the thickness is of 0.05 mm, and relates to the technical field of welding. The method comprises the following steps of: cutting the pure titanium foil to be welded into required sizes; selecting two pure titanium foils (4) and (7), and removing oil stains at the peripheries of the sides to be welded thereof; assembling the two pure titanium foils between fixtures of a tooling system; lapping the sides to be welded for about 0.1 to 0.2 mm so as to ensure a welding seam on grooves (6) of base plates of the fixtures; driving a welding torch to move along the welding seam (9) above the welding seam by a motor on the tooling system; and adopting a pulse current for welding. The welding method for the micro-plasma arc welding of the pure titanium foil realizes the butt welding of the micro-plasma arc welding of the pure titanium foil of 0.05 mm, solves the problems of the deformation and burning of the welding of the pure titanium, saves welding cost without adding a filling metal in the welding seam, is favorable for industrial popularization, and fills the blank of the micro-plasma arc welding in the field of pure titanium foils.

Owner:SHANGHAI UNIV OF ENG SCI

PROCESS AND METHOD TO INCREASE THE HARDNESS OF Fe-Cr-C WELD OVERLAY ALLOY

ActiveUS20080230155A1High hardnessResistance to abrasive wearFurnace typesHeat treatment furnacesSufficient timeMechanical components

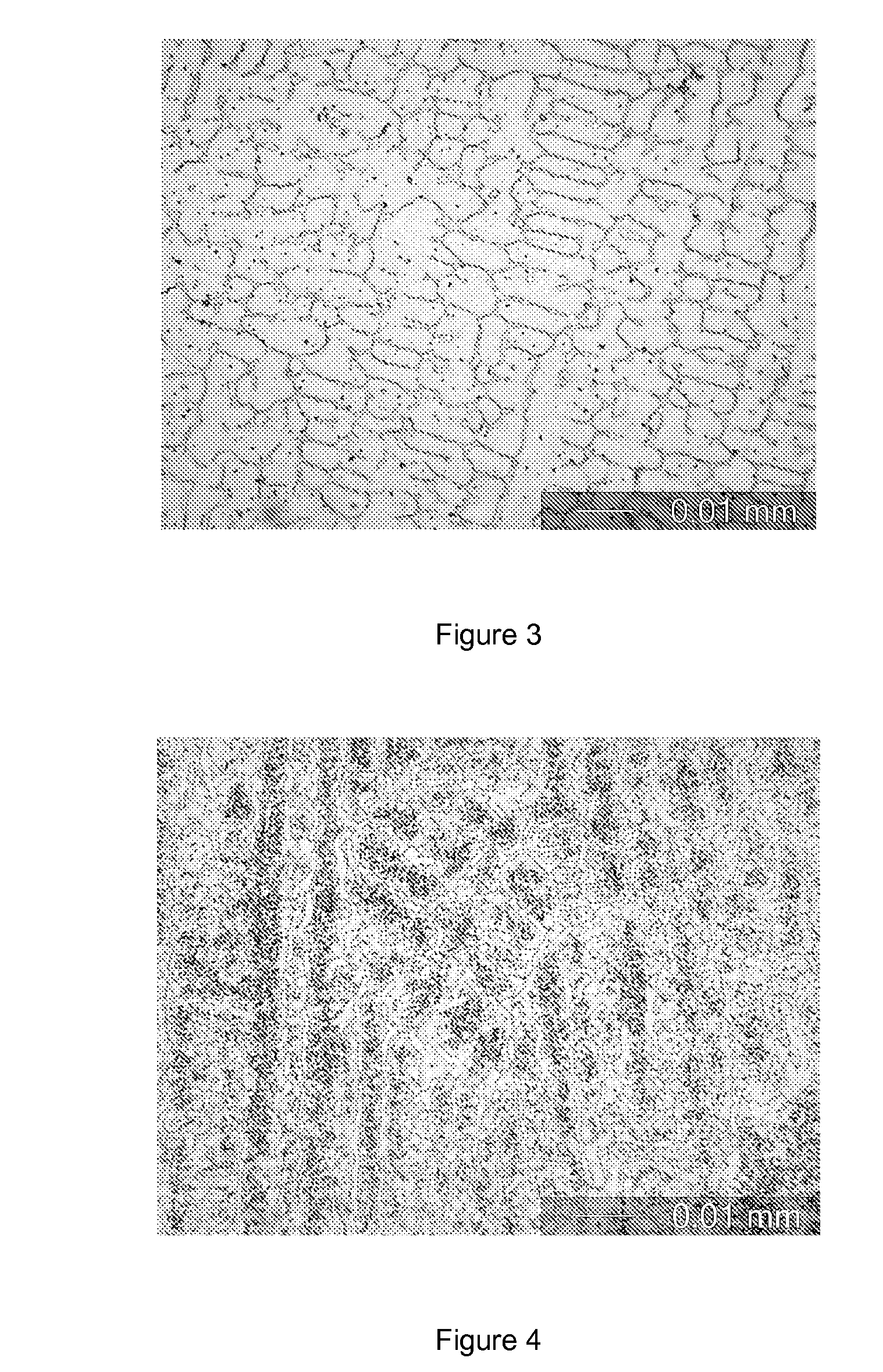

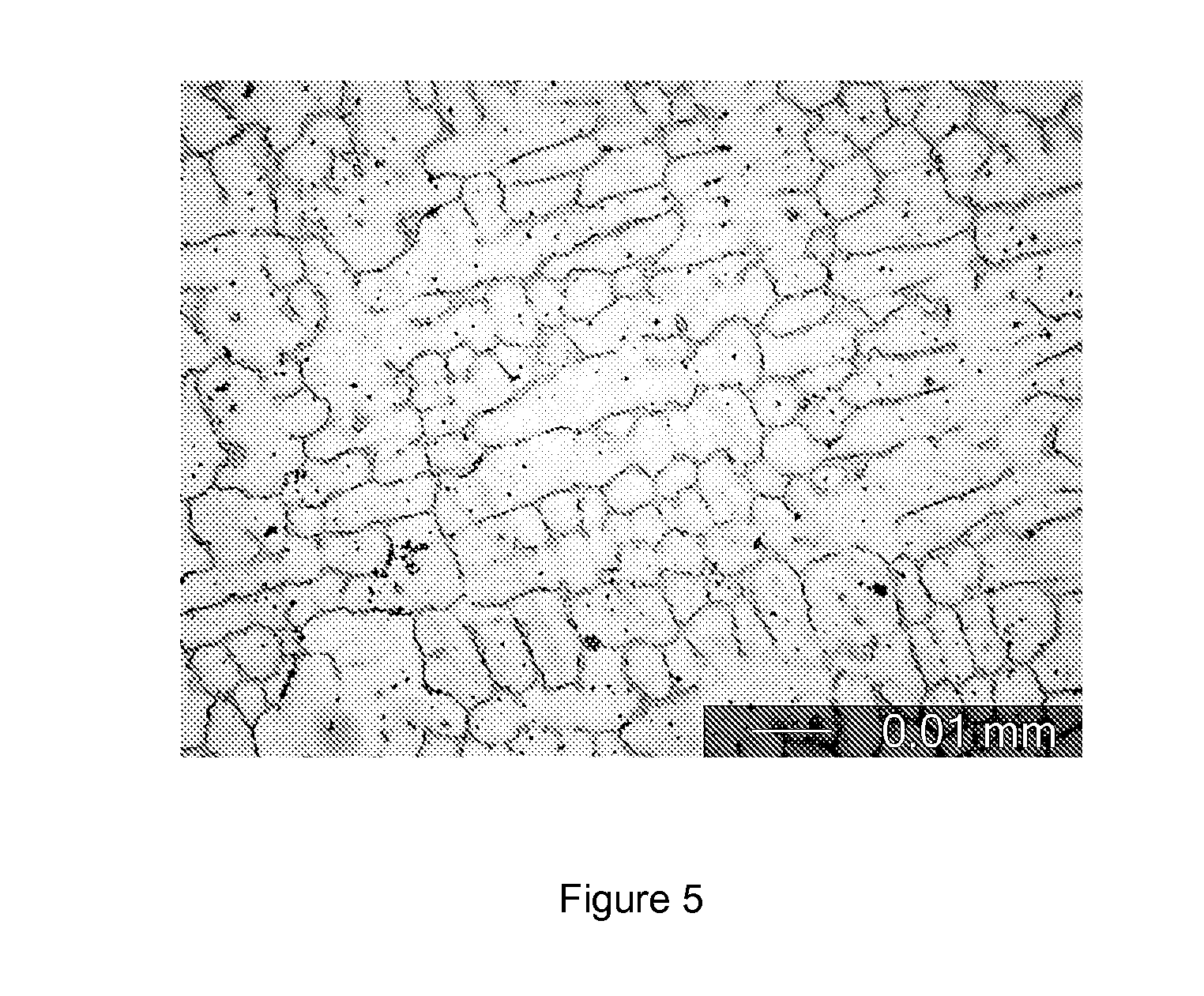

A method of preparing a mechanical component with an Fe—Cr—C hardfacing weld overlay alloy for improving the resistance of the mechanical component to abrasion, erosion or erosion / corrosion for use in very abrasive, erosion or erosive / corrosive environments by significantly increasing the hardness of the weld overlay is disclosed. To improve the resistance to abrasion, erosion or corrosion, a weld overlay of a Fe—Cr—C hardfacing alloy is applied onto the surface of a metallic component, such as tubes, pipes, or vessels. Welding and cladding methods including gas-metal-arc welding (GMAW), gas-tungsten-arc welding (GTAW), and laser cladding may be utilized. Then, the component is heat-treated at elevated temperatures for a sufficient time, resulting in additional hardening and thus further increasing the weld overlay's resistance to abrasion, erosion, or erosion / corrosion.

Owner:AZZ WSI

Non-gas metal arc welding 3 D adding material repair device and repair method

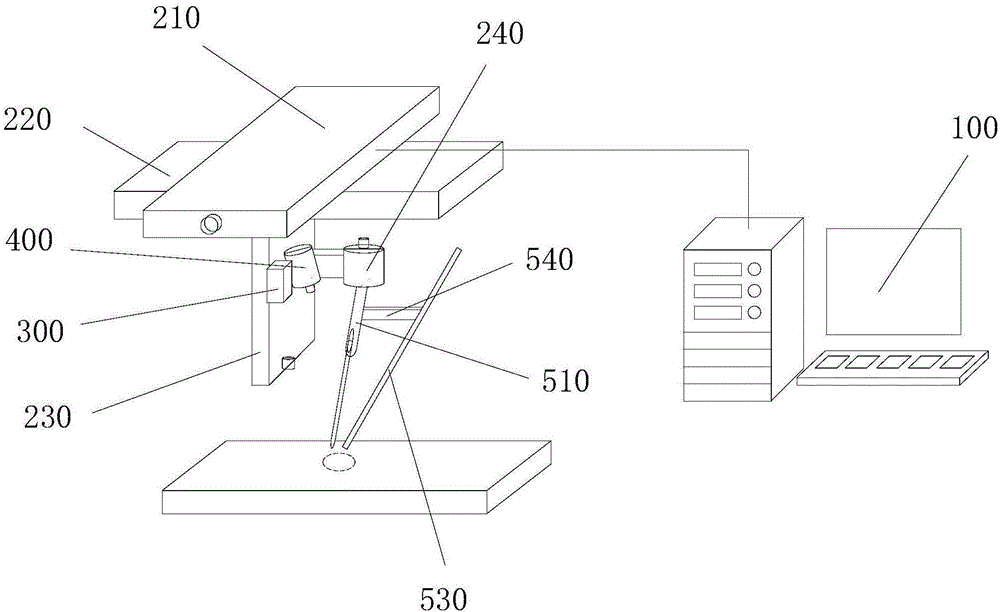

InactiveCN106141374AReduce missing solderReduce the situationArc welding apparatusMelting tankDefect repair

The invention discloses a non-gas metal arc welding 3 D adding material repair device and repair method. The repair device comprises a controller, a four-axis linkage platform, a laser vision sensor, an infrared vision sensor, a clamp, a non-metal arc welding torch, a wire feeding unit and a welding wire disc. The repair method comprises the steps that a defective workpiece is installed on a repair workbench; the laser vision sensor is driven to scan a defective three-dimensional outline; the controller rebuilds the defective three-dimensional outline; specific welding parameters are determined; the controller drives the infrared vision sensor to scan a molten pool, time-frequency parameters of a molten pool image are obtained, a compensation control code is generated according to the time-frequency parameters of the molten pool image, and the set welding parameters are corrected in real time; and after repair, the laser vision sensor is driven again to scan the defective three-dimensional outline, whether the repaired workpiece reaches the standard is determined, and if not, defects are repaired again till defect repair reaches the standard. The repair device is simple in structure, convenient to operate and high in reliability and adaptability.

Owner:GUANGDONG UNIV OF TECH

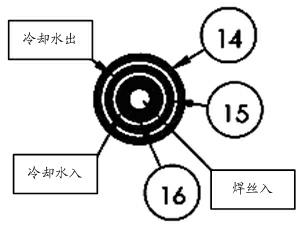

Novel narrow-gap gas metal arc welding gun

InactiveCN102319943ASolve the problem of fusion deficiencyEasy to use and flexibleElectrode supporting devicesGas metal arc weldingEngineering

The invention relates to a novel narrow-gap gas metal arc welding gun, a guide mechanism is arranged on the lower end of a rod assembly, and is inclined relative to the central axis of the rod assembly, and the end of the guide mechanism is provided with a tip. The invention effectively solves the problem of narrow-gap welding that sidewall fusion is defective, and also solves the problems of welding gun cooling and accidental sidewall arcing, and the novel narrow-gap gas metal arc welding gun is flexible and convenient to use, and has the advantages of stability, reliability, higher welding efficiency, better welding quality and more stable welding process. The novel narrow-gap gas metal arc welding gun is suitable for all the fields which have high requirement on welding efficiency, welding quality and welding economy and can use the narrow-gap welding technology, and is applicable to the arc welding of metal materials in the industries of electric power, ships, buildings, transportation and the like, and the advantage is more obvious for the narrow-gap welding of thick-walled members, particularly when the requirement on welding quality and welding efficiency is high.

Owner:SHANGHAI JIAO TONG UNIV

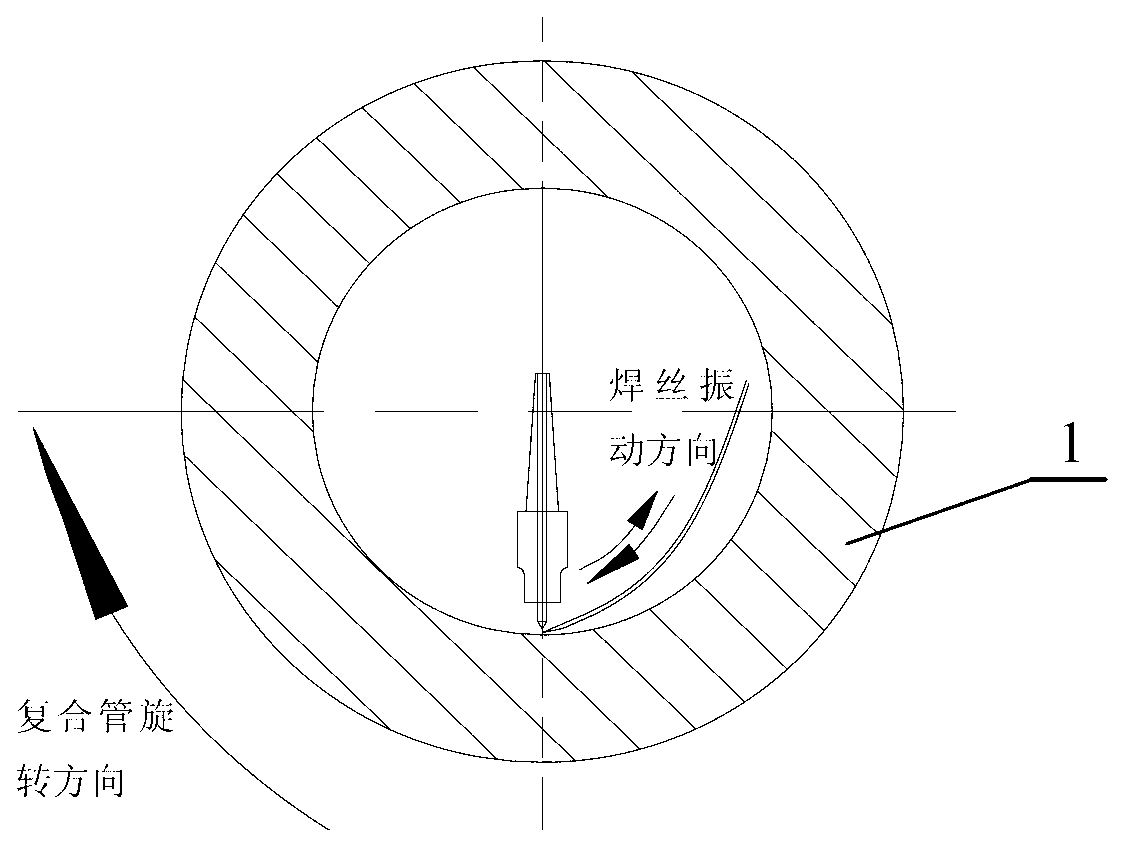

Vibrating wire-feeding surfacing method

The invention relates to a vibrating wire-feeding method which is characterized in that right and left swinging of a welding gun is combined with reciprocating vibration of a welding wire; the automatic wire-feeding process is accompanied by the axial vibration of the welding wire; a molten welding material is deposited on the internal wall of a pipe, and the fluidity of a welding pool is greatly improved, so as to further improve the surfacing efficiency; the vibrating welding wire can uniformly stir the molten pool in the melting process of the welding wire, especially for the material with poor fluidity, such as nickel-base alloy, so that gas can escape rapidly when metal in the molten pool is stirred, and hot welding cracks and pores are reduced; as the vibrating wire-feeding stirs the molten pool, solidification and crystallization in the molten pool are uniform; the metallurgical structure of a surfacing layer is uniform and exquisite; the mechanical property of the surfacing layer is greatly superior to those of normal argon tungsten-arc welding and gas metal-arc welding; the quality of a surfacing joint is improved to a great extent; the property is good; the yield of products is greatly increased; and the property of the surfacing joint is greatly improved.

Owner:XIAN SUNWARD AEROSPACE MATERIAL CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com