Welding method for micro-plasma arc welding of pure titanium foil

A technology of plasma arc and welding method, which is applied in the field of plasma arc welding, can solve problems such as poor operability, inconsistent weld seam conditions, and difficult welding process of pure titanium foil, so as to save costs, solve deformation and burn-through, and benefit The effect of industrial promotion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

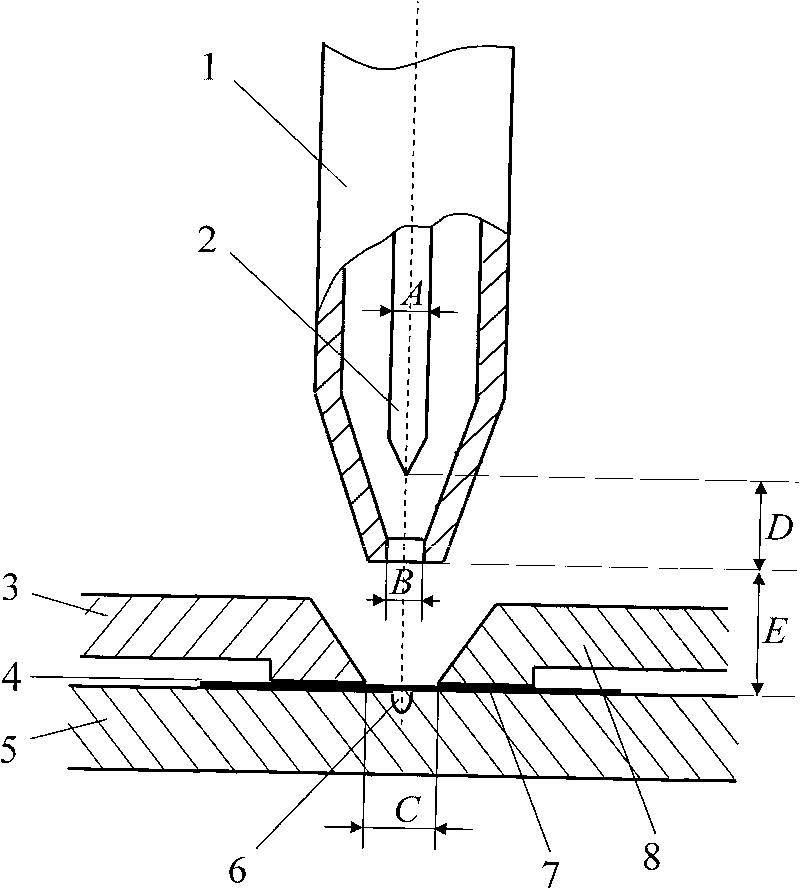

[0023] The present invention will be further described below in conjunction with the accompanying drawings and embodiments

[0024] 1. Select pure titanium foil with a thickness of 0.05mm with a smooth surface, smooth and no scratches, its grade is TA0 or TA1, and cut it into N pieces of the required size with special scissors. Make sure that the edges of each piece to be welded are Smooth without burrs.

[0025] 2. Select two of them, pure titanium foil 4 and pure titanium foil 7, for pretreatment before welding. Use a cotton ball dipped in acetone to carefully wipe off the oil around the edges of the two 0.05mm pure titanium foils to be welded. At this time, the edges to be welded cannot be damaged.

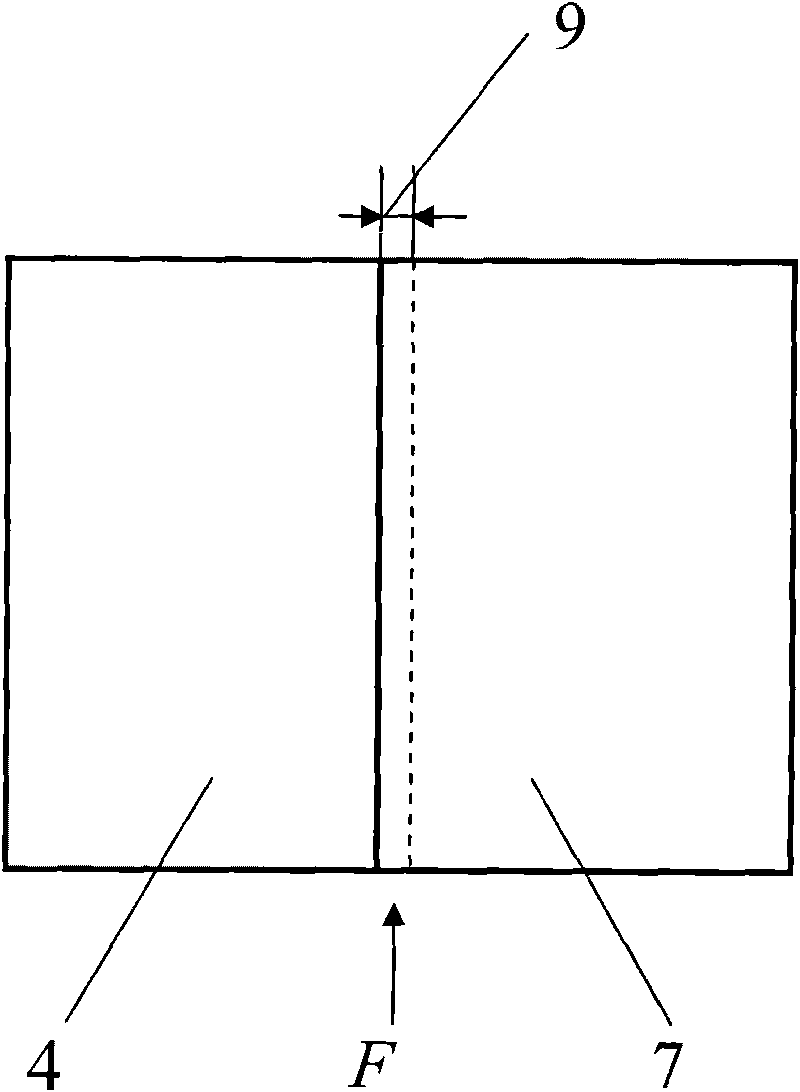

[0026] 3. Assemble the two pieces of pure titanium foil after pretreatment. First lift the pressure plate 3 and pressure plate 8 of the fixture on the tooling system, and use a pressure plate 3 to clamp the pure titanium foil 4 first, and make sure that the edge to be welded ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com