Partially prestressed concrete electric pole and preparation method thereof

A concrete and prestressed technology, applied in the direction of manufacturing tools, structural elements, building components, etc., can solve the problems of no bearing capacity prestressed concrete poles, products can not meet the design load requirements, etc., to improve the tensile strength and resistance. The effect of cracking and prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

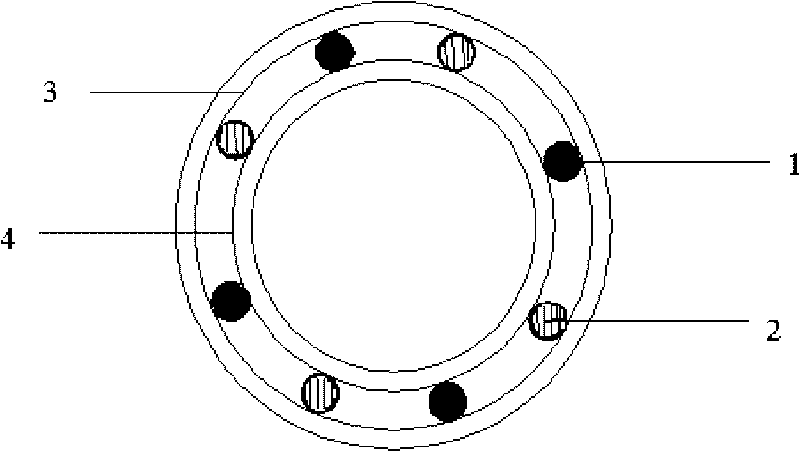

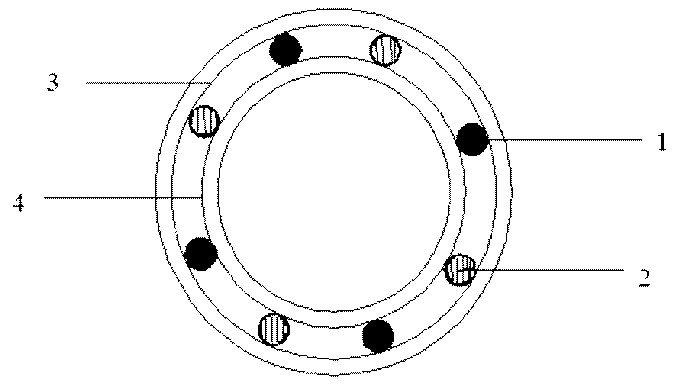

[0033] 8 pieces of heterosexual steel bars with a diameter of 9.0mm are used as prestressed steel bars for electric poles, and 8 pieces of grade II threaded steel bars with a diameter of 18mm are used as non-prestressed steel bars for electric poles. process; such as figure 1 As shown, the prestressed steel bars and non-prestressed steel bars are evenly spaced and crossed along the circumferential direction, and the spiral bars and erecting rings can be made of commonly used materials for electric poles. The distance between the spiral ribs is 1500mm at both ends, the inner distance is 50mm, and the rest of the section is 100mm; set up a 500mm long HPB235 steel bar for the vertical ring. Strictly control the welding quality of the pole frame (according to the requirements of chapters 4 and 5 in the industry standard JGJ18-2003 "Reinforcement Welding and Acceptance Regulations"), clean up the pole mold, and place the welded pole frame.

[0034] The sand is screened and cleaned...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com