Patents

Literature

2023results about How to "Solve the deformation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

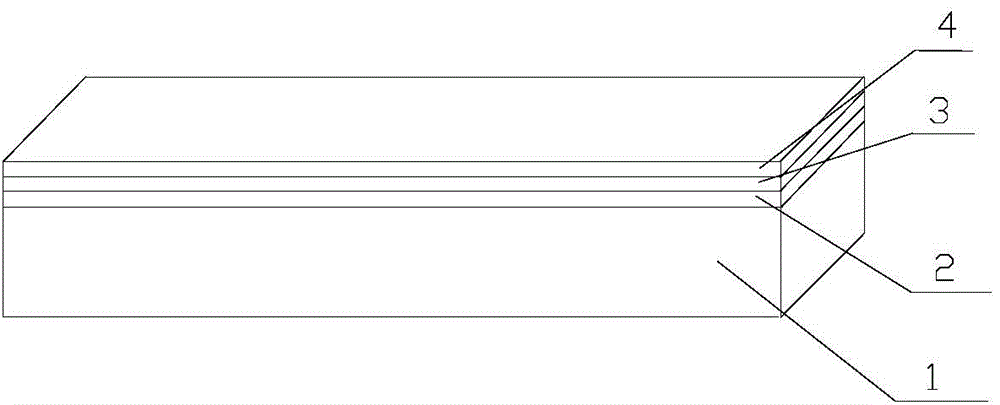

Organic/inorganic composite porous isolating membrane, preparation method thereof and electrochemical device

ActiveCN103441230AImprove breathabilityImprove conductivityHybrid capacitor separatorsCell seperators/membranes/diaphragms/spacersPorous coatingInorganic particle

The invention provides an organic / inorganic composite porous isolating membrane, a preparation method thereof and an electrochemical device. According to the first aspect of the invention, the organic / inorganic composite porous isolating membrane comprises a porous base material and an organic / inorganic composite porous coating coated on at least one surface of the porous base material, wherein the organic / inorganic composite porous coating comprises inorganic particles, a binding agent and organic particles with at least two swelling degrees, and the organic particles are swelled by a plasticizer. The preparation method of the organic / inorganic composite porous isolating membrane is used for preparing the organic / inorganic composite porous isolating membrane described in the first aspect of the invention. According to the third aspect of the invention, the electrochemical device comprises the organic / inorganic composite porous isolating membrane described in the first aspect of the invention. Therefore, the organic / inorganic composite porous isolating membrane can form an excellent interface, so that a risk that the risk of blocking holes by the organic particles is reduced, breathability of the organic / inorganic composite porous isolating membrane is improved, and electrical conductivity of the organic / inorganic composite porous isolating membrane is improved.

Owner:DONGGUAN AMPEREX TECH +1

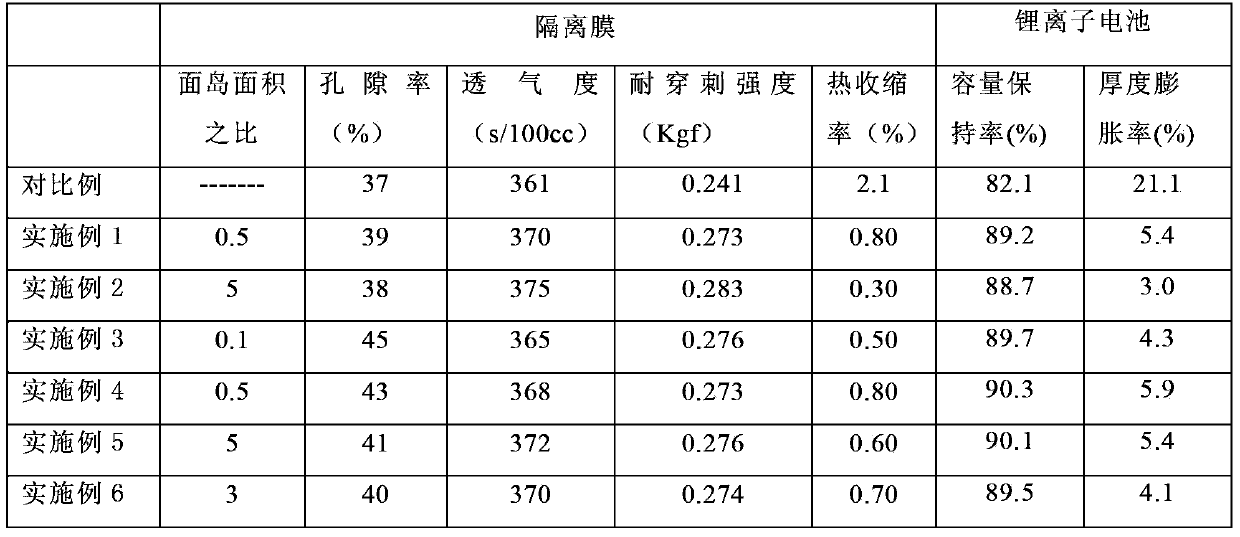

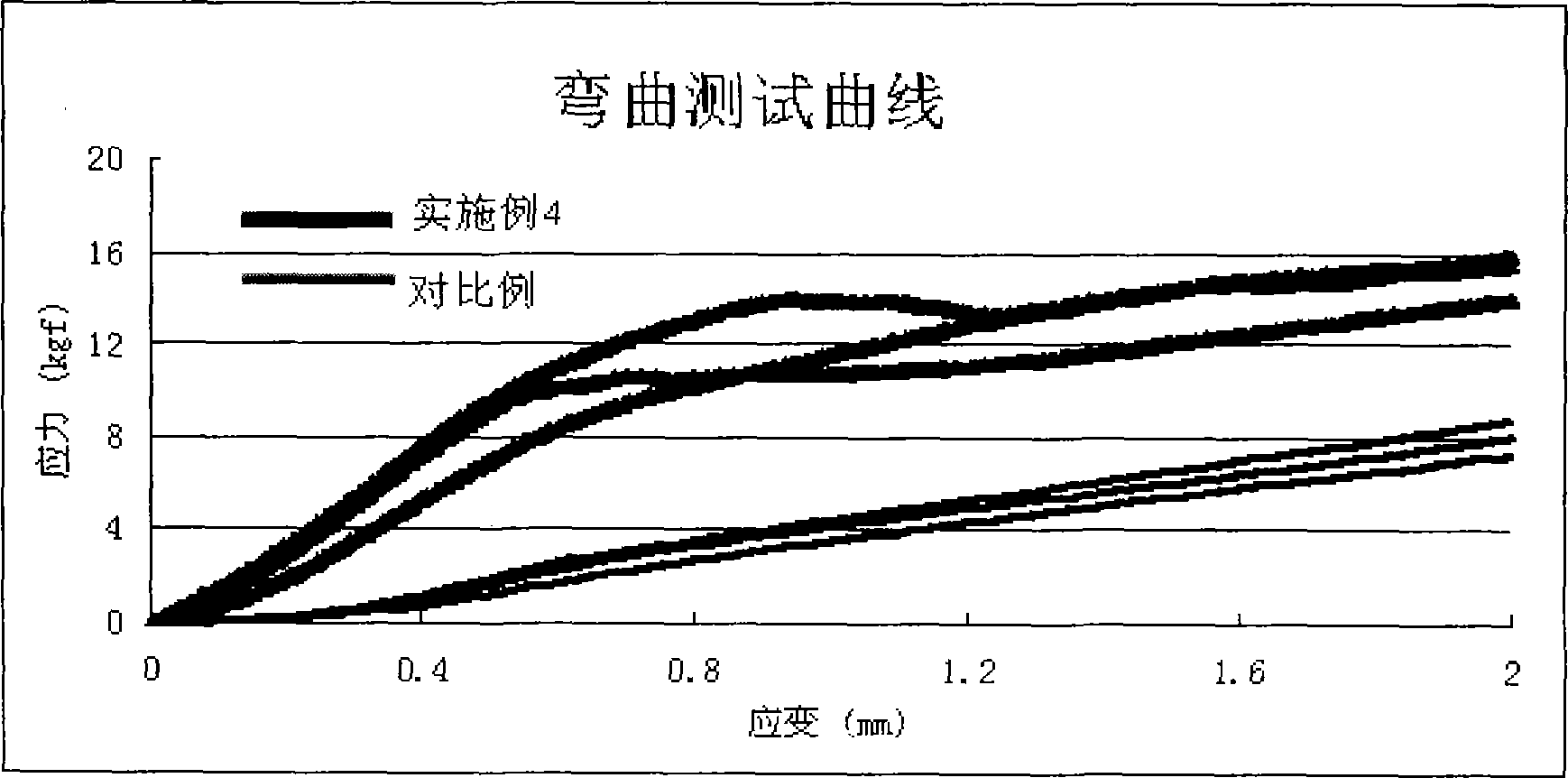

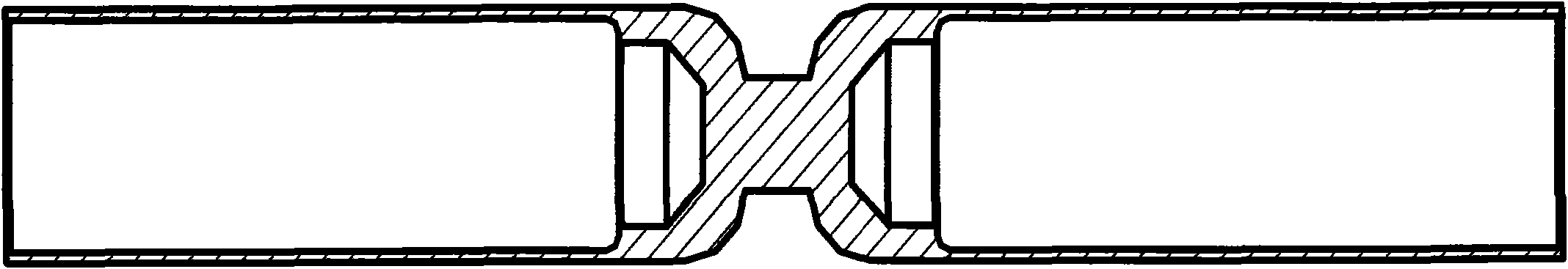

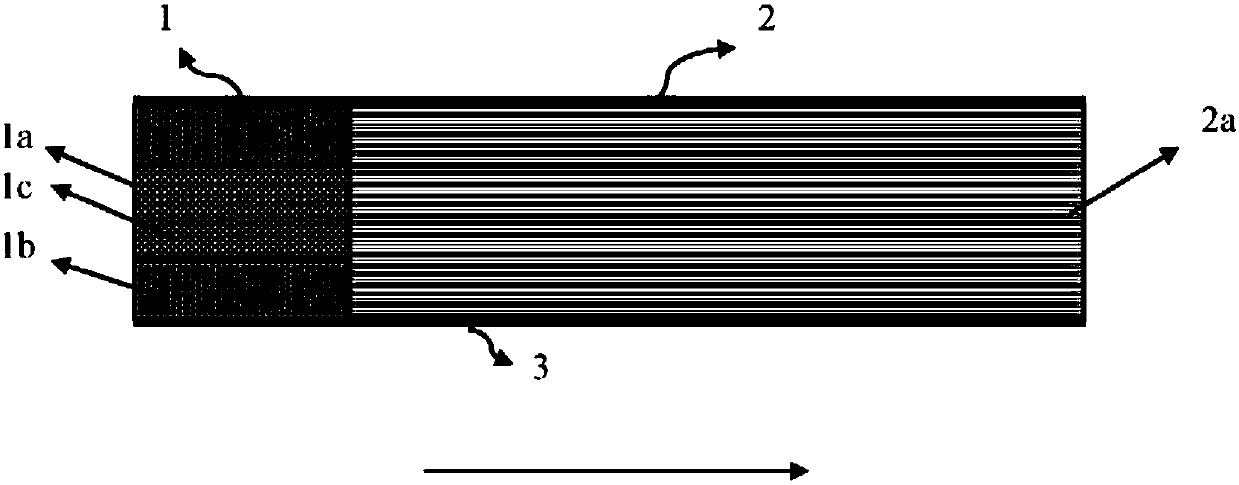

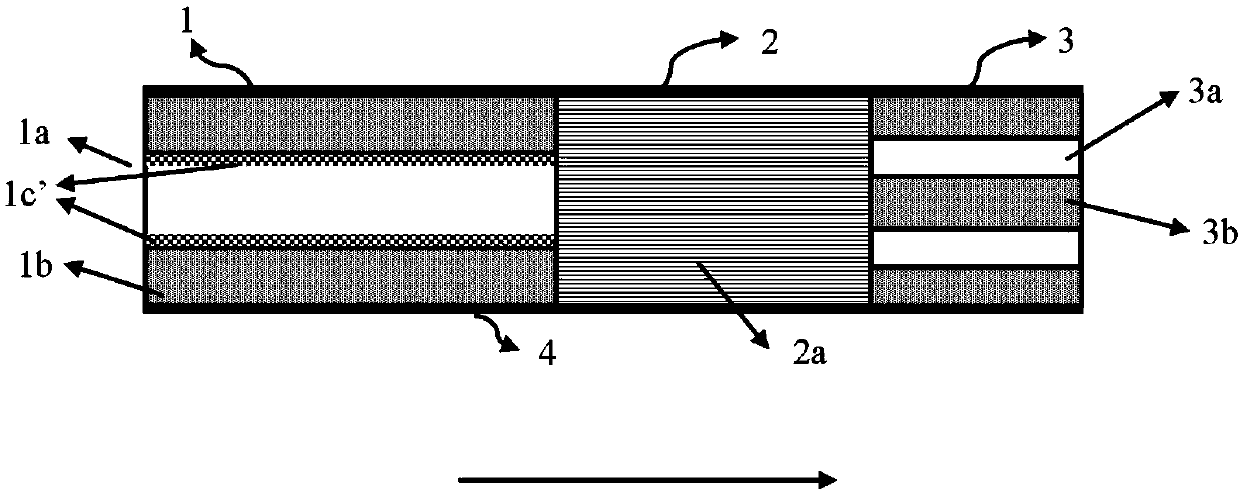

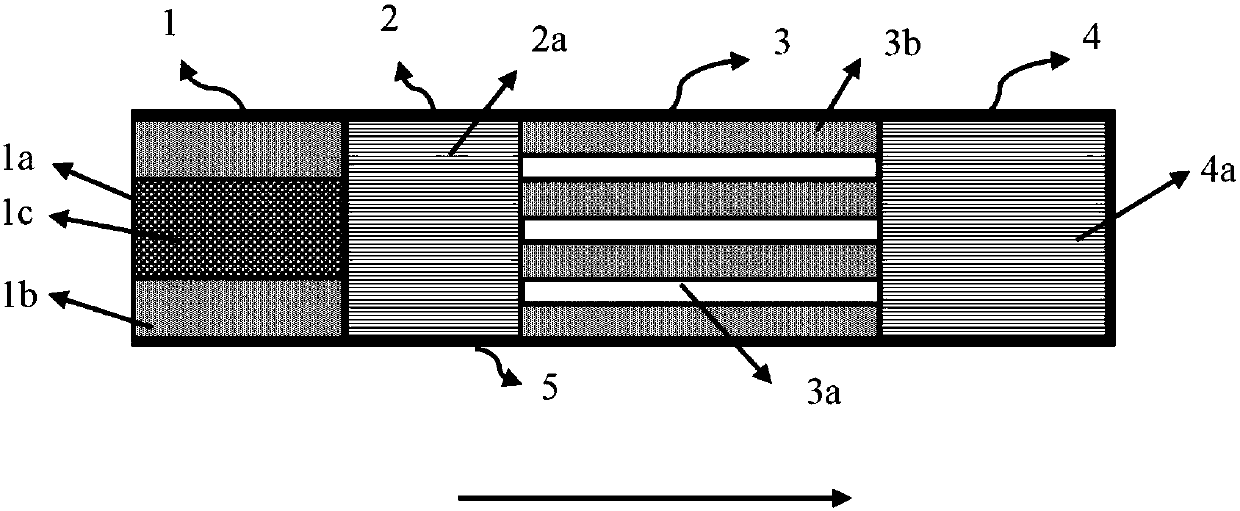

Polymer lithium ion battery and diaphragm thereof

ActiveCN102610773AImprove thermal stabilityImprove mechanical propertiesSecondary cellsCell component detailsCyclic processSwelling capacity

The invention belongs to the technical field of polymer lithium ion batteries, in particular to a diaphragm for the polymer lithium ion battery. The diaphragm comprises a multihole base material, wherein an inorganic substance coating layer and an organic substance coating layer are coated on at least one surface of the multihole base material; and the organic substance coating layer is in island-type and / or linear distribution and coated on the surface of the multihole base material and / or the inorganic substance coating layer. Compared with the prior art, due to the inorganic substance coating layer, the diaphragm can keep relatively high heat stability and mechanical performance, so that the lithium ion battery has high safety performance; the organic substance coating layer has high imbibition swelling capacity, and an interface has high stability, so that the manufactured lithium ion battery has perfect mechanical performance; due to the distribution characteristic of the organic substance coating layer, spaces are provided for charging and discharging processes of a pole piece and a circulation process; and the problem of deformation of the polymer lithium ion battery is well solved. Furthermore, the invention also discloses a polymer lithium ion batter with the diaphragm.

Owner:NINGDE AMPEREX TECH +1

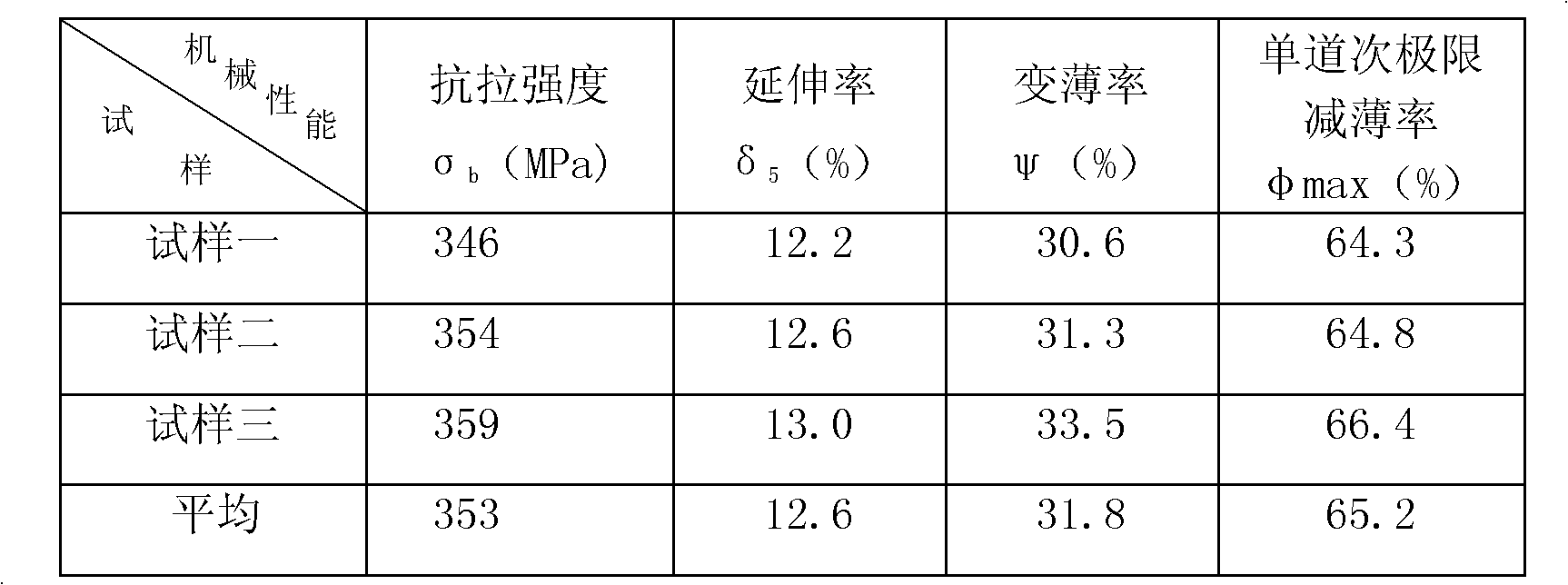

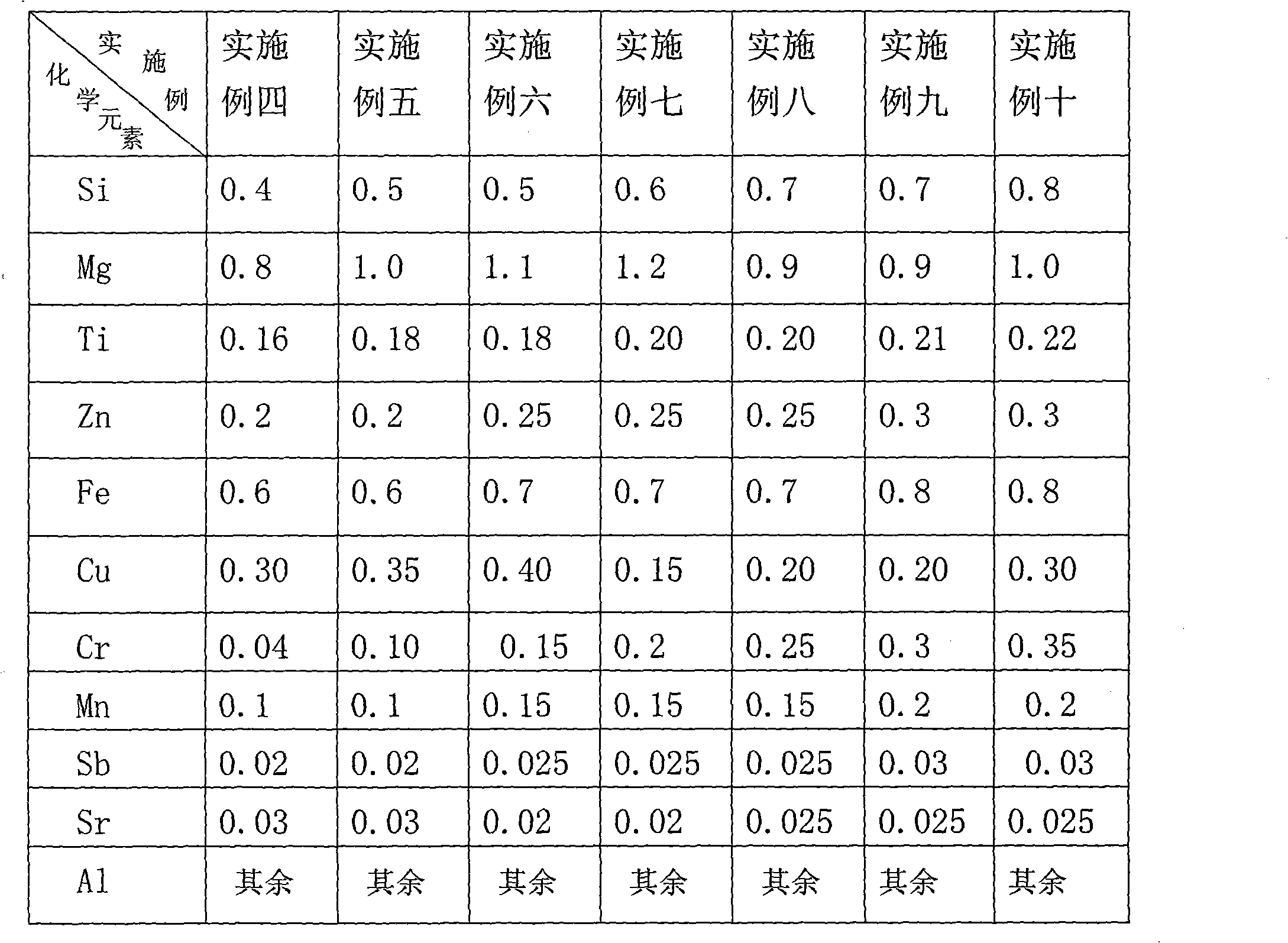

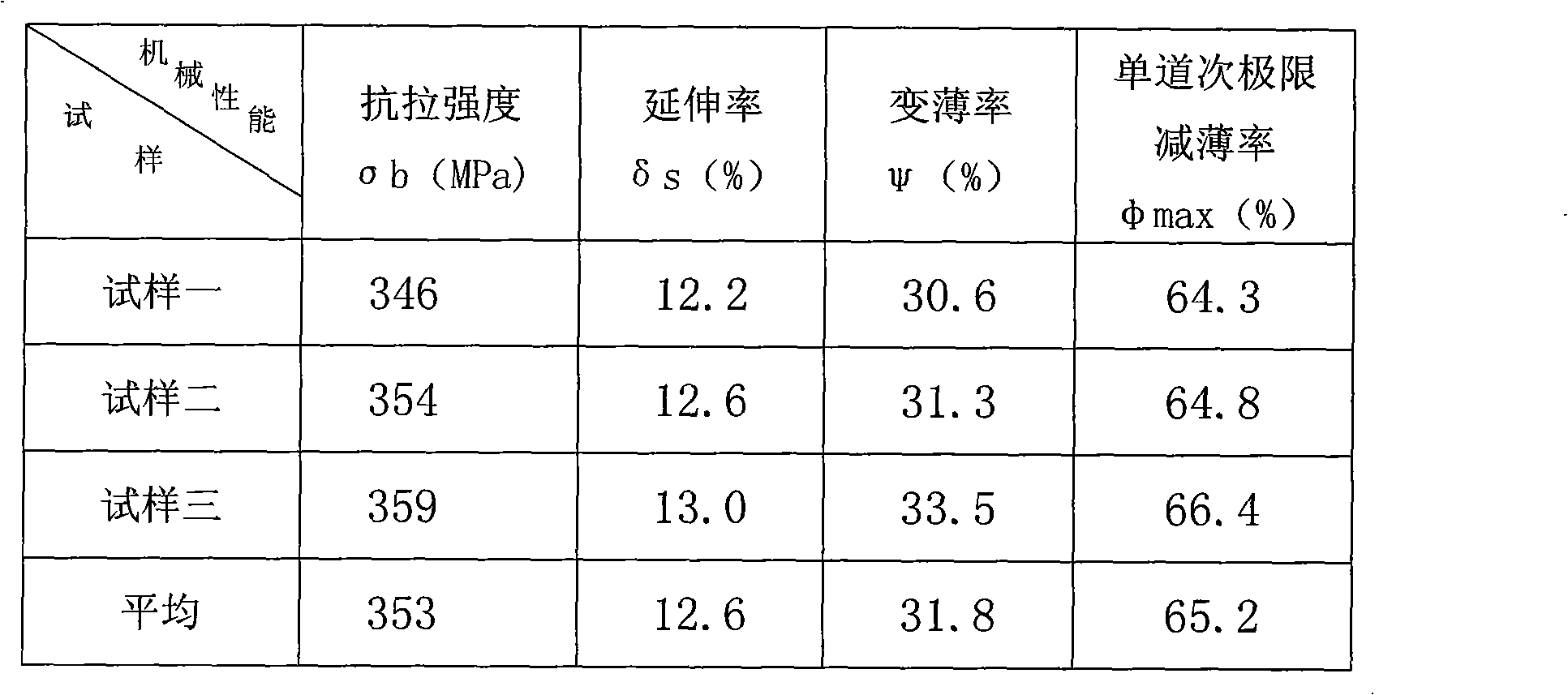

Manufacturing method of high-strength automobile aluminum-alloy rim material

The invention relates to a manufacturing method of a high-strength automobile aluminum-alloy rim material, which relates to a manufacturing method of automobile fitting materials. The manufacturing method comprises the following steps of: preparing materials; smelting; adding a refiner; adjusting components; refining; casting; quenching; carrying out aging treatment; and packaging to prepare the high-strength automobile aluminum-alloy rim material which comprises 0.4-0.8 percent of Si, 0.8-1.2 percent of Mg, 0.16-0.22 percent of Ti, 0.2-0.3 percent of Zn, 0.6-0.8 percent of Fe, 0.15-0.4 percent of Cu, 0.08-0.32 percent of Cr, 0.1-0.2 percent of Mn, 0.02-0.06 percent of RE rare earth, 0.02-0.06 percent of Zr, 0.02-0.06 percent of Sr and the balance of Al. The invention has reasonable process parameter and simple manufacturing method, and the manufactured aluminum-alloy rim material has the advantages of high strength, good mechanical performance and the like and is suitable for being popularized and used in small, medium and large automobiles.

Owner:卢森锴

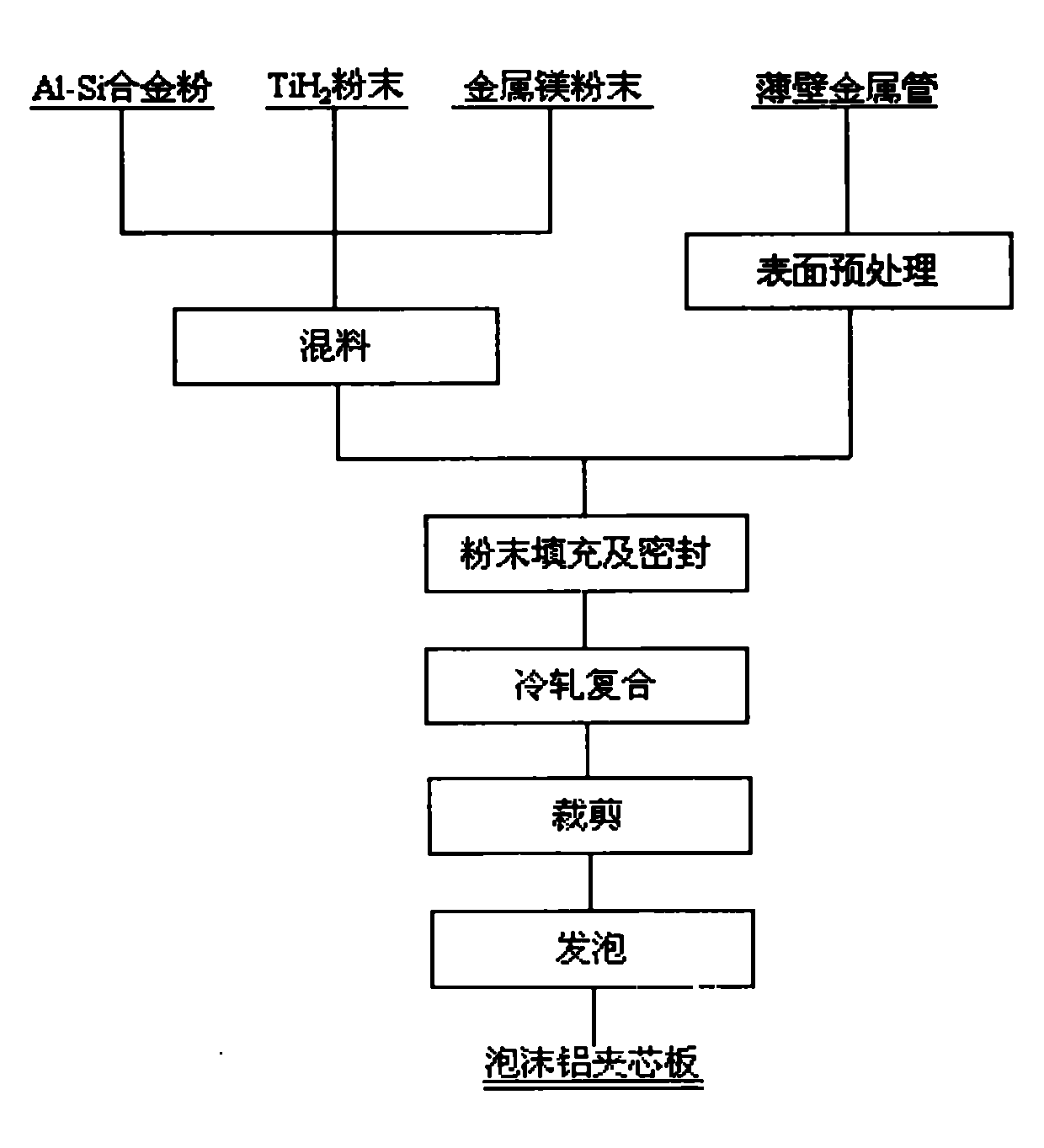

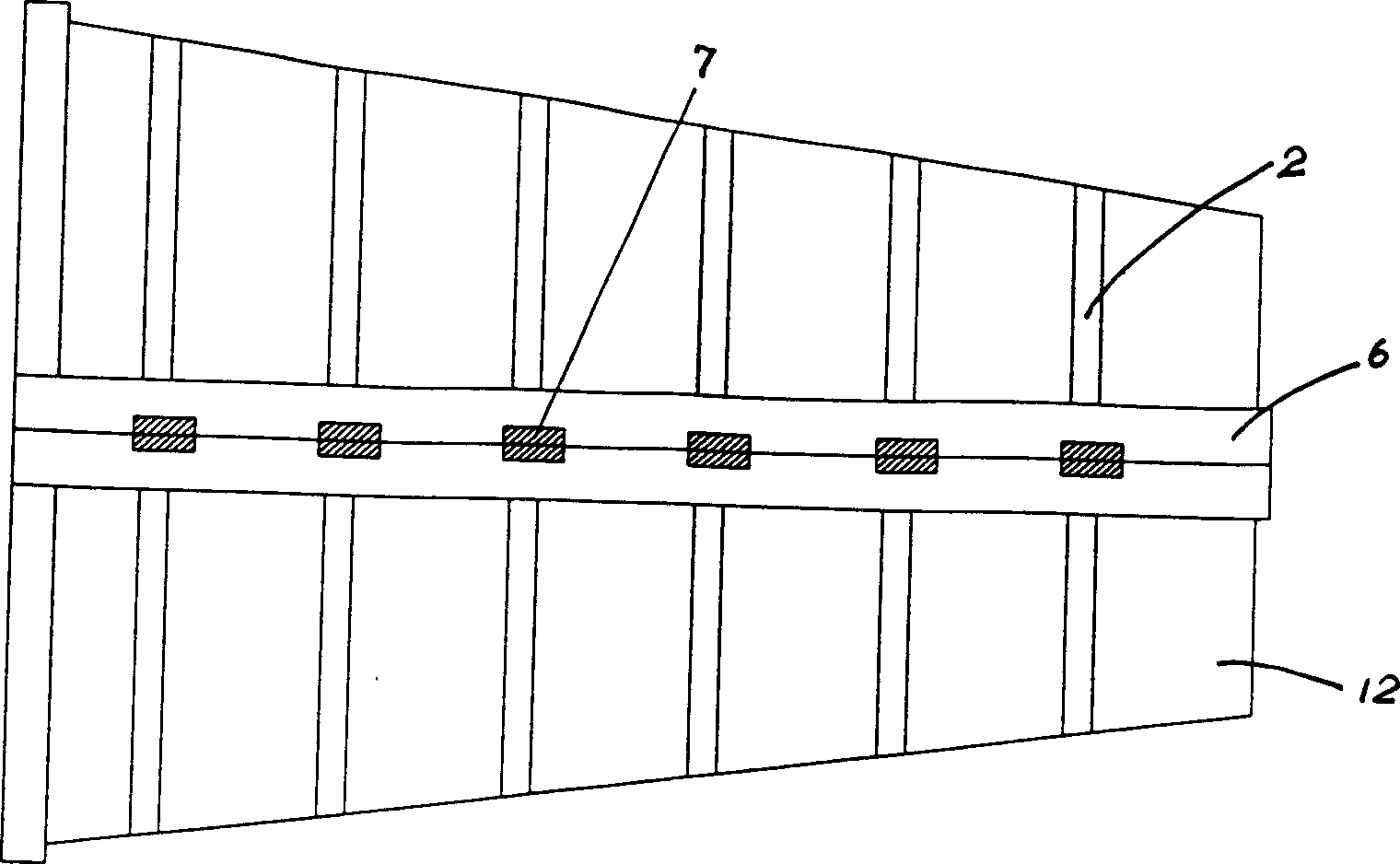

Method for manufacturing foamed aluminum sandwich plate

The invention relates to a method for manufacturing a foamed aluminum sandwich plate, which belongs to the field of porous foam metal and laminar composite materials. The method comprises the following steps of: uniformly mixing aluminum-silicon alloy powder prepared by an atomization method, and foaming agent titanium hydride powder and metal magnesium powder in a certain ratio; filling the powder into a thin-wall steel (or aluminum alloy) tube with one sealed end; sealing the other end of the tube after powder filling and preparing a rolled blank; rolling and compounding at a slow speed on a cold rolling mill; trimming an obtained composite plate and cutting a foamed preformed blank according to the size of a foaming mold; foaming the preformed blank in a steel mold in a limited way; adjusting foaming temperature and foaming time as required; and foaming at a high temperature for a short period of time to obtain a high-quality foamed aluminum sandwich plate with a uniform foam structure in a core layer, good interface bonding, high thickness accuracy and excellent plate profile. The method has the outstanding characteristics of low equipment requirement, high plate profile accuracy of a product, high three-point bending strength and the like and is advantaged technology suitable for mass industrial production of foamed aluminum sandwich structural materials.

Owner:NORTHEASTERN UNIV

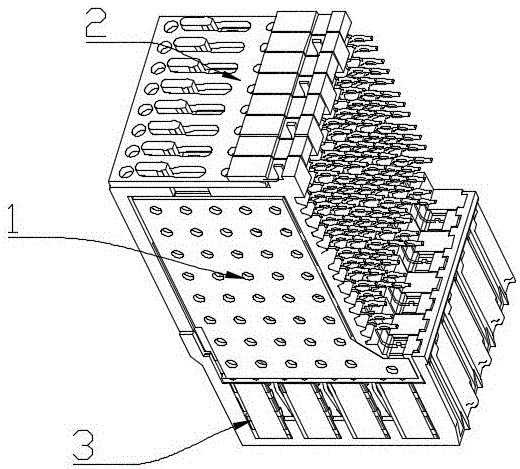

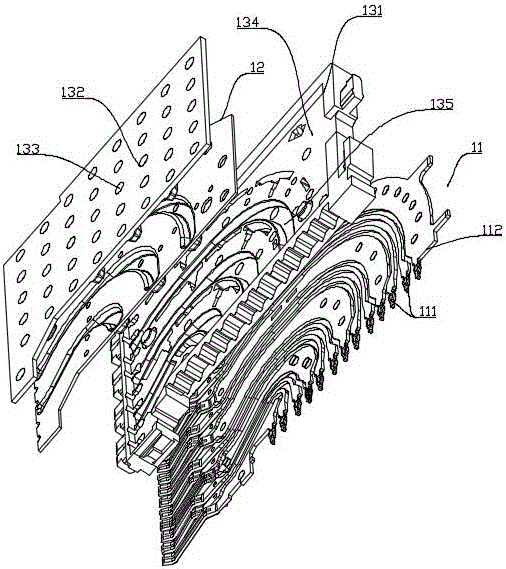

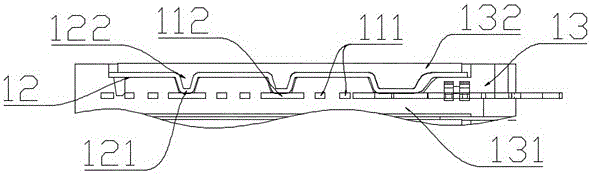

High-speed electric connector and signal module thereof, and molding method of signal module

ActiveCN106207569AImprove firmnessSolve easy deformationContact member assembly/disassemblyCoupling device detailsElectricityEngineering

The invention relates to the field of connectors, in particular to a high-speed electric connector and a signal module thereof, and a molding method of the signal module. The high-speed electric connector comprises the signal module; the signal module comprises a contact part; a shield sheet is arranged on at least one side of the contact part; the signal module further comprises an insulator; and the insulator is molded on the contact part and the shield sheet in an injection molding manner to combine the contact part and the shield sheet. The insulator of the signal module of the electric connector is packaged on the contact part and the shield sheet in an injection molding manner, so that the firm degree of the signal module is strengthened and the problem that the signal module of an existing high-speed electric connector is easy to deform is solved.

Owner:CHINA AVIATION OPTICAL-ELECTRICAL TECH CO LTD

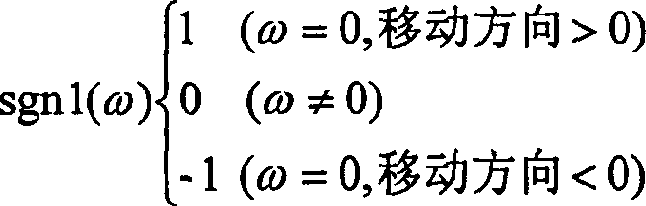

Robot arm control method and control device

By appropriately selecting a command value or an actually measured value as the angular velocity used for friction torque calculation, friction compensation can be effective in both cases when actively operating according to the angular velocity command and passively operating, that is, when being pushed by an external force . Also, after a collision is detected, when the motor rotation direction is opposite to the collision direction, the position control is switched to current control so that the motor generates torque in the opposite direction to the motor rotation direction, thereby reducing the motor rotation speed and weakening the collision energy. Thereafter, when the motor rotation speed becomes the set value or lower, the mode is set to flexible control, thereby eliminating deformation of the speed reduction device or the like caused by the collision. On the other hand, when the motor rotation direction and the collision direction are the same, the position control is directly transferred to the flexibility control without going through the current control. By performing operations according to the collision force, it is possible to weaken the collision torque.

Owner:PANASONIC CORP

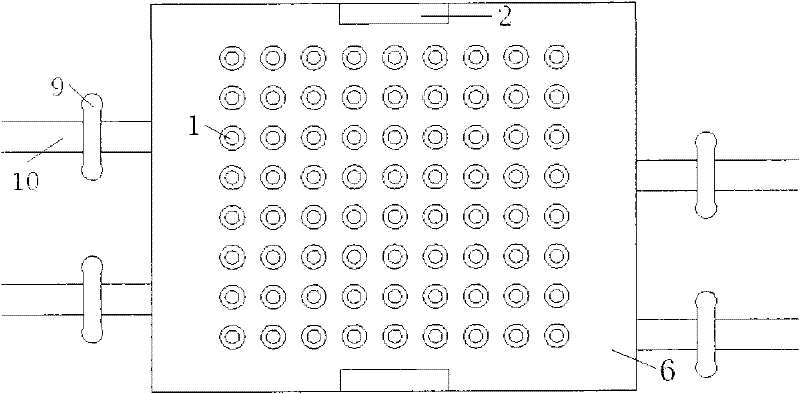

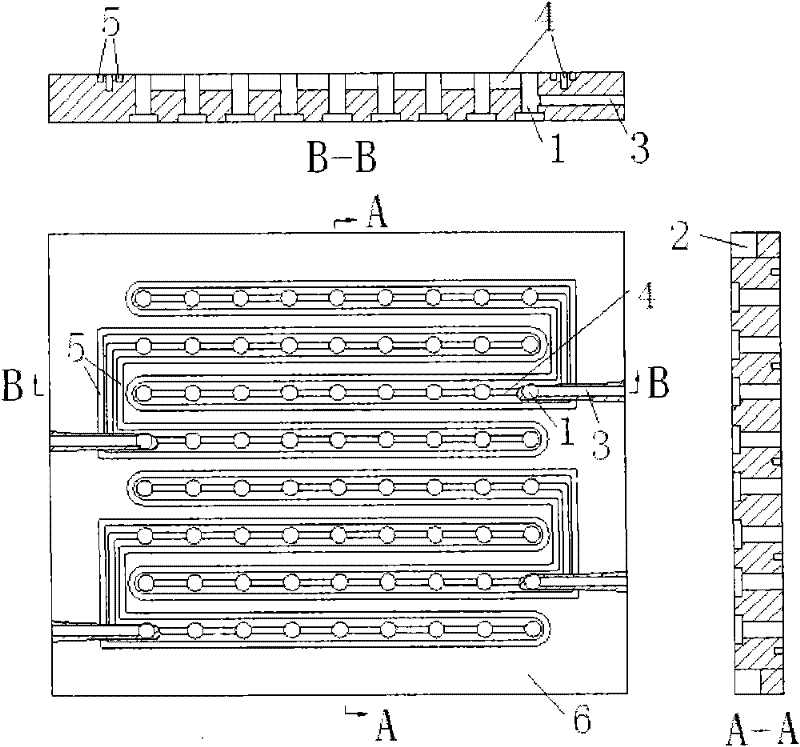

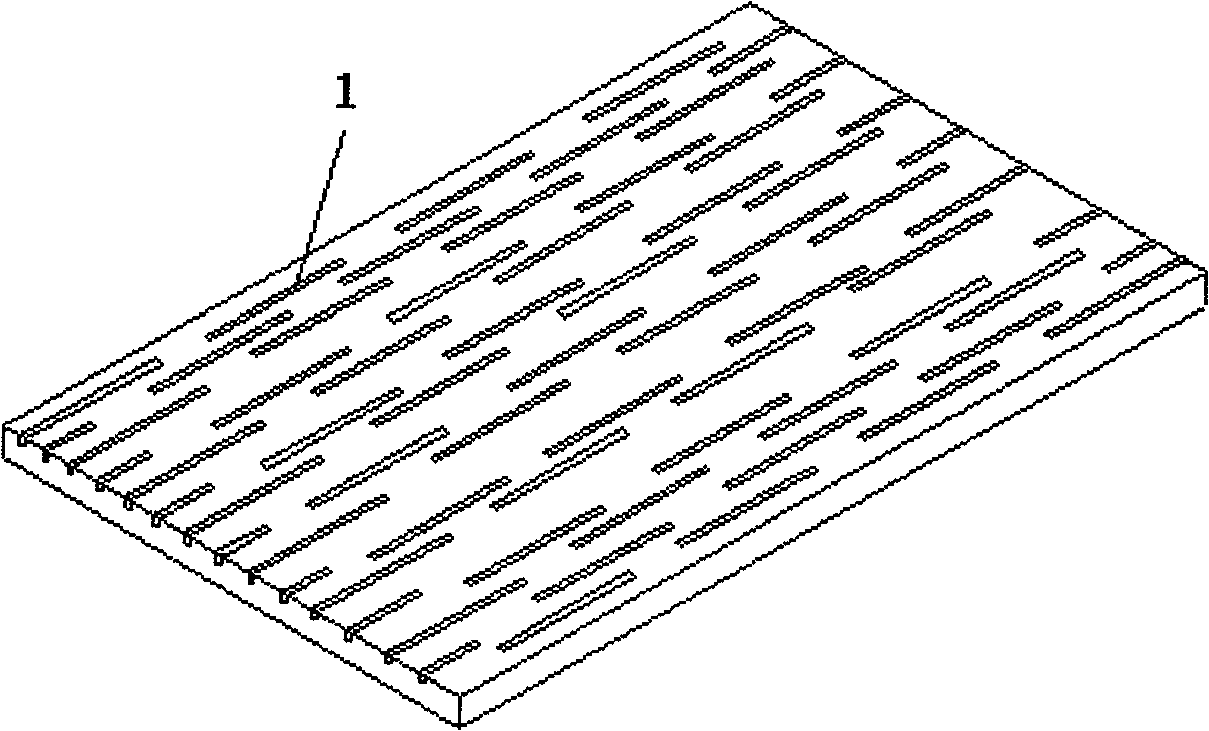

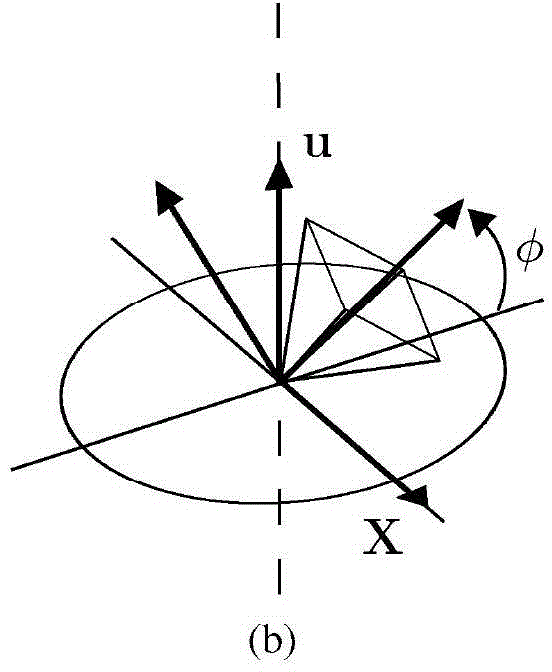

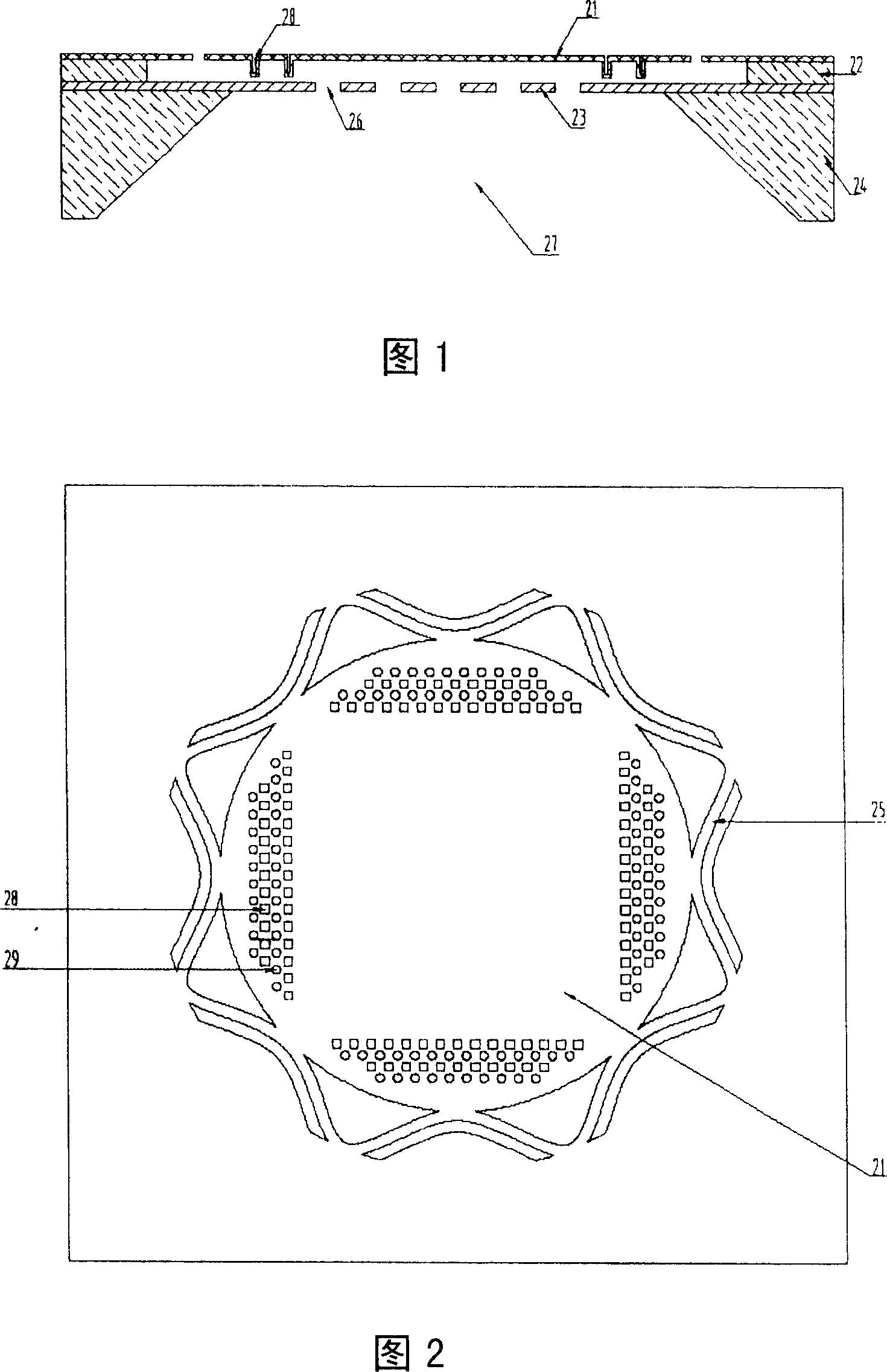

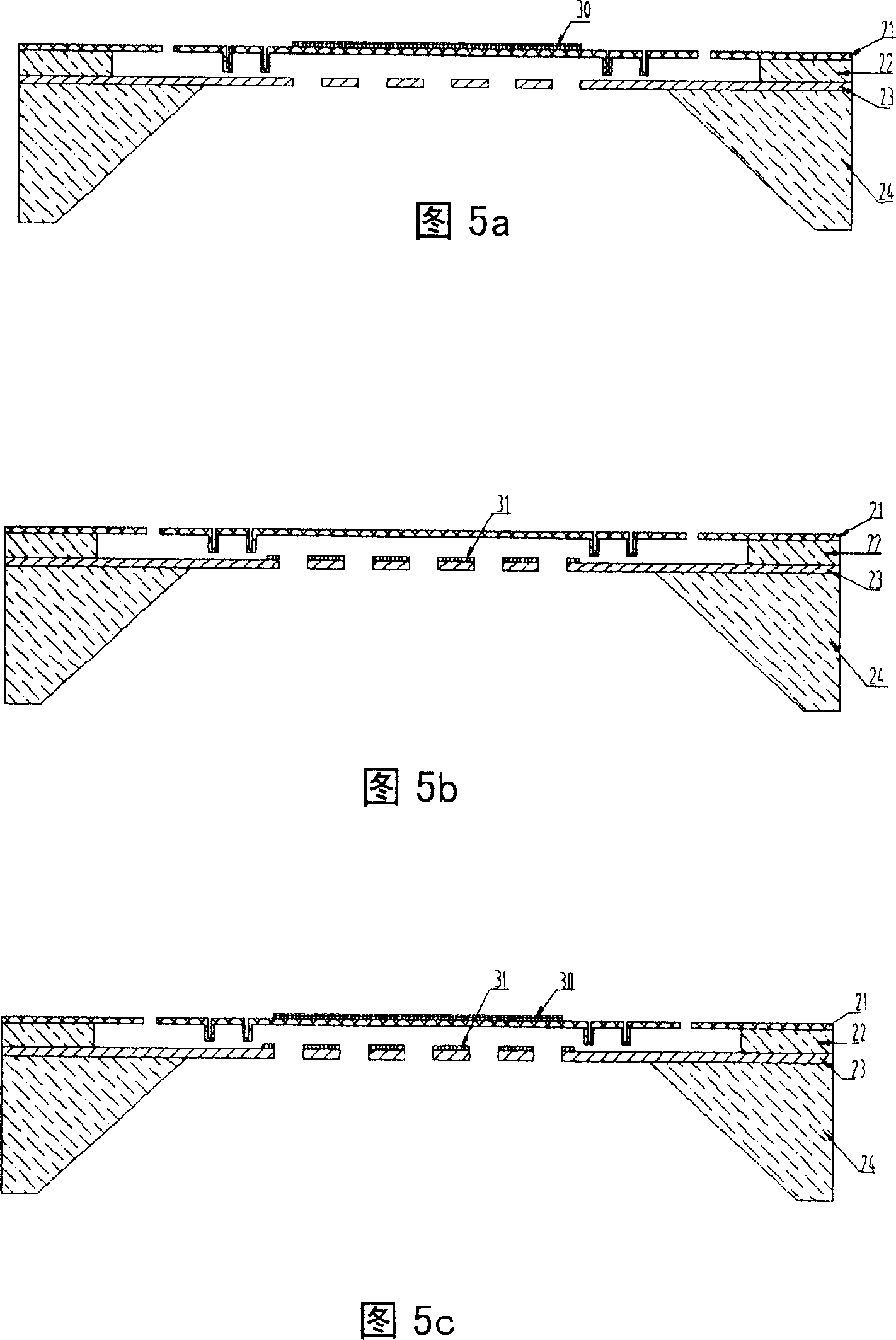

Vacuum adsorption equipment used for fixing thin-wall plane workpiece

InactiveCN102476300ASolve the deformationPlay a fastening rolePositioning apparatusMetal-working holdersVacuum pumpingPulp and paper industry

The invention discloses vacuum adsorption equipment used for fixing a thin-wall plane workpiece, comprising a vacuum adsorption plate and a sealing cover plate. N suction holes penetrating through the vacuum adsorption plate are arranged on the upper surface of the vacuum adsorption plate, m vacuum grooves which are not communicated are arranged on the lower surface of the vacuum adsorption plate, and each vacuum groove is communicated with a plurality of suction holes and is also communicated with an air suction pipe of a vacuum-pumping system. Periphery of each vacuum groove is provided with surrounding vacuum grooves and annular sealing grooves which are not communicated, each vacuum groove is internally filled with a sealing material, and m vacuum adsorption regions which are not communicated are formed on the upper surface of the vacuum adsorption plate by the vacuum grooves and the sealing cover plate. By combining plugs of the suction holes, the problem that workpiece adsorption failure is caused by the fact that one suction hole is suddenly sealed in a working process of a vacuum adsorption device, the vacuum adsorption problem that a workpiece body is provided with a through hole and the problem of cutting operation inside a workpiece in the vacuum adsorption fixed mode can be solved.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

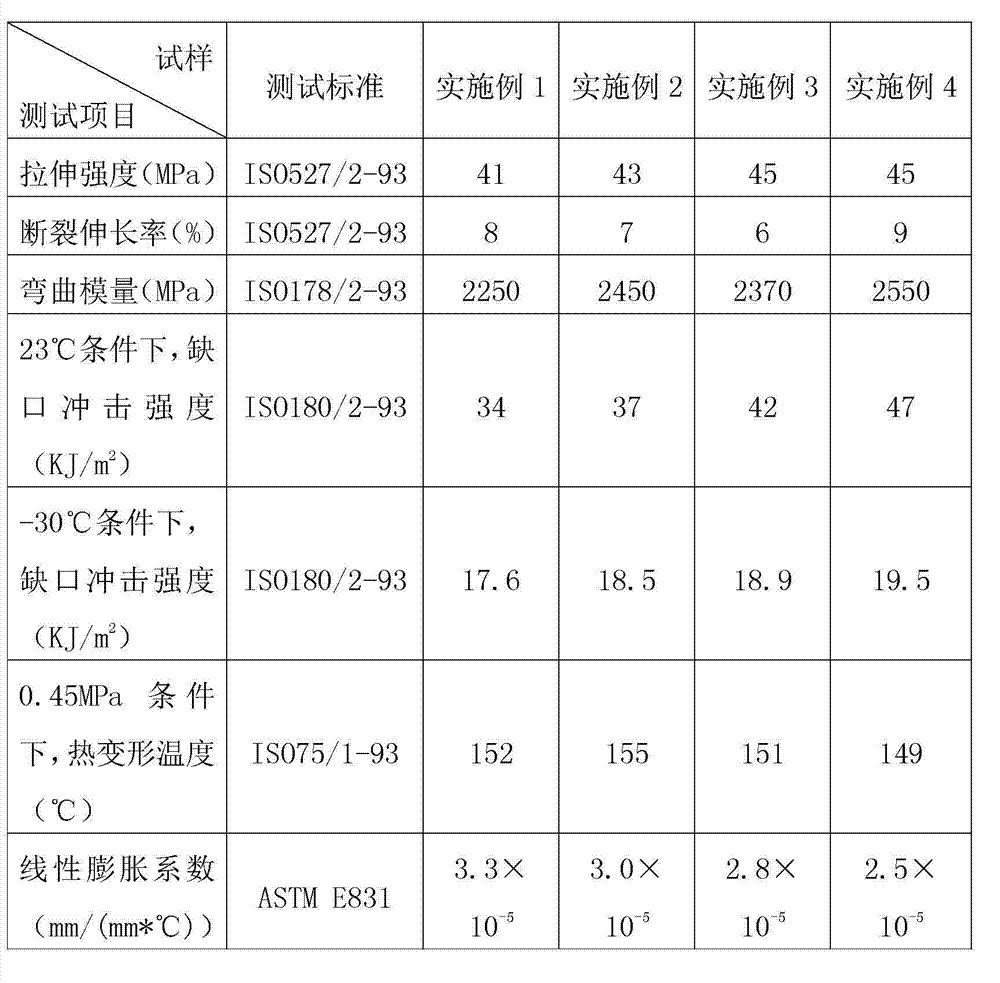

Glass fiber reinforced polypropylene composite material for car radiator grid and preparation process thereof

The invention discloses a glass fiber reinforced polypropylene composite material for a car radiator grid and a preparation process thereof. The composite material comprises the following components in percentage by weight: 32-78% of polypropylene, 0-2% of a thermal stabilizer, 0-2% of an additive, 0-2% of an illumination stabilizer, 0-2% of a nucleating agent, 5-20% of a flexibilizer, 2-10% of a compatilizer and 15-30% of chopped glass fiber. Due to the adoption of the chopped glass fiber for filling, the rigidity and the heat resistance of the material are greatly improved, the linear expansion coefficient (CLTE) of the material can be also reduced, and the problems of size change and deformation of a workpiece due to rapid change of external environment temperature are solved. The prepared composite material is excellent in heat resistance, high in rigidity, excellent in size stability and weather resistance and high in impact resistance, and satisfactorily meets the demand of the car radiator grid.

Owner:JIANGSU KINGFA SCI & TECH ADVANCED MATERIALS CO LTD

Nanometer ceramic spring producing method

InactiveCN1472448ASolve the problems of industrial productionSimple processLow internal friction springsHigh volume manufacturingSlurry

A process for preapring nano ceramic spring includes such steps as mixing ZrO2 nanoparticles with premixed liquid, ball grinding, vacuum deaerating, adding trigger moulding, solidifying demoulding, drying, heating to 700-1200 deg.C for 0.5-2 hr, degumming, immersing in slurry for 10-30 min, putting in supporter in powder, and sintering at 1400-1700 deg.C for 0.5-3 hr.

Owner:NANJING TECH UNIV

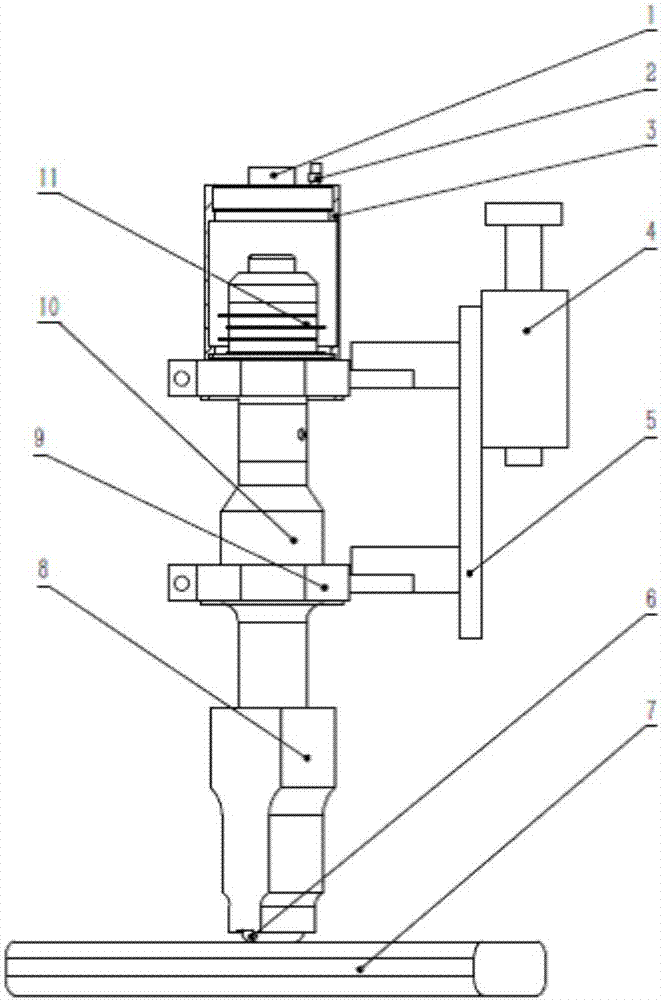

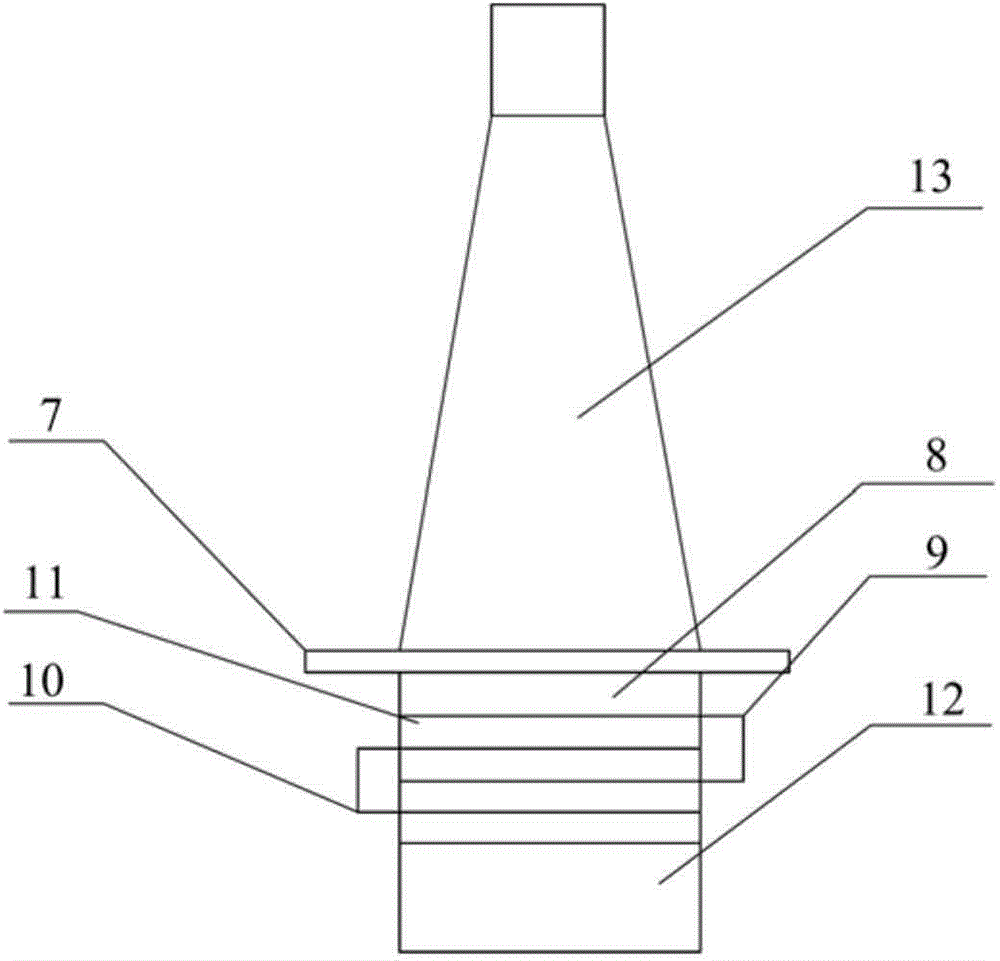

Ultrasonic and micro-forging composite device for improving microstructure and performance of additively manufactured metal and additive manufacturing method

ActiveCN107470628AImprove efficiencyHigh speedAdditive manufacturing apparatusIncreasing energy efficiencyComposite effectManufacturing technology

The invention provides an ultrasonic and micro-forging composite device for improving the microstructure and performance of additively manufactured metal and an additive manufacturing method. The ultrasonic and micro-forging composite device comprises an energy converter, a pneumatic slider, a pneumatic slider connection frame, an amplitude transformer, a tool head and a roller. The energy converter is arranged in an energy converter shell, the energy converter shell is provided with an inserting piece and a pipeline connector, the amplitude transformer is connected to the lower end of the energy converter, the tool head is connected below the energy converter, the roller is located between the tool head and a workpiece, and the pneumatic slider is connected with the energy converter shell and the amplitude transformer through the pneumatic slider connection frame. By means of the ultrasonic and micro-forging composite device, the advantages that ultrasonic impact frequency is high and deformation generated by mechanical rolling is large are combined, the composite effect of ultrasonic impact and continuous rolling micro-forging can be achieved, and the purpose of improving the microstructure of the additively manufactured metal and the mechanical performance of parts is achieved. Through organic combination of the ultrasonic and micro-forging composite device and the additive manufacturing method with an existing additive manufacturing technology, the technical bottleneck that structure control is easy while performance control is difficult in existing metal additive manufacturing is solved, and innovation and development of metal rapid forming and manufacturing technologies are induced.

Owner:HARBIN ENG UNIV +1

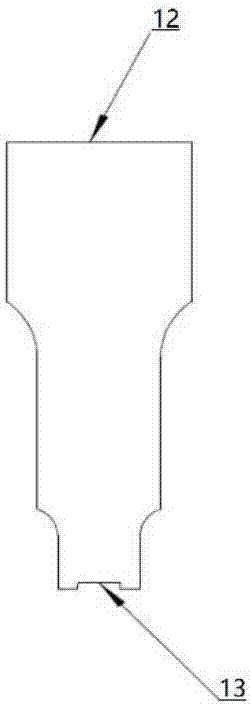

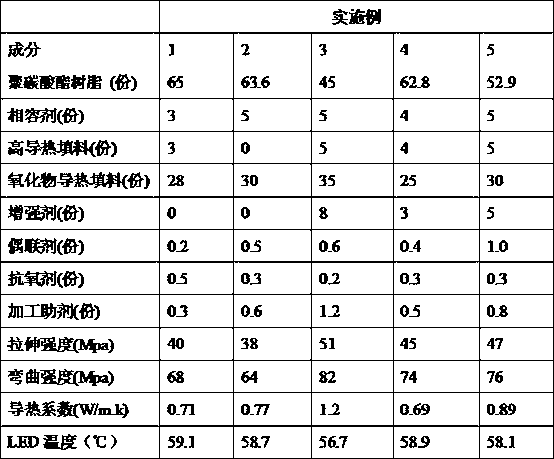

Heat conduction material co-extruded with optical diffusion material, and preparation method thereof

The invention relates to a heat conduction material co-extruded with an optical diffusion material, and a preparation method thereof, and relates to the field of polycarbonate composite materials. The heat conduction material is prepared by a polycarbonate (PC) resin, a compatilizer, a high heat conduction filling material, an oxide heat conduction filling material, a reinforcing agent, a coupling agent, an anti-oxidant and a processing auxiliary agent. The mass percentage of each component is as follows: 45-65 parts of the PC resin, 3-5 parts of the compatilizer, 0-5 parts of the high heat conduction filling material, 25-35 parts of the oxide heat conduction filling material, 0-8 parts of the reinforcing agent, 0.2-1.0 parts of the coupling agent, 0.2-0.5 part of the anti-oxidant and 0.3-1.2 parts of the processing auxiliary agent. The heat conduction material prepared by the method has excellent heat conduction performance and mechanical performance, can be co-extruded with an optical diffusion PC and processed into an LED fluorescent tube.

Owner:DONGGUAN XINLONG OPTOELECTRONICS MATERIAL

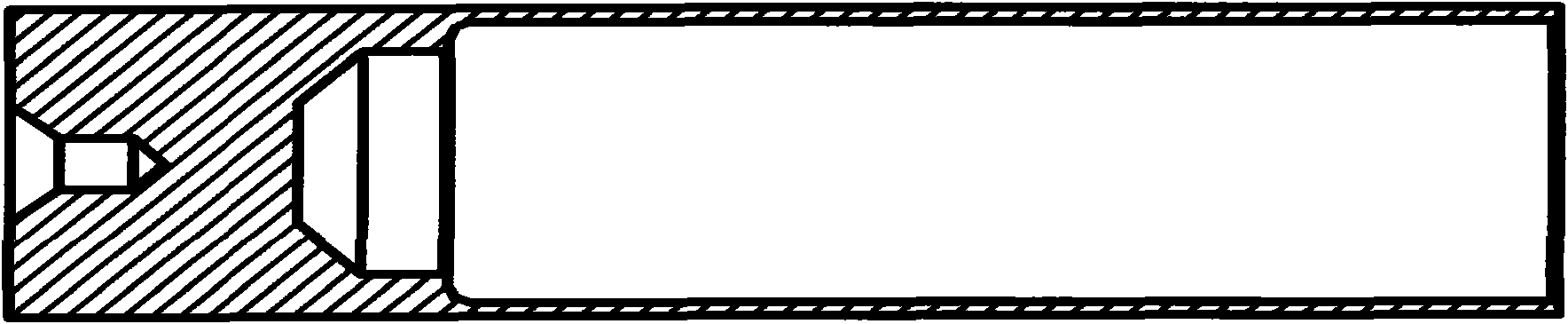

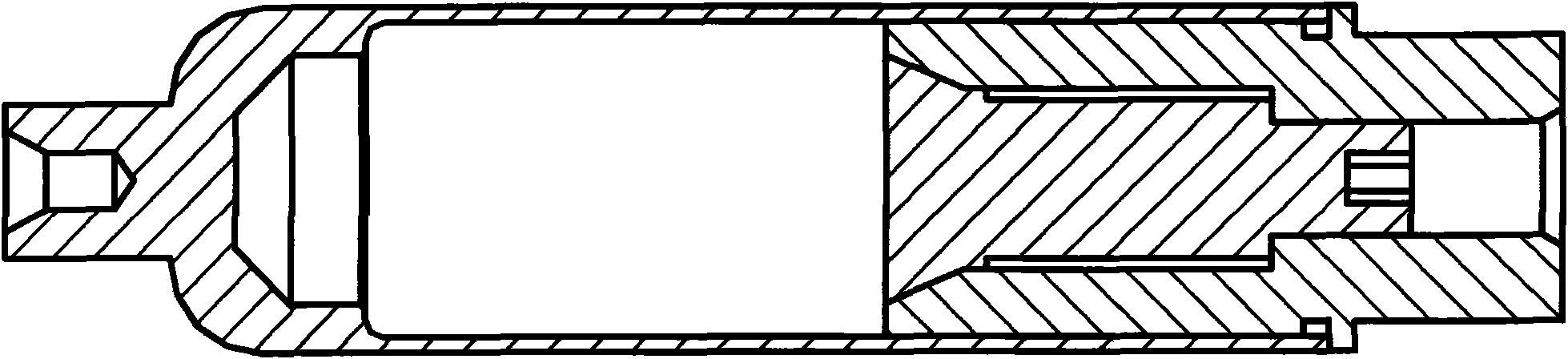

Processing method of parts with long shaft and thin wall and processing clamp thereof

InactiveCN102079045AReduce the difficulty of clampingReduce processing difficultyOther manufacturing equipments/toolsPositioning apparatusMetallic materialsMachining

The invention discloses a machining processing method of parts with a long shaft and a thin wall, belonging to the technical field of mechanical machining. The processing method comprises the following steps: firstly selecting the required metal material, then performing baiting, thermal refining, roughly machining, ageing at high and low temperatures, half precisely machining and precisely machining, and finishing the machining after the passed inspection; during the half precise machining, the outer circle of the part with the long shaft and thin wall is preserved with the machining residue; during the precisely machining, an expandable shoulder plunger piston clamp is used for matching with the part to machine; the other end of the part is reserved with a technical handle and provided with a central hole so as to locate through the outer diameter of the clamp and the inner hole of the part; and the outer diameter of the clamp is regulated so that the outer diameter is properly matched with the inner hole of the part. By using the processing method, the problems that the part with the long shaft and thin wall is easy to deform during the mechanical machining, is incapable of reaching the requirement of the technical parameter, and is low in machining yield are solved.

Owner:贵州航天控制技术有限公司

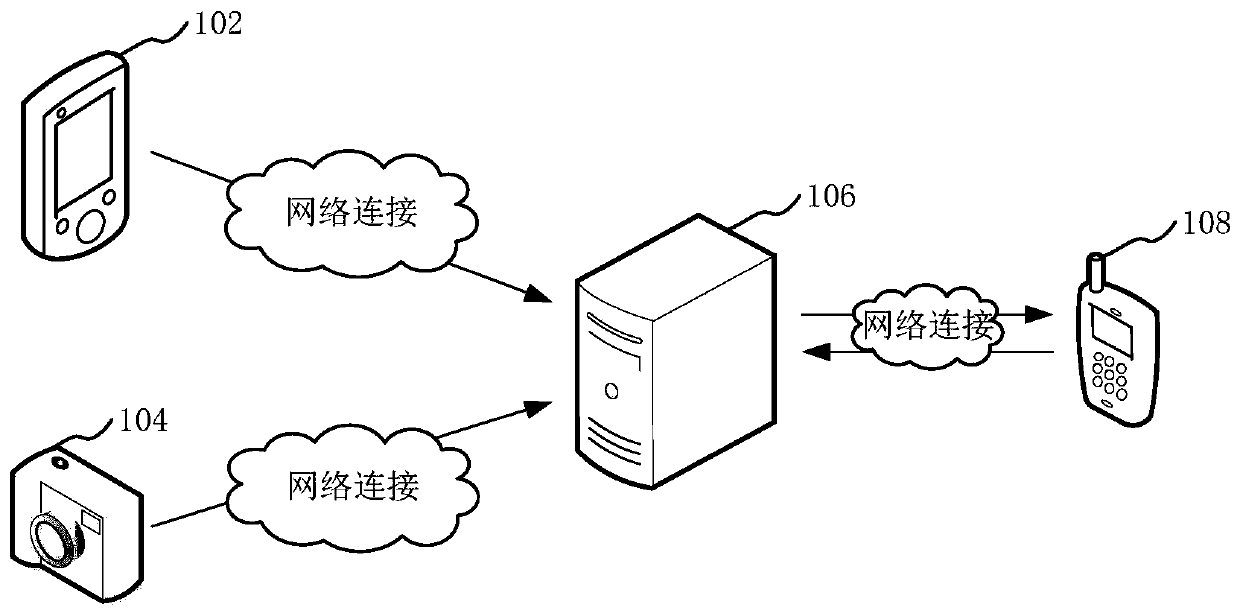

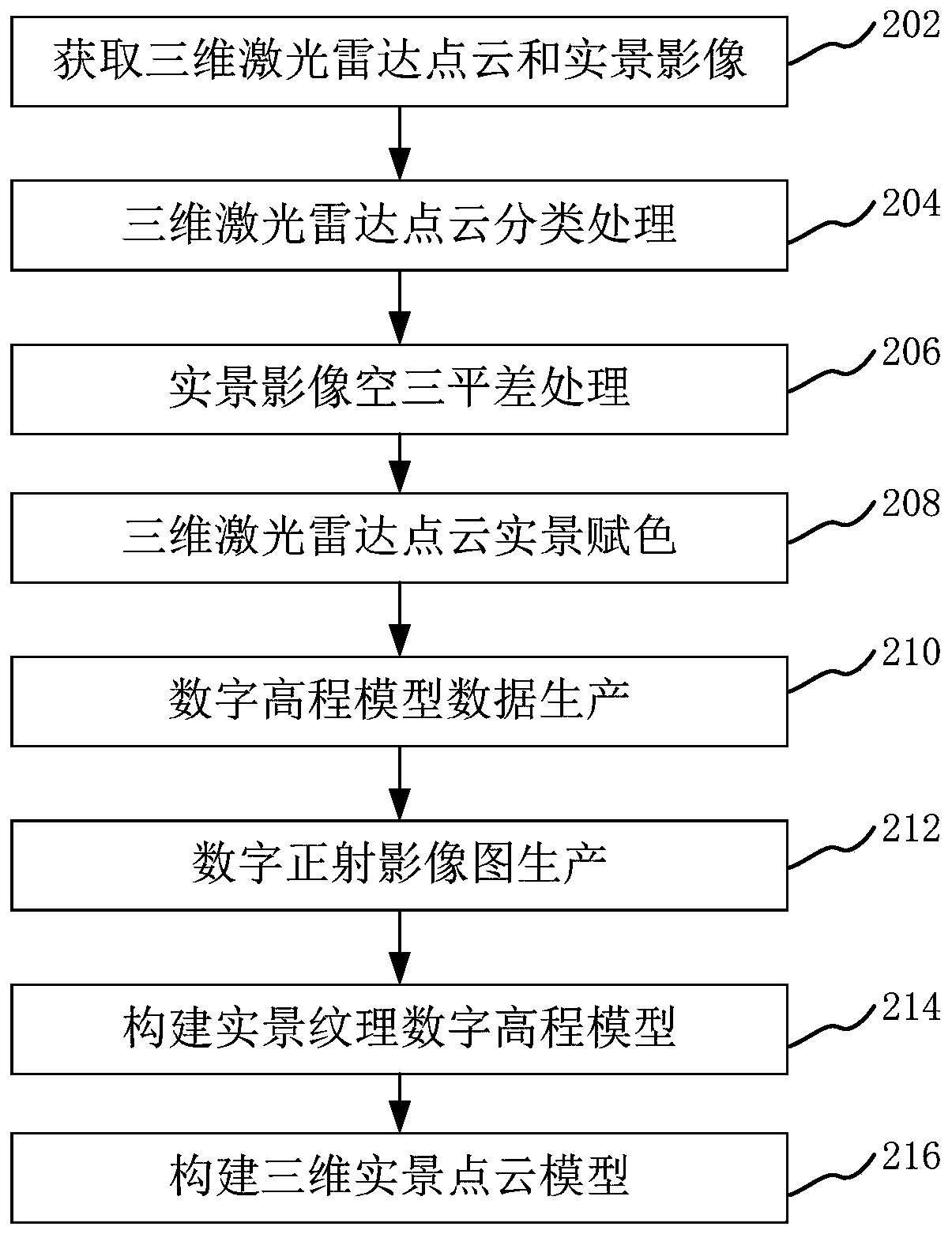

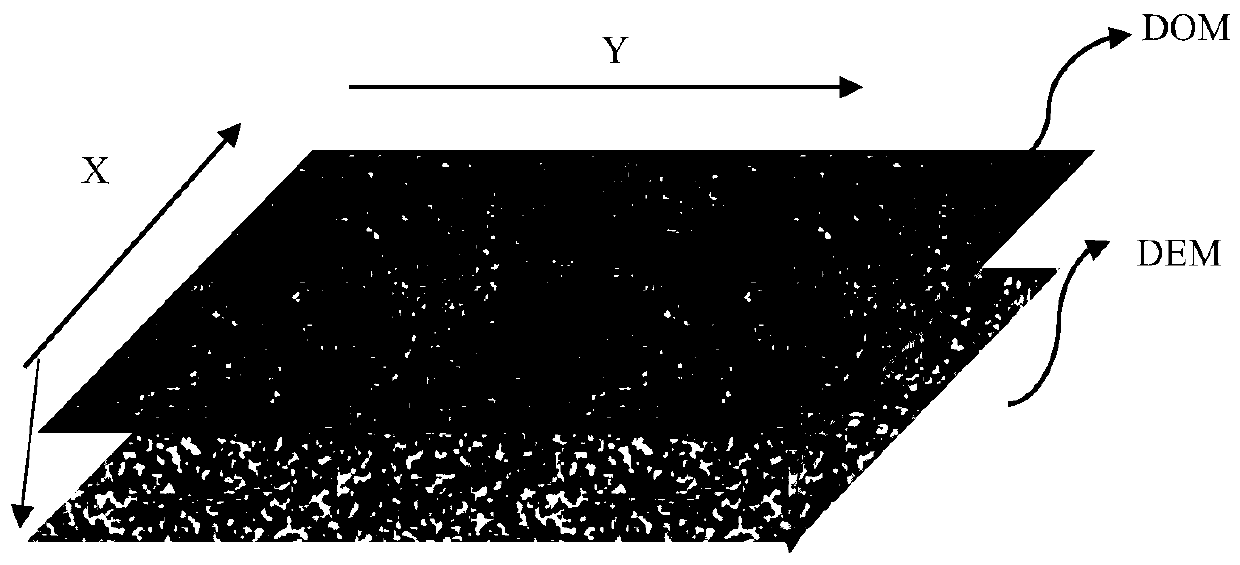

Method and device for generating three-dimensional live-action point cloud model

ActiveCN110570466AHigh precisionPromote recoveryImage enhancementImage analysisPoint cloudLive action

The invention relates to a three-dimensional live-action point cloud model generation method and device, computer equipment and a storage medium. The method comprises the following steps: acquiring three-dimensional laser radar point cloud data and a synchronous live-action image of a target; performing point cloud classification processing on the three-dimensional laser radar point cloud data toobtain surface point cloud data; performing aerial triangulation adjustment processing on the live-action image to obtain exterior orientation elements of the live-action image; performing live-actioncoloring processing on the three-dimensional laser radar point cloud data to obtain live-action texture three-dimensional laser radar point cloud data; generating digital elevation model data throughthe classified surface point cloud data; generating a digital ortho-image map according to the digital elevation model data and the exterior orientation elements of the live-action image; matching and constructing a live-action texture digital elevation model of the target; and matching the live-action texture digital elevation model with the live-action texture three-dimensional laser radar point cloud data to generate a three-dimensional real scenic spot cloud model of the target. The computing production pressure of a computer can be reduced.

Owner:GUANGZHOU JIANTONG SURVEYING MAPPING & GEOINFORMATION TECH

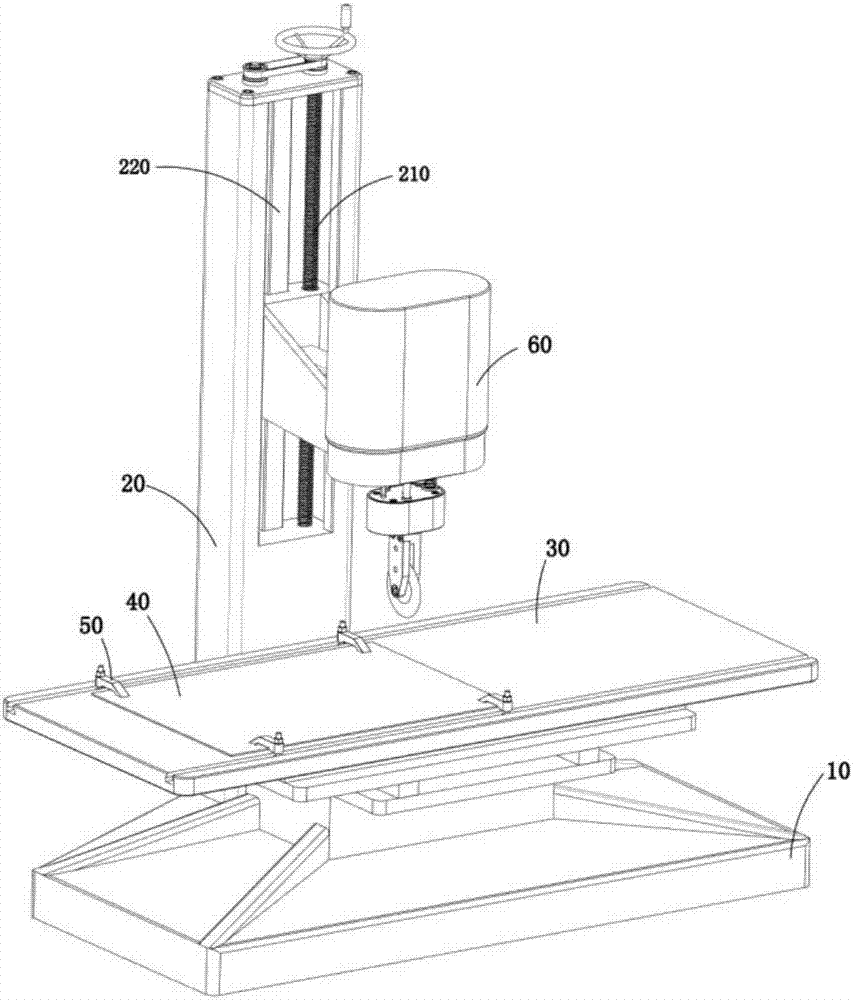

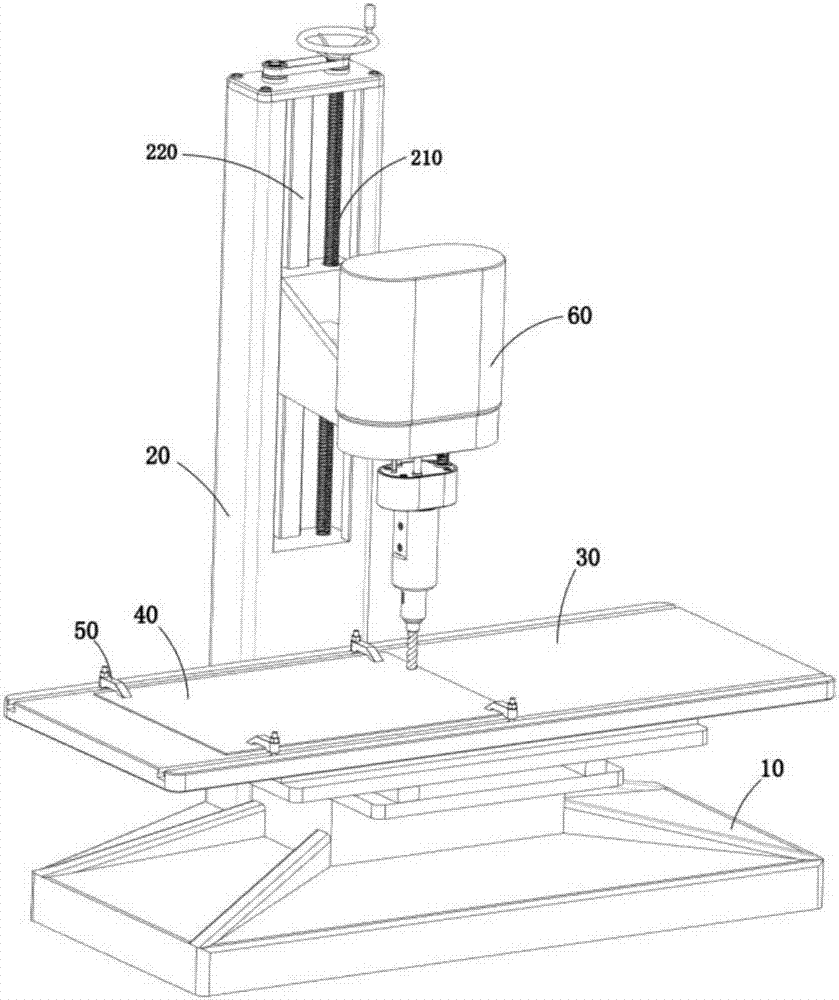

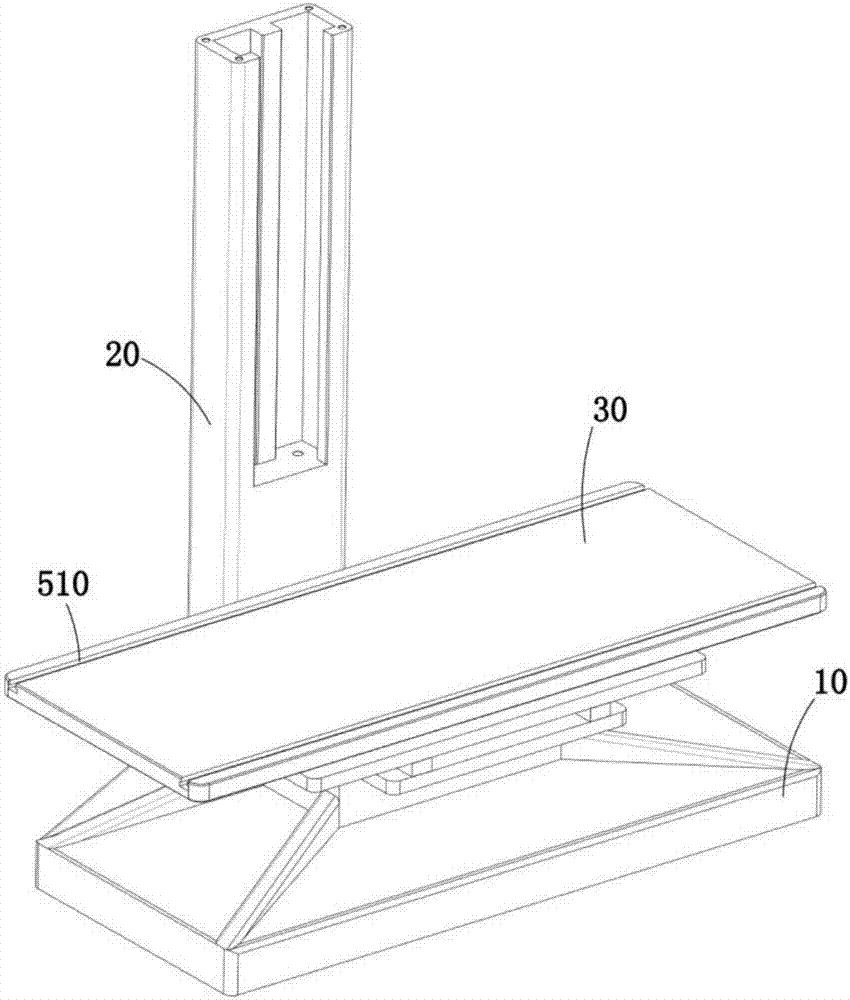

Dustless cutting machine applied to cutting of flat object

InactiveCN107030329ASolve the deformationRealize free reversing cuttingShearing machinesFeeding apparatusDocking stationMetal sheet

The invention discloses a dust-free cutting machine for cutting flat objects, which includes a bed, a stand, a workbench, and a cutting support mechanism. The workbench is horizontally installed on the upper end of the bed, and the stand is along the Z axis It is extended and fixedly connected with the bed body. The metal sheet to be processed is installed on the worktable surface of the workbench through the clamping device. The workbench can move in the X-axis and Y-axis directions in the horizontal direction. Move in the vertical direction; the cutting support mechanism also includes a connecting platform that is movably installed at the bottom of the main frame body. The connecting platform and the main frame body are connected by a guide rod. There are guide holes matching the guide rails, and the connecting table can move up and down along the guiding direction of the guide rod; the main frame body is respectively equipped with a cutting drive mechanism, a rotation drive mechanism and a pressure applying mechanism.

Owner:LUAN YONGZHEN GRIZZLY ELECTRICAL & MECHANICAL TECH CO LTD

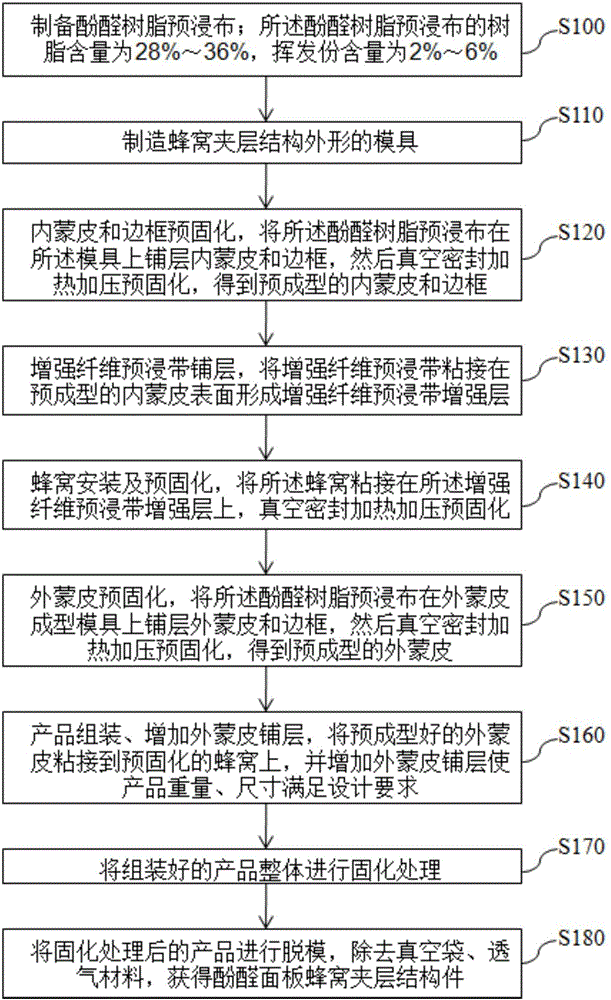

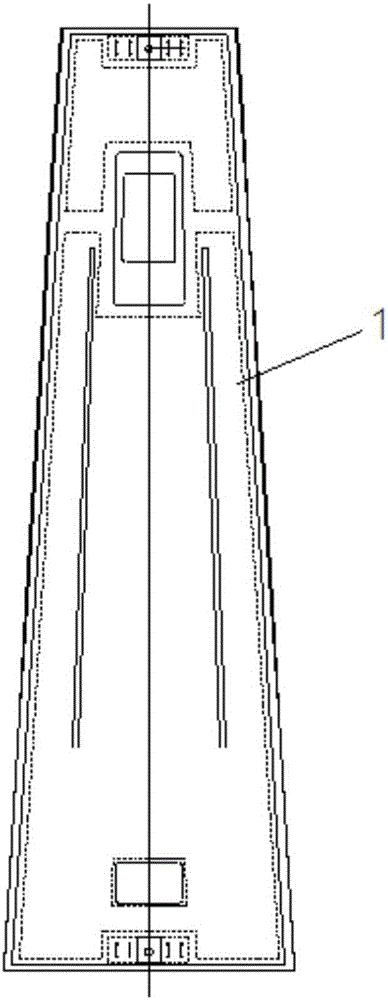

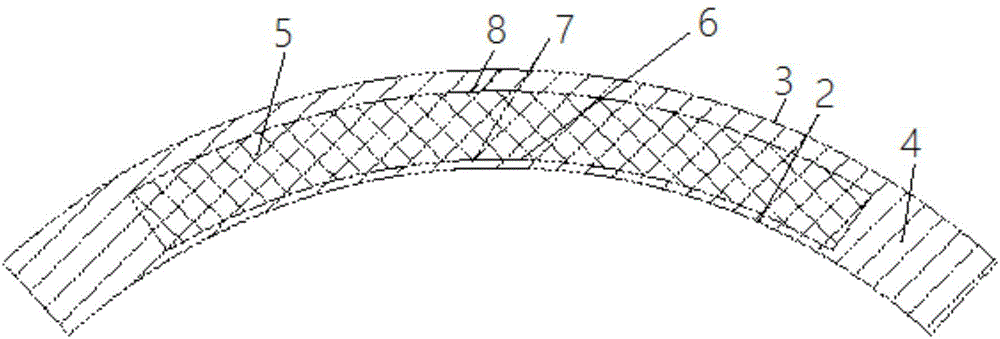

Method for molding phenolic panel honeycomb sandwich structural member

The invention discloses a method for molding a phenolic panel honeycomb sandwich structural member and belongs to the technical field of composite material molding. The phenolic panel honeycomb sandwich structural member comprises inner covering skin, outer covering skin, a frame, a honeycomb, a reinforcing fiber prepreg tape reinforcing layer, an inner glue film layer and an outer glue film layer. The method comprises preparing a phenolic resin prepreg cloth, preparing a mold having the honeycomb sandwich structure shape, pre-curing the inner covering skin and the frame, paving a reinforcing fiber prepreg tape through bonding the reinforcing fiber prepreg tape to the surface of the pre-molded inner covering skin to obtain the reinforcing fiber prepreg tape reinforcing layer, carrying out honeycomb installation and pre-curing, pre-curing the outer covering skin, assembling a product through paving the outer covering skin layer, integrally curing the assembled product and carrying out demolding. The method can mold a large-size honeycomb sandwich structure. The molded honeycomb sandwich structure does not deform, lose viscidity and produce bulge, has the size, weight and shape satisfying design requirements and has good ablation resistance.

Owner:HUBEI SANJIANG AEROSPACE GRP HONGYANG ELECTROMECHANICAL

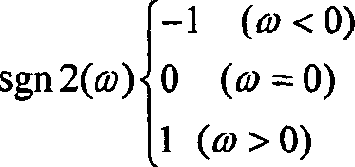

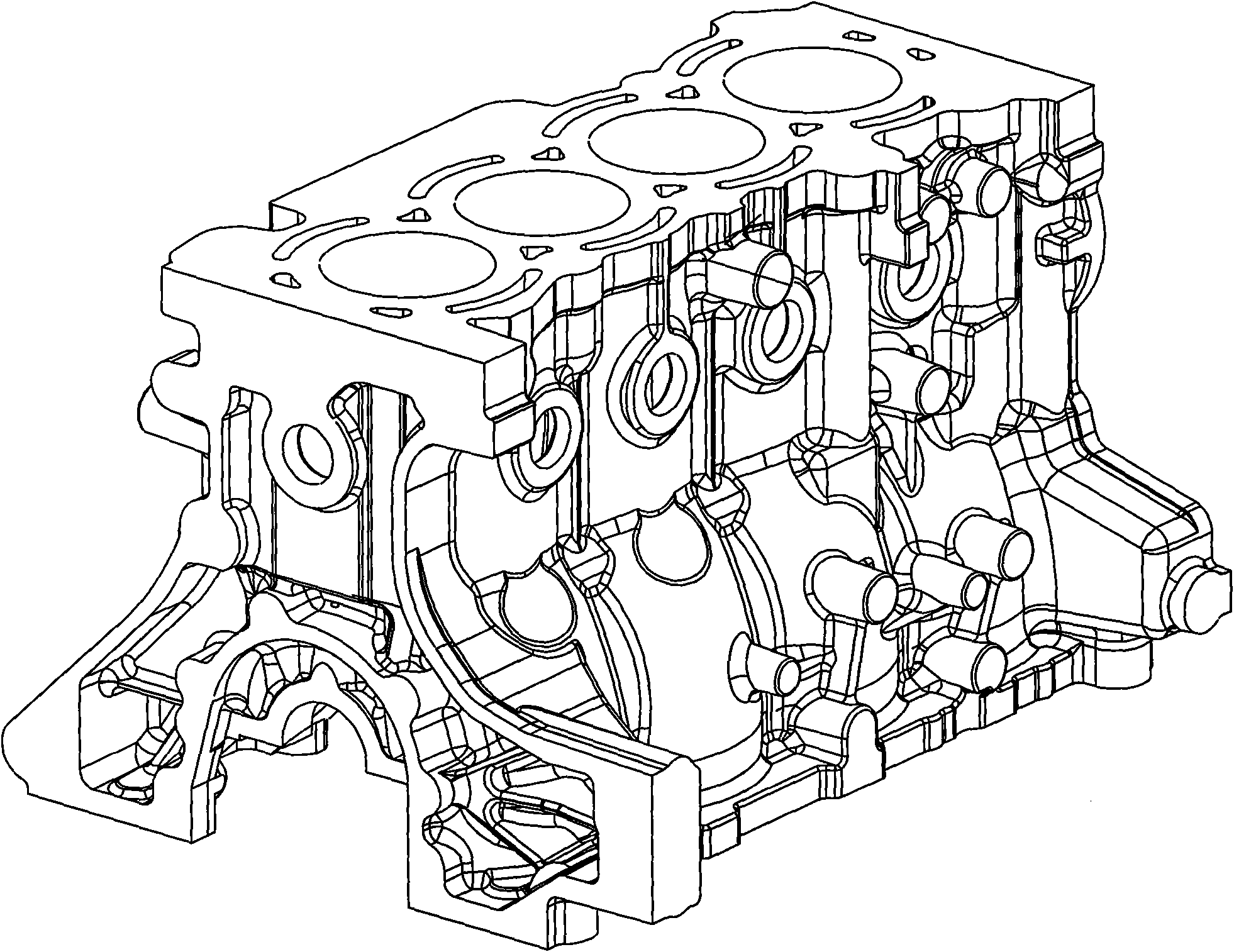

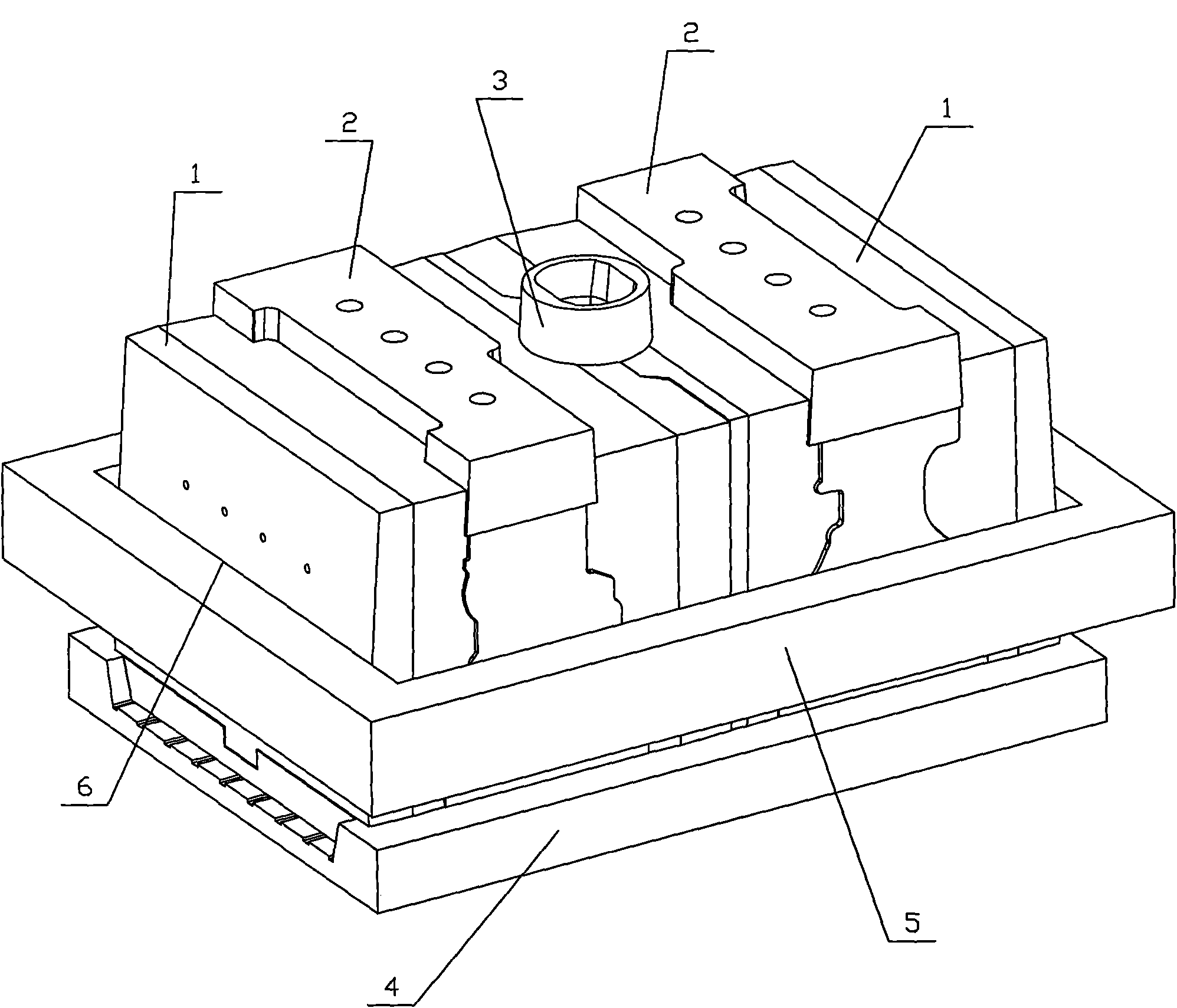

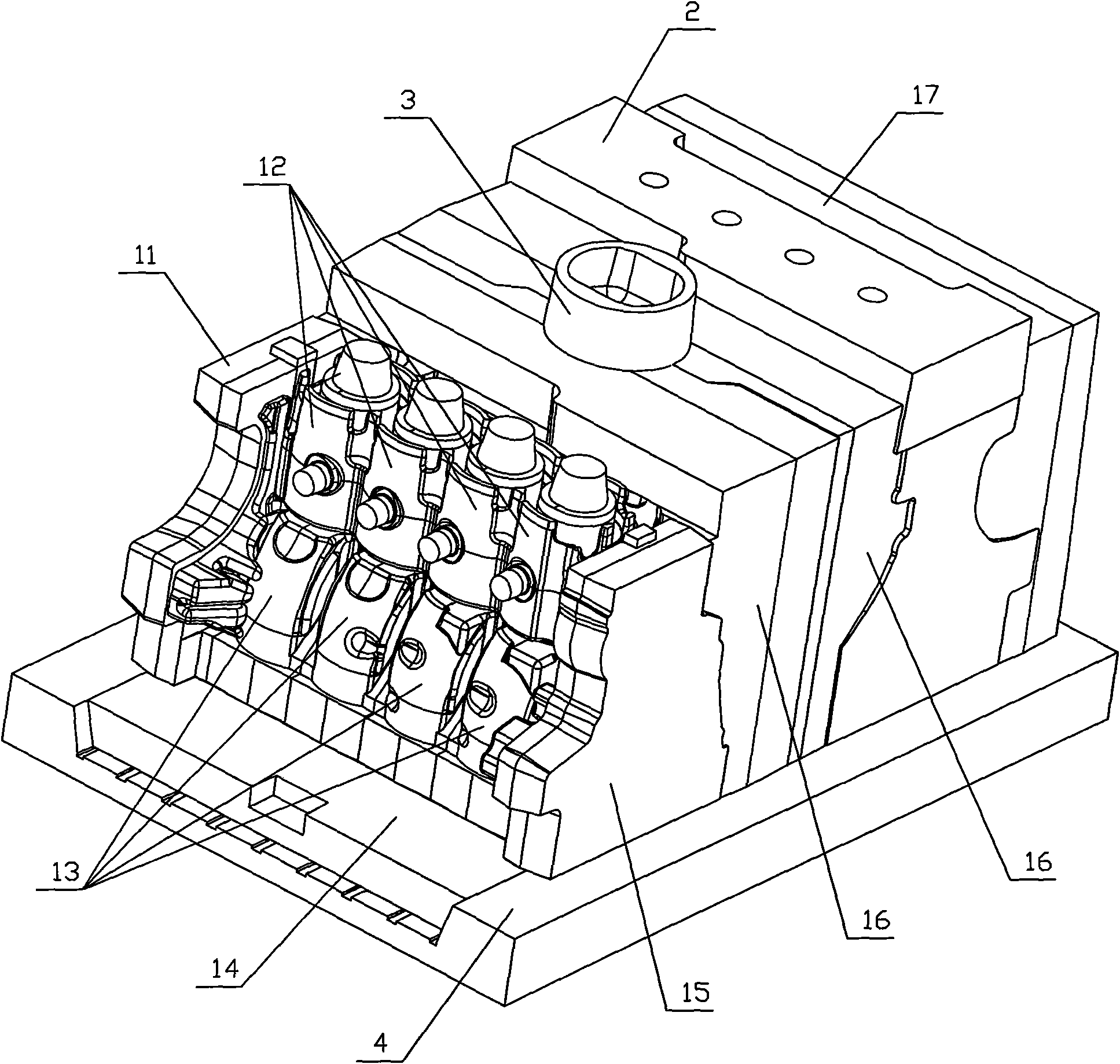

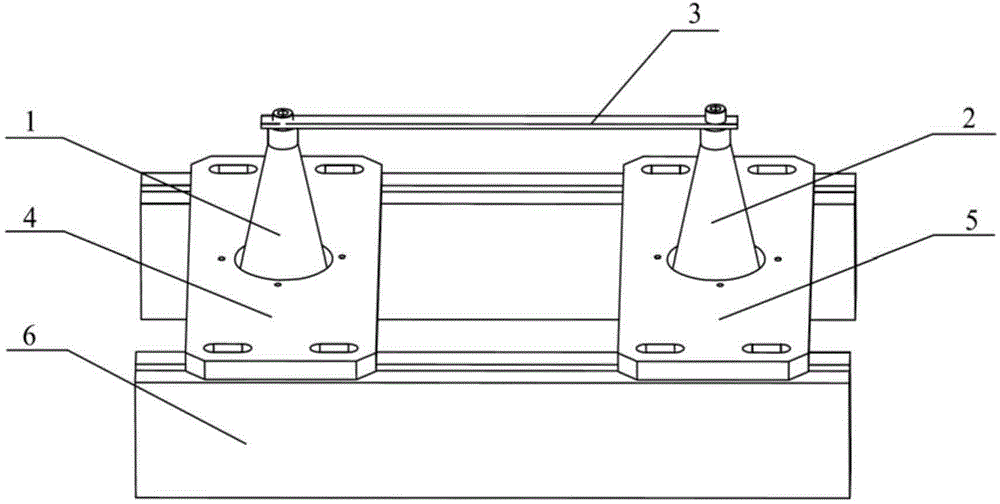

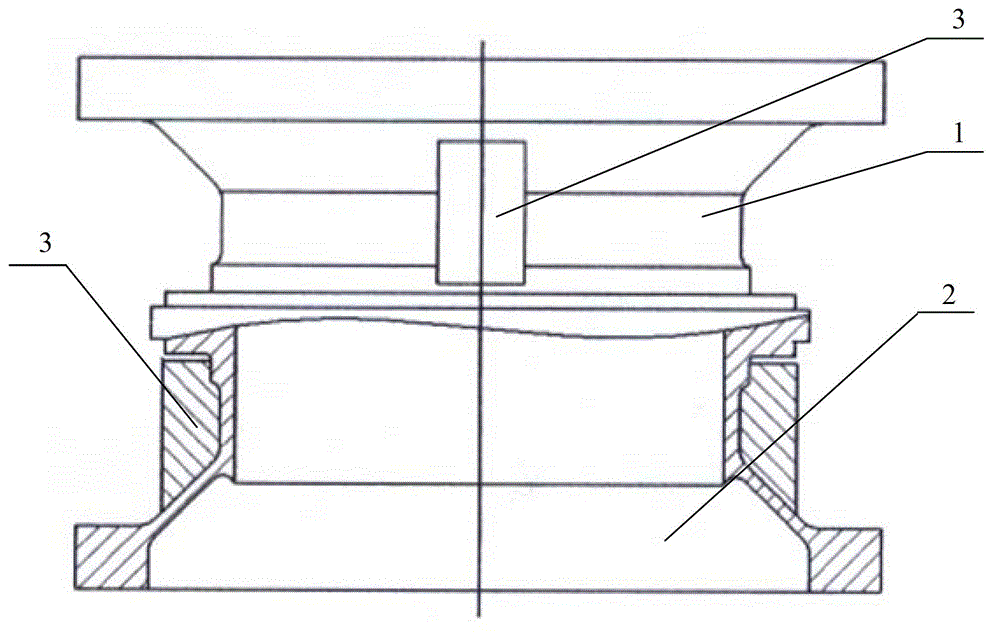

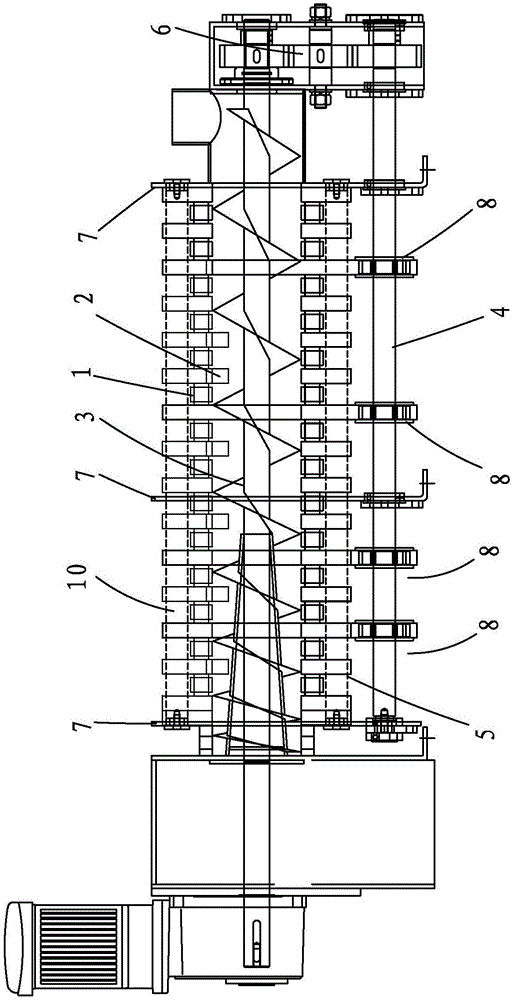

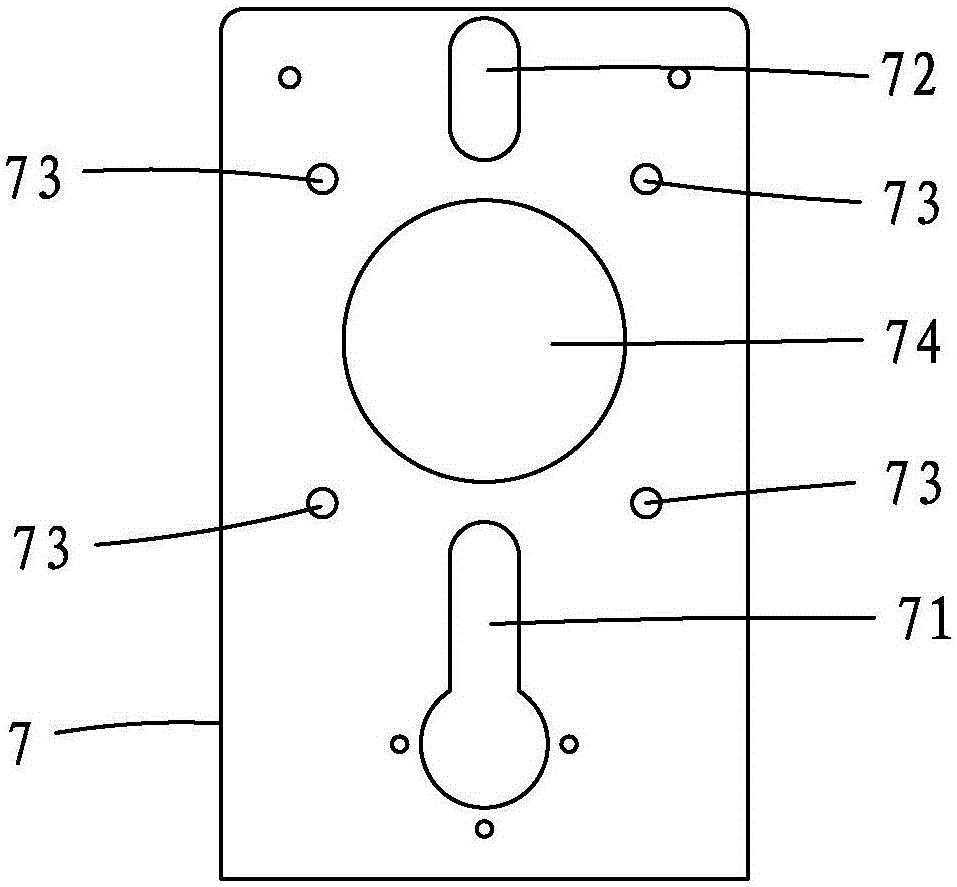

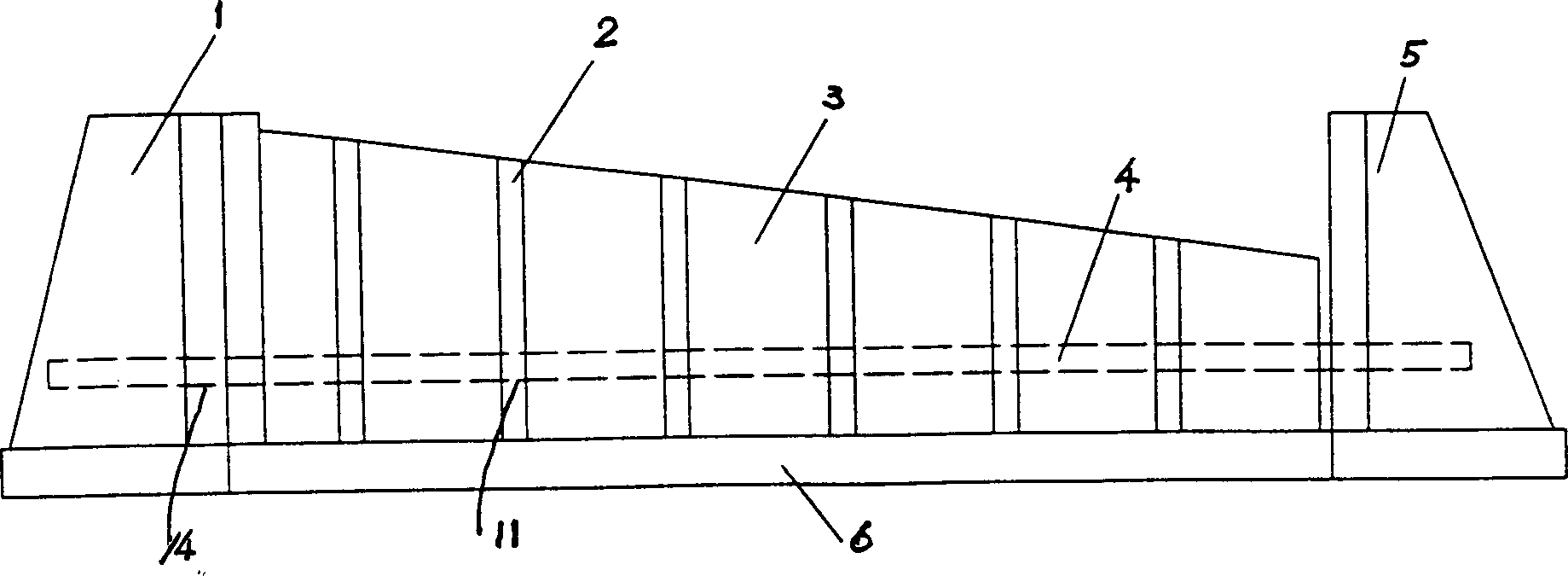

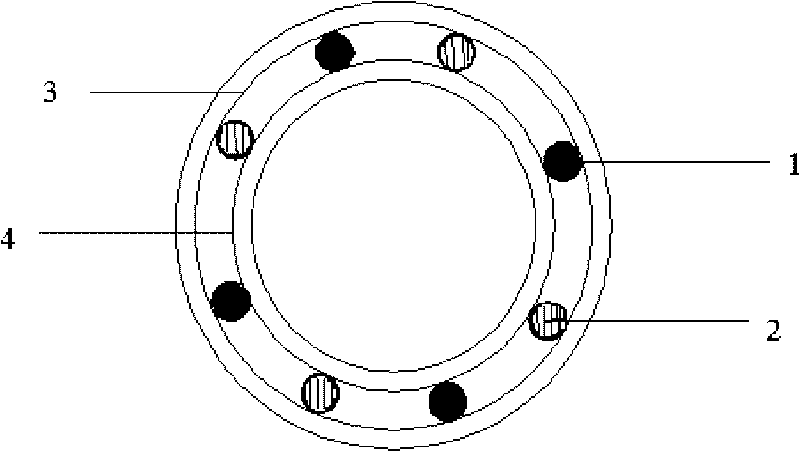

Core assembly pouring device for cylinder block casting in automobile engine

InactiveCN101817060ASolve the deformationReduce in quantityFoundry mouldsFoundry coresEngineeringCylinder block

The invention discloses a core assembly pouring device for a cylinder body casting in an automobile engine, comprising a base plate (4), two raiser cores (2), a sprue core (3), sand core assemblies (1) and a locking device (5), wherein the sand core assemblies (1) are connected on the base plate (4) and are locked by the locking device (5), the raiser core (2) and the sprue core (3) are located on the two adjacent sand core assemblies (1) which are clamped on the base plate (4), and the locking device (5) is sleeved and pressed outside the two sand core assemblies (1). By adopting the structure, the sand core of the cylinder body consists of a plurality of sand cores, and each sand core is composed of a plurality of small sand cores, thus reducing the size of each sand core, being beneficial to the forming of the sand cores and reducing casting defects of castings; and meanwhile, the number of the sand core assemblies is two, e.g. one die generates two castings, thus greatly improving production efficiency.

Owner:宁波强盛机械模具有限公司

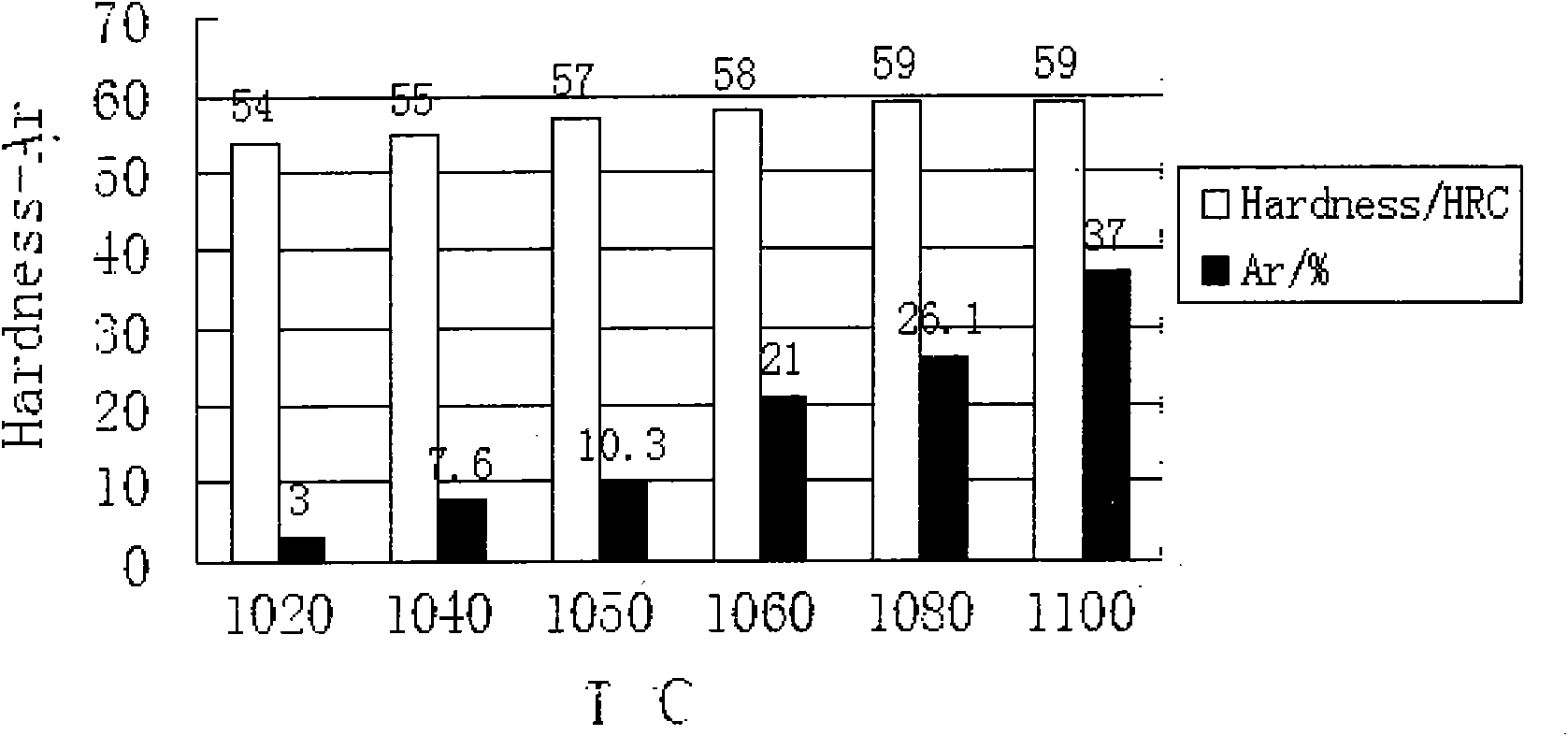

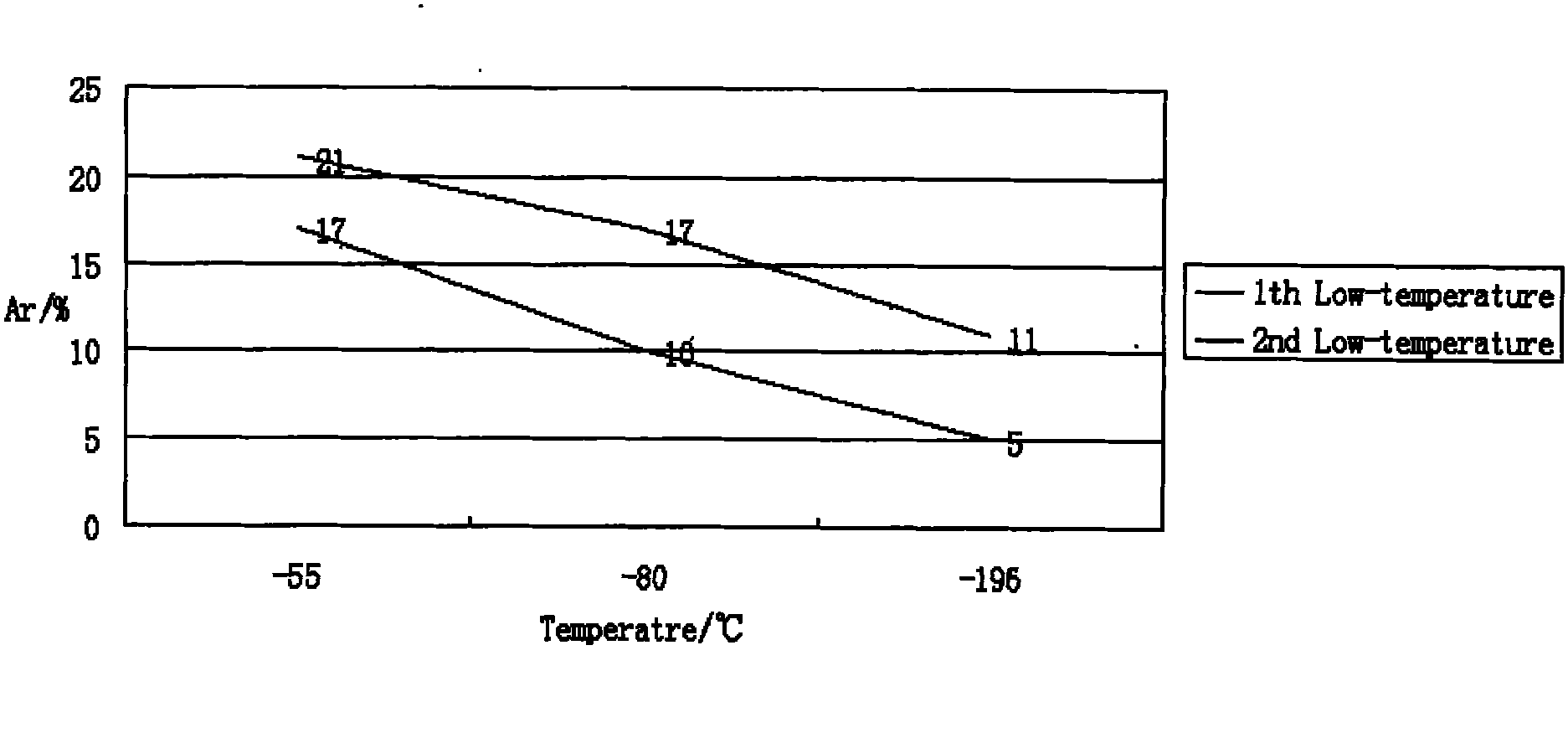

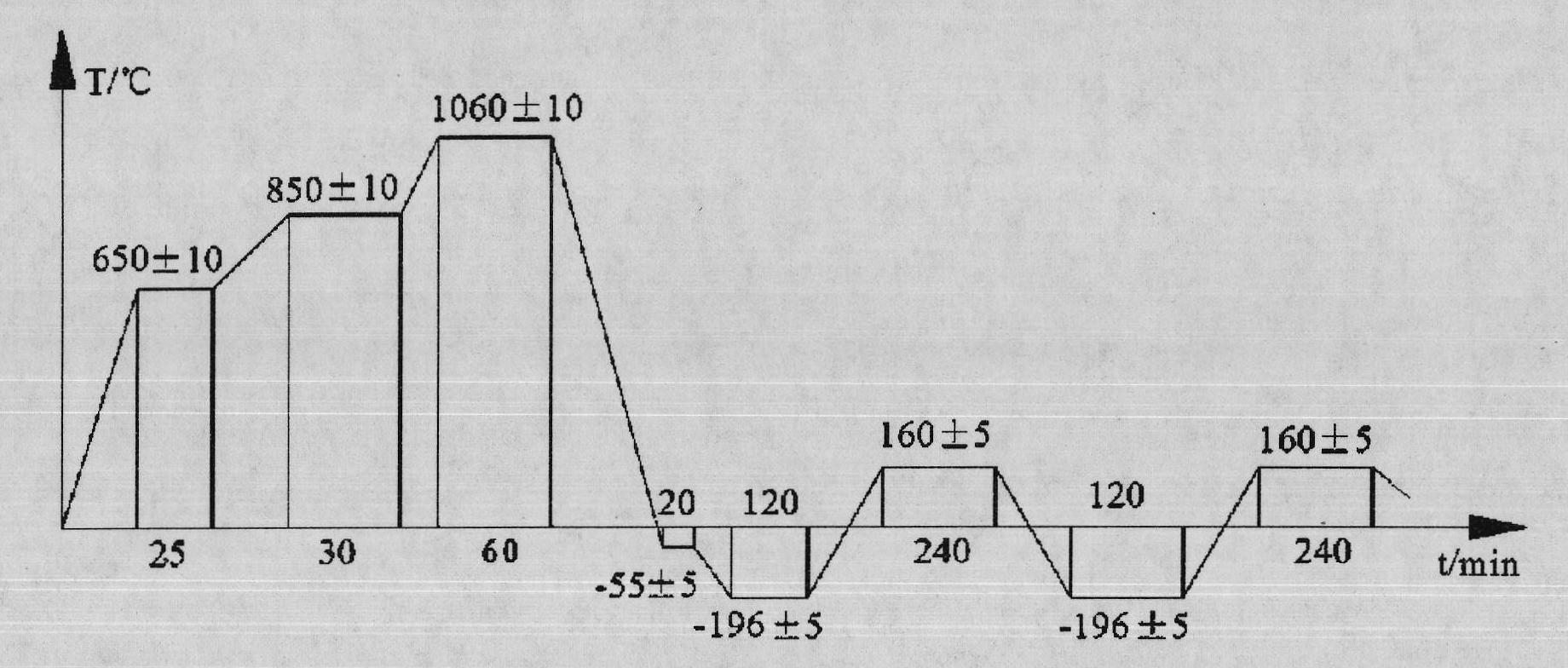

Thermal treatment technology of high-nitrogen stainless bearing steel

InactiveCN101935752AControl contentGuaranteed dimensional stabilityHeat treatment process controlCold treatmentRoom temperature

The invention discloses a thermal treatment technology of high-nitrogen stainless bearing steel, comprising the following steps of: primarily preheating at a temperature of 650+ / -10 DEG C and preserving the temperature for 25-35 min; secondarily preheating at a temperature of 850+ / -10 DEG C and preserving the temperature for 20-45 min; quenching at a temperature of 1060+ / -10 DEG C and preserving the temperature for 50-60 min; cooling to the room temperature after the quenching and performing cold treatment in half an hour at a temperature of -196+ / -5 DEG C for 2-3 h for twice; and warming to the room temperature after the cold treatment and performing tempering immediately at a temperature of 160+ / -5 DEG C for 4-4.5 h for twice. The best thermal treatment technology of 40Crl5Mo2VN high-nitrogen stainless bearing steel of the invention, which is finally determined on the basis of numerous experiments, not only effectively controls the content of the remained austenite to guarantee the size stability problem of the 40Crl5Mo2VN steel workpiece, but also solves the deformation problem and crack problem of the thermal treatment.

Owner:LUOYANG LYC BEARING

Ultrasonic suspension conveying device

InactiveCN104085691ASolve the deformationHigh energy utilization and electromechanical conversion efficiencyCharge manipulationNon-mechanical conveyorsHigh energyParticle contamination

The invention relates to an ultrasonic suspension conveying device. The ultrasonic suspension conveying device comprises a sending end ultrasonic transducer, a receiving end ultrasonic transducer, a conveying rail, a first support, a second support and a fixed rail. The two ends of the conveying rail are connected with the sending end ultrasonic transducer and the receiving end ultrasonic transducer respectively, the two ends of the fixed rail are connected with the first support and the second support respectively, the first support is connected with the sending end ultrasonic transducer, and the second support is connected with the receiving end ultrasonic transducer. By the adoption of the ultrasonic suspension conveying device, the multiple problems of deformation, surface scratches, particle contamination and silicon wafer accuracy reduction caused by mechanical conveying to silicon wafers in photovoltaic industry manufacture are effectively solved, objects with the large size and the small thickness are stably conveyed in a suspension mode without being limited by the characteristics of conveyed materials, the high energy utilization rate and high electro-mechanical transformation efficiency are achieved, and the ultrasonic suspension conveying device is simple, easy to operate, accurate and stable in conveying positioning and wide in application range.

Owner:EAST CHINA UNIV OF SCI & TECH

Method for processing split thin-walled parts

ActiveCN103143885AGood for deformation controlSolve the deformationMachining processComputer science

A method for processing split thin-walled parts belongs to the technical field of aero-engines. The method can be used for processing not only components of an aero-engine but also mechanical parts, and enables a processing stress and a residual stress, which are formed in the part processing process, to interact and cancel, so that the problem that the split thin-walled parts are deformed is solved. The method comprises the following steps: selecting a blank which adopts a ring-shaped forged piece for processing two parts; roughing the ring-shaped forged piece before welding; achieving heat treatment to remove the residual stress for roughing; semi-finishing; welding longitudinal mounting edges to enable the longitudinal mounting edges of the two parts to be in crossed distribution; conducting heat treatment to eliminate the welding stress; lathing a datum plane; cutting off to separate the two parts; linearly cutting the longitudinal mounting edges of the two parts; and respectively finishing the two parts.

Owner:SHENYANG LIMING AERO-ENGINE GROUP CORPORATION

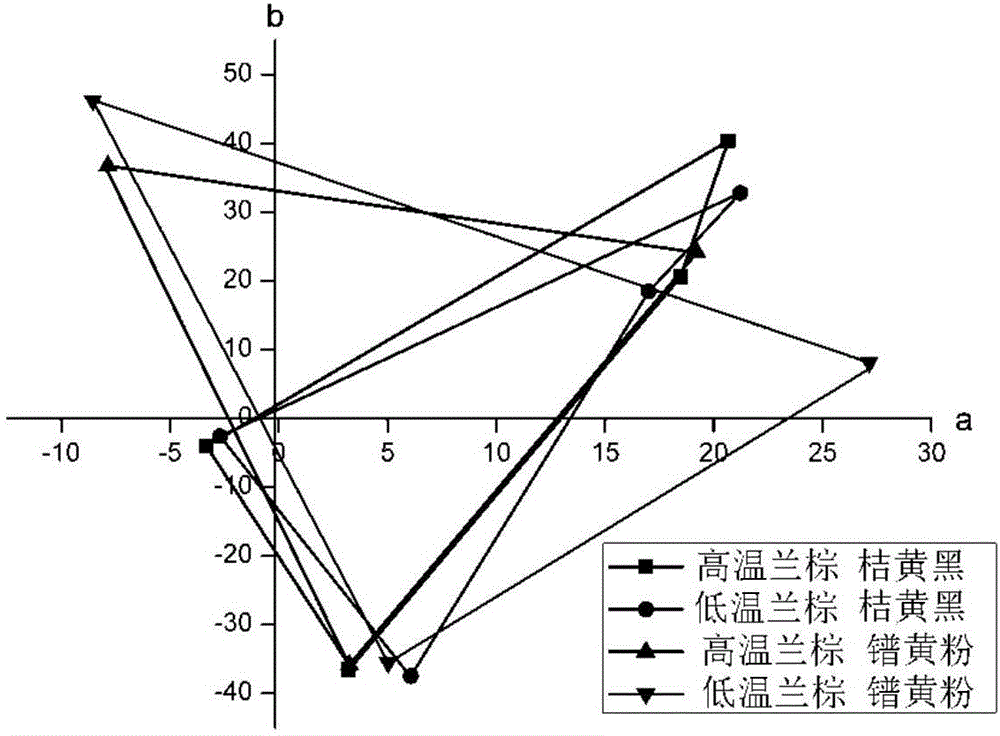

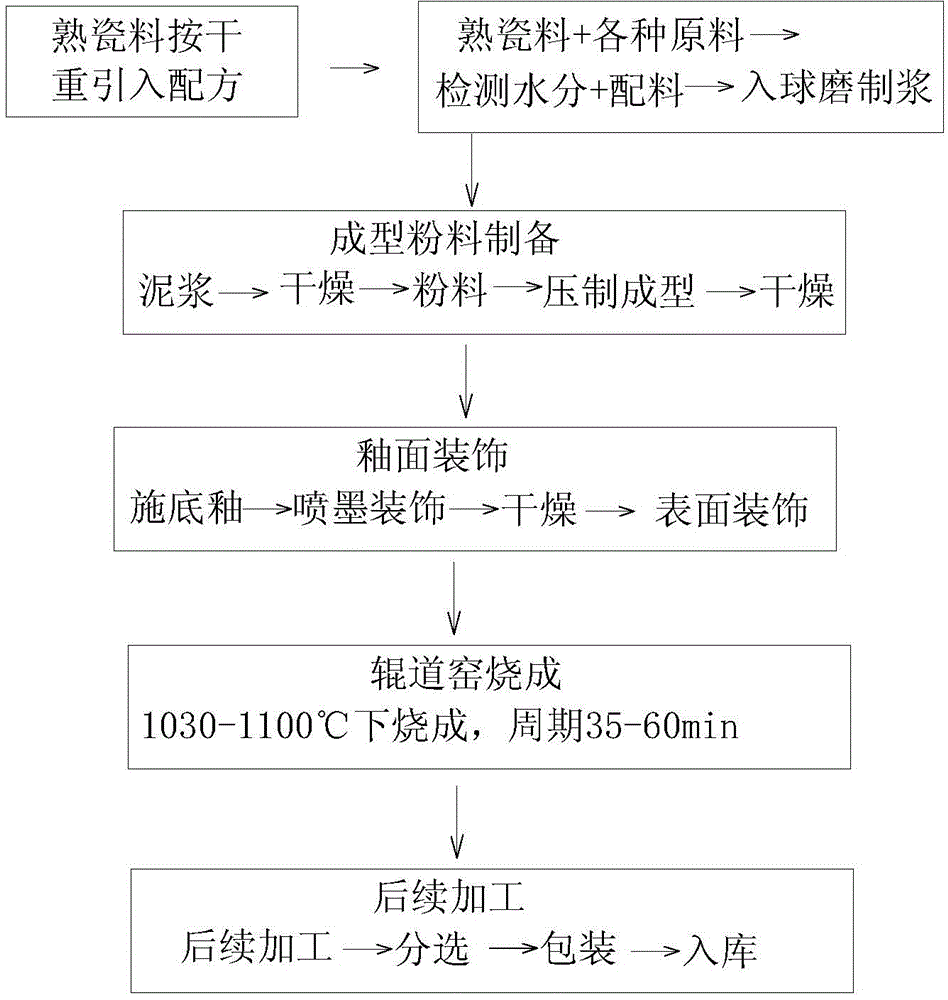

Wide-color-gamut inkjet glaze decorated ceramic floor tile and production process thereof

The invention relates to the technical field of ceramic tiles, and in particular relates to a wide-color-gamut inkjet glaze decorated ceramic floor tile and a production process thereof. A floor tile billet comprises the following components in parts by weight: 40-75 parts of a cooked porcelain material, 0-38 parts of porcelain stone, 20-30 parts of clay and 0-5 parts of a mineralizing agent; and a production method comprises the following steps: firstly performing conventional processes such as wet-process ball-milling, spray drying and dry-pressing molding on architectural ceramics to prepare a billet, by taking titanium series engobe as a ground glaze, combining engobe with a low-temperature ink-jet ink composition of interior wall tiles to perform inkjet decoration, and performing firing in a roller hearth kiln under the conditions that the firing temperature is 1030-1100 DEG C and the firing cycle is 35-60min to prepare a finished product, wherein the water absorption rate of the finished product is 0-3%, and the quality of the product can meet the national standard requirements. The wide-color-gamut inkjet glaze decorated ceramic floor tile disclosed by the invention has the beneficial effects that energy conservation and emission reduction can be achieved, and the firing temperature can be reduced by 50-100 DEG C compared with that of the same category of products; the technology bottleneck that titanium series opacified engobe can be yellowed when being applied in the floor tiles in a conventional high-temperature process can be effectively solved; and the color gamut range of an inkjet decorative layer of a glaze decorated ceramic tile can be significantly broadened.

Owner:JIANGXI HEMEI CERAMICS +1

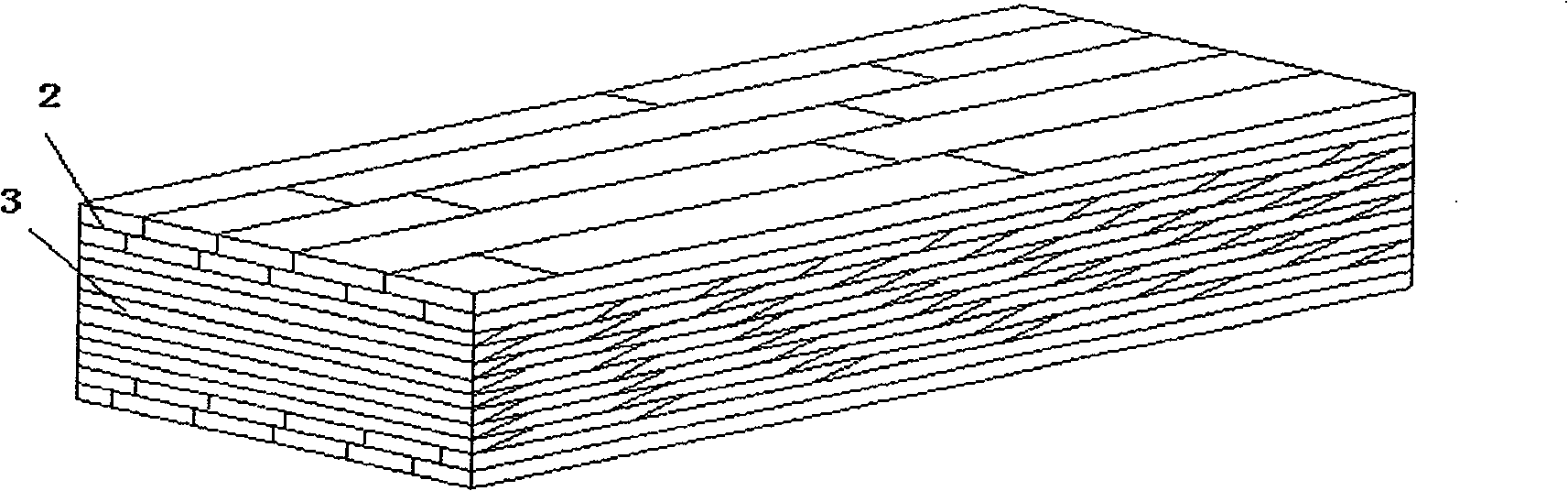

Super-thick bamboo-wood composite board and producing method thereof

ActiveCN101524858ASolve the problem of poor thermal conductivity that is difficult to produce by hot pressingSolve warpingPolyureas/polyurethane adhesivesAldehyde/ketone condensation polymer adhesivesAdhesiveEngineering

The invention provides a super-thick bamboo-wood composite board, which comprises a core board, a surface board and a back board, wherein the core board is a super-thick rotary-cut single board with the thickness of 6-12 mm, the surface board and the back board are made of bamboo, the core board comprises a plurality of super-thick single boards, the contiguous layers of the super-thick single boards are in the combination along the grain, a glue layer is arranged between contiguous single boards, the adhesive of the glue layer is an aqueous macromolecule isocyanate adhesive, the super-thick single boards of the core layer are single boards after the processing of stress degradation, and spot-shape or segment-shape crack grains are formed in the direction along the grain of the loosened surface of every single board. Compared with the prior composite board of the same thickness, the composite board has greatly-reduced glue amount and no deformation or distortion.

Owner:INST OF WOOD INDUDTRY CHINESE ACAD OF FORESTRY

Machining method of thin-walled deep-hole welded workpieces

The invention relates to the field of machining, in particular to a machining method of thin-walled deep-hole welded workpieces. The machining method includes the steps of performing machining; performing welding; performing annealing, to be specific, performing annealing at a high temperature after welding; performing rough machining and semi-finishing on a bore and outside by using the bore and the outside as mutual references, and performing cutting to obtain two workpieces; after cutting, performing heat treatment; performing finish boring on the bore with a floating borer, and with reserved allowance to be ground; performing ageing treatment; performing rough grinding on the bore; performing finish turning on the outside and an inner support edge, and machining an internal thread; performing finish grinding on the bore; performing other auxiliary steps; polishing the bore. By the use of the machining method, the problem that internal stress occurring during welding and machining stress co-act to deform a part during machining is solved; machining quality and various technical indexes of the thin-walled deep-hole welded workpieces are guaranteed; the technique is mature; machining quality is stable.

Owner:SHAANXI QIYUAN TECH DEV

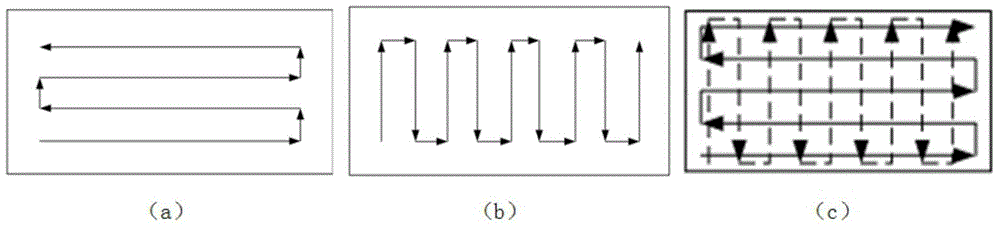

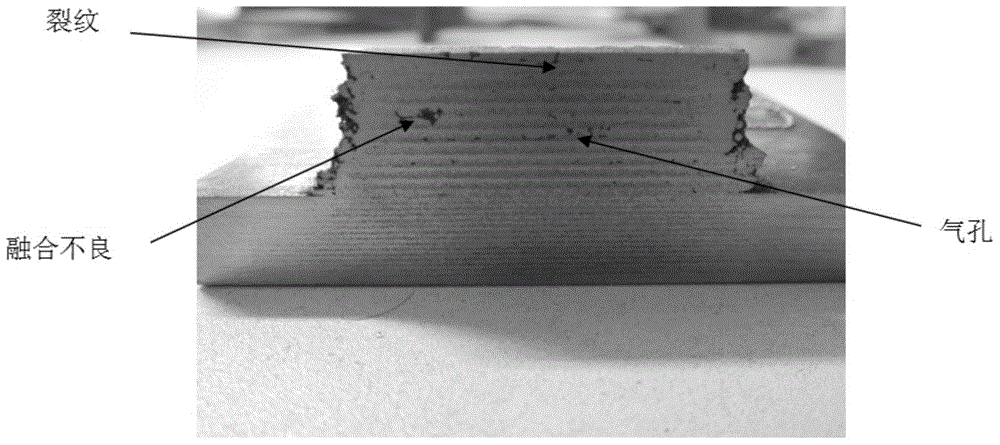

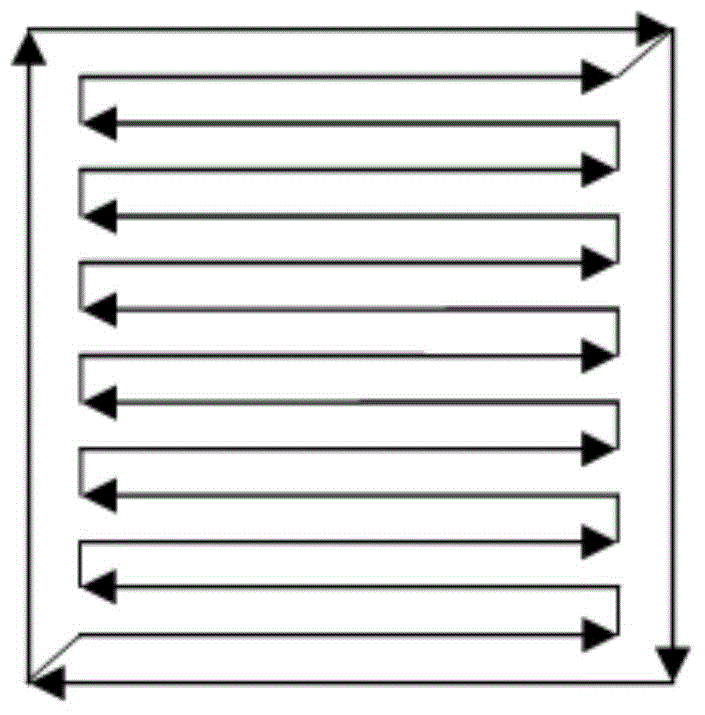

Laser additive manufacturing technology of high-temperature alloy parts

InactiveCN104785778AImplement defect controlControl internal defectsIncreasing energy efficiencyManufacturing technologyLaser scanning

The invention discloses a laser additive manufacturing technology of high-temperature alloy parts, and belongs to the technical field of laser additive manufacturing of metal powder. According to the invention, the technological parameter ranges of different high-temperature alloy materials are determined through basic technological experiments, and then additive manufacturing is carried out by adopting specific laser scanning paths and related internal defect control methods in the manufacturing process. The parts manufactured through the technology have the advantages that the forming efficiency is high, the cost is low, the internal quality is high, the automation degree is high and operation is easy. The high-temperature alloy parts capable of being applied industrially can be directly manufactured by adopting the technology, so that a new approach for manufacturing the high-temperature alloy parts is provided.

Owner:SHENYANG INST OF AUTOMATION - CHINESE ACAD OF SCI

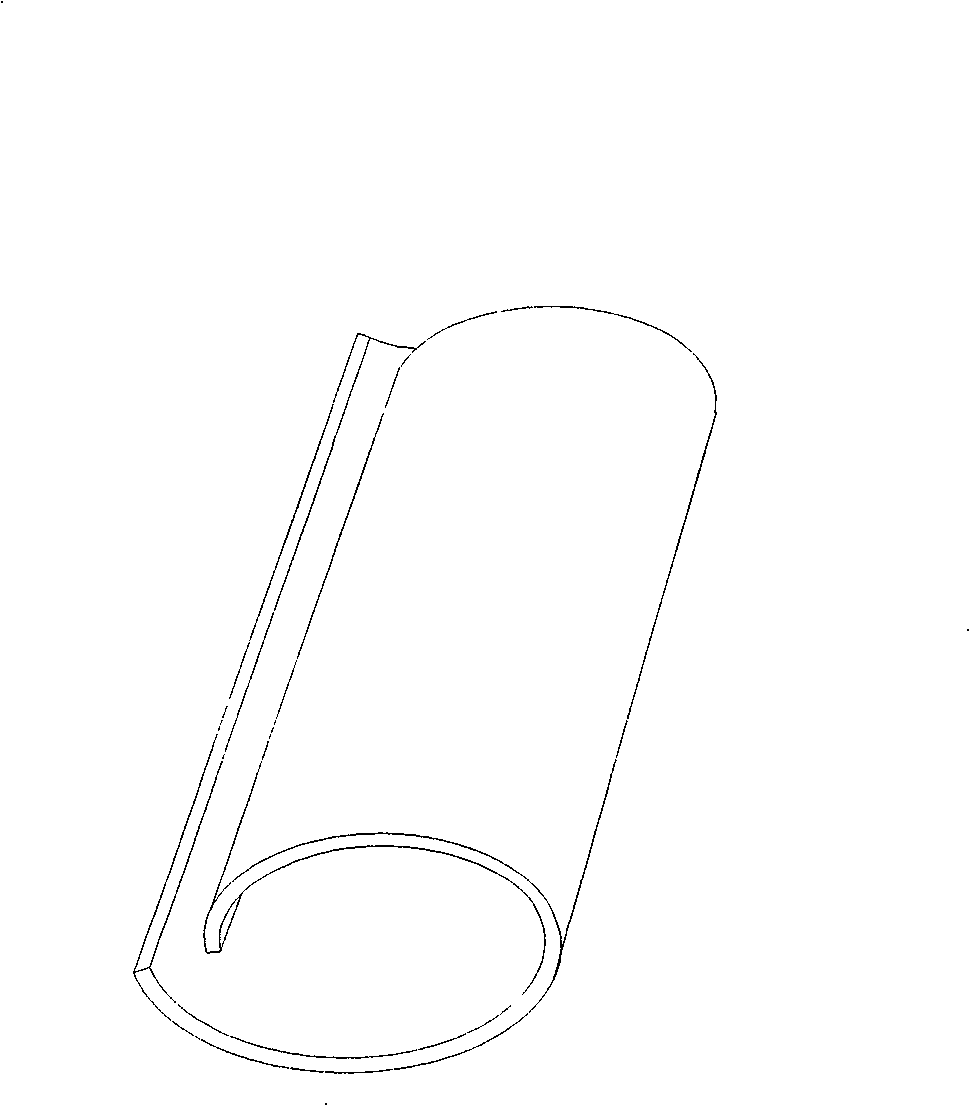

Composite cigarette filter tip capable of improving mouthfeel of novel cigarette and application thereof

ActiveCN107772530ASolve the deformationSolve the collapseTobacco smoke filtersManufacturing technologyEngineering

The invention relates to the technical field of tobacco manufacturing, in particular to a composite cigarette filter tip capable of improving mouthfeel of a novel cigarette and an application thereof.The composite cigarette filter tip capable of improving mouthfeel of the novel cigarette is obtained by composition of at least one solid section and at least one cigarette tow section. One or multiple hole channels are arranged in the solid section. As for a novel cigarette product, a tobacco section does not burn and generates smoke by depending on heat sources and other effects. The heating temperature is far lower than the burning temperature of a conventional cigarette. Hole channels arranged in the solid section help minimize the obstruction and interception effects of the filter tip upon smoke, reduce the loss of smoke in the filter tip and improve smoke concentration. Additionally, the hole channels in the solid section are filled with fragrant particles or coated with fragrant layers. When a user smokes the novel cigarette, the cigarette filter tip draws close to the tobacco section so that temperature goes high. Therefore, fragrant components are released at high temperatureto increase aroma concentration and enrich smoke. As a result, the mouthfeel of the novel cigarette is effectively improved.

Owner:CHINA TOBACCO GUIZHOU IND

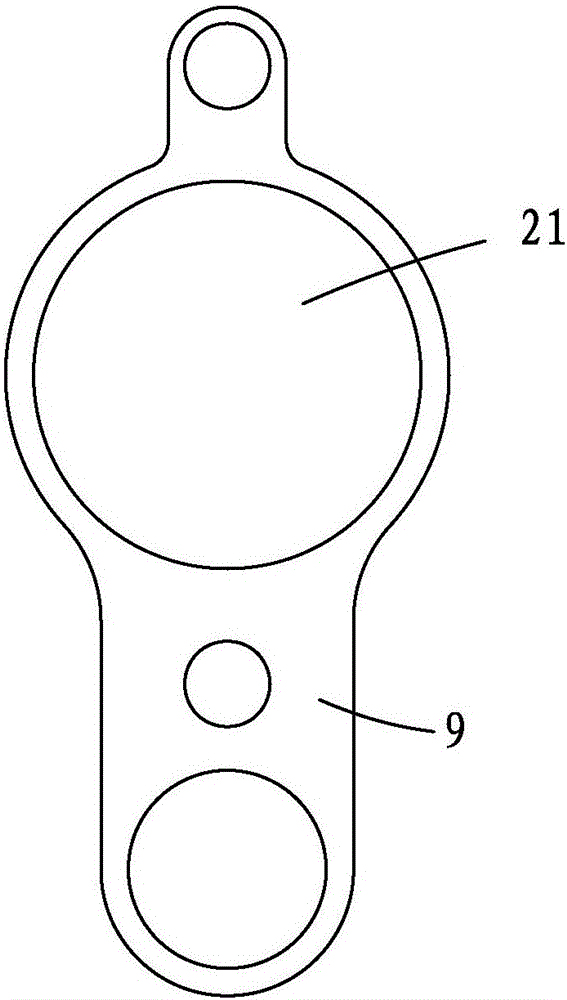

Wear-free laminated spiral solid-liquid separator

InactiveCN105833592ASolve the deformationSludge treatment by de-watering/drying/thickeningStationary filtering element filtersEngineering

A wear-free laminated spiral solid-liquid separator comprises fixed rings, moving rings and a spiral shaft, and the fixed rings and moving rings arranged in staggered manner are arranged radially on the spiral shaft; the wear-free laminated spiral solid-liquid separator also comprises a main drive rod and an auxiliary drive rod; the spiral shaft is connected with the main drive rod through a transmission mechanism; the main drive rod is supported through two or more support devices; the main drive rod is also provided with one or more eccentric devices; each eccentric device is connected with the auxiliary drive rod through a drive sheet; the auxiliary drive rod sleeves one end of the moving rings to connect all the moving rings in a whole; the spiral shaft drives the main drive rod to move through the transmission mechanism, the eccentric devices on the main drive rod drive the auxiliary drive rod to move, and the auxiliary drive rod drives all the moving rings to move. The drive rods herein rarely deform and are suitable for driving in large-sized equipment.

Owner:郑朝志

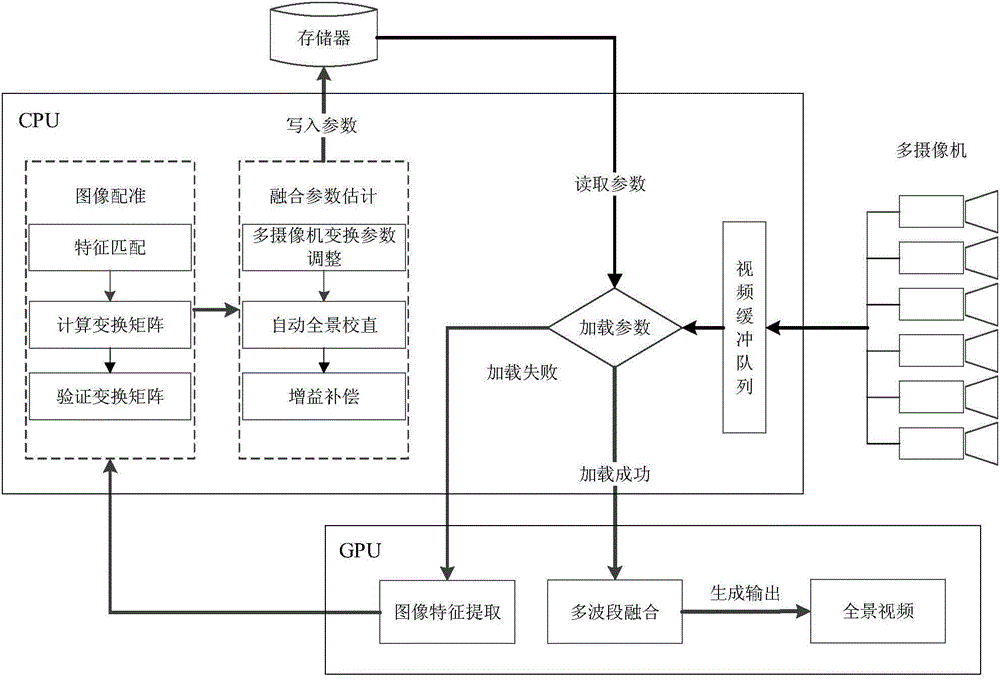

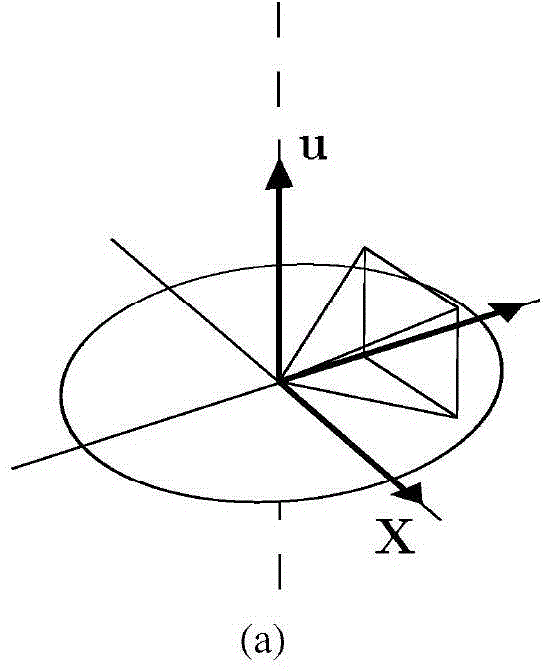

Mine multi-camera video fusion method based on GPU and CPU cooperative computing

InactiveCN104966063AAlleviate the status quo of poor real-time performanceSolve the deformationImage enhancementImage analysisMulti cameraUltrahigh resolution

The invention discloses a mine multi-camera video fusion method based on GPU and CPU cooperative computing and belongs to the mine multi-camera video fusion method. The method is characterized in that a GPU and CPU cooperative computing model is established, and thus current situation of poor real-time performance of an existing video fusion method is relieved; automatic matching is carried out by utilizing features of overlapped regions between adjacent video sources to determine relative position relation of the video sources, so that positions of cameras do not need to be assigned in advance, and automatic integration is realized; camera parameter bundle adjustment estimation and automatic alignment are carried out, so that the problem of deformation of panorama images after fusion is solved; and an exposure compensation and multiband fusion method is adopted, and finally, an ultrahigh-resolution large-visual angle mine mining (extraction) working face large-scale scene real-time integral video is generated, so that the method plays an important role for improving coal mining work efficiency and guaranteeing coal mine safety production. The advantages are that the multi-camera video fusion method utilizes the existing cameras of a coal mine fully to generate the mine mining (extraction) working face panorama video, thereby reducing equipment investment and improving safety of coal mine production.

Owner:CHINA UNIV OF MINING & TECH

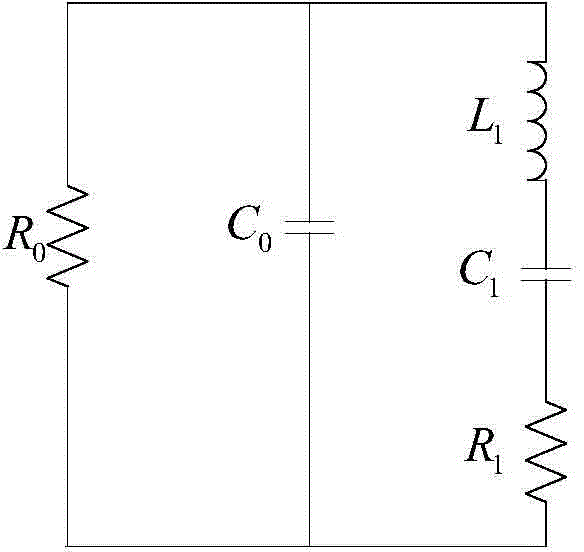

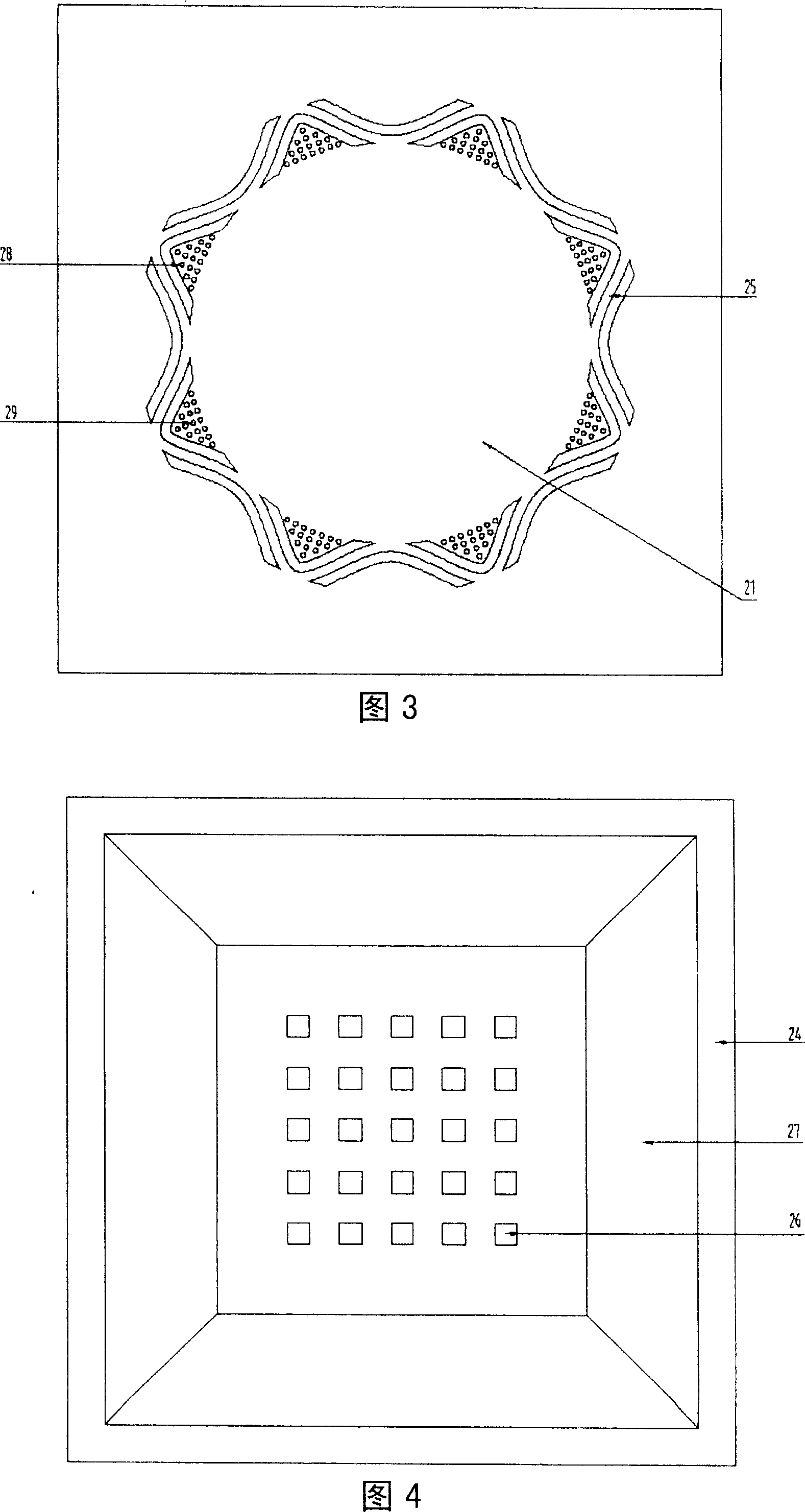

Semiconductor microphone chip

ActiveCN101098569ASolve the ruptureSolve the deformationSemiconductor electrostatic transducersElectrets selectrostatic transducerLow noiseEngineering

The invention relates to a semi-conductor microphone chip, belonging to microphone chip technique, as one capacitor structure which vibration membrane is above and back pole is below, wherein the vibration membrane via a waveform beam is connected with a frame and a support to completely release the left stress of the vibration membrane, the vibration membrane is provided with a plurality of array micro concaves to support the vibration membrane and reduce sound leakage, the vibration membrane is provided with a plurality of holes, to engage with the sound holes on the back pole in the microphone chip preparation to release a sacrificial layer between the vibration membrane and the back pole. The invention has high flexibility, low noise, and wide frequency band, while the produced chip has small volume, simple preparation and batch production.

Owner:GOERTEK MICROELECTRONICS CO LTD

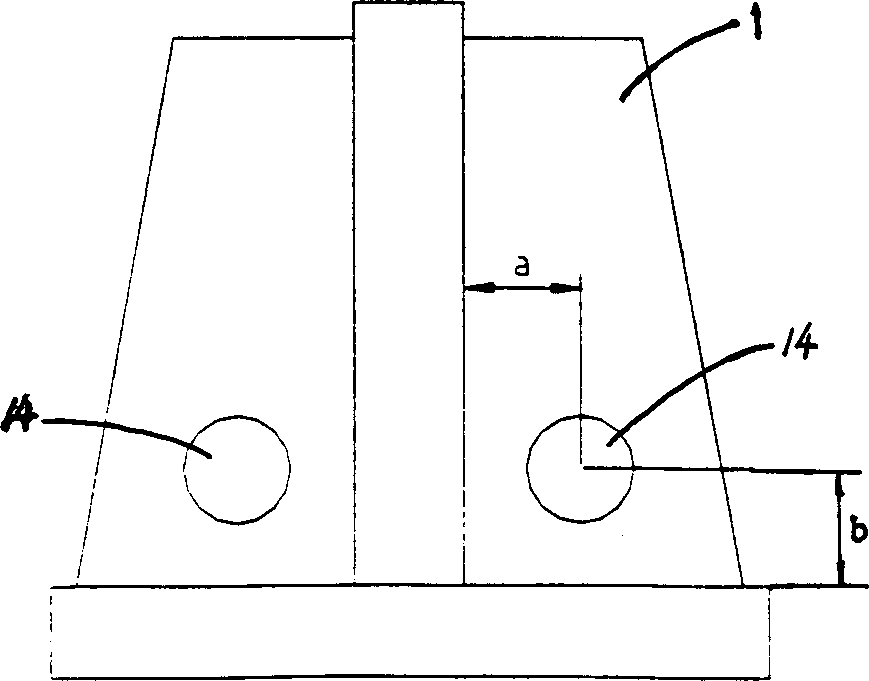

Low-speed diesel engine frame welding method

InactiveCN1405482ASolving Concentricity ProblemsSolve the deformationMachine framesWelding apparatusLow speedEngineering

A method for welding the frame of a low speed diesel engine. It includes the following steps: 1) By passing locating iron pipes through the screw holes in small iron plates, a number of small iron paltes are located between two bed-jigs according to the requirements of design, and spot welded on a guide plate and a triangle plate to form guide plate components. 2) The bilateral symmetric and located guide plate components are put symmetrically side by side and located by butt strap welding. 3) The welded and located bilateral guide plate component are welded in symmetry. 4) After welding, butt straps are removed, and the bila-teral guide plate components are separated. 5) with the help of the bed-jig, the bilateral guide plate components and a division plate are located on a cast-iron platform.

Owner:HUDONG HEAVY MACHINERY +1

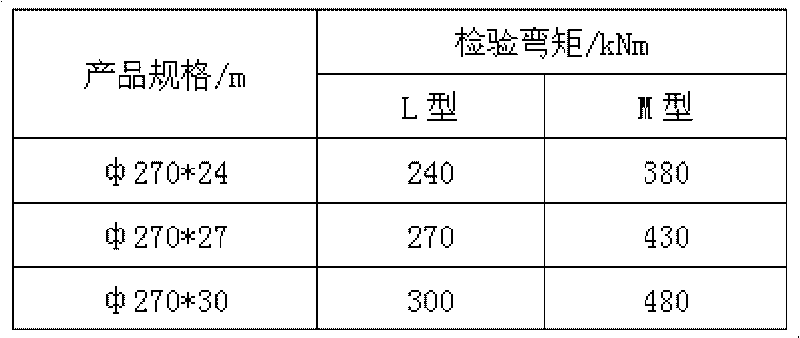

High strength automobile aluminium alloy wheel rim

The invention relates to a high strength automobile aluminium alloy wheel rim, in particular to an automobile wheel rim matched with oversize vehicles. The high strength automobile aluminium alloy wheel rim is made of high strength aluminium alloy material which comprises main chemical elements with the mass percent: 0.4-0.8% of Si, 0.8-1.2% of Mg, 0.16-0.22% of Ti, 0.2-0.3% of Zn, 0.6-0.8% of Fe,0.15-0.4% of Cu, 0.04-0.35% of Cr, 0.1-0.2% of Mn, 0.02-0.03% of Sb, 0.02-0.03% of Sr and the rest of Al. The automobile aluminium alloy wheel rim has high tensile strength which is 10% higher than that of the existing aluminium alloy wheel rim produced by 6061-T6, is good in mechanical property, enhances the rotatable performance of alloy when the structure is refined, and has the advantages ofwide application scope, low production cost and easy popularization and use.

Owner:HECHI UNIV

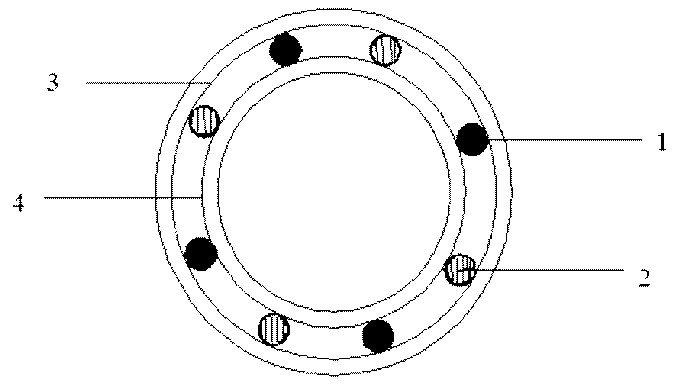

Partially prestressed concrete electric pole and preparation method thereof

InactiveCN101718153AHigh strengthImprove plasticityCeramic shaping apparatusTowersCrack resistancePre stress

The invention belongs to the technical field of concrete electric poles, in particular to a partially prestressed concrete electric pole and a preparation method thereof. The partially prestressed concrete electric pole is formed by casting concrete on an electric pole frame which comprises a spiral reinforcement, reinforcing steel bars and an erect ring, wherein reinforcing steel bars comprise prestressed reinforcing steel bars and non-prestressed reinforcing steel bars which are alternately distributed on the circumference. The invention adopts two kinds of reinforcing steel bars to be circularly, uniformly and alternately crossed and matched, improves the tensile strength and the crack resistance of the partially prestressed concrete electric pole, prolongs the service life of the electric pole, has low manufacture cost and is particularly suitable for line modification of counties and cities.

Owner:SICHUAN CHINA STRUCTURE RESIDENTIAL IND

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com