Patents

Literature

200results about How to "Solve the collapse" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

High-efficiency plugging oil-base drilling fluid and preparation method thereof

ActiveCN103045210AEffective blockingPrevent penetrationDrilling compositionAlkalinityDifferential pressure

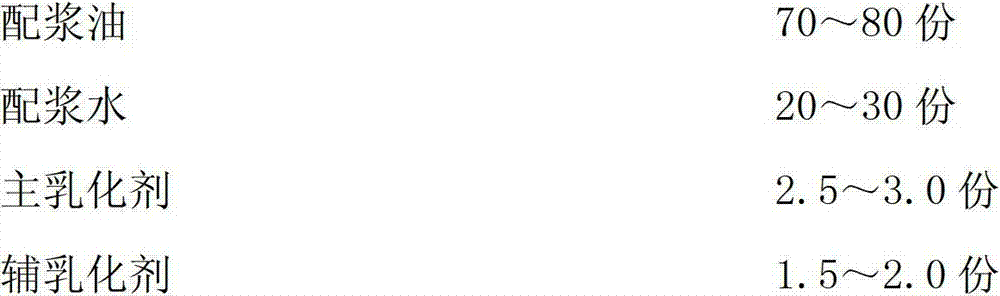

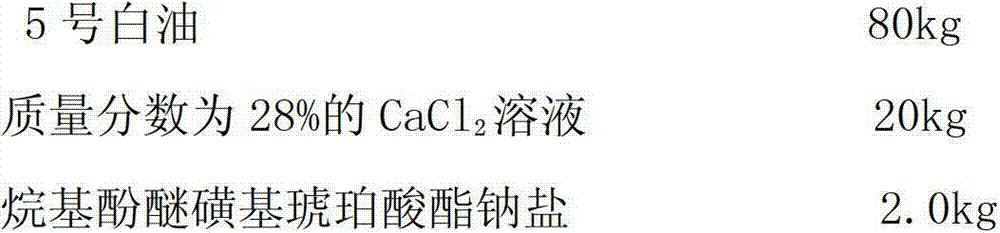

The invention discloses a high-efficiency plugging oil-base drilling fluid and a preparation method thereof. The drilling fluid is prepared from the following raw materials in parts by mass: 70-80 parts of slurrying oil, 20-30 parts of slurrying water, 2.5-3.0 parts of main emulsifier, 1.5-2.0 parts of auxiliary emulsifier, 2.0-2.5 parts of wetting agent, 2.0-2.5 parts of flow pattern regulator, 2.5-3.0 parts of fluid loss agent, 1.5-2.0 parts of alkalinity regulator, 0.5-0.8 part of extracting agent and 7-9 parts of plugging material. A weighting material is added so that the density of the drilling fluid reaches 1.45-1.56 g / cm<3>. By utilizing the well-drilling positive differential pressure, the high-efficiency plugging oil-base drilling fluid quickly implements bridging, filling and filming to plug the formation fractures on the well wall surface and near the well wall, effectively prevents the drilling fluid and filtrate thereof from permeating into microfractures, enhances the bearing capacity of the formation, has favorable plugging effect, and is beneficial to the stability of the well wall.

Owner:CHINA PETROLEUM & CHEM CORP +1

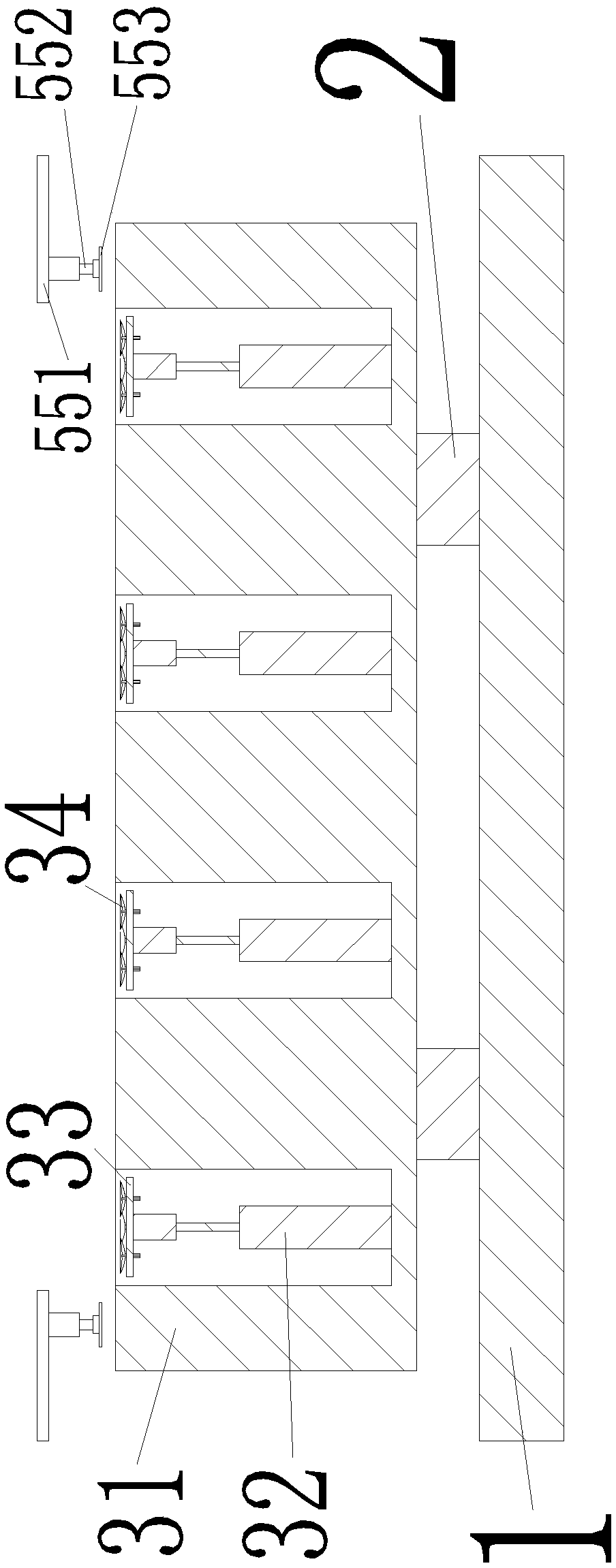

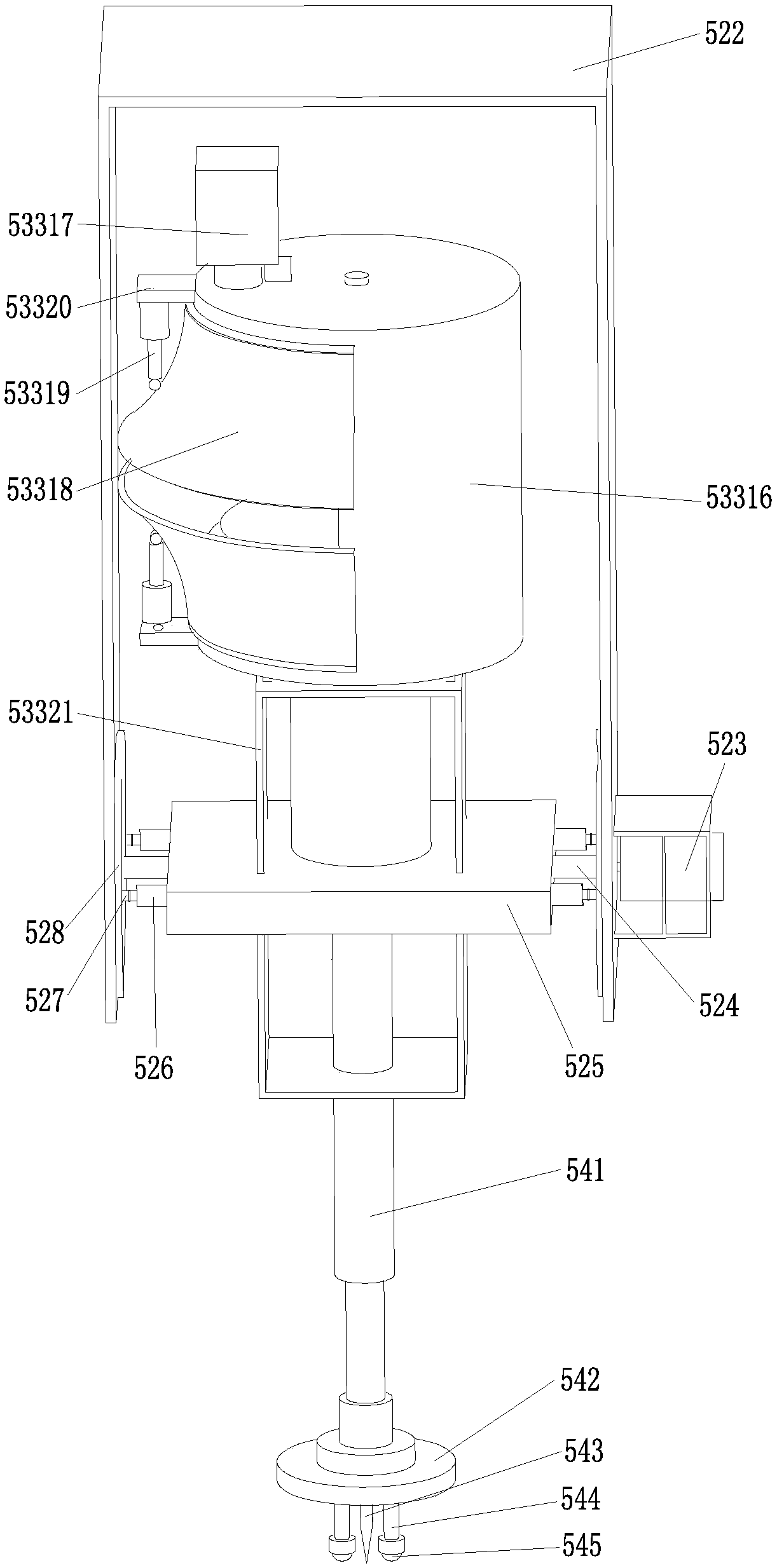

Loose-soft rock soil stratum reverse circulation casing-following drilling tool and drilling process

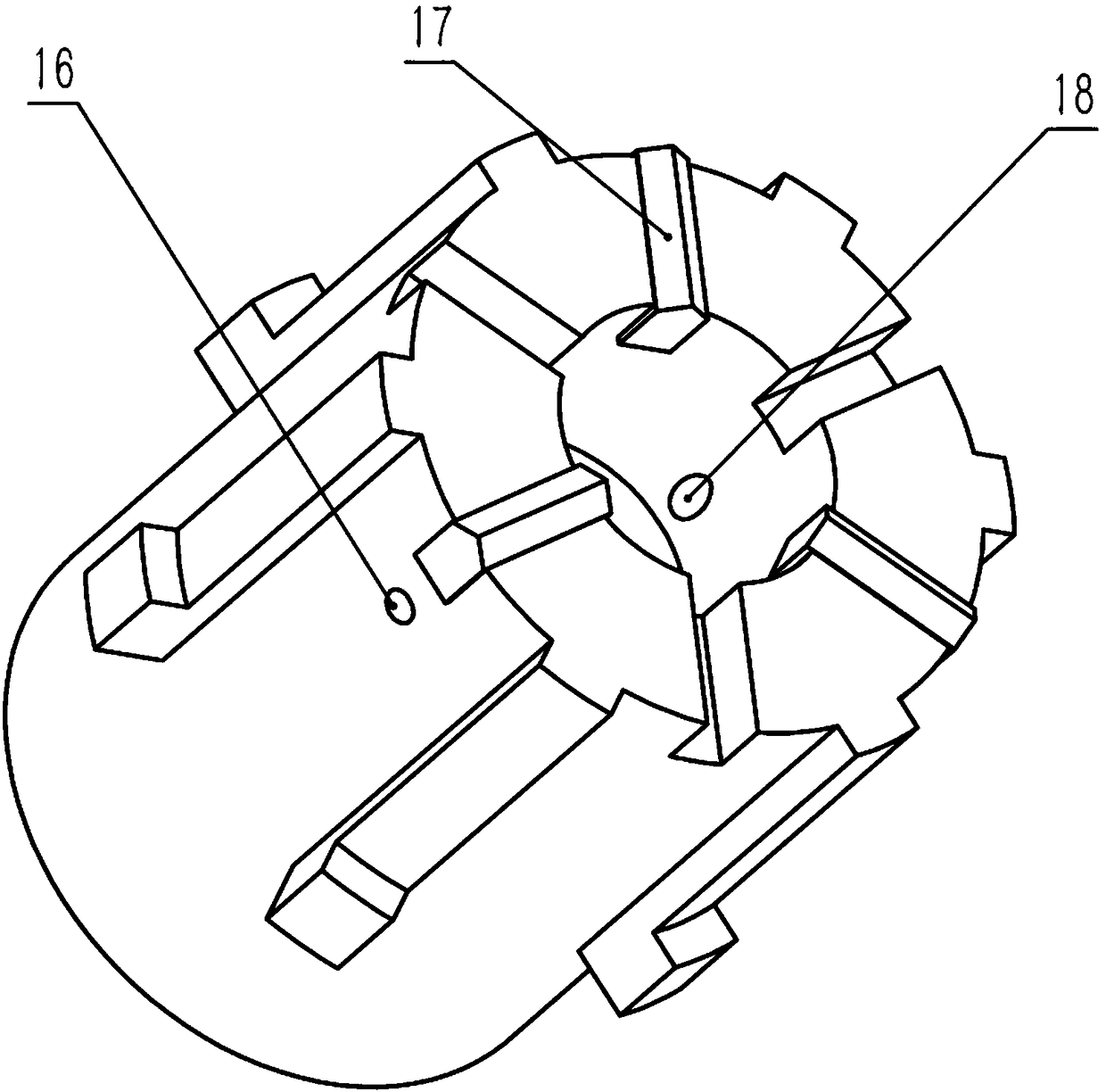

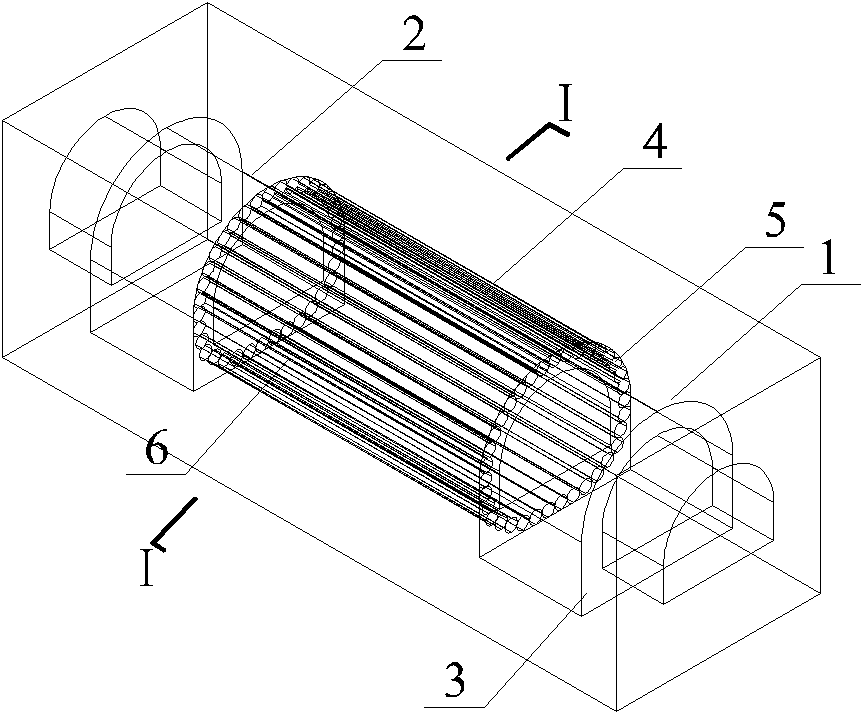

PendingCN108086930AImprove migration efficiencyImprove connection strengthDrilling rodsConstructionsAugerHelical blade

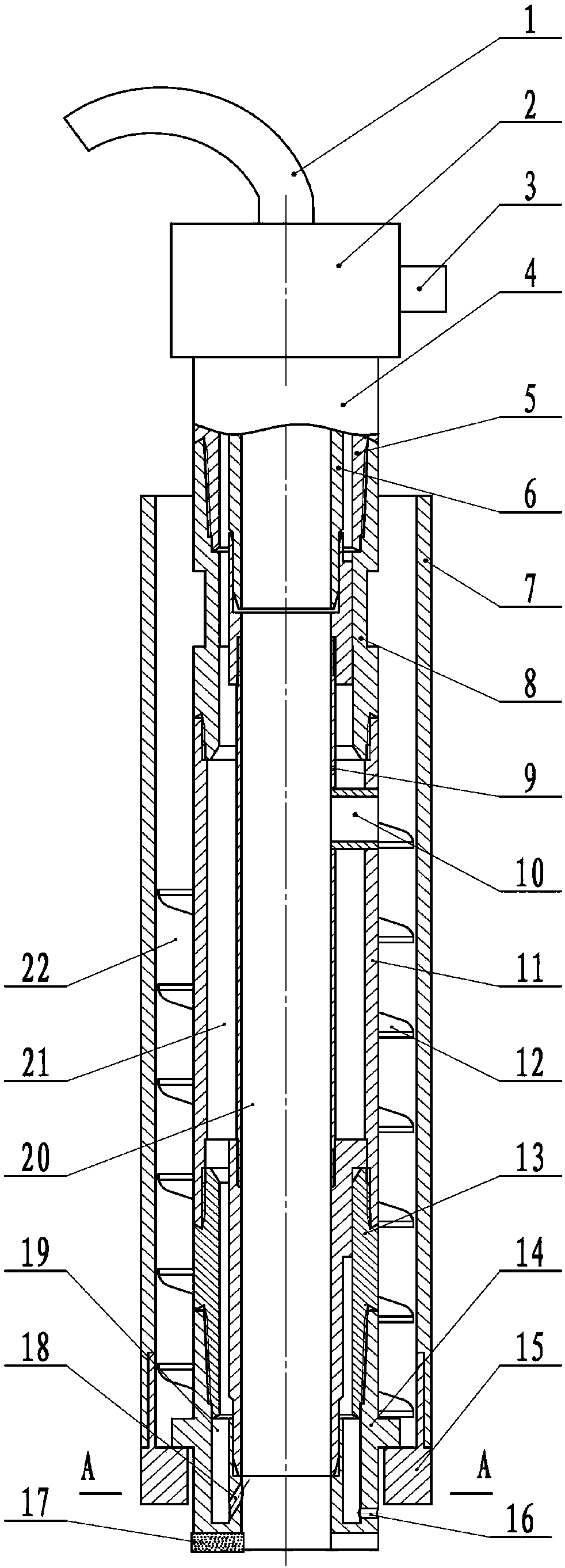

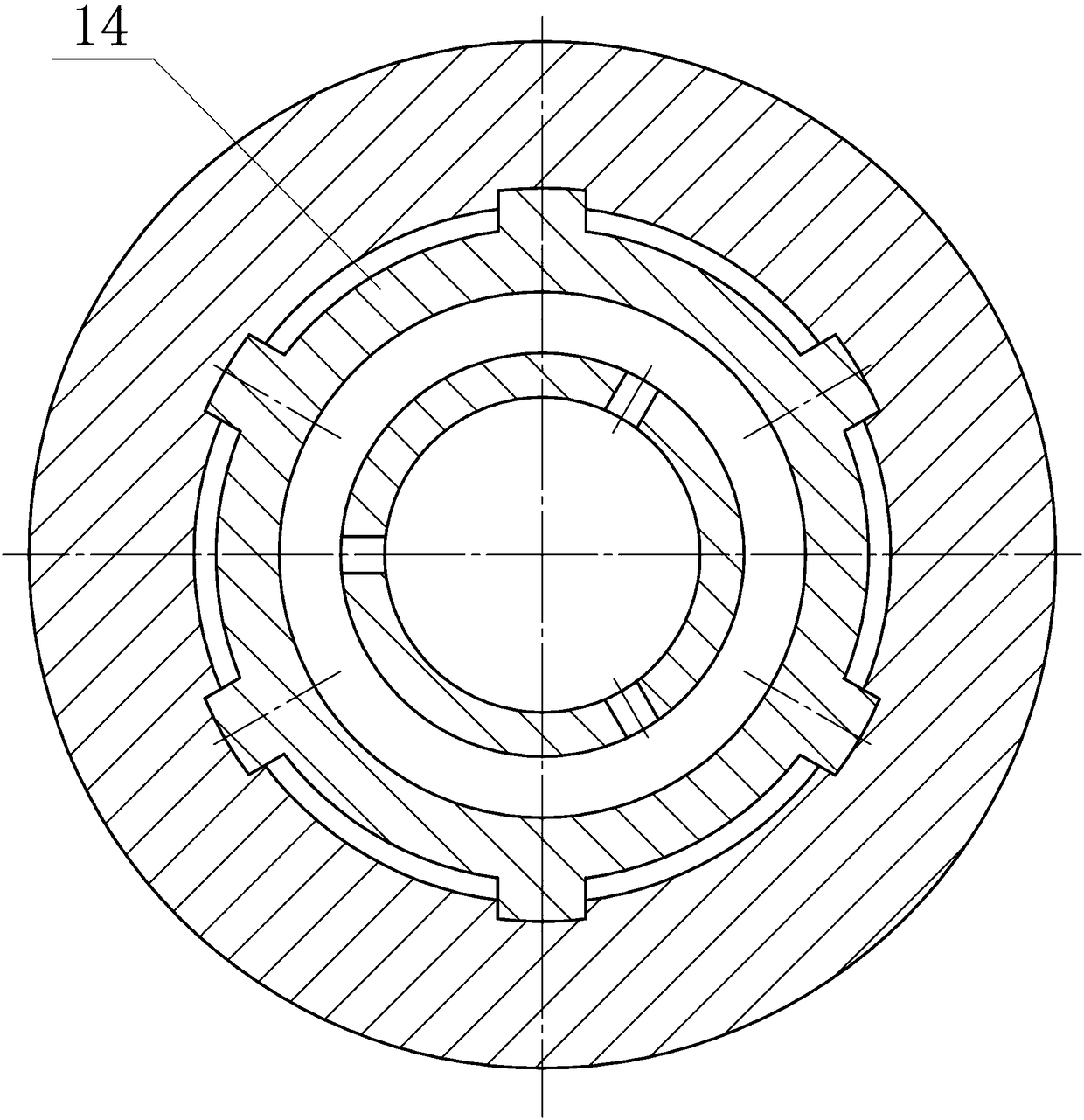

The invention discloses a loose-soft rock soil stratum reverse circulation casing-following drilling tool and a drilling process. The drilling tool is of a coaxial three-passage structure and comprises a double-wall drilling stem, an auger stem, a drilling bit, a casing and a casing shoe, a central hole of an inner tube of the double-wall drilling stem and a central hole of an inner tube of the auger stem form a slag discharging passage, an annular gap between the inner tube of the auger stem and an outer tube of the auger stem forms an air incoming passage, and an annular gap between the outer tube of the auger stem and the casing forms an outer ring passage; compressed air enters the drilling bit through the air incoming passage and then is diverted and used for assisting a cutting bladeto break a stratum and realize reverse circulation deslagging. Drillings suspended in the outer ring passage go up along spiral blades, enters a deslagging passage through a deslagging window and then returns to the ground surface. Reverse circulation deslagging through a fluid medium and deslagging assisted by the spiral blades are adopted in the process of drilling, so that casing-following drilling is realized to protect hole walls, the problems of bit burying and difficulty in deslagging and hole forming in the process of loose-soft rock soil drilling can be solved, and integration of drilling, collapse preventing, dedusting and wall protecting is realized.

Owner:JILIN UNIV

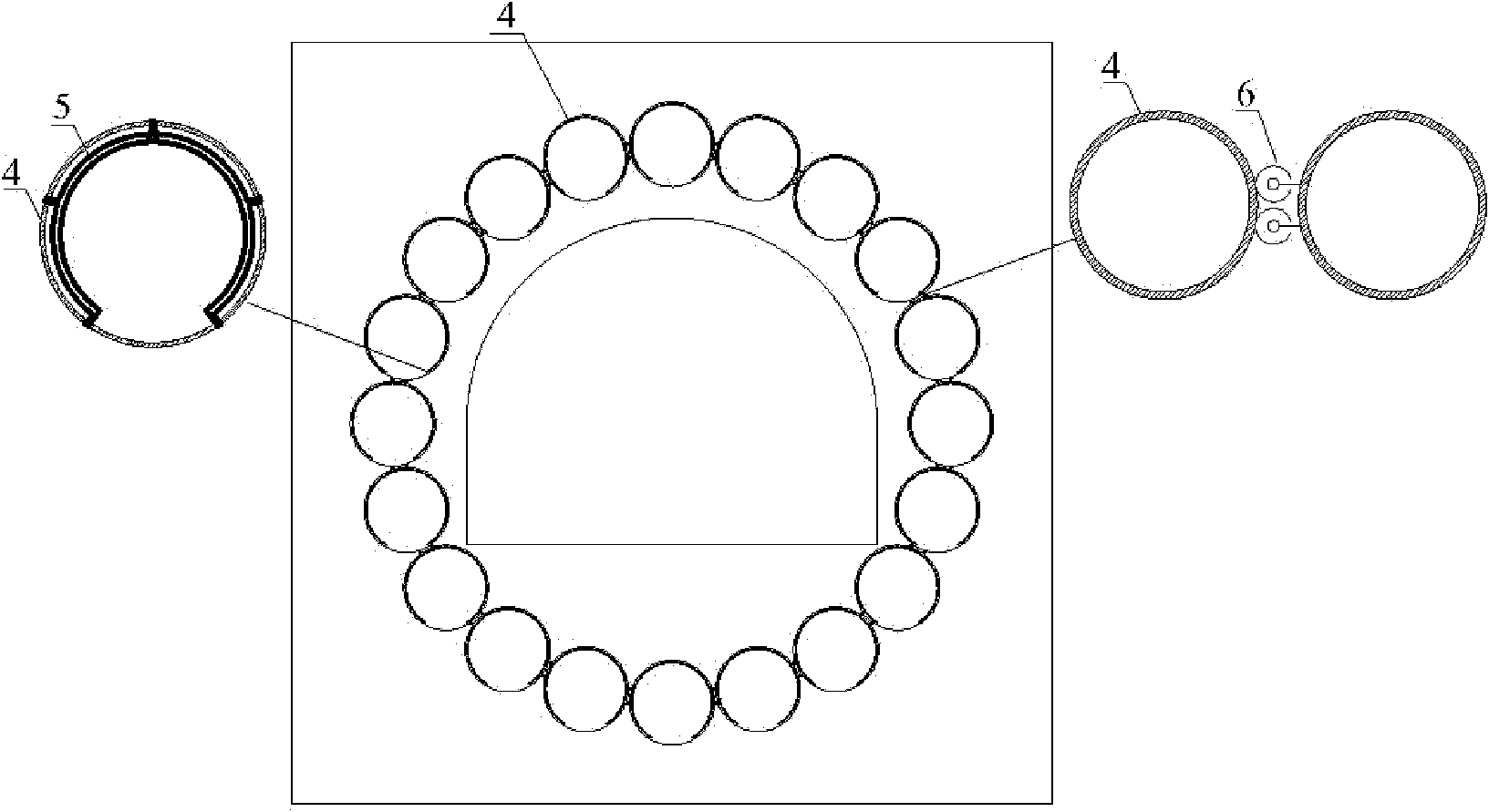

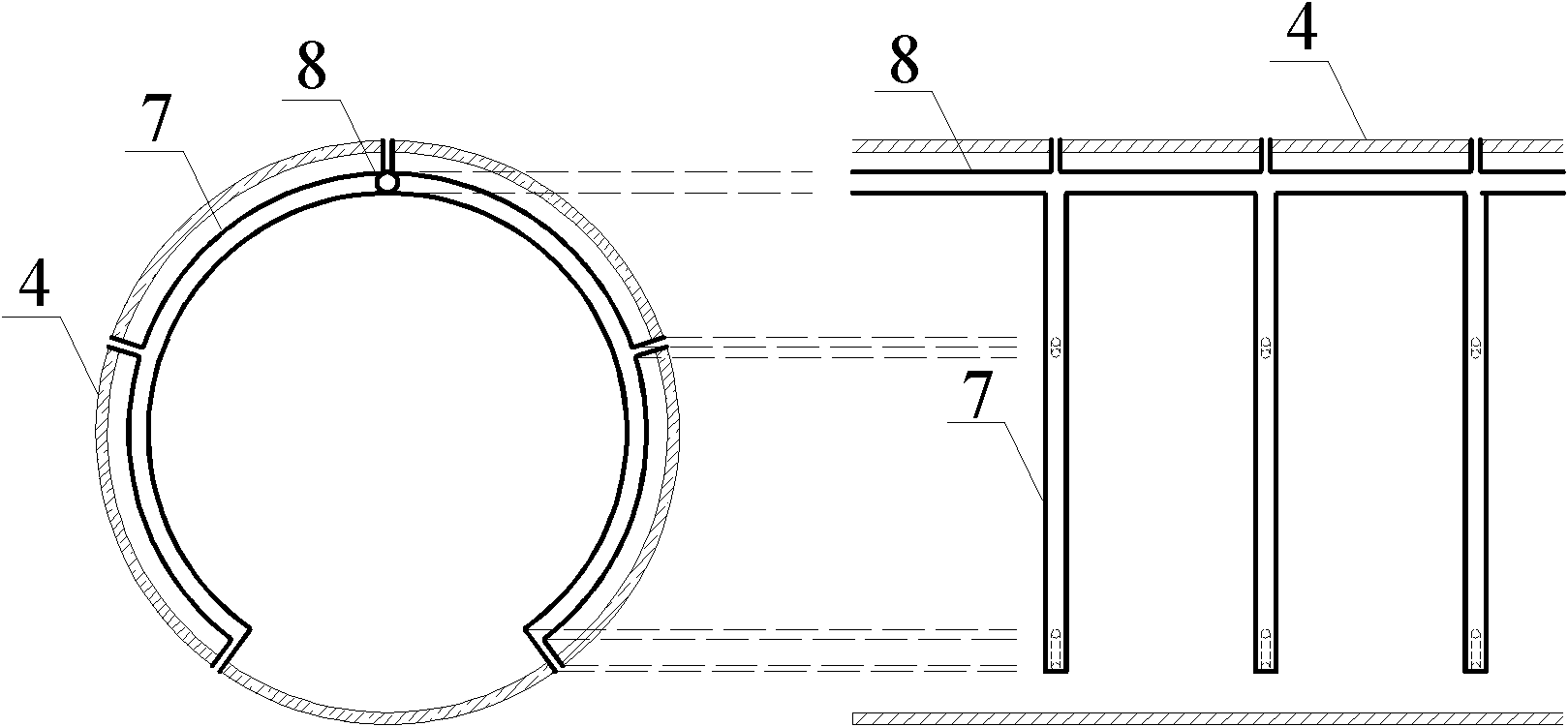

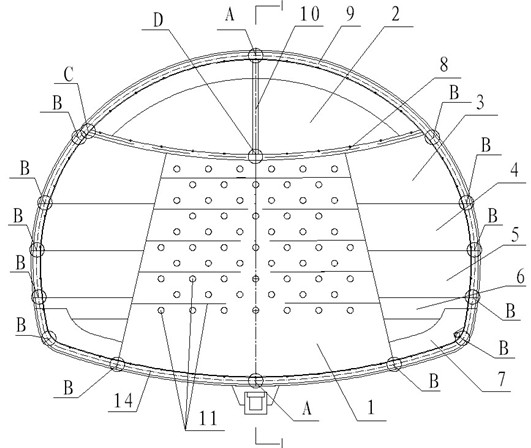

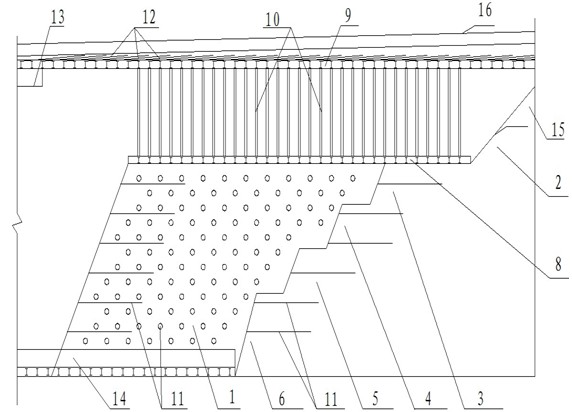

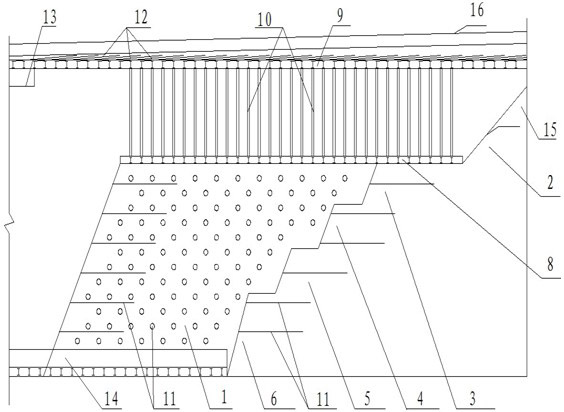

Tubal curtain advanced support constructing method for deep mine roadway of coal mine passing through fault fracture zone

InactiveCN102031974ASolve the collapseSolve the film gangUnderground chambersTunnel liningFracture zoneEngineering

The invention discloses a tubal curtain advanced support constructing method for a deep mine roadway of a coal mine passing through a fault fracture zone. The method comprises the following steps: A, constructing an initial workshop and a receiving workshop at two ends of the fault fracture zone respectively; B, reinforcing roadways of the initial workshop and the receiving workshop by adopting astepwise combined support scheme; C, reinforcing by adopting advanced grouting according to the lithologic fracture condition of the opening; D, jacking steel tubes to the receiving workshop through the fault fracture zone from the initial workshop sequentially according to round or elliptical fracture surfaces by utilizing a soft rock tube push bench; E, in a process of jacking the steel tube, injecting a drag-reducing and lubricating material through an annular grouting system which is preset in the tube, and injecting plain concrete in the steel tube to form a tubal curtain protector; and F, performing subsequent excavation support on the roadway in the tubal curtain body after the concrete in the tube reaches a designing age. The method is simple, safe and reliable, has remarkable effect for safe excavation on a roadway with fracture densely distributed zone which has high stress, is soft to fracture and developed in fissure water.

Owner:WUHAN UNIV

Construction method for wind-blown sand tunnel

ActiveCN102134998ASolve the collapseEasy constructionUnderground chambersTunnel liningBearing capacityEnvironmental geology

The invention discloses a construction method for a wind-blown sand tunnel, belonging to the construction field of tunnels. The construction method for the wind-blown sand tunnel is realized by the following steps: 101: construction of upper steps; 102: construction of lower steps; 103: construction of inverted arch combining parts; 104: construction of secondary lining; and 105: ring closing of inverted arch. Aiming at the loose, soft and unstable geometrical conditions of sand layers, wind-blown sand layers and the like, the construction method for the wind-blown sand tunnel solves the problems of collapse due to frequent sand leakage, and deformation of supporting in the normal construction method; the inverted arch combining parts are constructed firstly, therefore, the bearing capability of the wall corner foundation of a primary supporting is enhanced, the side pressure transferred by soil bodies at two sides is inhibited effectively, simultaneously conditions are created for achieving the aim that the deformation of the primary supporting finally tends to be stable by quickly starting the construction of the secondary lining; the excavation is carried out according to the characteristics of the tunnel, such as long distance, ultra-shallow buried layer, large profile and granular bulk rocks, the technical difficult problems in the field are overcome, therefore, the construction method provides important guide significance for the construction of the tunnels of similar geometrical conditions.

Owner:CHINA RAILWAY NO 2 ENG GRP CO LTD +1

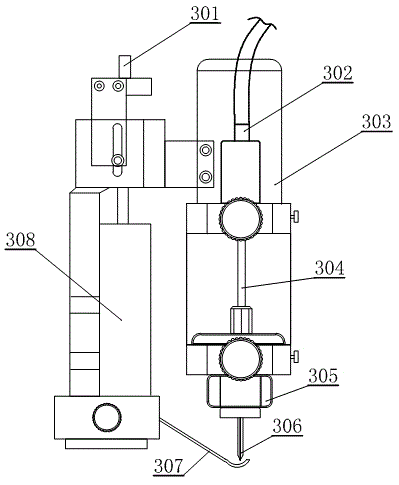

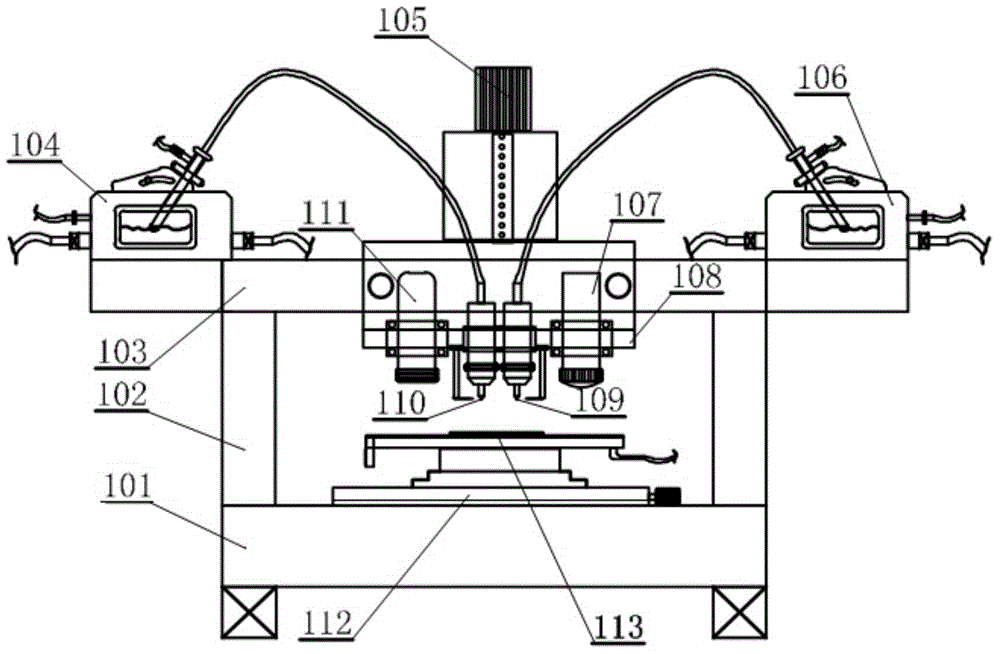

3D ink-jet printer for printing electronic circuit board through ultrasonic atomization nanometer suspending liquid

InactiveCN104014790ATroubleshoot direct printing issuesSafe and convenient man-machine operationEvaporationEngineering

The invention discloses a 3D ink-jet printer for printing an electronic circuit board through ultrasonic atomization nanometer suspending liquid. The 3D ink-jet printer comprises an ultrasonic atomization nanometer suspending liquid device, a nanometer fine ink-jet printing device, an industrial positioning camera, a video monitor, an infrared laser micro-fusion-covering device, a heatable vacuum absorption workbench, a three-coordinate movable sliding table and a control portion. According to the 3D ink-jet printer, the nanometer suspending liquid to be printed is atomized based on an ultrasonic double-cavity atomization method, the nanometer suspending liquid is sent to a controllable nanometer fine ink-jet printing device through a guide pipe under the action of auxiliary gas and is directly printed on a substrate in a non-contact mode through a fine ceramic nozzle, the printed nanometer sizing agent is solidified and dried through the method of bottom plate heating or infrared laser micro fusion covering, evaporation of the solvent in the sizing agent, gasification of an organic clad layer and fusion of nanometer particles are accelerated, and therefore the electronic circuit board with high conductivity and micron-size line width is formed. The 3D ink-jet printer can directly print a conducting layer, an insulating layer, a protective layer and a solder mask and can print semiconductor components and parts.

Owner:张远明

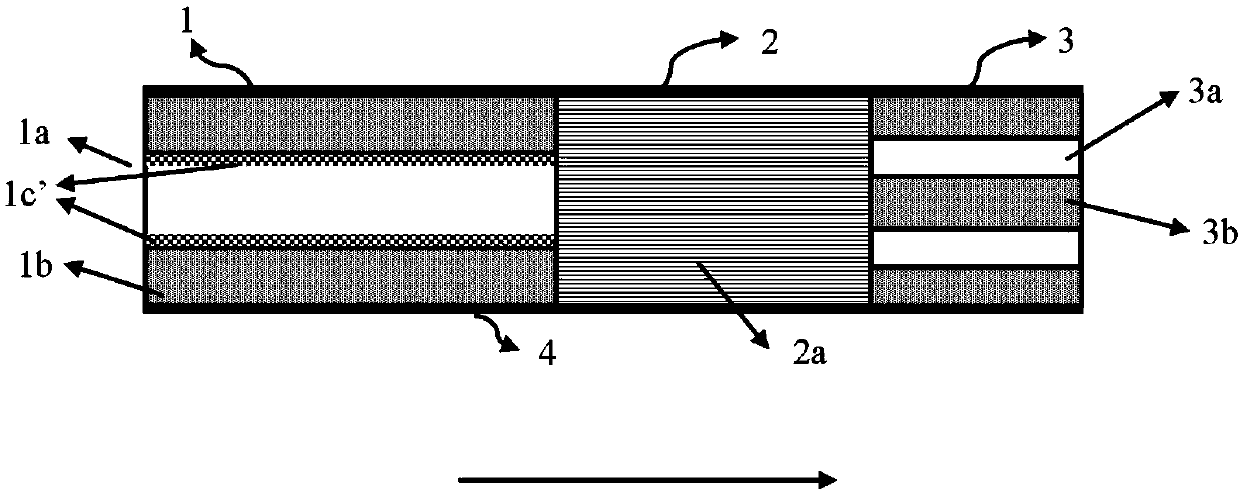

Composite cigarette filter tip capable of improving mouthfeel of novel cigarette and application thereof

ActiveCN107772530ASolve the deformationSolve the collapseTobacco smoke filtersManufacturing technologyEngineering

The invention relates to the technical field of tobacco manufacturing, in particular to a composite cigarette filter tip capable of improving mouthfeel of a novel cigarette and an application thereof.The composite cigarette filter tip capable of improving mouthfeel of the novel cigarette is obtained by composition of at least one solid section and at least one cigarette tow section. One or multiple hole channels are arranged in the solid section. As for a novel cigarette product, a tobacco section does not burn and generates smoke by depending on heat sources and other effects. The heating temperature is far lower than the burning temperature of a conventional cigarette. Hole channels arranged in the solid section help minimize the obstruction and interception effects of the filter tip upon smoke, reduce the loss of smoke in the filter tip and improve smoke concentration. Additionally, the hole channels in the solid section are filled with fragrant particles or coated with fragrant layers. When a user smokes the novel cigarette, the cigarette filter tip draws close to the tobacco section so that temperature goes high. Therefore, fragrant components are released at high temperatureto increase aroma concentration and enrich smoke. As a result, the mouthfeel of the novel cigarette is effectively improved.

Owner:CHINA TOBACCO GUIZHOU IND

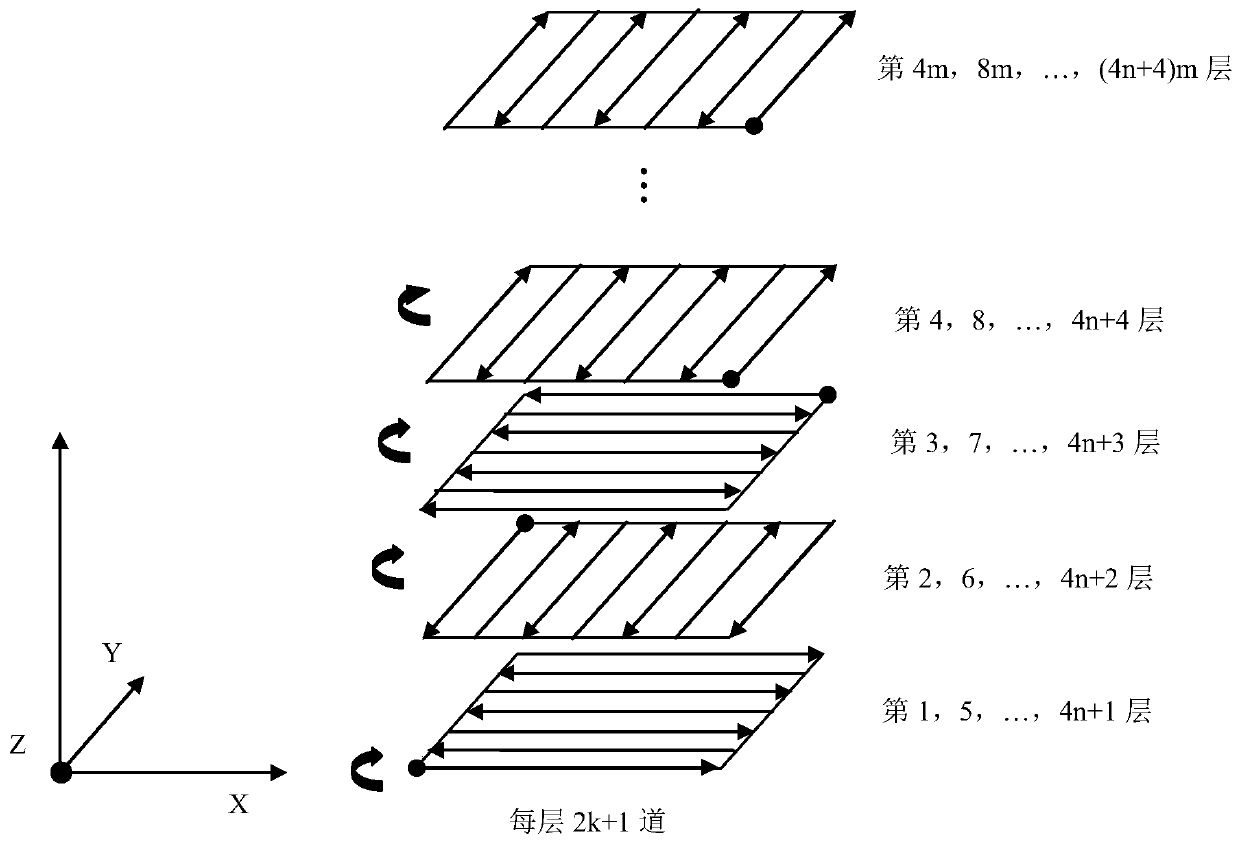

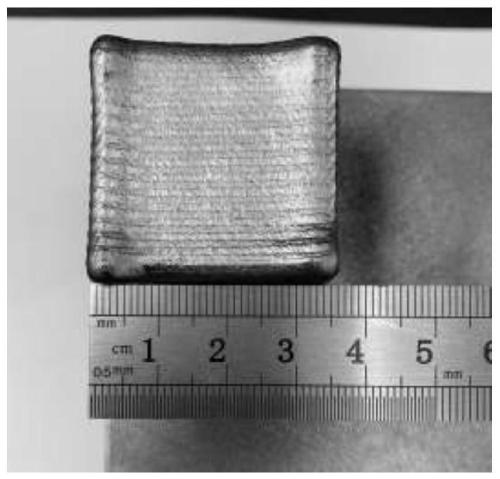

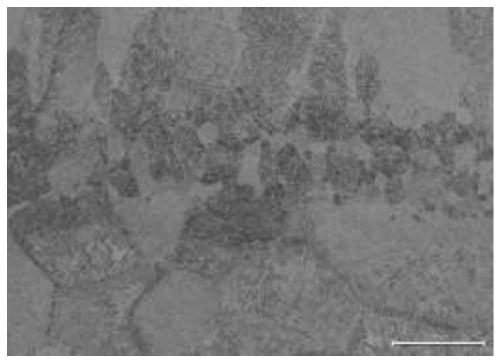

Laser additive repair method for titanium alloy valve rod

InactiveCN111451500AEasy to implementLow costAdditive manufacturing apparatusIncreasing energy efficiencySurface cleaningTest sample

The invention discloses a laser additive repair method for a titanium alloy valve rod. The laser additive repair method for the titanium alloy valve rod comprises the following steps: optimizing parameters and carrying out a multi-pass multi-layer laser additive experiment through an earlier-stage single-pass laser additive process experiment for a titanium alloy powder, and carrying out metallographic observation on a cladding layer to obtain the optimal process parameters; carrying out laser additive manufacturing printing for a performance test sample piece of the titanium alloy on a titanium alloy substrate, completing a performance test, evaluating a test result, and determining a repair process; carrying out photographing recording on an area to be repaired, and completing surface cleaning; carrying out accurate clamping on the titanium alloy valve rod, and locking the end part by a center; reserving machining allowance in an additive repair damage area carrying out coaxial powder feeding through laser, setting a scanning path to be spiral forward, enabling the left end and the right end of a starting point position to be alternating and rotate clockwise with time difference,and controlling temperature rise of the workpiece; and adopting fluorescence detection, machining according to the requirement of a drawing to restore a size, and delivering and using. According to the laser additive repair method for the titanium alloy valve rod, the requirement of safe use for the titanium alloy valve rod in a life cycle is guaranteed by optimizing the laser additive process parameters and a scanning path strategy.

Owner:航发优材(镇江)增材制造有限公司

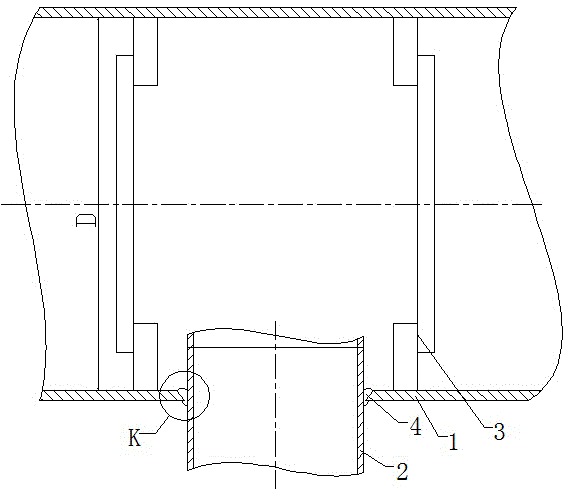

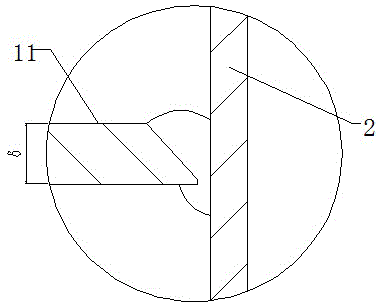

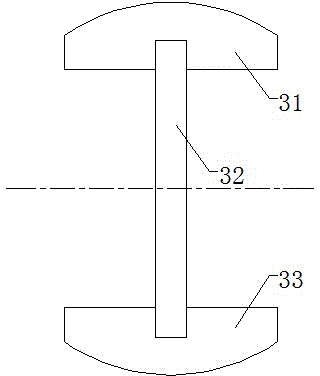

Method for controlling deformation generated when connection pipe is welded to large-diameter thin-wall barrel

ActiveCN104588958ASolve the collapseSolve the problem of cylinder deformationWelding/cutting auxillary devicesAuxillary welding devicesEngineeringSpot welding

The invention relates to the field of thin-wall workpiece welding and discloses a method for controlling deformation generated when a connection pipe is welded to a large-diameter thin-wall barrel. According to the method, the amount of actual deformation is small. When the large-diameter thin-wall barrel is welded to the connection pipe connected with the large-diameter thin-wall barrel, an inner groove is adopted as a connection pipe groove in the barrel, and the two sides of the connection pipe groove in the barrel are provided with inner supports used for supporting the inner wall of the barrel; after the connection pipe is connected with the barrel through spot welding, the position of the connection pipe is adjusted, so that the connection pipe is located below the barrel, a circumferential welding line of the connection pipe is divided into an even number of welding line segments, welding of each welding line layer is completed through two rounds of segmented symmetry welding, welding of a half of each welding line segment in the length direction is completed in each round of segmented symmetry welding, and the next layer is welded after all the welding line segments on the upper layer are welded. The whole welding line is divided into a plurality of regions, a layered and regional welding sequence of the welding line is worked out, and therefore heat input is controlled well, welding deformation is reduced, and the problems that the large-diameter connection pipe droops and the barrel deforms are solved.

Owner:DONGFANG BOILER GROUP OF DONGFANG ELECTRIC CORP

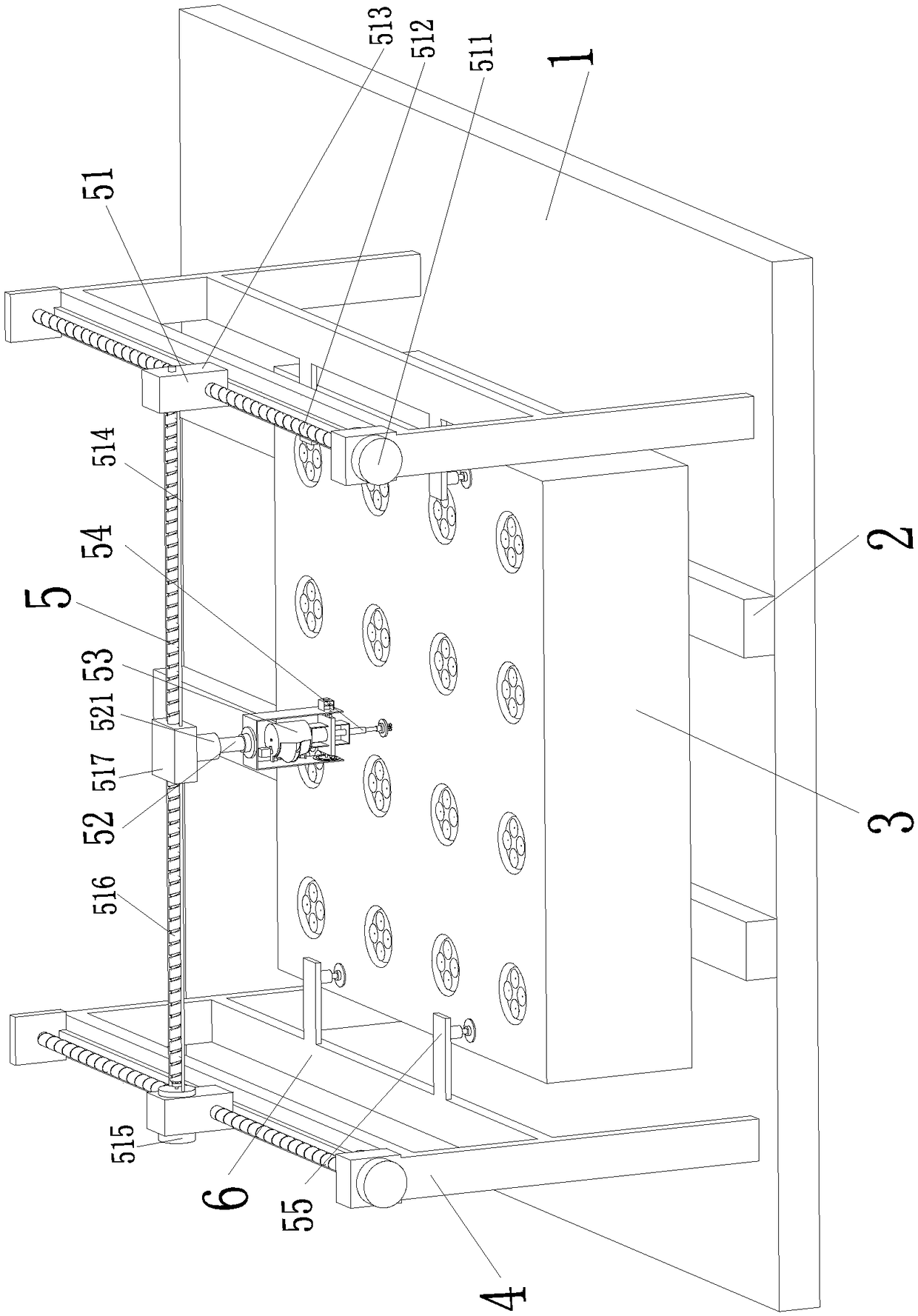

Intelligent cutting and polishing production line for deep processing of glass and deep processing method of glass

ActiveCN108840556APrevent slippingSlip off withoutEdge grinding machinesGlass severing apparatusEngineeringDeep processing

The invention relates to an intelligent cutting and polishing production line for deep processing of glass and a deep processing method of glass. The production line comprises a bottom plate, an electric support slider, a support device, feeding support frames, an execution device and a support frame transverse plate, wherein the electric support slider is mounted in the middle of the bottom plate, the support device is mounted on the electric support slider, the feeding support frames are symmetrically mounted at left and right ends of the bottom plate and adopt an inverted U-shaped structure, the support frame transverse plate is arranged between inner walls of middles of the feeding support frames, and the execution device is mounted between the two feeding support frames. During working, the glass is conveyed onto the support device, the support device fixes the glass, then, the execution device cuts and edges the glass, manual operation is not required during processing, glass breakage caused by operation errors is avoided, the labor intensity of workers is reduced, the working efficiency is improved, and a cutting and edging procedure integrated continuous processing functionduring deep processing of the glass can be realized.

Owner:ALL GLASS SUQIAN

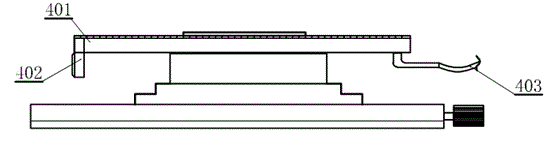

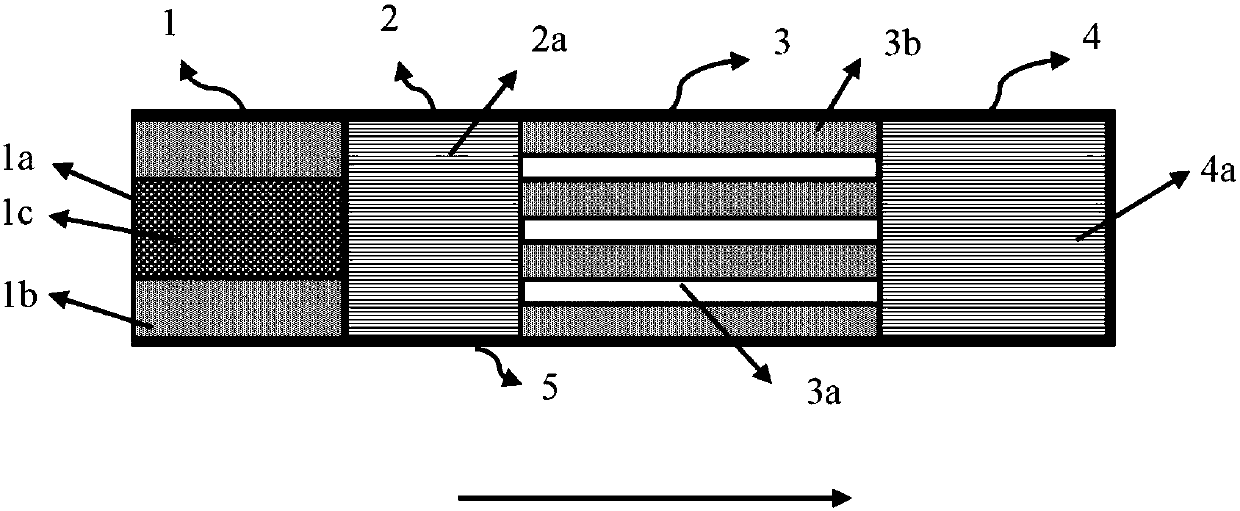

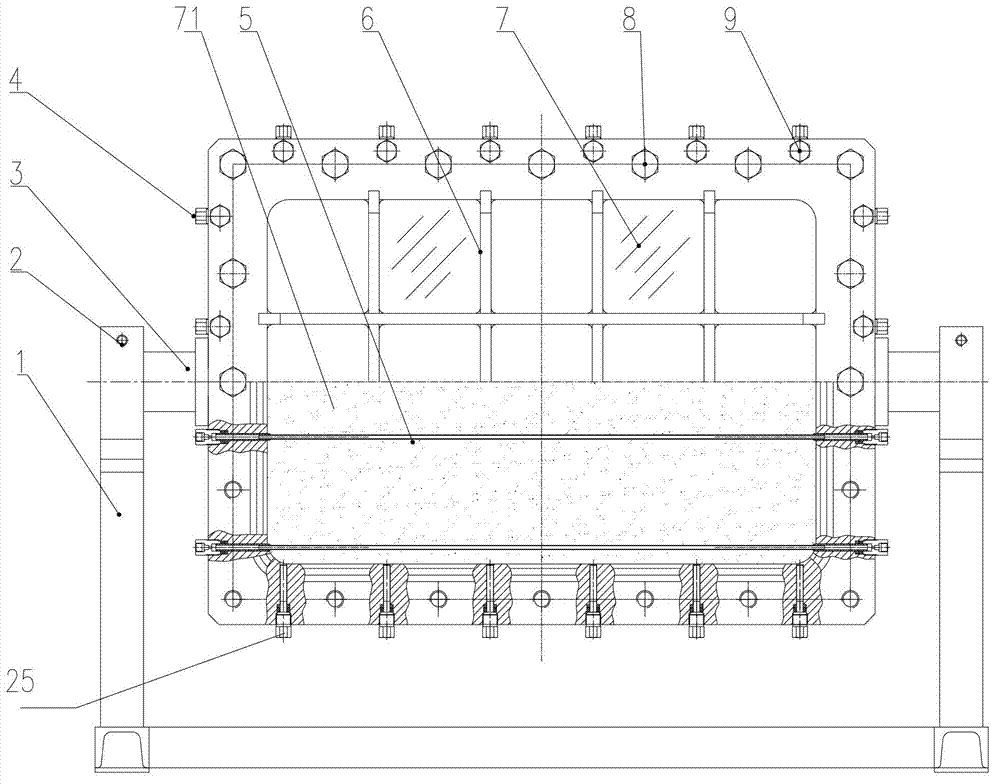

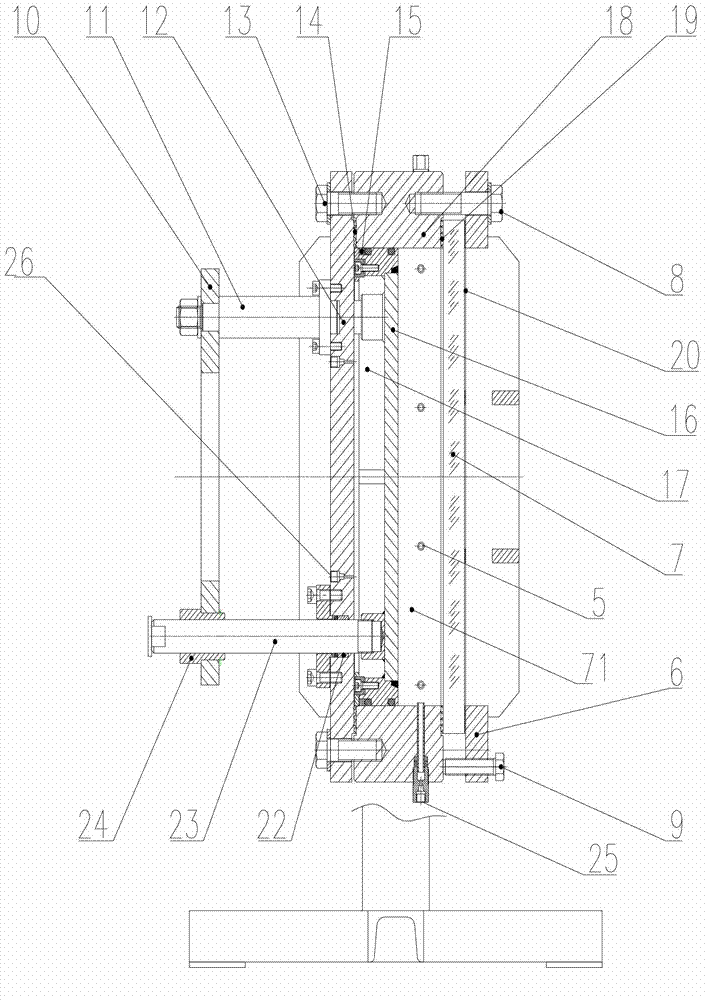

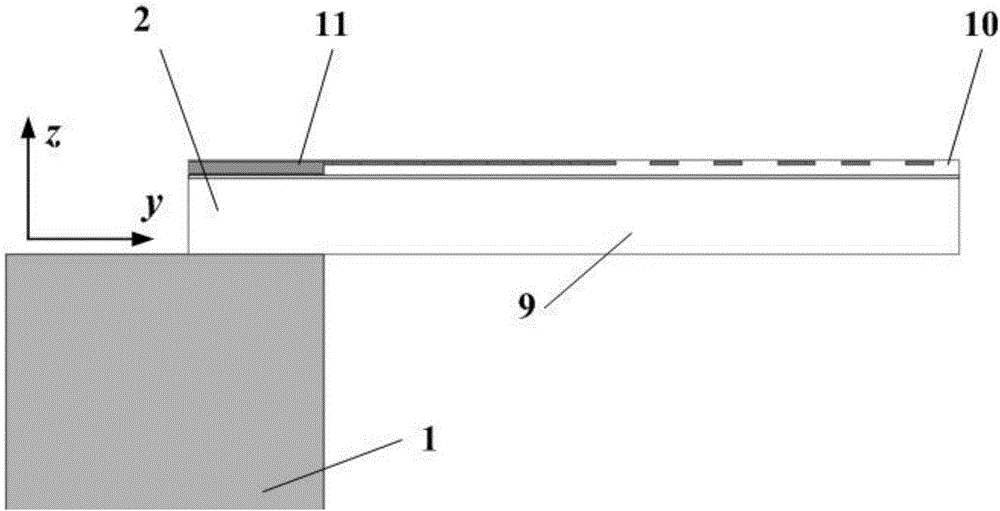

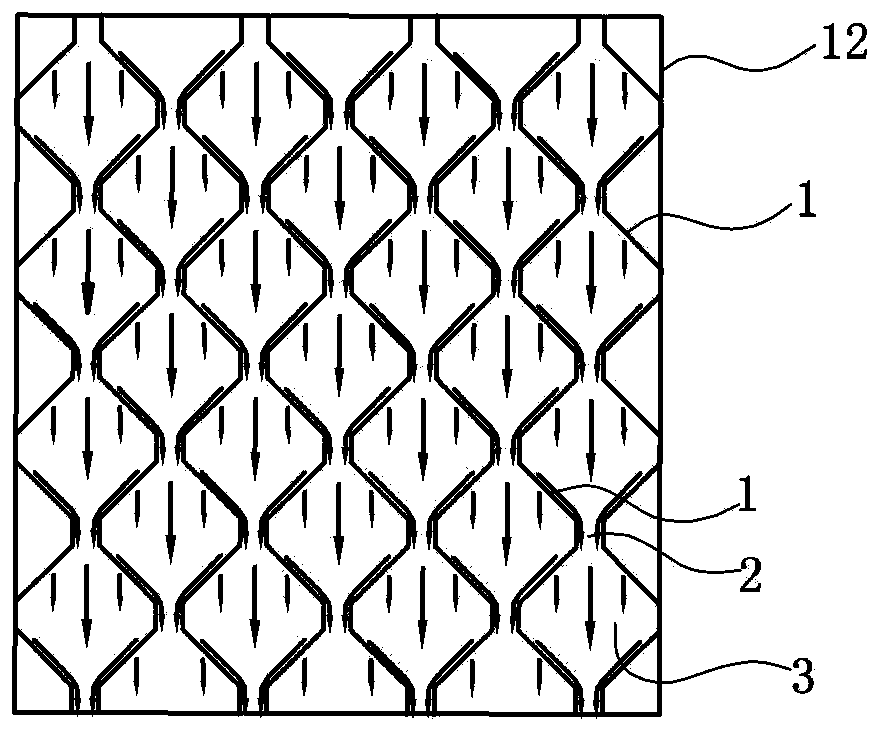

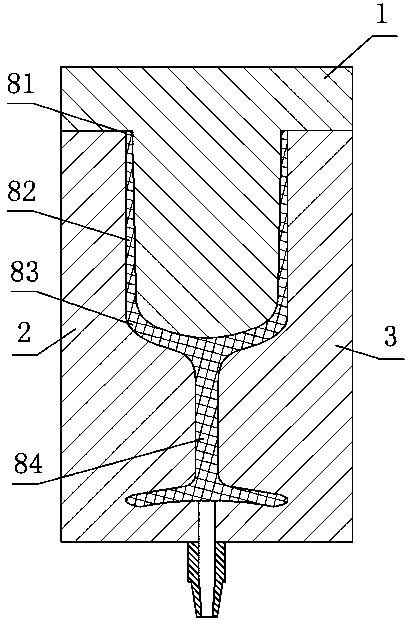

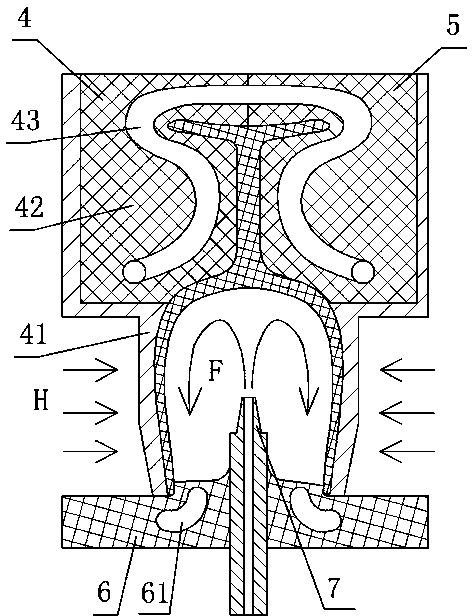

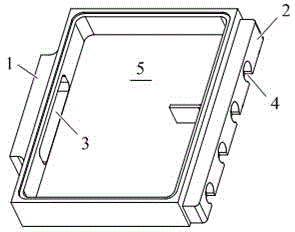

Two-dimensional rational extrusion oil gas transporting poly-graphic physical simulation device

The invention provides a two-dimensional rational extrusion oil gas transporting poly-graphic physical simulation device. The two-dimensional rational extrusion oil gas transporting poly-graphic physical simulation device comprises a model main body for filling a two-dimensional material model, a cover plate and a pressing plate provided with a piston, wherein the cover plate is made of transparent glass and is provided with a supporting surface for supporting the two-dimensional material model; and the two-dimensional material model is positioned between the cover plate and the pressing plate provided with the piston, and the pressing plate provided with the piston is used for extruding the two-dimensional material model on the cover plate. According to the invention, the two-dimensional material model is compacted by the piston, the situation that the graphic cover plate fractures and an instrument is damaged because of overdosage compaction of the two-dimensional material model is avoided; the problem that model filling is failed due to obvious deformation or collapse generated by insufficient compaction of the two-dimensional material model is solved; and the problem of multi-solution of a transportation conduction system due to invisible deformation or collapse generated by insufficient compaction of the two-dimensional material model is solved, therefore the authenticity of experiment phenomenon and experimental result is ensured.

Owner:PETROCHINA CO LTD

Temperature-adjustable polyurethane material for car cover and preparation method of temperature-adjustable polyurethane material

ActiveCN104530377AGood compatibilitySolve problems prone to migrationHeat-exchange elementsForeign objectEthanol

The invention discloses a temperature-adjustable polyurethane material for a car cover. The temperature-adjustable polyurethane material is characterized in that a complex phase change material is contained in a polyurethane material formula, and the complex phase change material is prepared by the following steps of adsorbing a phase change material on an inorganic porous material, then spraying an ethanol and water solution of a silane coupling agent, and drying. The polyurethane material is soft polyurethane foam containing the phase change material. The polyurethane material used as an interlayer of the car cover can not only play a protecting role in a car when the car is impacted by foreign objects, but also prevent the in-car temperature of the car parked outside in summer from being too high, and the in-car temperature in winter from being too low.

Owner:LIMING RES INST OF CHEM IND

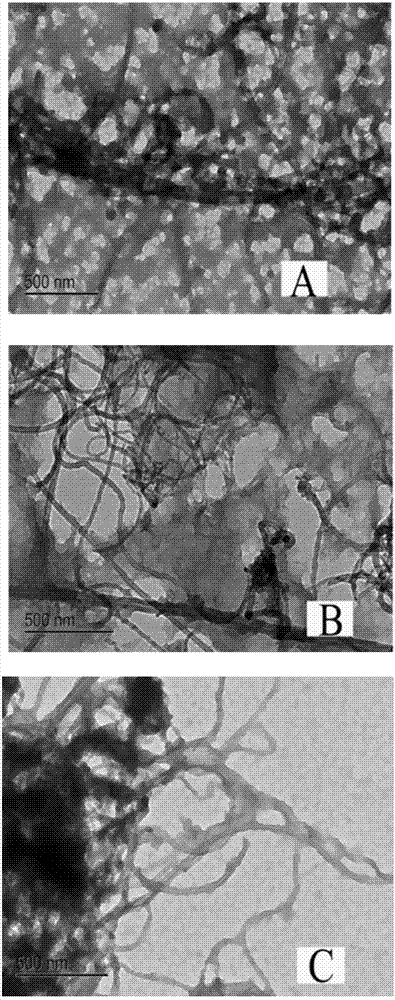

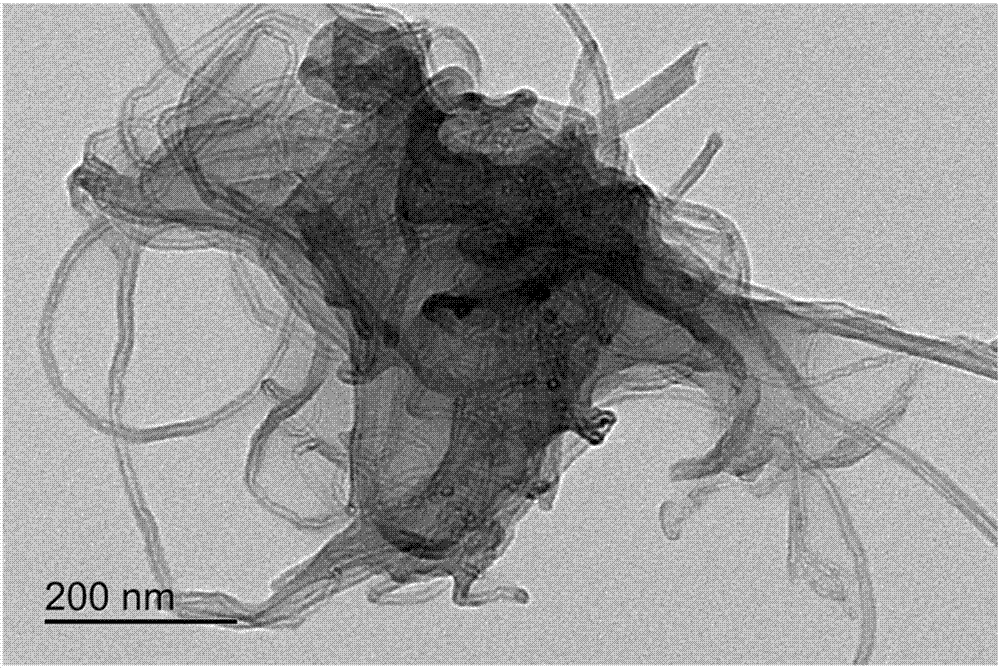

Lignin-based hard carbon/carbon nanotube composite material and preparation method and application thereof in negative electrode materials of lithium ion batteries

ActiveCN107959006ALarge specific surface areaHigh degree of graphitizationCell electrodesSecondary cellsOrganic solventCarbon nanotube

The invention belongs to the technical field of negative electrode materials of lithium ion batteries and discloses a lignin-based hard carbon / carbon nanotube composite material and a preparation method and application thereof in the negative electrode materials of the lithium ion batteries. The preparation method includes steps: respectively ultrasonically dispersing lignin and carbon nanotubes into organic solvent aqueous solution, mixing, adding alkali for adjusting pH to alkaline, and ultrasonically uniformly dispersing; adding acid for adjusting pH to 1-4, standing, and separating to obtain a lignin / carbon nanotube compound; adding the compound and an activating agent into water, heating, well stirring, heating and drying to obtain a lignin-based hard carbon / carbon nanotube compositematerial precursor; carbonizing the precursor to obtain the lignin-based hard carbon / carbon nanotube composite material. A surface area range of the lignin-based hard carbon / carbon nanotube compositematerial prepared according to the method is 500-3000m<2> g<-1>, activation time is 0.5-6h, and the lignin-based hard carbon / carbon nanotube composite material can be applied to the negative electrodematerials of the lithium ion batteries.

Owner:SOUTH CHINA UNIV OF TECH

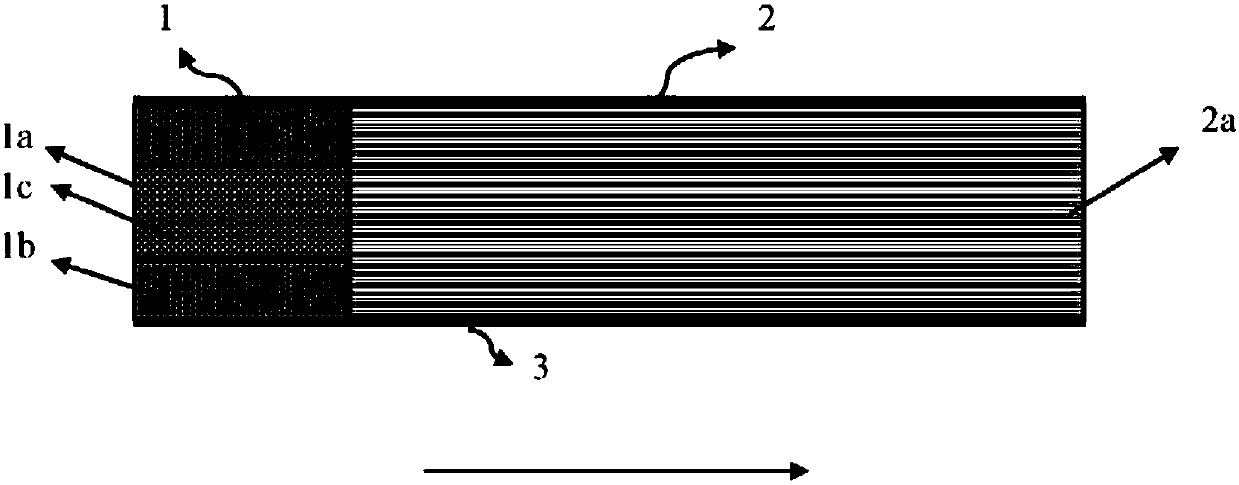

High temperature-resistant filter tip of cigarette, preparation method and application thereof

InactiveCN107772529ASolve the deformationSolve the collapseTobacco smoke filtersManufacturing technologyEngineering

The invention relates to the technical field of tobacco manufacture, in particular to a high temperature-resistant filter tip of a cigarette, a preparation method and application thereof. The high temperature-resistant filter tip of the cigarette is formed by composition between a high temperature-resistant function section and a tow section. The high temperature-resistant function section is formed by processing a high temperature-resistant material. Therefore, problems of a conventional filter tip of a cigarette are effectively resolved. The conventional filter tip of the cigarette is not likely to deform, sink and fuse by preventing the structure from damage at high temperature. One or multiple airflow channels is / are arranged in the high temperature-resistant function section. According to the length proportions of the high temperature-resistant function section and the tow section as well as pressure drop of the tow section and other factors, sizes, numbers and position distribution of the one or multiple airflow channels in the high temperature-resistant function section are regulated. Due to a hollow structure of the high temperature-resistant function section, obstruction,interception and other effects of the filter tip are reduced. The loss of smoke in the filter tip is lowered. Therefore, fluidity of smoke is enhanced.

Owner:CHINA TOBACCO GUIZHOU IND

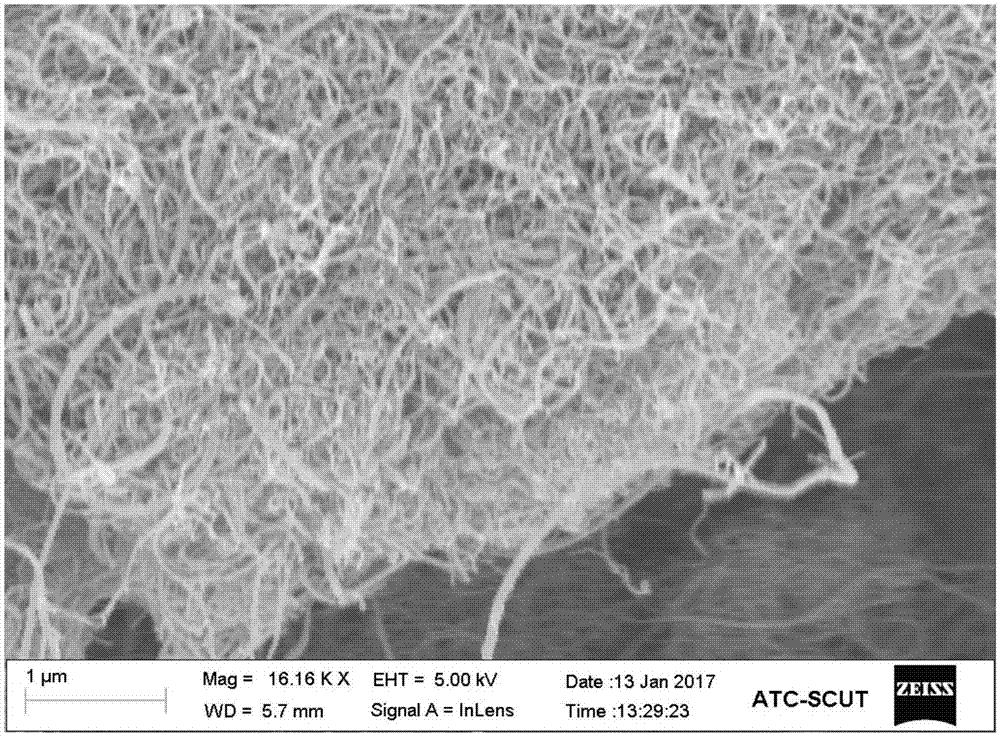

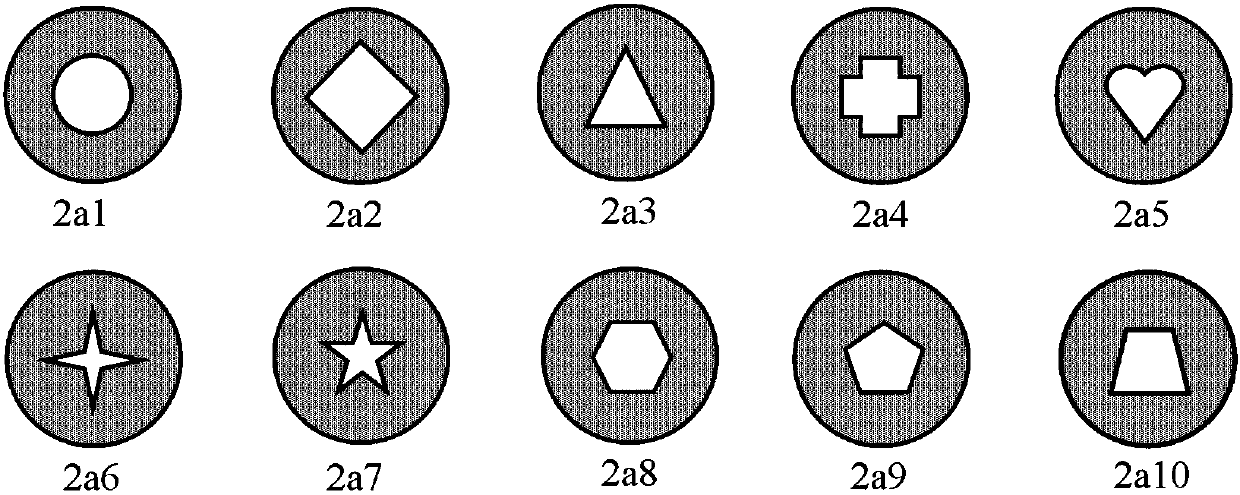

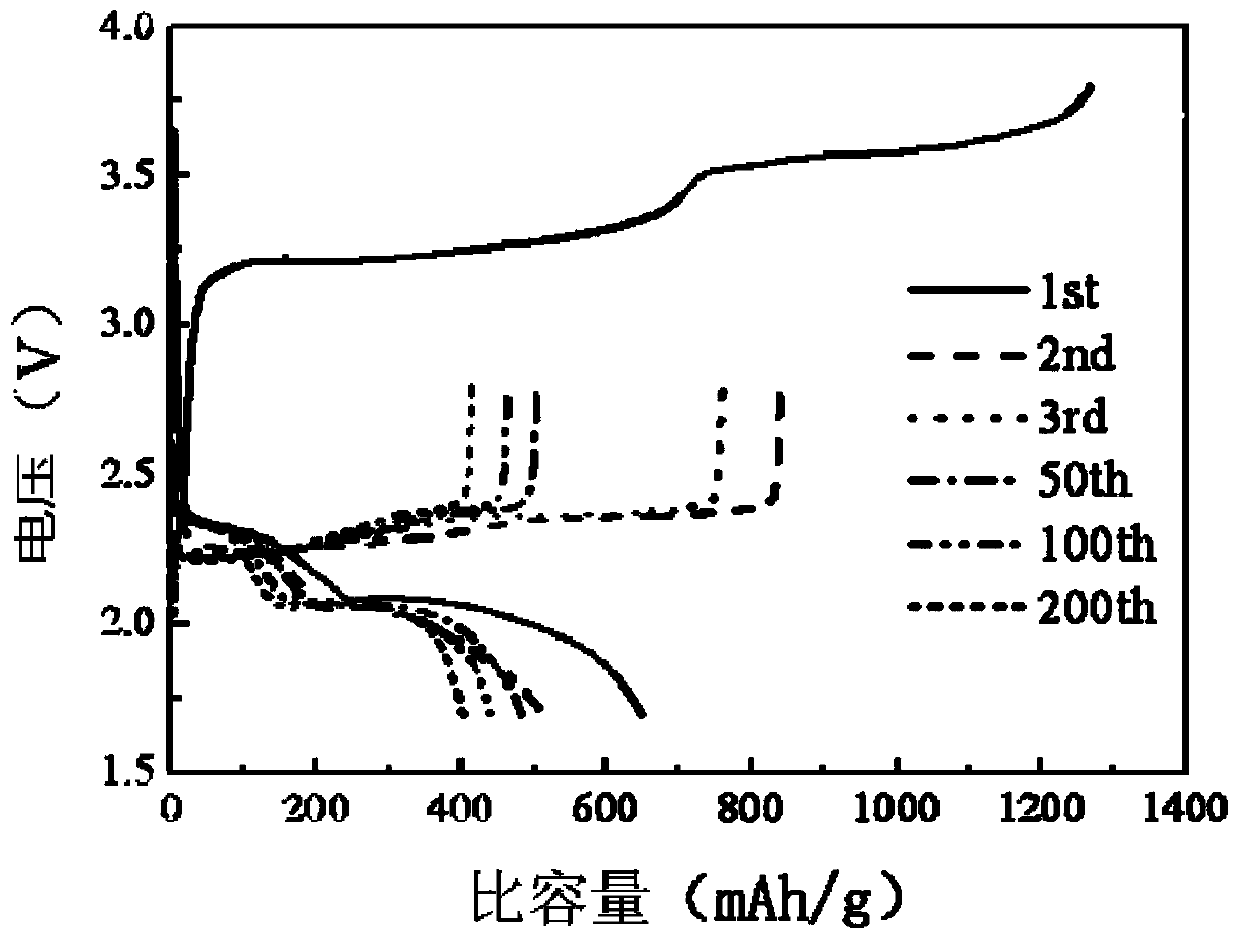

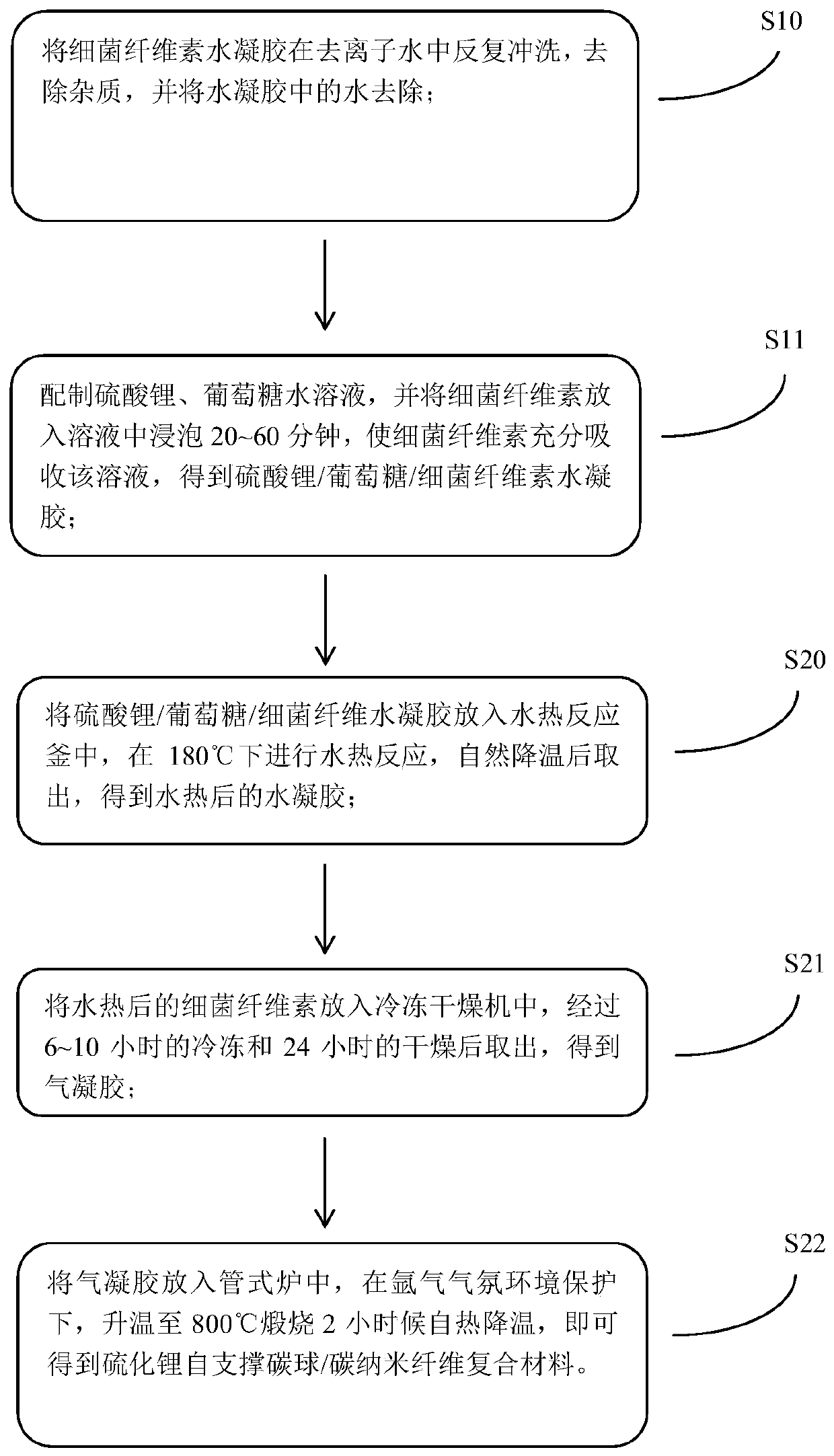

Preparation method for lithium sulfide self-supporting carbon sphere/carbon nanofiber composite material, and lithium-sulfur battery

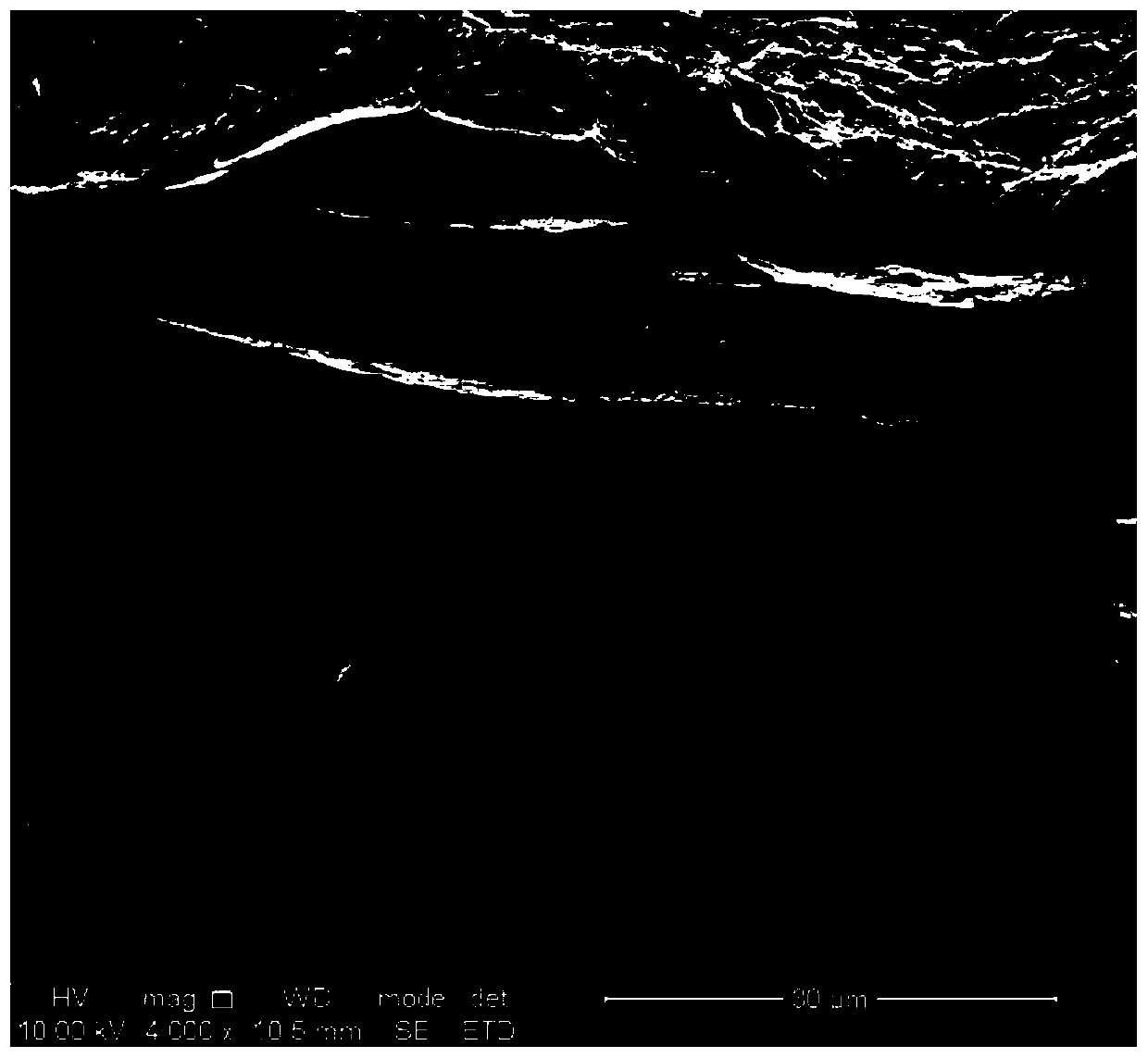

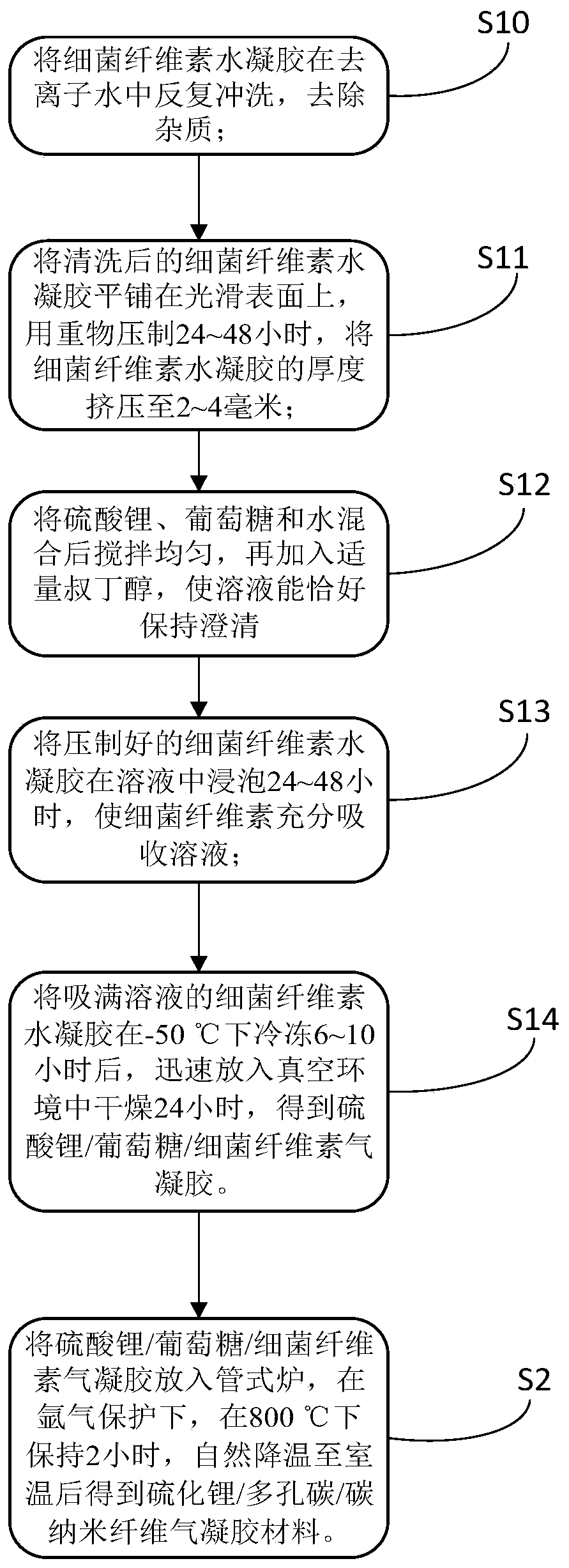

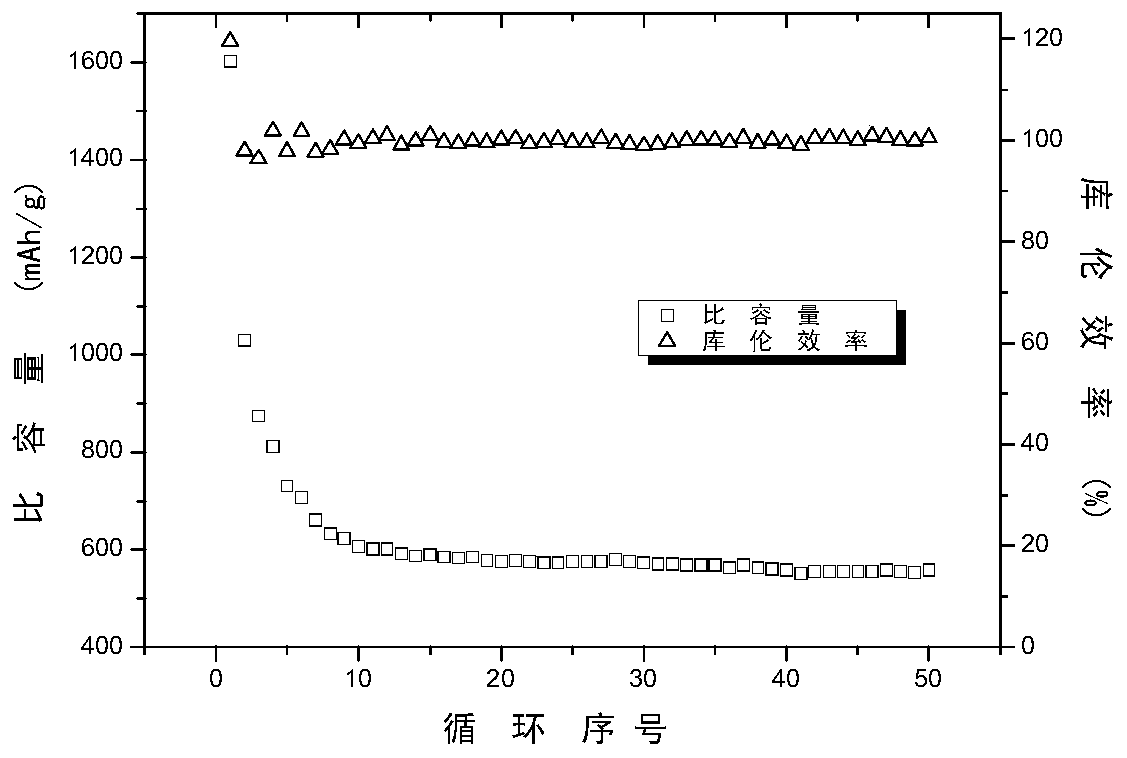

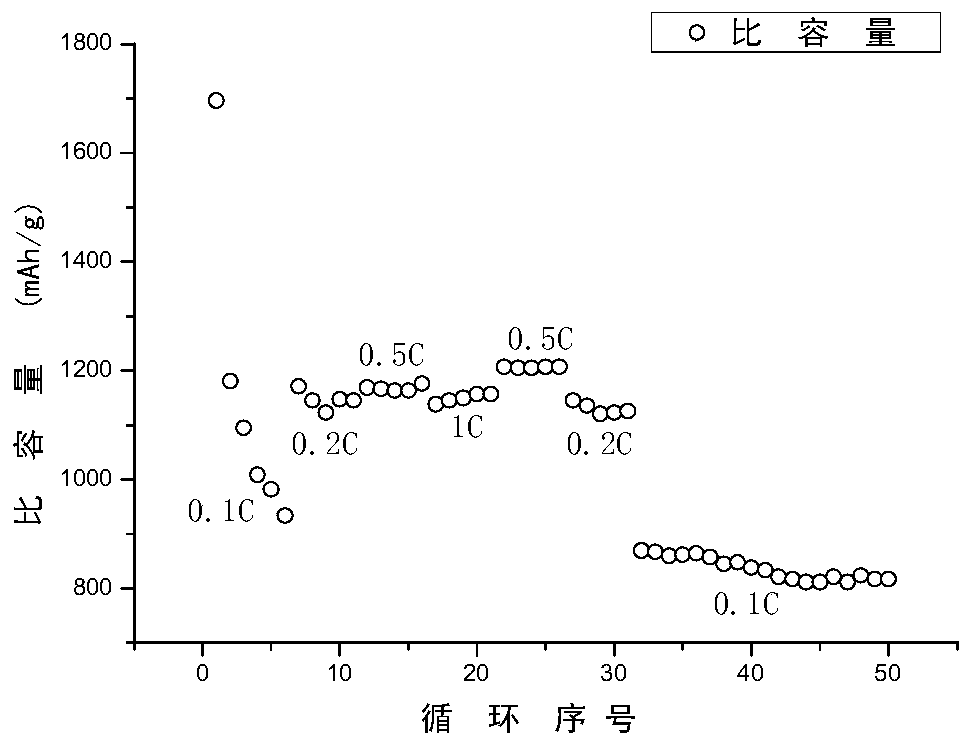

ActiveCN110212180AEasy transferGuaranteed normal transmissionMaterial nanotechnologyCell electrodesCarbonizationCarbon nanofiber

The invention discloses a preparation method for a lithium sulfide self-supporting carbon sphere / carbon nanofiber composite material, and a lithium-sulfur battery. The preparation method comprises thesteps of S1, preparing lithium sulfate / glucose / bacterial cellulose hydrogel composite material; and S2, converting glucose in the lithium sulfate / glucose / bacterial cellulose hydrogel composite material into carbon spheres, enabling lithium sulfate to be better coated with a carbon material, slowing down diffusion of polysulfide lithium, and converting bacterial cellulose into carbon nanofibers, so that the carbon sphere / carbon nanofiber aerogel composite material is formed. According to the technical scheme, an adhesion agent does not need to be added, and then an electrode is formed by direct self-supporting after carbonization; and meanwhile, a carbon sphere structure and a carbon nanofiber network structure can be constructed, and lithium sulfide nanoparticles in the structure are effectively coated, so that the electron conductivity in the electrode can be improved, the transmission efficiency of electrons in the electrode is improved, the "shuttle effect" is inhibited, and the performance of the lithium-sulfur battery is improved.

Owner:HANGZHOU DIANZI UNIV

Method for preparing lithium-sulfur battery cathode material by using bacterial cellulose hydrogel

ActiveCN109962222AMitigates low electronic conductivityReduce diffuseCell electrodesPorous carbonCarbon nanofiber

The invention discloses a method for preparing a lithium-sulfur battery cathode material by using bacterial cellulose hydrogel, comprising the following steps of S1, preparing a lithium sulfate / glucose / bacterial cellulose aerogel composite material; and S2, converting the lithium sulfate in the lithium sulfate / glucose / bacterial cellulose aerogel composite material into lithium sulfide, convertingthe glucose into porous carbon, and converting the bacterial cellulose into carbon nanofibers. The method can construct a carbon nanofiber meshed structure, and the lithium sulfide nanoparticles in the structure are coated with the porous carbon, thereby improving the electron transmission efficiency in an electrode, suppressing a shuttling effect, and solving the problem of electrode collapse during lithium-sulfur battery charging and discharging so as to improve the performance of the lithium-sulfur battery.

Owner:HANGZHOU DIANZI UNIV

Electrocondution slurry for solar cell and manufacturing method thereof

ActiveCN103295662ASolve the collapseAvoid Bonding VacuumNon-conductive material with dispersed conductive materialCable/conductor manufactureElectrical batteryElectrically conductive

Electrocondution slurry comprises silver powder, glass powder and an organic carrier, wherein the glass powder comprises boron lead silicate glass and hydrate, and the lead silicate is I-II main-species hydrate of the periodic table of the elements. A solar cell sheet manufactured by the electrocondution slurry manufactured by the glass powder is high in photoelectric conversion efficiency and large in depth-width ratio.

Owner:BYD CO LTD

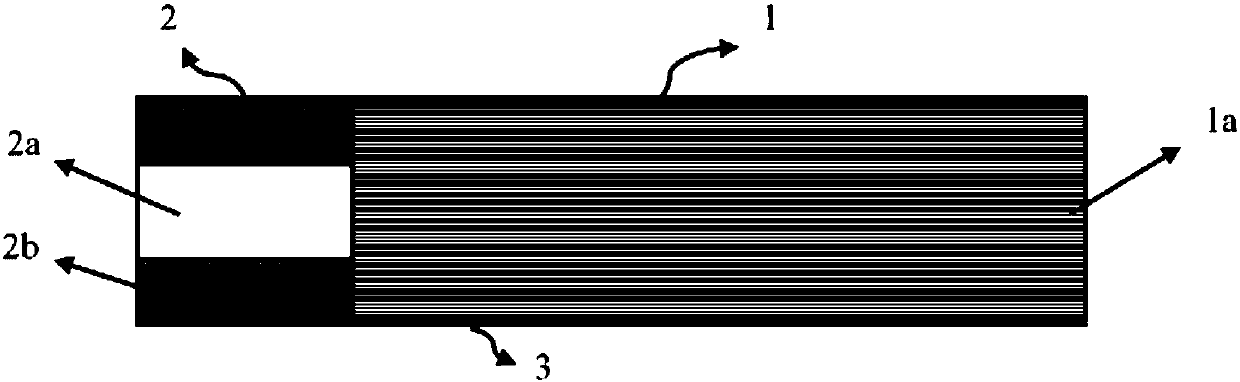

Thin-wall aluminum alloy three-plate butting one-time fusion welding process method

The invention discloses a thin-wall aluminum alloy three-plate butting one-time fusion welding process method, which specifically comprises the following steps of: 1, preparing welding workpieces which comprise a box plate (1) and a stud partition plate (2), wherein the upper end and the lower end of the stud partition plate (2) are embedded into the box plate (1) and protrude out of the box plate (1), and the protrusion is 2 mm; 2, preparing welding process equipment to guarantee uniform stressing of a head region to be welded; 3, cleaning the welding workpieces and clamping the welding workpieces on the welding process equipment; 4, setting welding parameters on a welding machine and welding the welding workpieces; and 5, disassembling the welding process equipment and removing the welding workpieces. Through the method, the problems of difficulty in realizing welding of a thin-wall aluminum alloy box body structure in a narrow space and high probability of collapse and burn-through and difficulty in repair of welding of an aluminum alloy thin plate existing in the conventional fillet weld and butting weld are solved.

Owner:BEIJING HANGTIAN XINFENG MECHANICAL EQUIP

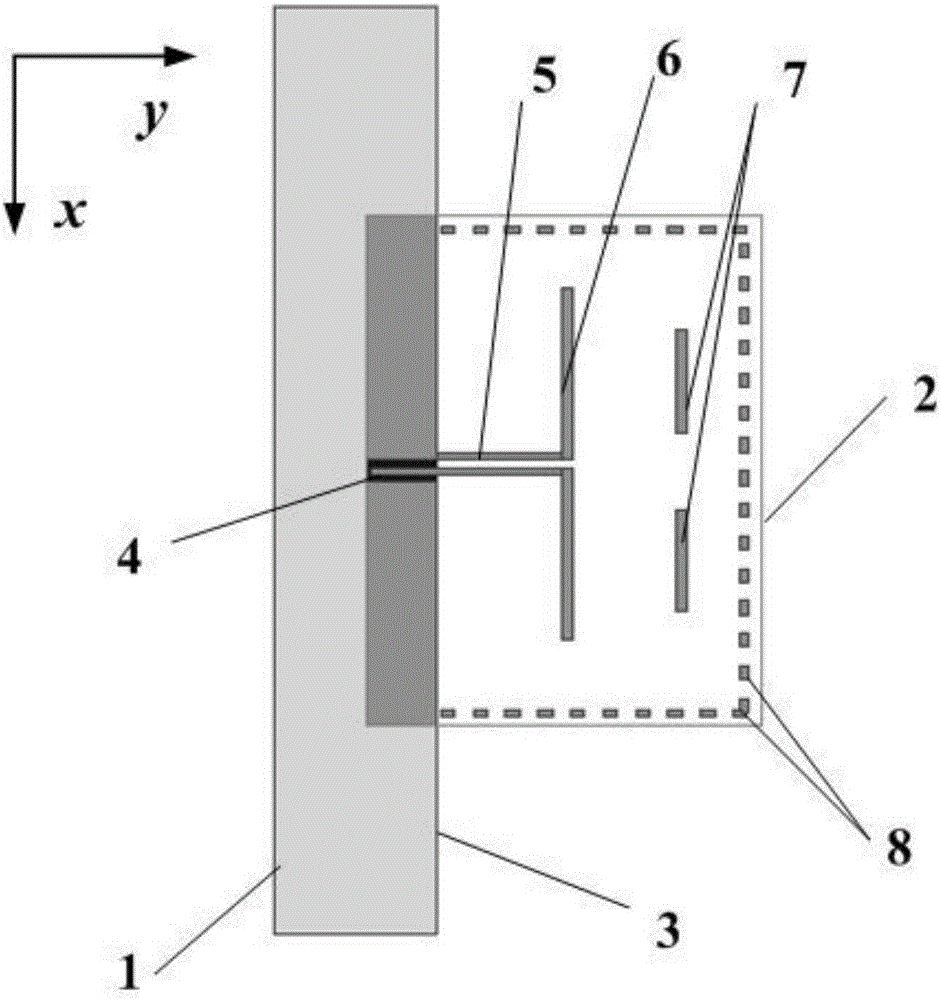

MMW SMMW silicon-based on-chip end-on-fire antenna

InactiveCN106848562ASolve the collapseSimple structureAntenna supports/mountingsRadiating elements structural formsElectricityPhase control

The invention discloses an MMW (millimeter Wave) SMMW (Sub Millimeter wave) silicon-based on-chip end-on-fire antenna. The antenna includes a metal support table and an on-chip antenna arranged on one side of the metal support table. The on-chip antenna includes a silicon substrate, a SiO2 layer arranged on the upper surface of the silicon substrate and a metal wiring layer arranged on the upper surface of the upper silicon substrate and one side of the SiO2 layer. The metal wiring layer is disposed on one side, adjacent to the metal support table, of the on-chip antenna. The metal wiring layer is provided with a CPW feed port. The SiO2 layer is provided with parallel double lines connected with the CPW feed port and is provided with a yagi antenna active vibrator connected with the parallel double line. One side face, adjacent to the on-chip antenna, of the metal support table is provided with a reflecting face. The reflecting face and a grounding face of the CPW feed port are combined into a transmitter. The antenna provided by the invention has advantages of simple structure, small size, high efficiency, high gain and engineering convenience and meets application requirements in fields of MMW, SMMW imaging, communication and phase control array and the like.

Owner:成都中宇微芯科技有限公司

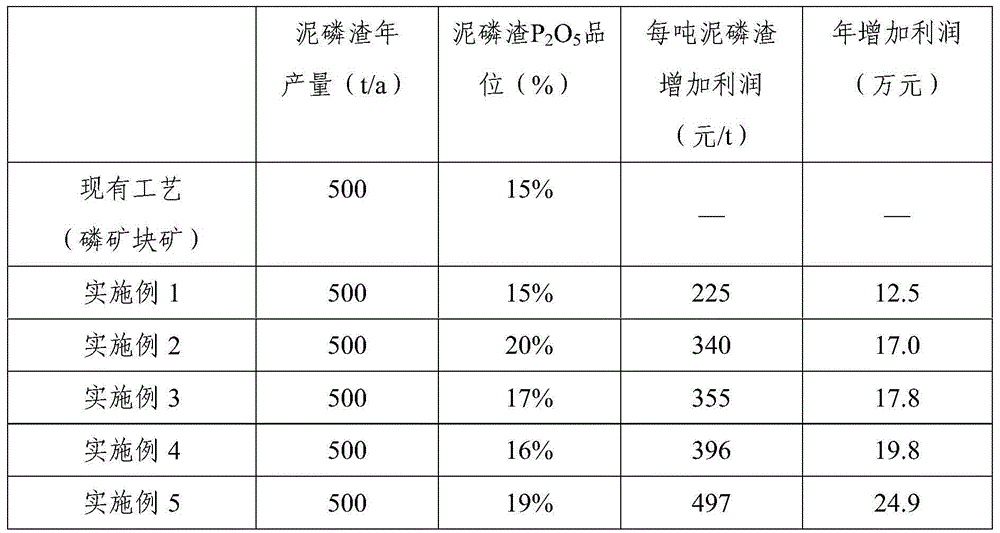

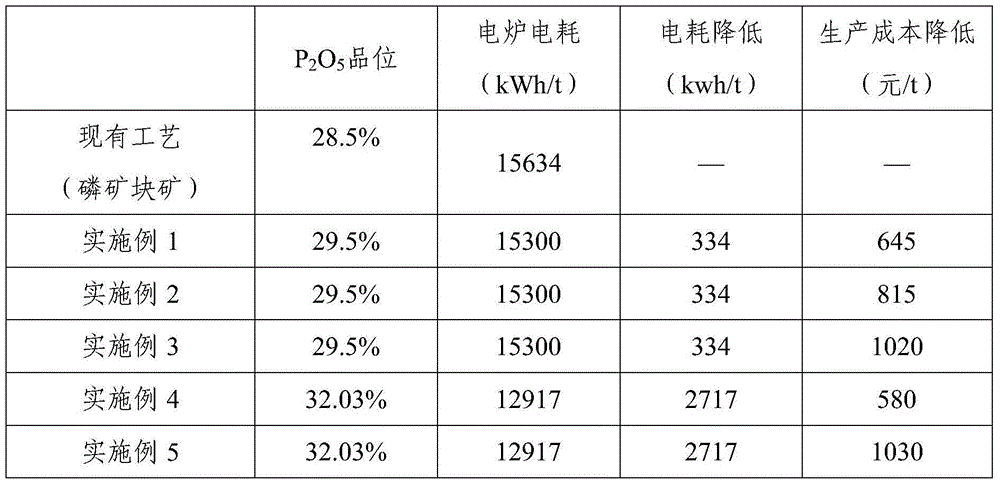

Method for producing yellow phosphorus with phosphor residue slag and ground phosphate rock

InactiveCN104925773ASolve the use problemDoes not affect productivityPhosphorus compoundsSlagPhosphor

The invention provides a method for producing yellow phosphorus with phosphor residue slag and ground phosphate rock. The phosphor residue slag and the ground phosphate rock are mixed according to the proportion being 1:1.0-3.0, a binder is added, a mixed material is obtained, the mixed material is equalized to be pressed into pallets, drying and solidification on the pallets are carried out, and the pallets are fed into a yellow phosphorus electric furnace for preparing the yellow phosphorus. By means of the method, comprehensive utilization of resources is achieved, environment pollution is reduced, and the aim of comprehensively using the phosphor residue slag and the ground phosphate rock is effectively achieved.

Owner:CHENGDU LESHI CHEM ENG

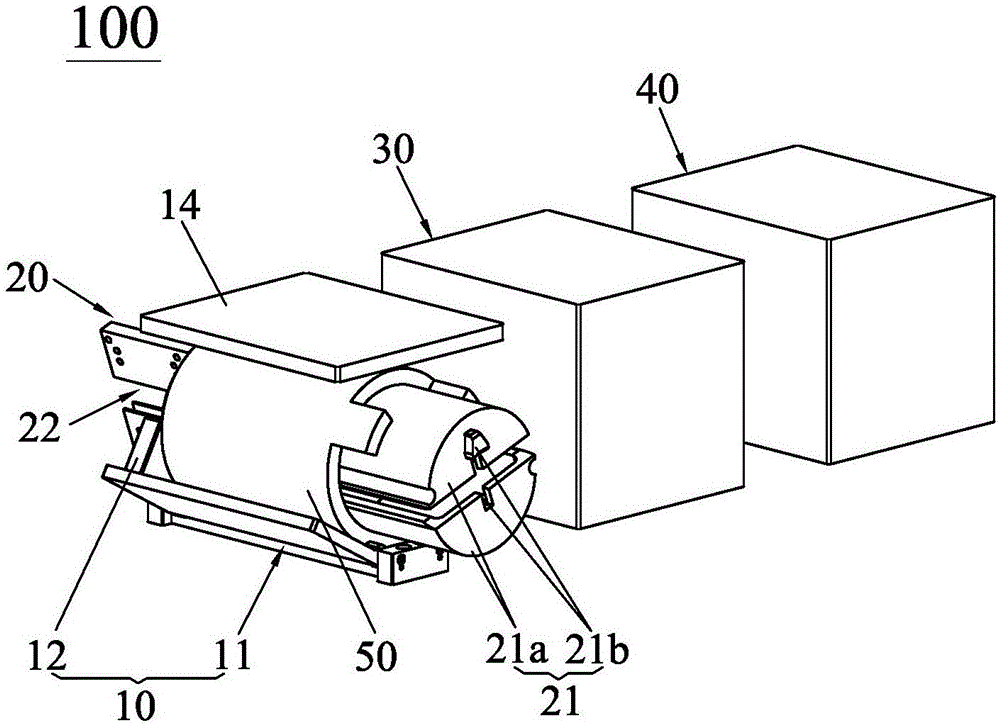

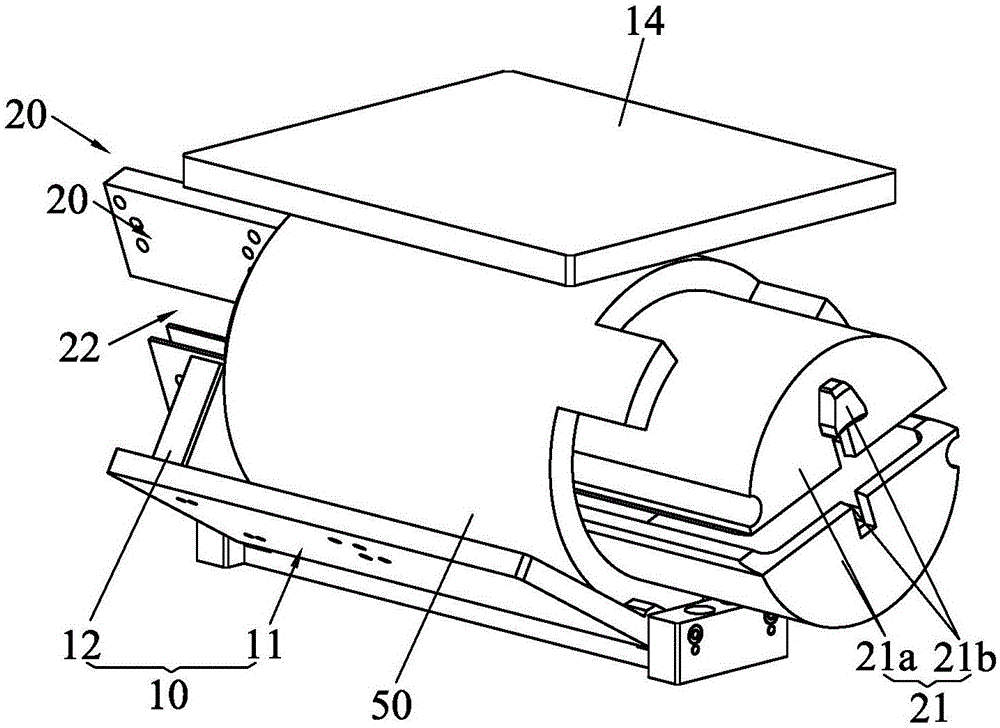

Auxiliary unloading device for circular wound needle, cable core winding equipment and cable core forming method

ActiveCN106711491ASolve the unloading problemQuality assuranceAssembling battery machinesFinal product manufactureEngineeringMechanical engineering

Owner:东莞市博拓锂电科技有限公司

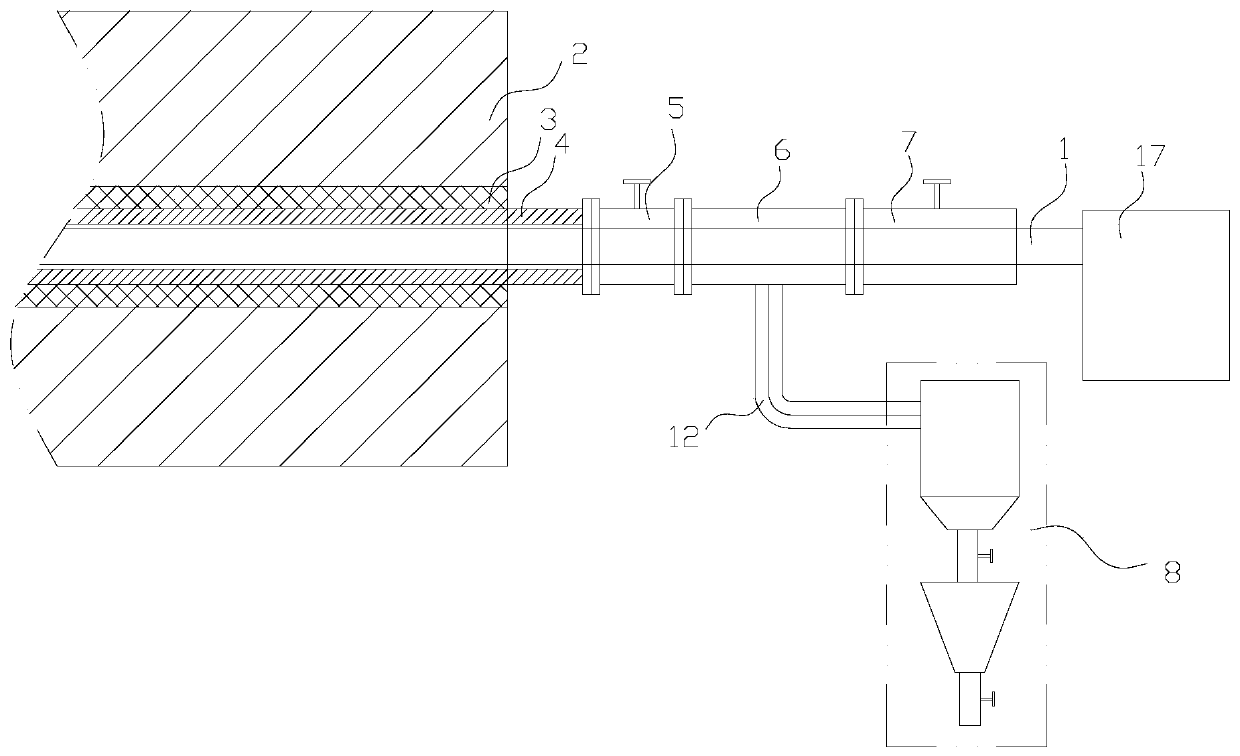

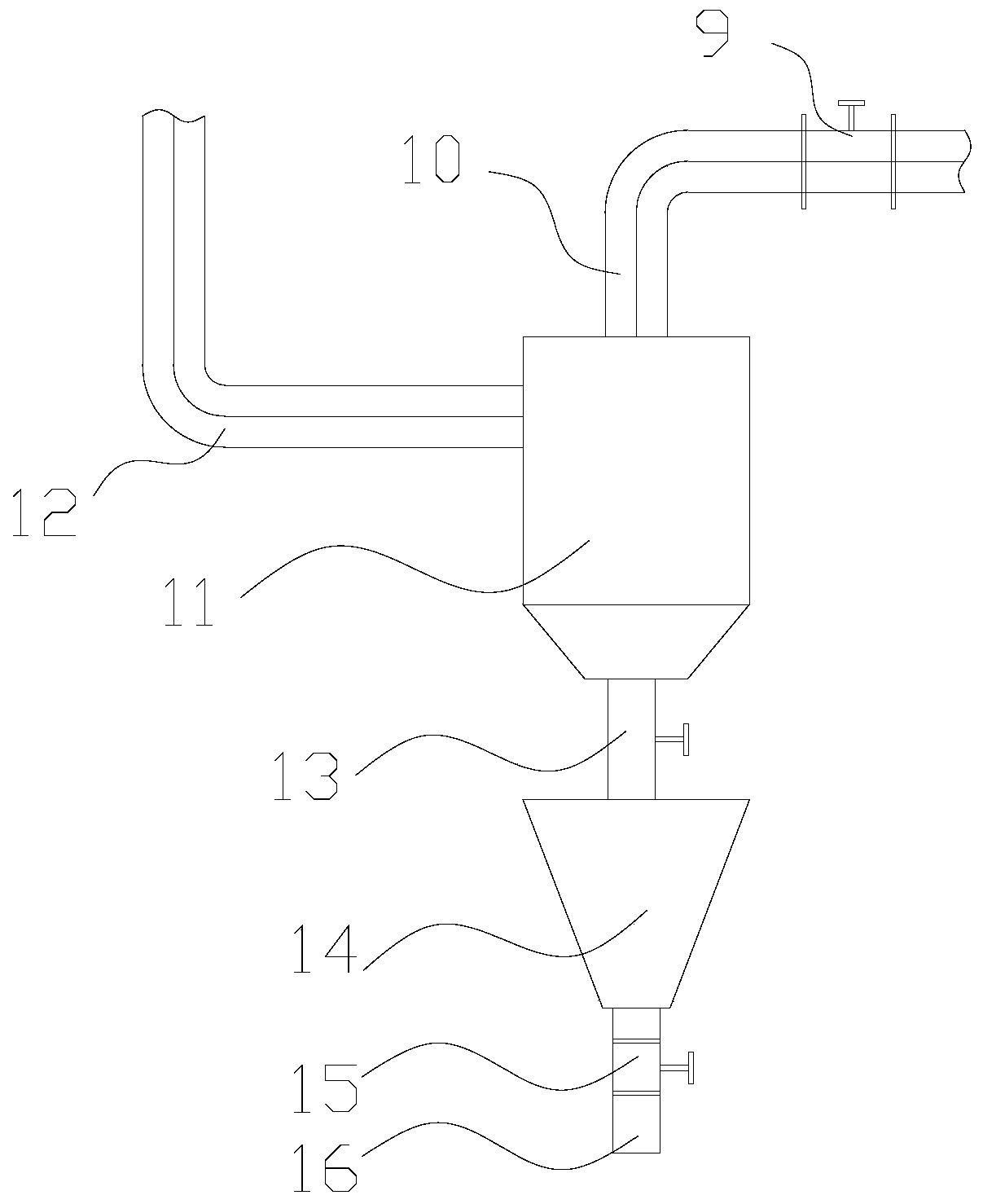

Drilling device for underground gas holes and drilling method thereof

PendingCN110374497AIncrease concentrationIncrease drawConstructionsLiquid/gas jet drillingSlagHydrostatic pressure

The invention discloses a drilling device for underground gas holes and a drilling method thereof. Firstly, sleeve holes are drilled in a drainage area; hole sealing sleeves are fixedly sealed in orifices; then, the hole sealing sleeves are connected with drilling devices; during drilling, the internals of drilled holes are pressurized through hollow drill rods and filled with cooling liquid to achieve a hole wall supporting effect; after holes are drilled through rock layer sections, wall protecting mud is injected in rock layers in a pressurized mode, and a certain static water pressure is formed in the holes to achieve a rock wall stabilizing effect; clear water is used for drilling after entering coal seams; water and slag generated in the drilling process are separated by a water-slagseparation device to realize secondary utilization of resources; after final holes are drilled in, drainage pipelines are replaced in the holes in a pressurized state for flow pressure-reduced drainage; and through the flow pressure-reduced drainage method, the problem of blockage of hole wall gaps by the speed-sensitivity effect can be prevented, the gas quantity attenuation efficiency of the gas holes is reduced, and the gas extracting quantity is increased.

Owner:田振林

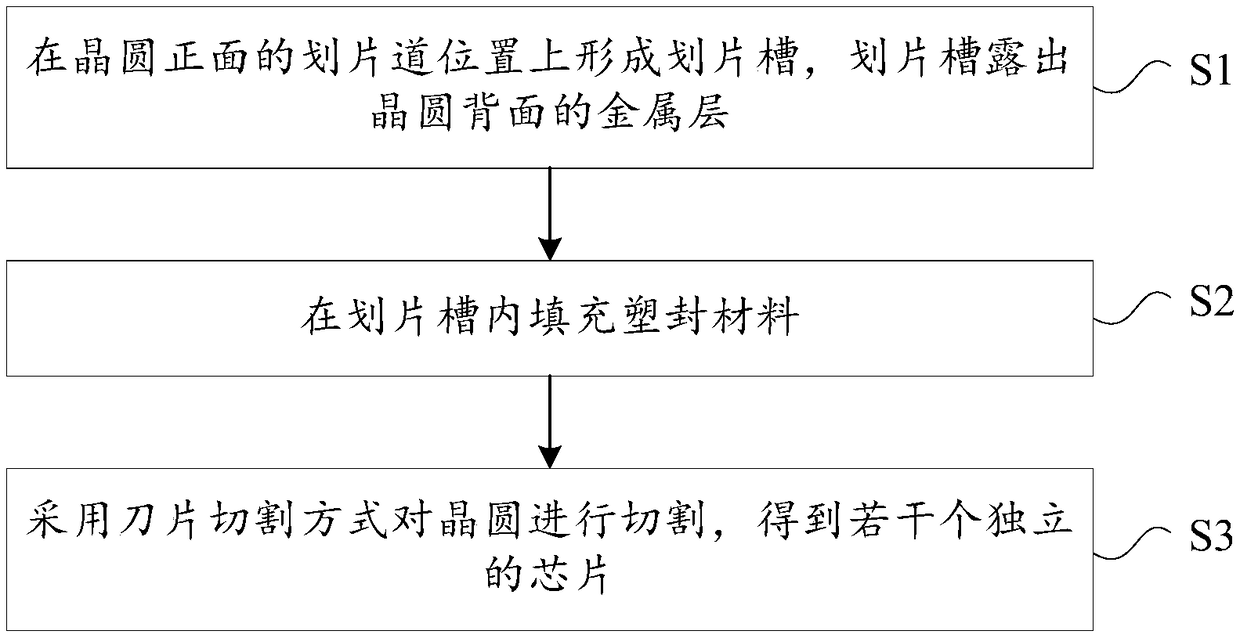

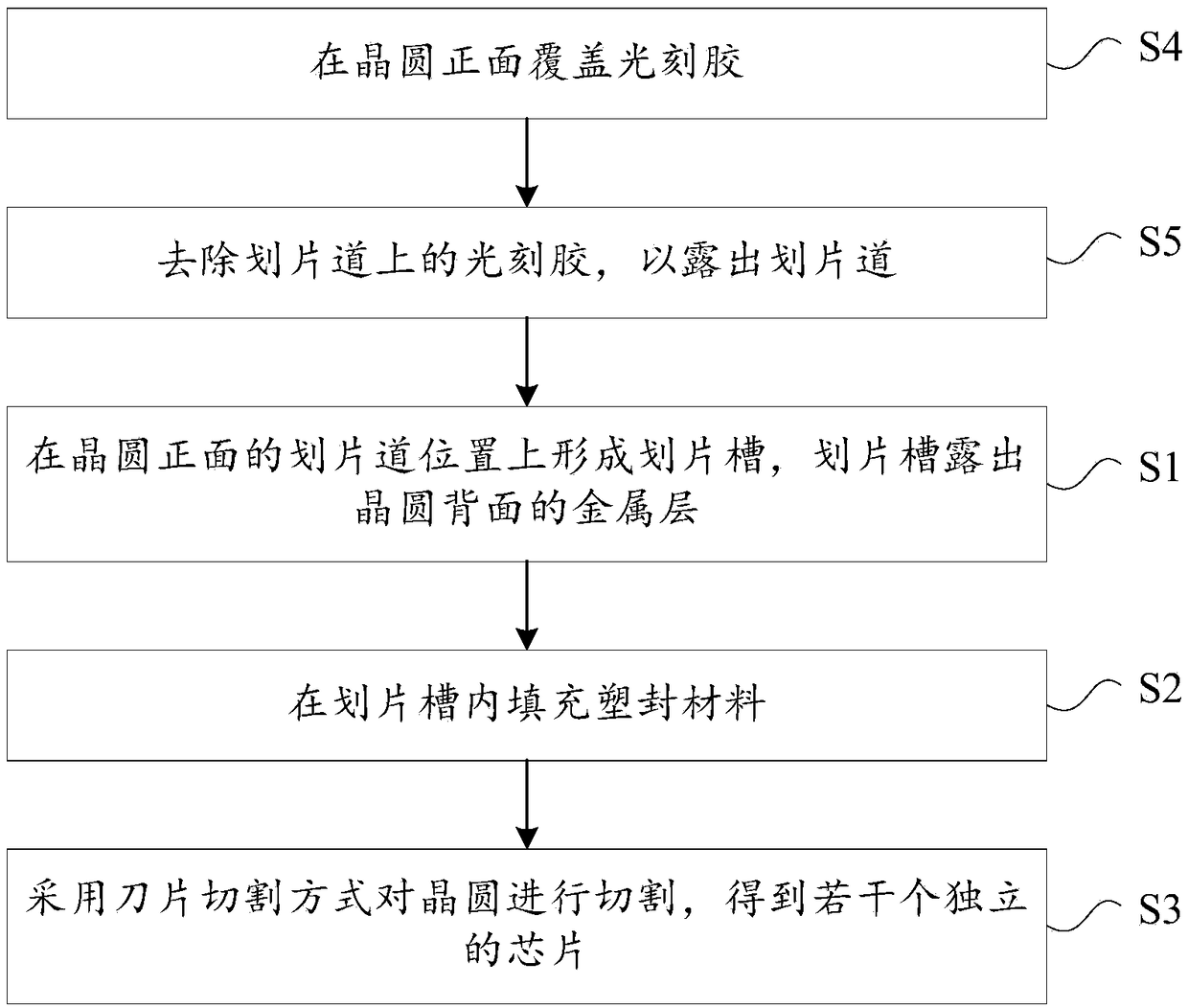

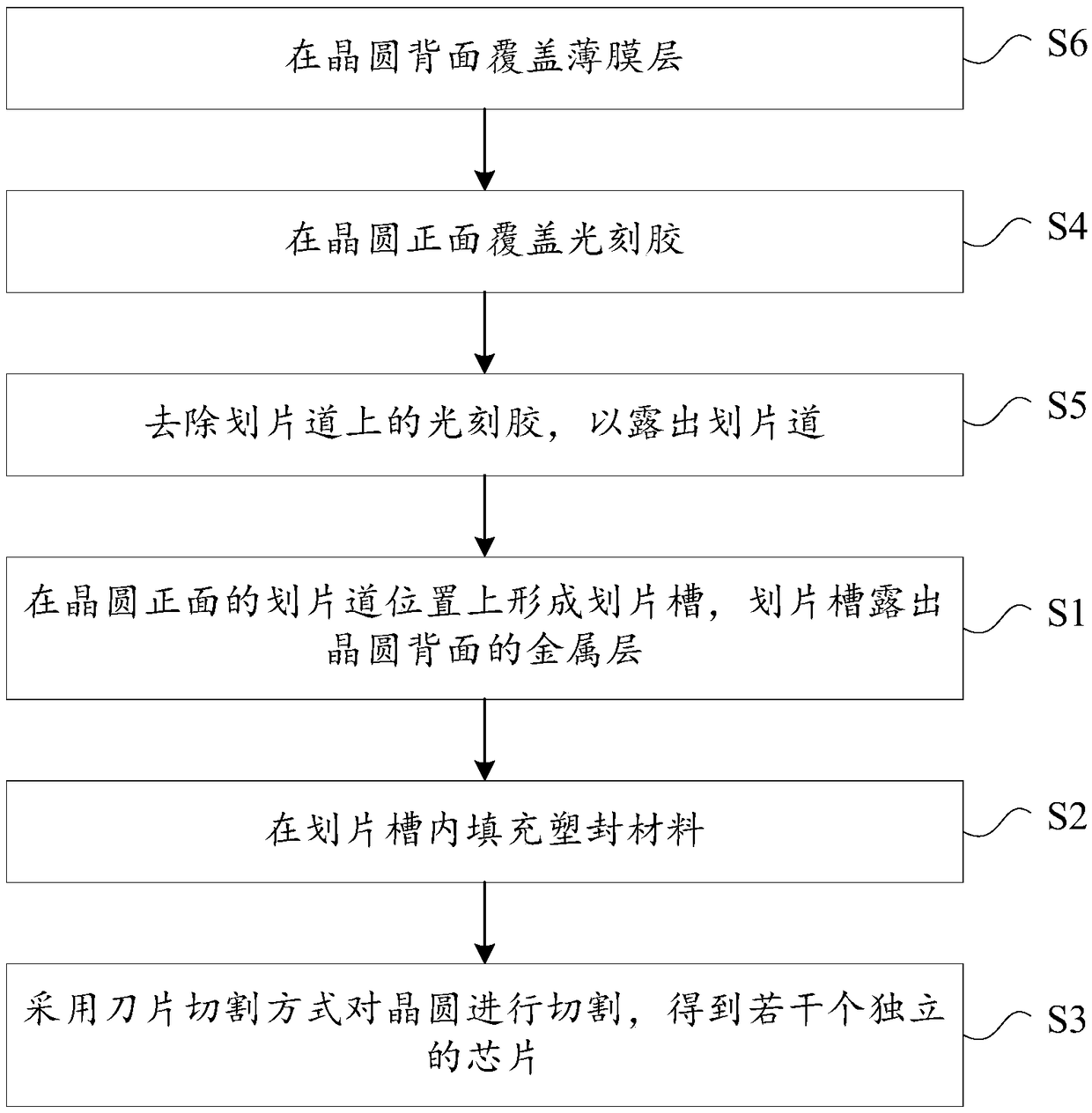

Scribing method of power chip and semiconductor device

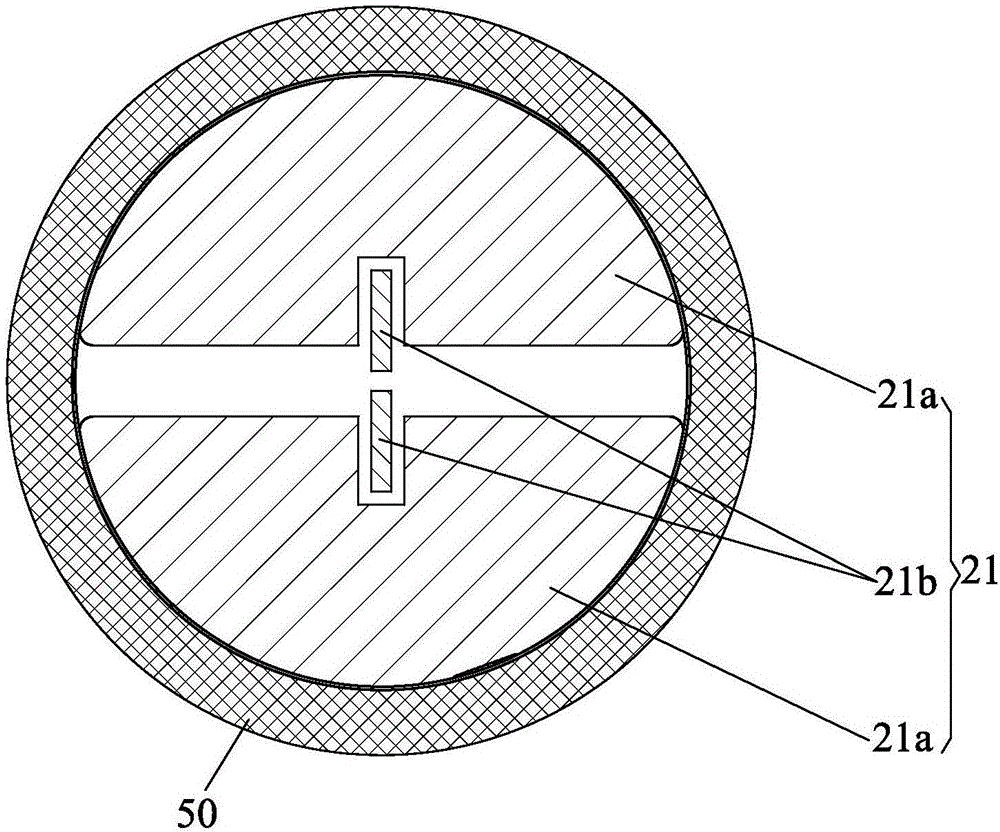

ActiveCN109449084AImprove the withstand voltage levelSolve the collapseSemiconductor/solid-state device manufacturingState of artPlastic packaging

The invention discloses a scribing method of a power chip and a semiconductor device. The scribing method includes following steps: forming scribing grooves at positions of scribing channels on the front surface of a wafer, wherein the scribing grooves expose a metal layer at the backside of the wafer; filling in the scribing grooves with plastic packaging materials; and cutting the wafer by employing a blade cutting mode to obtain a plurality of independent chips. According to the scribing method of the power chip, the scribing grooves are firstly prepared on the front surface of the wafer and extend to the metal layer at the backside of the wafer so that the cutting strength for subsequent mechanical cutting by employing diamond grinding wheel scribing can be greatly reduced; later, theplastic packaging materials are filled in the scribing grooves so that sidewalls of the chips are protected by the plastic packaging materials, and the withstand voltage grade of the chips is improved; and finally, the plurality of independent power chips are obtained by cutting of the wafer through the blade so that the problem of edge breakage at edges of the front surfaces and the backsides ofthe scribed chips due to scribing of the power chips through the mechanical cutting mode in the prior art is solved.

Owner:GLOBAL ENERGY INTERCONNECTION RES INST CO LTD

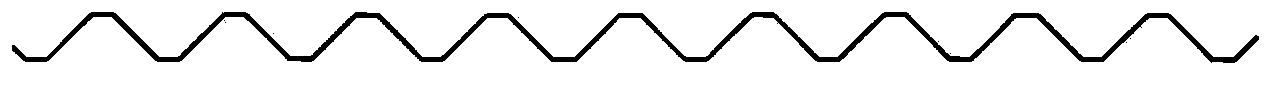

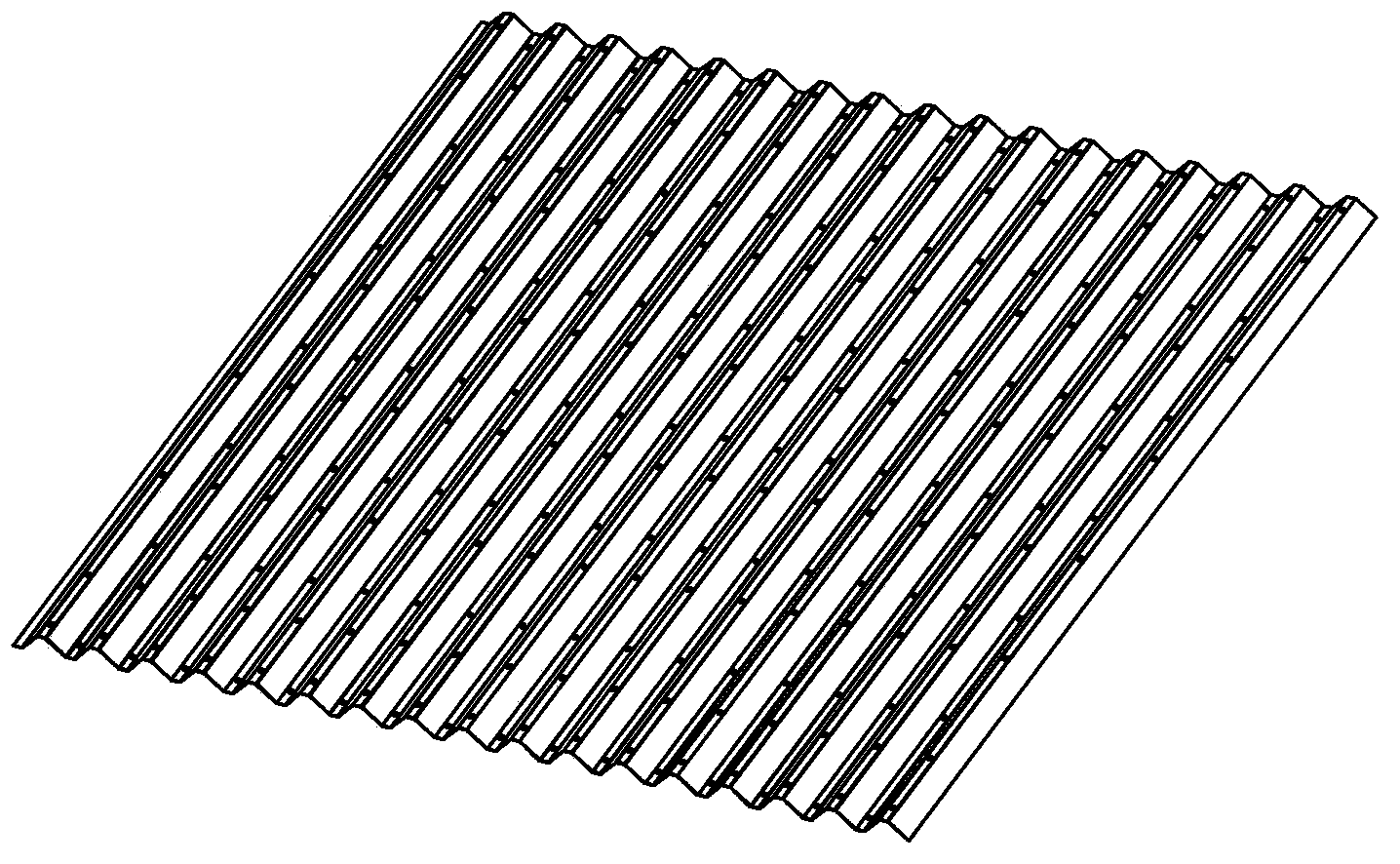

Horizontal flow precipitation separation device

InactiveCN103405946AAvoid disturbing effectPrevent resuspensionSedimentation settling tanksSludgeWater flow

The invention relates to a horizontal flow precipitation separation device. The horizontal flow precipitation separation device is characterized by comprising multiple corrugated plates arranged in a precipitation pond, wherein each corrugated plate is vertically arranged relative to a horizontal plane, the adjacent corrugated plates are symmetrically arranged and are spaced, and the smallest interval of the adjacent corrugated plates serves as a sludge discharging channel. Compared with the prior art, the horizontal flow precipitation separation device preserves the advantages that a flow direction and a precipitate sludge discharging direction are mutually vertical without interfering with each other, the disturbance between the horizontal flow and a precipitate is avoided, the submerged sludge is prevented from suspending again, meanwhile, a sludge discharging manner is optimized, the vertical sludge discharging channel is adopted, when stream horizontally flows through a stream channel, suspended solids are collided with a frame of the stream channel to rapidly precipitate, and slide downwards along the frame to enter the sludge discharging channel so as to directly precipitate to the bottom of the precipitation pond, and a wobble plate does not need to bear load, so that a problem of load-bearing of the wobble plate caused by large precipitate quantity is solved.

Owner:ZHEJIANG DEAN TECH

Method for producing yellow phosphorus from phosphate rock powder and carbon powder

InactiveCN104891461ASolve the use problemDoes not affect productivityPhosphorus compoundsPhosphateYellow phosphorus

The invention provides a method for producing yellow phosphorus from phosphate rock powder and carbon powder. The method comprises steps as follows: the phosphate rock powder and the carbon powder are mixed in a production ratio and are pressed to form pellets after a binding agent is added, the pellets are dried and solidified, silica is added, and the mixture is sent into a yellow phosphorus electric furnace to prepare the yellow phosphorus. With the adoption of the method, the production cost of the yellow phosphorus can be averagely reduced by more than 800 yuan / ton; the problem about comprehensive utilization of the phosphate rock powder and the carbon powder is solved, and the problems of arching, material collapse and electrode breakage of the yellow phosphorus electric furnace are completely solved; the method has remarkable effects in the aspects of improvement of the yellow phosphorus production environment and realization of cleaner production.

Owner:CHENGDU LESHI CHEM ENG

Molding process for plastic red wine goblet

The invention discloses a molding process for a plastic red wine goblet. The molding process comprises (a) injection molding, (b) mold clamping, (c) heating, (d) blow molding, and (e) de-molding and polishing treatment. In the blow molding process, the plastic red wine goblet is fixed in an inverted way, a goblet opening is downward, a nozzle of a high-pressure blower gun is upward and is used for blowing air to the bottom of a goblet body, and the air is blown for 8 to 12 seconds after die assembly, and the air pressure is kept to be 25-28MPa. In the heating process, a local heating method is adopted, only the middle of the goblet body is heated and softened, and a stem part and the goblet opening are cooled for hardness maintenance thereof. According to the molding process, a bad effect caused by collapsing of the goblet opening in the blow molding process is avoided, an annular rib structure which is added at the goblet opening and is used for fixing the goblet opening is eliminated, the plastic red wine goblet has a good molding effect, and the appearance of the plastic red wine goblet is in full accordance with that of a glass or quartz red wine goblet.

Owner:王磊

Drilling fluid for drilling of fractured igneous rock formation and preparation method of drilling fluid

The invention relates to a drilling fluid for drilling of a fractured igneous rock formation and a preparation method of the drilling fluid in the field of petroleum drilling. The drilling fluid is prepared from components in parts by weight as follows: 1,000 parts of water, 3-4 parts of drilling fluid bentonite, 2-3 parts of sodium carbonate, 2-3 parts of a polymer coating agent, 2-3 parts of potassium polyacrylate or a metal cation polymer, 5-10 parts of an organic amine inhibitor, 20-30 parts of an anti-sloughing reinforced wall fixation agent, 20-30 parts of sulfonated phenol formaldehyderesin, 5-10 parts of a sulfonate copolymer filtrate reducer, 20-30 parts of walchowite, 10-20 parts of an anti-salt and temperature-resistant fluid loss agent, 20-40 parts of superfine calcium carbonate, 50-70 parts of potassium chloride, 0-10 parts of an organic anti-friction compound and 10-20 parts of a nano-micro blocking agent, and the weight is increased to 1.30-1.85 g / cm<3> with a density weighting agent. The drilling fluid has good temperature resistance and lubricating property and excellent inhibition property and anti-sloughing wall fixation property and can effectively prevent thefractured igneous rock formation from collapsing; the rock carrying capability of the drilling fluid can be substantially improved, repeated grinding of larger falling blocks nearby a drill bit is prevented, the frictional resistance is reduced, the mechanical drilling speed is increased, and underground safety is guaranteed.

Owner:CHINA PETROLEUM & CHEM CORP +1

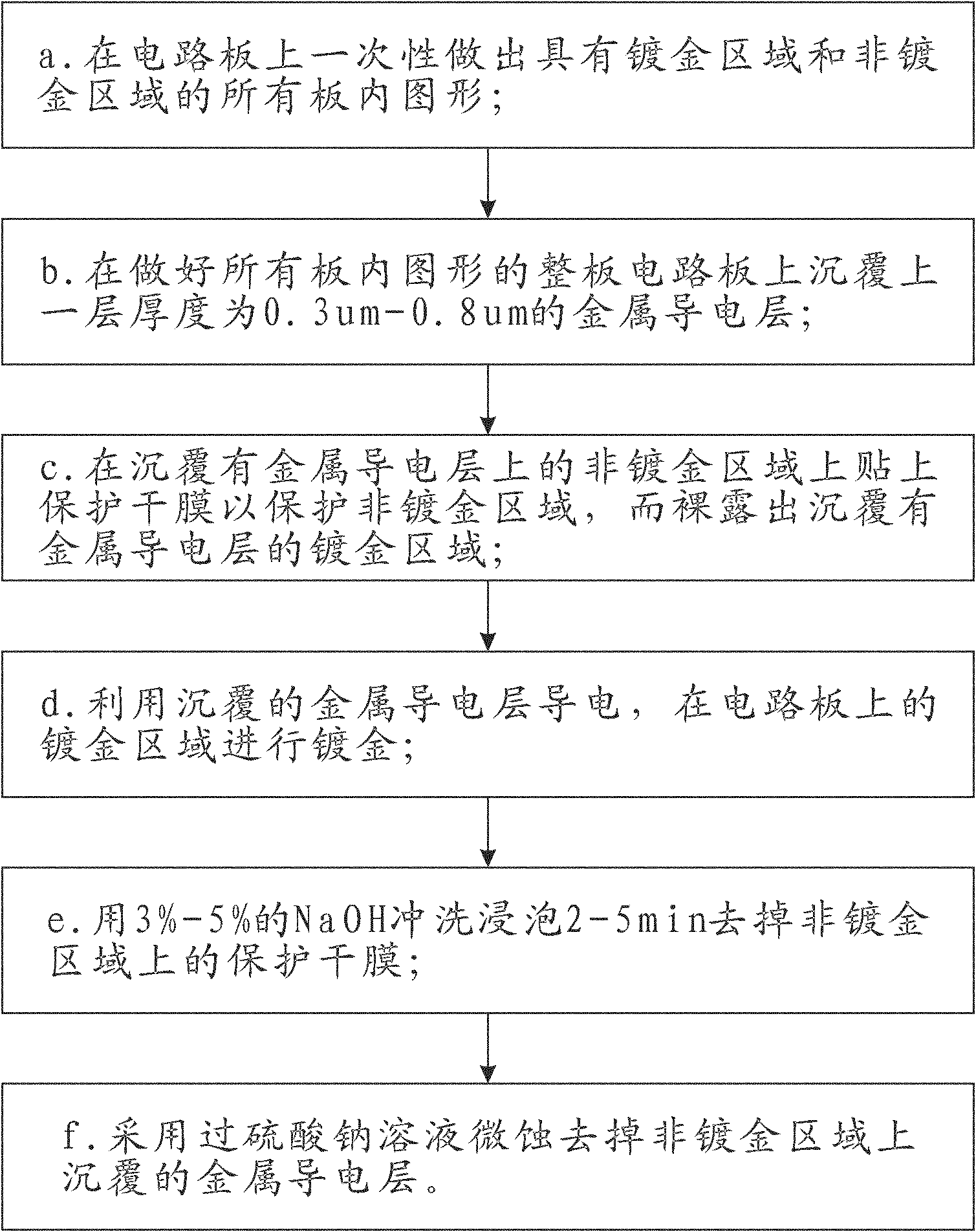

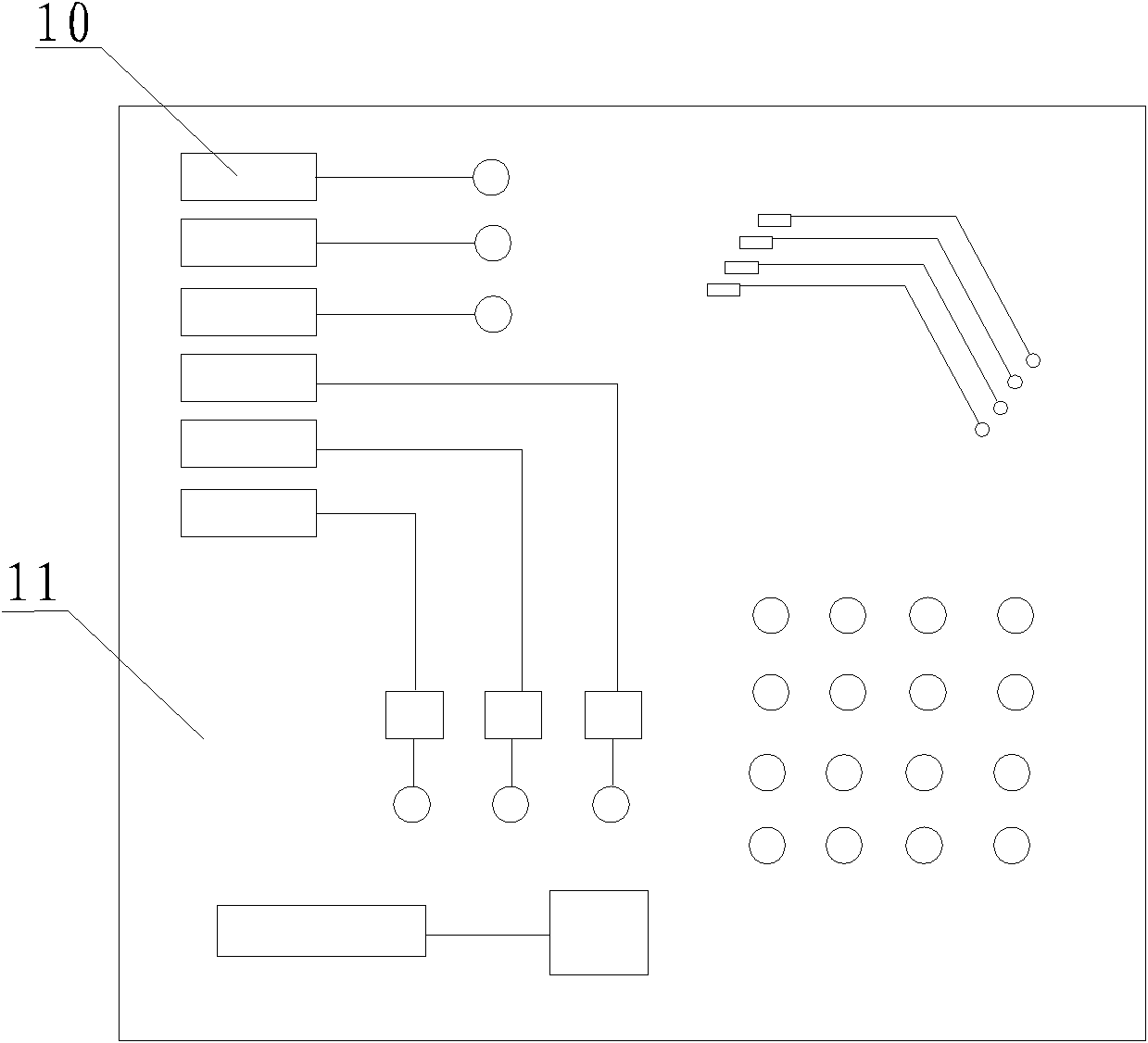

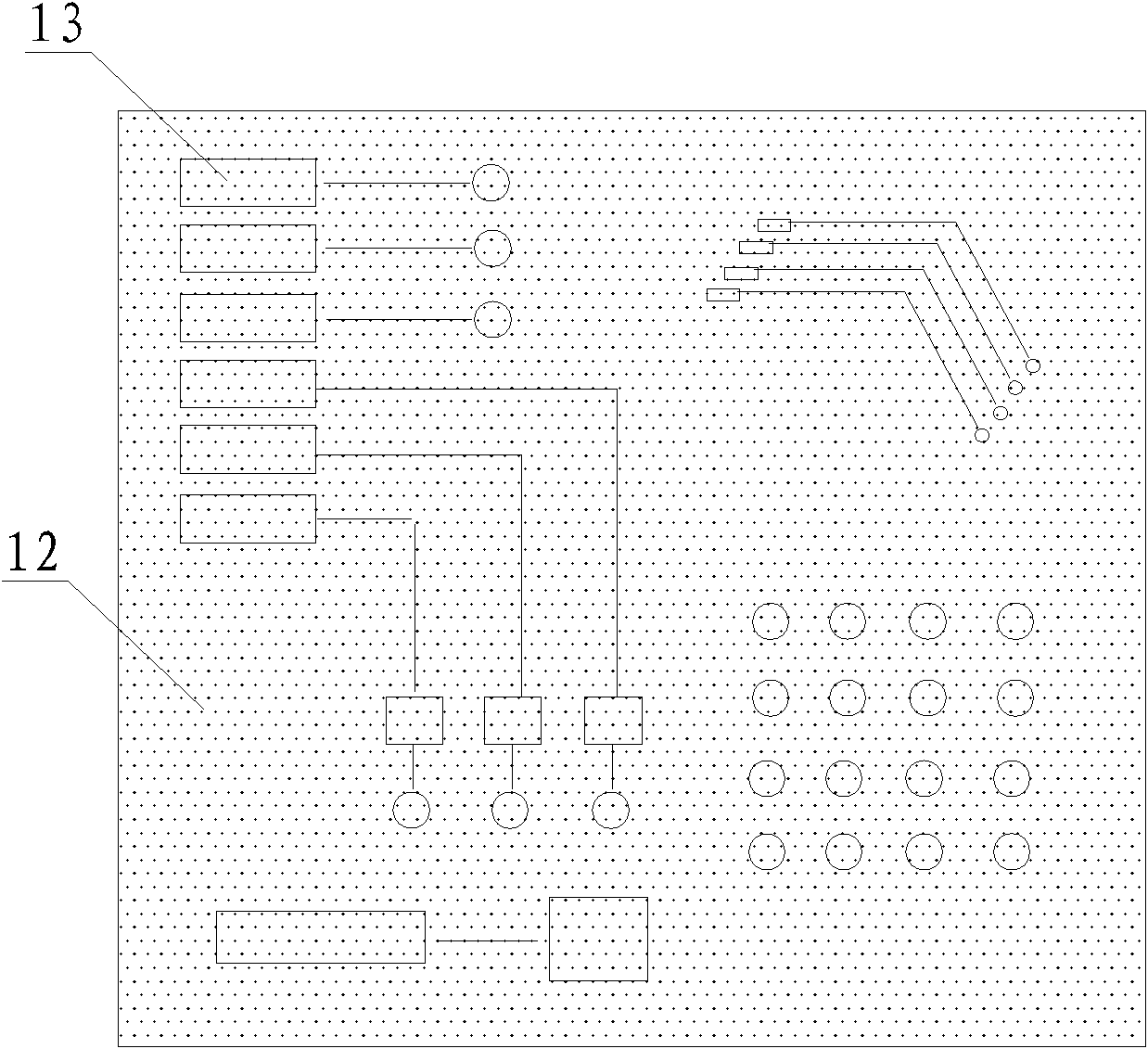

Manufacturing process of whole gold-plated panel

InactiveCN102026491ASolve the collapseCollapse will not occurConductive pattern reinforcementMicroetchingMetal

The invention discloses a manufacturing process of a whole gold-plated panel, comprising the following steps: a. all in-panel graphs with gold-plated regions and non gold-plated regions are manufactured on a circuit board by one time; b. a metal conducting layer with the thickness of 0.3-0.8mu m is coated on the circuit board of the whole panel with manufactured in-panel graphs in a settling way; c. a protective dry film is adhered on the non gold-plated region coated with a metal conducting layer to protect the non gold-plated region, and the gold-plated region coated with a metal conducting layer is exposed; d. the coated metal conducting layer is utilized for electric conduction, and gold plating is carried out on the gold-plated region of the circuit board; e. the protective dry film on the non gold-plated region, which is flushed and soaked by 3-5 percent NaOH for 2-5 minutes, is removed; and f. a sodium peroxydisulfate solution is used for removing the metal conducting layer on the non gold-plated region through microetching. The process in the invention overcomes the disadvantages of gold plating diffusion coating, under etching, poor gold plating quality, collapsed gold plating regions and process limitations in the prior art.

Owner:SHENNAN CIRCUITS

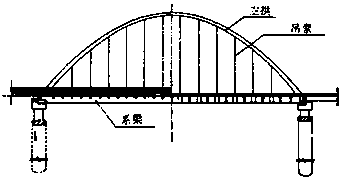

Self-anchored cable-stayed tied arch bridge

PendingCN111335142AIncrease stiffnessImprove leaping abilityBridge structural detailsBridge erection/assemblyContinuous beamBridge engineering

The invention discloses a self-anchored cable-stayed tied-arch bridge. The bridge is a beam, arch and cable novel combined system bridge with a main span adopting through rigid arch rib rigid tie barsand a Nielson system flexible inhaul cable, the main span and a side span are three continuous spans, and cable-stayed self-anchored single-rib arches, double-rib arches or multi-rib arches and stiffening beams are arranged between side span continuous beams and arch ribs. And the double-rib arches and the multi-rib arches are transversely and rigidly connected through the cross beams and the wind braces to form a single-width, double-width or multi-width bridge. The bridge adopts a novel construction method of synchronous section-by-section suspension pouring or suspension splicing of beamsand arches. The novel bridge is large in spanning capacity, large in bearing capacity, novel in construction method, low in construction cost, self-balanced in beam arch, safe, free of risks, attractive in appearance, high in applicability and wide in application range. The tied-arch bridge can regain new vitality, the spanning capacity of the combined system bridge is further improved, and the combined system bridge is worthy of application and popularization in bridge engineering of expressways, railways, cities, countries and the like in China.

Owner:淮安市公路事业发展中心

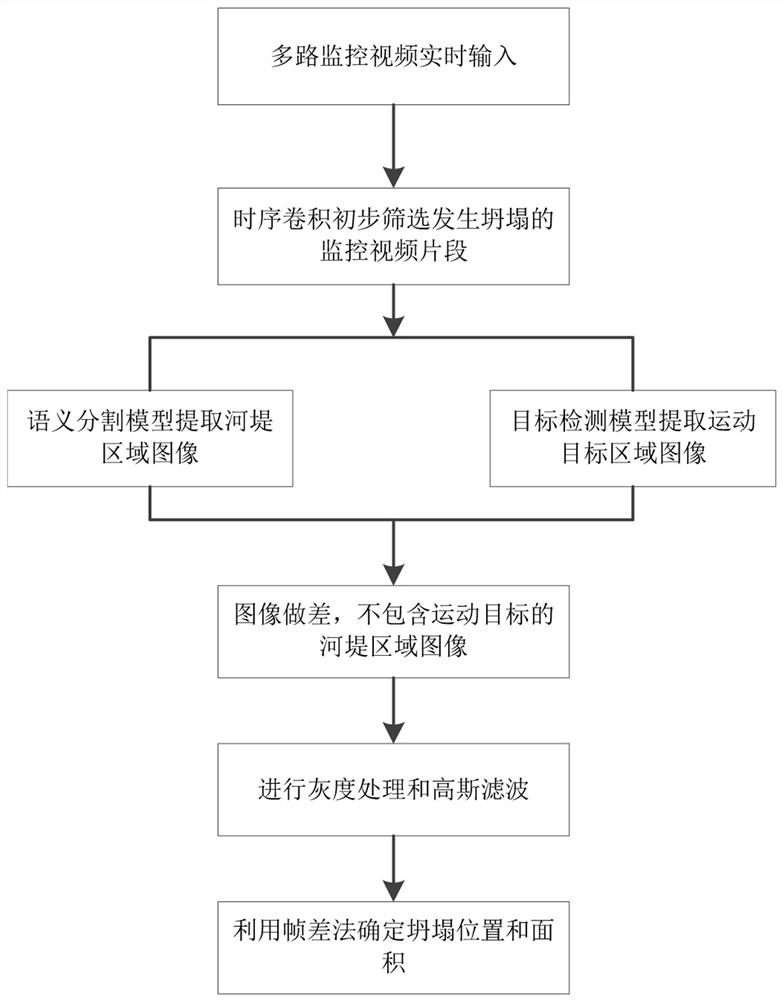

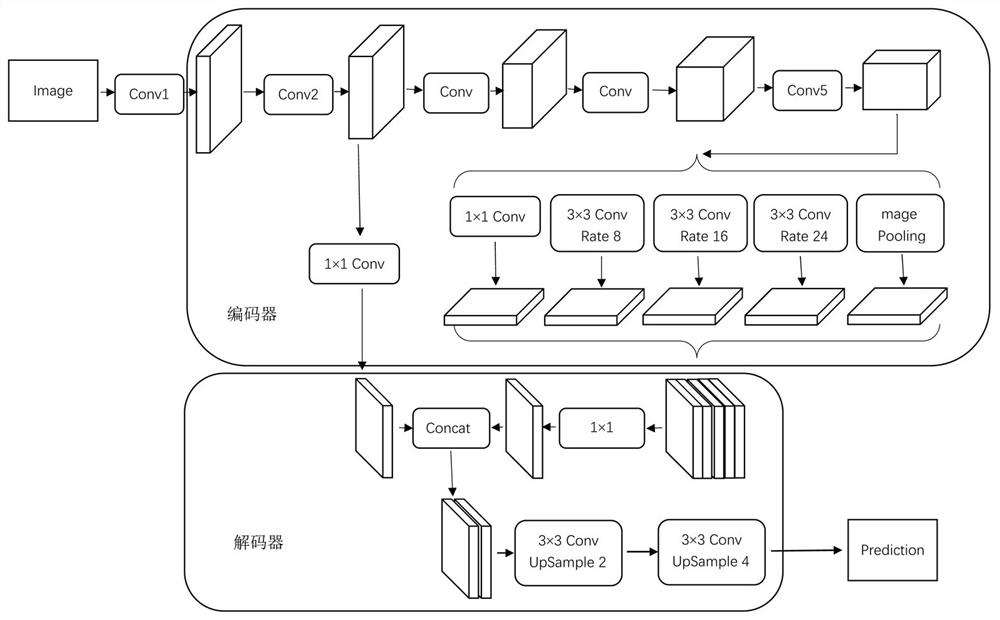

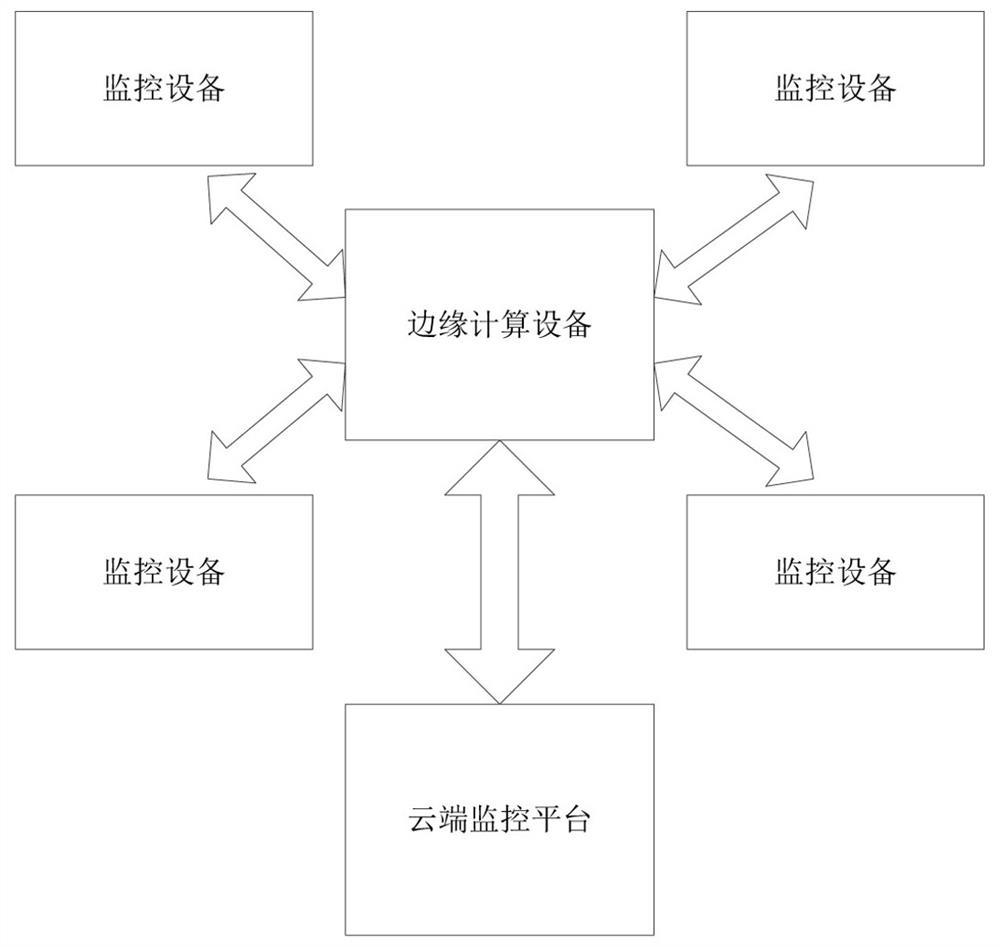

Automatic river levee collapse monitoring method

PendingCN111862143AAccurate detectionAccurately determineImage enhancementImage analysisLevee CollapseImage subtraction

The invention provides an automatic river levee collapse monitoring method. The method comprises the following steps: 1, acquiring monitoring videos of multiple paths of monitoring equipment in real time, and performing preliminary screening on the monitoring videos by using a time sequence convolution dynamic change monitoring video frame detection model to acquire monitoring video clips possiblyhaving river levee collapse; 2, performing moving target detection on the obtained monitoring video clip by using a moving target detection model to obtain a moving target region image; performing semantic segmentation detection on the obtained monitoring video clip by using a river levee detection semantic segmentation model, and extracting a river levee region image; 3, performing image subtraction on the extracted river levee area and the obtained moving target area to obtain a river levee area image not containing the moving target; 4, creating a Gaussian filter, performing gray processing and Gaussian filtering on the obtained river levee area image without the moving target, and establishing a background template; and 5, finally, determining the collapse position and area by utilizing a frame difference method.

Owner:郑州信大先进技术研究院

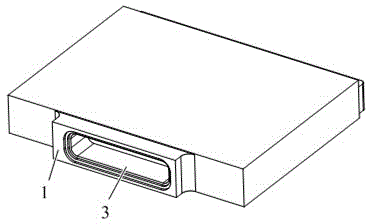

Processing method of aluminum-silicon shell

ActiveCN104923839ASolve crackingSolve the collapseMilling cuttersWorkpiecesEngineeringMachining process

The invention provides a processing method of an aluminum-silicon shell. The method includes the steps of (1) milling surfaces; (2) milling a rectangular stepped hole; (3) milling circular stepped holes; (4) milling an inner chamber. According to the method, the use of alloy-coating end mills which are of high hardness and good abrasive resistance allows blades to keep sharp for a long time and effectively avoids defects such as edge breakage and cracks during machining process of aluminum-silicon composites; dry cutting is utilized, pollution to the shell by cutting fluid and coolant is removed, and the quality of the back-end coating of the shell is improved; the use of the method for processing the aluminum-silicon shell has the advantages of high efficiency, good operability and good quality consistency of processed products.

Owner:NO 43 INST OF CHINA ELECTRONICS TECH GRP CETC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com