Laser additive repair method for titanium alloy valve rod

A laser additive and repair method technology, applied in the direction of additive processing, process efficiency improvement, additive manufacturing, etc., can solve the problems of strong tissue stress and mechanical constraint, complex thermal stress, large generation, etc., and the method is reliable. , easy to achieve, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] A TC4 valve stem laser additive repair method, comprising the following steps:

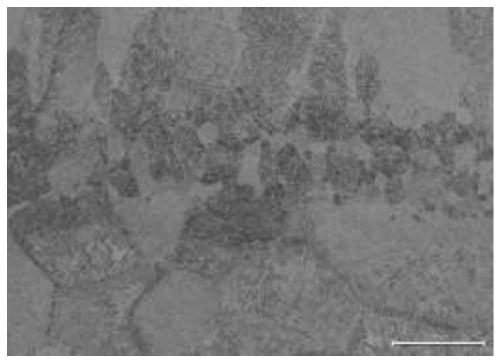

[0031] Step 1: Through the previous TC4 powder laser additive single-channel process experiment, optimize 3 sets of suitable parameters for multi-channel multi-layer laser material additive experiments, conduct metallographic observation on the cladding layer, and obtain the best process parameters (such as image 3 ).

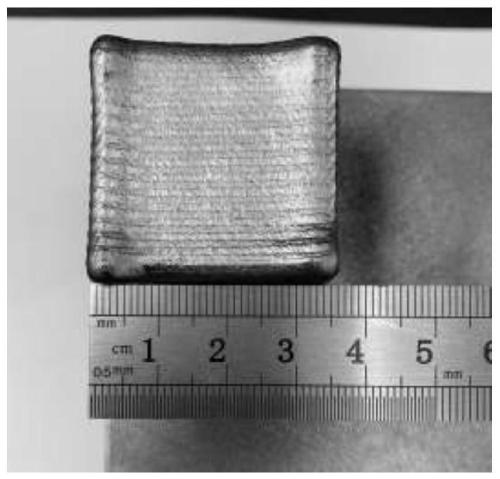

[0032] Step 2: Before repairing the titanium alloy valve stem, perform laser additive manufacturing of the titanium alloy performance test sample on the titanium alloy substrate (such as figure 2 ), and complete the tensile, impact and fatigue performance tests, evaluate the test results, and determine the final laser cladding repair process;

[0033] Step 3: Take photos and record the area to be repaired of the TC4 valve stem. The diameter of the valve stem is 60mm, the length of the area to be repaired is 200mm, and the depth of one side is 0.8mm, and the mechanical cle...

Embodiment 2

[0044] A TA2 valve stem laser additive repair method, comprising the following steps:

[0045] 1. Confirmation of valve stem wear

[0046] A certain type of valve stem, the material is TA2, the wear form: intensive scratches, the wear depth is about 0.5mm on one side, the length is 250mm, and the diameter is 65mm.

[0047] 2. Repair process and inspection

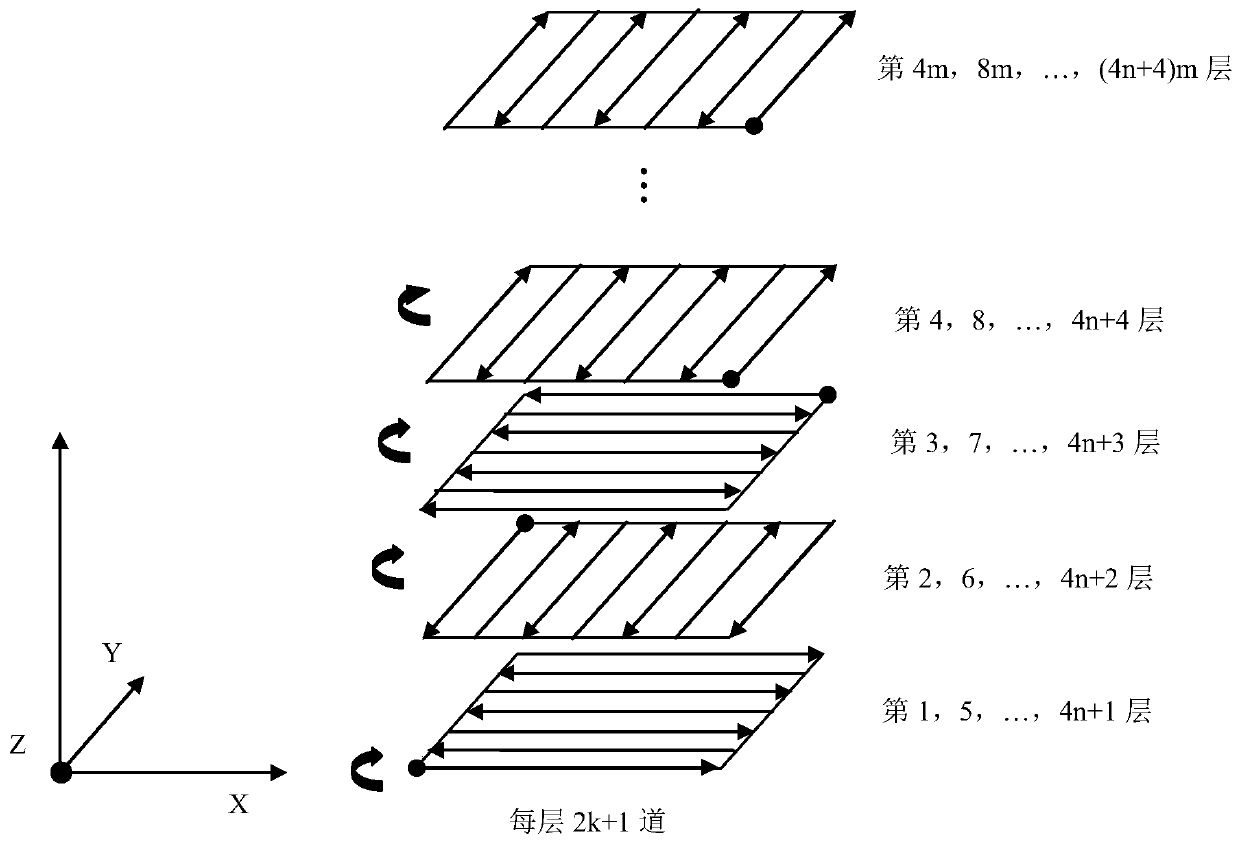

[0048] Step 1: Through the previous TA2 powder laser additive single-channel process experiment, 4 sets of suitable parameters were optimized for multi-channel multi-layer laser material additive experiments, and metallographic observation was carried out on the cladding layer to obtain the best process parameters (such as Figure 4 ). The optimal process experimental parameters of laser cladding are: laser power 800W, scanning speed 10mm / s, light spot 3mm, powder feeding volume 4g / min, powder feeding helium flow rate 5L / min, protective argon gas flow rate 20L / min, overlap rate 50%. The scanning path form of the multi-l...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com