Patents

Literature

101results about How to "Solve the problem of stomata" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Semiautomatic argon tungsten-arc welding technological process of bimetal compounding sea pipe

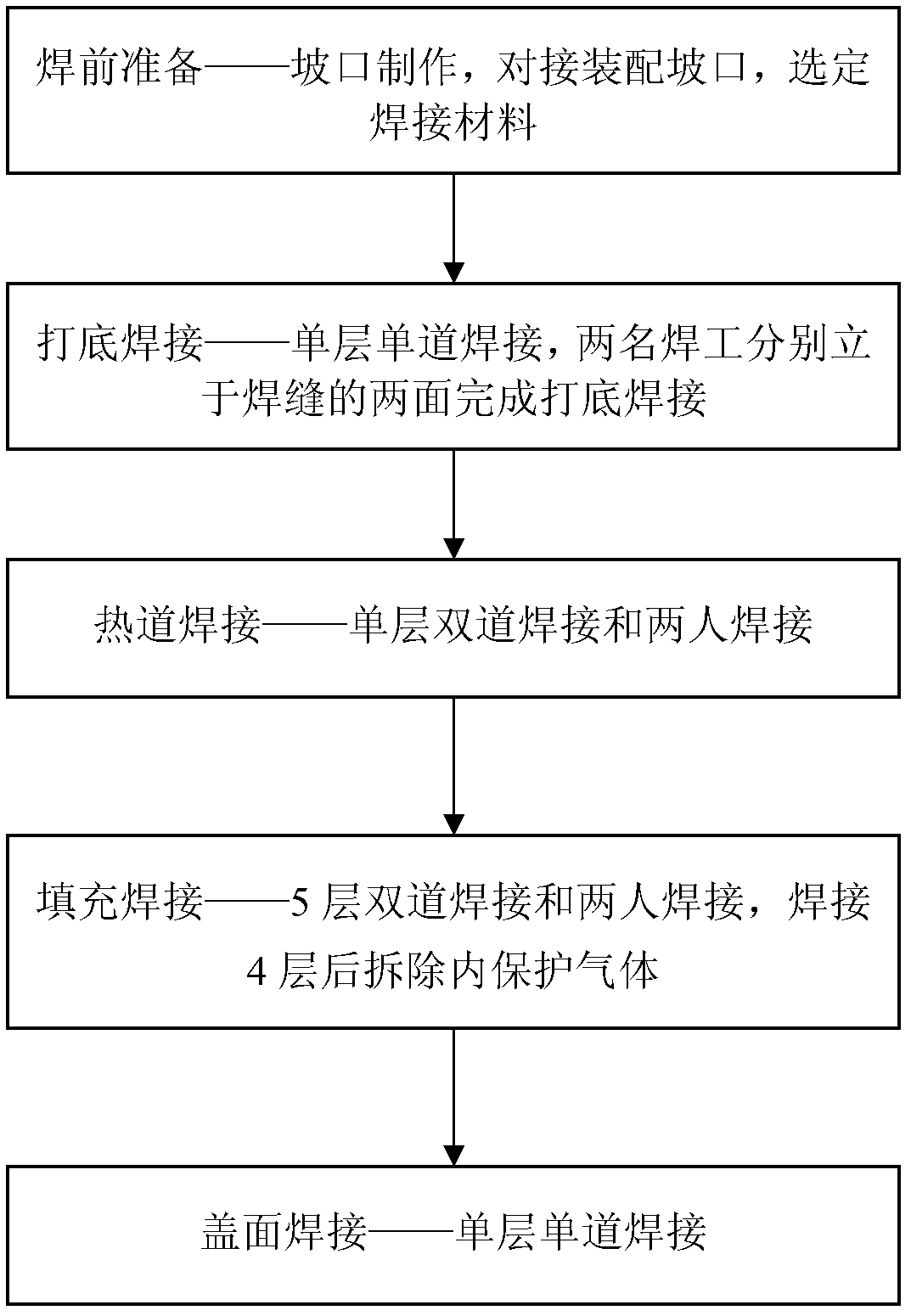

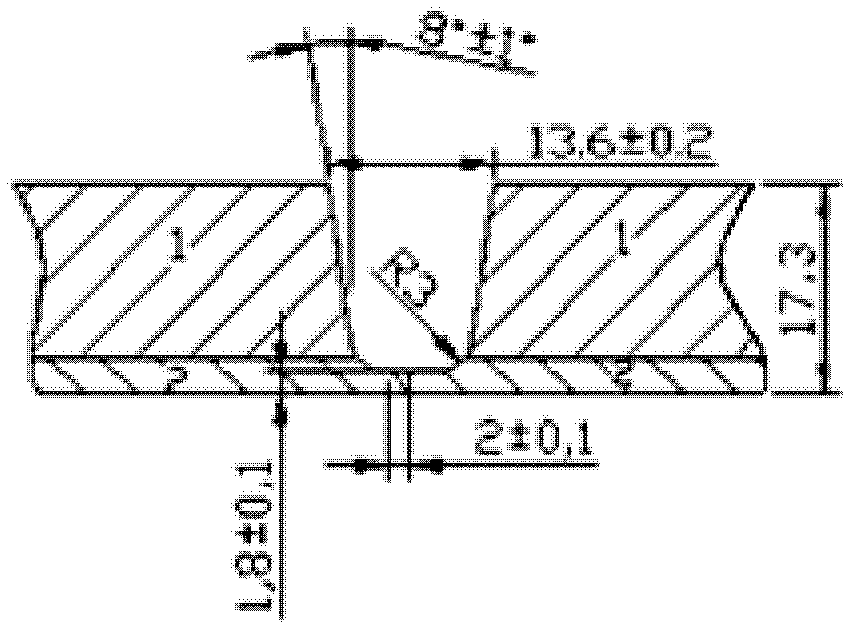

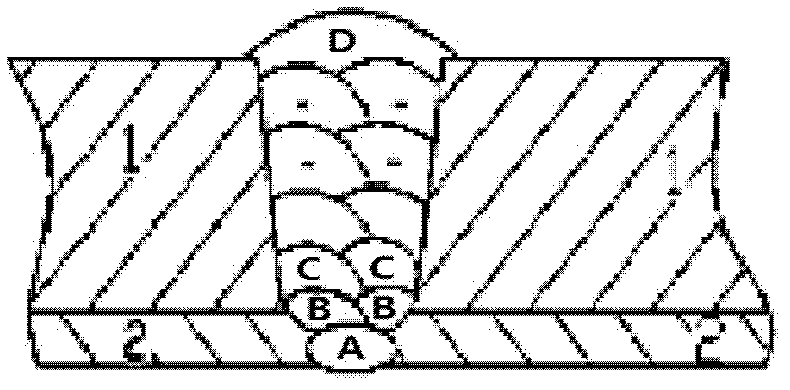

The invention relates to a semiautomatic argon tungsten-arc welding technological process of a bimetal compounding sea pipe, a labour hand-held semi-automatic welding gun welding is adopted, a wire feeder continuously feeds wires, and argon gas is utilized as protective gas. The technological process comprises the following operation steps of: firstly, procedure preparation before welding: manufacturing a groove, picking up fitting the groove, and selecting a welding material; secondly, backing welding process: adopting single layer one-pass welding, wherein two welders respectively stand thetwo sides of a welding seam so as to finish the backing welding; thirdly, hot-runner welding procedure: adopting single layer two-way welding and two-person welding; fourthly, filling welding procedure: adopting five-layer two-way welding and the two-person welding, and dismantling the protective gas after welding four layers; and fifthly, a cover surface welding process: adopting the single layer one-pass welding. The technological process provided by the invention has the advantages of high welding quality, small labour intensity, low construction cost, and high production efficiency; and the technological process is suitable for a compounding submarine pipeline and welding procedure of a subsidiary vertical pipe of the compounding submarine pipeline, and is suitable for the welding of a deep water composite material pressure container and deep water pipe manifold nickel base alloy and the like.

Owner:CHINA NAT OFFSHORE OIL CORP +2

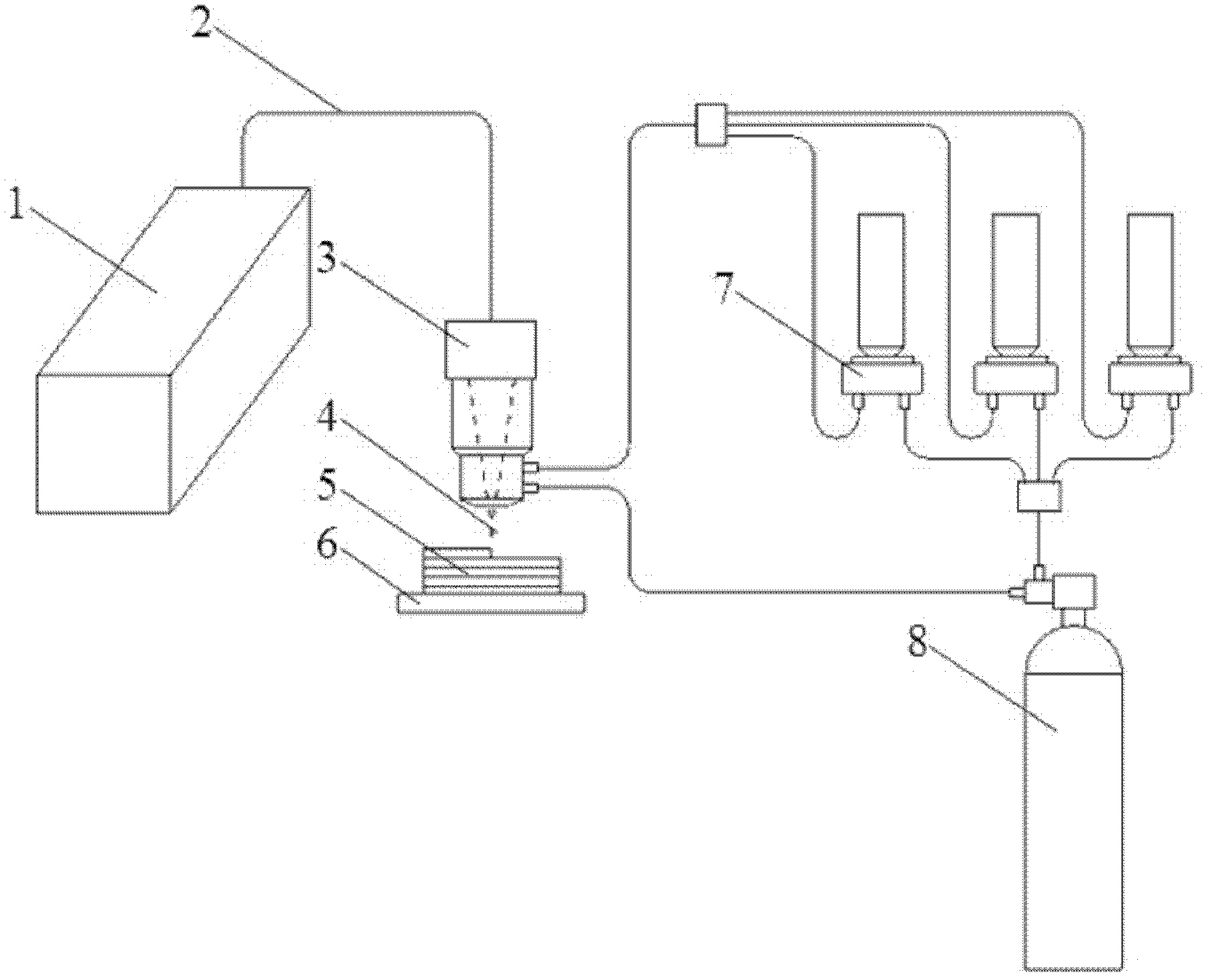

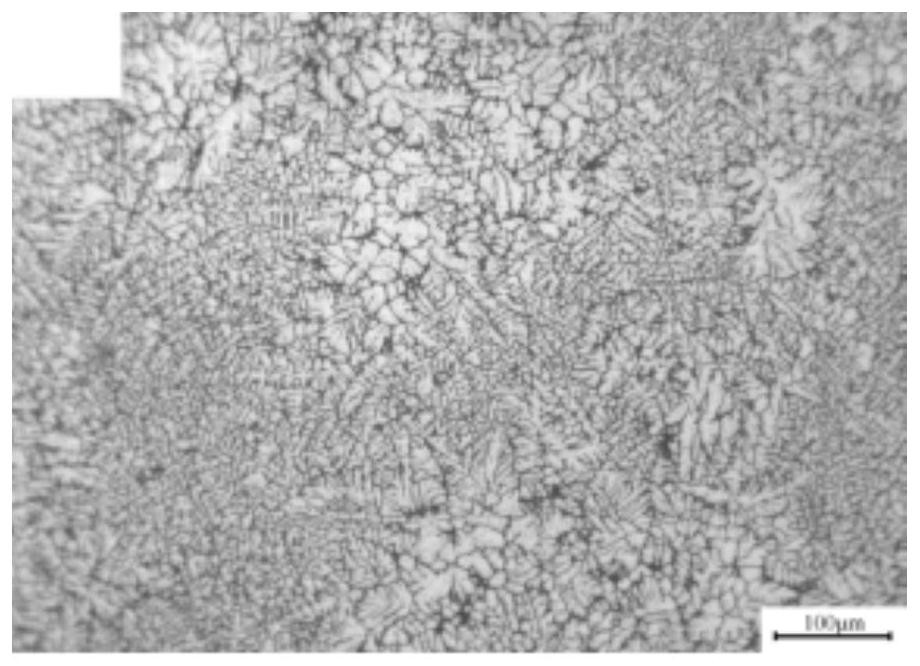

Laser additive repair method for titanium alloy valve rod

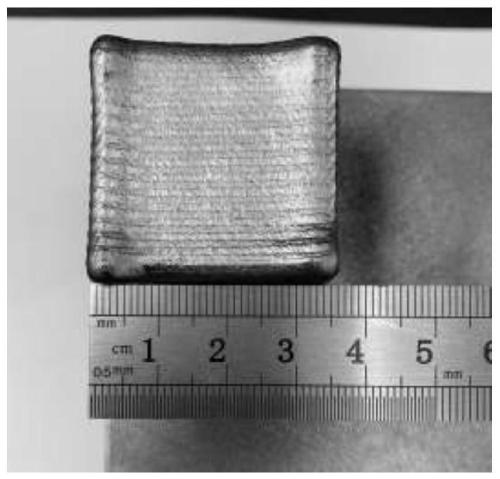

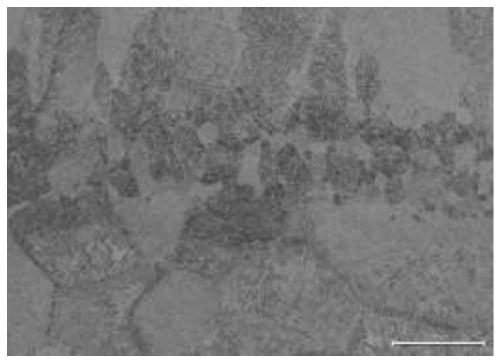

InactiveCN111451500AEasy to implementLow costAdditive manufacturing apparatusIncreasing energy efficiencySurface cleaningTest sample

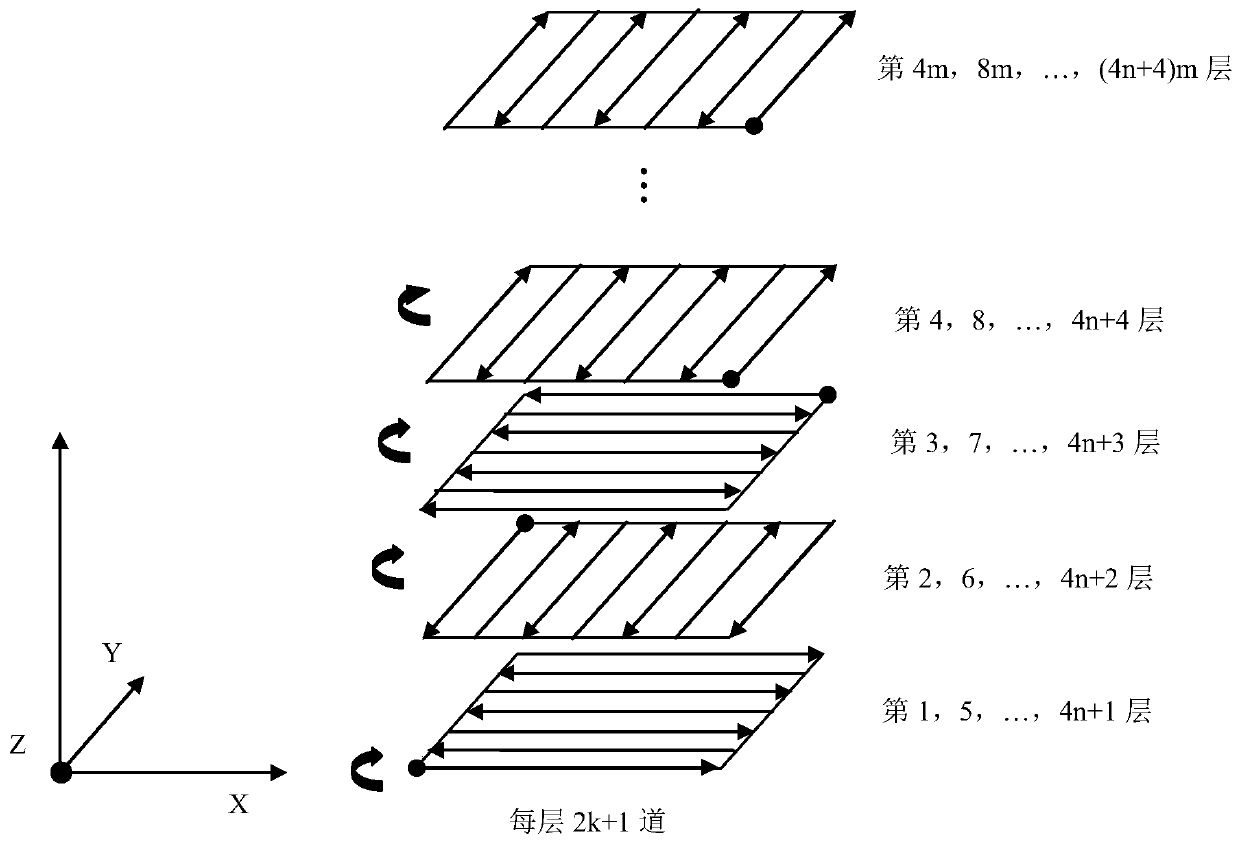

The invention discloses a laser additive repair method for a titanium alloy valve rod. The laser additive repair method for the titanium alloy valve rod comprises the following steps: optimizing parameters and carrying out a multi-pass multi-layer laser additive experiment through an earlier-stage single-pass laser additive process experiment for a titanium alloy powder, and carrying out metallographic observation on a cladding layer to obtain the optimal process parameters; carrying out laser additive manufacturing printing for a performance test sample piece of the titanium alloy on a titanium alloy substrate, completing a performance test, evaluating a test result, and determining a repair process; carrying out photographing recording on an area to be repaired, and completing surface cleaning; carrying out accurate clamping on the titanium alloy valve rod, and locking the end part by a center; reserving machining allowance in an additive repair damage area carrying out coaxial powder feeding through laser, setting a scanning path to be spiral forward, enabling the left end and the right end of a starting point position to be alternating and rotate clockwise with time difference,and controlling temperature rise of the workpiece; and adopting fluorescence detection, machining according to the requirement of a drawing to restore a size, and delivering and using. According to the laser additive repair method for the titanium alloy valve rod, the requirement of safe use for the titanium alloy valve rod in a life cycle is guaranteed by optimizing the laser additive process parameters and a scanning path strategy.

Owner:航发优材(镇江)增材制造有限公司

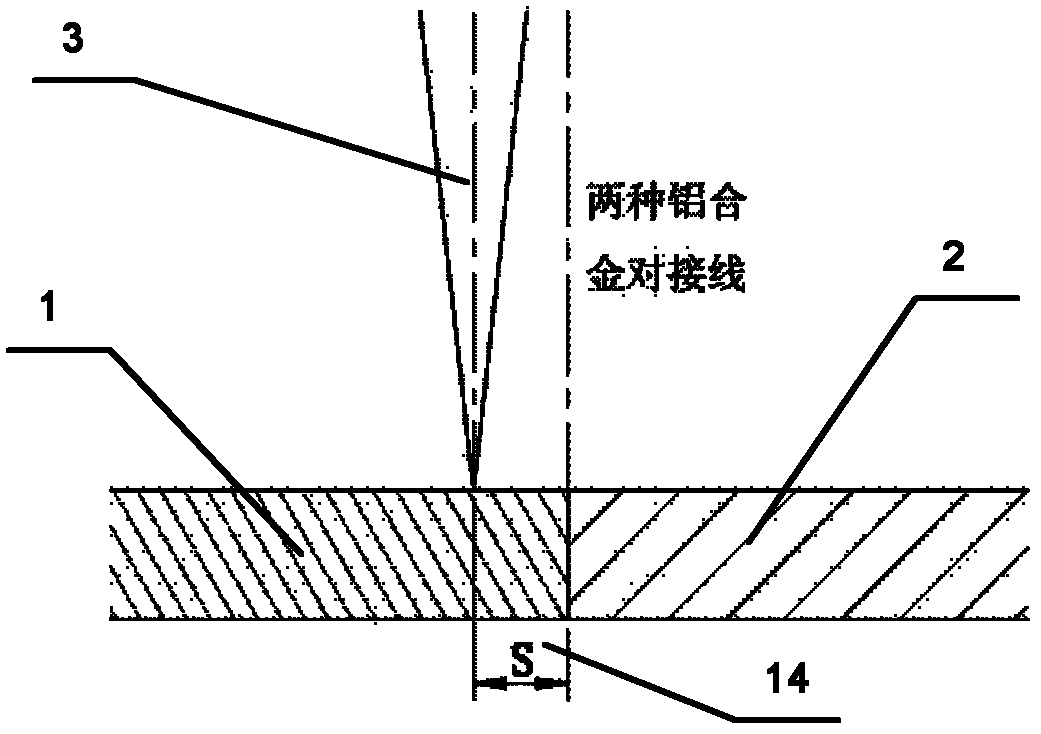

Method for connecting 2XXX and 7XXX heterogeneous aluminum alloy by laser filler wire

InactiveCN102357734AWeld firmlyReduce the temperatureLaser beam welding apparatusAdditive ingredientButt joint

The invention discloses a method for connecting 2XXX and 7XXX heterogeneous aluminum alloy by the laser filler wire, which is suitable for the connection field of 2XXX and 7XXX-series of heterogeneous aluminum alloy. The method comprises the following steps of: firstly, assembling two aluminum alloy plates to be welded into a butt joint mode; regulating position relationship among a laser focal point, the wire falling point of an aluminum alloy welding wire and a butt joint gap between two aluminum alloy plates to ensure that the laser beam, the welding wire and the welded aluminum alloy plates are positioned on the reasonable opposite positions; and adopting reasonable welding parameters, laser power, welding speed, wire conveying speed and the like, utilizing AlCu or Alsi welding wires as filler material in the welding process to regulate the ingredient of the welding line and improve the performance of the joint. According to the method, the problems that the 2XXX and 7XXX heterogeneous aluminum alloy is difficult to connect, the welding line is softened during melting, and heat checking tendency exists can be solved.

Owner:BEIJING UNIV OF TECH

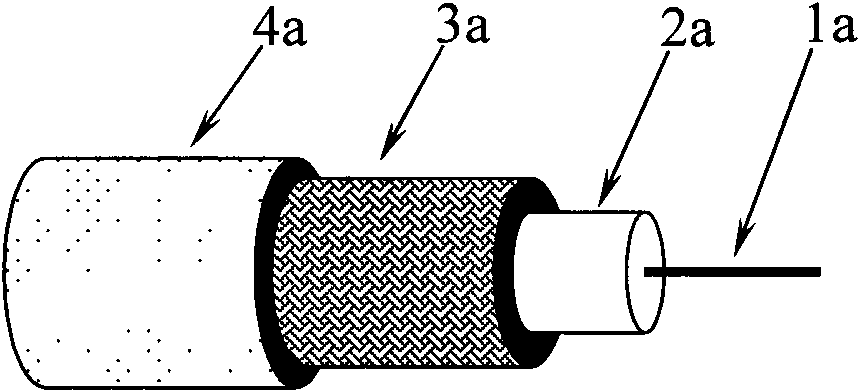

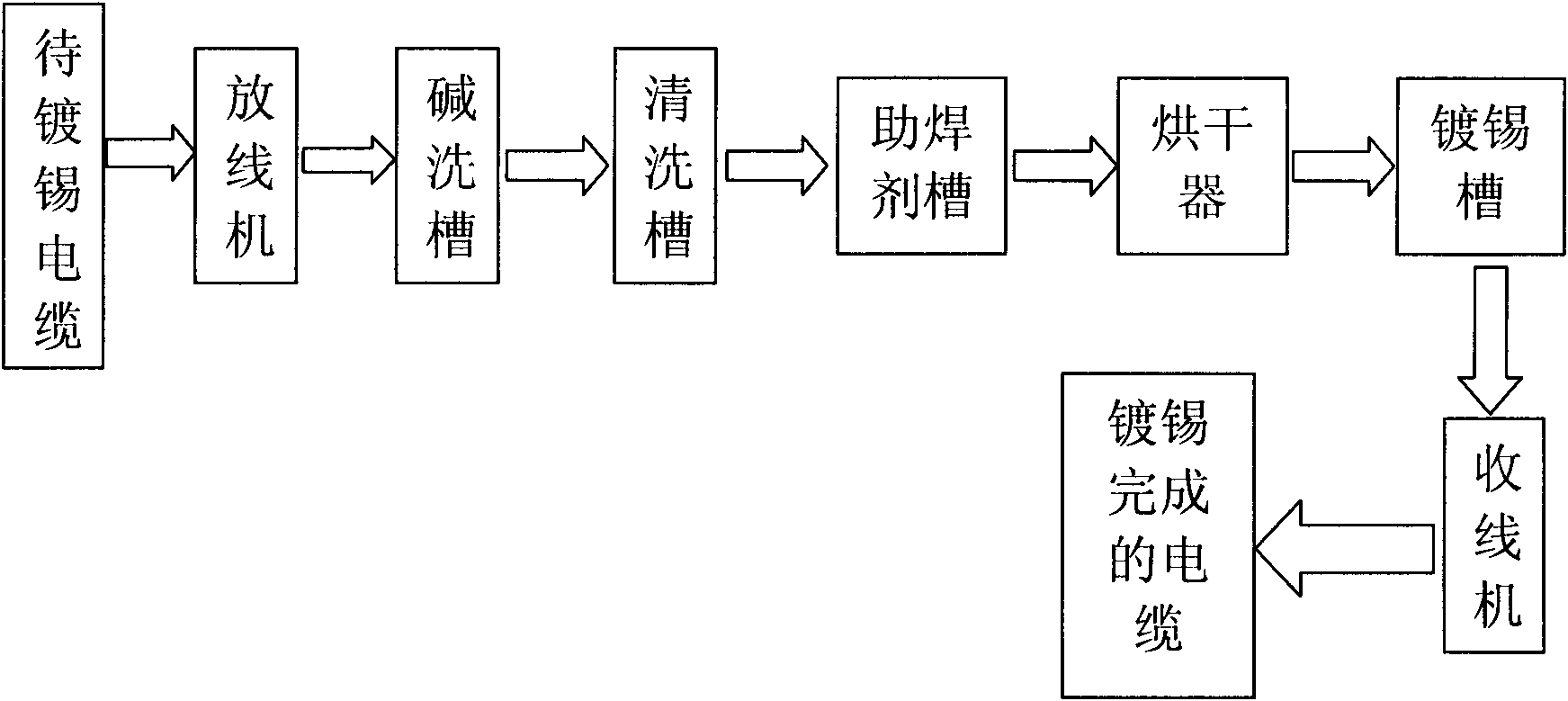

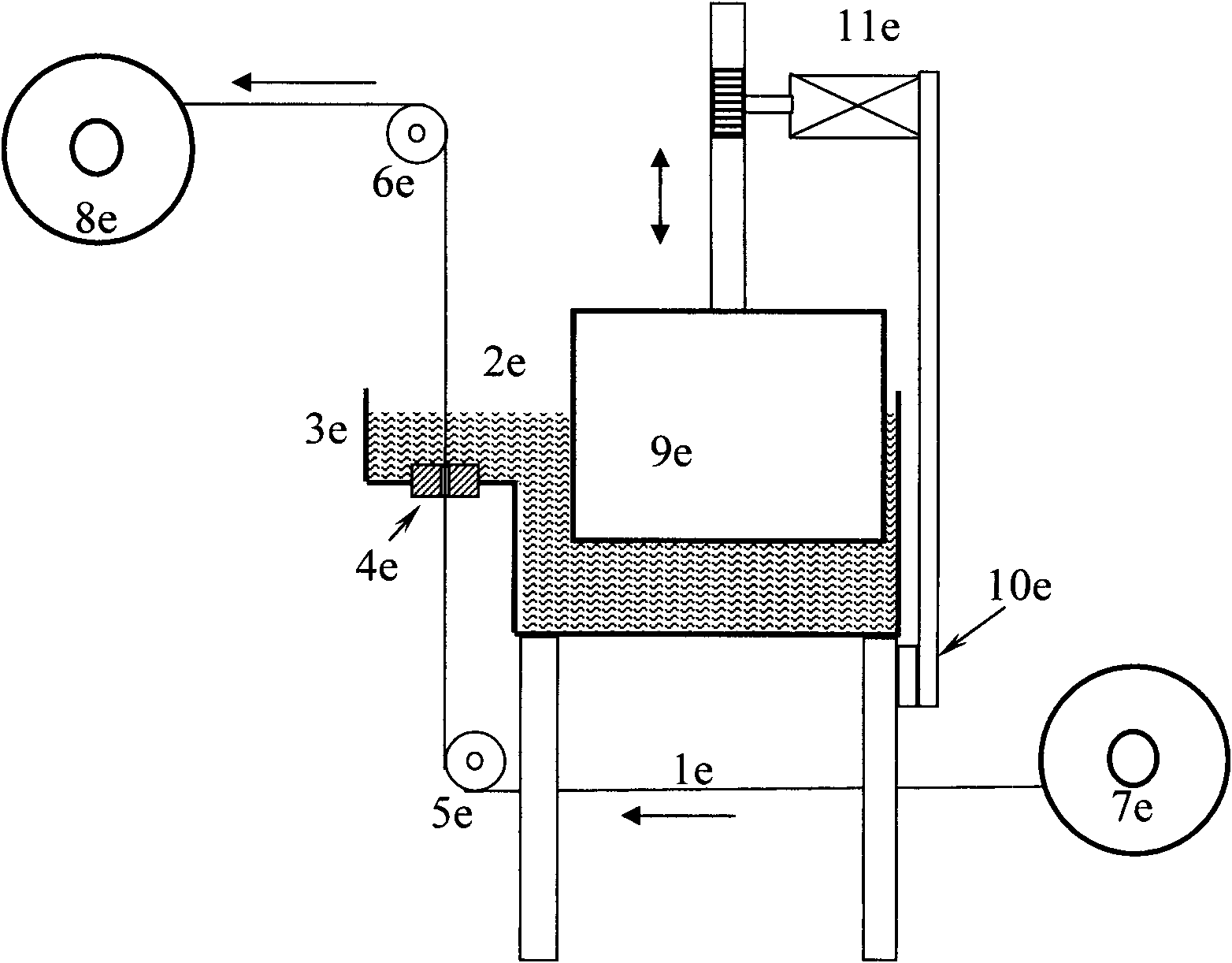

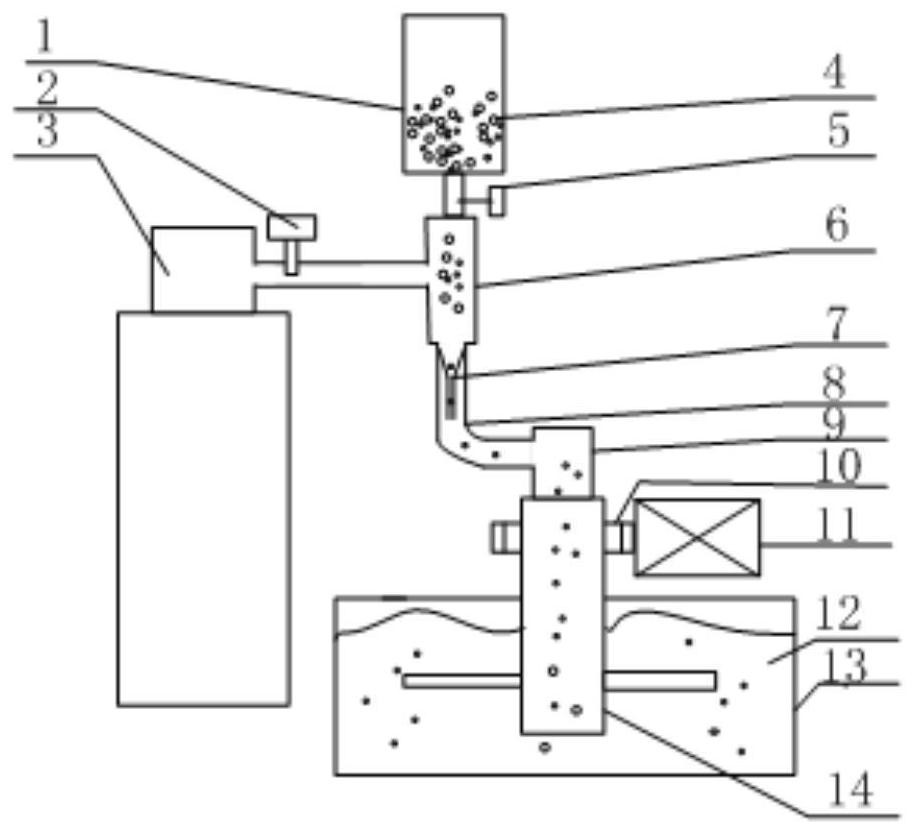

Vertical tinning equipment for semi-flexible coaxial cable shielding layer and tinning method thereof

InactiveCN101603166AShort staySolve the lack of adhesionHot-dipping/immersion processesEngineeringTinning

The invention provides vertical tinning equipment for a semi-flexible coaxial cable shielding layer, which comprises a pay off machine and a wire-receiving machine for paying out and receiving wires, a tinning groove, a lower guide wheel positioned below the tinning groove and an upper guide wheel positioned above the tinning groove; and the tinning groove is arranged on a stand. The invention also provides a vertical tinning method for the semi-flexible coaxial cable shielding layer; the method is a two-step method rapid tinning process which comprises a pretreatment process and a vertical tinning process. The invention has the advantages that the vertical tinning equipment and the vertical tinning method are used to tin the semi-flexible coaxial cable shielding layer, shorten the residence time of a cable in the tinning groove and the immerging length in tin liquid, effectively solve the problems of air vents existing in the coaxial cable tinning process and insufficient adhesive force of a tin layer to a shielding net and improve the tinning quality; and simultaneously, a high tinning speed and the two-step method tinning process are adopted, so the production efficiency is improved and the waste of material head and tail of the cable are reduced.

Owner:QIDONG CHUANGLU NEW MATERIAL CO LTD

CaO-MgO-Al2O3-SiO2 microcrystalline glass and preparation method thereof

InactiveCN102173592ALower crystallization activation energyImprove growth indexDevitrificationActivation energy

The invention discloses a CaO-MgO-Al2O3-SiO2 microcrystalline glass which is composed of glass aggregate and oxide nucleating agent accounting for 3wt% of glass aggregate, wherein the glass aggregate is composed of the following components in percentage by weight: 50-55wt% of SiO2, 6-10wt% of MgO, 15-18wt% of CaO, 10-12wt% of Al2O3, 3-6wt% of Na2O and / or K2O, 8wt% of CaF2 and 1wt% of Sb2O3. The invention simultaneously provides a preparation method of the CaO-MgO-Al2O3-SiO2 microcrystalline glass. In the CaO-MgO-Al2O3-SiO2 microcrystalline glass, nucleating agent of oxide and fluoride is adopted, so that the devitrification activation energy of a system is lowered, a crystal growth index is improved, and the devitrification capability of the microcrystalline glass is greatly enhanced, thereby bringing convenience for preparing the microcrystalline glass with a whole method.

Owner:ZHEJIANG UNIV

Processing method of sand core in engine aluminum alloy cylinder metal mould low-pressure casting

ActiveCN101497109AReduce moisture contentLack of angerFoundry mouldsFoundry coresPressure castingMetal mold

The invention relates to a casting technique, in particular to a method for processing a metal mold low-pressure casting medium sand core for an aluminum alloy cylinder of an engine, wherein a method for coating a coating layer, removing water content and drilling vent holes is adopted to process the sand core so as to achieve the aim of preventing phenomena of sand inclusion, air holes, looseness, cracks, and the like.

Owner:SHANGHAI AISHIDA AUTOMOTIVE COMPONENTS

Transition phase assisted low-temperature sintering method of boron nitride multi-phase ceramic

ActiveCN105198443AConducive to initial sintering densificationFacilitate the realization of initial sintering densificationCeramic sinteringBoron nitride

The invention discloses a transition phase assisted low-temperature sintering method of boron nitride multi-phase ceramic and relates to a sintering method of boron nitride multi-phase ceramic. The invention aims at solving the problems that the crystal grains of the prepared multi-phase ceramic are coarse and the mechanical performance is poor for a reason that the sintering temperature of the existing boron nitride multi-phase ceramic. The method comprises the following steps: 1) preparing composite sintering assistant powder; 2) preparing composite powder; 3) increasing the temperature of the composite powder under a vacuum or inert atmosphere condition, increasing pressure and then decreasing the temperature to obtain the boron nitride multi-phase ceramic. The compactness of the boron nitride multi-phase ceramic prepared by adopting the method disclosed by the invention can reach more than 95 percent, the crystal grains of the material are fine and the comprehensive mechanical performance is excellent. The invention belongs to the field of preparation of boron nitride multi-phase ceramics.

Owner:HARBIN INST OF TECH

Oil-resistant wear-resistant coating material

InactiveCN105968888AGood antifouling performanceRelieve interface residual stressAntifouling/underwater paintsPaints with biocidesIonWear resistant

The invention discloses an oil-resistant wear-resistant coating material, which is prepared from the following raw materials (by weight): 5-8 parts of aluminium oxide, 12-15 parts of glass glaze, 13-15 parts of triethoxyvinylsilane, 70-80 parts of zirconia ceramic powder, 8-10 parts of alumina sol, 2-3 parts of copper oxide, 6-8 parts of graphene, a proper amount of anhydrous ethanol and a proper amount of deionized water. By ingenious utilization of adhesion property of glass glaze, the coating has good adhesion with a base material. The prepared coating contains no toxic or harmful substances, has high strength, is simple to prepare, is low-cost, and has a wide range of application.

Owner:MAANSHAN JINSHENG IND DESIGN

Novel reinforcement technique of 6XXX aluminum alloy welding joint

InactiveCN103572180AIncrease densityImprove mechanical propertiesSolution treatmentUltimate tensile strength

The invention discloses a novel reinforcement technique of a 6XXX aluminum alloy welding joint, mainly solves the defects such as high cost, large equipment and noise, complex operation, workpiece damage, additional consumption of materials and energy, additional increment of workpiece weight and residual stress, reduction of workpiece plasticity and air hole mingling in the traditional reinforcement methods of the 6XXX aluminum alloy welding joint, and achieves the reinforcement effect to the 6XXX aluminum alloy welding joint. The technique comprises the specific operation steps of solution treatment, subzero treatment and ageing treatment. The technique has the advantages of simple technique, low cost, ideal reinforcement effect, energy conservation, environmental protection and largely improved strength and plasticity, can effectively solve the problems of air holes and mingling inside the joint, and has excellent industrial application prospect.

Owner:葛鹏

Iron white copper and austenitic stainless steel arc melting and welding method

ActiveCN101323043ASolve the problem of prone to thermal cracksSolve the problem of stomataArc welding apparatusWelding/soldering/cutting articlesAustenitic stainless steelMetallic Nickel

The invention discloses an electric arc melting welding method of copper-nickel-iron alloy and austenitic stainless steel, which is an electric arc melting welding method that adopts the direct current welding power supply with the output current being more than 300A, uses pure helium as protective gas and adds nickel-copper alloy welding wires for welding a welded joint between a thick-wall large-diameter copper-nickel-iron alloy pipe and the austenitic stainless steel in the welding process. The method is characterized in that in the welding process, a tungsten electrode with the diameter of Phi3.2 to 4mm is adopted, the pure helium is used for protection and the nickel-copper alloy welding wires of Phi 2 to 4mm are added for welding; at the same time, the welding current is guaranteed to reach 180 to 300A and the flow volume of the protective gas is 10 to 15L per minute. The method has the positive effects of solving the problems of the welding of the welded joint between the thick-wall large-diameter copper-nickel-iron alloy and the austenitic stainless steel, so as to avoid the problem that hot cracking and stomata are easy to appear in the welding process.

Owner:渤海造船厂集团有限公司

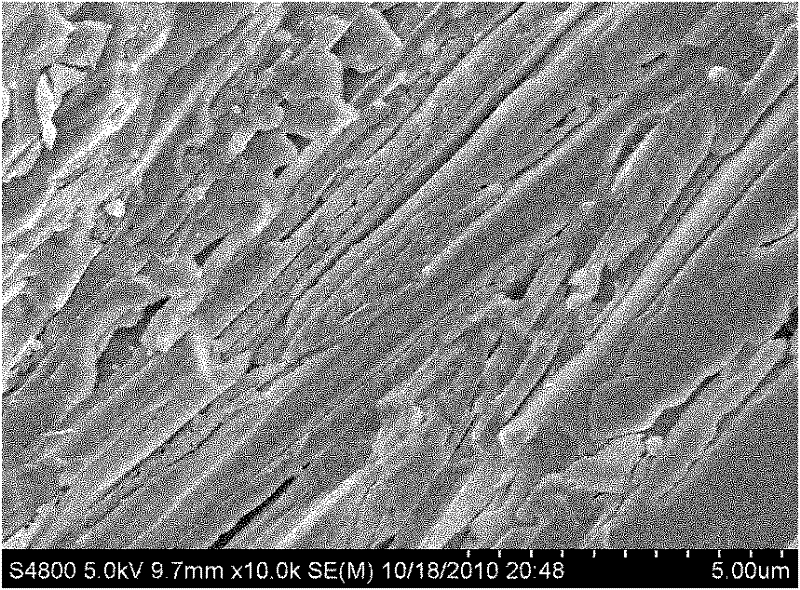

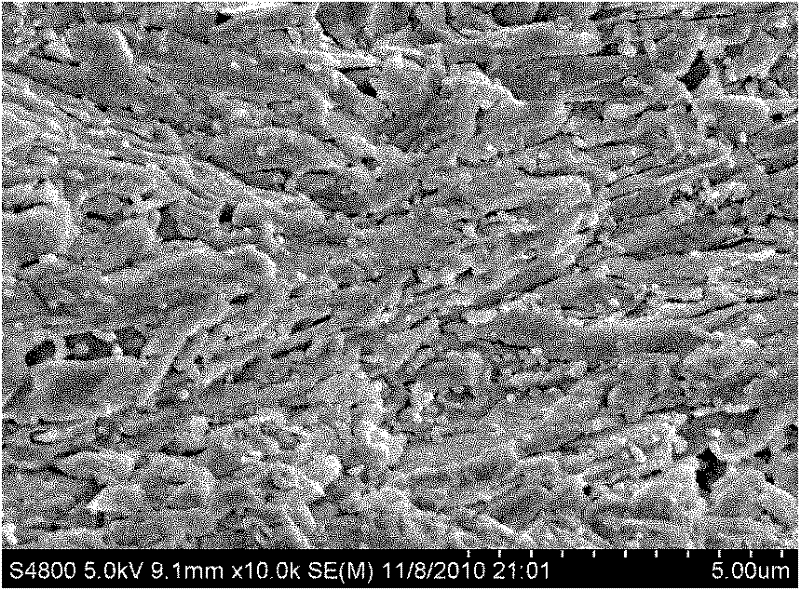

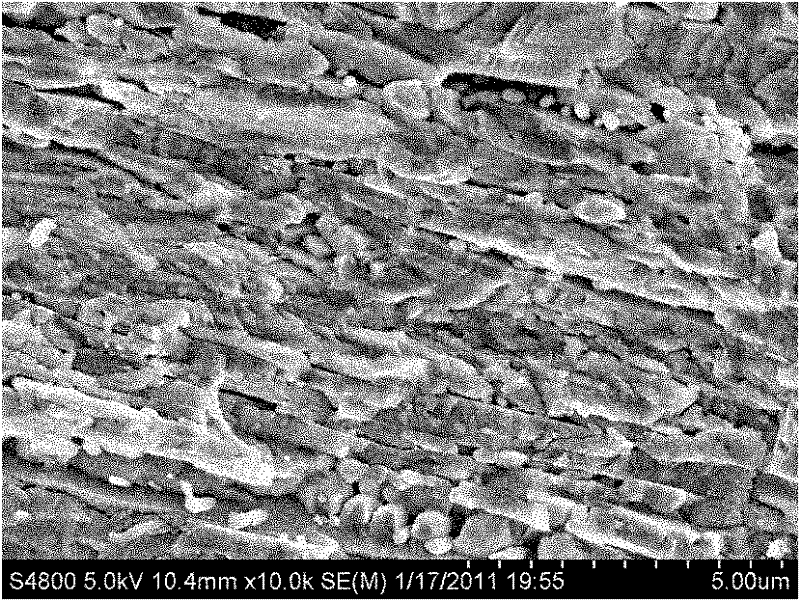

Process for preparing permanent magnetic ferrite through two-stage ball milling and mixture

The invention relates to the field of electromagnetic materials, and particularly provides a process for preparing permanent magnetic ferrite through two-stage ball milling and mixture. The process comprises the following steps: mixing a ferrite pre-sintering material, steel balls and water in a ball mill, sequentially adding boric acid and ammonium hydrogen carbonate, performing ball milling, precipitating and discharging. Particularly, the boric acid and ammonium hydrogen carbonate are added in the ball milling process instead of boric acid, thereby solving the problems of strontium escape in the production process of the current permanent magnetic ferrite product, gas hole formation in the sintering process, high product cracking possibility and the like; the yield is improved; the ammonium hydrogen carbonate is low in price, thereby effectively lowering the cost; and remarkable economic benefits are achieved.

Owner:JINTAN MAGNETIC MATERIAL

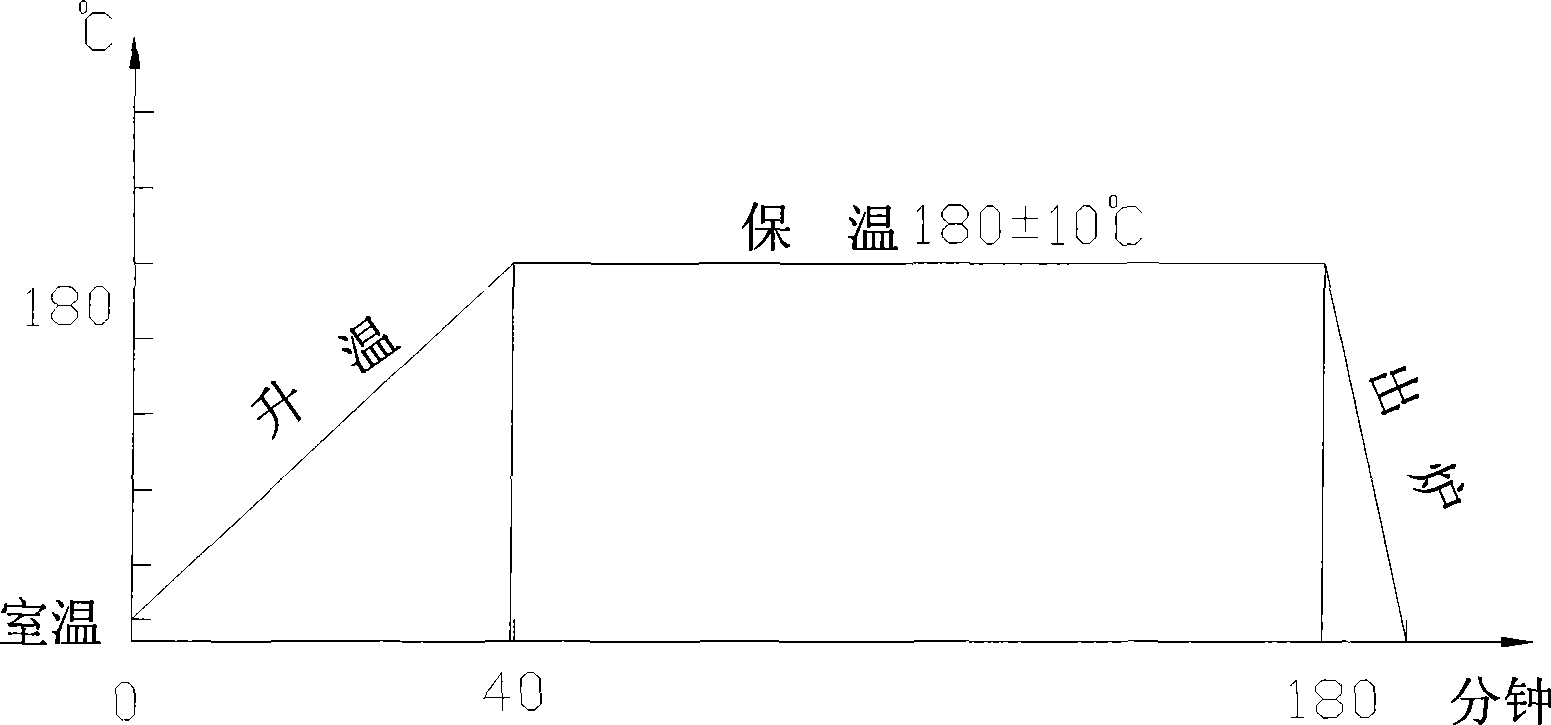

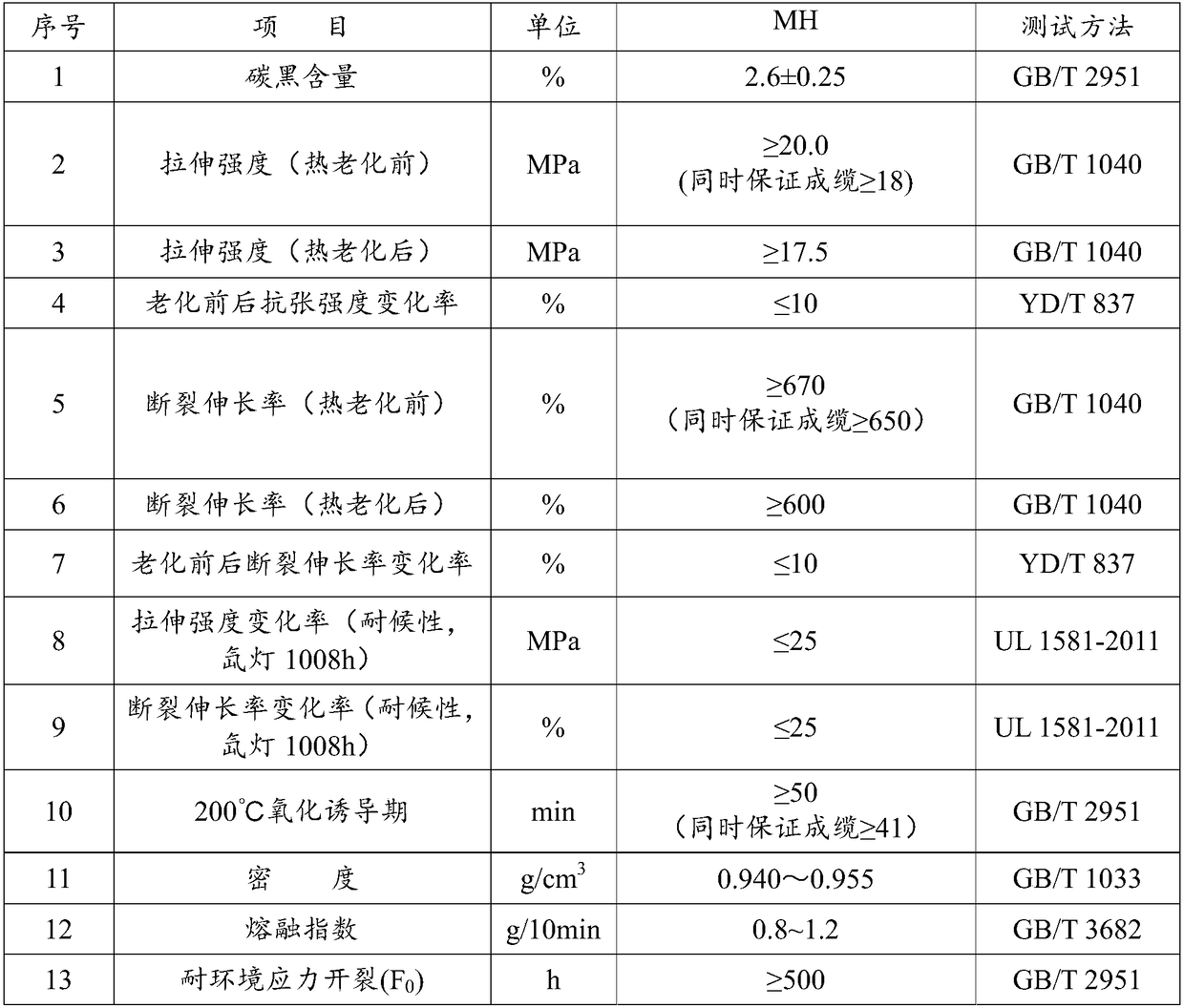

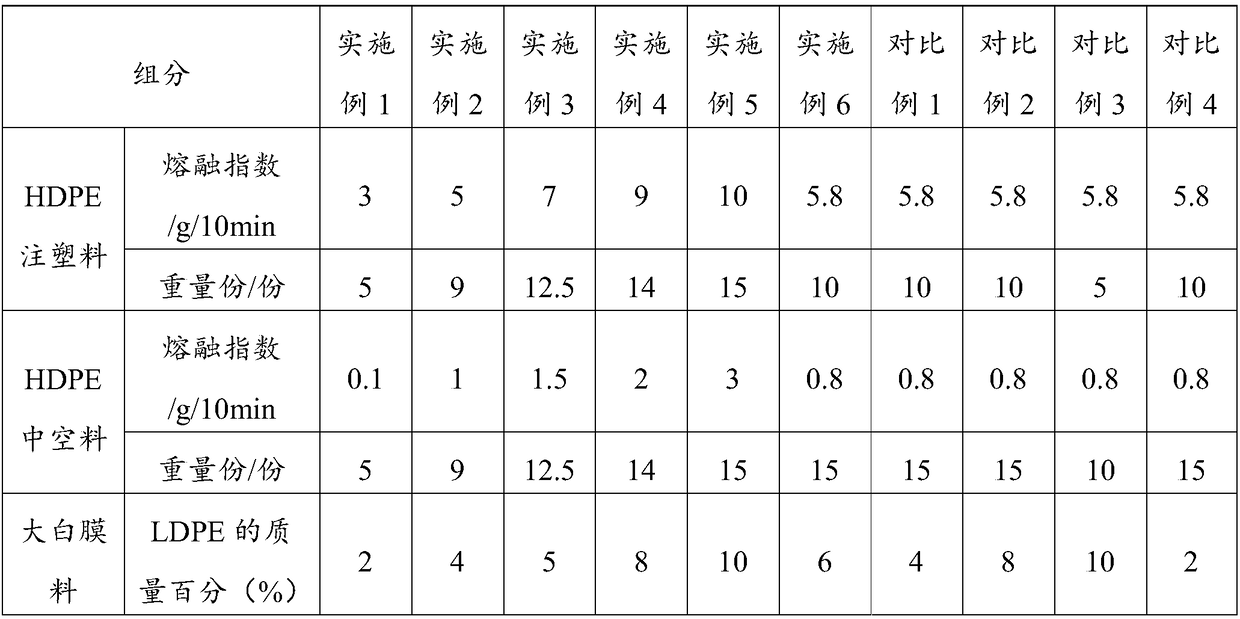

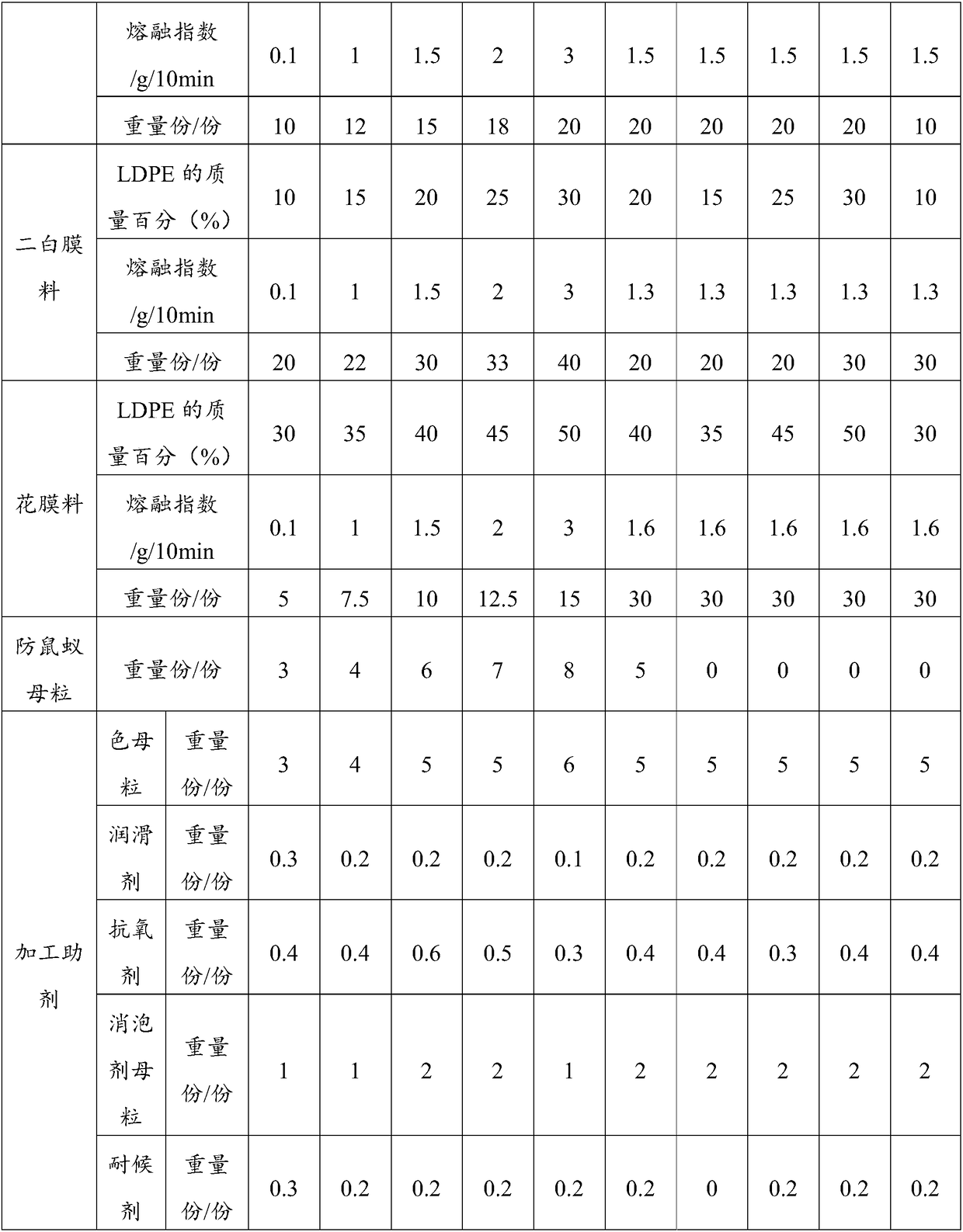

Regenerated PE jacket material and preparation method and application thereof

InactiveCN109456523AWide variety of sourcesSolve the problem of stomataPlastic/resin/waxes insulatorsManufacturing technologyWeather resistance

The invention relates to a regenerated PE jacket material and a preparation method and application thereof and belongs to the field of cable production and manufacturing technology and regenerated resource recycling. The regenerated PE jacket material comprises, by weight, 5 to 15 parts of high-density polyethylene injection molding material, 5 to 15 parts of high-density polyethylene hollow material, 10 to 20 parts of large white film material, 20 to 40 parts of secondary white film material, 5 to 15 parts of heat transfer film material, 3 to 8 parts of rat and ant resisting master batch, and5 to 8 parts of processing aid. The regenerated PE jacket material adopts the waste polyethylene in life, agricultural films, industrial films and the like as raw materials, so that the raw materialsare wide in source, and the economical benefit is significant; the mechanical performance of the regenerated PE jacket material of the invention can reach the industrial standard, and has the advantages of long-acting rat and ant resistance, smooth appearance of a formed cable, weather resistance, and environment stress cracking resistance; and the preparation method is simple in process, high inefficiency and high in industrialized production efficiency.

Owner:KINGFA SCI & TECH CO LTD +1

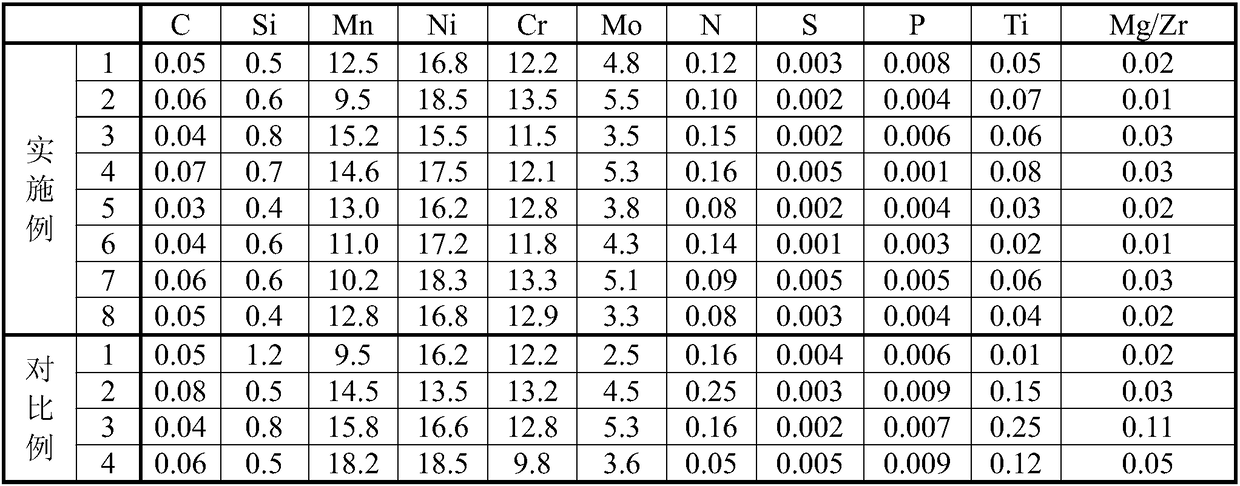

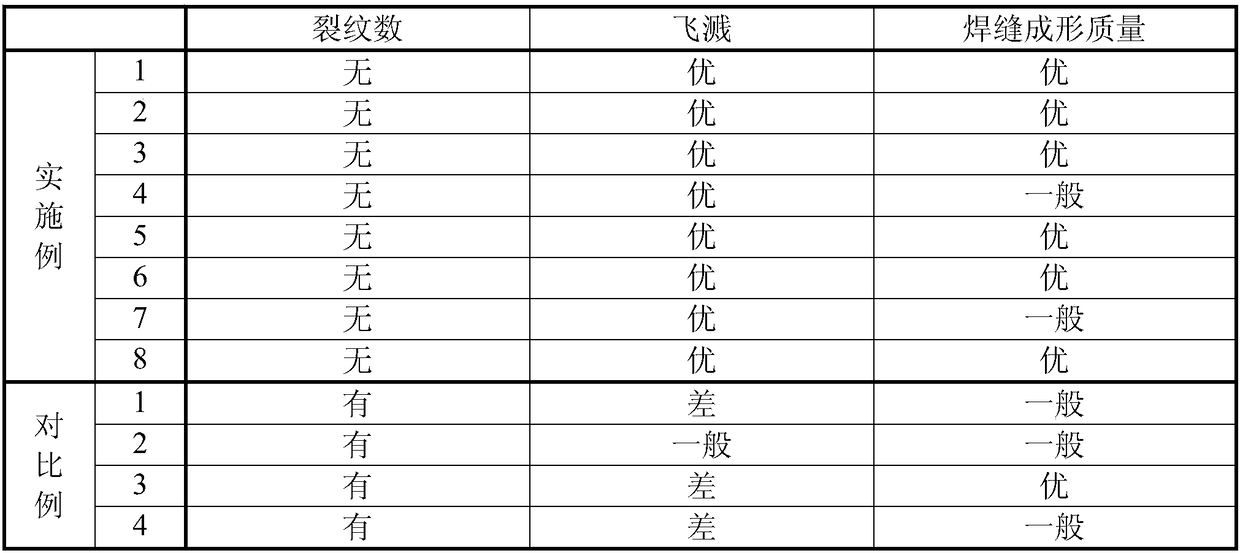

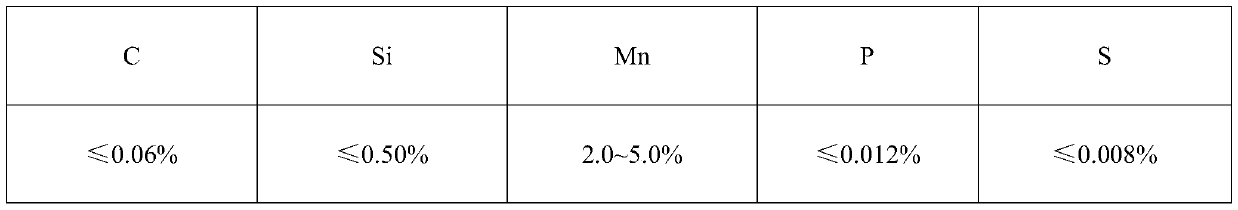

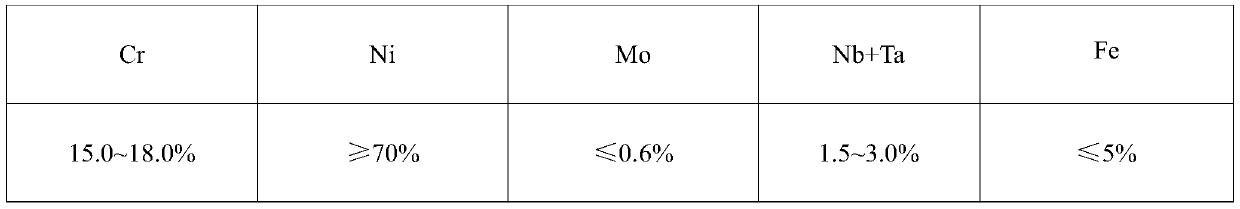

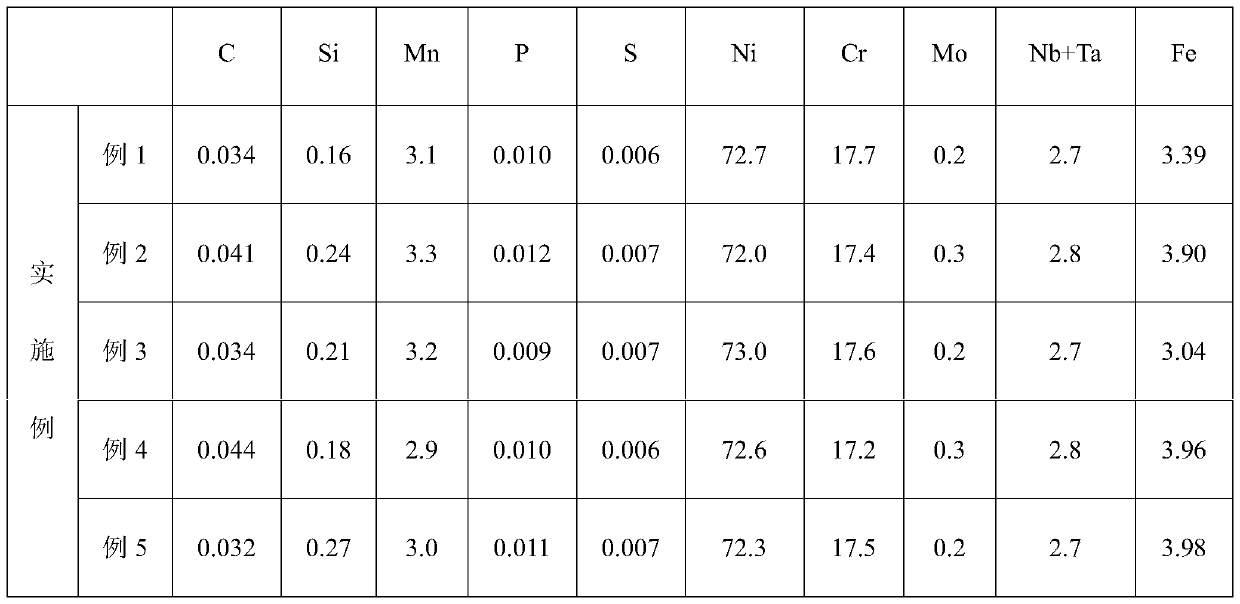

Welding wire for ultralow-temperature steel

InactiveCN108067762ASolve the problem of stomataSimple welding processWelding/cutting media/materialsSoldering mediaMetallurgyMaterials science

The invention relates to a welding wire for an ultralow-temperature steel. The welding wire, comprises, by weight, no more than 0.06% of C, 0.1%-1.0% of Si, 9%-16% of Mn, 14%-20% of Ni, 10%-14% of Cr,3%-6% of Mo, no more than 0.2% of N, 0.005%-0.20% of Ti, and the balance Fe and impurity elements. The welding wire can be used for welding superconductive fusion-cooled components.

Owner:张宇

Coating material with high adhesion with matrix

The invention discloses a coating material with high adhesion with a matrix. The coating material is prepared from the following raw materials (by weight): 12-15 parts of glass glaze, 70-80 parts of alumina ceramic powder, 3-4 parts of carboxymethylcellulose sodium, 4-5 parts of sodium silicate, 1.6-2 parts of tin dioxide, 0.6-0.8 part of boron glass powder, 4-6 parts of silica sol, 2-3 parts of copper-nickel alloy, 0.6-0.9 part of cobalt oxide, 1.2-1.5 parts of sodium carbonate, 6-8 parts of titanium carbide, a proper amount of anhydrous ethanol and a proper amount of deionized water. The ceramic coating provided by the invention has a simple preparation process, is low-cost and is convenient to coat. The prepared coating has good cold and hot hardness and wear-resistance, has high adhesion with a matrix, is not easy to fall off, and is worth of promotion.

Owner:MAANSHAN JINSHENG IND DESIGN

9% Ni steel matched nickel-based welding rod special for overhead welding

ActiveCN111590240AReduce distractionsReduce porosityWelding/cutting media/materialsSoldering mediaSlag (welding)Nichrome

The invention discloses a 9% Ni steel matched nickel-based welding rod special for overhead welding. The welding rod is composed of a welding core and a coating, wherein the outer wall of the weldingcore is coated with the coating, the coating accounts for 0.3-0.5% of the total weight coefficient of the welding rod, the welding core is a nickel-chromium-iron welding core, and the coating is composed of a CaCO3-MgCO3-CaF2 low-hydrogen slag system with high alkalinity. The welding rod has excellent all-position weldability, especially overhead welding position weldability, and extremely low overhead welding shooting porosity; and the welding rod has excellent overhead welding property, stable electric arc, excellent deslagging property and excellent weld joint forming property, the weldingrod has extremely low overhead welding porosity, and the overhead welding high-definition radiographic inspection TOFD shooting qualification rate can reach 99.5% or above.

Owner:KUSN GINTUNE WELDING

Magnesium aluminum alloy welding method

ActiveCN104400196ASimple methodEasy to operateArc welding apparatusWelding/soldering/cutting articlesAsbestosMagnesium

The invention provides a magnesium aluminum alloy welding method which comprises the following steps: cleaning a welding region on the surface of a to-be-welded magnesium aluminum alloy board; carrying out preheating treatment on the to-be-welded magnesium aluminum alloy board in the welding region; carrying out spot-welding fixed connection on the magnesium aluminum alloy board by using a metal inert-gas welding machine. The method disclosed by the invention is simple, is easy to operate, and is suitable for industrial popularization and use; the magnesium aluminum alloy board is clamped and fixed by using a foam asbestos board, so that heat preservation time of a weld pool between welding grooves of two workpieces can be long and the phenomena of incomplete fusion, incomplete penetration of air holes and cracks are difficult to generate; the magnesium aluminum alloy welding method effectively solves the problems of the air holes and blended impurities; the internal air holes and the blended impurities of a welding joint treated by the method disclosed by the invention are basically eliminated; the strengthening effect is ideal and the comprehensive mechanical performance of the material is greatly promoted; the magnesium aluminum alloy welding method is energy-saving and environmental-friendly.

Owner:WUXI FUMEI LIGHT ALLOY TECH

Composite metal pipe with internal glass coating and preparation process of composite metal pipe

The invention provides a composite metal pipe with an internal glass coating and a preparation process of the composite metal pipe. The inner surface of a base body of the metal pipe is coated with glass slurry, and the uniform and smooth glass protection coating is formed after sintering. The glass slurry is the mixture of one or more of glass powder and metal powder. The preparation process comprises the steps that (1) glass slurry raw materials are weighed, adhesives are added into the glass slurry raw materials, and then mixing and ball milling are conducted to prepare coating slurry witha good suspension property; (2) the coating slurry is smeared on the inner surface of the metal pipe through a centrifugal machine with a drying device and then is dried and cured, so that a uniform green body with a certain thickness is formed; and (3) the metal pipe with the green body is dried in a kiln and sintered at a low temperature, so that the composite metal pipe with the internal glasscoating is obtained. According to the composite metal pipe with the internal glass coating, the glass coating contains a certain amount of metal powder so that the expansion coefficient of the coatingcan be regulated, the coating and the base body are bonded tightly, the corrosion resistance, the abrasion resistance and the aging resistance are excellent, and accordingly, the service life of themetal pipe is prolonged.

Owner:王双喜

Fine casting method of dish type casting products

InactiveCN101380661AUnique craftIncrease productivityFoundry mouldsFoundry coresMaterials scienceCasting

The invention discloses a refining method for a disk casting product, and the invention is characterized in that the method is carried out according to the following steps: preparing a sand mixture; adding the sand mixture into a bottom sand box, vibrating and then arranging the sand mixture on a flat working ground; arranging a prepared membrane-coated sand mixture shell into the bottom sand box and flatting tightly, adding a filter screen sheet and adding the sand mixture into an upper sand box, vibrating and taking out the manufactured upper sand box and arranging the upper sand box laterally; finishing an upper casting opening and a lower casting opening as well as removing the floating sand thereof; then locating and overlapping the upper sand box with the bottom sand box and screwing the fixing cards on the handles of the upper sand box and the lower sand box; casting an iron liquor and taking out a product after cooling; cleaning the sand.

Owner:武胜琛兰机械制造有限公司

Heatproof anticorrosion coating material

InactiveCN105967688AImprove antioxidant capacityImprove heat resistanceCeramic coatingOxidation resistant

The invention discloses a heatproof anticorrosion coating material, which is prepared from the following raw materials (by weight): 13-15 parts of glass glaze, 20-25 parts of spodumene, 68-80 parts of zirconia ceramic powder, 2-3 parts of titanium diboride, 6-8 parts of tungsten carbide, 1.2-1.5 parts of petroleum coke, 1.5-1.7 parts of wood chip, a proper amount of anhydrous ethanol and a proper amount of deionized water. The ceramic coating which is prepared by plasma spraying and laser cladding technologies contains no toxic or harmful substances, has high strength, good heat resistance, strong corrosion resistance and strong weather-proof oxidation-resistant properties, is simple to prepare, is low-cost, and has a wide range of application.

Owner:MAANSHAN JINSHENG IND DESIGN

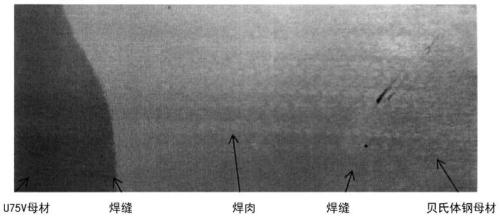

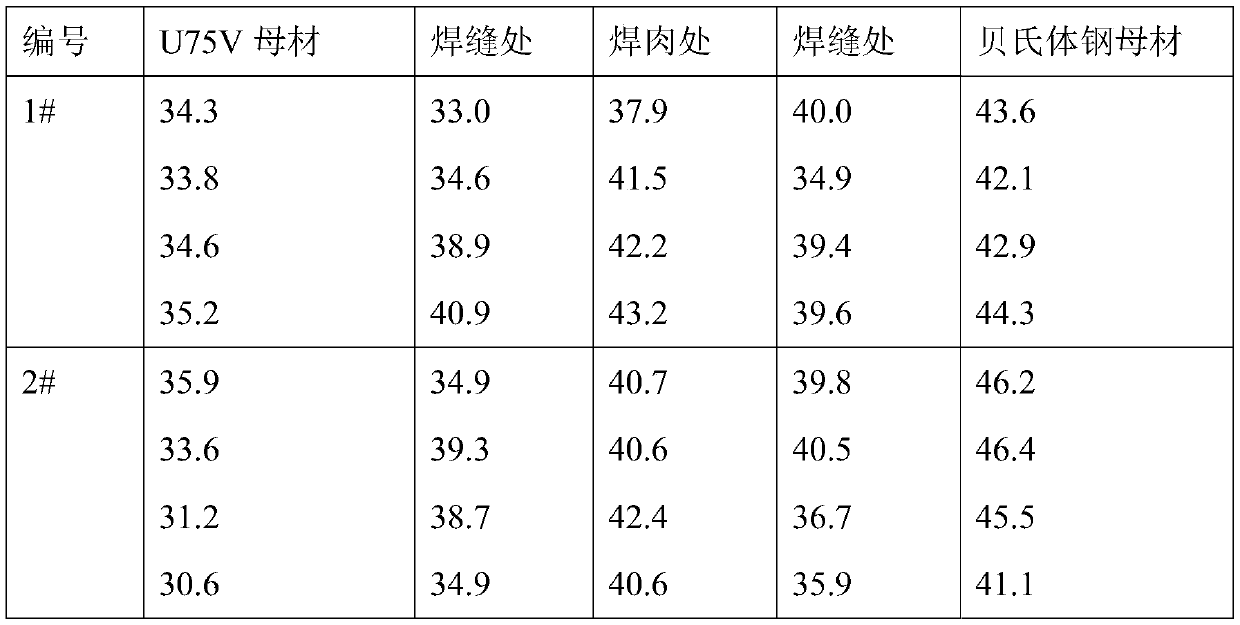

Aluminothermic welding method of seamless steel rail

PendingCN111590192AGuaranteed temperatureGuaranteed interface temperatureRailsMetal working apparatusAl powderIron powder

The invention relates to an aluminothermic welding method of a seamless steel rail. A welding flux comprises C, Si, Mn, Cr, Ni, Mo, V, aluminum powder and oxide and iron powder, the process comprisesthe following steps of polishing, derusting and dehumidifying a steel rail; preheating the steel rail until the rail head turns red; igniting and preheating the aluminothermic welding flux, and reacting and pouring; after pouring, heating the steel rail at 250-300 DEG C within the position, 500 mm away from the outside of a sand mold frame, of the two sides of the sand mold frame; knob removing,meanwhile, keeping the temperature of the steel rail at 250-300 DEG C within the position, 500 m away from the outside of the sand mold frame, of the two sides of the sand mold; cooling the welded junction to 500 DEG C, performing hot grinding, cooling weld metal part after the hot grinding, keeping the temperature of the steel rail at 250-300 DEG C within the position, 500 m away from the outsideof the sand mold frame, on the two sides of the sand mold frame in the process till the weld metal part reaches 250-300 DEG C, and performing cover heat preservation on the welded junction for 20 min; and removing the cover, and naturally cooling to room temperature. The method ensures the welding quality.

Owner:BEIJING TEYE IND & TRADE

Laser near net shaping method of low-porosity titanium alumina ceramic piece

ActiveCN102627472AInhibition of heated growthDegree of inhibitionCeramicwarePorosityLaser processing

The invention discloses a laser near net shaping method of a low-porosity titanium alumina ceramic piece. Laser net shaping is performed on titanium alumina ceramic powder by using a laser processing system. The laser near net shaping method specifically comprises the following steps of: mixing the titanium alumina ceramic powder and SiC powder, drying and then placing in a powder feeder; connecting a laser processing head with a Nd:YAG solid laser through a transmission optical fiber; and realizing the laser net shaping of the low-porosity titanium alumina ceramic piece by controlling continuous movement of the processing head by taking argon gas as powder feeding and protecting gas. According to the laser near net shaping method, on one hand, the laser net shaping of the low-porosity titanium alumina ceramic piece can be realized, and on the other hand, the complexity of parameter optimization is simplified; the introduction of other adverse problems is avoided; and thus, a feasibleparameter range is expanded and the production efficiency is increased.

Owner:DALIAN UNIV OF TECH

Ceramic coating material for exhaust equipment

InactiveCN105967693AImprove thermal conductivityImprove wear resistanceMolten spray coatingCeramic coatingComposite ceramic

The invention discloses a ceramic coating material for exhaust equipment. The material is prepared from the following raw materials (by weight): 13-15 parts of glass glaze, 1-2 parts of polysiloxane, 75-80 parts of silicon nitride ceramic powder, 1.5-2 parts of water glass, 2-3 parts of carbon nanotube, 0.2-0.4 part of a titanate coupling agent, 1-1.3 parts of nano-aluminum zinc oxide, 0.6-1 part of teflon, 1.2-1.4 parts of ferric oxide, 6-8 parts of chromic oxide, 3-4 parts of a waterborne acrylic emulsion, 0.8-1 part of zircon sand and a proper amount of deionized water. The prepared composite ceramic coating has high toughness, high wear resistance, fire resistance and the like, has strong surface adhesion with a base material, has long service life, has excellent antifouling property, and is worth of promotion.

Owner:MAANSHAN JINSHENG IND DESIGN

Weather-resistant ceramic coating material

InactiveCN105967683AReduce crackingImprove adhesionMolten spray coatingAlkali freeHexagonal boron nitride

The invention discloses a weather-resistant ceramic coating material, which is prepared from the following raw materials (by weight): 14-18 parts of glass glaze, 2-3 parts of zeolite, 78-85 parts of zirconia ceramic powder, 4-6 parts of alumina sol, 1.3-1.5 parts of molybdenum disulfide, 0.5-0.8 part of barium sulfate, 0.4-0.6 part of 0.6% aluminate coupling agent, 1.1-1.4 parts of nickel powder, 2-3 parts of a fluoro-silicon emulsion, 4-6 parts of hexagonal boron nitride, 1-2 parts of bismuth oxide, 0.8-1 part of antimony oxide, 3-5 parts of alkali-free glass powder, a proper amount of anhydrous ethanol and a proper amount of deionized water. The ceramic coating effectively improves bonding strength of a surface ceramic material and a matrix, maintains good antifouling, heat-conducting and weather-resistant properties, has long service life, and is worth of promotion.

Owner:MAANSHAN JINSHENG IND DESIGN

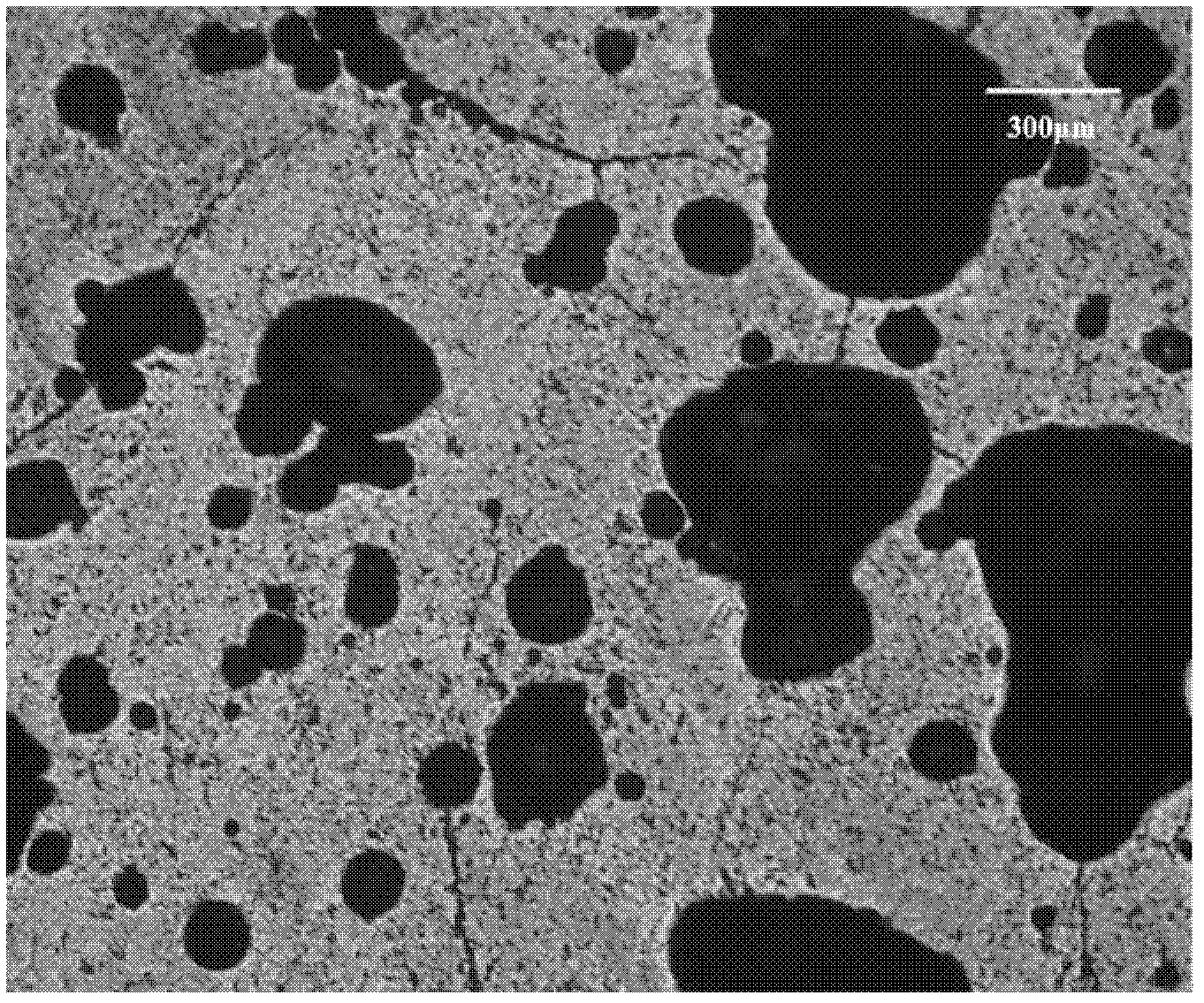

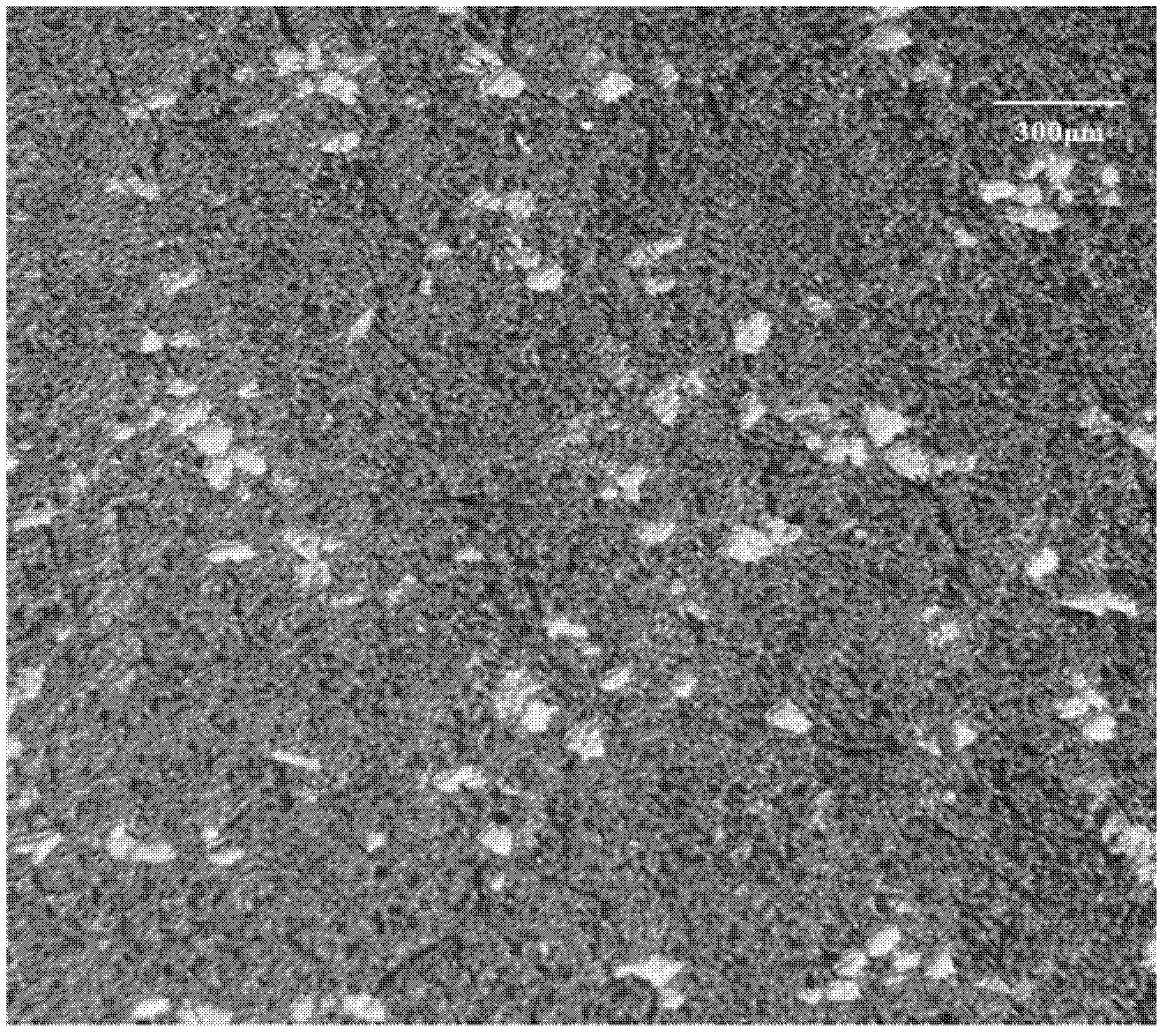

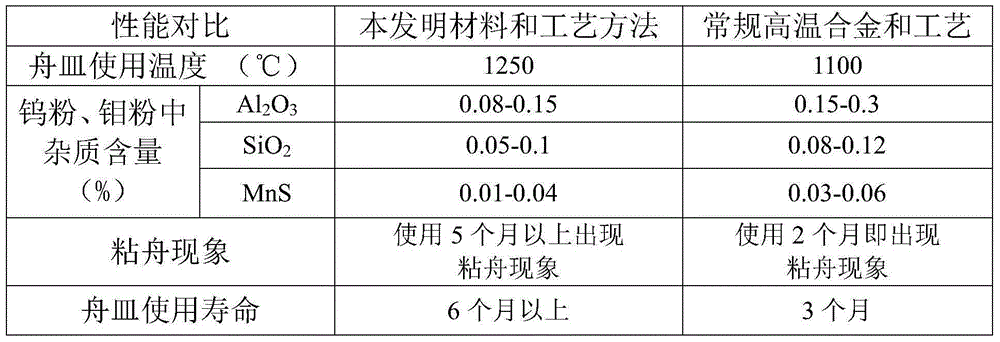

Material for manufacturing boat and process method for manufacturing boat through material

ActiveCN105220016AImprove appearance qualityReduce manufacturing costFoundry mouldsFoundry coresReducing atmosphereUltimate tensile strength

The invention discloses a material for manufacturing a boat and a process method for manufacturing the boat through the material. The material comprises, by weight, 58%-62% of Ni, 0-0.2% of Ti, 0-0.15% of Si, 0-0.1% of C, 0-0.05% of Re, and the balance W and other impurities. The boat manufactured from the material through the process method has higher high-temperature strength performance under the conditions of a reducing atmosphere with the high temperature of 1250 DEG C, and can be used for six moths without deformation or cracking. Besides, in the using process, the phenomenon that materials adhere to the boat hardly occurs, the impurity content of reduced tungsten powder and the impurity content of reduced molybdenum powder can be reduced significantly, and the production efficiency and quality of the tungsten powder and the molybdenum powder are improved effectively.

Owner:CHENGDU XINGYU PRECISION CASTING

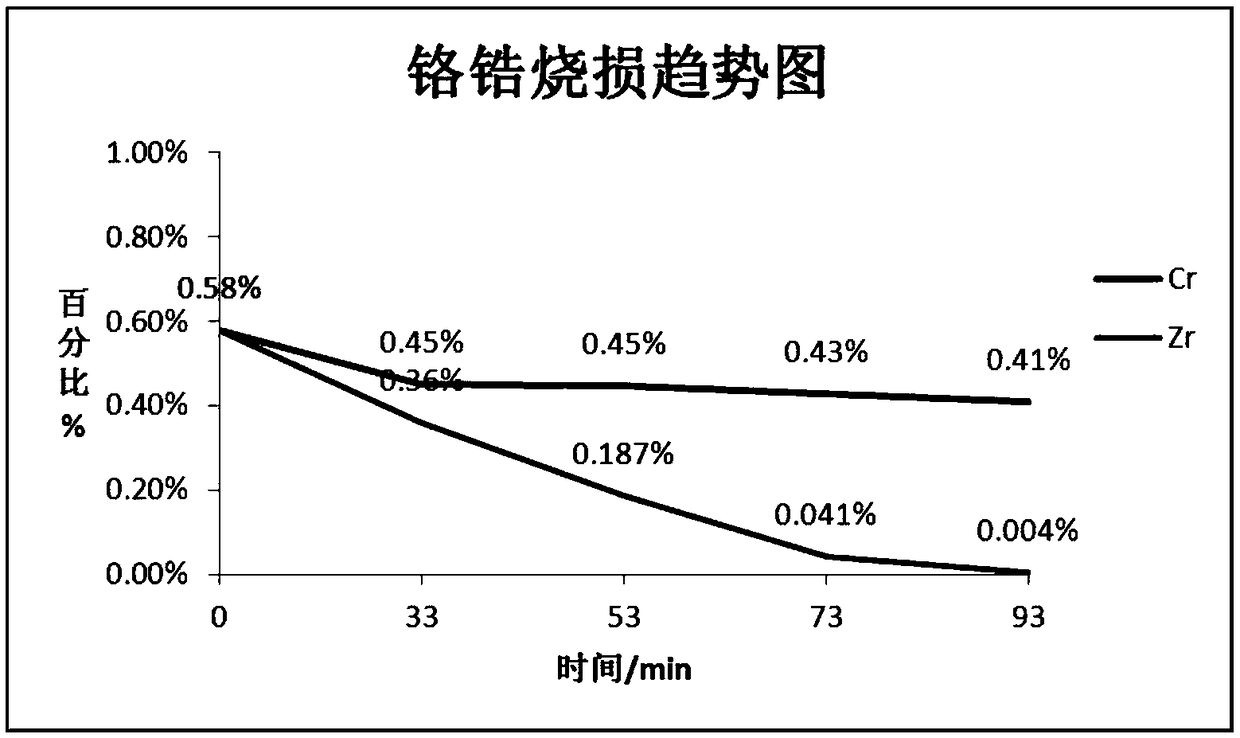

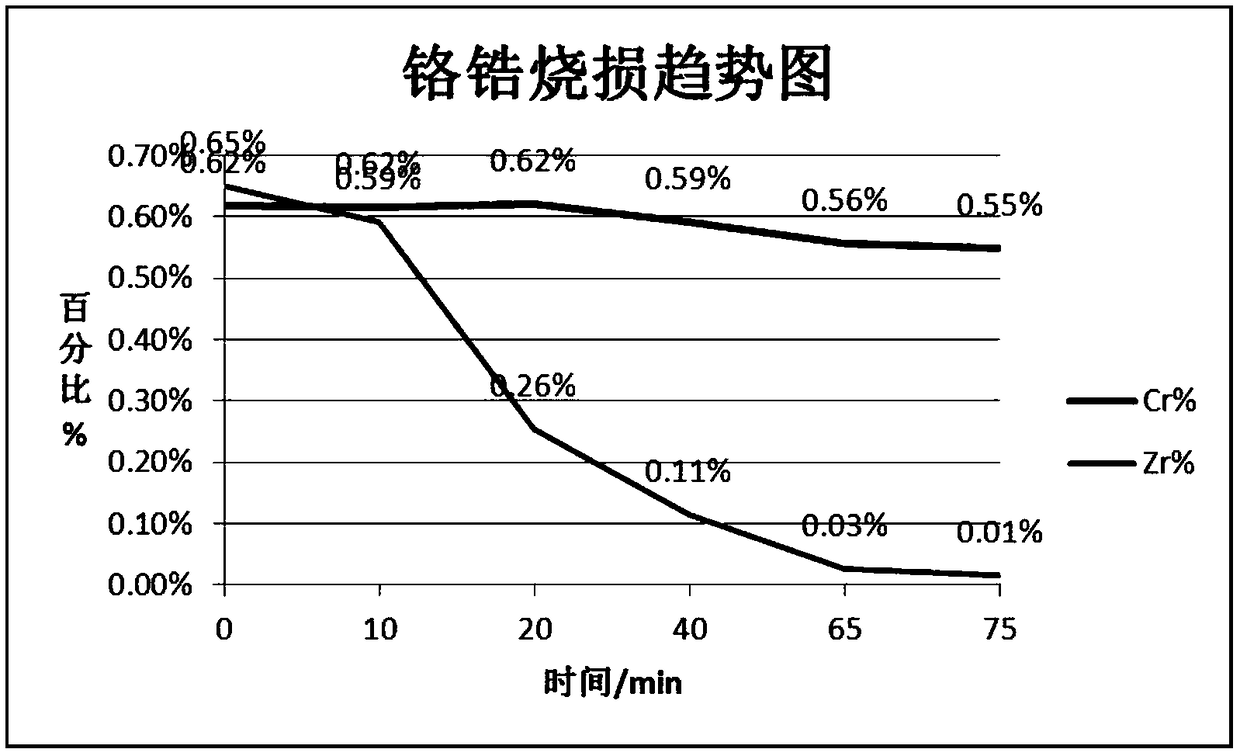

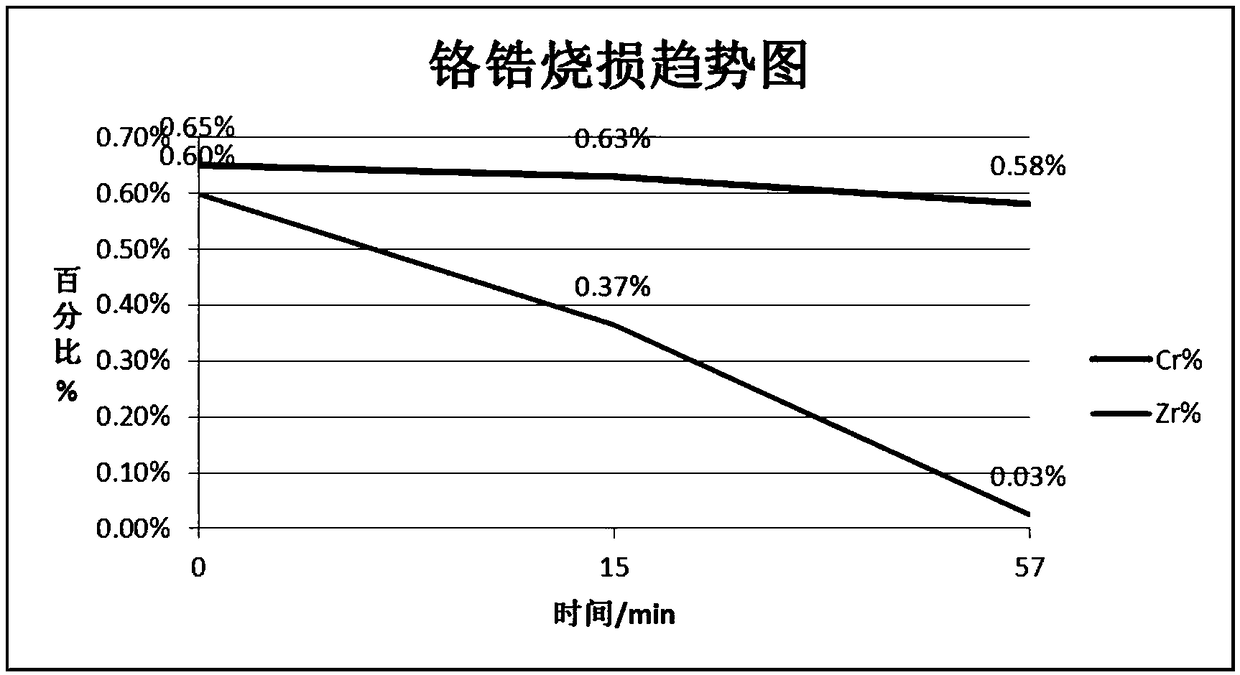

Covering agent for chromium zirconium copper smelting as well as preparation method and use method thereof

The invention discloses a covering agent for chromium zirconium copper smelting as well as a preparation method and a use method thereof. The covering agent is mainly prepared from the following components in percentage by mass: 40 to 80 percent of silicate, 10 to 30 percent of carbonate, 5 to 20 percent of fluoride, 5 to 8 percent of chlorine salt, 5 to 10 percent of boron salt and 0 to 5 percentof oxide. The preparation process of the covering agent for chromium zirconium copper smelting is simple, environmentally-friendly and pollution-free; when the covering agent is applied to chromium zirconium copper smelting, the burning loss of zirconium in a cast ingot can be reduced from 80 to 100 percent in the past to 30 to 40 percent after 30-minutes heat preservation; and the covering agentis convenient to use, has very significant effect and solves the problem that air holes occur in a casting blank caused by the fact that the melt sucks air.

Owner:JINTIAN COPPER GROUP CORP NINGBO

Automobile brake disc casting die and technology

ActiveCN105562602AImprove work efficiencySolve the problem of error-prone boxesFoundry mouldsFoundry coresImpurityMaterials science

The invention discloses an automobile brake disc casting die and technology. A sand mold is fixed between an upper tool and a lower tool and comprises upper sand mold bodies and a lower sand mold body. A plurality of cavities are formed in the upper side of the lower sand mold body. The upper sand mold bodies are fixed in the cavities. The upper tool is provided with an upper sand mold fixing mechanism used for downwards pressing the upper sand mold bodies. A molten iron channel communicating with the bottoms of the cavities is formed in the bottom of the lower sand mold body. A molten iron channel bottom tray for sealing the molten iron channel is arranged on the lower tool. Exhaust gaps are formed between the circumferences of the upper portions of the upper sand mold bodies and the cavities. Molten iron is directly poured into the molten iron channel through a sprue gate in the middle of the lower sand mold body and then enters the cavities from bottom to top, the molten iron flows from bottom to top at a constant speed, and air and some impurities in the cavities are directly discharged upwards through the exhaust gaps. The casting die has the beneficial effects that the casting yield is increased, the casting cost is reduced, and the labor intensity is lowered.

Owner:杨合军

Method of manufacturing straight-winding thin-wall hollow rotor cup

ActiveCN106100251AExtended use timeImprove uniformityManufacturing stator/rotor bodiesApplying solid insulationEngineeringUltimate tensile strength

The invention discloses a method of manufacturing a straight-winding thin-wall hollow rotor cup, which comprises steps of coil winding, wire arrangement, primary reinforcement, welding, heating and setting, secondary reinforcement and the like. The secondary reinforcement step comprises sub steps of insulated potting, vacuum gas escape processing and stepwise solidification processing sequentially on the winding coil, and after cooling and demolding, the straight-winding thin-wall hollow rotor cup is obtained. The problems that the straight-winding thin-wall hollow rotor cup in the prior art is not high in strength, gas holes exist, and the cup wall uniformity is poor can be solved, and the molding rate of the straight-winding thin-wall hollow rotor cup and the qualified rate of products can be improved.

Owner:XIAN MICROMOTOR RES INST

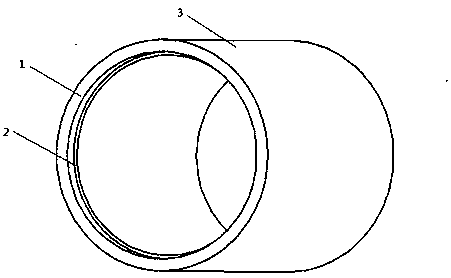

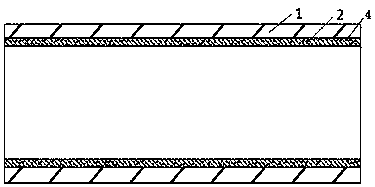

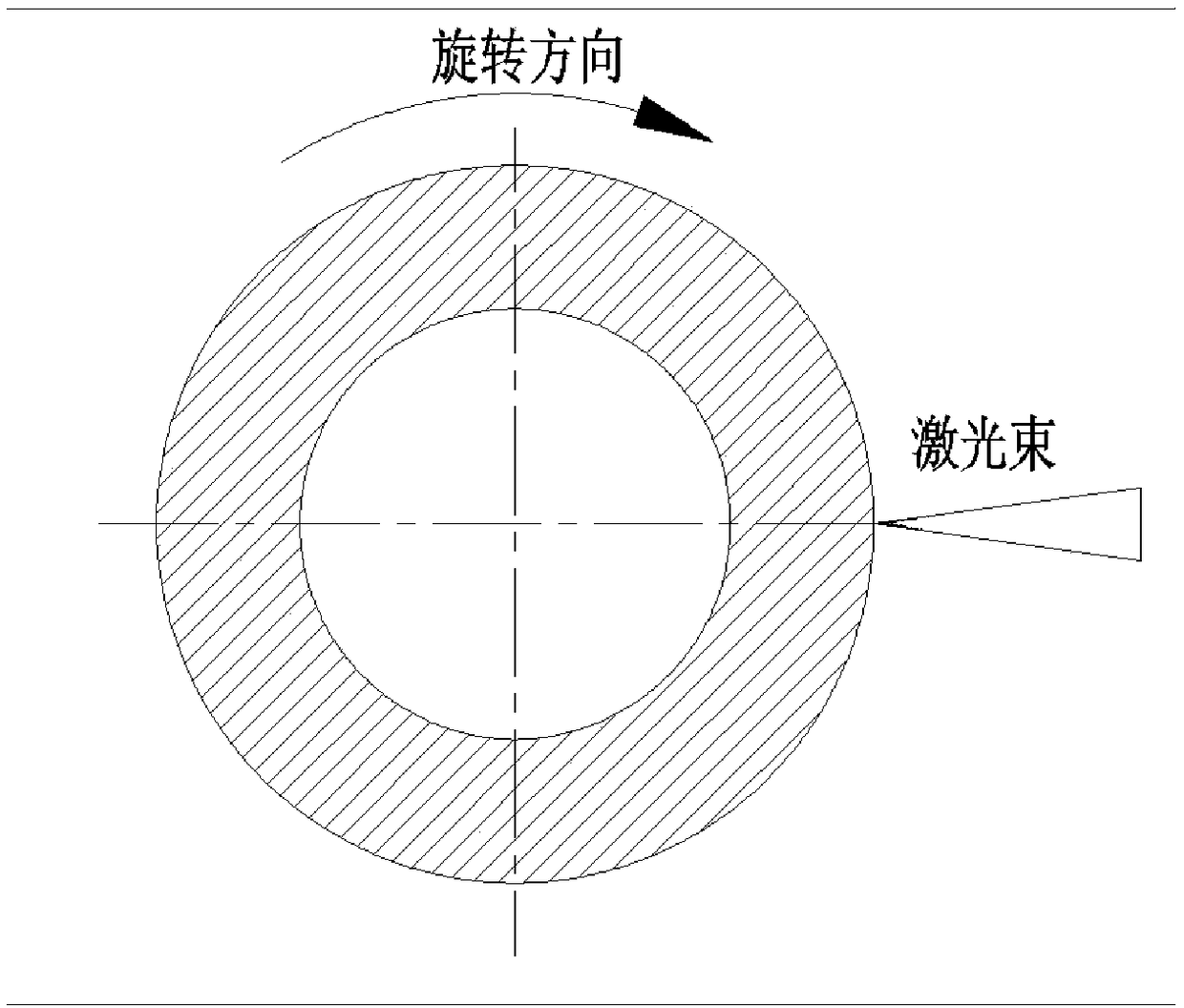

Circular seam lock bottom connector and manufacturing and welding method thereof

ActiveCN109454330ASolve the problem of stomataImprove symmetryLaser beam welding apparatusEngineeringClosed cavity

The invention provides a circular seam lock bottom connector and a manufacturing and welding method thereof. The method mainly comprises the steps of connector design, part preparing, welding preparing, assembling and spot welding, and formal welding. The connector design mainly focuses on the problem that due to the non-penetration state of laser welding of the lock bottom connector, air holes are formed easily, a groove is designed in a lock bottom part, the groove achieves the penetration state of laser welding on the structure, and the problem of the air holes can be solved. In order to relieve the situation that due to the groove, when gas in a closed cavity is heated and swelled in the welding process, small holes of laser welding and a molten bath are disturbed, and the welding stability is influenced, a ditch is designed in the lock bottom part, the ditch can communicate with the closed cavity and the outside, when heated swelling and cooling shrinkage occur in the laser welding process, the gas in the cavity breathes freely and circulates with the outside, the gas pressure in the cavity is stable, and thus disturbance on the molten bath for the laser welding and the smallholes is avoided.

Owner:SHANGHAI SPACE PRECISION MACHINERY RES INST

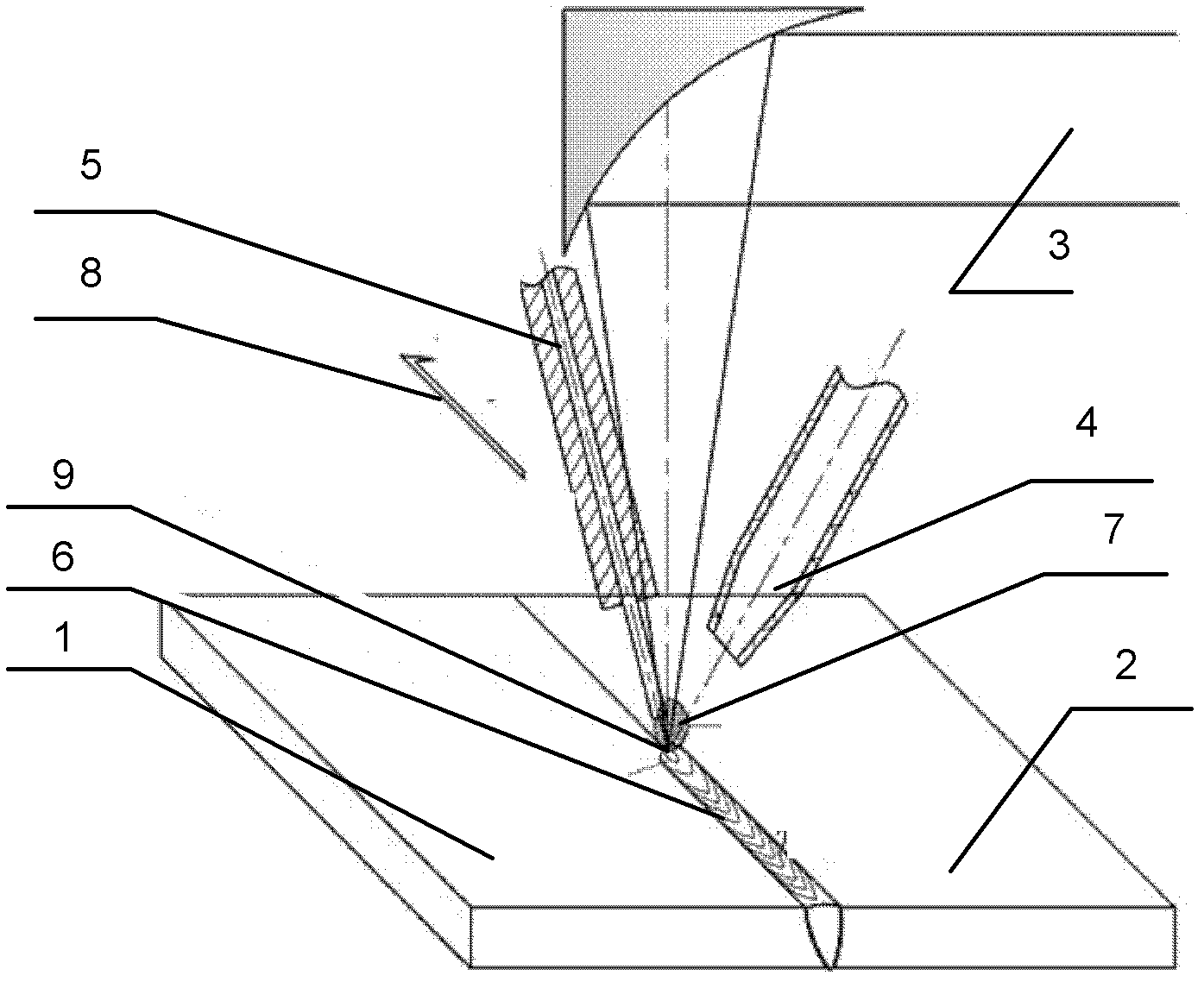

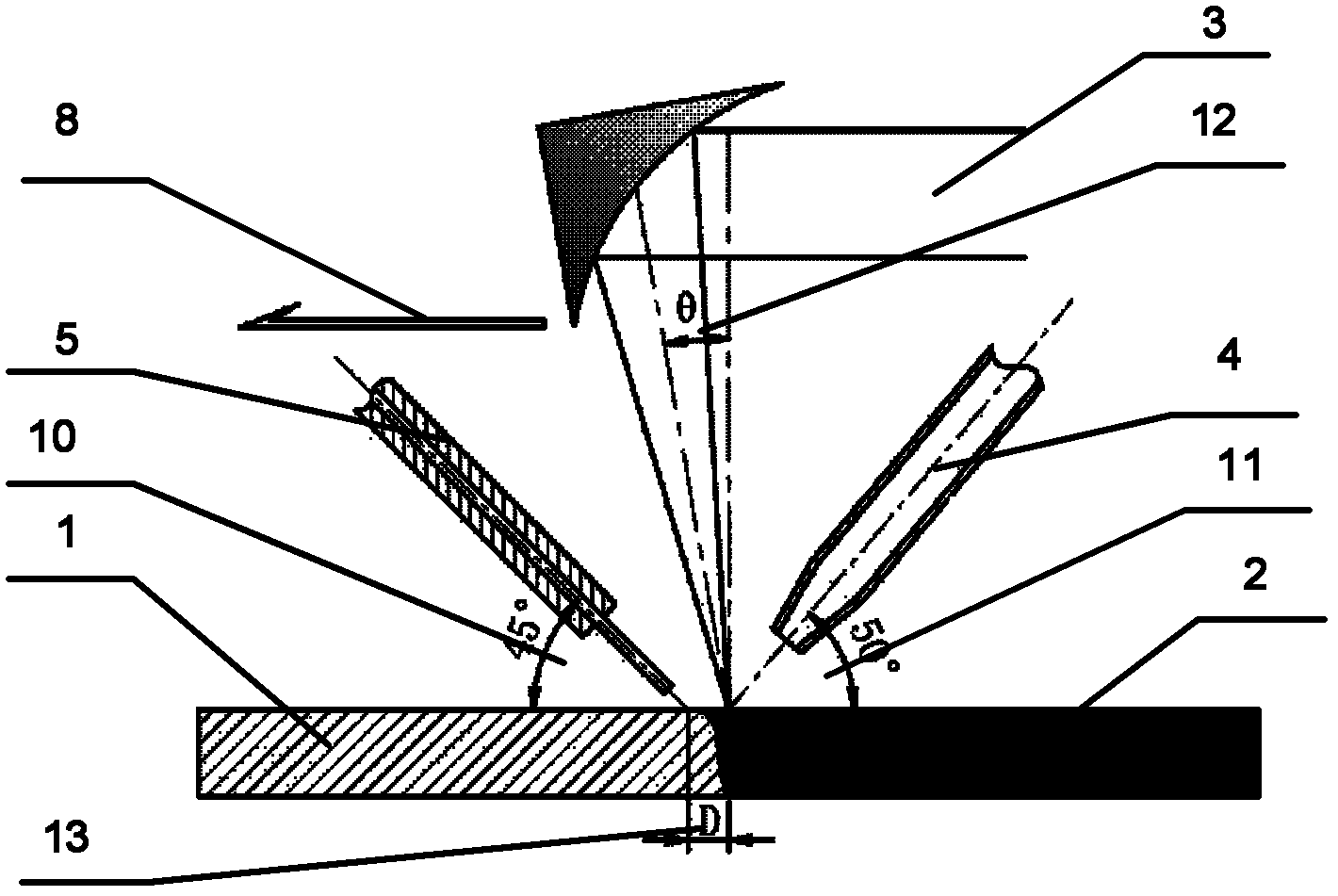

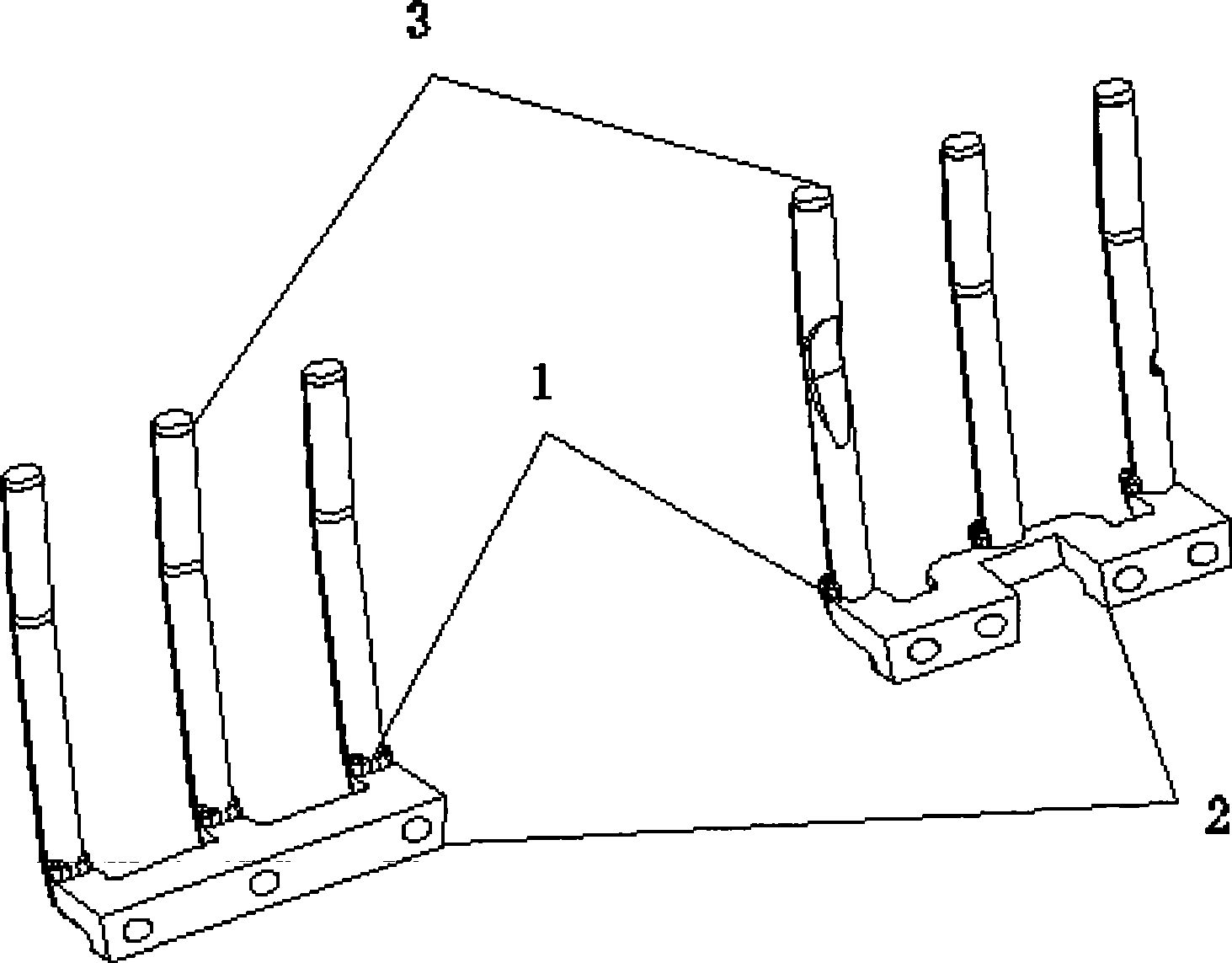

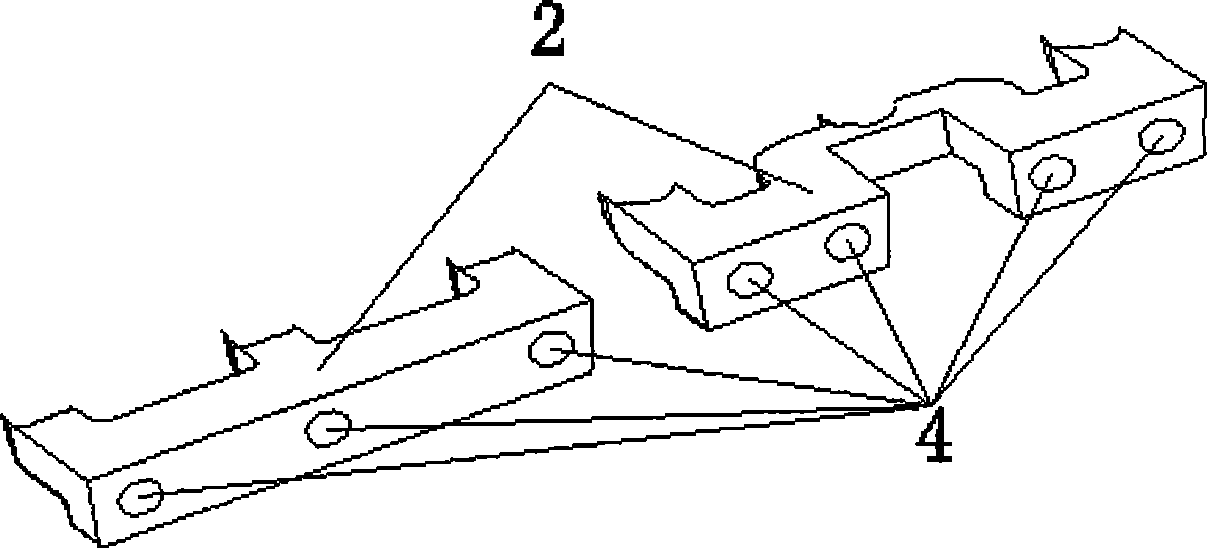

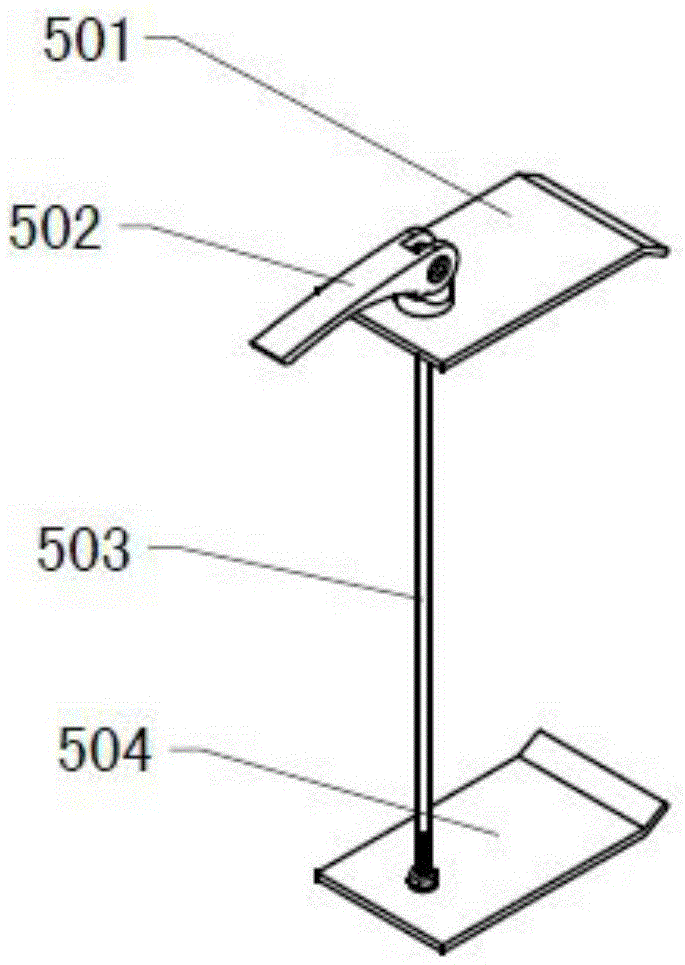

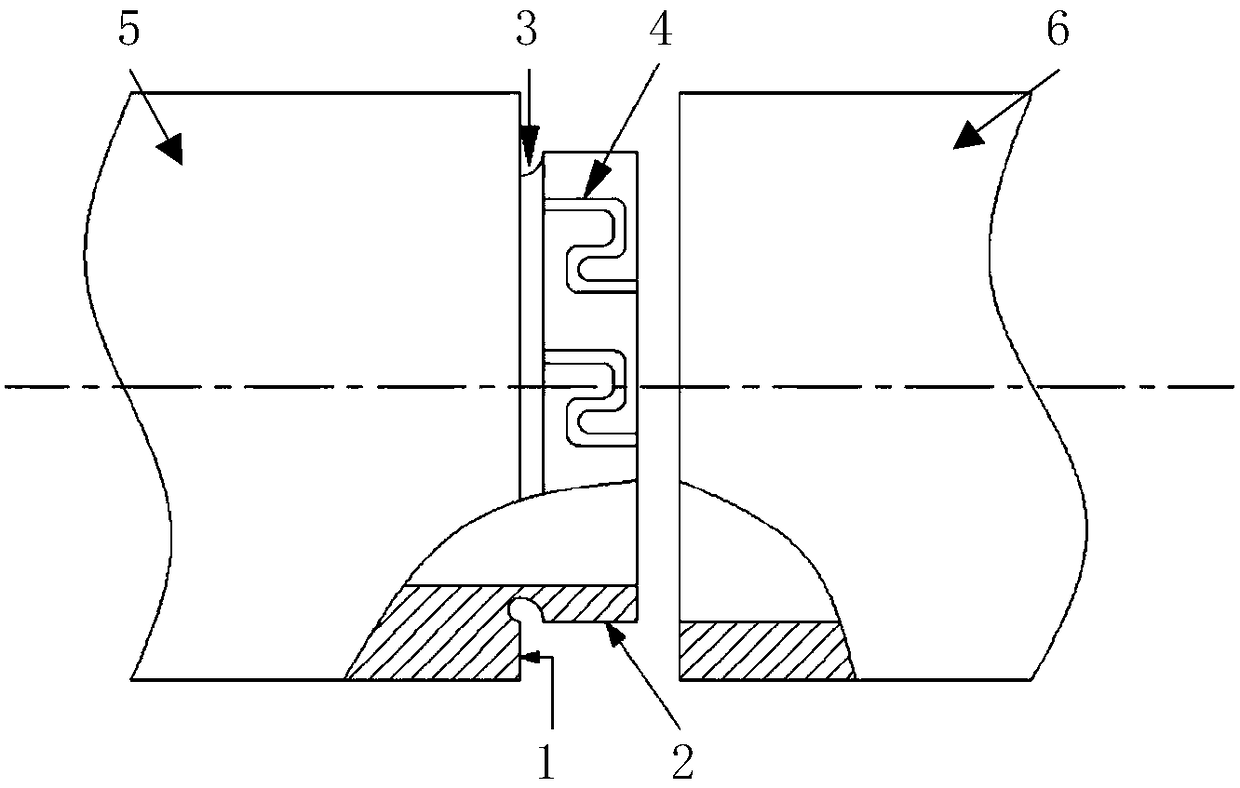

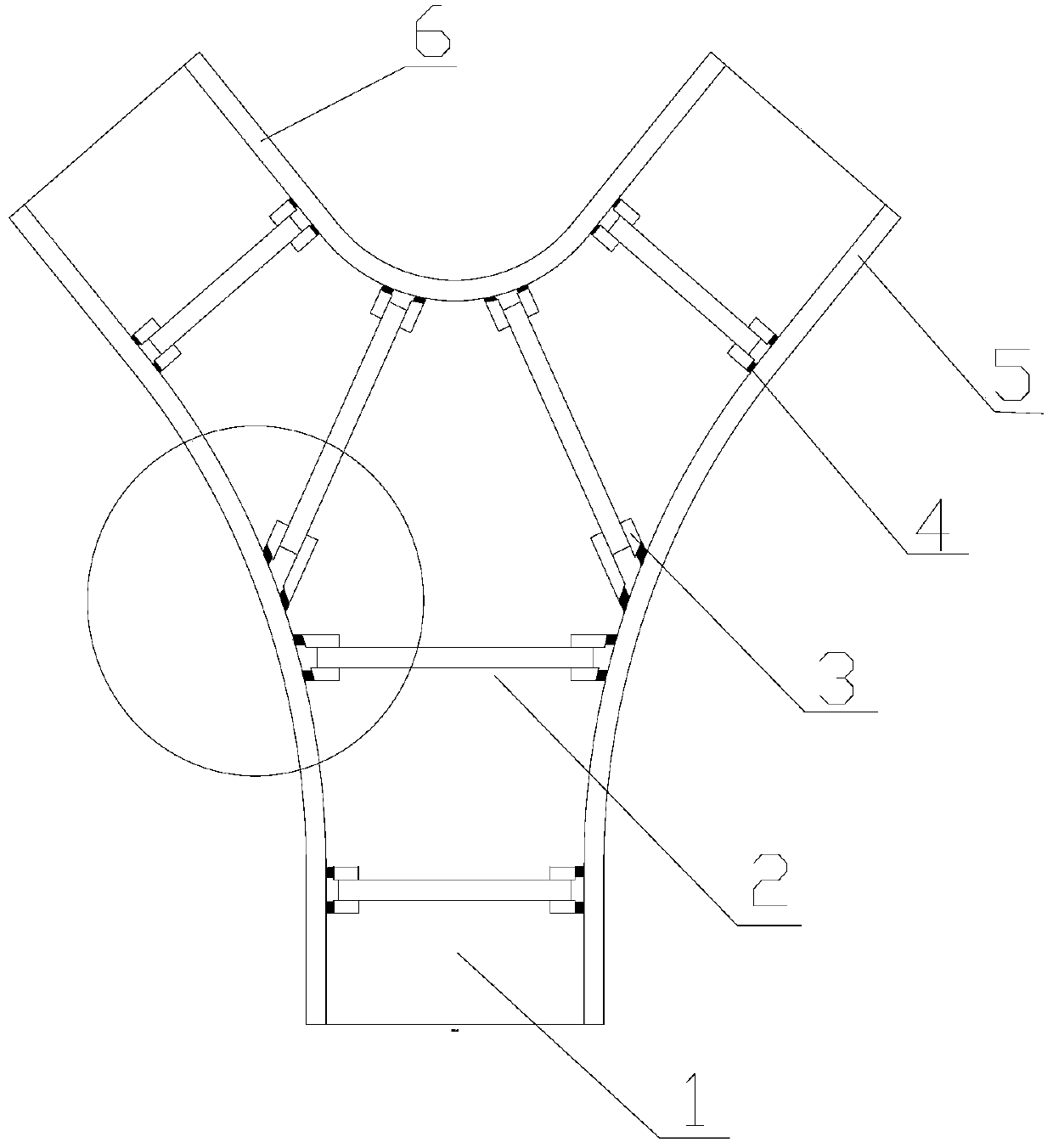

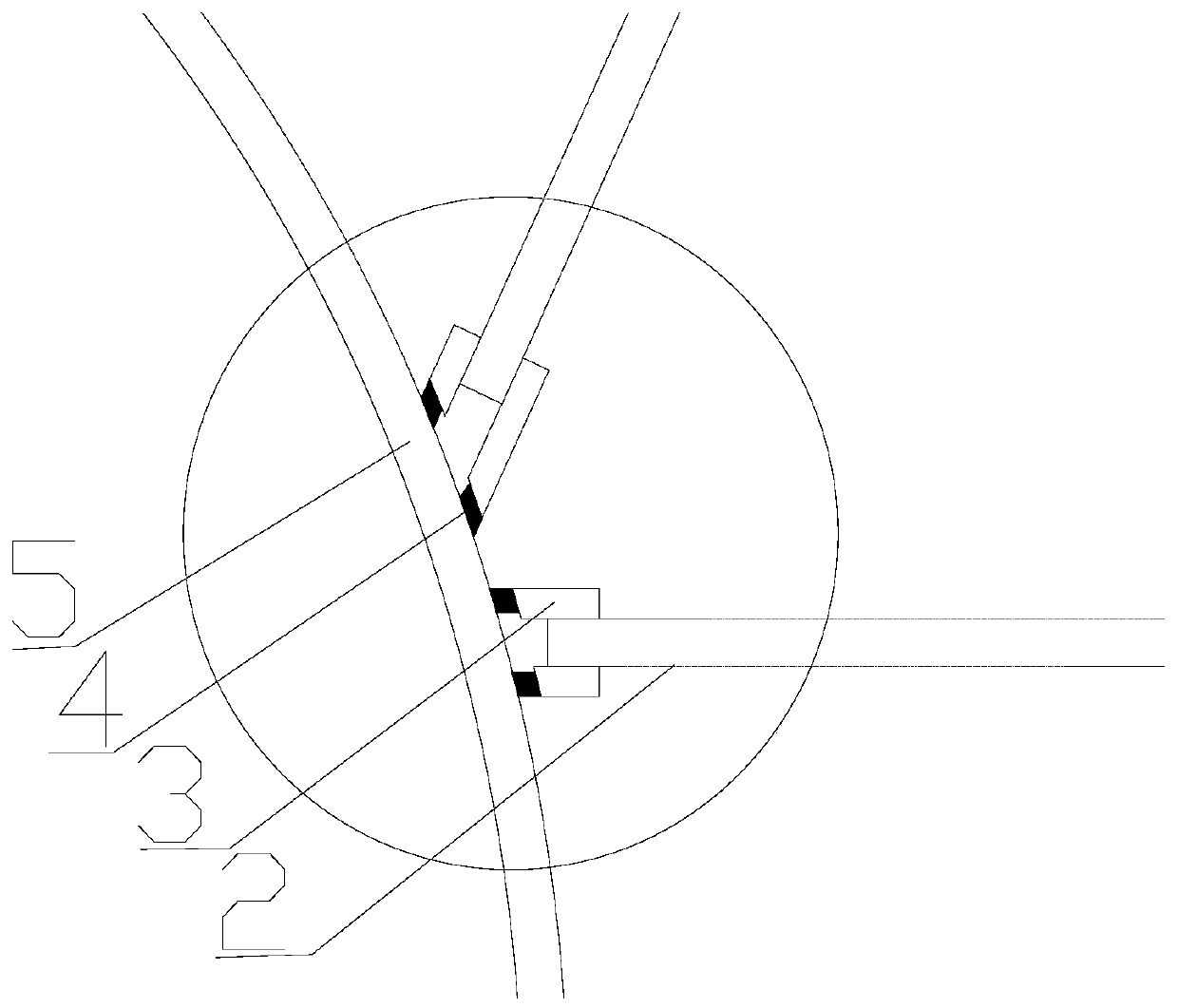

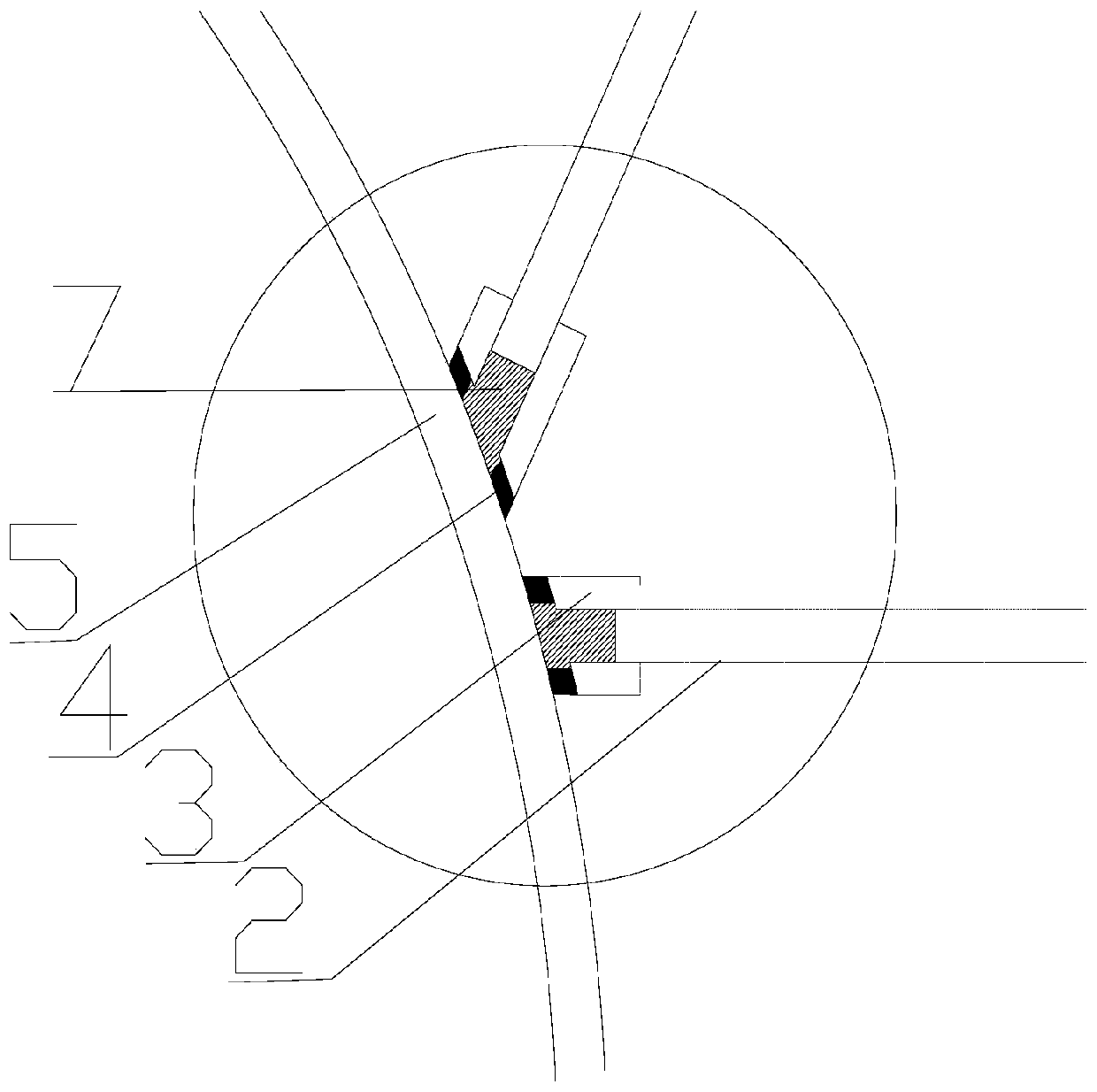

Electro-slag-welding welding construction method for partition plate of special-shaped box-type structure

The invention discloses an electro-slag-welding welding construction method for a partition plate of a special-shaped box-type structure, and belongs to the technical field of building steel structureconstruction. The special-shaped box-type structure comprises a Y-shaped wing plate (1), the partition plate (2), an electro-slag-welding liner strip (3), refractory mud (4), a first web plate (5), asecond web plate (6), and an electro-slag-welding welding seam (7). The assembly gap between the electro-slag-welding liner strip and the web plates on the partition plate of the special-shaped box-type structure is sealed by using the refractory mud, the fitting tightness of the electro-slag-welding liner strip and the web plates are ensured, the quality problems such as unmelting, slag sandwiching, pores, melt spillage of a melt pool in the electro-welding welding process of the partition plate of the special-shaped box-type structure is effectively solved, the electro-slag-welding full-fusion welding quality is ensured, and the method has the advantages that the problem such as the lower pass rate is solved, and the electro-slag-welding welding pass rate of the partition plate of the special-shaped box-type structure is effectively improved.

Owner:BEIJING SHOUGANG CONSTR GROUP

High-entropy alloy particle refined and reinforced aluminum-based composite material and preparation method thereof

PendingCN113088746AImprove high temperature stabilityImprove antioxidant capacityHigh entropy alloysAlloy substrate

The invention discloses a high-entropy alloy particle refined and reinforced aluminum-based composite material and a preparation method thereof. According to the material, high-entropy alloy particles prepared after mechanical alloying are added into a molten aluminum alloy substrate through a gas dispersing and stirring device to be stirred and dispersed, then vibration degassing is carried out, and finally a casting technology is adopted to prepare a formed part of the high-entropy alloy particle reinforced aluminum-based composite material. According to the process, the high-entropy alloy particles added into the melt are dispersed through the gas dispersing and stirring device, the contact area and wettability of the high-entropy alloy particles and aluminum alloy are increased, agglomeration is avoided, macroscopic and microscopic dispersion is uniform, the interface bonding property is improved, nucleation particles are greatly increased in the whole substrate during solidification, grains are refined, the structure is improved, and the performance is enhanced.

Owner:SHANGHAI INST OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com