Semiautomatic argon tungsten-arc welding technological process of bimetal compounding sea pipe

A technology of argon tungsten arc and welding technology, which is applied in the direction of metal processing equipment, welding equipment, arc welding equipment, etc., can solve the problems of unsuitable welding of composite pipelines, waste of manpower, material and financial resources, and influence of pipeline welding speed, etc., to save auxiliary equipment The effect of reducing working time, reducing labor intensity and improving welding efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

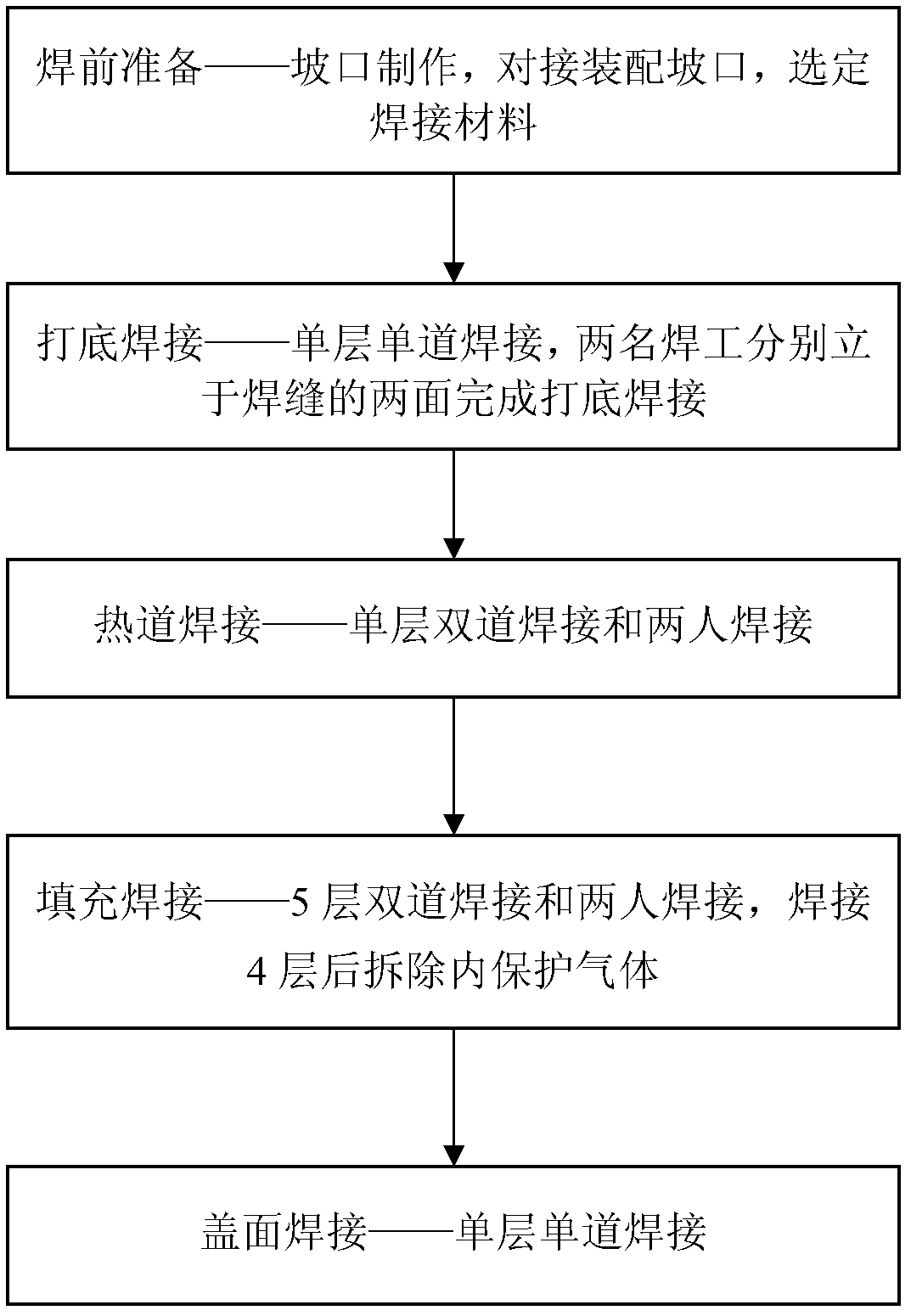

[0048] The specification of bimetallic composite sea pipe is Φ219.1×14.3+3mm, in which the base material is PSL2X65SMLS material according to API standard, and the inner lining is 316L stainless steel material. The main steps of the process are as follows:

[0049] 1. Preparation process before welding:

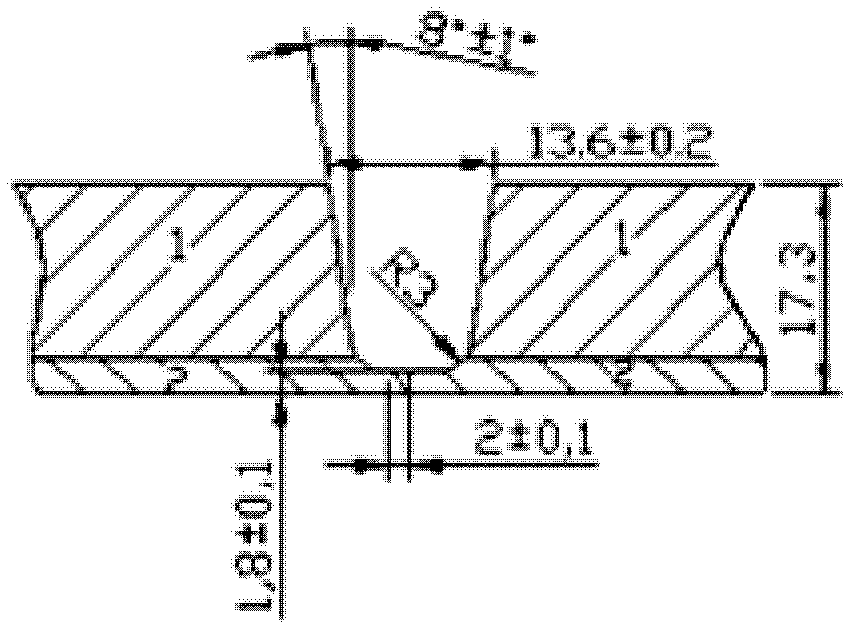

[0050] 4) Groove production: prepare a single-sided "J"-shaped groove by machining, with a slope angle of 8°, a blunt edge thickness of 1.7mm, and a transition arc radius of 3mm.

[0051] 5) Butt joint assembly groove: the clearance is required to be 0mm, and check to confirm that there are no defects in the welded parts and edges.

[0052] 6) Selected welding materials: ARCOS 625 and Atlantic 316L.

[0053] Welding consumables are selected based on the principle of high matching. The yield strength of welding consumables is 80-200Mpa higher than that of the base metal to ensure that the mechanical properties and corrosion resistance of the welded joints meet the requiremen...

Embodiment 2

[0072] The specification of bimetallic composite sea pipe is Φ219.1×14.3+3mm, in which the base material is PSL2X65SMLS material according to API standard, and the inner lining is 316L stainless steel material. The main steps of the process are as follows:

[0073] 1. Preparation process before welding:

[0074] 1) Groove production: A single-sided "J"-shaped groove is prepared by machining, with a slope angle of 9°, a blunt edge thickness of 1.9mm, and a transition arc radius of 3mm.

[0075] 2) Butt joint assembly groove: the clearance is required to be 0mm, and check to confirm that there are no defects in the welded parts and edges.

[0076] 3) Selected welding materials: ARCOS 625 is used as filler welding and cover welding materials, Atlantic 316L is used as bottom welding and hot pass welding materials.

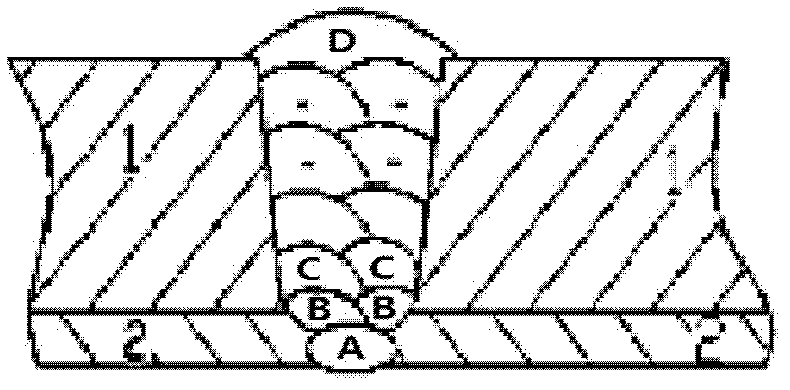

[0077] 2. Bottom welding process:

[0078] The bottom welding process adopts single-layer single-pass welding.

[0079] The semi-automatic tungsten argon shielded ...

Embodiment 3

[0095] The specification of bimetallic composite sea pipe is Φ219.1×14.3+3mm, in which the base material is PSL2X65SMLS material according to API standard, and the inner lining is 316L stainless steel material. The main steps of the process are as follows:

[0096] 1. Preparation process before welding:

[0097] 1) Groove production: Prepare a single-sided "J"-shaped groove by machining, with a slope angle of 7°, a blunt edge thickness of 1.8mm, and a transition arc radius of 3mm.

[0098] 2) Butt joint assembly groove: the clearance is required to be 0mm, and check to confirm that there are no defects in the welded parts and edges.

[0099] 3) Selected welding materials: ARCOS 625 is used as filler welding and cover welding materials, Atlantic 316L is used as bottom welding and hot pass welding materials.

[0100] 2. Bottom welding process:

[0101] The bottom welding process adopts single-layer single-pass welding.

[0102] The semi-automatic tungsten argon shielded weld...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com