Laser-electric arc composite heat source high-speed welding method of ultrahigh strength steel

A technology of ultra-high-strength steel and composite heat source, applied in laser welding equipment, arc welding equipment, welding equipment, etc., can solve problems such as large line energy, reduced effect of laser stable arc, and large energy input

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

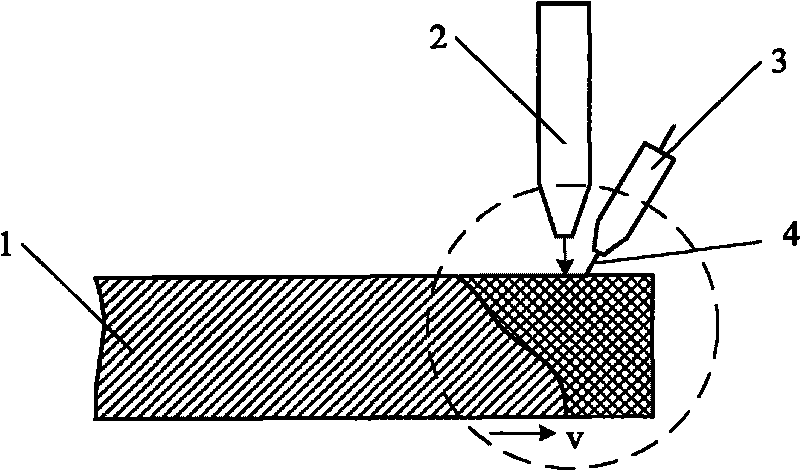

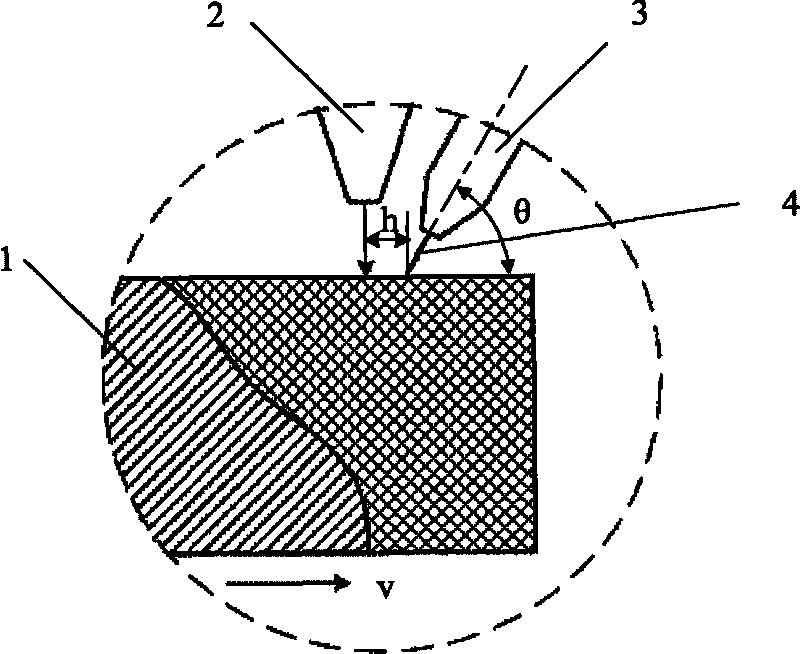

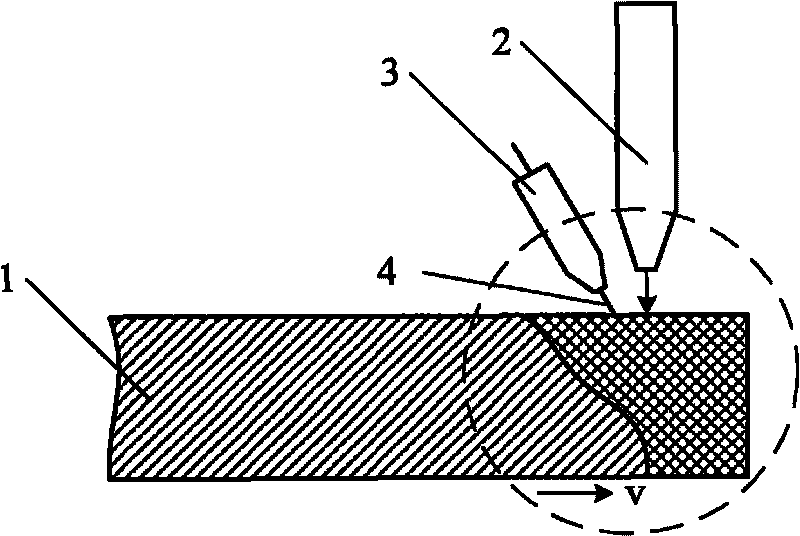

[0008] The present invention is specifically realized like this, see image 3 , Figure 4 As shown, the laser-arc composite heat source is used for welding. The laser uses CO 2 One of lasers, Nd:YAG lasers, disk lasers, fiber lasers, and semiconductor lasers. Such as the use of DC050 type CO made by German Rofin company 2 The laser has a maximum output power of 5kW, an output wavelength of 10.6μm, and a continuous wave laser output. It uses a focusing lens with a focal length of 350 and a defocus of -1mm. The arc adopts one of single-filament GMAW arc, double-filament GMAW arc, MIG arc and MAG arc. For example, the YD-350AG2HGE microcomputer welding waveform control pulse MIG / MAG welding machine manufactured by Japan Panasonic Company is used, and the matching YW-35AL1HAE wire feeder uses stainless steel welding wire with a diameter of 1.2mm. The welding workpiece 1 is high-strength steel or ultra-high-strength steel. Such as ultra-high-strength steel with a thickness of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com