Patents

Literature

75results about How to "No crack defect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

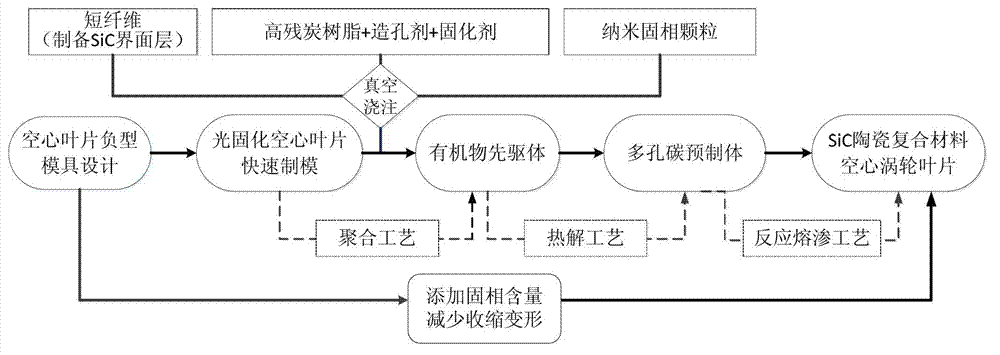

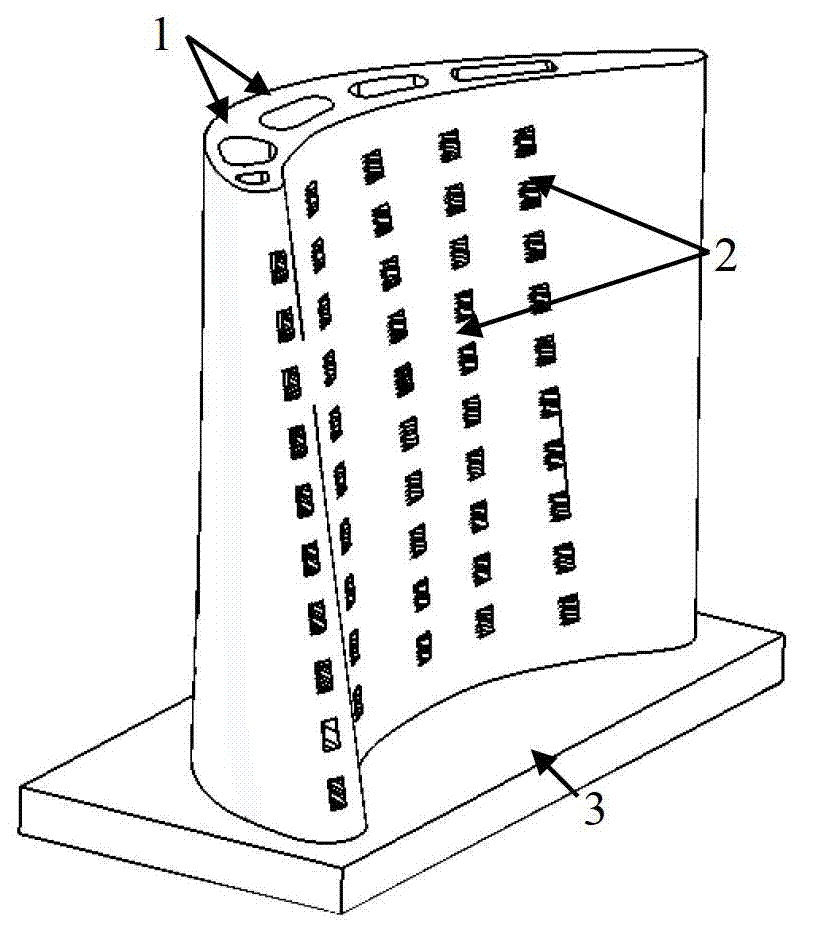

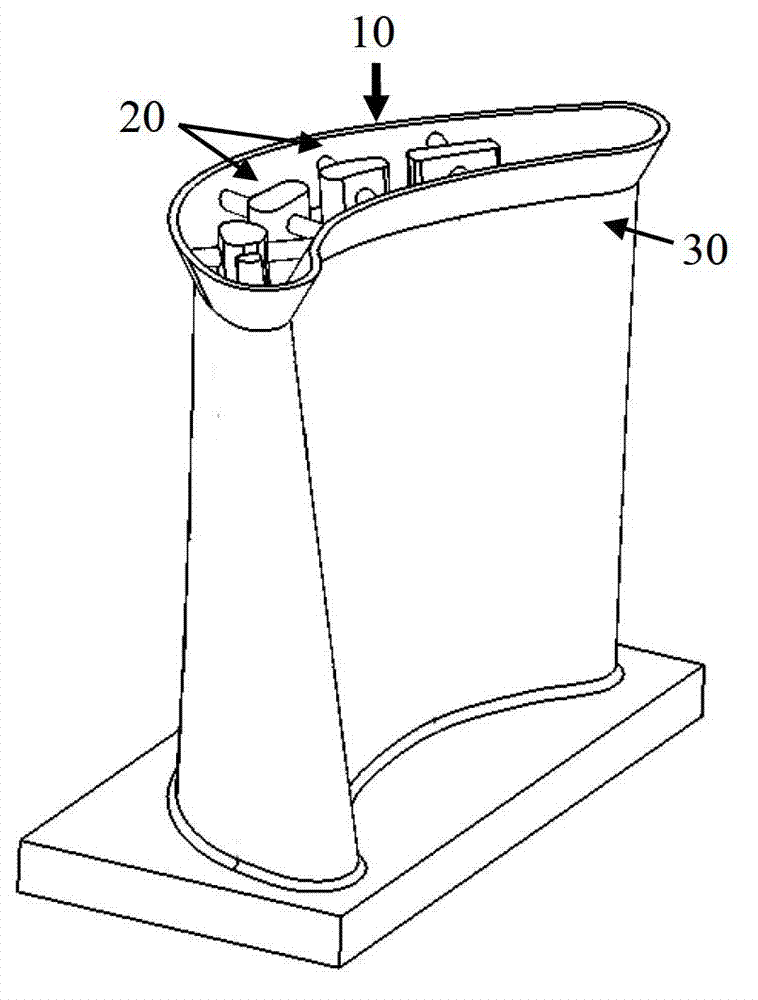

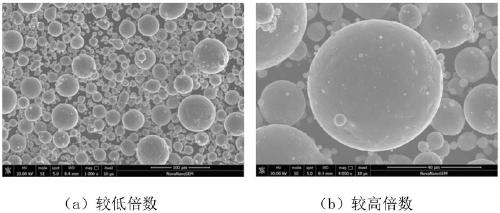

Preparation method of fiber-toughened SiC ceramic-based composite material three-dimensional member

The invention discloses a preparation method of a fiber-toughened SiC ceramic-based composite material three-dimensional member. The method comprises the following steps: adding fiber to liquid-state high char yield resin, pouring to a photo-curing mold, performing polymerization and curing on the resin, then manufacturing a controllable porous carbon preform through a thermolysis method, then performing high-temperature siliconizing, and preparing a SiC ceramic matrix by in-situ reaction of silicon on a carbon support to realize the manufacturing of the SiC ceramic-based composite material three-dimensional member. The method has the characteristics of near net shape formed variable cross-section complex structure, no crack defects, short production period, low cost and the like, and can be applied to development and manufacturing of blades of engines and other aerospace high-temperature-resistant complex structure parts.

Owner:XI AN JIAOTONG UNIV

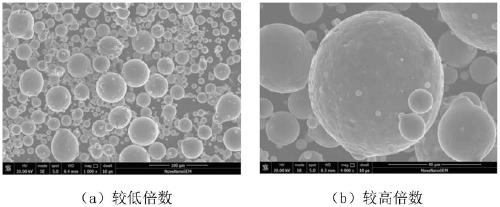

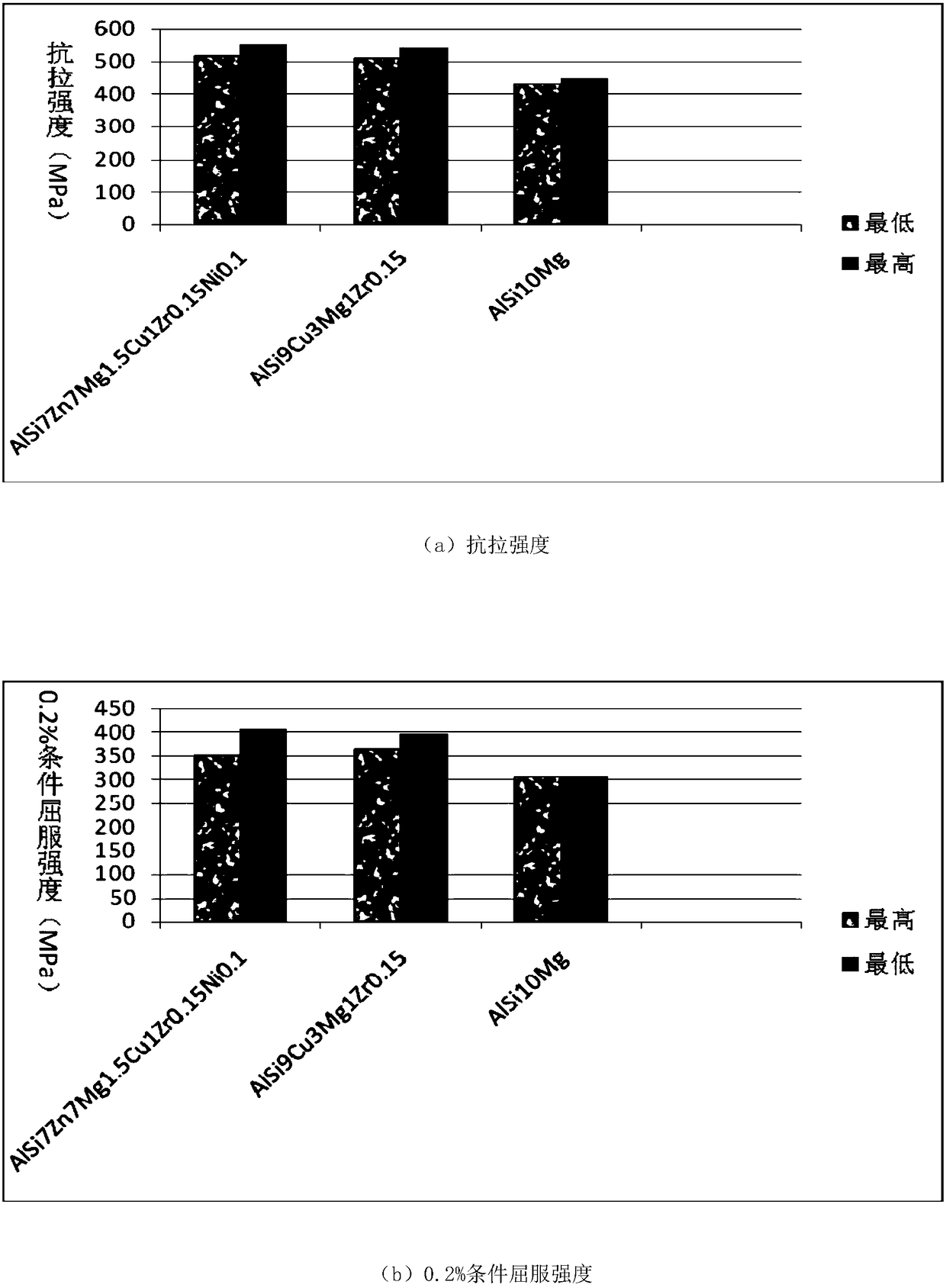

High-strength aluminum alloy for additive manufacturing and preparation method of high-strength aluminum alloy powder

ActiveCN109280820AGuaranteed yieldAvoid oxidation burnAdditive manufacturing apparatusTransportation and packagingTest sampleMedium frequency

The invention provides a high-strength aluminum alloy for additive manufacturing and a preparation method of high-strength aluminum alloy powder. The high-strength aluminum alloy powder is prepared byadopting a gas atomization process. The preparation method comprises the following steps of: firstly, melting an Al-Si-Zn-Cu-Mg-X alloy prefabricated ingot by adopting a medium frequency induction furnace, then powdering by adopting a supersonic speed gas atomization process, sieving and preparing powder of different specifications for additive manufacturing. A test sample obtained by adopting the high-strength aluminum alloy powder through additive manufacturing has compact texture without crack defects, the strength of extension exceeding 500MPa and the elongation exceeding 3%; the strengthperformance of the test sample is obviously superior to the strength performance of additive manufacturing test samples of AlSi10Mg, AlSi7Mg and AlSi12; and the performances of the test sample are also superior to the performances of additive manufacturing test samples of conventional 2000 series and 7000 series alloys. The alloy powder can be used for preparing aluminum alloy parts with compacttexture, complicated shapes and high strength in an additive manufacturing method to meet the requirements of use occasions on high specific strength and complicated shapes in the fields of aviation,spaceflight and automobiles.

Owner:AVIC BEIJING INST OF AERONAUTICAL MATERIALS

Pulsed switch-on preheating flash butt welding process for steel rims of heavy trucks

InactiveCN102107320ANo crack defectHigh degree of automationResistance welding apparatusButt weldingEngineering

The invention discloses a pulsed switch-on preheating flash butt welding process for steel rims of heavy trucks, which belongs to the technical field of welding, and comprises the steps of blanking, reeling, flattening, welding condition setting, fitting, pulsed flash preheating, continuous flash, charged upsetting, pressure maintaining, clamp loosening, deburring, and the like. The process is characterized by comprising the controlled process parameters as follows: the overhanging length is 20-50mm; the flash allowance is 5-12mm; the upset allowance is 5-10mm; the upset force is (2-3)*105 N; the clamp force is (3-6)*105 N; the pulsed switch-on preheating process is (4-10) times*(0.5-1.2) s, (0.1- 0.2) s per pulse; the preheating and welding voltage is 10.8-14.6 V; the flash time is14-30s; and the upset charged time: 0.3-2s. The process disclosed by the invention has the advantages that the degree of automation is high; the process is suitable for welding steel rims (thickness: 3-8mm, width: 300-400mm) of heavy trucks, and after the welded steel rims are sequentially subjected to trimming, flaring, roll shaping and expanding, the welded joints have no crack defect.

Owner:SHOUGANG CORPORATION +1

Production technology of steel containing sulphur easy cuwtting

The invention provides a process technique of using continuous casting process to produce sulfur-containing easy-to-cut steel SUM43, during melting, contolling sulfur content in the steel according to the medium-top limit required by steel composition, and contolling the Mn content to the top limit; necessarily firing molten steel in tunish to above 1000 deg.C; as electric melting, adding high-sulfur iron in 30%-50%; adding sulfur in refining furnace by sulfur iron block and sulfur-feeding iron wire process; the continous casting stage adopts a course-control mthod and the controlling cooling strength of secondary-cooling system: adopting a secondary-cooling system, the front stage adopts all-water spray cooling and the back stage adopts steam-water spray cooling, and automatically regulating the spray water rate of the secondary cooling. The surface finish of cast blanks reaches grade 6 above; over 90% of cast blanks have no crackes on the surfaces. The sulfur iron and sulfur-feeding iron wire process can accurately control sulfur content.

Owner:NANJING NANGANG IND DEV CO LTD

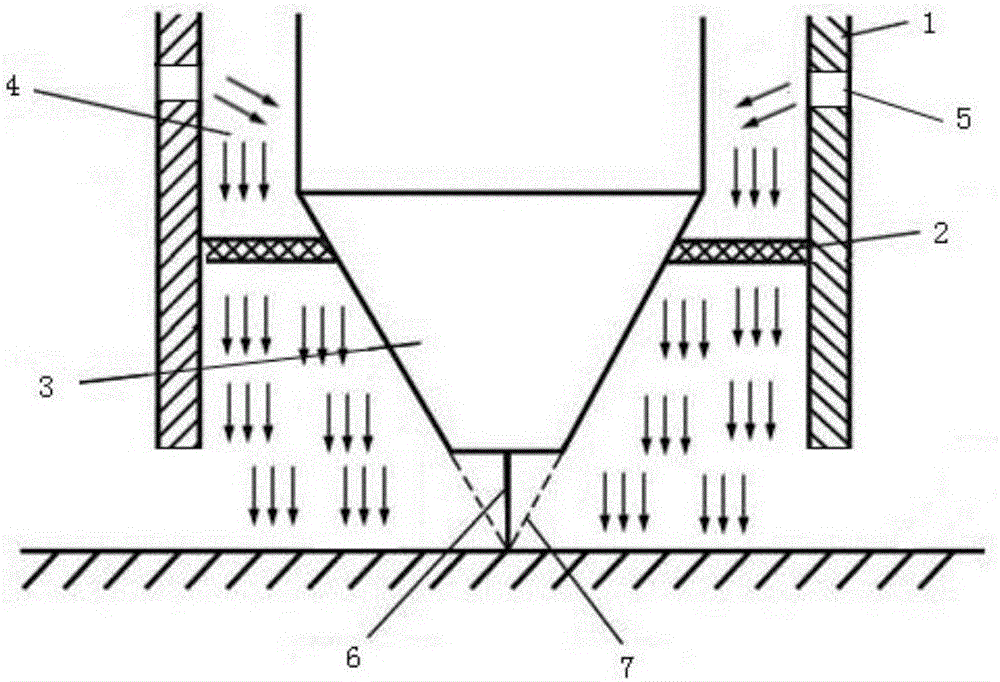

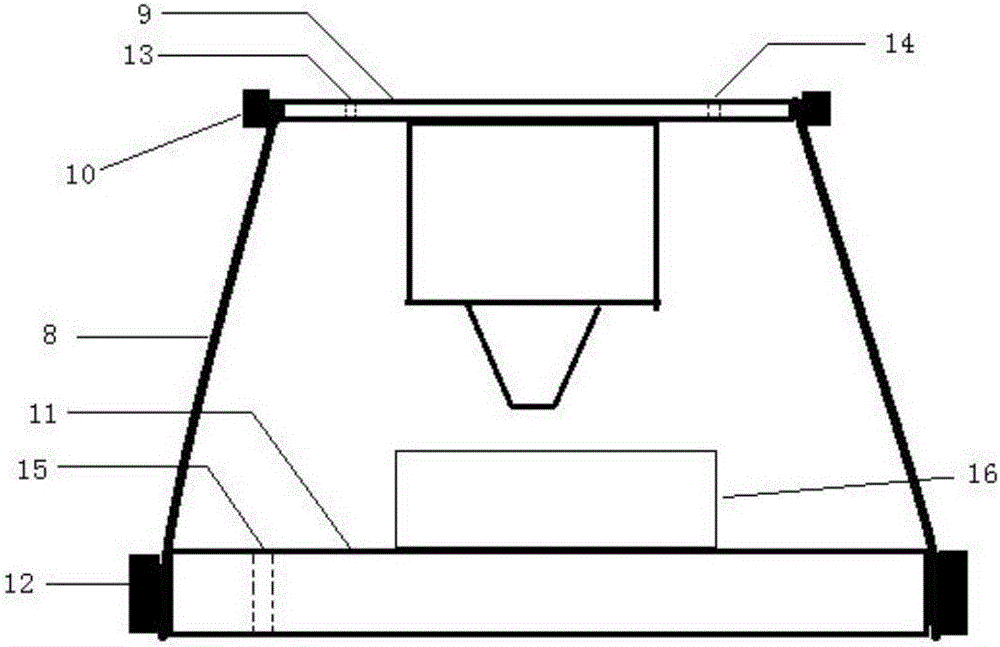

Method for adopting laser cladding to repair TC4-DT titanium alloys

ActiveCN105821408AReduce distortionNo crack defectMetallic material coating processesLaser processingTitanium

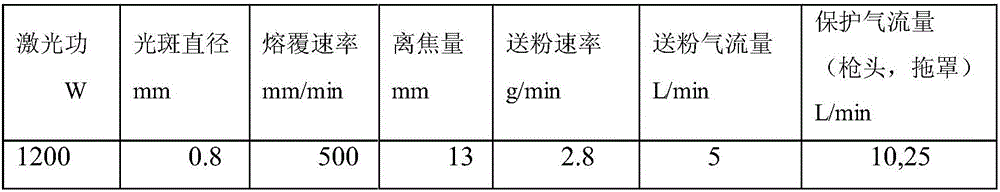

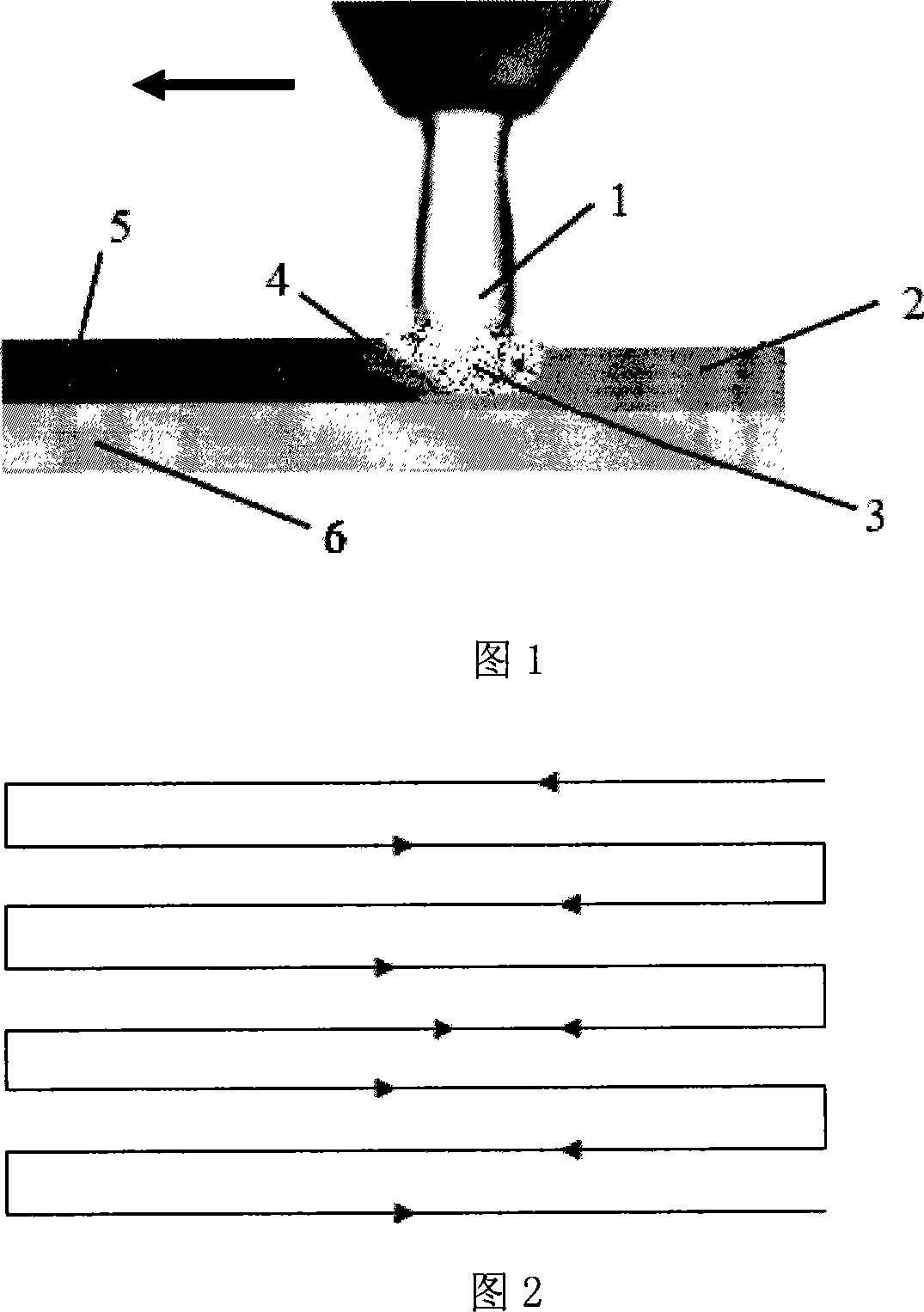

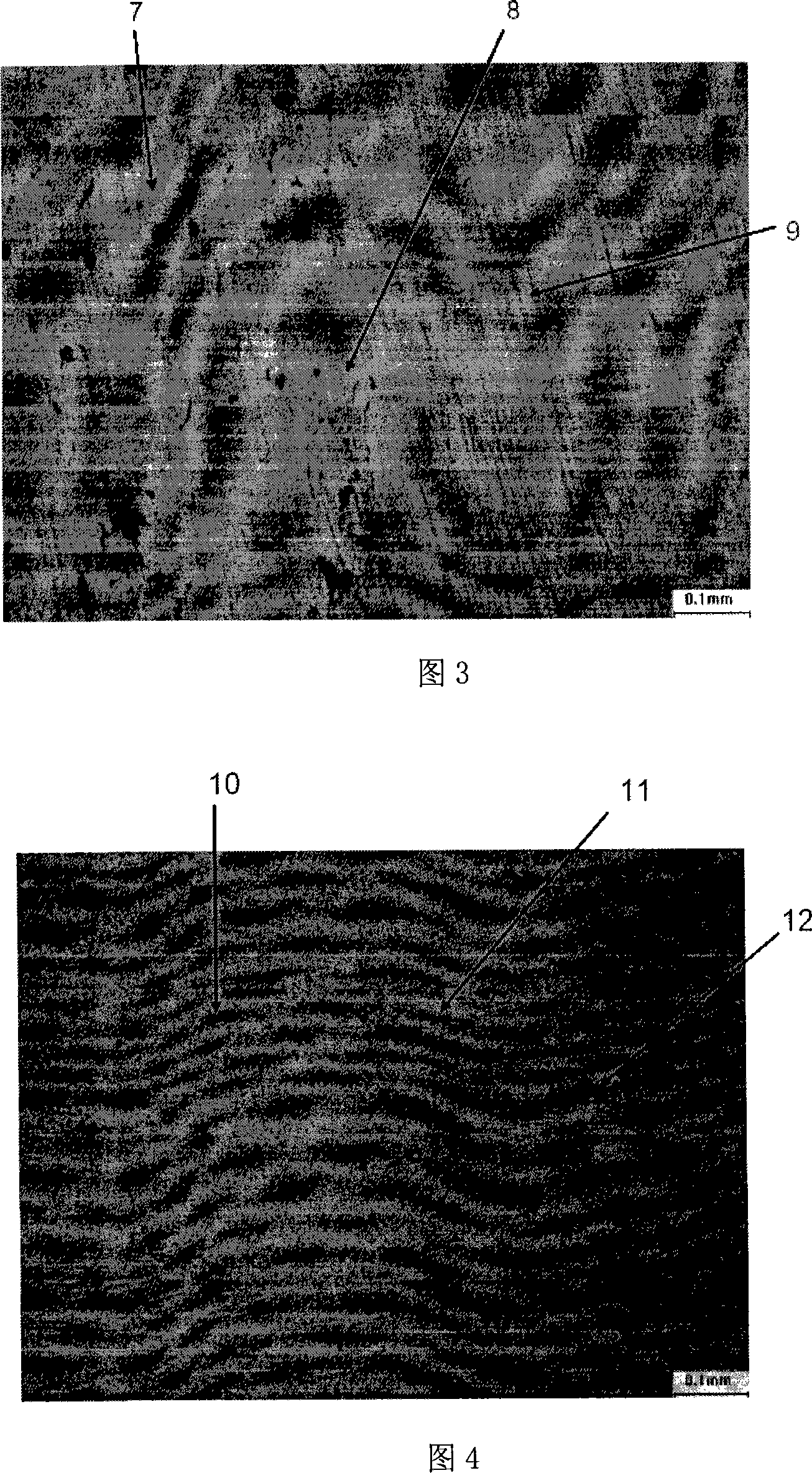

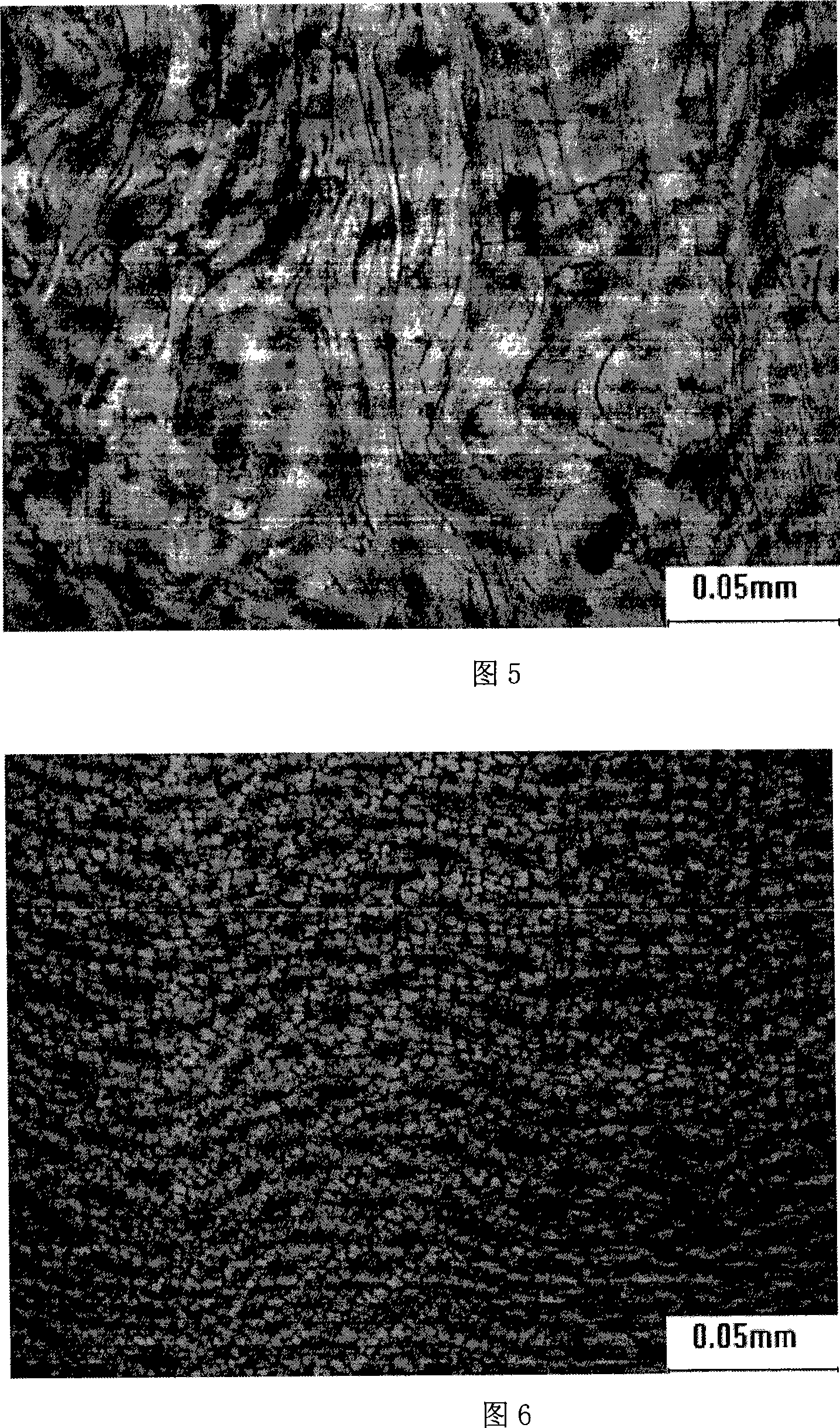

The invention belongs to the technical field of laser processing, relates to a process method for adopting laser cladding to repair TC4-DT forged pieces, and is mainly used for maintenance of the processing out-of-tolerance and the service damage of TC4-DT titanium alloys. The method directs at TC4-DT titanium alloys, TC4-DT powder is selected and used as a cladding material; a cylindrical additional dragging cover is mounted at the front end of a laser cladding head; a mesh copper sheet is arranged inside the additional dragging cover and is located between the laser cladding head and the dragging cover; air holes are formed in the dragging cover. Through the method, reasonable laser cladding process parameters are used for repairing the TC4-DT forged pieces with the processing out-of-tolerance or the service damage; the deformation of the repaired parts is very small and is controlled within a tolerance range; the repaired positions are free of crack defects; and the service life of the repaired workpiece is prolonged. The method can be carried out in the atmosphere or argon-filled environment, is convenient to operate and adjust, and is suitable for repairing the parts.

Owner:AVIC BEIJING INST OF AERONAUTICAL MATERIALS

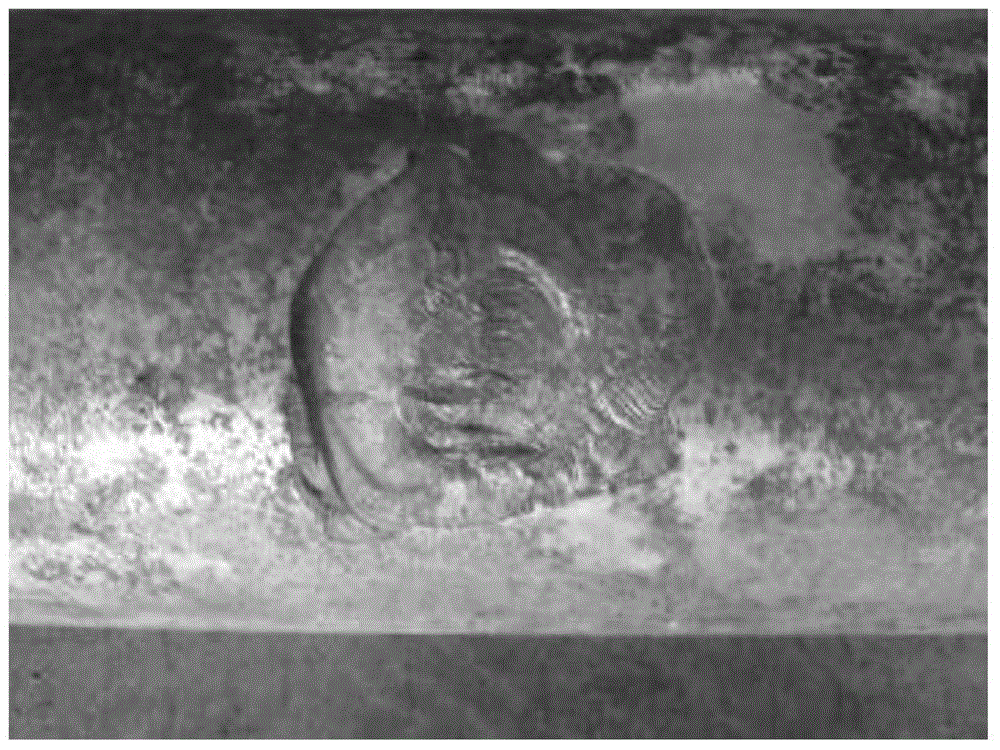

Process for repairing pits in titanium alloy aircraft sliding rail in argon arc welding way

ActiveCN103949757ARestore sizeReduce use costArc welding apparatusVehicle componentsStressed stateTitanium alloy

The invention belongs to the technical field of welding, relates to a process for repairing pits in a titanium alloy aircraft sliding rail in an argon arc welding way, and is particularly applied to the repair of the pits in the titanium alloy aircraft sliding rail after long-term serving in the field of maintenance of aircraft engines. According to the method, reasonable argon arc welding process parameters are used for repairing the pits in a pitted titanium alloy aircraft sliding rail workpiece, and the surface compressive stress state is recovered by shot peening strengthening after repair; the deformation of the repaired sliding rail is slight, and is controlled within a tolerance range; a repaired part is free of crack defects; the operational performance of the repaired workpiece is recovered; the titanium alloy aircraft sliding rail repaired by the method passes verification before installation, and is successfully installed for use.

Owner:AVIC BEIJING INST OF AERONAUTICAL MATERIALS

Method for preventing selective laser melting nickel-based superalloy from cracking

ActiveCN111906311AHigh densityNo crack defectAdditive manufacturing apparatusIncreasing energy efficiencySelective laser meltingSuperalloy

The invention provides a method for preventing a selective laser melting nickel-based superalloy from cracking, and belongs to the field of additive manufacturing. According to the method, a workpiecewhich is high in density, free of crack defects and excellent in mechanical property is prepared by reducing low-melting-point phase forming elements Zr and B in the nickel-based superalloy and adjusting the total content of Al and Ti in the alloy to be smaller than or equal to 4.5wt% in combination with special selective laser melting (SLM) process parameter control. Through the method, component design is reasonable, the preparation process is simple, and the obtained workpiece has excellent properties and is convenient to apply on a large scale.

Owner:CENT SOUTH UNIV

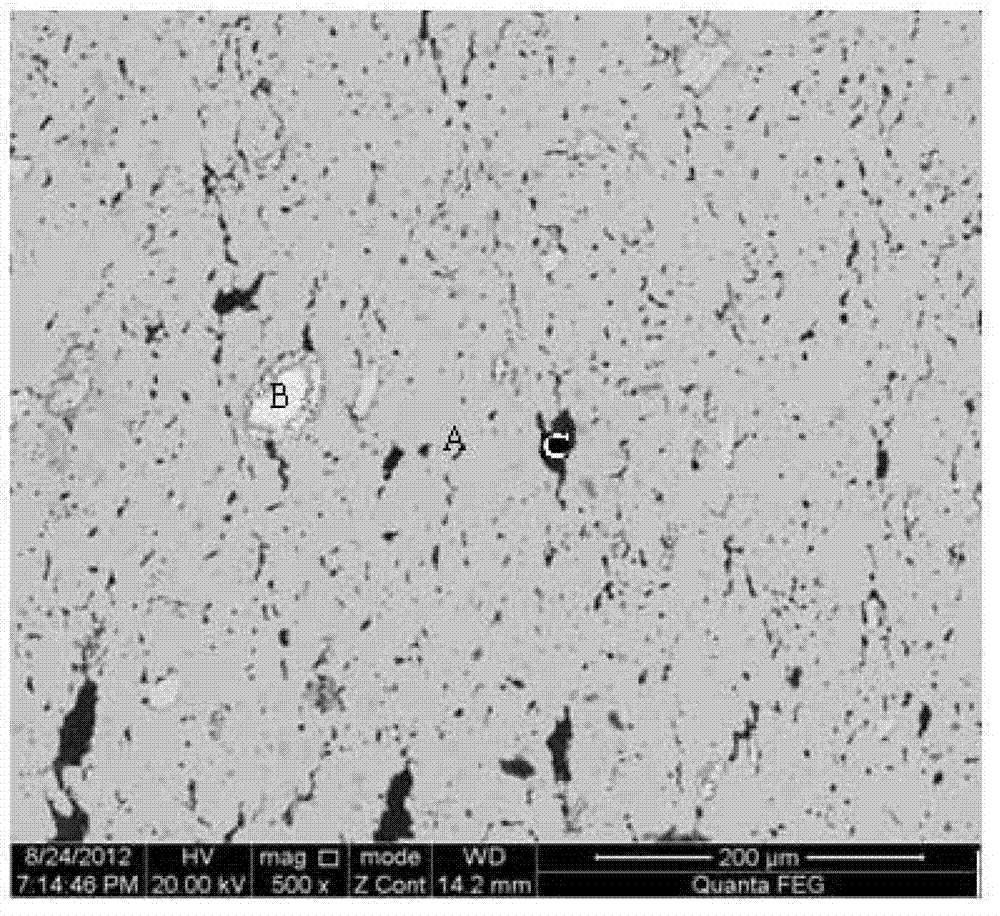

Method for preparing ceramic-metal composite material cladding layer

InactiveCN101186999AGood arc column stabilitySmall heat affected zoneMolten spray coatingManufacturing efficiencyMicrometer

Provided is a process for preparing a cladding layer of ceramic-metallic composite material, belonging to the technical field of superficial treatment. The technique includes that the surface of a metallic member is cleaned, unoiled and sprayed sand, enabling the surface of the metallic member to be roughened, then the method of electric arc spraying or plasma spraying is employed to prepare the coating layer of ceramic-metallic composite material on the surface of the metallic member, the scanning remelting of the coating layer is carried out by utilizing a plasma arc gun with micro beam and the like. The parameters of the invention include that a compression nozzle of the plasma arc gun with the diameter of 0.6 to 1.3 millimeters is chosen, the ionized gas flow is 0.08 to 0.2 liter every minute, the protective gas flow is two to three liters every minute, the plasma arc current is 10 to 30A when the thickness of the coating layer is less than 600 micrometers, the plasma arc current is 25 to 60A when the thickness of the coating layer is 600 to 1500 micrometers, the distance between the head portion of the plasma arc gun with micro beam and the surface of the coating layer is two to five millimeters, and the relative move speed of the plasma arc gun with micro beam to the member is two to eight millimeters every second. The invention has the advantages of simple technique, stable quality, low cost and high manufacture efficiency.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

Welding forming method of thin invar alloy

InactiveCN102240851AAchieve weldingContinuously adjustable widthLaser beam welding apparatusInvar alloyShielding gas

The invention discloses a welding forming method of a thin invar alloy. The welding is carried out by adopting an Nd: YAG laser device. The welding forming method comprises the steps of: fixing the invar alloy in a fixture and then installing the invar alloy on a workbench; adjusting the pulse width and the pulse frequency of the Nd: YAG laser device, relative position of the laser and the thin invar alloy and the pressure of a side-blown protective gas; determining proper laser average line energy density; and carrying out forming welding on the thin invar alloy. The welding of the invar alloy is realized directly by using the laser, so that extra welding wires are not needed while welding. The pulse width, the pulse frequency and the defocusing amount of the laser device are continuously adjustable, so that the invar alloy of 0.5-2 mm in thickness can be formed by autogenous welding. And the pulse laser line energy density of the Nd: YAG laser device in the invention is between 100-900 J / mm, therefore, the welding line without obvious positive and negative weld reinforcements and pores and cracks can be realized, and follow-up processes to the welding line are not needed.

Owner:DALIAN UNIV OF TECH

Technical method for repairing block falling defect of flap sliding rail chromium-plated surface through laser cladding

ActiveCN111593343ANo sheddingExtended service lifeMetallic material coating processesLaser processingChromium coating

The invention relates to a technical method for repairing a block falling defect of a flap sliding rail chromium-plated surface through laser cladding, and belongs to the technical field of laser processing. The method is mainly used for repairing abrasion defects of an airplane flap sliding rail. According to the method, ultra-high-strength steel powder good in weldability and good in abrasion resistance is selected to serve as a cladding material for a 30CrMnSiNi2A ultra-high-strength steel workpiece, and reasonable laser cladding process parameters are adopted to repair the sliding workingsurface of the flap sliding rail. A chromium-plated layer of the non-repair surface in the repair process does not fall off; no crack defect exists on the repair portion; and the abrasion resistance of a repair structure is equivalent to that of an original matrix material, so that the service life of the workpiece is prolonged. A certain type of airplane flap sliding rail repaired through the method has been installed and applied.

Owner:AVIC BEIJING INST OF AERONAUTICAL MATERIALS

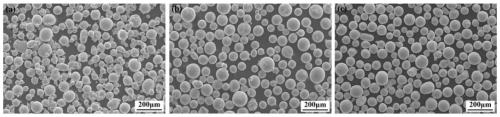

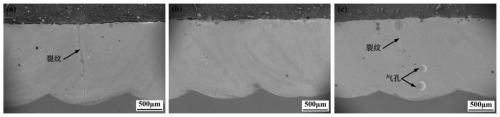

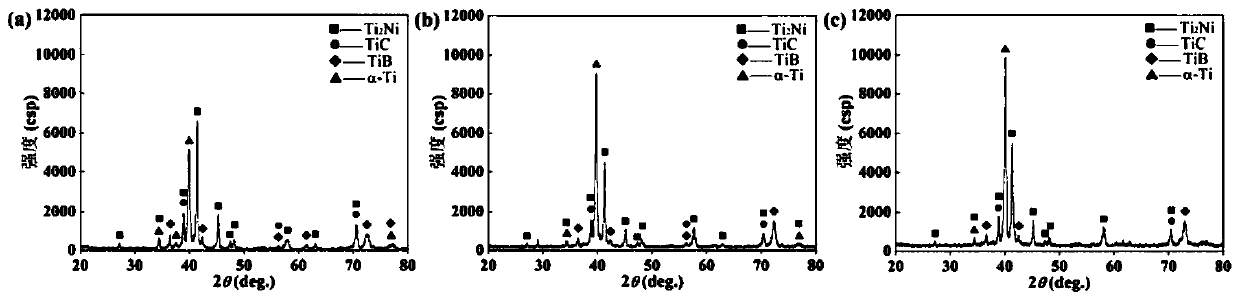

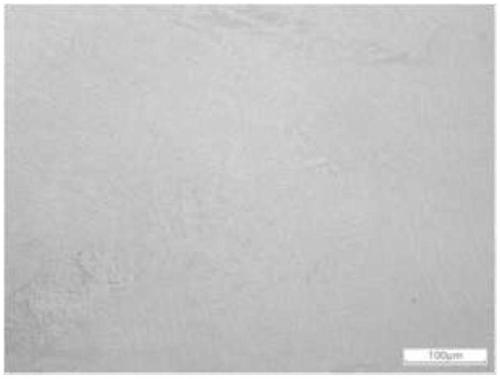

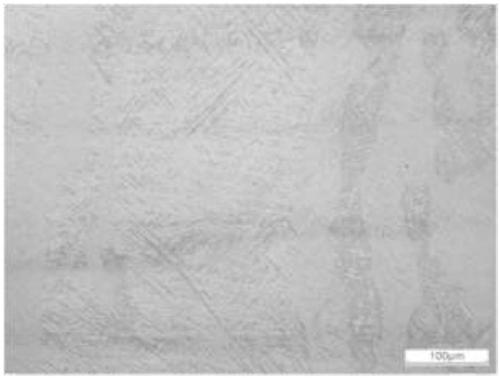

Copper-bearing titanium-based wear-resisting laser cladding layer on surface of titanium alloy and preparation method of copper-bearing titanium-based wear-resisting laser cladding layer

InactiveCN111118493AImprove toughnessInhibit growthMetallic material coating processesSurface engineeringTitanium

The invention belongs to the field of titanium alloy surface engineering, and particularly relates to a copper-bearing titanium-based wear-resisting laser cladding layer on the surface of a titanium alloy and a preparation method of the copper-bearing titanium-based wear-resisting laser cladding layer. Cladding layer comprises 65wt% of TC4 powder, 25-35wt% of Ni60 powder and 0-10wt% of Cu powder.The TC4 powder comprises 6.36wt% of Al, 4.06wt% of V, 0.011wt% of N, 0.05wt% of Fe, 0.077wt% of O and the balance Ti. The Ni60 powder comprises 15.5wt% of Cr, 0.8wt% of C, 3.5wt% of B, 4.0wt% of Si, 5.0wt% of Fe, 3.0wt% of W and the balance Ni. The purity of the Cu powder is larger than 99%. The forming quality of the laser cladding layer is improved, the friction and wear performance of the surface of the titanium alloy can be obviously improved, and the service life of the titanium alloy can be prolonged.

Owner:CIVIL AVIATION UNIV OF CHINA

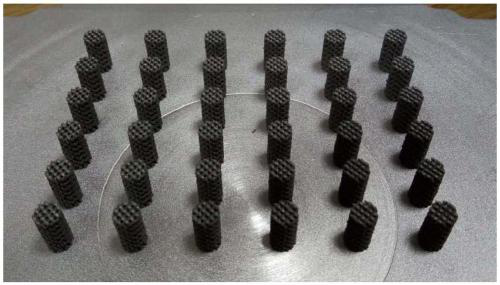

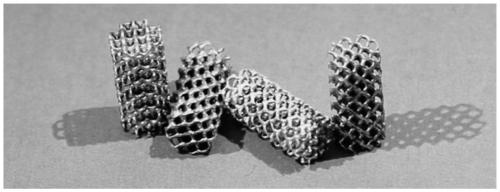

Preparation method of porous magnesium rare earth alloy implant based on laser selective melting (SLM) additive manufacturing technology

ActiveCN110394447AHigh strengthHigh modulusAdditive manufacturing apparatusIncreasing energy efficiencyManufacturing technologyRare earth

The invention provides a preparation method of a porous magnesium rare earth alloy implant based on a laser selective melting (SLM) additive manufacturing technology. The method comprises the following steps that 1, components of magnesium rare earth alloy powder are selected; 2, the magnesium rare earth alloy powder is preheated; 3, a substrate is preheated; 4, a three-dimensional model of the porous magnesium rare earth alloy implant is drawn; 5, a porous magnesium rare earth alloy implant entity is stored into an output format file in an STL format and transmitted to layering software, a bottom surface support is added, and slicing treatment is carried out; 6, the porous magnesium rare earth alloy implant entity is printed; 7, the porous magnesium rare earth alloy implant molding pieceand the substrate are cut and separated; and 8, electrochemical polishing treatment is carried out. The porous implant prepared by the method has uniform hole wall thickness, no crack defect and highoverall strength and modulus; and the porous implant prepared by the method is better matched with the strength and modulus of human bones.

Owner:SHANGHAI JIAO TONG UNIV

Nickel-based high-temperature alloy turbine supporting base argon arc welding repairing method

InactiveCN110216413AReduce use and maintenance costsReduce use costArc welding apparatusMetallic NickelArc welding

The invention discloses a nickel-based high-temperature alloy turbine supporting base argon arc welding repairing method. The nickel-based high-temperature alloy turbine supporting base argon arc welding repairing method comprises the following steps that firstly, a nickel-based high-temperature alloy welding wire consistent to a supporting base in material component is selected; secondly, surfacetreatment is conducted before repairing; thirdly, a protection cover is pasted on the supporting base through aluminum foil paper, then, inward argon inflation is constantly conducted through an airpipe, the back face of a welding line is arranged in the closed argon protection environment, and the supporting base to which the aluminum foil is pasted is arranged in a special anti-deformation tool; fourthly, argon arc welding repairing is conducted, the notch position is completely and fully welded, complete full welding is achieved through visual checking, the phenomena of undercuts and pitsare avoided, and repair welding is conducted several times till repair welding is finished; fifthly, postweld heat treatment is conducted; sixthly, grinding machining is conducted; and seventhly, lossless detection is conducted. By means of the nickel-based high-temperature alloy turbine supporting base argon arc welding repairing method, the usage and maintenance cost of the engine turbine supporting base is reduced, and the repaired part is free of crack defects.

Owner:航发优材(镇江)增材制造有限公司

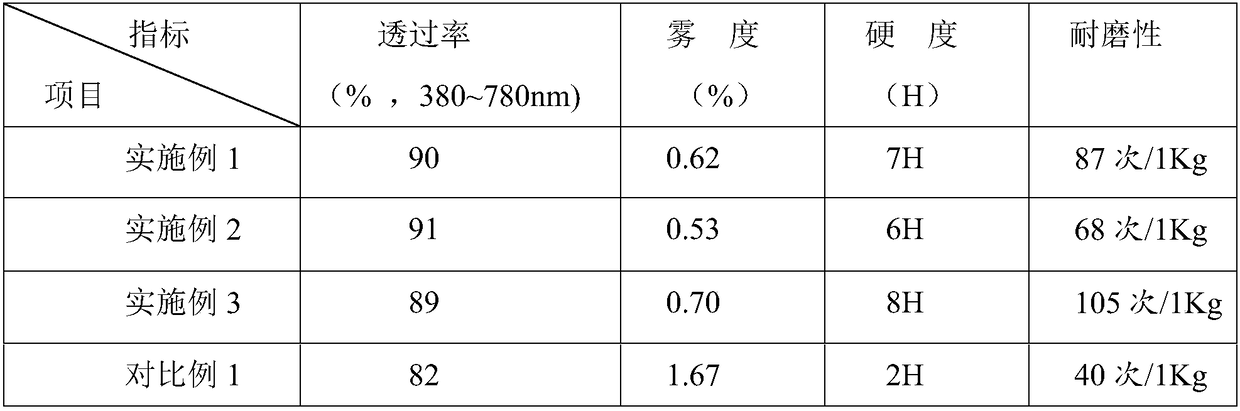

White graphene composite resin hardening liquid and preparation method of PET hardened layer

ActiveCN108219608AInhibition of oligomer precipitationHigh mechanical strengthPolyurea/polyurethane coatingsIn situ polymerizationWear resistant

The invention relates to the technical field of flexible electronic film materials, in particular to a white graphene composite resin hardening liquid and a preparation method of a PET hardened layer.The hardening liquid is prepared from, in parts by weight, 30-90 parts of polymer resin, 10-60 parts of a diluent, 0.01-10 parts of a photoinitiator and 0.1-15 parts of modified white graphene. The modified white graphene is polymer-coated and modified white graphene obtained after 2-10 layers of white graphene are sequentially subjected to surface lipophilic treatment and in-situ polymerizationmodification. The hardening liquid is applied to the surface of a PET substrate, ultraviolet curing is performed after thermal curing film formation, and the white graphene composite PET hardened layer is obtained. The problems that existing PET resin hardened layers are not wear-resistant, prone to scratching and large in warping and have oligomer or small molecule precipitation are solved; the defects that silicon dioxide resin PET hardened layers have poor transmittance and haze and have conducting function failure caused by cracking during postprocessing can be overcome.

Owner:GUANGDONG NANOLUTION SCI & TECH CO LTD

Manufacturing method of special welding material for electron beam welding of YGH-60 hard alloy and 45 steel

InactiveCN102962454AImprove plasticityGood high temperature plasticityElectron beam welding apparatusWelding/cutting media/materialsIron powderNiobium

The invention discloses a manufacturing method of a special welding material for electron beam welding of YGH-60 hard alloy and 45 steel, and relates to an electron beam welding method of dissimilar materials. The manufacturing method solves the technical problems that the available brazed connection method for the hard alloy and the steel has complicated procedures and a fusion welding connection method causes cracks easily. The manufacturing method comprises the steps that 8.3-8.5% of iron powder, 0.45%-0.55% of niobium powder, 0.75%-0.85% of yttrium powder, 0.45%-0.55% of carbon powder and the balance of nickel powder are weighed according to weight percentages, and added into a powder mixing machine to be mixed, and obtained mixed powder is pressed and then put into a vacuum furnace for sintering, therefore, the special welding material for the electron beam welding of the YGH-60 hard alloy and the 45 steel is obtained. The special welding material can be used to weld the dissimilar materials.

Owner:ZHUZHOU HARD ALLOY GRP CO LTD +1

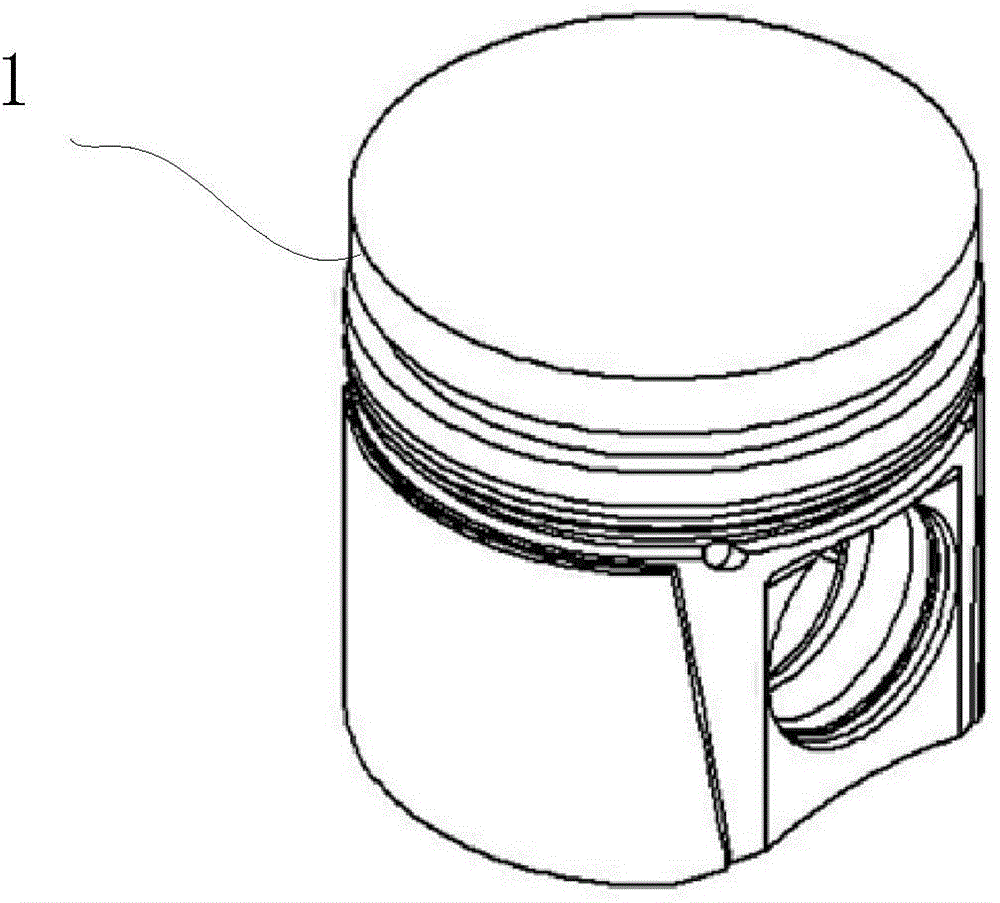

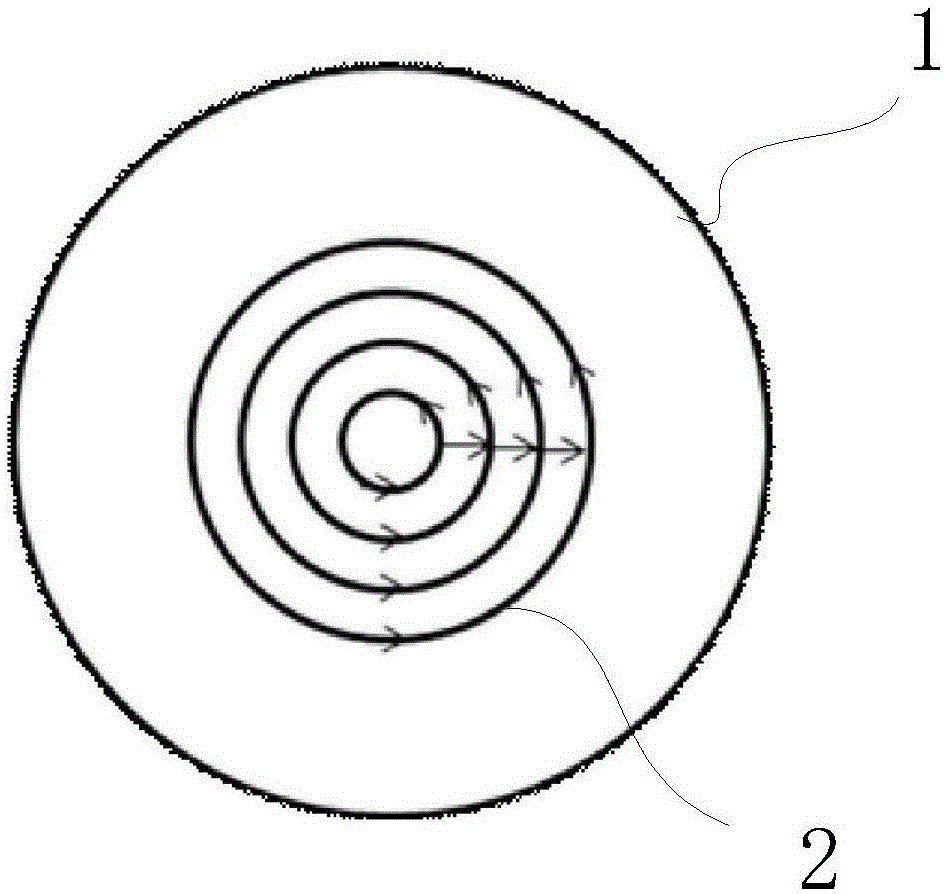

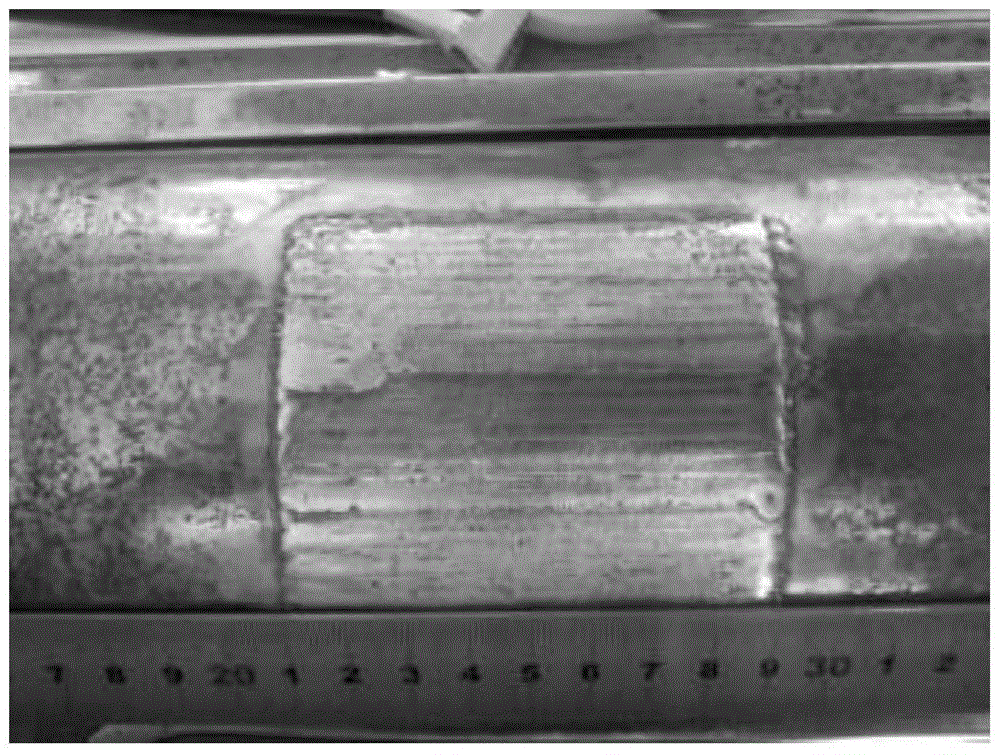

Piston top surface thermal fatigue-resistance alloy coating laser cladding method

ActiveCN106283034AExtended service lifeThickness is easy to controlMetallic material coating processesThermal fatigueAlloy coating

The invention discloses a piston top surface thermal fatigue-resistance alloy coating laser cladding method. The method comprises the following steps: the top surface of a piston blank is mechanically pretreated; a laser walking trajectory is set according to the piston top surface structure; Co-Cr-W alloy powder is used as a cladding material, and is synchronously added to the piston top surface during laser walking; the laser cladding is performed for the piston top surface; and a thermal fatigue-resistance alloy coating layer formed on the piston top surface is a cladding layer. The piston top surface thermal fatigue-resistance alloy coating laser cladding method selects the proper cladding material to embed the laser cladding technology in the piston manufacturing process flow; the thermal fatigue-resistance alloy coating layer metallurgically bonded with a matrix, with controllable thickness and without crack defect is prepared on the piston top surface; and the piston service life is prominently prolonged.

Owner:INST OF MECHANICS - CHINESE ACAD OF SCI

Heat treatment method

A related heat treatment method is characterized in that heat treatment is performed on a medium / high-carbon steel continuous cast slab and a medium / high-carbon alloy steel continuous cast slab. The medium / high-carbon steel continuous cast slab comprises, in percent by mass, 0.25-1.35% of C, 0.10-0.37% of Si, 0.25-0.80% of Mn, P <=0.035%, and S <=0.030%. The medium / high-carbon alloy steel continuous cast slab comprises, in percent by mass, 0.25-1.50% of C, 0.10-2.10% of Si, 0.30-2.60% of Mn, P <=0.035%, S <=0.035%, Cr <=4.50%, V <=1.20%, Mo <=1.20%, Ni <=4.60%, and B <=0.004%. The heat treatment steps comprise that the temperature of the slab entering a heat treatment furnace is 150 DEG C-850 DEG C, the slab heat-treatment warm-keeping temperature is 300-850 DEG C, the slab heat-treatment warm-keeping time is 3-40 hours, the temperature of the slab exhausted from the furnace after being subjected to heat treatment is 150-550 DEG C, the slab heat-treatment heating speed is 5-250 DEG C / h, and the slab heat-treatment cooling speed is 5-100 DEG C / h. The continuous cast slabs subjected to heat treatment does not have crack defects.

Owner:SHANXI TAIGANG STAINLESS STEEL CO LTD

Deformable aluminum alloy metal powder material for additive manufacturing and preparation method thereof

InactiveCN107649675AEliminate crack defectsNo crack defectAdditive manufacturing apparatusTransportation and packagingAlloyMetal powder

The invention discloses a deformable aluminum alloy metal powder material for additive manufacturing and further discloses a preparation method for the deformable aluminum alloy metal powder for additive manufacturing. The deformable aluminum alloy metal powder material is composed of the following components of, by mass, 0.40-0.65% of Si, 0.1-0.7% of Fe, 0.15-0.4% of Cu, 0.05-0.15% of Mn, 0.8-1.2% of Mg, 0.04-0.35% of Cr, 0.05-0.25% of Zn, 0.01-0.15% of Ti, 0.2-0.5% of Sc and the balance Al, wherein the sum of the mass percentages of all the components is 100%. Through the deformable aluminumalloy metal powder for additive manufacturing, the cracking problem of existing 6061 aluminum alloy powder in the process of additive manufacturing is solved.

Owner:XIAN BRIGHT ADDTIVE TECH CO LTD

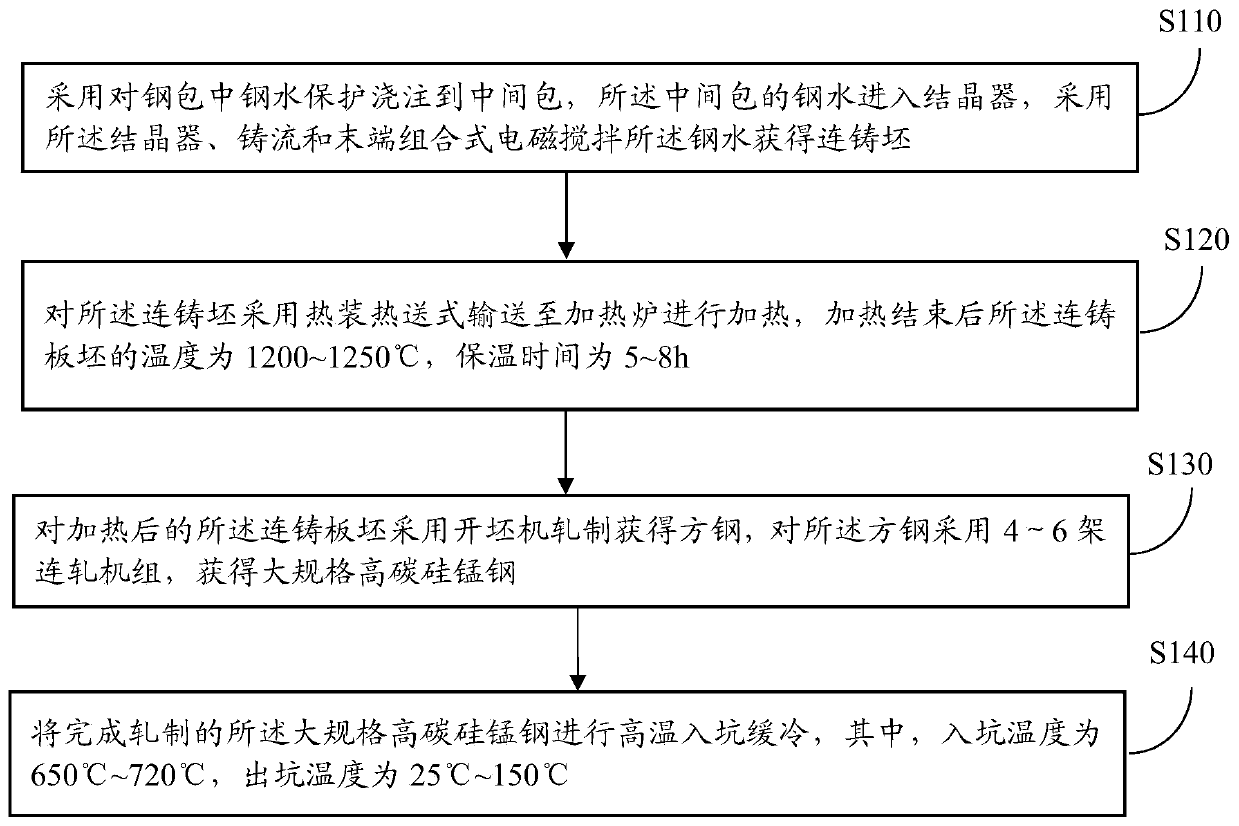

Large-specification high-carbon silicon manganese steel and manufacturing method thereof

The invention discloses large-specification high-carbon silicon manganese steel and a manufacturing method thereof. The high-carbon silicon manganese steel comprises, by mass, 0.60-1.20% of C, 0.38-0.80% of Si, 1.00-1.90% of Mn, less than or equal to 0.020% of P, less than or equal to 0.005% of S, 0.02-0.06% of Al, 0.020-0.050% of Nb, 0.01-0.04% of Ti, 0.025-0.065% of V, 0.08-0.31% of Cr, 0.10-0.50% of Mo, and the balance Fe and inevitable impurities. According to the high-carbon silicon manganese steel and the manufacturing method, the technical problem of poor center quality of large-specification high-carbon silicon manganese steel produced in the prior art is solved, the continuous casting production of the large-specification high-carbon silicon manganese steel is realized, internal shrinkage cavities of a continuous casting billet are successfully welded, inner porosity is greatly improved, low-power center porosity, general porosity and pattern segregation of the large-specification high-carbon silicon manganese steel are less than or equal to 1.5 grade, the low-power cross section has no defects of residual shrinkage cavities and cracks, and the qualified rate of flaw detection reaches 95% or more is achieved.

Owner:江苏联峰实业有限公司

Preparation method of high-hardness and high-strength expanding pyramid of mechanical expanding mill

The invention discloses a preparation method of a high-hardness and high-strength expanding pyramid of a mechanical expanding mill. The preparation steps are as follows: (1) smelting, spheroidizing, inoculating and casting; (2) annealing; (3) plugging holes with refractory clay and asbestos, blocking grooves, sealing center holes so that the preparation works are completed; (4) charging the expanding pyramid of which the large end downwards faces into a tooling of which the bottom is a plane, placing the tooling inside a well-type heating furnace and drying the refractory clay so as to complete the charging operation; (5) by controlling the temperature-raising speed and the temperature-raising temperature, heating; (6) by controlling the temperature-raising speed, the temperature-raising temperature and the temperature-raising time, austenitizing; (7) by controlling the time and temperature, carrying out three-stage quenching; and (8) by controlling the time and temperature, tempering. The high-hardness and high-strength austenitic-bainitic nodular cast iron expanding pyramid subjected to above treatment steps has no defects such as quenching cracks, high quenching depth, good compressive strength, impact toughness and hardness, can meet the needs of machining and cannot be deformed after machining. The expanding pyramid is suitable for preparing steel tubes having steel grade of X60-X80 and wall thickness of 10-18 mm.

Owner:HUNAN UNIV OF SCI & TECH

A method for preparing gradient coatings by laser cladding to repair cold rolls

ActiveCN104404510BImprove toughnessHigh bonding strengthMetallic material coating processesSand blastingOptoelectronics

The invention relates to a method for restoring a cold roll through preparing a gradient coating via laser cladding. The method comprises the following steps: 1) carrying out polishing, cleaning and sand blasting on the to-be-restored area of the cold roll; 2) paving a brazing flux on the surface of the to-be-restored area of the cold roll, paving brazing filler metal powder on the brazing flux and preparing a first transition layer through a high-temperature heating manner; 3) pacing transition material powder on the surface of the first transition layer and preparing a second transition layer through laser cladding; 4) paving alloy powder on the surface of the second transition layer and preparing a third gradient layer through laser cladding. The method starts with the structural design of a cladding layer, and the cladding layer is designed into an alloy gradient layer with a multilayer structure, so that the problem that the cold roll is easy to crack, relatively low in bonding strength and easy to fall off after the restoration is solved.

Owner:九江中科神光科技有限公司

Near alpha titanium alloy metal powder material used for additive manufacturing and preparing method thereof

ActiveCN109648073AReduce the ratioEliminates tendency to crackAdditive manufacturing apparatusTransportation and packagingMetal powderTitanium alloy

The invention discloses a near alpha titanium alloy metal powder material used for additive manufacturing. The powder material comprises, by mass percent, 3.1 to 6.2% of Al, 1.0 to 2.1% of Zr, 0.4 to1.8% of Mo, 0.6 to 2.3% of V, 0.2 of Fe, 0.1% of Sn, 0.1% of C, 0.05% of N, 0.01% of H, 0.13% of O, 0.30% of inevitable impurities and the balance Ti, and the mass percent of the above components is 100%. The invention further discloses a preparing method of the near alpha titanium alloy metal powder material used for additive manufacturing. The method is used for the near alpha titanium alloy metal powder material, and the problem that an existing titanium alloy powder cannot meet the part strength need is solved.

Owner:XIAN BRIGHT ADDTIVE TECH CO LTD

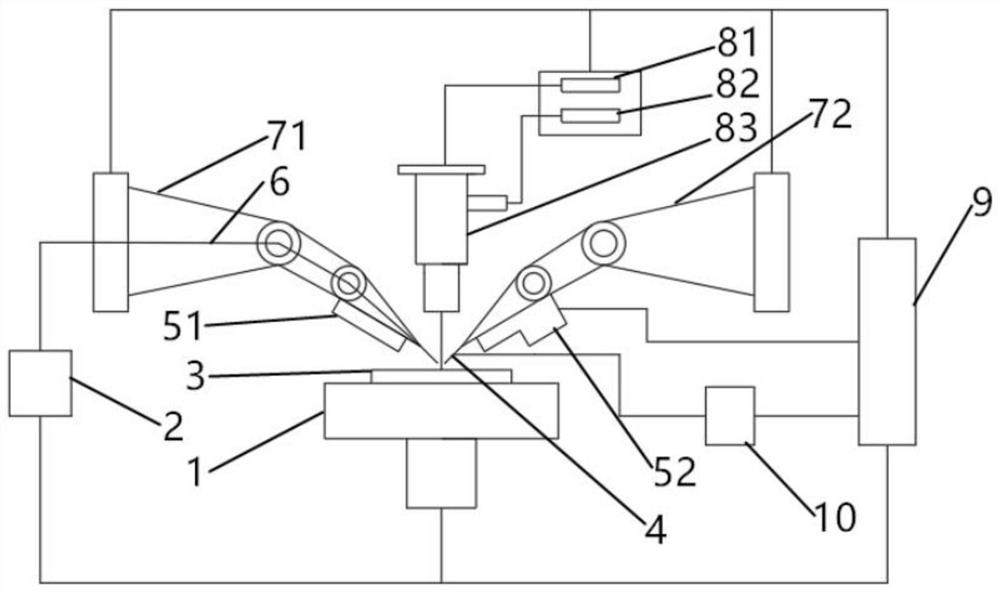

Intelligent braze coating device and braze coating method

ActiveCN112548258AFlat surfaceImprove bindingMetal working apparatusSolder feeding devicesCoated surfaceControl system

The invention relates to an intelligent braze coating device and a braze coating method. The intelligent braze coating device comprises a movable workbench, a wire feeding mechanism, two industrial robots, a coating temperature field monitoring device, a coating contour monitoring device, a high-energy beam generator and a control system, wherein the two industrial robots, the coating temperaturefield monitoring device and the coating contour monitoring device are all arranged above the movable workbench, one of the two industrial robots is used for providing wire brazing filler metal, the other one of the two industrial robots is used for providing a braze coating heat source, the wire feeding mechanism is used for conveying wire-shaped or tubular brazing filler metal to the robots, anda high-energy beam emitter provides a heat source for the robots through a high-energy beam emitting head. A prepared coating is a cladding layer which is smooth in surface, good in combination with base metal, free of crack defects and compact in structure. From the perspective of equipment platform development, the problems that manual braze coating is poor in stability and uneven in coating thickness are solved.

Owner:NORTH CHINA UNIV OF WATER RESOURCES & ELECTRIC POWER

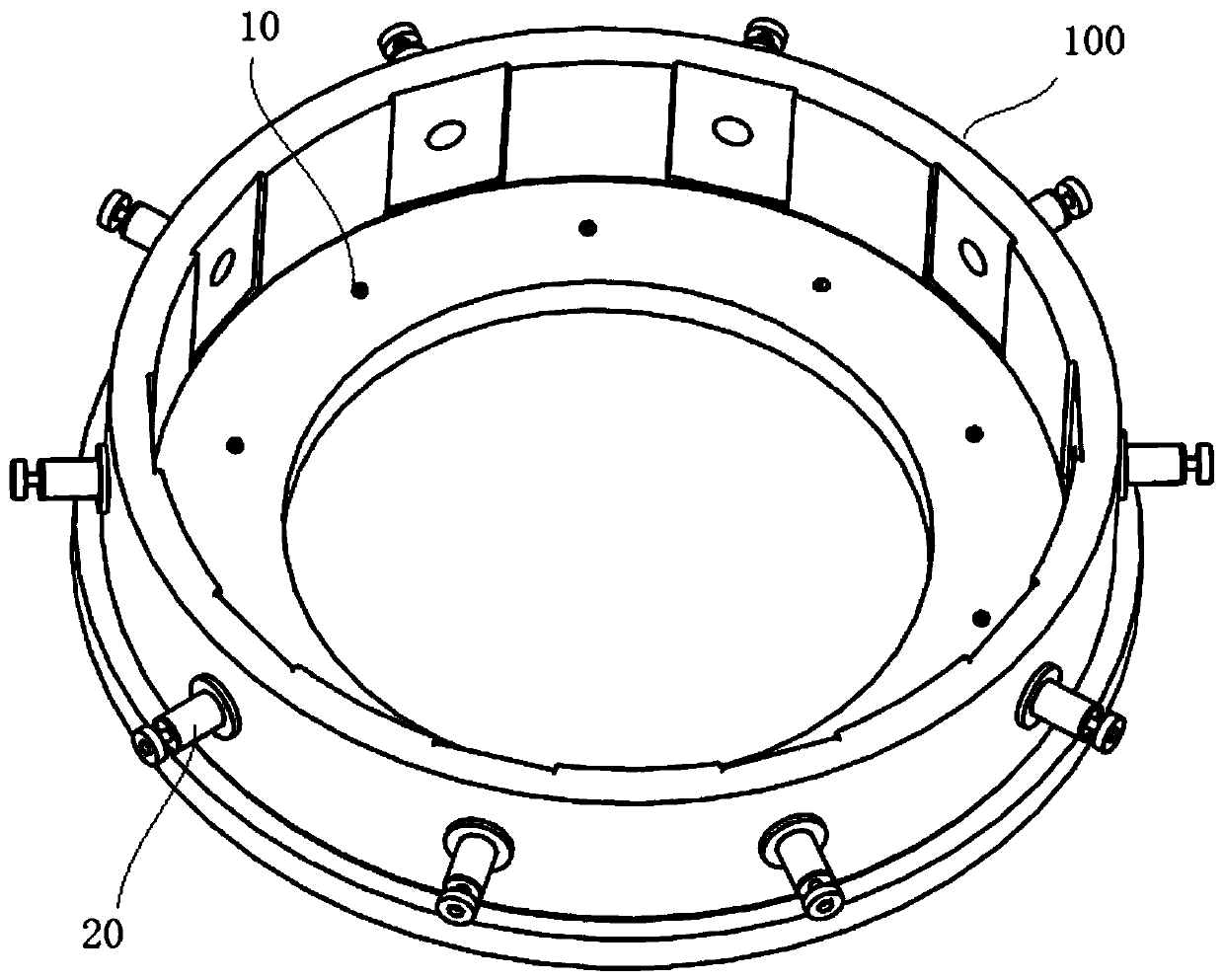

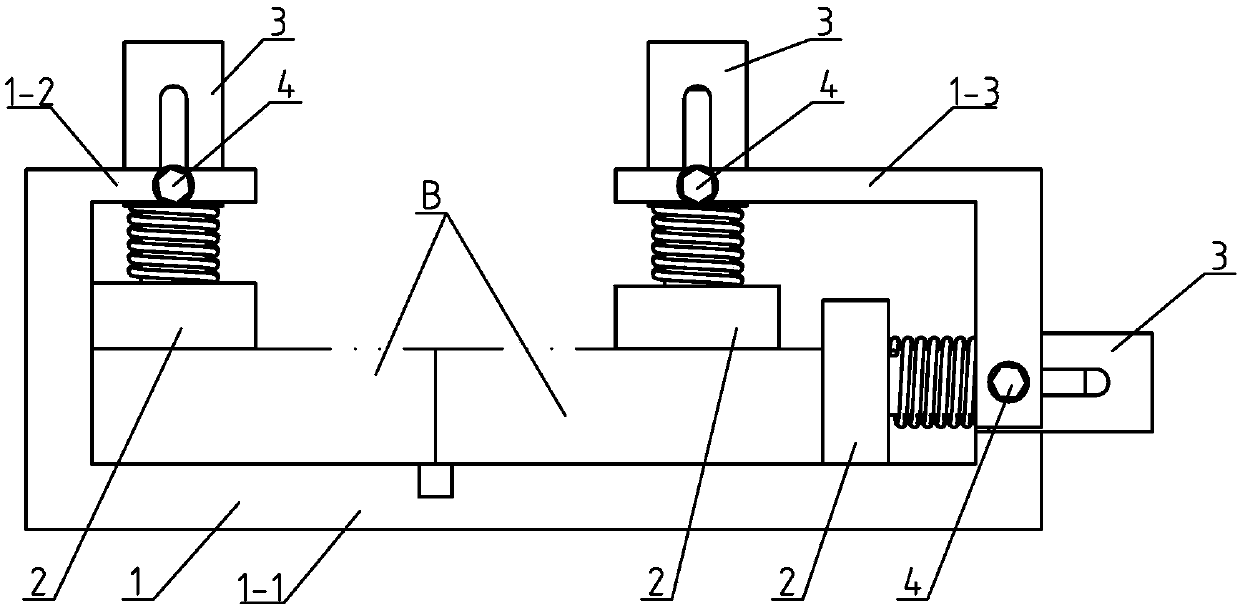

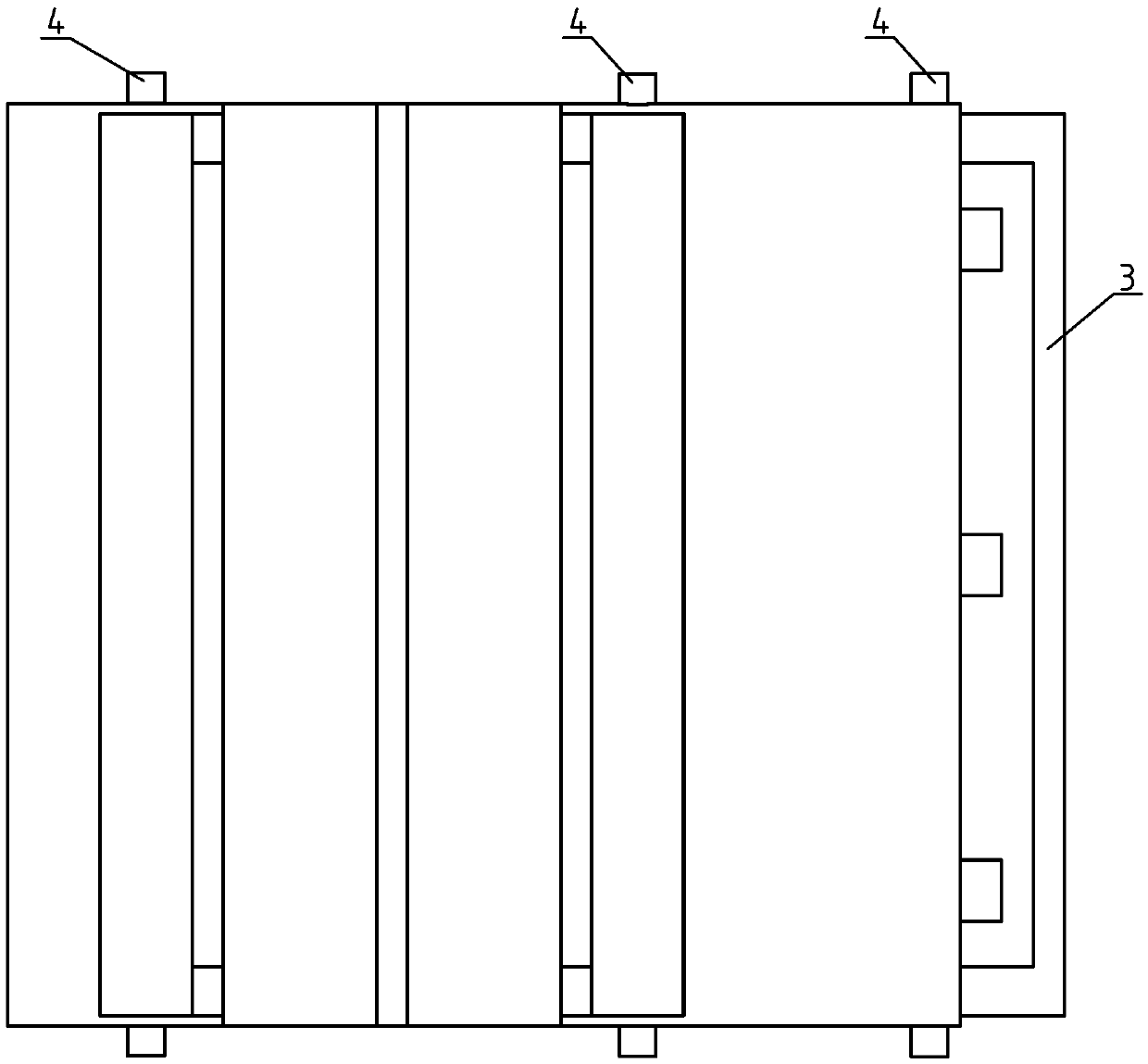

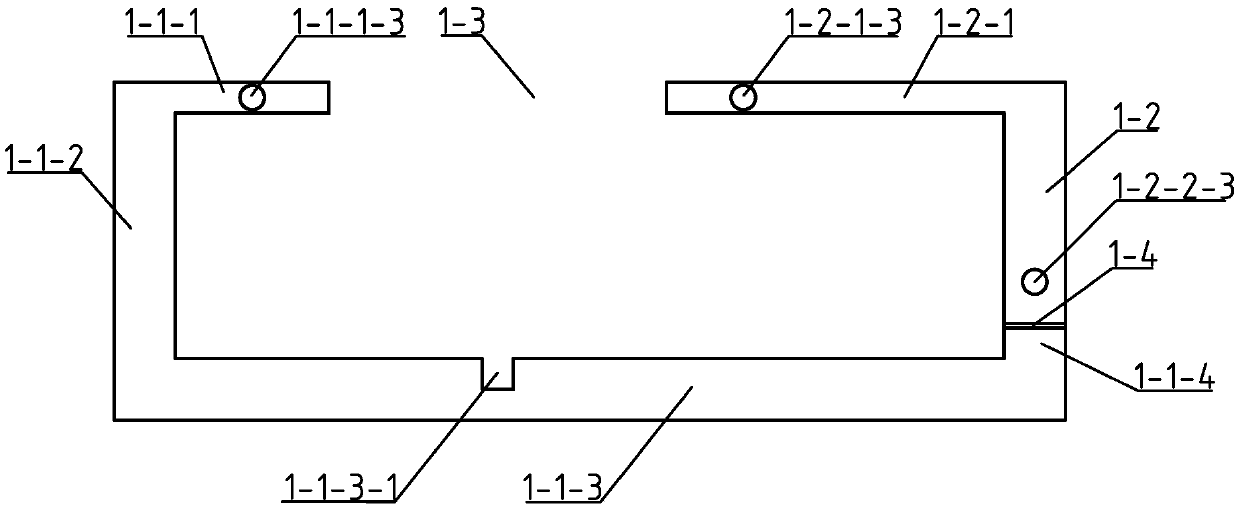

Elastic-rigid coupling regulating and controlling aluminum alloy sheet electron beam welding stress deformation fixture

InactiveCN109604799ALarge amount of deformationAvoid damageWelding/cutting auxillary devicesAuxillary welding devicesCouplingElectron

The invention discloses an elastic-rigid coupling regulating and controlling aluminum alloy sheet electron beam welding stress deformation fixture. The problems of crack defect caused by large residual stress caused during rigid constraint and damage to the surface of a test piece caused by point constraint in the welding process are solved. The fixture comprises a fixture shell, three constraintdevices, three constraint baffles and three connecting elements. The three constraint devices are all arranged in the fixture shell, constraint heads arranged on the inner side of an upper end plate on the left side penetrate through left side constraint head mounting holes, constraint heads arranged on the inner side of an upper end plate on the right side penetrate through right side constrainthead mounting holes, and constraint heads arranged on the inner side of a right vertical plate penetrate through lower mounting holes; a constraint baffle is arranged on the outside of each row of constraint heads, the two ends of the constraint baffles are separately arranged in corresponding roughening clamping openings, the constraint baffles are connected with the fixture shell through the connecting elements, and gap of 3mm-8mm are arranged between the constraint baffles and the constraint heads. The elastic-rigid coupling regulating and controlling aluminum alloy sheet electron beam welding stress deformation fixture is used for regulating and controlling the deformation of the plate welding stress.

Owner:HARBIN INST OF TECH

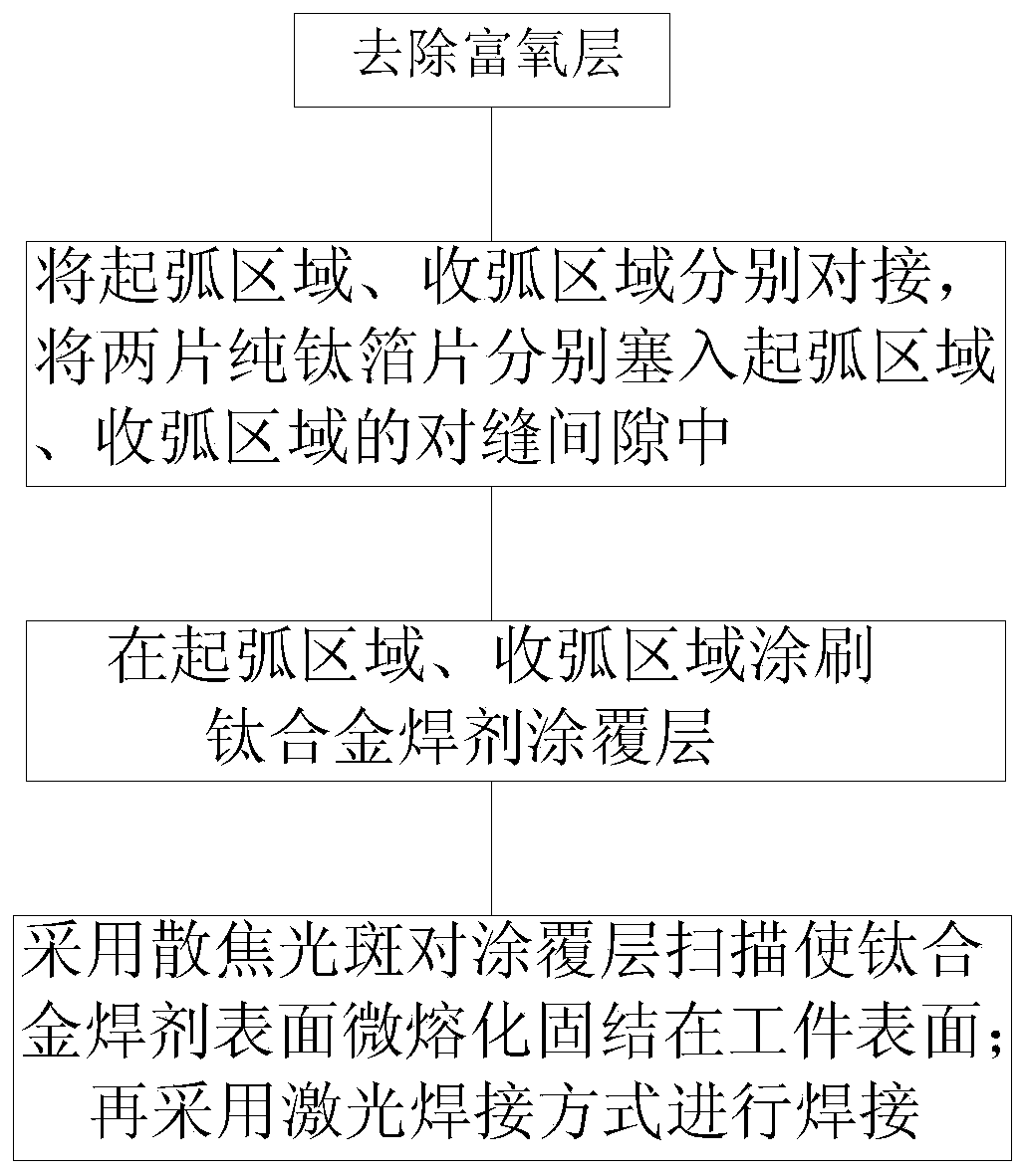

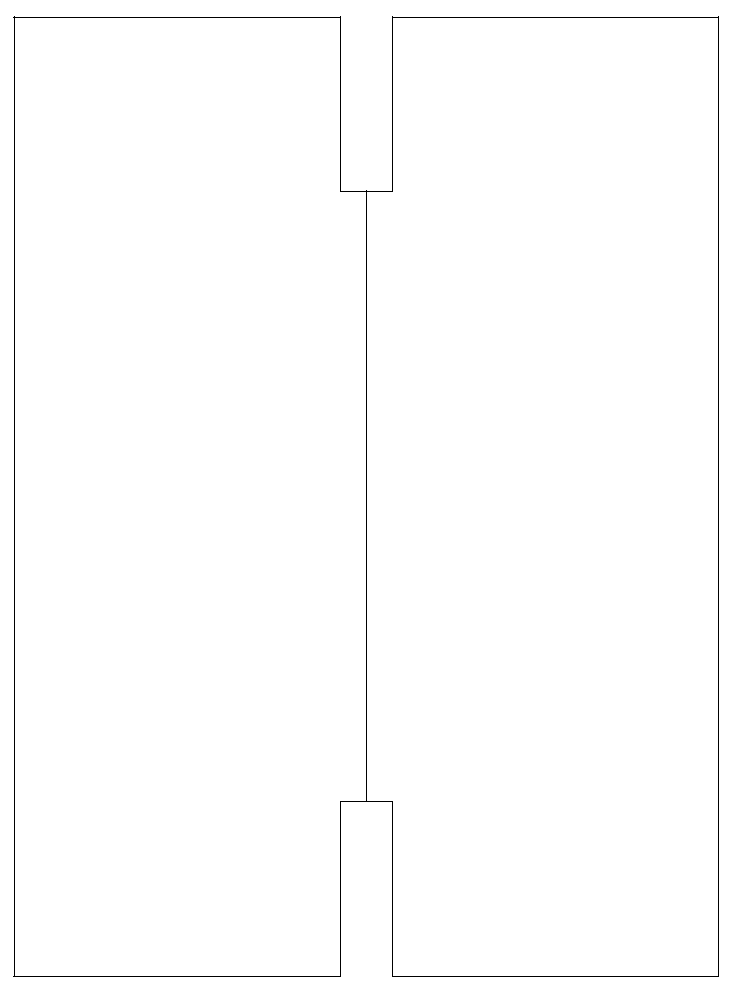

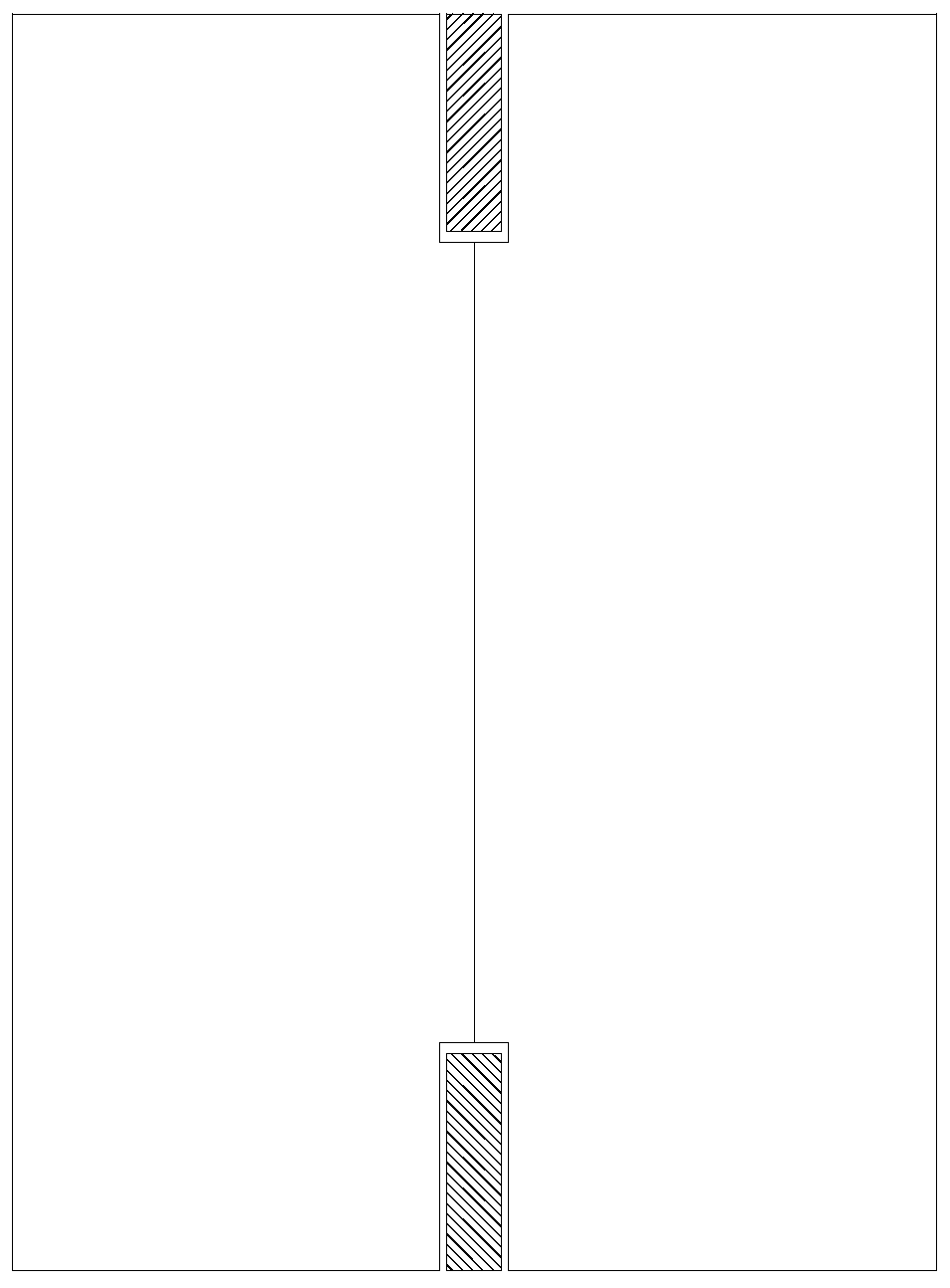

Control method for eliminating weld crack of high temperature titanium alloy plate

InactiveCN110860792AImprove stabilityImprove structural strengthWelding/cutting media/materialsWelding/soldering/cutting articlesButt weldingLaser scanning

The invention relates to a control method for eliminating weld cracks of high temperature titanium alloy plates. The control method includes the steps that removing oxygen-enriched layers in arc starting areas and arc closing areas; butt jointing the arc staring areas and the arc closing areas of the high temperature titanium alloy plates to be welded correspondingly; selecting two pieces of titanium foil and inserting the titanium foil into the gap between the arc starting areas and the gap between the arc closing areas of the high temperature titanium alloy plates to be welded; painting a layer of titanium alloy flux coating in each arc starting area and arc closing area; adopting defocused speckle to laser scanning the coatings, and enabling the surface of titanium alloy flux to be slightly melted and solidified in the arc starting areas and arc closing areas; and adopting laser welding method to weld butt welds of the high temperature titanium alloy plates to be welded. The controlmethod greatly improves the stability of laser welding welds of titanium alloy material, further improves the structural strength of titanium alloy material, and is widely used in the fields of aerospace and people livelihood field.

Owner:AVIC BEIJING AERONAUTICAL MFG TECH RES INST

Technology of welding and repair for defects of E grade steel coupler and coupler yoke

The invention discloses a technology of welding and repair for a workpiece, particularly to a technology of welding and repair for defects of an E grade steel coupler and a coupler yoke. The technology is characterized in that the technology comprises the steps as follows: a, before welding and repair, the coupler and the coupler yoke are integrally heated under a temperature of 250 to 300 DEG C, and the heat is preserved for 0.5 to 1.5 hours; b, welding and repair treatment is conducted; after welding and repair, the coupler and the coupler yoke are melted down, and the heat is preserved; under the temperature, furnace cooling is conducted; and the temperature of the coupler and the coupler yoke is reduced to be lower than and equal to 150 DEG C; and c, tapping is conducted. Compared with the prior art, the technology has the advantages of simple process, easy operation, no crack defect, and good welding and repair quality.

Owner:CRRC DALIAN CO LTD

Die casting method for casting 80 t-grade large forged ingots through bottom casting method

The invention discloses a die casting method for casting 80 t-grade large forged ingots through a bottom casting method. The die casting method adopts the bottom casting method to cast; and key control parameters comprise molten steel casting superheat degree, steel ingot body casting time, steel ingot cap port casting time, demolding after casting and buckle red ladle stacking slow cooling control. The method is convenient and feasible in operation, can improve the steel ingot internal quality, reduces such defects as steel ingot head looseness and shrinkage, can prevent steel ingot surface cracks, and reduces wastes caused by crack defects in die casting of the 80 t-grade large forged ingots. The method adopts lower superheat degree and longer casting time; after steel ingots are cast bynot lower than 24 h, buckle red ladles are stacked and slowly cooled by 5-7 days; after longer demolding time and stacking and slow cooling time, the after-forging flaw detection GB / T6402-2008 three-level pass percent is not lower than 99.05%; no surface crack defect is generated; and excellent internal quality and surface effect are achieved.

Owner:WUYANG IRON & STEEL

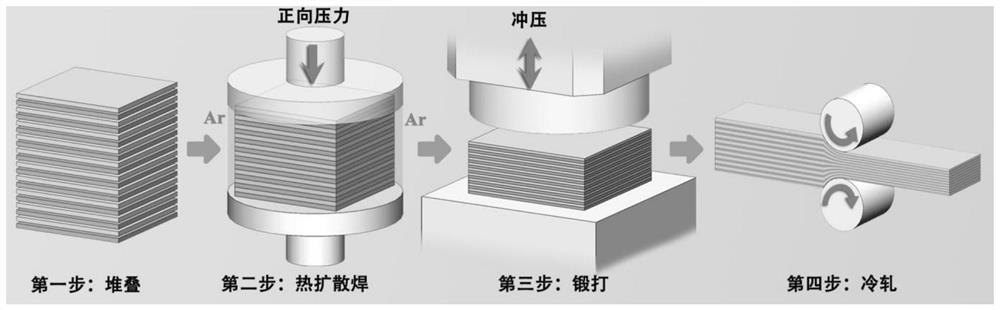

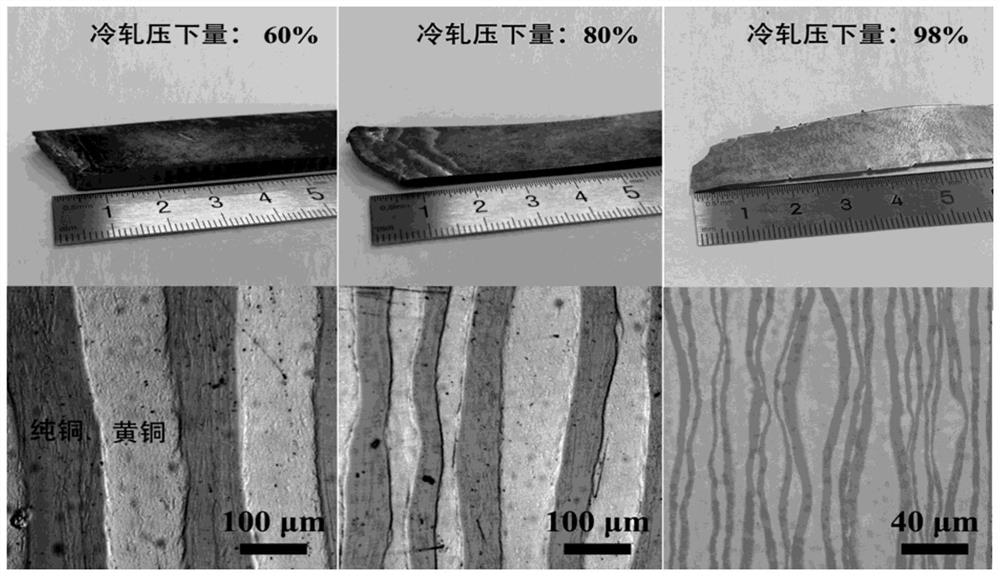

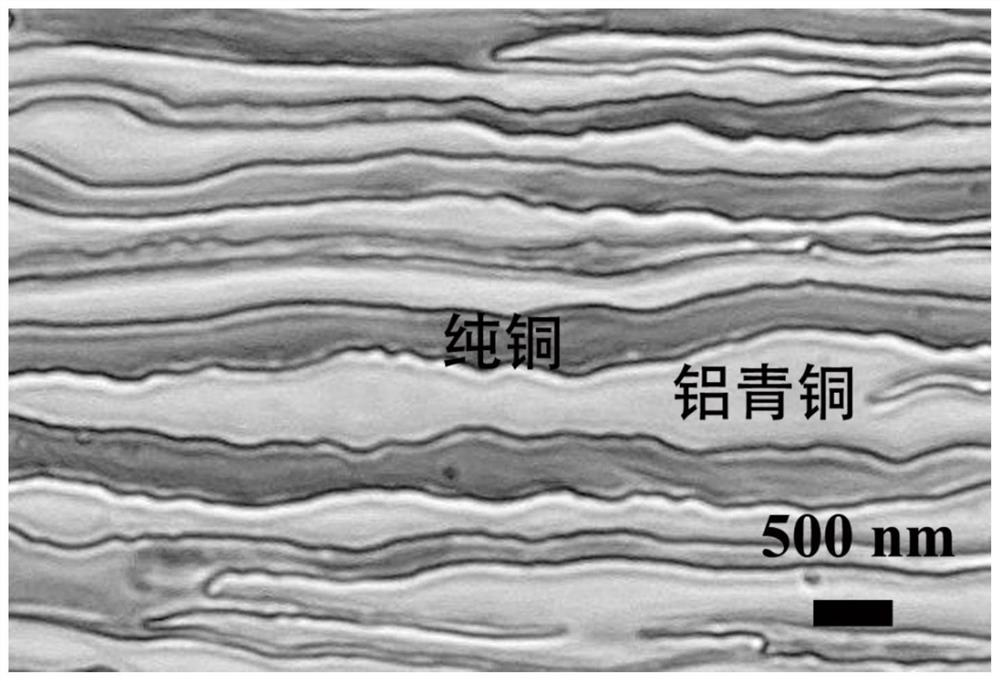

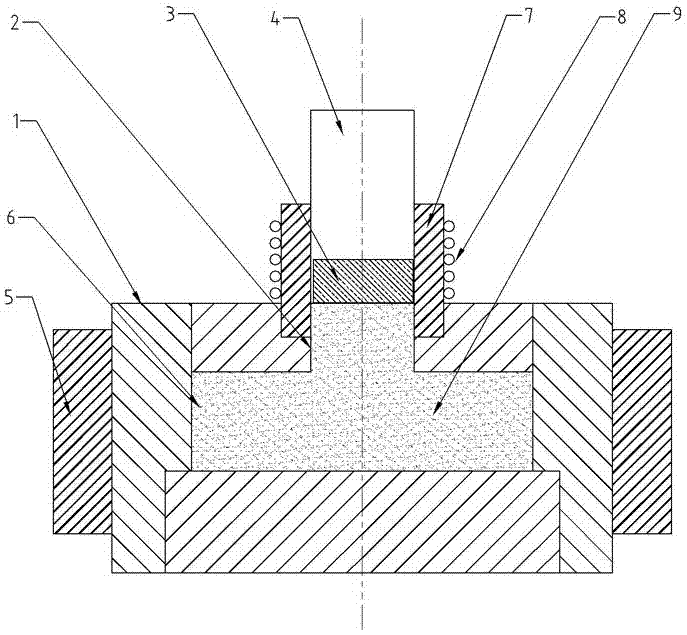

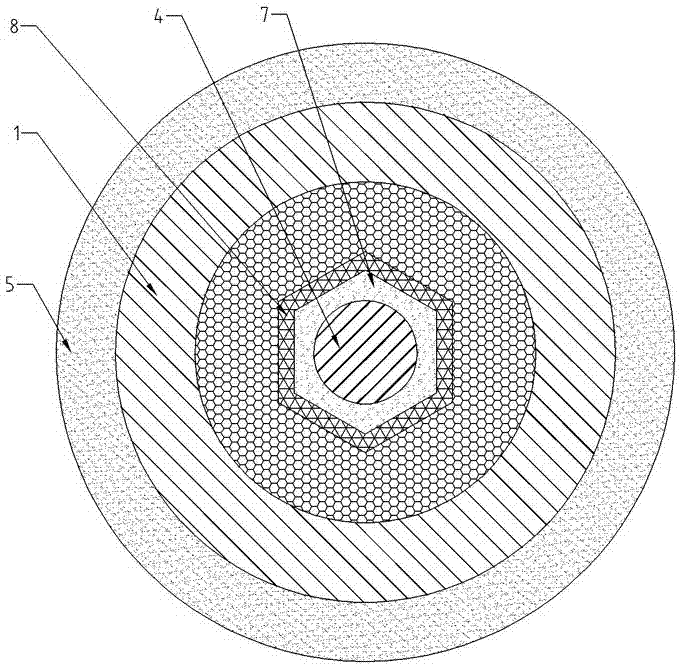

Micro-nano layer-shaped copper/copper alloy composite board and preparation method thereof

PendingCN113634597AAvoid utilizationAvoid associativityAuxillary arrangementsMetal rolling arrangementsMicro nanoMetallurgy

The invention provides a micro-nano layer-shaped copper / copper alloy composite board and a preparation method thereof. Copper and copper alloy boards with the thickness ranging from 0.5 mm to 2 mm are stacked in a multi-layer manner, then the copper and copper alloy boards are tightly welded together through a thermal diffusion welding treatment means, then the thickness of the boards is reduced to 10 mm or below through a forging treatment process, and finally, the micro-nano layer-shaped copper / copper alloy composite board / foil is obtained through a traditional rolling technology. Compared with the prior art, layers of the board are firmly combined, the number of layers and the thickness of the board are controllable, and the thickness of the composite board can reach the thickness of a foil.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY AND SCIENCE

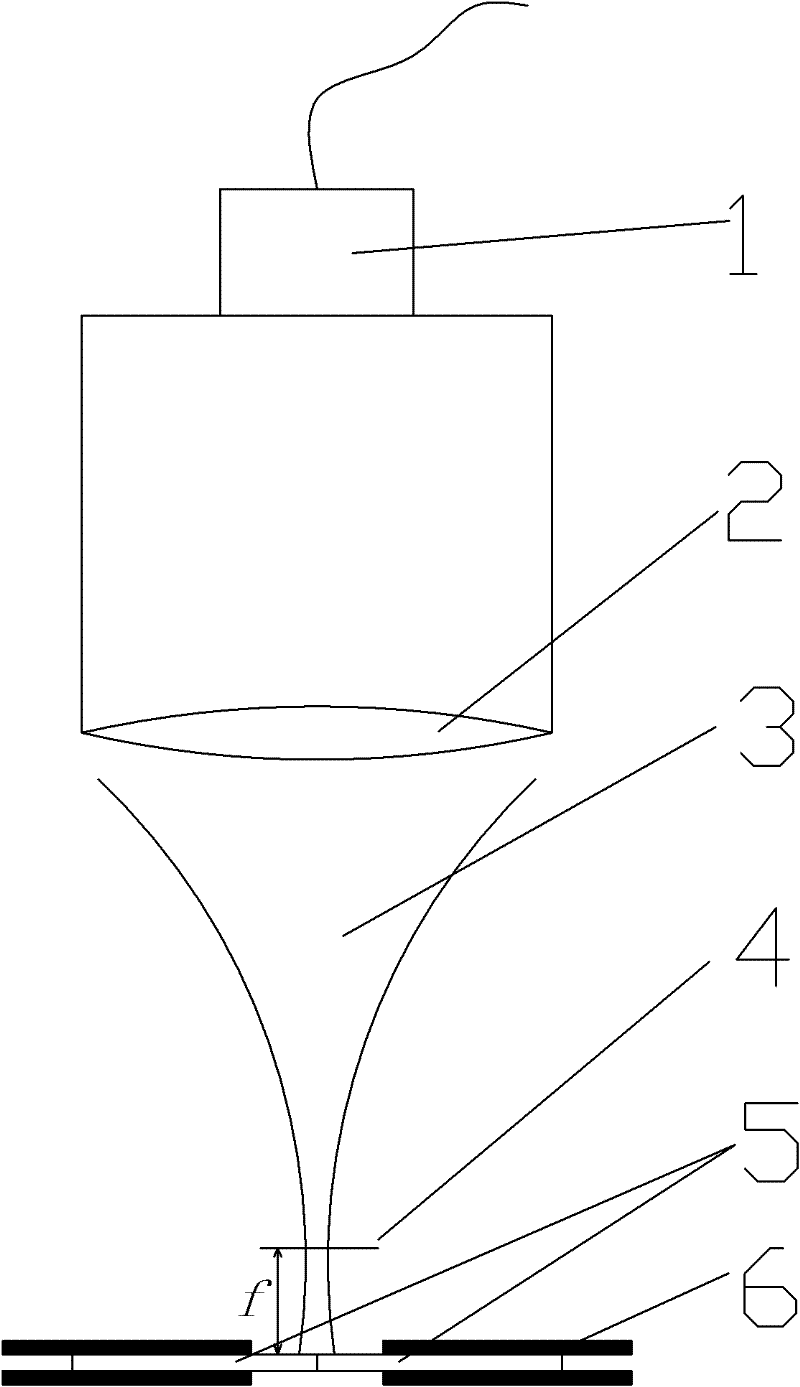

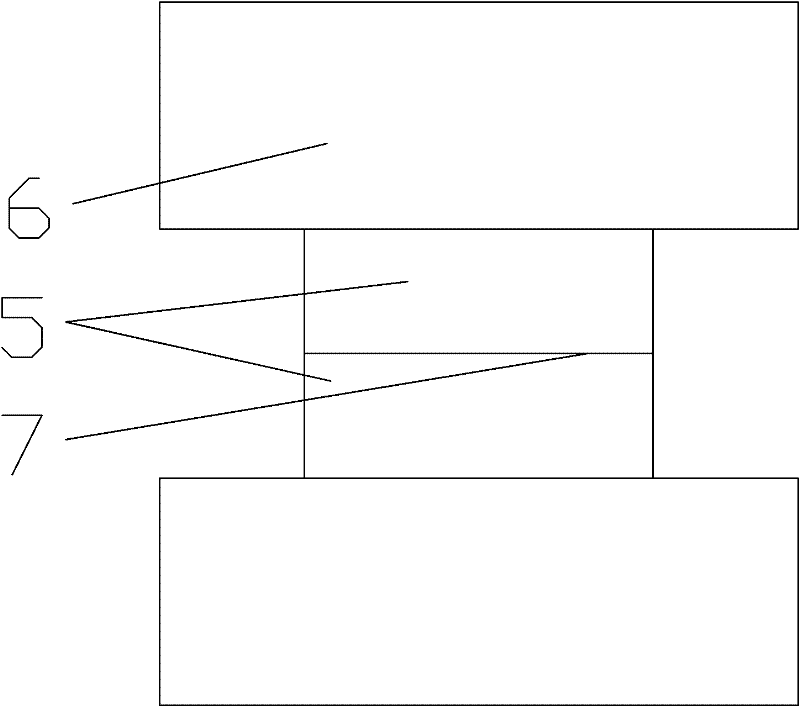

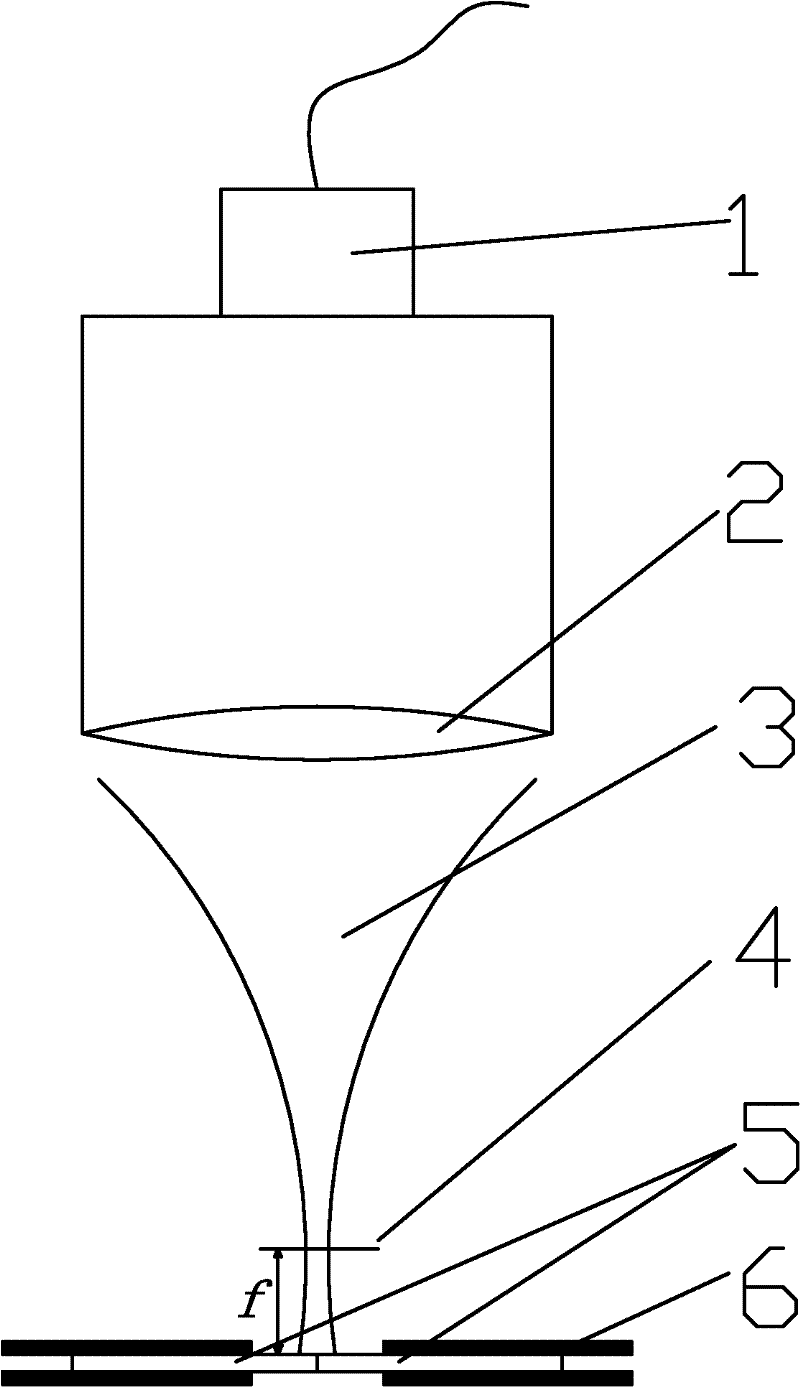

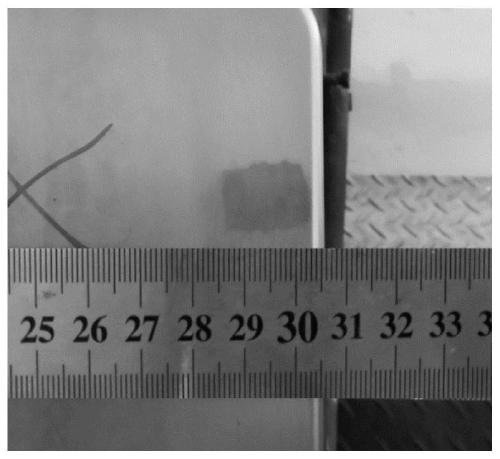

Preparation process and preparation device of lead bismuth alloy for nuclear reactor

InactiveCN107574323AIncrease effective contact with water cooling cycle for heat transferNo gravity segregationOptical rangefindersNuclear energy generationNuclear reactor coreNuclear reaction

The invention provides a preparation process and a preparation device of a lead bismuth alloy for a nuclear reactor. The preparation process comprises the following steps: 1) preparing raw materials;2) blowing a crucible and materials inside a furnace with nitrogen; 3) with a nitrogen protection device, powering on a medium-frequency sensing furnace to melt an alloy; and 4) casting by using a lead bismuth alloy casting mold. The preparation device comprises the medium-frequency sensing furnace and the lead bismuth alloy casting mold, wherein a water cooling jacket is arranged outside the leadbismuth alloy casting mold; a coil heating device is arranged at a casting hole; and a hydraulic rod is arranged at the casting hole, so that the stability of the crystallization process after casting is ensured, and the lead bismuth alloy is prevented from segregation. Equipment used in the preparation process is simple in structure, and no vacuum smelting or vacuum casting is needed.

Owner:HUNAN JINWANG BISMUTH

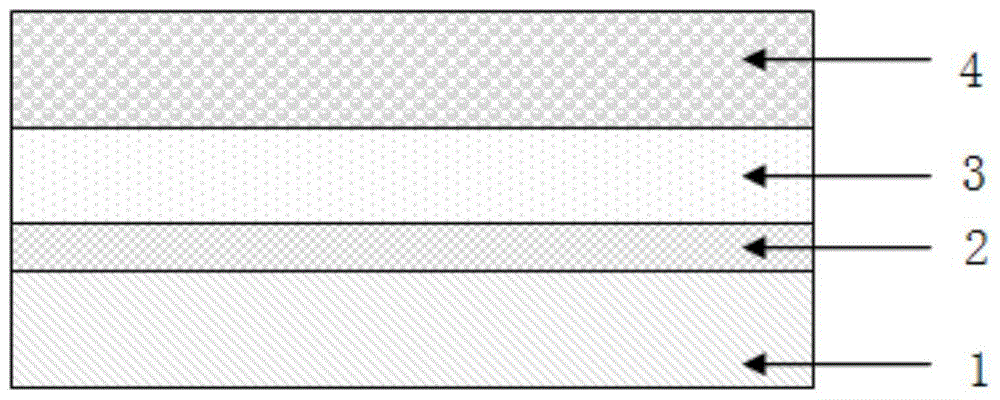

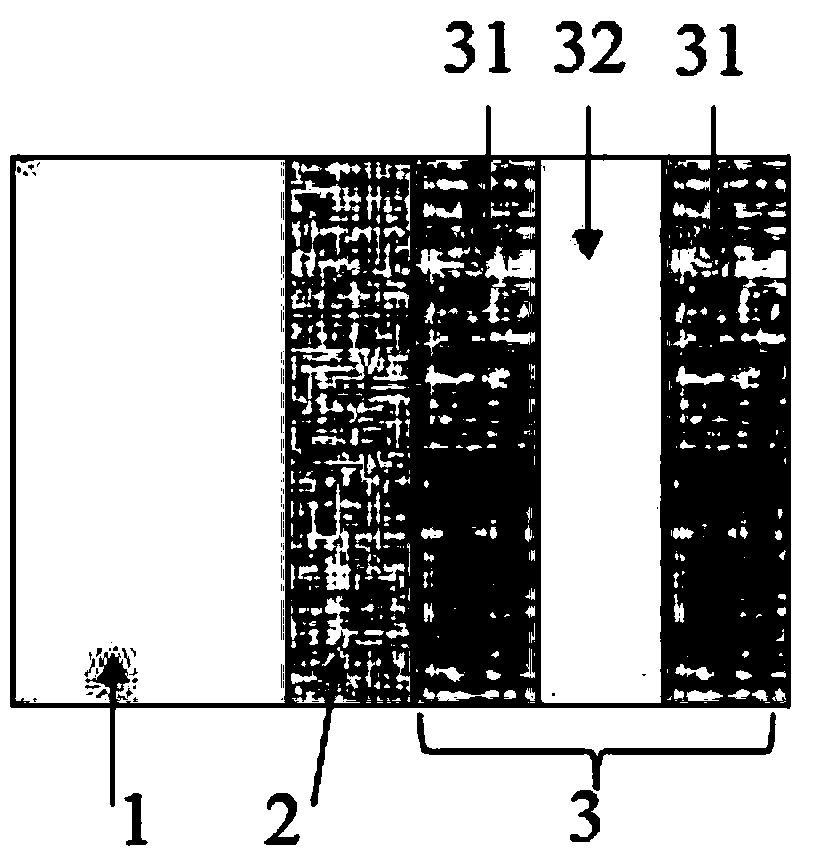

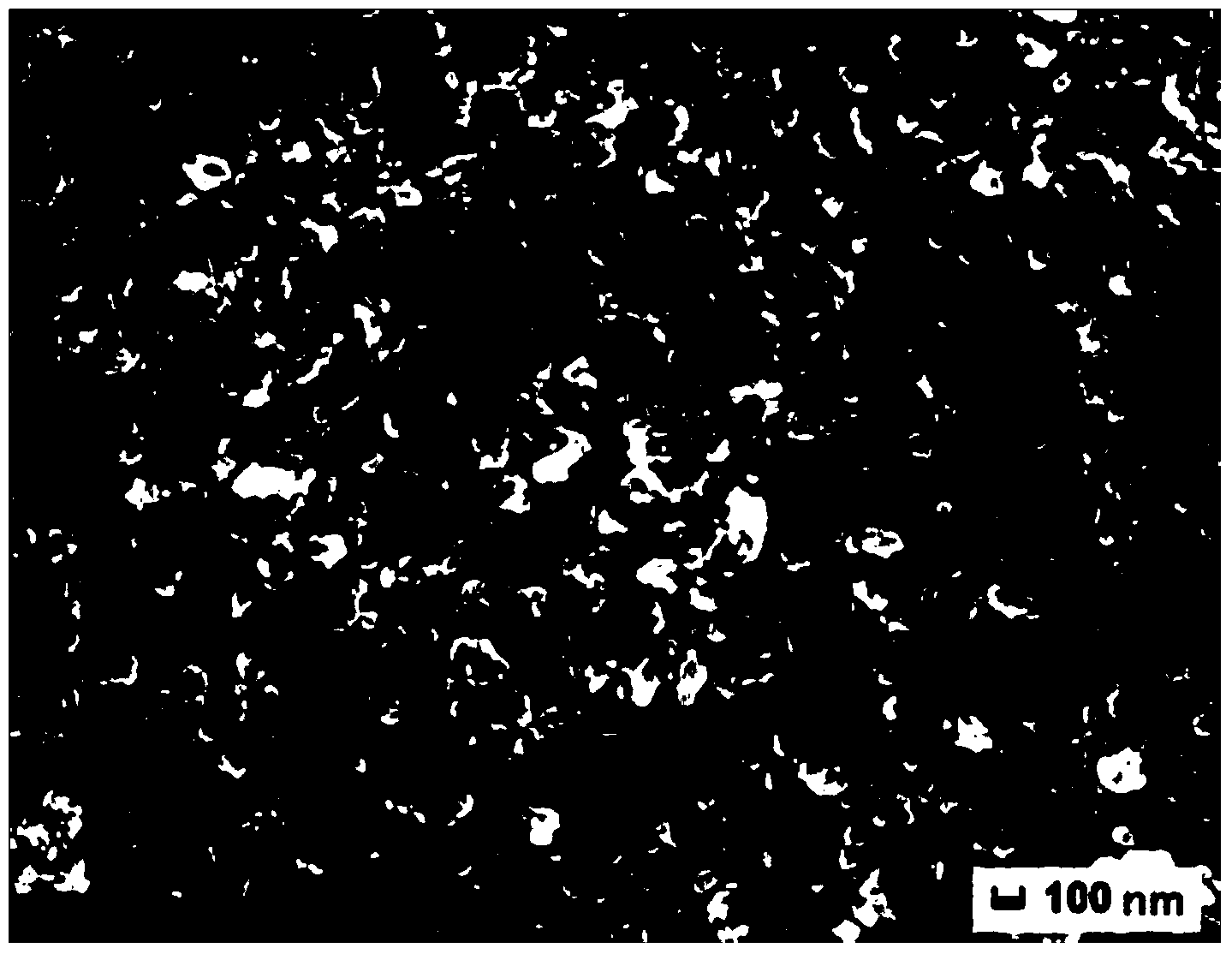

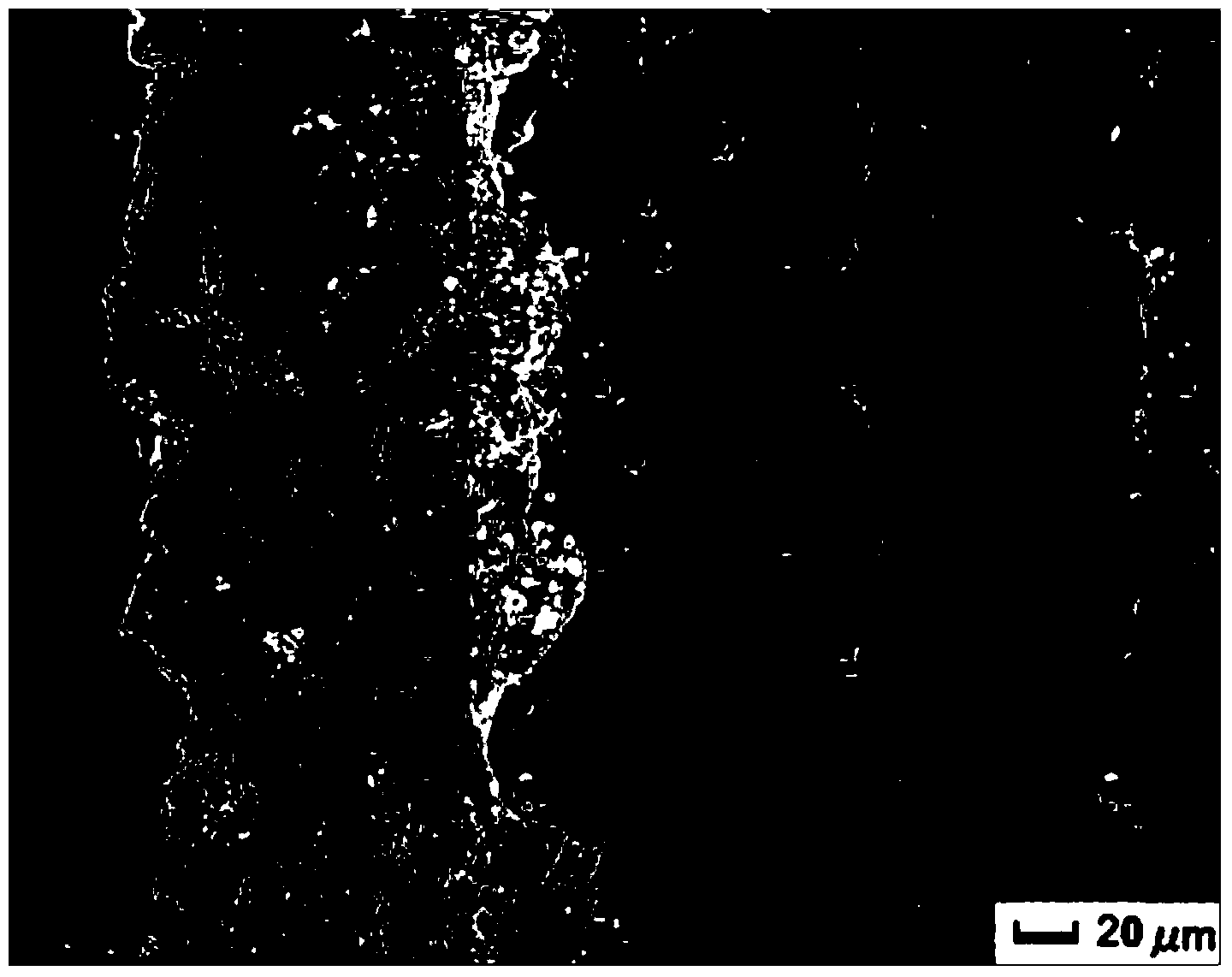

Coating structure with sandwich nano ceramic layer and preparation method of coating structure

ActiveCN104388930AImprove toughnessImprove ductilityLayered productsMetallic material coating processesSurface engineeringTemperature resistance

The invention relates to the field of material surface engineering, and particularly relates to a coating structure with a sandwich nano ceramic layer and a preparation method of the coating structure. The coating structure with the sandwich nano ceramic layer disclosed by the invention comprises a transition layer and a ceramic layer, wherein one surface of the transition layer and a base body are in metallurgical bonding; the other surface of the transition layer and the ceramic layer are in metallurgical bonding; the ceramic layer is a sandwich structure ceramic layer; common ceramic layers are arranged on the upper and lower layers; and the nano ceramic layer is arranged in the middle layer. The coating with the sandwich nano ceramic layer has excellent high temperature resistance and relatively good tenacity and malleability, and is wide in use and long in service life. According to the preparation method of the coating structure disclosed by the invention, different coating structures with the sandwich nano ceramic layers can be prepared on various high-temperature alloy surfaces; the method is simple and efficient, and is contributed to reserving the nano characteristics of the coating.

Owner:NANJING ZHONGKE SHENGUANG TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com