Preparation method of porous magnesium rare earth alloy implant based on laser selective melting (SLM) additive manufacturing technology

A laser selective melting, magnesium rare earth alloy technology, applied in the preparation of porous magnesium rare earth alloy implants, laser selective melting additive manufacturing technology to prepare porous implants, can solve the problem of large differences in porous structure wall thickness, human bone Poor matching, low overall strength and modulus, etc., to achieve high overall strength and modulus, achieve functional and structural strength, and good consistency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

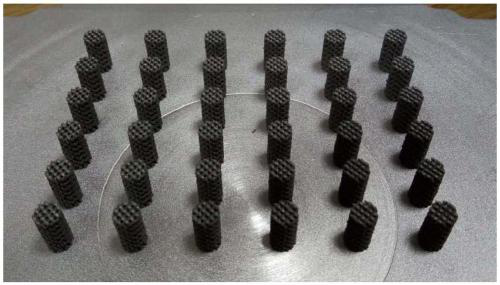

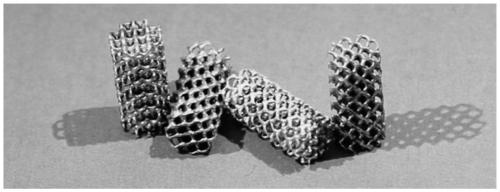

[0038] see Figure 1-2 . Such as Figure 1-2 As shown, the embodiment of the present invention provides a method for preparing a porous magnesium rare earth alloy implant based on laser selective melting (SLM) additive manufacturing technology, comprising the following steps:

[0039] Step 1, selecting the components of the magnesium rare earth alloy powder;

[0040] Step 2, preheating the magnesium rare earth alloy powder in a vacuum drying oven, the preheating time is 1.5h, and the preheating temperature is 100°C;

[0041] Step 3, selecting a magnesium rare earth alloy with the same composition as the magnesium rare earth alloy powder in step 1 as the substrate, and preheating the substrate;

[0042] Step 4, draw a three-dimensional model of the porous magnesium rare earth alloy implant on the computer through three-dimensional design software, and generate a porous magnesium rare earth alloy implant entity, wherein the porous pore diameter is 500 μm, and the porous wall ...

Embodiment 2

[0060] The embodiment of the present invention provides a method for preparing a porous magnesium rare earth alloy implant based on selective laser melting (SLM) additive manufacturing technology, comprising the following steps:

[0061] Step 1, selecting the components of the magnesium rare earth alloy powder;

[0062] Step 2, preheating the magnesium rare earth alloy powder in a vacuum drying oven, the preheating time is 1.5h, and the preheating temperature is 100°C;

[0063] Step 3, selecting a magnesium rare earth alloy with the same composition as the magnesium rare earth alloy powder in step 1 as the substrate, and preheating the substrate;

[0064] Step 4, draw a three-dimensional model of the porous magnesium rare earth alloy implant on the computer through three-dimensional design software, and generate a porous magnesium rare earth alloy implant entity, wherein the porous pore diameter is 500 μm, and the porous wall thickness is 300 μm;

[0065] Step 5. Save the por...

Embodiment 3

[0081] The embodiment of the present invention provides a method for preparing a porous magnesium rare earth alloy implant based on selective laser melting (SLM) additive manufacturing technology, comprising the following steps:

[0082] Step 1, selecting the components of the magnesium rare earth alloy powder;

[0083] Step 2, preheating the magnesium rare earth alloy powder in a vacuum drying oven, the preheating time is 1.5h, and the preheating temperature is 100°C;

[0084] Step 3, selecting a magnesium rare earth alloy with the same composition as the magnesium rare earth alloy powder in step 1 as the substrate, and preheating the substrate;

[0085] Step 4, draw a three-dimensional model of the porous magnesium rare earth alloy implant on the computer through three-dimensional design software, and generate a porous magnesium rare earth alloy implant entity, wherein the porous pore diameter is 500 μm, and the porous wall thickness is 300 μm;

[0086] Step 5. Save the por...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| elastic modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com