Patents

Literature

1415 results about "Laser line" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

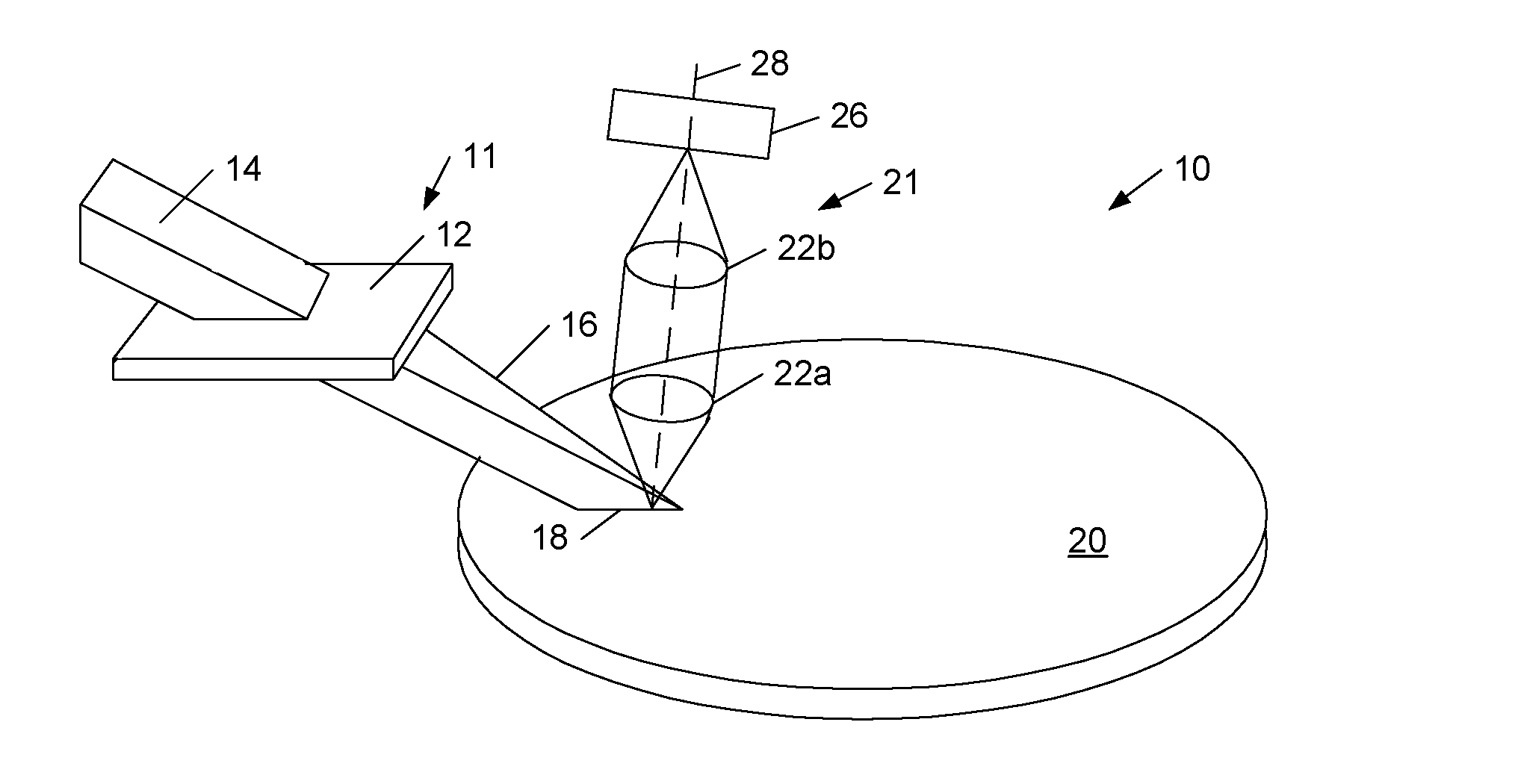

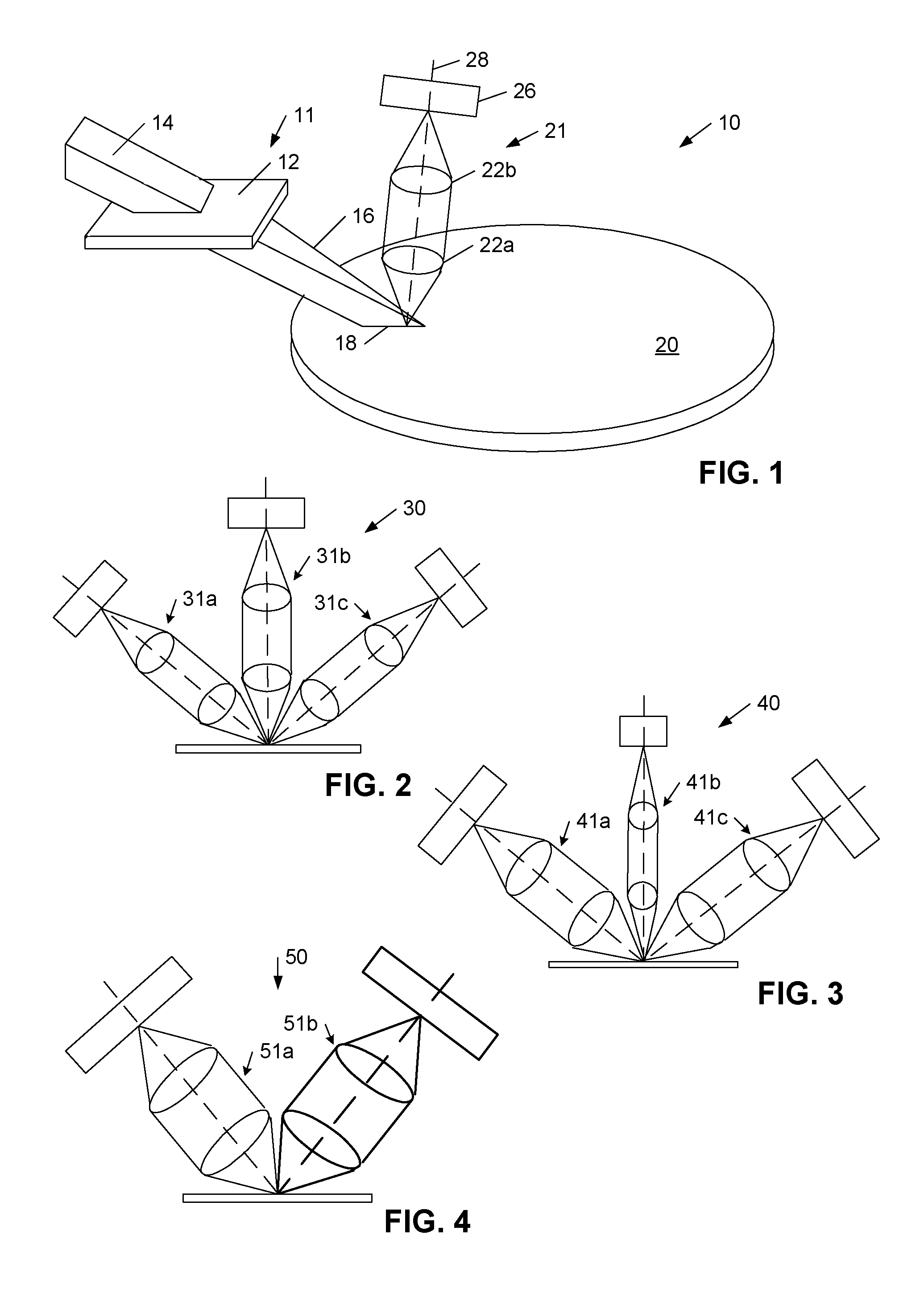

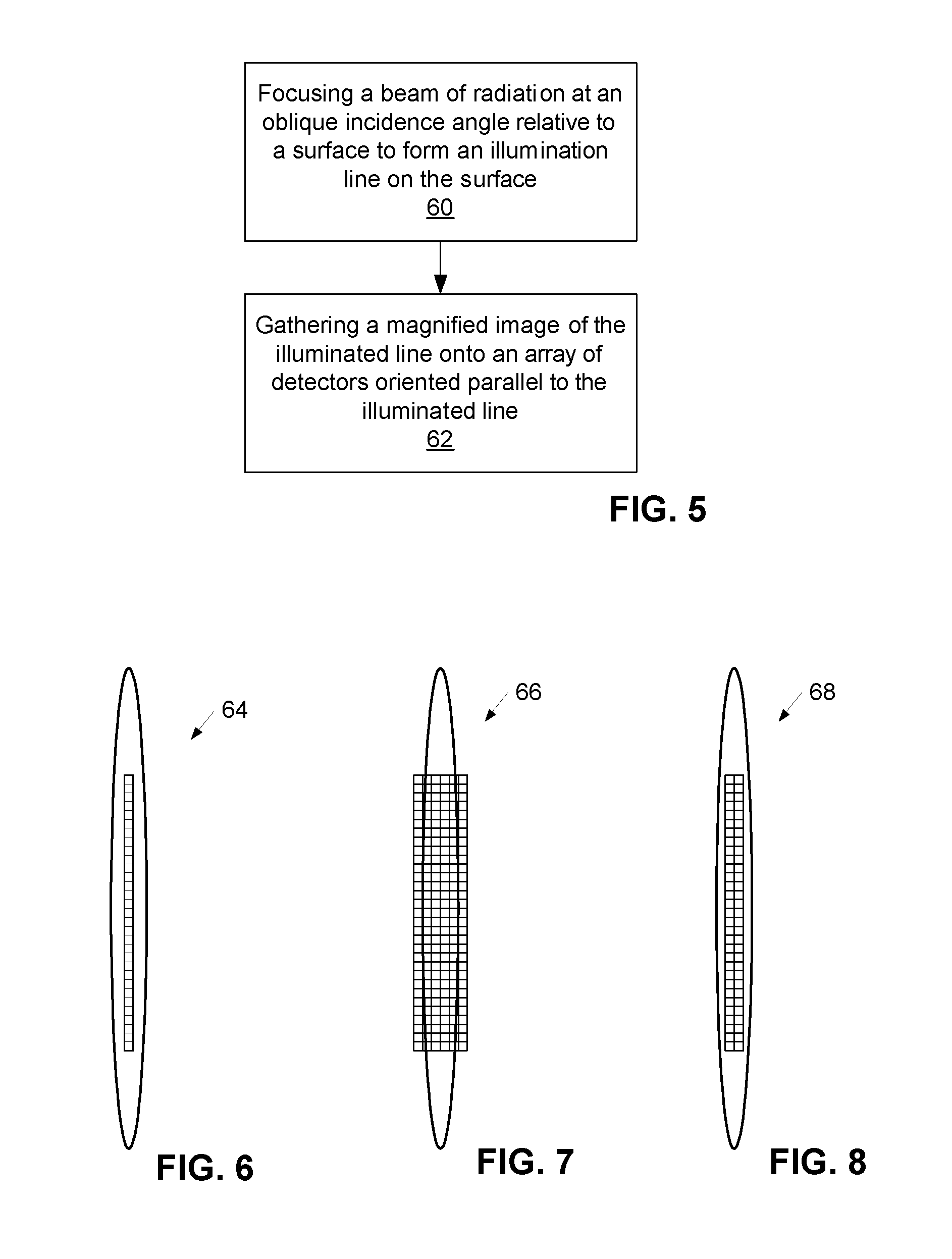

Surface inspection system using laser line illumination with two dimensional imaging

A surface inspection apparatus and a method are provided which include an illumination system configured to focus a beam of radiation at a non-orthogonal incidence angle to form an illumination line on a surface substantially in a plane of incidence of the focused beam. The apparatus and method further include a collection system configured to image the illumination line onto an array of detectors oriented parallel to the illumination line. The collection system includes an imaging lens for collecting light scattered from the illumination line, a focusing lens for focusing the collected light, and the array of detectors, each configured to detect a corresponding portion of the illumination line. The collection system may be configured to image the illumination line such that the width of the imaged illumination line on the array of detectors is larger than the pixel size of the detectors along the same direction.

Owner:KLA TENCOR TECH CORP

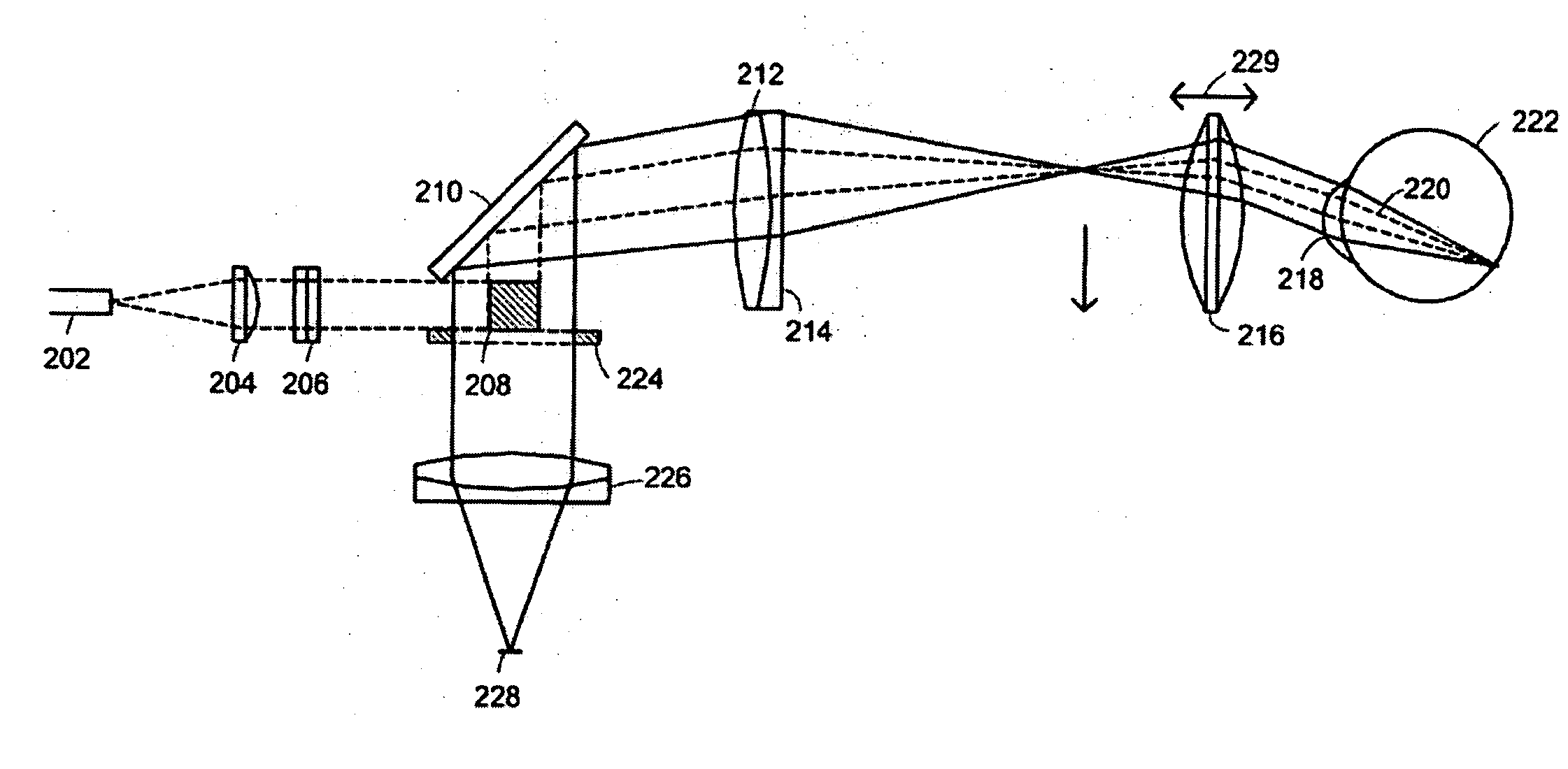

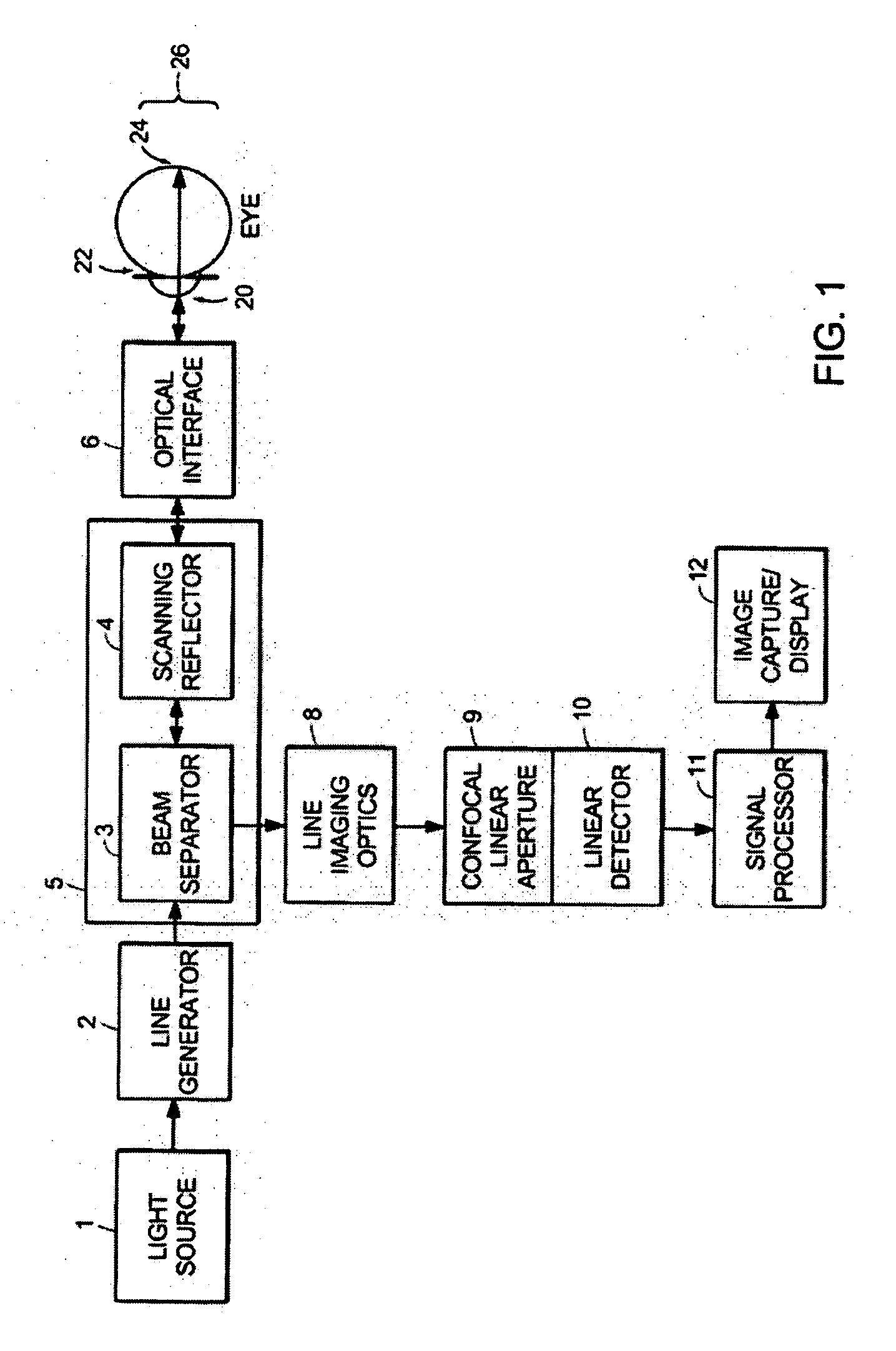

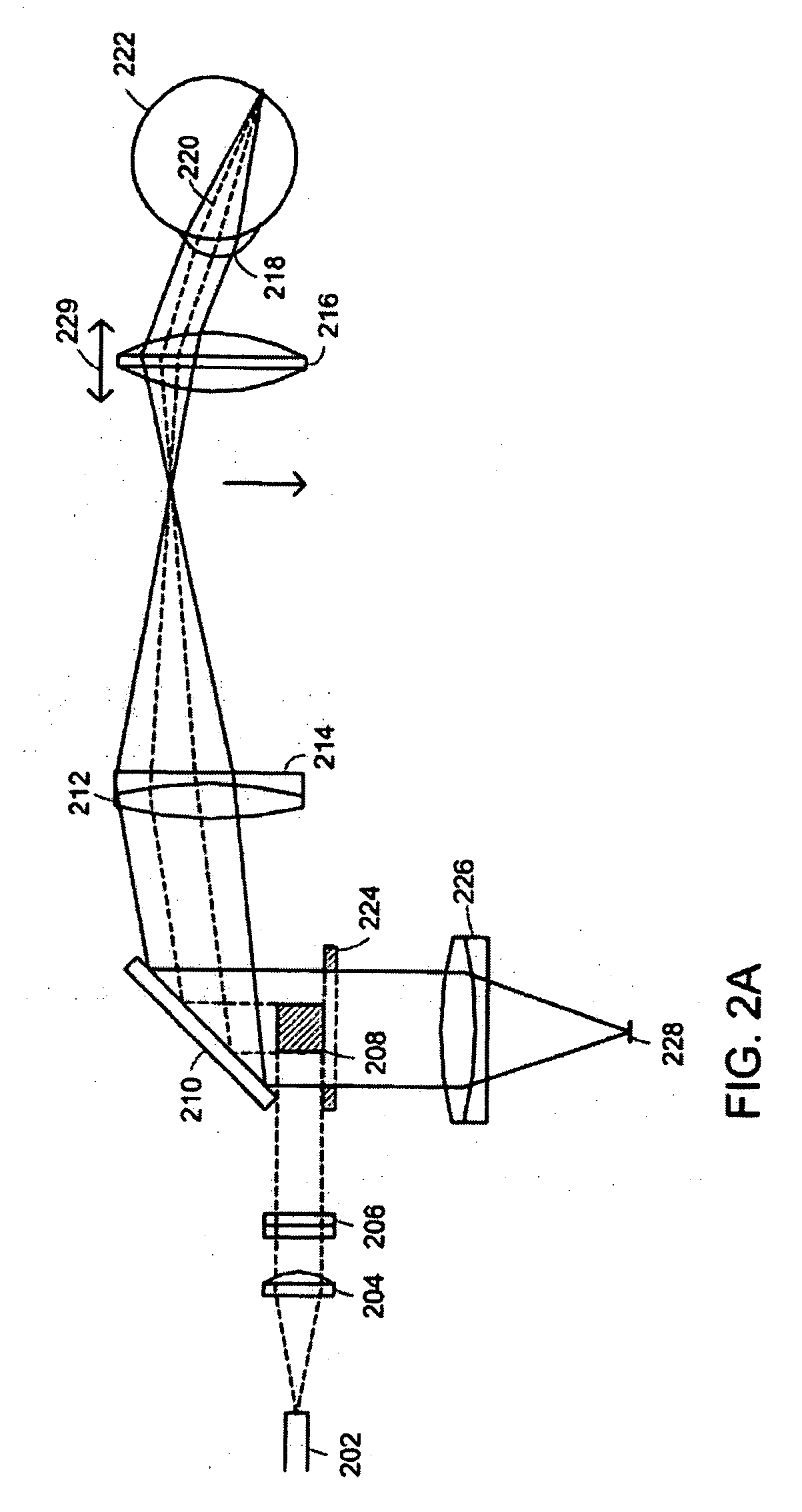

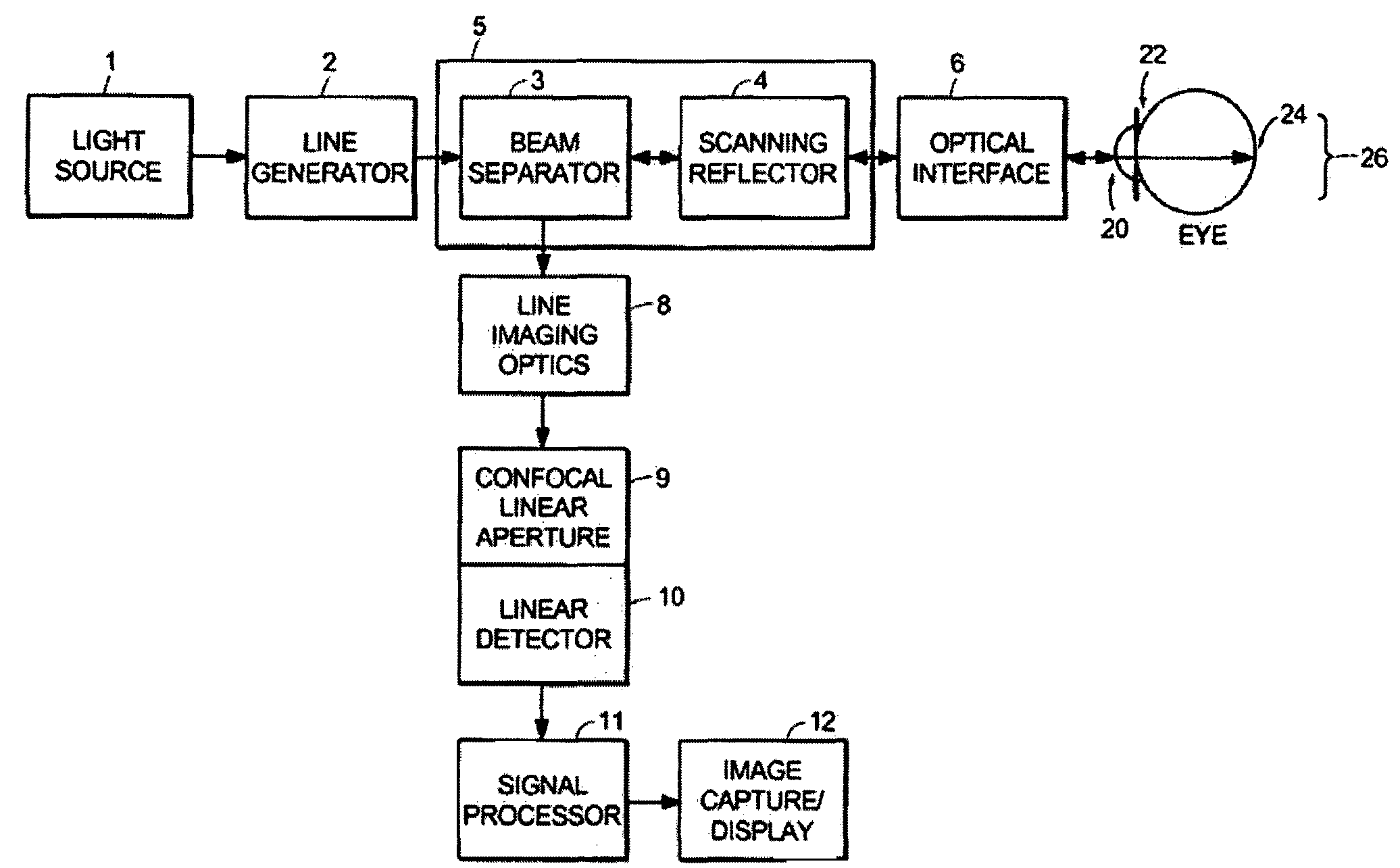

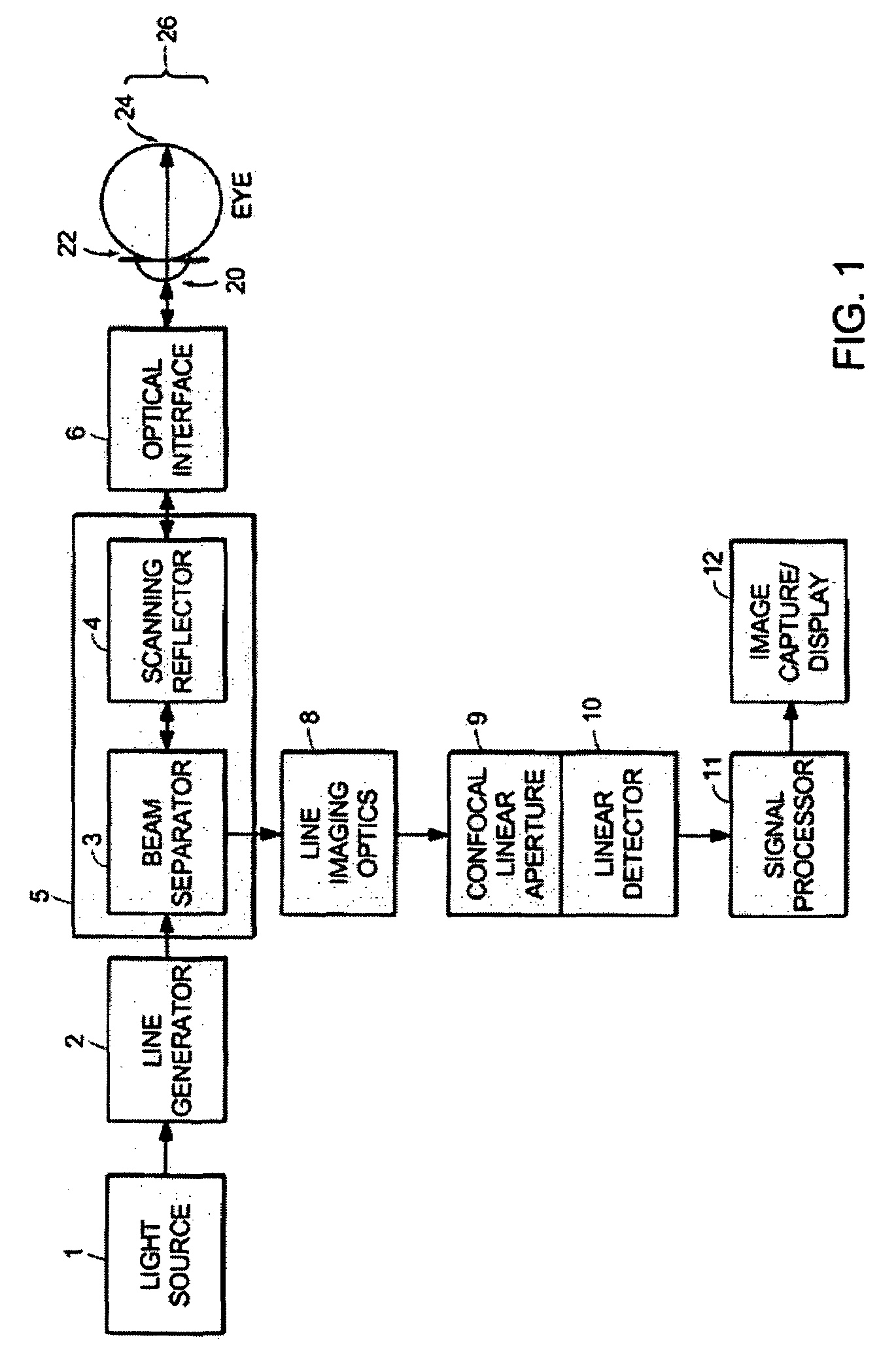

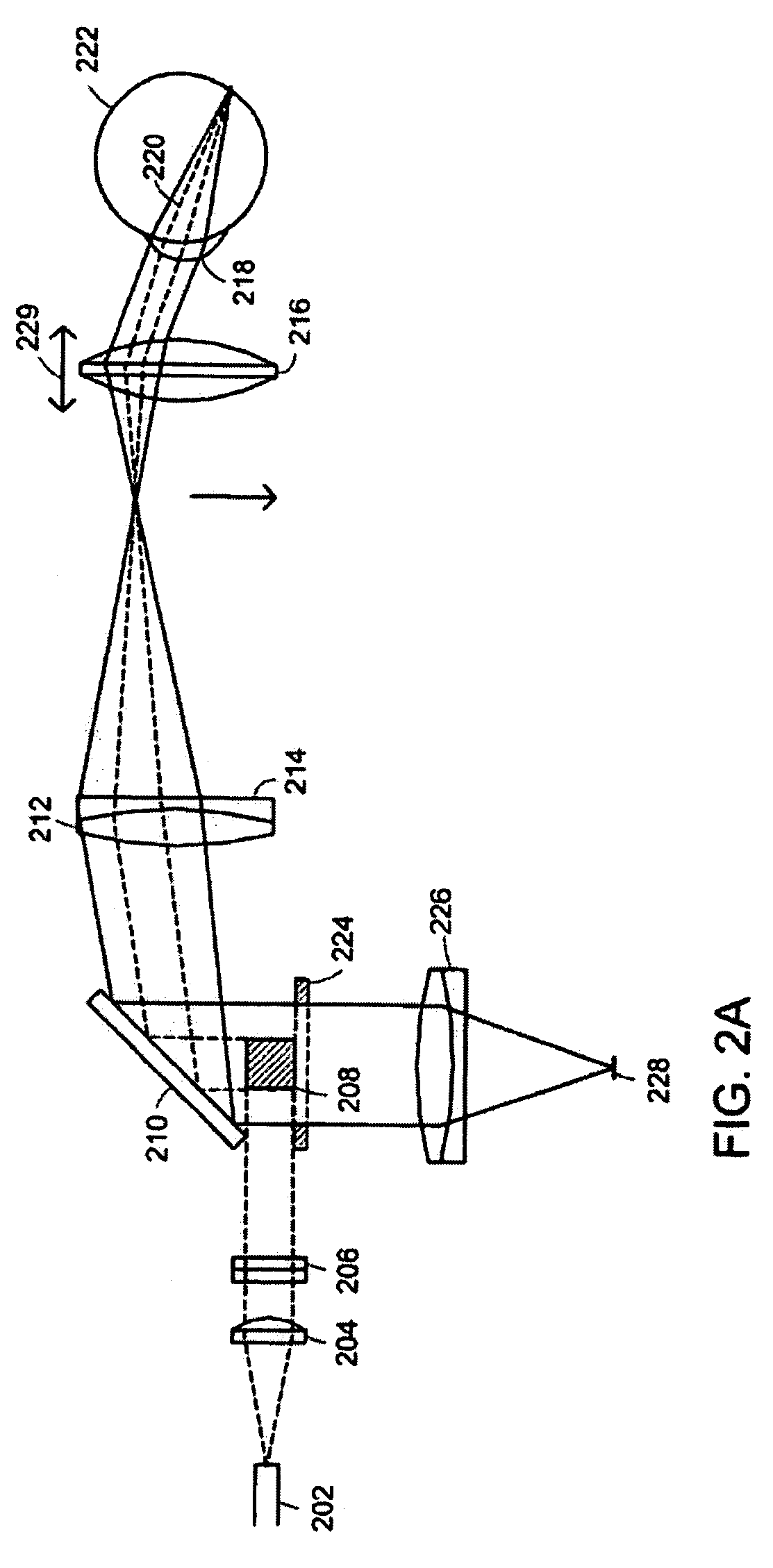

Monitoring blood flow in the retina using a line-scanning laser ophthalmoscope

Real time, high-speed image stabilization with a retinal tracking scanning laser ophthalmoscope (TSLO) enables new approaches to established diagnostics. Large frequency range (DC to 19 kHz), wide-field (40-deg) stabilized Doppler flowmetry imaging is described for human subjects. The fundus imaging method is a quasi-confocal line-scanning laser ophthalmoscope (LSLO). The retinal tracking system uses a confocal reflectometer with a closed loop optical servo system to lock onto features in the ocular fundus and automatically re-lock after blinks. By performing a slow scan with the laser line imager, frequency-resolved retinal perfusion and vascular flow images can be obtained free of eye motion artifacts.

Owner:PHYSICAL SCI

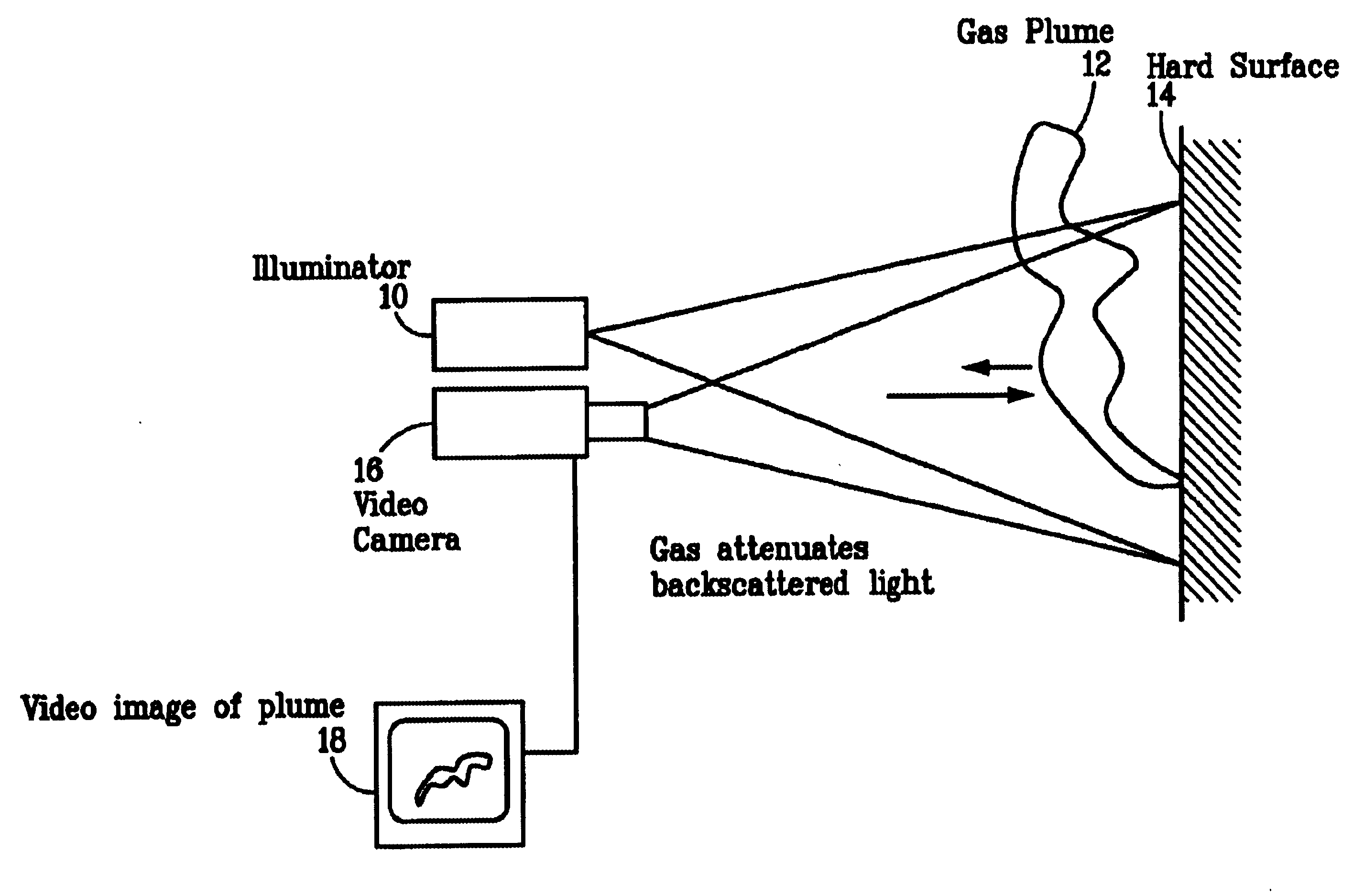

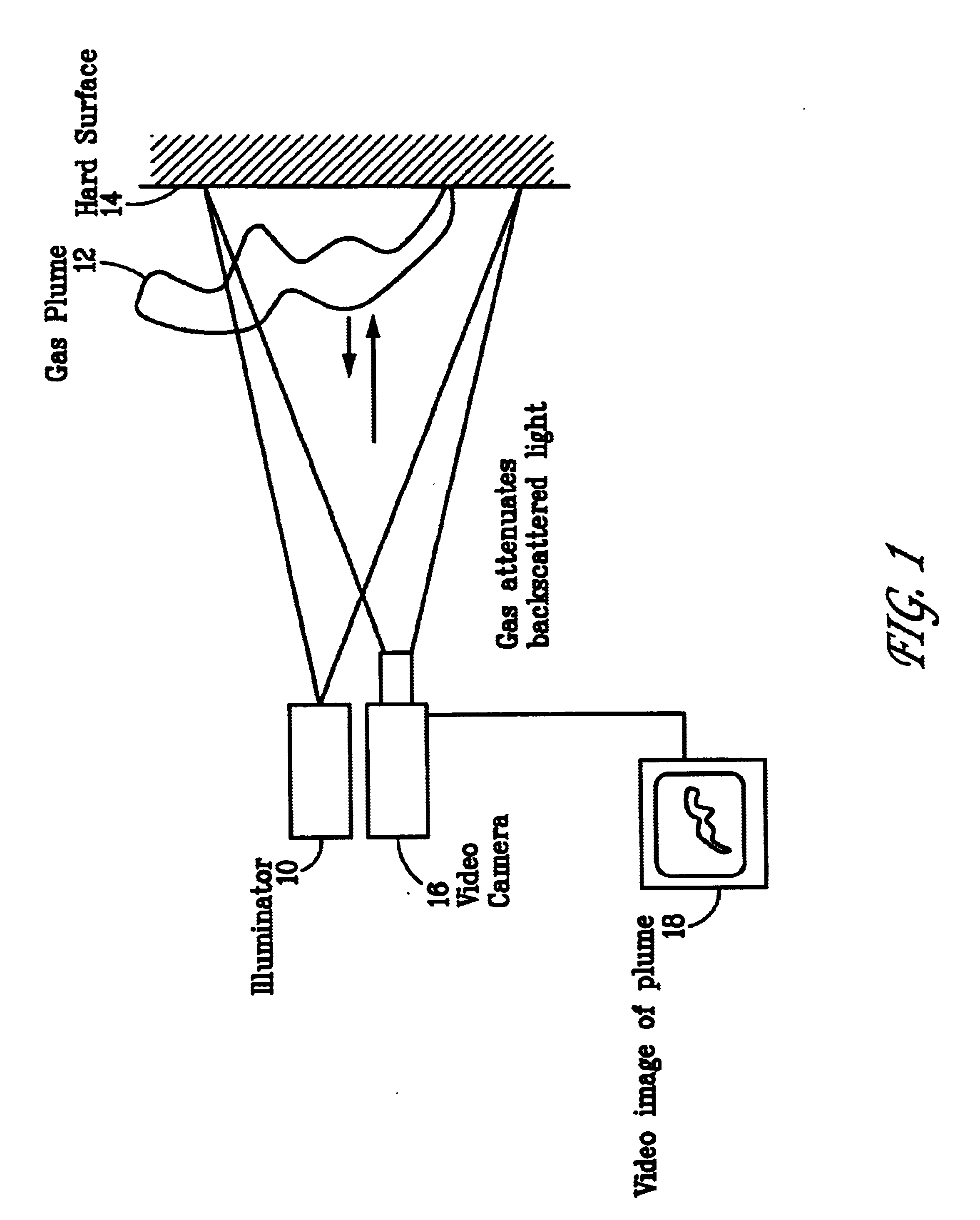

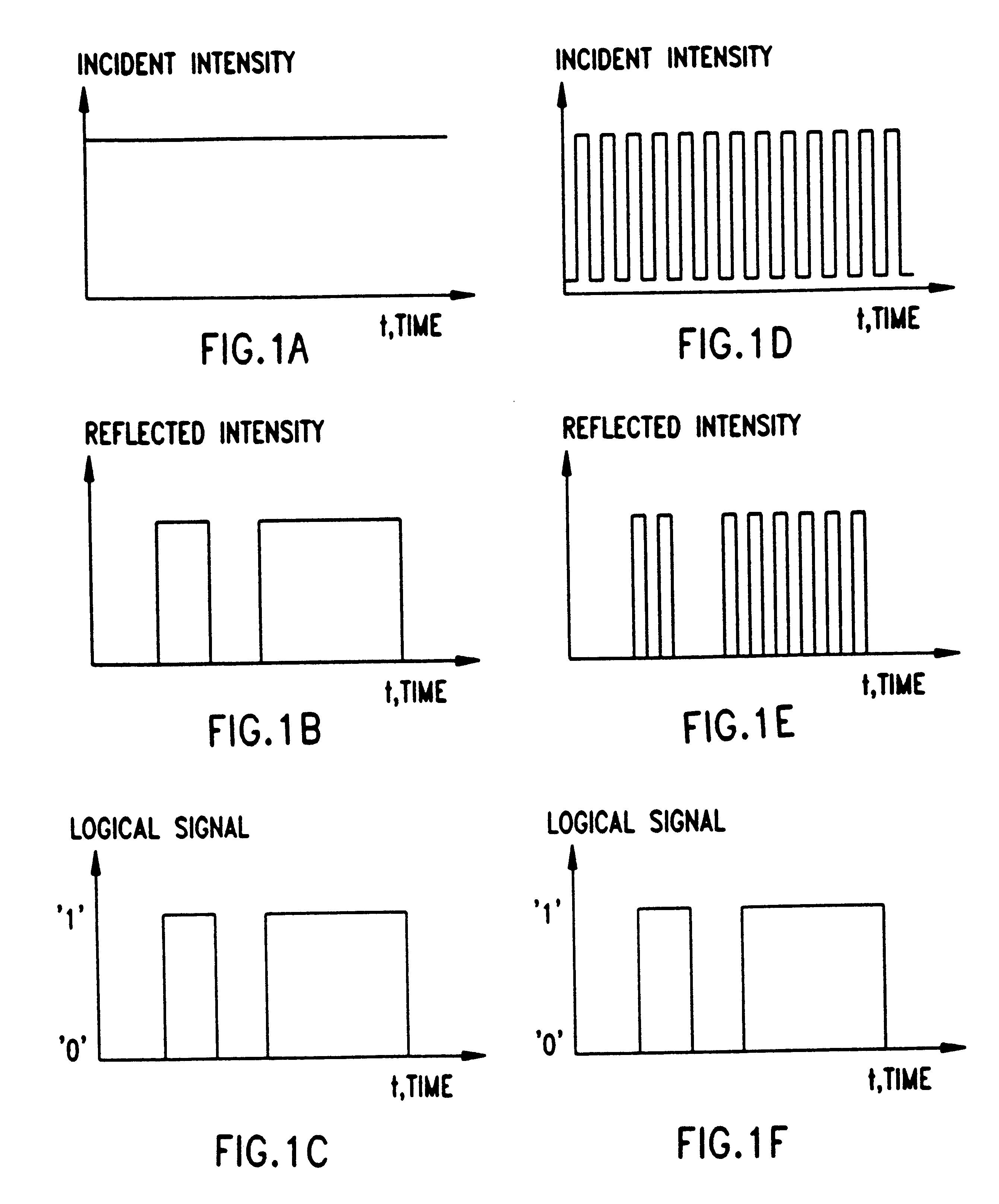

Pulsed laser linescanner for a backscatter absorption gas imaging system

InactiveUS6690472B2Enhanced signalMaximize attenuationScattering properties measurementsColor/spectral properties measurementsMobile vehicleFluence

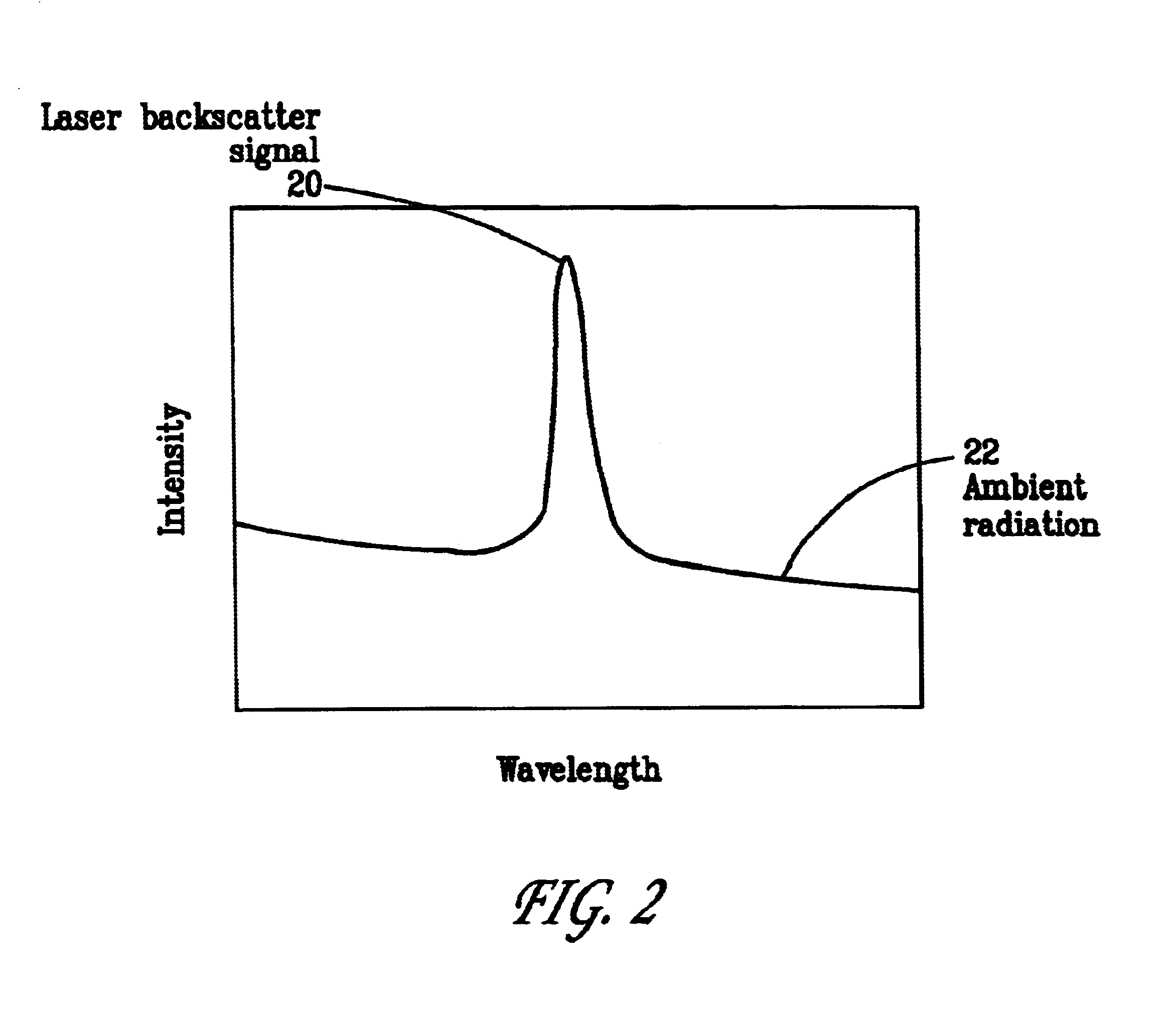

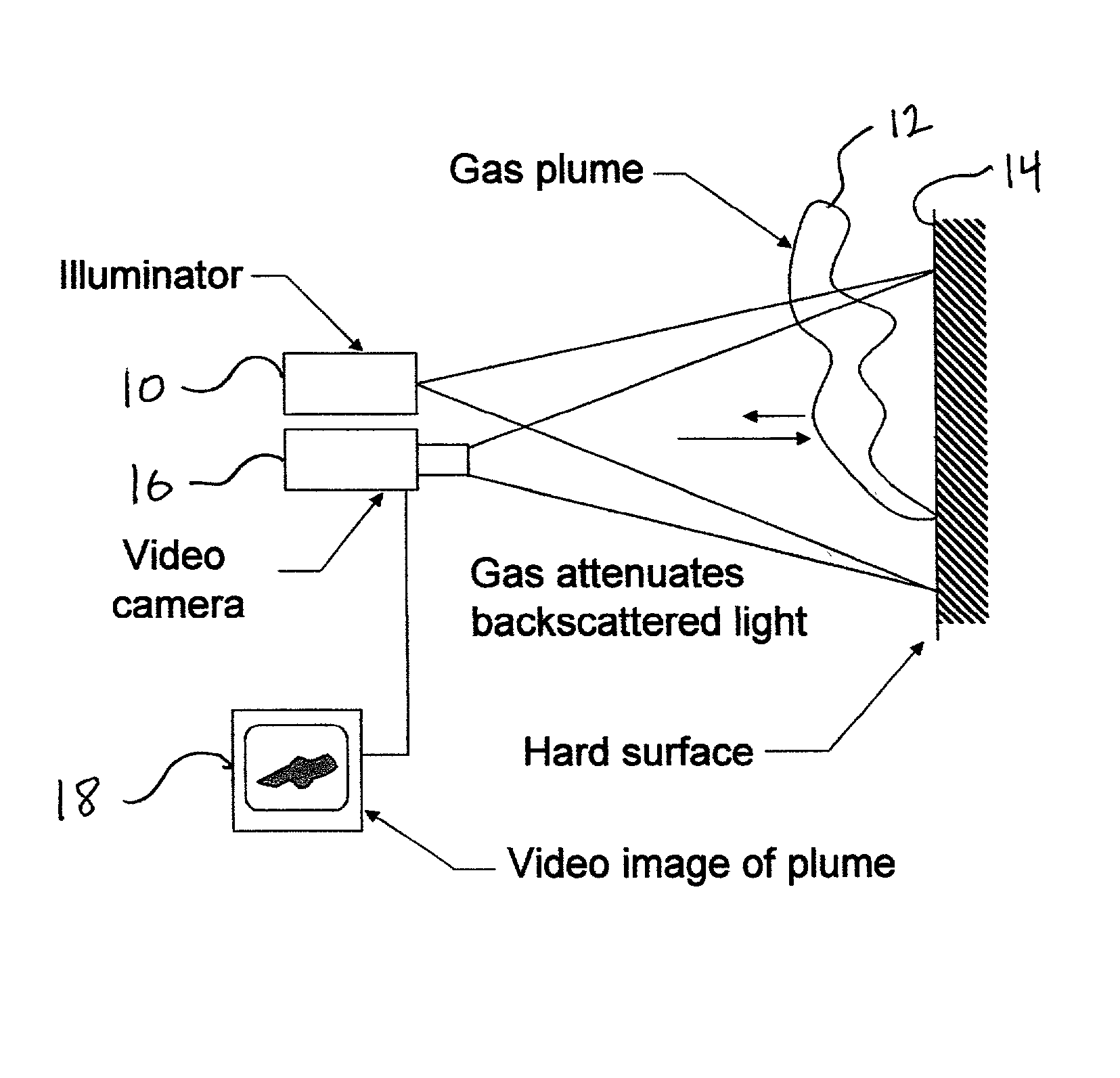

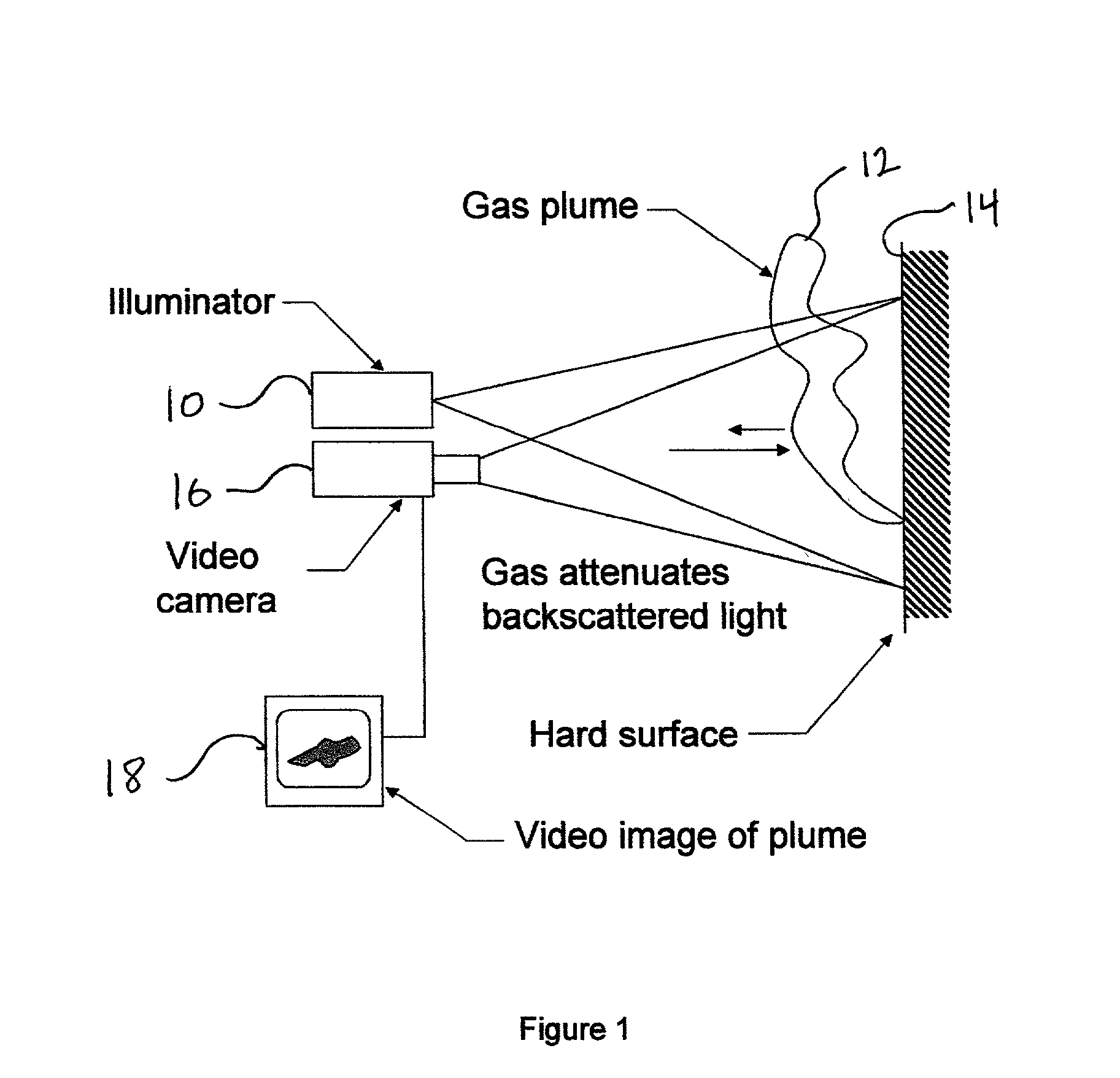

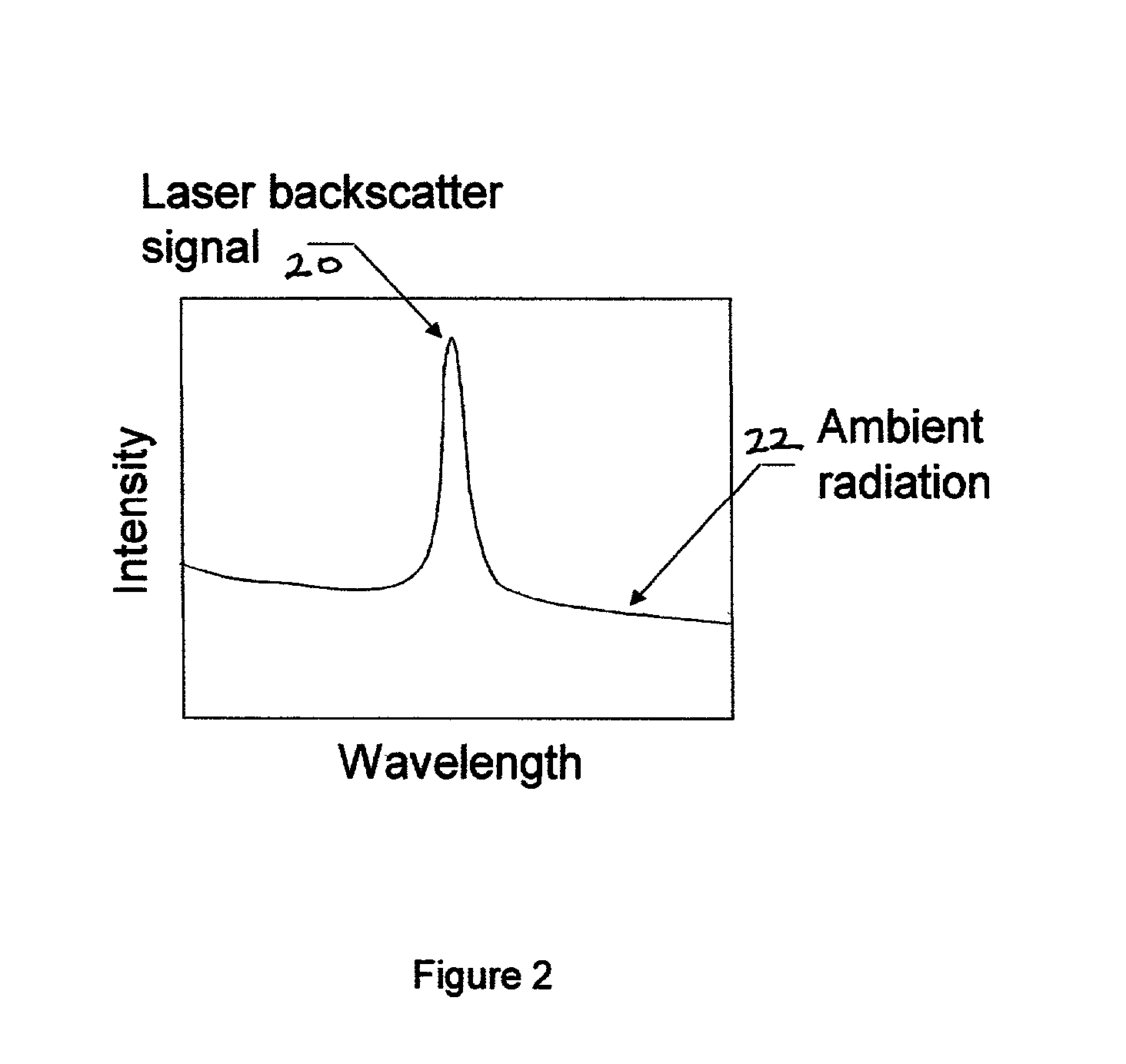

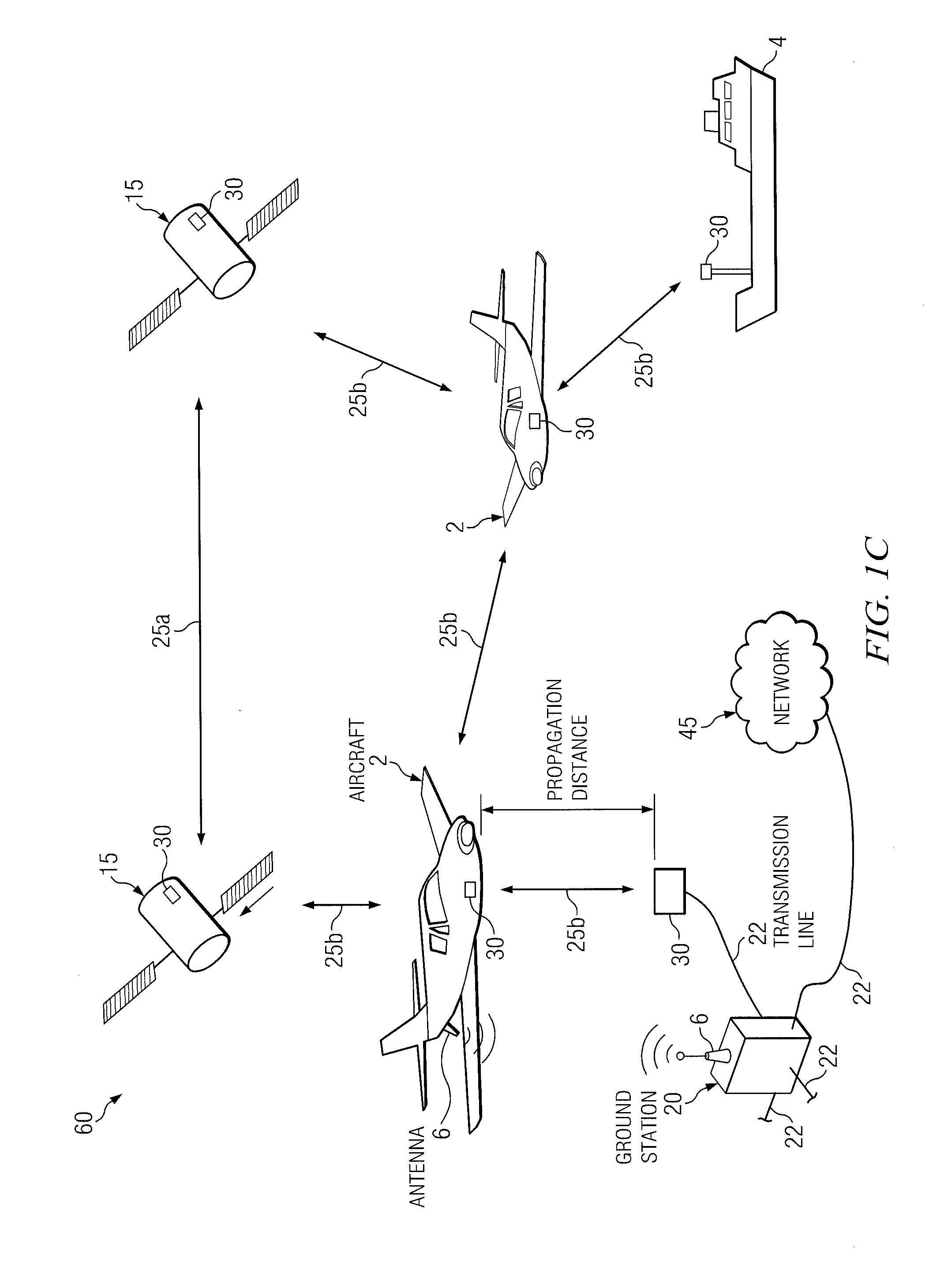

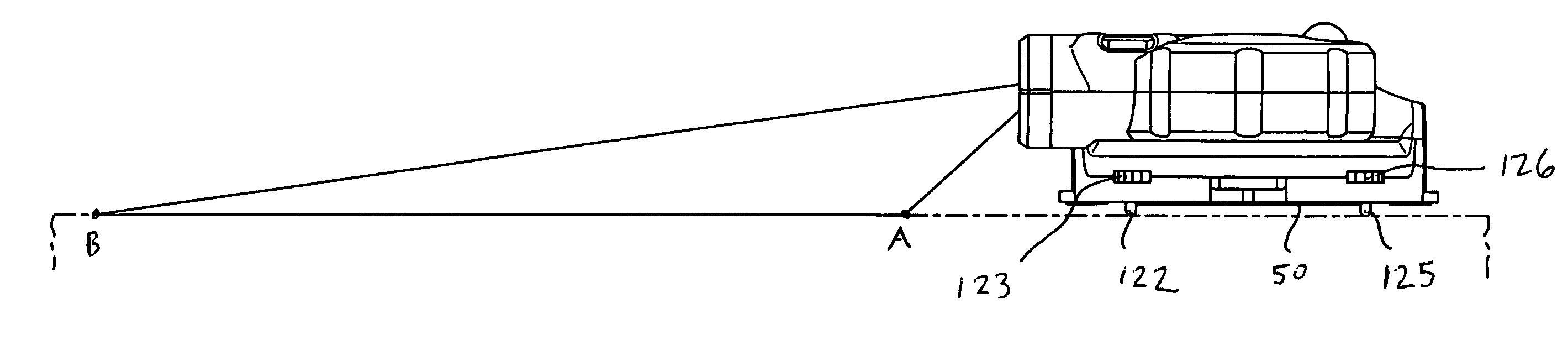

An active (laser-illuminated) imaging system is described that is suitable for use in backscatter absorption gas imaging (BAGI). A BAGI imager operates by imaging a scene as it is illuminated with radiation that is absorbed by the gas to be detected. Gases become "visible" in the image when they attenuate the illumination creating a shadow in the image. This disclosure describes a BAGI imager that operates in a linescanned manner using a high repetition rate pulsed laser as its illumination source. The format of this system allows differential imaging, in which the scene is illuminated with light at least 2 wavelengths-one or more absorbed by the gas and one or more not absorbed. The system is designed to accomplish imaging in a manner that is insensitive to motion of the camera, so that it can be held in the hand of an operator or operated from a moving vehicle.

Owner:SANDIA NAT LAB

Pulsed laser linescanner for a backscatter absorption gas imaging system

InactiveUS20020071122A1Enhanced signalMaximize attenuationScattering properties measurementsTransmissivity measurementsFluenceRadiation

An active (laser-illuminated) imaging system is described that is suitable for use in backscatter absorption gas imaging (BAGI). A BAGI imager operates by imaging a scene as it is illuminated with radiation that is absorbed by the gas to be detected. Gases become "visible" in the image when they attenuate the illumination creating a shadow in the image. This disclosure describes a BAGI imager that operates in a linescanned manner using a high repetition rate pulsed laser as its illumination source. The format of this system allows differential imaging, in which the scene is illuminated with light at least 2 wavelengths-one or more absorbed by the gas and one or more not absorbed. The system is designed to accomplish imaging in a manner that is insensitive to motion of the camera, so that it can be held in the hand of an operator or operated from a moving vehicle.

Owner:SANDIA NAT LAB

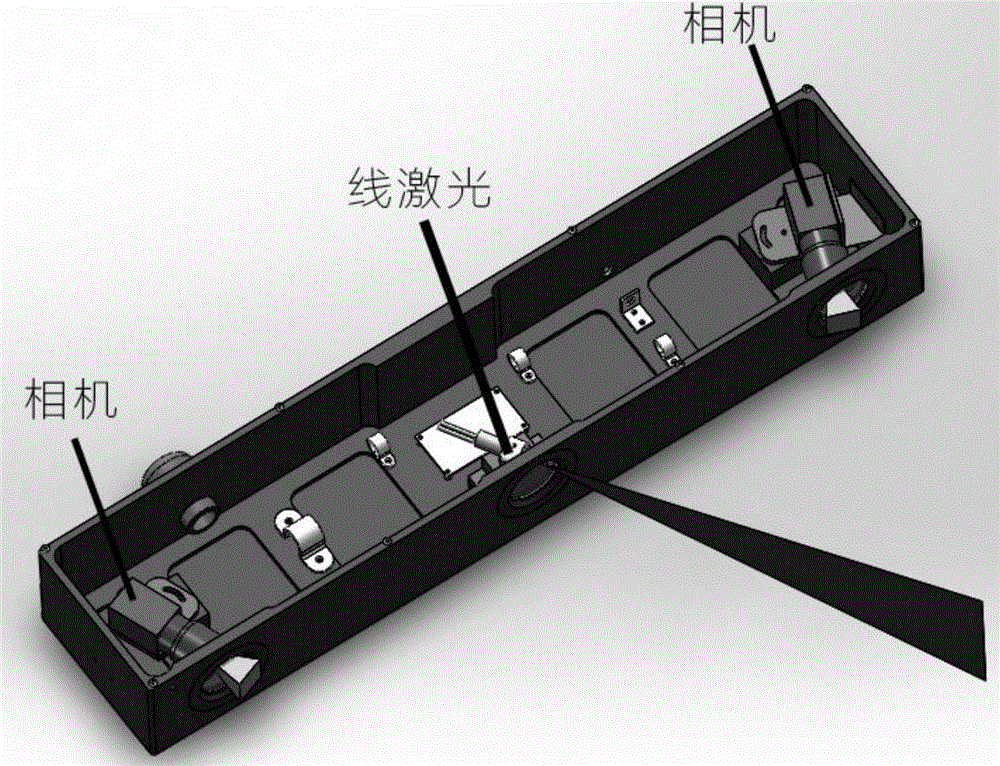

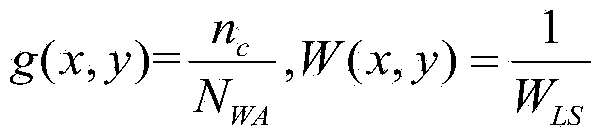

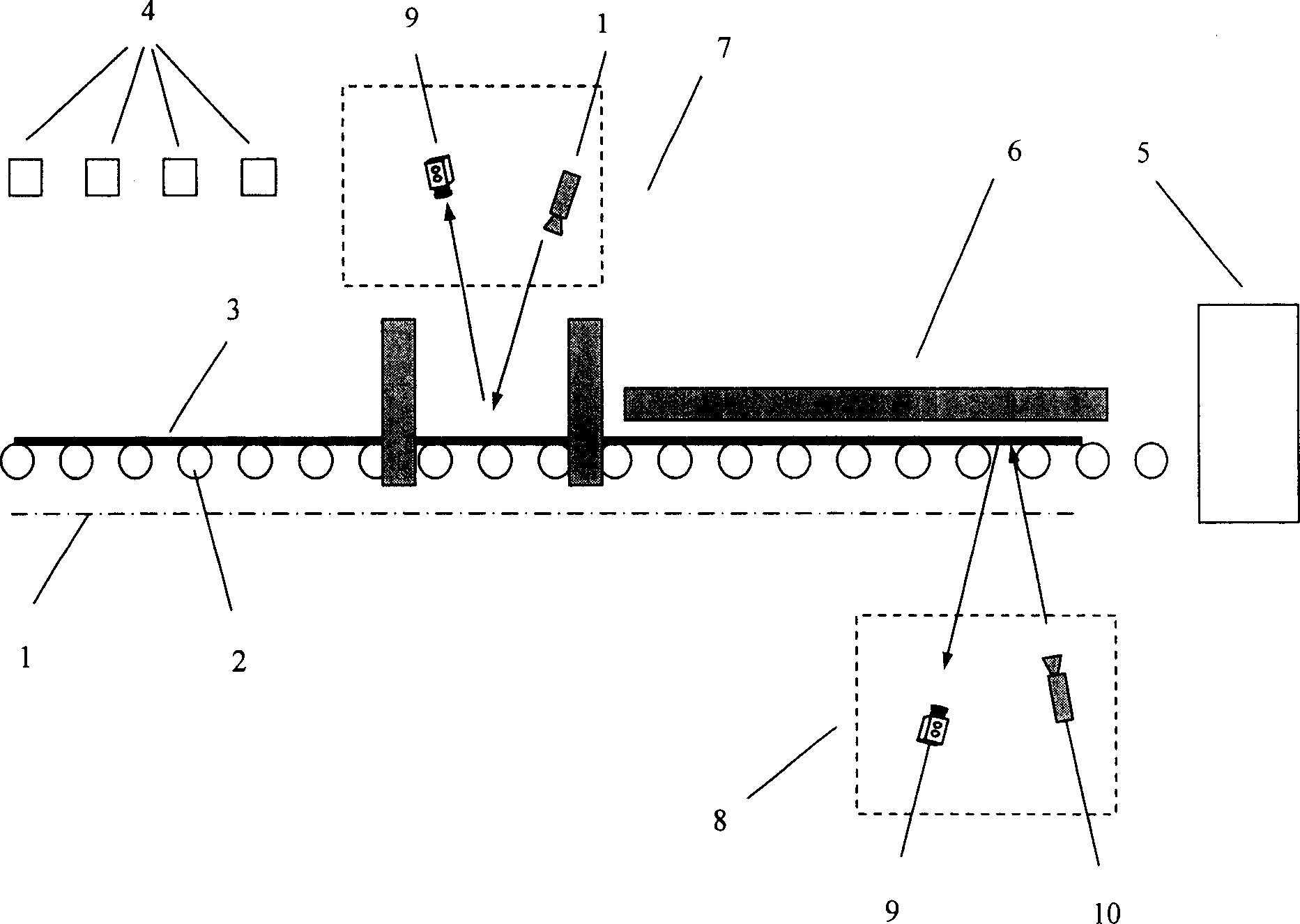

Control method of manipulator grabbing control system based on binocular stereoscopic vision

ActiveCN106041937AAchieve placementRealize the assemblyProgramme-controlled manipulatorPoint cloudTriangulation

The invention discloses a control method of a manipulator grabbing control system based on binocular stereoscopic vision. The control method comprises the following steps: camera parameters are calibrated, and a teaching manipulator is used for realizing conversion of a camera coordinate system and a manipulator coordinate system; line laser performs an arc surface scanning cloud motion, and a camera acquires images; laser lines of the images shot by the camera are respectively extracted; the positions of the laser lines are precisely determined by using a sub pixel algorithm; the homonymy point matching is performed for the laser lines extracted in the images; three-dimensional space coordinates of all points on the laser lines are calculated through a triangular measuring principle to finish scanning of workpieces in a scene so as to obtain point cloud data in the viewing field of the camera; a workpiece point cloud template is built, a manipulator grabbing point position is selected, and the obtained point cloud data is matched with the workpiece point cloud template to calculate a conversion relation of the two; the manipulator grabbing point position in the point cloud template is converted to a present coordinate, is converted to a coordinate under the manipulator coordinate system, and is transferred to the manipulator; and the manipulator finishes actuation actions.

Owner:HENAN ALSONTECH INTELLIGENT TECH CO LTD

Monitoring blood flow in the retina using a line-scanning laser ophthalmoscope

Real time, high-speed image stabilization with a retinal tracking scanning laser ophthalmoscope (TSLO) enables new approaches to established diagnostics. Large frequency range (DC to 19 kHz), wide-field (40-deg) stabilized Doppler flowmetry imaging is described for human subjects. The fundus imaging method is a quasi-confocal line-scanning laser ophthalmoscope (LSLO). The retinal tracking system uses a confocal reflectometer with a closed loop optical servo system to lock onto features in the ocular fundus and automatically re-lock after blinks. By performing a slow scan with the laser line imager, frequency-resolved retinal perfusion and vascular flow images can be obtained free of eye motion artifacts.

Owner:PHYSICAL SCI

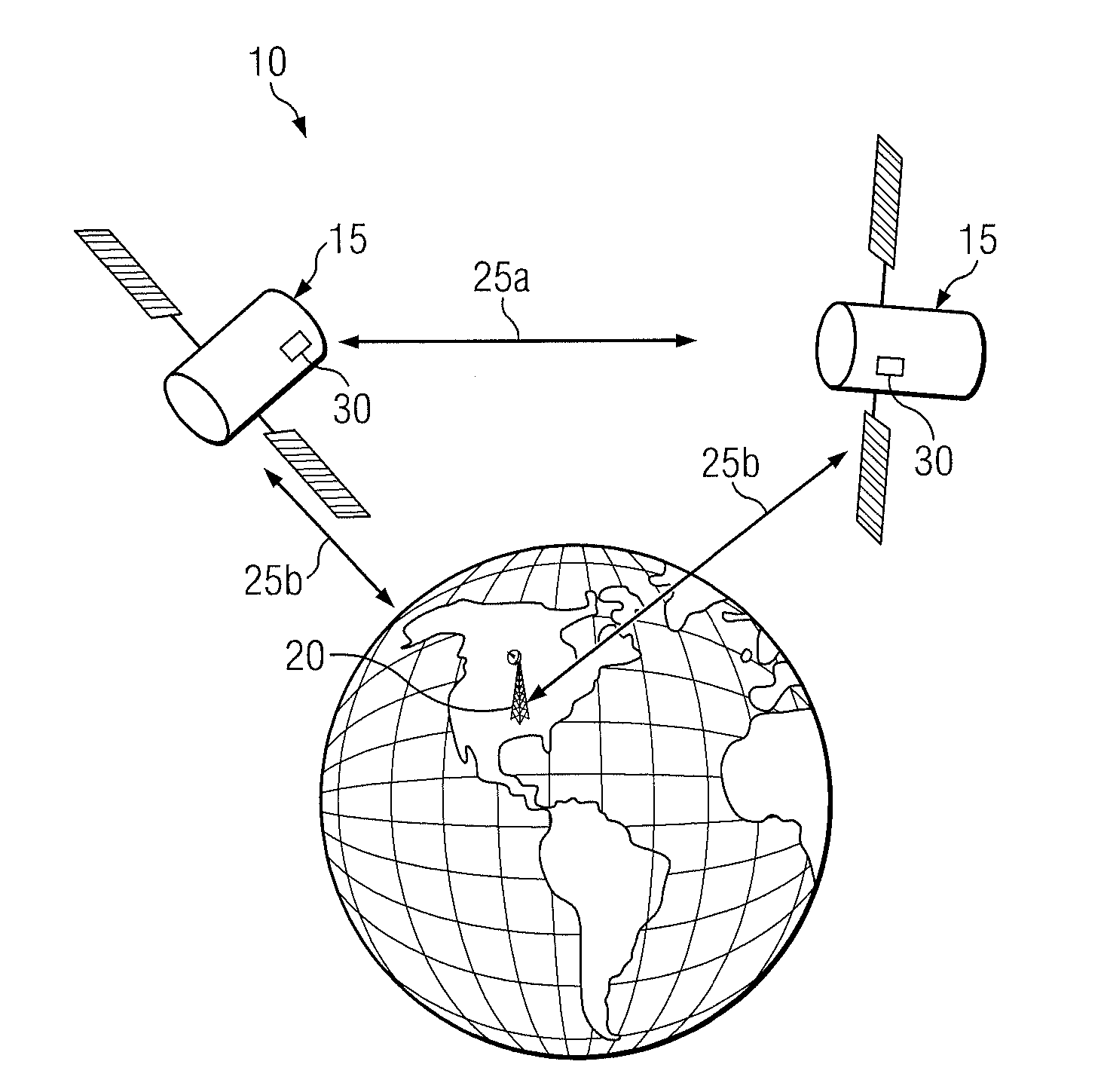

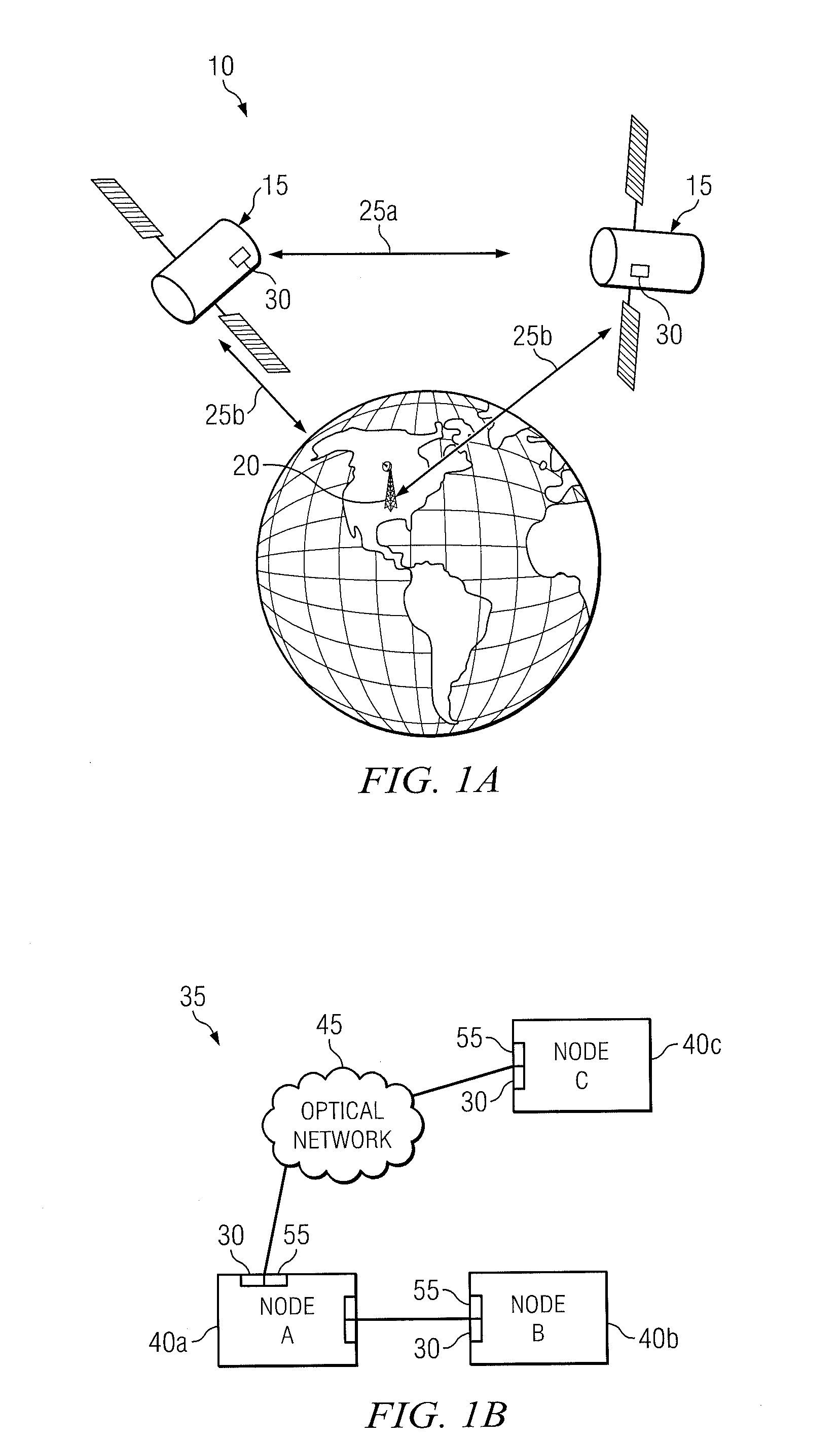

Method and apparatus for phase shift keyed optical communications

ActiveUS20110274429A1High data rateConstructionsModulated-carrier systemsTransceiverOptical communication

A burst-mode differential phase shift keying (DPSK) communications system according to an embodiment of the present invention enables practical, power-efficient, multi-rate communications between an optical transmitter and receiver. An embodiment of the system utilizes a single interferometer in the receiver with a relative path delay that is matched to the DPSK symbol rate of the link. DPSK symbols are transmitted in bursts, and the data rate may be varied by changing the ratio of the burst-on time to the burst-off time. This approach offers a number of advantages over conventional DPSK implementations, including near-optimum photon efficiency over a wide range of data rates, simplified multi-rate transceiver implementation, and relaxed transmit laser line-width requirements at low data rates.

Owner:MASSACHUSETTS INST OF TECH

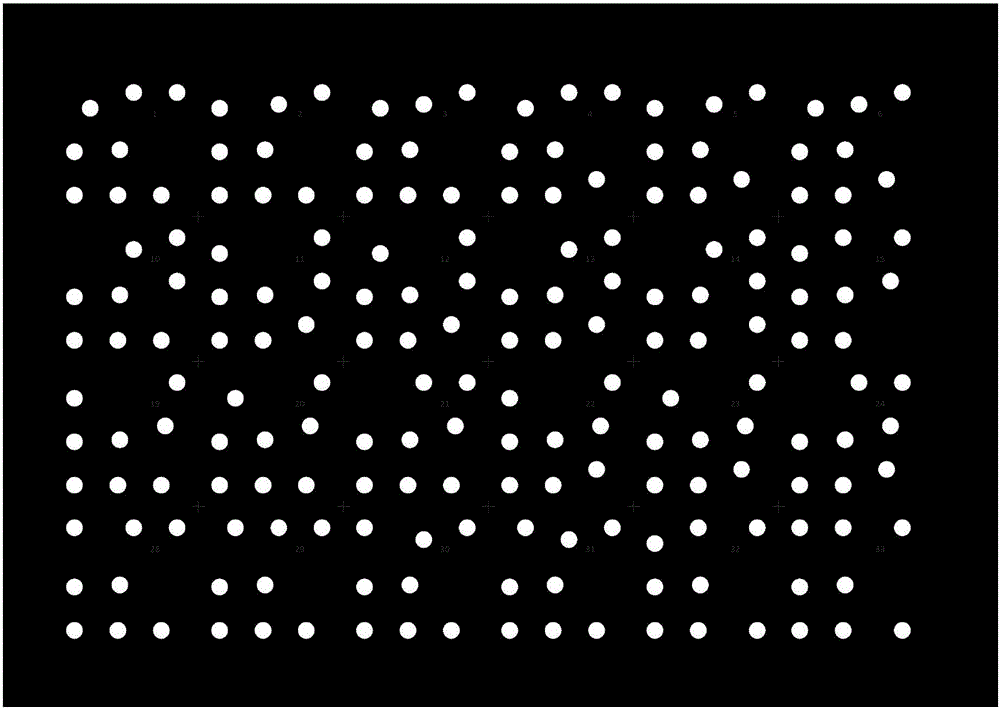

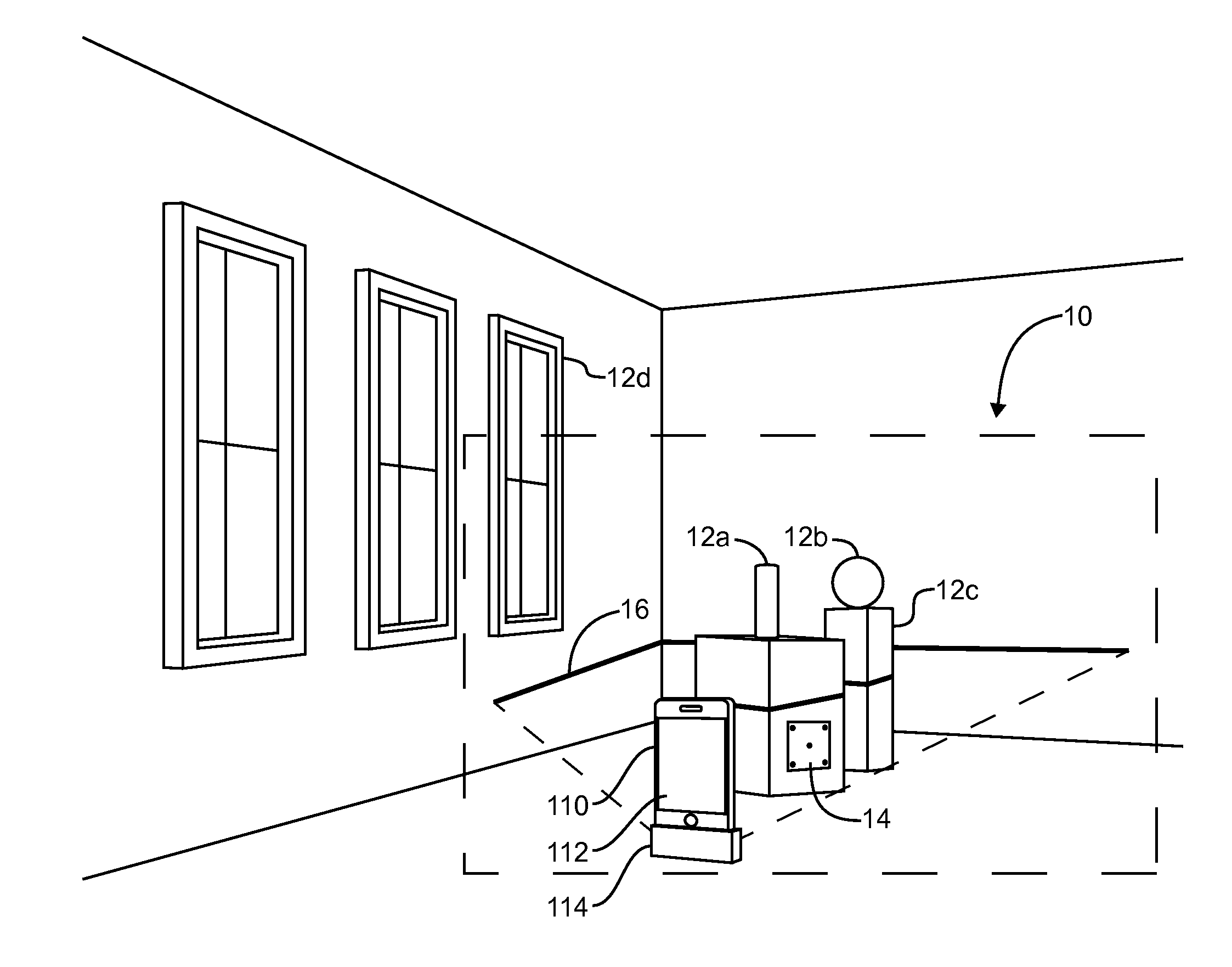

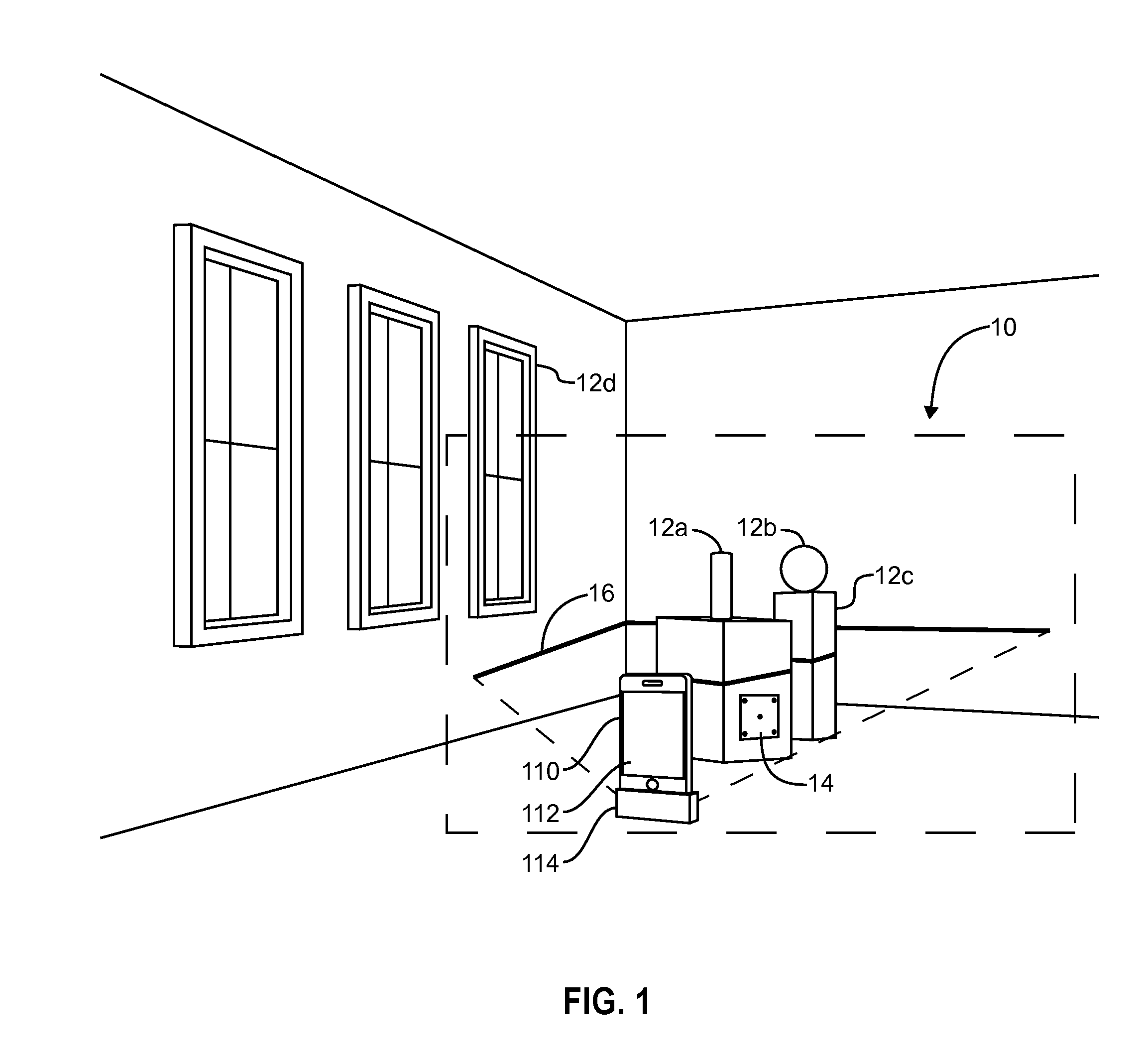

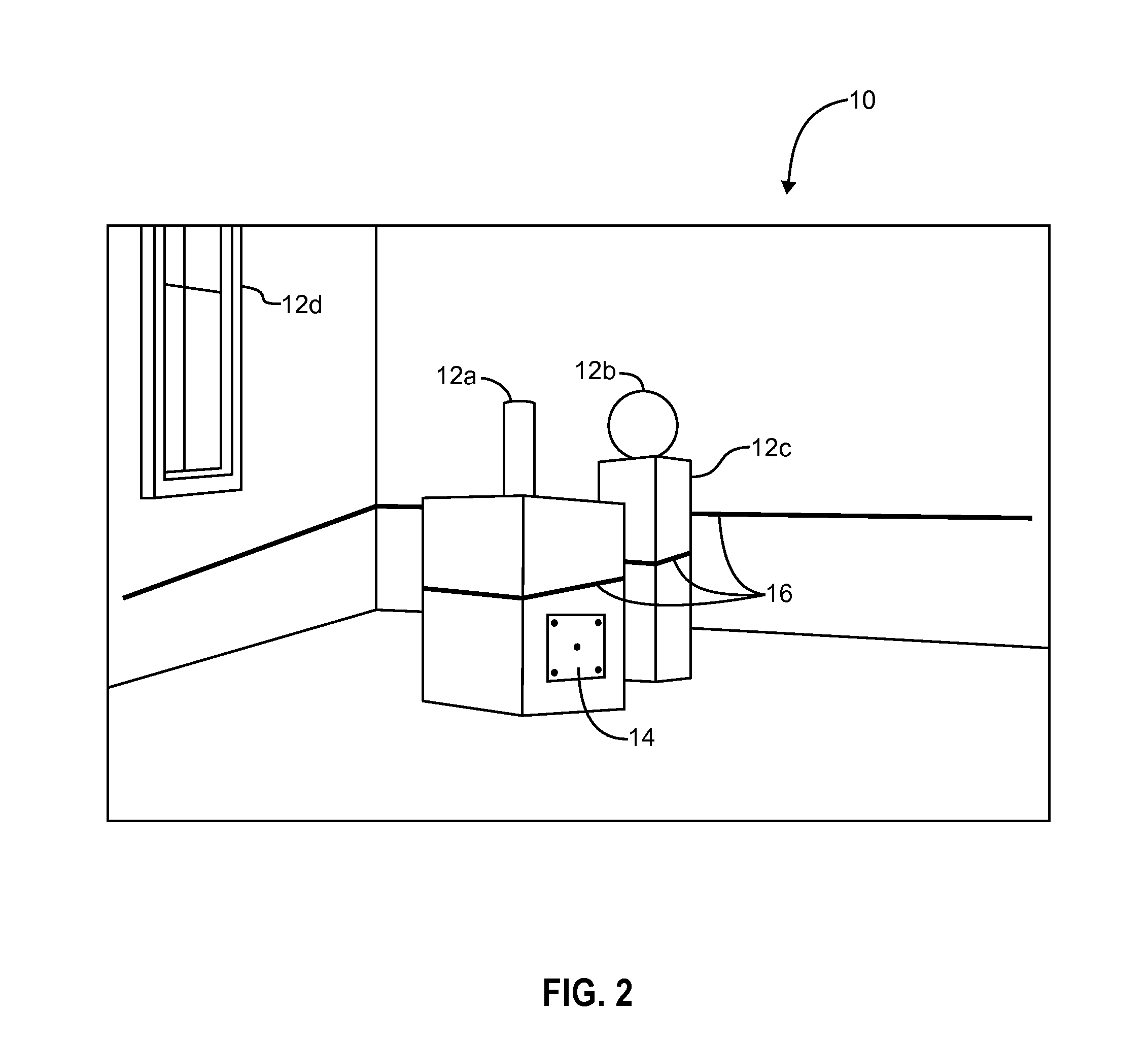

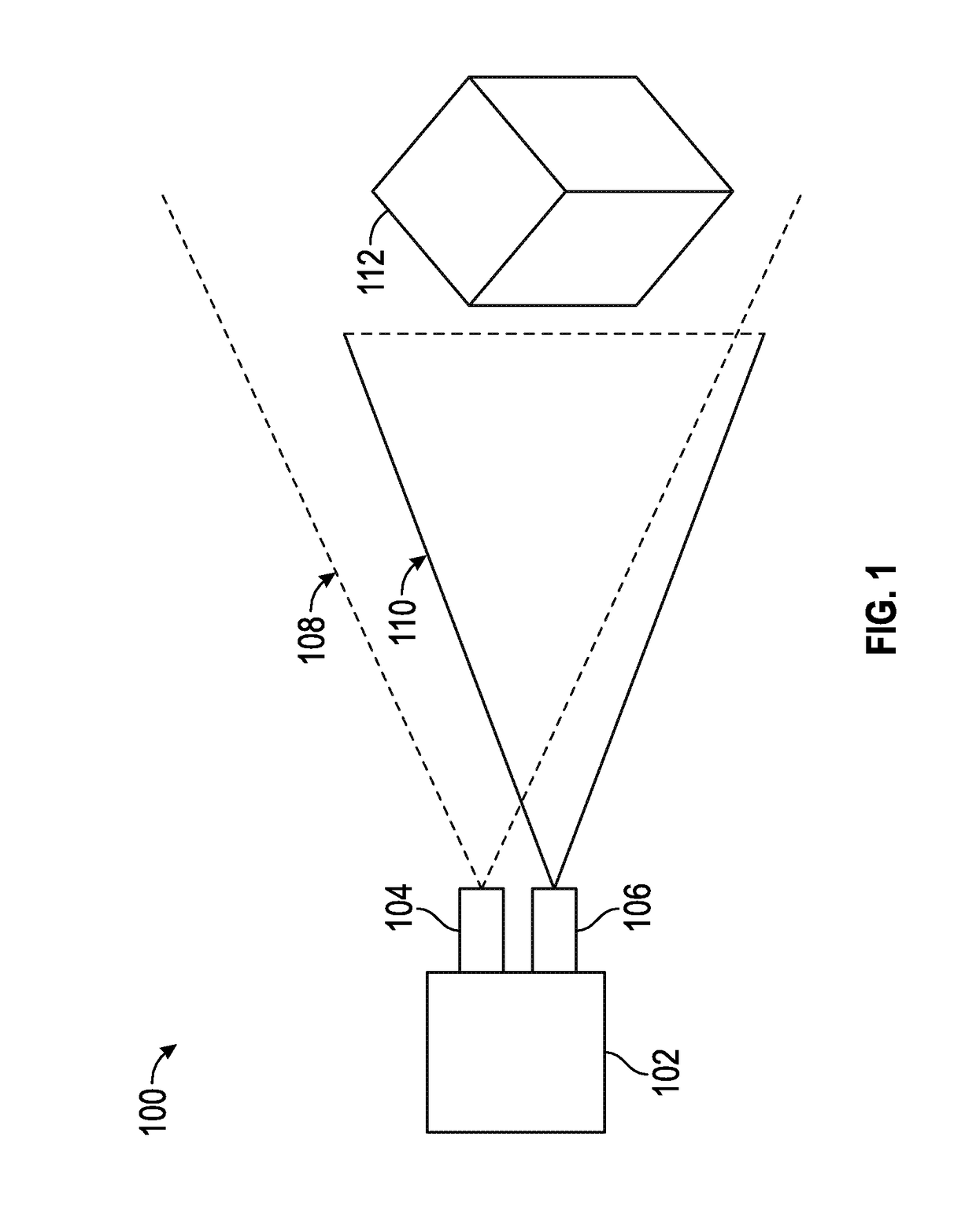

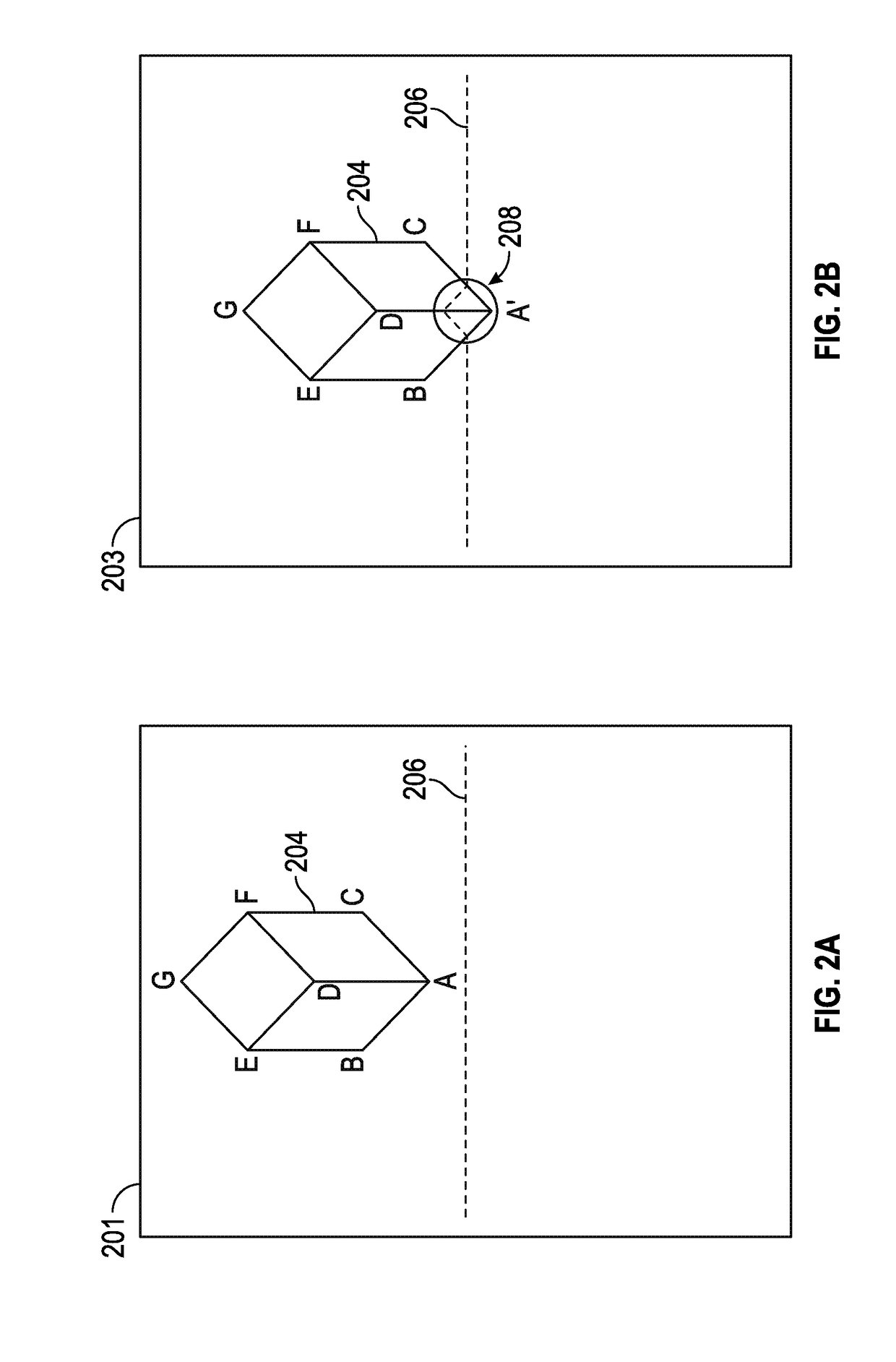

Multiple template improved 3D modeling of imaged objects using camera position and pose to obtain accuracy

3D Modeling System and Apparatus for mobile devices with limited processing capability is disclosed. This invention uses the standard camera and computing resources available on consumer mobile devices such as smart phones. A light projector (e.g. laser line generator) is attached as an accessory to the mobile device or built as a part of the mobile device. Processing requirements are significantly reduced by including known object(s) or reference template(s) in the scene to be captured which are used to determine the pose / position of the camera relative to the object or scene to be modeled in a series of camera pose / position sequences. The position / pose of the camera and projector for each sequence is facilitated by image distortions of known dimensions of reference template or known object in a sequence of captured images.

Owner:JOVANOVIC DEJAN +3

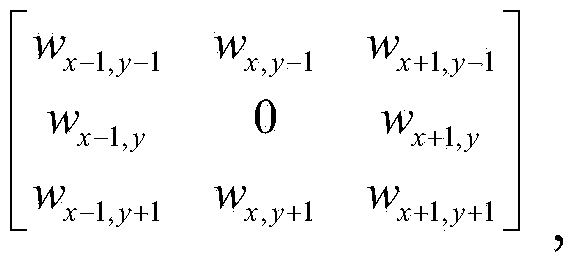

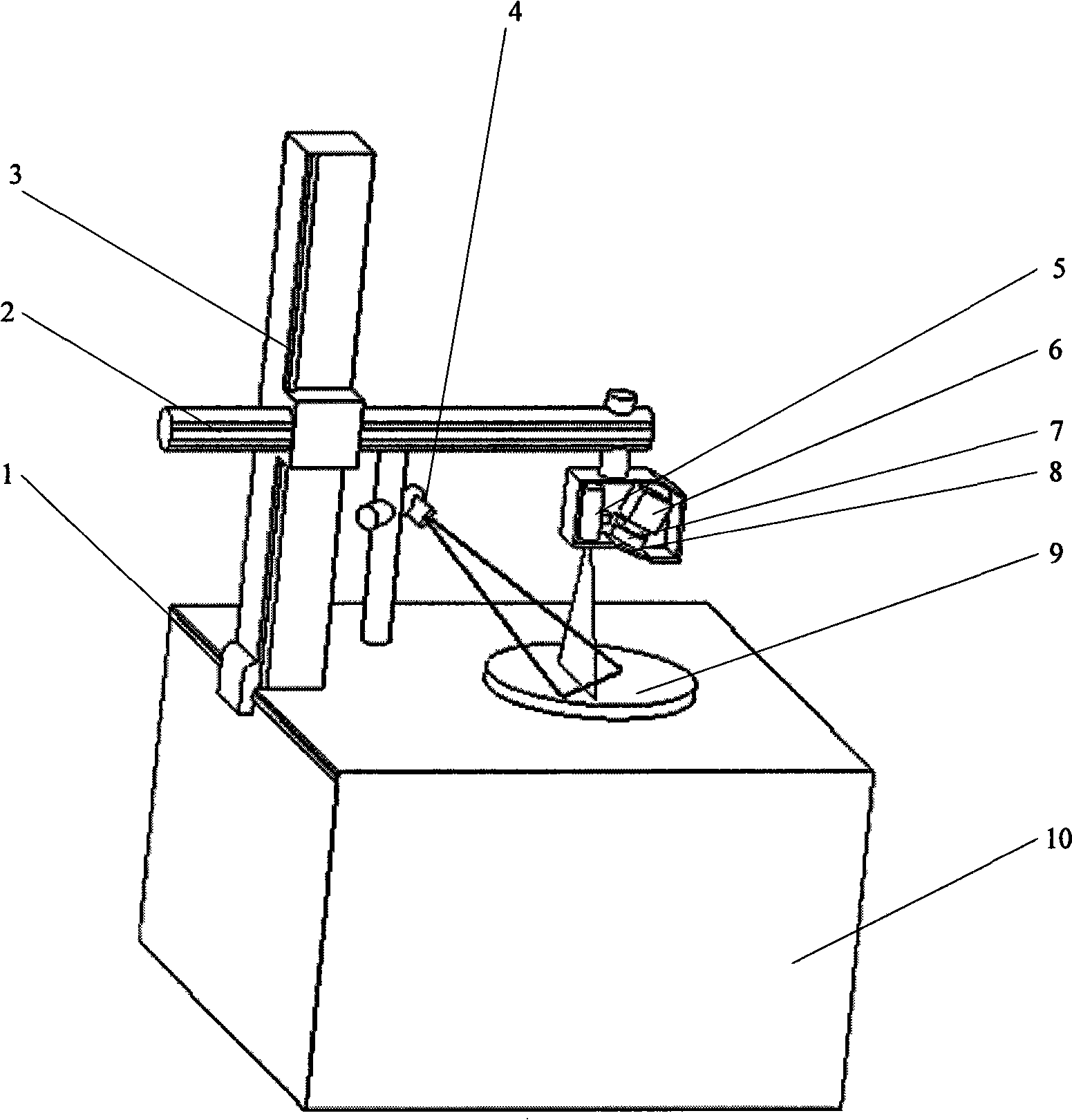

Pavement crack detecting device and method based on depth and gray level images

ActiveCN104005325ASolve detection difficultiesFix quick transitionsRoads maintainenceGray levelRoad surface

The invention discloses a pavement crack detecting device and method based on depth and gray level images. The pavement crack detecting device comprises a carrier platform (1), a camera shooting device (6), a line laser (7) and a calculating device (8), wherein the camera shooting device, the line laser and the calculating device are located on the carrier platform. The carrier platform (1) is used for moving in the pavement direction in the crack detecting process. The line laser (7) is used for emitting laser light perpendicular to a pavement while the carrier platform (1) moves. The camera shooting device (6) is used for continuously shooting laser lines, reflected by the pavement, of the linear laser light in a slant mode while the carrier platform (1) moves, imaging is conducted on a pavement fracture surface every time shooting is performed, and image data of the laser lines of a plurality of pavement fracture surfaces are generated. The calculating device (8) is used for generating depth data and gray level data of the corresponding pavement fracture surface according to the image data of the laser lines of each pavement fracture surface and splicing the depth data and the gray level data of each pavement fracture surface to form image data of a section of the pavement so as to conduct crack recognition.

Owner:WUHAN WUDA ZOYON SCI & TECH

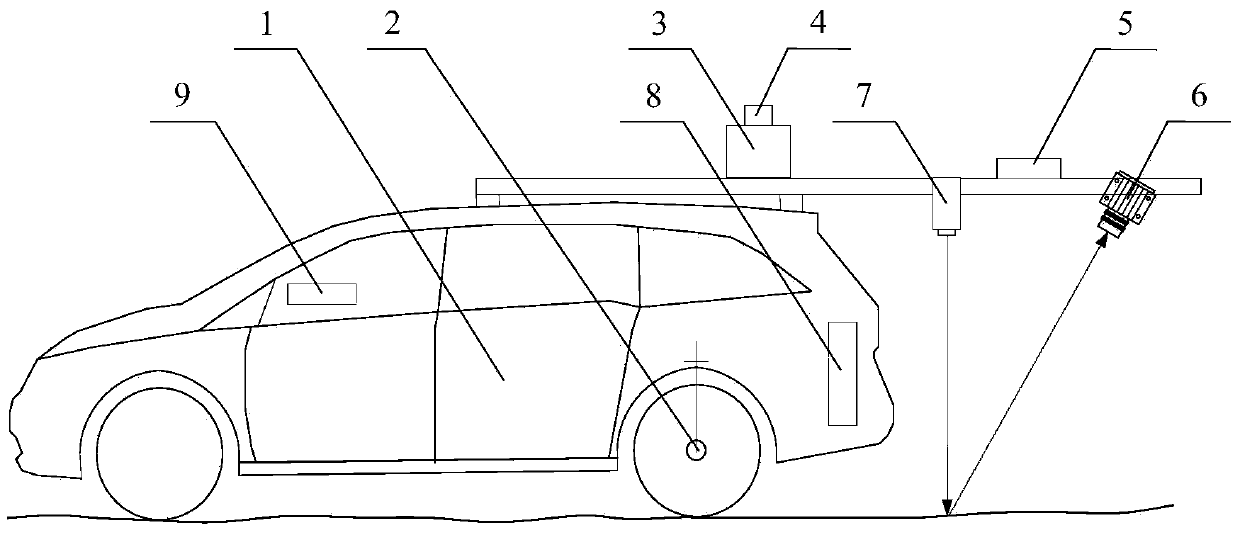

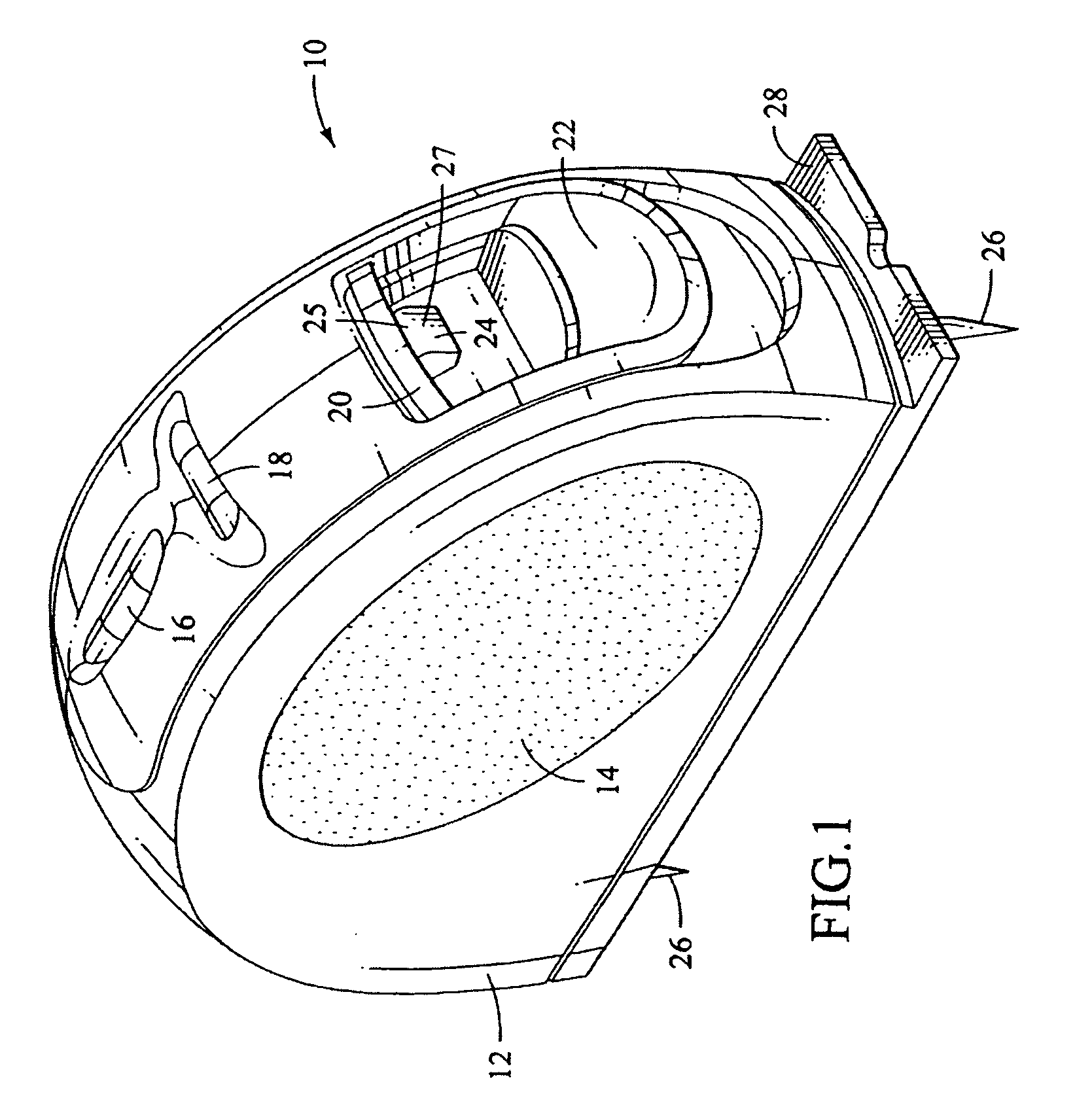

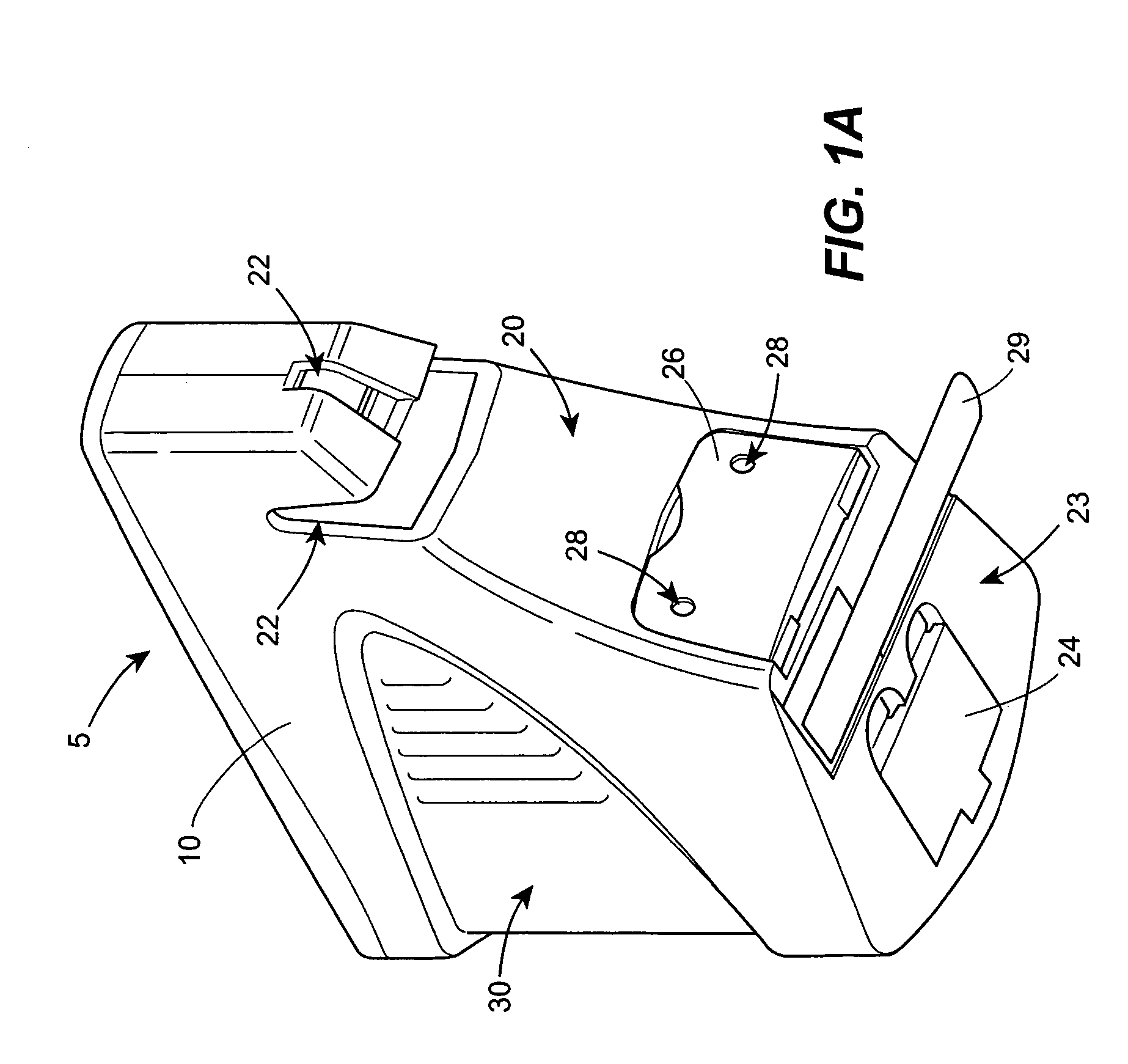

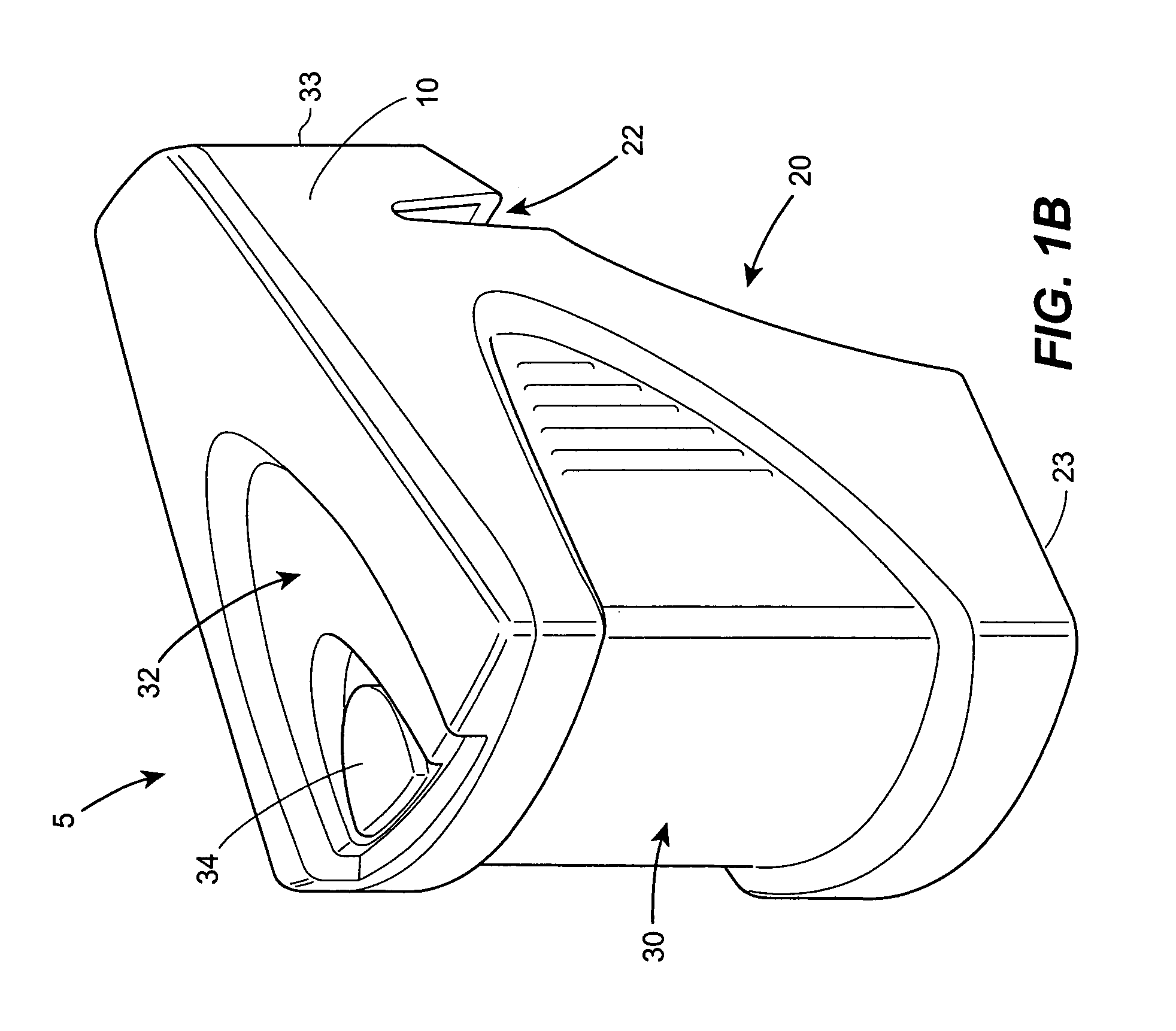

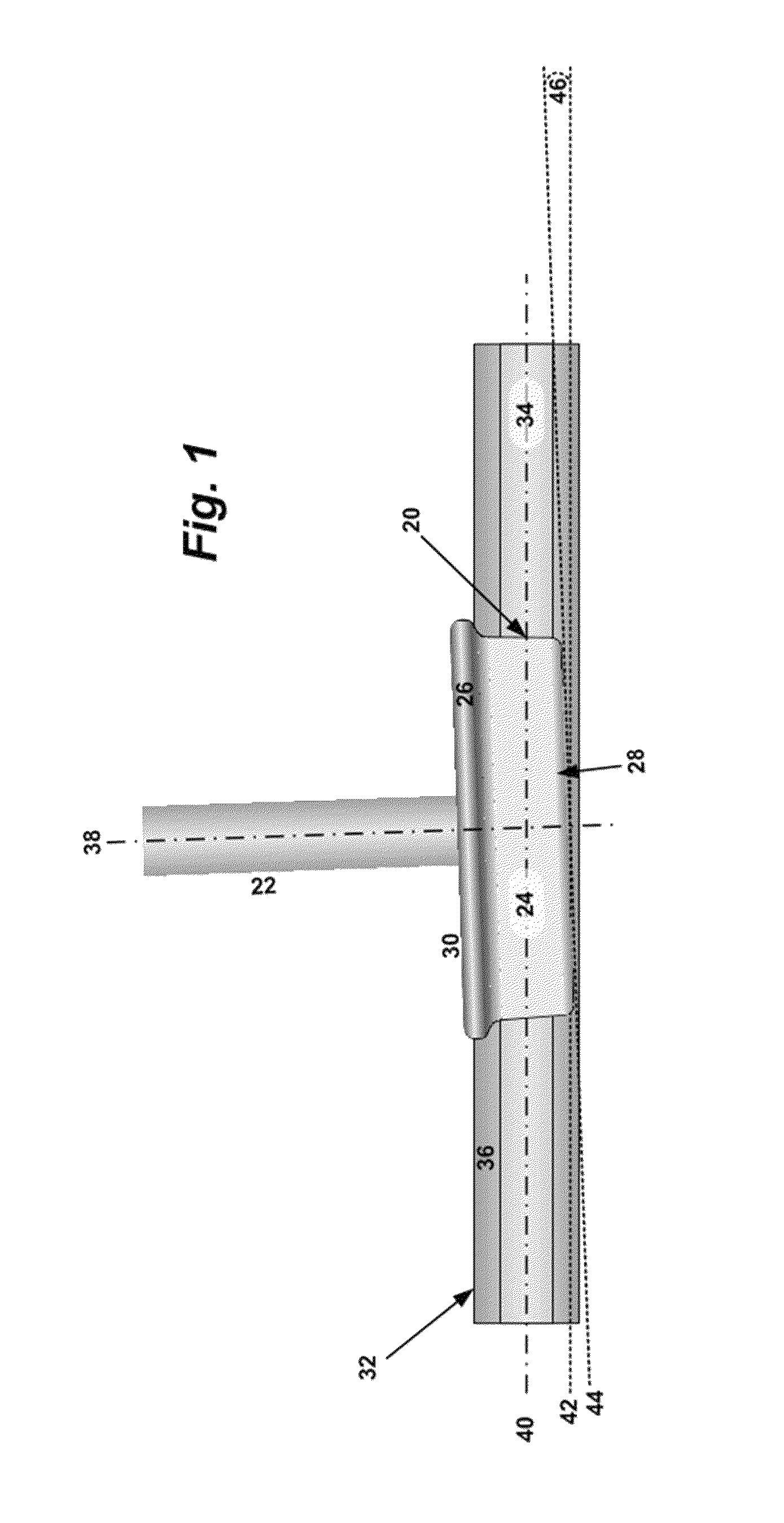

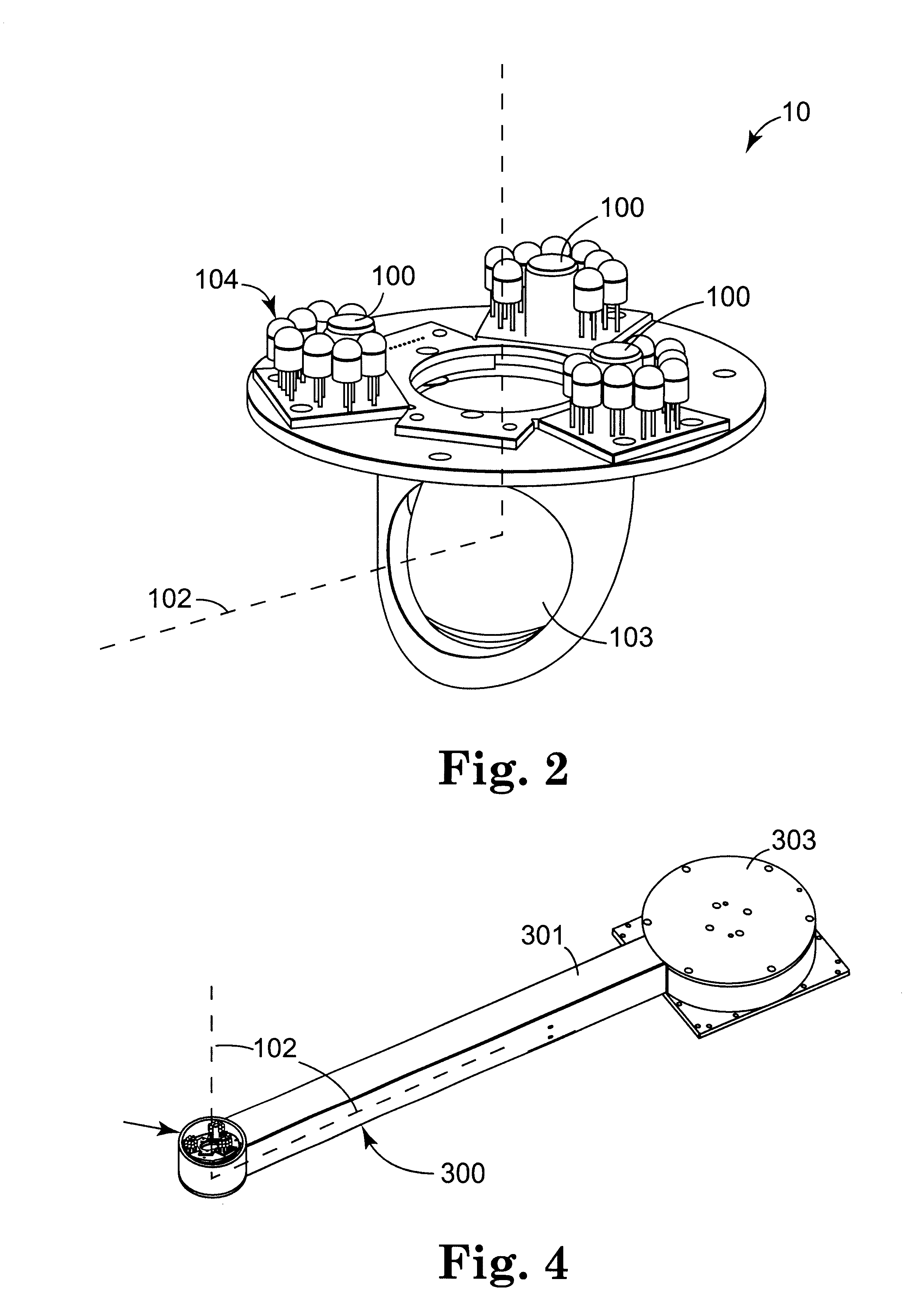

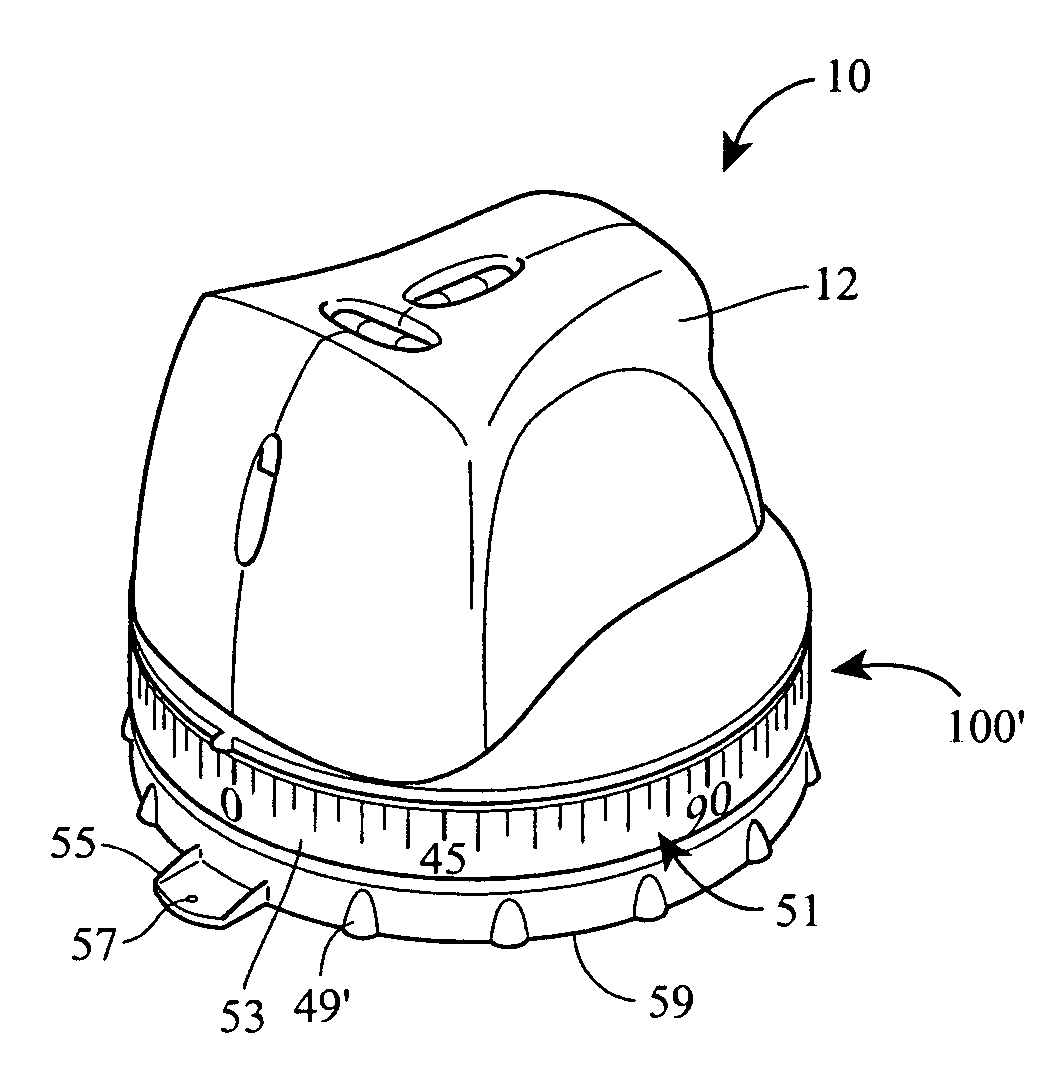

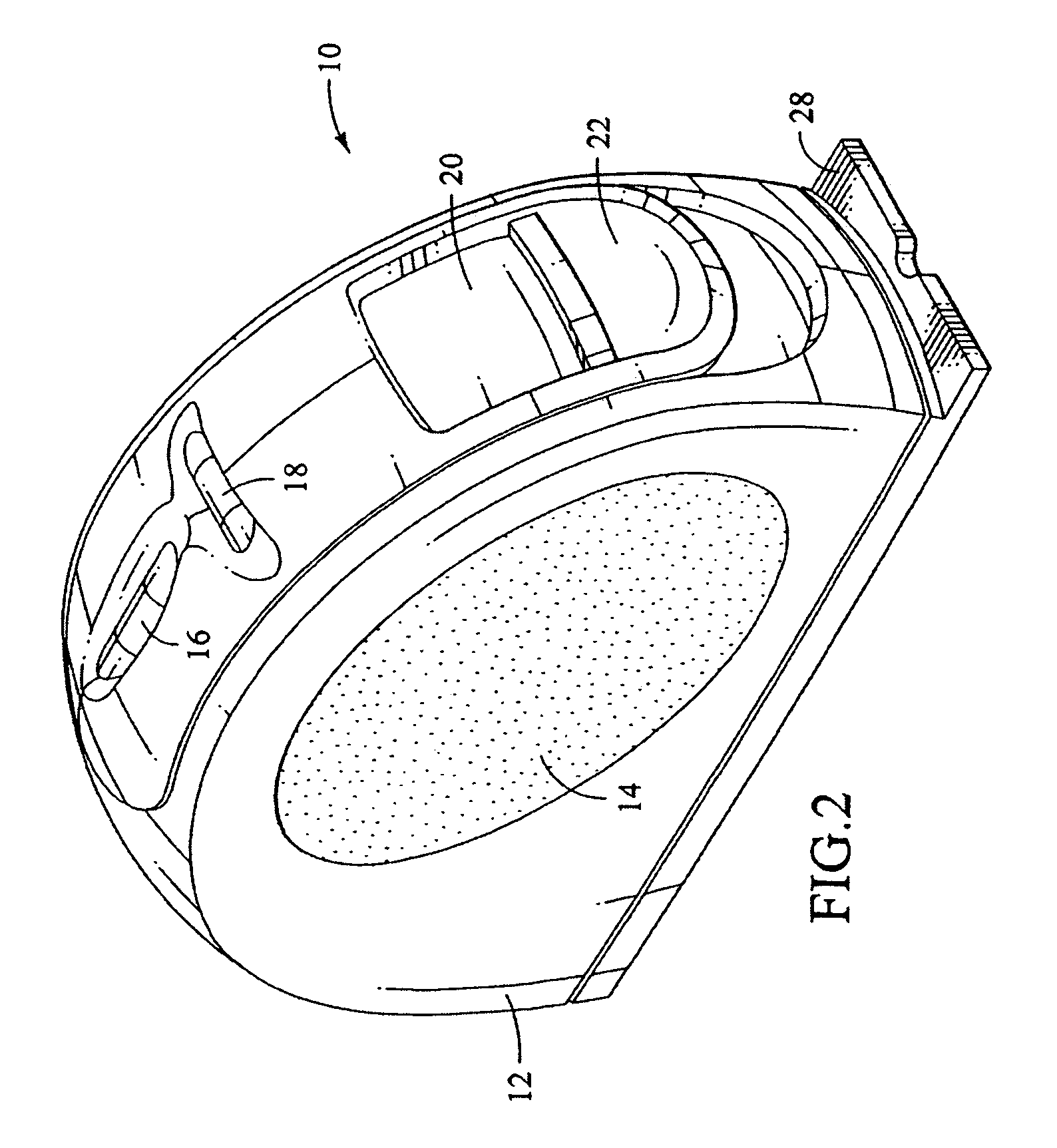

Laser line generating device with swivel base

A laser alignment device includes a laser generating device, an upper attachment portion, and a lower attachment portion. The laser generating device includes a housing and a laser generator. The upper attachment portion is disposed near a bottom of the housing, and the lower attachment portion is pivotally and / or rotationally connected to the upper attachment portion.

Owner:IRWIN IND TOOL CO

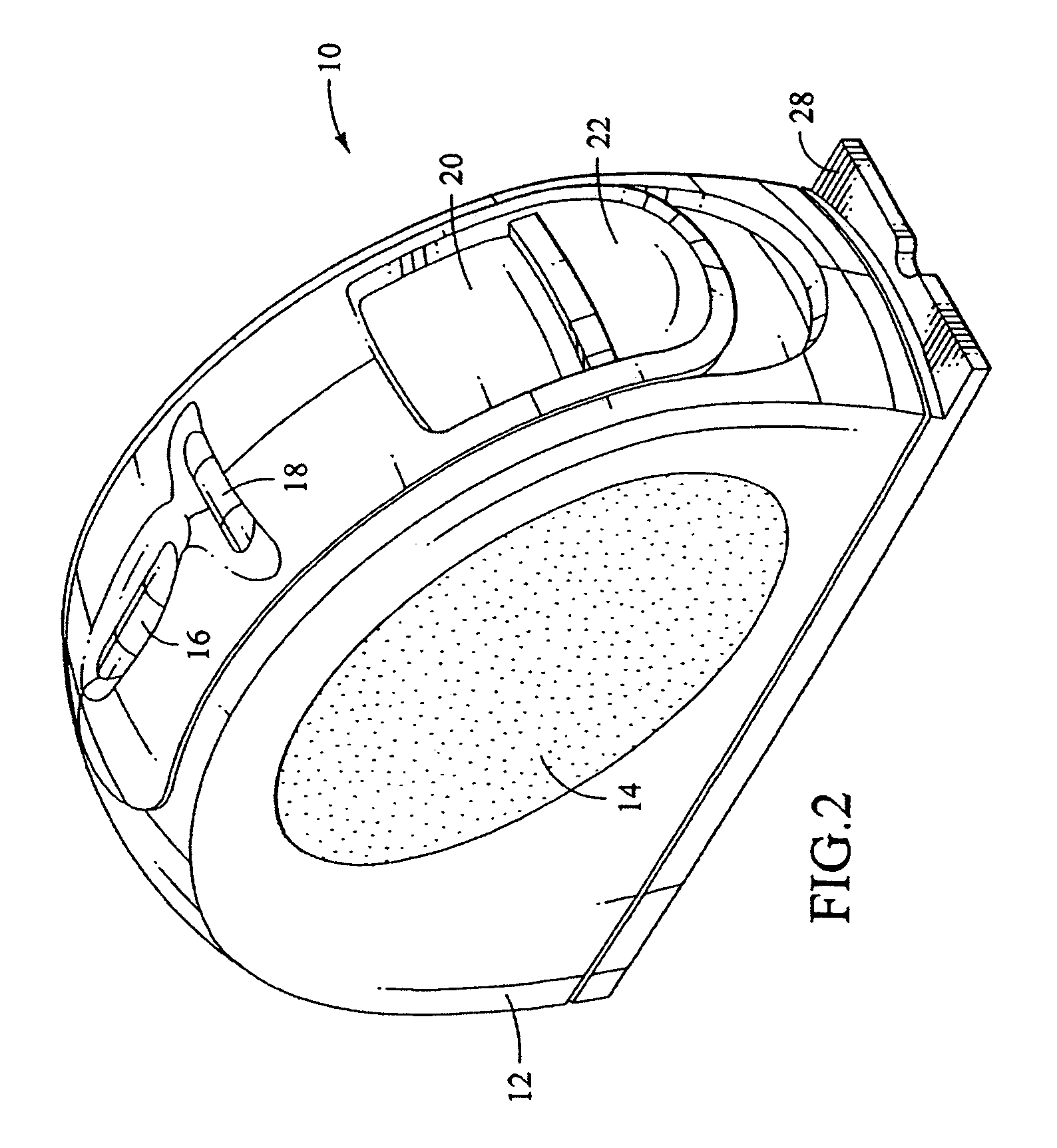

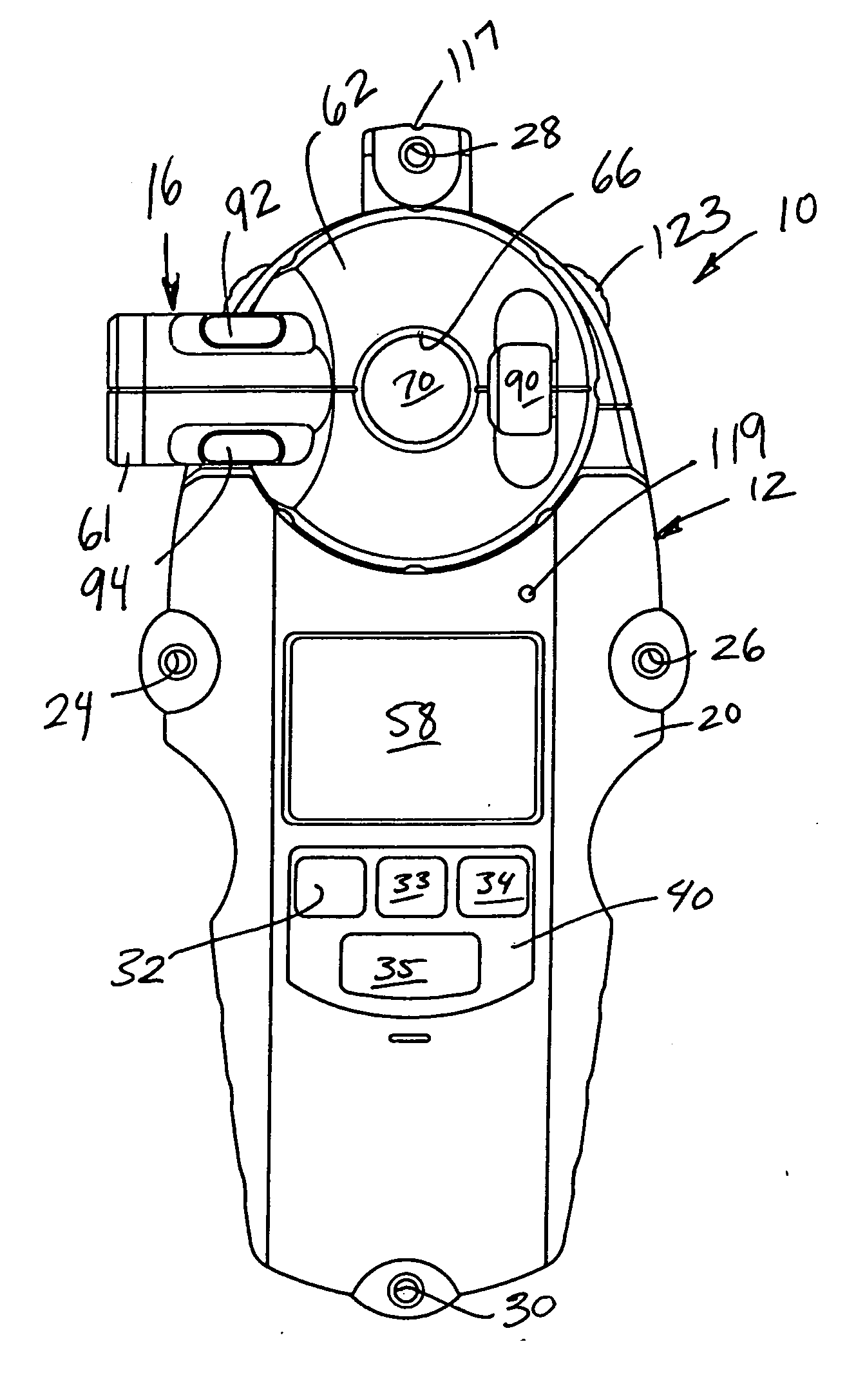

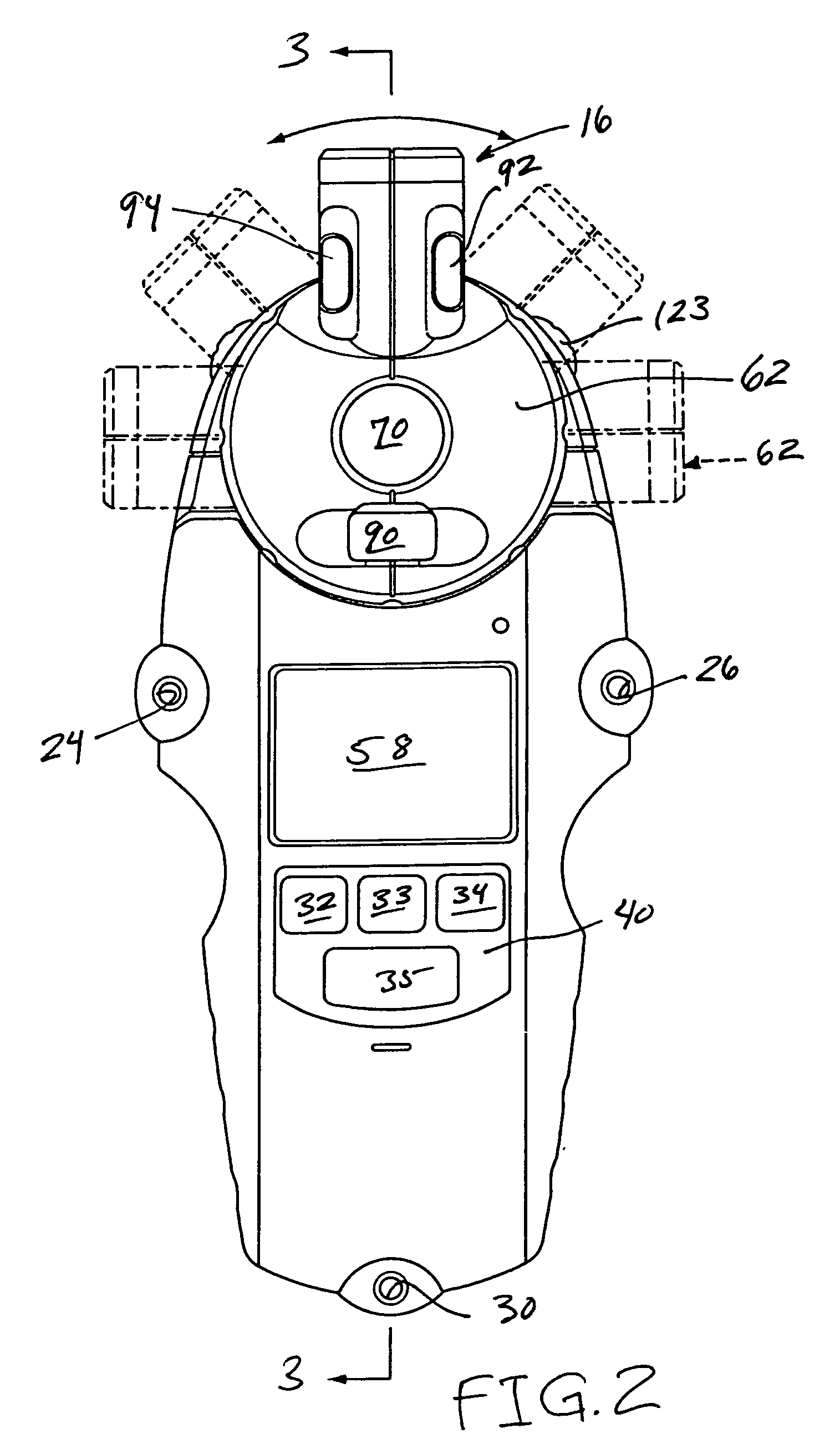

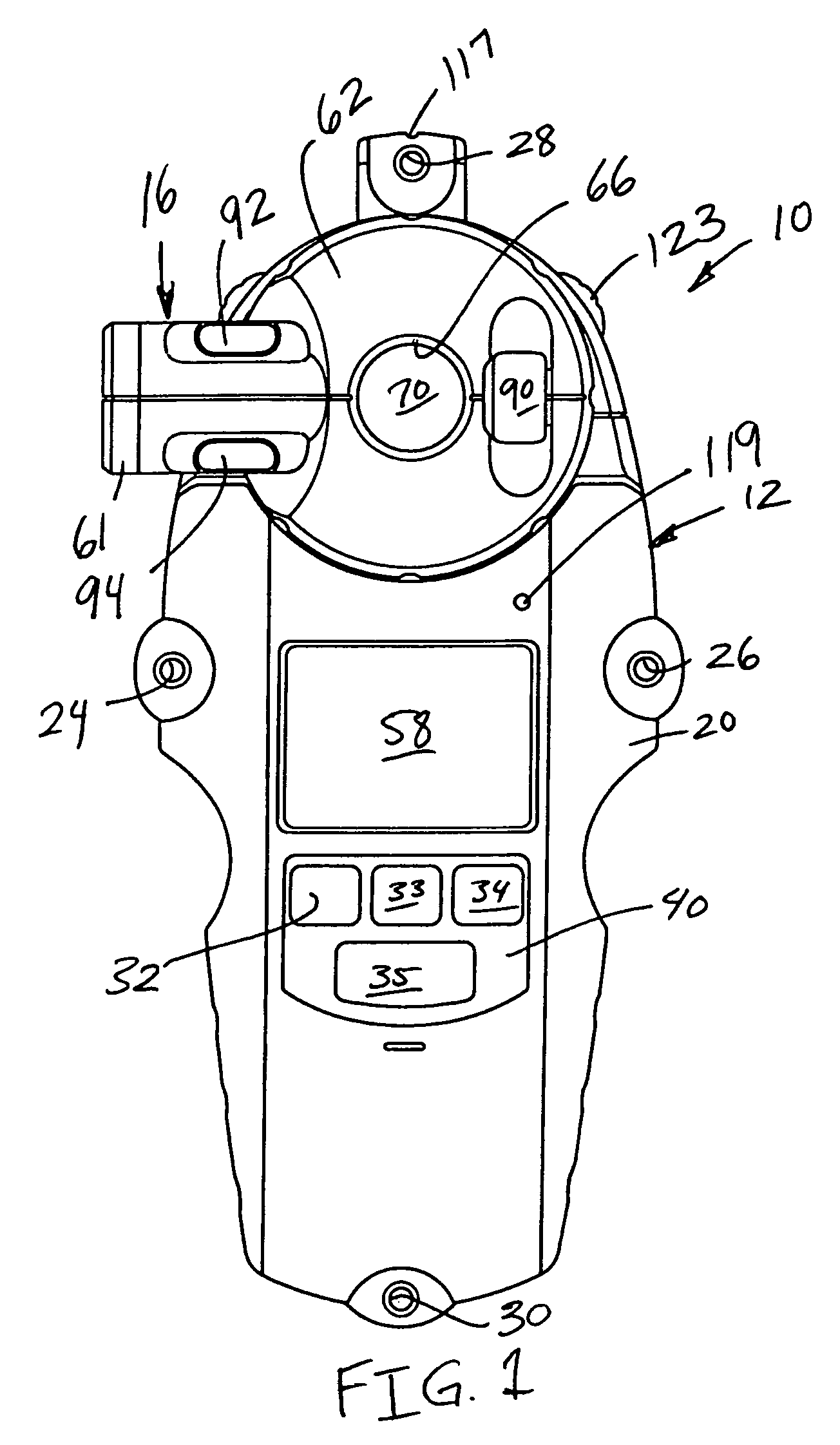

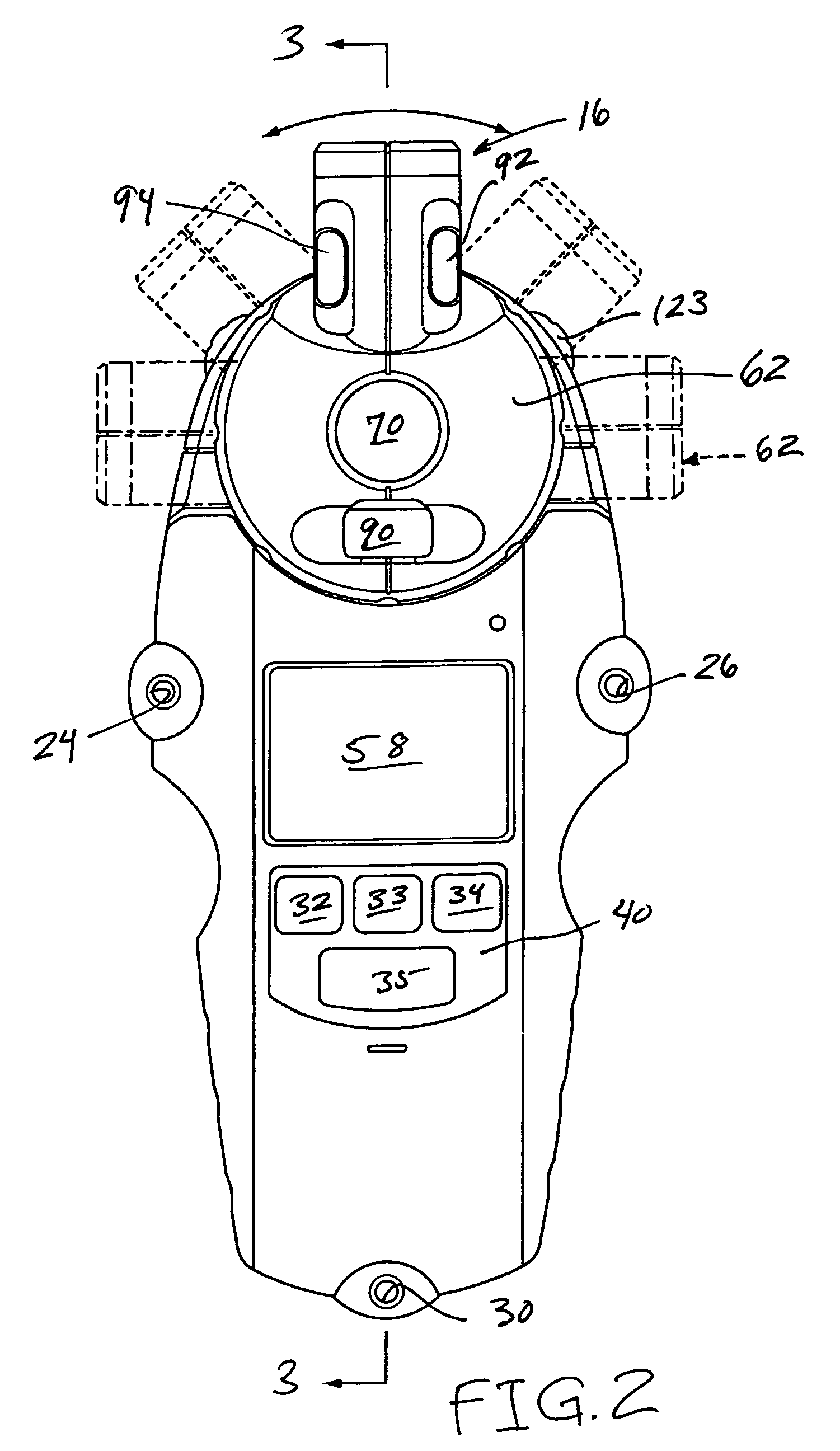

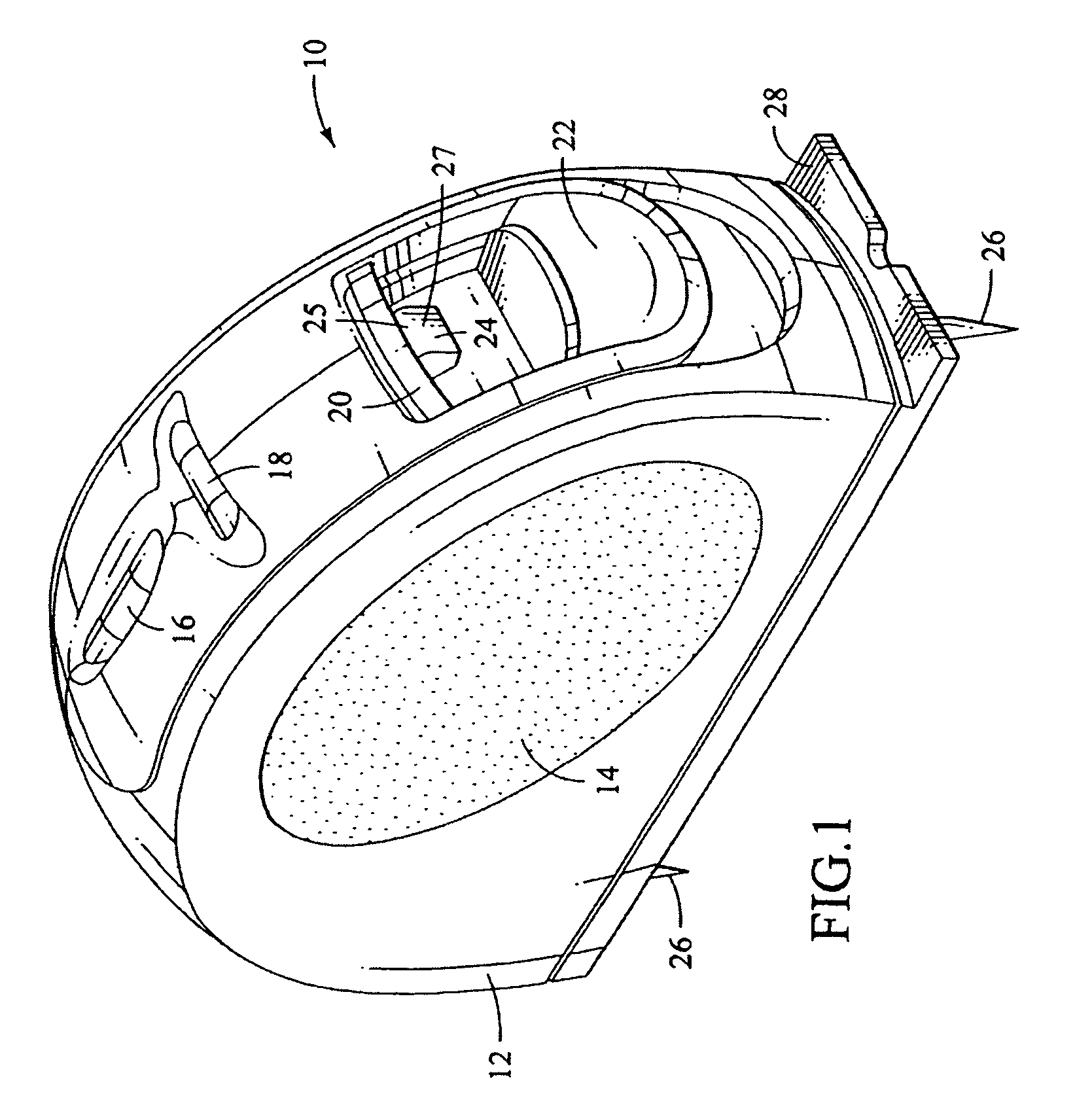

Studfinder and laser line layout tool

A layout tool includes an object detector constructed and arranged to detect the location of a vertically extending edge portion of an object hidden from view behind a generally vertically extending wall surface, a light source that is capable of projecting a line of light along the wall surface, and an angular orientation mechanism operably coupled to the light projection mechanism. The angular orientation mechanism is operable to establish that the line of light is vertical. The light source and the object detector are operatively interengaged such that when a vertically extending edge is detected by the object detector, a vertically extending line of light projected on the surface by the light source indicates the location of a vertically extending edge portion of the hidden object.

Owner:STANLEY WORKS THE

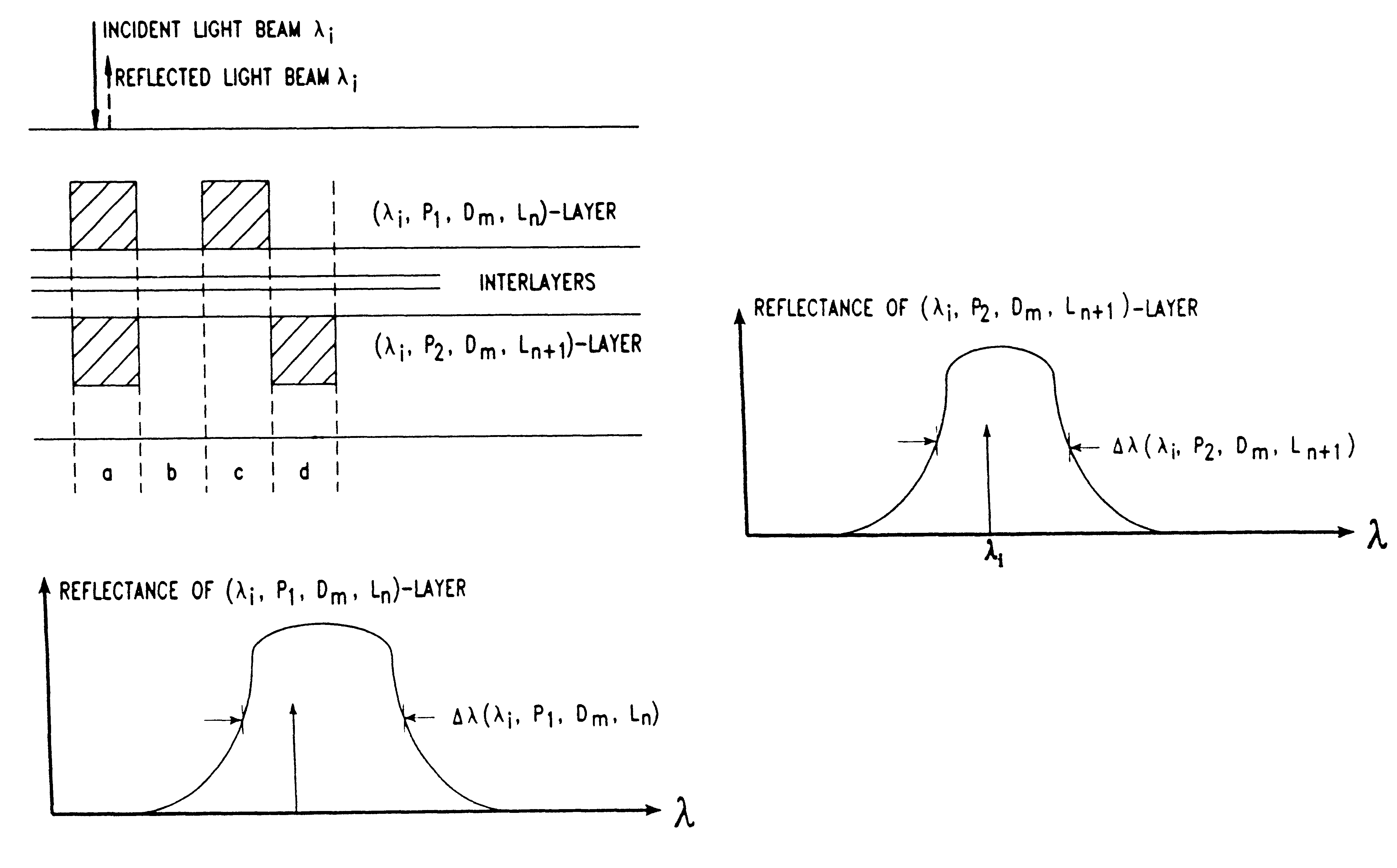

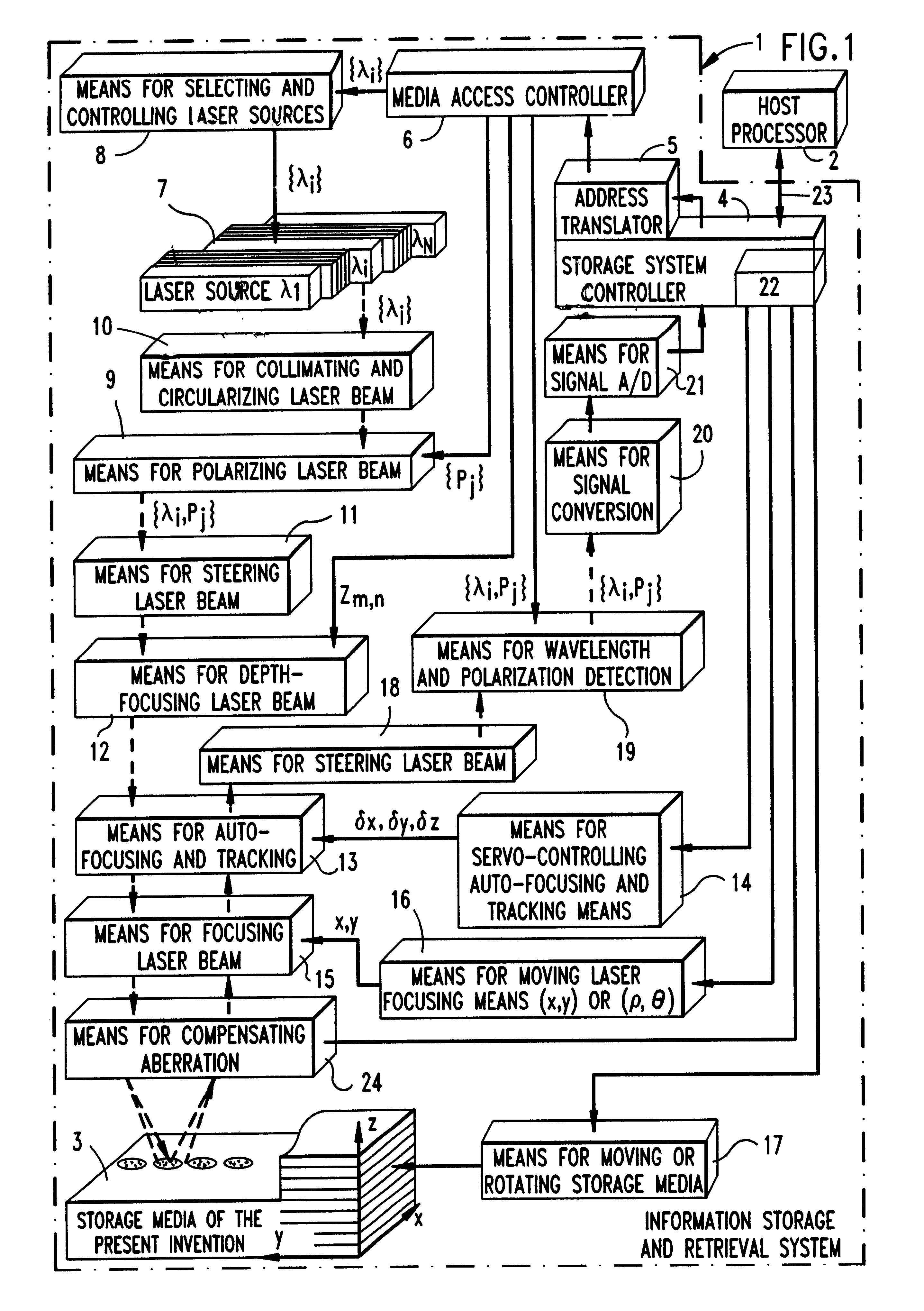

Multi-layer optical recording media and system for recording and reproducing information data

InactiveUS6498775B1Precise alignmentOptical beam sourcesRecord information storageEngineeringOptical recording

Disclosed is a novel multi-layered optical recording media and system for recording and reproducing information data. The multi-layered topical recording media has M information storage decks, and each information storage deck has N information storage layers, and each information storage layer has a pair of information storage structures. Each paired information storage structure has a characteristic wavelength and polarization state, and from which recorded information can be read by a laser beam having similar wavelength and polarization-state characteristics. In the illustrative embodiment, the multi-layered optical recording media of the present invention has MxNx2 information storage layers which can be read using only N laser lines (i.e. spectral components), thereby providing a 2M-fold increase in information storage capacity over prior art systems. The information storage and retrieval system of the present invention is completely backward compatible to allow for the reading of conventional CD-ROM devices.

Owner:REVEO

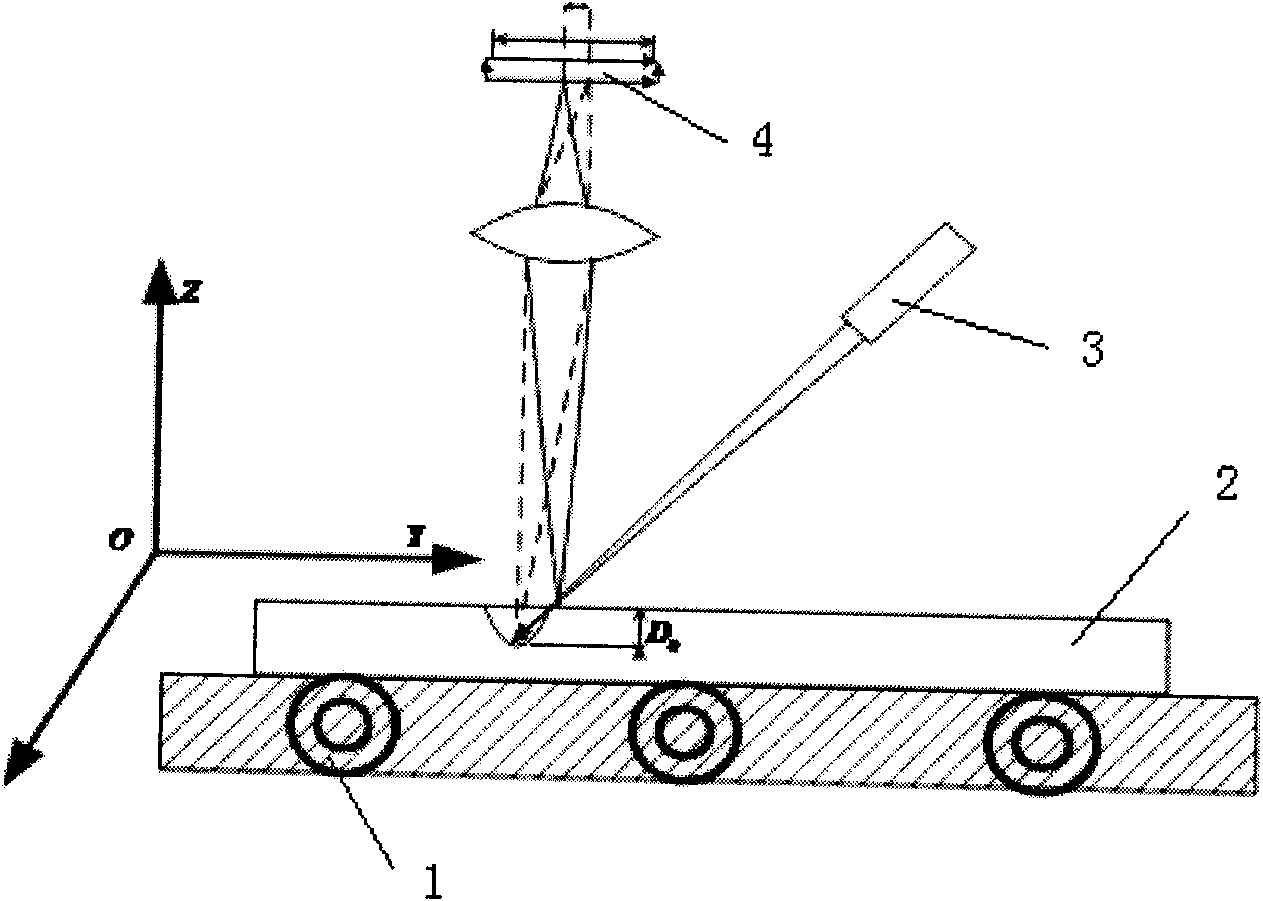

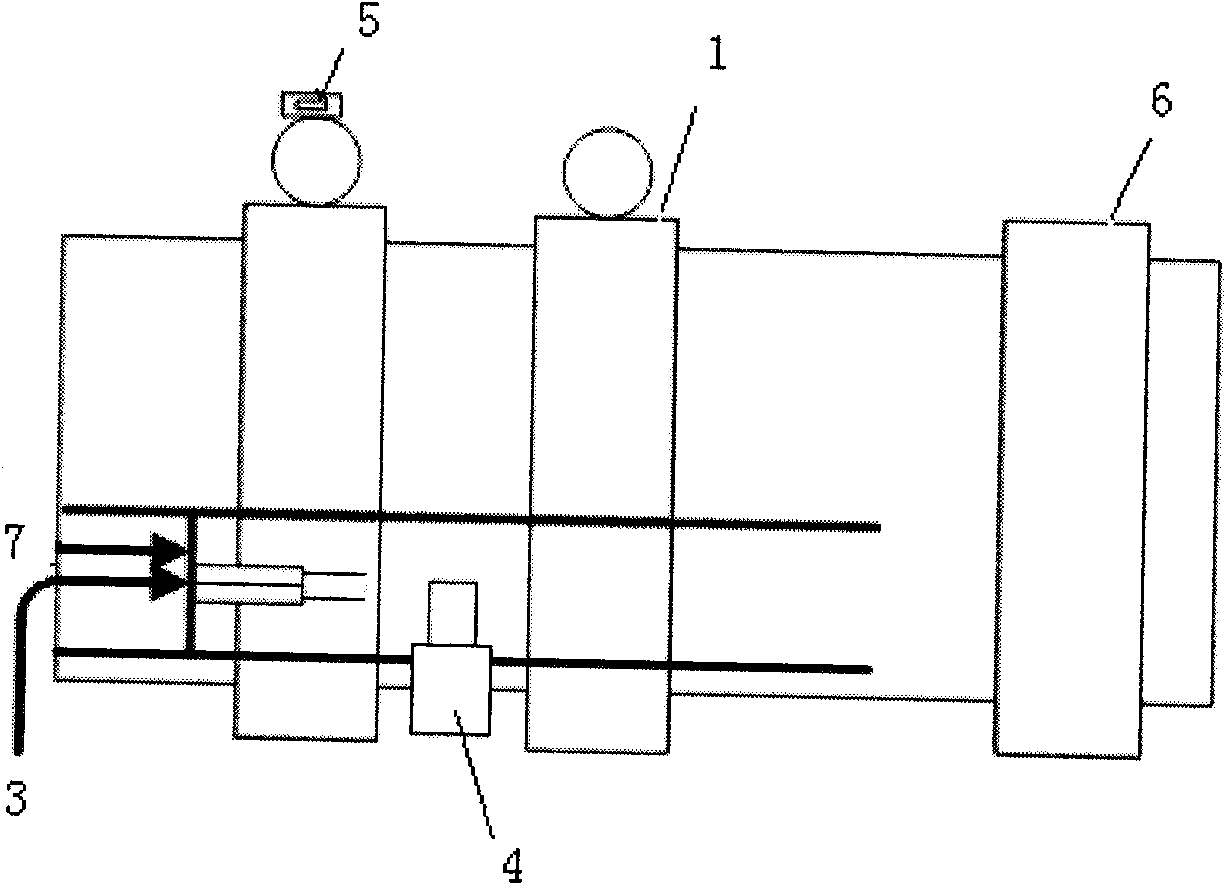

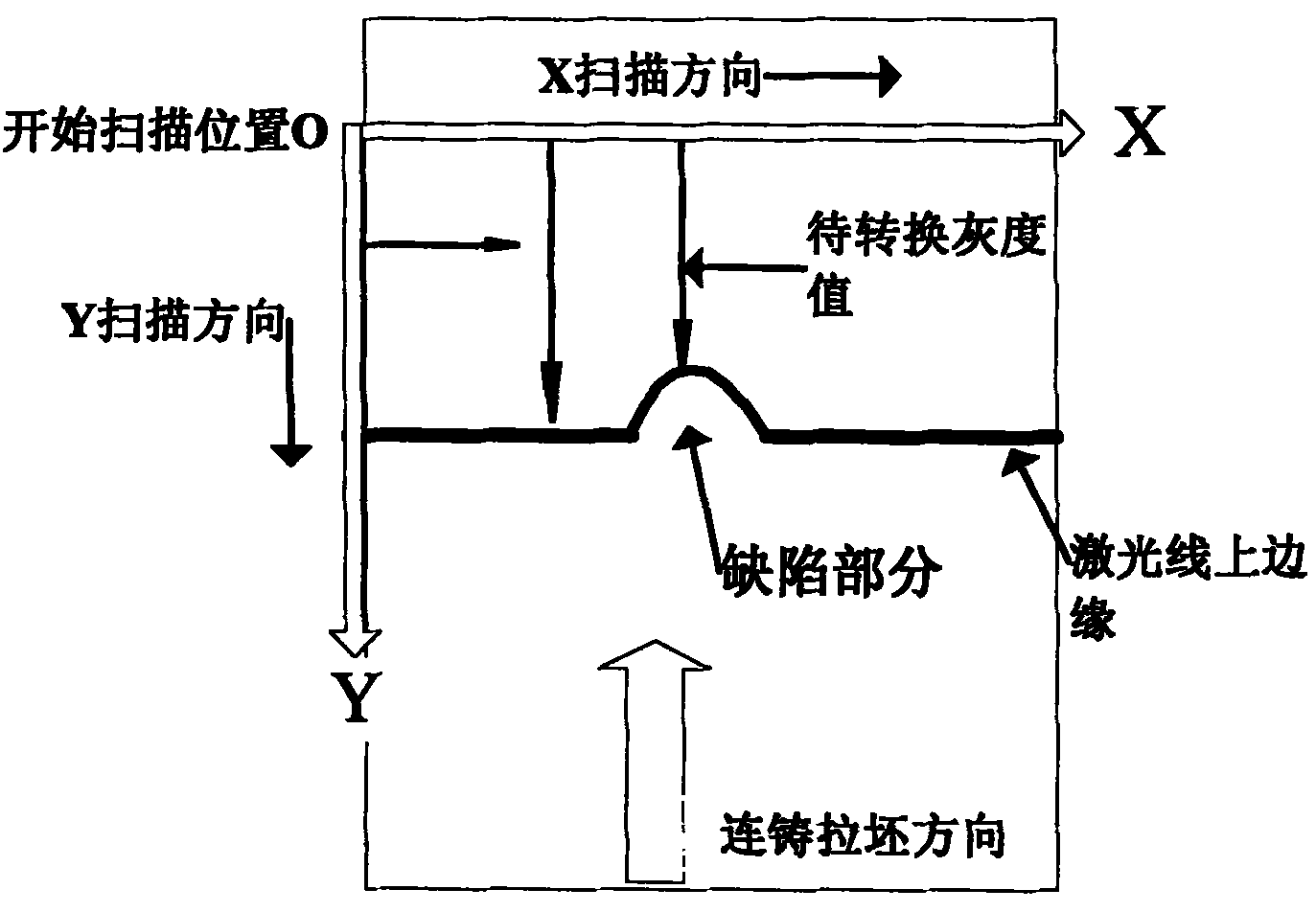

Laser scanning imaging nondestructive inspection method for hot continuous casting blank surface defects

InactiveCN101871895ASuppress interferenceAccurate identificationMaterial analysis by optical meansUsing optical meansLaser transmitterDot matrix

The invention discloses a laser scanning imaging nondestructive inspection method for hot continuous casting blank surface defects, comprising the following steps: 1) transversely irradiating a casting blank by a laser emitter to obtain a laser line; 2) scanning the laser line by utilizing an area array CCD image sensor; 3) extracting information representing the defect depths from the laser line so as to obtain a one-dimensional distance dot matrix formed by assembling the defect depths of the casting blank at the transverse position; and 4) mapping the one-dimensional distance dot matrix into gray level images with different gray levels; 5) splicing the gray level images at different transverse positions of a hot blank so as to obtain a whole gray level image; and 6) identifying the defects on the surface of the casting blank and reconstructing a casting blank surface tri-dimensional topographic image. The intention can effectively inhibit interference from a flaky scale on the high temperature casting blank surface which is not a defect but presents a defect state and water films so as to avoid the pseudo-defects from influencing detection precision, accurately identify defect target images and realize quantized detection of the defect depths, thereby realizing online detection of the defect states and depths of the surface of the casting blank under a high temperature state.

Owner:CHONGQING UNIV

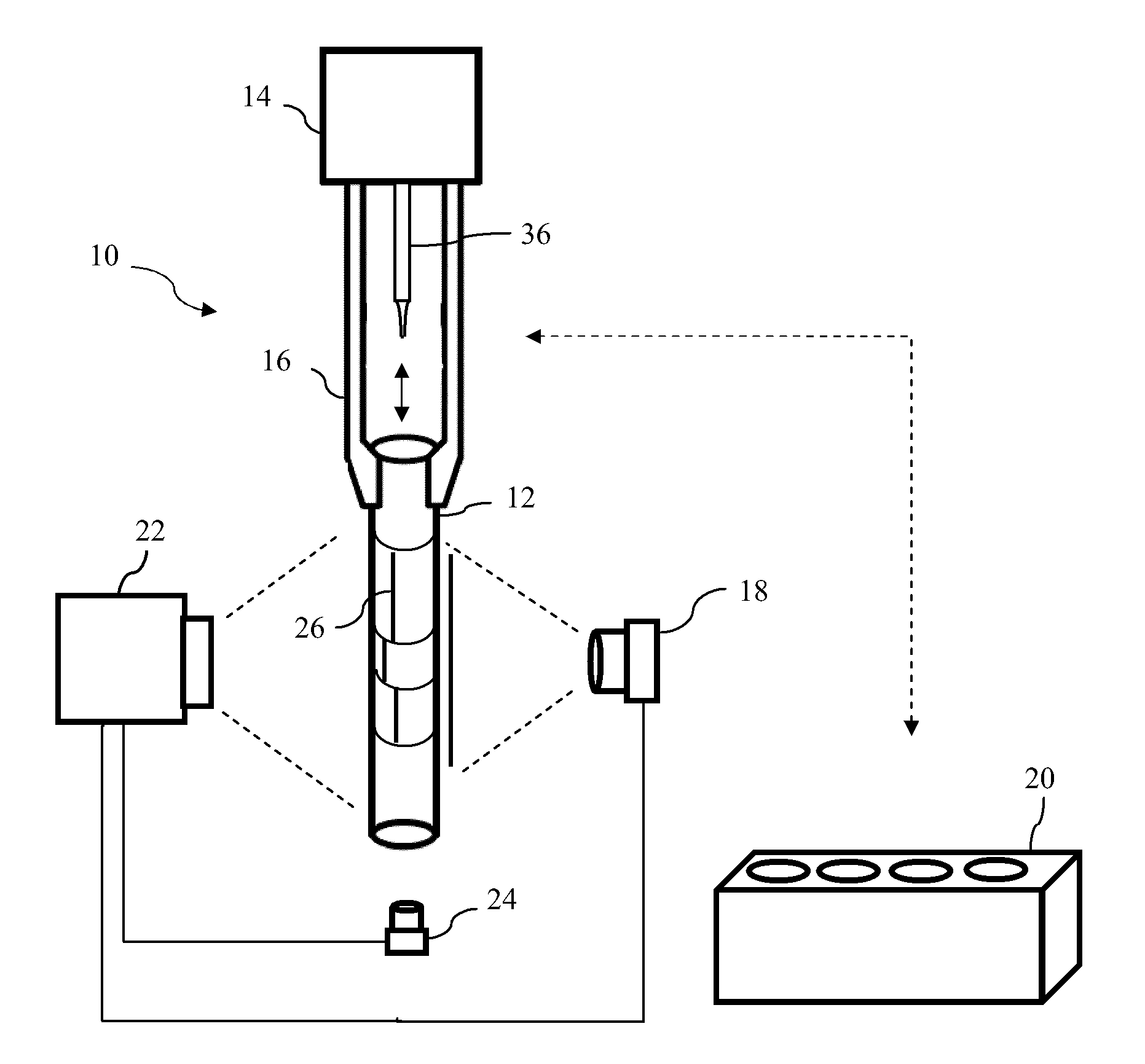

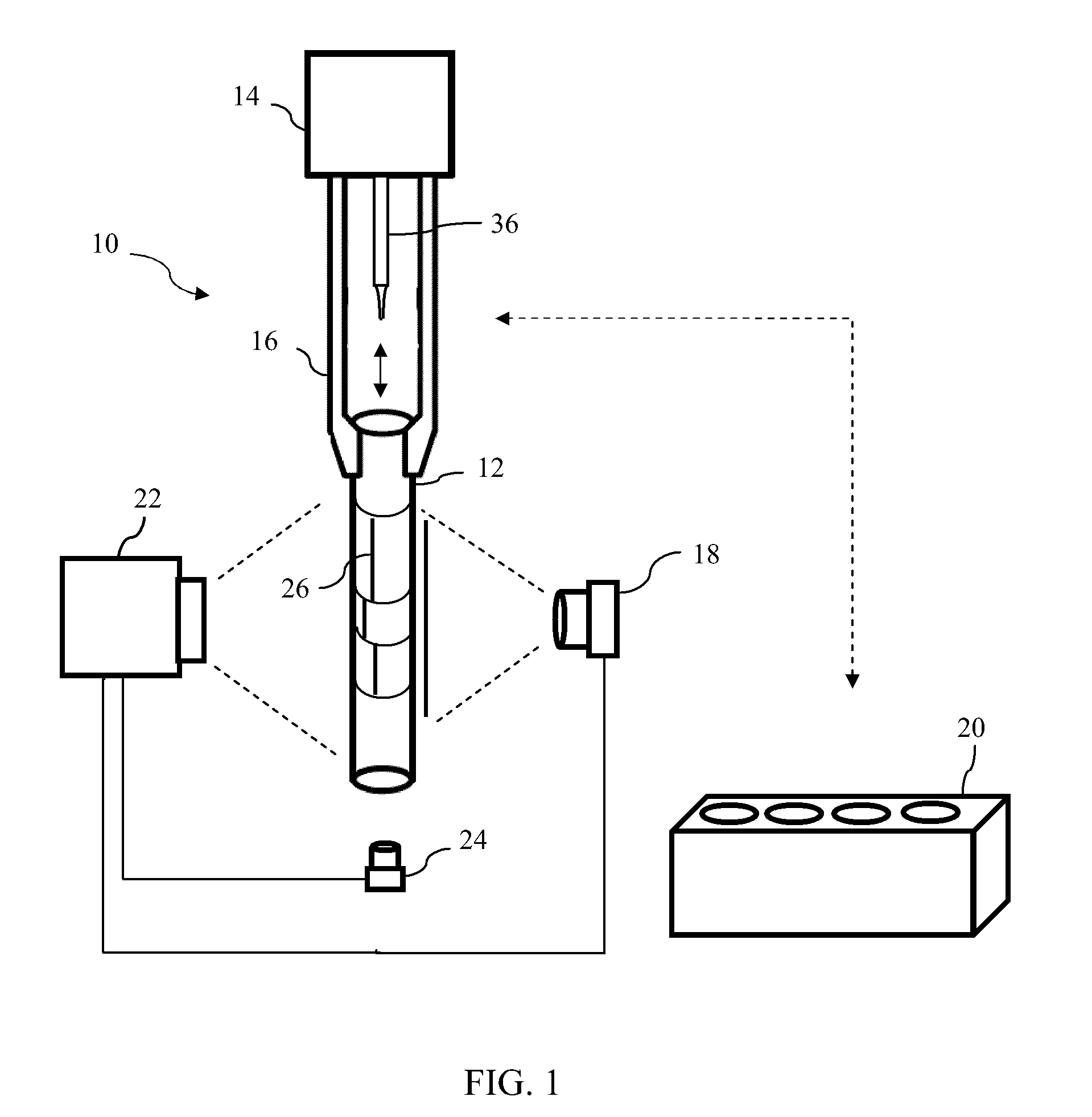

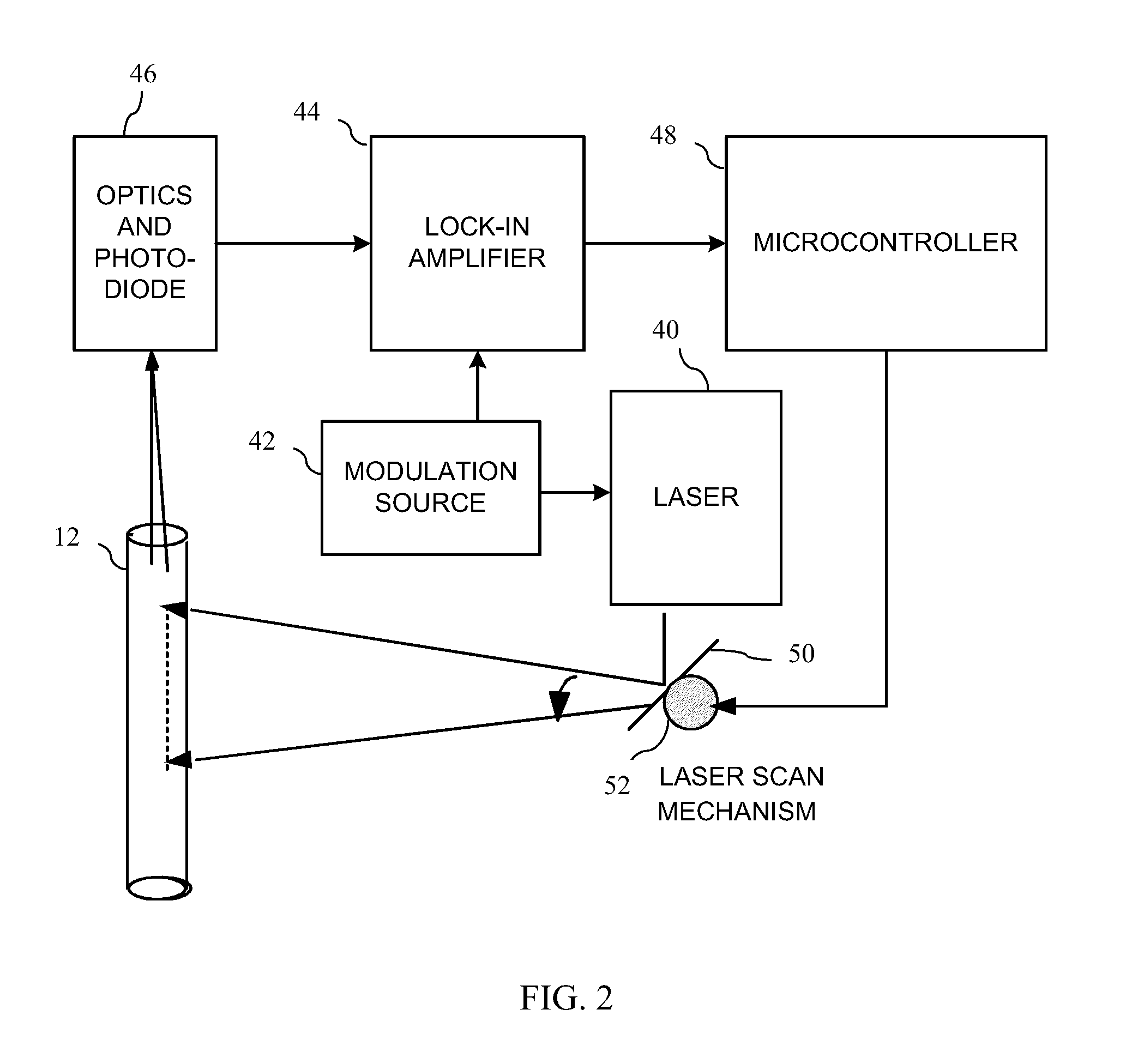

System and method for detection of liquid level in a vessel

ActiveUS20110056290A1Investigating moving fluids/granular solidsScattering properties measurementsMicrocontrollerOptical property

A system and method for identifying the levels of one or more liquids in a vessel using an optical imager and one or more appropriately positioned light sources and an optical imager for capturing digital images of the illuminated vessel. A laser line generator is positioned oppositely from the imager and oriented to project a laser line through the vessel so that it may be imaged by the imager. A second light source, such as an LED, may be positioned above or below the vessel and oriented to project light downwardly or upwardly through the vessel and its contents. Captured images of the vessel are then processed by a programmable device, such as a microcontroller, to determine the levels of materials in the vessel based on the optical characteristics revealed in the captured image.

Owner:NOVANTA CORP

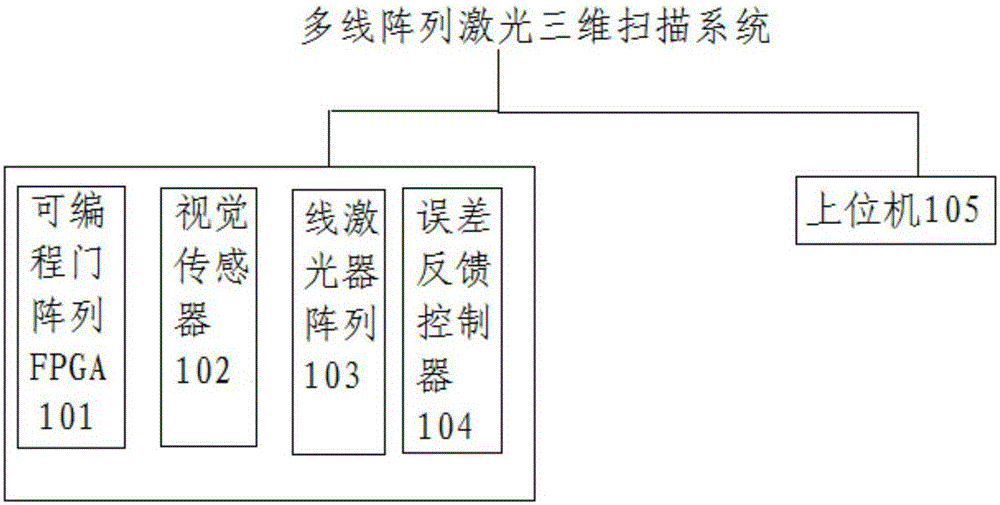

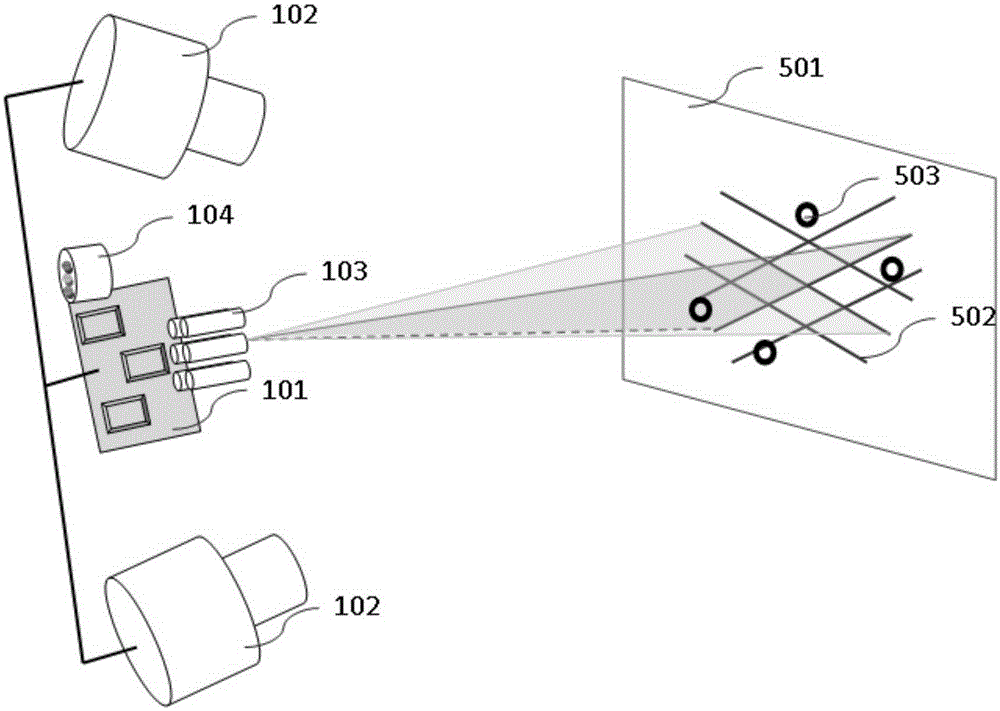

Multi-line array laser three-dimensional scanning system and method

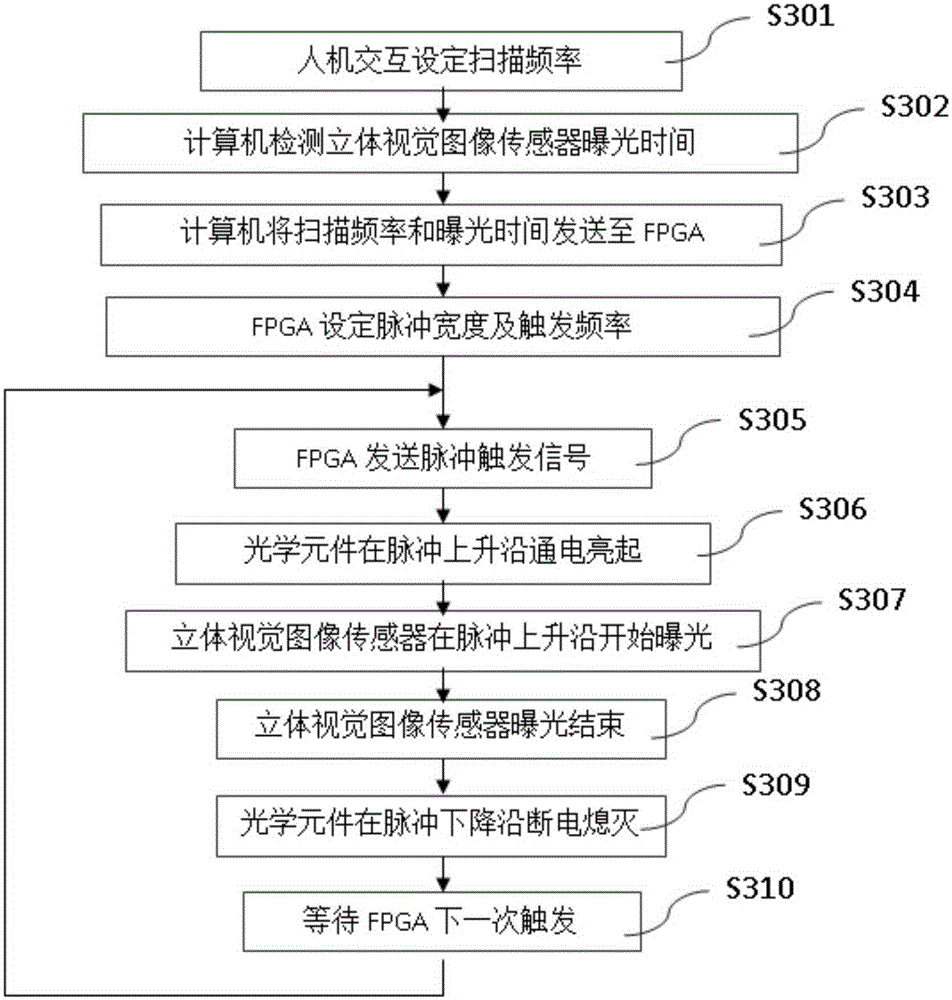

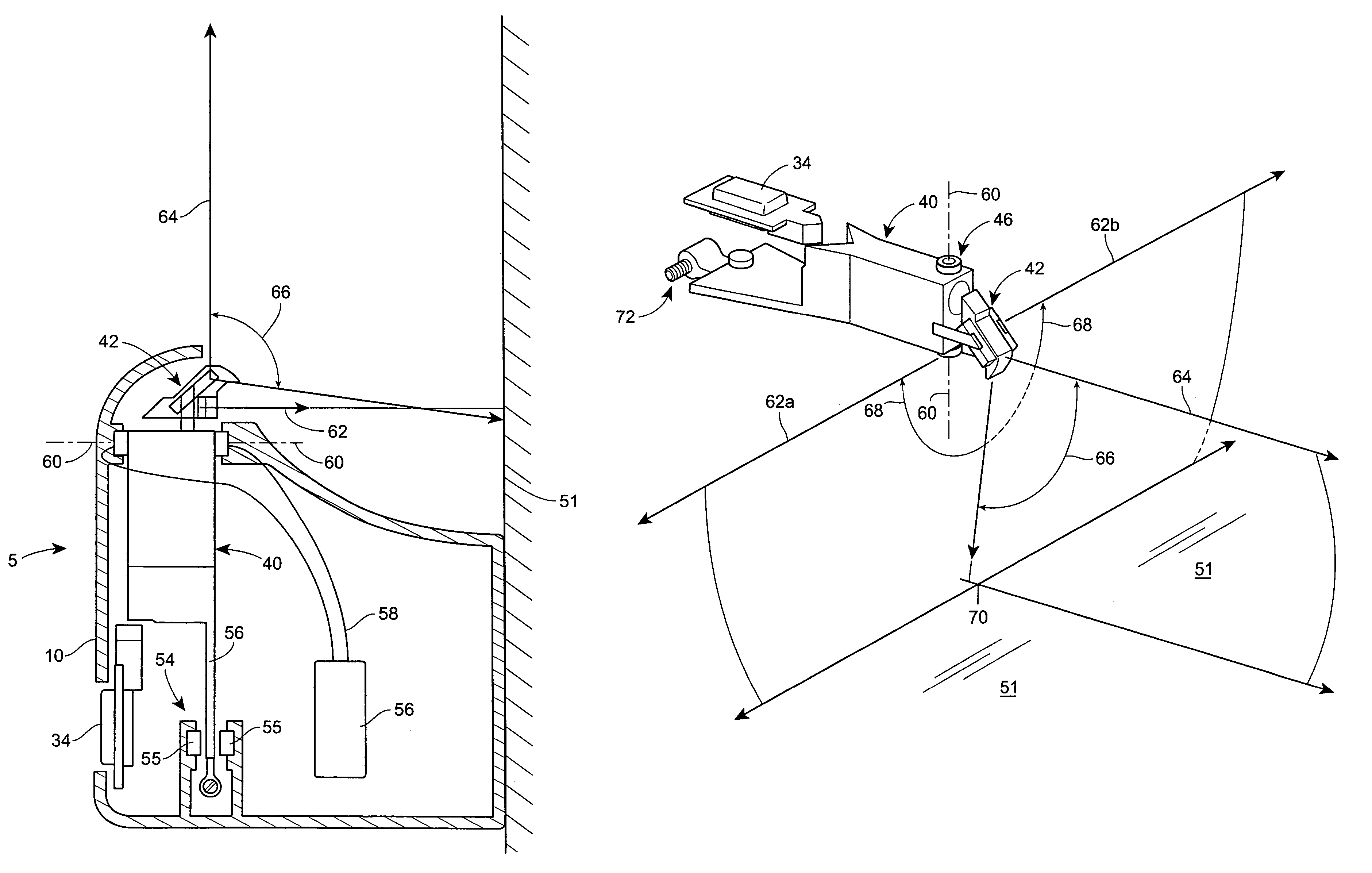

ActiveCN105203046ALow costImprove efficiencyUsing optical meansObservational errorFpga implementations

The invention provides a multi-line array laser three-dimensional scanning system and method. Accurate synchronism and logic control of the multi-line array laser three-dimensional scanning system can be achieved through an FPGA, a line laser unit array serves as a projection pattern light source, trigger signals are sent to a stereoscopic vision image sensor and the line laser unit array through the FPGA, an upper computer receives image pairs shot by the stereoscopic vision image sensor, laser line array patterns in the image pairs are subjected to encoding, decoding and three-dimensional reconstruction, three-dimensional reconstruction and matching alignment of three-dimensional feature points between different moments are conducted on surface feature points of an object to be measured, and matching calculation is subjected to prediction and error correction through an optical tracking technology. The system and method are used for registration and connection of time domain laser three-dimensional scanning data, meanwhile, measuring error grades are evaluated in real time and fed back to an error feedback controller for adjusting indication, and therefore laser three-dimensional scanning with low cost and high efficiency, reliability and accuracy is completed accordingly.

Owner:BEIJING TENYOUN 3D TECH CO LTD

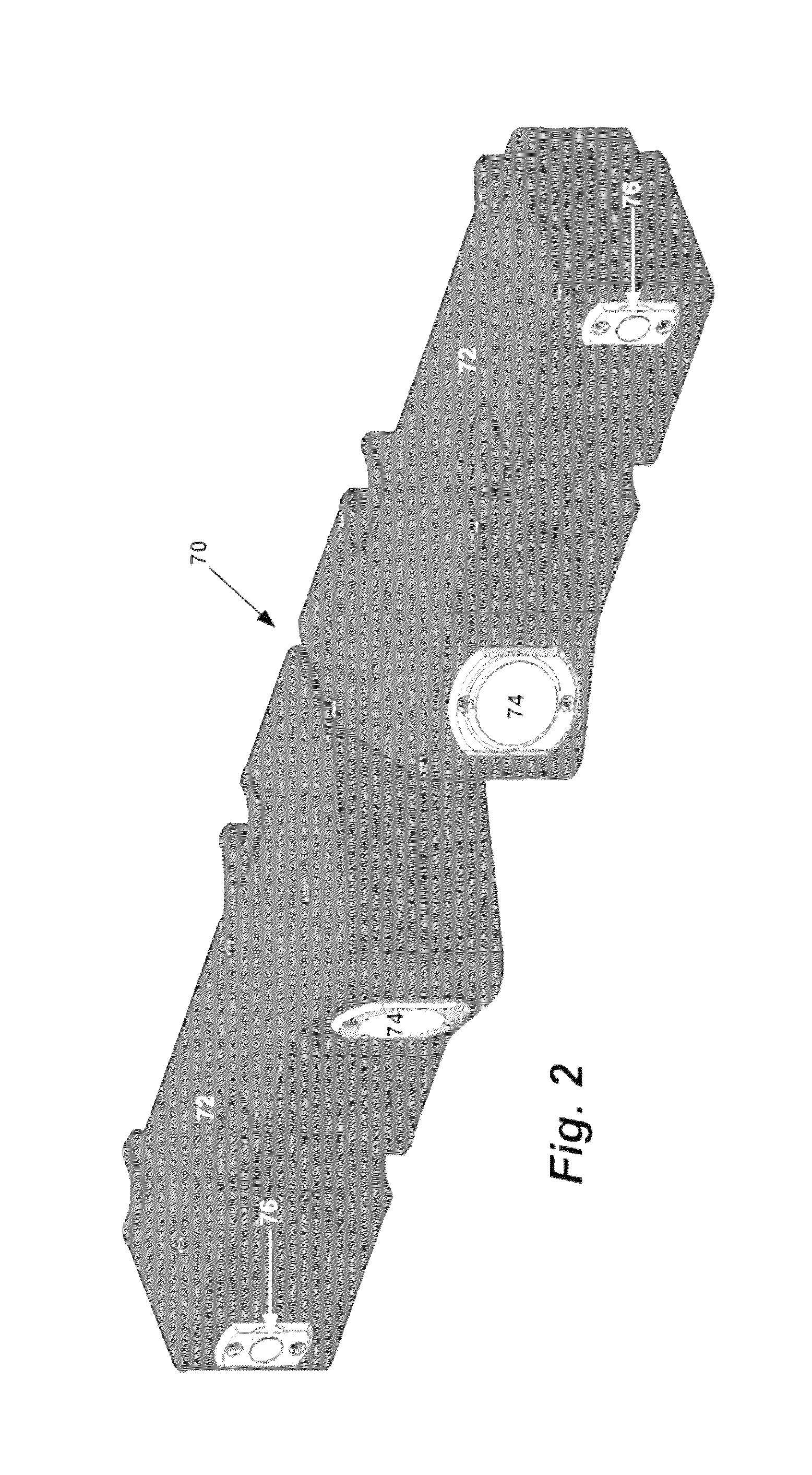

Intersecting laser line generating device

Owner:IRWIN IND TOOL CO

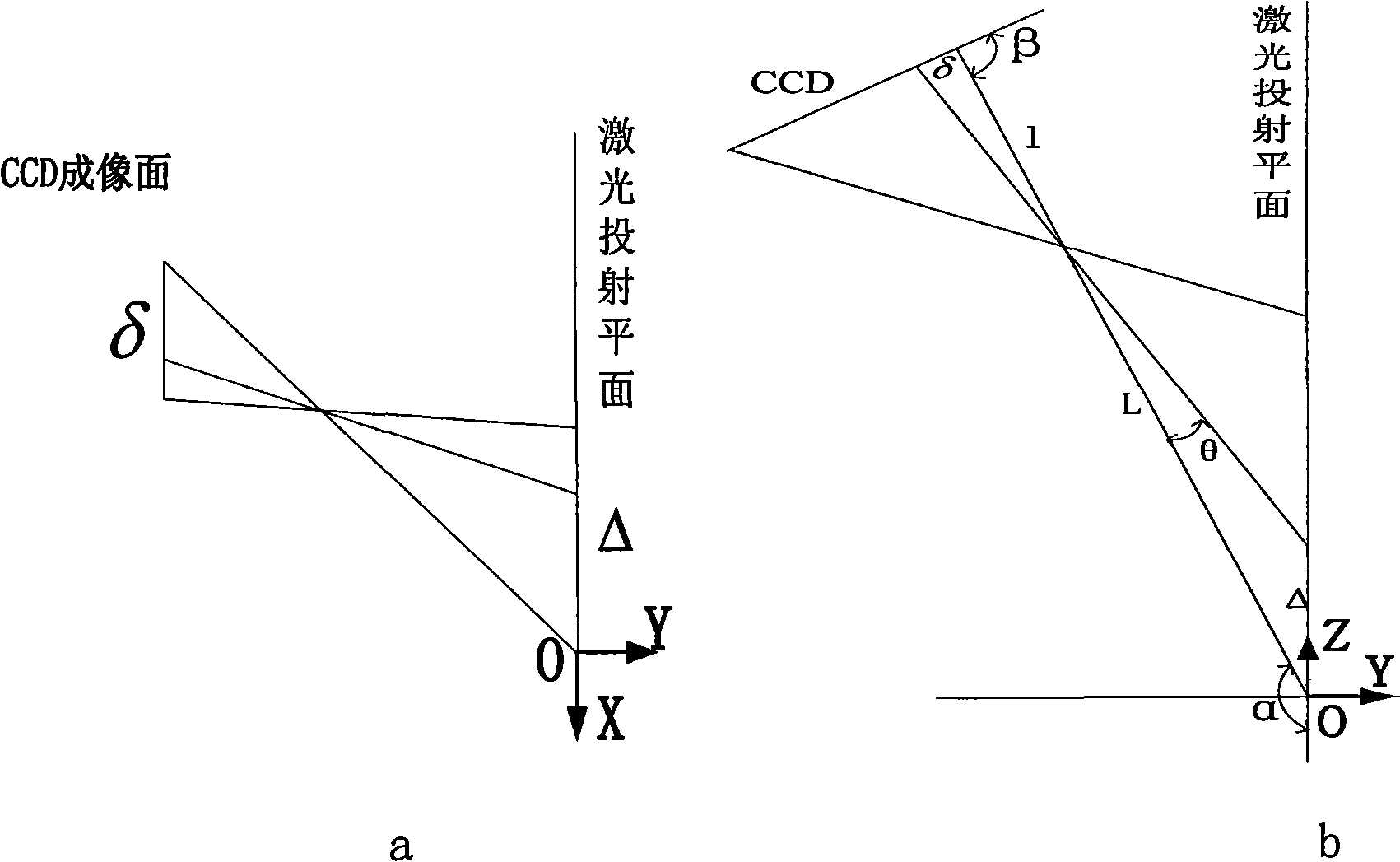

Laser line scanning feeler geometric transformation calibration and curved face interpolation correcting method and apparatus

The invention discloses a method for the geometric transformation calibration and the curved surface interpolation modification of a laser line scanning probe, and a device; the noncontact measurement technology is adopted to be used for the accurate calibration and further modification of the probe of a laser line scanning three-dimensional profile measuring system; the method carries out calculation on the basis of the basic measuring principle of a probe system and completely eliminates calibration theory errors brought by the traditional calibration method (such as a polyfit calculation method, etc.). In the detailed parameter calculating process, the statistical analysis technologies of curve analysis and least squares, etc., are adopted by the algorithm; therefore, the requirement of multiscale calibration caused by the related factors of lens distortion, probe assembly and adjustment error, etc. to different calibration areas is fully considered on the basis that the basic principle is fully met, thus leading the probe to have excellent stability and operability.

Owner:XI AN JIAOTONG UNIV

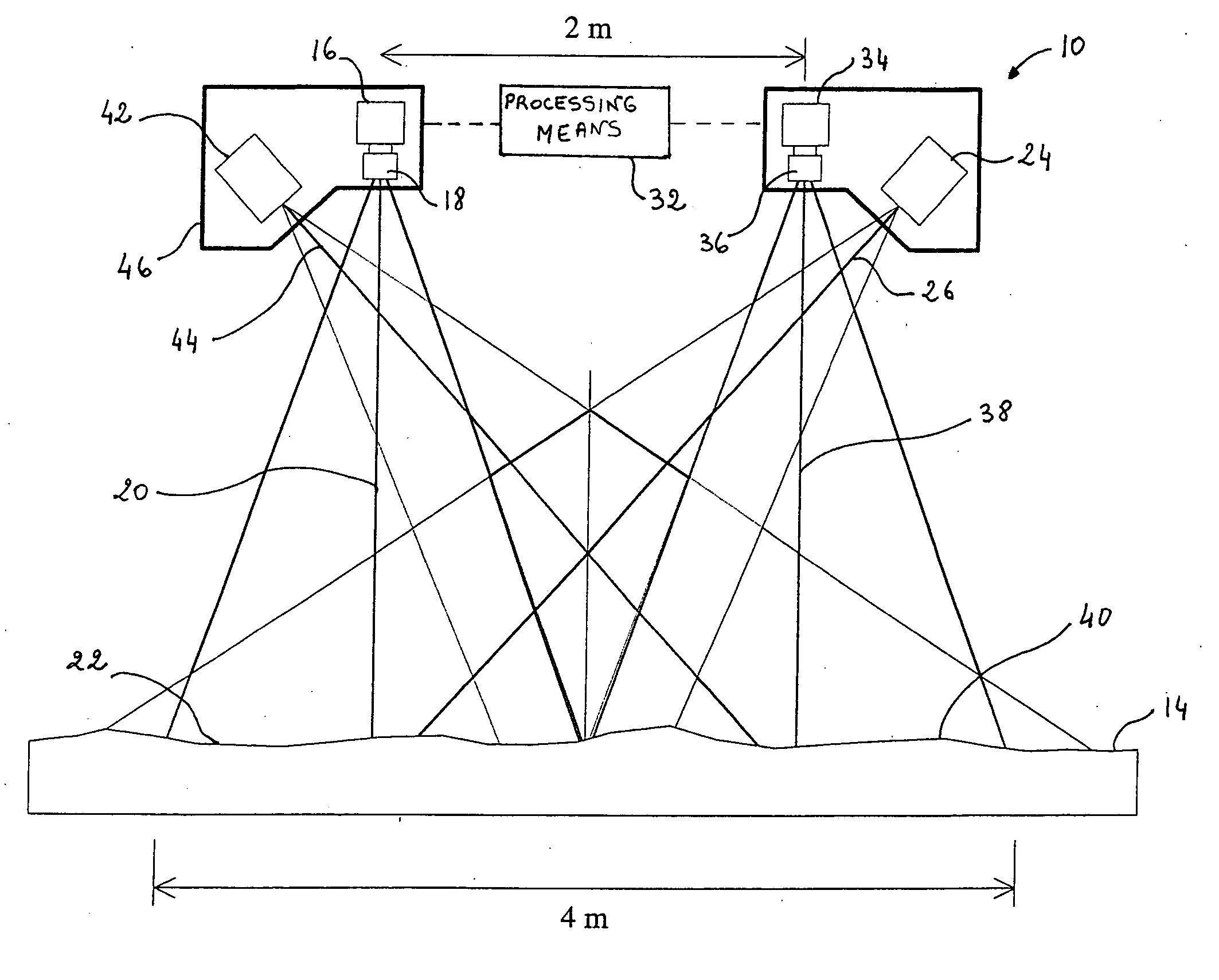

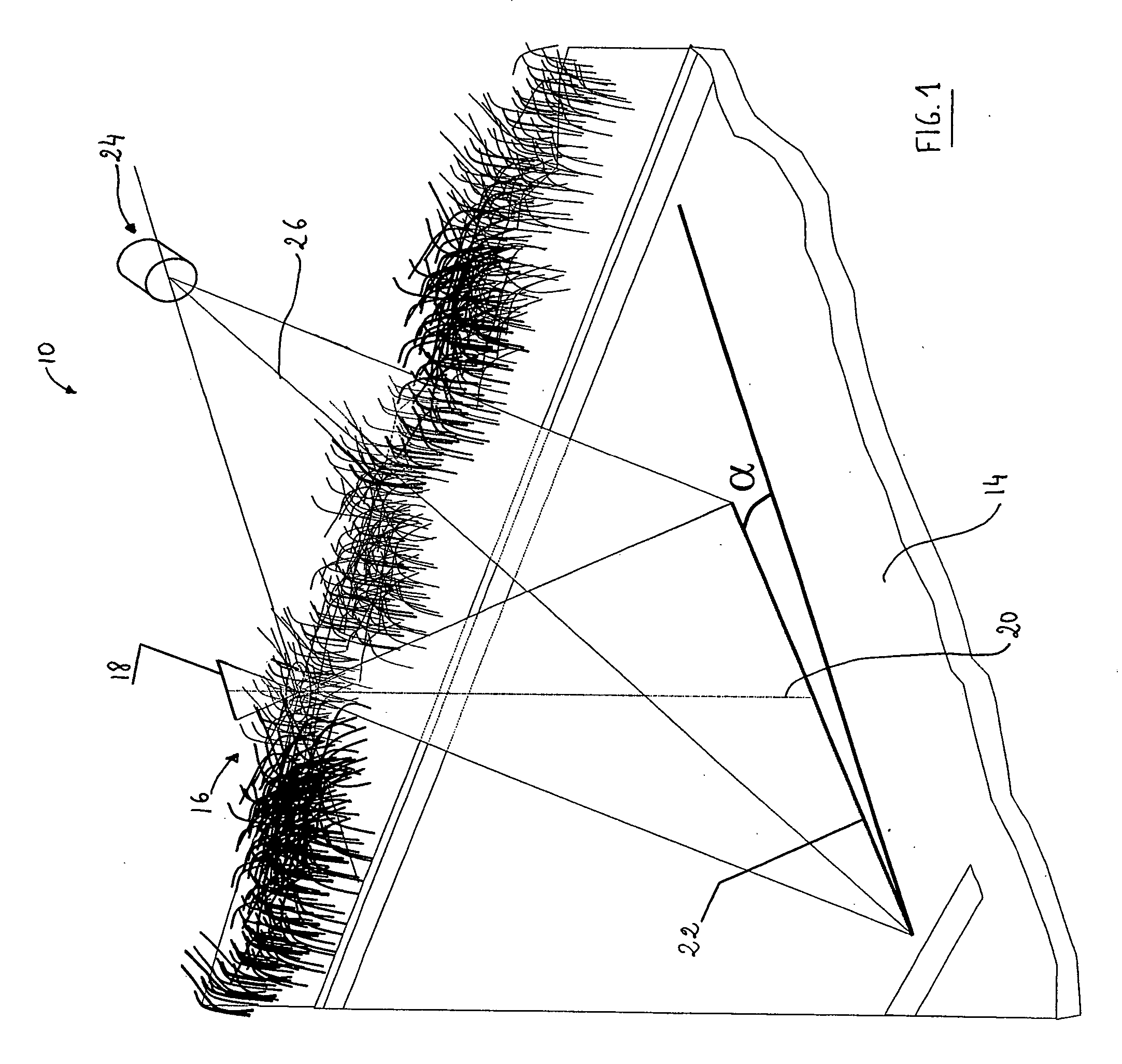

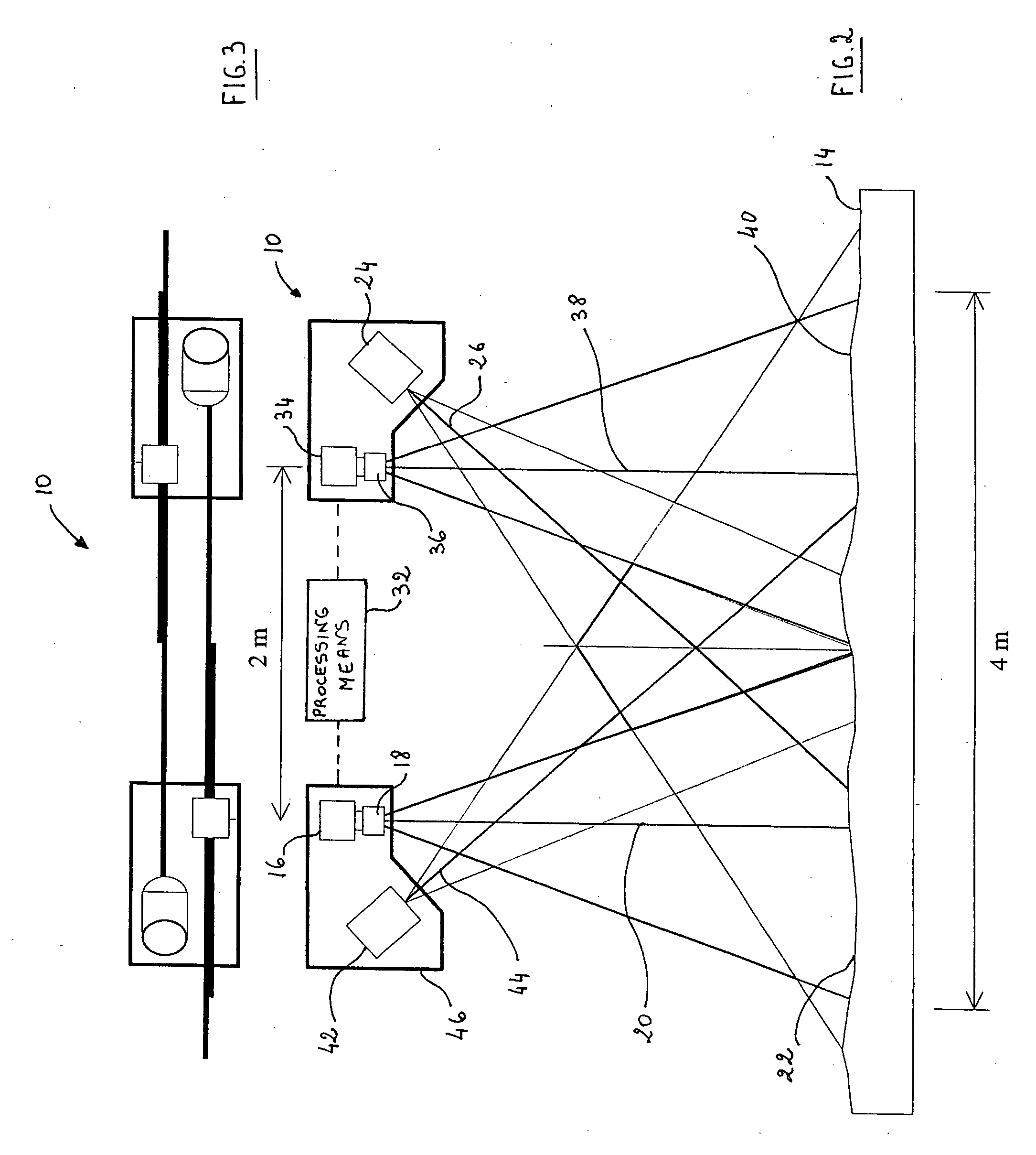

Vision system and a method for scanning a traveling surface to detect surface defects thereof

ActiveUS20060274930A1Material analysis by optical meansCharacter and pattern recognitionImage contrastEngineering

There is provided a vision system and a method for scanning a traveling surface such a road to detect surface defects thereof such as cracks. The vision system, which is mountable on a vehicle, is provided with a linear imaging system for imaging successive adjacent transversal linear portions of the traveling surface as the vehicle advances. The vision system is also provided with laser line projecting means angularly projecting a laser line onto the transversal linear portion of the traveling surface to be imaged in a substantially coplanar relationship with the linear imaging system. The present vision system is particularly devised to be immune to surrounding light conditions variations to provide optimum cracks image contrast for both transverse and longitudinal cracks.

Owner:INSTITUT NATIONAL D'OPTIQUE

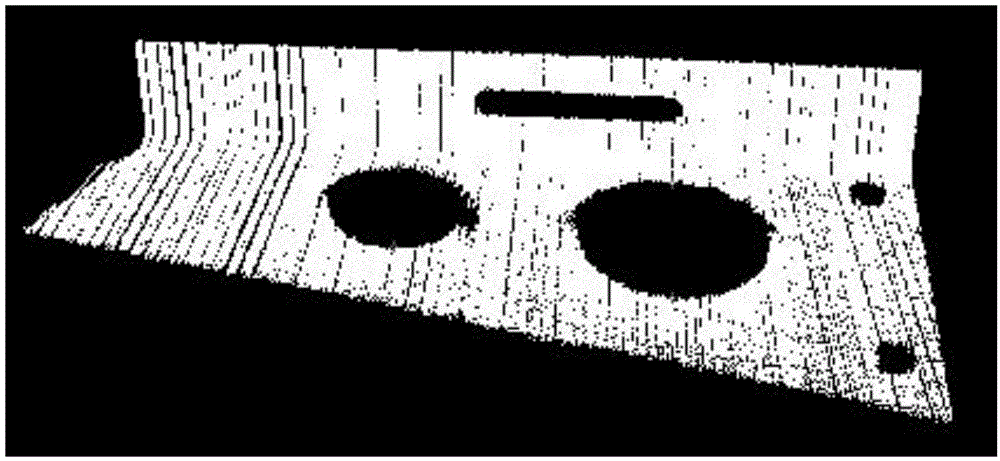

Three-dimensional object model reconstruction system and method based on laser images

InactiveCN103236076ASmall and convenientSimple structureImage analysis3D modellingPoint cloudMedicine

Disclosed is a three-dimensional object model reconstruction system and method based on laser images. The system comprises a computer, a single chip microcomputer, a stepping motor, a rotary cradle head, a laser device, a camera, a chessboard calibration plate and a three-legged support. The reconstruction process includes: according to a classical Zhang Zhengyou chessboard calibration method, acquiring calibrated images and generating camera parameters through a hardware system; and controlling the single chip microcomputer by the aid of software so as to control the stepping motor in real time, enabling the surface of a target object to be scanned by laser rays by 360 degrees, performing real-time shooting by the camera to obtain a target image, importing the target image into the computer to be used for selective acquisition of point cloud, obtaining a spatial three-dimensional coordinate of the point cloud by the aid of a laser triangulation measurement method, and reconstructing a three-dimensional model of the target object.

Owner:WUHAN UNIV

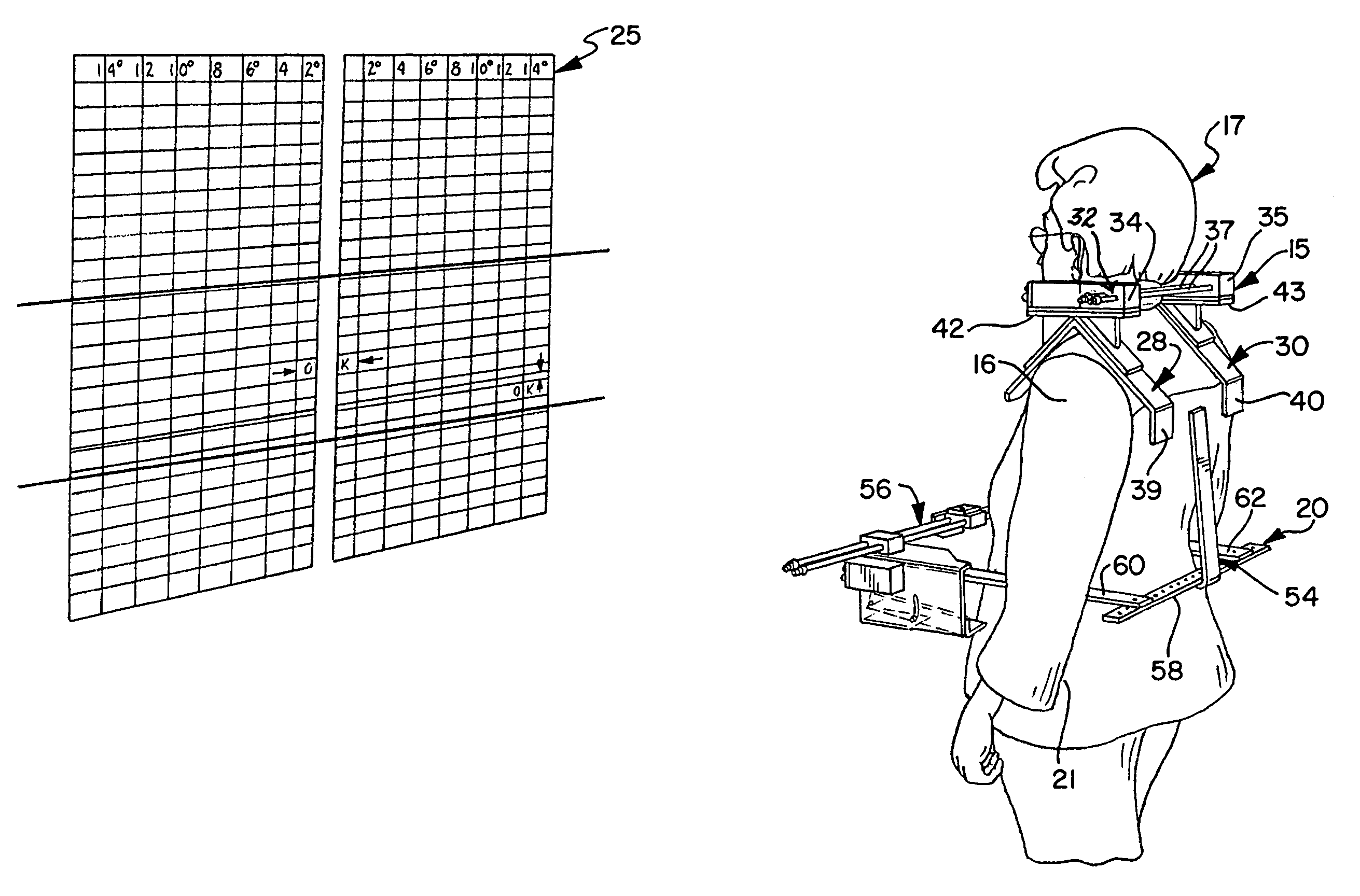

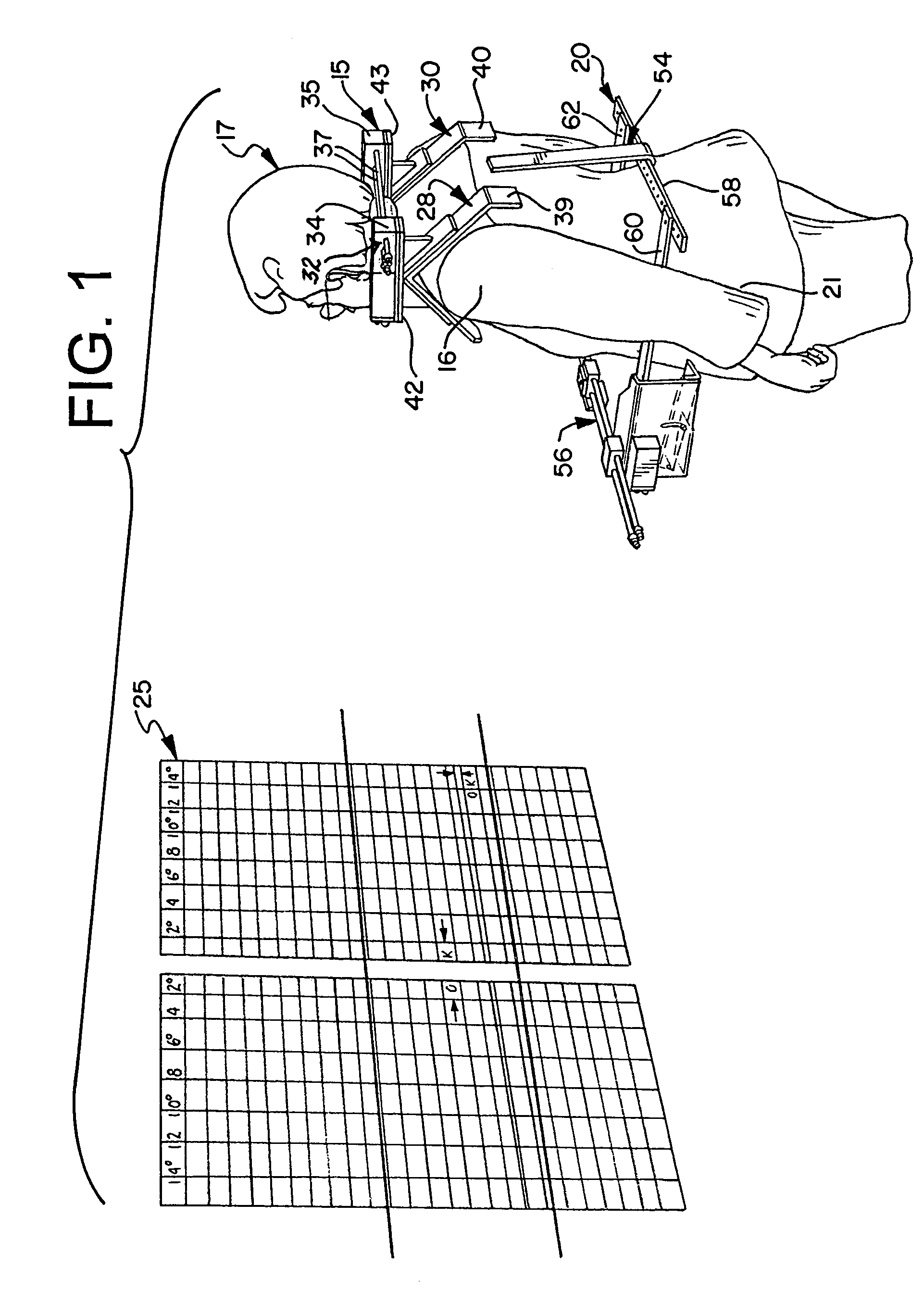

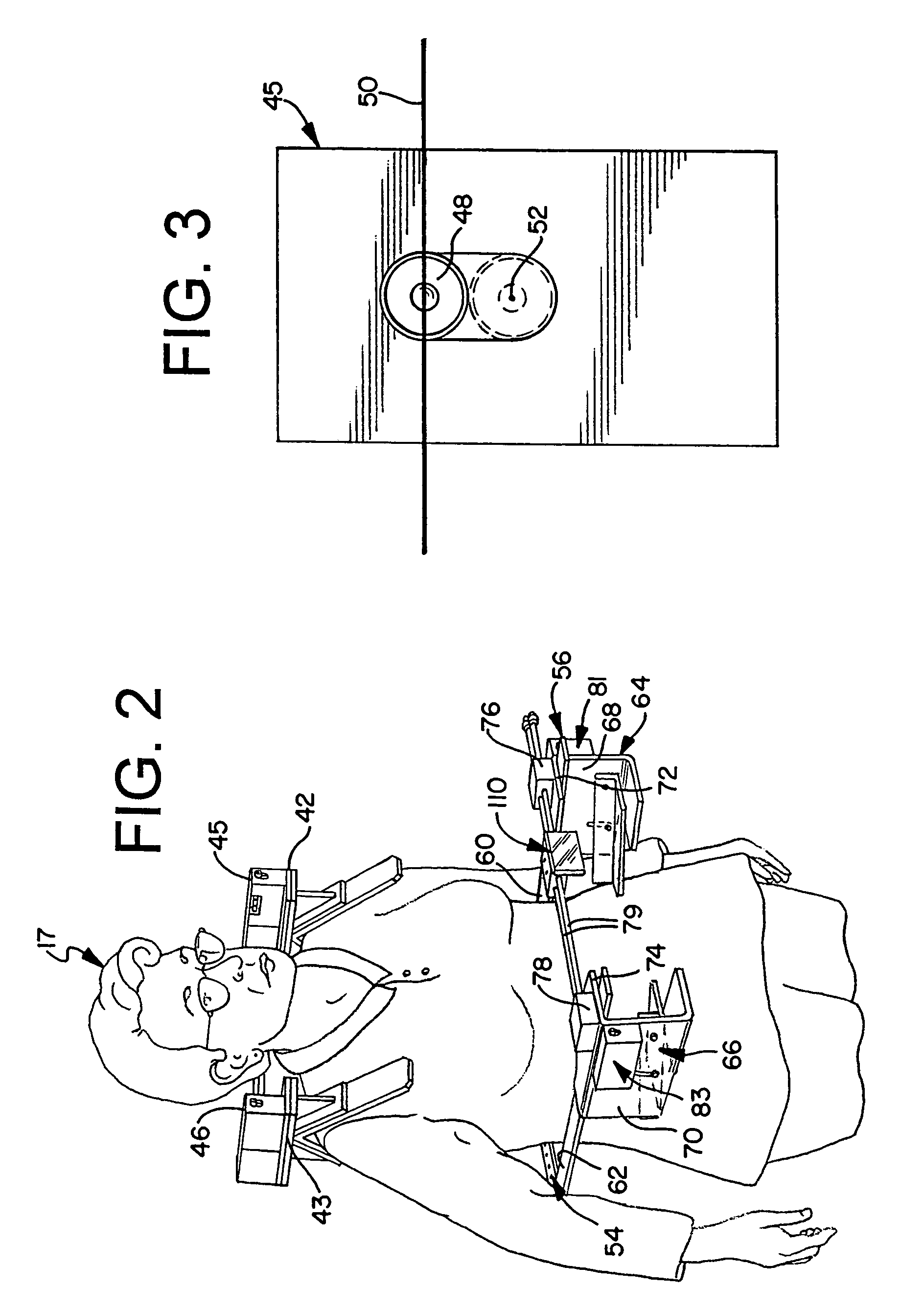

Method and apparatus for measuring spinal distortions

InactiveUS7131952B1Accurately and inexpensively overcomesReduce usageMeasurement devicesSurgeryProtractorPelvic girdle

A method and apparatus for measuring the spinal distortions of a person with laser sources prior to and after chiropractic treatment of a patient to differentiate between spinal distortions prior to and subsequent to any treatment. The apparatus includes a wall chart having measurement indicia, shoulder and / or pelvic girdle harnesses or frames mounted on a patient and each having means for projecting laser line and / or dot beams onto the wall chart for measuring spinal tilt and torque. A unique protractor is provided to coact with the wall chart and the laser line beam to measure spinal tilt. A laser source for projecting a vertical line beam measures abnormalities in posture by projecting the beam to a side of a patient.

Owner:DICKHOLTZ SR MARSHALL +1

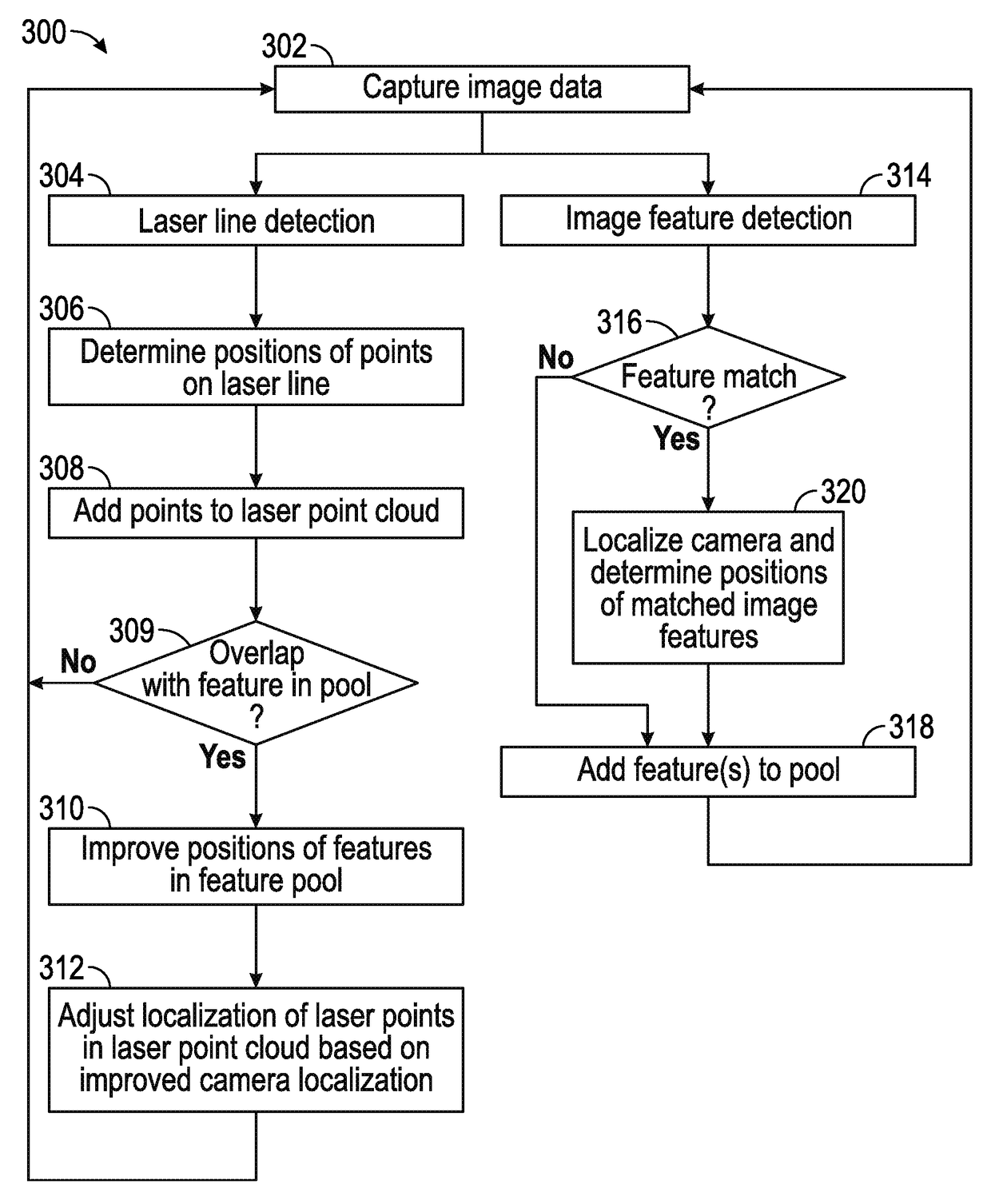

Laser-enhanced visual simultaneous localization and mapping (SLAM) for mobile devices

InactiveUS20170374342A1Improve accuracyImprove robustnessImage analysisUsing optical meansSimultaneous localization and mappingMobile device

Laser-enhanced visual simultaneous localization and mapping (SLAM) is disclosed. A laser line is generated, the laser line being incident on an object and / or environment. While the laser line is incident on the object, one or more images of the object with the laser line incident on the object are captured. The camera is localized based on one or more characteristics of the laser line incident on the object. In some examples, improved feature localization provided by the laser line provides more accurate camera localization, which, in turn, improves the accuracy of the stitched mesh of the object / environment. As such, the examples of the disclosure provide for improved camera localization and improved three-dimensional mapping.

Owner:ISEE INC

Online detecting method and device for hot rolling strip surface fault based on laser line light source

InactiveCN1900701AImprove spotlight effectGood monochromaticityOptically investigating flaws/contaminationLaser lightGreen laser

Using laser line in high brightness emitted from linear light source of green laser in great power irradiates surface of hot rolling strip steel. Linear array CCD camera collects laser light reflected from surface of strip steel online so as to obtain image on surface of strip steel. Based on different properties of light reflectivity between defect area and no defect area on surface of strip steel, the invention carries out process and analysis for image on surface of strip steel collected by camera, so as to determine whether there are defects on surface of strip steel and sort the defects. The invention does not need of unpacking roller, installing baffle, uses fewer light sources so as to lower cost of hardware, and maintenance cost. Since laser light possesses good condensation performance and monochromaticity, images on surface of strip steel collected by camera are in good quality. Thus, tiny defect can be detected.

Owner:UNIV OF SCI & TECH BEIJING

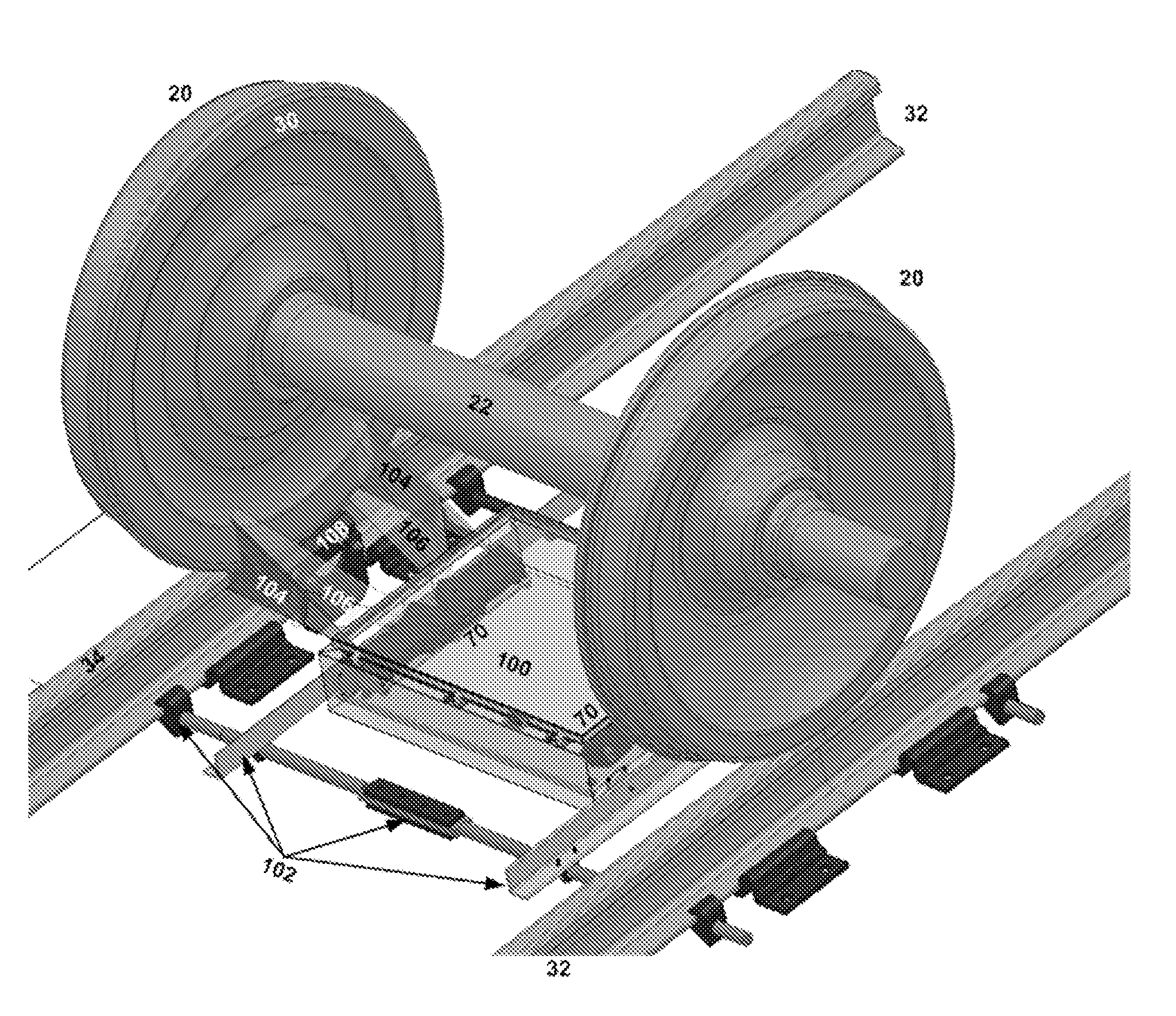

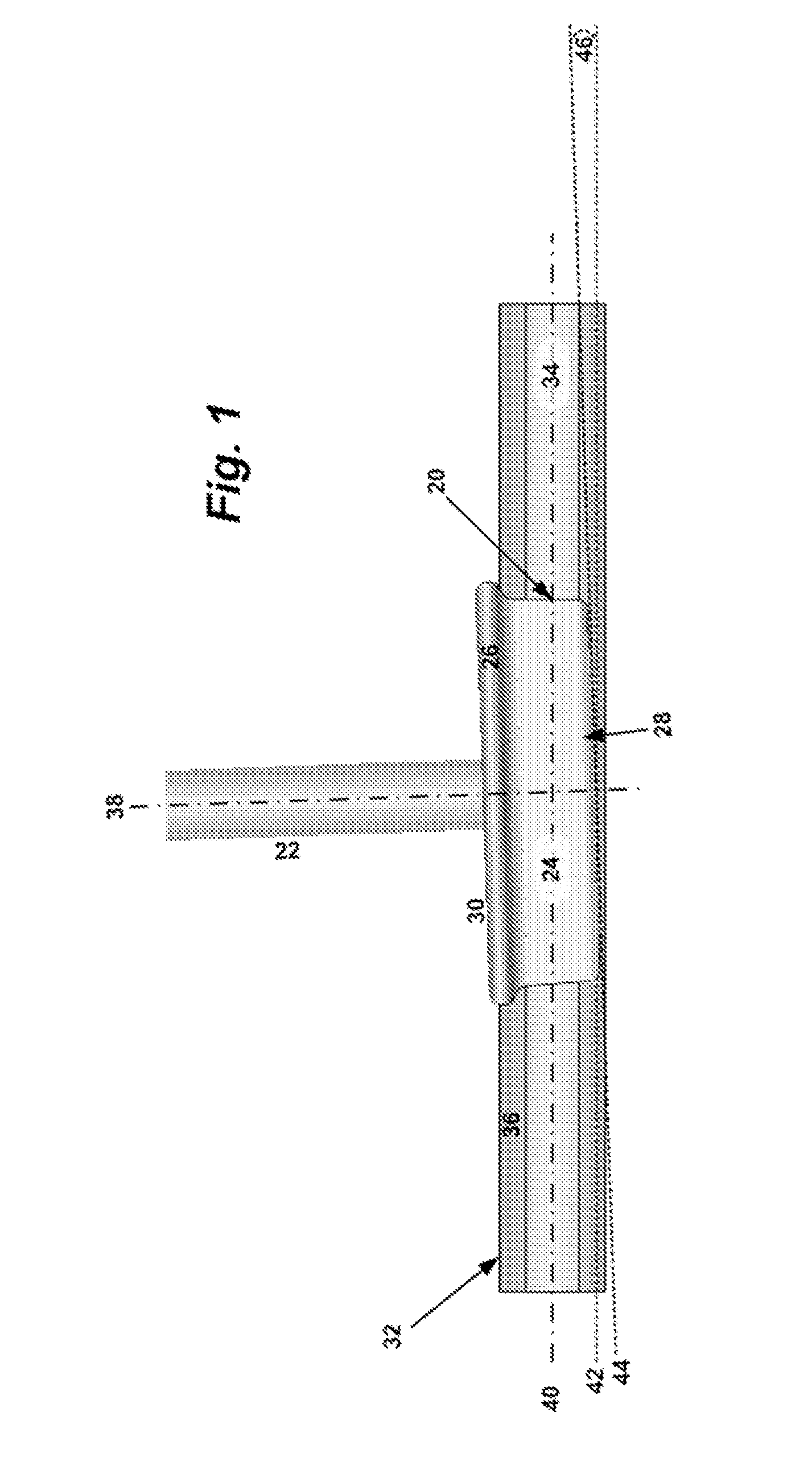

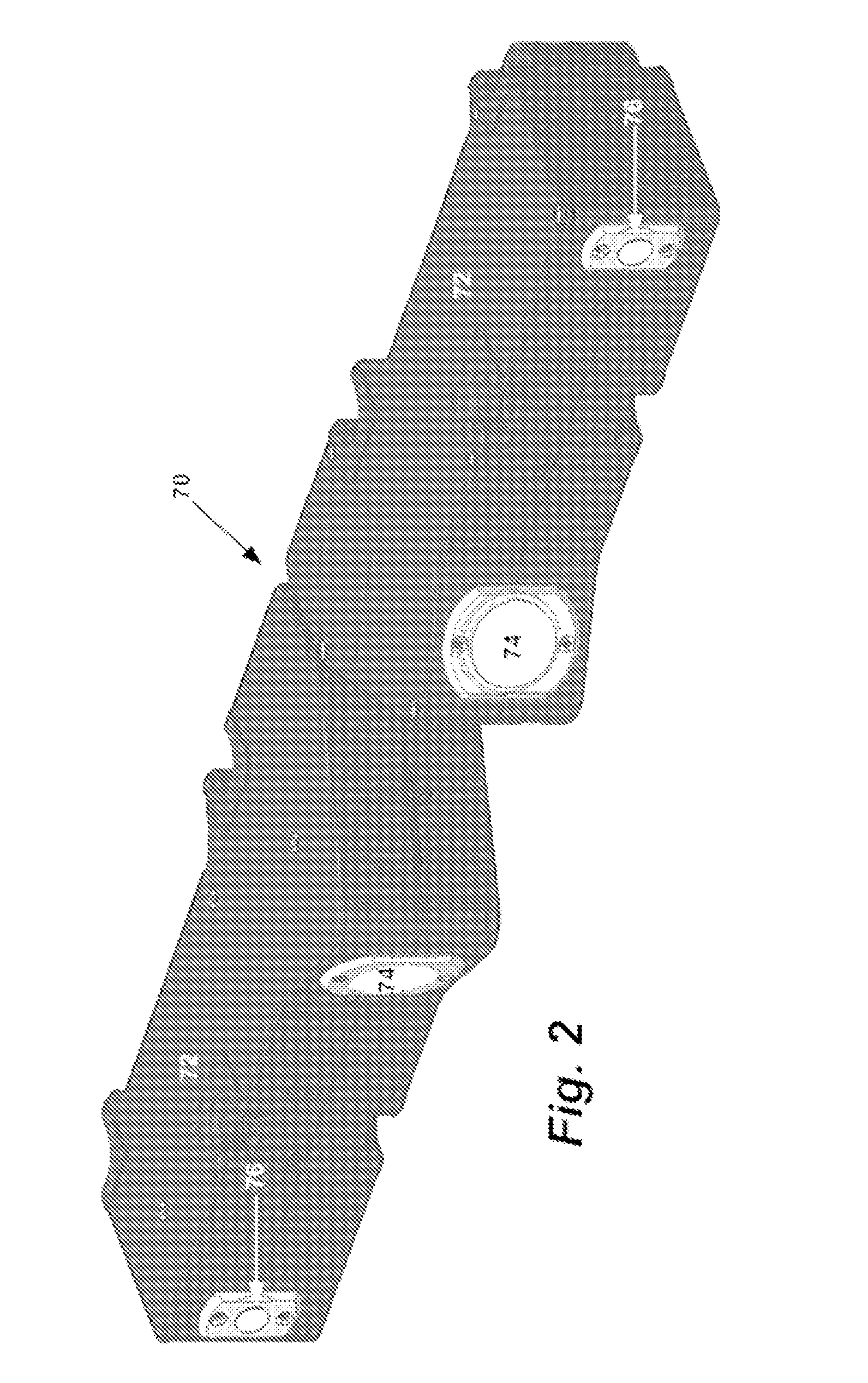

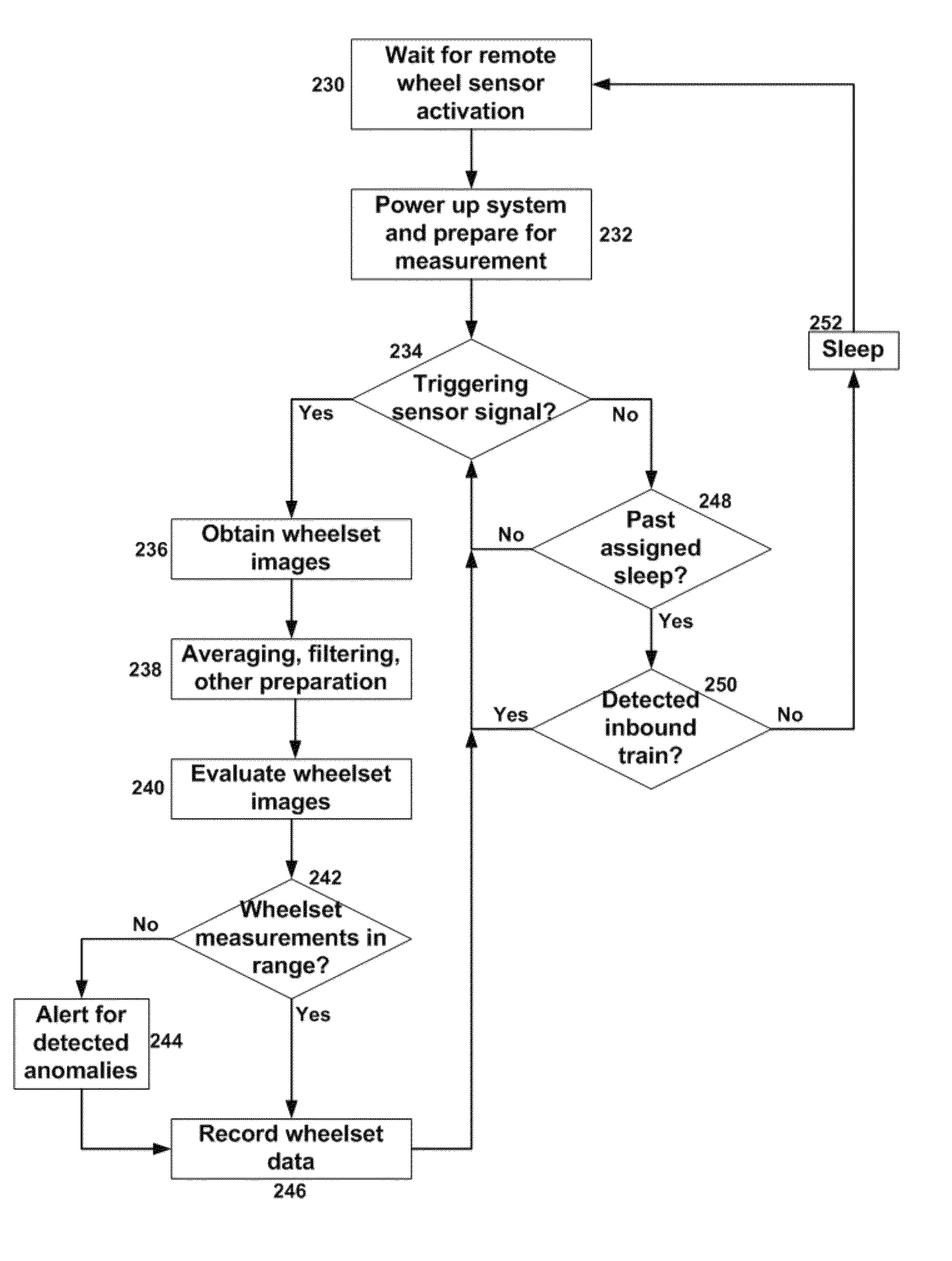

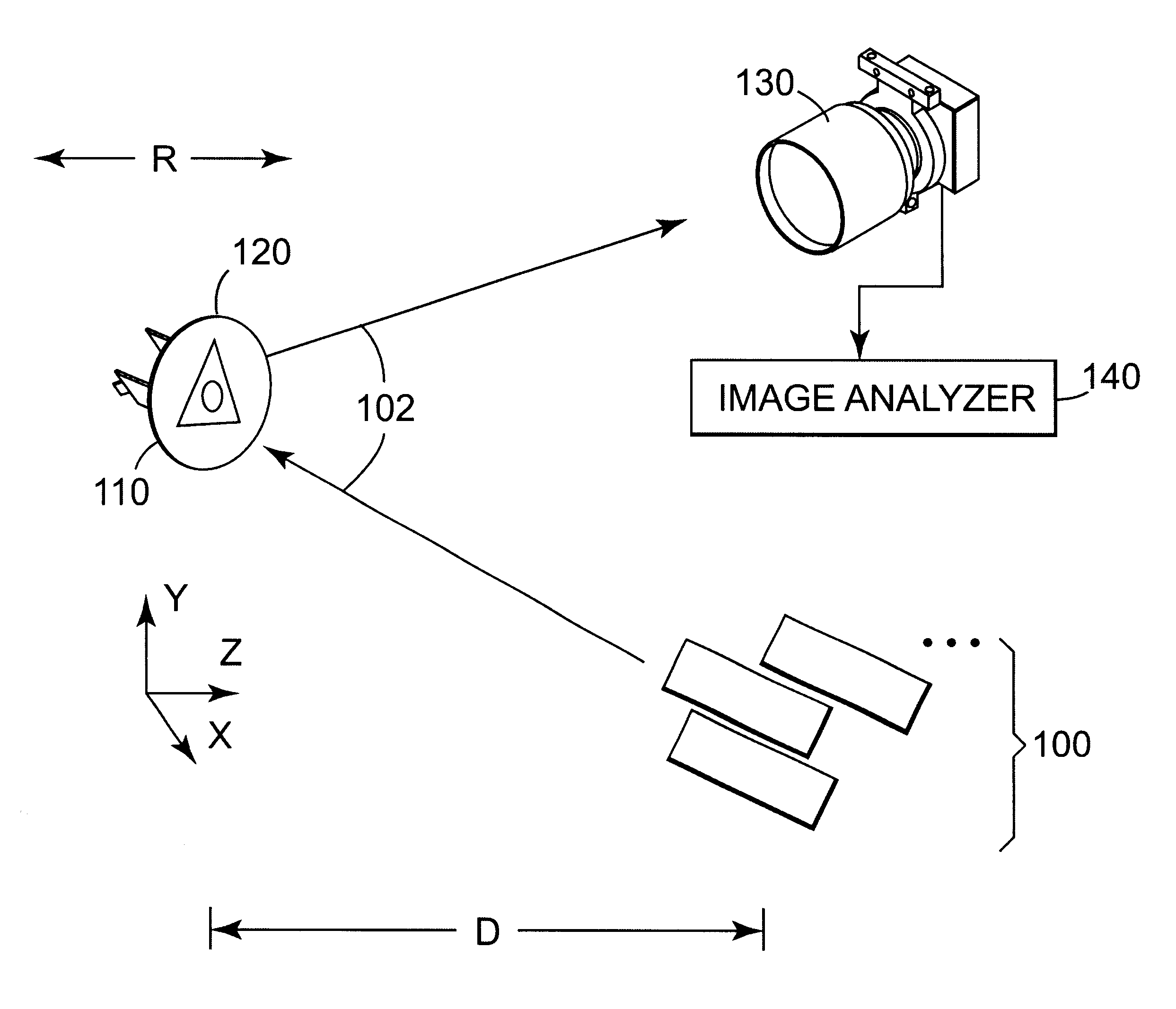

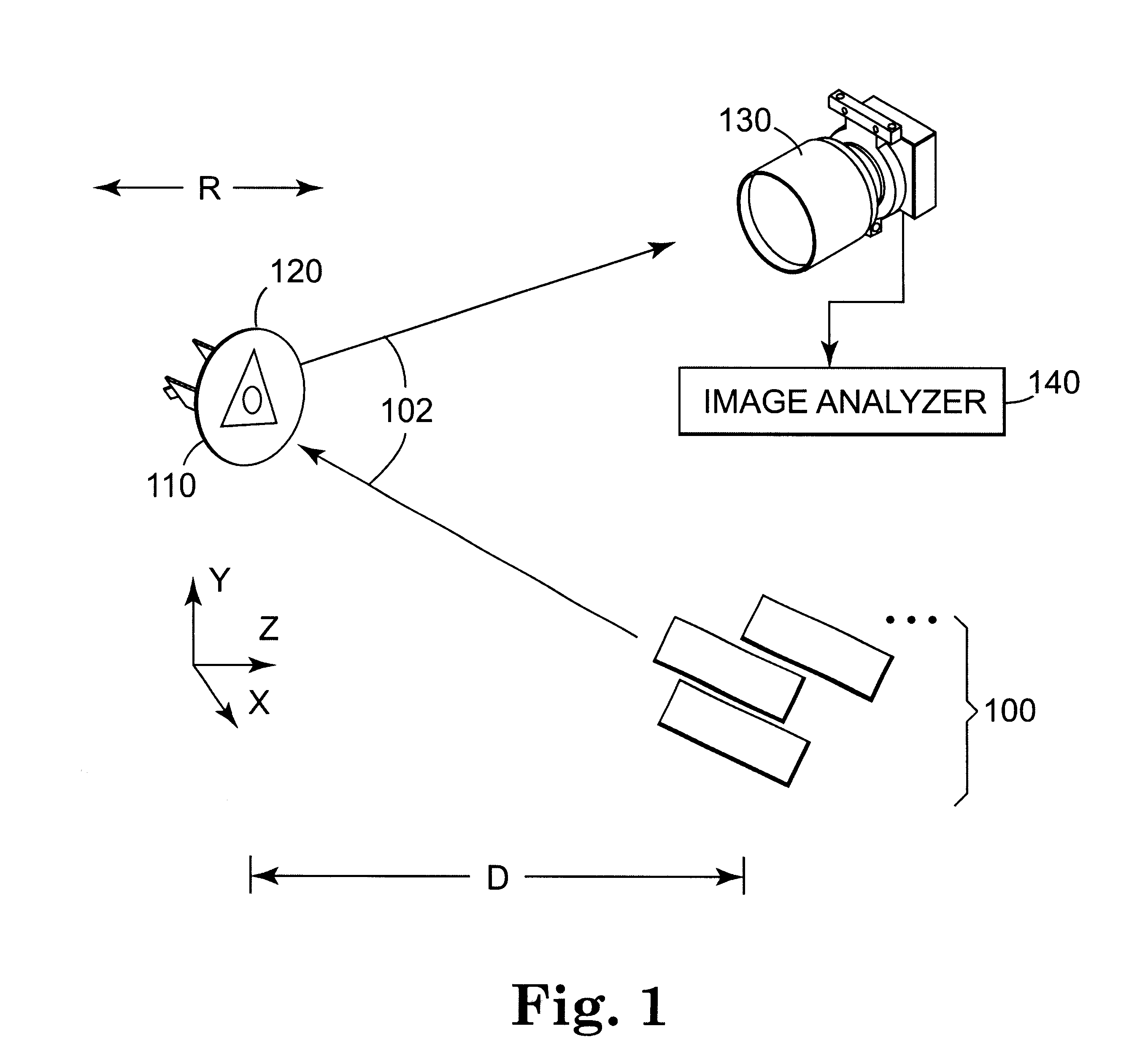

Wayside Measurement of Railcar Wheel to Rail Geometry

ActiveUS20130313372A1Eliminate errorsReduce needWheel-rims surveying/measuringRailway profile gaugesTriangulationTrackway

Considerable damage to rails, wheels, and trucks can result from geometric anomalies in the wheelsets, rails, and truck hardware. A solution for identifying and quantifying geometric anomalies known to influence the service life of the rolling stock or the ride comfort for the case of passenger service is described. The solution comprises an optical system, which can be configured to accurately perform measurements at mainline speeds (e.g., greater than 100 mph). The optical system includes laser line projectors and imaging cameras and can utilize structured light triangulation.

Owner:INT ELECTRONICS MACHINES

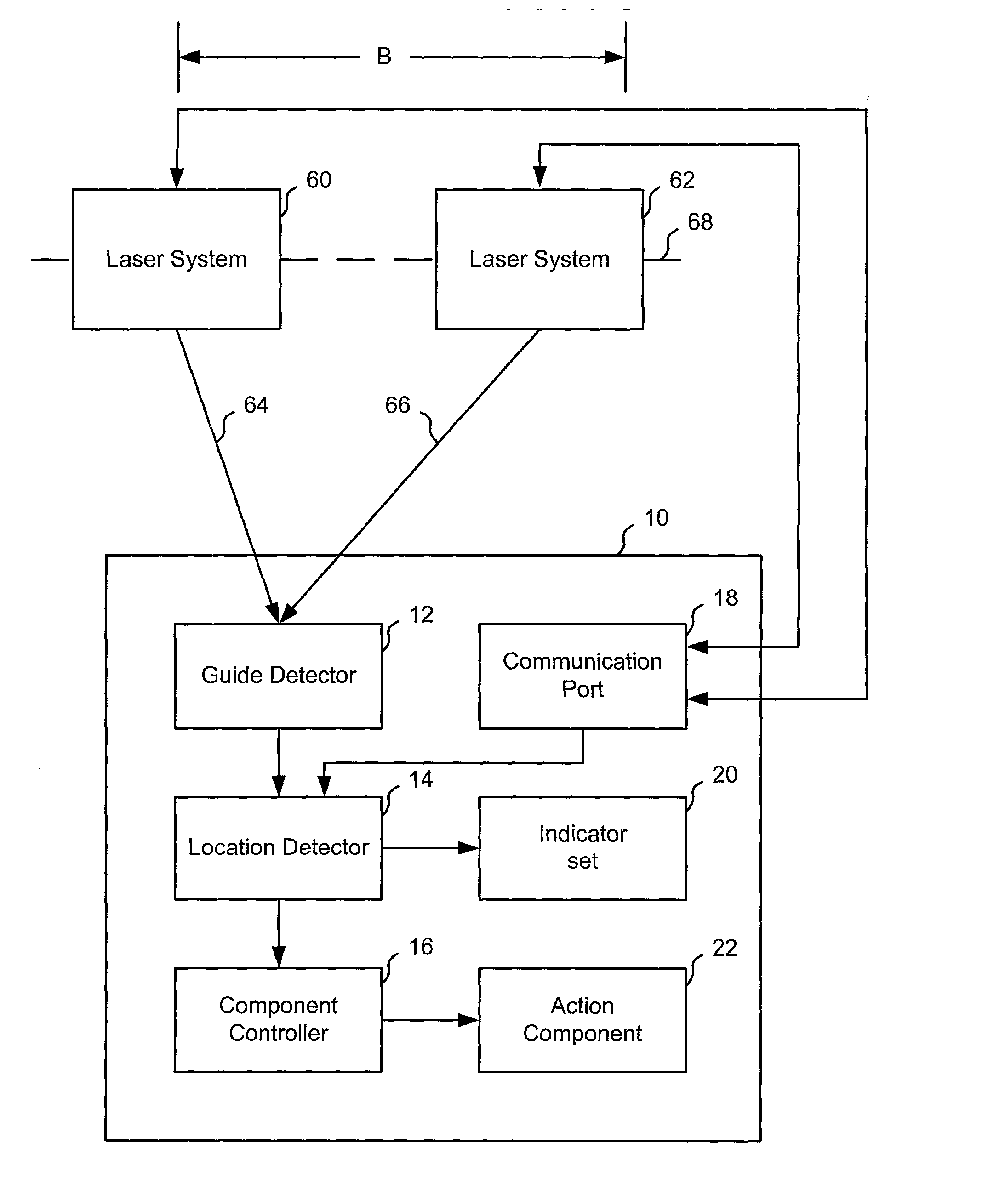

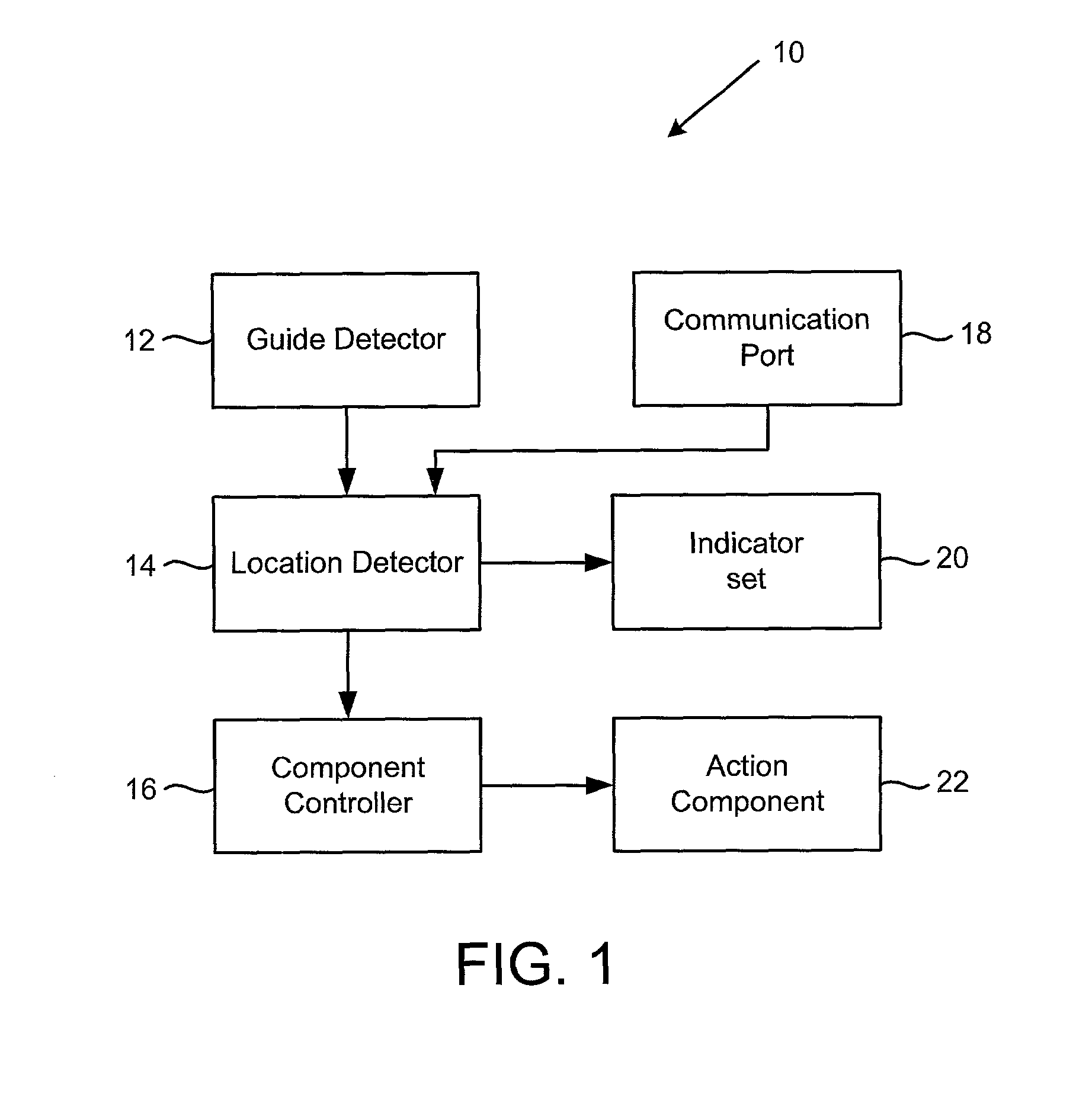

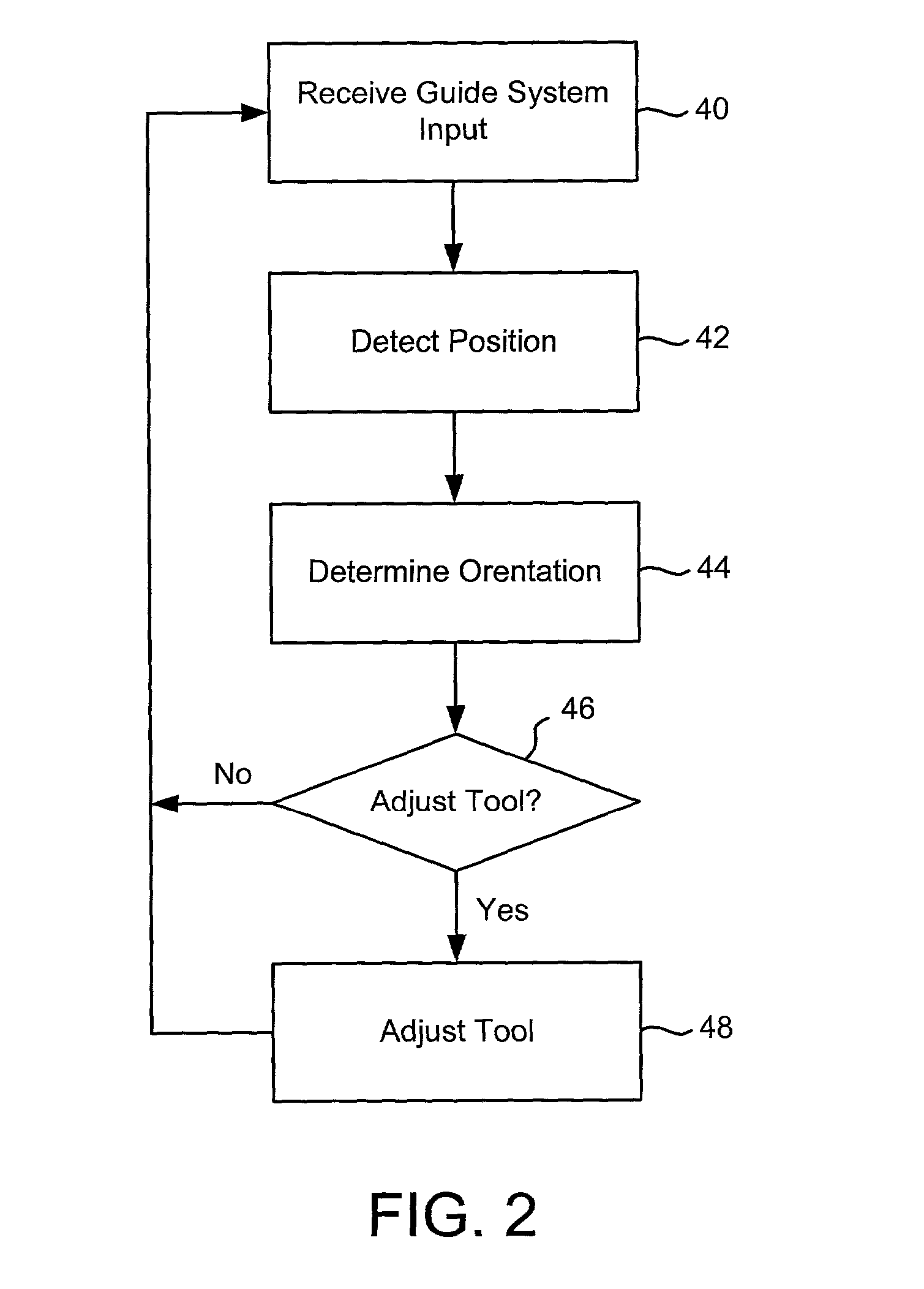

Detecting tool orientation, alignment, depth, and leveling

A tool is employed in conjunction with alignment, depth, and level detectors. The tool can use all or some of these detectors. The alignment detector provides an orthogonal laser line grid on an incident surface when the detector has a predefined relationship with the surface. The depth detector emits two sets of parallel laser planes that converge with each other. When the laser planes impact on an incident surface two sets of lines are formed. The laser lines from one laser plane set move closer to the lines from the other laser plane set as the depth detector moves closer to the surface-showing changes in depth or distance. The level detector employs two converging laser planes. An operator positions the level detector above an incident surface, so the laser planes' line of intersection appears on the surface if the surface is level. If the surface is not level, lines separate from each laser plane appear on the surface-signaling the need for a level adjustment. Some versions of the tool have the ability to detect their own orientation and make adjustments based on the orientation. Example tools include nail guns, jigsaws, circular saws, routers, and drills.

Owner:ROBERT BOSCH CO LTD

Wayside measurement of railcar wheel to rail geometry

ActiveUS8925873B2Reduce needReduce impactOptical rangefindersWheel-rims surveying/measuringTriangulationTrackway

Owner:INT ELECTRONICS MACHINES

Range measurement system

InactiveUS6392744B1The relationship is accurateReduce the impactOptical rangefindersReflex reflectorsGraphicsObject based

A system and method for accurate measurement of distance and location of an object. The system comprises low-cost optical signal generators, aligned in a known configuration, to project a two-dimensional geometric figure on the object to be measured, or on a target attached to the object. The system captures an image of the projected figure, determines the exact geometry (e.g., area or circumference) of the figure, and calculates the exact distance to the object based on comparison of that geometry to the known configuration of the laser line generators. The invention simultaneously determines relative X and Y position of the object, thereby giving accurate X, Y, and Z coordinates.

Owner:ANALOG TECH

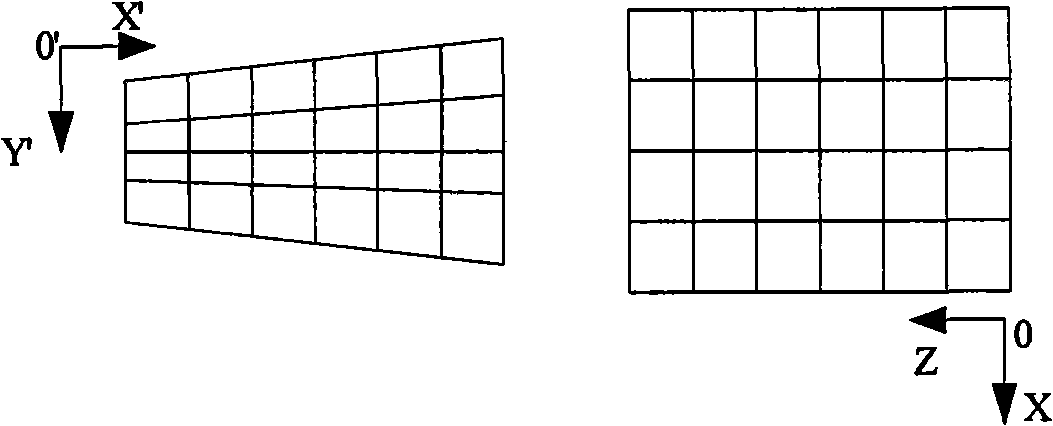

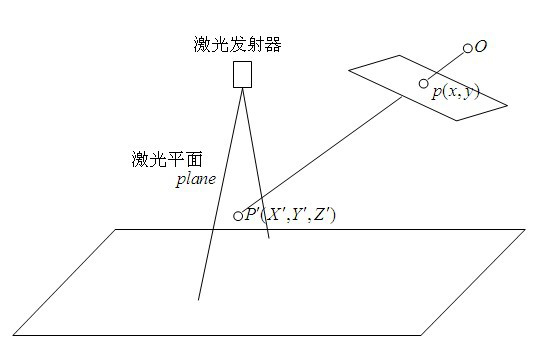

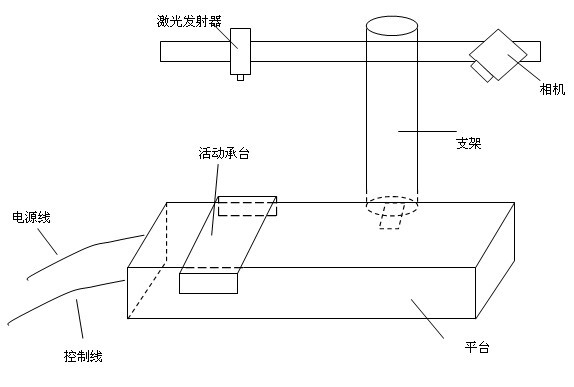

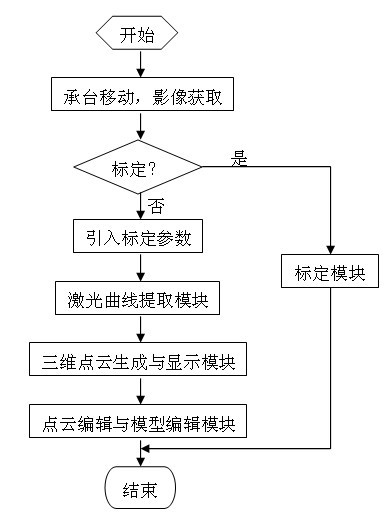

Monocular structured light-based three-dimensional modeling method

InactiveCN101986350ALow priceHigh precisionPhotogrammetry/videogrammetry3D modellingTriangulationDimensional modeling

The invention discloses a method for quickly acquiring an object surface model, which comprises the following steps of: (1) automatically controlling the movement of a bearing platform and acquiring qualified sequence images through software; (2) accurately marking a laser plane, a camera parameter and a bearing platform movement space through coordinate of each marking point of a marking block, position of a laser line on the image and relative relationship between an object space point and the laser line; (3) accurately extracting the image coordinate sequence of the laser line; (4) reading the marking parameter, and obtaining a three-dimensional coordinate point cloud of an object by using forward intersection of triangulation principle; and (5) obtaining a complete three-dimensional model by using Polyworks equal point cloud processing software for editing. The method can quickly reconstruct the three-dimensional surface model of the object, and can judge whether to meet the requirements by using the quickly generated accurate three-dimensional model.

Owner:WUHAN UNIV

Studfinder and laser line layout tool

Owner:STANLEY WORKS THE

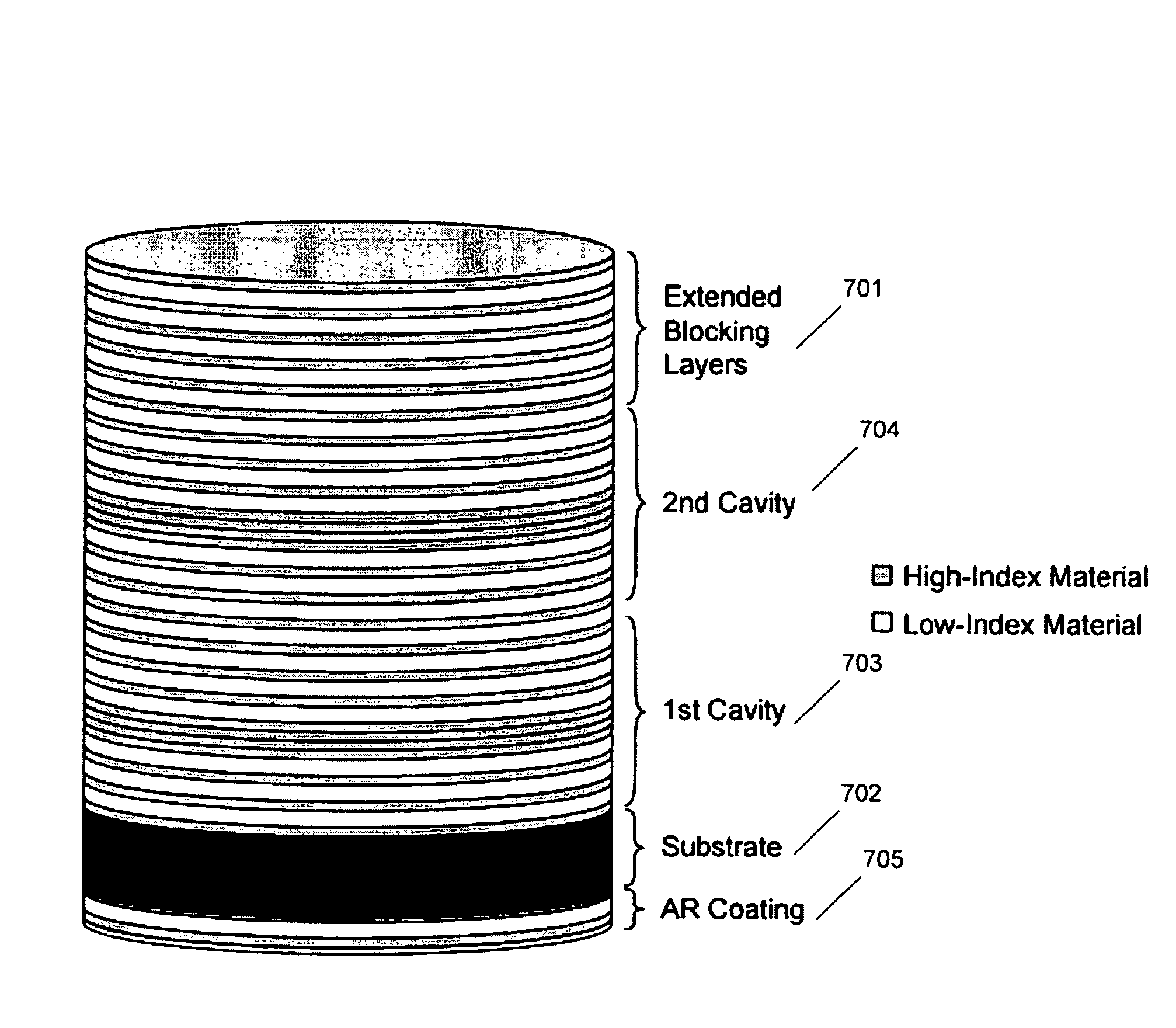

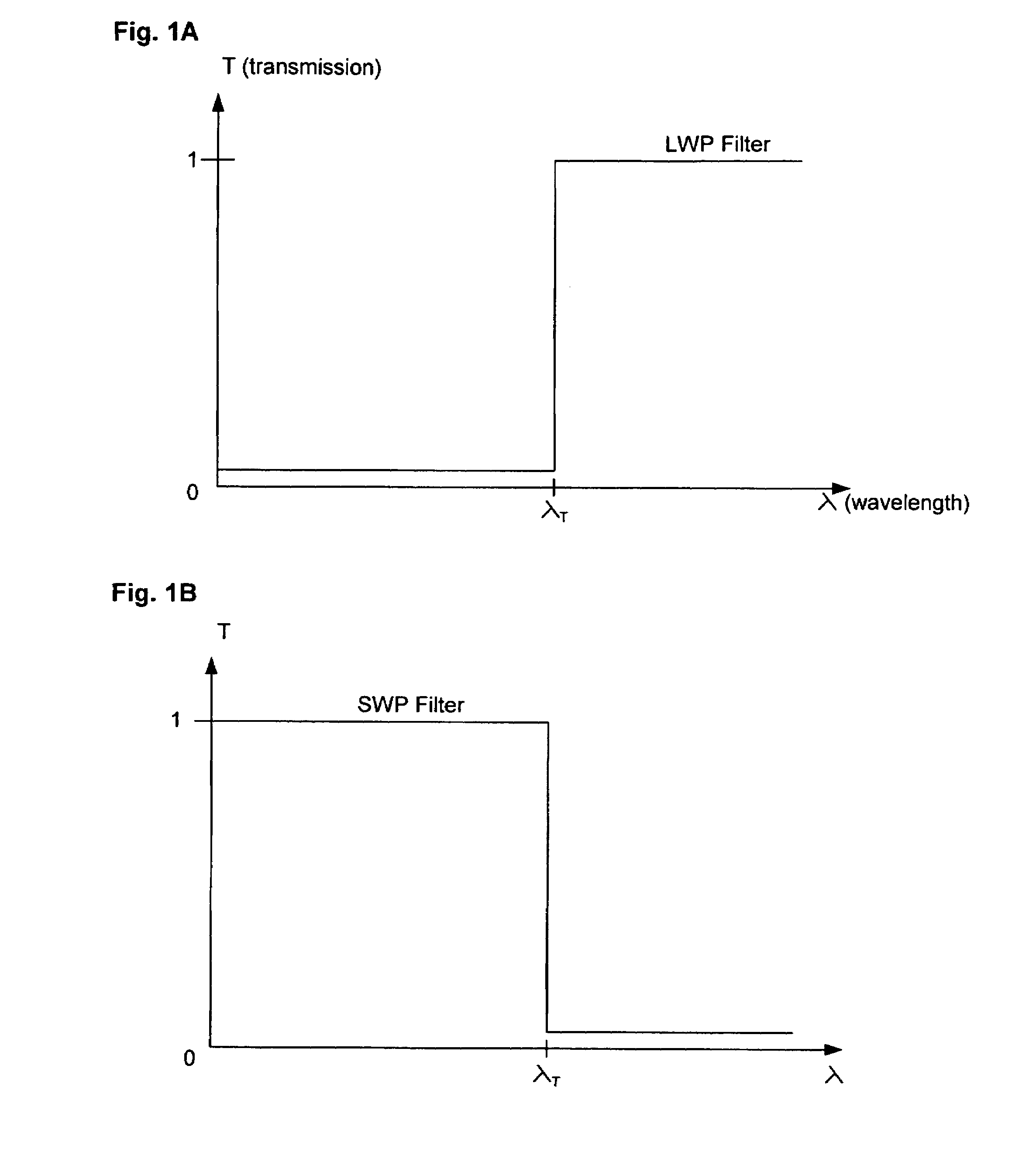

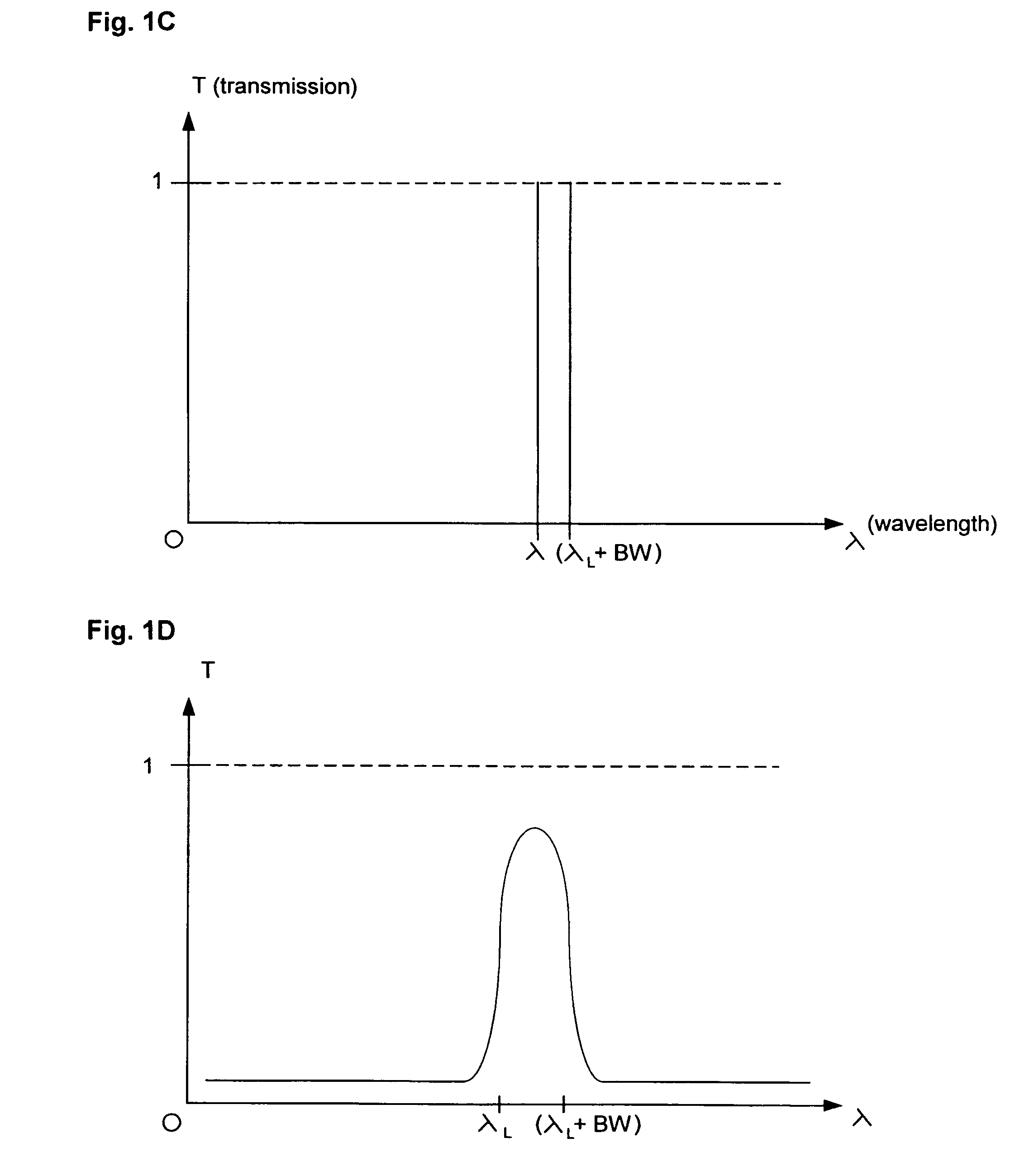

Method of making high performance optical edge and laser-line filters and resulting products

ActiveUS7119960B1Transmission bandwidth becomes narrowImprove transmittanceOptical elementsEdge filterTransmittance

High performance optical edge and laser-line filters and methods of making the same are disclosed. The optical edge filters have an edge steepness greater than about 0.8% as measured by dividing (a) the edge width from the 50% transmission wavelength to the optical density 6 (“OD6”) wavelength by (b) the 50% transmission wavelength. The optical edge filters also have an average transmission above about 95%. The laser-line filters have an extremely high transmission in the passband (greater than 90%), an extremely narrow transmission bandwidth, and achieve blocking with an optical density (OD) greater than 5 at wavelengths that differ from the laser wavelength by less than 1% of the laser wavelength. The methods for making such filters accurately determine when deposition of each layer of the filter should terminate.

Owner:IDEX HEALTH & SCI

Laser line generating device with swivel base

A laser alignment device includes a laser generating device, an upper attachment portion, and a lower attachment portion. The laser generating device includes a housing and a laser generator. The upper attachment portion is disposed near a bottom of the housing, and the lower attachment portion is pivotally and / or rotationally connected to the upper attachment portion.

Owner:IRWIN IND TOOL CO

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com