Patents

Literature

370 results about "Laser plane" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

High precision GPS/RTK and laser machine control

InactiveUS6433866B1Angle measurementLaser using scattering effectsMachine controlDifferential correction

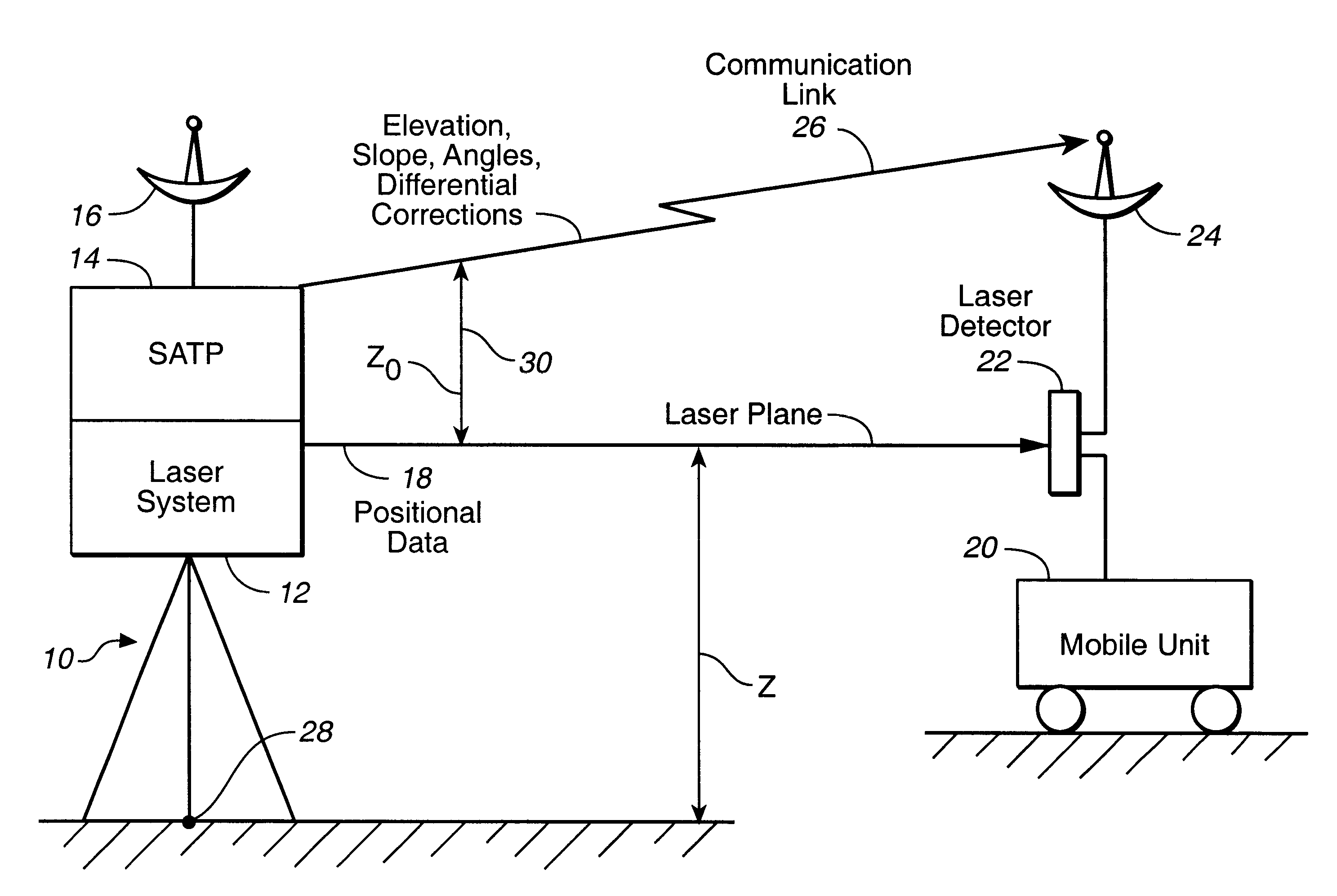

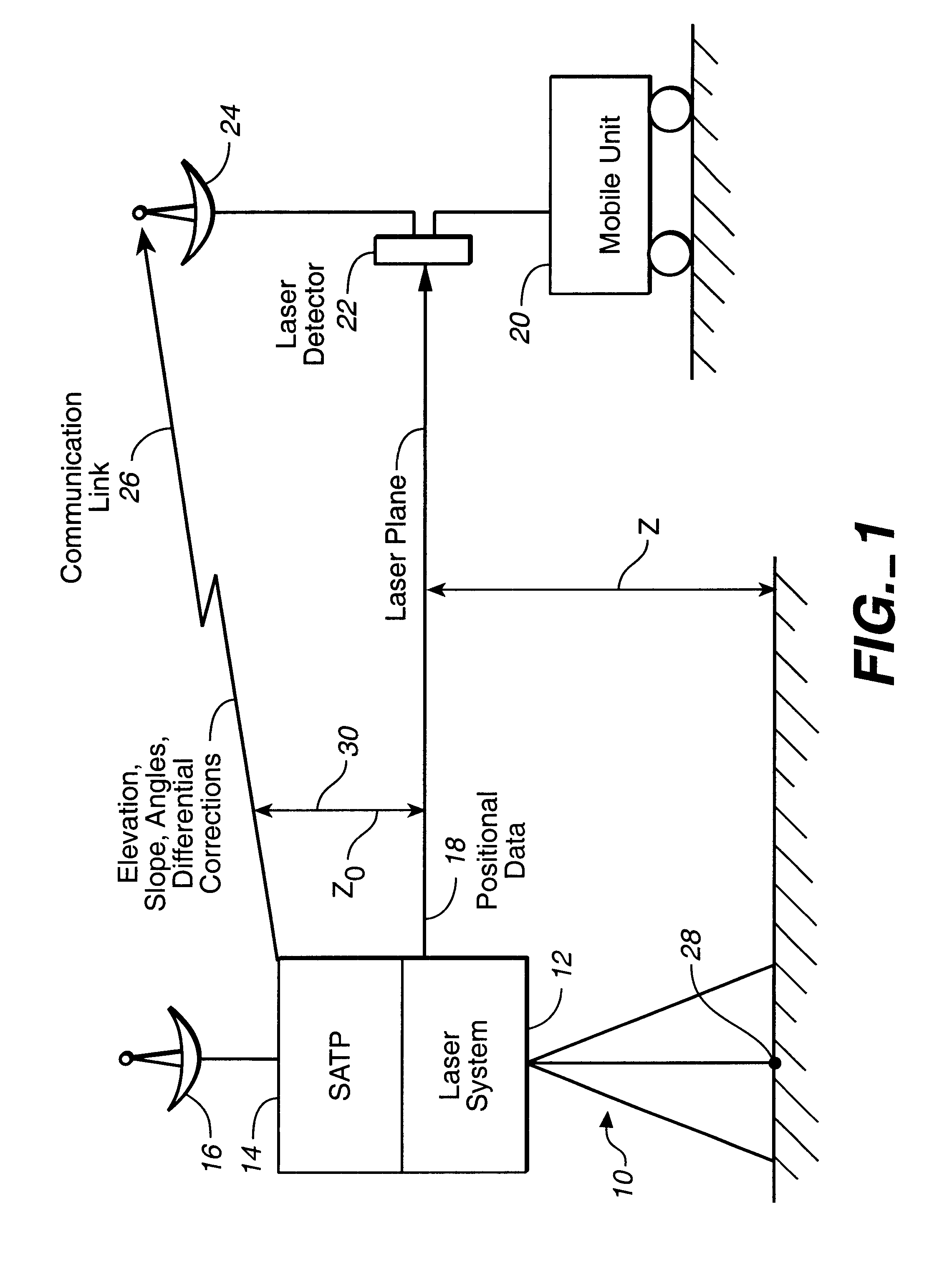

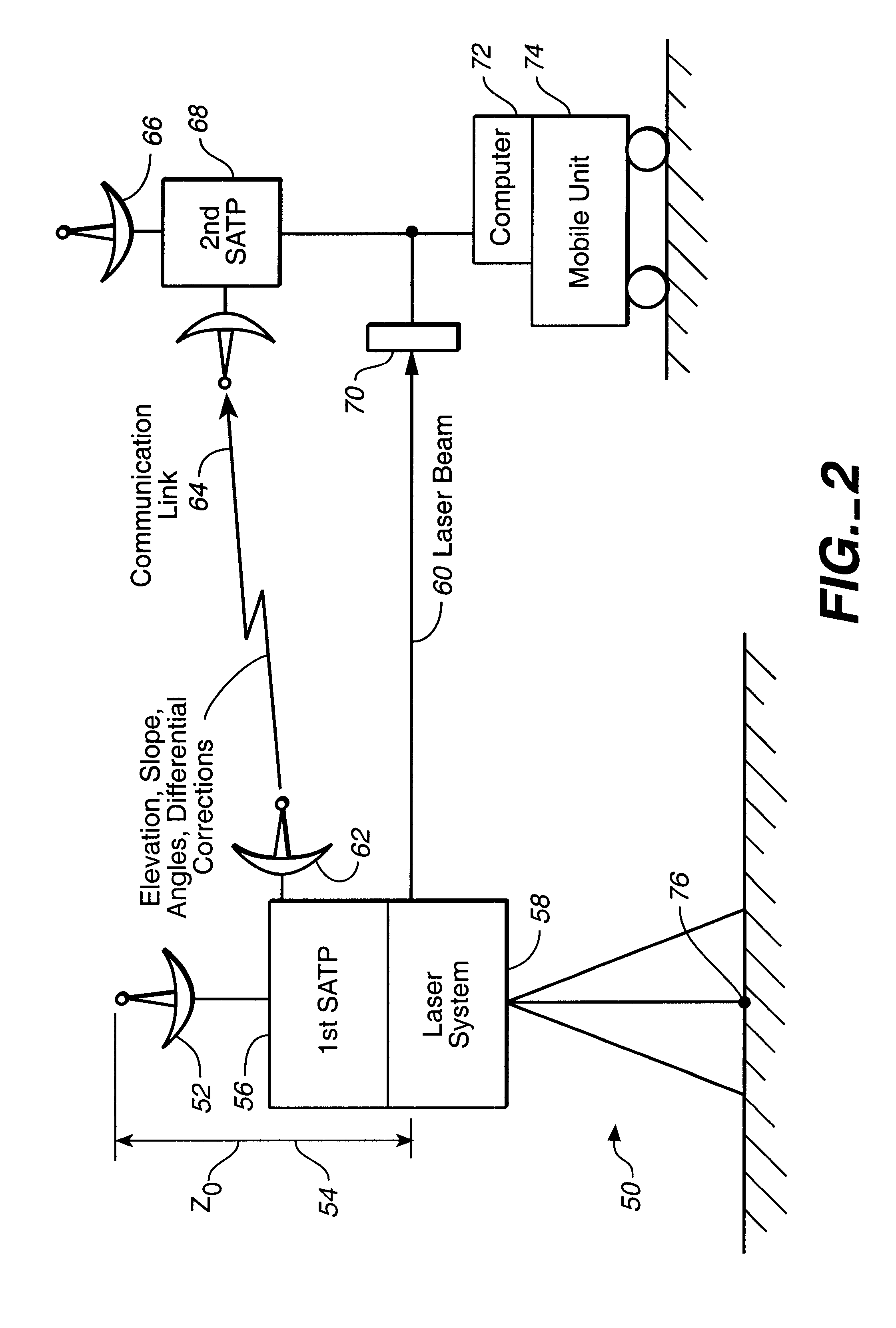

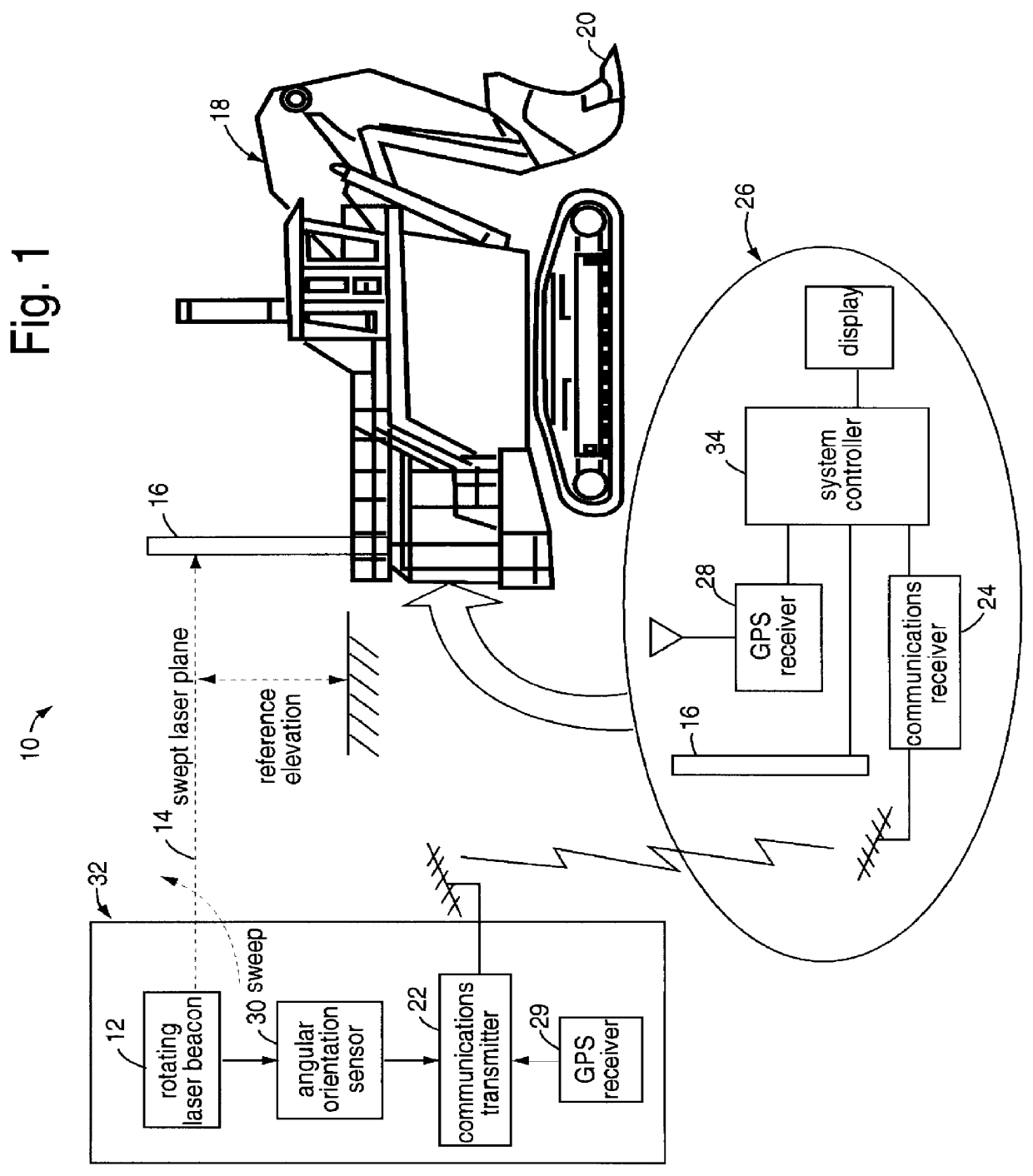

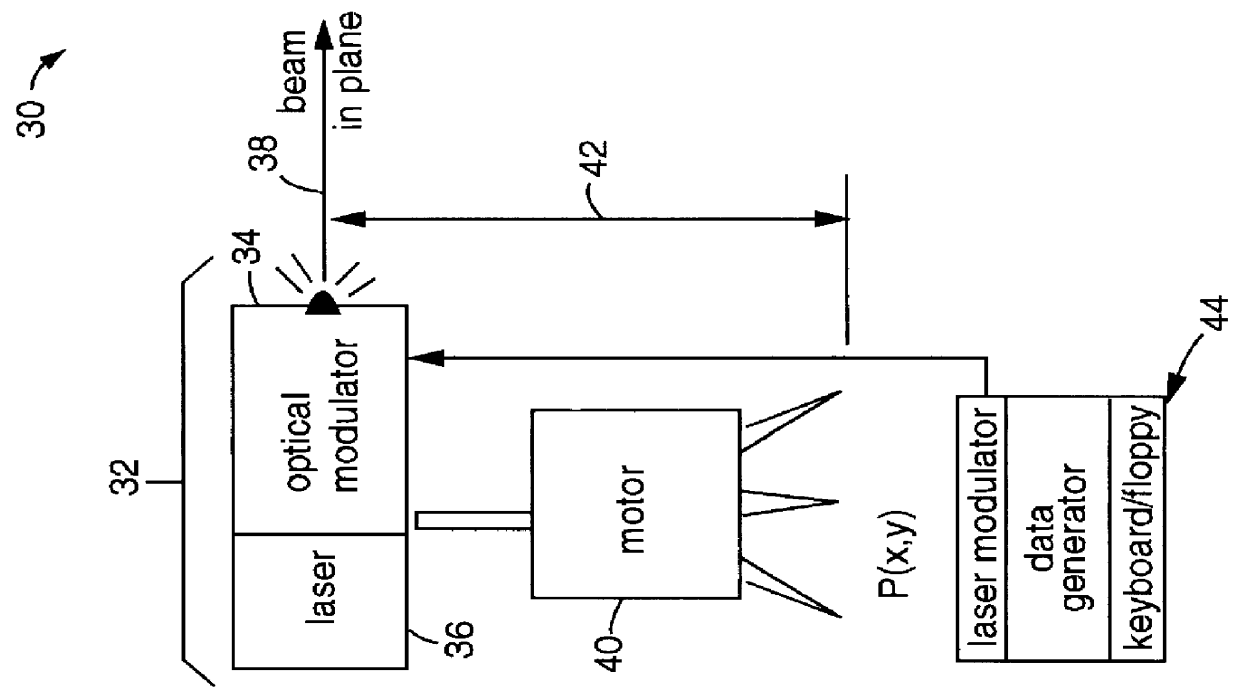

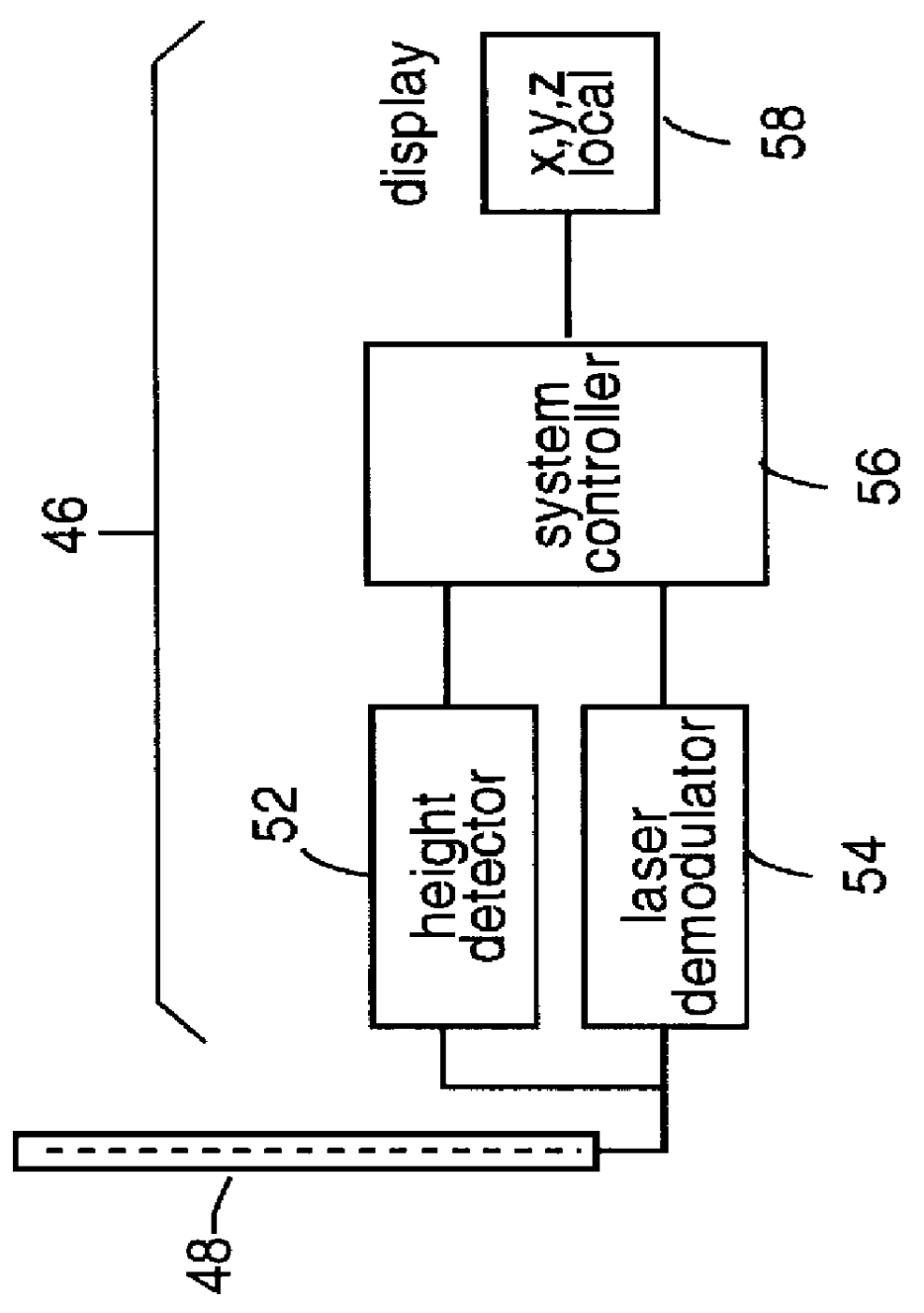

The integrated laser and satellite positional system receiver is disclosed. The integrated laser and satellite positioning system receiver can provide a plurality of mobile units with a laser plane data determined with a millimeter relative accuracy. The integrated laser and differential satellite positioning system receiver can also generate and transmit the differential correctional data to a plurality of mobile units. Each mobile unit equipped with a mobile satellite positioning system receiver can use the differential correction data and the high precision laser plane data to improve its position determination capabilities.

Owner:TRIMBLE NAVIGATION LTD

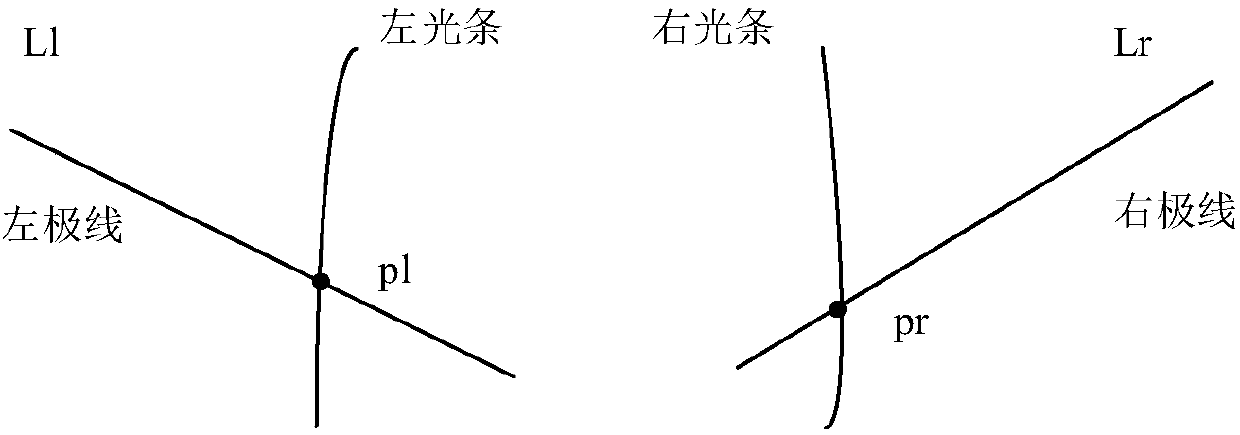

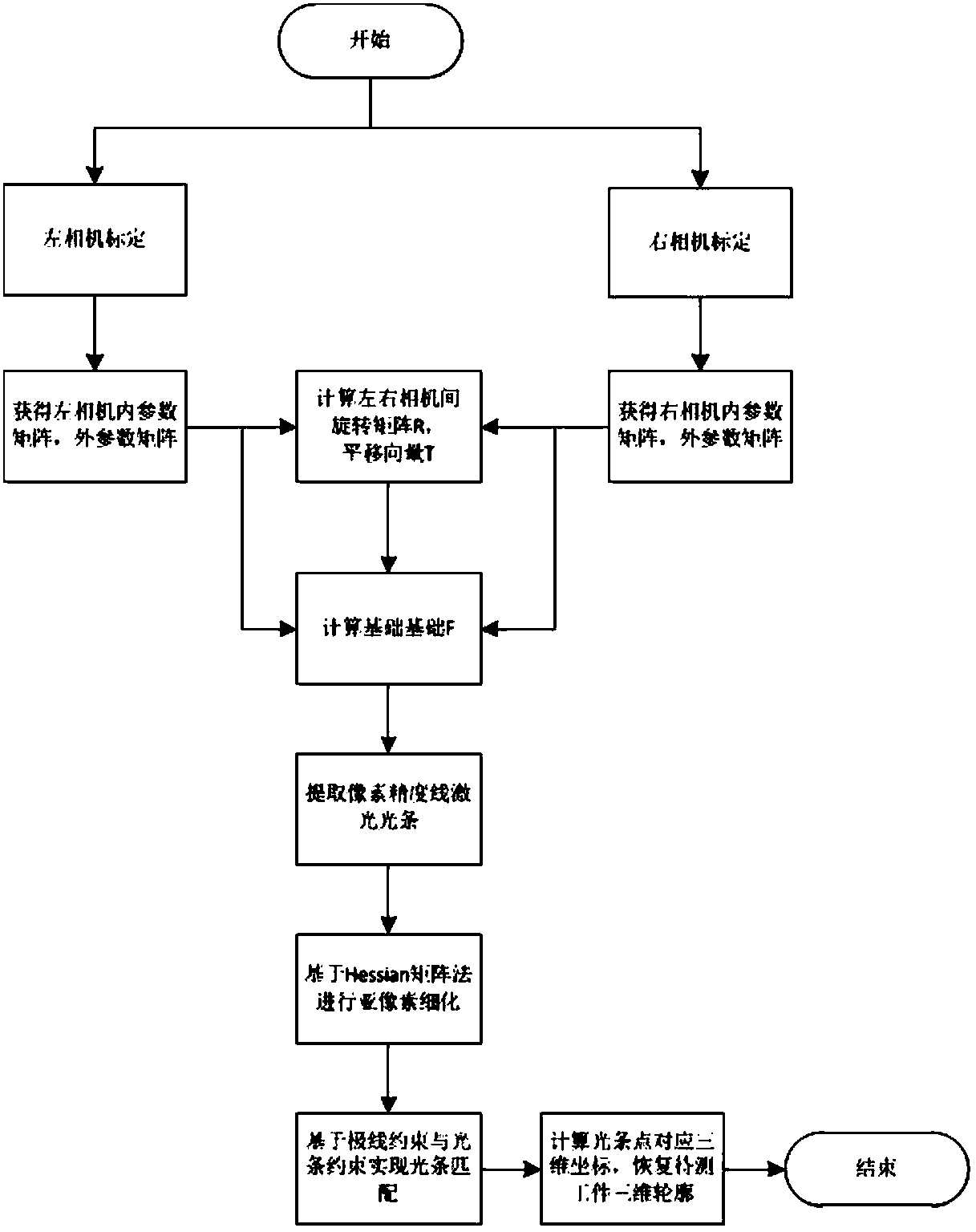

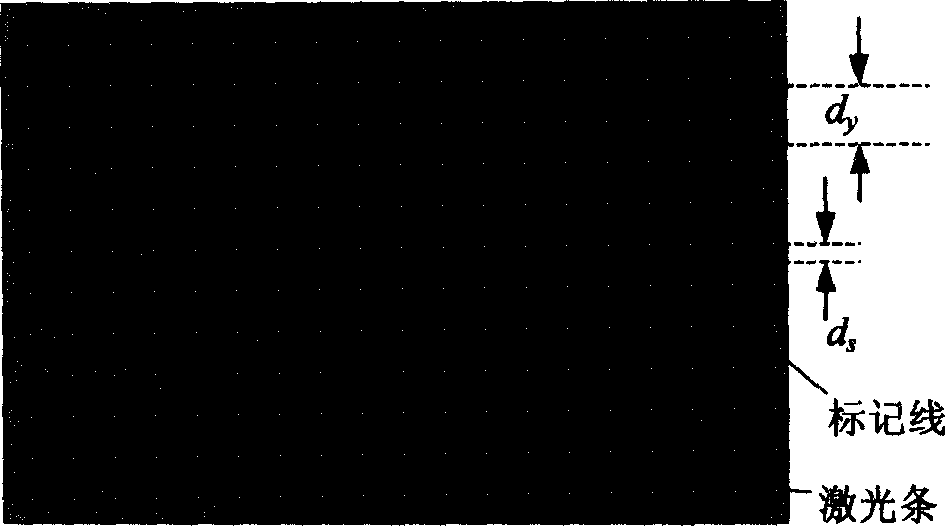

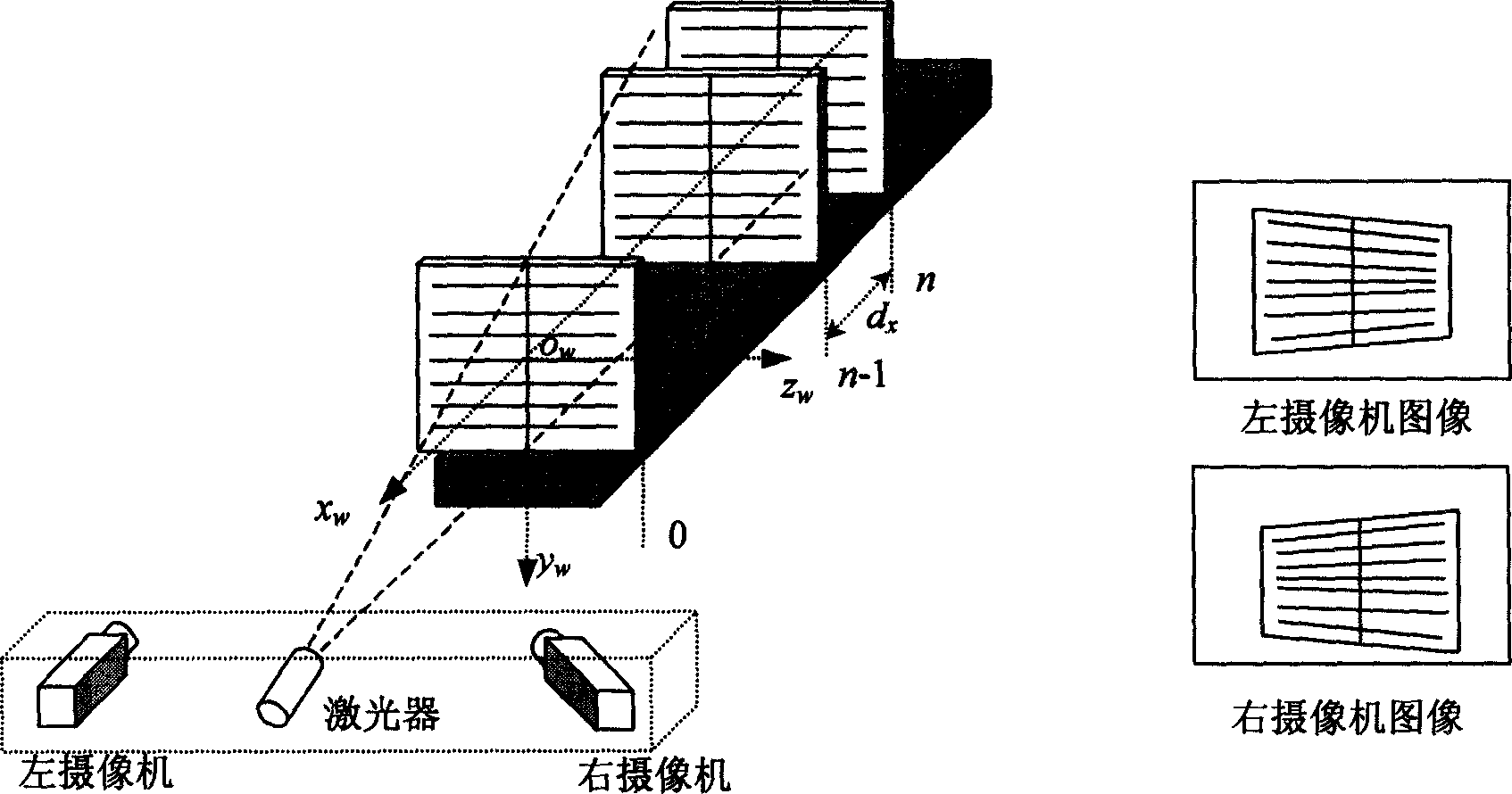

Binocular stereo vision three-dimensional measurement method based on line structured light scanning

InactiveCN107907048AReduce the difficulty of matchingImprove robustnessUsing optical meansThree dimensional measurementLaser scanning

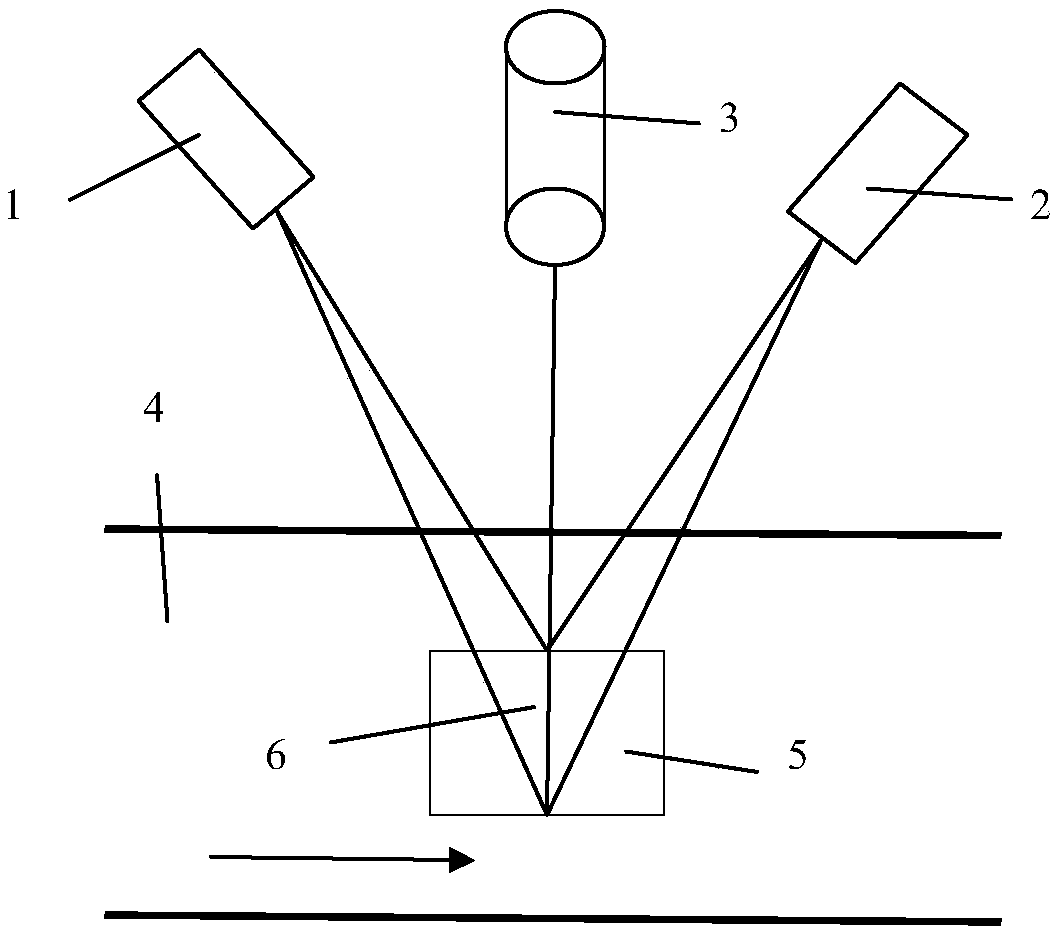

The invention discloses a binocular stereo vision three-dimensional measurement method based on line structured light scanning, which comprises the steps of performing stereo calibration on binocularindustrial cameras, projecting laser light bars by using a line laser, respectively acquiring left and right laser light bar images, extracting light bar center coordinates with sub-pixel accuracy based on a Hessian matrix method, performing light bar matching according to an epipolar constraint principle, and calculating a laser plane equation; secondly, acquiring a line laser scanning image of aworkpiece to be measured, extracting coordinates of the image of the workpiece to be measured, calculating world coordinates of the workpiece to be measured by combining binocular camera calibrationparameters and the laser plane equation, and recovering the three-dimensional surface topography of the workpiece to be measured. Compared with a common three-dimensional measurement system combininga monocular camera and line structured light, the binocular stereo vision three-dimensional measurement method avoids complicated laser plane calibration. Compared with the traditional stereo vision method, the binocular stereo vision three-dimensional measurement method reduces the difficulty of stereo matching in binocular stereo vision while ensuring the measurement accuracy, and improves the robustness and the usability of a visual three-dimensional measurement system.

Owner:CHANGSHA XIANGJI HAIDUN TECH CO LTD

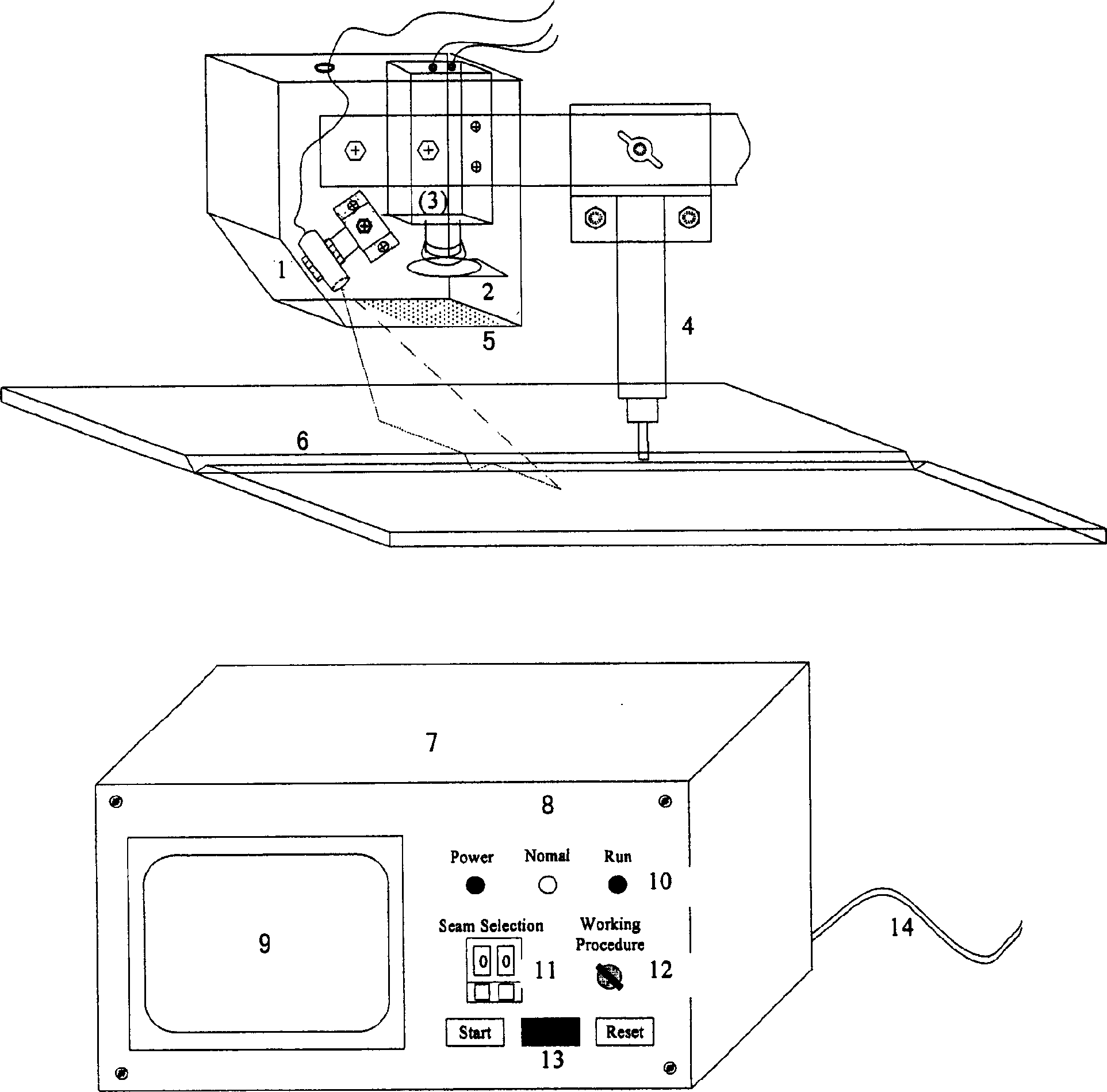

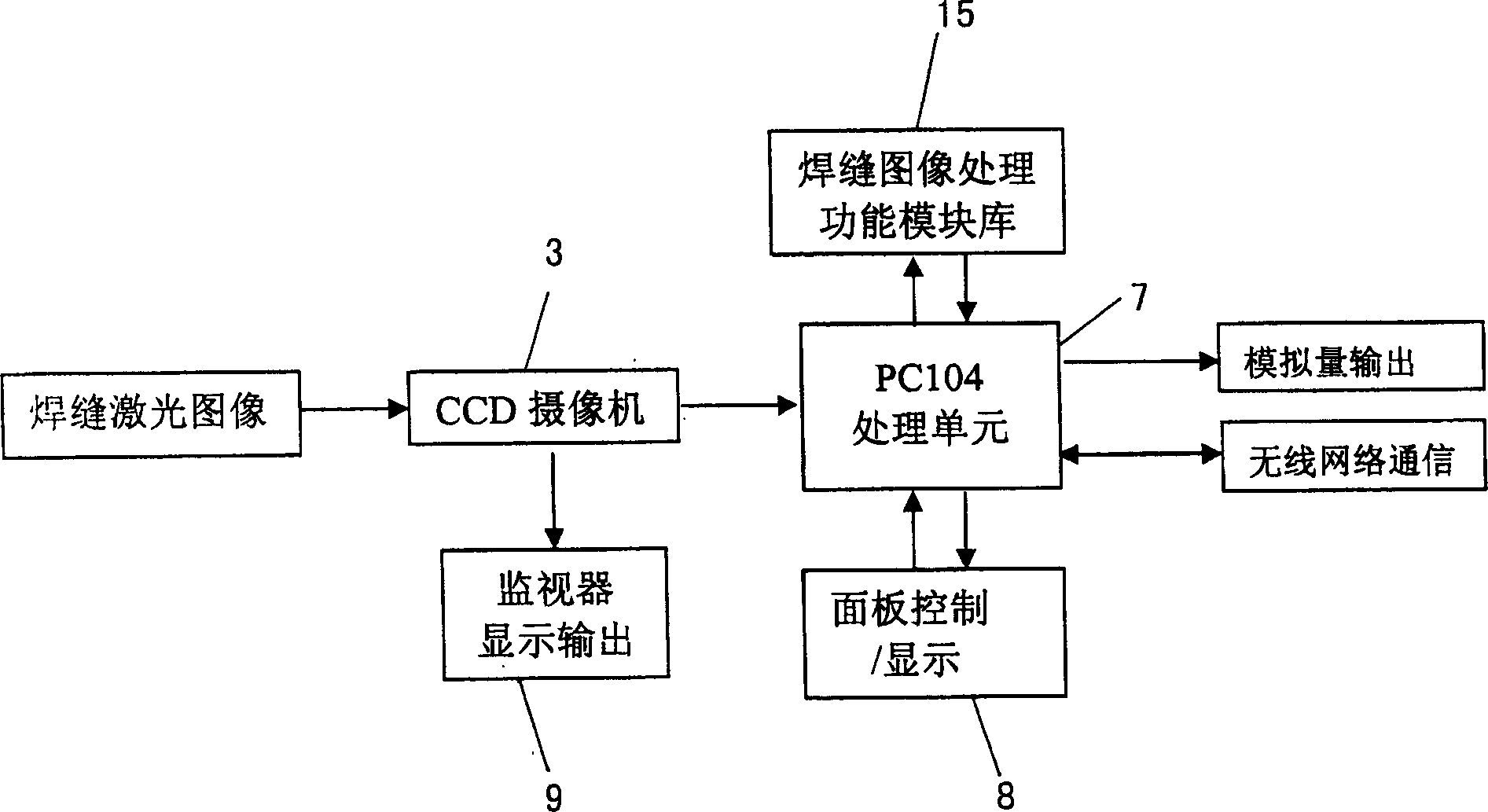

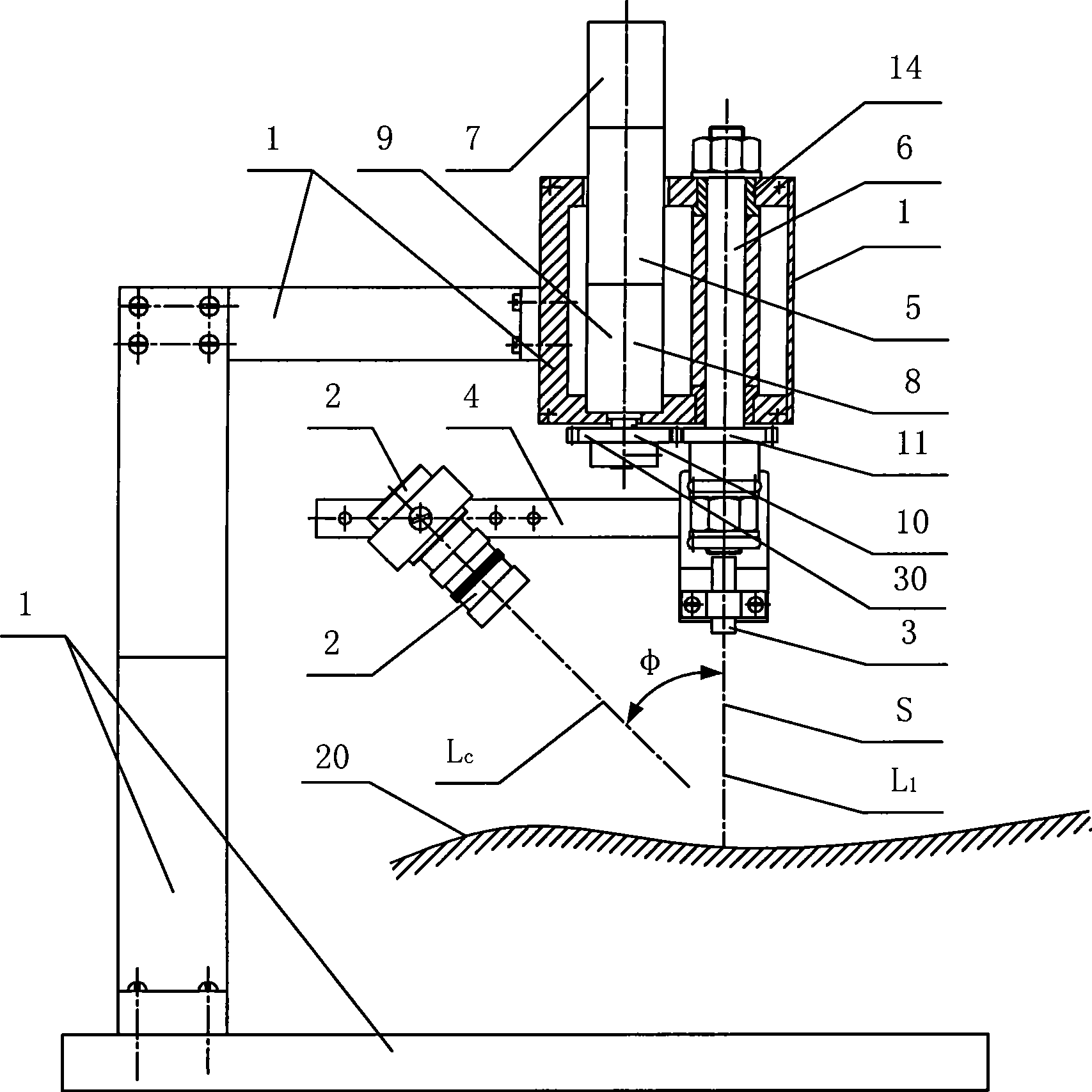

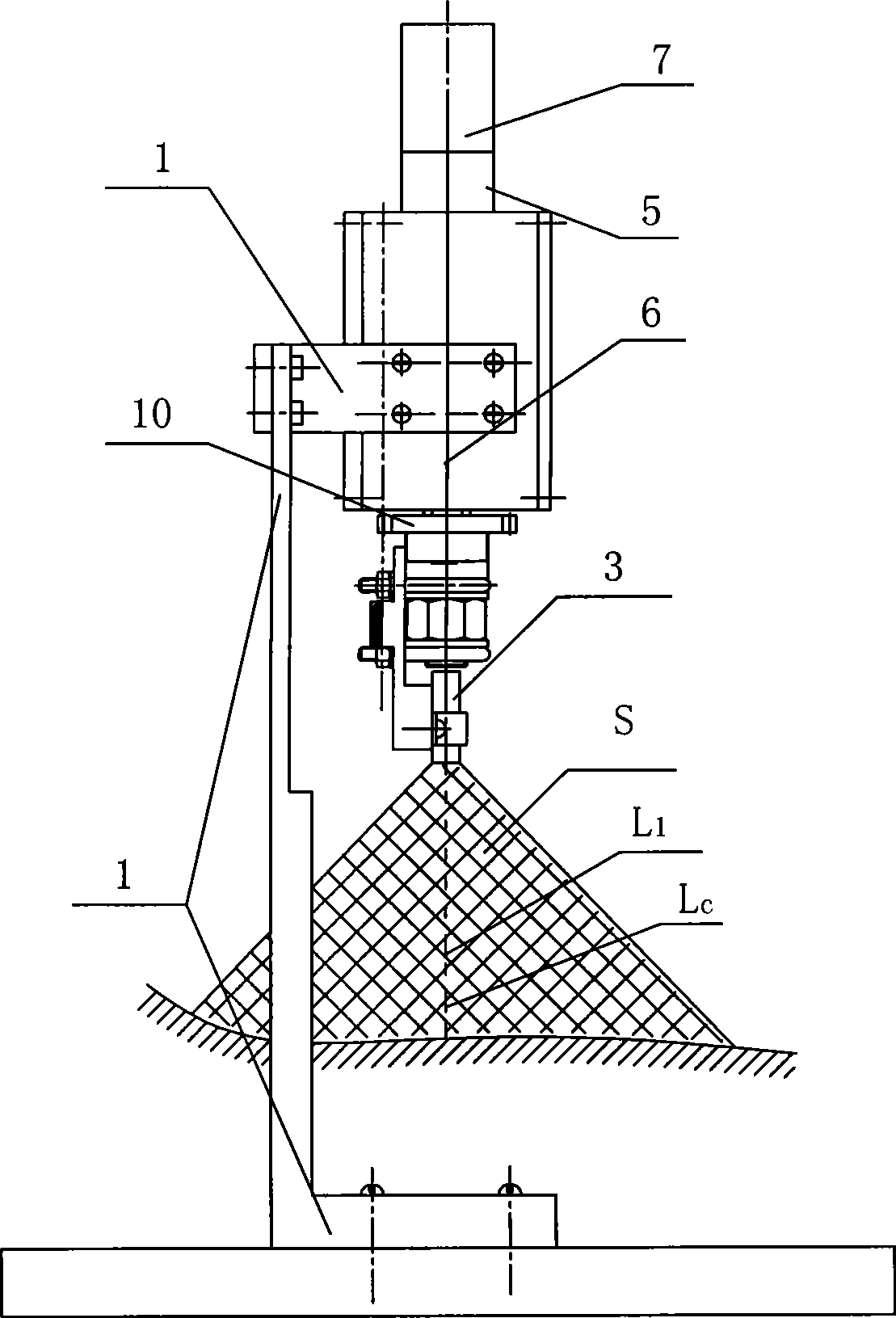

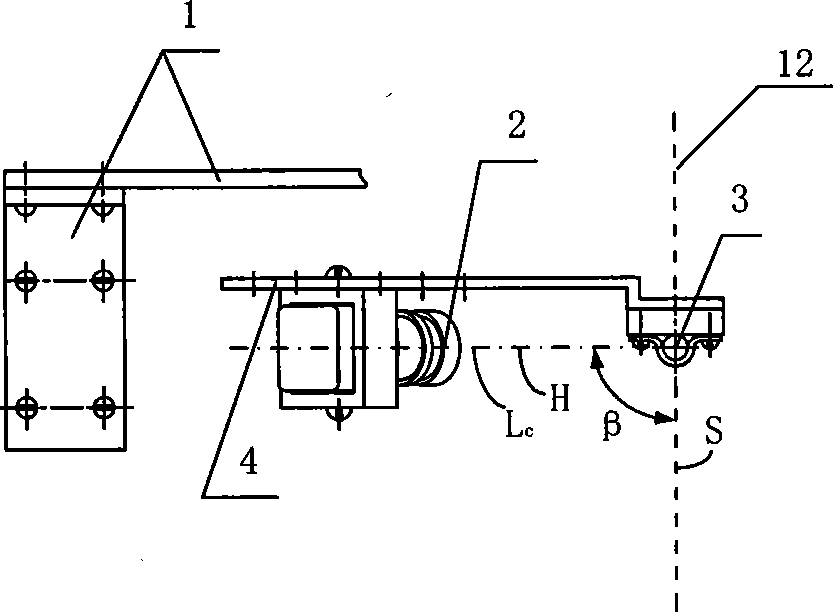

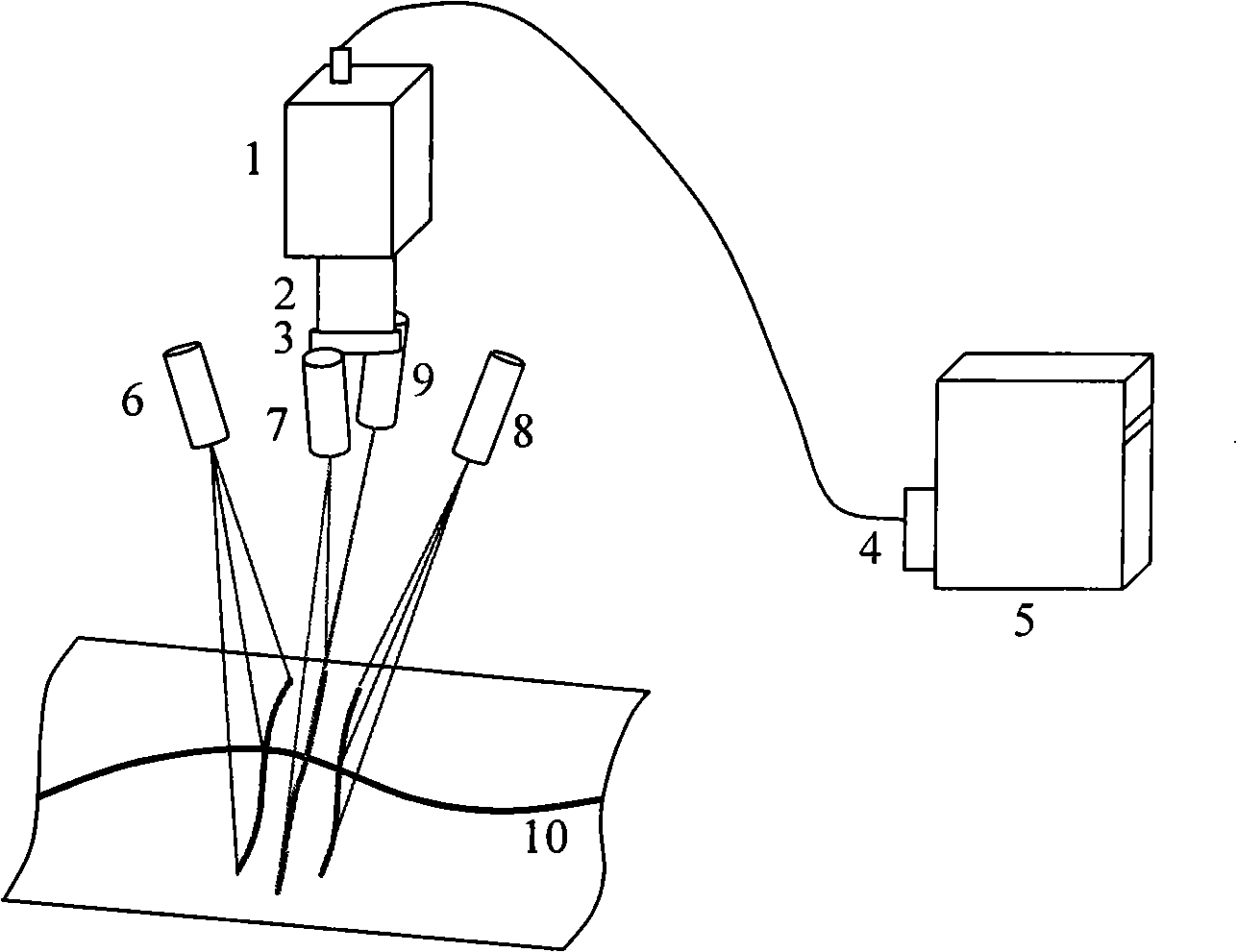

Welding seam tracking sight sensor based on laser structure light

The present invention relates to robot technology, and is weld seam tracking sight sensor based on laser structure light. The welding seam tracking sight sensor has laser as the light source of structure light, and consists of laser, video camera, monitor, treating unit, etc. By means of forming laser plane with laser beam in a cylindrical mirror, projecting the laser plane to a workpiece to generate laser fringes, acquiring the laser image of weld seam with a visual sensor, calculating weld seam positions through image processing and converting into analog signal or radio signal, the present invention controls welding robot for automatic weld seam tracking. Different weld seam processing modules for different kinds of weld seam are developed. The present invention has high weld seam position measuring precision, raised anti-jamming capacity and high versatility and flexibility.

Owner:INST OF AUTOMATION CHINESE ACAD OF SCI

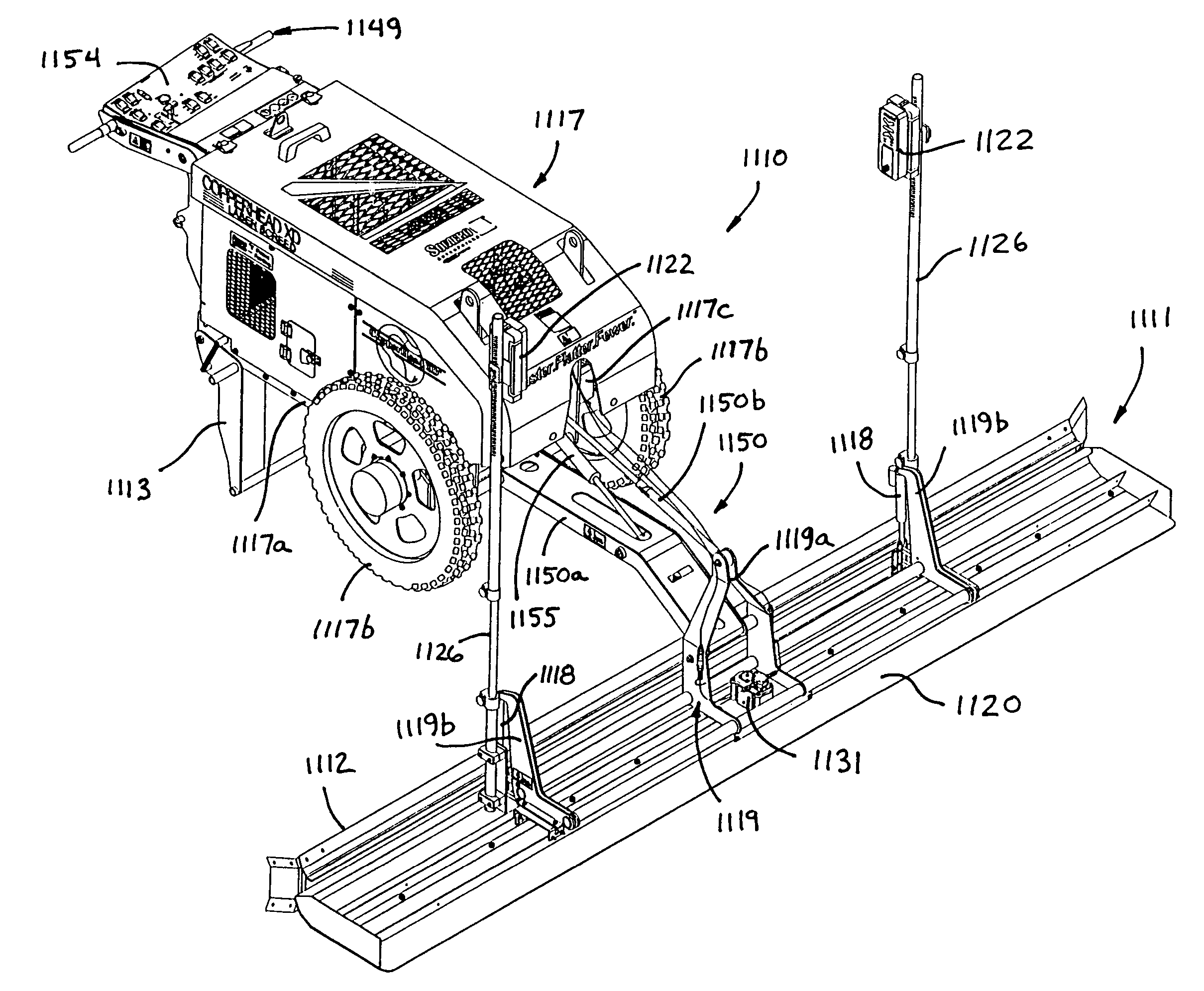

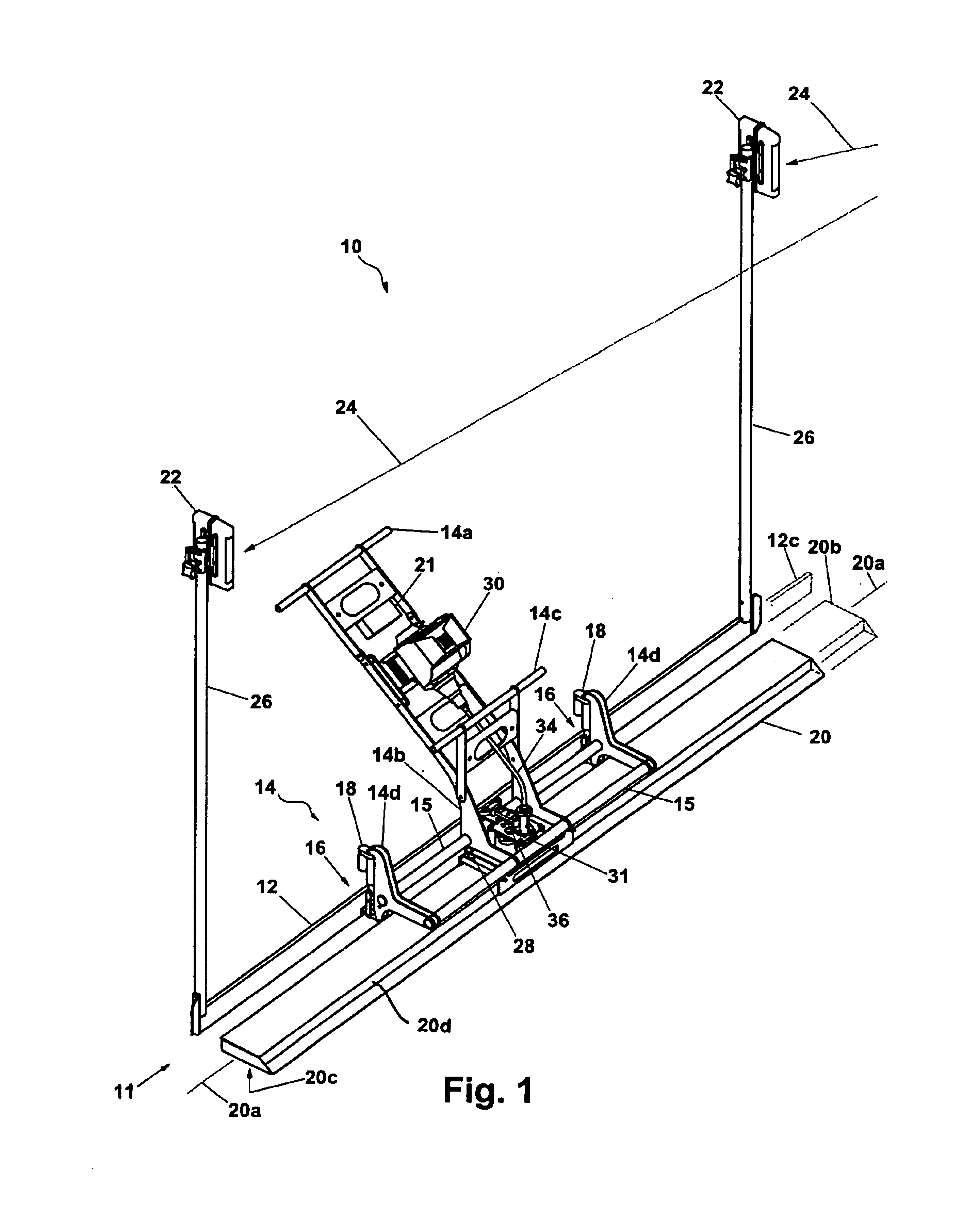

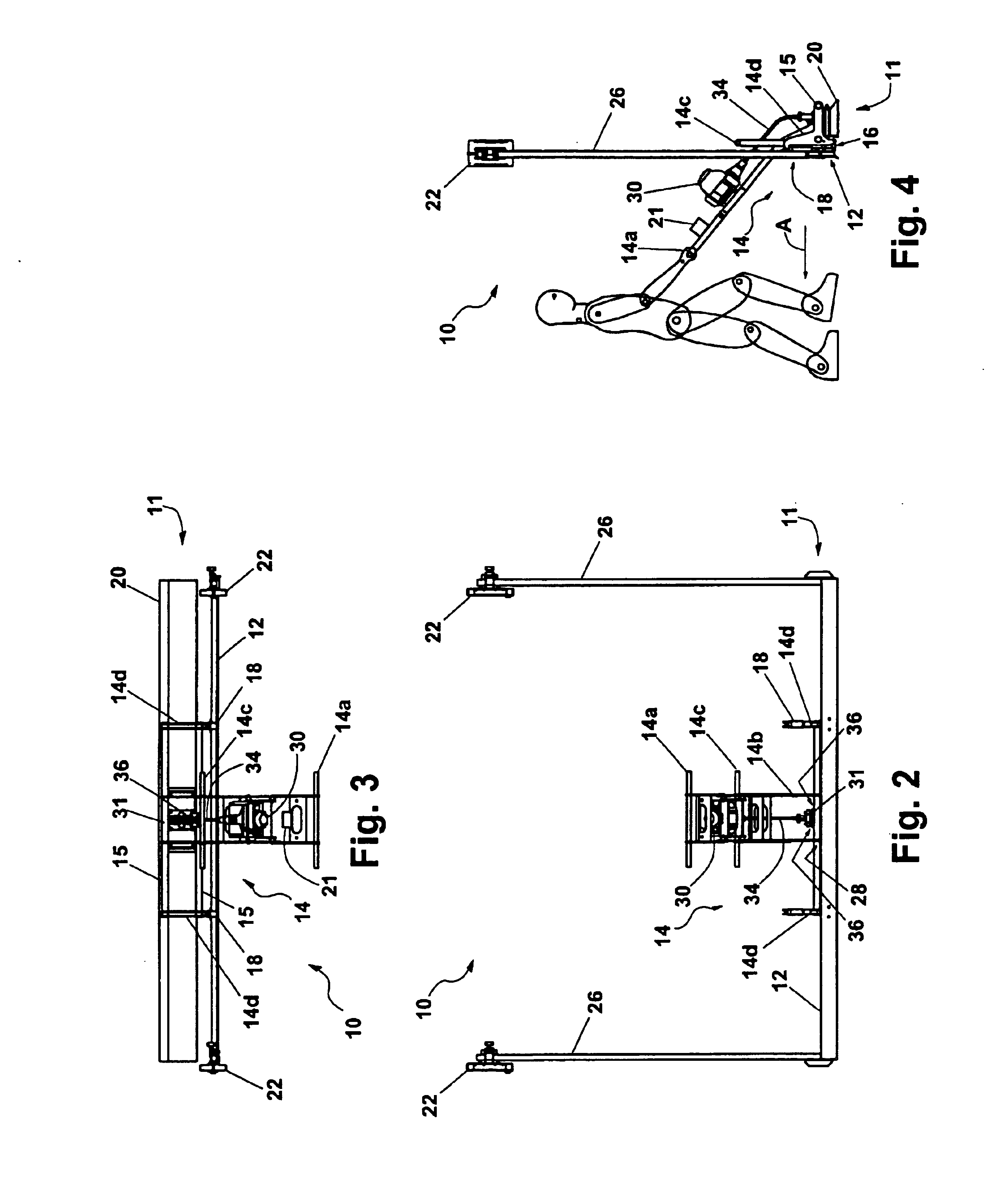

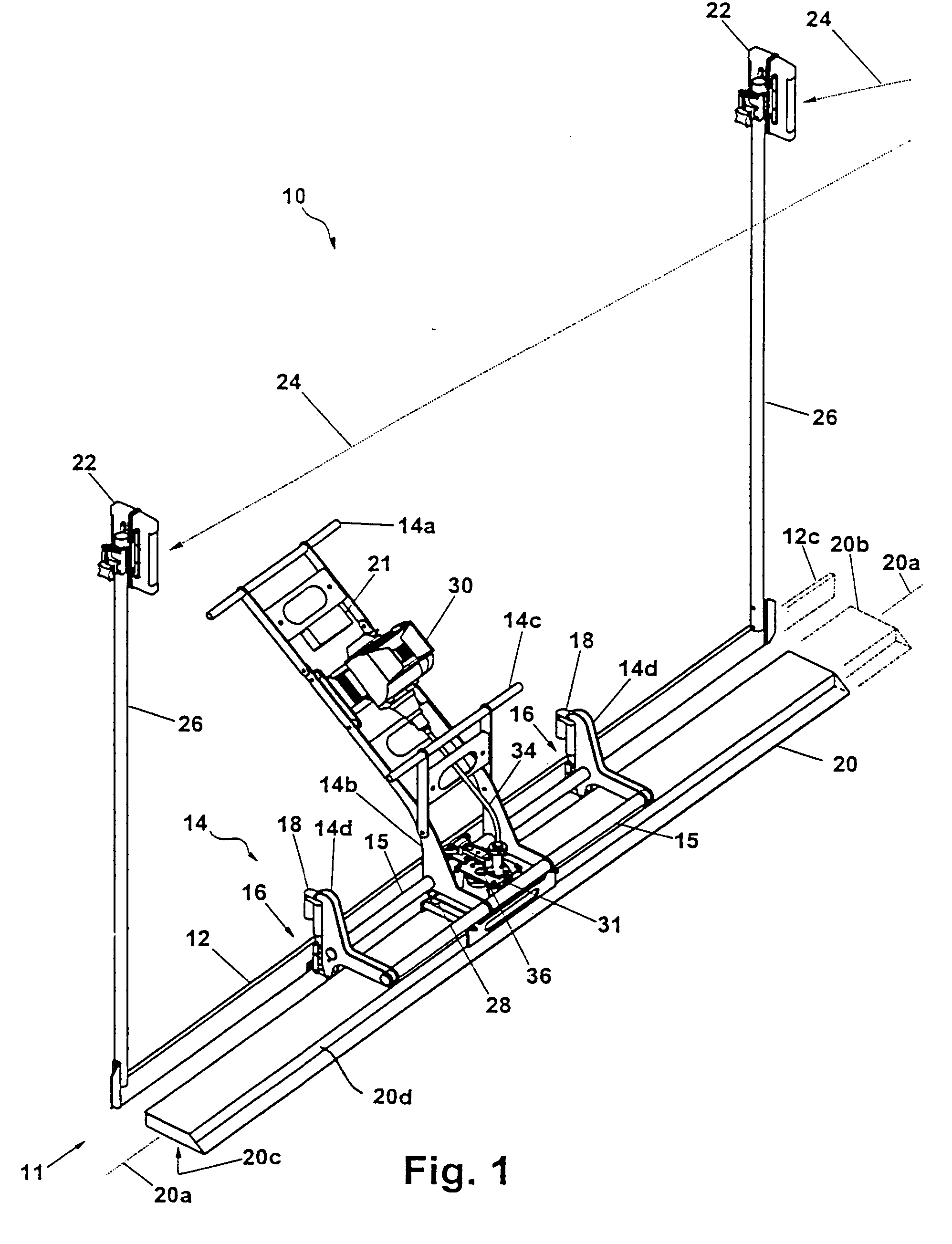

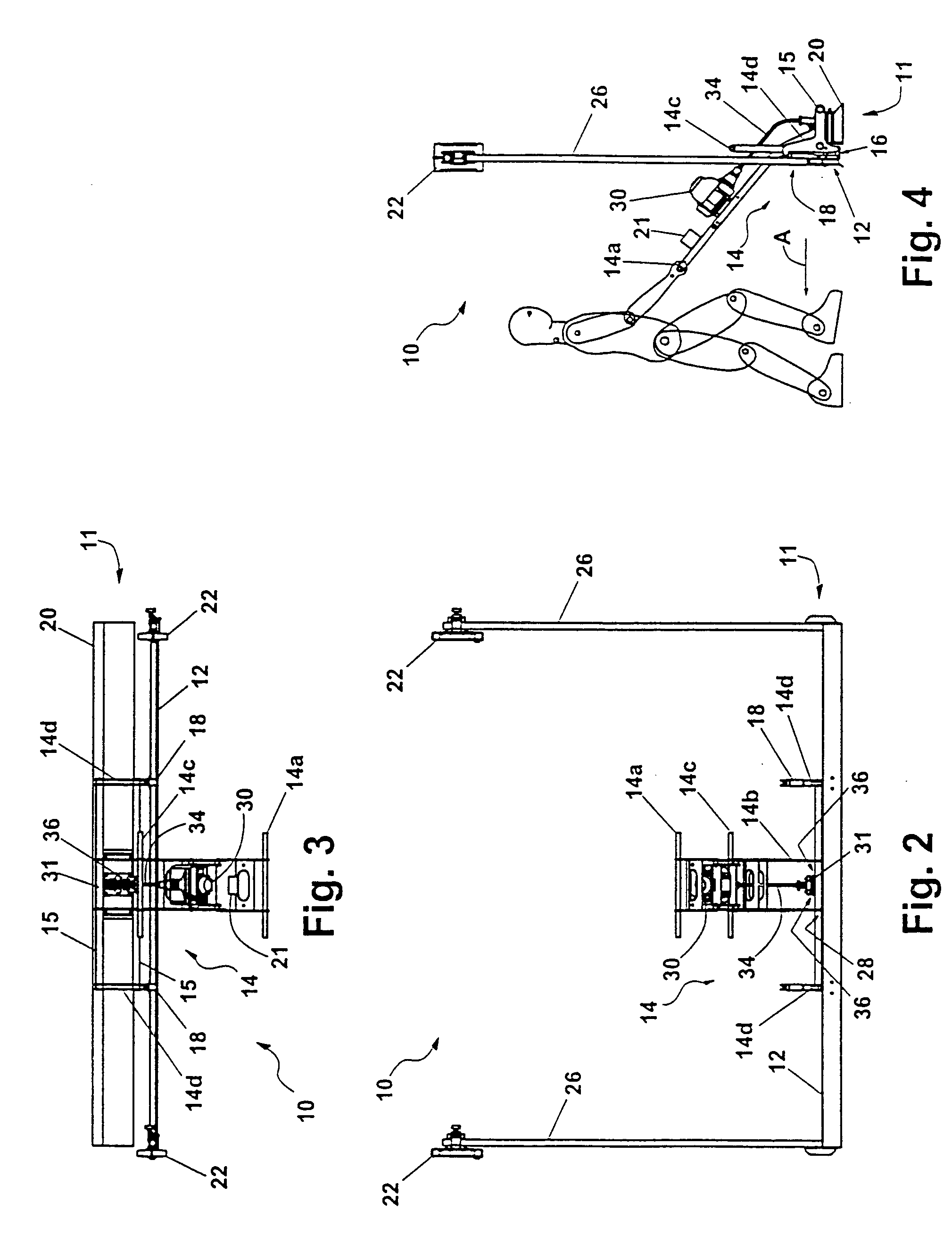

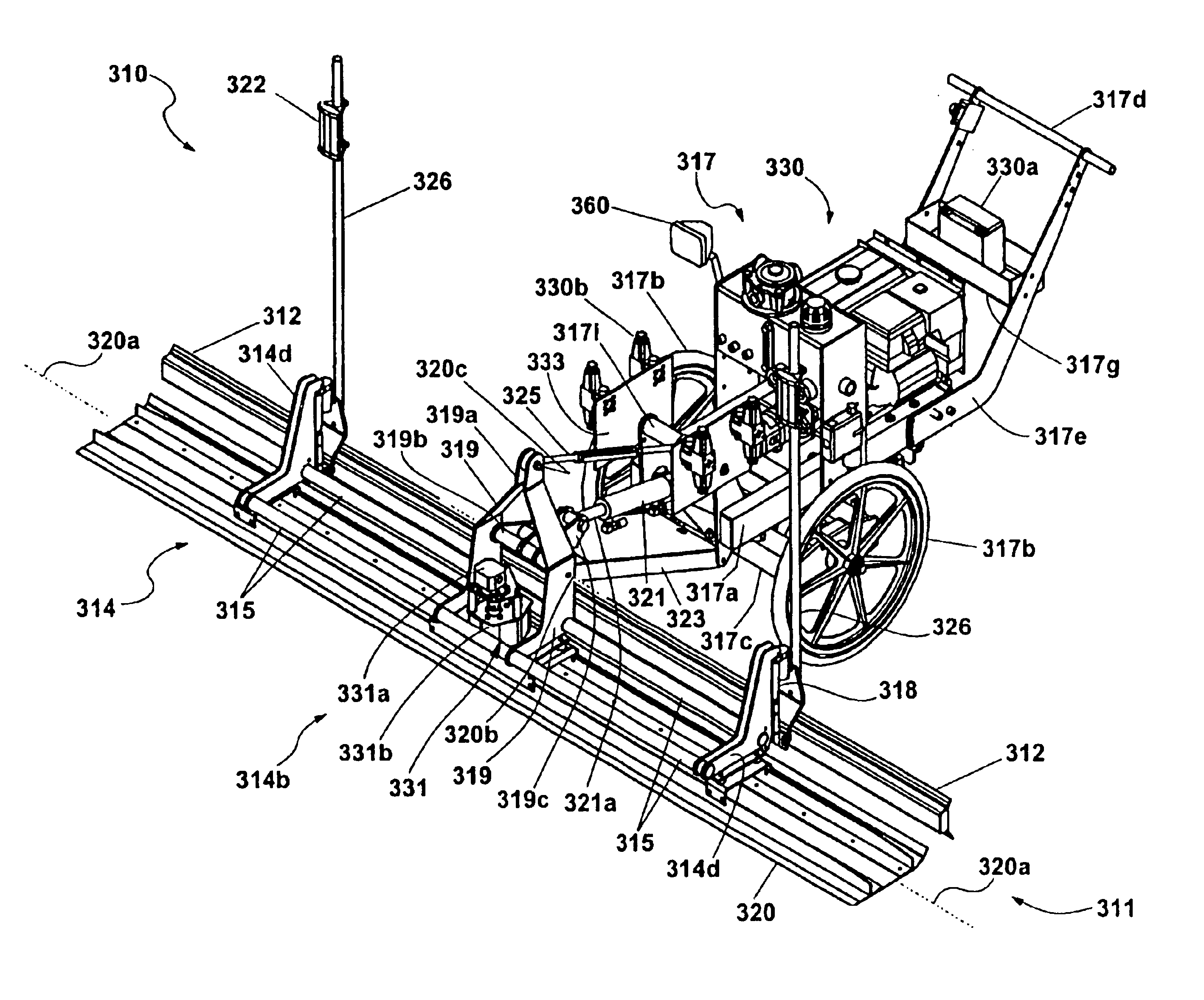

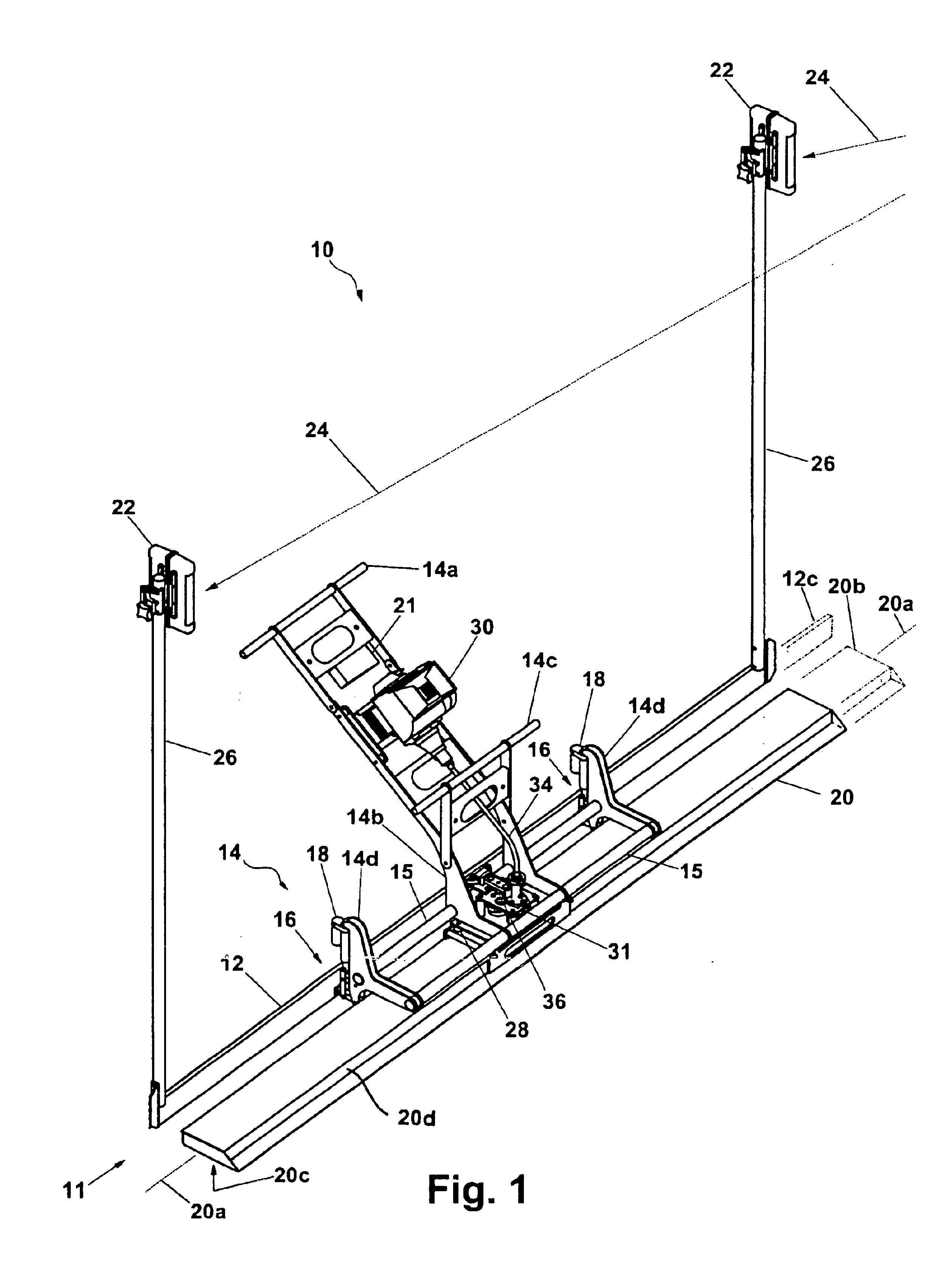

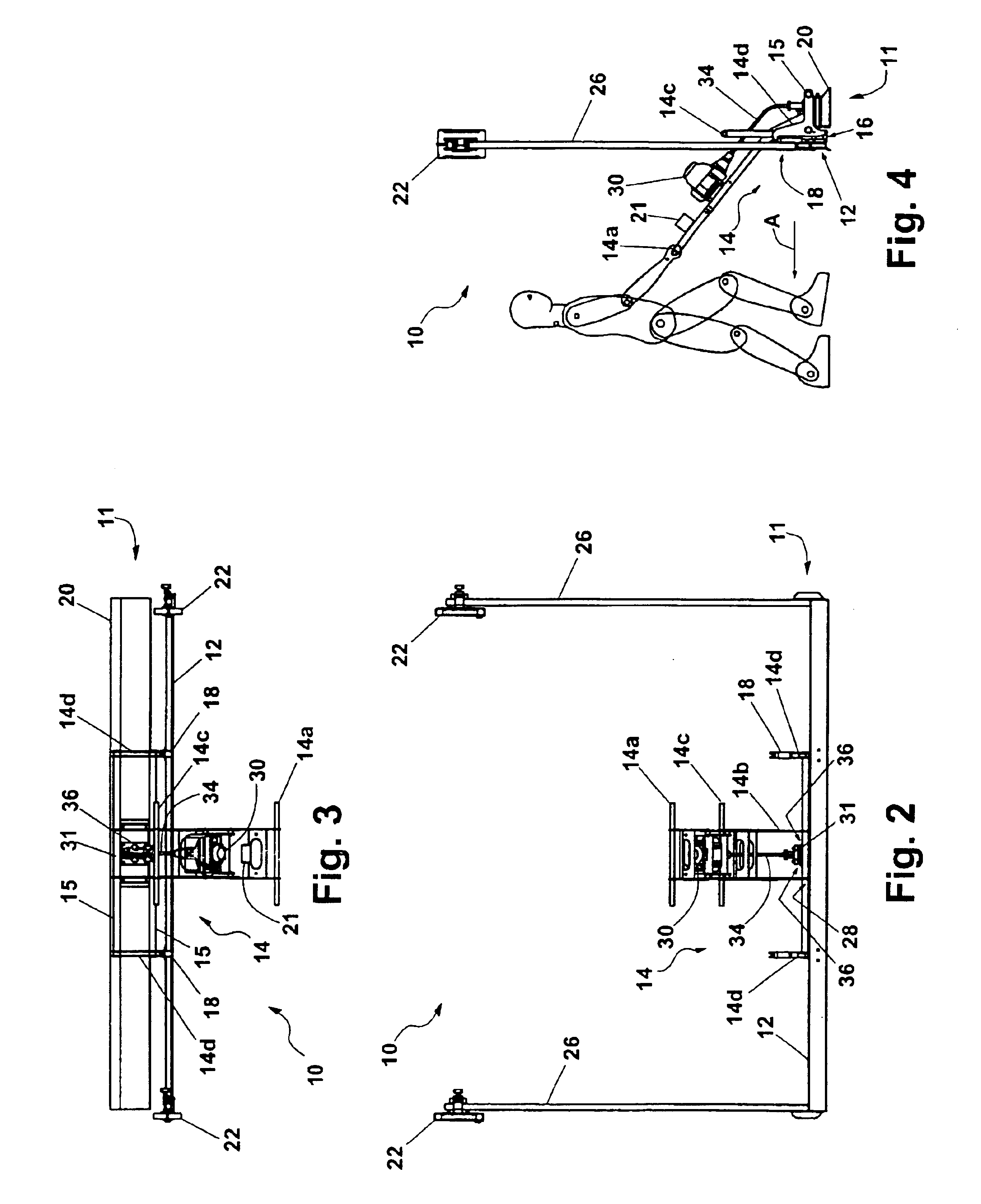

Apparatus for screeding uncured concrete surfaces

InactiveUS7121762B2Improve accuracyEasy to operateRoads maintainenceBuilding material handlingControl systemEngineering

A screeding apparatus for screeding and smoothing an uncured concrete surface includes a vibrating member and a grade setting device adjustably mounted to said vibrating member. The screeding apparatus may include a wheeled support which at least partially supports the vibrating member and / or the grade setting device. The grade setting device is vertically adjustable, such as via a laser plane responsive control system, to set or indicate the desired grade of the concrete surface as the screeding apparatus is moved over and through the uncured concrete. The level of the screeding apparatus may be automatically adjustable to maintain a desired level and angle of attack of the vibrating member. The vibrating member may be activated only when the screeding apparatus is moved in a screeding direction so as to reduce depressions that otherwise may occur if the vibrating member vibrates on the uncured concrete when not moving.

Owner:SOMERO ENTERPRISES INC

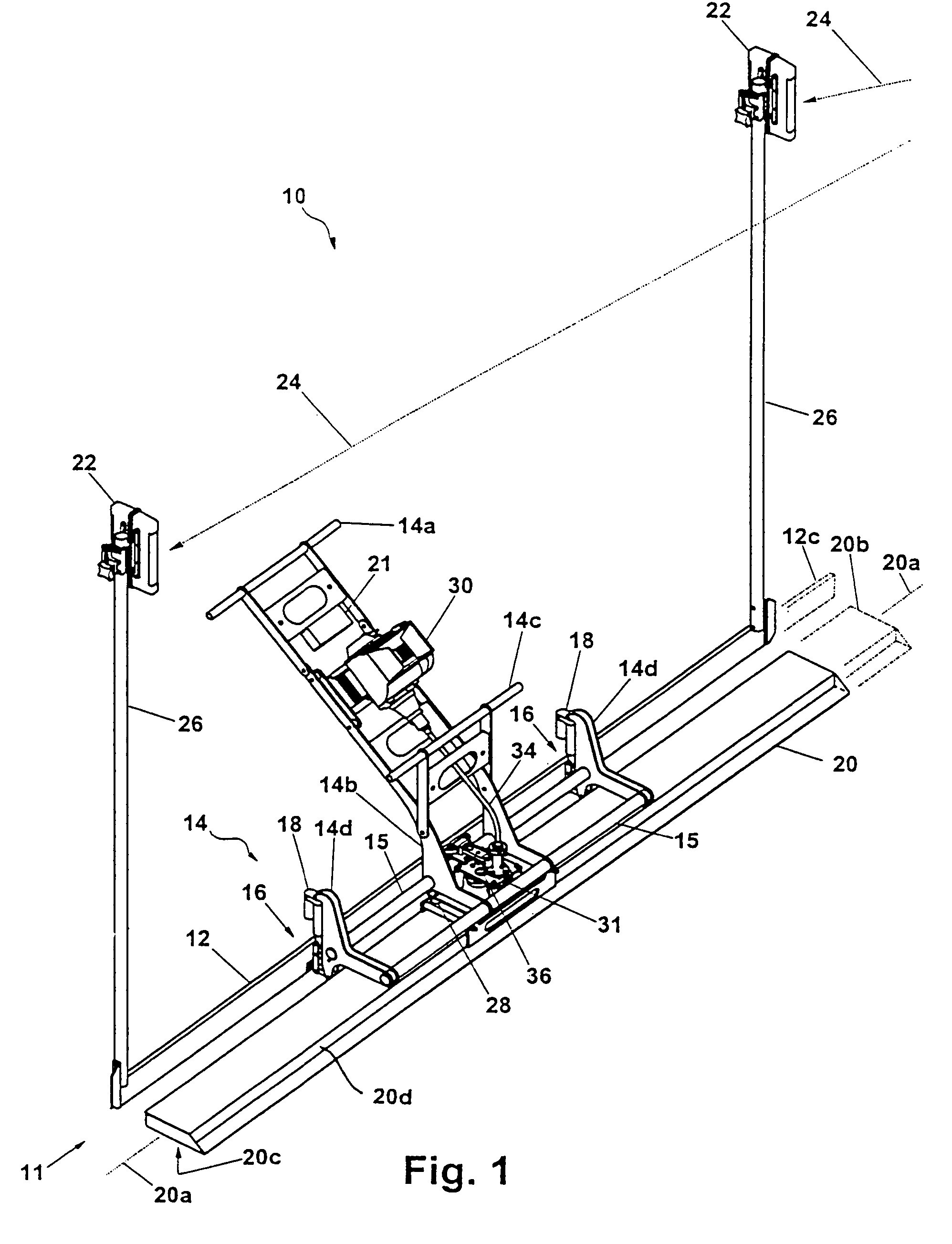

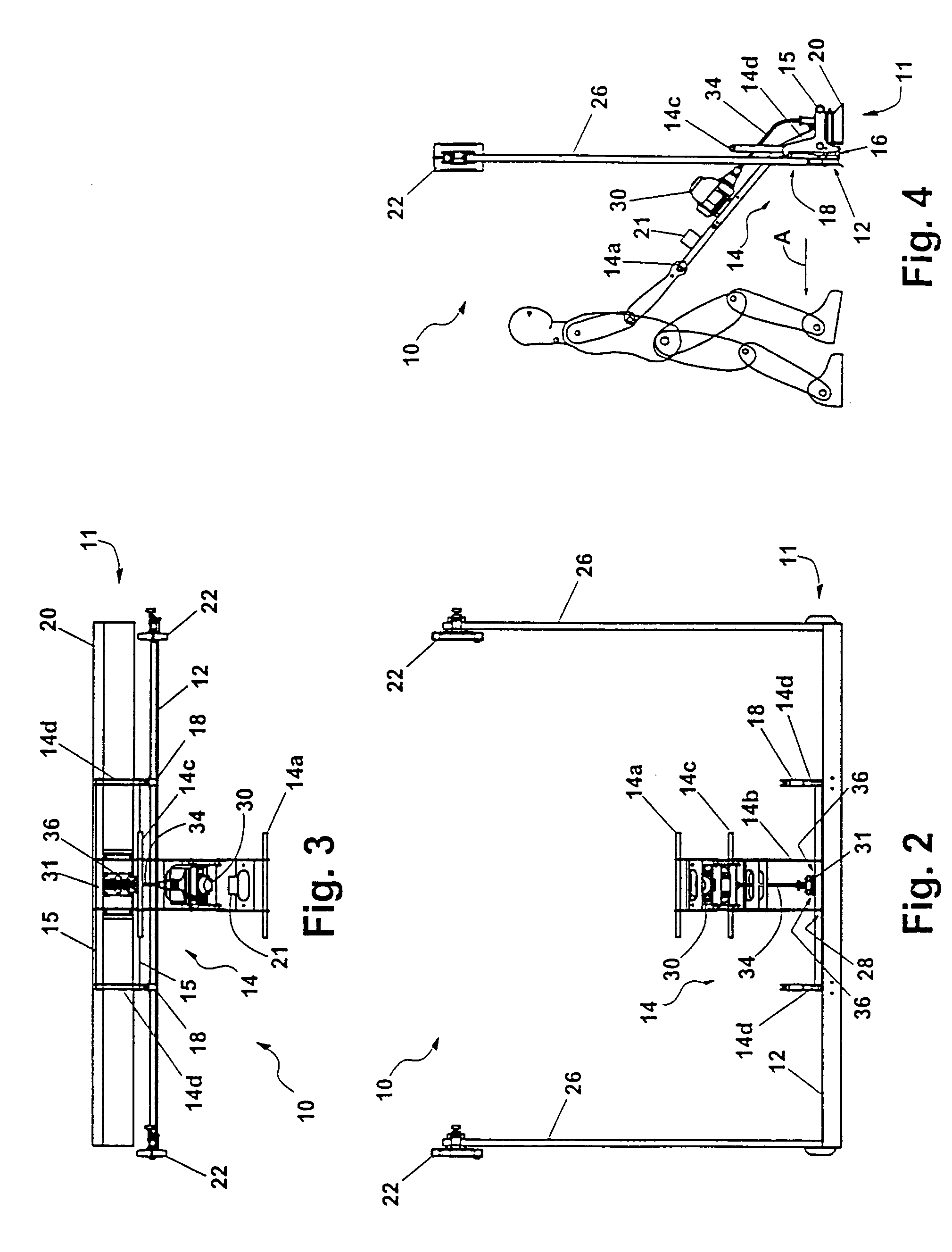

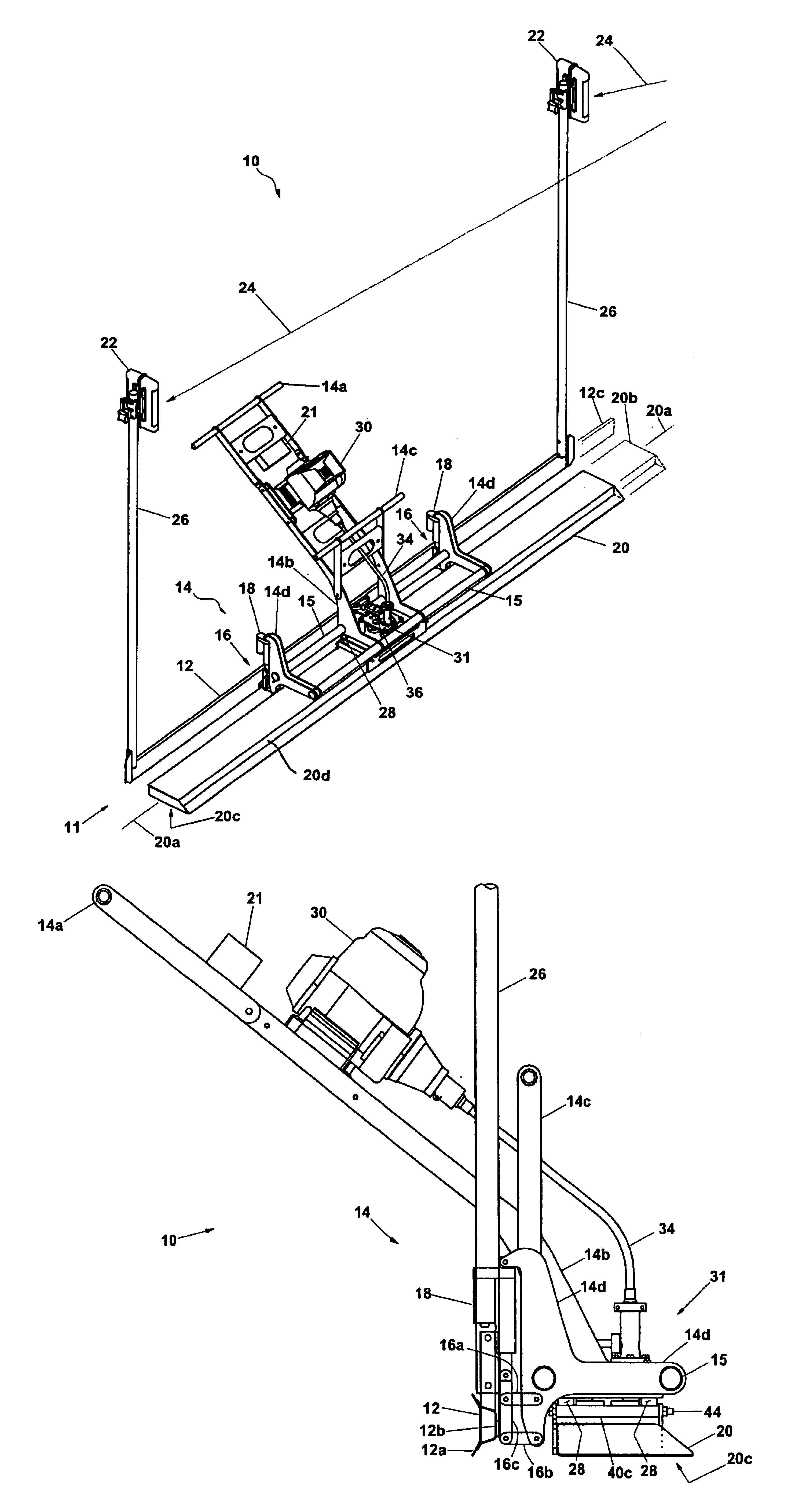

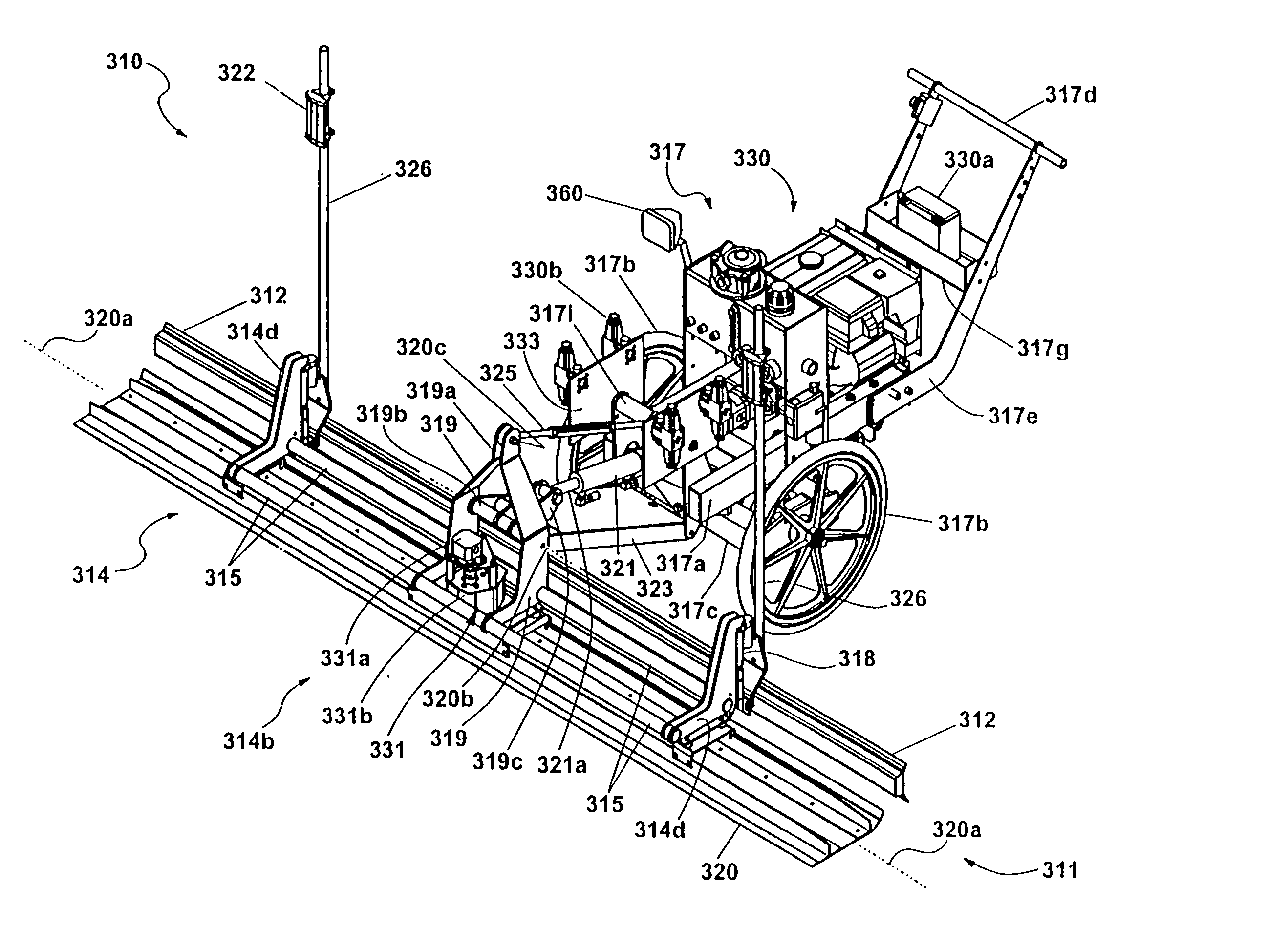

Light weight apparatus for screeding and vibrating uncured concrete surfaces

InactiveUS6976805B2Reduce needImprove accuracyRoads maintainenceBuilding material handlingControl systemEngineering

A lightweight screeding apparatus for screeding and smoothing an uncured concrete surface includes a concrete surface working member, such as vibrating beam or member, and a grade setting device adjustably mounted to said vibrating beam. The screeding apparatus may include a wheeled support which at least partially supports the vibrating beam and / or the grade setting device. The wheels of the wheeled support may be powered or driven to assist an operator in moving the screeding apparatus over and through the uncured concrete. The grade setting device is vertically adjustable to set or indicate the desired grade of the concrete surface as the screeding apparatus is moved over and through the uncured concrete. The grade setting device may be adjusted by means of a laser plane responsive control system.

Owner:SOMERO ENTERPRISES INC

Apparatus for screeding uncured concrete surfaces

InactiveUS20050069385A1Improve accuracyEasy to operateRoads maintainenceBuilding material handlingControl systemMechanical engineering

A screeding apparatus for screeding and smoothing an uncured concrete surface includes a vibrating member and a grade setting device adjustably mounted to said vibrating member. The screeding apparatus may include a wheeled support which at least partially supports the vibrating member and / or the grade setting device. The grade setting device is vertically adjustable, such as via a laser plane responsive control system, to set or indicate the desired grade of the concrete surface as the screeding apparatus is moved over and through the uncured concrete. The level of the screeding apparatus may be automatically adjustable to maintain a desired level and angle of attack of the vibrating member. The vibrating member may be activated only when the screeding apparatus is moved in a screeding direction so as to reduce depressions that otherwise may occur if the vibrating member vibrates on the uncured concrete when not moving.

Owner:SOMERO ENTERPRISES INC

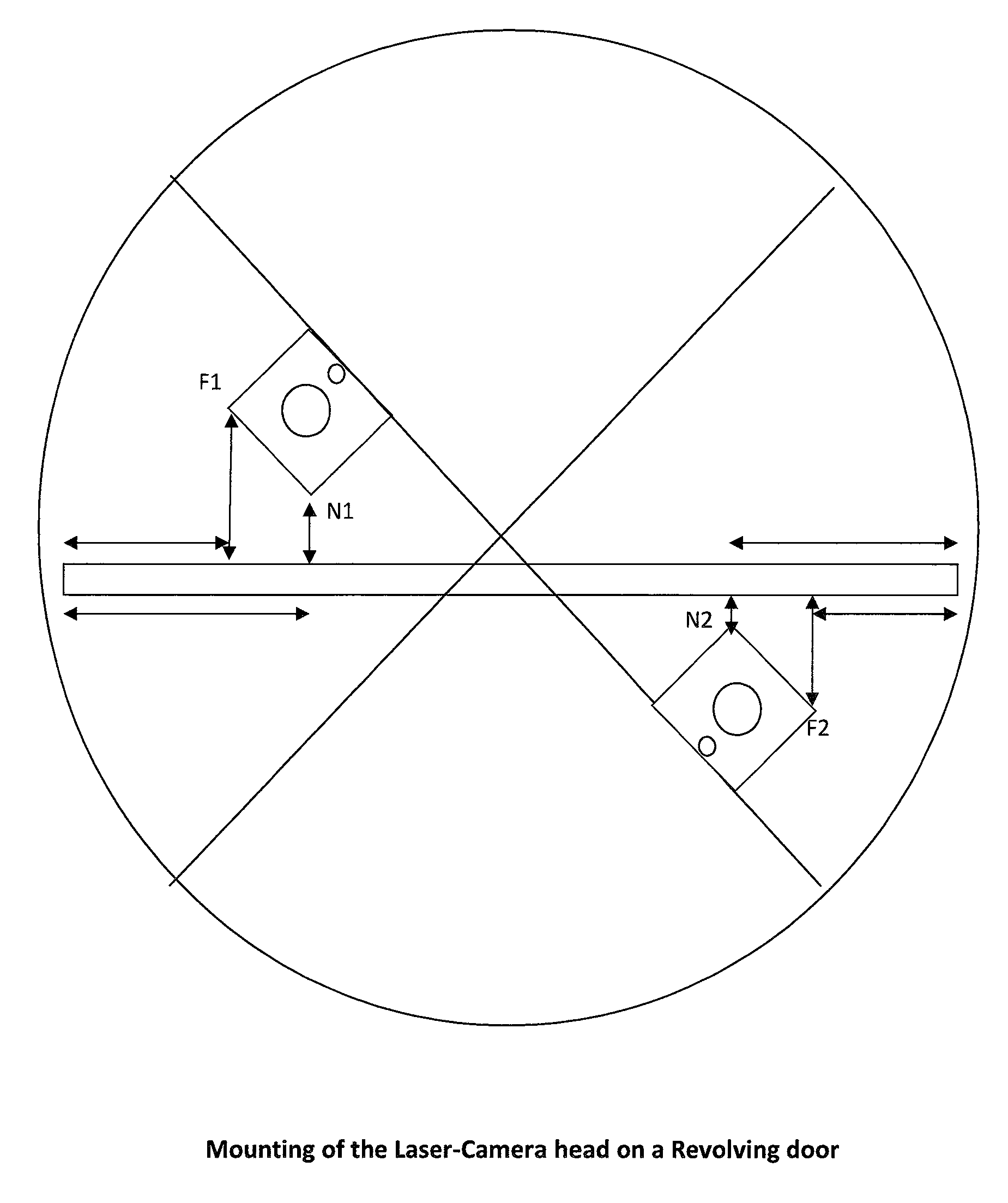

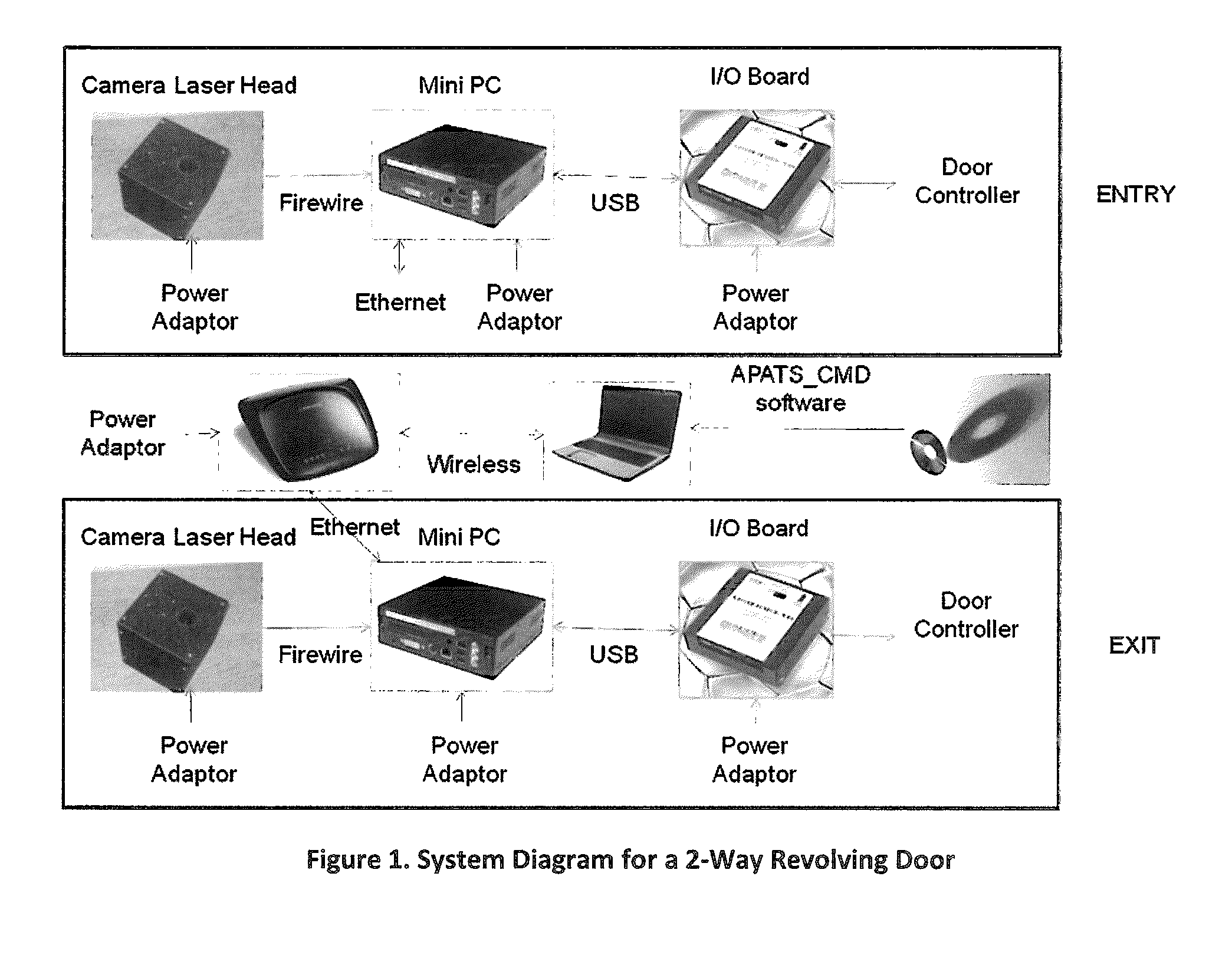

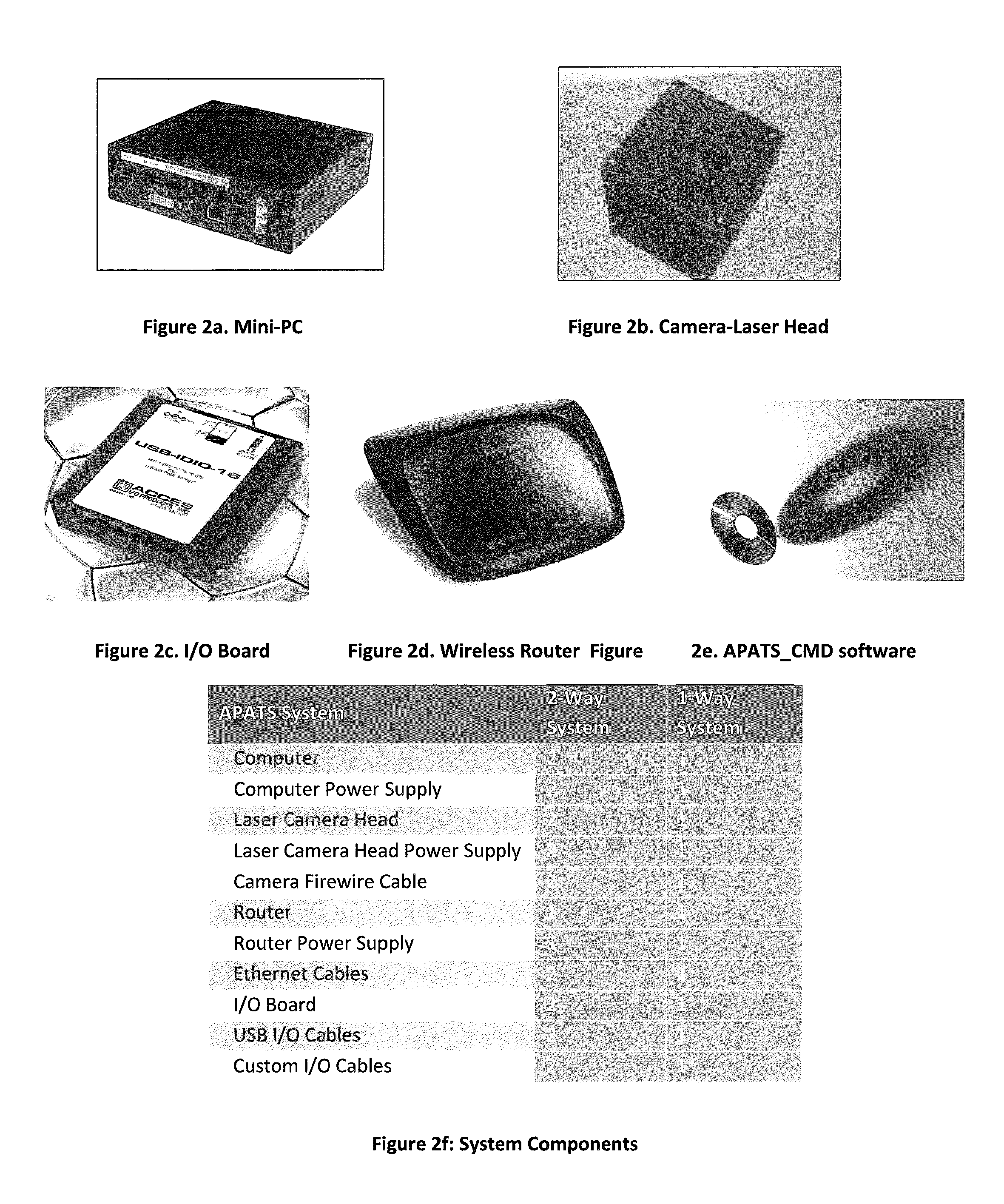

Method for moving object detection using an image sensor and structured light

A method for detecting moving objects including people. Enhanced monitoring, safety and security is provided through the use of a monocular camera and a structured light source, by trajectory computation, velocity computation, or counting of people and other objects passing through a laser plane arranged perpendicular to the ground, and which can be setup anywhere near a portal, a hallway or other open area. Enhanced security is provided for portals such as revolving doors, mantraps, swing doors, sliding doors, etc., using the monocular camera and structured light source to detect and, optionally, prevent access violations such as “piggybacking” and “tailgating”.

Owner:NICHANI SANJAY +1

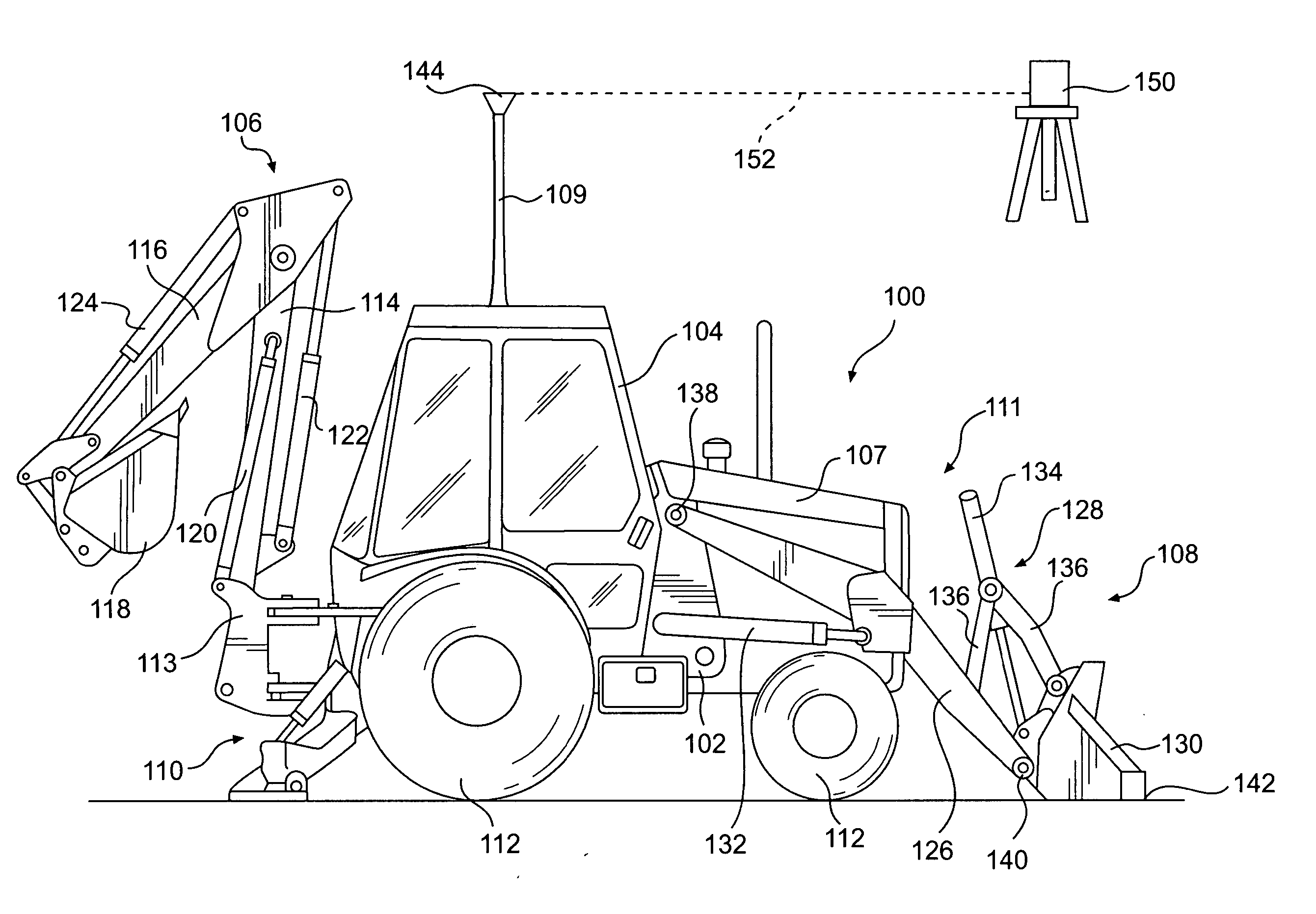

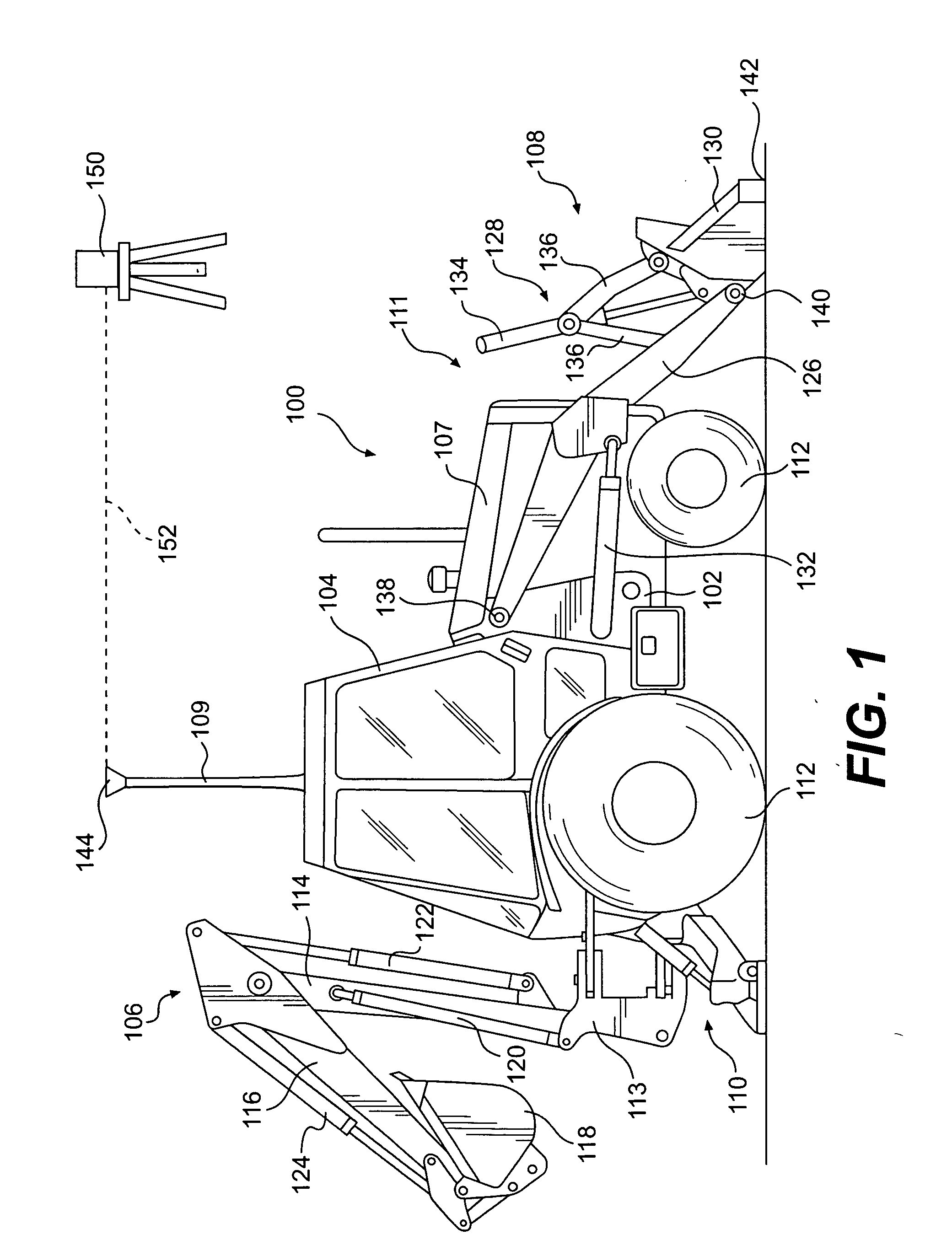

Multiple simultaneous laser-reference control system for construction equipment

A number of laser beam stations emit vertically separated parallel planes and / or ray-planes of laser light that can be discriminated by their respective plane elevations, modulation of the laser light, time synchronizing, etc. Identifying the laser plane would also imply an identification of the source laser beam station, and thus a precise indication of the elevation at the point of optical intercept. Alternatively, a single laser beam station is used that can emit several different monochromatic color planes and / or ray-planes of laser light. Monochromatic laser diodes, for example, are used for point-light sources and rotating or on-end conical mirrors are used to convert the diode laser light to the required monochromatic color planes and / or ray-planes of laser light. Receivers, generally held on masts attached to motor grader, bulldozer, loader, and excavator machines are used to sense the vertical reference position of the monochromatic color planes and / or ray-planes of laser light, relative to the earth cutting blade of the machine. Fixed-color filters, color filter wheels, and / or linear array photodetectors are used to discriminate amongst the colors and to exactly sense the plane of intersection with the machine. The results of the sensing are either displayed to an equipment operator for manual adjustment of the blade to an automatic servo control system connected to hydraulically control the blade.

Owner:TRIMBLE NAVIGATION LTD

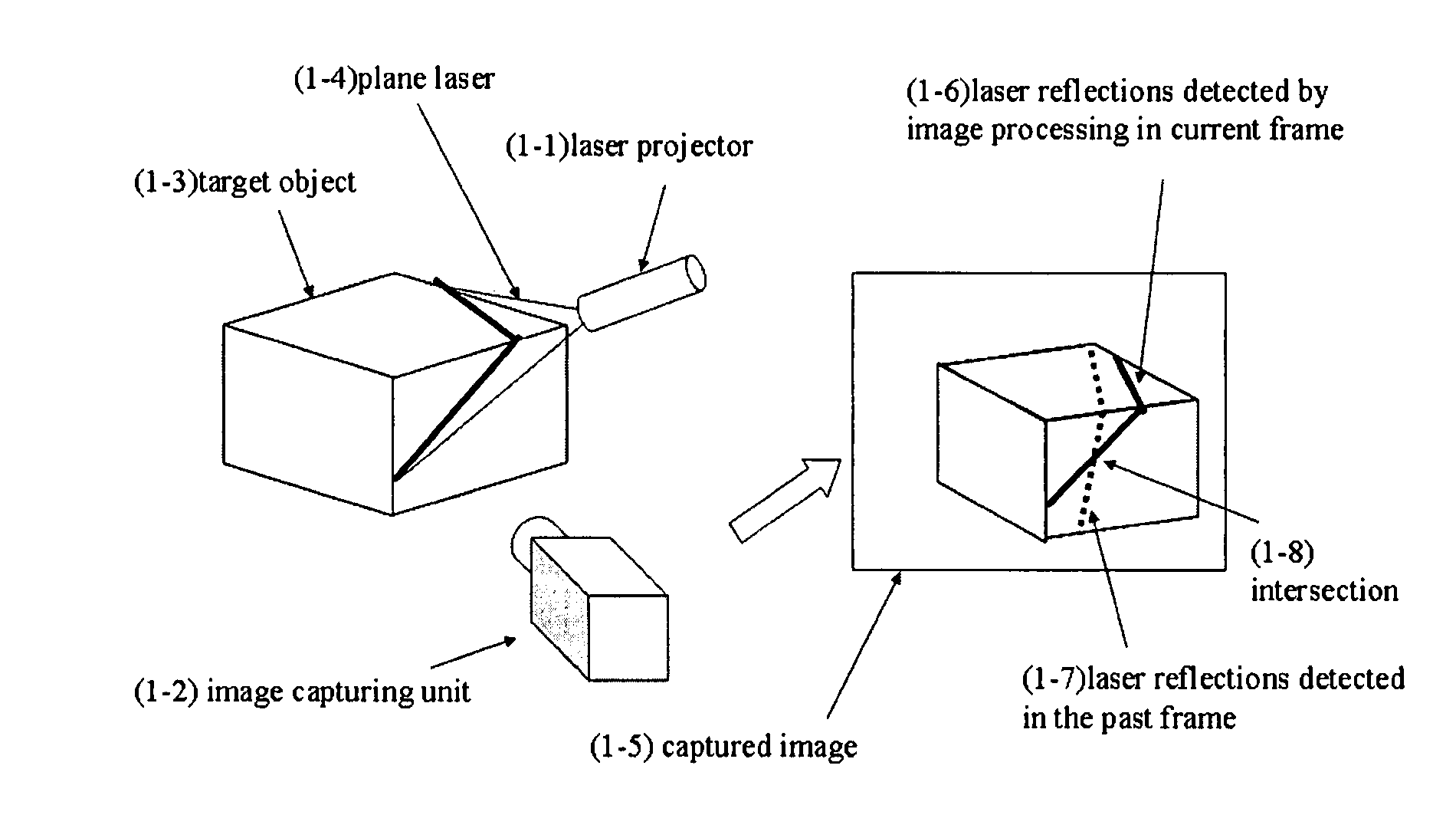

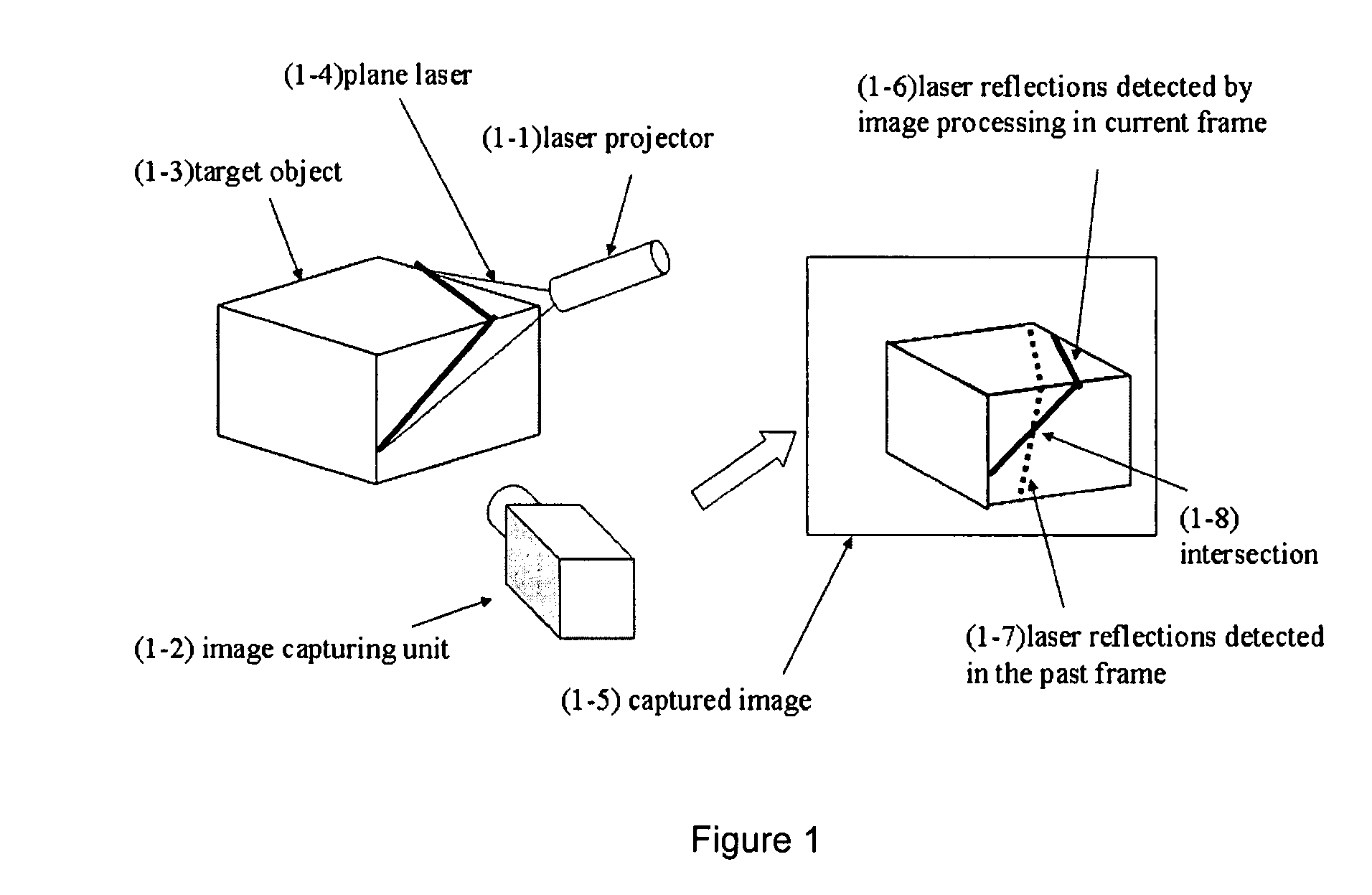

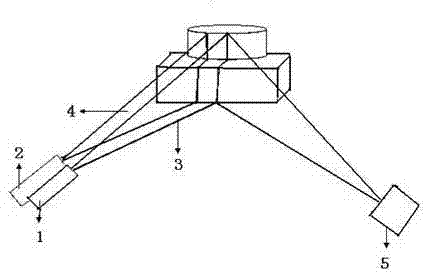

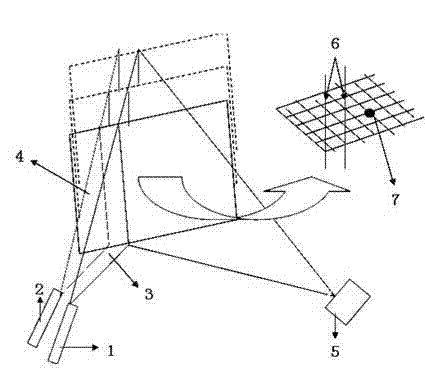

Three-dimensional shape measuring method and apparatus for the same

InactiveUS20090040532A1Improve practicalityImprove accuracyUsing optical meansTriangulationLight beam

A three-dimensional shape measuring apparatus includes a line laser light source (1) and an image capturing device (2). A three-dimensional shape measuring method and apparatus is characterized by irradiating a line laser beam to an object (3) to be measured from a laser projecting device, imaging points (6) irradiated with the laser beam by the image capturing device (2, detecting points on taken images as intersections (8), each of the points being detected from the taken images and being detected as a common point where line laser beams pass, deriving equations including the positions of the laser planes and the three-dimensional positions of the intersections as unknowns based on the detected intersections, determining the three-dimensional positions of the intersections and the positions of the laser planes by solving the derived equations as simultaneous equations, calculating by triangulation the three-dimensional positions of the points irradiated with the laser beams other than the intersections by using the positions of laser planes, and obtaining the three-dimensional shape of the object by repeating the series of processes.

Owner:TECHNODREAM21

Lightweight apparatus for screeding and vibrating uncured concrete surfaces

InactiveUS6953304B2Reduce needImprove accuracyRoads maintainenceBuilding material handlingLaser planeEngineering

A lightweight screeding apparatus for screeding and smoothing an uncured concrete surface includes a concrete surface working member, such as vibrating beam or member, and a grade setting device adjustably mounted to said vibrating beam. The screeding apparatus may include a wheeled support which at least partially supports the vibrating beam and / or the grade setting device. The wheels of the wheeled support may be powered or driven to assist an operator in moving the screeding apparatus over and through the uncured concrete. The grade setting device is vertically adjustable to set or indicate the desired grade of the concrete surface as the screeding apparatus is moved over and through the uncured concrete. The grade setting device may be adjusted by means of a laser plane responsive control system.

Owner:SOMERO ENTERPRISES INC

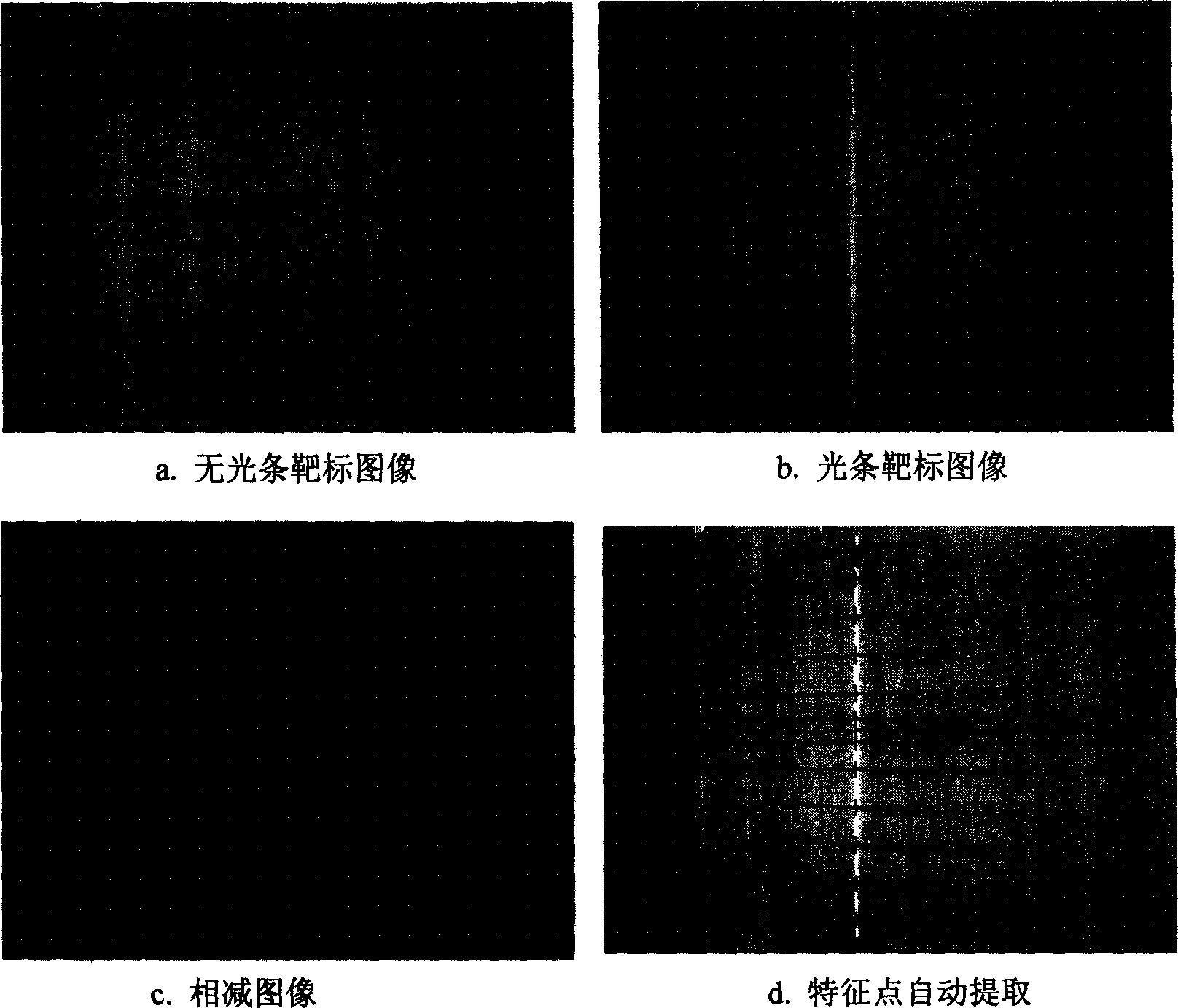

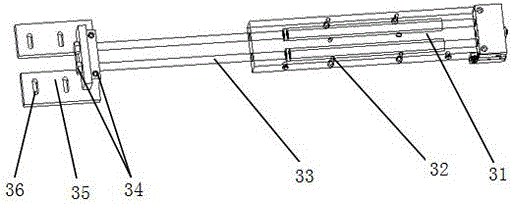

Compatible and accurate calibration method for double eye line structure photo-sensor and implementing apparatus

InactiveCN1595054AAccurate Light Plane ParametersUsing optical meansMathematical modelIntersection of a polyhedron with a line

This invention relates to laser high-accuracy three-dimensional coordinate measurement, which in detail relates to a binocular structure photo-sensor compatibility calibration and its operation apparatus. In order to calibrate the photo plane parameters of the binocular structure photo-sensor, it unites the space coordinates measured of the left and right cameras. The technique project adopted in this invention is the following: the operation apparatus comprises left and right cameras, laser machine, and target and also movable guide rail with the target fixed on; the target plane is vertical to the moving direction of the guide rail which ensures the plane is vertical to the project laser plane. Besides, it is to identify the axis coordinates in the space coordinate system of the cross points of the each lines and photo bars in the target and brings the coordinates to the photo-sensor mathematical model for computation and get sensor parameters.

Owner:TIANJIN UNIV

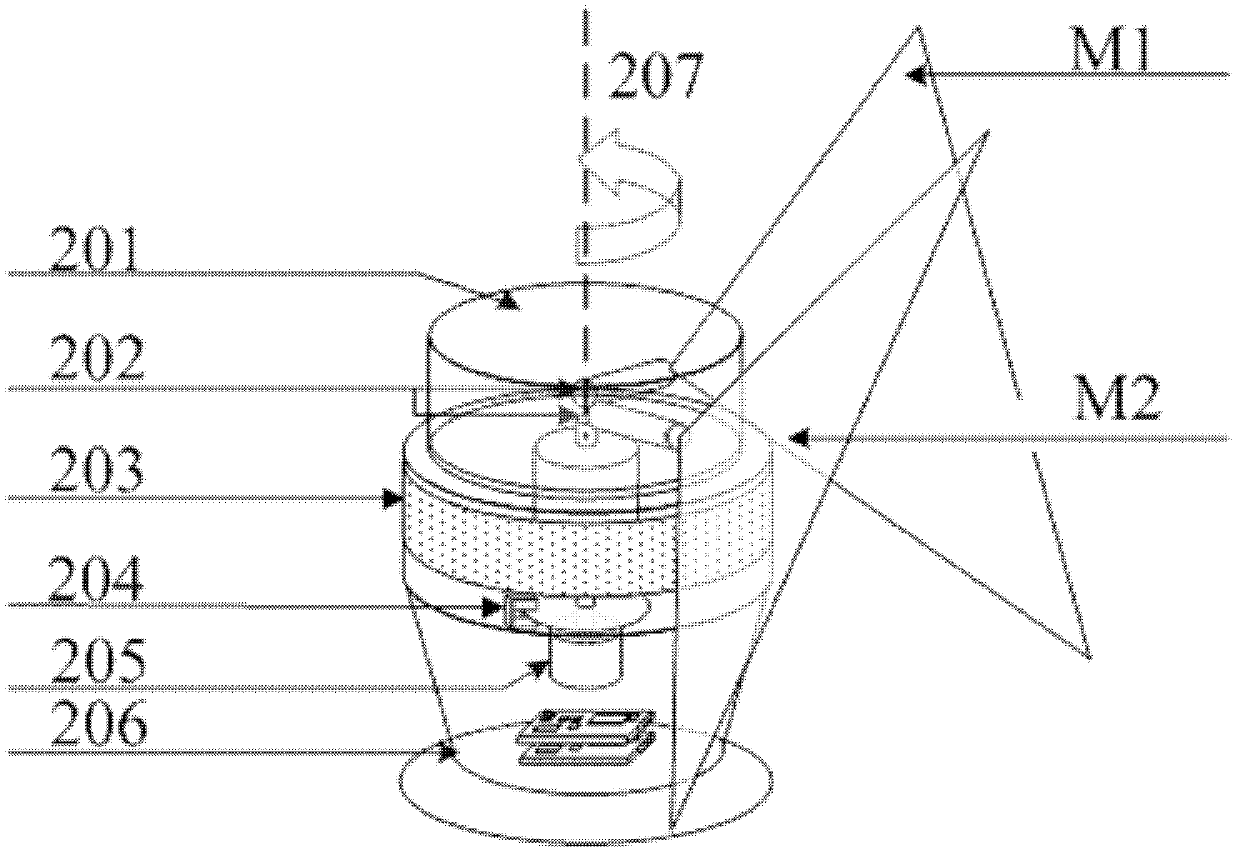

Line-shaped laser vertical rotation type three-dimensional appearance measuring apparatus and method thereof

InactiveCN101476881AAvoid inconvenienceHigh precisionUsing optical meansRotational axisMeasurement device

The invention relates to a device and a method for measuring a horizontal laser vertically rotary three-dimensional shape, and belongs to the technical field of computer vision measurement. The device comprises a base, a camera, a horizontal laser, a motor, a rotational axis, an angle measuring element, a driving circuit, a switching circuit and a controller, wherein the camera and the horizontal laser are fixedly connected with the rotational axis of which a central line is positioned in a laser plane of the horizontal laser; the included angle between an observation plane formed by the central line of the rotational axis and a focal center of a lens and the laser plane is between 80 and 100 DEG; and the included angle between the central line of the rotational axis and an optical axis of the lens is between 40 and 50 DEG. The device can detect edge information in various directions, realize high-precision measurement of the three-dimensional shape of object surfaces, and avoid the inconvenience caused by rotation of objects in the prior method, has a simple structure, low cost and high measurement precision, and is suitable for surface detection of the objects with various dimensions.

Owner:WUXI RES INST OF APPLIED TECH TSINGHUA UNIV +1

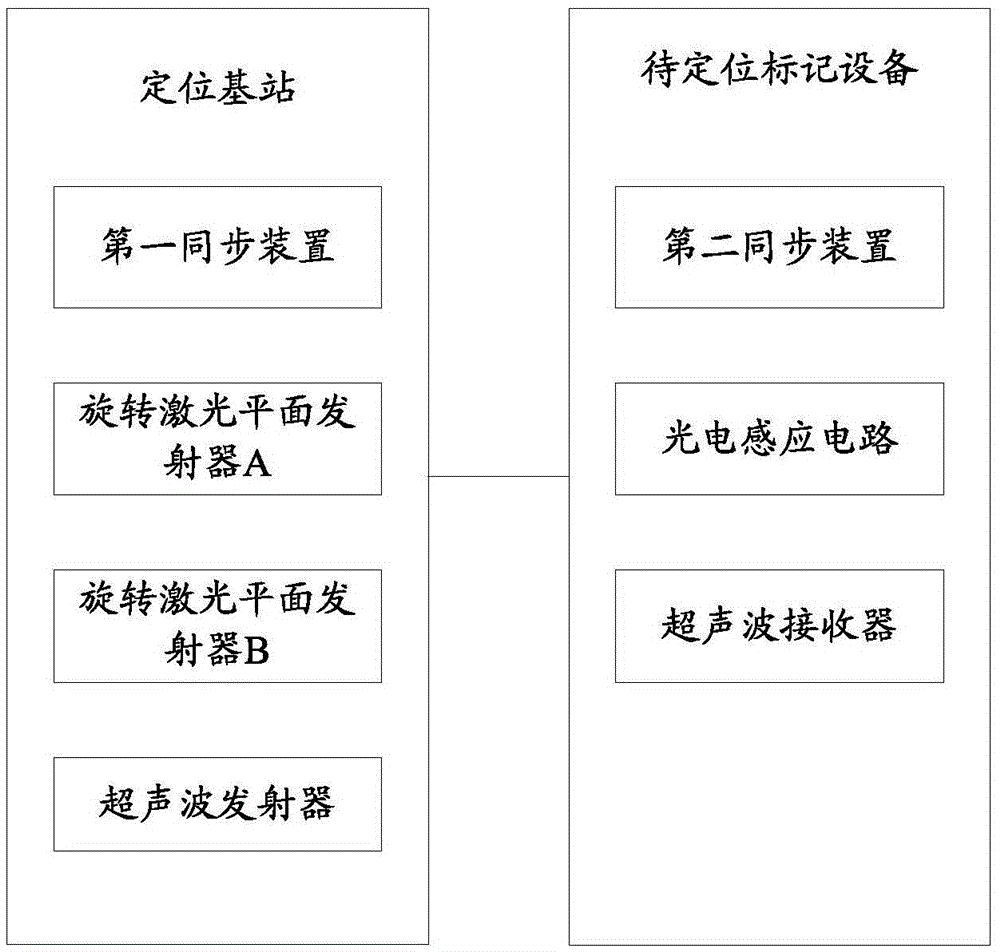

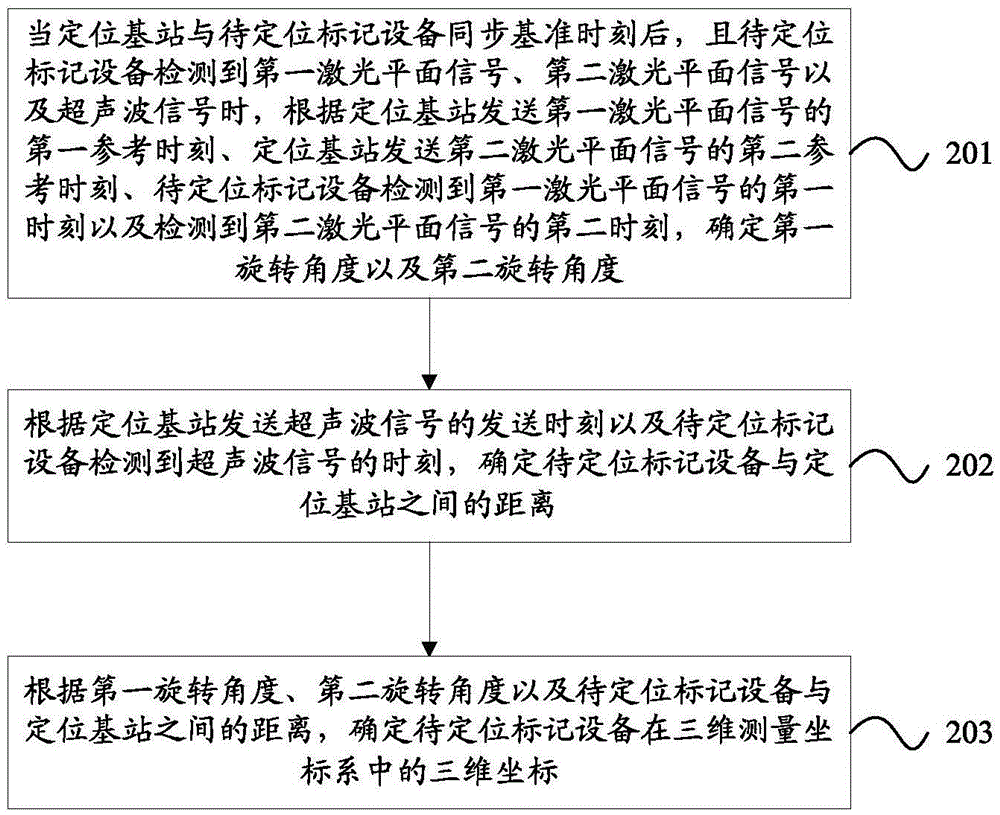

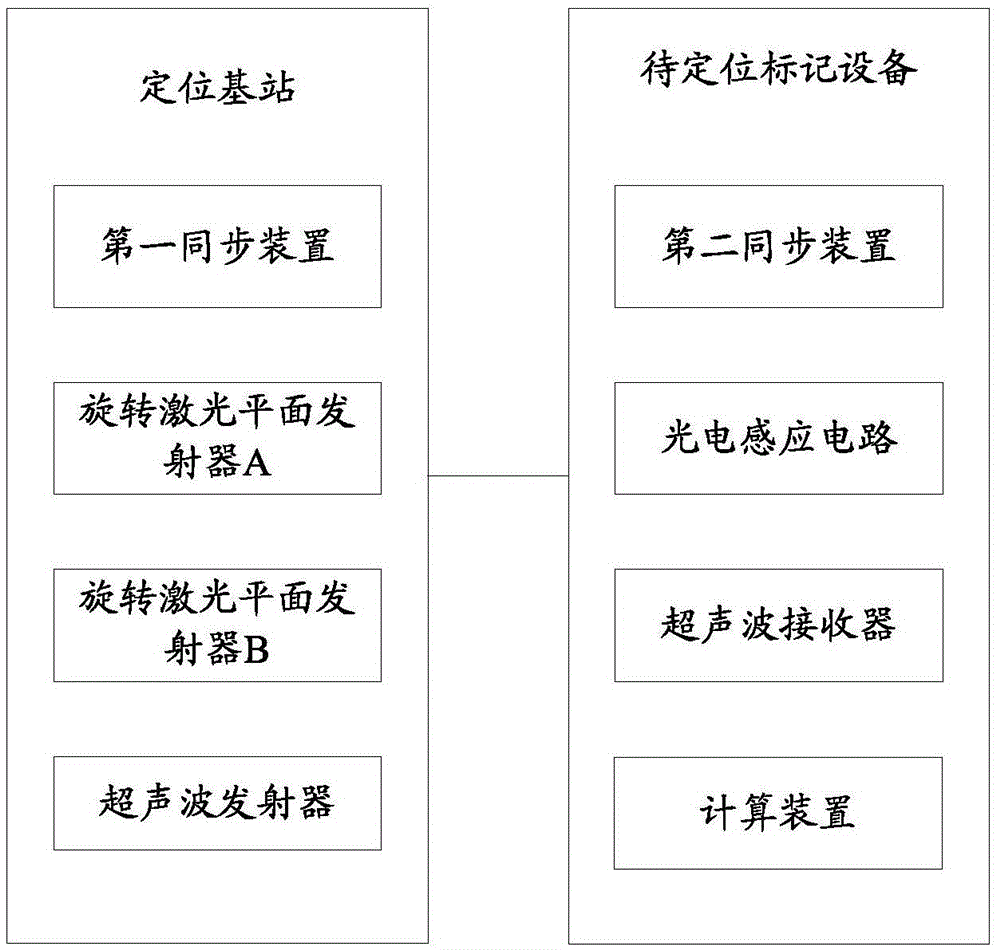

Three-dimensional space detection system, positioning method and system

InactiveCN105607034ADesigned for easy miniaturizationHigh positioning accuracyPosition fixationNavigation instrumentsThree-dimensional spaceSupersonic waves

The invention discloses a three-dimensional space detection system, a positioning method and a system, the positioning system comprises a positioning base station, a to-be-positioned marking device and a calculating device, the positioning base station synchronizes a standard time with the to-be-positioned marking device, transmits a supersonic wave signal, rotatably transmits a first laser plane signal around a first rotating shaft and rotatably transmits a second laser plane signal around a second rotating shaft which is vertical to the first rotating shaft; the to-be-positioned marking device synchronizes the standard time from the positioning base station and detects the supersonic wave signal, the first laser plane signal and the second laser plane signal; the calculating device is used for determining a three-dimensional space coordinate of the to-be-positioned marking device according to the time of the to-be-positioned marking device detecting the supersonic wave signal, the time of the same detecting the first laser plane signal and the time of the same detecting the second laser plane signal. The system and the method can realize indoor precision positioning based on the supersonic wave signal and the laser signals.

Owner:NOLO CO LTD

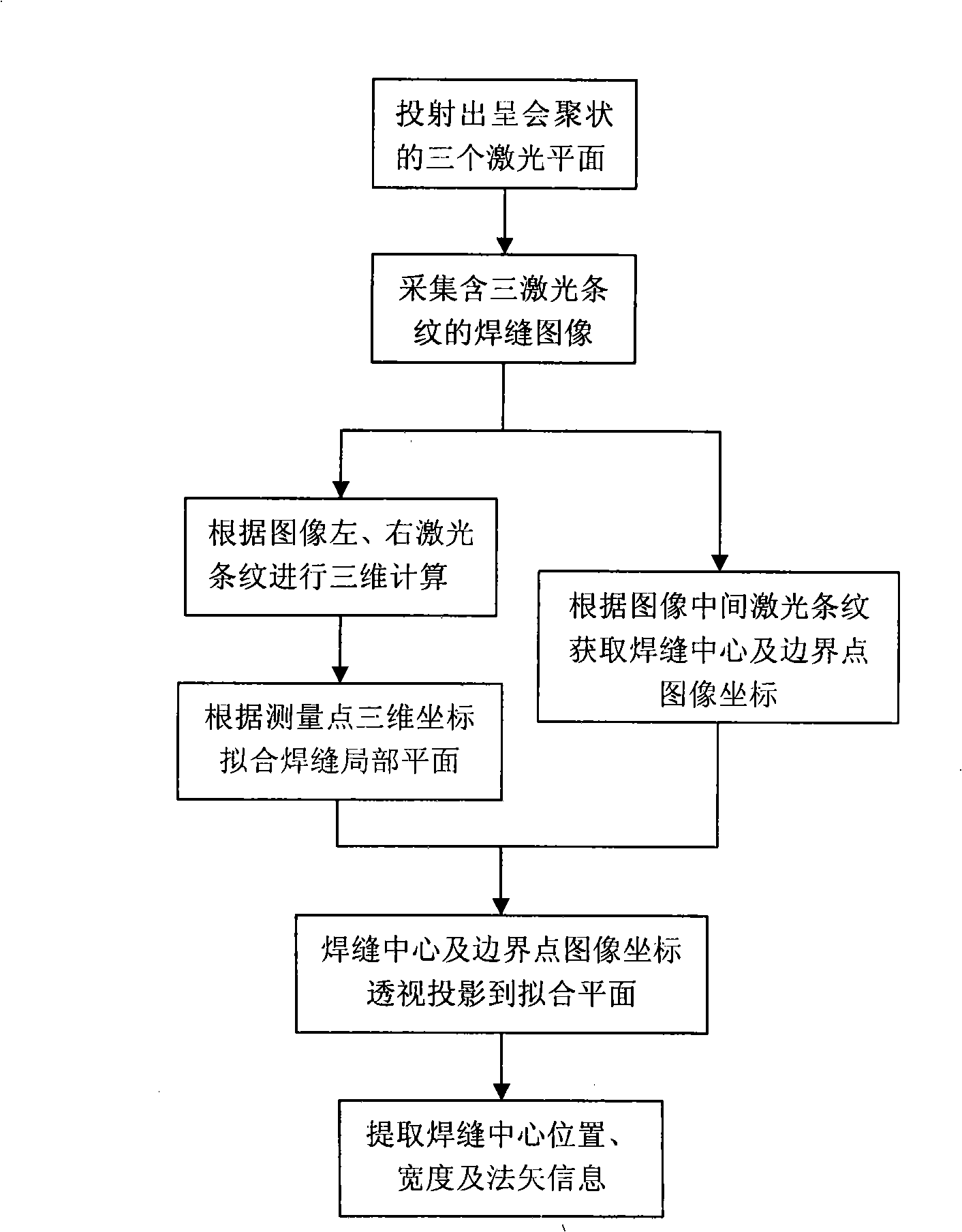

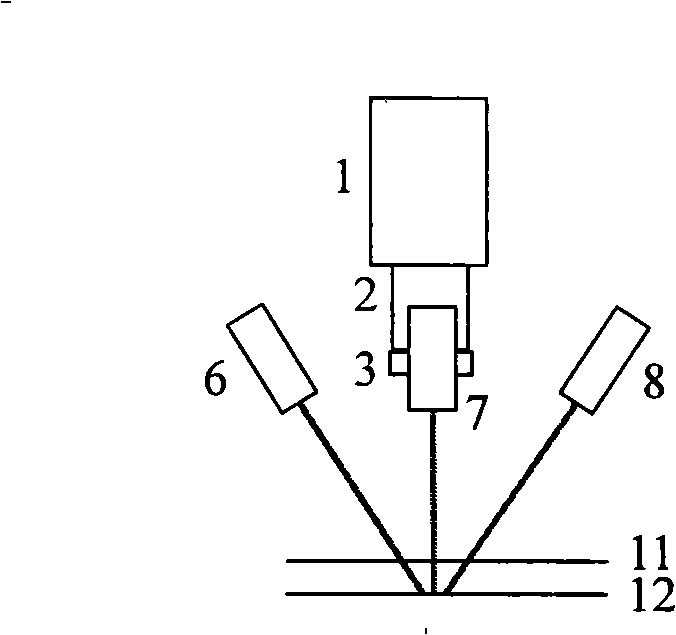

Laser welding narrow butt-jointed seam measurement method and device

The invention relates to a measuring method of a strictured butt-jointed seam in laser welding, and a device; two-dimension and three-dimension visual information is combined together organically, the information of three-dimension position, normal vector and weld width of a seam center is obtained at a same measurement position by carrying out calibration to a CCD camera and two laser planes and utilizing a seam image containing three laser stripes. The device comprises a telecentric lens, the CCD camera, an image grabbing card, a band-pass filter and a computer. Each linear light source laser projects three converged laser planes, the laser stripes formed by the intersection of all the laser planes and the plane which is vertical to the principal optic axis of the CCD camera are approximately parallel. The first and third linear light source lasers are symmetrically installed on the left and the right sides of the CCD camera and form the angles of 15 degrees to 60 degrees with the principal optic axis of the CCD camera; the second linear light source laser is symmetrically installed at the front side or the back side of the CCD camera and forms the angles of 10 degrees to 30 degrees with the principal optic axis of the CCD camera. The device has simple structure, with rich measurement information.

Owner:HUAZHONG UNIV OF SCI & TECH +1

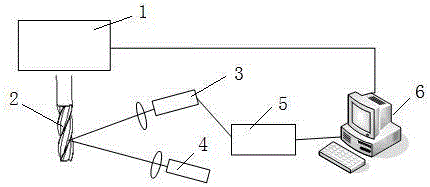

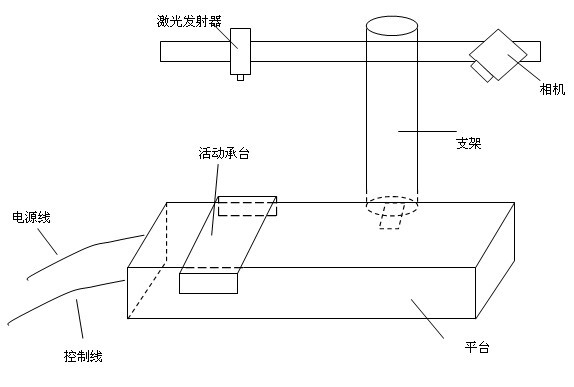

In-site measuring method and device of cutter abrasion

InactiveCN106840028ARealize presence detectionRealize automatic in-situ measurementUsing optical meansImaging processingMicrometer

The invention discloses an in-site measuring method and device of cutter abrasion, and belongs to the technical field of the in-site measuring method and device of cutter abrasion. The method comprises the first step of installing a linear structure laser device and a CCD camera on the lateral of a cutter, wherein the CCD camera is connected to a computer through an image collecting card; the second step of making ray laser be vertically projected to the knife blade of the cutter, wherein deformed laser rays image on a photosensitive surface of the CCD camera and are then transmitted to the computer; the third step of obtaining a two-dimensional size of a ray bar point on a laser plane through image processing and calibration calculation; the fourth step of making the device rotate along with the cutter to scan the cutter for one round to obtain three-dimensional size data of the whole cutter; the fifth step of comparing the three-dimensional size data with a standard cutter three-dimensional model to obtain abrasion loss. The in-site measuring method and device of cutter abrasion have the advantages that the cost is low, the precision is high, the strip image information is easy to obtain, the practicability is high, the active control is achieved, the measuring precision at the micrometer level can be reached, and thus the measuring method and device of cutter abrasion are suitable for in-site measuring of cutter abrasion.

Owner:HUBEI UNIV OF ARTS & SCI

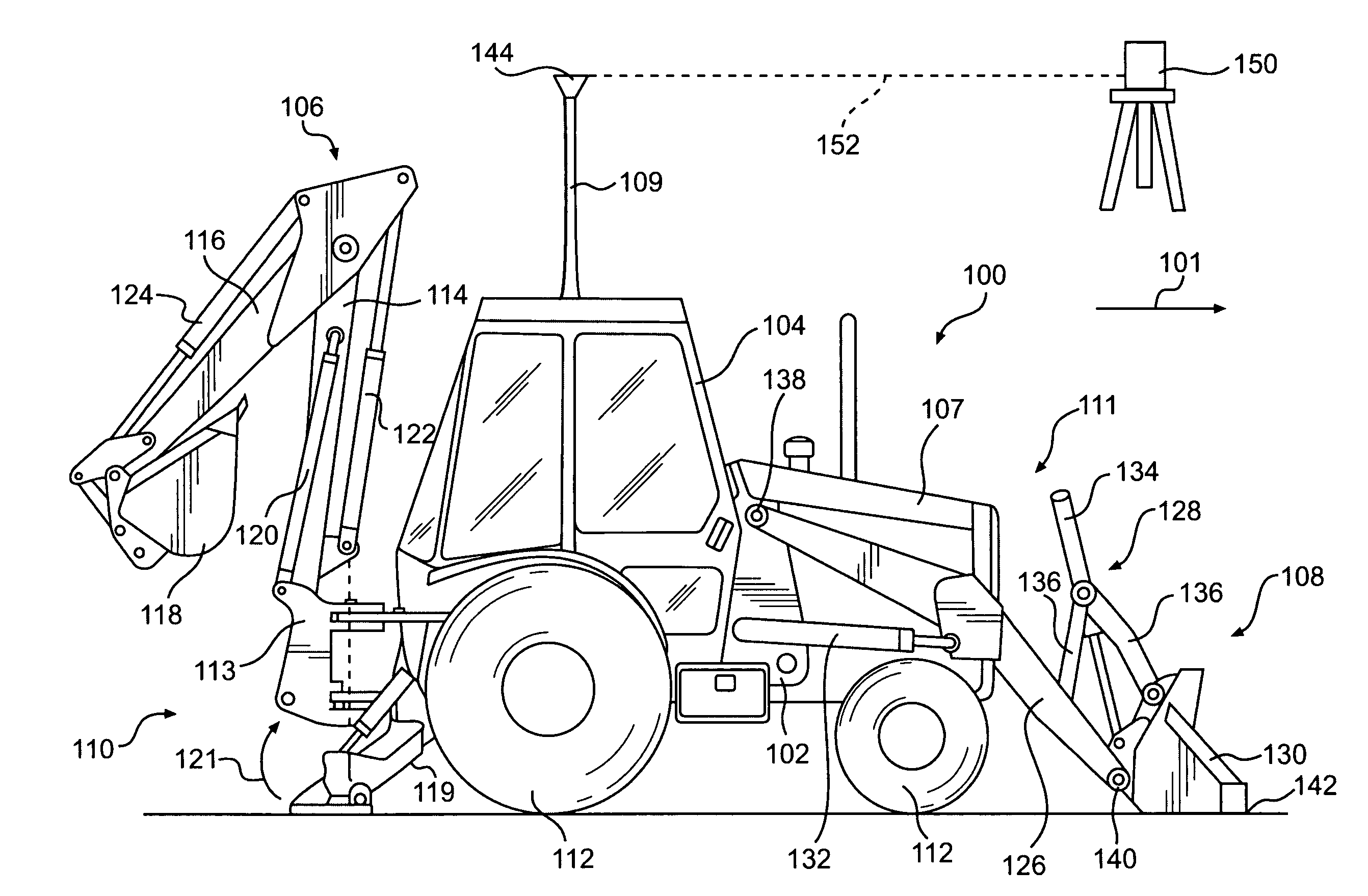

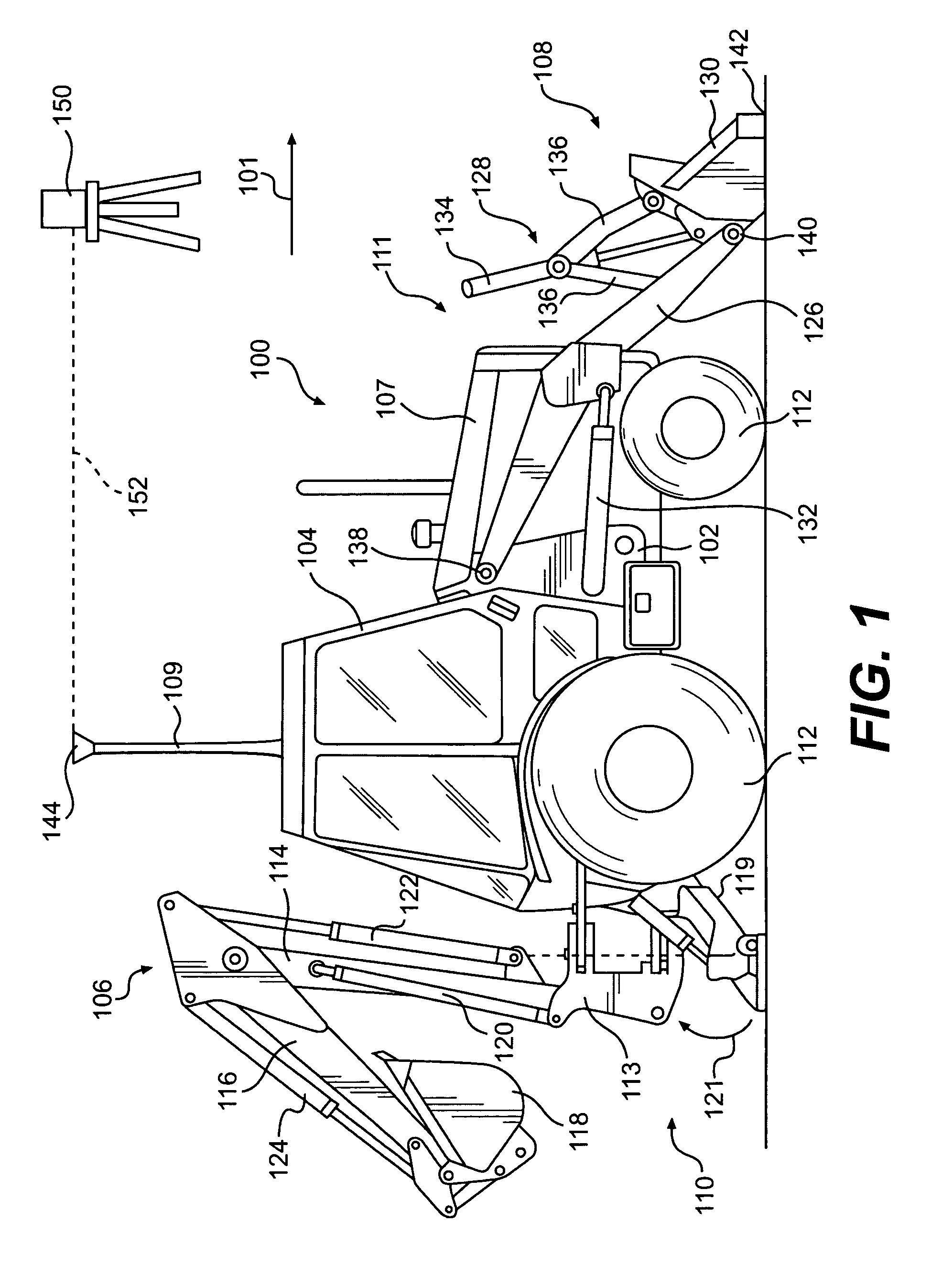

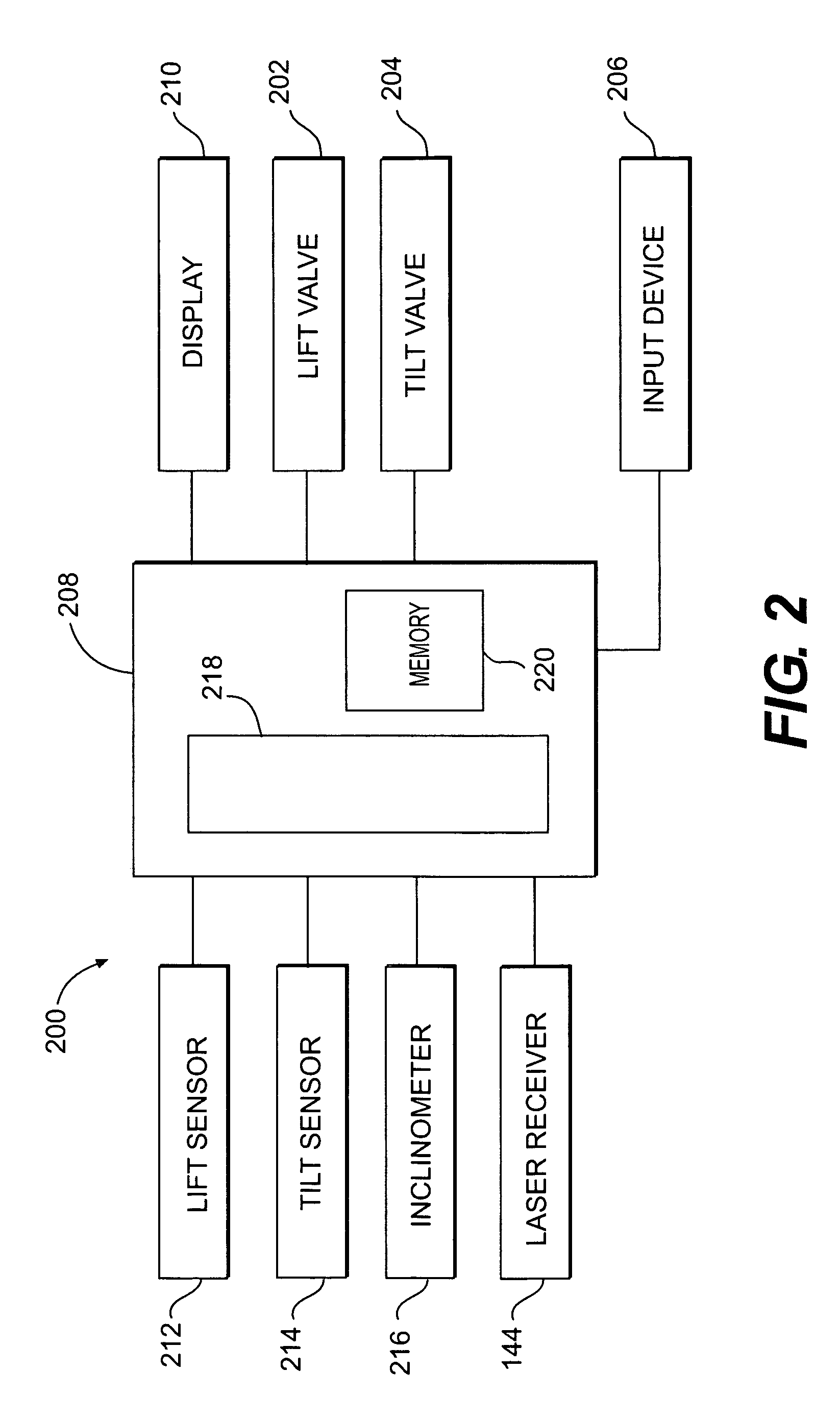

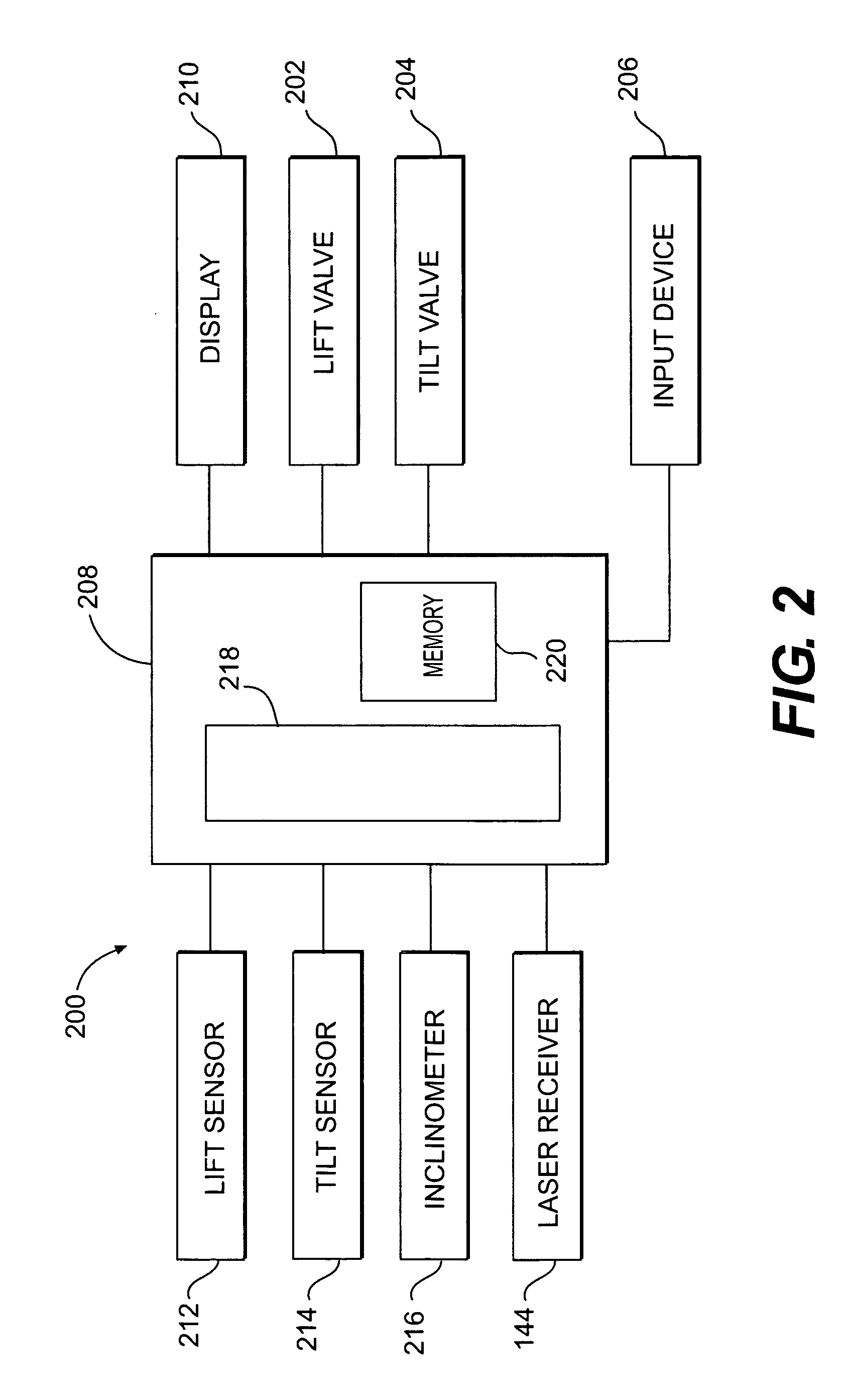

Grading control system

ActiveUS7293376B2Analogue computers for trafficMechanical machines/dredgersMarine engineeringControl system

A grading control system for a work machine having a work implement for grading along a grade defined by a laser plane generator is disclosed. The system includes tilt and lift actuators associated with the work implement and configured to selectively tilt, raise and lower the work implement. A laser receiver is configured to receive a laser signal indicative of a desired grade. The laser receiver is configured to communicate a height signal indicative of a position of the work machine relative to the laser plane. A lift sensor is configured to communicate a lift signal indicative of a lift position of the work implement. A control module is configured to generate and communicate a control signal based on the height and lift signals to actuate at least one of the lift and tilt actuators to maintain the work implement at a position substantially corresponding to the desired grade.

Owner:CATERPILLAR INC

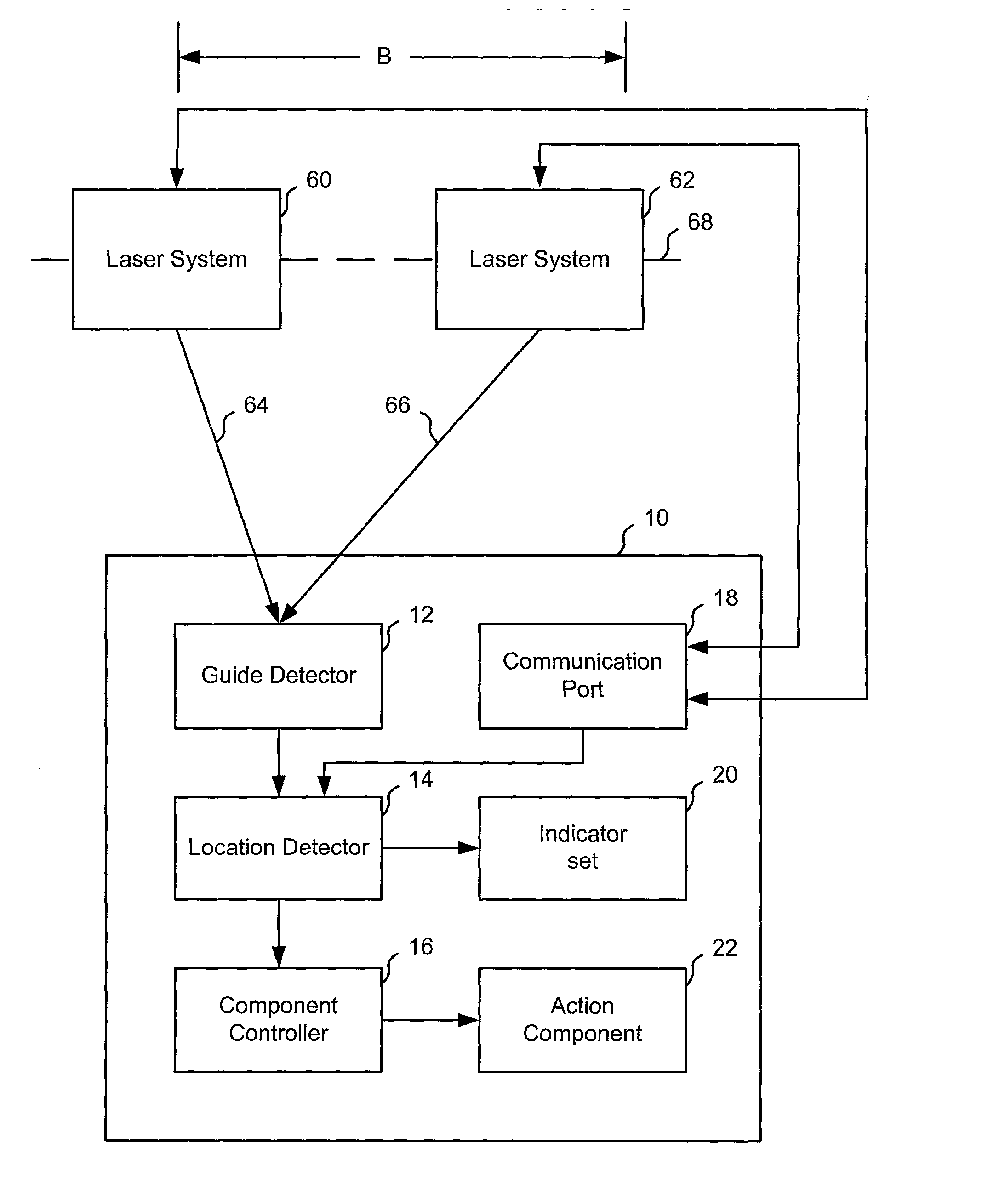

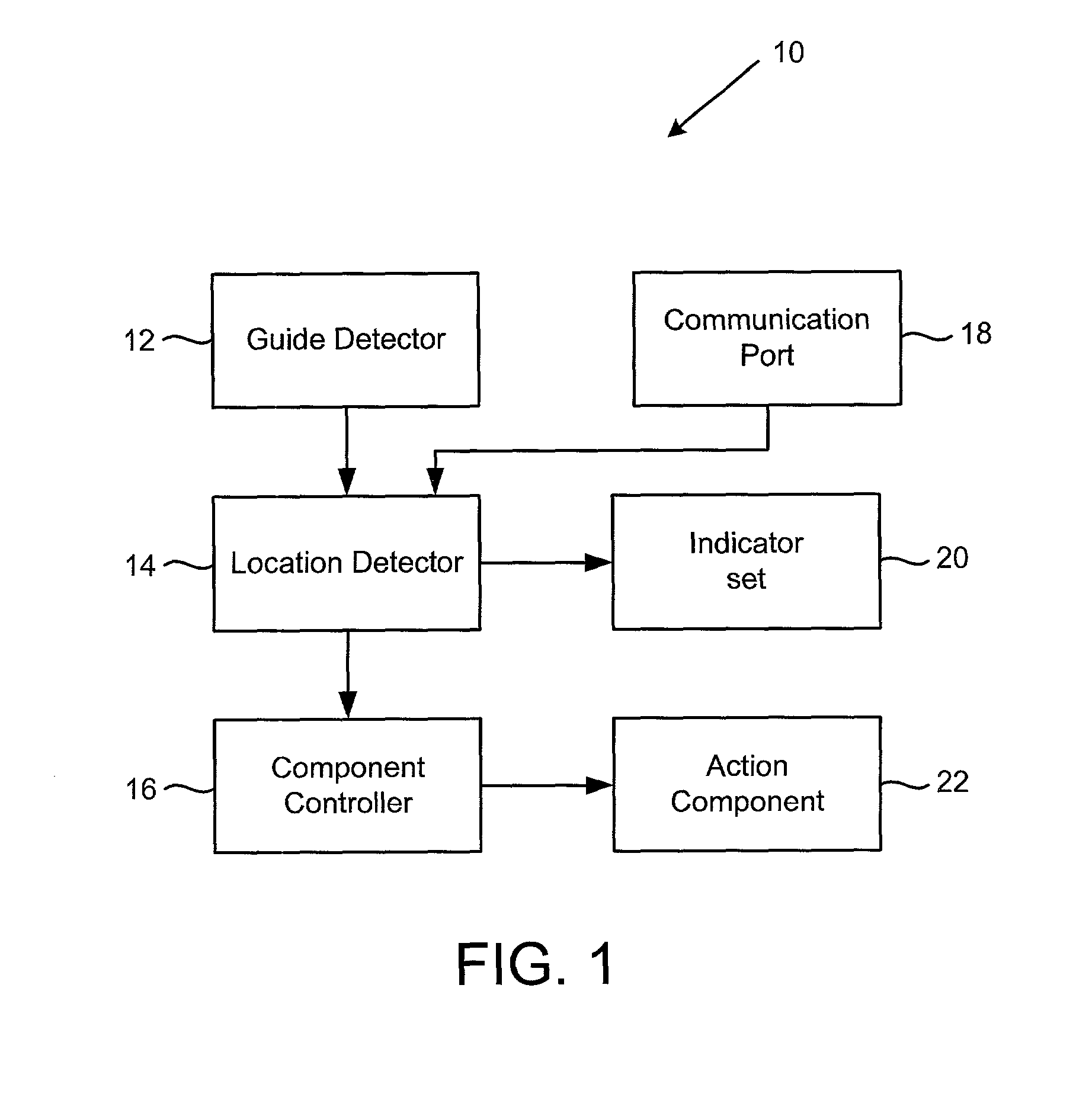

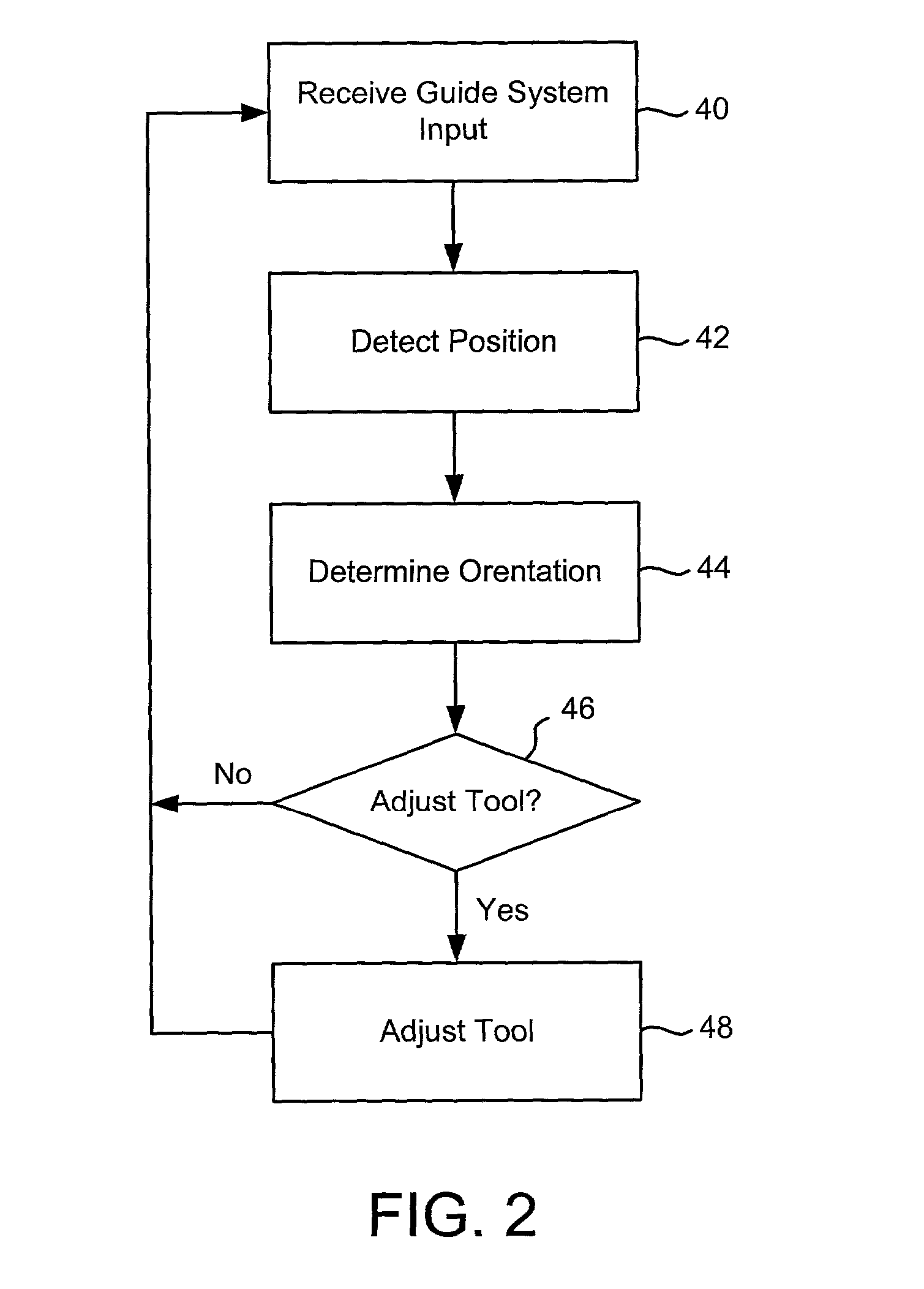

Detecting tool orientation, alignment, depth, and leveling

A tool is employed in conjunction with alignment, depth, and level detectors. The tool can use all or some of these detectors. The alignment detector provides an orthogonal laser line grid on an incident surface when the detector has a predefined relationship with the surface. The depth detector emits two sets of parallel laser planes that converge with each other. When the laser planes impact on an incident surface two sets of lines are formed. The laser lines from one laser plane set move closer to the lines from the other laser plane set as the depth detector moves closer to the surface-showing changes in depth or distance. The level detector employs two converging laser planes. An operator positions the level detector above an incident surface, so the laser planes' line of intersection appears on the surface if the surface is level. If the surface is not level, lines separate from each laser plane appear on the surface-signaling the need for a level adjustment. Some versions of the tool have the ability to detect their own orientation and make adjustments based on the orientation. Example tools include nail guns, jigsaws, circular saws, routers, and drills.

Owner:ROBERT BOSCH CO LTD

Three-dimensional information detection method based on two-line laser

InactiveCN102297658AImprove stabilityHigh precisionUsing optical meansThick lineThree dimensional measurement

The invention discloses a three-dimensional information detection method based on dual laser and belongs to the technical field of three-dimensional measurement. The method comprises the following steps of: adopting two lasers, and respectively solving laser plane equations of the first laser and the second laser; collecting an object image containing dual laser by utilizing a camera in the eventof detecting the three-dimensional information of an object, and solving a centre line of each laser thick line; and rebuilding three-dimensional data by utilizing inner parameters of the camera and the laser plane equations of both lasers. Compared with the single-laser measurement method, because of large information amount, the method disclosed by the invention specifically has higher stability, reliability and accuracy; and simultaneously, the operation requirements are simple, thus the method has the important application in detecting the surface three-dimensional information of objects.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

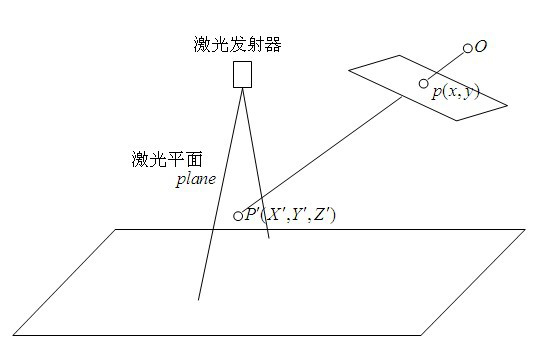

Monocular structured light-based three-dimensional modeling method

InactiveCN101986350ALow priceHigh precisionPhotogrammetry/videogrammetry3D modellingTriangulationDimensional modeling

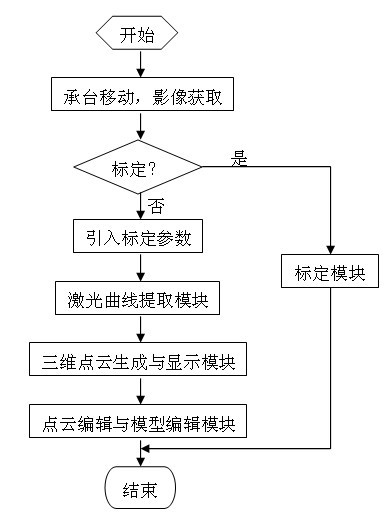

The invention discloses a method for quickly acquiring an object surface model, which comprises the following steps of: (1) automatically controlling the movement of a bearing platform and acquiring qualified sequence images through software; (2) accurately marking a laser plane, a camera parameter and a bearing platform movement space through coordinate of each marking point of a marking block, position of a laser line on the image and relative relationship between an object space point and the laser line; (3) accurately extracting the image coordinate sequence of the laser line; (4) reading the marking parameter, and obtaining a three-dimensional coordinate point cloud of an object by using forward intersection of triangulation principle; and (5) obtaining a complete three-dimensional model by using Polyworks equal point cloud processing software for editing. The method can quickly reconstruct the three-dimensional surface model of the object, and can judge whether to meet the requirements by using the quickly generated accurate three-dimensional model.

Owner:WUHAN UNIV

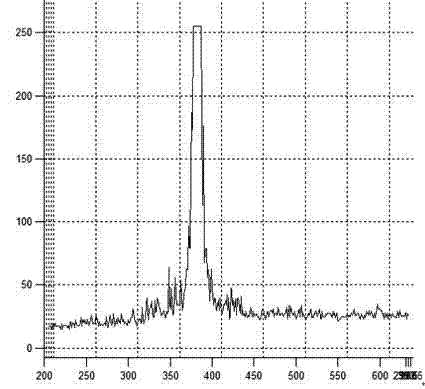

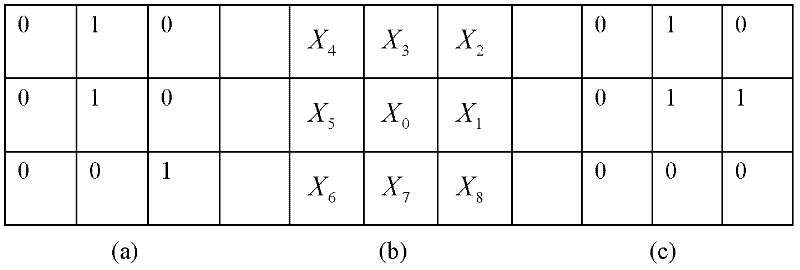

Method for acquiring laser meat image by double-laser triangle method

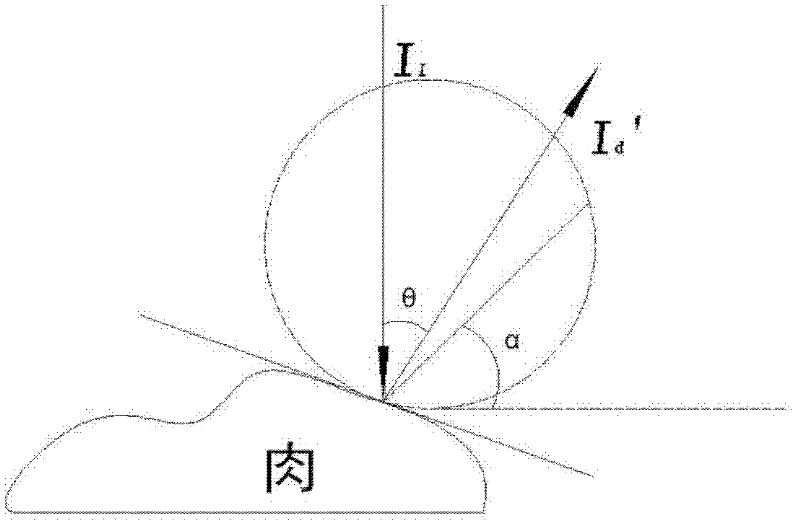

ActiveCN102353684AReduce reflectionReduced scattering effectOptically investigating flaws/contaminationUsing optical meansMultiple frameCcd camera

The invention discloses a method for acquiring a laser meat image by a double-laser triangle method. The method comprises the following steps of: 1) establishing a view field; 2) storing a gradient different between a laser meat curve and a laser plane reference curve which serves as meat thickness information to be a laser image meat thickness curve, and combining multi-frame laser meat thickness curves into a laser image according to an acquisition sequence; 3) unifying two laser images acquired by a left charge coupled device (CCD) camera and a right CCD camera to be under the same coordinate; and 4)splicing the laser images acquired at left and right angles under the unified coordinate into the same laser image to form a complete meat laser image.

Owner:NANJING FORESTRY UNIV

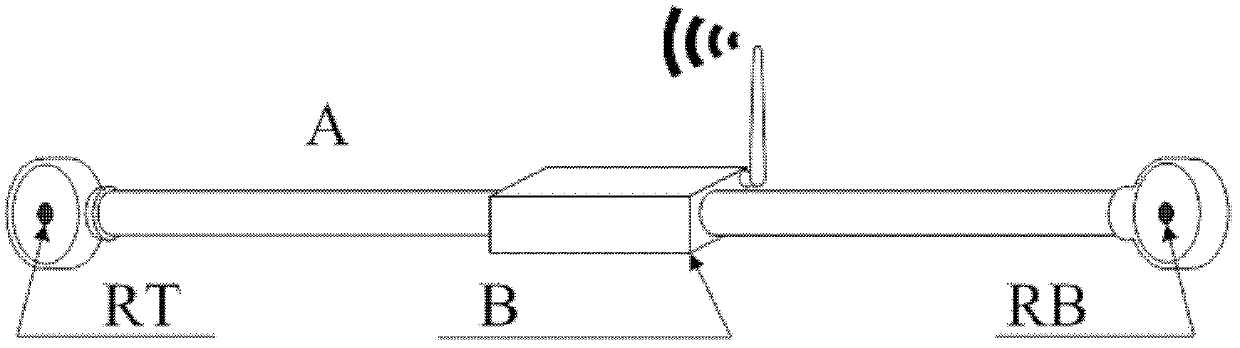

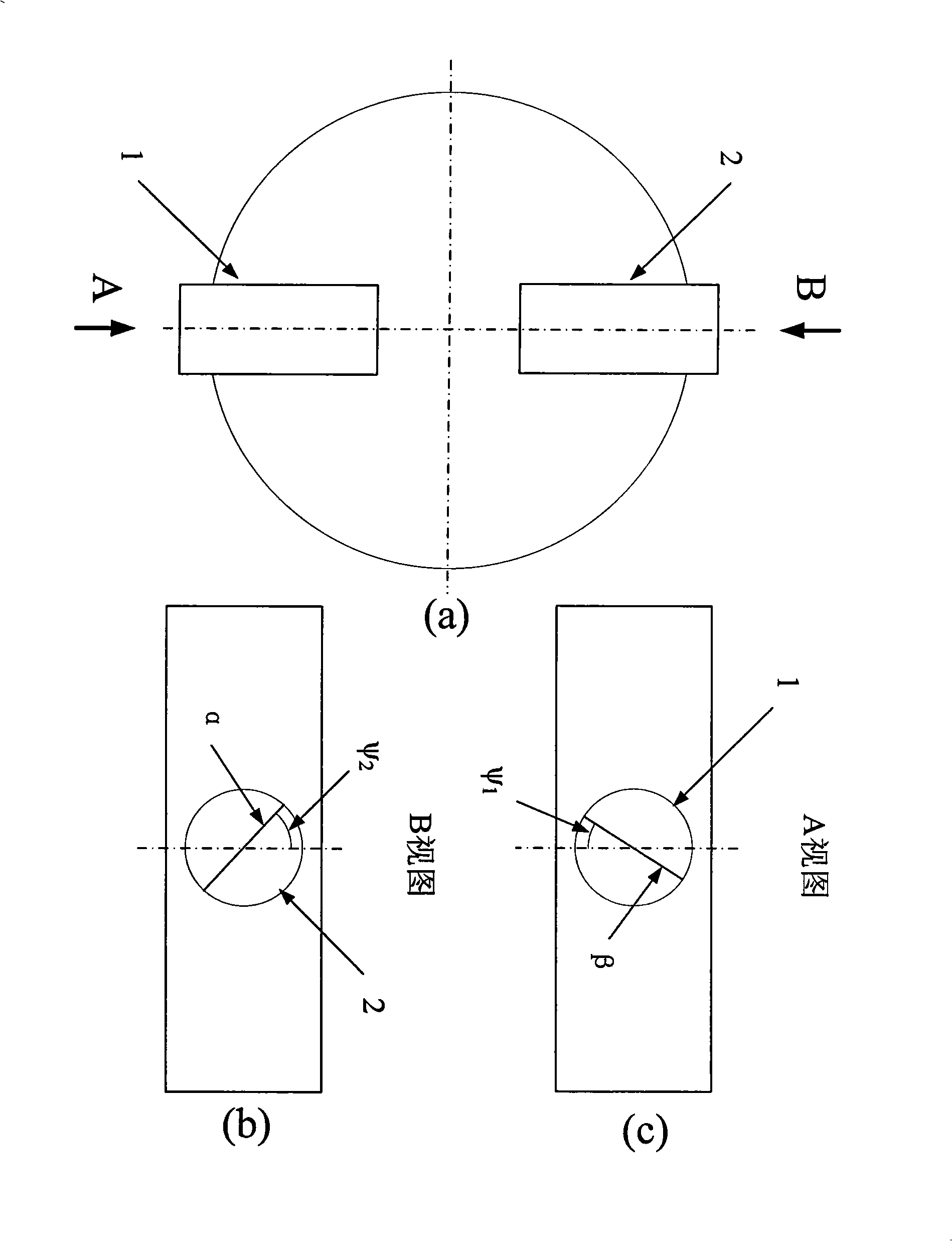

Quick orientating method of work space measuring and positioning system by standard rod

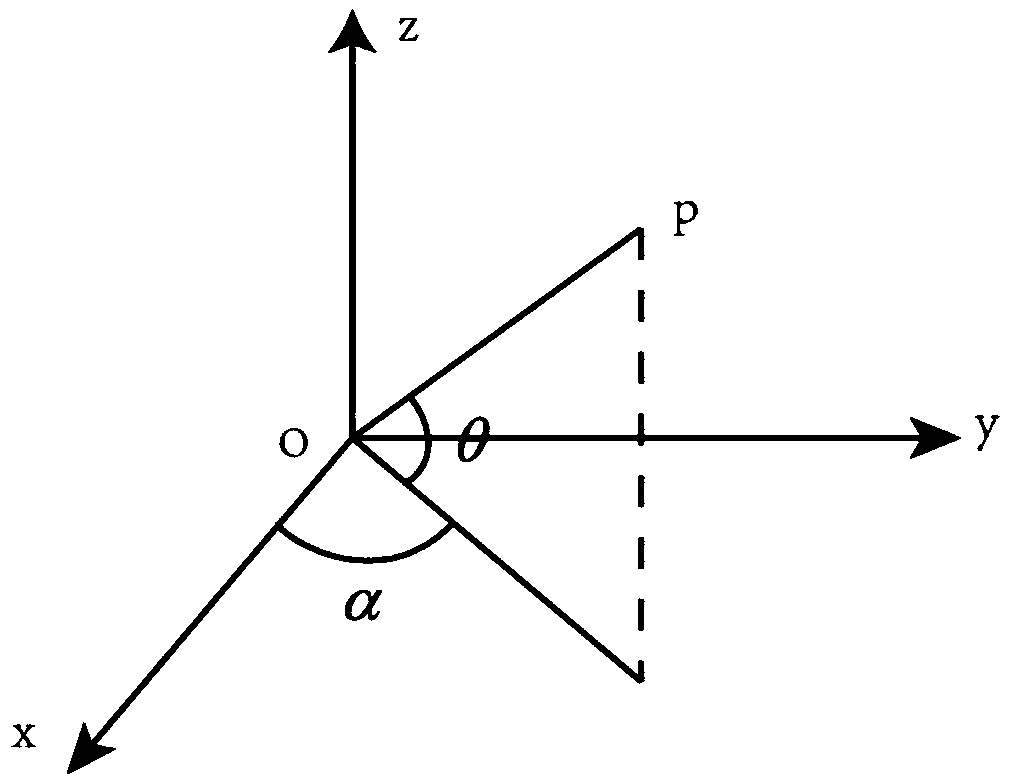

ActiveCN102384717AImprove networking efficiencyReduce use costUsing optical meansEngineeringPositioning system

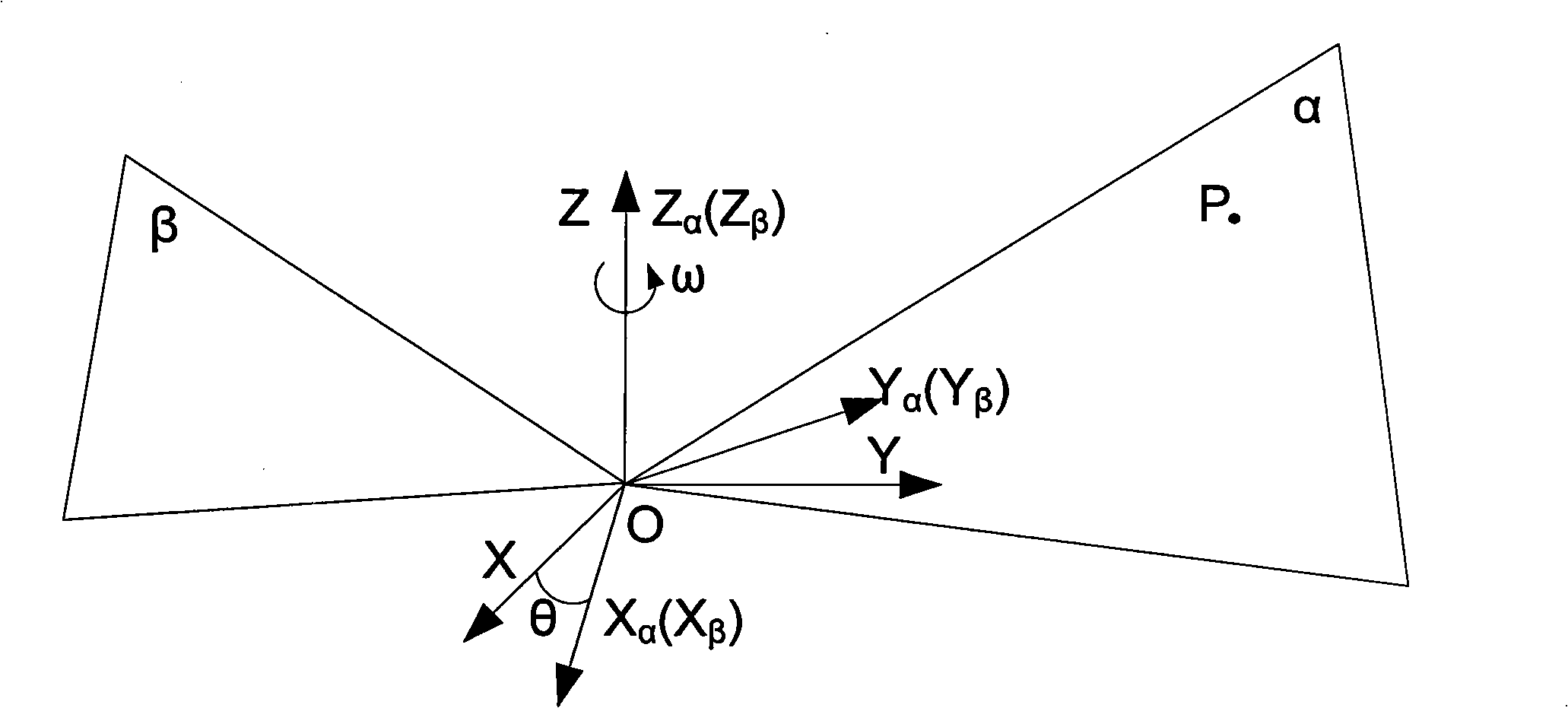

The invention provides a quick orientating method of a work space measuring and positioning system by a standard rod, which comprises the steps of: calibrating the standard rod; measuring the rotating angle values theta 1 and theta 2 of a rotating table of a transmitting station when two rotating laser planes transmitted out from the transmitting station respectively reach a receiver; obtaining the equation parameter of the rotating light plane equation of the two rotating laser planes transmitted out from the transmitting station under the self coordinate system according to the rotating angle values theta 1 and theta 2 of the rotating table of the transmitting station; and resolving the azimuth angle and the pitch angle of the receiver under the self coordinate system of the transmitting station, so that global orientation is realized, and the like. The method can be used for globally orienting independent of auxiliary equipment, and the positioning and the putting of a work space measuring and positioning system (WMPS) system are not strictly required when the method is used for orientation, so that the use cost of the system can be effectively reduced. One person can complete the field orientation of the WMPS system only within ten minutes by adopting the orientating method provided by the invention, so that the networking measurement efficiency of the WMPS system can be greatly improved, therefore, the quick orientating method is very suitable for industrial fields.

Owner:TIANJIN UNIV

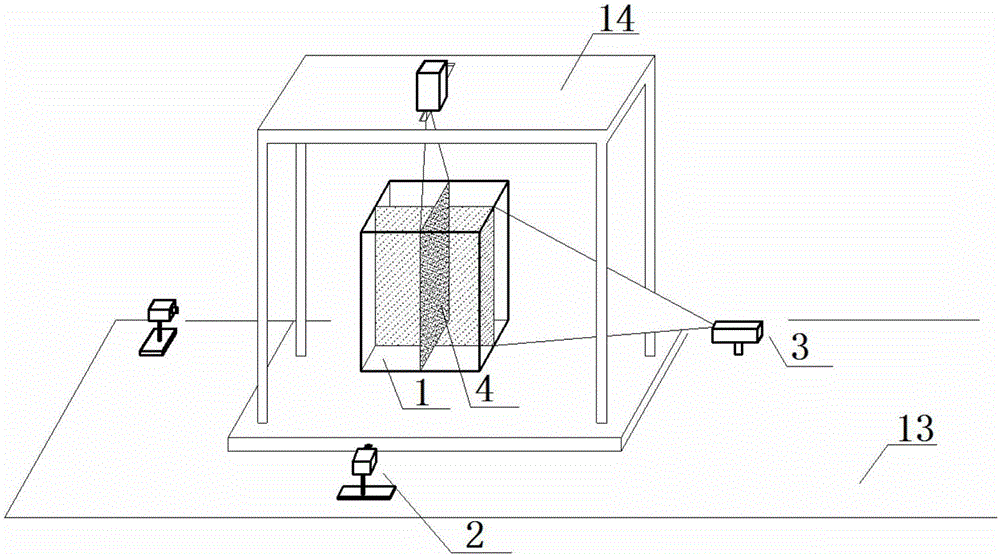

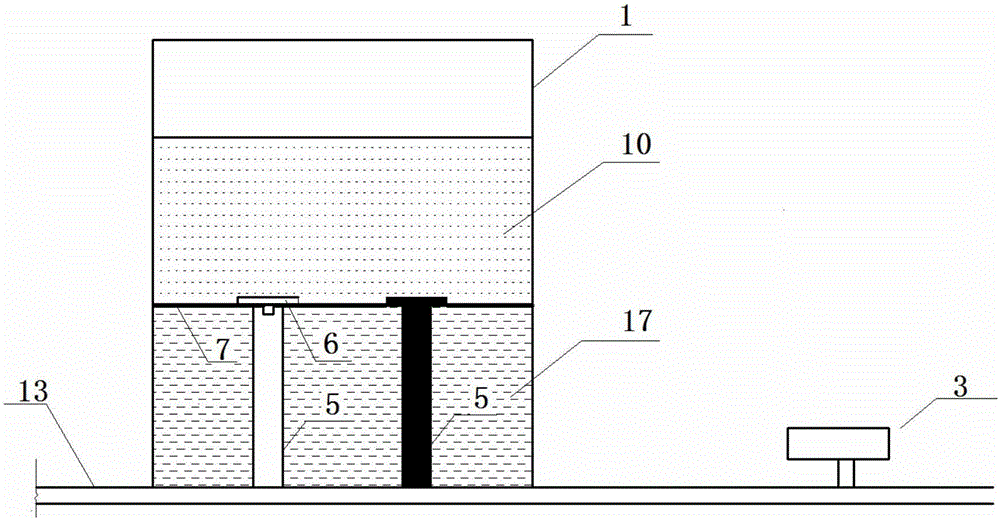

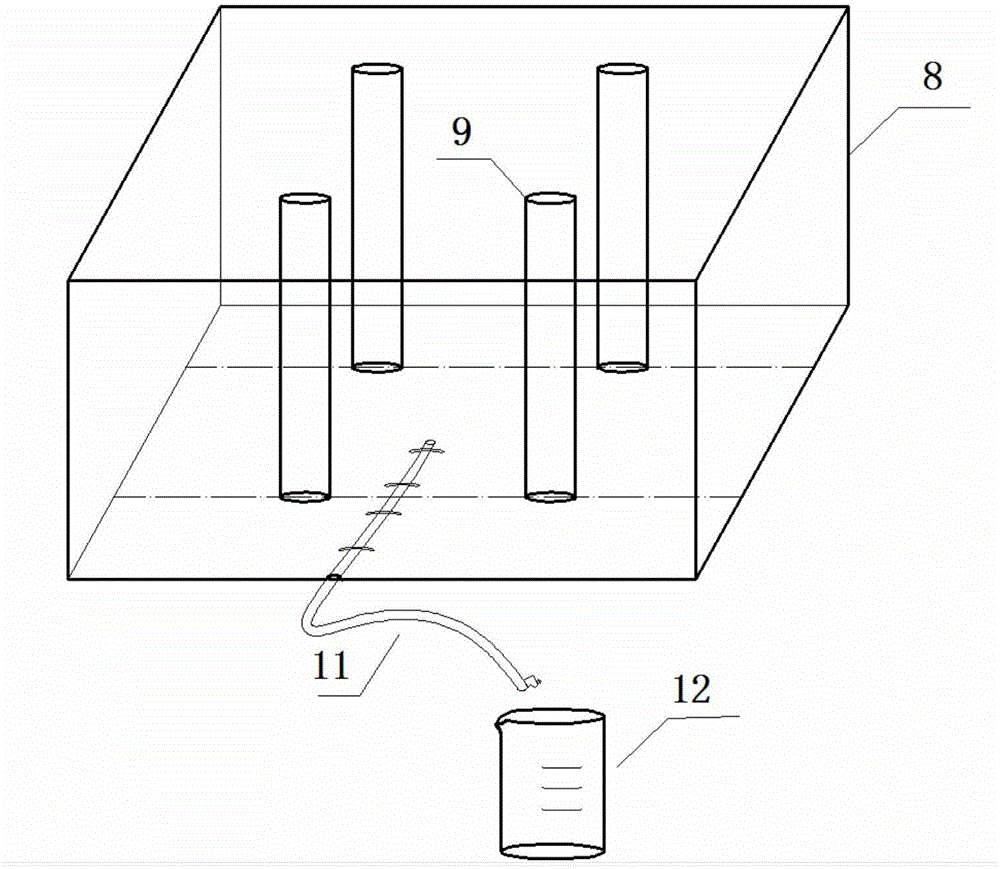

Pile-supported embankment transparent soil model testing device and method

The invention discloses a pile-supported embankment transparent soil model testing device and method. The device comprises a model groove, transparent soil, a pile body, a water bag, a water pipe, an industrial camera, and a laser emitter. The box-type water bag is placed on the bottom of the model groove made of organic glass. A pile hole position is reserved in the box-type water bag. A pile hole is reserved in the box-type water bag. A pile can be inserted into the pile hole in the box-type water bag. Under the assistance of transparent soil, the soil arch effect of embankment soil under self-weight load can be simulated by discharging the water in the box-type water bag. The invention also discloses a testing method of the testing device. The testing method comprises steps of installing pile and water bag, constructing a transparent soil embankment, slowly discharging water from the water bag, taking pictures of the laser plane by the industrial camera during the water discharging process, and analyzing the pictures to obtain the three dimensional deformation characteristics. The provided device and method have the advantages that high precision realtime measurement on the internal deformation of soil can be achieved, the macroscopic shape change of spacial soil arch can be observed, multiple work conditions can be simulated, the size of the testing device is small, the test operation is convenient, and the efficiency is improved.

Owner:重庆大学建筑规划设计研究总院有限公司

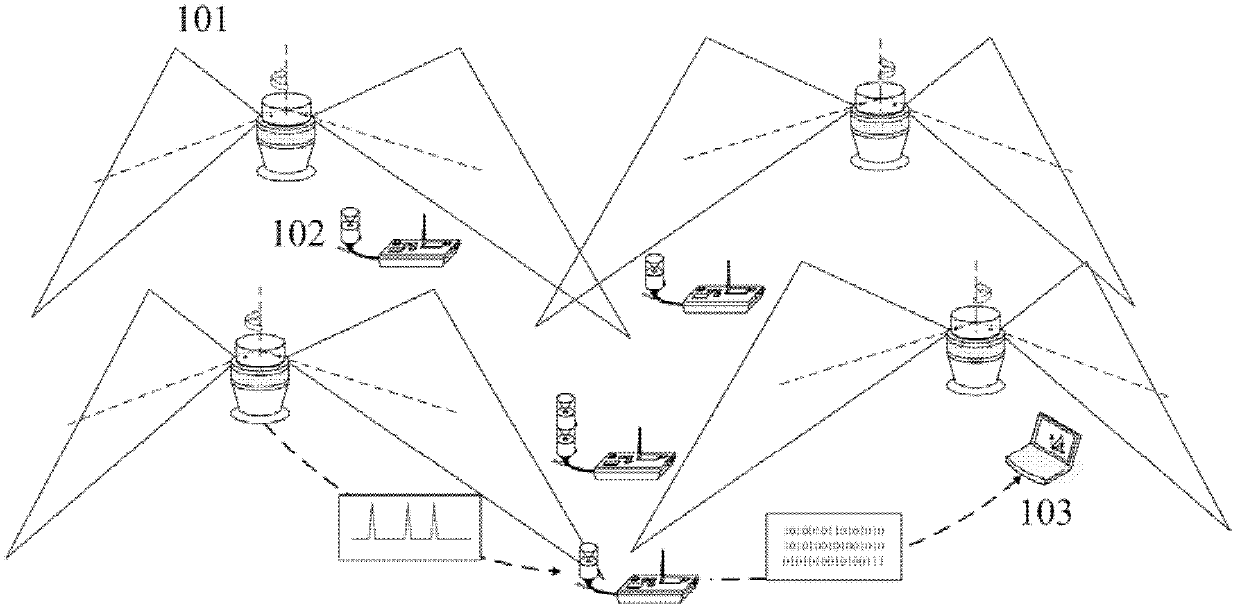

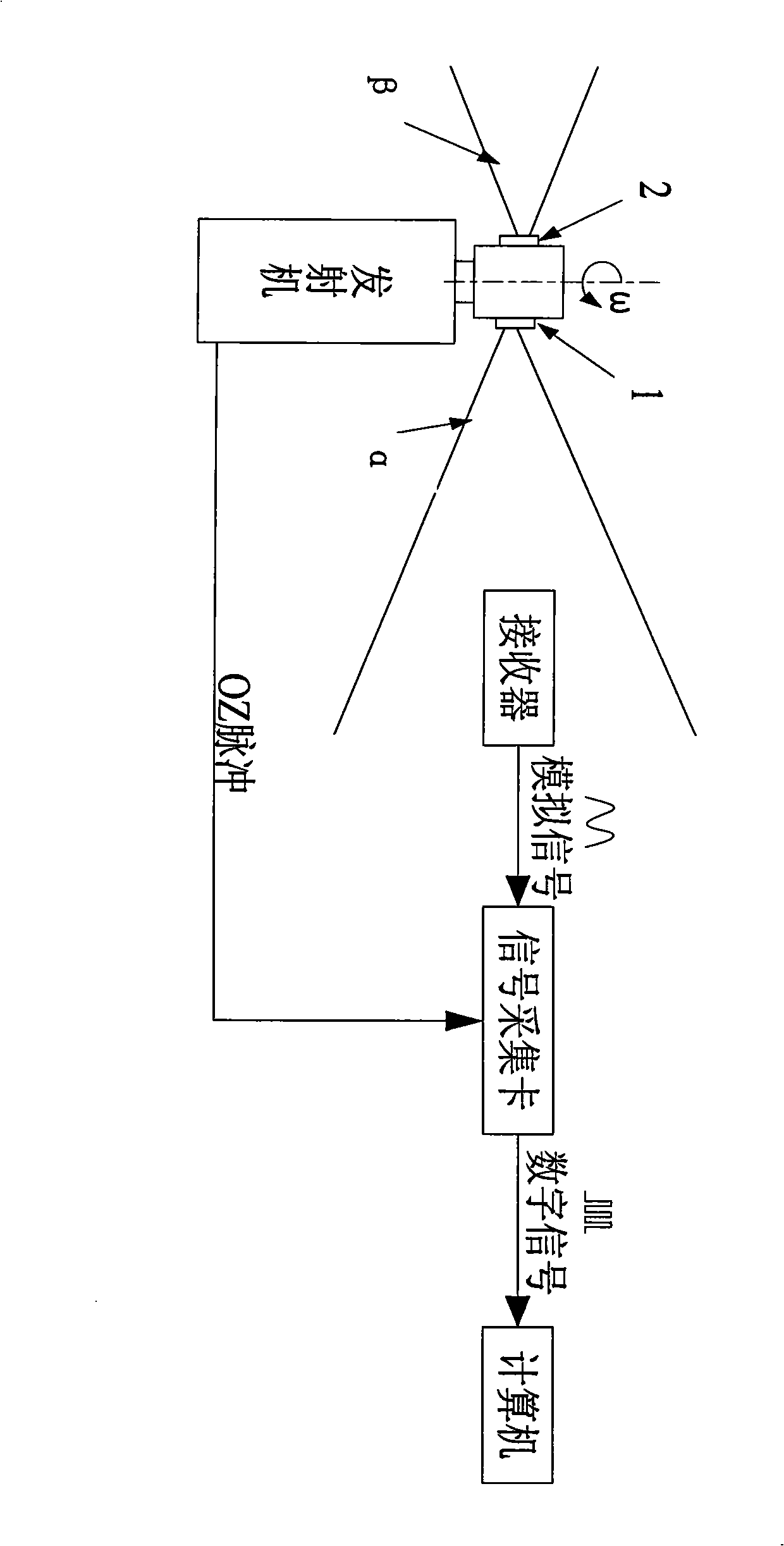

Space positioning method based on double-rotating laser plane transmitter network

InactiveCN101329165ALow costFast measurement speedUsing optical meansLaser transmitterSpatial positioning

The invention discloses a space locating method that is based on a network of planar dual-rotation laser transmitters, the rotation of three or more than three rotating transmitters are driven by an alternate current servo motor, the rotating transmitters that have two linear laser devices arranged on the head part transmit laser signals continuously to the surrounding space, the time distance of OZ pulse between a laser peak position that is sampled by a receiver module that takes a photocell as a sensor and a time origin is converted into a rotating angle of a laser plane, and consequently, the equation of the laser plane where measured points are positioned is deduced, an equation of a straight line that runs through the measured points is further obtained, an equation set is built according to the intersection method of multiple lines, and finally the equation set is solved by the least square method, thus obtaining the coordinate positions of the measured points. The space locating method avoids object aiming when measuring, and improves measuring speed and efficiency.

Owner:XI AN JIAOTONG UNIV

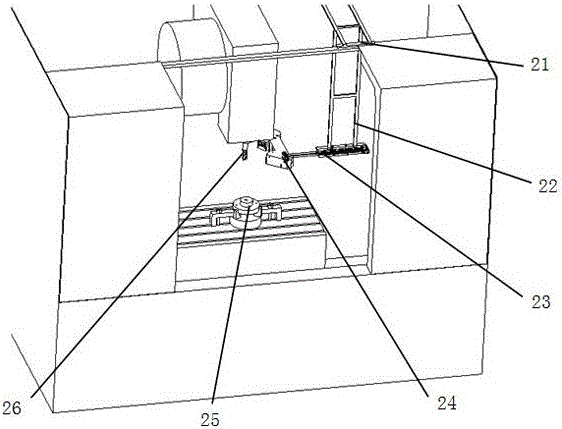

Method for calibrating machine tool follow-up laser scanning coordinates on basis of space standard balls

InactiveCN106354094ARealize 3D coordinate measurementExpand the range of measurement applicationsProgramme controlComputer controlLaser scanningComputer science

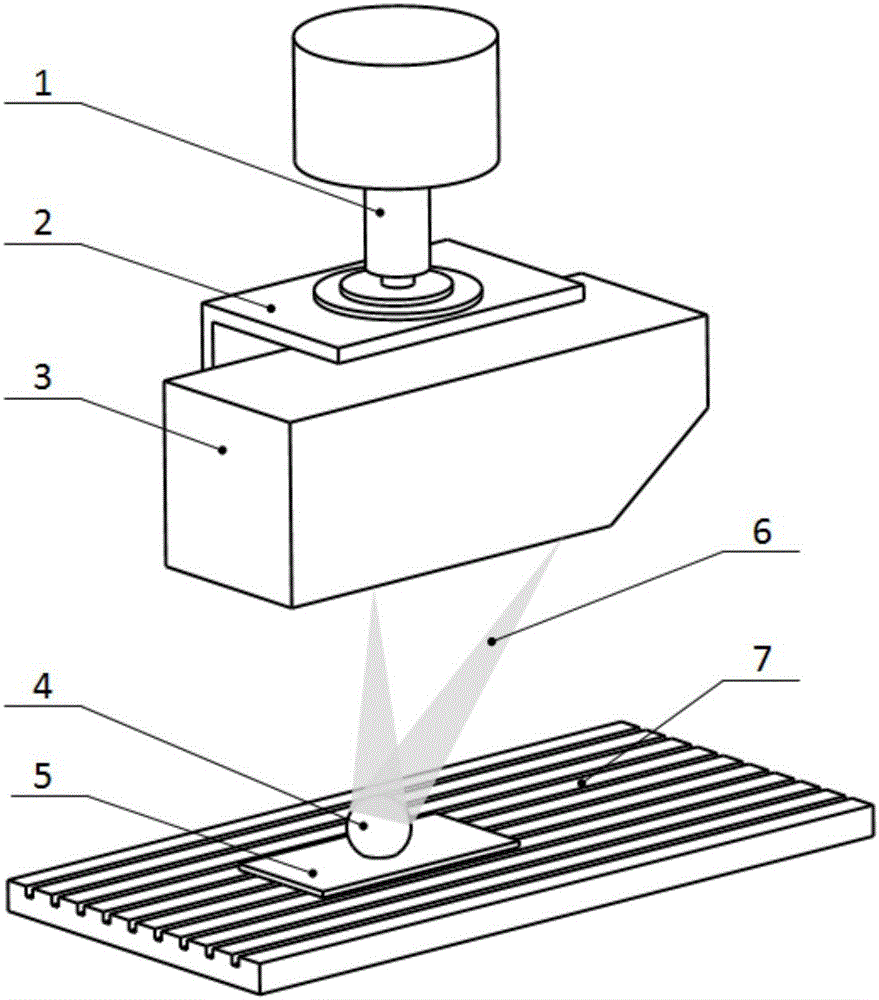

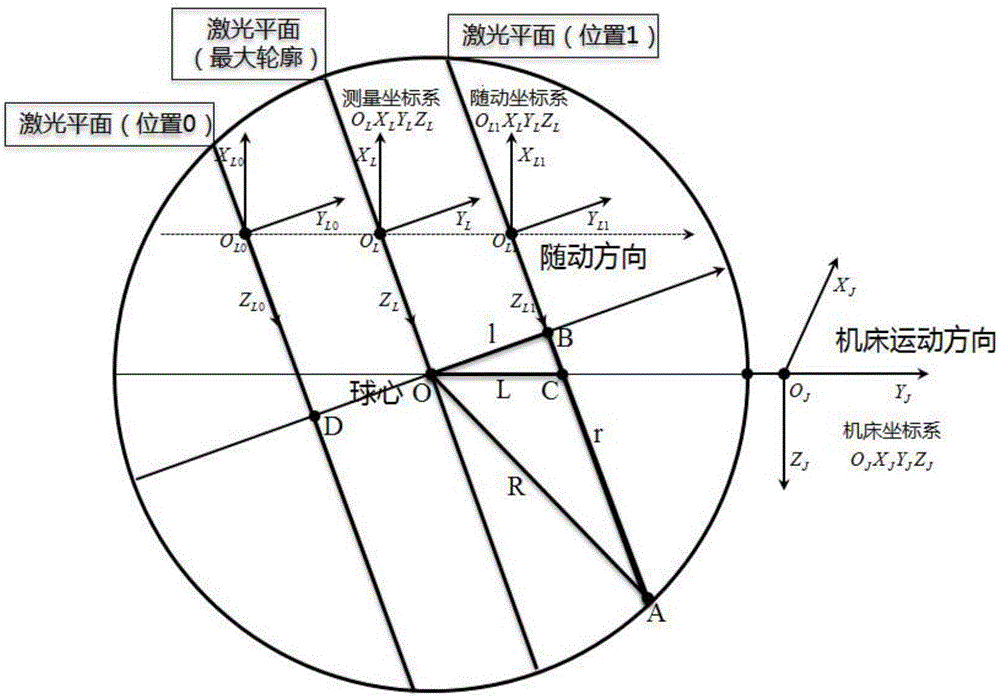

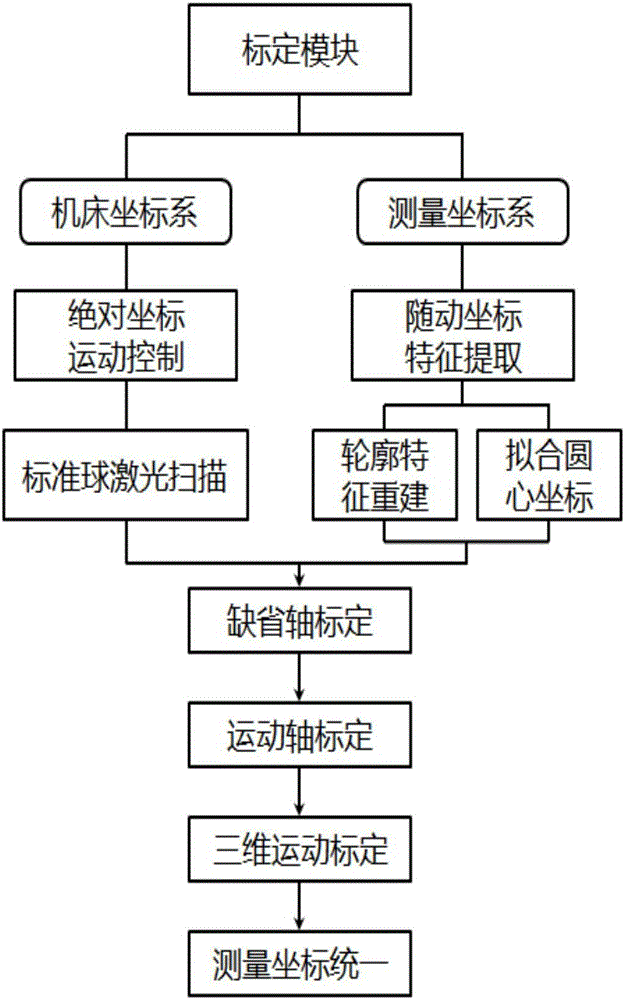

The invention discloses methods for calibrating machine tool follow-up laser scanning coordinates on the basis of space standard balls, belongs to the field of vision measurement, and relates to a method for calibrating machine tool follow-up laser scanning coordinates on the basis of space standard balls. The method includes providing third-dimension data for linear laser measurement sensors by movement modules of machine tools; scanning, measuring and fitting circle centers of the space standard balls with known radiuses and unifying data of coordinate systems of the machine tools and linear laser measurement coordinate systems; calibrating default axes of the measurement coordinate systems according to movement of the machine tools and movement of laser planes; calibrating measurement axes; integrally calibrating three-dimensional movement to obtain scale transformation matrixes of the coordinate systems of the machine tools and the measurement coordinate systems. The method has the advantages that the shortcoming that only two-dimensional data can be measured by the traditional laser measurement sensors is overcome, the measurement application ranges of the linear laser measurement sensors can be effectively expanded, and the method has a broad application prospect.

Owner:DALIAN UNIV OF TECH

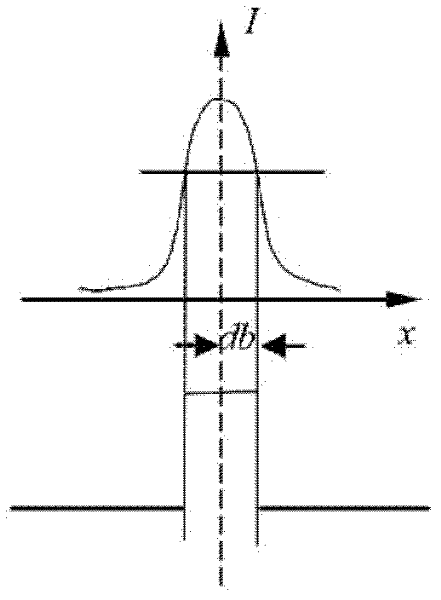

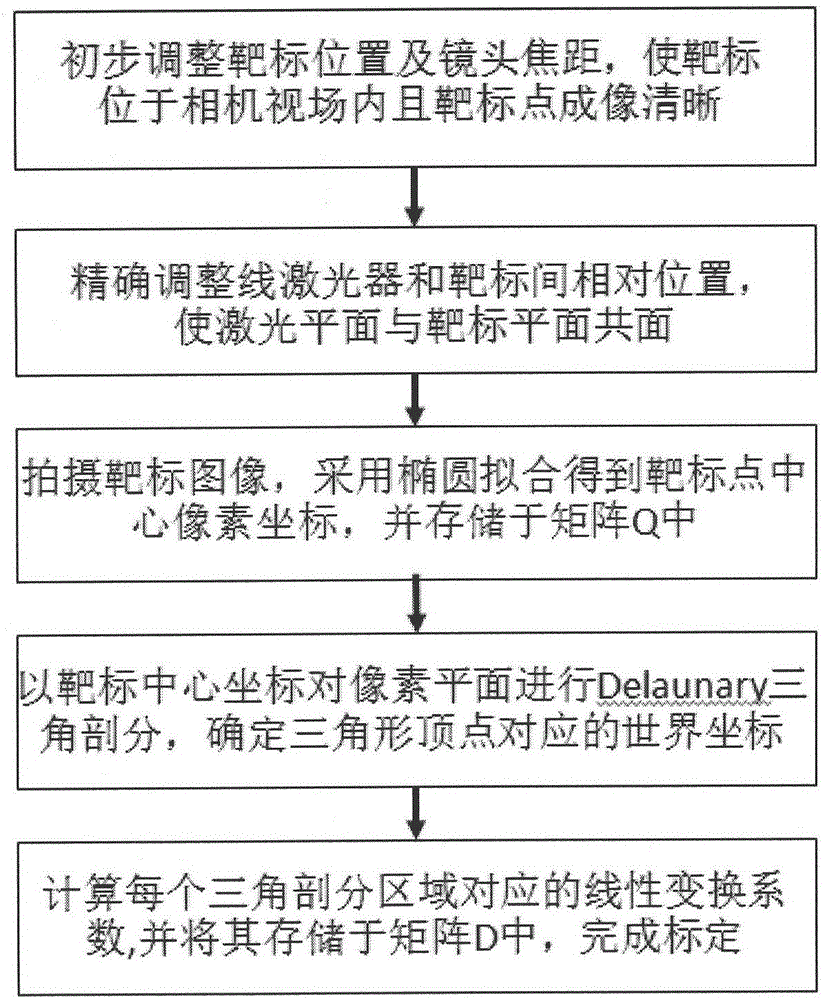

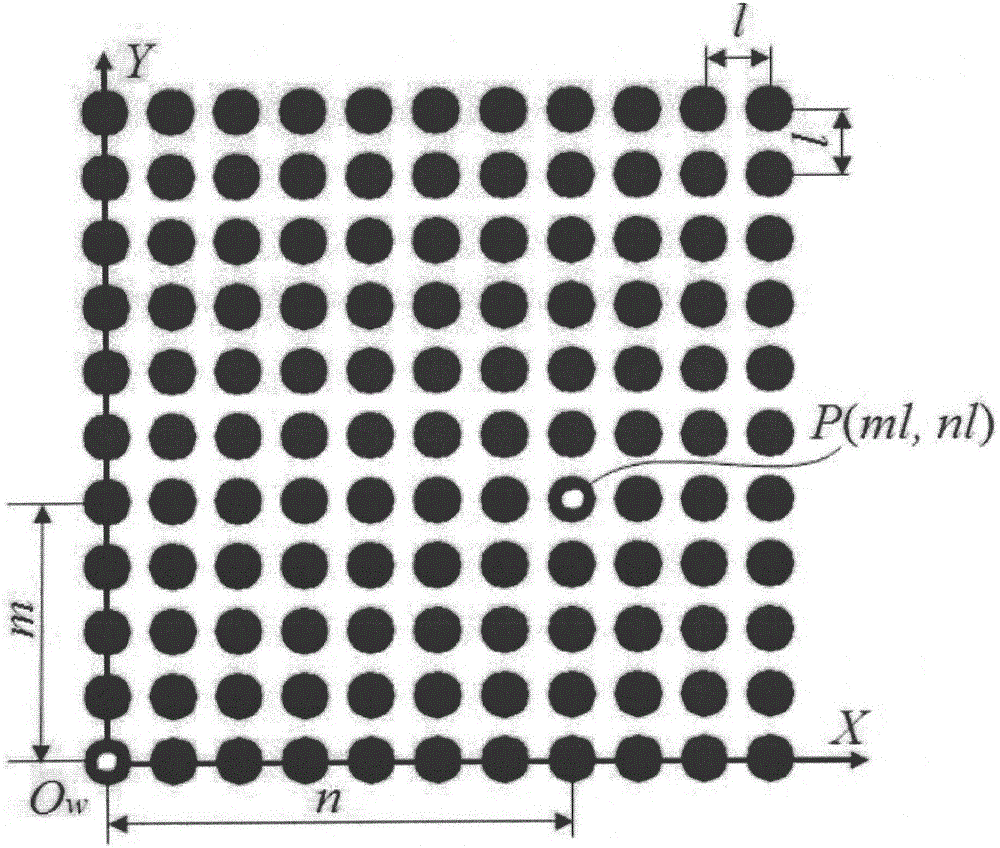

Numerical value calibration method for line structured light vision sensor

The invention discloses a numerical value calibration method for a line structured light vision sensor. The method comprises steps: an equidistantly-arranged dot array is made as a calibration target, the target position and a focal length are initially adjusted to enable the target to be completely placed in a view field of a camera, and a target point image is distinct; the relative position between a line structured laser plane and the calibration target is precisely adjusted to enable the laser plane and the target plane to be coplanar; the power supply of the laser is cut off, the focal length of the camera is adjusted precisely again, the target image photographed by the camera is ensured to be distinct, an ellipse fitting method is adopted to obtain pixel coordinates of each target point center, and the pixel coordinates are stored in a matrix Q; the target center coordinates in the matrix Q are used for carrying out Delaunary triangulation on the pixel plane, the point at the left corner of the target is marked as the original point of a world coordinate system 0WXY, and world coordinates corresponding to a vertex are determined; and a linear transformation coefficient corresponding to each triangulation area is calculated, and the linear transformation coefficient is stored in a transformation coefficient matrix D. The calibration method of the invention is simple and easy to operate, the computing efficiency is high, and the calibration precision is good.

Owner:HEBEI UNIVERSITY OF SCIENCE AND TECHNOLOGY

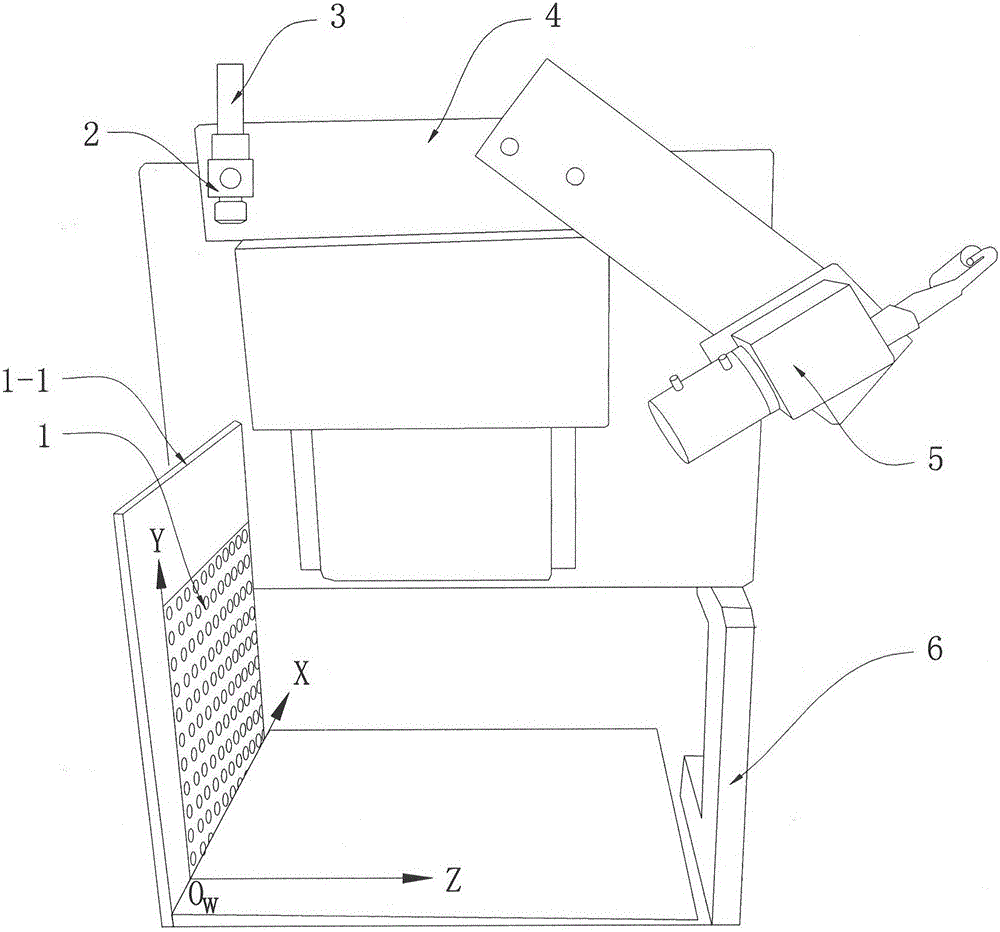

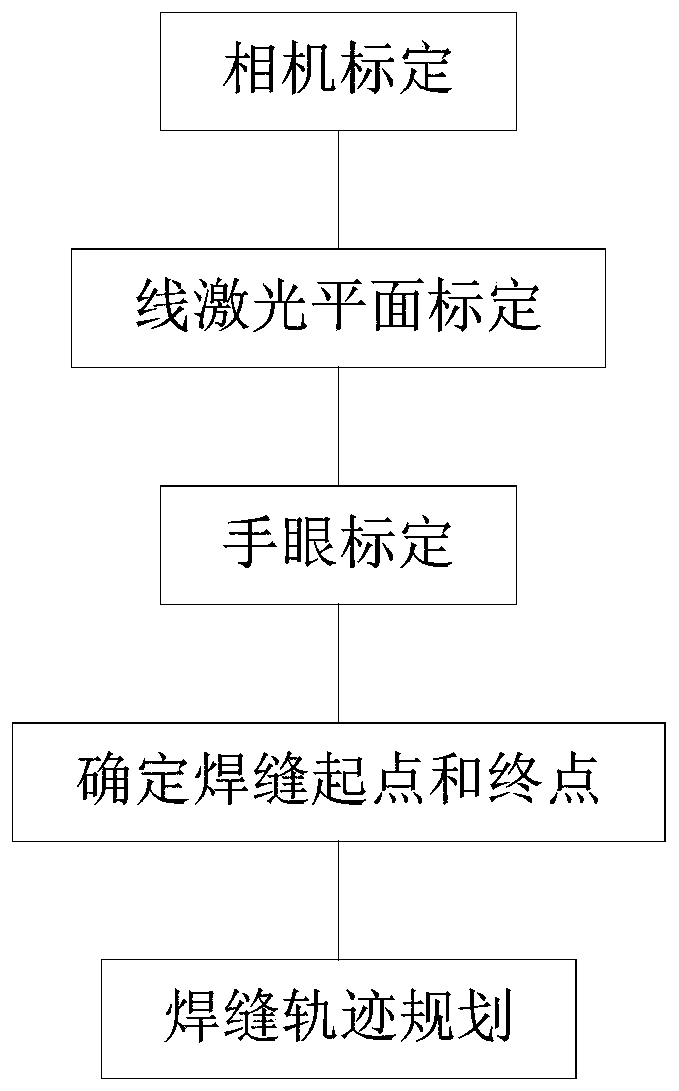

Intelligent three-dimensional autonomous weld joint tracing method

InactiveCN110245599ATrace implementationTracking and solvingImage enhancementProgramme-controlled manipulatorAcute angleHand eye calibration

The invention belongs to the technical field of automatic welding, and provides an intelligent three-dimensional weld joint autonomous tracking method which comprises the following steps: S1, camera calibration: a camera shoots and acquires image information of calibration plates at different spatial positions, establishes a corresponding equation set according to the shot image information, and obtains an internal parameter matrix and an external parameter matrix through analysis; s2, line laser plane calibration; s3, hand-eye calibration; s4, determination of a welding seam starting point and a welding seam ending point; and s5, welding seam track planning. According to the intelligent three-dimensional autonomous welding seam tracing method, any type of weld grooves is identified by utilizing an image algorithm; a linear laser triangulation method and a vision and robot calibration algorithm are adopted to autonomously plan a motion path, so that autonomous tracking of a welding line in any three-dimensional space is realized, three-dimensional orientation information of a welding line groove is obtained, and tracking of a right-angle or acute-angle inflection point is realized in a self-adaptive pre-swing manner.

Owner:深圳市超准视觉科技有限公司

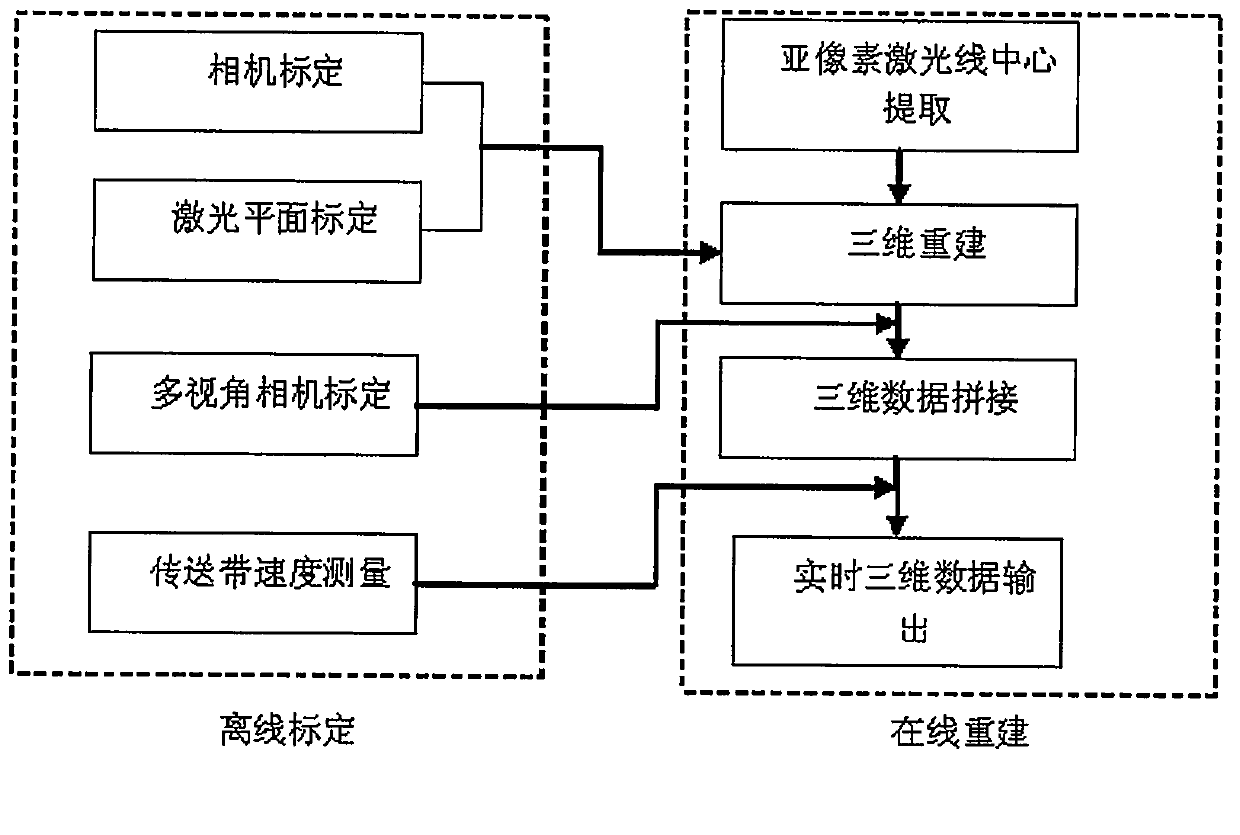

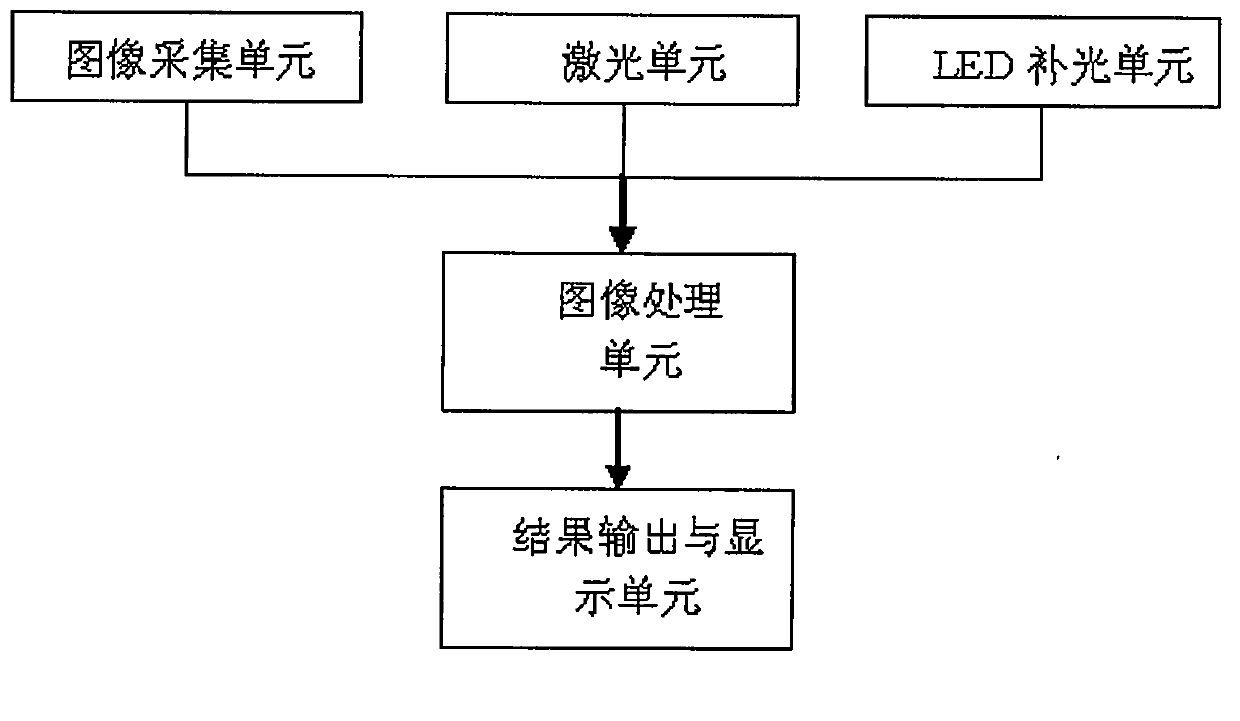

Multi-view three-dimensional online reconstruction method

The invention provides a multi-view three-dimensional online reconstruction method. The method includes the following steps: internal parameters of a camera are calibrated and laser plane equation parameters are calibrated under a camera coordinate system and an average operating speed of a conveyor belt which conveys an object is obtained through measurement; when the object which reaches the conveyor belt moves continuously, laser ray radiates different positions of the object and three-dimensional data is obtained when the laser ray radiates a specific position of the object according to the laser plane equation parameters and the cameral internal parameters; and according to the average operating speed, complete three-dimensional data of the surfaces of the object is obtained. Compared with the prior art, the multi-view three-dimensional online reconstruction method is capable of reconstructing complete three-dimensional data of surfaces (except the lower surface) of an object on a production line in a multi-view real-time manner and providing complete three-dimensional data information to online detection.

Owner:SHANGHAI DEEP IND INSPECTION TECH CO LTD

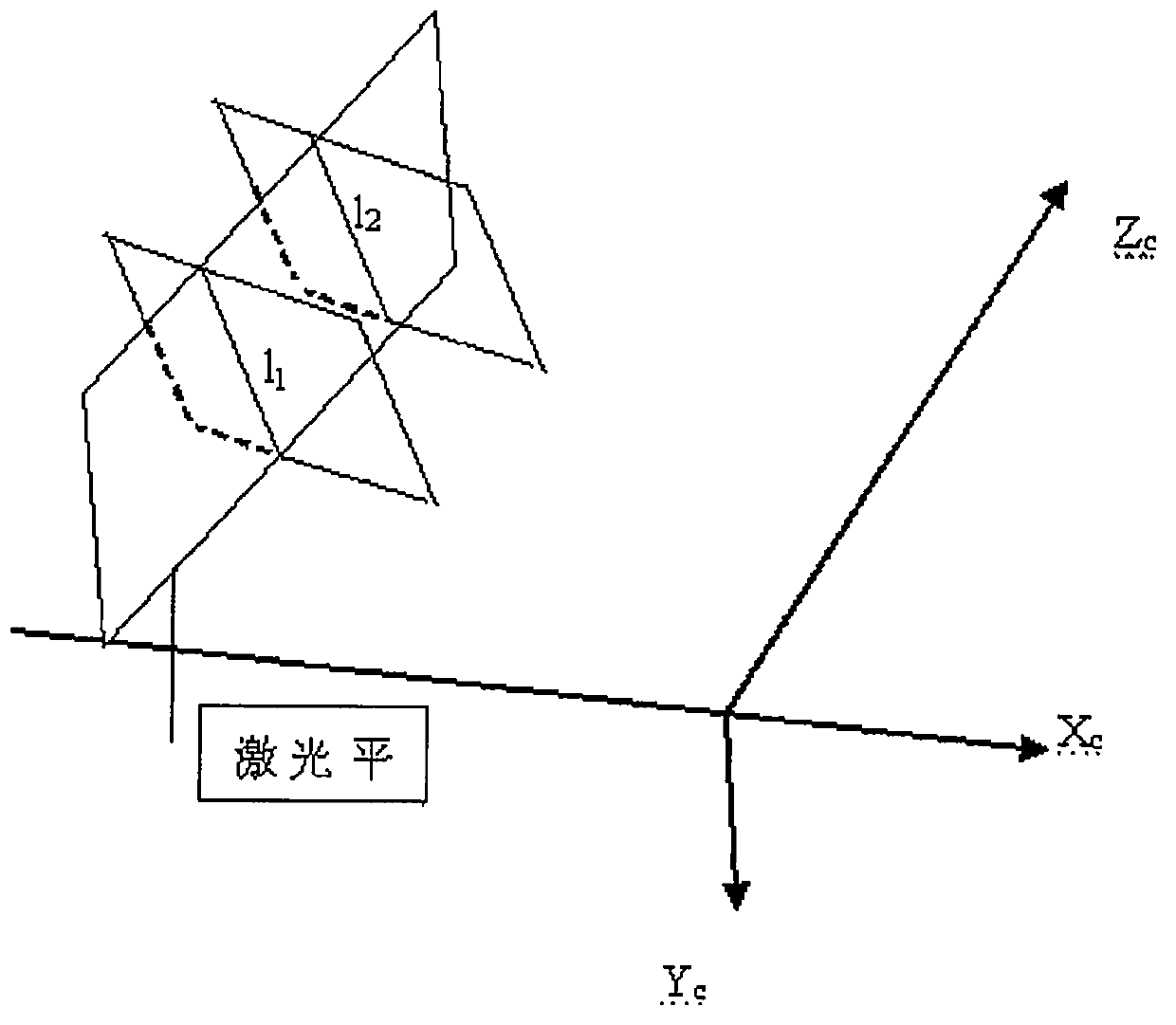

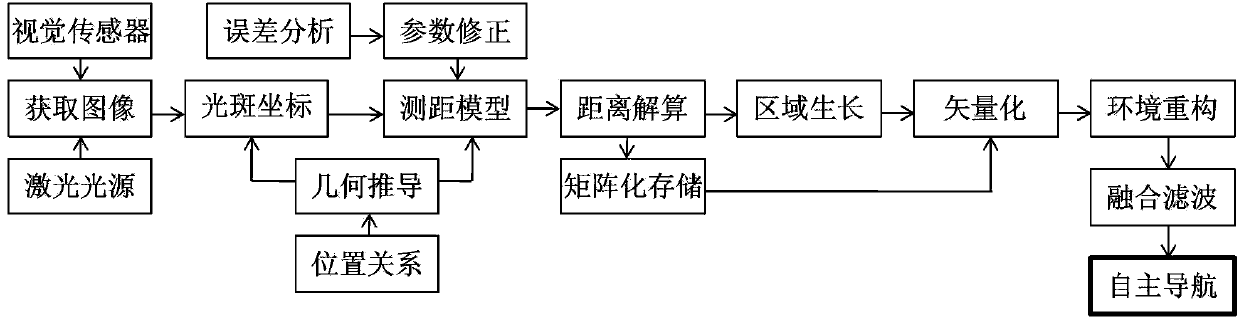

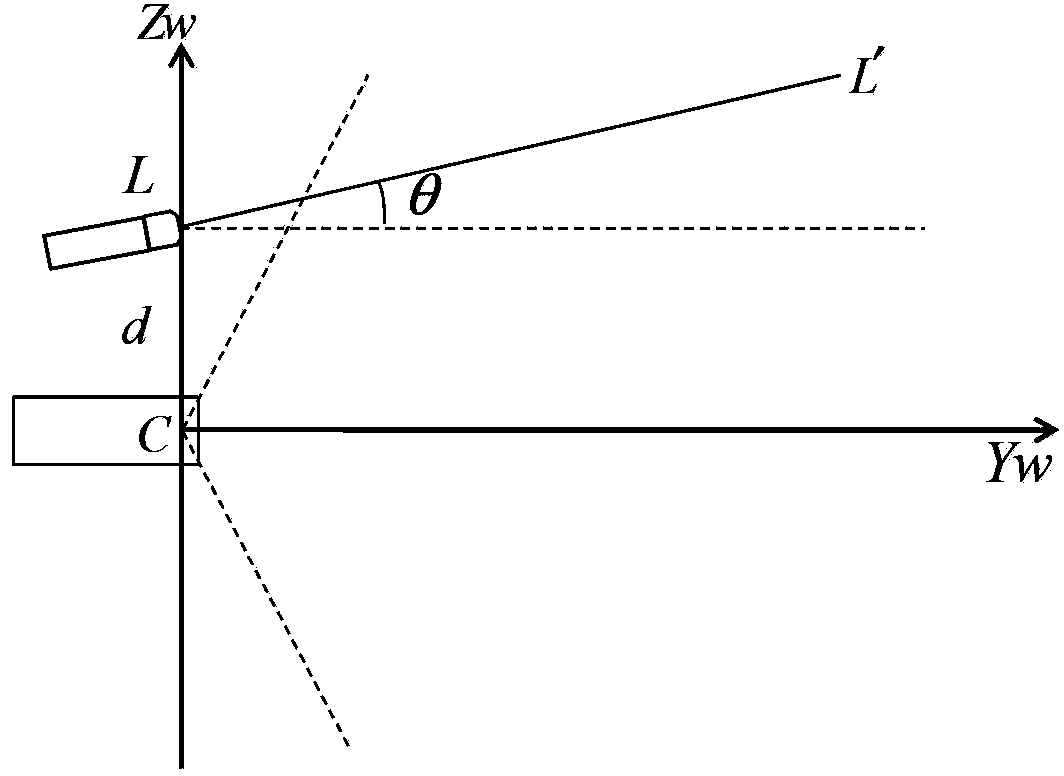

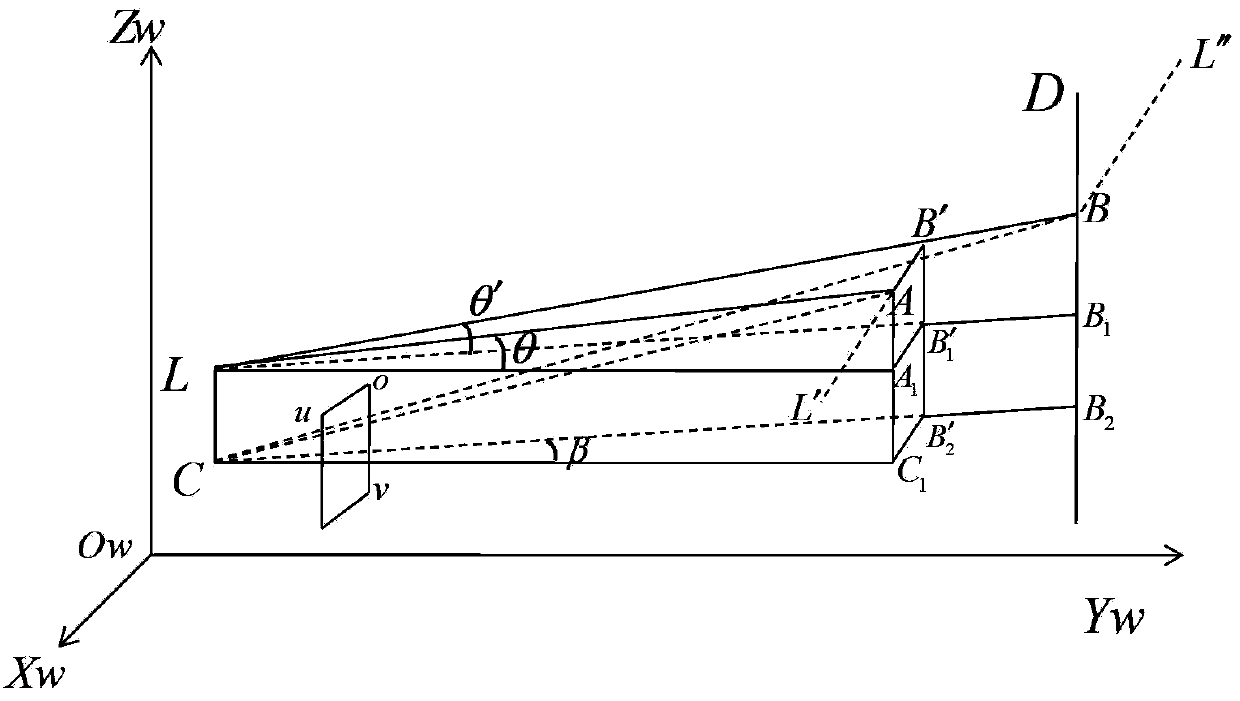

Vision navigating method for movement carrier based on laser plane assistance

ActiveCN103424112AReduce computationShort solution timeOptical rangefindersNavigation instrumentsLaser lightYield ratio

The invention discloses a vision navigating method for a movement carrier based on the laser plane assistance. The method comprises the following steps: building a distance measurement and environment system, determining the position of a rectangular bright spot to be detected in an image, determining the center coordinate of the rectangular bright spot, obtaining a geometric distance measurement model, correcting the distance measurement model, segmenting the visual image, determining a local vectorization environmental space with distance information, positioning the position of the carrier per se, and building a global environmental space. Through the adoption of the method different from the traditional movement carrier autonomous navigation middle distance obtaining method, a laser plane is introduced as an auxiliary means, a single or a plurality of vision sensors are combined, the threadlike bright spot formed by the reflection of the laser plane on an object to be irradiated is fully utilized and taken as an cooperated distance measurement target, and the geometric relationship between the vision sensor and a laser light source is effectively utilized, so that the requirements for the precision, yield ratio and real-time performance of the distance calculating can be met. Therefore, the method is a reliable navigation method, and can be applied to a movement carrier autonomous navigation system.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

Grading control system

ActiveUS20060123673A1Raise and low workAnalogue computers for trafficMechanical machines/dredgersMarine engineeringControl system

A grading control system for a work machine having a work implement for grading along a grade defined by a laser plane generator is disclosed. The system includes tilt and lift actuators associated with the work implement and configured to selectively tilt, raise and lower the work implement. A laser receiver is configured to receive a laser signal indicative of a desired grade. The laser receiver is configured to communicate a height signal indicative of a position of the work machine relative to the laser plane. A lift sensor is configured to communicate a lift signal indicative of a lift position of the work implement. A control module is configured to generate and communicate a control signal based on the height and lift signals to actuate at least one of the lift and tilt actuators to maintain the work implement at a position substantially corresponding to the desired grade.

Owner:CATERPILLAR INC

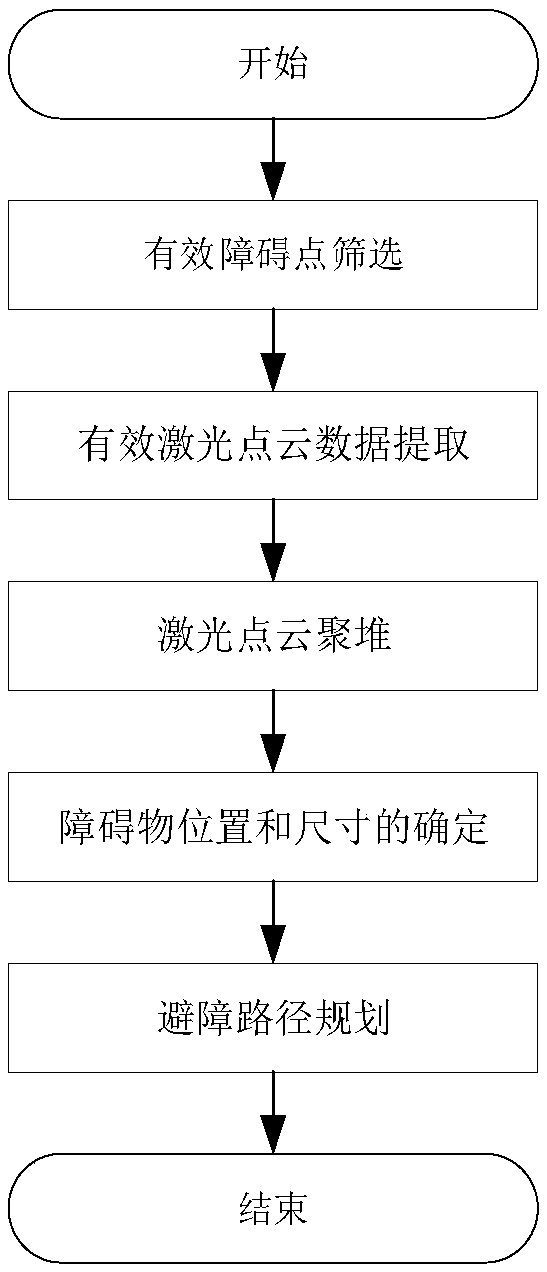

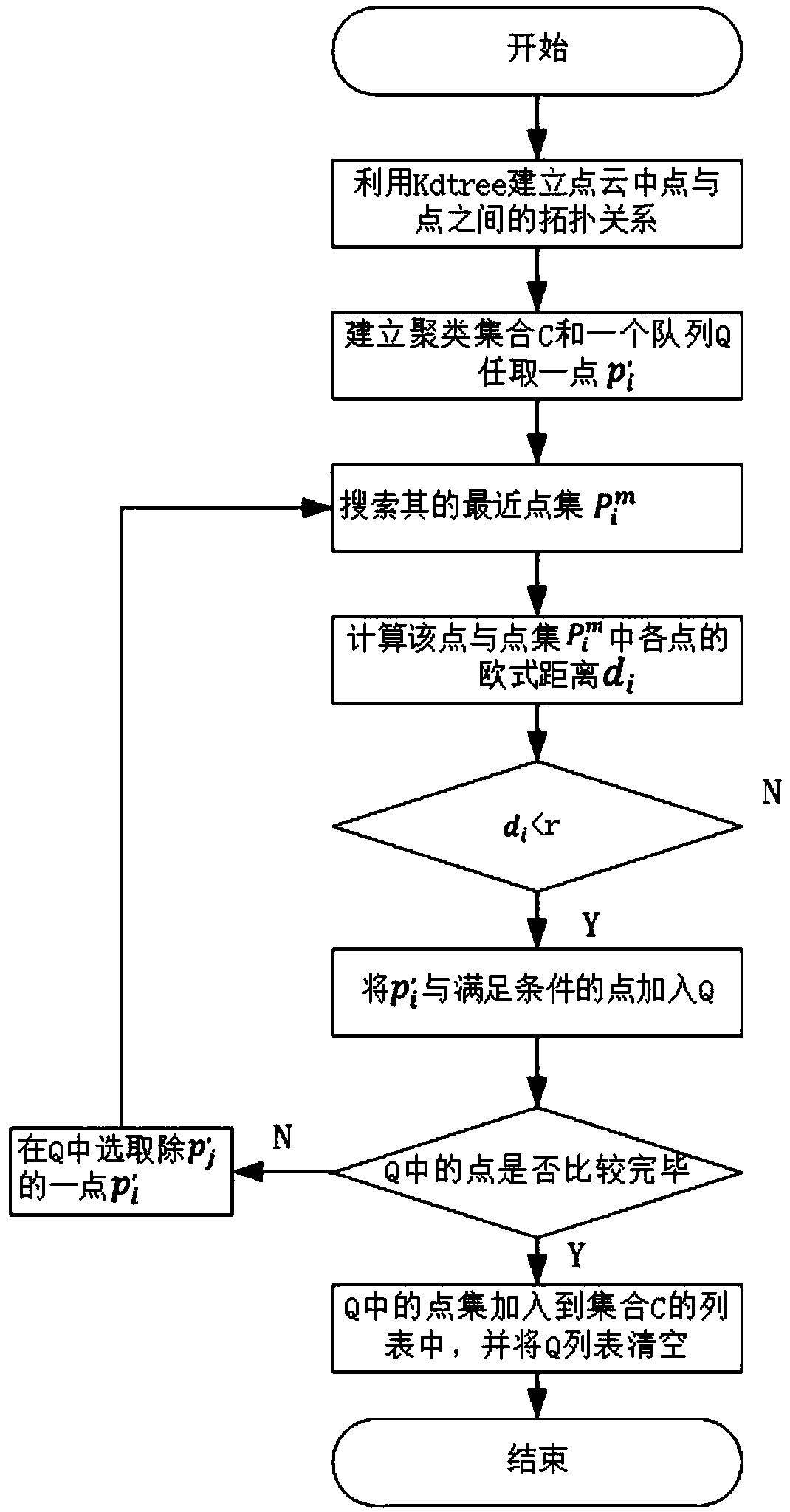

Intelligent obstacle avoidance method for robot based on three-dimensional laser

InactiveCN109144072AImprove real-time performanceImprove accuracyPosition/course control in two dimensionsPoint cloudLaser sensor

The invention provides an intelligent obstacle avoidance method for a robot based on three-dimensional laser, and relates to the field of robots. According to the invention, laser point cloud data ina three-dimensional laser plane emitted by a three-dimensional laser sensor is mapped into two-dimensional laser point cloud data, characteristic laser point cloud data corresponding to an obstacle isextracted by using the Euclidean clustering method, position and size information of the obstacle is calculated according to the extracted characteristic laser point cloud data, and finally the obstacle avoidance path of the robot is planned by using the cubic Bezier curve so as to realize effective obstacle avoidance of the robot. According to the obstacle avoidance method provided by the invention, the robot can obtain information of an unknown obstacle, and the timeliness and accuracy of obstacle avoidance navigation of the robot are improved.

Owner:YIJIAHE TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com