Numerical value calibration method for line structured light vision sensor

A visual sensor and line structured light technology, applied in the direction of instruments, optical devices, measuring devices, etc., can solve the problems of small number of calibration points, extraction error calibration accuracy, limited measurement range, etc., and achieve simple production, simple method and low cost. low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The specific implementation manners of the present invention will be further described below in conjunction with the accompanying drawings, so as to make the technical solution of the present invention easier to understand and grasp.

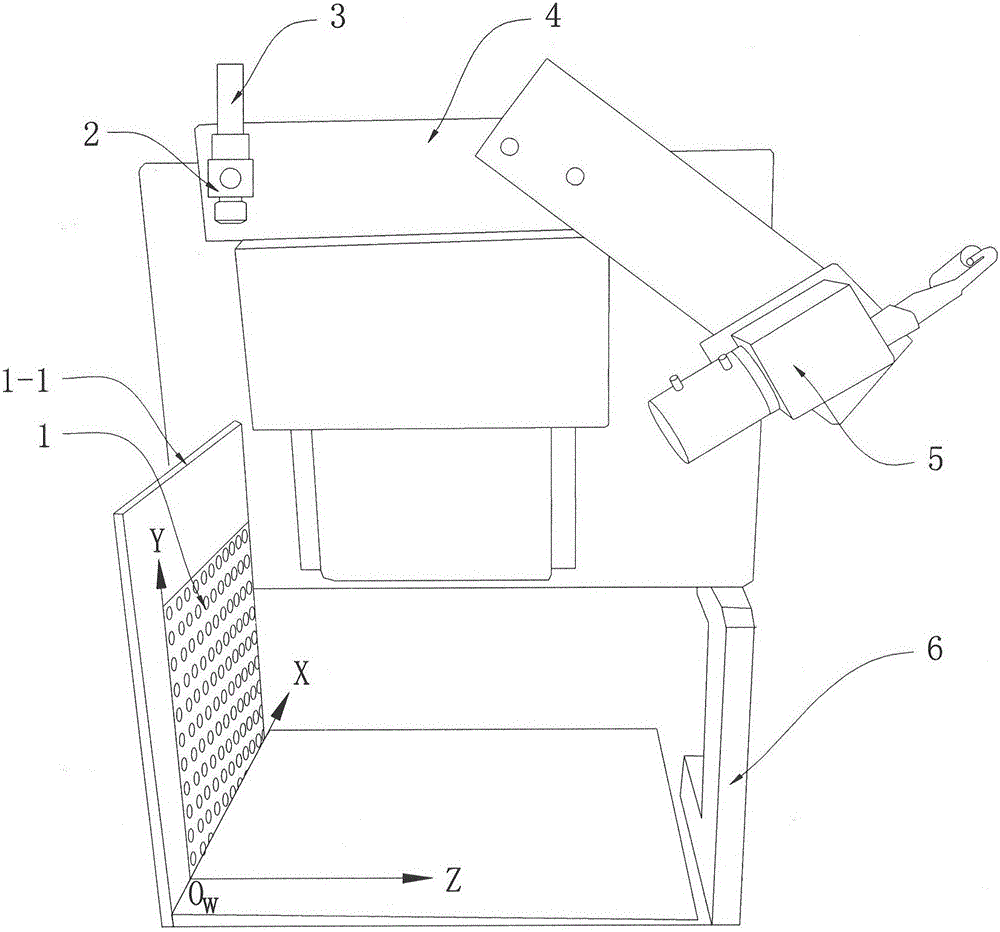

[0042] figure 1 It is a calibration diagram of a line structured light vision sensor, which is composed of a calibration target 1, a laser fixing sleeve 2, a line laser 3, a connecting frame 4 between the line laser and the camera, a camera 5, and a vertical support 6, and is characterized in that:

[0043] The calibration target 1 is placed vertically, and the target plane coincides with the laser plane emitted by the line laser 3;

[0044] In order to meet the requirement that the target plane coincides with the laser plane, the shape of the line laser 3 should be cylindrical, and can be rotated at a specific angle in the laser fixing sleeve 2; the laser fixing sleeve 2 is characterized by a Circular sleeve, its inner diameter is sligh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com