Method for calibrating machine tool follow-up laser scanning coordinates on basis of space standard balls

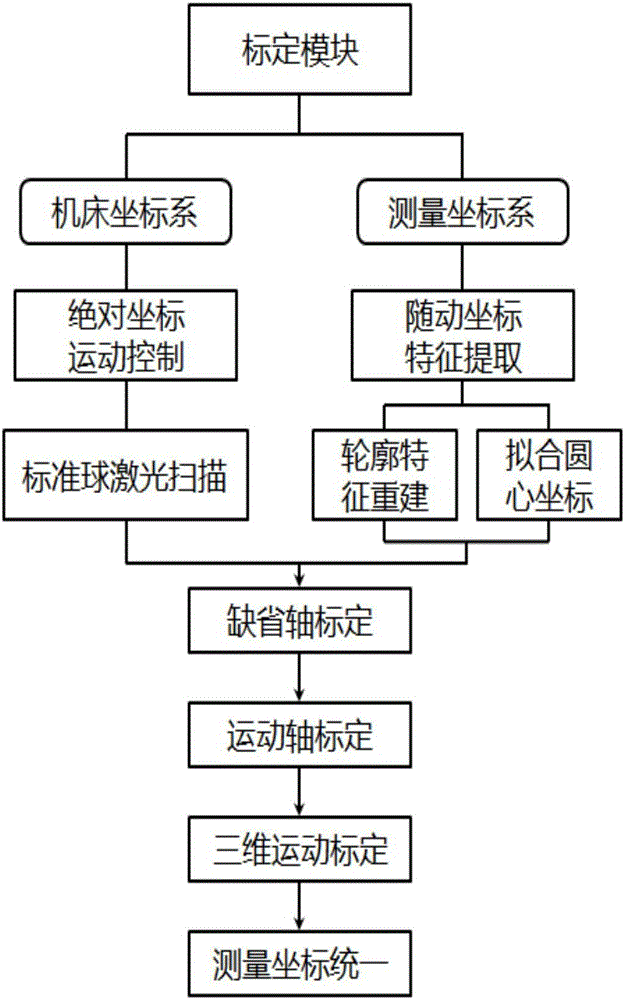

A technology of laser scanning and coordinate calibration, applied in the field of visual measurement, can solve the problems of low calibration efficiency of measurement points and complicated calculation of calibration methods.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The specific implementation of the present invention will be described in detail below in conjunction with the accompanying drawings and technical solutions.

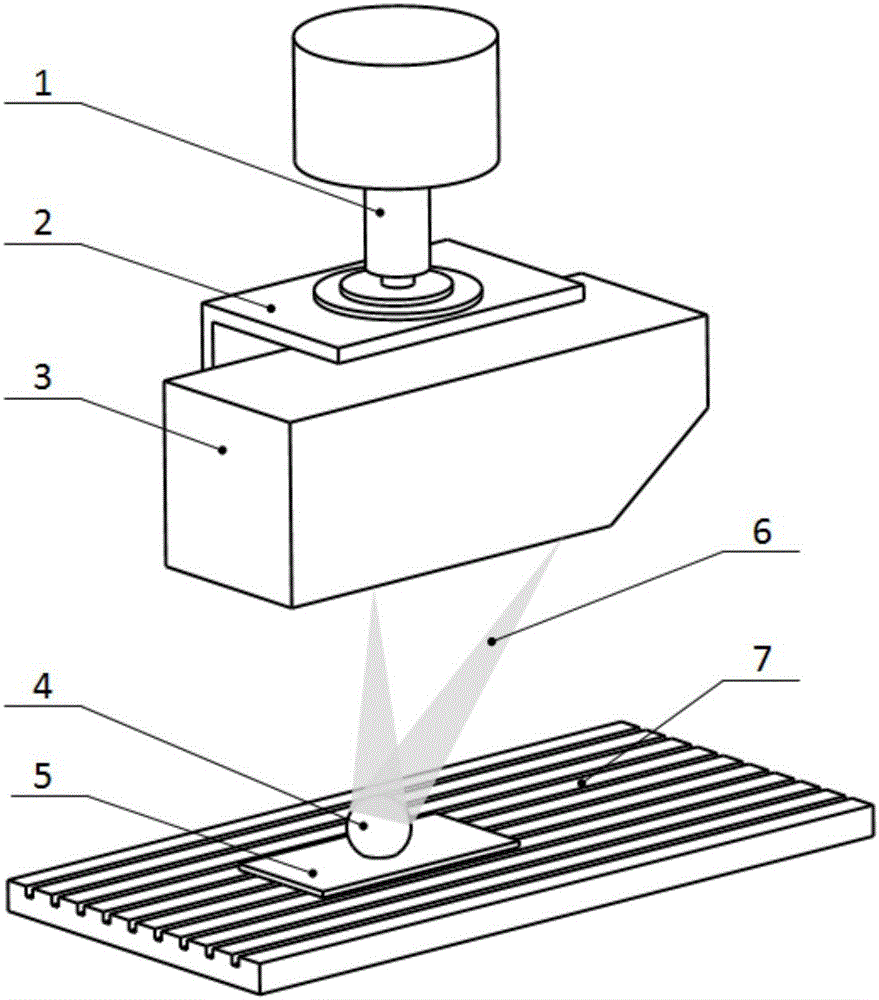

[0034] The line laser measuring sensor 3 selected in this embodiment is the 2420 type measuring instrument of LMI Company, the standard ball 4 selected is a matt ceramic ball with a standard diameter of 10.0134mm, and the machine tool is a Codd CNC machine tool.

[0035] The first step, selecting and arranging the spatial standard sphere

[0036] Relevant preparatory work should be carried out before the calibration of the line laser measurement sensor 3, such as figure 1 As shown, it is necessary to install the laser measurement sensor 3 on the spindle 1 of the CNC machine tool through the sensor connecting plate 2, install the calibration standard ball 4 on the standard ball fixing plate 5, and place it on the workbench 7 of the machine tool, turn on the line laser The measuring sensor 3 adjusts the position o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com