In-site measuring method and device of cutter abrasion

A tool wear and measurement method technology, which is applied in the direction of measuring devices, optical devices, instruments, etc., can solve the problems of inability to guarantee the accuracy of detection results and many interference factors in detection, and achieve real-time active control, low cost, and improved workpiece quality. The effect of machining accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] Below in conjunction with accompanying drawing, the present invention is described in further detail:

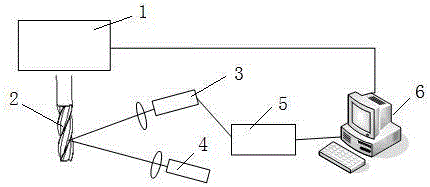

[0025] Measuring principle such as figure 1 shown. The tool 2 is installed on the tool holder on the main shaft of the CNC machine tool 1, and is driven by the tool holder to rotate with the main shaft during work. The CCD camera 3 and the line structure laser 4 are horizontally arranged on the side of the tool 2 , the CCD camera 3 is connected to the image acquisition card 5 , and the image acquisition card 5 is connected to the computer 6 . The line laser of the line structure laser 4 is projected vertically onto the cutting edge of the tool 2, and is modulated and deformed by the surface topography of the tool 2. The deformed laser line is imaged on the photosensitive surface of the CCD camera 3 placed at a certain angle to form a light strip image, image acquisition card 5. Transmit the light strip image to the computer 6; after image processing and calculation,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com