Patents

Literature

303 results about "Three Dimensional Size" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

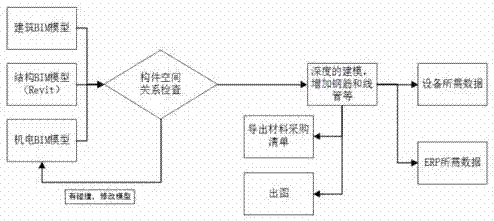

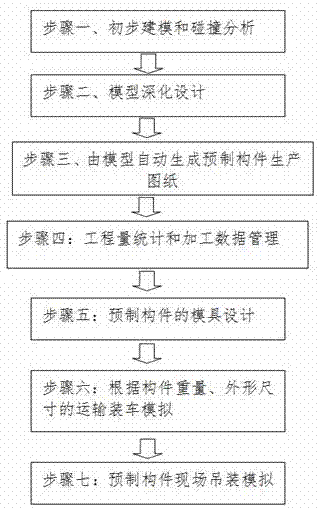

Assembled building deepening design method based on BII software

ActiveCN107967399AImprove accuracyImprove efficiencyGeometric CADSpecial data processing applicationsProduction drawingCollision analysis

The invention provides an assembled building deepening design method based on BII software. The assembled building deepening design method comprises the following steps of 1, conducting preliminary modeling and collision analysis; 2, conducting model deepening design; 3, automatically generating member production drawing through a model; 4, conducting engineering amount statistics and processing data management; 5, designing a mold of a prefabricated member; 6, conducting transportation vehicle-loading simulating and optimizing according to the member weight and the profile size; 7, conductingfield hoisting and simulating of the prefabricated member, and optimizing the hoisting sequence. Aiming at defects of an existing prefabricated member deepening design method, it is adopted that firstly, a three-dimensional model is modeled before deepening design drawing is drawn, a three-dimensional examination method is adopted, after the space conflict relation between the prefabricated member is excluded, the drawing is generated, a large amount of modification of the drawing is avoided, parts in the model all have the accurate three-dimensional size, material information and member subordination relationship, a member material list can be generated simply by conveying the information, and thus an accurate and efficient effect is achieved.

Owner:GUANGDONG JIAN YUAN CONSTR ASSEMBLY IND CO LTD

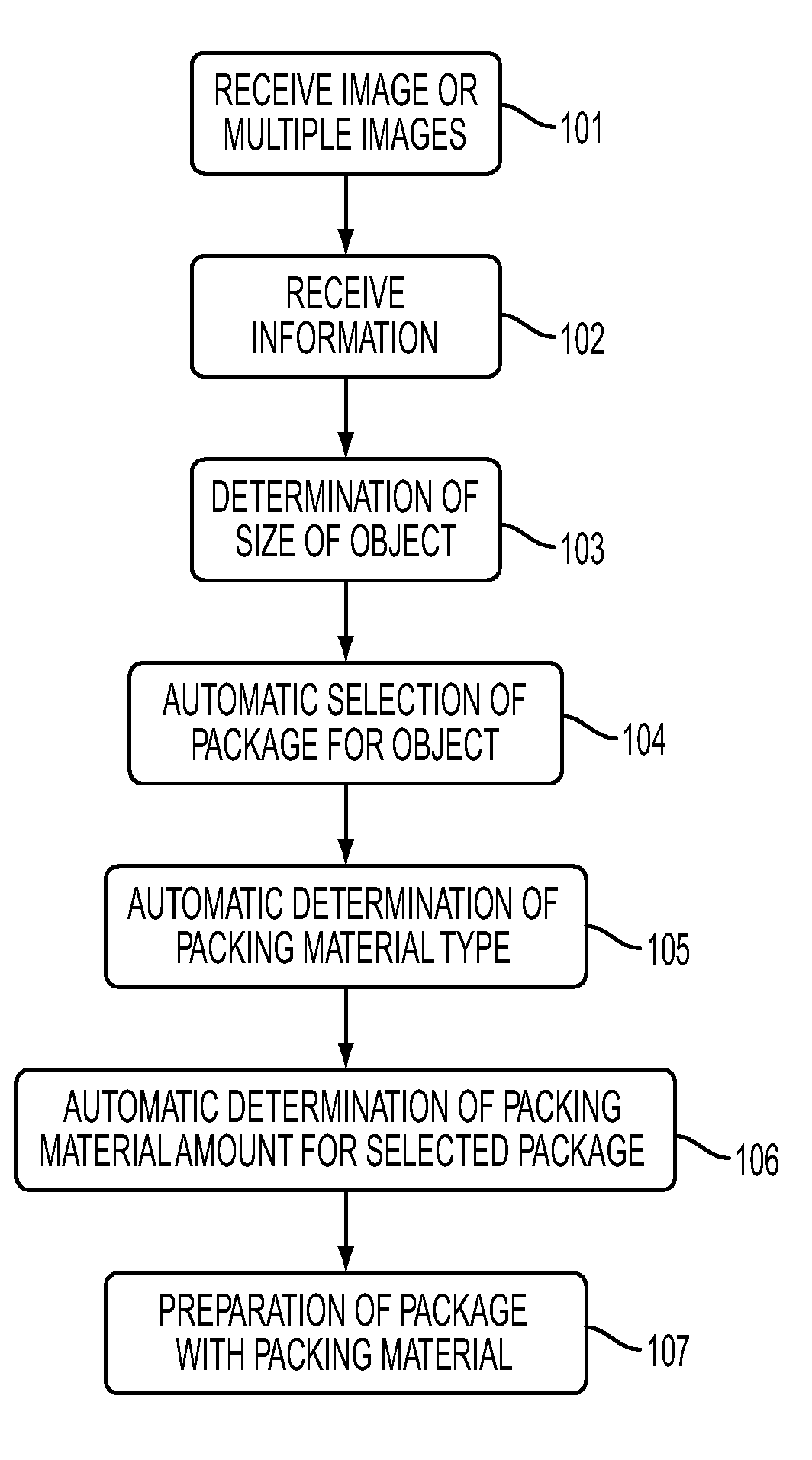

Custom packaging solution for arbitrary objects

Owner:XEROX CORP

Custom packaging solution for arbitrary objects

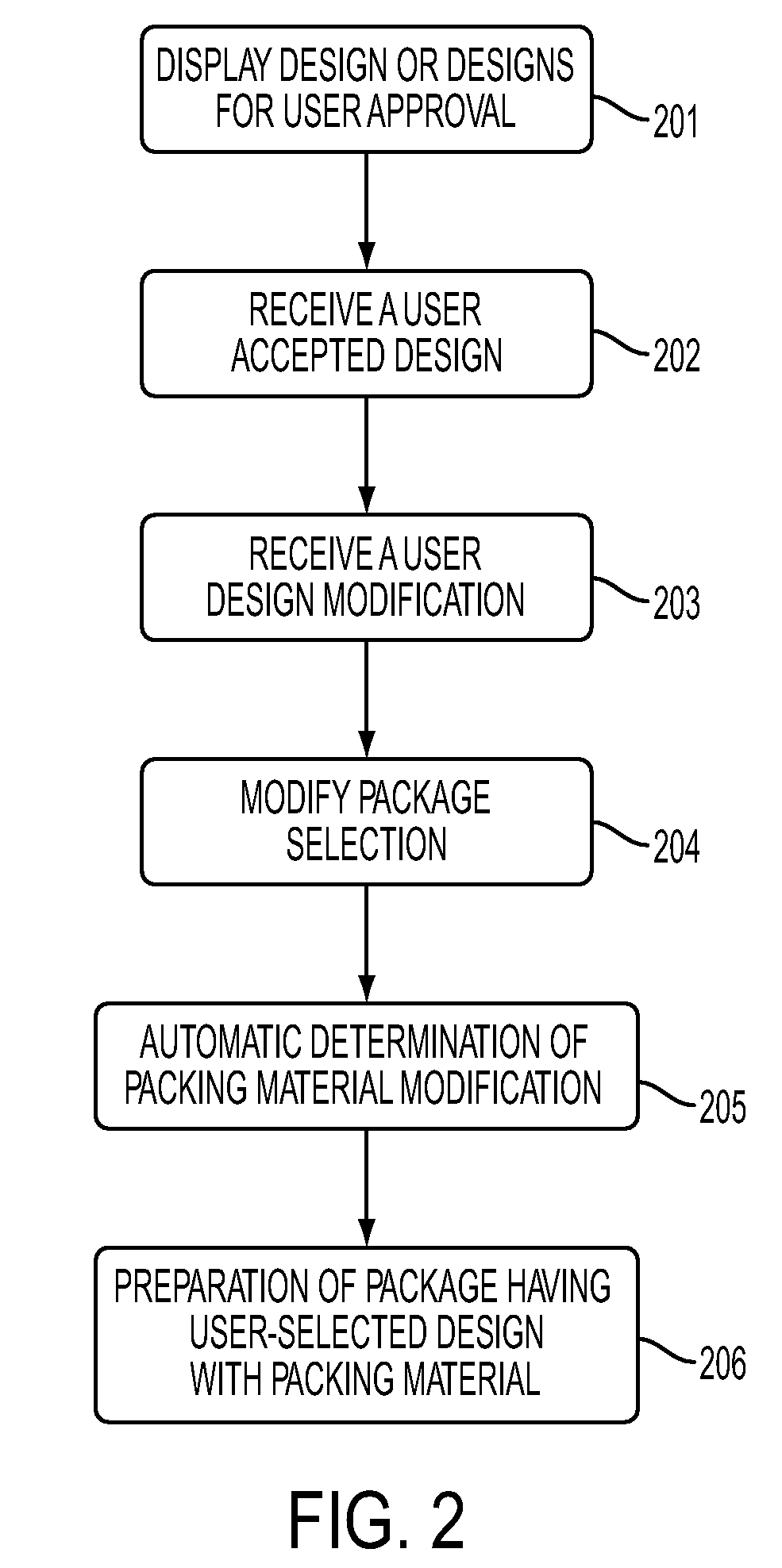

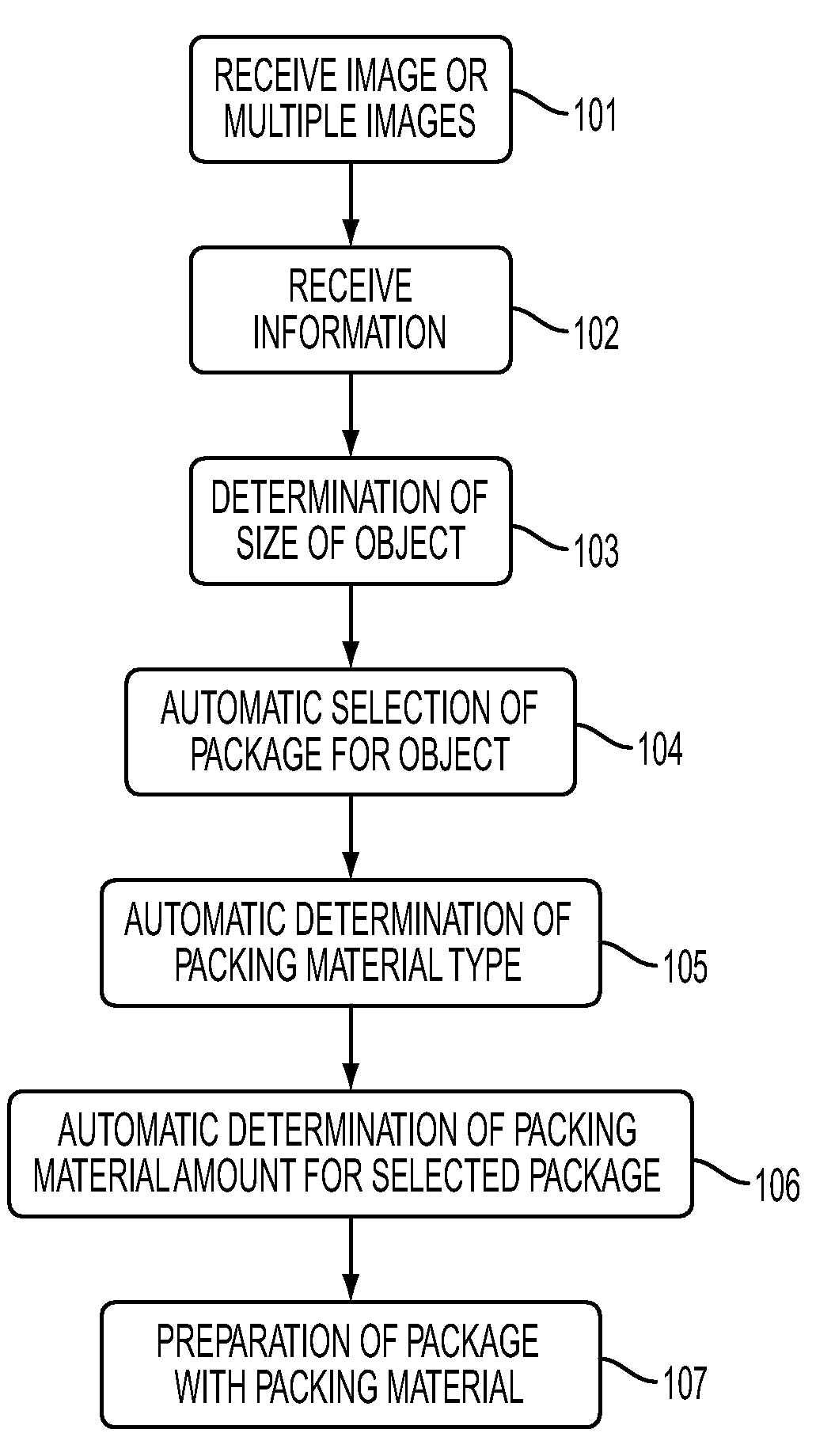

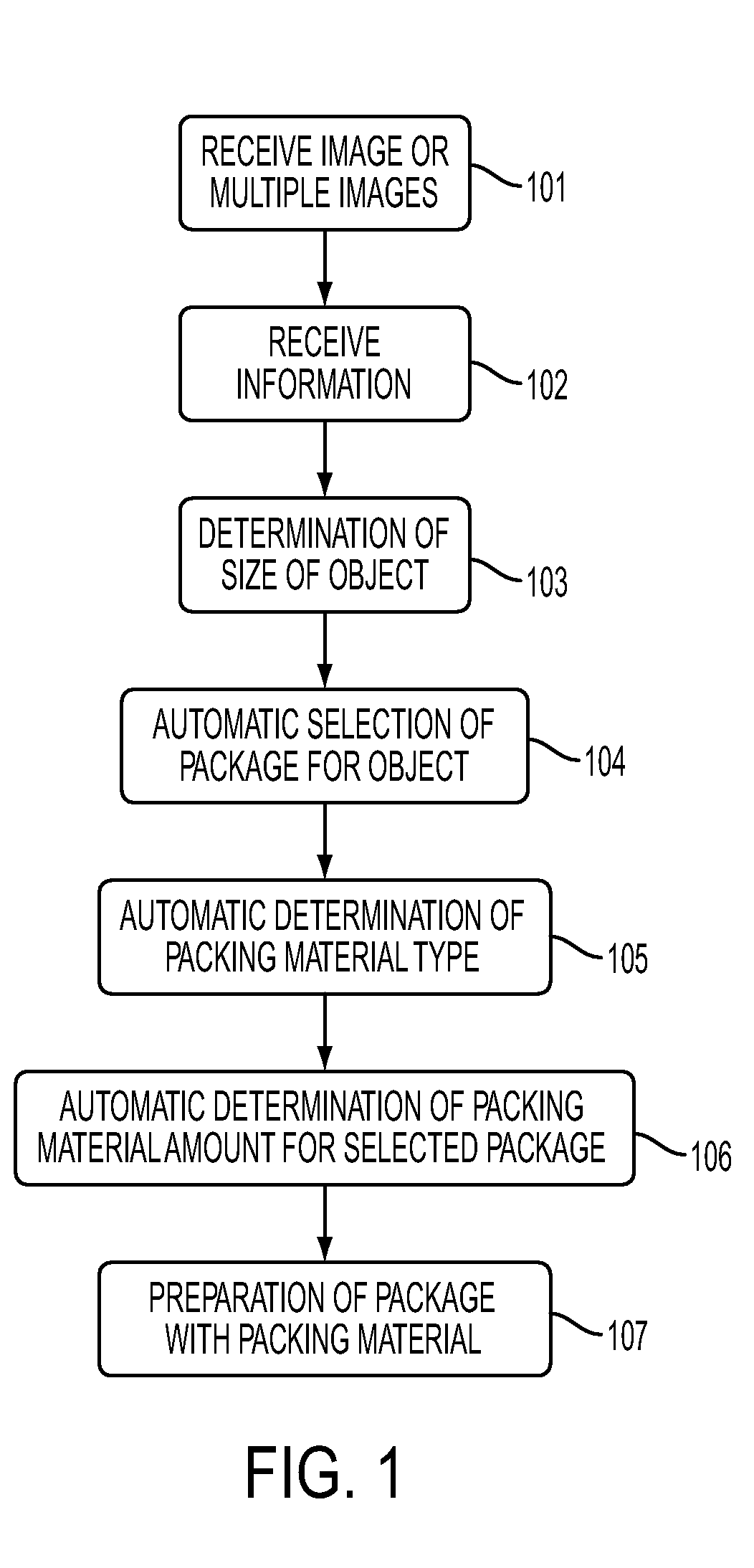

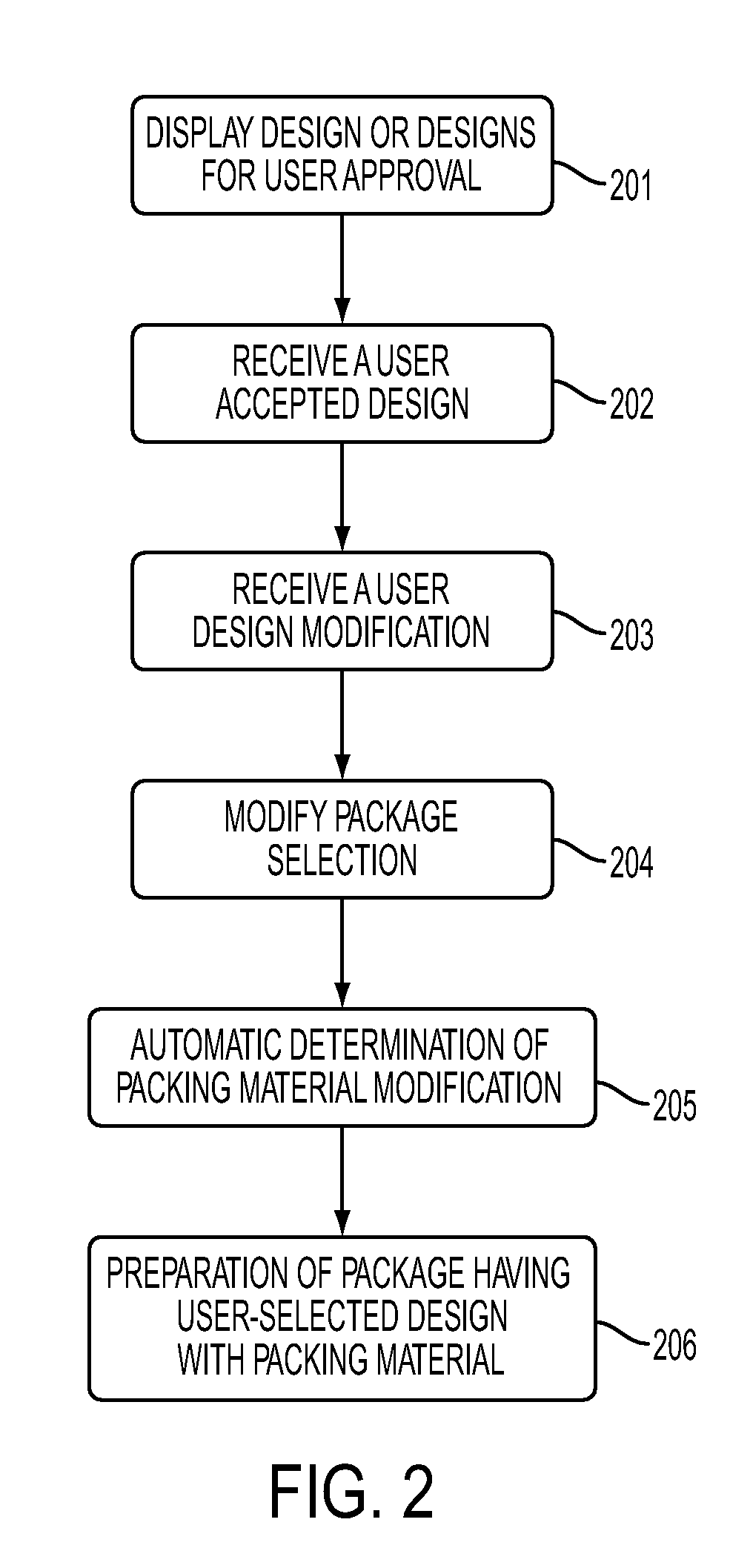

A method of producing a custom packaging system for arbitrary objects. A first image of an object to be packaged is received via an electronic user interface. Information relating to the material properties of the object may be received as well via the interface. A three dimensional size for the object is determined. At least one package for the object is automatically selected. Based on the material properties, a packing material type is automatically determined. Based upon the size and the selected package, a packing material amount is determined. Further printing options are permitted.

Owner:XEROX CORP

Additive manufacturing surface defect, internal defect and shape composite detection method and device

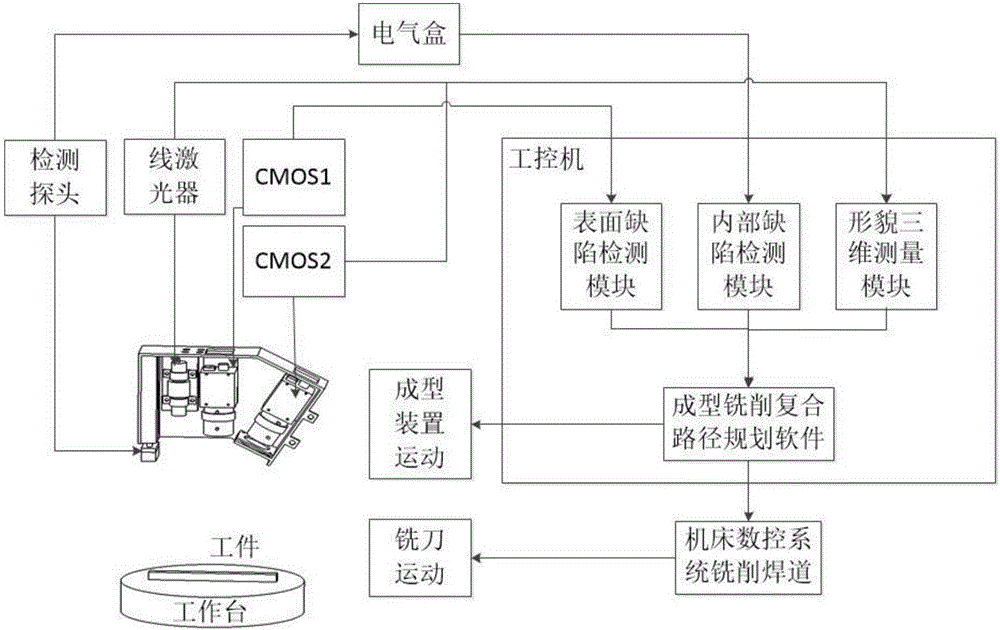

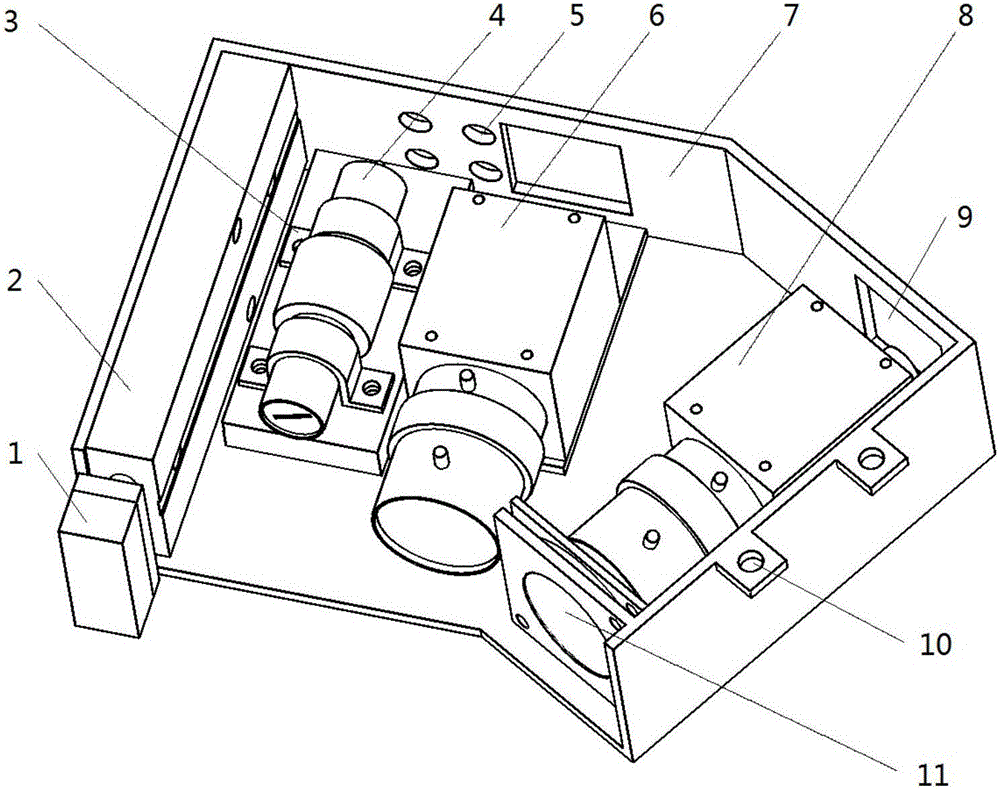

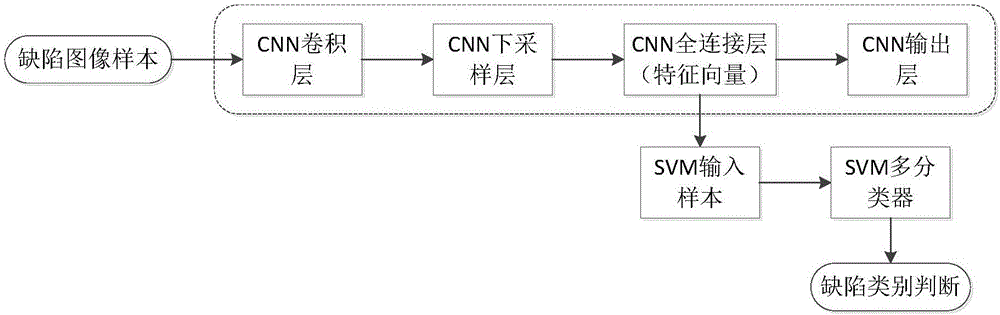

ActiveCN106338521AReal-time detectionOptically investigating flaws/contaminationUsing optical meansCMOSMagnetic disturbance

The invention discloses an additive manufacturing surface defect, internal defect and shape composite detection device which comprises a surface defect detection system, an internal defect detection system, a shape three-dimensional measurement system and a clamping device, wherein the surface defect detection system comprises a first CMOS industrial camera; the internal defect detection system comprises an air cylinder and a detection probe; the detection probe is used for generating a magnetic field to be close to the detected surface and establish magnetic mutual action with a workpiece to form a magnetic disturbance environment; the shape three-dimensional measurement system comprises a line laser, a light filter and a second CMOS industrial camera. The device can perform real-time and comprehensive detection on the surface defect, the internal defect and the shape three-dimensional size in additive manufacturing, transmits data to an industrial personal computer for analysis, interacts with forming milling composite route planning software, and can control a shaping device in real time to perform formation and generate a milling code and control a milling cutter to perform milling on the additive manufacturing surface.

Owner:HUAZHONG UNIV OF SCI & TECH

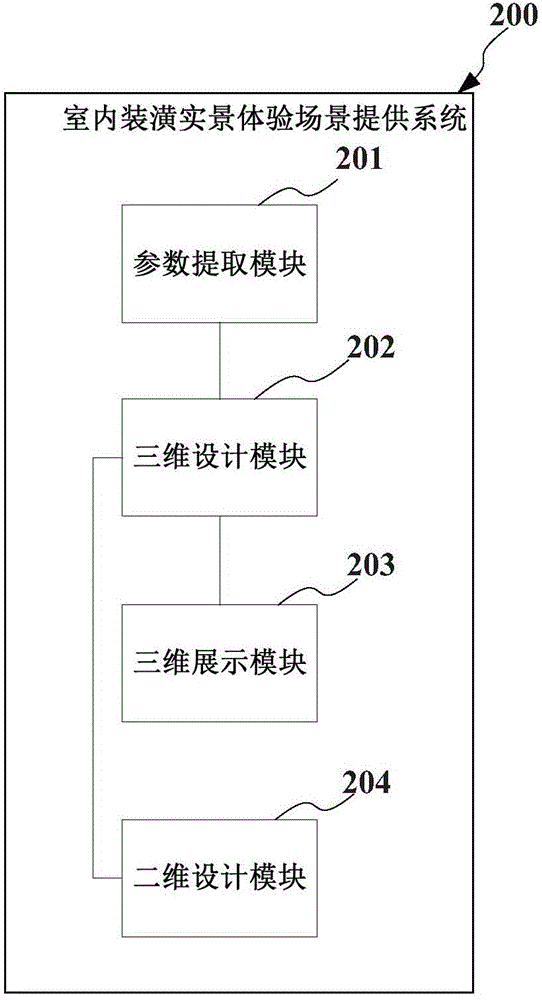

Interior decoration situational experience scene providing method and system

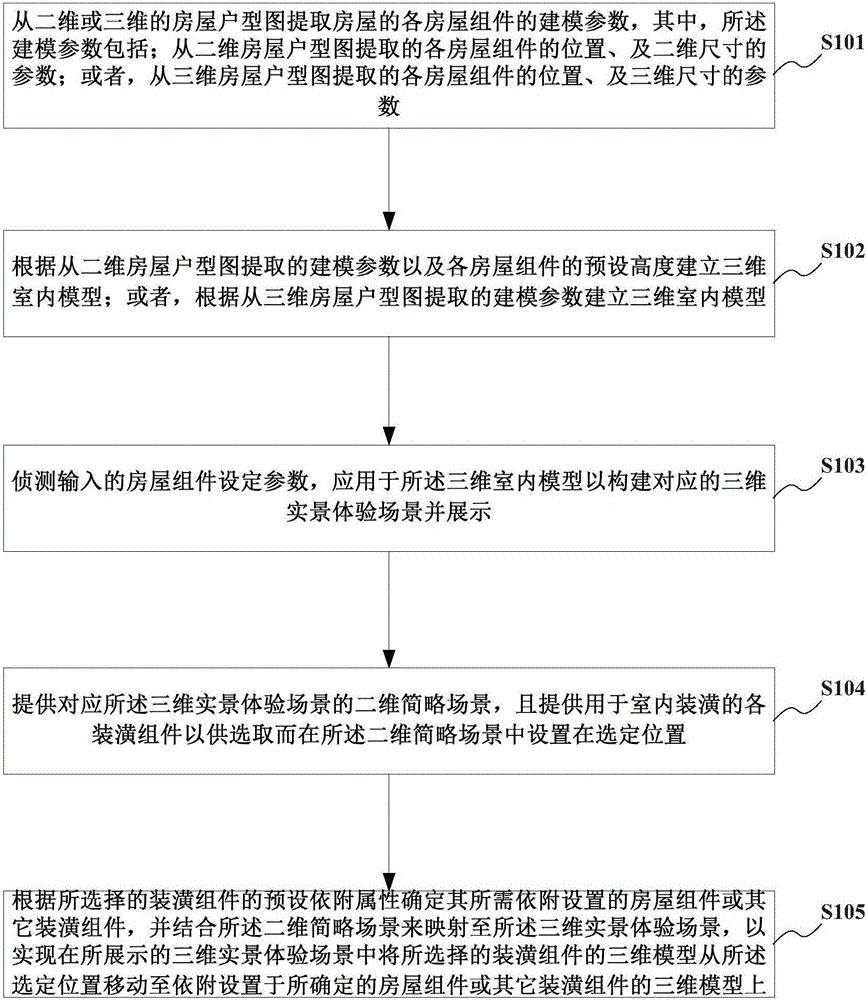

InactiveCN106096153AGood for business efficiencySave time, effort and costDetails involving 3D image dataBuying/selling/leasing transactionsBusiness efficiencySimulation

The invention relates to an interior decoration situational experience scene providing method and system. The method comprises the steps that modeling parameters of all building components of a building are extracted from a two-dimensional or three-dimensional building floor plan, or parameters of positions and three-dimensional sizes of all the building components are extracted from the three-dimensional building floor plan; a three-dimensional interior model is built according to the modeling parameters extracted from the two-dimensional building floor plan and the preset heights of all the building components, or the three-dimensional interior model is built according to the modeling parameters extracted from the three-dimensional building floor plan; input building component setup parameters are detected and applied to the three-dimensional interior model to build and display a corresponding three-dimensional situational experience scene, the building components or other decoration components which need to be attached and arranged are determined according to the preset position parameters of the selected decoration components, and arrangements are correspondingly achieved in the three-dimensional situational experience scene; interior decoration experience is rapidly and efficiently achieved, and the business efficiency is promoted.

Owner:上海营匠网络科技有限公司

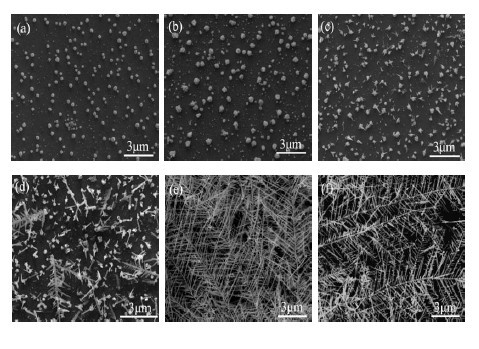

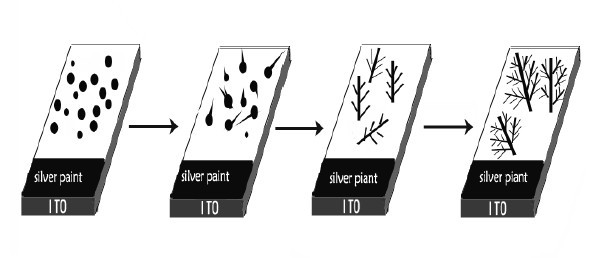

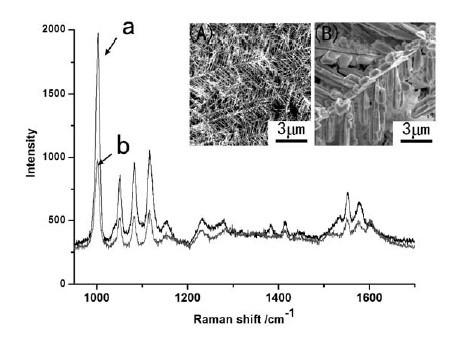

Silver nanodendrite surface enhanced Raman scattering (SERS) substrate, and preparation method and application thereof

InactiveCN102181891AUniform shapeSize is easy to controlRaman scatteringNanotechnologyThree Dimensional SizeRaman scattering

The invention discloses a silver nanodendrite surface enhanced Raman scattering (SERS) substrate, and a preparation method and application thereof, relating to the technical field of nanomaterial science and Raman detection. The SERS active substrate is of silver dendrites which are distributed evenly, and the three-dimensional sizes of dendrites are adjustable. The preparation method of the invention is characterized in that the silver nanodendrites are electrically deposited on commercially available ITO (Indium-doped Tin Oxide) conductive glass by adopting a constant current deposition method and using a silver nitrate solution as electrolyte without adding any other auxiliary. The preparation method of the invention has the advantages of simple, convenient fast (30s) preparation process, low cost, small current and low voltage, and the silver dendrites can be transferred to any substrate (paper, other metal sheets or plastic sheets). The substrate obtained by the method disclosed by the invention has high stability and ordered and controllable structure, and exhibits quite high sensitivity in Raman spectrum detection.

Owner:WENZHOU UNIVERSITY

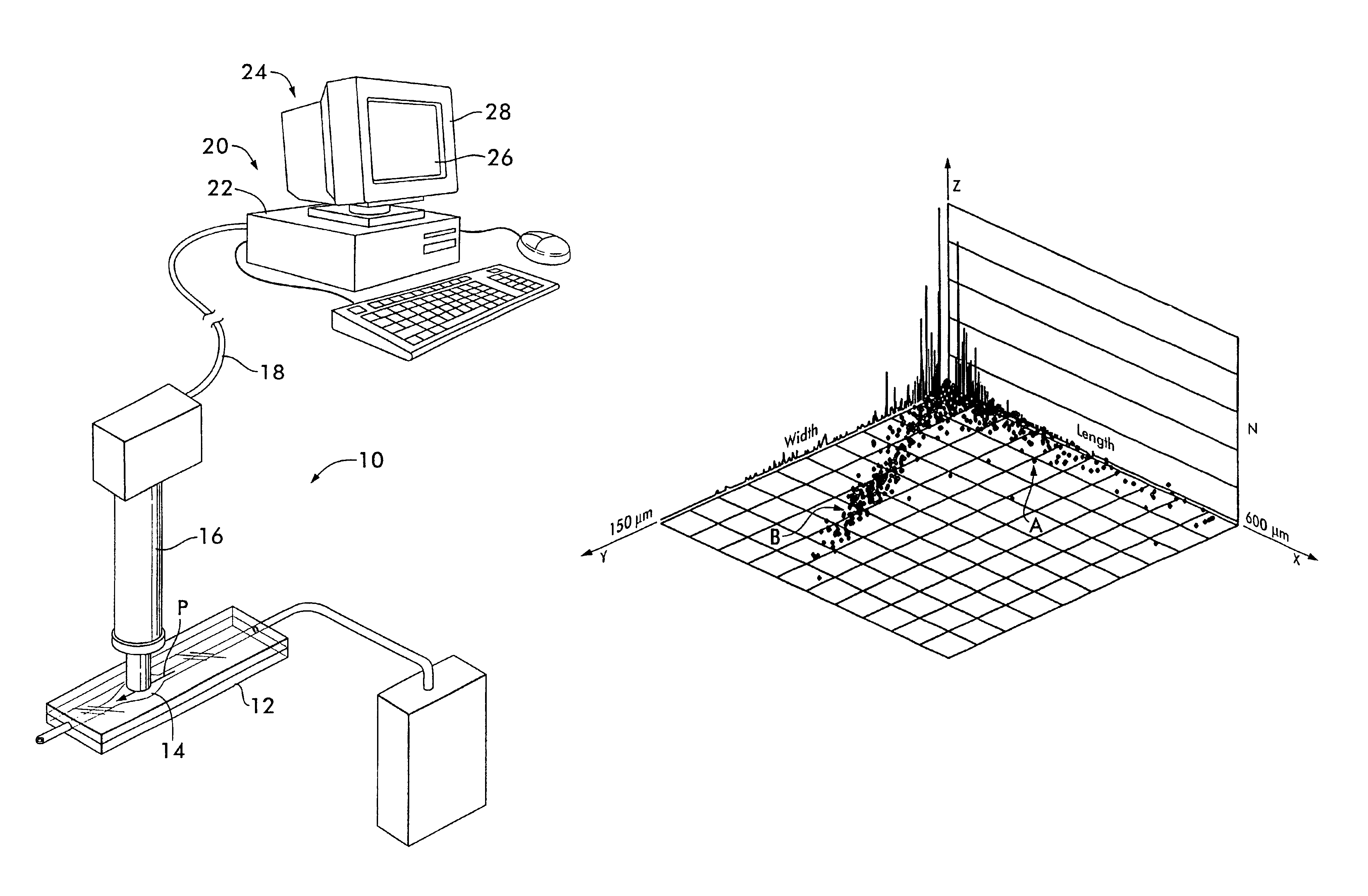

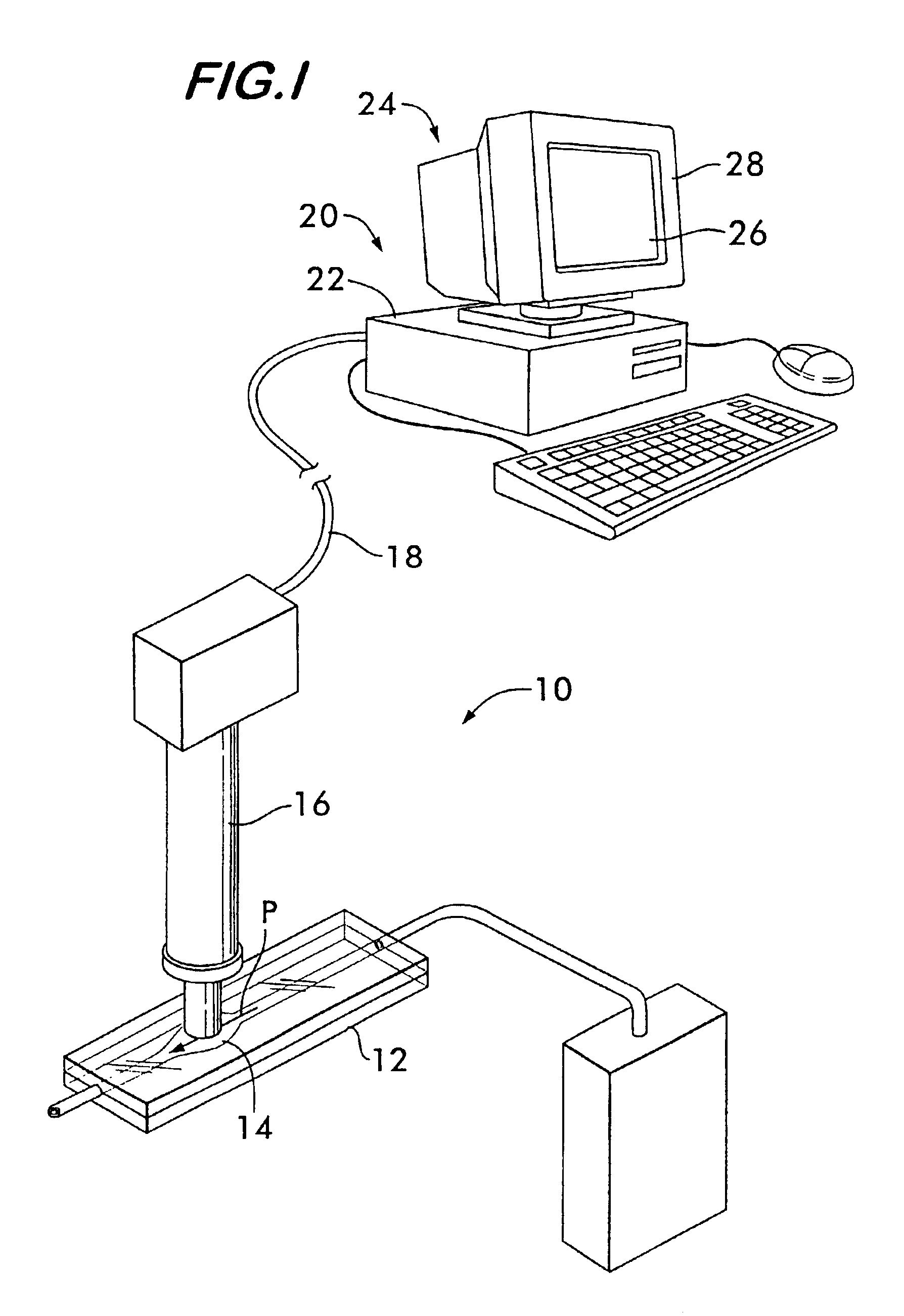

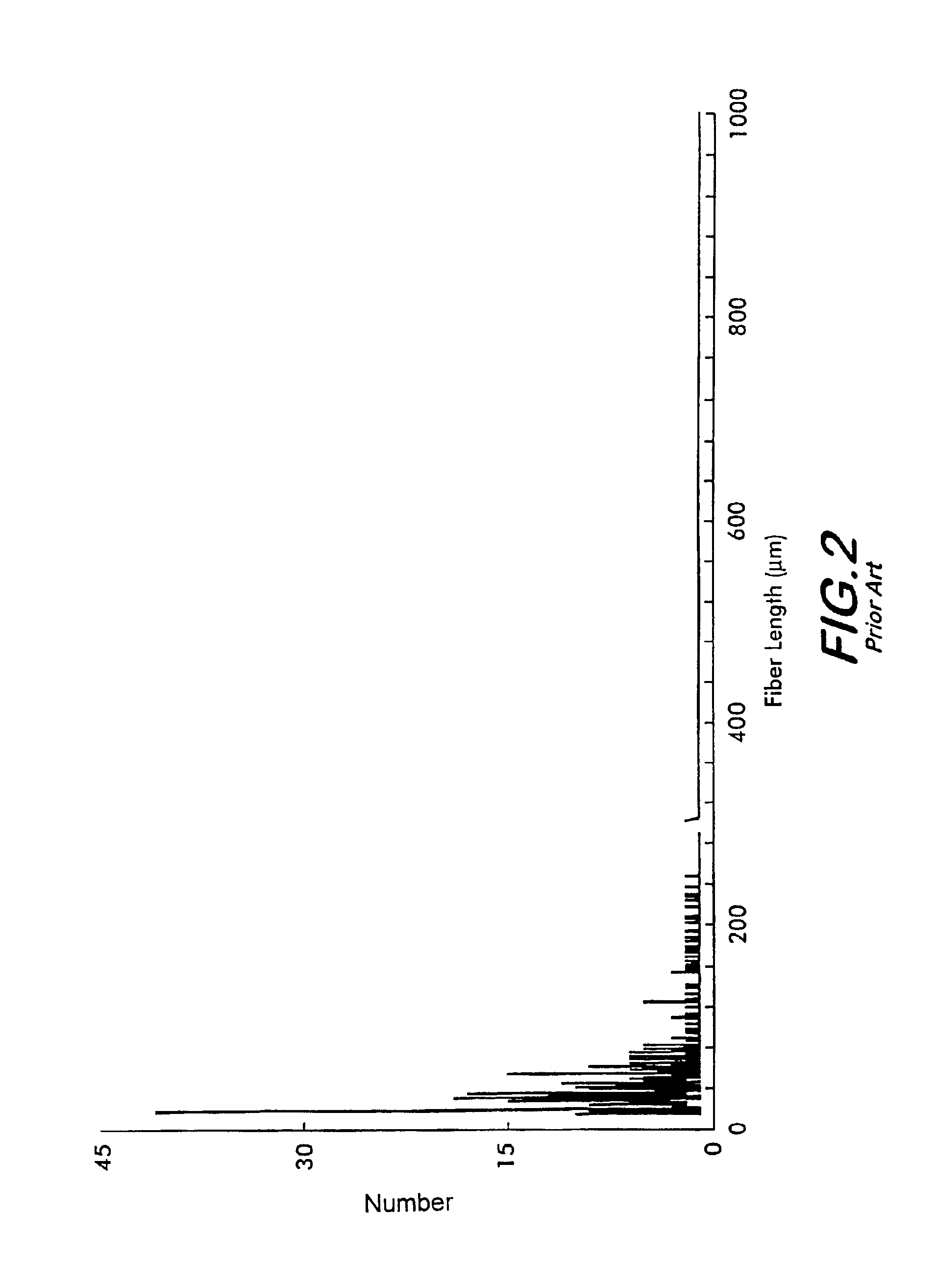

Simultaneous measurement and display of 3-D size distributions of particulate materials in suspensions

An apparatus and method in which a still image, or still images, are obtained of a plurality of particles suspended in a fluid medium. Each still image is transferred to an image analyzing unit that measures a set of dimensional characteristics per particle for particles appearing in the image and determine an occurrence characteristic for particles having a matching set of dimensional characteristics. Preferably, a three dimensional representation of the characteristics is displayed in real time. More preferably, the displayed three-dimensional representation is continuously updated and further entries are accumulated on the display as image analysis is performed. The display provides information to a viewer enabling the viewer to determine a shape distribution of the particles within the suspension even when multiple particle shapes are present.

Owner:COULTER INTERNATIONAL CORPORATION

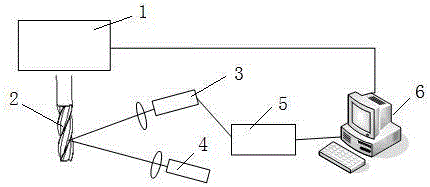

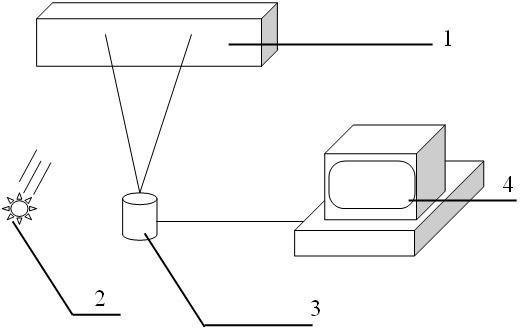

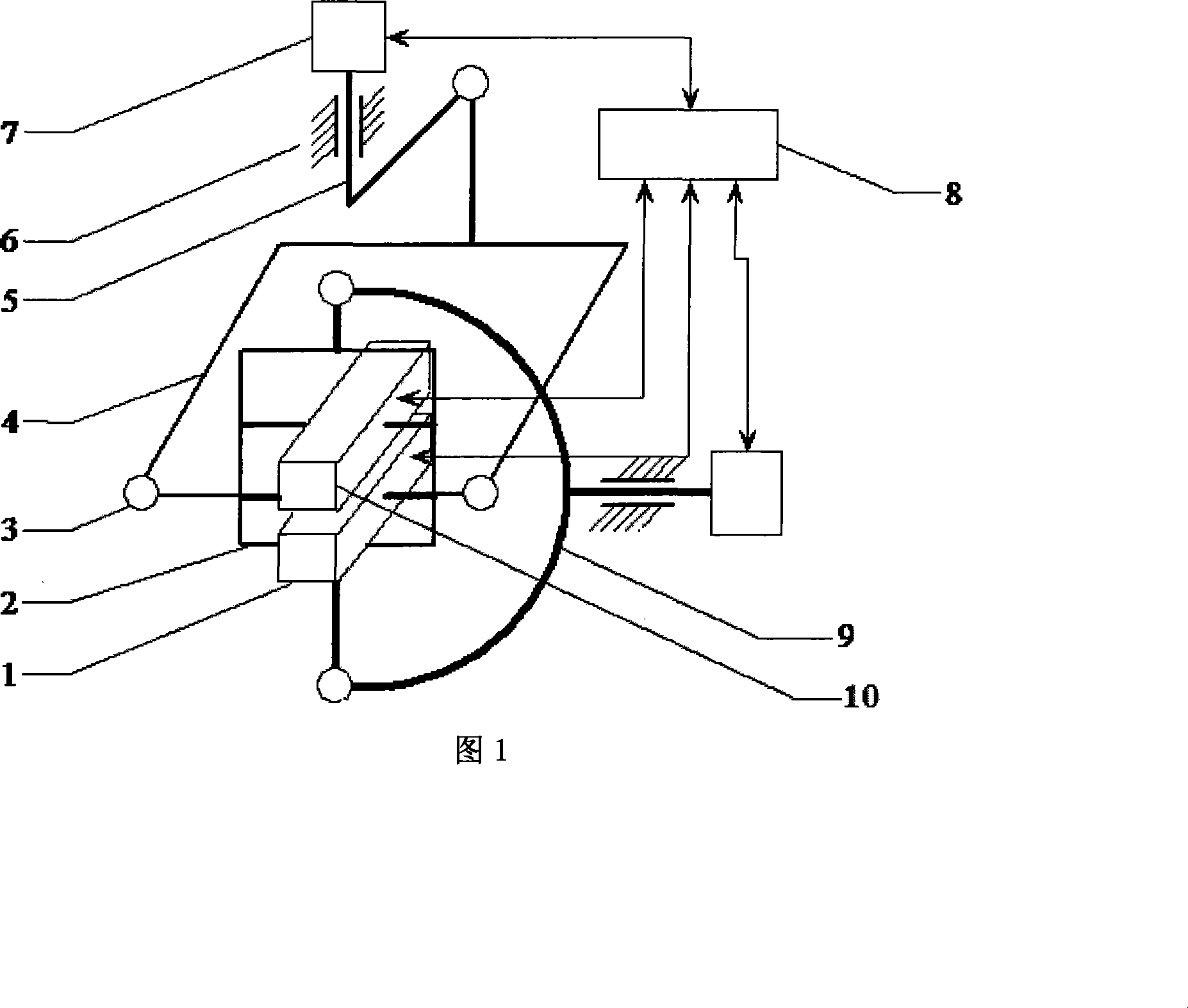

In-site measuring method and device of cutter abrasion

InactiveCN106840028ARealize presence detectionRealize automatic in-situ measurementUsing optical meansImaging processingMicrometer

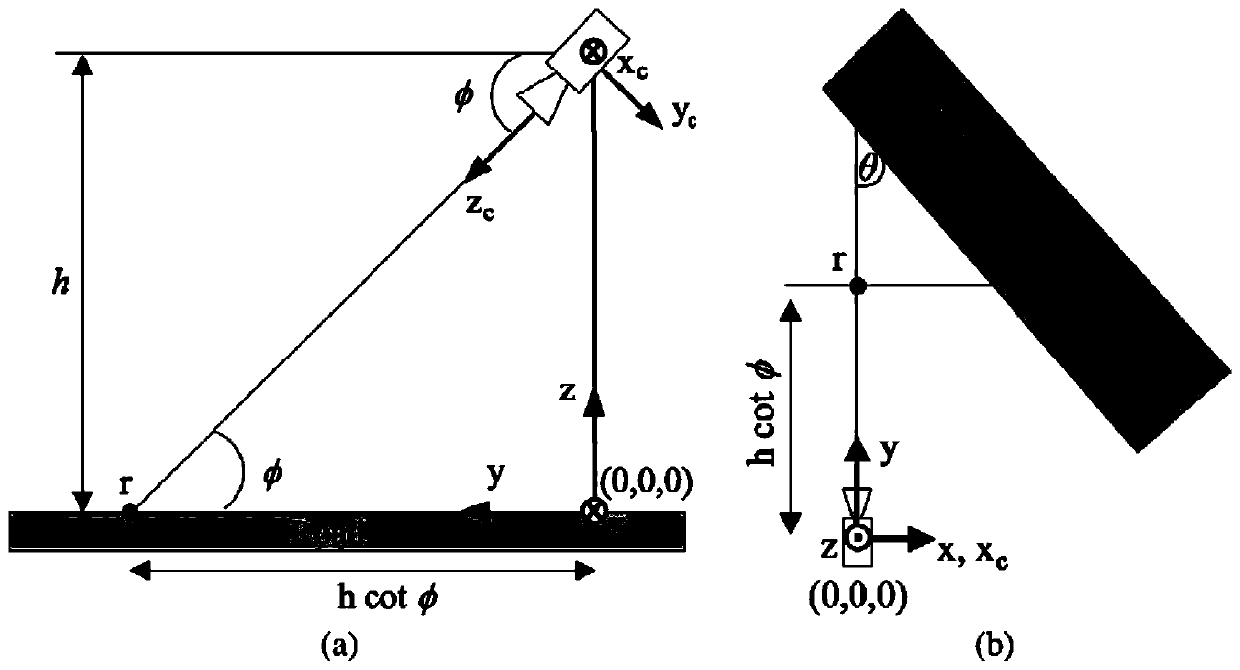

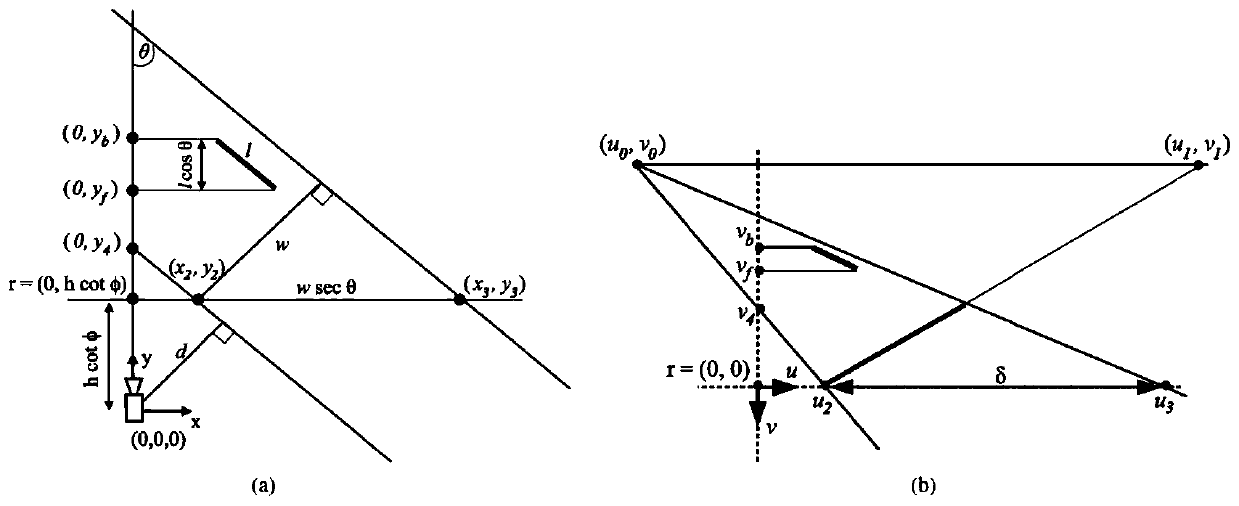

The invention discloses an in-site measuring method and device of cutter abrasion, and belongs to the technical field of the in-site measuring method and device of cutter abrasion. The method comprises the first step of installing a linear structure laser device and a CCD camera on the lateral of a cutter, wherein the CCD camera is connected to a computer through an image collecting card; the second step of making ray laser be vertically projected to the knife blade of the cutter, wherein deformed laser rays image on a photosensitive surface of the CCD camera and are then transmitted to the computer; the third step of obtaining a two-dimensional size of a ray bar point on a laser plane through image processing and calibration calculation; the fourth step of making the device rotate along with the cutter to scan the cutter for one round to obtain three-dimensional size data of the whole cutter; the fifth step of comparing the three-dimensional size data with a standard cutter three-dimensional model to obtain abrasion loss. The in-site measuring method and device of cutter abrasion have the advantages that the cost is low, the precision is high, the strip image information is easy to obtain, the practicability is high, the active control is achieved, the measuring precision at the micrometer level can be reached, and thus the measuring method and device of cutter abrasion are suitable for in-site measuring of cutter abrasion.

Owner:HUBEI UNIV OF ARTS & SCI

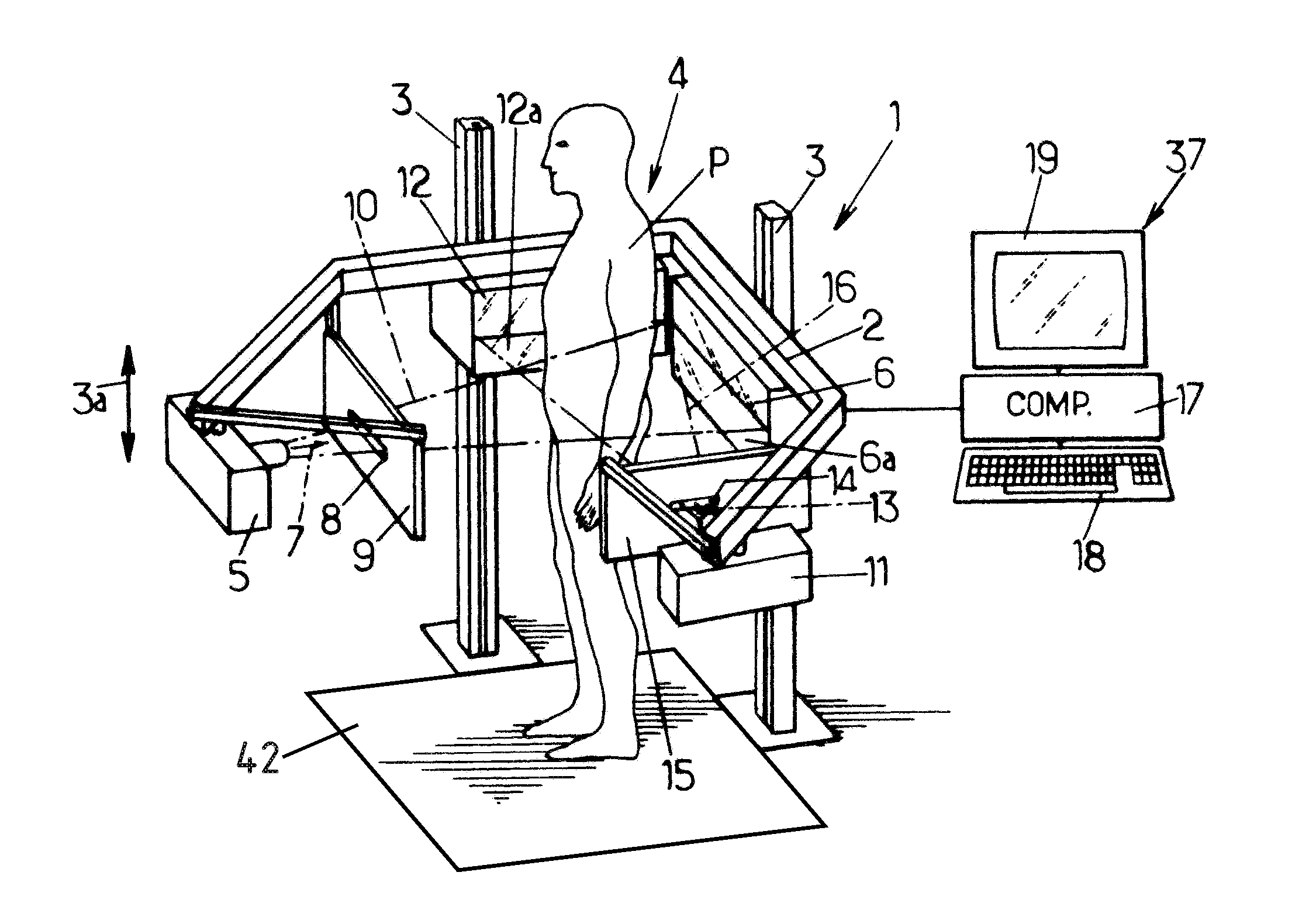

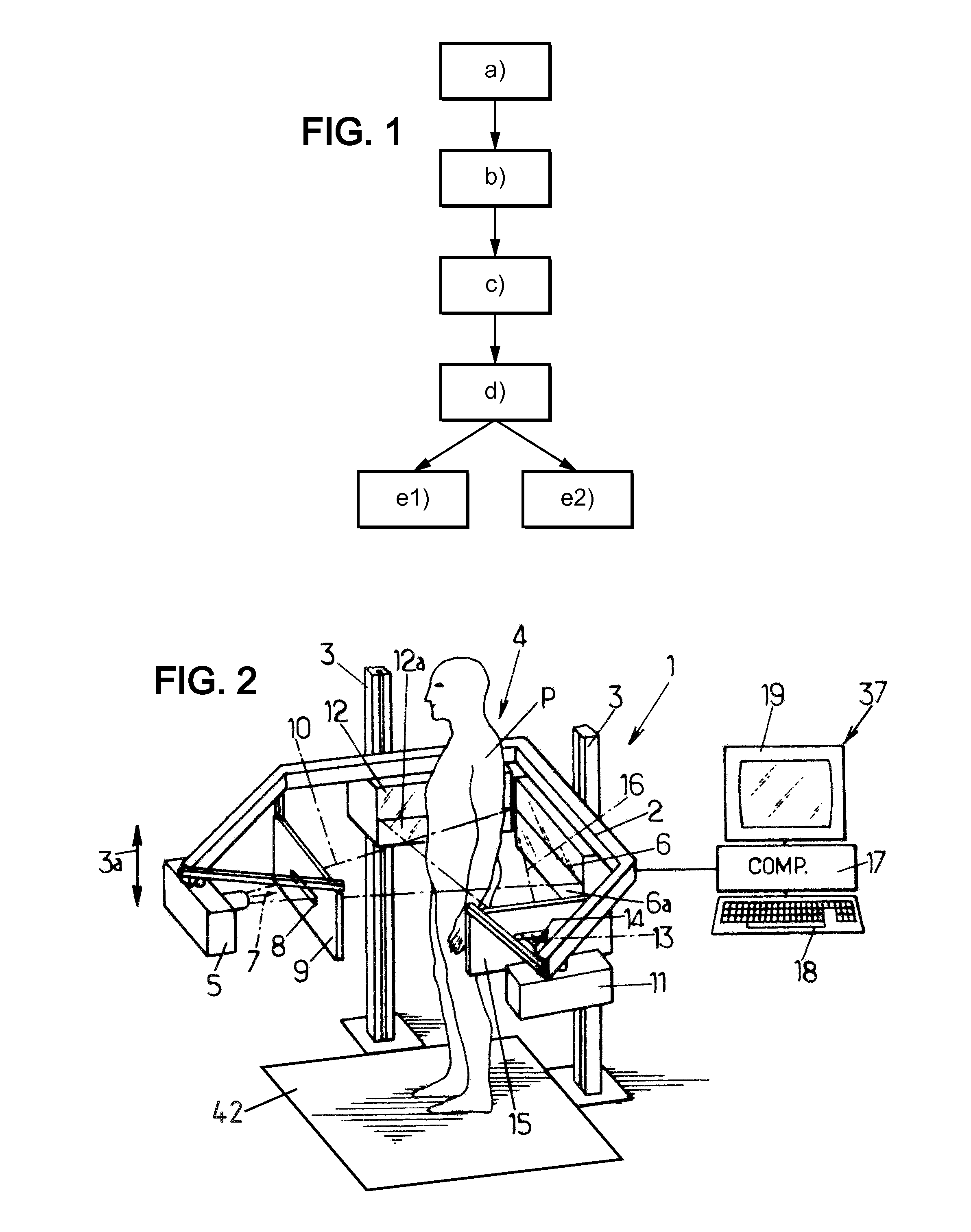

Method for designing a patient specific orthopaedic device

ActiveUS20160100907A1Accurate and reliable and inexpensiveInexpensive and reliableDiagnosticsComputer-aided planning/modellingOrthopaedic deviceThree Dimensional Size

A method for designing a patient specific orthopaedic device intended for an osteoarticular structure of a patient, based on at least two two-dimensional radiographic images of the osteoarticular structure taken respectively in two offset image-taking directions, comprising the following steps: b) locating anatomical points on the radiographic images; c) determining at least one three-dimensional geometrical feature of the patient by matching the anatomical points b) located at step b); d) determining at least one three-dimensional size parameter of the orthopaedic device based on the geometrical feature of the patient determined at step c).

Owner:EOS IMAGING

Method for performing three-dimensional printing on biological ceramic bracket based on light-cured molding, and application

ActiveCN107296985AIncreased intensityHigh precisionAdditive manufacturing apparatusTissue regenerationThree Dimensional SizeRepair material

Owner:GUANGDONG UNIV OF TECH

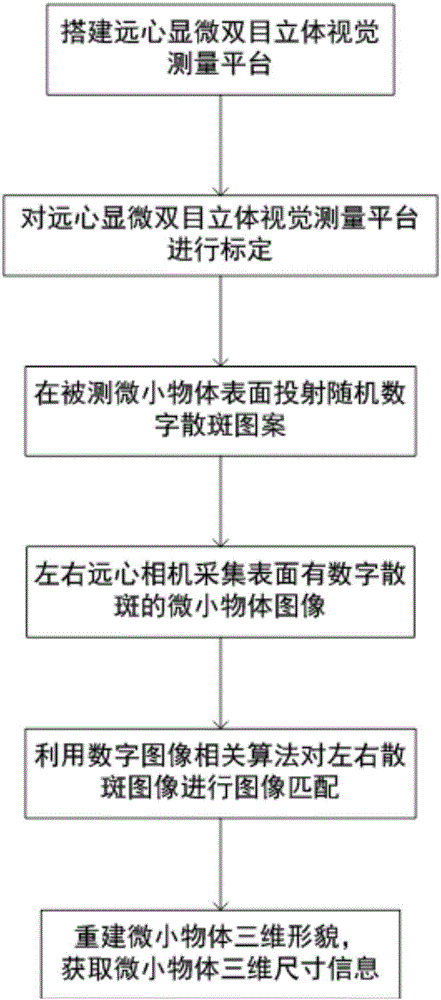

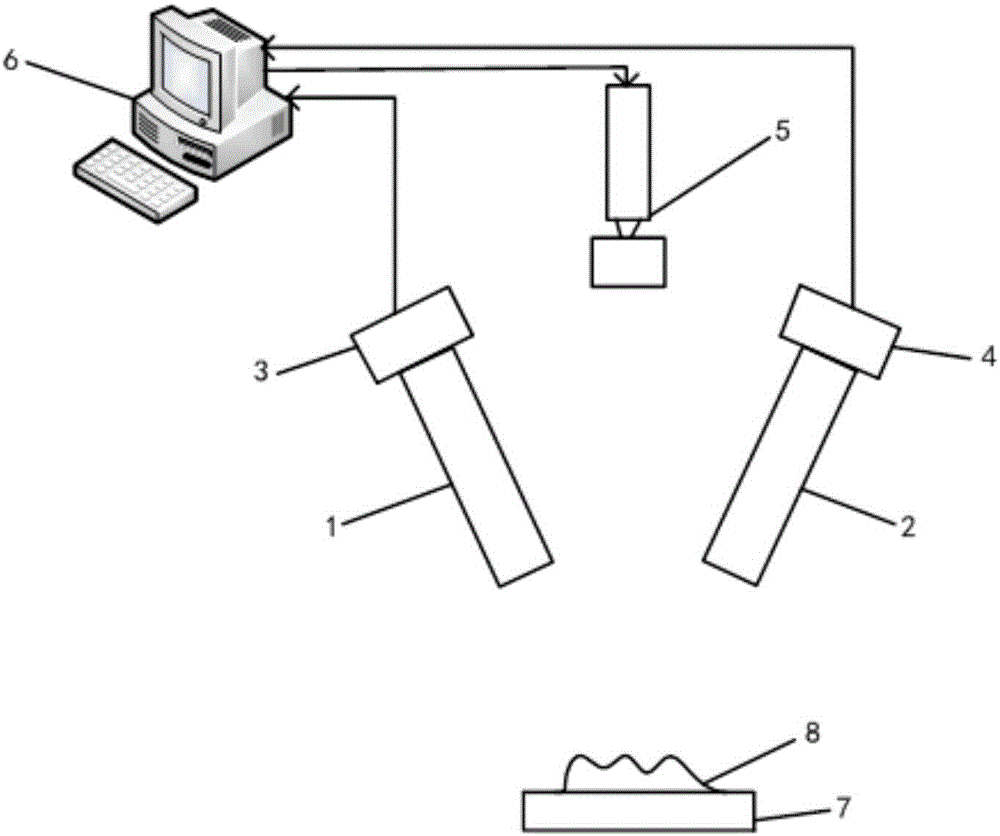

Digital speckle-based telecentric microscopic binocular stereoscopic vision measurement method

ActiveCN106595528AClear surface coverageIncrease contrastUsing optical meansFast measurementPoint cloud

The invention discloses a digital speckle-based telecentric microscopic binocular stereoscopic vision measurement method. The method includes the following steps that: 1) a telecentric microscopic binocular stereoscopic vision measurement platform is built; 2) the measurement platform is calibrated, the inner and outer parameters and relative position relations of a left telecentric camera and a right telecentric camera are determined; 3) a digital speckle pattern is projected onto the surface of a tiny object through a projector; 4) the left telecentric camera and the right telecentric camera are utilized to simultaneously shoot the to-be-measured tiny object of which the surface is covered with the digital speckle pattern, and a left speckle pattern and a right speckle pattern are acquired; 5) image matching is performed on the left speckle pattern and the right speckle pattern, matching relations of corresponding points in the left speckle pattern and the right speckle pattern are obtained, and the three-dimensional point cloud data of the tiny object are obtained according to the inner and outer parameters and relative position relations of the left telecentric camera and the right telecentric camera; and 6) the three-dimensional form of the tiny object is reconstructed according to the three-dimensional point cloud data, and the three-dimensional size information of the to-be-measured tiny object is obtained. The digital speckle-based telecentric microscopic binocular stereoscopic vision measurement method has the advantages of fast measurement speed, high measurement precision and the like.

Owner:HUAZHONG UNIV OF SCI & TECH

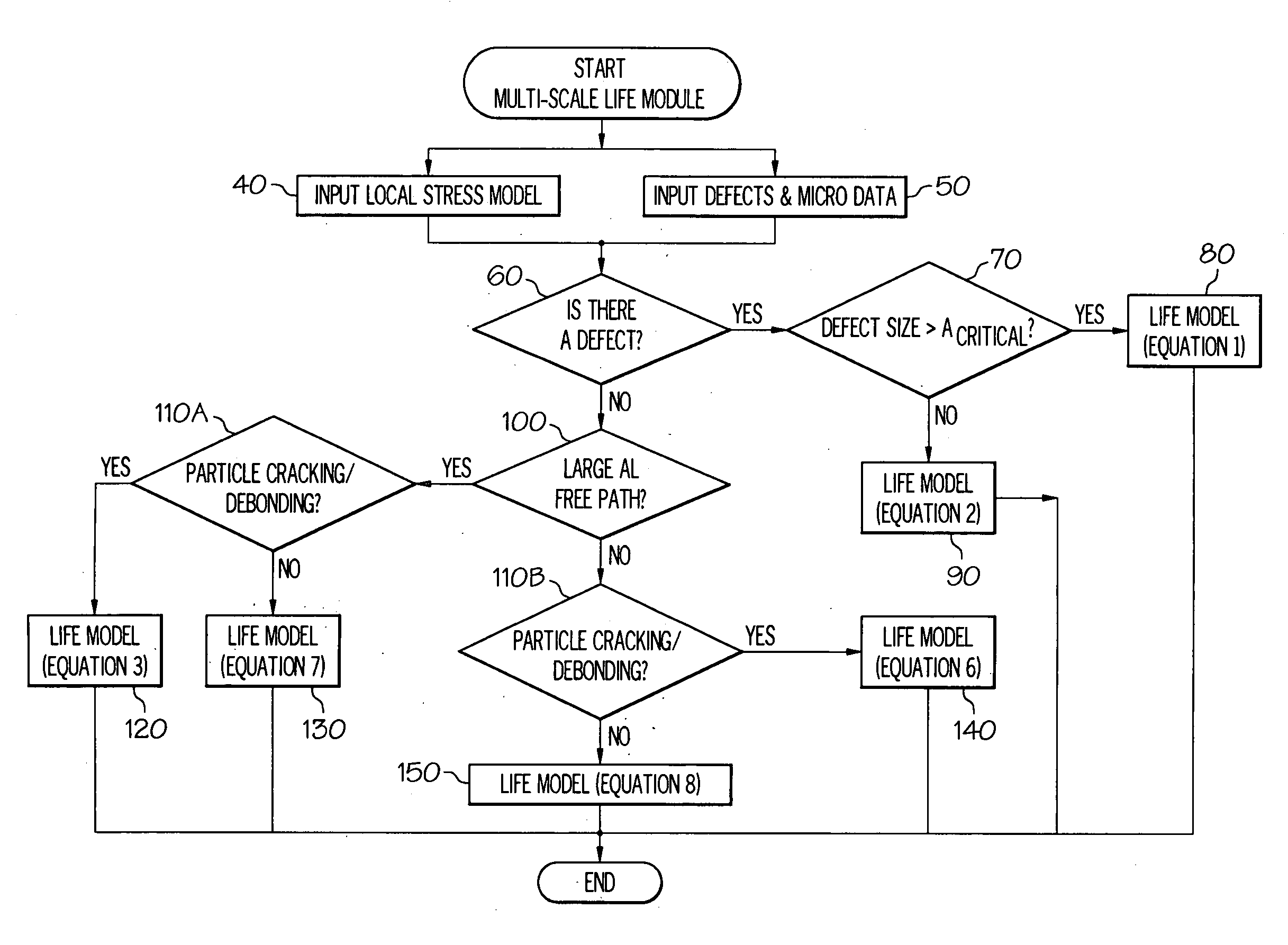

Methods and systems to predict fatigue life in aluminum castings

InactiveUS20090276166A1Accurately fatigue propertyAccurate of fatigue propertyPlug gaugesDigital computer detailsCrazingCasting defect

Methods and systems of predicting fatigue life in aluminum castings that combines extreme values of both casting flaws and microstructures with multiscale life models. The multiscale life models account for differing fatigue crack initiation based on the size scale of the defect and microstructure features, including provisions for generally millimeter scale casting flaws, generally micrometer scale second phase particles by cracking or debonding, or submicrometer scale dislocation interactions with precipitates which form persistent slip bands. In the presence of casting flaws, the fatigue initiation life is negligible and the total fatigue life is spent in propagation of a fatigue crack from such flaws. In the absence of casting flaws, however, the total fatigue life is spent in both crack initiation and propagation, except for the case where fatigue cracks initiate from large second phase particles in a coarse microstructure. The extreme values of casting flaws, second phase particles, mean free path through an aluminum matrix or grain sizes are obtained from extreme value statistics when two or three dimensional sizes of casting flaws and microstructure features are provided by either direct measurement or analytical prediction. The upper bound flaw or microstructure feature size is calculated by extreme value statistics.

Owner:GM GLOBAL TECH OPERATIONS LLC

Method for arranging at most article in finite dimension three dimensions

The invention relates to a method to arrange the most articles and goods in a container; prior container loading technologies are only limited in designing the optimum arrangement locations for the articles and goods through software calculation for a plurality of dimensions of regular articles and goods. However, for arrangement of many irregular articles and goods, both space utilization rate of containers and working efficiency are so low that fine schemes can be gained always through multiple rounds of repeated arrangement. The invention is characterized by performing dimension measurement, weighting, categorization and numbering for article and goods in different sizes, different dimensions and different properties with a weighting device, a laser scaner or a projection grate; put all the following information into a computer: All dimension measurement data, weight data, property data, category and coding data for articles and goods, and three-dimensional data of a container; the computer utilizes a pre-compiled software to calculate the optimum arrangement scheme for the articles and goods inside the container, and then, output the optimum arrangement scheme. The method can fulfill scanning for irregular articles and goods, and optimize calculation before an average space efficiency is anticipated to reach 95%.

Owner:张斌

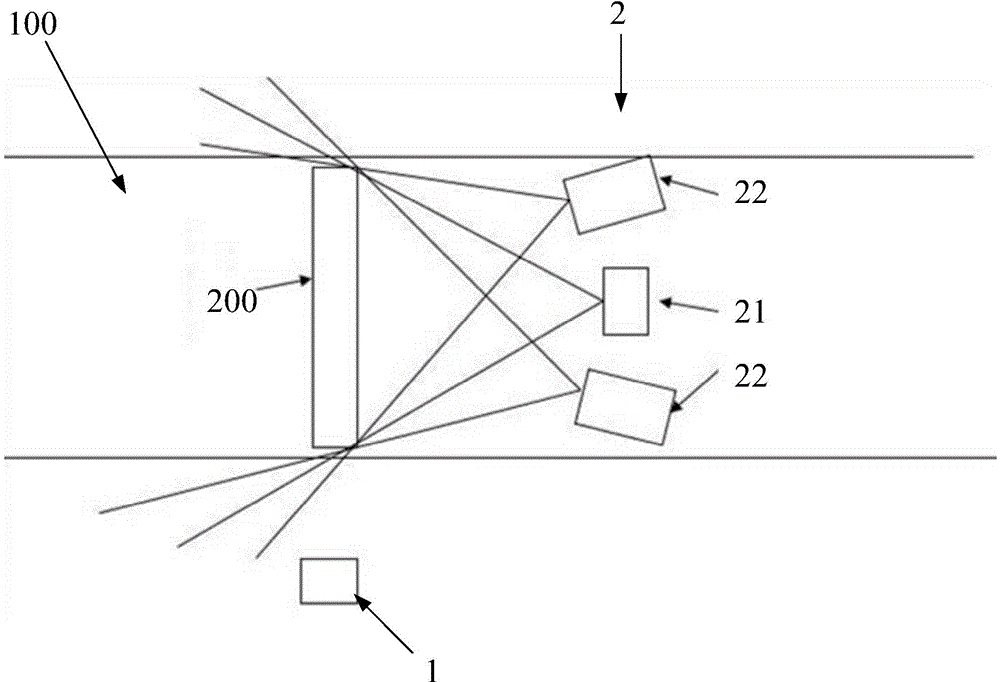

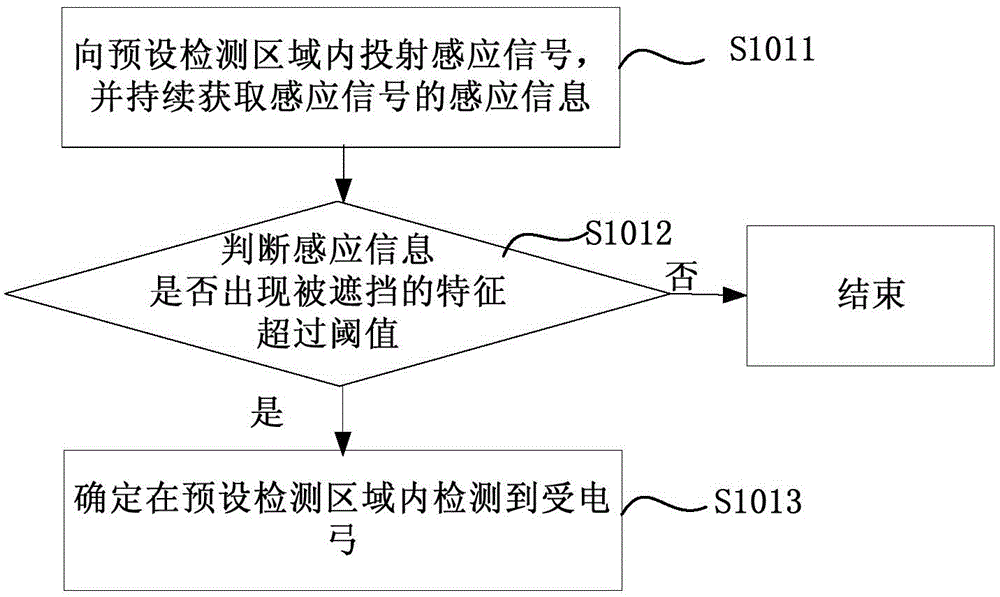

Monitoring method and device for operating state of pantograph

ActiveCN104567729AImprove detection efficiencyTimely detectionUsing optical meansElectricityThree Dimensional Size

The invention discloses a monitoring method and device for the operating state of a pantograph. The method comprises the steps that whether the pantograph is detected or not is judged in a preset detection area which covers an overhead line system where the pantograph passes; when the pantograph is detected in the preset detection area, a three-dimensional information collection module is started to carry out image data collection on the pantograph; image data collected by the three-dimensional information collection module are analyzed and processed, a pantograph three-dimensional size model is built, and size information of the pantograph is extracted. In the running process of a train, the size information of the pantograph such as the thickness of a sliding board of the pantograph can be detected conveniently and rapidly in time, and therefore it is ensured that the pantograph is in a normal running state, the fault detection efficiency of the pantograph is greatly improved, and it is avoided that due to faults of the pantograph, accidents of the pantograph are caused.

Owner:SUZHOU NEW VISION SCI & TECH

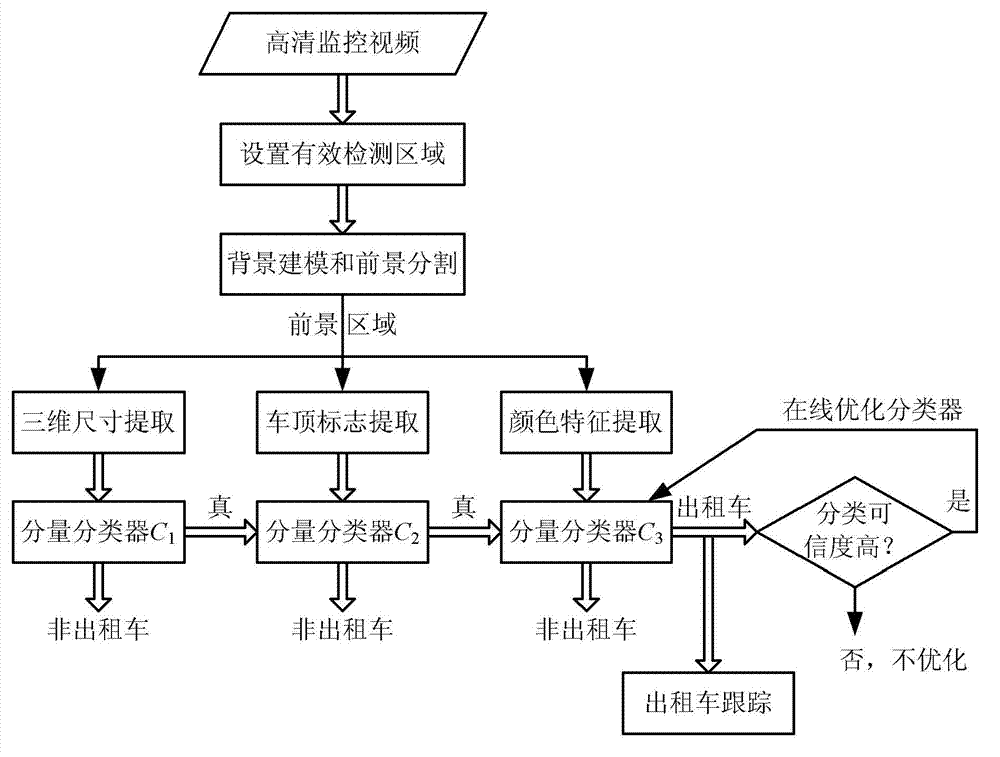

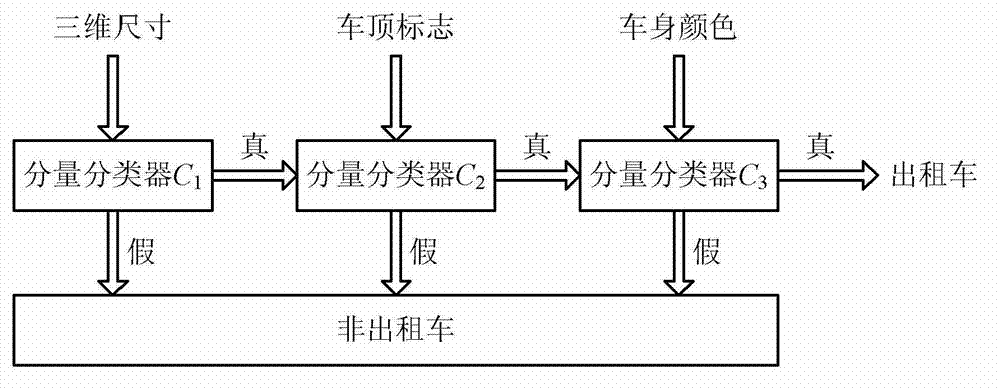

Taxi identifying method and system based on high-definition video

InactiveCN103093249AHigh precisionImprove robustnessRoad vehicles traffic controlCharacter and pattern recognitionFeature extractionSimulation

The invention discloses a taxi identifying method and a taxi identifying system based on a high-definition video. The method mainly consists of the steps of target feature extraction, pattern classifier designing, taxi tracking and the like. Firstly, foreground regions are divided accurately in the high-definition surveillance video, each foreground region is severed as a goal and goal features such as three-dimensional sizes, car roof marks and car body colors are calculated. Then a pattern classifier is designed to identify a taxi efficiently with utilizing the features. Finally, the identified taxi is tracked continuously until the identified taxi travels out an effective detection area and repetitive identification of the taxi can be avoided. The invention further discloses the system based on the high-definition video. The system comprises a high definition camera, a fill-in light and an industrial personal computer. The taxi identifying method and the taxi identifying system based on the high-definition video overcomes the defect in taxi identifying aspect of existing vehicle type recognition. The taxi identifying method and the taxi identifying system based on the high-definition video is powerful support to city taxi management and dispatch and has obvious engineering application value.

Owner:INST OF AUTOMATION CHINESE ACAD OF SCI +1

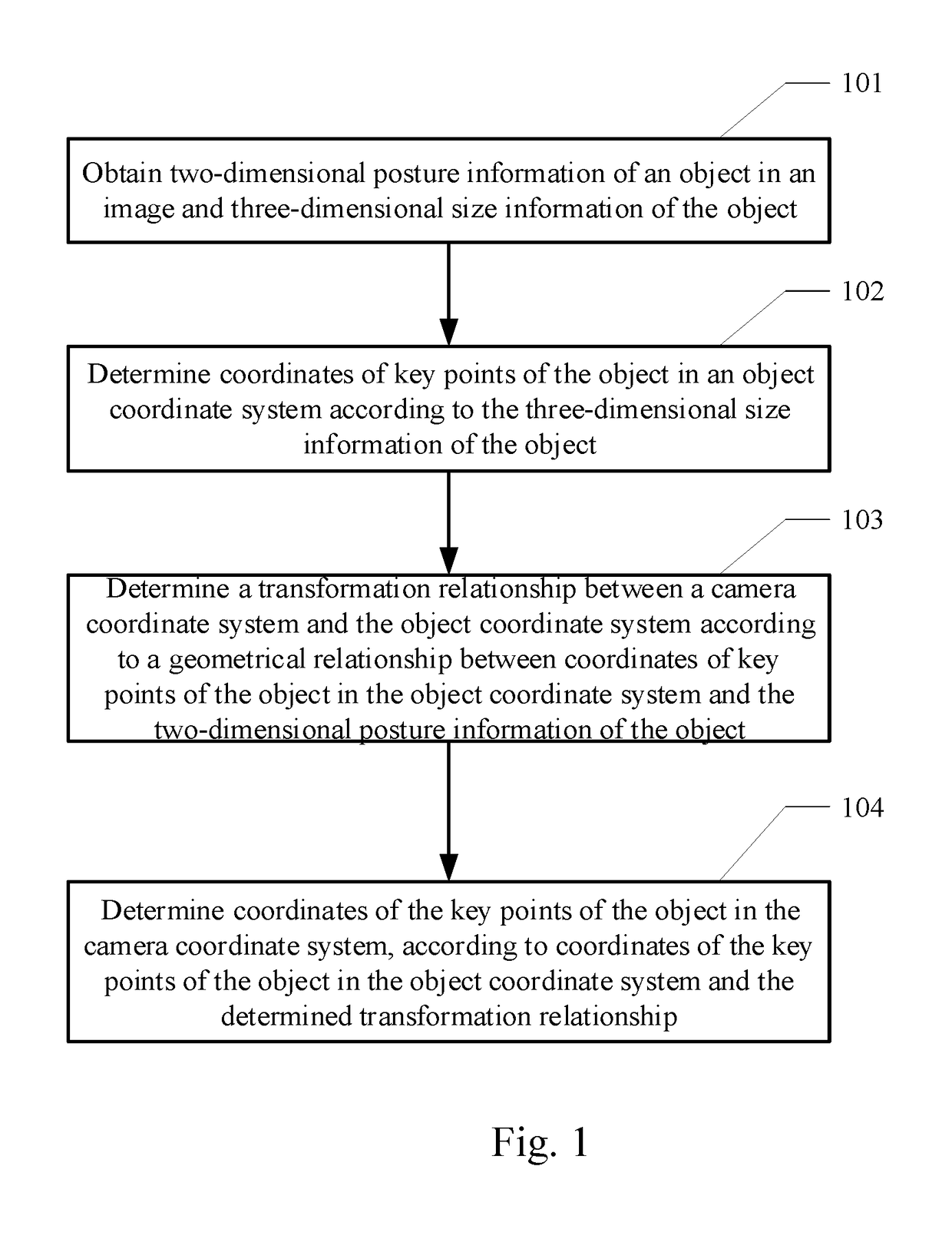

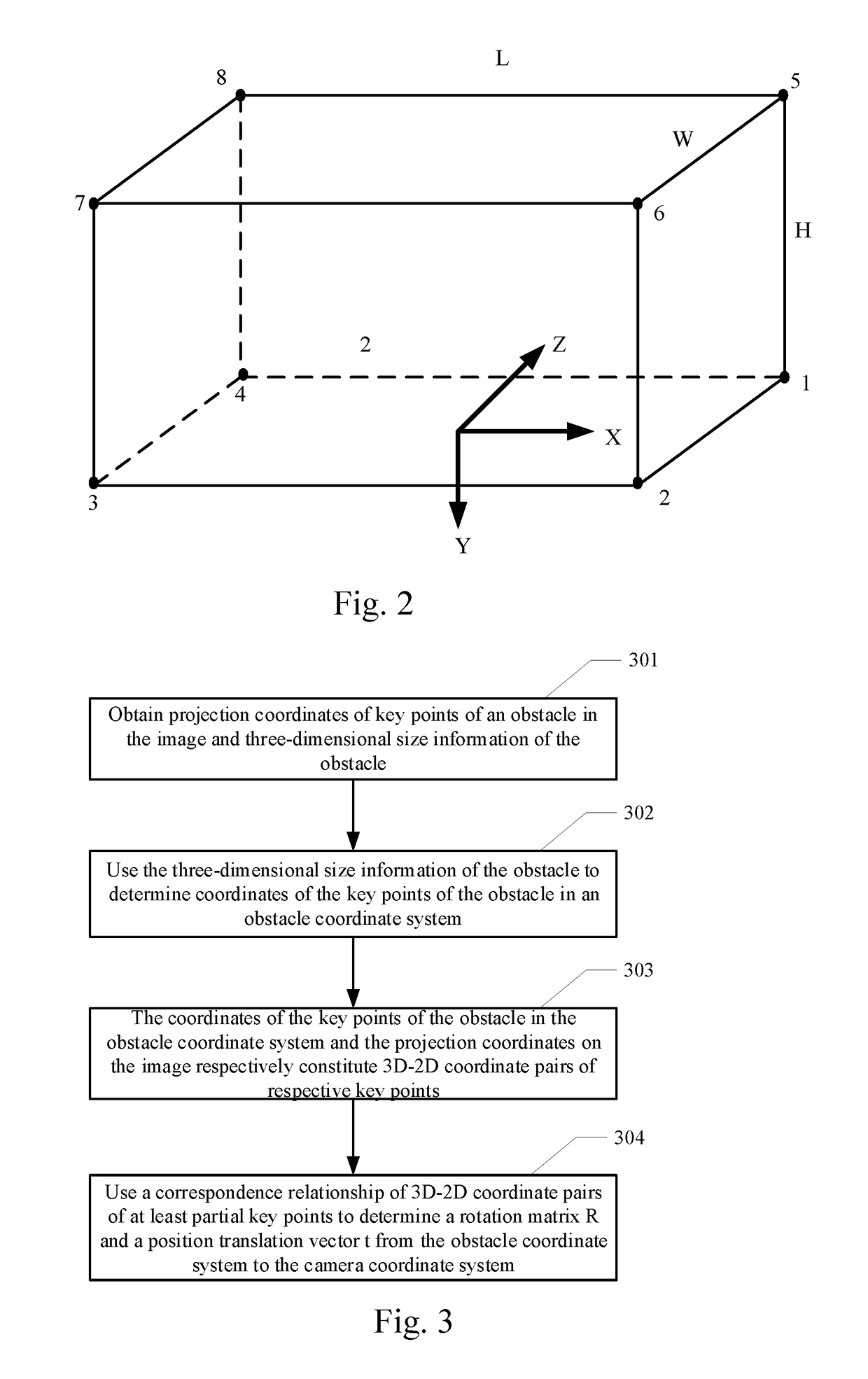

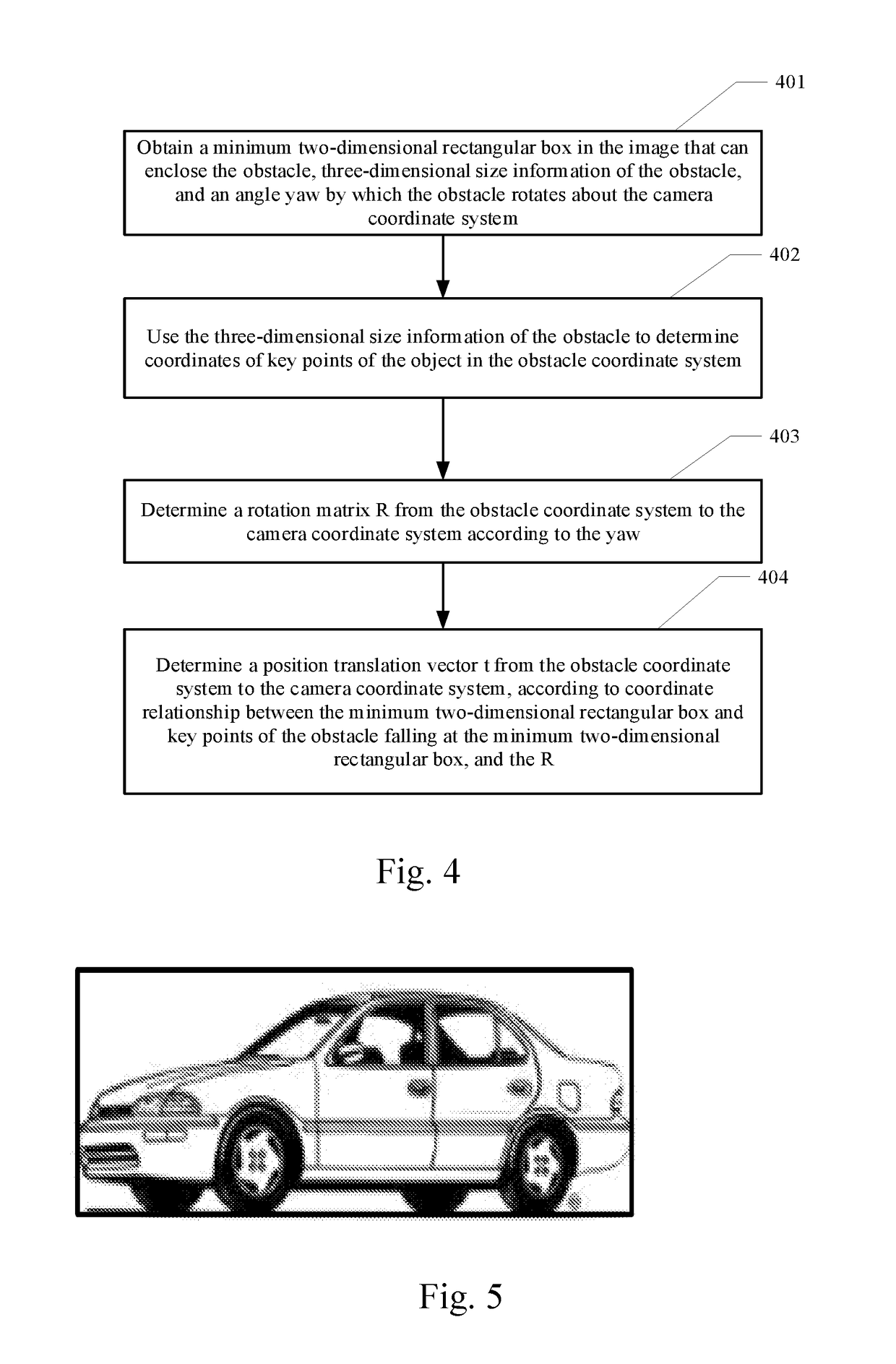

Three-dimensional posture estimating method and apparatus, device and computer storage medium

The present disclosure provides a three-dimensional posture estimating method and apparatus, a device and a computer storage medium, wherein the method comprises: obtaining two-dimensional posture information of an object in an image and three-dimensional size information of the object; determining coordinates of key points of the object in an object coordinate system according to the three-dimensional size information of the object; determining a transformation relationship between a camera coordinate system and the object coordinate system according to a geometrical relationship between coordinates of key points of the object in the object coordinate system and the two-dimensional posture information of the object. Application of this manner to the field of autonomous driving may implement mapping a detection result of a two-dimensional obstacle to a three-dimensional space to obtain its posture.

Owner:APOLLO INTELLIGENT DRIVING (BEIJING) TECHNOLOGY CO LTD

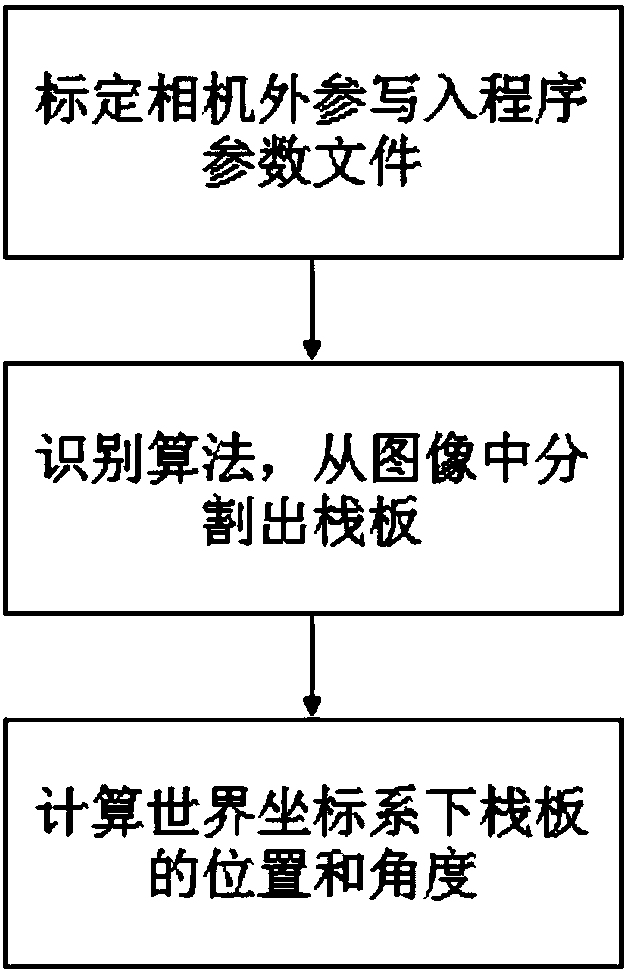

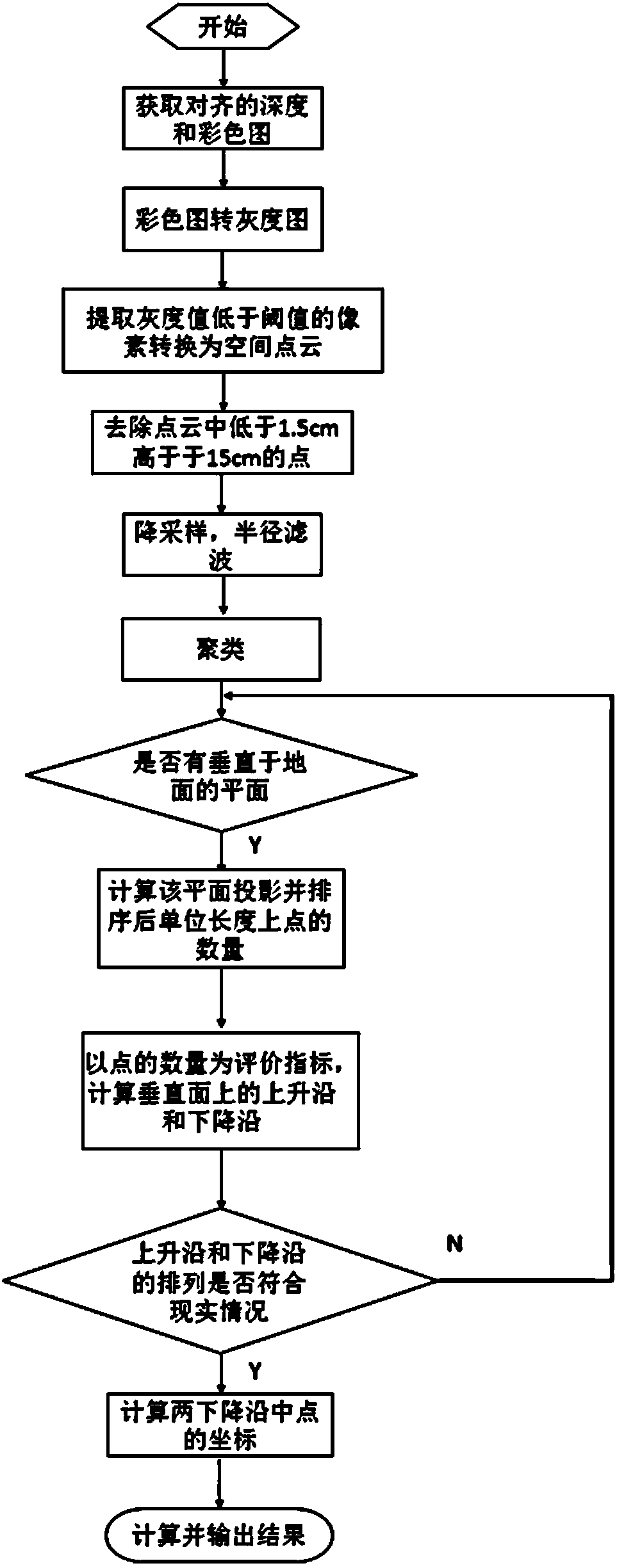

Kinect-based pallet dynamic identification and location method and system, and medium

ActiveCN107610176AAccurate identificationImprove robustnessImage analysisPoint cloudThree Dimensional Size

The invention provides a Kinect-based pallet dynamic identification and location method and system, and a medium. The method comprises the steps of first, calculating extrinsic camera parameters; second, acquiring color and depth images, aligning the color and depth images, screening out effective points according to gray-scale and depth data and converting the effective points into a point cloud;third, pre-processing the point cloud obtained in the second step; fourth, performing Euclidean clustering on the point cloud processed in the third step; fifth, processing a cluster obtained in thefourth step, and extracting a characteristic plane; sixth, matching a characteristic plane point cloud with a front end surface of a pallet; and seventh, performing geometry calculation, and determining a position and a deflection angle of the pallet relative to a world coordinate system origin. The method and system have the beneficial effects that the pallet is identified mainly based on the characteristic of the front end surface of the pallet as well as the three-dimensional size of the pallet, the robustness is high, a set target point in the pallet can be identified accurately and a geometric center of the pallet can be calculated when only a half end surface is seen, the dynamic performance is high, and accurate location is realized.

Owner:STANDARD ROBOTS CO LTD

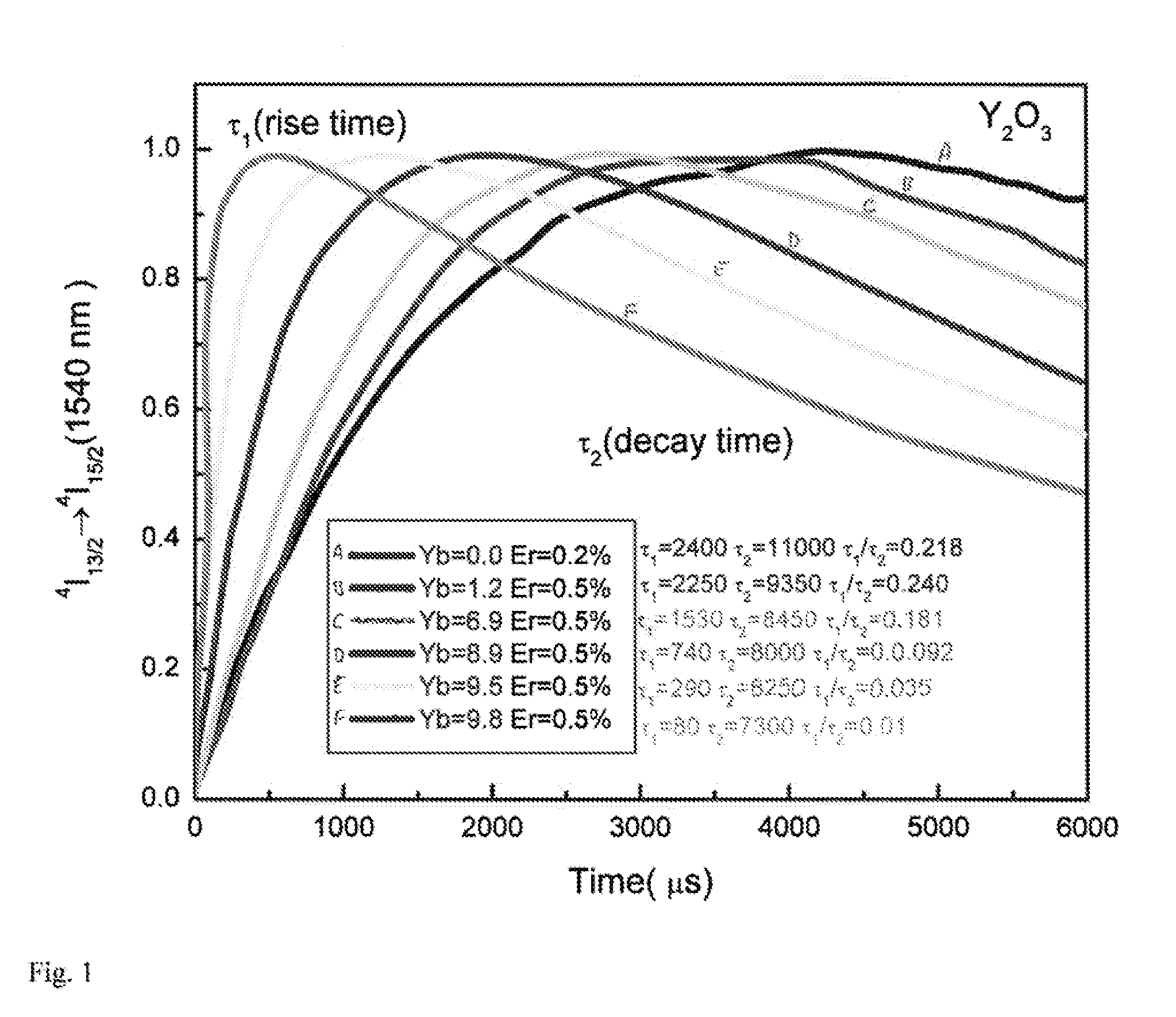

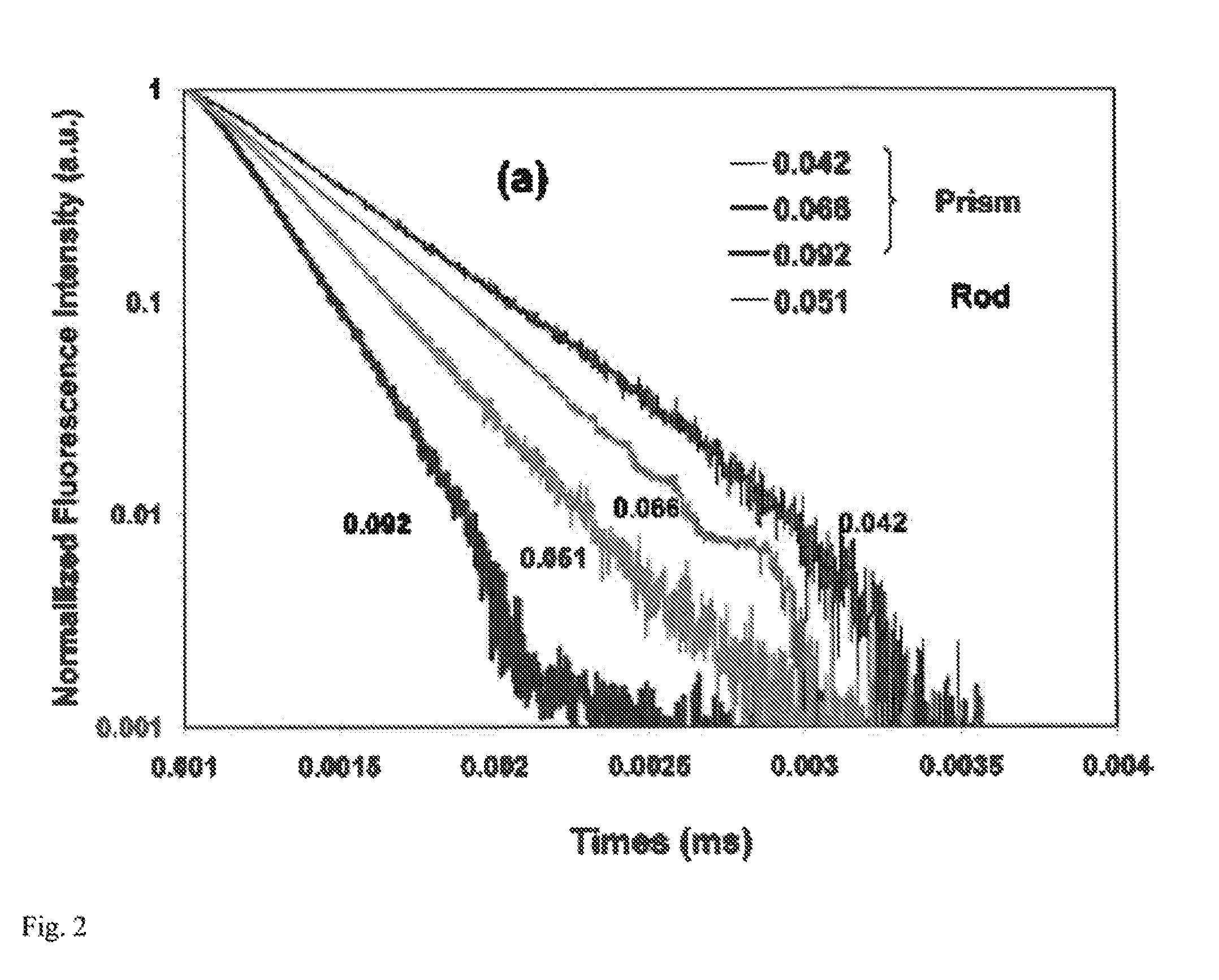

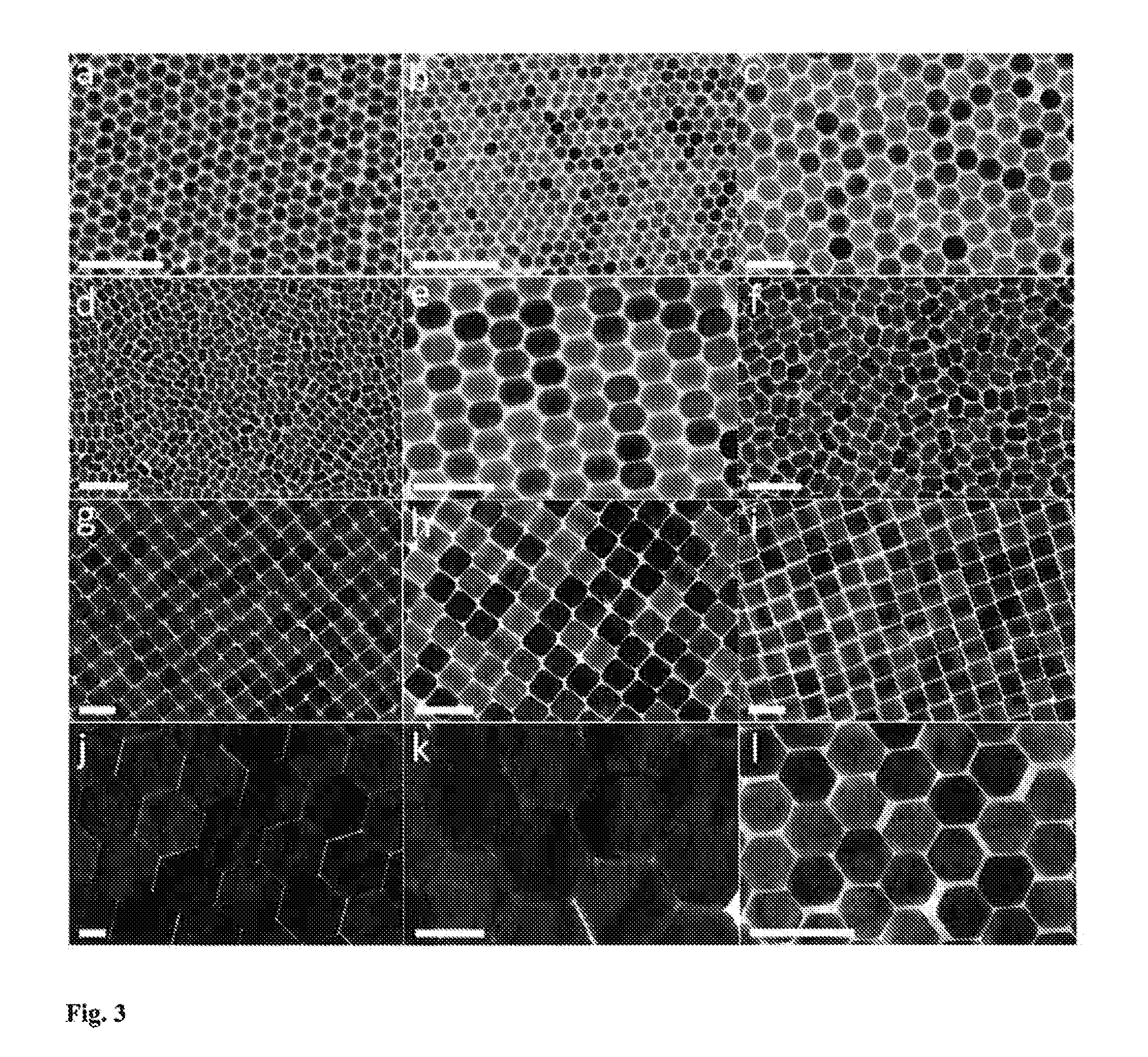

Morphologically and size uniform monodisperse particles and their shape-directed self-assembly

ActiveUS9181477B2Increase in sizeQuench reactionMaterial nanotechnologyFrom normal temperature solutionsRare earthLanthanide

Monodisperse particles having: a single pure crystalline phase of a rare earth-containing lattice, a uniform three-dimensional size, and a uniform polyhedral morphology are disclosed. Due to their uniform size and shape, the monodisperse particles self assemble into superlattices. The particles may be luminescent particles such as down-converting phosphor particles and up-converting phosphors. The monodisperse particles of the invention have a rare earth-containing lattice which in one embodiment may be an yttrium-containing lattice or in another may be a lanthanide-containing lattice. The monodisperse particles may have different optical properties based on their composition, their size, and / or their morphology (or shape). Also disclosed is a combination of at least two types of monodisperse particles, where each type is a plurality of monodisperse particles having a single pure crystalline phase of a rare earth-containing lattice, a uniform three-dimensional size, and a uniform polyhedral morphology; and where the types of monodisperse particles differ from one another by composition, by size, or by morphology. In a preferred embodiment, the types of monodisperse particles have the same composition but different morphologies. Methods of making and methods of using the monodisperse particles are disclosed.

Owner:THE TRUSTEES OF THE UNIV OF PENNSYLVANIA +1

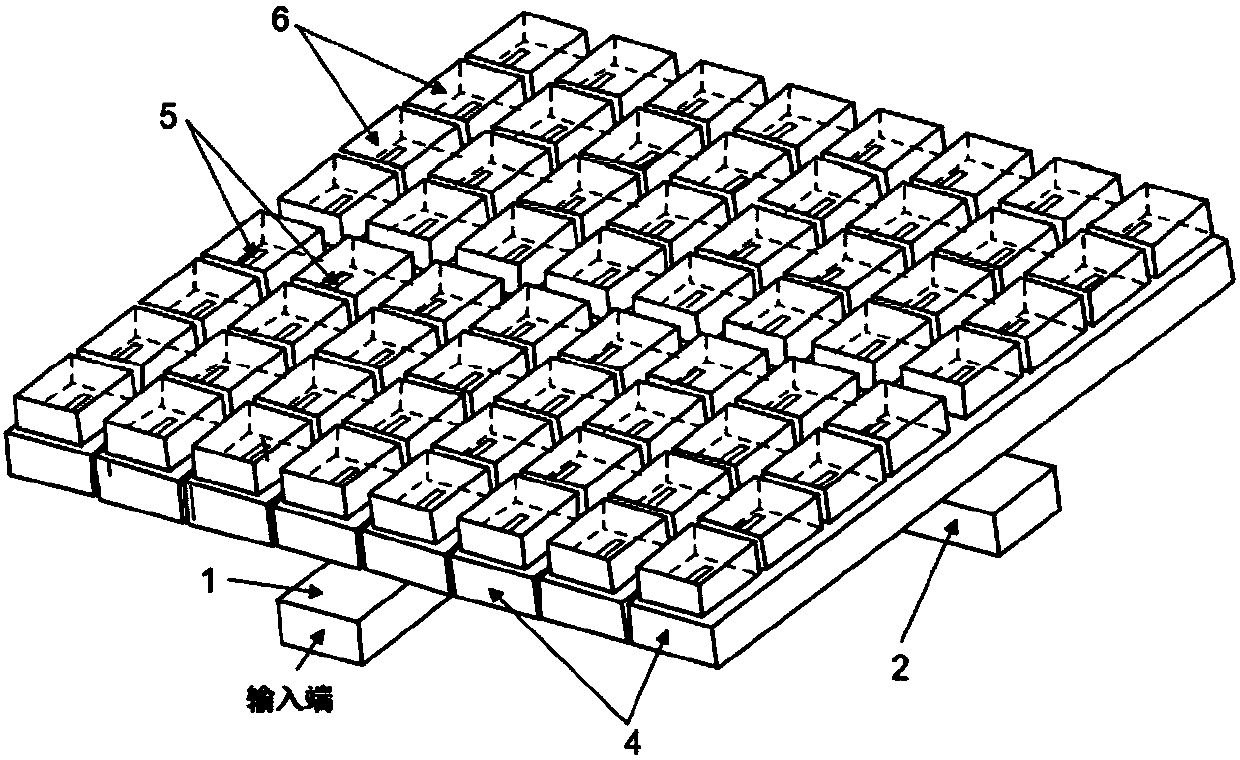

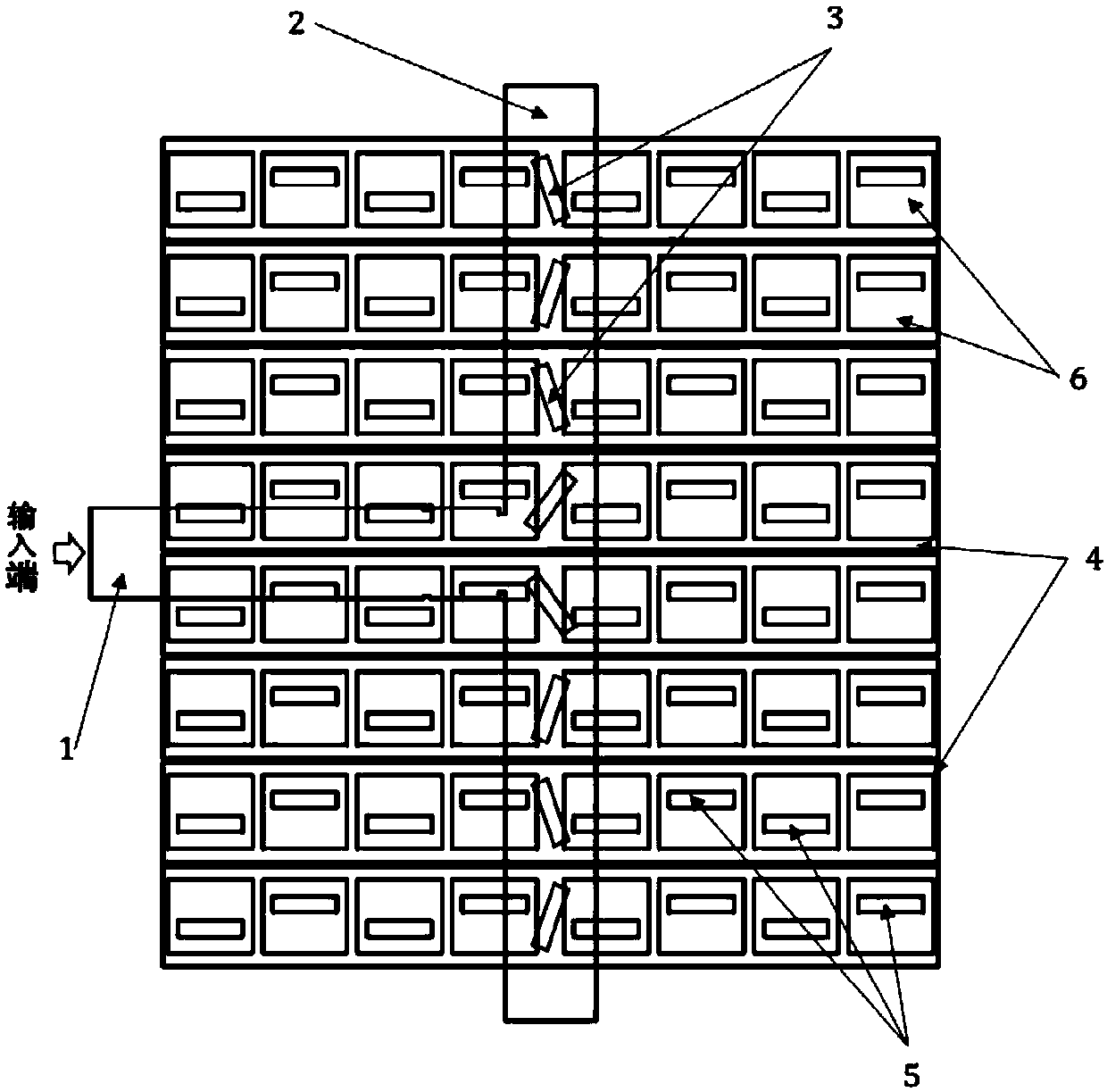

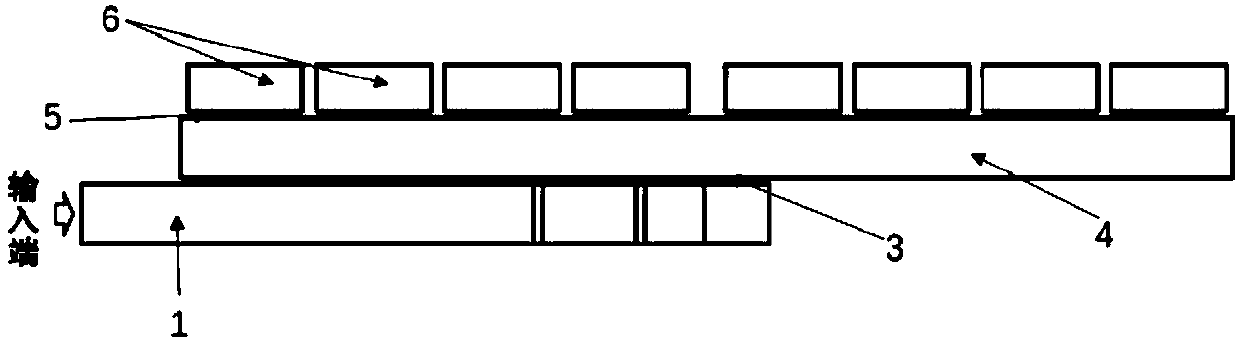

Two-dimensional waveguide slot array antenna having decoupling structure and design method thereof

InactiveCN107910642AAdjustable thicknessAdjust insertion depthAntenna couplingsSlot antennasRadiation bandwidthAntenna bandwidth

The invention relates to a two-dimensional waveguide slot array antenna having a decoupling structure and a design method thereof and relates to a waveguide slot antenna. The antenna sequentially comprises a T-shaped power splitter main waveguide, a feed waveguide, coupling slots, a radiation waveguide, radiation slots and an open air cavity from down to up. The antenna has the decoupling structure, the open air cavity is added outside the radiation slot, the mutual coupling effect between the radiation slots is suppressed by optimizing the three-dimensional size of the air cavity, and antennabandwidth constraints of mutual coupling in large-scale arrays are effectively ameliorated. According to antenna bandwidth design requirements, the proper antenna feed network is designed, through antenna sub-arrays, the integral antenna is simplified into multiple sub-arrays, so antenna bandwidth is ameliorated, and design difficulty is reduced; the quantity of radiation slots and coupling slotsin series connection in each sub-array is small, a resonant array can be employed for design, namely a standing wave array form, and matching bandwidth and radiation bandwidth of the antenna sub-arrays are greatly improved through specifically employing the overloaded technology.

Owner:XIAMEN UNIV

Side-by-side package separating device and method

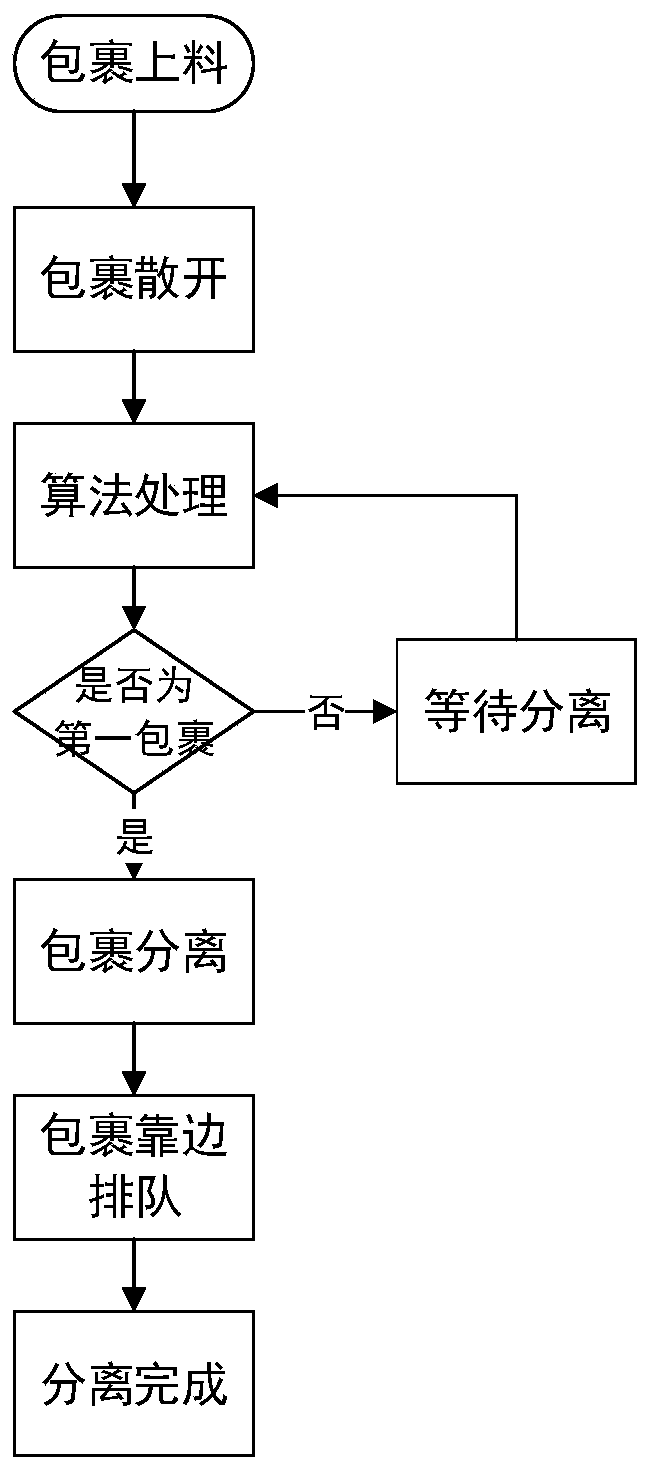

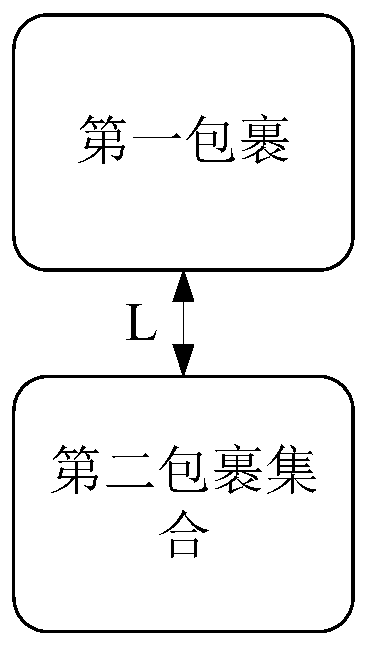

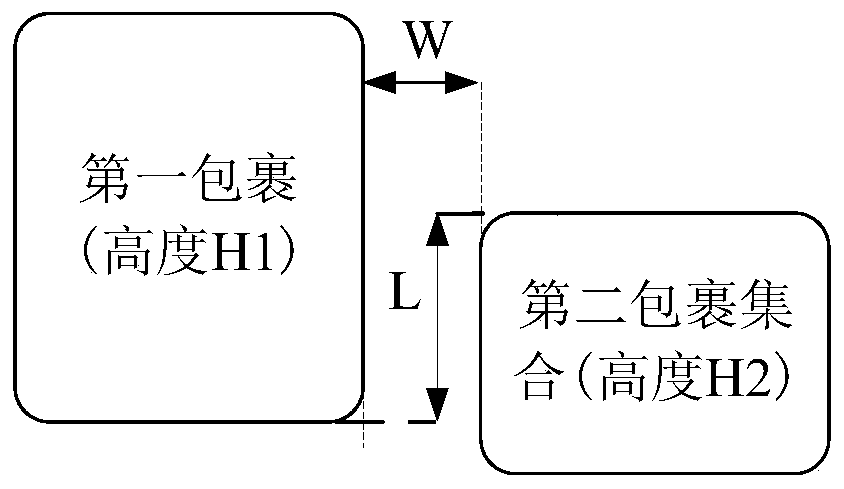

PendingCN110961361AApplicable to fully automatic operation requirementsNo need for manual loadingSortingConveyor partsAlgorithmRecognition algorithm

The invention discloses a side-by-side package separating device and method. The method is characterized by firstly dispersing and opening a gap, then photographing by applying an image recognition algorithm, and identifying a position relationship between adjacent packages so as to specifically separate the packages at a foremost position one by one; and realizing high-speed separation and single-queue conveying of batch packages, realizing a maximum rate of subsequent single code scanning operation, reducing an omission ratio and improving efficiency of overall sorting operation. The separation method comprises the following steps of dispersion, dispersing the packages arriving at a dispersion device from a conveying line through an angle difference existing in a conveying direction, wherein a gap is reserved between the adjacent packages; detection and recognition, photographing and recognizing the detected packages through a visual recognition device, and obtaining a three-dimensional size and real-time position data of each package; separating, applying different conveying speeds to the identified adjacent packages through a separating device; identifying that a first packageat a front position arrives at a side-approaching device at a higher speed, and so on; and single row queuing, forwardly conveying the different packages arriving at the side-approaching device in sequence in a single-row queue mode.

Owner:QINGDAO KENGIC AUTOMATION EQUIP CO LTD

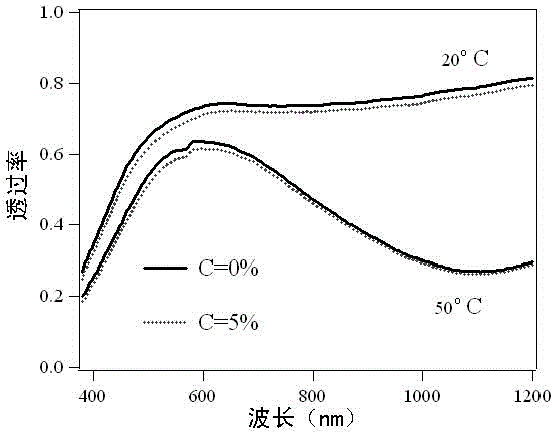

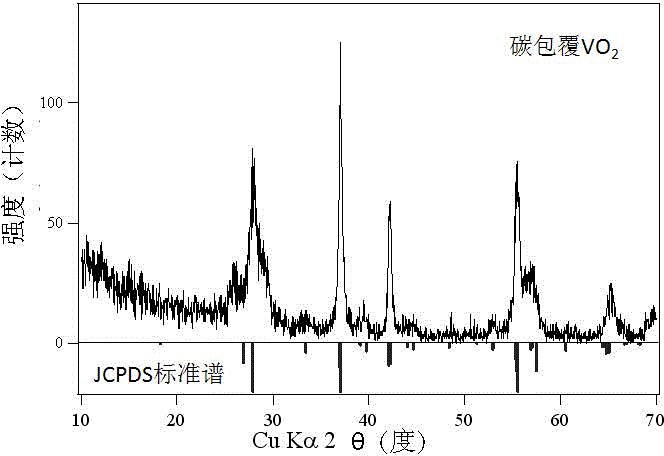

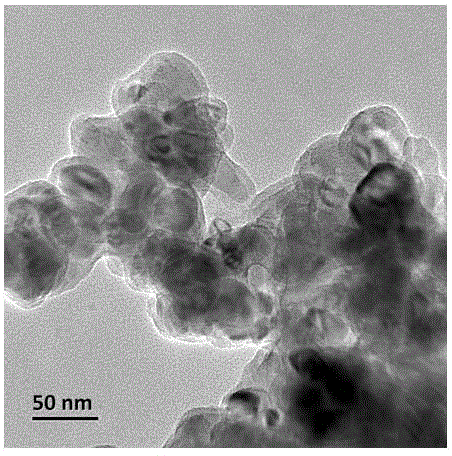

Carbon-coated vanadium dioxide nanoparticles and preparation method thereof

ActiveCN103554997AImprove stabilityExcellent optical propertiesMaterial nanotechnologyInorganic pigment treatmentNanoparticleThree Dimensional Size

The invention relates to carbon-coated vanadium dioxide nanoparticles and a preparation method thereof. The particles consist of rutile-phase nano vanadium dioxide kernels and carbon shells covering the rutile-phase nano vanadium dioxide kernels, wherein the rutile-phase nano vanadium dioxide kernels are approximately square nanoparticles with a length-diameter ratio of being less than 3 and a three-dimensional size of being less than 100 nm; the thickness of the carbon shells are 1-10 nm; the carbon shells account for less than 20 percent by weight of the mass fraction of the particles. The preparation method comprises the following steps: synthesizing the rutile-phase vanadium dioxide nanopowder by using hydrothermal reaction; adding a carbon source into hydrothermal reaction liquid; then performing hydrothermal reaction to perform in-situ carbon coating. The carbon-coated vanadium dioxide nanopowder has superior thermochromic performance, good stability, low cost and high yield and is suitable for large-scale production. The nanopowder can be widely applied to energy-saving coatings, flexible energy-saving films or energy-saving glass of buildings and automobiles.

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI

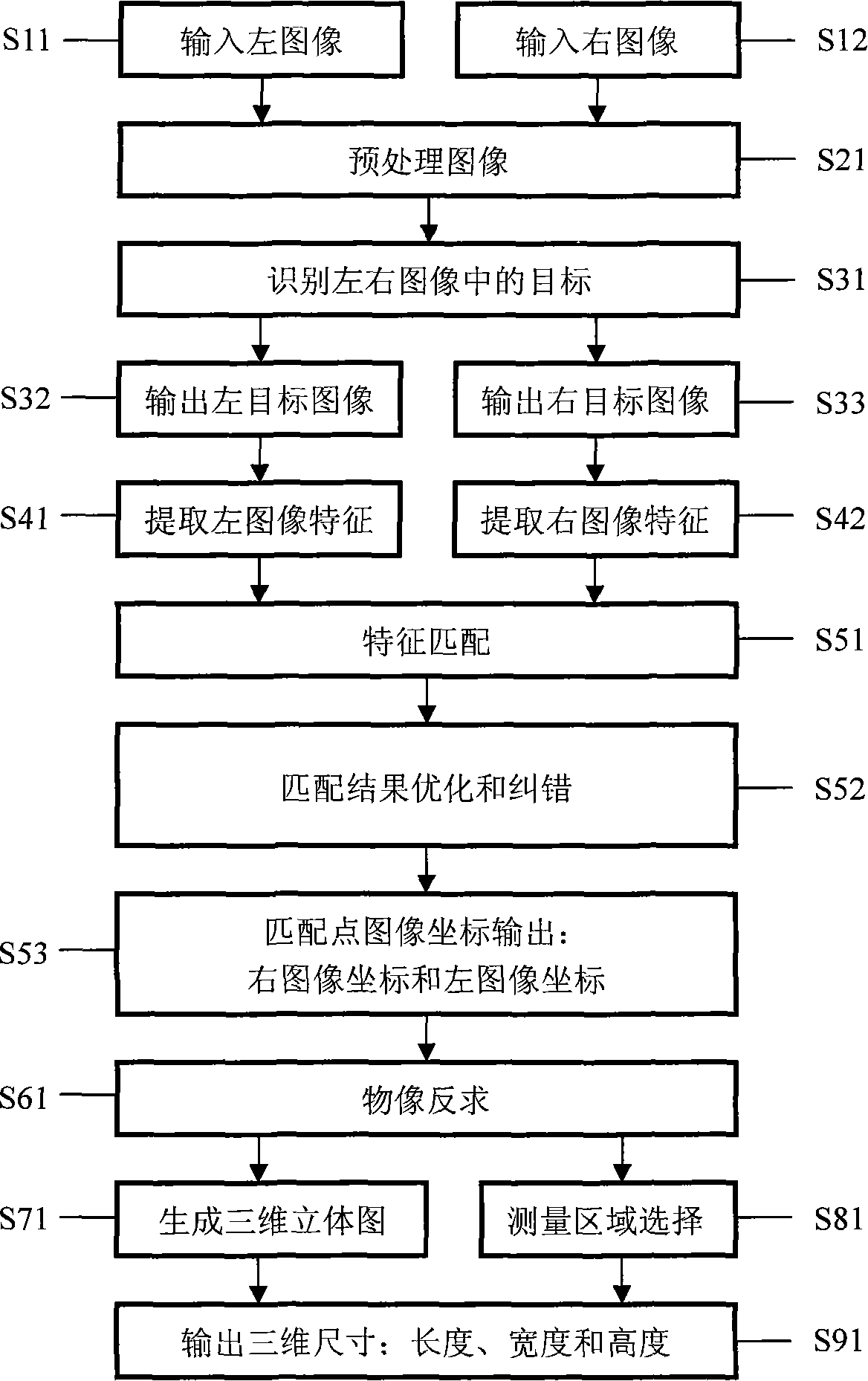

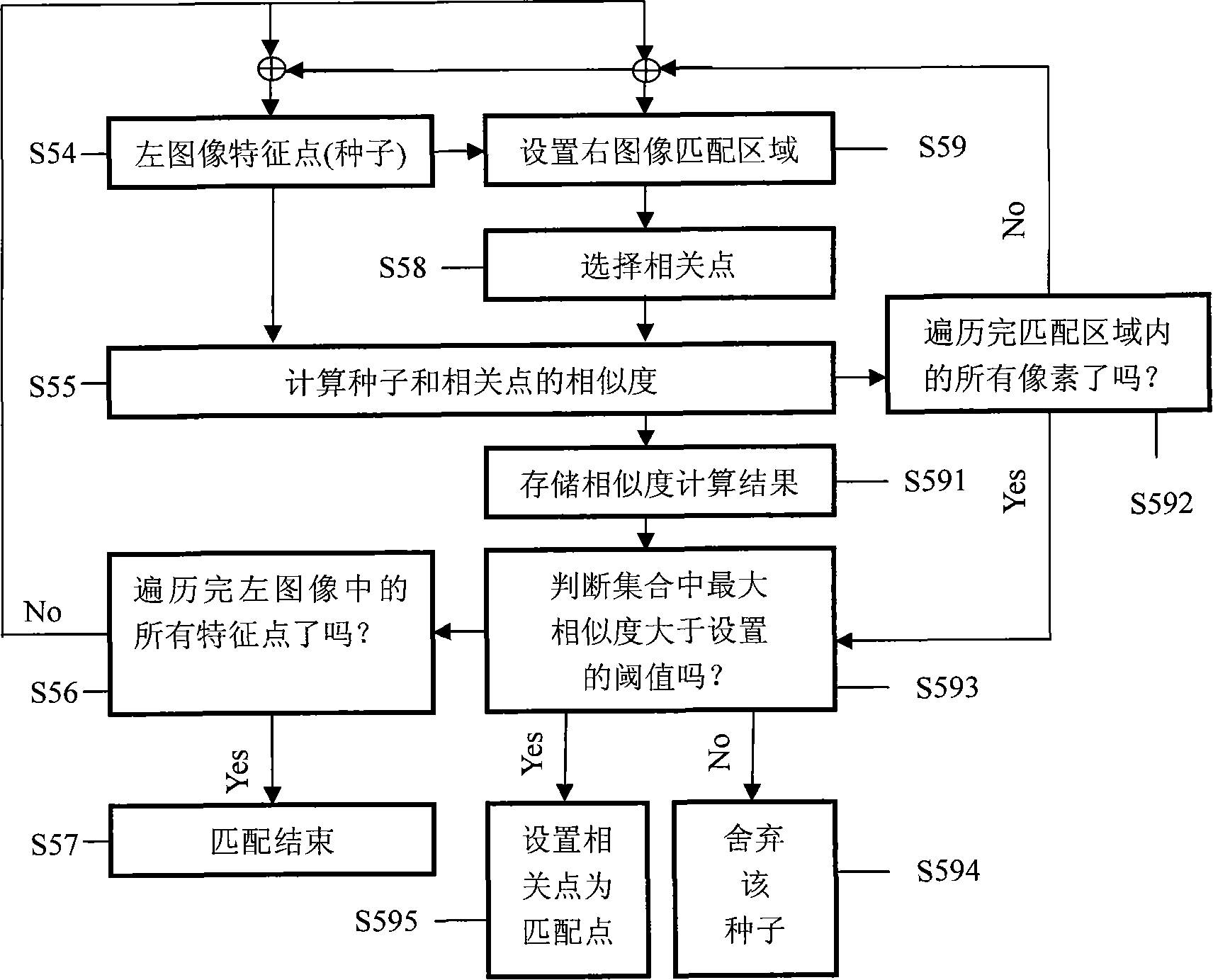

Method for rapidly detecting micro-structure three-dimensional dimension stereoscopic picture

InactiveCN101251373AMatching result optimization and error correctionImprove efficiencyCharacter and pattern recognitionUsing optical meansMicro structureThree Dimensional Size

The invention relates to a quick detection method for a microstructure three-dimensional stereo image, in particular to a method of establishing a matching relation through a stereo image pair and calculating the length, width and height of the microstructure through an object image inverse engineering model. The method comprises the following main steps of: preprocessing the images, picking up feature points in the images, matching the features, carrying out the optimization and error correction for matching results, carrying out the object image inverse engineering and outputting sizes of the three dimensions. The method which belongs to the non-contact type measurement without damaging the surface of a sample can ensure the measurement precision of the system. Simultaneously the method improves the detection speed through generating a stereo surface, thereby bringing about a simpler and quicker operating flow. The method is a computer-aided measuring method with high efficiency.

Owner:BEIJING UNIV OF TECH

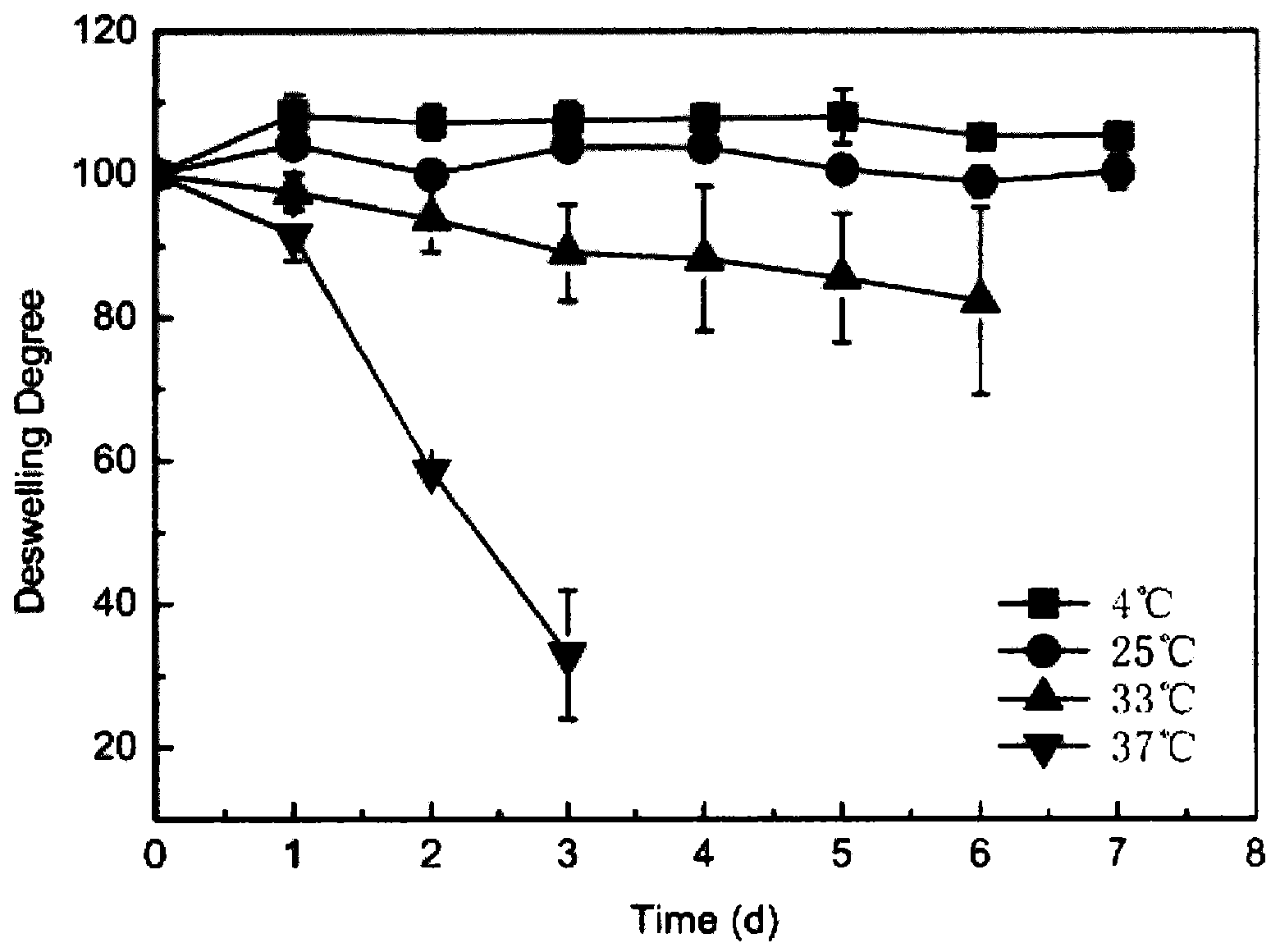

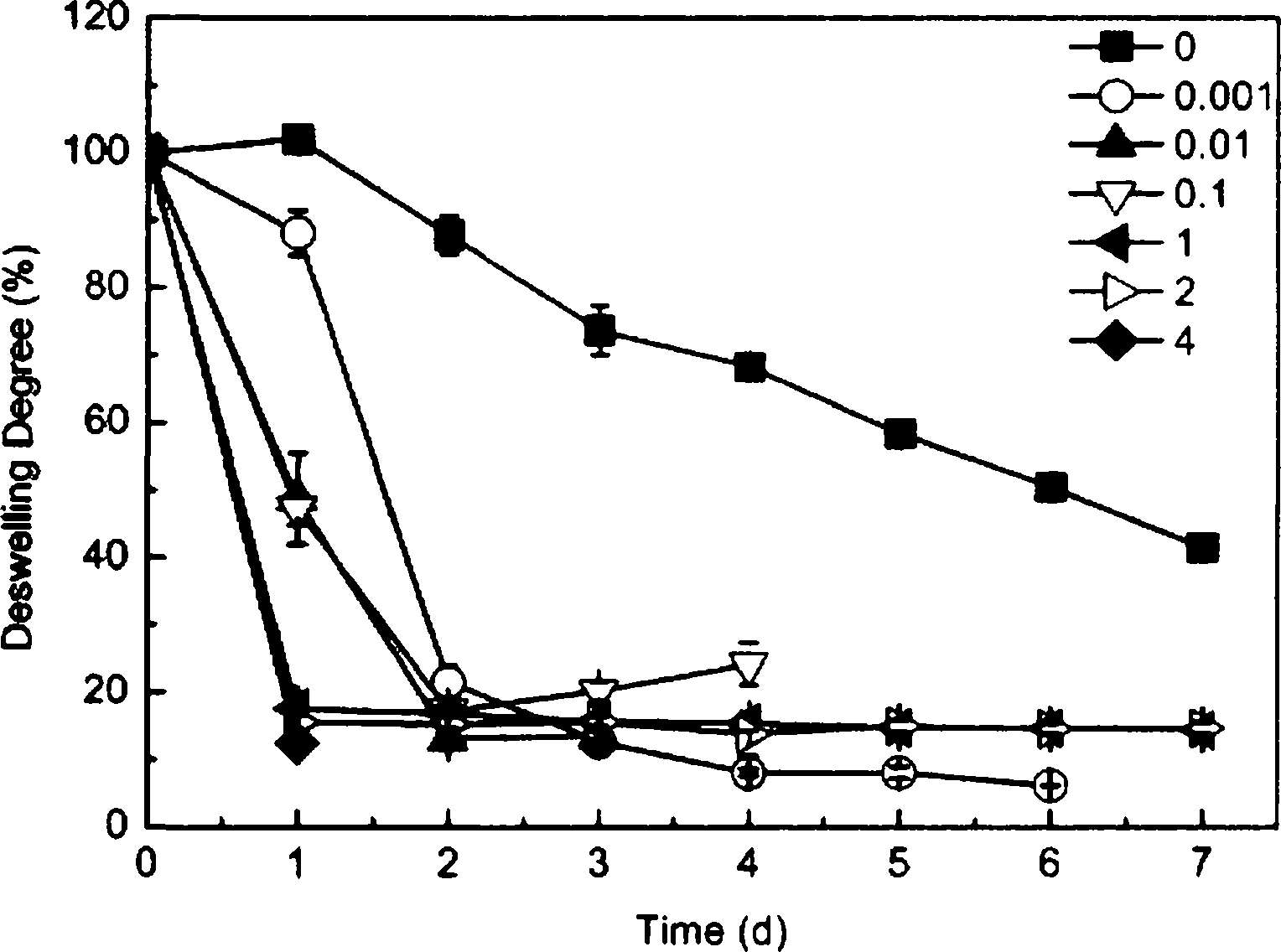

High-strength collagen gel and preparation method thereof

ActiveCN104231288AHigh mechanical strengthIncrease the degree of cross-linkingMacromolecular non-active ingredientsProsthesisCross-linkThree Dimensional Size

The invention relates to high-strength collagen gel. The collagen gel is characterized in that the high-strength collagen gel undergoes three-dimensional size shrinkage by immersing radiation cross-linked low-density collagen hydrogel in water or an aqueous solution for a period of time and maintaining a certain temperature; the compression modulus is increased by 2-5 times that of the low-density collagen hydrogel after self-shrinkage by solution immersion; and the high-strength collagen gel has a three-dimensional structure or high porosity, and the pore diameter is distributed in a gradient manner. The invention further relates to a method for preparing the high-strength collagen gel.

Owner:北京同威典石技术有限公司

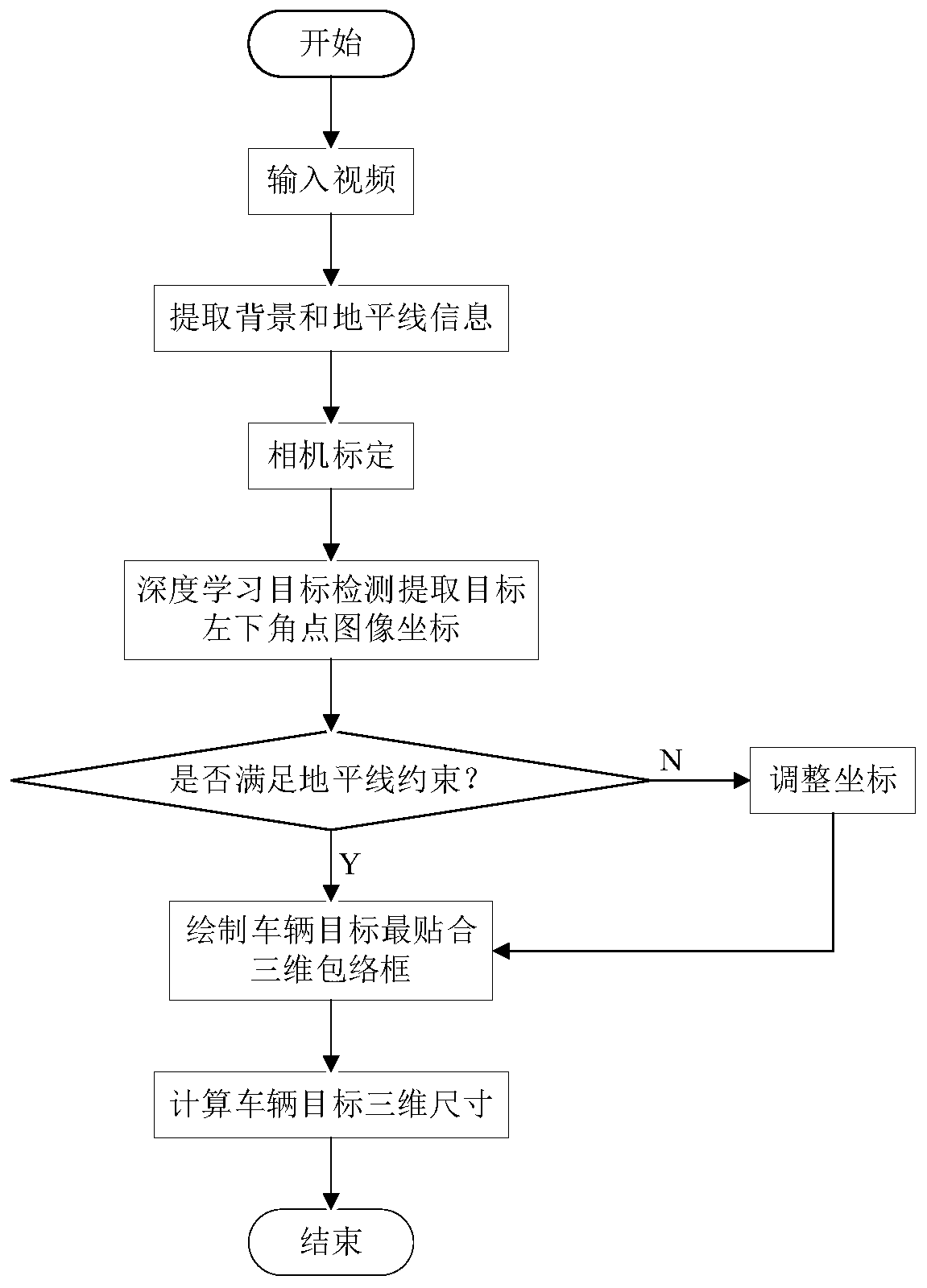

Vehicle target three-dimensional information acquisition method based on PTZ pan-tilt camera

ActiveCN110148169ASatisfy the demand for accurate acquisition of traffic parametersSimple methodImage enhancementImage analysisHorizonThree Dimensional Size

The invention discloses a vehicle target three-dimensional information acquisition method based on a PTZ pan-tilt camera. The vehicle target three-dimensional information acquisition method includes the steps: identifying a vehicle target in a video frame through a deep learning method; and obtaining coordinates of a three-dimensional envelope reference point of the vehicle target in an image coordinate system, drawing a three-dimensional envelope frame which is most suitable for the vehicle target according to the coordinate information and the constraint of the horizon, and calculating three-dimensional size information of the vehicle target by utilizing a calibration result, thereby finishing acquisition of three-dimensional information of the vehicle target. The vehicle target three-dimensional information acquisition method can adapt to different road traffic scenes, and uses the pan-tilt camera to extract a large number of vehicle targets in the scene to complete the process of three-dimensional information acquisition. The vehicle target three-dimensional information acquisition method is simple to implement and good in universality, can be applied to three-dimensional information acquisition in various road scenes, and is accurate in result.

Owner:西安翱翔机电科技有限公司

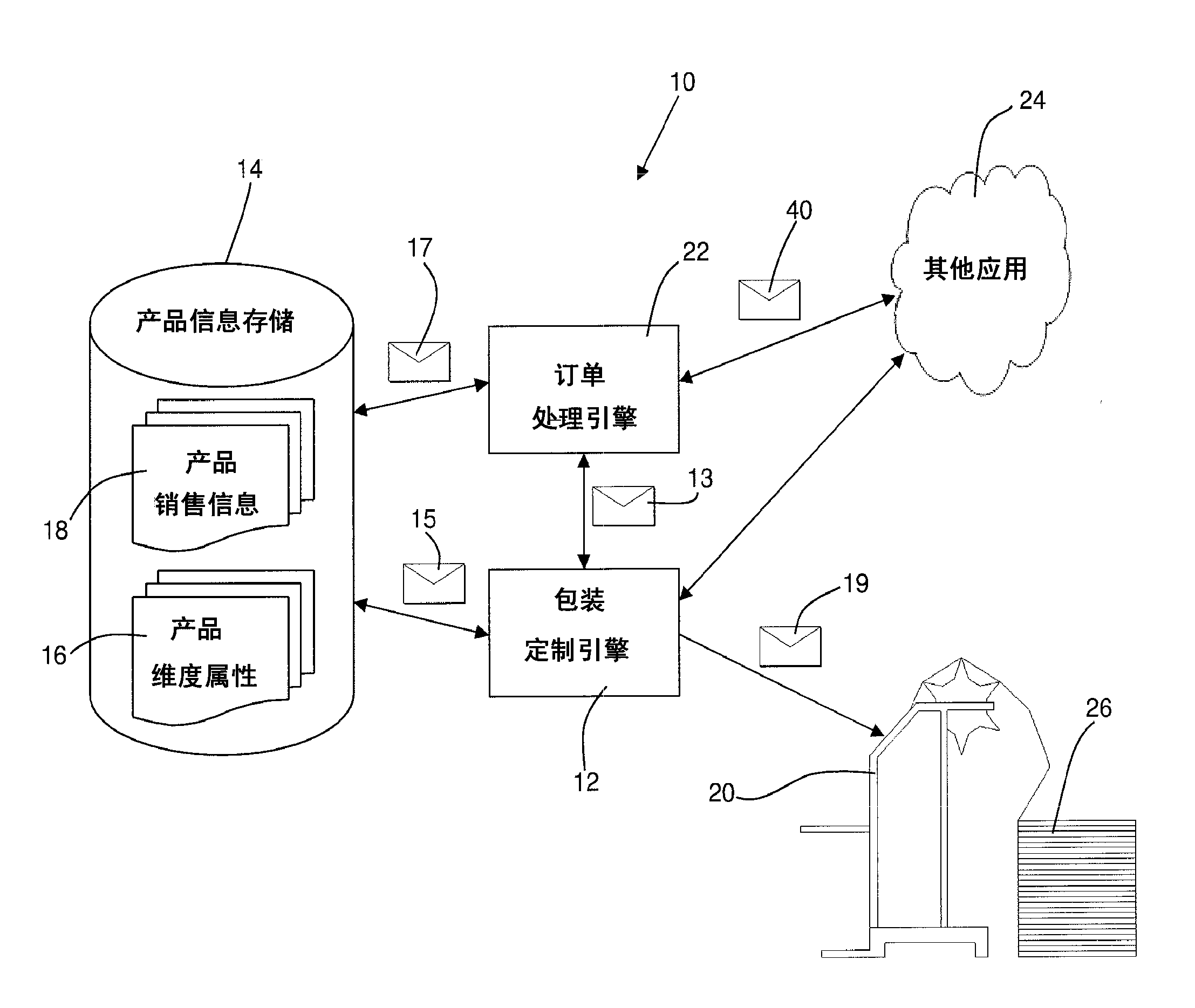

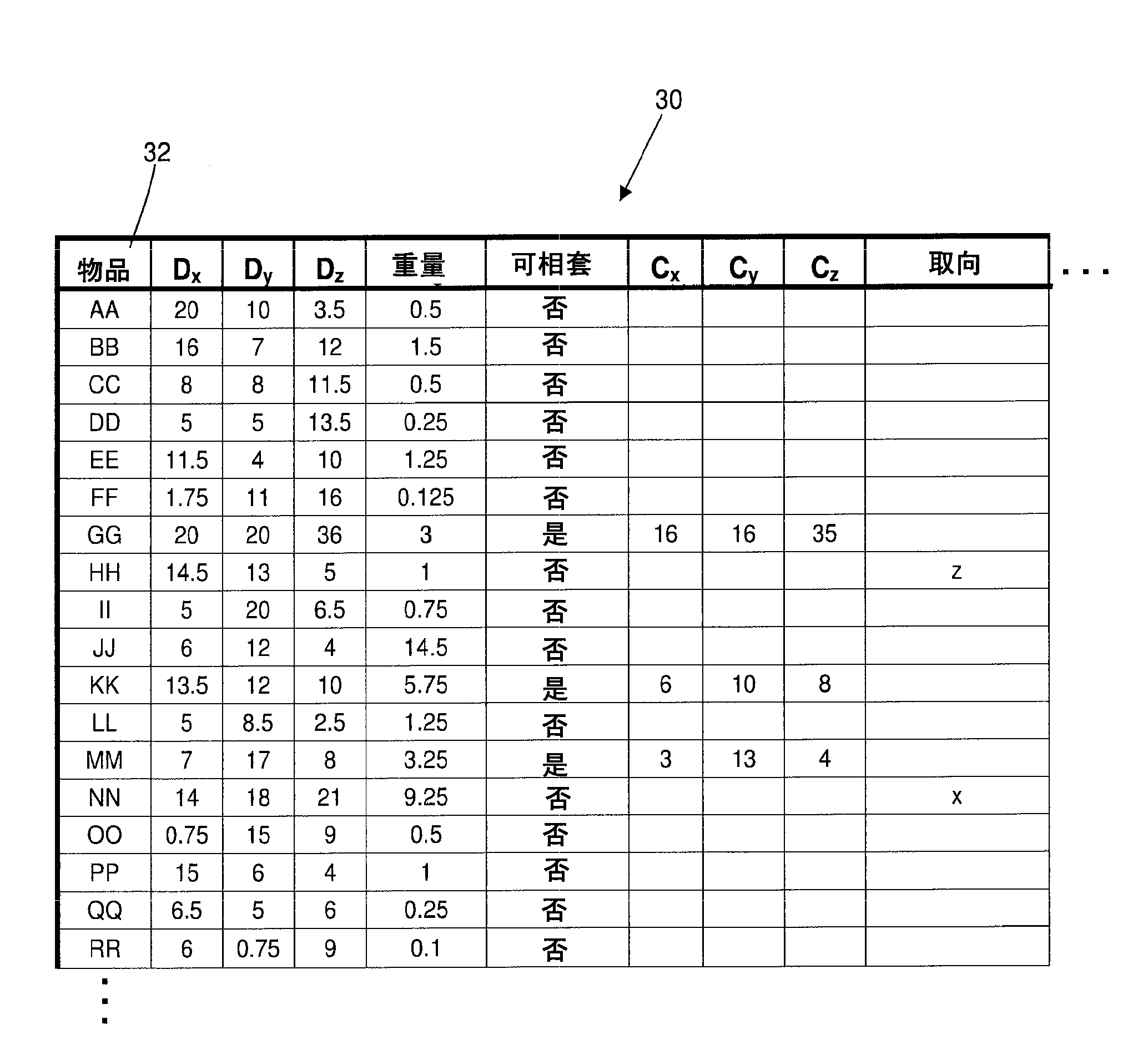

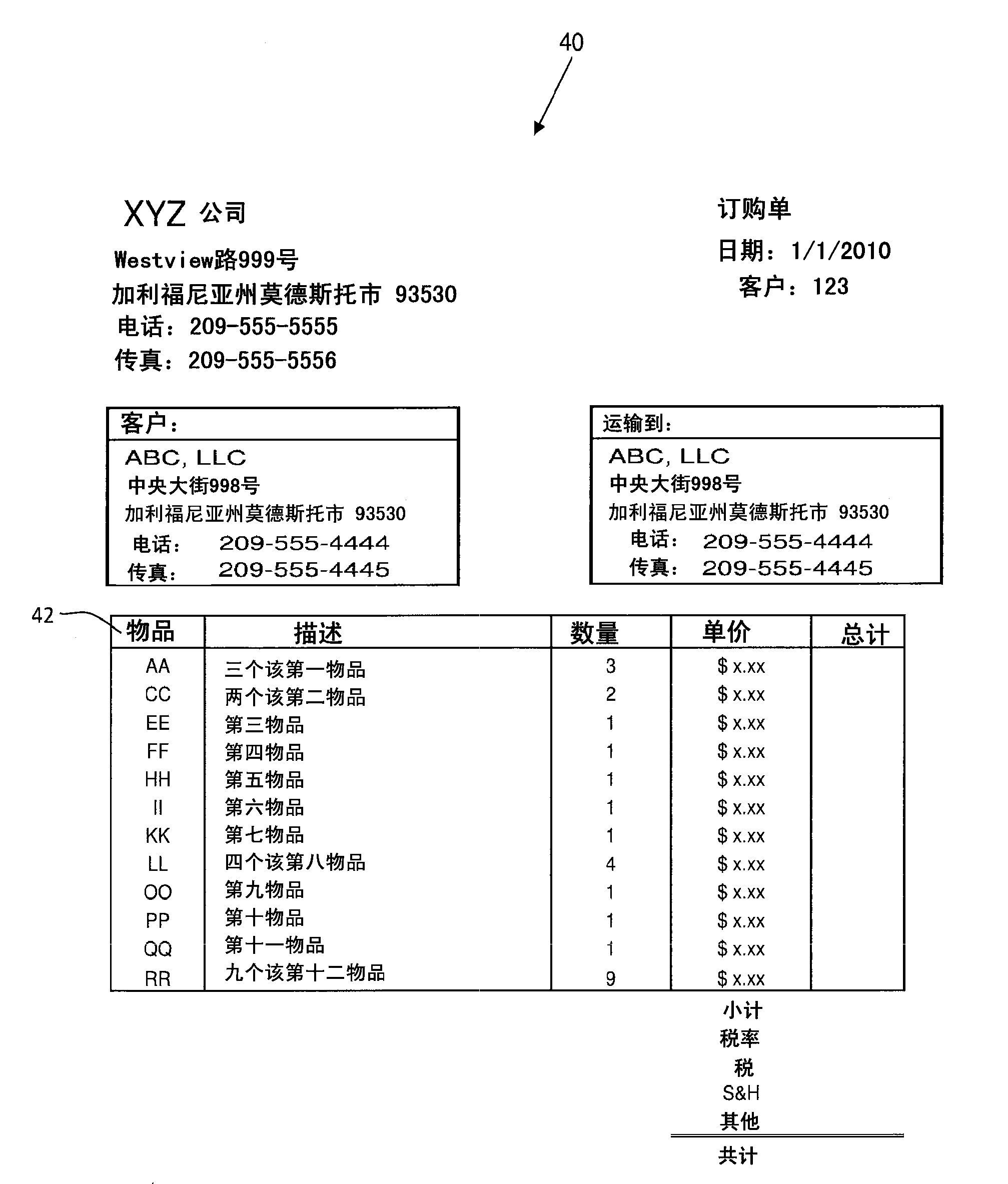

Creating on-demand packaging based on stored attribute data

Methods, computer-readable media, and systems described herein relate to producing on-demand packaging. For example, packaging can be automatically produced on-demand and be sized and configured for use with a customized set of items. In one aspect, a request for multiple items is received and a packaging customization engine accesses an information store that includes information about each of the requested items. The information may include dimensional information about the three-dimensional size of the items. The packaging customization engine may use the dimensional information to simulate a model arrangement of all of the requested items, and then calculate the dimensions of a box or other package that can provide a precise fit for the items when physically arranged consistent with the model arrangement.

Owner:PACKSIZE LLC

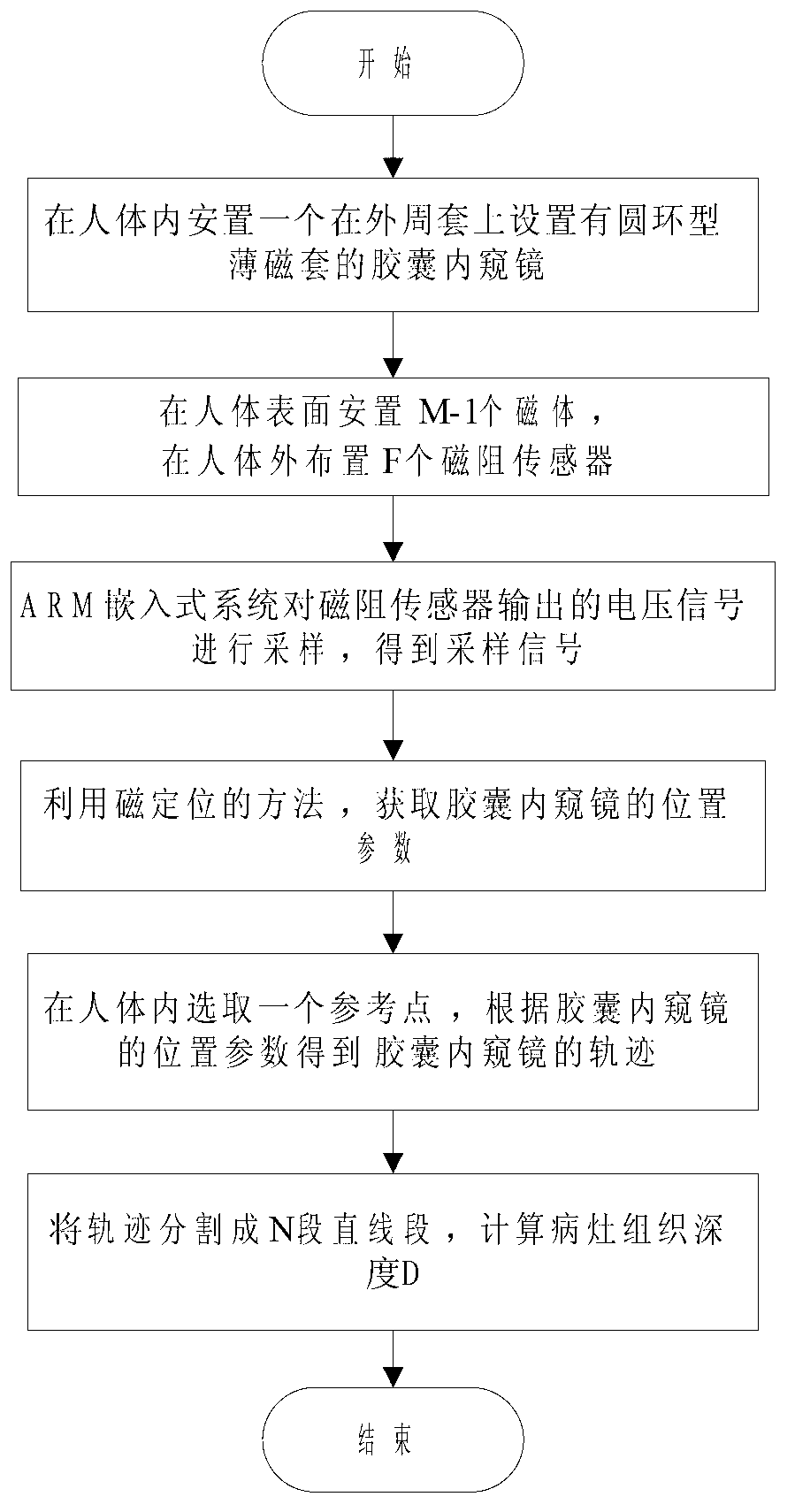

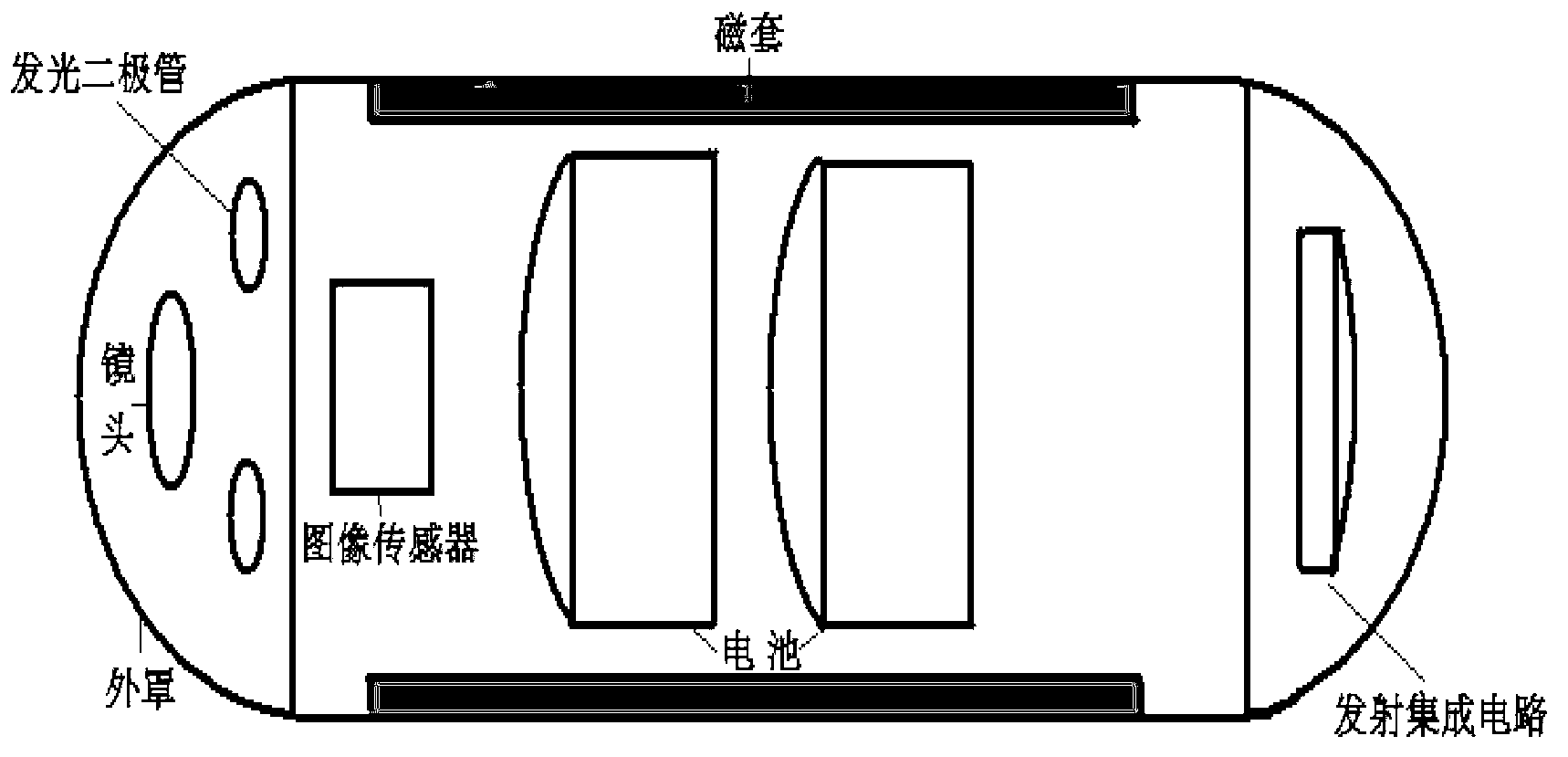

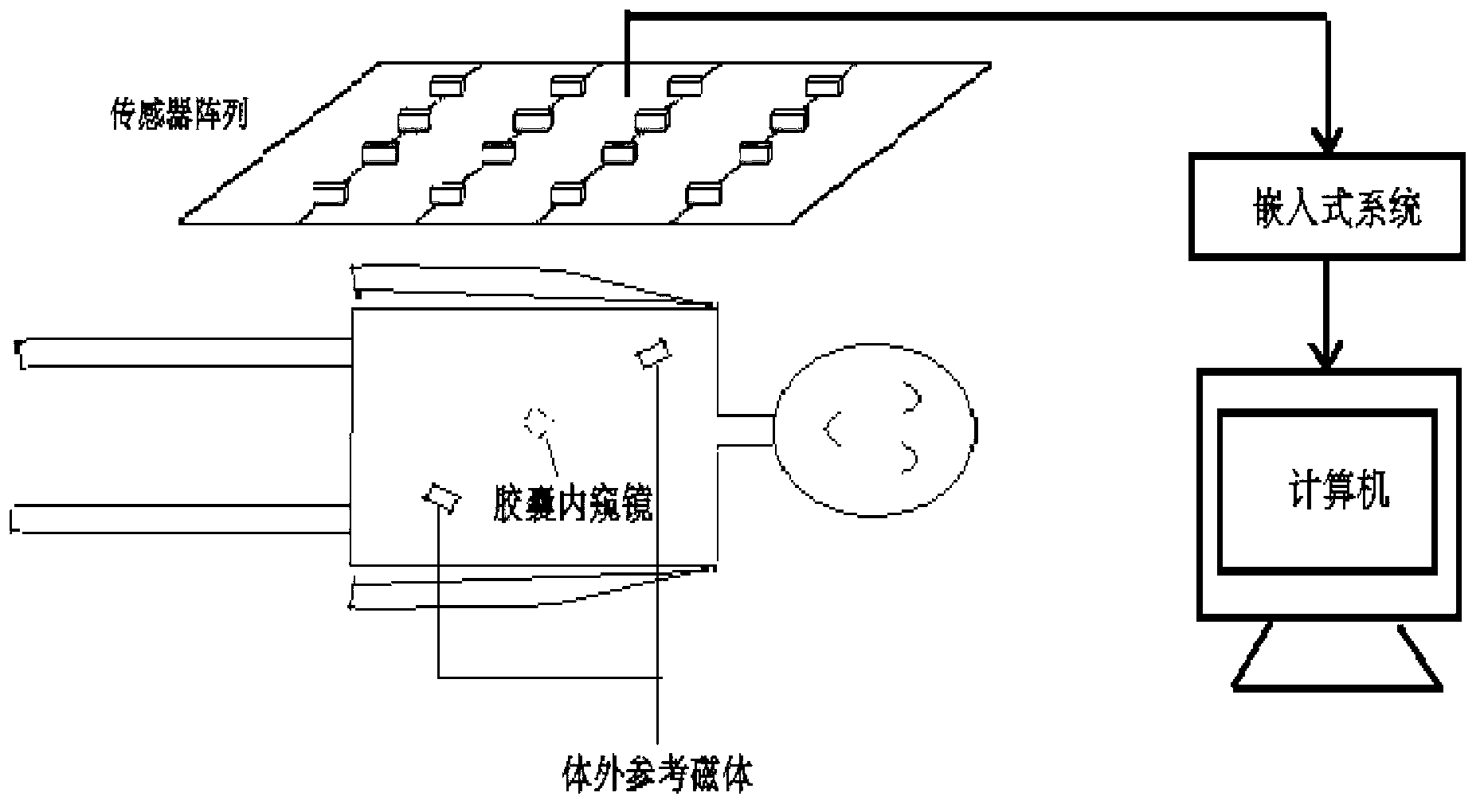

Method for measuring depth and three-dimensional size of nidus tissue by capsule endoscope

InactiveCN103300862AEffective and accurate diagnosis and treatment operationsEasy to determineDiagnostic recording/measuringSensorsHuman bodyMedicine

The invention provides a method for measuring depth and three-dimensional size of a nidus tissue by a capsule endoscope, which comprises the following steps: a location parameter of the capsule endoscope is obtained by utilizing a magnetic positioning method, then corresponding to a start point, a track of the capsule endoscope is obtained according to the location parameter of the capsule, the track is divided to various sections of straight lines, and the depth, corresponding to start point, of the nidus tissue is ensured by calculating each straight line; and images photographed before and after motions of the capsule endoscope is utilized to obtain a rotation angle of the capsule endoscope around a central main shaft after motion of the capsule endoscope, a three-dimensional location of feature points in the nidus tissue is calculated by the location parameter and a direction parameter of the capsule endoscope obtained by combining with the magnetic localization method, and the three-dimensional size of the nidus tissue is obtained according to the three-dimensional location of the feature points. The method has the advantages of being capable of weakening or eliminating the influence of human motion for the working of the capsule endoscope in a human body, and accurately realizing the measuring for the depth and the three-dimensional size of the nidus tissue.

Owner:NINGBO INST OF TECH ZHEJIANG UNIV ZHEJIANG

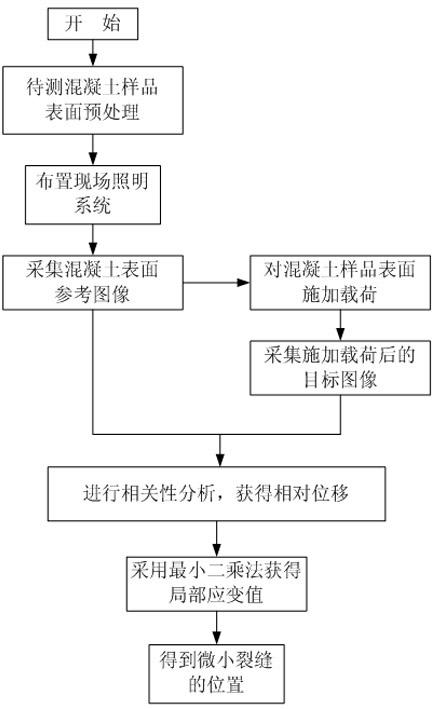

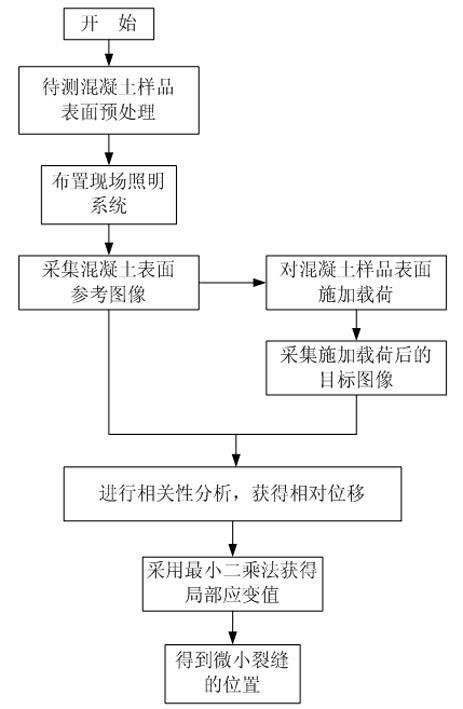

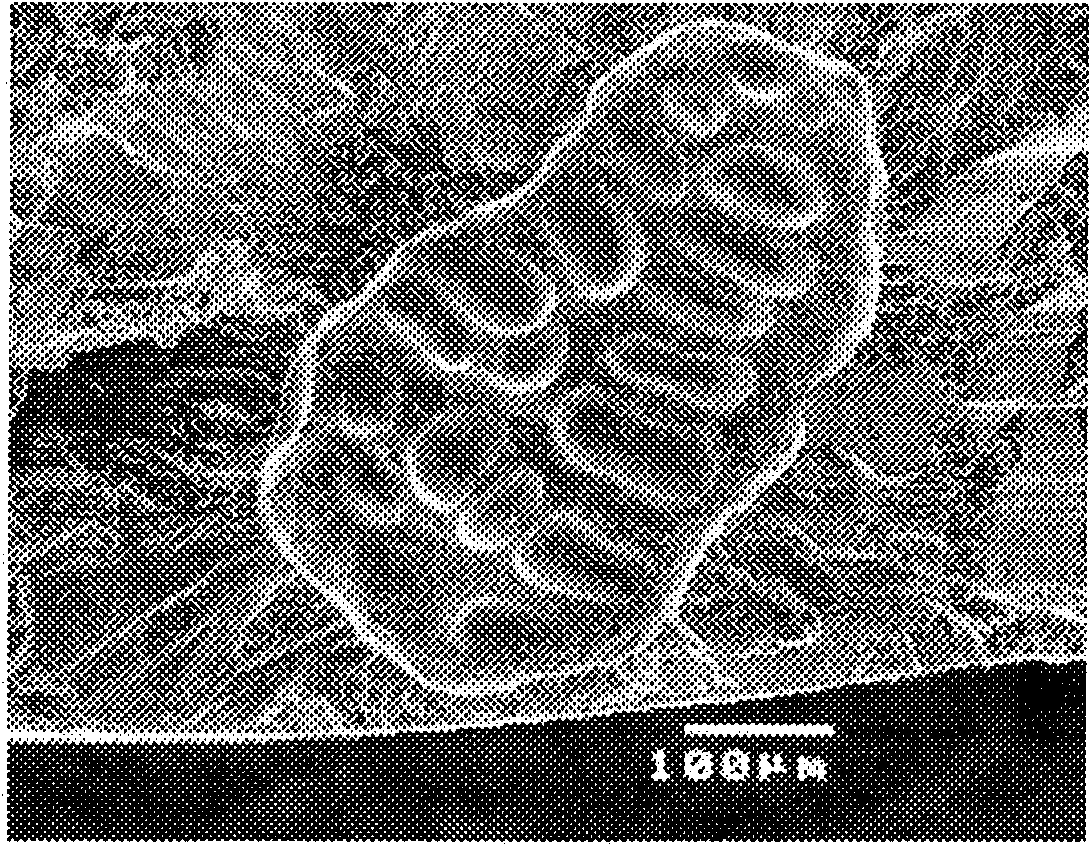

Method for positioning tiny crack on surface of concrete

InactiveCN102305795ANo damageOptically investigating flaws/contaminationUsing optical meansThree Dimensional SizeDigital image

The invention discloses a method for positioning a tiny crack on the surface of concrete, which is based on a related technique of a digital image. Correlation matching is carried out on two surface images of a concrete structure before and after deformation under the action of a certain load, so as to obtain the spatial position of each point before and after deformation on the surface in a full field; the change of the spatial position is a placement field; accurate stress field distribution can be obtained through fitting optimization and differential processing on the curved surface; and the features of the stress field distribution can be automatically identified by a computer so as to judge a strange region, thus the position of the crack is judged. The method disclosed by the invention can be used for identifying the position of the tiny crack on the surface of the concrete; as for the sample the maximum three-dimensional size of which is 10m, the tiny crack the width of which is more than 10 microns can be identified, and the advantages of no contact and no damage on the sample can be achieved.

Owner:HOHAI UNIV

Methods and systems to predict fatigue life in aluminum castings

The invention relates to methods and systems to predict fatigue life in aluminum castings. Methods and systems of predicting fatigue life in aluminum castings that combines extreme values of both casting flaws and microstructures with multiscale life models. The multiscale life models account for differing fatigue crack initiation based on the size scale of the defect and microstructure features,including provisions for generally millimeter scale casting flaws, generally micrometer scale second phase particles by cracking or debonding, or submicrometer scale dislocation interactions with precipitates which form persistent slip bands. In the presence of casting flaws, the fatigue initiation life is negligible and the total fatigue life is spent in propagation of a fatigue crack from such flaws. In the absence of casting flaws, however, the total fatigue life is spent in both crack initiation and propagation, except for the case where fatigue cracks initiate from large second phase particles in a coarse microstructure. The extreme values of casting flaws, second phase particles, mean free path through an aluminum matrix or grain sizes are obtained from extreme value statistics whentwo or three dimensional sizes of casting flaws and microstructure features are provided by either direct measurement or analytical prediction. The upper bound flaw or microstructure feature size is calculated by extreme value statistics.

Owner:GM GLOBAL TECH OPERATIONS LLC

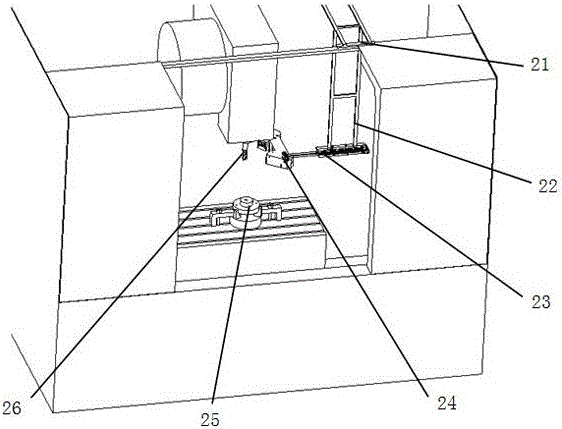

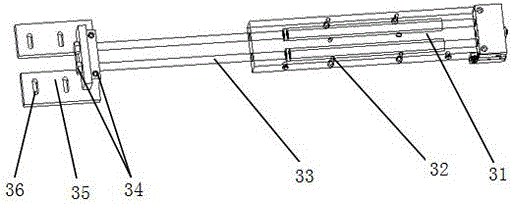

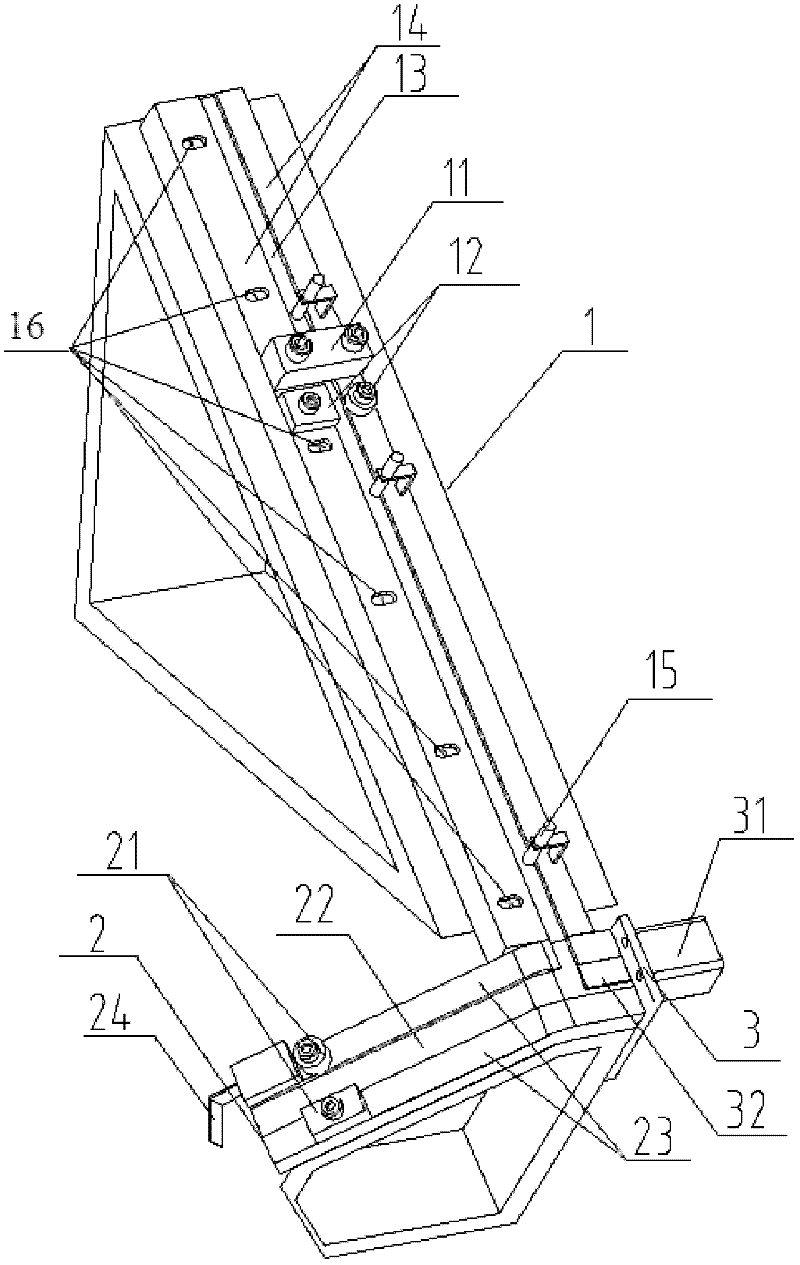

Large-sized forgeable piece three-dimensional size and temperature on-line detection device

InactiveCN101216294AIncrease stiffnessImprove scanning accuracyRadiation pyrometryUsing optical meansMeasurement deviceThree Dimensional Size

The invention relates to an online measurement device for measuring three-dimensional contour and temperature of large forgings, comprising a high-temperature laser ranger, an infrared thermometer and a two-DOF parallel rotary scanning frame. The two-DOF parallel rotary scanning frame comprises a motion platform, hinges, an outer frame, a driving rod, a chassis, two motors and an inner frame, wherein a set of opposite sides of the motion platform is connected with the inner frame via the hinge, the inner frame is connected with one motor and installed on the chassis, the other set of opposite sides of the motion platform is connected with the outer frame via the hinge, and the outer frame is connected with the driving rod via the hinge, and the driving rod is connected with the other motor in parallel and installed on the chassis. The high-temperature laser ranger and the infrared thermometer are fixedly installed on the motion platform, the high-temperature laser ranger, the infrared thermometer and the two motors are connected with a computer via data lines, so as to realize three-dimensional scanning measurement. The invention has simple structure, can realize non-contact and long-distance measurement, and can obtain the three-dimensional contour, size and temperature information at the same time.

Owner:SHANGHAI JIAO TONG UNIV

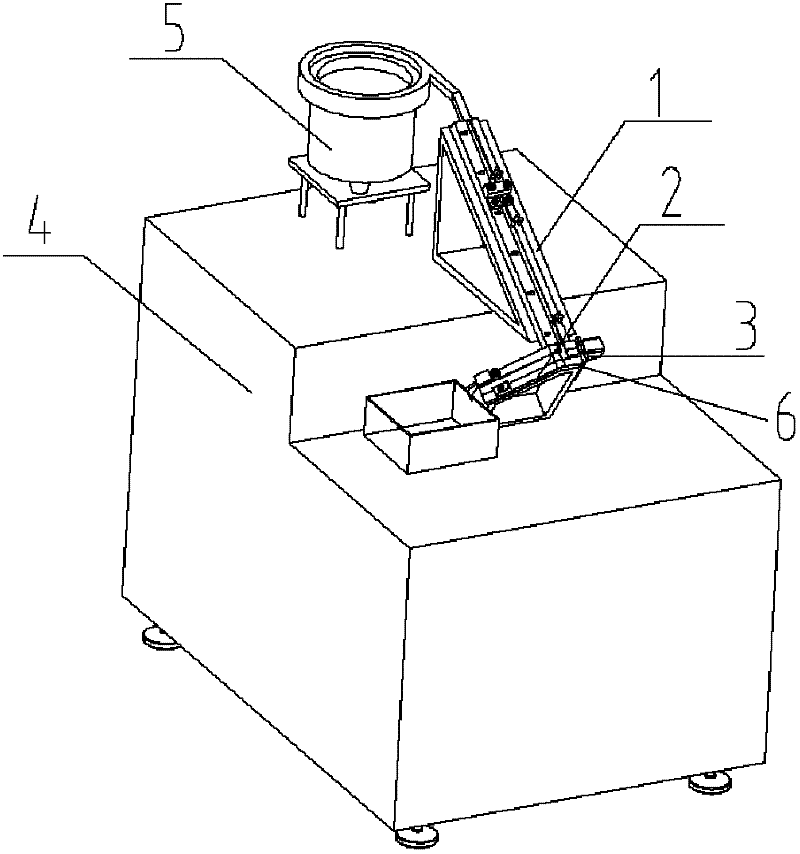

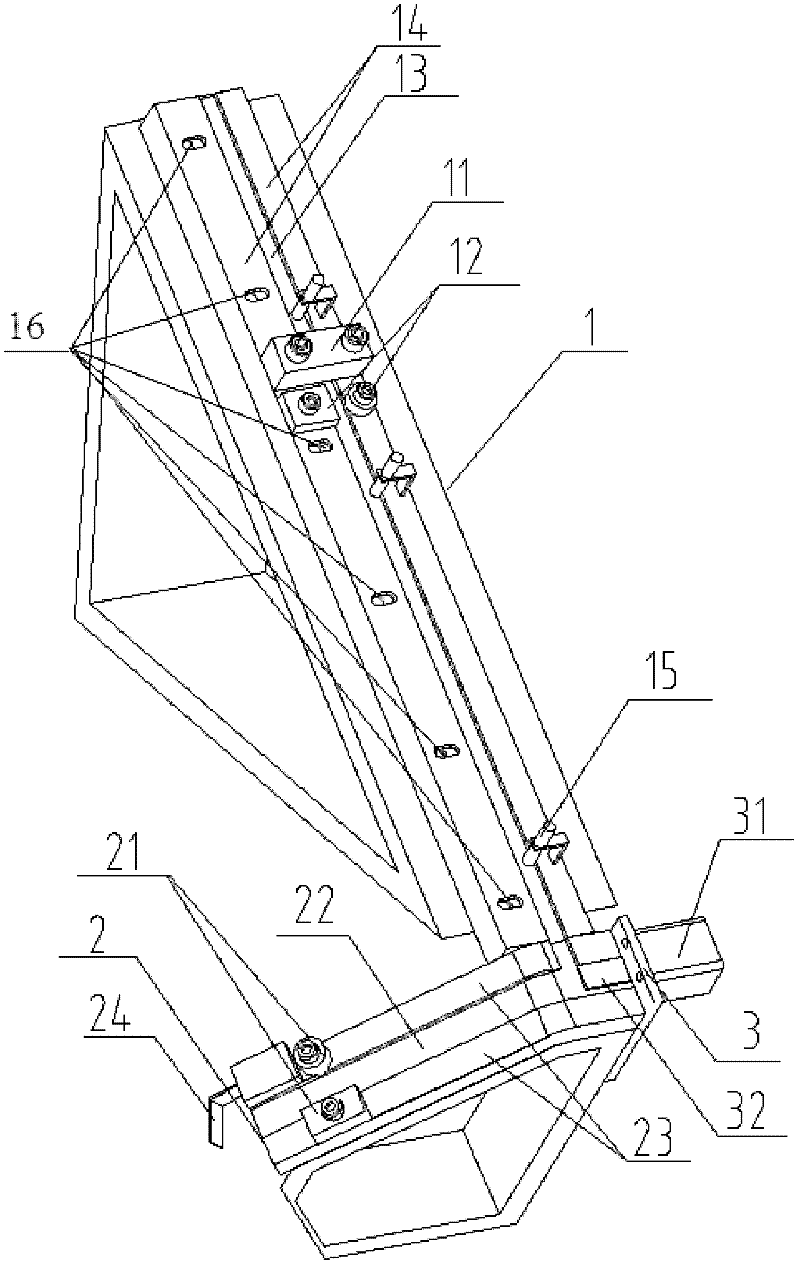

Three-dimensional size sorting device for products

ActiveCN102366746ARealize automatic measurementHigh sorting accuracySortingThree Dimensional SizeEngineering

The invention discloses a three-dimensional size sorting device for products. The three-dimensional size sorting device comprises a first conveying passage, wherein a height limiting device and a first width limiting device are arranged on the first conveying passage; a second conveying passage is arranged at the tail end of the first conveying passage, the first conveying passage is smoothly transitioned to the second conveying passage, and the second conveying passage is vertically arranged relative to the first conveying passage; and a second width limiting device is arranged on the second conveying passage. The three-dimensional size sorting device has the advantages of realization of automatic measurement of three size features of products and high sorting precision.

Owner:NINGBO YUNSHENG +4

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com