Methods and systems to predict fatigue life in aluminum castings

a technology of aluminum castings and fatigue life, applied in the field of methods and systems of predicting fatigue life in aluminum castings, can solve the problems of predominance of presence in the calculation of fatigue life, and achieve the effect of accurate forecasting of fatigue life and accurate estimation of casting fatigue properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

Multiscale Life Models

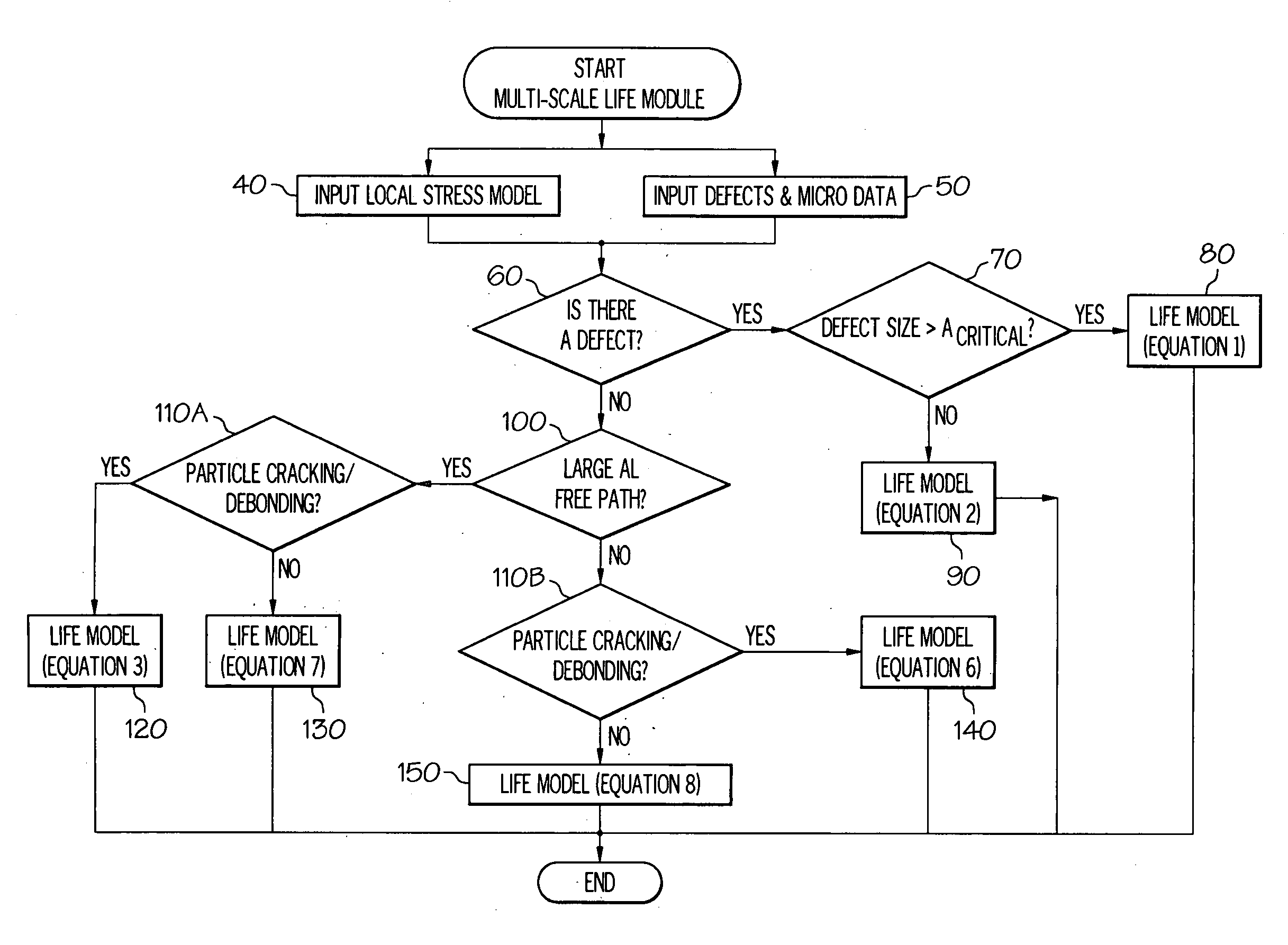

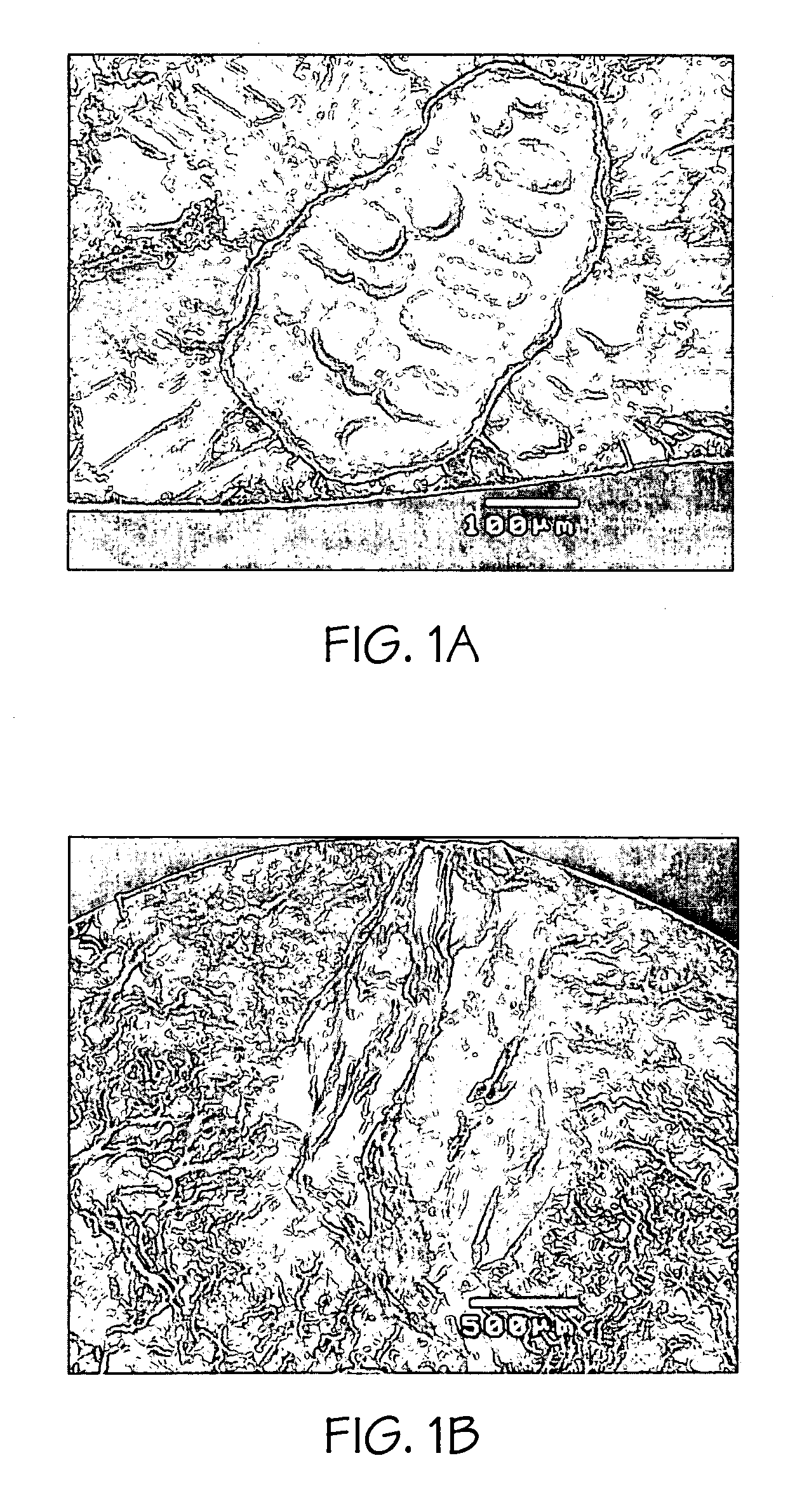

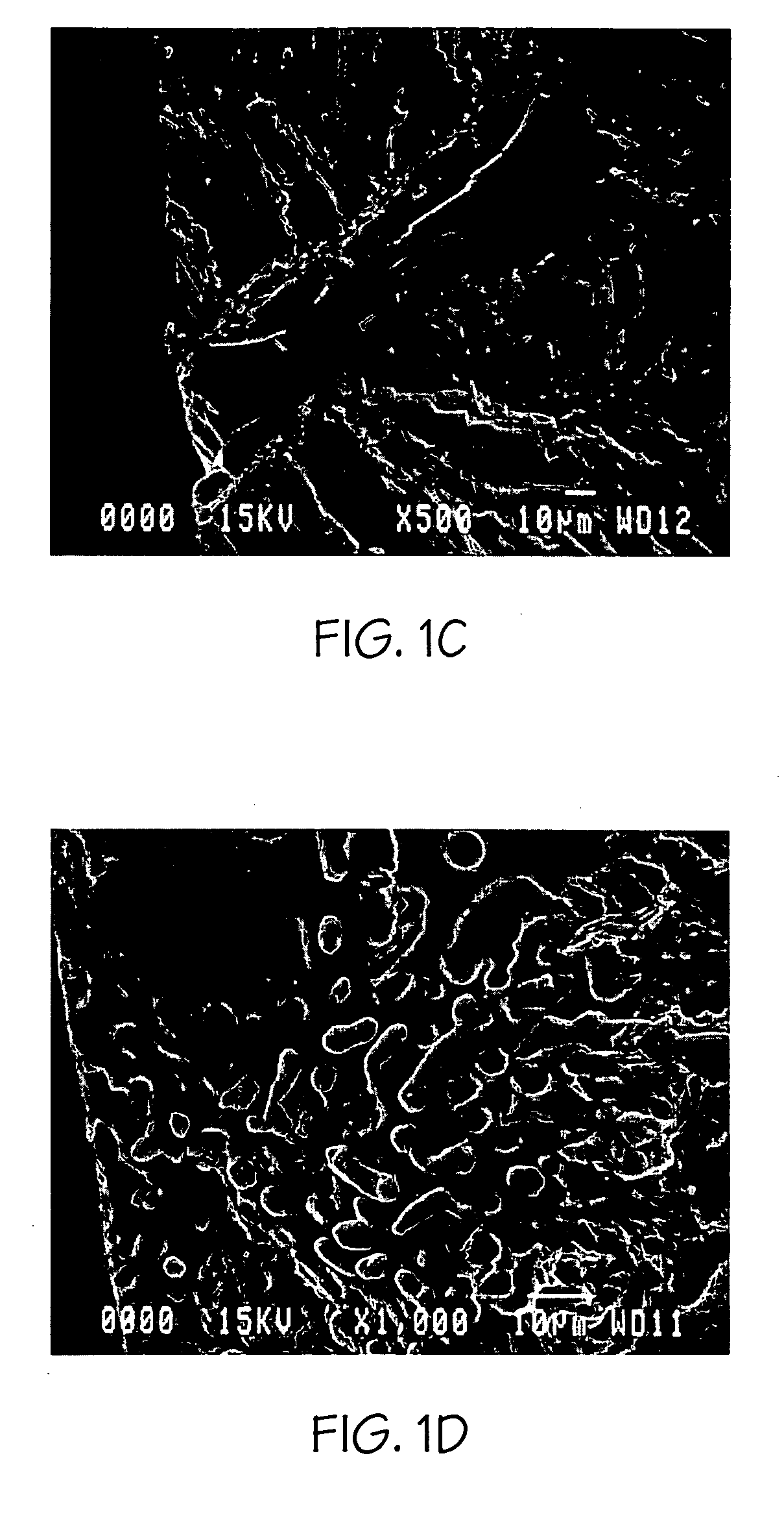

[0031]Referring initially to FIGS. 1A through 1F, magnified photos of the various fatigue crack initiation sites are shown. The probability of having a casting flaw (such as porosity or oxides) in a given portion of the casting depends on many factors. Likewise, in any given portion of an aluminum casting, the aluminum matrix and second phase particles are always present. However, the mean free path through the aluminum matrix (using SDAS as a measure of mean free path in hypoeutectic Al—Si alloys) and scale of the second phase particles mainly depend on how fast that portion of casting cooled during solidification. As discussed above, MSF modeling involves determining fatigue properties of castings having, or assumed to have, numerous crack initiator sizes, including those of relatively large (i.e., millimeter) scale flaws, medium (i.e., micrometer) scale secondary phase particles and their cracking or debonding, and generally small (i.e., submicron) scale int...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com