Centrifugal composite modified indefinite chilled cast iron roller and preparation method thereof

An infinite chilled cast iron, centrifugal compound technology, applied in the direction of roll, metal rolling, metal rolling, etc., can solve the problems of aggravating roll failure, increasing the brittleness of the matrix, etc., to achieve good toughness and wear resistance, radial hardness The effect of low drop, high strength and hardness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

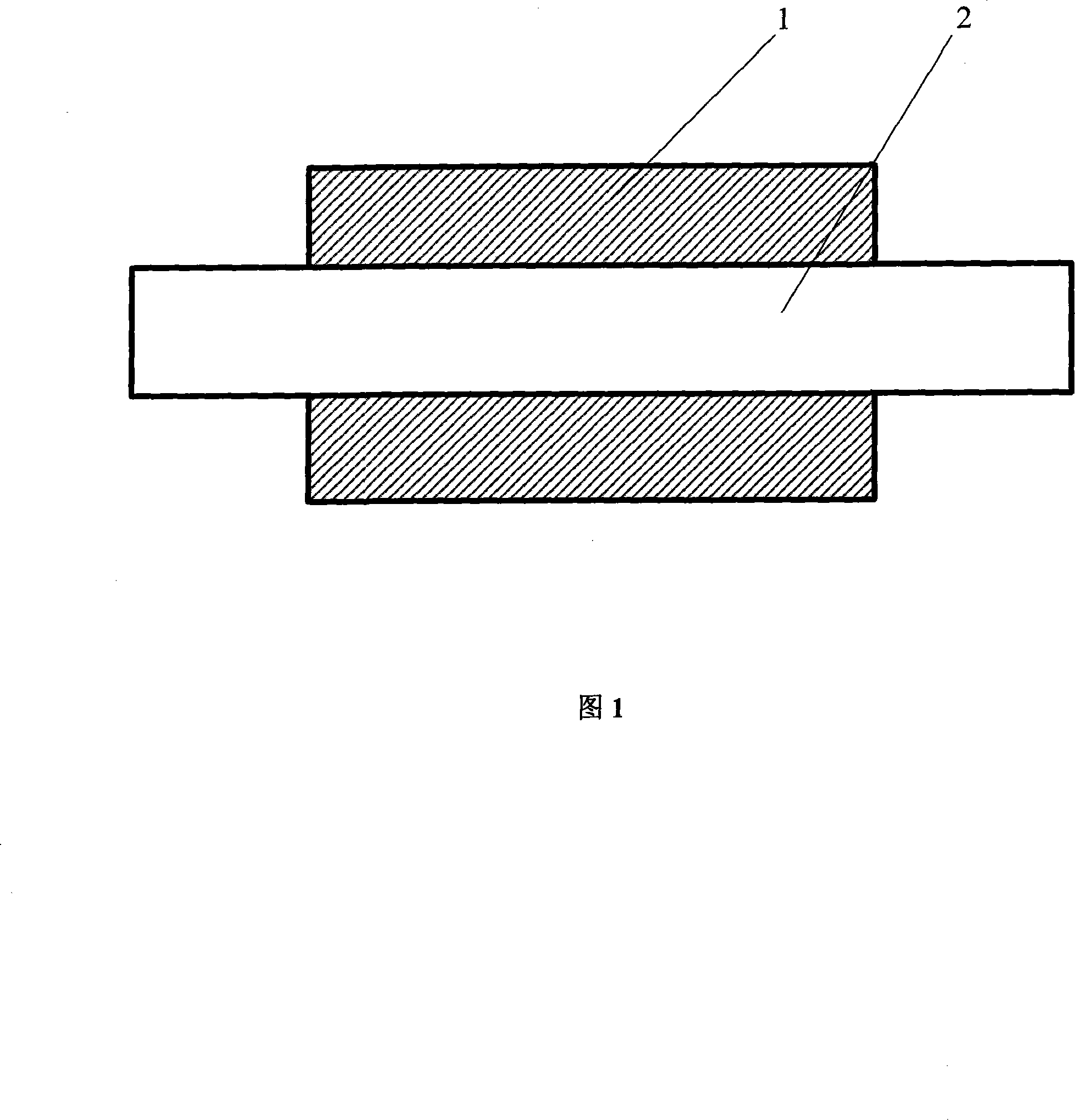

Image

Examples

Embodiment 1

[0044] The centrifugal composite improved infinite chilled cast iron roll prepared in this embodiment is produced in an intermediate frequency induction furnace with a capacity of 750 kilograms, and its manufacturing process steps are:

[0045] ①Heating and melting common steel scrap, pig iron, ferrochrome, ferrosilicon, ferromolybdenum, nickel plate and copper plate.

[0046] ② After adjusting the composition in front of the furnace, raise the temperature to 1482°C, add deoxidizer aluminum, and add ferro-niobium, ferro-titanium and ferro-vanadium into the furnace after removing slag.

[0047] ③ Embed in the ladle with a mass ratio of 1.03% yttrium-based rare earth magnesium nodulizer and 0.38% copper-magnesium alloy with the mass ratio of the above raw materials, and compact the iron filings on the upper cover. The spheroidization treatment is carried out by dam-type flushing method, and at the same time, 0.85% ferrosilicon is flushed with the flow for inoculation treatment, ...

Embodiment 2

[0057] The centrifugal composite improved infinite chilled cast iron roll prepared in this embodiment is produced by an intermediate frequency induction furnace with a capacity of 1000 kilograms, and its manufacturing process steps are:

[0058] ①Heating and melting common steel scrap, pig iron, ferrochrome, ferrosilicon, ferromolybdenum, nickel plate and copper plate.

[0059] ② After adjusting the composition in front of the furnace, raise the temperature to 1465°C, add deoxidizer aluminum, and add ferro-niobium, ferro-titanium and ferro-vanadium into the furnace after removing slag.

[0060] ③ Embed in the ladle with a mass ratio of 0.90% yttrium-based rare earth magnesium nodulizer and 0.45% copper-magnesium alloy with the mass ratio of the above raw materials, and compact the iron filings on the upper cover. The spheroidization treatment is carried out by dam-type flushing method, and at the same time, 0.66% ferrosilicon is flushed with the flow for inoculation treatment,...

Embodiment 3

[0070] The centrifugal composite improved infinite chilled cast iron roll prepared in this embodiment is produced by an intermediate frequency induction furnace with a capacity of 1500 kilograms, and its manufacturing process steps are:

[0071] ①Heating and melting common steel scrap, pig iron, ferrochrome, ferrosilicon, ferromolybdenum, nickel plate and copper plate.

[0072] ② After adjusting the composition in front of the furnace, raise the temperature to 1498°C, add deoxidizer aluminum, and add ferro-niobium, ferro-titanium and ferro-vanadium into the furnace after removing slag.

[0073] ③ Embed in the ladle with a mass ratio of 0.80% yttrium-based rare earth magnesium nodulizer and 0.50% copper-magnesium alloy with the mass ratio of the above raw materials, and compact the iron filings on the upper cover. The spheroidization treatment is carried out by dam-type flushing method, and at the same time, 1.00% ferrosilicon is flushed with the flow for inoculation treatment,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| flexural strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com