Patents

Literature

536 results about "Ferromolybdenum" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

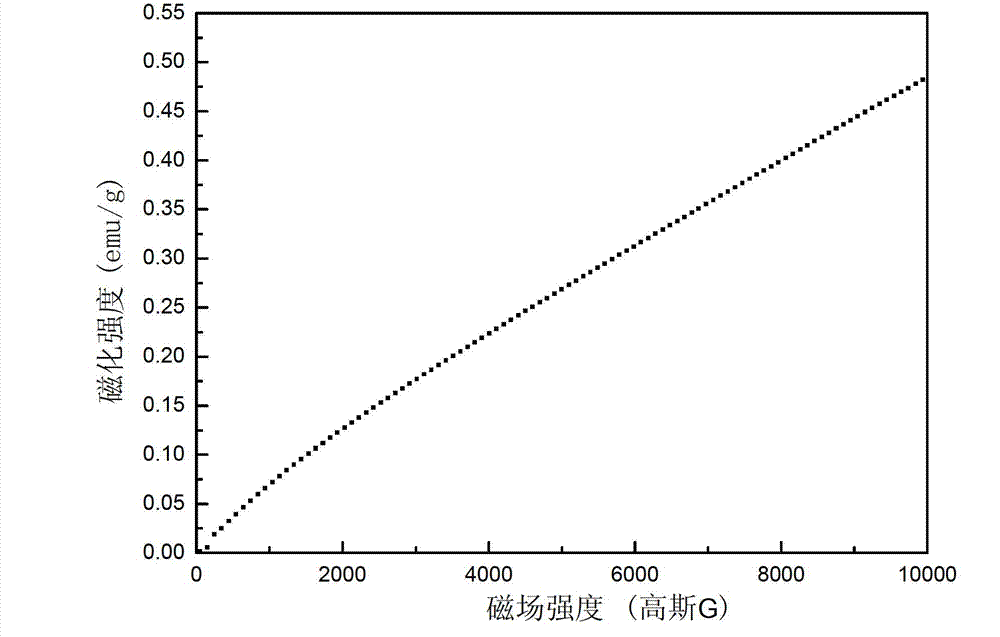

Ferro molybdenum is an important iron-molybdenum metal alloy, with a molybdenum content of 60-75% It is the main source for molybdenum alloying of HSLA steel.

Preparation method of wear-resistant high-chromium cast iron

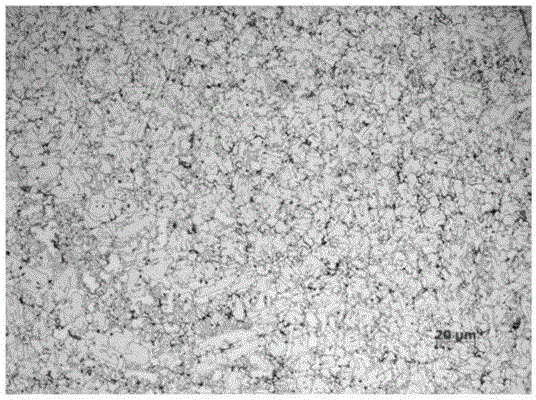

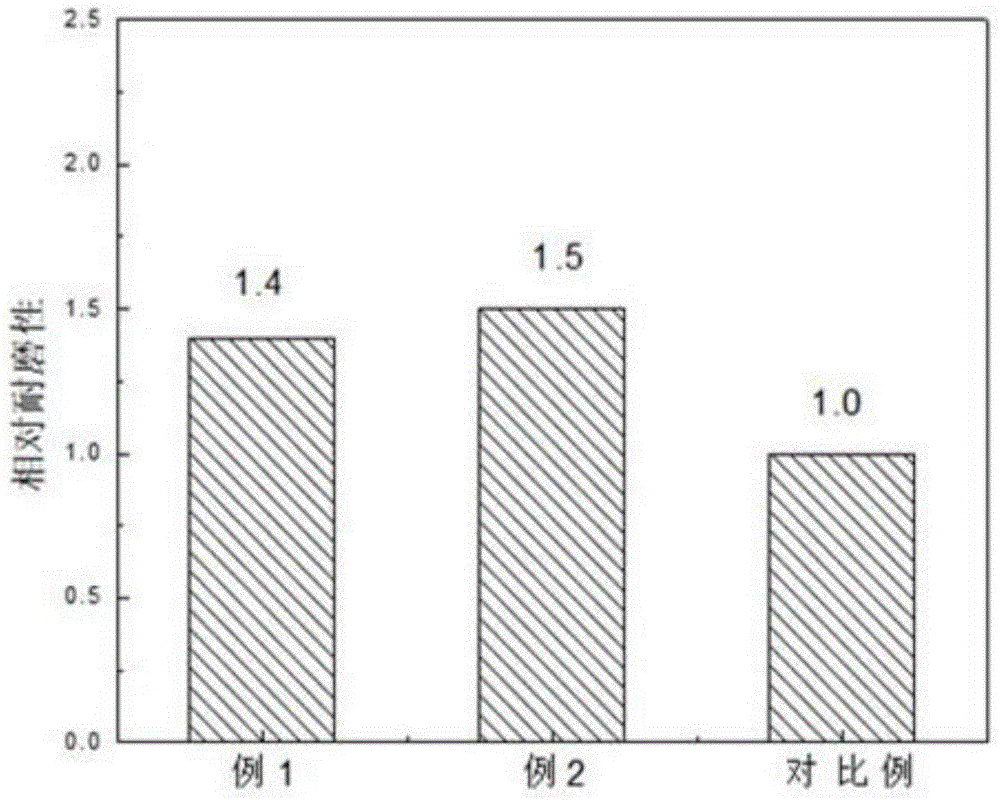

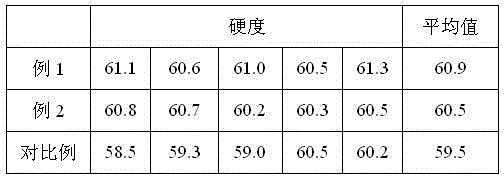

The invention discloses a preparation method of wear-resistant high-chromium cast iron and belongs to the technical field of metal materials. According to the preparation method, common scrap steel, carburant, ferrochromium, ferromolybdenum, copper plates, ferrochromium nitride, ferrosilicon, ferromanganese, ferroboron and aluminum are smelted in an electric furnace so as to form the wear-resistant high-chromium cast iron. The molten wear-resistant high-chromium cast iron comprises the following chemical components in percentage by mass: 3.0-3.5% of C, 18-25% of Cr, 0.3-0.5% of Mn, 0.3-0.5% of Si, 0.18-0.25% of N, 0.5-0.8% of Mo, 0.2-0.4% of B, 0.08-0.12% of Al, 0.5-1.0% of Cu, less than 0.05% of S, less than 0.05% P and the balance of Fe. Molten iron is treated with an inoculator when taken out from the electric furnace, and is treated with a suspending agent when poured, so as to obtain fine solidification structures. Therefore, the wear-resistant high-chromium cast iron has excellent properties.

Owner:BEIJING UNIV OF TECH

High-boron high-speed steel roller material and smelting process thereof

ActiveCN102994692AHigh yieldEasy to useProcess efficiency improvementElectric furnaceMetallic aluminumSilicon alloy

The invention provides a high-boron high-speed steel roller material and a smelting process thereof. The smelting process of the high-boron high-speed steel roller material comprises the following steps: firstly, adopting Q235 waste steel, ferrotungsten, ferromolybdenum, ferrovanadium, high carbon ferro-chrome, metal copper, metal aluminum, calcium-silicon alloy, rare earth ferrosilicon magnesium alloy, ferrocolumbium, ferroboron, ferrosilicon, vanadium-nitrogen alloy, zirconium ferrosilicon and ferrotitanium as materials for smelting low-alloy high-speed molten steel in an electric furnace; then, adding the ferrovanadium and part of ferroboron to carry out alloying in a discharging process; finally, adding part of ferroboron and composite modificator in a casting ladle, adding the vanadium-nitrogen alloy, the zirconium ferrosilicon, the ferrosilicon and part of ferroboron in the casting process. The obtained casting piece has a little alloy elements, excellent abrasive resistance and good thermal fatigue resistance. When the high-boron high-speed steel roller material is used as a roller, the service life is prolonged by more than six times relative to a high nickel-chrome infinite cast-iron roller, and prolonged by 20% relative to a high-vanadium high-speed steel roller. Moreover, the roller is safe to use and reliable.

Owner:YUNNAN HEAVY EQUIP MFG GRP

Ultra supercritical heat-resistant steel welding rod and production method thereof

InactiveCN103737199AGood workmanshipGood mechanicalWelding/cutting media/materialsSoldering mediaFerrosiliconManganese

The invention discloses an ultra supercritical heat-resistant steel welding rod which is composed of an H08A core wire and coating wrapping the surface of the core wire, wherein contents of sulfur, phosphorus, arsenic, aluminum and the like in the H08A core wire are low, and the coating comprises components of 30%-39% of marbles, 22%-30% of fluorites, 6%-9% of rutiles, 7.5%-8.6% of ferromolybdenum, 29%-31% of chromium metal, 5%-9% of silica powder, 2%-5% of ferrosilicon, 1%-1.8% of ferrovanadium, 0.4%-0.8% of ferroniobium, 1.8%-2.8% of nickel powder, 0.4%-0.8% of sodium carbonate, 0.4%-0.8% of carboxyl methyl cellulose (CMC), 0.2%-0.6% of amorphous graphite, 0.6%-1.5% of nitrogen-bearing ferrochromium, 1.6%-3% of electrolytic manganese, 3%-3.8% of cobalt powder and 4%-5% of ferroboron.

Owner:ATLANTIC CHINA WELDING CONSUMABLES

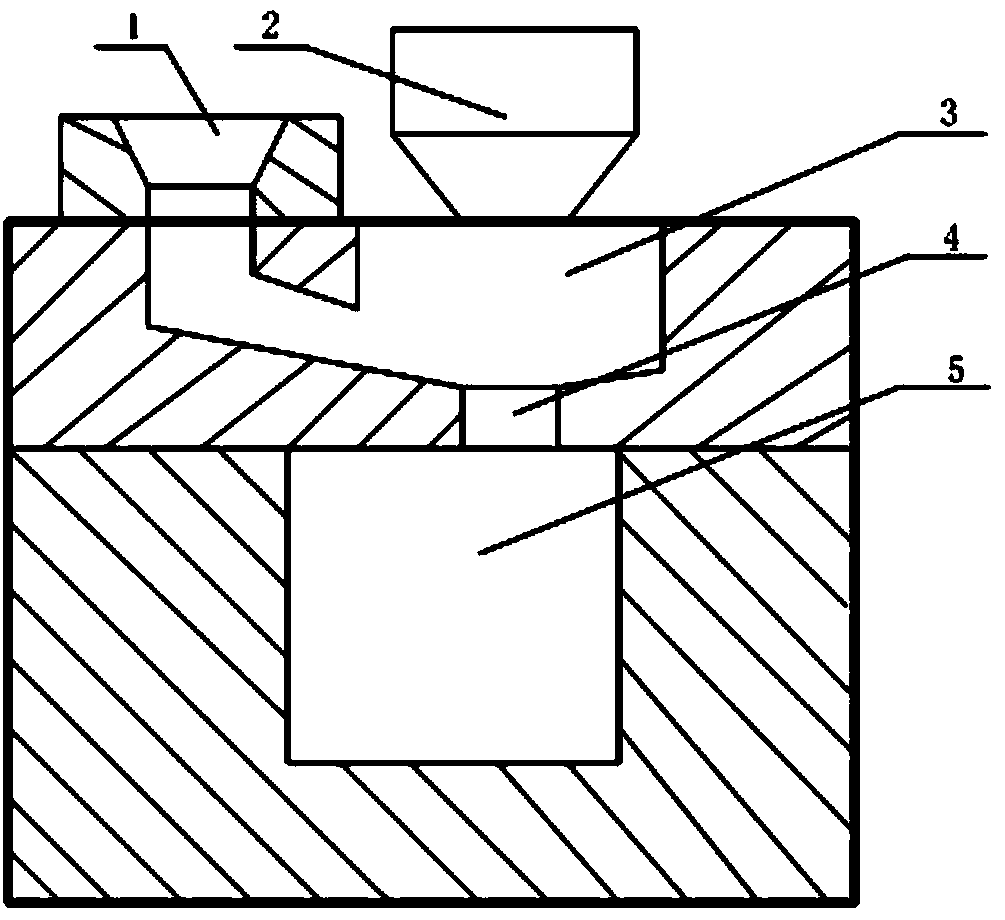

Special flux-cored wire for surfacing repair of BD roller

InactiveCN101804530AHigh hardnessImprove wear resistanceWelding/cutting media/materialsSoldering mediaHigh carbonManganese

The invention discloses a special flux-cored wire for surfacing repair of a BD roller, which consists of a tube skin and a flux core, wherein the tube skin is an H08A steel strip, and the flux core comprises the following components by weight percent: 15-25% of high-carbon ferrochrome, 2-10% of micro-carbon ferrochrome, 5-7% of metal manganese, 6-12% of ferromolybdenum, 3-10% of ferrotungsten, 5-10% of ferrovanadium, 0.5-6% of ferrotitanium, 0.3-5% of yttrium-based rare-earth, 1-3% of ferrocolumbium, 4-10% of cryolite and 10-50% of ferrous powder, wherein the filling coefficient is 30-45%. The special flux-cored wire selects a Cr-Mo-W-V alloy system with optimal alloy matching and carries out Ti-Nb-Re micro-alloy grain refinement, thereby leading a surfacing repair layer to have the advantages of high hardness, high wear resistance, high toughness and high anti-cold and hot alternating thermal fatigue performance, and exponentially prolonging the service life of the BD roller after surfacing repair in comparison with the BD roller after the ordinary roller flux-cored wire repair.

Owner:邯郸市永固冶金备件有限公司

Wear-resistant overlaying flux-cored wire

InactiveCN104325232ASimple welding processA large amountWelding/cutting media/materialsSoldering mediaElectrolysisFerrosilicon

The invention relates to a wear-resistant overlaying flux-cored wire. The wear-resistant overlaying flux-cored wire comprises a low-carbon steel outer layer and a flux core inner layer, wherein the filling coefficient of a flux core is 45-55 percent, and the overlaying flux-cored wire is characterized in that the flux core comprises the following components in parts by weight: 1-6 parts of microcrystalline graphite, 1-4 parts of aluminum-magnesium alloy, 1-2 parts of fluoride, 1-2 parts of silicate, 1-3 parts of titanate, 1-2 parts of carbonate, 30-80 parts of high carbon ferro-chrome, 15-45 parts of metal chromium carbide, 5-10 parts of electrolytic chromium powder, 3-6 parts of high carbon ferromanganese, 1-4 parts of rare earth ferrosilicon, 2-6 parts of ferrosilicon, 4-10 parts of ferromolybdenum, 5-10 parts of ferrotungsten, 5-10 parts of ferrovanadium, 4-10 parts of ferrocolumbium, 4-10 parts of ferrotitanium and 1-4 parts of ferroboron. The wear-resistant overlaying flux-cored wire has the advantages of good hardness, wear resistance and anti-cracking performance.

Owner:李永锋

Soldering wire material containing nitrogen alloyed alloy core in form of hard surface

InactiveCN1562552AGuaranteed performanceIncrease productivityWelding/cutting media/materialsSoldering mediaHigh carbonNitrogen

A nitrogen alloyed welding wire with hard surface and alloy core for repairing on manufacturing rolling roller, mine machinery and large digger features that its core powder is prepared from alloy powder and mineral powder through mixing, and contains rutile, high-carbon ferrochromium, low-carbon ferrochromium, Si Al-Mg alloy, Mn, ferromolybdenum, ferrovanadium, ferrotictanium, Ni, chromium nitride and Fe. The nitrogen is used to replace part of carbon for alloying, so improving anticracking performance.

Owner:HUAZHONG UNIV OF SCI & TECH

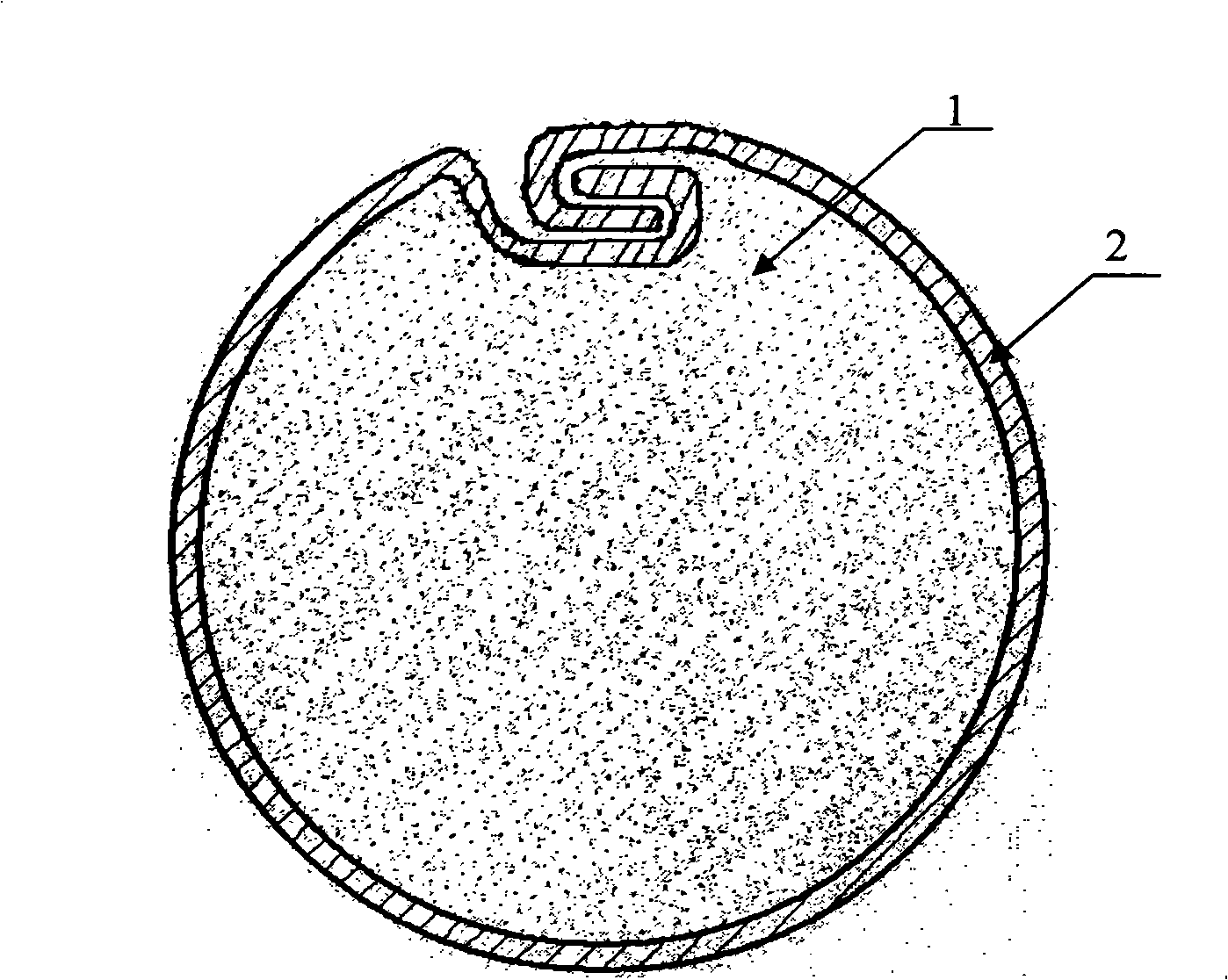

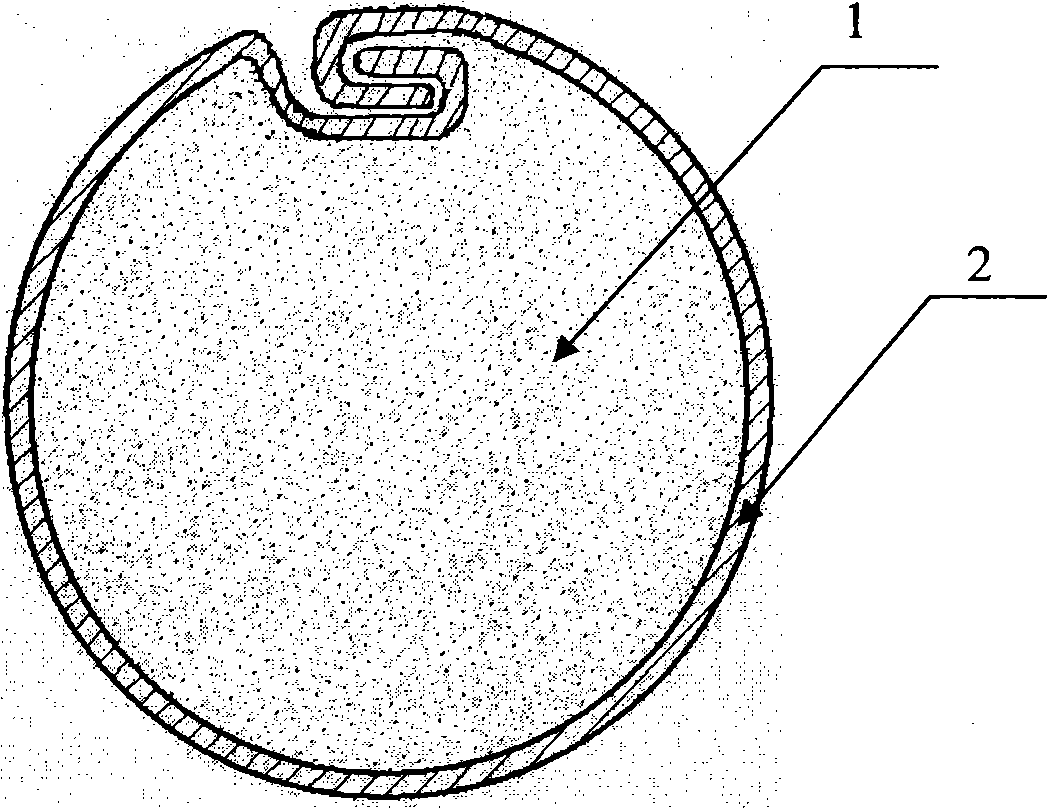

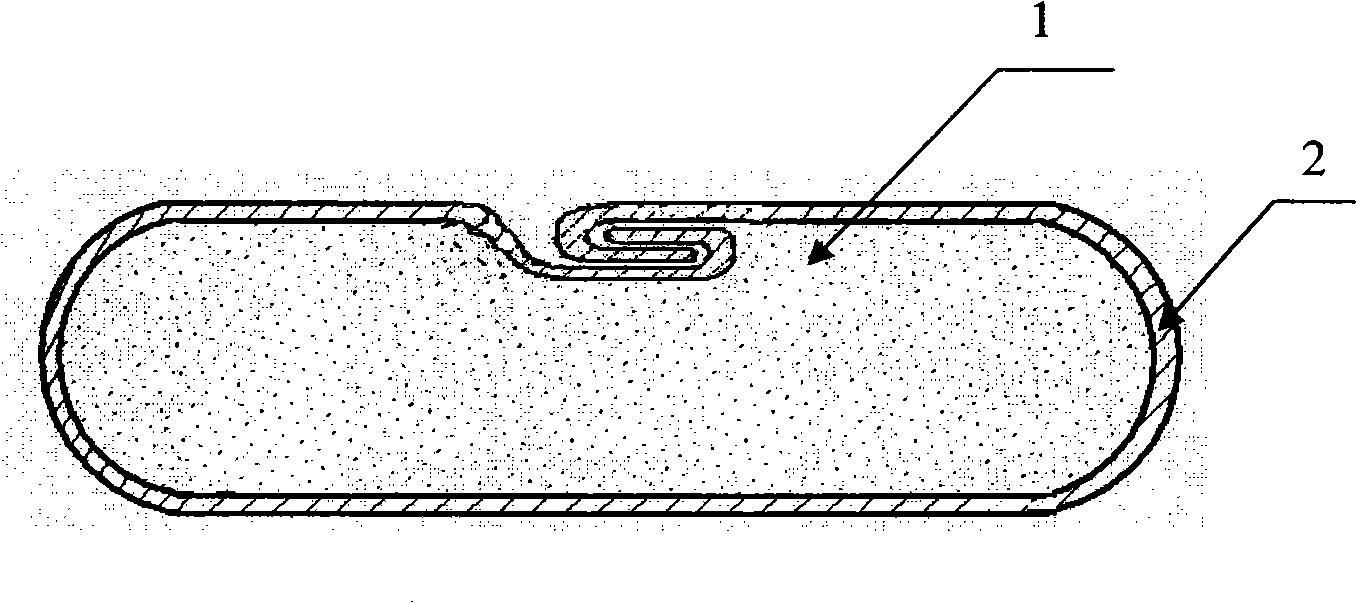

Flux-cored steel belt for build-up welding and preparation method thereof

InactiveCN101306493AIncrease varietyIncrease weld widthWelding/cutting media/materialsSoldering mediaHigh carbonFerrosilicon

The invention discloses a resurfacing welding used drug cored steel strap and the preparation method. The steel strap is prepared from a mild steel strap and drug powder enwrapped therein, the shape of the steel strap is a tube with the longitudinal cross-section to be in a long and flat shape or in a similar rectangle shape, the longitudinal length can be determined randomly, and the transverse sides of the steel strap are connected in a seam manner or a related joint manner; the drug powder is uniformly filled in the tube rolled from the steel strap, wherein the particle diameter of the drug powder is smaller than 120 Mum, the components include (by weight) 45-70 parts of high carbon ferrochrome, 5-35 parts of ferrovanadium, 1-8 parts of No.75 ferrosilicon, 1-10 parts of high carbon ferromanganese, 2-16 parts of ferroboron, 1-8 parts of ferrotitanium, 0-5 parts of ferroniobium, 2-8 parts of ferromolybdenum, 0-10 parts of graphite, 0-5 parts of fluorite and 0-6 parts of potassium titanate. The drug cored steel strap adopting the invention can efficiently improve the abrasion resistance of the metal on the resurfacing welding layer and the stability of the electric arc, and can be coiled into coils, thereby being suitable for continuous automatic resurfacing welding.

Owner:SHANDONG UNIV

Special flux-cored wire for carrying out preheating-free and heat treatment-free surfacing repair and reproducing on shaft and gear parts

InactiveCN102019520AImprove wear resistanceImprove thermal fatigue resistanceWelding/cutting media/materialsSoldering mediaCrack resistanceNiobium

The invention belongs to the field of material science and engineering and relates to a special flux-cored wire for carrying out preheating-free and heat treatment-free surfacing repair and reproducing on shaft and gear parts. The special flux-cored wire comprises the following chemical compositions in percentage by weight: 5 to 10 percent of fluorite, 20 to 40 percent of high-carbon ferrochrome, 5 to 10 percent of high carbon ferromanganese, 5 to 10 percent of ferrosilicon, 5 to 10 percent of ferromolybdenum, 10 to 15 percent of rare earth oxide, 15 to 20 percent of metallic nickel, 2 to 5 percent of ferrovanadium, 2 to 5 percent of ferrocolumbium, 2 to 5 percent of ferrotitanium, 0.1 to 0.5 percent of graphite, 5 to 15 percent of iron powder, 0.5 to 2 percent of nitride and 1 to 3 percent of aluminum magnesium alloy. A sheath of the special flux-cored wire is a low-carbon steel strip. The special flux-cored wire can be suitable for open arc welding or submerged arc welding. The series flux-core wire for surfacing can carry out surfacing repair and reproducing on the shaft and gear parts under the conditions that preheating is free before surfacing and heat treatment is free after surfacing. The surfacing metal has high crack resistance. The performance of the repaired parts is equal to or even superior to that of the original parts. The special flux-cored wire is convenient to use on site. The hardness range is between HRC20 and HRC45. The service life of the repaired parts is about 3 times longer than that of the original parts.

Owner:YANSHAN UNIV

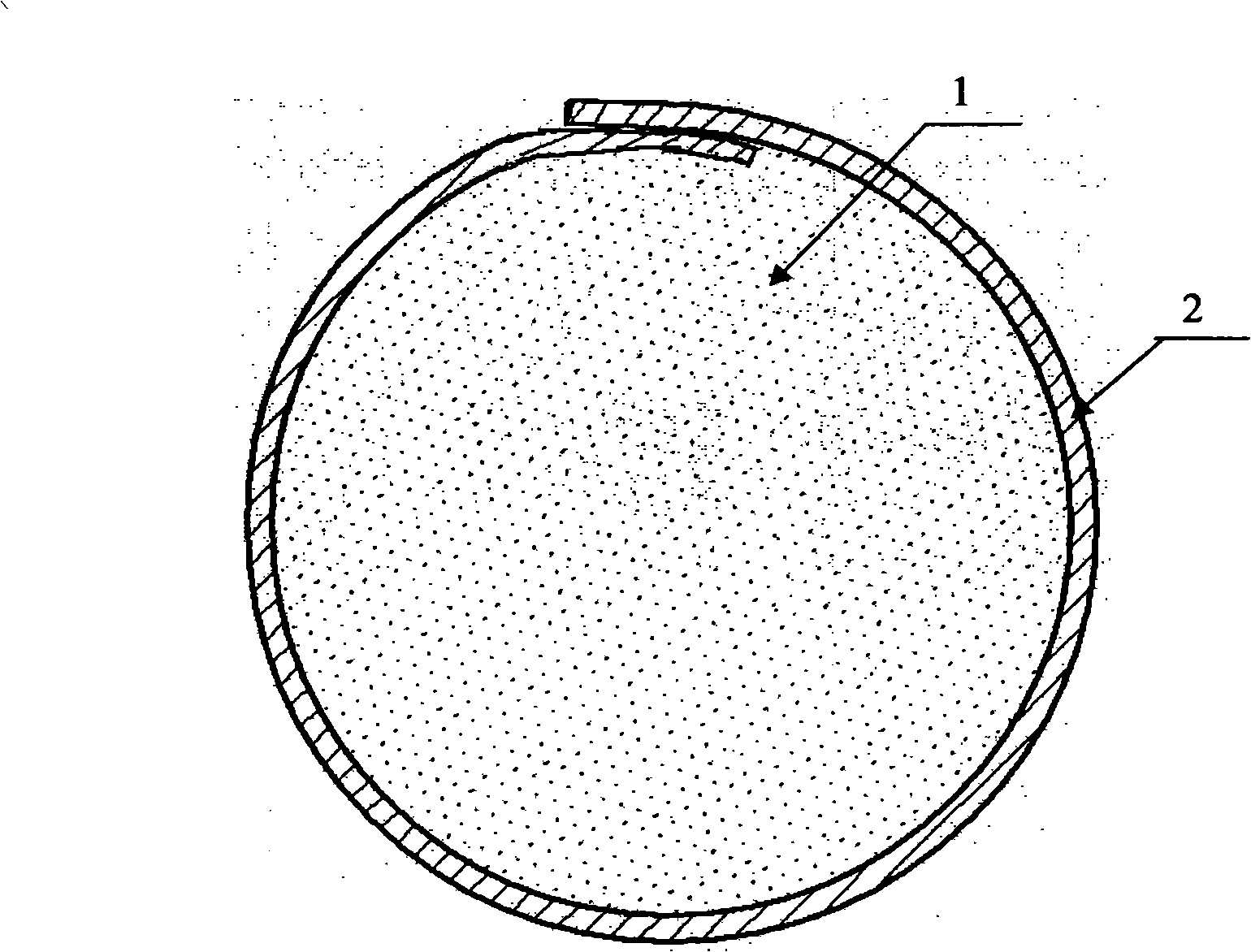

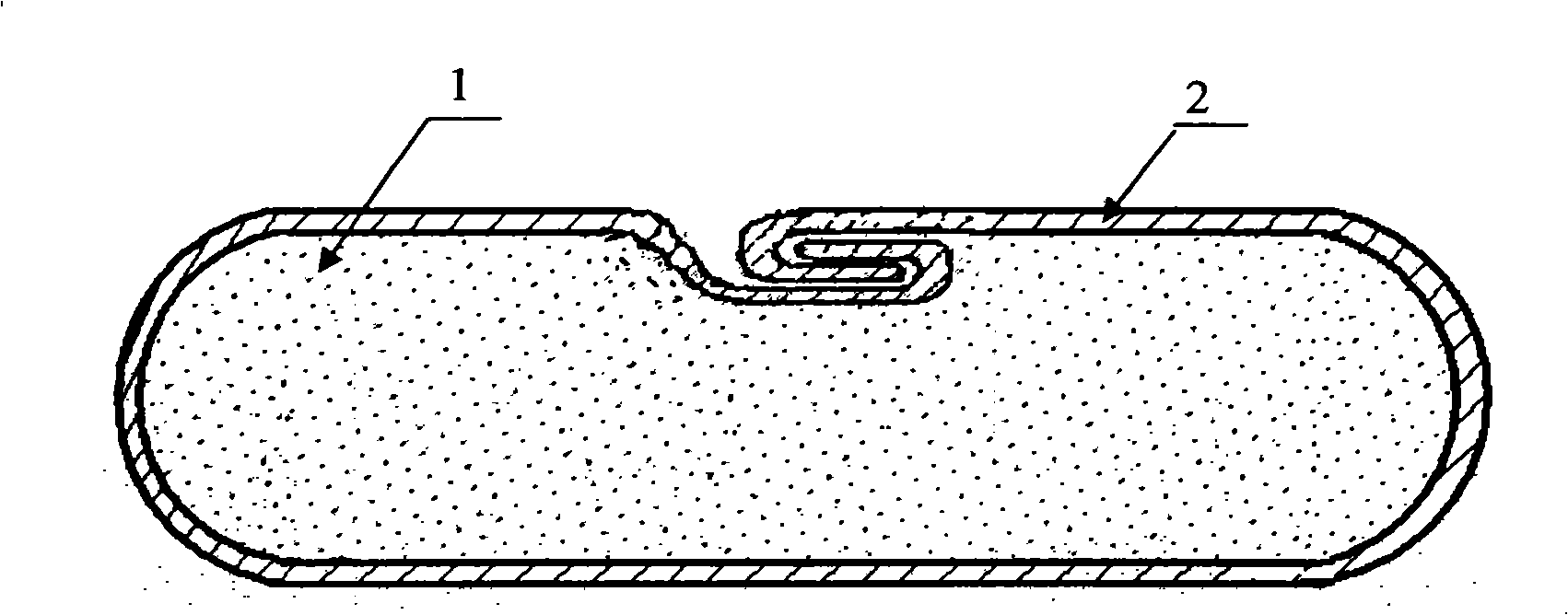

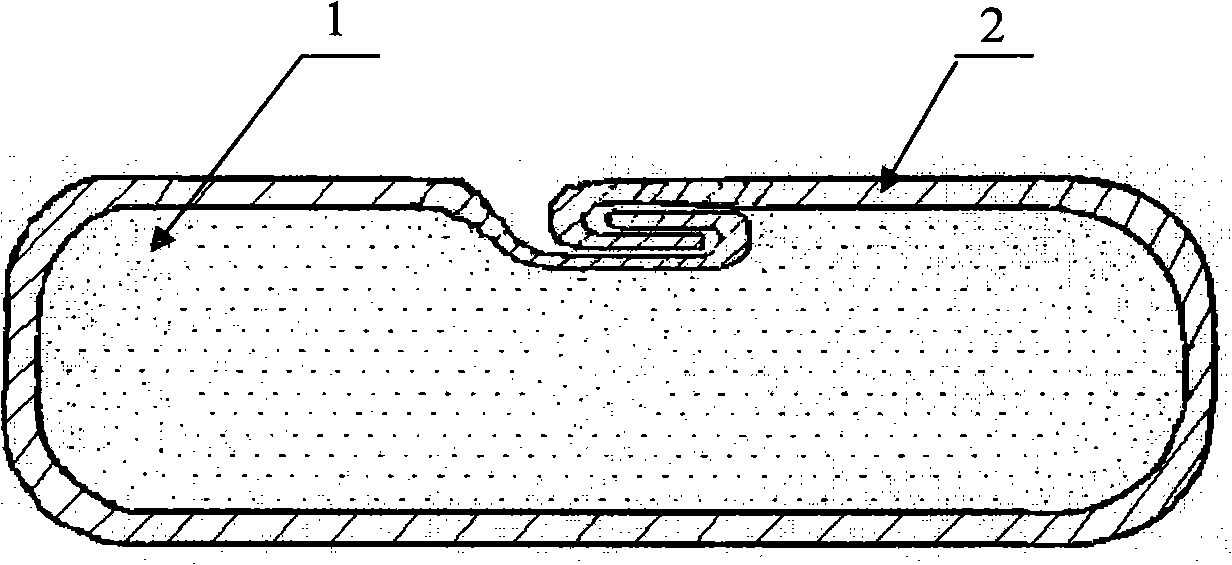

Tube wire for overlaying welding and preparation thereof

InactiveCN101301709AOvercome the shortcomings of a single ingredientIncrease varietyWelding/cutting media/materialsSoldering mediaHigh carbonFerrosilicon

The invention provides a tubular electrode used for surfacing welding, which is prepared by low-carbon steel band and powder grains wrapped in the low-carbon steel band, wherein, the longitudinal cross-section of the tubular electrode is a long flat shape or rectangle-similar; the powder grains in the pipe have the granularity of 50 meshes; according to the portions by weight, the powder comprises the components as follows: 40-70 portions of high-carbon ferrochrome, 5-30 portions of ferrovanadium, 0-6 portions of 75# ferrosilicon, 1-9 portions of high-carbon ferromanganese, 0-8 portions of aluminium-magnesium alloy, 2-15 portions of ferroboron, 1-6 portions of ferrotitanium, 2-8 portions of ferromolybdenum, 0-8 portions of graphite, 0-5 portions of fluorite and 0-6 portions of potassium titanate; the longitudinal length of the tubular electrode is 300-500mm; one end of the tubular electrode is provided with a flat area with the width of 8-68mm, thickness of 0.5-1.5mm and length of 8-20mm. The tubular electrode of the invention has large surfacing welding seam, beautiful forming and high surfacing welding efficiency, is easier to realize the automatic surfacing welding compared with the conventional electrodes, and can carry out the production of large batches.

Owner:SHANDONG UNIV

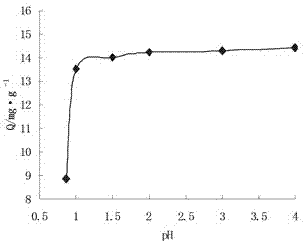

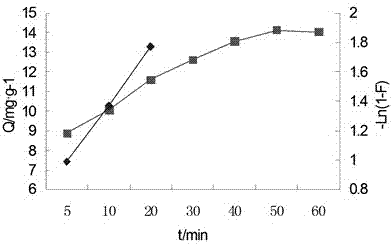

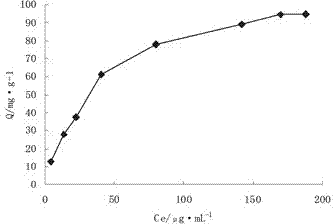

Method for microbiological leaching of uranium-molybdenum ore and enrichment and separation of uranium and molybdenum

The invention discloses a method for microbiological leaching of uranium-molybdenum ore and enrichment and separation of uranium and molybdenum. The method comprises a microbiological leaching method of uranium-molybdenum ore and an enrichment and separation method of uranium and molybdenum in a leachate; in the leaching method, an oxidizing agent for leaching the uranium-molybdenum ore is biological high iron, namely an acidophilous acidithiobacillus ferrooxidans solution containing the biological high iron. The method comprises the following specific steps: firstly crushing the uranium-molybdenum ore so that the crushed materials with the granularity of above 200 meshes account for more than 50% of the total amount and the crushed materials with the granularity of 30 meshes account for not more than 10% of the total amount; then infiltrating the crushed uranium-molybdenum ore in a biological oxidizing agent solution, carrying out solid-liquid separation after infiltrating, and then carrying out ion exchange on the microbiological leachate of the uranium-molybdenum ore by using 201*7 resins, and carrying out iron elution, uranium elution and molybdenum elution. In the method, the uranium leaching rate is above 80%, the molybdenum leaching rate is within the range from 60% to 70% or above, and the molybdenum leaching rate is increased by 20-30%; the uranium, molybdenum and iron in the leachate are eluted by using a PH1.0 solution by virtue of an ion exchange column, and the removal rate of the iron is above 95%, the adsorption rate of the uranium and the molybdenum is not affected, the uranium and the molybdenum adsorbed on the resin are desorbed by using different desorption reagents step by step, and the recovery rate of the uranium and the molybdenum is above 80%.

Owner:EAST CHINA UNIV OF TECH

Weather-proof flux core wire used for coating-free bridge steel and preparing method of weather-proof flux core wire

ActiveCN106475706AImprove mechanical propertiesStable welding arcWelding/cutting media/materialsSoldering mediaSlagManganese

The invention discloses a weather-proof flux core wire used for coating-free bridge steel and a preparing method of the weather-proof flux core wire. The weather-proof flux core wire is composed of a steel skin and a powder core. The powder core comprises, by weight percent, 2%-8% of ferro-boron, 0.01%-2% of ferromolybdenum, 1%-6% of fluoride, 1.5%-8% of zircon sand, 2%-7% of magnesium powder, 2%-5% of quartz sand, 2%-8% of silicon iron, 5%-19% of electrolytic manganese, 1%-5% of ferromanganese, 1%-6% of nickel powder, 1%-8% of chromium metal, 1%-8% of copper powder, 2%-9% of ferrotitanium, 0.1%-5% of feldspar, 2%-8% of sodium titanate, 20%-40% of rutile and the balance iron powder. Compared with the prior art, the weather-proof flux core wire is stable in welding arc and little in splashing, slag removing is easy, a welding joint is formed attractively, the weather-proof flux core wire is suitable for all-position welding, the mechanical performance of the welding joint is good, the impact toughness at the temperature of minus 40 DEG C is larger than 80 J, and very high corrosion resistance is achieved.

Owner:ATLANTIC CHINA WELDING CONSUMABLES

Gas-shielded overlaying flux cored soldering wire for repairing hot-forging mould

ActiveCN102029482ASimple welding processGood welding wire crack resistanceArc welding apparatusWelding/cutting media/materialsCrack resistanceFerrosilicon

The invention discloses a gas-shielded overlaying flux cored soldering wire for repairing a hot-forging mould, which is manufactured by taking SPCC-SD cold-rolling low-carbon steel belts as raw materials of a soldering wire and utilizing a conventional flux cored transient alloy way, a universal flux cored standard and a flux cored soldering wire manufacturing technique. The soldering wire flux core contains fluoride, calcium carbonate, feldspar, magnesia and alloy powder according to a proportion, wherein the fluoride comprises calcium fluoride, sodium fluoride and barium fluoride, and the alloy powder contains iron powder, high-carbon ferrochrome, electrolytic manganese, ferrosilicon, ferromolybdenum, ferrovanadium, nickel powder, tungsten powder and cobalt powder. The invention has the following beneficial effects: because the gas-shielded overlaying flux cored soldering wire takes CO2 or a gas mixture with volume percentage ratio of 80% Ar and 20% CO2 as the protective gas, the gas-shielded overlaying flux cored soldering wire has the advantages of great soldering technique, stable electric arc, less splash, easy deslagging, good crack resistance, great high-temperature hardness and thermal fatigue resistance, continuous soldering and improvement on production efficiency.

Owner:TIANJIN YONGCHANG WELDING WIRES

High-wearing high performance-cost ratio flux-cored wire

InactiveCN101181766AImprove wear resistanceImprove toughnessWelding/cutting media/materialsSoldering mediaIron powderMetal alloy

The invention discloses a flux-cored wire with high abrasion resistance and high performance / cost ratio, an external wrapper of which adopts H08A low carbon steel. The invention is characterized in that: a filling rate of the wire is 30 to 70 percent, percentages by weight of components of the wire and other components are: powdered graphite is 2 to 12 percent, high carbon ferrochromium is 25 to 85 percent, mid-carbon fe-mn is 2 to 15 percent, 45 ferrosilicon alloy is 1 to 7.5 percent, ferrovanadium is 1 to 26 percent, ferromolybdenum is 1 to 10 percent and reduced iron powder accounts for the residual percentage. The beneficial effects of the invention are that: the wire is processed through ordinary metal alloy powder lot, no pure metal or compound is needed, and the cost is relatively lower but the abrasion resistance is relatively higher, thereby being favorable for popularizing and applying widely.

Owner:徐龙江

Titanium carbide ceramic-enhanced visible arc self-shielded flux-cored wire for high-chromium cast iron

InactiveCN102248325AEasy to use on siteImprove wear resistanceWelding/cutting media/materialsSoldering mediaMachine partsWear resistant

The invention discloses a titanium carbide ceramic-enhanced visible arc self-shielded flux-cored wire for high-chromium cast iron, and the flux-cored wire provided by the invention comprises the following chemical components in percentage by weight (wt%): 60 to 70% of high-carbon ferrochrome, 1 to 2% of high-carbon ferromanganese, 1 to 3% of ferrosilicon, 1 to 3% of ferrovanadium, 1 to 3% of ferromolybdenum, 2 to 8% of TiC, 15 to 25% of graphite, and 1 to 2% of aluminum / magnesium powders; and the flux-cored wire has a low-carbon steel strip serving as an outer wrapper. The flux-cored wire is made by use of flux-cored wire production equipment which has a flux powder filling rate of 37%to 45%, and drawn by a wire drawing machine 2 to 5 times until the outside diameter of the flux-cored wire reaches the level F4. The flux-cored wire disclosed by the invention can be applied to overlay-welding under the conditions of no preheating before welding and no heat treatment after welding, and is very convenient in on-site use. By virtue of overlay-welding using the flux-cored wire disclosed by the invention, deposited metals have a high hardness up to HRC63-67 and better wear resistance andare not liable to stripping, and the service lives of large-sized high-chromium cast iron wear-resistant parts are 2 to 4 times those of integrally-machined parts.

Owner:YANSHAN UNIV

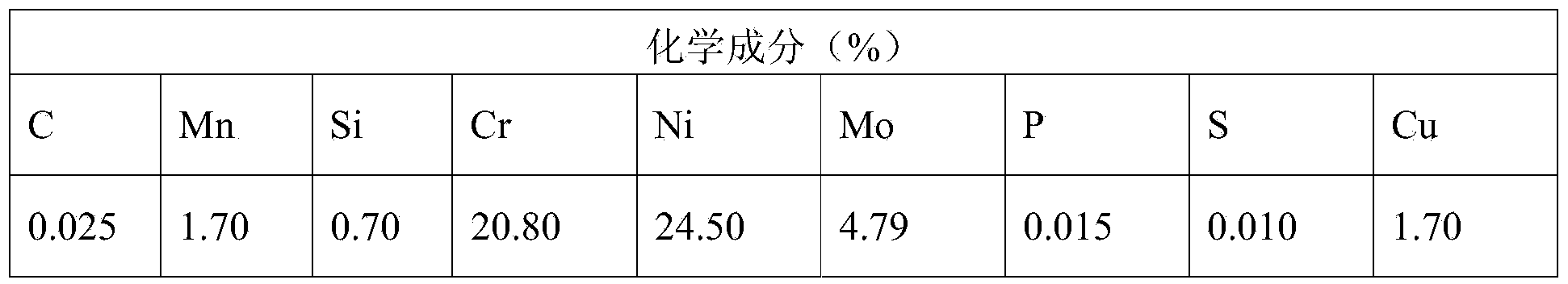

Superaustenitic stainless steel electrode

ActiveCN103921018AThe amount of addition is adaptableReduce lossWelding/cutting media/materialsSoldering mediaElectrolysisPhosphoric acid

The invention provides a superaustenitic stainless steel electrode. A coating of the superaustenitic stainless steel electrode at least comprises the following components, by mass, 35 to 45 percent of rutile, 2 to 5 percent of titanium dioxide, 6 to 12 percent of marble, 6 to 12 percent of dolomite, 1 to 3 percent of quartz, 3.5 to 6.5 percent of cryolite, 4 to 8 percent of dehydrated feldspar, 3 to 5 percent of dehydrated phlogopite, 6 to 8 percent of chromium metal, 6 to 8 percent of electrolytic manganese, 3 to 6 percent of ferrotitanium, 1 to 2 percent of chromium oxide green, 2 to 4 percent of nickel powder, 0.5 to 1.5 percent of ferromolybdenum and 0.5 to 1.5 percent of sodium alginate. The coating of the superaustenitic stainless steel electrode is formed by mixing all the components according to the proportions, potassium and sodium are added to be mixed with sodium silicate, and the coating coats a core wire H02Cr20Ni25Mo4Cu to form the electrode. Carbon content is extremely low, comprehensive corrosion of sulfuric acid and phosphoric acid can be resisted, the corrosion of acetic acid at any temperature and in any concentration under ordinary pressure can be resisted, and an ideal welding material is provided for steel for manufacturing various strong acid storing and transporting containers.

Owner:HUBEI CHUANWANG SPECIAL WELDING MATERIALS

Abrasive surface electrode of efficient high-hardness

InactiveCN101073861AImprove melting efficiencyImprove deposition efficiencyWelding/cutting media/materialsSoldering mediaHigh carbonBoron carbide

The invention is concerned with wear-resisting build up deposited electrode with high efficiency and high rigidity. It relates to Phi4 H08A cored wire, covering with Phi9 outer diameter. The compose of covering is 3 to 5 percent of silver-graphite, 2 to 6 percent of Boron carbide, 2 to 3 percent of carborundum, 3 to 5 percent of ferromolybdenum, 3 to 5 percent of ferrovanadium, 5 to 10 percent of tungsten carbide, 8 to 16 percent of high carbon ferrochrome, 2 to 3 percent of manganese and 72 percent of iron powder. It changes the existing covering structure by adding lots of iron powder, some kinds of alloy element without adding any ore powder. This method increases the melting efficiency and deposition efficiency with buildup deposited metal rigidity of HRC65 to 68 and certain obdurability and without knocking the sediment in the middle of the multi-pathway and multi-layer to continuous build up deposited welding. This is fit for carbon construct ional steel, the buildup deposited welding to low alloy steel and some middle, high alloy steels, and the wear-resisting situation to the abrasion of milling grain.

Owner:XIANGTAN UNIV

Alloy powder material for Fe-based nonmagnetic cladding layer and cladding layer preparing method

InactiveCN103042317AHigh hardnessImprove wear resistanceMolten spray coatingPlasma welding apparatusChromium carbideFerrosilicon

The invention discloses an alloy powder material for a Fe-based nonmagnetic cladding layer and a cladding layer preparing method, and belongs to the field of surface coating. The alloy powder comprises reduction ferrous powder, electrolytic manganese powder, high carbon ferro-chrome, ferro-molybdenum, ferrosilicon, ferro-boron, chromium carbide and boron carbide, and comprises following elementary compositions: 5-20wt% of Cr, 15-30wt% of Mo, 1-4wt% of C, 0.5-3wt% of B, 0.1-1.5wt% of Si, 0-15wt% of Mn, and the balance Fe. The Fe-based multi-element alloy cladding layer is prepared by plasma arc overlaying technology. The prepared cladding layer is nonmagnetic, high in hardness, and less prone to cracking and generating other cladding defects.

Owner:BEIJING UNIV OF TECH

Sintered flux for two phase stainless steel

InactiveCN102039498AWelding specifications are stableEasy to remove slagWelding/cutting media/materialsSoldering mediaSlag (welding)SS - Stainless steel

The invention discloses a sintered flux for two phase stainless steel. The sintered flux comprises the dry powder components by weight percent: 24-32% of MgO, 12-23% of CaF2, 12-18% of ZrO2, 10-15% of Al2O3, 9-14% of SiO2, 2-10% of CaO, 1-3% of rare earth fluoride, 0.5-2% of sodium fluosilicate, 0.5-2% of chromium oxide green, 0.5-2% of deoxidier, 2-8% of alloying agent, and the balance chromium metal, wherein the deoxidier is Si-Fe in which the content of Si is not less than 70%, and the alloying agent contains 1.5-2.5% of ferromolybdenum in which the content of molybdenum is not less than 50%. The sintered flux disclosed by the invention is matched with ER2209 solder wires, is suitable for the welding and overlaying of two phase stainless steel containing 22% of Cr; the welding is ruled and stable, the slag detachability is excellent, and the weld pass is even in width, moderate in pile height, smooth in transition; the defects of gas pits, intermediate crystallization lines, slag bonding and the like are overcome; and the flux has high content of deposited metal ferrite, excellent mechanical property and corrosion resisting property.

Owner:LUOYANG SHUANGRUI SPECIAL ALLOY MATERIALS

Double-phase stainless steel electric welding bar

InactiveCN101817123AHigh strengthGood formabilityWelding/cutting media/materialsSoldering mediaArc stabilityElectrolysis

The invention discloses a double-phase stainless steel electric welding bar, and relates to the stainless steel electric welding field of electric arc welding. The invention provides a novel titanium-calcium type double-phase stainless steel electric welding bar, which has good welding performance such as little splash, low cost, good slag removal performance and the like. The electric welding bar is characterized in that: according to the coating formula, the electric welding bar comprises the following components in part by weight: 35 to 38 parts of rutile, 8 to 10 parts of natural mica, 1 to 2 parts of potassium titanate, 5 to 7 parts of marble, 10 to 12 parts of iron powder, 1 to 2 parts of bentonite, 2 to 3 parts of electrolytic manganese, 3 to 5 parts of fluorite, 1 to 2 parts of potassium feldspar, 1 to 2 parts of sodium alginate, 2 to 3 parts of chromium nitride, 20 to 24 parts of chromium metal, 8 to 10 parts of ferromolybdenum, 2 to 4 parts of magnesite, 2 to 4 parts of nickel powder and 1 part of Teflon. The welding process performance of the stainless steel welding bar is improved, and particularly the application range of the stainless steel welding bar is enlarged during welding, so the double-phase stainless steel electric welding bar has good welding performance such as good electric arc stability, little splash, low cost, good slag removal performance and the like.

Owner:SHANGHAI ATLANTIC WELDING CONSUMABLES

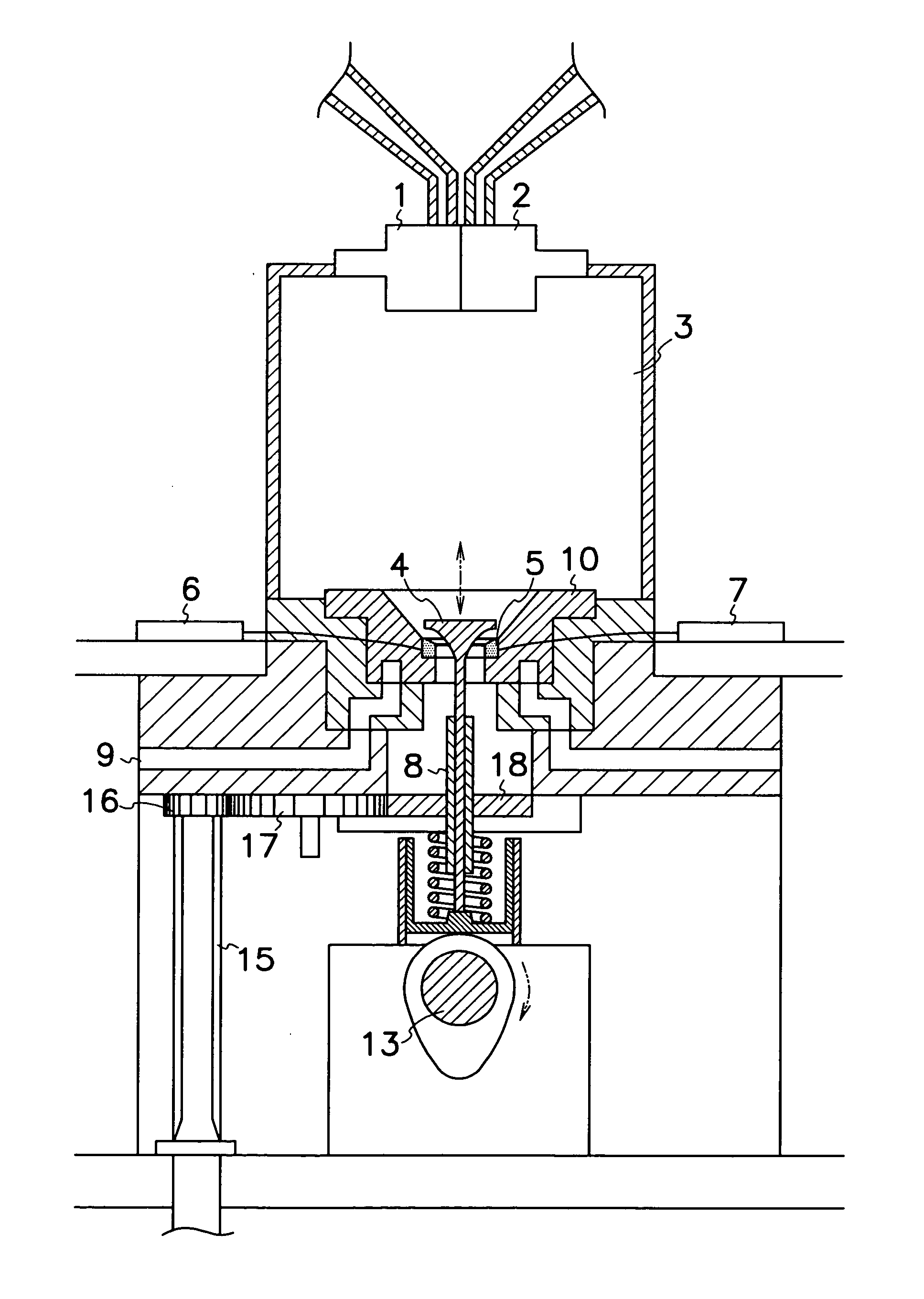

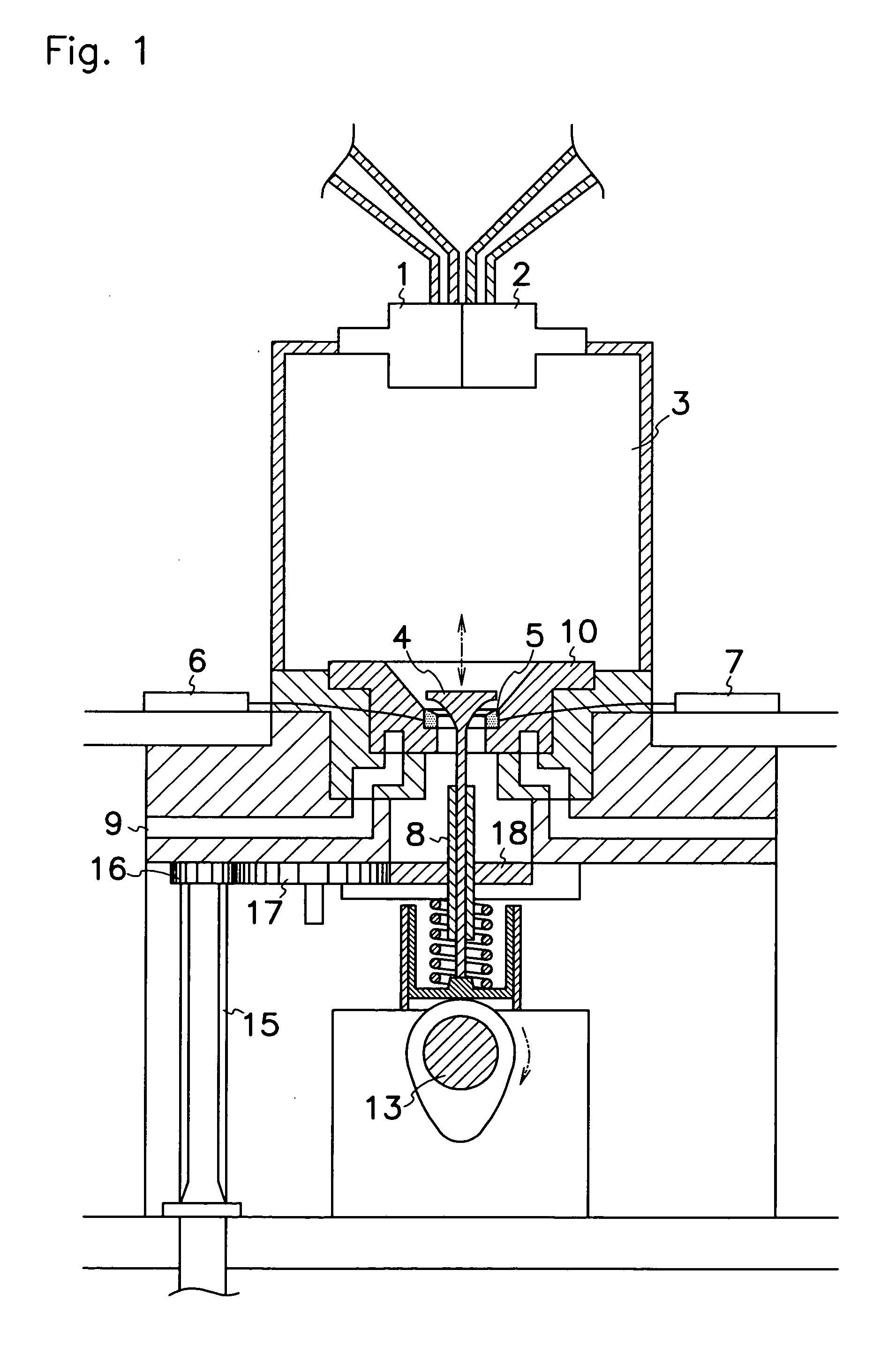

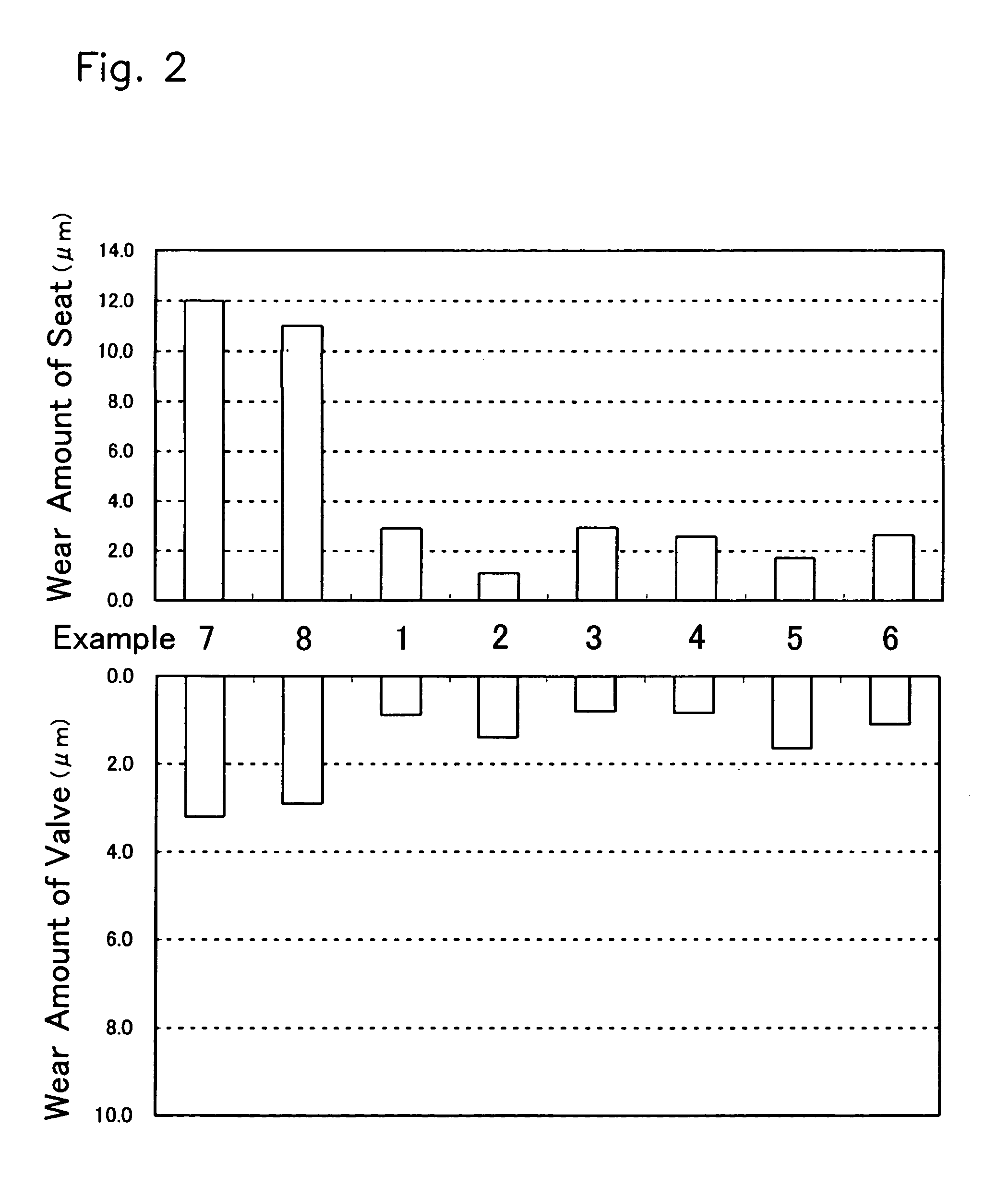

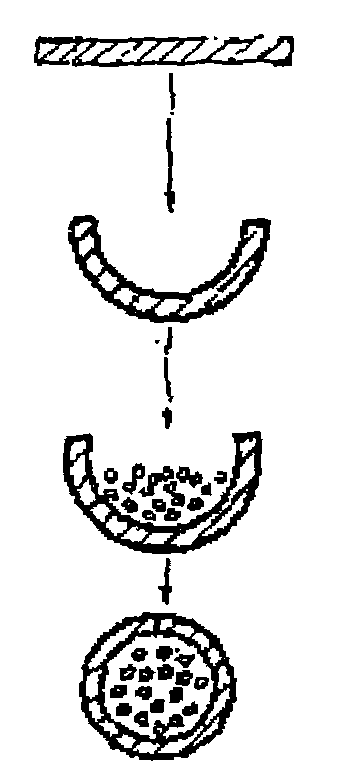

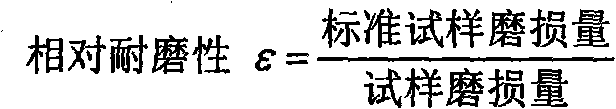

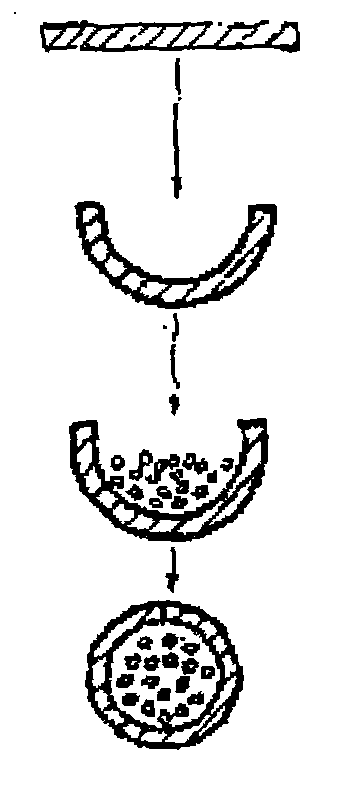

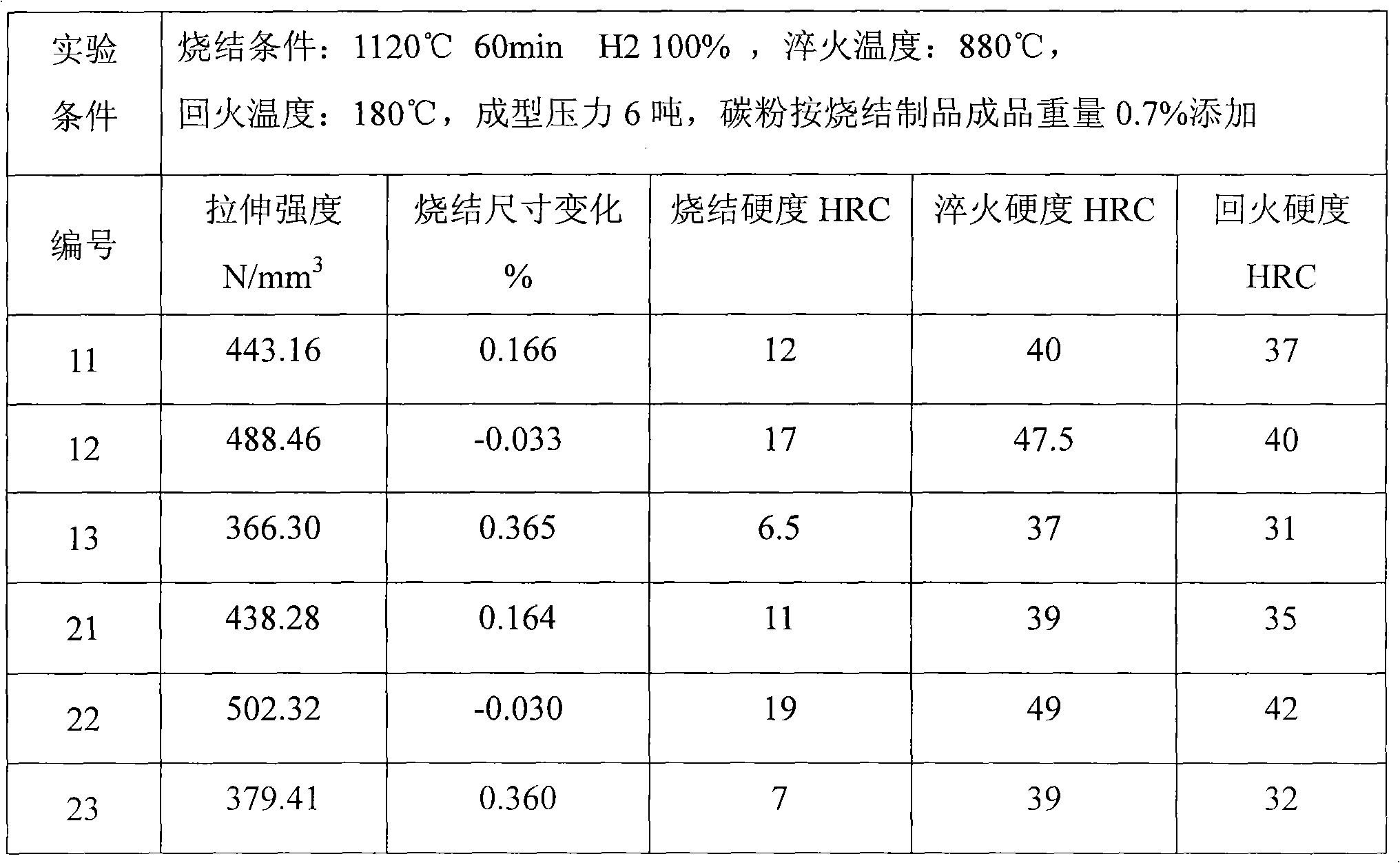

Iron-based sintered alloy with dispersed hard particles

An iron-based sintered alloy having improved thermal and mechanical strength is provided. The iron-based sintered alloy with dispersed hard particles comprises: a matrix comprising, by weight, 0.4 to 2% silicon (Si), 2 to 12% nickel (Ni), 3 to 12% molybdenum (Mo), 0.5 to 5% chromium (Cr), 0.6 to 4% vanadium (V), 0.1 to 3% niobium (Nb), 0.5 to 2% carbon (C), and the reminder of iron (Fe); and hard particles comprising 60 to 70% molybdenum (Mo), 0.3 to 1% boron (B), 0.1% or less carbon (C), and the reminder of iron (Fe). The hard particles are dispersed in the matrix in an amount in the range of 3 to 20% based on the entire alloy. They are sintered to produce the iron-based sintered alloy. Addition of boron into the ferromolybdenum hard particles enhances the wettability of the ferromolybdenum hard particles to prevent the hard particles from falling off the matrix. Thus, the adhesive property between the matrix and the hard particles is improved, thereby enhancing the thermal and mechanical strength of the iron-based sintered alloy.

Owner:RIKEN CO LTD

High-hardness self-protecting cold roll build-up welding flux-cored wire

The invention discloses a high-hardness self-protecting cold roll build-up welding flux-cored wire, and belongs to the field of welding in material processing. The flux-cored wire is mainly applied to build-up welding repair of cold rolls of steel mills. The flux-cored wire is characterized in that: the outer surface of the powder cored wire is an H08A cold rolling steel strip; and the powder of the powder cored wire comprises the following components in percentage by mass: 25 to 45 percent of high carbon ferrochrome, 5 to 15 percent of chromium metal, 4 to 8 percent of ferromolybdenum, 5 to 10 percent of manganese metal, 4 to 8 percent of No.75 silicon iron, 4 to 10 percent of aluminum magnesium alloy, 6 to 12 percent of ferrocolumbium, 4 to 10 percent of ferrotungsten, 4 to 12 percent of nickel powder and 4 to 18 percent of iron powder. A coating prepared by build-up welding has high hardness (Rockwell hardness (HRC): 55 to 60) and excellent abrasion resistance; and a self-protecting build-up welding mode is adopted, namely a protective gas source and a flux are not needed in the build-up welding process, and slag knocking is not needed in the build-up welding process, so automatic production is easy to realize.

Owner:BEIJING SURYEE SCI & TECH

Supercritical ferrite and heat-resistant steel matched electrode and production method thereof

ActiveCN103071946AReasonable tensile strengthReasonable shock valueWelding/cutting media/materialsSoldering mediaElectrolysisNiobium

The invention discloses a supercritical ferrite and heat-resistant steel matched electrode, which consists of a core wire and coating. The coating comprises the following components by mass percentage: 28-40 percent of marble, 18-28 percent of fluorite, 1.5-4 percent electrolytic manganese, 2-5 percent of ferrosilicon, 4-10 percent of silica powder, 20-26 percent of chromium metal, 1-1.8 percent of nickel powder, 4-5 percent of ferromolybdenum, 0.4-0.8 percent of ferrocolumbium, 0.2-0.6 percent of amorphous graphite, 3-8 percent of ferrotitanium, 0.4-0.8 percent of soda ash, 0.4-0.8 percent of CMC, 1-1.8 percent of ferrovanadium and 0.6-1.5 percent of ferrochrome nitride. The matched electrode provided by the invention is used for welding supercritical steam turbine ZG1Cr10MoVNbN steel with T91 / P91 pipe heat-resistant steel. Welds after welding have excellent performances such as higher strength, high toughness and better 100-thousand-hour endurance strength similar to the performance of bodies.

Owner:ATLANTIC CHINA WELDING CONSUMABLES

Flux-cored wire for nickel base alloy

The invention relates to a flux-cored wire for nickel base alloy. The flux-cored wire comprises a nickel base alloy steel band and flux core powder, wherein the inside of the nickel base alloy steel band is filled and packaged with the flux core powder in a filling rate of 18%-22%; and the flux core powder comprises the following components in percentage by weight: 9%-13% of metal chromium powder, 33%-36% of metal nickel powder, 1%-2.5% of metal manganese powder, 16%-20% of rutile, 1%-3% of ferrosilicon, 0.5%-2% of ferrotitanium, 3%-6% of feldspar, 3%-5% of quartz, 1%-2.5% of rare earth fluoride, 1%-3% of cryolite, 5%-7% of ferrocolumbium, 6%-8% of ferromolybdenum, 1%-3% of calcium fluoride and the balance of iron powder. The flux-cored wire has excellent performance.

Owner:BEIJING JINWEI WELDING MATERIAL +1

Self-shielded flux-cored wire for extrusion roller remanufacturing

InactiveCN104959746AImprove bindingImprove toughnessWelding/cutting media/materialsSoldering mediaFerrosiliconManganese

The invention discloses a self-shielded flux-cored wire for extrusion roller remanufacturing. A mild-carbon steel strip is employed as the skin of the self-shielded flux-cored wire. The component of the flux comprises, by mass, 20%-40% of high carbon ferrochrome, 20%-40% of chromium carbide, 5%-20% of ferromolybdenum, 1%-10% of ferrovanadium, 1%-5% of ferroniobium, 1%-5% of graphite, 1%-5% of aluminum-magnesium, 1%-4% of electrolytic manganese, 1%-4% of ferrosilicon and 1%-4% of ferroboron, and the weight ratio is 44%-52%. The hardness of the surfacing alloy manufactured by the use of the self-shielded flux-cored wire can reach HRC60, and the surfacing alloy is fine and uniform in crack, is high in wear resistance, is high in shock resistance, and is suitable for being employed as a working layer in an extrusion roller remanufacturing process in a cement plant.

Owner:盐城市成功机械制造有限公司

High-chromium-manganese austenitic steel alkalescent full-position gas-protection flux-cored wire

InactiveCN101428376AImprove ductilityReduce splashWelding/cutting media/materialsSoldering mediaSlagFerrosilicon

The invention discloses a high chromium and manganese type austenite steel alkali full-position gas shielded flux-cored wire, which comprises a 0Cr17 stainless steel band sheath and flux cored, wherein, the flux cored is prepared by mixing the following components by the weight percentages: 4-10 percent of rutile, 1-5 percent of feldspar, 0.5-2 percent of sodium carbonate, 8-15 percent of fluorspar, 0.5-1.5 percent of sodium fluosilicate, 40-68 percent of manganese powder or low carbon ferromanganese, 1.5-20 percent of chromium powder, 0-15 percent of nickel powder, 2-4 percent of graphite, 0-15 percent of molybdenum powder or ferromolybdenum, 0.5-4.5 percent of ferrosilicon and iron powder in balancing amount. The invention has the advantages that the ductility of the welding wire is good, the diameter is small, the small-scale welding can be conducted, the impurity content is low, and the hot cracking resistance is good; meanwhile, the splashing degree of the welding wire is low, the welding mold is good, the slag detachability is good, the excellent processing property such as the full-position welding can be conducted, and the production efficiency of the welding is high.

Owner:TIANJIN SAINTEAGLE WELDING CO LTD

High-alloy martensite type refractory steel air-protecting flux-cored wire

InactiveCN101041215ASimple welding processImprove mechanical propertiesArc welding apparatusWelding/cutting media/materialsManganeseMaterials processing

The invention relates to a gas shield flux-cored wire of high alloy martensite heat-resistant steel, belonging to the welding field in material processing project. The outer skin of wire adopts low carbon steel belt. It is characterized in that components of flux-core are 29-41% of chromium powder by wt, 4.5-7% of ferrotungsten by wt, 2.5-8% of manganese, 1-2.5% of ferromolybdenum by wt, 0.75-2% of nickel powder by wt, 0.75-1.25% of ferrovanadium by wt, 20-35% of TiO2 by wt, 4-10% of quartz by wt, 1-3% of MnO2 by wt, 1-3% of Al2O3 by wt, 1-3% of Al-Mg alloy by wt and 1.5-6.25% of iron powder by wt. when the flux-cored wire is used in welding the wire line metal not only has higher intensity and impact toughness but also excellent welding process performance and all-position welding adaptability.

Owner:北京金太阳药芯焊丝有限公司

Gas shield build-up welding flux-cored wire for hot-forging die

ActiveCN104588915AExtended service lifeHigh hardnessWelding/cutting media/materialsSoldering mediaManganeseFerrosilicon

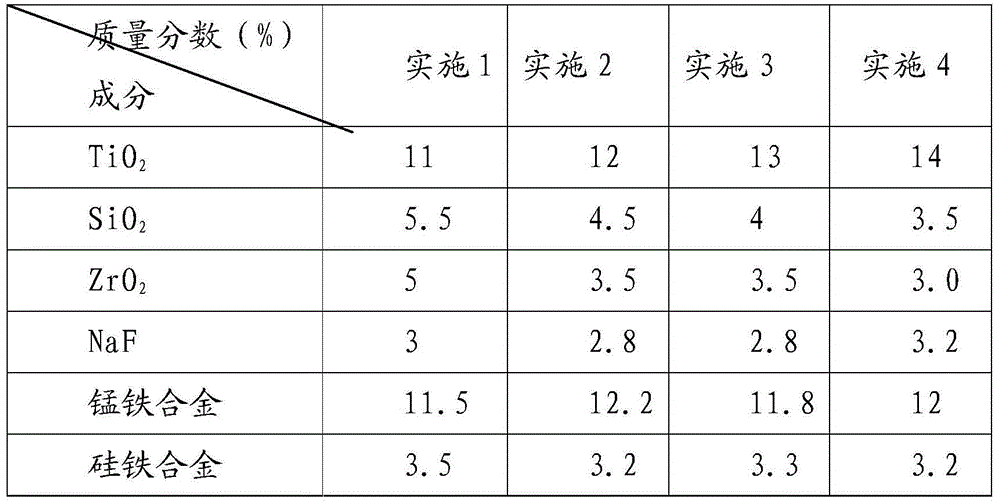

The invention discloses a gas shield build-up welding flux-cored wire for a hot-forging die. The gas shield build-up welding flux-cored wire comprises a steel strip welding wire skin and a flux core, wherein the steel strip welding wire skin comprises, by mass, 0.01-0.04% of C, 0.19-0.26% of Mn, not greater than 0.03% of Si, not greater than 0.010% of S, not greater than 0.015% of P, 0.010-0.045% of Als, not greater than 0.003% of Ca, not greater than 0.005% of N and the balance being Fe and unavoidable impurities; flux core powder comprises, by mass, 10-20% of TiO2, 2-7% of SiO2, 2-7% of ZrO2, 2-6% of NaF, 8-15% of ferromanganese, 2-6% of ferrosilicon, 4-8% of metallic nickel, 8-14% of metallic chromium, 10-16% of ferrochrome, 8-15% of ferro-molybdenum, 8-13% of metallic tungsten, 1-4% of ferrovanadium, 2-7% of metallic cobalt and the balance being iron powder. The gas shield build-up welding flux-cored wire can meet the requirement of the hot-forging die for build-up welding and also has a good welding processing property. Weld metal has high hardness and relatively good toughness.

Owner:天津大桥金属焊丝有限公司

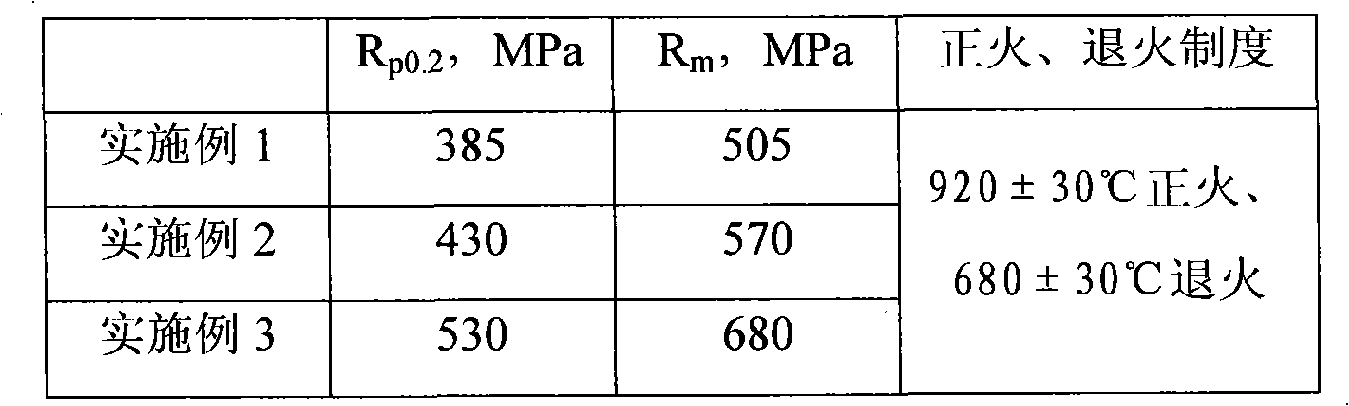

Normalization anneal treatment resistant heat-resistant steel wire solder and use method thereof

InactiveCN101342650AReduce consumption costReduce manufacturing costWelding/cutting media/materialsSoldering mediaHigh carbonFerrosilicon

The invention provides a normalized and annealed treatment resistant refractory steel electrode, comprising 40-60 portions of marble, 18-2. portions of fluorite, 5-7 portions of quartz, 11-13 portions of ferrotitanium, 3-7 portions of ferrosilicon, 1.5-3 portions of medium carbon ferromanganese, 2.5-3.5 portions of ferromolybdenum, 4.5-7.5 portions of high carbon ferrochrome and 0.5-1.5 portions of soda, and after being mixed uniformly, 16-23 portions of sodium silicate is added. The butt core H08A is extruded and formed into semi-finished product through an oil press typed electrode extruder, and the finished product is made after being dried with low temperature of 80 DEG C and high temperature of 400 DEG C. Before welding, the electrode should be dried for one hour under the temperature of 350-400 DEG C. The direct current is directly connected reversely while welding with the current of 150-180A, arc voltage of 22-28V, welding speed of 100-200mm / min and interpass temperature of 160-220 DEG C. The welding seam after being processed with heat treatment has excellent high temperature usability, which can satisfy the requirements that Rp0.2 is equal to or more than 275 MPa and Rm is equal to 450-685 MPa.

Owner:725TH RES INST OF CHINA SHIPBUILDING INDAL CORP

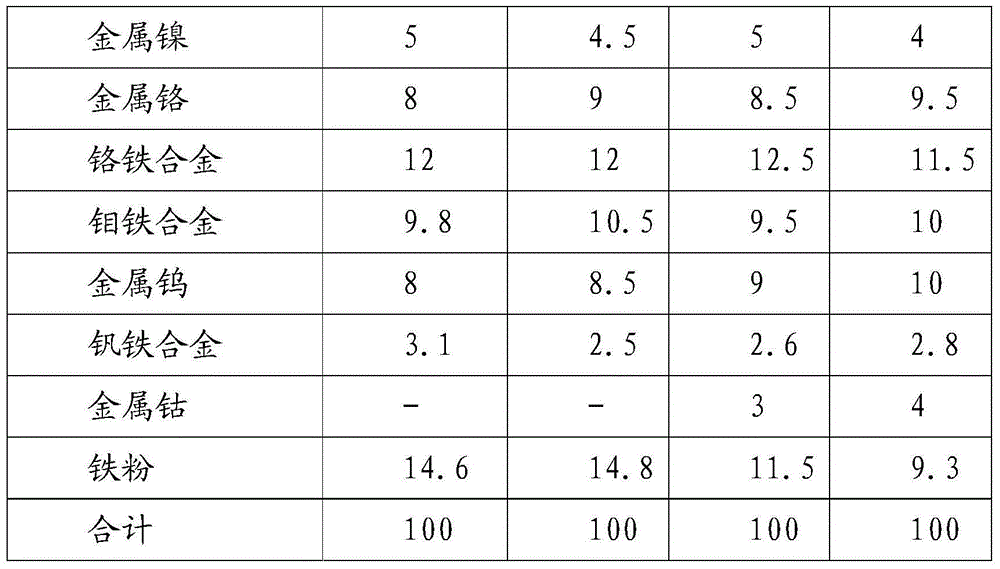

Water atomization diffusion alloy powder and preparation method thereof

ActiveCN102101174AHomogeneous microstructureImprove mechanical propertiesChemical compositionSmelting process

The invention belongs to the field of powder metallurgy, and more particularly relates to a preparation method of water atomization diffusion alloy powder, which is characterized in that ferro-molybdenum is firstly added in the smelting process, and water atomization pre-alloyed powder can be prepared; and nickel powder and copper powder are mixed into the water atomization pre-alloyed powder for diffusion treatment. The preparation method has the operation steps of: 1) adding the ferro-molybdenum after smelting; 2) carrying out water atomization; 3) reducing; and 4) adding nickel powder and copper powder and diffusing by a reduction furnace. The prepared water atomization diffusion alloy powder comprises the chemical composition by weight percent: 0.001-0.2% of C, 0-0.5% of Si, 0-0.5% of Mn, 0-0.05% of P, 0-0.050% of S, 0.1-5.0% of Ni, 0.1-3% of Mo, 0.1-5.0% of Cu and the balance of Fe. The invention has the beneficial effects that alloying elements can be further completely alloyed in the diffusion process; and composition segregation of the alloying elements can not be caused in the processes of transportation and mixing treatment.

Owner:ANGANG (ANSHAN) METALLURGY POWDER MATERIAL CO LTD

High wear resistance surfacing alloy material containing multiphase metal ceramics

ActiveCN101879670AImprove performanceInhibit growthWelding/cutting media/materialsSoldering mediaHigh carbonRare earth

The invention relates to a high wear resistance surfacing alloy material containing multiphase metal ceramics and belongs to the technical field of the material. The high wear resistance surfacing alloy material comprises the following ingredients in percentage by weight: 25 to 50 percent of ferrochrome, 1 to 10 percent of ferrotitanium, 1 to 10 percent of ferrovanadium, 0.1 to 5 percent of rare earth material, 1 to 7 percent of ferroboron, 0.4 to 8 percent of ferromolybdenum, 0.5 to 5 percent of aluminium powder, 0.4 to 7 percent of ferronickel, 0.1 to 10 percent of powder material, 8 to 15 percent of sodium potassium silicate, 0.1 to 5 percent of carbon black and the balance of ferrum, wherein the granularity is between 70 and 140 meshes. When the high wear resistance surfacing alloy material containing the multiphase metal ceramics of the invention is adopted to carry out carbon arc surfacing or plasma surfacing, the operation method is simple and the cost is low. Compared with a manual wear-resistance surfacing electrode, the high wear resistance surfacing alloy material is easy to obtain a surfacing layer with high carbon content, high hardness and high wear resistance and has the advantages of firm combination of hard phases and a matrix, high performance of resisting abrasive wear and wide application range.

Owner:LIAONING TECHNICAL UNIVERSITY +1

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com