Preparation method of wear-resistant high-chromium cast iron

A technology of high chromium cast iron and ferrochrome, which is applied in the field of preparation of wear-resistant cast high chromium cast iron and high chromium cast iron by suspension casting and flow inoculation treatment, which can solve the problems of high brittleness, large amount of precious alloy elements added, and high production cost , to achieve the effect of promoting toughness, fine solidification structure and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

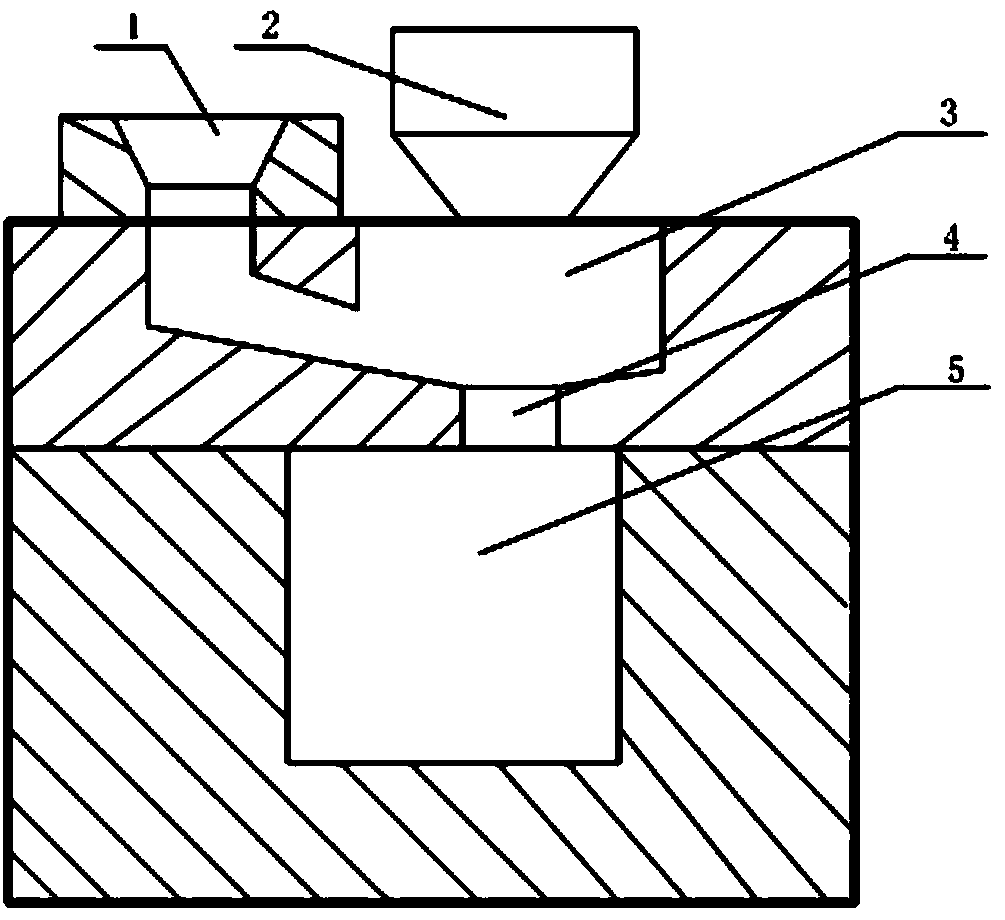

Image

Examples

Embodiment 1

[0019] The wear-resisting casting high chromium cast iron of the present invention is smelted with 250 kilograms of medium-frequency induction furnaces, and its manufacturing process steps are:

[0020] (1) Crushing ferroalloys with mass fractions of 2.53%C, 0.48%Bi, 0.81%B, 0.65%Mn, 1.51%Si, 0.039%P, 0.033%S, and the balance of Fe into ferroalloys with a particle size of 0.5-1.0mm Pills, the mass fraction is 2.01%C, 3.12%Ca, 4.85%Ba, 2.62%Ti, 12.07%Si, 0.51%Mn, 0.036%P, 0.021%S, and the intermediate iron alloy with Fe balance is crushed to a particle size of 2~ Small pieces of 5 mm, ferroalloy shot and intermediate ferroalloy were dried at 200°C for 4 hours, and then used for suspension casting and inoculation treatment respectively.

[0021] (2) Use ordinary steel scrap, recarburizer, ferrochrome, ferromolybdenum, copper plate, ferrochromium nitride, ferrosilicon, ferromanganese, ferroboron and aluminum to melt wear-resistant high-chromium cast iron in an electric furnace, a...

Embodiment 2

[0026] The wear-resisting casting high chromium cast iron of the present invention is smelted with 250 kilograms of medium-frequency induction furnaces, and its manufacturing process steps are:

[0027] (1) Crush ferroalloys with mass fractions of 2.99%C, 0.33%Bi, 0.98%B, 0.97%Mn, 2.90%Si, 0.036%P, 0.038%S, and the balance of Fe to ferroalloys with a particle size of 0.5-1.0mm Pills, the mass fraction is 2.48%C, 4.92%Ca, 3.01%Ba, 4.80%Ti, 14.99%Si, 0.98%Mn, 0.033%P, 0.017%S, and the intermediate iron alloy with Fe balance is crushed to a particle size of 2~ Small pieces of 5 mm, ferroalloy shot and intermediate ferroalloy were dried at 250°C for 3 hours, and then used for suspension casting and inoculation treatment respectively.

[0028] (2) Use ordinary steel scrap, recarburizer, ferrochrome, ferromolybdenum, copper plate, ferrochromium nitride, ferrosilicon, ferromanganese, ferroboron and aluminum to melt wear-resistant high-chromium cast iron in an electric furnace, and we...

Embodiment 3

[0032] The wear-resisting casting high chromium cast iron of the present invention is smelted with 250 kilograms of medium-frequency induction furnaces, and its manufacturing process steps are:

[0033] (1) Broken ferroalloys with mass fractions of 2.82%C, 0.43%Bi, 0.91%B, 0.73%Mn, 2.36%Si, 0.041%P, 0.035%S, and the balance of Fe to ferroalloys with a particle size of 0.5-1.0mm Pills, the mass fraction is 2.33%C, 4.14%Ca, 3.78%Ba, 3.95%Ti, 14.02%Si, 0.83%Mn, 0.038%P, 0.022%S, and the intermediate iron alloy with Fe balance is crushed to a particle size of 2~ Small pieces of 5 mm, ferroalloy pellets and intermediate ferroalloy were dried at 230°C for 4 hours, and then used for suspension casting and inoculation treatment, respectively.

[0034] (2) Use ordinary steel scrap, recarburizer, ferrochrome, ferromolybdenum, copper plate, ferrochromium nitride, ferrosilicon, ferromanganese, ferroboron and aluminum to melt wear-resistant high-chromium cast iron in an electric furnace, a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

| Macro hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com