Gas shield build-up welding flux-cored wire for hot-forging die

A technology of gas shielding and hot forging dies, which is applied to welding media, manufacturing tools, welding equipment, etc., can solve the problems of general welding process performance and short service life, and achieve good toughness, improved service life and low cost of use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-4

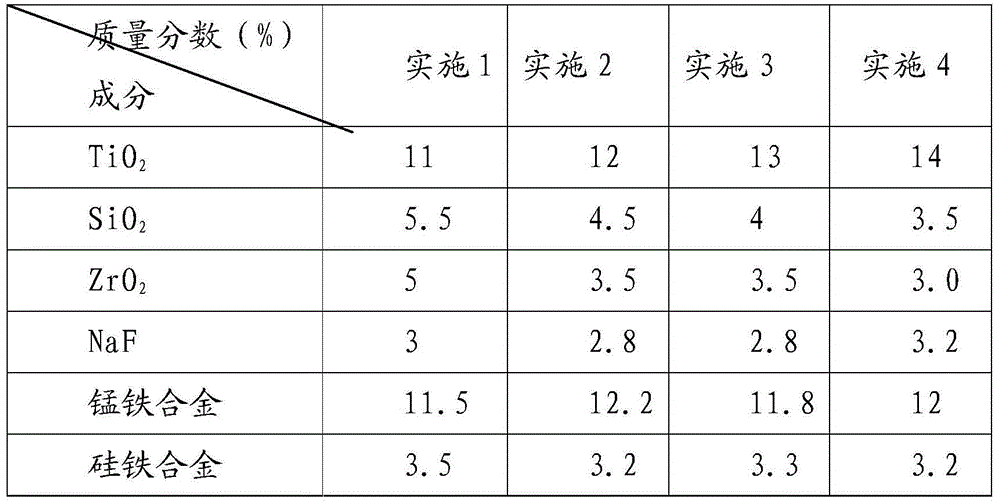

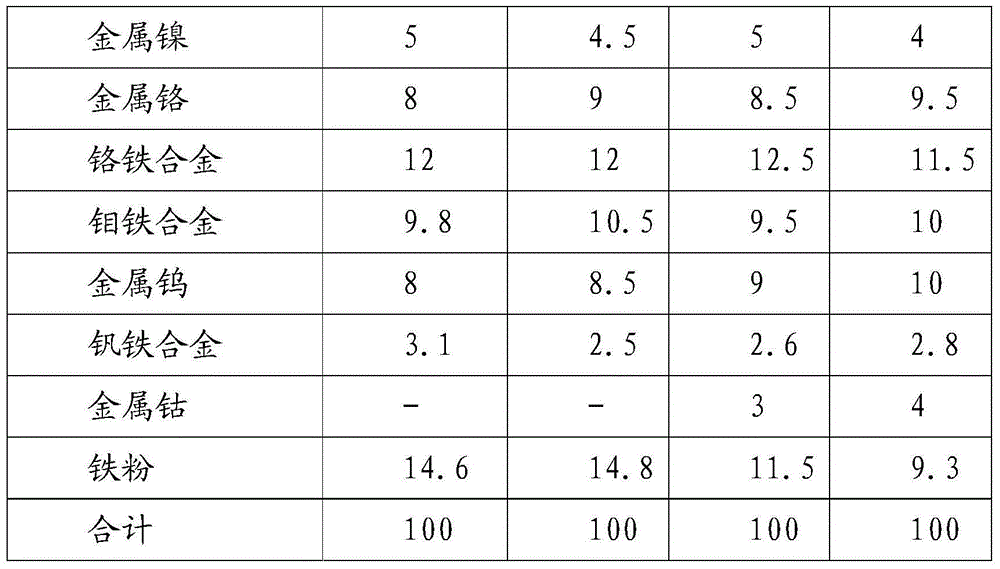

[0027] Embodiment 1-4 prepares welding wire of the present invention:

[0028] Prepare the medicinal powder according to the ratio in Table 1, and bake the medicinal powder; mix and stir the baked medicinal powder; select the steel strip with the above ingredients, and cut the steel strip to a suitable size; send the medicinal powder and steel strip to The forming machine is used for rolling production; according to the requirements, the rolled semi-finished product is drawn to the required size; the finished welding wire is vacuum packaged.

[0029] The mass fraction of the prepared welding wire powder is shown in the following table:

[0030] Table 1

[0031]

[0032]

experiment example 1

[0033] Experimental Examples 1-4 The hardness and service life tests of the flux-cored wires prepared in Examples 1-4 are shown in Table 2.

[0034] Table 2

[0035] project

[0036] The service life of the test mold on the thermal friction press has increased from the previous 1000-1300 pieces to 1600-2460 pieces, especially with the addition of cobalt, the service life has been significantly improved.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com