Patents

Literature

908 results about "Remanufacturing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Remanufacturing is "the rebuilding of a product to specifications of the original manufactured product using a combination of reused, repaired and new parts". It requires the repair or replacement of worn out or obsolete components and modules. Parts subject to degradation affecting the performance or the expected life of the whole are replaced. Remanufacturing is a form of a product recovery process that differs from other recovery processes in its completeness: a remanufactured machine should match the same customer expectation as new machines.

Chemical vapor deposition apparatus capable of controlling discharging fluid flow path in reaction chamber

InactiveUS8876974B2Reduce widthSemiconductor/solid-state device manufacturingChemical vapor deposition coatingSusceptorGas phase

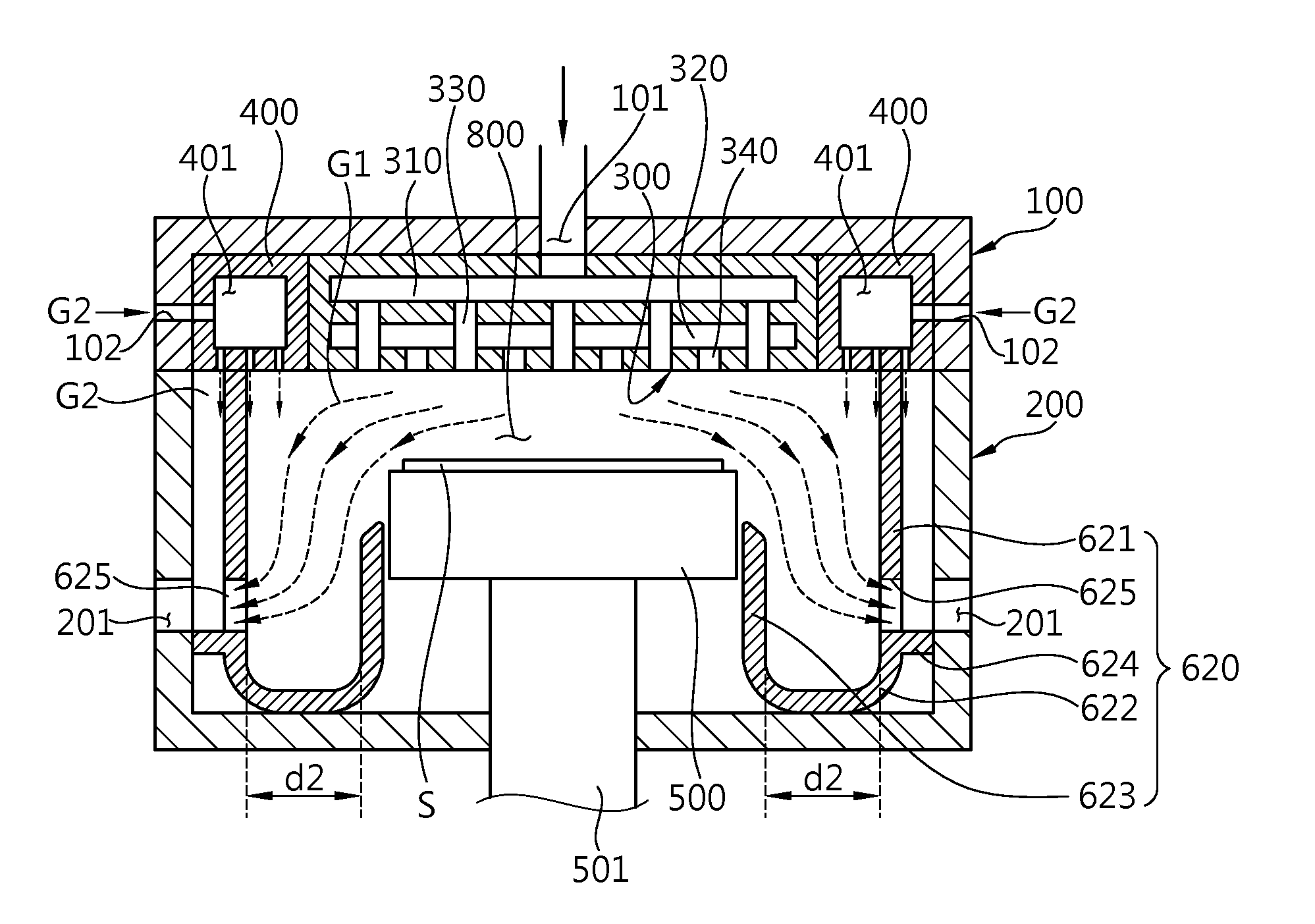

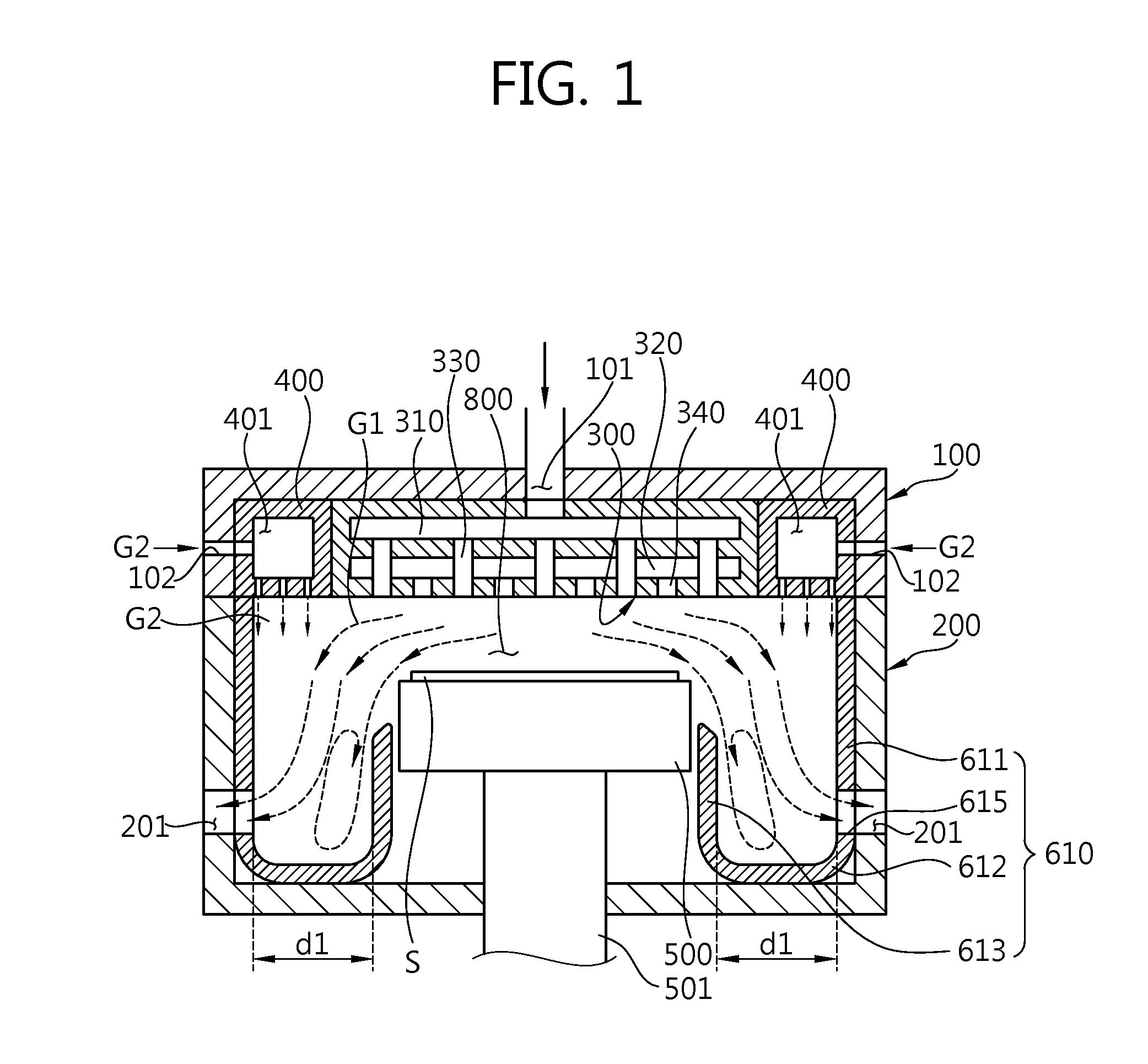

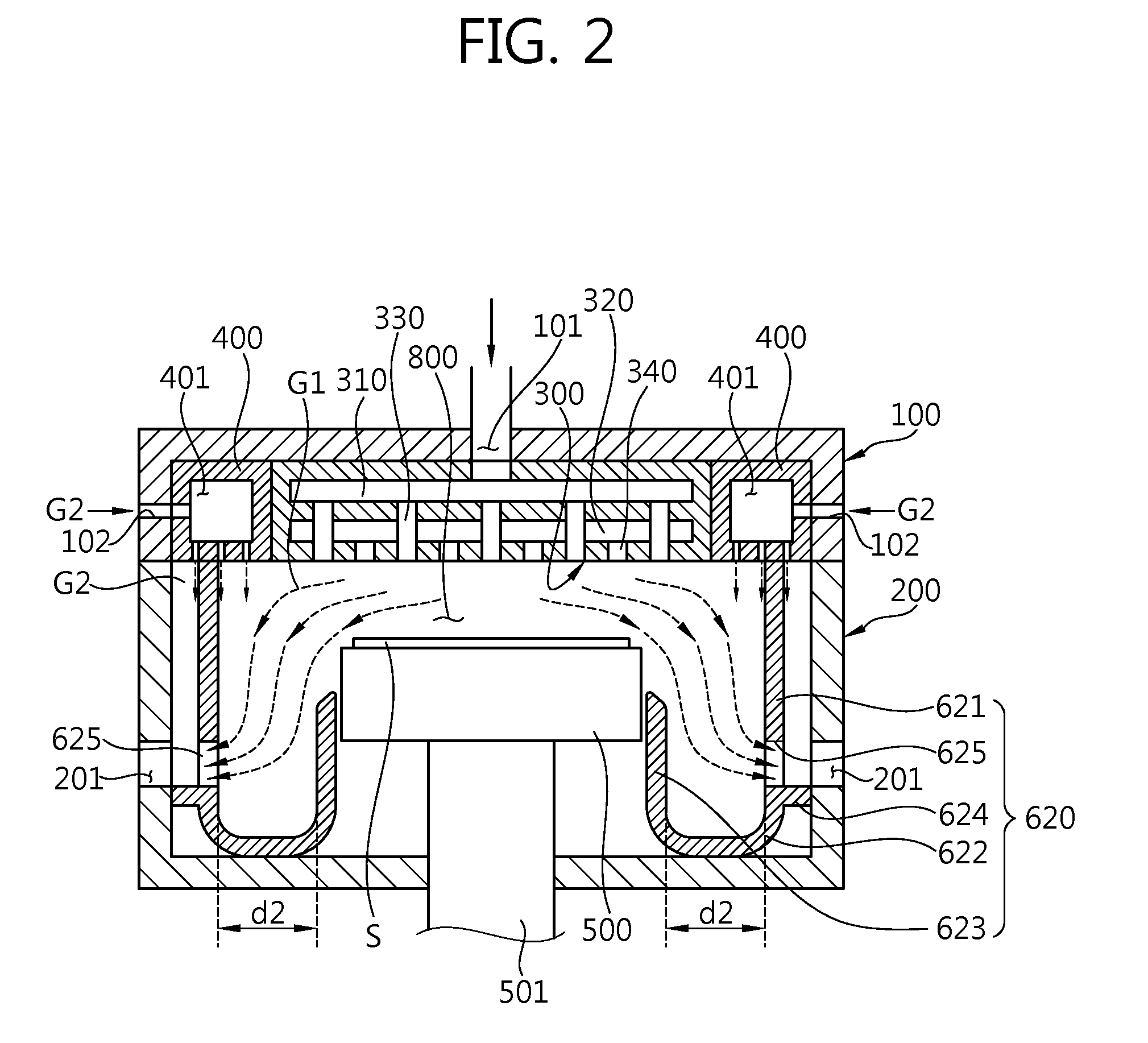

A chemical vapor deposition apparatus is equipped to control the width of a gas discharge path between a susceptor and an inner surface of a chamber without having to resort to redesign and remanufacturing of the apparatus. The chemical vapor deposition apparatus includes: a chamber; a susceptor positioned inside the chamber and on which a substrate can be loaded; a shower head injecting a processing gas toward the substrate; and a guide unit detachably installed inside the chamber to guide the processing gas such that the processing gas injected from the shower head is discharged through a chamber hole formed in the chamber.

Owner:LIGADP

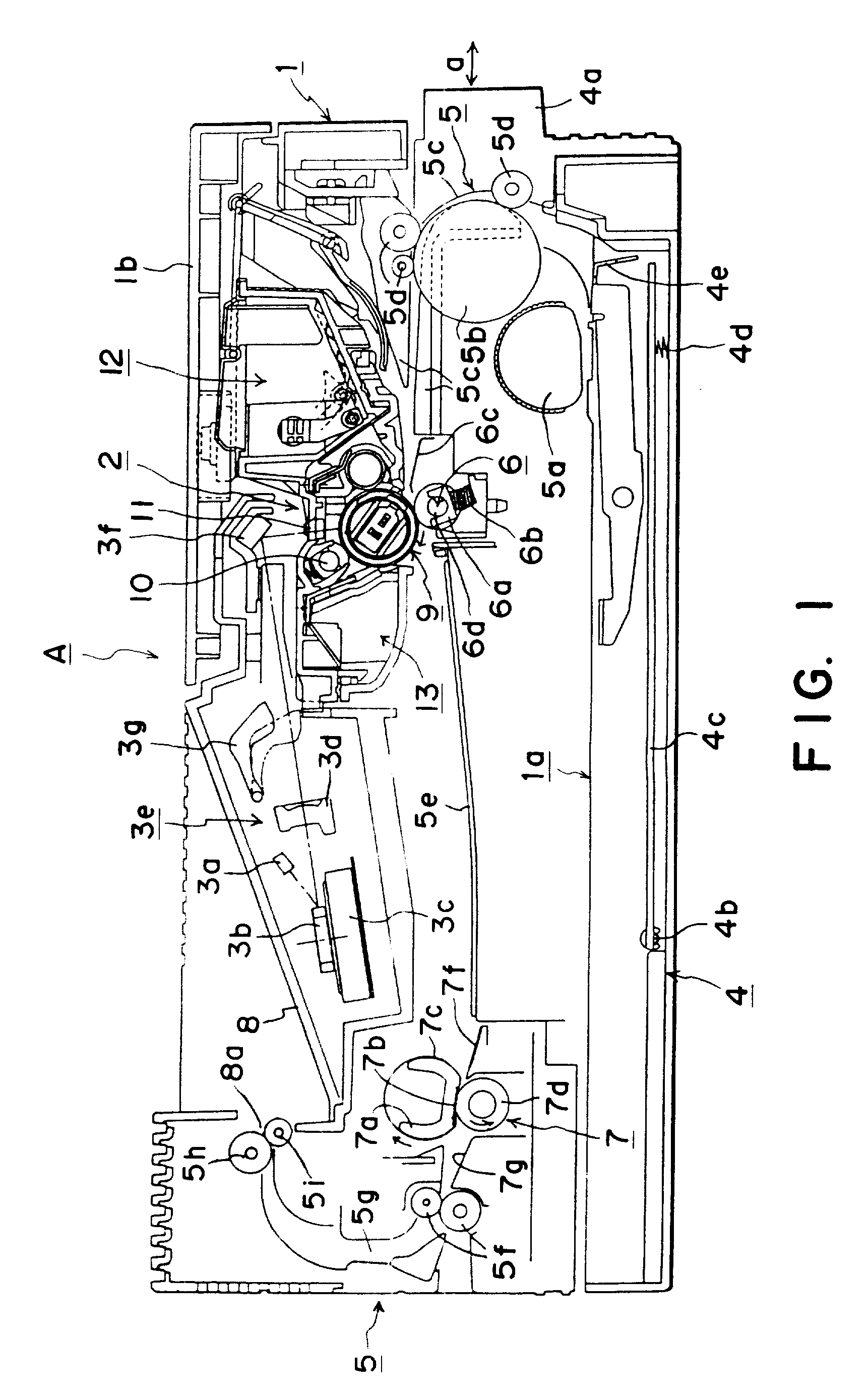

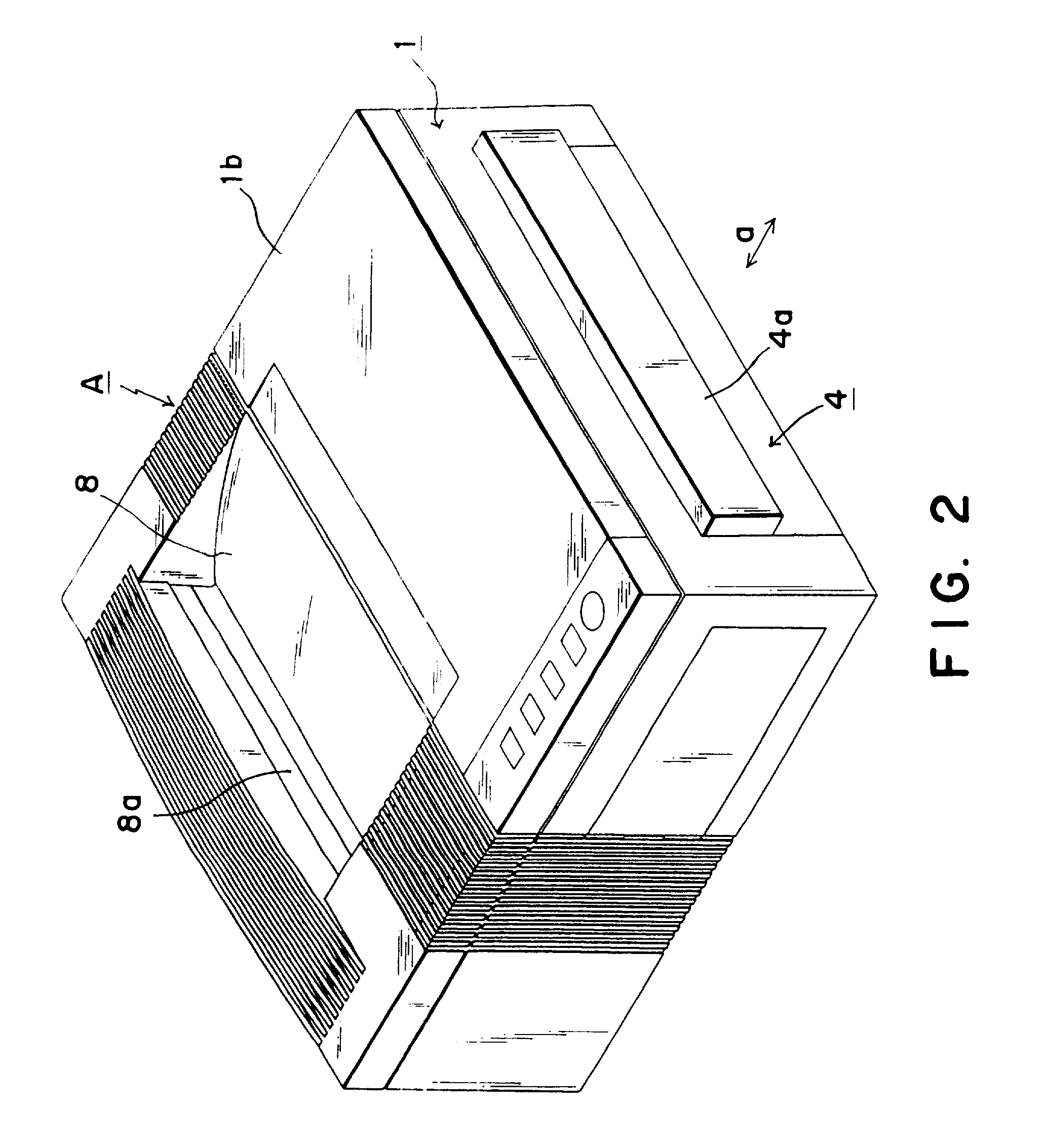

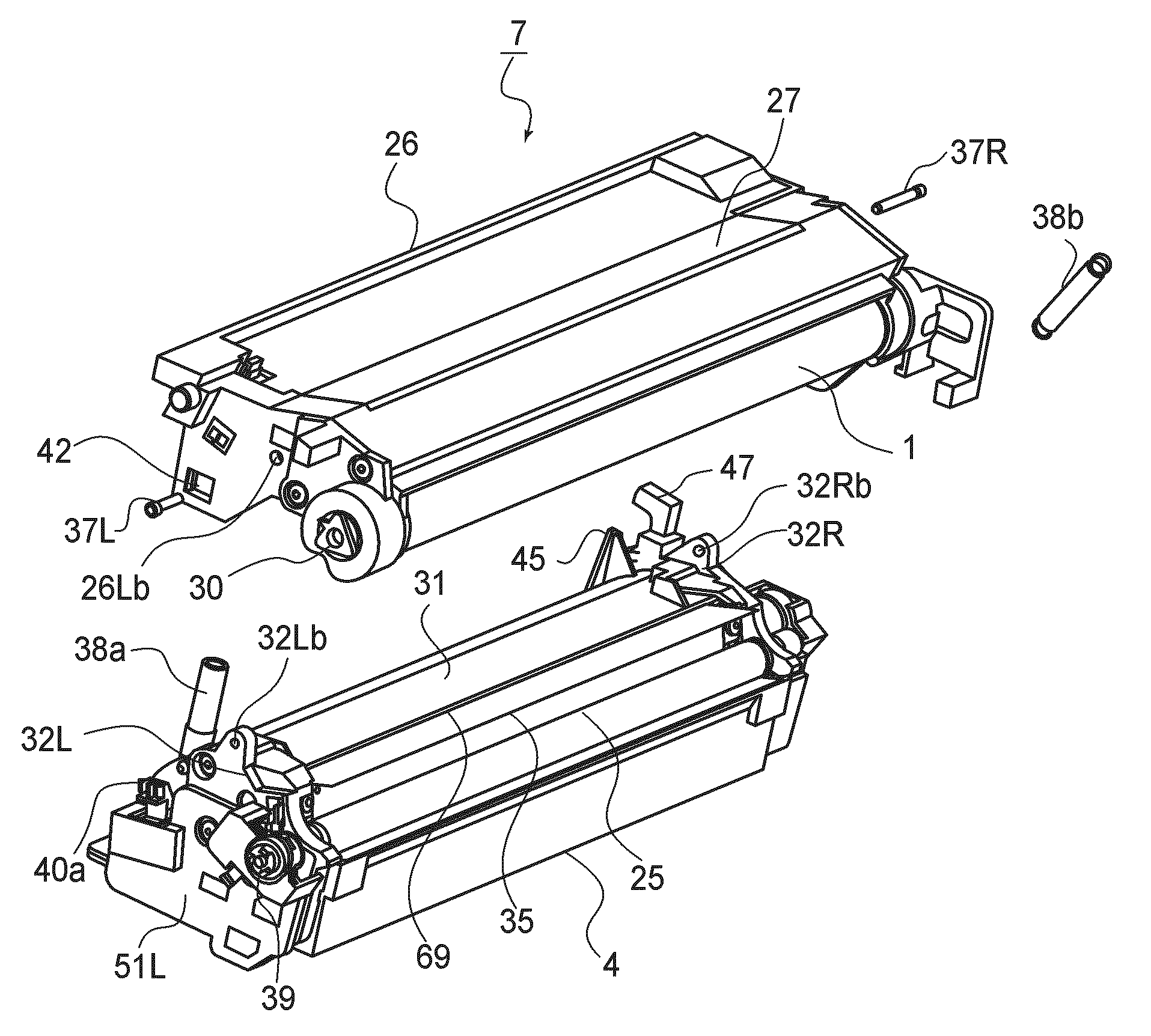

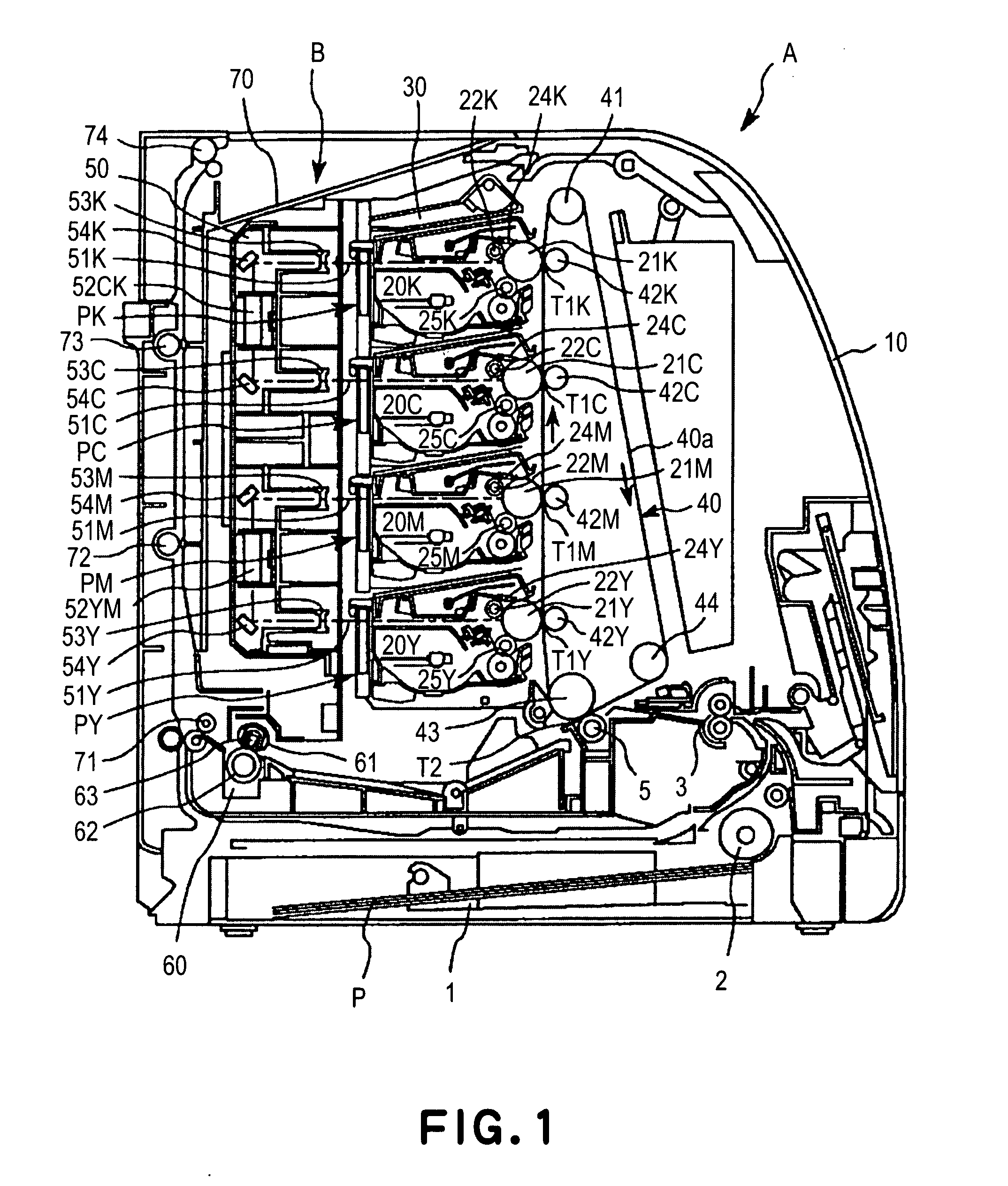

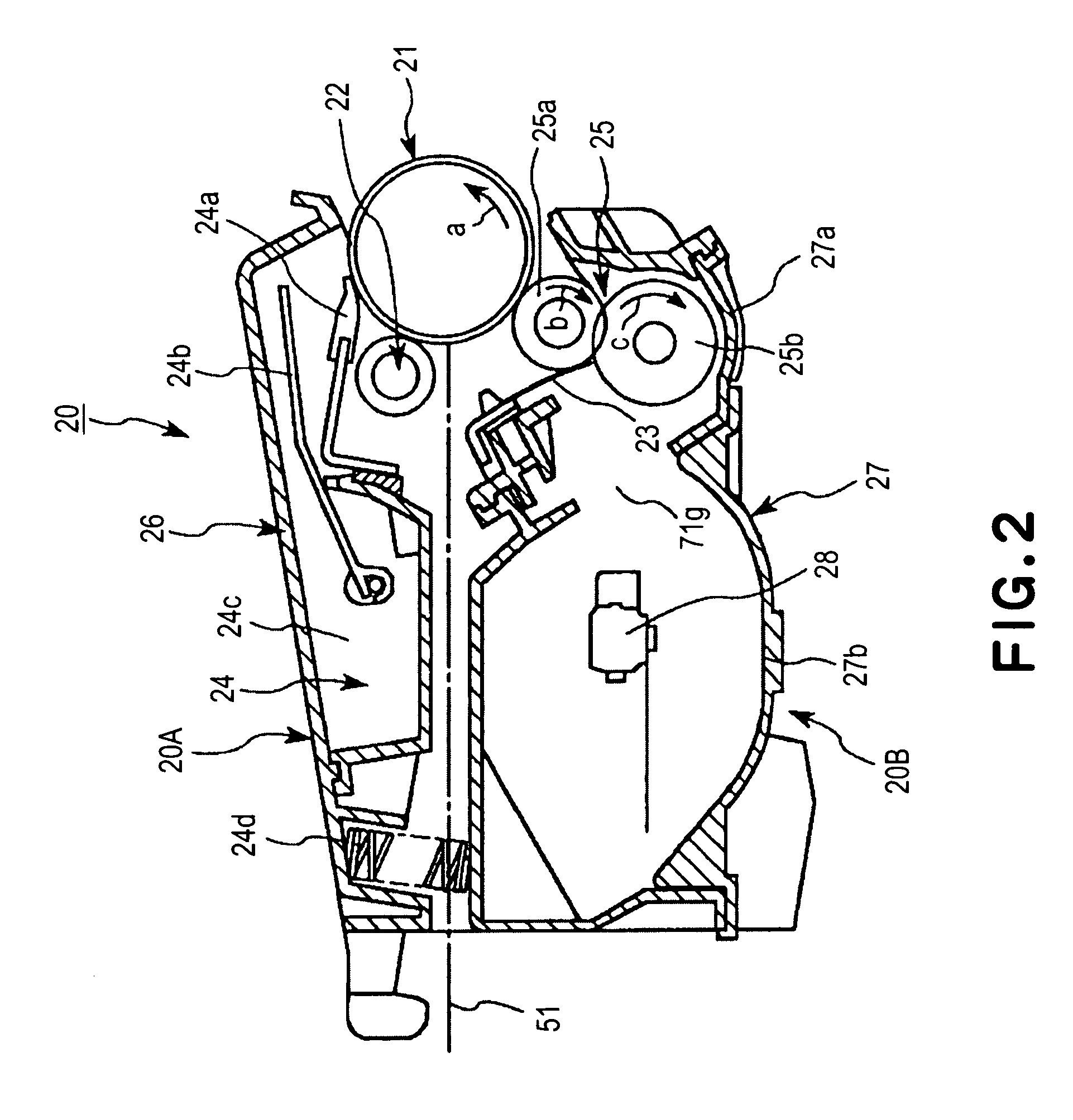

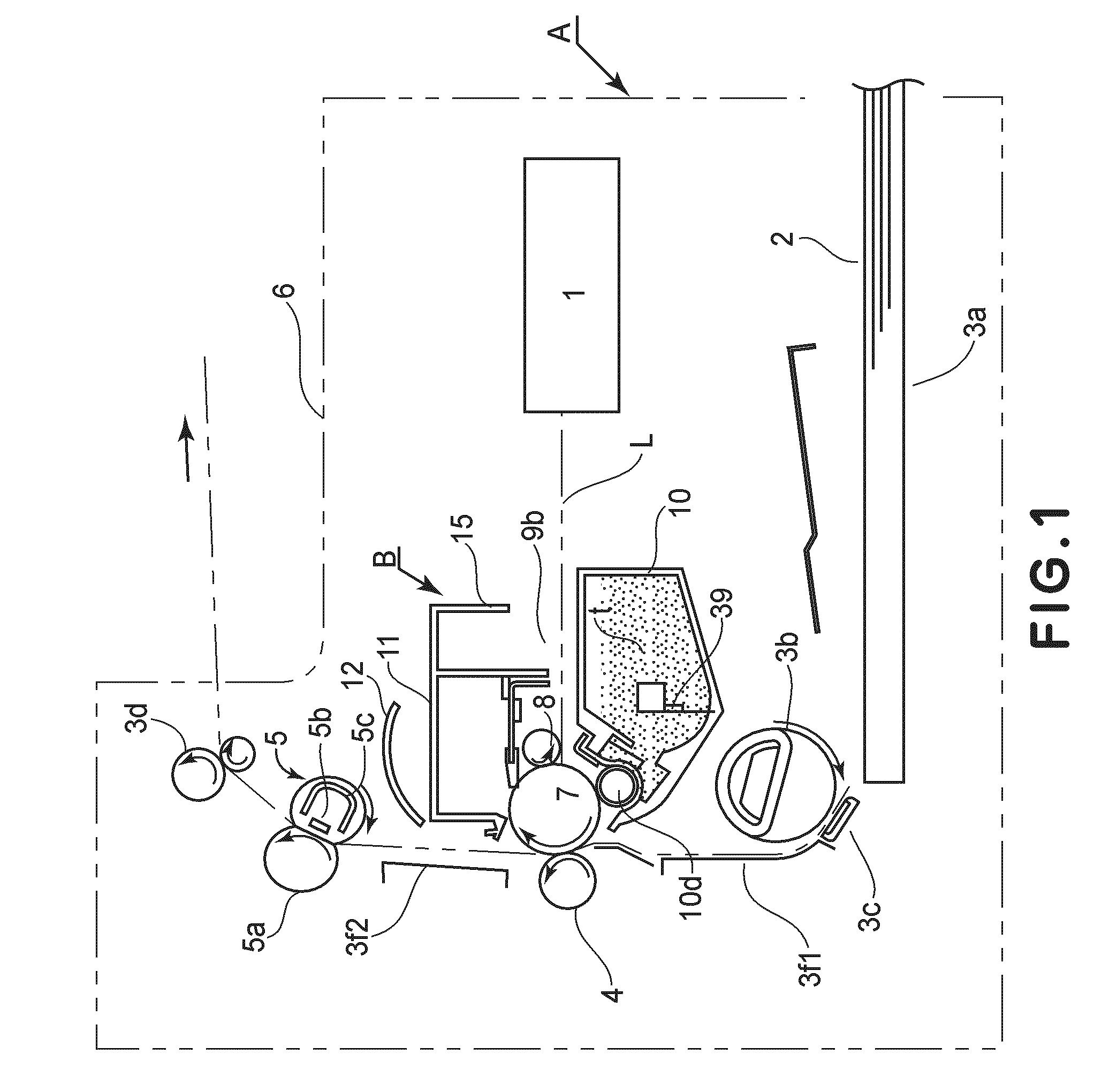

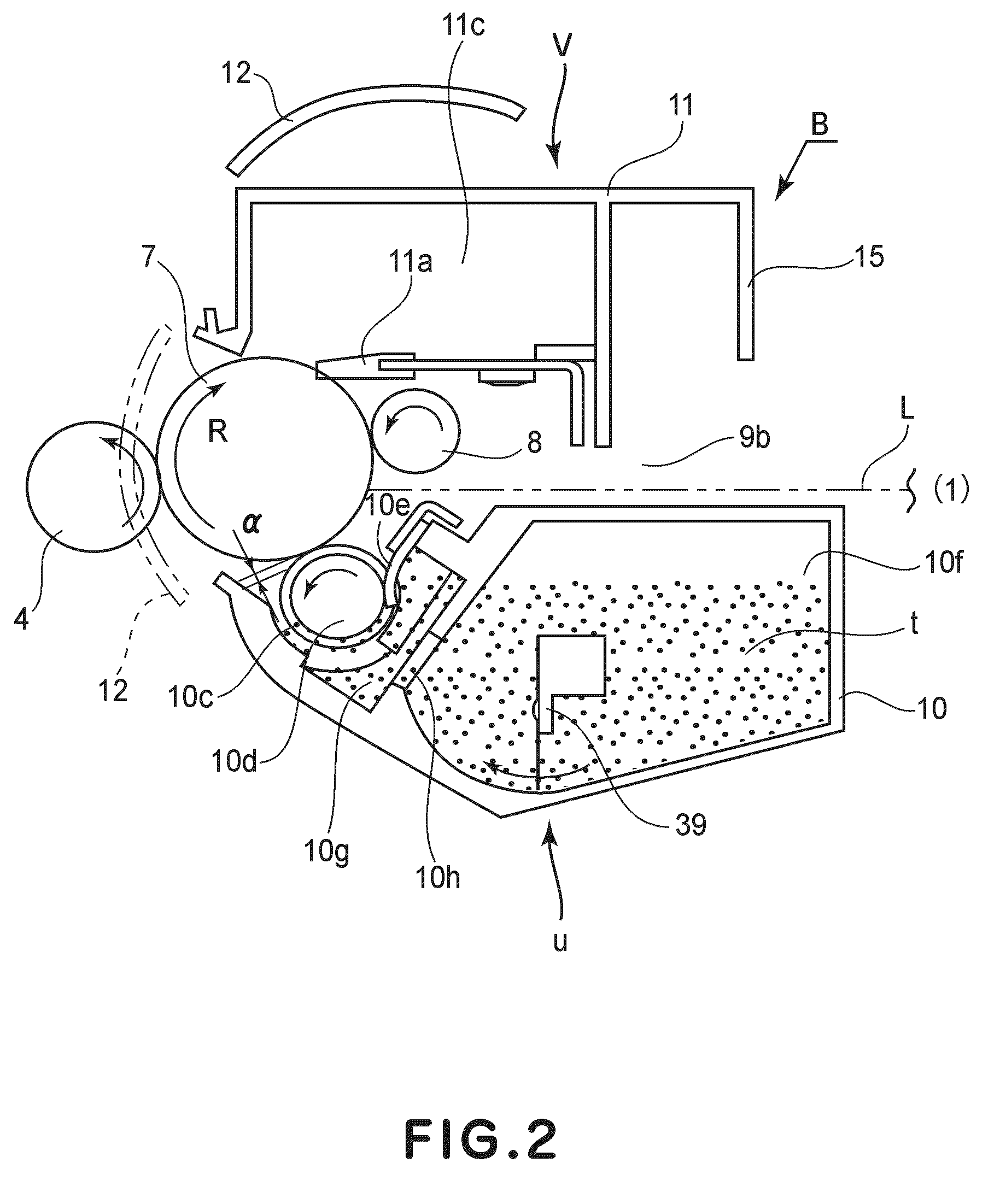

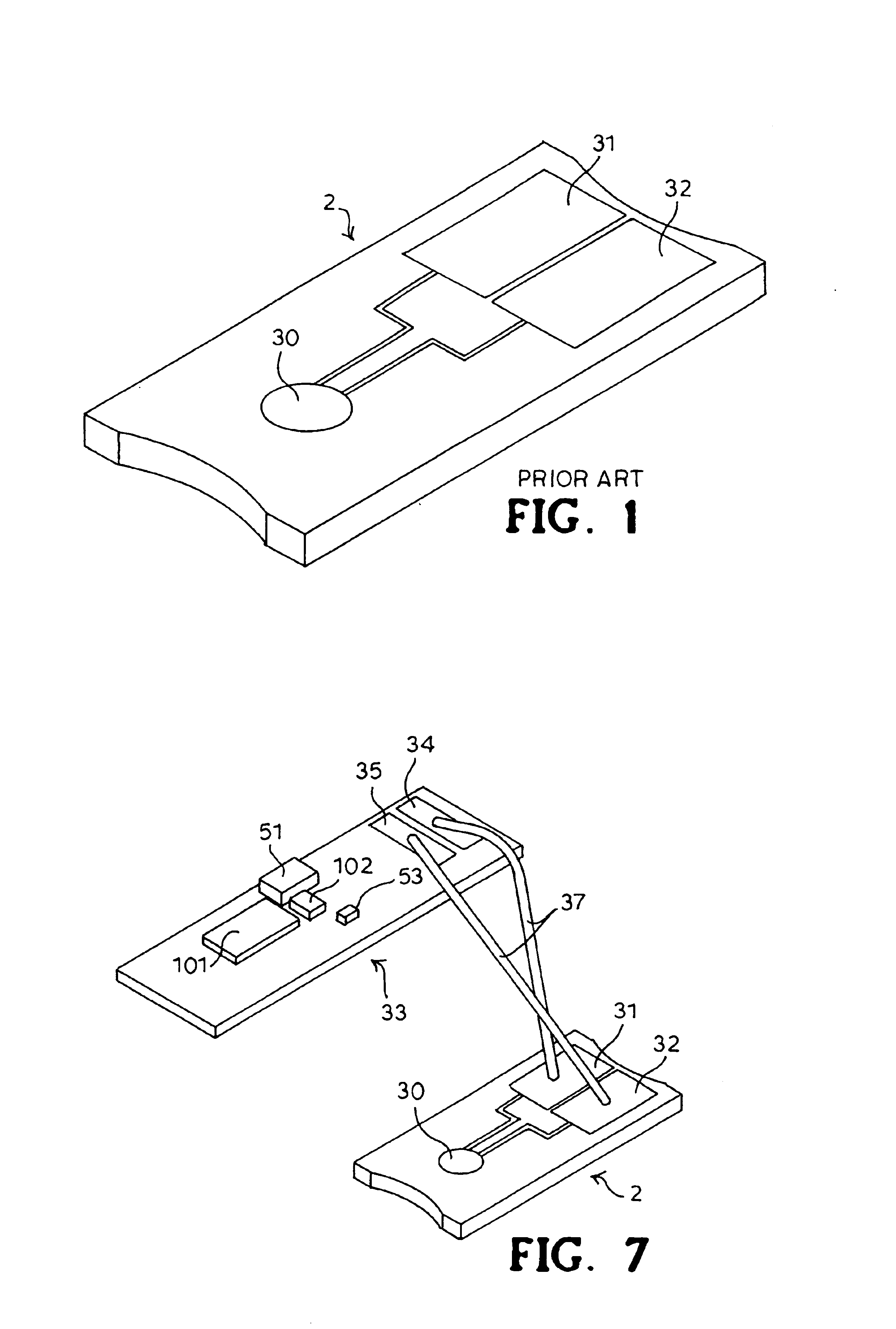

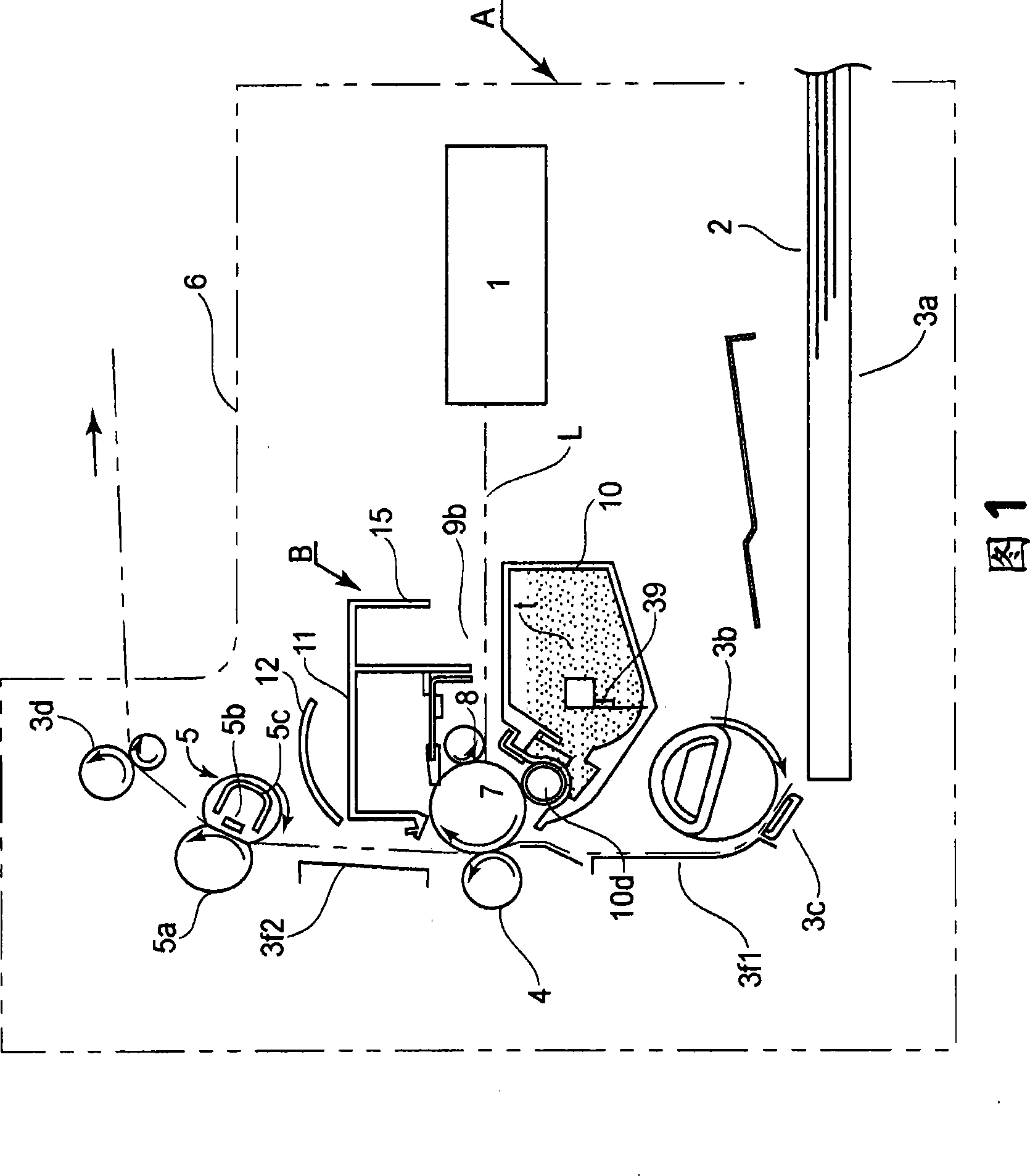

Process cartridge remanufacturing method

InactiveUS6931226B2Simple methodElectrographic process apparatusIndustrial engineeringRemanufacturing

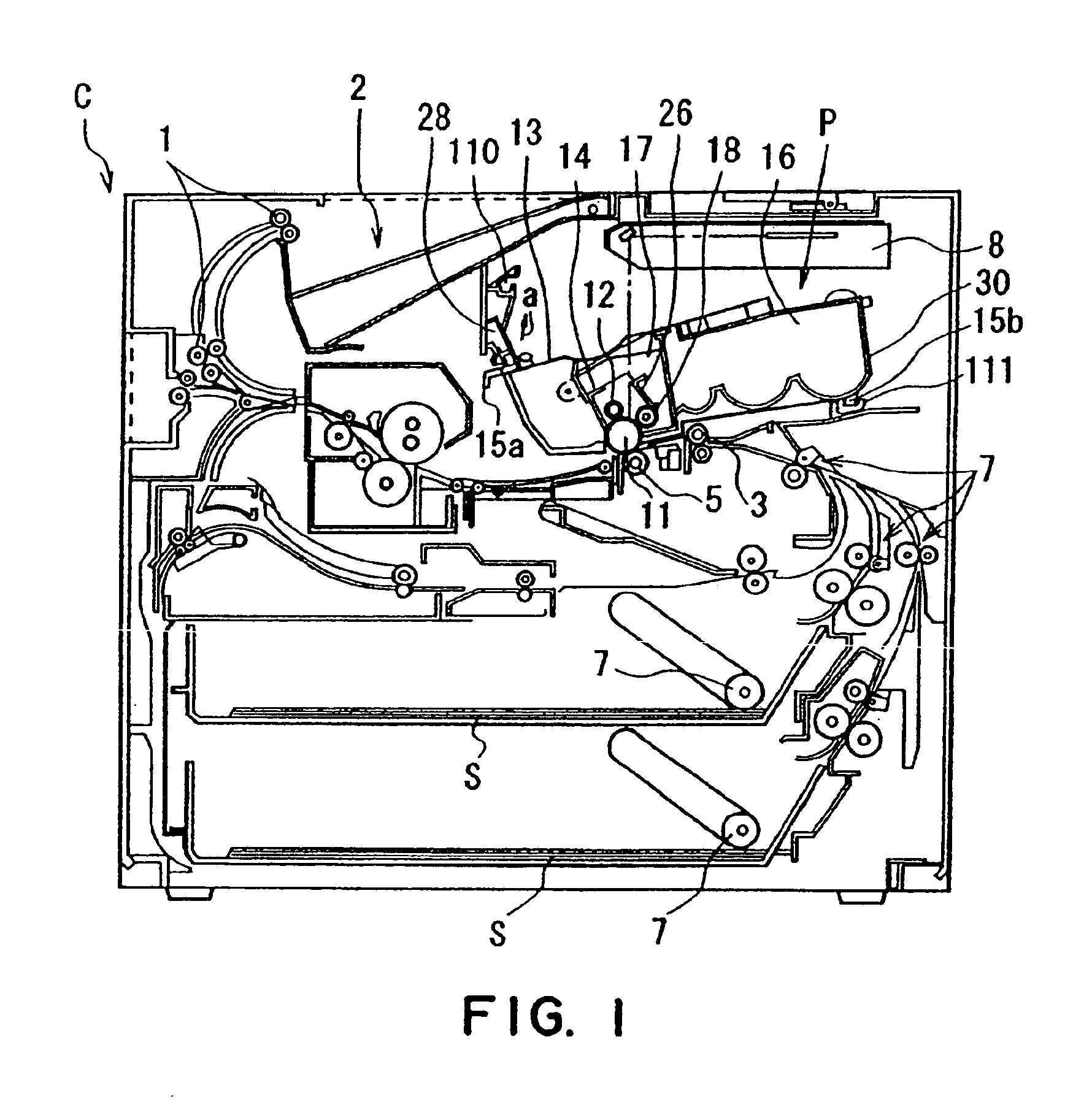

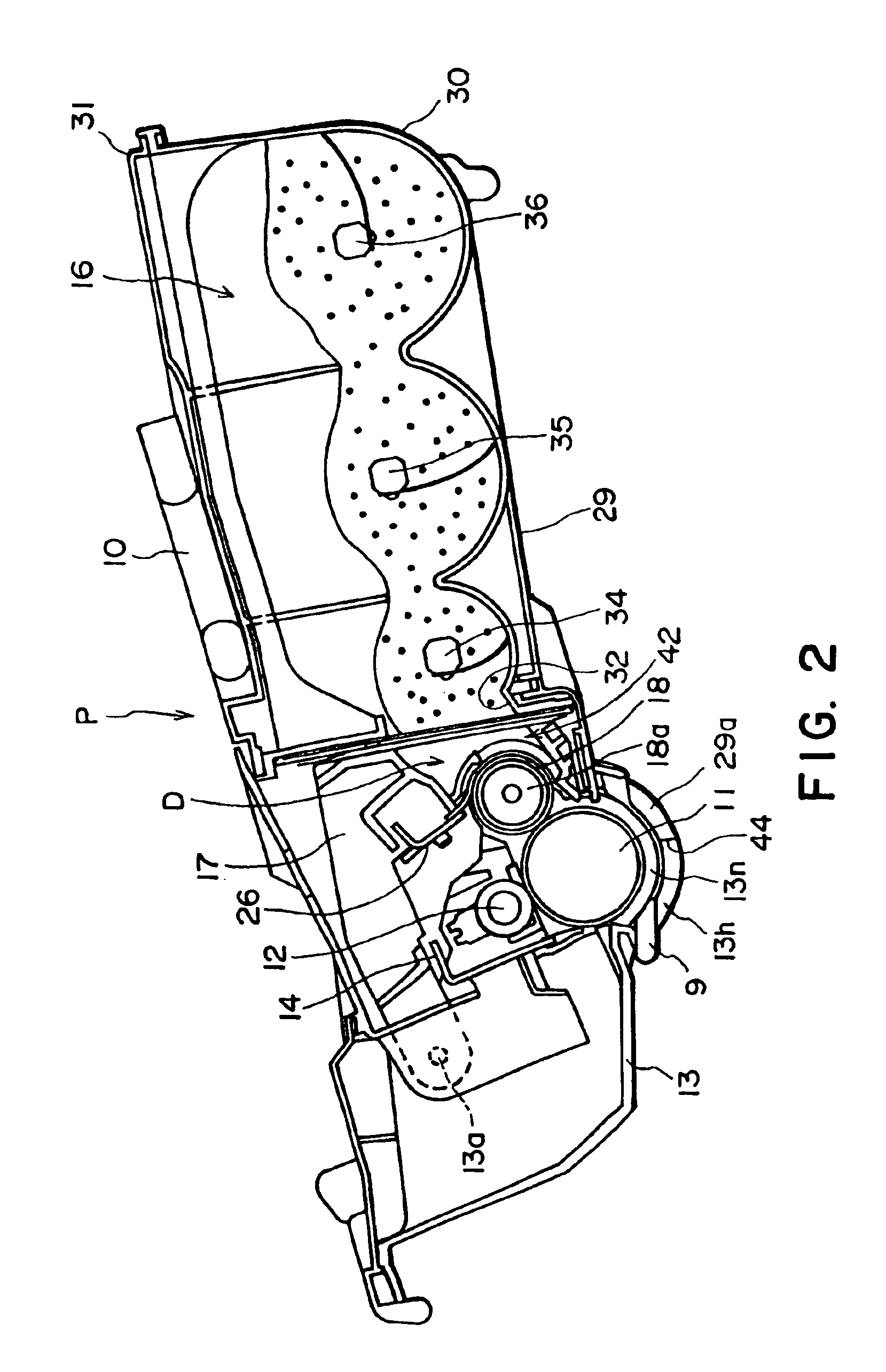

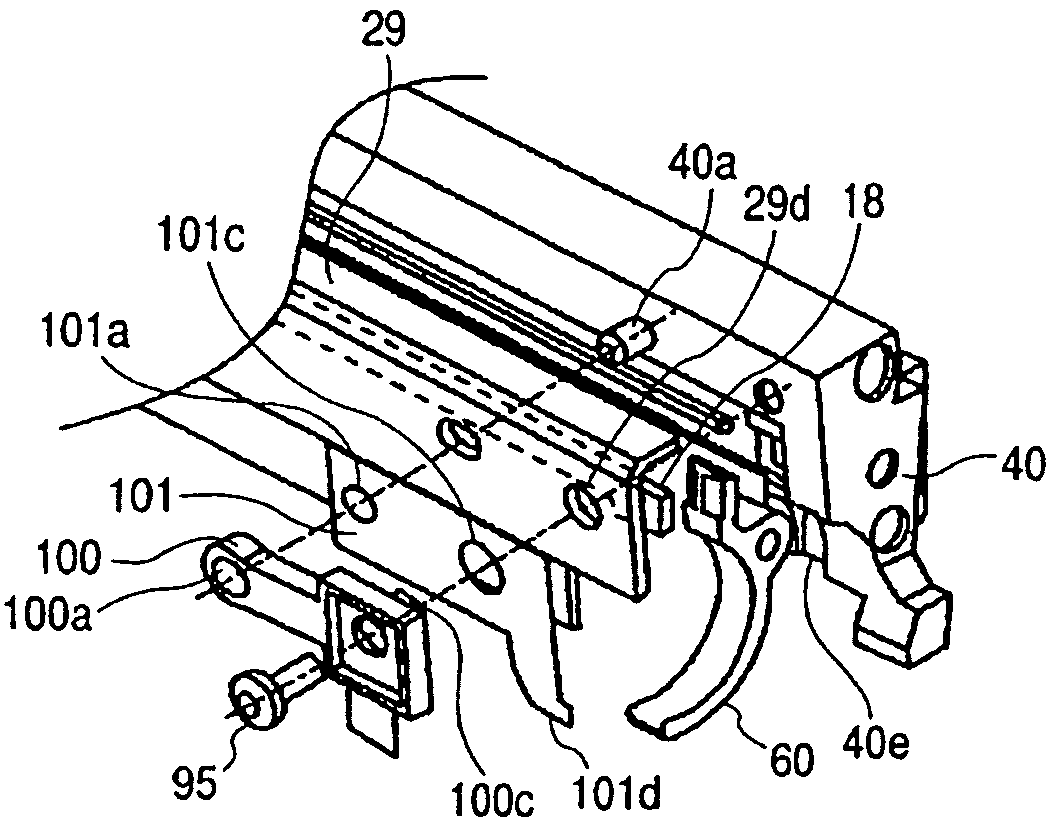

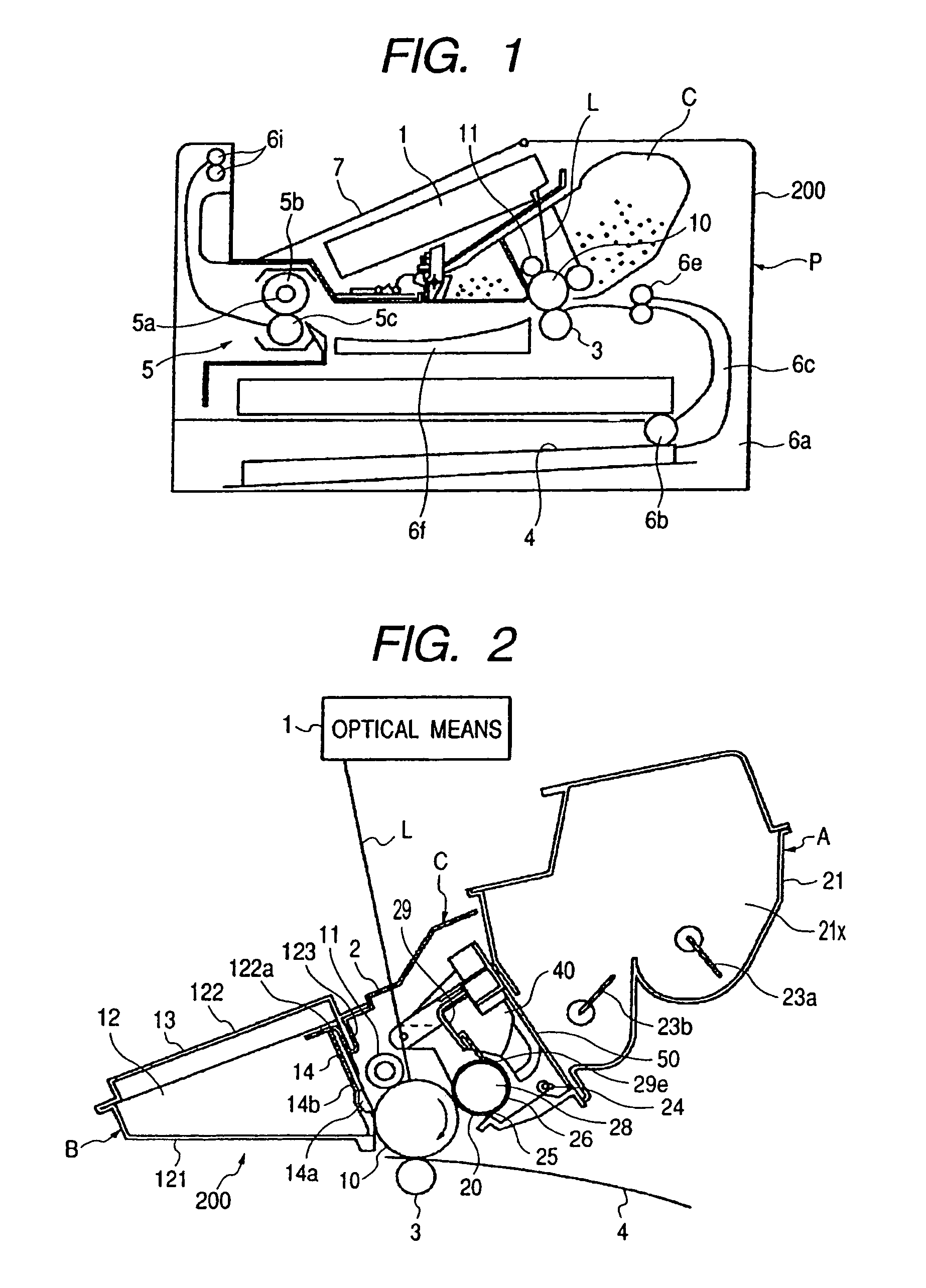

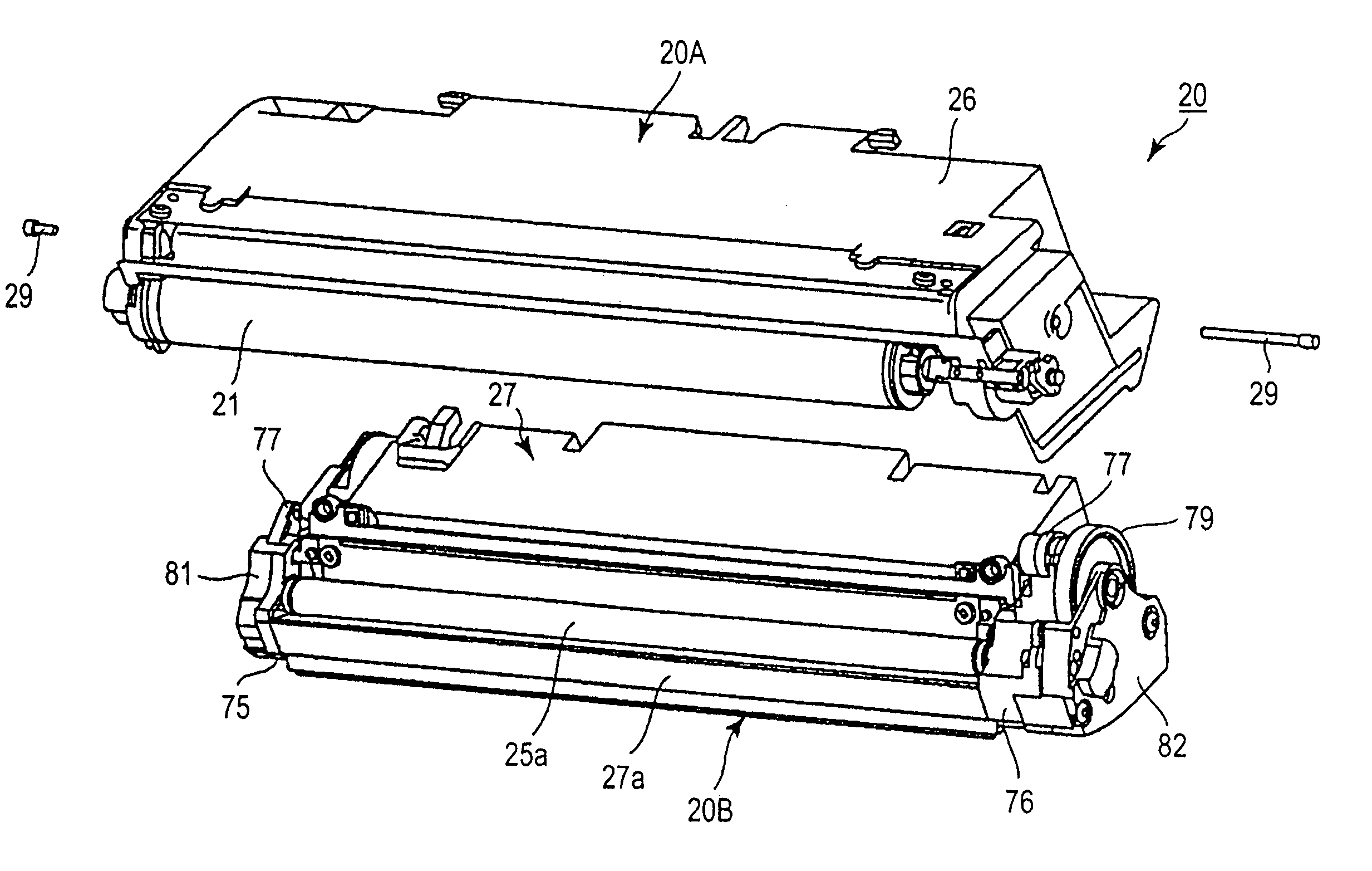

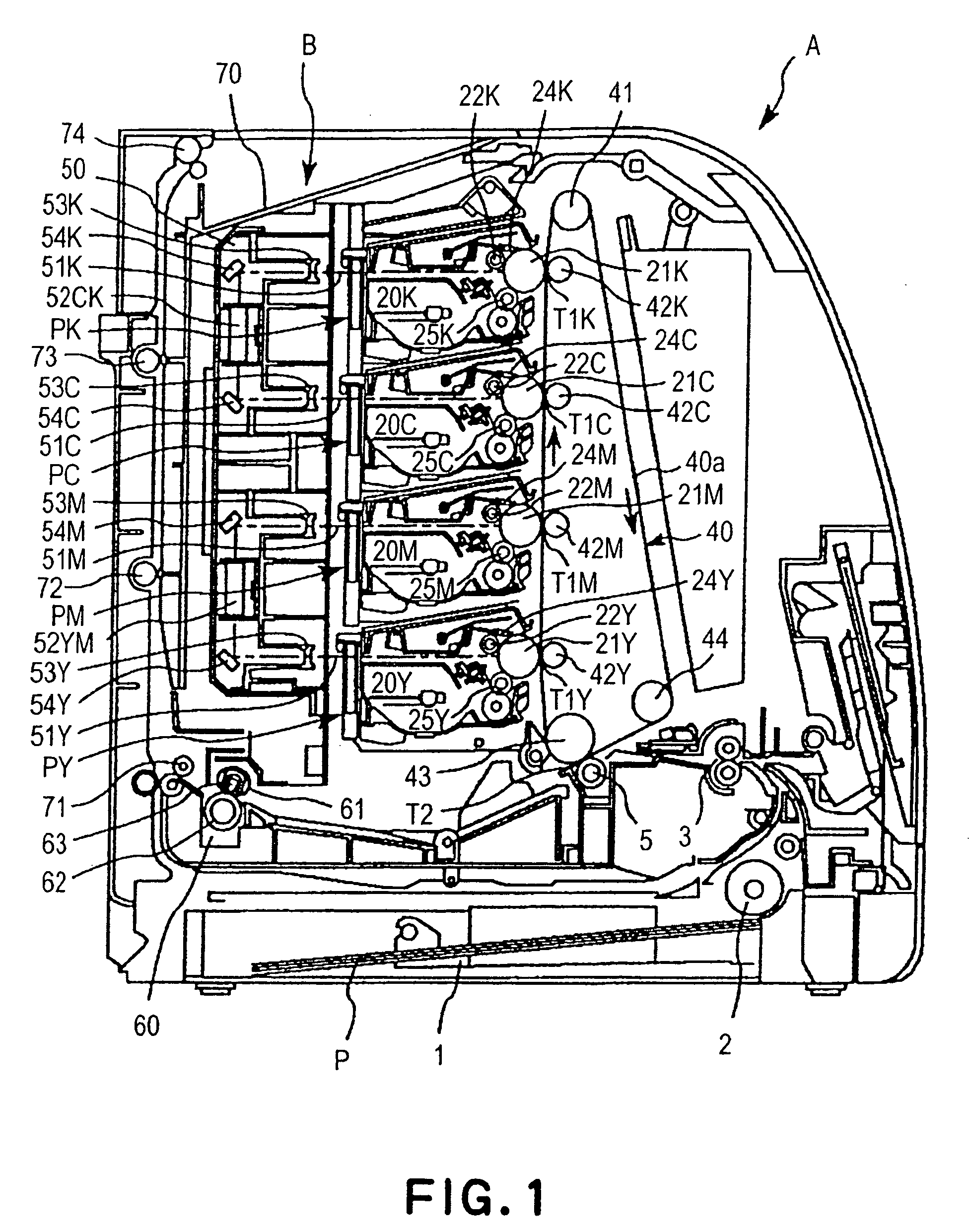

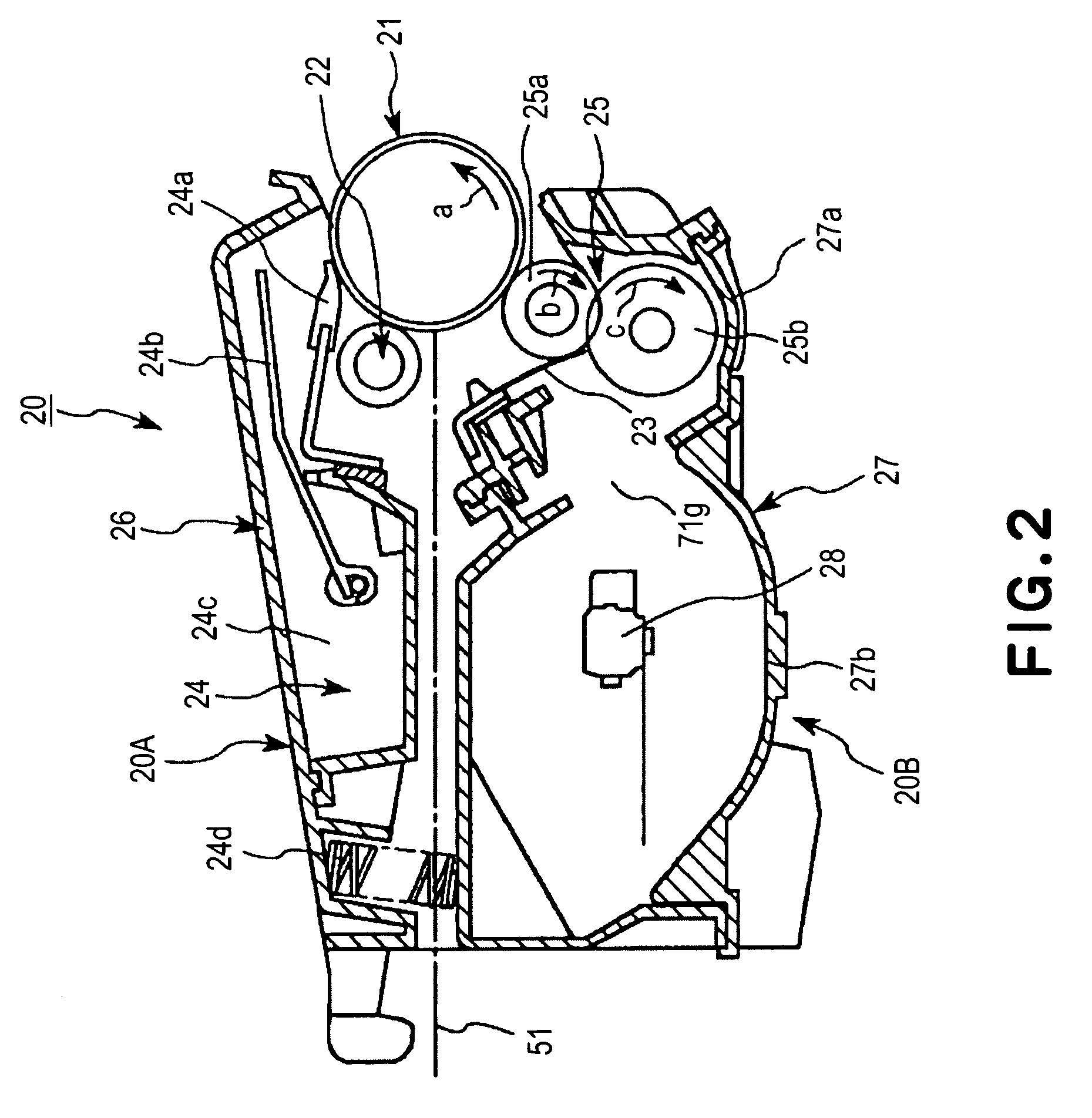

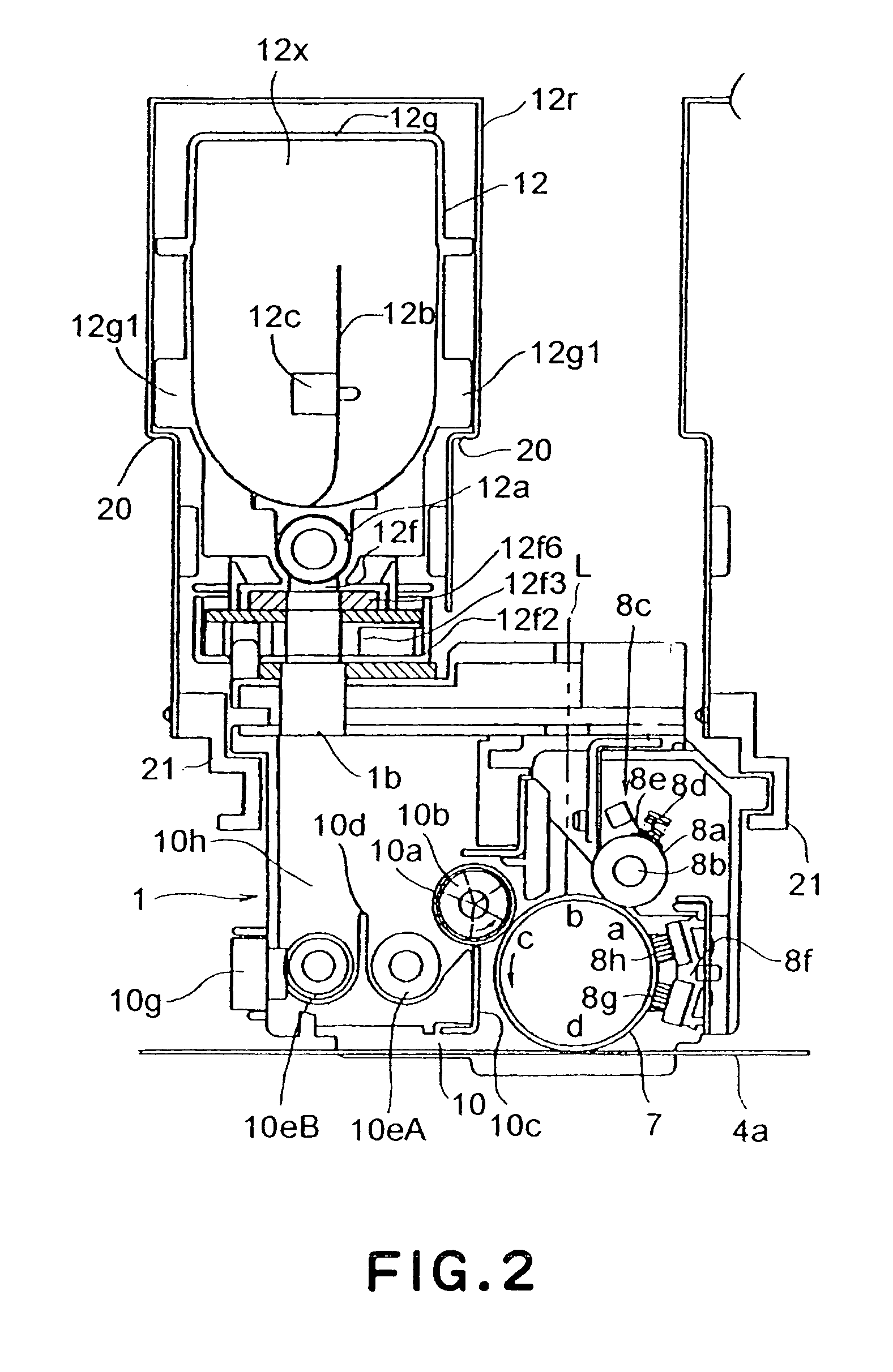

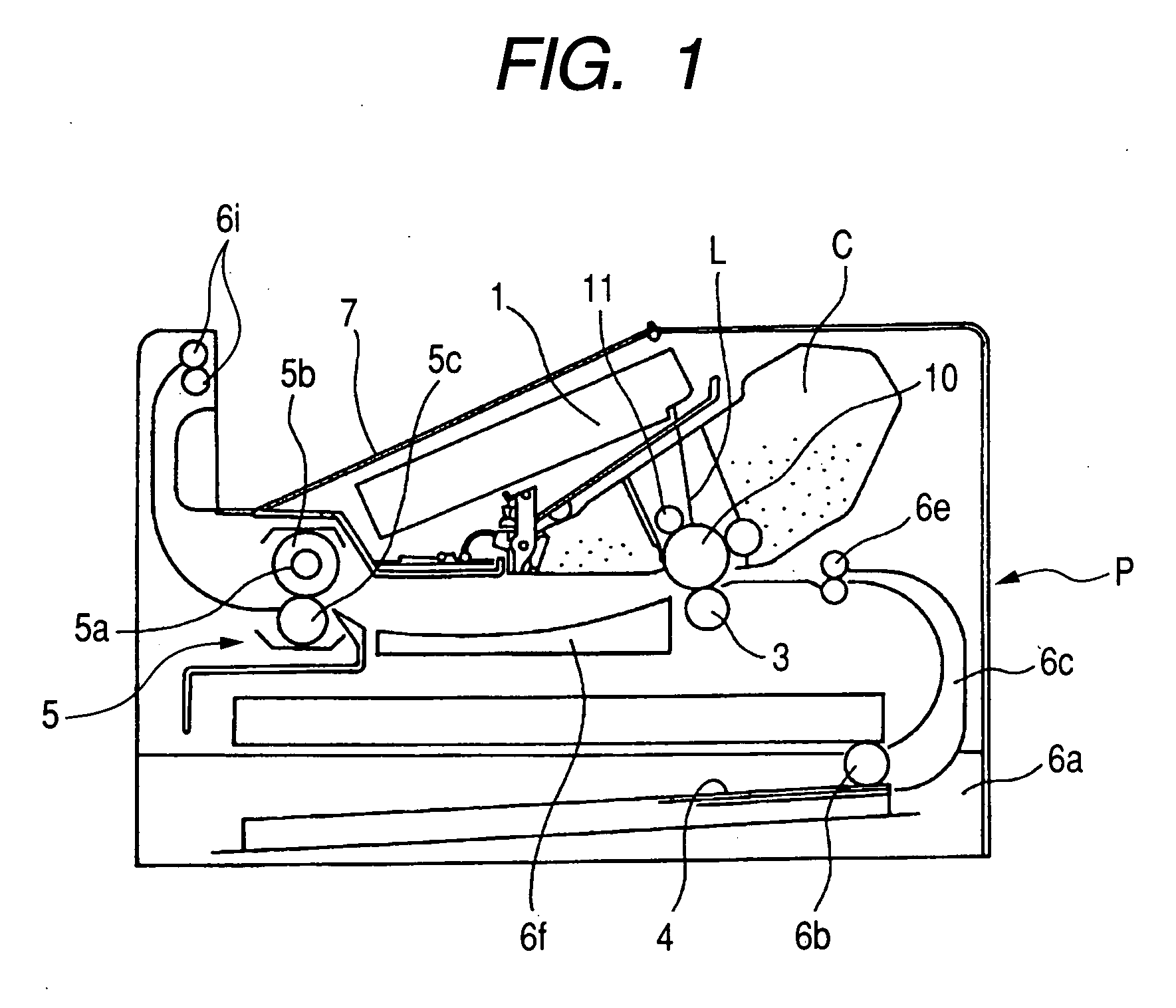

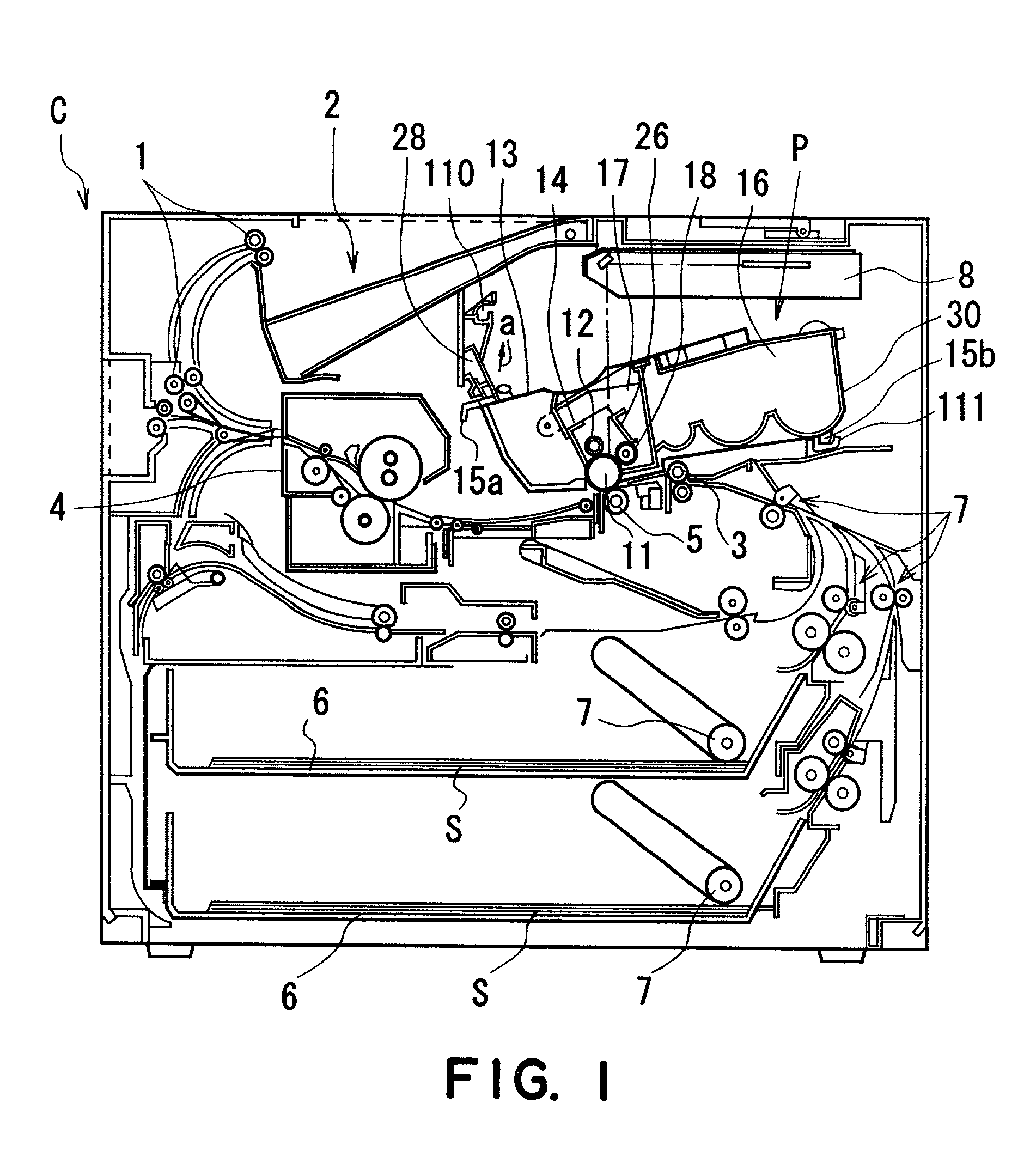

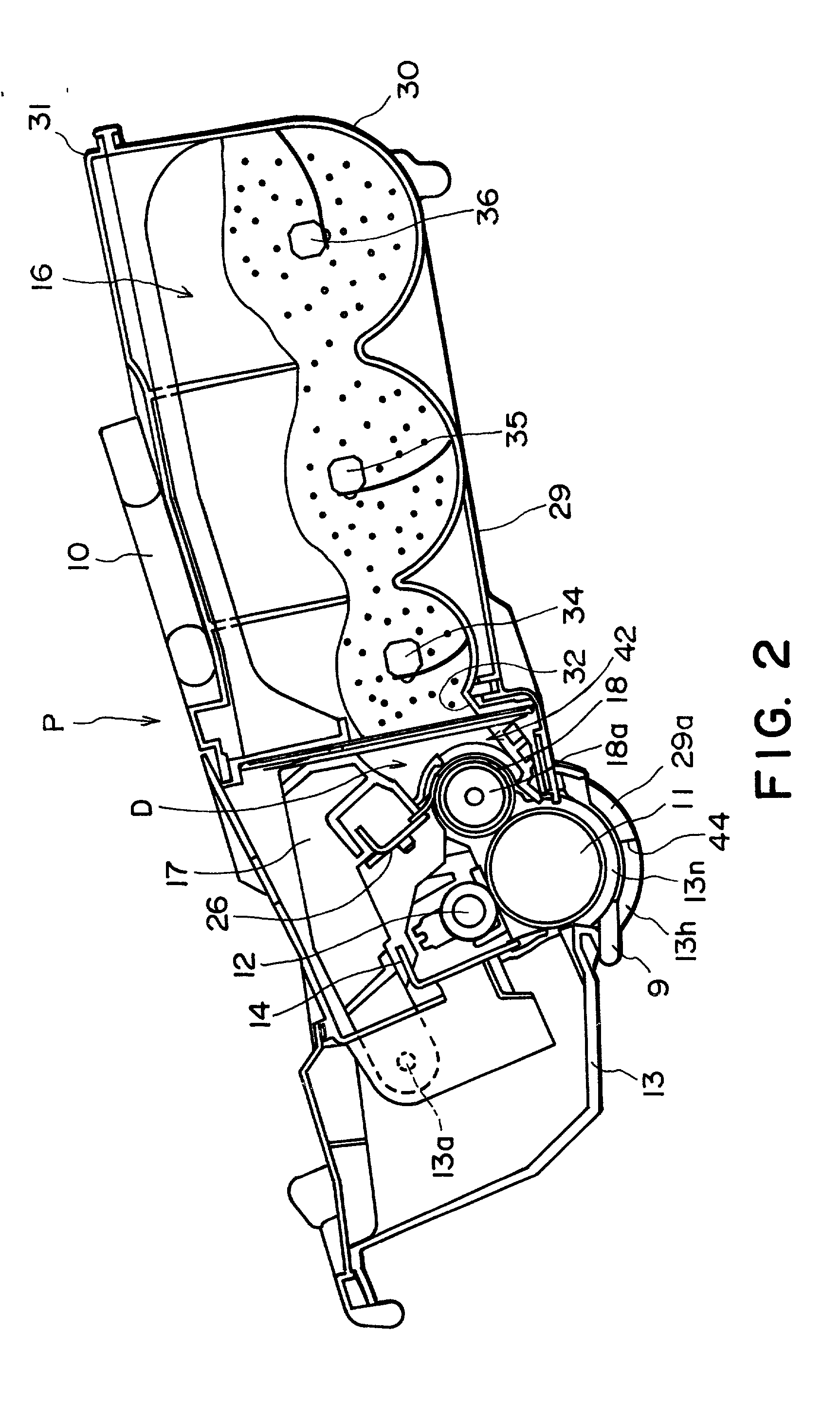

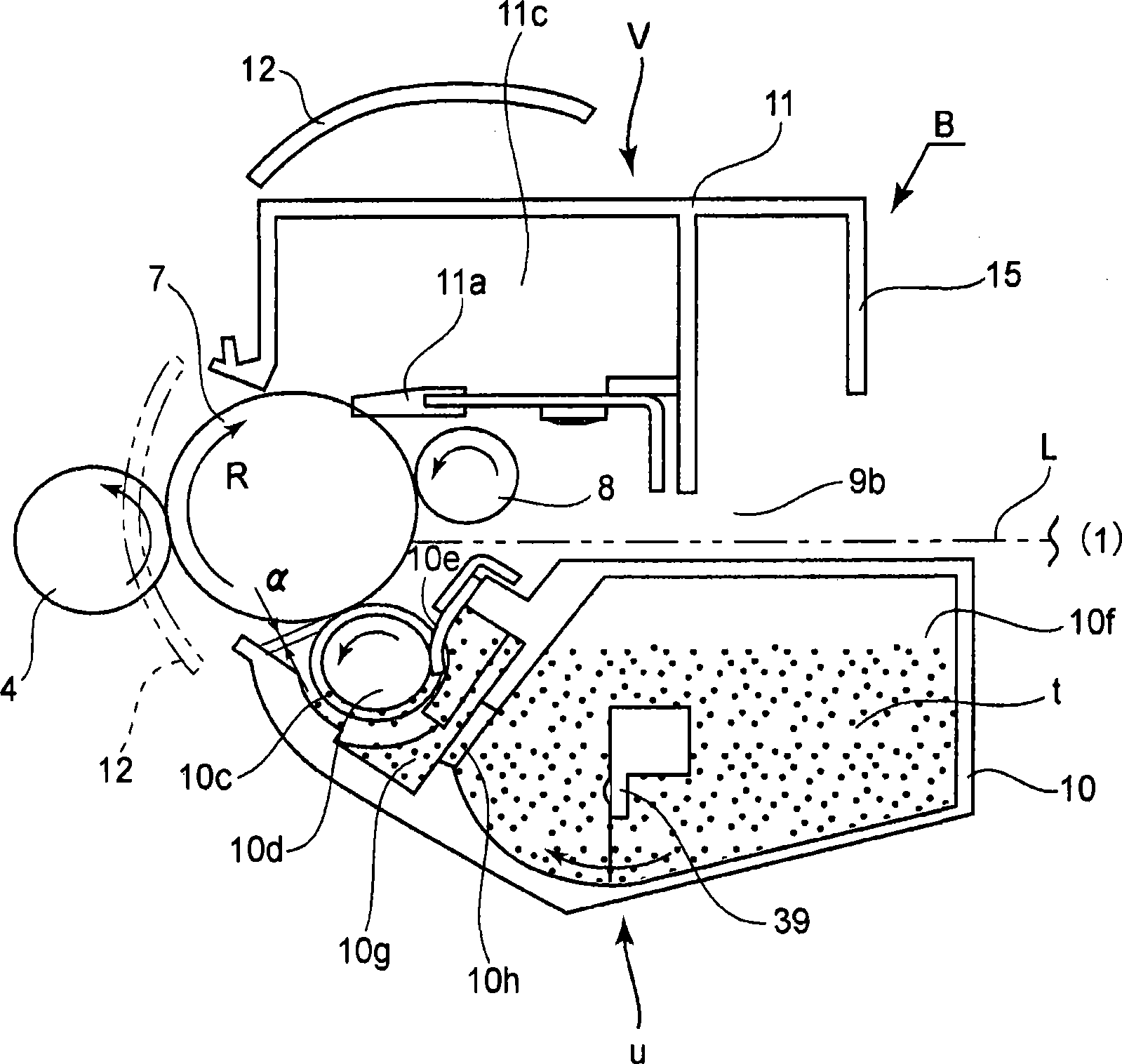

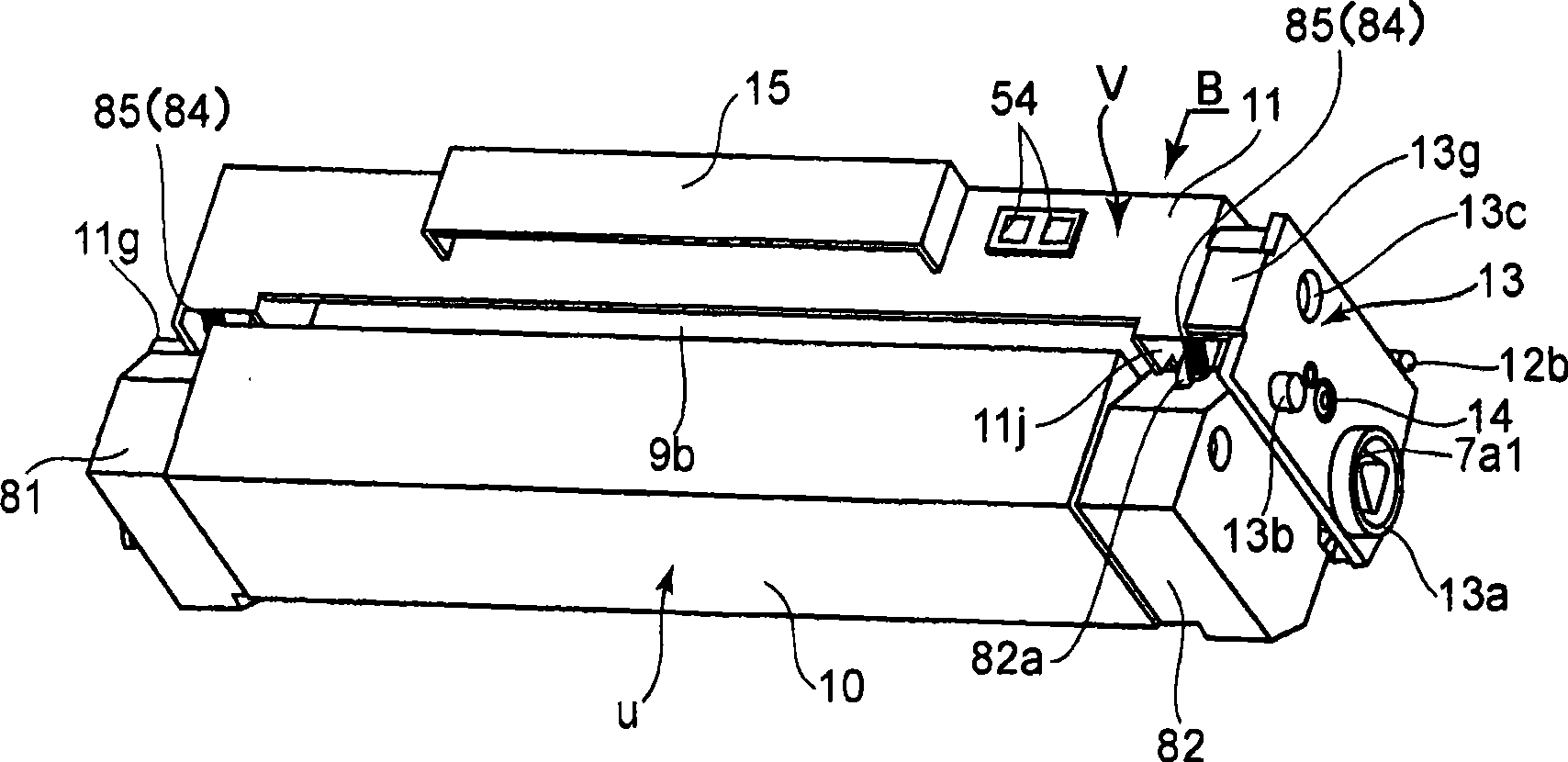

A remanufacturing method for a process cartridge includes (a) removing the second end cover at the other longitudinal ends of the drum frame, the developing frame and the developer frame; (b) removing a drum shaft rotatably supporting the drum; (c) separating the drum and the developing roller from each other; (d) moving the drum outwardly from the process cartridge, so that the drum is inclined, and then removing the drum from the drum frame; (e) inserting one end of a new drum such that a driving force receiving portion is exposed outside the drum frame, and inserting the drum shaft from outside of the drum frame; (f) opening a filling port provided in the developer accommodating portion, refilling the developer and then closing the filling port; and (g) fixedly mounting a second end cover to the other longitudinal ends of the drum frame, the developing frame and the developer frame.

Owner:CANON KK

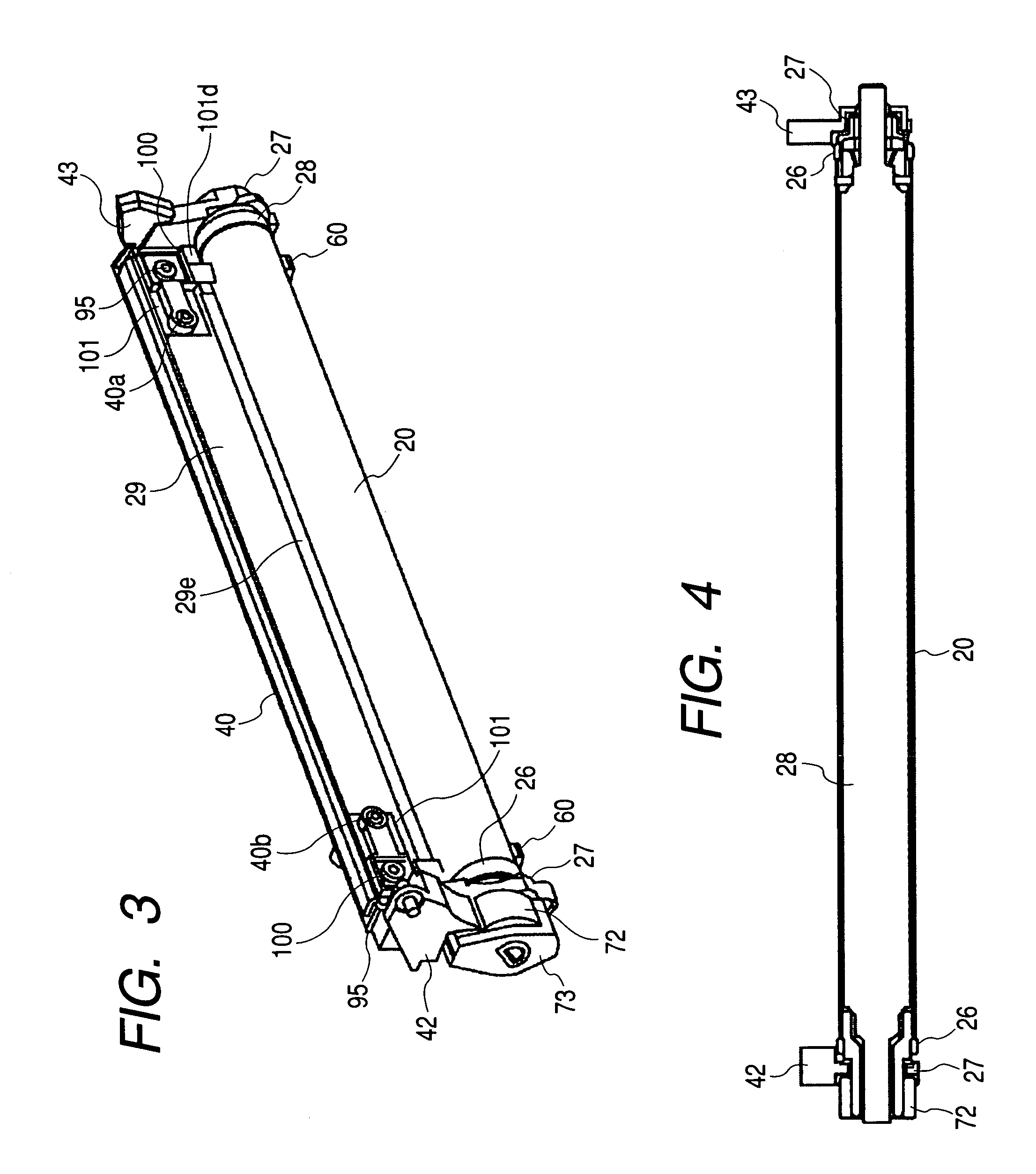

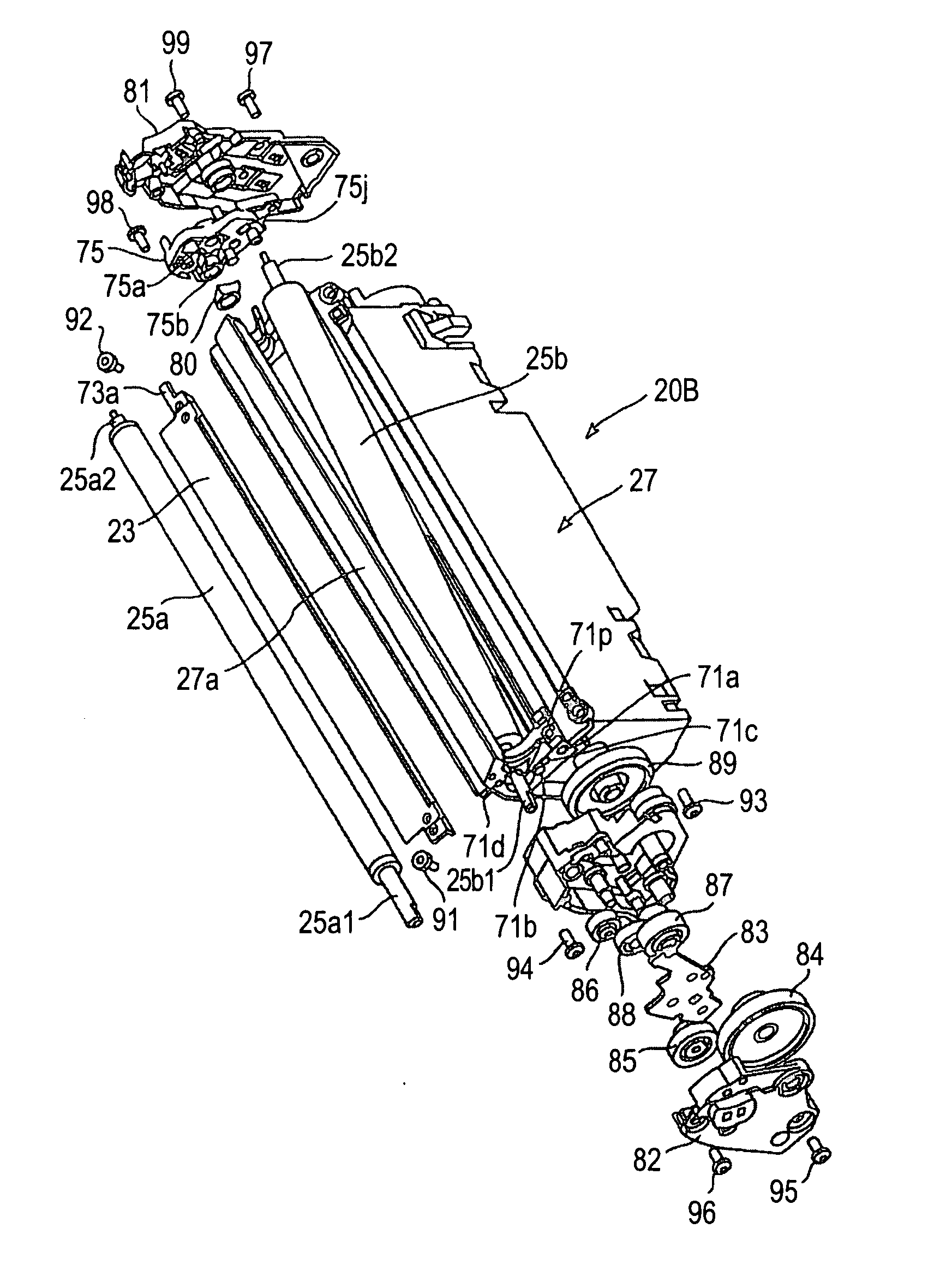

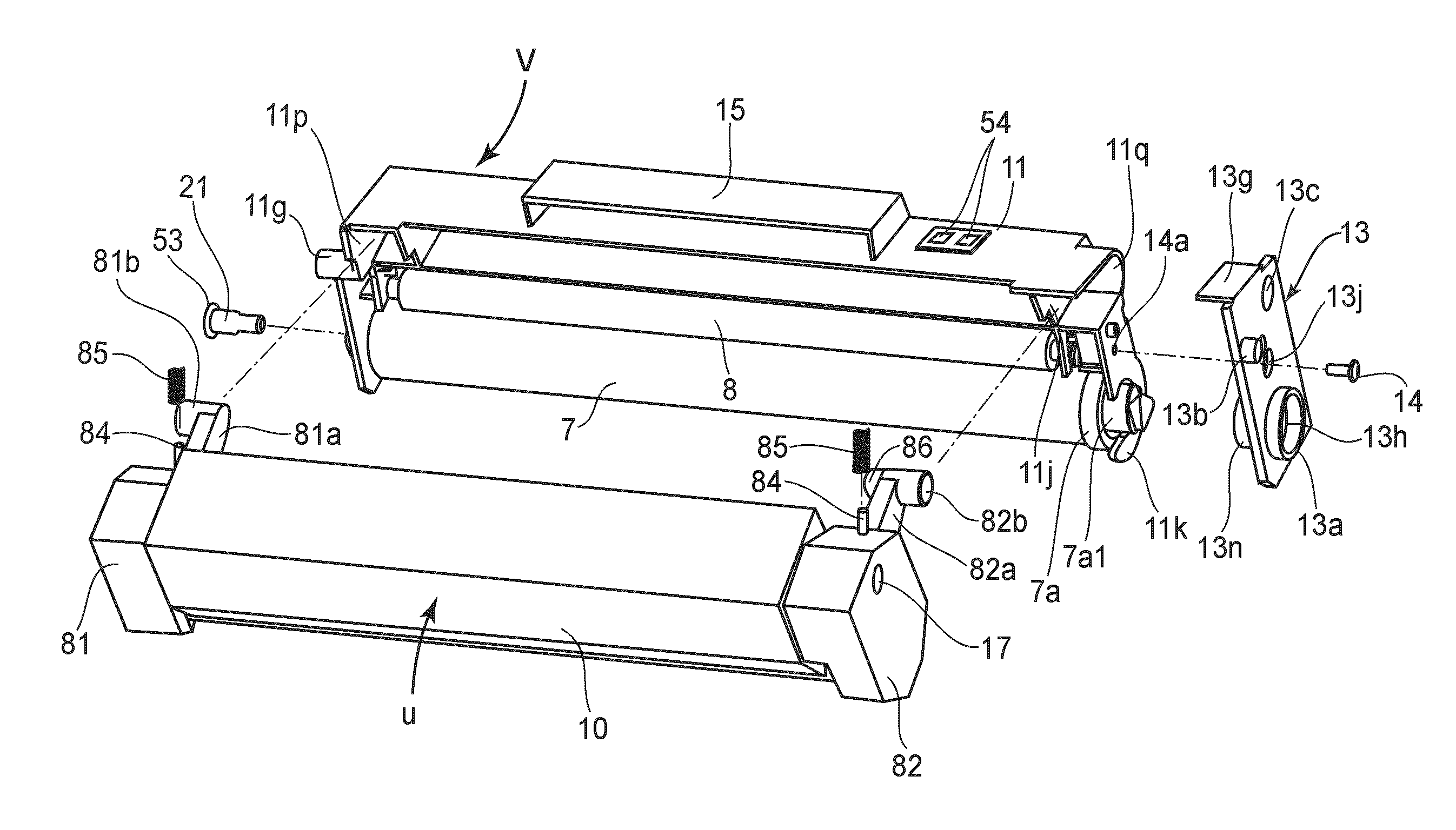

Process cartridge assembling method, process cartridge remanufacturing method, and connecting member

A simple method for remanufacturing a process cartridge which includes removing a first cover, removing a second cover, separating frames, removing a fixing pin, removing a developing roller, refilling developer, positioning provisionally a supporting frame to a developing frame, attaching the developing roller, attaching the supporting frame, connecting a first frame and connecting a second frame.

Owner:CANON KK

Remanufacturing method for process cartridge

InactiveUS7162181B2Simple methodArc welding apparatusElectrographic process apparatusEngineeringRemanufacturing

Owner:CANON KK

Remanufacturing method for process cartridge, process cartridge and image forming apparatus

InactiveUS6272300B1Easy to useReduce decreaseElectrographic process apparatusImaging equipmentIndustrial engineering

A remanufacturing method of a process cartridge detachably mountable to an image forming apparatus includes disassembling the process cartridge into a first frame having a developer accommodating portion for accommodating a developer and a second frame having a developer carrying member for carrying the developer supplied from the developer accommodating portion toward an image bearing member, thus exposing an opening of the first frame for permitting movement of the developer from the first frame to the second frame; removing residual which is resulted from a covering member having been used for sealing the opening and which remains around the opening, wherein the covering member has a sealing portion for sealing the opening and an extension for permitting the sealing portion to be torn with a part thereof remaining around the opening to open the opening, by pulling the extension, wherein the residual is a part of the sealing portion; mounting a fresh covering member to seal the opening; then supplying the developer accommodating portion with a fresh developer; and then engaging the first and second frames together.

Owner:CANON KK

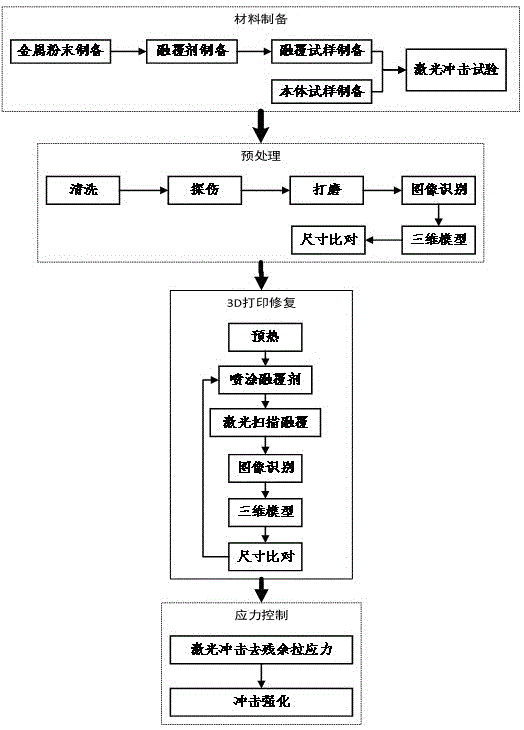

Metal part remanufacturing method adopting stress control and 3D printing

InactiveCN105154870ALarge deformationDimensional accuracy is easy to controlAdditive manufacturing apparatusMetallic material coating processesUltimate tensile strength3d printer

The invention discloses a metal part remanufacturing method adopting stress control and 3D printing. The metal part remanufacturing method comprises steps as follows: firstly, a body sample and a cladding sample of a metal part are prepared, and laser parameters required by the same residual compressive stress are acquired through laser shock; secondly, a to-be-repaired metal part is preprocessed, a repairing area and a repairing allowance of the part are determined with an image recognition method; the metal part is subjected to cladding repair layer by layer by the aid of a laser 3D printer, and the size of a repaired part reaches the originally designed size of the part; finally, residual tensile stress is eliminated through the laser shock, and then a residual compressive stress layer is formed on the working surface of the metal part with a laser shock processing method. According to the metal part remanufacturing method, the part repairing is performed by adopting laser 3D printing, the overall deformation of the part is not large, further, the repairing size precision is easy to control, and follow-up processing is not required; the repaired parts acquire equal overall strength, a value of residual compressive stress of a part surface strengthening layer after the laser shock processing keeps balance, and the service life of the remanufactured part is prolonged.

Owner:GUANGDONG UNIV OF TECH

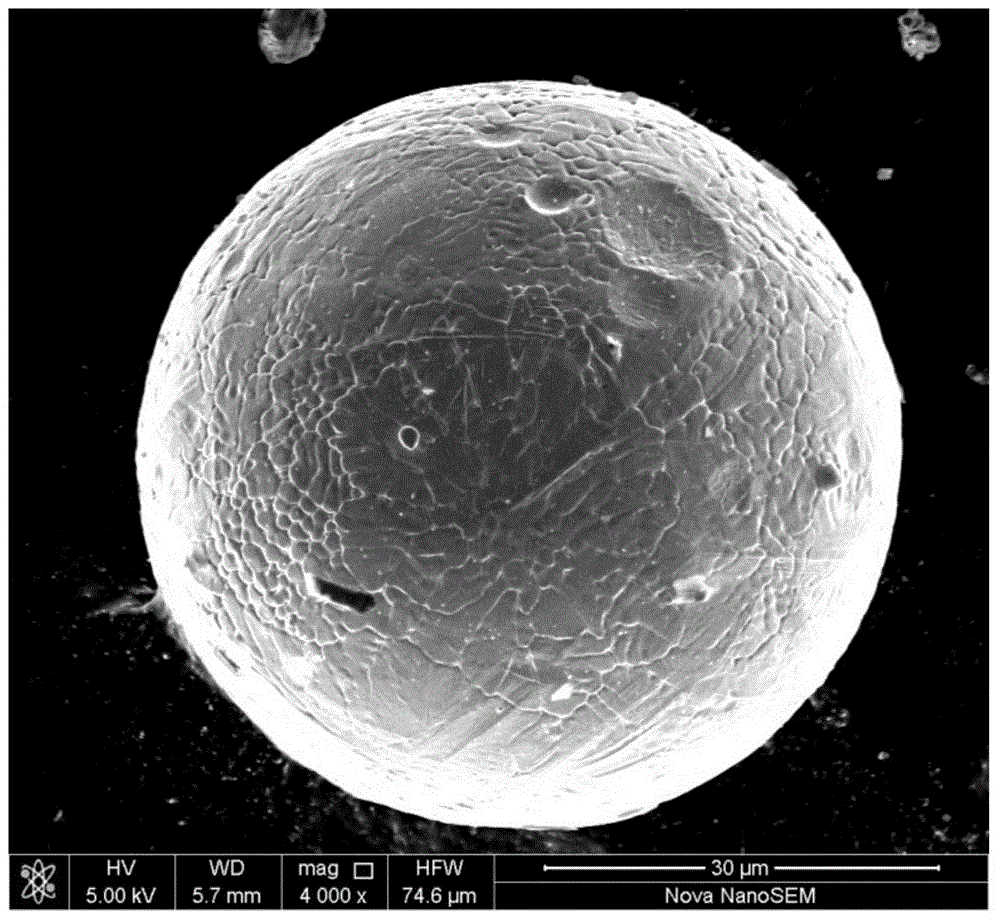

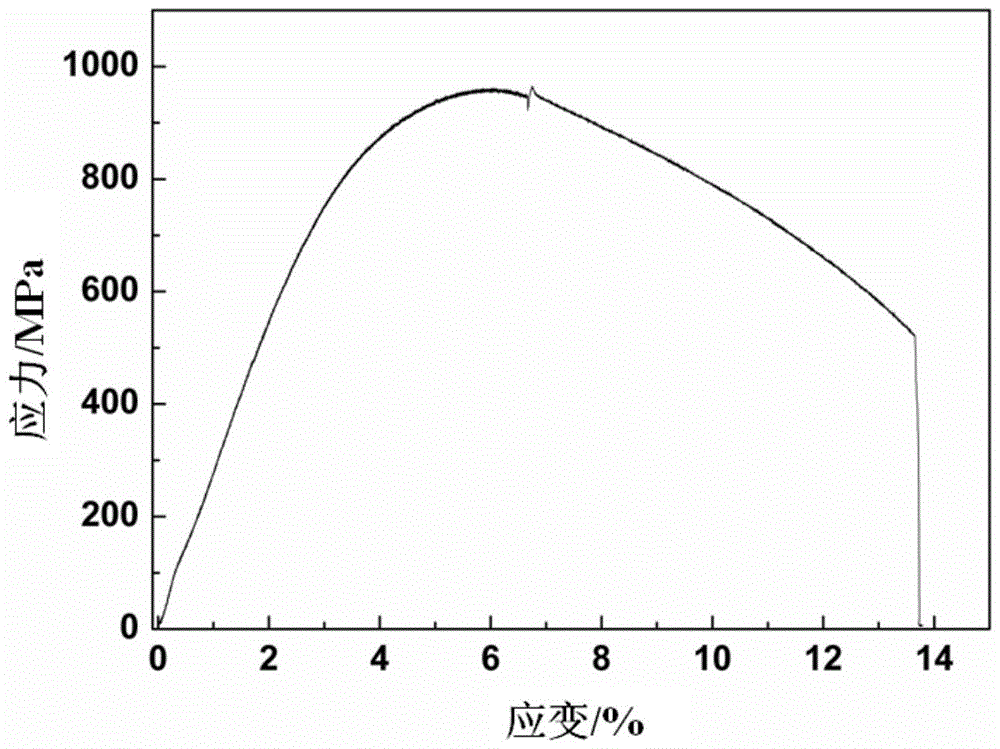

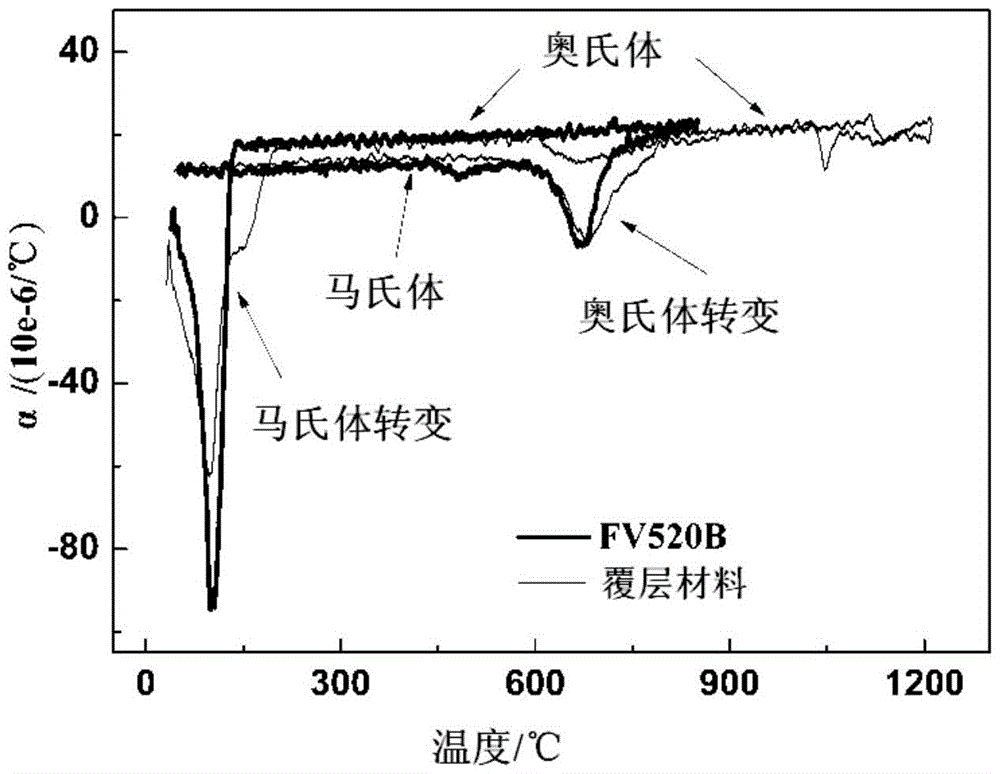

Alloy powder used for laser remanufacturing of martensitic stainless steel parts and preparation method

ActiveCN105039869ASolve and improve formabilitySolve and improve crack resistanceMetallic material coating processesSlagMartensitic stainless steel

The invention provides alloy powder used for laser remanufacturing of FV520B martensitic stainless steel parts and a preparation method. The chemical components of the alloy powder include, by weight percentage, 0.01-0.3% of C, 12-17% of Cr, 3-7% of Ni, 0.4-2% of Mo, 0.1-2% of Mn, 0.15-0.55% of Nb, 0-3% of Cu, 0.05-2% of Si, 0-1.6% of B and the balance Fe. The preparation method of the alloy powder is a vacuum melting-high pressure gas atomization method. The alloy powder can have the density and the thermal expansion coefficient which are similar to those of FV520B materials when precipitation hardening elements, deoxygenation slag forming elements and elements used for lowering the martensite phase transformation point are added and the weight percent content of all the elements are regulated; the residual stress level is lowered through the martensite phase transformation accompanying effect; and therefore the problems of cracks, deformation and the like are greatly relieved, and the forming property, the anti-cracking property and the process stability are achieved and improved when the FV520B parts are subjected to laser remanufacturing through the alloy powder.

Owner:ACADEMY OF ARMORED FORCES ENG PLA

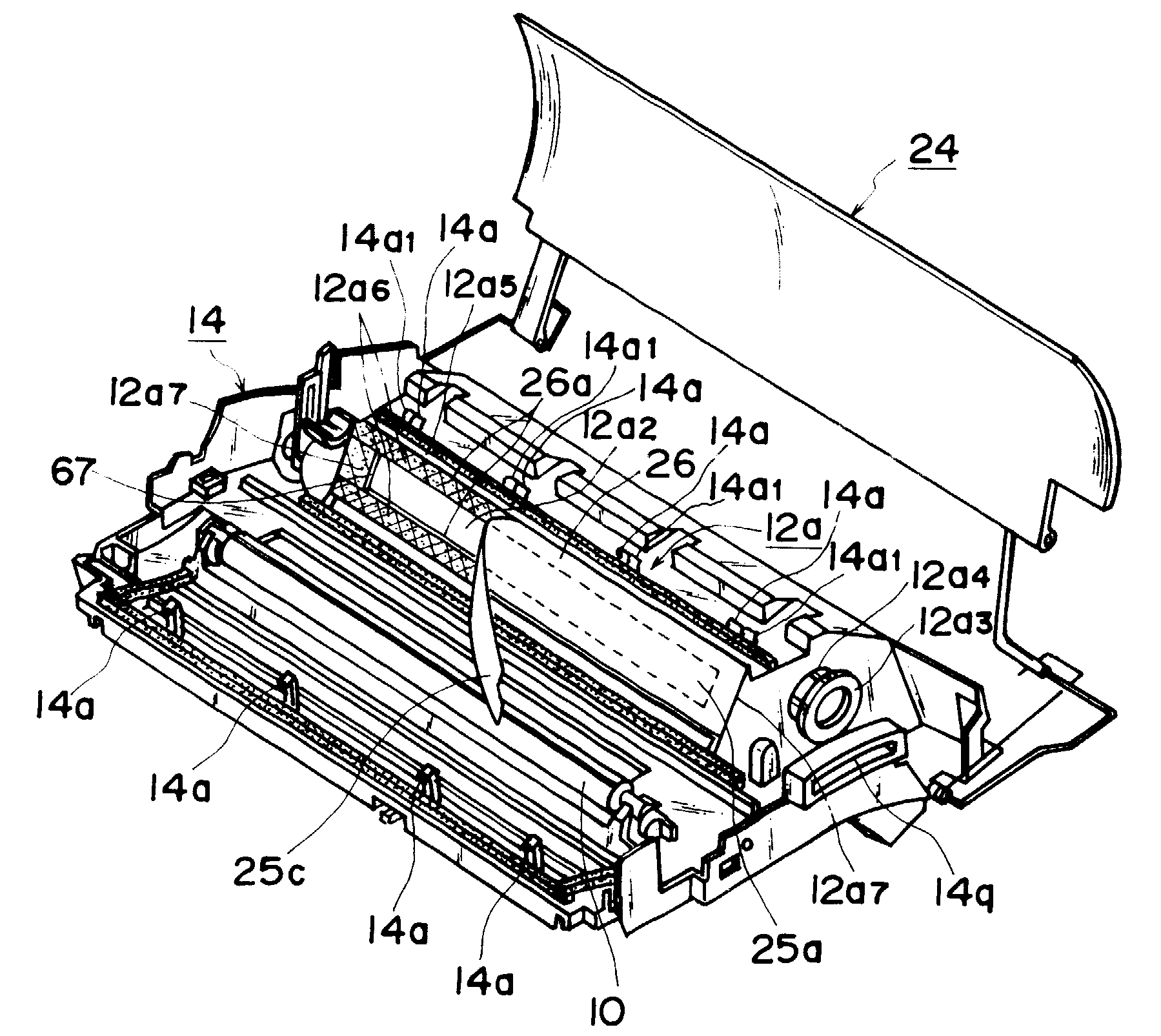

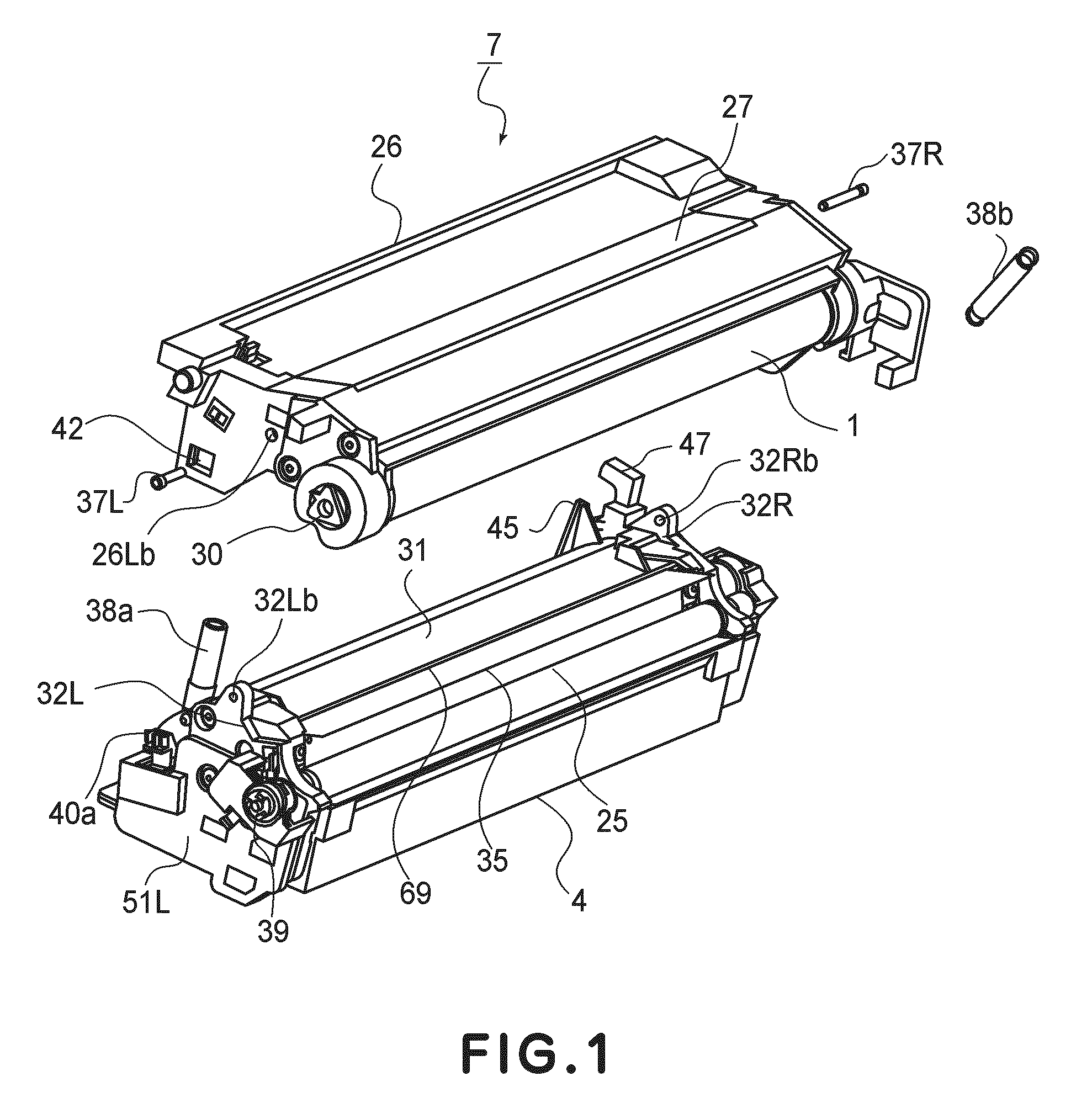

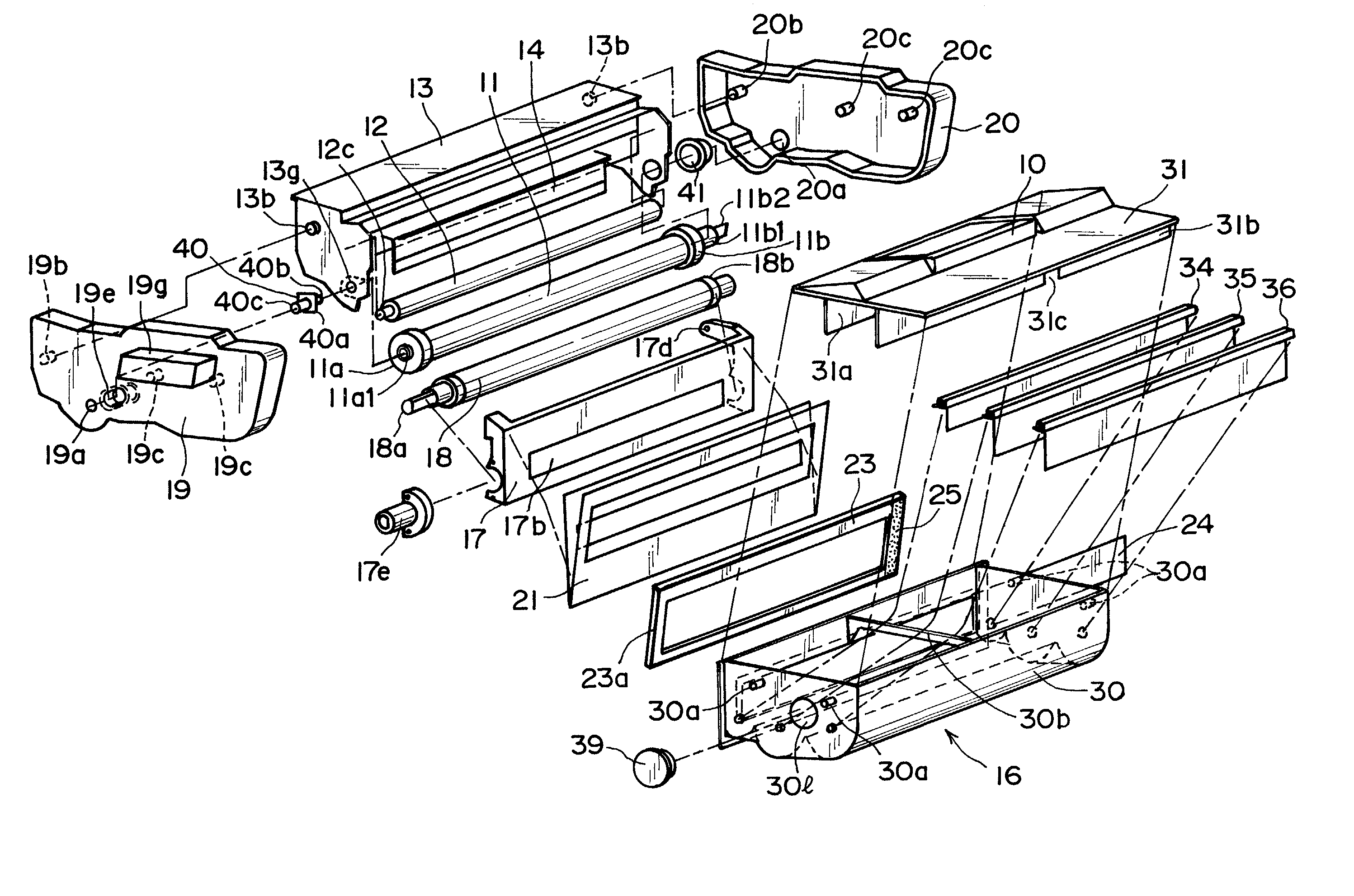

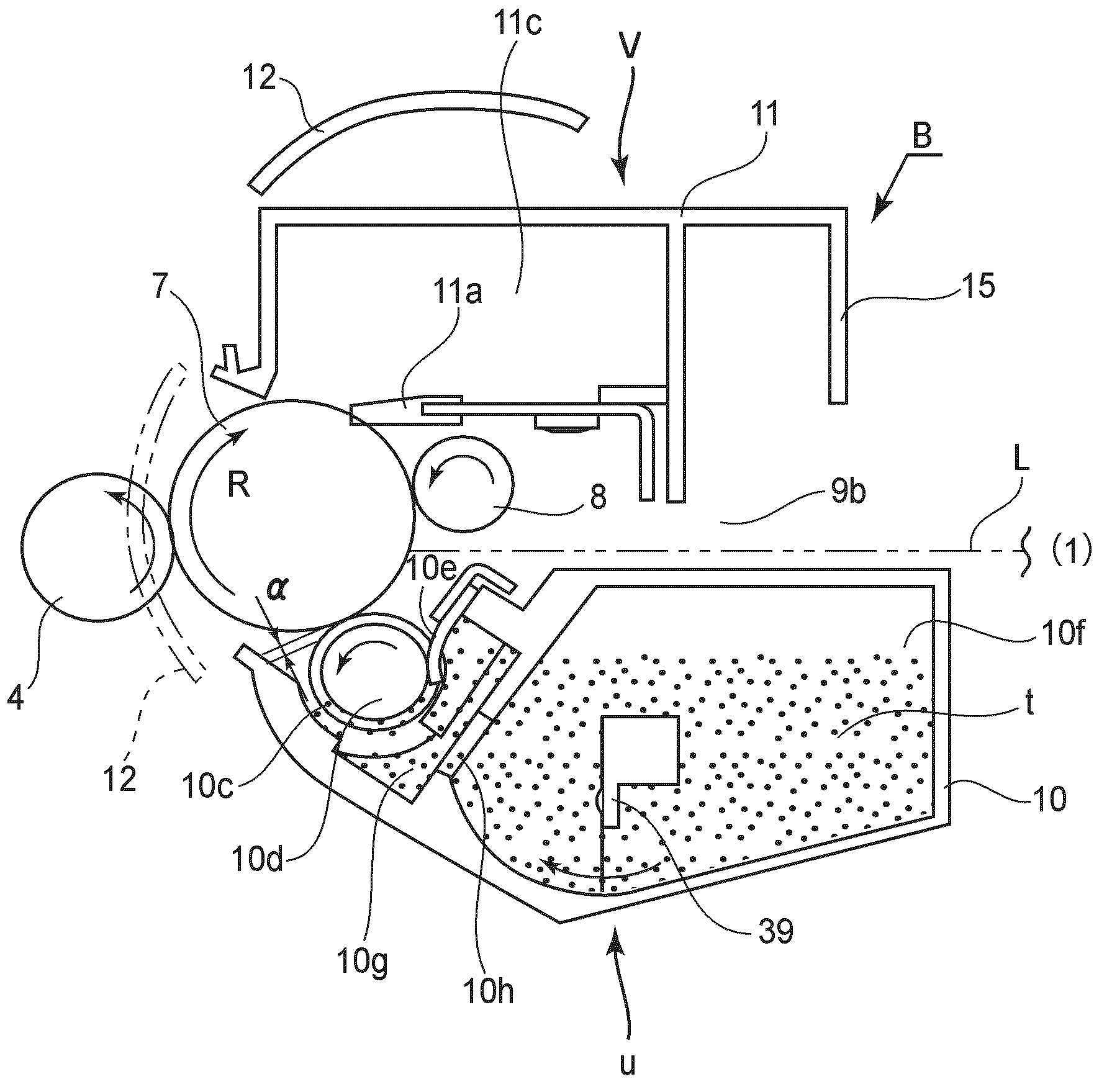

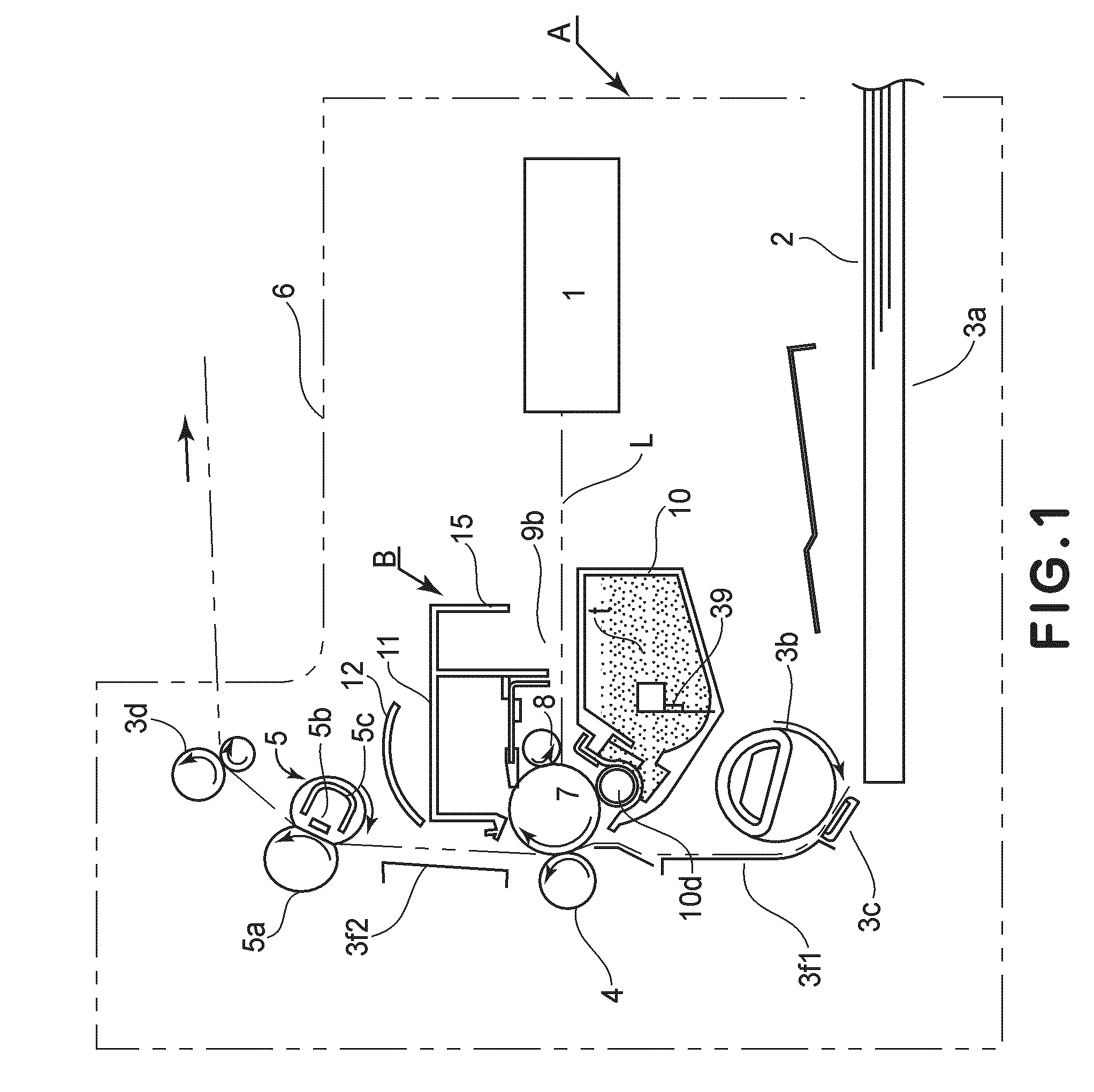

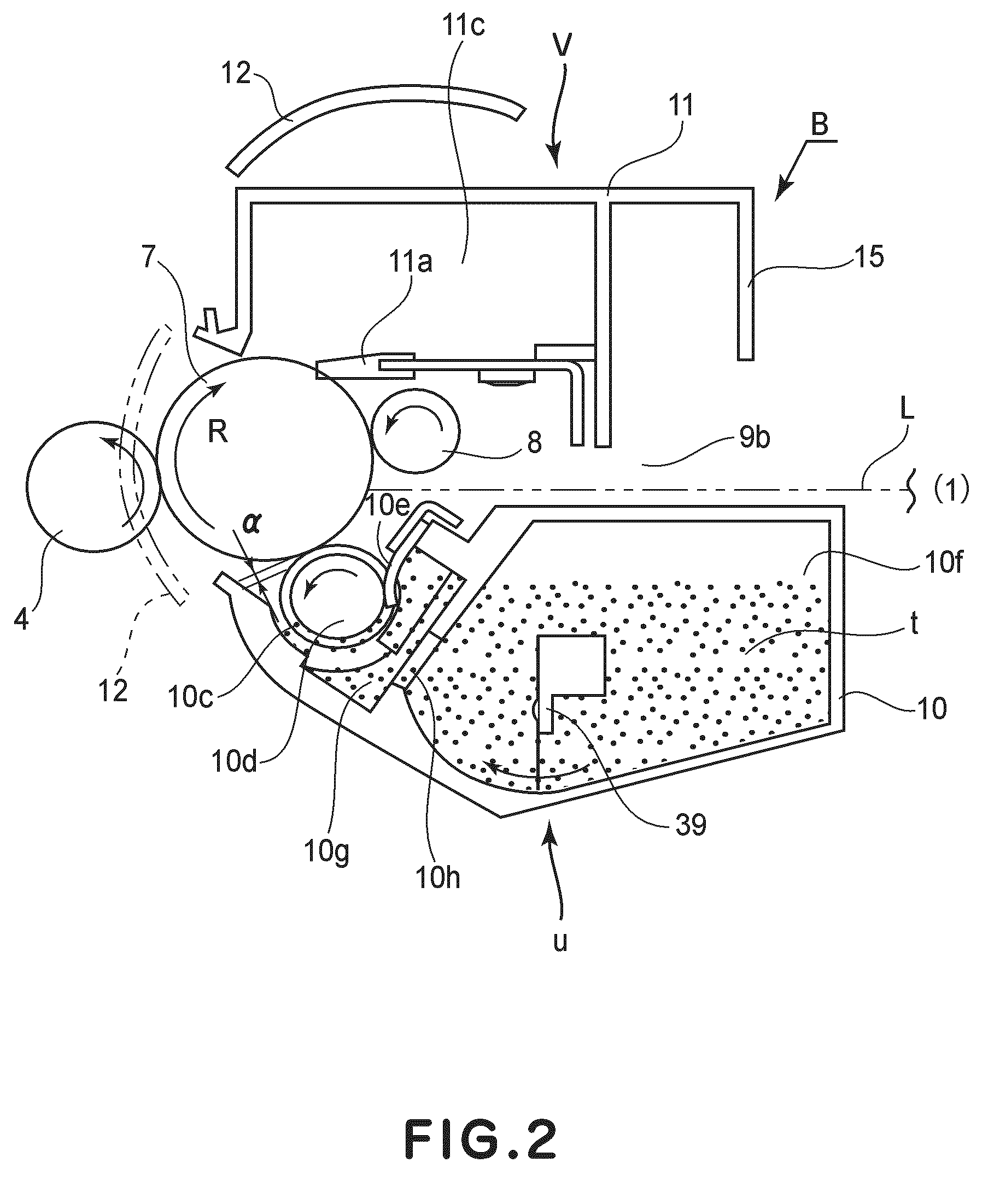

Process cartridge and assembling, disassembling remanufacturing method therefor

ActiveUS20090297208A1Easy to assembleEasy to disassembleElectrographic process apparatusLatent imageEngineering

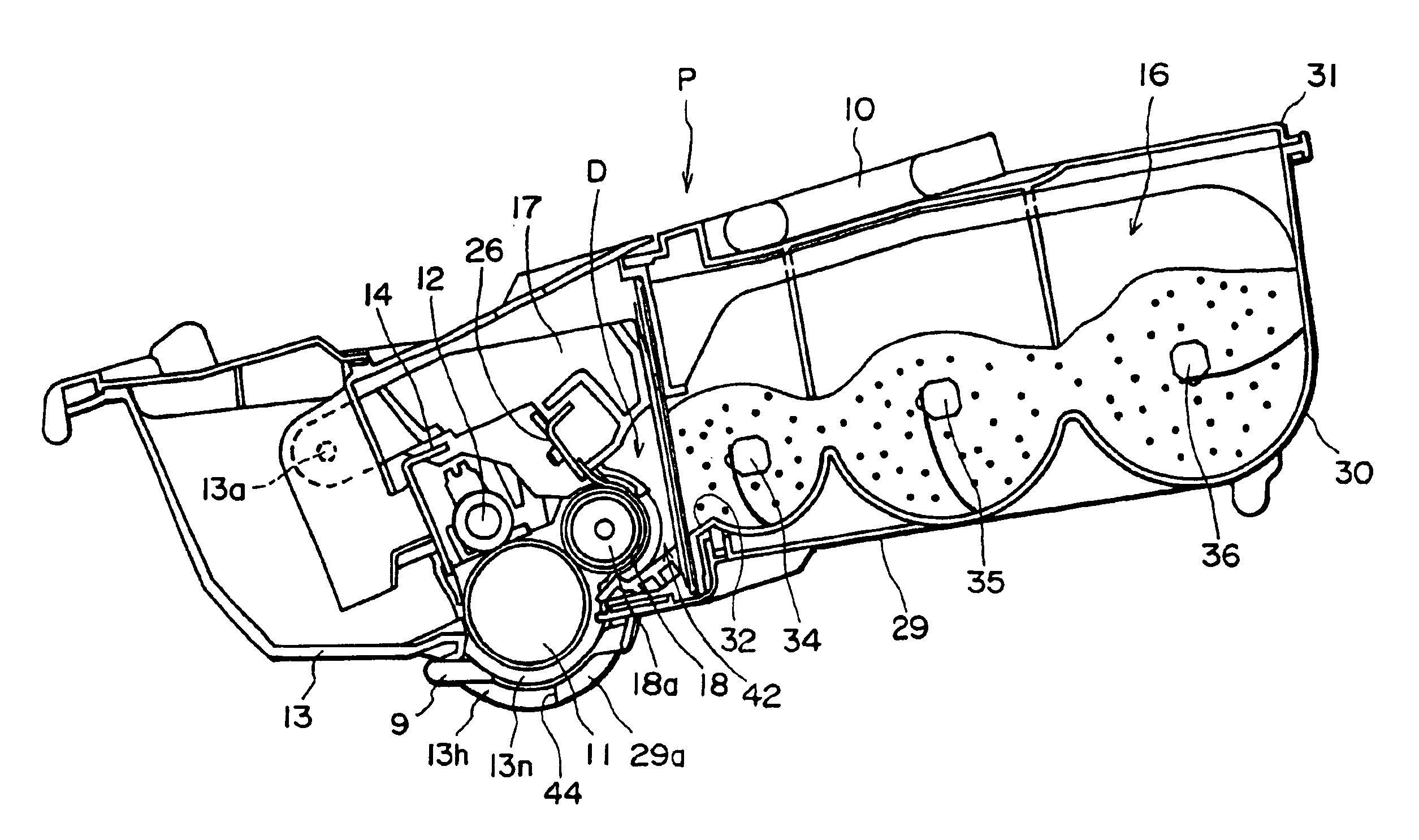

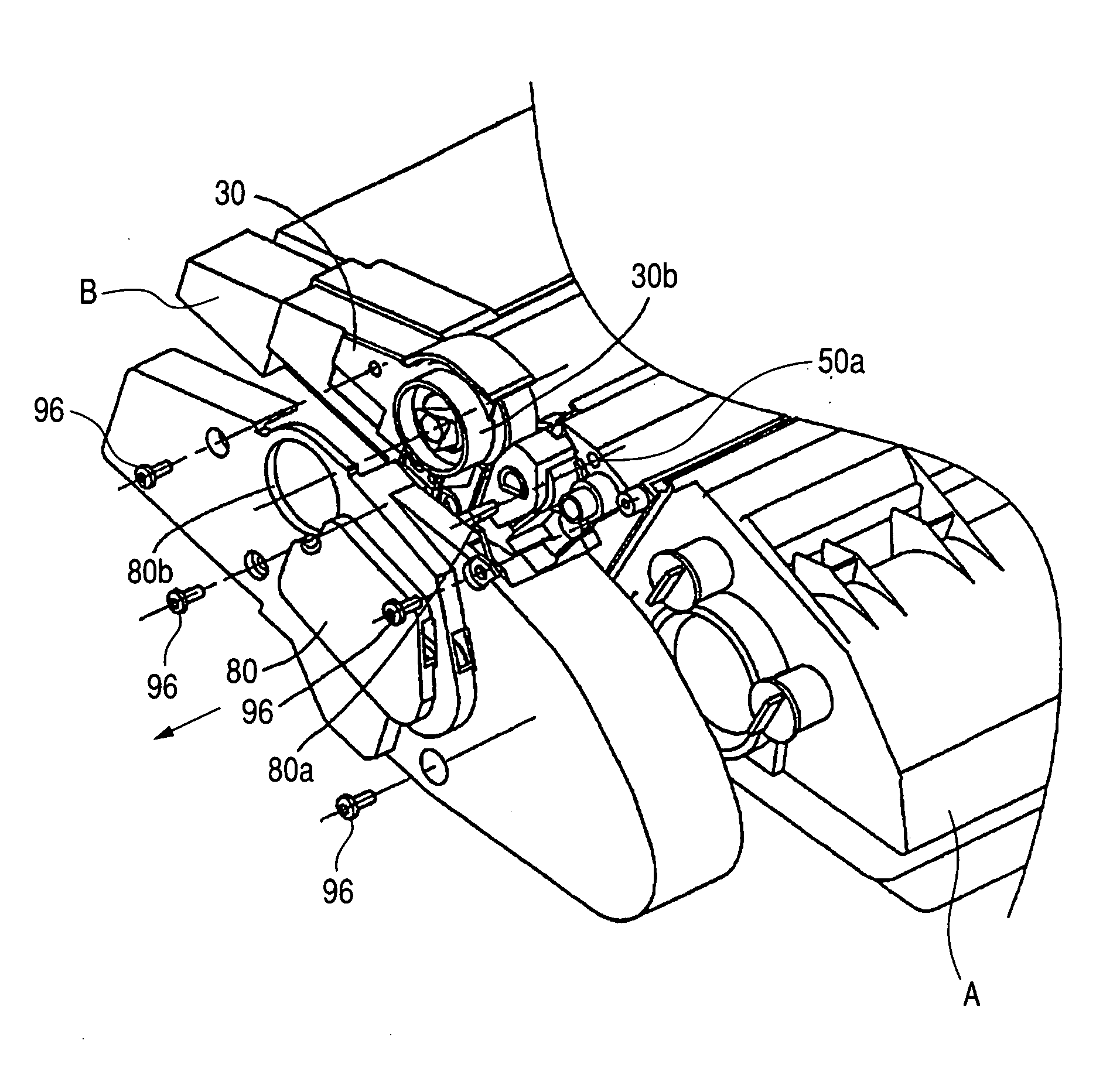

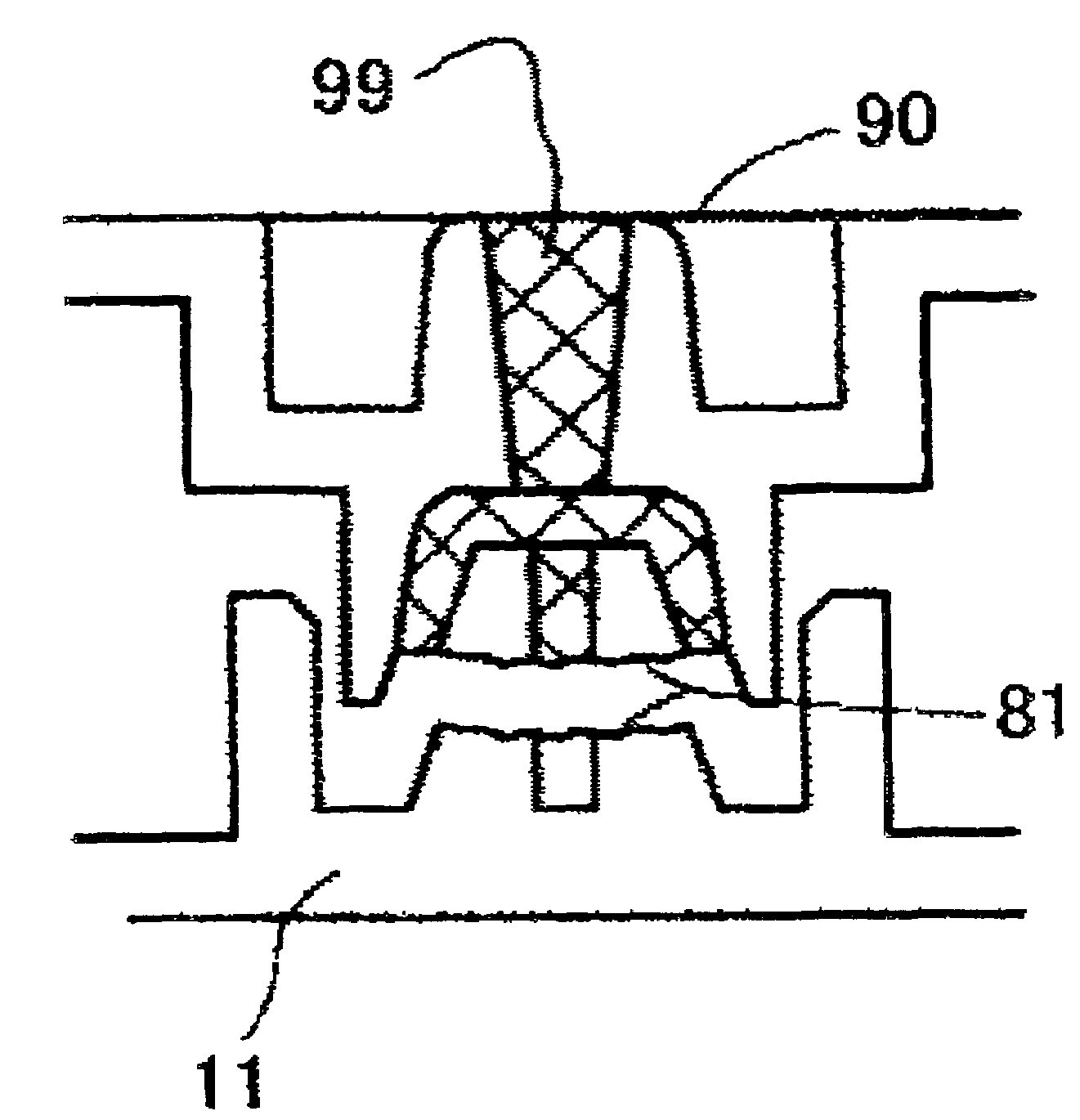

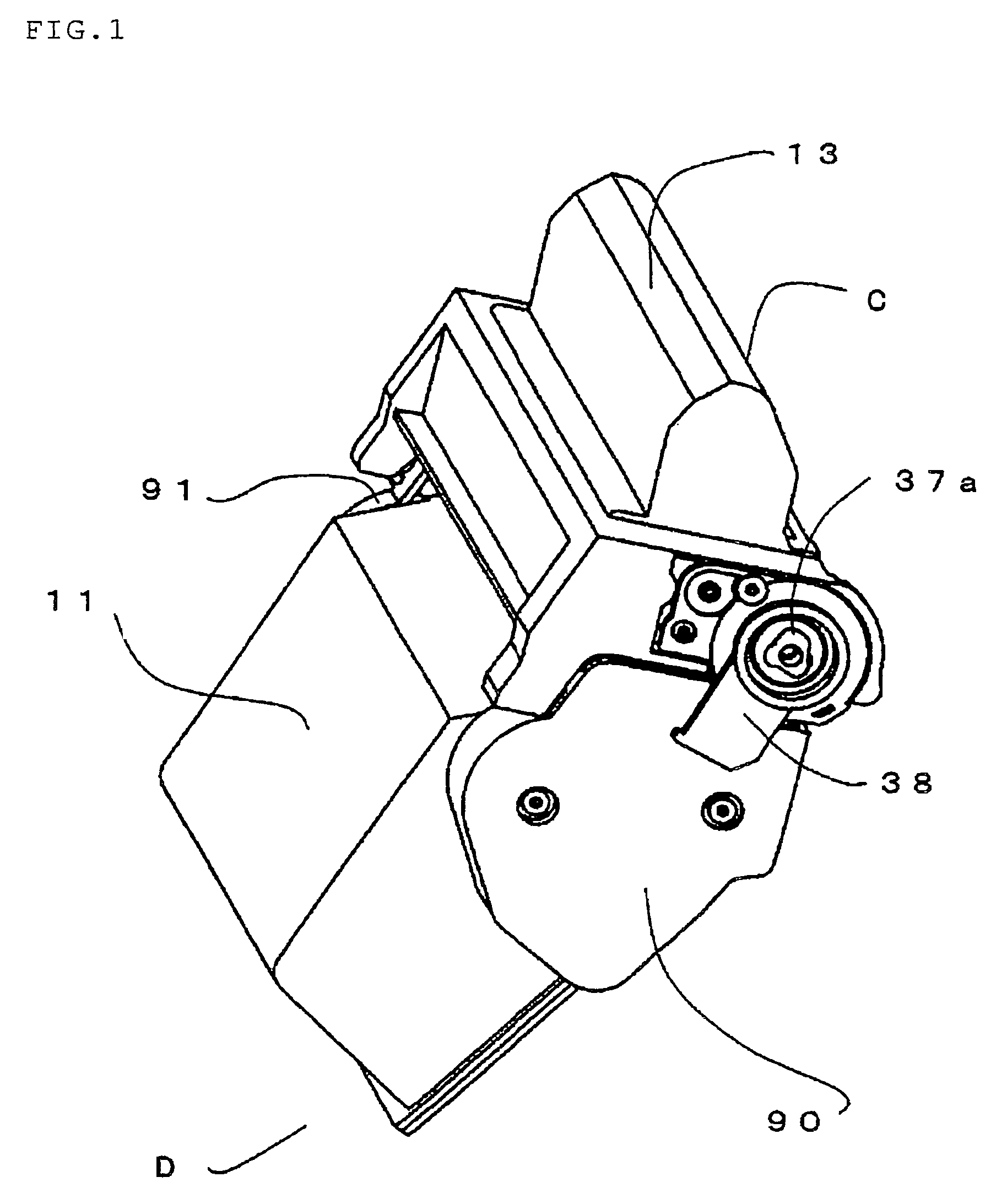

An assembling method for a process cartridge the assembling method includes a step of preparing a drum unit supporting a electrophotographic photosensitive drum; a step of preparing a developing unit supporting a developing roller for developing a electrostatic latent image formed on the electrophotographic photosensitive drum a developer supplying roller for supplying a developer to the developing roller and a developer accommodating portion having a developer supply opening; a unit coupling process of coupling the drum unit and the developing unit with each other; a first-end developing-device spacing member mounting step after the unit coupling process of engaging with a opening provided at a first end portion of the drum unit a first-end developing-device spacing member provided rotatably about a shaft at a first end portion of the developing unit to regulate rotation of the developing unit relative to the drum unit; and a second-end developing-device spacing member mounting step of engaging, with a projection provided at a second end portion of the drum unit, a second-end developing-device spacing member provided rotatably about a shaft at a second end portion of the developing unit to regulate rotation of the developing unit relative to the drum unit.

Owner:CANON KK

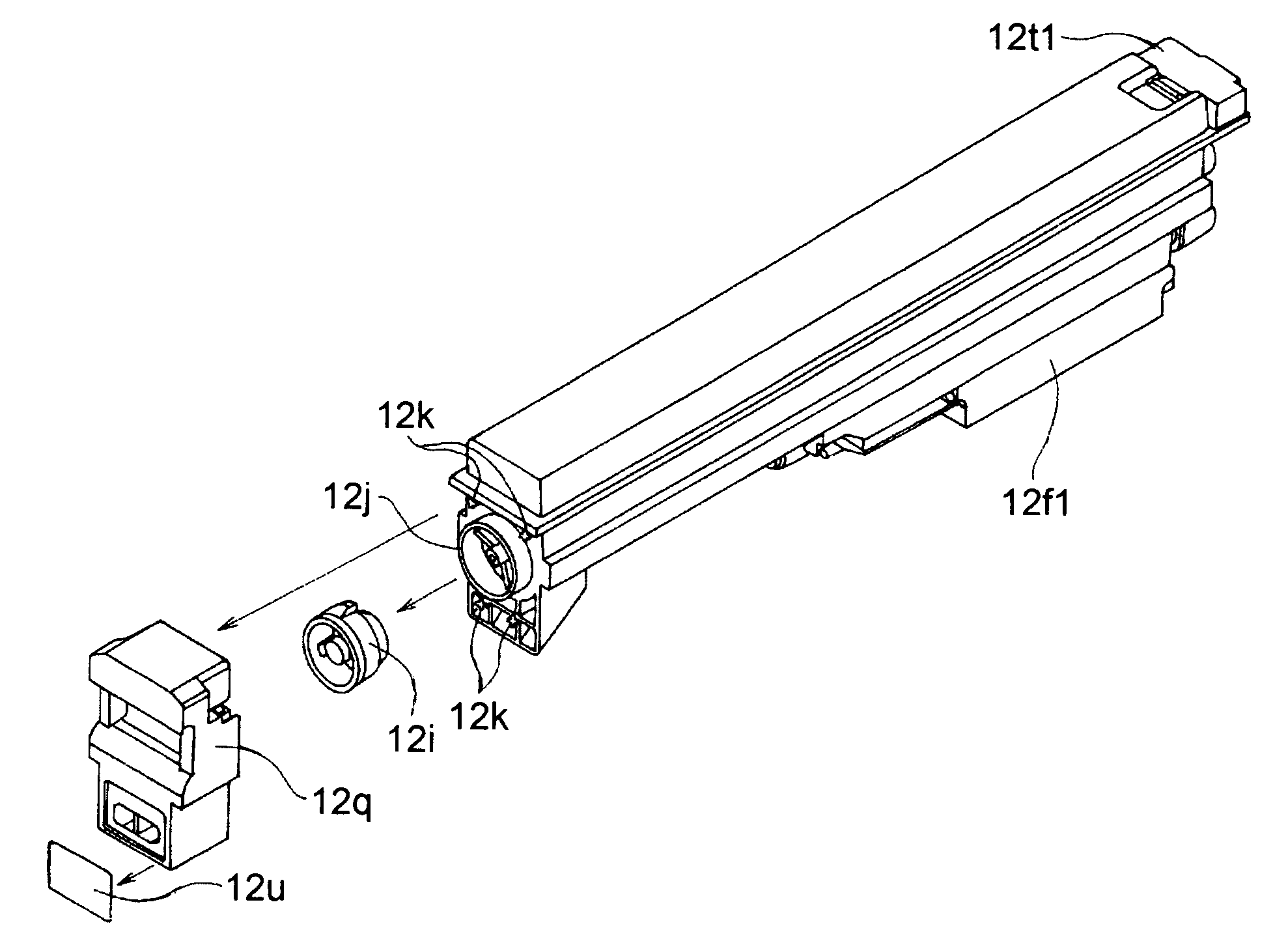

Remanufacturing method for toner supply container

InactiveUS6968141B2Simple methodPrevent leakagePowdered material dispensingElectrographic process apparatusImaging equipmentRemanufacturing

A remanufacturing method for a developer supply container detachably mountable to a main assembly of an image forming apparatus, the developer supply container including a frame, a developer accommodating portion for accommodating a developer to be used by a developing device of the image forming apparatus, a developer filling opening for filling the developer into the developer accommodating portion, a capping member for closing the developer filling opening, and a cap covering member covering the capping member, the cap covering member being fixed by welding to the frame, the remanufacturing method including a cap covering member dismounting step of dismounting the cap covering member from the frame by separating cap covering member from the frame at a welded portion; a capping member dismounting step of dismounting the capping member to open the developer filling opening; a developer filling step of filling the developer with the developer filling opening; a capping member mounting step of closing the developer filling opening by a capping member; a cap covering member mounting step of mounting the cap covering member to the frame.

Owner:CANON KK

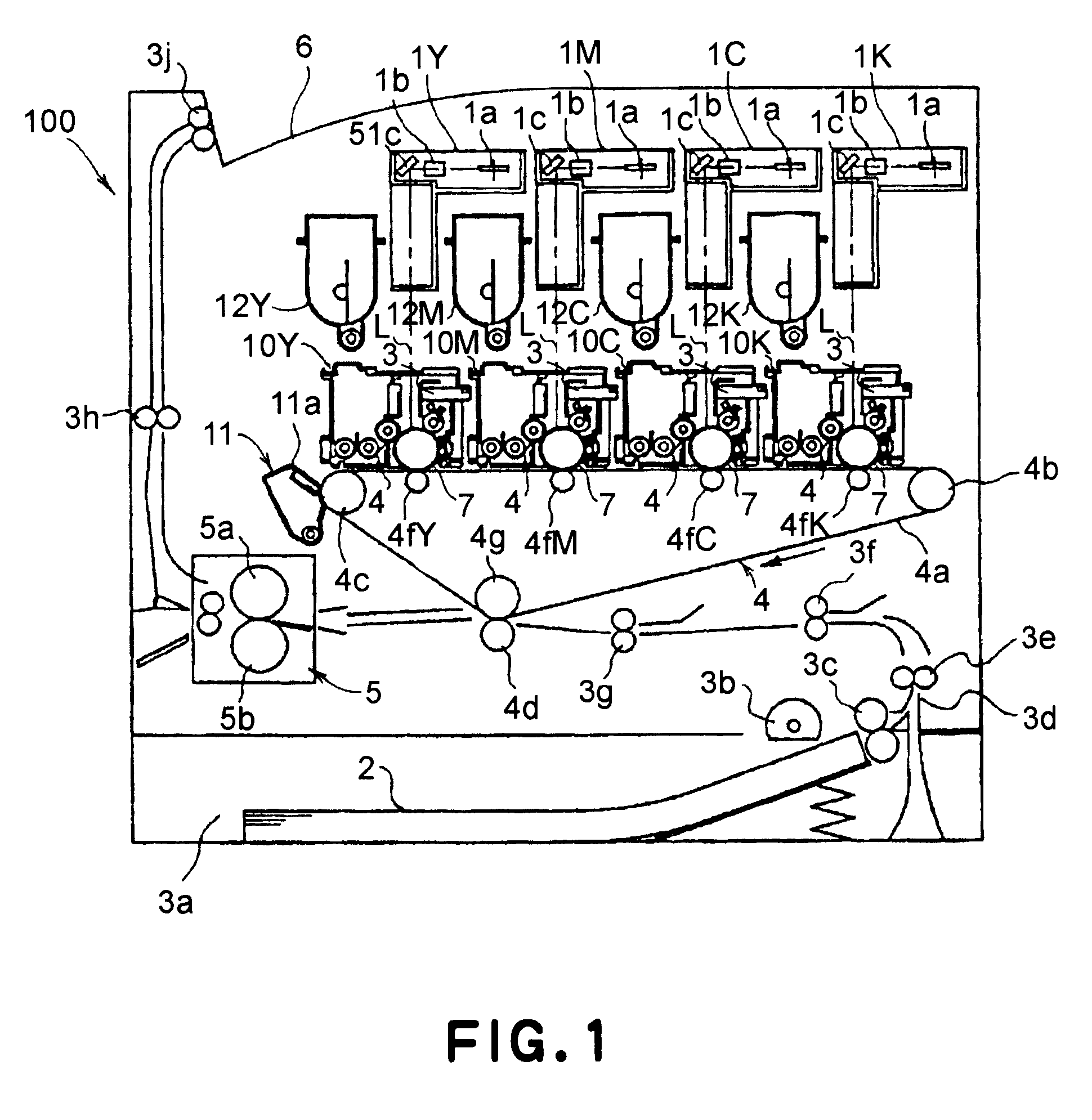

Process cartridge remanufacturing method

InactiveUS20050232654A1Simple processSimple methodElectrographic process apparatusEngineeringRemanufacturing

A process cartridge remanufacturing method including: detaching, at one longitudinal end of a process cartridge, a first cover member from a drum frame and a developing frame; detaching, at the other longitudinal end, a second cover member from the drum frame and the developing frame; detaching a drum supporting member from the drum frame; separating the developing frame and the drum frame; detaching a developing roller from the developing frame; filling a developer containing portion with the developer from a developer supply port provided on the developing frame; mounting a developing roller to a developing frame; mounting, at the one end, a photosensitive drum to a drum frame; securing the drum frame and the developing frame in position at the one end by a first cover member; securing the drum frame and the developing frame in position at the other end by a second cover member; temporarily mounting a drum supporting member to support the photosensitive drum at the other end; and mounting the drum supporting member and the second cover member to the drum frame by mounting a fixation member to a mounting hole provided in the second cover member by using the screw.

Owner:CANON KK

Remanufacturing method for process cartridge

InactiveUS20050115043A1Simple methodArc welding apparatusElectrographic process apparatusEngineeringRemanufacturing

A process cartridge remanufacturing method including the steps of: (a) separating photosensitive drum and developing units; (b) dismounting a first side cover member; (c) a dismounting a first gear group from a first bearing member; (d) dismounting a supporting member from the first bearing member; (e) dismounting a second gear group from the first bearing member; (f) dismounting the first bearing member; (g) dismounting a developing roller; (h) dismounting a developing blade; (i) filling a developer into a developer accommodating portion; (j) mounting the developing blade; (k) mounting the developing roller; (l) mounting the second gear group, (m) mounting the supporting member; (n) mounting the first gear group; (o) mounting the first side cover member; and (p) rotatably connecting the photosensitive drum and developing units.

Owner:CANON KK

Process cartridge remanufacturing method

A remanufacturing method for a process cartridge detachably mountable to a main assembly of an electrophotographic image forming apparatus, includes (a) an end cover removing step of cutting a fixing portion between the second end cover and the drum frame and cutting a fixing portion between the second end cover and the developer frame, and removing the second end cover at the other longitudinal ends of the drum frame, the developing frame and the developer frame; (b) a drum shaft removing step of removing, at the other ends, a drum shaft rotatably supporting the electrophotographic photosensitive drum at the other ends; (c) a roller separating step of applying forced to the drum frame, the developing frame and the developer frame in directions crossing with a longitudinal direction of electrophotographic photosensitive drum so as to separate the electrophotographic photosensitive drum and the developing roller from each other; (d) a drum removing step of moving the electrophotographic photosensitive drum outwardly from the process cartridge at the other end of electrophotographic photosensitive drum, while keeping the forces applied to the drum frame, the developing frame and the developer frame, so that electrophotographic photosensitive drum is inclined, and then removing the electrophotographic photosensitive drum from the drum frame; (e) a drum mounting step of inserting one end of a new electrophotographic photosensitive drum having at one end a driving force receiving portion for receiving a driving force for rotating the electrophotographic photosensitive drum from the main assembly of the electrophotographic image forming apparatus when process cartridge is mounted to the main assembly of the electrophotographic image forming apparatus, such that driving force receiving portion is exposed outside the drum frame, and inserting the drum shaft at the other end from outside of the drum frame, thus mounting a new drum electrophotographic photosensitive drum to the drum frame; (f) a developer refilling step of opening a filling port provided in the developer accommodating portion, refilling the developer and then closing the filling port; and (g) an end cover mounting step of fixedly mounting a second end cover to the other longitudinal ends of the drum frame, the developing frame and the developer frame.

Owner:CANON KK

Method of remanufacturing cartridge and remanufactured cartridge

A method of remanufacturing a cartridge detachably mountable in an electrophotographic image-forming apparatus body and composed of styrene-based resin compositions at least in part, characterized by including the steps of: (1) dividing the cartridge into at least two parts; and (2) bonding at least one of the divided parts with another one of the divided parts and / or a component other than the divided parts by use of a terpene solvent.

Owner:CANON KK

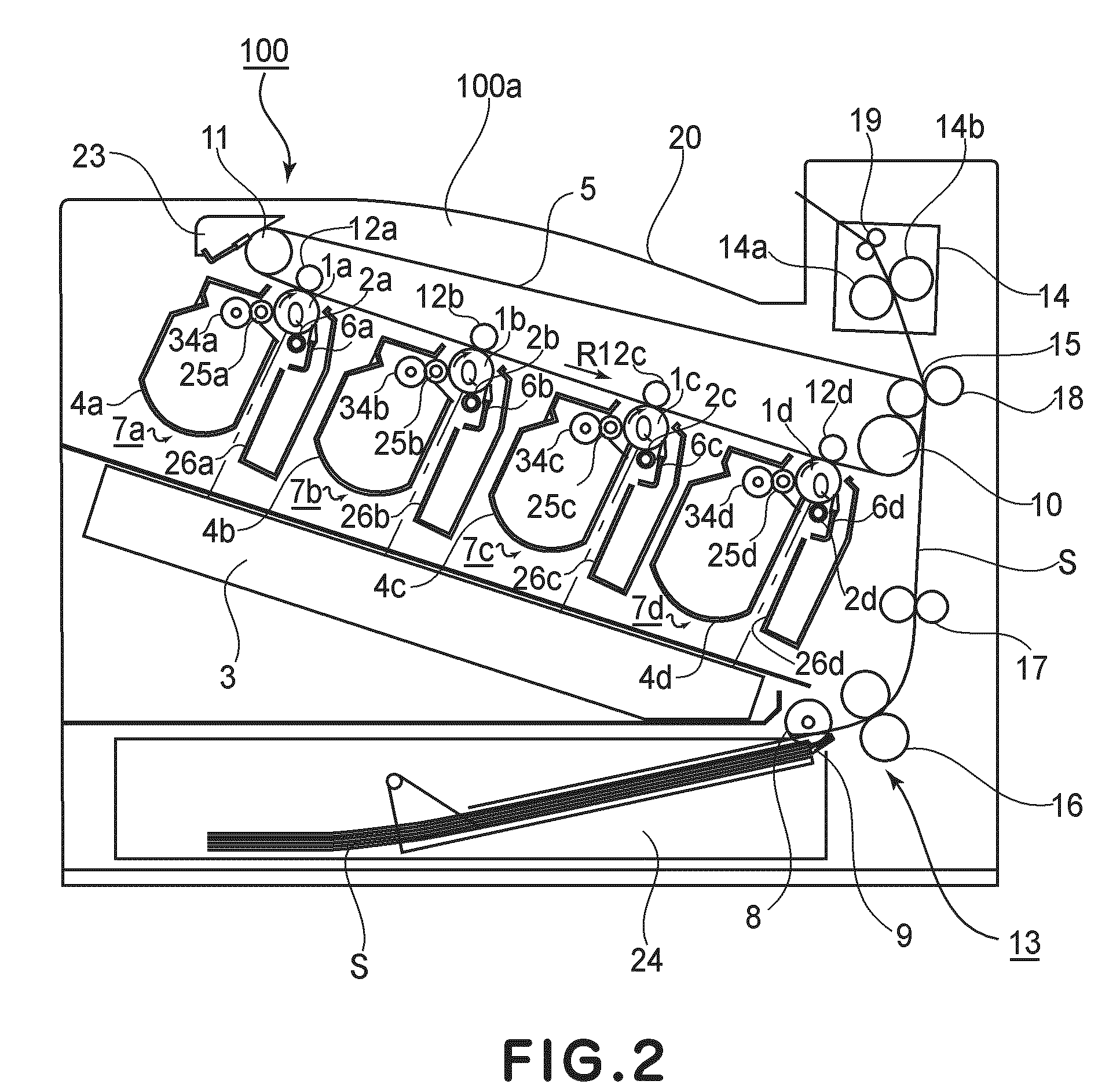

Process cartridge remanufacturing method

ActiveUS20090110434A1Simpler in terms of the refilling of developerElectrographic process apparatusRemanufacturingEngineering

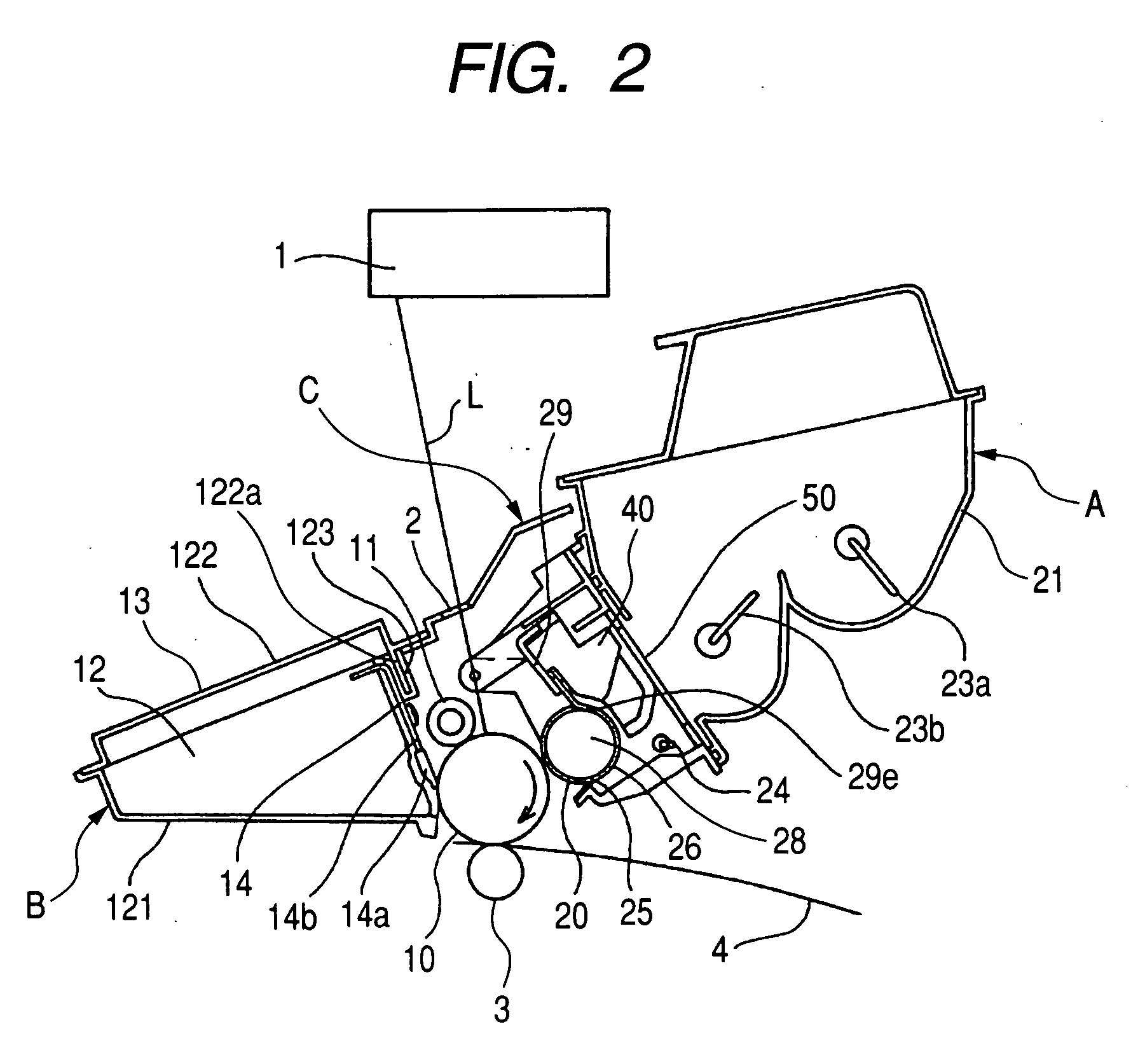

A remanufacturing method includes dismounting, from one end of a drum frame, a supporting member while rotatably supporting one end of a drum and a developing device frame; separating the two frames; dismounting the drum; mounting one end of a fresh drum to the other end of the drum frame; a refilling developer into a developer accommodating portion of the separated developing device frame; and swingably connecting the developing device frame and the drum frame by mounting the supporting member to one end of the drum frame, while rotatably supporting, by the supporting member, the one end of the drum of the drum frame to which the fresh drum has been mounted and swingably supporting the one end of the developing device frame to the developer accommodating portion of which the developer has been refilled, by the drum frame.

Owner:CANON KK

Process cartridge remanufacturing method

ActiveUS8238784B2Simpler in terms of the refilling of developerElectrographic process apparatusIndustrial engineeringRemanufacturing

A remanufacturing method includes dismounting, from one end of a drum frame, a supporting member while rotatably supporting one end of a drum and a developing device frame; separating the two frames; dismounting the drum; mounting one end of a fresh drum to the other end of the drum frame; a refilling developer into a developer accommodating portion of the separated developing device frame; and swingably connecting the developing device frame and the drum frame by mounting the supporting member to one end of the drum frame, while rotatably supporting, by the supporting member, the one end of the drum of the drum frame to which the fresh drum has been mounted and swingably supporting the one end of the developing device frame to the developer accommodating portion of which the developer has been refilled, by the drum frame.

Owner:CANON KK

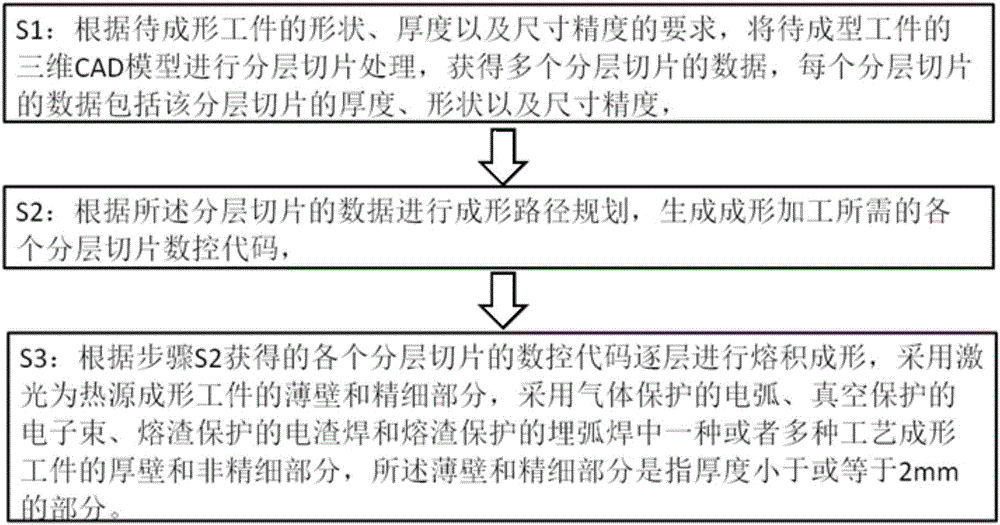

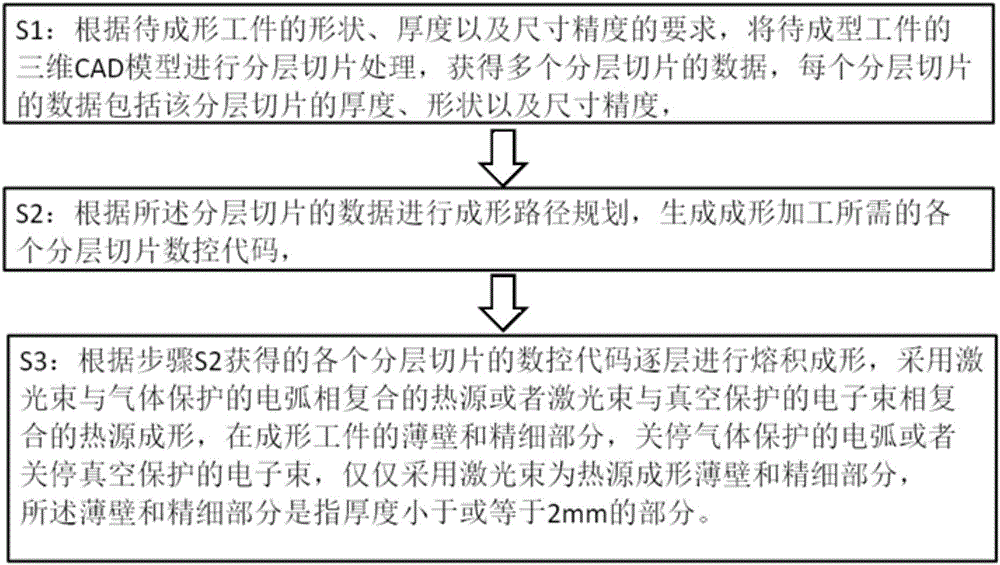

Deposition forming manufacturing method of parts and molds

ActiveCN105945281AImprove mechanical propertiesImprove metallurgical qualityAdditive manufacturing apparatusIncreasing energy efficiencyElectricityStructure property

The invention discloses a deposition forming manufacturing method of parts and molds, and belongs to the field of non-mold growing manufacturing and remanufacturing. The method comprises the following steps that S1, the three-dimensional CAD model of a workpiece to be formed is subjected to hierarchical slicing; S2, the CNC codes of all hierarchical slices are acquired; S3, deposition forming is conducted layer by layer according to the CNC codes of all the hierarchical slices, the fine portions of the workpiece are formed by laser, and one or more technologies in electric arc welding, electron beam welding, electroslag welding and submerged-arc welding is or are adopted to form the thick wall and the non-fine portions of the workpiece; or in the S3, a heat source which is compounded by laser beams and gas protection electric arcs or a heat source which is compounded by the laser beams and vacuum protection electronic beams is adopted for forming the thin wall and the fine portions of the workpiece, and the gas protection electric arcs or the vacuum protection electron beams are shut down. According to the deposition forming manufacturing method, direct deposition forming can be achieved to obtain parts and molds which are stable in structure property and high in manufacturing precision and are provided with thin walls or fine portions.

Owner:HUAZHONG UNIV OF SCI & TECH

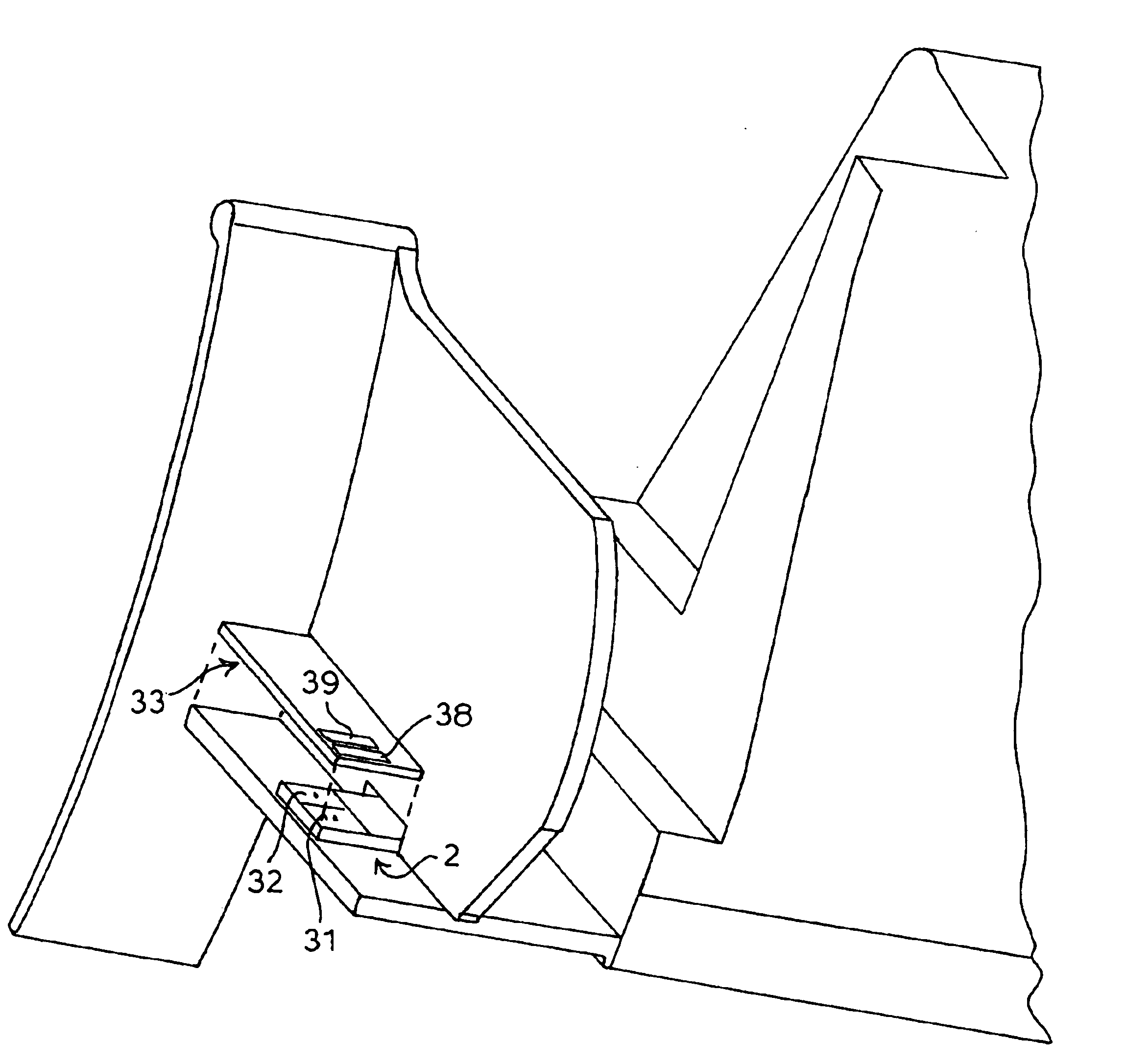

Method and apparatus for repairing and electronic circuit in a remanufactured replaceable consumable

InactiveUS6882810B2Function increaseIncrease flexibilityElectrographic process apparatusSingle useInformation storage

In the toner cartridge recycling and remanufacturing industry, used xerographic products are reconditioned, repaired, and some are refilled with toner. Part of the refurbishment process is the replacing of used and worn components, including an electronic circuit, which has been spent. The electronic circuit is a critical component of the replaceable consumable unit and is used by the printer to store information used in the operation of the printer. Information stored in this electronic circuit relates to how much toner is remaining, the cartridge type, operating characteristics, and so forth. Some of these circuits have been designed for a one-time use application. For example, once the printer has determined that all of the usable toner has been consumed, the printer will essentially turn off the circuit in a replaceable consumable unit and the replaceable consumable unit will no longer function. In the remanufacturing process, a secondary electronic circuit can be attached to this non-functioning circuit in order to allow the replaceable consumable unit to operate once more. The nature of the present invention is directed at the process of repairing this non-functioning circuit and the resulting repaired unit.

Owner:APEX SEMICON (USA) CO LTD

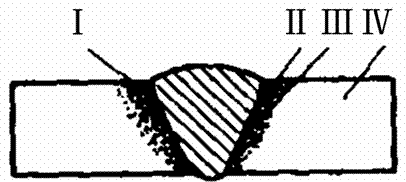

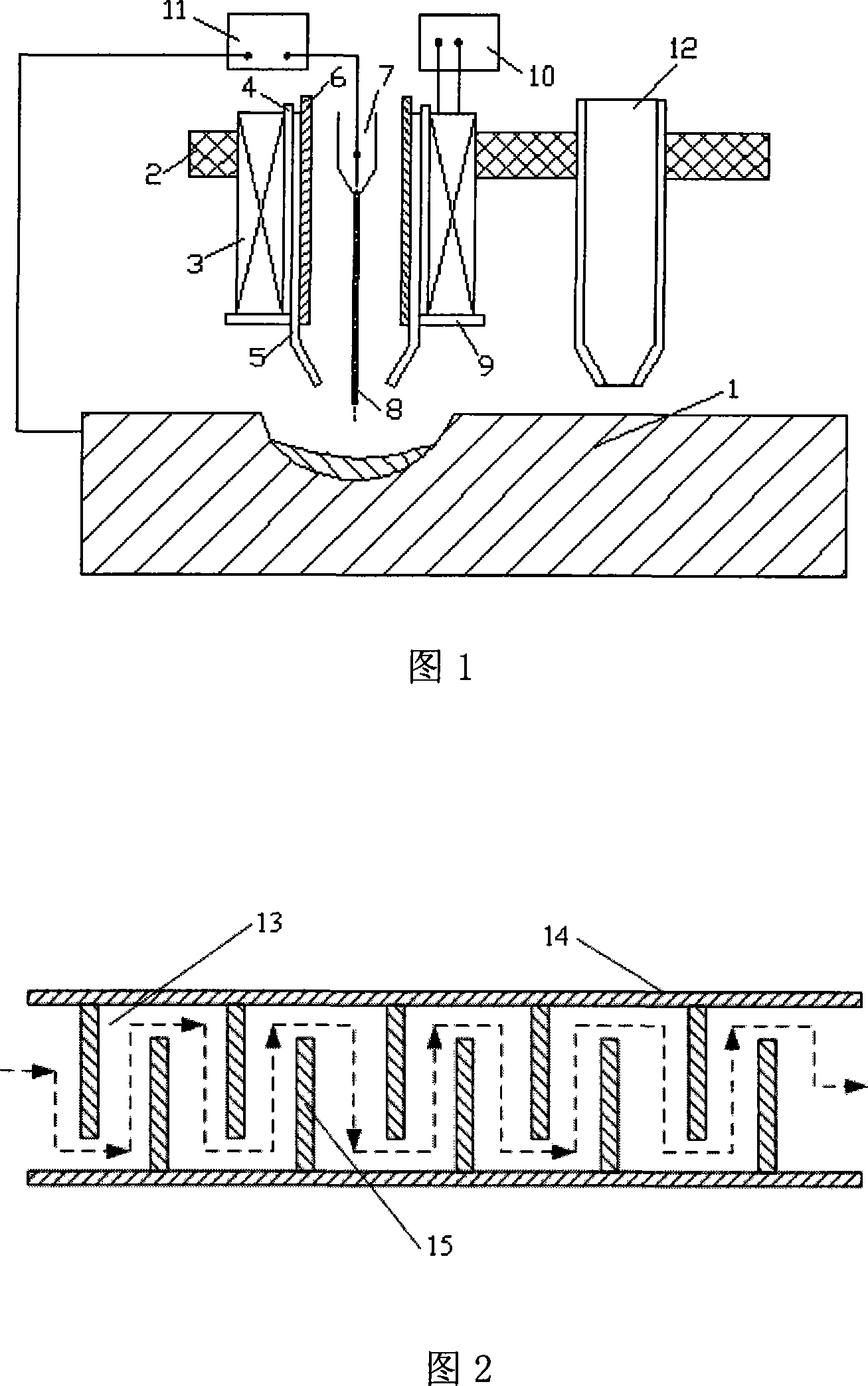

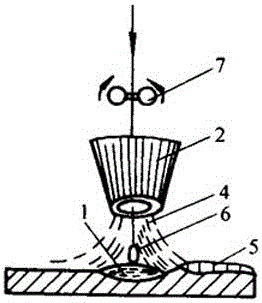

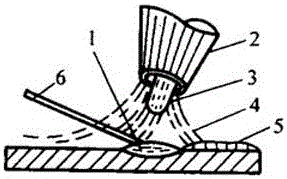

Method and device for remanufacturing sheet metal welding piece by utilizing laser

InactiveCN102886606AAchieve remanufacturingAccelerated microstructure movementWelding/soldering/cutting articlesMetal working apparatusMetal sheetCw laser

The invention discloses a method and a device for remanufacturing a sheet metal welding piece by utilizing laser and relates to the field of non-traditional machining. The method comprises the following steps of: closing cracks by employing continuous laser re-molten cracks and neighboring area; then heating the surface of the joint of the sheet welding piece in a dynamic strain ageing temperature area; and performing laser shock processing on the surface of the joint of the sheet welding piece by utilizing a double-sided laser impact method. According to the device, the sheet welding piece can be compositely strengthened and remanufactured, the cracks on the surface of the welding line are closed, the air holes inside the welding line are eliminated, the tensile strength of the joint of the sheet welding piece is improved, and the service life of the sheet welding piece is prolonged.

Owner:JIANGSU UNIV

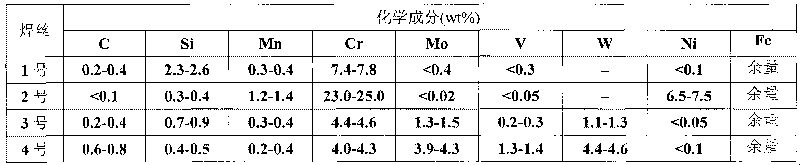

Method for quick repair welding, restoring and reproducing of high-alloy cold-working mould

The invention relates to a process technology and a method aiming at the simple, convenient and effective repair welding, restoring and reproducing of a cold-working die, which belongs to the technical field of high-alloy cold-working die steel. In the method, hard-face knife edges or molding shape faces which satisfies the requirements are produced on a failed cold-working die through resurfacing welding mainly by the process steps of the preheating treatment of a die to be restored before repair welding, the adoption of a specific welding wire, the determination of welding high-frequency current, the postweld heat treatment and the like, so the failed die carries out the punching task of more than tens of thousands times again. The method solves the problems of high carbon equivalent and difficult welding of high-alloy steel, recycles the failed die of a producer after repair welding and restoration, can enhance the service life of the die, reduces the maintenance cost of the die and enhances the production efficiency.

Owner:SHANGHAI UNIV

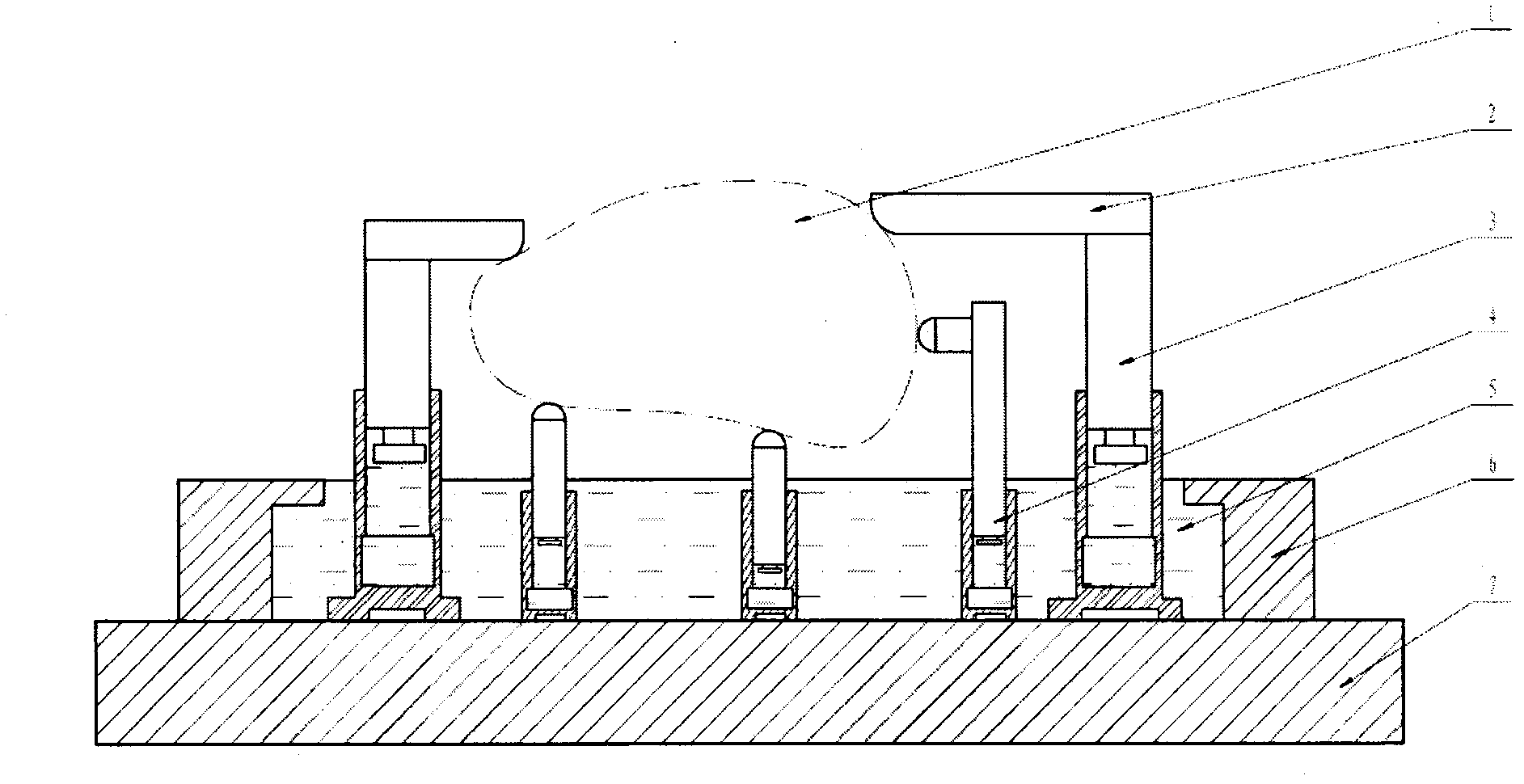

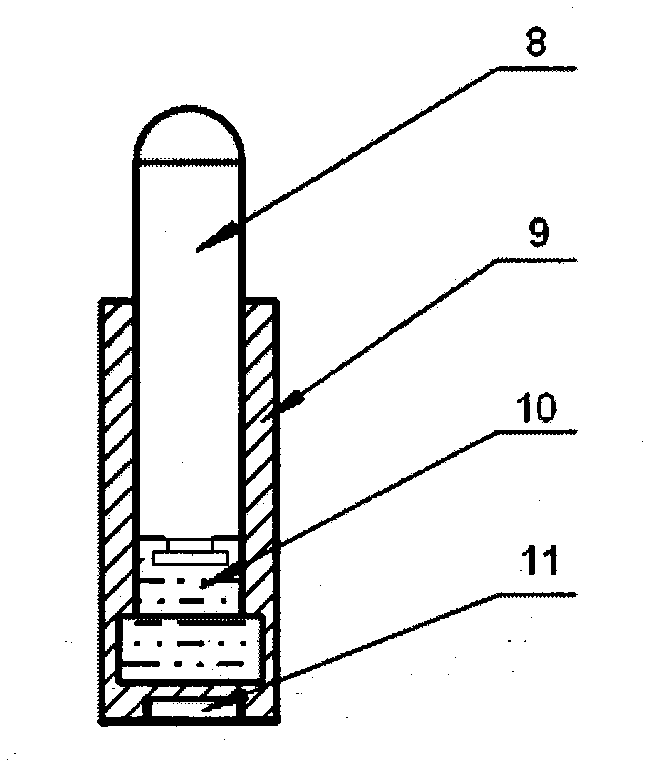

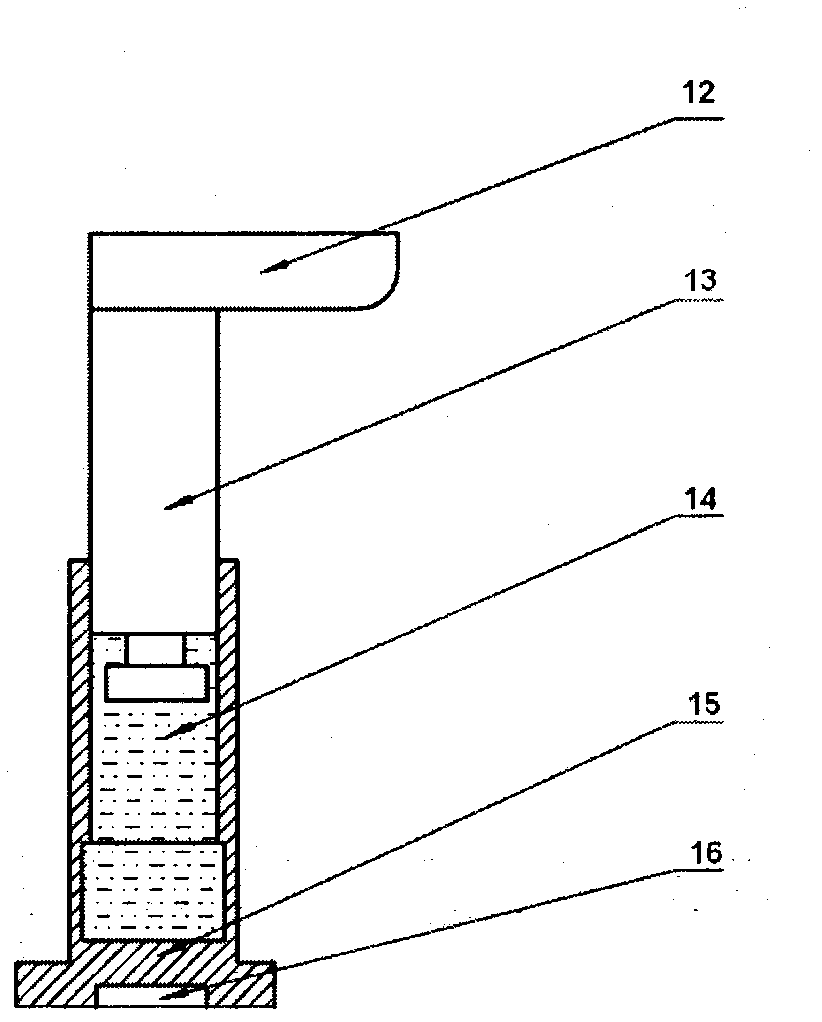

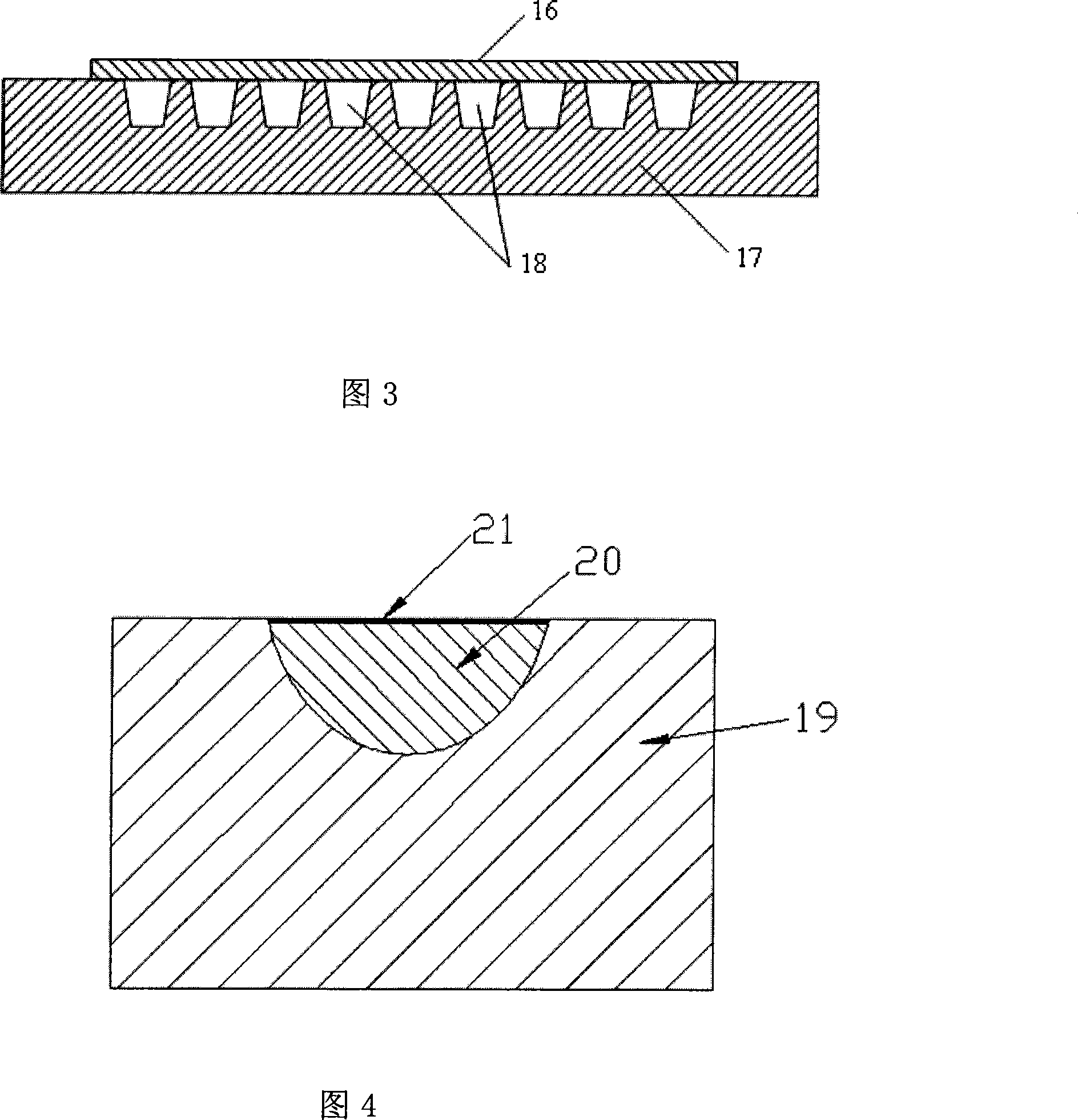

Flexible clamp based on phase-change material

InactiveCN102825484AEasy to manageEasy maintenanceWork holdersPositioning apparatusMagnetPhase-change material

The invention provides a really flexible clamp device capable of clamping parts with any complex shapes and sizes. The flexible clamp device provided by the invention comprises a base, a phase-change material cavity, a phase-change material, a locating body, a clamping body and the like. The phase-change material cavity is connected to the base through a bolt; the locating body is placed on the base through a numerical control locating machine and adsorbed on the base through a bottom permanent magnet; the clamping body is placed on the base through the numerical control locating machine and adsorbed on the base through the bottom permanent magnet; and phase-change material is cast so that the locating body, the clamping body, the phase-change material cavity and the base are fixedly connected to form a clamp. The length of the locating body can be continuously adjusted, the height of the clamping body can be continuously adjusted, and positions of the locating body and the clamping body can be arranged randomly, so that clamping the parts with any complex shapes and sizes is realized. The clamp is simple in part shape, low in manufacturing precision requirement and low in clamp manufacturing cost; and the phase-change material can be repeatedly used so as to be easy for remanufacturing and cyclic utilization.

Owner:JIANGNAN UNIV

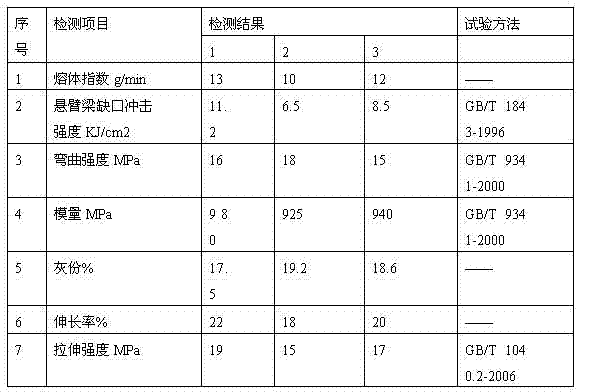

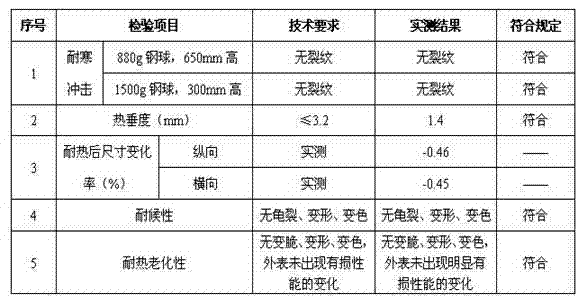

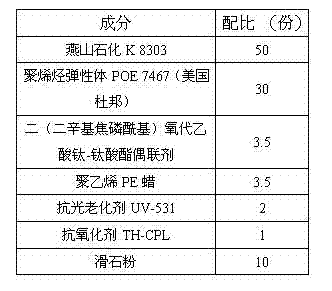

Method for recycling thermoplastic polypropylene plastic parts of scraped automobile

InactiveCN102173007AAvoid problems that are difficult to recycleSolve the problem of strong bonds that are difficult to removePlastic recyclingThermoplasticEngineering

The invention belongs to the field of recycling of waste plastics of scraped automobiles, and relates to a method for recycling thermoplastic polypropylene plastic parts of a scraped automobile. The method comprises the following steps of: manually disassembling nonmetallic inner and outer ornaments and structural parts of the scraped automobile, manually sorting thermosetting plastic parts and thermoplastic plastic parts, further manually sorting the thermoplastic polypropylene plastic parts, manually disassembling and separating metallic linkage parts, circuits and the like of the sorted thermoplastic polypropylene plastic parts, performing two-stage crushing on the polypropylene plastic parts, performing ferromagnetic sorting on two crushed materials respectively to separate out metallic scraps, separating out fine metallic scraps and metallic paint by using a roller direct-current high-voltage corona and electrostatic composite electric field sorter, performing sampling performance detection on the cleaned and dried materials, adding a modifier according to the detection results and the using requirements, granulating, and manufacturing automobile plastic members by using the materials. By using the method, the plastic recycling problem of the scraped automobile is solved, broken plastic resources of the scraped automobile are recycled, environmental pollution is avoided, the energy consumption is low, and the additional value is high.

Owner:路洪洲 +3

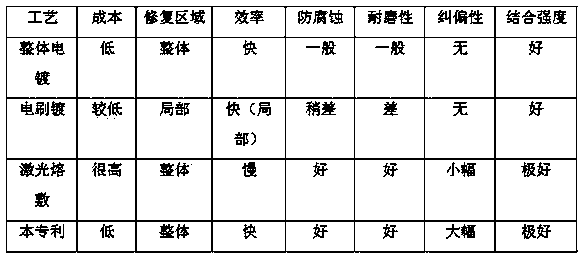

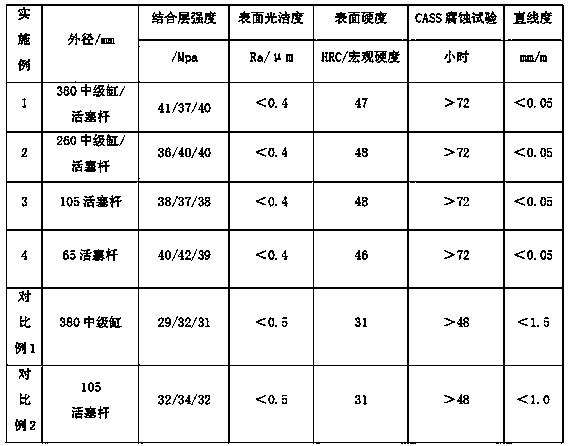

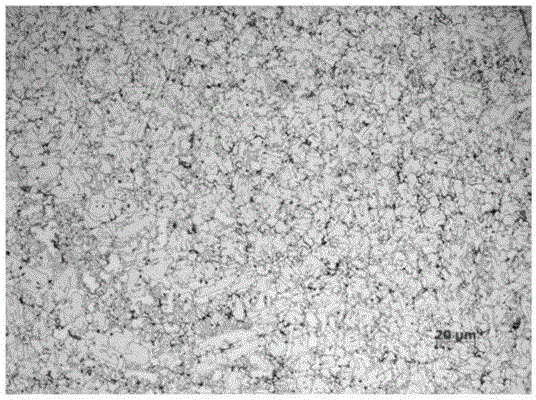

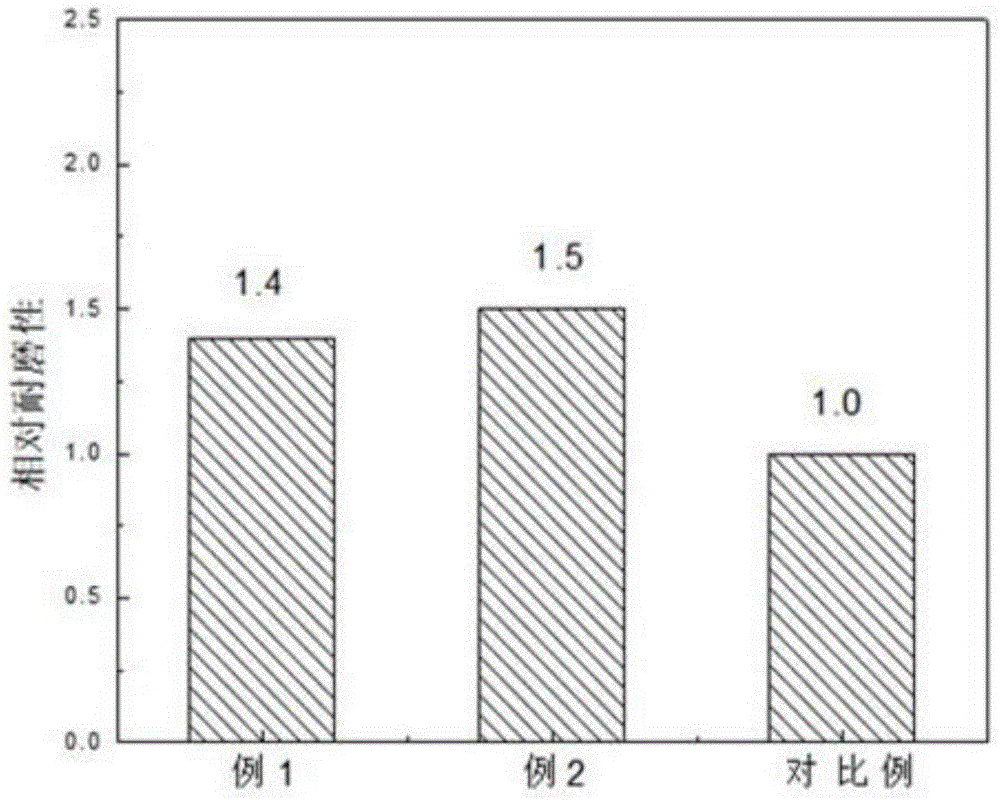

Method for repairing and remanufacturing outer surface of piston rod of hydraulic cylinder or outer surface of intermediate cylinder

ActiveCN104191152AHigh surface macrohardnessImprove wear resistanceArc welding apparatusHydraulic cylinderMetal filament

The invention provides a method for repairing and remanufacturing the surface of a piston rod of a hydraulic cylinder or the outer surface of an intermediate cylinder for coal mines. Aiming at remanufacturing after the surface of the piston rod of the hydraulic cylinder or the outer surface of the intermediate cylinder for the coal mines is damaged and fails, the long-term practice is combined, a metal wire adopting the specific metal powder proportion is creatively designed to serve as a powder core wire, and namely the metal wire is formed by wrapping the metal powder with Cr, Ni and Fe as the main ingredients through a stainless steel foil layer; based on the arc thermal spraying process method, the surface is repaired and remanufactured creatively, and on the premise that the corrosion resistance and the hardness of the repaired layer of the surface are equal to those of the surface treated through the surface laser cladding technology, consideration is given to the good economic applicability and the good practical production efficiency; an existing electroplating technology can be completely replaced, and the method has the wide application and popularization prospects in repairing of the piston rod of the hydraulic support oil cylinder and the intermediate cylinder for the coal mines.

Owner:SHAANXI TIANYUAN MATERIALS PROTECTION TECH

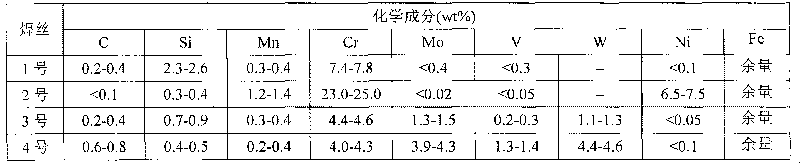

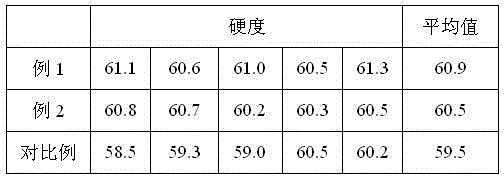

Self-shielded flux-cored wire for extrusion roller remanufacturing

InactiveCN104959746AImprove bindingImprove toughnessWelding/cutting media/materialsSoldering mediaFerrosiliconManganese

The invention discloses a self-shielded flux-cored wire for extrusion roller remanufacturing. A mild-carbon steel strip is employed as the skin of the self-shielded flux-cored wire. The component of the flux comprises, by mass, 20%-40% of high carbon ferrochrome, 20%-40% of chromium carbide, 5%-20% of ferromolybdenum, 1%-10% of ferrovanadium, 1%-5% of ferroniobium, 1%-5% of graphite, 1%-5% of aluminum-magnesium, 1%-4% of electrolytic manganese, 1%-4% of ferrosilicon and 1%-4% of ferroboron, and the weight ratio is 44%-52%. The hardness of the surfacing alloy manufactured by the use of the self-shielded flux-cored wire can reach HRC60, and the surfacing alloy is fine and uniform in crack, is high in wear resistance, is high in shock resistance, and is suitable for being employed as a working layer in an extrusion roller remanufacturing process in a cement plant.

Owner:盐城市成功机械制造有限公司

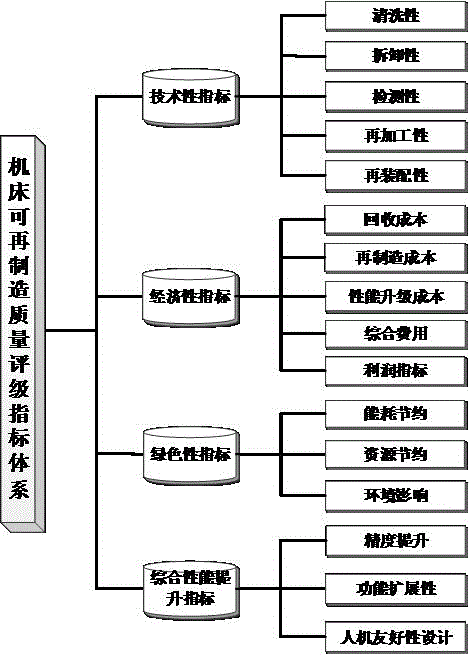

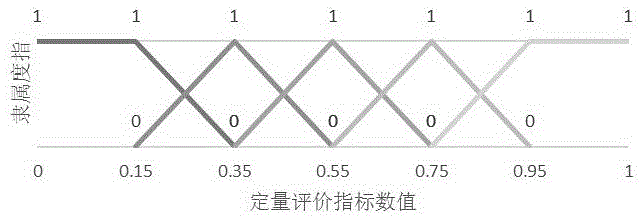

Obsolete machine tool remanufacturing quality evaluation method

The invention discloses an obsolete machine tool remanufacturing quality evaluation method, and mainly solves the problems that remanufacturing quality evaluation is difficult due to the fact that the quality and the service condition of an obsolete machine tool are uncertain. The remanufacturing quality evaluation indicator system of the obsolete machine tool is comprehensively and systematically constructed from the aspects of technical, economic, environment-friendly and comprehensive performance improvement. The evaluation method based on combination of the order relation and fuzzy comprehensive evaluation is put forward based on the system so that quantitatively and qualitatively combined remanufacturing quality evaluation can be realized, the problems that the existing evolution method is high in subjectivity and complex in computational process and then low in evaluation efficiency and poor in accuracy can be solved, and thus the remanufacturing quality evaluation result of the obsolete machine tool is enabled to be more objective and reasonable and meet the actual situation of remanufacturing engineering.

Owner:SHENYANG POLYTECHNIC UNIV

Composite reinforcement method for TiC/TiB2 base metal ceramic on surface of roller

ActiveCN102618867AImprove performanceImprove surface qualityMolten spray coatingSuperimposed coating processOperabilityAlloy

The invention discloses a composite reinforcement method for TiC / TiB2 base metal ceramic on the surface of a roller, and belongs to the technical field of metallurgical machinery. The composite reinforcement method comprises the processing steps of: cleaning the roller; performing plasma spraying of nickel base alloy or overlaying the nickel base alloy on the cleaned roller; turning the roller according to requirements of a steel groove rolling system to meet the technical requirements; and cladding on the surface of the roller by using an electric spark deposition process to form the TiB2 / TiC base metal ceramic by using a TiB2 / TiC base metal ceramic electrode. The composite reinforcement method has the advantages that: the roller performance is greatly improved and fixed-roller-diameter rolling can be guaranteed, so that the process stability in a rolling process is guaranteed, meanwhile, the service life of the roller is greatly prolonged, the roller consumption is reduced, and the steel rolling operability and the steel surface quality are improved. Compared with processes such as overlaying and laser, the composite reinforcement method can be used for repairing of primary and intermediate rolling roller, and most importantly, the composite reinforcement method can be directly used for surface treatment of the roller of a finishing mill group, so that remanufacturing of thesurface of the roller is realized.

Owner:HUNAN 3T NEW MATERIAL

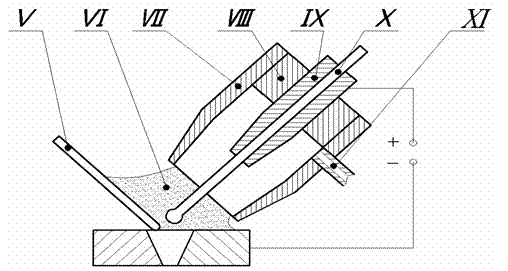

Method and equipment for waste and old mold electromagnetic weld deposit repair and surface modification

InactiveCN101239413AEffective coordinationEffective rationalityWelding accessoriesBiochemical engineeringHardness

The invention relates to an electro-magnetism weld deposit renovation and surface modification method for waste and old dies, comprising following steps: cleaning and preheating the waste and old dies, performing weld deposit on the portion of the waste and old dies where renovation and surface modification are needed by using an arc source weld deposit method adding impulse shooting flow electrical arc controlled by an externally-applied magnetic field; treating the dies to achieve a needed technique requirement. The invented method breaks off the two limits contradictory with each other which are high melt covering ratio and low dilution ratio of weld deposit, realizes effective cooperativeness and reasonable unification of weld deposit quality and efficiency, reduces cost of weld deposit and dies, and improves competitive power; resolves the contradictory problem of high hardness and low flexility in waste and old dies renovation field; protects electro-magnetism weld deposit novel heat source by using impulse revolving shooting flow gas innovationally, renovates the waste and old dies by utilizing characteristics of high efficiency, high quality, distortion and controllable temperature of the electrical arc heat source. The invention provides the related device also.

Owner:CHONGQING UNIV

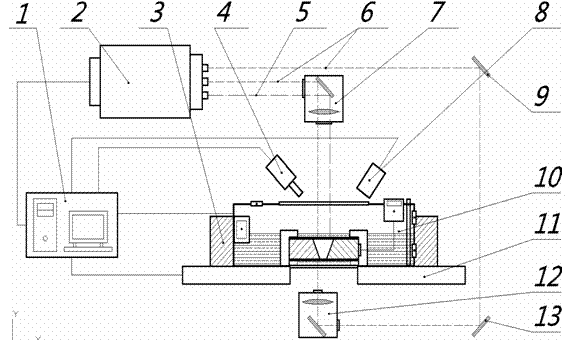

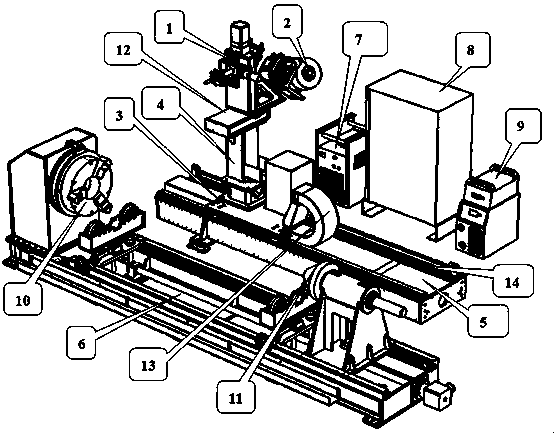

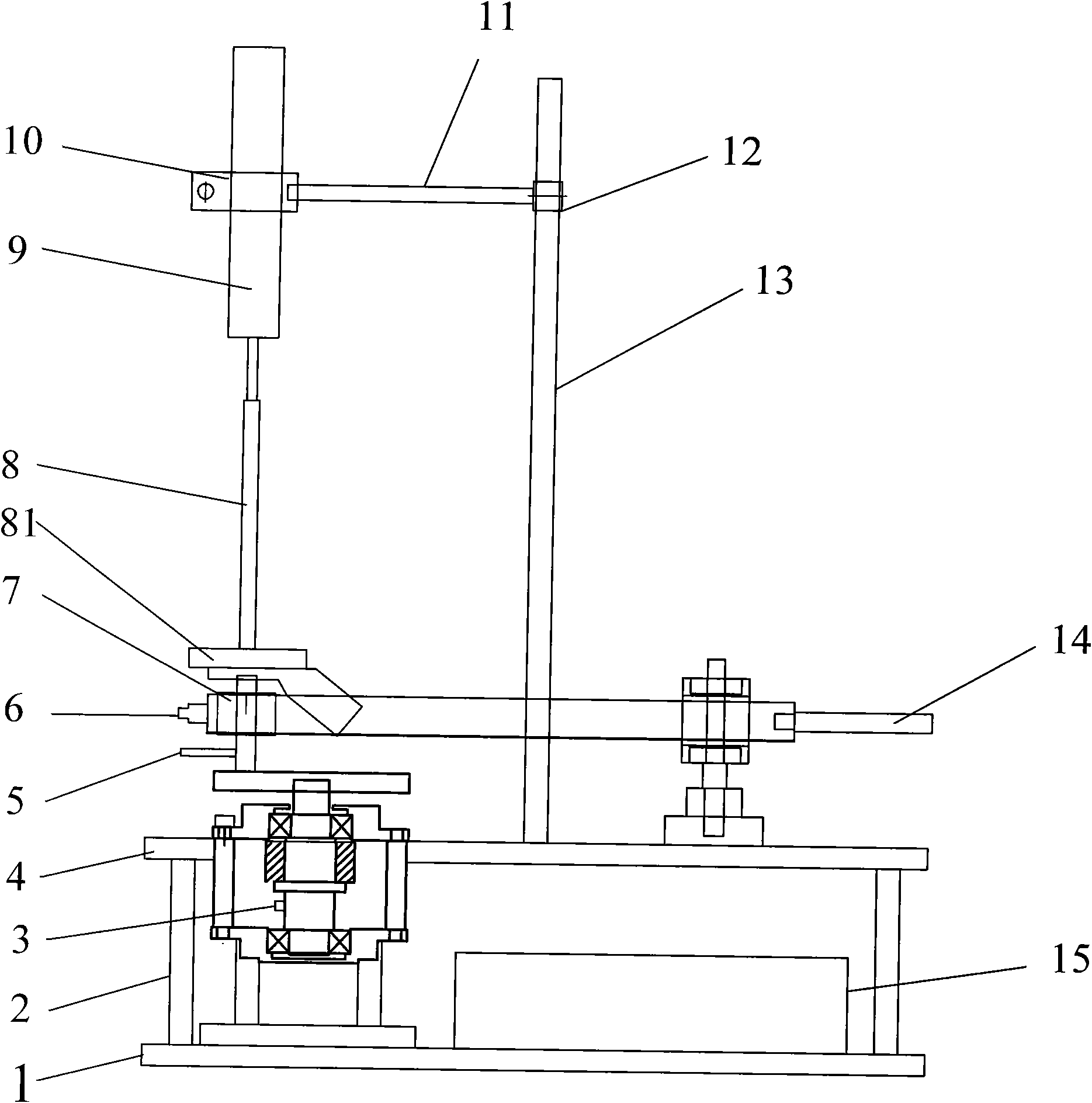

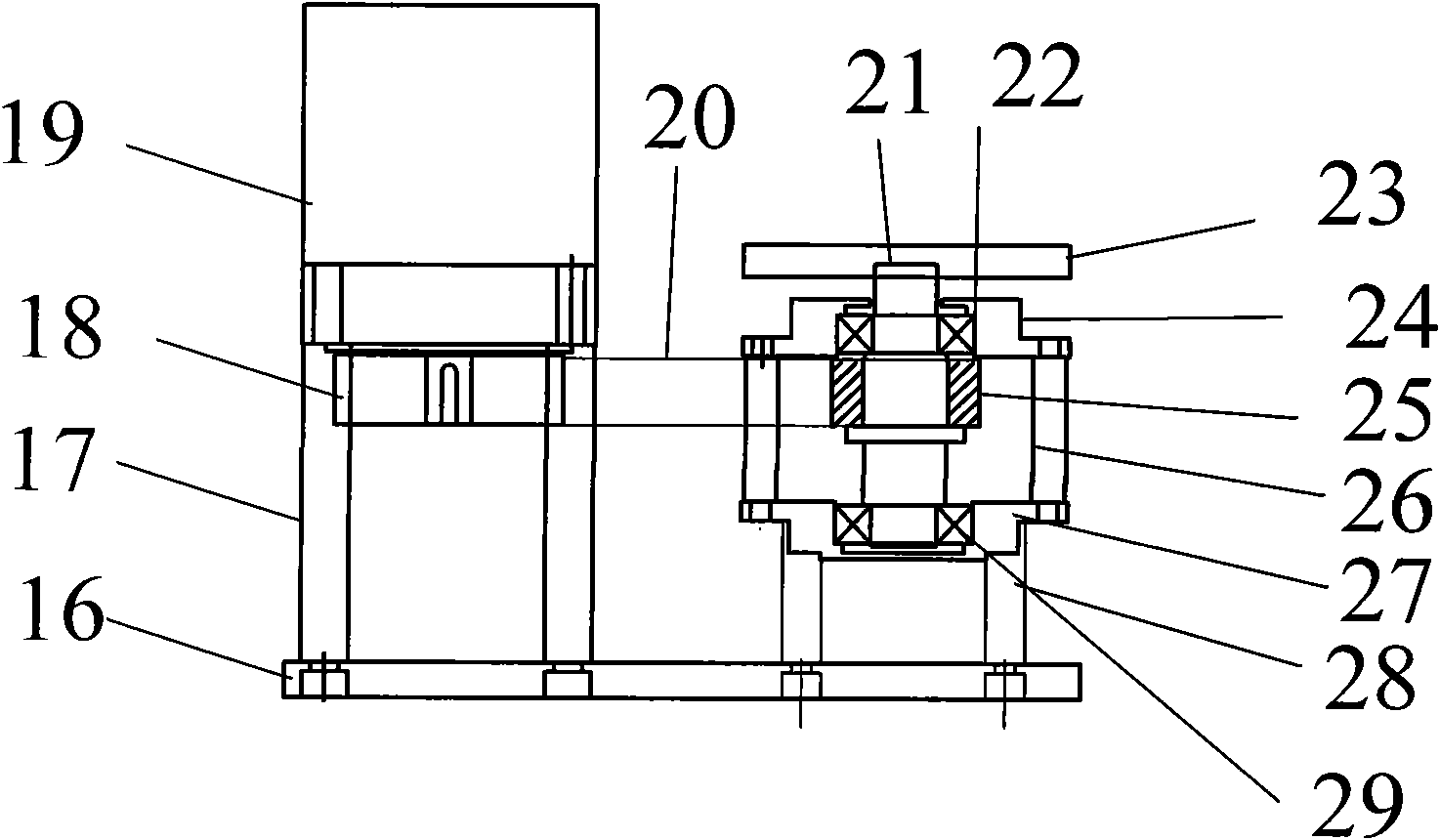

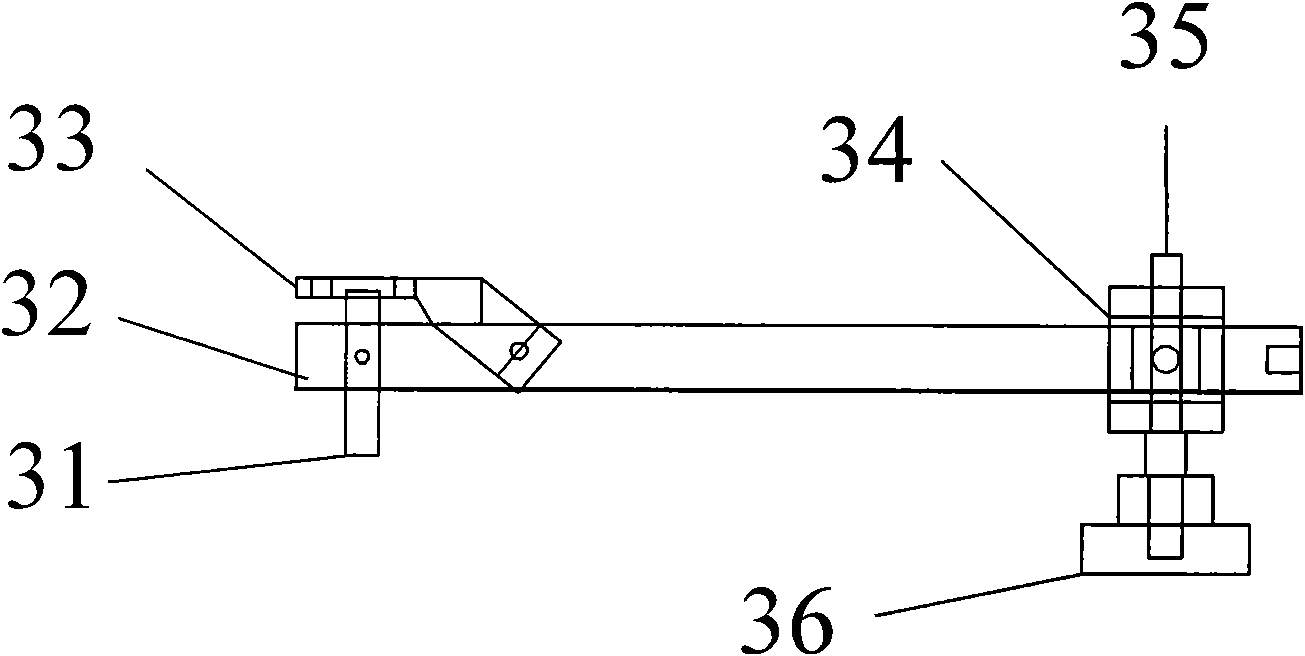

Remanufactured part surface coating accelerated wear life testing machine and detection method thereof

ActiveCN101957296AAccurate acquisition of wear lifeEasy extractionInvestigating abrasion/wear resistanceMicro nanoOriginal data

The invention discloses a remanufactured part surface coating accelerated wear life testing machine. The testing machine comprises a friction driving component, a freedom degree loading component and a signal test acquisition component. The invention introduces a displacement sensor and an acceleration sensor, increases characteristic parameters currently mainly including friction coefficient and wear quantity for judging the coating wear invalidation and enriches the means of accurately acquiring the wear life of spray coating. A test life data alarm value is set in advance; and when the alarm value is reached, data acquisition is automatically ended and a test report is generated so as to facilitate extraction of the wear life and provide original data for subsequent test research. The testing machine has compact structure and high stability and can implement long-time conventional wear life tests as well as accelerated wear tests under four acceleration conditions of heavy load, addition of micro-nano abrasive grains into lubricating oil, dry friction and high rotation speed by adjusting friction pair setting. The invention has good application prospect.

Owner:ACADEMY OF ARMORED FORCES ENG PLA

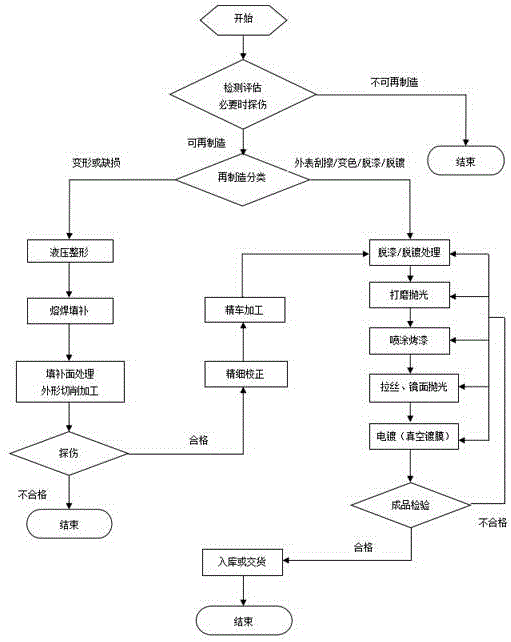

Remanufacturing process of automobile aluminum alloy hub

The invention discloses a remanufacturing process of an automobile aluminum alloy hub, which comprises the following steps: S1, detecting and evaluating: determining if the hub has remanufacturing value; S2, distinguishing repair types: comprising two types, wherein one is appearance scratching / discoloring / paint peeling / plating peeling and the other one is deformation or defect; for the aluminum alloy hub subjected to appearance scratching / discoloring / paint peeling, sequentially implementing the following steps of S3-S8; and for the deformed or defective aluminum alloy hub, sequentially implementing the following steps of S9, S10, S11 and S12; S3, performing paint peeling treatment; S4, polishing; S5, spraying baking varnish; S6, performing wire drawing; S7, electroplating (vacuum coating); S8, inspecting finished products: for qualified finished products, putting the products in a storage and delivering the goods, and for unqualified finished products, returning to the preceding steps and performing treatment; S9, performing hydraulic shaping; S10, performing fusion welding and filling; S11, treating the weld-up surface; and S12, performing flaw detection: performing fine correction and finish turning on the aluminum hub subjected to flaw detection and sequentially implementing the steps of S3-S8.

Owner:上海车功坊智能科技股份有限公司

Process cartridge remanufacturing method

ActiveCN101424917ASimple Process Cartridge Remanufacturing MethodElectrographic process apparatusEngineeringImaging equipment

A remanufacturing method includes dismounting, from one end of a drum frame, a supporting member while rotatably supporting one end of a drum and a developing device frame; separating the two frames; dismounting the drum; mounting one end of a fresh drum to the other end of the drum frame; a refilling developer into a developer accommodating portion of the separated developing device frame; and swingably connecting the developing device frame and the drum frame by mounting the supporting member to one end of the drum frame, while rotatably supporting, by the supporting member, the one end of the drum of the drum frame to which the fresh drum has been mounted and swingably supporting the one end of the developing device frame to the developer accommodating portion of which the developer has been refilled, by the drum frame.

Owner:CANON KK

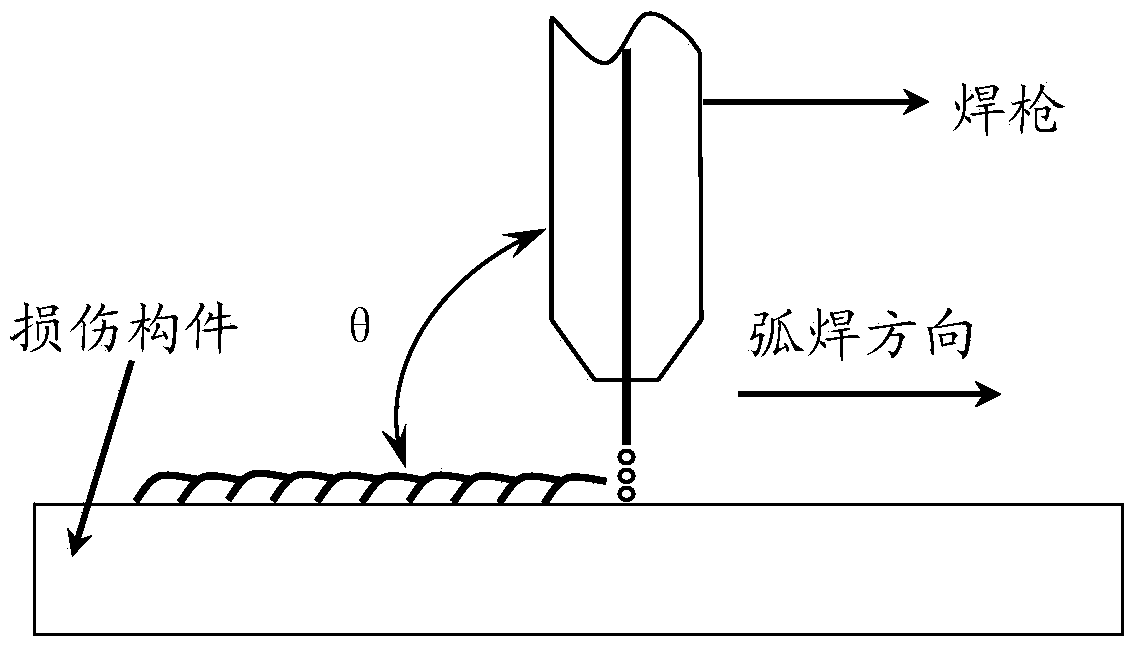

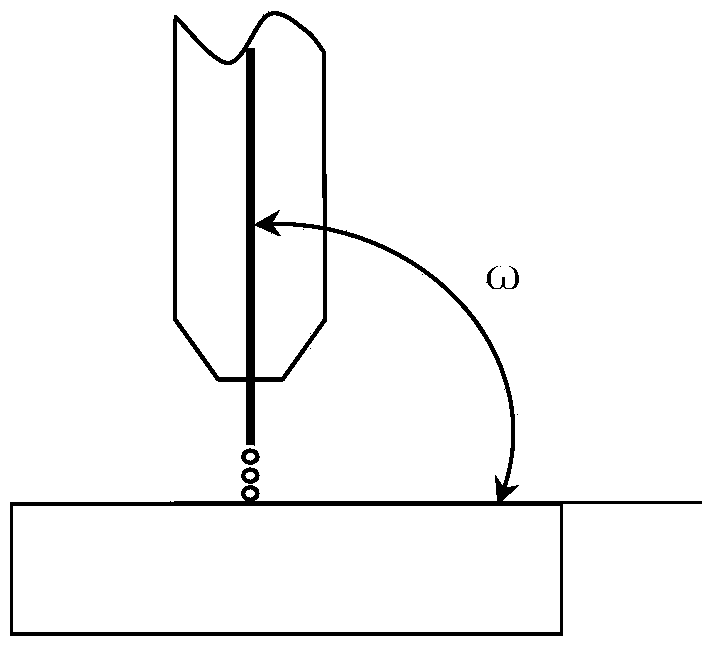

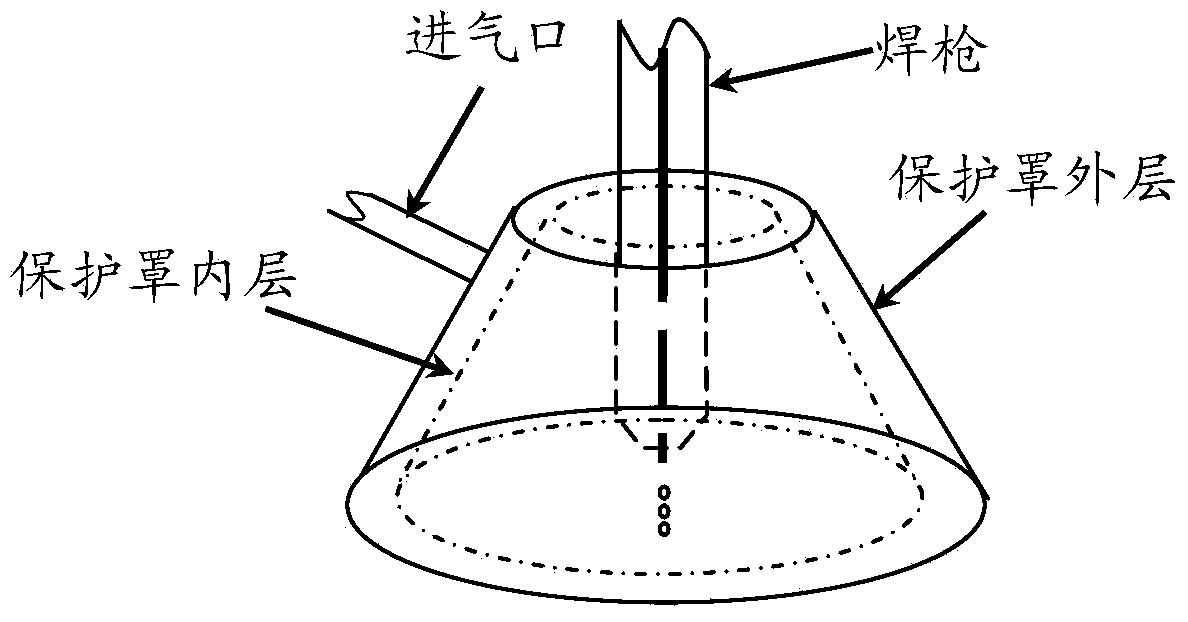

Titanium and titanium alloy component arc welding adding material remanufacturing method

ActiveCN104014912ASmall sizeImprove performanceWelding/cutting media/materialsWelding/soldering/cutting articlesAttitude controlShielding gas

The invention discloses a titanium and titanium alloy component arc welding adding material remanufacturing method. In the arc welding adding material remanufacturing process, the pulse MIG welding technology is adopted, the mode of metal transfer is spray transfer, a double-microdomain adjusting mode is adopted in gas protection, the appearance structure is a bell jar type or a ship type, and a front stretching and back extending mode is adopted in protection gas supplying and non-supplying; the inclination angle theta and the inclination angle omega of opposite welding lines of a welding gun are controlled; argon or argon-helium or helium-argon or helium is adopted as the double-microdomain protection gas; an arc welding robot is adopted to control the moving speed and posture of the welding gun. The titanium and titanium alloy component arc welding adding material remanufacturing method solves the problems of gas protection, technology optimization and quality control in the titanium and titanium alloy component MIG arc welding adding material remanufacturing, adding material remanufacturing of abraded or broken titanium and titanium alloy components is achieved, the gas protection structure is simple, easy to use and good in protection effect, a sealing gas chamber is not needed, more than 40 percent of materials can be saved, the thermal input can be reduced by more than 20 percent, and the titanium and titanium alloy component arc welding adding material remanufacturing quality is improved.

Owner:ACADEMY OF ARMORED FORCES ENG PLA

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com