Method and device for remanufacturing sheet metal welding piece by utilizing laser

A laser remanufacturing, metal sheet technology, applied in laser welding equipment, manufacturing tools, welding equipment, etc., can solve the problems of fracture failure, impracticality, fatigue strength of welded parts, etc., to improve mechanical properties, refine crystal grain effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

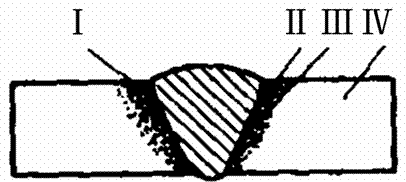

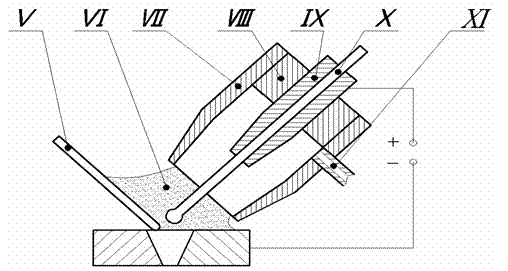

[0036] This embodiment uses 2219 aluminum alloy with a size of 200×100×10 mm (length×width×thickness). Use a tungsten argon arc welding device to weld two 2219 aluminum alloy thin plates into one body, such as figure 2 As shown, the welding joint form is: butt joint, beveled, joint gap is 0.2mm, M55TIG welding wire is selected, welding equipment is manual argon arc welding, welding current is 150A, and the material is mechanically polished to remove the oxide film before welding. Considering factors such as welding equipment accuracy and operator skills, there may be defects such as oxidation, pores, cracks, unhardened, slag inclusion, embrittlement, etc. at the joints of the welding parts, which reduce the strength of the weld to varying degrees. , Plasticity and corrosion resistance, etc., such as Image 6 As shown in (a), there will be a small amount of pores in the section of the weld area of the weldment.

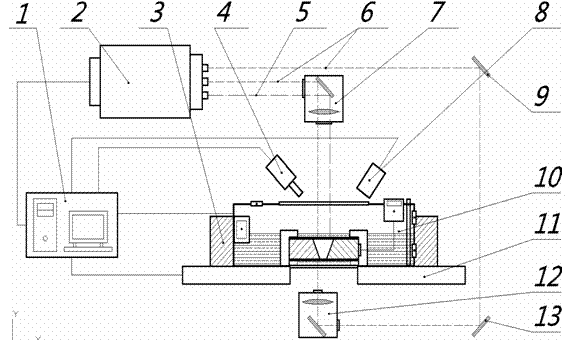

[0037] use image 3 The system detects the cracks at the joints o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com