Patents

Literature

202 results about "Fracture failure" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Fracture is a form of failure where the material separates in pieces due to stress, at temperatures below the melting point.

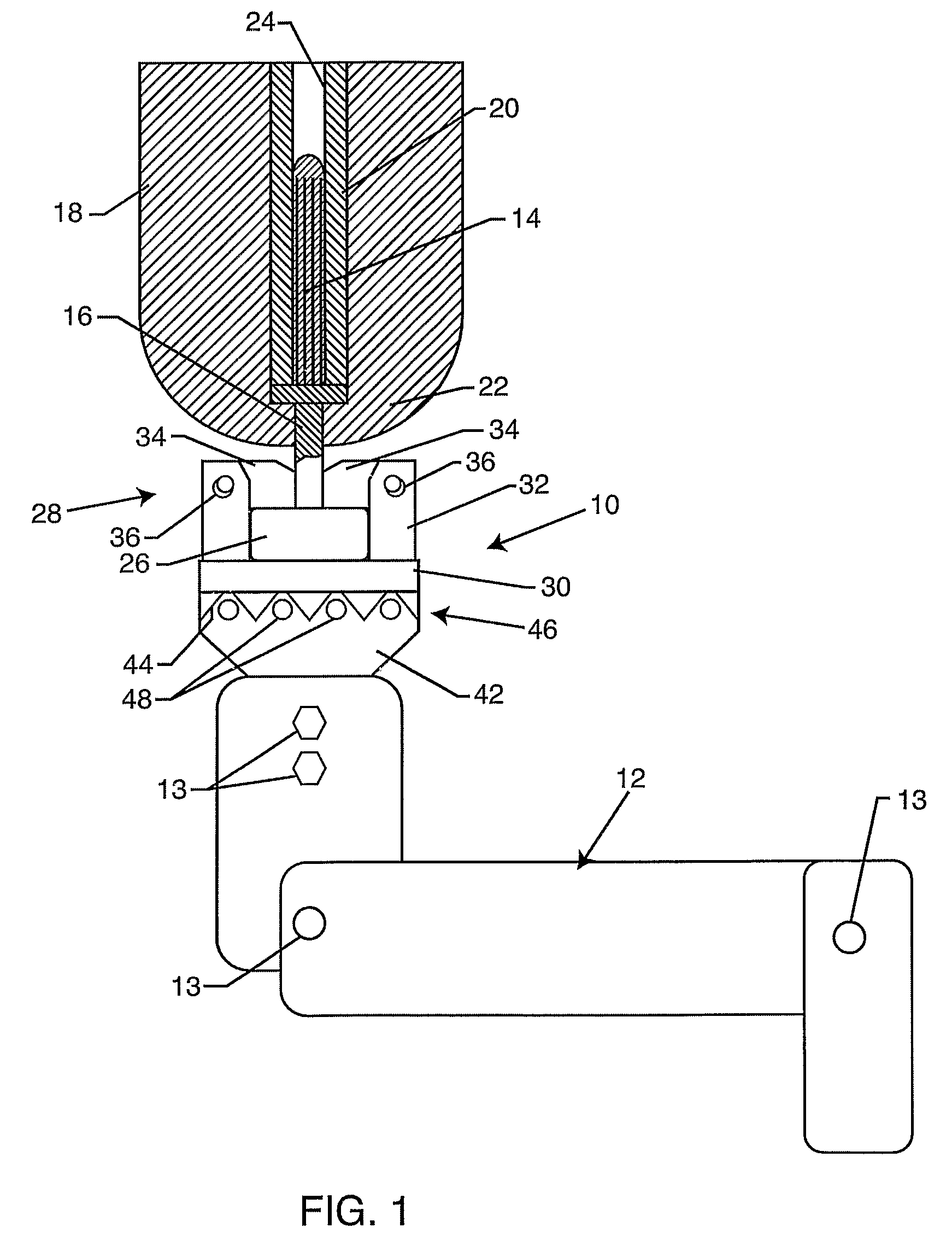

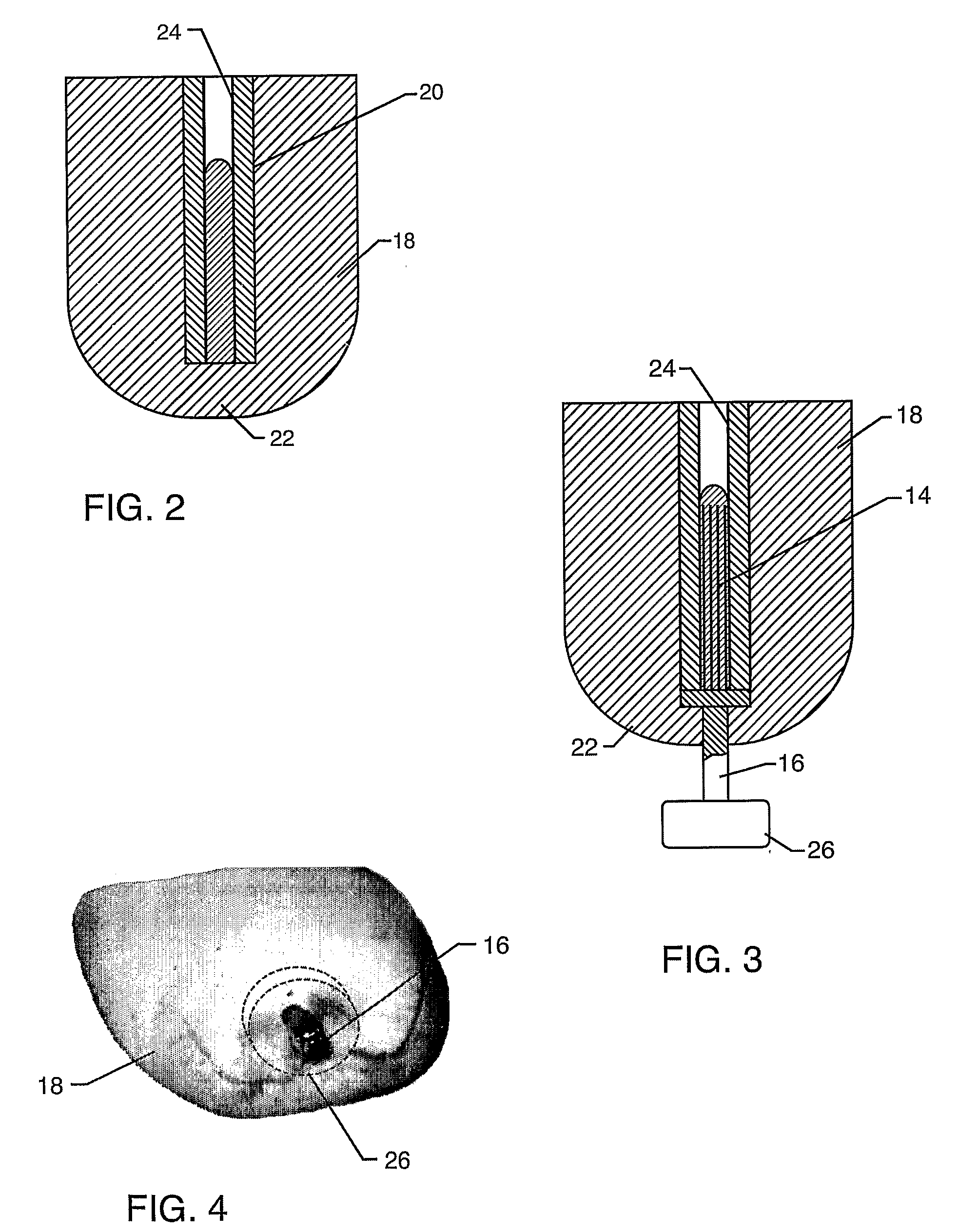

Dynamic bioabsorbable fastener for use in wound closure

InactiveUS7112214B2Prevent and reduce deformationAvoid deformationJoint implantsStaplesBiomedical engineeringBioabsorbable polymer

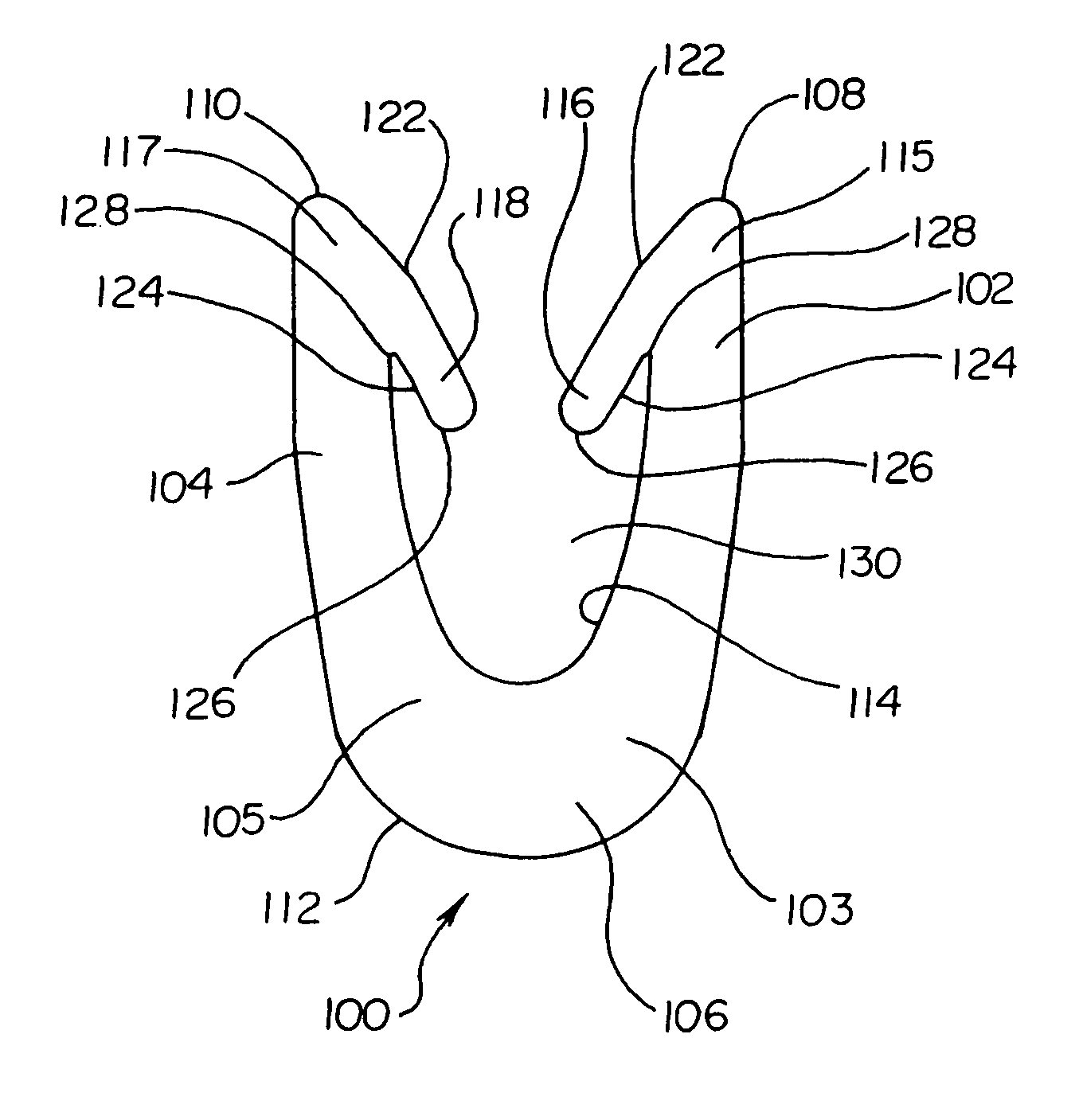

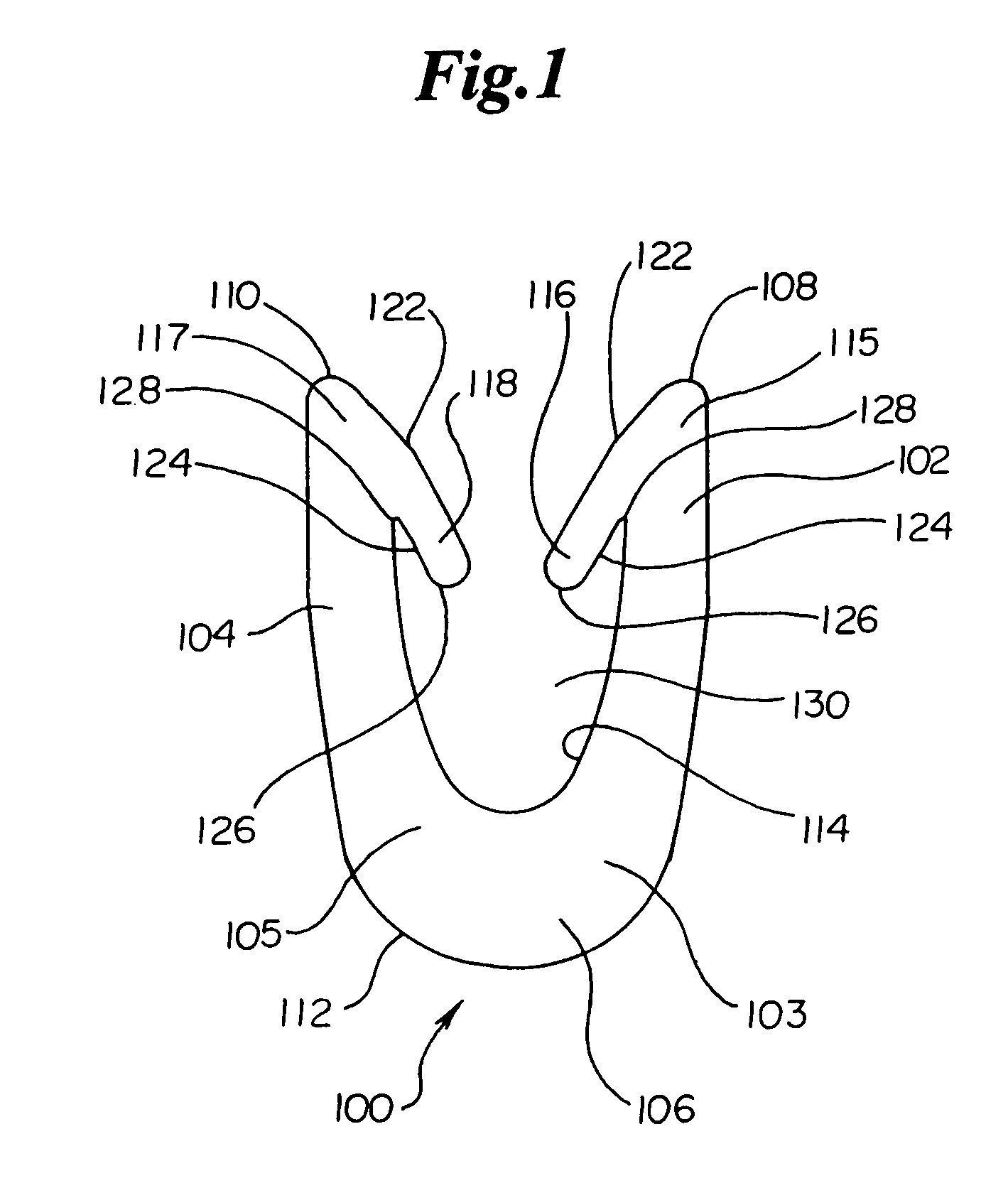

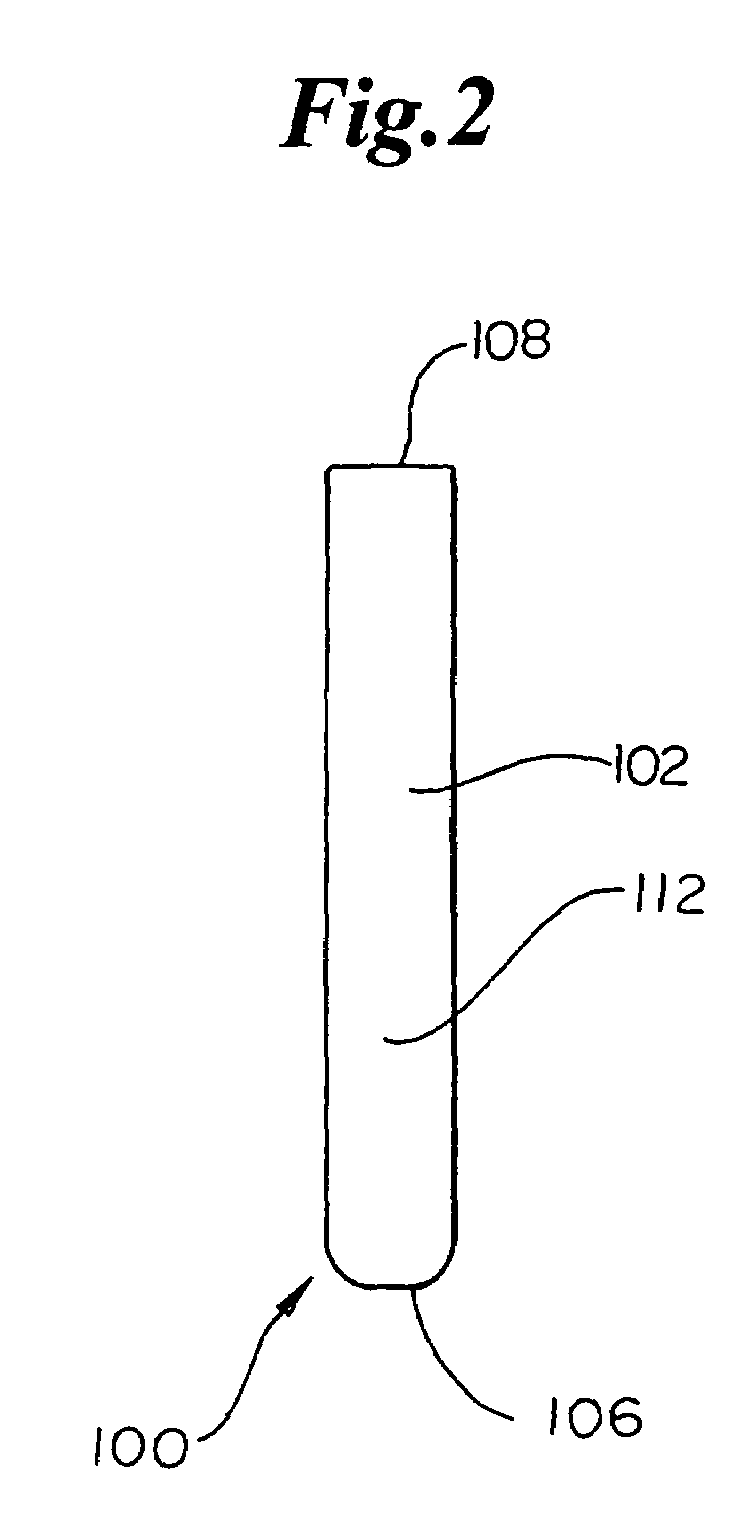

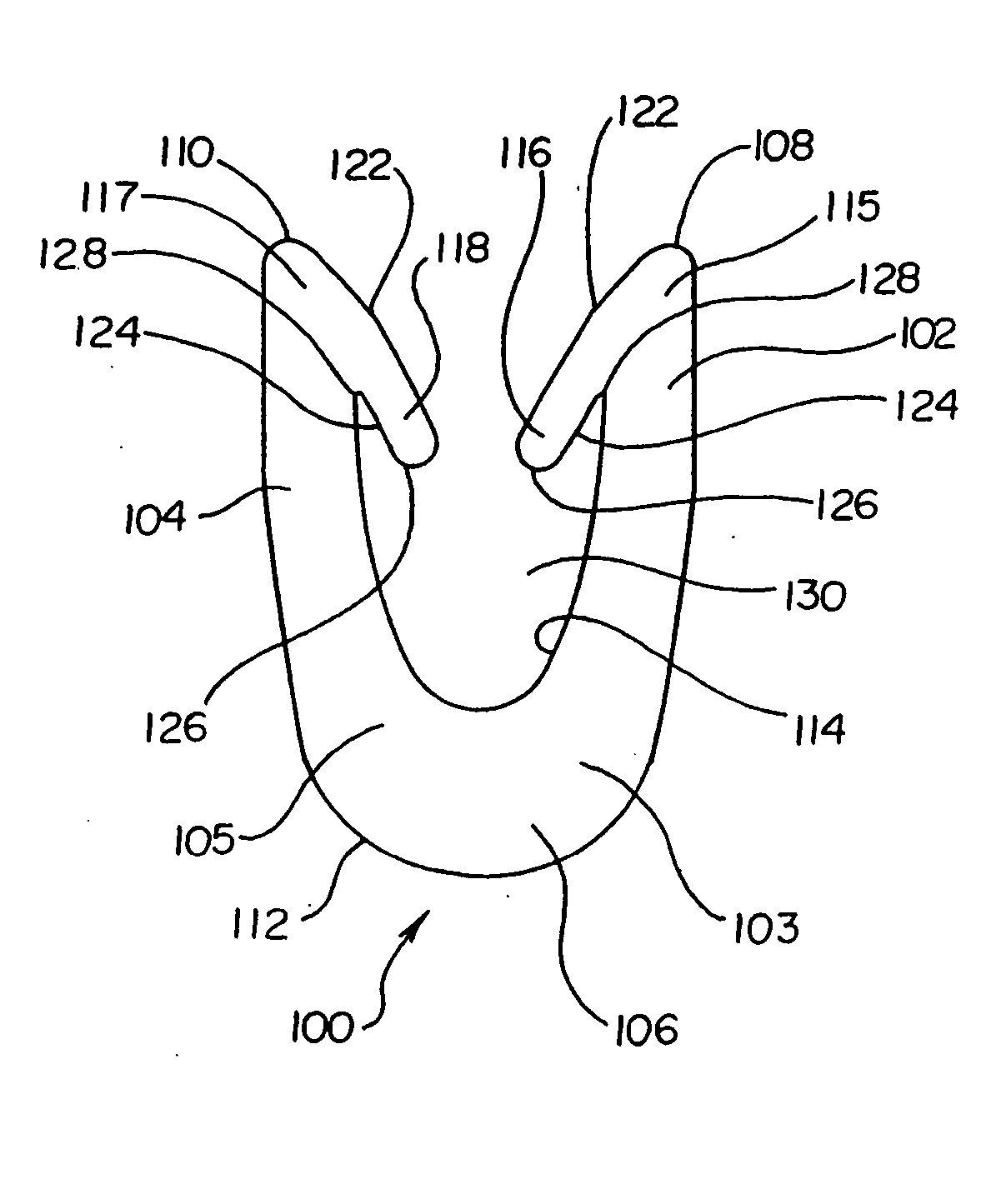

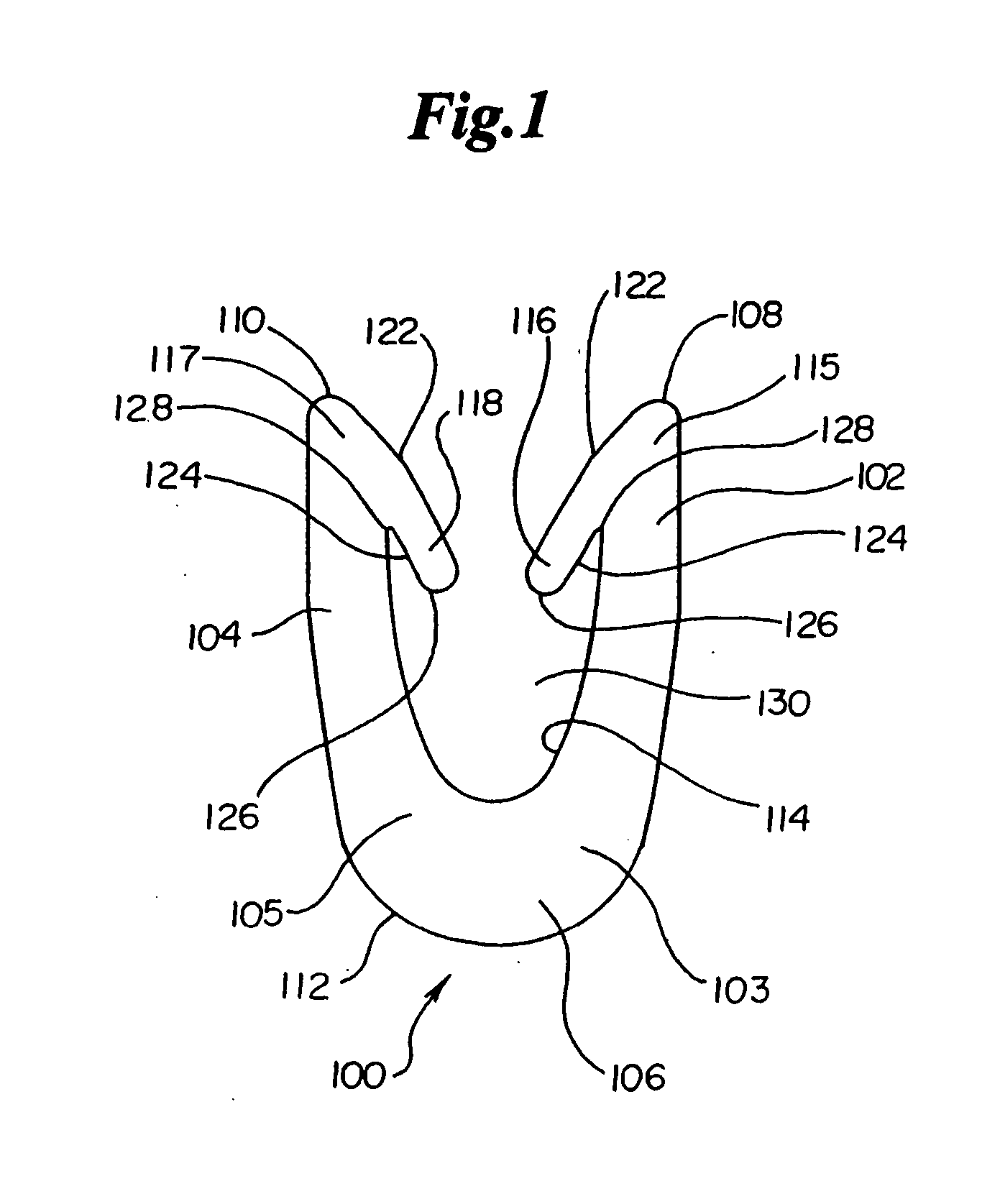

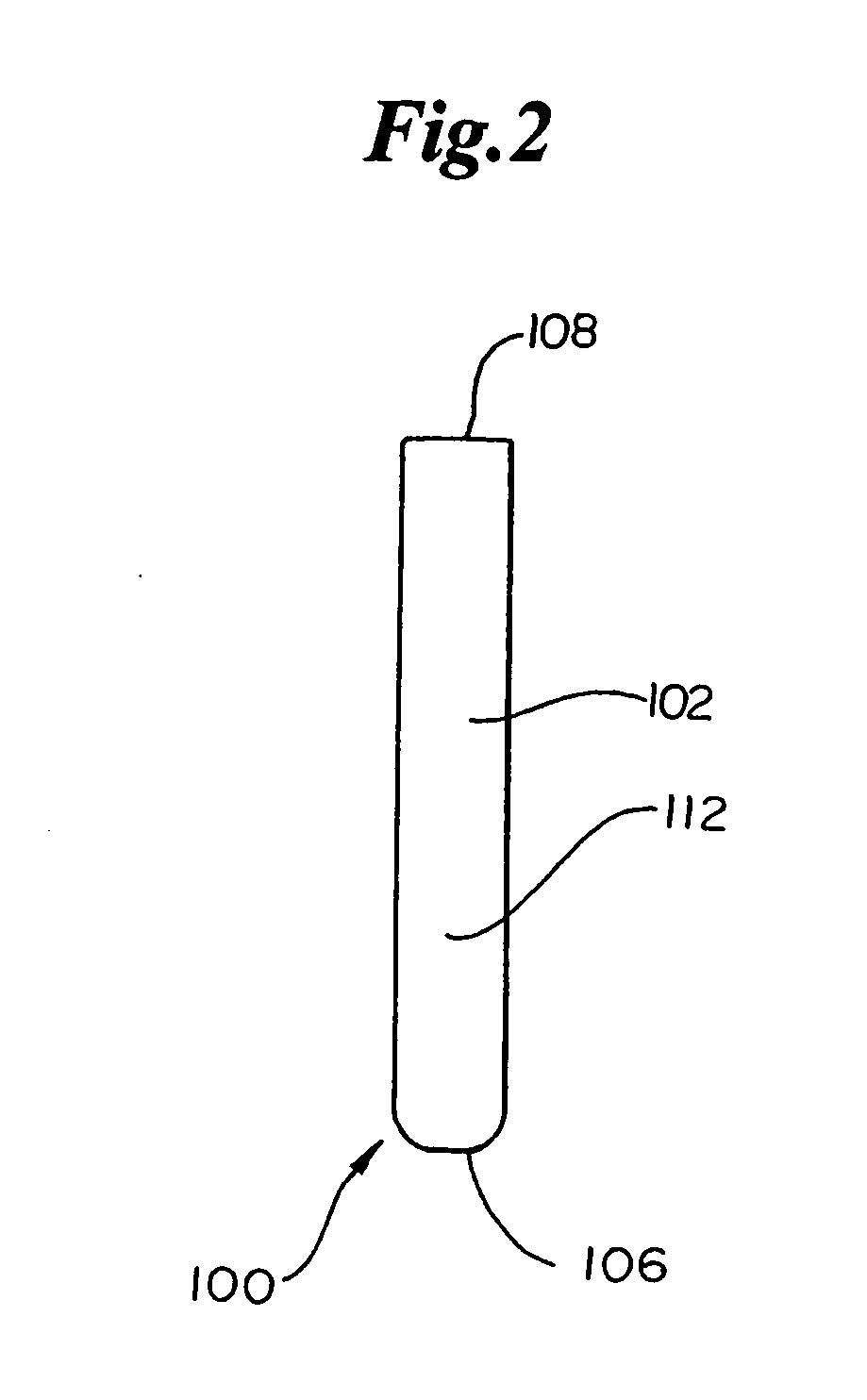

A fastener for insertion into pierced openings of a tissue wound has a body formed of a generally bioabsorbable polymer defining an initial capture area internal to the body. The body includes a pair of arms, each with an inwardly projecting cleat operably joined at an elbow portion defining an internal elbow angle. The arms are operably joined to a backspan at a shoulder portion defining an internal shoulder angle. A durable tissue retention zone is defined between the cleat and the arm. The elbow portion and the internal elbow angle define an insertion width greater than a width of the pierced openings resulting in the pierced openings stretching over the cleat and being elastically retained within the durable tissue retention zone. The fastener initially captures wound tissue in the initial capture area and then dynamically reforms in response to lateral stresses applied by the wound tissue without a fracture failure of the fastener until a minimum degradation period.

Owner:INCISIVE SURGICAL

Dynamic bioabsorbable fastener for use in wound closure

InactiveUS20050182444A1Prevent and reduce deformationAvoid deformationStaplesJoint implantsBiomedical engineeringBioabsorbable polymer

A fastener for insertion into pierced openings of a tissue wound has a body formed of a generally bioabsorbable polymer defining an initial capture area. The body includes a pair of arms, each with an inwardly projecting cleat operably joined at an elbow portion defining an internal elbow angle. The arms are operably joined to a backspan at a shoulder portion defining an internal shoulder angle. A durable tissue retention zone is defined between the cleat and the arm. The elbow portion and the internal elbow angle define an insertion width greater than a width of the pierced openings resulting in the pierced openings stretching over the cleat and being elastically retained within the durable tissue retention zone. The fastener captures wound tissue in the initial capture area and then dynamically reforms in response to lateral stresses without a fracture failure of the fastener until a minimum degradation period.

Owner:INCISIVE SURGICAL

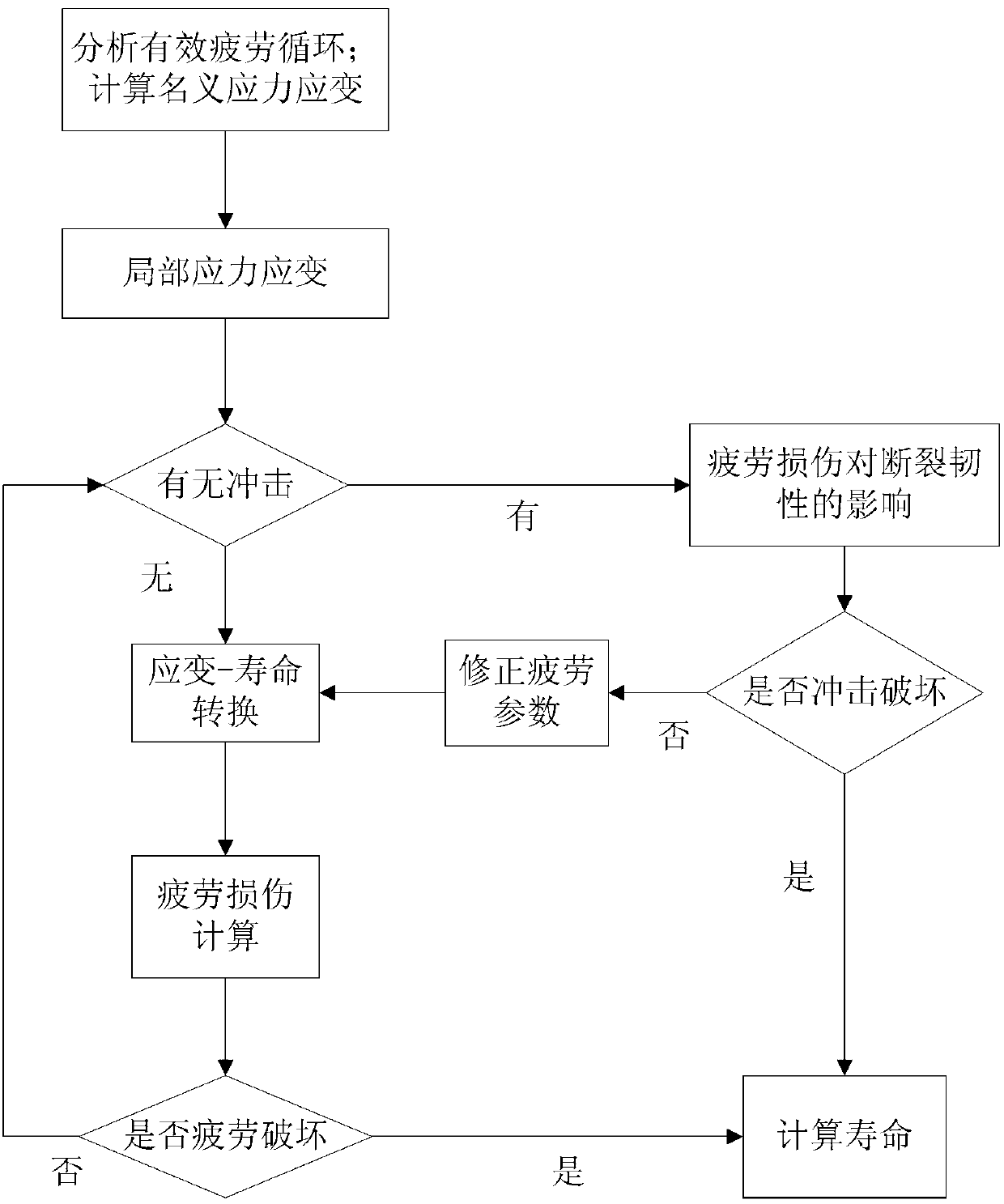

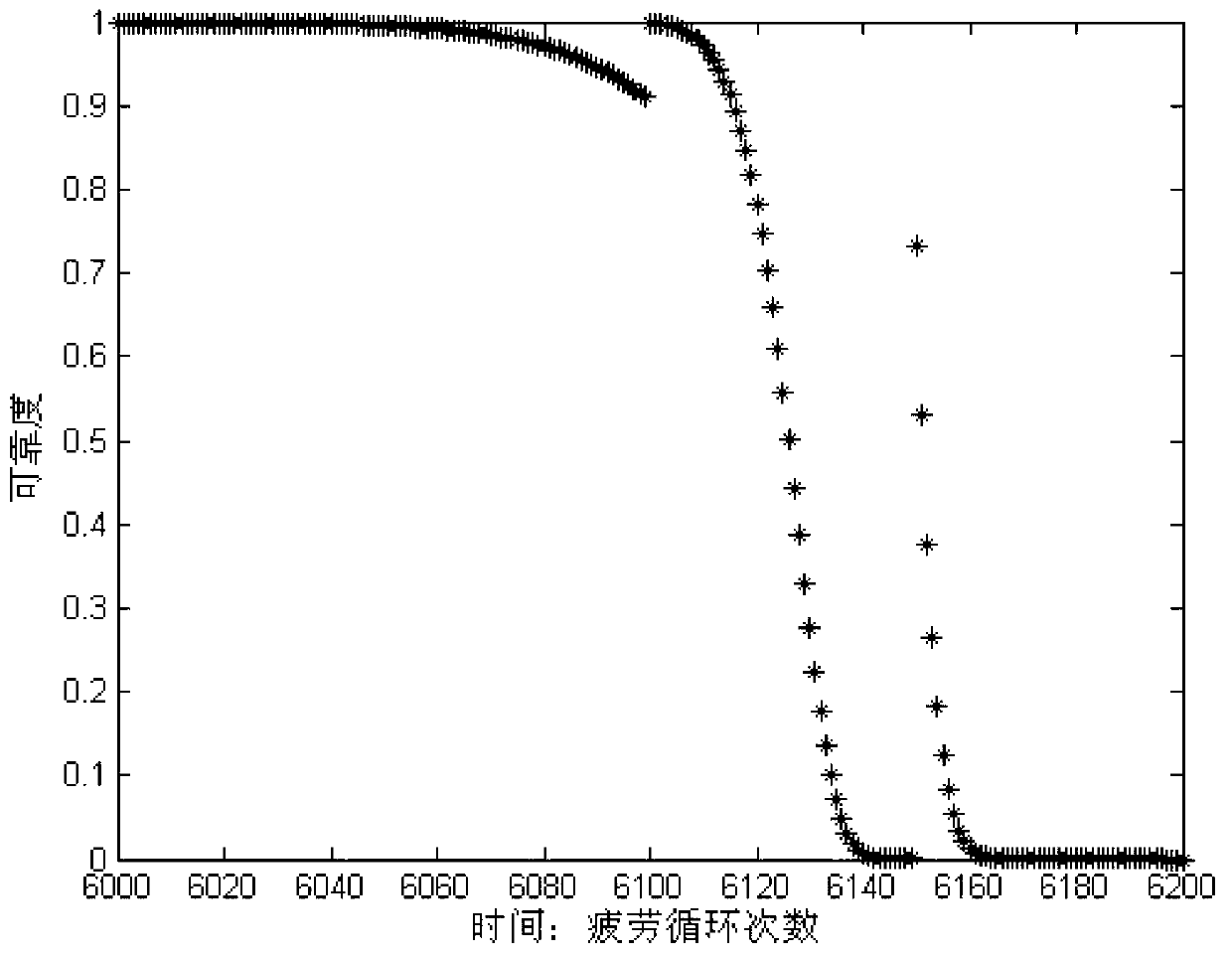

Damage calculation method for low-cycle fatigue and high-strength impact coupling based on local stress strain method

InactiveCN103344515AAccurate fatigue damage analysis resultsMaterial strength using repeated/pulsating forcesFatigue damageFatigue loading

The invention relates to a damage calculation method for low-cycle fatigue and high-strength impact coupling based on a local stress strain method. The damage calculation method comprises the following steps of: (1) analyzing a fatigue load spectrum, calculating nominal stress strain of each stage of multiple stages of amplitude-variable fatigue load spectra, and converting the nominal stress strain into local stress strain; (2) calculating fatigue life and damage corresponding to each stage of fatigue load local strain when a product is impacted; (3) calculating the fatigue life and the damage corresponding to each stage of the fatigue load local strain when the product is impacted and the impact is in an influence range, and considering the damage probability in a fatigue circulation unit when the product is impacted; (4) calculating impact performance influenced by fatigue accumulated damage; and (5) calculating comprehensive degree of reliability. Compared with a conventional fatigue damage calculation method, the damage calculation method has the advantages that the influence of high-strength impact on the fatigue damage, the influence of fracture failure caused by direct impact to the life of the product and the influence of the fatigue accumulated damage to the shock resistance of the product are considered, and the fatigue-impact life and the degree of reliability of the product can be well evaluated under a complex environment.

Owner:BEIHANG UNIV

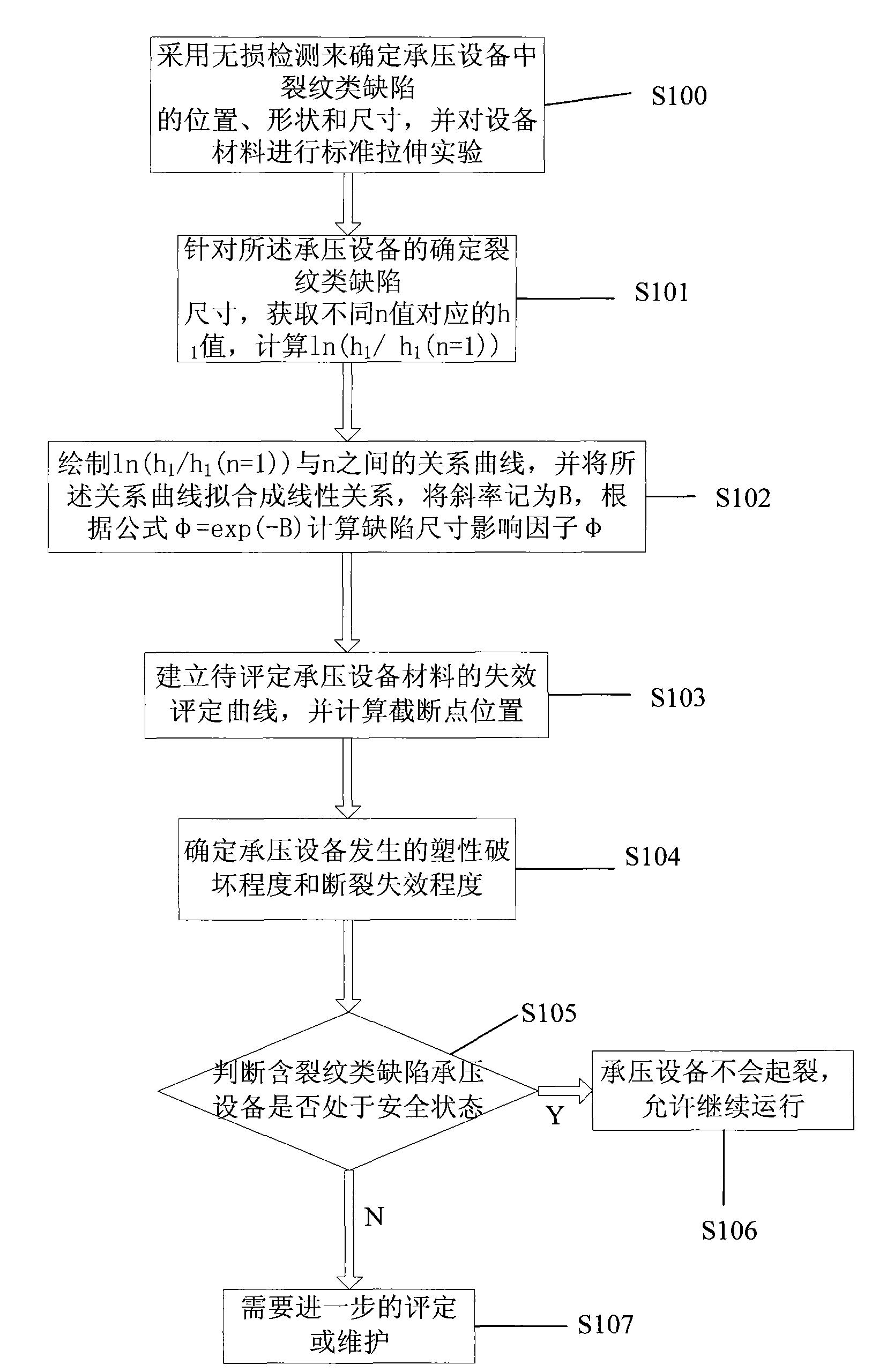

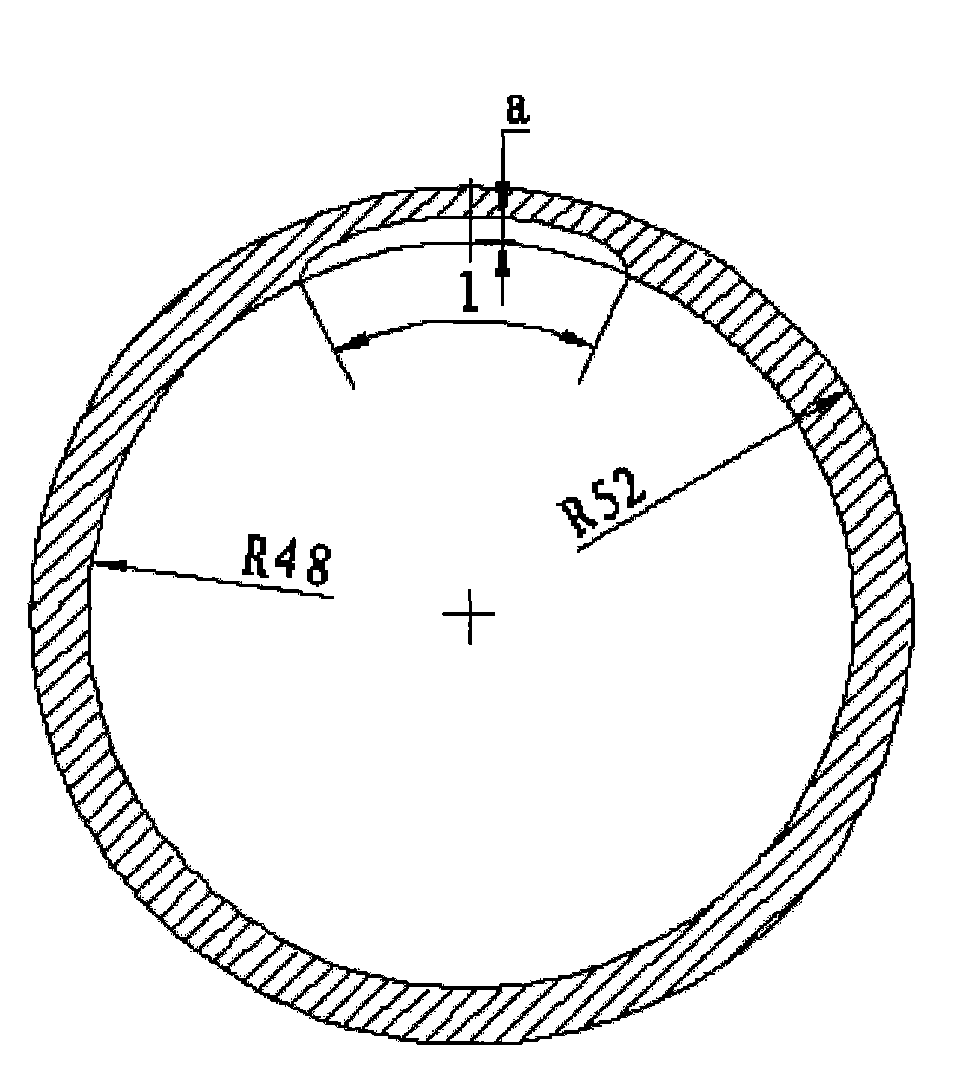

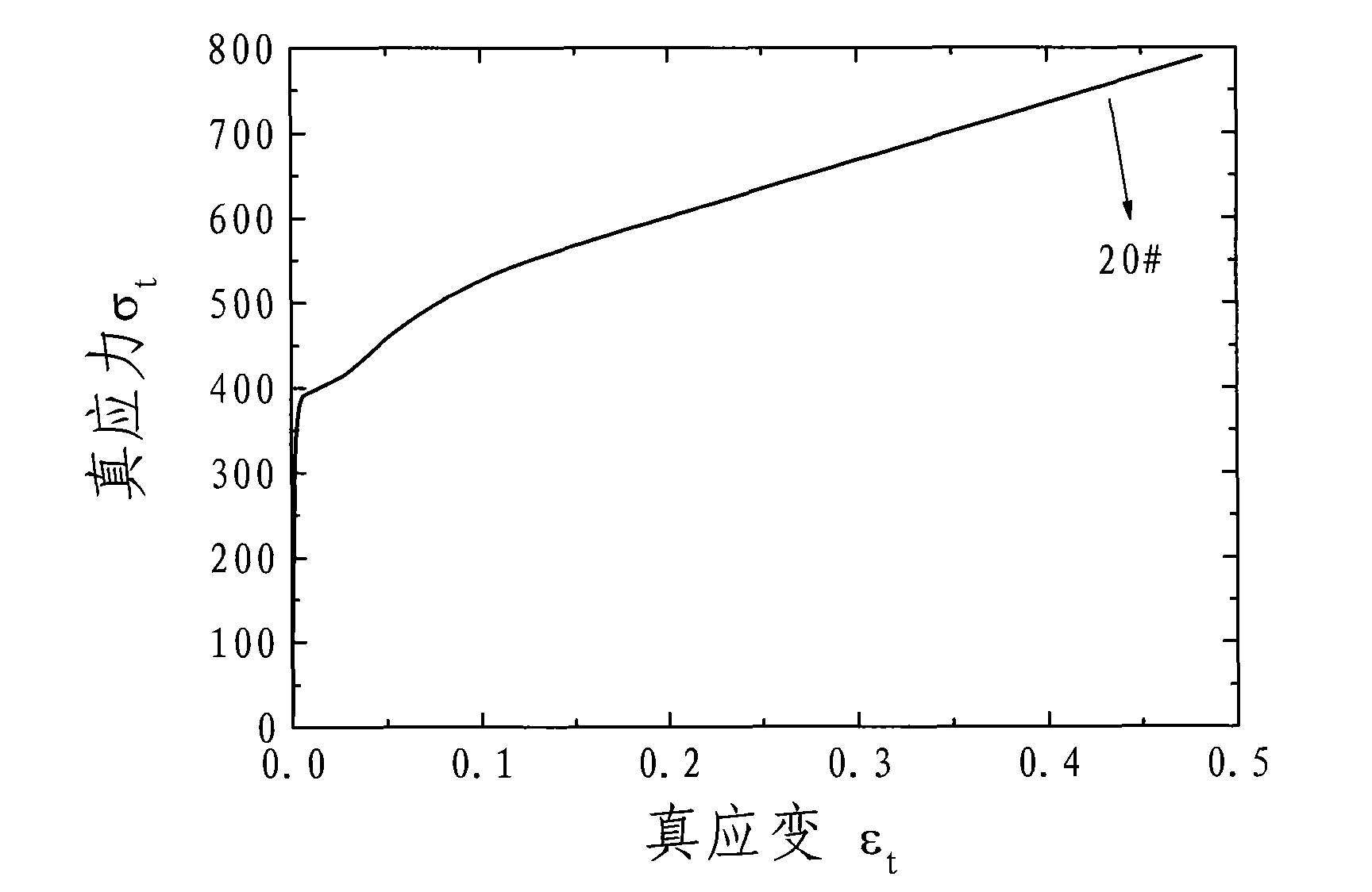

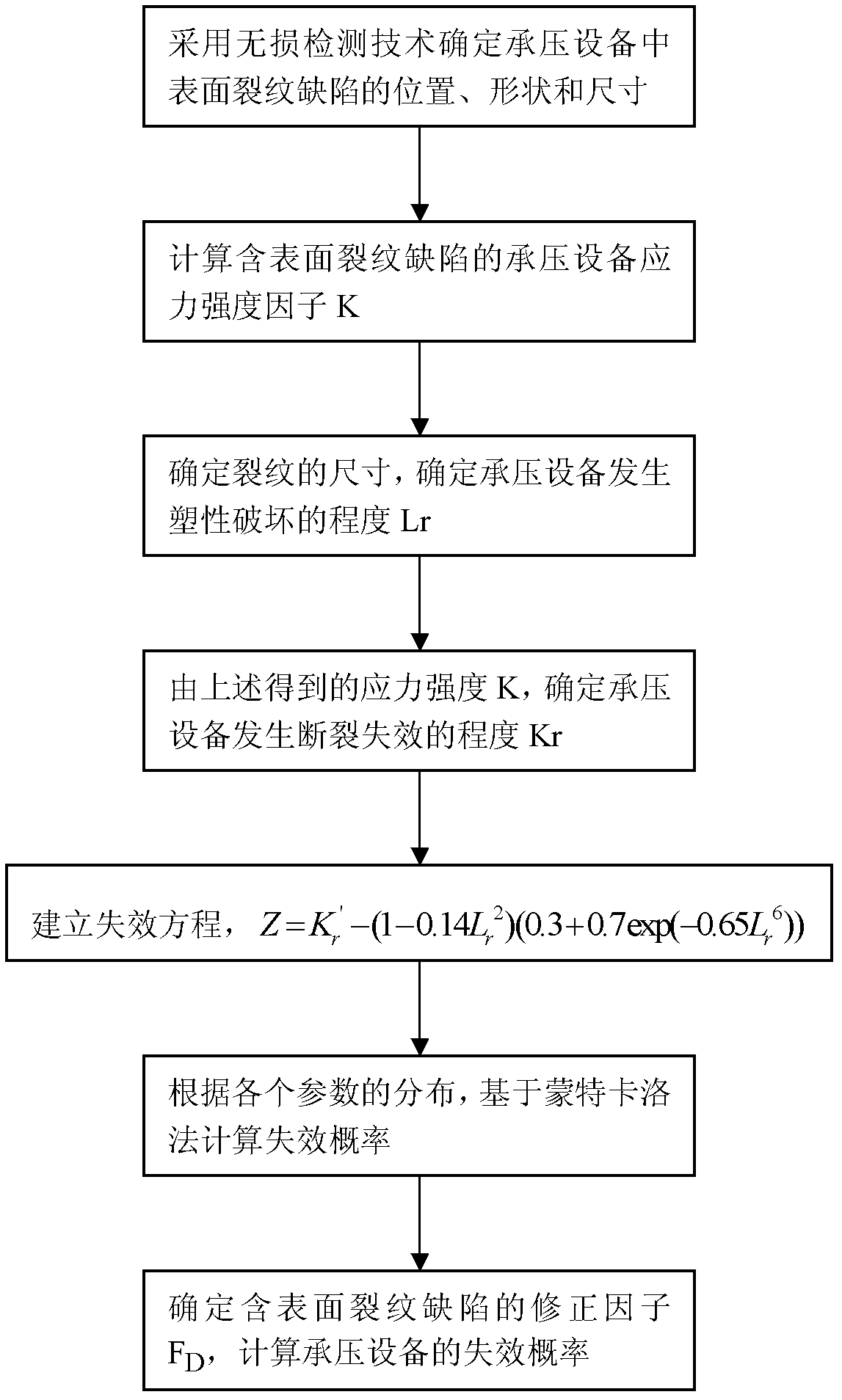

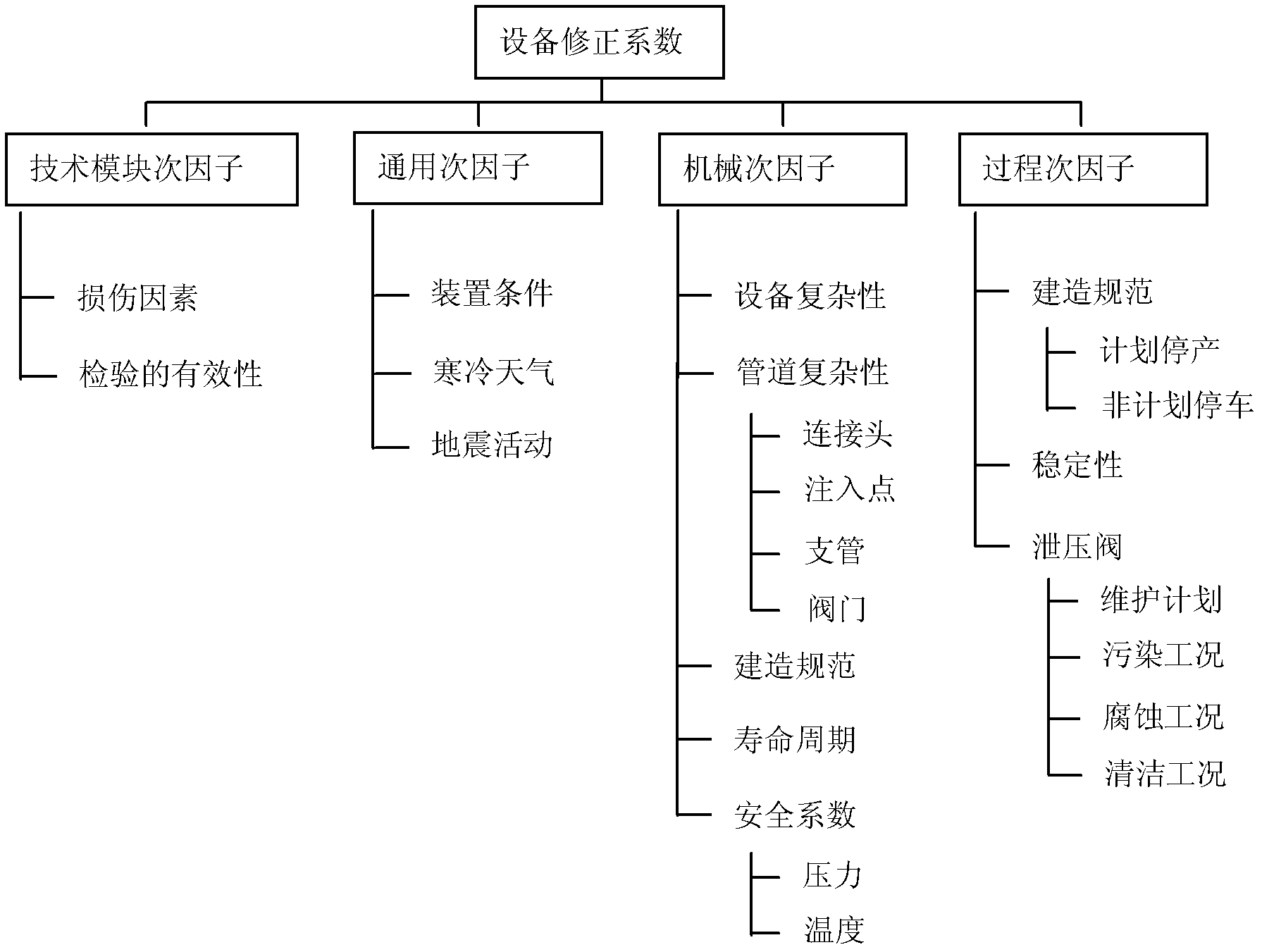

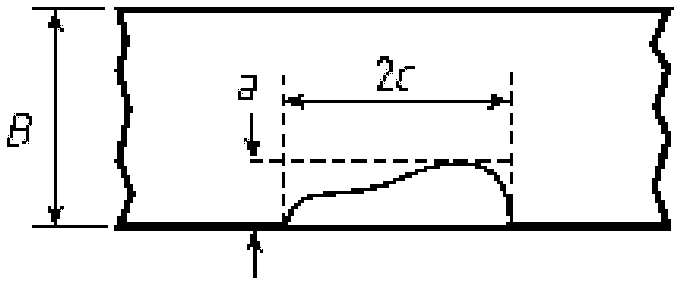

Safety evaluating method of pressure equipment containing crack defects

InactiveCN101975695AAccurately reflectAvoid mockingMaterial strength using tensile/compressive forcesDefect sizeLinear relationship

Owner:EAST CHINA UNIV OF SCI & TECH

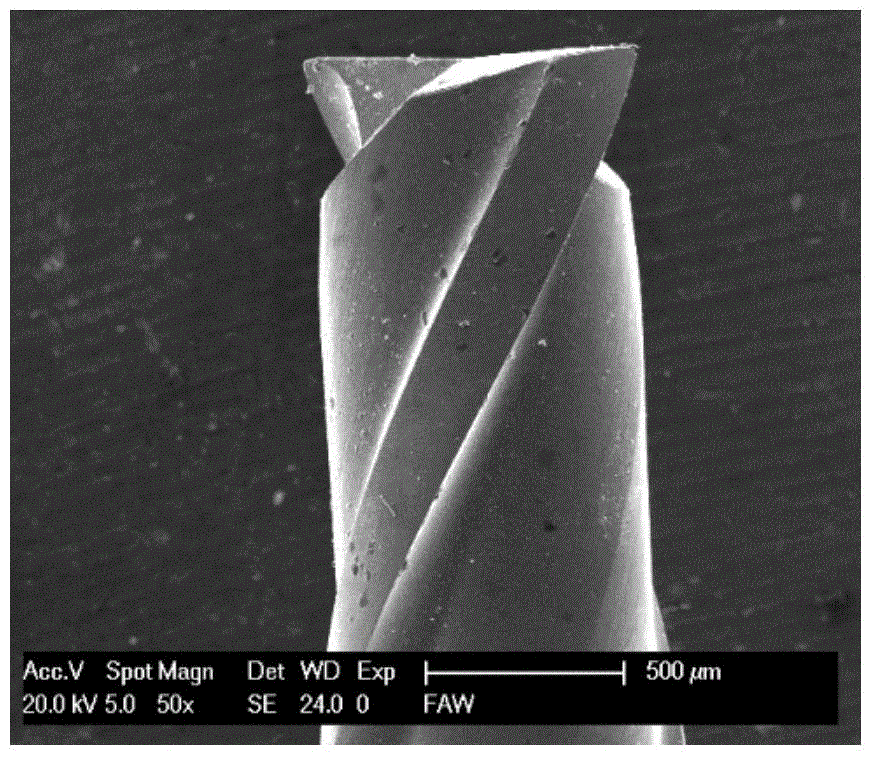

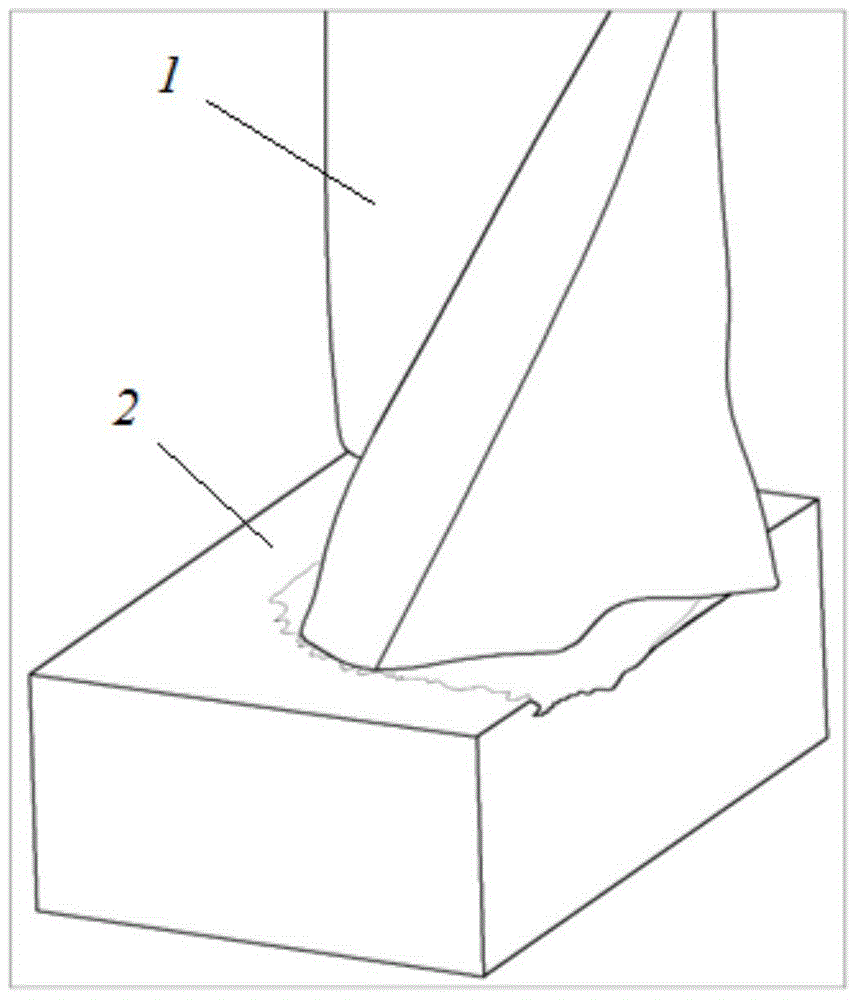

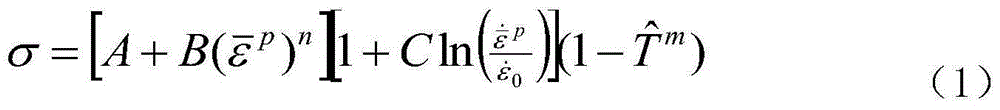

Simulation method for residual stress prediction of micro-milling nickel-based superalloy

ActiveCN105117547AEasy to predictAchieve forecastSpecial data processing applicationsMilling cutterScanning electron microscope

The invention provides a simulation method for residual stress prediction of micro-milling nickel-based superalloy, belongs to the field of finite element simulation cutting, and relates to a finite element simulation method for residual stress prediction analysis in the cutting processing process of difficult-to-process materials of the nickel-based superalloy. According to the simulation method, the finite element simulation method is used; the elastic-plastic constitutive relationship of materials is considered; and a Johnson-Cook fracture failure criterion is used for judging the failure, so that residual stress prediction values under different cutting parameters can be obtained. A micro-milling cutter for experiments is shot into a picture through a scanning electron microscope; the picture is drawn into a micro-milling cutter solid model through software; a three-dimensional processed workpiece model is built; and the model is subjected to lattice division. The method has the advantages that the surface residual stress can be measured, and the residual stress in the depth direction can also be measured, so that the problem of measurement difficulty of the residual stress in the depth direction in the measurement process is solved. The cost is reduced, and the labor is saved. In a prediction model, the cutting parameters are variable; and the prediction on the surface residual stress of the difficult-to-process materials is effectively realized.

Owner:DALIAN UNIV OF TECH

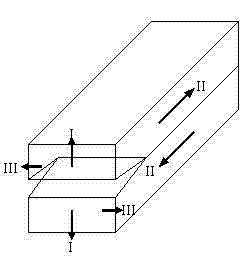

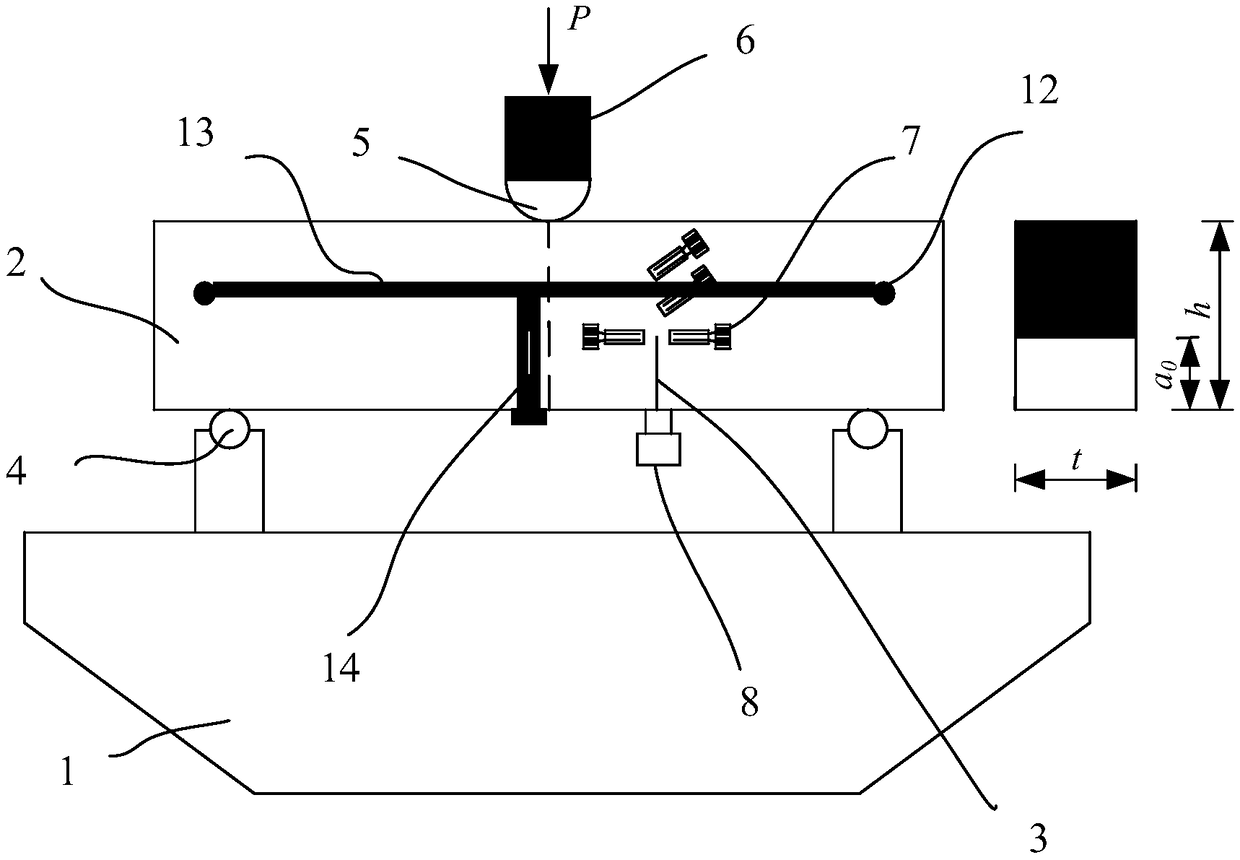

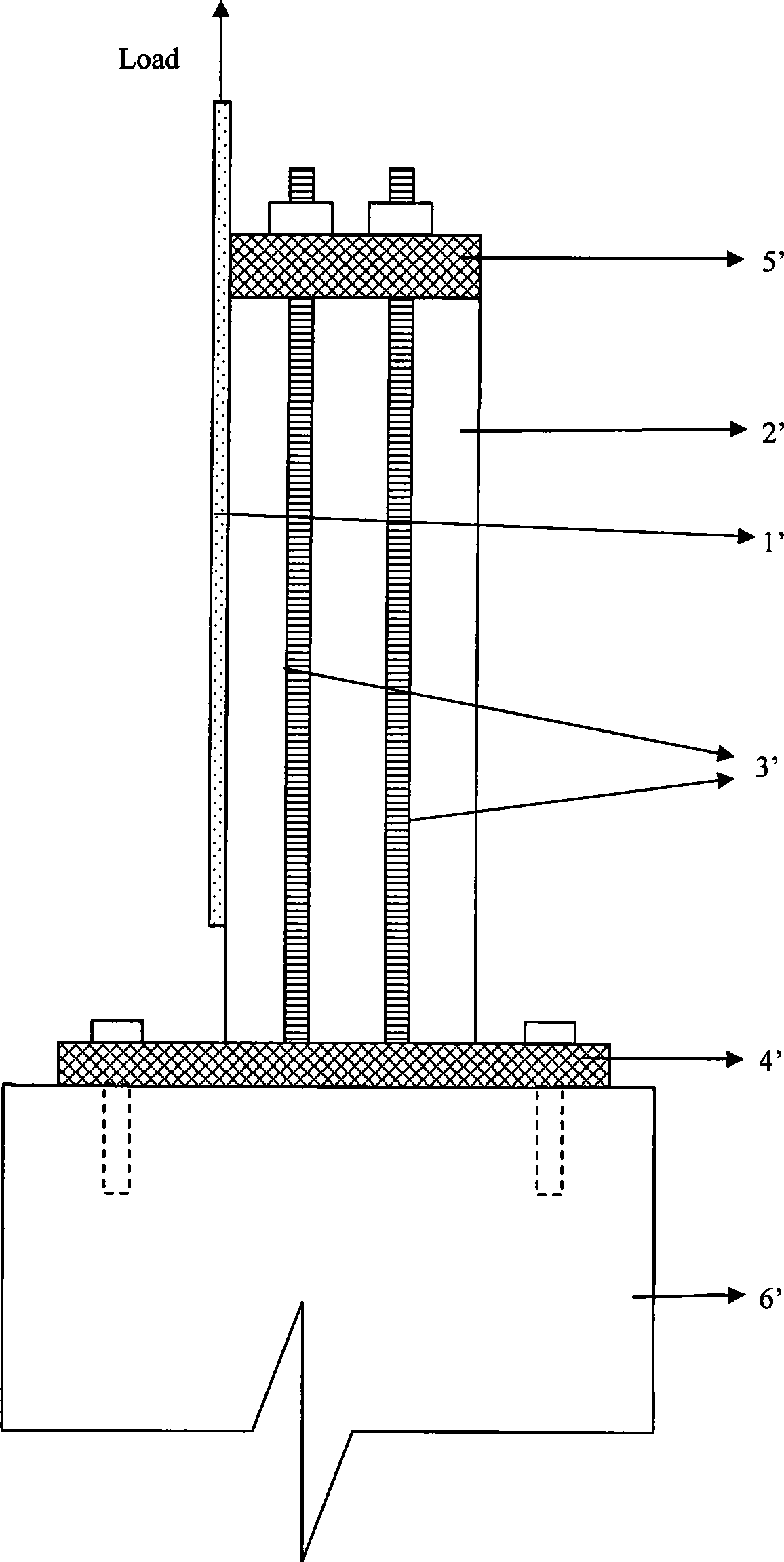

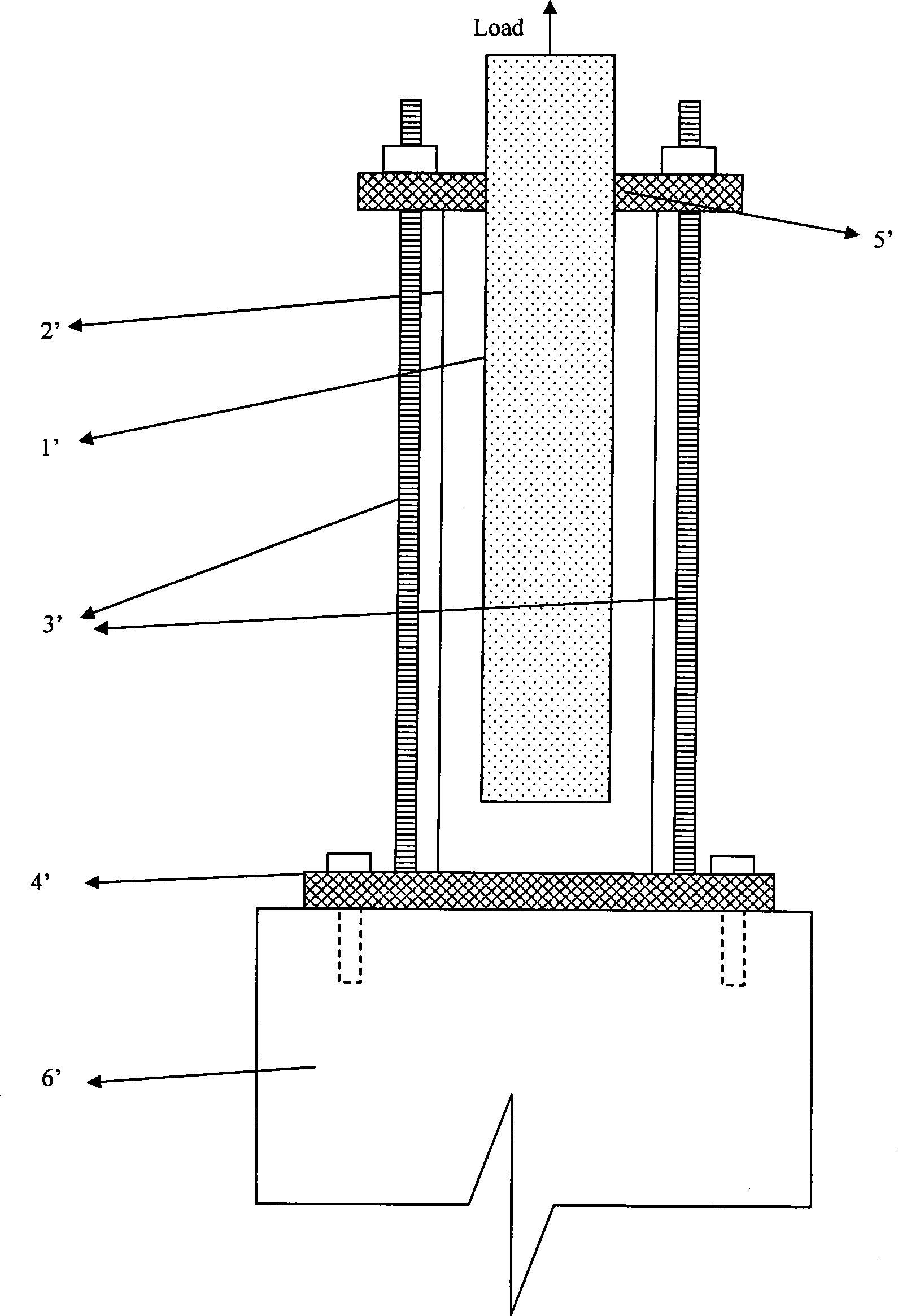

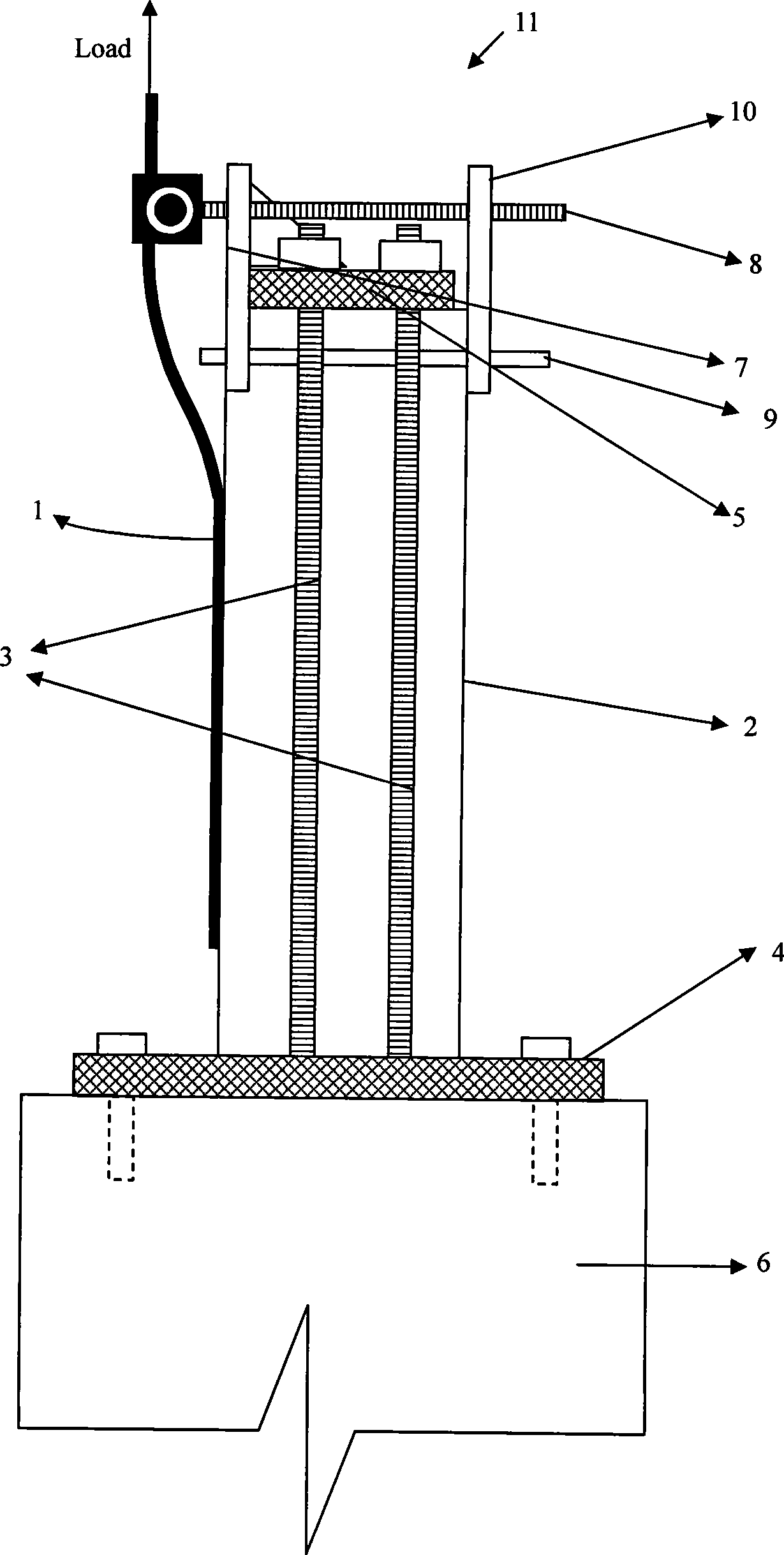

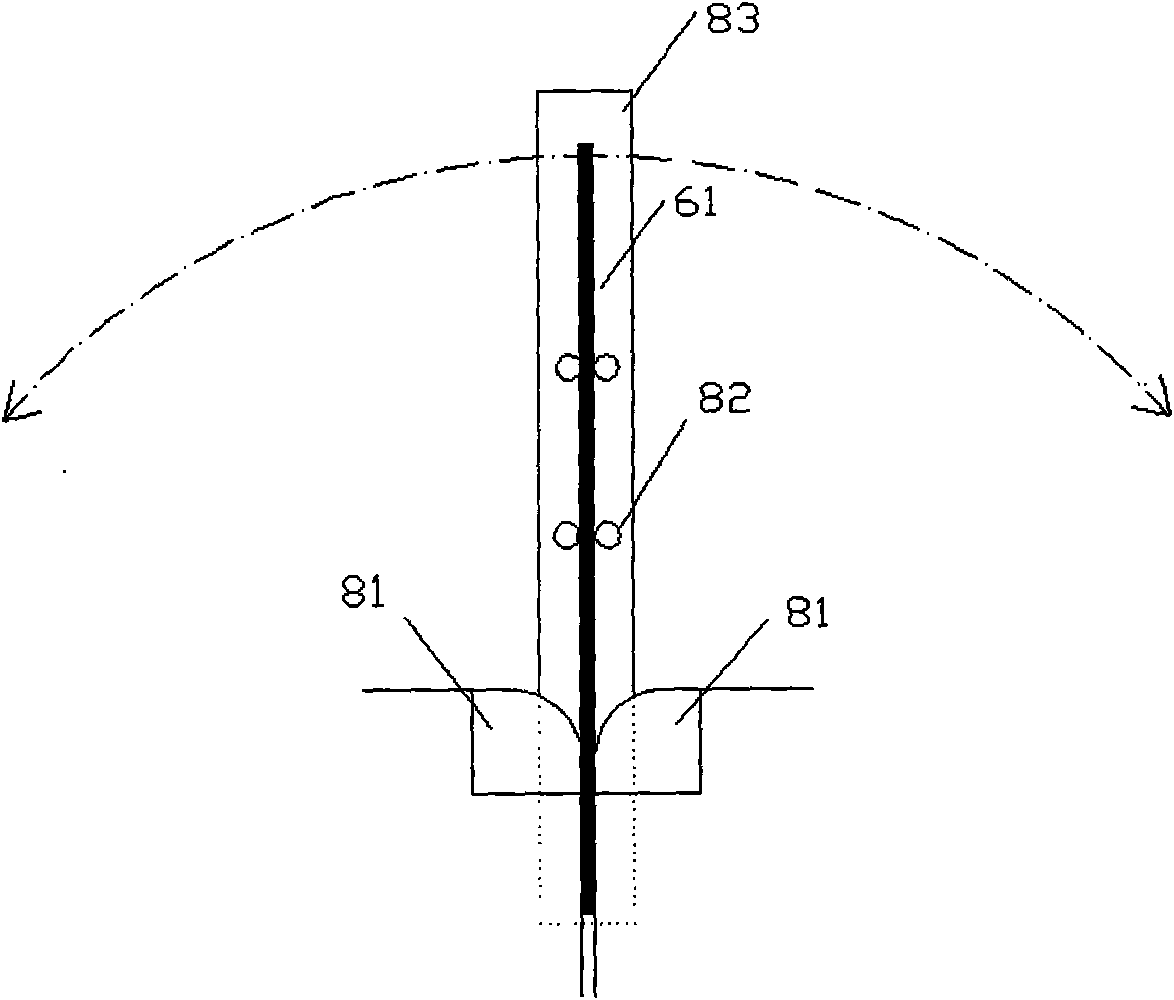

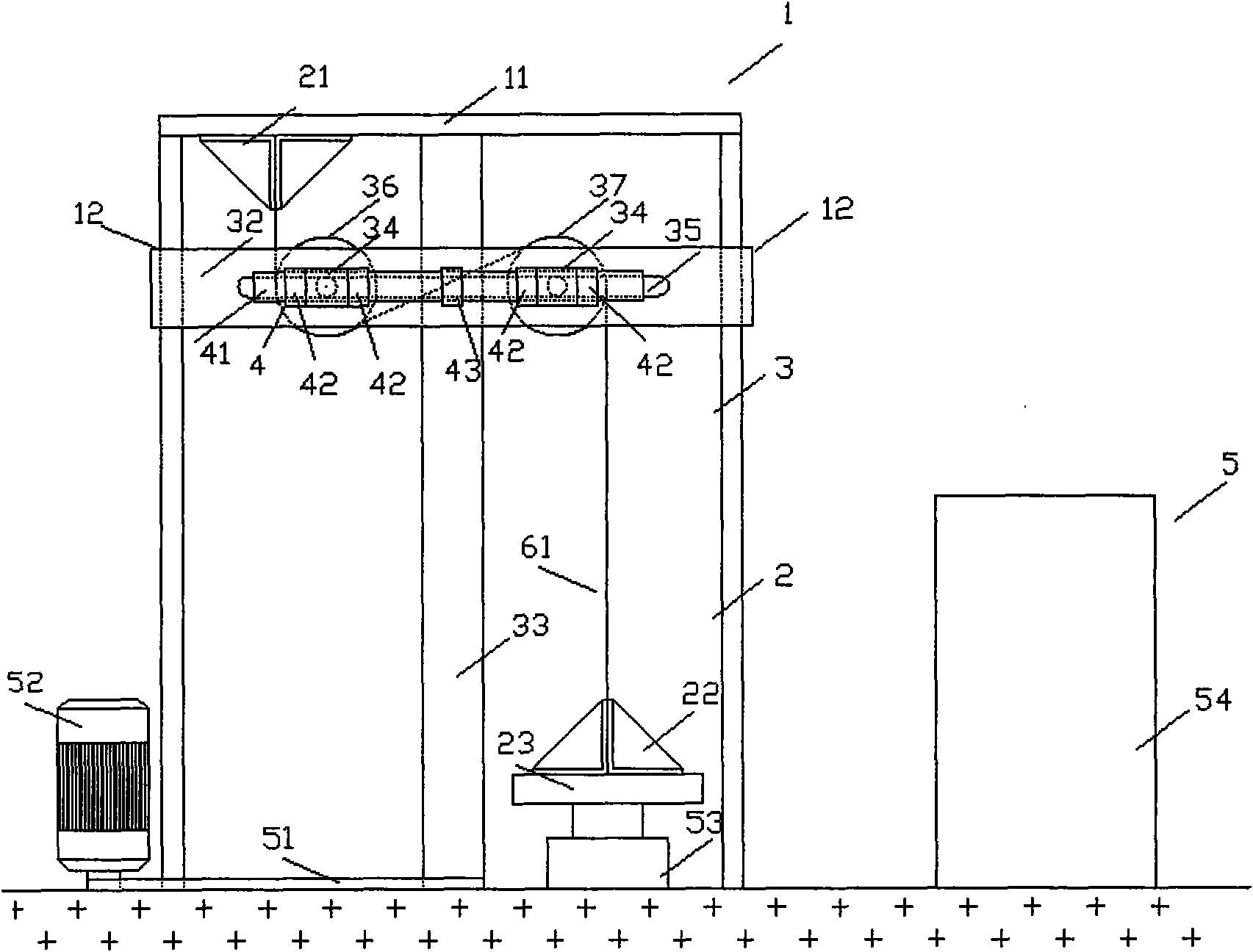

Testing device and method of soil body II-type fracture damage

ActiveCN102128742AThe test data is accurate and reliableFacilitate mechanical analysisStrength propertiesType fractureTest sample

The invention discloses a testing device of soil body II-type fracture damage. A front stop iron and a thrust providing device are respectively connected to two ends of a base, and the front stop iron or the thrust providing device is in sliding connection with the base; the power output part of the thrust providing device is connected with one end of a load sensor, and the other end of the load sensor is connected with a thrust plate; the signal output ends of the load sensor and a displacement sensor are both connected to a computer; the load sensor detects a load applied to a test sample; and the displacement sensor detects the deformation of the test sample in a test. The invention has the beneficial effects that the loading state of the test sample in the whole testing process is kept as a pure II-type, and the damage to the test sample is II-type fracture damage, thereby ensuring that the test data is accurate and credible, and facilitating the later mechanical analysis.

Owner:昌泰建设集团有限公司

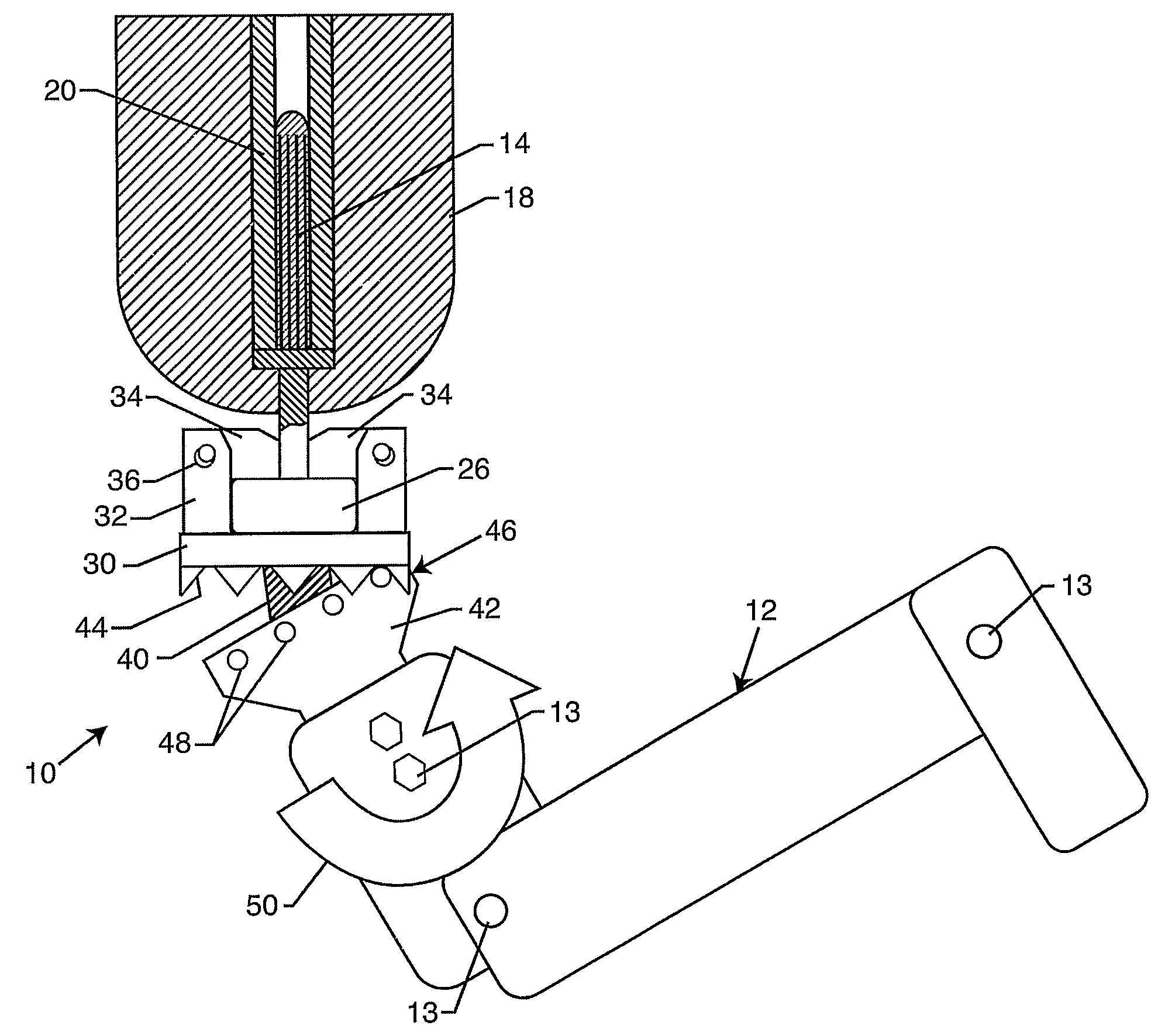

Releasible Attachment System For a Prosthetic Limb

A releasable attachment system is provided for use with a bone anchored post and related external prosthesis such as a prosthetic limb or the like, wherein the attachment system includes a safety release mechanism designed to release or break away when encountering an excess mechanical load. The bone anchored mounting post is implanted for direct affixation to patient bone, and carries or is connected to a fixator structure protruding through soft skin tissue and the like at the end or stump of an amputated limb for mechanical connection to the external prosthesis. The safety release mechanism accommodates substantially normal patient movement throughout a corresponding range of substantially normal mechanical loads, but releases in the presence of an excess load to prevent undesirable fracture failures.

Owner:UNIV OF UTAH RES FOUND

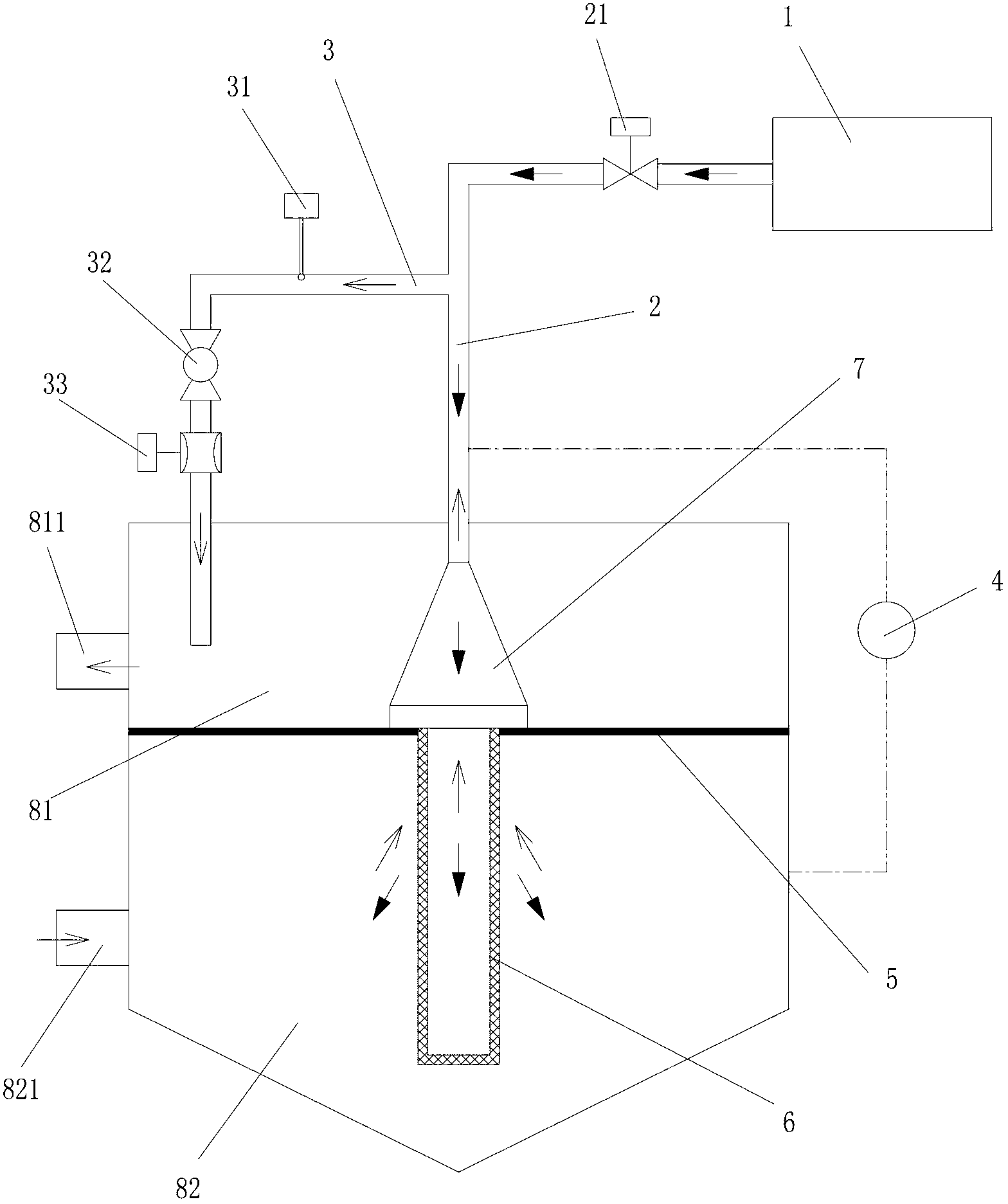

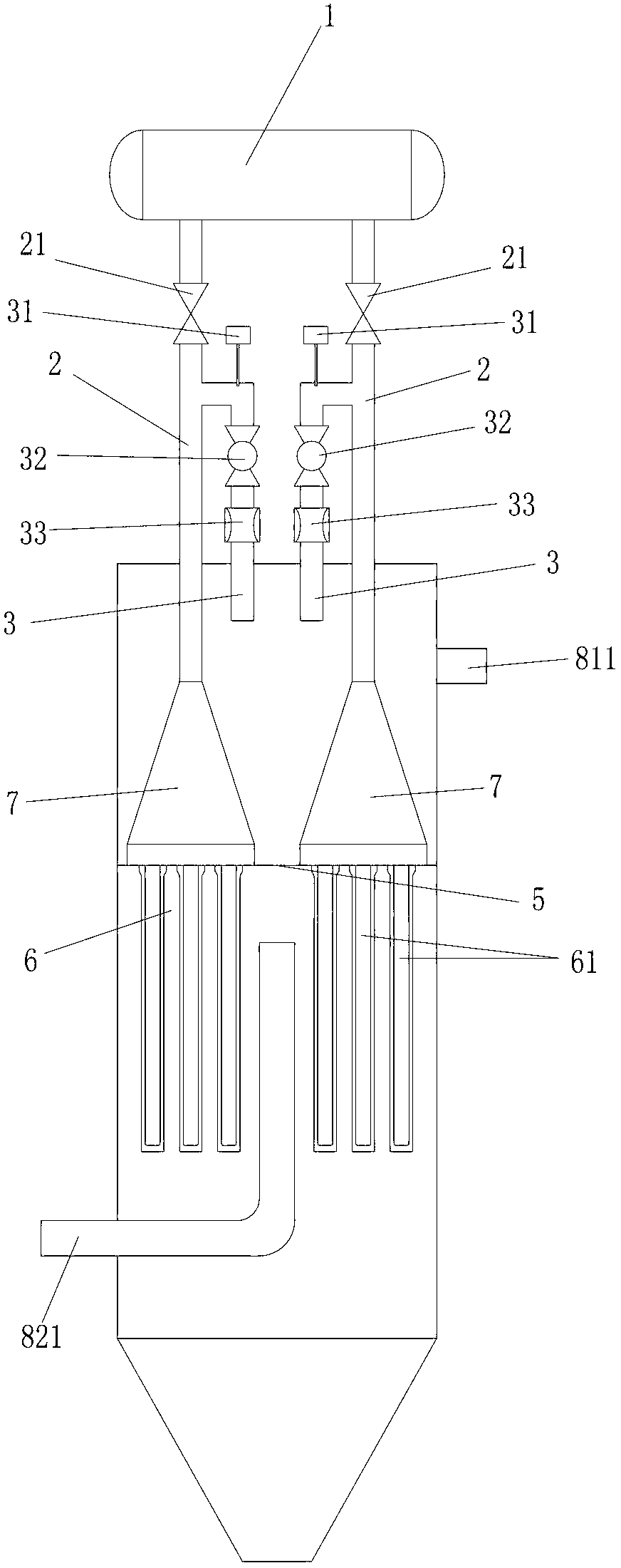

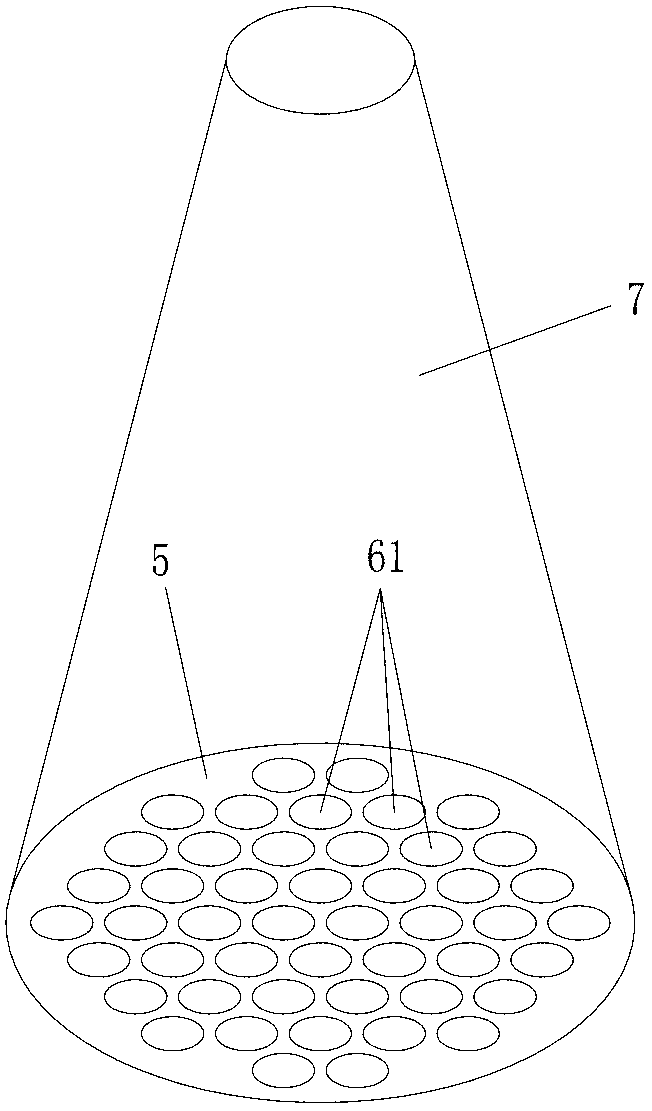

Pulse reverse blowing ash removal device of ceramic filter

ActiveCN102698546AReduces the possibility of fracture failureReduce resistanceDispersed particle filtrationCouplingDifferential pressure

The invention relates to a pulse reverse blowing ash removal device of a ceramic filter. The pulse reverse blowing ash removal device is characterized in that a filtering unit and an air collecting chamber are arranged on a tube plate of the filter; a clean gas chamber is arranged at the upper part of the tube plate of the filter, and a dusty gas chamber is arranged at the lower part of the tube plate of the filter; the pulse reverse blowing ash removal device comprises a reverse blowing gas storage tank; a reverse blowing pipeline which is in tight coupling with the top of the gas collecting chamber of the filtering unit is arranged on the reverse blowing gas storage tank; a pulse reverse blowing valve is arranged in the reverse blowing pipeline; a clean gas leading-out pipeline is connected on the reverse blowing pipeline between the top of the gas collecting chamber and the pulse reverse blowing valve, and an outlet end of the clean gas leading-out pipeline is arranged in the clean gas chamber; a dust concentration monitoring meter, a gas outlet control valve and a flow meter are arranged in the clean gas leading-out pipeline; and a differential pressure sensor is arranged between the dusty gas chamber and an outlet at the top end of the gas collecting chamber of the filtering unit. The pulse reverse blowing ash removal device provided by the invention can realize the cyclic regeneration of a ceramic filter tube by adopting a lower reverse blowing pressure and reduces the possibility of fracture failure of the ceramic filter tube.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

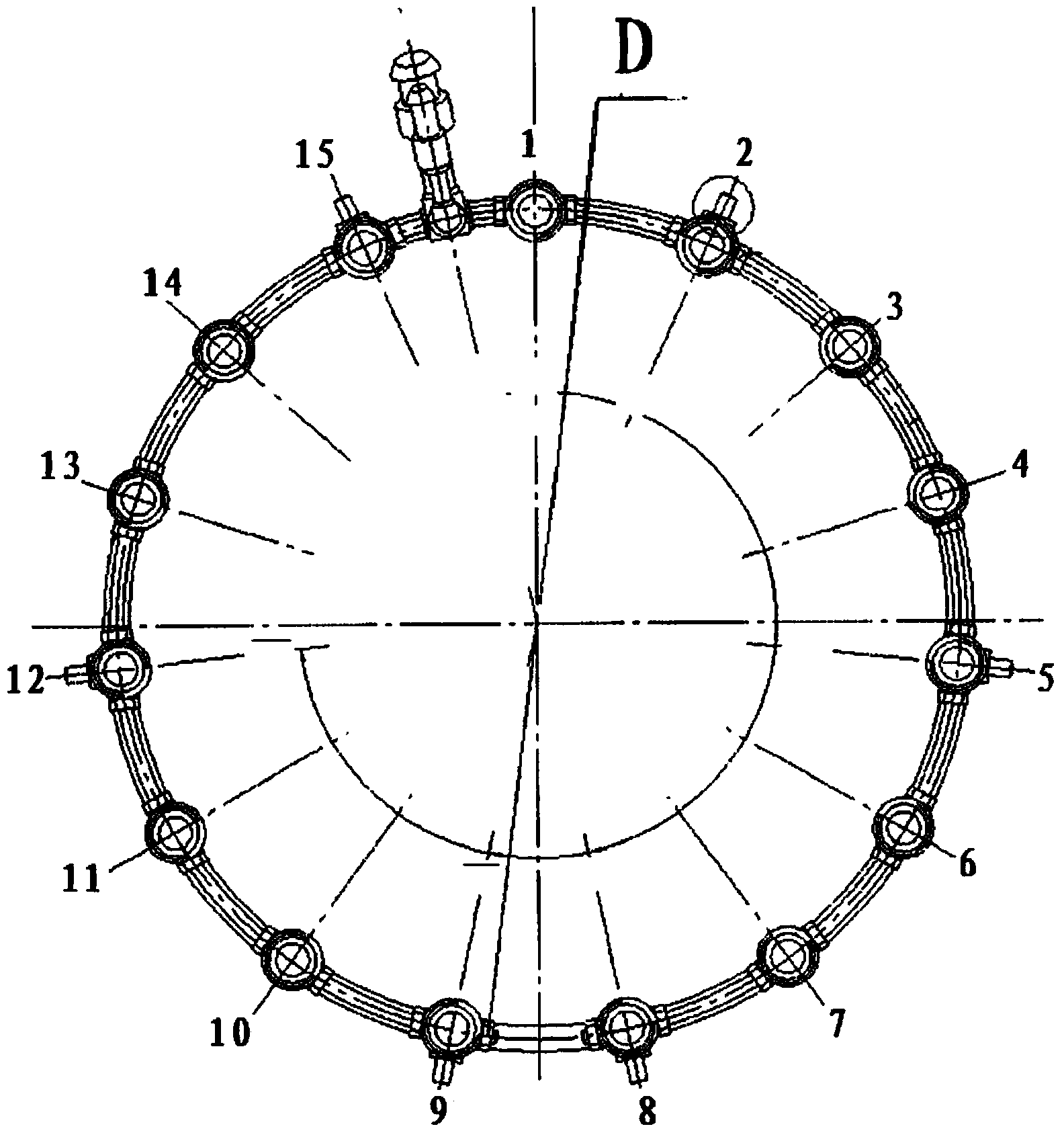

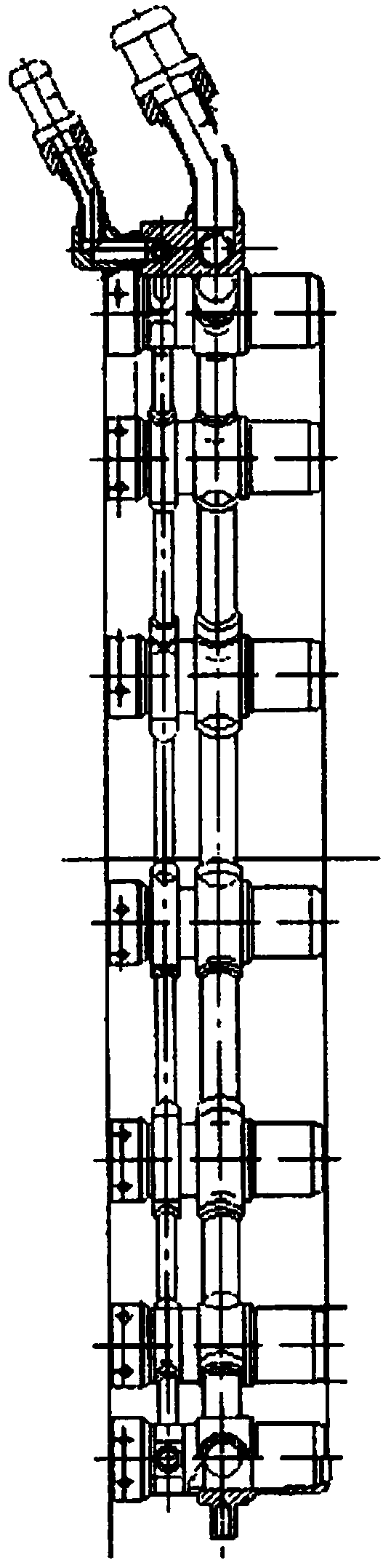

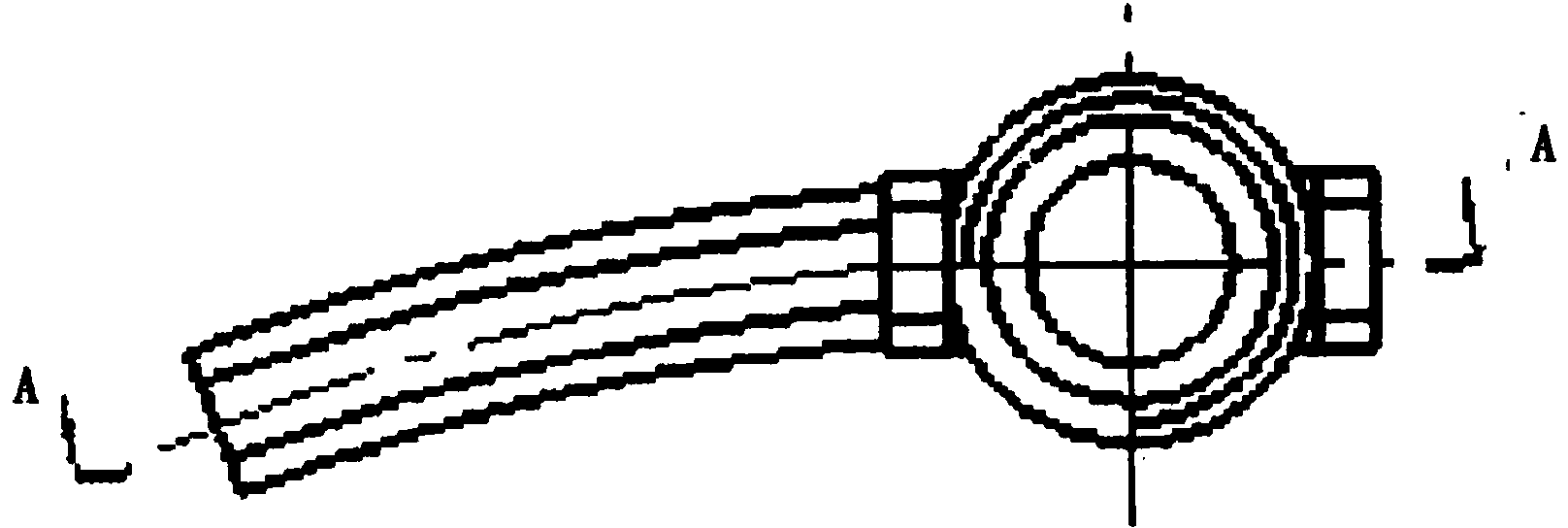

Method for machining fuel manifold with nozzles and of welding structure

ActiveCN103586639AImprovement of welding deformationDimensional accuracy qualifiedArc welding apparatusWork holdersFriction weldingEngineering

The invention discloses a method for machining a fuel manifold with nozzles and of a welding structure. The method includes the welding step, the thermal treatment step and the boring step. Assembly and positioned welding are conducted on each nozzle shell and each pipe at the position, located on the middle arc increasing position, of a small-section welding clamp, and 15 sets of welded nozzle assemblies are formed and corrected at the position; assembly and positioned welding are conducted on every two sets of nozzle assemblies at the middle arc increasing position of the welding clamp according to the general drawing position, and the welded nozzle assemblies are corrected on the original welding clamp; in the process of forming half rings of the manifold, assembly and positioned welding are conducted on each welding seam at the middle arc increasing position of the welding clamp, and the welded welding seams are corrected on the original welding clamp; eventually positioned welding is conducted on the two half rings on the original welding clamp, and the two welded half rings are corrected. The method has the advantages that the welding deformation phenomenon is obviously improved, size accuracy is qualified, the method smoothly passes long test evaluation, the quality is stable, and no fracture failure in the engine test process occurs.

Owner:SHENYANG LIMING AERO-ENGINE GROUP CORPORATION

Quantitative risk analysis method of pressure bearing equipment containing surface crack defects

InactiveCN102628769AThe calculation result is accurateEasy to getSpecial data processing applicationsStrength propertiesNon destructiveStress strength

Owner:NANJING UNIV OF TECH

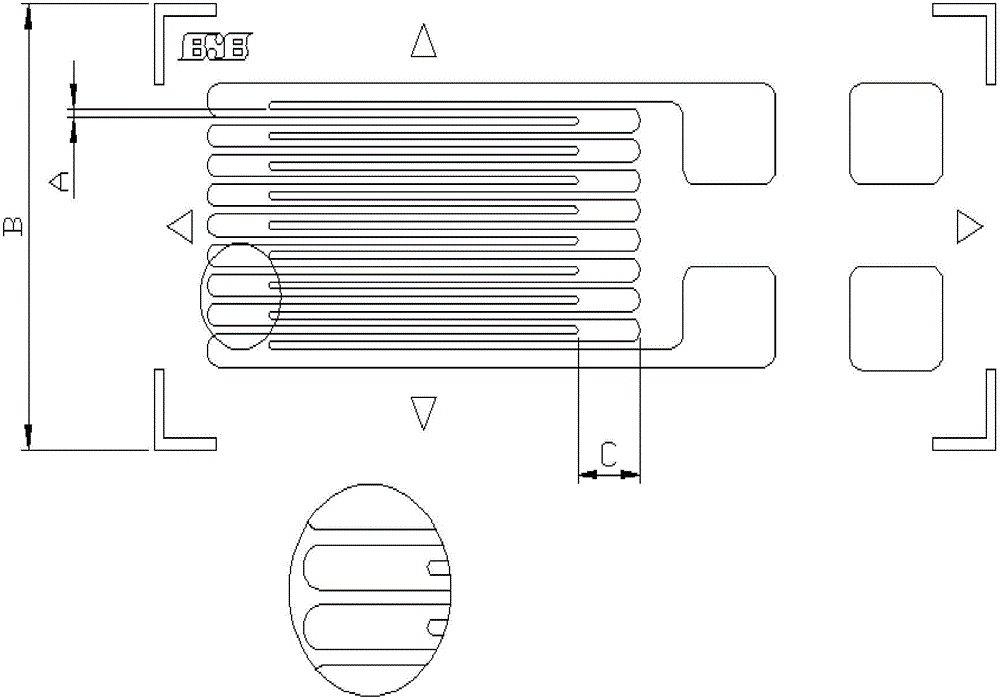

Strain meter for plastic deformation test and manufacturing and calibration method thereof

ActiveCN103604363ANot easy to break and damageImprove ductilityElectrical/magnetic solid deformation measurementAlloyVacuum annealing

The invention provides a strain meter for a plastic deformation test and a manufacturing and calibration method of the strain meter. The strain meter comprises a substrate, a sensitive grid and a sealing layer, wherein the sensitive grid is obtained by subjecting constantan and tinsel alloy formed in a cold rolling mode to vacuum annealing at 350-550 DEG C for three to six hours. The sensitive grid of the strain meter is obtained by subjecting the constantan and tinsel alloy formed in the cold rolling mode to vacuum annealing, and is good in ductility and elongation and capable of completely meeting measurement requirements of plastic deformation, so that the sensitive grid is not prone to rupture failures in the plastic deformation process.

Owner:ZHONGHANG ELECTRONICS MEASURING INSTR

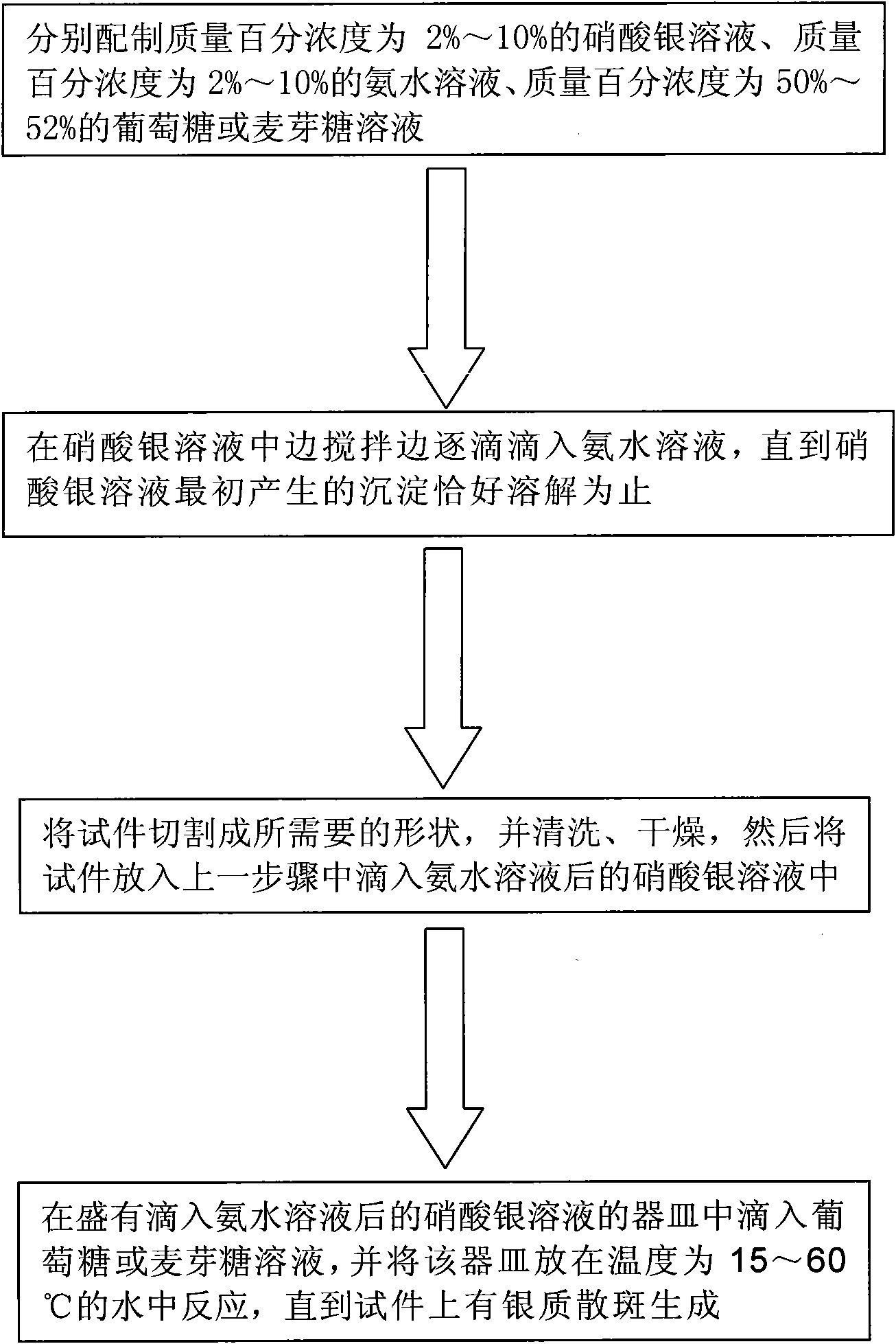

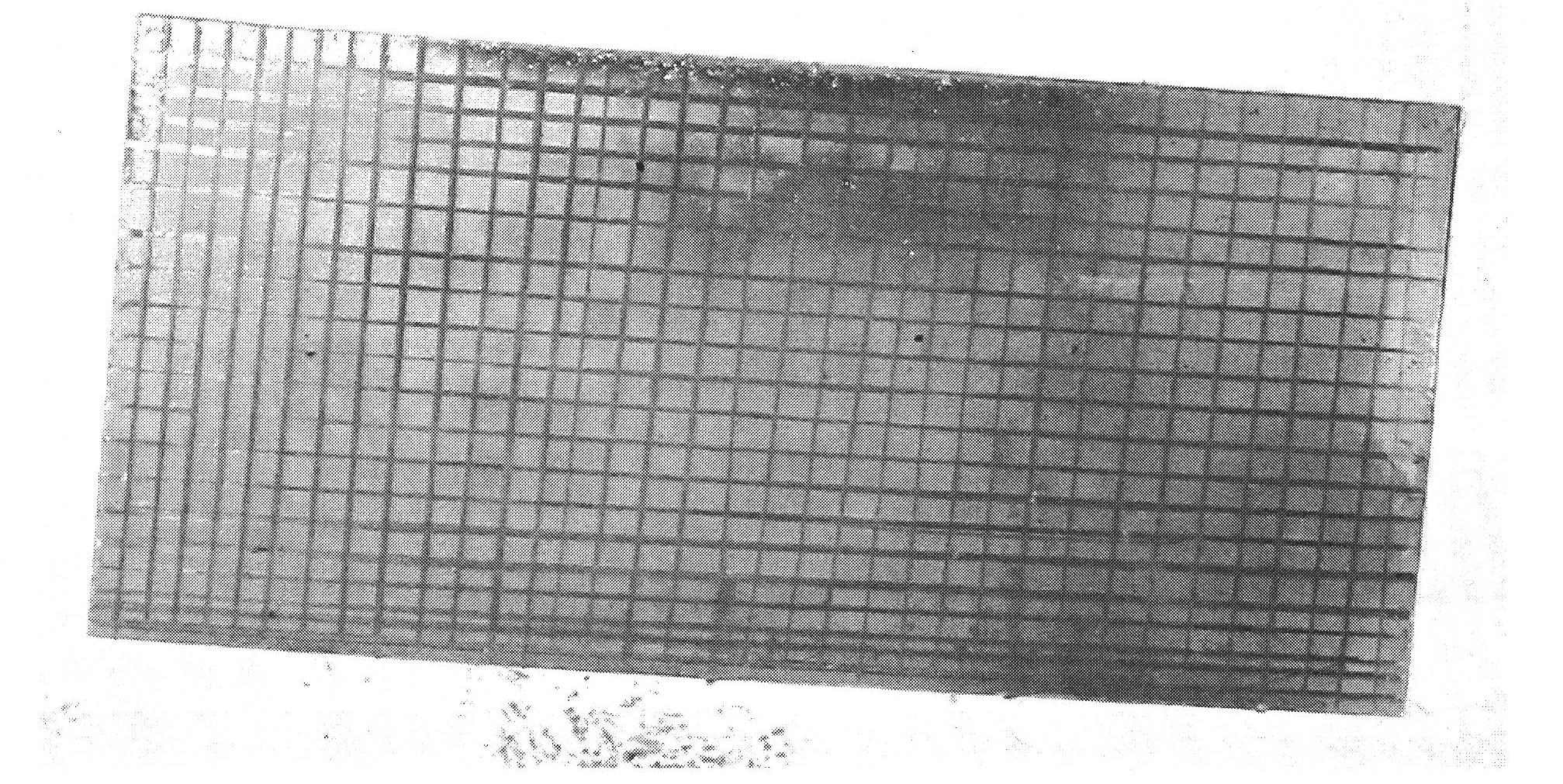

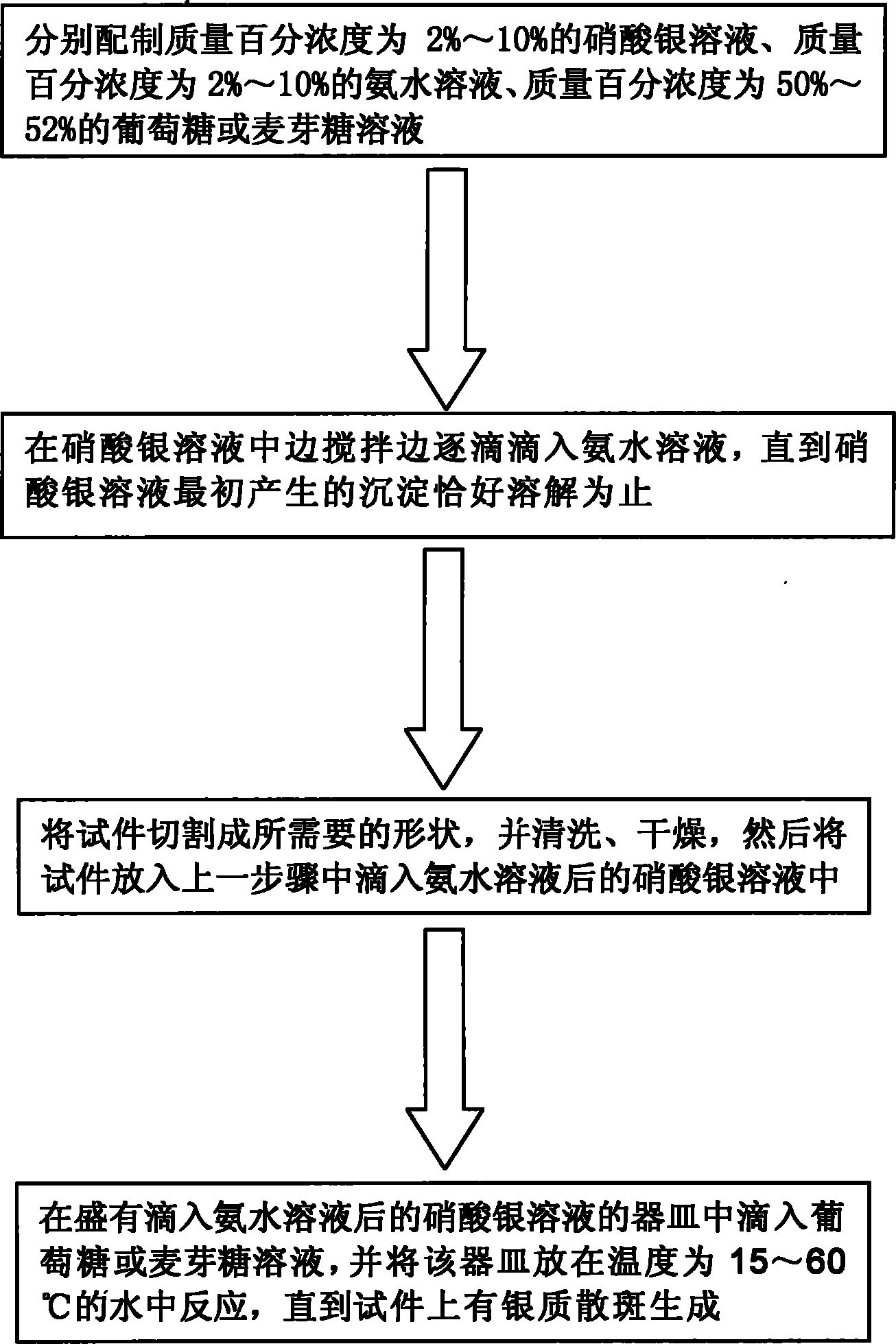

Manufacturing method of high-temperature speckle

The invention relates to a manufacturing method of high-temperature speckles, which belongs to the technical fields of optical device manufacture and photomechanics. The invention has the technical characteristic that high-temperature resistant speckles are manufactured on the surface of a material by utilizing a chemical reaction method. Silver speckles can be generated on the surface of the material put into solution which is prepared from silver nitrate powder, ammonia water, glucose powder and purified water according to a proper proportion in a certain temperature environment. The speckles can resist about 900 DEG C of temperature and can be matched with a digital image correlation method to finish the optical measurement of mechanical performance in multiple complicated loaded states, such as heat shock, fracture and the like of the material in a high-temperature environment. The invention has novel thought, simple and flexible operation and strong feasibility.

Owner:TSINGHUA UNIV

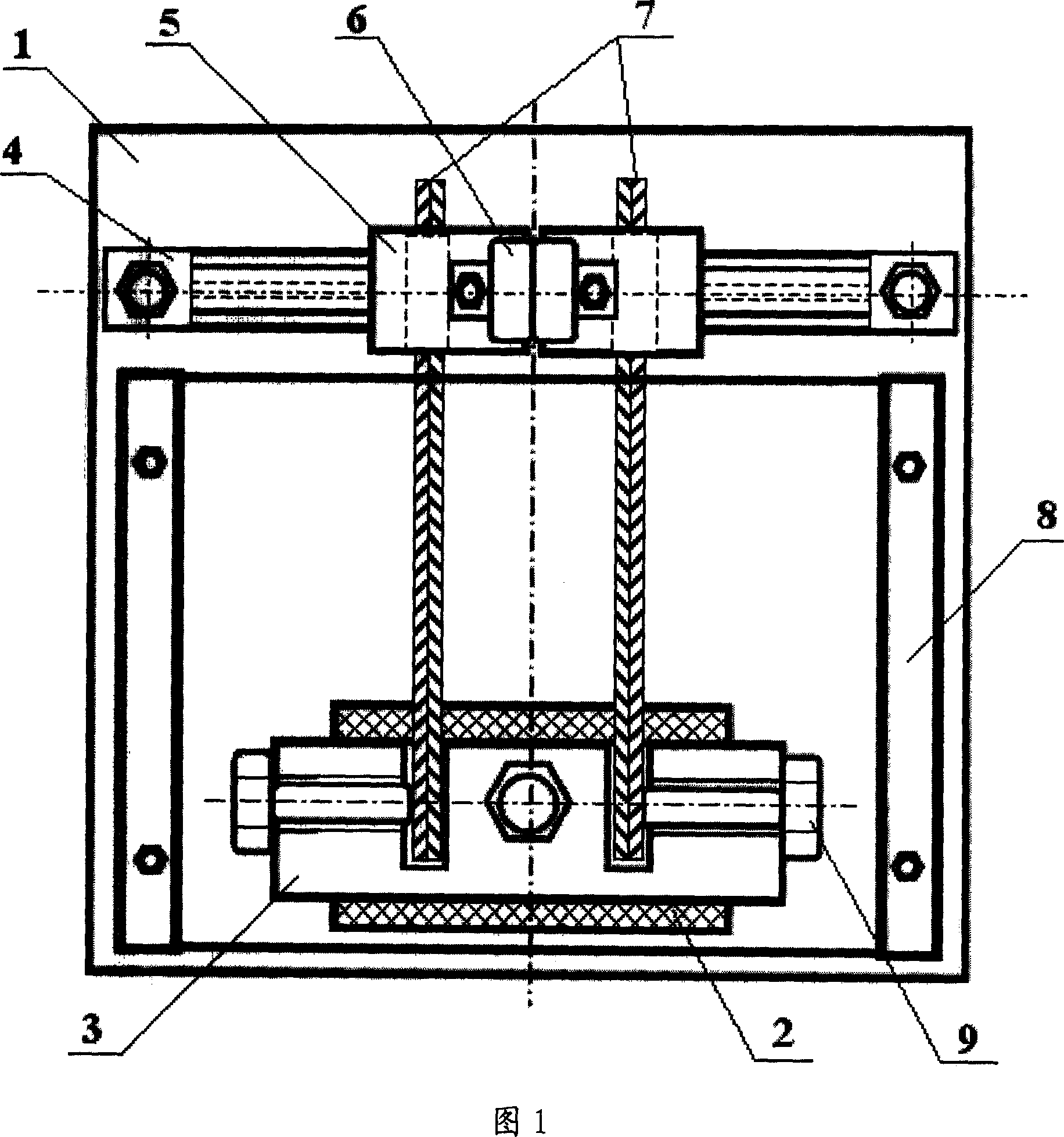

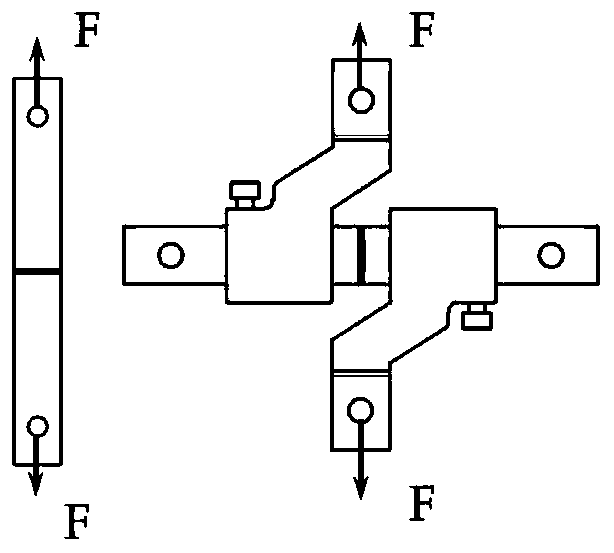

Nano-wire in-situ stretching device in scanning electron microscope and method therefor

InactiveCN1995963ASingular mechanical propertiesSimple structureSurface/boundary effectMaterial strength using tensile/compressive forcesNanowireScanning electron microscope

The invention relates to a scanning electron microscope nanometer line original tensile device and method. It controls the heater to make the dual metal plate bending, drive slide of dual metal plate moving linearly along the track to both sides, tensile the nanometer line fastened on the sample bench, recording the tensile acted plastic tensile deformation and fracture failure, matching the dynamic performance of the nanometer line and the microstructure change, revealing the tensile deformation mechanism, fracture failure mode, brittle-ductile transition and so on of one dimension nanometer dynamic performance. It is simple, easy to control, realizing the original position one line measurement of the nanometer line dynamic feature.

Owner:BEIJING UNIV OF TECH

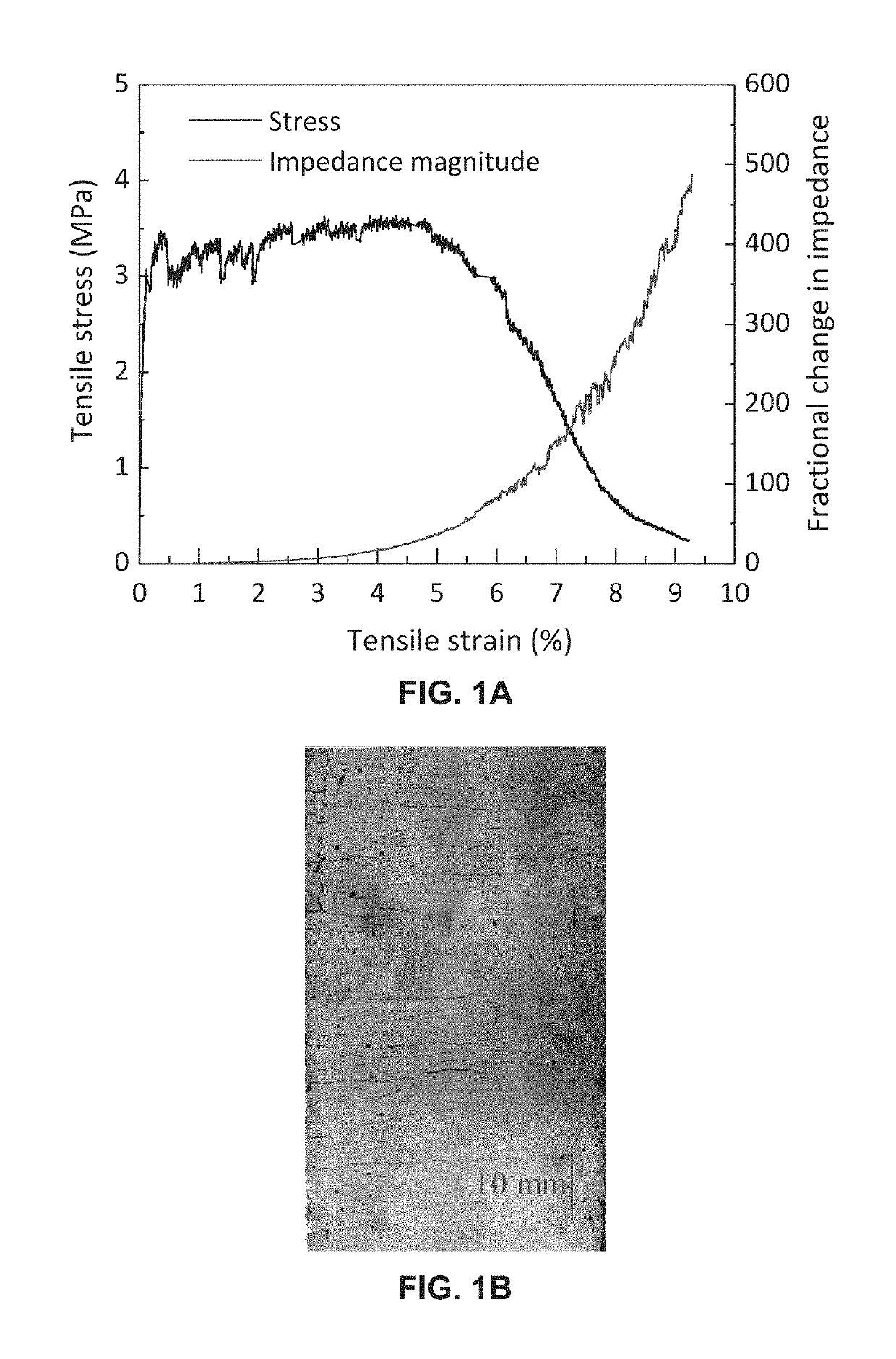

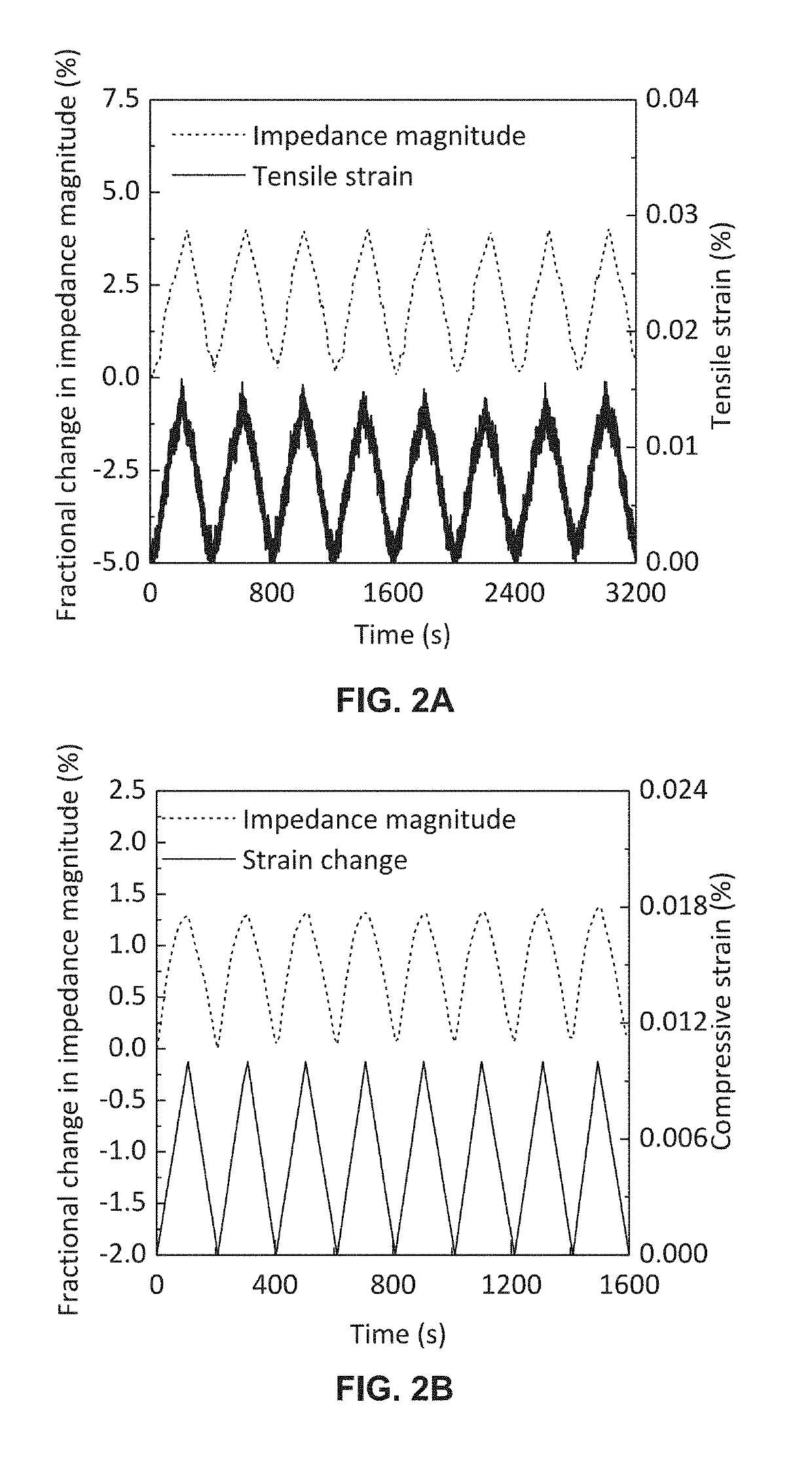

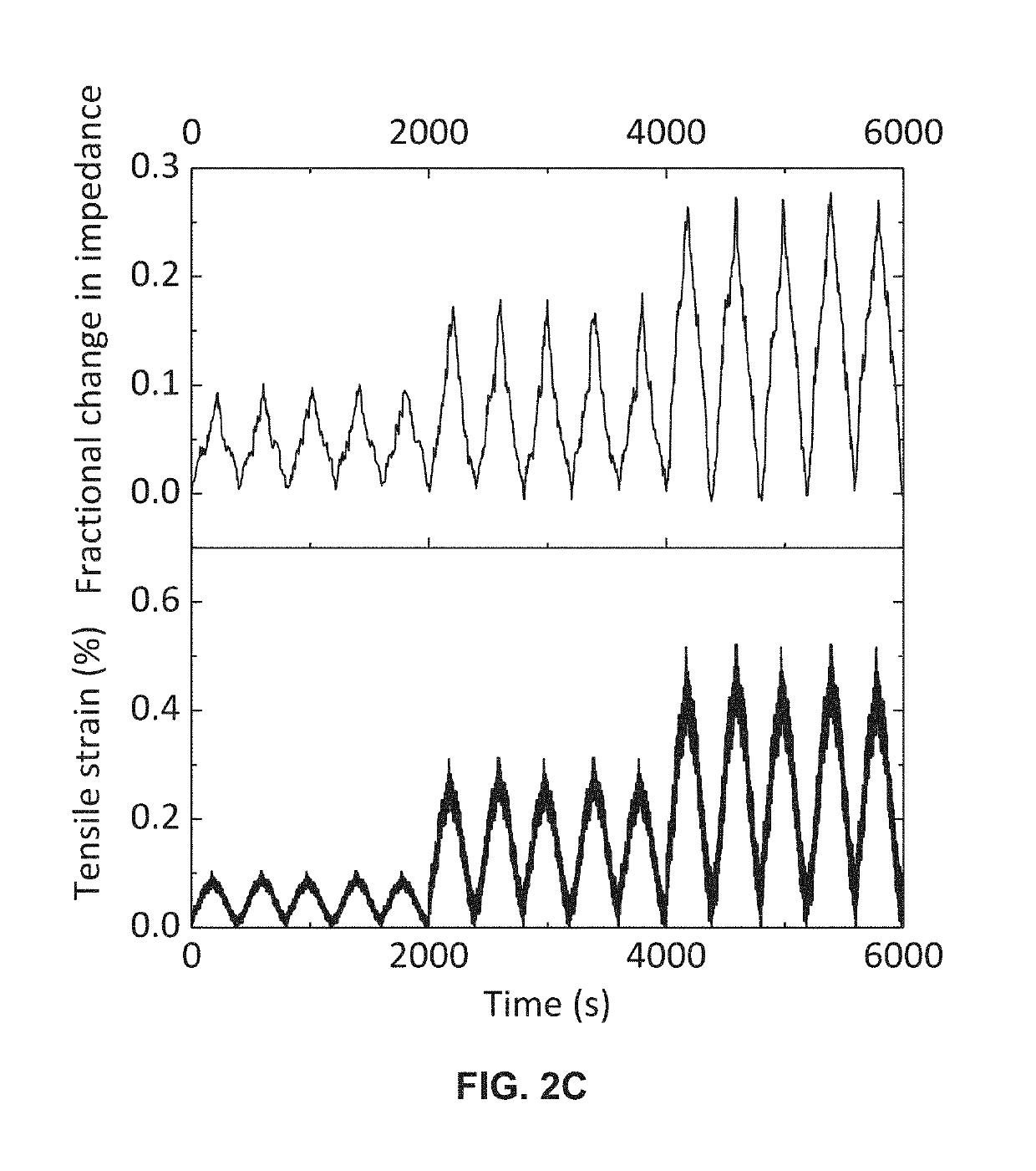

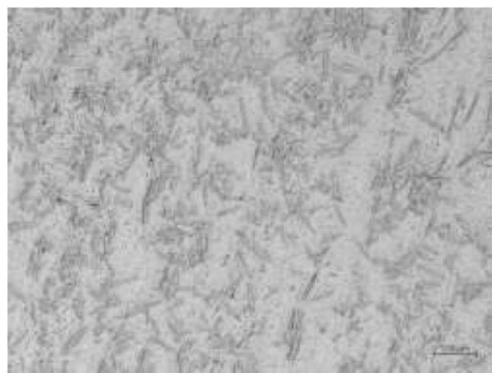

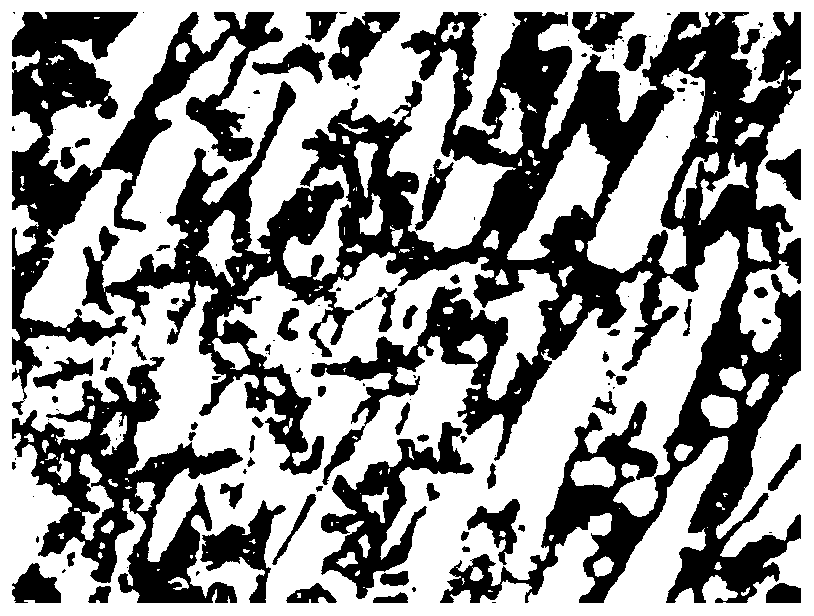

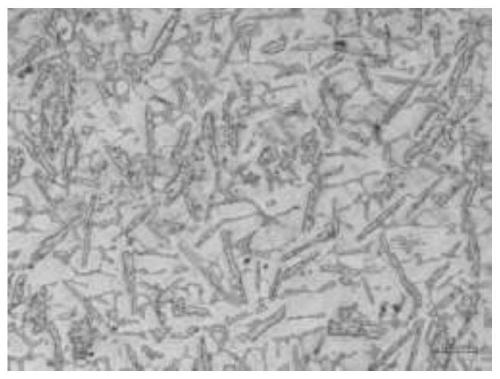

Multi-functional cementitious materials with ultra-high damage tolerance and self-sensing ability

PendingUS20190202738A1Large tensile ductilityLarge fracture energySolid waste managementCeramicwareDamage toleranceRetrofitting

Cementitious materials having high damage tolerance and self-sensing ability are described herein. These materials may replace conventional concrete to serve as a major material component for infrastructure systems with greatly improved resistance to cracking, reinforcement corrosion, and other common deterioration mechanisms under service conditions, and prevents fracture failure under extreme events. These materials can also be used for the repair, retrofitting or rehabilitation of existing concrete structures or infrastructure systems. Furthermore, these materials may offer capacity for distributed and direct sensing of cracking, straining and deterioration with spatially continuous resolution wherever the material is located, without relying on installation of sensors. The present invention relates to multifunctional cementitious structural or infrastructure materials that integrate self-sensing with damage tolerance for improving safety, extending service life, and health monitoring of structures, components, and infrastructure systems.

Owner:RGT UNIV OF CALIFORNIA

Preparation method of high temperature resistant Cu-Cr-Nb-Ce alloy for combustion chamber lining of aero-engine

ActiveCN110218897AReduced mechanical propertiesImprove physicsCombustion chamberUltimate tensile strength

The invention discloses a preparation method of high temperature resistant Cu-Cr-Nb-Ce alloy for the combustion chamber lining of an aero-engine and belongs to the technical field of manufacture of the combustion chamber lining material of the aero-engine. The preparation method mainly comprises the following steps: 1, preparing and proportioning materials; 2, carrying out vacuum induction melting; 3, casting; 4 carrying out electrode induction gas atomization; and 5, carrying out powder canning hot extrusion. The Cu-Cr-Nb-Ce alloy has higher high temperature resistant strength and excellent ductility, Cr and Nb in the alloy can form LAVES (Cr2Nb) phase, and the LAVES (Cr2Nb) phase is still stable when the temperature is higher than 1600 DEG C, so that the Cu-Cr-Nb-Ce alloy is dispersion strengthening copper alloy of plenty of Cr2Nb hardening phases; the Cr2Nb hardening phases can refine and control the grain size of copper to further improve the strength of copper alloy; in addition,the Cr2Nb hardening phases can prevent the phenomenon that the crystal particle is thick and large or the grain boundary is oxidized or melts when the material is at the high temperature, so that fatigue, and ablation, crack and fracture failure of a hot end part are avoided when the material is at the high temperature; and the Cu-Cr-Nb-Ce alloy is an extremely attractive material used at the hightemperature environment.

Owner:SHAANXI SIRUI ADVANCED MATERIALS CO LTD

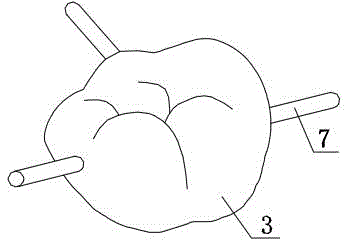

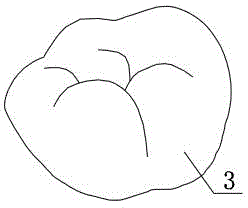

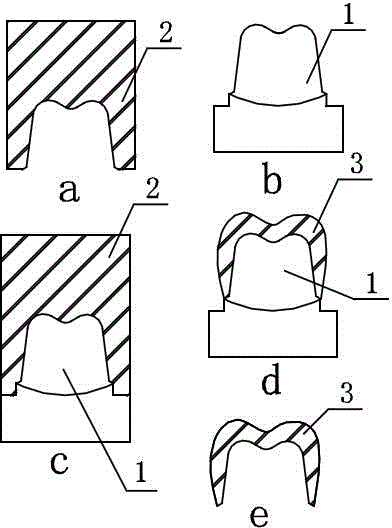

Wet forming production method of dental all-ceramic restoration

The invention discloses a wet forming production method of a dental all-ceramic restoration. According to the method, a prefabricated ceramic block is not used for processing, and in production processes, a support column is not required for fixing the ceramic block and the restoration, so that the process steps of manually removing the support column by milling to separate the formed restoration and the surrounding ceramic block and burnishing and polishing the excessively rough outer surface of the restoration caused by removing the support column by milling are avoided, and the risks of disintegration of the restoration and premature fracture failure are further reduced. A ceramic hard biscuit for milling processing is produced by adopting a wet forming technology, and compared with the ceramic block which is formed by dry pressing and partially sintered, the microscopic structure is more uniform and contains fewer particle packing defects. Through milling processing of the ceramic hard biscuit which is not sintered, the surface finish which is higher than that obtained by processing the ceramic block which is partially sintered can be obtained. The dental all-ceramic restoration produced by adopting the technical scheme of the invention has the advantages of no connection points for the support column on the outer surface, no partial milling marks and ceramic cracks, bright and clean surface, uniform and consistent structure and high reliability.

Owner:HANGZHOU ERRAN TECH

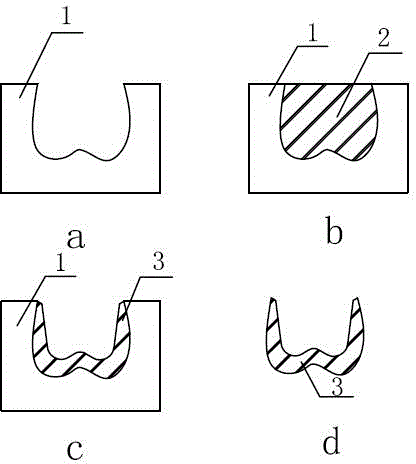

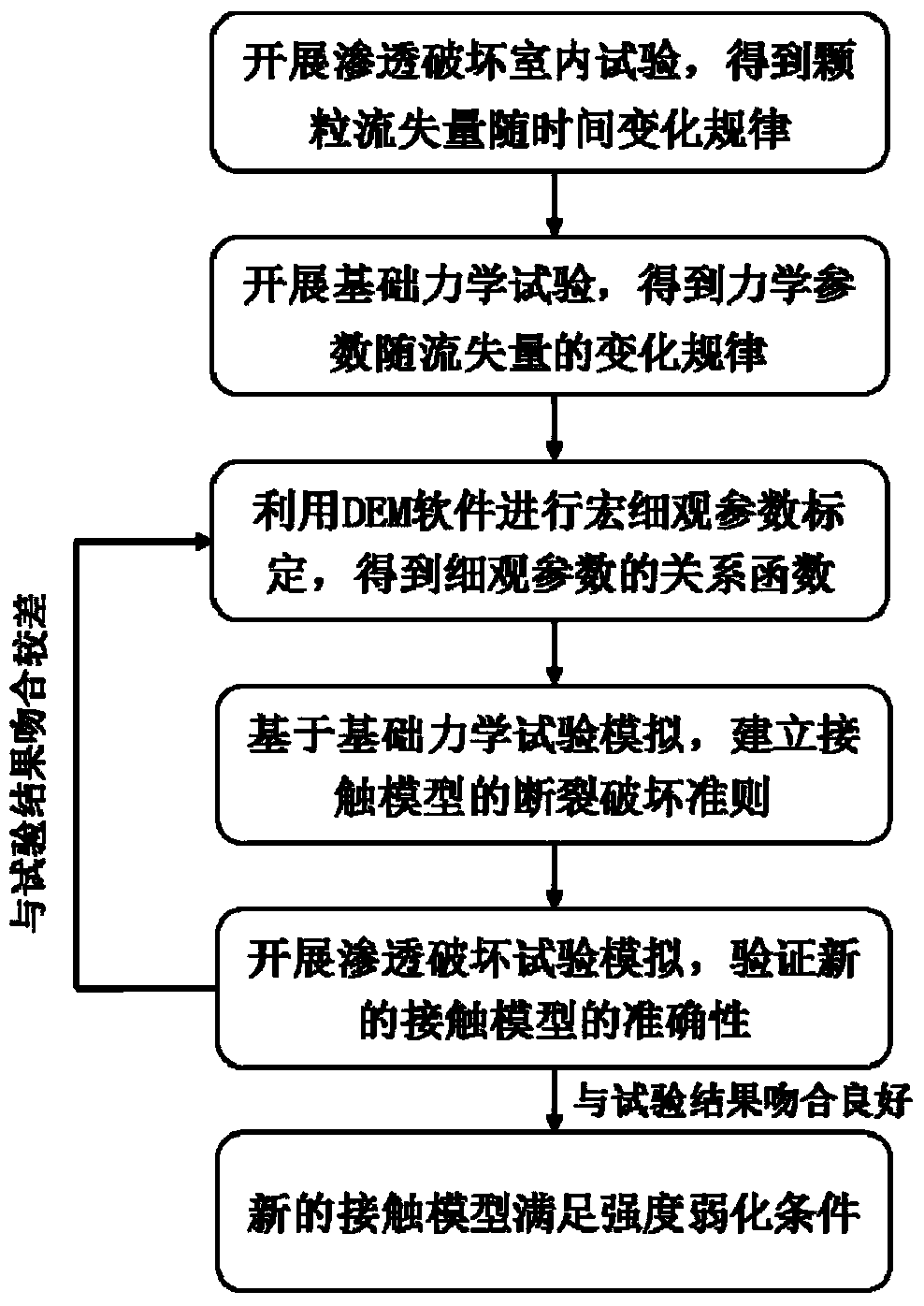

DEM contact model construction method capable of reflecting weakening of seepage to rock-soil mass strength

ActiveCN111024588AMaterial strength using tensile/compressive forcesMaterial strength using steady shearing forcesSoil scienceSoil mass

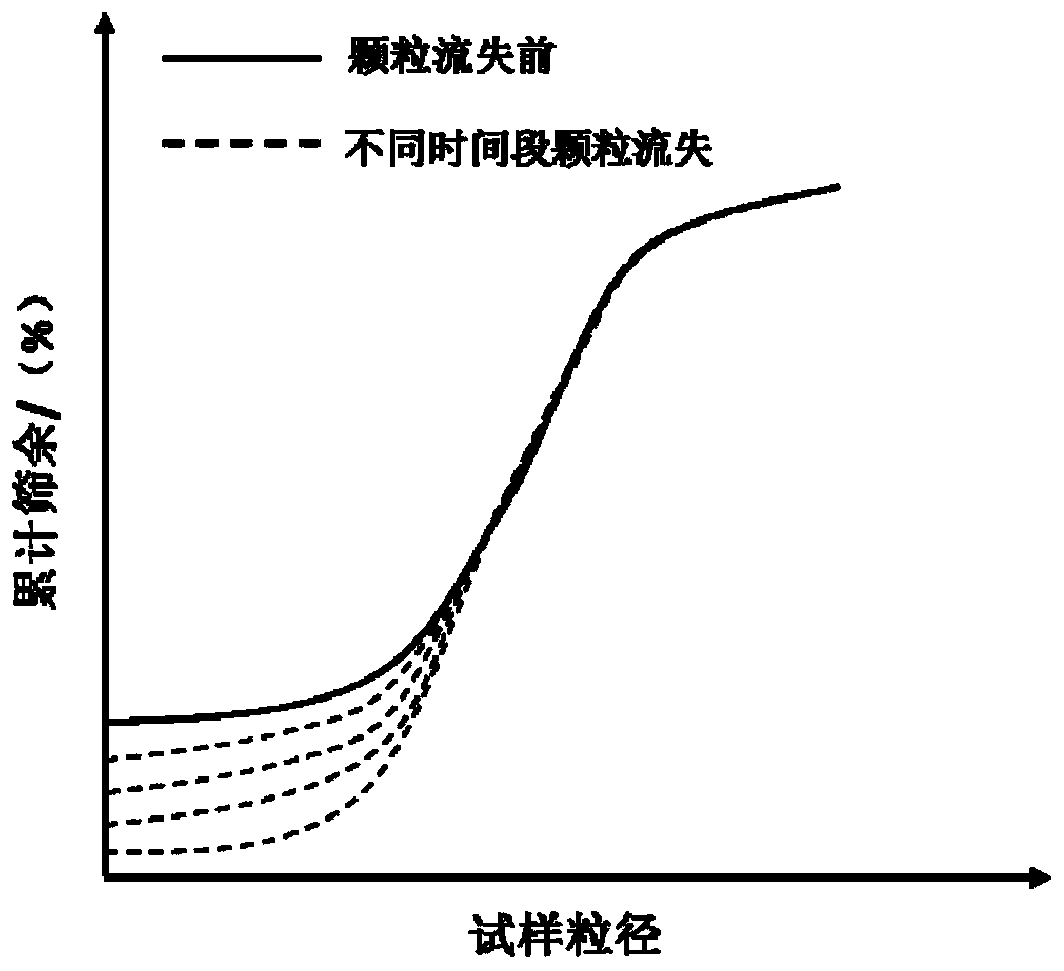

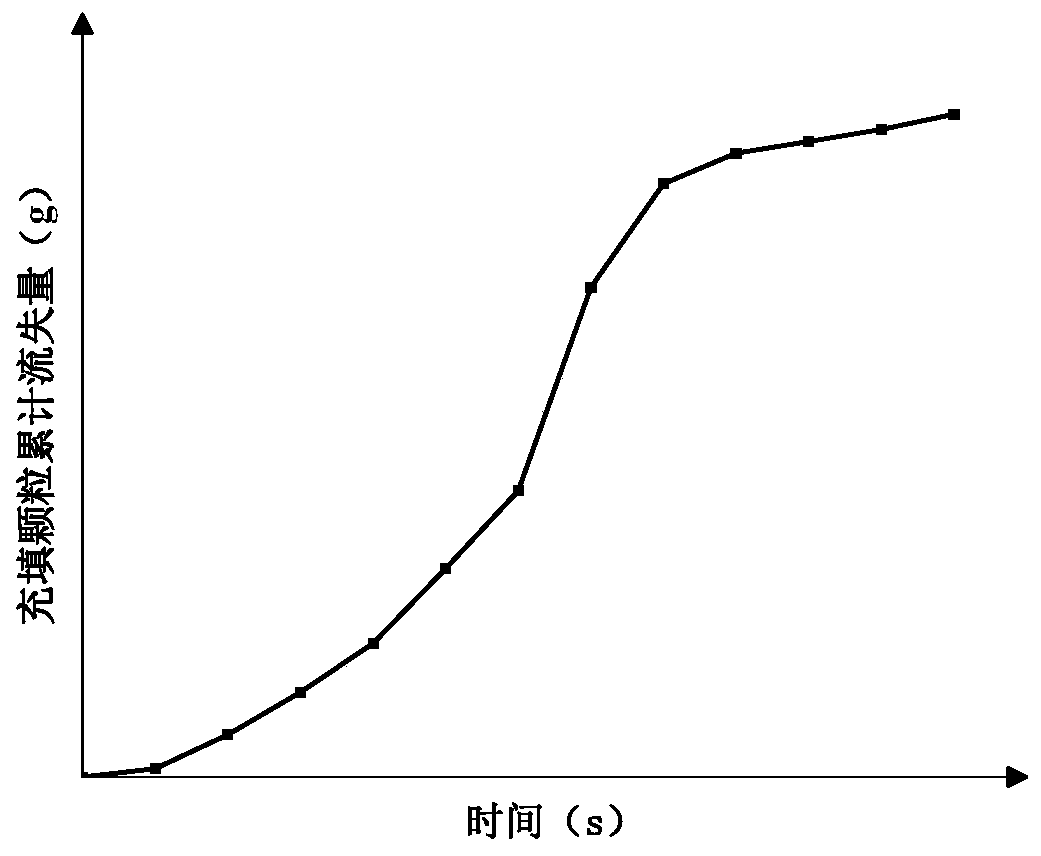

The invention provides a DEM (Digital Elevation Model) contact model construction method for reflecting weakening of seepage to rock-soil mass strength, which comprises the following steps: selectinga filling body in a disaster-causing structure to obtain a change rule of accumulated loss amount of the filling body along with time under the action of seepage and a change rule of mechanical parameters of the filling body along with the loss amount of the filling body; carrying out test simulation, and determining a relation function of each group of corresponding mesomechanics parameters in each time period and DEM contact model mesomechanics parameters capable of representing the change rule of the macromechanics parameters of the filling body; embedding each mesoscopic parameter relationfunction into an existing particle contact model, carrying out test simulation, and updating the fracture failure criterion of the contact model according to the corresponding relation of macro-mesoscopic strength when the model is damaged, so as to realize the simulation of the continuous weakening process of the filling body strength; and based on an indoor seepage failure test, establishing aseepage failure discrete element calculation model, and simulating the seepage failure process of the rock-soil body by adopting the obtained particle contact model and the fracture criterion thereof.

Owner:SHANDONG UNIV

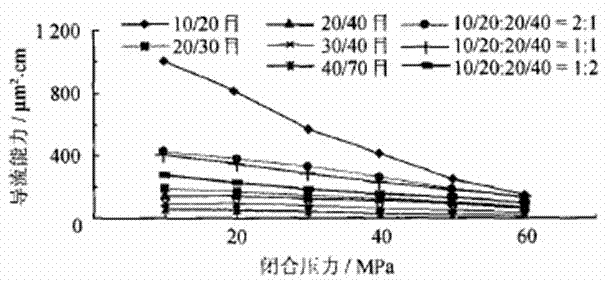

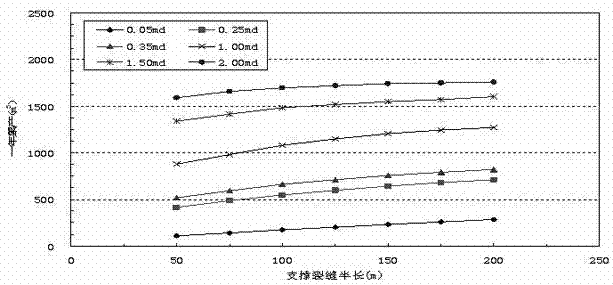

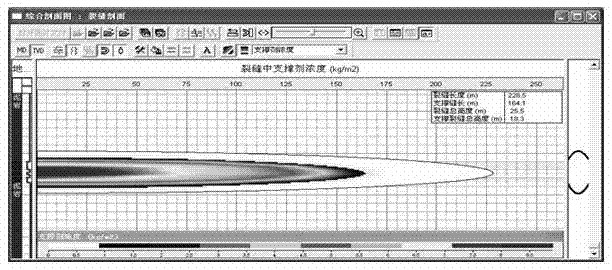

CO2 refracturing process technology for low-permeability gas well

The invention belongs to the technical field of oil exploitation, and relates to a refracturing modification process for a low-permeability and low-yield gas well, in particular to a CO2 refracturing process technology for a low-permeability gas well. The CO2 refracturing process technology is used for performing secondary fracturing construction for an implemented well, comprises analysis and optimization before fracturing and fracturing construction, and is characterized in that the analysis and optimization before fracturing comprises fracturing failure analysis, fracturing material optimization and construction parameter optimization, and the specific process technology is implemented according to steps of fracturing failure analysis, fracturing material optimization, construction parameter optimization and refracturing construction. According to the CO2 refracturing process technology for the low-permeability gas well, a CO2 foam fracturing technology and low-damage cleaning fracturing liquid are used for performing a modification test for a low-yield gas well by analyzing a reservoir, the flowback rate of the fracturing liquid and the yield of the low-yield gas well are increased effectively, and damage to the reservoir is effectively reduced.

Owner:CHINA NAT PETROLEUM CORP CHUANQING DRILLING ENG CO LTD CHANGQING DOWNHOLE TECH CO

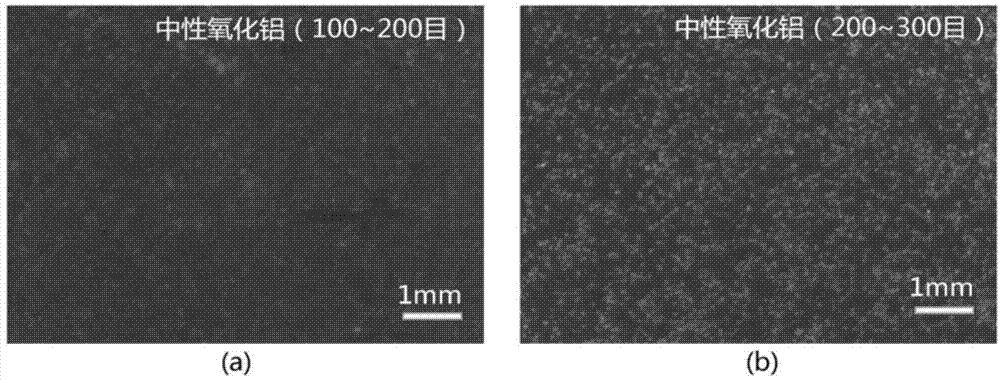

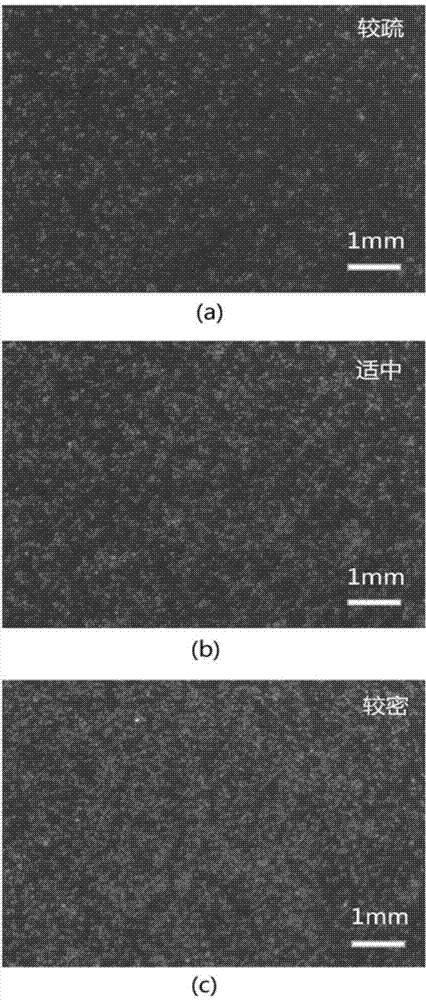

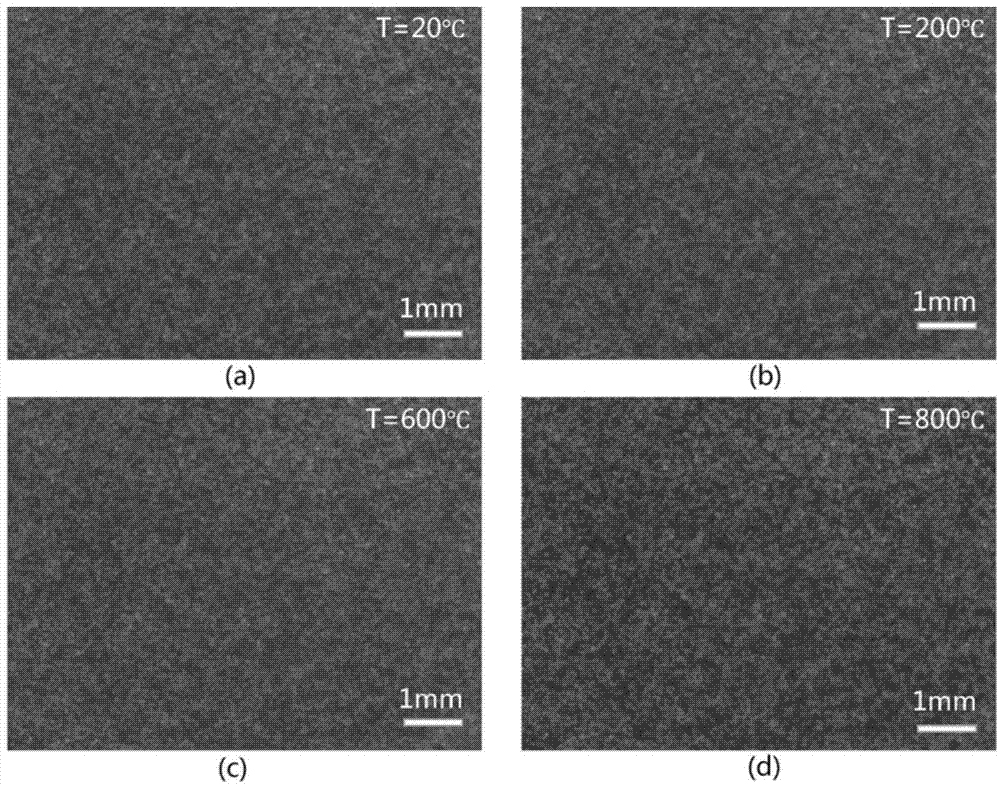

DIC weld dynamic strain measurement based high-temperature speckle preparation method

ActiveCN104777021AImprove bindingLow costPreparing sample for investigationOptical measurementsDigital image

The invention relates to a DIC weld dynamic strain measurement based high-temperature speckle preparation method. The DIC weld dynamic strain measurement based high-temperature speckle preparation method comprises the following steps: preparing a double-component aluminosilicate into pasty high-temperature resistant glue; grinding, polishing, coating the surface of a substrate material cleaned by alcohol with the high-temperature-resistant glue, then scattering a layer of evenly distributed high-temperature-resistant particles on the high-temperature-resistant glue, and modifying the surface of the substrate material; curing the high-temperature-resistant glue, and thus preparing high-temperature-resistant speckles on the surface of the substrate material. Compared with the prior art, the speckles obtained by the method can resist temperature of around 800 DEG C; the preparation method is especially suitable for the measurement of digital images of weld dynamic strain and also can be applied to the measurement of mechanical performance under the conditions of material stretching, crack damage and the like at high-temperature environment, is novel in concept, is simple to operate, is low in preparation cost, and has wide application prospect in the high-temperature optical measurement mechanical performance.

Owner:SHANGHAI JIAO TONG UNIV

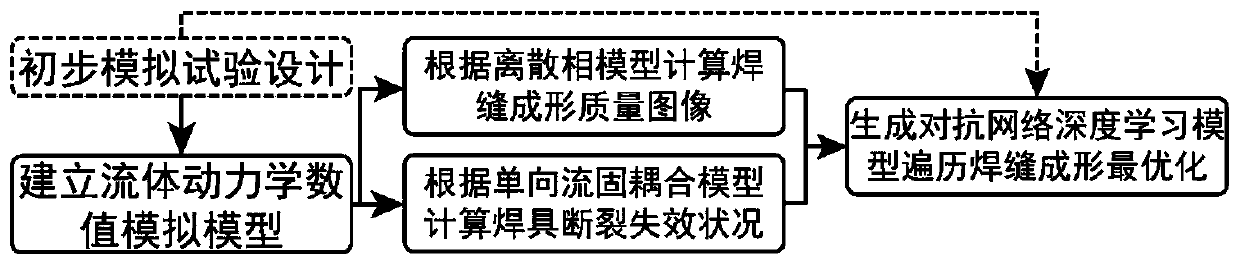

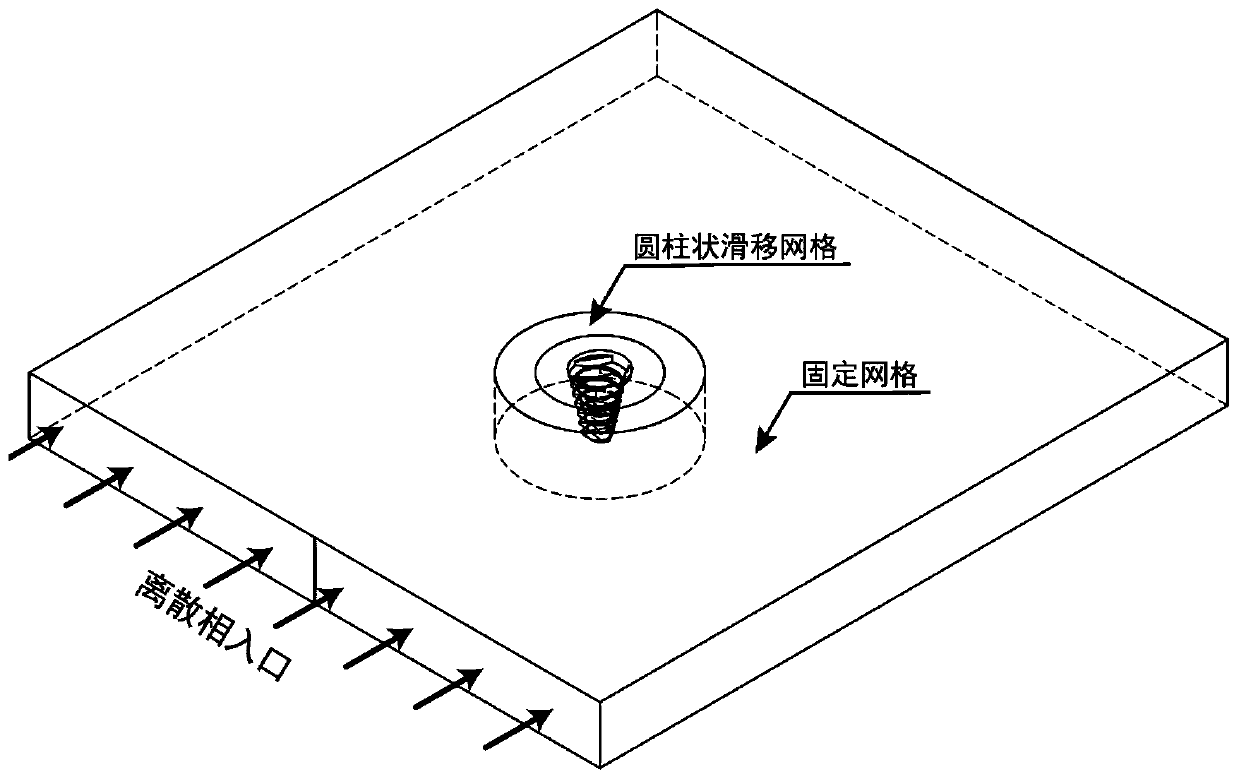

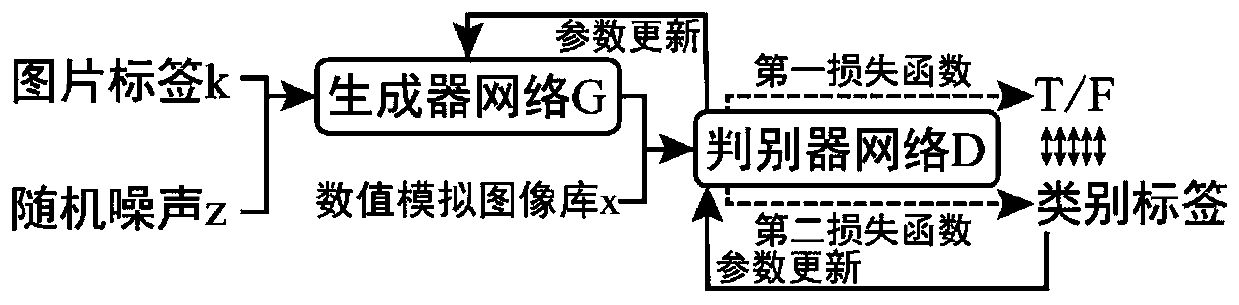

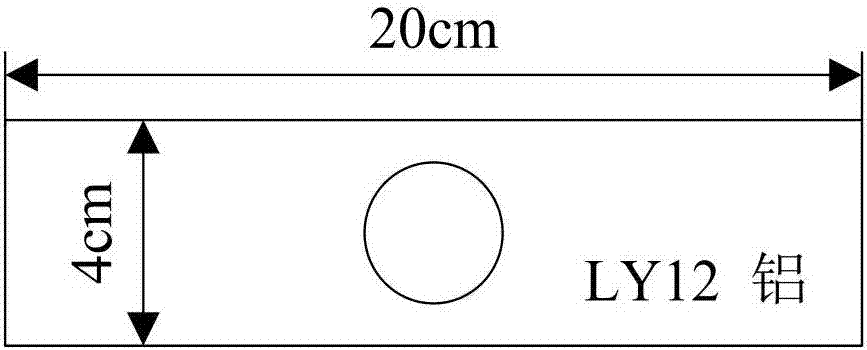

Friction stir welding line forming prediction optimization method based on numerical simulation and deep learning

ActiveCN110008554AReduce consumption costAvoid time costGeometric CADDesign optimisation/simulationGenerative adversarial networkEngineering

The invention provides a friction stir welding line forming prediction optimization method based on numerical simulation and deep learning, and belongs to the technical field of friction stir welding.The method comprises the following steps: step 1, setting three times of simulation tests as a data test set; step 2, calculating distribution conditions of a material flow field and a temperature field in a welding process; step 3, calculating the fracture failure condition of the friction stir welding tool under different parameters, and calculating the forming quality and defect distribution condition of the welding line under different parameters; and step 4, traversing all the process parameters and the welding line forming result of the welding tool structure by using the generative adversarial network deep learning model to obtain a welding line forming optimization result on the premise of ensuring the reliable work of the welding tool. The method aims at providing an effective universality prediction method for optimizing the friction stir welding process in production, and has the advantages that time consumption is reduced, the material cost is reduced, and the prediction accuracy is high.

Owner:HARBIN INST OF TECH

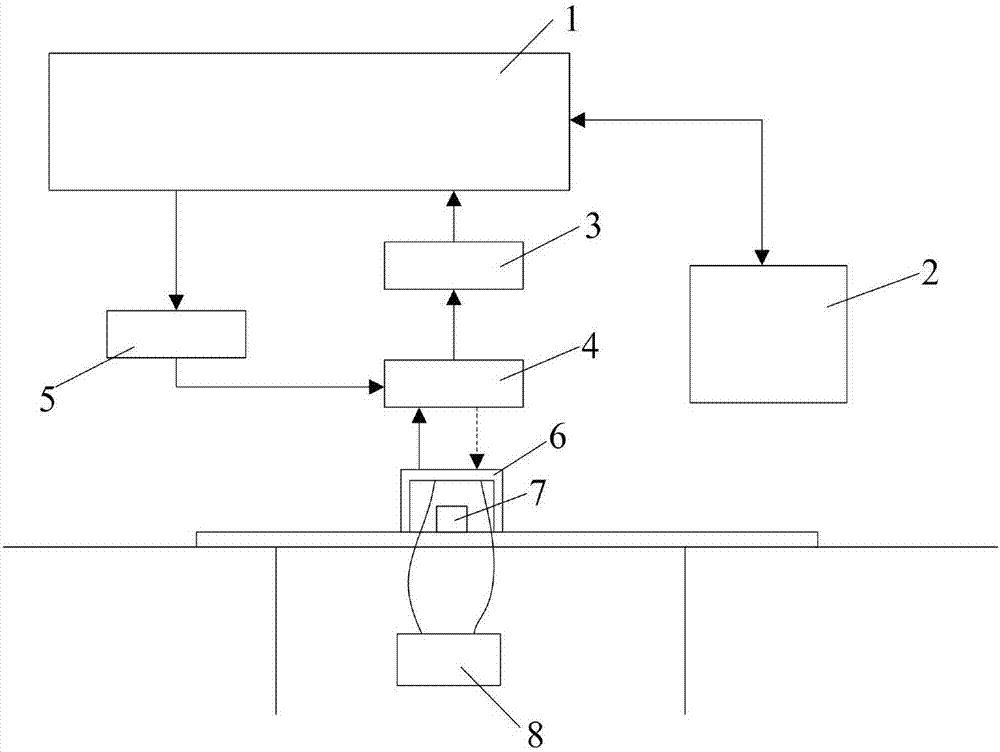

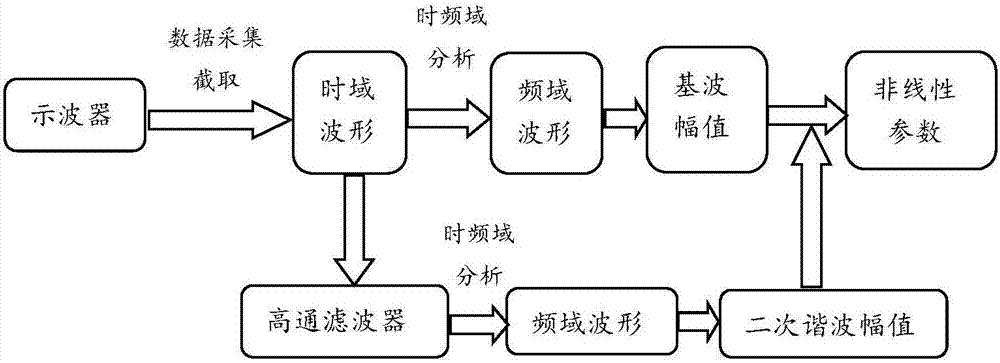

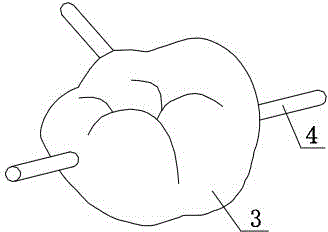

Non-linear ultrasonic on-line monitoring metal material strain changing method

ActiveCN106949861AReduce project riskWith commercial applicationUsing subsonic/sonic/ultrasonic vibration meansHigh energyMetallic materials

The present invention discloses a non-linear ultrasonic on-line monitoring metal material strain changing method, belonging to the metal material fatigue damaging analysis technology field. A probe is arranged at the middle portion of a piece to be tested, two ends of the piece to be tested are fixed, a weight is hung at the middle portion of the piece to be tested, and the gravity of the weight is employed to generate stretching for the piece to be tested to generate fatigue. A support frame for monitoring strain on line is made on the piece to be tested, and the support frame is internally provided with an ultrasonic energy transducer. The high energy pulse signal output end of a nonlinear acoustics detection device performs interaction with the ultrasonic transducer through 50 Ohm impedance matching and a duplexer to receive reflected supersonic wave signals through reflection of the piece to be tested. The non-linear ultrasonic on-line monitoring metal material strain changing method can realize online monitoring of the metal materials to estimate in-service workpiece mechanics status under external load long-term effect so as to reduce the engineering project risk caused by metal workpiece fracture failure, solve defects of high cost and complex operation of a current device and have business application and popularization values.

Owner:ZHONGBEI UNIV

Milling forming production method of dental all-ceramic restoration

The invention discloses a milling forming production method of a dental all-ceramic restoration. In production processes, a support column is not required for fixing a ceramic block and the restoration, so that the process steps of manually removing the support column by milling to separate the formed restoration and the surrounding ceramic block and burnishing and polishing the excessively rough outer surface of the restoration caused by removing the support column by milling are avoided, and the risks of disintegration of the restoration and premature fracture failure are further reduced. Under the condition of being supported by a model material block, the milling of the ceramic block is more conductive to processing a thin-walled neck edge, and particularly, the milling of a ceramic hard biscuit which is not sintered is more conductive to improving the degree of finish of the outer surface of the dental all-ceramic restoration. The dental all-ceramic restoration produced by adopting the technical scheme of the invention has the advantages of no connection points for the support column on the outer surface, no partial milling marks and ceramic cracks, bright and clean surface, uniform and consistent structure and high reliability.

Owner:HANGZHOU ERRAN TECH

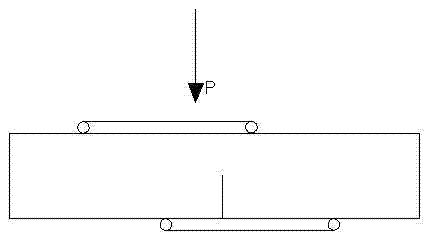

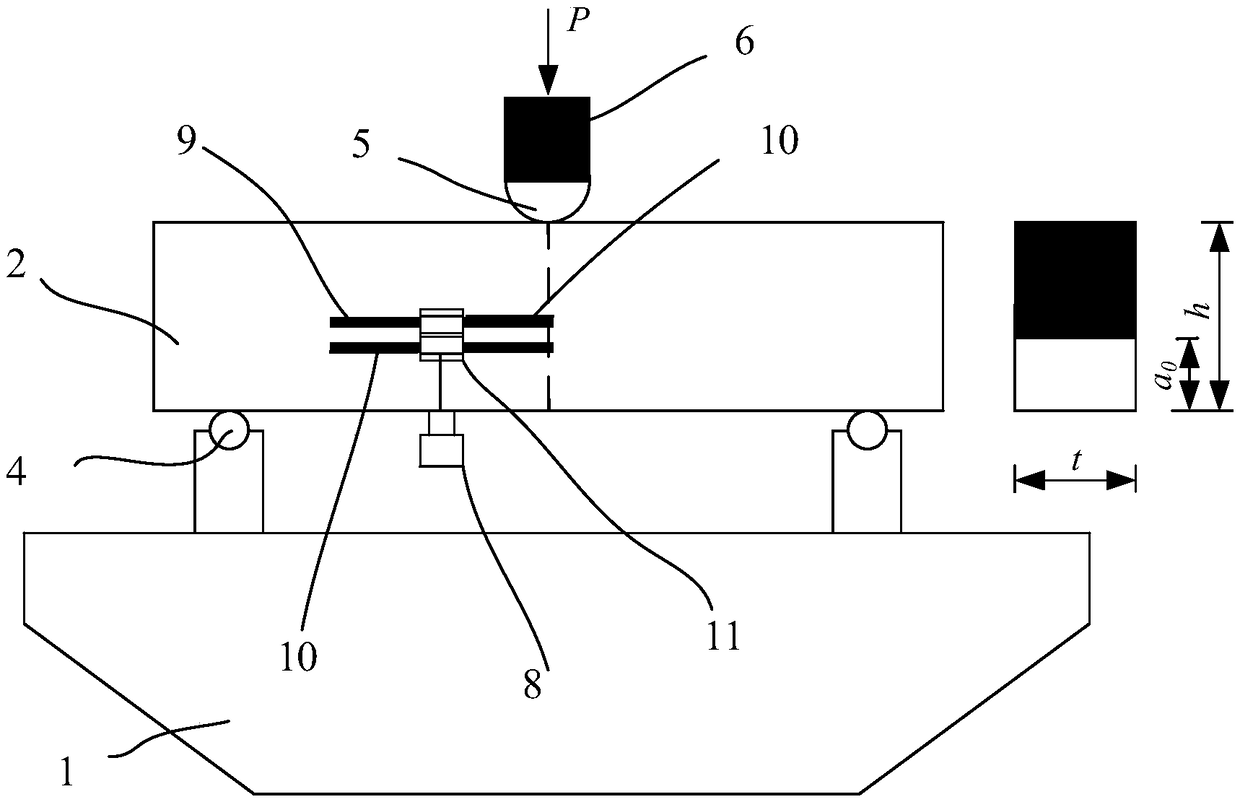

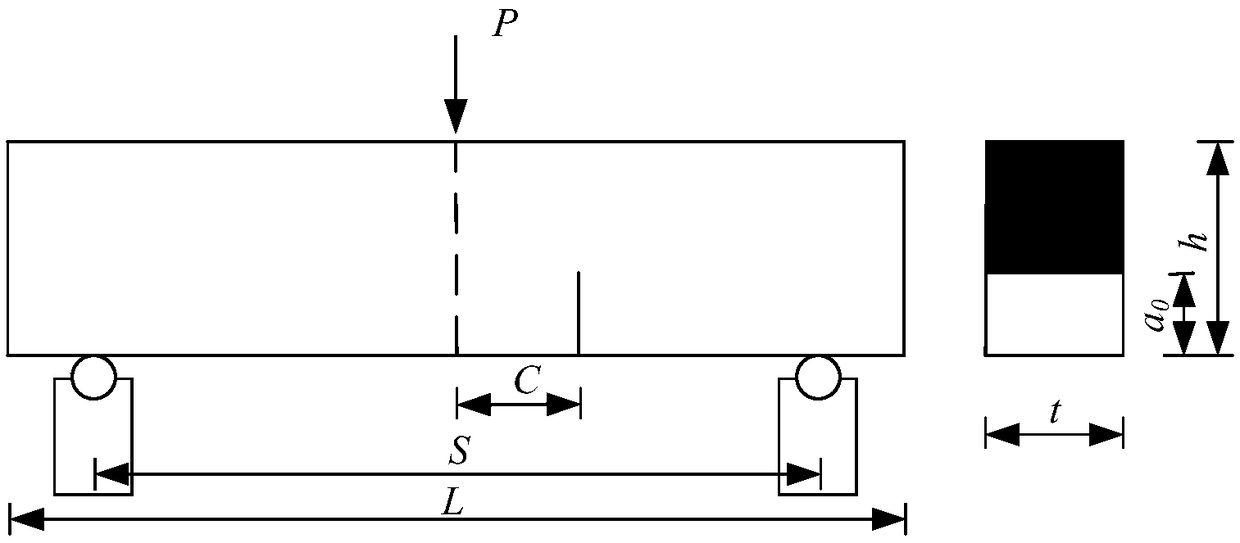

Concrete I-II compound crack fracture performance test method

ActiveCN109507041AEasy to operateComplete fracture processMaterial strength using steady shearing forcesCompound fracturesEngineering

The invention relates to a concrete I-II compound crack fracture performance test method, and belongs to the technical field of physical test methods. According to the method, an upright and sloping three-point bent beam is adopted for testing, and on a fracture tip, a central symmetry mode is adopted for fixing a clamping extensometer cushion block, so that I-type failure crack opening displacement in a I-II compound fracture failure process is determined; in a calculation process, with the help of a double K fracture theory, a fracture angle function f(theta) is introduced to obtain compoundcrack fracture toughness under different fracture angle conditions, and a more accurate concrete I-II compound fracture coherency equation can be built. By means of the method, safety assessment of the structure fracture performance is achieved, an existing finite element numerical simulation technology is broken through, accurate judgement of the common compound fracture mechanical performance is completed, and a basis is provided for the long-term stability and the fracture toughness of a concrete crack.

Owner:SHANGHAI BAOYE GRP NANJING BUILDING +1

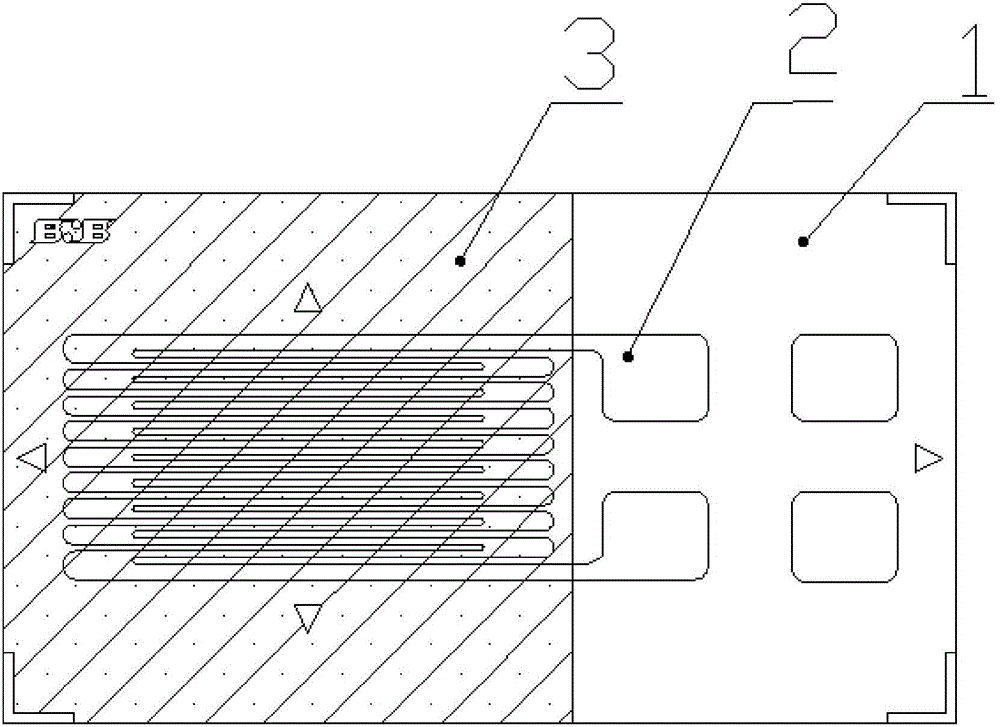

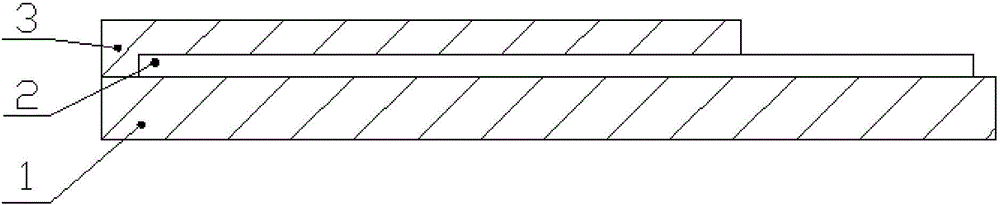

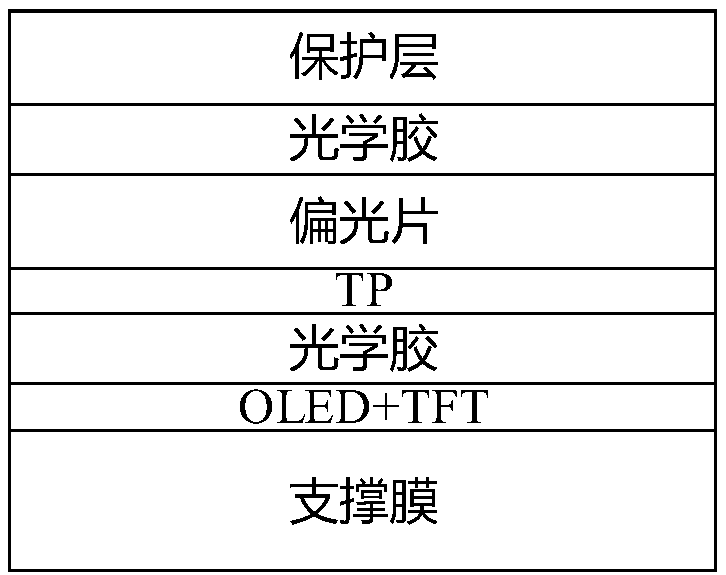

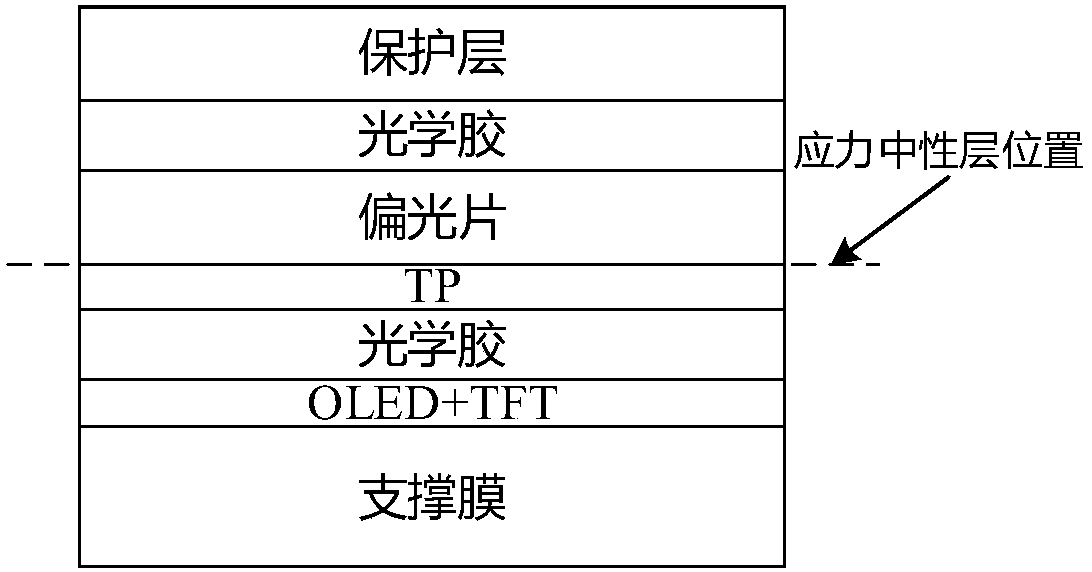

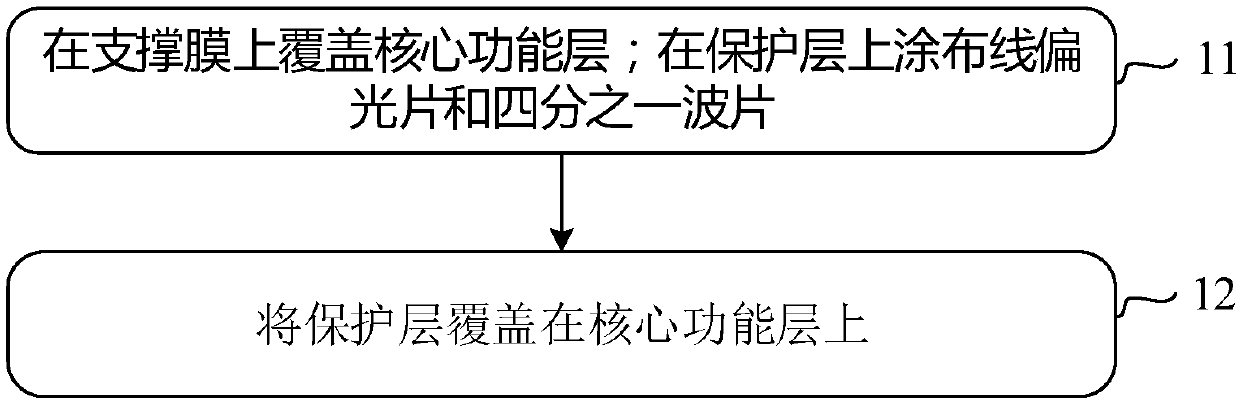

Display panel and manufacturing method thereof

PendingCN109546009AReduced risk of fracture failureReduce the number of stacksSolid-state devicesSemiconductor/solid-state device manufacturingPolarizerEngineering

The invention discloses a manufacturing method of a display panel. The manufacturing method is used for solving the problem that the bending life of a display panel is affected since a functional layer of a flexible folding module has a risk of fracture failure when being bent in the prior art. The manufacturing method comprises the steps of: covering a core functional layer on a supporting film,wherein the core functional layer comprises a touch screen, an OLED and a thin film transistor; coating a line polarizer and a quarter wave plate on a protective layer; and covering the protective layer on the core functional layer. The invention further discloses the display panel.

Owner:GUANGZHOU GOVISIONOX TECH CO LTD

Fracture test device with double-material interface

InactiveCN101520386AAccurate calculationFacilitate experimental researchMaterial strength using steady bending forcesMaterial strength using steady shearing forcesEngineeringMixed mode

The invention provides a fracture test device with a double-material interface, which comprises a fatigue machine, a bottom plate fixed on the fatigue machine, a second material placed on the bottom plate, a pressure plate placed on the second material, and a first material of which one end is attached to the second material, wherein the fracture test device with the double-material interface also comprises a top plate fixed on the pressure plate and a freely telescopic post rod system placed on the top plate; and the post rod system comprises a support rod fixed on the top plate, a support block connected to one end of the support rod, and a post rod passing through the support block. The fracture test device with the double-material interface not only can accurately simulate the fracture breakage of a slippage type mode and a hybrid mode of the double-material interface, but also can accurately obtain various key parameters required by calculating the fracture energy of the fracture mode.

Owner:SOUTHEAST UNIV

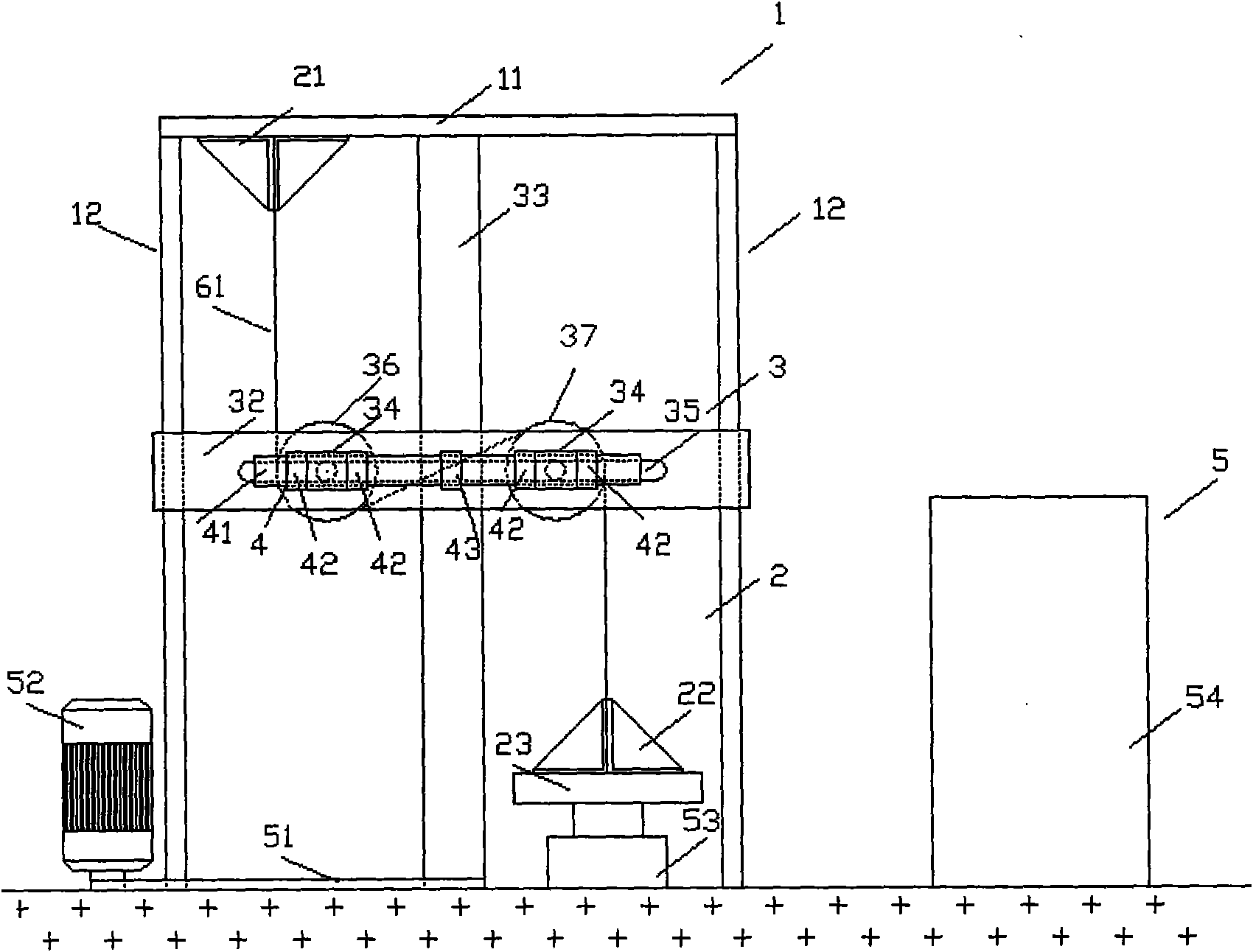

Device and method for repeated bending tests under complex load

ActiveCN101561380AEasy to testMaterial strength using repeated/pulsating forcesSupporting systemControl system

The invention relates to a device and a method for repeated bending tests under complex load, which belong to the technical field of detection. The device comprises the following parts: a supporting system as a system framework, a tension loading system provided with two clamping devices for performing tension loading on a sample by fixing two ends of the sample on the clamping devices, a bending loading system provided with bending rollers for achieving the bending loading of the sample without changing the tension loading applied to two ends of the sample through an S-shaped bending passage formed by the bending rollers, an adjusting system for adjusting the distance between the bending rollers, and a control system which is connected with and controls the tension loading system and the bending loading system respectively so that the tension loading system and the bending loading system are controllable, wherein the bending loading system performs repeated bending on a sample target area fixed in the tension loading system so that the tensioning and the bending processes are loaded simultaneously and are broken and damaged in the target area. The invention also provides the method for performing the repeated bending tests under the complex load through the device.

Owner:SHOUGANG CORPORATION

Uniform stress criterion-based bonding structure fracture failure analysis method

InactiveCN110175396AAchieving Strength PredictionSolve the problem that the real failure does not fit wellDesign optimisation/simulationSpecial data processing applicationsElement modelStressed state

The invention discloses a uniform stress criterion-based bonding structure fracture failure analysis method, which is characterized by comprising the following steps of 1, carrying out the quasi-static tensile tests on the bonding joints with different tension-shear ratios to obtain the initial failure loads and the initial failure areas of the bonding joints with different tension-shear ratios, 2, establishing a finite element model of a bonding joint with the same test size and different tension-shear ratios, and applying the initial failure load to a position, corresponding to the initial failure area, in the finite element model to obtain an initial failure point and initial failure stress, 3, obtaining the equivalent forces of the bonding joints with different tension-shear ratios ina complex stress state, and 4, establishing a finite element model of the bonding joint needing to be subjected to fracture failure analysis, applying the one-way stress, when the stress is greater than or equal to the maximum equivalent stress, starting to fail the glue layer of the bonding joint, determining a failure unit, deleting the failure unit, and recording the corresponding failure stress.

Owner:JILIN UNIV

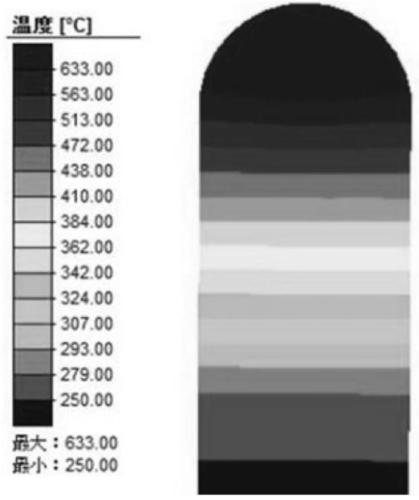

Mechanical property and fracture failure simulation modeling method for welded joint

PendingCN111523183AImprove accuracyAvoid imprecisionGeometric CADDesign optimisation/simulationClassical mechanicsElement modeling

The invention discloses a mechanical property and fracture failure simulation modeling method for a welded joint. The method comprises the following steps of: before finite element modeling; firstly,determining the temperature change conditions of different areas in the welding process; slicing a weld template, performing testing to obtain material constitutive parameters of each tensile sample;during finite element modeling, applying material constitutive parameters of each tensile sample to each micro-area, so that different micro-regions have different mechanical property parameters, themechanical property of the micro-region of the welding joint is accurately described, the modeling precision and the modeling accuracy are greatly improved, and the problem that the model is inaccurate due to the fact that the whole welding joint adopts constitutive parameters of the same material is avoided.

Owner:HUNAN UNIV

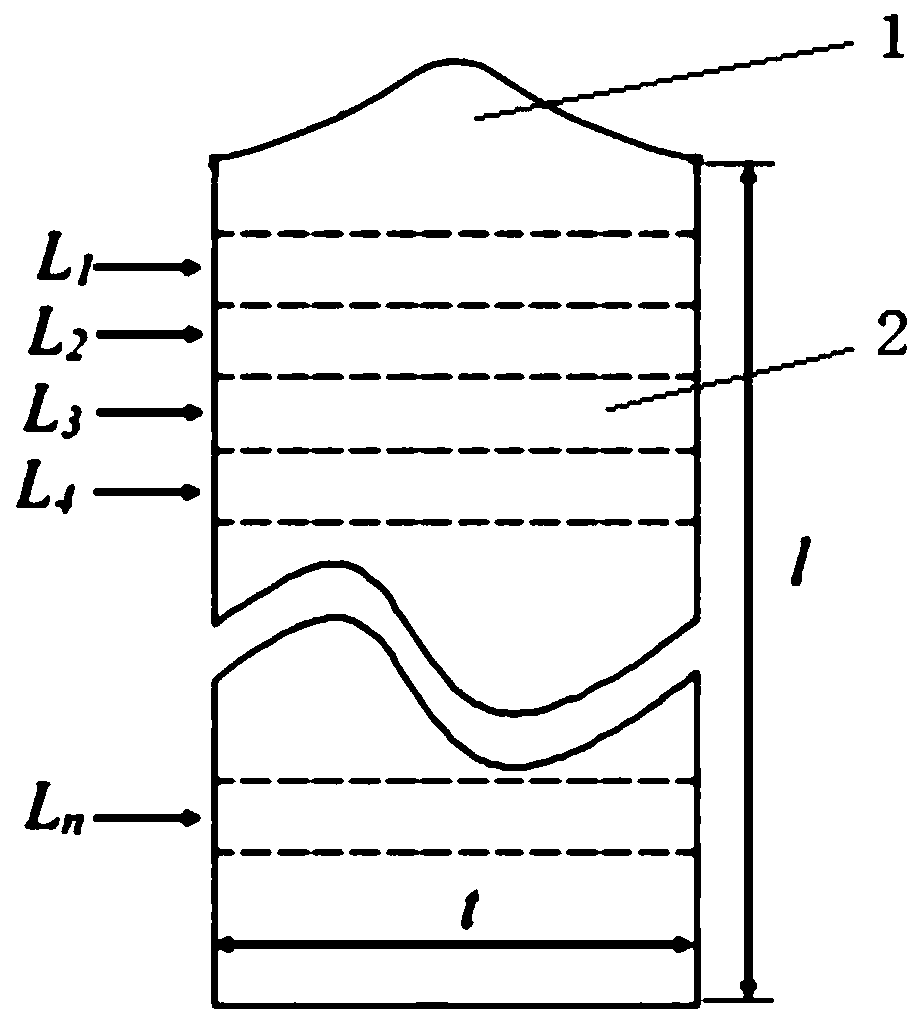

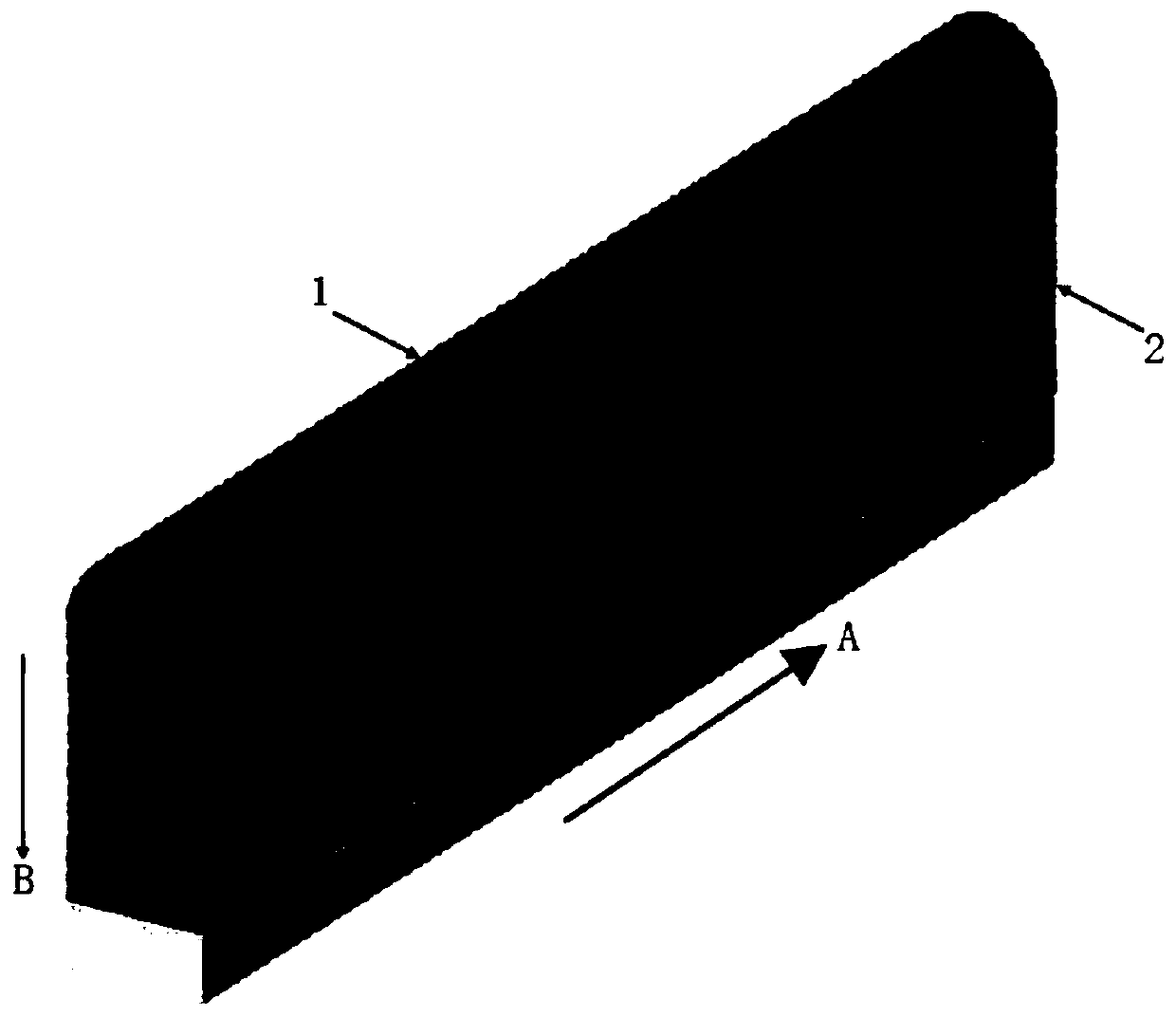

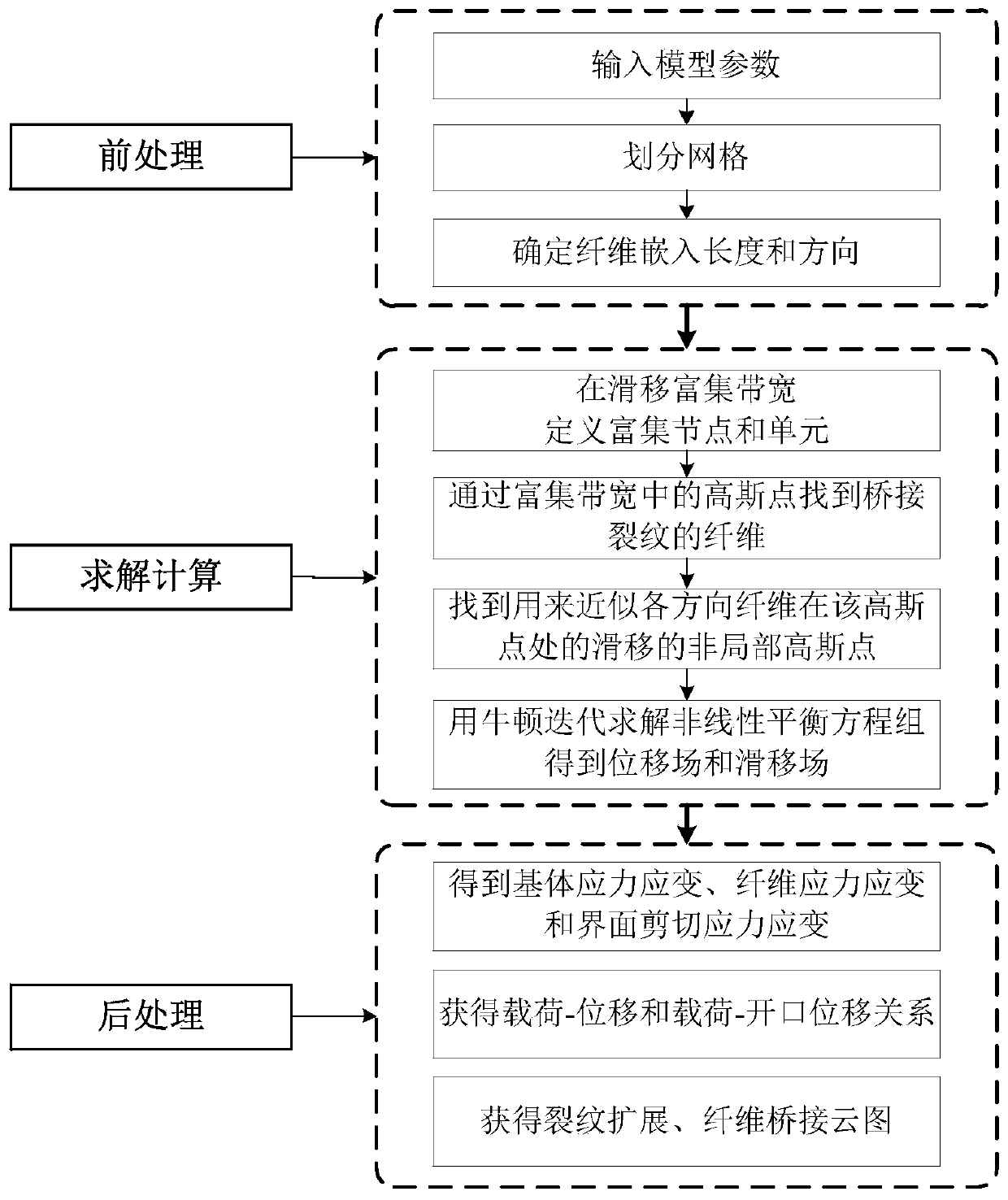

Fracture failure behavior prediction method of micro-nano fiber reinforced composite material

ActiveCN110598293ARealize the bridging effectAccurate predictionSpecial data processing applicationsMicro nanoStress distribution

The invention discloses a fracture failure behavior prediction method of micro-nano fiber reinforced composite material. The method comprises the following steps of describing mechanical behaviors ofthe composite material through a multi-scale method, and establishing a slippage-enrichment bandwidth model of any fiber embedding length and a non-local slippage model of fibers in any direction; calculating fiber stress distribution and global load displacement response of the crack bridging area; by applying load and boundary conditions and iteratively updating cracks, acquiring a stress-strain relationship and a load displacement curve, making stress-strain information transmission from a fiber reinforced composite material mesoscopic model to macroscopic multi-field coupling and acquiring an analysis result of composite material mesoscopic local characteristics on macroscopic global load displacement response. According to the invention, the fracture failure process of the compositematerial can be accurately simulated while the bridging effect of the fibers is realized.

Owner:SHANGHAI JIAO TONG UNIV

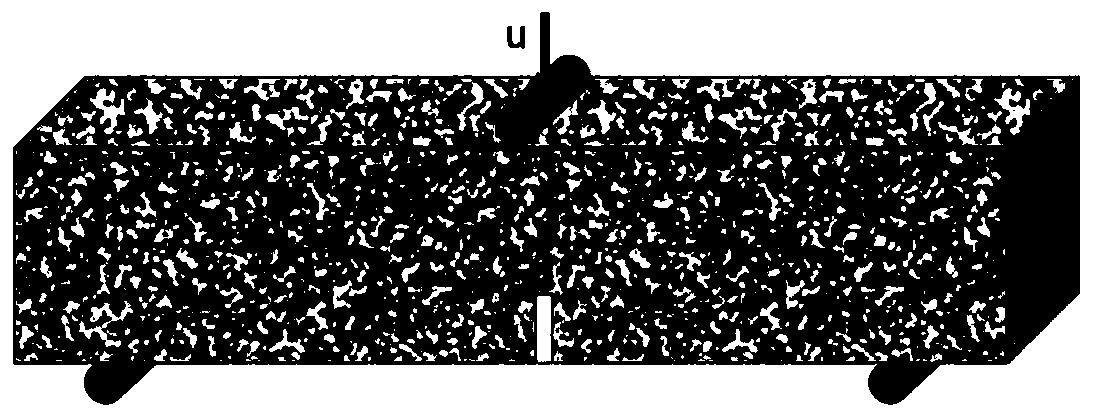

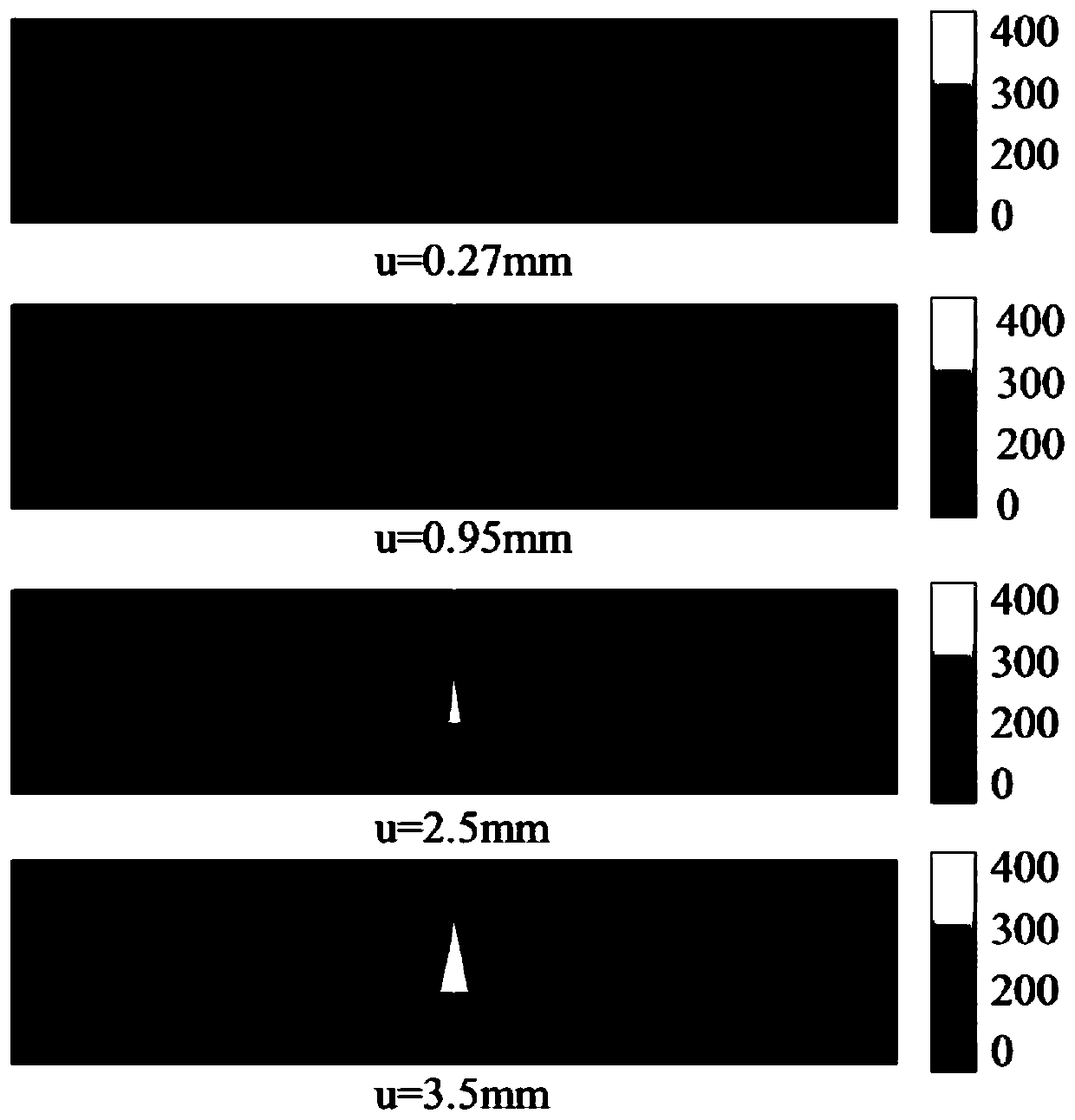

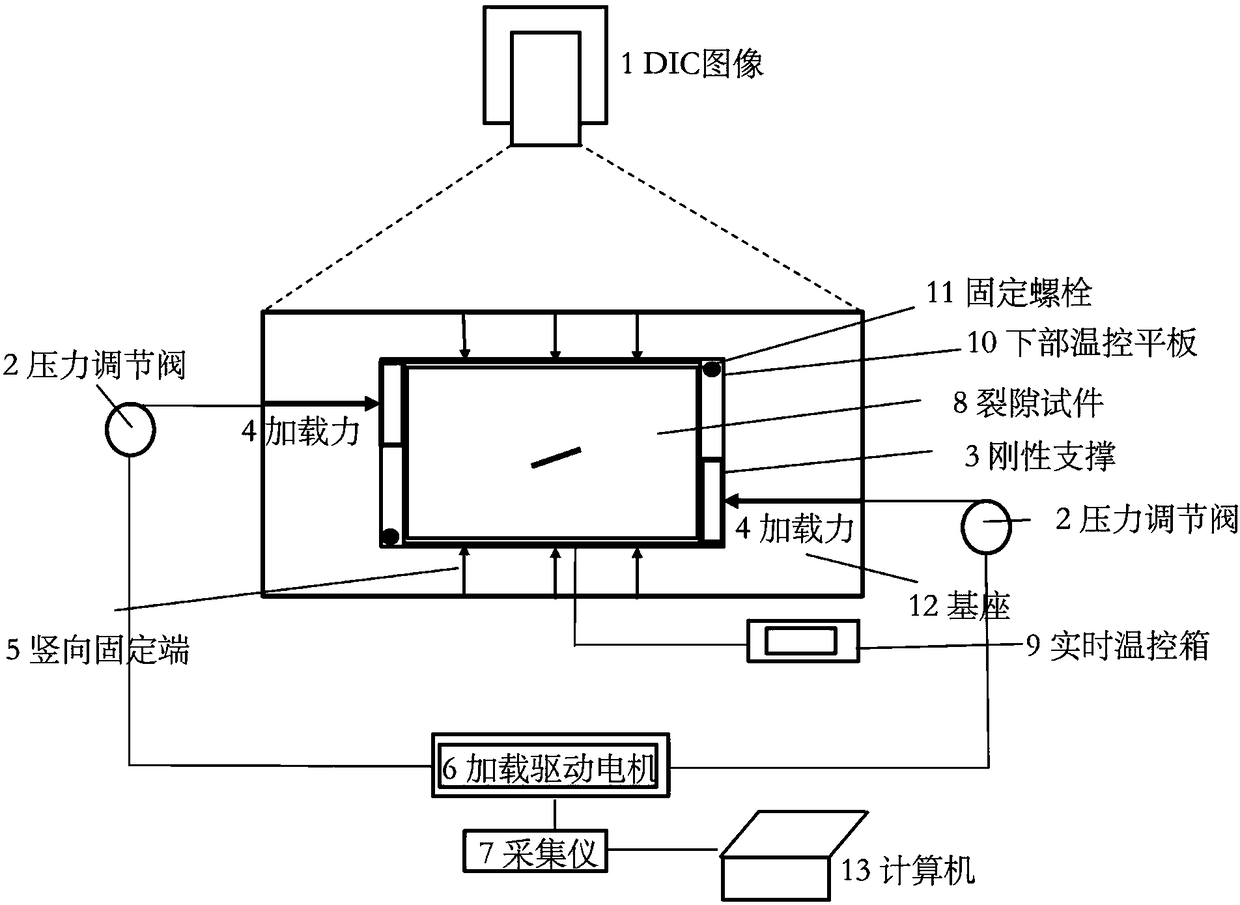

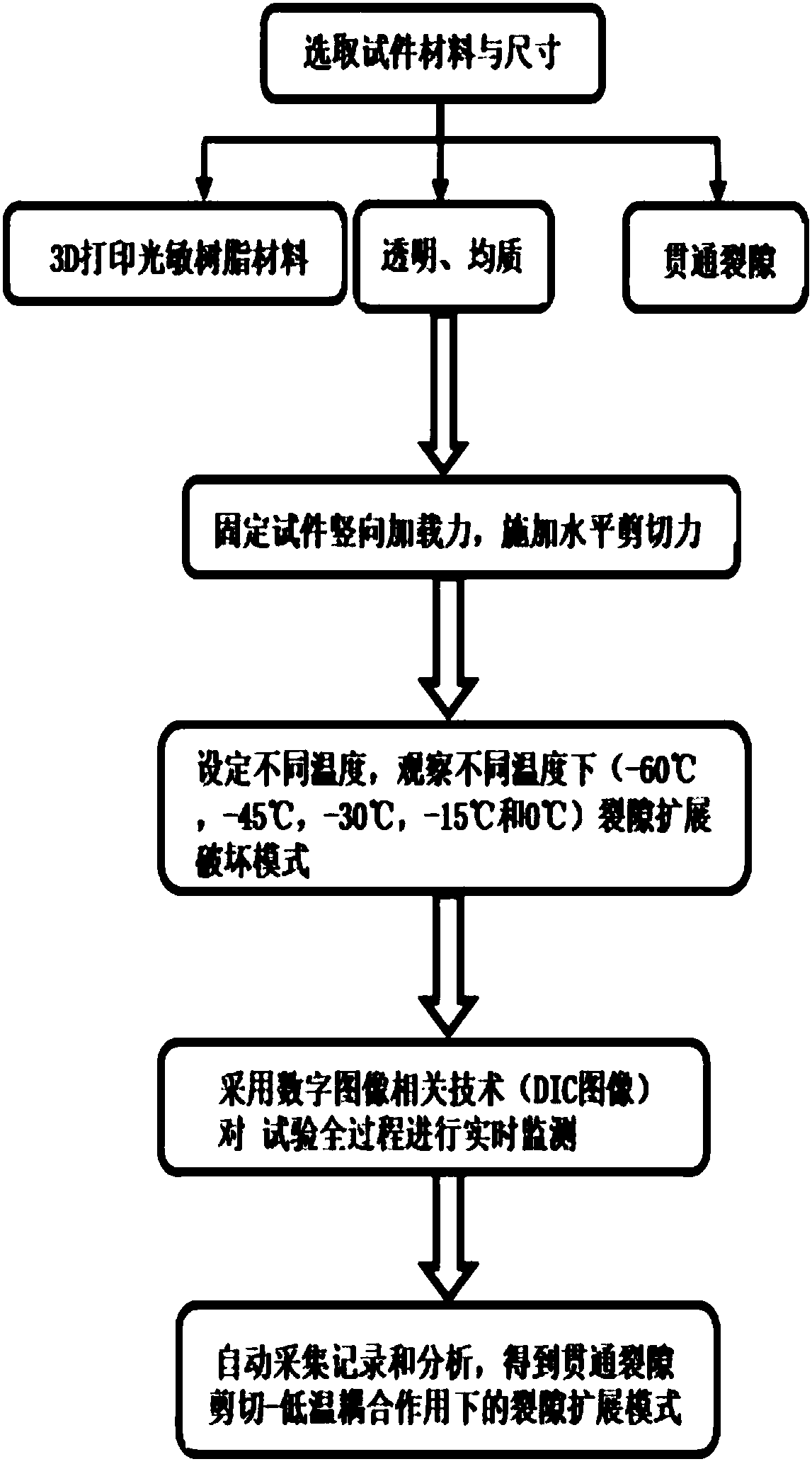

Shear-and-low-temperature coupling experimental device and method for through cracks

ActiveCN108204916ABrittleEasy to processPreparing sample for investigationMaterial strength using steady shearing forcesTemperature controlEngineering

The invention relates to a shear-and-low-temperature coupling experimental device and method for through cracks. The device comprises a DIC image, a loading driving motor, a collecting instrument, a base and a computer; a lower temperature control flat plate is fixed on the upper surface of the base, and the lower temperature control flat plate is connected with a real-time temperature control box, a crack test piece is fixedly placed on the real-time temperature control box, upper transparent tempered glass is placed on the upper surface of the crack test piece, and the upper transparent tempered glass and the lower temperature control flat plate are fixed together by fixing bolts; the crack test piece has a vertical fixed end in the vertical direction, rigid supports are fixed to the left and right sides of the crack test piece in the horizontal direction, the left rigid support and the right rigid support are staggered up and down relative to the center of the crack test piece, a pressure regulating valve is arranged on each loading force, and the loading force is controlled through the pressure regulating valve. The crack test piece is a 3D printing test piece. The device usesa photosensitive resin material to simulate the actual situation of the actual rock non-straight cracks, which can improve the fracture damage understanding of the cracks under stress.

Owner:HEBEI UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com