Method for machining fuel manifold with nozzles and of welding structure

A fuel manifold and welding structure technology, applied in welding equipment, metal processing equipment, manufacturing tools, etc., can solve the problems of out of tolerance nozzle housing position, large residual stress, fracture failure, etc., and achieve improved welding deformation and stable quality. , the effect of qualified dimensional accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

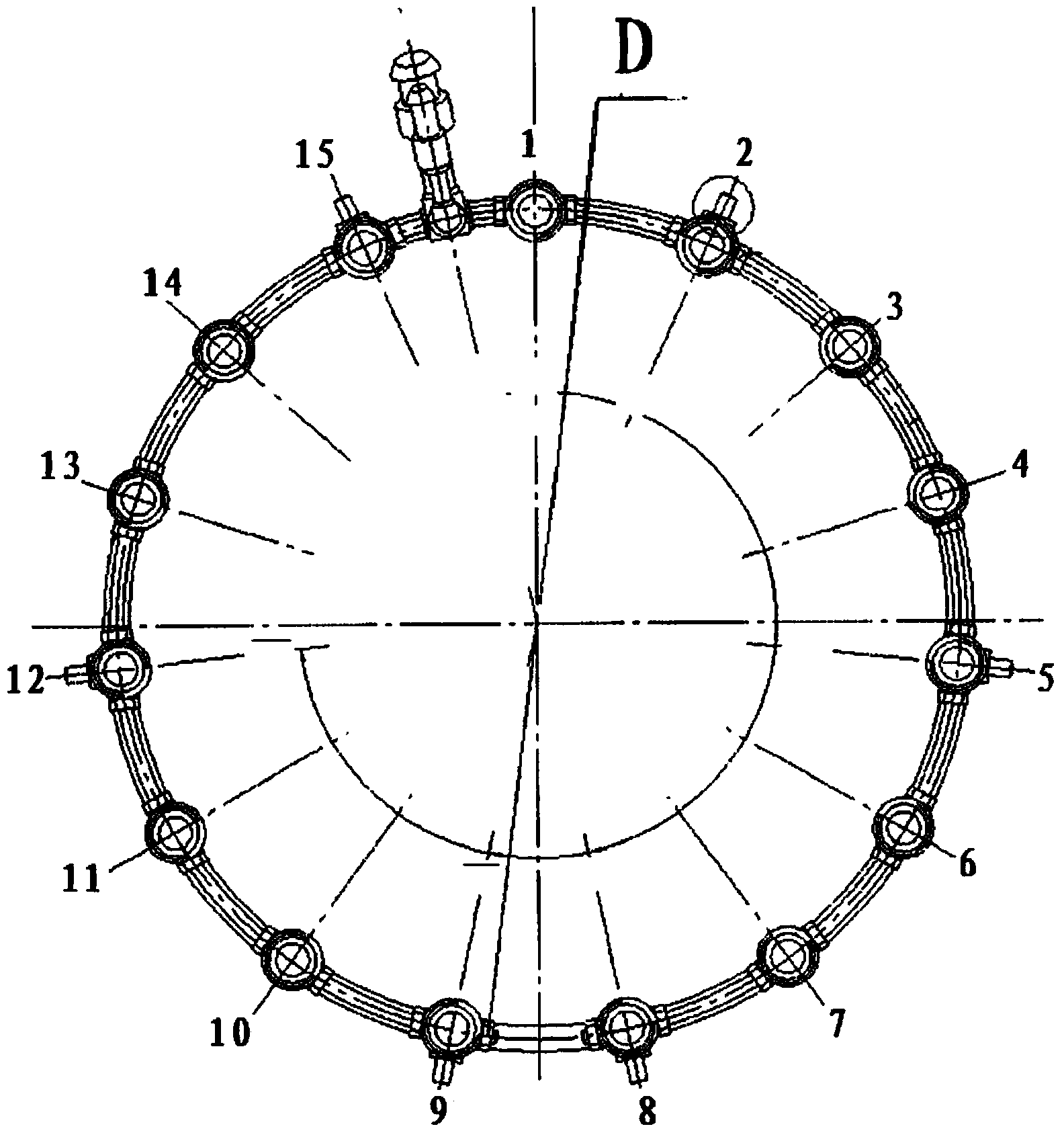

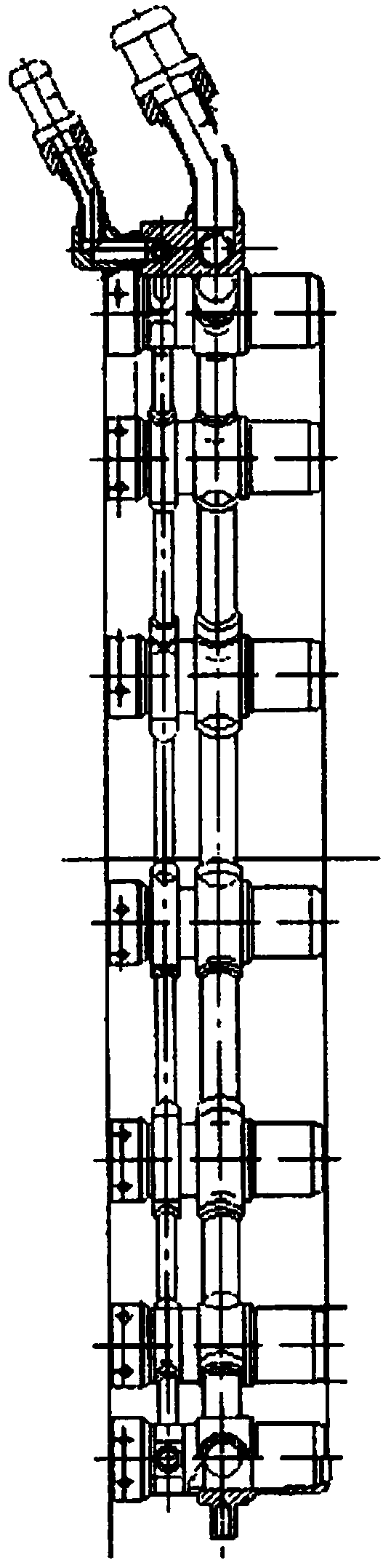

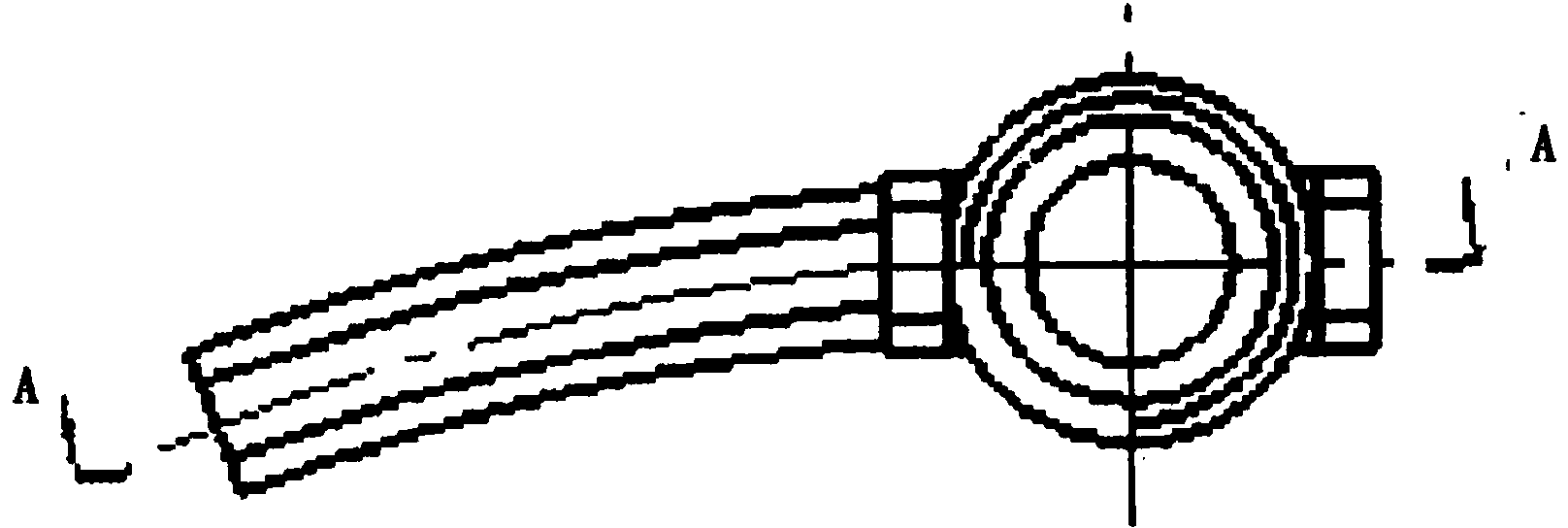

[0023] The present invention will be described in detail below with reference to the drawings, such as Figure 1-1 to Figure 6 As shown, the part consists of 15 nozzle housings 1, 2, 3, 4, 5, 6, 7, 8, 9, 10, 11, 12, 13, 14, 15 (6 of which have mounting pins, respectively It is made by argon arc welding of 2, 5, 8, 9, 12, 15) and Φ8 and Φ15 pipes. At the same time, the main and auxiliary oil inlet pipes are welded, and there are as many as 65 welds. The drawing of the manifold requires that the position of 15 nozzle housings and 6 mounting pins should not be greater than 0.5. In the initial stage of the development process, the nozzle shell and the tube were assembled and welded into a manifold ring at one time, and 6 mounting pins were bored after heat treatment and correction. Due to the smaller diameter D caused by welding deformation, the out-of-tolerance position of the nozzle housing and the larger residual stress, fracture failure occurred during the engine test run.

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com