Machining clamp and machining method for curved surface vent groove of thin-wall sheet metal part

A processing method and technology for sheet metal parts, applied in metal processing equipment, metal processing machinery parts, manufacturing tools, etc., can solve the problems of low processing efficiency, difficult processing of parts ventilation grooves, easy to be scrapped, etc., to reduce labor intensity, The dimensional accuracy is qualified and the effect of ensuring consistency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment example 1

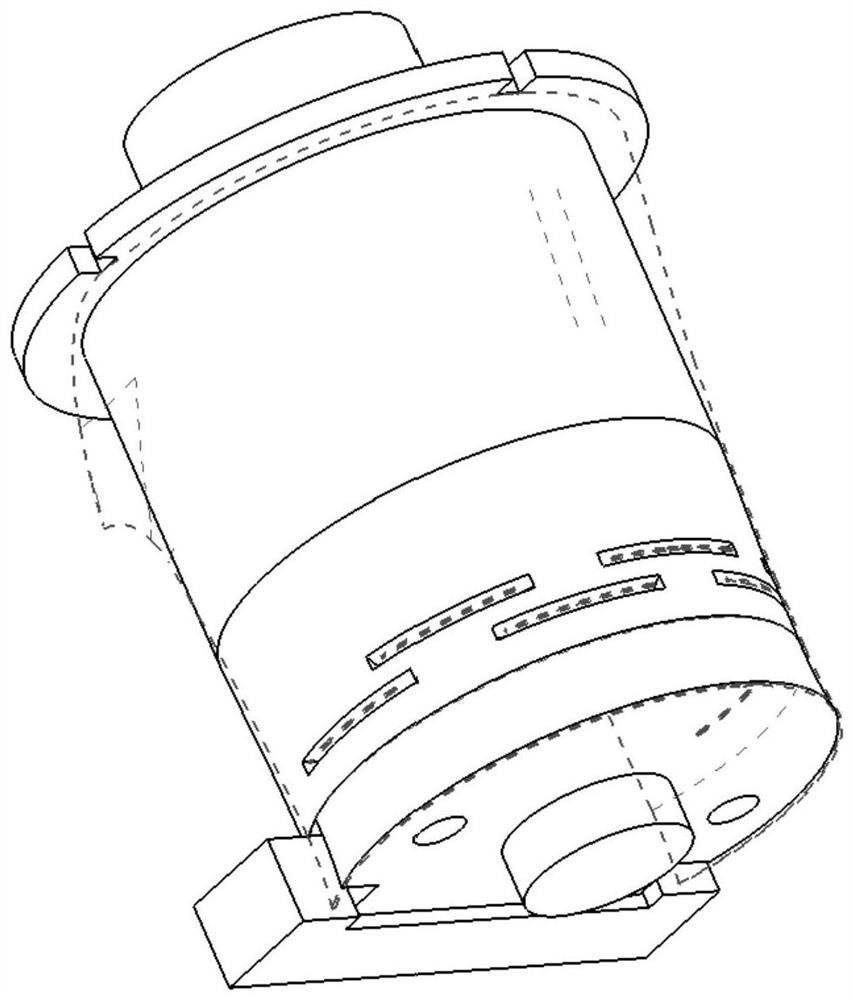

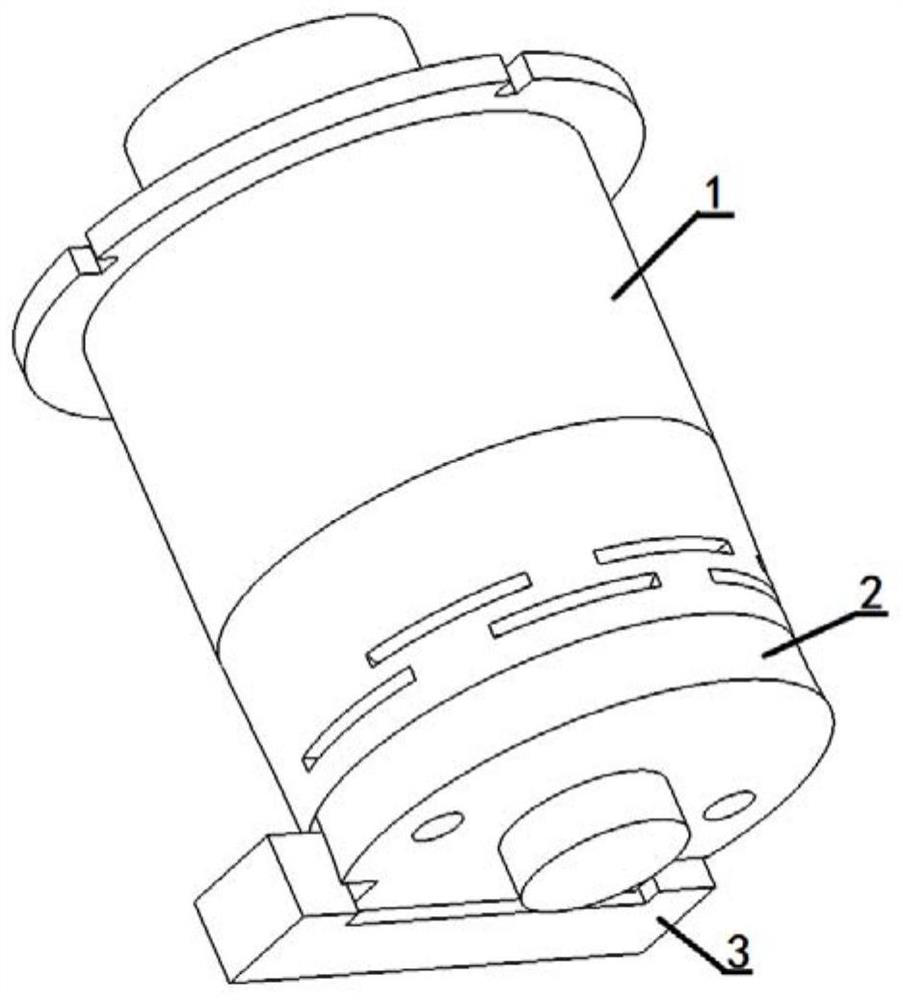

[0039] Implementation Case 1: Barrel

[0040] The barrel-shaped part is made of aluminum alloy. There are 7 ventilation grooves on the surface of the part. The groove width is 1.2mm and the length is about 50mm. It is symmetrically distributed along the central axis of the part. The center line on the molding die is led to the part, and then the barrel is fixed on the combined fixture, and then clamped as a whole on the vise of the CNC milling machine. The center line on the part is used as the reference point for processing rotation, and the milling machine is processed at the same time. The knife goes down at a constant speed, and the processing sequence is to process the left ventilation groove at the reference point rotation angle first, then rotate back to the reference point to reverse the rotation angle, and process the right ventilation groove until all the ventilation grooves are processed. During this process, a period of After the groove is machined, proceed to the ...

example 2

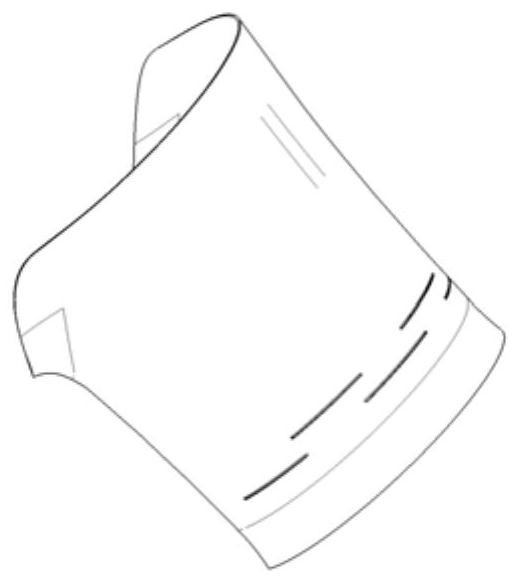

[0041] Case 2: hat brim

[0042] The material of the hat brim is aluminum alloy. There are 15 ventilation grooves on the surface of the part, the groove width is 1.2mm, and the length is 15-30mm. They are symmetrically distributed along the central axis of the part. Lead the centerline on the molding die to the part, then fix the brim piece on the combination fixture, take the centerline on the part as the reference point for processing rotation, and at the same time, the milling cutter moves down at a constant speed, and the processing sequence is based on the reference point rotation The angle is to process the left ventilation groove first, then rotate back to the reference point to reverse the rotation angle, and process the right ventilation groove until all the ventilation grooves are processed. Otherwise, processing the same groove multiple times will produce processing step marks.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com