Patents

Literature

1005results about How to "Meet the needs of mass production" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

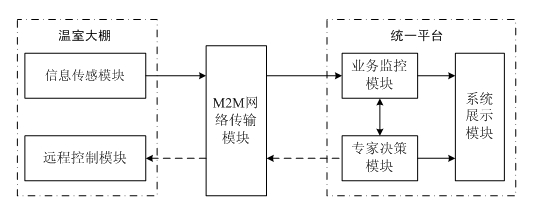

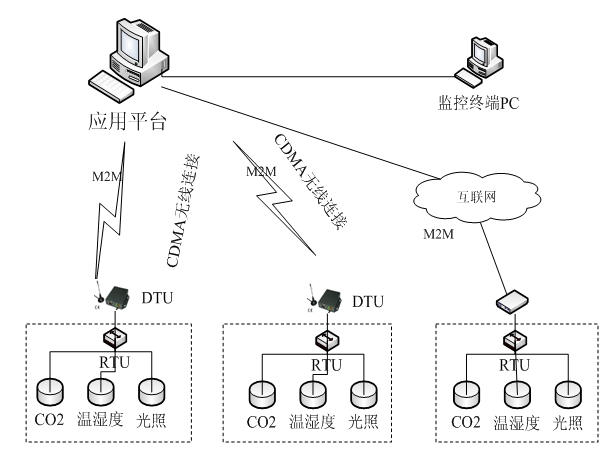

Remote monitoring and intelligent control system and method of agricultural greenhouse based on M2M framework

InactiveCN102035876AMeet the needs of productionMeet the needs of mass productionData processing applicationsClimate change adaptationAutomatic controlThird generation

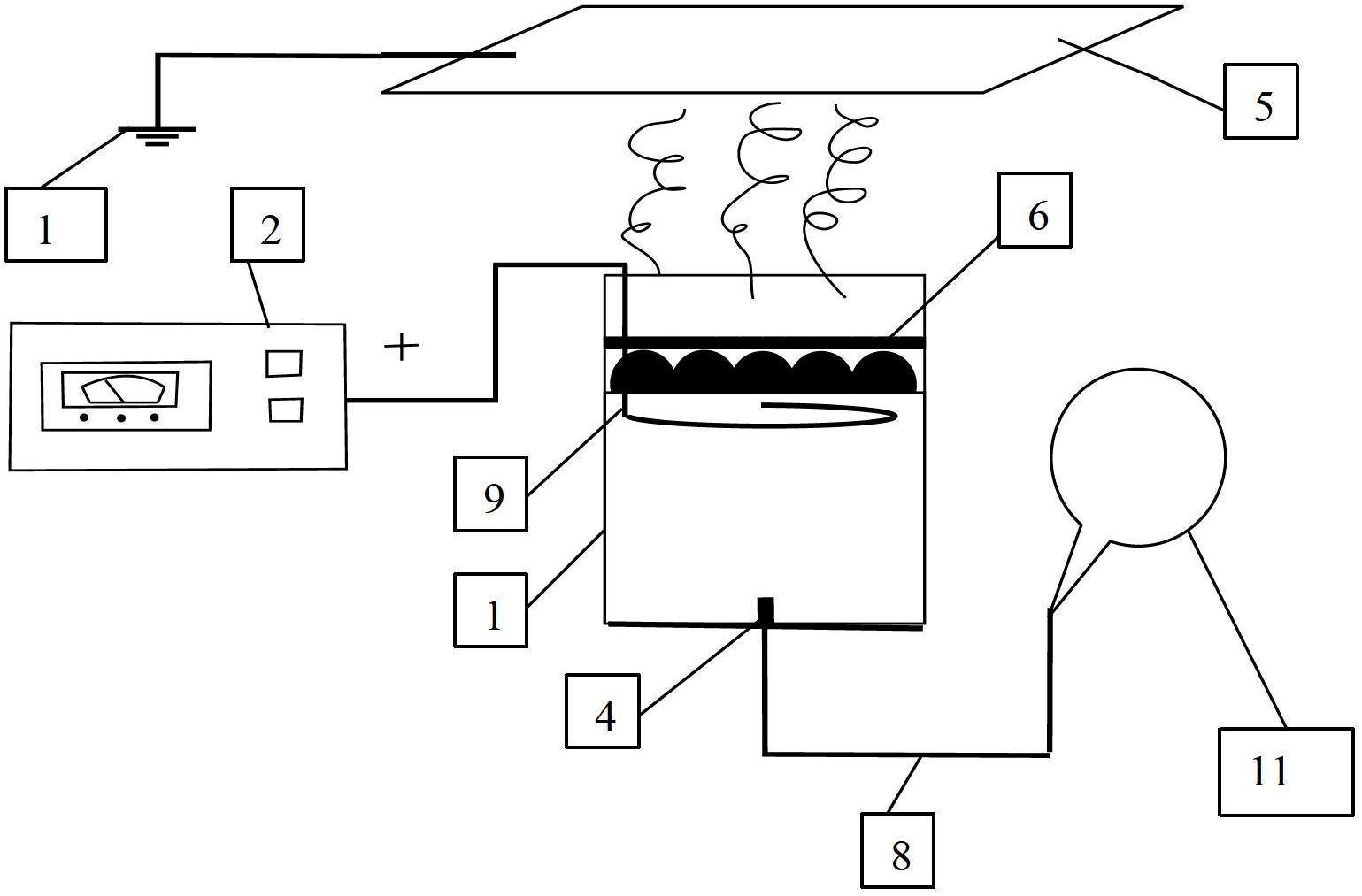

The invention discloses a remote monitoring and intelligent control system and method of an agricultural greenhouse based on an M2M framework. The system comprises an information acquisition module, an M2M network transmission module, a service monitoring module, an expert decision module, a system display module and a remote control module. The method comprises: firstly, deploying a plurality of environmental parameter sensors in a glasshouse to collect key information; then, in an M2M mode, sending the key information to a centered platform via the Internet or the 3G network; storing, displaying and analyzing data in the centered platform; combining with a crop model and an expert system to output decision information; and issuing a control order via the Internet or the 3G network. The system can avoid the limitation of the local automatic control system of the common greenhouse and realizes the situation that the production in a plurality of greenhouses is supported on one platform, thus the system has good expansibility and supports scale application. The system provides the means for checking systems and issuing orders on the Internet and a mobile terminal, is convenient and can transmit information by the broadband Internet and the 3G communication network.

Owner:JIANGSU HONGXIN SYST INTEGRATION

Automatic cleaning machine

InactiveCN102698988AAvoid harmHigh degree of automationElectrostatic cleaningFlexible article cleaningAlcoholSpray nozzle

The present invention discloses a cleaning machine, especially to an automatic cleaning machine for cleaning a mobile phone screen. The cleaning machine comprises a rack which is provided with an alcohol pressure cylinder; a conveyor belt wheel which is provided with a conveyor belt; an unreeling wheel which is rotatingly connected with the rack and provided with a non-dust cloth roller; a retrieving wheel rotatingly connected with the rack, one end of a non-dust cloth discharged by the non-dust cloth roller is wound on the retrieving wheel through a stretching wheel; a rolling wheel driving motor, a rotating shaft of which is connected with the unreeling wheel or the retrieving wheel; a cleaning motor which is arranged between the unreeling wheel and the retrieving wheel, a rotating shaft of the cleaning motor is an eccentric shaft, the eccentric shaft is connected with a friction block, the alcohol pressure cylinder is connected with a nozzle through a pipeline, and the opening direction of the nozzle is toward the unreeling wheel. By adopting the cleaning machine, problems that the mobile phone screen needs to be cleaned by people, the efficiency is low, the labor intensity is large, human body can be damaged, costs are high can be solved, and certain beneficial effects can be realized.

Owner:青岛有信印刷机有限公司

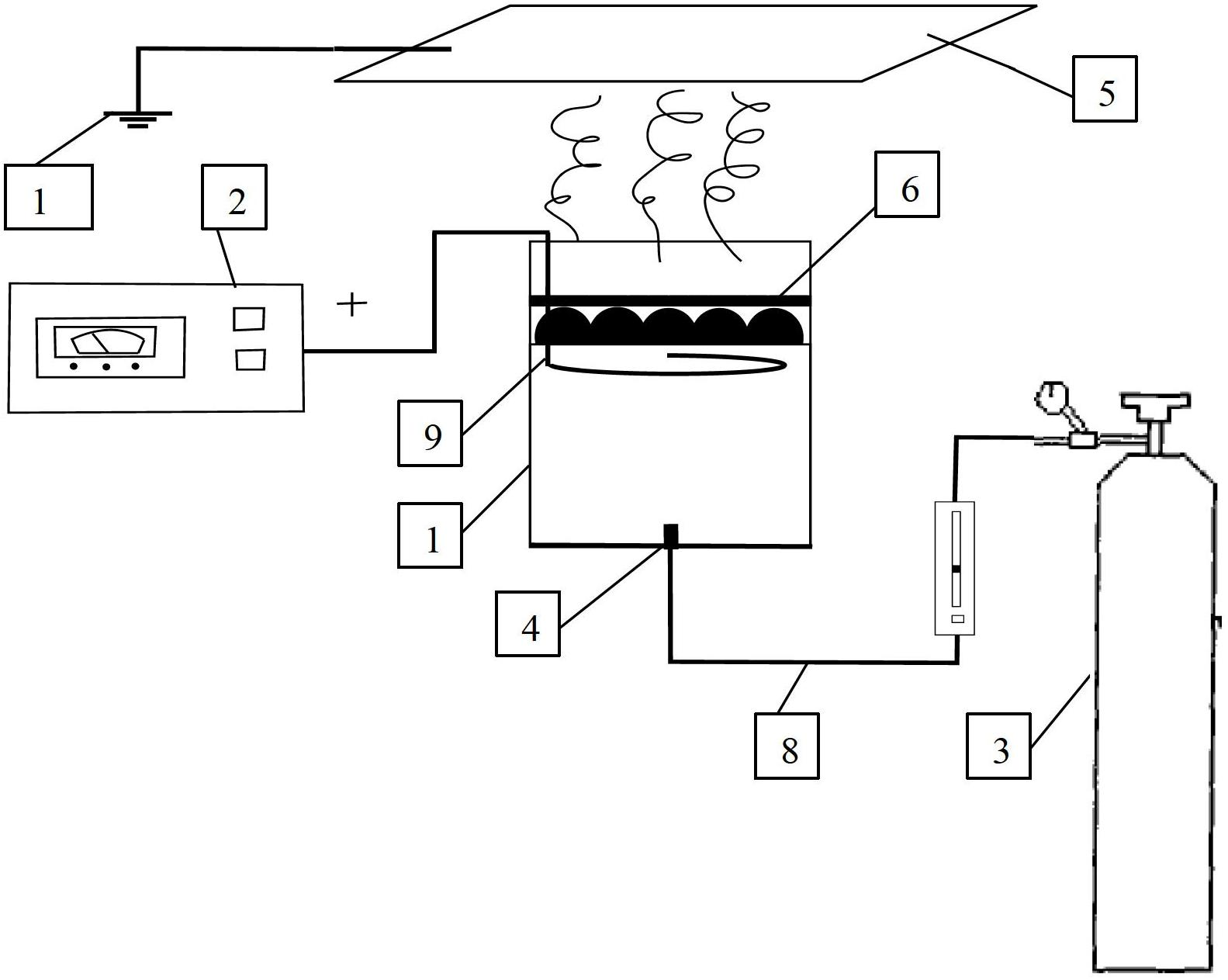

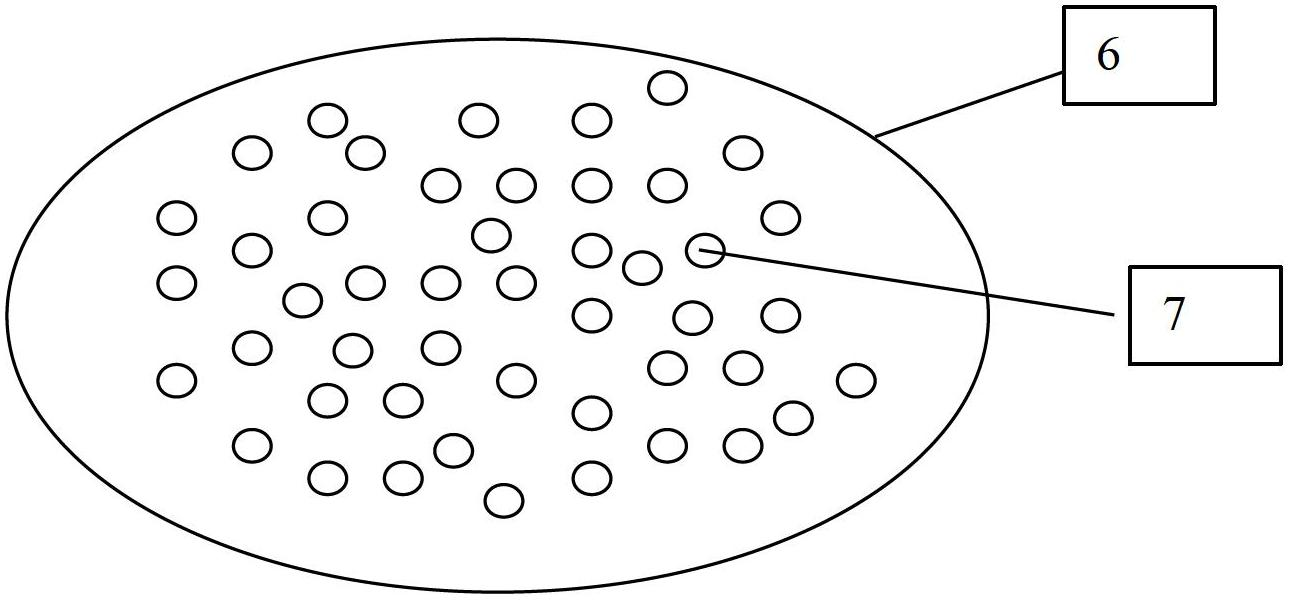

Porous bubble electrostatic spinning device

InactiveCN102660783ARealize large-scale productionIncrease productivityArtificial thread manufacturing machinesFilament/thread formingSprayerAir pump

A porous bubble electrostatic spinning device comprises a liquid storage tank, a high pressure electrostatic generator, an air pump, a sprayer, and a dash receiver, wherein the sprayer is connected with the air pump through an air duct, the dash receiver is connected with a grounded electrode, an opening is arranged at the upper end of the liquid storage tank, the liquid storage tank is connected with the high pressure electrostatic generator through a metal electrode, the liquid storage tank is internally provided with a middle flat plate, and a plurality of small holes with adjustable diameters are formed in the middle flat plate in a penetrating way. As the small holes are formed in the middle flat plate, solution in the liquid storage tank generates a large quantity of bubbles through the plurality of small holes under the action of the air pump. When filed stress is greater than surface tension of the solution, and jet flow is ejected from the top of the bubbles and is deposited on the dash receiver to form a large amount of nanofiber. The porous bubble electrostatic spinning device can produce the nanofiber in a large scale, so that according to the device, the production efficiency is high, the production cost is low, the equipment is simple, the operation is easy, the adaptability is high and the requirement of batch production can be met.

Owner:SUZHOU UNIV

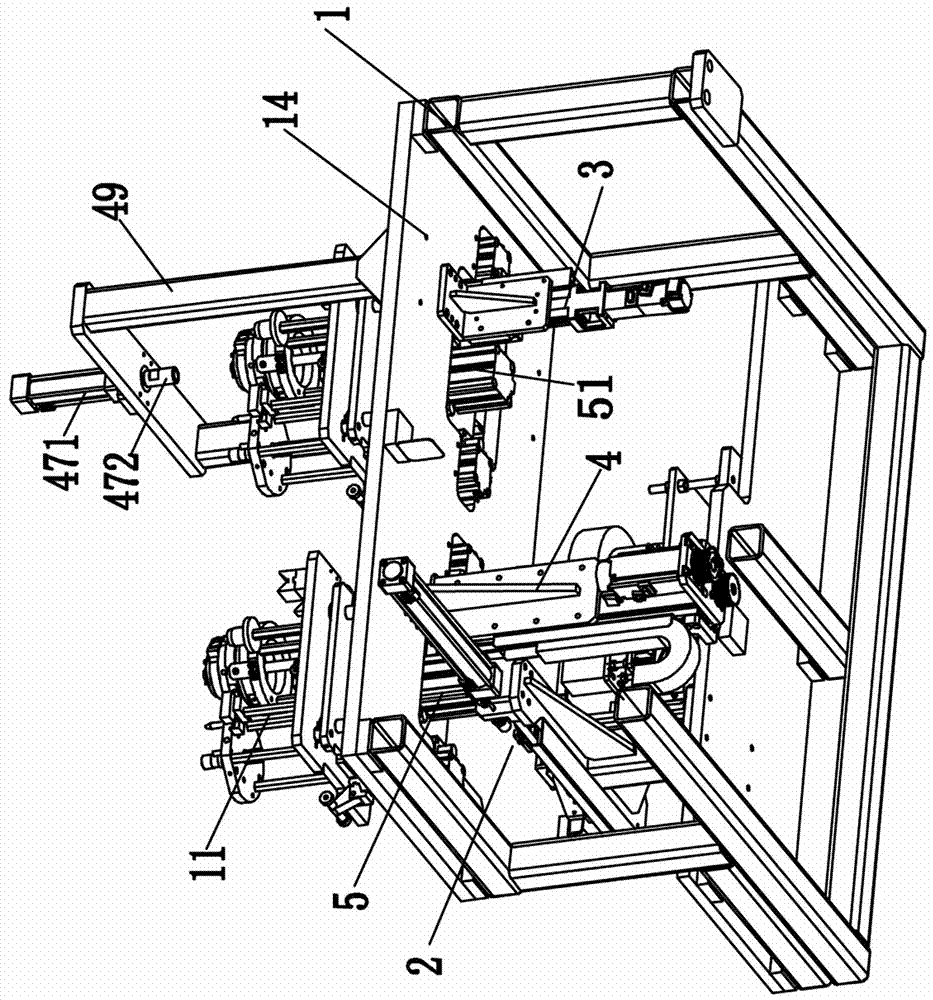

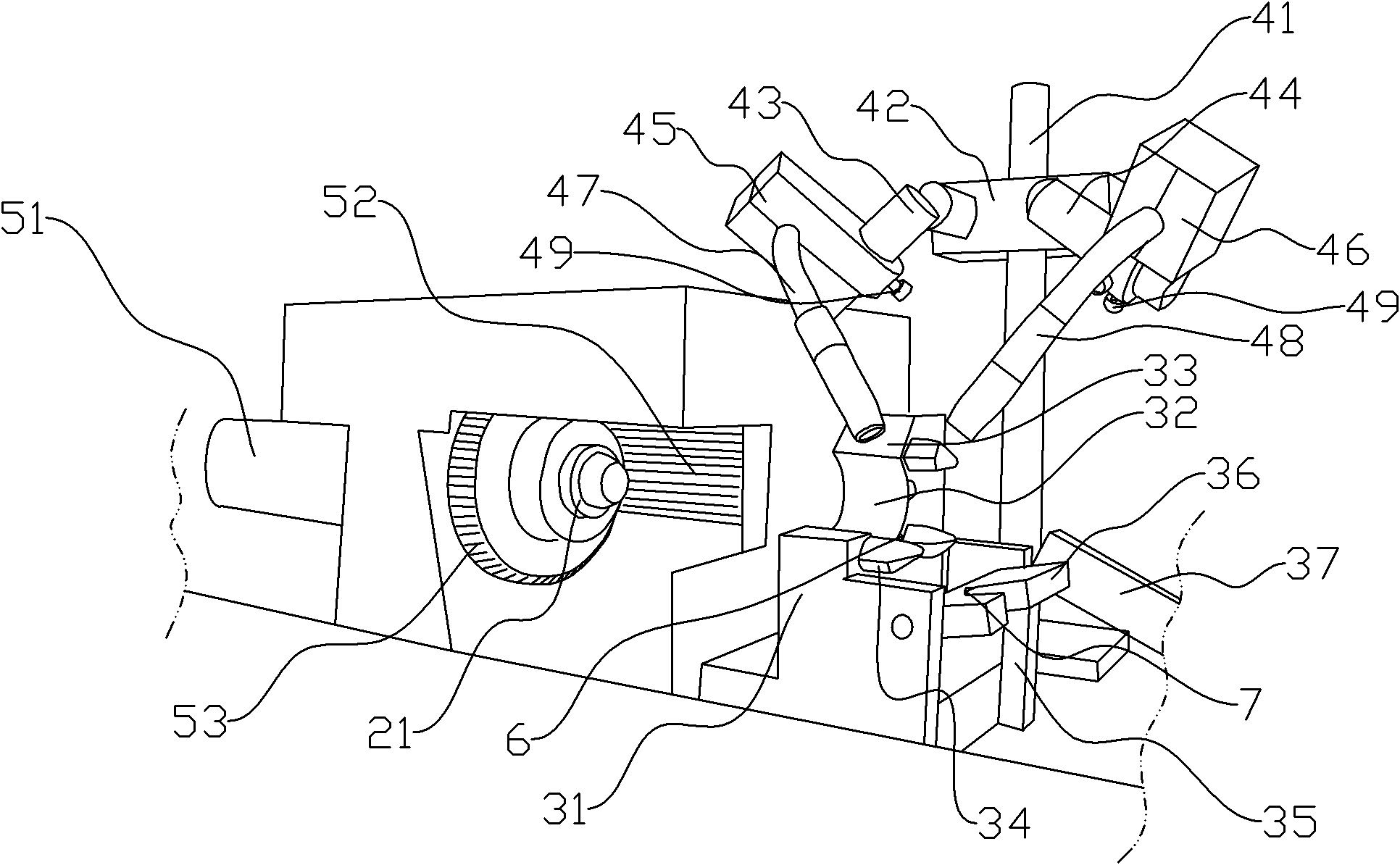

Loading and unloading manipulator

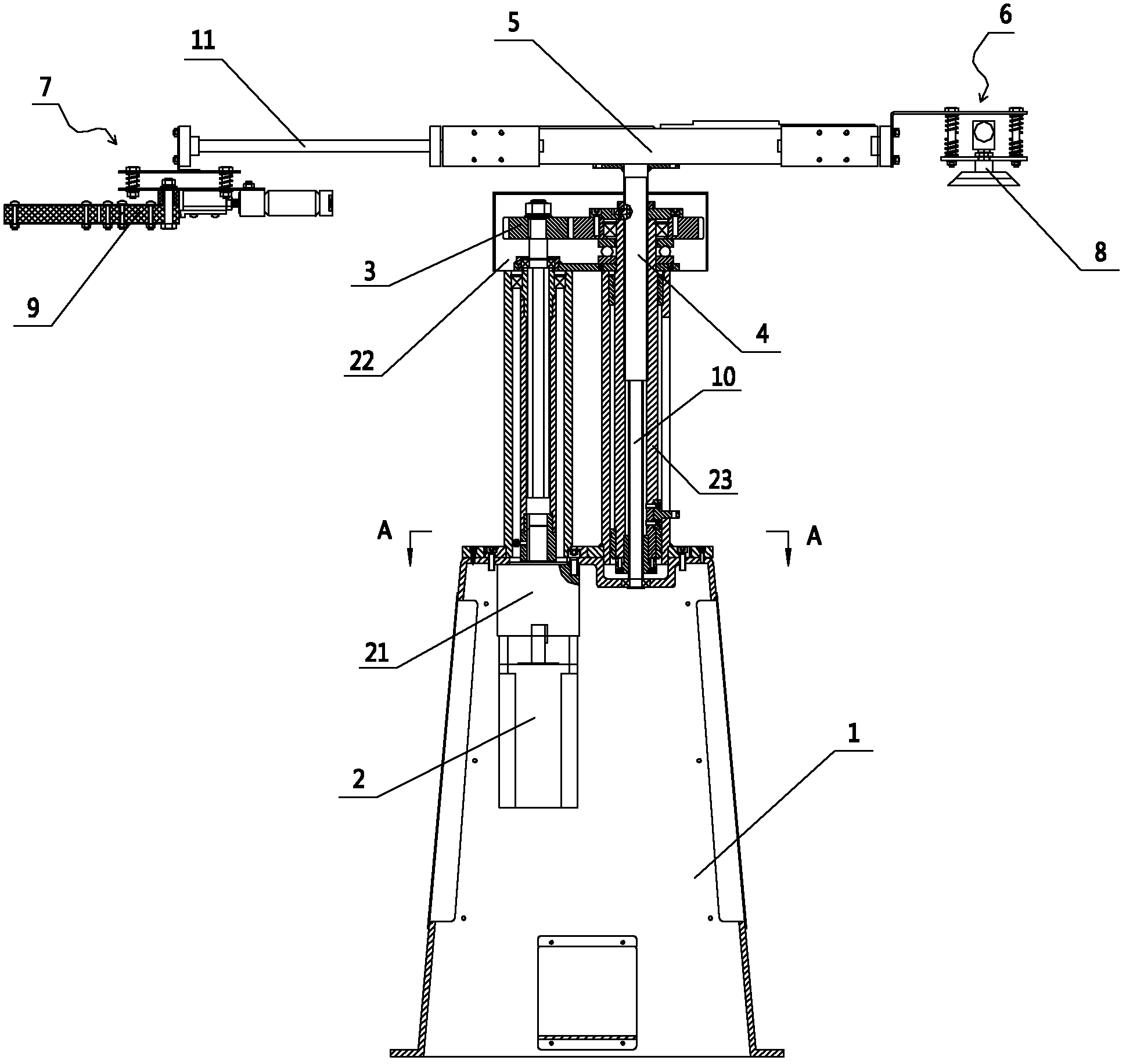

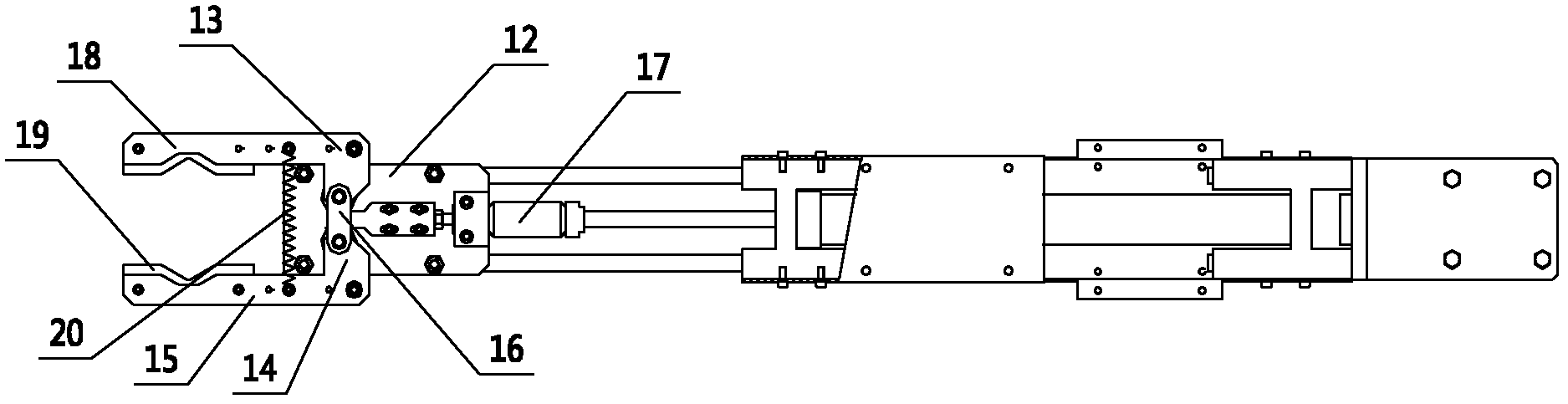

InactiveCN102554920AReduce labor costsReduce manufacturing costProgramme-controlled manipulatorMetal-working feeding devicesRotary stageRotational axis

The present invention relates to a loading and unloading manipulator which is characterized by comprising a workbench, a motor, a speed reducing device, a rotating shaft, a rotating platform, a loading mechanism and an unloading mechanism. The motor is controlled by a controller and fixed in the workbench; the input end of the speed reducing device is connected with the motor, and the output end is connected with a gear pair in a gear box; the other end of the gear pair is connected with the rotating shaft; the rotating shaft is arranged vertically; two ends of the rotating shaft are arranged above the workbench through screws; one rotating platform is fixed on the top end of the rotating shaft, and the rotating platform is perpendicular to the rotating shaft; the loading mechanism and the unloading mechanism are fixed on two ends of the rotating platform; the loading mechanism is a sucking disc; and the unloading mechanism is a clamping claw. Due to the adoption of the loading and unloading manipulator during the mechanical processing, the manpower and the production cost are reduced effectively, the occurrence of personal safety accident in the production process is avoided, the requirement of the mass production of the modern industry is met, the production efficiency is improved, and the great economic benefits are brought to the manufacturers.

Owner:SUZHOU YUEHAI STRETCHING MACHINERY

Walnut kernel peeling method

The present invention relates to a method for removing walnut kernel seed cover under the condition of normal temperature after the walnut kernel is frozen at low-temperature. It is characterized by that for dried walnut kernel the walnut kernel is soaked in the water with 0-10deg.C, after the walnut kernel is reconstituted, the walnut kernel is frozen; for fresh walnut kernel whose water content is greater than or equal to 45% it has no need of reconstitution, can be directly frozen; its freeze temperature is -5 - -25deg.C; after a lyer of ice cover is formed on the walnut kernel surface, the walnut kernel can be taken out and can be placed at normal temperature or into water with 30-60deg.C to melt the ice cover, then a manual method or mechanical method can be adopted to strip seed cover of walnut kernel. Its technological process includes the following steps: reconstitution, freezing, melting, stripping seed cover so as to obtain finished product.

Owner:SHANDONG INST OF POMOLOGY

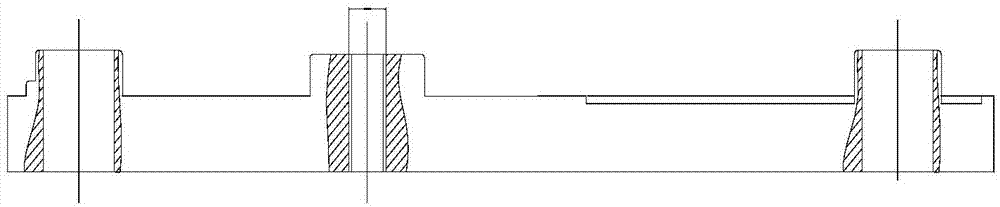

Technology method for connecting three-body structure of titanium aluminum alloy turbine rotation shaft

InactiveCN101596665AAvoid shockAddress reliabilityBlade accessoriesMachines/enginesInterference fitImpeller

The invention relates to a technology method for connecting a three-body structure of a titanium aluminum alloy turbine rotation shaft, belonging to the technical field of mechanical processing technology design. The three-body structure of the titanium aluminum alloy turbine rotation shaft comprises a titanium aluminum alloy turbine impeller, a K418 high-temperature alloy transition sleeve and a 42 CrMo alloy steel shaft, wherein the K418 high-temperature alloy transition sleeve and the 42 CrMo alloy steel shaft rub through end surfaces and welded with each other, and then the K418 high-temperature alloy transition sleeve and the titanium aluminum alloy turbine rotation shaft are connected with each other through the interference fit of outside diameters and inside diameters. The invention has simple technology and stable and reliable stretch-proof strength and property.

Owner:CHINA NORTH IND GRP NO 70 RES INST +1

Processing method of green bud tea

The invention discloses a processing method of green bud tea, comprising the following steps: paving tea leaves on a tea groove, wherein the paving thickness is 10-15cm; ventilating with an assistant blower, wherein the paving time is 10-14h; water-removing the tea leaves, wherein the cylinder temperature of the tea inlet end is 269-275 DEG C, the middle section temperature is 253-260 DEG C, the tea outlet end temperature is 219-225 DEG C, the leaves temperature is 102-108 DEG C, and; the water removing time is 1min25s-1min30s; directly putting the water removed tea leaves to a vibration groove, and putting the tea leaves into a wind selector, sending the selected tea leaves to a microwave water removing machine through a transporter, wherein the temperature of the water removing machine is 120 DEG C, the tea leaves temperature is 46-49 DEG C, the rotary speed is 1100r / min, and the water removing time is 50s; grading, carding, shaping, drying, infrared flavor enhancing. The method canincrease the shape, color and smell of green bud tea.

Owner:贵州湄潭兰馨茶业有限公司

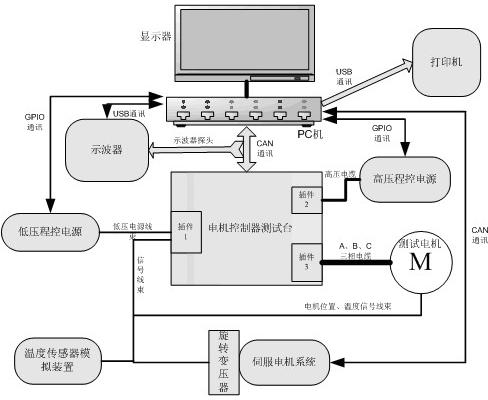

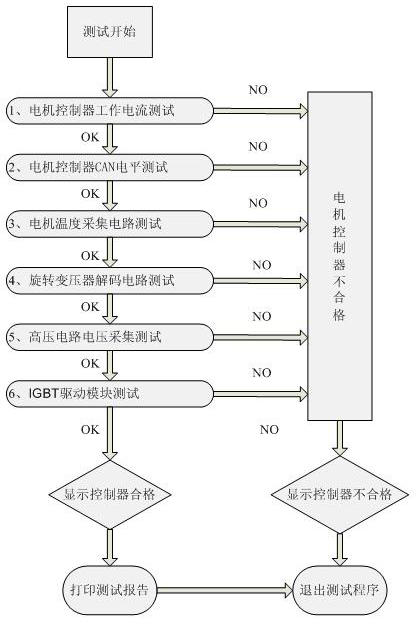

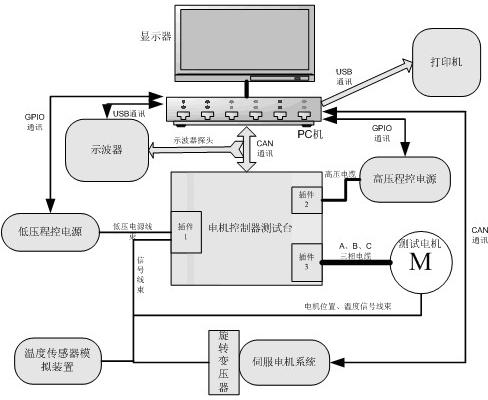

Intelligent testing system and testing method for motor controller of electric vehicle

ActiveCN102566568AEasy to operateMeet the needs of mass productionCurrent/voltage measurementElectronic circuit testingLow voltageInterference factor

The invention relates to an intelligent testing system for a motor controller of an electric vehicle. The system comprises a low-voltage program-controlled power supply, a high-voltage program-controlled power supply, an oscilloscope, a probe, a rotary transformer, a servo motor system, a temperature sensor simulation device, a motor controller test bench, a test motor and a personal computer (PC) machine. The testing system and a testing method have the advantages of reduction in human testing interference factors, high testing accuracy, high testing speed and high efficiency, are simple in operation, and meet the requirement for batch production of motor controllers.

Owner:奇瑞新能源汽车股份有限公司

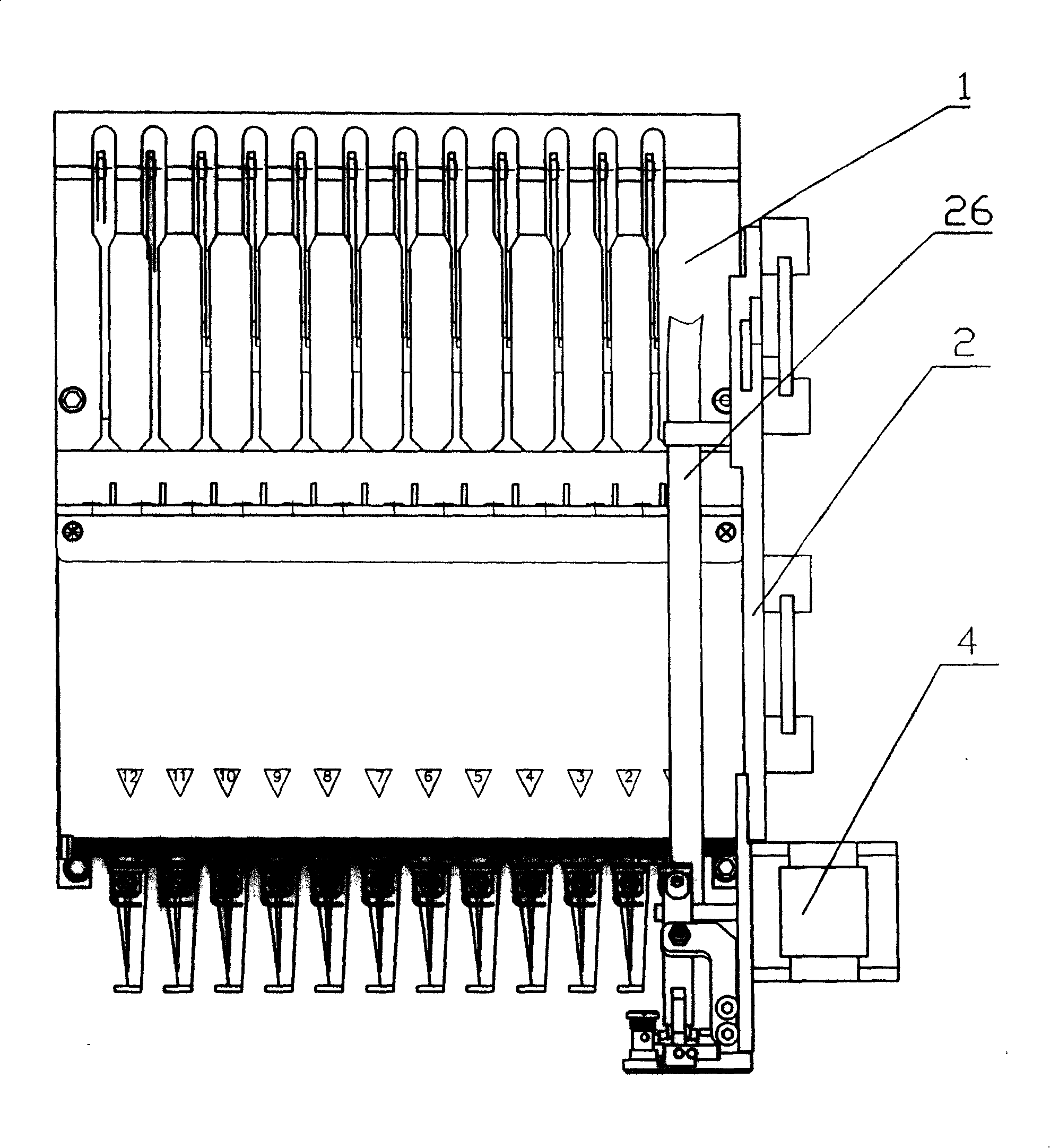

Bead embroidering mechanism for computer embroidering machine

InactiveCN101235583ARealize automatic deliveryIncrease productivityAutomatic machinesFeedersElectric machineryEngineering

The invention relates to a beads enchasing mechanism of a computerized embroidery machine, which is characterized in that a stepping motor which is only controlled by a computer is installed on frame work which is composed of a bottom board and a motor plate, a motor connecting bar is installed on a shaft of the motor, the other end of the motor connecting bar is hinged with an actuation link, the other end of the actuation link is hinged with a bead push-rod, a fixed lever component is installed on the bottom board on one side of the push-rod, a rotatable lever component is installed on the other side, and a connecting base which is provided with a discharge port and is connected with a material feeding pipe is arranged on the fixed lever, The mechanism can be installed on a needle bar frame of the computerized embroidery machine in match with various lifting devices and can realize automatic enchasing of the beads on various embroideries.

Owner:浙江珠光集团临海电脑刺绣设备有限公司

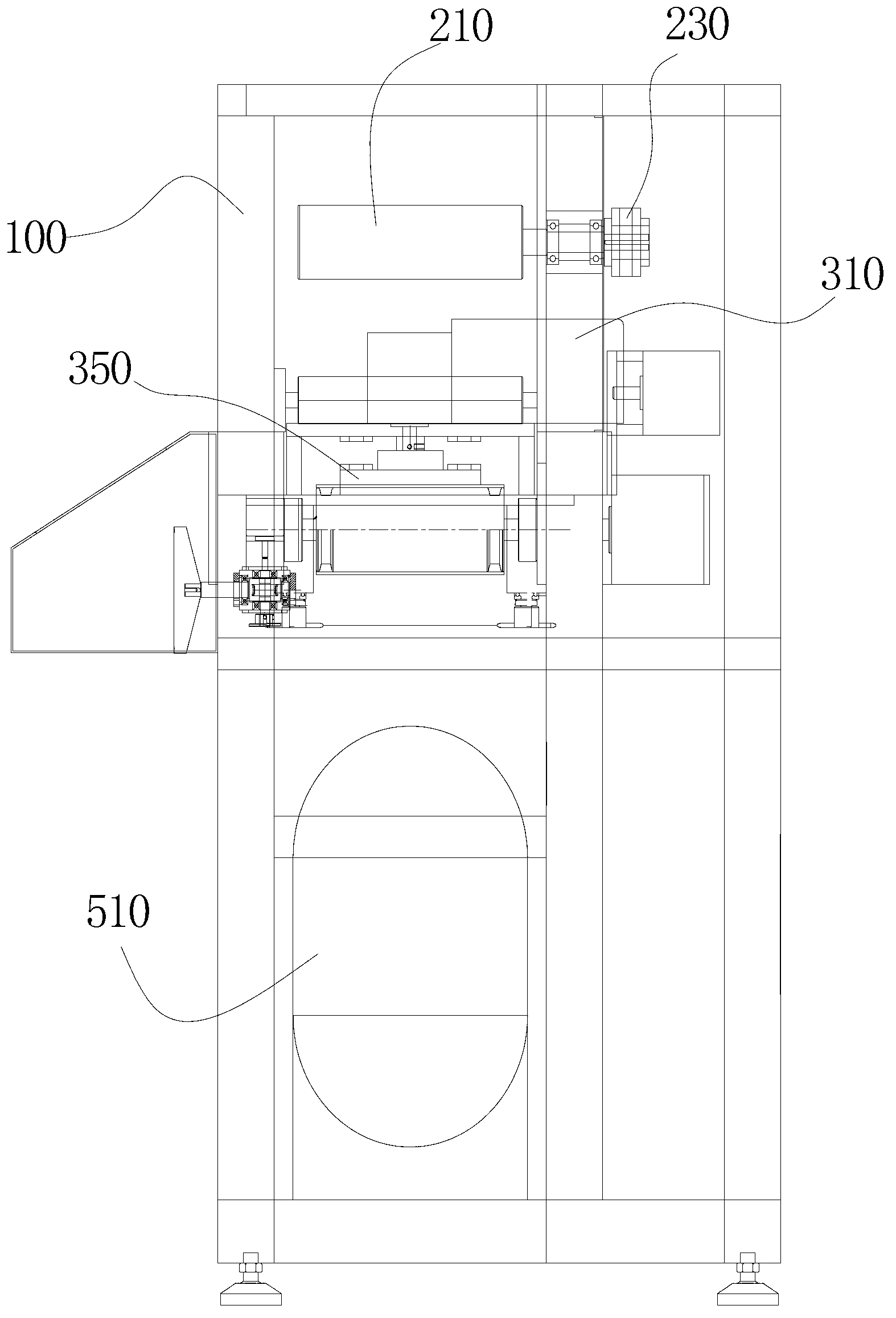

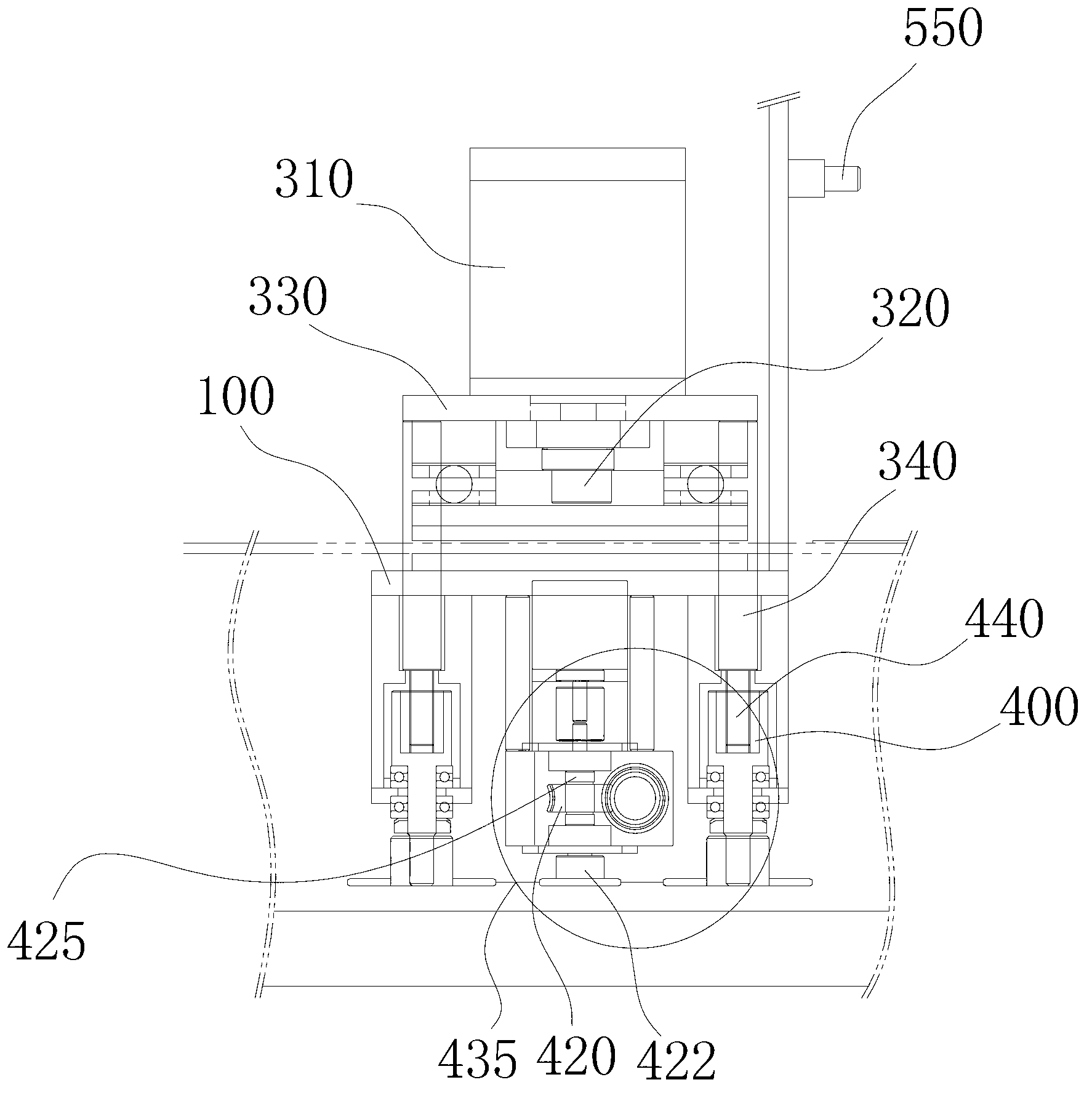

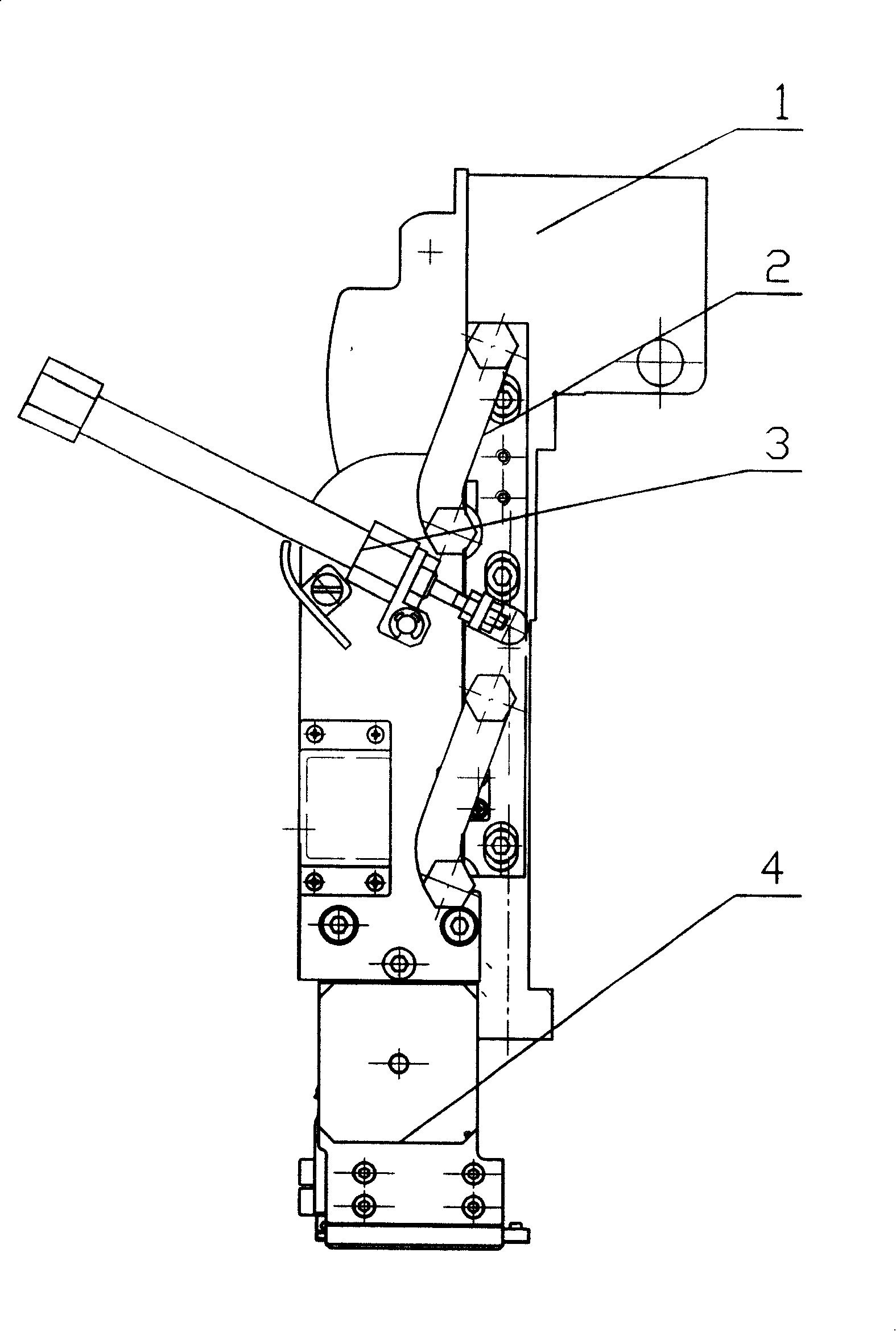

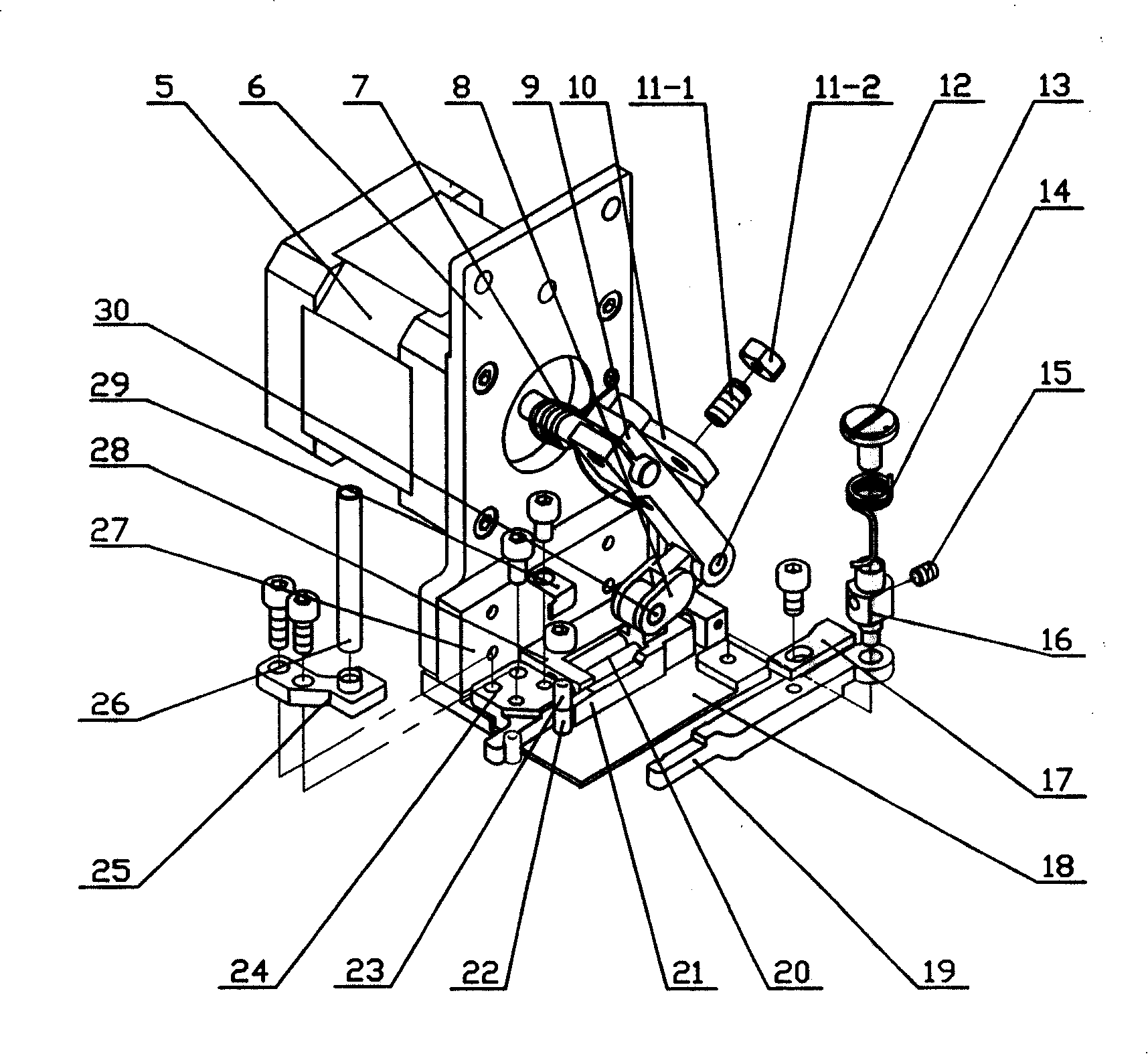

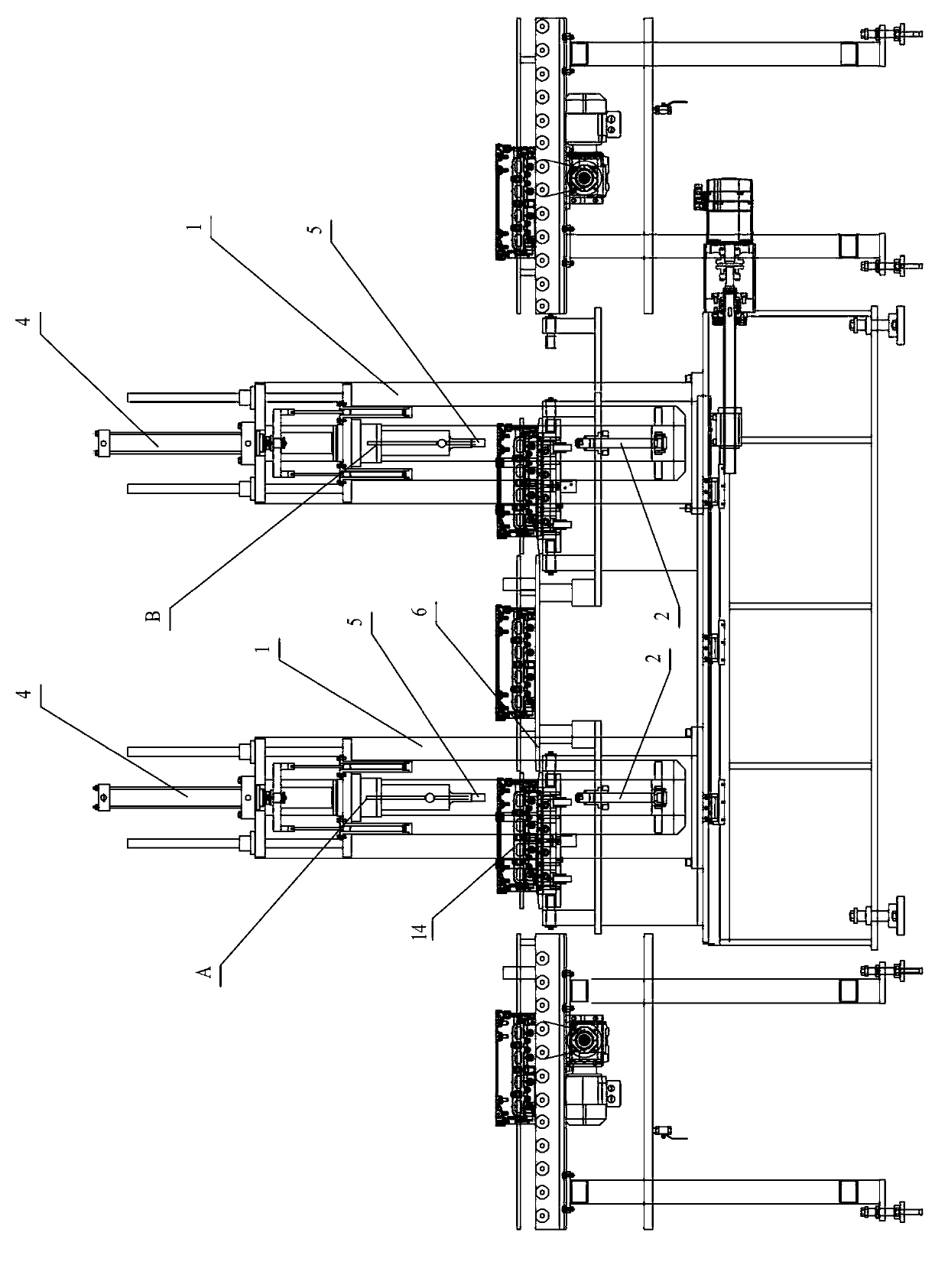

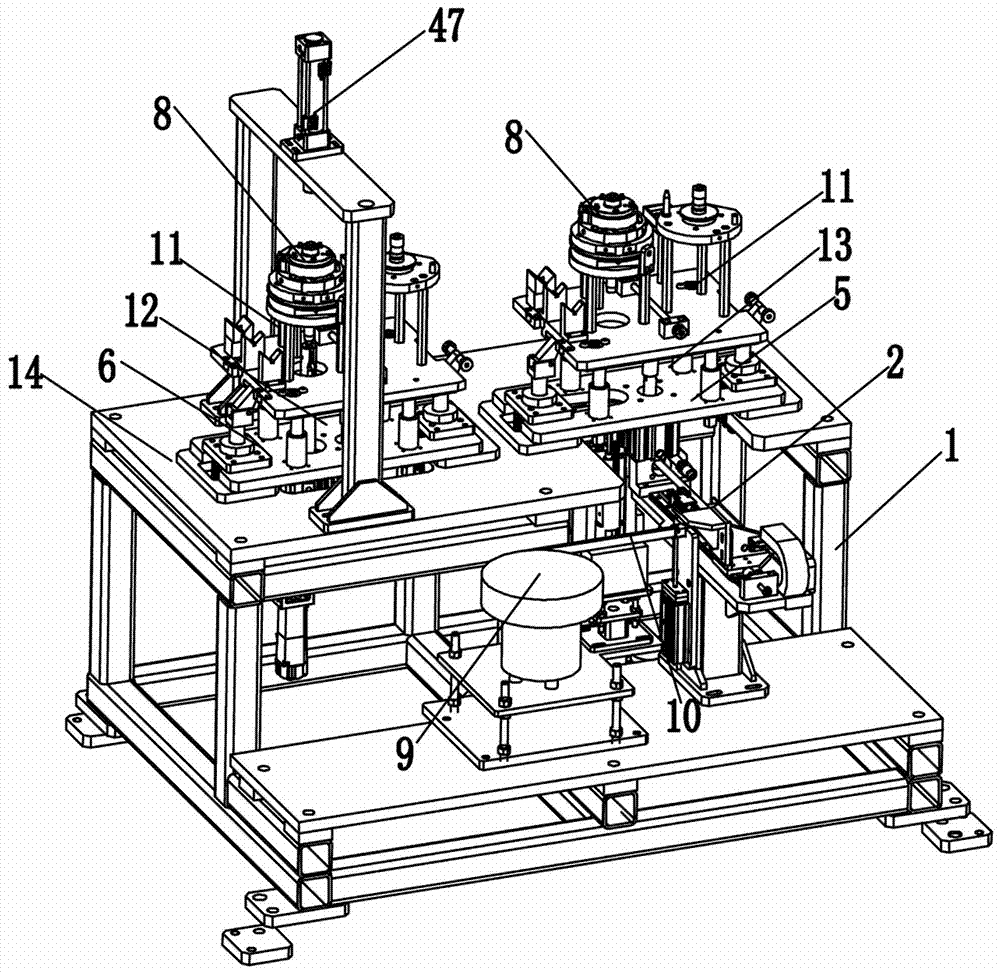

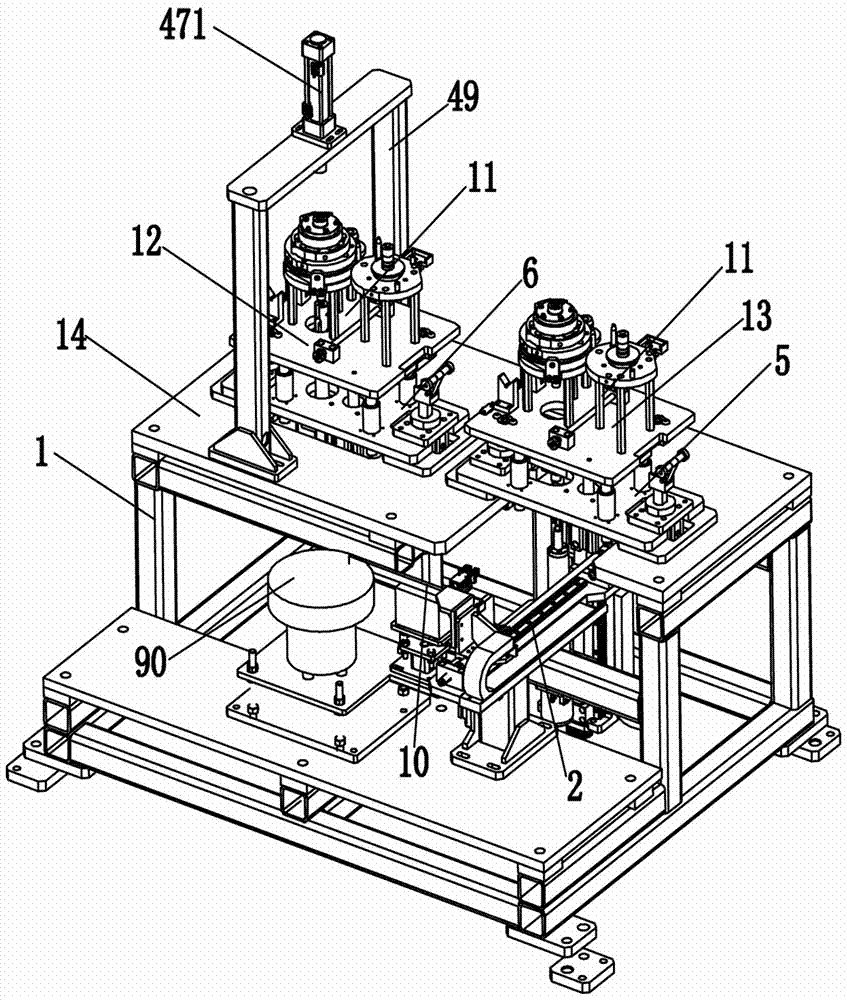

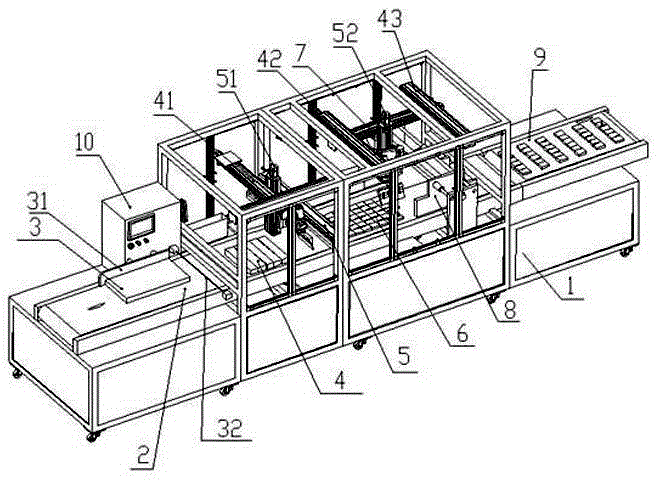

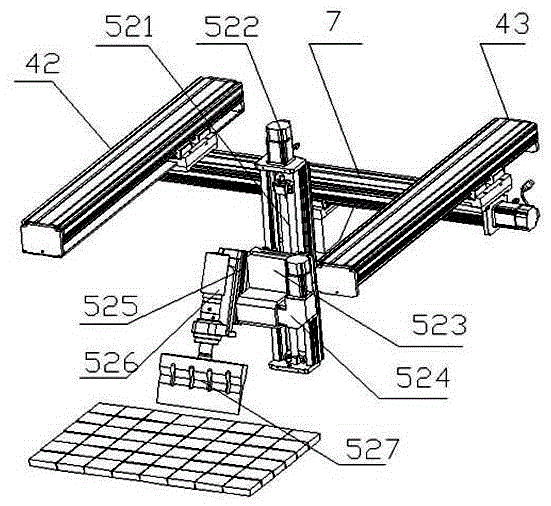

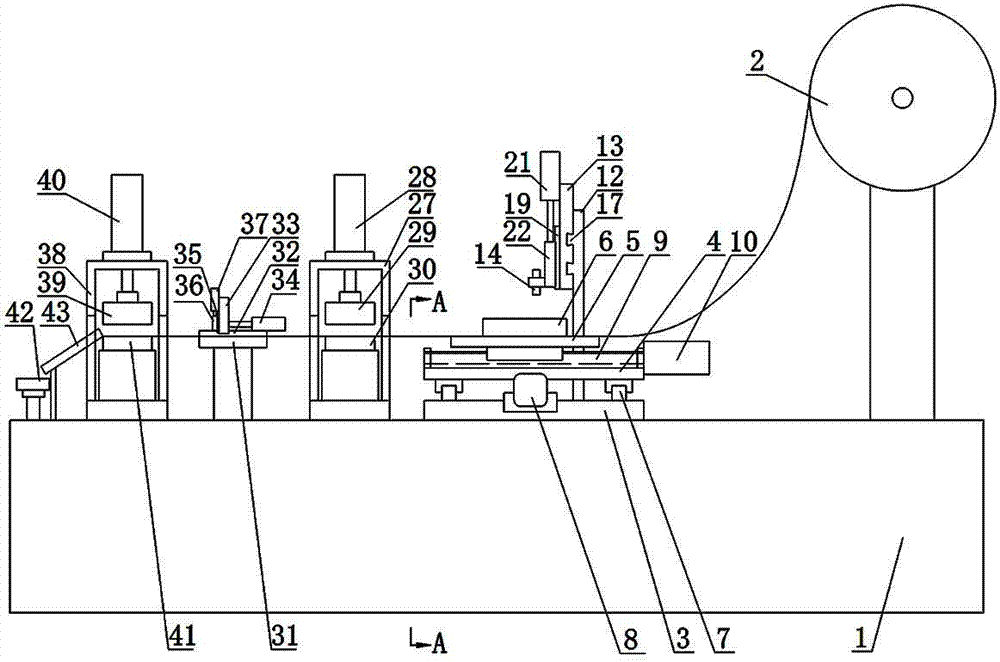

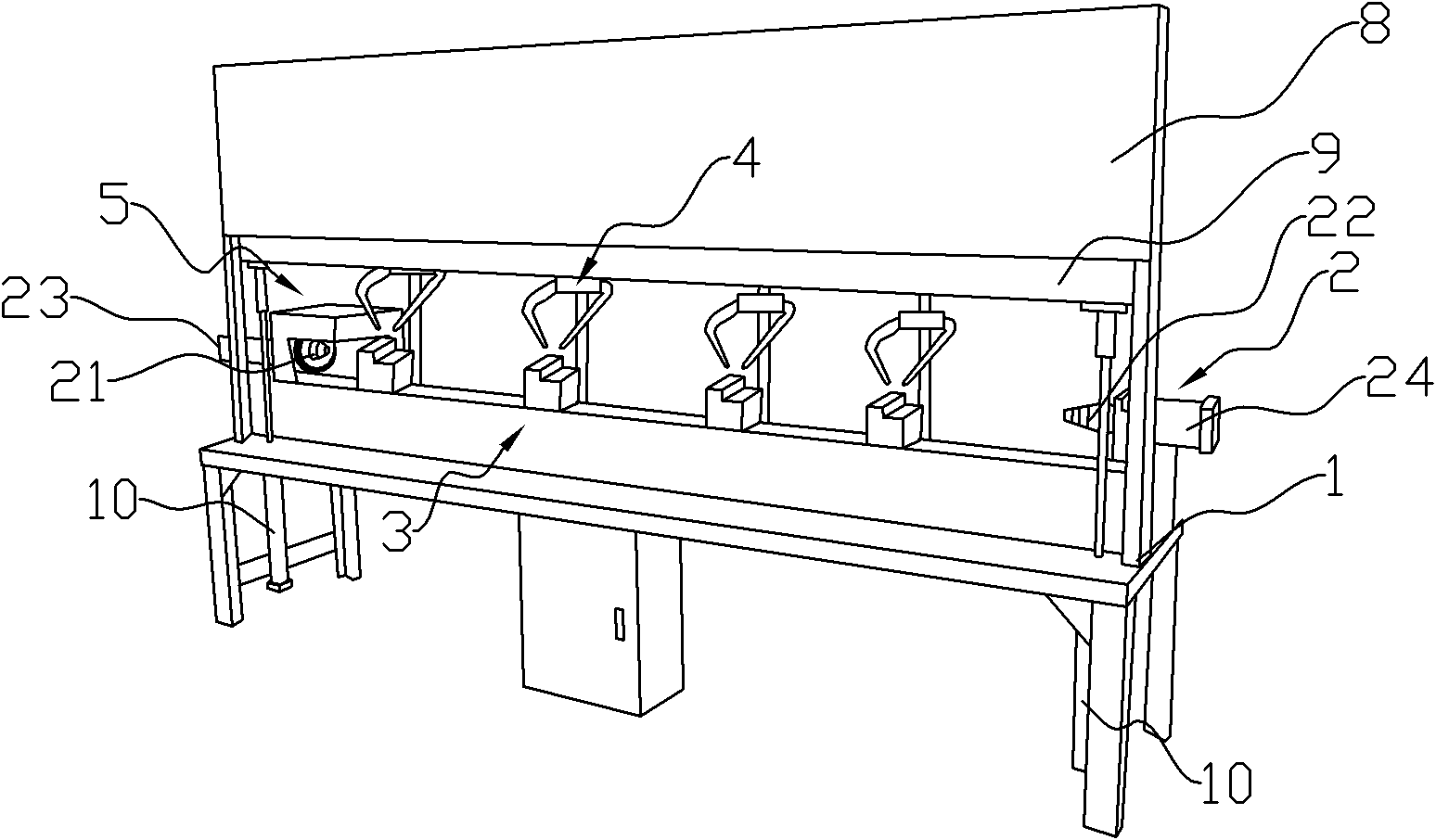

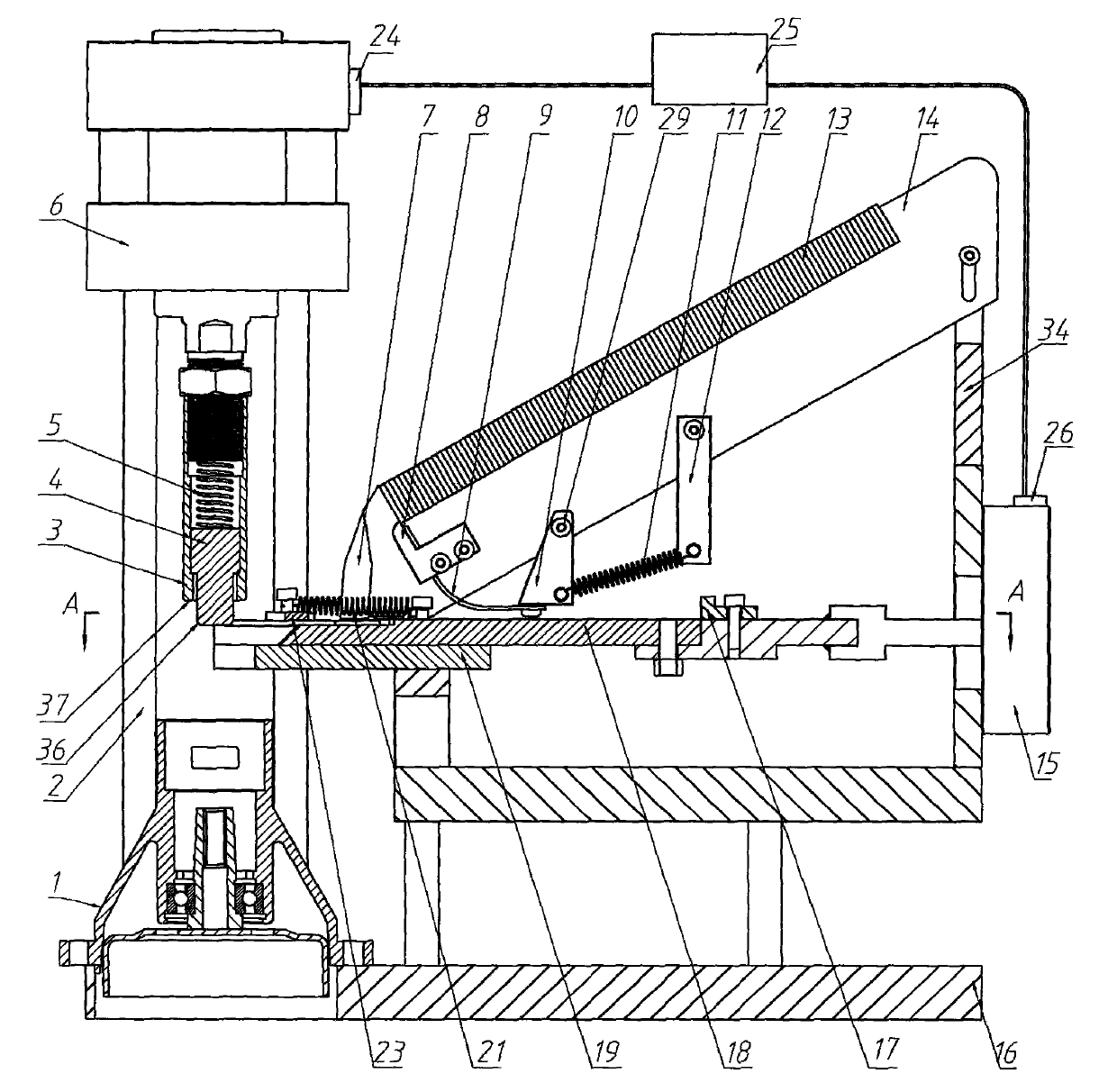

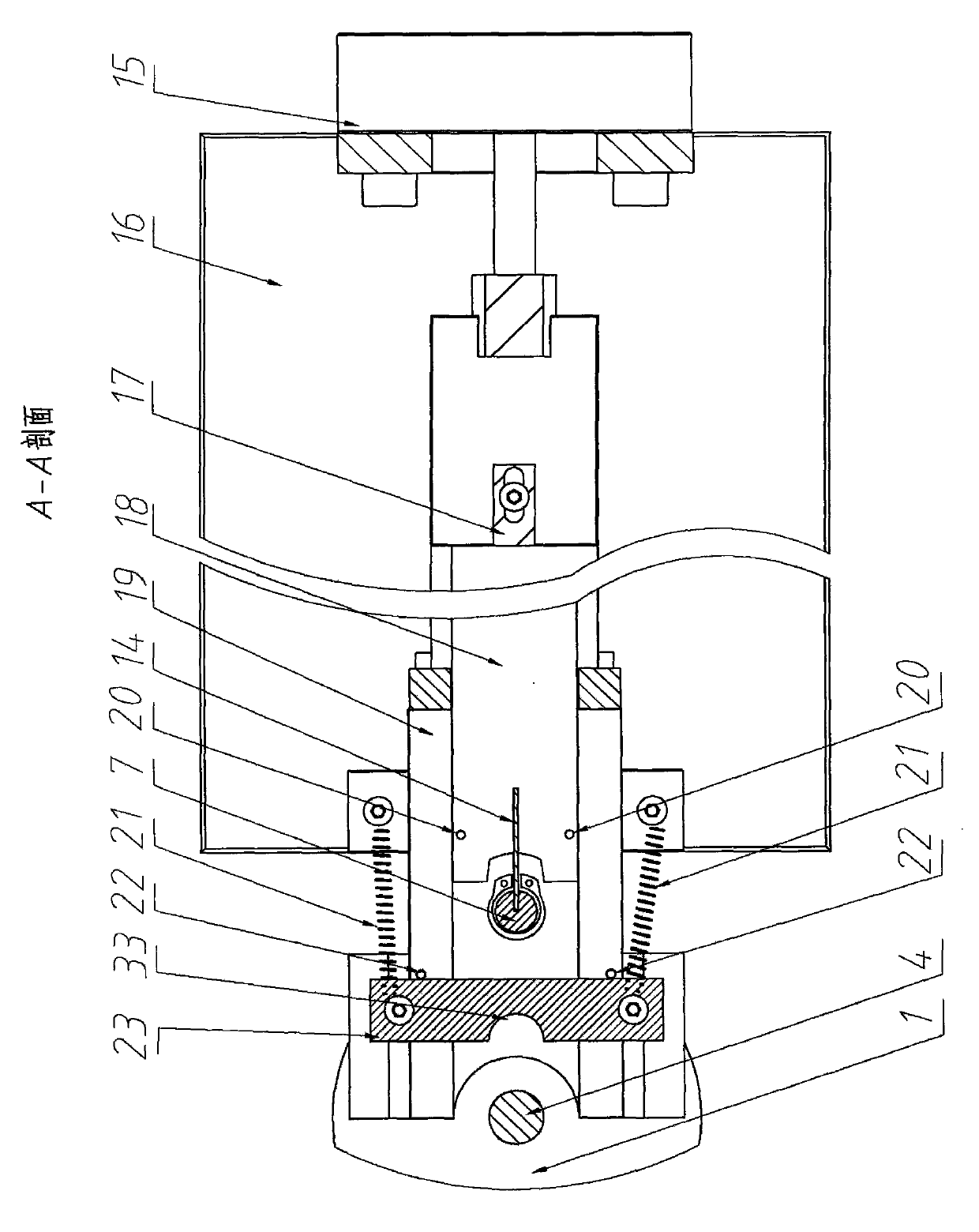

Press fitting device for guide pipe and seat retainer of engine cylinder head

InactiveCN103009042AImprove work efficiencyMeet the needs of mass productionMetal working apparatusCylinder headGuide tube

The invention relates to a press fitting device for the guide pipe and the seat retainer of an engine cylinder head. The press fitting device is based on control of a main control unit, and comprises a conveying and clamping mechanism and a press fitting mechanism, wherein the conveying and clamping mechanism is used for conveying the engine cylinder head to a press fitting station and clamping the engine cylinder head; the press fitting mechanism is used for press-fitting the seat retainer and the guide pipe of the engine cylinder head; a clamping device of the conveying and clamping mechanism is arranged between a seat retainer press fitting station and a guide pipe press fitting station during press fitting; and the press fitting mechanism is mounted on a fixed supporting mechanism used for supporting the press fitting device in a sliding manner. The embodiment of the invention is simple in structure, can finish the press fitting operation of the guide pipe and the seat retainer of the engine cylinder head automatically, and does not need working personnel to conduct press fitting, thereby improving the production efficiency greatly, and meeting the batched production.

Owner:GREAT WALL MOTOR CO LTD

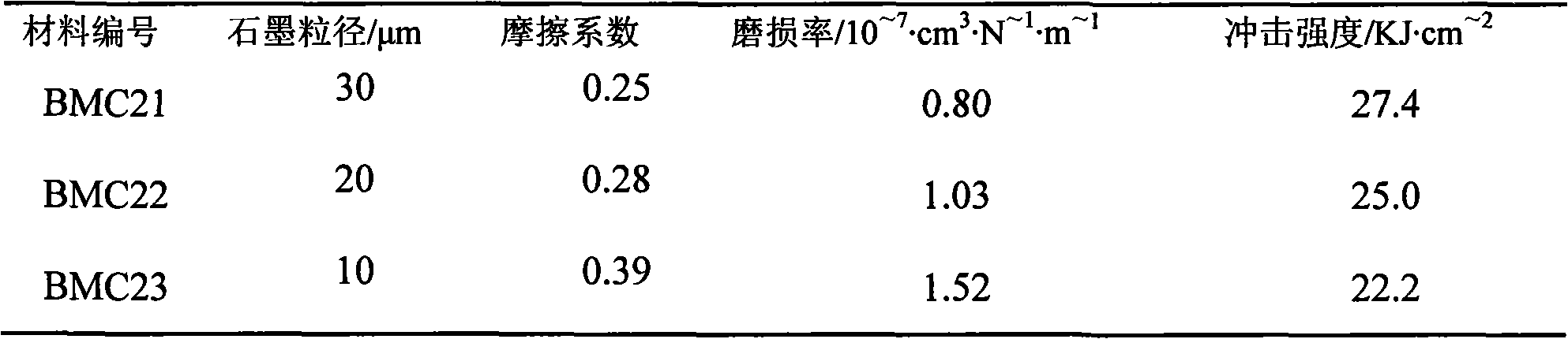

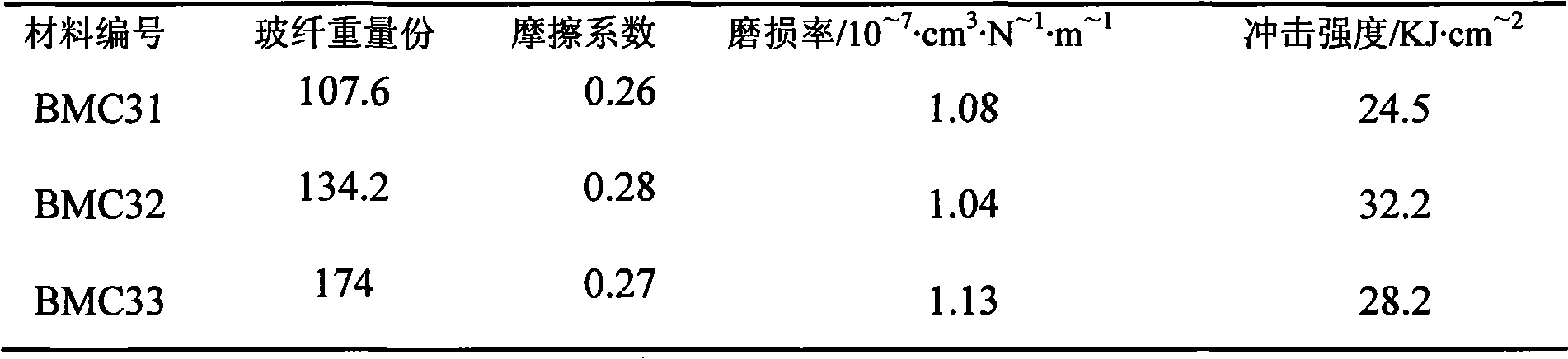

Self-lubricating wear-resisting agglomerate moulding material

The invention relates to a self-lubricated abrasion-proof lumpy molding compound. The premix of the molding compound contains an unsaturated polyester resin in an amount of 60 to 80 parts by mass; a low shrink additive in an amount of 20 to 40 parts by mass; an internal molding lubricant in an amount of 3 to 5 parts by mass; an inorganic filler in an amount of 140 parts to 170 parts by mass; an initiator in an amount of 0.5 to 2 parts by mass; a thickening agent in an amount of 0.5 to 1.5 parts by mass; a lubricant in an amount of 10 to 40 parts by mass; a reinforcing material in an amount of 83.5 to 188 parts by mass. The total number of the parts of the unsaturated polyester resin and the low shrink additive is 100. The self-lubricated abrasion-proof lumpy molding compound has excellent mechanical property and acid and alkali corrosion resistance, and is light in weight so as to save fuel and discharge little pollution. The invention is designed freely; the components are integral; the dimensional stability is excellent; the surface is smooth; the components can be self-lubricated without needing other lubricants for reducing friction; the molding compound can be used for molding once; and molded products have accurate sizes and good surfaces, thus avoiding machining, heat treatment and surface modification of metal abraded parts; in addition, the production cycle is short.

Owner:NINGBO HUAYUAN FRP ELECTRICAL APPLIANCE MFR

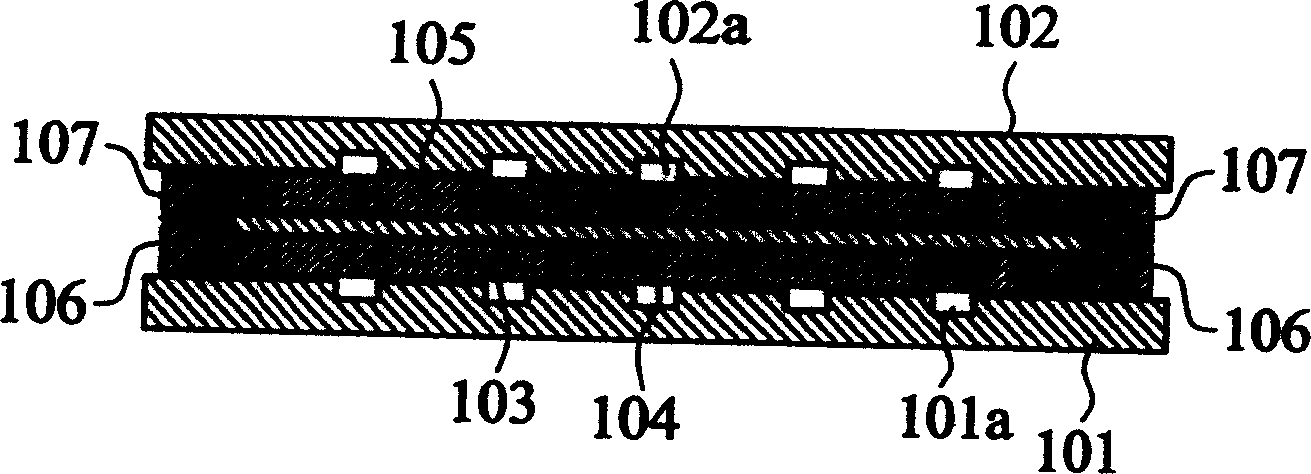

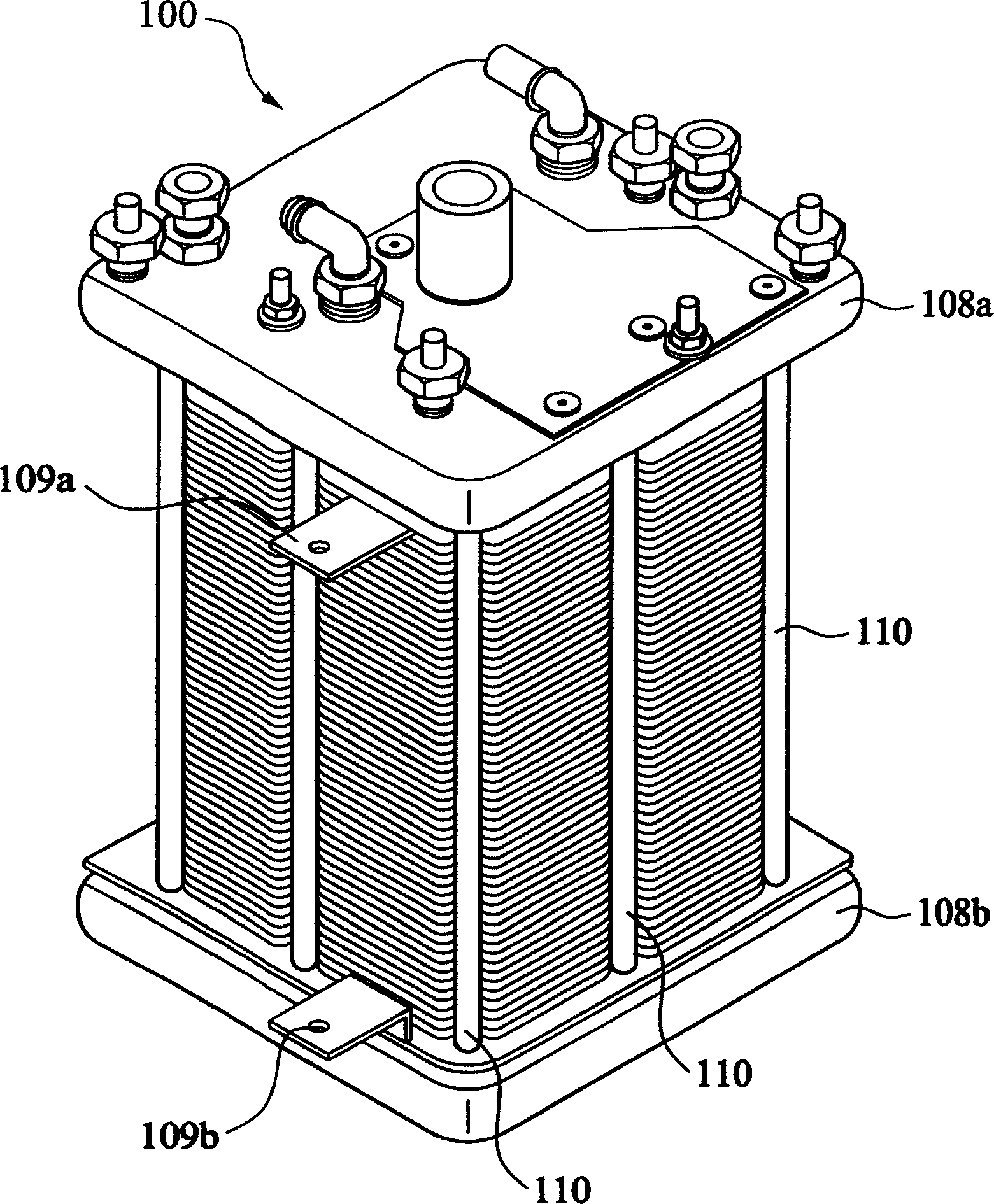

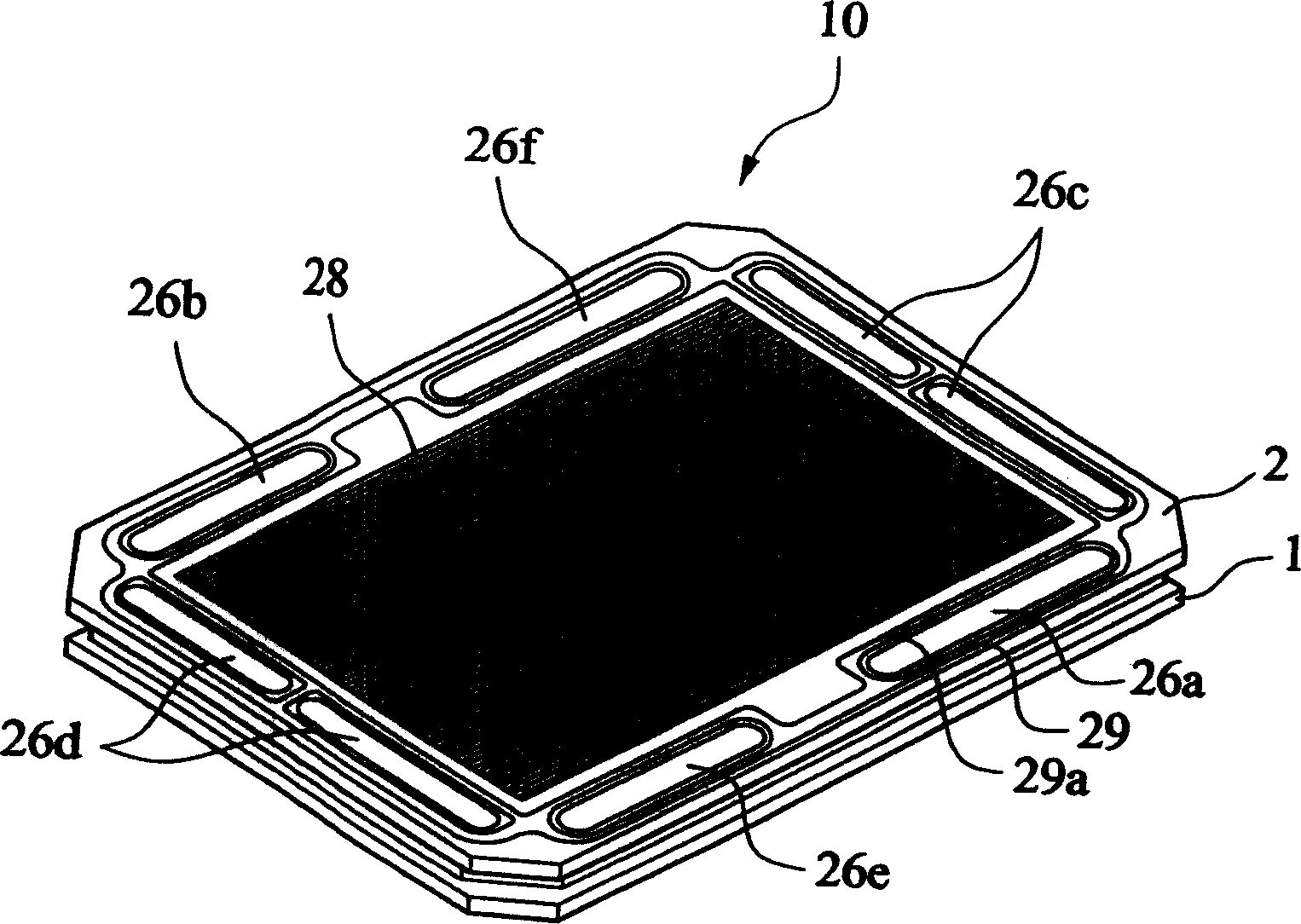

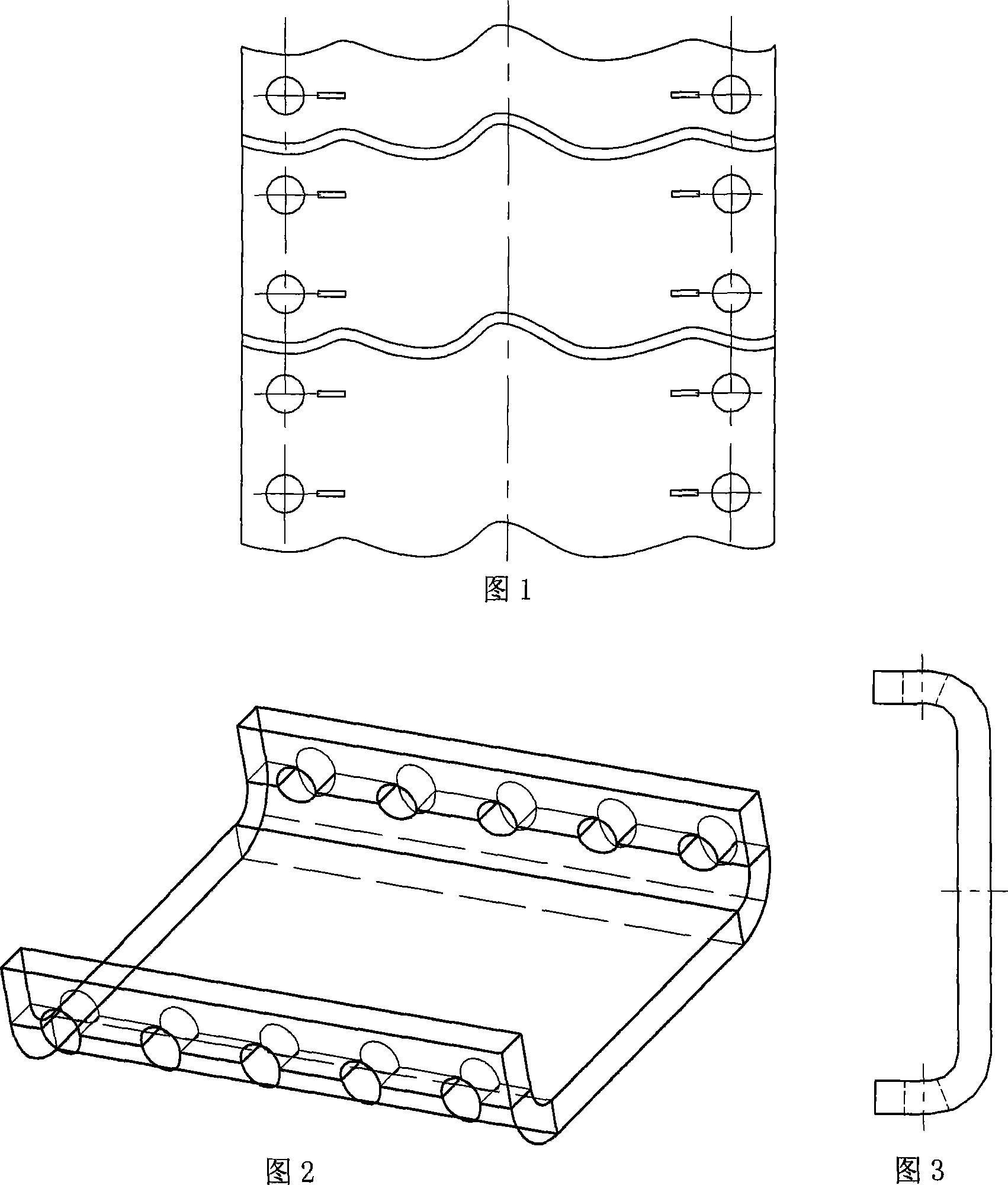

Seal structure for modularized proton exchange film fuel cell

ActiveCN1635643AEasy to make and constructImprove qualityFuel cells groupingCell component detailsEngineeringElectrical and Electronics engineering

A sealed structure of modularized proton exchange membrane fuel battery, which contains a round concave part and an extended round part in positive plate of said fuel battery, a round concave part and interconnected extended concave part in negative plate, silica gel pre-coated in circumference area corresponded round concave part and extended round concave part in positive and negative plate, before the gel solidified the positive plate, membrane assembly and negative plate are align laminated and pressed to form enclosed round surface and the proton exchange membrane is tightly pressed and located at the intermediate position to make the through holes between positive plate and negative plate respectively form enclosed round surface.

Owner:ASIA PACIFIC FUEL CELL TECH

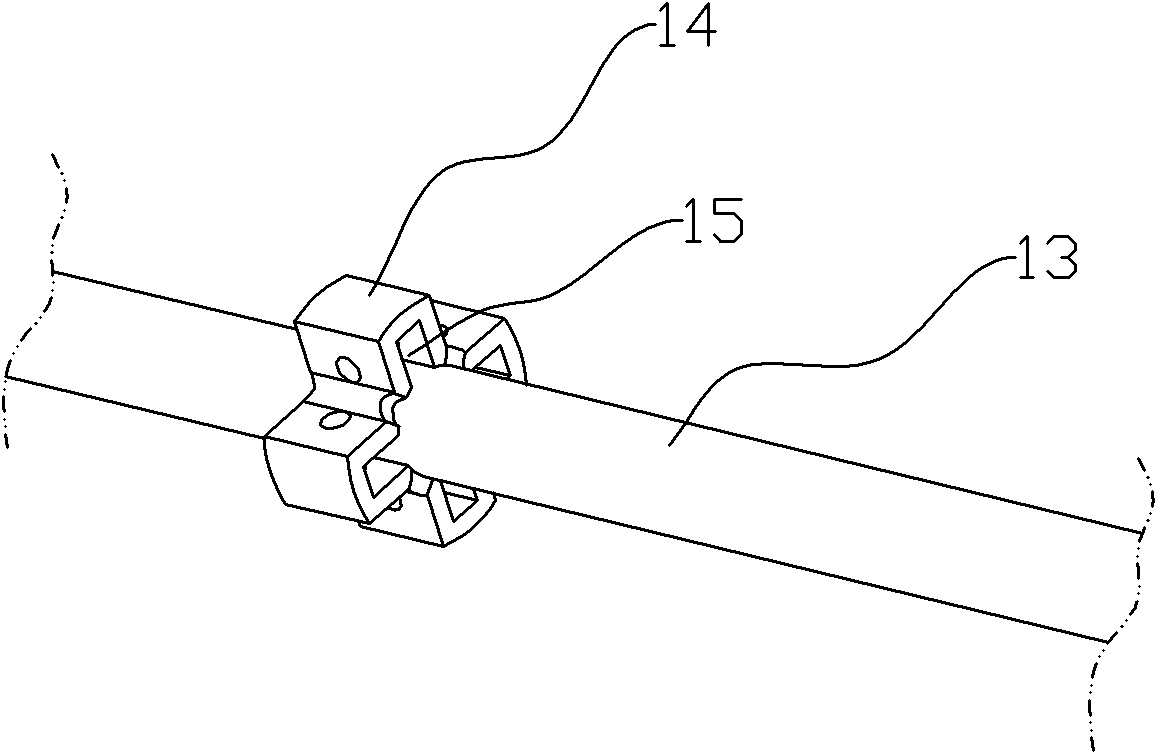

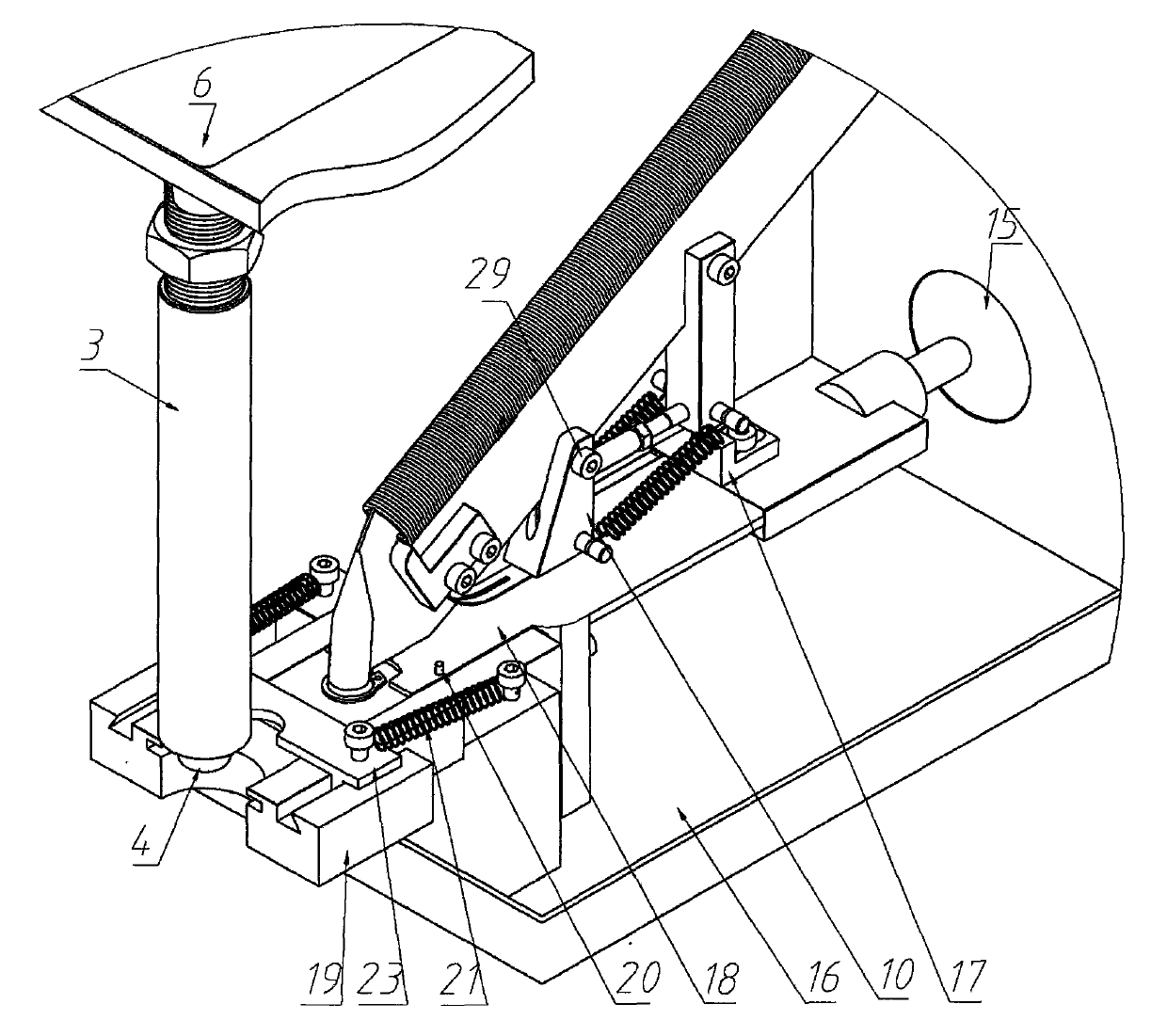

Online mounting equipment for crankshaft spring of pump body

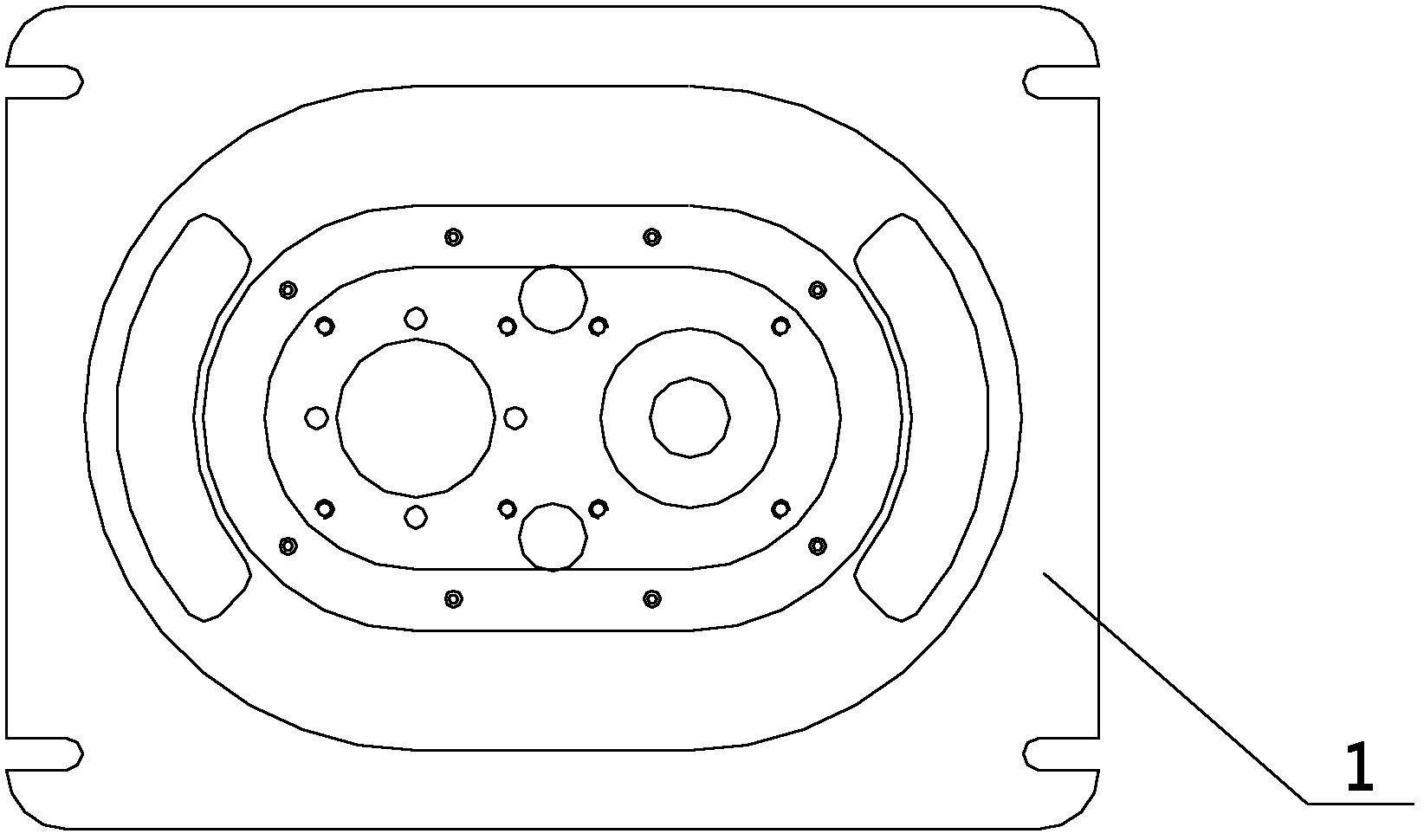

ActiveCN107470890AAccurate control of jacking depthConsistent jacking depthMetal working apparatusEngineeringAssembly line

The invention relates to online mounting equipment for a crankshaft spring of a pump body. The online mounting equipment comprises a rack, a vibrating charging mechanism, a feeding mechanism, a first assembly disc jacking mechanism, a spring pre-jacking mechanism, a second assembly disc jacking mechanism, a spring jacking-in-place and detecting mechanism and a pressing mechanism, wherein a workbench is arranged on the rack. The online mounting equipment for the crankshaft spring of the pump body is of an online mounting form, and can realize whole-line automatic butt-joint for a compressor pump body assembly line. Work of charging, feeding, pre-mounting, mounting, detecting and the like of a crankshaft conical spring is separately realized through the vibrating charging mechanism, the feeding mechanism, the first assembly disc jacking mechanism, the spring pre-jacking mechanism, the second assembly disc jacking mechanism, the spring jacking-in-place and detecting mechanism and the pressing mechanism, and therefore, the online mounting equipment is high in production efficiency, is efficient and accurate in discharging and loading, improves rhythm of online mounting very well, and can meet large-scale production needs.

Owner:SANHE IND AUTOMATION EQUIP CO LTD SHUNDE DISTRICT FOSHAN CITY

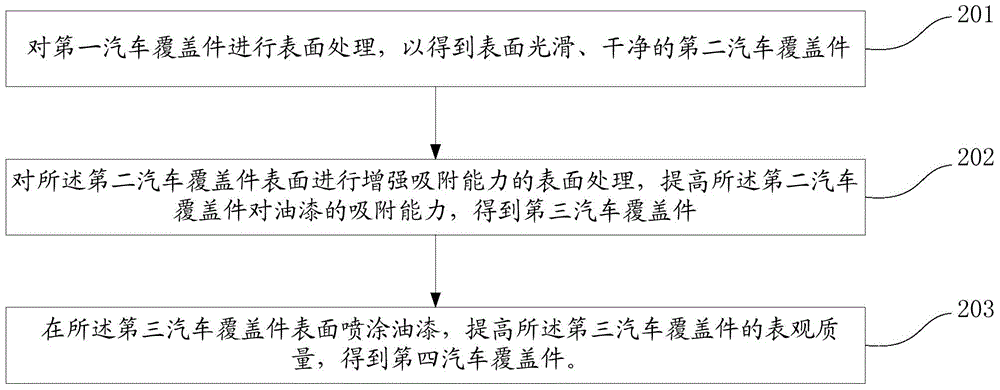

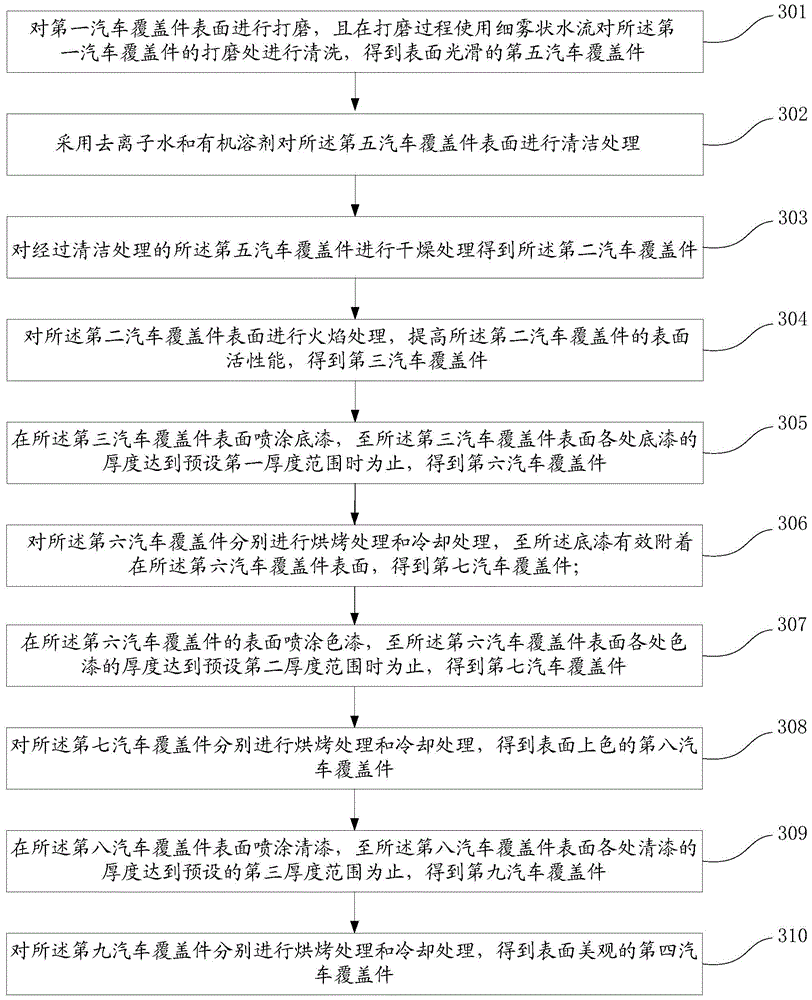

Automobile covering element spray coating method

ActiveCN104826784AGuarantee the appearance qualityMeet the needs of mass productionPretreated surfacesSpecial surfacesSpray coatingEngineering

The invention discloses an automobile covering element spray coating method, and belongs to the field of automobile part manufacturing. The method comprises the following steps that a first automobile covering element is subjected to surface treatment to obtain a second automobile covering element with the smooth and clean surface; the surface of the second automobile covering element is subjected to surface treatment for enhancing the adsorption capability, the adsorption capability of the second automobile covering element on the paint is improved, and a third automobile covering element is obtained; the paint is sprayed and coated on the surface of the third automobile covering element to obtain a fourth automobile covering element. The automobile covering element spray coating method has the advantages that the second automobile covering element is subjected to the surface treatment for enhancing the adsorption capability, so that on the basis that the paint can be effectively adsorbed onto the surface of the third automobile covering element, the surface depression of the third automobile covering element can be filled through increasing the thickness of the paint, the puttying or the lime scraping is avoided, the spray coating schedule is accelerated, and the whole spray coating operation period is shortened, so that the method can be applied to large-scale automobile spray coating processing, and the current automobile large-scale production requirements are met.

Owner:CHERY AUTOMOBILE CO LTD

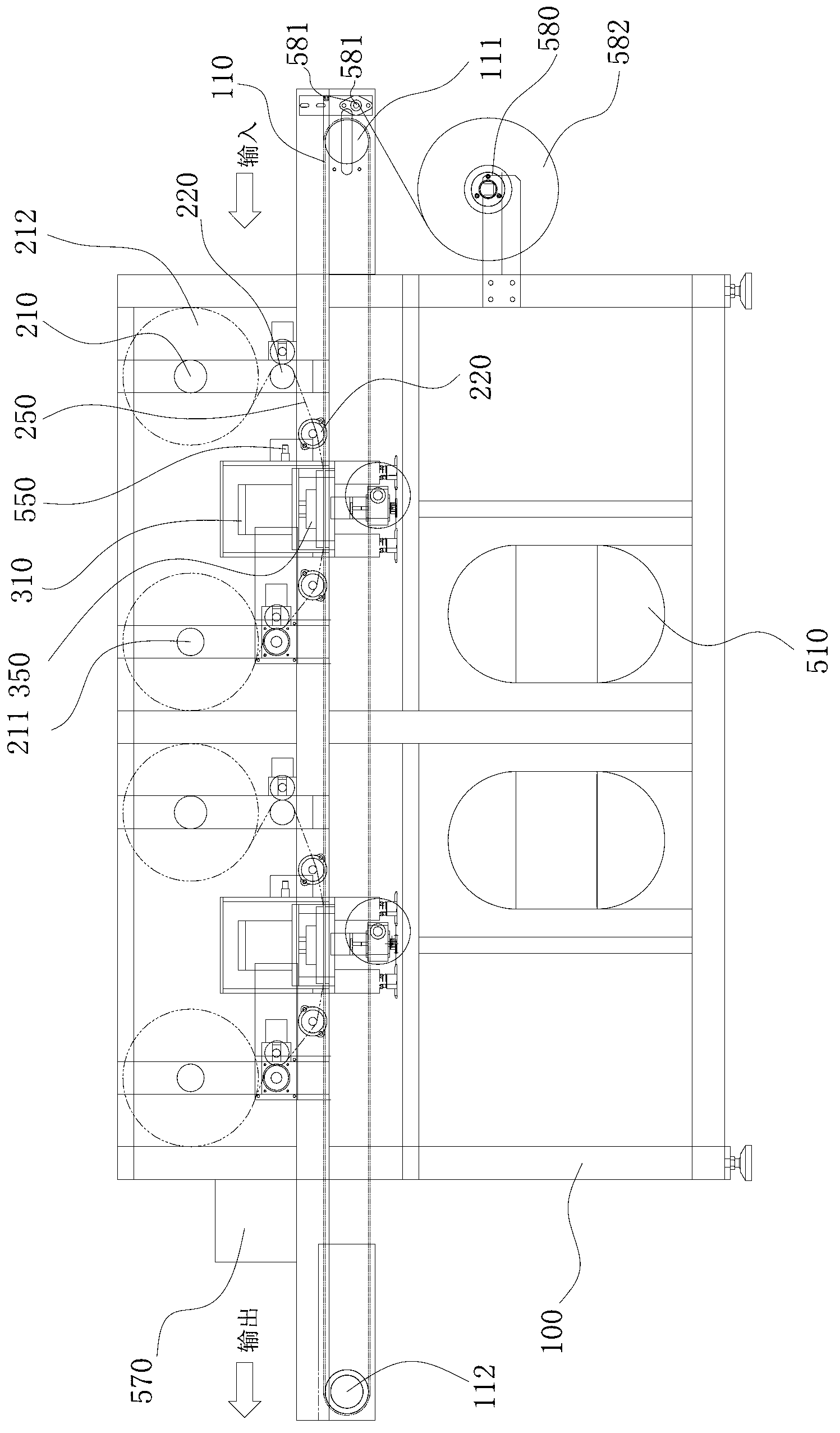

Ultrasonic automatic food cutting production line

ActiveCN105291156AUniform size cutShorten the production cycleMetal working apparatusProduction lineUltrasonic vibration

The invention discloses an ultrasonic automatic food cutting production line. The ultrasonic automatic food cutting production line comprises a machine table, a food conveying belt, a position where food is placed by hand, a food positioning baffle, a transverse cutting station, a first transverse cutting sliding assembly, a first ultrasonic cutting mechanism, a front and rear waste material pushing combination mechanism, a vertical cutting station, a longitudinal cutting sliding assembly, a second transverse cutting sliding assembly, a third transverse cutting sliding assembly, a second ultrasonic cutting mechanism, an automatic left and right waste material pushing combination mechanism and a finished product conveying belt. By means of the ultrasonic automatic food cutting production line, reference positioning of food can be achieved, food can be conveyed, and remaining waste materials on the edges of front food and rear food can be full automatically recycled through the front and rear waste material pushing combination mechanism; remaining waste materials on the edges of left food and right food can be full automatically recycled through the left and right waste material pushing combination mechanism; finished food is conveyed through the finished product conveying belt and is full automatically discharged; the intelligent degree of the production line is high; an ultrasonic vibration steel wire or blade is arranged and can be used for cutting food in a layered manner, and efficiency is high; and compared with the prior art, manpower does not need to participate in operation in the whole process, a cutting mold does not need to be replaced, and cost is low.

Owner:DONGGUAN BRDASON ULTRASONIC EQUIP CO LTD

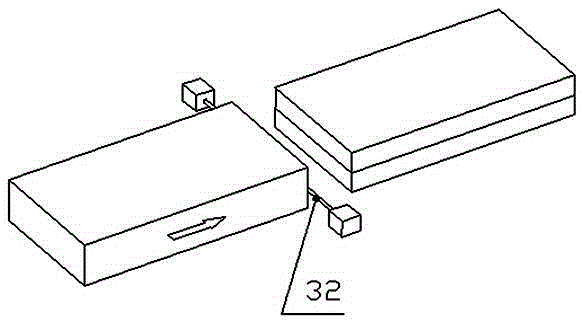

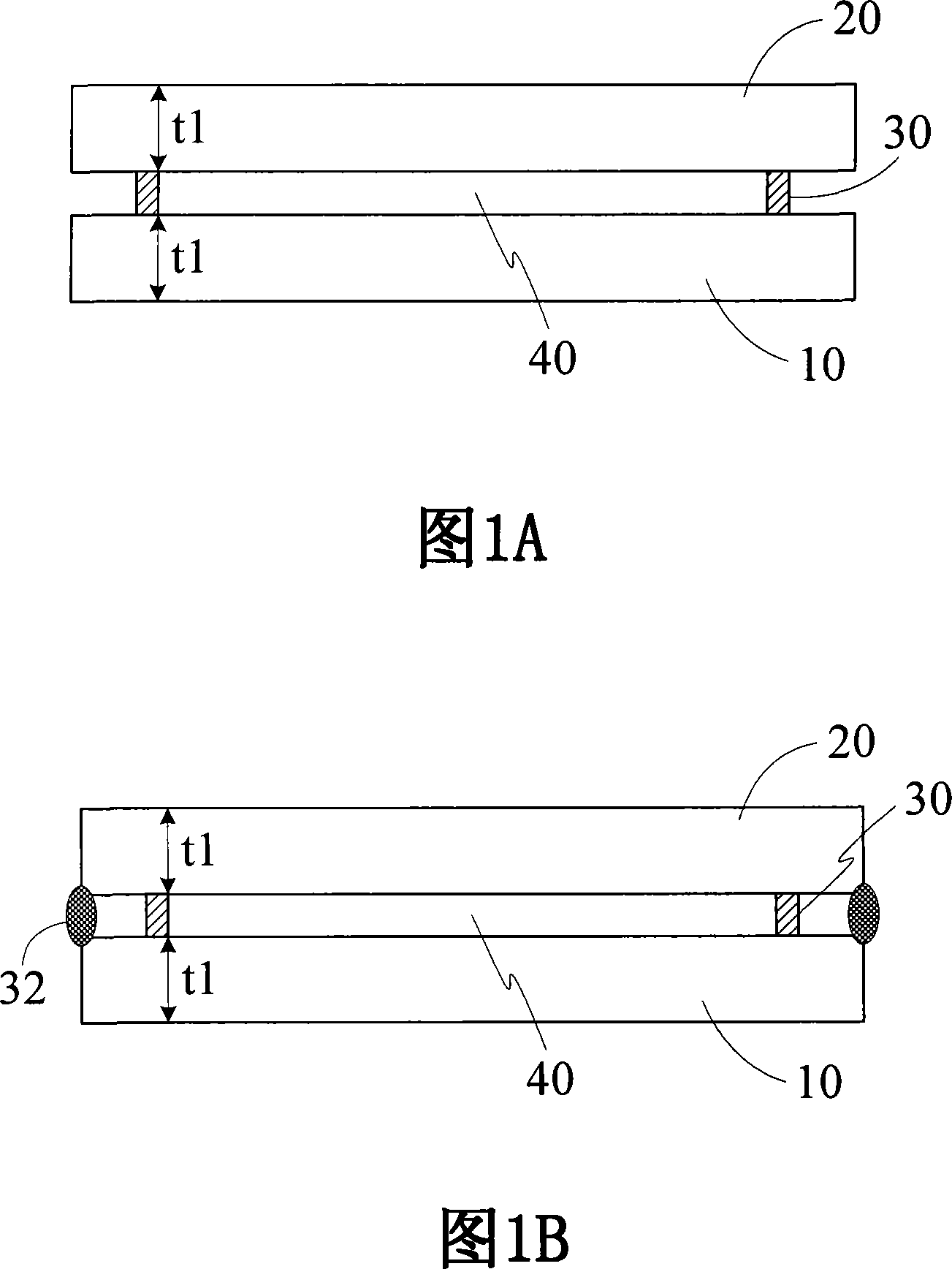

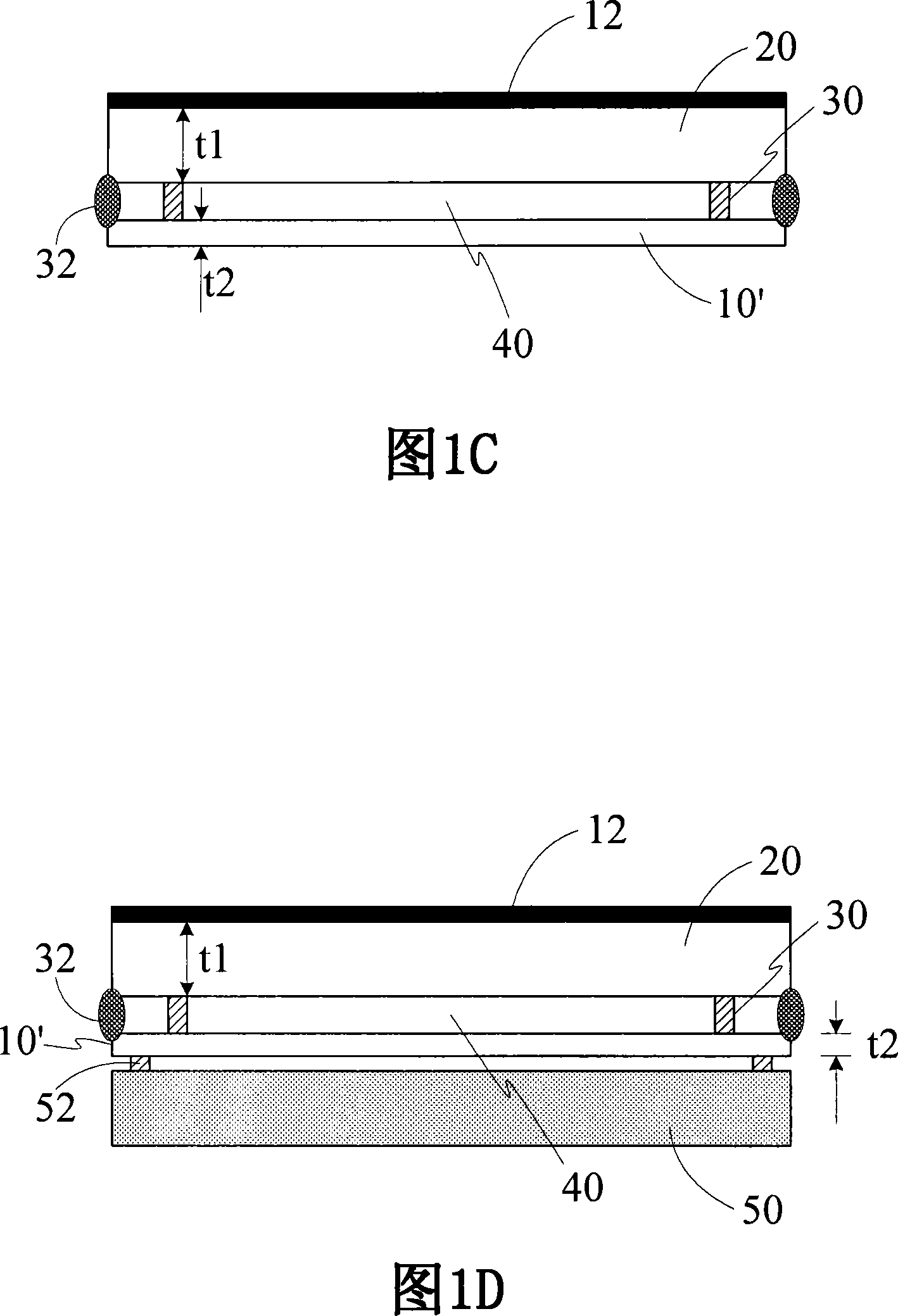

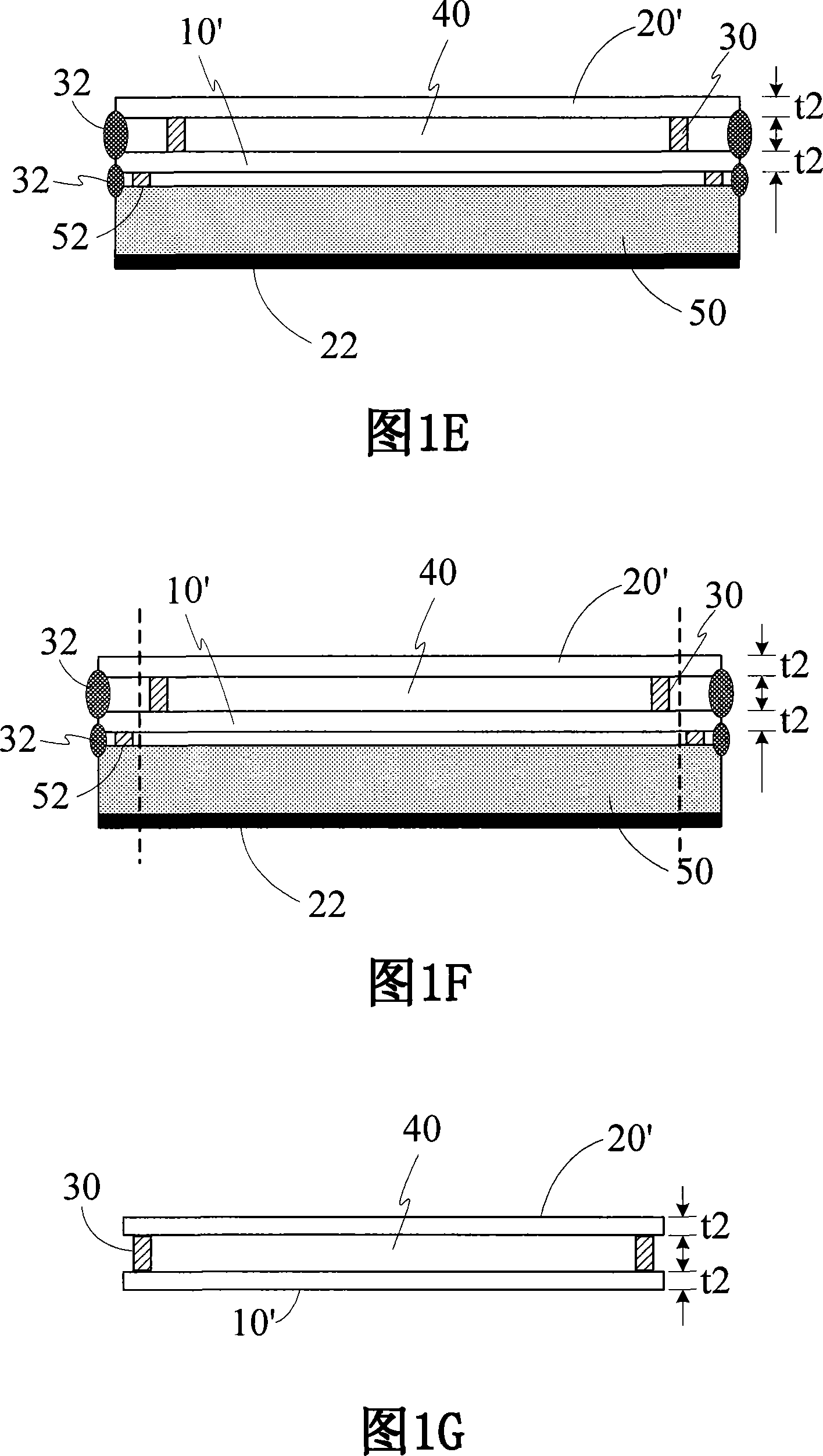

Method for thinning display panel device

InactiveCN101201490AReduce thicknessGood thinning effectEdge grinding machinesNon-linear opticsDisplay deviceThinning

The invention relates to a method for thinning a display panel device; the display panel device comprises a first substrate and a second substrate. The method for thinning the display panel device comprises the following steps: firstly, the first substrate is thinned and the thinned first substrate is supported by a bearing device, secondly, the second substrate is thinned. The manufacturing method of the invention can provides better thinning effect and can meet the requirement of mass production.

Owner:AU OPTRONICS CORP

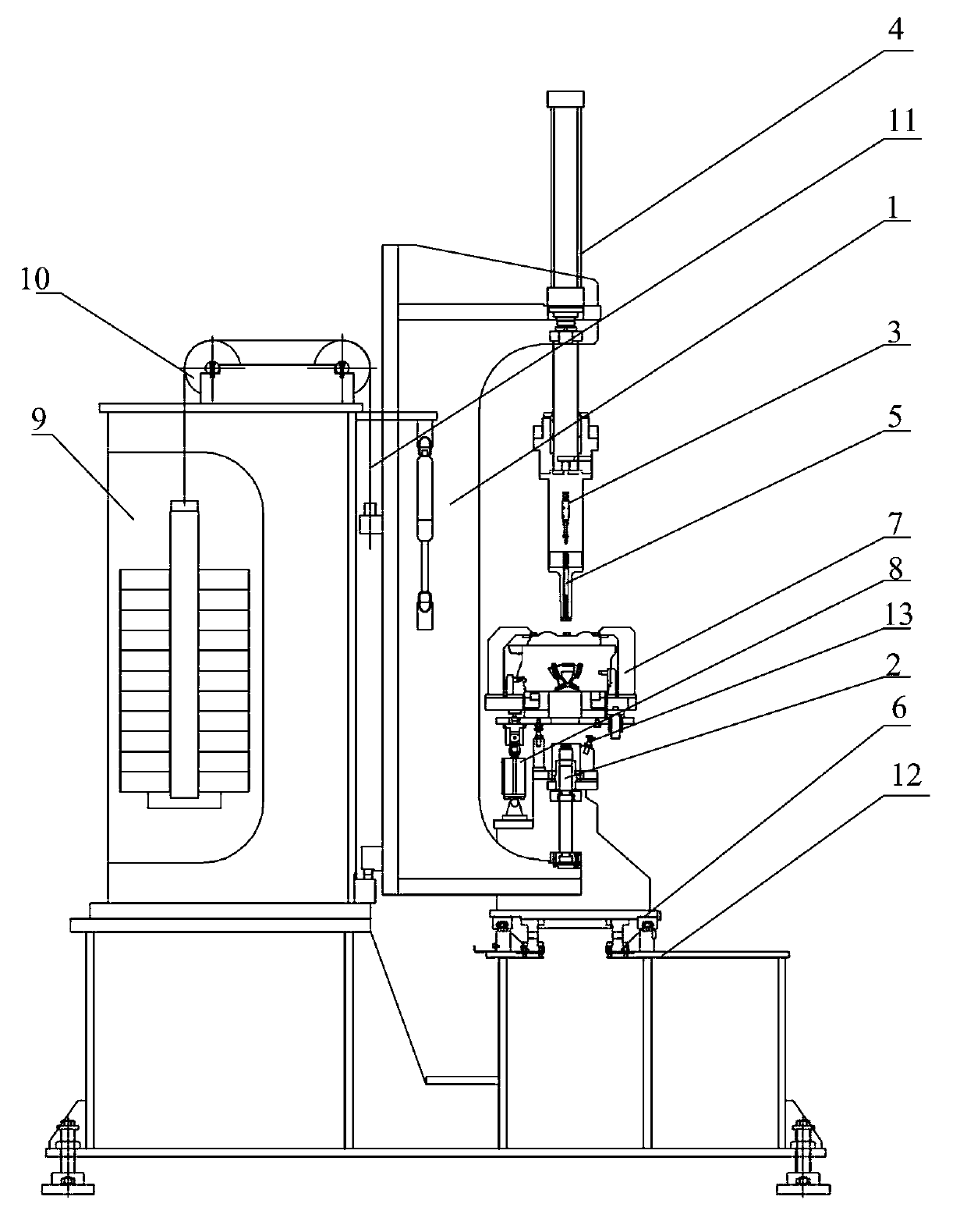

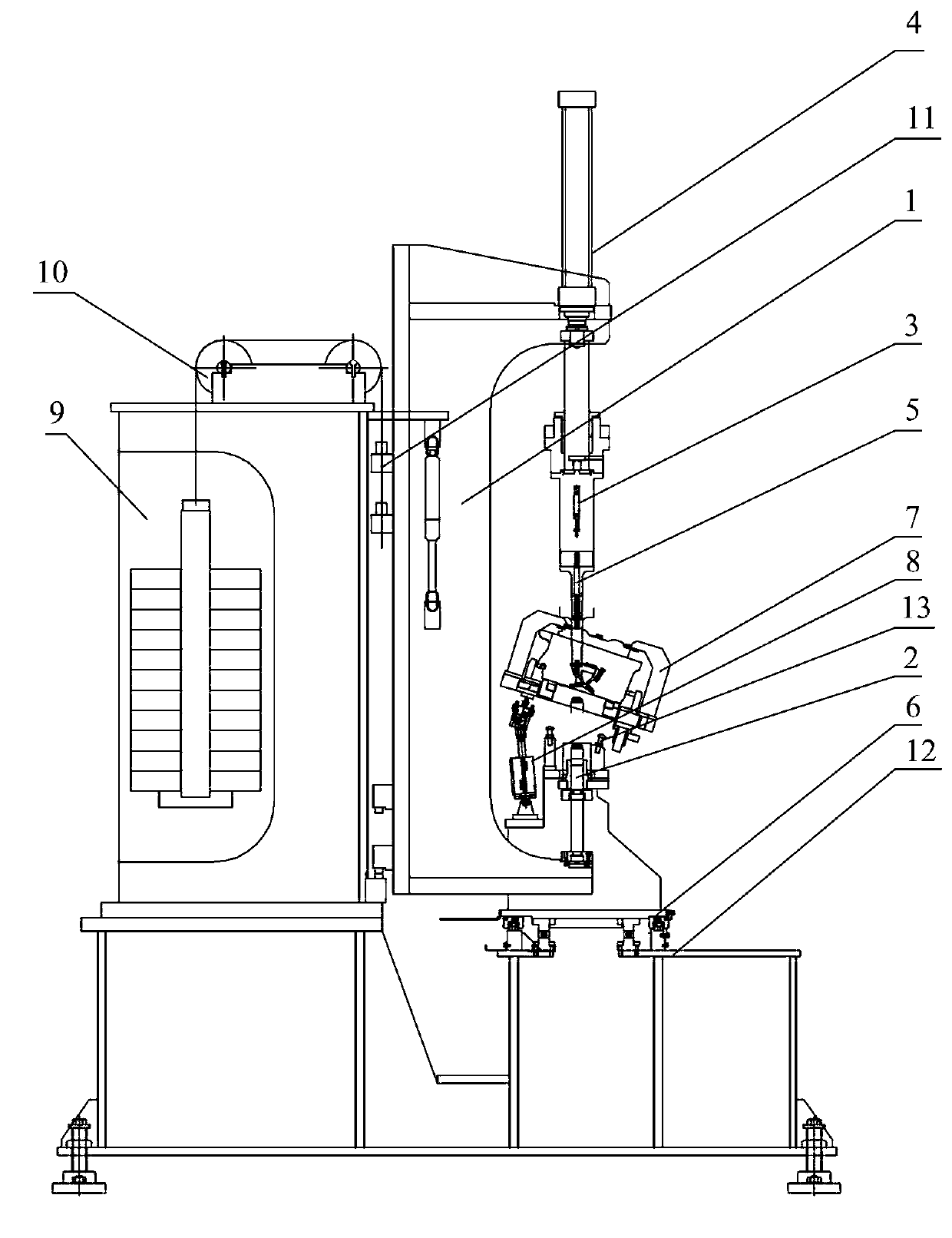

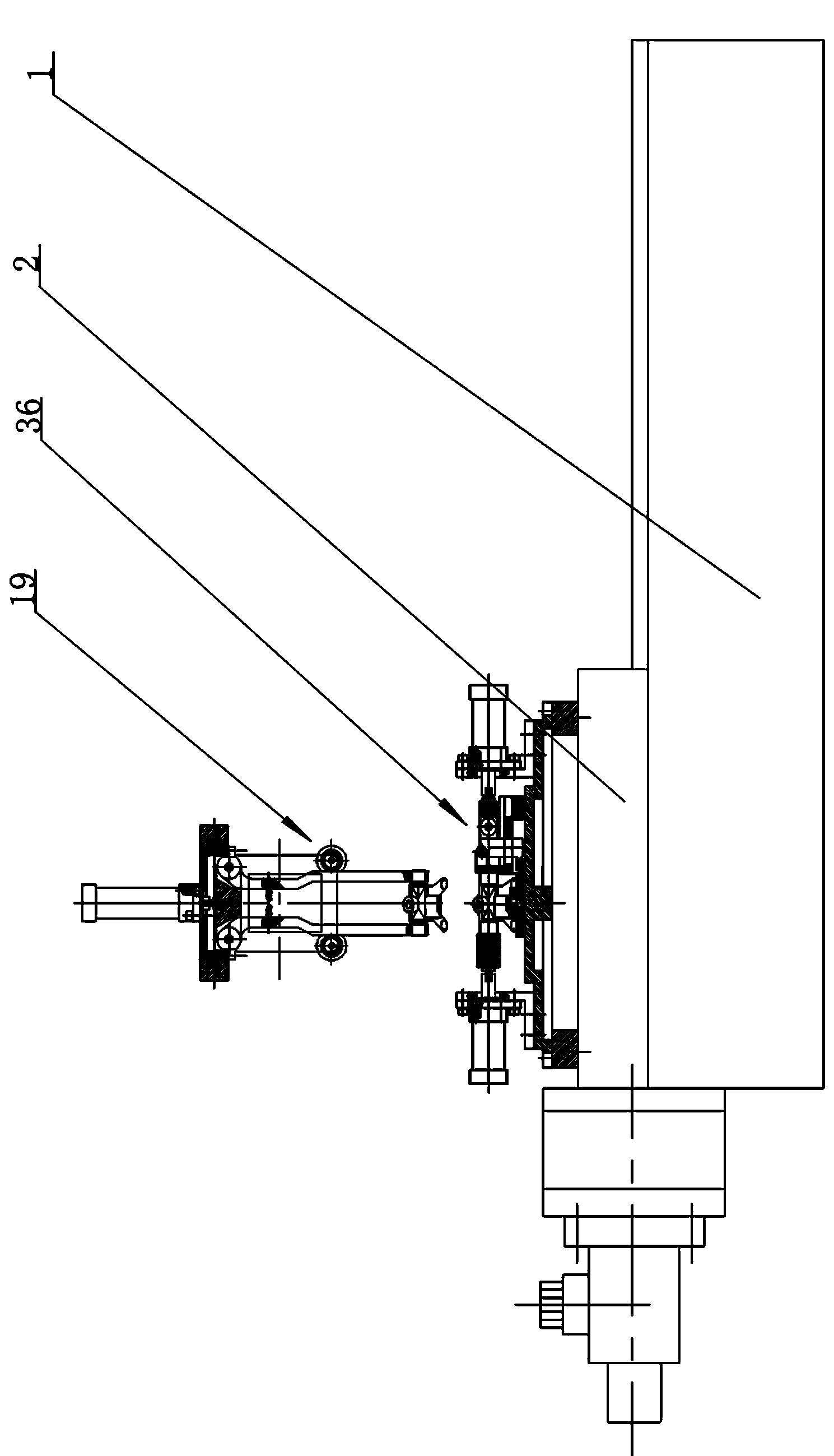

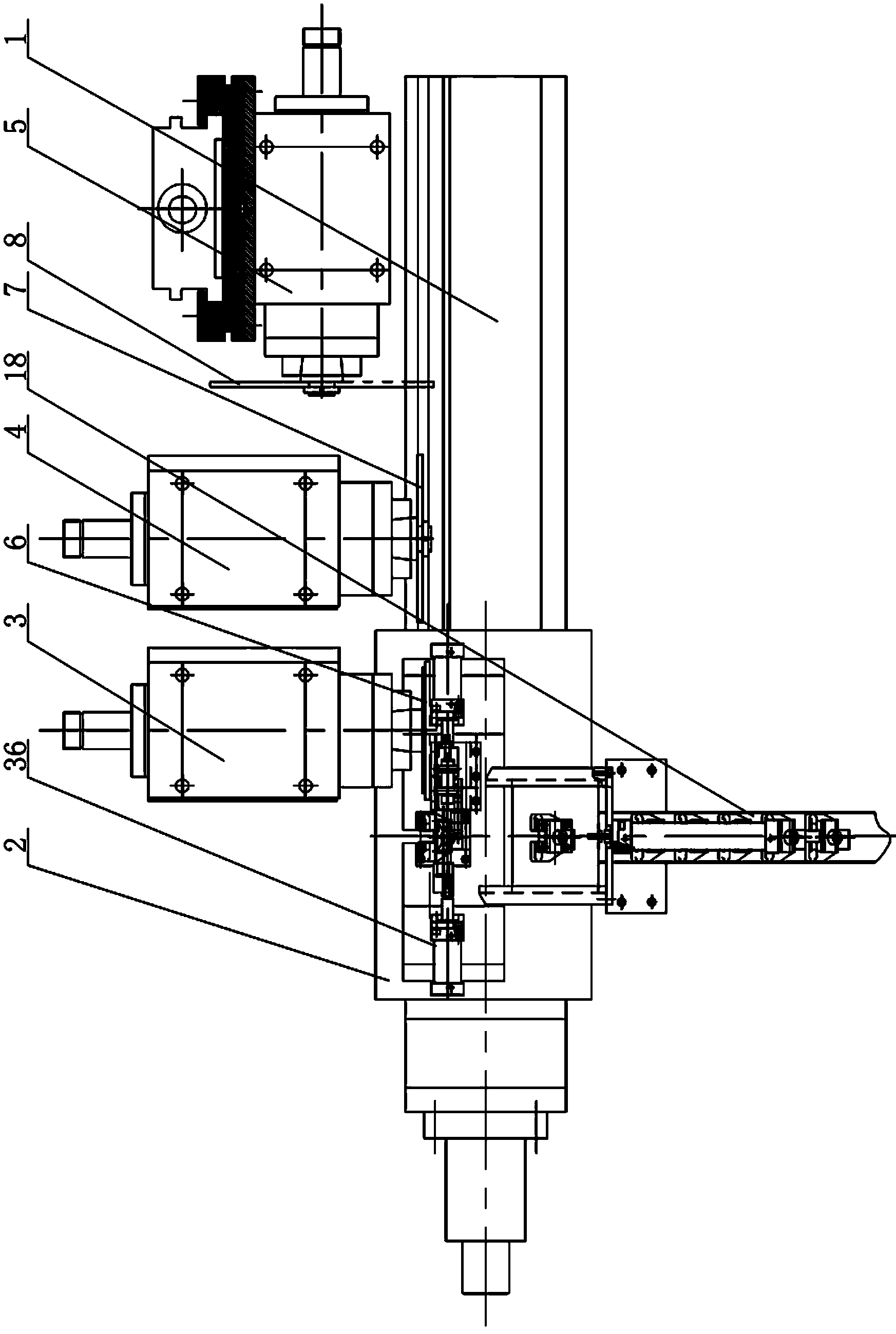

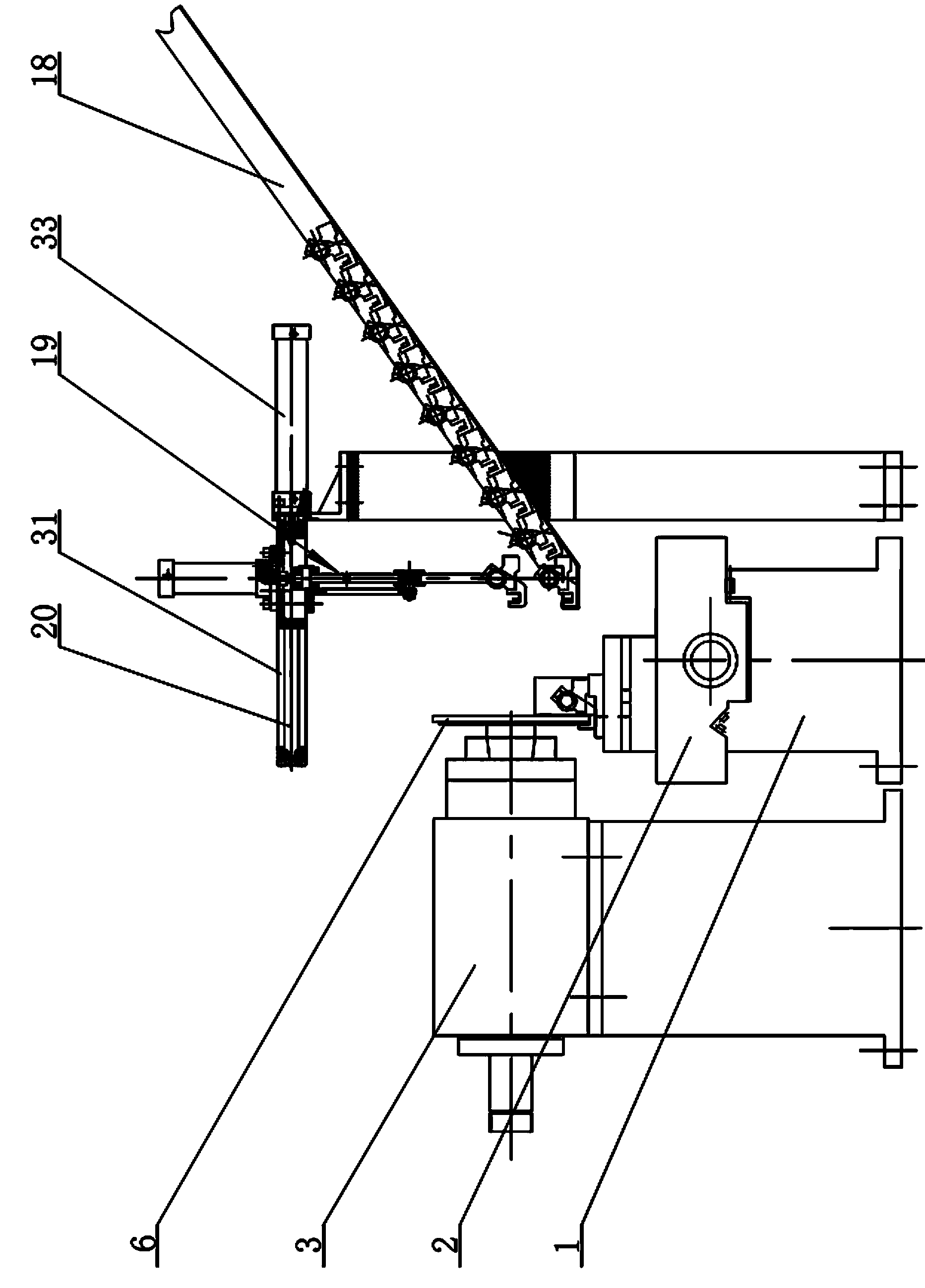

Automatic automobile shifting fork machining machine tool

InactiveCN103920918ARealize automatic processingMeet the needs of mass productionMilling equipment detailsMetal working apparatusBatch productionEngineering

The invention relates to an automatic automobile shifting fork machining machine tool which mainly solves the problems that conventional automobile shifting fork machining equipment is low in production efficiency, the product quality is difficultly controlled, the machining cost is high and automation is difficultly realized. The automatic automobile shifting fork machining machine tool is characterized in that a numerical control sliding table (2) which slides along a machine tool body (1) is arranged on the machine tool body (1); a first milling power head (3), a second milling power head (4) and a third milling power head (5) are arranged on one side of the machine tool body (1); a pneumatic tool (36) is arranged on the numerical control sliding table (2); a workpiece conveying slideway (18), a pneumatic mechanical hand (19) and a sliding rack (20) are arranged on one side of the numerical control sliding table (2); the pneumatic mechanical hand (19) can lift up and down and move horizontally. By adoption of an automatic clamping tooling, the pneumatic mechanical hand and the numerical control sliding table, automatic production is realized, the production efficiency and product quality are improved, the machining cost is reduced, and the requirement of batch production of automobile shifting forks is met.

Owner:珠海市金蓝五金机电设备有限公司

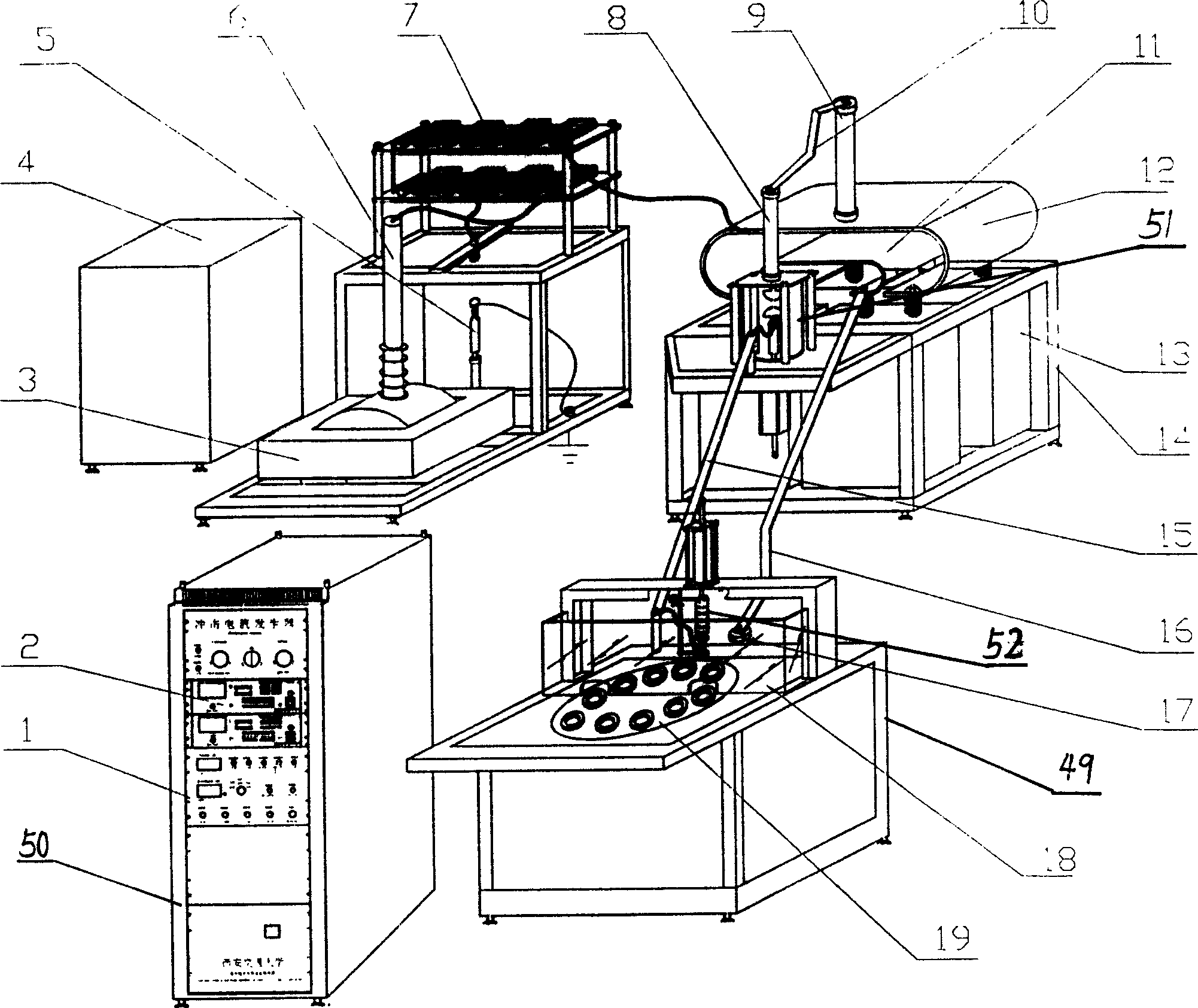

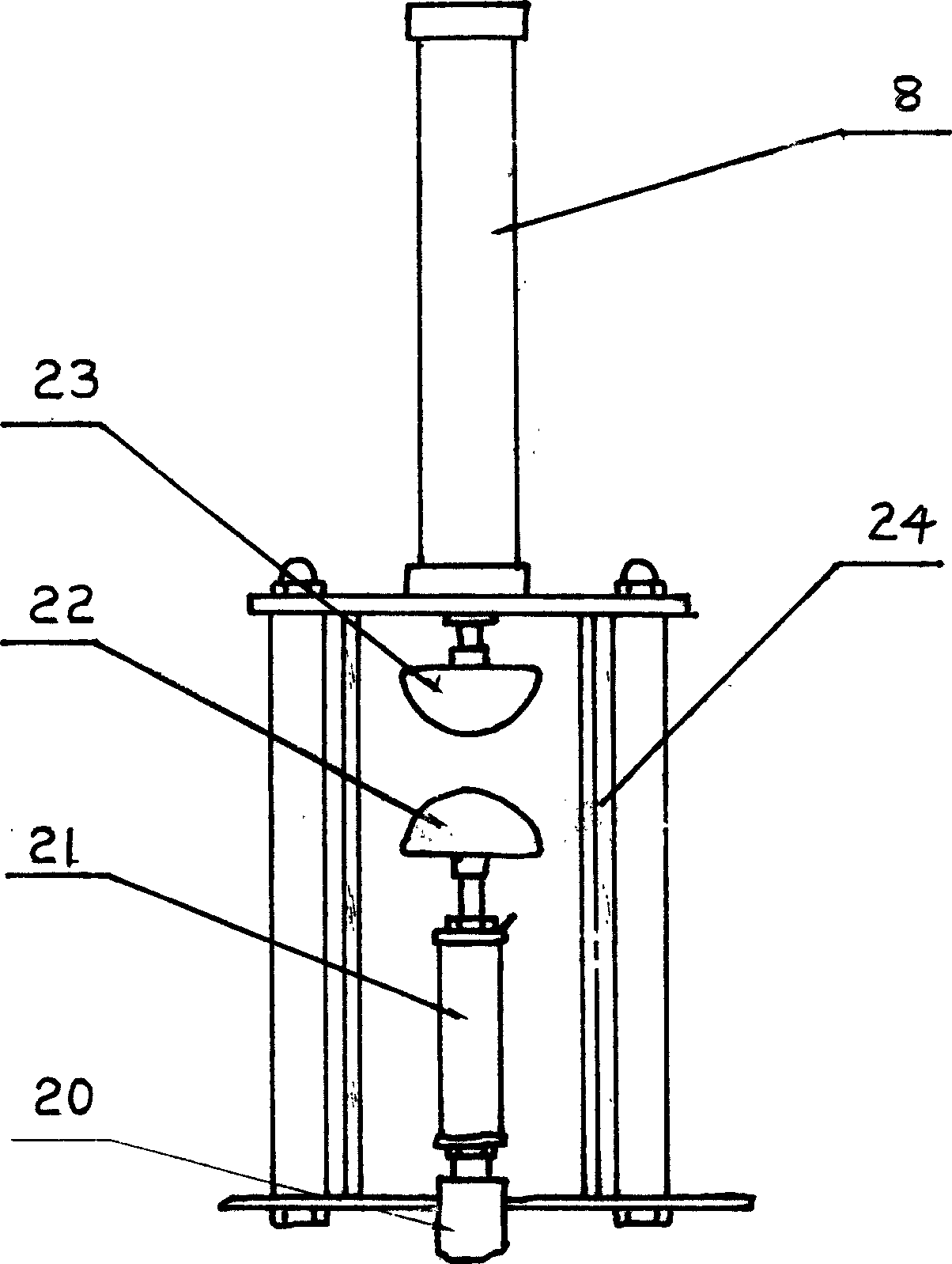

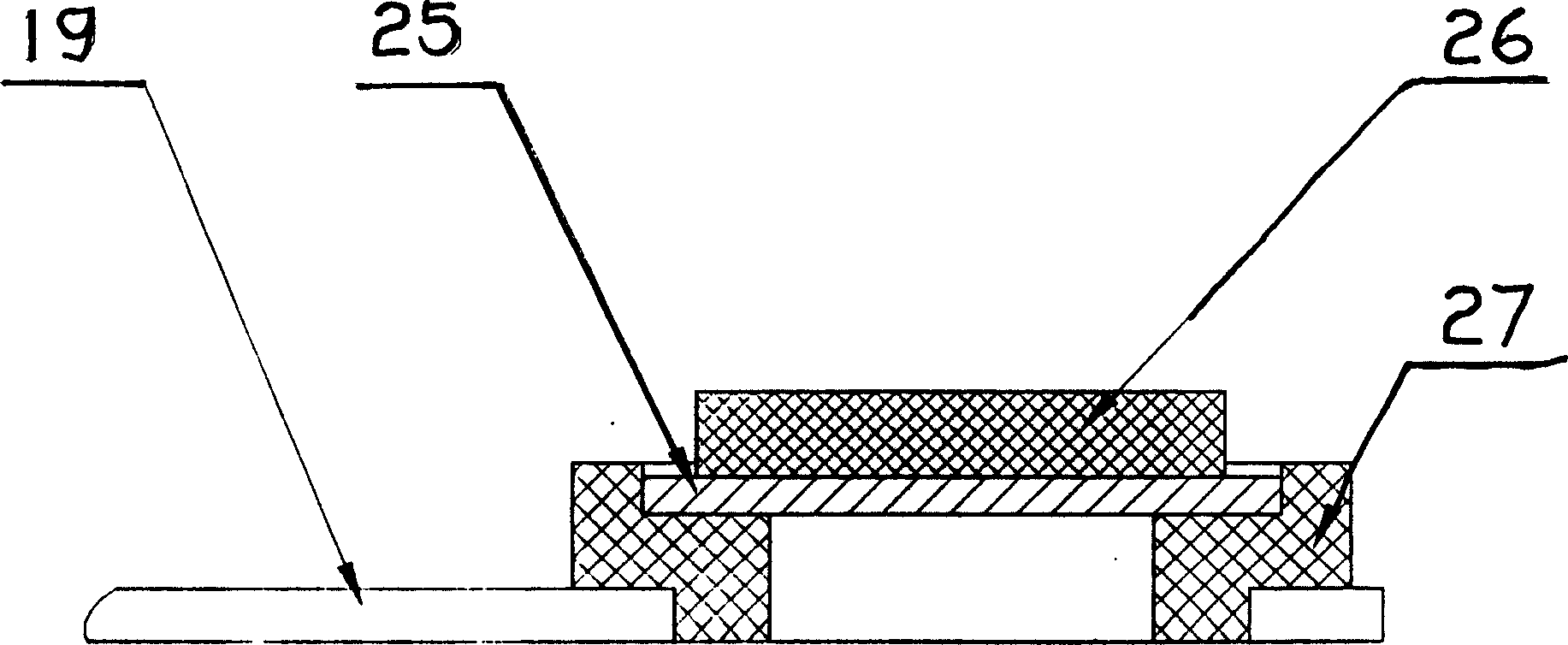

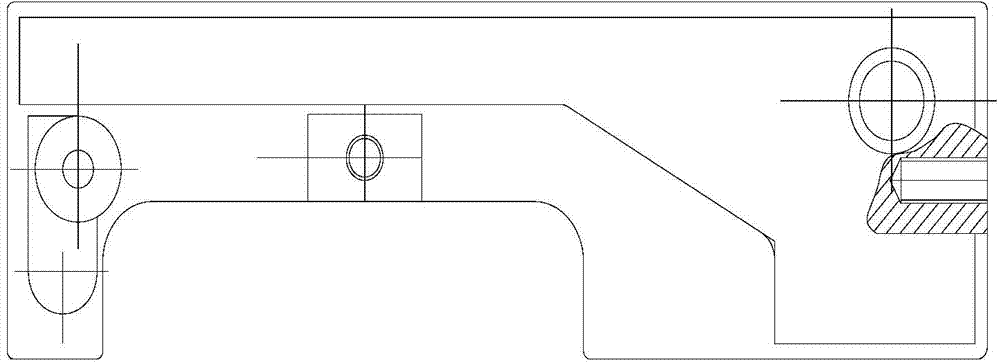

Device for measuring impulse current of non-linear metal oxide resistor disc

InactiveCN1560641AMeet the needs of mass productionFast surge current electrical performance automatic testResistance/reactance/impedenceCapacitanceMetal framework

The invention is a impacting current testing device based on nonlinear metal oxide resistance plate, which includes a energy storing component arranged in the metal frame and waveform forming resistance, inductance, the conductive metal boards connects the electrodes of the capacitance together, the high voltage end of the capacitance is connected to the discharging device, the discharging device is connected to the high voltage end of testing electrode on the transmitting mechanism of the resistance plate, the transmitting mechanism uses step-by-step motor to drive the metal turnplate, when the resistance plate rotates the position of the clamping piece mechanism, the metal turnplate stops automatically, the piece clamping mechanism act automatically. When the piece clamping mechanism measures that there has resistance plate, the discharging gas is connected automatically, completes one discharging process. The invention has merits of automatic localization, automatic discharging, and automatic grounding functions.

Owner:XI AN JIAOTONG UNIV

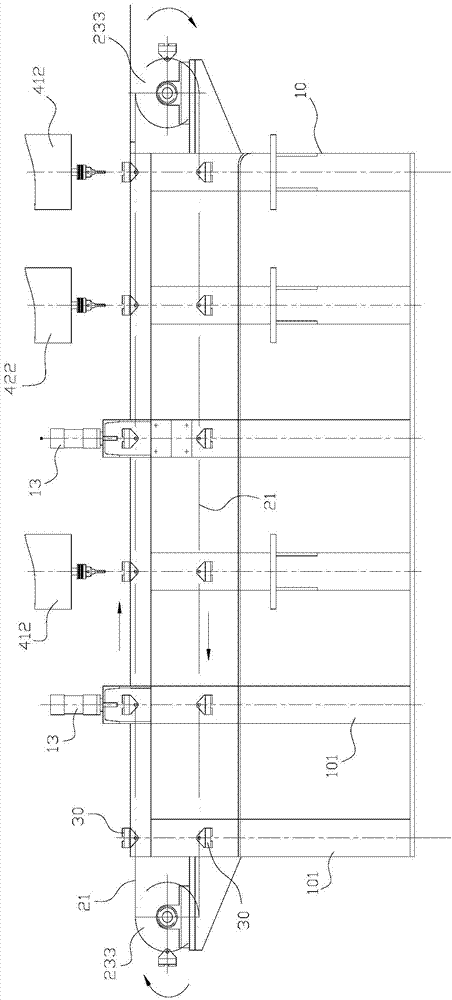

Full-automatic drilling production line and production process thereof

InactiveCN103753217ANo offsetEnsure accuracy andOther manufacturing equipments/toolsProduction lineMotor drive

The invention discloses a full-automatic drilling production line and a production process thereof. The full-automatic drilling production line is used for performing drilling or tapping treatment on workpieces. The full-automatic drilling production line comprises a frame, a conveying device, a plurality of carriers, a drilling device and a tapping device, wherein a bearing platform is arranged on the frame; the conveying device is arranged on the frame, and comprises a conveyor belt and a stepping motor, and the stepping motor drives the conveyor belt to run; the plurality of carriers are used for holding the workpieces, and arranged on the conveyor belt at intervals; the tapping device comprises a drilling machine and a first push mechanism, and the tapping device is arranged on the frame and used for drilling the workpieces on the carriers; the tapping device comprises a tapper and a second push mechanism, and the tapping device is arranged on the frame and located behind the drilling device, and used for tapping the drilled workpieces on the carriers. The full-automatic drilling production line is capable of realizing the production of workpieces with holes (and / or threaded holes) efficiently, accurately and automatically, stable and reliable, and also capable of meeting the requirements of large-scale production.

Owner:GUANGZHOU VOCATIONAL COLLEGE OF SCI & TECH

Novel method for white fungus cultivation

InactiveCN101117621ASolve the contradiction between supply and demandExtended supply timeFungiTremellaPlanting seed

The present invention relates to a planting method of edible fungus, and provides a new method for white fungus planting. The method includes steps as follows: the raw material of a substrate is mixed, bagged and sterilized, the planting seed of white fungus is inoculated and planted, and the grew fungus is picked, the fungus age of the planting seed of the white fungus is 6 to 10 days; the planting steps are described as follows: after being inoculated, the planting seed is planted for 16 days when the planting temperature is 23 to 25 DEG C, adhesive plaster at the opening of an aperture is torn, the aperture is not expanded, after 5 to 6 days, the side of the opening of the aperture of a fungus bag, namely the side of the fungus bag is pulled a crack at the bag film by a blade. The application provides that the most ideal fungus age of the planting seed of white fungus is 6to 10 days, compared with the decided fungus age, the ideal fungus age is shortened 5 to 9 days, thereby quickening the fungus seed supplying time, increasing production amount of fungus seed, efficiently solving the supply and demand contradictory of fungus seed at the midseason for white fungus producing, and meeting the demands for big amount of production. In addition, the new technology that the fungus bag increases oxygen and produces white fungus provided by the application has the advantages of convenient operation, quickened white fungus producing, few pedicel heads of white fungus, and higher quality than the original products.

Owner:钟冬季

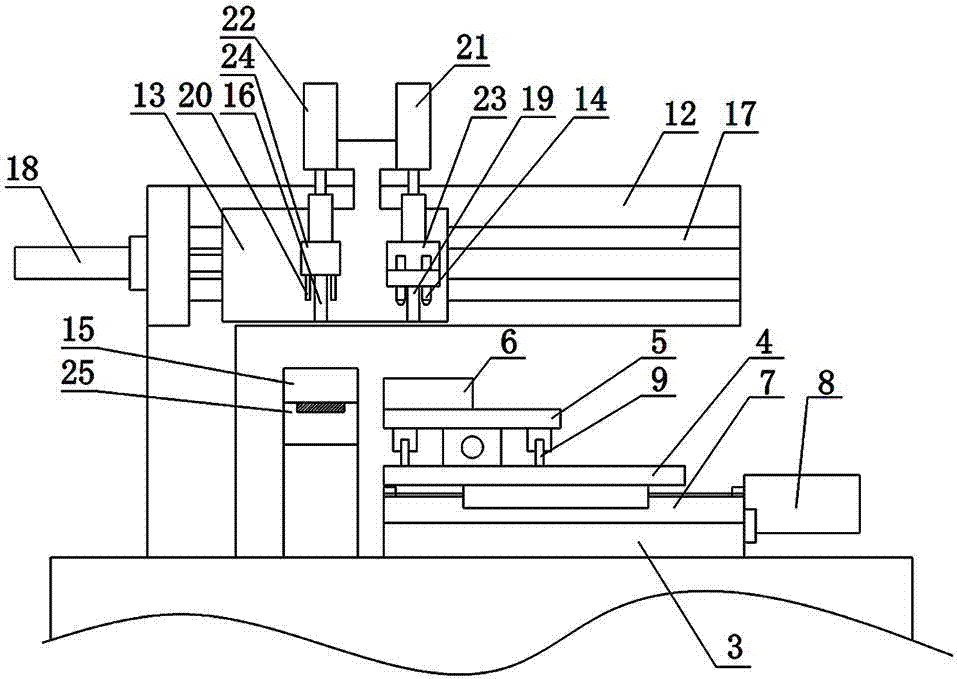

Automatic riveting device

The invention discloses an automatic riveting device which comprises a rack (1), a material belt placing disk (2), a rivet loading device, a riveting and pressing device, a material dragging device and a cutting device. The material belt placing disk (2), the rivet loading device, the riveting and pressing device, the material dragging device and the cutting device are sequentially arranged on the rack (1), the material belt placing disk (2) is installed on the rack (1) through a rotating shaft, the rivet loading device comprises a rivet feeding device and a rivet installing device, a material storing groove (42) is further arranged on the rack (1) at a discharging end of the cutting device, and a discharging guide rail (43) is arranged between the cutting device and a discharging groove and fixedly installed on the rack (1). The automatic riveting device has the advantages of being simple in structure, convenient to use and capable of saving labor costs, reducing labor intensities of operators, achieving full automatic production of loading, installing, riveting and cutting, greatly improving production and processing efficiencies and guaranteeing uniform processing qualities.

Owner:CHENGDU HOMIN TECH

Large-scale breeding method of Borneol Cinnamomum camphora

ActiveCN102630459AGood repeatabilityReduce vitrificationHorticulture methodsPlant tissue cultureDisease damageBiology

The invention relates to a large- scale breeding method of Borneol Cinnamomum camphora. The method comprises the following steps of: breeding a plantlet obtained through unique cuttage treatment by utilizing a current-growth lignified branch of strongly disease-resistant, no pest and disease damage and grown-up seed tree for about one year, acclimatizing, subculturing and propagating a sterile material after obtaining the sterile material with the current germinal sprout as an explant, secondly carrying out strong seeding rootage cultivation, and finally cultivating seeding in a greenhouse. According to the method disclosed by the invention, induced, propagated, strengthened and rooting culture mediums are optimized and improved, the stable growth of the sterile material can be effectively ensured, the sizes of sprouts are uniform, vitrification or defoliation of a tissue culture seedling can be avoided, the strong tissue culture seedlings can be obtained for sure, the repeatability is strong, an acclimation period and a subculture period are stable, a browning situation is reduced, a propagation coefficient is improved, the survival rate of planting in a greenhouse is improved, asubculture block mass cutting method determines the growth and the propagation coefficient of later-stage materials and can meet requirements of large-scale production.

Owner:SUNSHINE HORTICULTURE

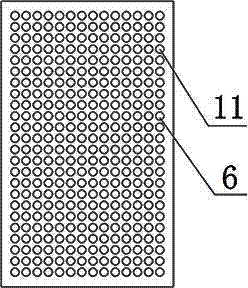

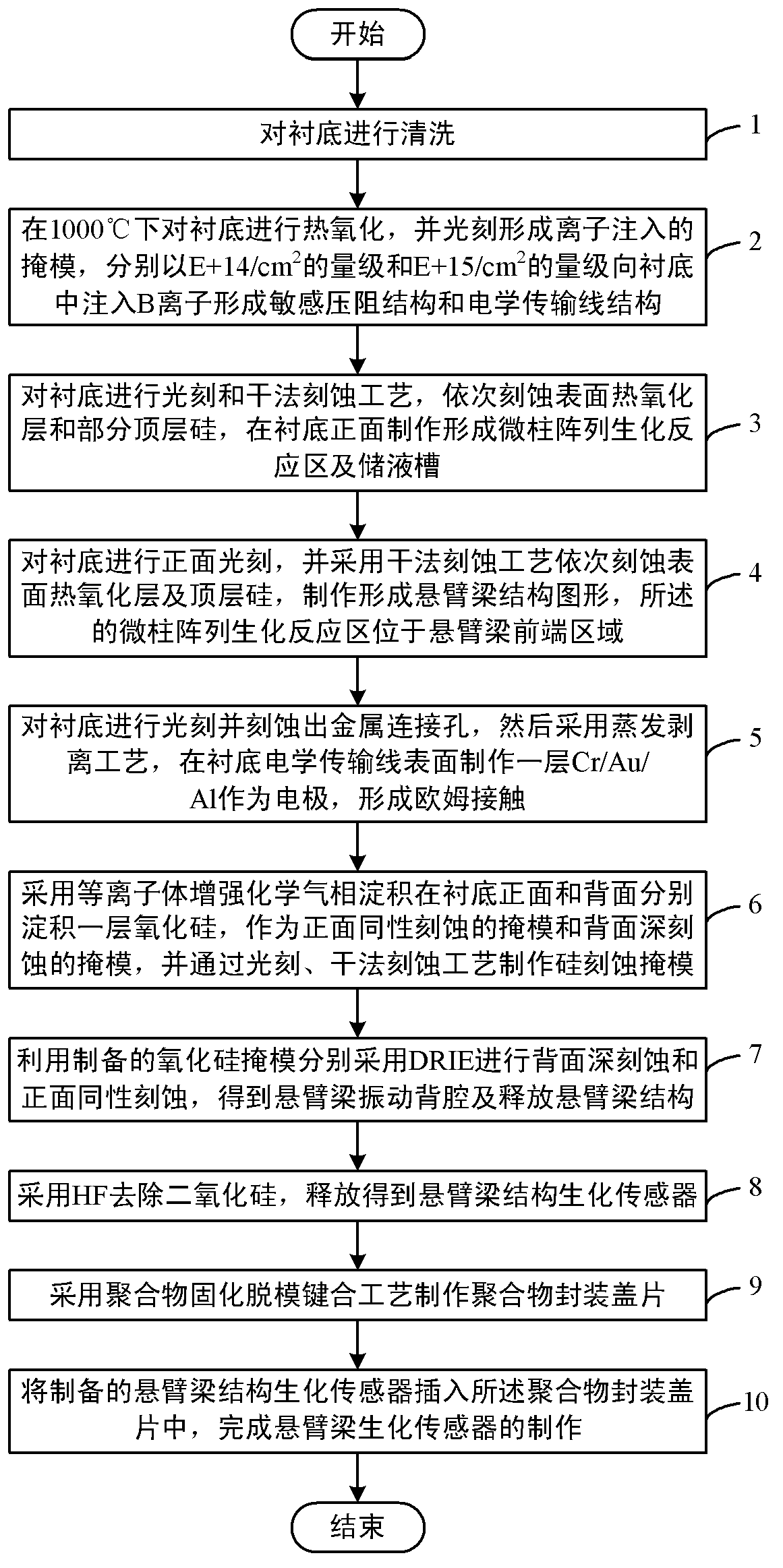

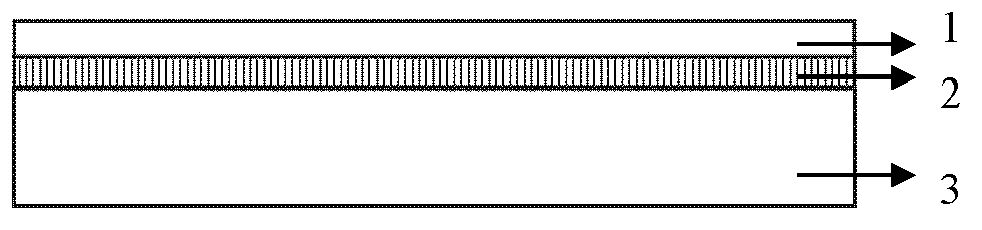

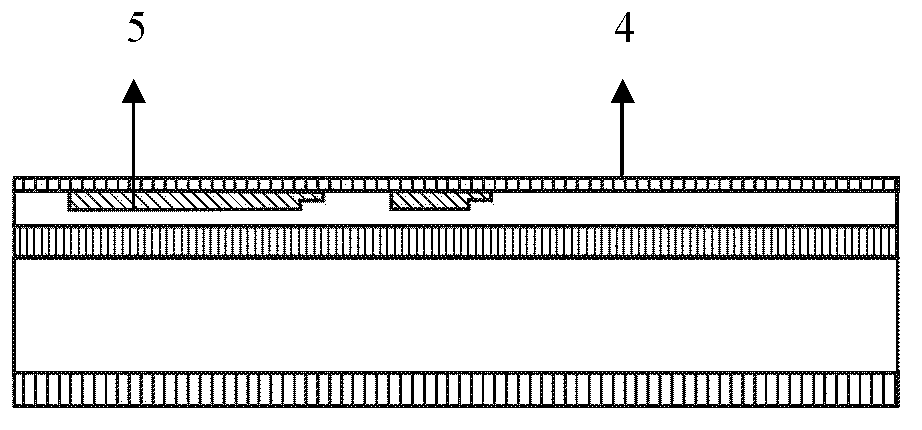

Production method of high-sensitivity biochemical sensor based on resonance type micro-cantilever structure

ActiveCN103303862AHigh sensitivityRealize high-precision mass productionPrecision positioning equipmentDecorative surface effectsResistive sensorsMicro nano

The invention discloses a production method of a high-sensitivity biochemical sensor based on a resonance type micro-cantilever structure. The biochemical sensor is produced on a silicon substrate by using a micro-nano processing technology and taking a cantilever as a structural unit, namely the cantilever and an affiliated structure thereof are produced on a silicon slice by using a photoetching technology and a dry etching technology; an electrical induction element is produced by using an ion injection technology and an electronic beam evaporation technology, so that the element has a function of self-detecting a detection signal; a package cover slice is produced by a design die by a polymer solidifying, demolding and bonding technology. According to theproduction method, the production precision and the yield of the high-sensitivity biochemical sensor are greatly improved; the production method can be used for producing the sensors on a large scale; the production cost is effectively reduced. Moreover, the production method can be also applied to production of micro-electromechanical system (MEMS) devices with other structures, such as a double-end fixed supporting structure, a interdigital accelerator and other capacitance and resistance type sensors.

Owner:INST OF SEMICONDUCTORS - CHINESE ACAD OF SCI

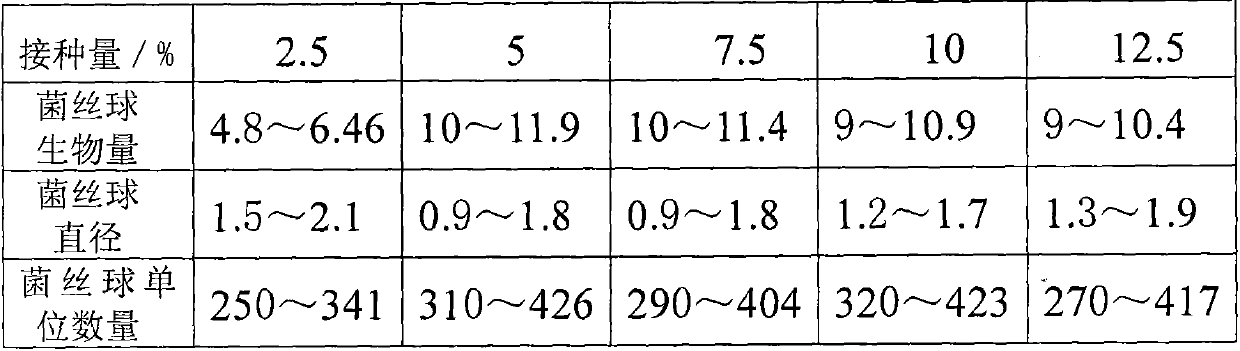

Agaricus Bisporus liquid spawn and preparation method thereof

InactiveCN103782801ASolve the problem of prone to aging and degenerationPromote growthHorticultureSucroseMonopotassium phosphate

The invention discloses an Agaricus Bisporus liquid spawn and a preparation method thereof. The Agaricus Bisporus liquid spawn is produced by means of three-level propagation through slant and shake-flask media and a fermenter medium. The slant and shake-flask media comprise components including 100-200g of potato, 50-150g of cow dung, 10-30g of glucose, 1-2.5g of mono potassium phosphate, 0.5-2g of magnesium sulfate and 1-4g of peptone; the fermenter medium of every 50 liters of water is composed of 2-4kg of potato, 1-3kg of cow dung, 0.5-1kg of bran, 0.2-0.4 kg of corn powder, 0.5-1kg of sucrose, 30-60g of mono potassium phosphate, 20-30g of magnesium sulfate, 120-150 mg of vitamin B and 40-50g of defoamer. By application of the Agaricus Bisporus liquid spawn and the preparation method thereof, the problem that mycelia are prone to aging and degradation during growth is solved; the liquid spawn is of globular mycelia with uniform age, high activity and fast running; a high-running spawn center is formed after the liquid spawn is inoculated to solid media, with uniform fruiting achieved; the preparation cost is only one-tenth of that of solid spawn; the growth cycle of fermenter spawn is 7-9 days, and thus spawns on a large scale can be cultured within a short time.

Owner:CHAOYANG XINYUAN AGRI DEV

Making process of stainless steel belt for composite aluminium-steel contact rail

InactiveCN101020283AQuality improvementImprove performanceShearing machinesOther manufacturing equipments/toolsPunchingSteel belt

The present invention discloses the making process of stainless steel belt for composite aluminum-steel contact rail. The making process includes the following steps: uncoiling stainless steel belt, flattening, punching surface holes, gradual cold bending to form in a special cold bending apparatus and cutting to required size. The present invention has reasonable technological process, continuous production, high product quality, high production efficiency and other advantages.

Owner:南京赛彤铁路电气化有限公司

Equipment for welding vertical rod and buckling disc of scaffold and method for welding scaffold

InactiveCN102672401AImprove machining accuracyIncrease productivityWelding/cutting auxillary devicesAuxillary welding devicesHigh volume manufacturingWelding

The invention discloses equipment for welding a vertical rod and a buckling disc of a scaffold and a method for welding the scaffold. The welding equipment comprises a machine frame, wherein a vertical rod positioning mechanism and a buckling disc positioning mechanism are arranged on the machine frame respectively; a welding device is arranged above the buckling disc positioning mechanism; and a power mechanism for driving a vertical rod to rotate by the vertical rod positioning mechanism is also arranged on the machine frame. According to the equipment for welding the vertical rod and the buckling disc of the scaffold, the vertical rod and a buckling disc are clamped and positioned by the vertical rod positioning mechanism and the buckling disc positioning mechanism, the lateral surface of connecting the buckling disc and the vertical rod is welded by utilizing a welding device, and the vertical rod is driven to turn over automatically by the power mechanism, so that manual welding is replaced, the machining accuracy and production efficiency are improved, and the requirement of batch production is met.

Owner:开平市鹏峰金属棚架厂

Automatic press-fitting unit for shaft retainer rings

ActiveCN103465003AReduce labor intensityMeet the needs of mass productionMetal working apparatusEngineeringControl system

The invention discloses an automatic press-fitting device for shaft retainer rings. The automatic press-fitting device comprises a press-fitting unit, a conveying device, a support device, a pusher, and a control system. The automatic press-fitting unit is characterized in that under control of the control system, the shaft retainer rings are accurately conveyed to a press-fitting assembly position one by one through automatic one-by-one conveying with a conveying assembly and ordered pushing with a push assembly; the shaft retainer rings are sleeved to the end of a pressure head by attraction of the magnetized pressure head of the press-fitting assembly along a guide slide post; the shaft retainer rings are finally press-fitted into a retainer ring groove of a workpiece under the punching action of the pressure head and guiding action of the guide slide post; accordingly, the shaft retainer rings are automatically press-fitted. The backward assembly method of mounting shaft retainer rings with manual support pliers is replaced; parts of a brush cutter are automatically assembled; large-scale efficient high yield is achieved; the fast-changing development requirements of the brush cutter industry in China are met.

Owner:SHANDONG HUASHENG PESTICIDE APPL MACHINERY CO LTD

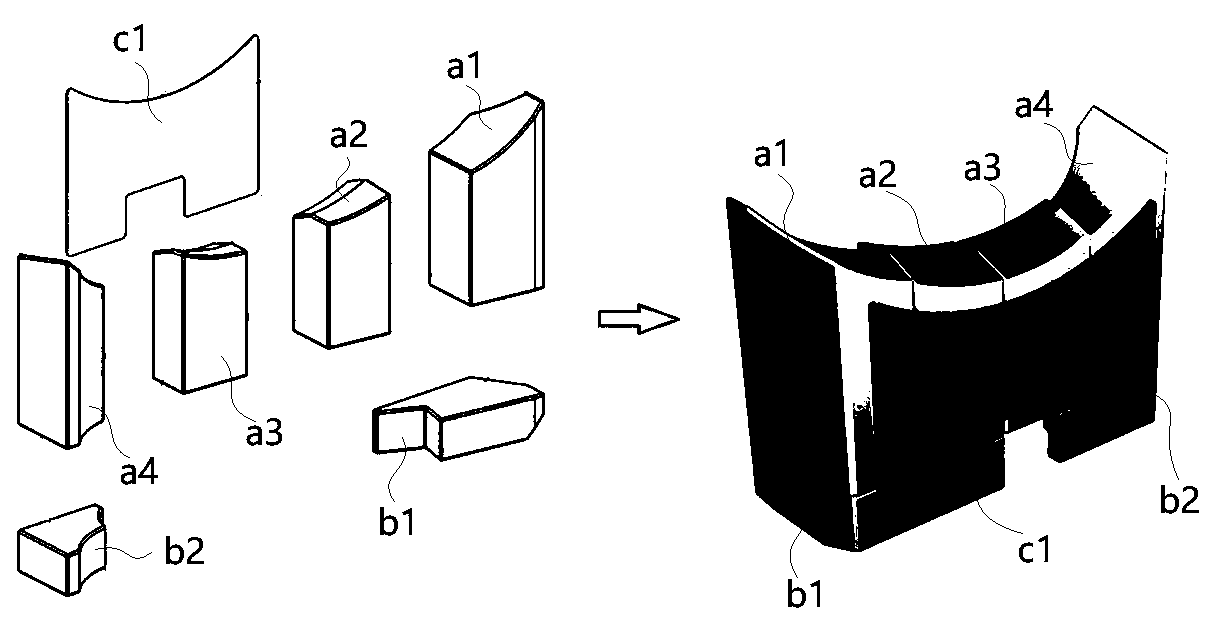

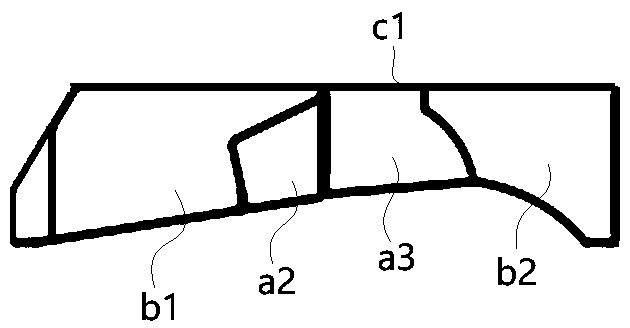

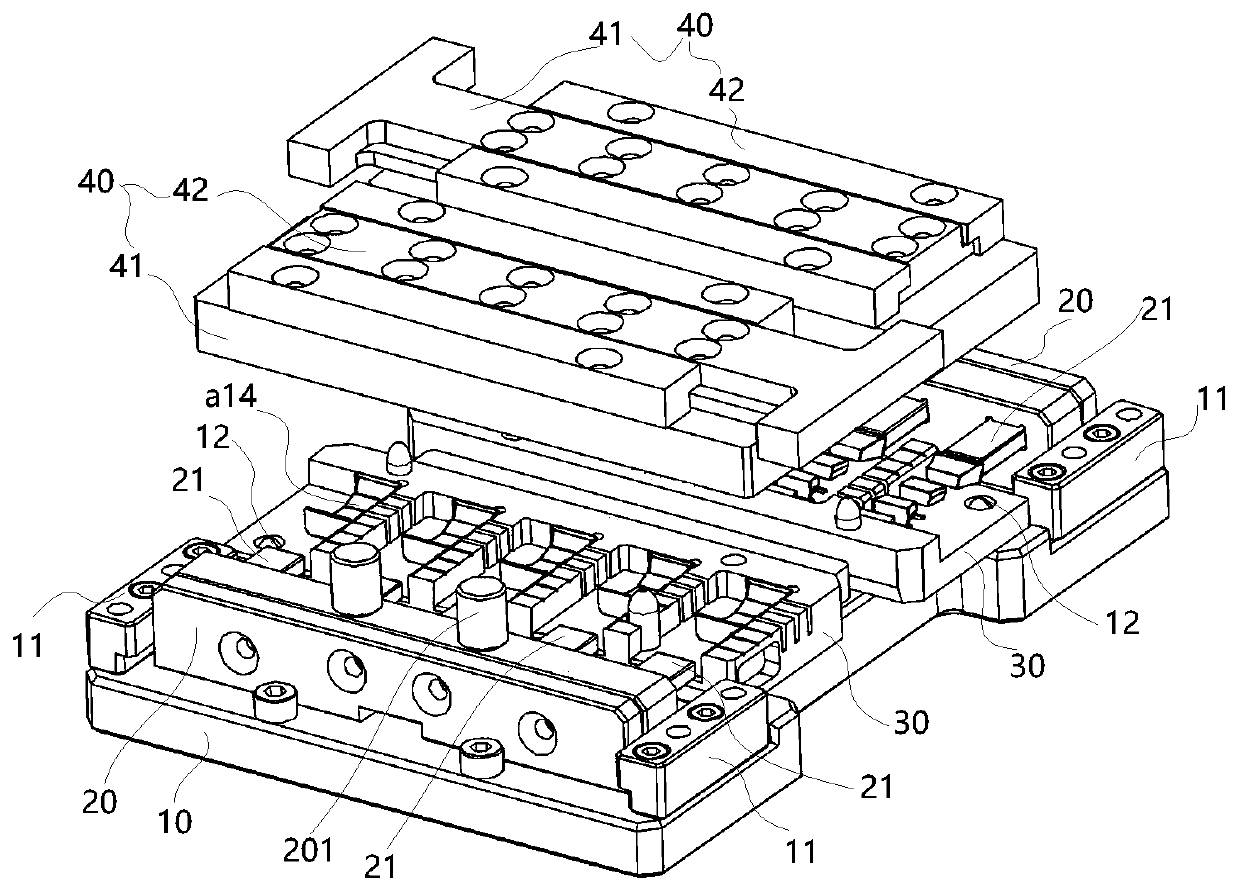

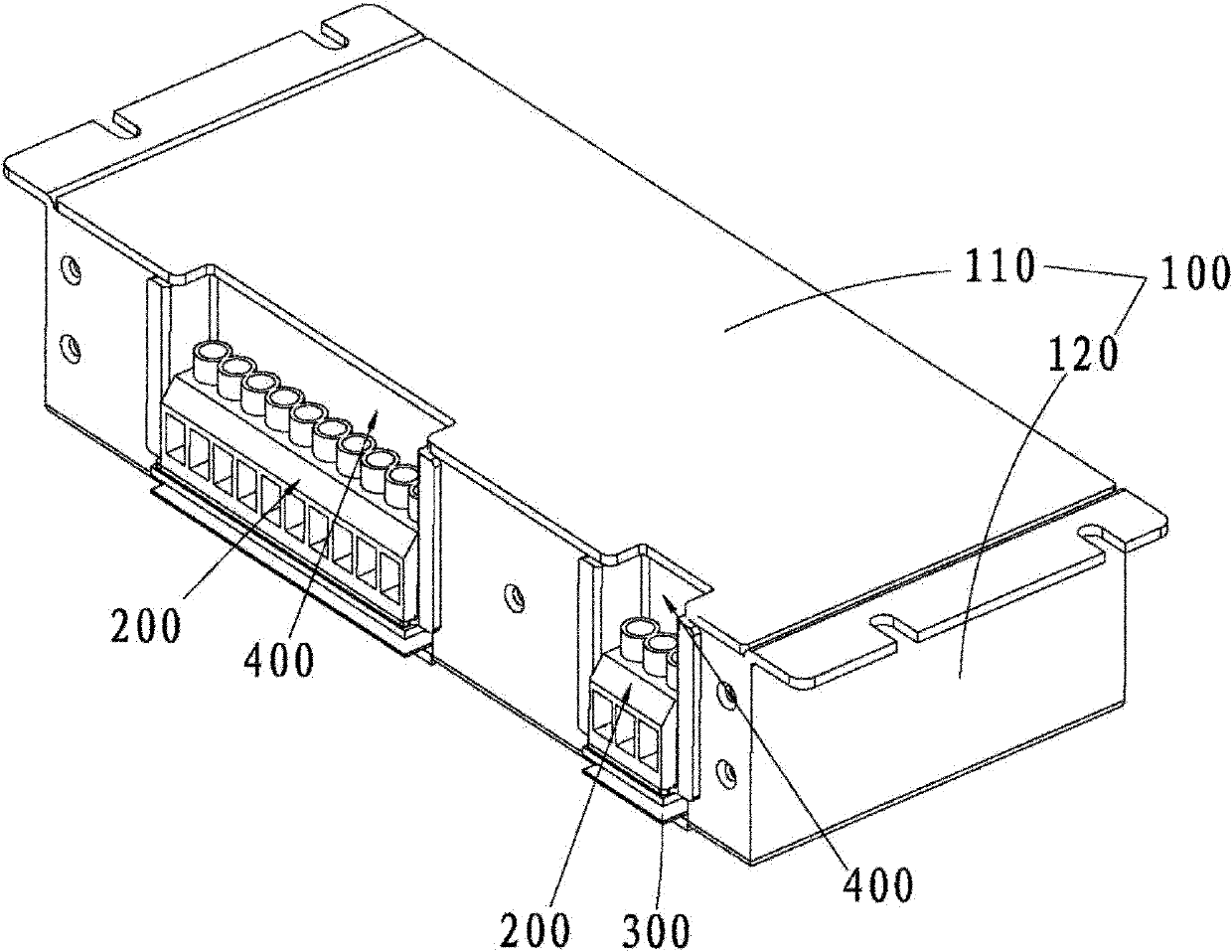

Press-fitting fixture for special-shaped combined magnet

PendingCN111365337AIncrease productivityImprove consistencyMaterial gluingInductances/transformers/magnets manufactureEngineeringMagnet

The invention relates to a press-fitting fixture for a special-shaped combined magnet. The press-fitting fixture for the special-shaped combined magnet comprises a baseplate and a sliding block, and further comprises two positioning plates, wherein two groups of sliding block limited blocks and two sliding blocks are arranged on the baseplate; the two positioning plates are arranged on the baseplate and are located between the two sliding blocks; a plurality of magnet assembly grooves are formed in the positioning plates; the opening directions of the magnet assembly grooves faces the slidingblocks; a plurality of push rods which respectively correspond to the magnet assembly grooves are arranged on the sliding blocks; and when the sliding blocks slide towards the middle parts of the positioning plates, the push rods can press a plurality of special-shaped magnet blocks in the magnet assembly grooves into the magnet assembly grooves to form a first special-shaped combined magnet. Thepress-fitting fixture has the beneficial effects that the press-fitting fixture can assist workers to quickly complete the press-fitting combination of the special-shaped combined magnet, has high production efficiency and good product consistency, and meets the needs of large-scale mass production.

Owner:信阳圆创磁电科技有限公司

Powder pesticide for macleaya cordate plant

InactiveCN1351835AChange soil structureNon-toxic to humans and animalsBiocideArthropodicidesPesticideMacleaya

The pesticide power of macleaya cordata plant is prepared with natural plant material and through sorting, crushing to 60-100 mesh, putting it into a stainless steel reactor, adding water to the stainless steel reactor make material become damp, heating to 40-60 deg.C for 3-5 hr while stirring, then taking out, stoving, and grinding to 300-450 mesh into powder product. The pesticide is used to spray on leaves of crop, mix with seed and treat soil, and has high efficiency, wide pesticidal spectrum, low toxicity and other advantages.

Owner:段民生 +1

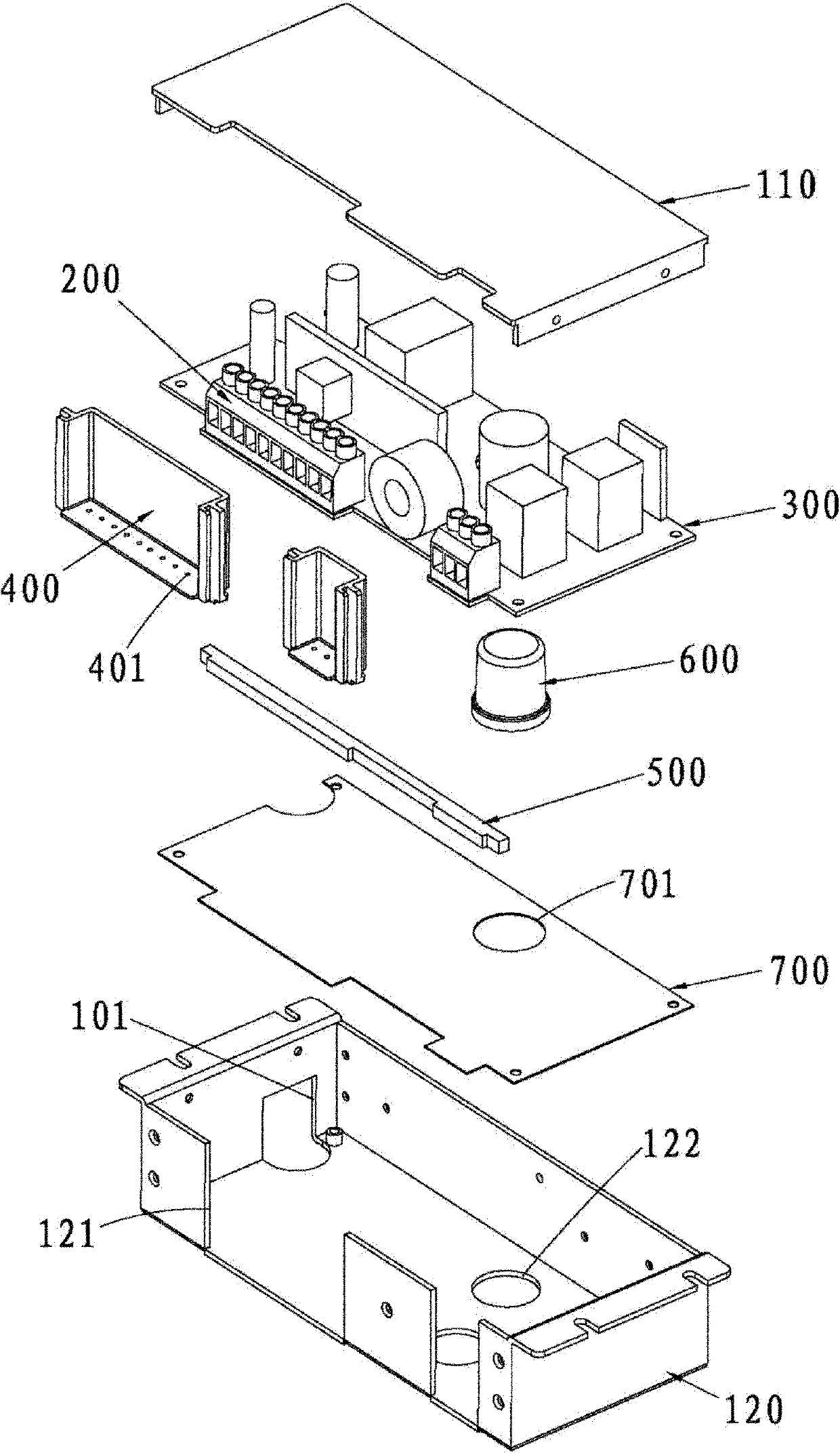

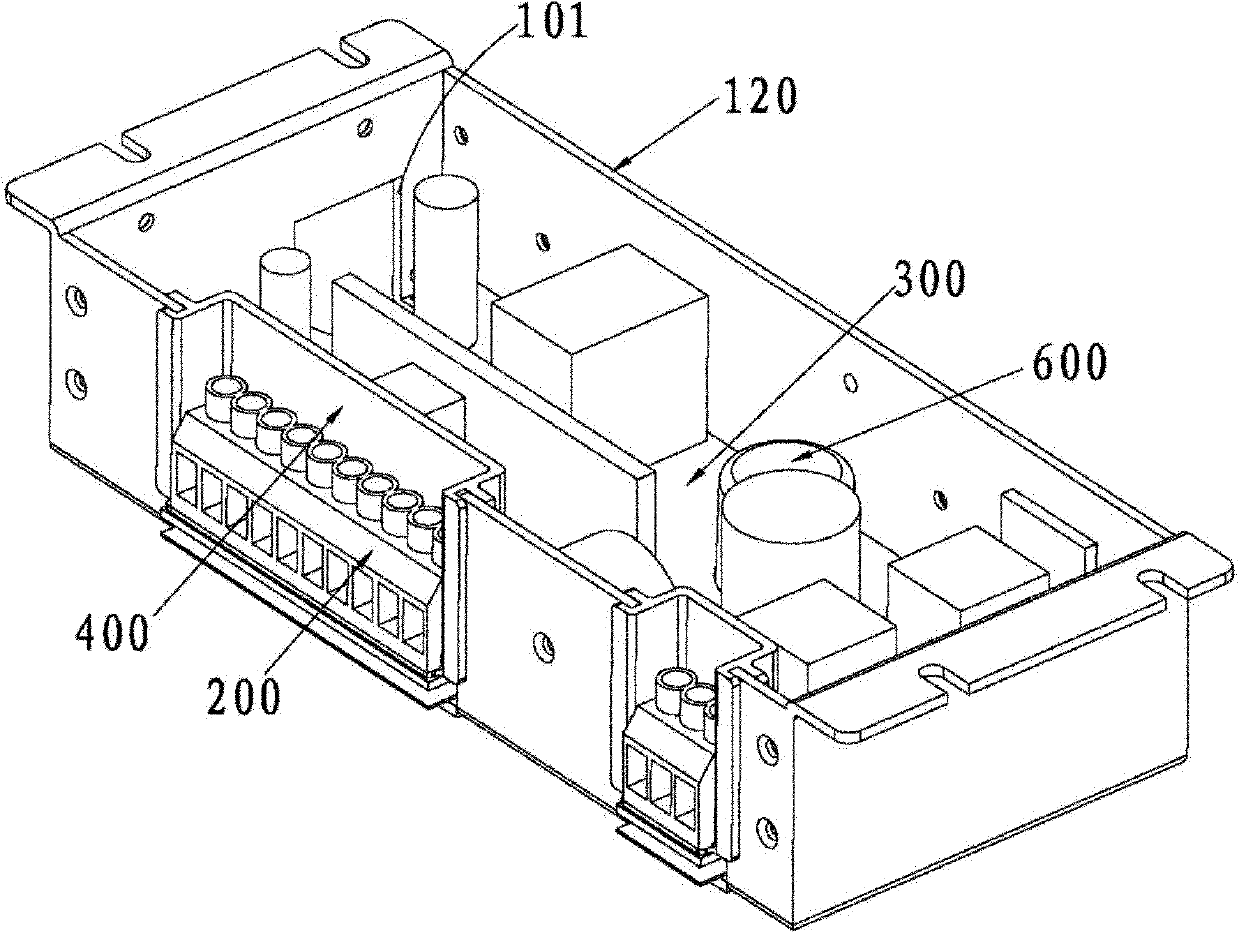

Lamp driver and glue filling method of electric shell assembly

InactiveCN102563577AAvoid wastingReduce workloadLiquid surface applicatorsLighting heating/cooling arrangementsElectricityEffect light

The invention is applicable in the technical field of lighting devices and discloses a lamp driver and a glue filling method of an electric shell assembly. The lamp driver comprises a wiring terminal and a shell assembly. A circuit board member is arranged in the shell assembly; a gap is arranged on the shell assembly; and a barricade member is arranged at the gap. The wiring terminal is arranged at the outer side of the shell assembly; a through hole is arranged on the barricade member; a pin of the wiring terminal is threaded in the through hole and is electrically connected on the circuit board member; and glue is filled in a cavity of the shell assembly. The glue filling method includes the steps of: dividing the shell assembly into an upper cover and a back shell which is provided with at least one gap; arranging the barricade member at the gap; arranging the wiring terminal at the outer side of the barricade member; and threading the pin of the wiring terminal into the barricade member, welding the pin on the circuit board member, and filling glue into the cavity. With the glue filling method of the electric shell assembly, the lamp driver is high in production efficiency and low in production cost.

Owner:OCEANS KING LIGHTING SCI&TECH CO LTD +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com