Self-lubricating wear-resisting agglomerate moulding material

A mass molding compound and self-lubricating technology, applied in the field of self-lubricating and wear-resistant mass molding compound, can solve the problems of no friction parts and poor wear resistance, and achieve the effect of reducing friction, good wear resistance and accurate product size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] Example 1: Self-lubricating wear-resistant bulk molding compound (CBMC) with different colloidal graphite powder content

[0044] Graphite content is the most important factor that determines the self-lubrication of the product. Depending on the application to different mechanical sliding or friction parts, the required self-lubrication is different. The selection of different graphite content will have different effects on the self-lubricating wear-resistant bulk molding compound (CBMC).

[0045] The first step: Weigh according to the formula components, the following are the mass parts:

[0046] 70 parts of unsaturated polyester resin

[0047] Polystyrene 30 parts

[0049] 70 parts of aluminum hydroxide

[0050] 90 servings of calcium carbonate

[0051] 1 part of tert-butyl peroxybenzoate TBPB

[0052] Calcium hydroxide 0.8 parts

[0053] 10 parts of 38μm colloidal graphite powder

[0054] BYK~330 1 copy

[0055] 6mm glass fiber 55 servings

...

Embodiment 2

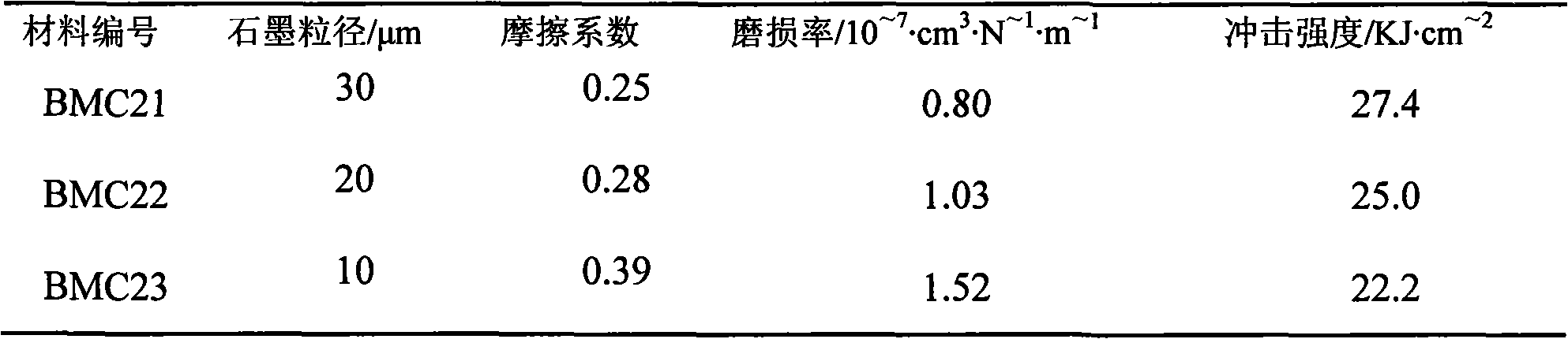

[0068] Example 2: Self-lubricating wear-resistant bulk molding compound (CBMC) with different graphite particle diameters

[0069] Weigh according to the formula components:

[0070] Unsaturated polyester resin 60 parts

[0071] Polystyrene 40 parts

[0073] 80 parts of aluminum hydroxide

[0074] 80 servings of calcium carbonate

[0075] 1 part of tert-butyl peroxybenzoate TBPB

[0076] Calcium hydroxide 0.8 parts

[0077] 20μm colloidal graphite powder 30 parts

[0078] BYK~330 1 copy

[0079] 6mm glass fiber 55 servings

[0080] 12mm glass fiber 45 parts

[0081] The production process is the same as in Example 1. Because the lubricating performance of graphite depends on the size of the graphite flakes, the larger the flakes, the smaller the friction coefficient and the better the lubricating performance. Table 2 shows the different effects of choosing different graphite particle sizes on the self-lubricating wear-resistant bulk molding compound ...

Embodiment 3

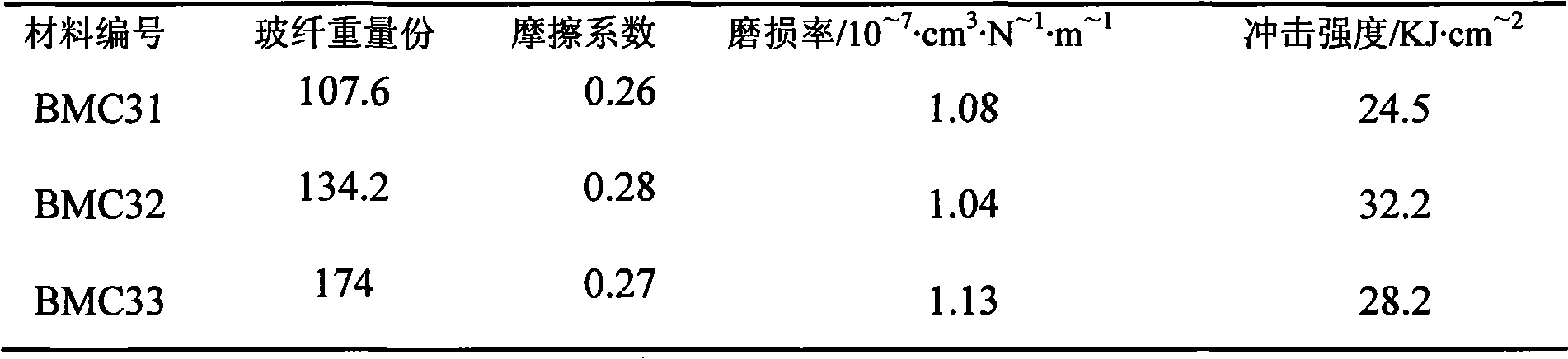

[0085] Example 3: Self-lubricating wear-resistant bulk molding compound (CBMC) with different glass fiber content

[0086] Weigh according to the above preferred formula components:

[0087] 70 parts of unsaturated polyester resin

[0088] Polystyrene 30 parts

[0090] 90 parts of aluminum hydroxide

[0091] 70 servings of calcium carbonate

[0092] 1 part of tert-butyl peroxybenzoate TBPB

[0093] Calcium hydroxide 0.8 parts

[0094] 20μm colloidal graphite powder 30 parts

[0095] BYK~330 1 copy

[0096] 6mm glass fiber 35 parts

[0097] 12mm glass fiber 75 parts

[0098] The production process is the same as in Example 1. As a reinforcing material, glass fiber has a greater impact on the mechanical properties of the material, and has no major effect on the friction and wear properties, but it also has a certain impact. This is mainly related to the nature of the glass fiber itself and the interface between the glass fiber and the matrix. The visco...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com