Patents

Literature

124results about How to "Meet mass production" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

TM-polarization GaAsP/GaInP active-region 808nm quantum-well laser

InactiveCN103457158AReduce oxidationReduce internal lossOptical wave guidanceLaser detailsLower limitOhmic contact

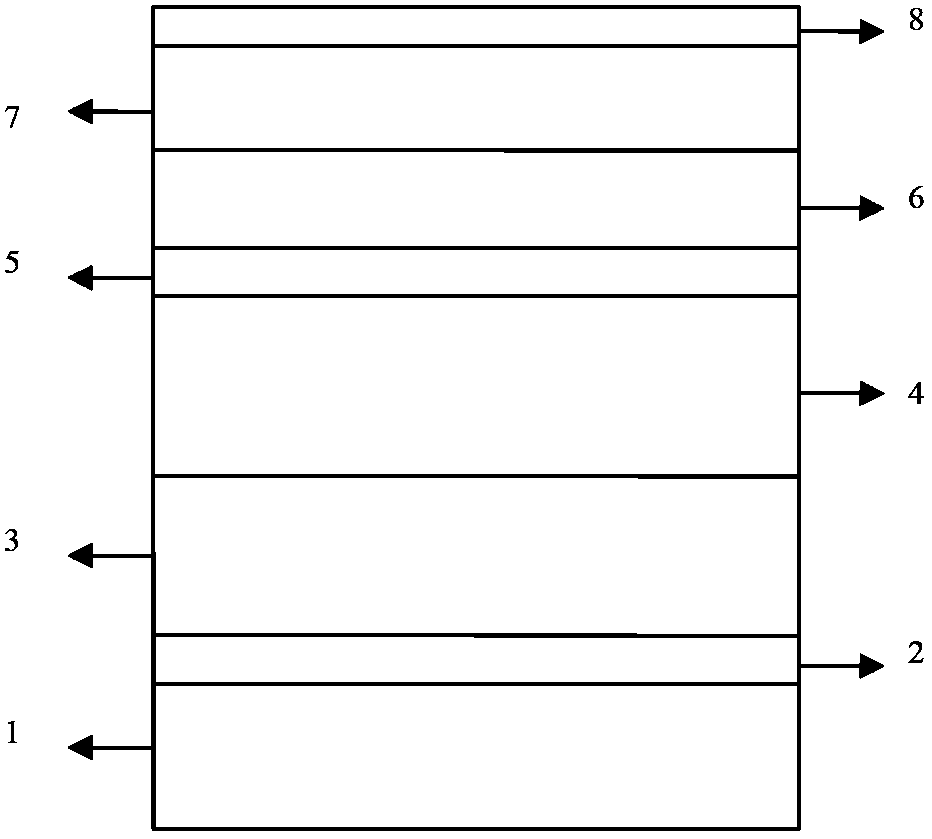

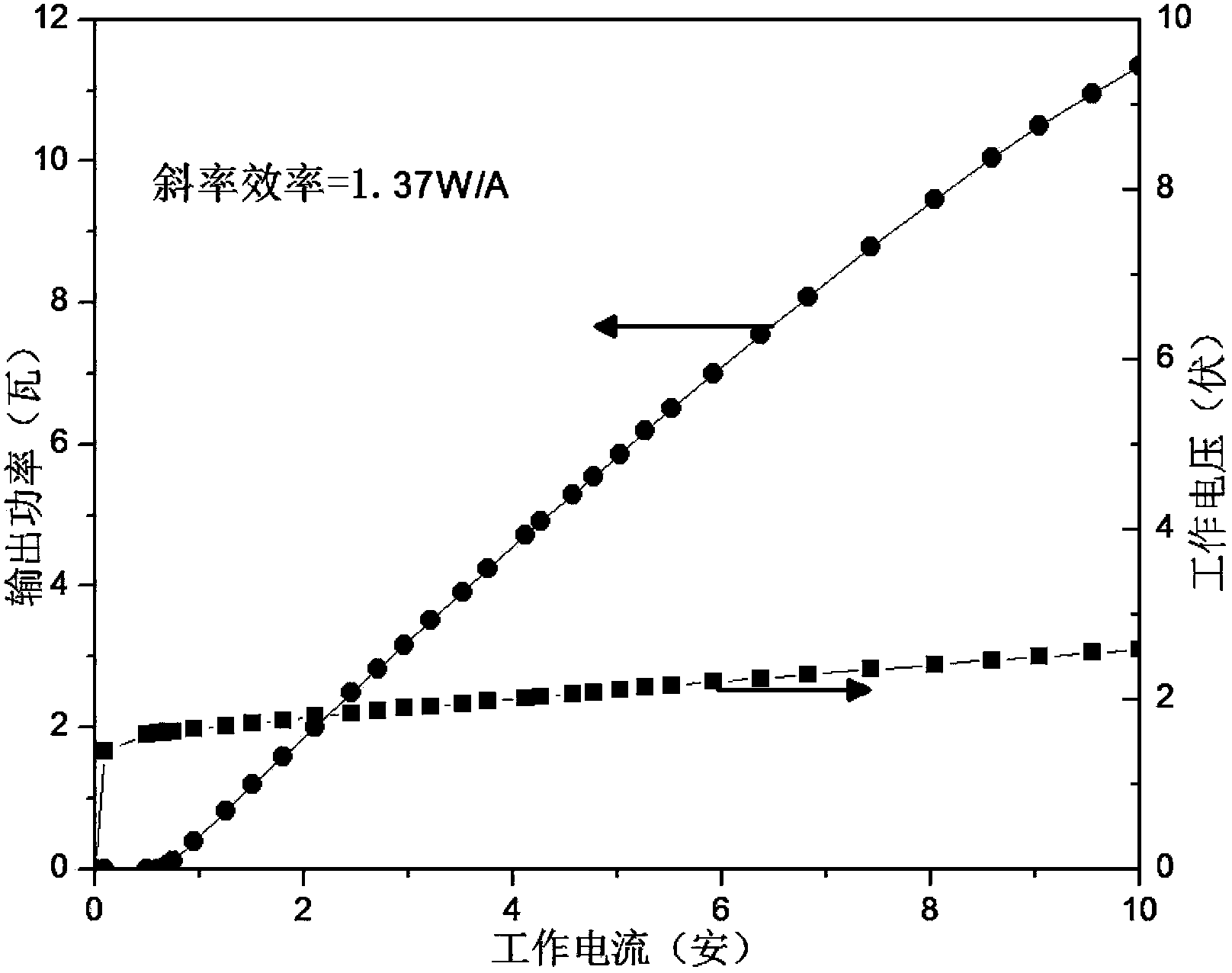

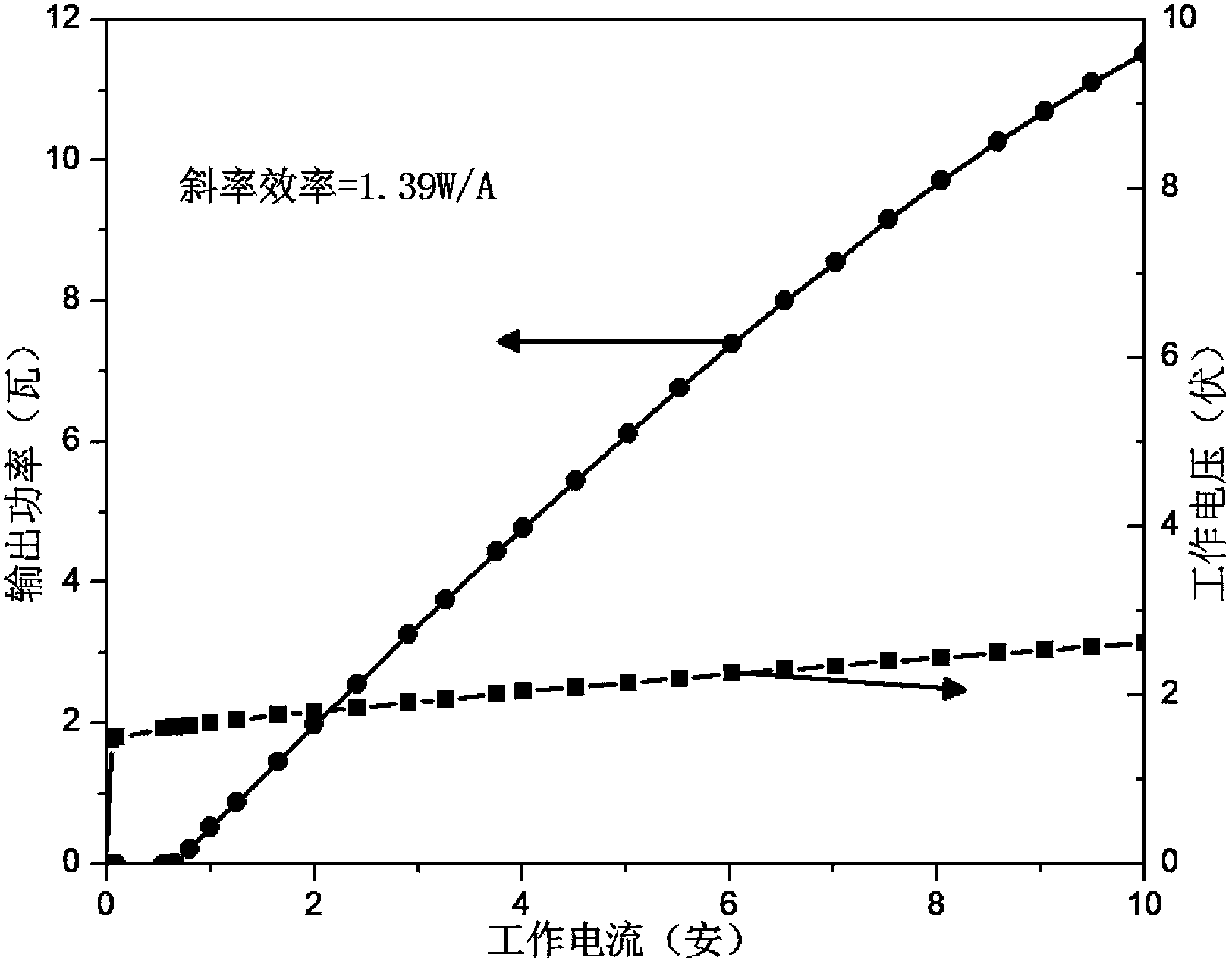

The invention provides a TM-polarization GaAsP / GaInP active-region 808nm quantum-well laser. The laser structurally comprises a substrate, a buffer layer, a type-N lower limit layer, a lower waveguide layer, a quantum well layer, an upper waveguide layer, a type-P upper limit layer, and an ohmic contact layer sequentially from bottom to top. The upper waveguide layer and the lower waveguide layer are made of aluminum-free material GaInP. The quantum well layer is made of GaAsP material. The waveguide layer and the quantum well layer form a wide-waveguide aluminum-free active region. The laser has the advantages that the influence of Al oxidization, growth interface roughness and accessory electric field at cavity surface upon the reliability in high power output, long service life and the like of the laser can be reduced effectively, the waveguide layer and the limit layers are optimally designed into wide-waveguide asymmetric structures, and internal loss can be reduced effectively, and maximum output power and reliability can be improved.

Owner:Shandong Huaguang Optoelectronics Co. Ltd.

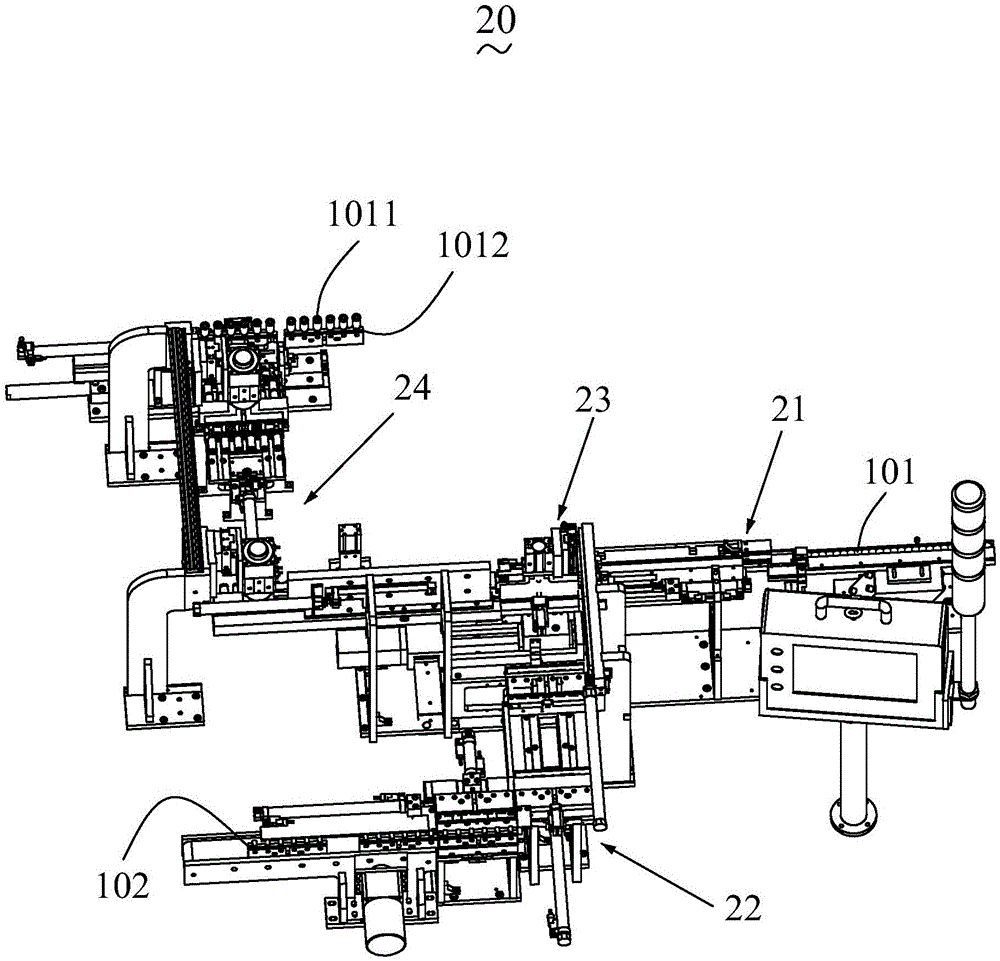

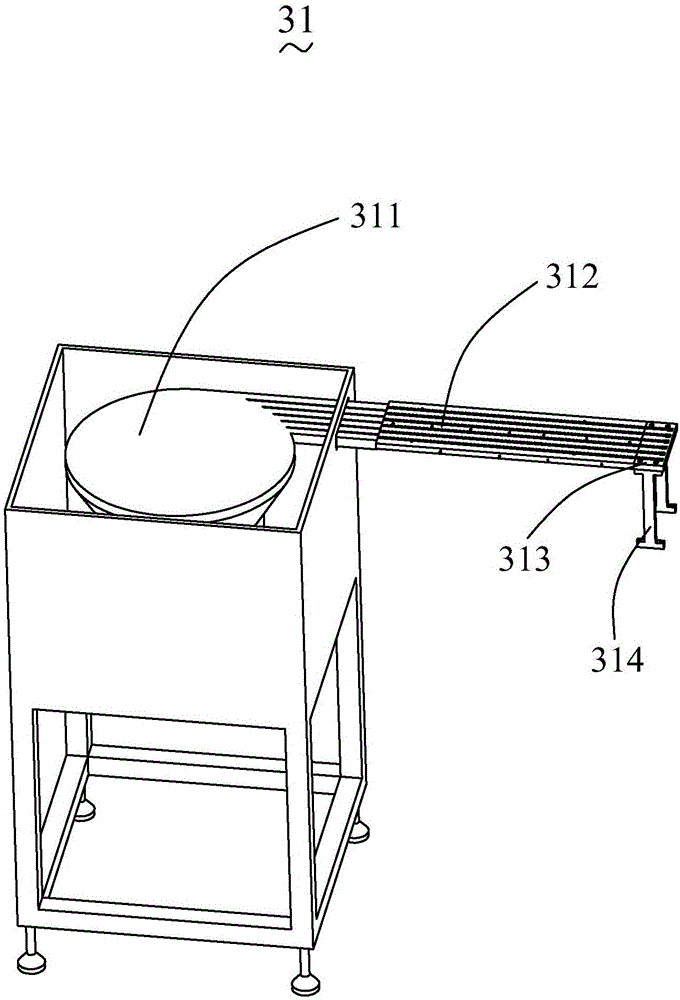

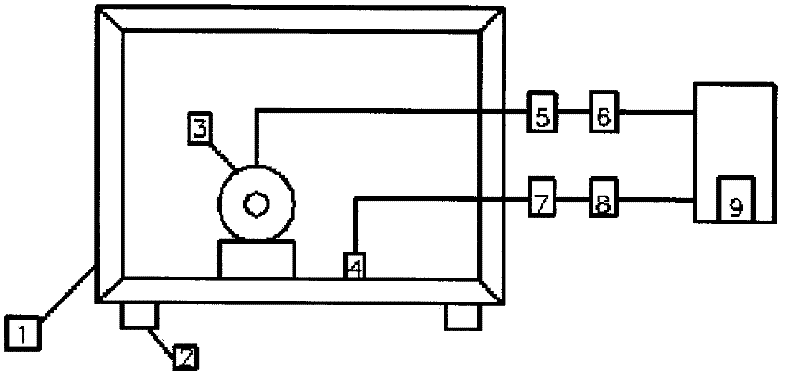

Full-automatic battery spot welding equipment

PendingCN106624309AContinuous weldingFast solderingResistance welding apparatusButt weldingEngineering

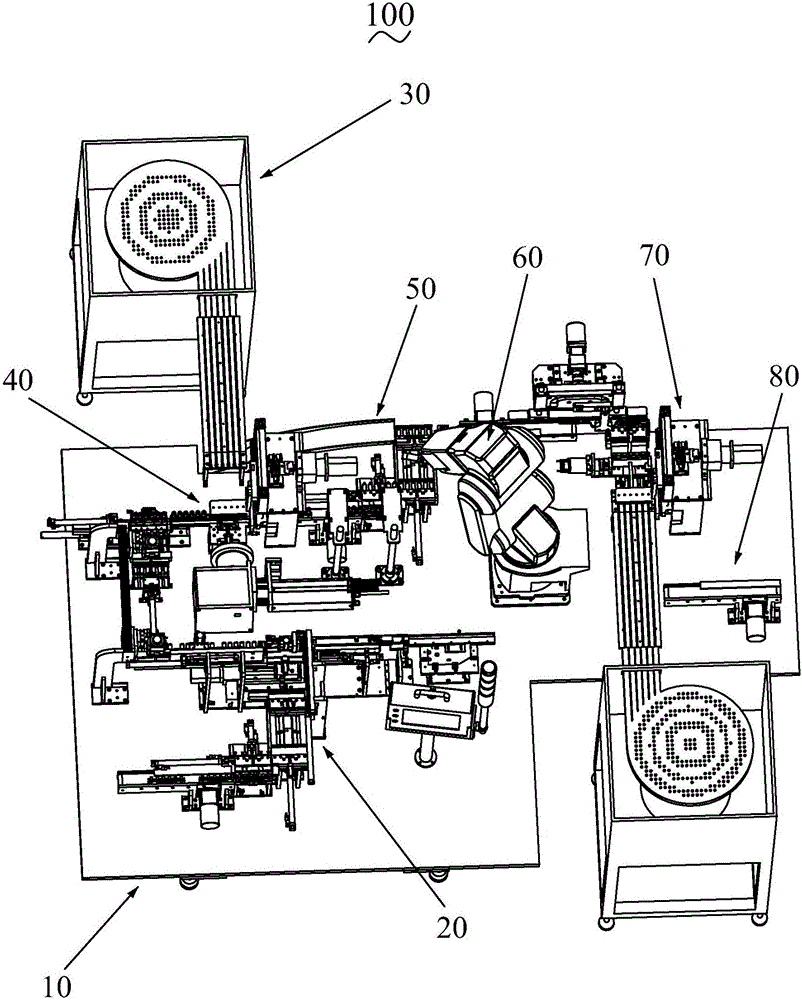

The invention provides full-automatic battery spot welding equipment. The equipment comprises a rack and a battery carrying mechanism, two material charging mechanisms, a spot welding mechanism, a detection mechanism, a transfer mechanism, a butt welding mechanism and a discharging mechanism which are arranged on the rack. According to the full-automatic battery spot welding equipment, full-automatic operation can be achieved, battery charging and transportation, screw / double-screw bolt charging and transportation, screw and battery spot welding, CCD detection, unqualified product screening, double-screw bolt and battery butt welding, product outputting and other operation are integrated, screws and double-screw bolts can be welded to the two ends of a battery continuously and rapidly, batched production is met, and the precision of product machining can be improved.

Owner:OPTIMUM BATTERY CO LTD

Rooting method of tissue culture and rapid propagation of eucalyptus dunni

InactiveCN101331853AIncrease the multiplication factorMeet mass productionHorticulture methodsPlant tissue cultureBudCell budding

The invention discloses a Eucalyptus dunnii group culture fast propagation rootage method, which comprises the following steps: (1) asepsis seedling cultivation; (2) bud subculture multiplication; (3) test-tube seedling rejuvenation; (4) inducing rootage; (5) transplanting the test-tube seedling, etc. In the invention, after the multiplication cultivation and rejuvenation cultivation, the asepsis seedling is inoculated in a first rootage culture medium and a second rootage culture medium for inducing a complete plant, thus solving the problem that the propagation coefficient of Eucalyptus dunnii group culture is low, in particular to the problem that the rootage is difficult; by utilizing the technical proposal of the invention, a large number of seedlings can be provided in a short time so as to replace the expensive imported seeds and satisfy the heavy demand of the large-scaled industrial seedling and the market.

Owner:SHANDONG FOREST SCI RES INST

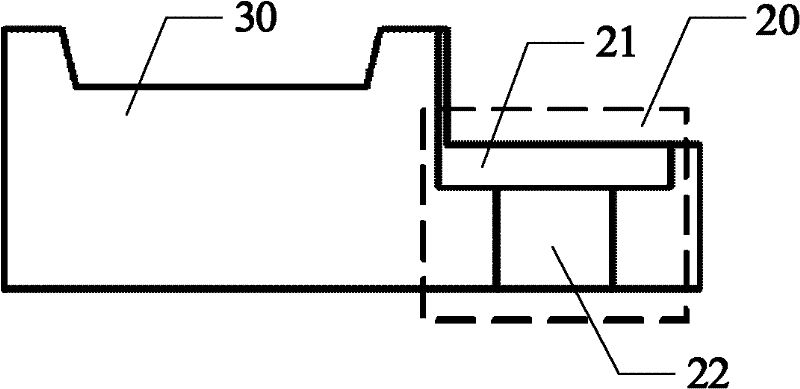

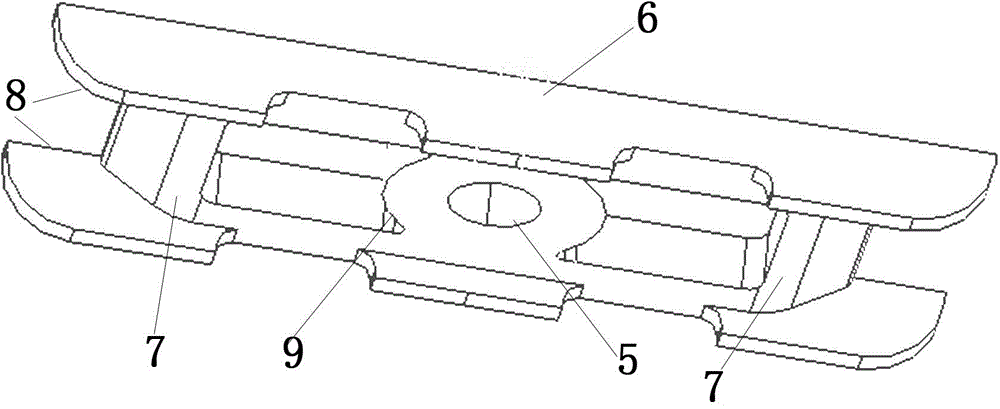

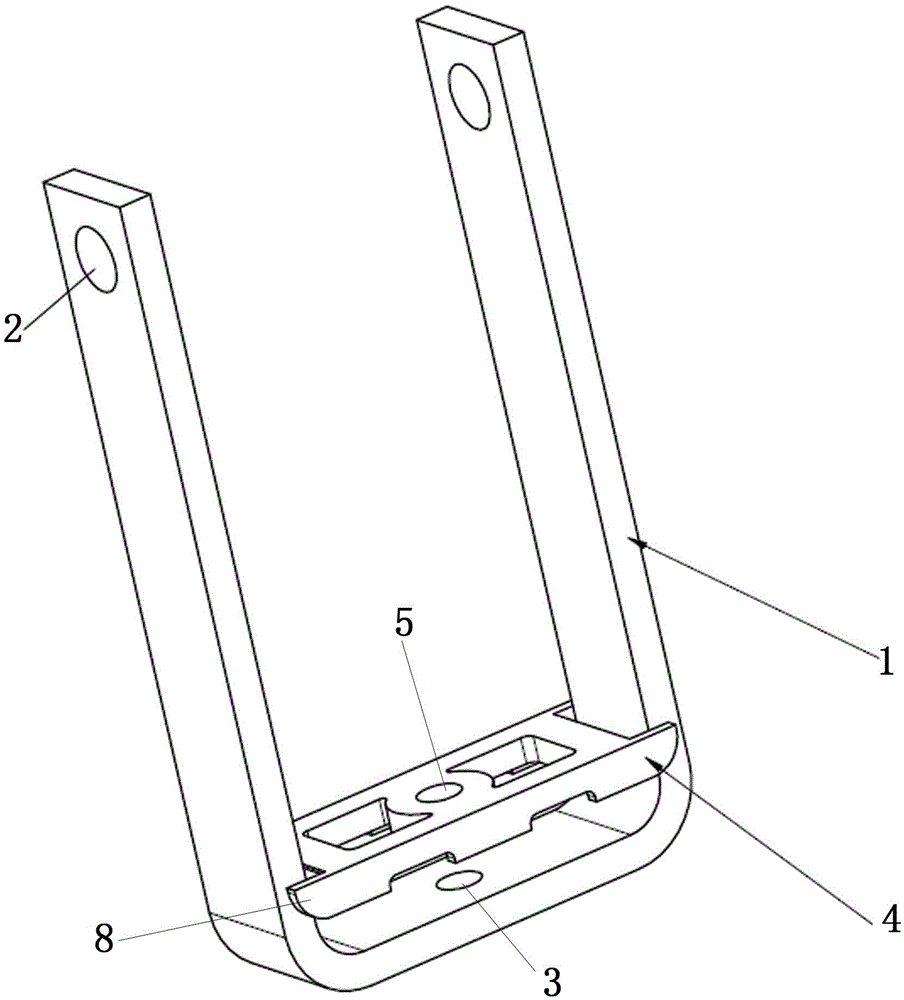

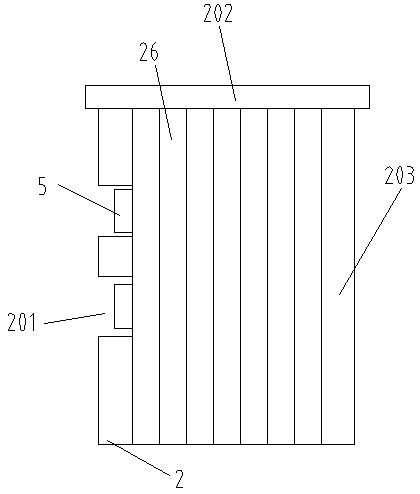

Discrete igbt modules and substrates

InactiveCN102299144AQuick installationGuaranteed flatnessSemiconductor/solid-state device detailsSolid-state devicesMechanical engineeringCeramic substrate

The invention discloses a discrete IGBT module and a substrate, the substrate includes: a groove matching with the IGBT, for placing the IGBT; a through hole matching with a screw, for installing the screw, so that the substrate is fixed to the radiator metal plate. The discrete IGBT module and substrate proposed by the present invention can realize rapid installation of IGBT, high assembly efficiency, and can meet mass production; through the cooperation of discrete IGBT and ceramic substrate, the heat dissipation effect is good; the good insulation performance of ceramic substrate is used to solve the problem of Effective insulation between the IGBT and the radiator metal plate; keep the thickness of the substrate consistent with the thickness of the surrounding components to ensure the flatness of each component during installation.

Owner:佛山市顺德区和而泰电子科技有限公司

Preparation method of titanium alloy bar of universal resetting screw seat

ActiveCN111534715AEffective grain size refinementReduce residual stressWire straightening devicesTemperature control deviceOrthopedic departmentManufactured material

The invention belongs to the technical field of machining of medical titanium alloy materials and particularly relates to a preparation method of a titanium alloy bar of a universal resetting screw seat. The chemical ingredients of titanium alloy comprise, by mass percentage, 5.9%-6.4% of Al, 3.9%-4.4% of V, 0.15%-0.22% of Fe, 0.09%-0.13% of O, not larger than 0.05% of C, not larger than 0.005% ofH, not larger than 0.01% of N and the balance Ti. The preparation method comprises the steps that firstly, a round bar blank is obtained through the procedures of smelting, forging, and rolling; thena beta single-phase section homogenization annealing treatment process is adopted to obtain a homogeneous fine-grained acicular martensite structure, an electrifying straightening and hyperbolic straightening combined process is used for straightening, the electrifying straightening temperature is controlled to be less than 780 DEG C, and a balanced residual stress state is obtained; and finally,stress relief annealing and centerless grinding are conducted to obtain the finished bar. The preparation method of the titanium alloy bar of the universal resetting screw seat can produce a medicalTi-6Al-4V alloy bar basically free of stress, the Ti-6Al-4V alloy bar has excellent fatigue life, and a qualified raw material is provided for manufacturing of universal resetting screw seats of orthopedic medical instruments.

Owner:中科锐金山东钛业科技有限公司

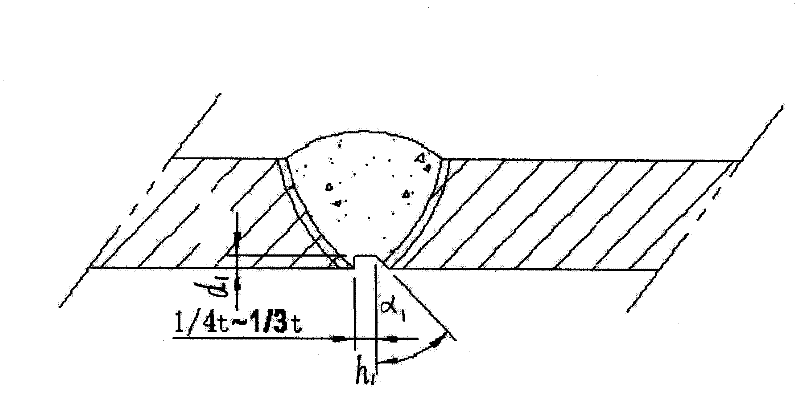

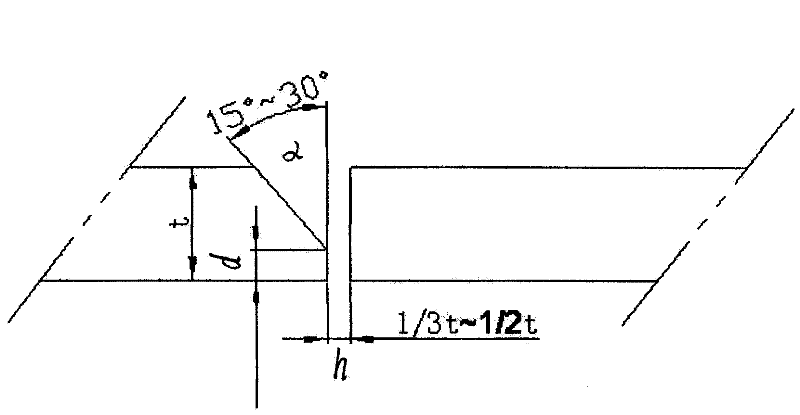

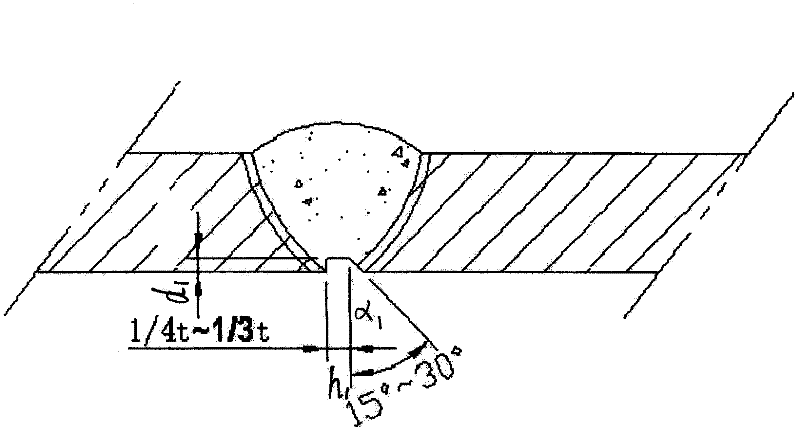

Welding method of stainless steel thin plate

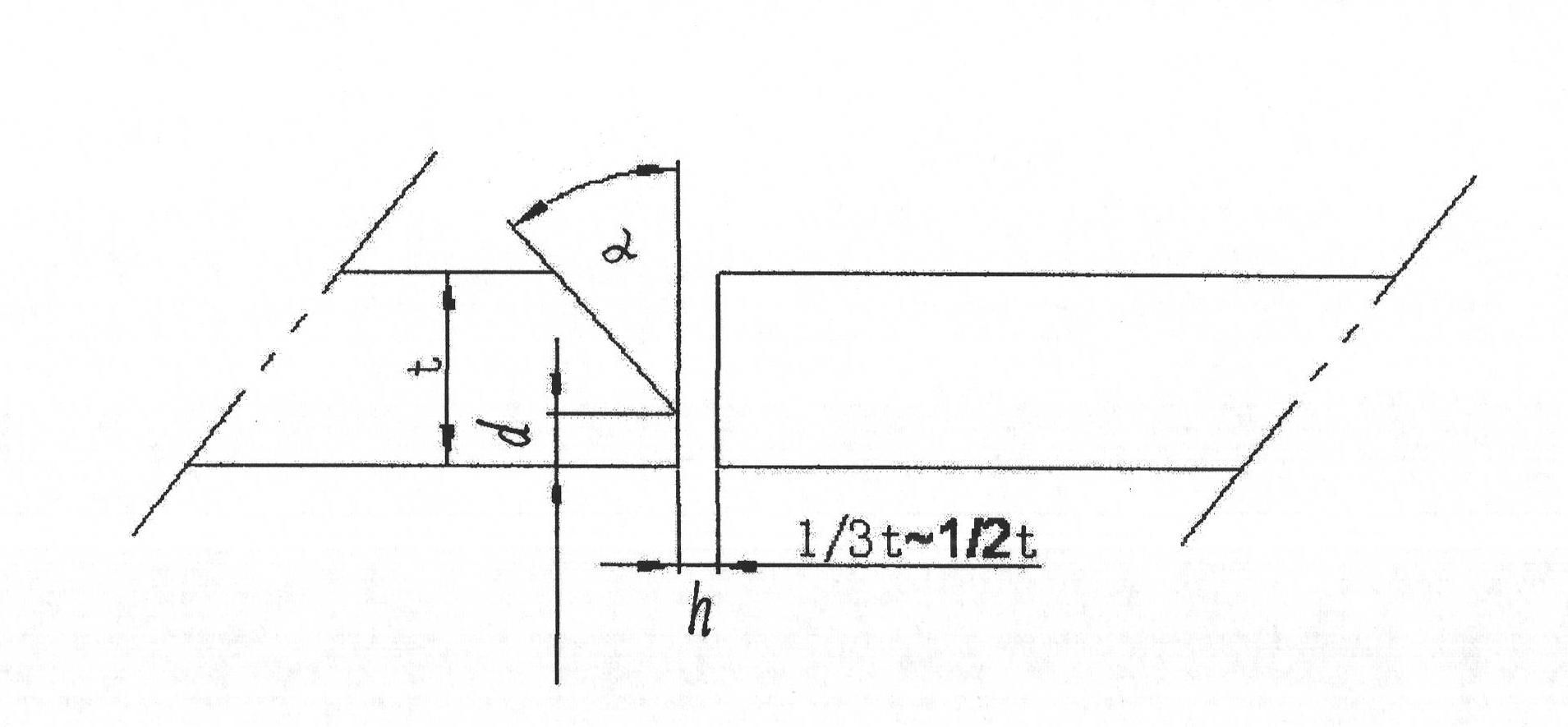

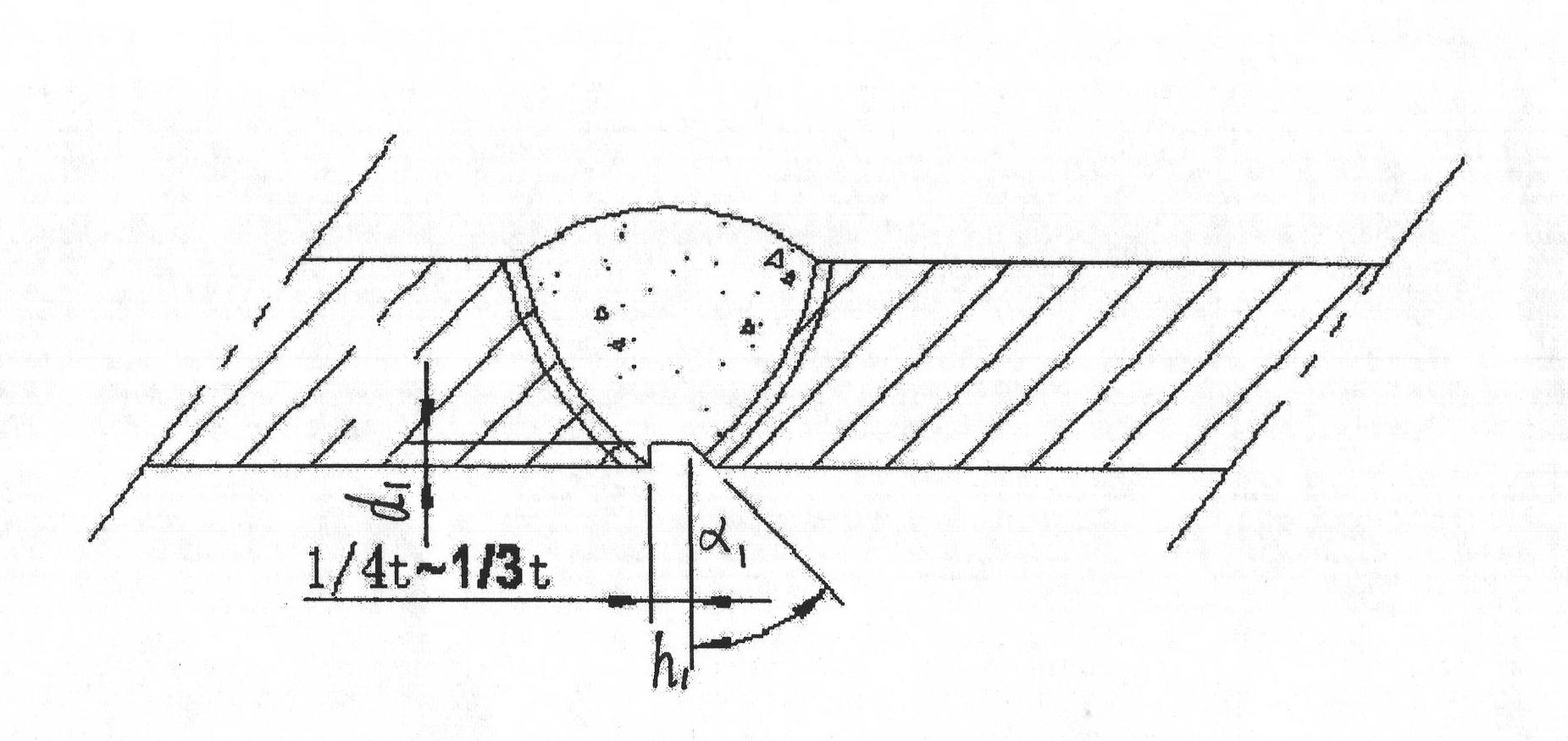

ActiveCN102416522AEasy to manufactureWelding process parameters are clearArc welding apparatusMelting tankActive agent

The invention discloses a welding method of a stainless steel thin plate, which is between an active tungsten electrode argon arc welding method and the conventional stainless steel welding method. In the method, a mixed gas of oxygen or carbon dioxide and argon is used an active protective gas; after a molten pool is formed, welding is performed according to the following set process parameters:the welding current I is 10<5> to 11<5>A, the welding speed v is 90 to 110mm.min<-1>, the arc length L is 3.5mm, and the active protective gas flow Q is 13L.min<-1>; and the length L of the welding joint of welding of each welding rod with a length L1 is controlled between 0.85L1 and L1. The stainless steel thin plate welding method is formed by selecting various groove machining and welding process parameters and repeatedly performing process tests, and avoids requiring use of active agent, allows grooves to be machined conveniently, makes process parameter definite, ensures process stability, allows the welding quality to meet batch-production requirements and allows products to meet set technical requirements on products.

Owner:TANGSHAN CAOFEIDIAN DISTRICT SHOUYAN MACHINERY CO LTD

Forging technology for abnormal structure of TC18 titanium alloy raw material

ActiveCN105441845AChange distribution statusWell organizedHeating/cooling devicesPhase changeTitanium alloy

The invention belongs to the technical field of forging technologies, and discloses a forging technology for an abnormal structure of a TC18 titanium alloy raw material. The forging technology comprises the following steps: a, carrying out beta forging above a phase change point on blanks by 1-2 fire, wherein forging temperature is 15-30 DEG C above the phase change point, and deformation is controlled to be between 20% and 40%; b, carrying out forging below the phase change point on the blanks by more than 2 fire, wherein the forging temperature is 20-40 DEG C below the phase change point, and the deformation is controlled to be between 15% and 30%; and c, carrying out beta forging above the phase change point on the blanks by 1 fire, wherein the forging temperature is 10-20 DEG C above the phase change point, and the deformation is controlled to be 15% and 25%. By the technology, the structure defect of fine-crystal bright bands can be avoided effectively, and TC18 titanium alloy free forge pieces can be produced in batches.

Owner:中国第二重型机械集团德阳万航模锻有限责任公司

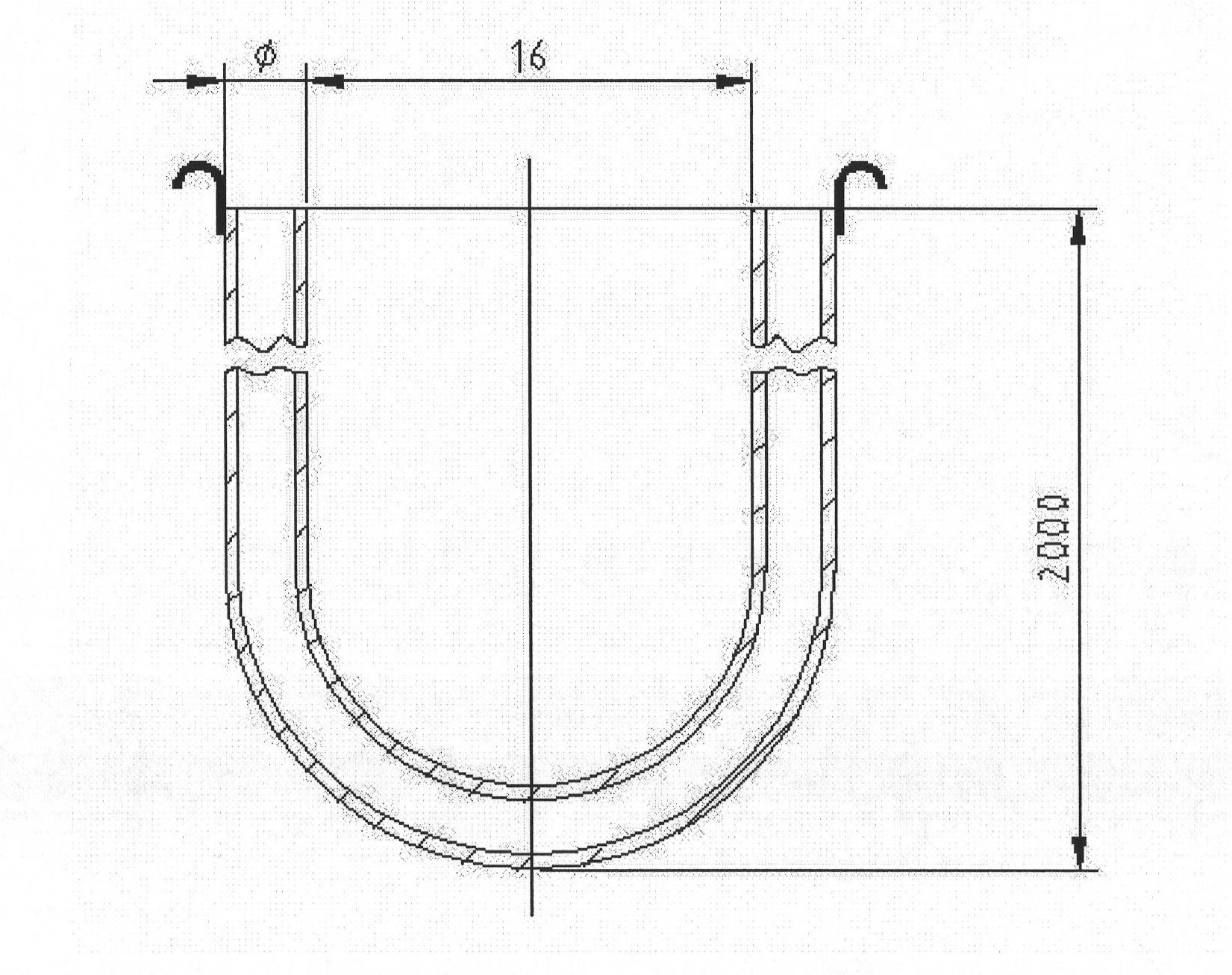

Stainless steel sheet welding method capable of preventing weld cracks

The invention discloses a stainless steel sheet welding method capable of preventing weld cracks. The method comprises the following steps: preheating a welding place to 80-120 DEG C; melting the surface of a welding bead to be welded by using moderate current tungsten electrode arc; with oxygen or mixed gas of carbon dioxide and argon as active protection gas, performing welding according to thefollowing set technological parameters after a molten pool is formed: welding current I: 115-125A, welding speed V: 110-125 mm / min, arc length L: 4 mm, and flow Q of active protection gas: 14L / min; controlling the length L of a welding seam of each welding rod with length L1 to be in a range that L is not less than 0.75L1 and not larger than L1; and in the welding process, hanging the U-shaped cooper pipes filled with cooling water on the two sides of the welding seam so as to accelerate the cooling of the welding seam while welding. In the invention, by controlling the welding preheating temperature and adding a welding cooling assistant device, the aim of controlling cracks is achieved.

Owner:TANGSHAN CAOFEIDIAN DISTRICT SHOUYAN MACHINERY CO LTD

Preparation of urban sculpture material from construction waste and method for preparing urban sculpture from urban sculpture material

InactiveCN106904918ASave resourcesLow costSolid waste managementOrnamental structuresSodium silicateScrap

The invention relates to preparation of an urban sculpture material from construction waste and a method for preparing an urban sculpture from the urban sculpture material. The urban sculpture material comprises the following raw materials by weight: solid construction waste, water, aluminoferrite cement, nanometer nickel borate whiskers, boiler fly ash beads, perlite particles, expanded polystyrene particles, basalt fiber, sodium silicate, anhydrous calcium sulfate, calcium lignin sulphonate, isobutyltriethoxysilane, gypsum powder, 107 glue and an accelerator. The sculpturing method comprises the following successive steps: preparing a bearing framework for the sculpture; preparing a surface coating layer; crushing construction waste into particles by using a pulverizer and a grinder; adding the crushed construction waste particles into an agitator; adding the rest raw materials into the agitator and a mixer and carrying out mixing under stirring so as to obtain a wet mixed material; coating the coating layer with the wet mixed material so as to form a basic contour layer of the sculpture; leaving a wet mixed material inlet in the top of the sculpture in advance; when the sculpture is placed at a set position, injecting the wet mixed material into a cavity in the sculpture; and then treating the surface of the sculpture.

Owner:HARBIN UNIV

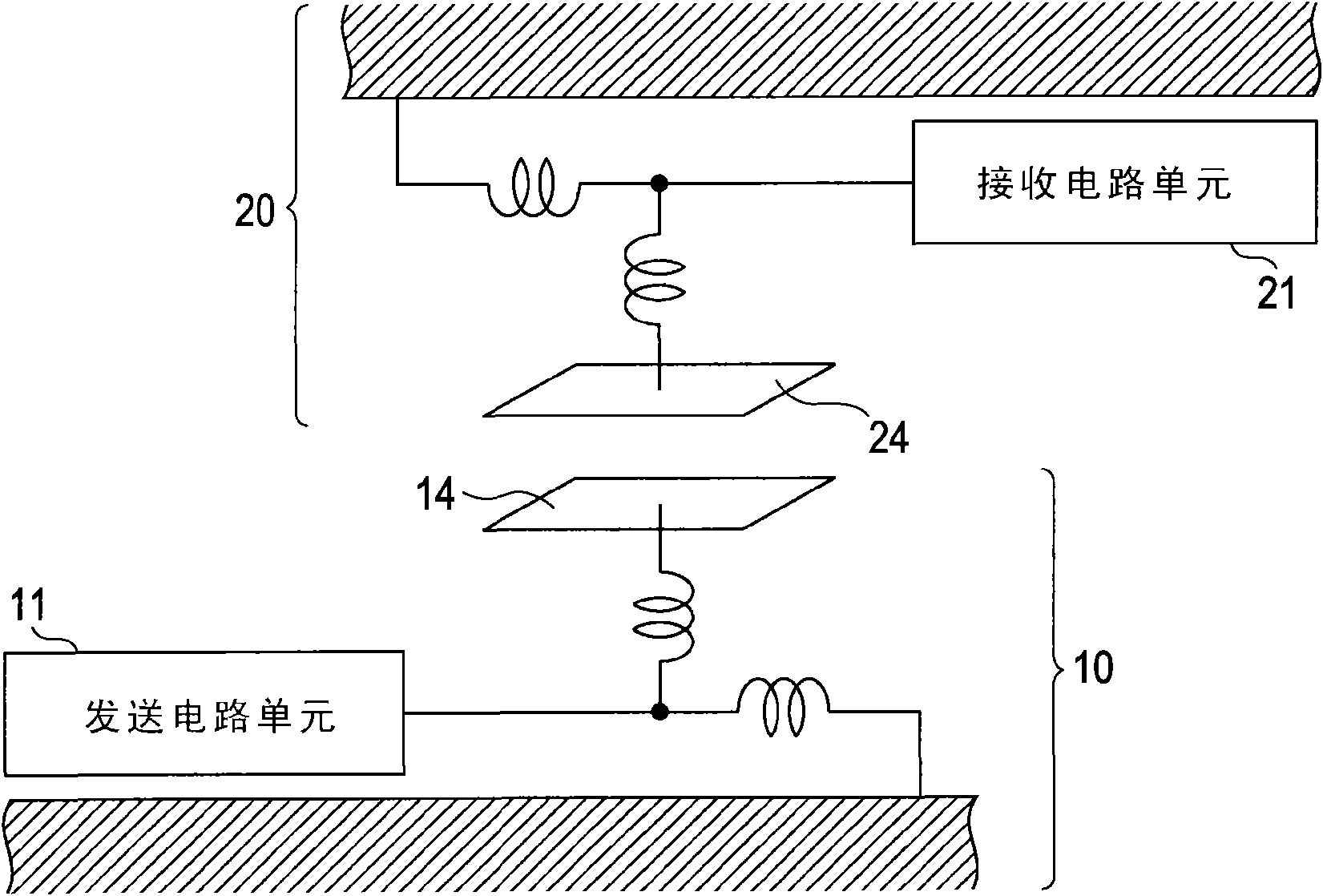

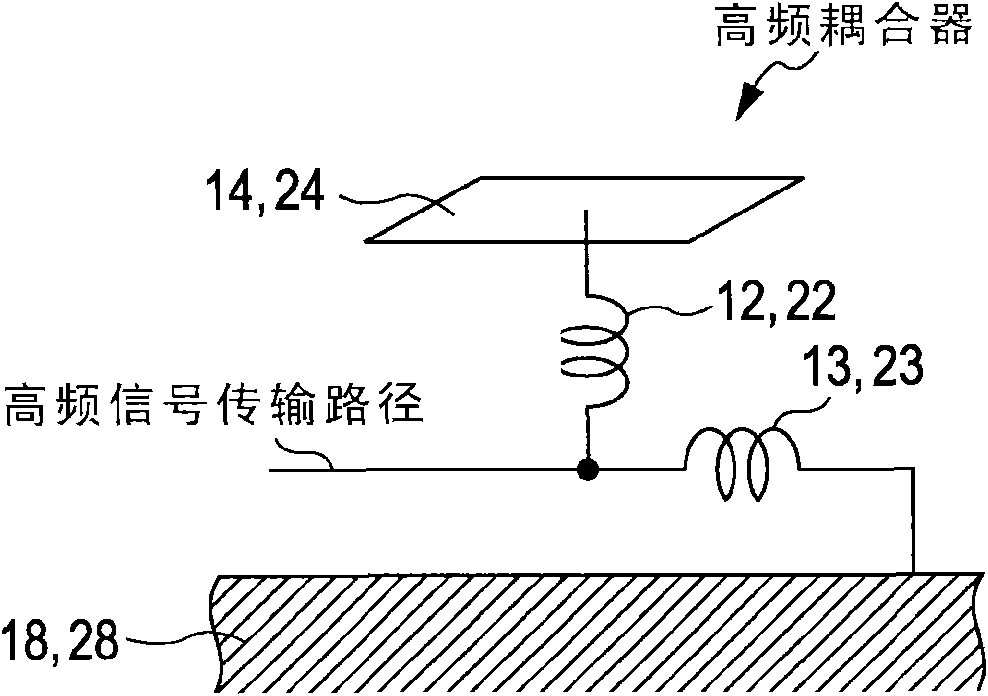

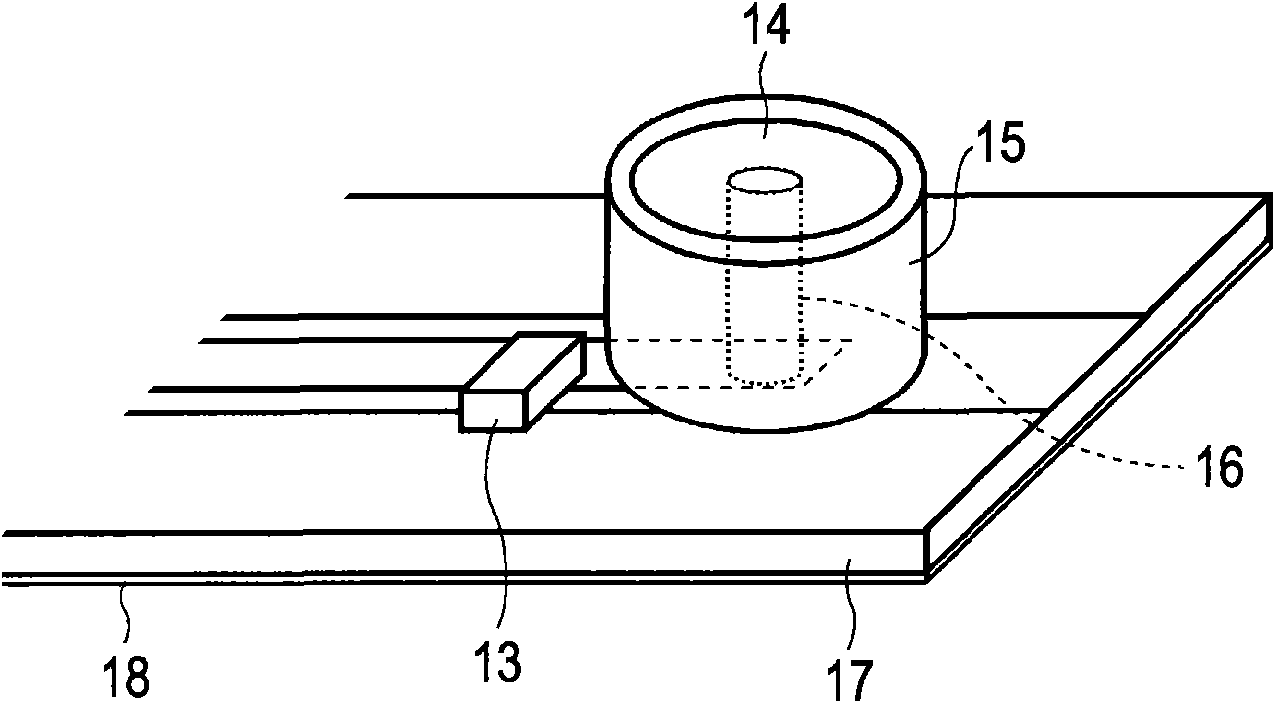

Communication device and high-frequency coupler

InactiveCN101854194AReduce the overall heightLow mechanical strengthNear-field systems using receiversAntennas earthing switches associationCouplingMirror image

A communication device includes a communication circuit unit, a transmission path, a ground, a coupling electrode, and a resonating unit. The resonating unit includes a first resonating unit connected to the transmission path and a second resonating unit having one end connected to the first resonating unit and another end short-circuited to the ground, the second resonating unit having terminals of the coupling electrode connected thereto. A microdipole is formed of a line segment connecting a center of charges stored in the coupling electrode and a center of mirror-image charges stored in the ground. The high-frequency signal is transmitted to a distant side disposed so as to face the communication device with an angle [theta] formed relative to a direction of the microdipole being approximately 0 degree.

Owner:SONY GRP CORP

High-temperature-resistant environment-friendly metal casting coating and preparation method thereof

InactiveCN105642821AImprove high temperature resistanceImprove crack resistanceFoundry mouldsFoundry coresSodium BentoniteCrack resistance

The invention discloses high-temperature-resistant environment-friendly metal casting coating and a preparation method thereof. The coating comprises, by weight, 3-5 parts of attapulgite clay, 12-15 parts of quartz powder, 5-12 parts of talcum powder, 4-10 parts of superfine glass powder, 1.5-4 parts of sodium silicate, 3-5 parts of bauxite, 3-8 parts of diatomaceous earth, 2-4 parts of bentonite, 6-10 parts of polyethylene glycol, 3-9 parts of organic siloxane, 5-9 parts of silicon resin, 6-12 parts of linseed oil water-soluble alkyd resin, 4-6 parts of triphenyltin hydroxide, 2-6 parts of lignosulfonic acid, 1-3 parts of oxidizing agents, 1-2 parts of wetting agents, 2-5 parts of defoaming agents, 4-9 parts of preservatives, 2-6 parts of bonding agents, 5-8 parts of curing agents and 75-90 parts of deionized water. Compared with the prior art, the casting coating prepared through the method has excellent high temperature resistance, crack resistance and scouring resistance, and is good in adhesiveness and air permeability; meanwhile, the produced coating is uniform, environmentally friendly, free of pollution, good in stability and adsorbability, and capable of meeting the requirements for mass production of large castings, and improves the surface quality of the castings.

Owner:TONGLING ANDONG CAST STEEL

Two-step seedling quick propagation method for hemerocallis tissue culture by using tender pedicel as explant

InactiveCN101897297AMeet mass productionFew stepsHorticulture methodsPlant tissue cultureSucroseCulture mediums

The invention discloses a two-step seedling quick propagation method for hemerocallis tissue culture by using tender pedicel as explant. The method comprises the following steps of: sterilizing the tender hemerocallis pedicel serving as the explant, then cutting the pedicel into sections of 1 to 1.5 centimeters, and inoculating the cut pedicel to an induction and differentiation culture medium; transferring sterile seedlings with the height of 4 to 6 centimeters and over 4 leaves to a rooting culture medium after 2.5 to 3 months to perform rooting culture medium; and when each tissue culture seedling grows over 3 roots and the adventitious root reaches a length of 2 to 4 centimeters, opening a bottle cap, hardening the seedlings for 3 to 4 days indoors, taking the tissue culture seedlings out of a culture bottle, washing the culture medium, and transplanting the seedlings to the sterilized culture medium, wherein the induction and differentiation culture medium: MS is used as a basic culture medium; 2 to 10 mg of 6-benzyladenine (6-BA), 0 to 2 mg of 2,4-dichlorphenoxyacetic acid (2,4-D), 0.2 to 1 mg of alpha-naphthylacetic acid (NAA), 4.5 g of agar and 30 g of cane sugar are added into each liter of basic culture medium; and the pH value of the culture medium is adjusted to 5.8. The rooting culture medium: 1 / 2MS is used as a basic culture medium; 0.1 to 2.0 mg of NAA, 4.5 g of agar and 15 to 30 g of cane sugar are added into each liter of basic culture medium; and the pH value of the culture medium is adjusted to 5.8. The method can massively propagate good-quality hemerocallis tissue culture seedlings in short time so as to meet the requirement of large-scale production, and reduces the steps of preparing the culture medium and transferring the bottle, so the method is simple and feasible and reduces the production cost.

Owner:浙江清华长三角研究院生物技术与医药研究所

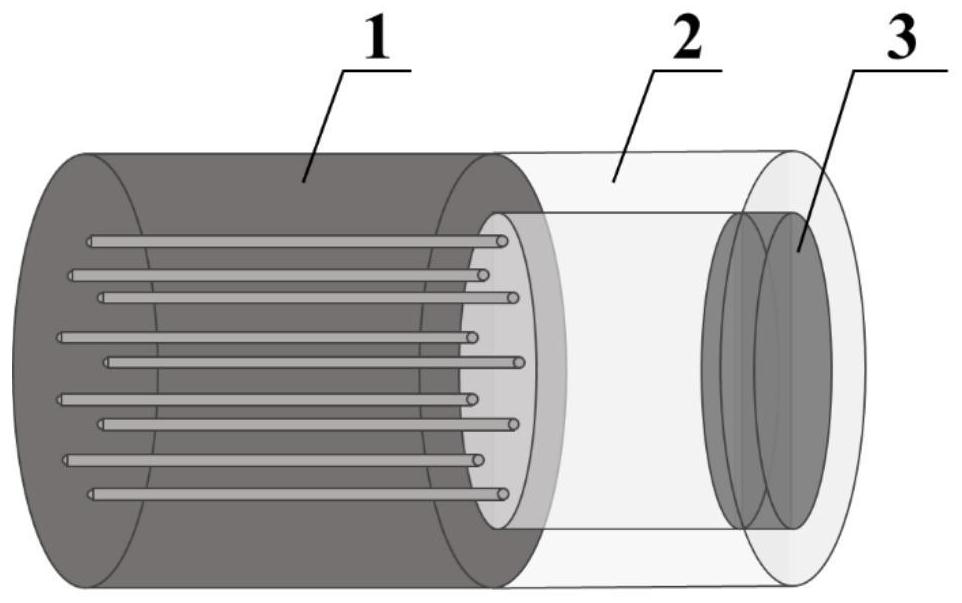

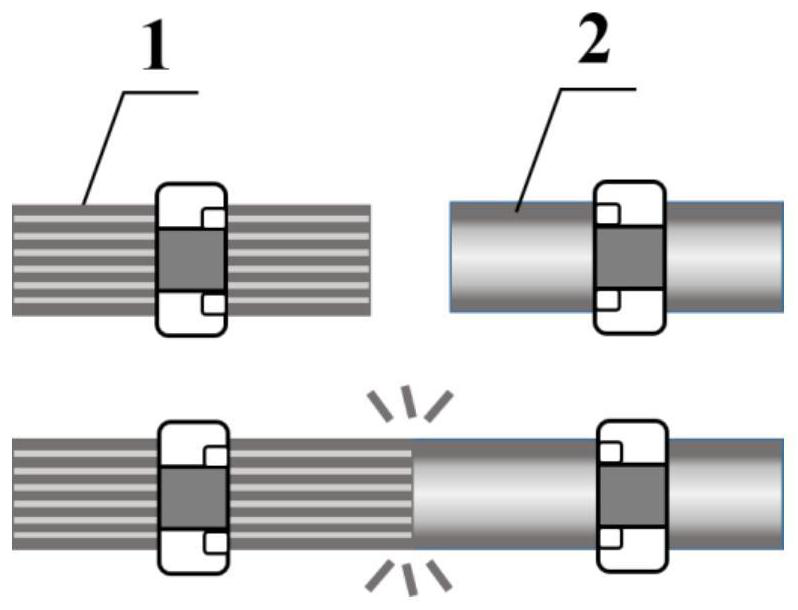

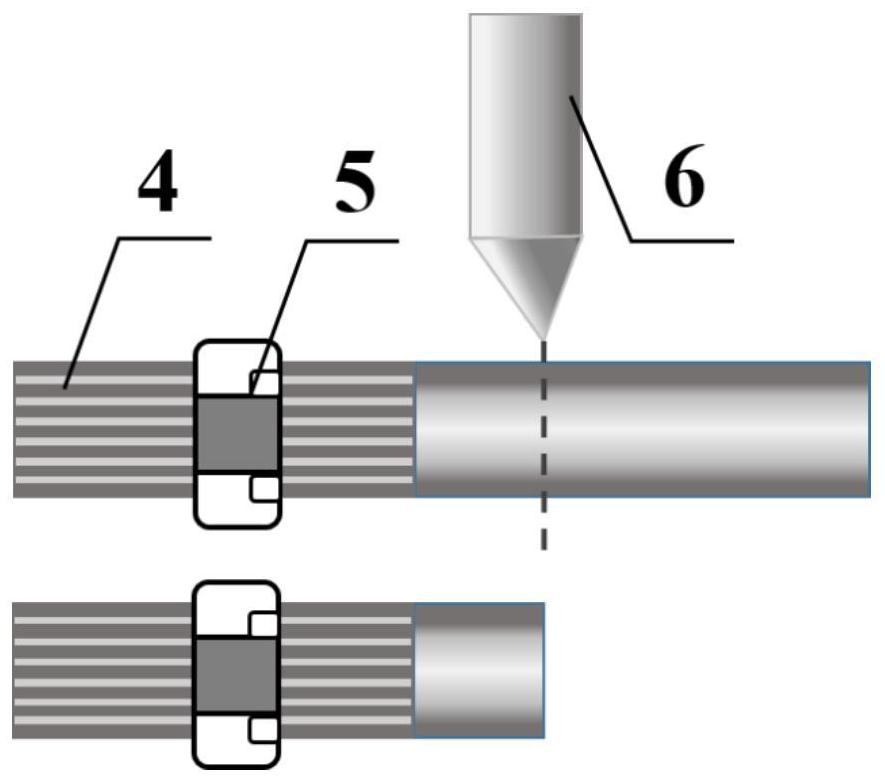

FP pressure sensor based on low-temperature coupling effect of photonic crystal fiber

ActiveCN113375844ASatisfy higher precision requirementsMeet mass productionForce measurement by measuring optical property variationPolymer thin filmsOptical pathlength

The invention discloses an FP pressure sensor based on a low-temperature coupling effect of a photonic crystal fiber. The FP pressure sensor comprises the photonic crystal fiber, a quartz capillary tube and a polymer film, the welding surface of the photonic crystal fiber and the quartz capillary tube and the inner surface of the polymer film form two parallel reflecting surfaces of an FP interferometer. When light in the photonic crystal fiber encounters the two reflecting surfaces, reflected light is generated, the two beams of reflected light interfere in the photonic crystal fiber to generate an interference spectrum, when the cavity length of the FP interferometer changes along with the measured pressure, the changing optical path difference between the two beams of reflected light causes the movement of the interference spectrum, and by detecting the movement amount of the interference spectrum, the change of the measured pressure is obtained. The FP pressure sensor is suitable for measuring the conditions that the environment temperature change is large, the temperature change needs to be compensated, and the measured water pressure is small, meanwhile, the requirement for high precision is met, the manufacturing process is simple, and the size is small.

Owner:BEIHANG UNIV

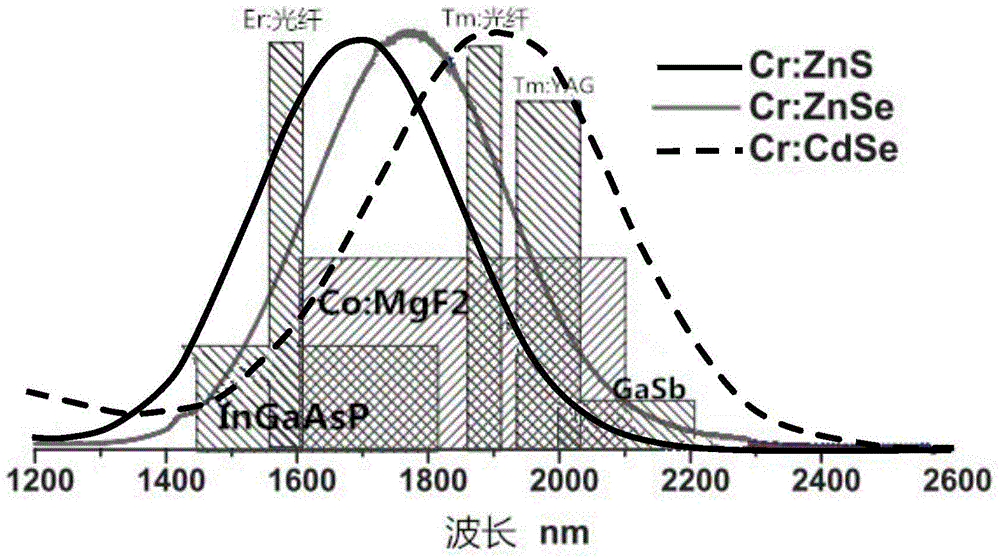

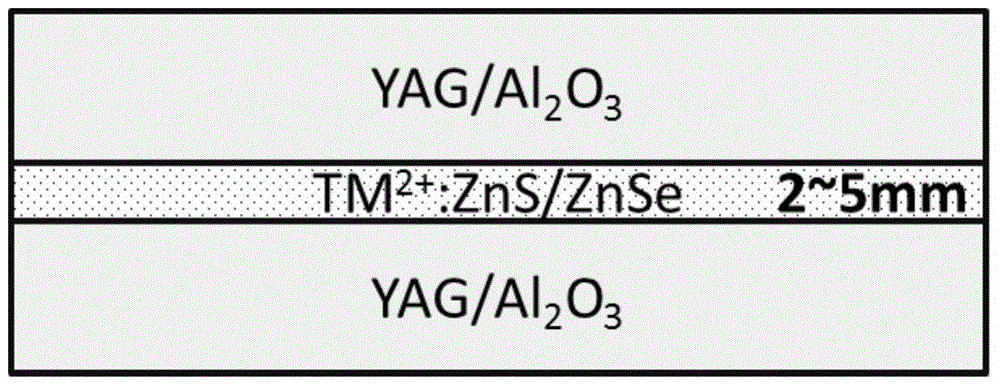

Transition-metal-doped zinc sulfide or zinc selenide planar waveguide material and preparation method

ActiveCN104441849ALower pumping thresholdImprove cooling effectCeramic layered productsZinc selenideHigh power lasers

The invention relates to a transition-metal-doped zinc sulfide or zinc selenide planar waveguide material and a preparation method. The transition-metal-doped zinc sulfide or zinc selenide planar waveguide material is characterized in that a YAG (yttrium aluminum garnet) or Al2O3 lath is respectively combined to two sides of transition-metal-ion-doped zinc sulfide or zinc selenide ceramic to form a sandwich planar waveguide structure, so that a heat-mirror effect of laser can be effectively controlled, and the intermediate infrared waveguide laser output is realized. By adopting the transition-metal-doped zinc sulfide or zinc selenide planar waveguide material, not only can the heat management be effectively realized by virtue of the sandwich composite structure, but also the mass production can be realized, and important significance on the development of a high-power laser technology and integrated optics can be realized.

Owner:SHANGHAI INST OF OPTICS & FINE MECHANICS CHINESE ACAD OF SCI

Preparation method of titanium alloy kirschner wire with high strength and plastic matching

The invention belongs to the technical field of medical titanium alloy material processing, and particularly relates to a preparation method of a titanium alloy kirschner wire with high strength and plastic matching. The titanium alloy is prepared from the chemical compositions in percentage by mass: 5.8% to 6.2% of Al, 3.8% to 4.2% of V, 0.15% to 0.2% of Fe, 0.08% to 0.13% of O, less than or equal to 0.05% of C, less than or equal to 0.005% of H, less than or equal to 0.01% of N and the balance of Ti; firstly, round bar billets are obtained by melting, forging and rolling processes, then a low-high-low hot deformation processing method and a composite processing method of a low-temperature hot deformation technology are adopted, and finally a finished wire is prepared by a processing method of stress relief annealing and centerless grinding. According to the preparation method, high-strength plastic Ti-6Al-4V alloy intramedullary needle wire for medical products can be produced, and qualified raw materials can be provided for manufacturing intramedullary needle products of orthopedic medical devices.

Owner:中科锐金山东钛业科技有限公司

Machining method for small NdFeB magnetic ring with high verticality requirement

ActiveCN105538108AMeet mass productionAchieve mass productionRevolution surface grinding machinesGrinding drivesSurface finishEngineering

The invention discloses a machining method for a small NdFeB magnetic ring with a high verticality requirement. A semi-finished small NdFeB magnetic ring product is obtained through the steps of grinding a small magnetic pillar in a centerless grinding mode, drilling an inner hole and cutting the thickness. Surface finishing is carried out on the upper surface and the lower surface of the semi-finished small NdFeB magnetic ring product through a high-precision two-surface grinding machine. Finishing is carried out on the outer diameter of the small NdFeB magnetic ring subjected to surface finishing through a high-precision centerless grinding machine. Finally, finishing is carried out on the inner diameter of the small NdFeB magnetic ring subjected to outer diameter finishing through an automatic bearing inner circle grinding machine. A machining allowance is reserved on the semi-finished small NdFeB magnetic ring product and then is eliminated through machining, and finally, the location degree of an inner hole of the small NdFeB magnetic ring relative to the outer diameter is smaller than 0.015 mm, and the verticality, measured with the inner hole as the benchmark, of the plane of the small magnetic ring is 0.01 mm-0.03 mm. The machining method for the small NdFeB magnetic ring with the high verticality requirement has the advantages that machining is achieved through mature automatic equipment, the machining method is simple, volume production of the small NdFeB magnetic ring can be realized, and the small NdFeB magnetic ring machined through the method can meet the verticality design requirement.

Owner:NINGBO YUNSHENG MAGNET DEVICES TECH +1

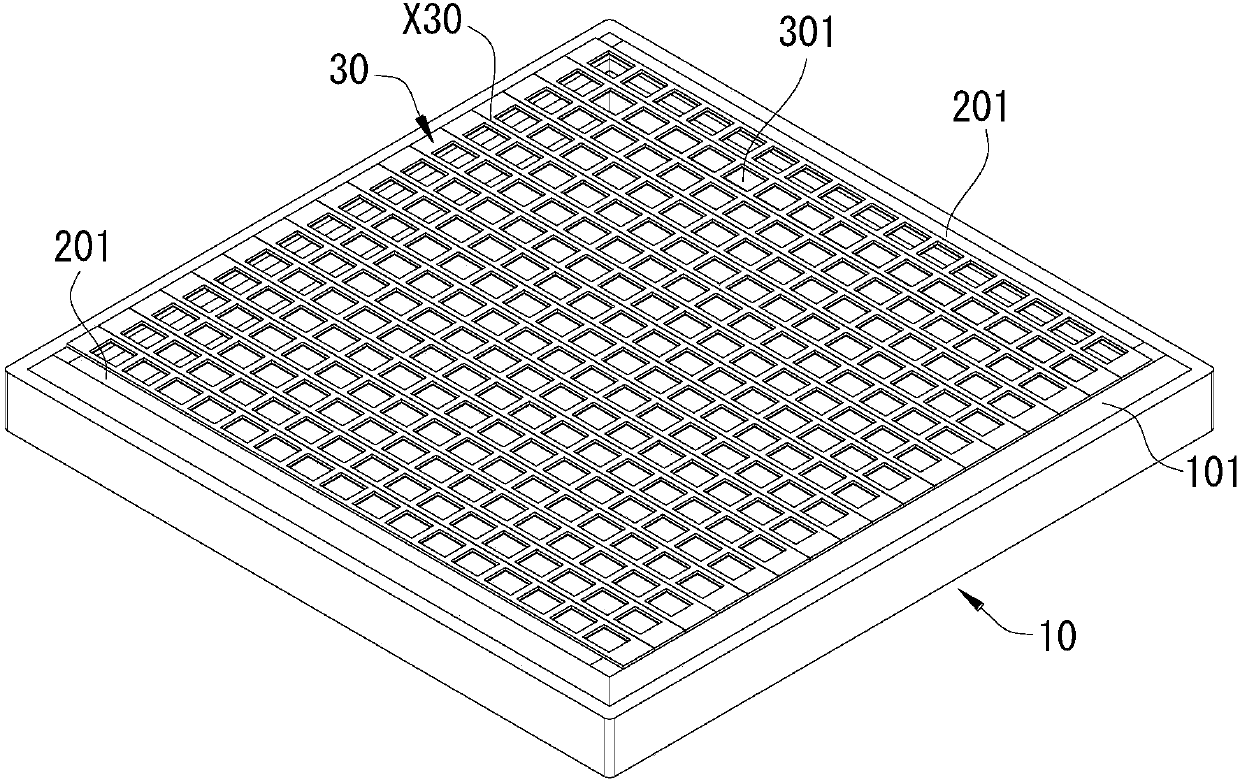

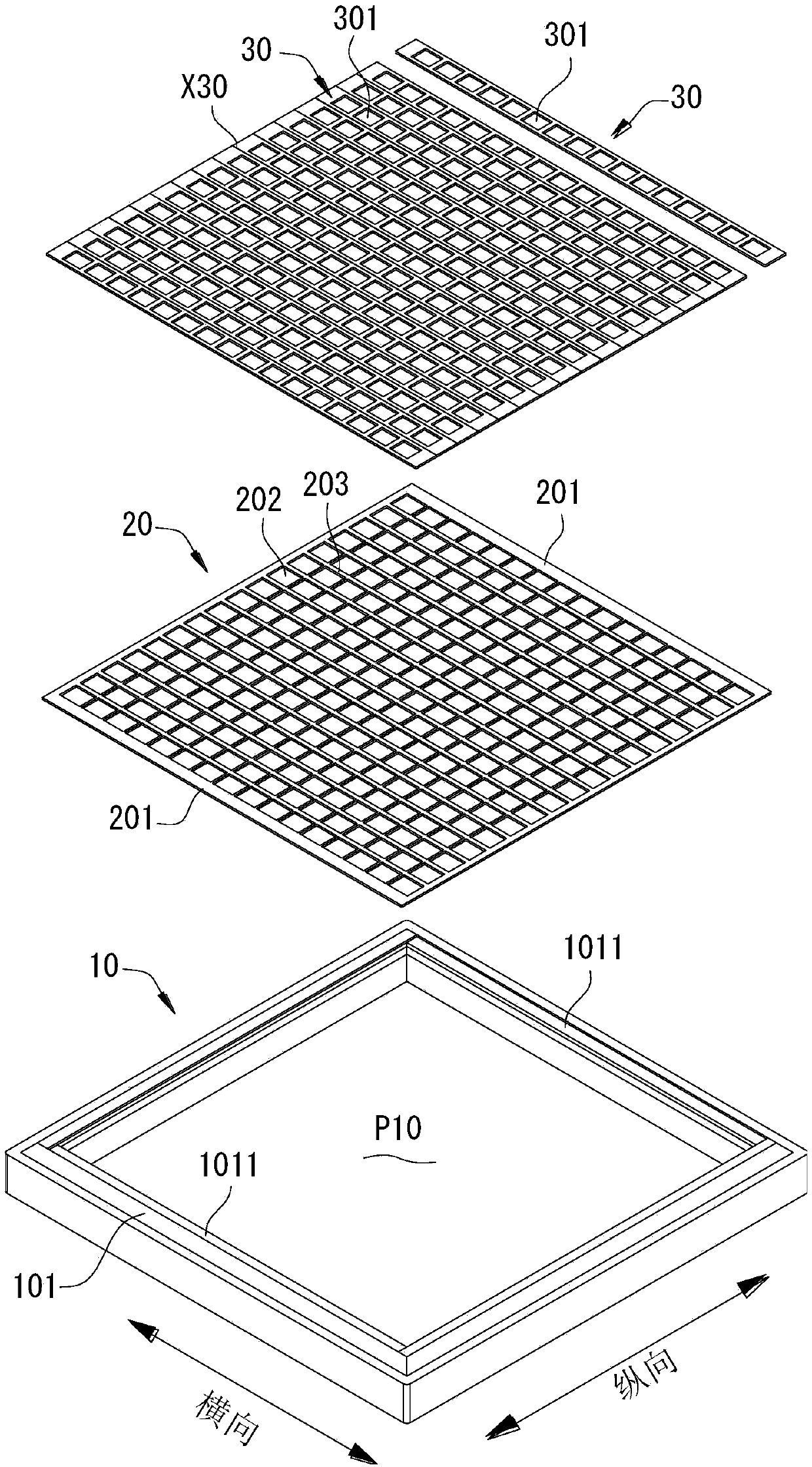

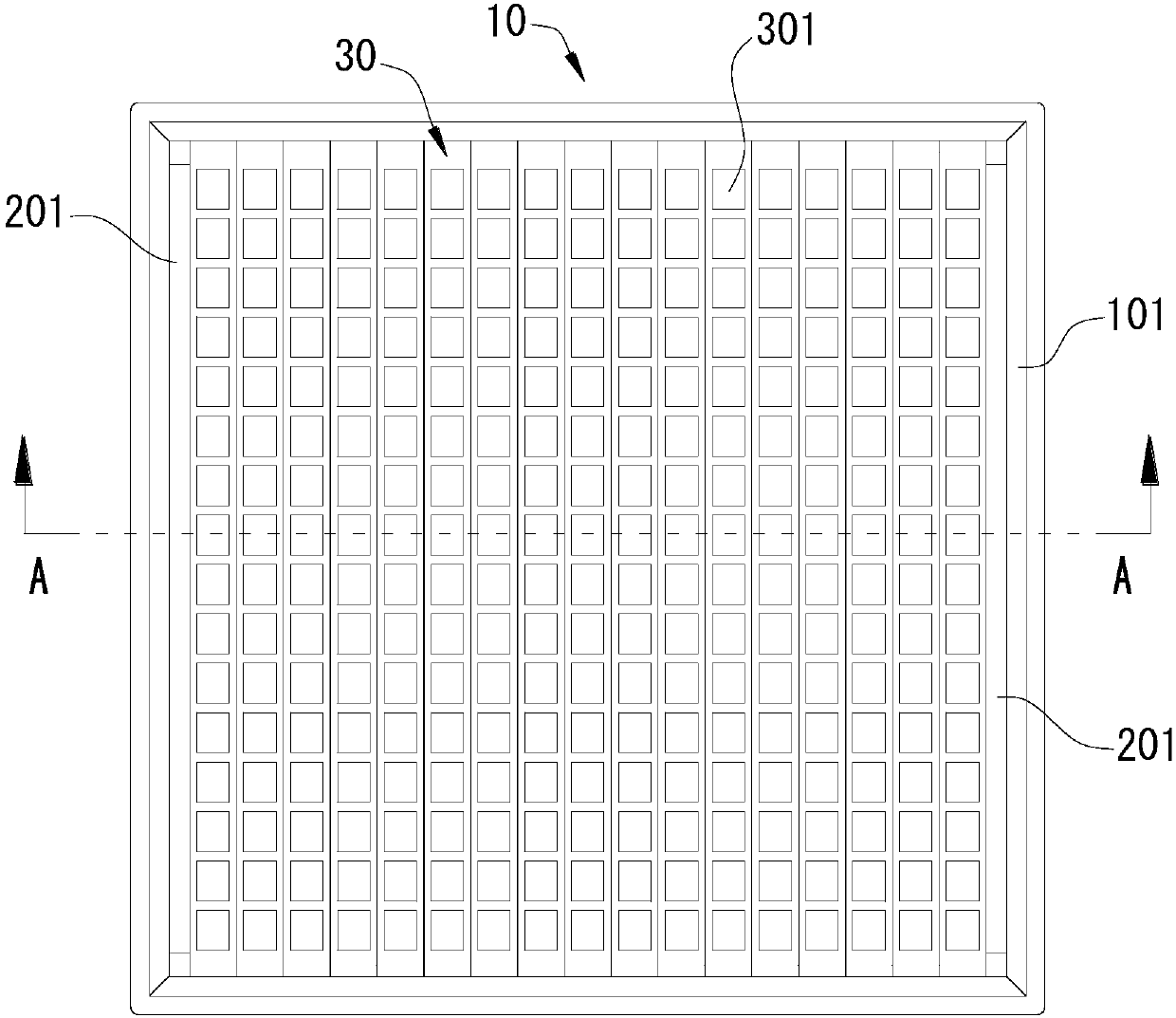

High-precision mask plate

PendingCN107815642AStable structureImprove yieldVacuum evaporation coatingSputtering coatingDisplay deviceStructural engineering

The invention discloses a high-precision mask plate which comprises a plate frame, multiple strip-shaped mask sheets and a supporting mask net. A hollow-out area is formed in the center of the plate frame. The periphery of the hollow-out area forms a frame edge. The top faces of two opposite edges on the plate edge are provided with strip-shaped grooves correspondingly. A spliced gap is formed between every two adjacent strip-shaped mask sheets. The two ends of each strip-shaped mask sheet are welded to the top faces of the other two opposite edges on the plate edge. Each strip-shaped mask sheet is provided with a mask pattern. The supporting mask net is located below the multiple strip-shaped mask sheets. The two opposite side edges on the supporting mask net extend to form welding edgescorrespondingly. The two welding edges are welded into two strip-shaped grooves correspondingly. The supporting mask net supports the multiple strip-shaped mask sheets and covers all the spliced gapswithout shielding all the mask patterns. According to the high-precision mask plate, the film coating requirement of a glass substrate with the large size can be met, batch production is achieved, theproduction efficiency is improved, and the requirements of a displayer for the yield and precision in the batch production process can also be met.

Owner:深圳浚漪科技有限公司

Ivory tint handicraft wood fan blank bleaching technique

InactiveCN1528575AColor fast to lightImprove impact strengthUmbrellasWood treatment detailsChemistryMetal

The invention is an ivory technical wooden fan blank bleaching technique, technical steps: (1), weight percent of each component in bleacher solution: 20-50% concentration oxydol 0.93457-0.71428, 5-30% concentration sodium hydroxide solution 0.01869-0.21428 and industrial alcohol 0.04674-0.071428; (2), bleaching: soaking separated fan blanks in the oxydol and sodium hydroxide solution for 5-10 hours, and fan edge in the oxydol, sodium hydroxide solution and alcohol solution for 10-12 hours; (3), washing: washing qualified fan blanks and edges by clear water to eliminate the solutions; (4)separating: making the fan blanks and edges whose whiteness is lower than 70% repeat the step (2); (5), drying: cold-placing the fan blanks and edges to dry, where water ratio is up to 12-14%. It keeps original property of timber, strong color lightfastness, etc.

Owner:NANJING FORESTRY UNIV +1

Quick-frozen Chinese cabbage making process

InactiveCN104585297AImprove qualityMeet mass productionFruits/vegetable preservation by freezing/coolingBiochemical engineeringImpurity

The invention relates to a quick-frozen Chinese cabbage making process which comprises the following steps: primarily processing; picking and cleaning; cleaning and re-checking; blanching; cooling with precooling water; draining by vibration; finally removing impurities; quickly freezing; cutting; clothing thin ice; and weighing and packaging. The quick-frozen Chinese cabbage making process provided by the invention can meet the requirement of batch production, and is high in freezing speed.

Owner:ANHUI DONGBAO FOOD

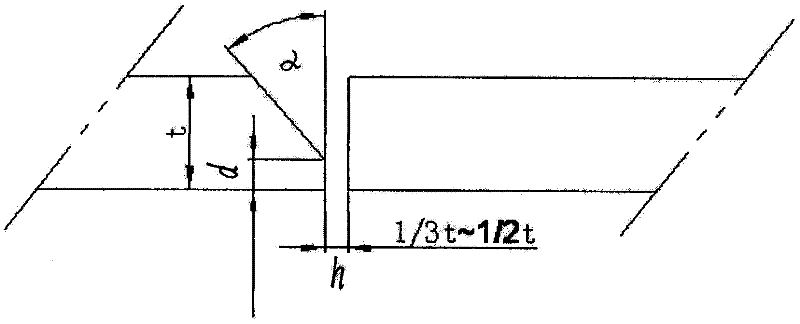

Welding method of carbon steel thin-plate box

ActiveCN102500890AReasonable choiceEasy to makeArc welding apparatusWorkpiece edge portionsCarbon steelBatch production

The invention provides a welding method of a carbon steel thin-plate box, comprising the following steps of: firstly, machining a reasonable bevel structure on a thin plate to be welded and welding by utilizing a submerged arc automatic welding way, wherein welding parameters are as follows: a welding current I is 38-48 A, a welding speed v is 80-100 mm / min<-1>, the flow Q of CO2 gas is 13 L.min<-1>; combining and welding all panels of the box and splicing the four sides and the bottom surface of the box; carrying out discontinuous spot welding before welding, wherein the gap between spaced points is 100 mm; and then additionally arranging an X-shaped supporting rod in the box to keep the rigidity of the welding process. The welding method provided by the invention is applicable to machining the carbon steel thin-plate box; and the welding process has the advantages of utilization of the automatic welding way, convenience for manufacturing the bevel, reasonable technological parameters and good process stability, and the welding quality can meet the requirements of batch production, thereby realizing technical indexes of the product design.

Owner:TANGSHAN CAOFEIDIAN DISTRICT SHOUYAN MACHINERY CO LTD

Plate spring clamp combined structure for heavy-load dumper

ActiveCN104595401AAdd transition designStress reliefLeaf springsResilient suspensionsSteel platesBatch production

The invention relates to a part for an automotive suspension, in particular to a plate spring clamp combined structure for a heavy-load dumper. The plate spring clamp combined structure for the heavy-load dumper comprises a clamp base which is connected between a plate spring and a U-shaped opening of a clamp; the clamp base is matched with the plate spring clamp for use; holes are formed in two sides, close to the U-shaped opening, of the plate spring clamp and are used for assembling connecting bolts; rivet holes are formed in the bottom the plate spring clamp and are used for riveting the bottommost piece of steel plate springs with the clamp base and the clamp through rivets; each of two ends of the clamp base is of a limiting structure which is used for limiting the plate spring clamp; riveting holes which are riveted with the steel plate spring pieces and the bottom edge of the clamp are formed in the middle structure of the clamp base; the plate spring clamp is made of a steel plate which is 8mm thick and 30mm wide in specification. The plate spring clamp combined structure is convenient to produce and convenient in assembly technology and meets the condition of batch production; the transitional design of the clamp base is added, so that the stress at the bending part of the clamp steel plate is eliminated; the design concept of the plate spring clamp continues to be used; the design life of the plate spring clamp is ensured.

Owner:HUBEI DAYUN AUTOMOBILE

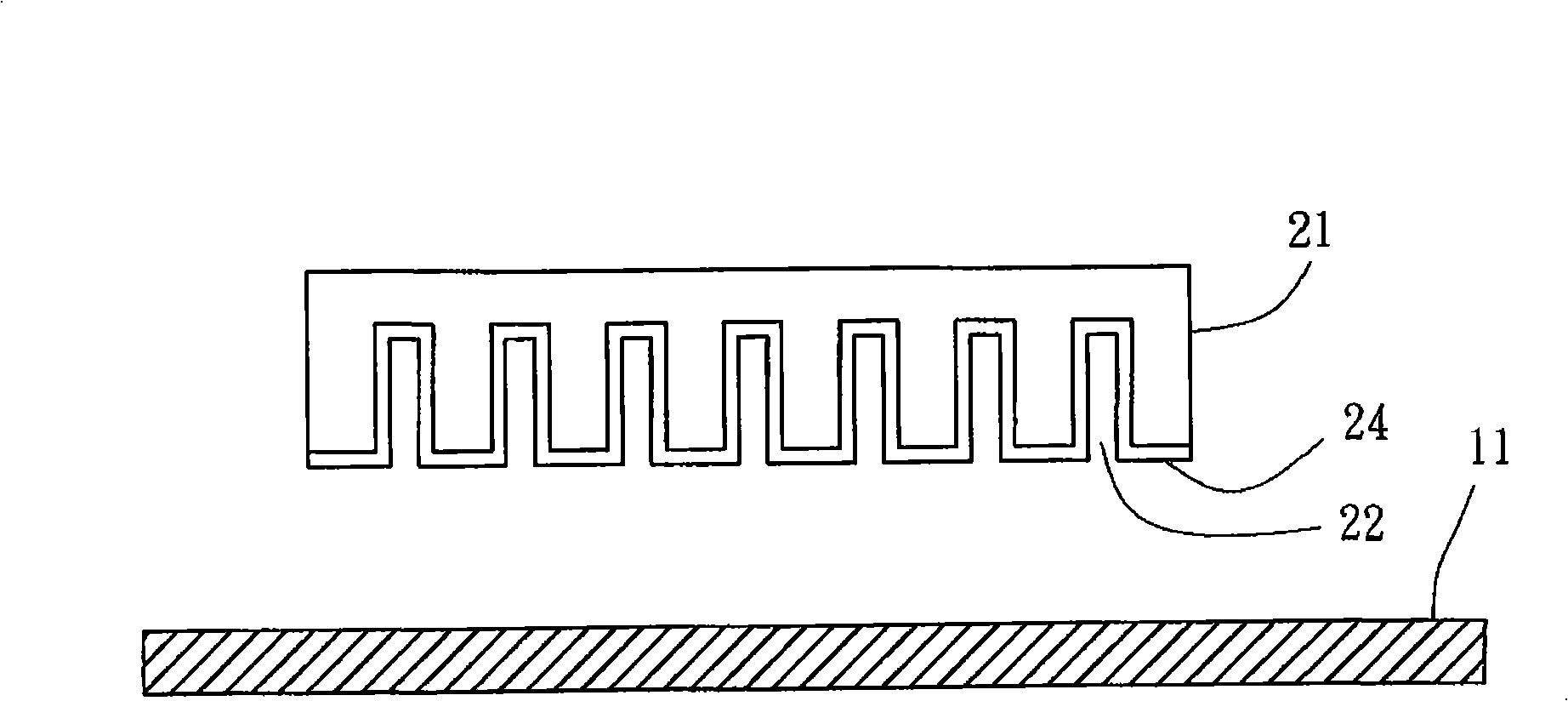

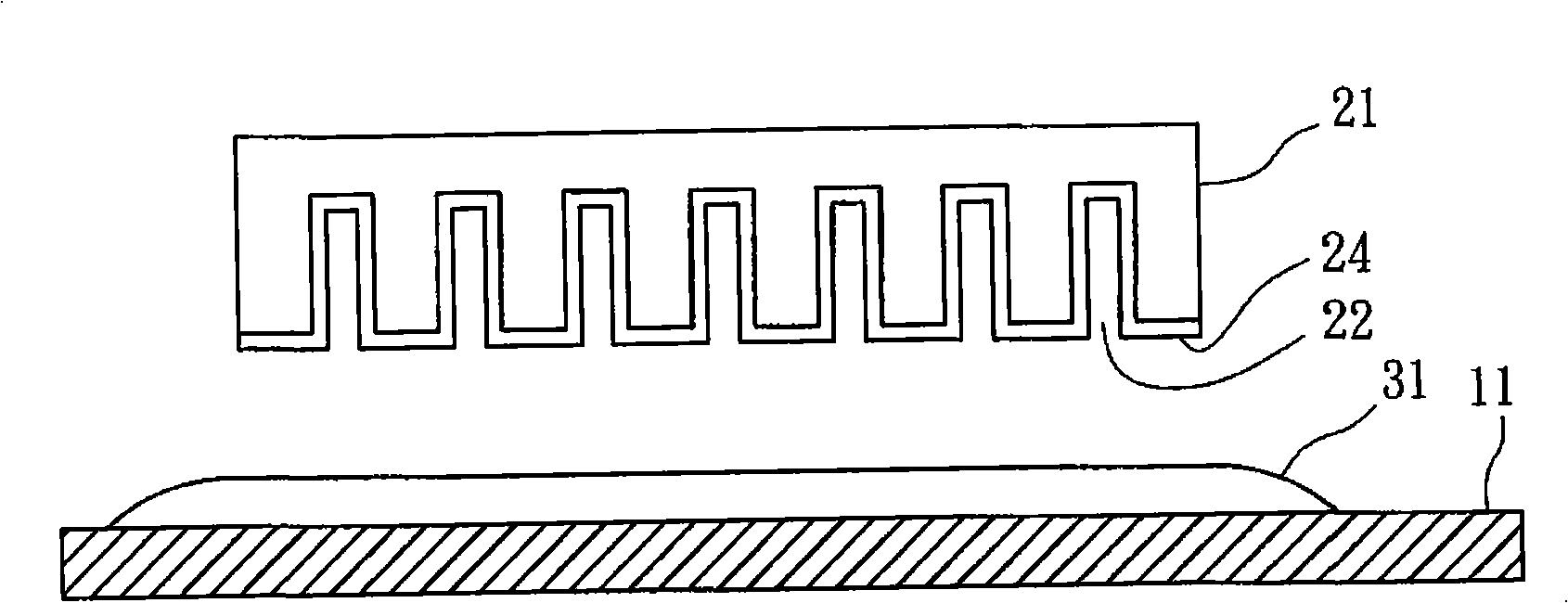

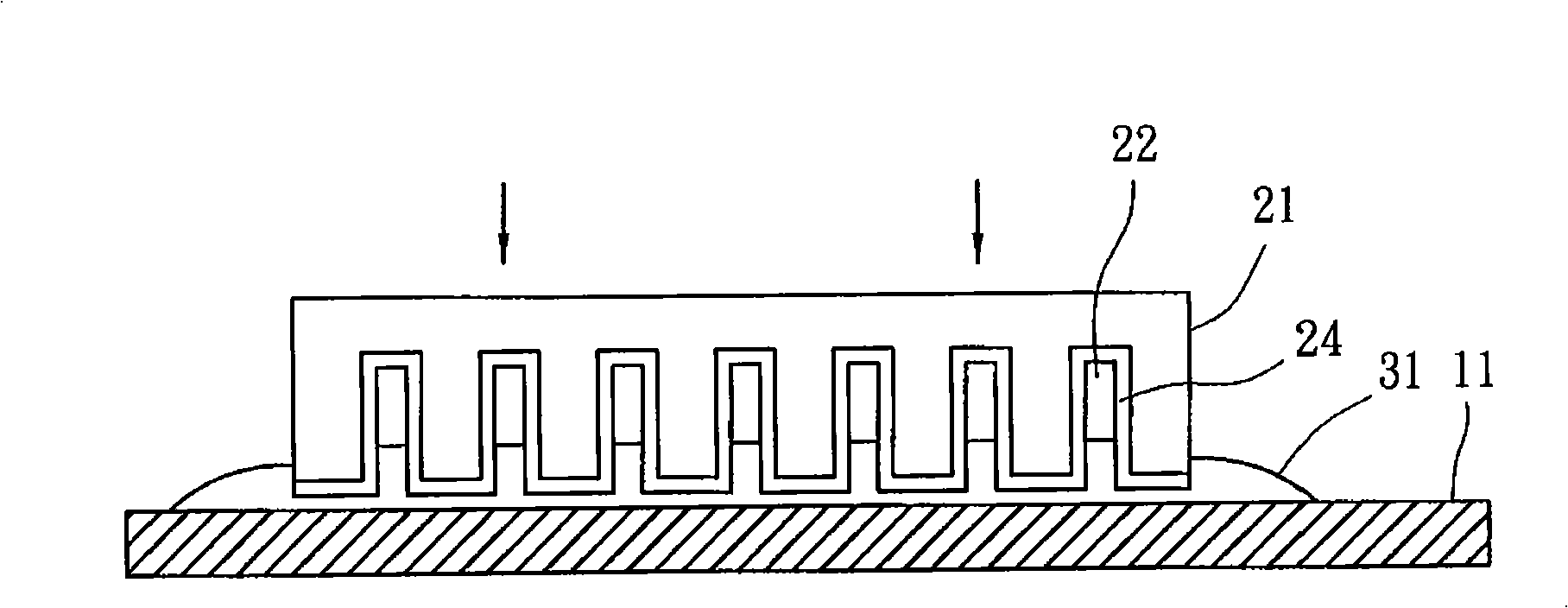

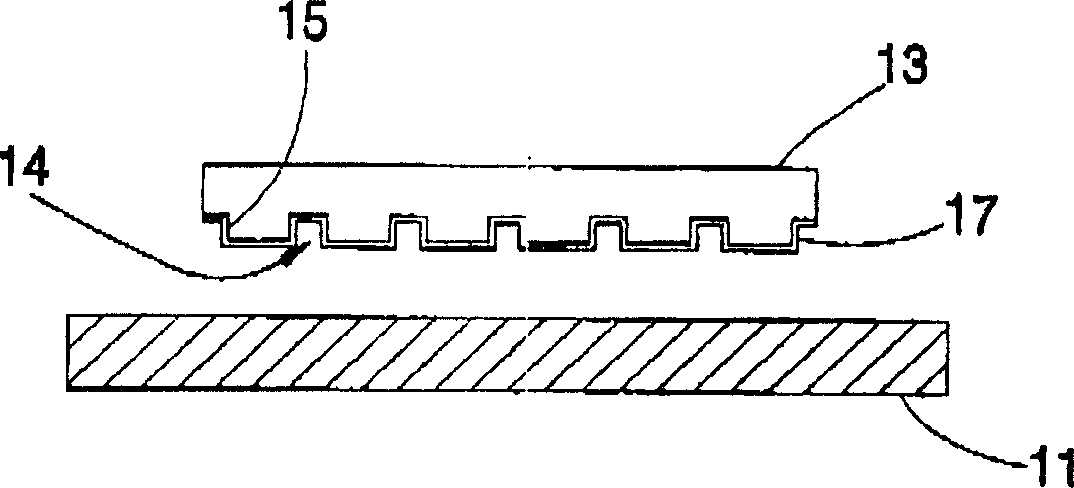

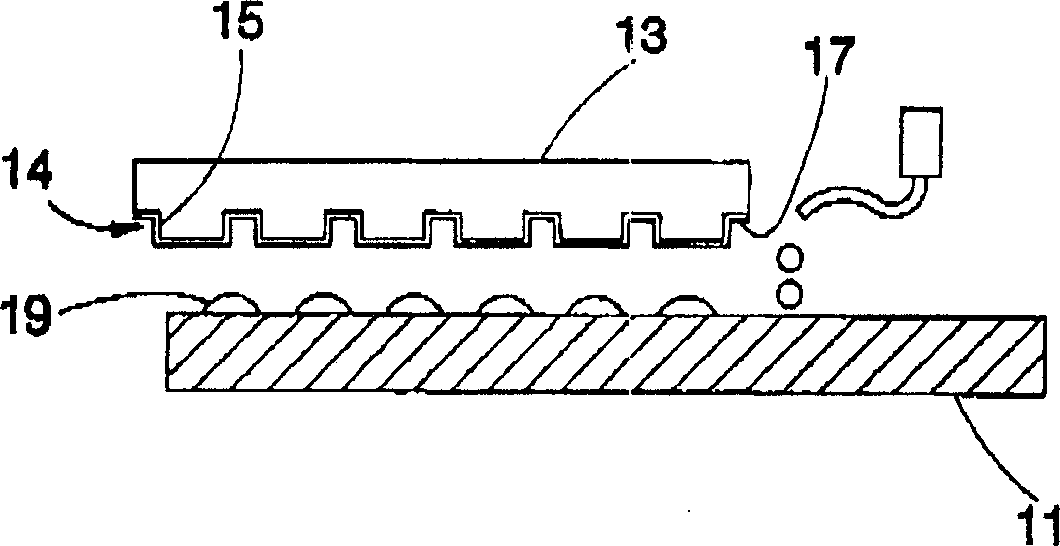

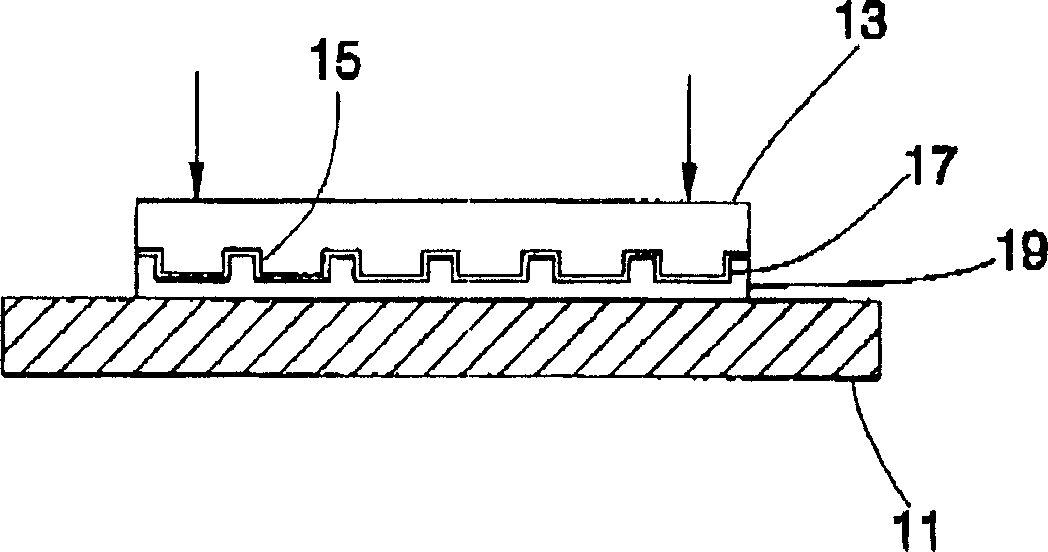

Viscous microstructure preparation method

InactiveCN101311828AMeet mass productionLow costSemi-permeable membranesPhotomechanical apparatusLiquid stateNanometre

A method for manufacturing viscosity microstructure comprises the procedures as follows: a) a base plate and a mould are prepared and the bottom of the mould is provided with a plurality of nano-scale sockets; b) a liquid impression layer is arranged on the base plate; c) the mould is pressed under the base plate, so the liquid impression layer goes into the socket to a preset depth, thus forming a substrate and a nano-bulge arranged on the substrate; and air in the socket is compressed; d) the impression layer is turned into solid state by solidification; and e) demoulding, the mould is pulled upwardly off the base plate. Due to the bounce produced by the compressed air in the socket, the nano-bulges formed in the socket can be withdrawn from the sockets easily. The substrate and the nano-bulges are combined together to form the viscosity microstructure. Therefore, the requirements of mass production and low cost can be met.

Owner:CONTREL TECH CO LTD

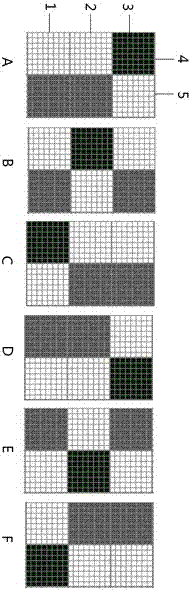

Single-weft gradual-change color-development double-warp three-weft jacquard fabric weaving method

ActiveCN107988682AMeet mass productionMeet technical requirementsSwivel-woven fabricsLappet-woven fabricsYarnEngineering

The invention relates to a single-weft gradual-change color-development double-warp three-weft jacquard fabric weaving method, and belongs to the technical field of lappet fabric weaving method. Warp-direction yarn composed of first warp and second warp and weft-direction yarn composed of first weft, second weft and third weft serve as treatment objects, organizational structure model is built, and chromogenic weave design, back weave design, binding weave design, color card weave process design, obtaining of maximum effective color-development number, digital pattern design and combination structure design are conducted to from a single-weft gradual-change color-development double-warp three-weft combination structure pattern, the density of weft and warp is designed, and according to thefabric combination structure pattern, a single-weft gradual-change color-development double-warp three-weft jacquard fabric can be obtained through weaving. The method can be applied to jacquard fabric weaving, and the single-weft gradual-change color-development jacquard fabric with the double-warp three-weft structure is obtained.

Owner:ZHEJIANG SCI-TECH UNIV

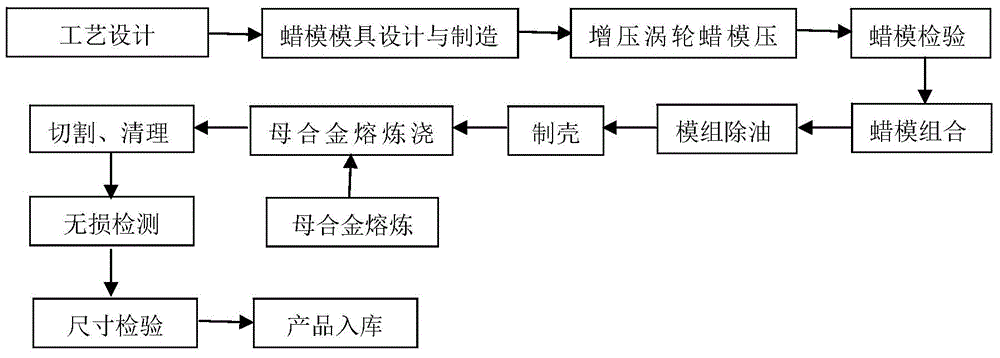

Casting process of turbine of turbocharger for gasoline engine

ActiveCN104399884ASolve the process route method of precision casting without marginHigh dimensional accuracyFoundry mouldsFoundry coresWaxSand blasting

The invention discloses a gasoline engine turbocharger marginless investment precision casting process, wherein the process comprises the following steps: 1) mold design and manufacturing of a wax mold; 2) pressing and inspection of the turbocharger wax mold; 3) combination and oil removal of a turbocharger wax mold set; 4) shell preparation of the turbocharger wax mold set; 5) vacuum smelting of a mother alloy for pouring; 6) vacuum melting and pouring of a turbocharger casting piece; 7) cleaning, cutting and sand blasting of a turbocharger mold shell, and polishing of a casting head; and 8) nondestructive testing of the turbocharger casting piece, and inspection of the surface and dimension of the casting piece. The marginless precision casting process path method easily satisfies the mass production, can meet the use requirements, solves a passenger car gasoline engine turbocharger charging turbine, achieves the nationalization problem of the component, and can be stable in batch production.

Owner:METALINK SPECIAL ALLOYS CORP

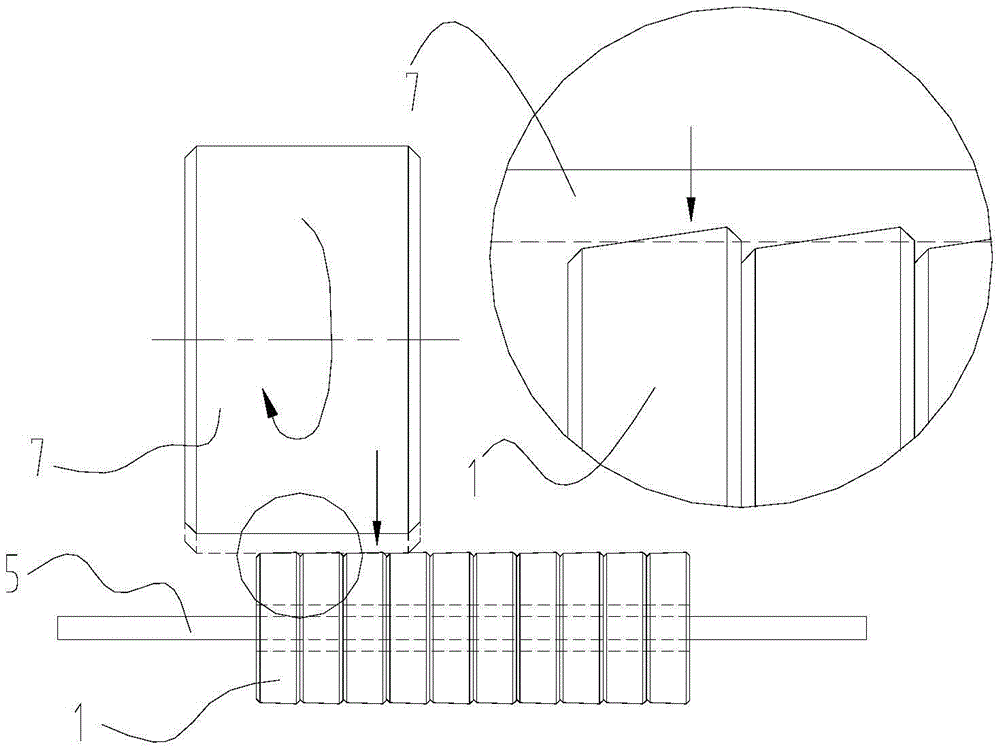

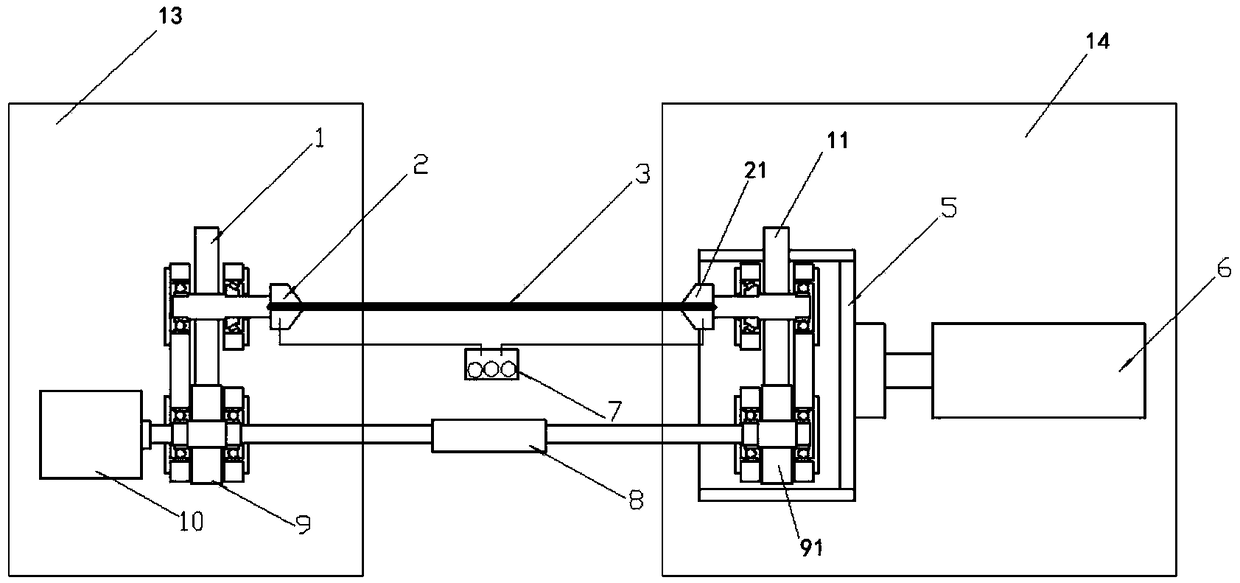

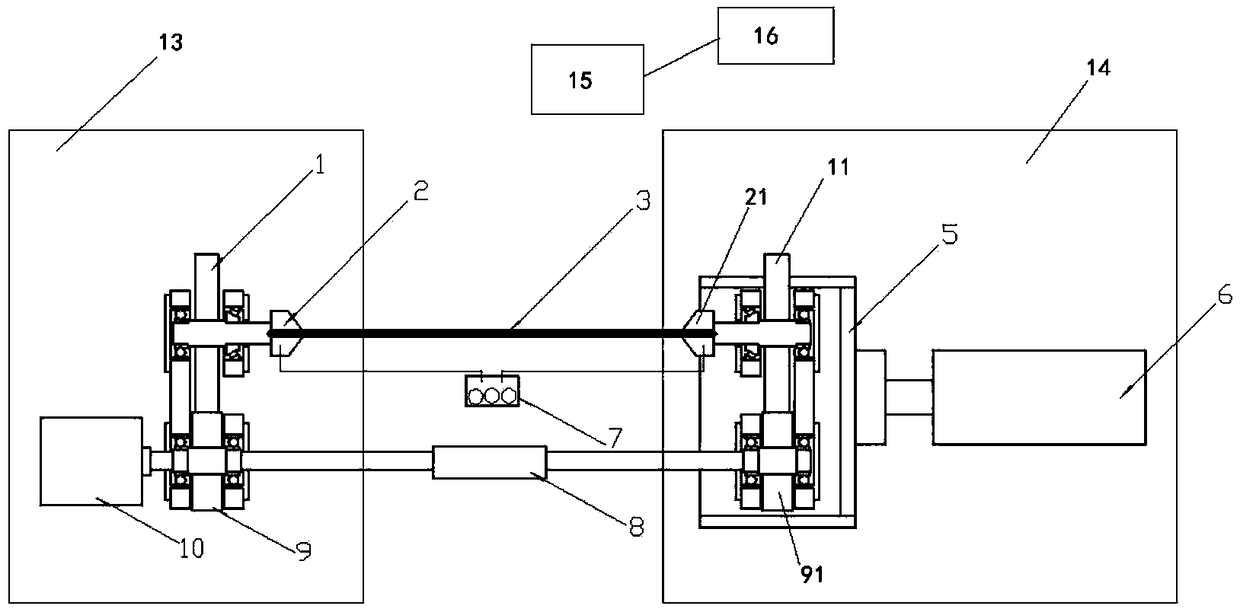

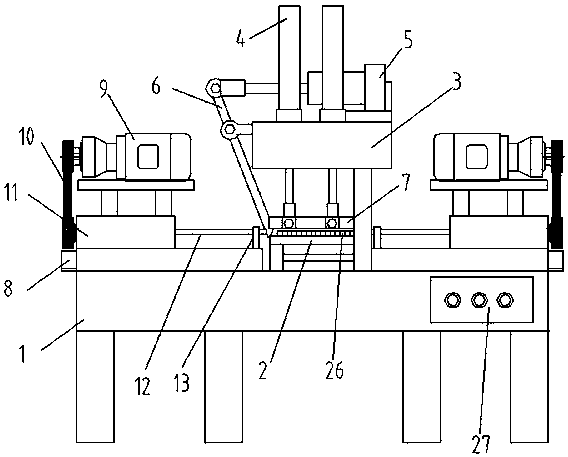

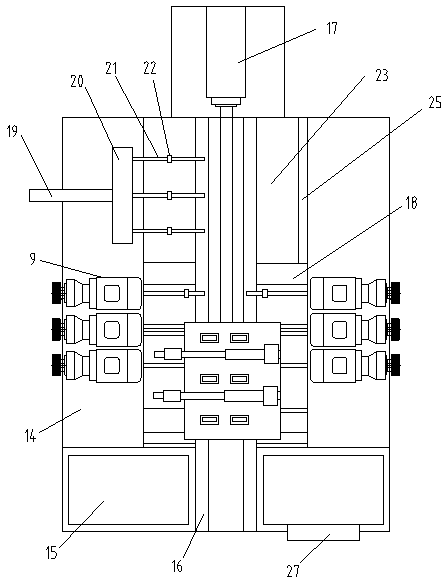

Dynamic alloy bar straightening mechanism, system and method, and dynamic alloy bar automatic straightening method

The invention discloses a dynamic alloy bar straightening mechanism, system and method and a dynamic alloy bar automatic straightening method. The dynamic alloy bar straightening mechanism comprises afixing assembly and a stretching assembly; the fixing assembly comprises a first rotary chuck (2), a first big gear (1) coaxially arranged with a rotary shaft of the first rotary chuck, a first smallgear (9) in transmission connection with the first big gear (1), and a speed reduction motor (10) with a power output shaft provided with the first small gear (9); and the stretching assembly comprises a second rotary chuck (21), a second big gear (11) coaxially arranged with a rotary shaft of the second rotary chuck (21), and a second small gear (91) in transmission connection with the second big gear (11). The problem that bars are softened and droop to be bent to affect the straightness accuracy due to straightening temperature rising can be effectively solved. The methods have the characteristics of being convenient to implement, rapid, mechanical and the like, operation is convenient, and the batch production and precision requirements can be met.

Owner:西安圣泰金属材料有限公司

Landscaping sculpture real sample modeling method

The invention relates to a landscaping sculpture real sample modeling method. The landscaping sculpture real sample modeling method comprises the following steps: selecting materials; drawing a pattern and manufacturing a scraping plate; decomposing the pattern by the scraping plate and manufacturing a template drawing; manufacturing a real sample baseboard; manufacturing a framework, covering the framework with a three-ply board, bonding the manufactured template drawing on the three-ply board and fixing to assemble a sculpture model; placing the sculpture model on the real sample baseboard, laying cement and bricks on the baseboard according to the sculpture model until sealing the top, filling edges and corners on the surface of the real sample with concrete, disassembling the scraping plate and the framework, grinding and polishing after the concrete on the surface of the real sample is solidified, thus obtaining the real sample modeling of the landscaping sculpture. The method can be used for manufacturing various landscaping sculpture real samples of complicated shapes; by using the manufactured real sample models, the complex and tedious sculpture task can be completed just by pouring in a production mode of molded pouring of reinforced concrete, the production speed is high, the cost is low, the requirement of batch production of the landscaping sculptures for urban beautification can be met.

Owner:纪汉伟

Bamboo cutting board processing technology

PendingCN108327013AReduce labor intensityReduce manufacturing costDrilling machinesCane mechanical workingAssembly lineFiber orientation

The invention discloses a bamboo cutting board processing technology which is characterized by comprising the following steps of ejecting, pressing and positioning bamboo splints according to a bamboofiber direction through a bamboo splint positioning mechanism; drilling longitudinal directions of the ejected, pressed and positioned bamboo splints through a drilling device; blowing away scraps for drilled holes through a scrap blowing device; and penetrating bolts into the holes so as to splice the bamboo splints. A bamboo cutting board processing device comprises a rack platform, the bamboosplint positioning mechanism for positioning the bamboo splints, the drilling device for drilling the bamboo splints after positioning the bamboo splints, the scrap blowing device for blowing the scraps after the bamboo splints are drilled, and a control device, wherein a set of assembly line equipment is formed according to the arrangement with an installation position sequence of a bamboo pressing position, a drilling position, a scrap blowing position and a bolt installing position, or a non-assembly line device is formed according to the arrangement with a staggered or ordered sequence without influencing a working state. According to the bamboo cutting board processing technology provided by the invention, the continuous operation can be realized, the product stability is high, the requirement on batch production can be effectively met, the labor intensity of workers is reduced, and the production cost of enterprises is greatly saved.

Owner:资溪县浙庆竹木有限公司

Production process of quick-frozen lily root

The invention relates to a production process of quick-frozen lily root. The production process of the quick-frozen lily root comprises the following sixteenth steps: selecting and storing raw materials; washing; peeling; trimming; vibrating and drying; maintaining; washing through bubbles; blanching; cooling by pre-cooling water; vibrating and drying; stirring mud; metering, boxing and forming; panning and stewing; quickly freezing; removing the lily root from a pan; checking and packaging. The production process of quick-frozen lily root provided by the invention can be used for meeting mass production, and is high in freezing speed and short in production process time.

Owner:ANHUI DONGBAO FOOD

Method for manufacturing nanometer paster

InactiveCN1840318AMeet mass productionCost reduction needsNanoinformaticsPhotomechanical apparatusUltraviolet lightsUltraviolet irradiation

The invention discloses a nanometer paster preparing method, which comprises the following steps: a) preparing one base plate and one die in the vacuum environment, wherein at least one of the base plate and die is clarity; the die is on base plate, which has one pressing surface; the pressing surface is installed nanometer emboss; the nanometer emboss installs release agent; b) the base plate is covered with liquid coining inlay which can be irradiated by ultraviolet light and then cure; c) the pressing surface of die presses base plate; the coining inlay is filled between nanometer emboss and base plate; d) ultraviolet irradiation makes ultraviolet transmit die or base plate to be clarity; irradiating the pressing inlay makes the pressing inlay cure; e) demoulding, the die is moved away the base plate; the pressing inlay forms line in respect of nanometer emboss; the pressing inlay is the nanometer paster.

Owner:CONTREL TECH CO LTD

Automobile spring material with good brittleness resistance and good rupture resistance

The invention discloses an automobile spring material with good brittleness resistance and good rupture resistance. The automobile spring material consists of the following elements in percentage by weight: 0.3% to 0.8% of carbon, 0.2% to 0.3% of silicon, 1.8% to 2.0% of manganese, 1.2% to 1.8% of nickel, 0.02% to 0.04% of cobalt, 0.002% to 0.03% of aluminum, 0.2% to 0.24% of chromium, 0.01% to 0.03% of neodymium, smaller than or equal to 0.015% of sulfur, smaller than or equal to 0.015% of phosphorus and the balance of iron and inevitable impurities. The automobile spring material disclosed by the invention is capable of totally satisfying the automobile performance requirements on impact resistance, brittleness resistance and rupture resistance and is also capable of realizing batch production and lowering the cost.

Owner:ANHUI HEKUANG MACHINERY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com