Patents

Literature

42results about How to "Continuous welding" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

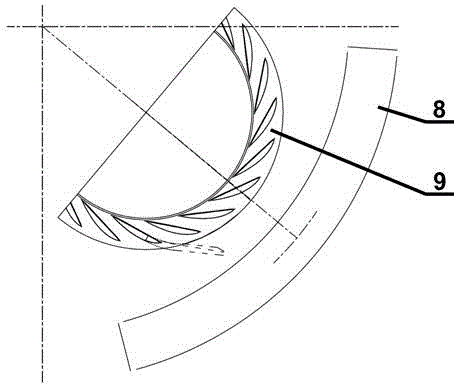

Horizontal fillet welding seam angle-wrapping process suitable for automatic welding

ActiveCN106312259AWelding looseWelding, the weld is full, and the size of the weld meets the loose requirementsArc welding apparatusFillet weldEngineering

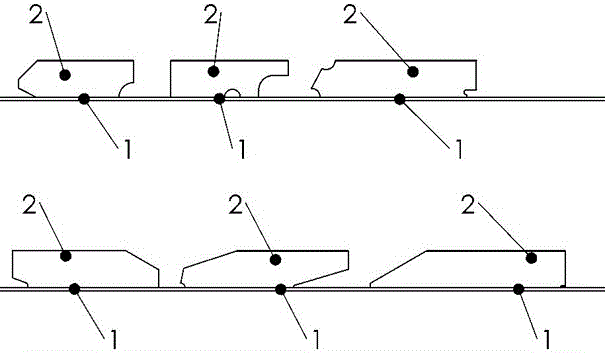

The invention provides a horizontal fillet welding seam angle-wrapping process suitable for automatic welding, and the horizontal fillet welding seam angle-wrapping process is suitable for unit vertical welding in a ship building process, adopts gas-shielded welding to carry out automatic welding to complete horizontal fillet welding seam angle-wrapping welding for a bottom plate and reinforcing ribs, and belongs to the technical field of gas-shielded welding automatic welding. According to the technical scheme adopted by the invention, two robots drive two welding guns; arcs are initiated from the two sides to drive the welding guns to move to the middle of the reinforcing ribs, so that angle-wrapped welding is completed, welding seams are full, and dimensions of the welding seams meet requirements. The horizontal fillet welding seam angle-wrapping process provided by the invention has the positive effects of reducing times of overlap welding, arc initiating and arc extinguishing, avoiding defects, reducing interferences of the welding guns and workpieces, especially reinforcing ribs with circular-arc holes in end parts, expanding automatic welding cover range and greatly simplifying trial teaching workload. The horizontal fillet welding seam angle-wrapping process is wide in scope of application, easily realizes automatic welding, has relatively low requirements on workpiece pairing, and improves welding quality and working efficiency.

Owner:TANGSHAN KAIYUAN AUTOWELDING SYST

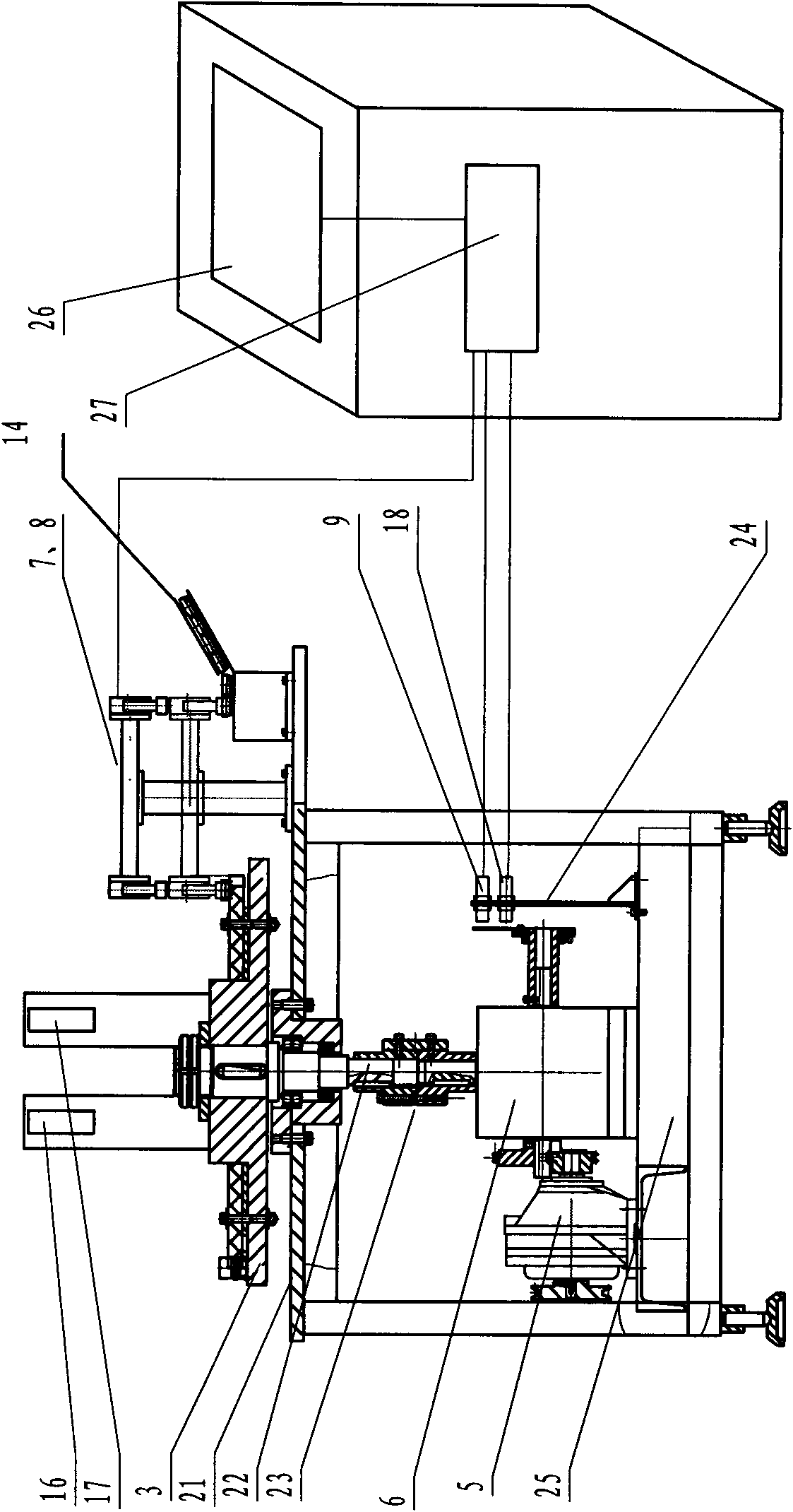

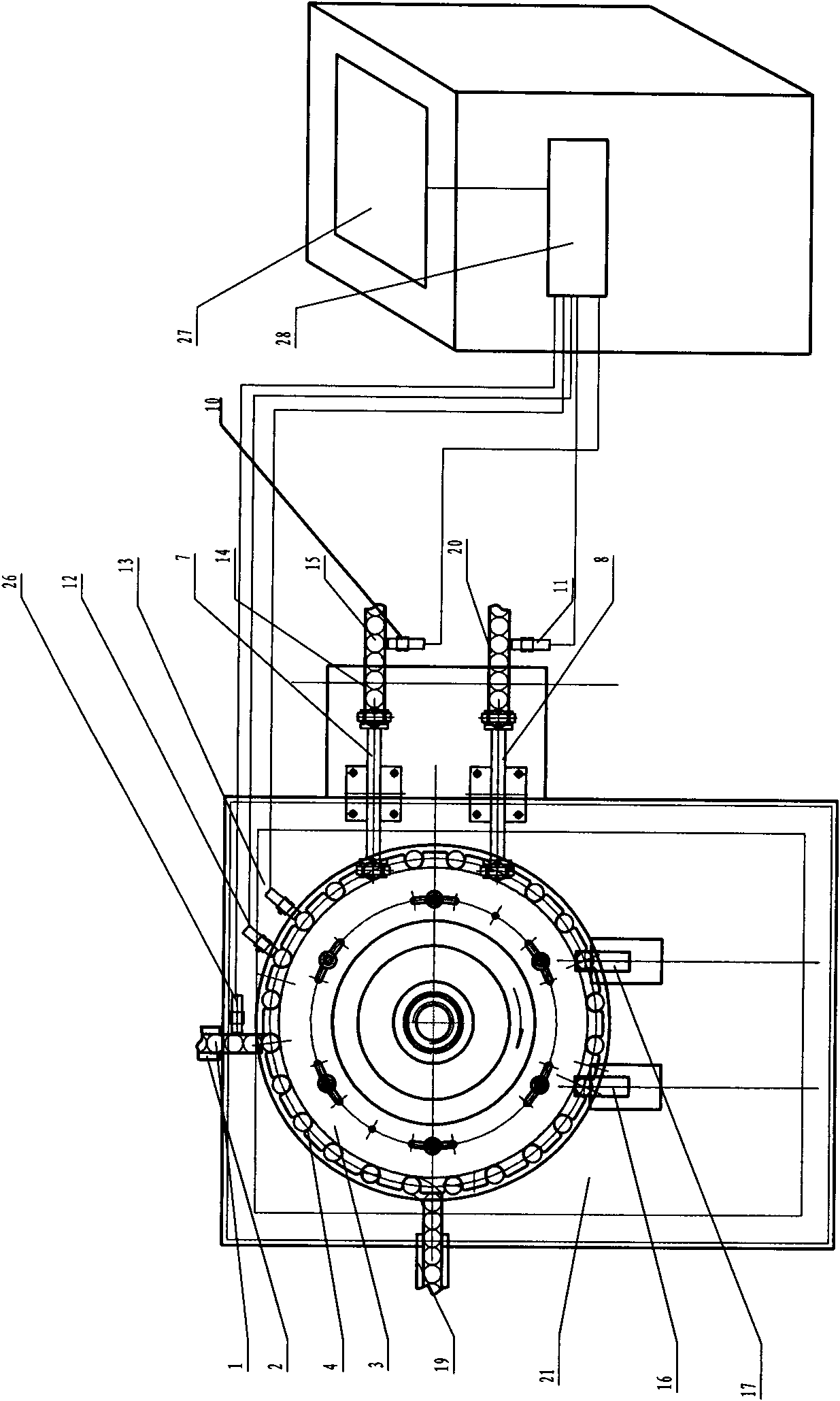

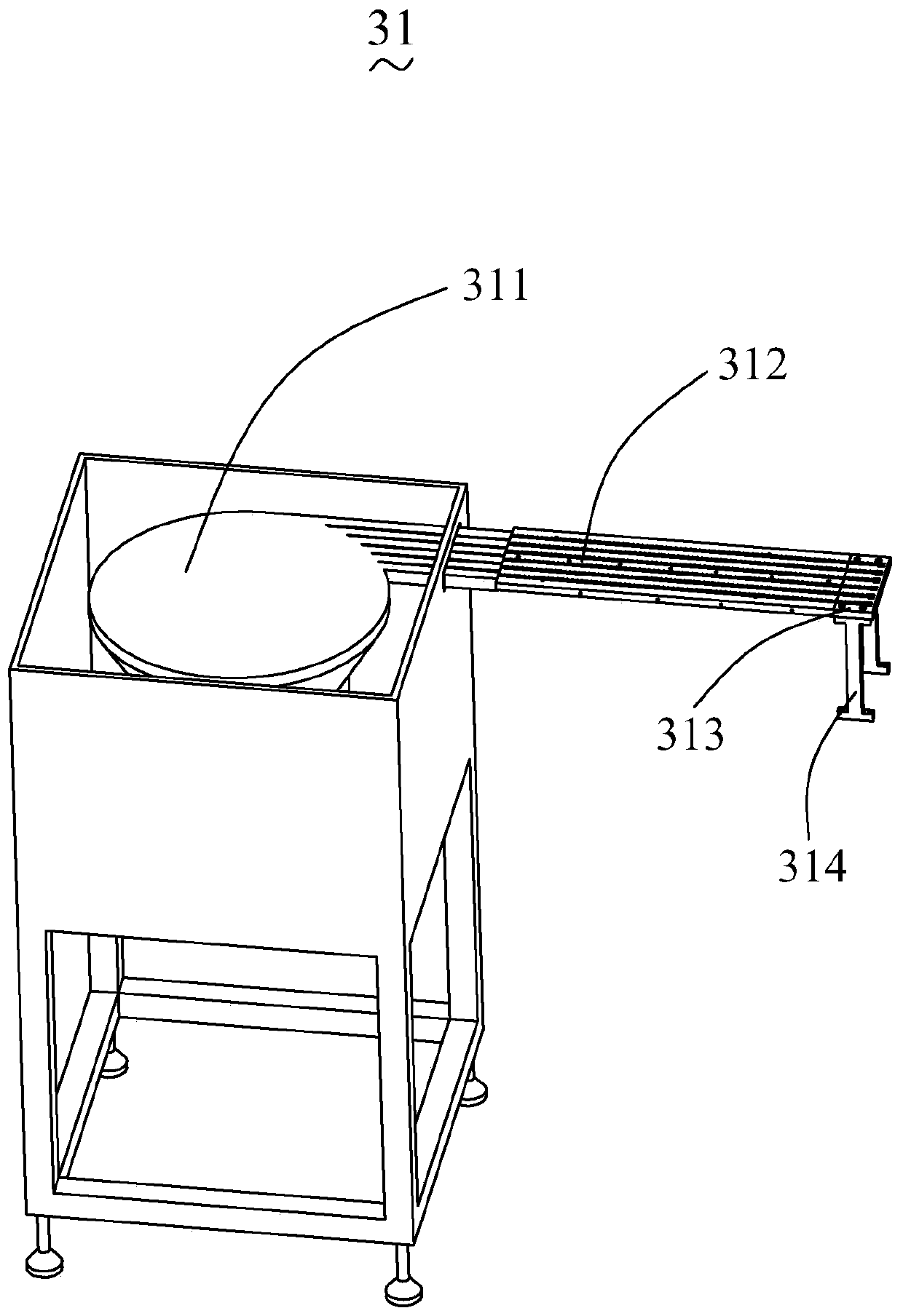

Full-automatic double-head ultrasonic plastic bottle cap welding device

InactiveCN102126287AContinuous weldingImprove reliabilityDomestic articlesUltrasonic weldingProgrammable logic controller

The invention discloses a full-automatic double-head ultrasonic plastic bottle cap welding device which comprises a bracket and a base (25). The device is characterized in that a spindle motor (5), a dividing box (6) and a synchronous sensor bracket (24) are fixed on the base (25); a tray (3) connected with a spindle is provided with a gear port (4), a bottle cap cylinder detection sensor (12) and a bottle cap cylinder detection sensor (13); the synchronous sensor bracket (24) is provided with a synchronous photoelectric sensor (9) and a synchronous photoelectric sensor (18); an ultrasonic welding head (16), an ultrasonic welding head (17), a pneumatic mechanical arm (7) and a pneumatic mechanical arm (8) are fixed on a working table (21); the pneumatic mechanical arm (7) and the pneumatic mechanical arm (8) are connected with a gear sleeve slideway (14) and a gear sleeve slideway (20), and the gear sleeve slideway (14) and the gear sleeve slideway (20) are respectively provided with a gear sleeve slideway sensor (10) and a gear sleeve slideway sensor (11); a bottle cap cylinder conveying belt (2) and an outlet piece conveying belt (19) are arranged below a bottle cap cylinder (1) on the tray (3), and a bottle cap cylinder conveying belt sensor (26) is arranged on the bottle cap cylinder conveying belt (2); all the sensors are connected with a PLC (Programmable Logic Controller) (28); and the PLC (28) is connected with a touch screen (27). The device greatly improves the working efficiency, the product quality and the operation safety.

Owner:LIPENG PACKING YANTAI CITY

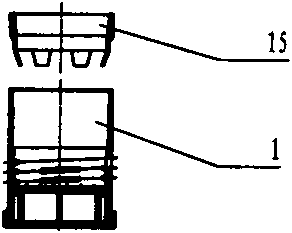

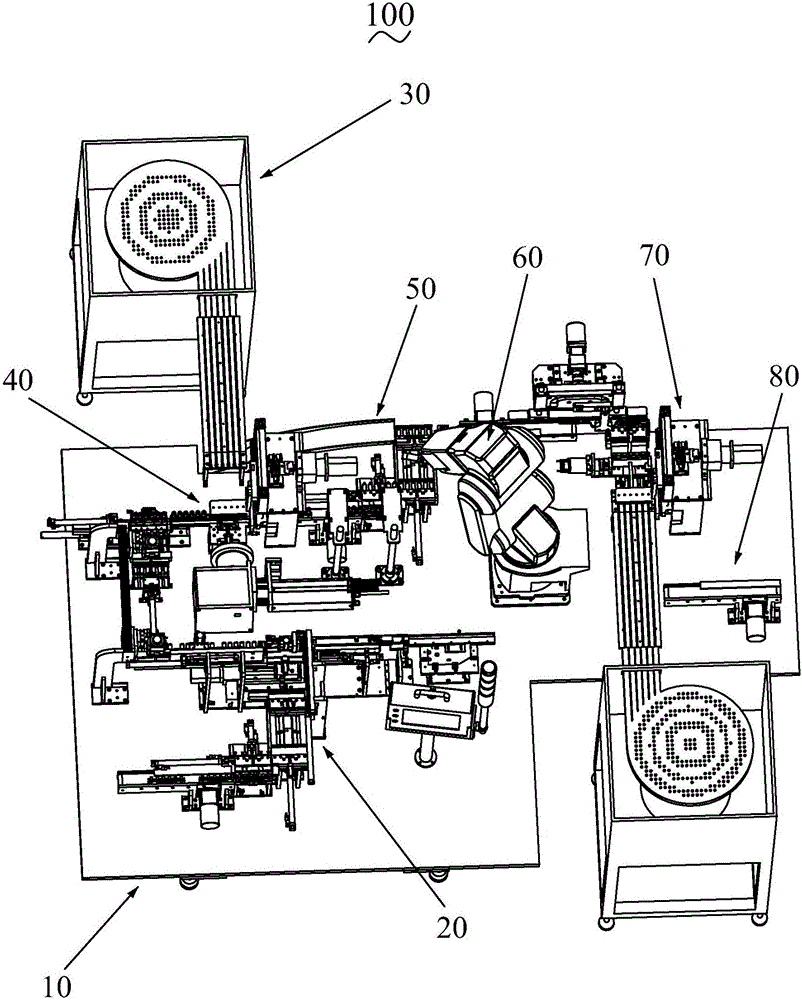

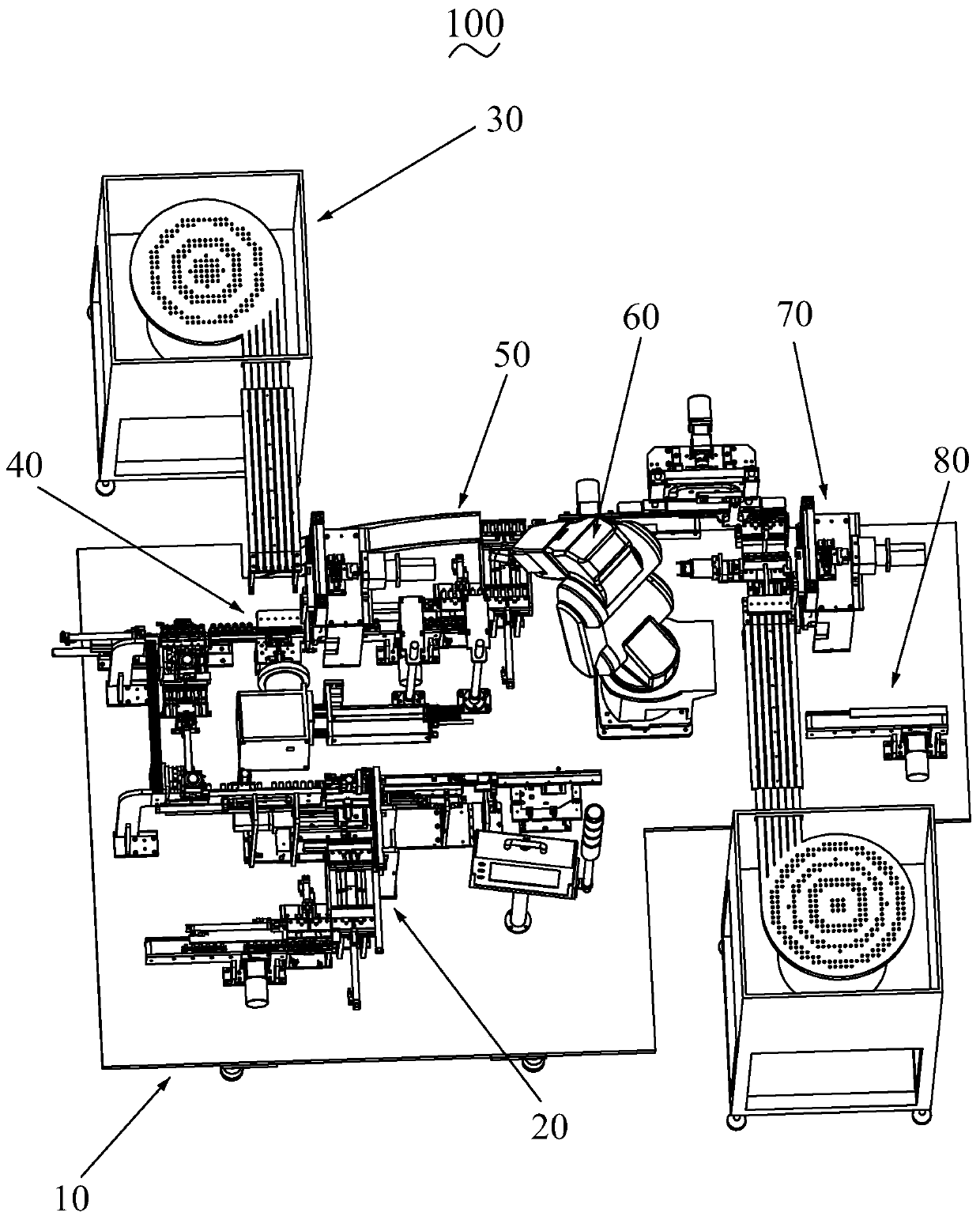

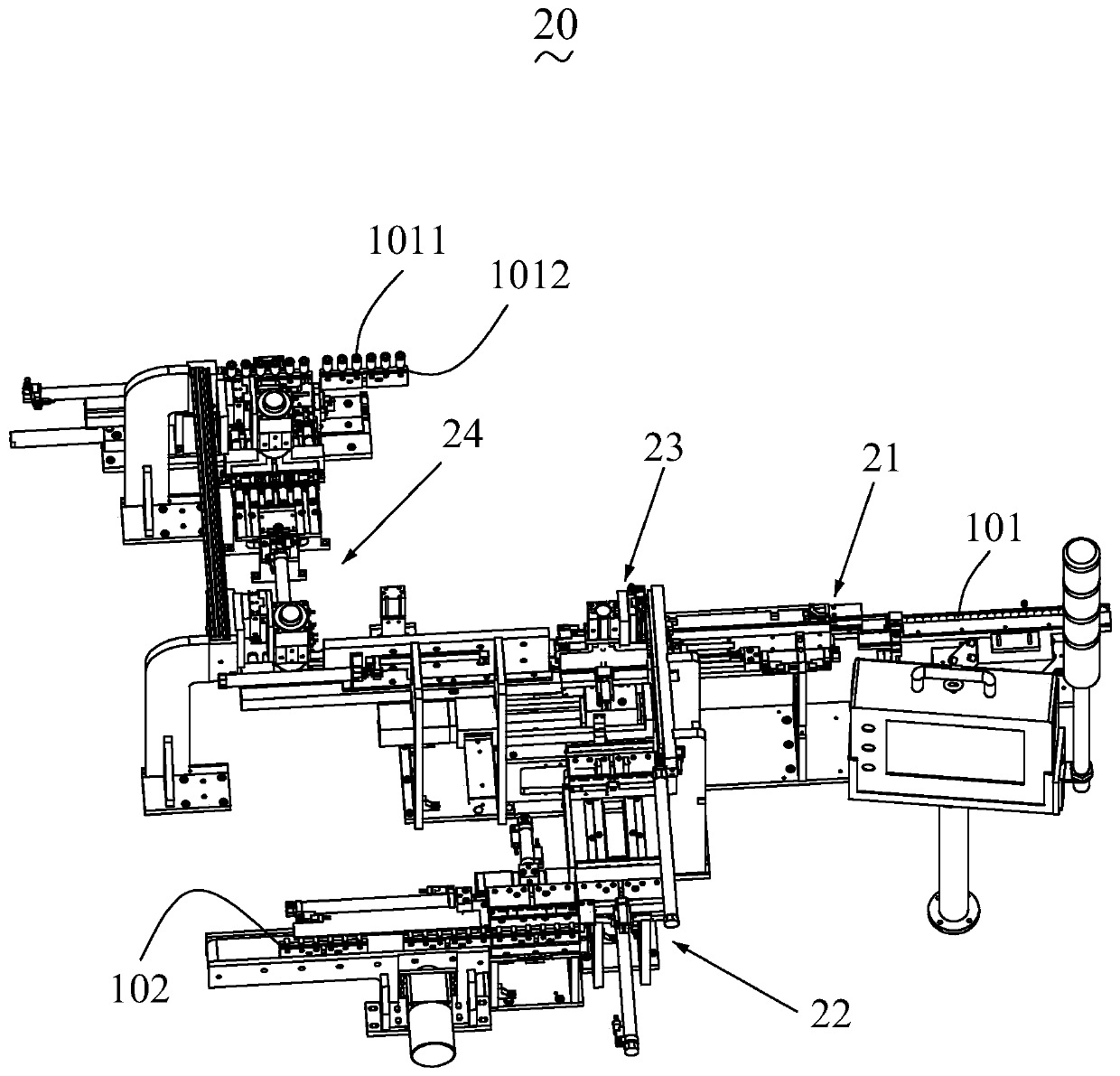

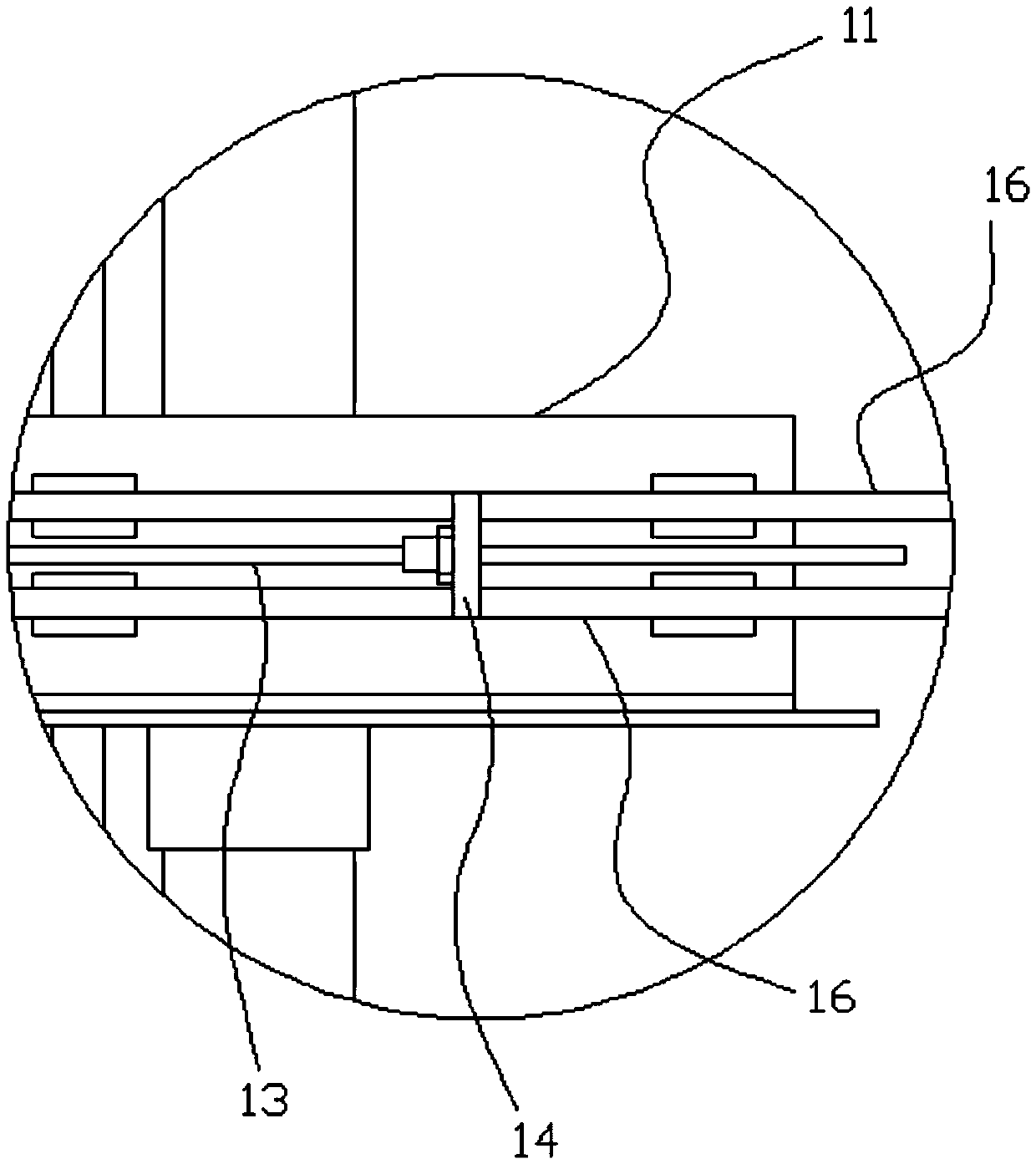

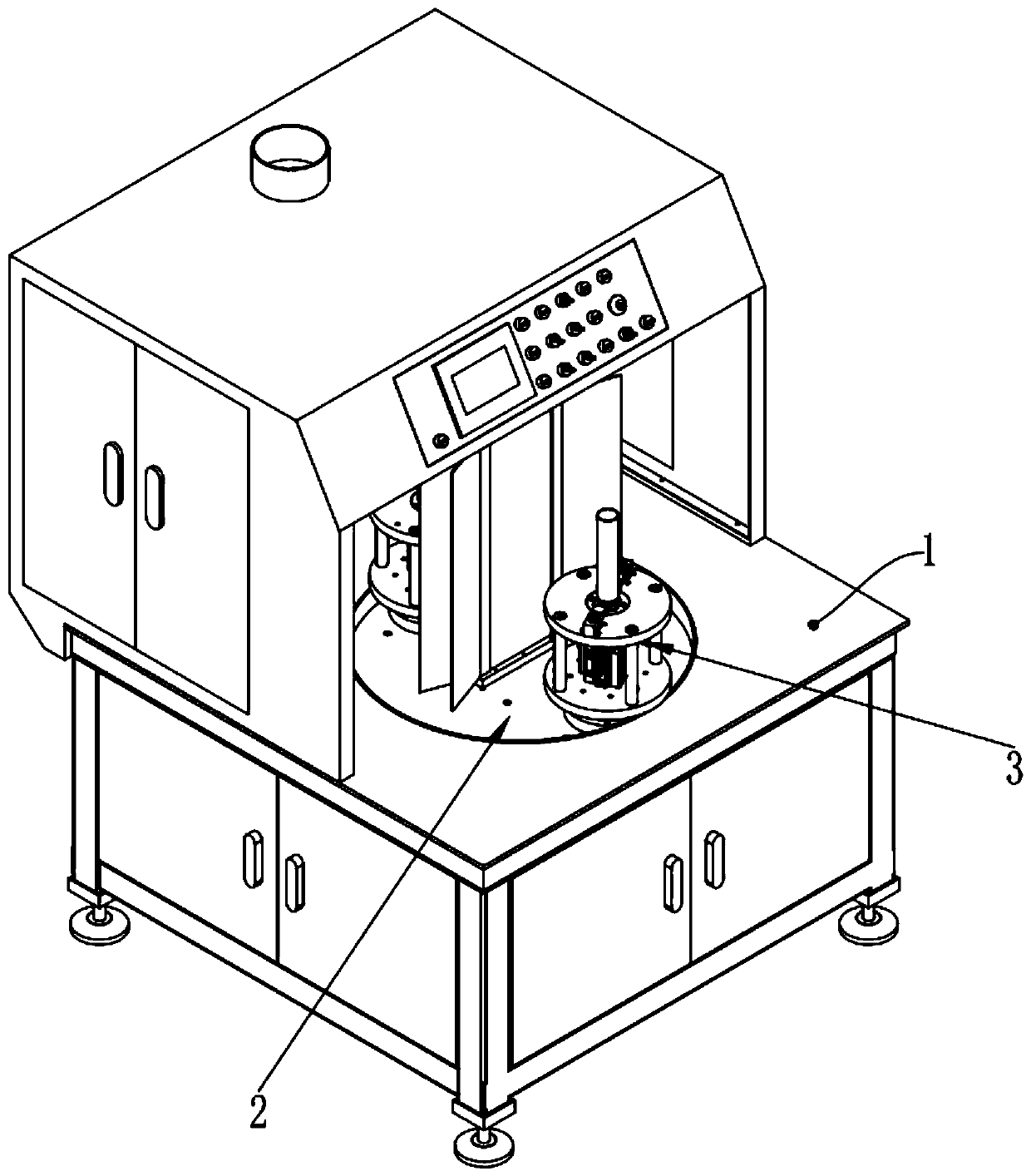

Full-automatic battery spot welding equipment

PendingCN106624309AContinuous weldingFast solderingResistance welding apparatusButt weldingEngineering

The invention provides full-automatic battery spot welding equipment. The equipment comprises a rack and a battery carrying mechanism, two material charging mechanisms, a spot welding mechanism, a detection mechanism, a transfer mechanism, a butt welding mechanism and a discharging mechanism which are arranged on the rack. According to the full-automatic battery spot welding equipment, full-automatic operation can be achieved, battery charging and transportation, screw / double-screw bolt charging and transportation, screw and battery spot welding, CCD detection, unqualified product screening, double-screw bolt and battery butt welding, product outputting and other operation are integrated, screws and double-screw bolts can be welded to the two ends of a battery continuously and rapidly, batched production is met, and the precision of product machining can be improved.

Owner:OPTIMUM BATTERY CO LTD

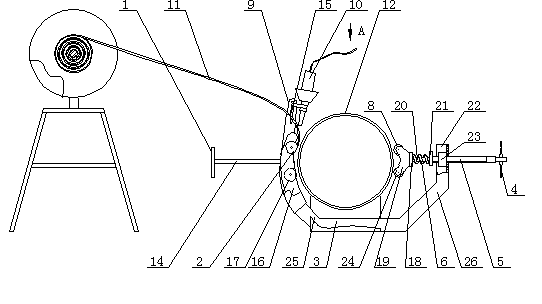

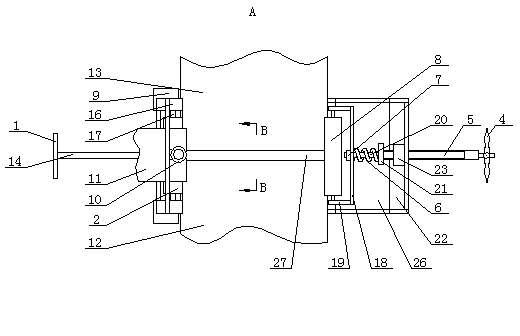

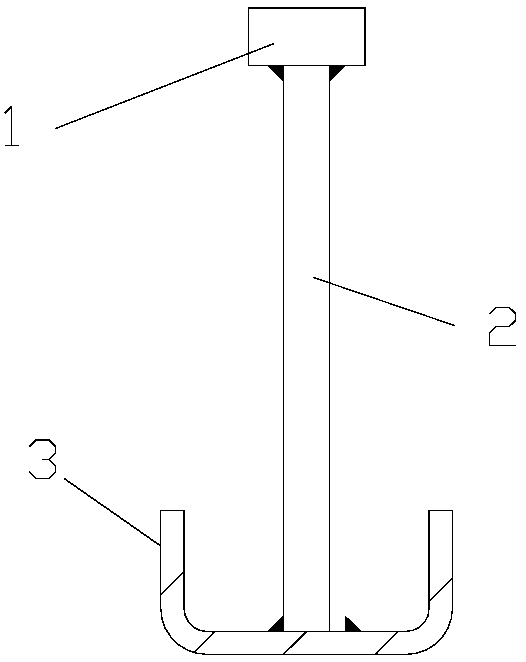

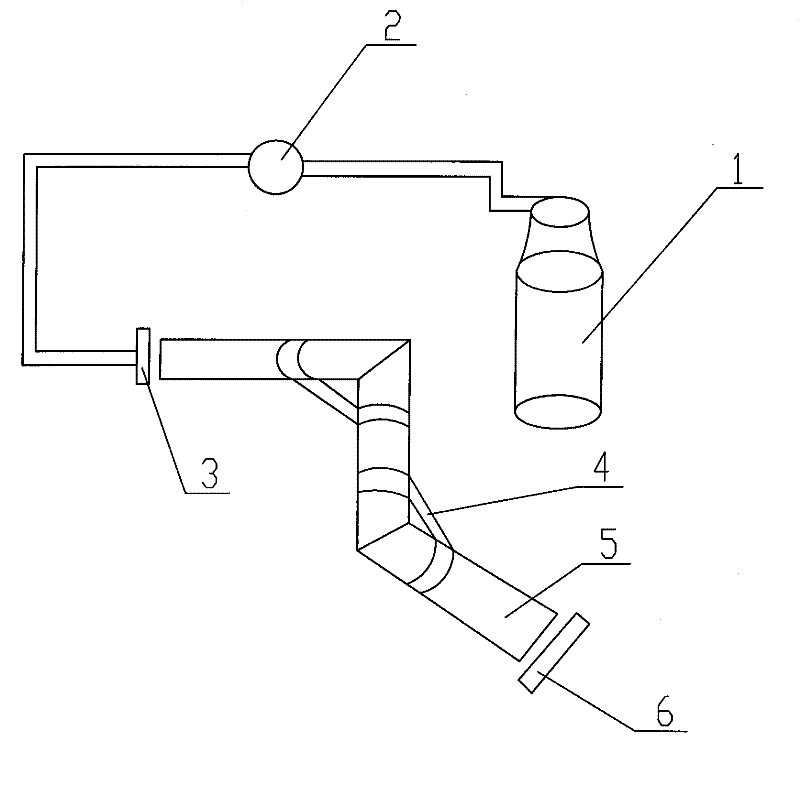

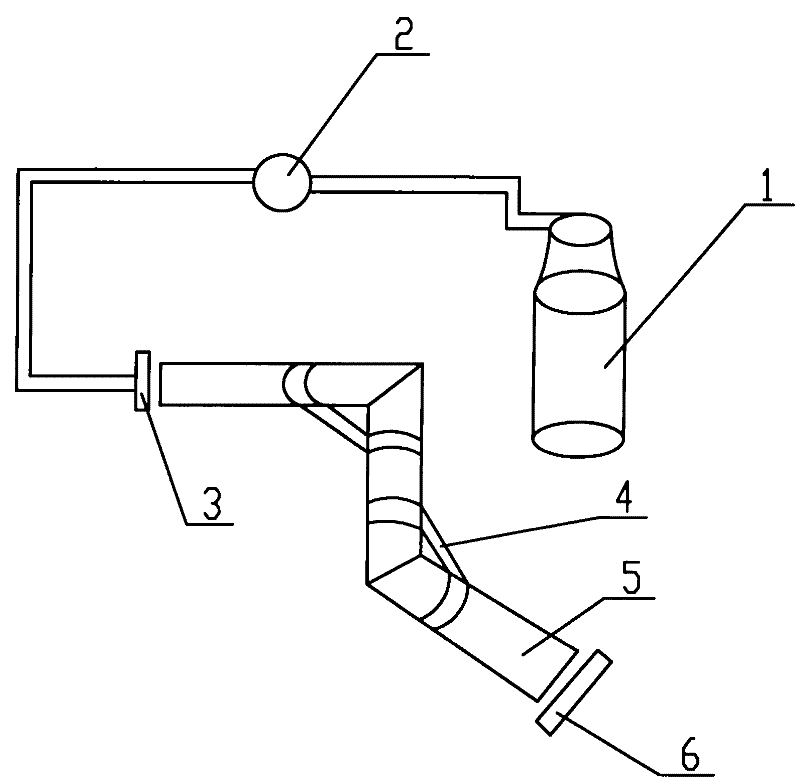

Method and welding machine for welding pipe by using ultra-high molecular weight polyethylene membrane belt through hot melting

The invention provides a method and a welding machine for welding a pipe by using an ultra-high molecular weight polyethylene membrane belt through hot melting. The method comprises the following steps of: (1) grinding the joint of a pipe to be connected or a common pipe to form an inclined surface; (2) aligning the joints of two pipes to each other and then flatly filling a V-shaped groove with a solder wire; (3) enabling the surface of the weld joint and the outer surfaces of the pipes to be in the same plane through an angle grinder; (4) covering the periphery of the pipe by using a welding machine; (5) towing one end of a single-sided membrane welding belt to the pipe weld joint so that the end of the membrane welding belt is held down by a roller; (6) starting a heat gun on the welding machine; and (7) rotating the welding machine so that the welding machine rotates along the peripheral joint of the pipe. The welding machine comprises a support, wherein the membrane welding belt made of ultra-high molecular weight polyethylene is arranged on the support; one end of the membrane welding belt is attached to the weld joint through a special-shaped holder; and the heat gun is fixed at one end of the special-shaped holder. The method provided by the invention is capable of quickly and firmly welding the joint of the ultra-high molecular weight polyethylene membrane pipe with the joint of the common polyethylene pipe.

Owner:SHUNFANG PIPES

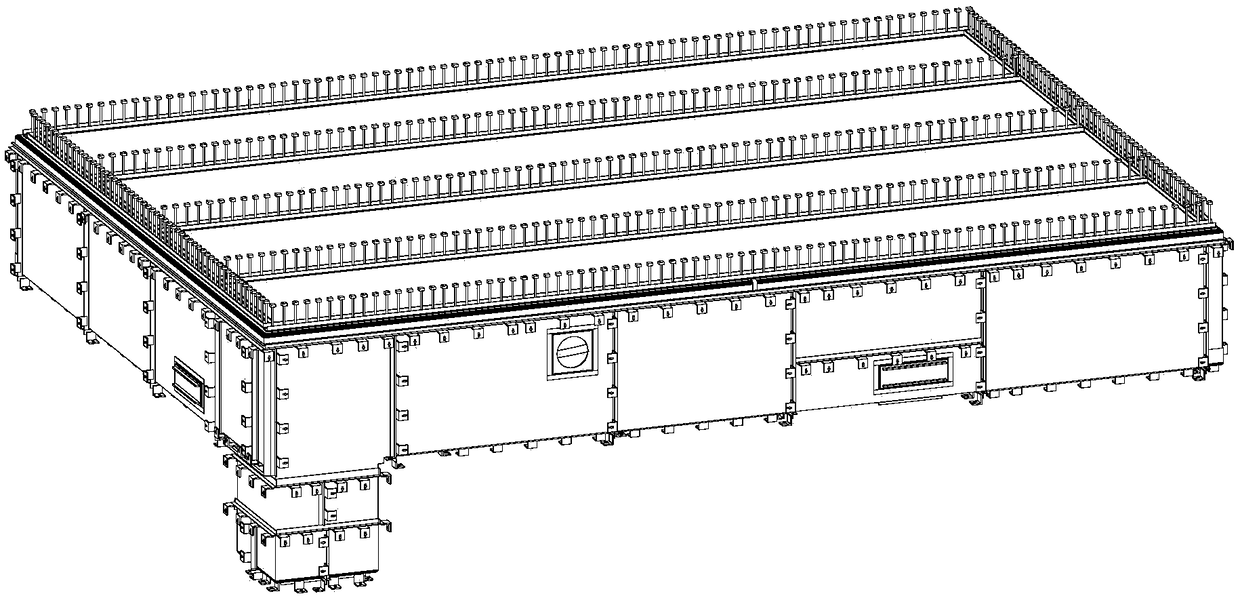

Stainless steel water tank for nuclear power station and welding method

InactiveCN108172313ARealize continuous weldingImprove welding productivityNuclear energy generationArc welding apparatusNuclear powerShielding gas

The invention discloses a stainless steel water tank for a nuclear power station and a welding method. The MIG semi-automatic welding is adopted for the welded weld joints: the electric arc burnt between the continuously-fed welding wire and the workpiece is used as a heat source, the welding wire is molten by the electric arc and is sent into the welding area, and the arc is protected by the protective gas sprayed out by a welding torch nozzle; the diameter of the welding wire is 0.8-1.2mm, the welding current is 42 -90 A, the arc voltage is 18-24 V, and the protective gas flow is 10-15 L / min, and the temperature between the layers is 5 DEGC <=T<=150 DEG C; the protective gas is the mixed gas of argon and helium, and the content ratio of the argon to helium is 15-20:85-80. The stainless steel water tank adopts MIG semi-automatic welding. Meanwhile, the fillet welding joints of the installation of an accessory structure, an anchor rib assembly pair, an anchor rib assembly, a top platepair, welded nails, a shooting plate groove pair, and a cover plate supporting system are welded. Full-position welding can be carried out, the welding speed is high, and the deposition efficiency ishigh.

Owner:CHINA CONSTR SECOND ENG BUREAU LTD +1

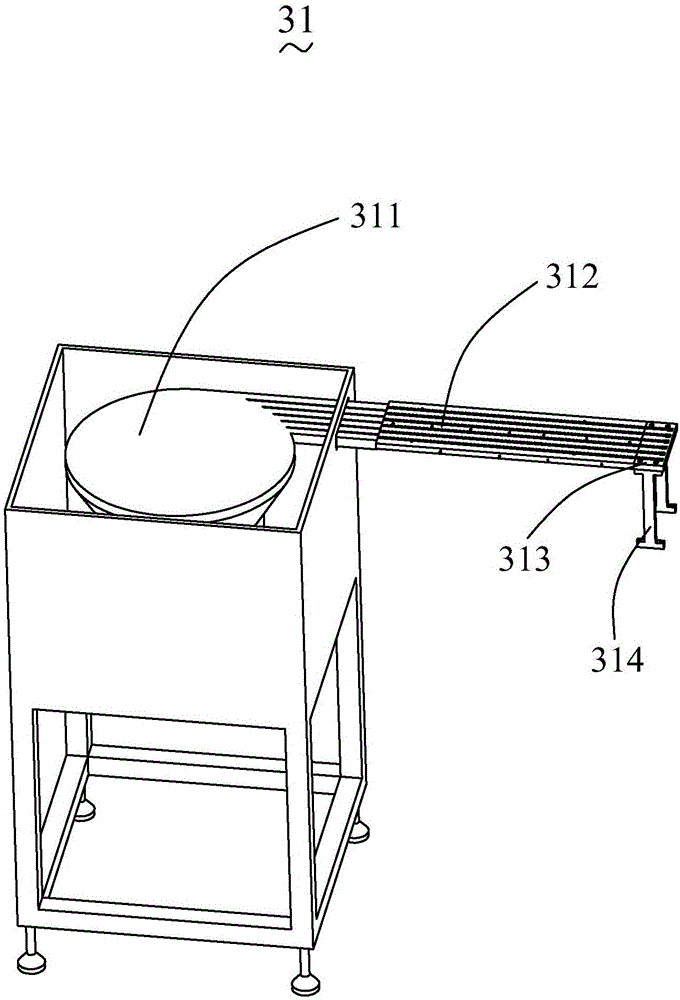

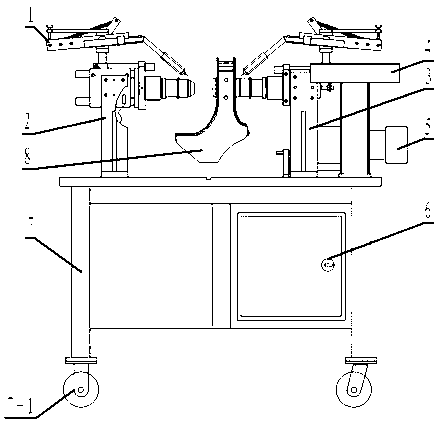

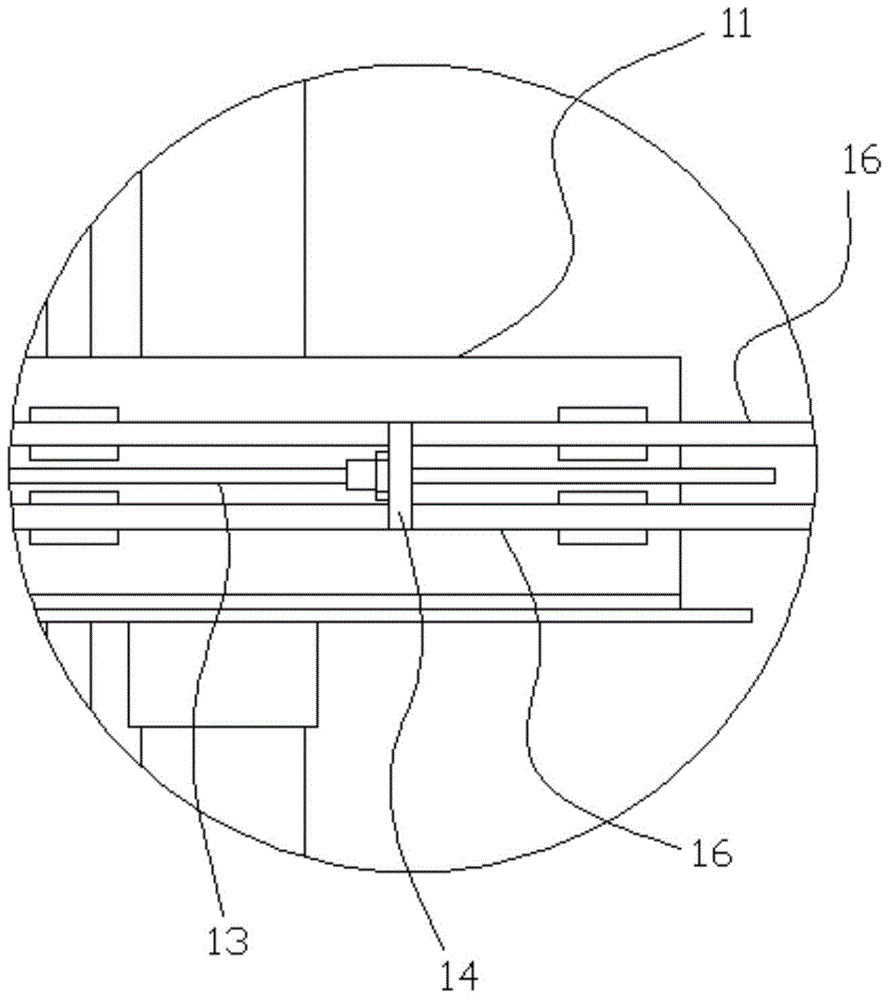

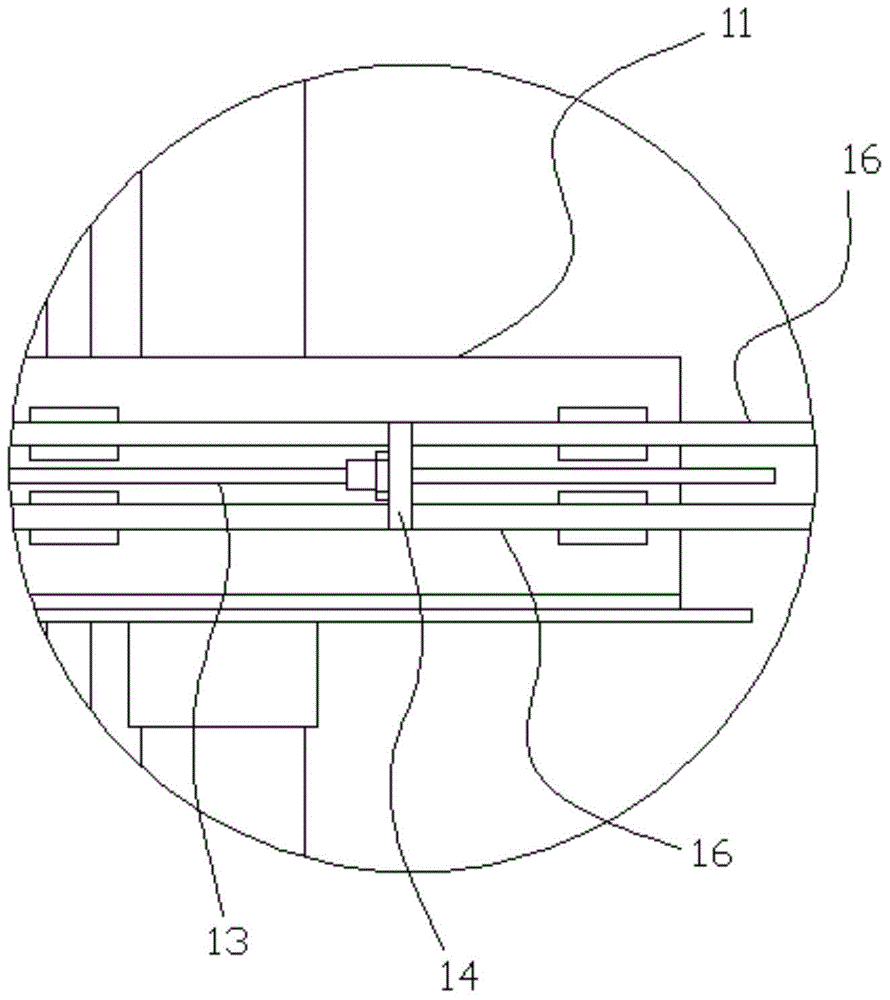

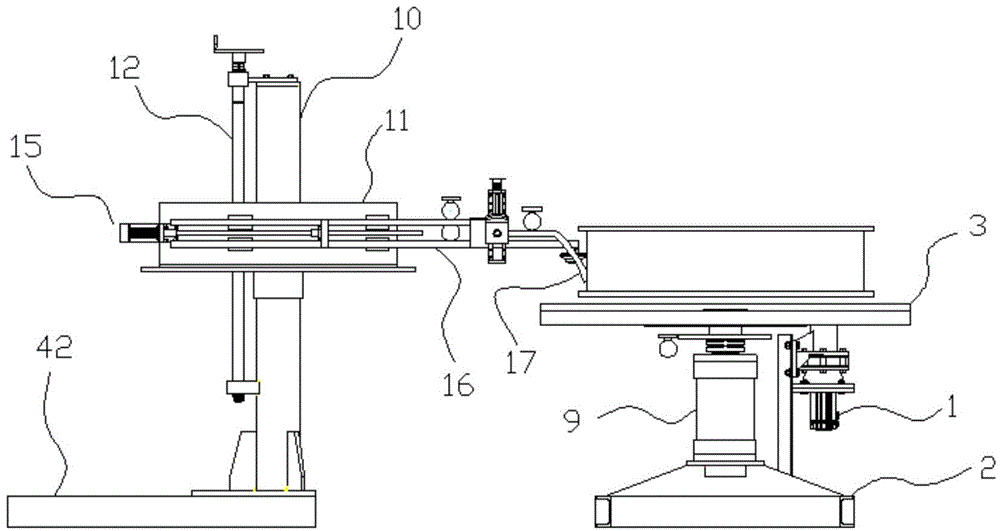

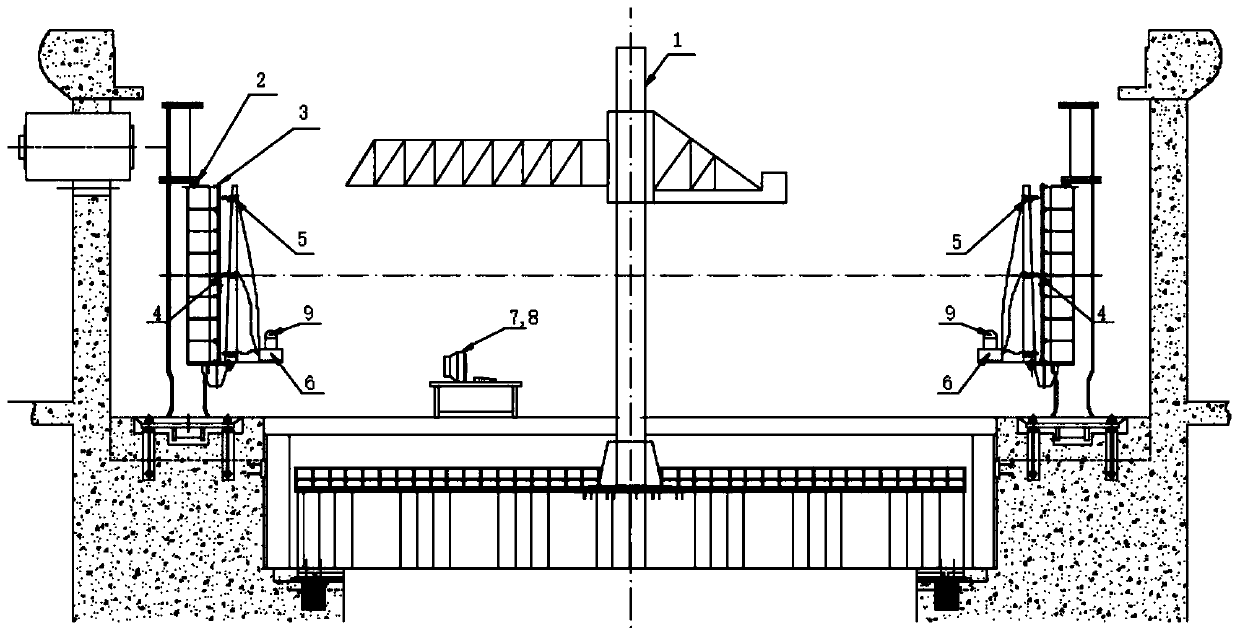

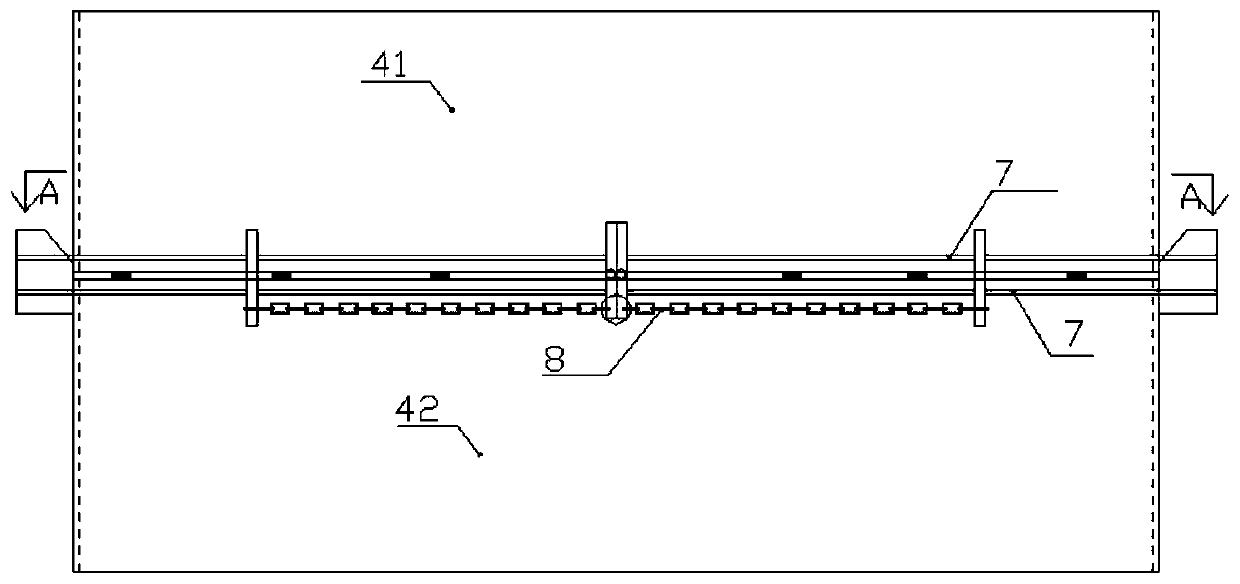

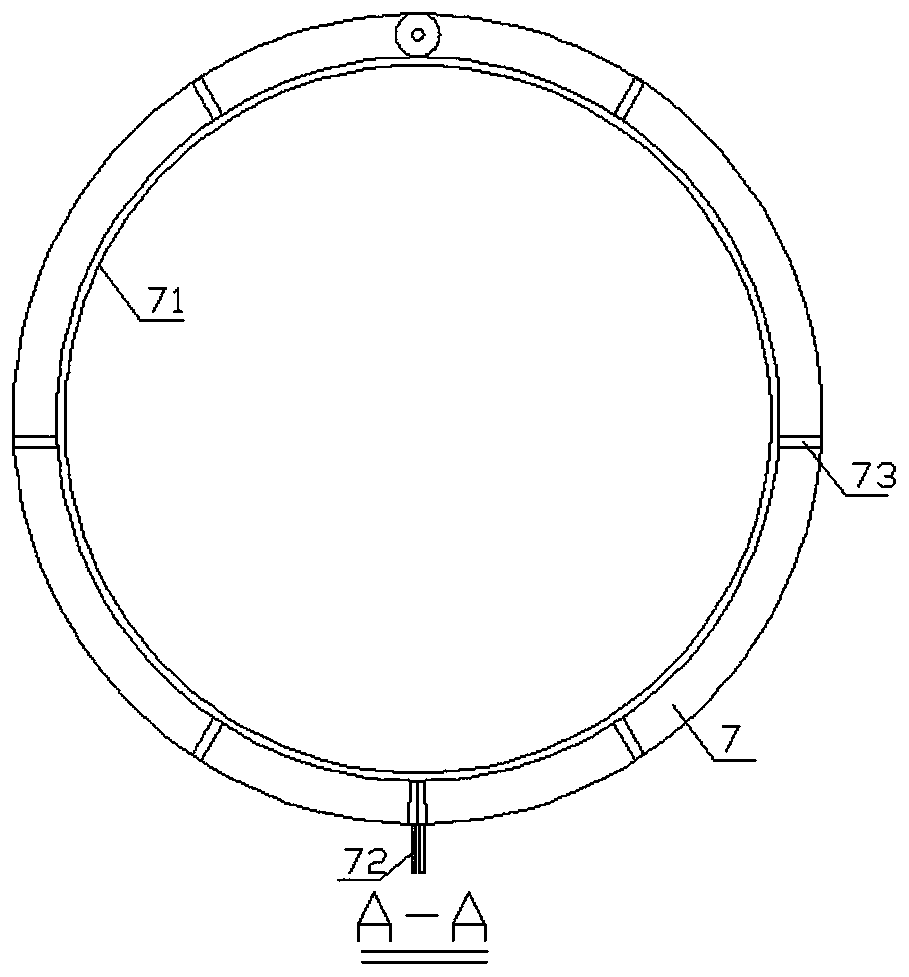

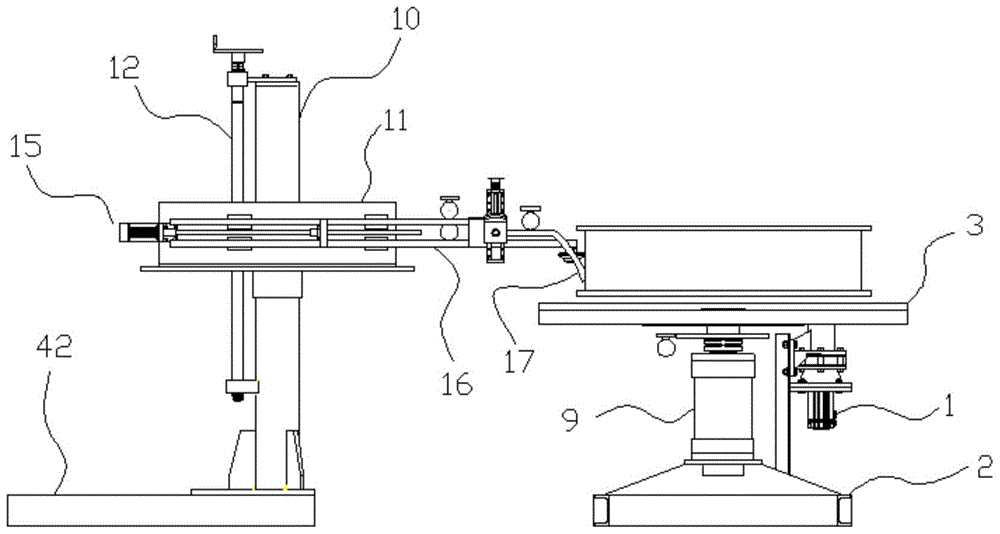

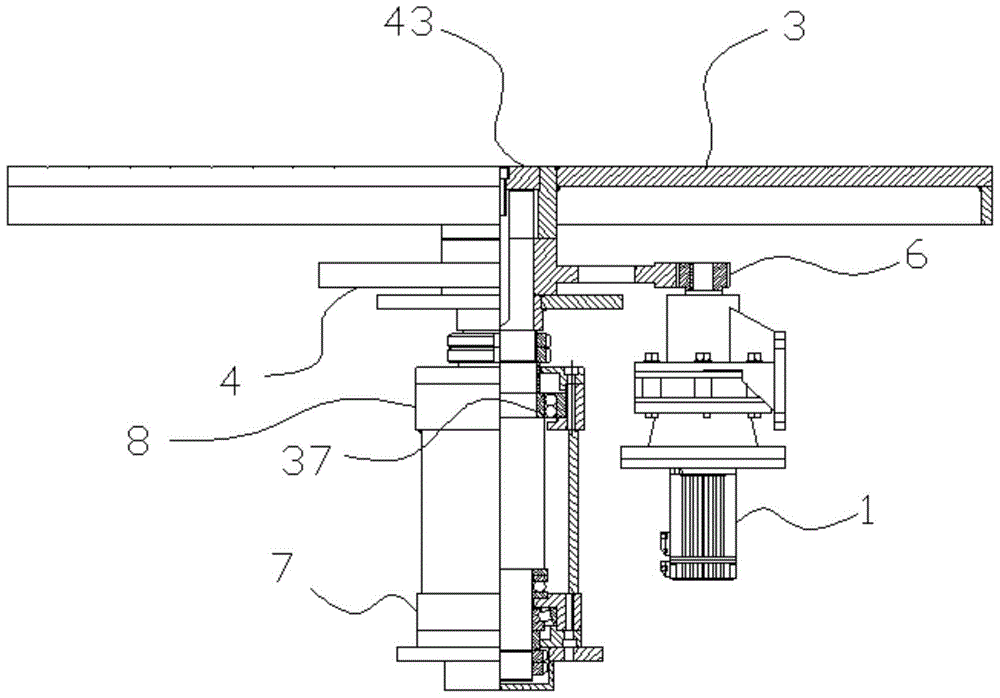

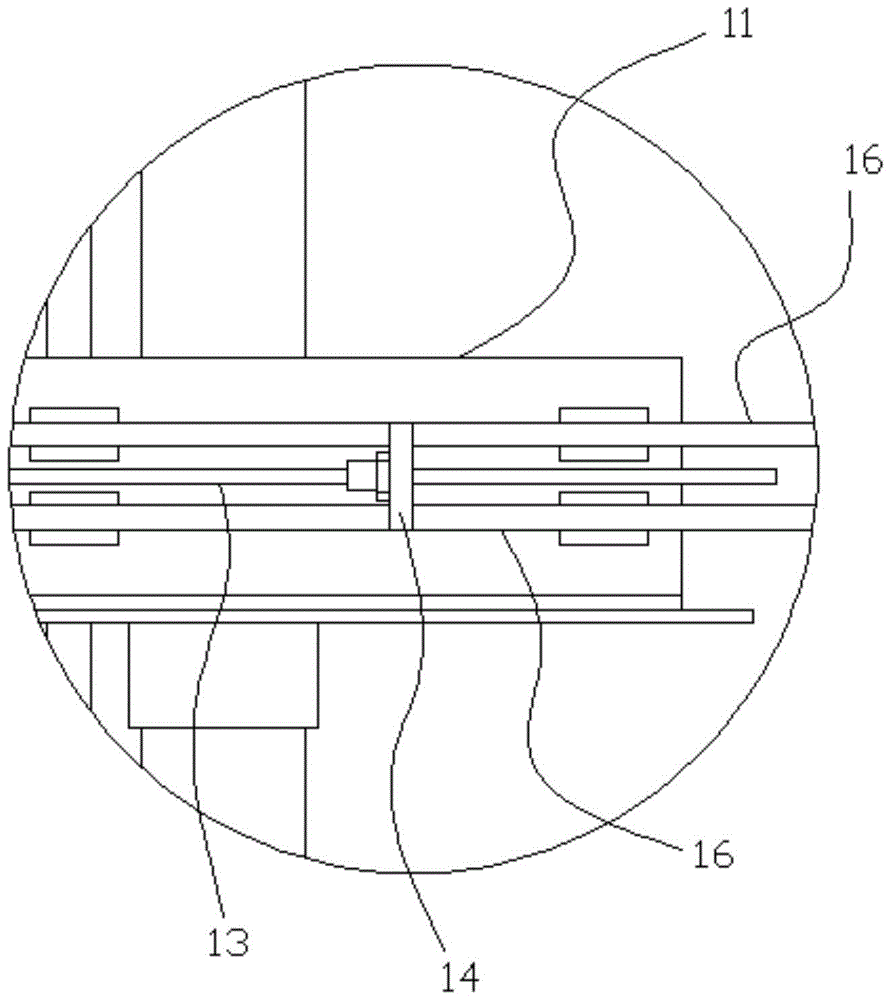

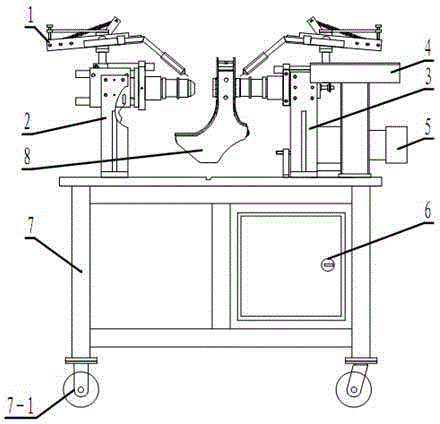

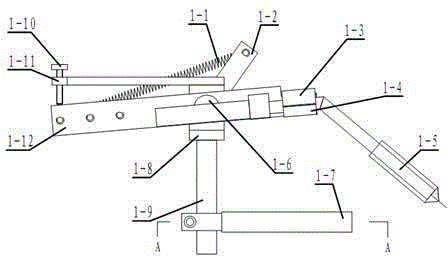

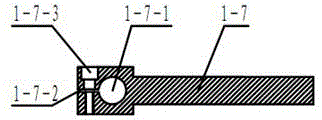

Automatic welding equipment for double annular welding beads

ActiveCN103008940AFulfill welding requirementsRealize continuous weldingWelding/cutting auxillary devicesAuxillary welding devicesAutomatic test equipmentCaster

An automatic welding equipment for double annular welding beads is used for solving problems of high equipment cost, low manual welding efficiency and hardly guaranteed welding quality of a welding robot. The automatic welding equipment comprises a welding gun position switching and welding gun clamping adjusting mechanism, a left side positioning mechanism, a right side positioning mechanism, an operation station, a power output mechanism, a control mechanism and a base stage, wherein the welding gun position switching and welding gun clamping adjusting mechanism comprises a left part and a right part, which are symmetric and respectively mounted together with the left side positioning mechanism and the right side positioning mechanism; the left side positioning mechanism, the right side positioning mechanism and the operation station are all fixed on the base stage; the power output mechanism is mounted together with the right side positioning mechanism; and a caster is arranged at the bottom of the base stage. The automatic welding equipment has the advantages of simple operation, convenient maintenance and low manufacturing cost; the welding efficiency can be increased, the product quality is improved, the welding operation condition is improved and the labor intensities of operators are reduced.

Owner:长城汽车股份有限公司平湖分公司

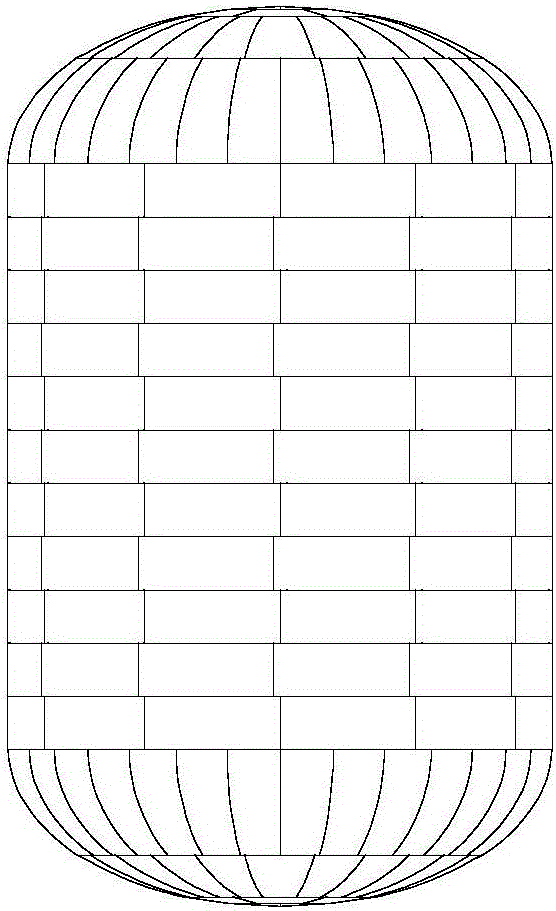

Automatic welding method of nuclear plant steel safety shell

ActiveCN103769727AReduce welding distortionGood low temperature impact toughnessWelding/cutting auxillary devicesArc welding apparatusWeld seamNuclear engineering

The invention relates to an automatic welding method of a nuclear plant steel safety shell and belongs to the technical field of nuclear plant building. The method adopts the match between a solid core welding wire and the active gas-shielded arc welding of a consumable electrode with specific process parameters, weaving welding is adopted for vertical welding seam,s and linear welding is adopted for horizontal annular seams. According to the method, internal and appearance qualities of the welding seams of the nuclear plant steel safety shell are improved, the safety is ensured, the efficiency for welding a thick plate of the steel safety shell is greatly improved, and the welding work period is obviously shortened.

Owner:CHINA NUCLEAR IND HUAXING CONSTR

Titanium and titanium alloy welding process

InactiveCN102294533AAvoid WeldingReduce energy consumptionWelding/cutting auxillary devicesArc welding apparatusTitaniumTitanium alloy

The invention discloses a titanium and titanium alloy welding process. In the process, firstly, the parts to be welded are fixed with clamps as required, and the top of the parts to be welded is blocked with a plug, and an argon-filled tube is installed at the other end. The interface is filled with argon through the argon cylinder and the argon filling pipeline. When the argon gas overflows from the joint of the parts to be welded, it is welded. The parts to be welded are all titanium products with a hollow center. The invention adopts external argon filling to the product, avoids vacuuming for welding, reduces energy consumption, improves production efficiency, and can also produce continuously; the equipment required by the invention is simple, and its cost is equivalent to that of conventional welding.

Owner:浙江五环钛业股份有限公司

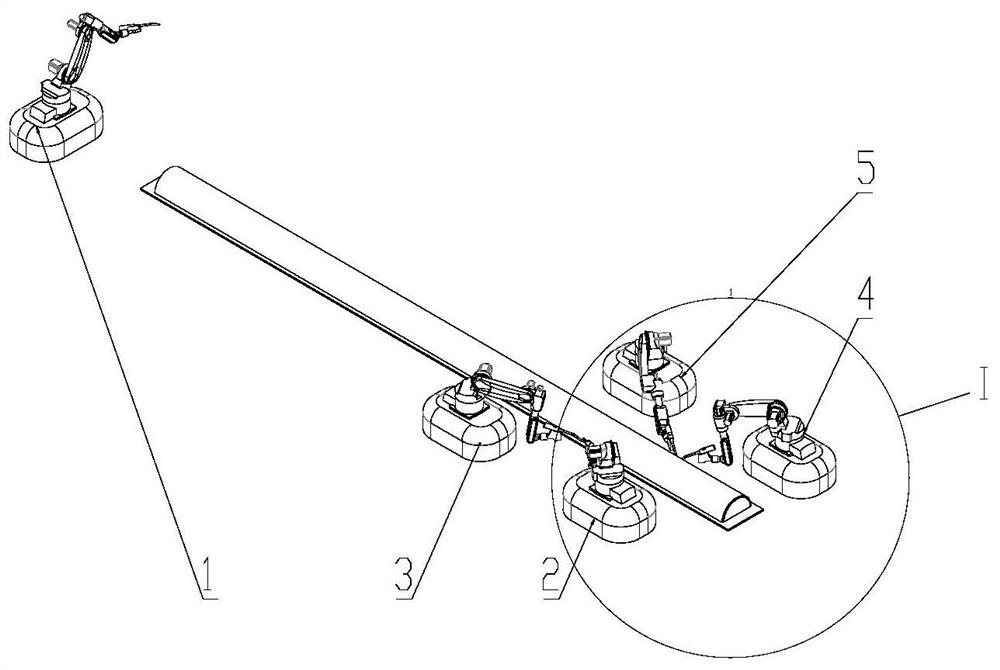

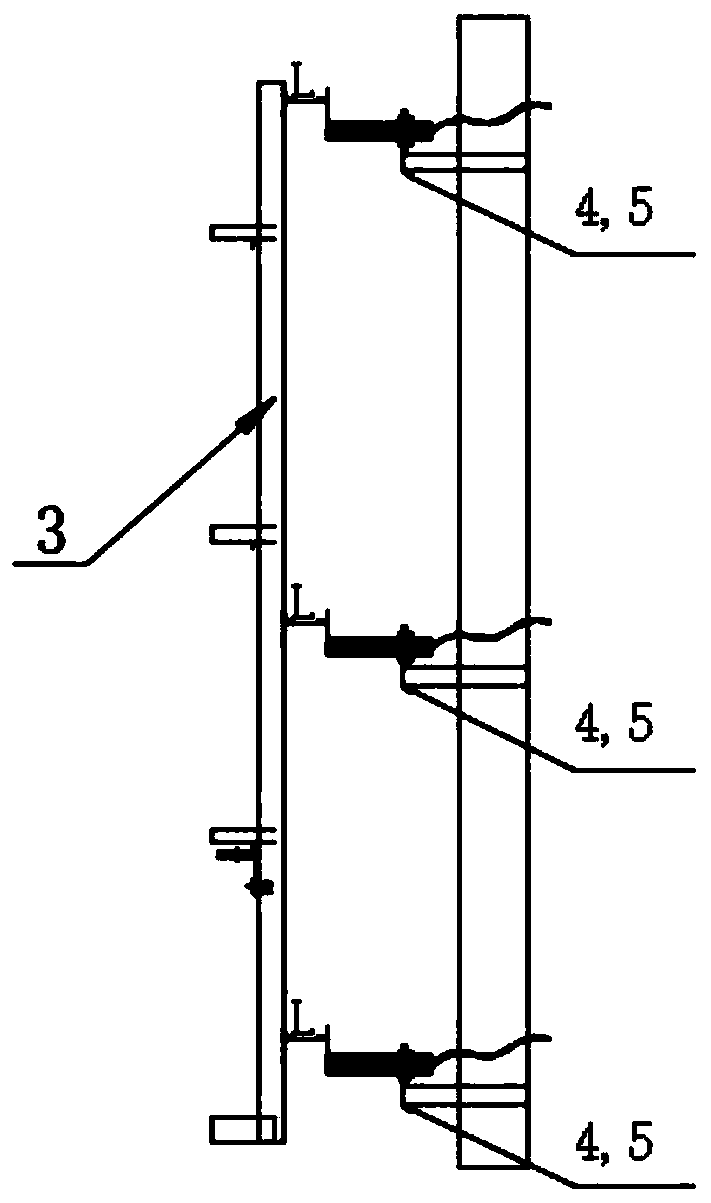

Long welding seam robot welding process

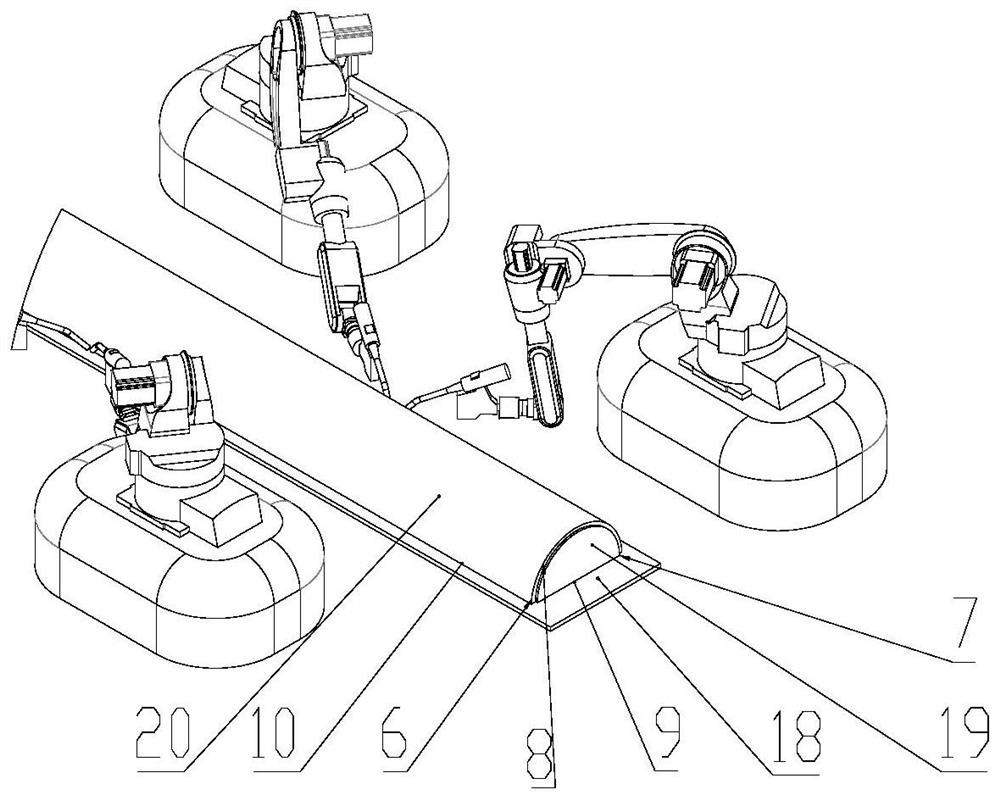

ActiveCN113714601AQuality improvementImprove welding qualityElectrode holder supportersManipulatorWeld seamManufacturing engineering

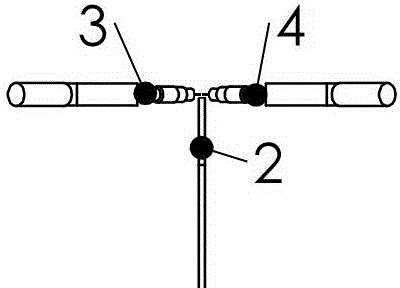

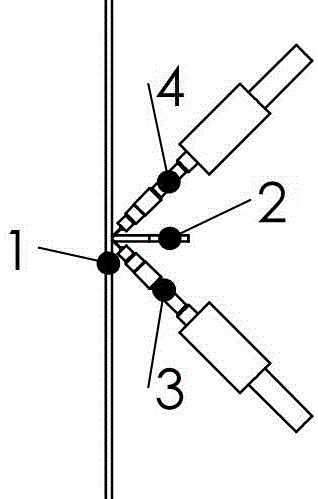

The invention belongs to the technical field of welding, and particularly relates to a long welding seam robot welding process. Closed-loop continuous sealing welding with forked welding seams and long welding seams of a workpiece is completed through cooperation of a plurality of composite welding robots, firstly, three welding robots are adopted for conducting welding arcing at the same time to form a common-welding-pool starting point, forked welding is conducted respectively, and the long welding seams are continuously welded alternately through two welding robots. And during arc stopping, two welding robots or three welding robots are used for terminating the common welding pool, and a closed welding seam is formed. No cold joint exists in the whole process, and the method is suitable for a sealing structure, so that the welding seam quality is further improved, and the welding quality is also improved.

Owner:潍坊新松机器人自动化有限公司

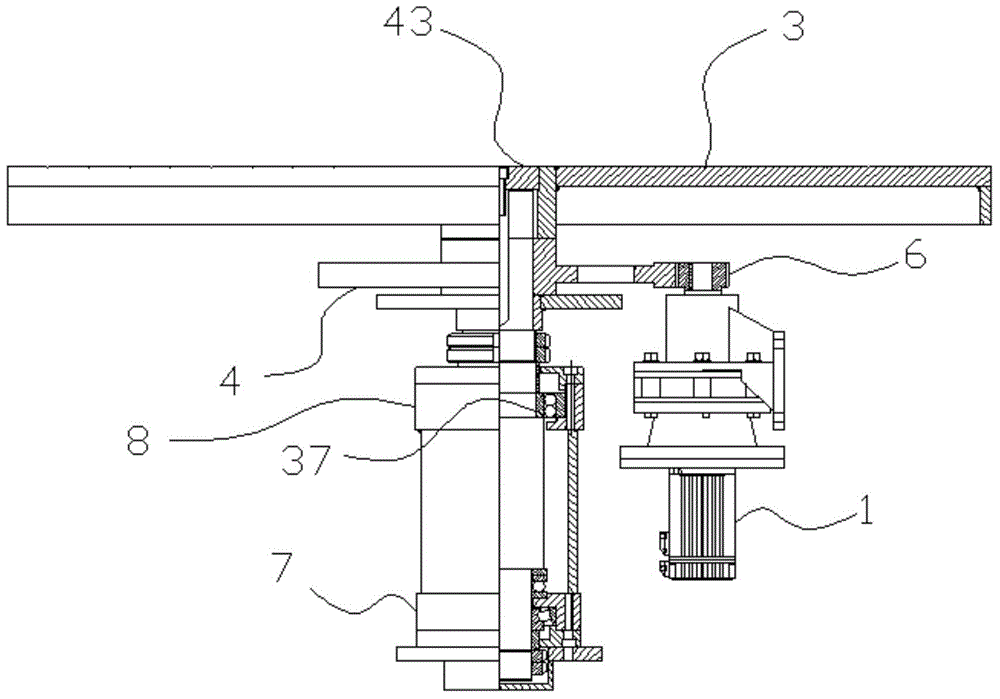

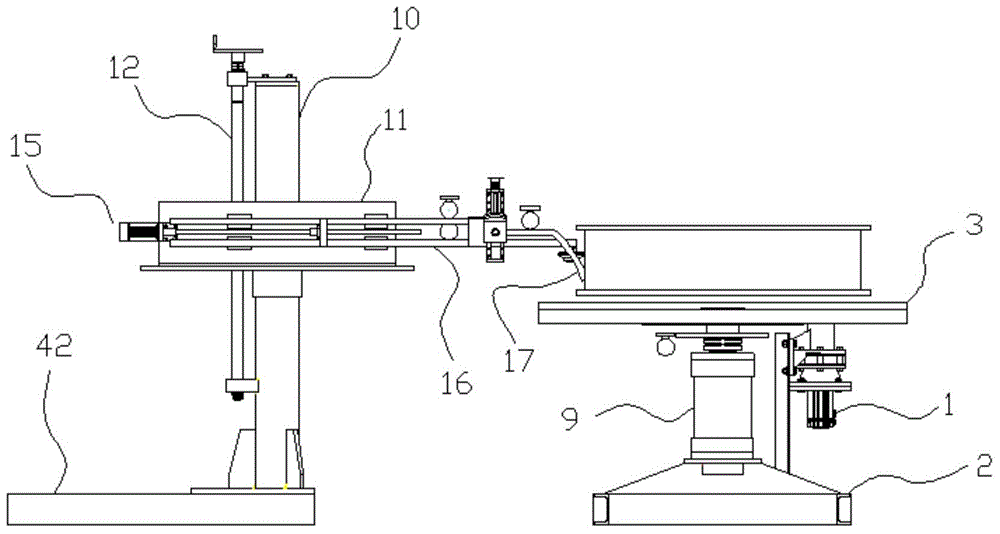

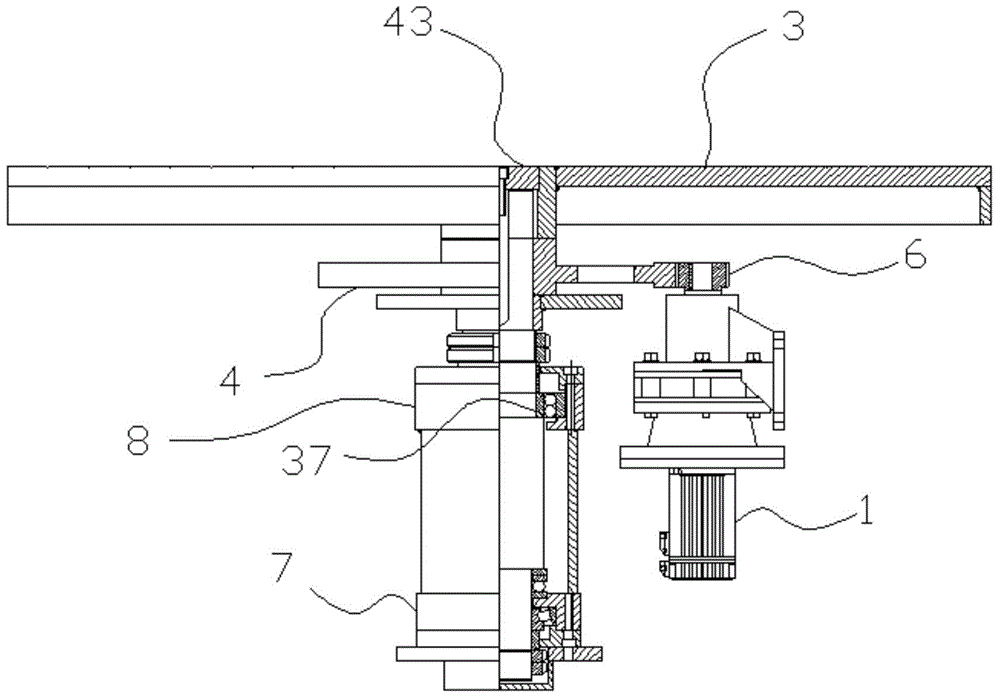

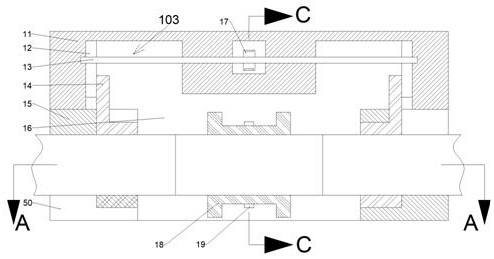

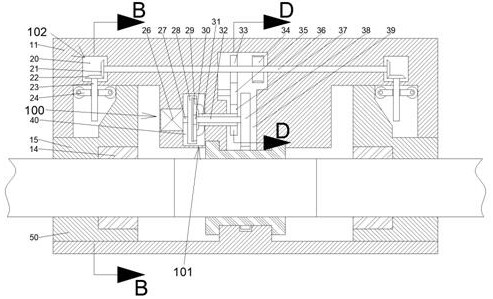

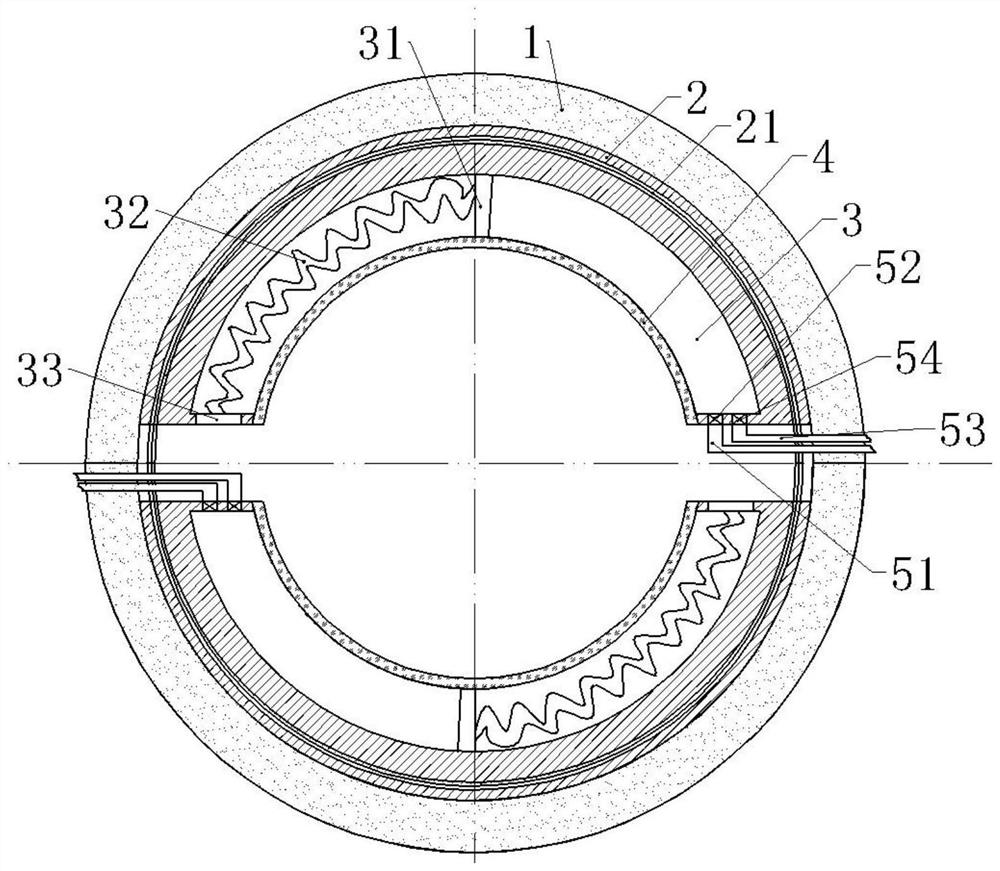

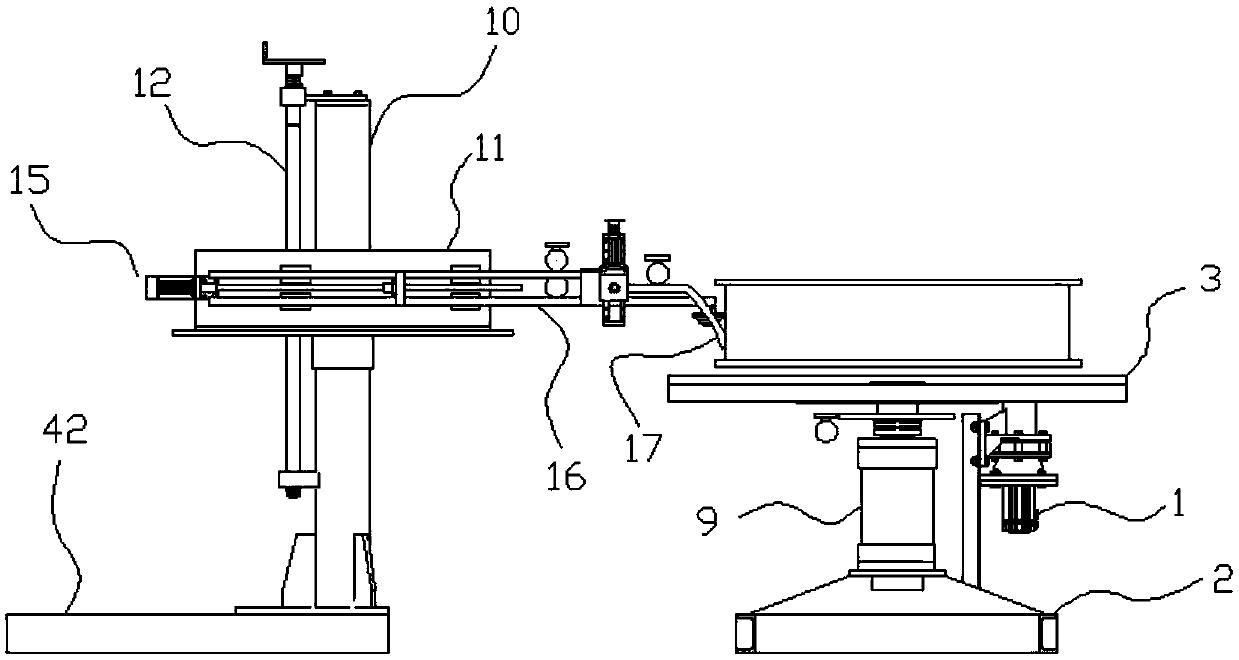

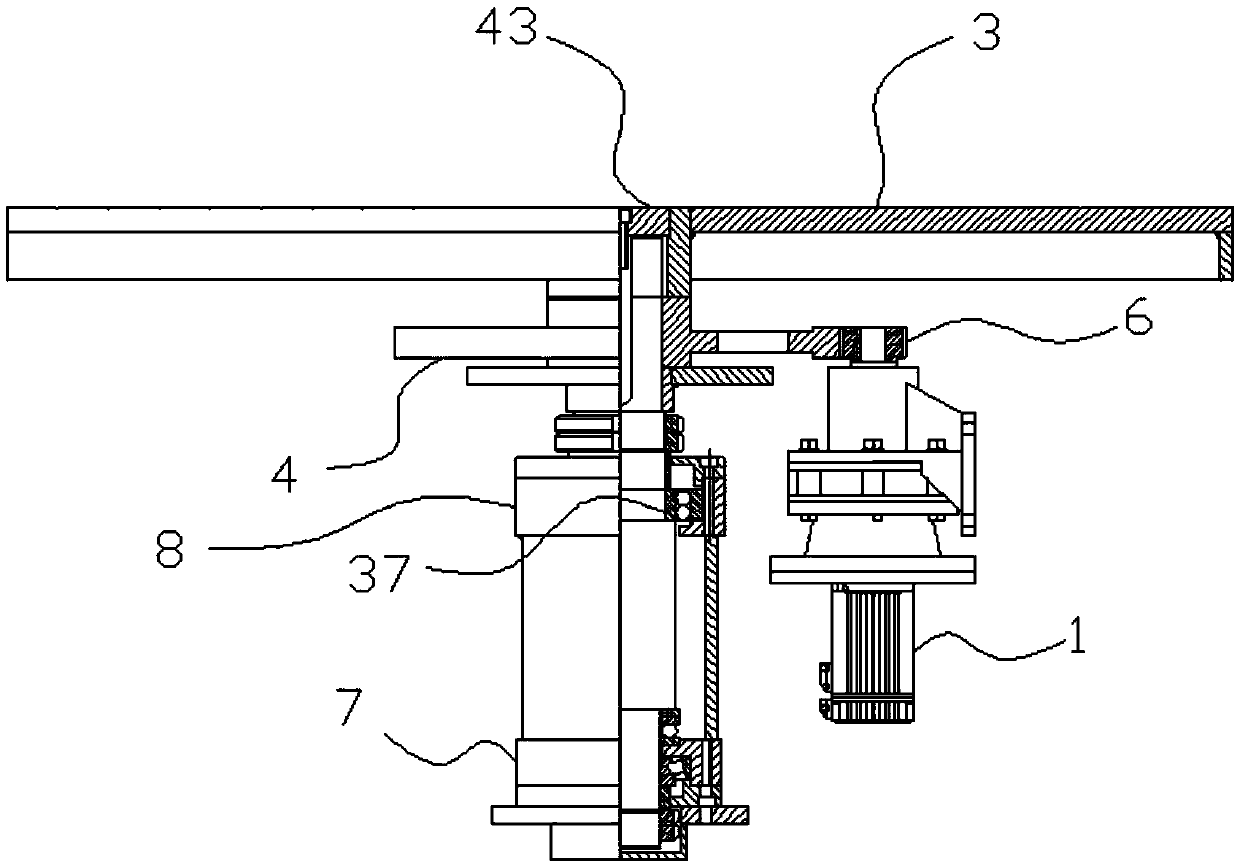

Welding machine

InactiveCN104907743AFirmly positionedThe welding process is continuousWelding/cutting auxillary devicesAuxillary welding devicesEngineeringWelding process

The invention discloses a welding machine, and aims at providing the welding machine which is reasonable in structure, can effectively position a to-be-welded machine shell, is high in smoothness and stability in the welding process, and can ensure the welding quality. The welding machine comprises a welding machine rotating part, a welding machine lifting part, a rotating motor and a welding gun assembly. The welding machine rotating part comprises a welding bottom frame, a horizontal positioning welding table and a welding table gear. The welding table gear is connected with a main rotating shaft. A positioning fixture is arranged on the positioning welding table. A speed reducer is connected with a rotating motor. An output shaft of the speed reducer is connected with an output gear which is meshed with the welding table gear. The welding machine lifting part comprises a stand column and a vertical adjusting lead screw assembly. A transverse adjusting lead screw assembly is arranged on the main welding part. The welding machine has the advantages that a welding gun and the to-be-welded part can be accurately aligned, positioning is firm, the welding process is ceaseless, the welding gun assembly is still during welding, the welding position is changed through the rotation of the to-be-welded machine shell, stability is high, and the welding quality is high.

Owner:宁波保世洁环境科技有限公司

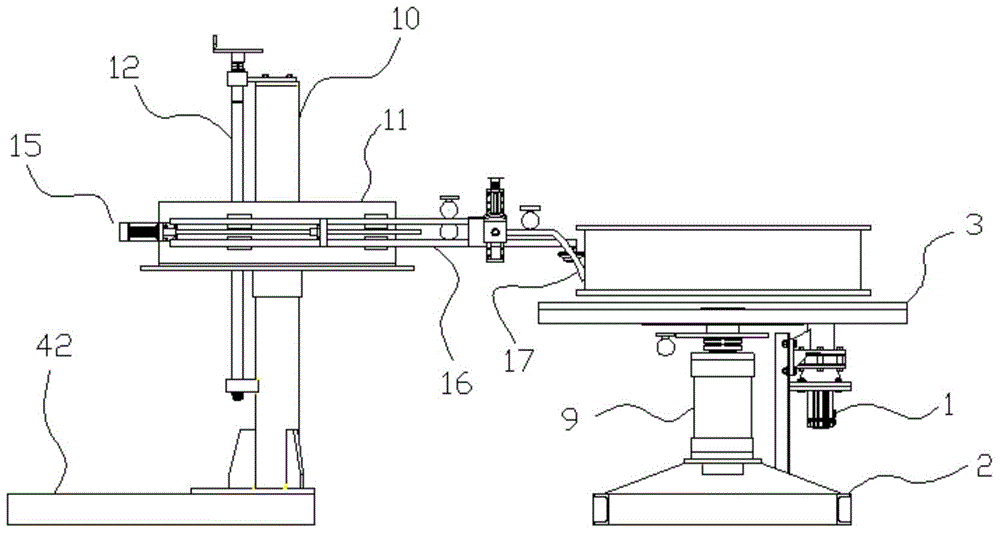

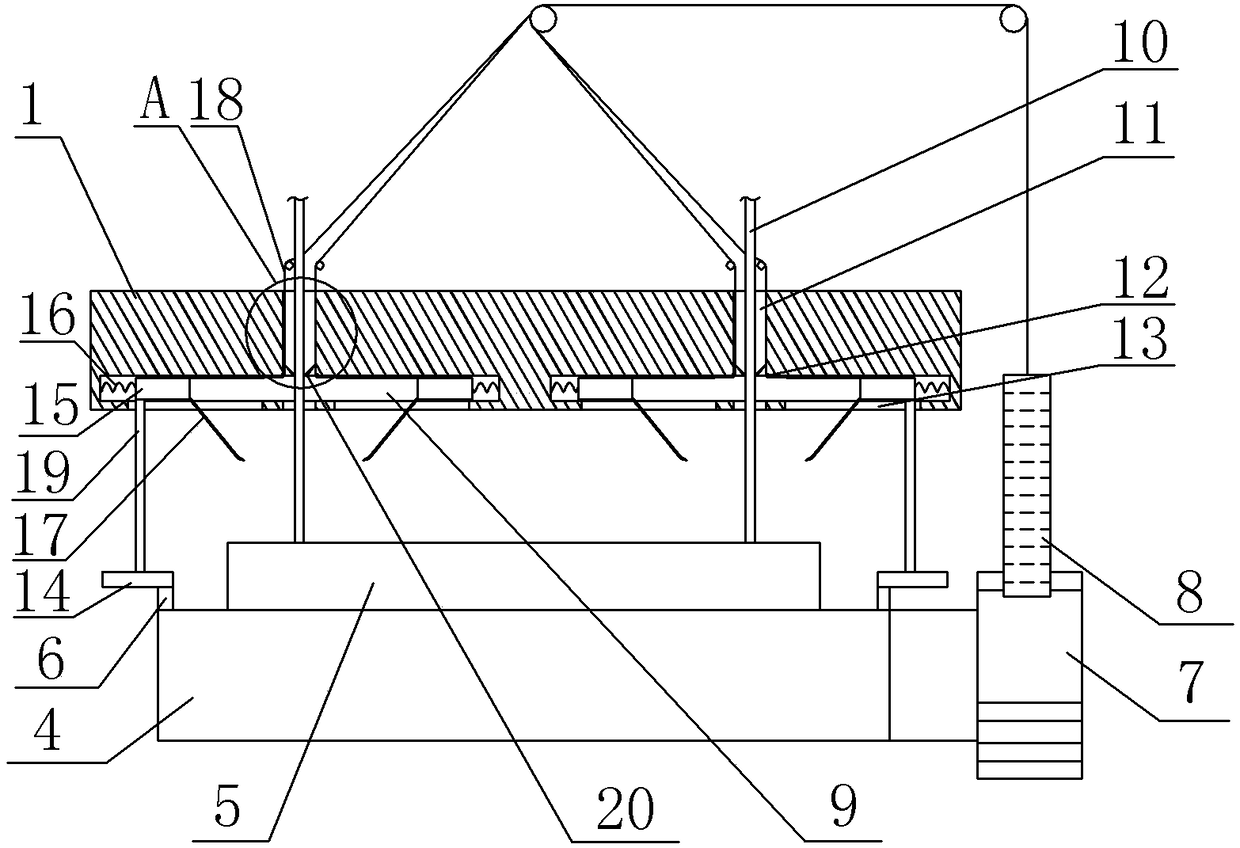

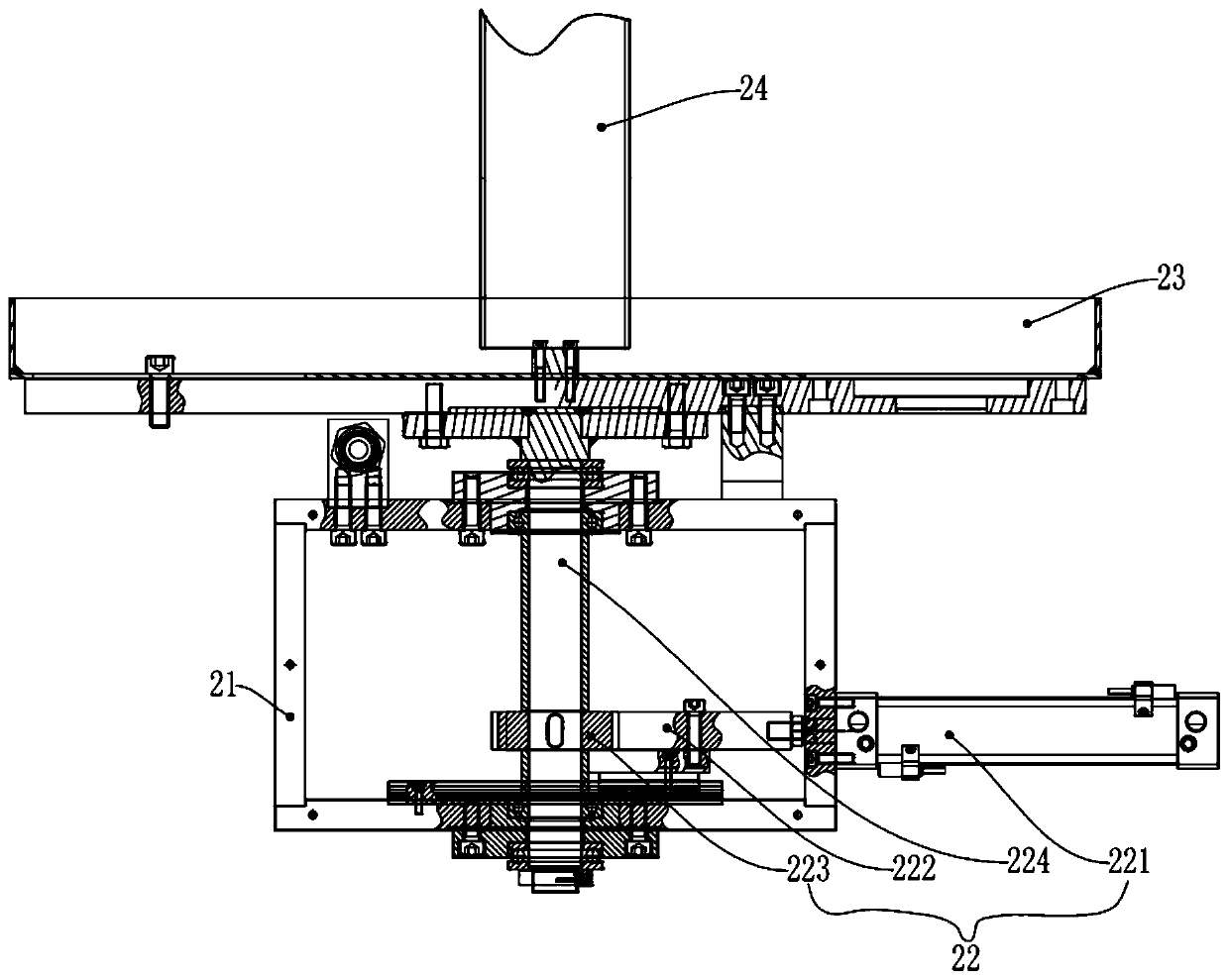

Butt welding device for draught fan half shells

InactiveCN104907750APrecise positioningContinuous weldingWelding/cutting auxillary devicesAuxillary welding devicesButt weldingGear wheel

The invention discloses a butt welding device for draught fan half shells. According to the butt welding device for draught fan half shells, the structure is simple, a machine enclosure to be welded can be positioned effectively, the fluency in the welding process is good, the stability is high, and the wielding quality can be guaranteed. The welding device comprises a welding machine rotating part, a welding machine lifting part, a rotating motor and a welding gun component. The welding machine rotating part comprises a welding bottom frame, a level positioning welding table and a welding table gear. The welding table gear is connected with a main rotating shaft. A positioning fixture is arranged on the positing welding table. The rotating motor is connected with a reducer. An output shaft of the reducer is connected with an output gear. The output gear is meshed with the welding table gear. The welding machine lifting part comprises stand pillars and a vertically-adjusting lead screw component. A horizontally-adjusting lead screw component is arranged on the main welding part. The butt welding device for draught fan half shells has the advantages that the welding gun can be aligned with a portion to be welded accurately, positioning is firmly, the welding process is continuous, a welding gun component does not move when welding is conducted, changing of welding position is realized through the rotation of the machine enclosure to be welded, the stability is good, and the welding quality is high.

Owner:宁波保世洁环境科技有限公司

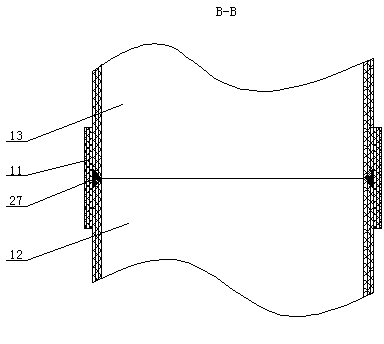

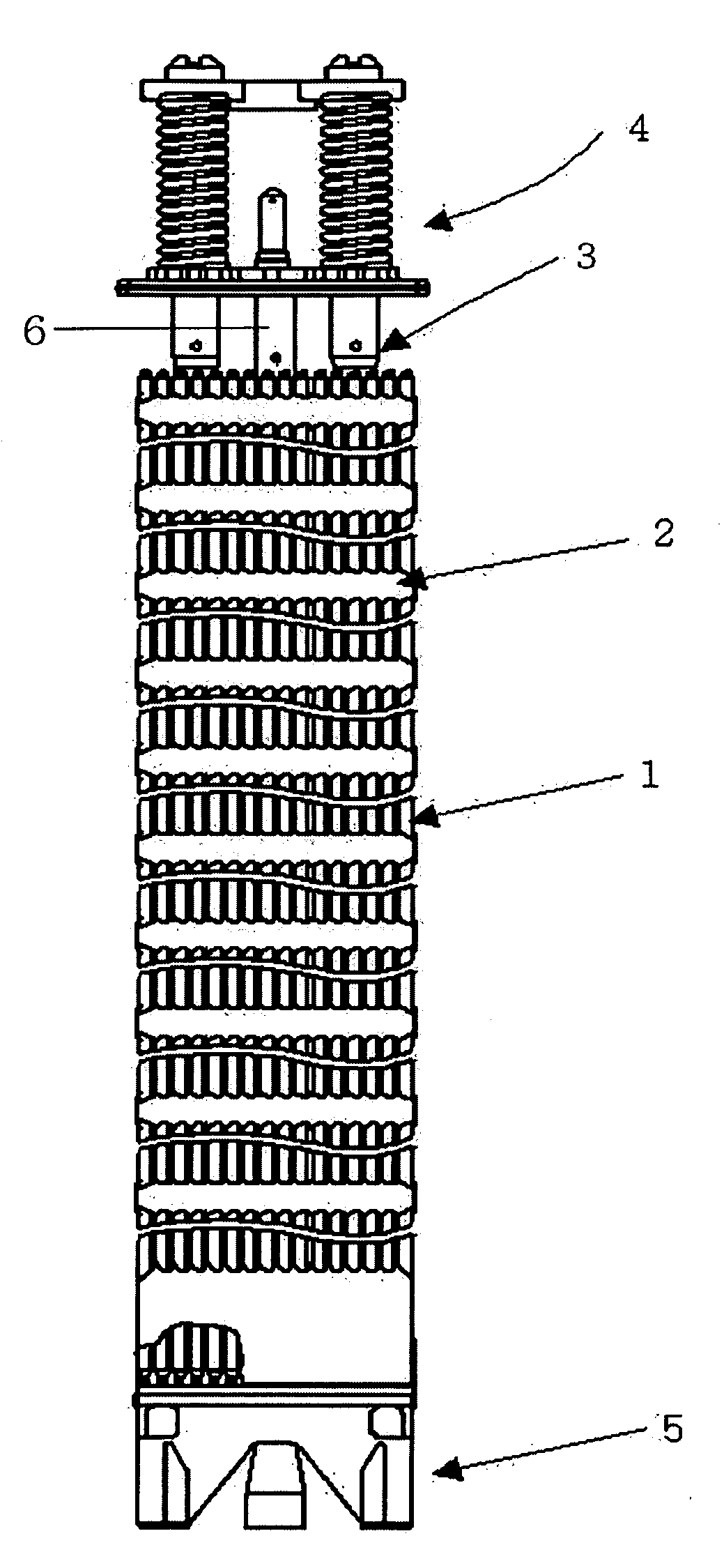

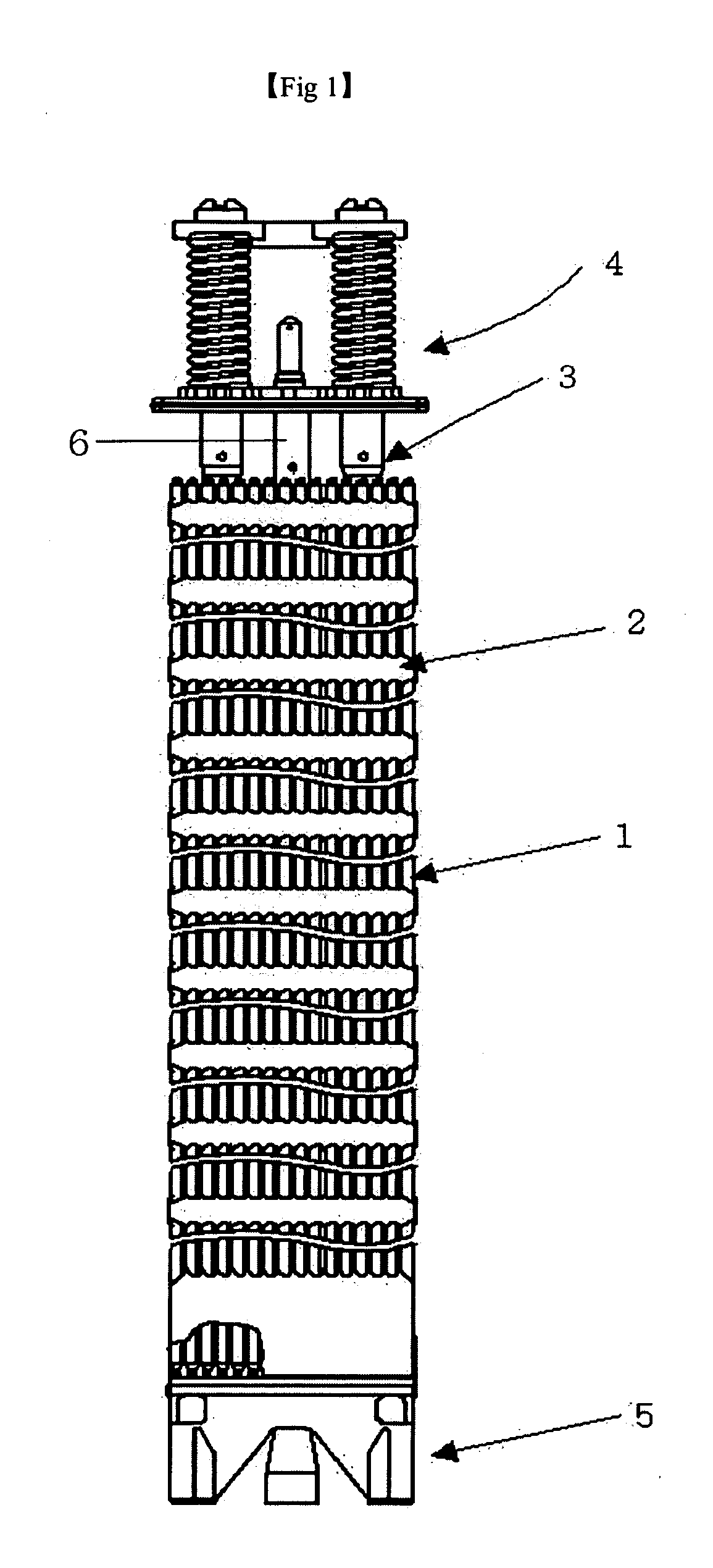

Multi-axis laser welding head for spacer grid

InactiveUS20100096369A1Easy to weldContinuous weldingNuclear energy generationFuel element assembliesLight beamEngineering

Disclosed therein is a multi-axis laser welding head for a spacer grid, which is one of essential components of a nuclear fuel assembly. More particularly, the multi-axis laser welding head for the spacer grid can be operated more smoothly and variously during the welding of the spacer grid to thereby weld the spacer grid more exactly and precisely. For this, the multi-axis laser welding head includes a welding head having a movement within a predetermined angle like the back and forth swing of the pendulum, and can irradiate a laser beam in various directions by having additional axis in comparison with the prior art.

Owner:KEPCO NUCLEAR FUEL CO LTD

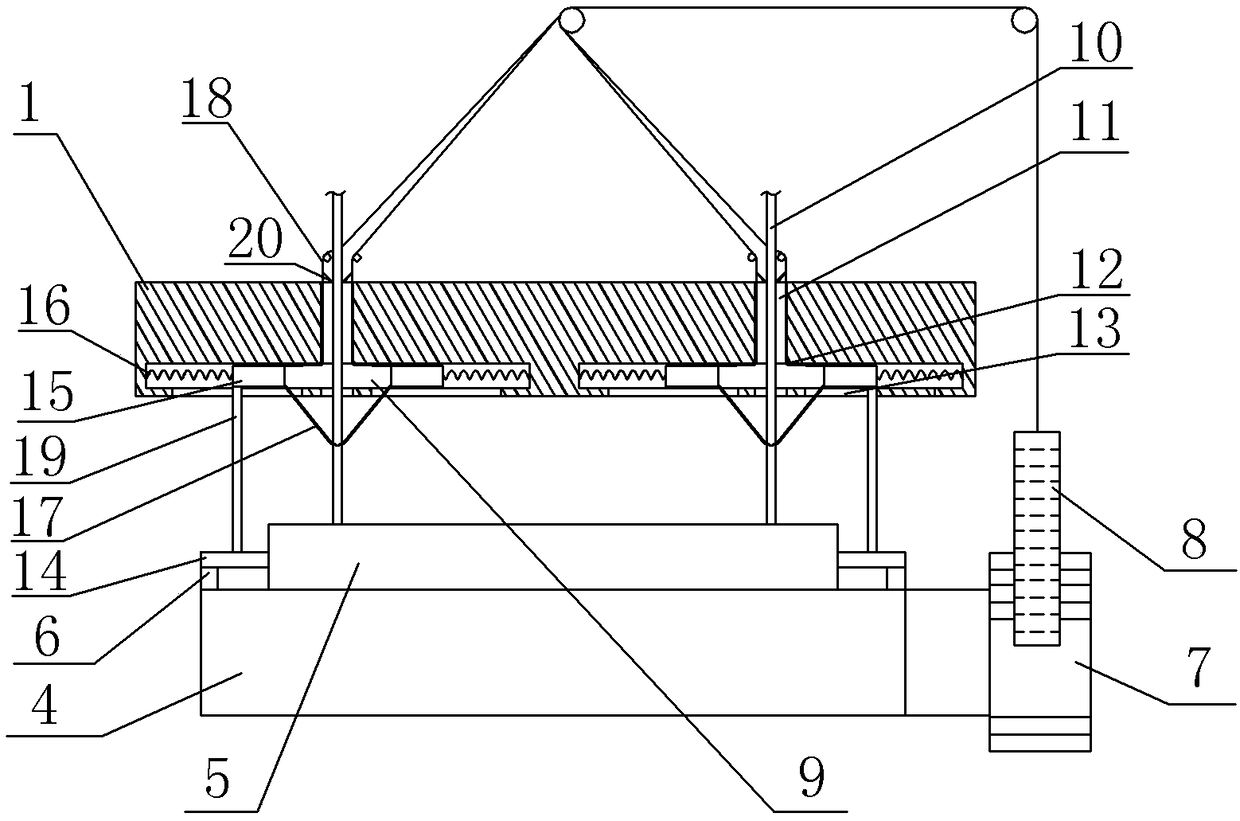

Machine shell welding device

InactiveCN104907670AFirmly positionedThe welding process is continuousWelding/cutting auxillary devicesElectrode holder supportersEngineeringSoldering gun

The invention discloses a machine shell welding device, and aims at providing the device which is reasonable in structure, can effectively position a to-be-welded machine shell, is high in smoothness and stability in the welding process, and can ensure the welding quality. The machine shell welding device comprises a welding machine rotating part, a welding machine lifting part, a rotating motor and a welding gun assembly. The welding machine rotating part comprises a welding bottom frame, a horizontal positioning welding table and a welding table gear. The welding table gear is connected with a main rotating shaft. A positioning fixture is arranged on the positioning welding table. The rotating motor is connected with a speed reducer. An output shaft of the speed reducer is connected with an output gear which is meshed with the welding table gear. The welding machine lifting part comprises a stand column and a vertical adjusting lead screw assembly. A transverse adjusting lead screw assembly is arranged on the main welding part. The machine shell welding device has the advantages that a welding gun and a to-be-welded part can be accurately aligned, positioning is firm, the welding process is ceaseless, the welding gun assembly is still during welding, the welding position is changed through the rotation of the to-be-welded machine shell, stability is high, and the welding quality is high.

Owner:宁波保世洁环境科技有限公司

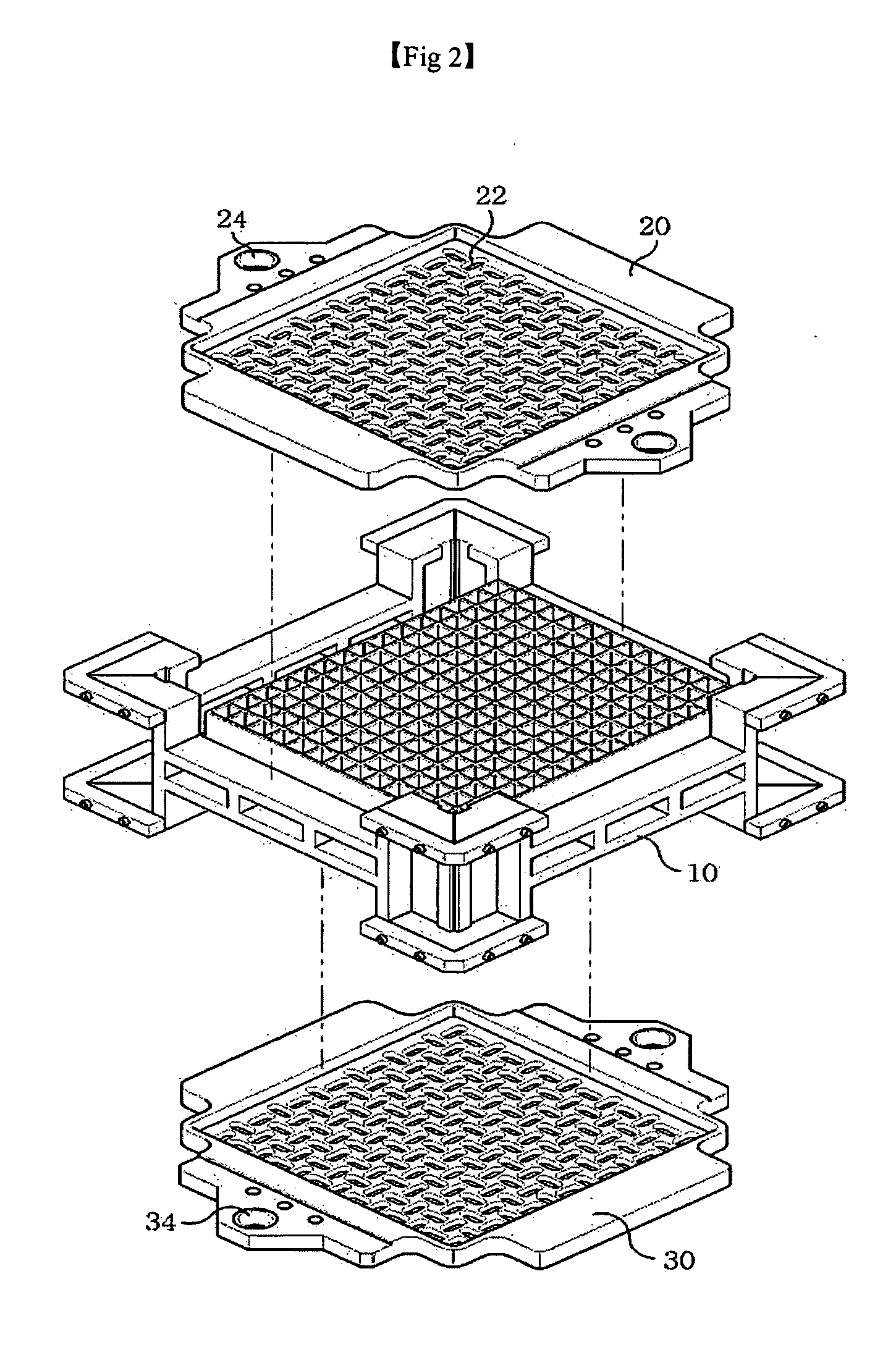

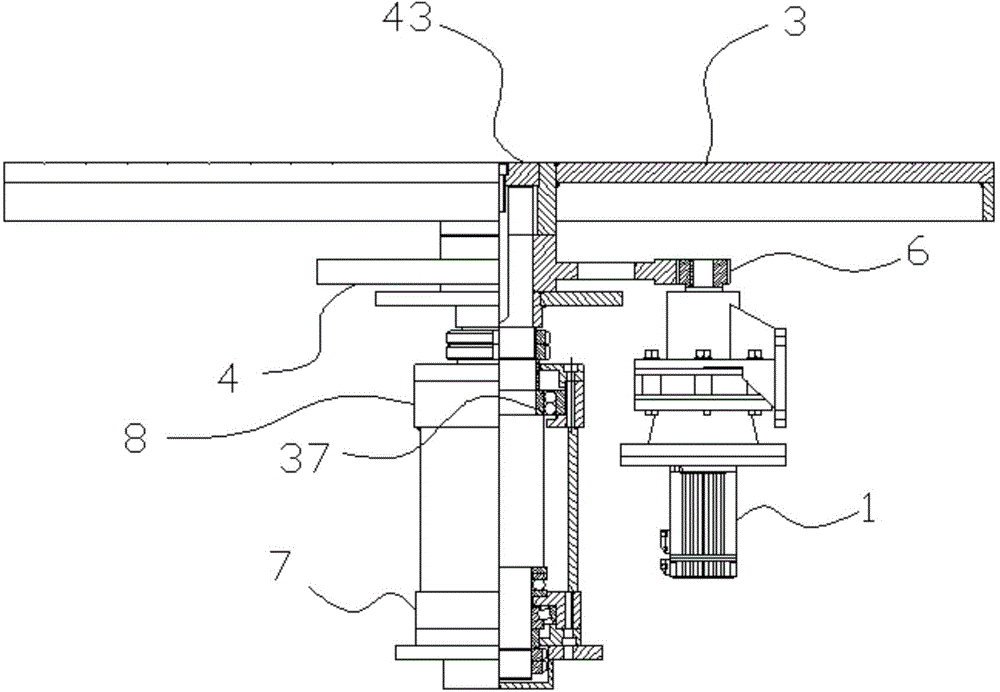

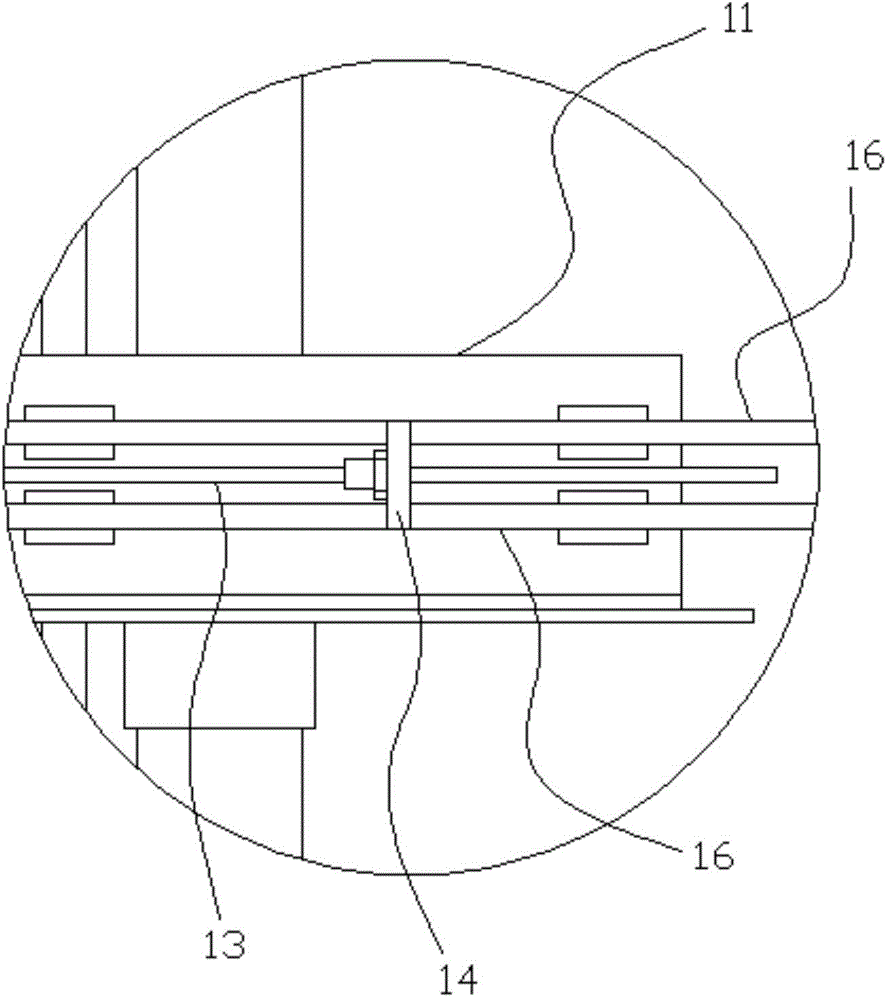

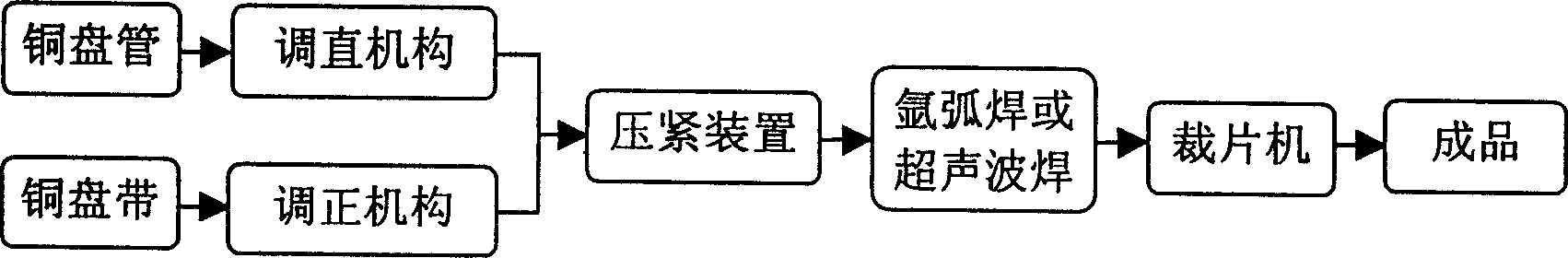

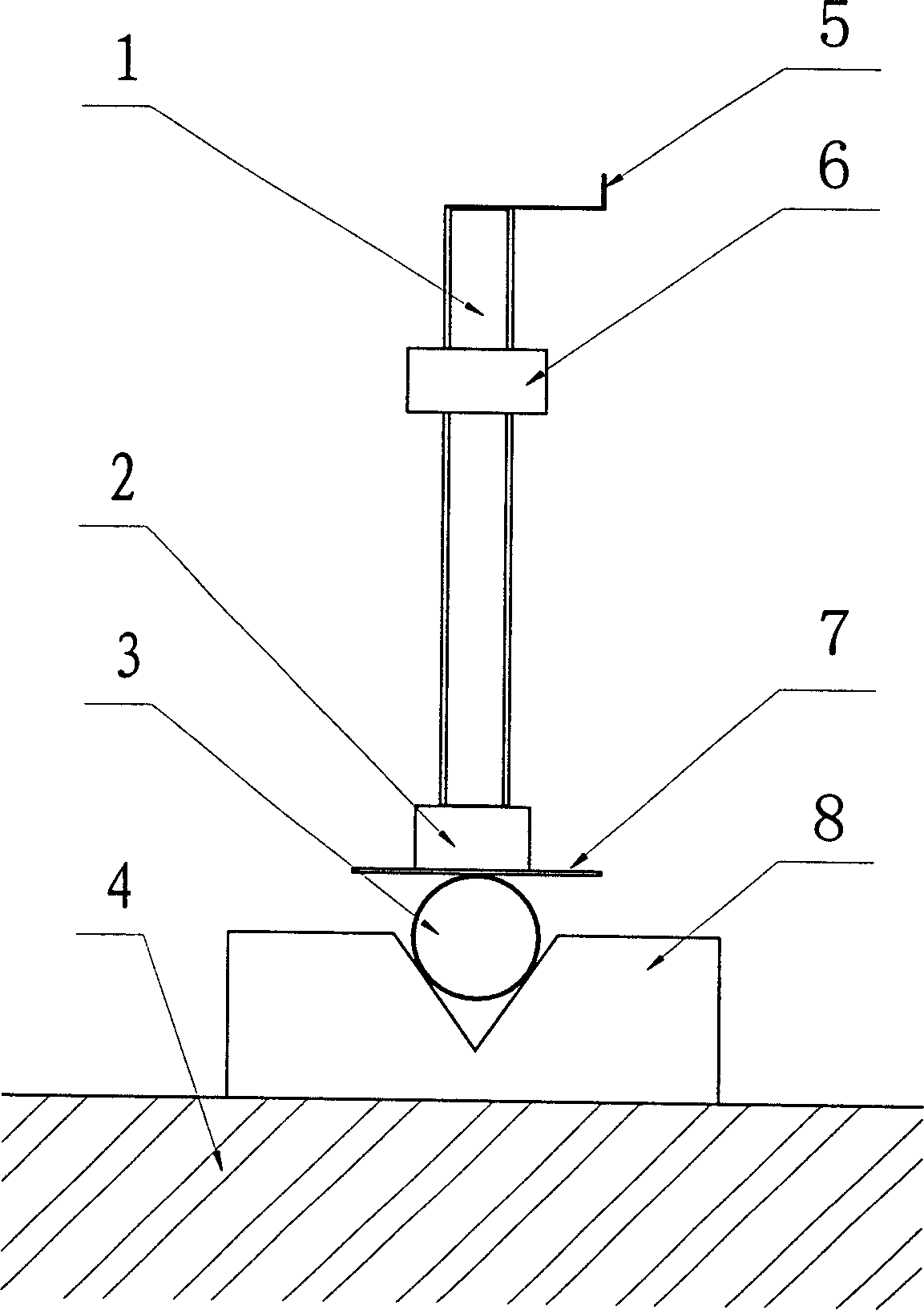

Continuous type heat collection strip welding method without medium and its compacting device

InactiveCN1457954AEasy to achieve continuous weldingReduce scrap rateArc welding apparatusNon-electric welding apparatusFixed frameEngineering

The present invention belongs to the field of no-medium welding technology. The technological process of no-medium welding continuous heat collecting strips includes the steps of regulation to straighten coil tube and align coil belt with the regulating mechanism; compacting the coil tube and the coil belt; argon arc welding or supersonic welding; and cutting to the required size in a cutting machine. The compacting device for no-medium welding continuous heat collecting strips consists of fixing frame and movable mechanism and has lower slot structure ad upper lead screw mechanism. The present invention has high production efficiency and product quality.

Owner:齐心

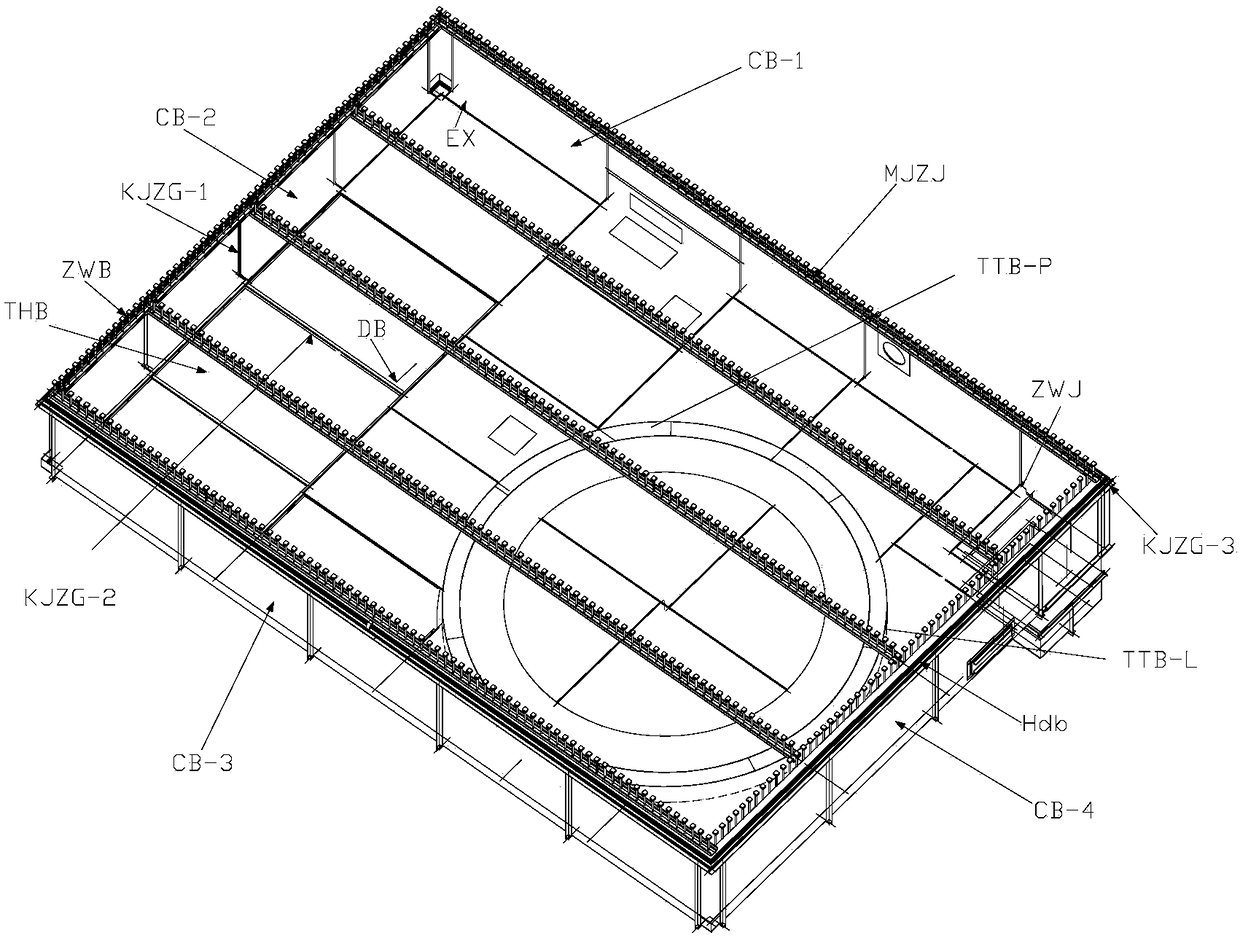

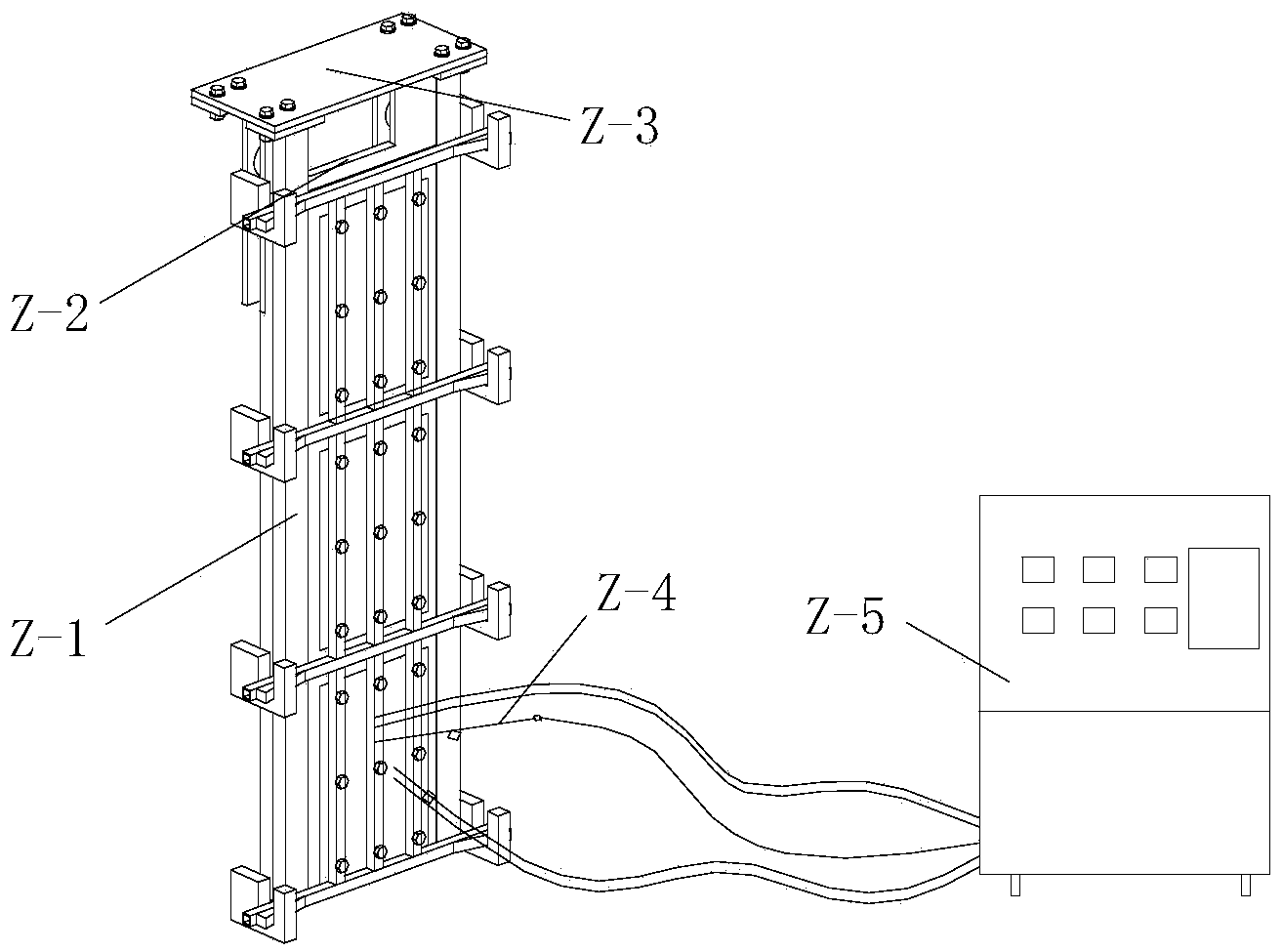

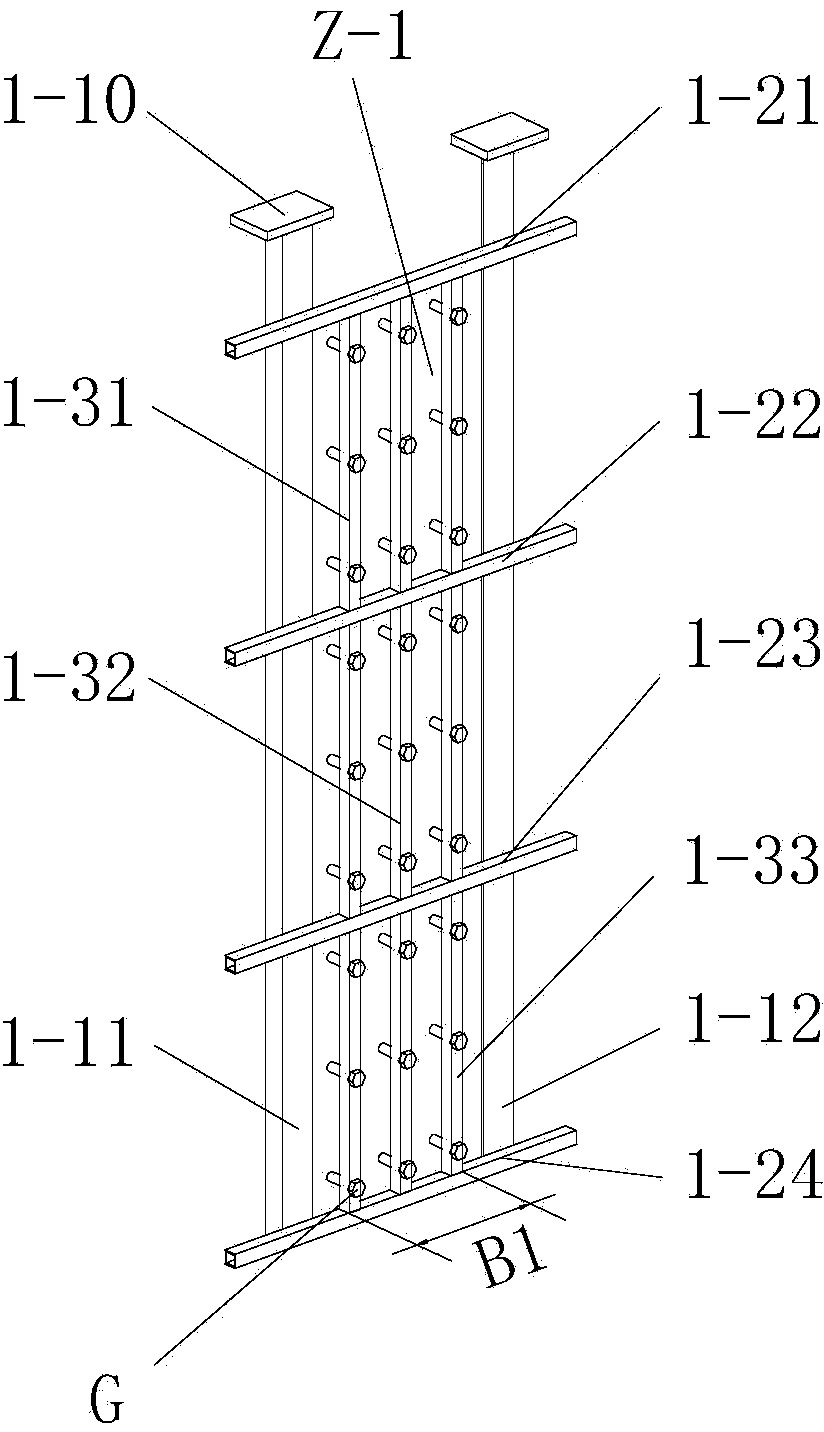

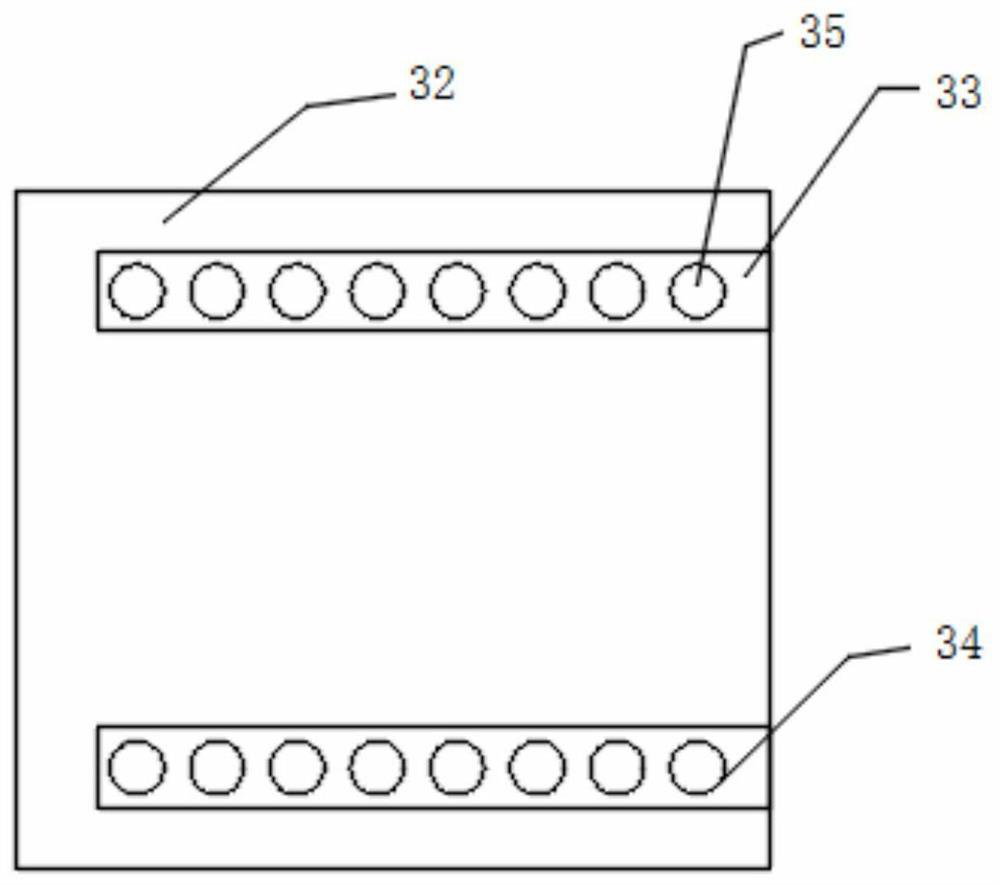

Automatic acquisition device for stator positioning rib welding deformation measurement data

PendingCN111366067AReal-time monitoring of size data changesRealize automatic recordingWelding/cutting auxillary devicesUsing electrical meansControl engineeringAlarm device

The invention discloses an automatic acquisition device for stator positioning rib welding deformation measurement data. The automatic acquisition device comprises a probe, a probe fixing support, a signal acquisition device, a terminal computer, automatic analysis software, output equipment, an alarm device and monitoring supports, wherein each monitoring support is composed of a support fixing frame, a support base and a support walking mechanism and is fixed to a lower annular plate of a stator annular plate; the probe fixing support comprises a supporting block, an adjustable cushion blockand a probe frame, the supporting block is welded and fixed to the support fixing frame, the adjustable cushion block is installed on the supporting block, the probe frame is welded and fixed to thefront end of the adjustable cushion block, and the probe is fixed to the probe frame; the signal acquisition device and the alarm device are fixed on a support base and are connected with the terminalcomputer through signals; the signal acquisition device is connected with the probe; and the terminal computer is provided with the automatic analysis software. The automatic acquisition device can perform automatic measurement, automatic recording, automatic analysis and real-time alarm, and can perform real-time monitoring when a stator positioning rib of a hydro-generator is welded.

Owner:SINOHYDRO BUREAU 7 CO LTD

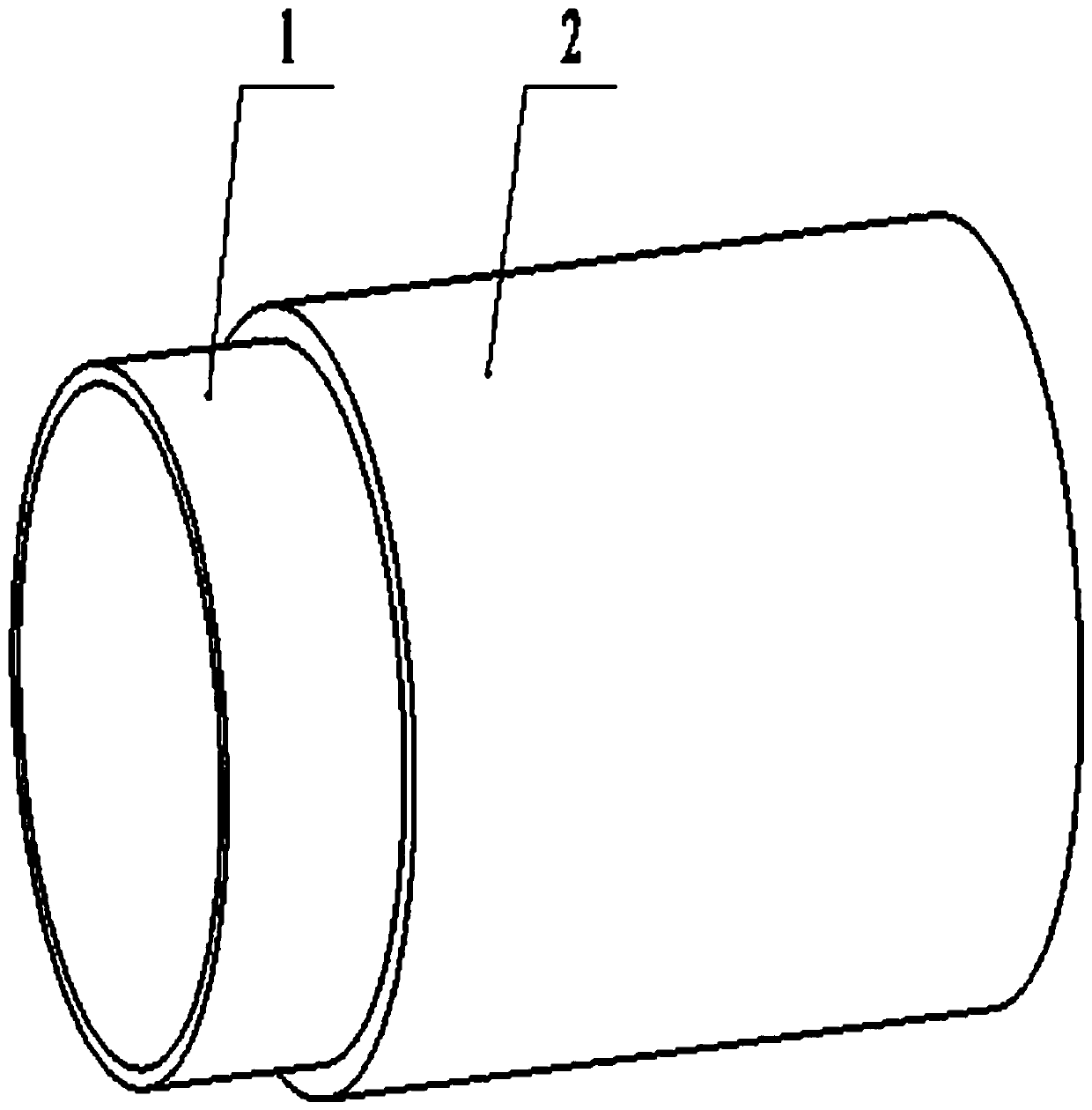

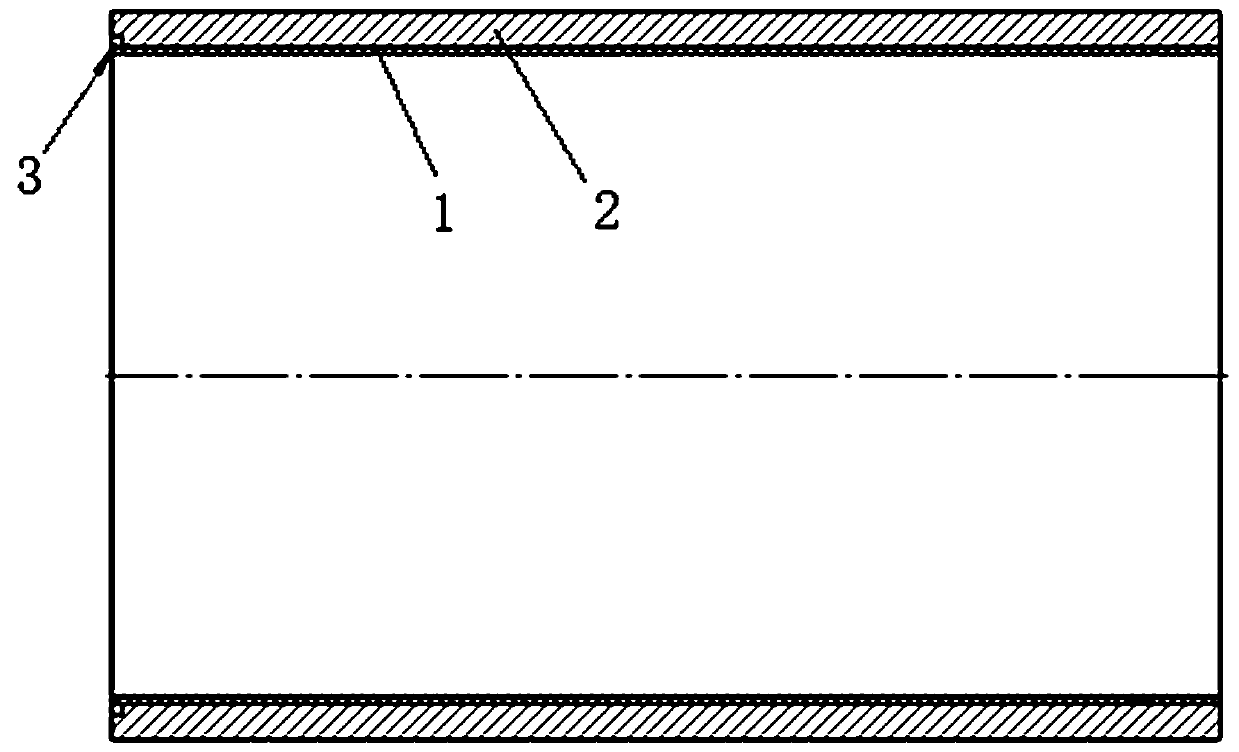

Butt welding technological method for plastic pipes with functional layers

The invention discloses a butt welding technological method for plastic pipes with functional layers and belongs to the technical field of composite pipe welding. Each plastic pipe is a composite pipecomposed of an inner wall layer and an outer wall layer, wherein the inner wall layer of the plastic pipe is made of weldable functional materials. The butt welding technological method comprises thefollowing steps that a V-shaped groove and an annular groove are machined in a butt-joint end face of each plastic pipe, end face butt-joint alignment is conducted the two plastic pipes, and the butt-joint end faces are welded. The annular grooves are machined in the end faces of the plastic pipes, thus when the butt-joint end faces of the two plastic pipes are welded, extruded materials of the outer wall layers enter the annular grooves located at the junctions of the inner wall layers and the outer wall layers, and the effect that the inner wall layers are welded into a continuous whole canbe ensured. With the adoption of the butt welding technological method, the problems that after heated, materials of outer wall layers are turned toward the interiors and outer walls of pipelines under the action of welding pressure, and consequently the inner wall functional layers are discontinuous due to flowing extrusion of thicker materials of outer wall layers on plastic of the inner wall functional layers are solved, and usability of the joint of the plastic pipes is ensured.

Owner:HUACHUANG TIANYUAN IND DEVING

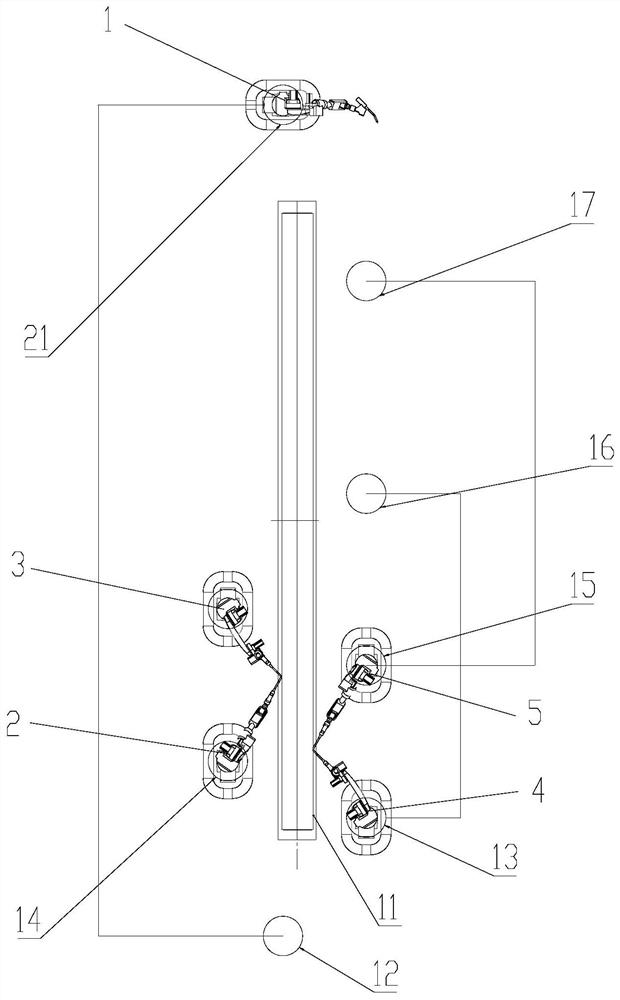

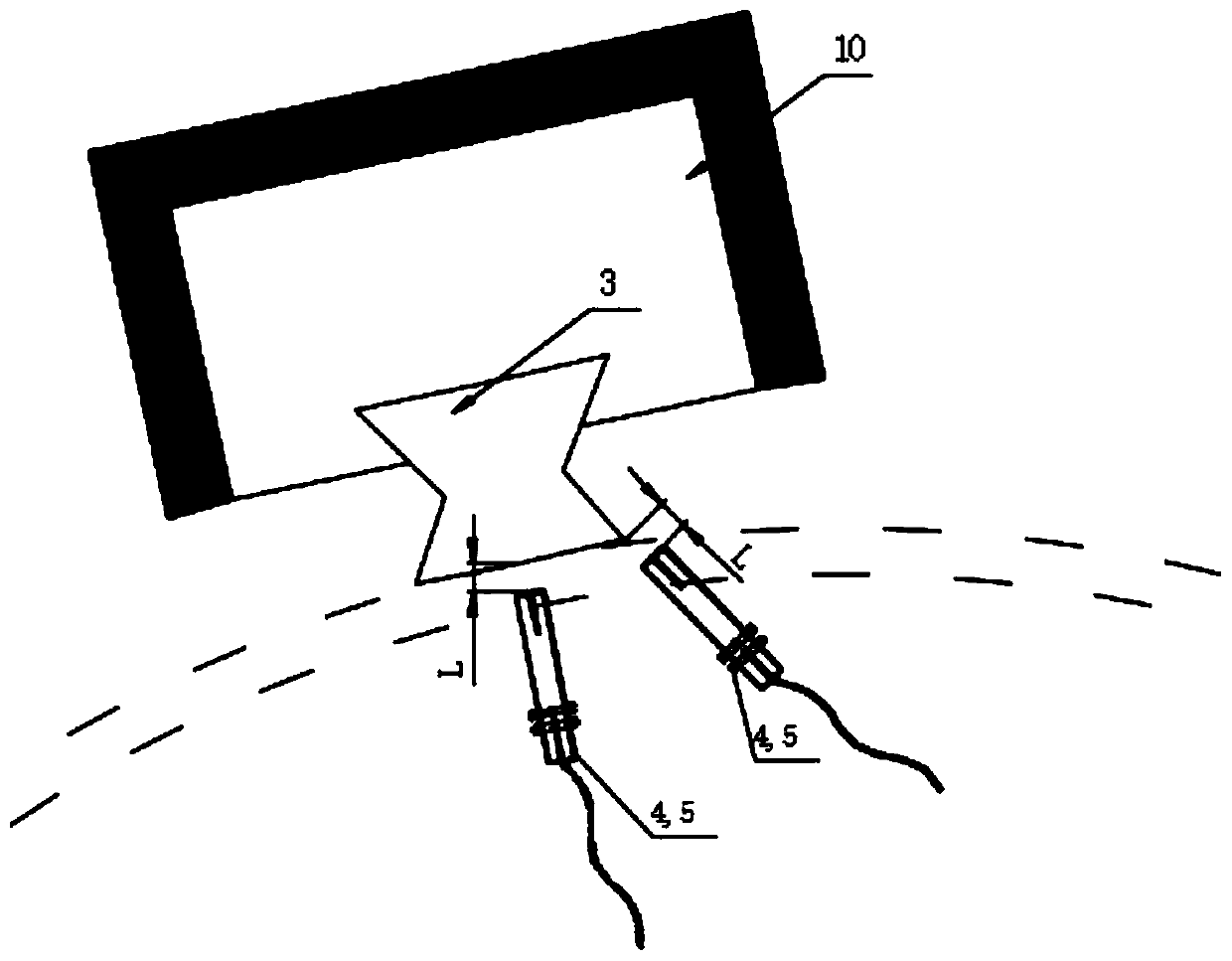

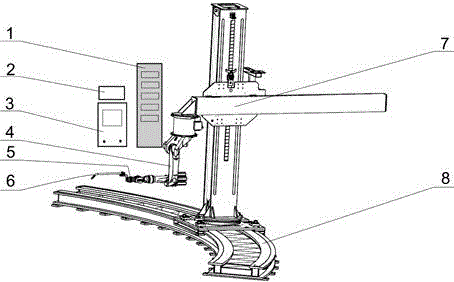

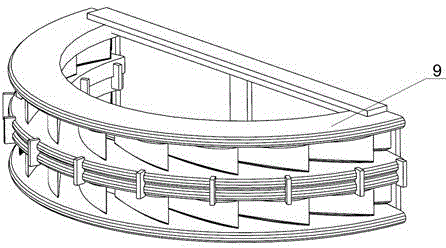

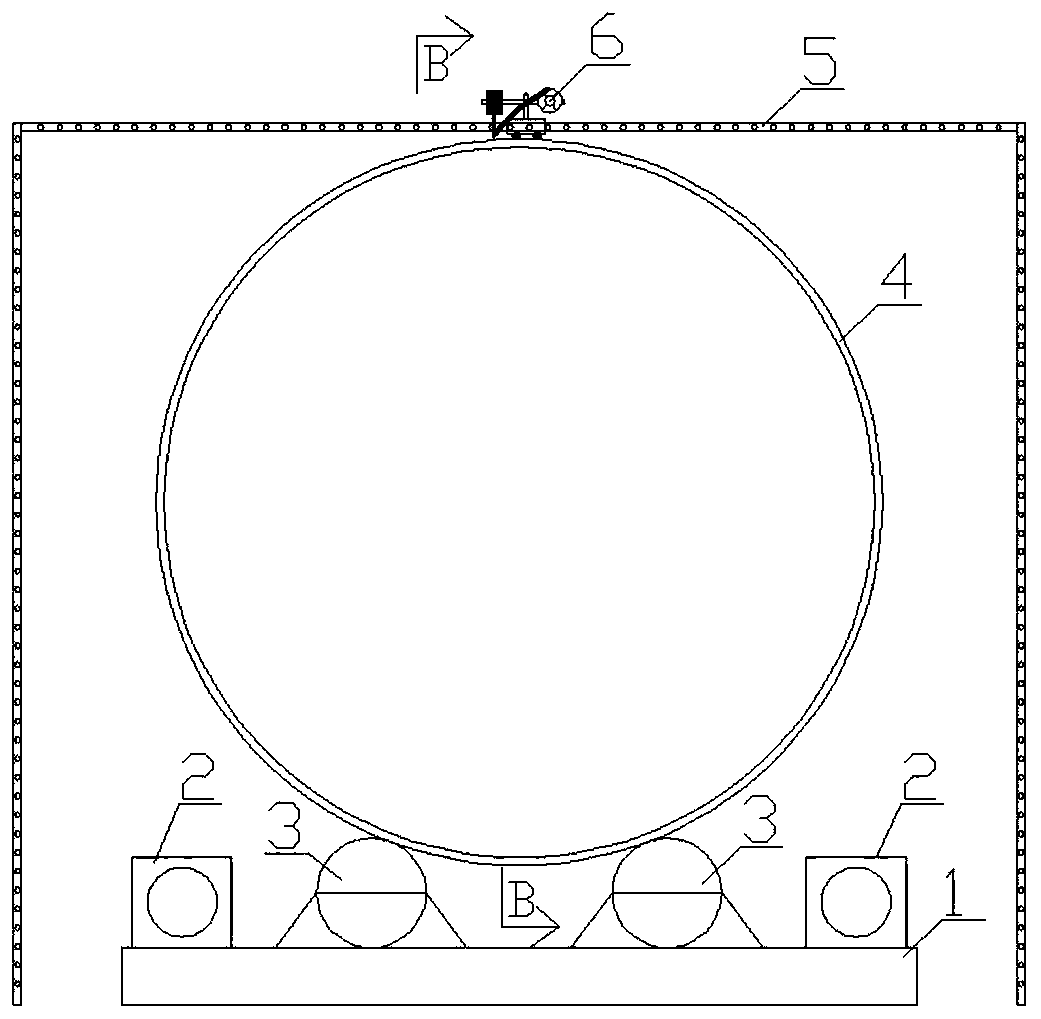

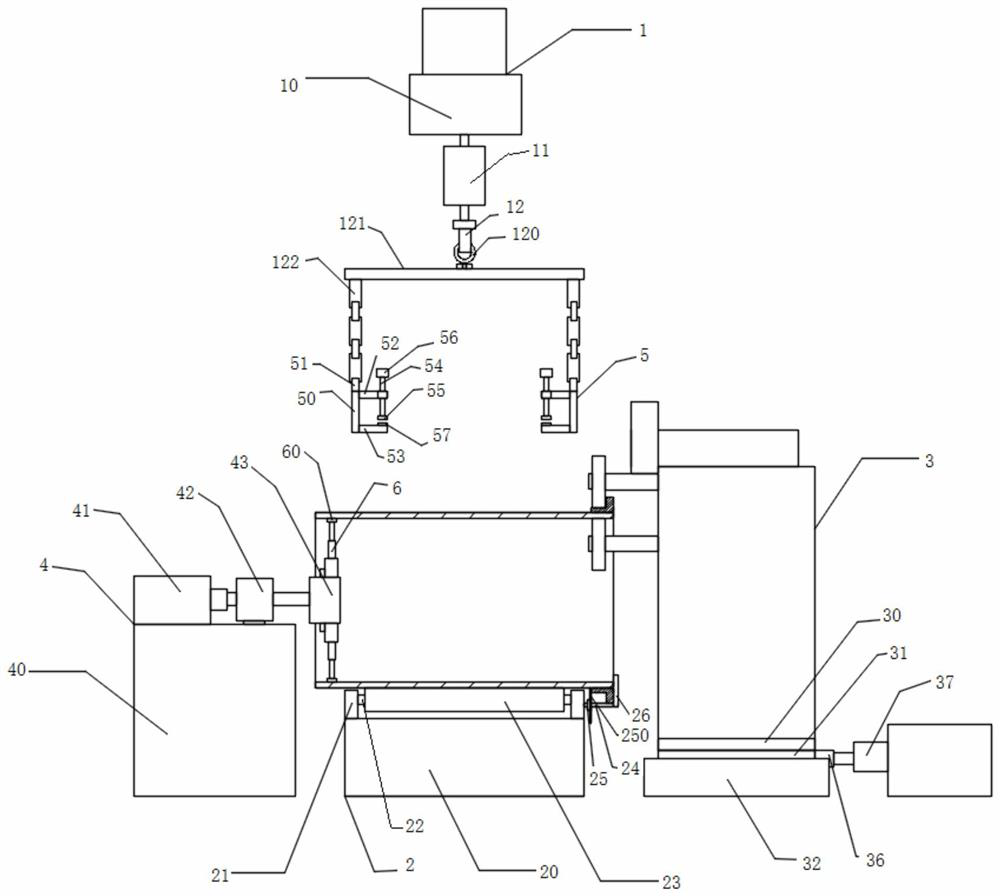

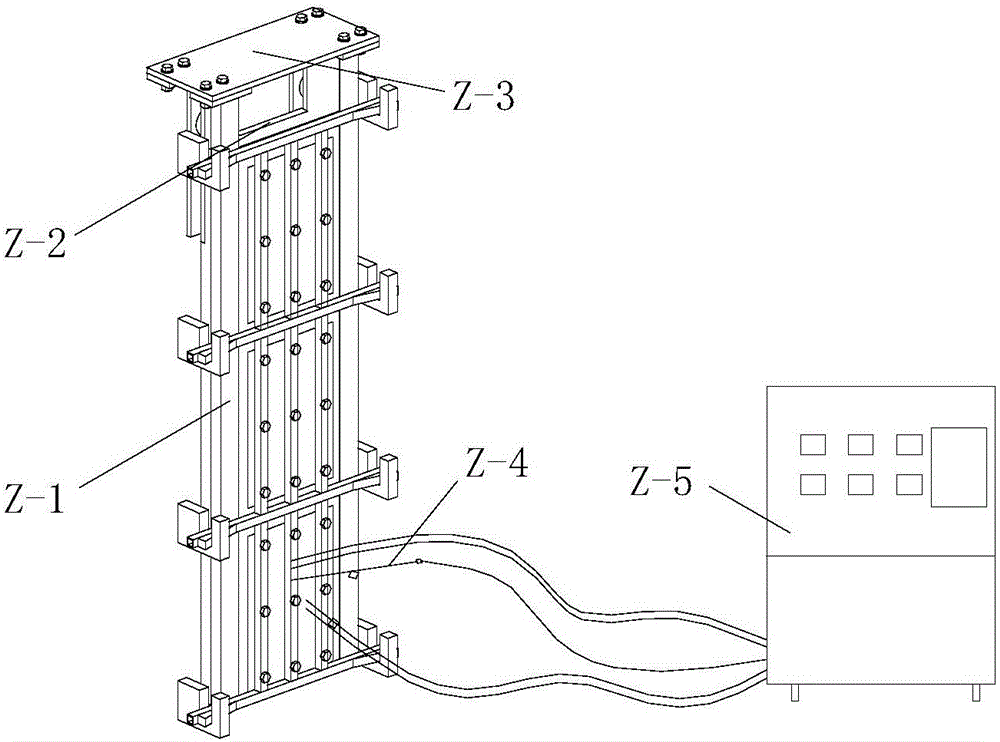

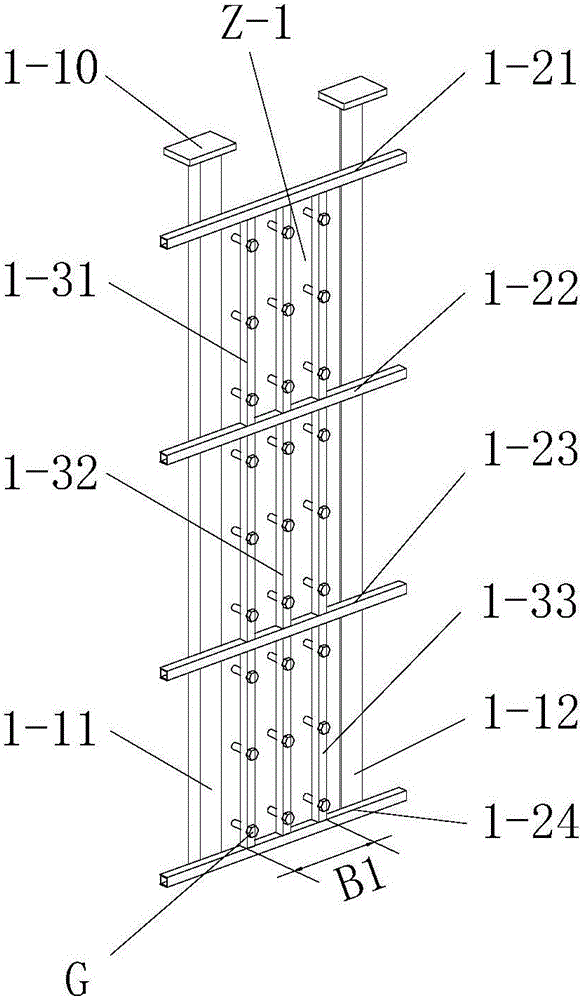

Method and device for welding water-wheel socket ring

ActiveCN103464870BEfficient automatic weldingReduced risk of collisionArc welding apparatusWater wheelEngineering

The invention provides a method and a device for welding a water-wheel socket ring. The method includes that for generation of welding tracks, establishing a three-dimensional model of a water-wheel socket ring according to size, assembly and positional relation of each part, taking feature points on an intersection line of fixed guide vanes and upper and lower annular plates every other 50-100mm, and matching all control points to obtain the continuous welding tracks of an individual fixed guide vane; integrally translating the welding tracks of the individual fixed guide vanes on the three-dimensional model of the water-wheel socket ring to perform local modification, and continuously generating the welding tracks of the whole water-wheel socket ring; assembling the water-wheel socket ring; pre-heating prior to welding; using a robot welding gun for automatic welding. By the method, a robot welding process is continuous and stable, welding quality stability is remarkably improved, and welding efficiency is improved by 3-4 times as compared to that of manual welding; labor intensity and security risk of a welding operator are lowered; welding lines generated are regular in shape and attractive, and the qualified rate of flaw detection is higher than that of the same type by manual welding.

Owner:DONGFANG ELECTRIC MACHINERY

Rapid assembly welding method for large diameter steel pipeline

InactiveCN111438428AReduce the difficulty of dockingImprove assembly efficiencyWelding/cutting auxillary devicesAuxillary welding devicesButt jointPipe

The invention discloses a rapid assembly welding method for a large diameter steel pipeline. The method comprises the steps that a circular butt joint device is manufactured; positioning support plates are evenly distributed at the mouth of a lower steel pipe to be welded, the butt joint device is placed on the support plates, and the butt joint device fastens the lower steel pipe after buckling;an upper steel pipe is aligned with the lower steel pipe for butt joint correction and pre-assembly; two sections of pre-assembled steel pipes are hoisted and placed on rotating bed-jigs horizontally;a submerged arc welding trolley is placed directly above the welding line of the two sections of steel pipes to be welded, and the travel direction of the trolley is consistent with the welding line;the linear speed of a large diameter steel pipeline is the same as the submerged arc welding trolley, and the rotation direction is opposite; after the entire welding line of the steel pipeline to bewelded is finished, the soldering flux residue is removed, and if welding defects are found, manual repair welding and polishing are processed. According to the rapid assembly welding method for thelarge diameter steel pipeline, horizontal welding, vertical welding and overhead welding can be converted into flat welding, and welding process is completed continuously, smoothly and fully-automatically.

Owner:CHINA FIRST METALLURGICAL GROUP +1

Positioning device for electronic component

ActiveCN108480897AContinuous weldingReduce manual labor intensityWelding/cutting auxillary devicesOther manufacturing equipments/toolsEngineeringElectronic component

The invention relates to the field of production of electronic components, in particular to a positioning device for an electronic component. The positioning device comprises a machine frame, a conveying mechanism, a cross beam and two positioning cutting mechanisms, wherein the conveying mechanism comprises a driving roller, a driven roller and a conveying belt; an intermittent gear is coaxiallyconnected on the driving roller, and a rack meshed with the intermittent gear is arranged on the machine frame in a mode of vertically sliding; a horizontal slideway is arranged in the cross beam, anda through hole for enabling a pin to pass through is vertically formed in the cross beam; each positioning cutting mechanism comprises a positioning block and two cutting units, and each cutting unitcomprises a sliding block, a tension spring, a cutting knife and a stay cord, the sliding block is arranged in the slideway in a sliding mode, one end of the tension spring is fixedly connected withthe cross beam, the free end of the tension spring is fixedly connected with the sliding block, the cutting knife is obliquely arranged on the sliding block, the positioning block is fixedly connectedwith the sliding block, one end of the stay cord is fixedly connected with the sliding block, the other end of the stay cord is fixedly connected with the rack, and a scraper is arranged on the staycord. According to the technical scheme, the positioning device can automatically position the electronic component and continuously weld the electronic component.

Owner:山东贝斯特信息科技有限公司

A spot welding method for fully automatic battery spot welding equipment

ActiveCN106624306BContinuous weldingFast solderingWelding/cutting auxillary devicesAuxillary welding devicesButt weldingSpot welding

Owner:保力新(内蒙古)电池有限公司

A seamless welding machine

ActiveCN111168224BGuaranteed integral connectionIncreased length rangeNon-electric welding apparatusStructural engineeringWeld strength

The invention discloses molecular staggered seamless welding machine equipment. The equipment comprises a main body, wherein a welding cavity is formed in the main body, a matching block is rotationally arranged in the welding cavity, the matching block is divided into an upper part and a lower part, the upper matching block and the lower matching block which correspond to each other vertically are connected through a screw rod, a welding gear capable of driving the matching block to rotate is arranged on the outer wall of the matching block, and bilaterally symmetrical upper fixing blocks arearranged in the welding cavity in a sliding mode. According to the equipment, the device is simple in structure, convenient to operate and maintain and continuous in welding process, integral connection of to-be-welded metal is guaranteed during welding, welding strength is greatly improved, meanwhile, personnel intervention is not needed in the welding process, dependence on the welding technology of welding personnel is reduced, personnel cost is reduced, rotating operation is not conducted on the welded metal during welding, the length range of weldable metal is greatly widened, the application capacity of the equipment is improved, and therefore the equipment has high use and popularization value.

Owner:江西瑞升科技股份有限公司

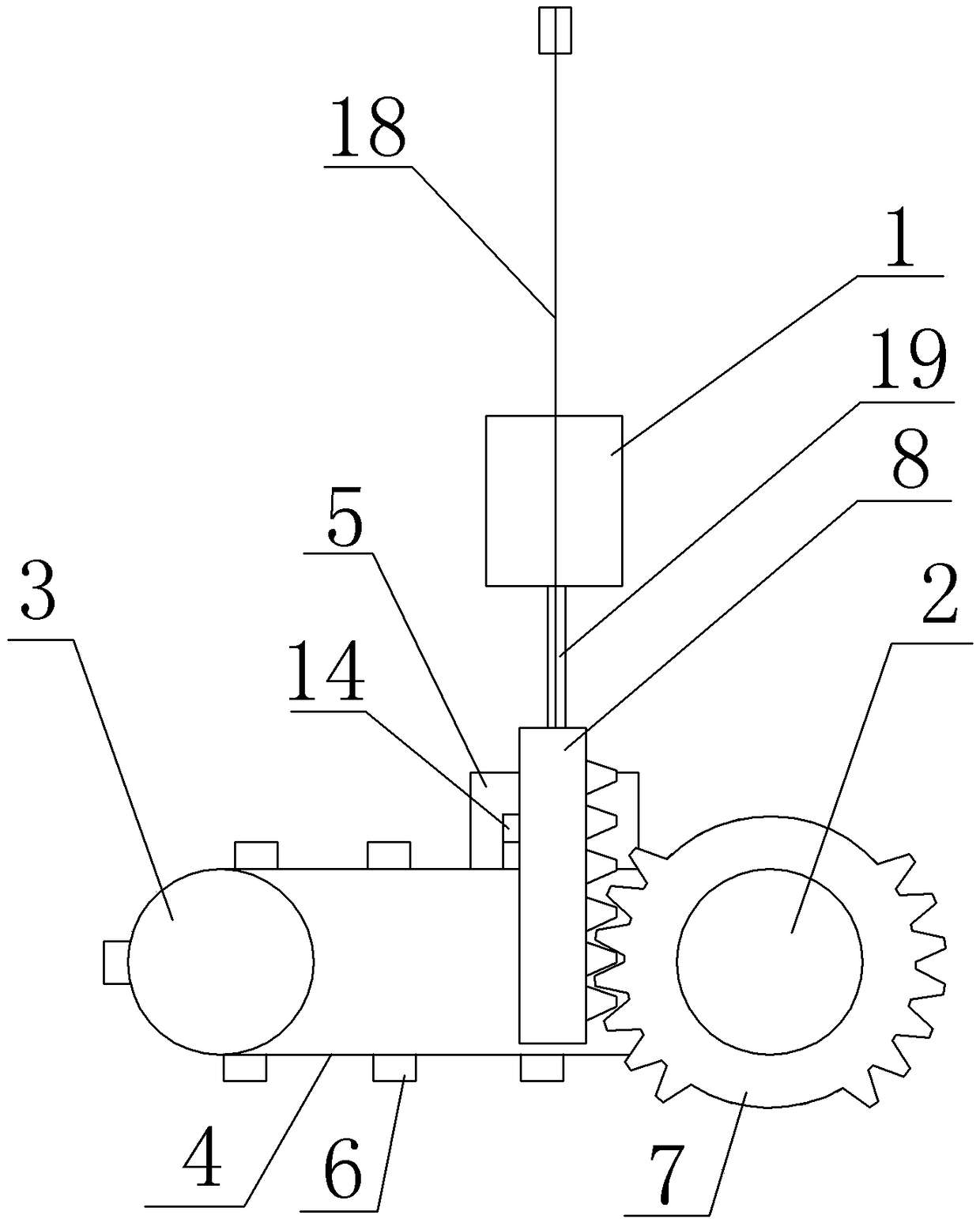

Eccentric sliding table positioner

ActiveCN109623249BWith eccentric slide functionEasy to weldWelding/cutting auxillary devicesAuxillary welding devicesEngineeringMachine

The invention belongs to the technical field of welding tooling equipment, and relates to an eccentric sliding table positioner, which includes a rotary base, on which a first rotary drive mechanism is installed, and the first rotary drive mechanism is connected to drive the eccentric slide table to rotate, and the eccentric The linear guide rail is rotated on the slide frame, and the small rotary fixed seat is slidably connected with the linear guide rail through the slider; the second rotary drive mechanism is installed on the small rotary fixed seat, and the second rotary drive mechanism is connected and drives the workpiece fixed seat to rotate. A workpiece fixing shaft is installed on the workpiece fixing seat, and the shaft end of the workpiece fixing shaft is threadedly connected with a workpiece locking nut. The positioner has the function of small rotation. When working, it can adjust the other eccentric holes of the workpiece to the center of the large rotary support through the small rotation. The operation is simple and convenient, and it meets the requirements of continuous welding.

Owner:JIANGSU DADE HEAVY IND

A chassis docking device

ActiveCN104907671BPrecise positioningContinuous weldingWelding/cutting auxillary devicesElectrode holder supportersButt jointReducer

The invention discloses a machine shell butt joint device, and aims at providing the butt joint device which is reasonable in structure, can effectively position a to-be-welded machine shell, is high in smoothness and stability in the welding process and can ensure the welding quality. The machine shell butt joint device comprises a welding machine rotating part, a welding machine lifting part, a rotating motor and a welding gun assembly. The welding machine rotating part comprises a welding bottom frame, a horizontal positioning welding table and a welding table gear. The welding table gear is connected with a main rotating shaft. A positioning fixture is arranged on the positioning welding table. The rotating motor is connected with a speed reducer. An output shaft of the speed reducer is connected with an output gear which is meshed with the welding table gear. The welding machine lifting part comprises a stand column and a vertical adjusting lead screw assembly. A transverse adjusting lead screw assembly is arranged on the main welding part. The machine shell butt joint device has the advantages that a welding gun and a to-be-welded part can be accurately aligned, positioning is firm, the welding process is ceaseless, the welding gun assembly is still during welding, the welding position is changed through the rotation of the to-be-welded machine shell, stability is high, and the welding quality is high.

Owner:宁波保世洁环境科技有限公司

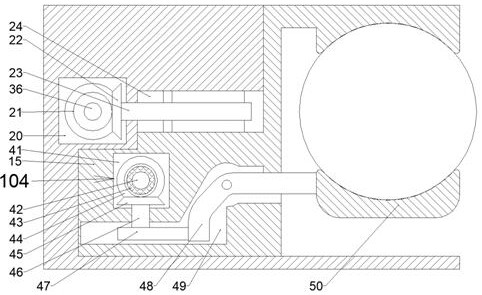

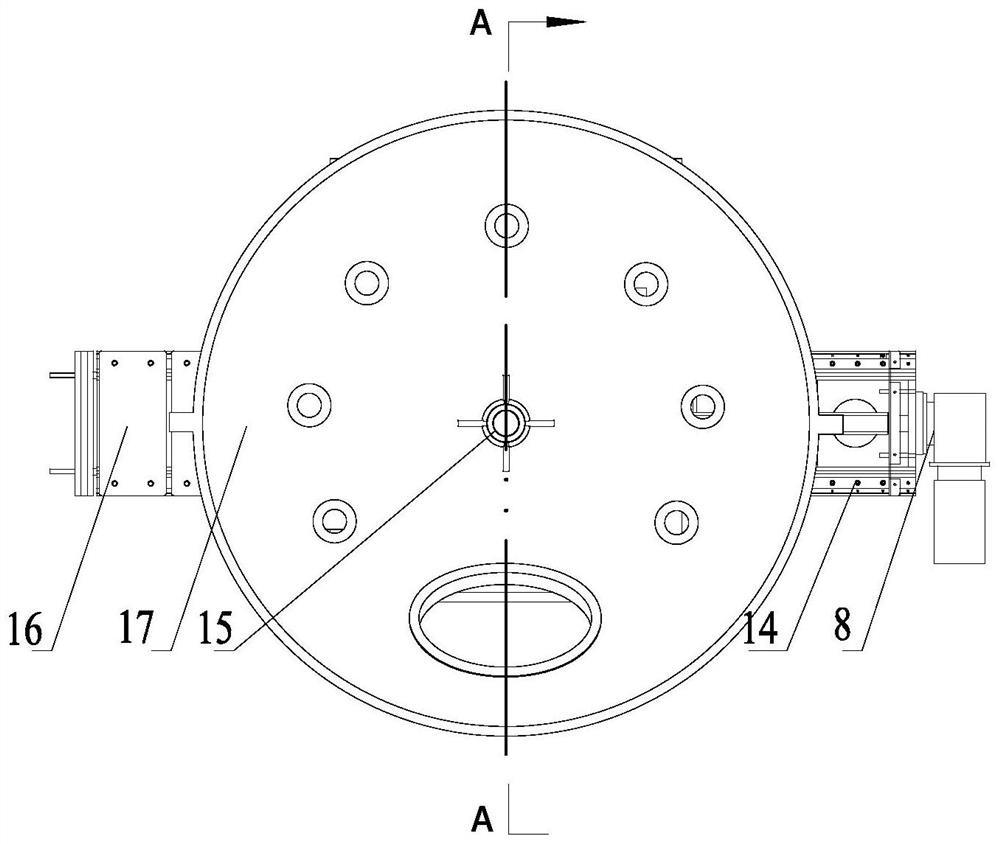

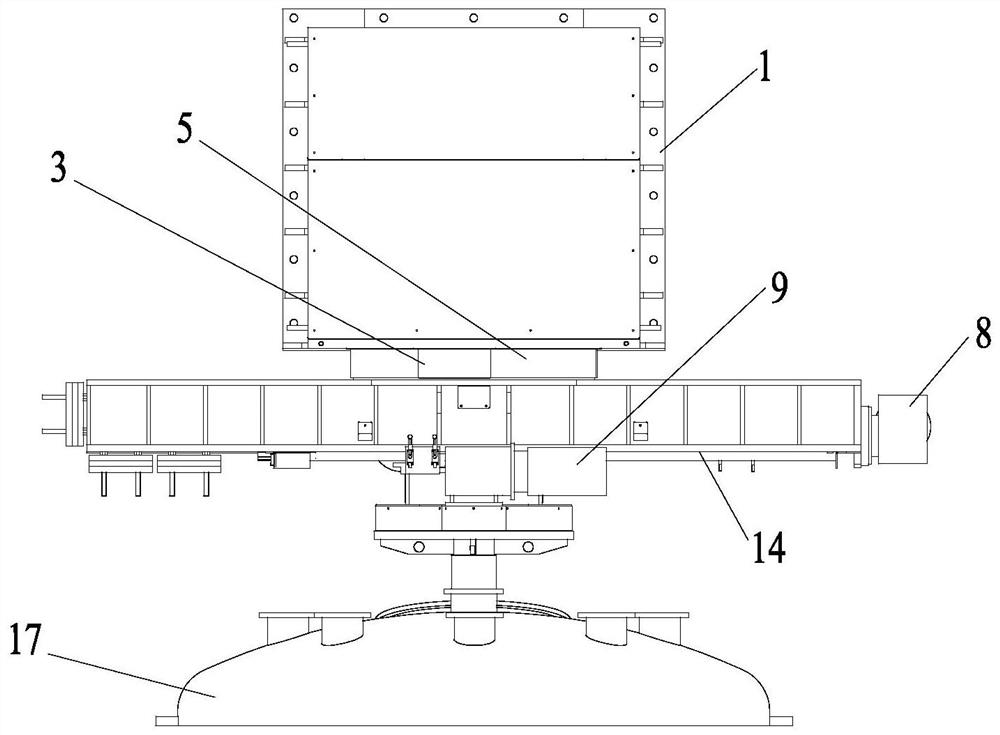

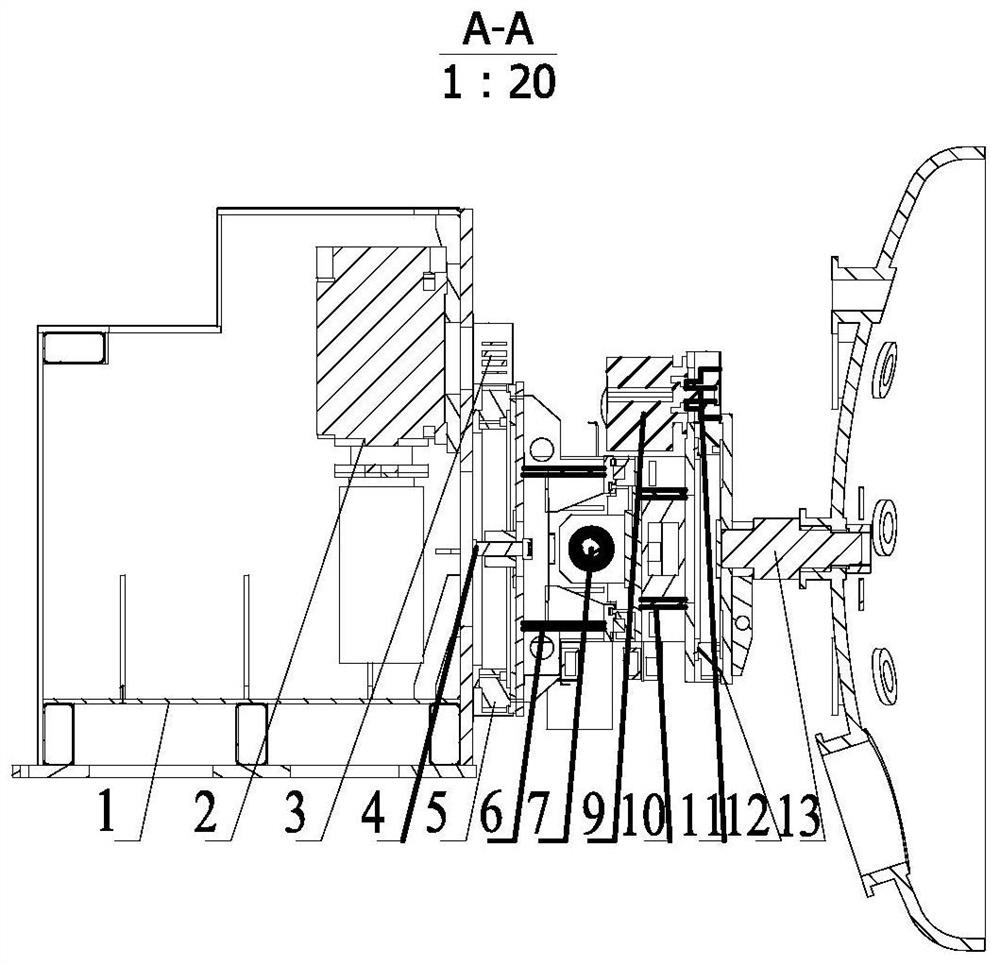

A welding resistance equipment for axial flow fan casing processing

ActiveCN111633315BContinuous weldingFast solderingWelding with roller electrodesEngineeringElectric resistance welding

Owner:SHANGHAI DE HUI SPECIFIC FAN +1

Automatic Welding Method for Steel Containment Vessel of Nuclear Power Plant

ActiveCN103769727BImprove low temperature impact toughnessStrong penetrating powerWelding/cutting auxillary devicesArc welding apparatusWork periodNuclear plant

The invention relates to an automatic welding method of a nuclear plant steel safety shell and belongs to the technical field of nuclear plant building. The method adopts the match between a solid core welding wire and the active gas-shielded arc welding of a consumable electrode with specific process parameters, weaving welding is adopted for vertical welding seam,s and linear welding is adopted for horizontal annular seams. According to the method, internal and appearance qualities of the welding seams of the nuclear plant steel safety shell are improved, the safety is ensured, the efficiency for welding a thick plate of the steel safety shell is greatly improved, and the welding work period is obviously shortened.

Owner:CHINA NUCLEAR IND HUAXING CONSTR

Automatic welding equipment for double annular welding beads

ActiveCN103008940BFulfill welding requirementsRealize continuous weldingWelding/cutting auxillary devicesAuxillary welding devicesAutomatic test equipmentEngineering

Owner:长城汽车股份有限公司平湖分公司

Intelligent welding device for steel-plastic composite pipe

PendingCN113733578AAffect the welding effectImprove cooling effectTubular articlesManufacturing engineeringSlide plate

The invention relates to the technical field of steel-plastic composite pipe machining equipment, and particularly discloses an intelligent welding device for a steel-plastic composite pipe. The device comprises a main machine and a clamp, and the clamp is electrically connected with the main machine through an electric wire. The clamp comprises two semicircular columnar clamping sleeves which are oppositely arranged. An electromagnetic heating component is fixed on each clamping sleeve, a cavity is formed in each electromagnetic heating component, and a sliding plate and a telescopic piece are arranged in each semicircular cylindrical cavity. The telescopic pieces are straightened when heated and are bent when cooled. A one-way water inlet valve and a one-way water outlet valve are arranged on each semicircular cylindrical cavity, and the inner side wall of each electromagnetic heating component is made of a conductor material. The device aims to solve the problem that after the welding of the steel-plastic composite pipe is completed, natural cooling needs to consume a large amount of time, so that the working efficiency is low.

Owner:贵州大愚智水智能科技有限公司

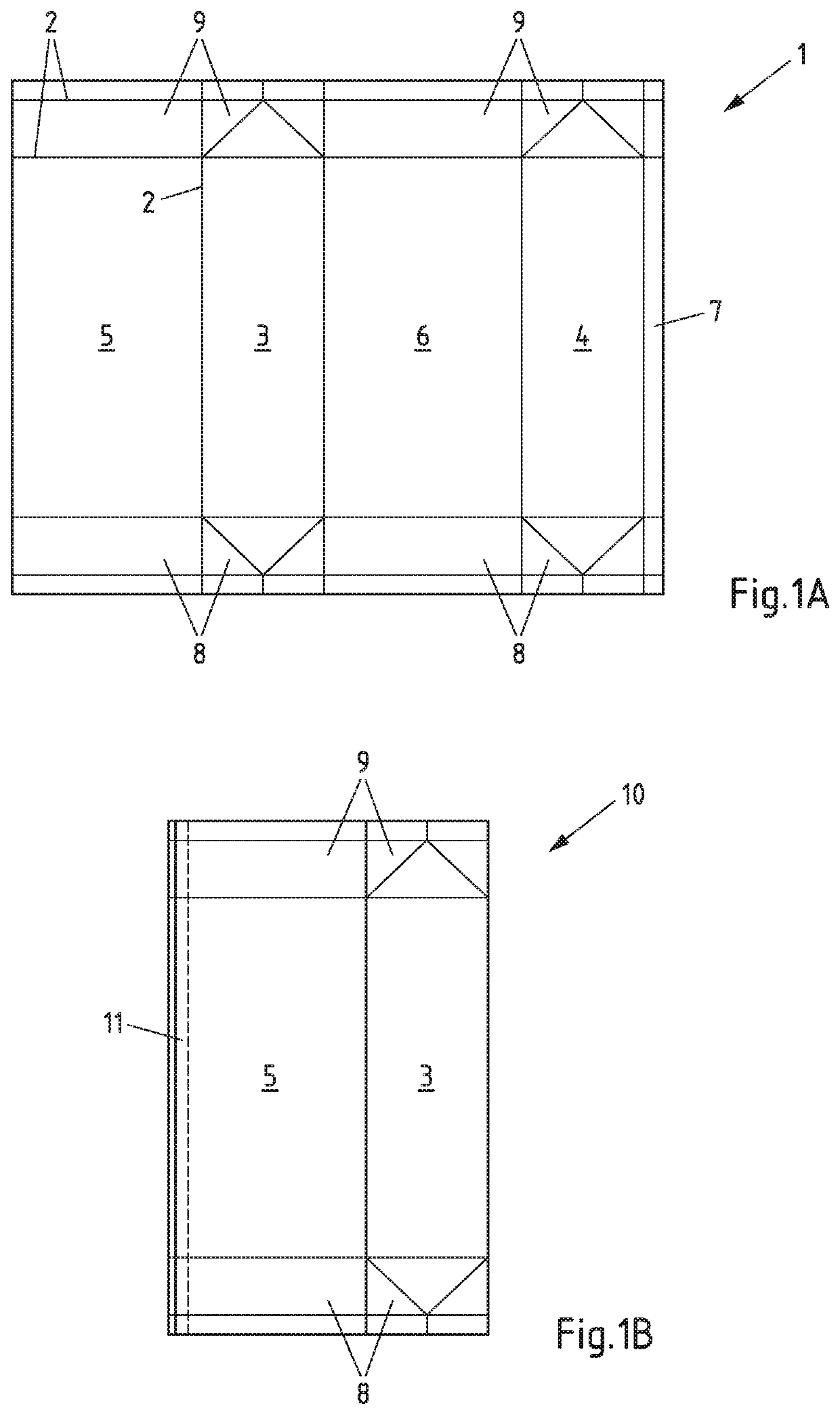

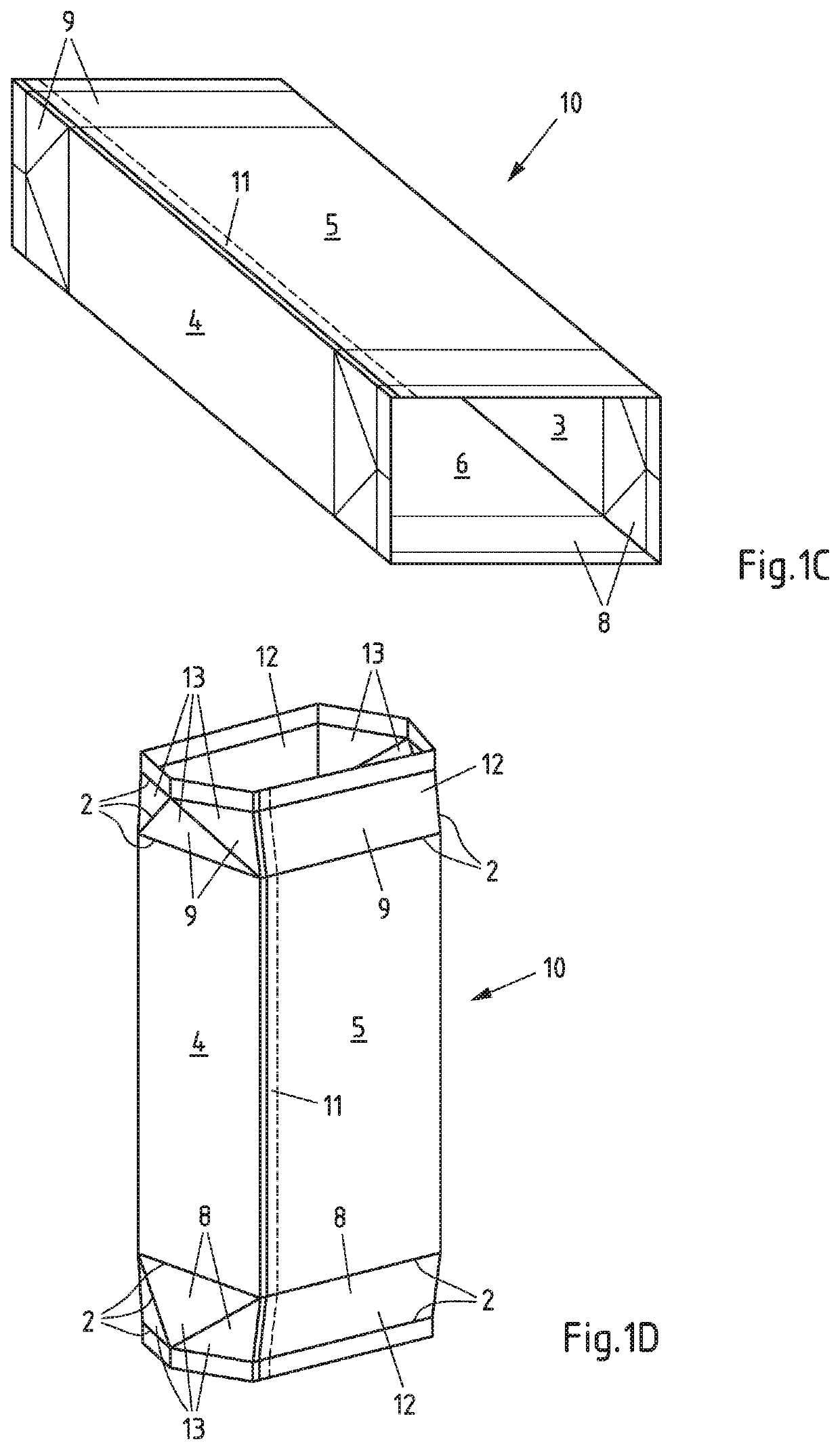

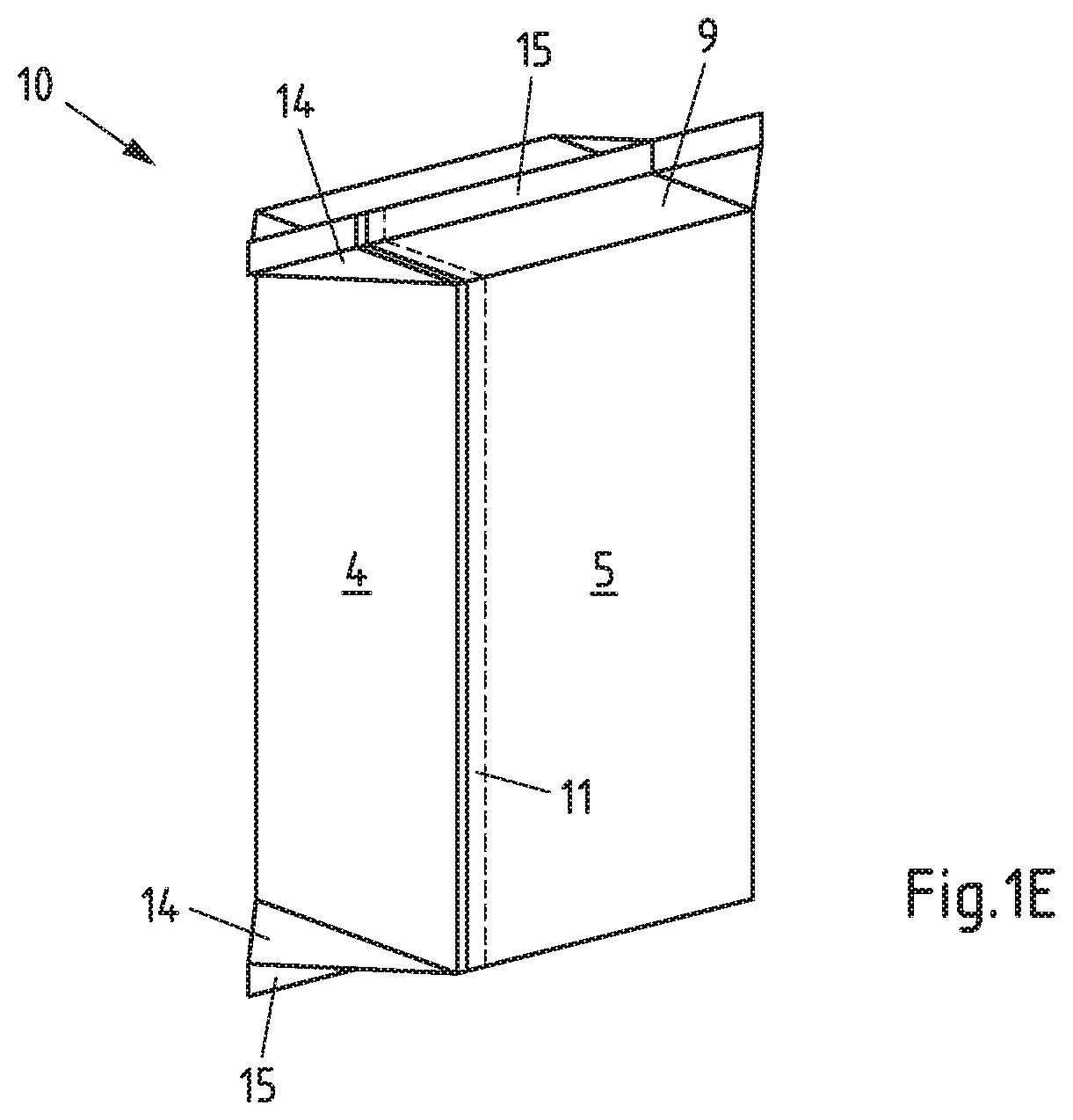

Device for processing, in particular for ultrasound welding, of packaging sleeves

A device for processing, in particular for ultrasound welding, of packaging sleeves and / or packagings includes at least two tools for processing, in particular for ultrasound welding, of packaging sleeves. Each tool has an operating region. The tools are supported in such a manner that there is produced between the operating regions a gap whose longitudinal direction corresponds to the transport direction of the packaging sleeves, and the tools are supported in such a manner that the size of the gap can be changed. In order also to enable continuous welding of the packaging sleeves in a reliable manner with changing material thicknesses, there is provided at least one parallel spring on which at least one of the tools is movably supported transversely relative to the transport direction of the packaging sleeves.

Owner:SIG TECH

a welding machine

InactiveCN104907743BPrecise positioningContinuous weldingWelding/cutting auxillary devicesAuxillary welding devicesEngineeringReducer

The invention discloses a welding machine, and aims at providing the welding machine which is reasonable in structure, can effectively position a to-be-welded machine shell, is high in smoothness and stability in the welding process, and can ensure the welding quality. The welding machine comprises a welding machine rotating part, a welding machine lifting part, a rotating motor and a welding gun assembly. The welding machine rotating part comprises a welding bottom frame, a horizontal positioning welding table and a welding table gear. The welding table gear is connected with a main rotating shaft. A positioning fixture is arranged on the positioning welding table. A speed reducer is connected with a rotating motor. An output shaft of the speed reducer is connected with an output gear which is meshed with the welding table gear. The welding machine lifting part comprises a stand column and a vertical adjusting lead screw assembly. A transverse adjusting lead screw assembly is arranged on the main welding part. The welding machine has the advantages that a welding gun and the to-be-welded part can be accurately aligned, positioning is firm, the welding process is ceaseless, the welding gun assembly is still during welding, the welding position is changed through the rotation of the to-be-welded machine shell, stability is high, and the welding quality is high.

Owner:宁波保世洁环境科技有限公司

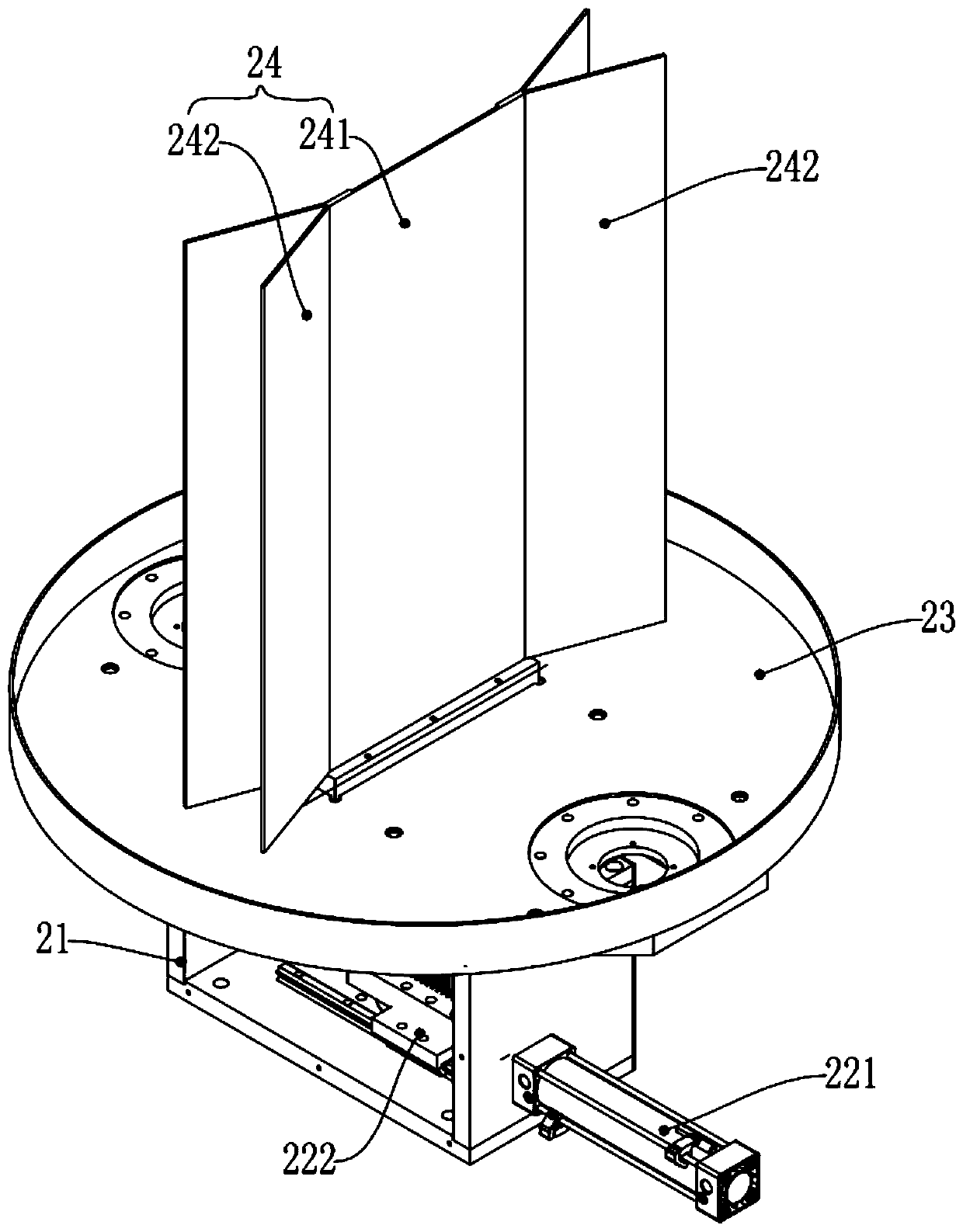

Welding device used for welding ring-shaped piece of steering pipe column

InactiveCN109719449AContinuous weldingGuarantee welding qualityWelding/cutting auxillary devicesAuxillary welding devicesMachining processSoldering gun

The invention discloses a welding device used for welding a ring-shaped piece of steering pipe column. The welding device comprises a rack, a transposition mechanism, clamping rotating mechanisms anda welding gun. The rotating mechanism is installed on the rack. The clamping rotating mechanisms are installed on the transposition mechanism. At least two clamping rotating mechanisms are arranged. The transposition mechanism is used for making the above two sets of clamping rotating mechanisms rotate by 180 degrees. Each clamping rotating mechanism comprises a swinging and rotating device, a column casing positioning device and a clamping device, wherein the swinging and rotating device is installed on the transposition mechanism, the column casing positioning device and the clamping deviceare connected to the output end of the swinging and rotating device, and the swinging and rotating device is used for driving the column casing positioning device and the clamping device to rotate. The welding gun is installed on the rack, and a welding flux outlet of the welding gun is aligned with the connecting position of the pipe column casing and the ring-shaped piece. By means of the welding device, the machining and production efficiency is high, the pipe column casing and the ring-shaped piece are well positioned and clamped in the machining process, and the welding effect is good.

Owner:广东精铟海洋工程创新研究有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com