Patents

Literature

32results about How to "Affect the welding effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

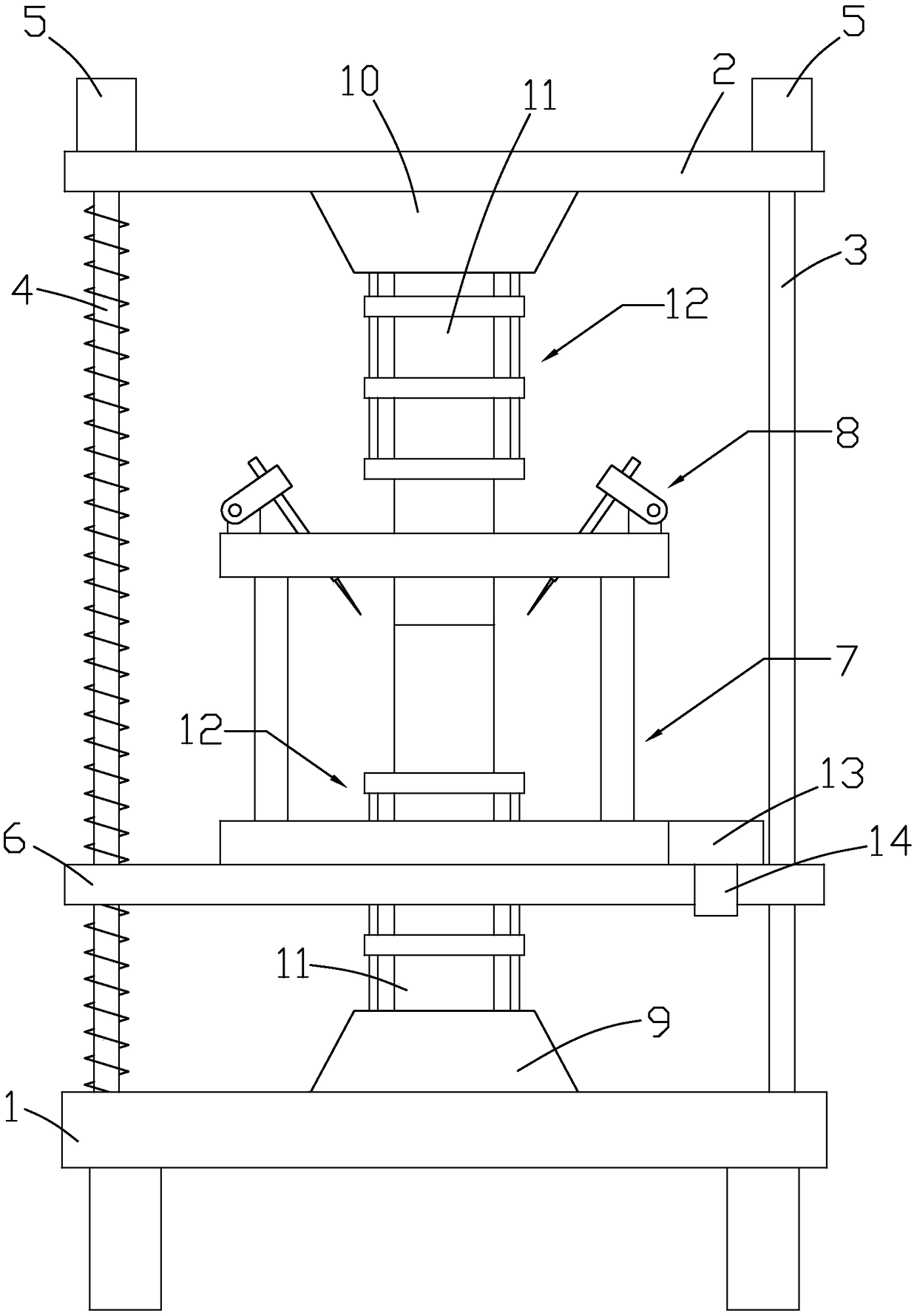

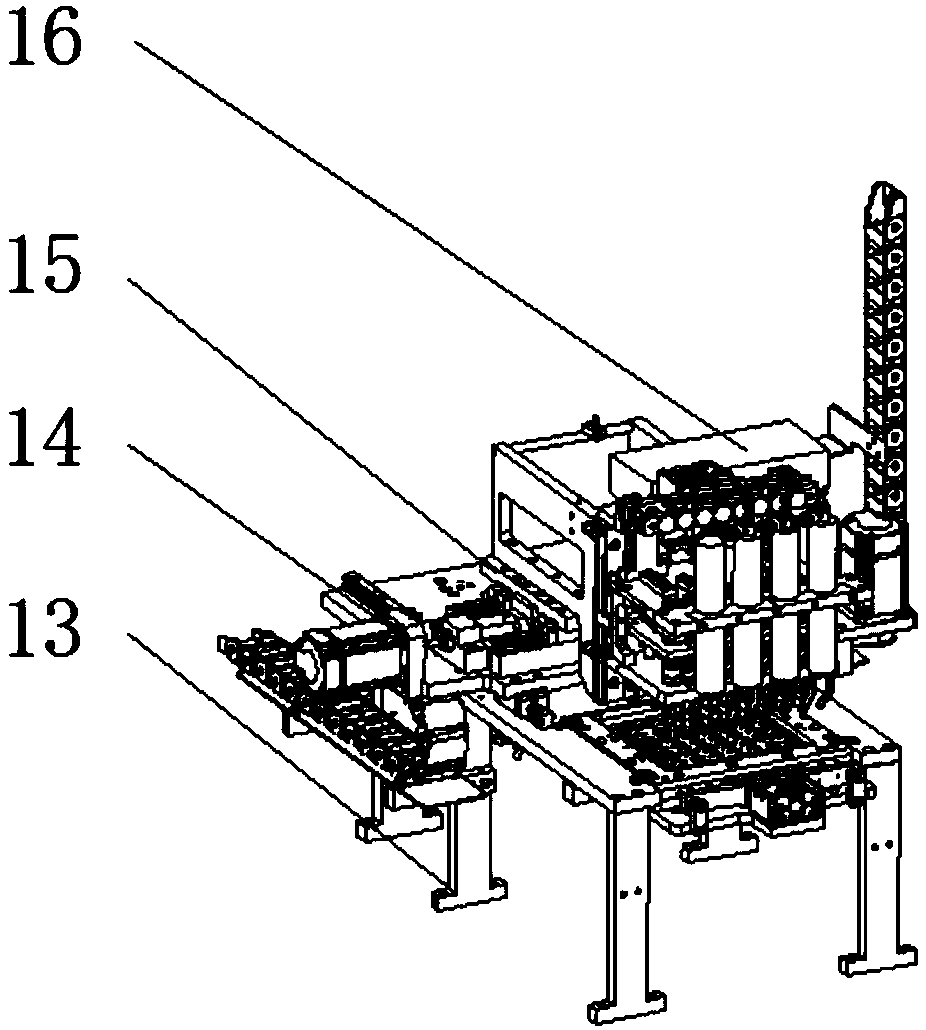

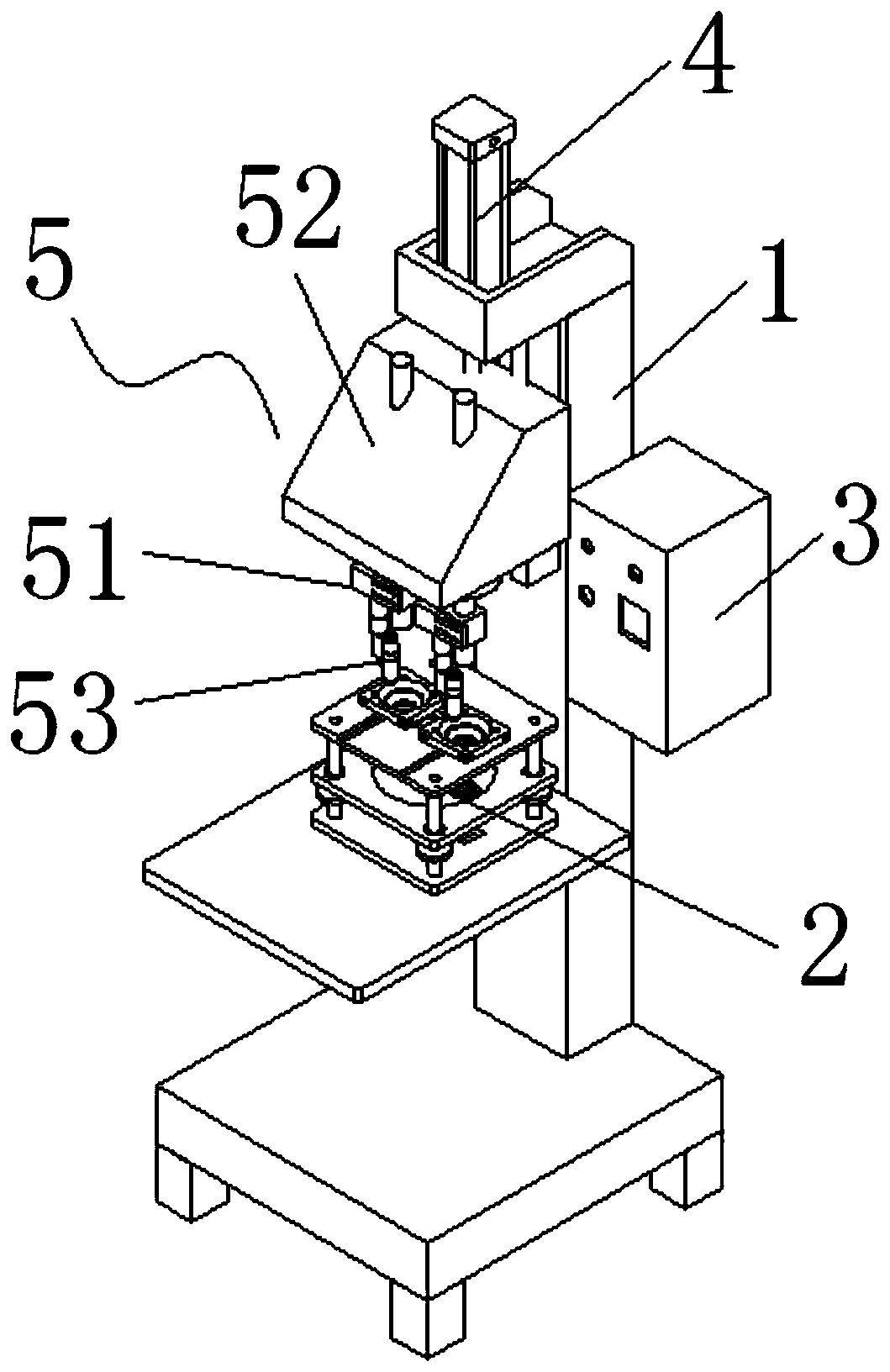

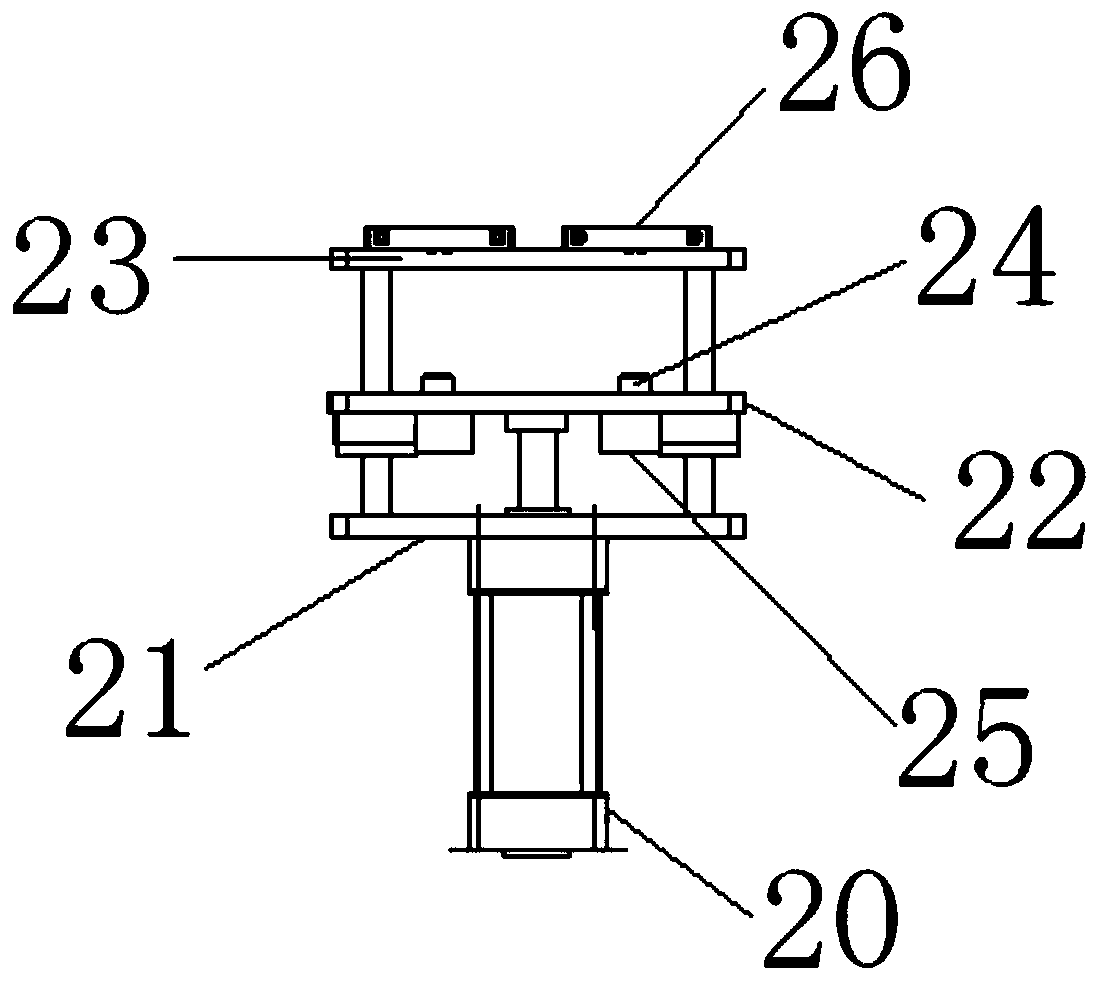

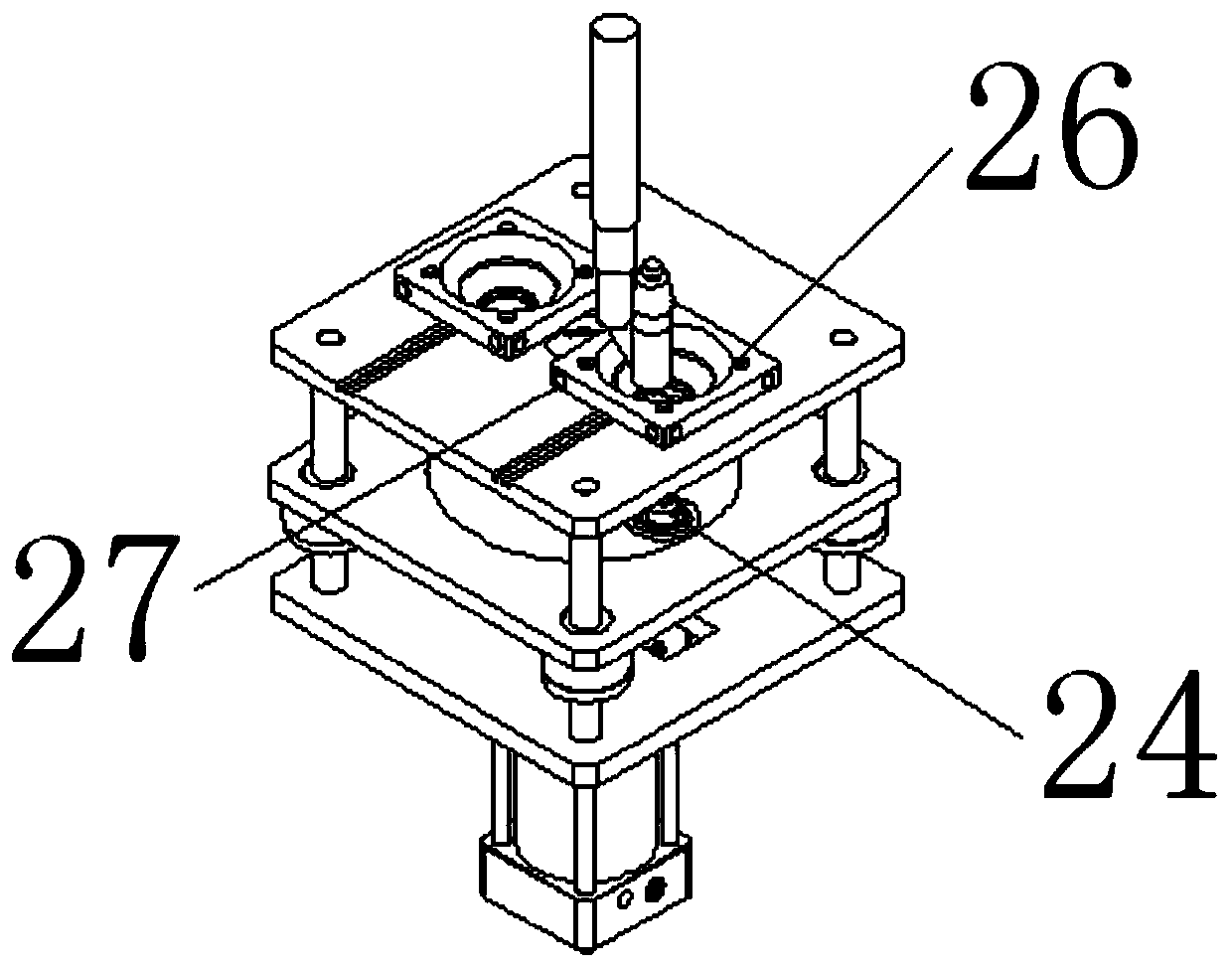

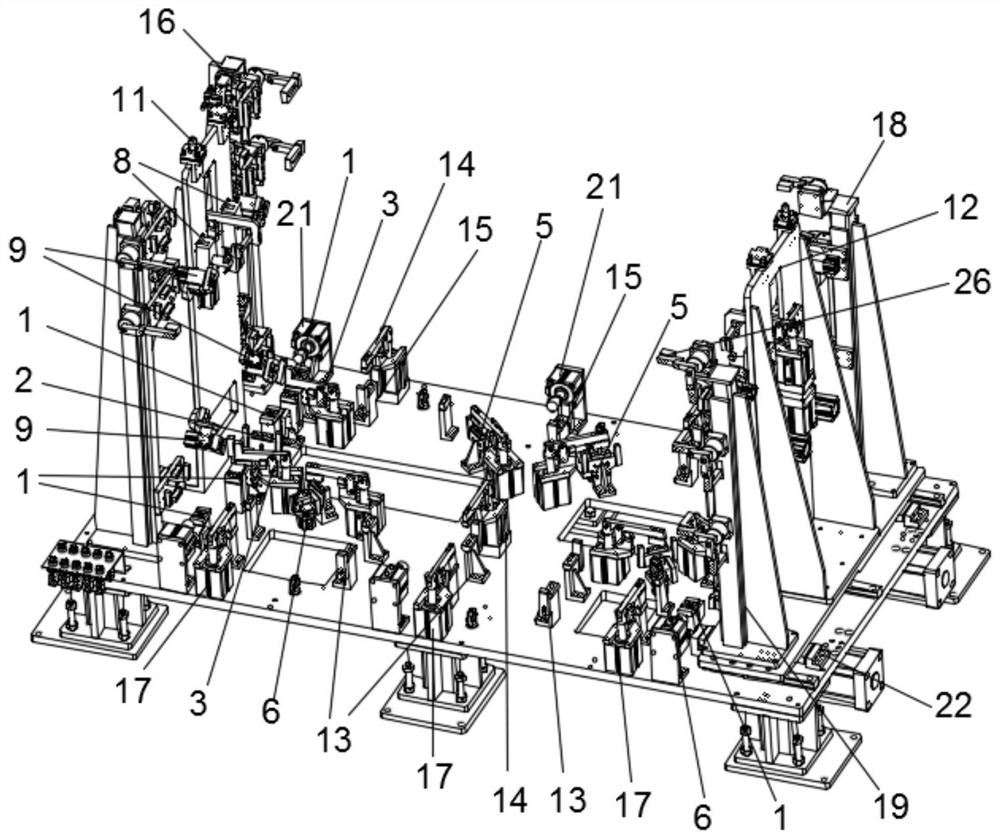

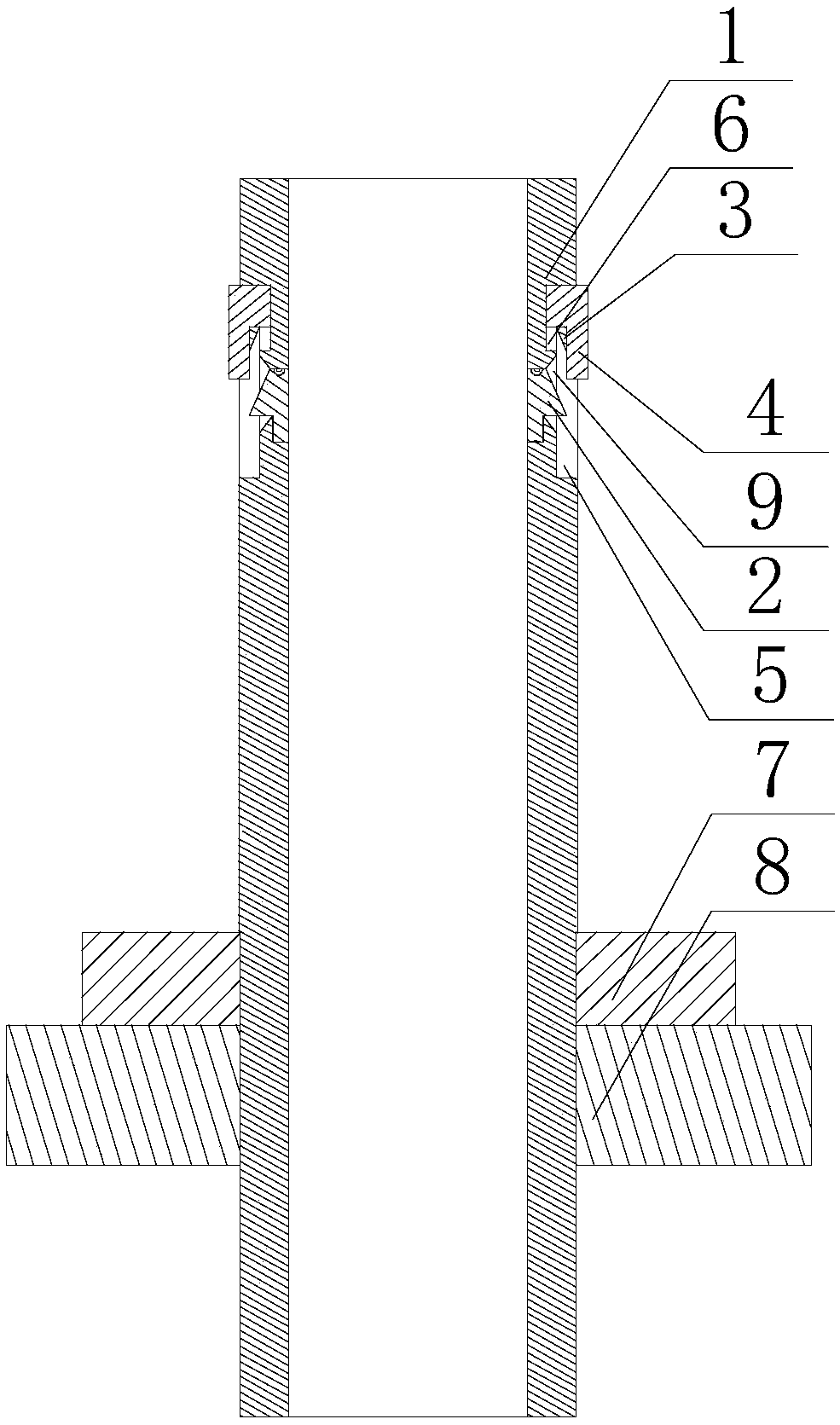

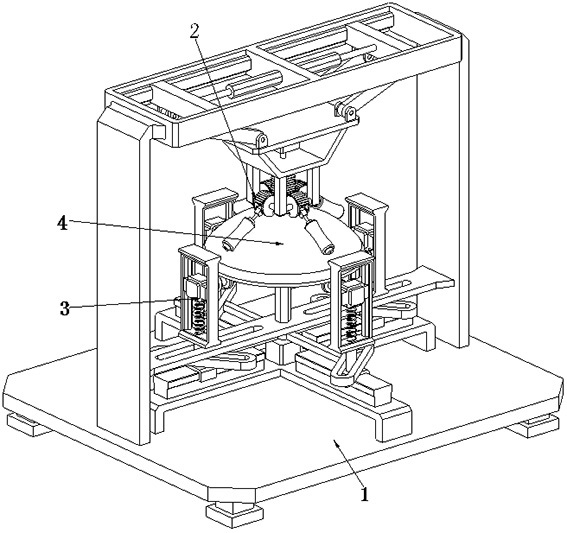

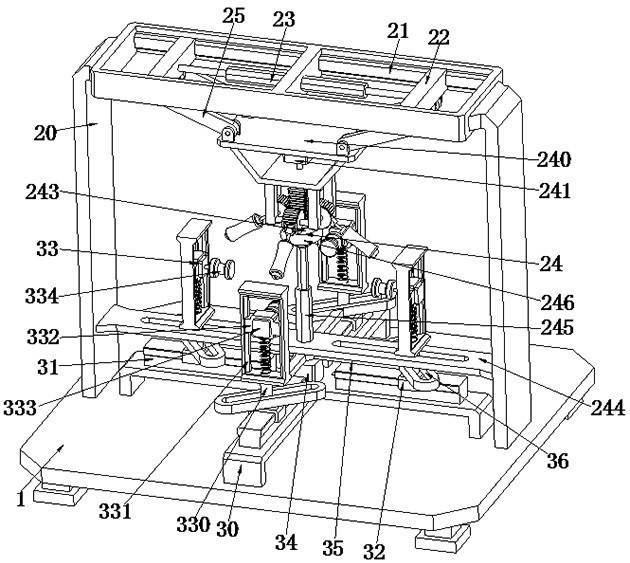

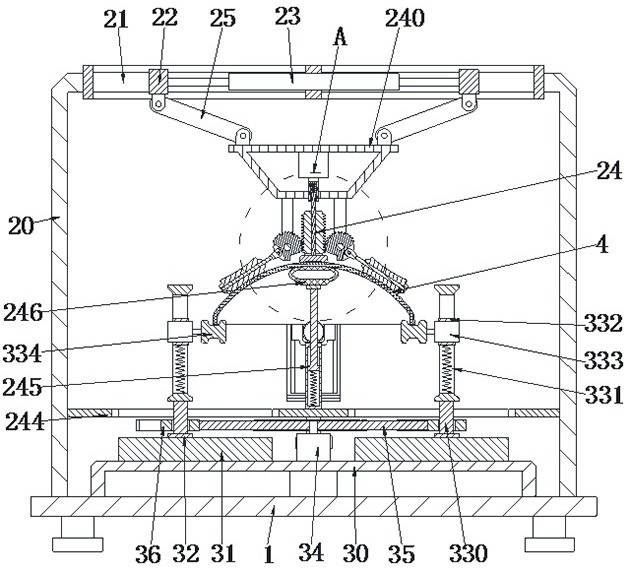

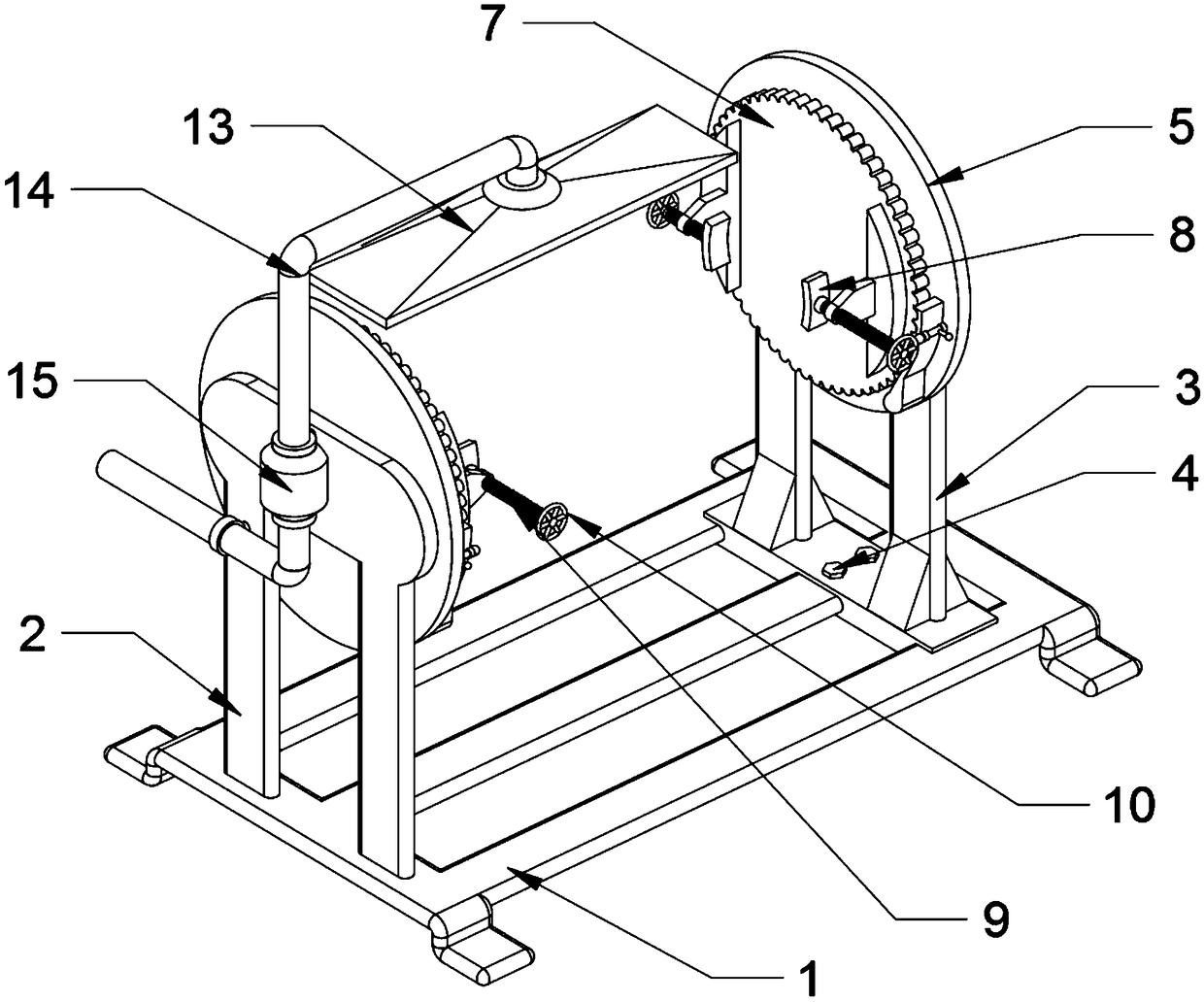

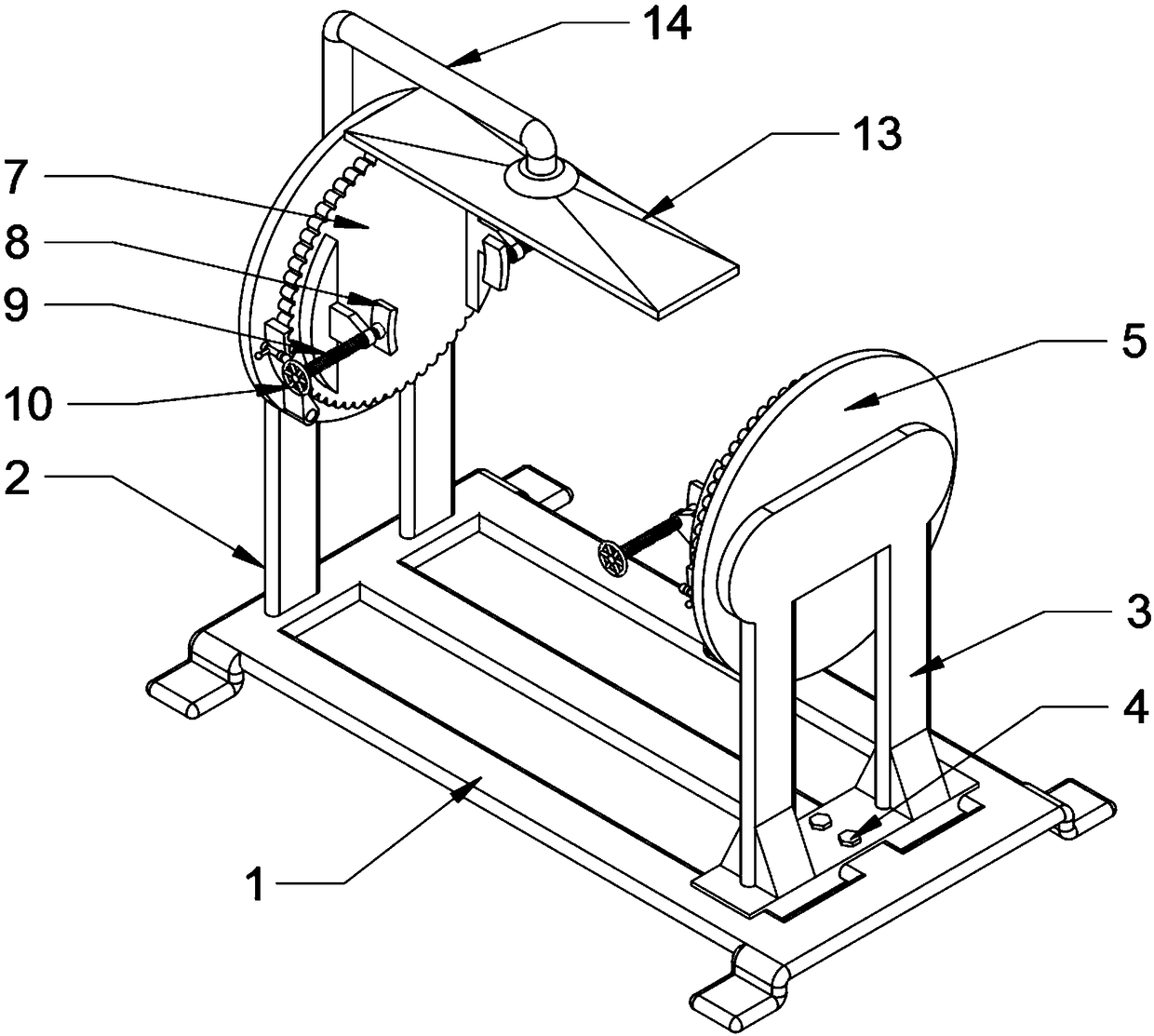

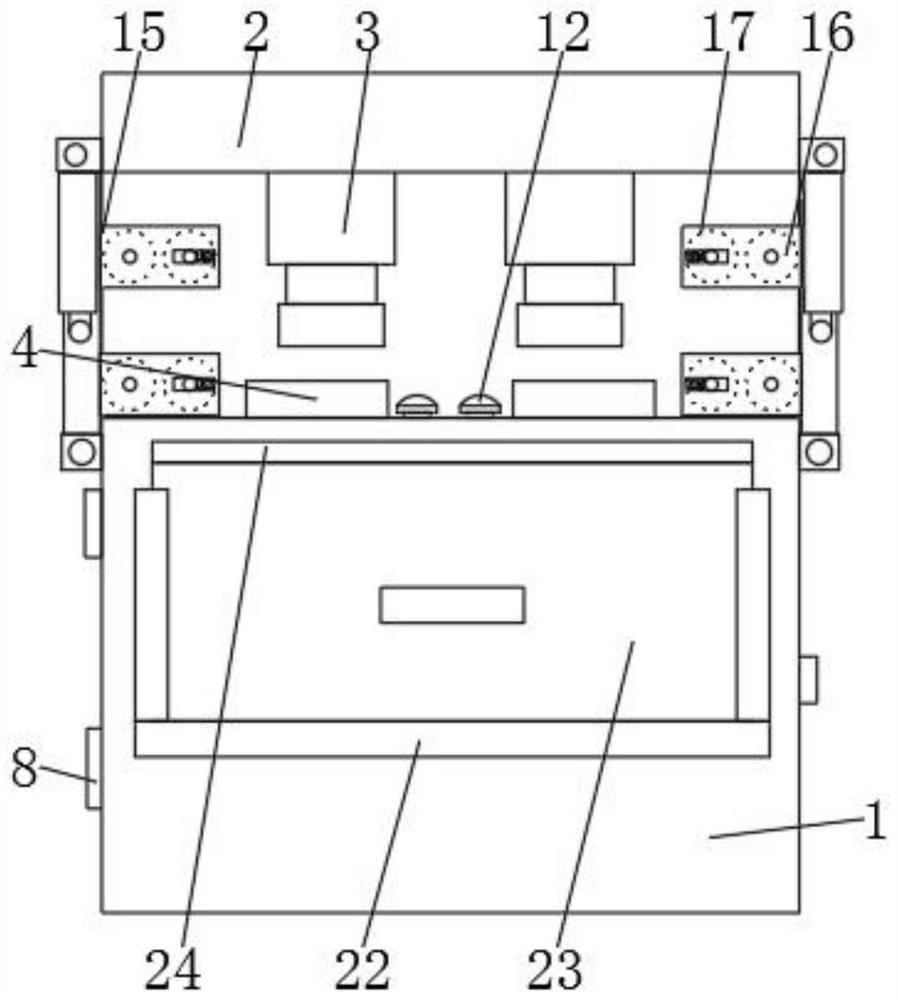

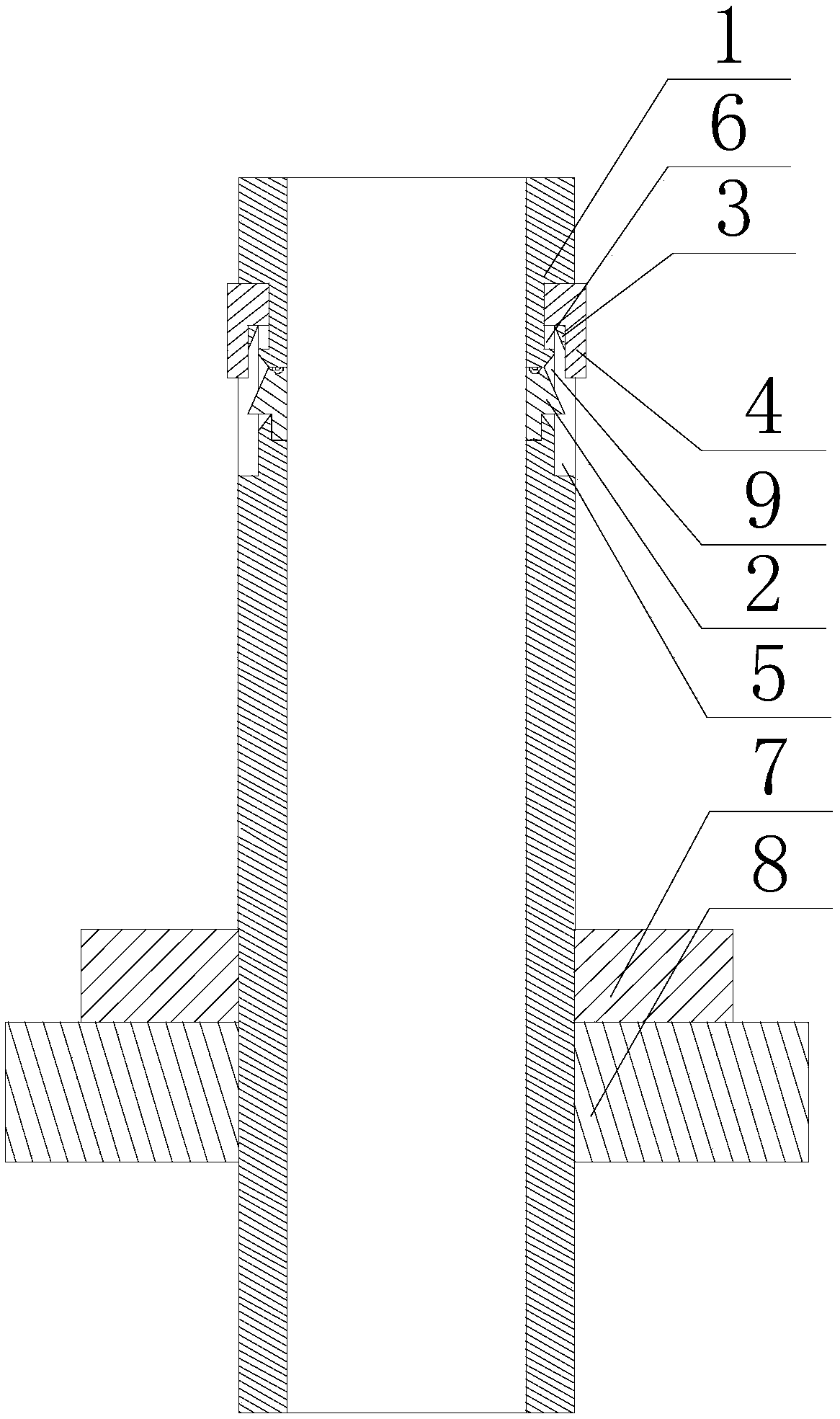

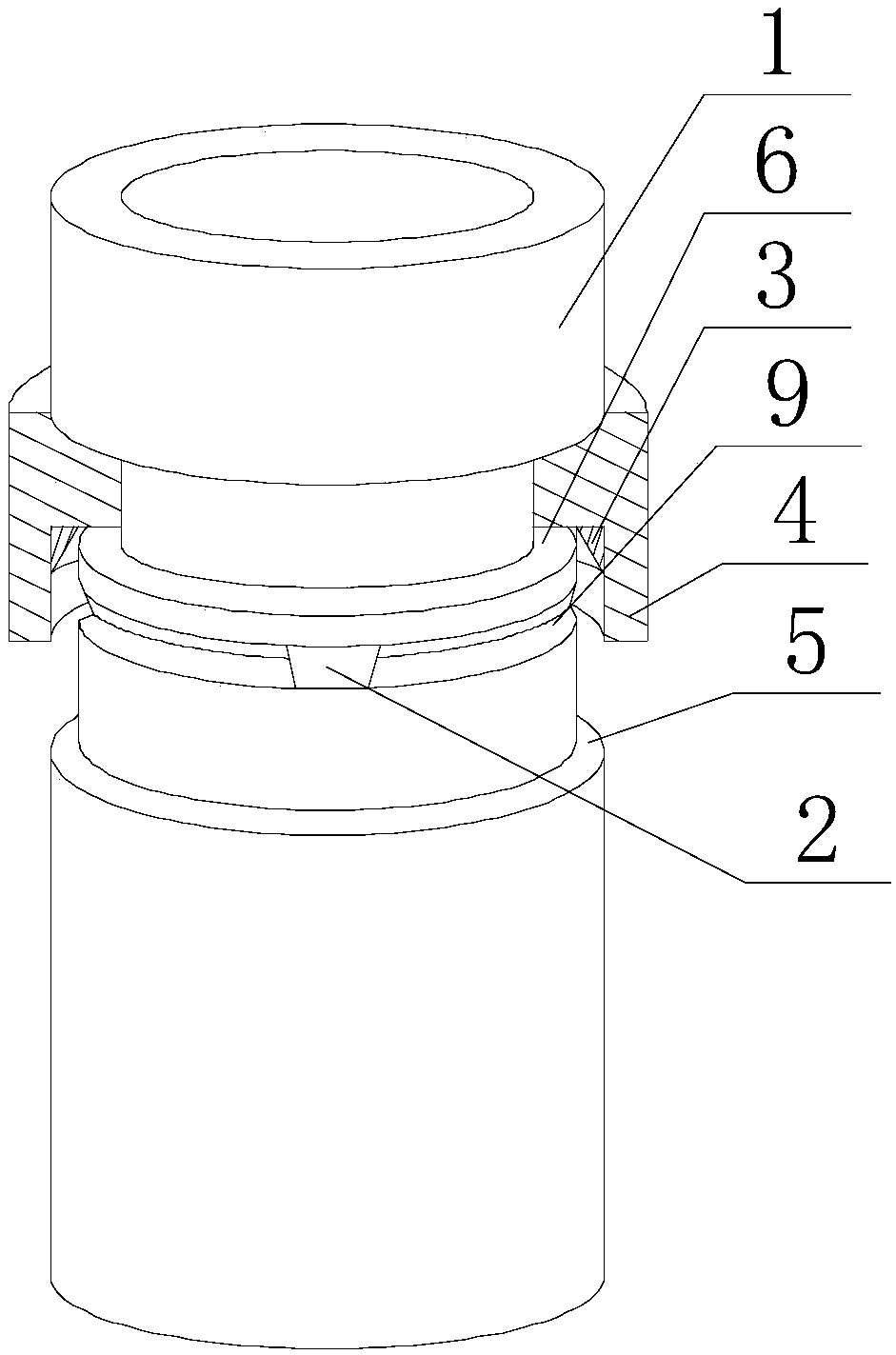

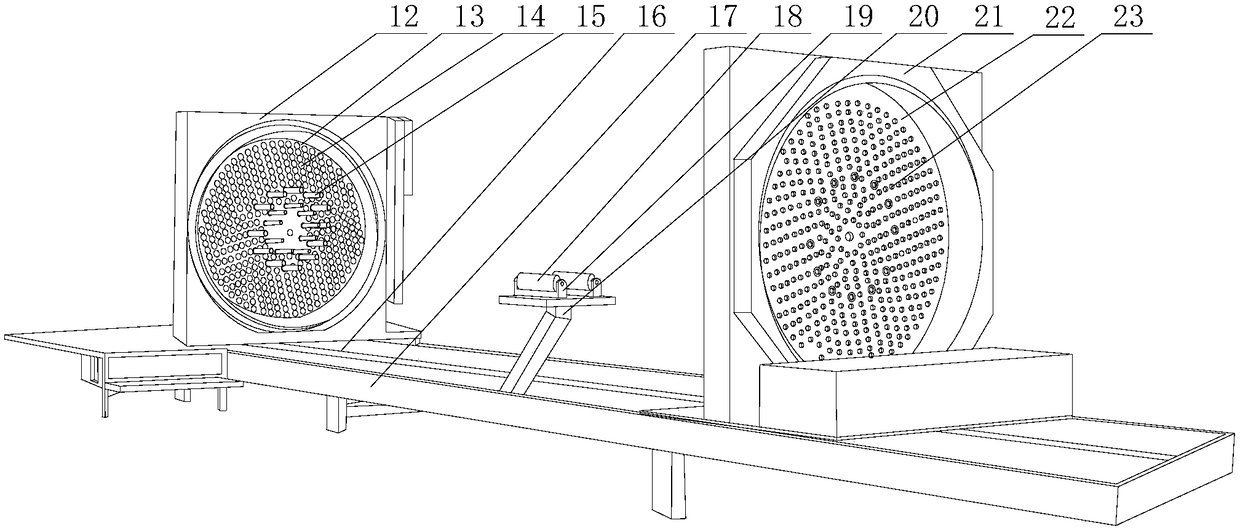

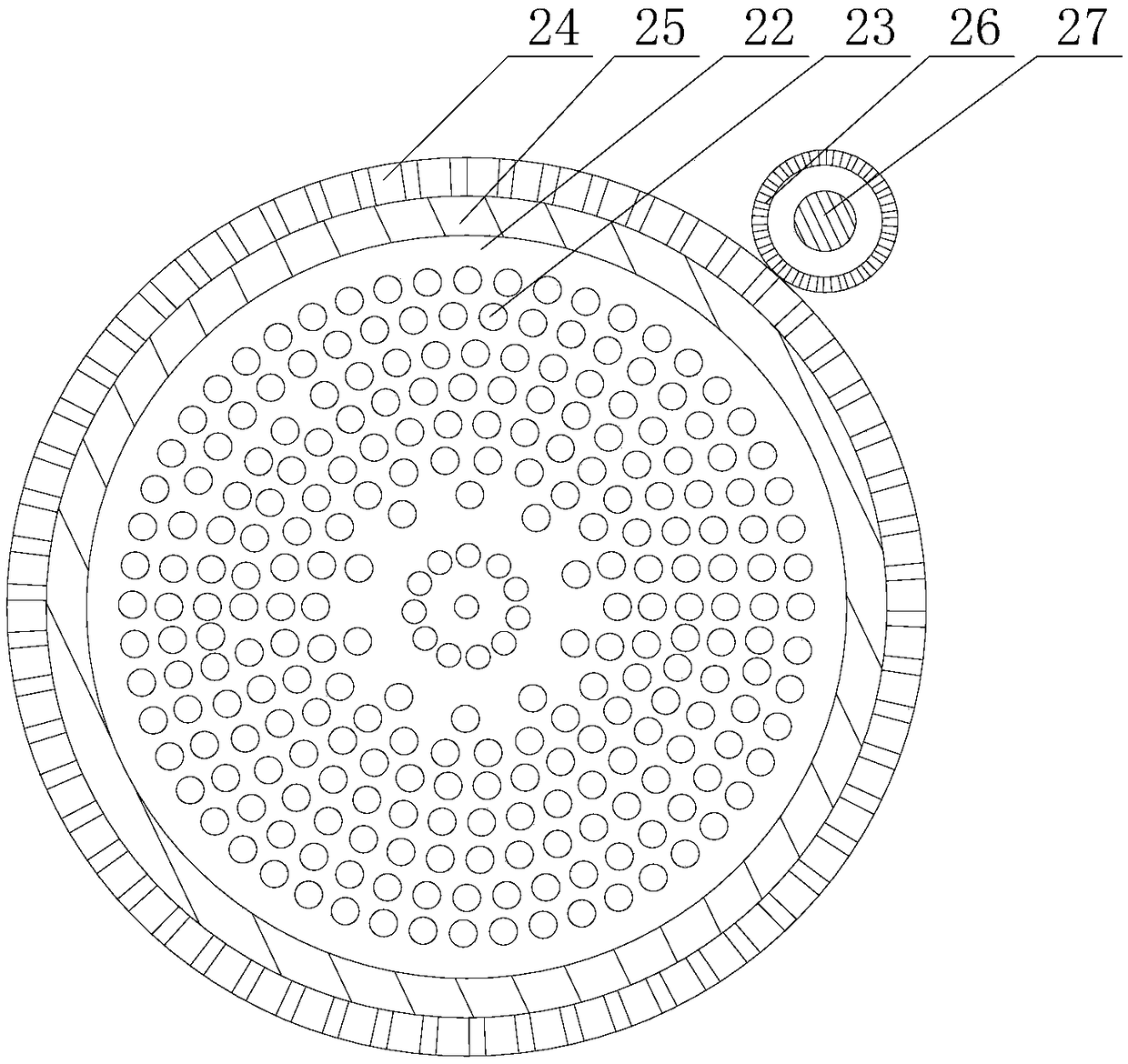

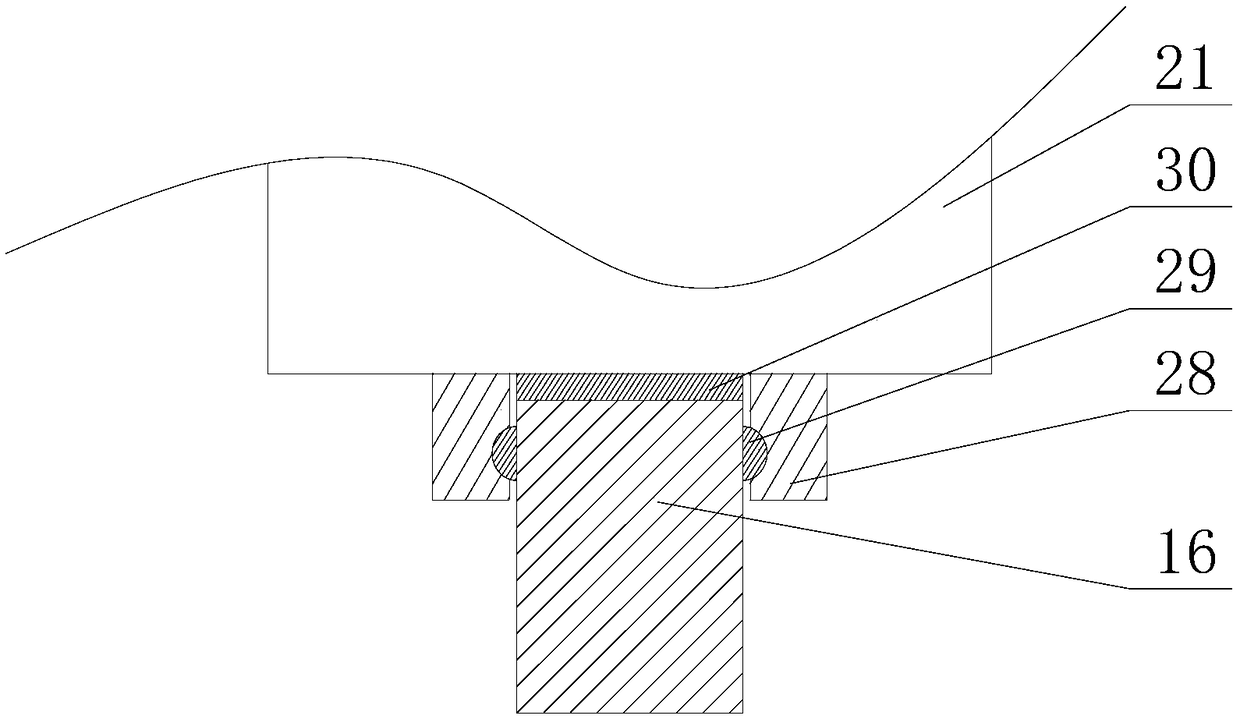

Welding device for pipeline sealing connection

ActiveCN109434341ASmooth rotationImprove stabilityWelding/cutting auxillary devicesAuxillary welding devicesEngineeringThreaded rod

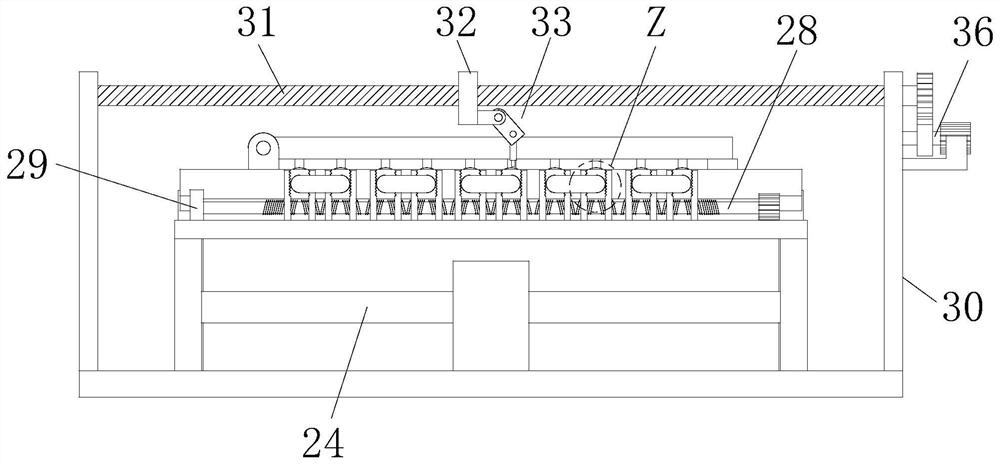

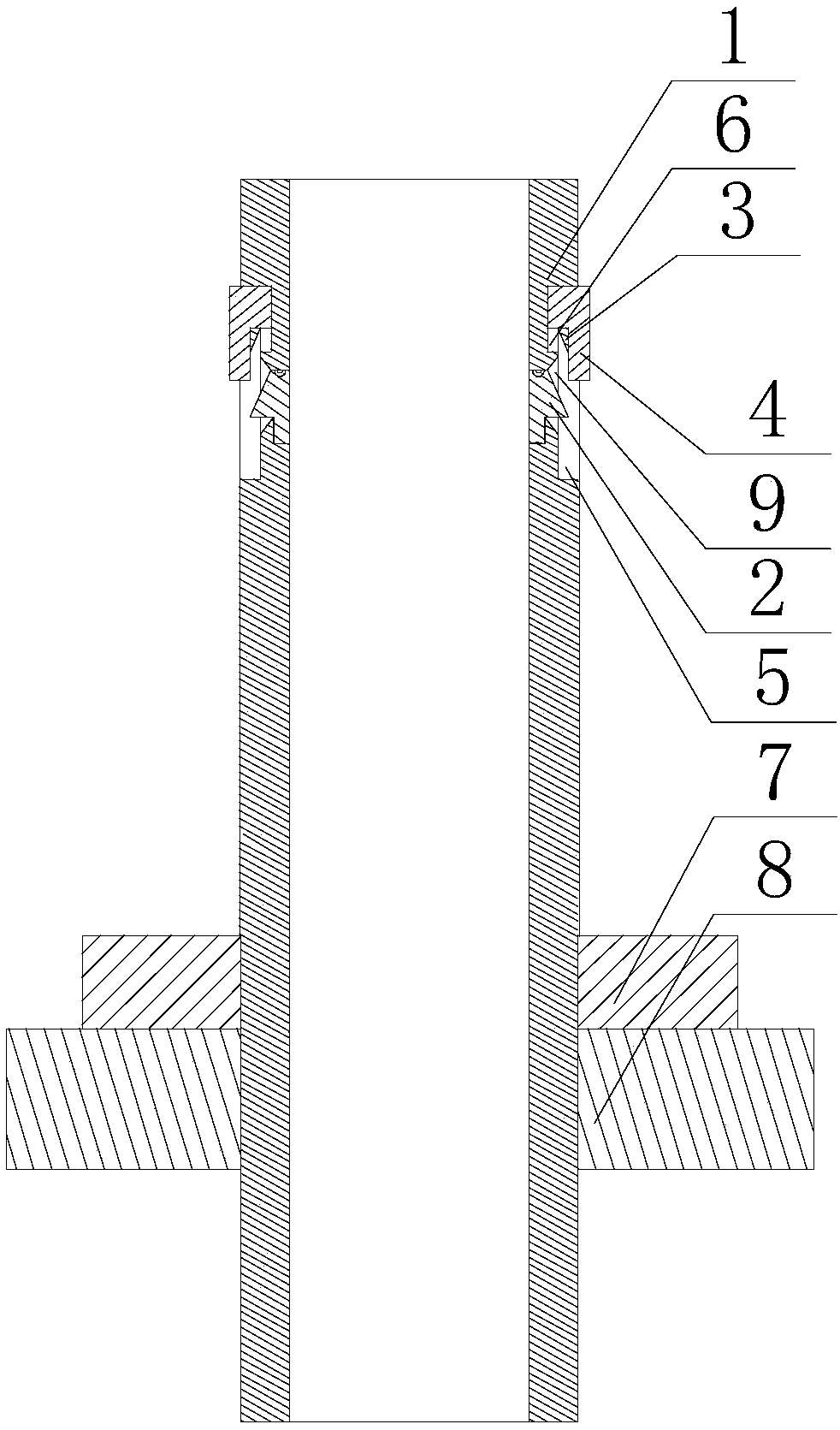

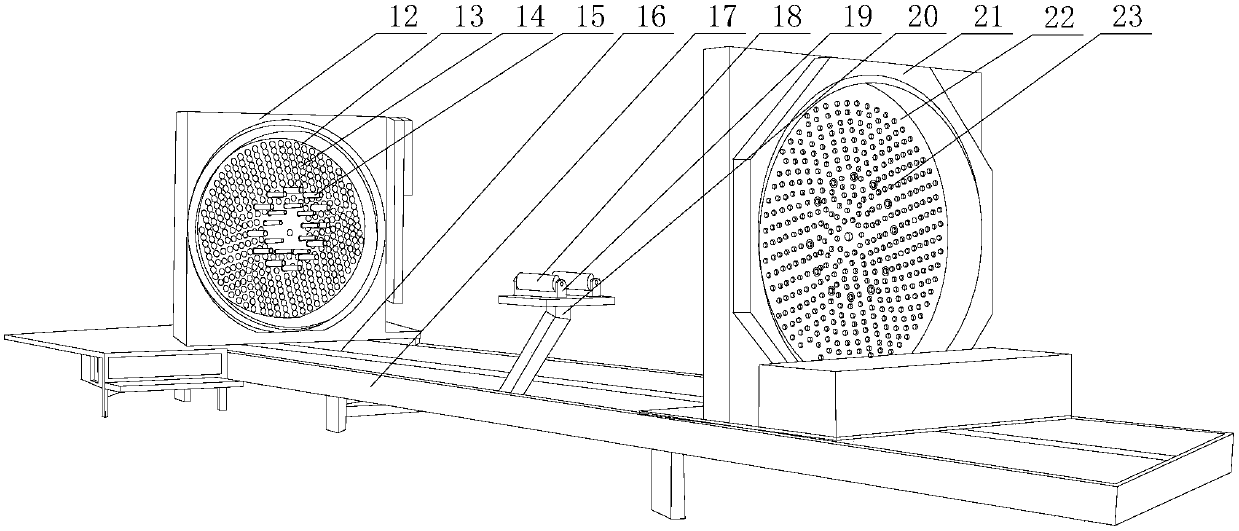

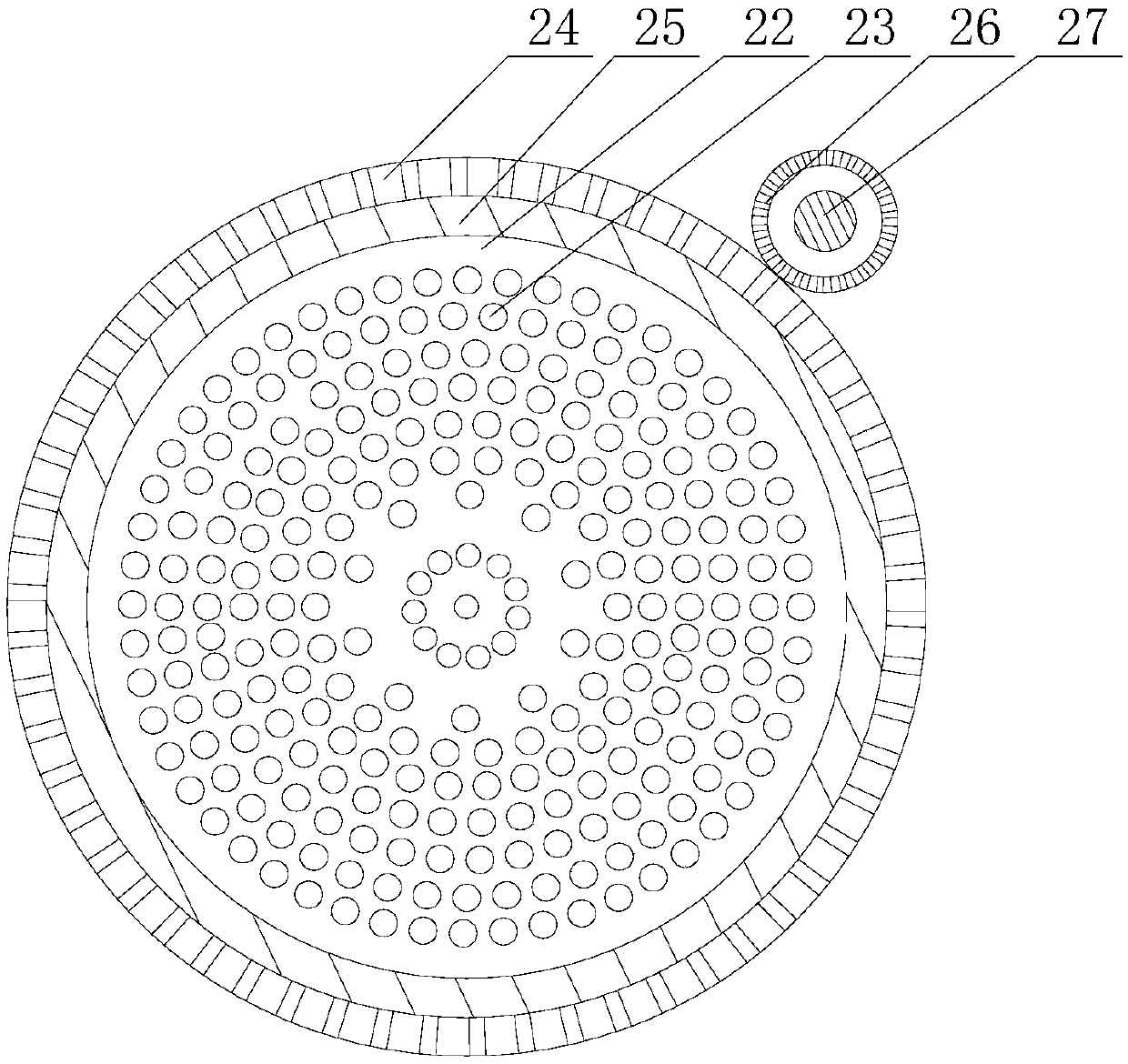

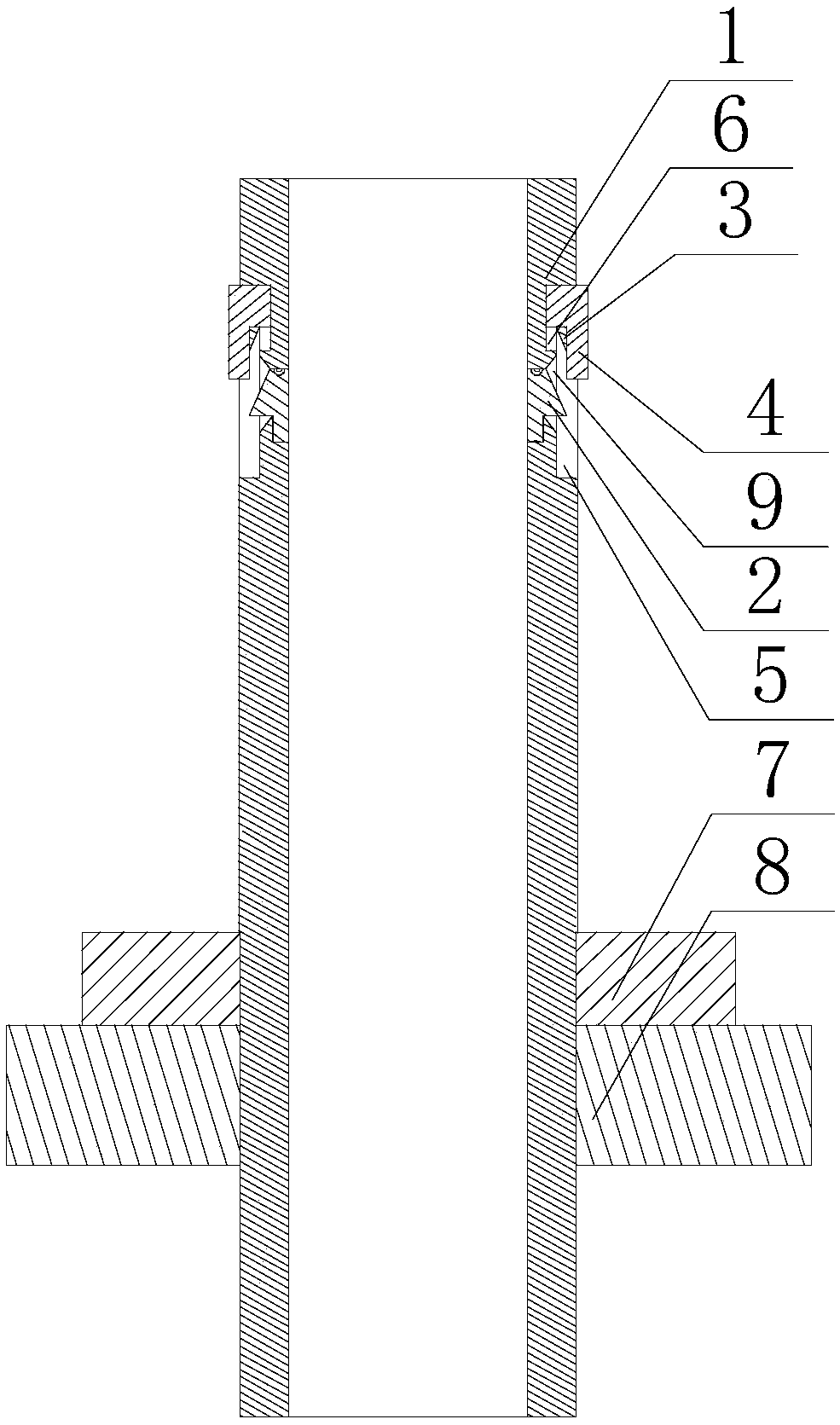

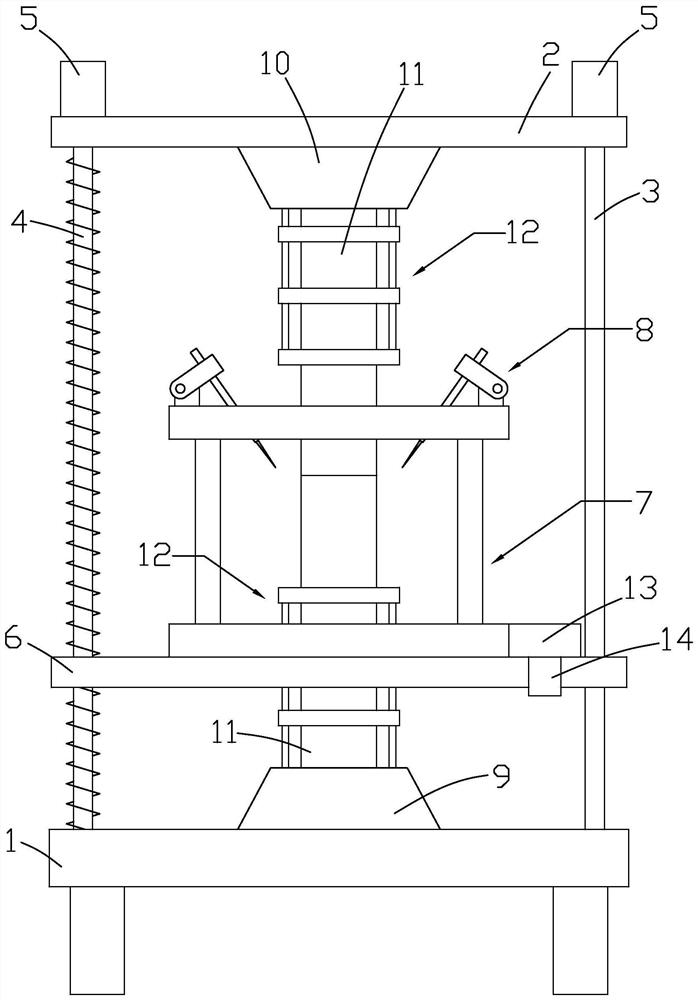

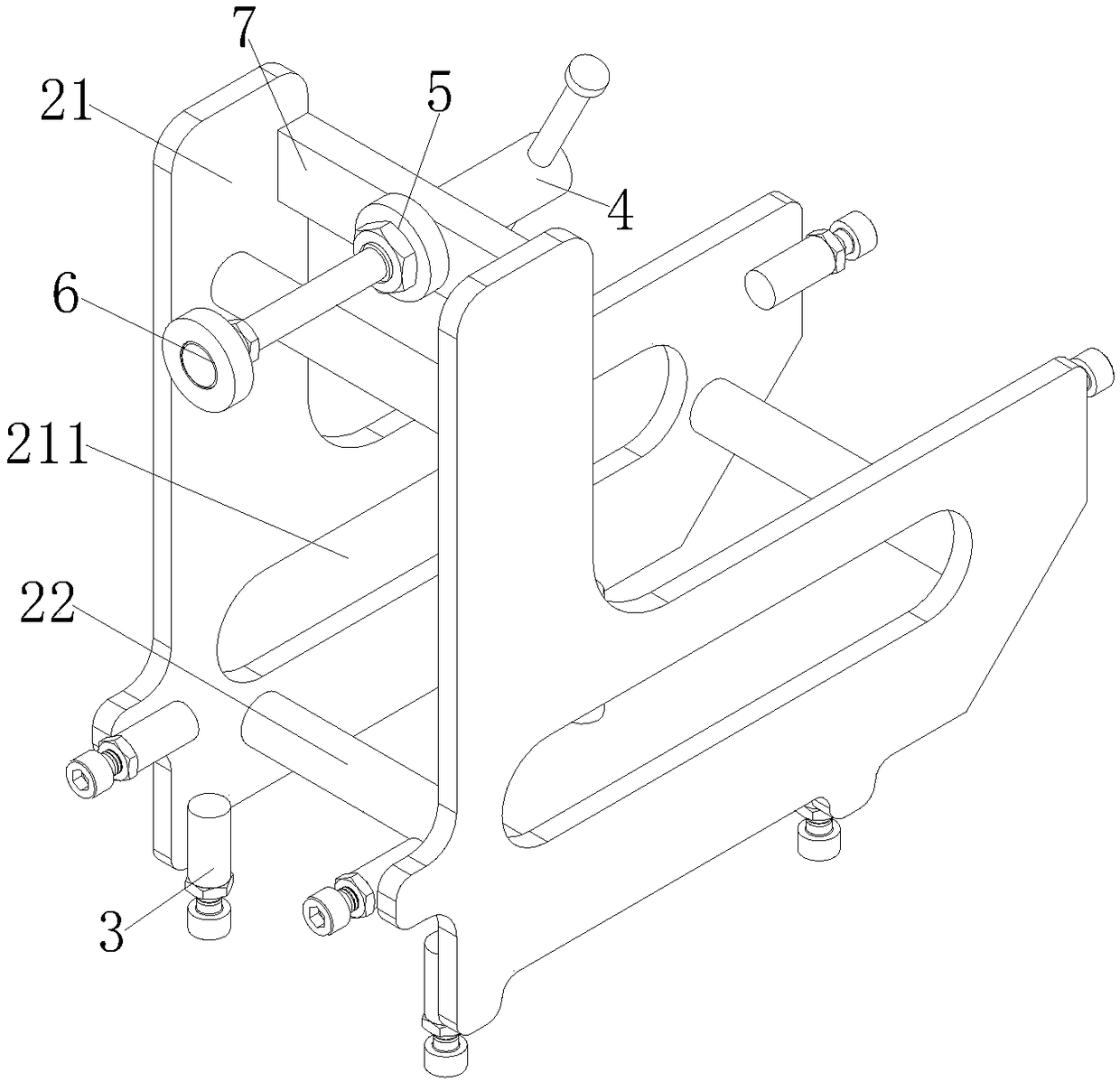

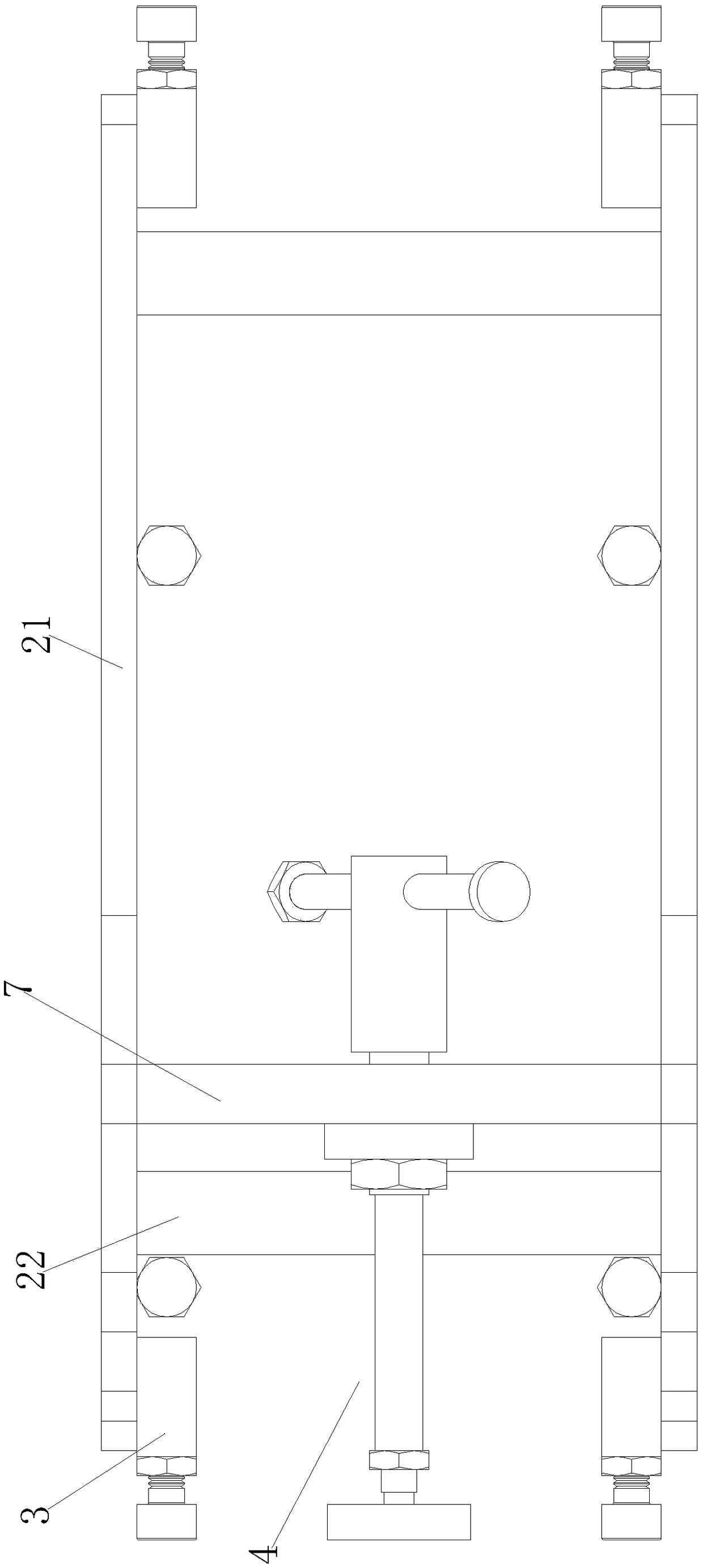

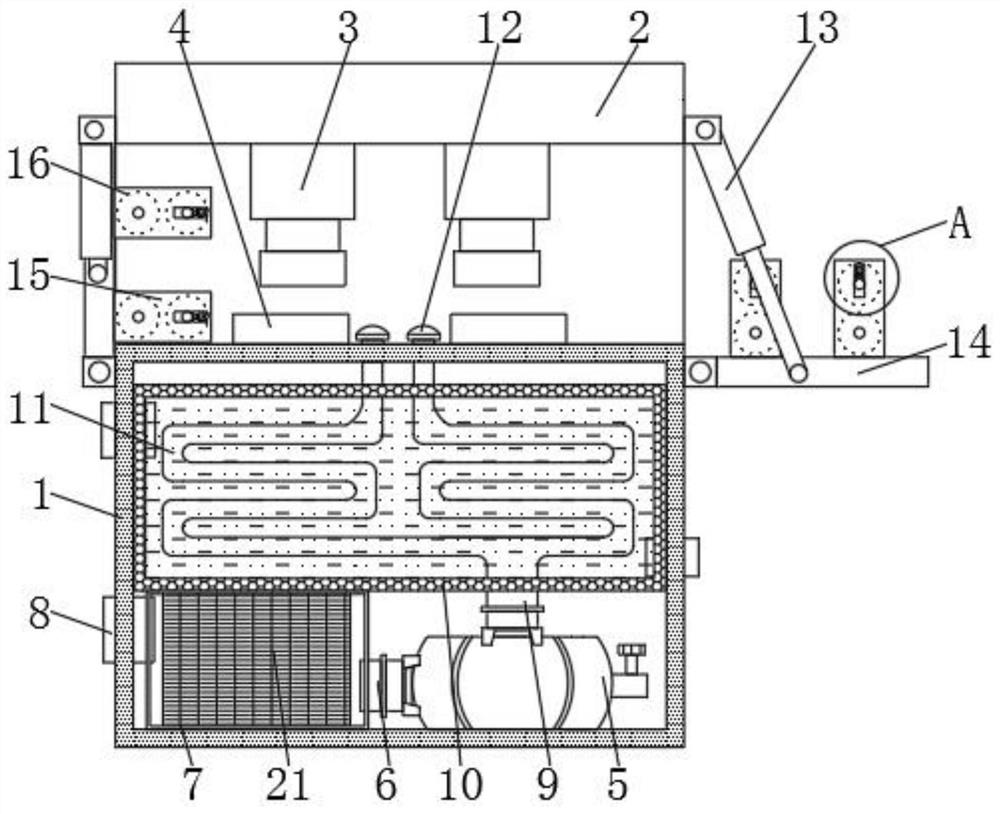

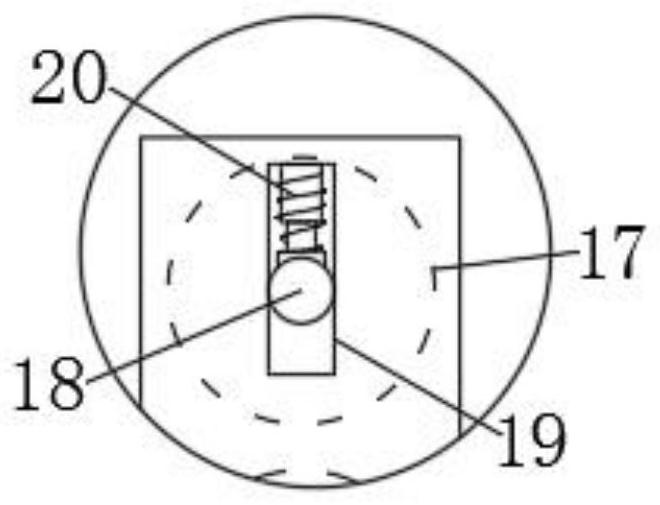

The invention discloses a welding device for pipeline sealing connection. The welding device for pipeline sealing connection comprises a base, a locating plate, a rotating mechanism, a welding mechanism and clamping and locating mechanisms. The base is connected with the locating plate through a stand column and a threaded rod. First motors are arranged at the top end of the threaded rod, and a lifting plate is connected between the stand column and the threaded rod in a moving mode. The rotating mechanism is connected to the lifting plate in a rotating mode, and the welding mechanism is connected to the rotating mechanism. A lower locating platform and an upper locating platform are arranged on the top surface of the base and the bottom surface of the locating plate correspondingly, and the clamping and locating mechanisms are arranged on the lower locating platform and the upper locating platform. Two pipeline test pieces are limited in the upper clamping and locating mechanism and the lower clamping and locating mechanism correspondingly and located on the same vertical straight line. The welding device for pipeline sealing connection is simple in structure and high in practicability, can conduct clamping and locating operation on two pipelines in the up-and-down direction, and can also adjust the height and the position of a welding mechanism, the requirement for sealing welding of pipelines with different lengths is met, the practicability of the welding device is greatly improved, and the working range of the welding device is greatly broadened.

Owner:纳木博(常州)智能装备有限公司

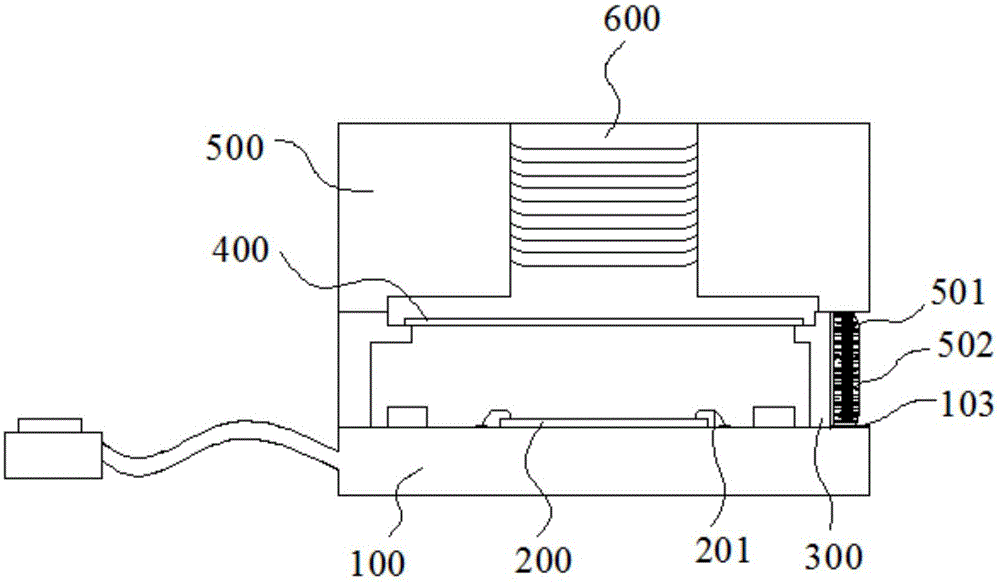

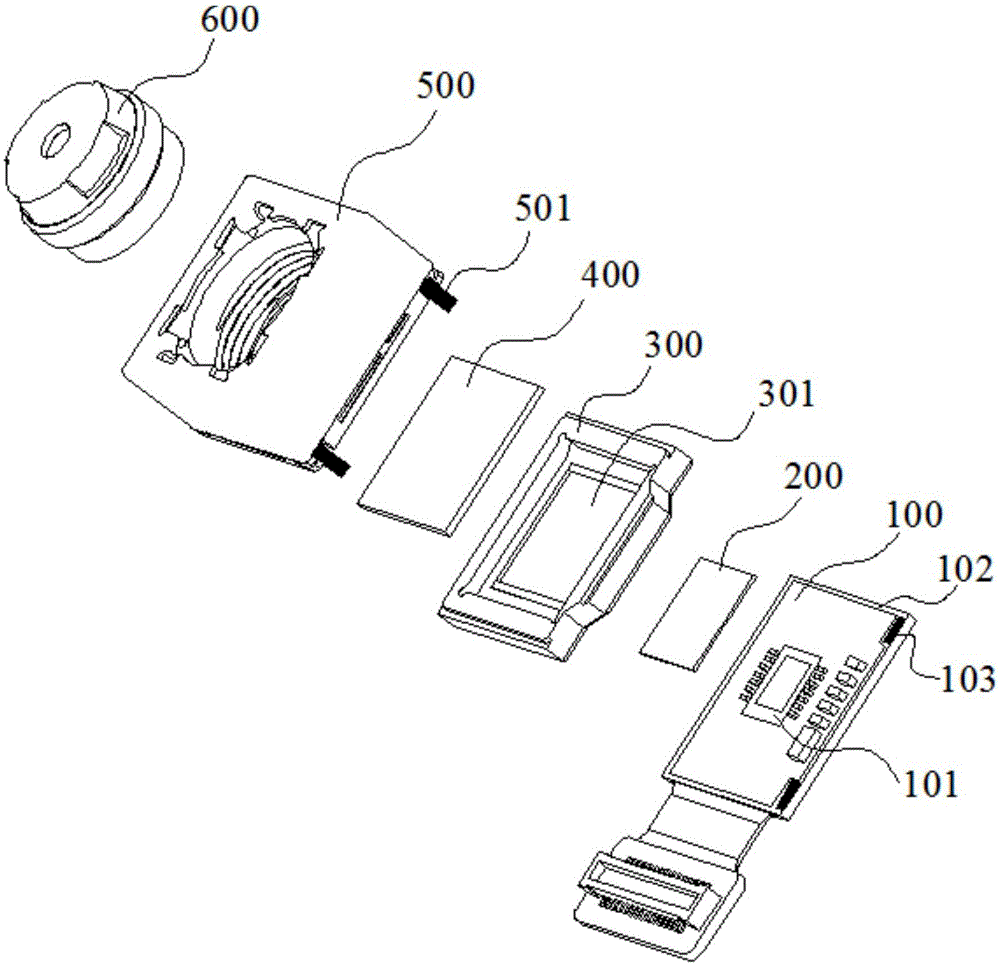

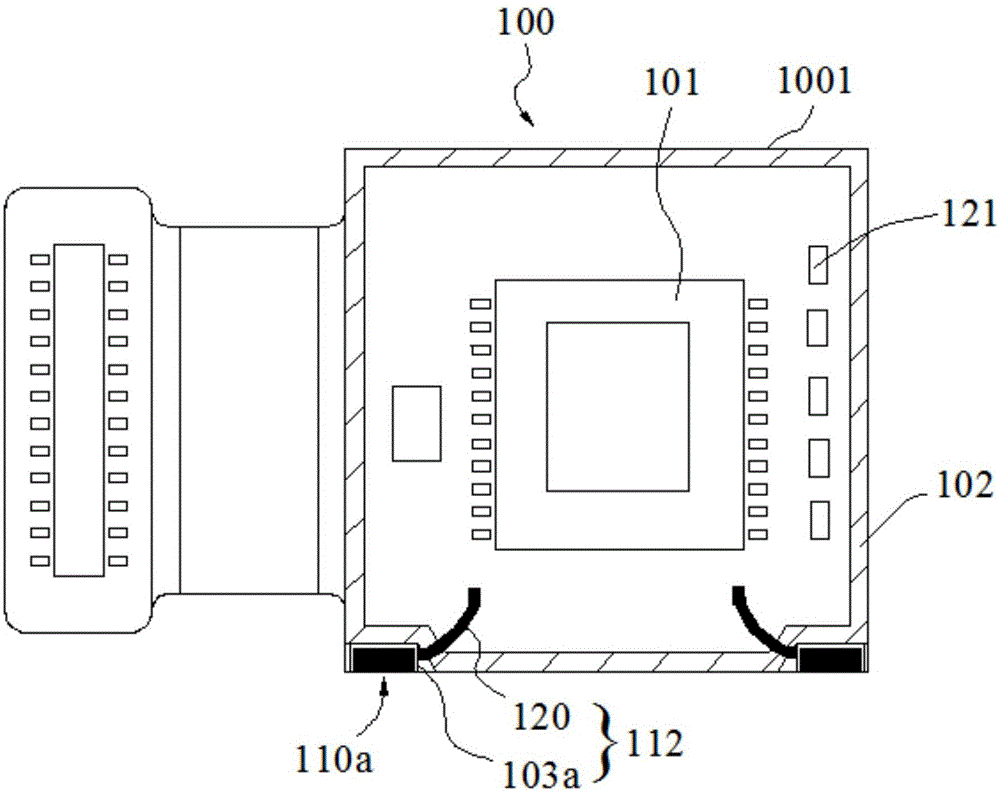

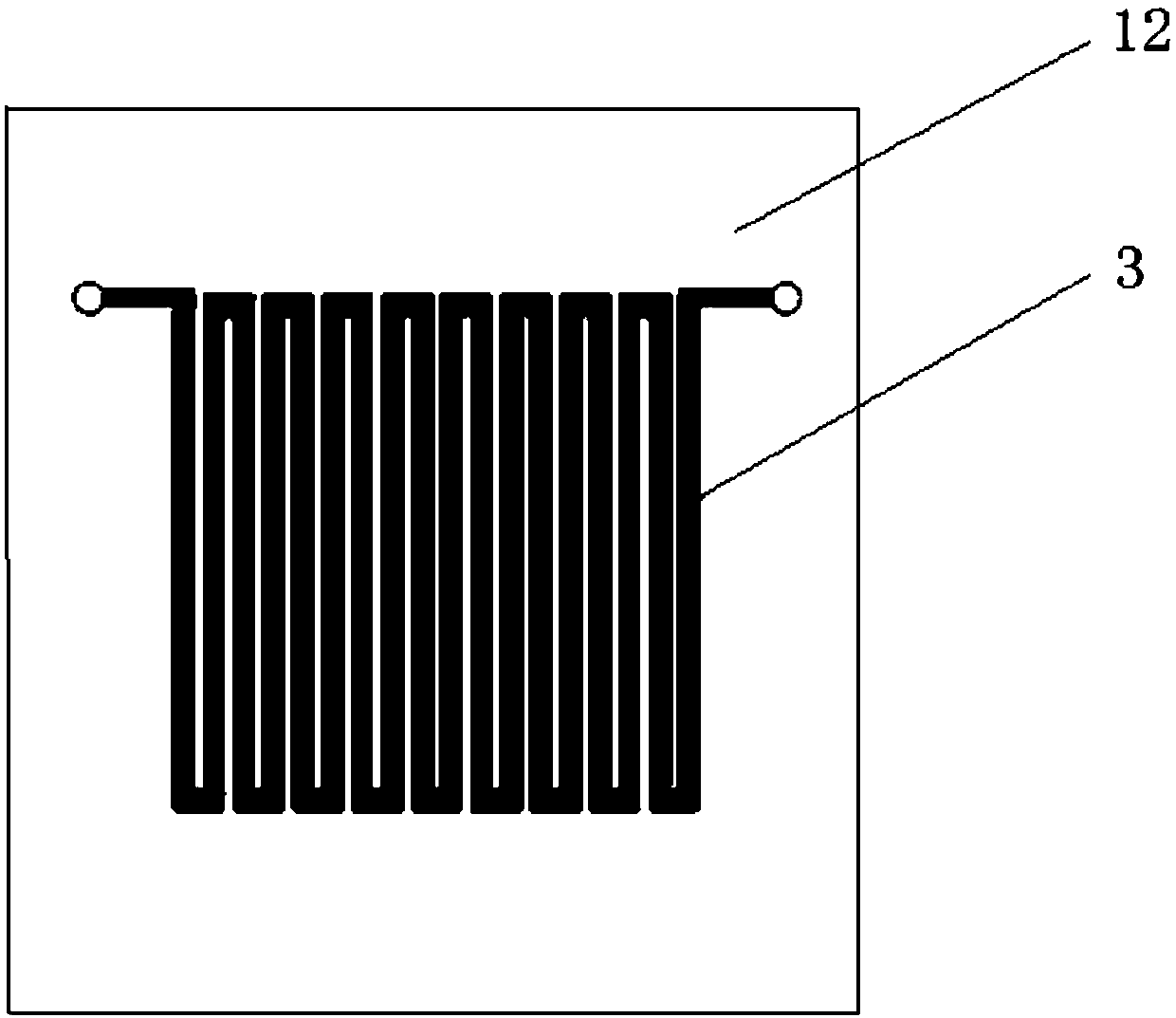

Camera module and circuit board thereof

InactiveCN105072319ANot easy to fall offAffect the welding effectTelevision system detailsColor television detailsCamera moduleEngineering

A circuit board comprises a substrate, and lines and bonding pads arranged on the substrate. Further, the circuit board comprises an ink protective layer which covers part of the lines. The ink protective layer is provided with ink windows corresponding to the bonding pads, and the edge of each ink window is lapped on the edge of the corresponding bonding pad. The invention further provides a camera module using the circuit board. As the edge of each ink window is lapped on the edge of the corresponding bonding pad, the bonding pads are not easy to fall off, glue water is effectively prevented from directly flowing to the bonding pads, and the influence of glue water to the effect of welding between a voice coil motor and the bonding pads of the circuit board is avoided.

Owner:NANCHANG O FILM OPTICAL ELECTRONICS TECH CO LTD +3

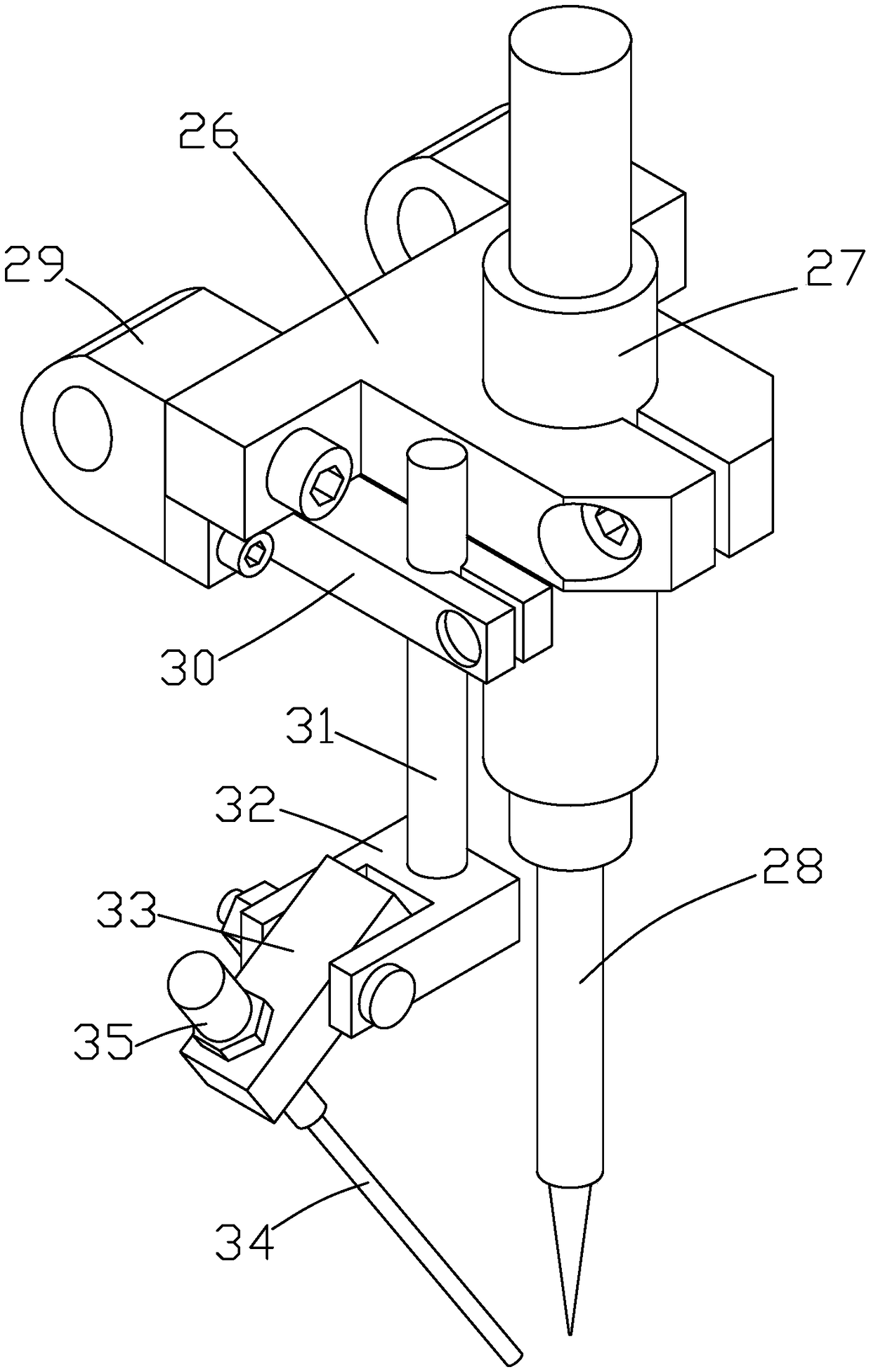

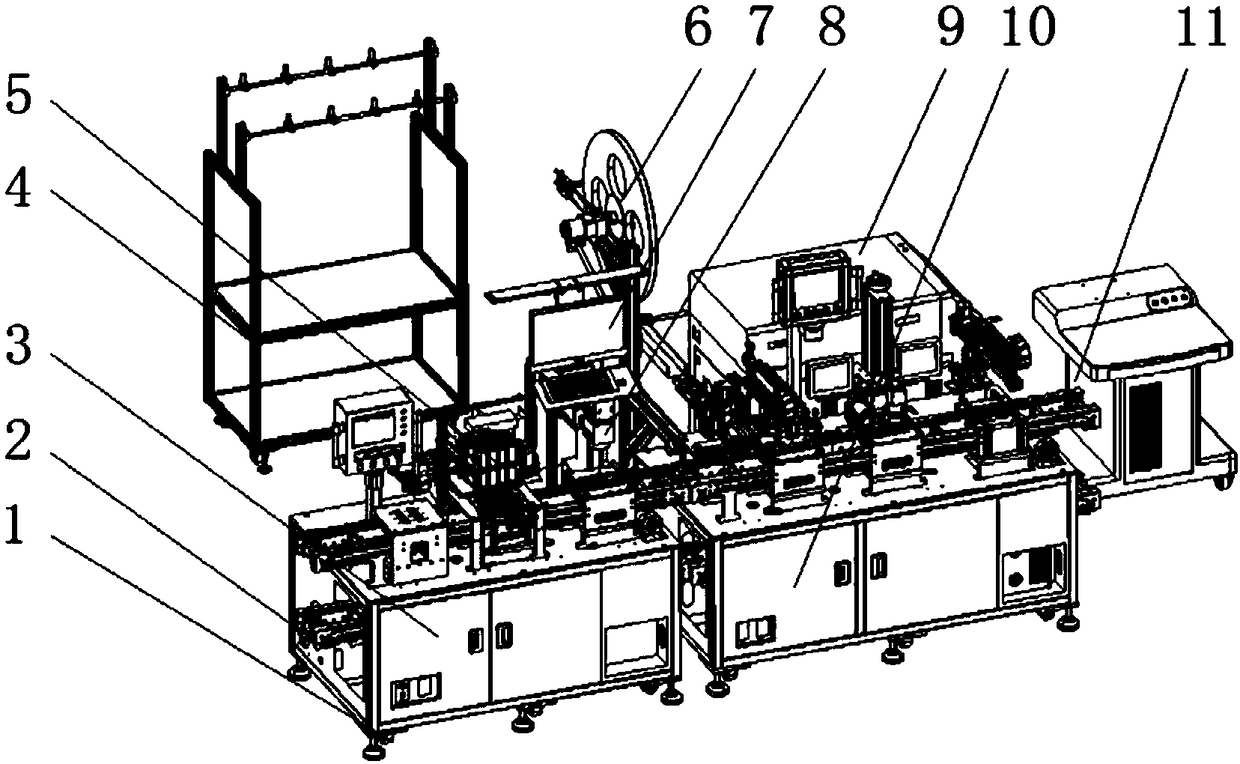

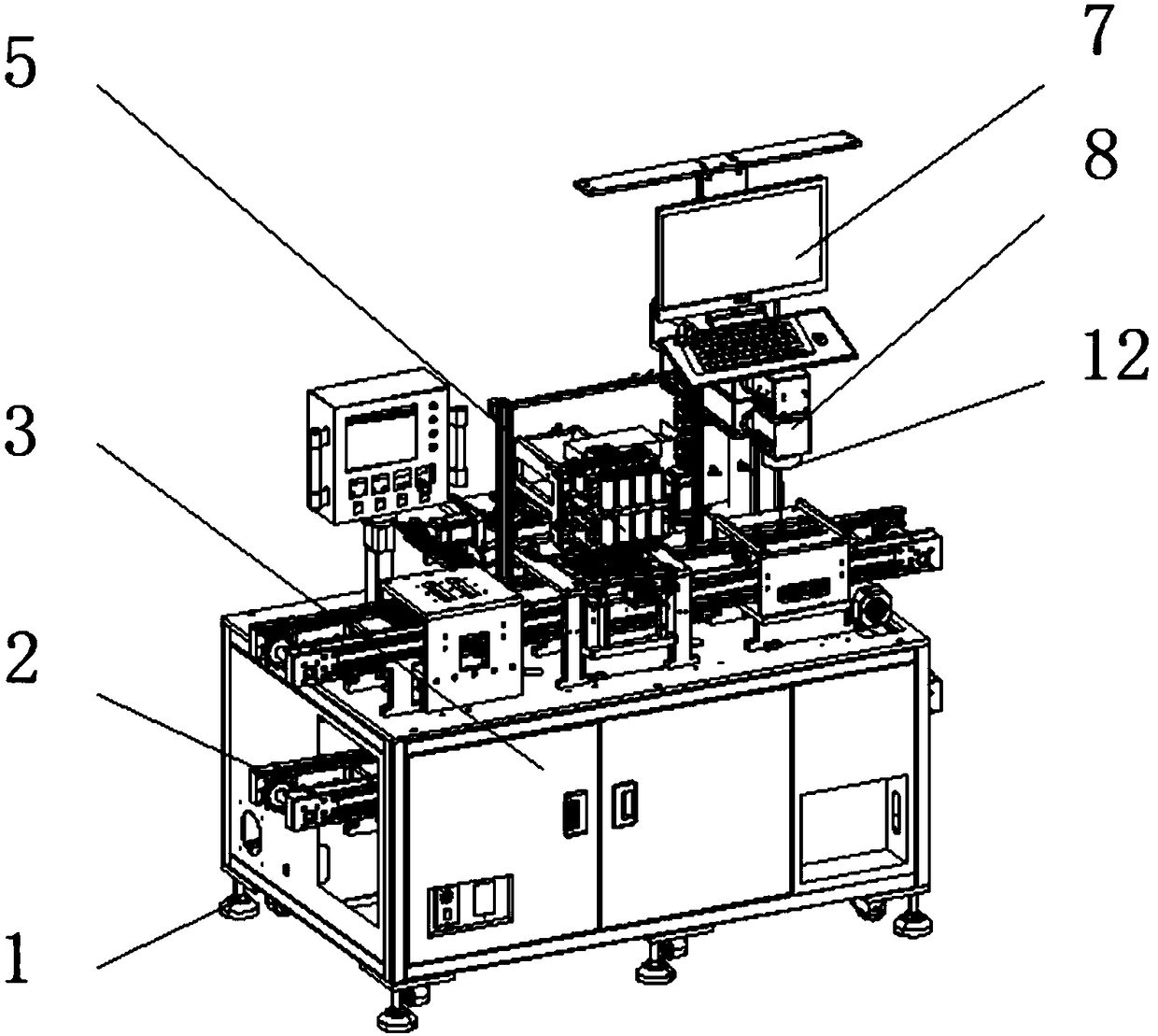

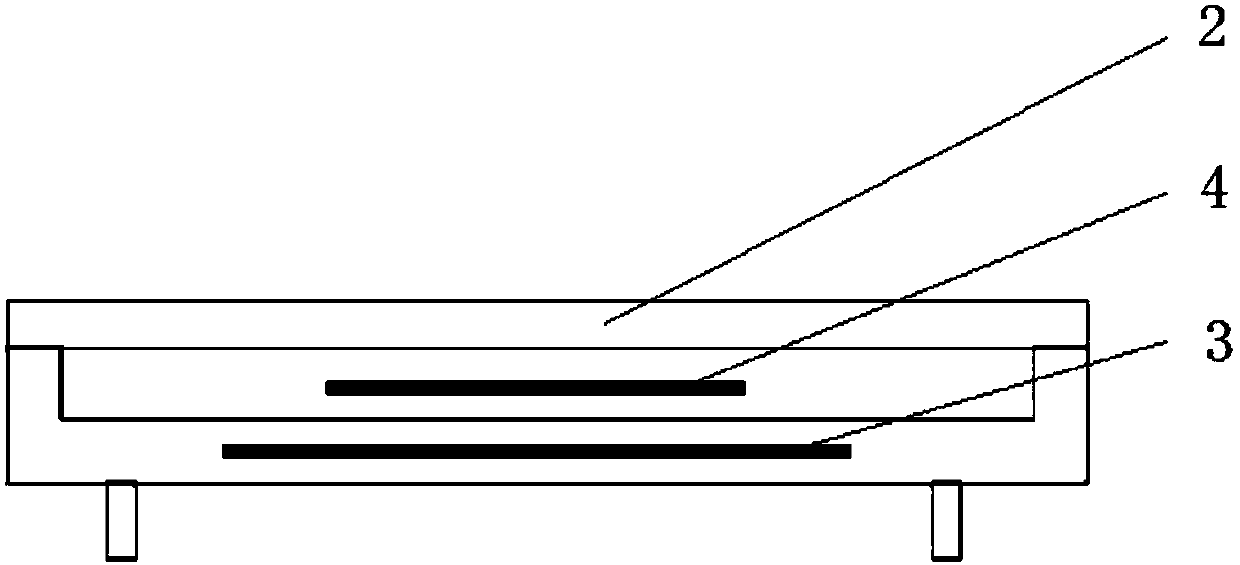

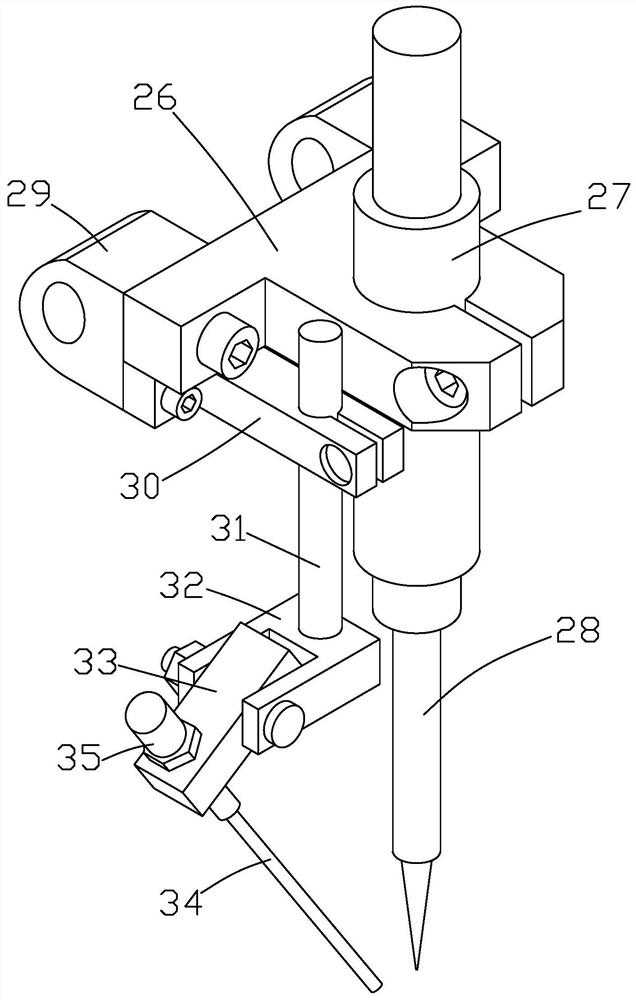

Automatic winding welding device

ActiveCN108074735AAffect the welding effectEasy to peel paint at restCoils manufactureWinding machineEngineering

The invention discloses an automatic winding welding device comprising a winding machine table, a welding machine table, an eight-axis synchronous winding and an up-and-down needle drawing mechanism.A wire discharging frame is mounted on one side of the winding machine table. An loading water circulation device is mounted in the winding machine table, a winding device is mounted at one end of thetop of the winding machine table through a support, a winding machine head left-right mechanism is mounted on the support on one side of the winding device, the welding machine table is mounted at one end of the winding machine table, and universal wheels are mounted at four corners at the bottom of each of the welding machine table and the winding machine table, a laser welding host is mounted at the top of the welding machine table, and a computer host is mounted at one end of the welding machine table far away from the winding machine table. According to the automatic winding welding device, by installation of a damping gasket, the stability of the whole device is improved, to achieve the effect of vibration reduction, and the influence on work progress and winding welding effects caused by vibration in work is avoided.

Owner:东莞市高东电子科技有限公司

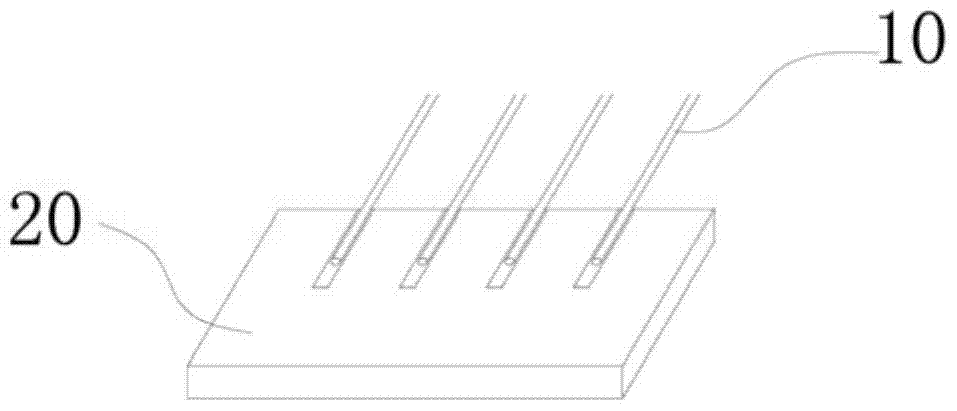

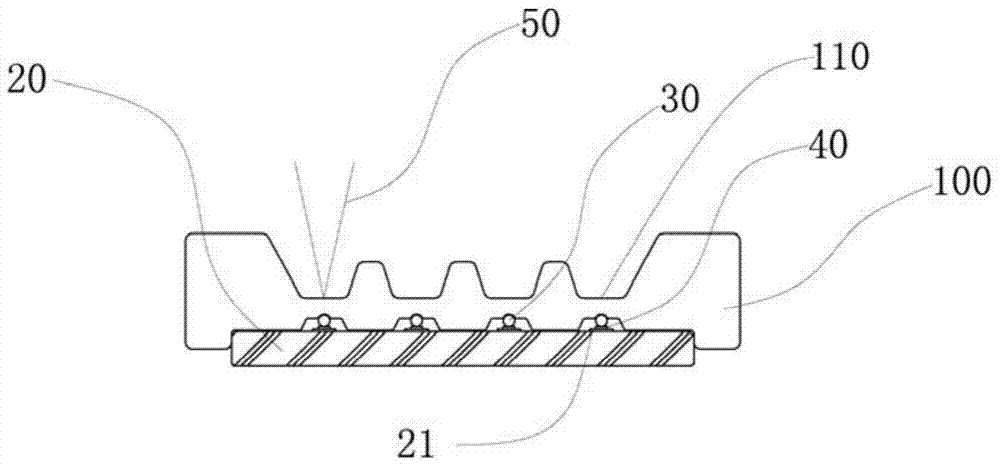

Tin soldering jig and laser tin soldering method

ActiveCN104625299AAffect the welding effectWelding/cutting auxillary devicesAuxillary welding devicesHigh energyHeat transmission

The invention relates to the field of laser tin solder, and provides a tin soldering jig. Heat conduction portions are arranged on the tin solder jig at intervals and are made of heat conduction materials, when the tin soldering jig is arranged on a soldering pad, the heat conduction portions make contact with to-be-soldered portions of a to-be-soldered product and compress the to-be-soldered portions and tin materials on the soldering pad, laser heats the heat conduction portions in an illumination mode and transmits heat to the to-be-soldered portions and the tin materials making contact with the to-be-soldered portions, and the tin materials are melted. The laser does not directly heat the tin materials, heat is transmitted to the tin materials in a heat transmission mode, the to-be-soldered product is welded, and high energy generated when the laser directly irradiates the product is prevented from affecting the welding effect of other to-be-soldered portions. The embodiment of the invention further provides a laser tin soldering method.

Owner:HANS LASER TECH IND GRP CO LTD

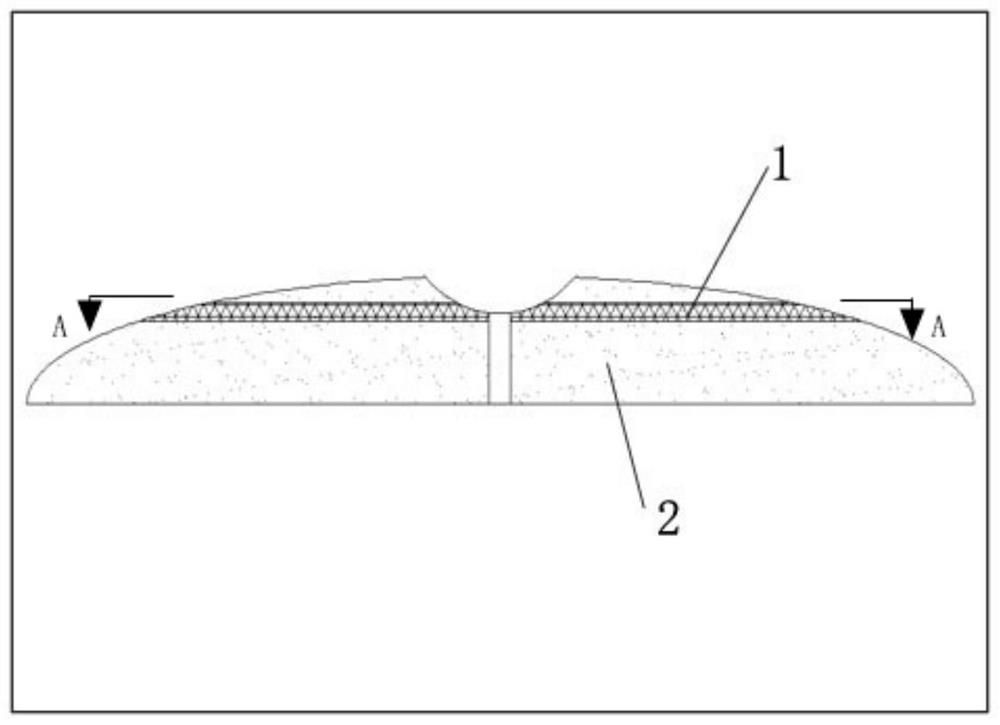

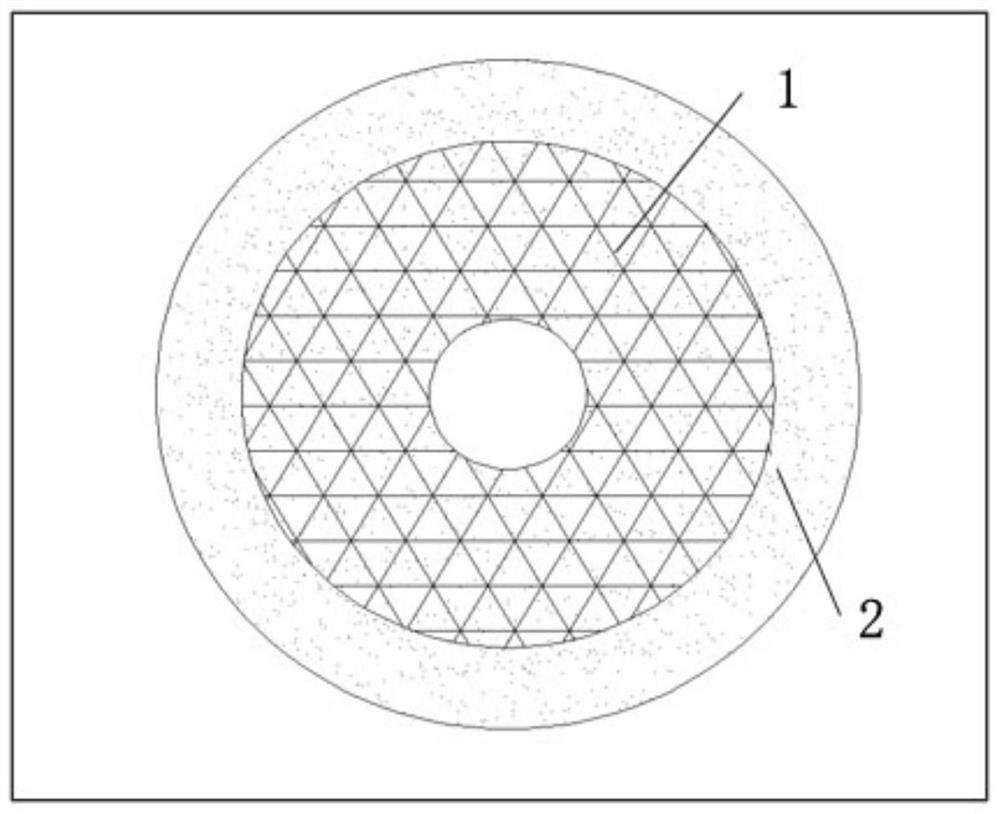

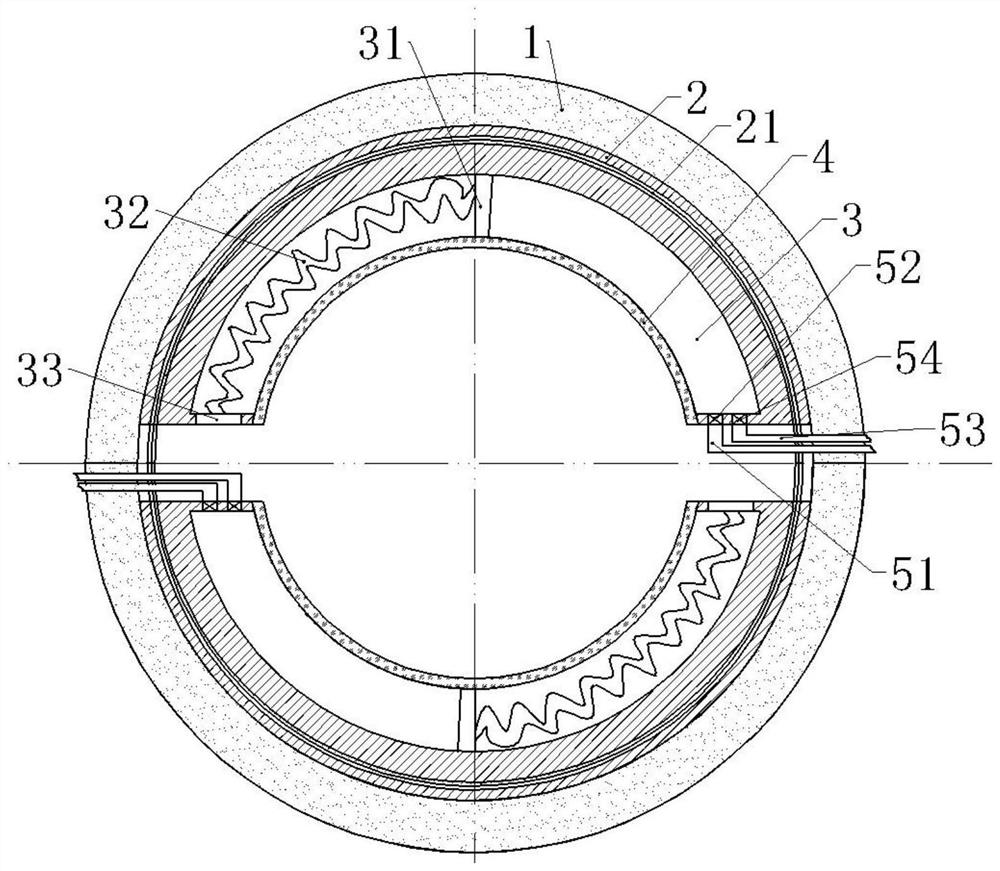

All-enclosuring type electric melting pipe piece and mfg. method

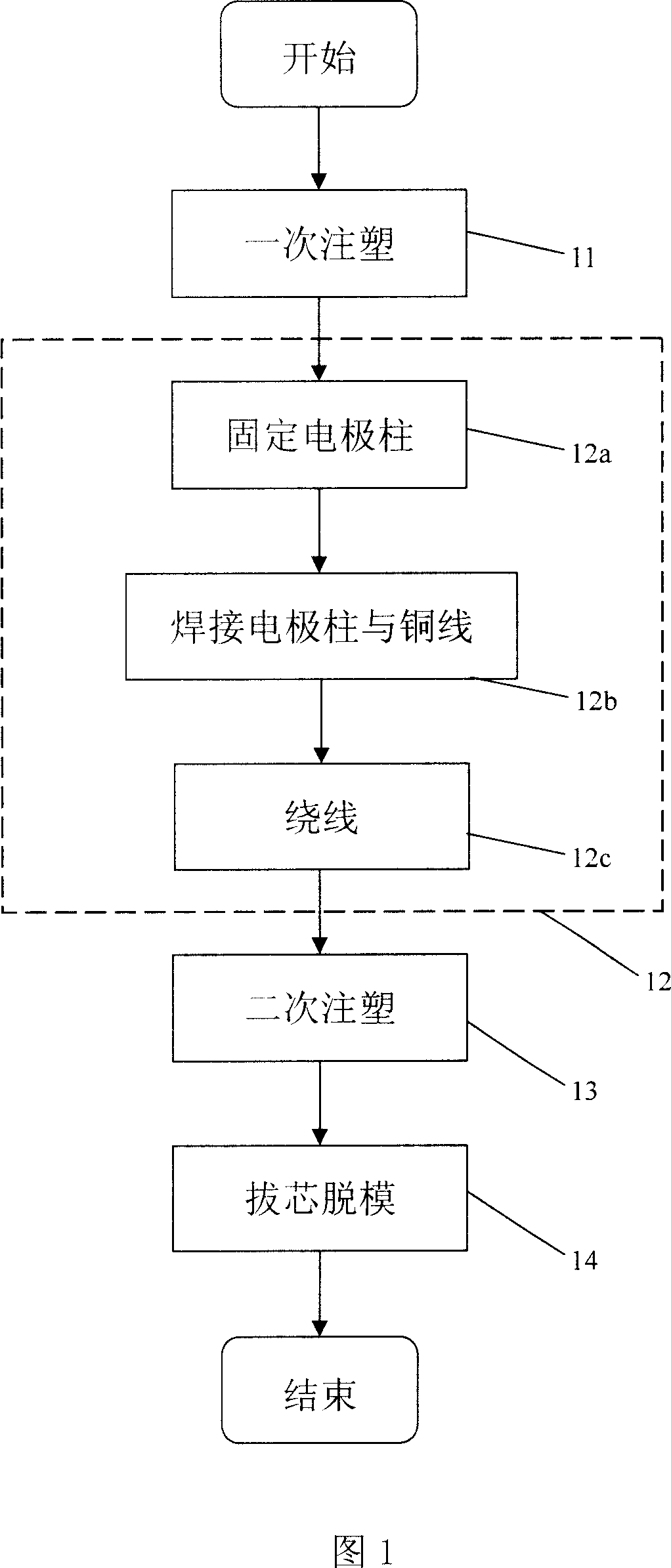

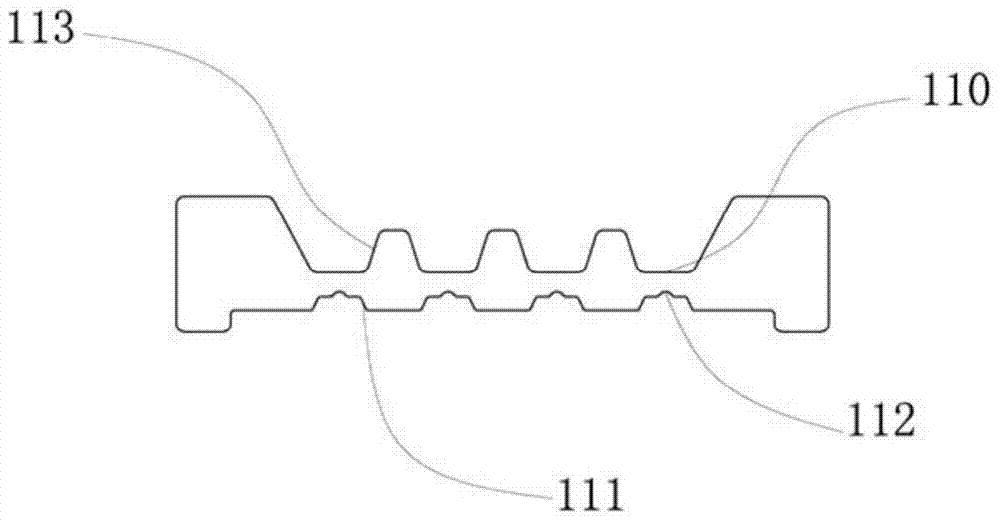

InactiveCN101025245ASolve the impact shift pull out problemSolve the problem of welding effectPipe connection arrangementsElectricityElectrical resistance and conductance

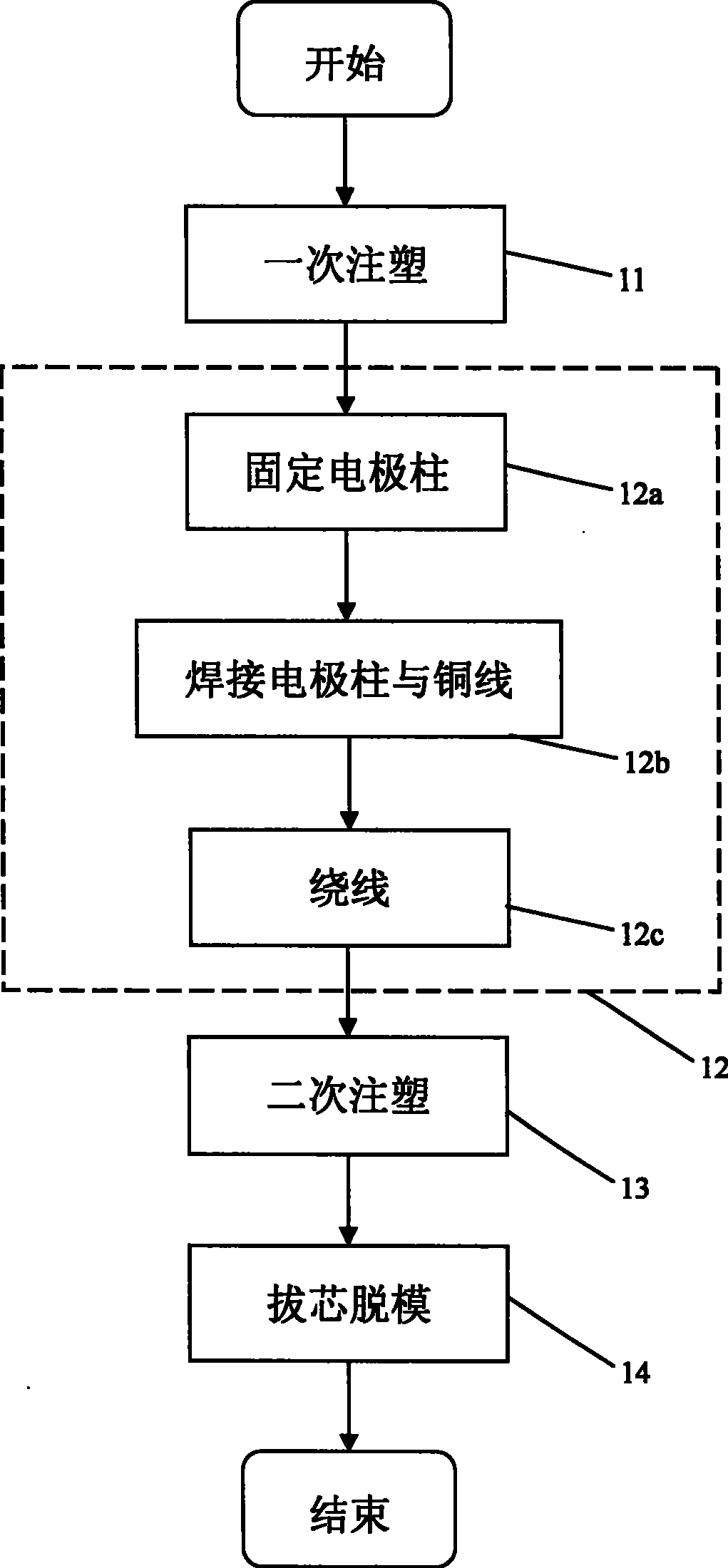

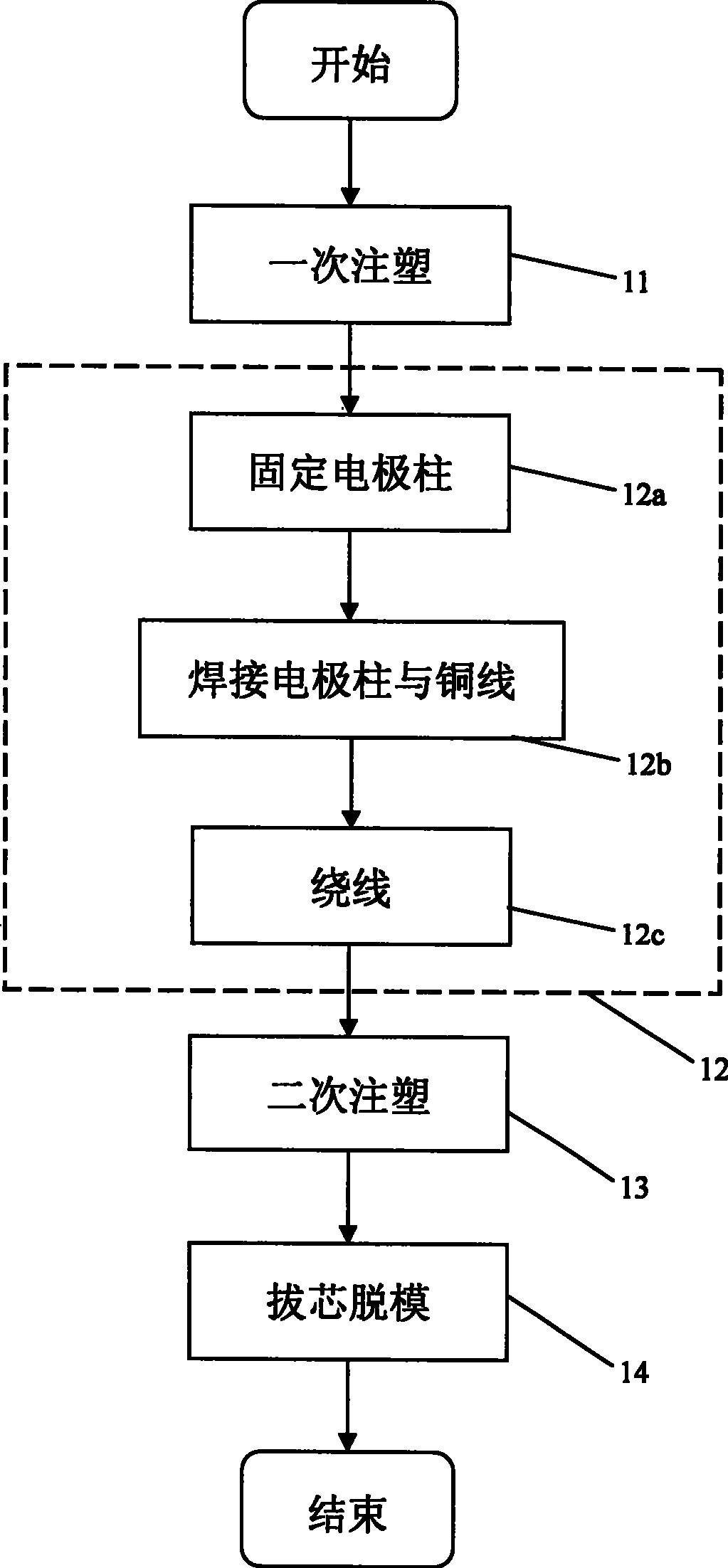

The invention discloses a full contained electric melting pipe and the manufacturing method thereof, adopting secondary injection moulding process, firstly pouring a parison of a certain thickness on a core stick, then fixing electrode column and welding electrode column and copper wire on the injection-moulded parison, then coiling and feeding the wired parison into a mould to pour to form an outer layer of a certain thickness, merging the parison and the outer layer into an organic whole, and fully containing the copper wire in the middle of the pipe, and finally after the finished product cools, adopting a core drawer to demould a complete pipe from the core stick. And the electric heating wire is fully contained inside the pipe, solving the problem of influencing welding effect by oxidizing of exposed resistance wire, and the inside surface of the pipe is smooth and has no traces of turning tool, thus unable to influence the welding effect.

Owner:潘刚

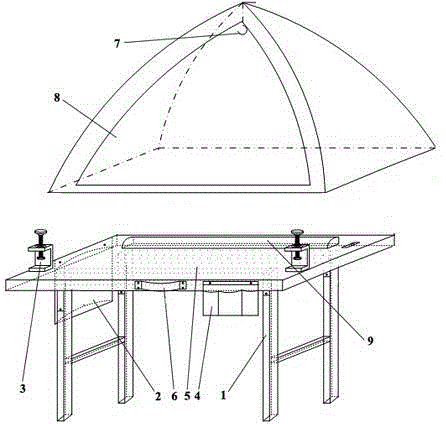

Special portable table for cable splicing

The invention relates to a special portable table for cable splicing. The special portable table comprises an operation table board, foldable support legs are arranged below the operation table board, cable clamps are fixed on two sides of the surface of the operation table board, a cover storage bag and a tool storage bag are arranged on the operation table board, an unfoldable cover is arranged in the cover storage bag, a telescopic rod is arranged on the surface of the operation table board, and a lamp is mounted on the telescopic rod. According to the above technical scheme, cables can be stably clamped on the operation table board, and the cover additionally arranged is used for preventing rain, snow and wind outside from influencing cable splicing. The support legs are of foldable structures, occupation space can be reduced during transport and carrying is facilitated.

Owner:STATE GRID CORP OF CHINA +1

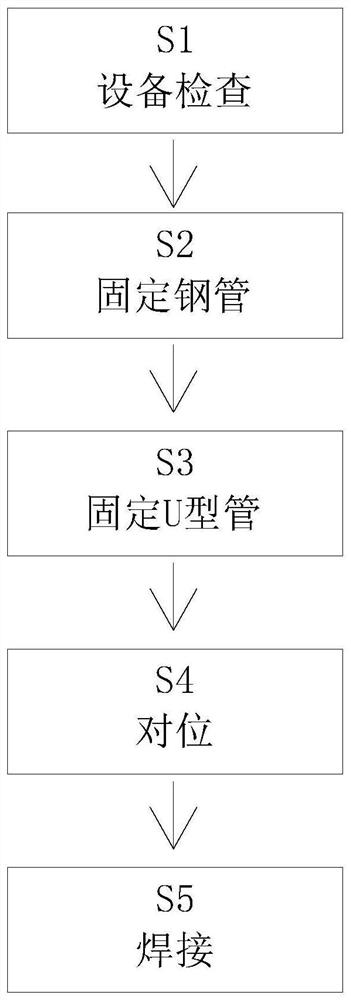

Welding process for manufacturing boiler economizer

InactiveCN113059299AImprove fitIncrease frictionWelding/cutting auxillary devicesAuxillary welding devicesPipeFriction force

The invention provides a welding process for manufacturing a boiler economizer. The welding process for manufacturing the boiler economizer adopts the following equipment for welding, the equipment comprises a base, a fixing device and a welding device, the lower end of the base is connected with the existing ground, the fixing device is installed at the upper end of the base, and the welding device is arranged above the fixing device. Through cooperation of a supporting plate and a fixing plate, a combined body of a steel pipe and a rib plate in the boiler economizer can be supported, through cooperation of a fixing rod and an arc-shaped block, the steel pipe can be limited and fixed, through an arc-shaped groove, the attaching degree between a supporting table and the steel pipe can be higher, meanwhile, by arranging a first sponge, the friction force between the steel pipe and the arc-shaped groove can be increased, so that the situation that the welding effect is affected due to the fact that the steel pipe slides or shakes relative to the arc-shaped groove in the alignment and welding process is avoided.

Owner:钱方

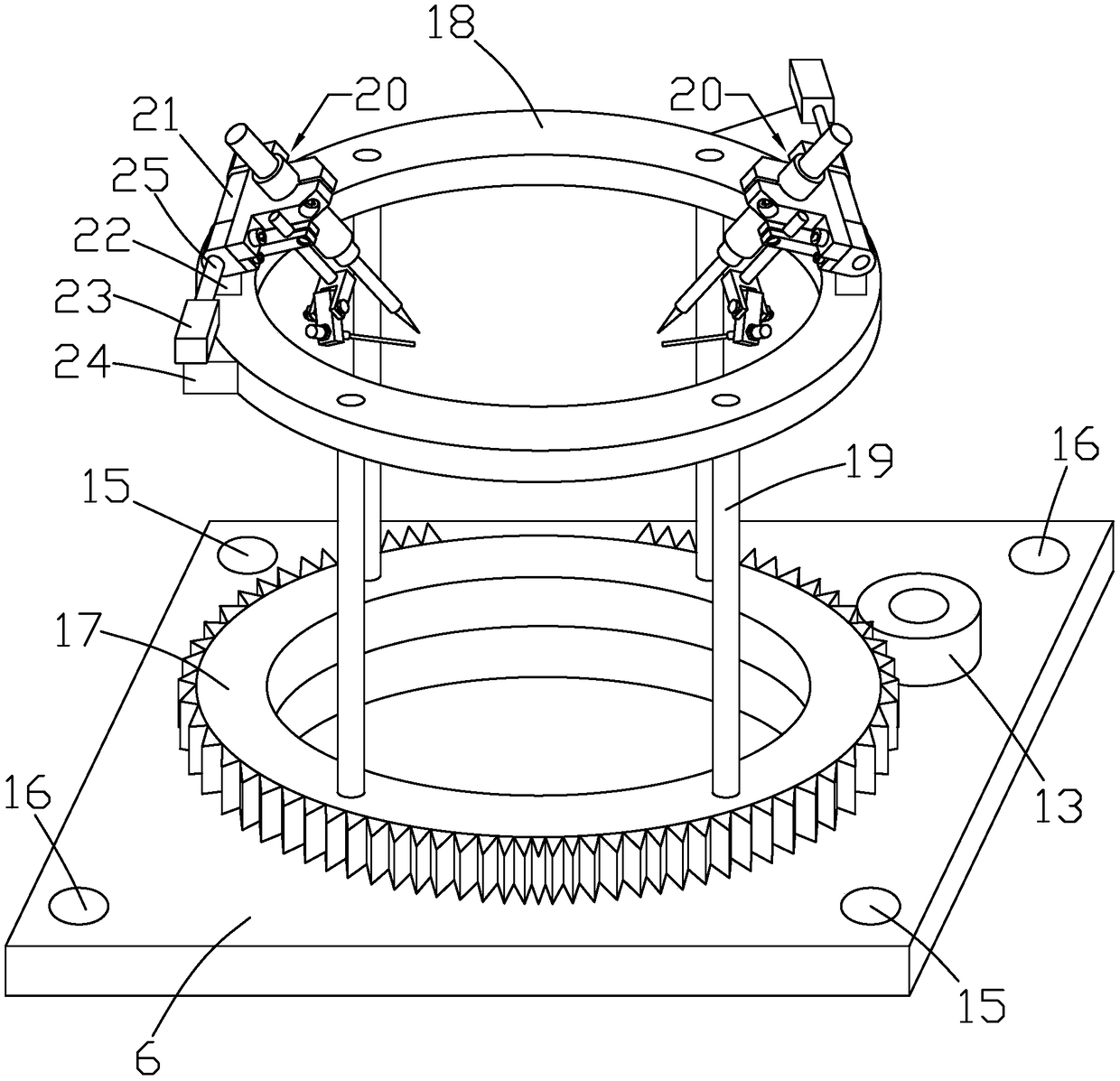

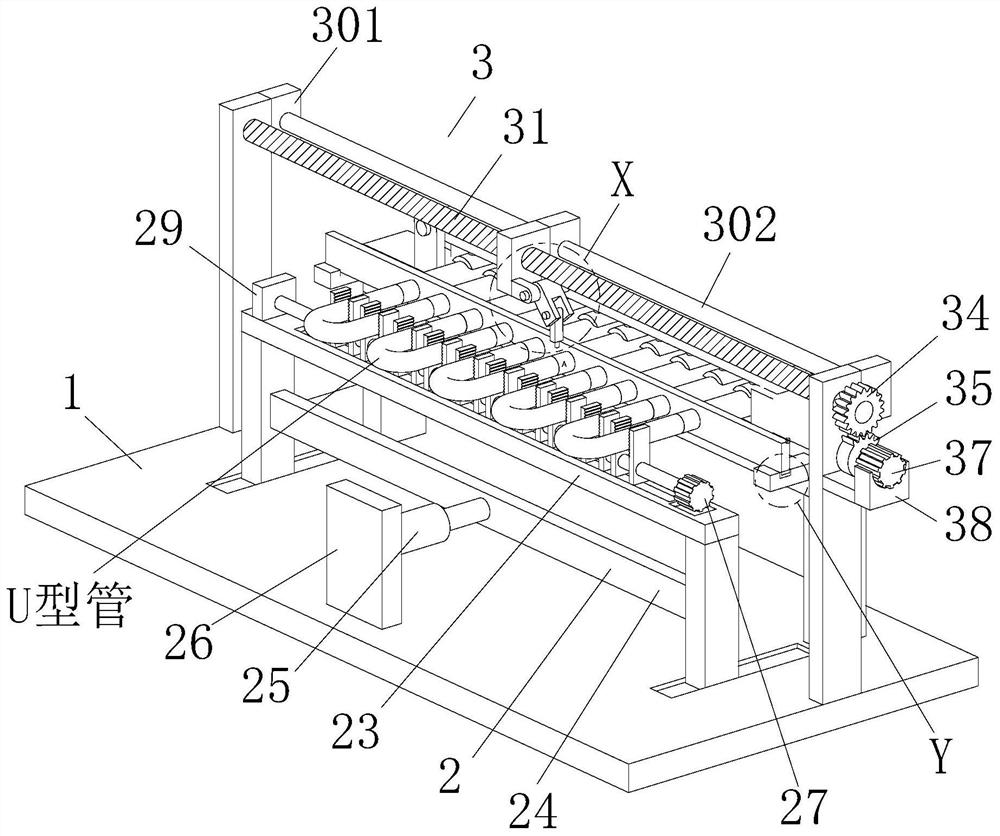

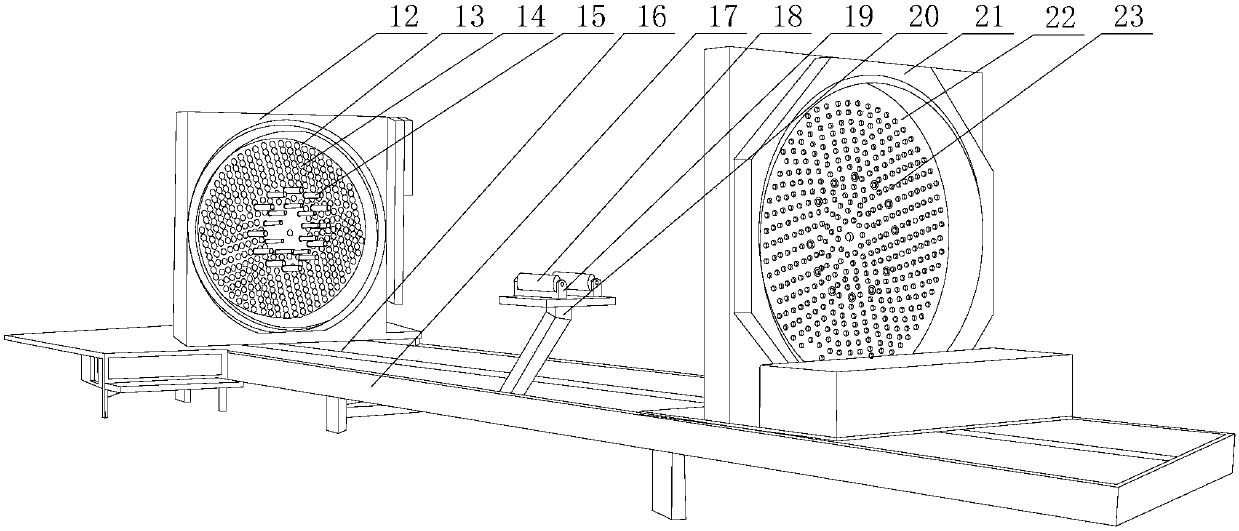

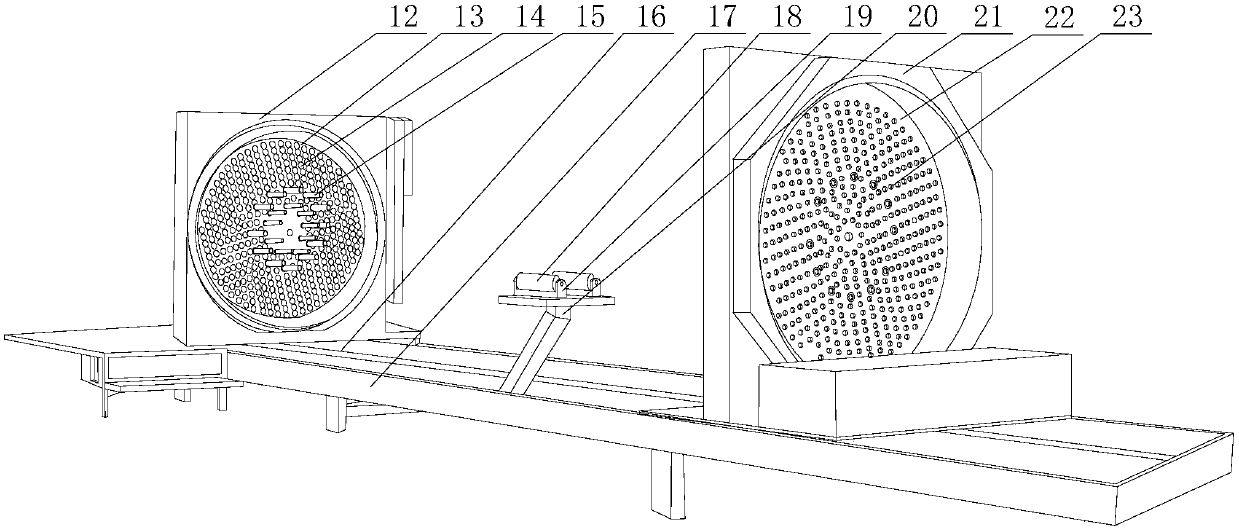

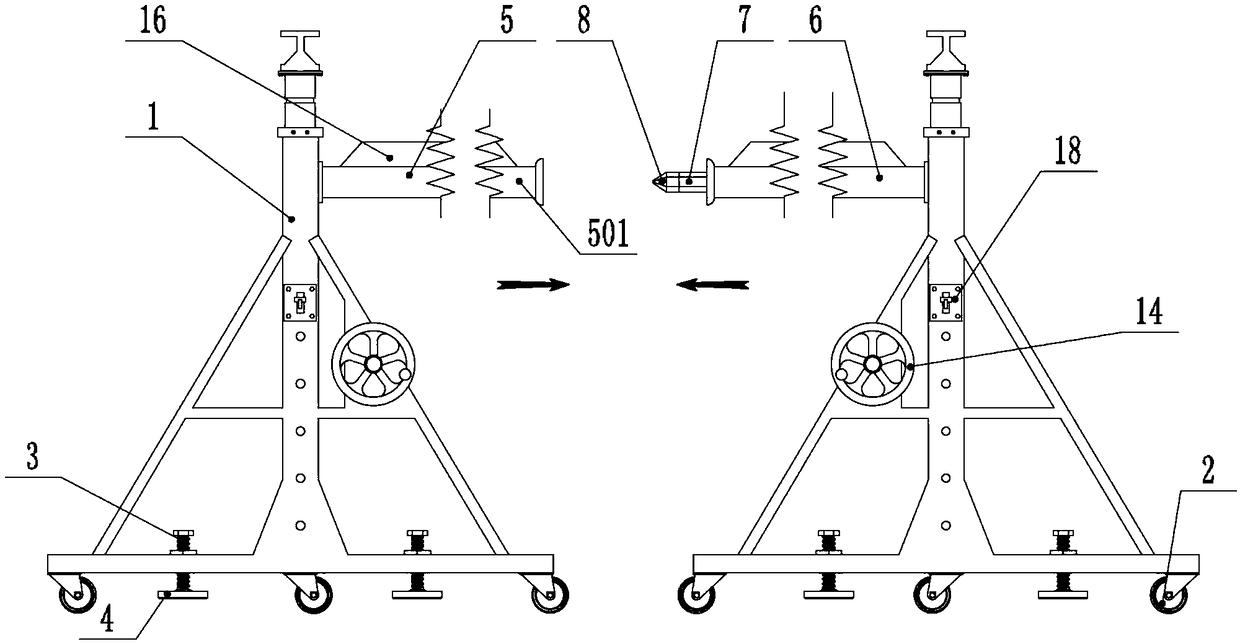

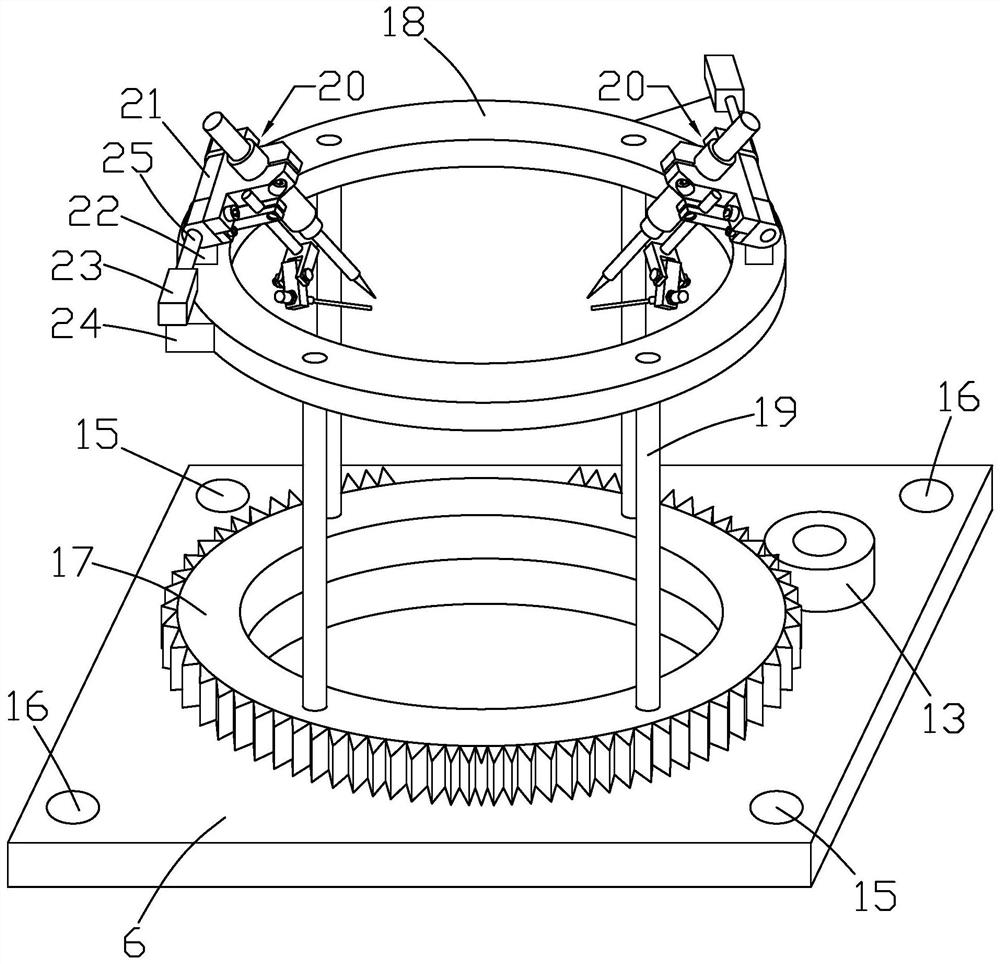

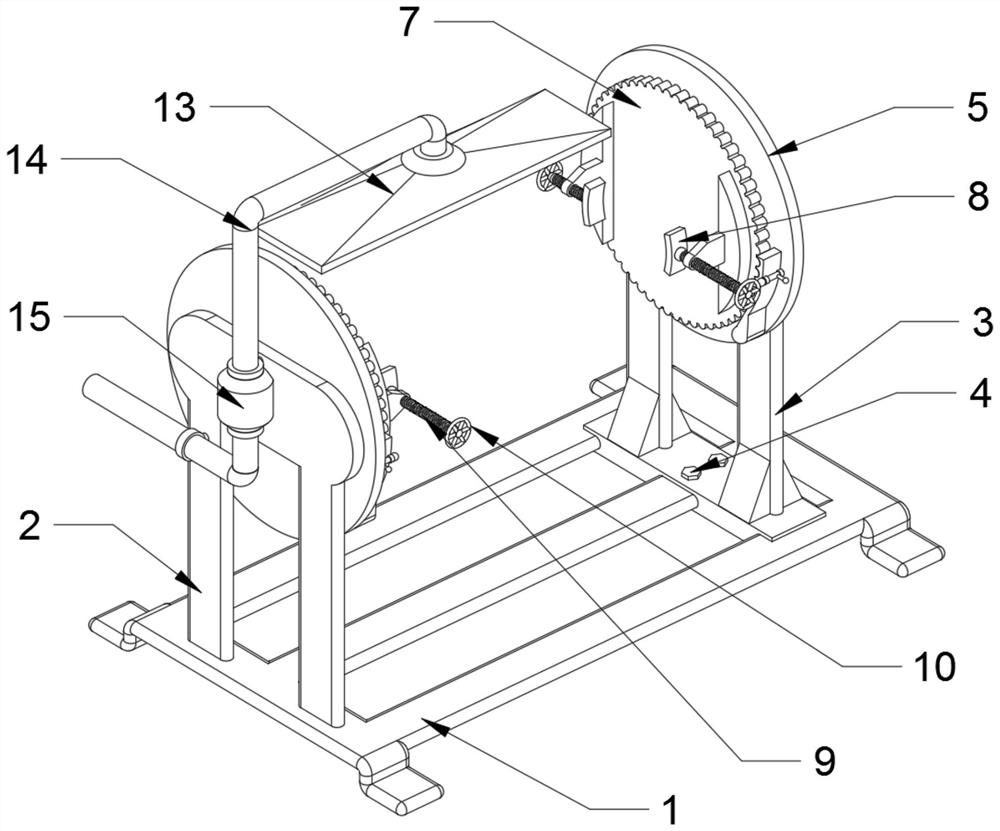

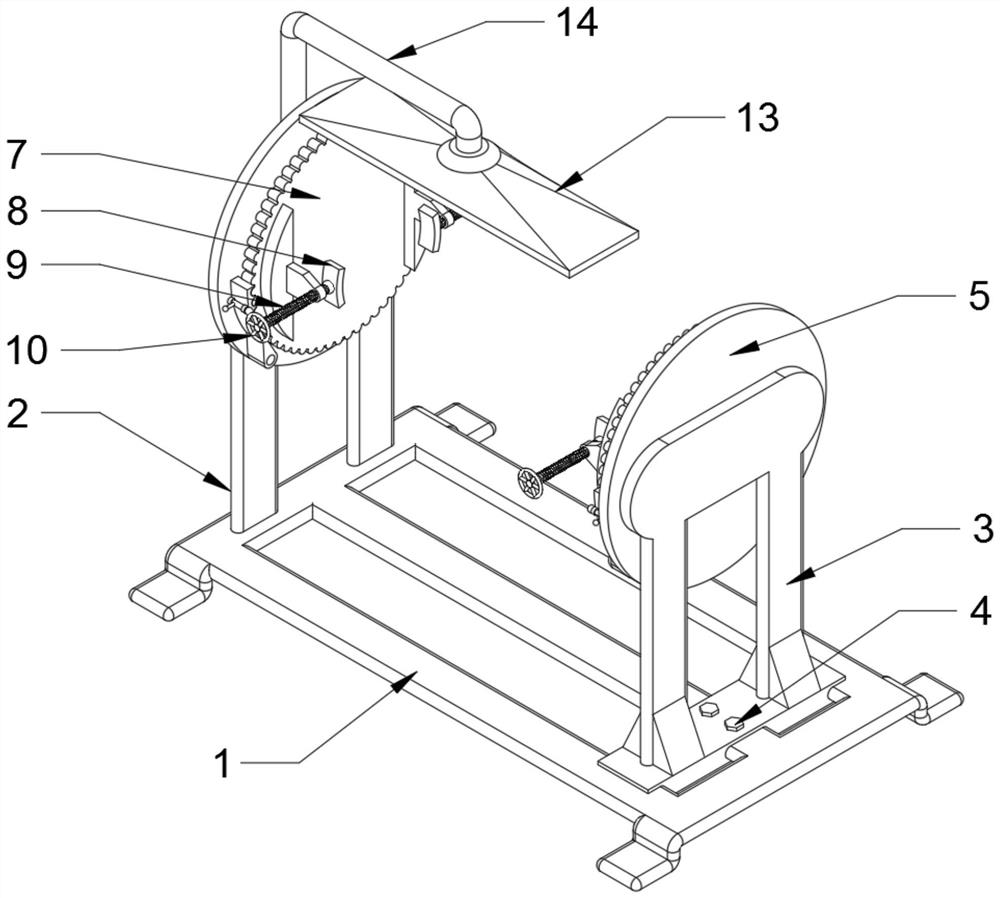

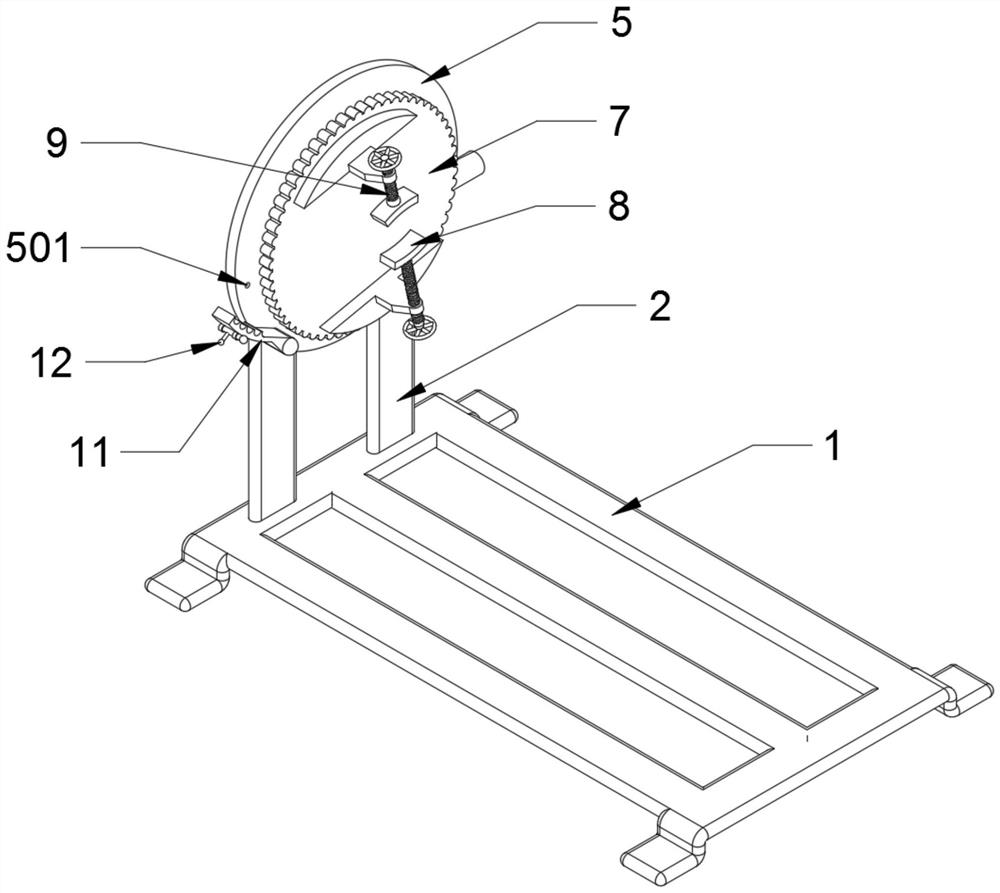

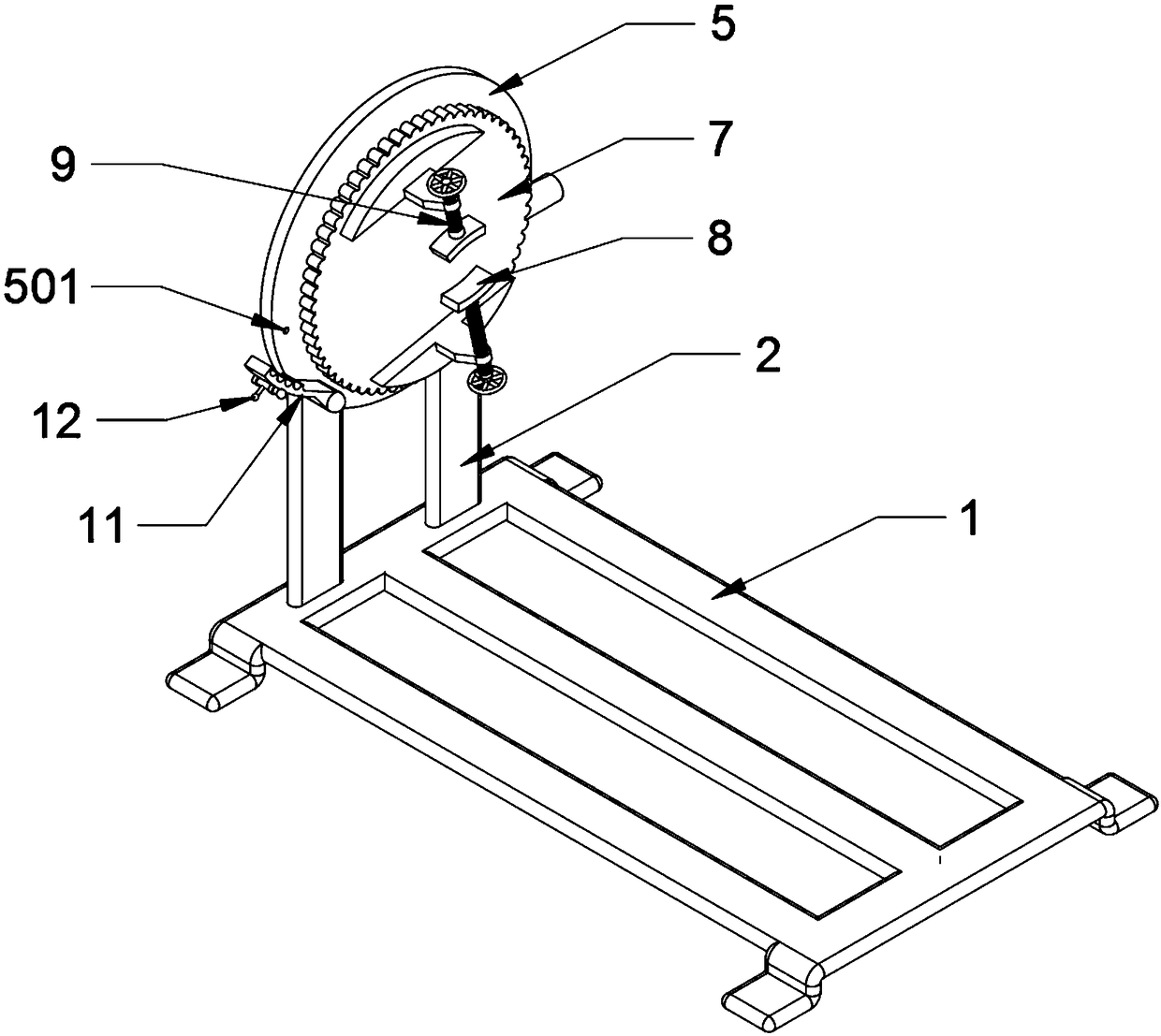

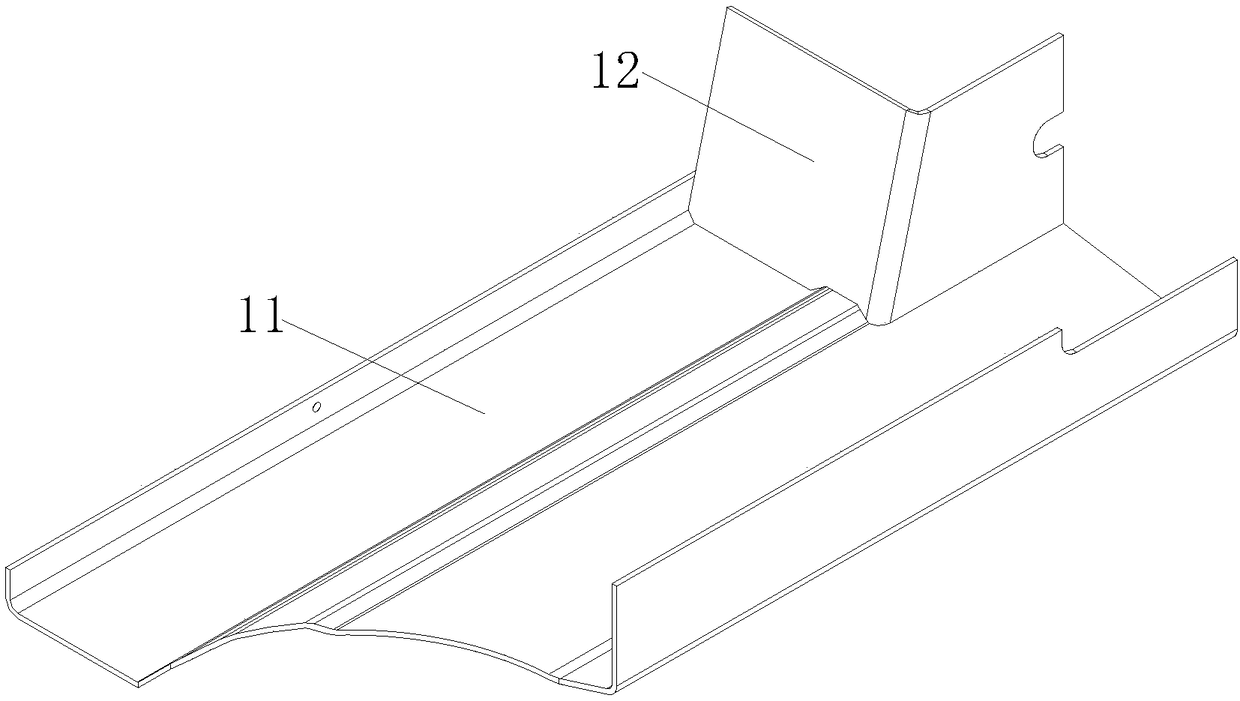

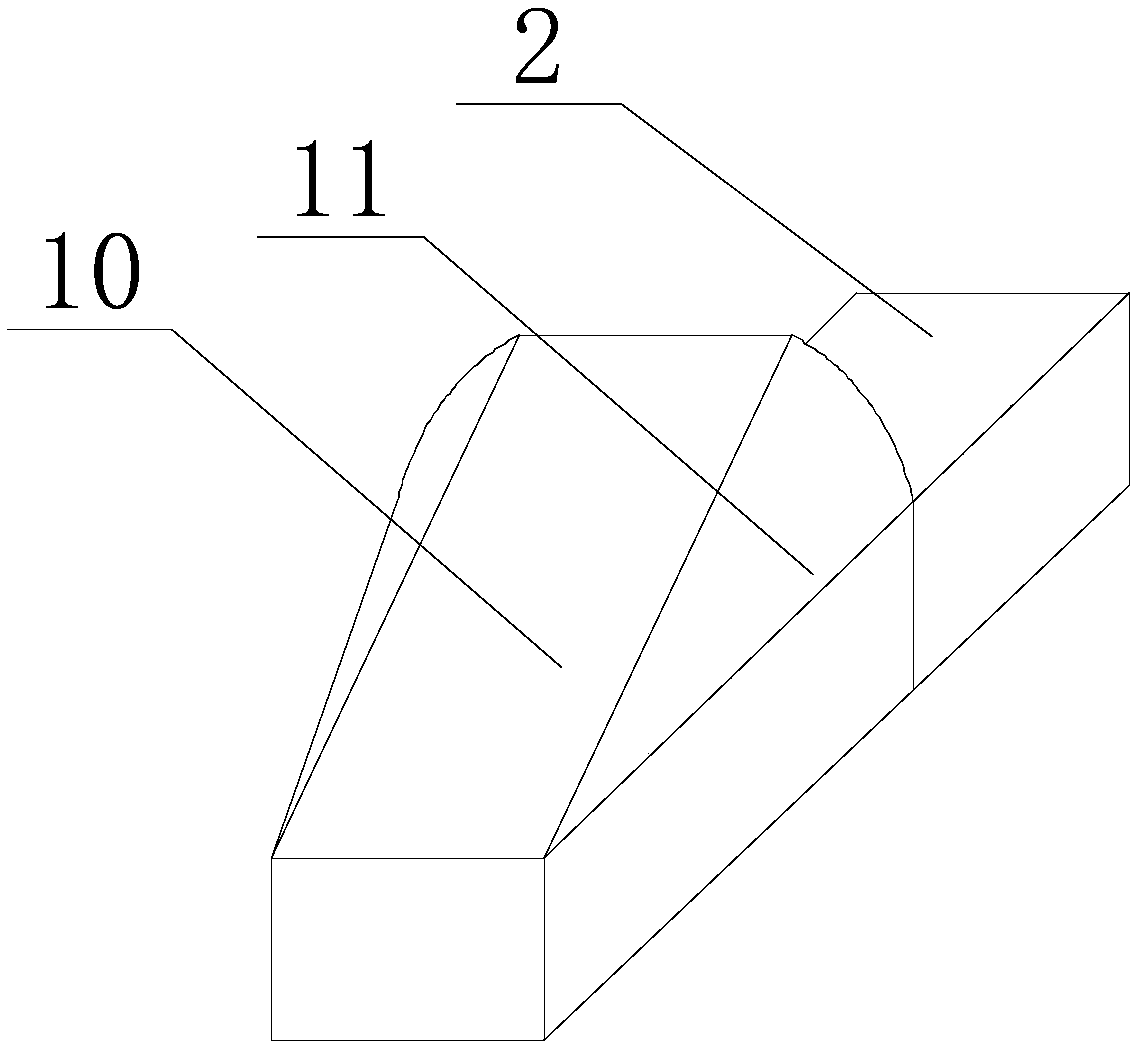

Implementation method of reinforcement cage forming device for pile hole foundation

ActiveCN107685127AAffect the welding effectGuaranteed StrengthMeshed-ring wire networkRebarAxial length

The invention discloses an implementation method of a reinforcement cage forming device for a pile hole foundation. The method includes: fixing a plurality of fixing components on a first rotary discand a second rotary disc to form two concentric and unidiameter circles; regulating the interval between a first support plate and a second support plate according to the axial length of a reinforcement cage, inserting a plurality of longitudinal reinforcing steel bars needed by the reinforcement cage into the fixing components on butt joint holes and mounting holes; starting a motor to allow themotor to drive a gear to mesh with a toothed belt, and allowing the second rotary disc to rotate inside two bearings, and allowing the first rotary disc to rotate synchronously; arranging transverse reinforcing steel bars on the reinforcement cage structure formed by the longitudinal reinforcing steel bars, and welding the connecting points of the transverse reinforcing steel bars and the longitudinal reinforcing steel bars until the transverse reinforcing steel bars completely wind the reinforcement cage structure. The method has the advantages that during the winding, the longitudinal reinforcing steel bars are constantly clamped and fixed by the fixing components, and the welding effect between the longitudinal reinforcing steel bars and the transverse reinforcing steel bars is prevented from being affected by the fact that the longitudinal reinforcing steel bars turn in barrels.

Owner:东莞市建安管桩有限公司

Pipe die welding method

InactiveCN109352198AOvercome crackingAffect the welding effectWelding apparatusWelding processPetroleum engineering

The invention discloses a pipe die welding method which comprises the following steps: S1, carrying out rust removal operation on a to-be-welded pipe die, and polishing the port of the pipe die to have metal luster; S2, carrying out washing operation on the pipe die after rust removal operation; S3, drying the washed pipe die; S4, preheating the to-be-welded pipe die; and S5, utilizing a welding gun and adopting an R307 welding rod to weld the joint seam of two to-be-welded pipe dies. The pipe die welding method solves the problem in the prior art that the welding technology is likely to causethe pipe die to crack.

Owner:WUHU XINXING DUCTILE IRON PIPES

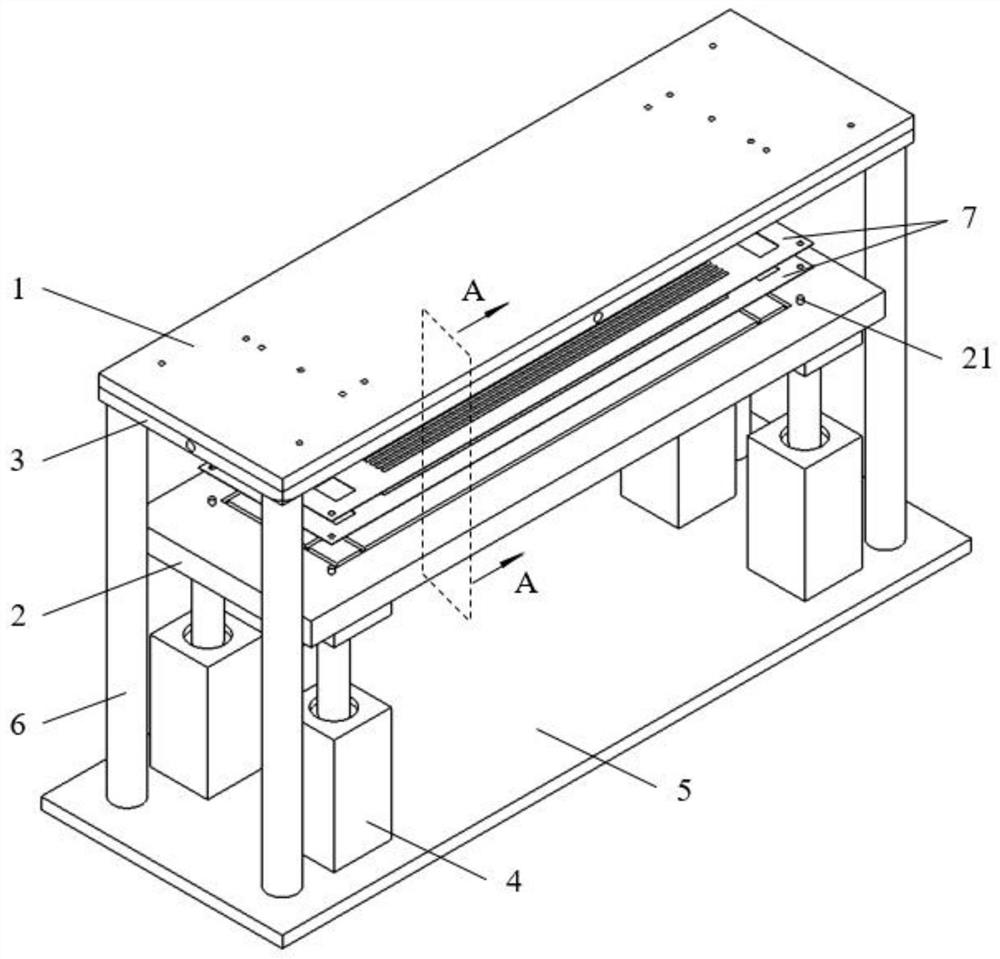

Cooling fin double-gun plasma welding machine

InactiveCN110756967AAffect the welding effectExtended service lifePlasma welding apparatusGear wheelEngineering

The invention discloses a cooling fin double-gun plasma welding machine. The cooling fin double-gun plasma welding machine comprises a support. A mold mechanism is arranged on the front side of the support, a lifting cylinder is arranged on the front side of the upper end of the support, and a double-gun gear rotating mechanism is arranged at the bottom of the lifting cylinder. The mold mechanismcomprises a jacking cylinder, a base plate, a moving lower mold plate, a fixed upper mold plate, guide sleeves, lower locating copper columns, lower locating stretching cylinders, upper locating copper square blocks and cooling water connectors. By the adoption of the integral structural design, the purpose that the inner circle edge welding can be fully automatically conducted on middle circularholes in two circular workpieces which are stacked together is achieved, the purposes that the labor intensity of workers can be greatly reduced, the service cost of an enterprise can be reduced are achieved, and utilization is more convenient. Double plasma welding guns can achieve synchronous welding, are high in welding efficiency and conduct locating on the stacked circular workpieces throughthe arranged mold mechanism, and therefore the double-gun gear rotating mechanism can have the advantages of being high in welding accuracy and good in welding effect, and the cooling fin double-gun plasma welding machine meets the requirement of the enterprise for the large-scale batch production.

Owner:DONGGUAN YUANYI AUTOMATION EQUIP

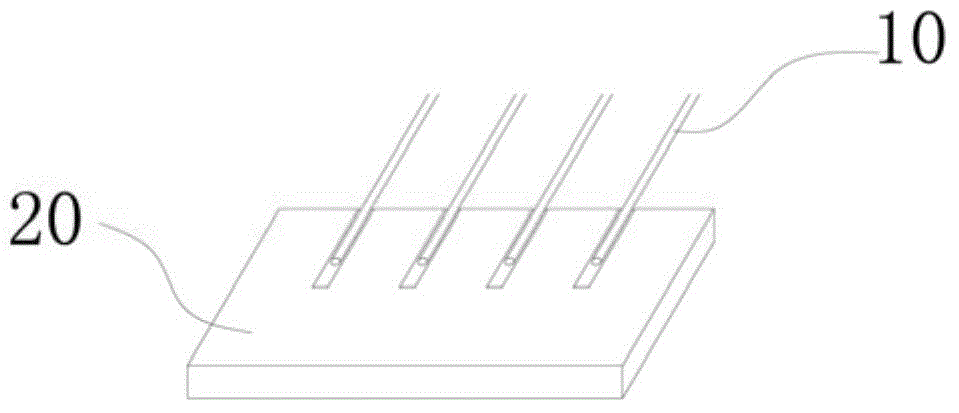

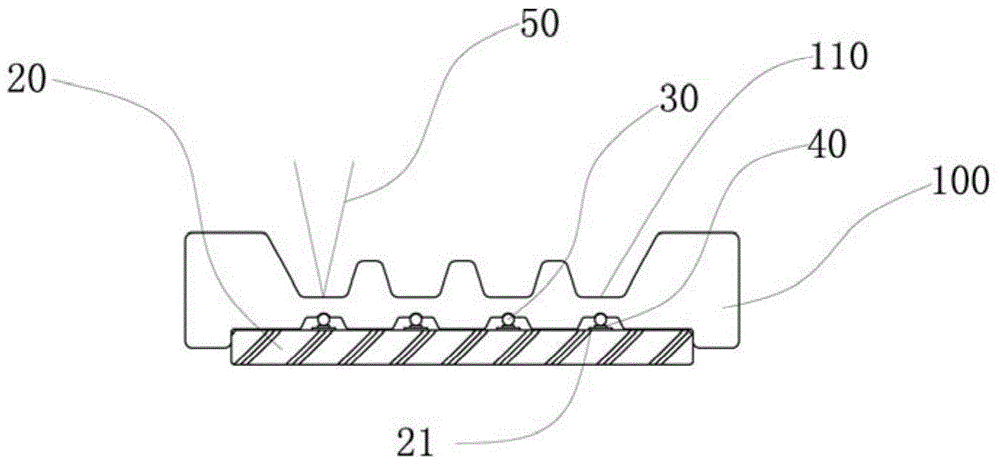

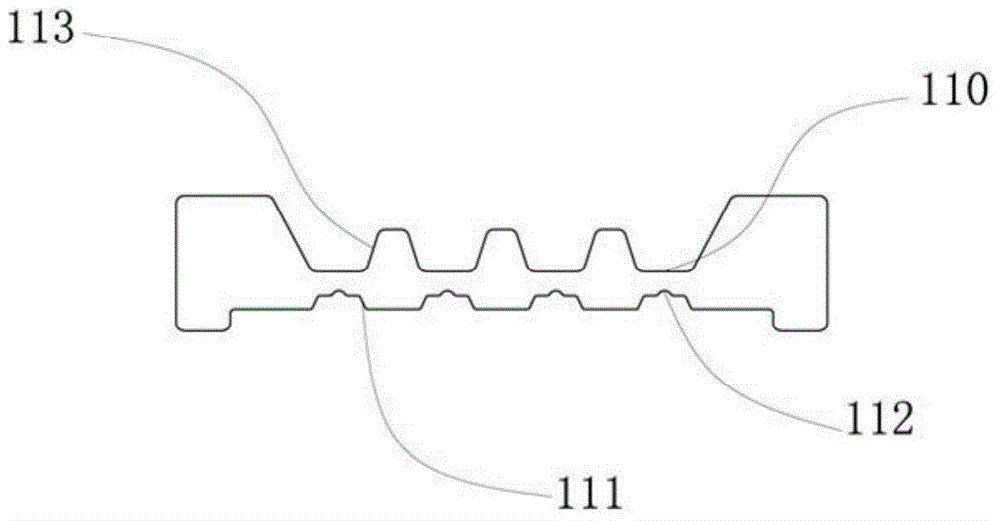

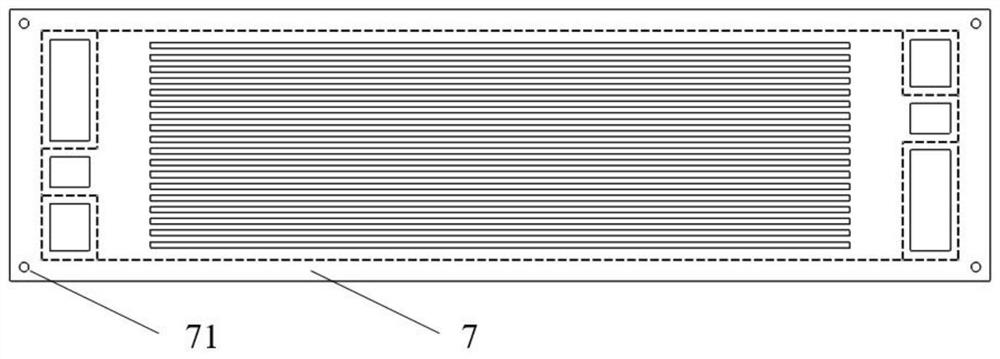

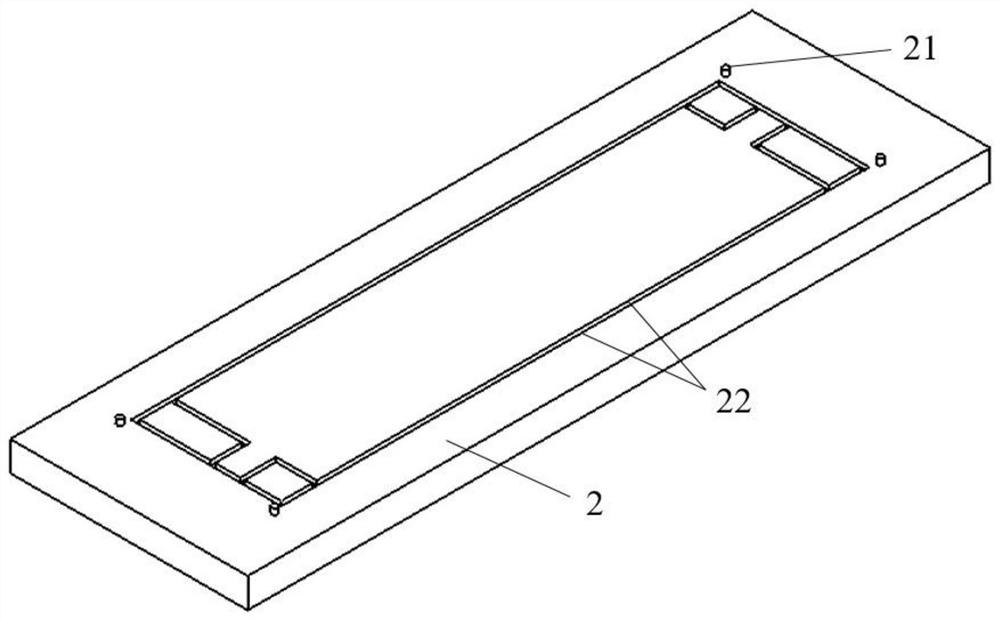

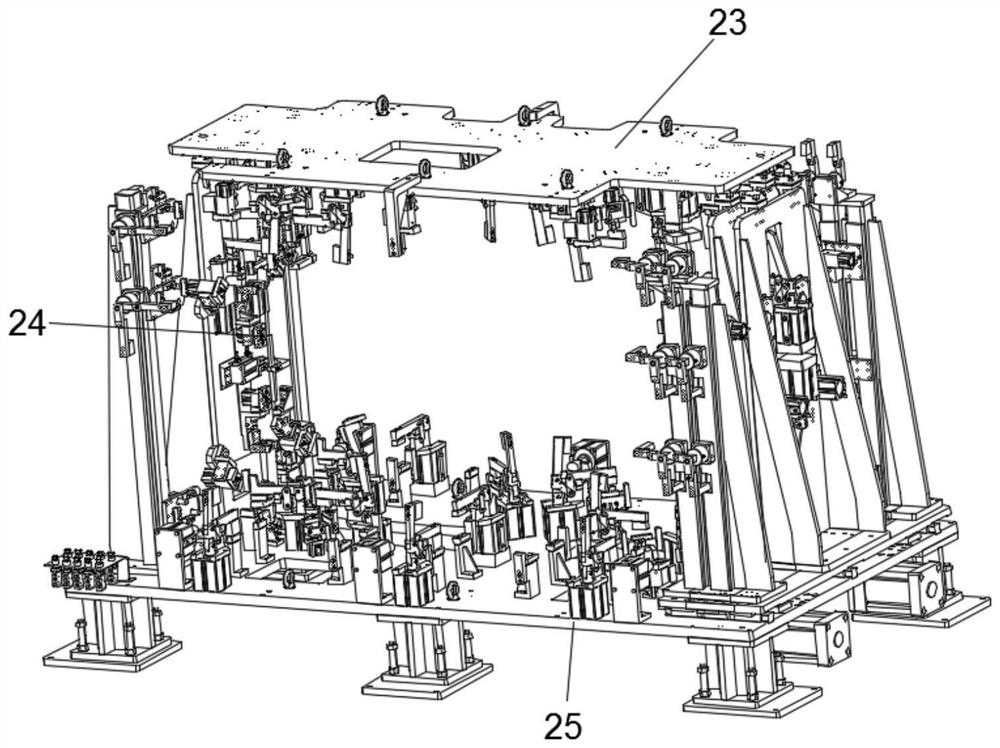

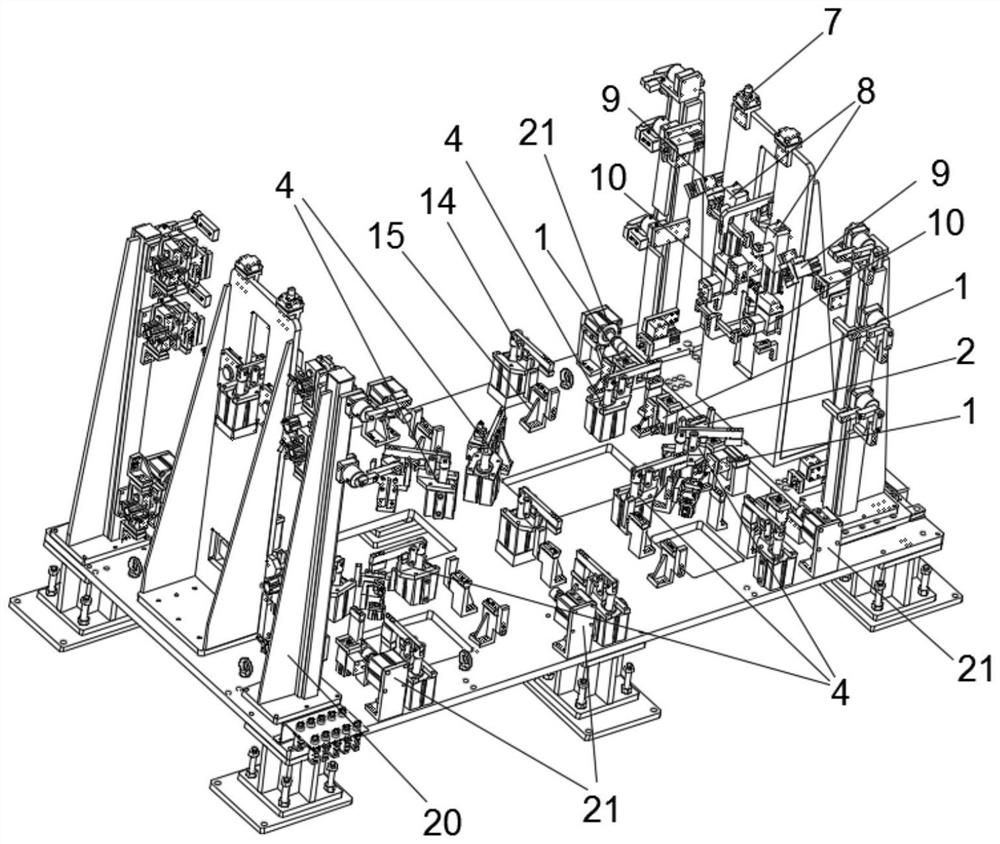

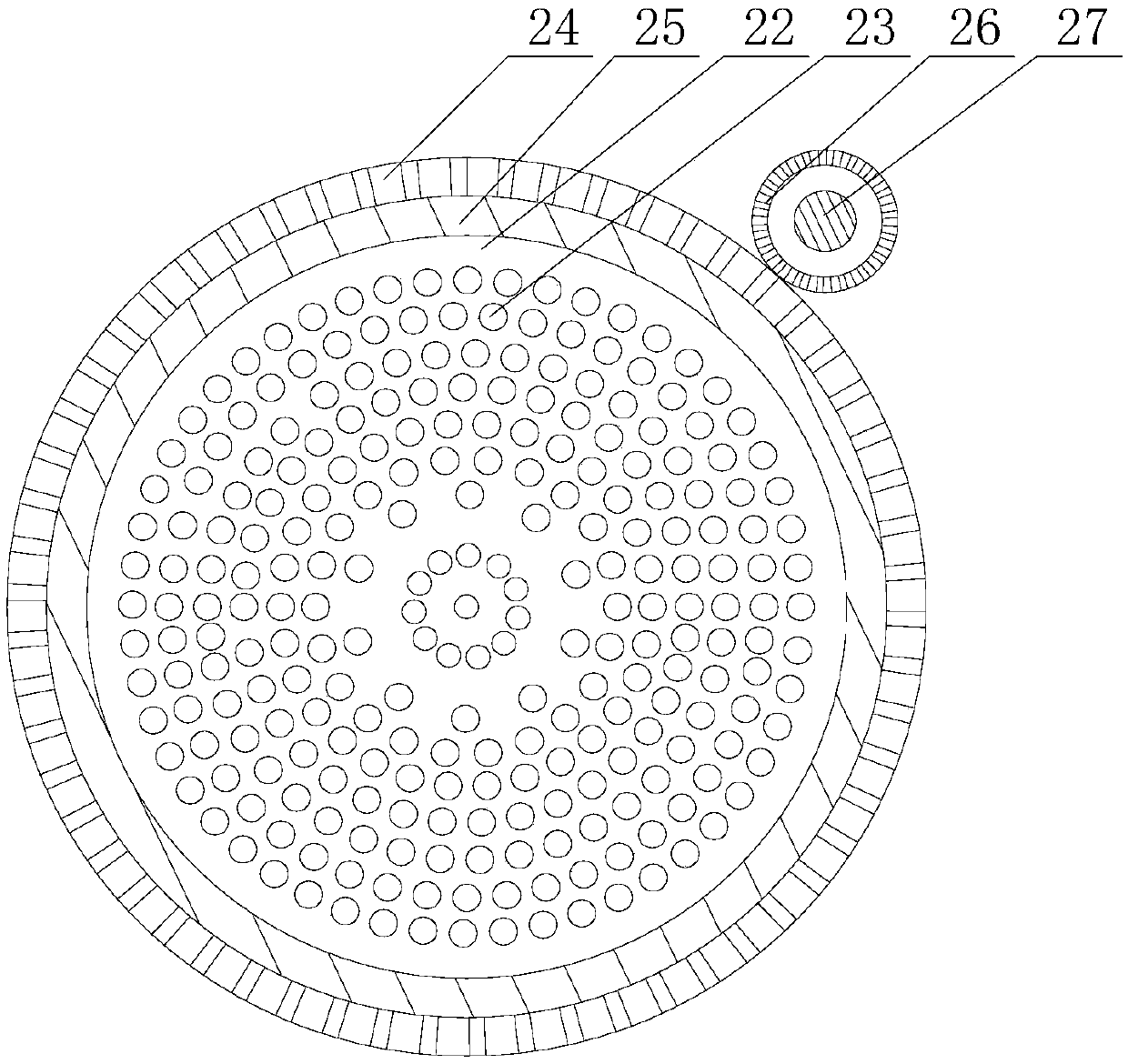

A fixture for laser welding of fuel cell bipolar plates

ActiveCN112548435BAffect penetrationAffect the welding effectWelding/cutting auxillary devicesAuxillary welding devicesFuel cellsEngineering

The invention relates to a fixture for laser welding of fuel cell bipolar plates, which belongs to the technical field of fuel cells. The fixture includes a first pressing plate, a second pressing plate, a profiling plate and a driving device, wherein the first pressing plate can transmit laser light; the second pressing plate is spaced apart from the first pressing plate, and the second pressing plate is used for To fix the bipolar plate; the profiling plate is fixed on the side of the first pressure plate close to the second pressure plate, and the profiling plate is provided with a laser avoidance groove for the laser to pass through and a smoke channel connected with the laser avoidance groove; the driving device drives the second pressure plate The first pressing plate and / or the second pressing plate move towards each other and clamp and fix the bipolar plate. After the bipolar plate is fixed by the clamp, the laser beam of the laser welding equipment can penetrate the first pressing plate and the laser avoidance groove to reach the bipolar plate, realizing one-time clamping and welding of the bipolar plate. At the same time, the smoke generated by welding is discharged from the laser avoidance groove through the smoke channel to prevent the smoke from affecting the penetration of the laser and affecting the welding effect of the laser.

Owner:DONGFENG MOTOR CORP HUBEI

Efficient full-automatic welding tool for energy storage cabinet

PendingCN114043141APrecise positioningEasy feedingWelding/cutting auxillary devicesAuxillary welding devicesStructural engineeringIndustrial engineering

Disclosed is an efficient full-automatic welding tool for the energy storage cabinet comprising a bottom plate and is characterized in that a plurality of bases are fixedly arranged on the lower wall of the bottom plate, and two first corner cylinders are fixedly arranged on one side of the upper wall of the bottom plate; the two first corner cylinders are fixedly arranged on one side of the upper wall of the bottom plate, two second corner cylinders corresponding to the first corner cylinders are fixedly arranged on the other side of the upper wall of the bottom plate, first corner positioning pins are arranged on the two first corner cylinders, second corner positioning pins are arranged on the two second corner cylinders, and two long-opening grooves and two short-opening grooves are formed in the bottom plate. A front frame assembly positioning device is arranged on the bottom plate, and three placing tables are fixedly arranged on the bottom plate. The invention has the advantages that parts and assemblies can be automatically limited, fool-proof and mistake-proof effects can be realized, workpieces can be prevented from deviating, multi-angle and multi-station linkage welding requirements of electric cabinets can be met by the aid of the overturning tables, unnecessary labor intensity of operators can be reduced by the aid of robot automation, and more time and energy can be saved to guarantee the efficiency and the quality of products.

Owner:FUJIAN JUNPENG COMM TECH

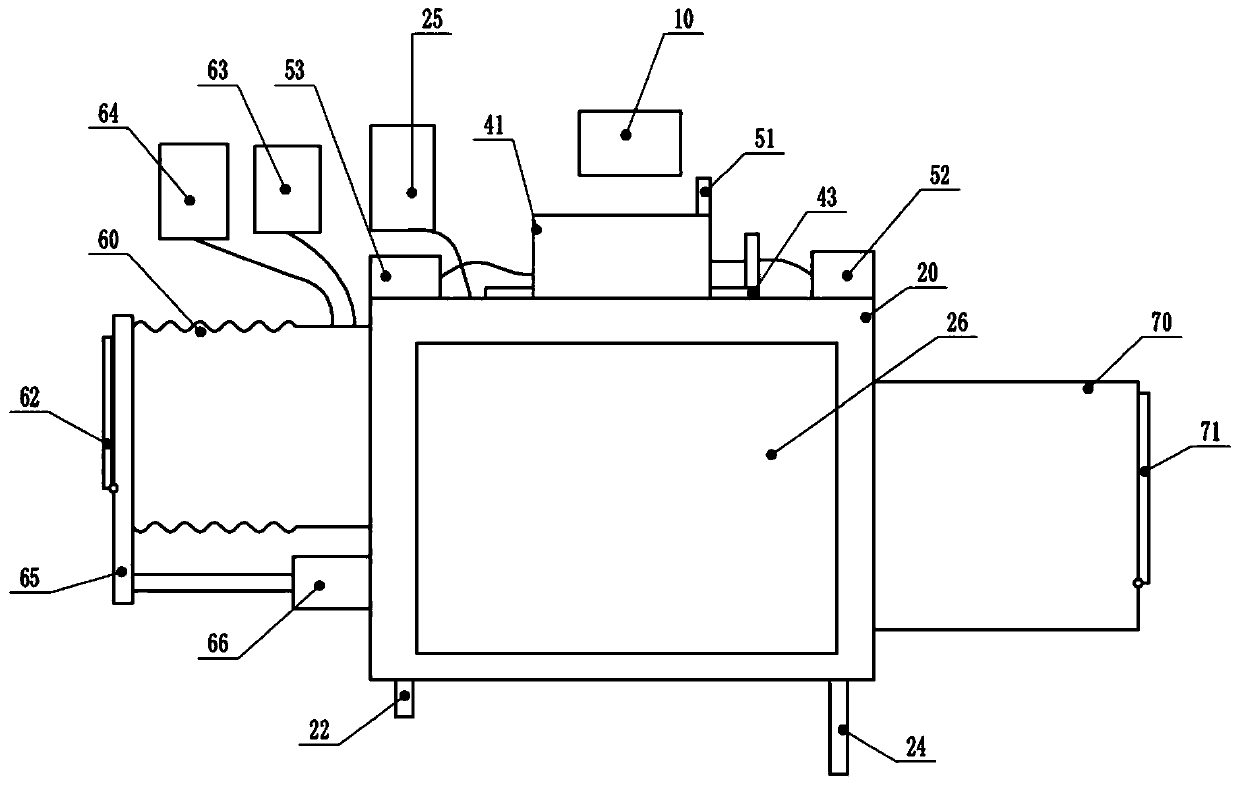

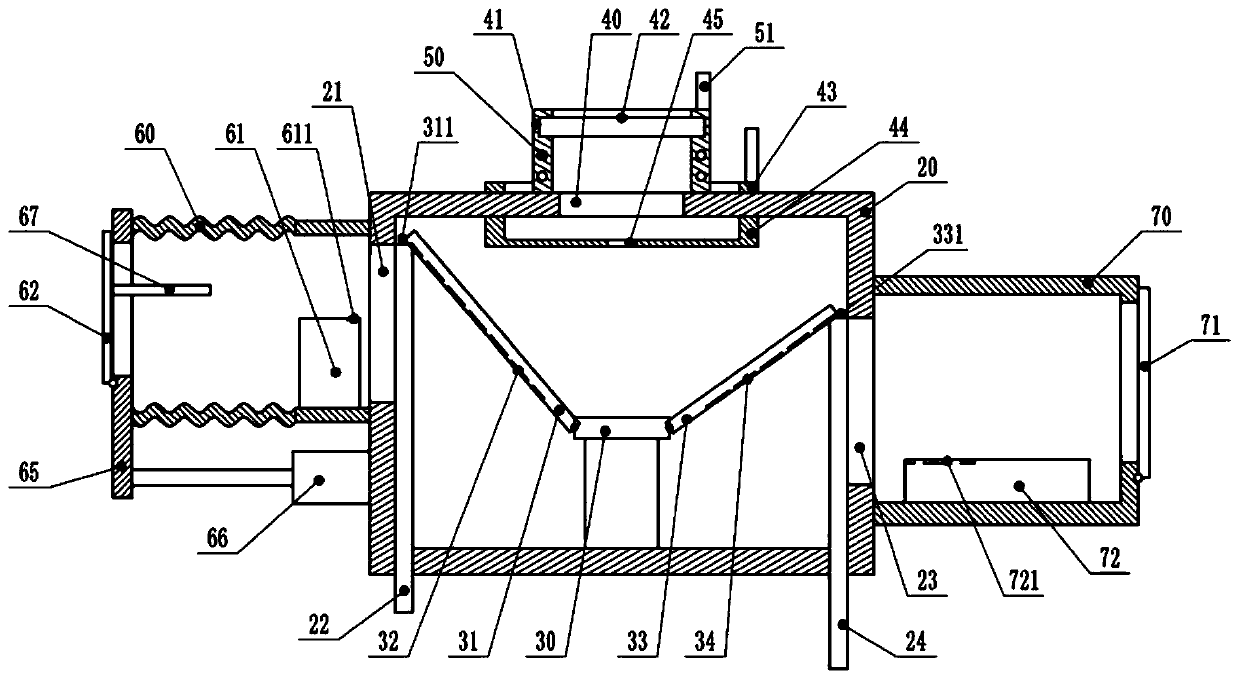

Intelligent laser welding device

ActiveCN109014574BGood welding performanceFast solderingLaser beam welding apparatusVacuum chamberLaser soldering

The application of the present invention belongs to the technical field of laser welding, and specifically discloses an intelligent laser welding device, including a laser head, a vacuum chamber, a workbench unit, and a laser transmission unit. The upper end of the vacuum chamber is provided with a transmission hole. The laser transmission unit is installed At the transmission hole of the vacuum chamber, the workbench unit is located in the vacuum chamber, and the laser beam emitted by the laser head is projected onto the workbench unit through the laser transmission unit to weld the workpiece. The other side of the vacuum chamber is provided with a discharge port, the sliding seal at the feed port is provided with a feed door, and the slide seal at the discharge port is provided with a discharge door. Compared with the prior art, the device greatly reduces the deposition of plasma plume on the laser transmission lens, thereby improving the quality of laser welding of the workpiece, effectively ensuring the vacuum environment, and simplifying the welding operation steps.

Owner:WENZHOU UNIV

Infrared detector and ceramic tube shell of built-in heater thereof

InactiveCN108046207AShort heating timeImprove heating efficiencySolid-state devicesFluid speed measurementHeating timeHeating efficiency

The invention provides a ceramic tube shell of a built-in heater of an infrared detector. The ceramic tube shell of the built-in heater comprises a ceramic tube shell body; and the ceramic tube shellof the built-in heater also comprises a heating device used for heating the ceramic tube shell body and melting the solder arranged between the ceramic tube shell body and a sealing cap, wherein the heating device is embedded inside the ceramic tube shell body. Compared with indirect heat transfer through external equipment in the prior art, the heating device of the ceramic tube shell provided bythe invention is embedded inside the ceramic tube shell body, and can directly heat the ceramic tube shell body; therefore, the heating time of the ceramic tube shell body is shortened, the heating efficiency of the solder is improved, the welding strength between the ceramic tube shell body and the sealing cap is increased, and the solid welding between the ceramic tube shell body and the sealing cap is realized.

Owner:IRAY TECH CO LTD

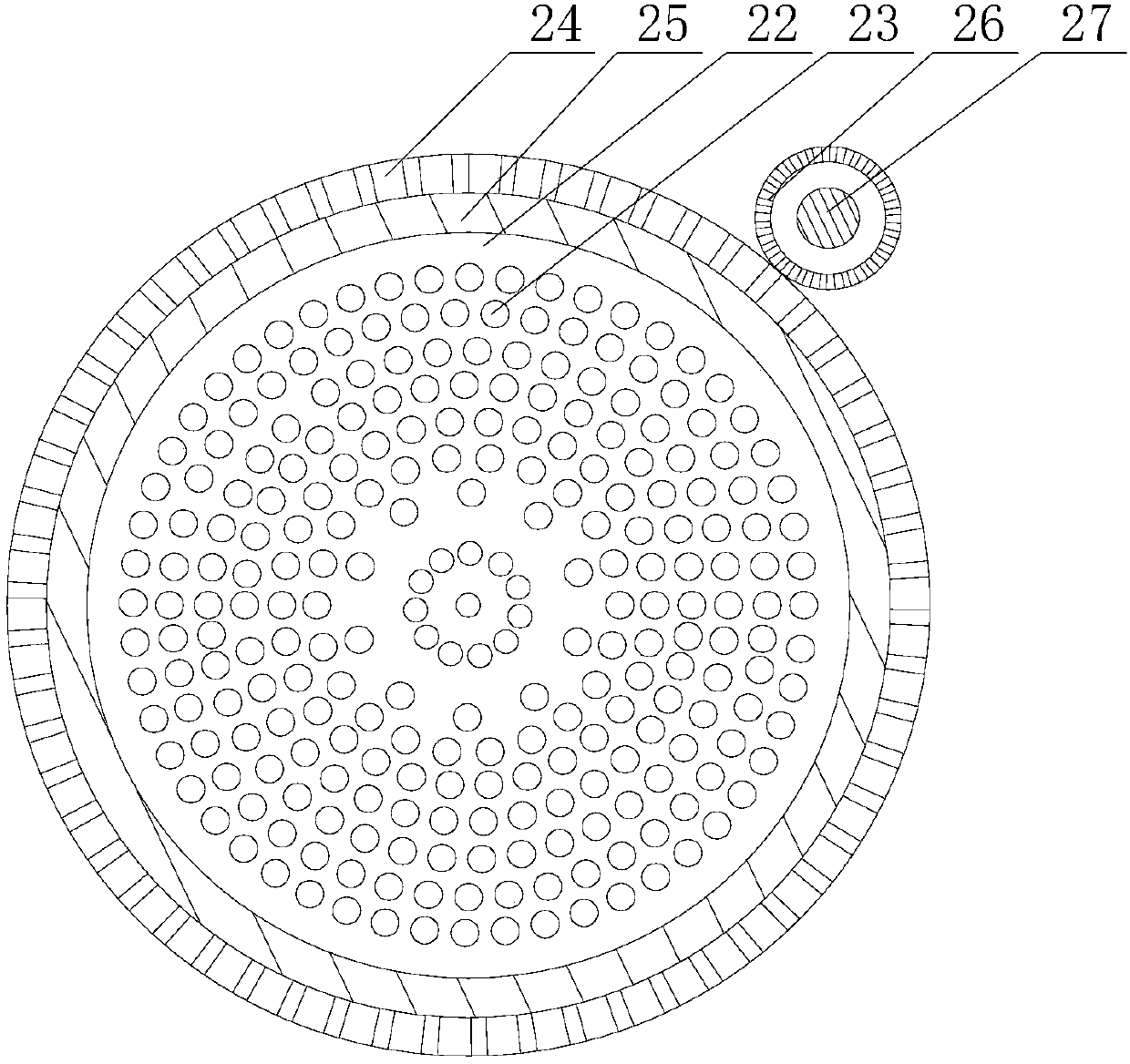

Reinforcement Cage Skeleton Forming Device for Pile Hole Foundation

The invention discloses a reinforcement cage forming device for a pile hole foundation. The reinforcement cage forming device comprises a base and a plurality of fixing components and is characterizedin that the middle of the base is provided with a guide rail, a first support plate is fixed at one end of the guide rail, a second support plate is slidably arranged at the other end of the guide rail, a first rotary disc is rotatably arranged on the first support plate and provided with a plurality of butt joint holes, the second support plate is rotatably provided with two coaxial bearings, agap exists between the two bearings, a second rotary disc opposite to the first rotary disc is rotatably arranged in the two bearings, the middle of the outer peripheral wall of the second rotary discis provided with a toothed belt, a motor is fixed on the second support plate, a gear is mounted at the output end of the motor, and the second rotary disc is provided with a plurality of fixing holes. The reinforcement cage forming device has the advantages that during winding, longitudinal reinforcing steel bars are constantly clamped and fixed by the fixing components, a welding effect betweenthe longitudinal reinforcing steel bars and transverse reinforcing steel bars is prevented from being affected by the fact that the longitudinal reinforcing steel bars turn in barrels, and the strength of a reinforcement cage is guaranteed.

Owner:宜昌市洋坤建筑有限公司

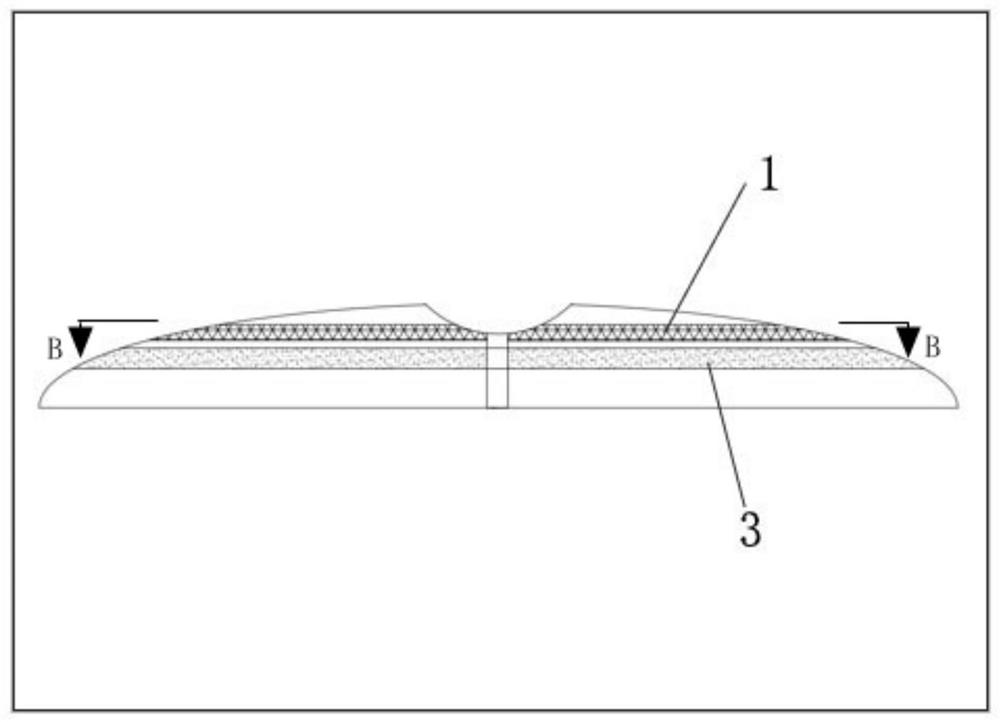

Fluorescent hot-melt gasket as well as preparation method and application thereof

ActiveCN113563662AConvenient laying and constructionImprove welding speedUnderground chambersSynthetic resin layered productsPolymer sciencePolyolefin

The invention belongs to the technical field of waterproof coiled material construction, and discloses a fluorescent hot-melt gasket as well as a preparation method and application thereof. The fluorescent hot-melt gasket is a fluorescent blending hot-melt gasket or a fluorescent interlayer hot-melt gasket; the fluorescent hot-melt gasket is prepared from the following components: polyolefin resin, an antioxidant, stearic acid amide and fluorescent master batch; and the fluorescent master batch comprises the following components: polyolefin resin, heavy calcium carbonate, a fluorescent agent and a coupling agent. Compared with a traditional hot-melt gasket, the fluorescent hot-melt gasket has the advantages that the welding speed can be remarkably increased, and the welding accuracy is guaranteed.

Owner:YUEYANG ORIENTAL YUHONG WATERPROOF TECH

Implementation method of steel frame forming device for pile hole foundation

ActiveCN107685127BAffect the welding effectGuaranteed StrengthMeshed-ring wire networkButt jointGear wheel

The invention discloses an implementation method of a reinforcement cage forming device for a pile hole foundation. The method includes: fixing a plurality of fixing components on a first rotary discand a second rotary disc to form two concentric and unidiameter circles; regulating the interval between a first support plate and a second support plate according to the axial length of a reinforcement cage, inserting a plurality of longitudinal reinforcing steel bars needed by the reinforcement cage into the fixing components on butt joint holes and mounting holes; starting a motor to allow themotor to drive a gear to mesh with a toothed belt, and allowing the second rotary disc to rotate inside two bearings, and allowing the first rotary disc to rotate synchronously; arranging transverse reinforcing steel bars on the reinforcement cage structure formed by the longitudinal reinforcing steel bars, and welding the connecting points of the transverse reinforcing steel bars and the longitudinal reinforcing steel bars until the transverse reinforcing steel bars completely wind the reinforcement cage structure. The method has the advantages that during the winding, the longitudinal reinforcing steel bars are constantly clamped and fixed by the fixing components, and the welding effect between the longitudinal reinforcing steel bars and the transverse reinforcing steel bars is prevented from being affected by the fact that the longitudinal reinforcing steel bars turn in barrels.

Owner:东莞市建安管桩有限公司

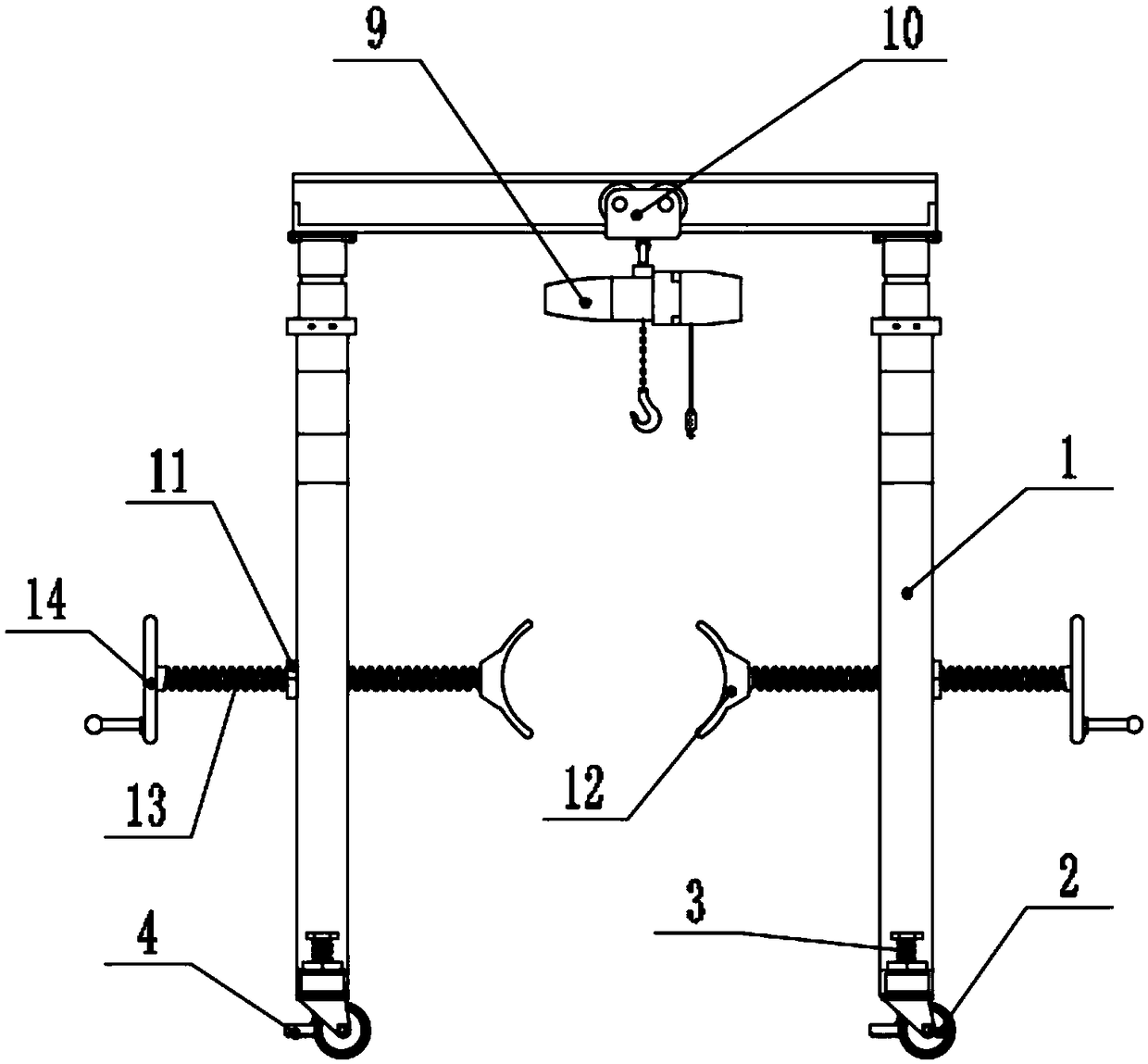

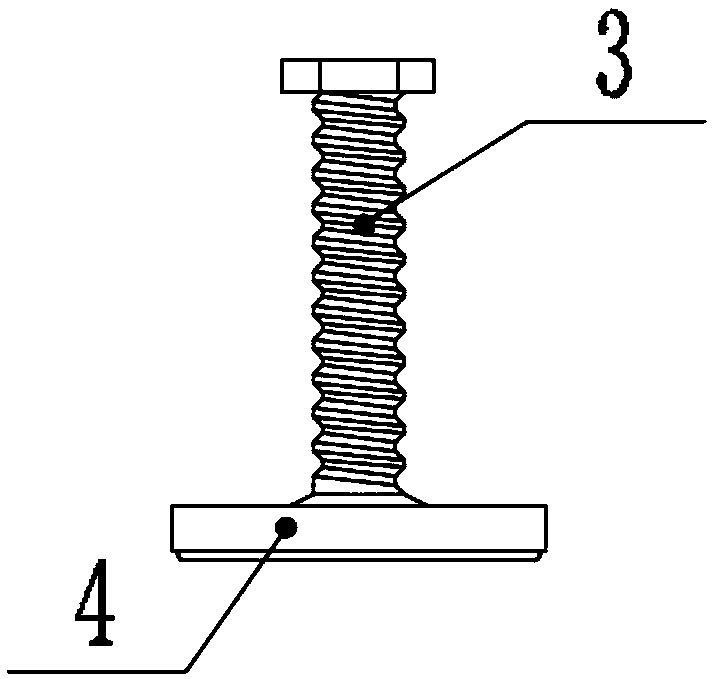

Portal frame device for welding steel pipe piles

InactiveCN108705226AEasy to fixAffect the welding effectWelding/cutting auxillary devicesAuxillary welding devicesArchitectural engineeringPortal frame

The invention provides a portal frame device for welding steel pipe piles. The portal frame device comprises flexible smoke discharging pipes and smoke discharging switches, wherein the tops of portalframe main bodies are I-shaped sliding rail structures; six universal wheels are mounted on the bottom end surfaces, the front end surfaces and the rear end surfaces of the portal frame main bodies;a total of eight fixed thread shafts are respectively mounted on the bottoms of two portal frame main bodies; the tops of the fixed thread shafts are hexagonal blocky structures; a total of eight fixed support plates are arranged; two ends of steel pipe piles in the hung state are fixed; the staff can conveniently and stably carry out the operation of welding the steel pipe piles in the later period; the influence on the welding accuracy of the steel pipe piles caused when the steel pipe piles shake back and forth in the portal frame main bodies can be avoided; with cooperation of the clampingthread shafts and hand wheels, the clamping diameters of two clamping blocks can be adjusted, so that the two clamping blocks are more capable of fixing the steel pipe piles with different diameter specifications; the fixing effect in the device can be improved.

Owner:梁玉燕

A welding device for sealing connection of pipelines

ActiveCN109434341BImprove practicalityImprove stabilityWelding/cutting auxillary devicesAuxillary welding devicesElectric machineryStructural engineering

Owner:纳木博(常州)智能装备有限公司

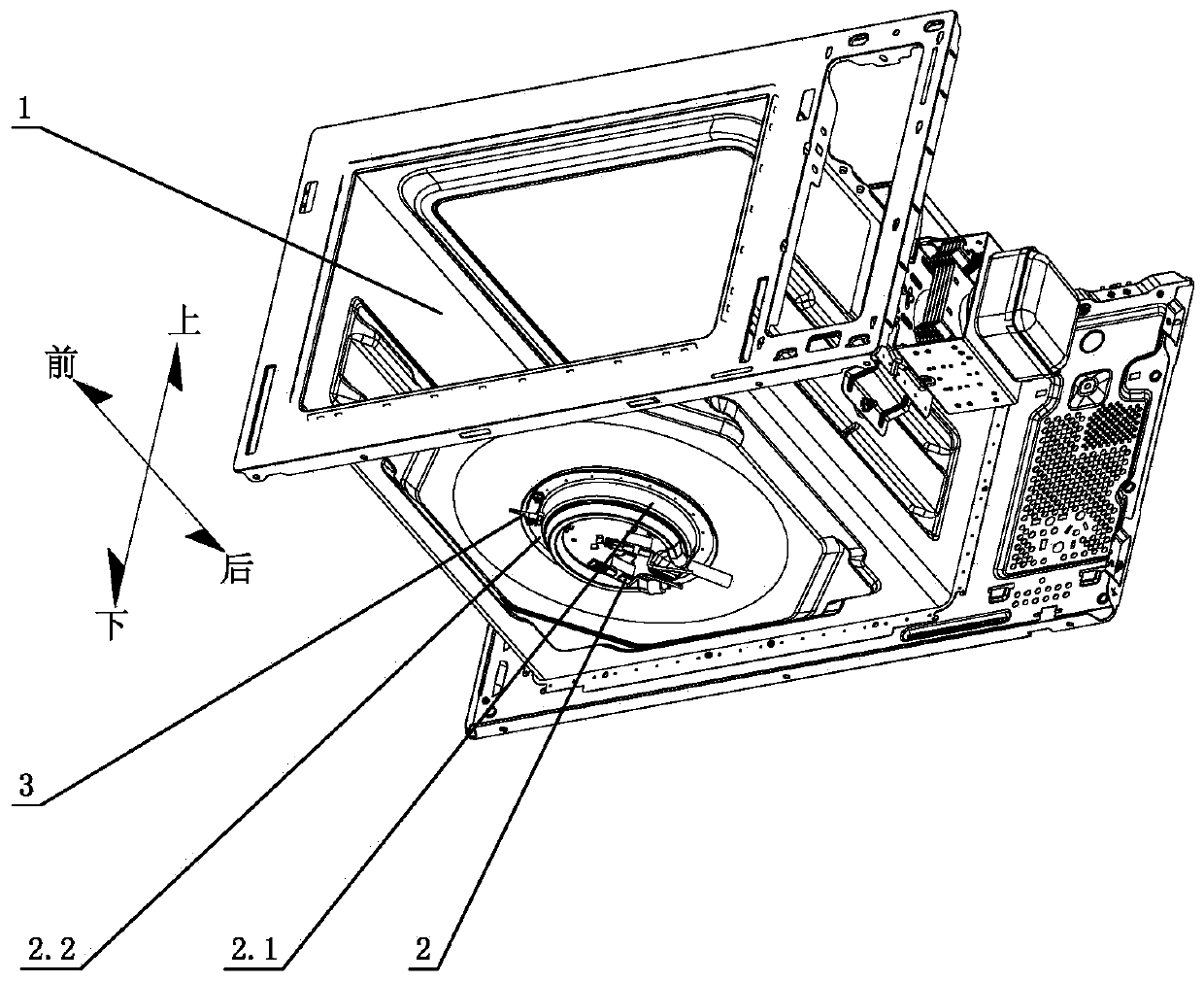

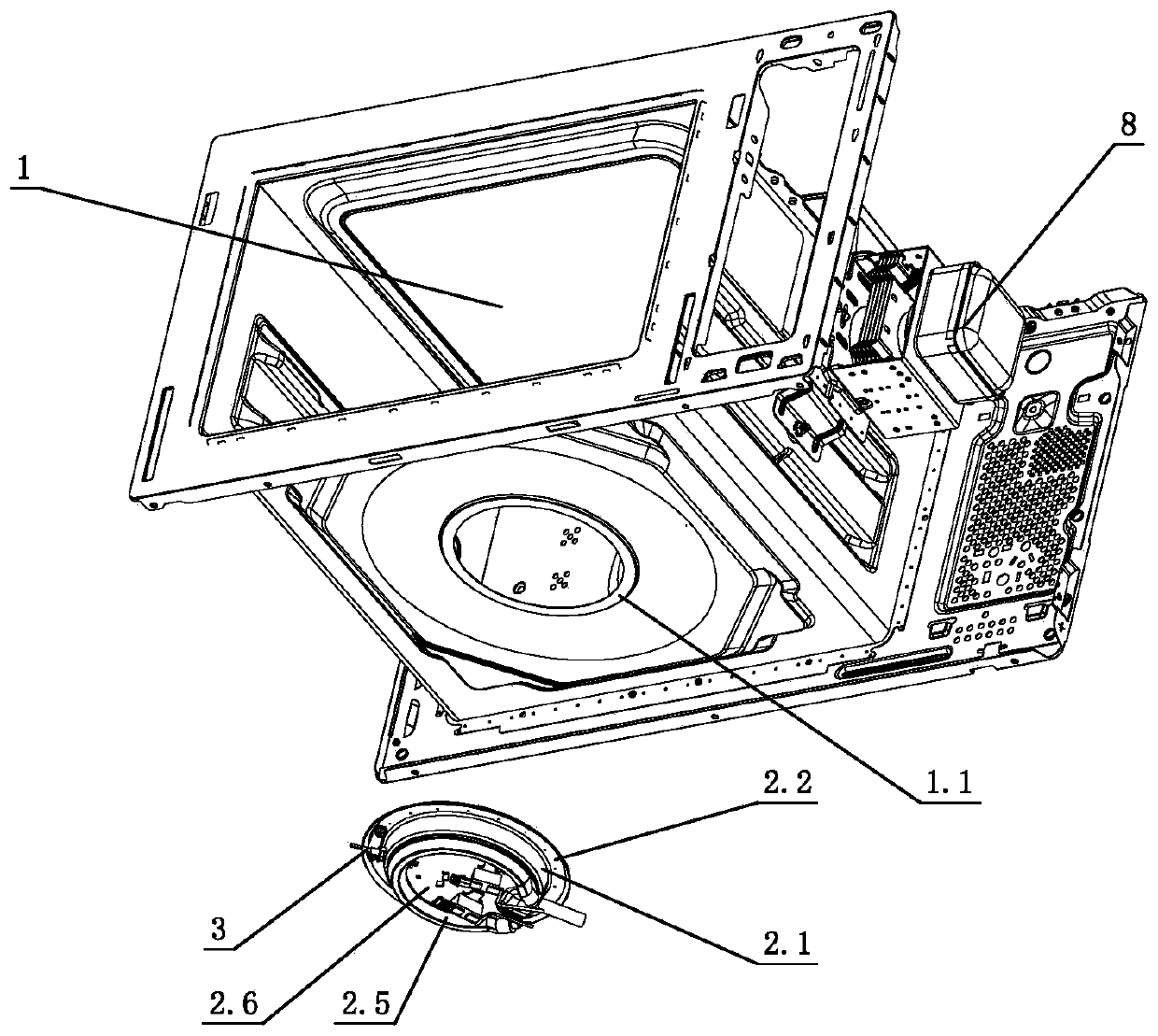

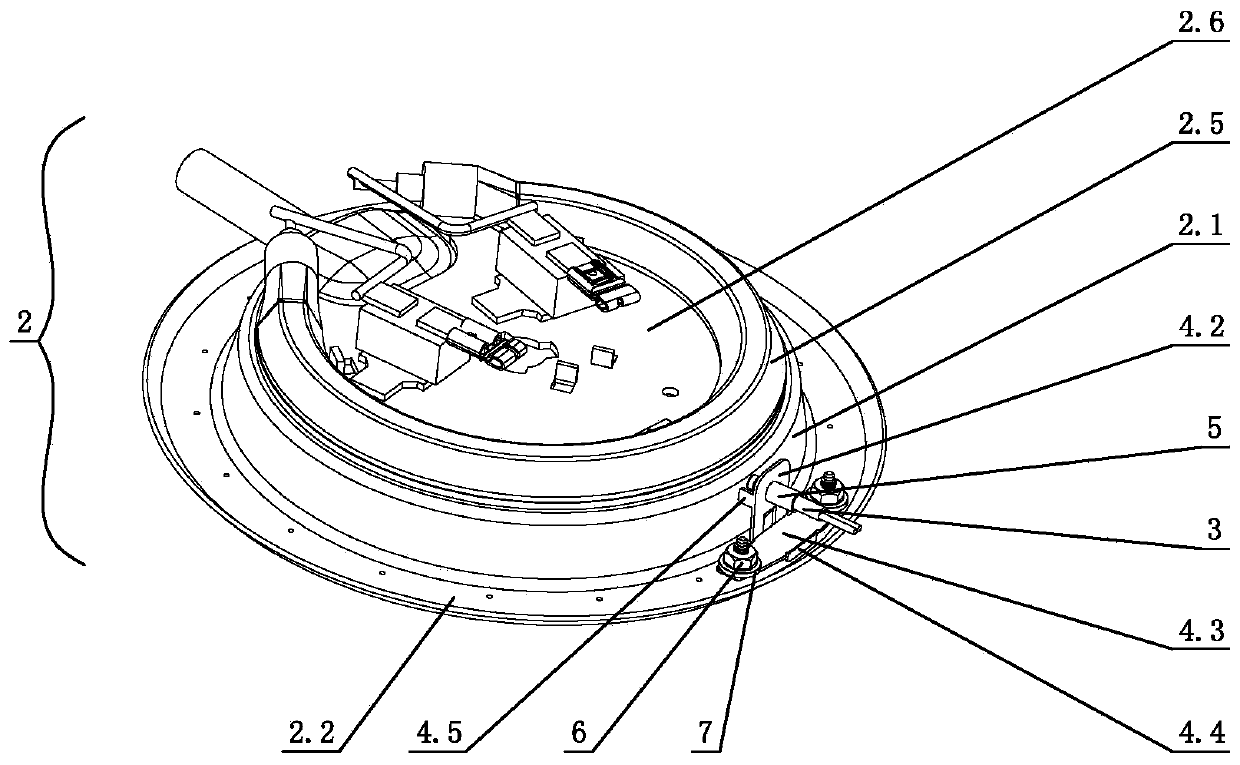

Temperature sensor fixation device for cooking evaporating tray of electric appliance

PendingCN110274701AShorten the timeIncreased sensitivityThermometer detailsThermometers using electric/magnetic elementsWater loadingBiomedical engineering

The invention relates to a temperature sensor fixation device for cooking an evaporating tray of an electric appliance. The fixation device comprises an evaporating tray assembly and a temperature sensor thereof. The evaporating tray assembly includes a water loading tray and a heat generating member connected to the water loading tray. A flange extends outwardly from the top of the peripheral wall of the water loading tray and is connected with the bottom wall of a cooking cavity; the temperature sensor and a limit fixing assembly are disposed outside the peripheral wall of the water loading tray; and the temperature sensor is fixed on the limit fixing assembly and one end of the temperature sensor is abutted against the outer surface of the peripheral wall of the water loading tray. Since the temperature sensor is in close contact with the outer surface of the peripheral wall of the water loading tray, the heat of the water loading tray can be transmitted to the temperature sensor effectively.

Owner:GUANGDONG GALANZ GRP CO LTD +1

A large-scale petrochemical pressure vessel head manufacturing polishing machine

ActiveCN113579977BPolished flatAffect the welding effectGrinding carriagesPolishing machinesPolishingMetallic materials

The invention relates to the technical field of metal material polishing, and is a large-scale petrochemical pressure vessel head manufacturing polishing machine, which includes a base, an auxiliary unit and a polishing unit. The base is provided with an auxiliary unit and a polishing unit, and the auxiliary unit is located in front of the polishing unit above. The present invention can solve the existing problems: polishing the welded end face of the head with a polishing block held by the worker is prone to the problem of unevenness of the welded end face of the head, and as a pressure vessel, the unevenness of the welded end face will lead to poor sealing performance of the weld, Therefore, the possibility of leakage of petrochemical products is increased, and the welding end face of the head is polished by the workers holding the polishing block. The polishing efficiency is low, which will affect the production efficiency of the pressure vessel, and a large amount of metal will be produced during the polishing process. Dust, metal dust will cause harm to workers' health.

Owner:烟台佑利技术有限公司

An auxiliary device for welding and assembly of automobile parts that can be rotated and adjusted

ActiveCN109500536BStable welding operationGuaranteed welding accuracyWelding/cutting auxillary devicesAuxillary welding devicesSupport planeWelding

Owner:柳州市银瑞车业有限公司

All-enclosuring type electric melting pipe piece and manufacture method

InactiveCN101025245BSolve the impact shift pull out problemSolve the problem of welding effectPipe connection arrangementsElectricityElectrical resistance and conductance

The invention discloses a full contained electric melting pipe and the manufacturing method thereof, adopting secondary injection moulding process, firstly pouring a parison of a certain thickness on a core stick, then fixing electrode column and welding electrode column and copper wire on the injection-moulded parison, then coiling and feeding the wired parison into a mould to pour to form an outer layer of a certain thickness, merging the parison and the outer layer into an organic whole, and fully containing the copper wire in the middle of the pipe, and finally after the finished product cools, adopting a core drawer to demould a complete pipe from the core stick. And the electric heating wire is fully contained inside the pipe, solving the problem of influencing welding effect by oxidizing of exposed resistance wire, and the inside surface of the pipe is smooth and has no traces of turning tool, thus unable to influence the welding effect.

Owner:潘刚

Automobile part welding auxiliary device capable of performing rotational adjustment

ActiveCN109500536AStable welding operationGuaranteed welding accuracyWelding/cutting auxillary devicesAuxillary welding devicesSupport planeSmoke

The invention provides an automobile part welding auxiliary device capable of performing rotational adjustment. The automobile part welding auxiliary device capable of performing rotational adjustmentcomprises a ventilation duct and a smoke exhaust fan; the bottom of a supporting frame is installed at the left end of the top end surface of a base, and a movable supporting frame is installed at the right end of the top end surface of the base; two positioning bolts are both mounted on the movable supporting frame; two bearing plates are each of a circular plate-like structure, and the two bearing plates are separately mounted at the top ends of the end surfaces of the inner sides of the supporting frame and the movable supporting frame; and locating grooves are formed in the bottoms of theend surfaces of the inner sides of the bearing plates. The fixation of the left and right ends of automobile parts need to be welded is facilitated, so that the automobile parts are more stable during the welding operation, and the welding precision of the automobile parts is guaranteed; and an adjustment plate and bearings are arranged, and the automobile parts in the fixed state are rotated andadjusted, so that the welding angle of the automobile parts is more in line with the welding requirements of workers, and the welding quality of the automobile parts is improved.

Owner:柳州市银瑞车业有限公司

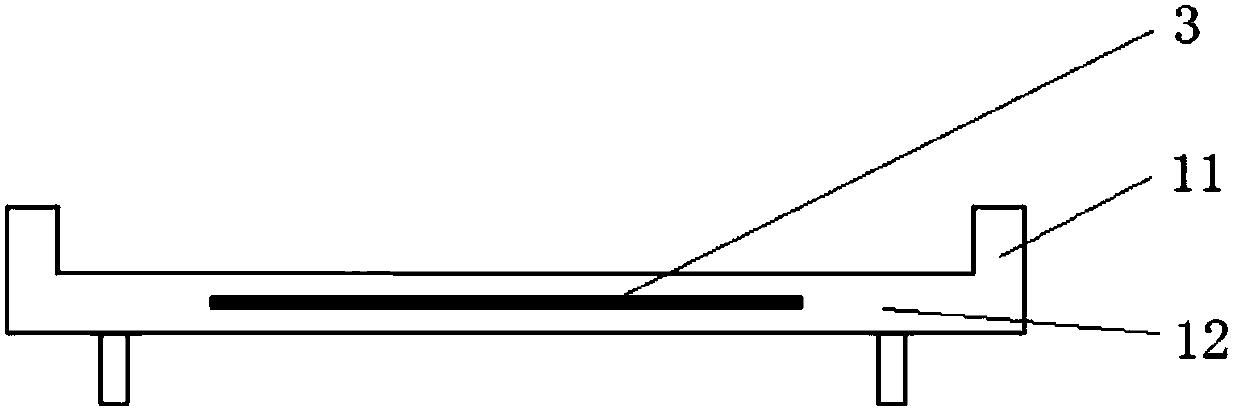

Positioning tool for forklift pedal assembly assembling and welding

PendingCN108747156AHigh precisionImprove efficiencyWelding/cutting auxillary devicesAuxillary welding devicesEngineeringMechanical engineering

The invention discloses a positioning tool for forklift pedal assembly assembling and welding. A forklift pedal assembly comprises an outer wall plate and a pedal; the positioning tool comprises a support assembly, a positioning assembly arranged on the support assembly, and an adjusting assembly arranged on the upper part of the support assembly; the support assembly comprises two vertically placed irregular plates in parallel; the adjusting assembly comprises an installation plate connected to the upper parts of the two irregular plates, an adjusting rod penetrating through the installationplate, a limiting part fixedly arranged on the adjusting rod, and an absorbing part arranged at one end, close to the pedal, of the adjusting rod. According to the positioning tool for forklift pedalassembly assembling and welding provided by the invention, the positioning tool is utilized for positioning various parts such as the outer wall plate and the pedal of the forklift pedal assembly, andoriginal manual scribing, assembling and welding are replaced, so that the assembling and welding accuracy and the assembling and welding efficiency of the forklift pedal assembly are greatly improved.

Owner:ANHUI HELI CO LTD

Butt welding machine for constructional engineering

InactiveCN112872564AEasy accessAvoid burnsResistance welding apparatusStructural engineeringManufacturing engineering

The invention provides a butt welding machine for constructional engineering. The butt welding machine comprises a supporting box, an L-shaped frame and a welding device, wherein the bottom of the L-shaped frame is fixed to the top of the supporting box; and the top of the welding device is arranged on the inner wall of the L-shaped frame. According to the butt welding machine for the constructional engineering, by arranging an air pump, a nozzle and other devices, after workpieces are welded, the workpieces can be rapidly cooled, workers can take the workpieces conveniently, scalding is avoided, potential safety hazards are reduced, the workpieces of the next batch can be rapidly placed, the welding efficiency is improved, due to the arrangement of a cooling box, a treatment box and other devices, the cooling box enables the temperature of air used for cooling to be lower, so that the cooling performance of the machine is enhanced, the workpieces are cooled more rapidly, the treatment box filters the air, dust impurities in the air are removed, and dust is prevented from entering into weld joints to affect the welding effect of the workpieces.

Owner:李天恩

Intelligent welding device for steel-plastic composite pipe

PendingCN113733578AAffect the welding effectImprove cooling effectTubular articlesManufacturing engineeringSlide plate

The invention relates to the technical field of steel-plastic composite pipe machining equipment, and particularly discloses an intelligent welding device for a steel-plastic composite pipe. The device comprises a main machine and a clamp, and the clamp is electrically connected with the main machine through an electric wire. The clamp comprises two semicircular columnar clamping sleeves which are oppositely arranged. An electromagnetic heating component is fixed on each clamping sleeve, a cavity is formed in each electromagnetic heating component, and a sliding plate and a telescopic piece are arranged in each semicircular cylindrical cavity. The telescopic pieces are straightened when heated and are bent when cooled. A one-way water inlet valve and a one-way water outlet valve are arranged on each semicircular cylindrical cavity, and the inner side wall of each electromagnetic heating component is made of a conductor material. The device aims to solve the problem that after the welding of the steel-plastic composite pipe is completed, natural cooling needs to consume a large amount of time, so that the working efficiency is low.

Owner:贵州大愚智水智能科技有限公司

Soldering jig and laser soldering method

ActiveCN104625299BAffect the welding effectWelding/cutting auxillary devicesAuxillary welding devicesHeat transmissionHigh energy

The invention relates to the field of laser tin solder, and provides a tin soldering jig. Heat conduction portions are arranged on the tin solder jig at intervals and are made of heat conduction materials, when the tin soldering jig is arranged on a soldering pad, the heat conduction portions make contact with to-be-soldered portions of a to-be-soldered product and compress the to-be-soldered portions and tin materials on the soldering pad, laser heats the heat conduction portions in an illumination mode and transmits heat to the to-be-soldered portions and the tin materials making contact with the to-be-soldered portions, and the tin materials are melted. The laser does not directly heat the tin materials, heat is transmitted to the tin materials in a heat transmission mode, the to-be-soldered product is welded, and high energy generated when the laser directly irradiates the product is prevented from affecting the welding effect of other to-be-soldered portions. The embodiment of the invention further provides a laser tin soldering method.

Owner:HANS LASER TECH IND GRP CO LTD

A kind of application method of clamping component for prefabrication of reinforcement cage of building foundation

The invention discloses an application method of a clamping assembly for prefabricating of a reinforcement cage of a building foundation. The application method comprises the following steps that twooppositely-arranged cylinder bodies are made to act on the two ends of a longitudinal bar correspondingly; one ends of the cylinder bodies penetrate through mounting holes in rotating discs, and nutsare screwed to enable the cylinder bodies to be fastened on the rotating discs; the ends of the longitudinal bar and the axes of the cylinder bodies are aligned till the ends of the longitudinal bar are inserted into the cylinder bodies; pressing rings are rotated and made to move in the direction close to clamping rings along the axes of the cylinder bodies, and contacting blocks arranged obliquely on pressing blocks are made to make contact with the inner side walls of annular bulges; the bulges squeeze the contact blocks to enable the inner side walls of the pressing blocks to get close tothe axes of the cylinder bodies, and thus squeezing between the inner side walls of the pressing blocks and the outer circumferential wall of the longitudinal bar is achieved; in this way, repeated operation is conducted on multiple residual longitudinal bars; and when the two ends of the multiple longitudinal bars are both fixed, transverse bars are wound on the outer wall of a reinforcement skeleton formed by the multiple longitudinal bars according to the spiral track, and the contact points of the transverse bars and the longitudinal bars are welded.

Owner:振中建设集团有限公司

A prefabricated columnar steel frame structure for high-rise building construction

ActiveCN107755604BAffect the welding effectGuaranteed StrengthWire networkButt jointArchitectural engineering

The invention discloses a columnar steel bar framework prefabricating device for high-rise building construction. The columnar steel bar framework prefabricating device for high-rise building construction comprises a base; a guide rail is arranged on the middle portion of the base; a first supporting plate is fixed to one end of the guide rail; a second supporting plate is arranged at the other end of the guide rail in a sliding manner; a first rotating disk is rotationally arranged on the first supporting plate, and is provided with a plurality of butt joint holes; two coaxial bearings are rotationally arranged on the second supporting plate, and a gap is reserved between the two bearings; a second rotating disk opposite to the first rotating disk is rotationally arranged in the two bearings; a tooth belt is arranged on the middle portion of the peripheral wall of the outer circle of the second rotating disk; a motor is fixed to the second supporting plate; a gear is installed at theoutput end of the motor; a plurality of fixing holes are formed in the second rotating disk; and a plurality of fixing assemblies are further included. In the winding process, longitudinal steel barsare clamped and fixed by the fixing assemblies all the time, and it is avoided that the longitudinal steel bars overturn in a barrel body, and consequently the welding effect between the longitudinalsteel bars and transverse steel bars is affected, so that the strength of a steel bar cage can be guaranteed.

Owner:陕西鑫业钢结构工程有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com