All-enclosuring type electric melting pipe piece and manufacture method

An electrofusion pipe fittings, all-inclusive technology, applied in the direction of pipes/pipe joints/pipes, pipe connection layout, mechanical equipment, etc., can solve problems such as the inability to obtain stable and high quality, the inability to achieve fully automatic production, and the rough inner surface of the pipe fittings. , to achieve the effect of high quality, smooth inner surface and excluding the influence of human factors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

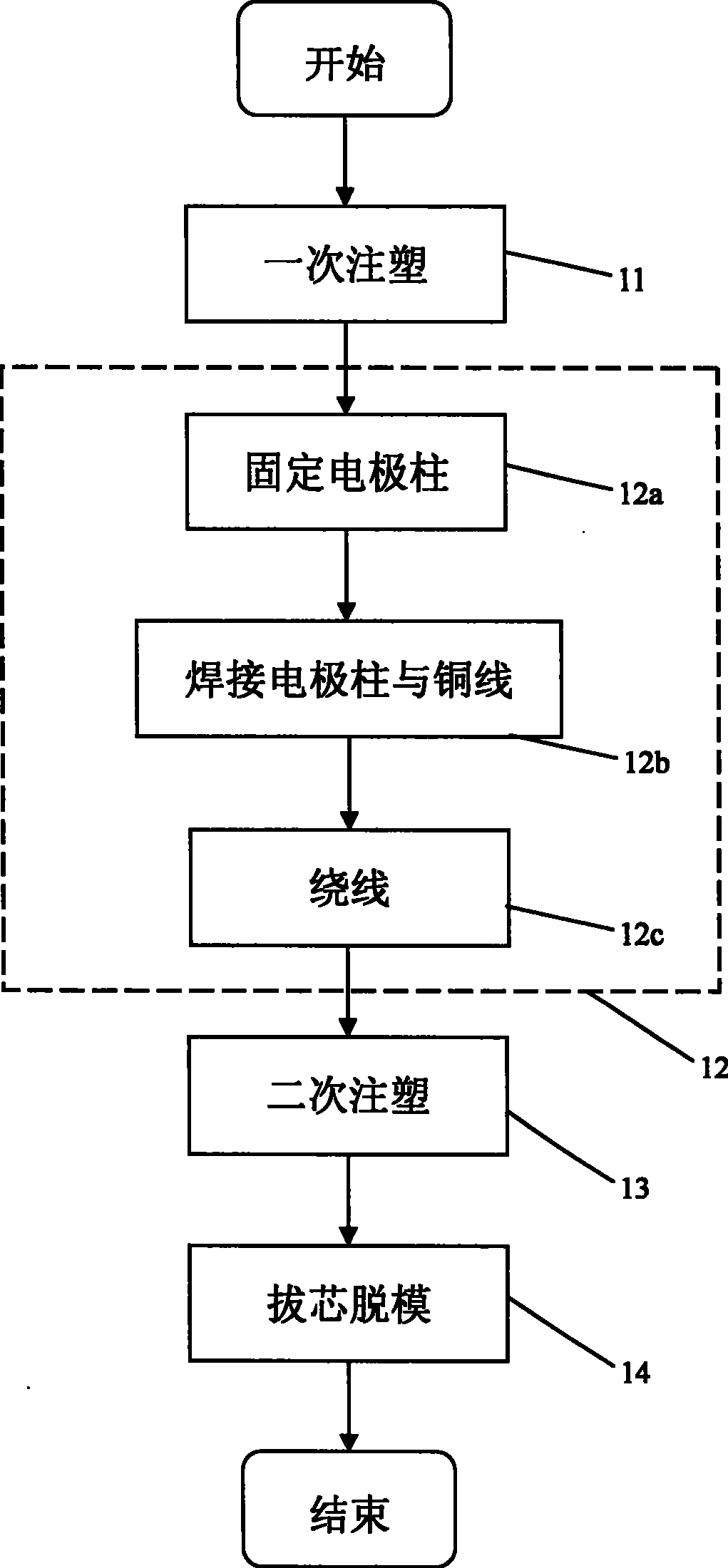

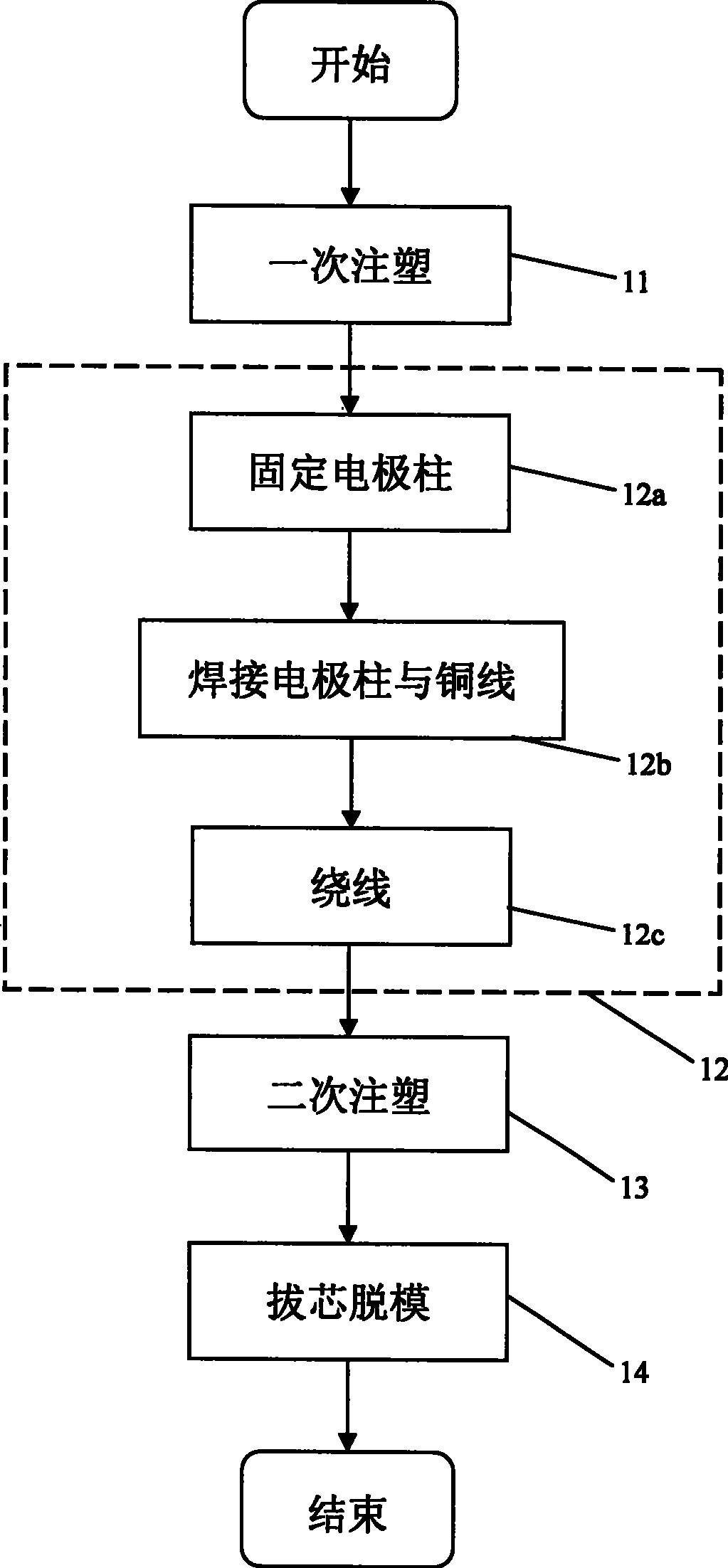

[0024] Such as figure 1 Shown is a flow chart of a manufacturing method of an all-inclusive electrofusion pipe fitting in the present invention. Including the following steps:

[0025] One-time injection molding 11: casting a shape blank with a certain thickness on the mandrel;

[0026] Integrated wiring 12: fix the electrode column on the injection molded blank, weld the electrode column and copper wire, and then wind the wire;

[0027] Secondary injection molding 13: Send the wired parison into the mold to cast an outer layer with a certain thickness, the parison and the outer layer are integrated, and the copper wire is completely contained in the middle of the pipe fitting; and

[0028] Core pulling and demoulding 14: After the finished product is cooled, use a core pulling device to demould the complete pipe from the mandrel.

[0029] The all-inclusive electrofusion pipe fittings produced by this method not only ensure the concealment of the copper wire, are not oxidiz...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com