Patents

Literature

319 results about "Tool marks" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

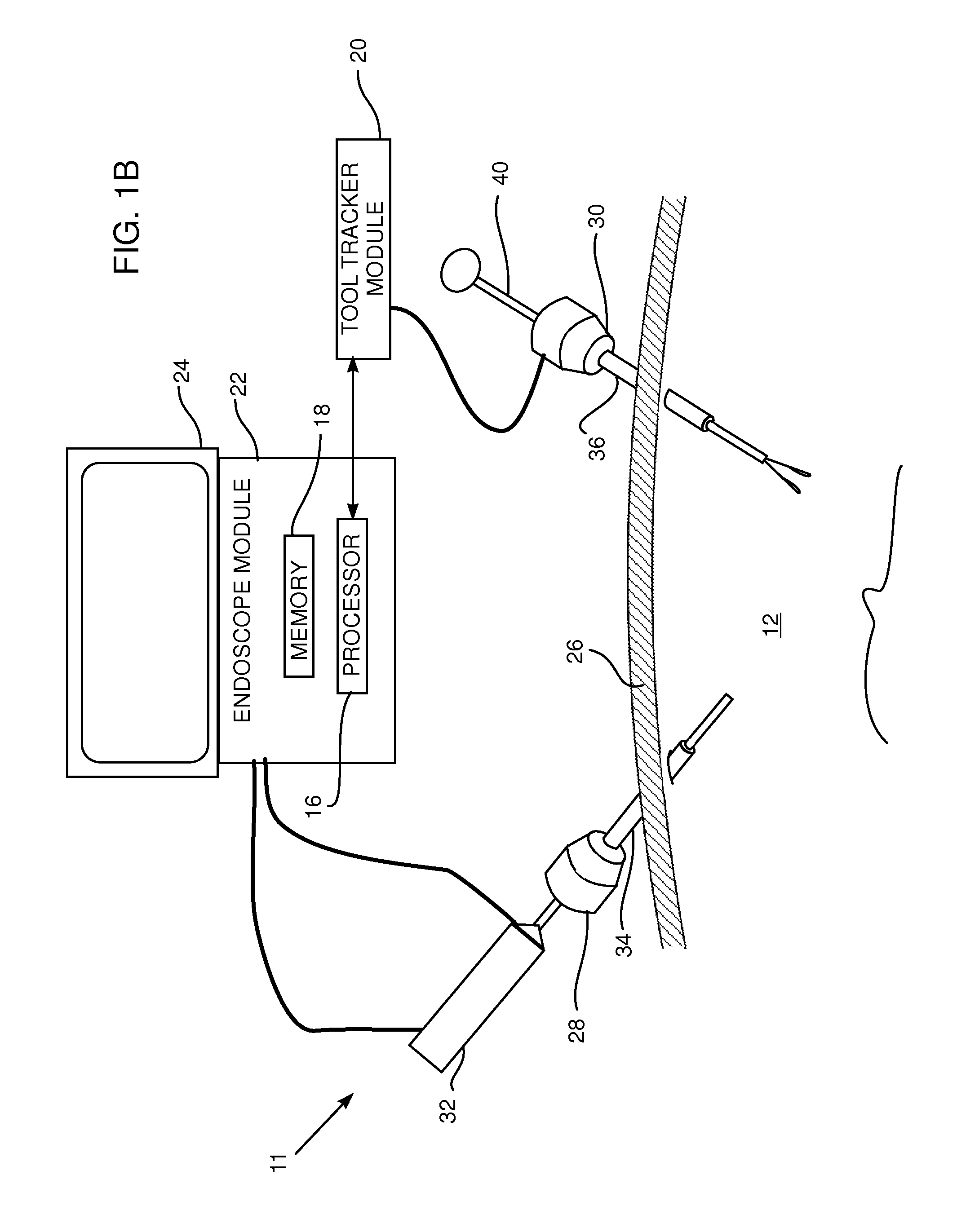

Automatic tool marking

Owner:GYRUS ACMI INC (D B A OLYMPUS SURGICAL TECH AMERICA)

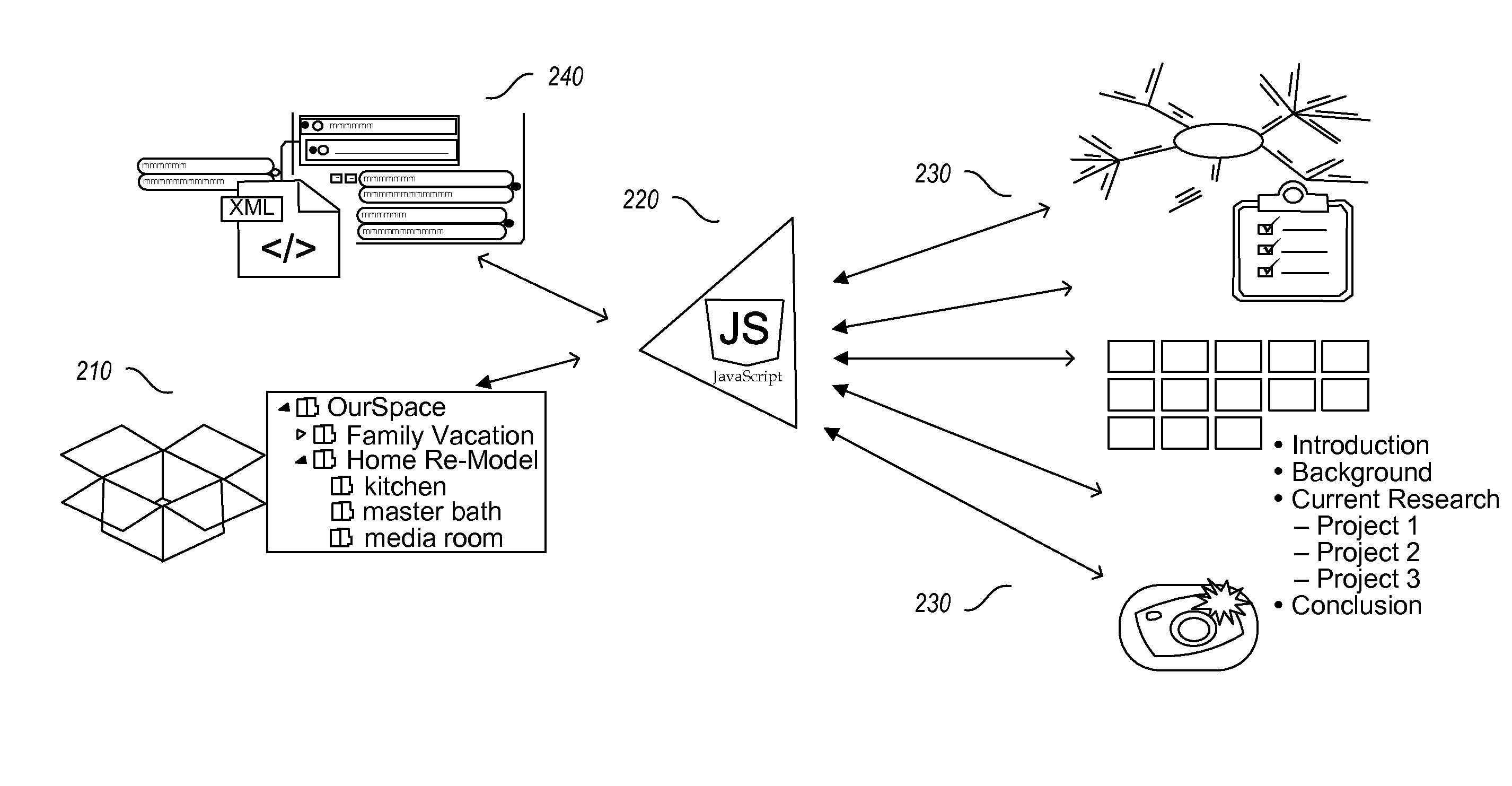

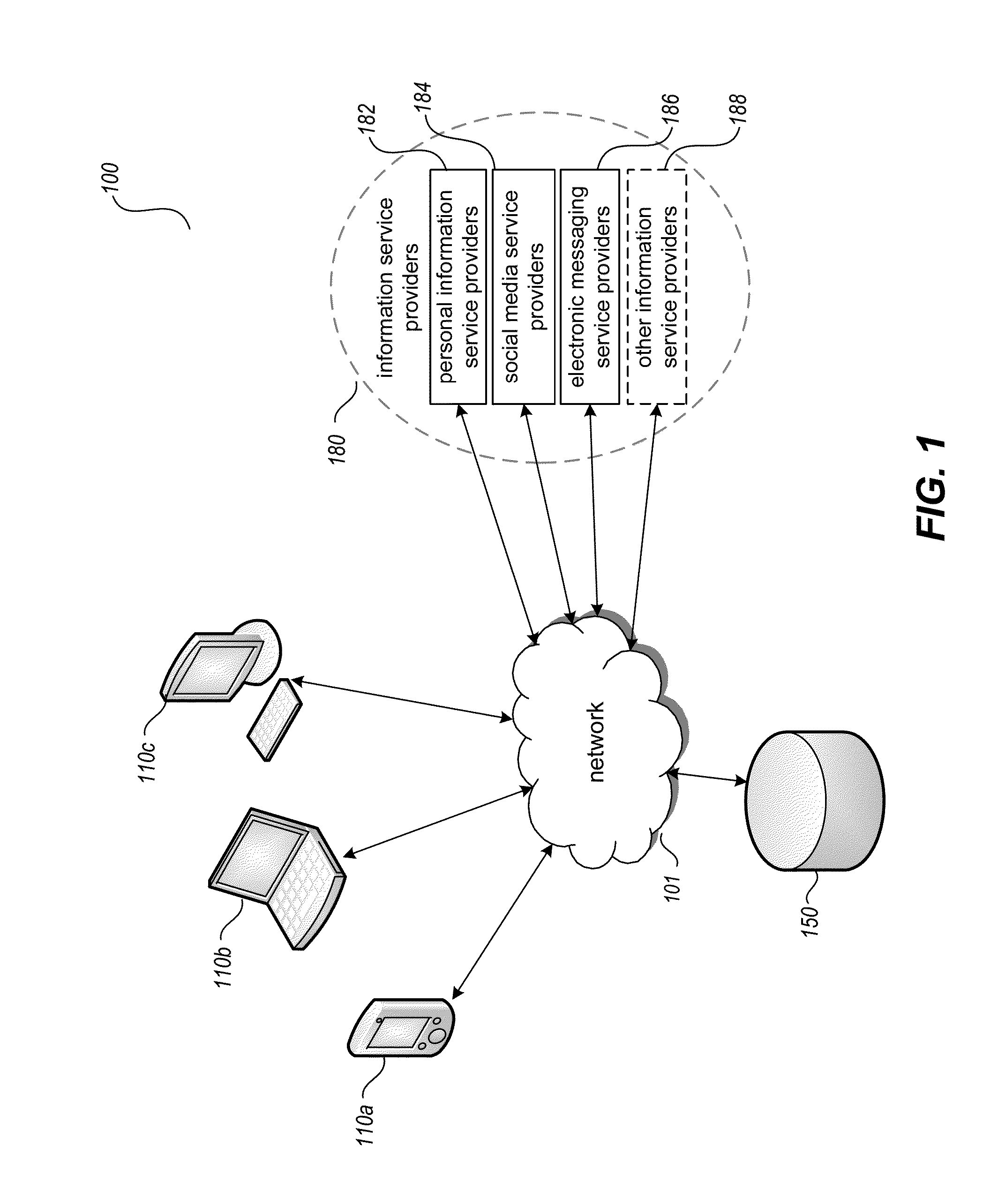

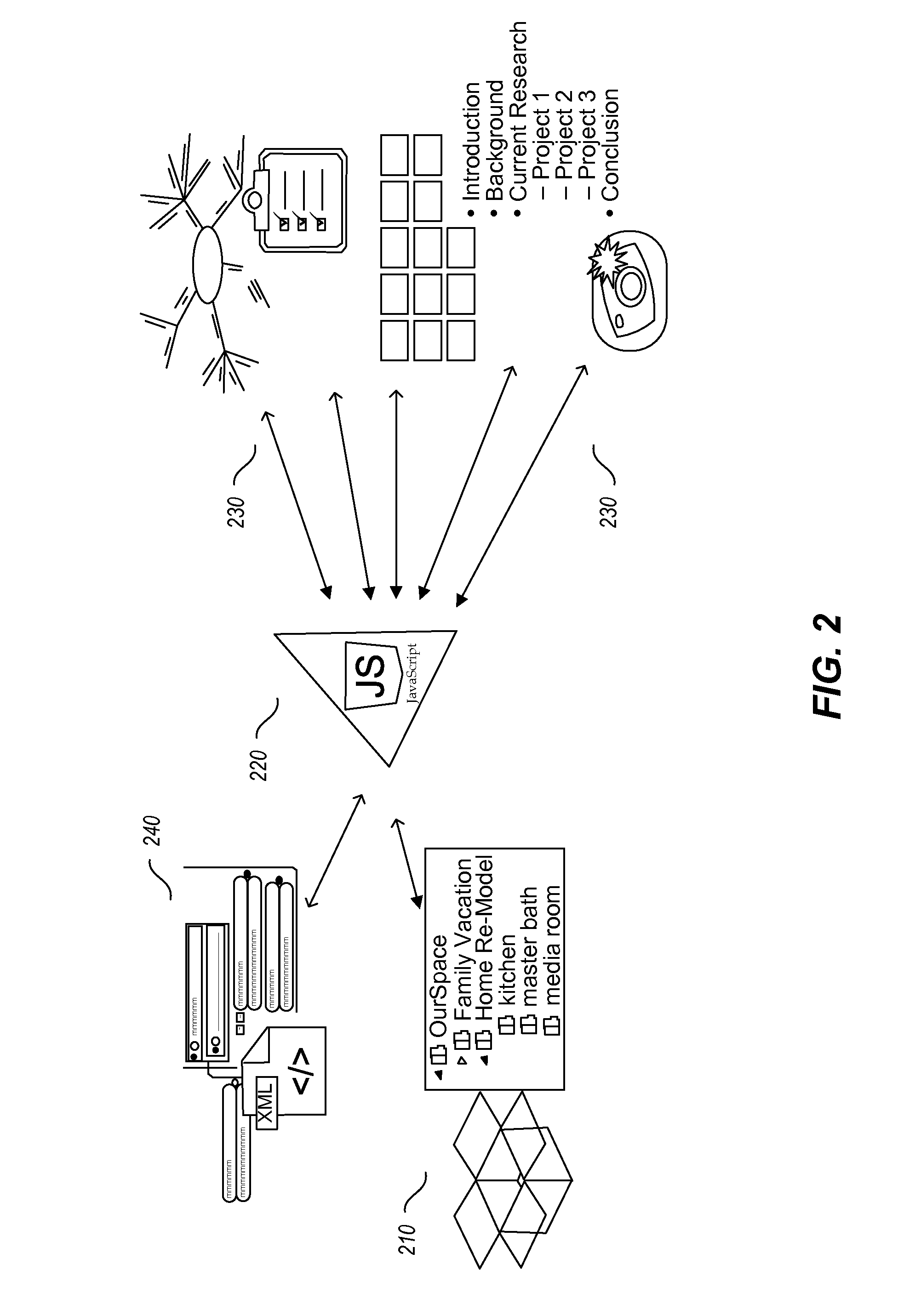

Aggregated information access and control using a personal unifying taxonomy

Techniques are described for providing users with aggregate access to and control over information from multiple storing applications and information services, and for enabling developers to integrate such aggregate access and control into applications. Textual markup language may represent the structure of grouping items. Examples using XML and XooML (“Cross Tool Mark-up Language,” an XML schema) are provided, such that users need not change the storing application or service in order for those users' informational structures to be represented.

Owner:JONES WILLIAM P

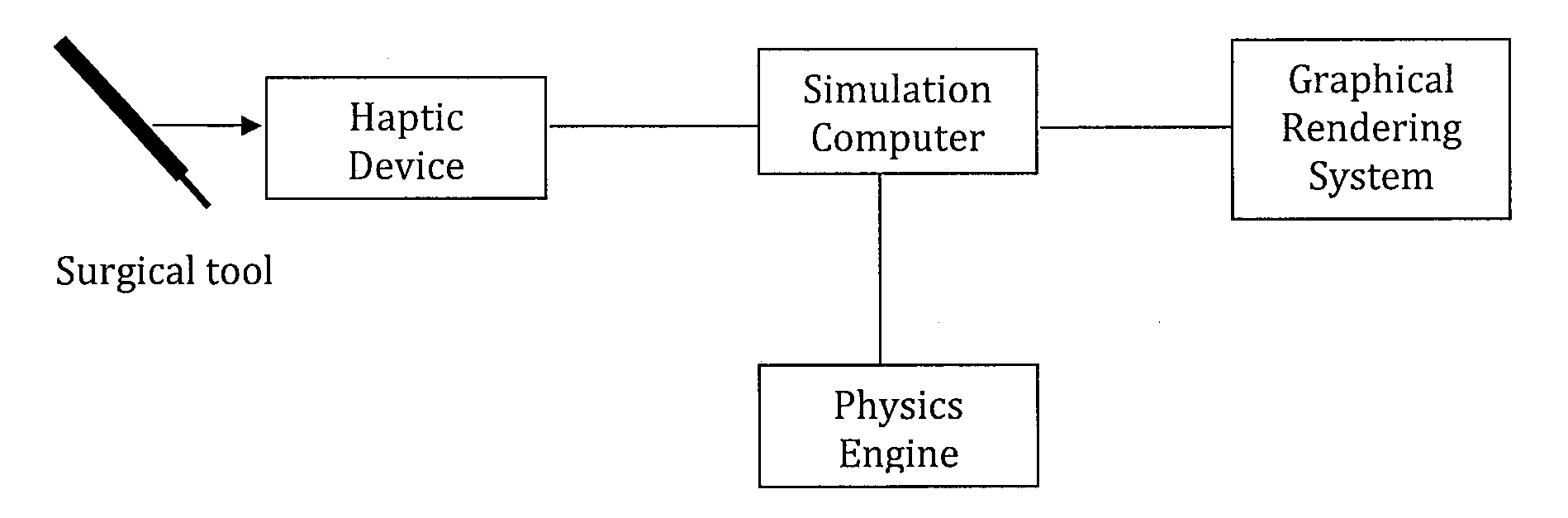

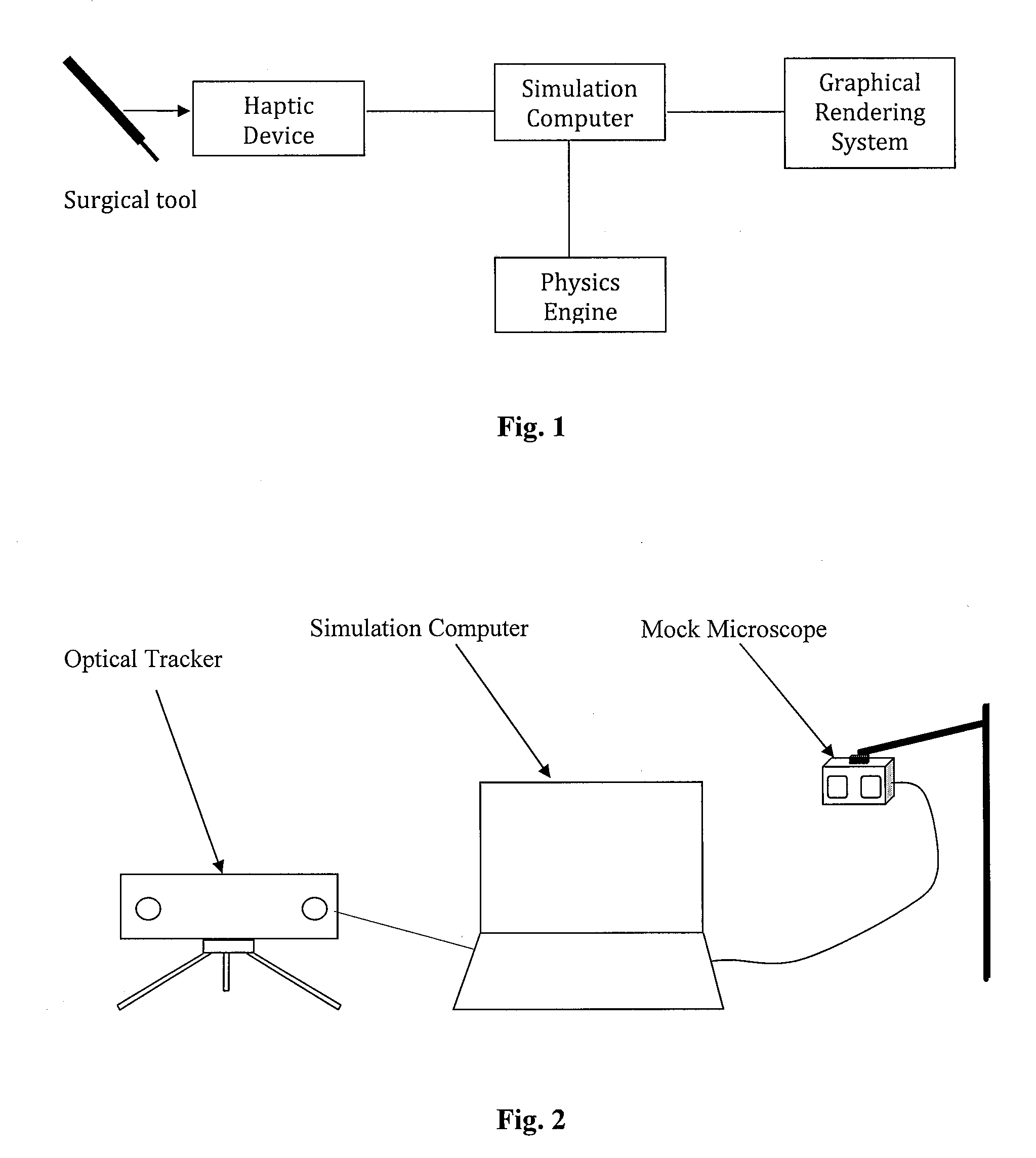

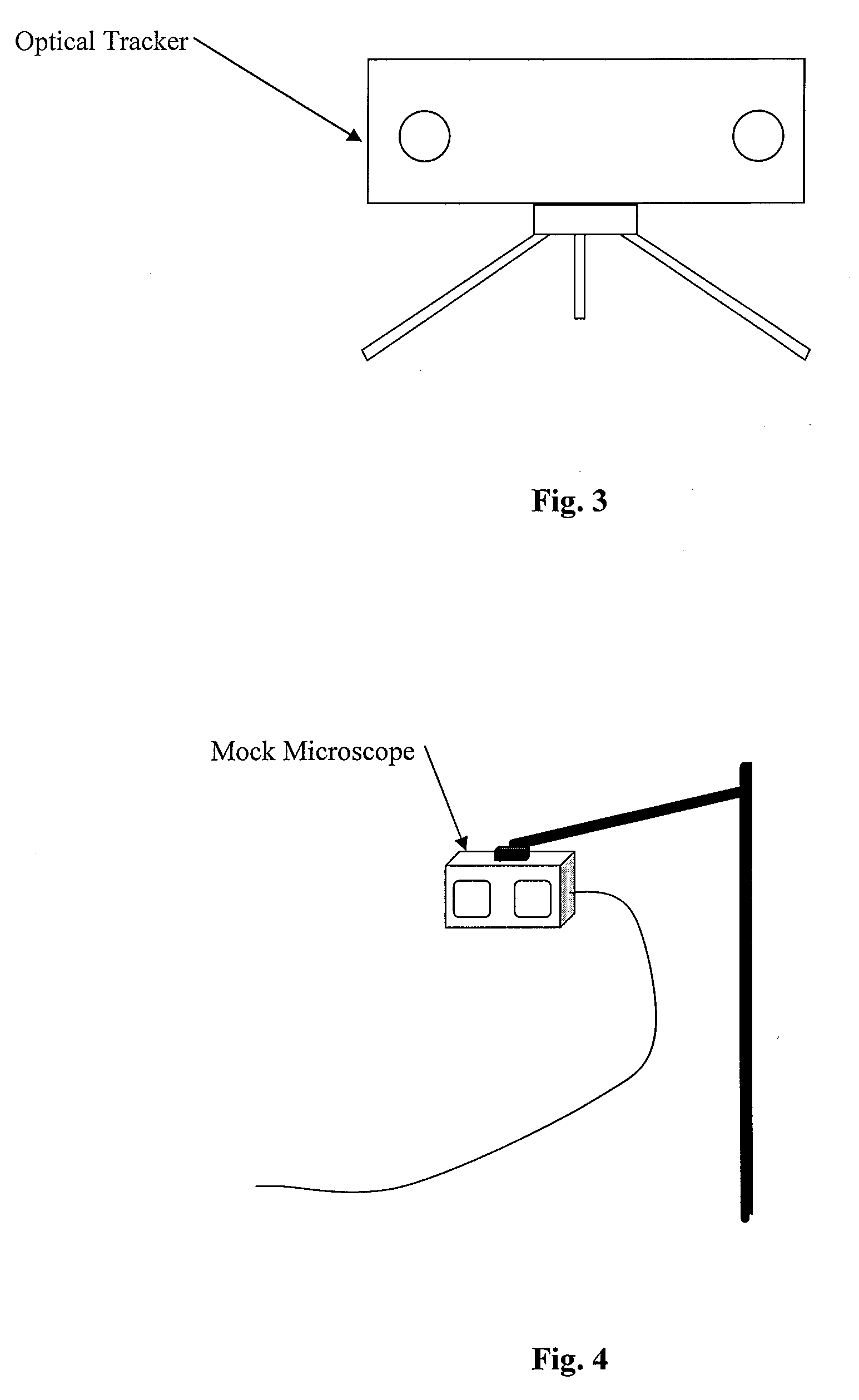

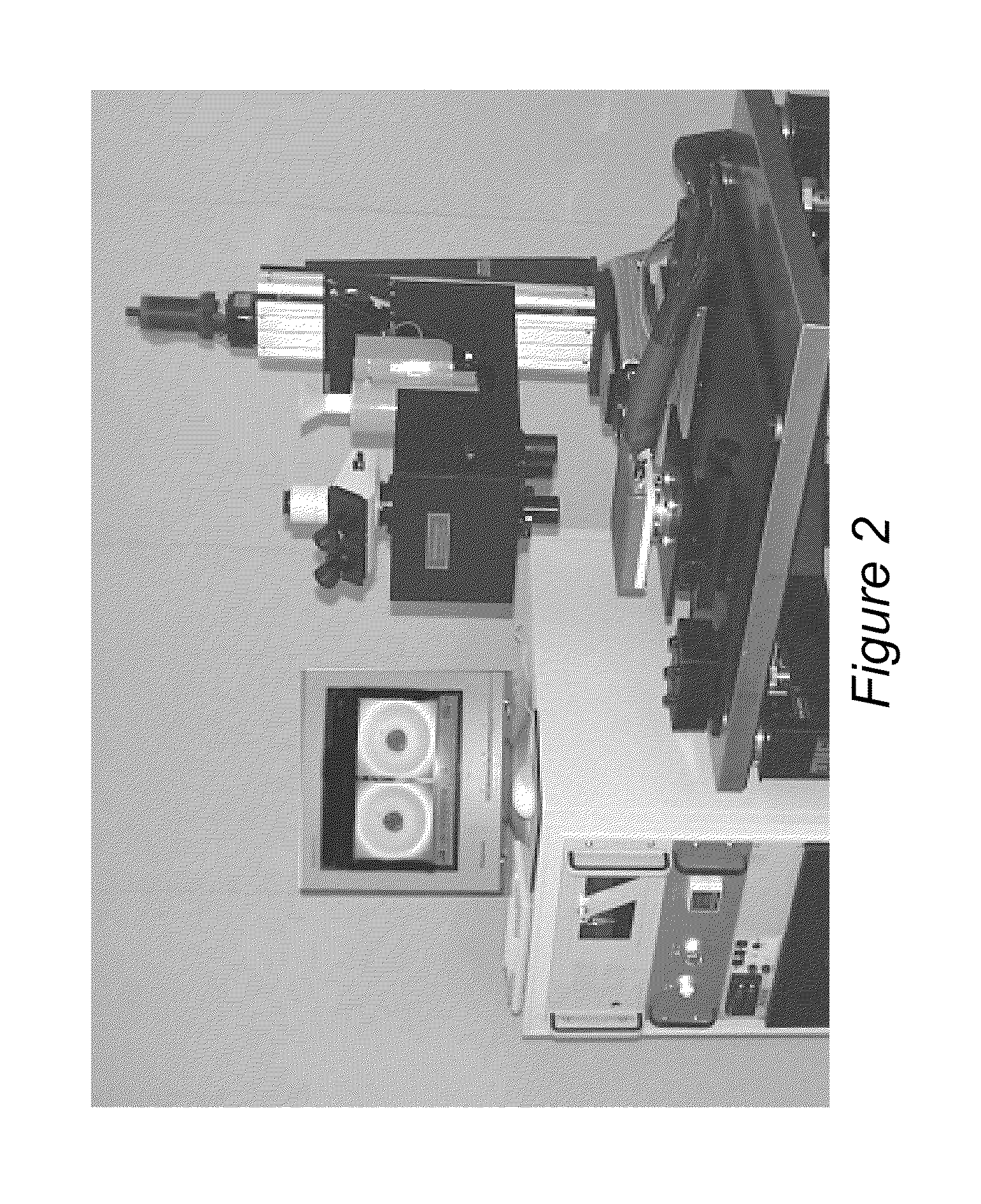

System, Method and Computer Program for Virtual Reality Simulation for Medical Procedure Skills Training

The present invention discloses a virtual reality medical procedure skills training simulator, particularly to be used in the field of ear-nose-throat surgery such as myringotomy. The simulator consists of medical procedural tools marked with physical markers, a tracking device to track the marker, a stereo display device to simulate a medical procedural microscope, and a computer system to enable the simulation.

Owner:UNIV OF WESTERN ONTARIO

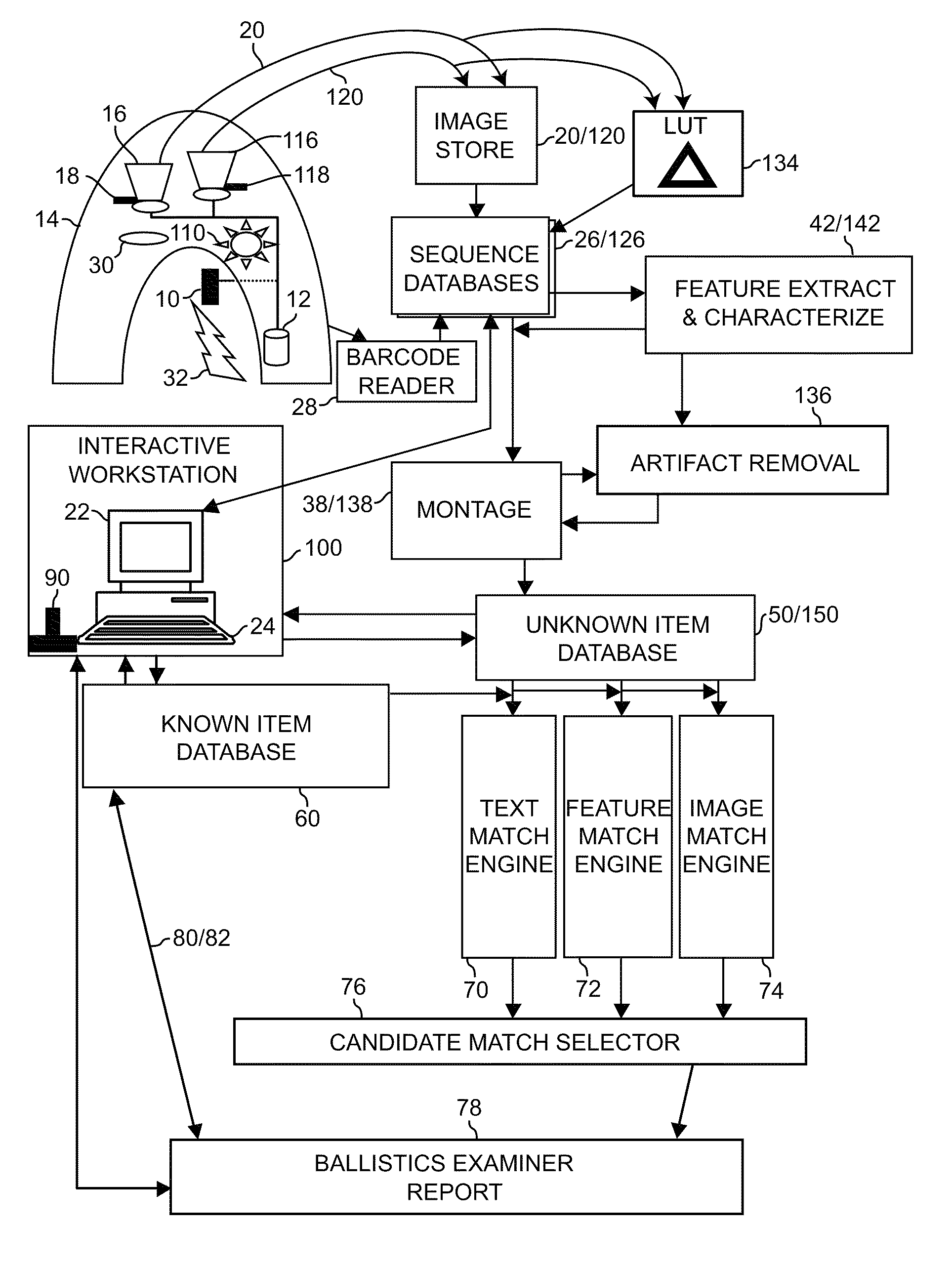

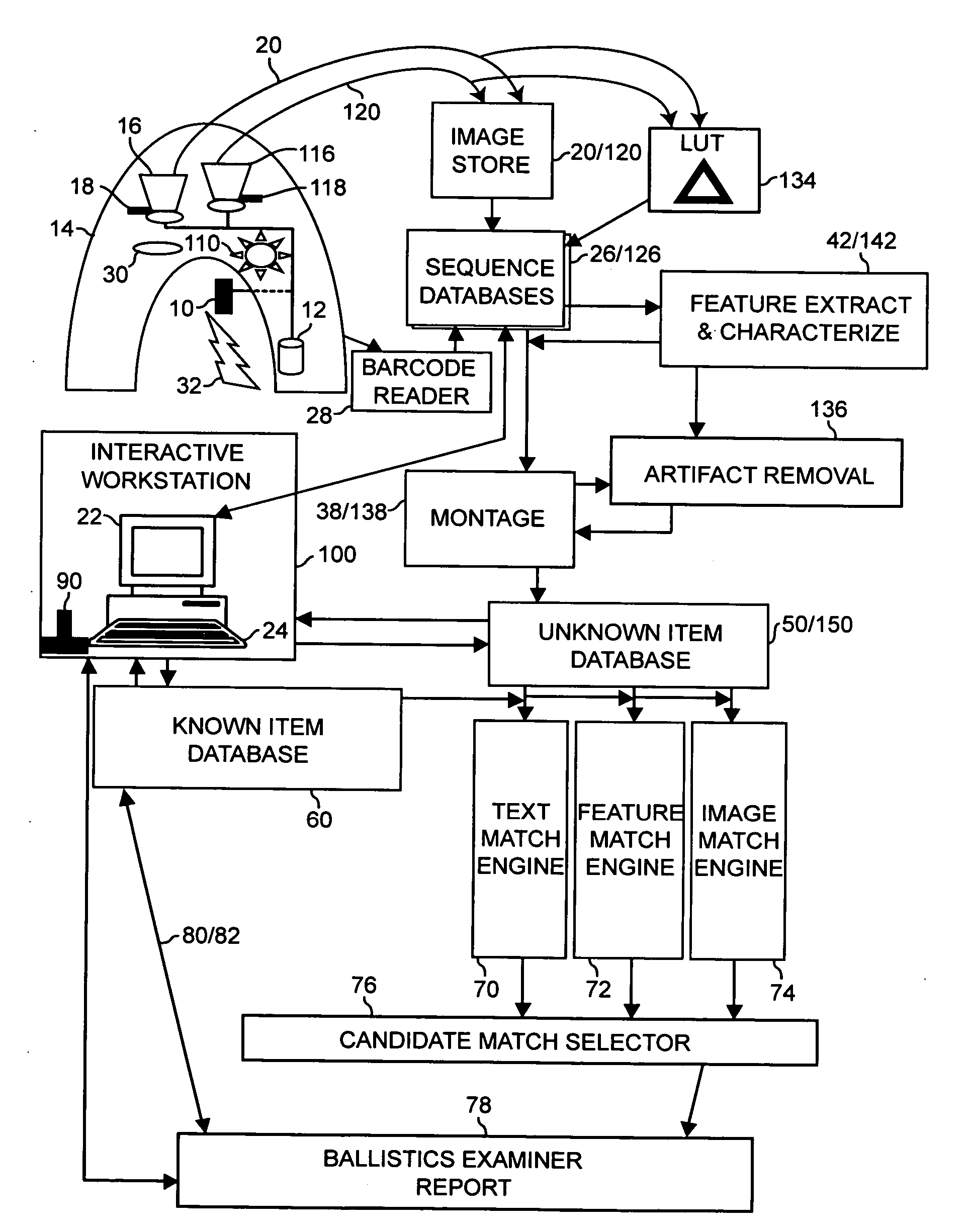

Method and apparatus for alignment, comparison and identification of characteristic tool marks, including ballistic signatures

InactiveUS7822263B1Quick matchAmmunition testingThree-dimensional object recognitionEngineeringMinutiae

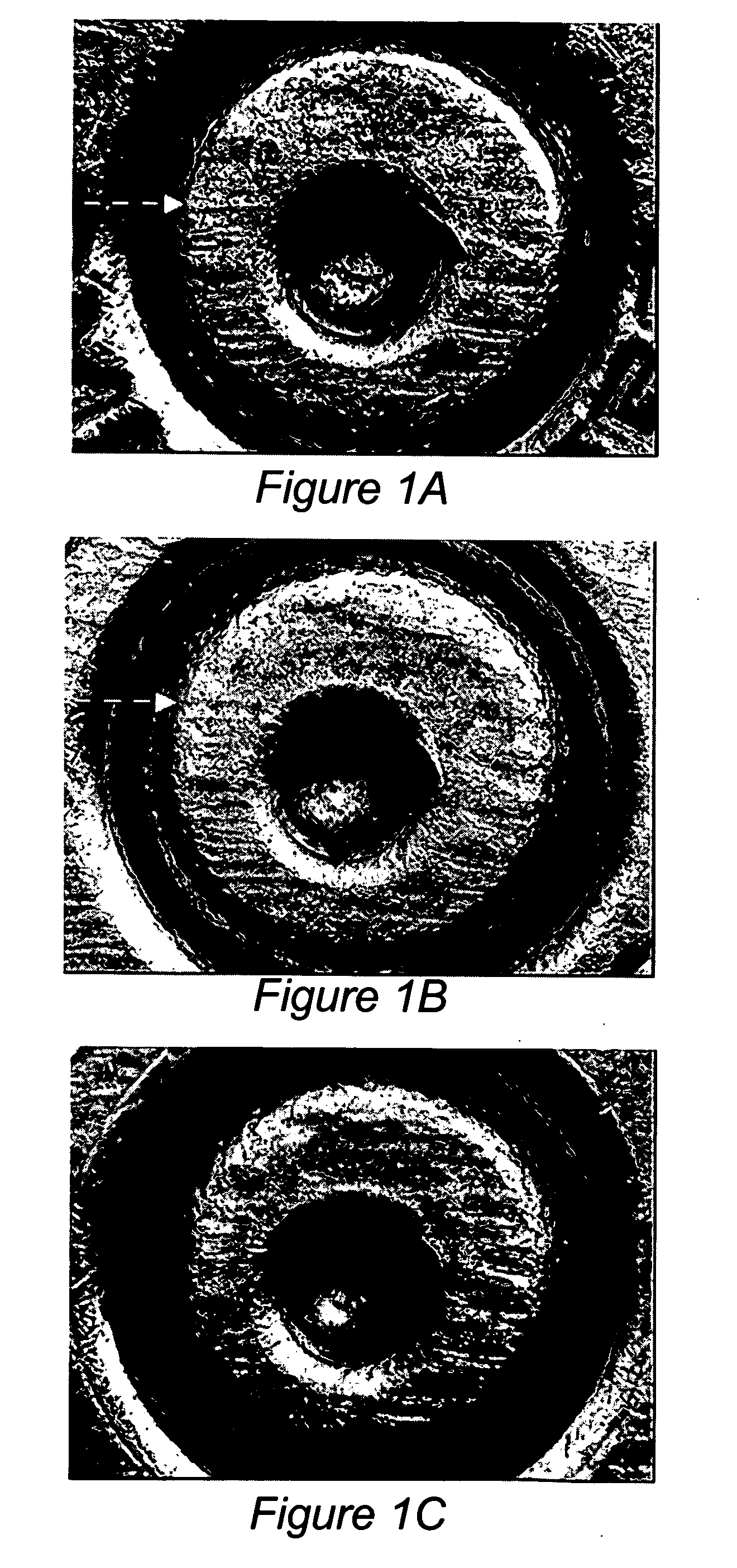

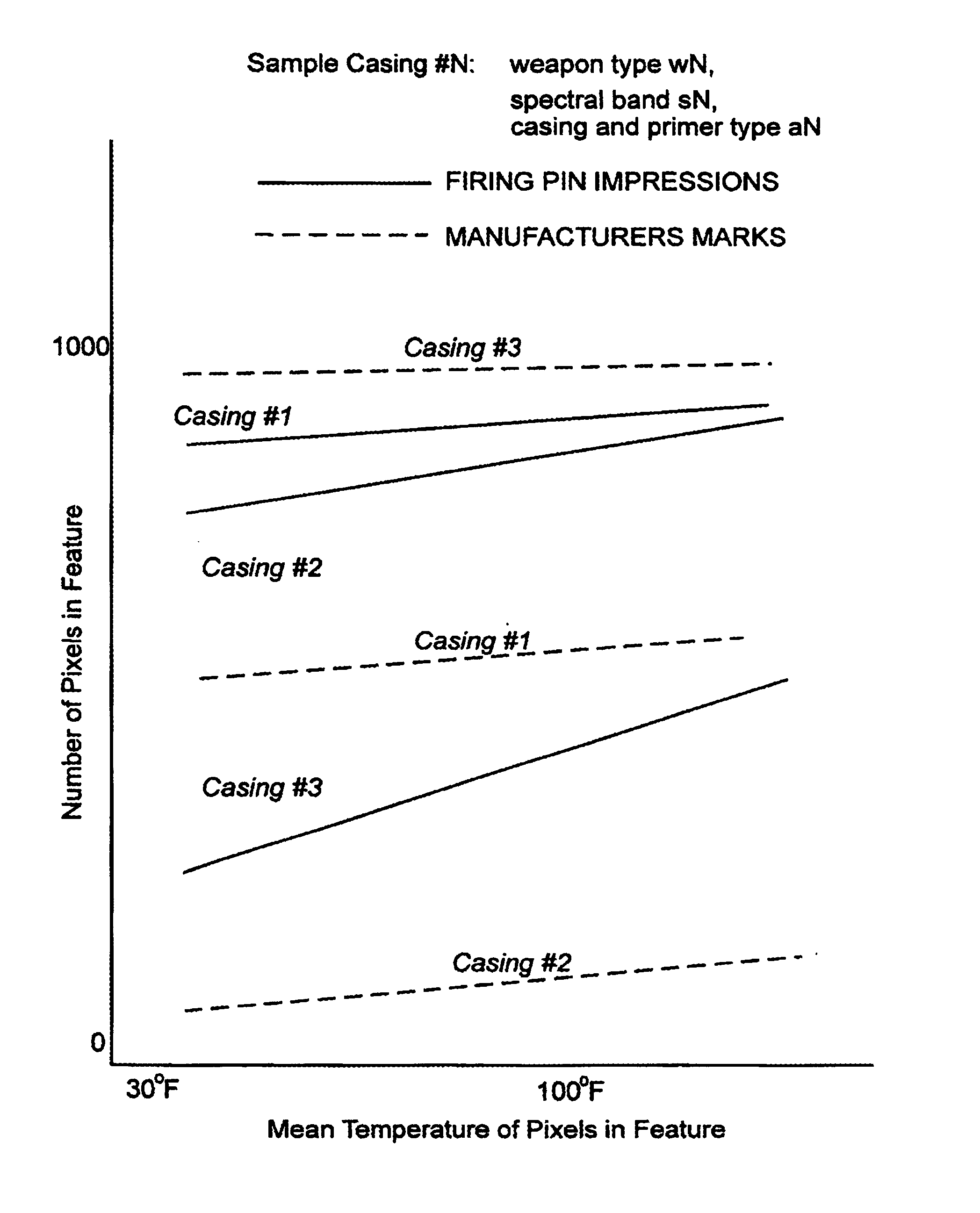

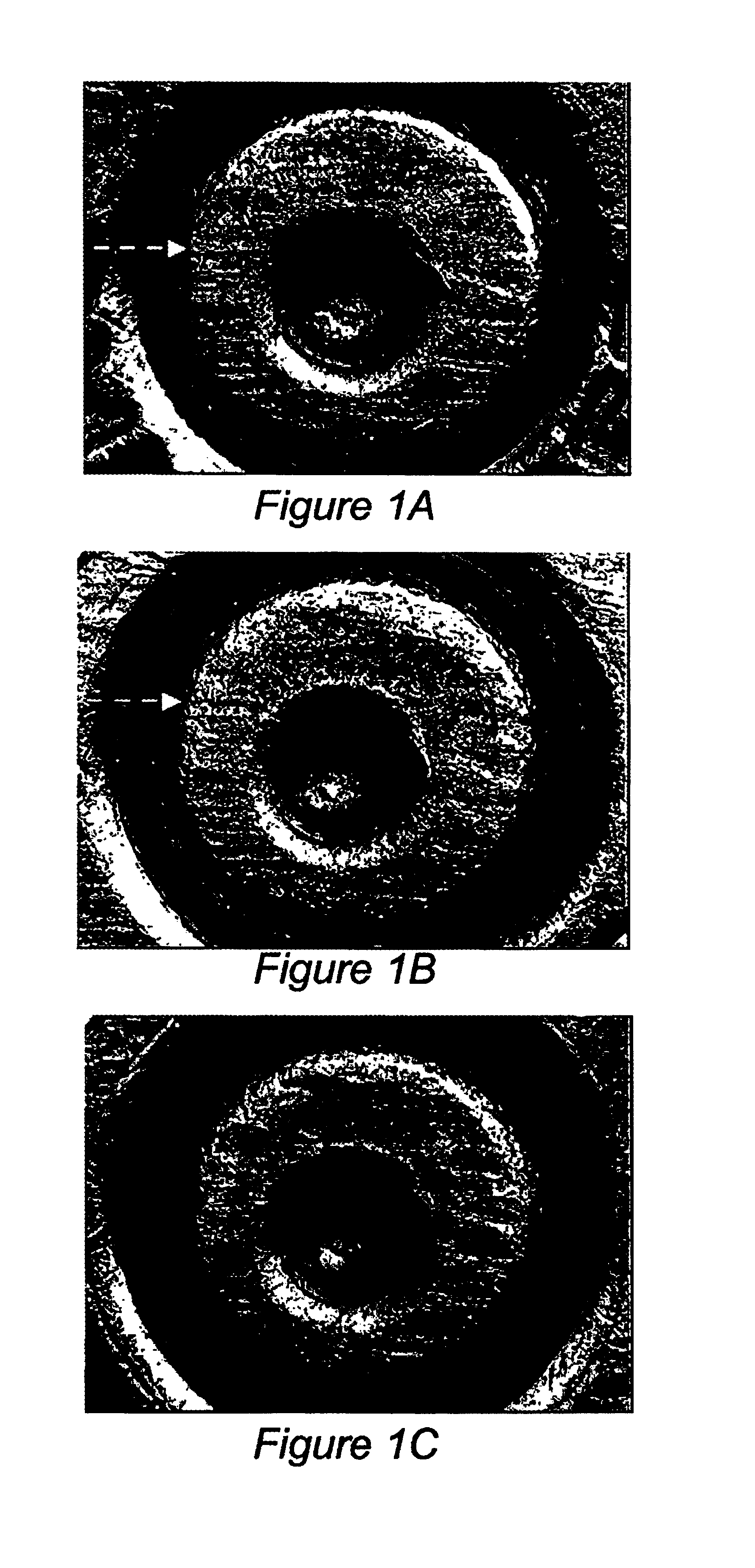

Systematic use of infrared imaging characterizes marks made on items and identifies the particular marking tool with better accuracy than use of visual imaging. Infrared imaging performed in total darkness eliminates shadows, glint, and other lighting variations and artifacts associated with visible imaging. Although normally used to obtain temperature measurements, details in IR imagery result from emissivity variations as well as thermal variations. Disturbing an item's surface texture creates an emissivity difference producing local changes in the infrared image. Identification is most accurate when IR images of unknown marks are compared to IR images of marks made by known tools. However, infrared analysis offers improvements even when only visual reference images are available. Comparing simultaneous infrared and visual images of an unknown item, such as bullet or shell casing, can detect illumination-induced artifacts in the visual image prior to searching the visual database, thereby reducing potential erroneous matches. Computer numerically controlled positioning of the toolmark relative to imaging sensors which use fixed focus optics with shallow depth of focus, varying focus distance and orientation systematically to construct a sequence of images, maximizes reliability of resulting images and their comparisons.

Owner:PROKOSKI FRANCINE J

Method and apparatus for alignment, comparison & identification of characteristic tool marks, including ballistic signatures

Systematic use of infrared imaging characterizes marks made on items and identifies the particular marking tool with better accuracy than use of visual imaging. Infrared imaging performed in total darkness eliminates shadows, glint, and other lighting variations and artifacts associated with visible imaging. Although normally used to obtain temperature measurements, details in IR imagery result from emissivity variations as well as thermal variations. Disturbing an item's surface texture creates an emissivity difference producing local changes in the infrared image. Identification is most accurate when IR images of unknown marks are compared to IR images of marks made by known tools. However, infrared analysis offers improvements even when only visual reference images are available. Comparing simultaneous infrared and visual images of an unknown item, such as bullet or shell casing, can detect illumination-induced artifacts in the visual image prior to searching the visual database, thereby reducing potential erroneous matches.

Owner:PROKOSKI FRANCINE J

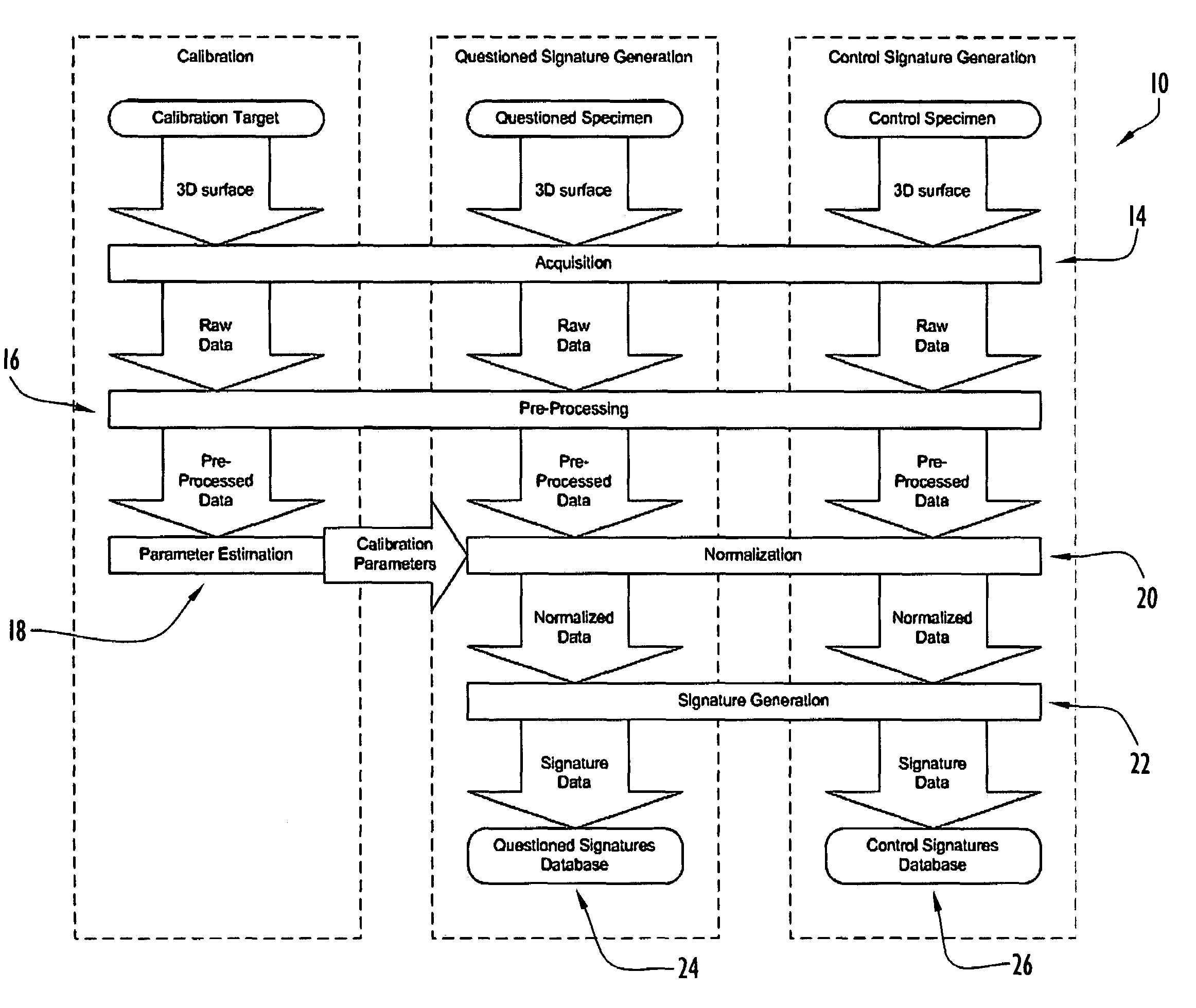

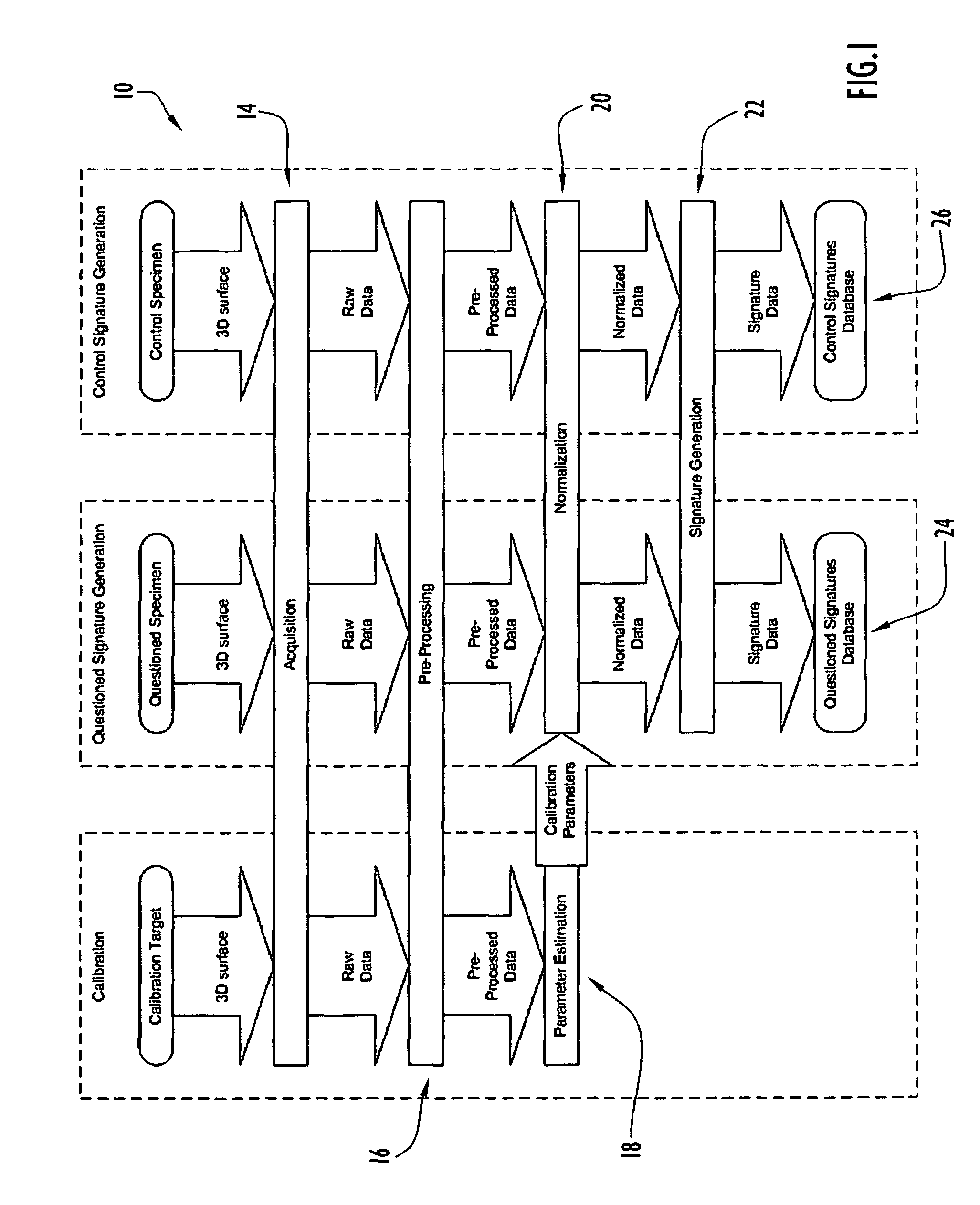

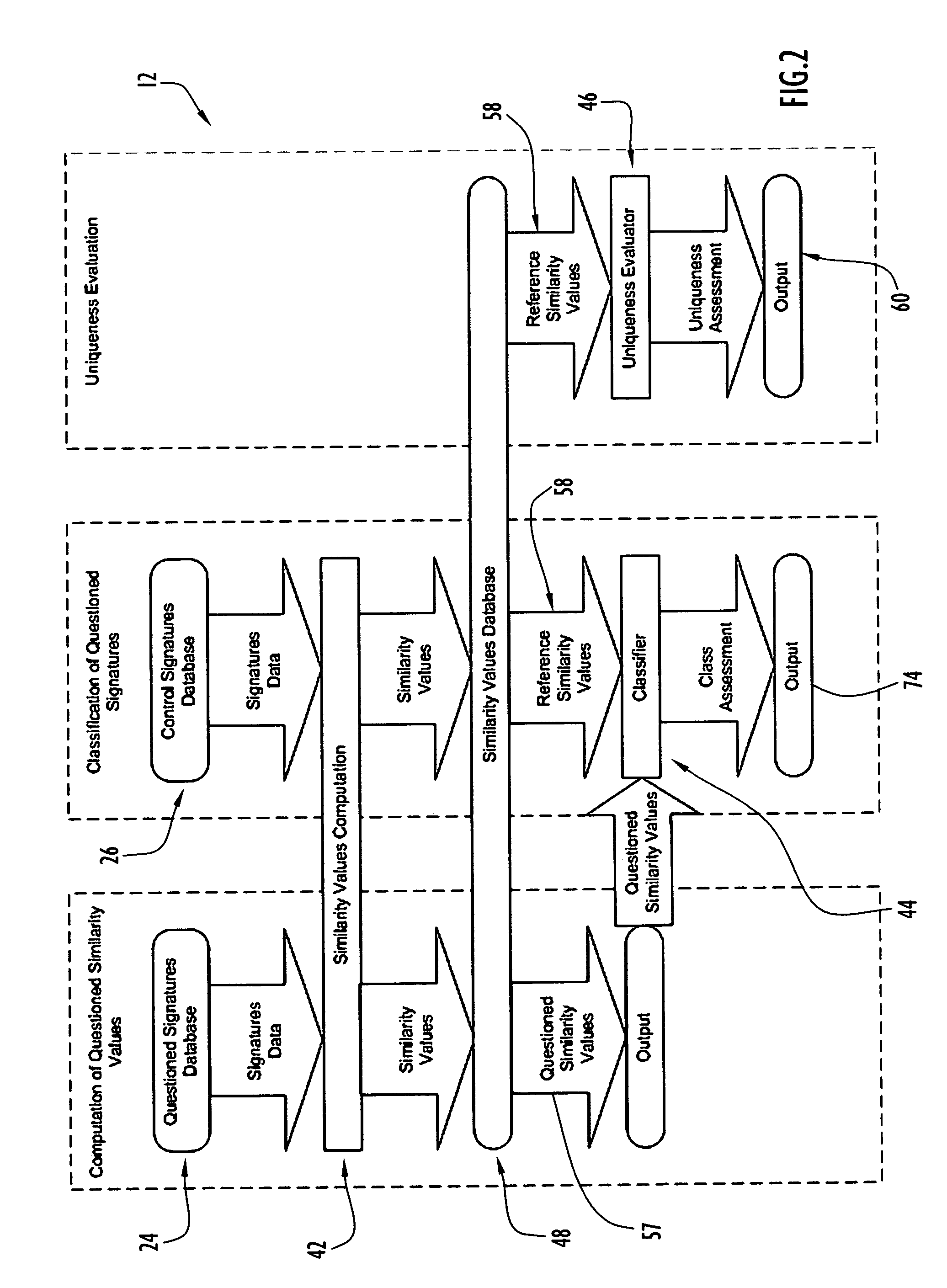

Automated system and method for tool mark analysis

An automated system for tool mark analysis includes an acquisition mechanism for acquiring 3D data of tool marks left on the surfaces of specimens by tools, a signature generation module for generating tool mark signatures from the acquired data, an analysis unit for comparing pairs of the tool mark signatures to obtain a numerical similarity value reflective of their similarity, and a database in which the similarity values are stored. An automated method for tool mark analysis involves the steps of acquiring the 3D data of tool marks, generating the tool mark signature, statistically evaluating pairs of the tool mark signatures, and providing a numerical similarity value for each pair of tool mark signatures reflecting the degree of similarity between the tool mark signatures of each pair. The method is carried out with automated assistance of a computer.

Owner:INTELLIGENT AUTOMATION LLC

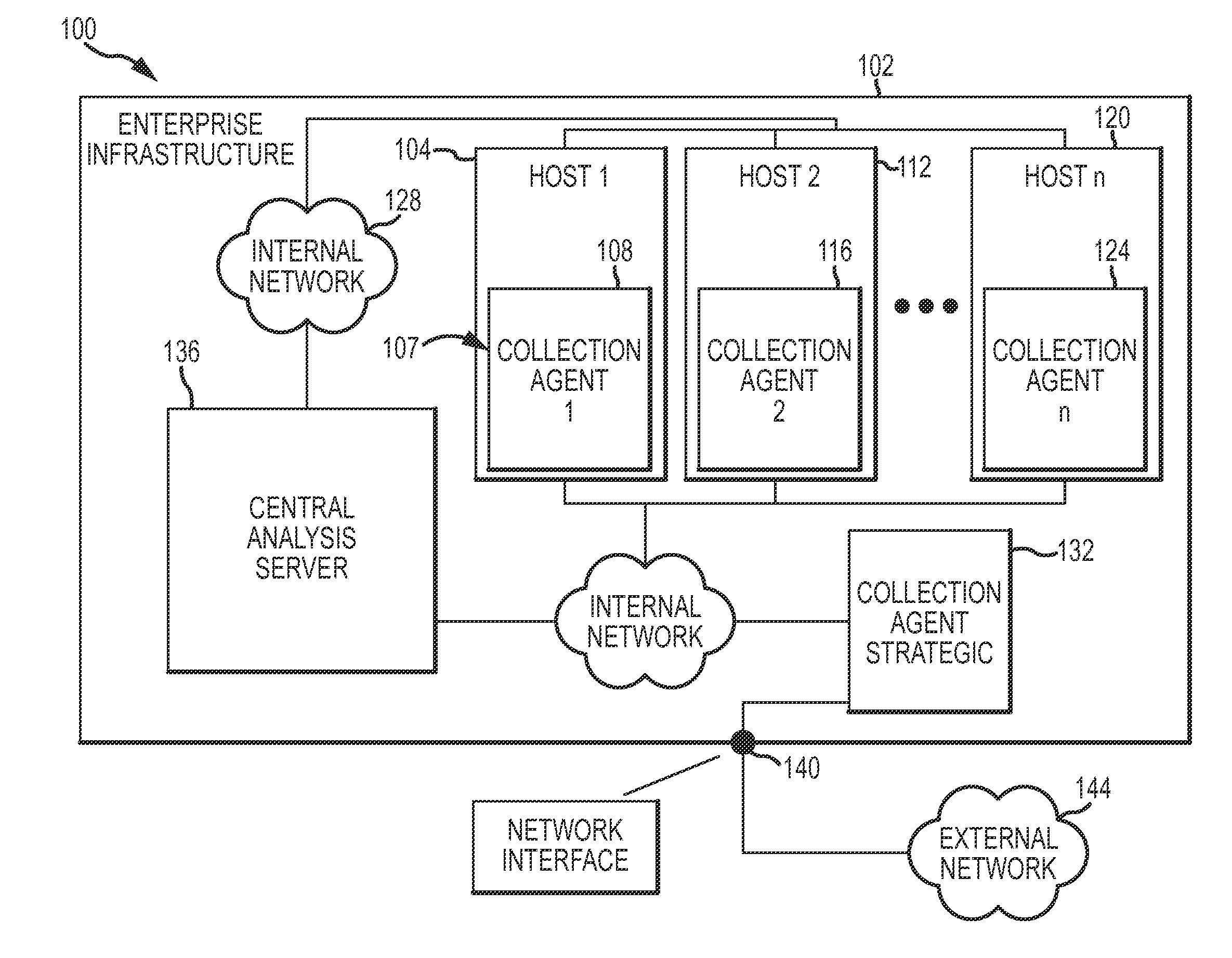

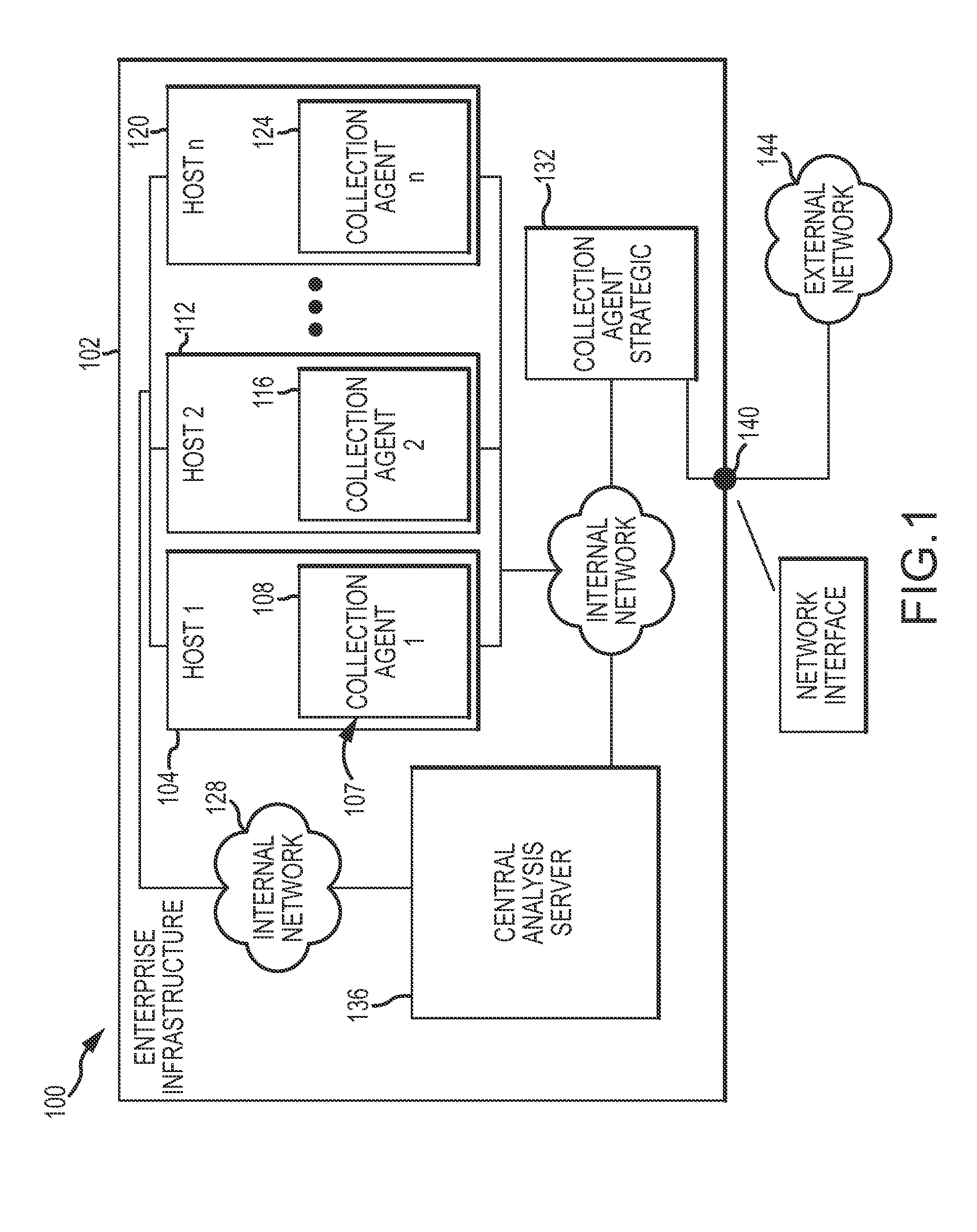

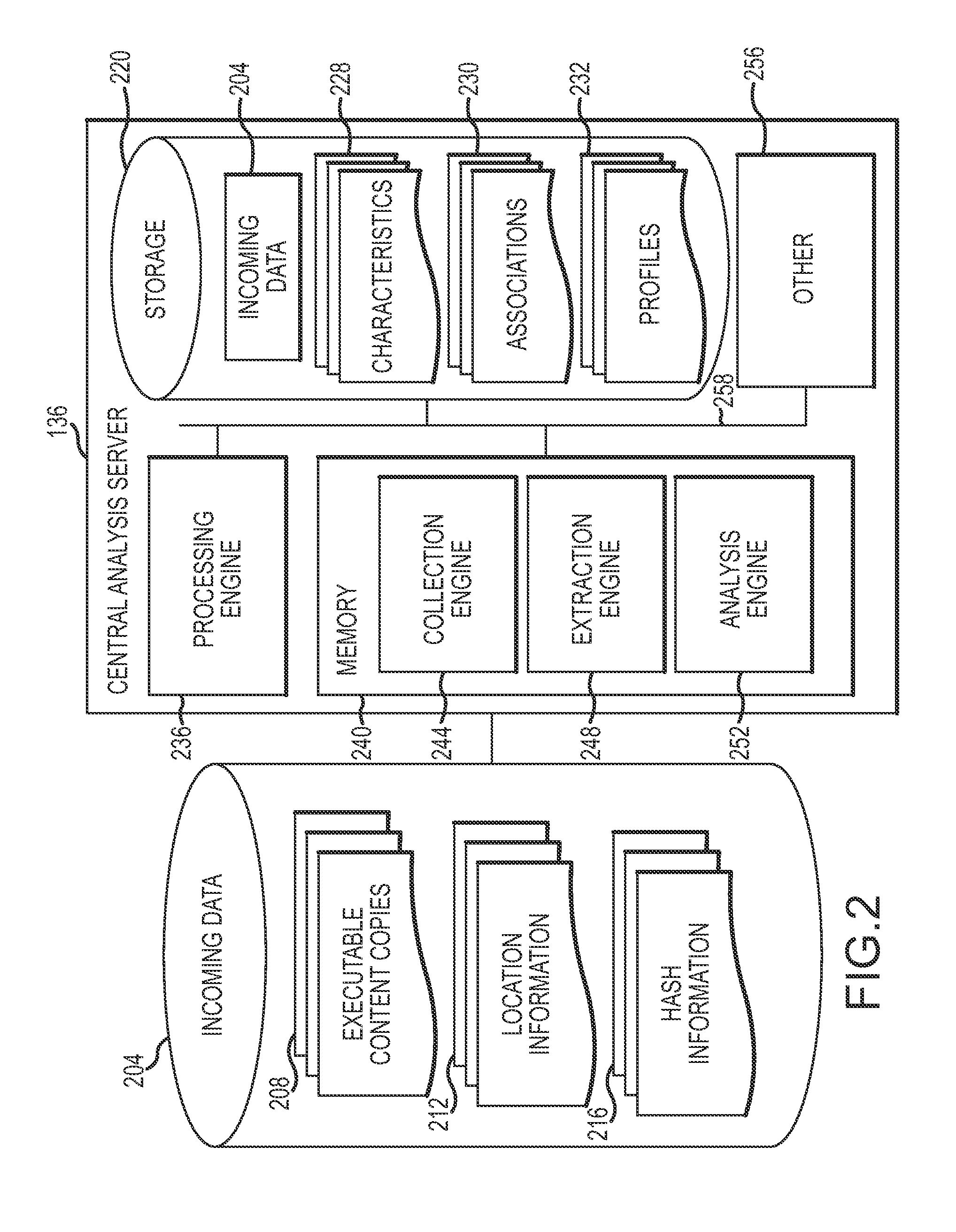

Composite analysis of executable content across enterprise network

ActiveUS20150047034A1Proactive defenseProactive responseMemory loss protectionError detection/correctionByteEnterprise networking

Identification, characterization and attribution of executable content within and across an enterprise infrastructure (e.g., hosts, subnets, routers, etc.) to provide situational awareness for cyber security for purposes of supporting proactive defense and response. Copies of executable content collected at one or more locations within an infrastructure (e.g., hosts, network edges, etc.) may be passed to a central analysis server whereby various characteristics of the executable content may be extracted or gleaned from the copies such as author marks (e.g., directory names), tool marks (e.g., compiler settings), behaviors (e.g., function extraction), patterns (e.g., byte sequences), text, and / or the like. The characteristics may be analyzed in various manners to build profiles of actors or organizations associated with (e.g., responsible for) executable content within the enterprise infrastructure.

Owner:LOCKHEED MARTIN CORP

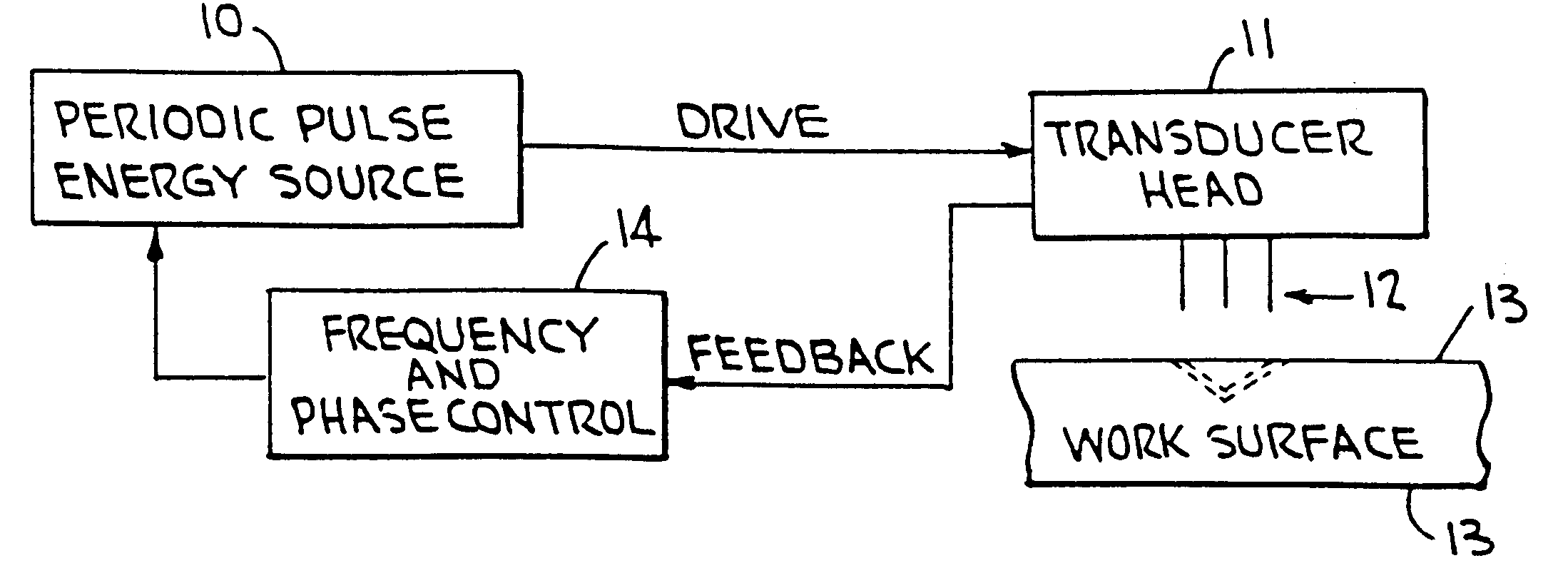

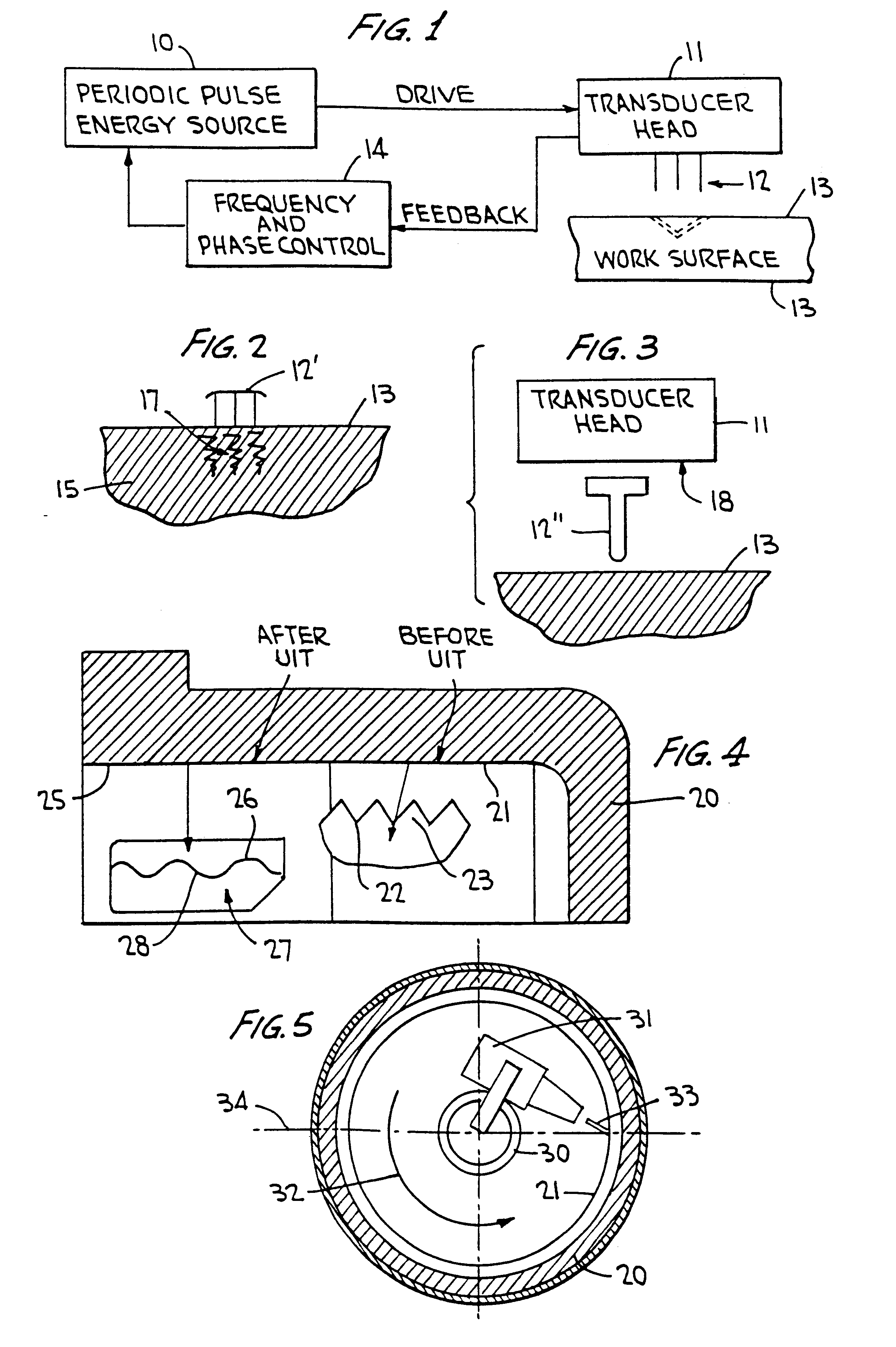

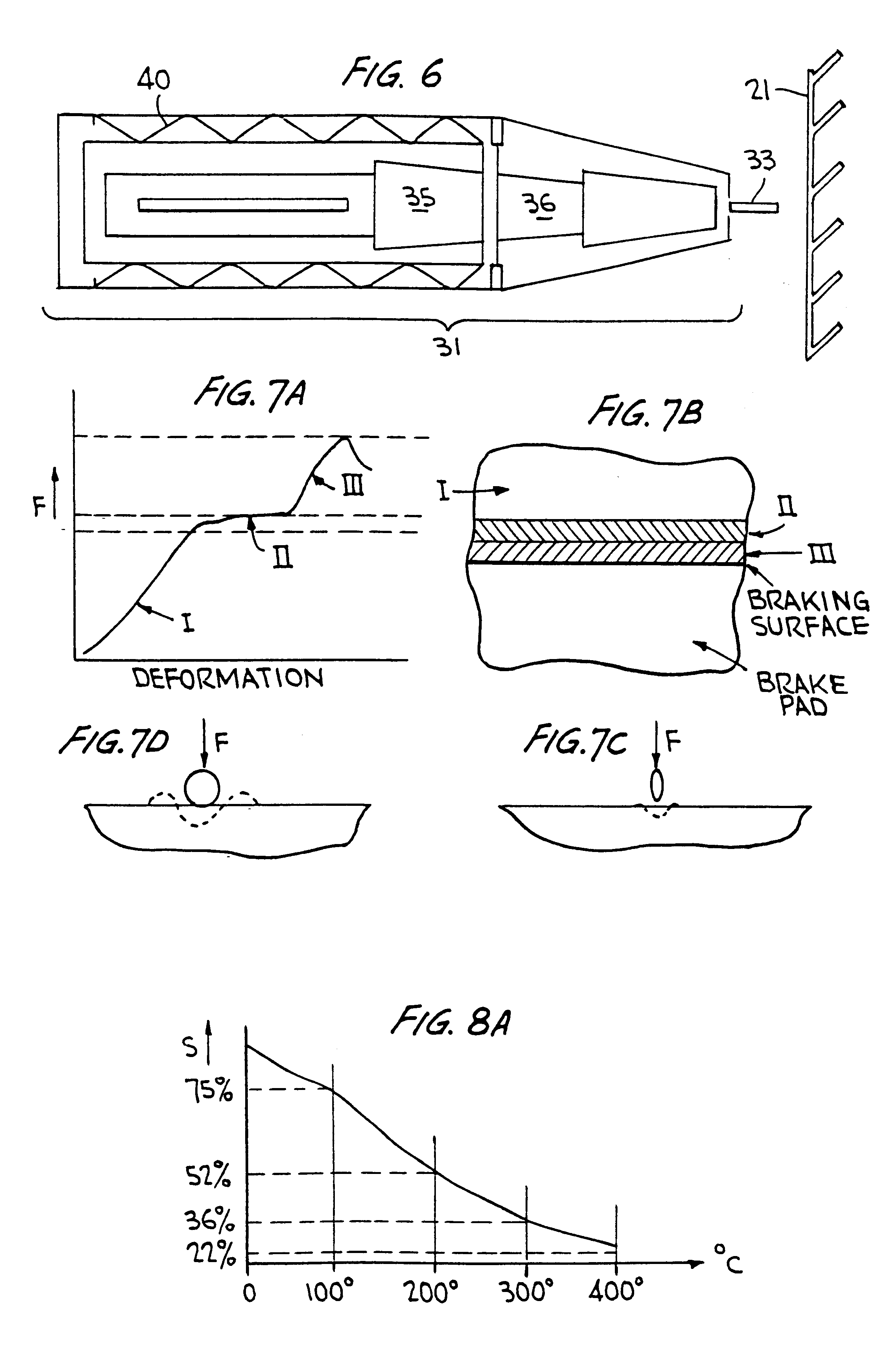

Ultrasonic machining and reconfiguration of braking surfaces

InactiveUS6458225B1Increasing braking service strengthProlong lifeFurnace typesHigh frequency current welding apparatusSurface layerUltrasonic machining

The novel methods, apparatus and reworked rotary braking surface product, for example those exhibited on interior cylindrical braking surfaces of a cast iron brake drum, serve to replace manufacturing defects exhibiting residual tensile stresses and outwardly directed tool marks with smooth compressed braking surfaces in a final manufacturing stage. The plastically deformed surface shape with reduced roughness and surface irregularities furthermore presents improved braking strength above the yield point and approaching the ultimate material strength of the base drum material. An ultrasonic transducer drives individual freely moving impact elements of a set at frequencies up to 55 kHz into the braking surface to effect plastic deformation at surface and sub-surface layers. Physically, the small sized ultrasonic transducer is inserted into a drum cylinder and driven by a lathe producing relative motion between the braking surface and the ultrasonically vibrating impact elements scanning only the braking surface in a readily controlled ultrasonic impact machining cycle for attaining specified braking surface performance.

Owner:UIT LLC

Method and apparatus for alignment, comparison and identification of characteristic tool marks, including ballistic signatures

InactiveUS7068808B1Minimises levelEasy to cleanImage enhancementAmmunition testingEmissivityThermal variation

Systematic use of infrared imaging characterizes marks made on items and identifies the particular marking tool with better accuracy than use of visual imaging. Infrared imaging performed in total darkness eliminates shadows, glint, and other lighting variations and artifacts associated with visible imaging. Although normally used to obtain temperature measurements, details in IR imagery result from emissivity variations as well as thermal variations. Disturbing an item's surface texture creates an emissivity difference producing local changes in the infrared image. Identification is most accurate when IR images of unknown marks are compared to IR images of marks made by known tools. However, infrared analysis offers improvements even when only visual reference images are available. Comparing simultaneous infrared and visual images of an unknown item, such as bullet or shell casing, can detect illumination-induced artifacts in the visual image prior to searching the visual database, thereby reducing potential erroneous matches.

Owner:PROKOSKI FRANCINE J

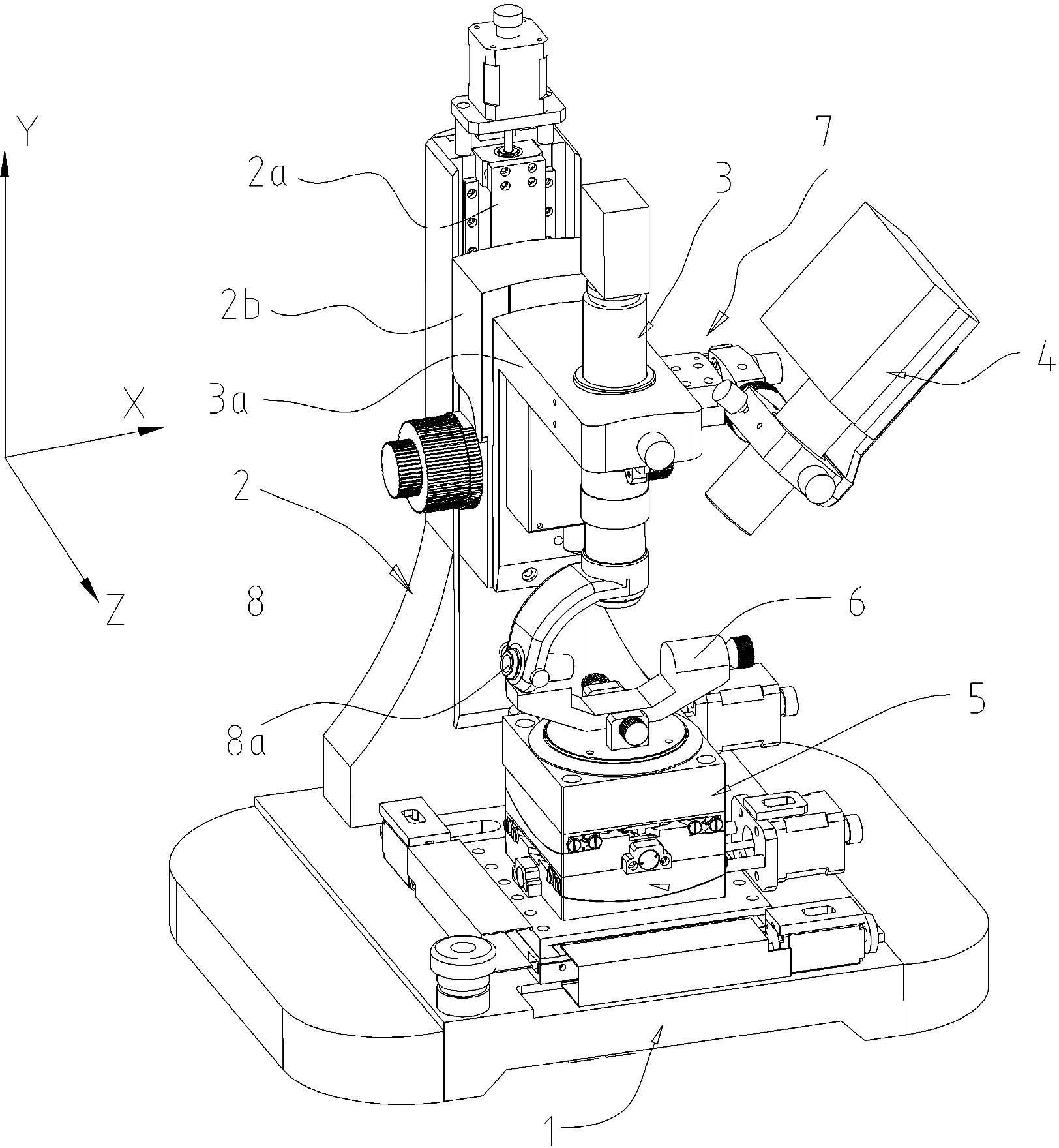

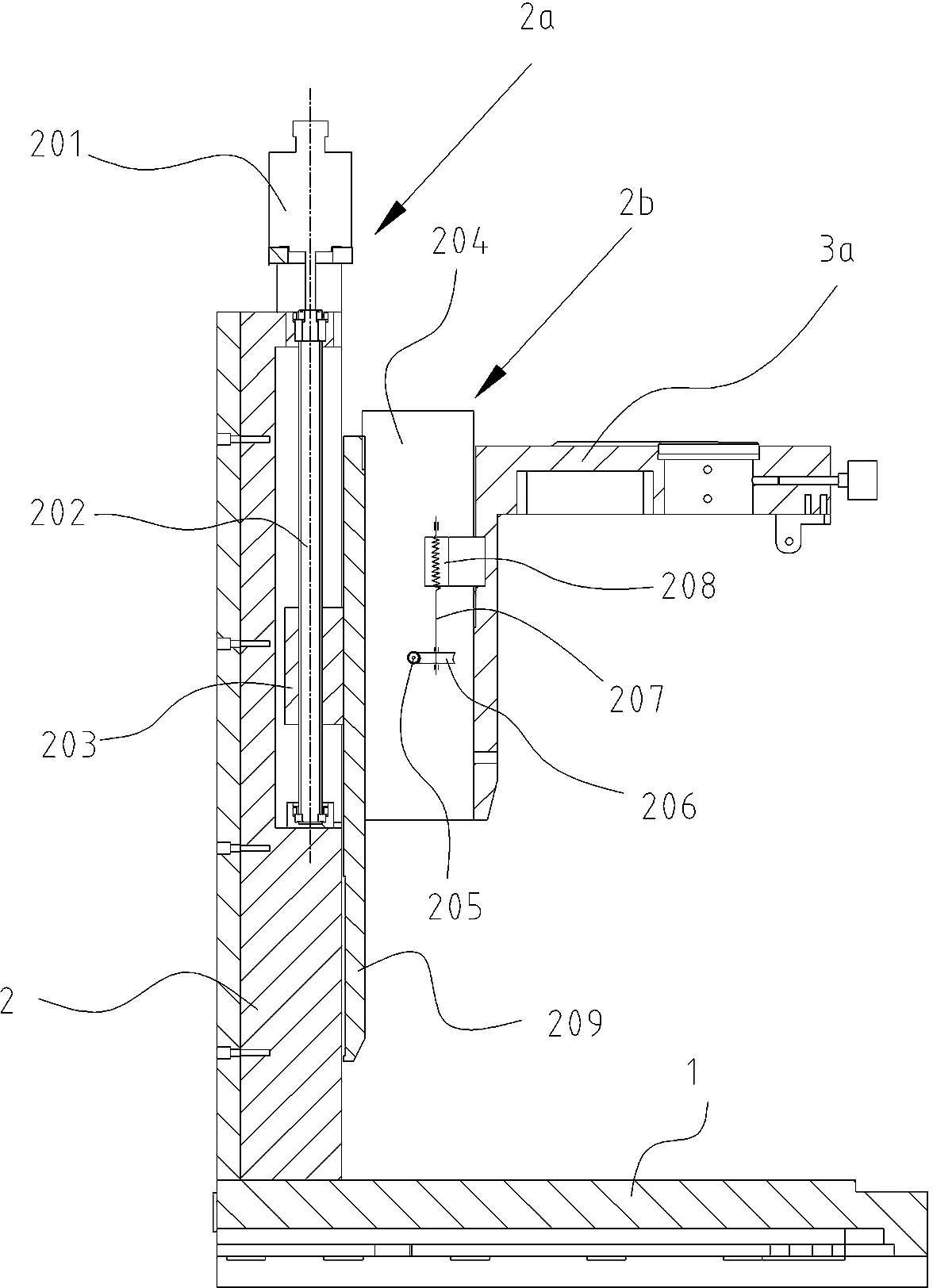

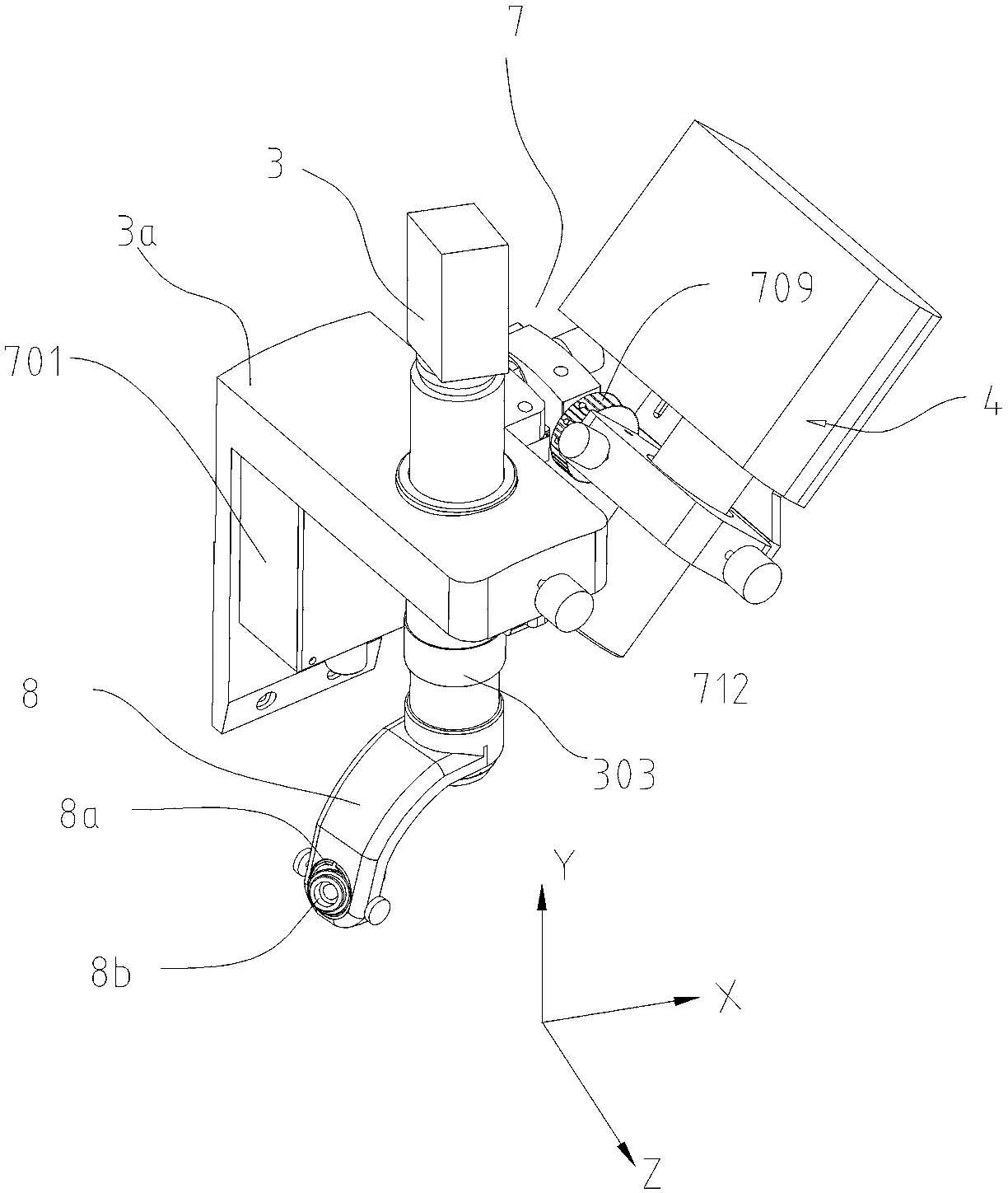

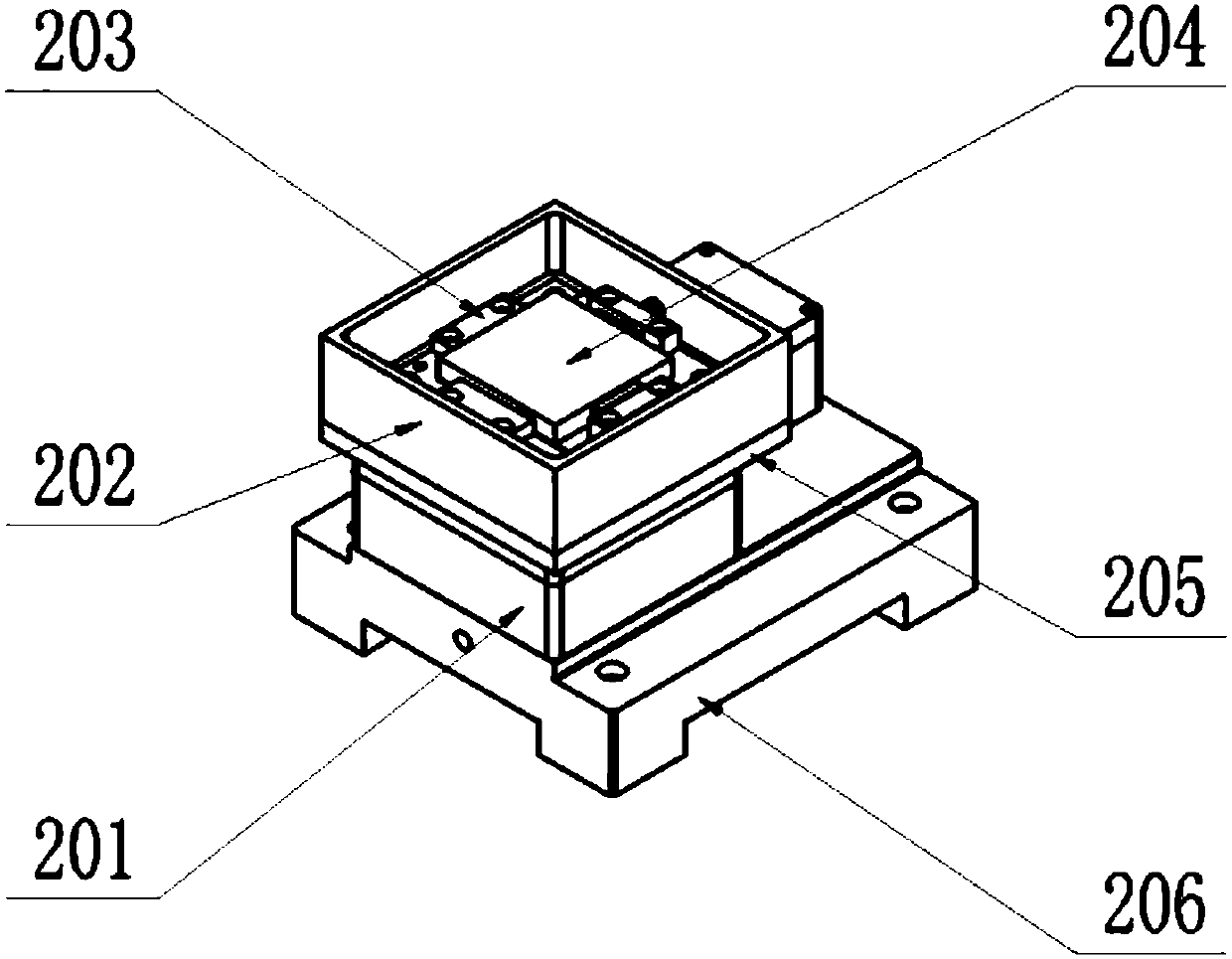

Three-dimensional topography mark comparison measuring instrument

InactiveCN102620684AImprove the level ofImprove work efficiencyUsing optical meansMicroscope cameraMeasuring instrument

The invention relates to a non-contact metering device of object surface topography reconstruction, in particular to a three-dimensional topography mark comparison measuring instrument for criminal investigation evidence such as bullets and tool marks identification. The comparison measuring instrument comprises a base (1), an upright column (2), a cradle head (5), a microscope camera (3) and a microscopic projector (4). The comparison measuring instrument provided by the invention has the advantages that the field of vision is variable through performing non-contact measurement to an observed sample; the resolution is adjustable; an electrically and manually combined multi-dimensional focusing cradle head and multiple clamps are adopted, so that the requirements of clamping and adjusting measurement posture of various detecting materials are satisfied; the structure is reasonable, the performance is stable and the operation is simple and convenient.

Owner:安徽国盾三维高科技有限公司

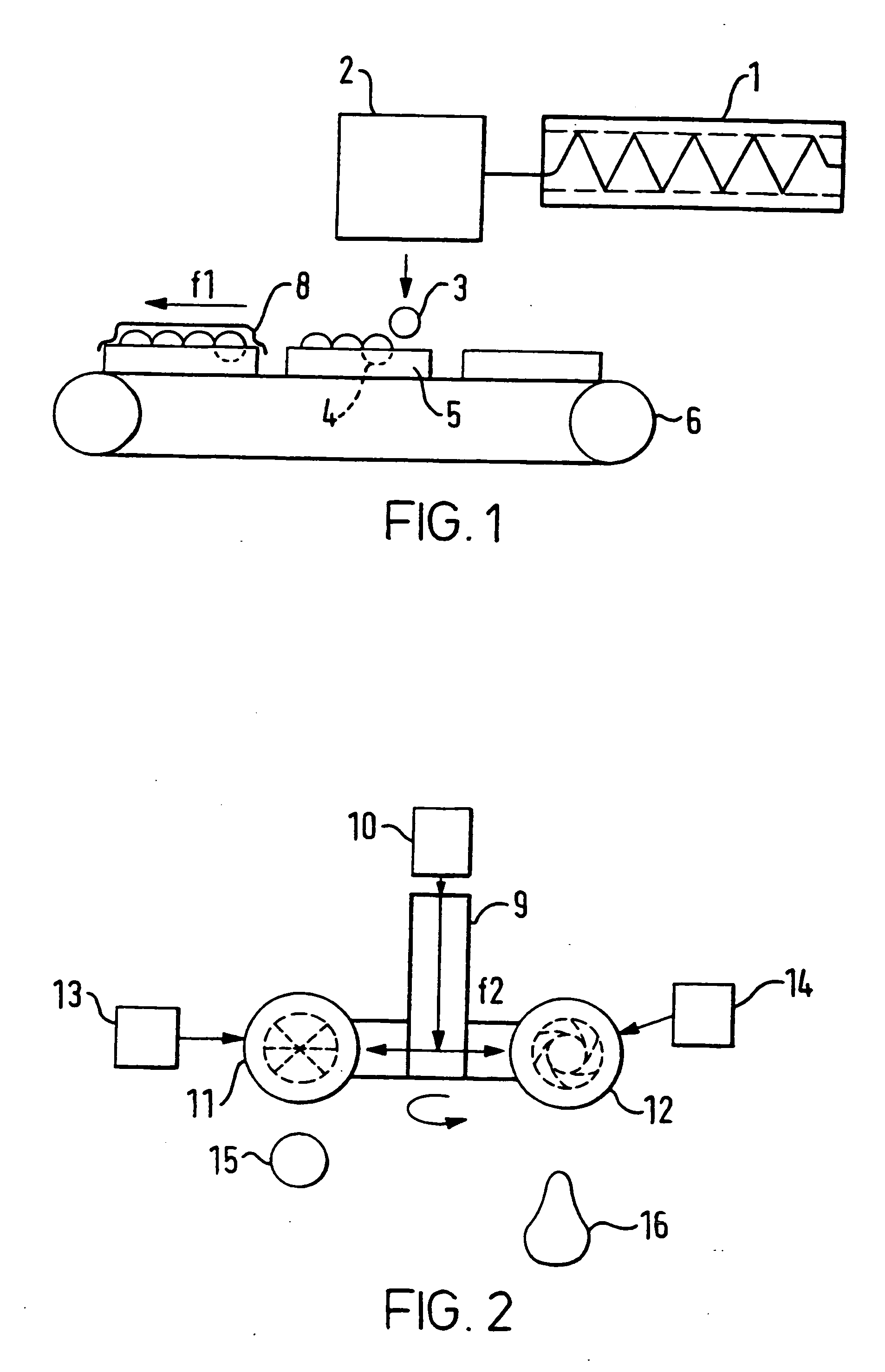

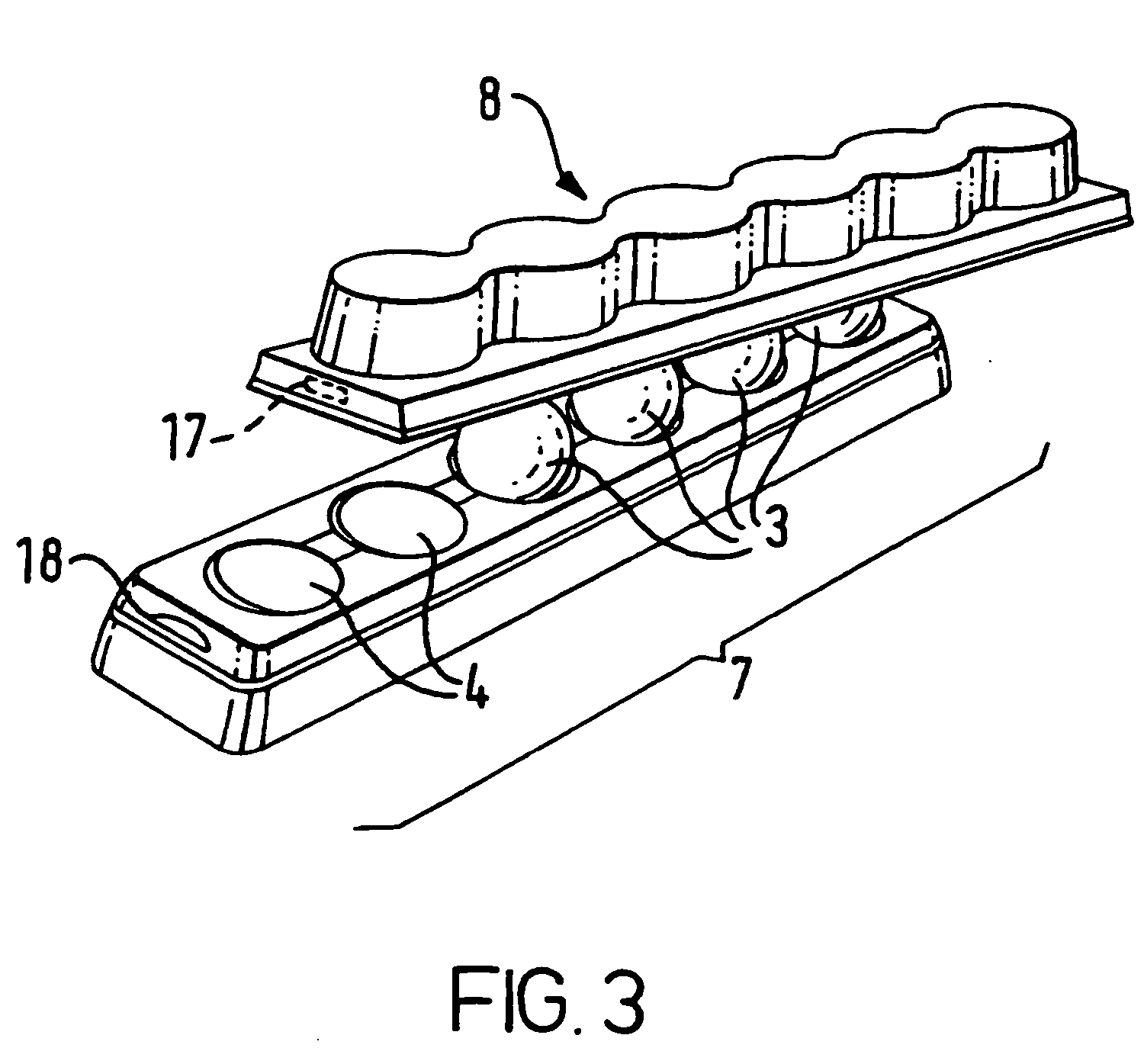

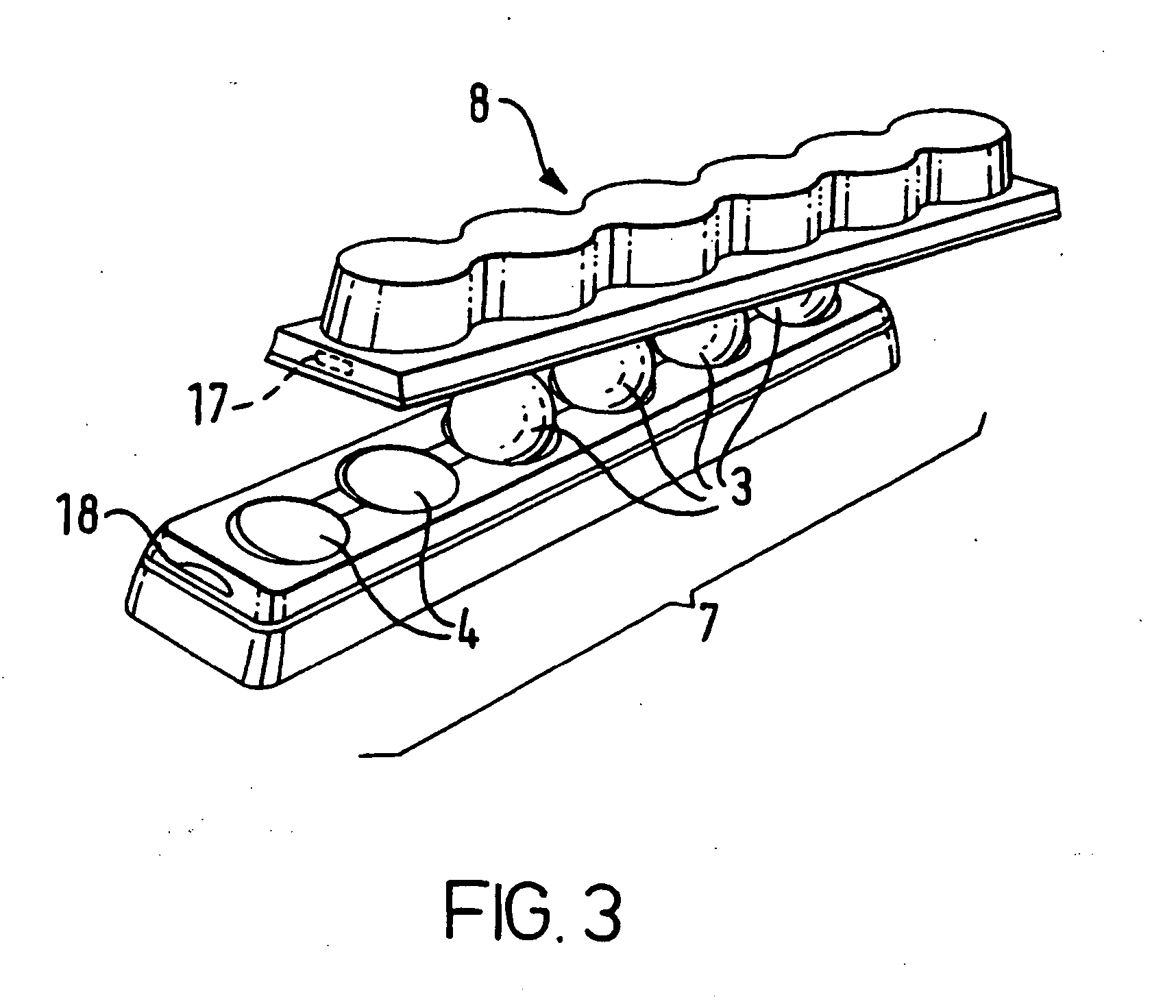

Round items of frozen confectionery and process of manufacture

A round item of frozen confectionery having an even roundness and a shape generated by revolution but essentially lacking an apex, rough edges and forming tool marks, In particular, the frozen confectionery has the form of a ball similar in appearance to a ball made non-industrially with an ice-cream scoop. These items are manufactured by extrusion-forming of a confectionery in the cold state.

Owner:MARCHON JEAN MICHEL +1

Method for processing GaN epitaxial substrate

InactiveCN101378002AReduce processing costsImprove processing efficiencySemiconductor/solid-state device manufacturingWaferingCompound (substance)

The invention provides a processing method which is used for GaN epitaxial substrate, comprising the following steps of: carrying out grinding for a single crystal rod cut so as to remove the tool marks of the chip; (2) conducting chemical mechanical polishing to the chip grinded so as to remove a damage layer which is caused by grinding; (3) carrying out annealing to the chip after chemical mechanical polishing so as to remove the damage of near-surface atoms, with the annealing temperature from 500 DEG C to 1500 DEG C, and the temperature preserving time from 10 hours to20 hours; (4) cleaning the chip polished so as to remove residual particles and pollutants on the near-surface thereof. The invention can obtain required substrate by just conducting simple chemical mechanical polishing, does not conducting super-precision chemical mechanical polishing, reduces the processing cost of the substrate, and improves the processing efficiency. The method which is simple and feasible greatly improves the light extraction efficiency thereof as the stripes of the near-surface graphics of the single crystal substrate manufactured are irregular arbitrary scratches.

Owner:SHANDONG UNIV

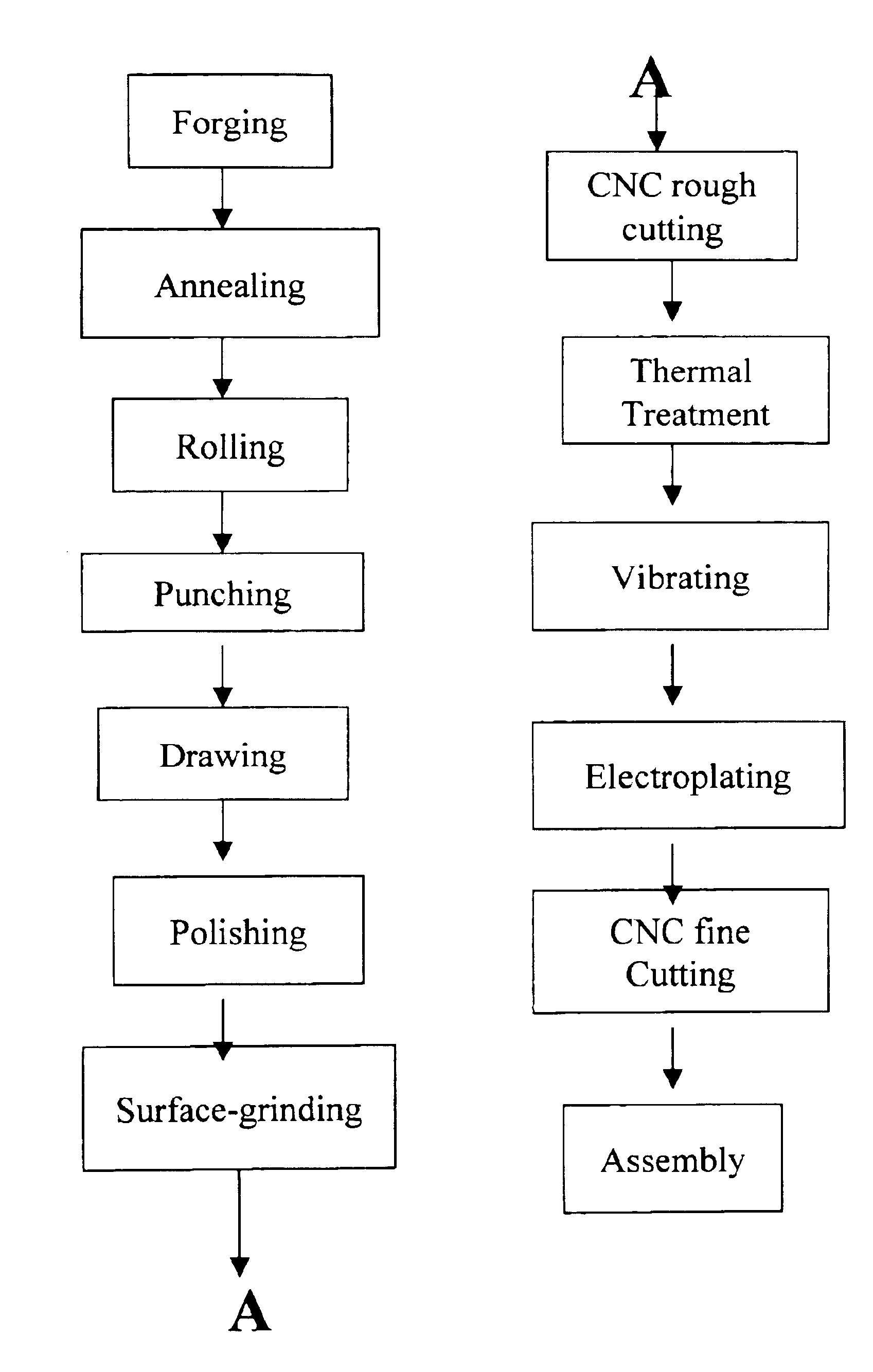

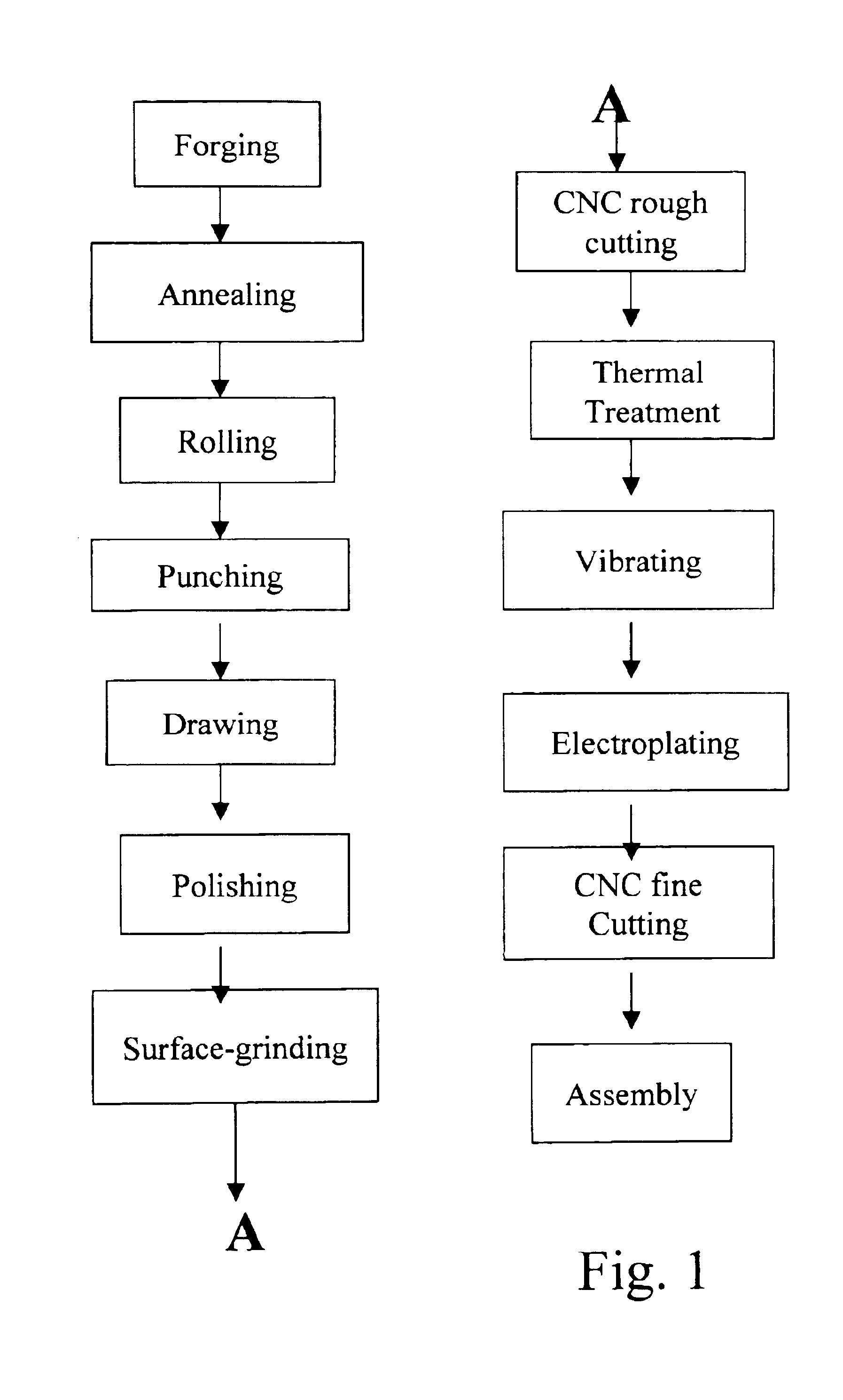

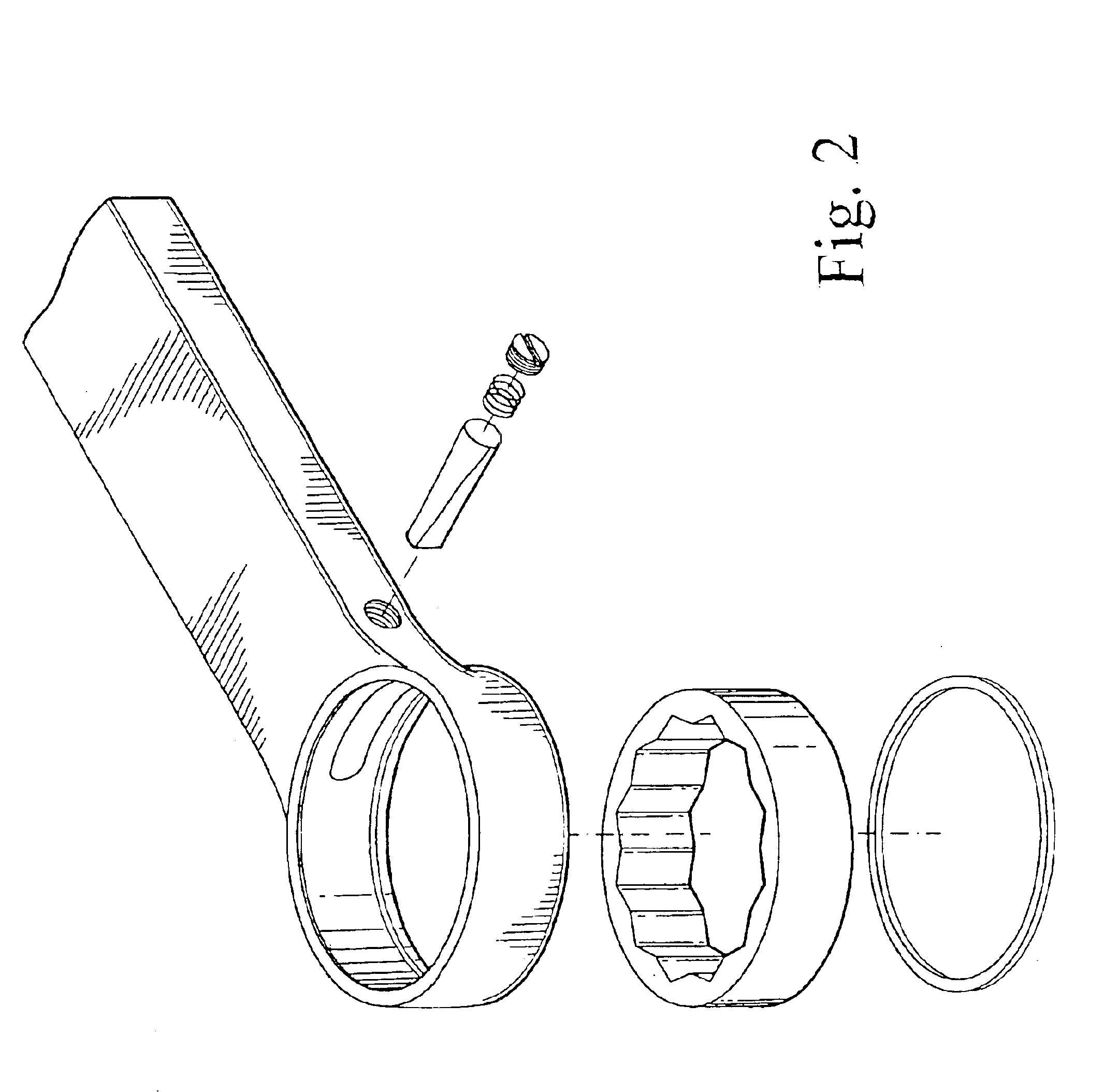

Wrench manufacturing process

A wrench manufacturing process for manufacturing a rotational-tube wrench comprises the steps of forging, annealing, rolling, punching, drawing, polishing, surface grinding, CNC rough cutting, thermal treatment, vibrating, electroplating, CNC fine cutting and assembling. The additional steps of thermal treatment and CNC or MC fine cutting not only enhance the structural toughness of the wrench but also guarantee high degree of roundness for the receptacle space thereof. The CNC or MC fine cutting also provides the inner wall of the receptacle space with fine tool marks so that the confinement strength of a rotational tube without ratchets therein can be significantly enlarged.

Owner:HSIEN CHIN CHING

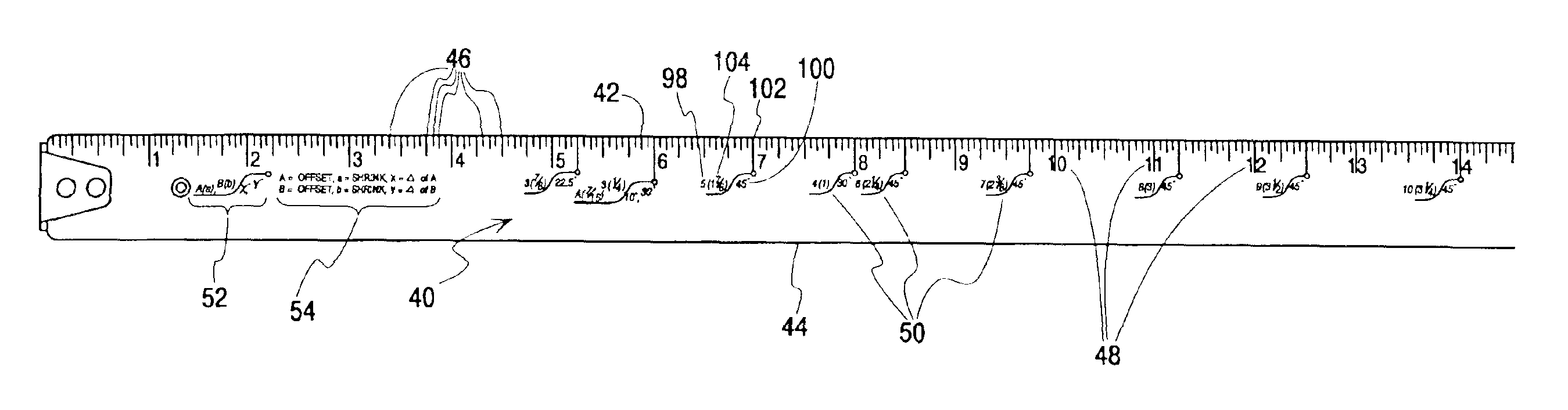

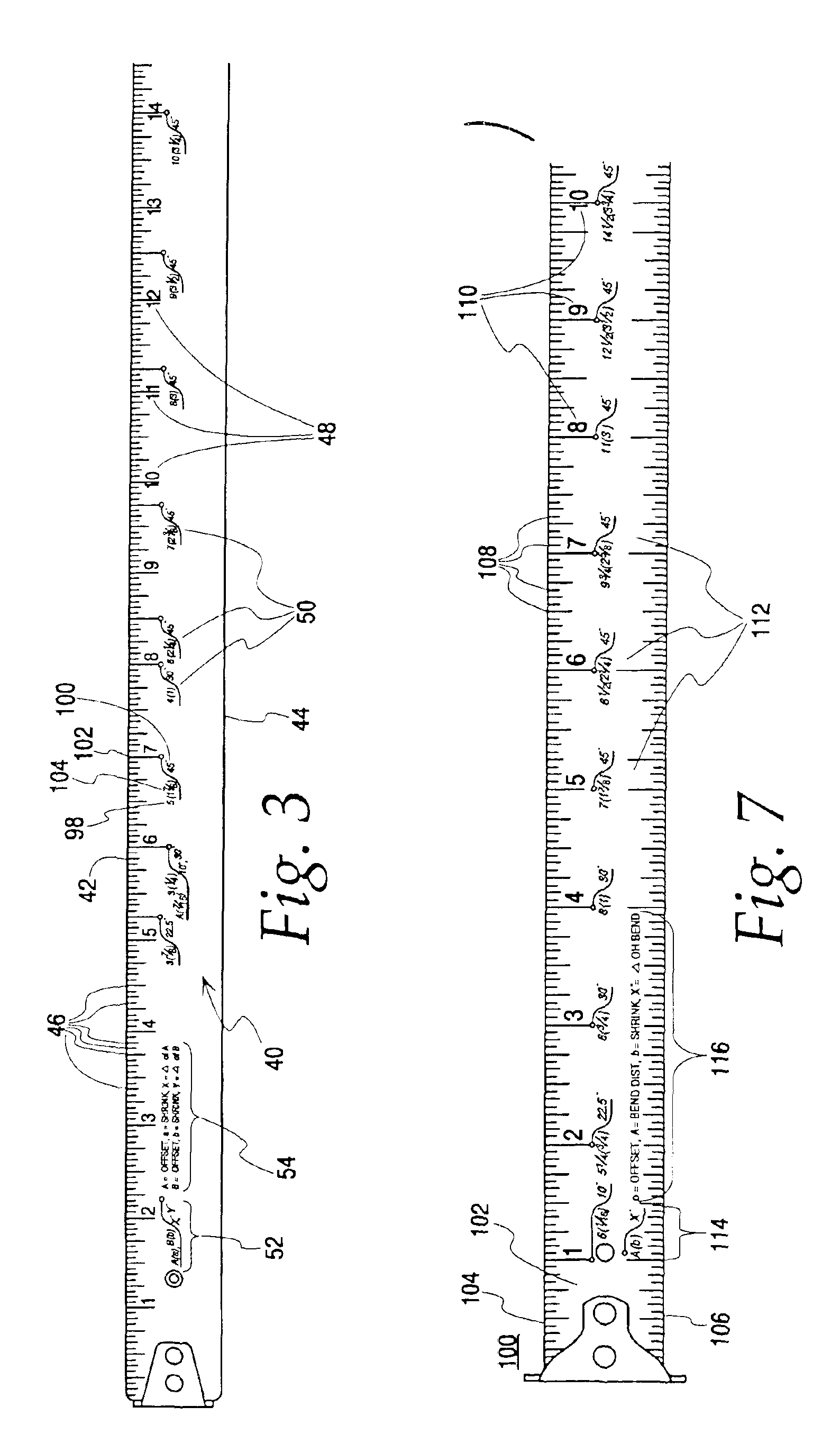

Offset tape measure

An offset tape measuring tool marked with standard English measurements includes integrated indicia for quick determination of distance between bends for a given offset depth and offset angle when installing conduit. Additional indicia may be included for the measurement of the shrinkage of the conduit with respect to the specified offset depths and angles. The integrated invention may be part of a standard tape measure strip to provide a convenient multi-purpose tool. Although the tool eliminates any external calculations or table reference typically necessary when bending conduit to clear an obstacle, it still provides an optional reference card for unique bends.

Owner:KLEIN TOOLS INC

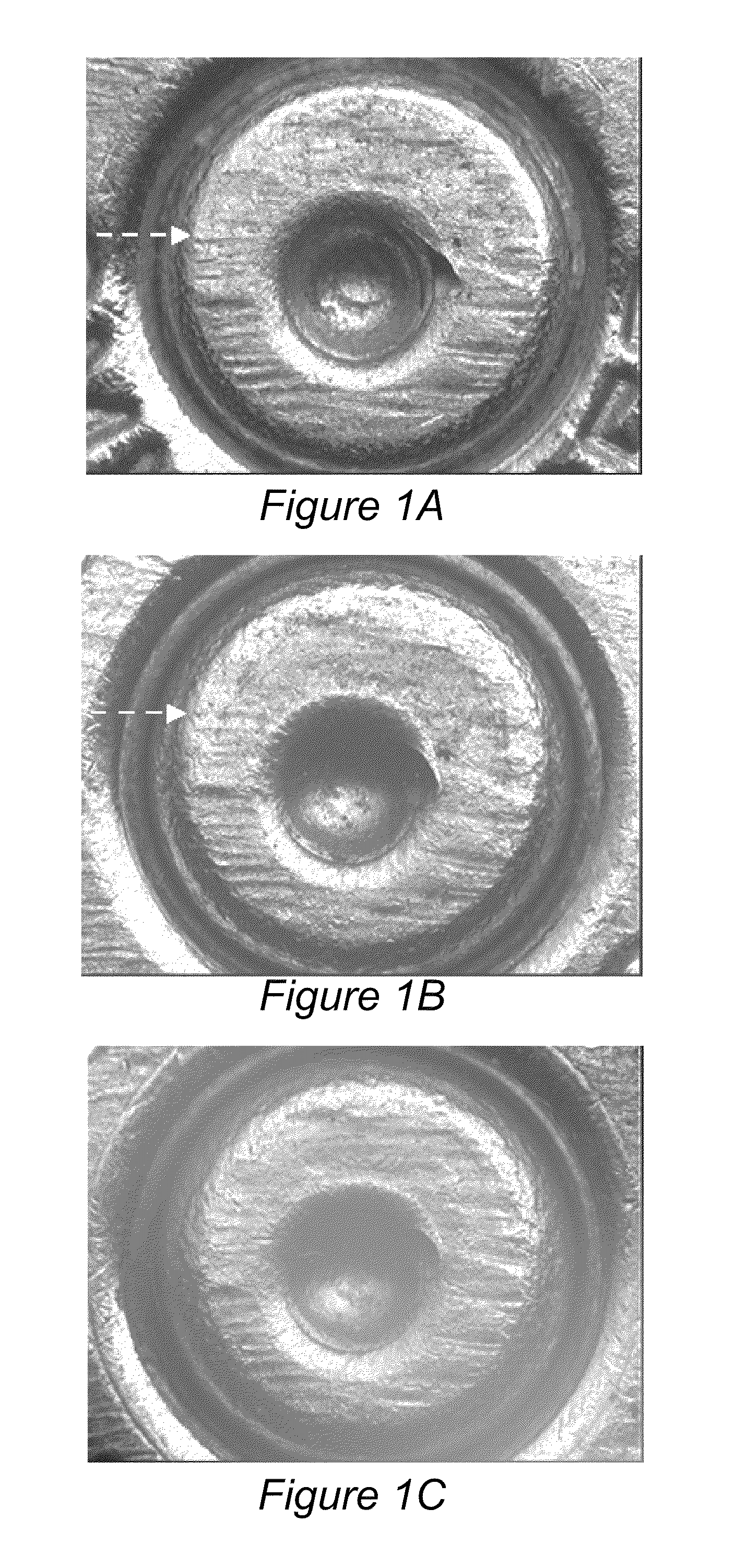

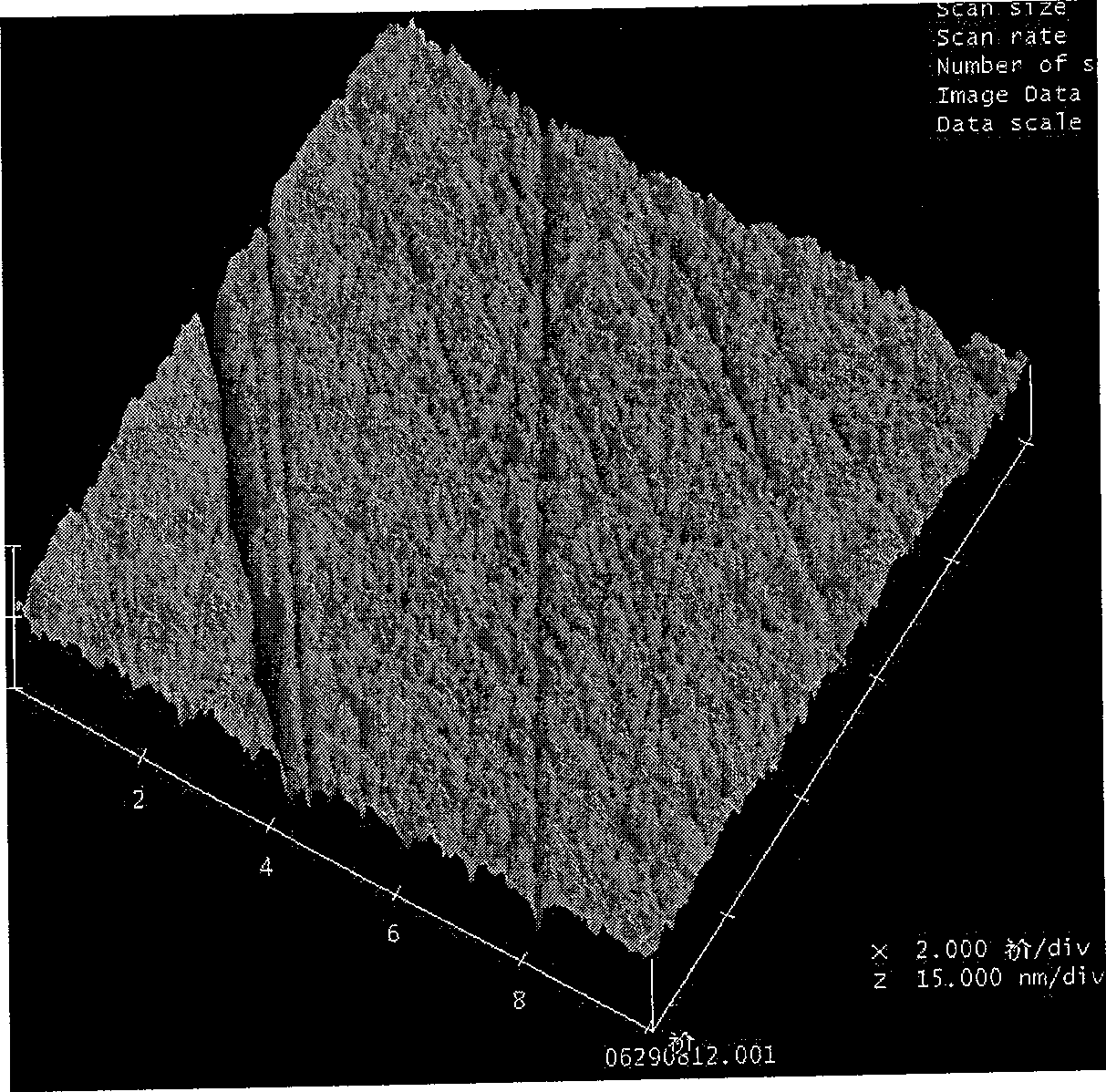

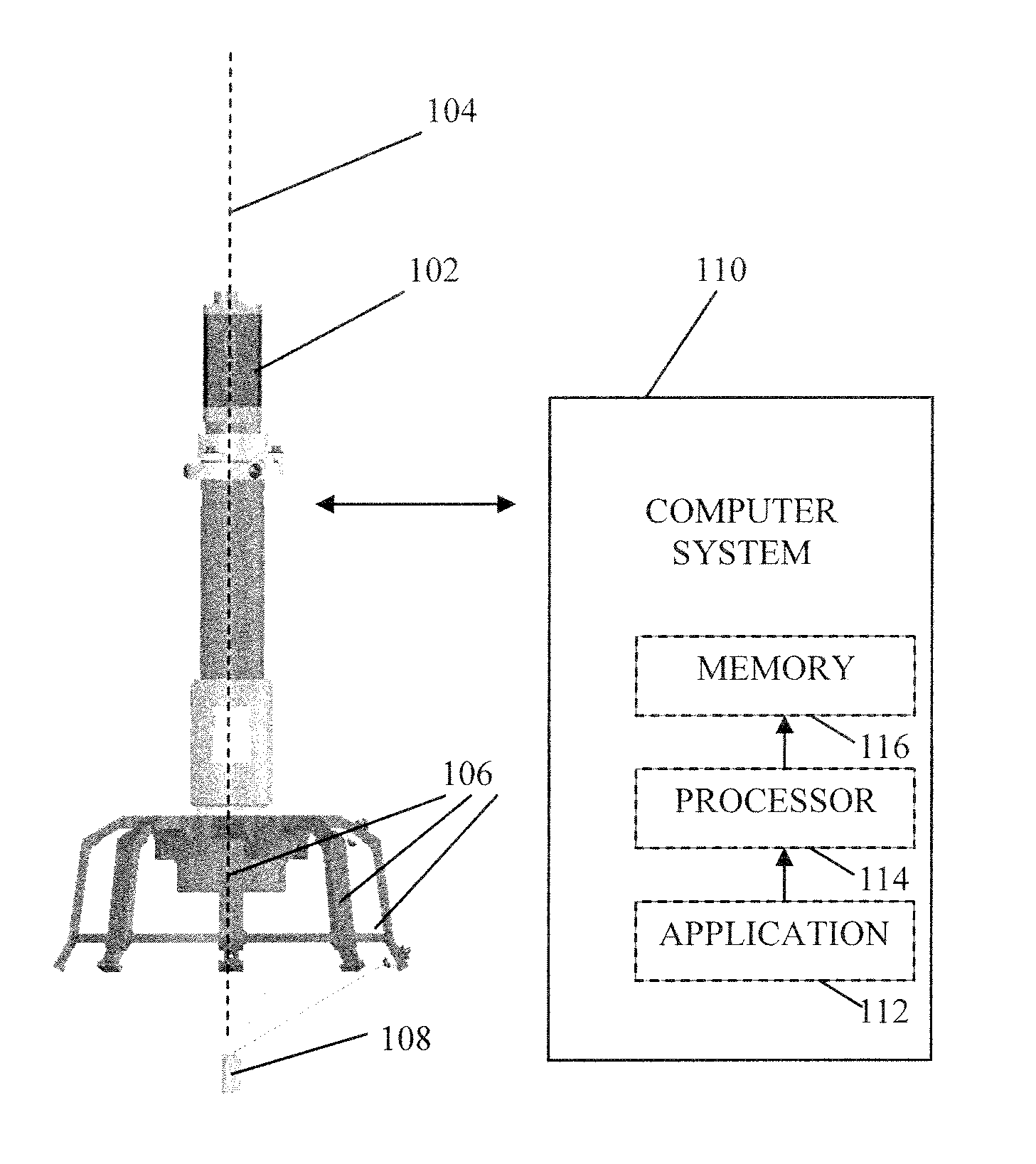

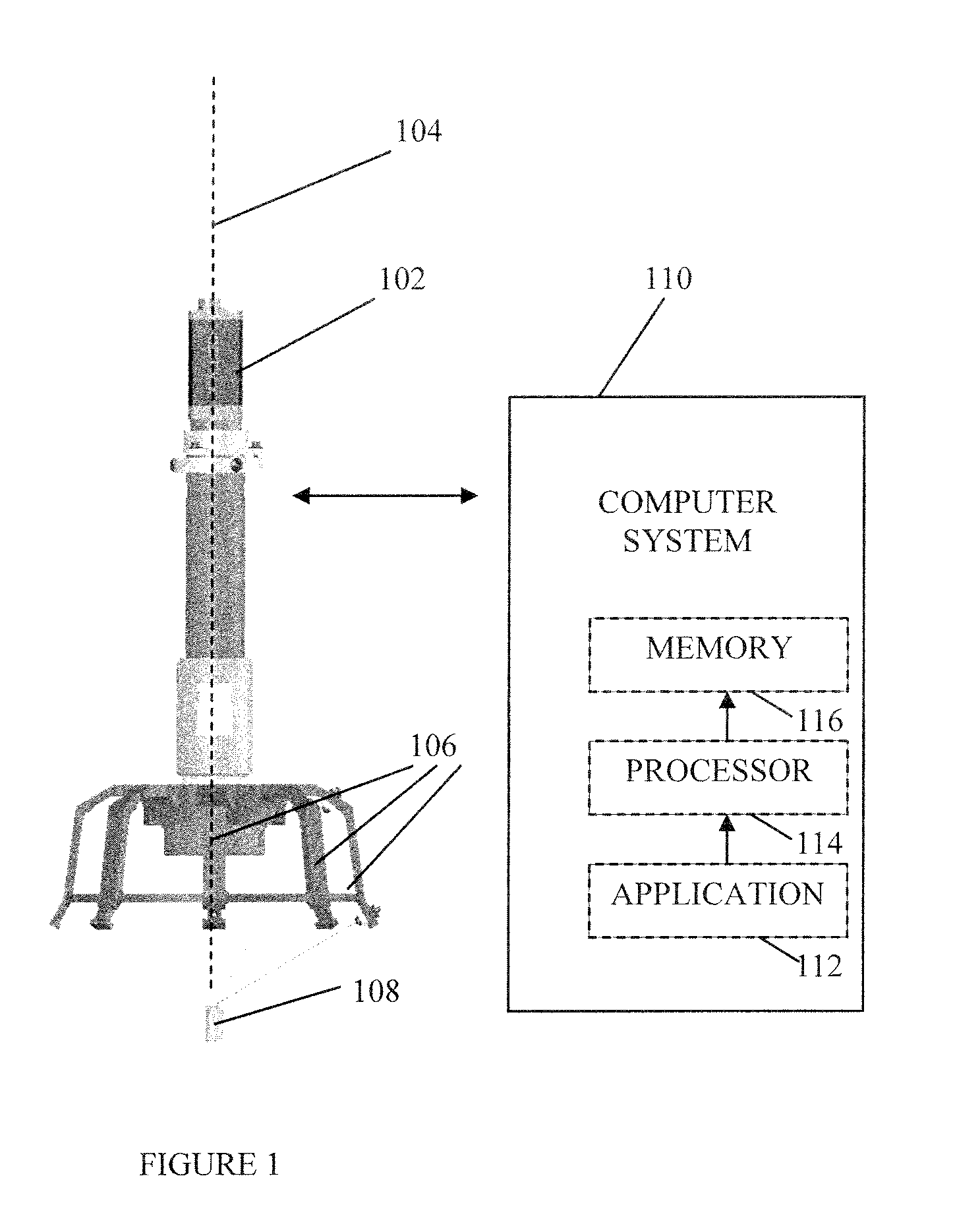

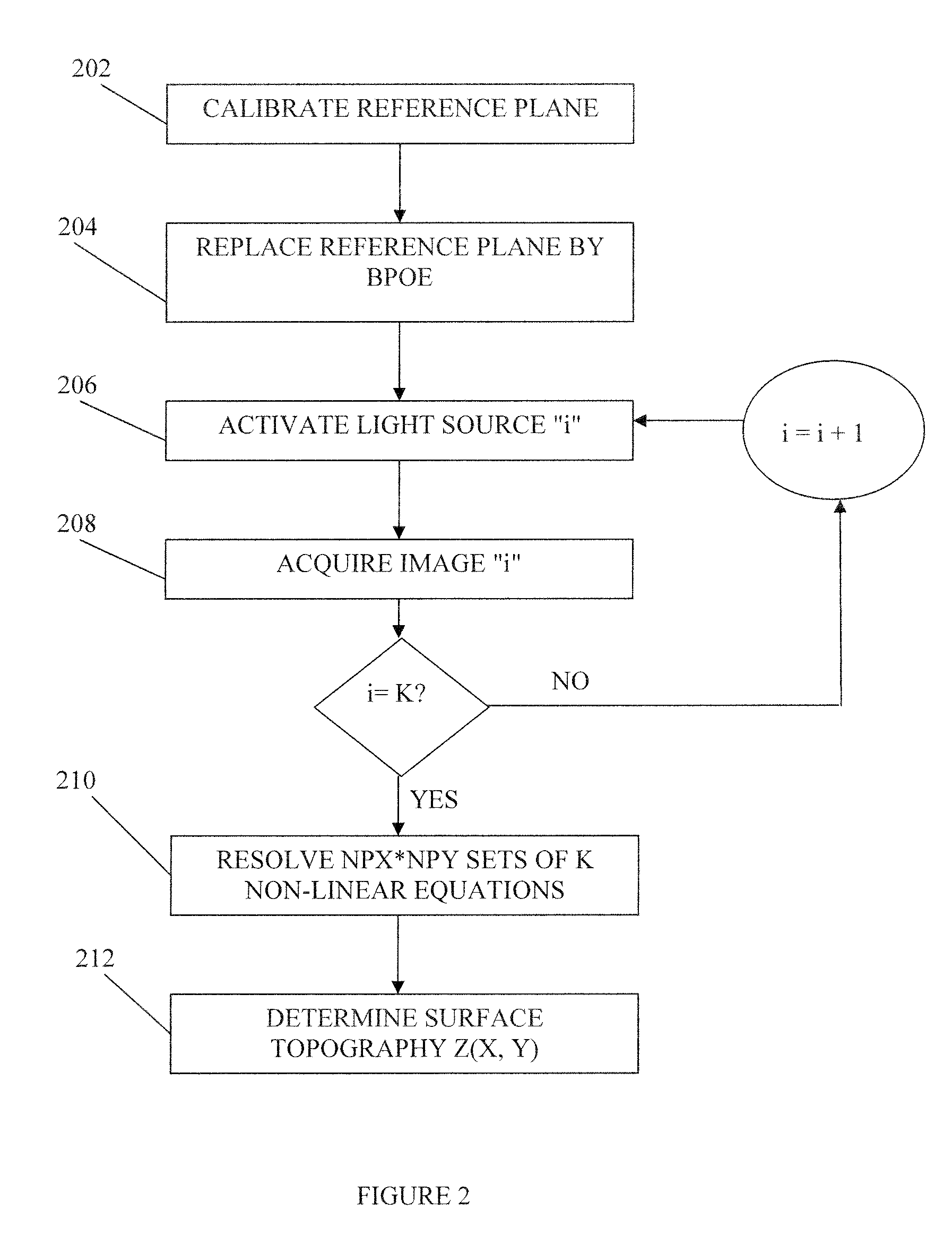

Acquisition of 3D topographic images of tool marks using non-linear photometric stereo method

There is described a method and 3D image acquisition system for addressing the specular nature of metallic surfaces in general, and ballistic pieces of evidence in particular, using photometric stereo by identifying and solving a plurality of sets of non-linear equations comprising a diffusive term and a specular term to determine a surface normal vector field N(x, y), and using N(x, y) to determine a 3D topography Z(x, y).

Owner:ULTRA ELECTRONICS FORENSIC TECH INC

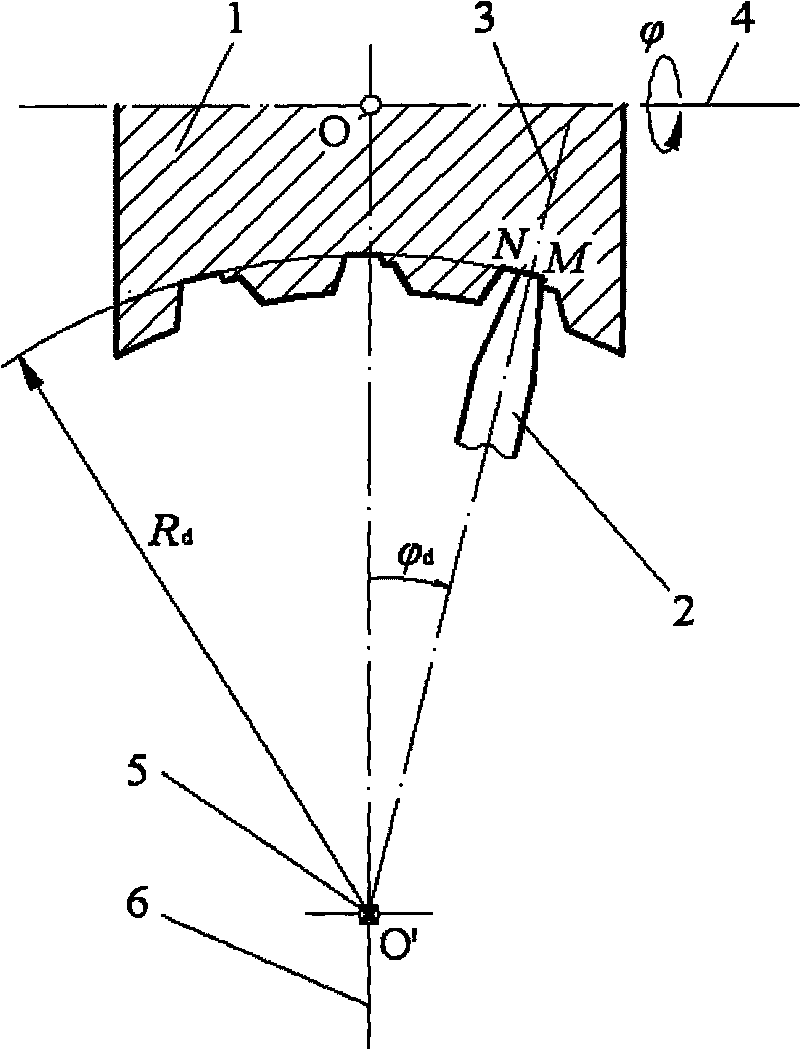

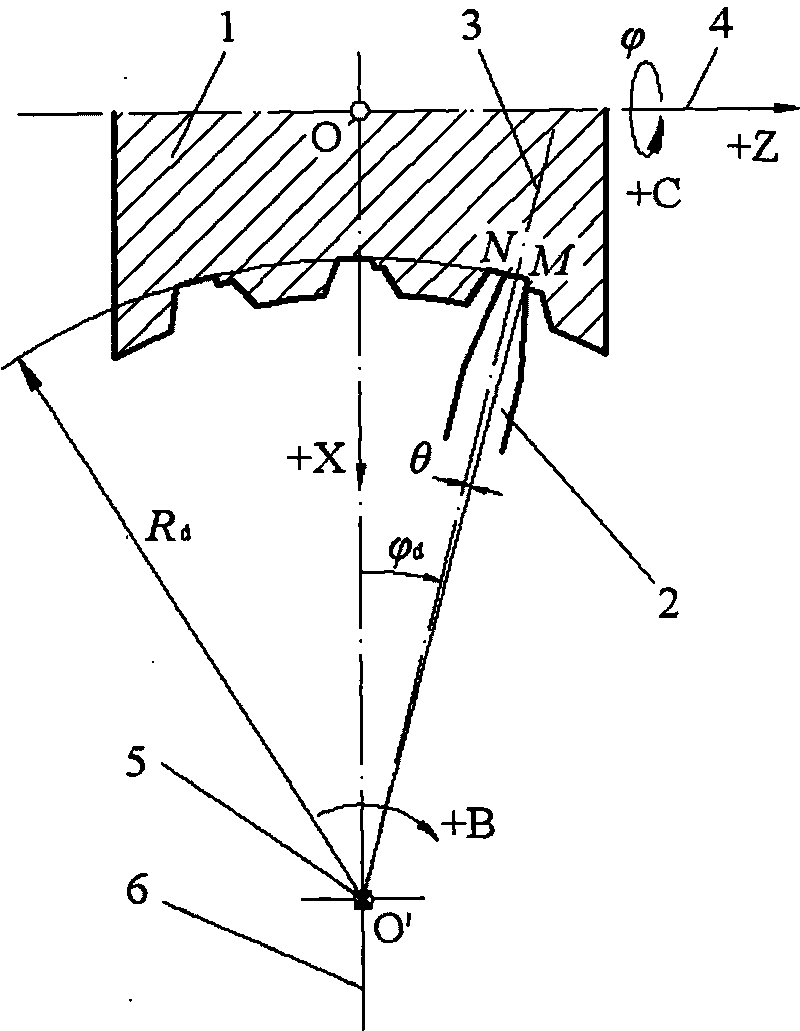

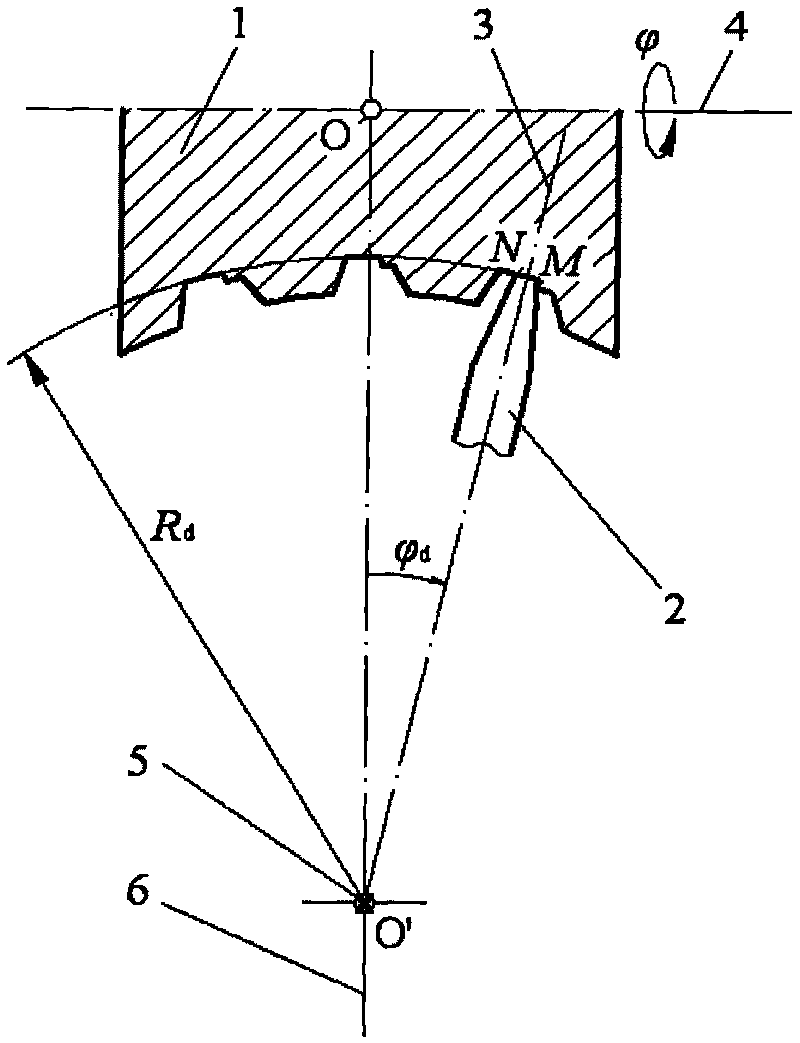

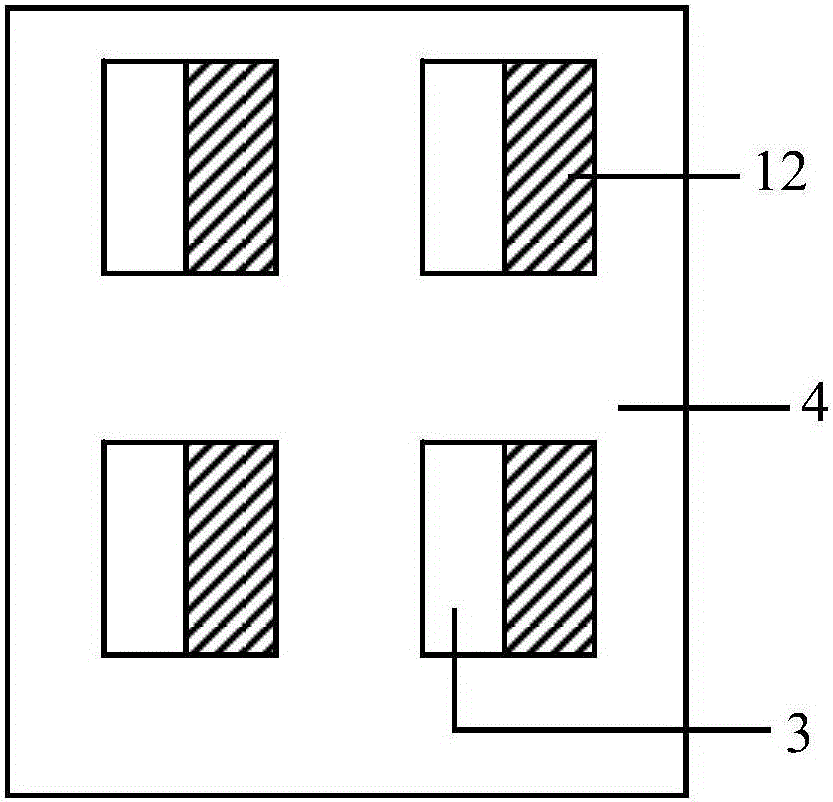

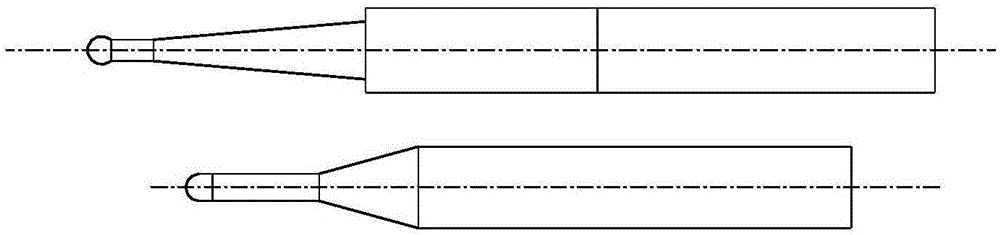

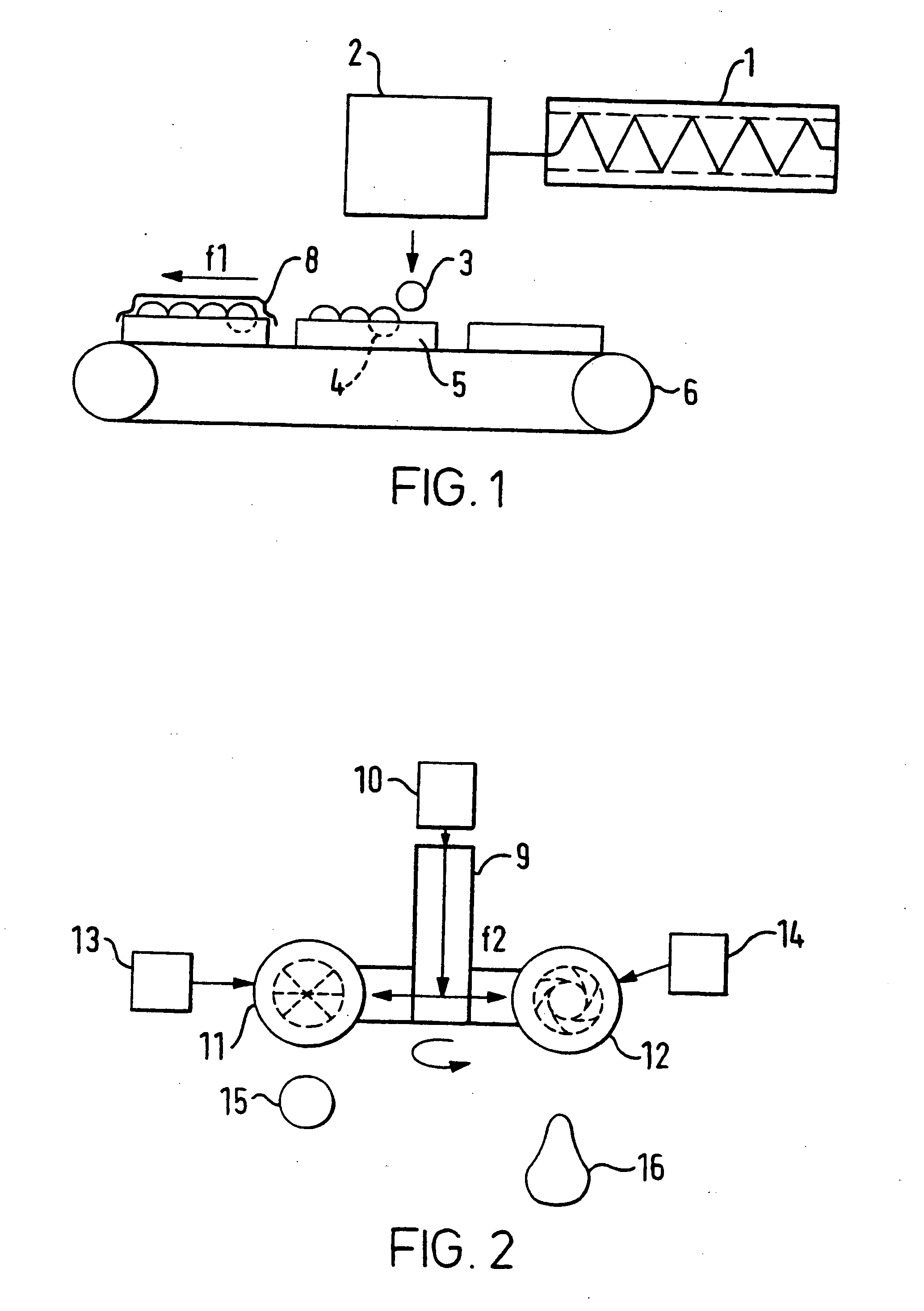

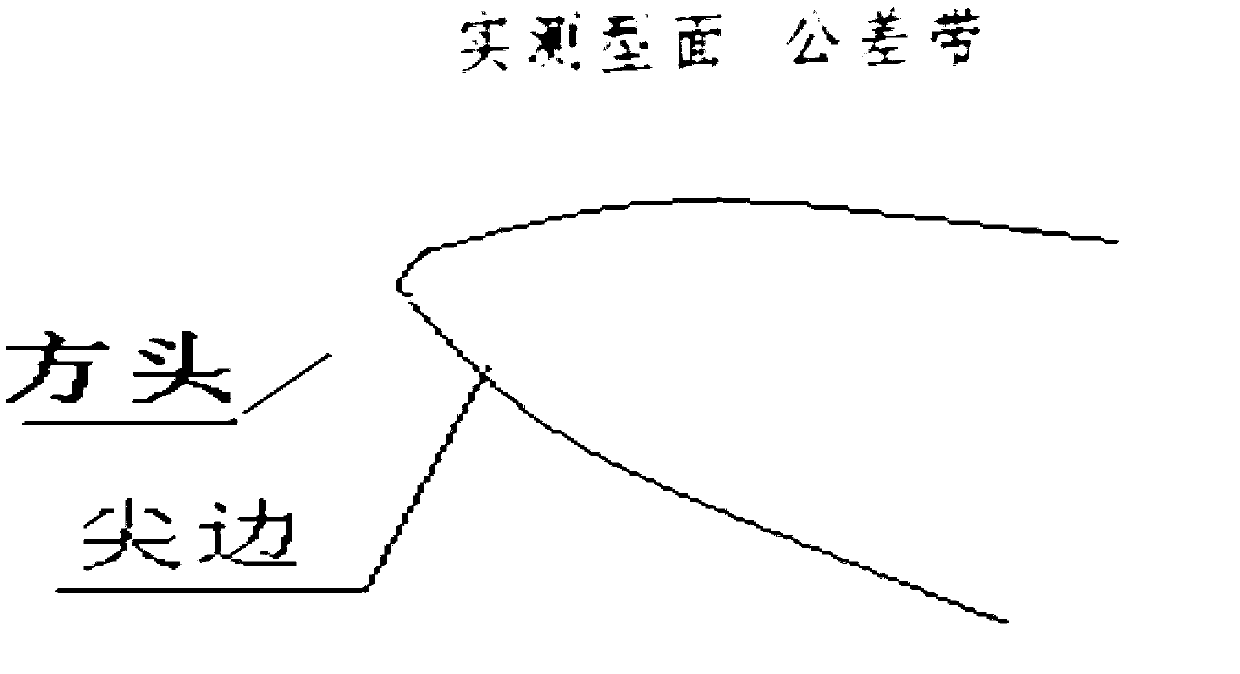

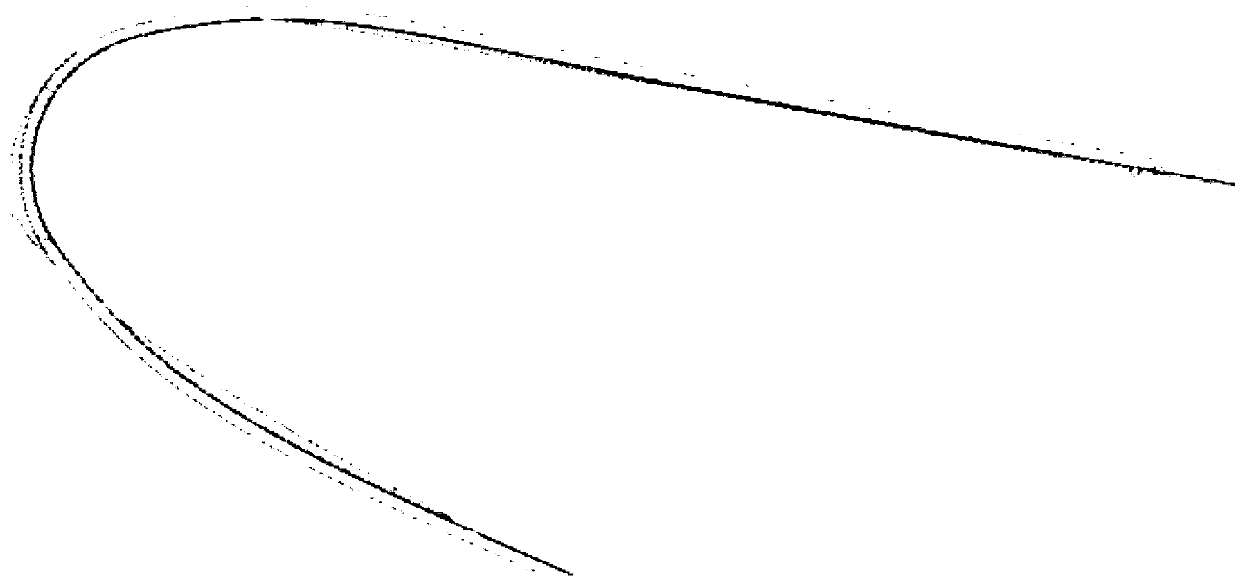

Rough machining method of helical surface of hourglass worm

ActiveCN101700576ASolve the homogenization problem of grinding allowanceTurning machinesWhole bodyRadius of gyration

The invention discloses a rough machining method suitable for helical surfaces of various hourglass worms, belonging to a method for machining hourglass worms. The invention adopts the technical scheme that a hourglass worm 1, a turning tool 2, a turning tool marking line 3, a worm axial line 4, a turning tool revolving axial line 5 and a common perpendicular thereof 6 are comprised, wherein the worm axial line and the turning tool revolving axial line are vertically interlaced, perpendicular foots are respectively O and O', the turning tool marking line 3 passing through the point O', a leftcutter point N and a right cutter point M are arranged in a plane determined by the worm axial line 4 and the common perpendicular 6, wherein the revolving radius of the left cutter point N and the revolving radius of the right cutter point M are Rd. According to a principle of hourglass worm forming, an annular surface with the radius of Rd and a series of corresponding points on a left helical surface and a right helical surface at different axial section parts when the corresponding center distance of the same helical groove of the hourglass worm 1 is OO' are obtained. A cutter point between the cutter points N and the cutter point M is used for turning the part on the current annular surface of the same helical groove of the hourglass worm 1 between an engaging-in end and an engaging-out end, and turning whole body of the same helical groove along with the continuous reduction of the center distance OO'. The invention solves the problem of hourglass worm grinding allowance homogenization.

Owner:CHINA AGRI UNIV

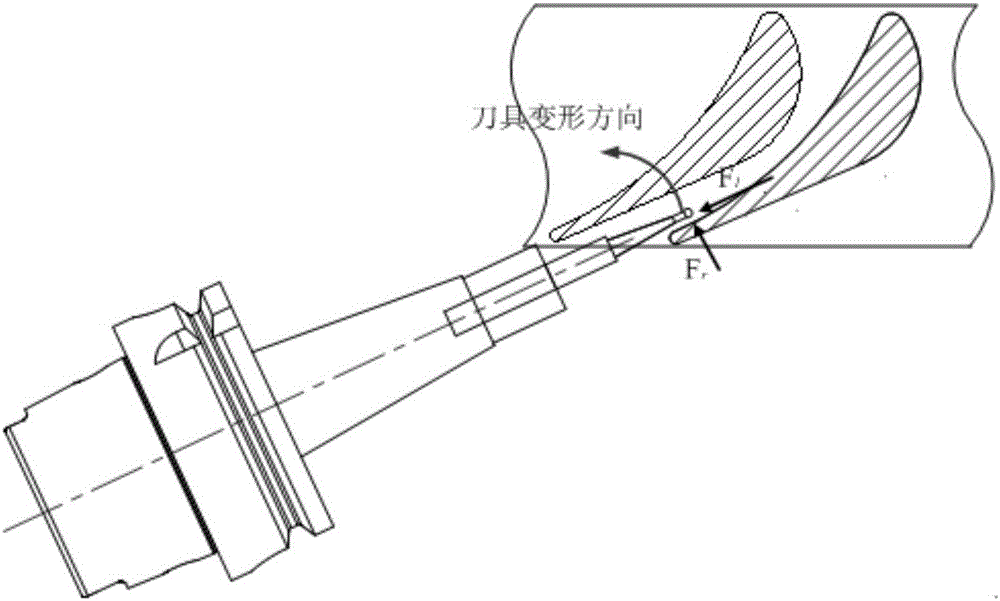

Machining technology of turbine blade with water corrosion prevention achieved by means of laser cladding

ActiveCN103659201AGuarantee the requirements of machining dimensional accuracyGuarantee cladding qualityStellite alloyDistressing

The invention provides a machining technology of a turbine blade with water corrosion prevention achieved by means of laser cladding. According to the machining technology of the turbine blade, the machining precision of the blade can be guaranteed, the fusion cladding amount is small, and tool loss is reasonable. The machining technology of the turbine blade with the water corrosion prevention achieved by means of laser cladding comprises the steps of (1) blank manufacturing; (2) forming through die forging; (3) heat treatment; (4) rough milling of the molded surface of a blank and milling of a laser cladding groove, wherein a certain redundant amount of a forge piece is removed through milling, and the laser cladding groove is machined until the laser cladding groove is within a certain tolerance range; (5) laser cladding of stellite in the laser cladding groove; (6) correction of a blade by means of a pressing machine after laser cladding; (7) radiographic and penetration inspection of a laser cladding area; (8) repairing welding of an unqualified portion, in the laser cladding area, of the blade through argon arc welding; (9) distressing and heat treatment; (10) comprehensive milling, wherein the blade is machined until the blade is within the tolerance range; (11) polishing, wherein machining tool marks on the surface of the blade are removed through polishing; (12) shot blasting of the surface of the blade.

Owner:WUXI TURBINE BLADE

Base-material-free adhesive tape processing technology avoiding tool marks on ultralight base films

InactiveCN105950036ASolve the problem of knife marksAvoid depthFilm/foil adhesivesEngineeringTool marks

The invention relates to a processing technology, in particular to a base-material-free adhesive tape processing technology avoiding tool marks on ultralight base films. The processing technology comprises the following steps: (1) first release films are composited on the upper surface and the lower surface of a base-material-free adhesive tape; (2) the base-material-free adhesive tape is shaped, wherein an adhesive tape die-cutting forming tool is used and punches the base-material-free adhesive tape in a certain shape, and adhesive tape waste and the first release films are removed; (3) a release film is shaped, a second release film and a first protection film are composited sequentially on the surface of the formed base-material-free adhesive tape, a release film die-cutting tool is used and punches the release film in a certain shape, the shaped release film is obtained, second release film waste and the protection film are removed, and the base-material-free adhesive tape is obtained. The base-material-free adhesive tape and the release films are processed separately, and accordingly, the phenomenon that the release films have tool marks and are easy to break is avoided.

Owner:SUZHOU ANJIE TECH

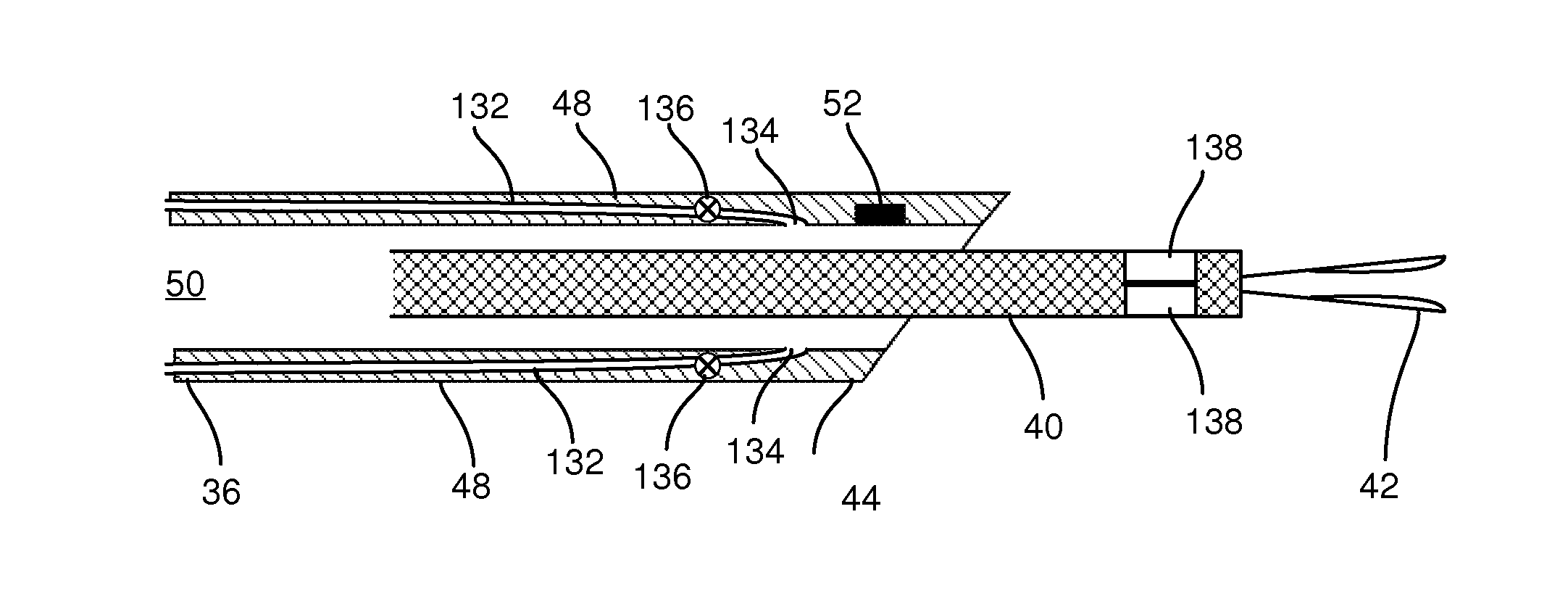

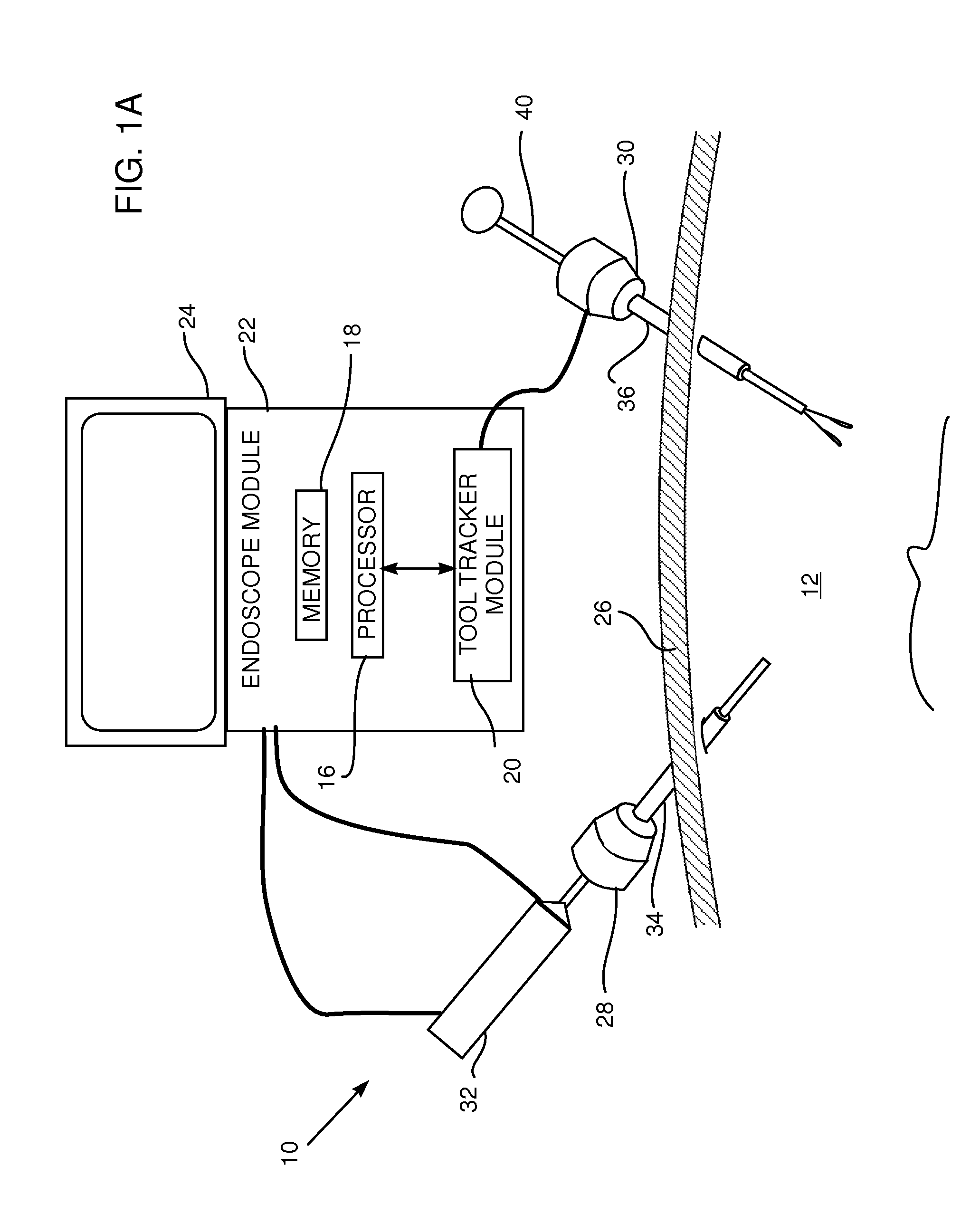

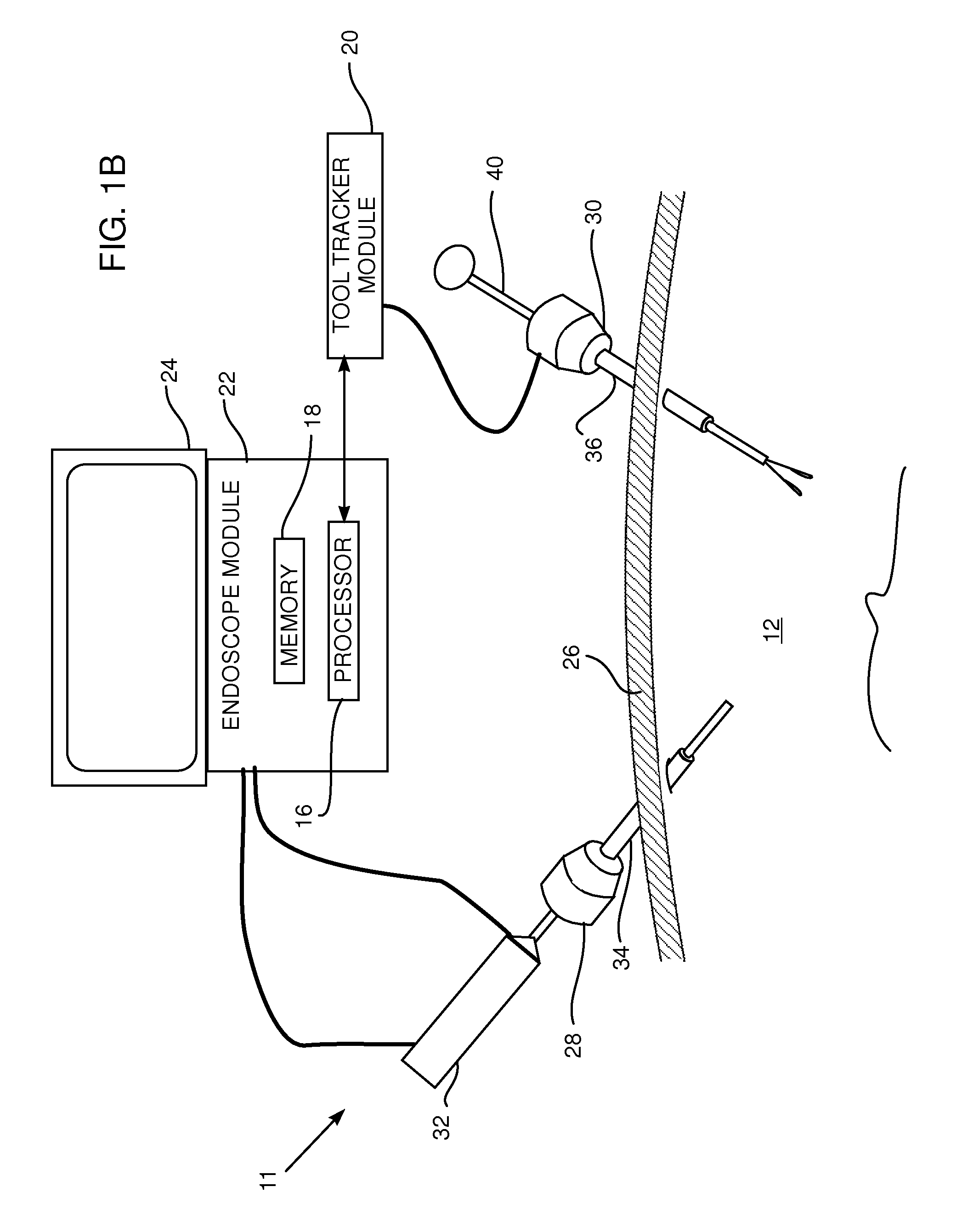

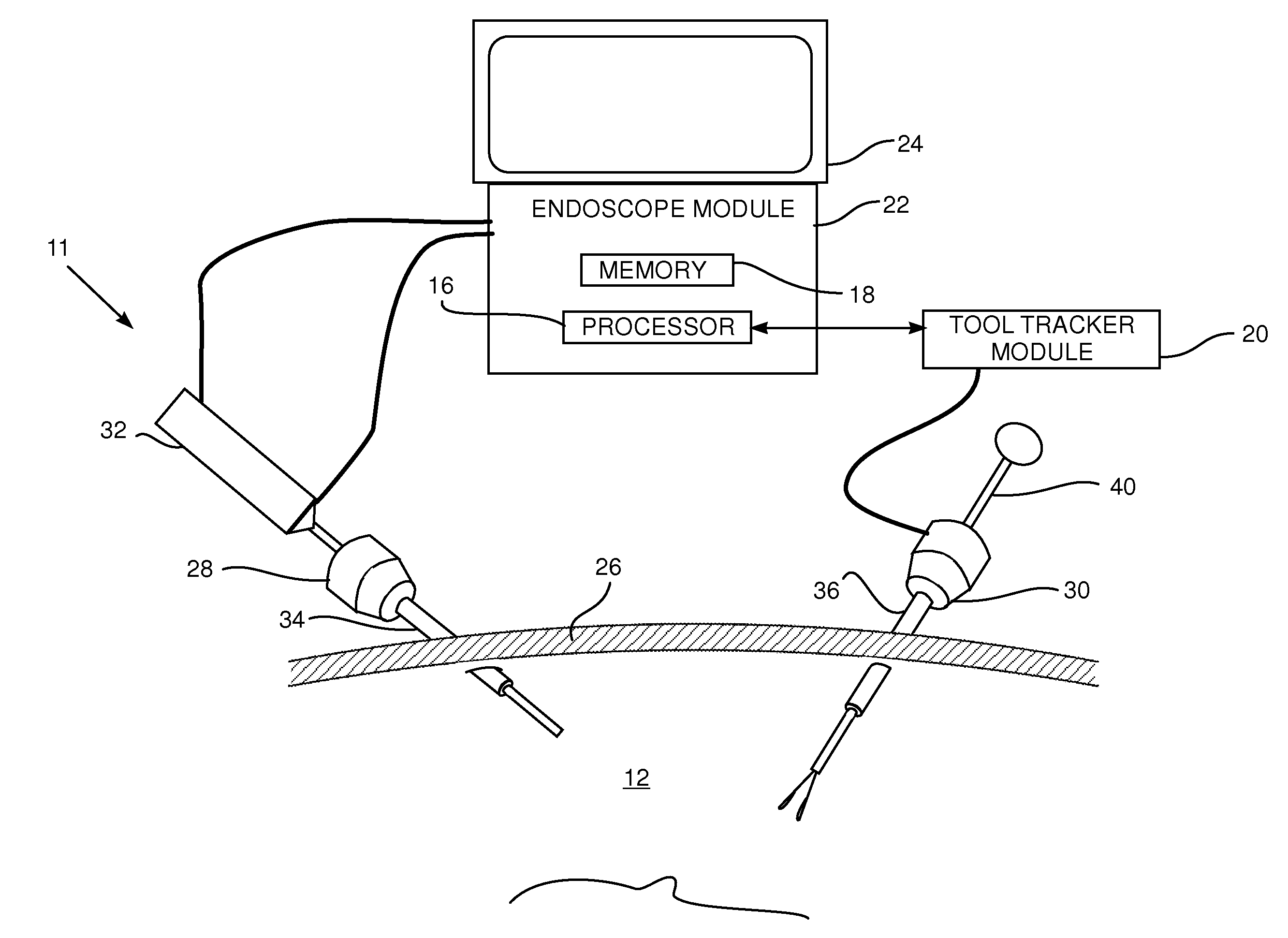

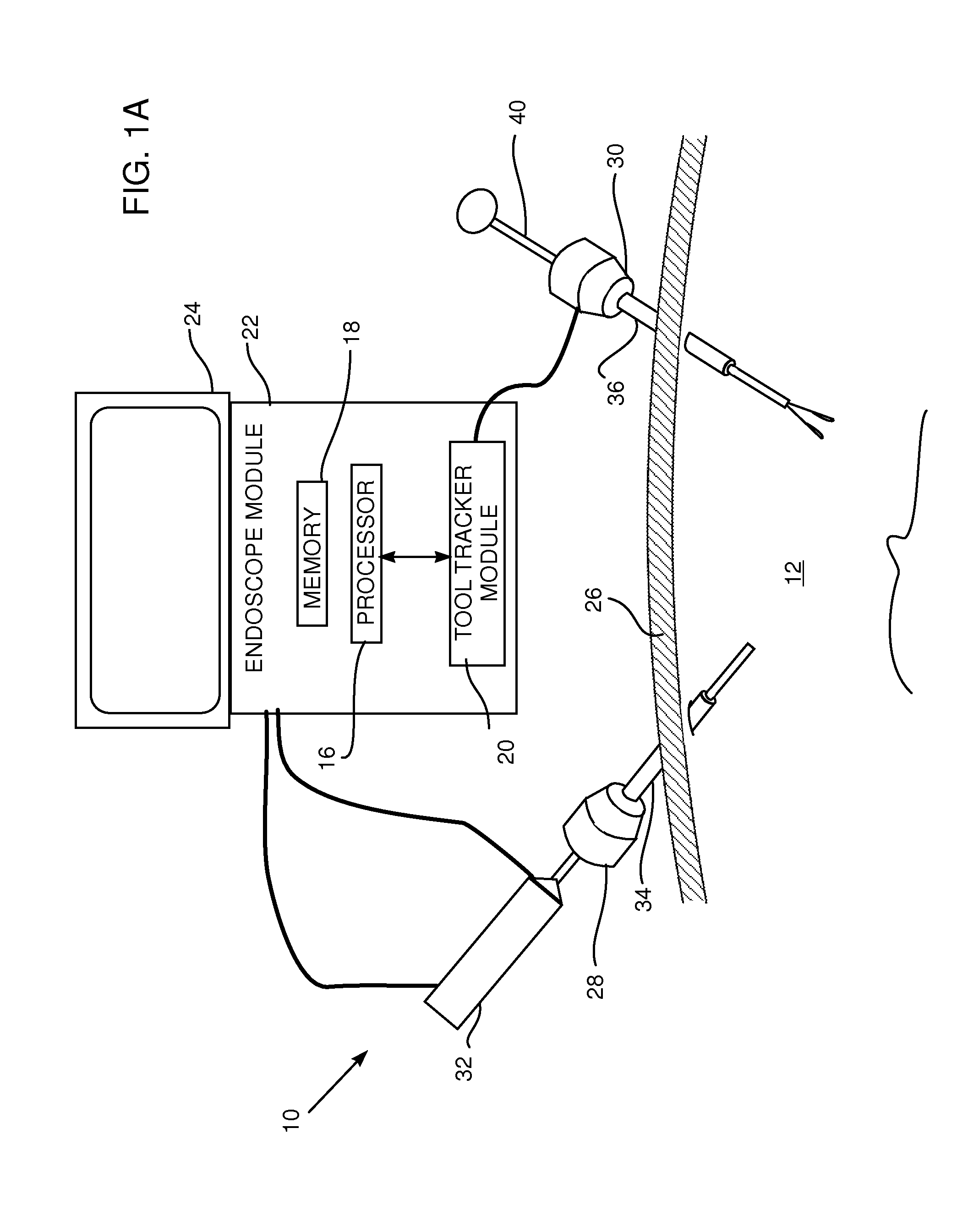

Automatic tool marking

Owner:GYRUS ACMI INC (D B A OLYMPUS SURGICAL TECH AMERICA)

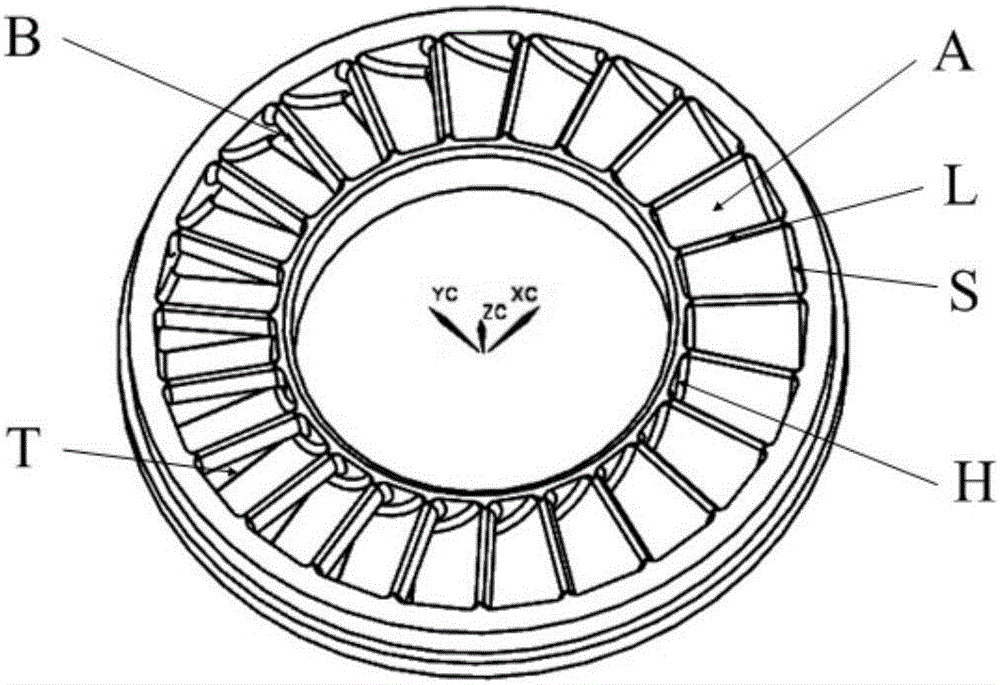

Shrouded impeller finish machining tool path planning method

The invention discloses a shrouded impeller finish machining tool path planning method. The shrouded impeller finish machining tool path planning method comprises the following seven steps of model establishment, tool selection, machining area division, blade profile curved surface reconstruction, tool center point computation, tool shaft vector computation and post-processing. According to the shrouded impeller finish machining tool path planning method, obtained finish machining tool path can be in a streamline direction, so that the product machining efficiency can be improved; by means of small-angle five-axis plunge milling, deformation of tools caused by radial component force can be greatly reduced, and the blade machining precision can be enhanced; tool marks generated by tool feeding at both ends can be reduced.

Owner:BEIJING POWER MACHINERY INST

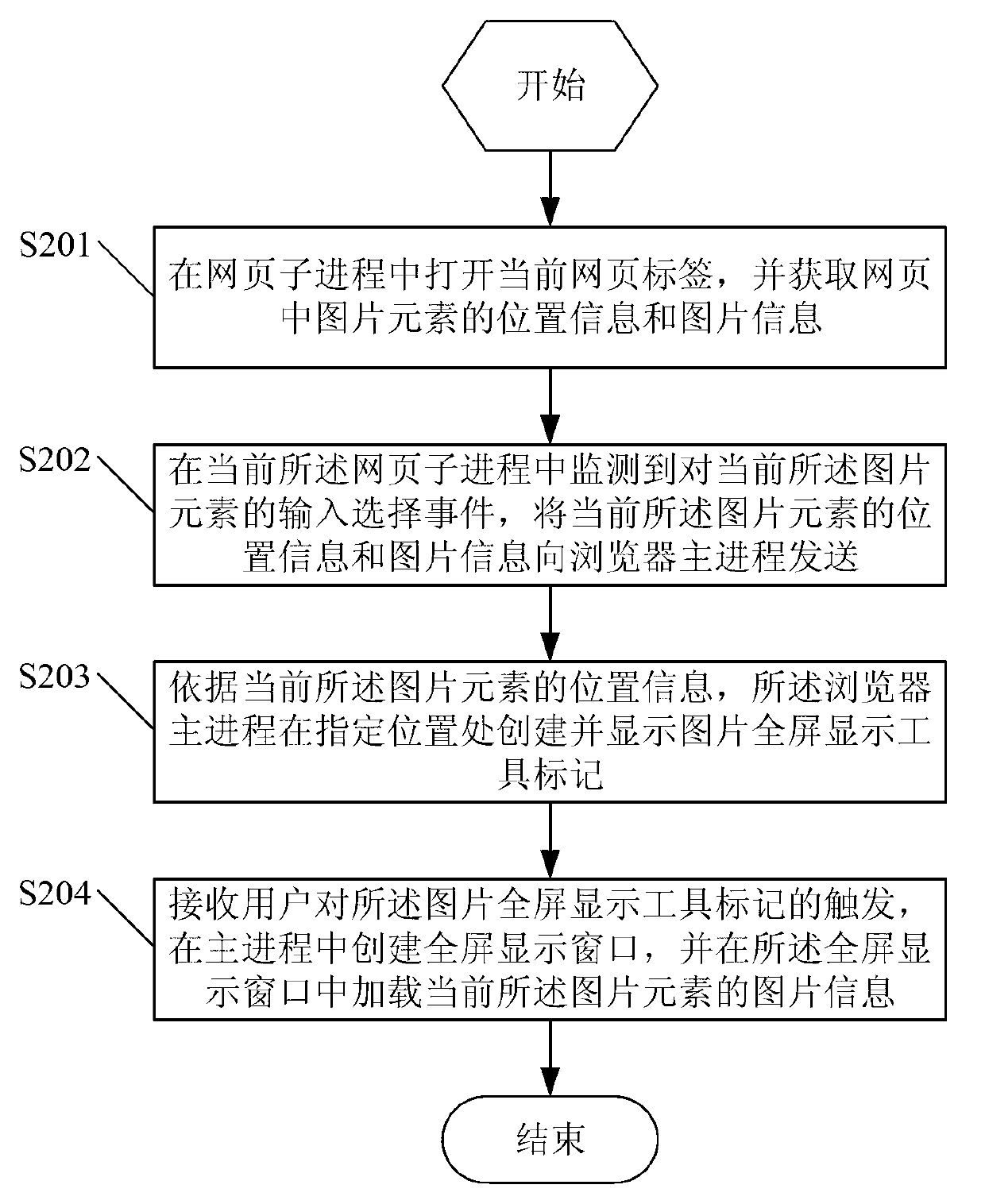

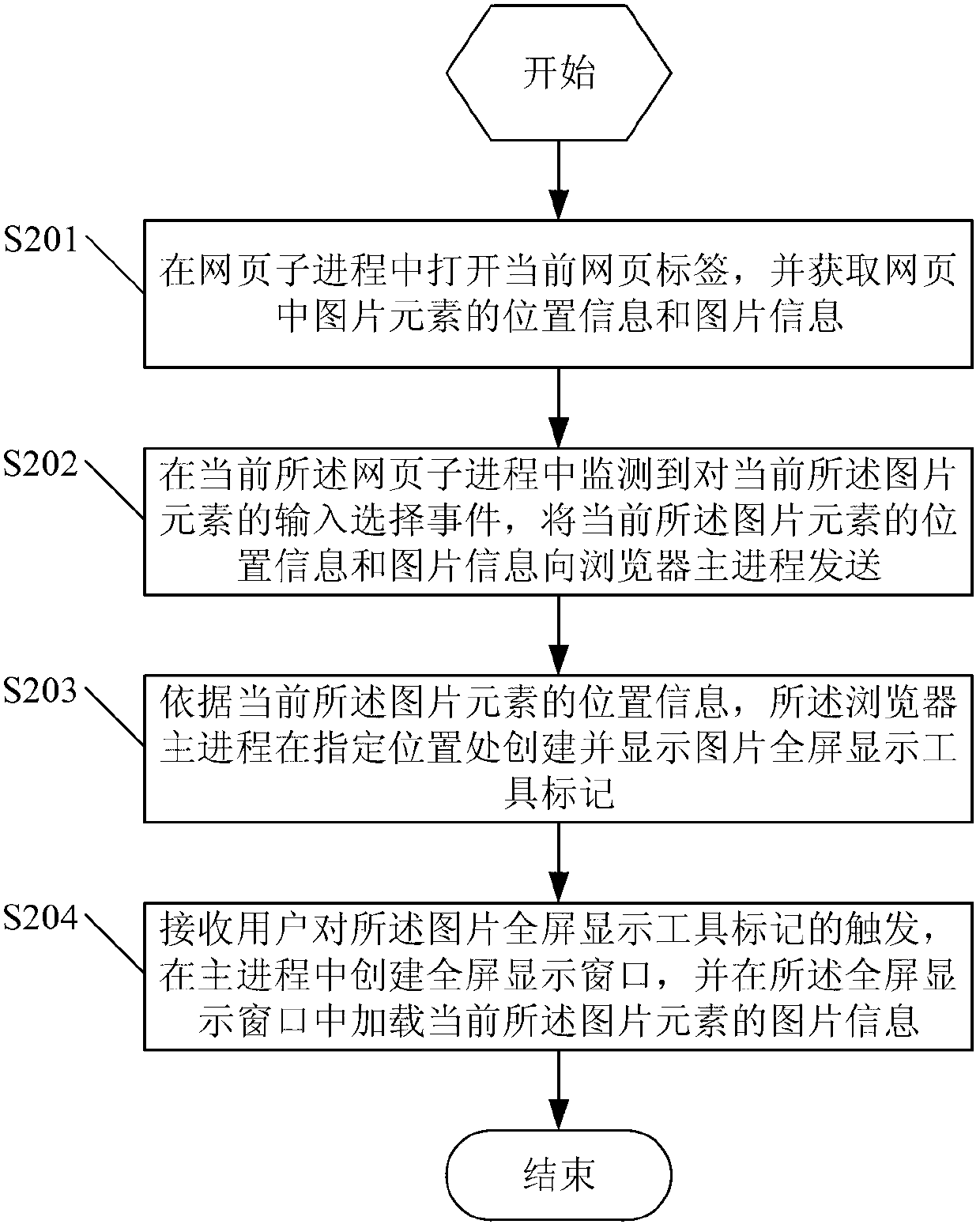

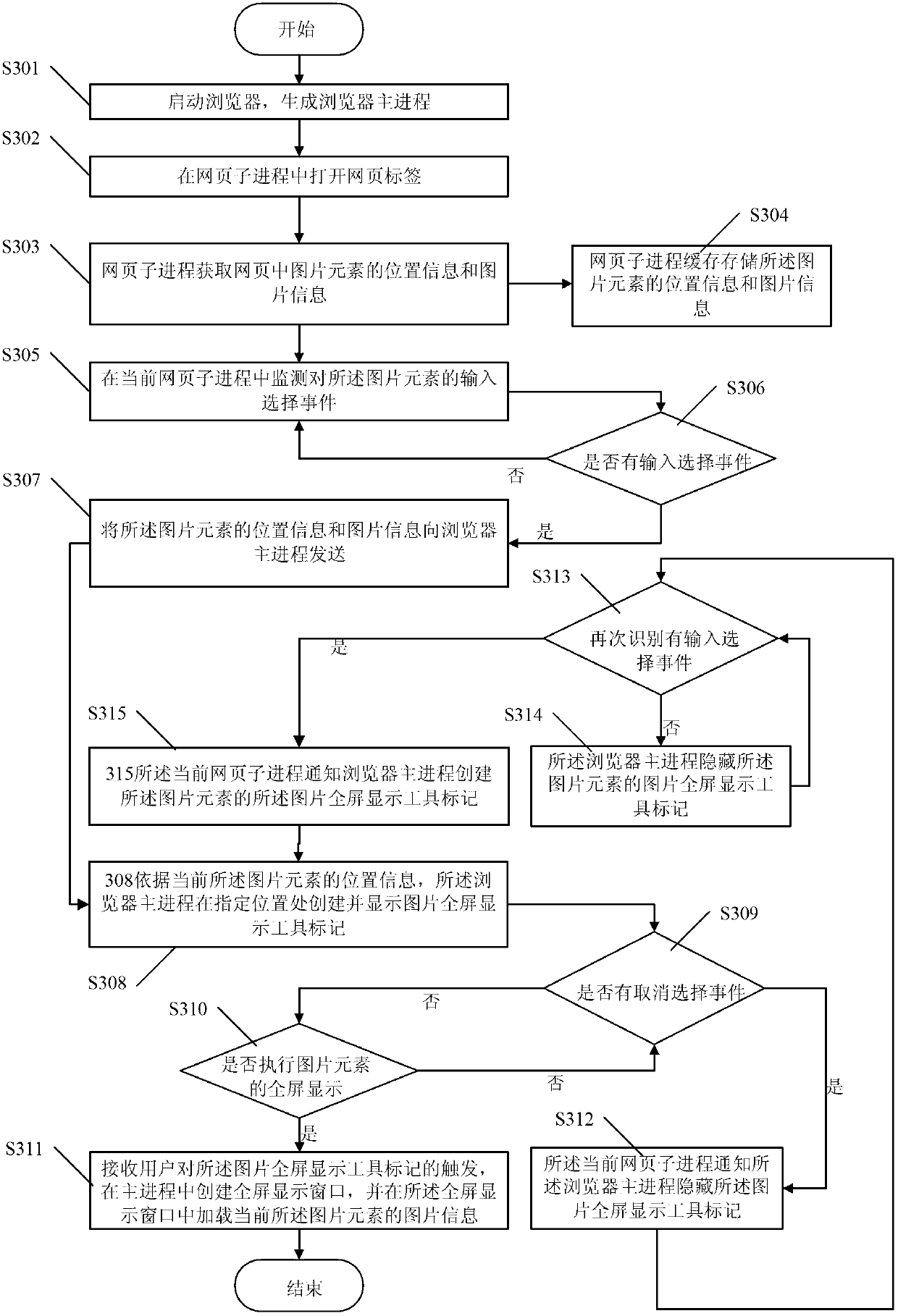

Full-screen browsing method and device for picture in web page

ActiveCN102999342ATroubleshootingReduce the burden onSpecial data processing applicationsSpecific program execution arrangementsInput selectionComputer graphics (images)

The invention discloses a full-screen browsing method and device for a picture in a web page. The method comprises the following steps of: opening a tag of a current web page in a sub-process of the web page, and obtaining position and picture information on picture elements in the web page; when a selection inputting event for the current picture elements is monitored in the sub-process of the current web page, sending the position and picture information on the current picture elements to a host process of a browser; according to the position information on the current picture elements, creating and displaying a picture full-screen display tool mark at a specified position by the host process of the browser; and receiving a trigger on the picture full-screen display tool mark from a user, creating a full-screen display window in the host process, and loading the picture information on the current picture elements into the full-screen display window. According to the method and the device, a mechanism for the full-screen browsing of picture elements in one or more webpage tags is established in the host process of the browser, so that the problem of browser failure caused when picture full-screen browsing is executed in the browser is solved.

Owner:BEIJING QIHOO TECH CO LTD

Round items of frozen confectionery and process of manufacture

A round item of frozen confectionery having an even roundness and a shape generated by revolution but essentially lacking an apex, rough edges and forming tool marks, In particular, the frozen confectionery has the form of a ball similar in appearance to a ball made non-industrially with an ice-cream scoop. These items are manufactured by extrusion-forming of a confectionery in the cold state.

Owner:NESTEC SA

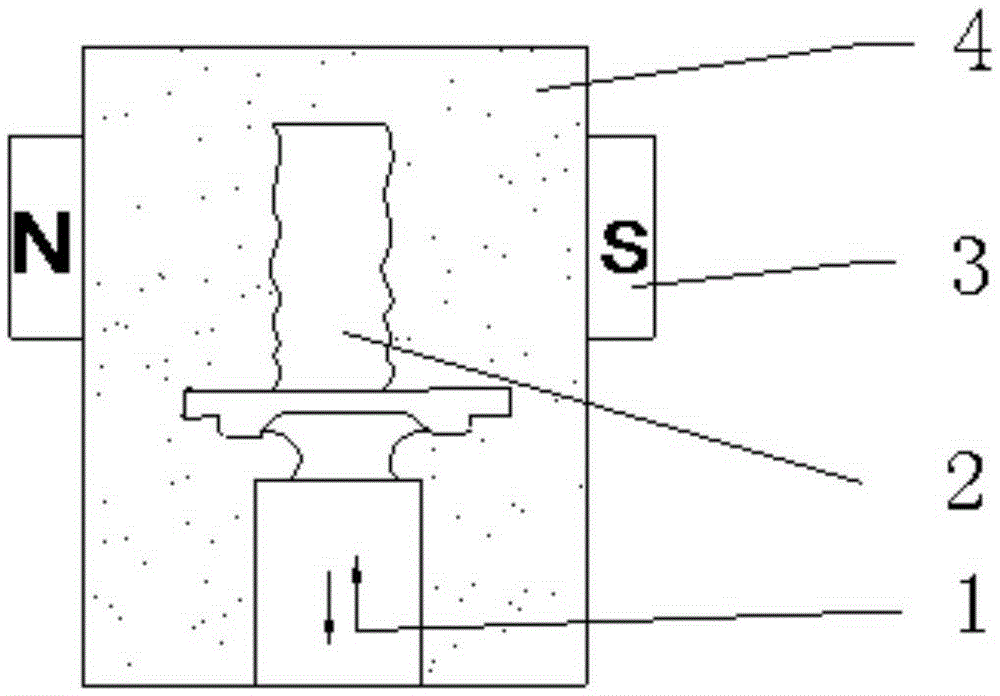

Automatic polishing method and device for finish-milling hook face

ActiveCN105397611AAchieve removalEdge grinding machinesPolishing machinesReciprocating motionPolishing

The invention discloses an automatic polishing method and device for a finish-milling hook face. A magnetic grinding material is adopted, and when no magnetic field is applied to the grinding material, the polishing process effect of the grinding material is the same as that of a common vibration burnisher; under the condition that the magnetic field is applied, the magnetic grinding material can condense into a whole; the grinding material can be well matched with the shape of ripples generated by milling tool marks on the surface of a blade, the waviness of the surface of the blade can be completely copied, and therefore a whole polishing medium can be formed on the periphery of the hook face of the blade; and when the blade does up-and-down reciprocating motion under the effect of a vibration source, the overall polishing medium can effectively remove residues of the milling tool marks, namely materials at peaks of the ripples on the surface of the blade. The automatic polishing method and device have the beneficial effects that the effect of free vibration burnishing can be achieved, the aim of selectively removing the tool marks can be achieved, and about 70% of working amount of manual polishing for tool mark removing can be replaced.

Owner:SHENYANG LIMING AERO-ENGINE GROUP CORPORATION

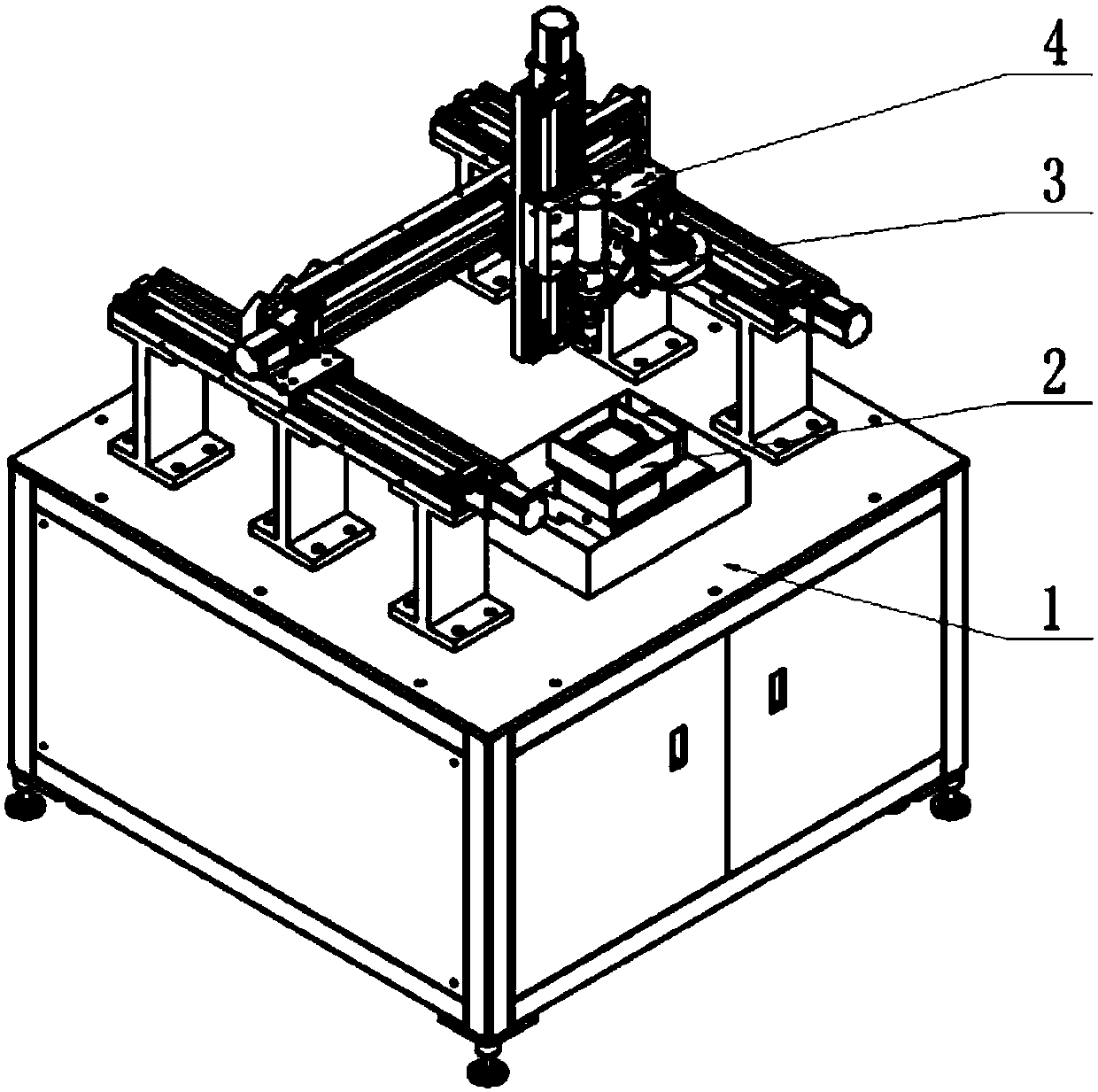

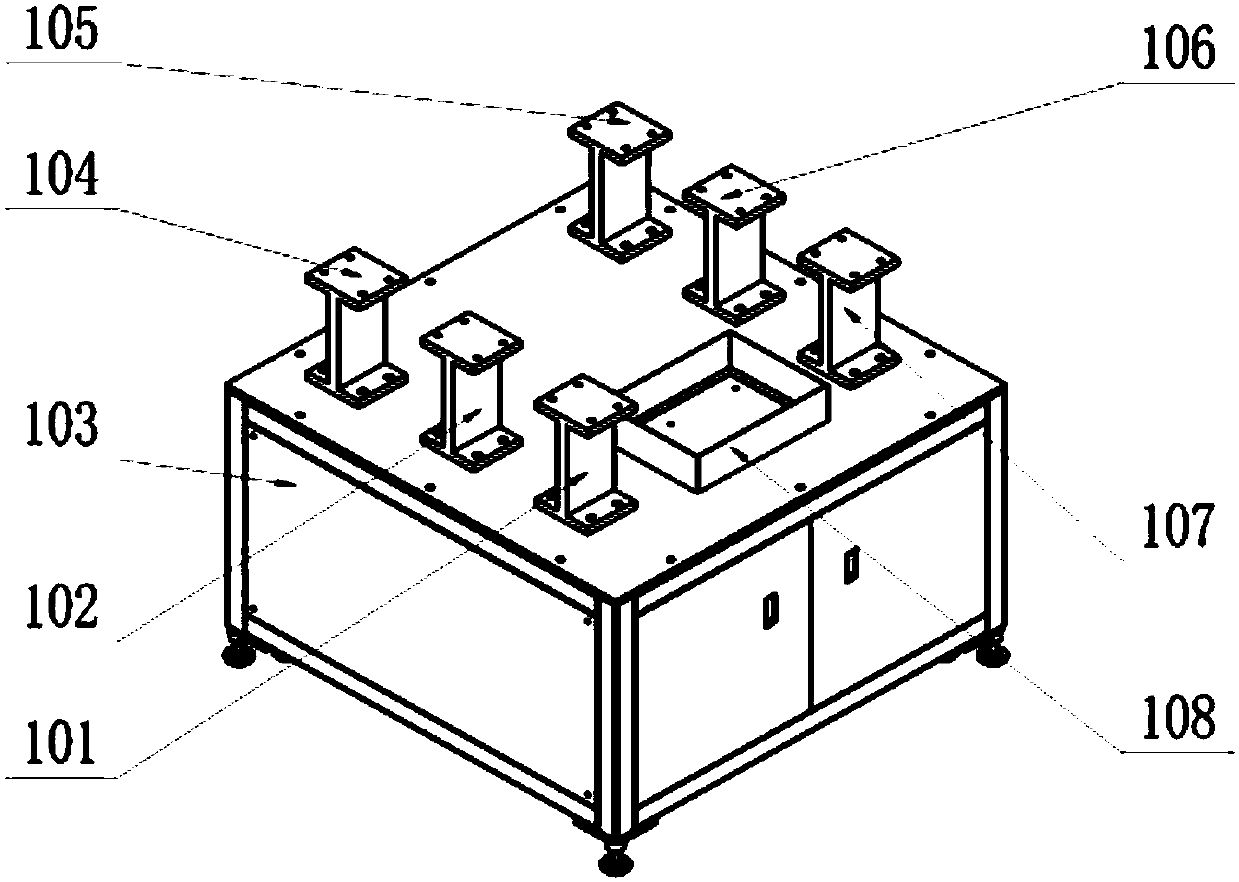

Electrorheological assisted ultrasonic tracking deburring device

PendingCN107775457ARealize finishingEdge grinding machinesGrinding carriagesNumerical controlImaging processing

The invention relates to an electrorheological assisted ultrasonic tracking deburring device and belongs to the field of ultraprecision machining and manufacturing. A rotating fixture working table and a servo movement mechanism are mounted on a table board of an equipment support seat of an equipment base, and a tool head is mounted on a slider of a Z-axis module of the servo movement mechanism.The electrorheological assisted ultrasonic tracking deburring device has the beneficial effects as follows: the tool head with ultrasonic vibrators and electrorheological assisting effect is loaded bya numerical control four-axis machine tool, surface defects such as microstructural burrs, tool marks, bulges and the like of a metal test piece are removed by abrasive grains under driving of recombination actions of supersonic vibration and electrorheological effect, submillimeter-scale microstructural finish machining of the metal test piece is realized, structural guarantee is provided for tracking machining of positioning and tracing for the surface defects such as burrs and the like by the aid of visual image processing, and the device can be widely applied to submillimeter-scale microstructural tracking finish machining of a metal mold.

Owner:JILIN UNIV

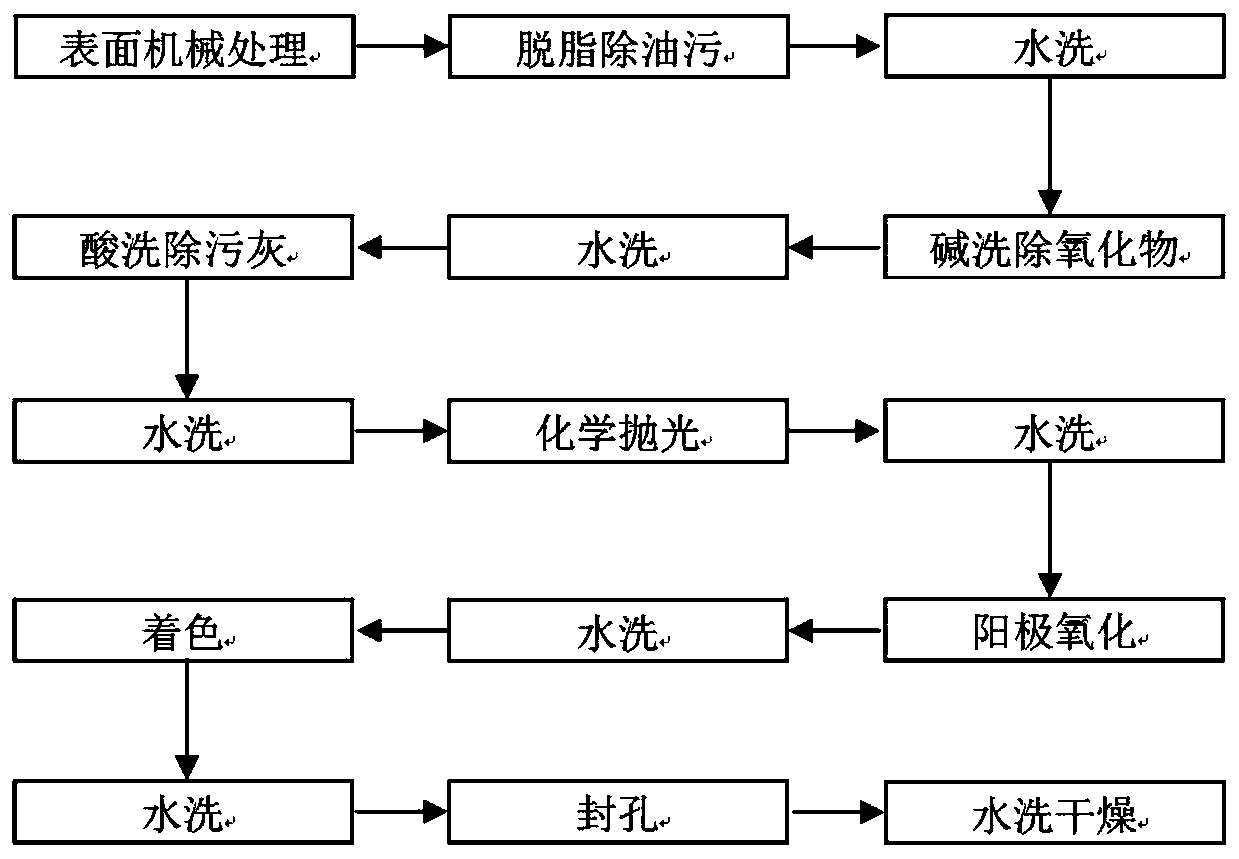

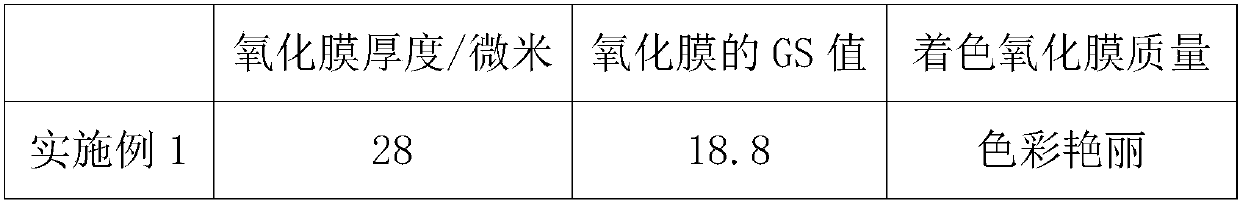

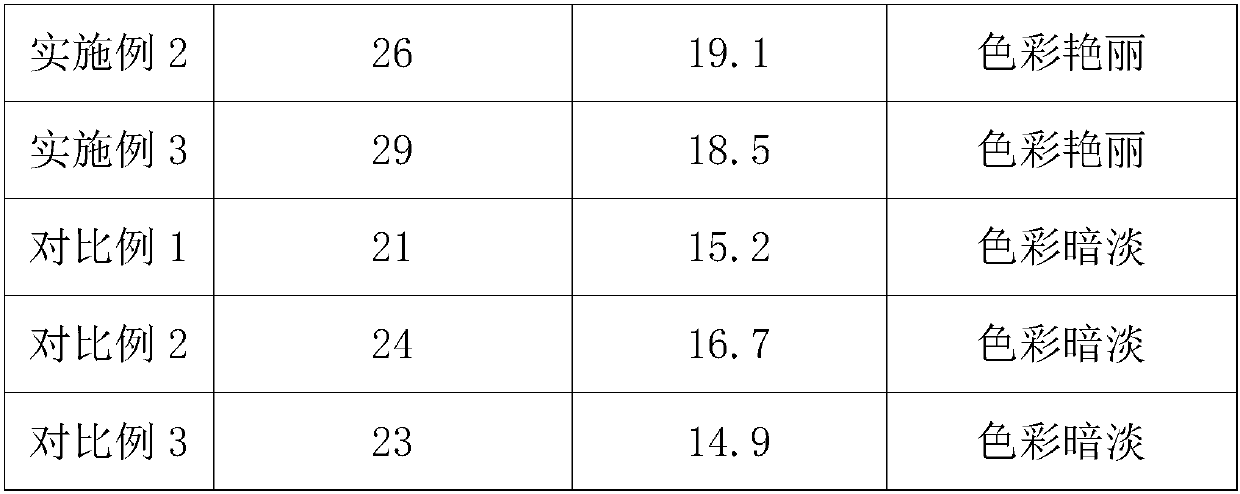

Surface treatment method of 3C product aluminum alloy outer parts and application

InactiveCN110306227AImprove poor permeabilityImprove densification performanceAnodisationTablet computerAcid washing

The invention provides a surface treatment method of 3C product aluminum alloy outer parts. The method comprises following steps in sequence: an aluminum alloy outer part is subjected to surface mechanical pretreatment, machining tool marks and burrs are removed, and a flat surface is obtained; degreasing is performed to remove greasy dirt on the surface; alkali washing is performed to remove a natural oxidation film on the surface, and an activated aluminum matrix is exposed; acid washing is performed to remove dirty ash on the surface; chemical polishing is performed, and a bright and smoothsurface is obtained; anodic oxidation is performed, and an oxidation film with micropores is formed on the surface; colorizing is performed, and a dyeing agent is deposited to enter the micropores inthe oxidation film; and finally, hole sealing is performed, and the micropores in the oxidation film are sealed. With the adoption of the method for surface treatment, the oxidation film is transparent and bright, the pores in the film are small and dense, the film thickness is uniform, various gorgeous colors can be obtained after coloring and hole sealing, and the aluminum alloy outer part hasexcellent attractive decorative effect and excellent wear resistance and corrosion resistance. The invention further provides an application of the surface treatment method to the 3C product aluminumalloy outer parts such as a smartphone and a tablet computer.

Owner:GUANGDONG INST OF MATERIALS & PROCESSING

Processing method of carved wood

The invention provides a processing method of carved wood, which belongs to the technical field of wood carving. According to the technical scheme, the processing method comprises the following steps: drawing a creative draft, and drawing and amplifying an outline onto a timber by utilizing an inked line; chiseling a rough blank: gradually chiseling the rough blank layer by layer from top to bottom, front to rear, surface to inside and shallow to deep, and gradually forming an outer profile and an inner profile of a piece of work; eliminating tool marks and chiseling residues in the rough blank by utilizing a fine carving and thin knife method; polishing the carved wood firstly by utilizing a piece of rough abrasive paper and then utilizing a piece of fine abrasive paper along the fiber direction of the wood; and coloring the carved wood by utilizing pigments and water in a ratio of 30:1, and scrubbing the carved wood after 12 hours later until the uniform gloss and smooth hand feeling are achieved. An ideal personal cutting way can be achieved only by mastering the skill and continuously accumulating the experience, and the artistic language reflected by wood grains-carving marks, smoothness-roughness, concave surfaces-convex surfaces, arrangement by circular knives, cutting by flat cutters, and the like can be achieved and cannot be shown by carving other materials.

Owner:吴晓琴

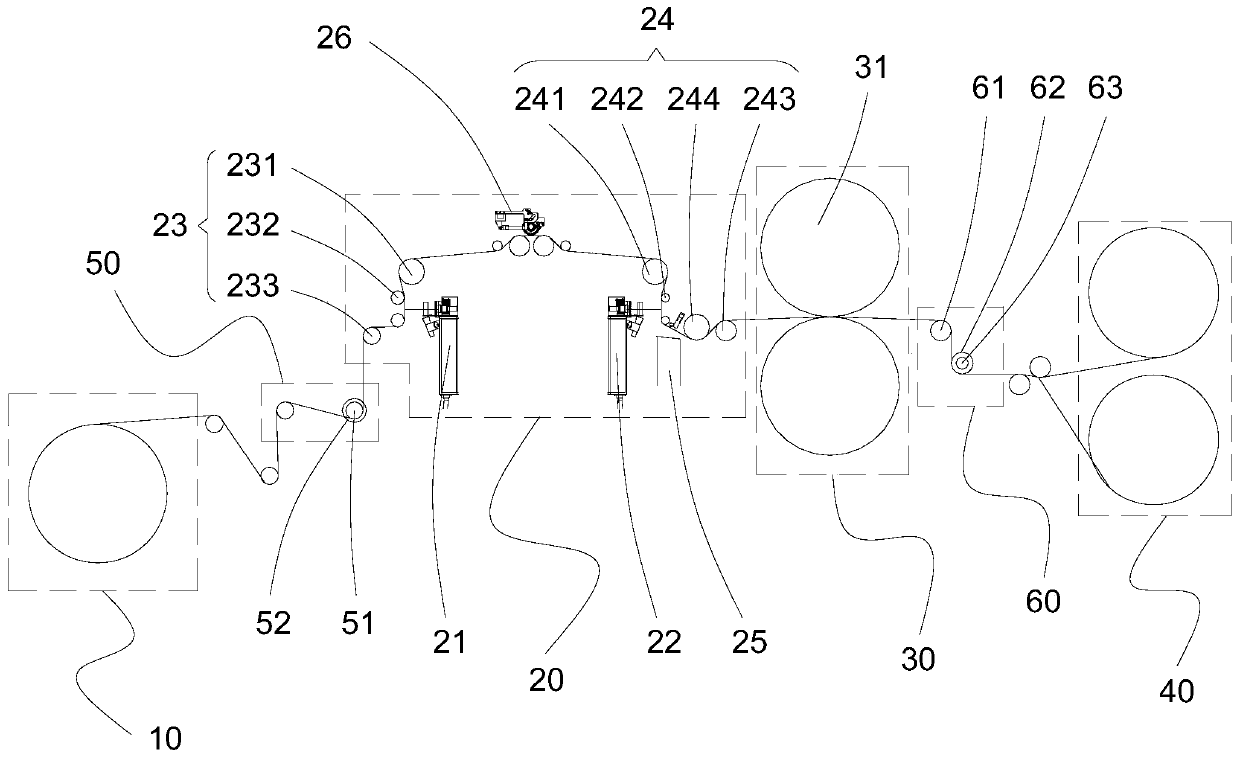

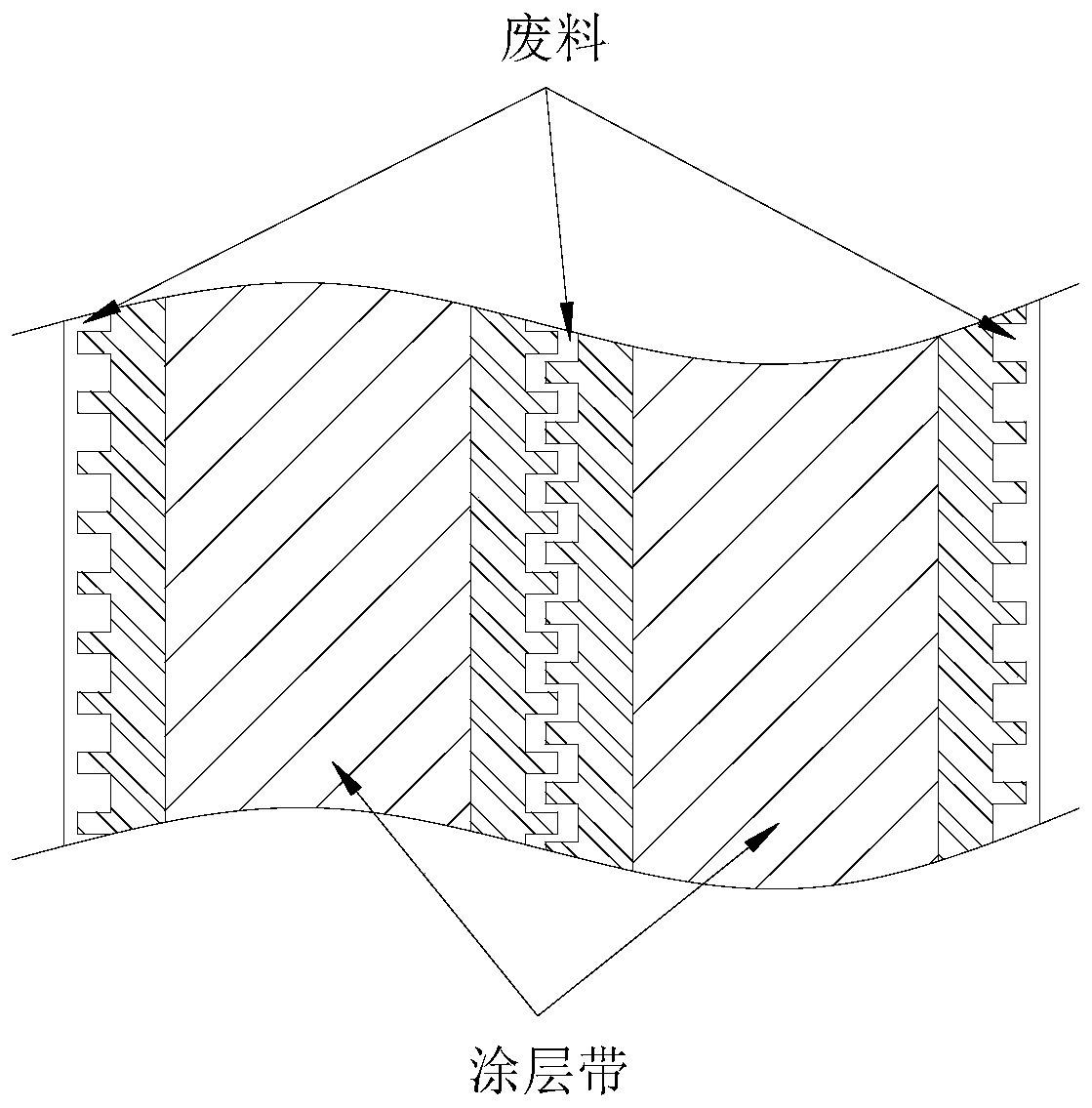

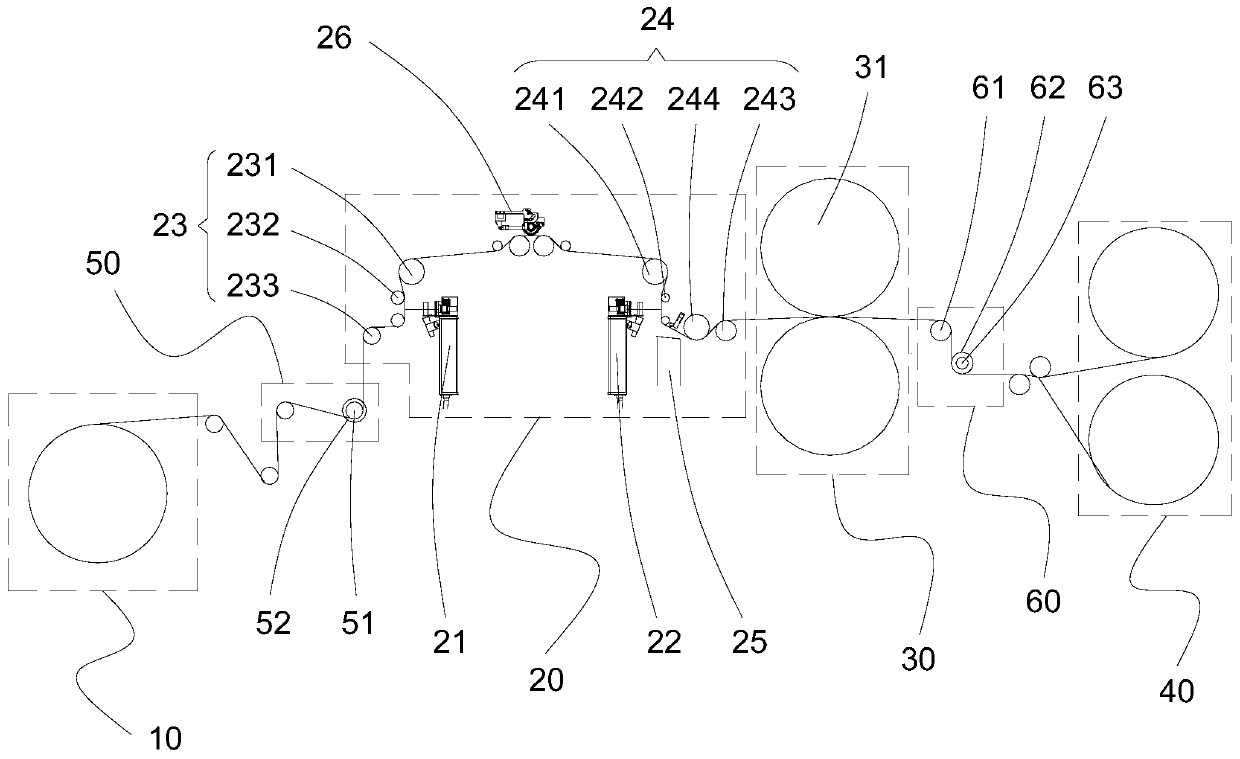

Cutting and forming device for battery pole piece with multiple coating tapes

PendingCN109848583AAvoid tension releaseHigh densityElectrode manufacturing processesConductorsPole pieceEngineering

The invention provides a cutting and forming device for a battery pole piece with multiple coating tapes. The cutting and forming device for the battery pole piece with the multiple coating tapes comprises an emptying mechanism, a cutting mechanism, a roll-forming mechanism and a receiving mechanism arranged sequentially, wherein the cutting mechanism comprises a first laser die cutting assembly,a second laser die cutting assembly, a feed roller assembly and a discharge roller assembly; the first laser die cutting assembly is located on one side, close to the emptying mechanism, of the secondlaser die cutting assembly; the output end of the first laser die cutting module directly faces the feed roller assembly; the output end of the second laser die cutting module directly faces the discharge roller assembly; and the roll-forming mechanism comprises two press rollers arranged oppositely. According to the cutting and forming device for the battery pole piece with the multiple coatingtapes provided by the invention, excessive tension release occurred on the coating tapes can be avoided, so that the density of the coating tapes is effectively improved; all slitting actions are omitted, and cutting and roll-forming are integrated into a whole, so that the production efficiency can be effectively improved, and the input cost can be reduced; and through the two groups of laser diecutting assemblies, the distance between die cutting tool marks can be effectively shortened, so that the materials can be effectively saved.

Owner:广东海中新能源设备股份有限公司

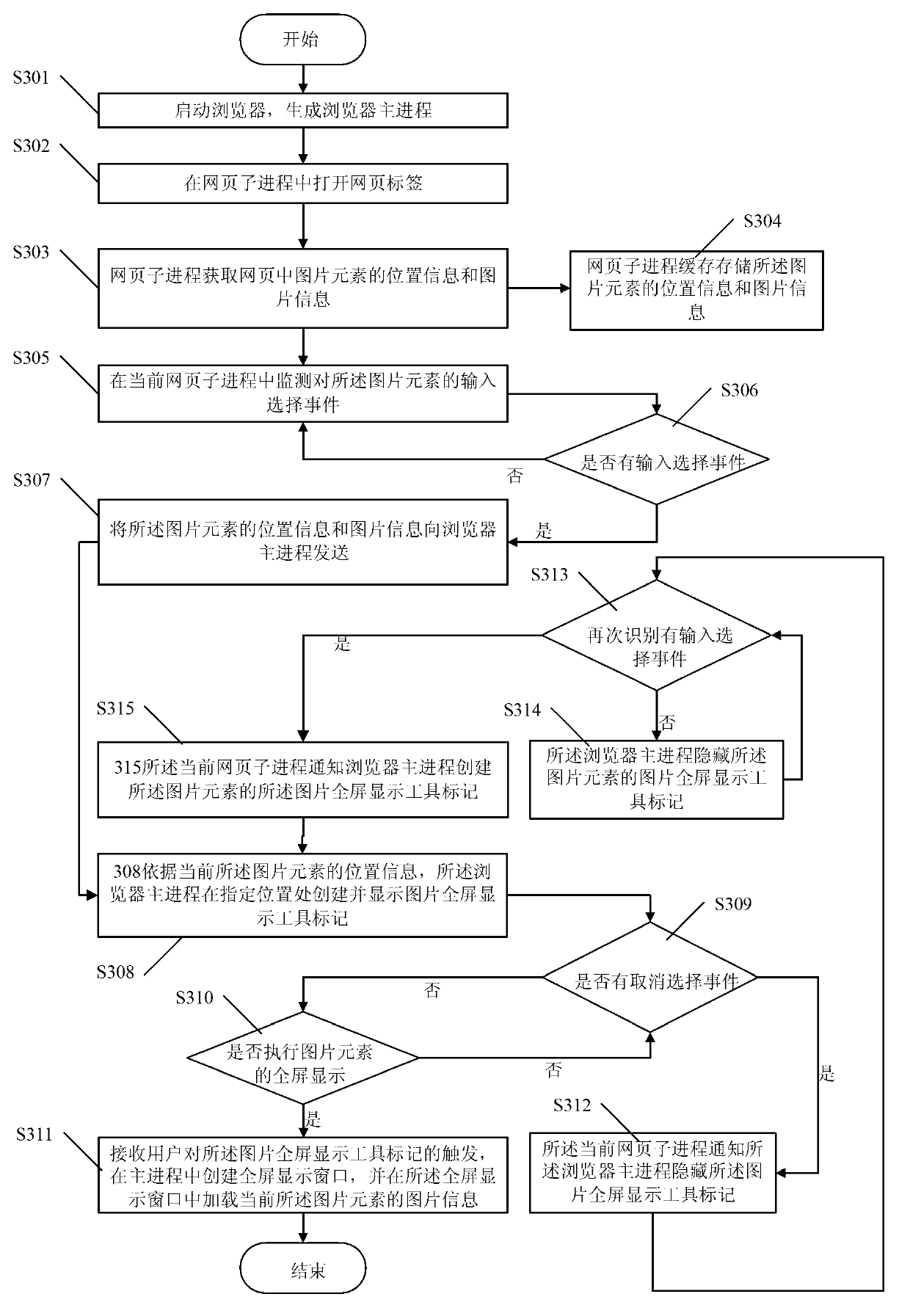

Full-screen picture browsing method and device for web page

ActiveCN102999341ATroubleshootingImprove the efficiency of full-screen browsingSpecific program execution arrangementsSpecial data processing applicationsFailure causesWeb page

The invention discloses a full-screen picture browsing method and device for a web page. The device comprises a creating and acquiring module, a monitoring and sending module, a creating and displaying module and a creating and loading module, wherein the monitoring and sending module and the creating and displaying module are further configured in such a manner that a sub-process of a current web page notifies a host process of a browser of hiding a picture full-screen display tool mark when a deselection event for picture elements is monitored in the sub-process of the current web page. According to the method and the device, a mechanism for the full-screen browsing of picture elements in one or more webpage tags is established in the host process of the browser, so that the problem of browser failure caused when picture full-screen browsing is executed in the browser is solved.

Owner:BEIJING QIHOO TECH CO LTD

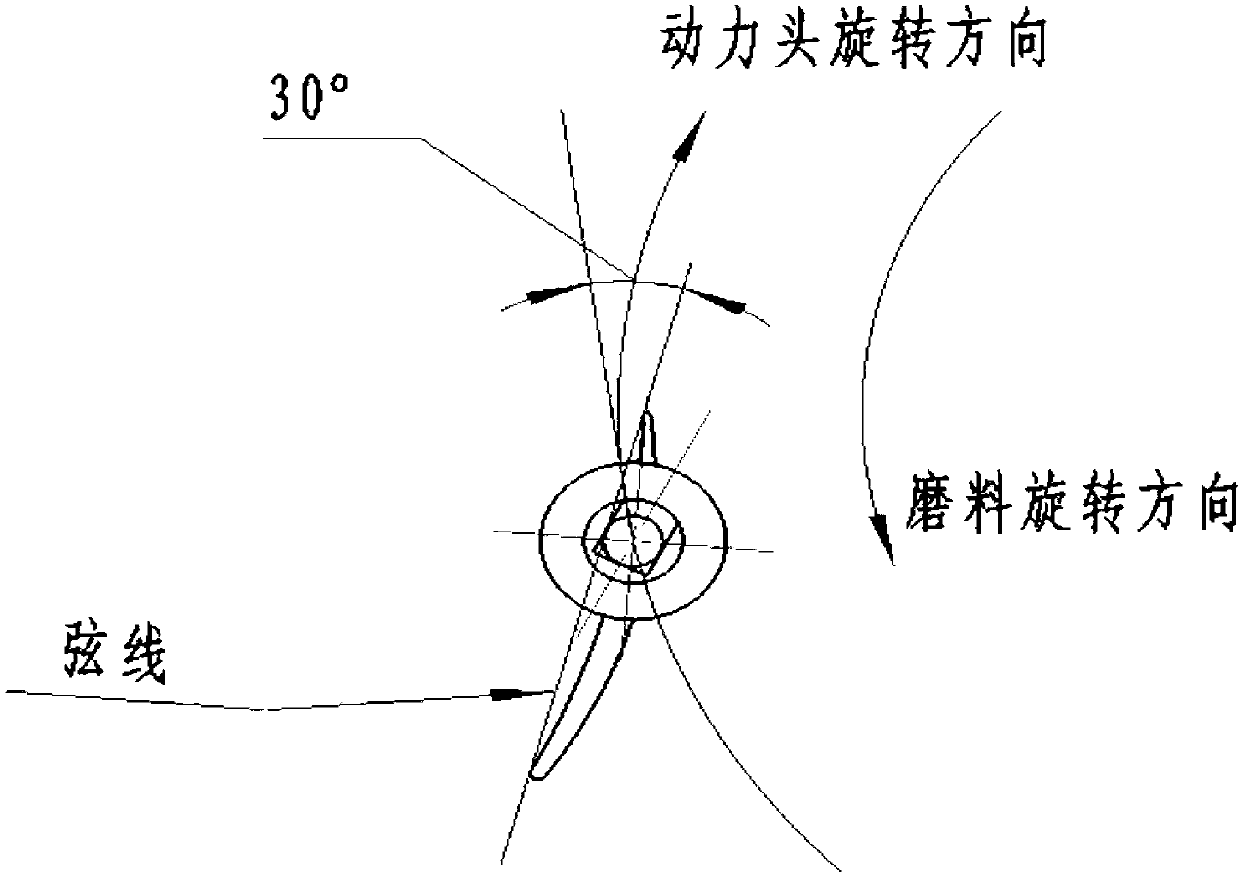

Mechanical finishing non-allowance process for removing tool marks of molded surface of blade body

InactiveCN103273412ANo problem of local over-removalUniform removalEdge grinding machinesPolishing machinesNumerical controlEngineering

Provided is a mechanical finishing non-allowance process for removing tool marks of the molded surface of a blade body. The finishing process, equipment, a clamp and machining parameters are optimized so that a finishing machining target can be achieved. The finishing process comprises the steps that coarse finishing machining and fine finishing machining are respectively conducted on the molded surface of the blade body, so that the tool marks on the molded surface and the radius R position of the front edge and the rear edge are removed respectively, and requirements for roughness are met. The selection of the equipment comprises the step that a spiral-flow type finishing machining device is selected. The design of the clamp comprises the step that the angle between a blade and the grinding material movement is 30 degrees through the clamp. The machining parameters include the rotating speed of a main shaft being 10-120rpm and the rotating speed of a roller being 10-50rpm. The mechanical finishing non-allowance process for removing the tool marks of the molded surface of the blade body has the advantage that machining quality is improved. The profile tolerance of the molded surface meets the requirement for the toughness degree of Ra0.4. The switch-over R of the front edge and the rear edge achieves the aim that the radius R of the front edge and the rear edge of the blade on which finishing machining is conducted keeps the circular degree state after numerical control milling is carried out. Distribution of pressure stress on the surface is more even than that of a manual finishing process.

Owner:SHENYANG LIMING AERO-ENGINE GROUP CORPORATION

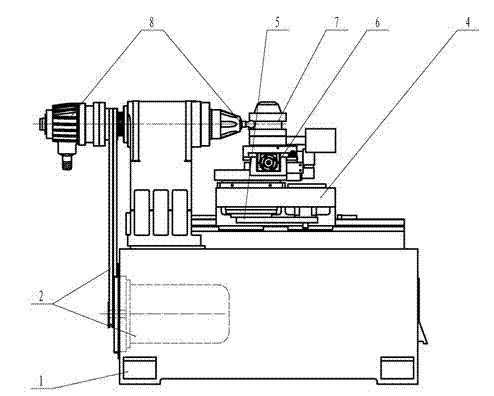

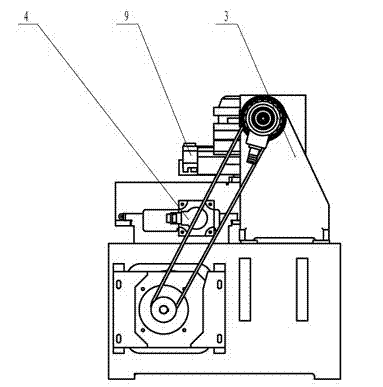

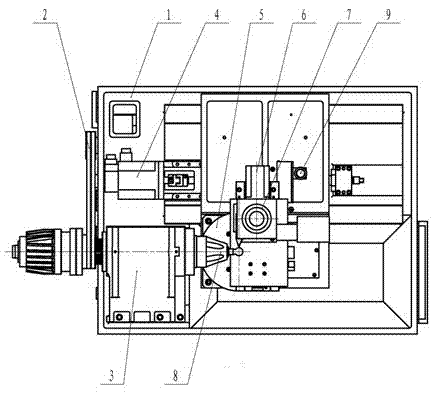

Numerical control spherical lathe

ActiveCN102500765AReduce processReduce turnover storageFeeding apparatusDriving apparatusNumerical controlEngineering

The invention discloses a numerical control spherical lathe, which comprises a base. A servo motor is arranged in the base, a spindle assembly is arranged on the base and connected with the servo motor through a speed reducing transmission device, and a workpiece clamping unit is installed at the front end of the spindle assembly. A Z-axle circle center locating unit is arranged on the base, a Y-axle rotating unit is installed on the Z-axle circle center locating unit, an X-axle radius feeding unit is installed on the Y-axle rotating unit, and the upper portion of the radius feeding unit is provided with a knife rest and a knife rest converting unit. The numerical control spherical lathe adopts a multiple-axle lathe system with a single coordinate system controlled by five shafts and the normal cutting principle. A cutting tool always aligns at the circle center like the fact that a compass describes a circle around a point, and accordingly the roundness is very high. When the numerical control spherical lathe performs processing, a cutting edge cutting error and an interpolation error which are caused by quadrant left-and-right cutting when an ordinary numerical control lathe cuts a round sphere do not occur, wherein the errors include tool marks of program translation and pause in quadrant passing process.

Owner:南京肯迈得机床制造有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com